Patents

Literature

797 results about "Heavy equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heavy equipment or heavy machinery refers to heavy-duty vehicles, specially designed for executing construction tasks, most frequently ones involving earthwork operations or other large construction tasks. Heavy equipment usually comprises five equipment systems: implementation, traction, structure, power train, control and information.

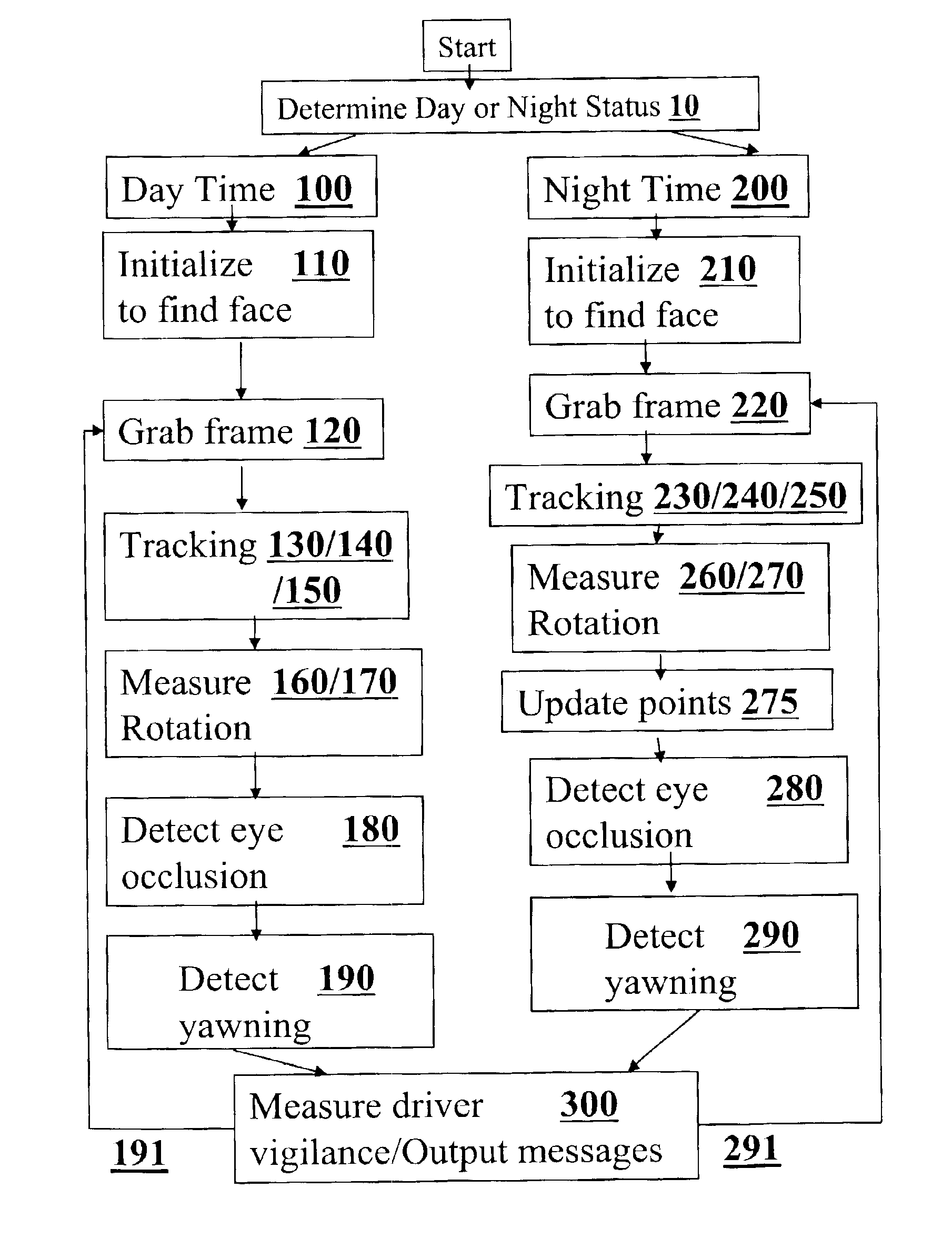

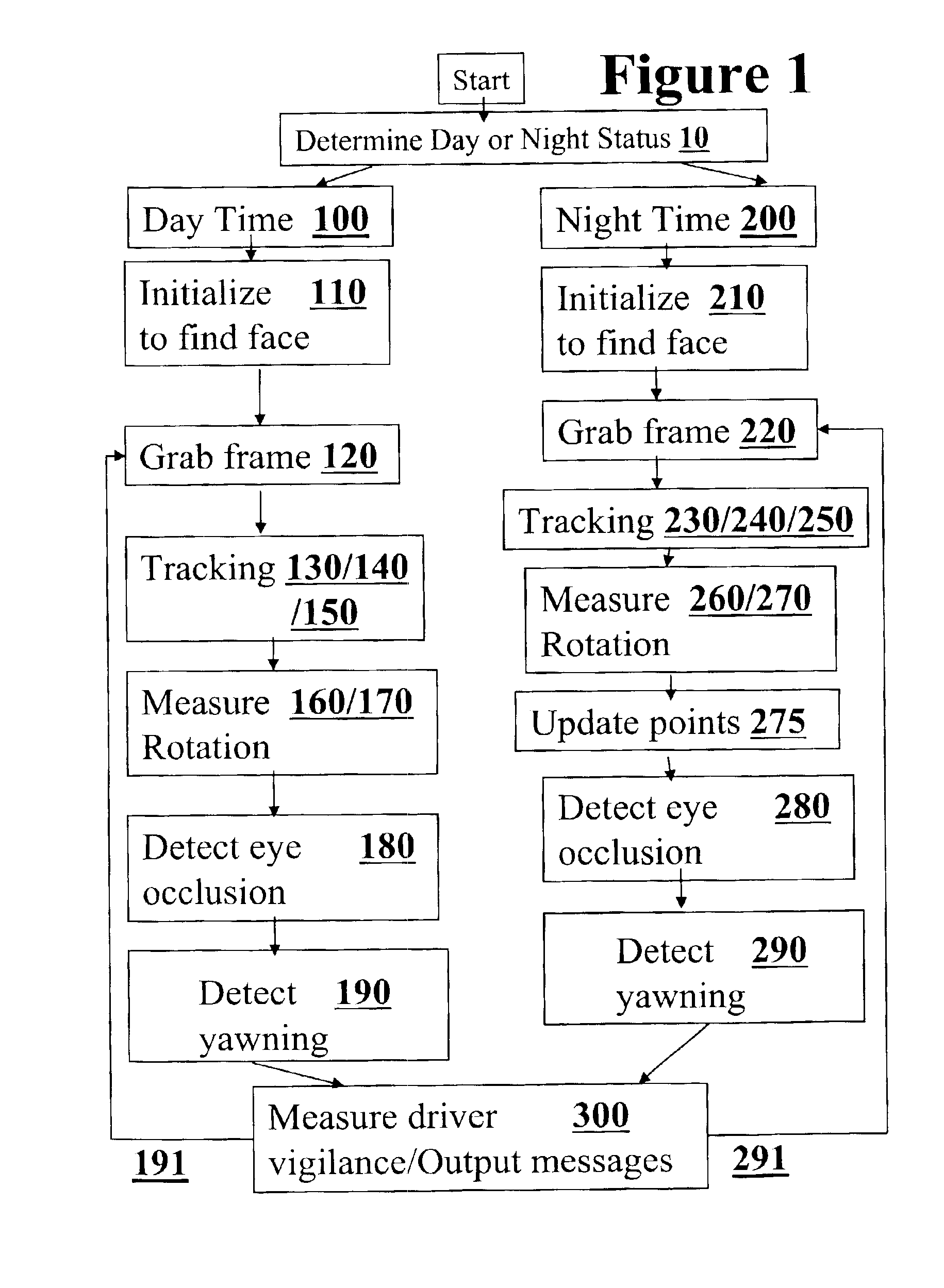

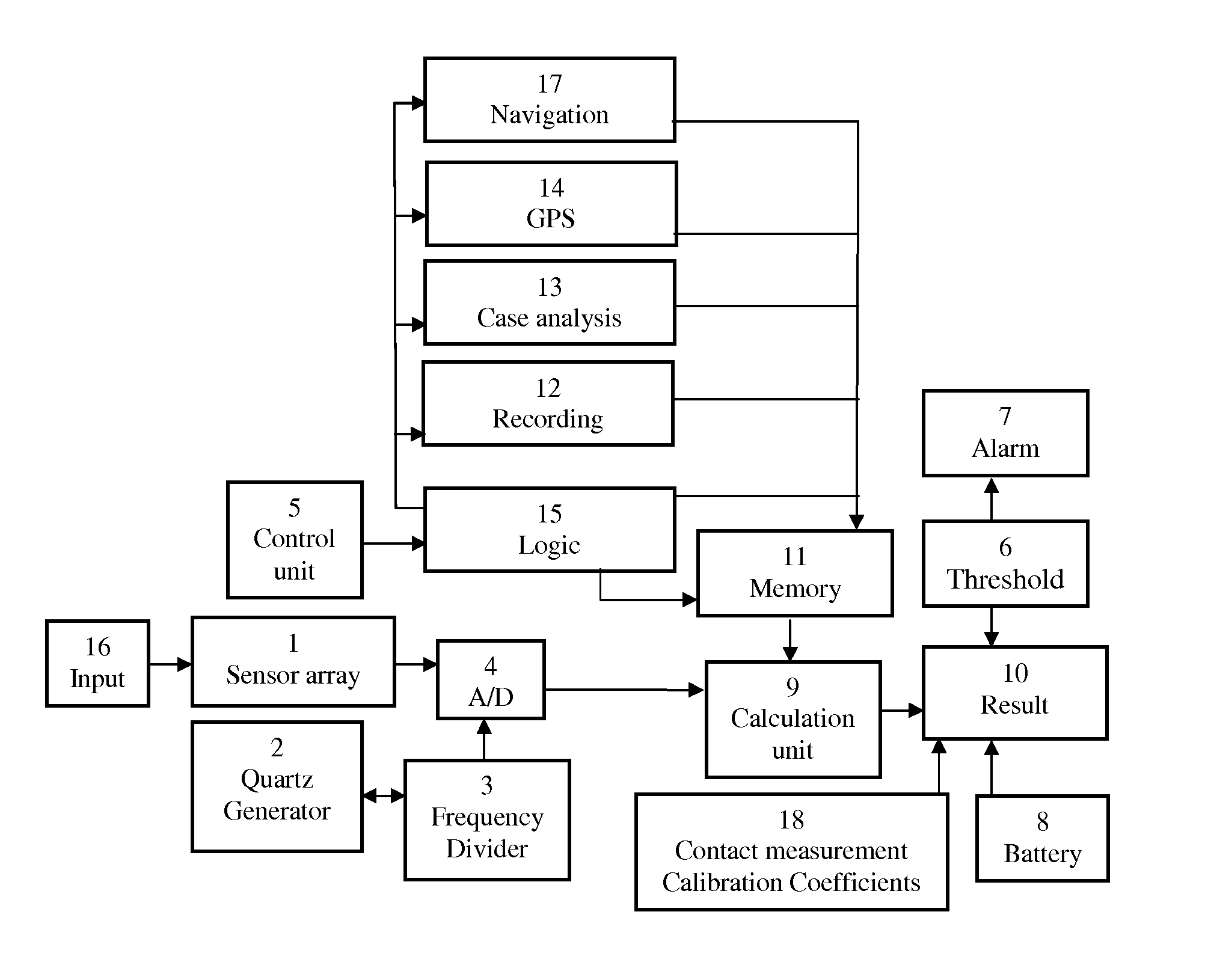

Algorithm for monitoring head/eye motion for driver alertness with one camera

InactiveUS6927694B1Easy to useApplicability to detecting driver fatigueColor television detailsClosed circuit television systemsEquipment OperatorDriver/operator

Visual methods and systems are described for detecting alertness and vigilance of persons under conditions of fatigue, lack of sleep, and exposure to mind altering substances such as alcohol and drugs. In particular, the intention can have particular applications for truck drivers, bus drivers, train operators, pilots and watercraft controllers and stationary heavy equipment operators, and students and employees during either daytime or nighttime conditions. The invention robustly tracks a person's head and facial features with a single on-board camera with a fully automatic system, that can initialize automatically, and can reinitialize when it need's to and provide outputs in realtime. The system can classify rotation in all viewing direction, detects' eye / mouth occlusion, detects' eye blinking, and recovers the 3D(three dimensional) gaze of the eyes. In addition, the system is able to track both through occlusion like eye blinking and also through occlusion like rotation. Outputs can be visual and sound alarms to the driver directly. Additional outputs can slow down the vehicle cause and / or cause the vehicle to come to a full stop. Further outputs can send data on driver, operator, student and employee vigilance to remote locales as needed for alarms and initiating other actions.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

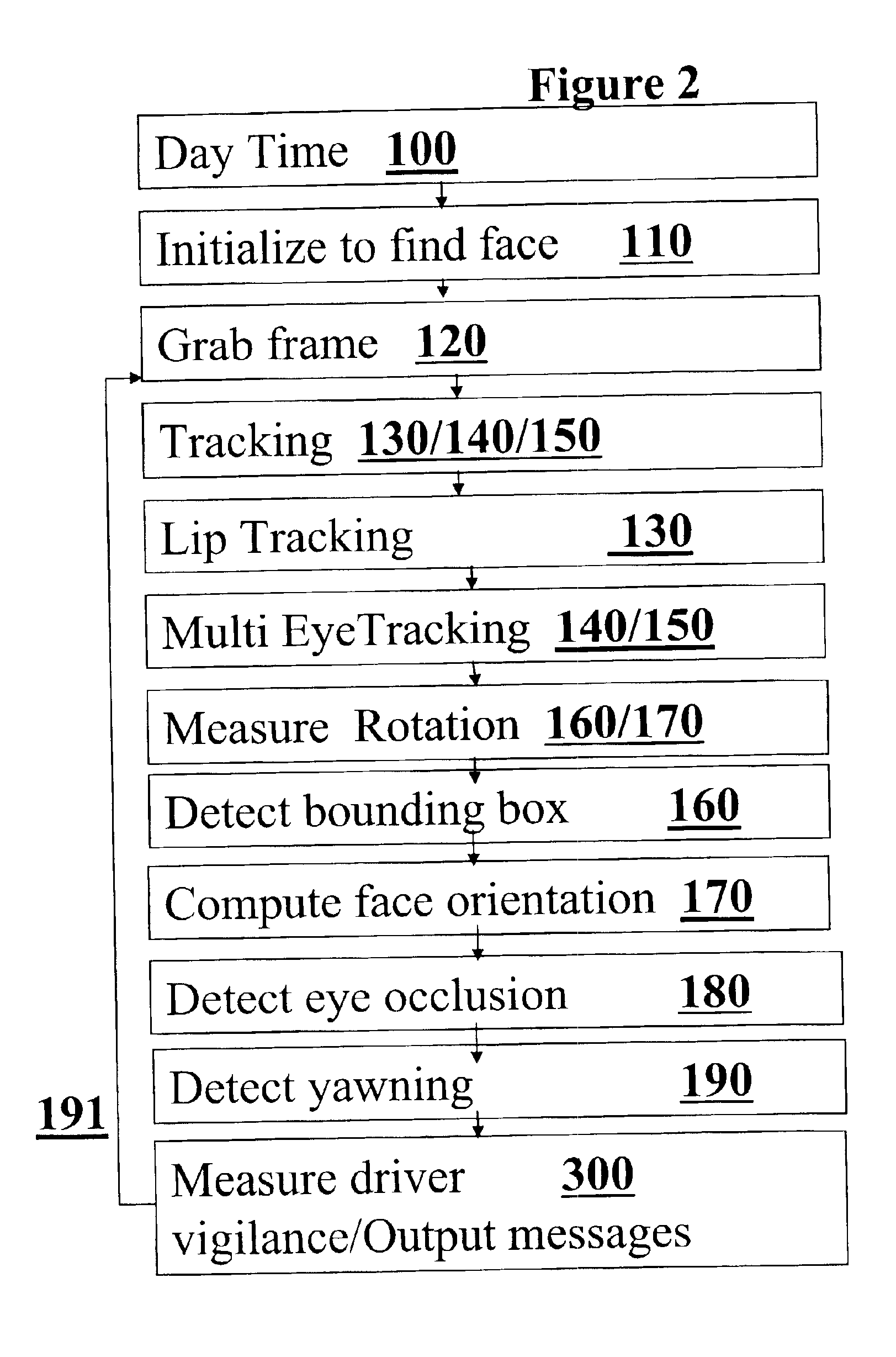

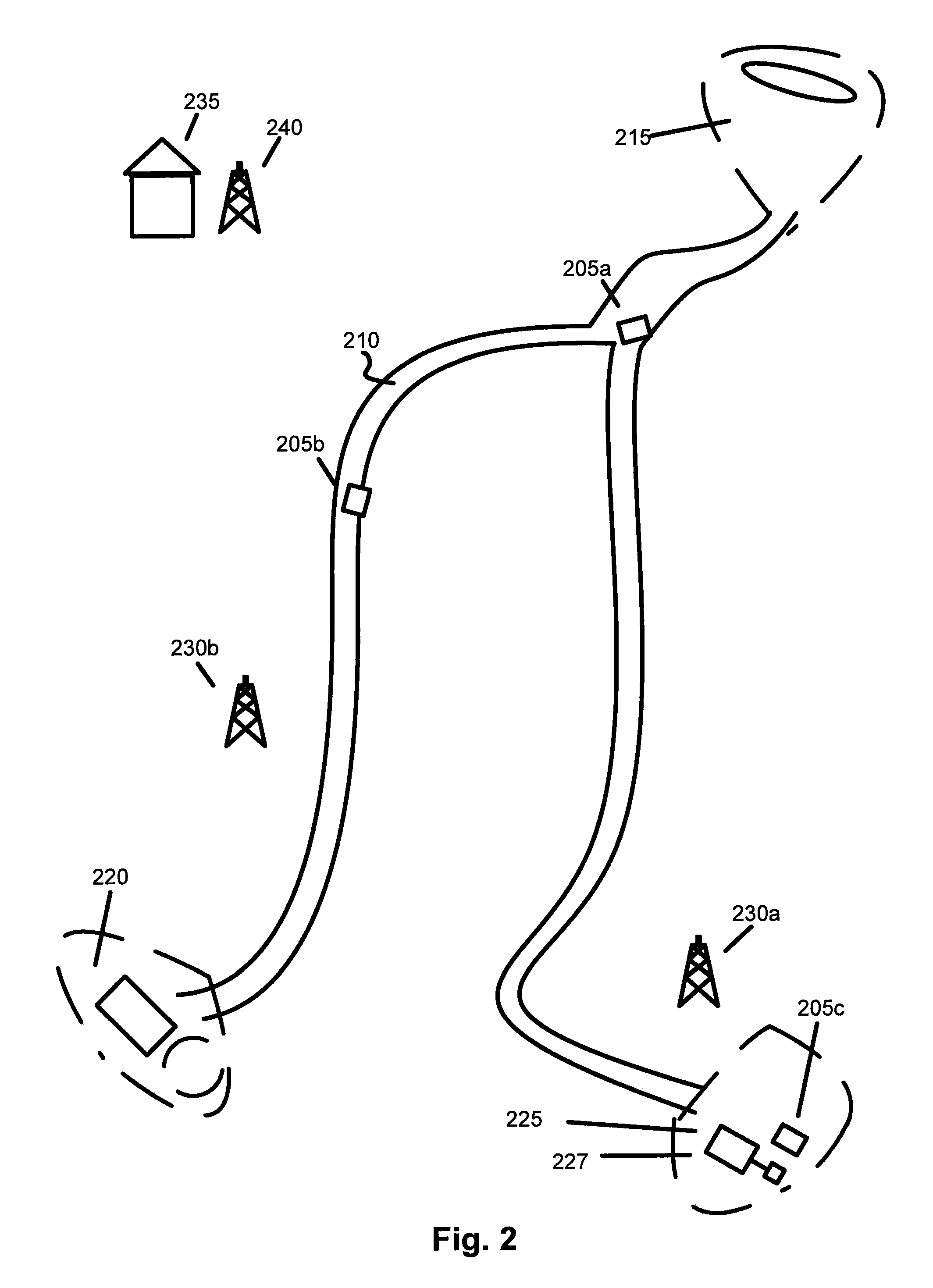

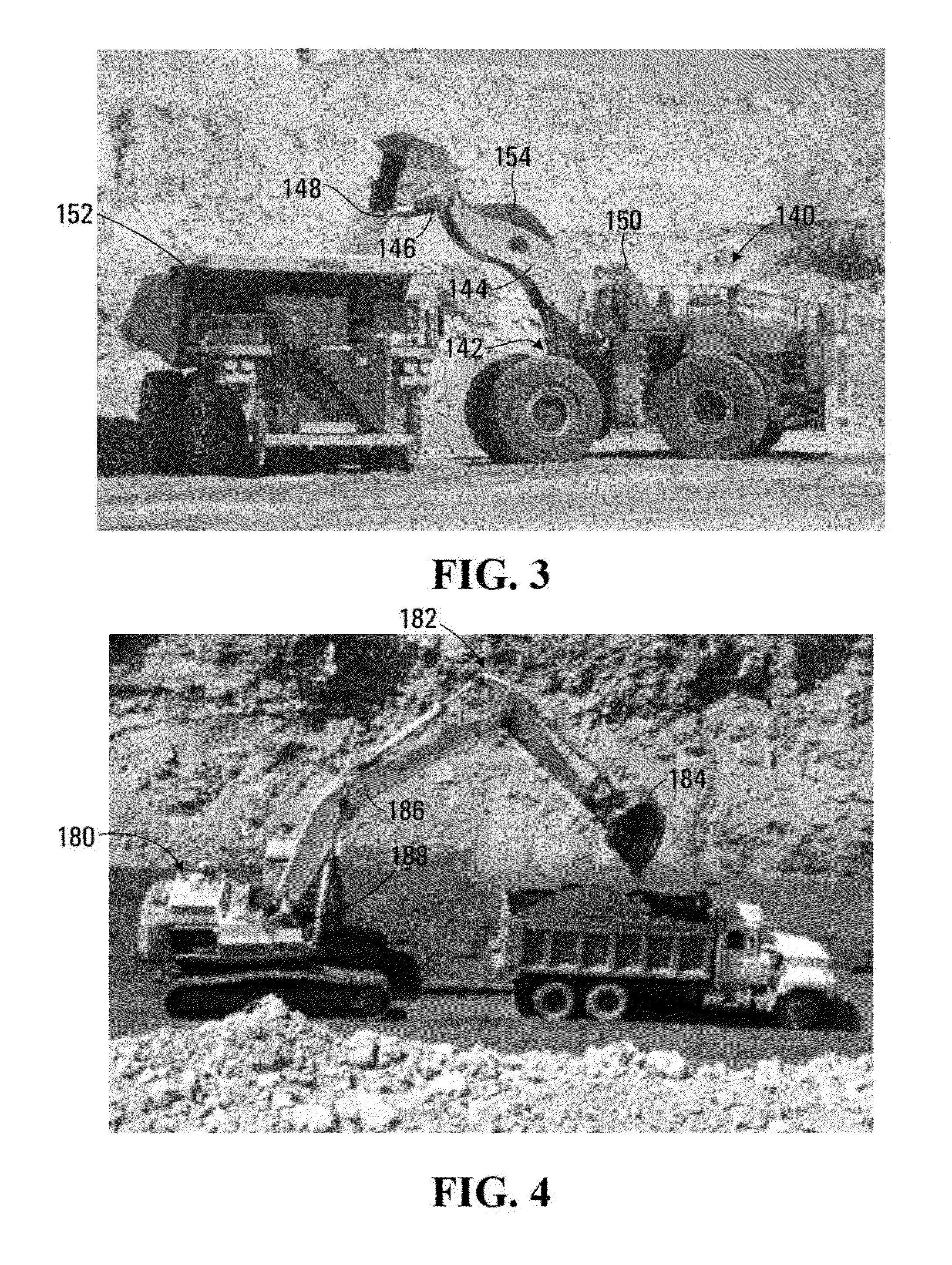

Guided maneuvering of a mining vehicle to a target destination

ActiveUS20130054133A1Guaranteed maximum utilizationMore confidenceInstruments for road network navigationRegistering/indicating working of vehiclesHeavy equipmentEngineering

A system and method for navigating a first heavy equipment to a target destination is provided. A location of the target destination is retrieved from a distributed objects database. The location of the target destination is at least partially determined by a position of a second heavy equipment. A position sensor identifies a current position and orientation of the first heavy equipment, and a path from the current position of the first heavy equipment to the location of the target destination is calculated. The calculated path is selected to avoid hazards. A progress of the first heavy equipment along the calculated path is monitored using the position sensor. When the first heavy equipment deviates from the calculated path, a message is outputted to an operator of at least one of the first heavy equipment and the second heavy equipment.

Owner:MODULAR MINING SYSTEMS

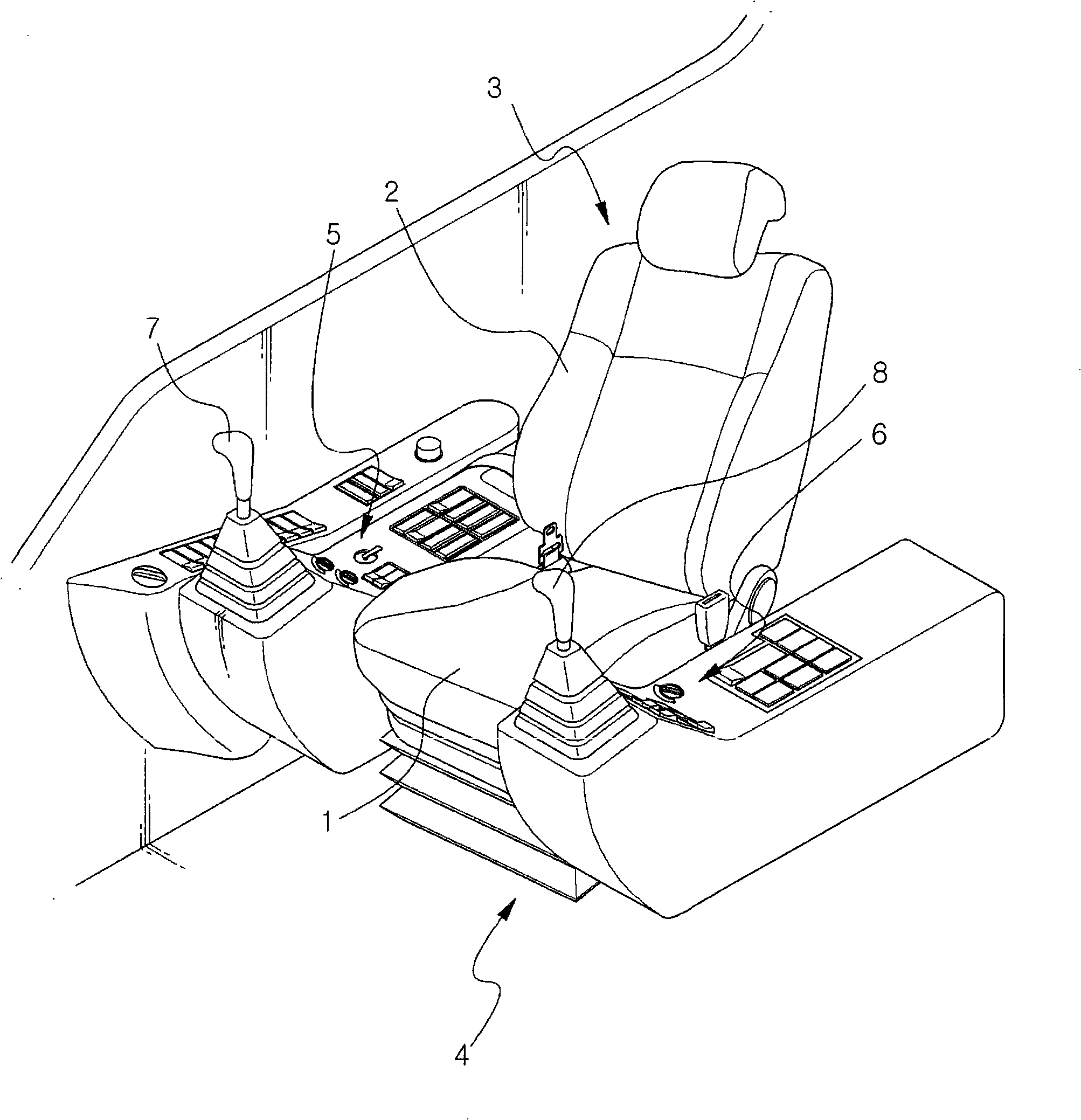

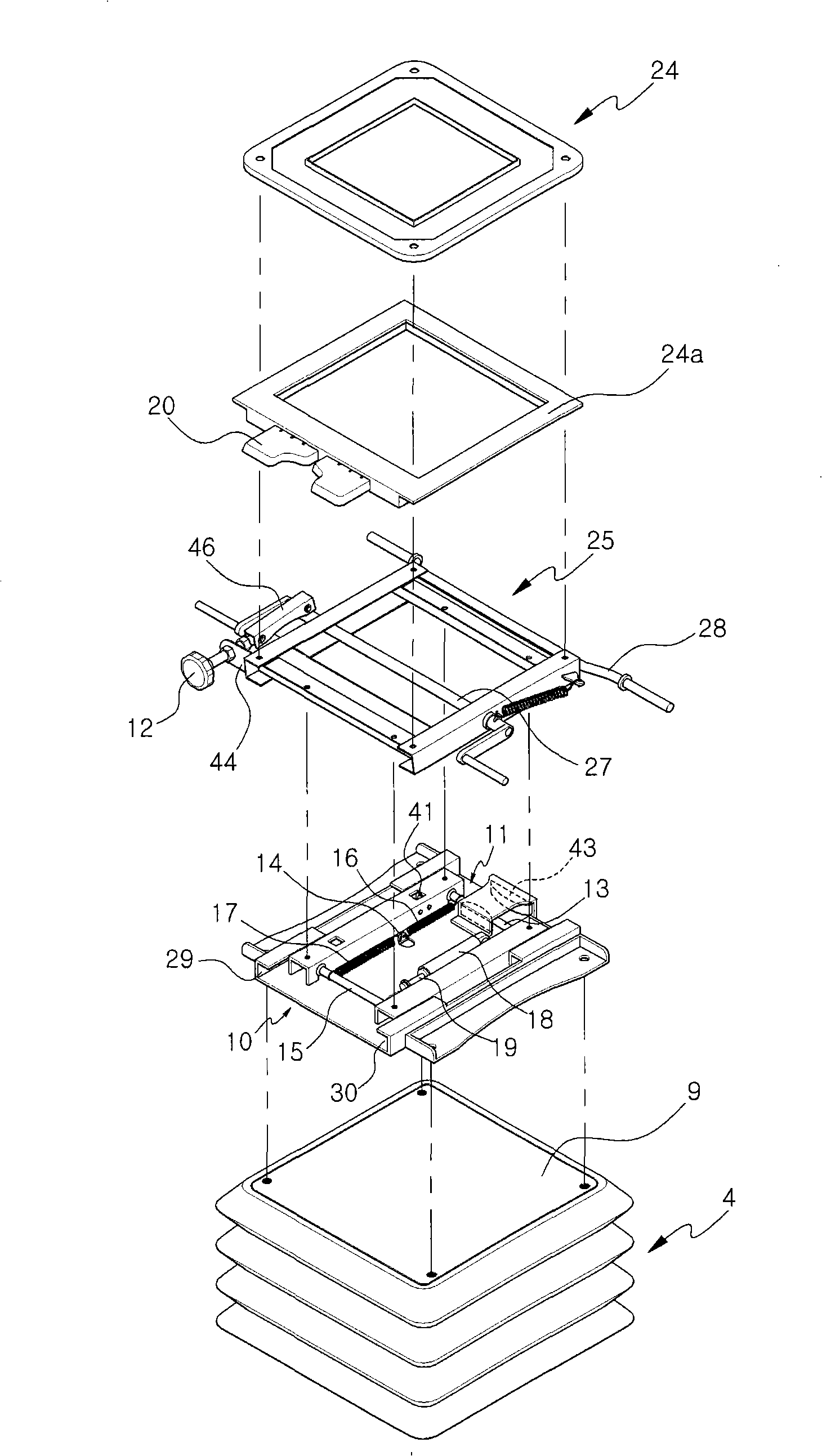

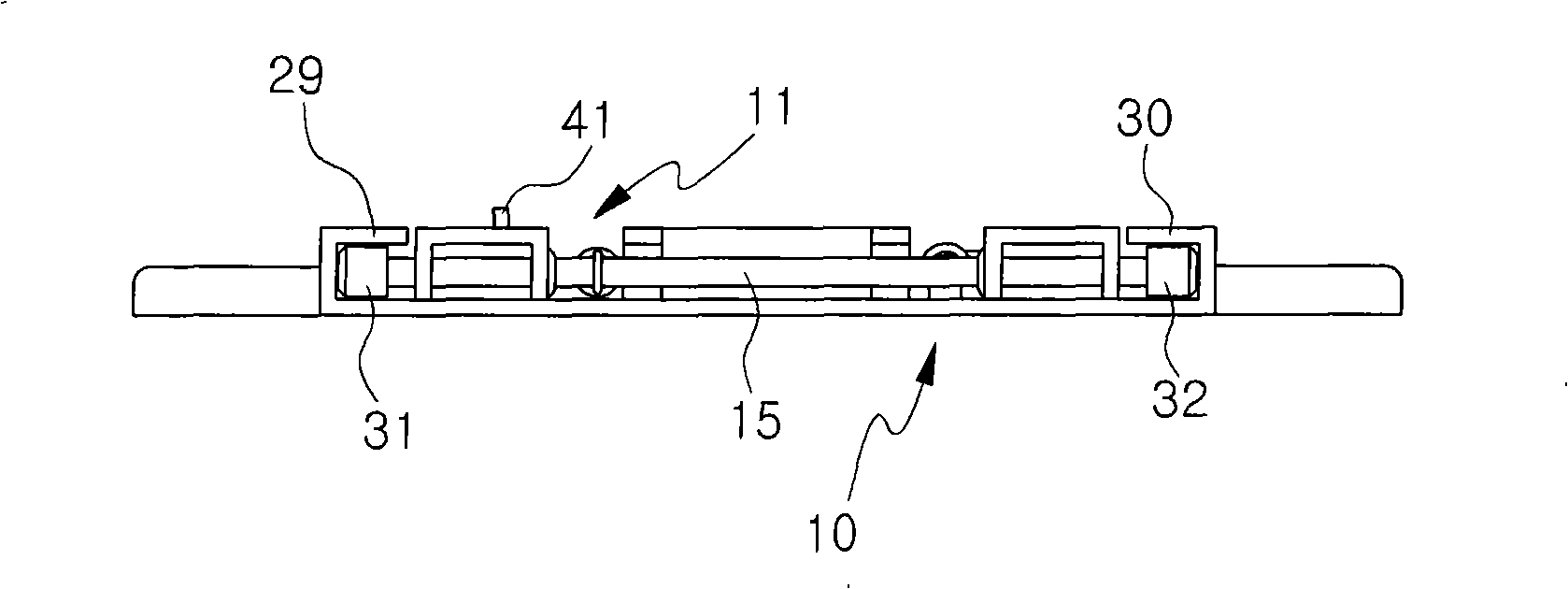

Seat for heavy equipment having buffer means in forward and backward directions

A seat for heavy equipment having a buffer means in forward and backward directions is provided, which can protect an operator by attenuating impact and vibration generated in a cab in forward and backward directions of an excavator in accordance with the driving of the buffer means in a main working mode of the excavator. The seat for heavy equipment is mounted on a suspension plate and is located between left and right console boxes.; The seat for heavy equipment includes a lower member mounted on the suspension plate; an upper member slidably mounted on the lower member in forward and backward directions of the equipment; a buffer means for attenuating impact and vibration generated in the forward and backward directions of the equipment; a tilting means including a frame, a hinge shaft, a driving shaft, and a control handle; and a locking means for locking and unlocking forward and backward movement of the upper member against the lower member when a pusher installed on one side of the frame is manipulated. In a main working mode of the equipment, a buffer function is performed through forward and backward movement of the upper member against the lower member, and when the main working mode is released, the buffer function is released.

Owner:VOLVO CONSTR EQUIP HLDG (SWEDEN) AB

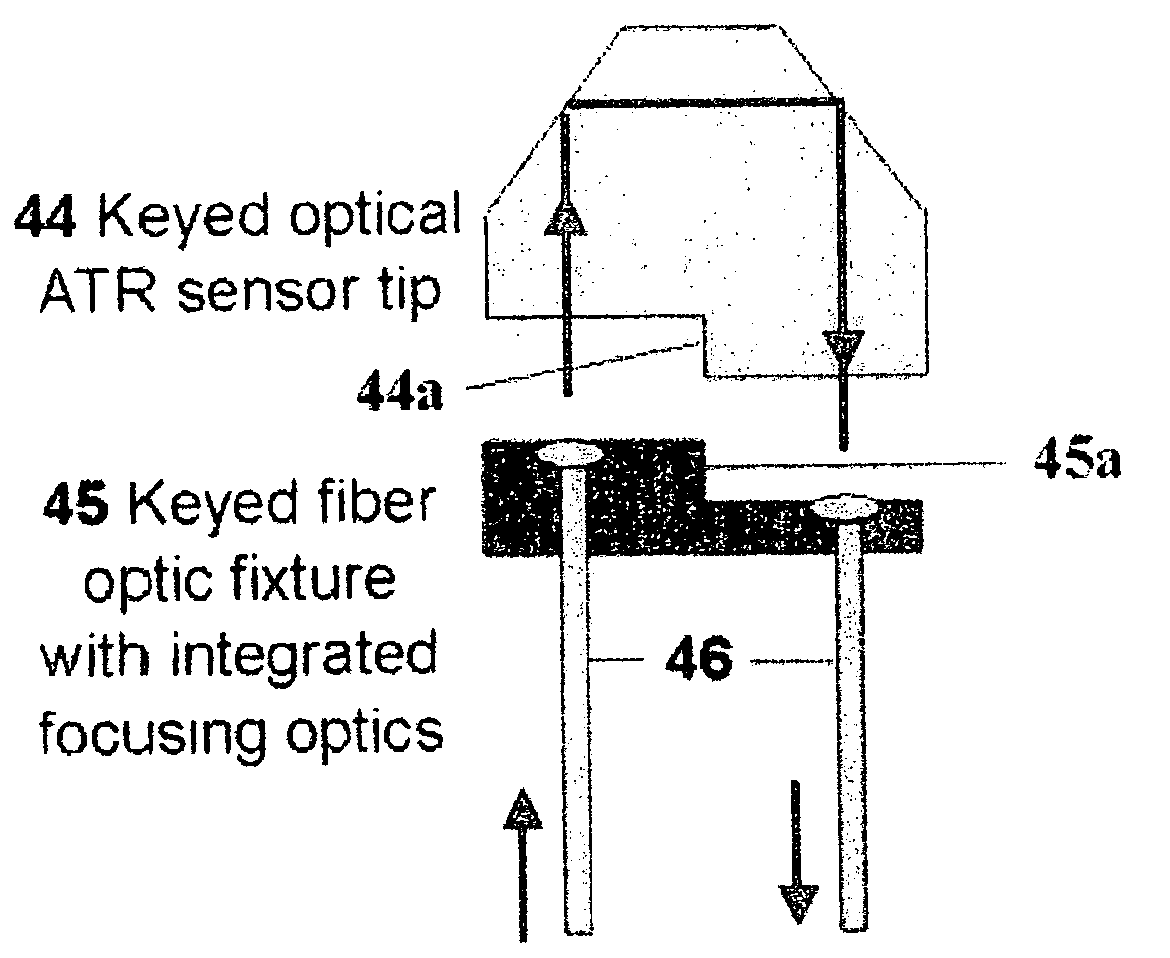

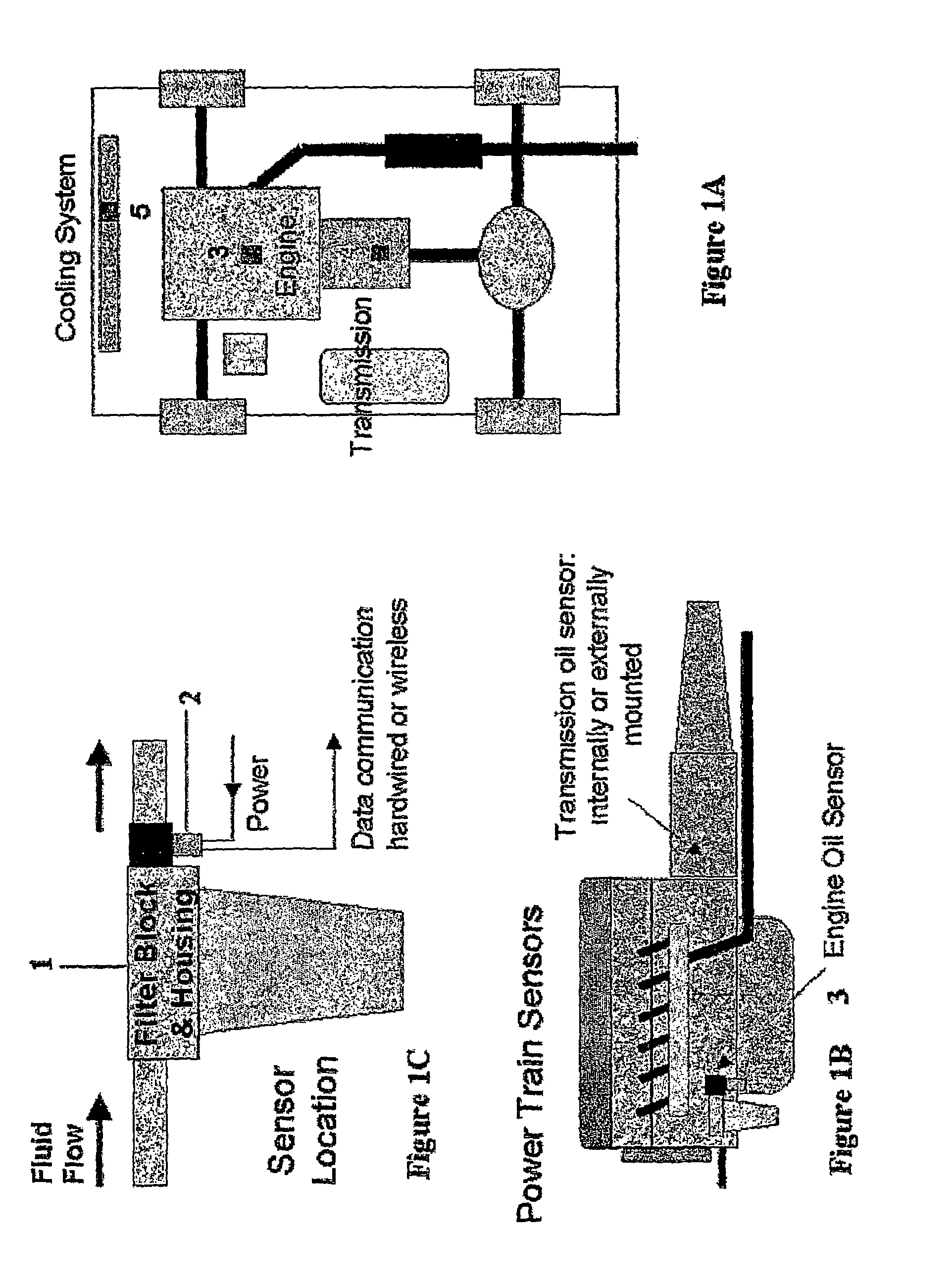

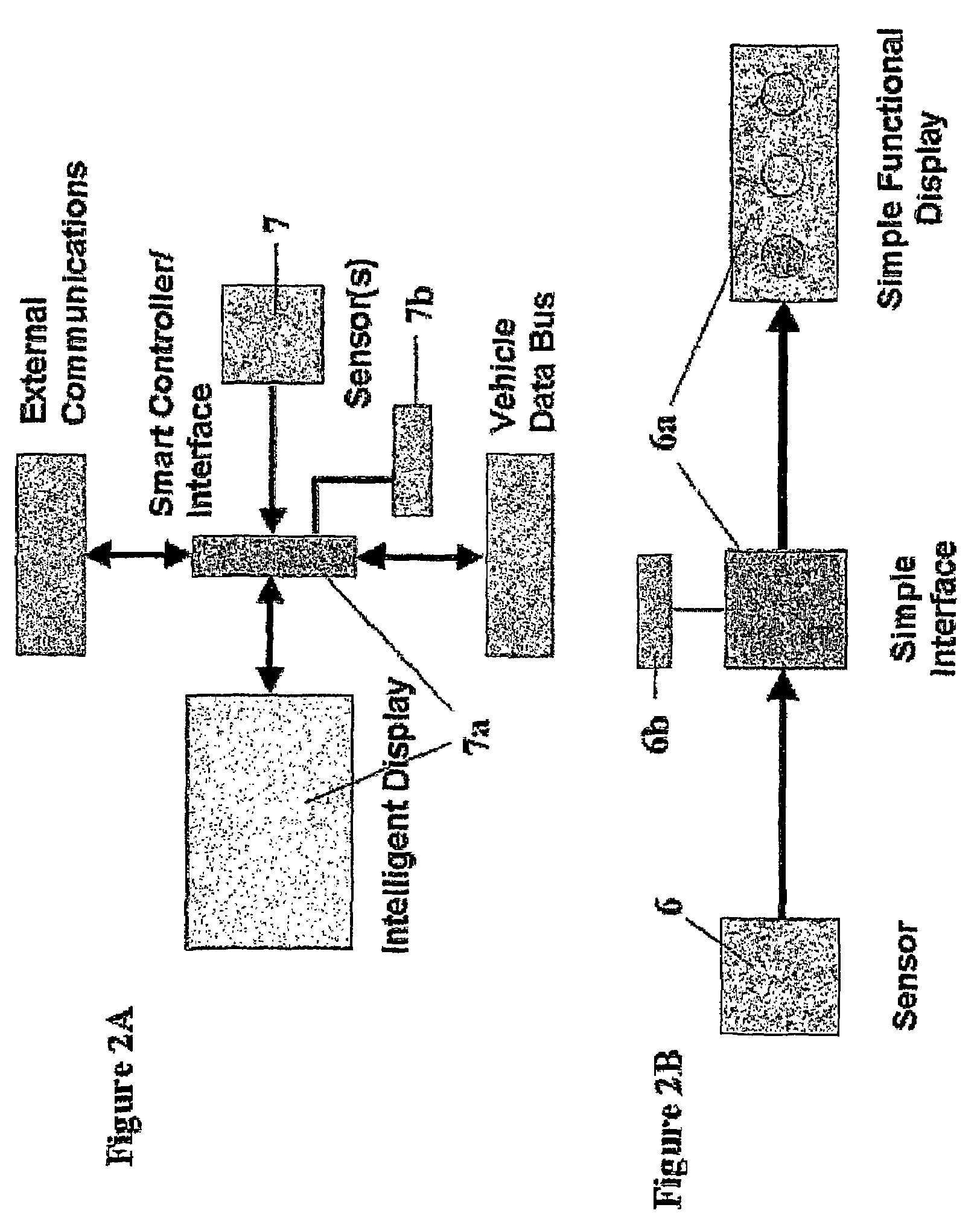

Low-cost on-line and in-line spectral sensors based on solid-state source and detectors combinations for monitoring lubricants and functional fluids

ActiveUS7339657B2Good surface protectionReduce dirtRadiation pyrometryPhotometryFluorescenceSpectral responsivity

A series of optical spectral sensors is based on a combination of solid-state sources (illumination) and detectors housed within an integrated package that includes the interfacing optics and acquisition and processing electronics. The focus is on low cost and the fabrication of the sensor is based on techniques that favor mass production. Materials and components are selected to support low-cost, high volume manufacturing of the sensors. Spectral selectivity is provided by the solid-state source(s) thereby eliminating the need for expensive spectral selection components. The spectral response covers the range from the visible (400 nm) to the mid-infrared (25,000 nm / 25.0 μm), as defined by the availability of suitable low-cost solid-state source devices. A refractive optical system is employed, primarily in an internal reflection mode, allowing a selection of sample handling tools, including, but not restricted to internal reflectance and transmittance. A secondary channel allowing for light scattering or fluorescence methods is an option. The targeted applications of the sensing devices are for lubricants and functional fluids in the heavy equipment, automotive and transportation industries. A source reference channel is included to provide measurement stability and temperature compensation.

Owner:SENTELLIGENCE

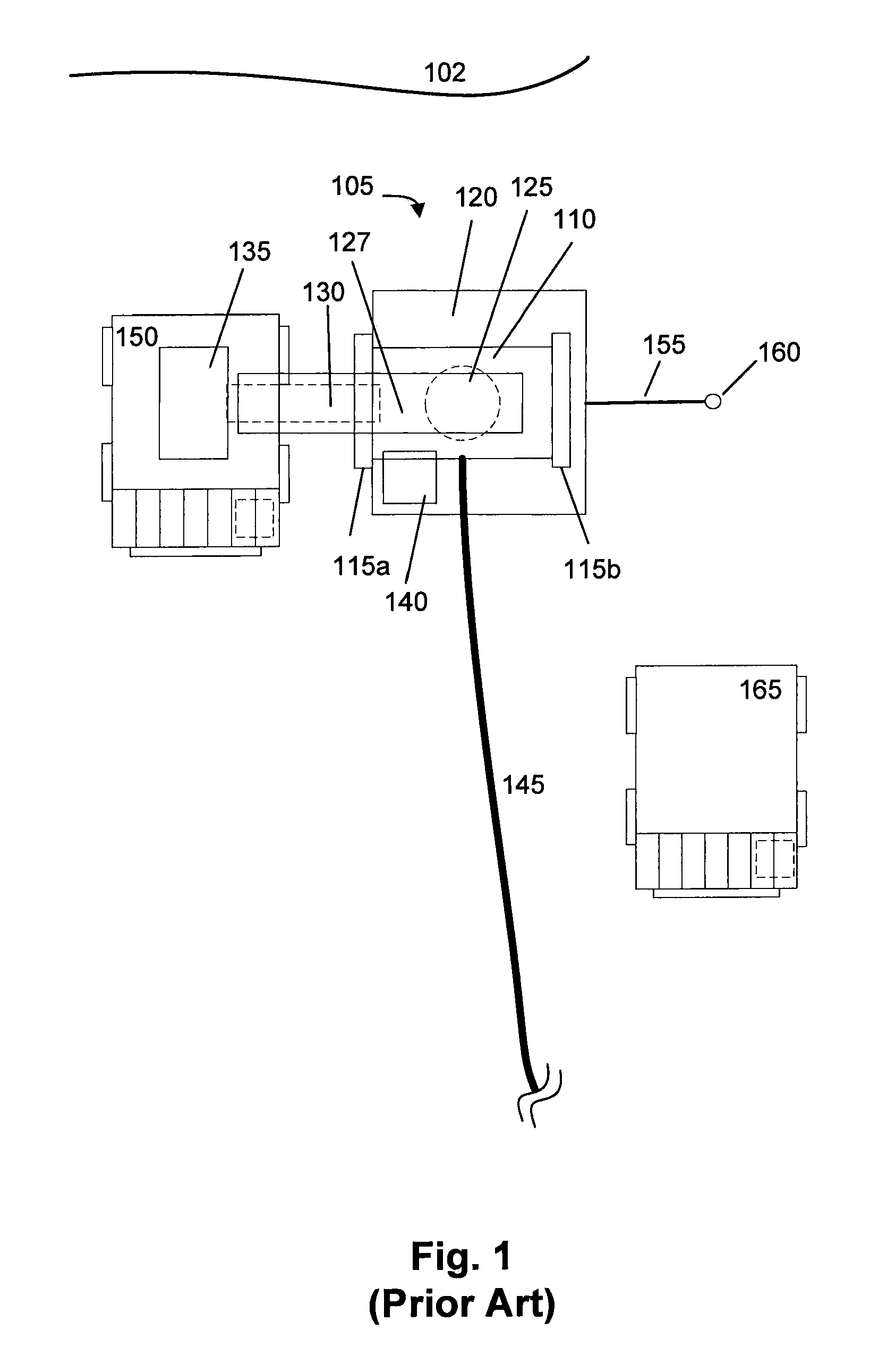

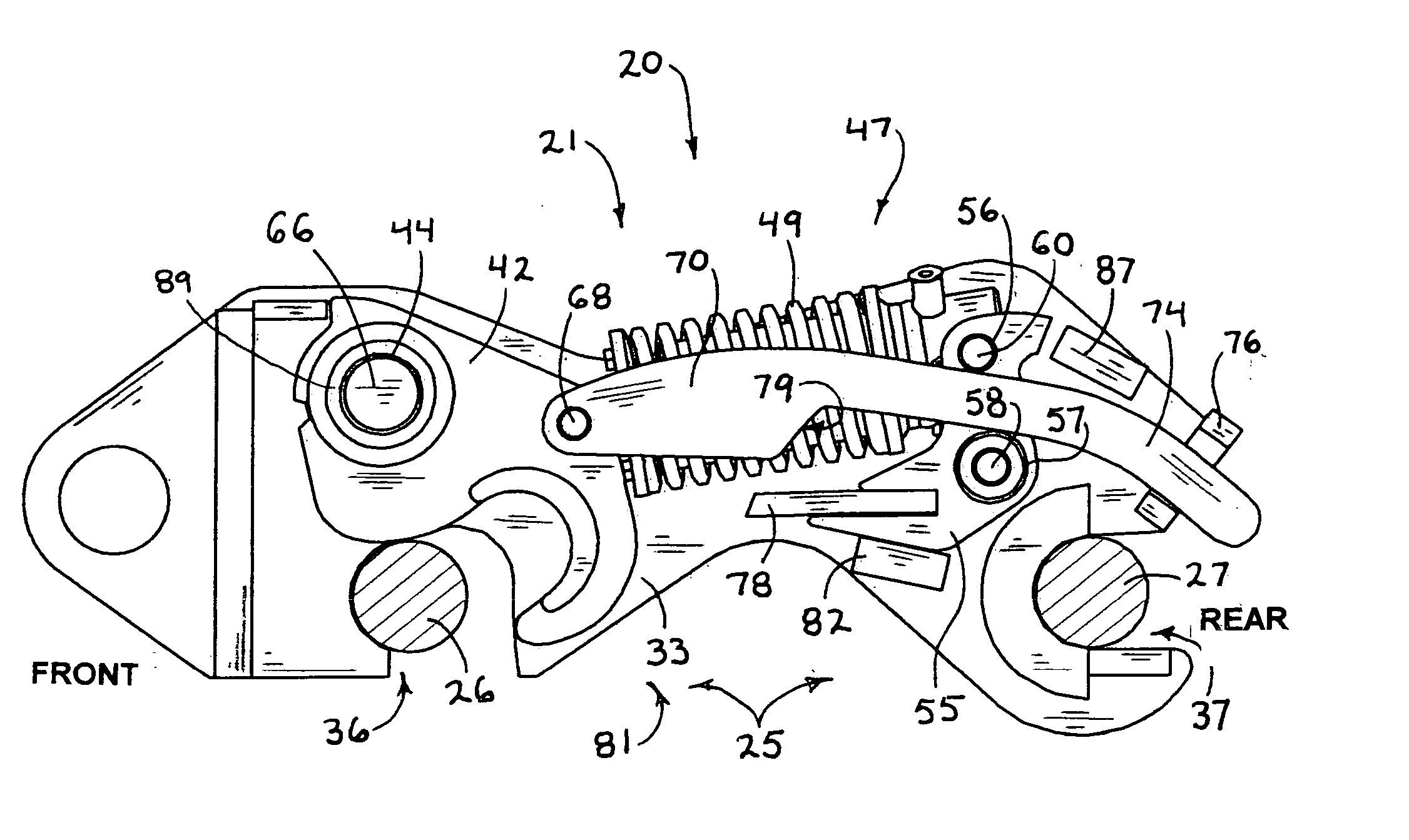

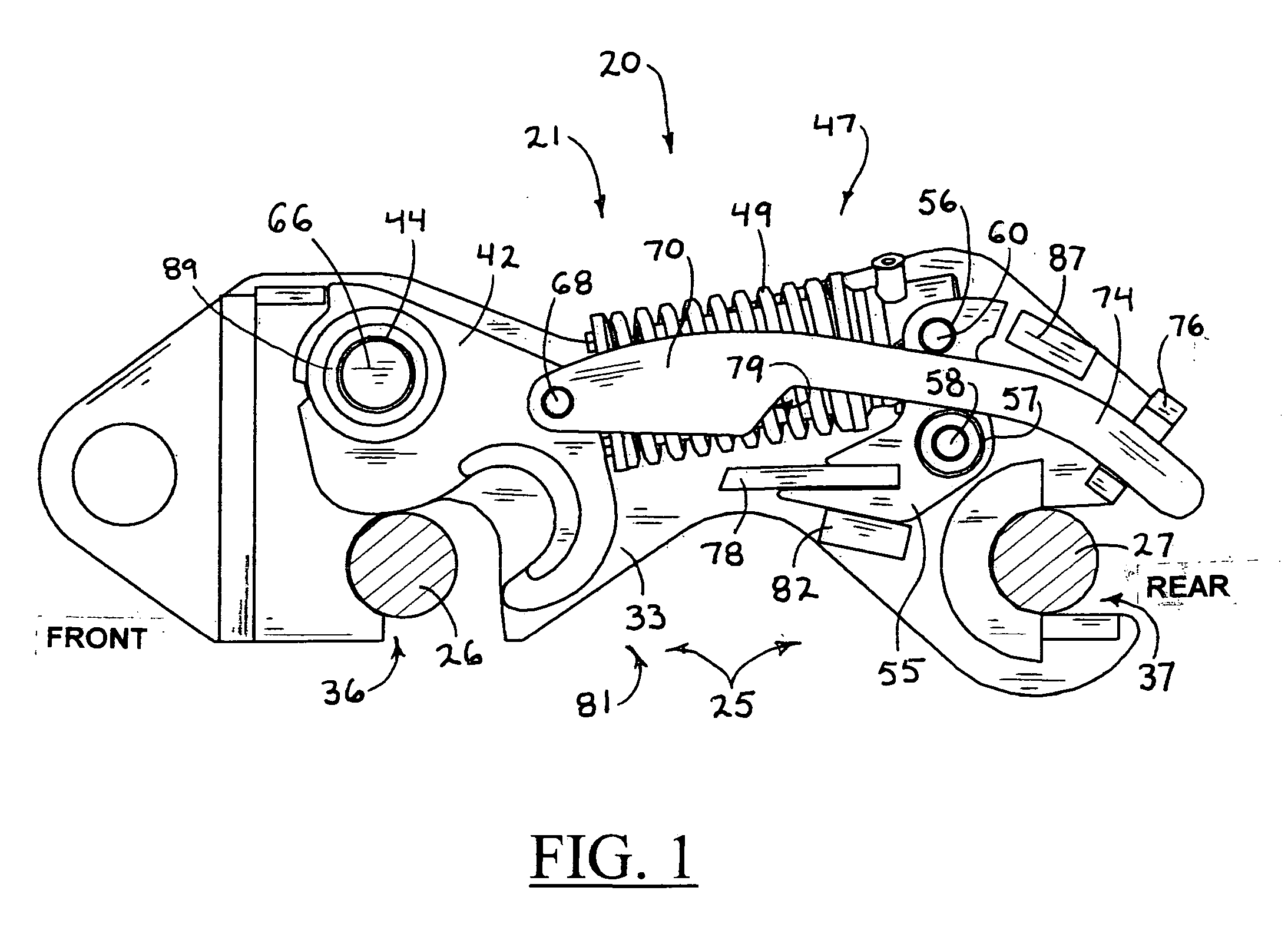

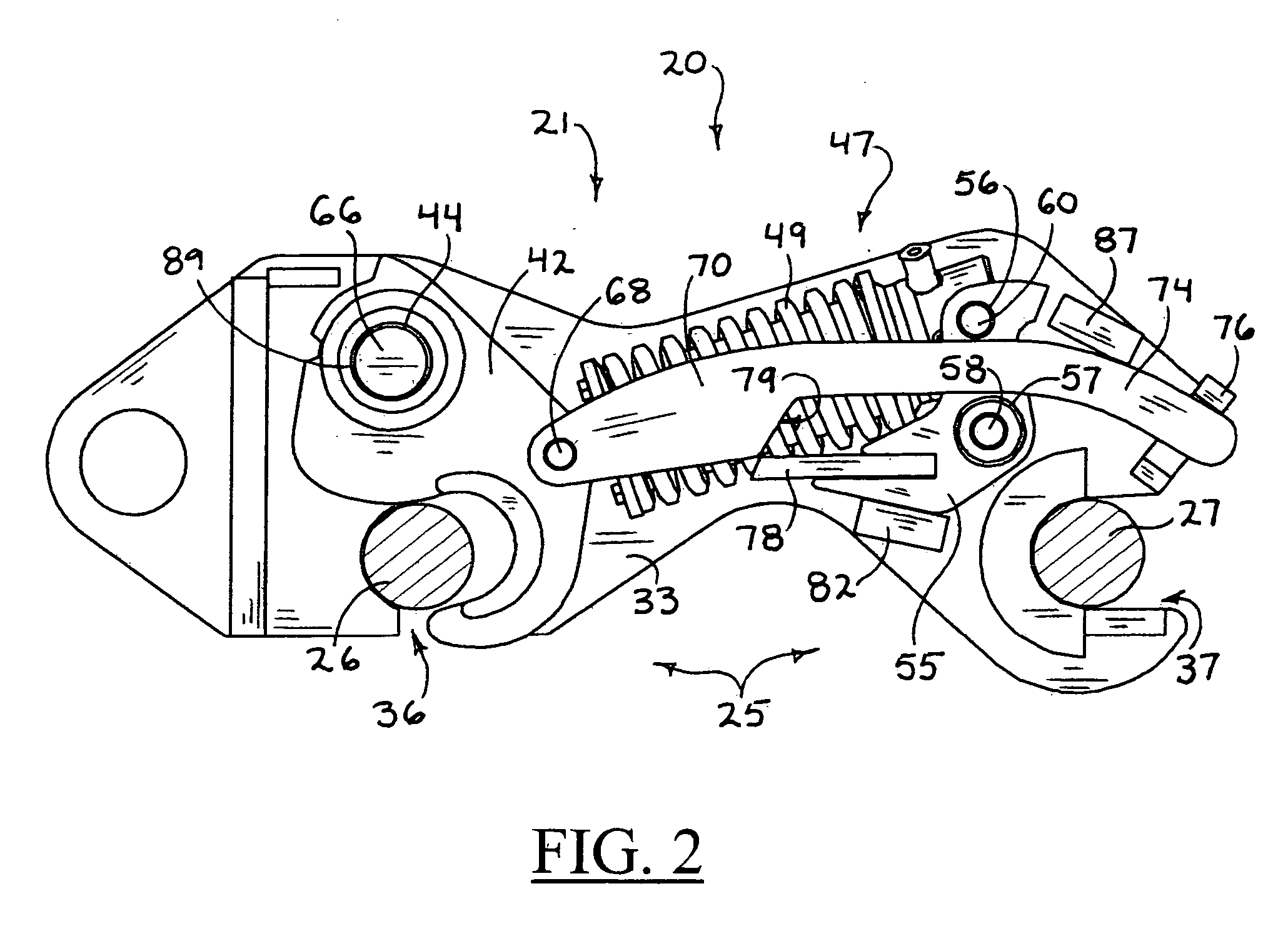

Quick coupler lock system

A quick coupler lock, for use as a safety to engage an attachment, such as a bucket or scoop, to a heavy equipment armature, as found in backhoes and excavators. The coupler lock prevents the unwanted release of auxiliary attachments. The coupler lock includes a coupler frame with a pin grabber, and a coupler hook rotated to engage a pin. The rotation of the coupler hook is accomplished by the extension or retraction of a coupler actuator, preferably a hydraulic cylinder held within a spring. The coupler actuator hingably connects to a pivoting lock lever. The action of the coupler actuator rotates the lock lever about the lever pin. A lock bar hingably attaches to the coupler hook and rotates with the coupler hook. The lock lever includes an arm that contacts the lock bar, to prevent movement of the coupler hook and prevent the unwanted release of the pin.

Owner:PSM

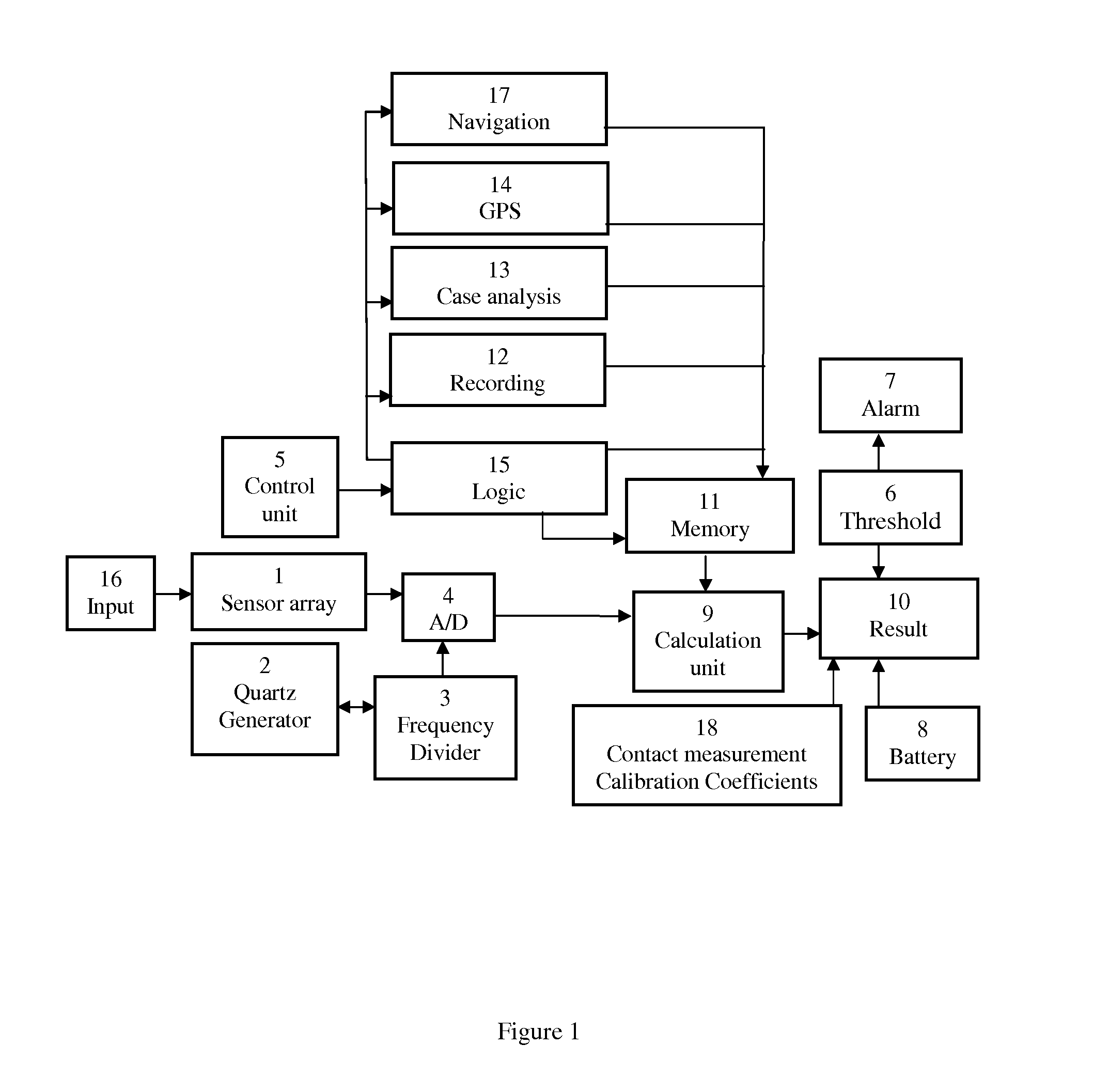

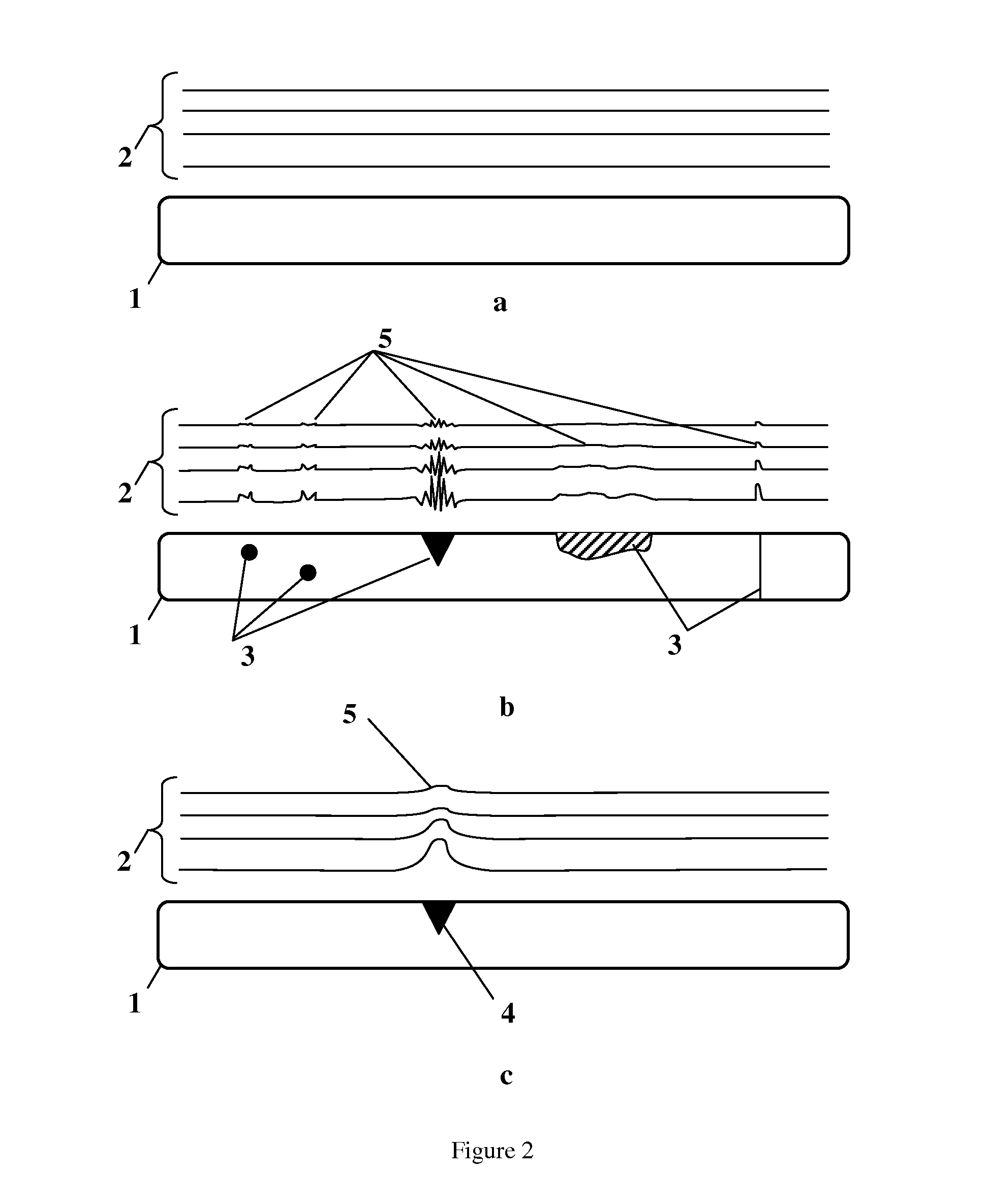

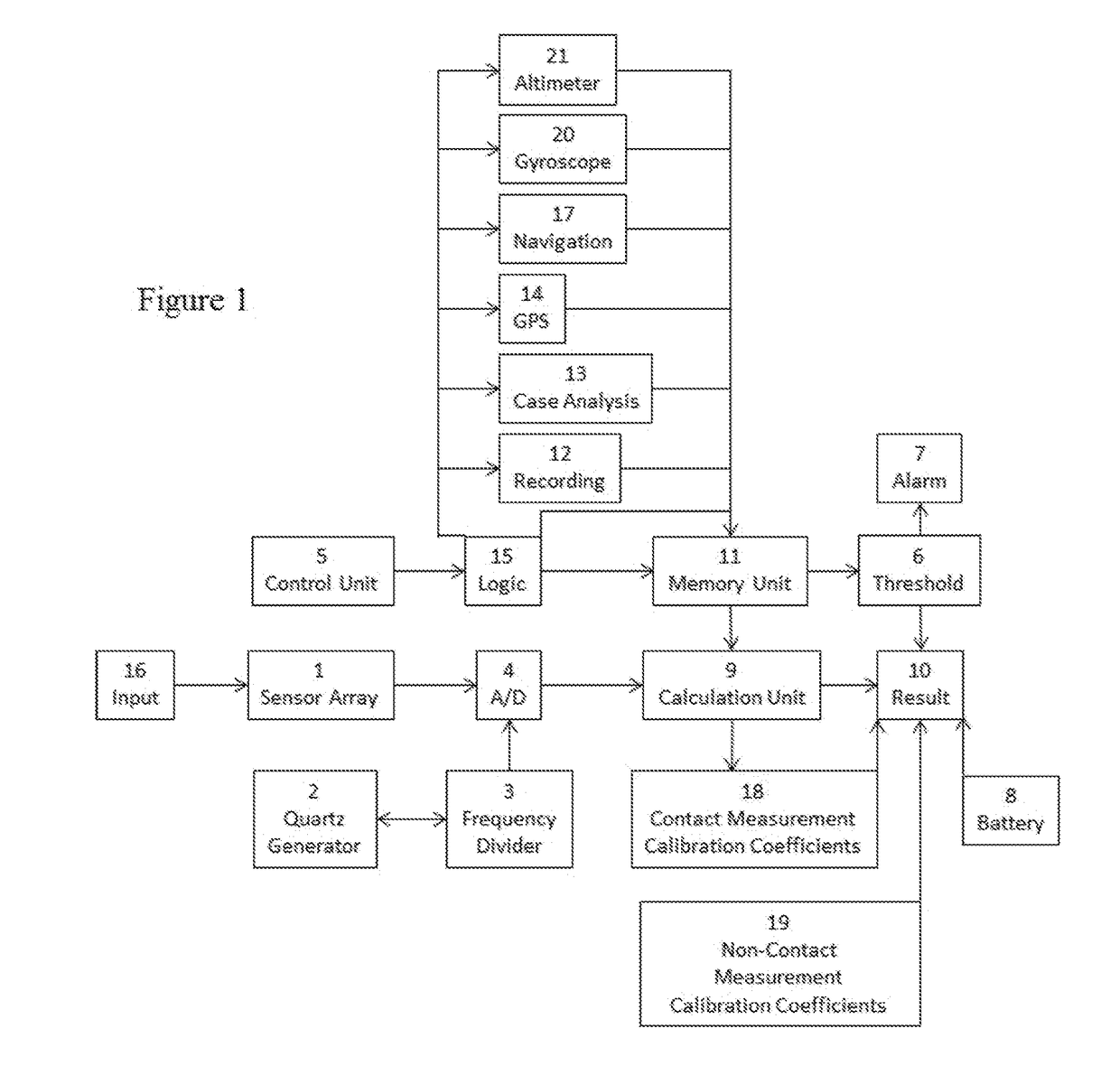

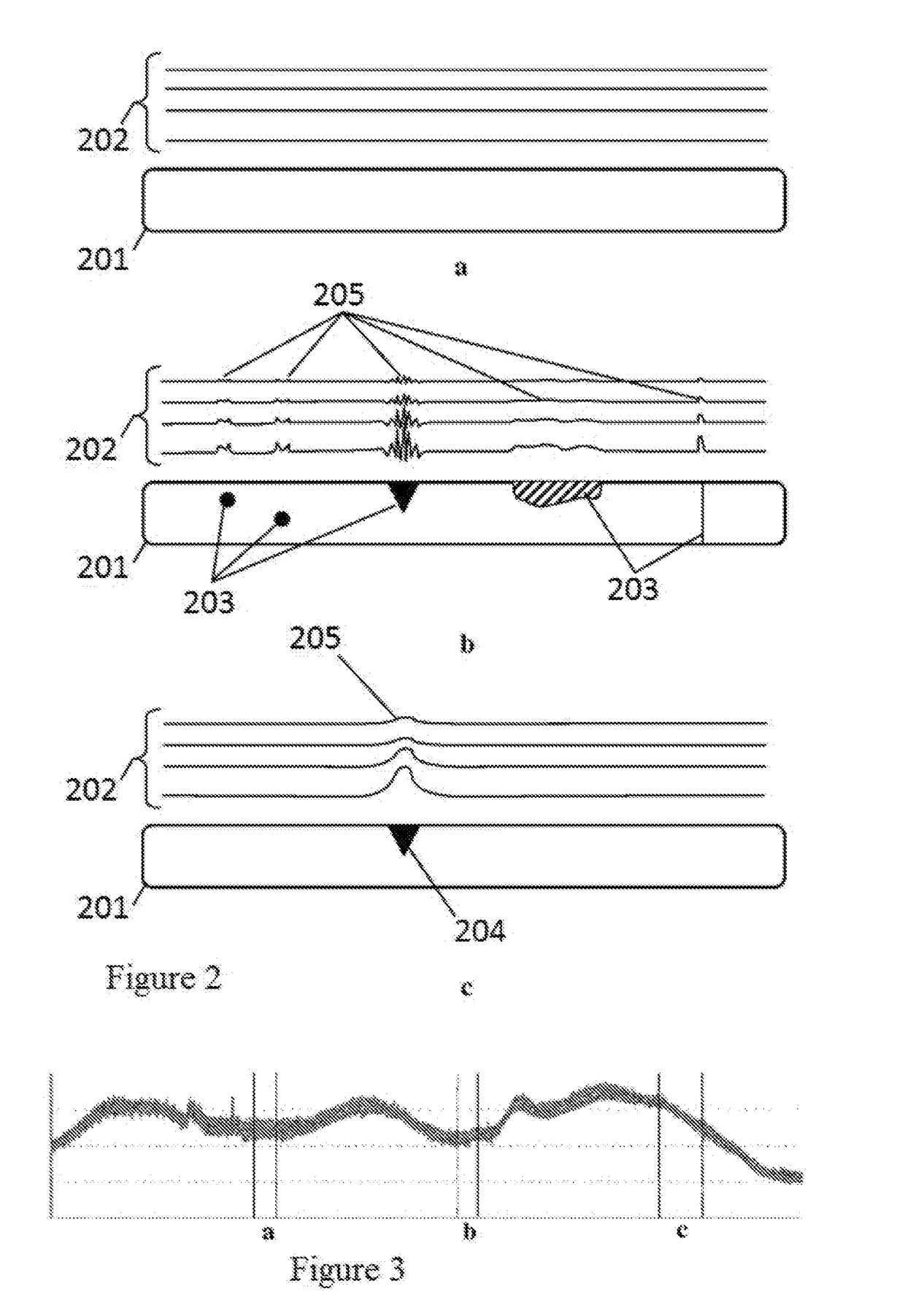

Apparatus for the non-contact metallic constructions assessment

ActiveUS8542127B1The result is accurate and reliableAnalysing solids using sonic/ultrasonic/infrasonic wavesElectrical measurementsHeavy equipmentHeavy duty

A device and method for discovering, identification and monitoring of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The technique is specifically optimized for extended, not-accessible underground and underwater metallic structures quality control, emergency alarms as well as timeline planning for structural repairs and maintenance work. Examples of the technique implementation include pipes for oil and gas industry, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

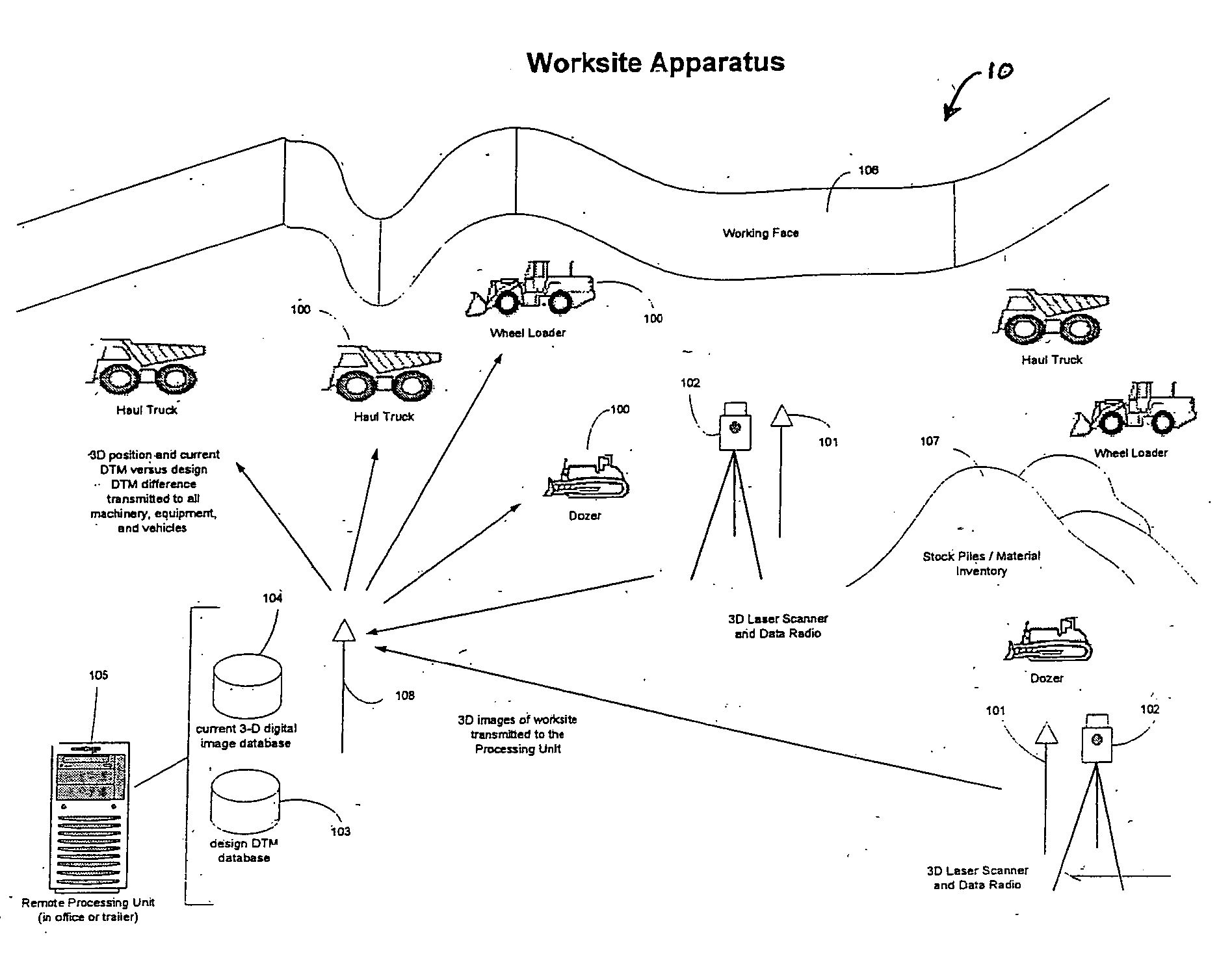

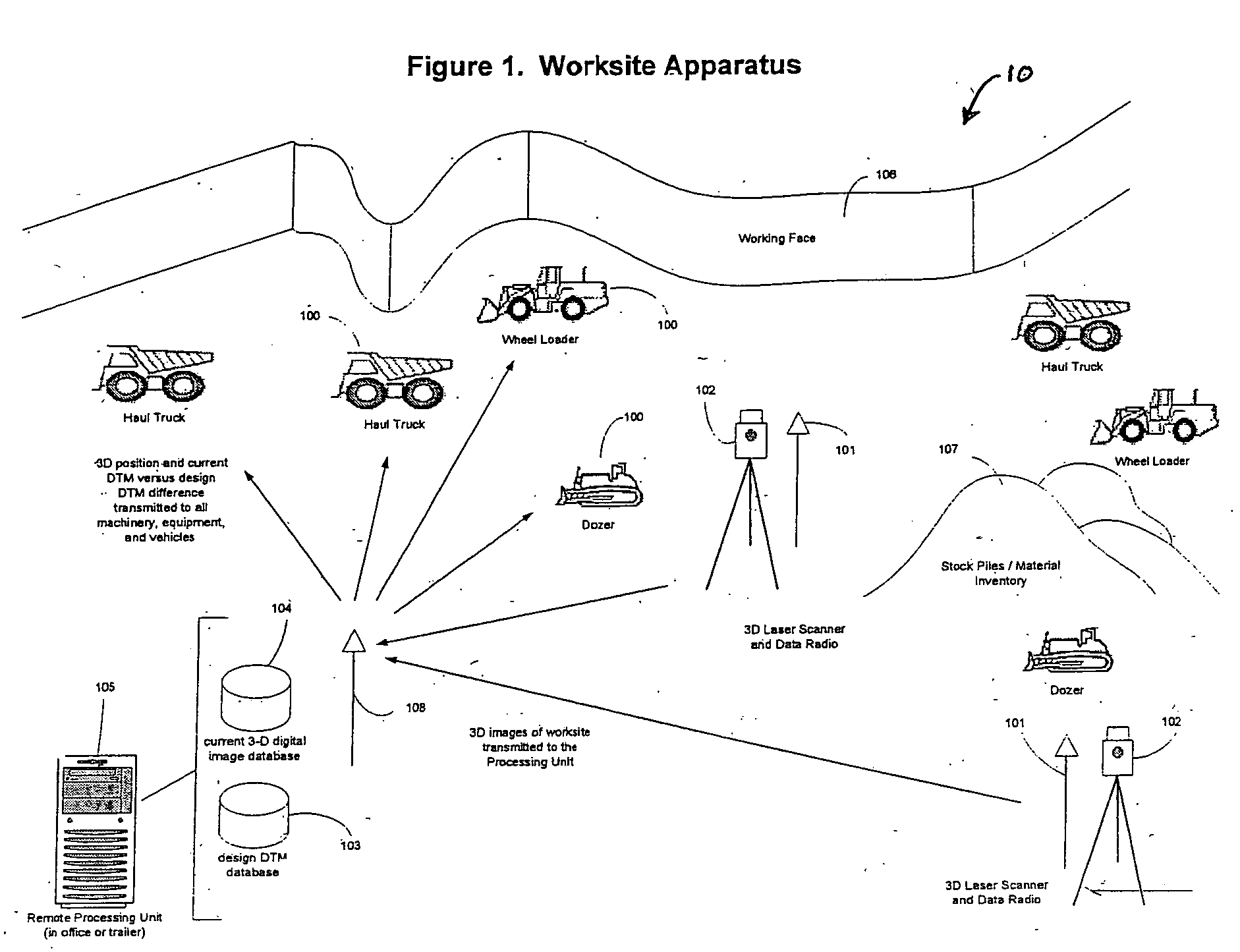

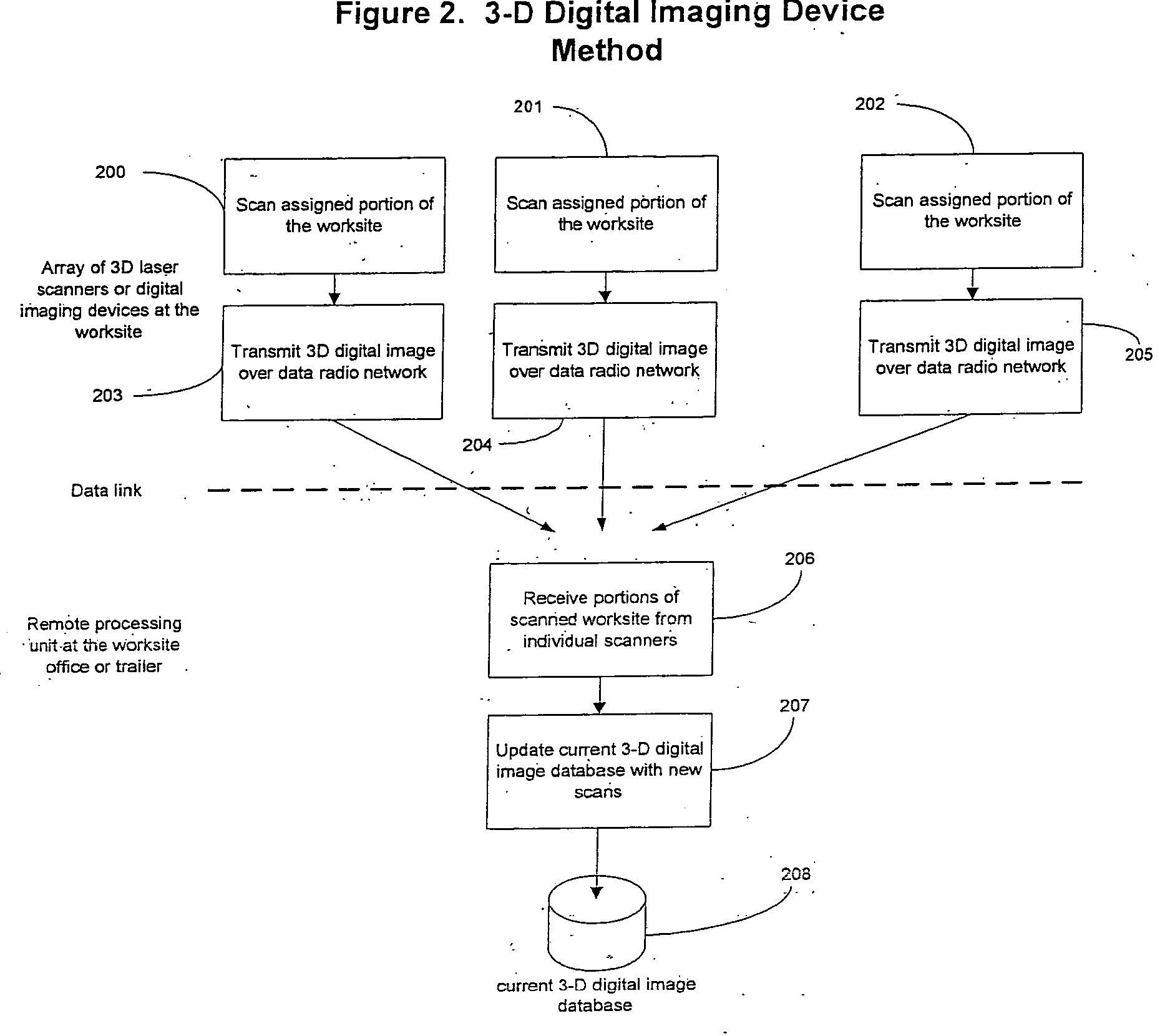

Method and apparatus for machine guidance at a work site

InactiveUS20050283294A1Advanced technologyAnalogue computers for trafficComputations using stochastic pulse trainsTerrainDigital imaging

A method and apparatus for providing machine guidance of all types of earthmoving machinery, other heavy equipment, and work site vehicles. The method and apparatus is applicable to any industrial work site such as a construction site, open pit mine, quarry operation, or landfill. The machinery, equipment, or vehicle is not required to be equipped with a positional receiver of any kind. The position of all machinery, equipment, and vehicles is performed by employing an array of 3D laser scanners (or any 3D digital imaging devices) positioned throughout the work site. 3D images of the work site are transmitted from the laser scanners to a remote processing unit via a data link or network. The processing unit analyzes the images and determines the position of the machinery, equipment and vehicles. The positions are transmitted to the machinery, equipment, and vehicles via the data link or network. The current Digital Terrain Model (DTM) of the work site is captured and stored in real time in the form of a 3-D digital image, as a by-product of scanning the work site and determining the position of the work site machinery, equipment, and vehicles. The remote processing unit compares the current DTM to the work site's design DTM and transmits the difference to the required machinery, equipment, and vehicles for feedback to their operators in real time.

Owner:LEHMAN ALLEN A JR +2

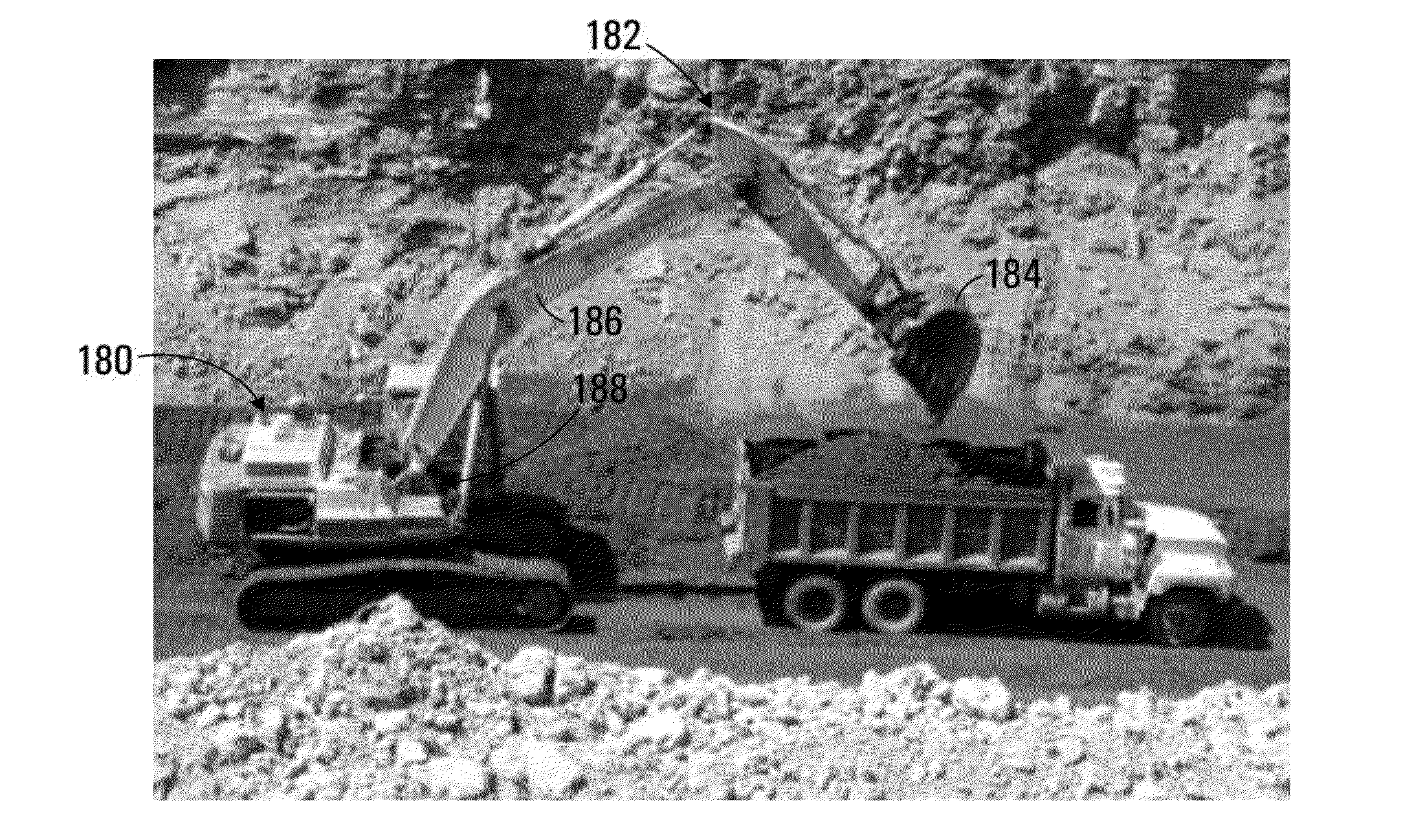

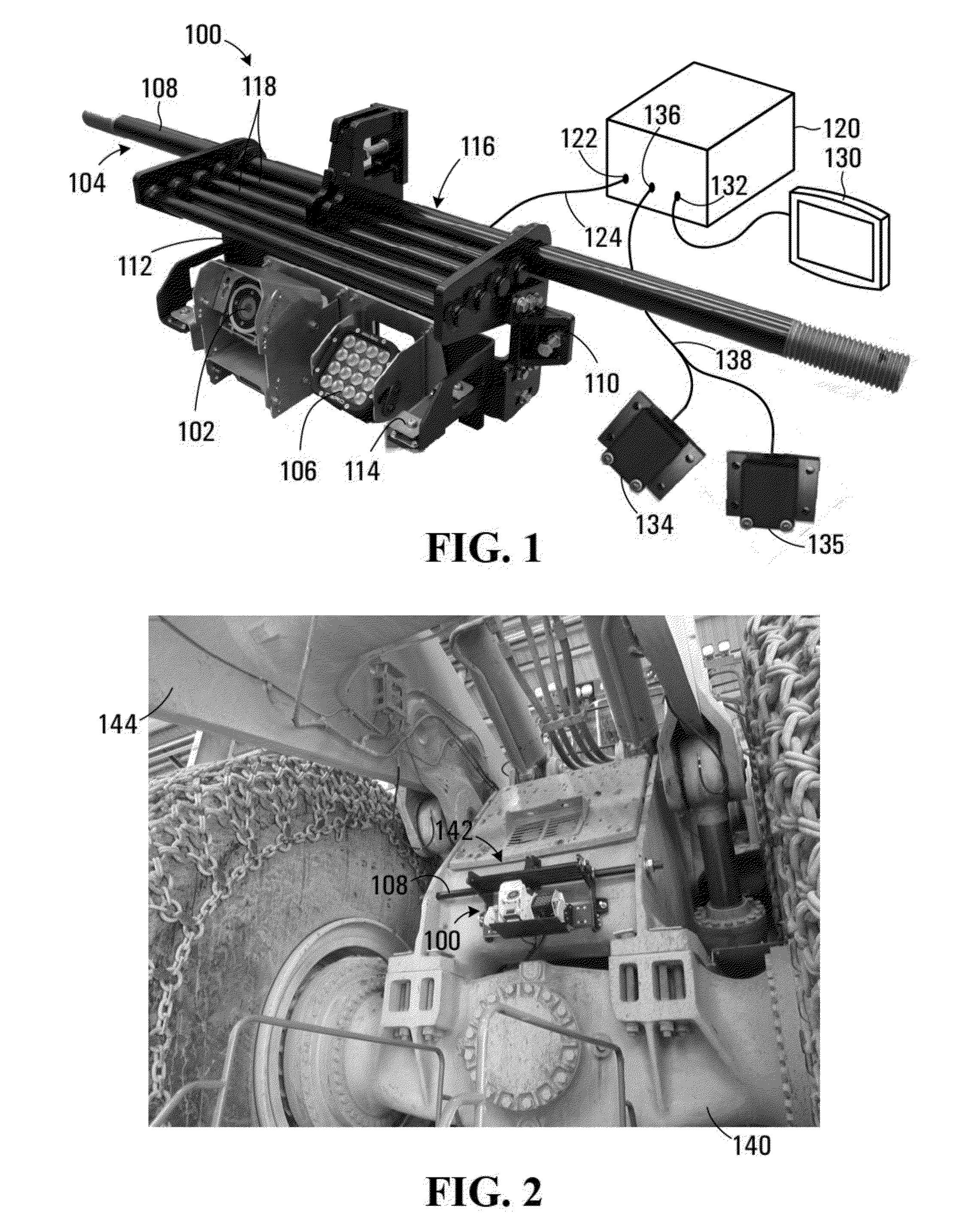

Method and apparatus for monitoring a condition of an operating implement in heavy loading equipment

InactiveUS20150085123A1Avoid damageMaterial analysis by optical meansStructural/machines measurementHeavy equipmentVisual perception

A method and apparatus for monitoring a condition of an operating implement in heavy equipment is disclosed. The method involves receiving a trigger signal indicating that the operating implement is within a field of view of an image sensor, and in response to receiving the trigger signal, causing the image sensor to capture at least one image of the operating implement. The method also involves processing the at least one image to determine the condition of the operating implement. A visual or audio warning or alarm may be generated for preventing significant damage to the processing equipment and avoid safety hazards involved.

Owner:MOTION METRICS INT CORP

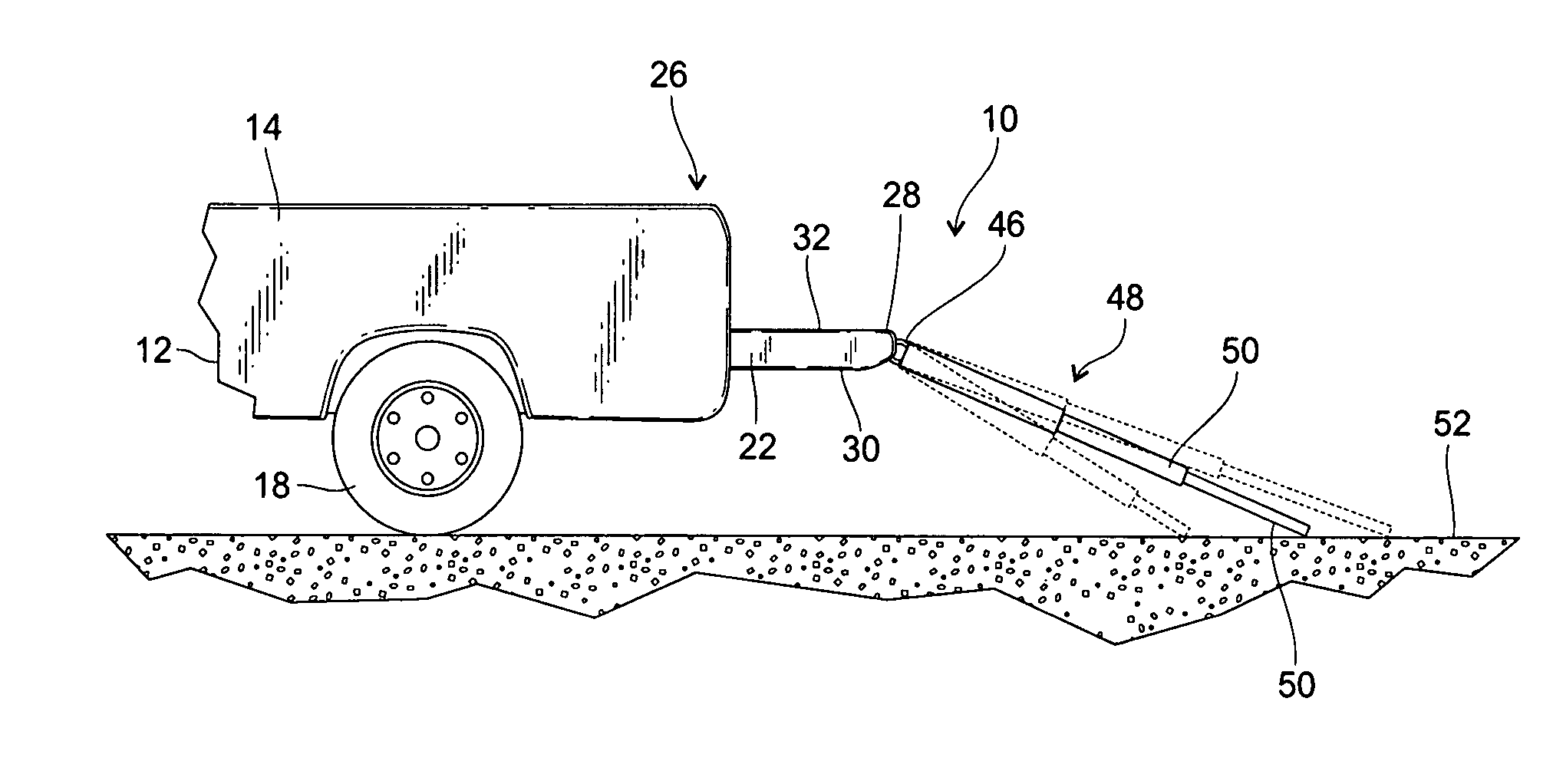

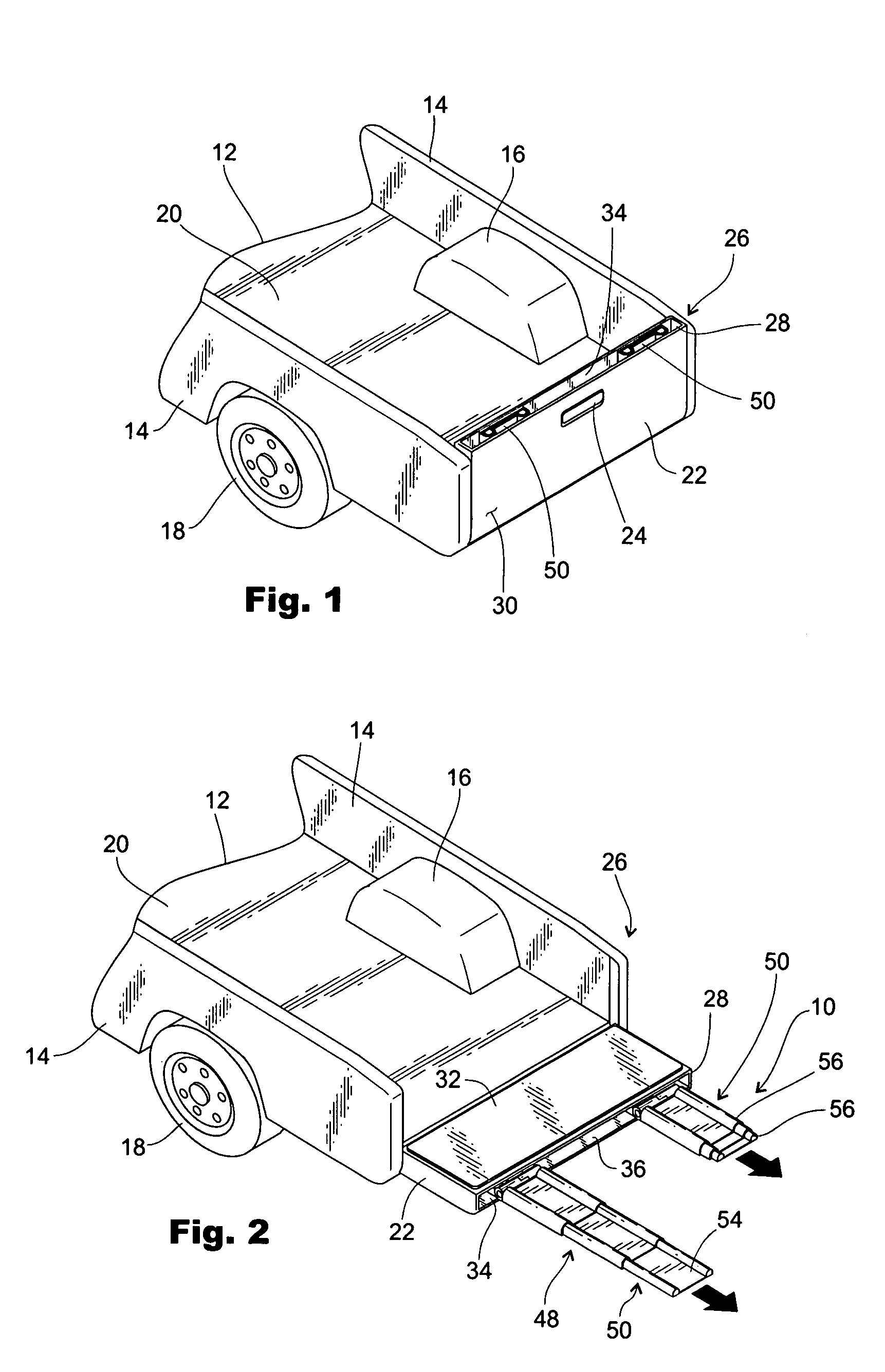

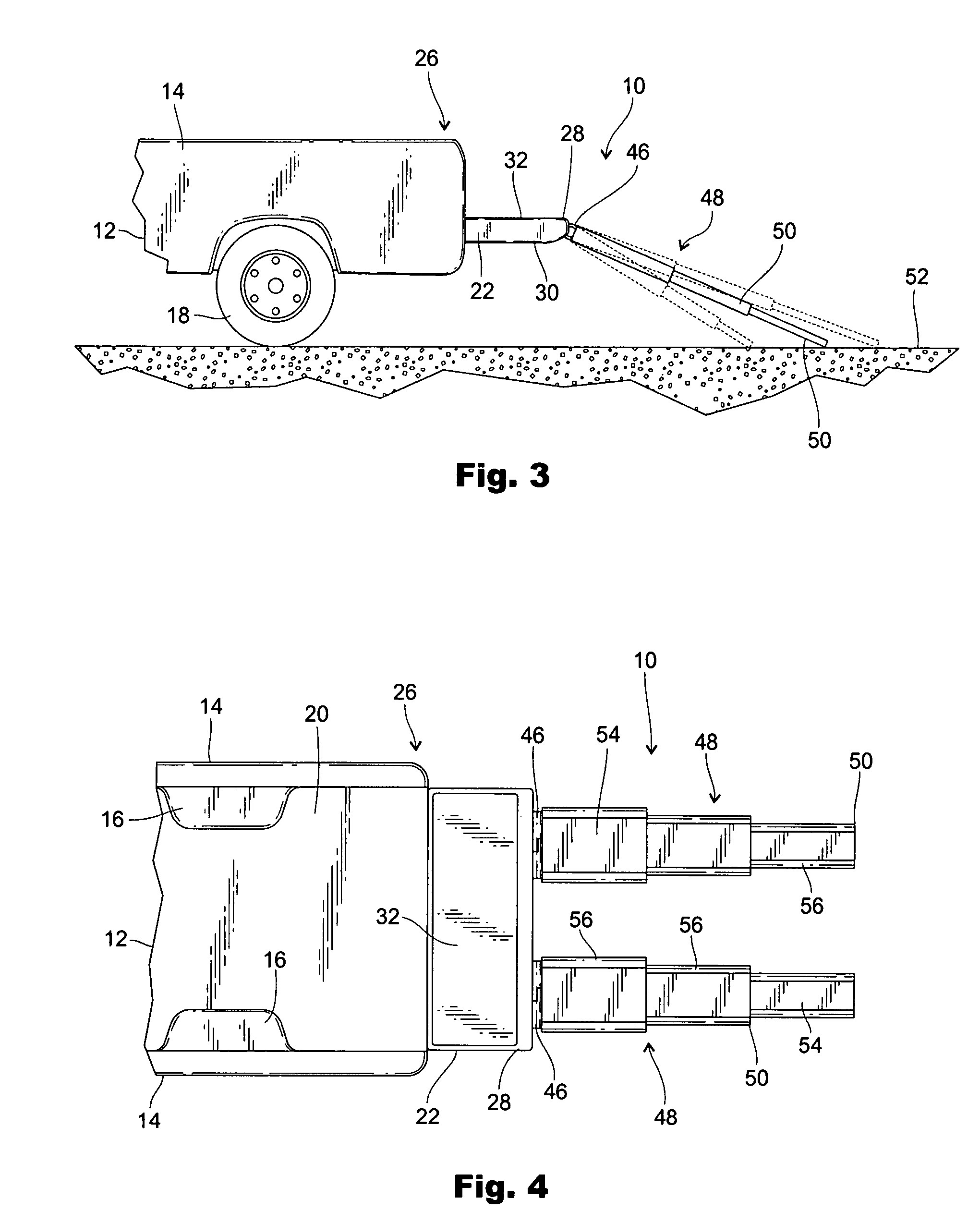

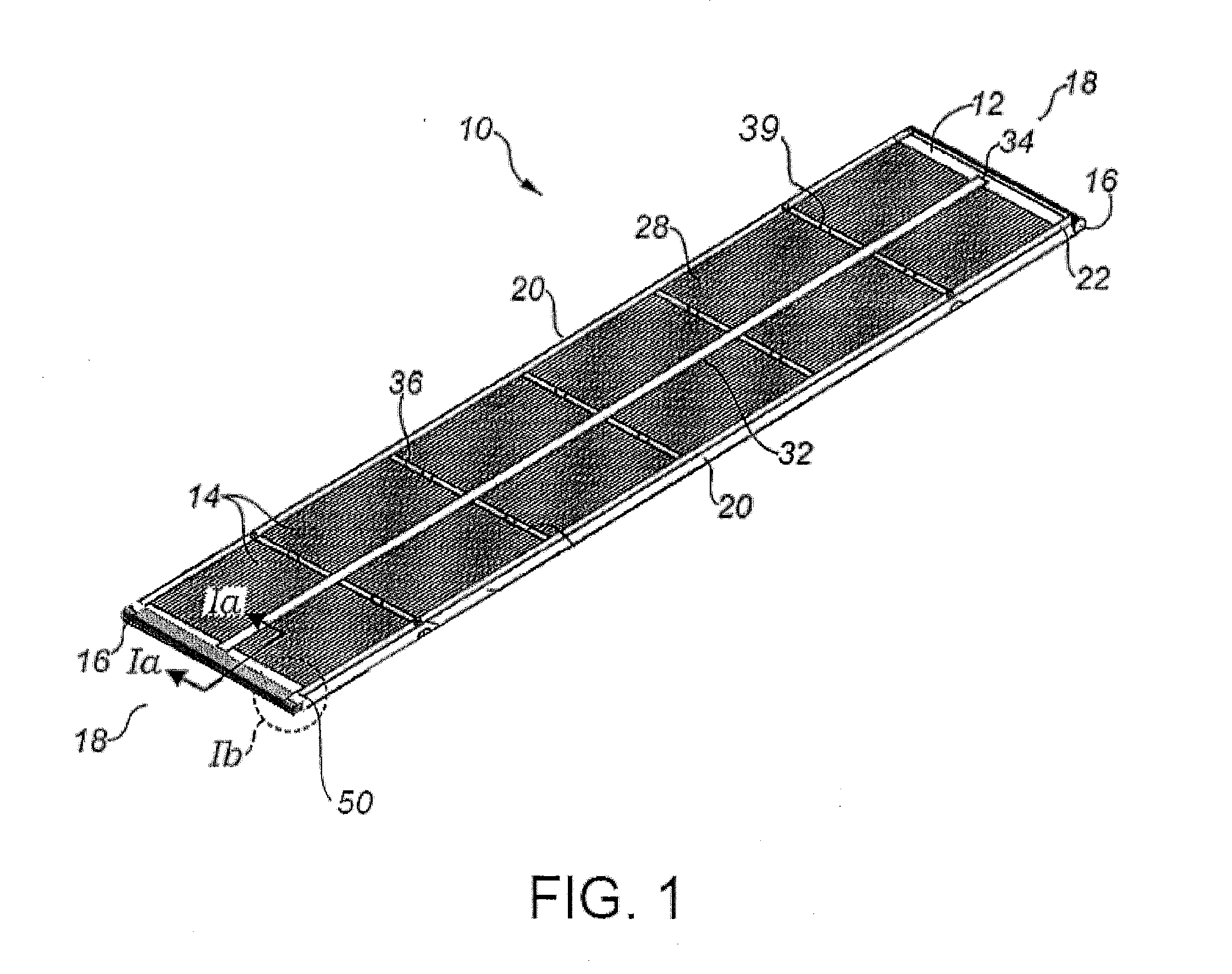

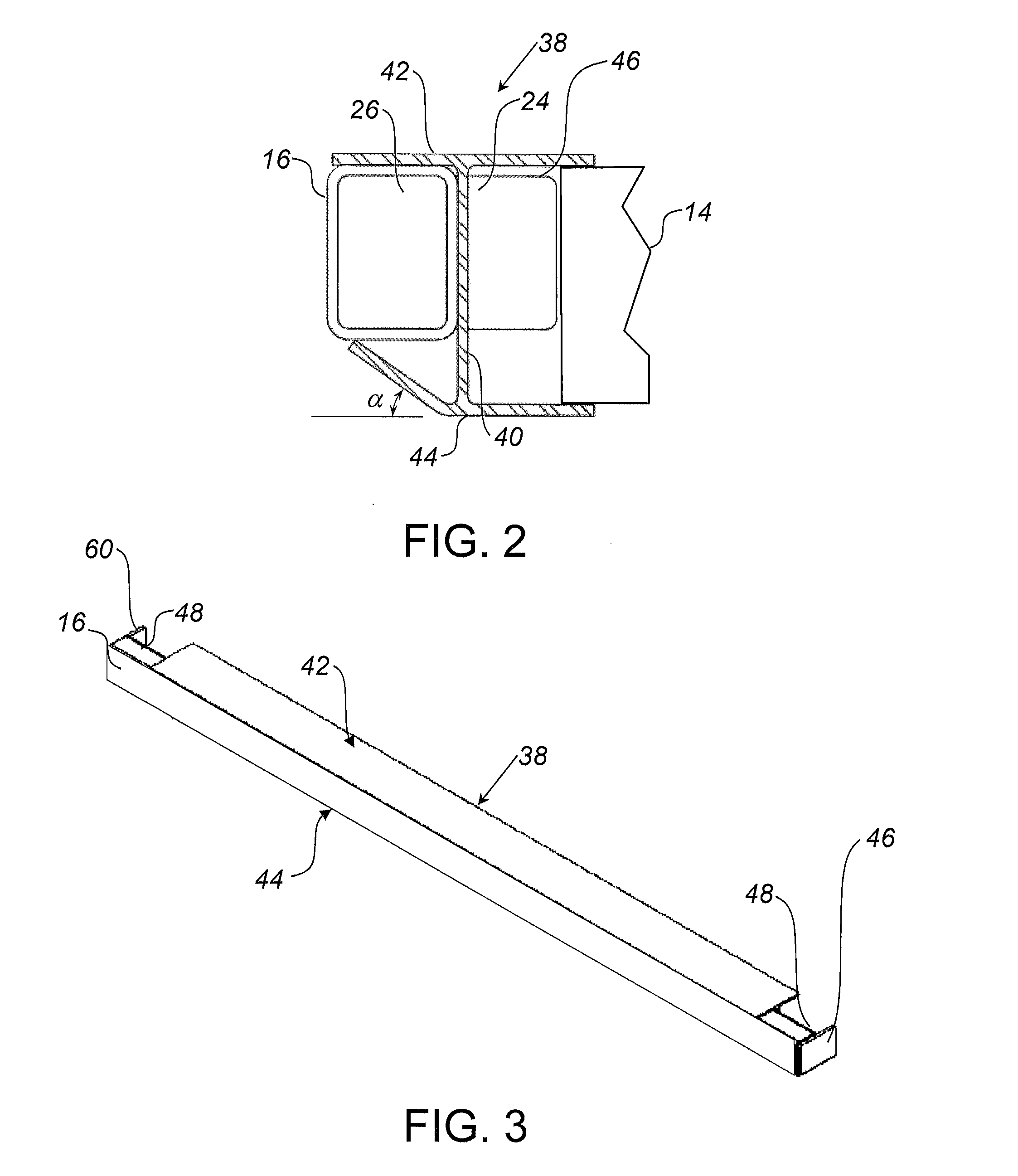

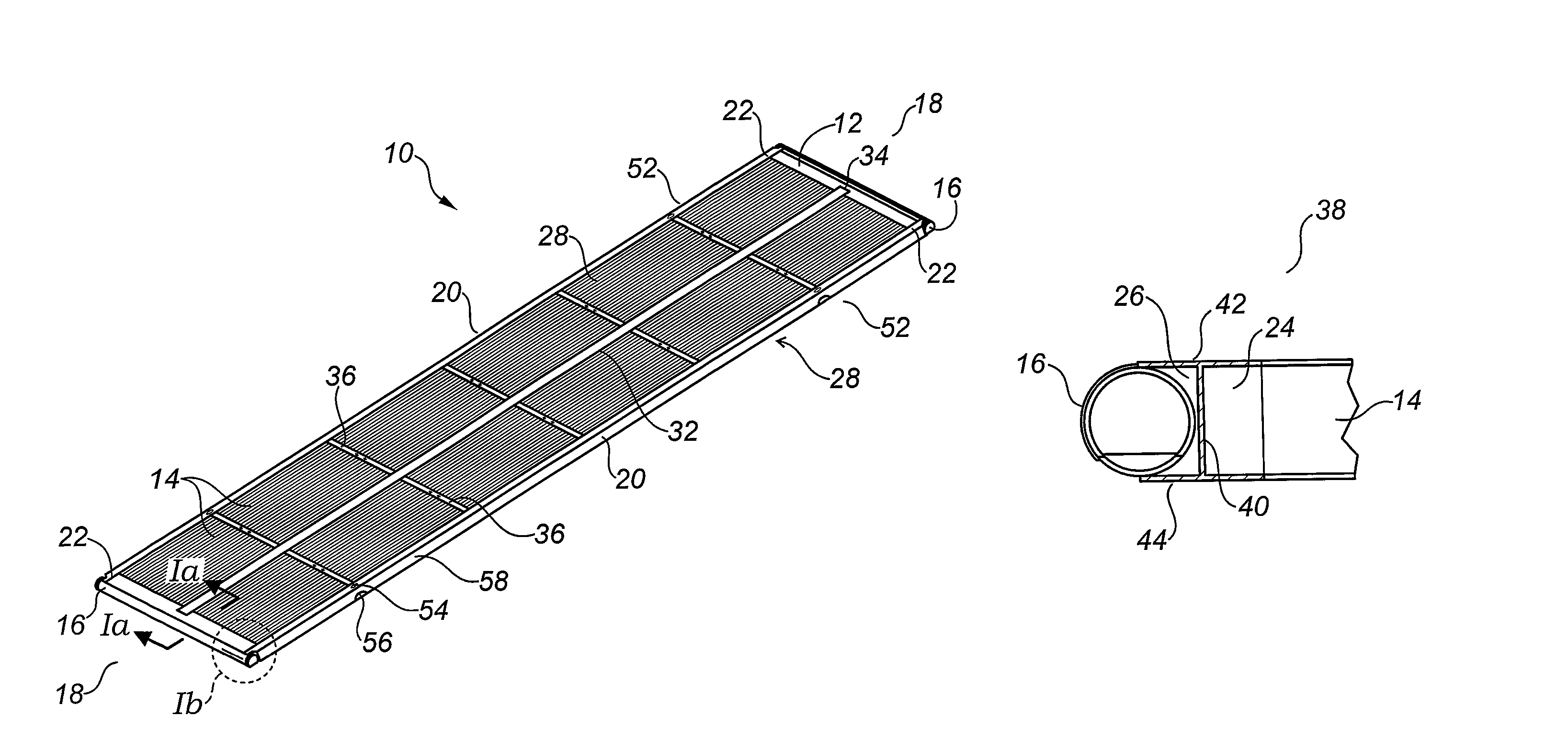

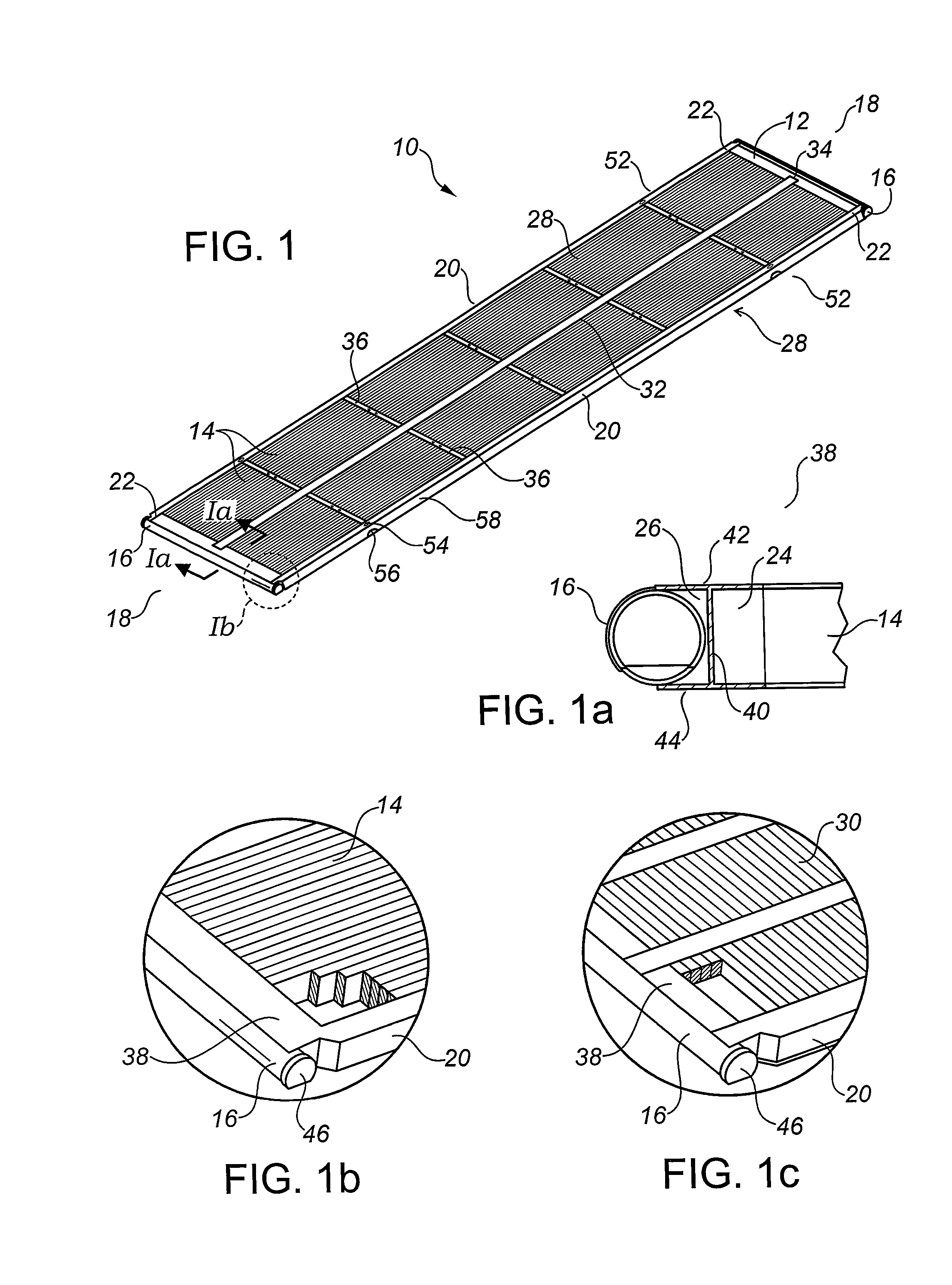

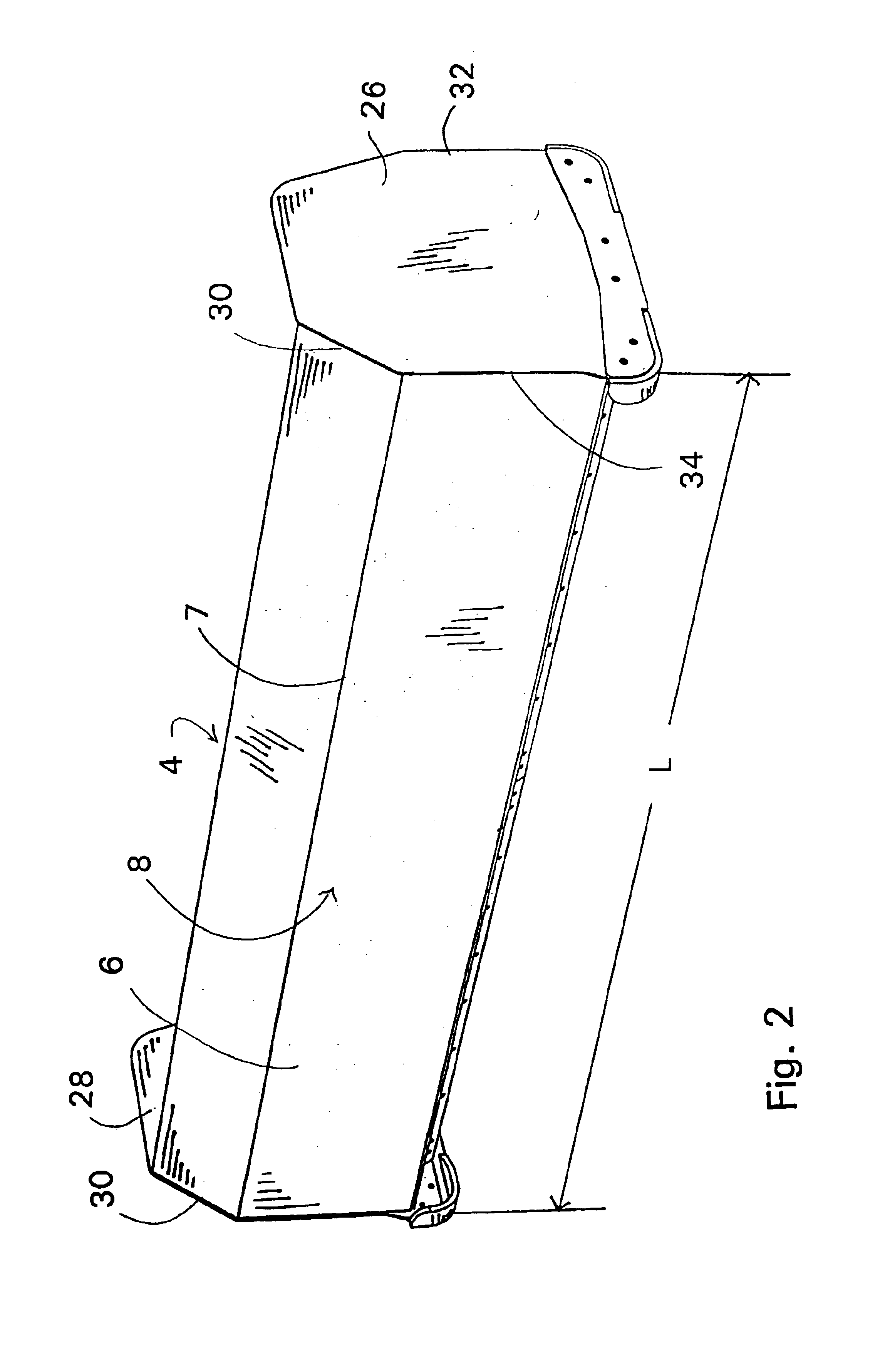

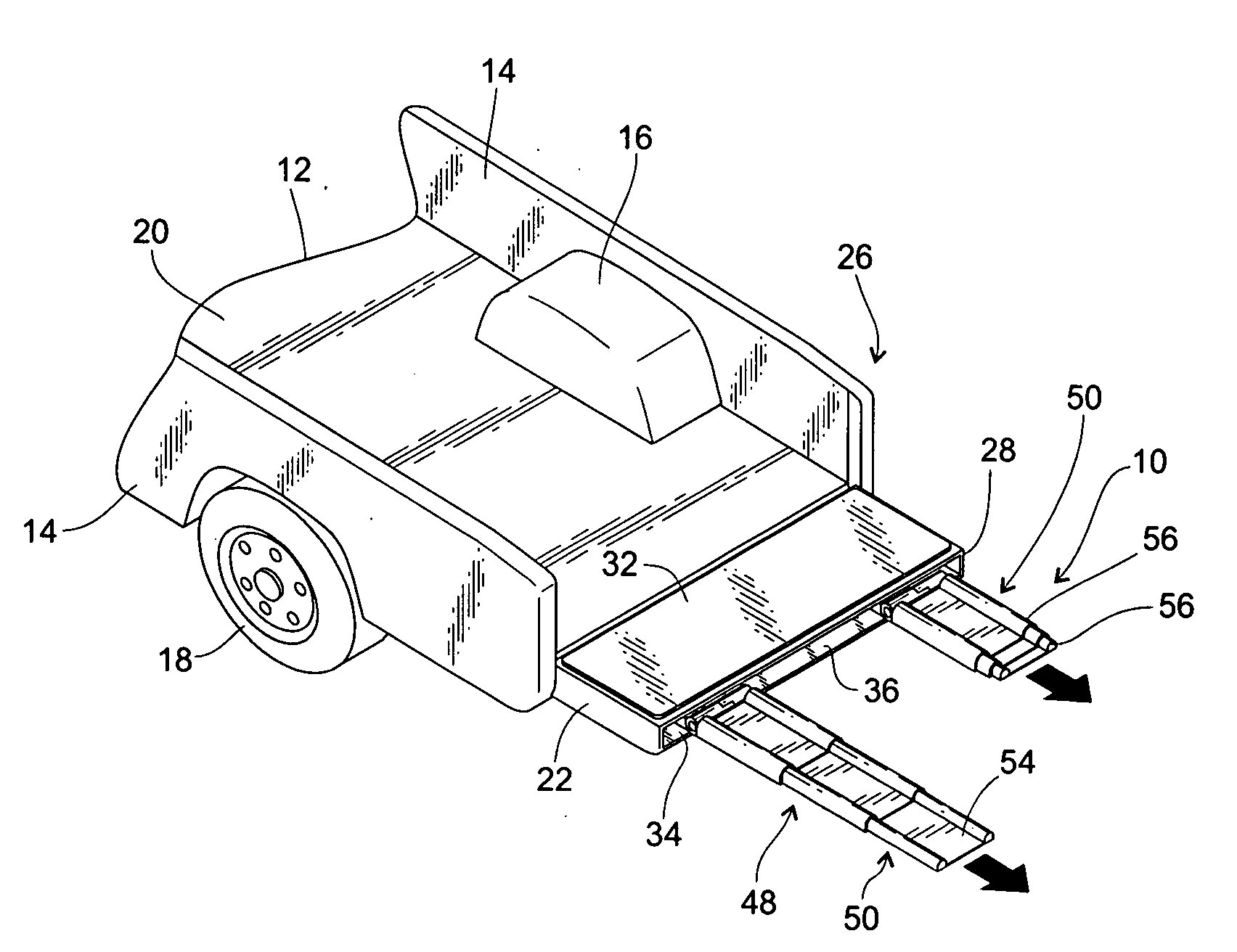

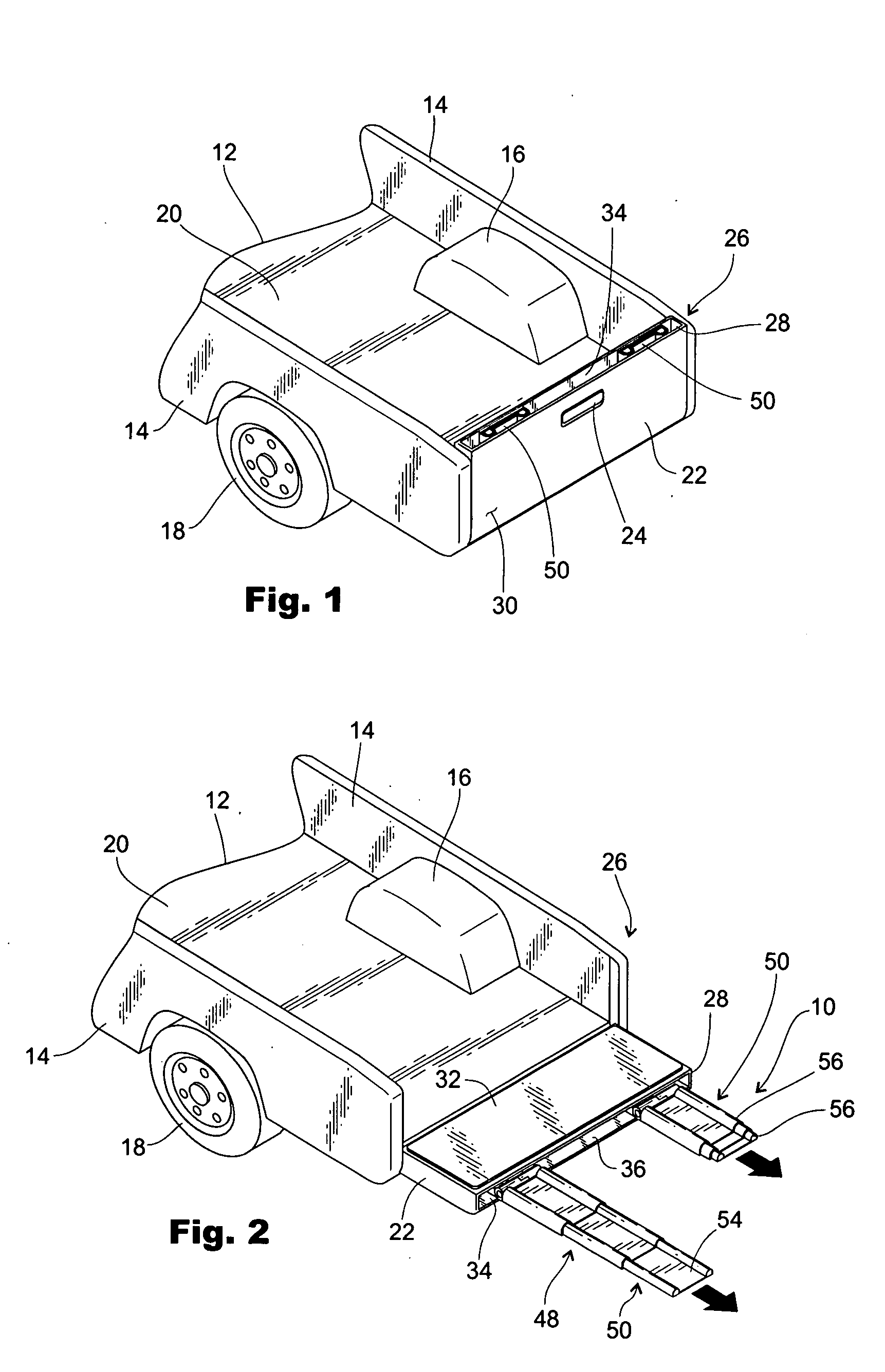

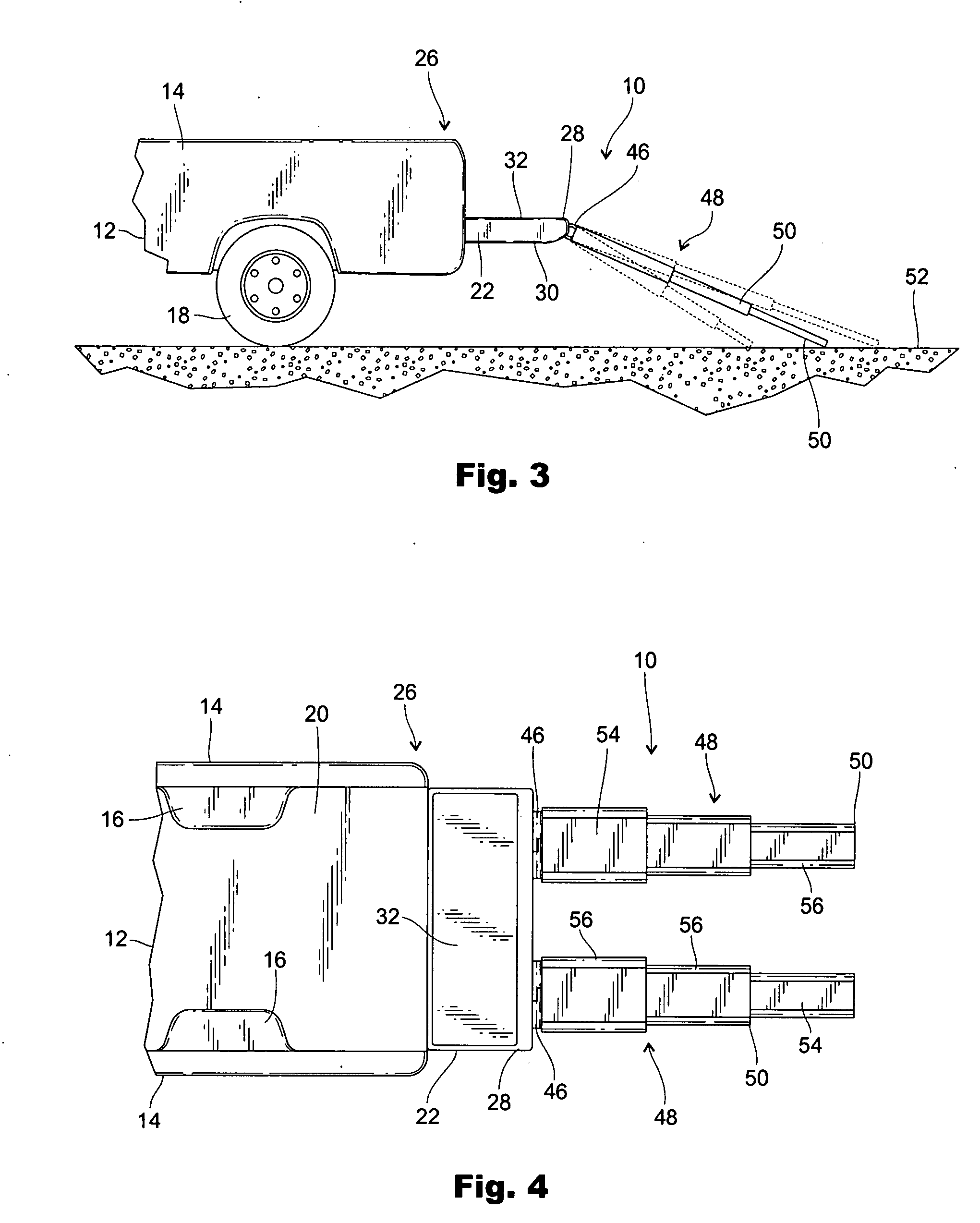

Ramp assembly for a vehicle tailgate

InactiveUS7549692B2Save spaceEliminates heavy liftingLoading/unloading vehicle arrangmentSuperstructure subunitsPickup truckHeavy equipment

A compact ramp and tailgate system for a vehicle tailgate includes a tailgate having an interior hollow cavity for collapsible storage therein of a pair of ramps that are also telescopically extendable therefrom for loading and unloading heavy equipment into and off the bed of the vehicle such as a pickup truck with each ramp mounted to a locking hinge that allows the ramps to pivot up to ninety degrees and each ramp composed of at least three ramp members of decreasing size starting from the largest ramp members that are pivotally interconnected to the locking hinges. The ramps are independently pivotable and slidably adjustable left and right relative to the tailgate and the longitudinal extension of the vehicle for properly aligning the ramps with respect to the wheels, rollers, casters, etc., of the equipment to be on loaded and off loaded.

Owner:WASHINGTON DERRON K

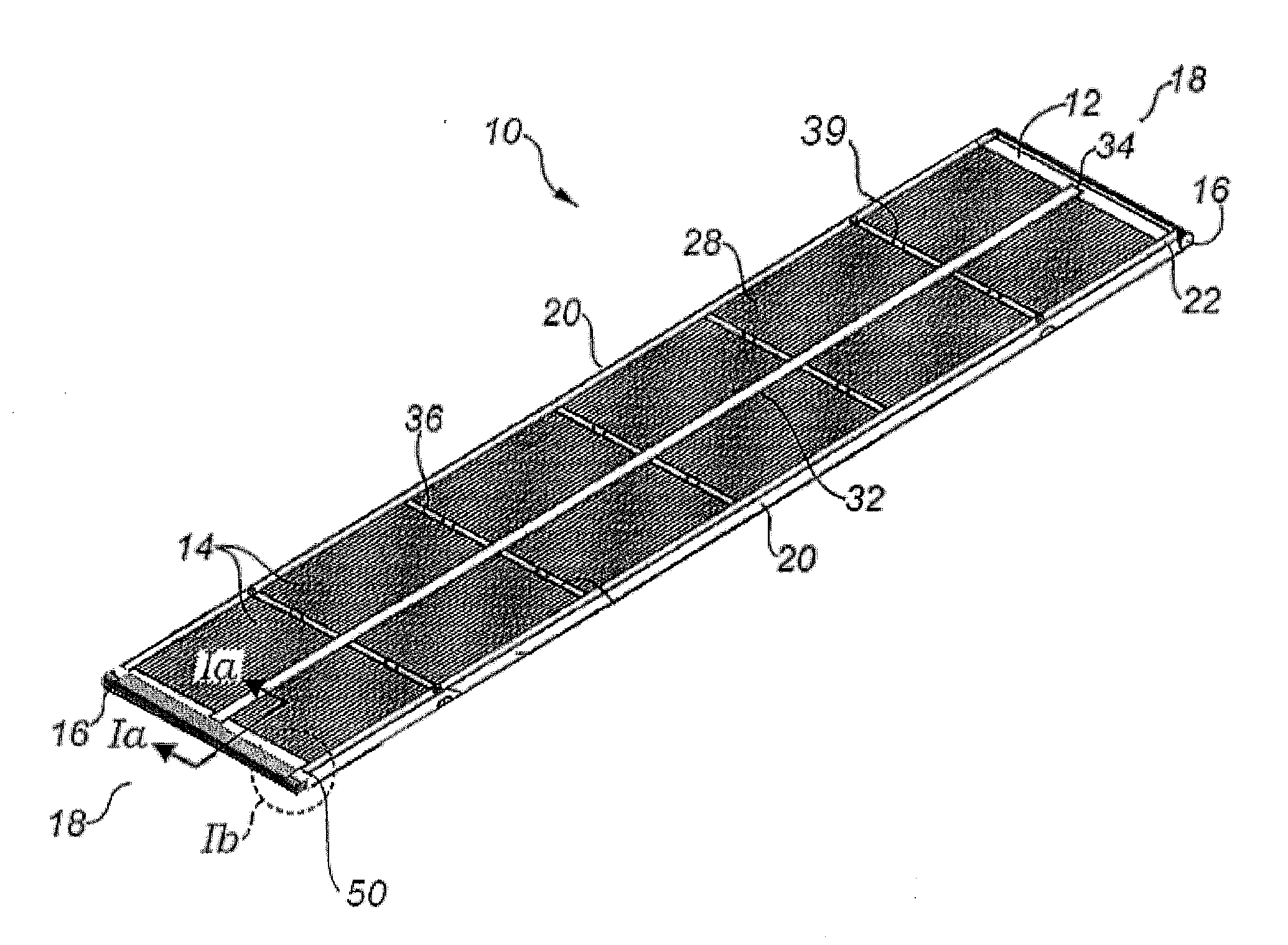

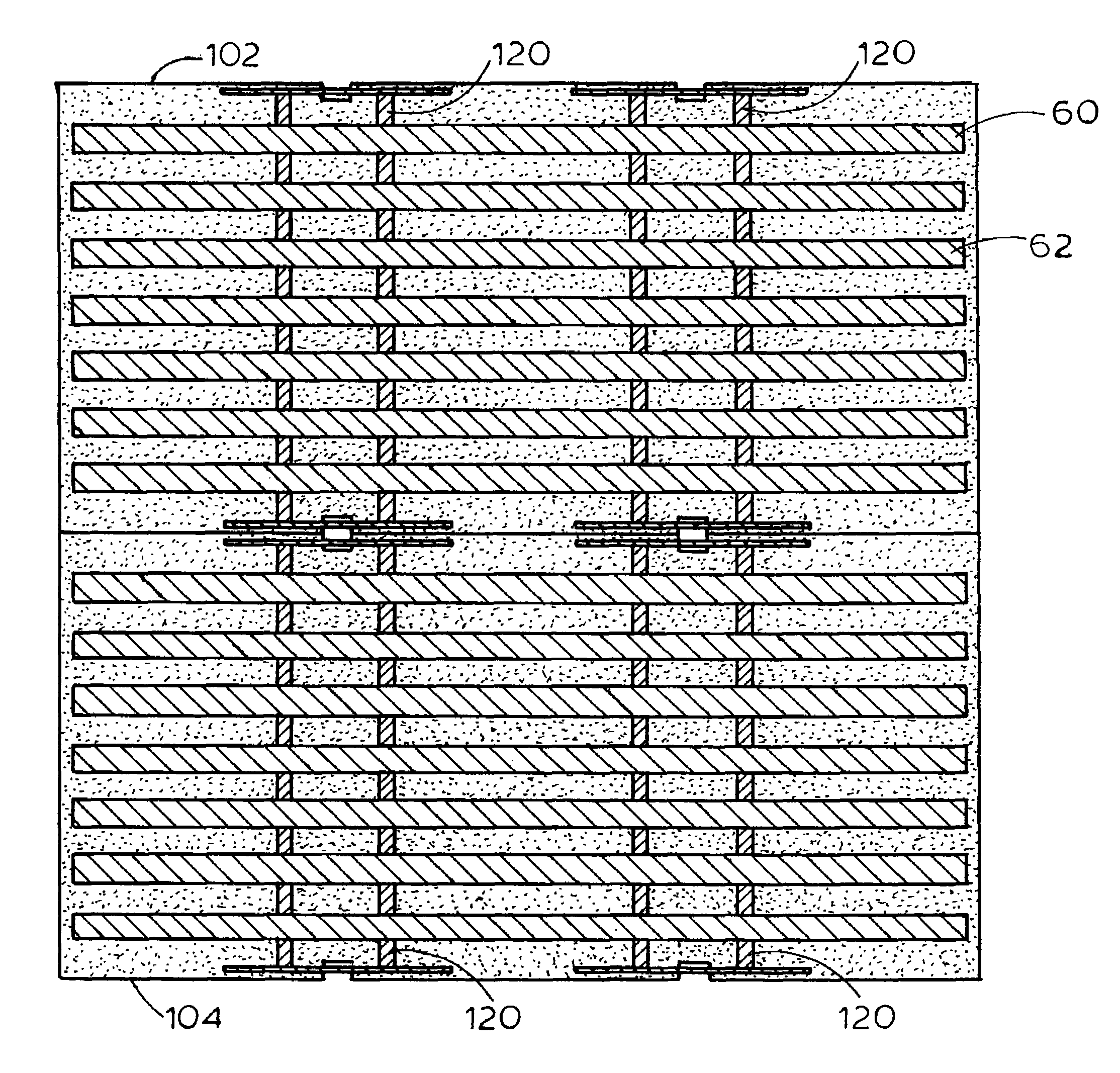

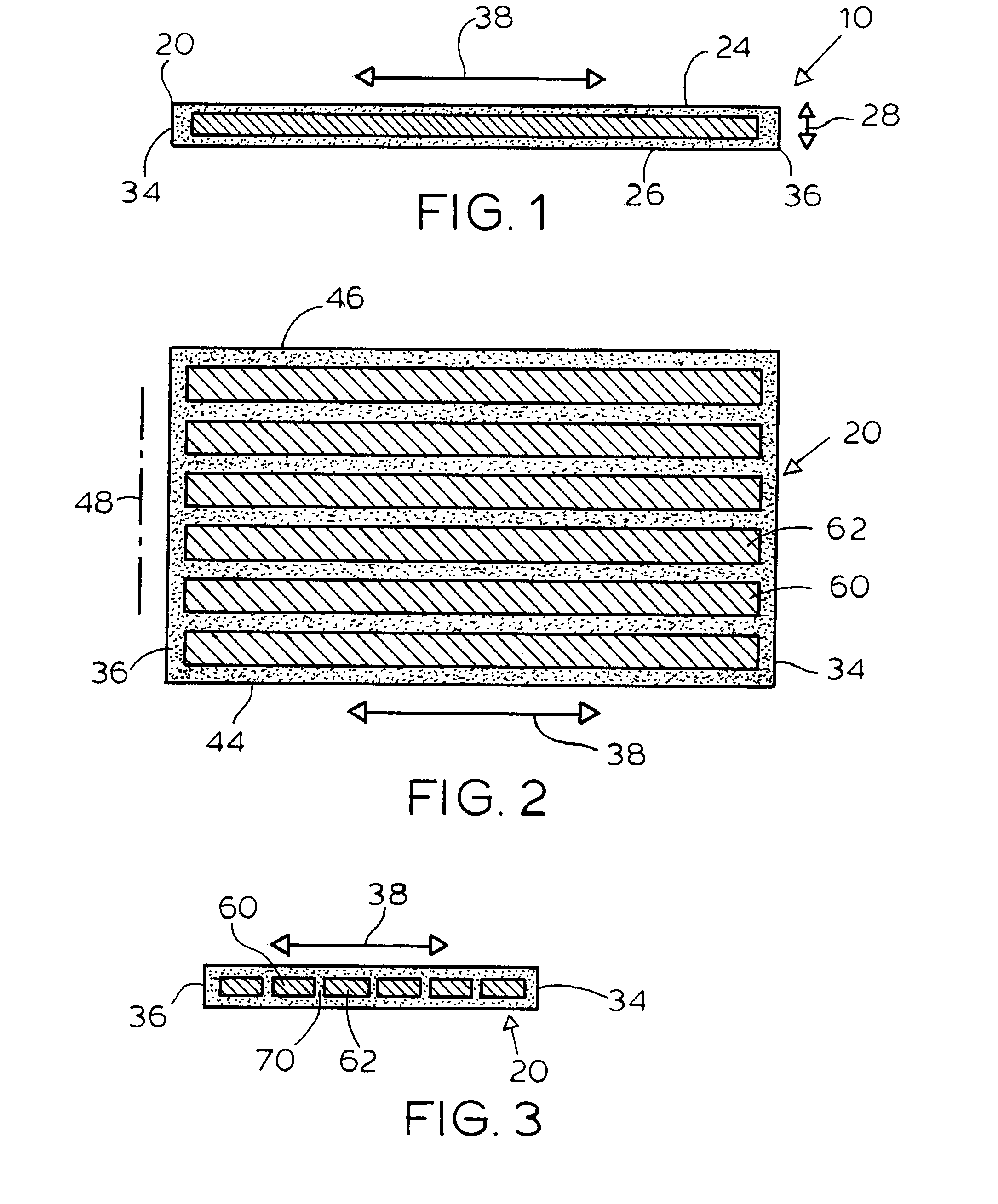

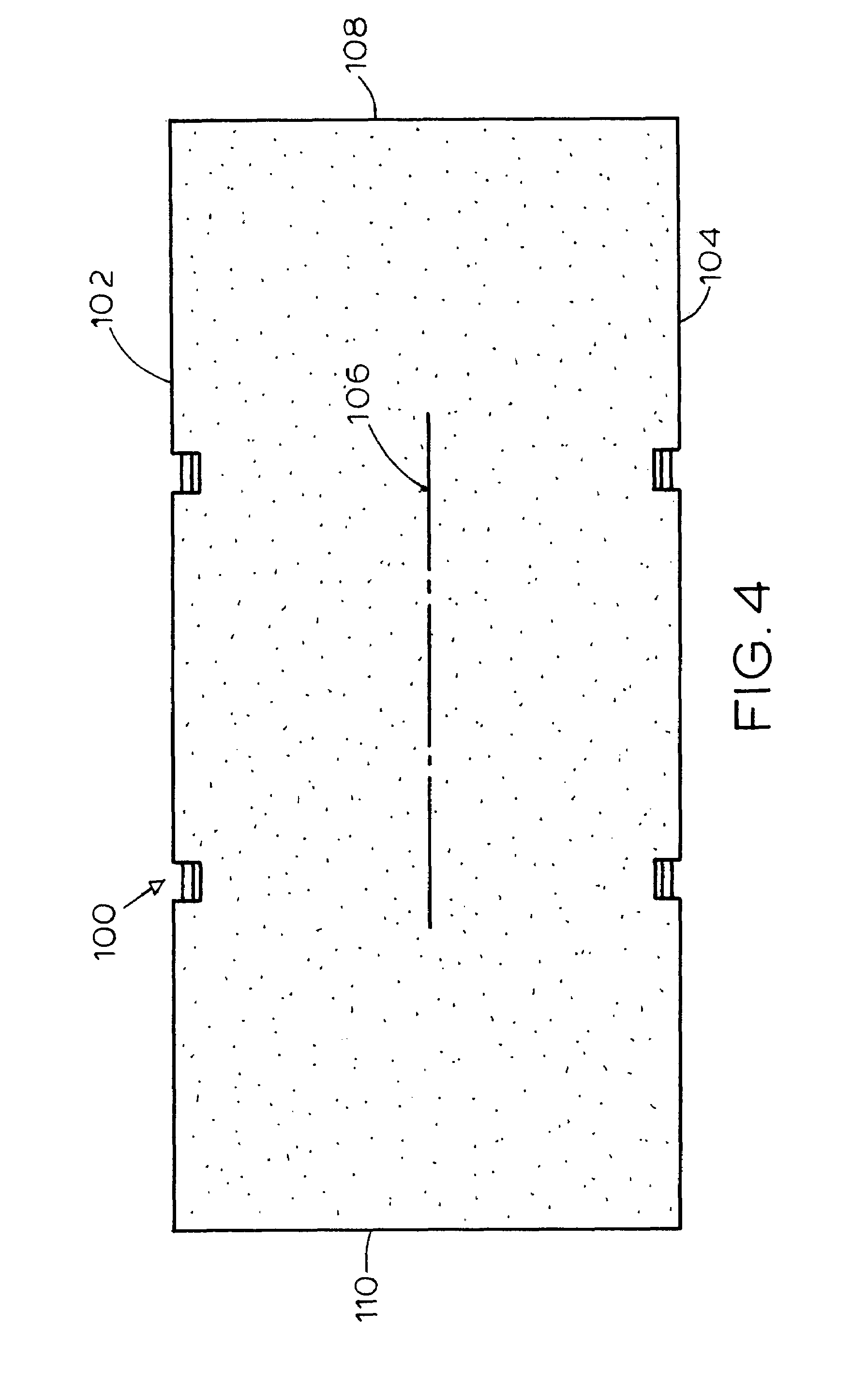

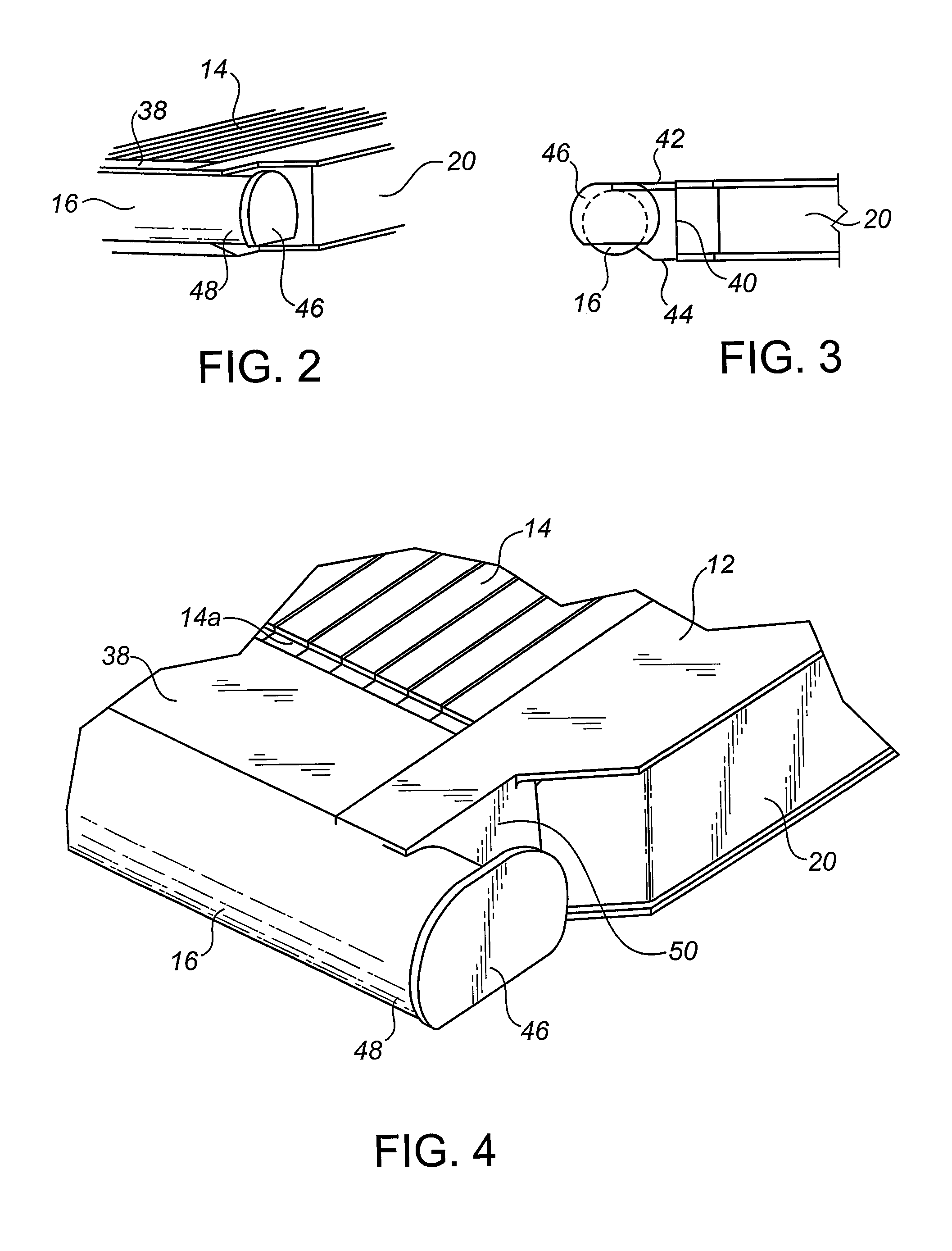

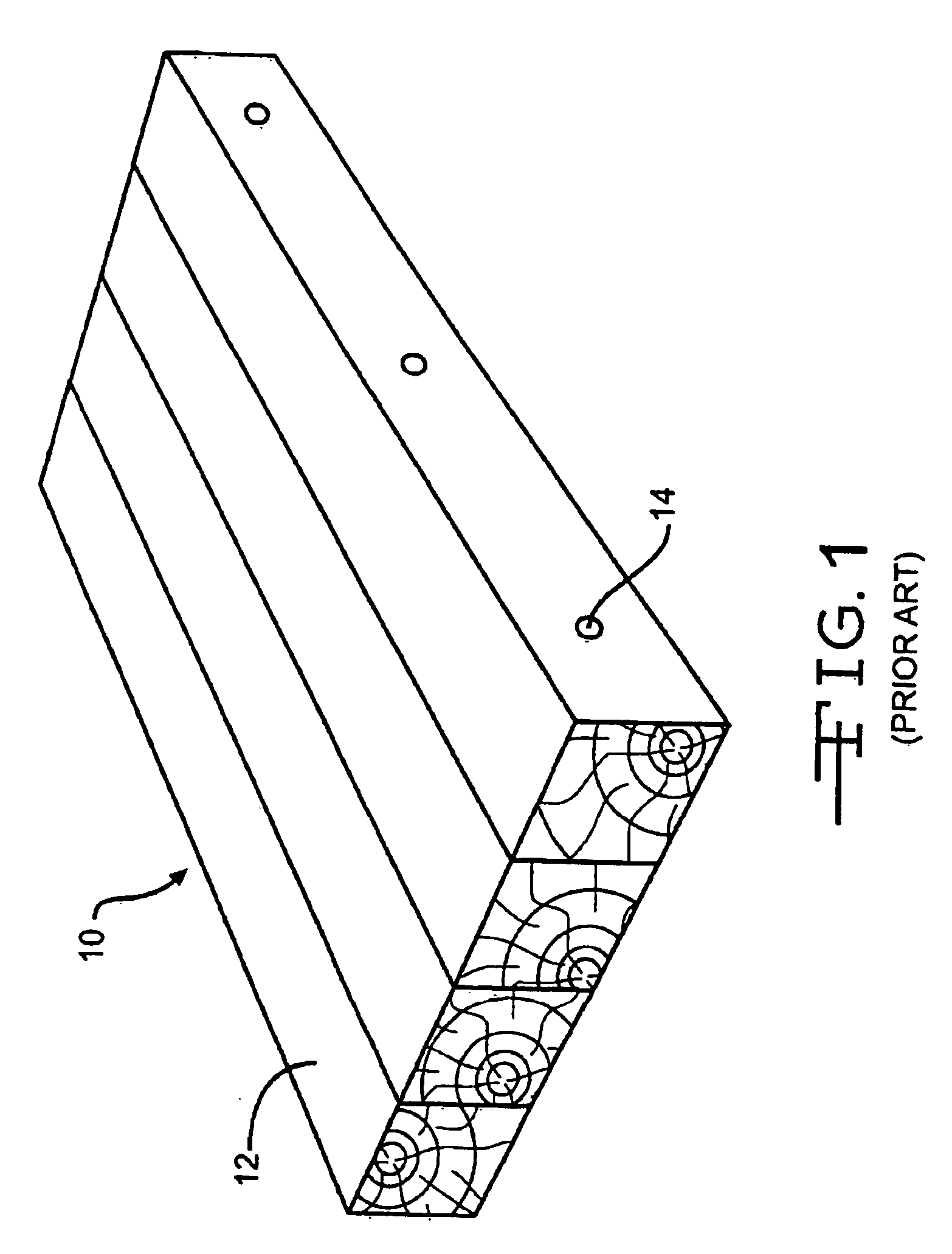

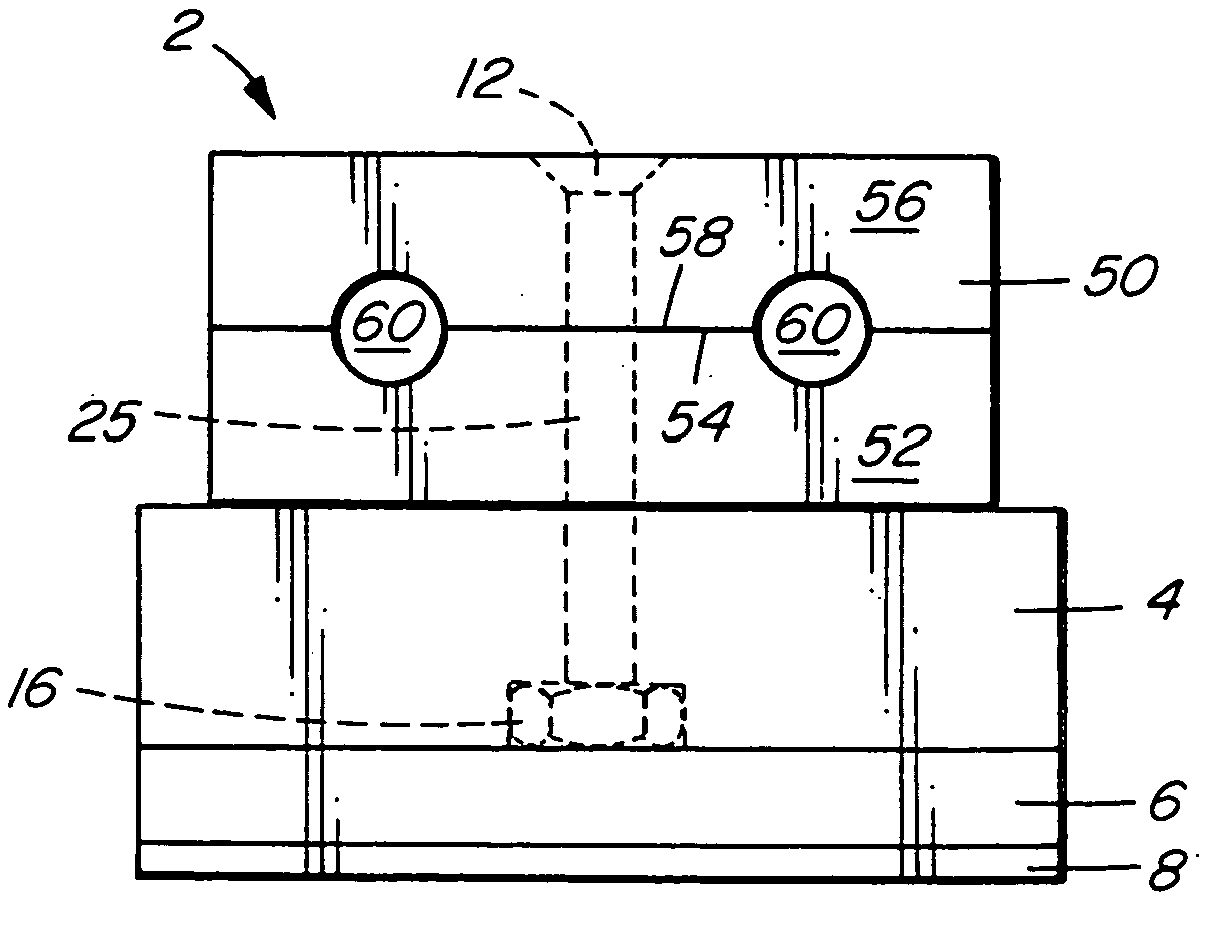

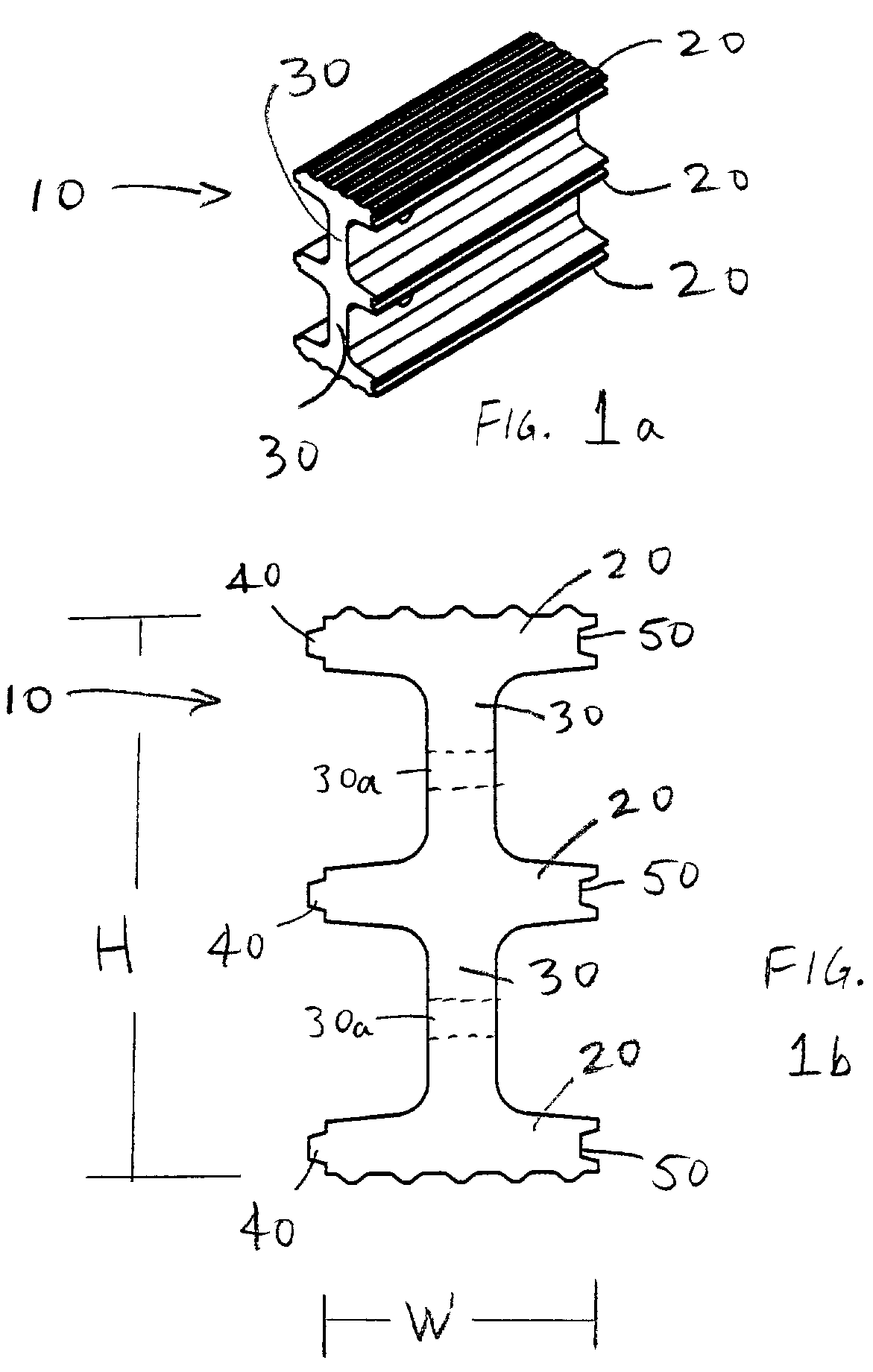

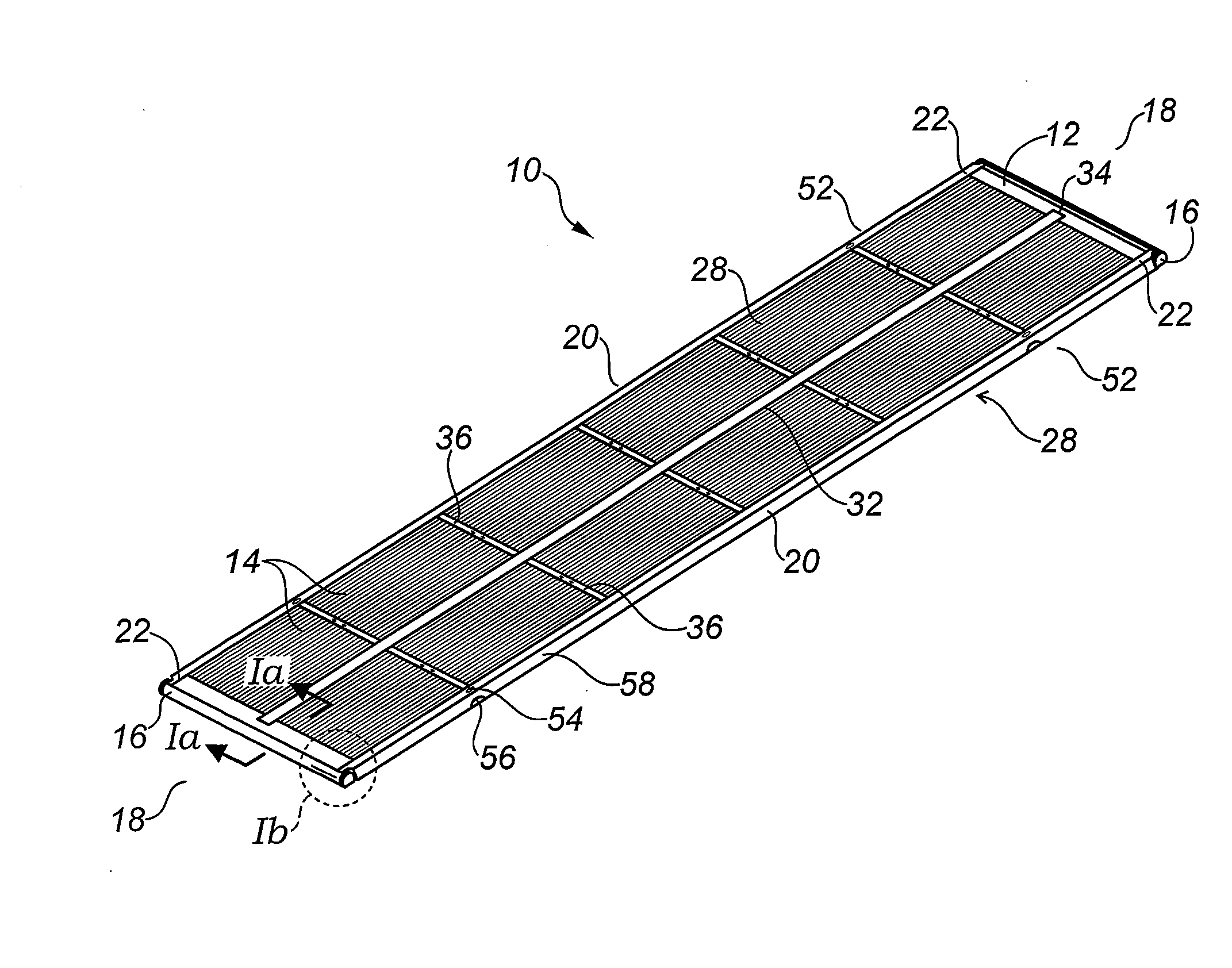

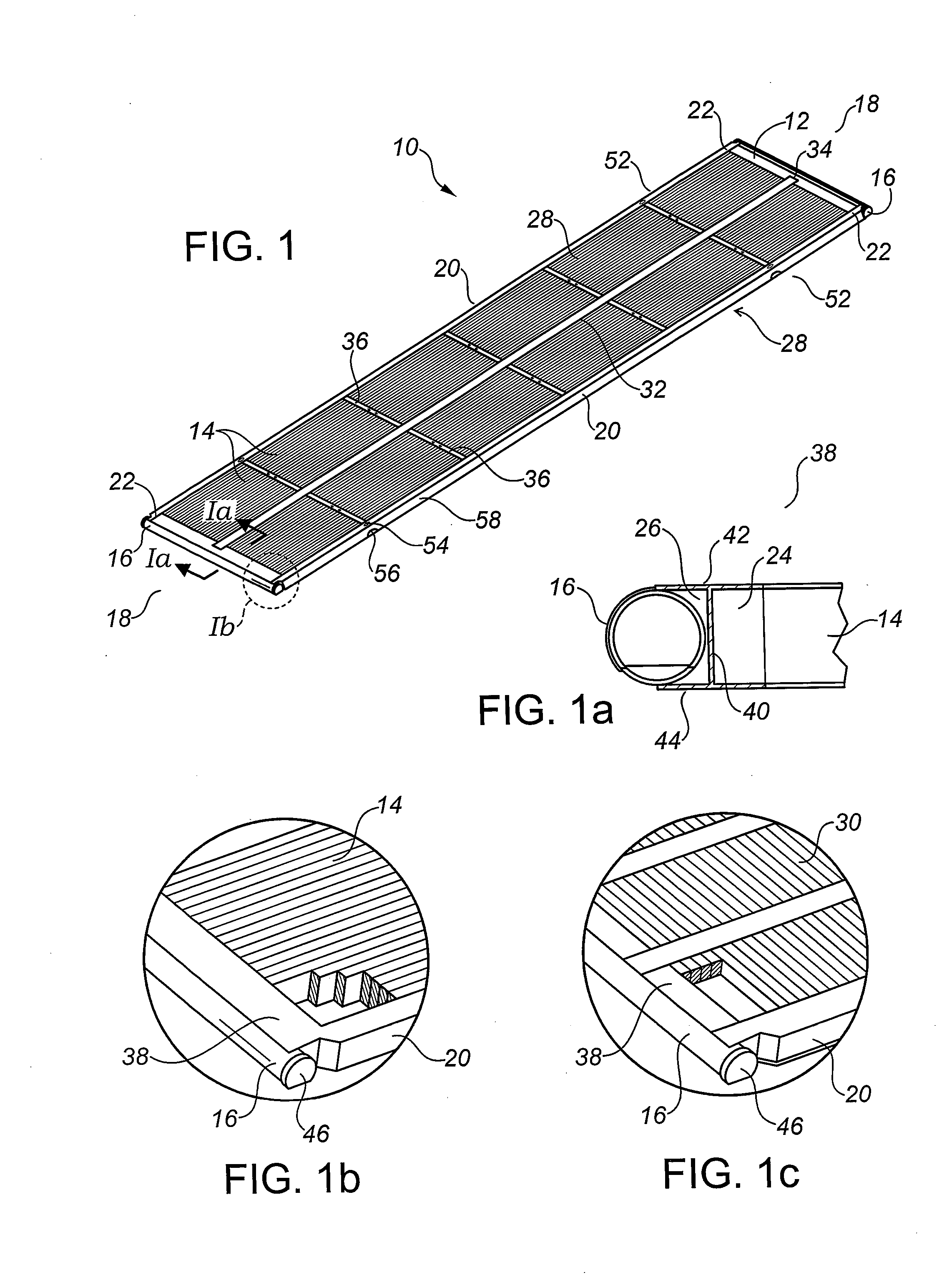

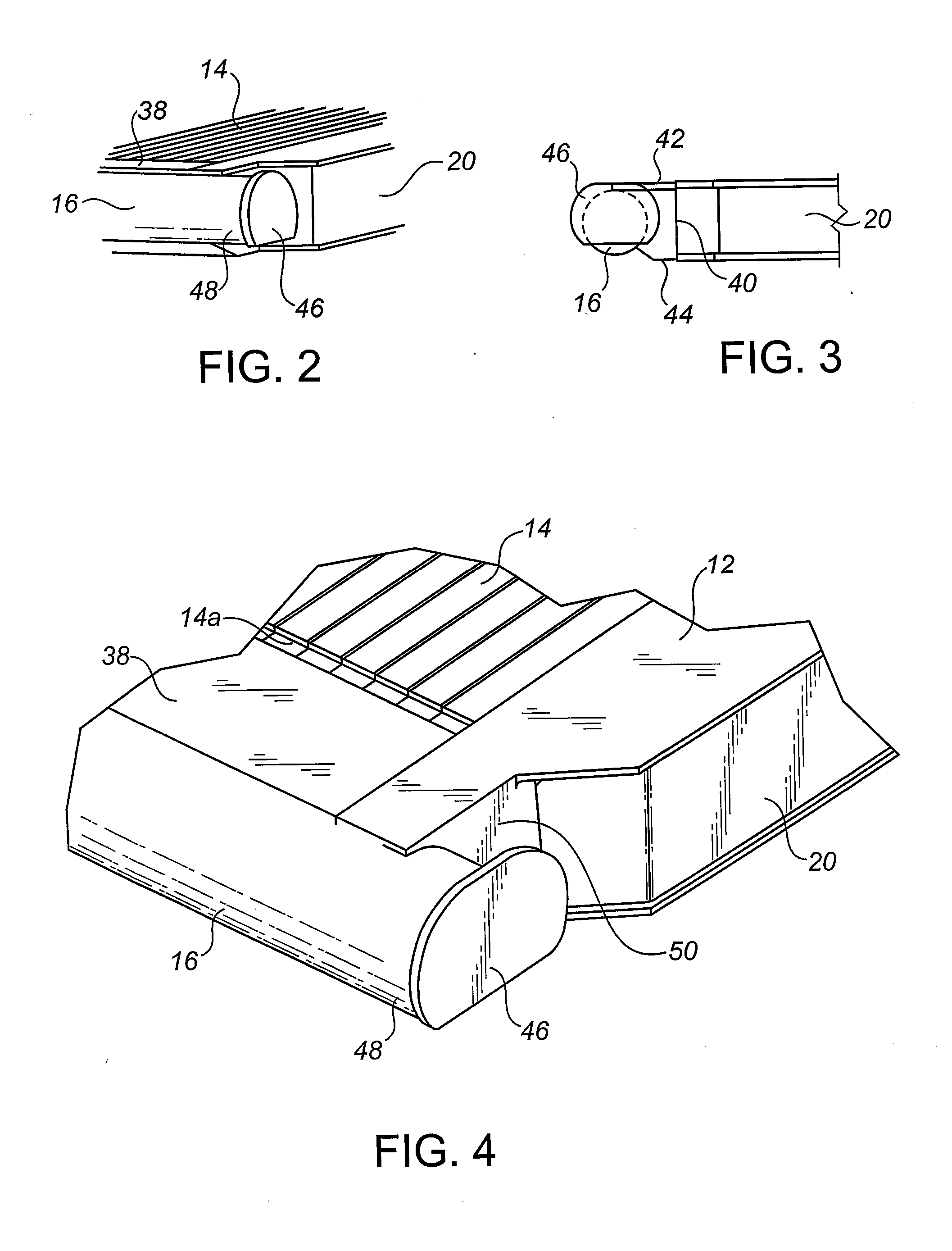

Ground cover mats with rectangular ends

Reinforced ground cover mats are used to facilitate the passage of heavy equipment and vehicles on wet or disturbed ground. The ground cover mats are comprised of boards contained within a peripheral metal frame having two substantially parallel opposing end members that are I-beams, the upper and lower horizontal flanges and vertical webs of which define an outer slot into which a reinforcing member is inserted such that the reinforcing member contacts the vertical web and upper and lower horizontal flanges. Flanged caps may be attached to the ends of the reinforcing member to retain a sling looped around the reinforcing member for pulling the mat.

Owner:MAXXIMAT

Temporary roadway element

A plurality of wood planks are embedded and encased in a one-piece rubber mat to form a monolithic one-piece roadway element. A special coupling means is used to couple one roadway element to an adjacent roadway element to form a roadway surface over which heavy equipment can traverse.

Owner:CHAMPAGNE EDITION

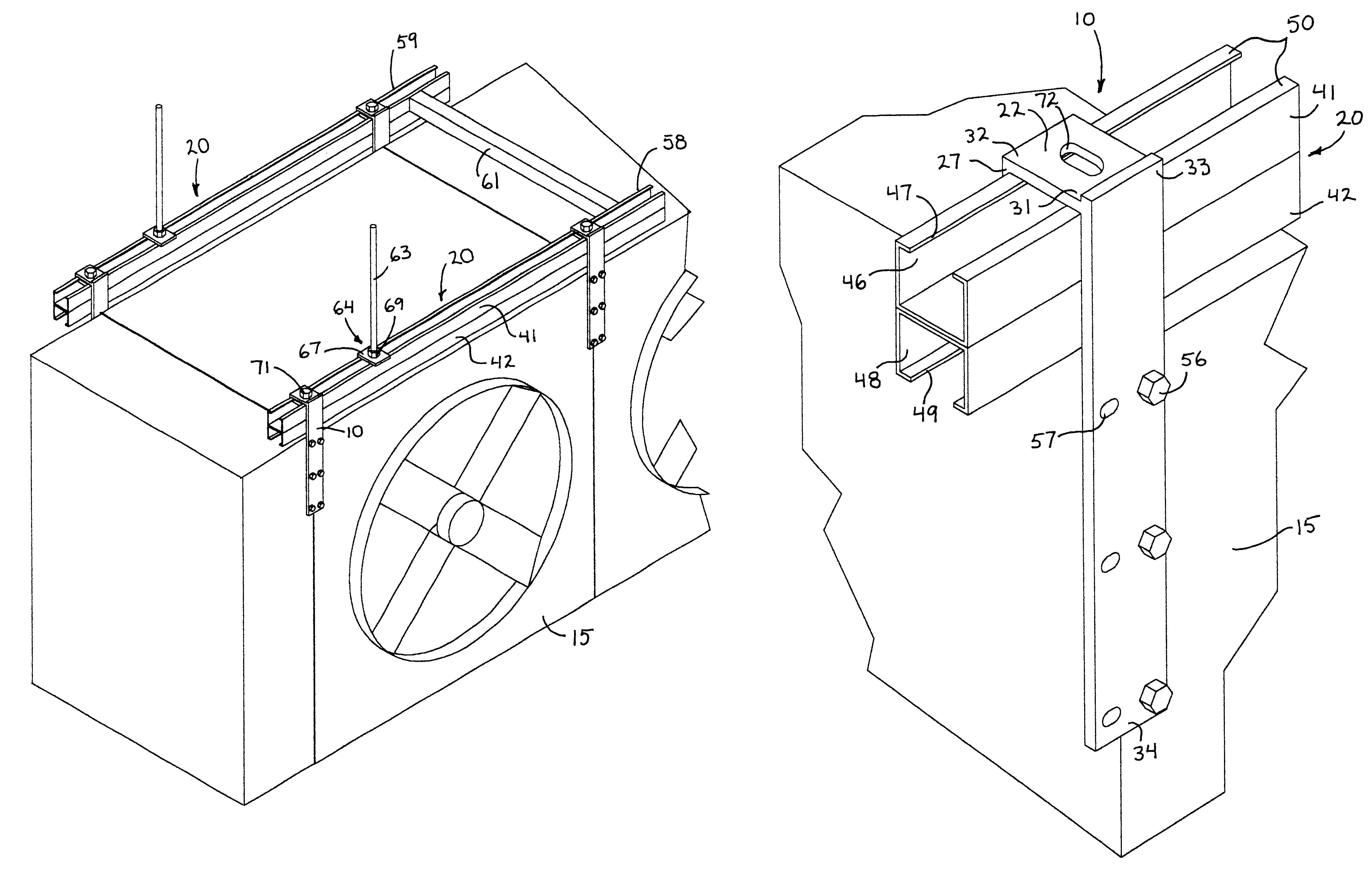

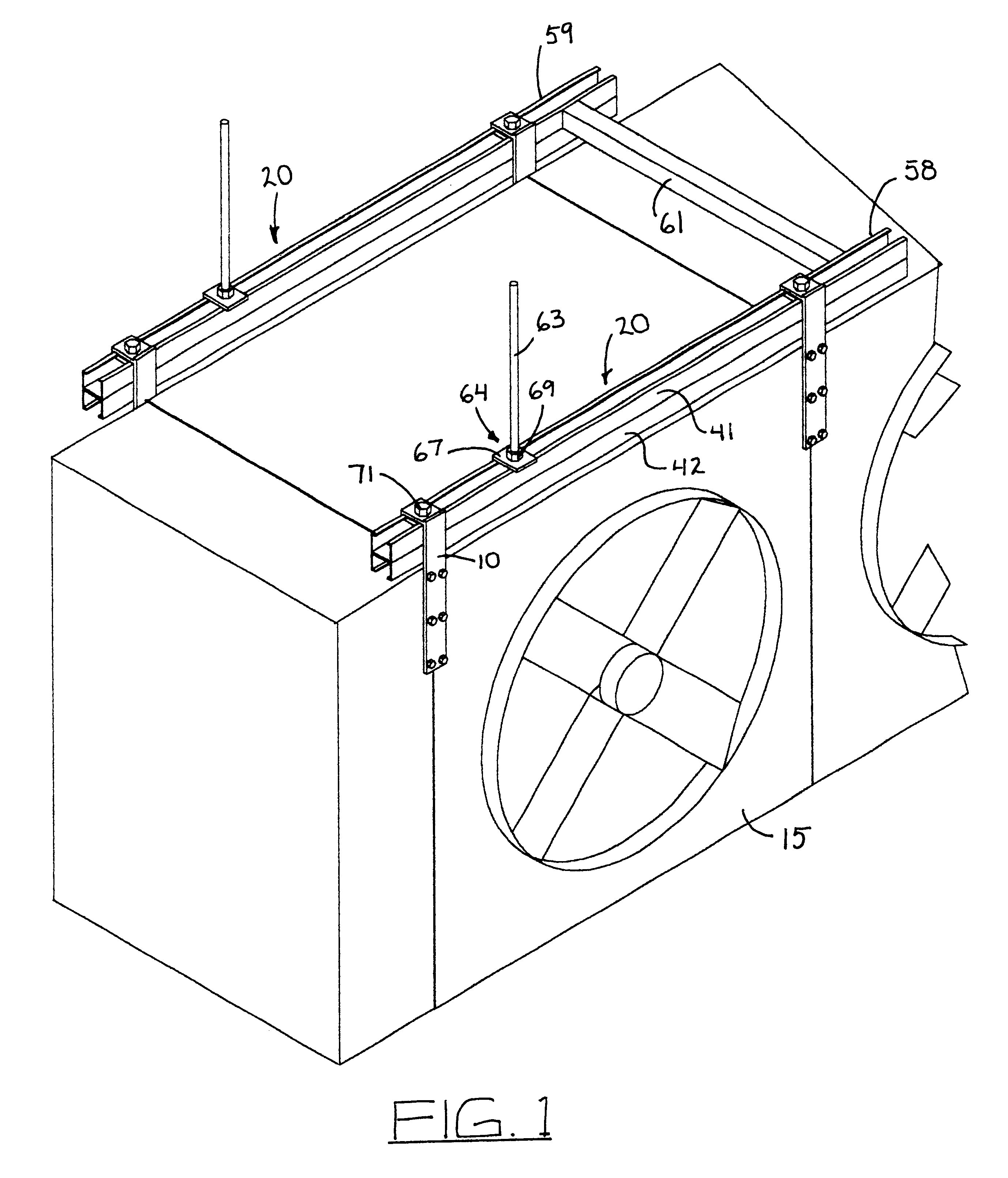

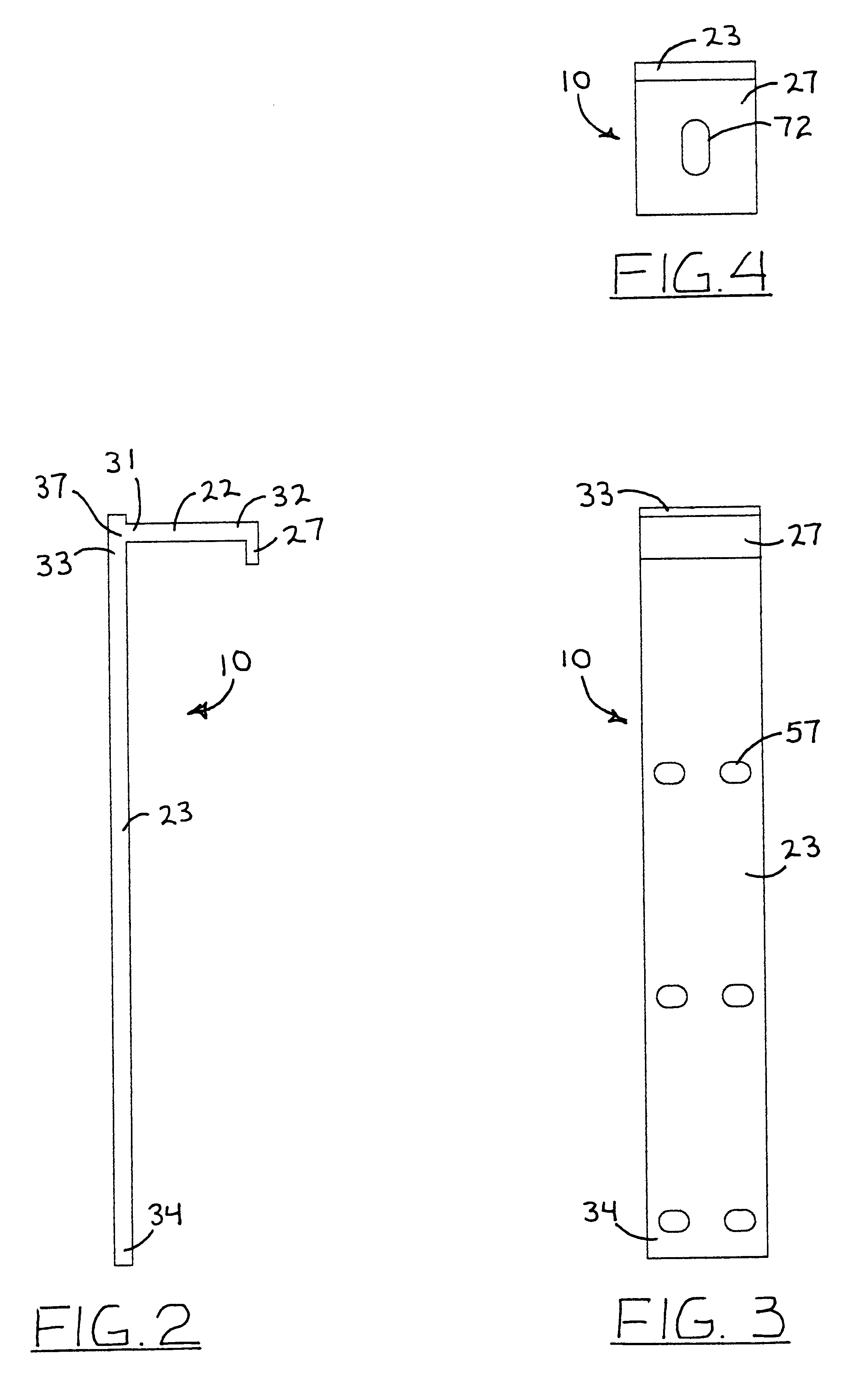

Hanger bracket for installing and supporting suspended equipment

InactiveUS6457692B1Reduce difficultyReduce riskCeilingsLighting and heating apparatusHeavy equipmentLocation Equipment

A hanger bracket for supporting suspended equipment from a support rail. The hanger bracket includes a rail cap adjoined to a side bar. The rail cap also includes a lip parallel to the sidebar. The rail cap rests on the top surface of the support rail. The lip adjoins to the rail cap at an opposite end of the rail cap from the sidebar. The hanger bracket, with the sidebar, the rail cap and the lip, has an inverted "J" shape. The sidebar of the hanger bracket mounts onto an element of the suspended equipment, so that the rail cap rests on a top surface of the support rail. A plurality of hanger brackets can support the equipment element on the support rail. The hanger bracket is first mounted to the equipment element of the overhead equipment, which is then lifted to raise the rail cap above a support rail. The equipment element is then shifted, to position the rail cap over the support rail. The equipment element is finally lowered to contact the rail cap with the top surface of the support rail. The hanger bracket can slide along the support rail to reposition the equipment element. The hanger bracket is intrinsically safe for hanging heavy equipment from a ceiling or roof structure as it utilizes the weight of the suspended equipment element to supplement the holding force of the hanger bracket, allowing the performance of several installation steps at the floor level.

Owner:NORTHWEST REFRIGERATION CONTRACTORS

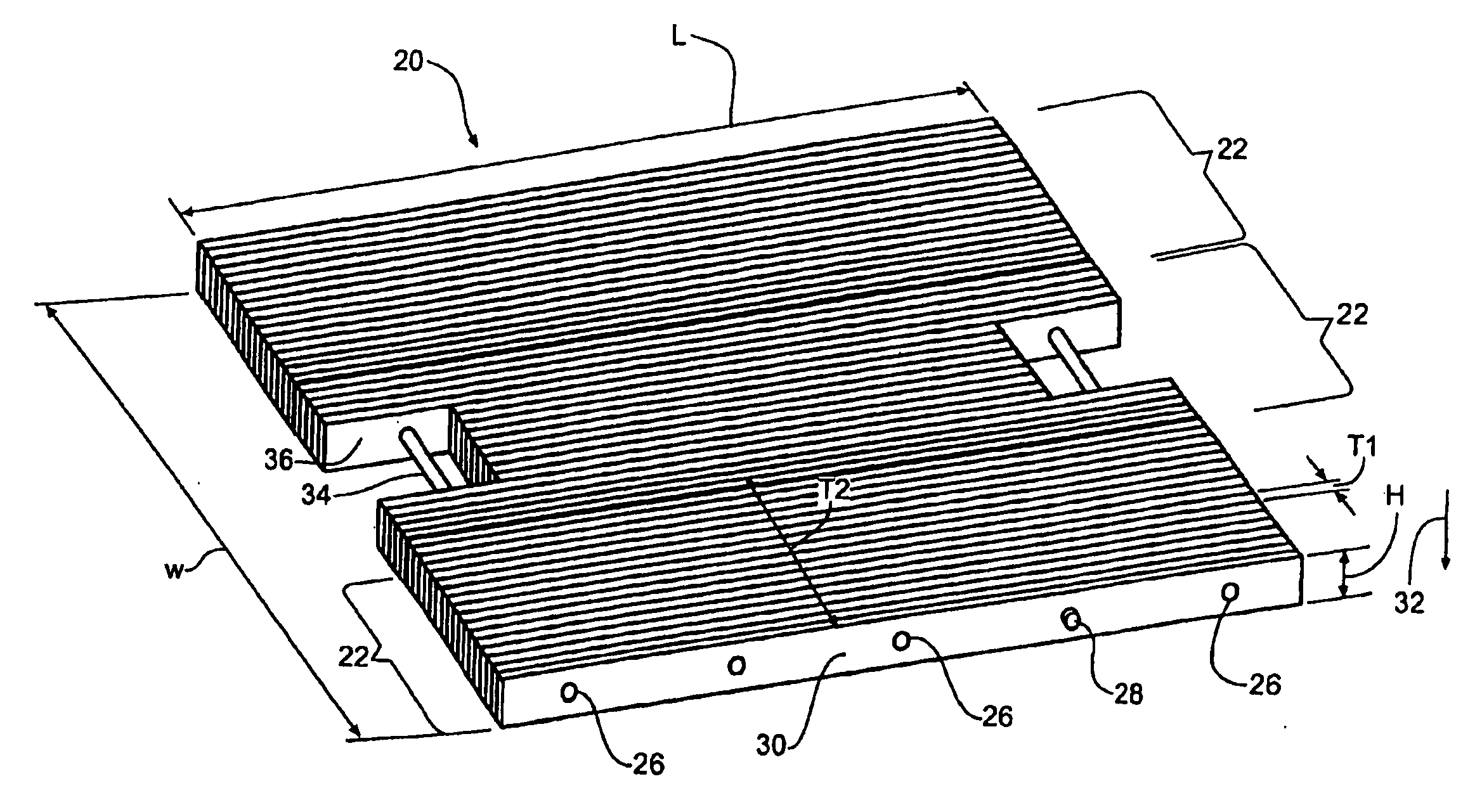

Reinforced ground cover mats

The invention is directed to reinforced ground cover mats which can be used to facilitate the passage of heavy equipment and vehicles on wet or disturbed ground. The ground cover mats are comprised of boards contained within a metal frame. A structural support in the form of an I-beam encases the boards and frame on one side, and a tubular member such as a pipe on the other side, thereby increasing the strength at the middle of the mat ends. Further, the tubular member can be modified at its ends to facilitate insertion of a sling and stacking of adjacent mats. The mat also comprises means for lifting, including passages through which chains or cable may be threaded, lifting shackle assemblies or pear link assemblies.

Owner:MAXXIMAT

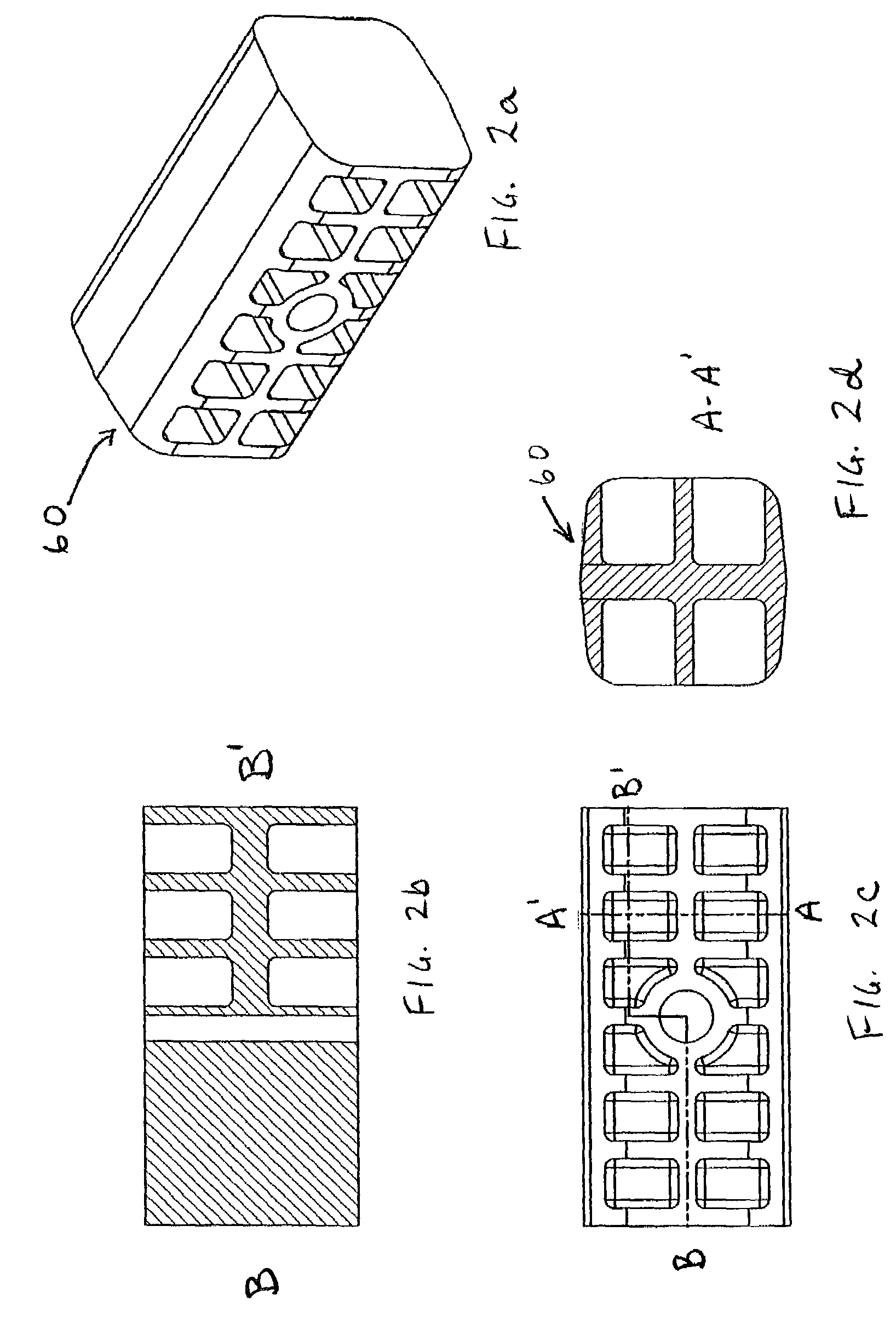

Interlocking laminated support mat

A laminated one-ply support mat comprised of a plurality of individual wood hat includes means for transferring load and interlocking with an adjacent one-ply The laminated one-ply support mat may be suitable for the construction of ads, flooring, or platforms to support heavy equipment. The laminated one-ply ay include a non-laminated member fastened to each side to prevent damage to the laminated support mat. The laminated one-ply support may be comprised of a individual wood laminations fastened together by a plurality of nuts and bolts support mat to be disassembled and repair in the field.

Owner:QUALITY MAT

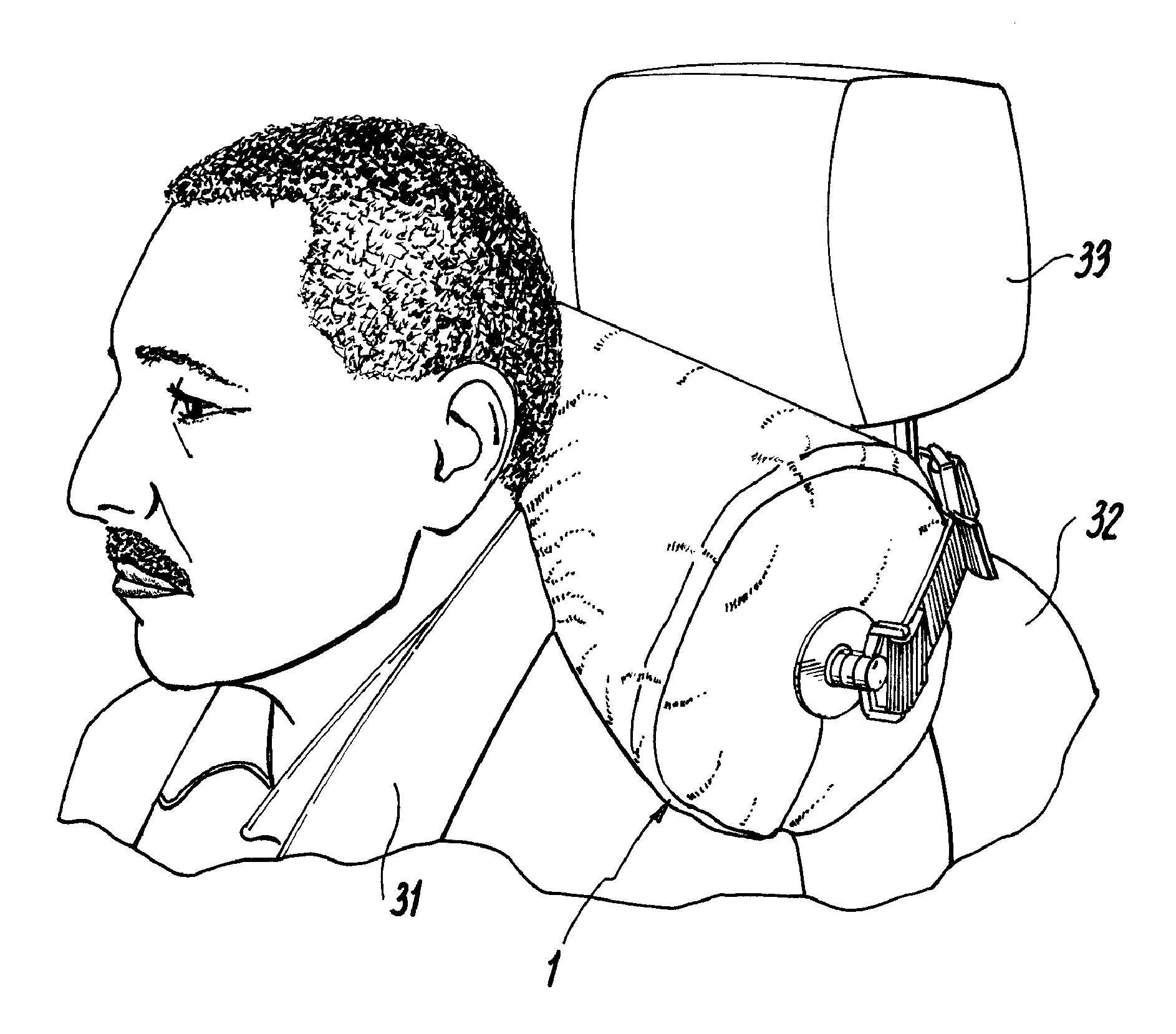

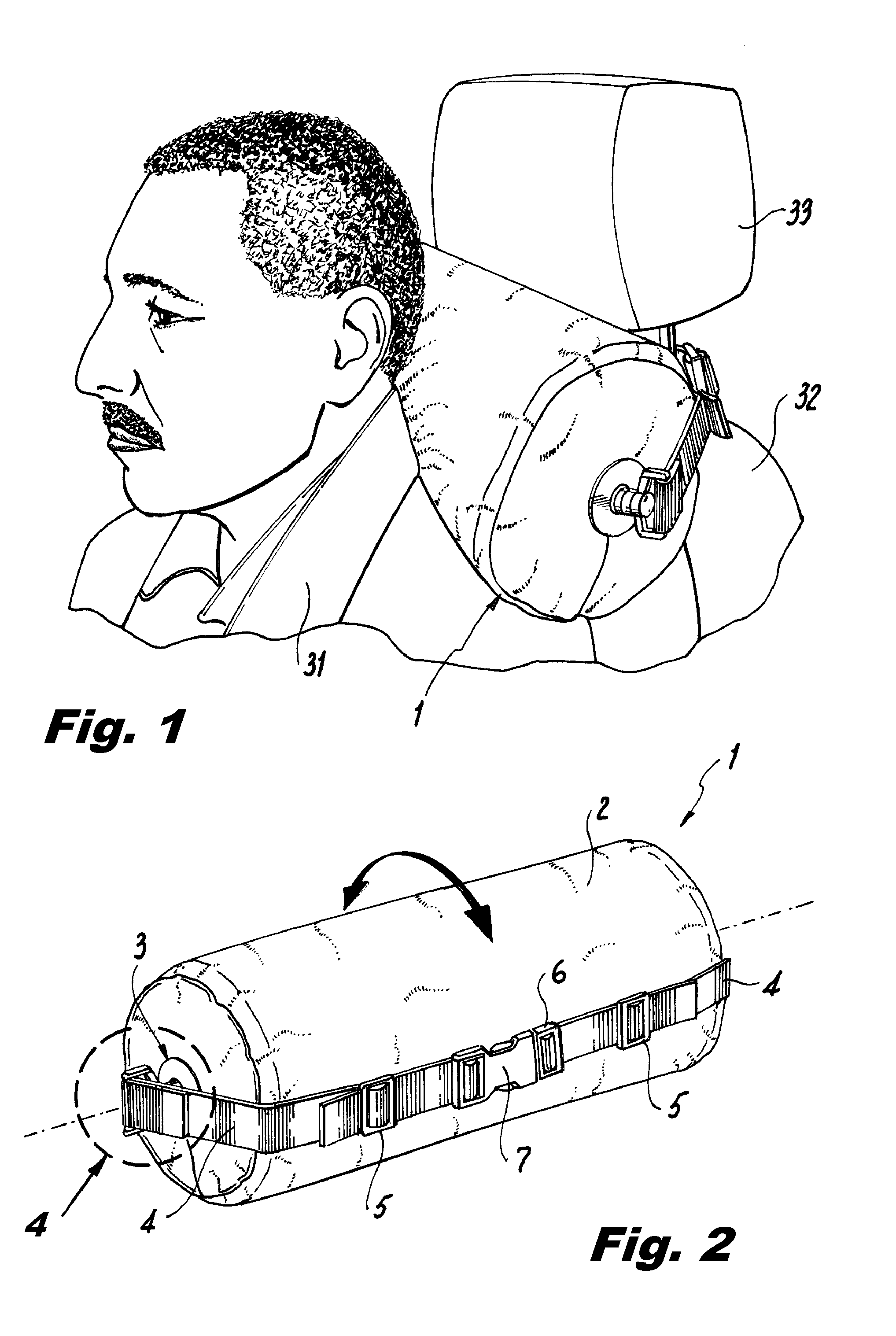

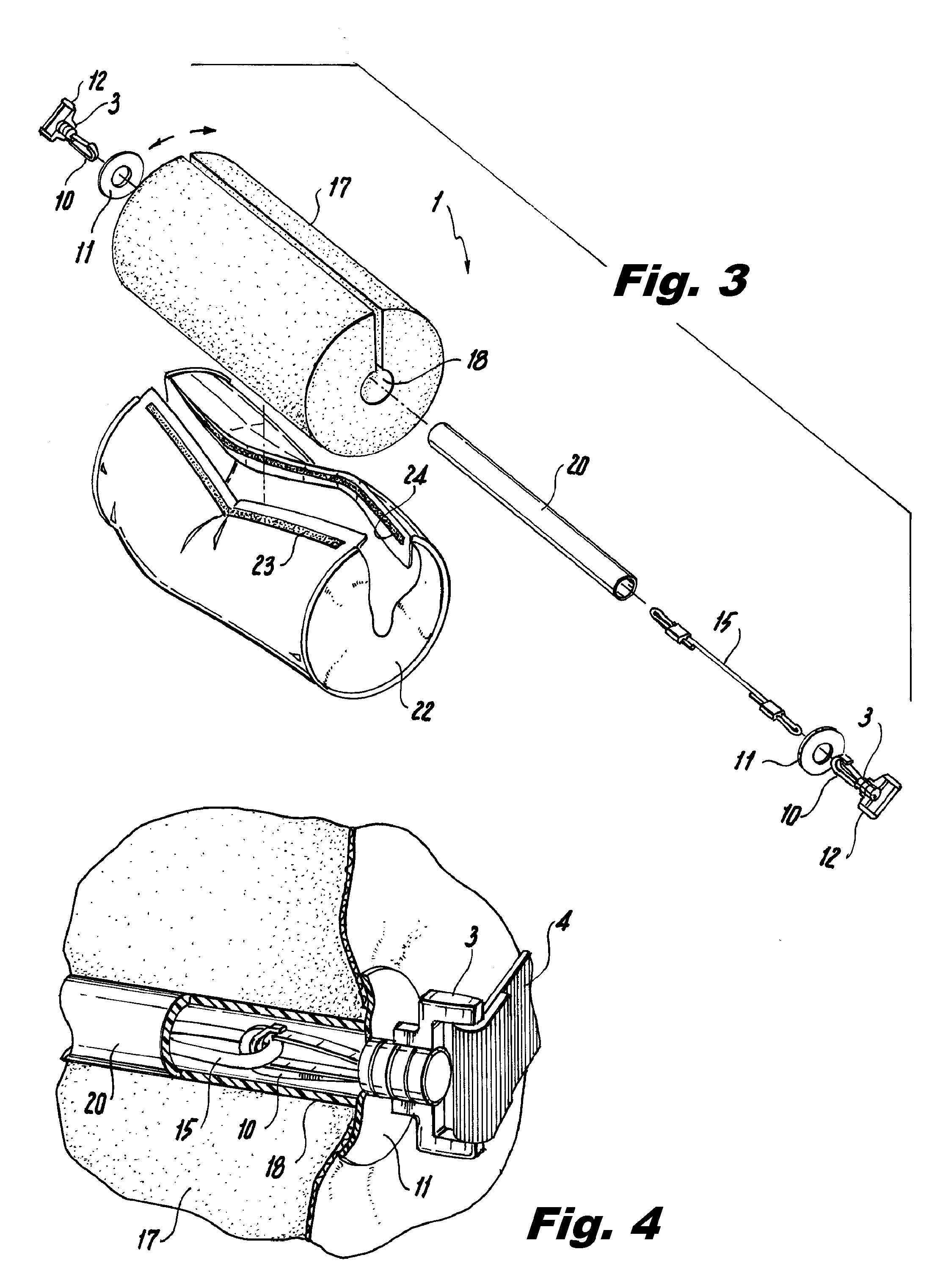

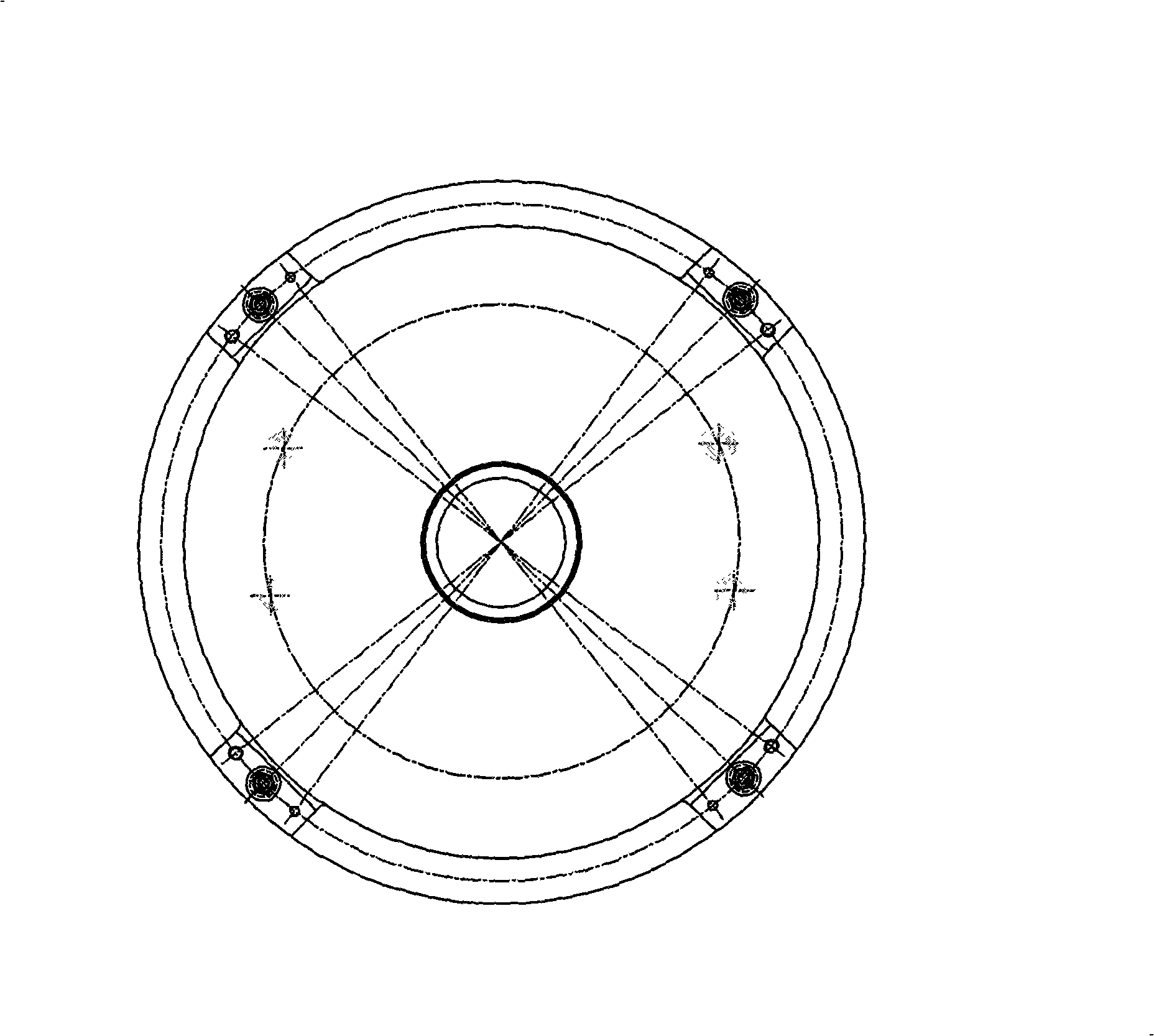

Rotatable cervical pillow for heavy equipment and other vehicles

InactiveUS20130119716A1Easy to disassembleSmooth rotationVehicle seatsOperating chairsHigh densityCervical pillows

A rotatable circular crossection cervical pillow is manually rotated in a continuous fashion as desired by a person whenever a fresh clean contact spot is sought, or a contact spot of variable support is sought, while the pillow is still attached to a seat back. The rotatable pillow is a cylinder of medium and / or firm high density polyurethane foam. An axial through-hole in the center permits the snug insertion of a rigid length of tubing to give the pillow axial rigidity. Swivel fixtures are attached at each end of the pillow by virtue of the central tube. A fabric cover with an opening closure covers the entire polyurethane cylinder snugly. Optionally the cover may carry therapeutic imparting elements therein. Straps with adjustable buckles are attached to each swivel fixture. Therefore, the cervical pillow rotates easily while still strap-attached to the seat back.

Owner:STRONCONI CHARLES J

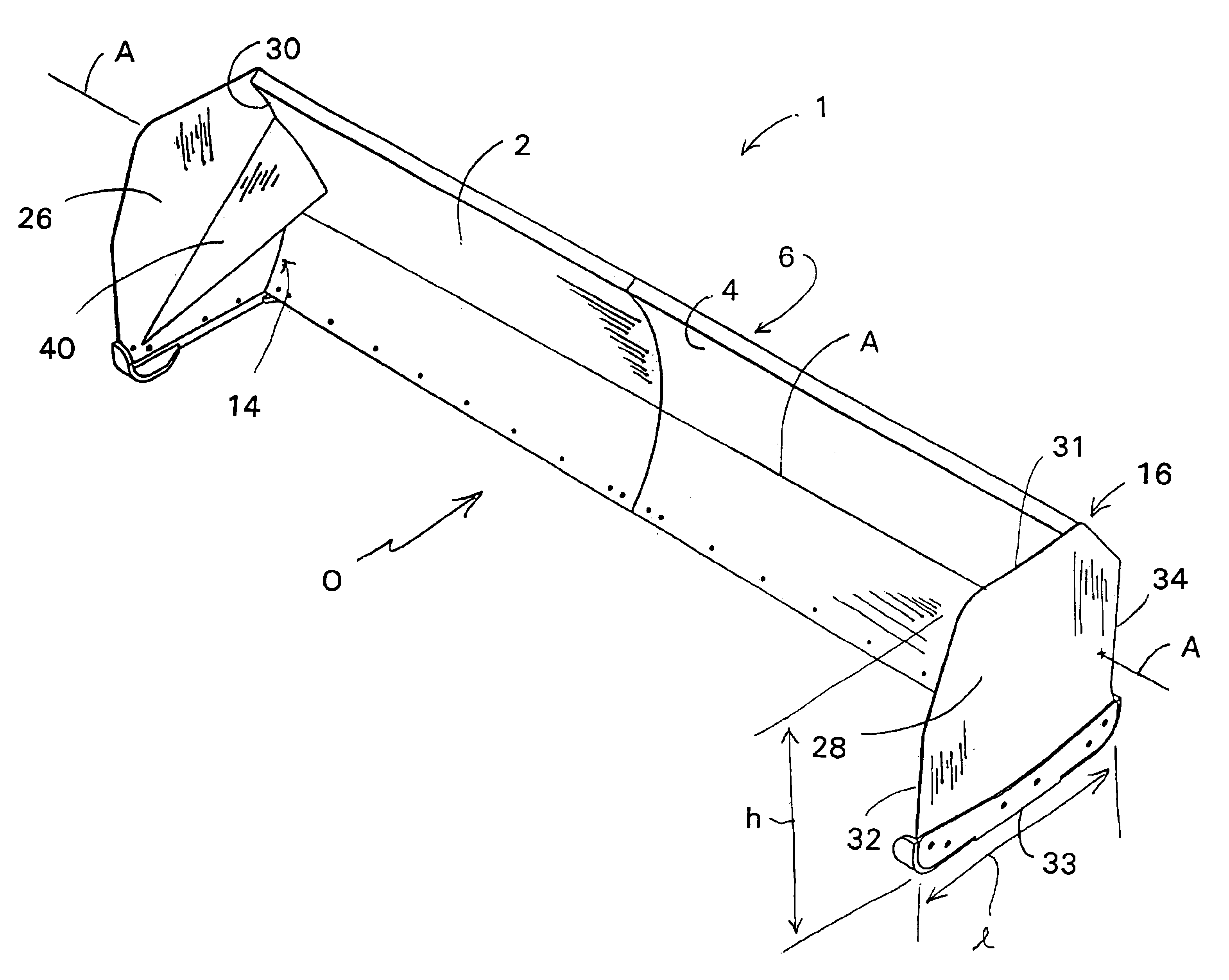

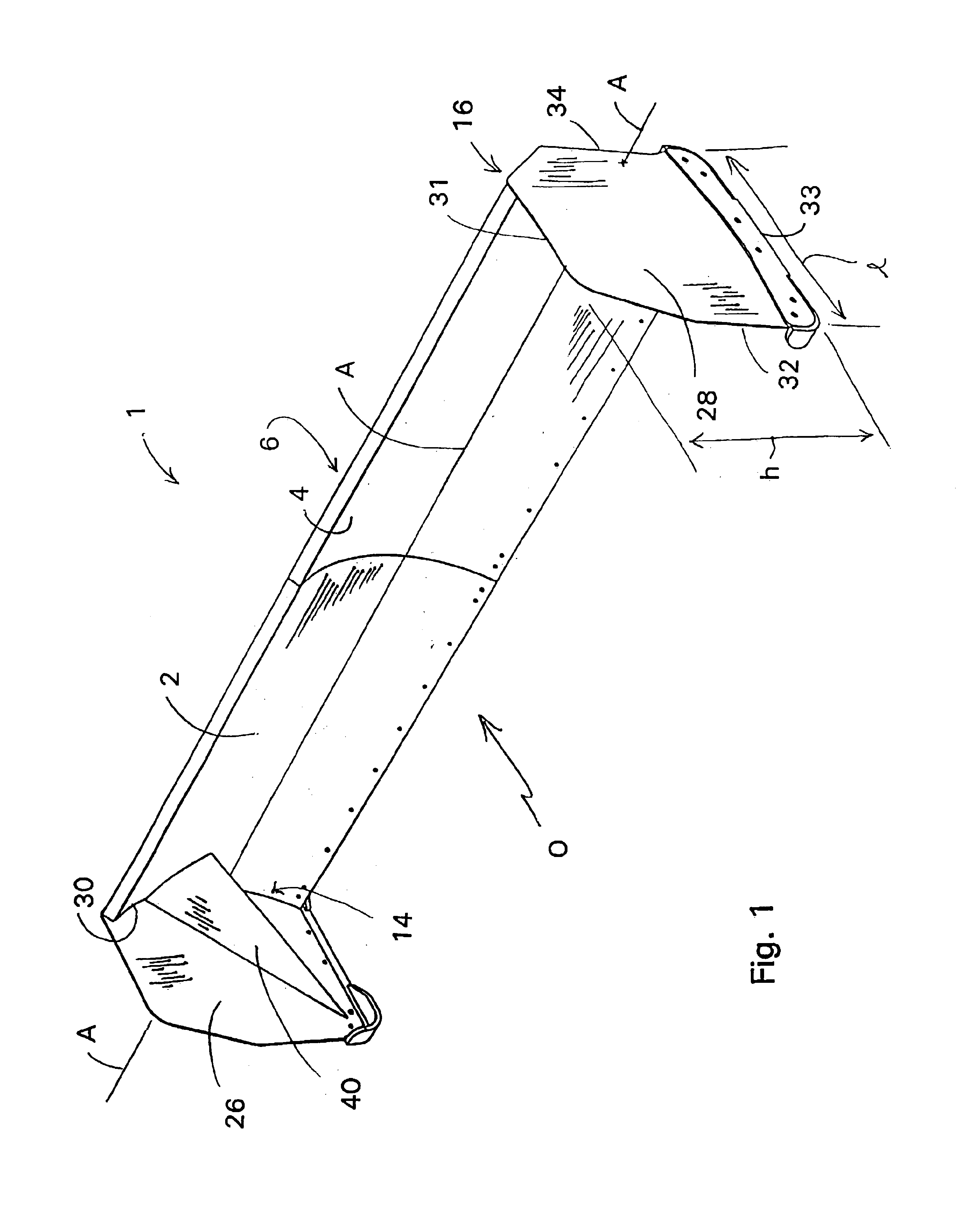

Materials moving blade

InactiveUS6845576B2Facilitate disengagementPromote sheddingMechanical machines/dredgersTilling equipmentsGusset plateEngineering

A materials pushing or moving blade for use with heavy equipment vehicles, for example, a bulldozer or loader, and more specifically to a method and apparatus for moving snow, specifically a snow moving blade having a reinforcing gusset for strengthening the extended sidewalls of the snow moving blade.

Owner:DEGELMAN IND LP

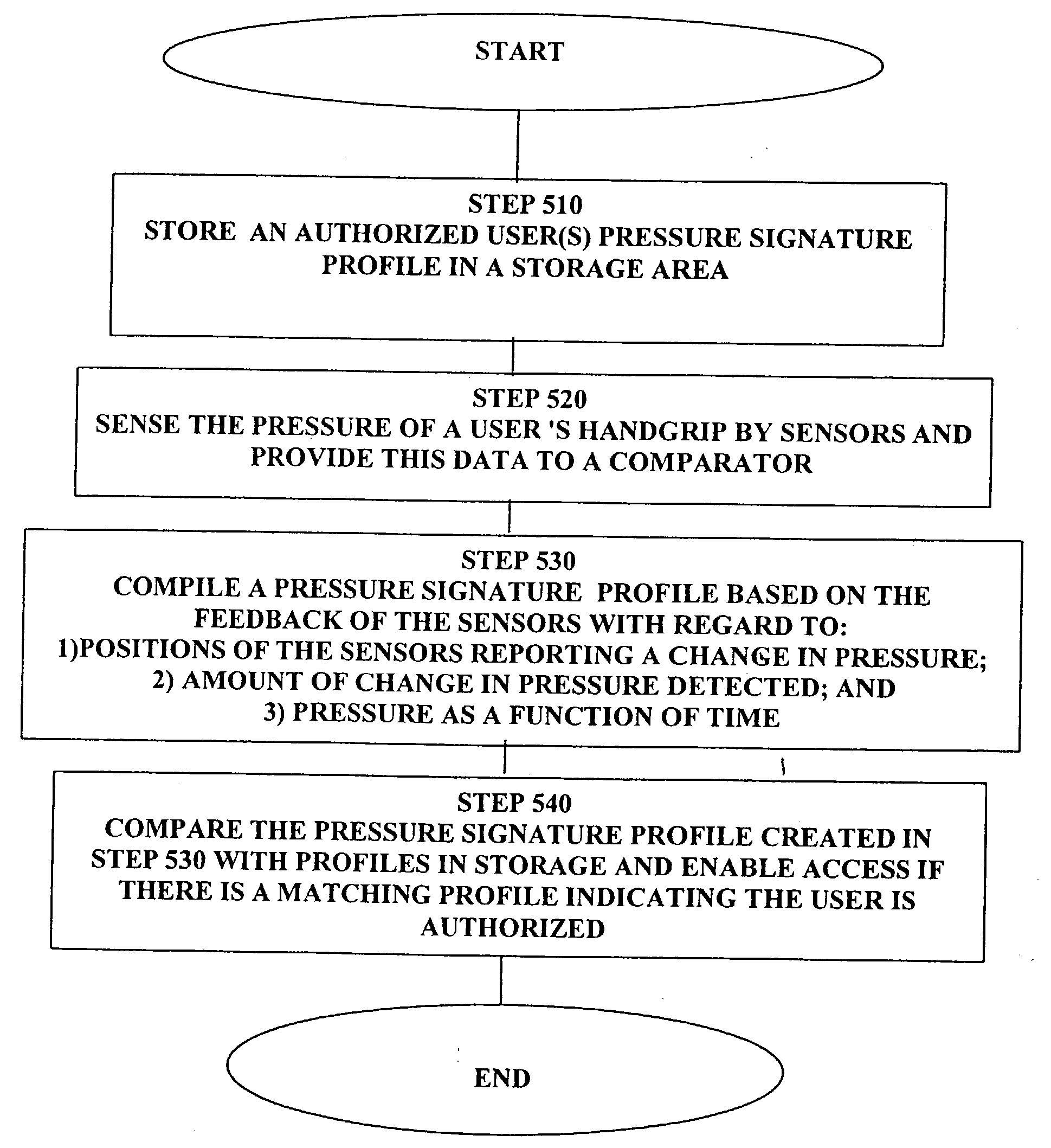

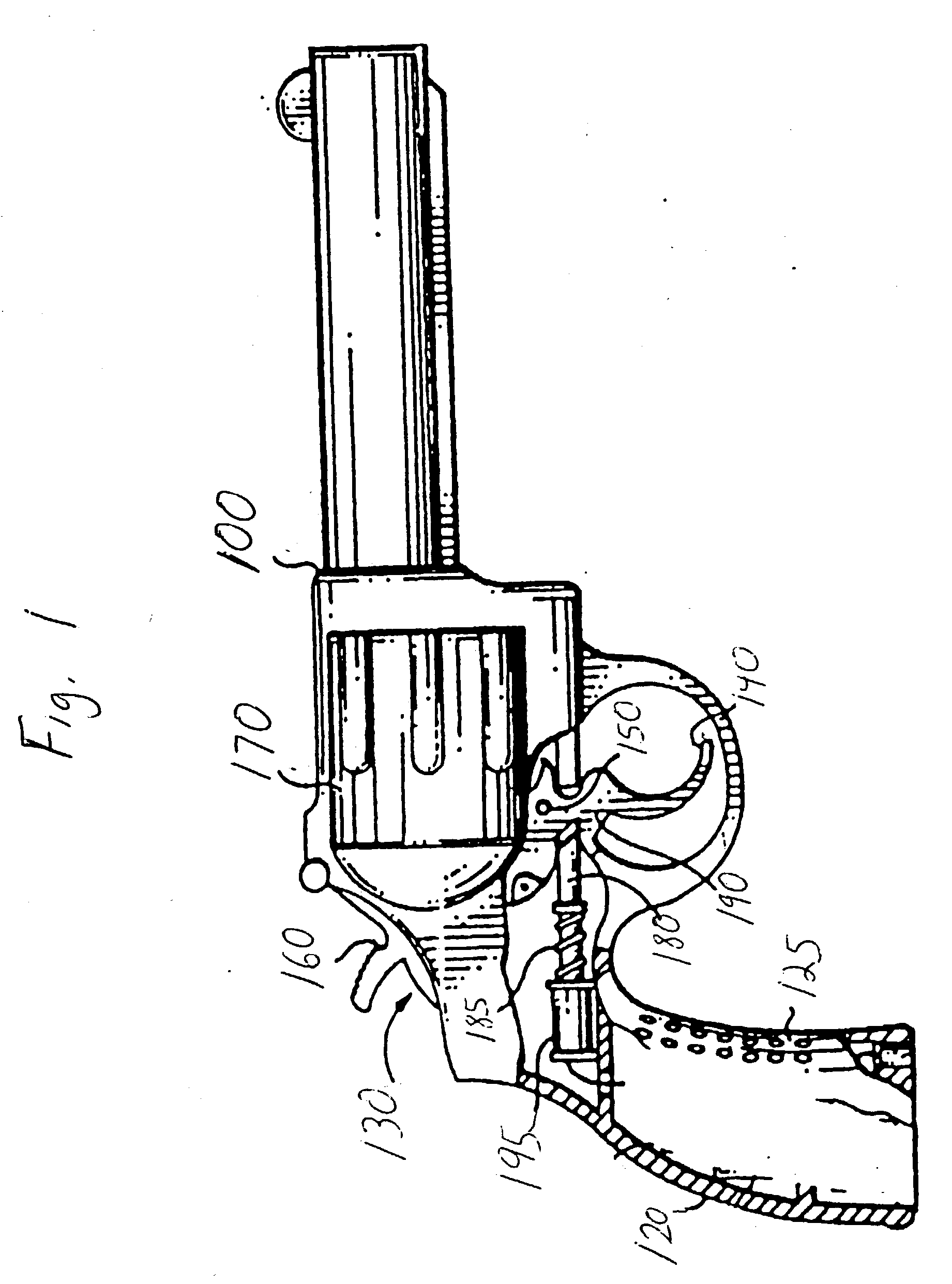

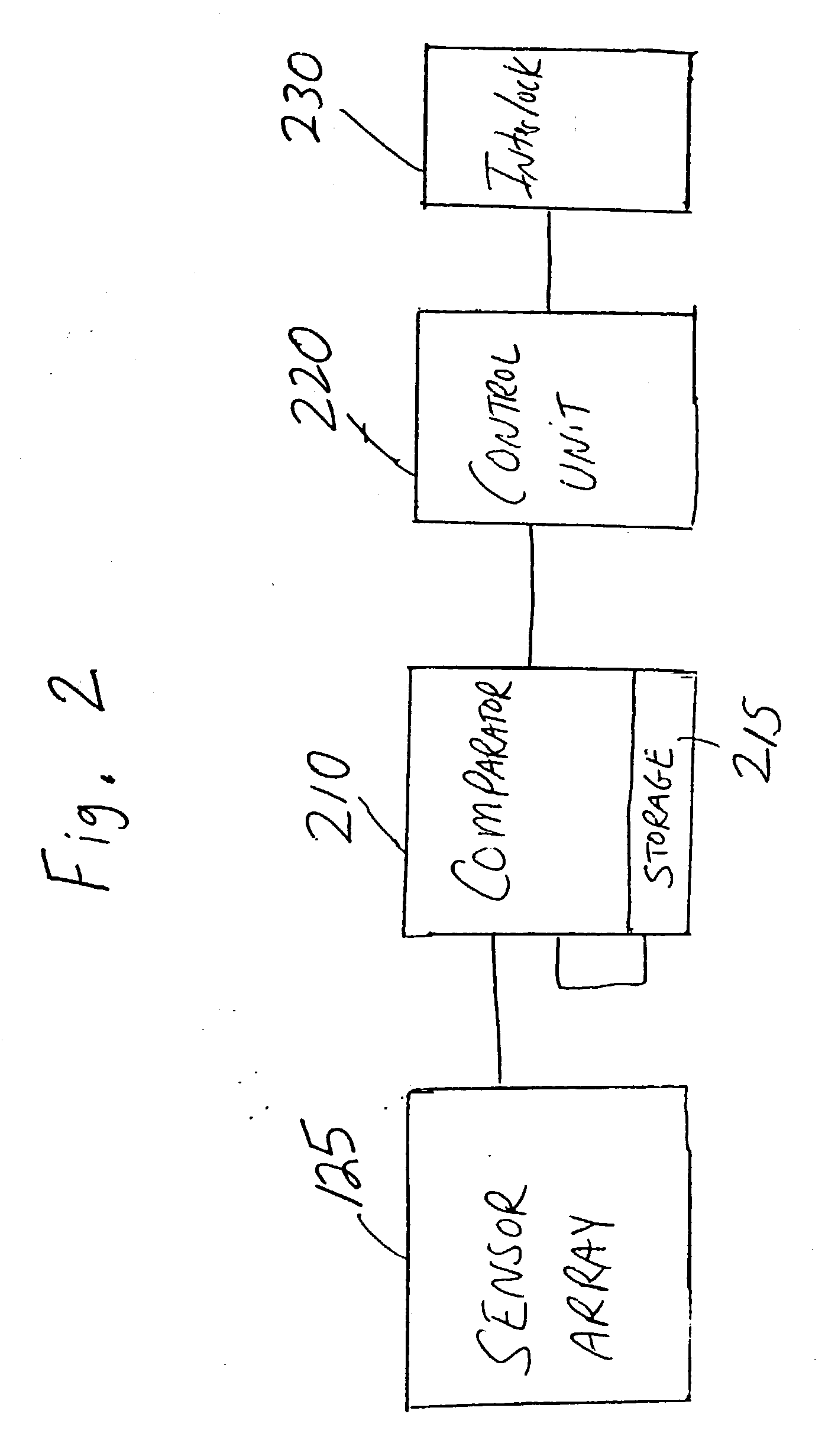

Authorized personnel biometric detection system preventing unauthorized use of aircraft and other potentially dangerous instruments

InactiveUS20060285725A1Avoid controlSafety arrangementElectric signal transmission systemsJoystickEngineering

An authorized pilot detection system and method for controlling a variety of potentially dangerous instrumentalities such as aircraft, land vehicles, amphibious vehicles and other hand-controllable equipment, is disclosed. The system with respect to aircraft includes an interlock for enabling / disabling one of a control wheel and a joystick for controlling movement of an aircraft; a biometric grip detector arranged on said one of a control and joy stick, said biometric grip detector comprising a plurality of pressure sensors for sensing a handgrip of a user on said one of a control wheel and joystick; a comparator for comparing a pressure signature profile compiled from an output from the plurality of pressure sensors with at least one pressure signature profile including: (a) hand position of the user's handgrip on said one of a control wheel and joystick as indicated by a change in pressure on at least one of the plurality of pressure sensors; (b) pressure as a function of position on the control wheel and joystick; and (c) pressure as a function of time. A control unit may disable the interlock to permit at least partial manual control of movement of the aircraft by the control wheel / joy stick when the comparator indicates that the signature profile matches at least one pressure signature profile in storage. Authorized access to other hand operated equipment such as power tools and heavy equipment are prevented according to the present invention.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

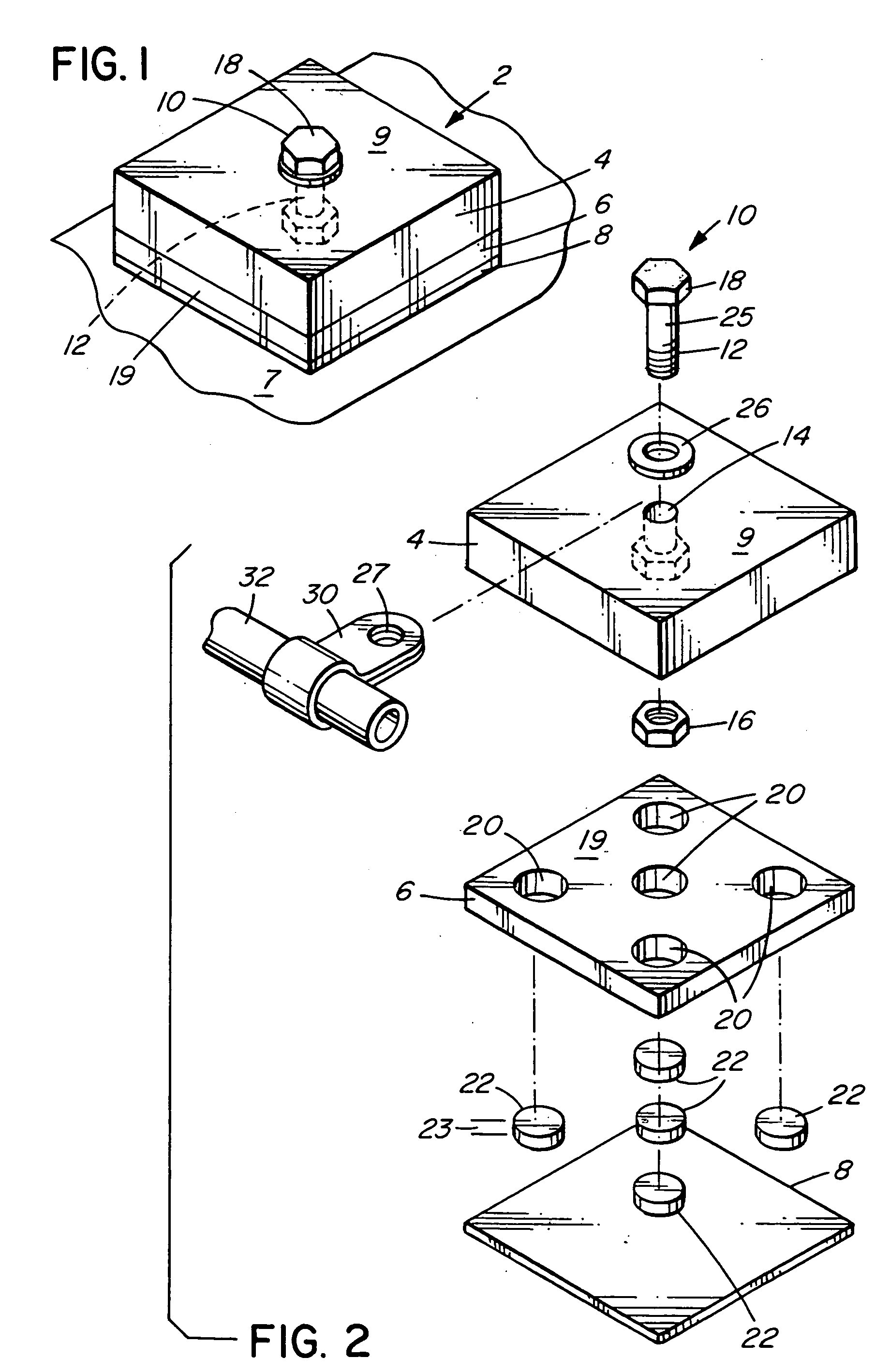

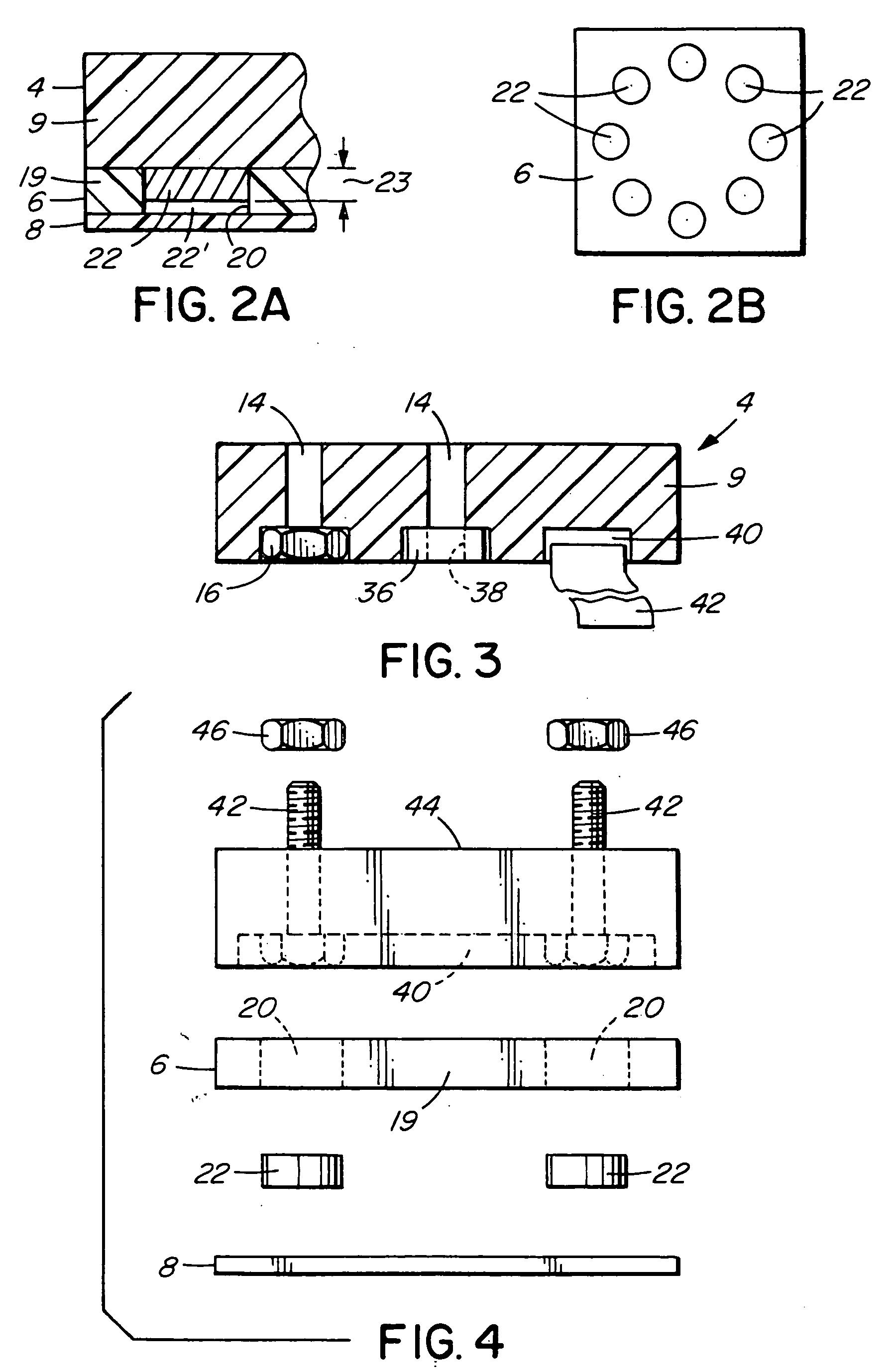

Magnetized mounting bracket

InactiveUS20050167547A1Avoid tearingQuick and efficient reconnectionPipe supportsPicture framesFire extinguisherEmergency light

An apparatus for mounting an object to a ferromagnetic surface comprising an upper support portion adapted to retain the object with a lower magnetic base to the support portion that is attractable to the ferromagnetic surface. A friction layer below the magnetic base separates the magnetic base from direct contact with the ferromagnetic surface whereby the magnetic base acts to releasably retain the support portion on the ferromagnetic surface and the friction layer acts to prevent slippage and provides cushioning. The mounting bracket is particularly suited to anchoring hoses, lines or cables to heavy equipment. The mounting bracket also useful for mounting equipment such as fire extinguishers or other safety equipment to a mounting location in a vehicle. Vehicle emergency lights or brake lights attached to the mounting bracket are readily installable on the exterior of a vehicle at any desired location and removable without damaging the vehicle finish.

Owner:MCLELLAN ROBIN S

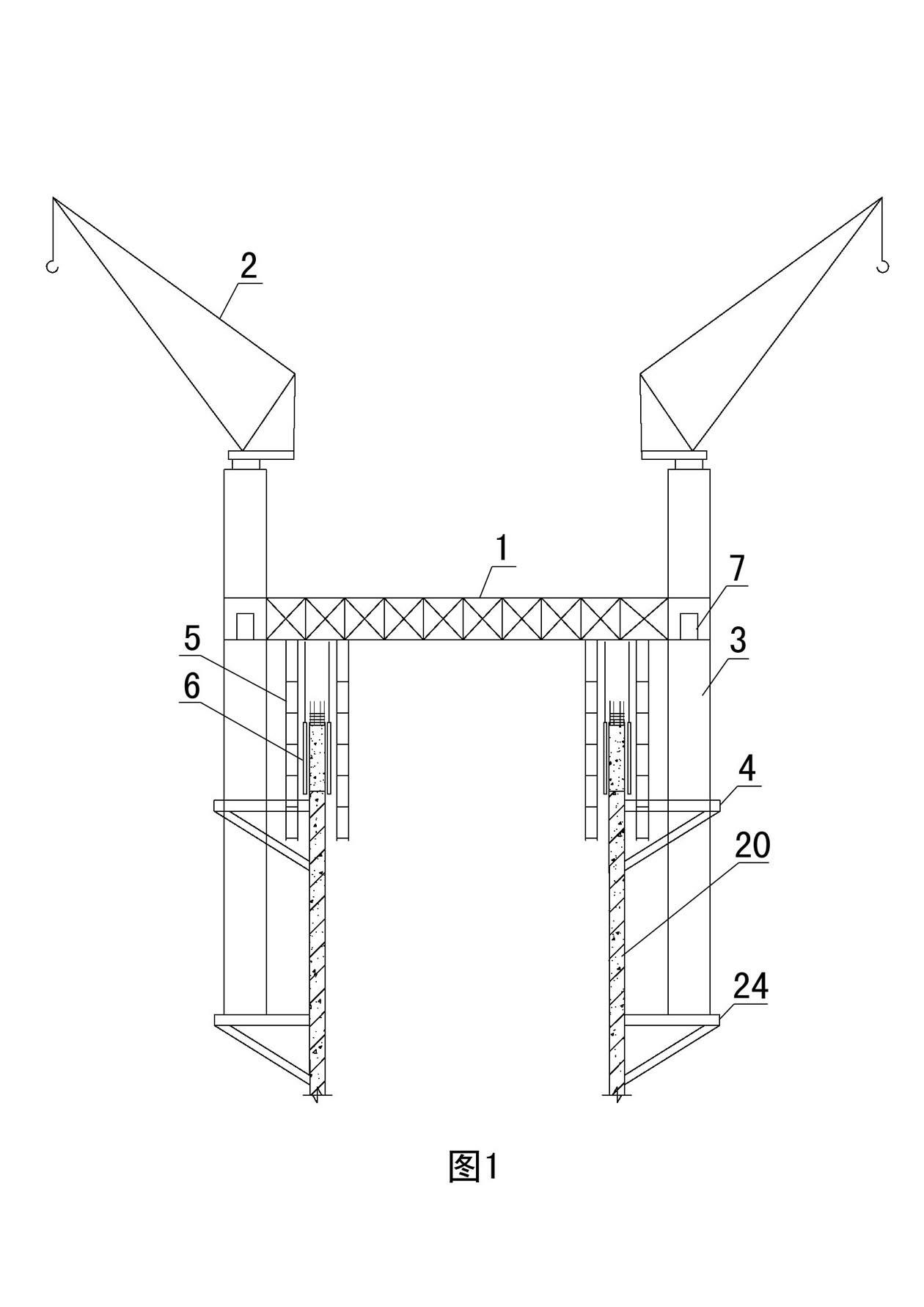

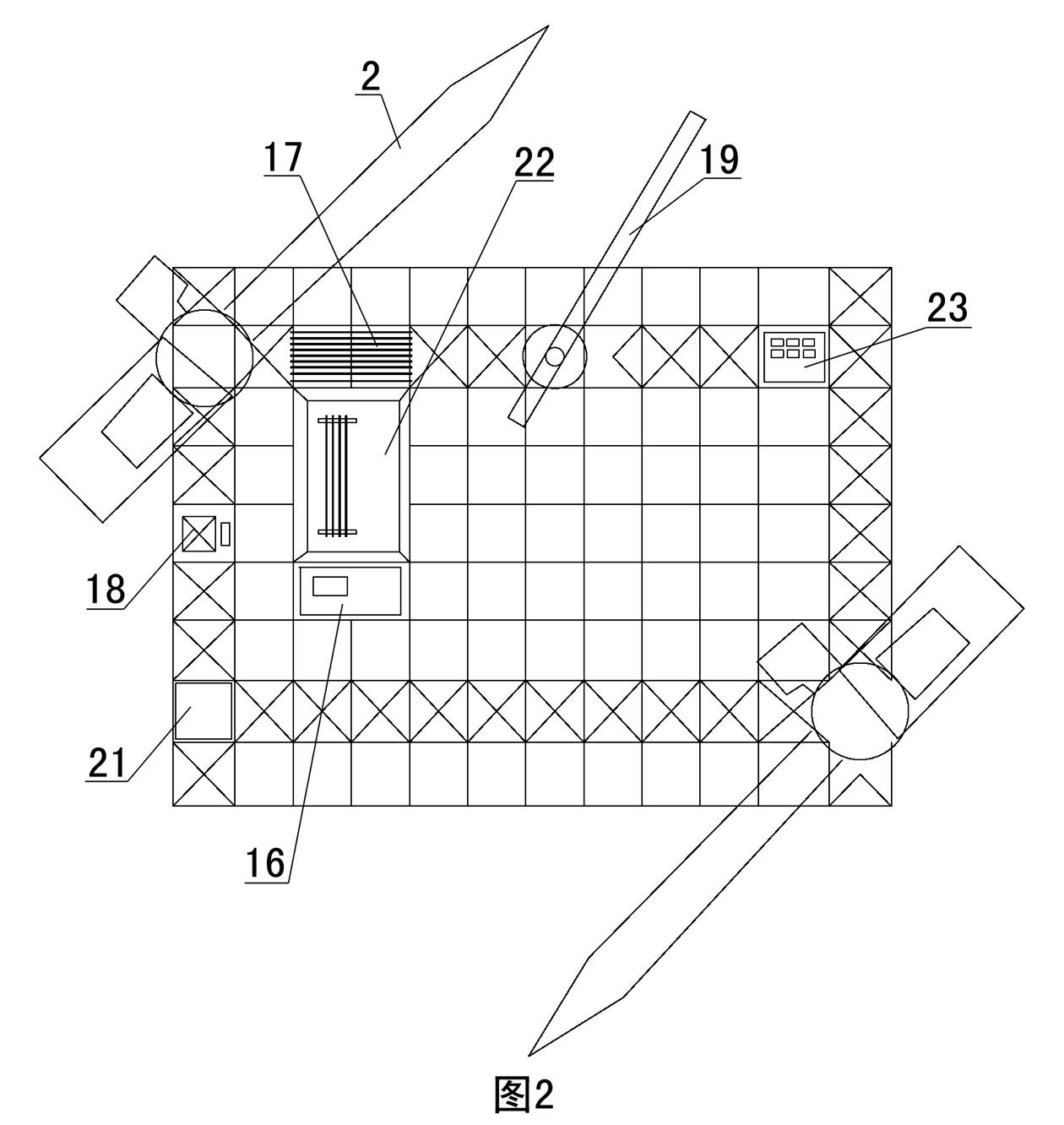

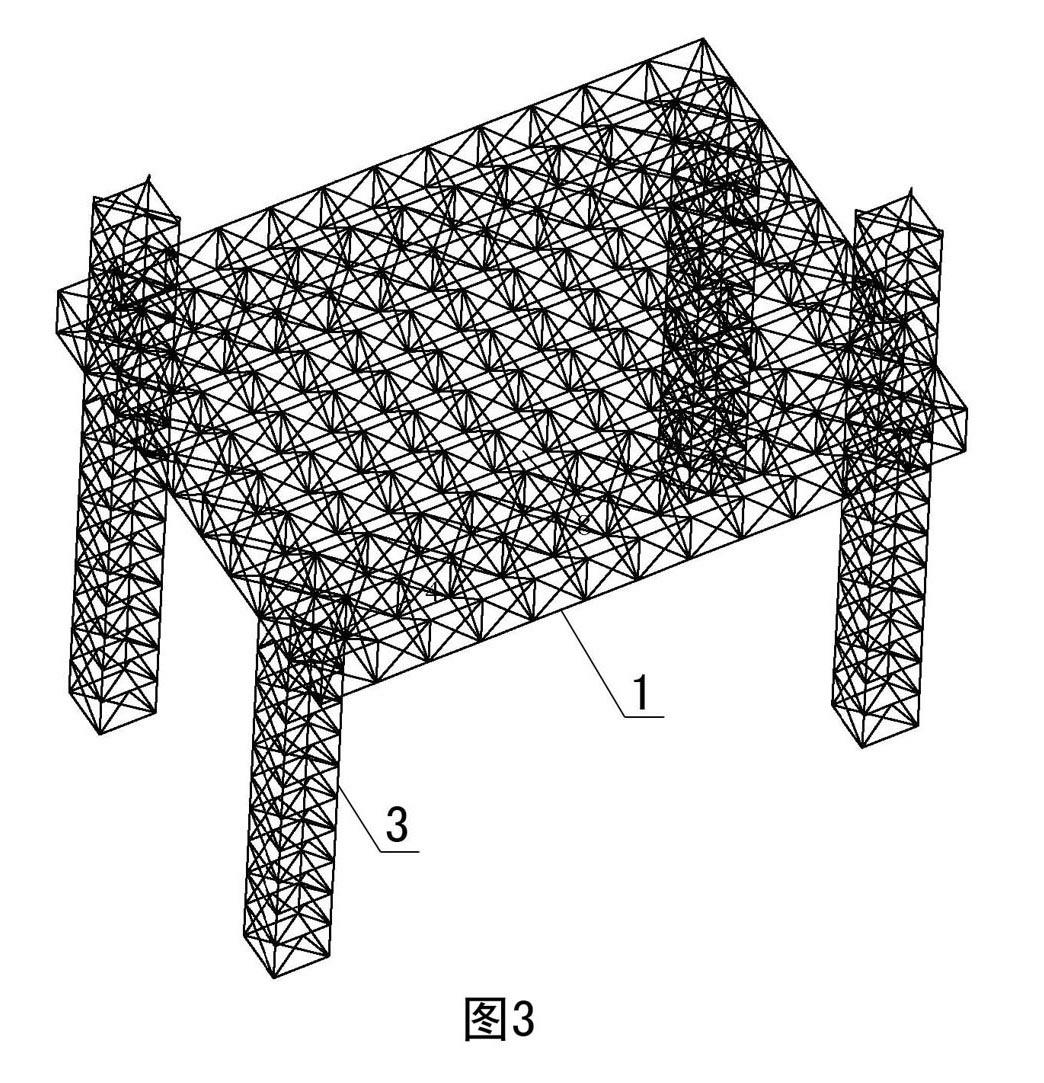

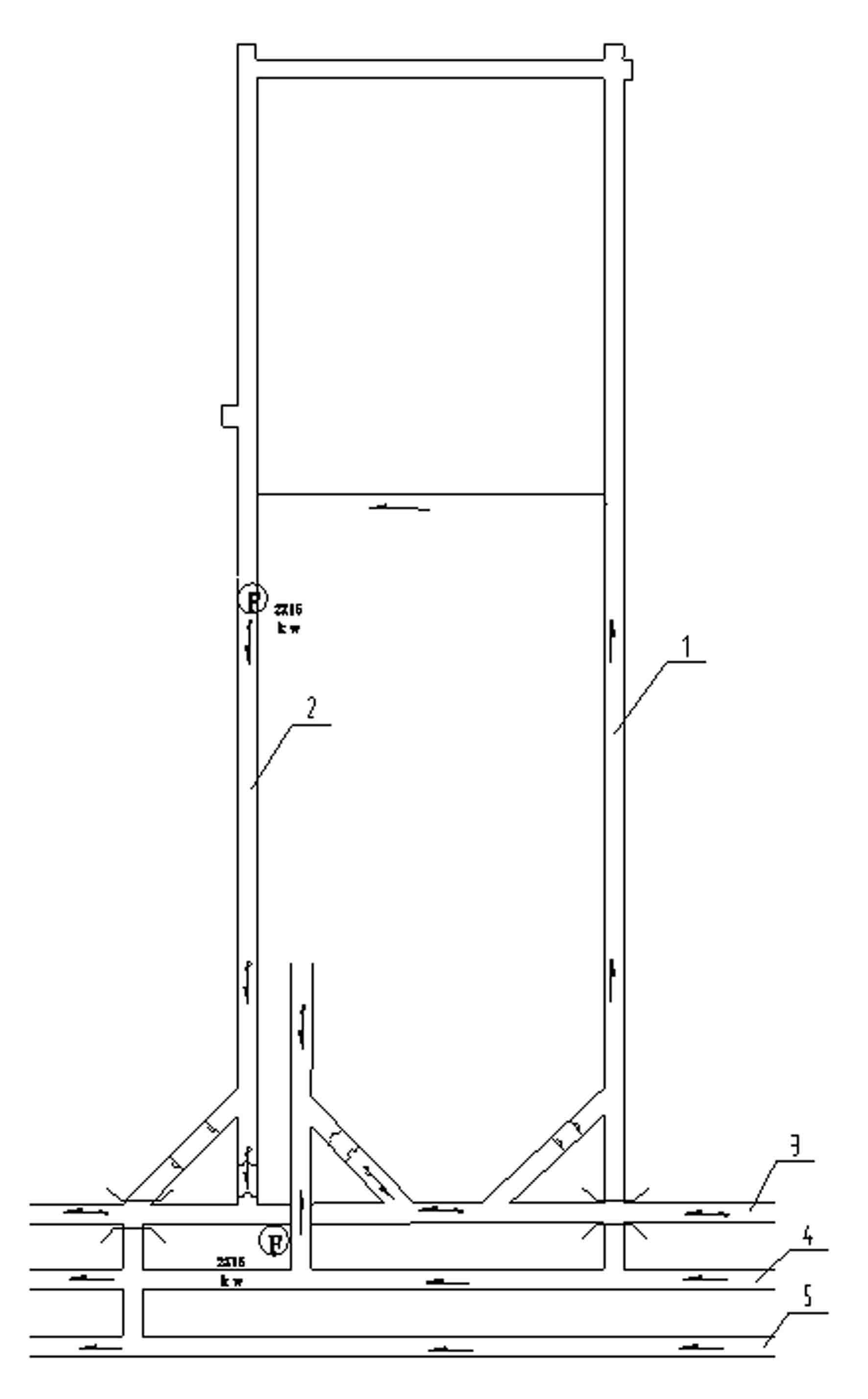

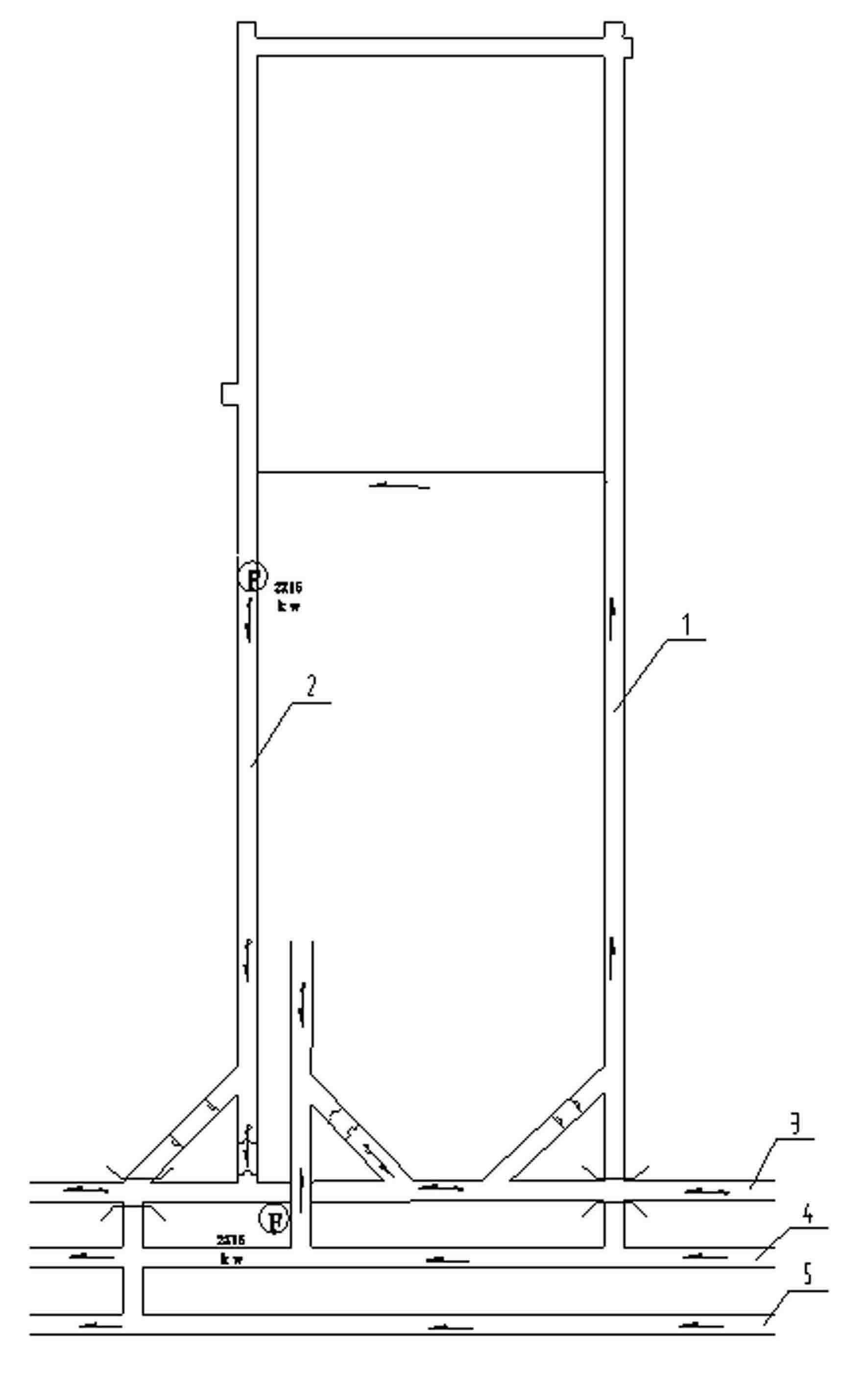

Self-jacking construction platform integrating vertical transportation equipment and mold base

ActiveCN102155089AFlexible arrangementSave timeBuilding support scaffoldsArchitectural engineeringTower crane

The invention discloses a self-jacking construction platform integrating a vertical transportation equipment and a mold base, which comprises a steel platform, construction equipment connected to the steel platform and a supporting jacking system used for connecting the steel platform to the top of a core tube of a high rise building in construction in a supporting way, wherein a spatial steel truss platform is adopted as the steel platform; the construction equipment comprises a hanging rack and a template which are arranged on the spatial steel truss platform, a tower crane, a concrete spreader, a resting place, a simple processing field, a monitoring and overhauling system, and a construction elevator, wherein the tower crane, the concrete spreader, the resting place, the simple processing field and the monitoring and overhauling system are erected on the top of the spatial steel truss platform; and the construction elevator is connected between the spatial steel truss platform and the core tube. The supporting jacking system comprises a supporting stand column, a supporting frame and a hydraulic jacking mechanism. The self-jacking construction platform is arranged flexibly, and the steel platform is supported by the supporting jacking system, therefore, heavy equipments such as the tower crane, the concrete spreader and the like can be directly arranged on the steel platform and rise synchronously with the steel platform so that the time and cost consumed by respective jacking of various large-scale construction equipments are saved, and the construction efficiency is greatly improved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

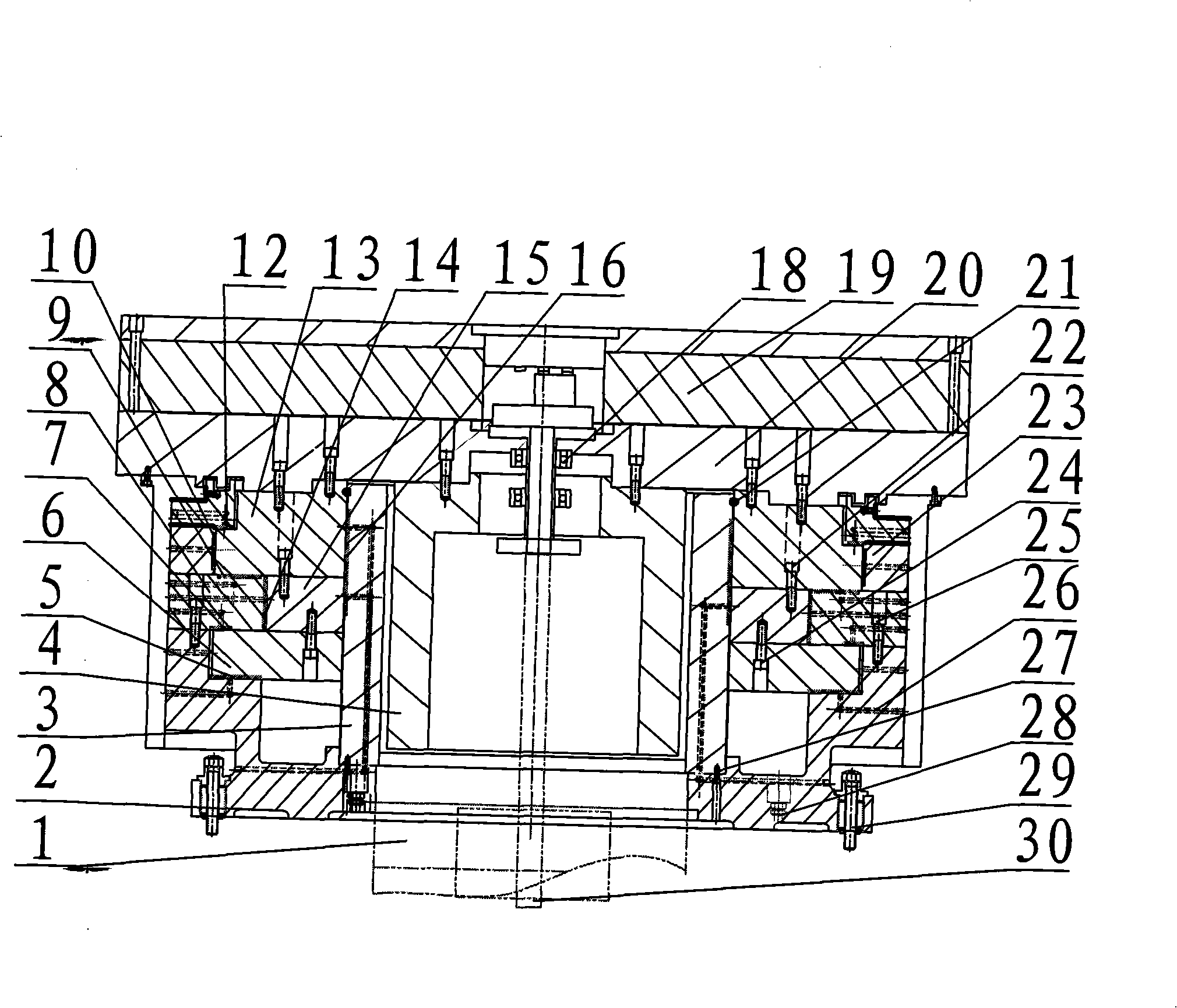

High precision high rigidity closed type fluid static pressure / dynamic-static pressure rotary table

ActiveCN101407024AImprove carrying capacityReduce volumeShaftsLarge fixed membersBall bearingKinematic pair

The invention provides a closed fluid static pressure / dynamic static pressure revolving worktable with high precision and rigidity, and relates to the field of automatic equipment of precision machinery. A plurality of axial bearings and radial bearings arranged along the axial direction are fixed by a plurality of slewing rings and bearing guide rails; the revolving worktable is provided with a balanced bearing to balance; kinematic pairs of a plurality of bearings rotate synchronously and are connected; fixed pairs of the bearings are connected through a base of the worktable; and sliding pairs of the radial bearings and bearing pairs of the axial bearings move rigidly, integrally and synchronously; and a relatively still sliding surface of the sliding pair of each bearing is provided with an oil chamber. Under the conditions that fluid pressure of the revolving worktable is same and the volume is equal, the axial rigidity, the radial rigidity and the bearing capacity are multiply improved, and the improved multiple is in direct proportion to the number of the bearings. The revolving worktable has the advantages of convenient design, simple manufacture, low cost, high precision and no abrasion. The revolving worktable is a key part of a high-precision metal working machinery, in particular to a functional part of large and oversize heavy equipment by using the key technology, and has more remarkable advantages in manufacturing equipment in the fields of navigation, astronavigation, large aircraft, and the like.

Owner:BEIJING PROSPER PRECISION MACHINE TOOL CO LTD

Ramp assembly for a vehicle tailgate

InactiveUS20090108614A1Eliminates heavy liftingImprove securityLoading/unloading vehicle arrangmentSuperstructure subunitsPickup truckEngineering

A compact ramp and tailgate system for a vehicle tailgate includes a tailgate having an interior hollow cavity for collapsible storage therein of a pair of ramps that are also telescopically extendable therefrom for loading and unloading heavy equipment into and off the bed of the vehicle such as a pickup truck with each ramp mounted to a locking hinge that allows the ramps to pivot up to ninety degrees and each ramp composed of at least three ramp members of decreasing size starting from the largest ramp members that are pivotally interconnected to the locking hinges. The ramps are independently pivotable and slidably adjustable left and right relative to the tailgate and the longitudinal extension of the vehicle for properly aligning the ramps with respect to the wheels, rollers, casters, etc., of the equipment to be on loaded and off loaded.

Owner:WASHINGTON DERRON K

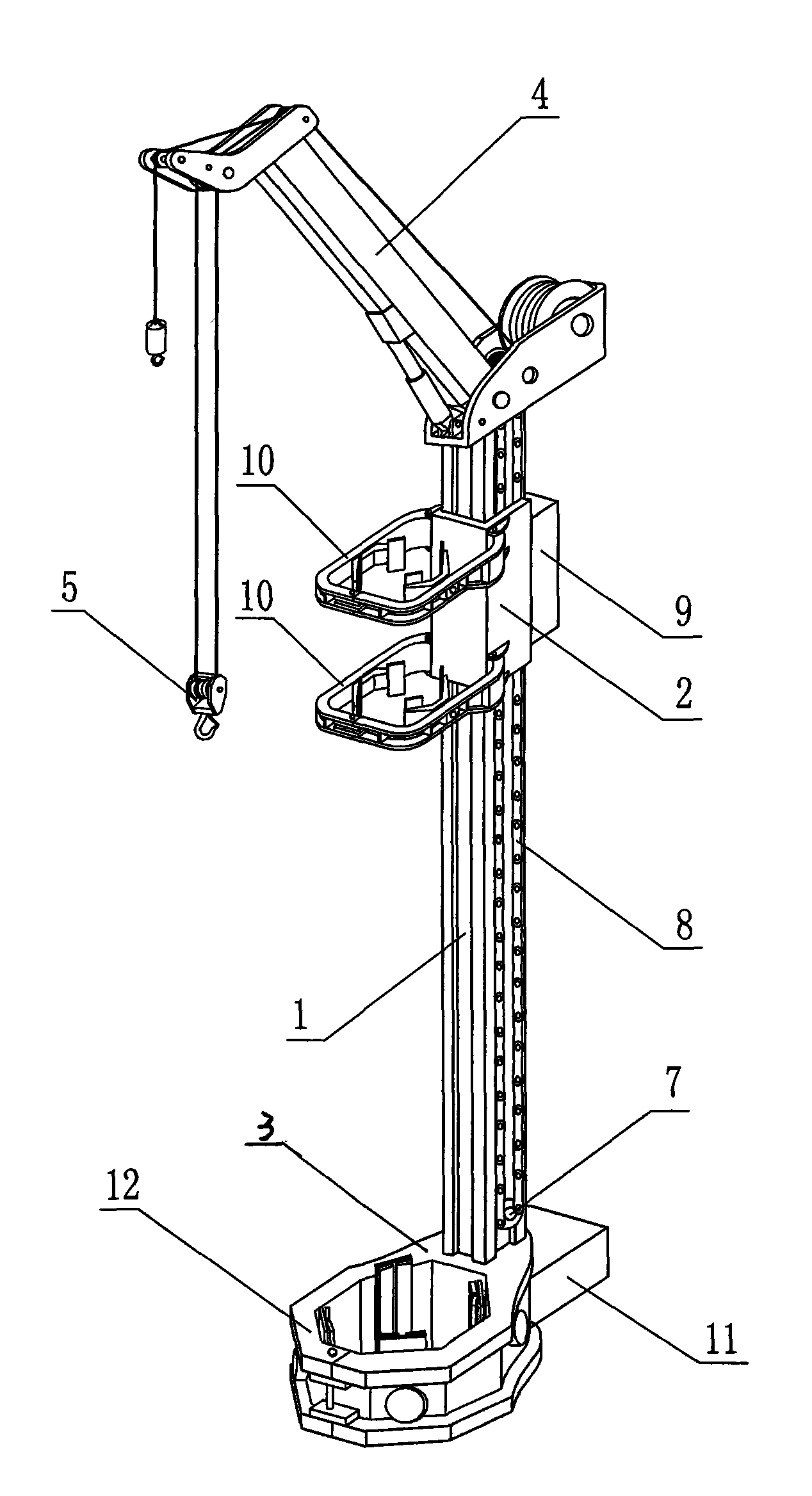

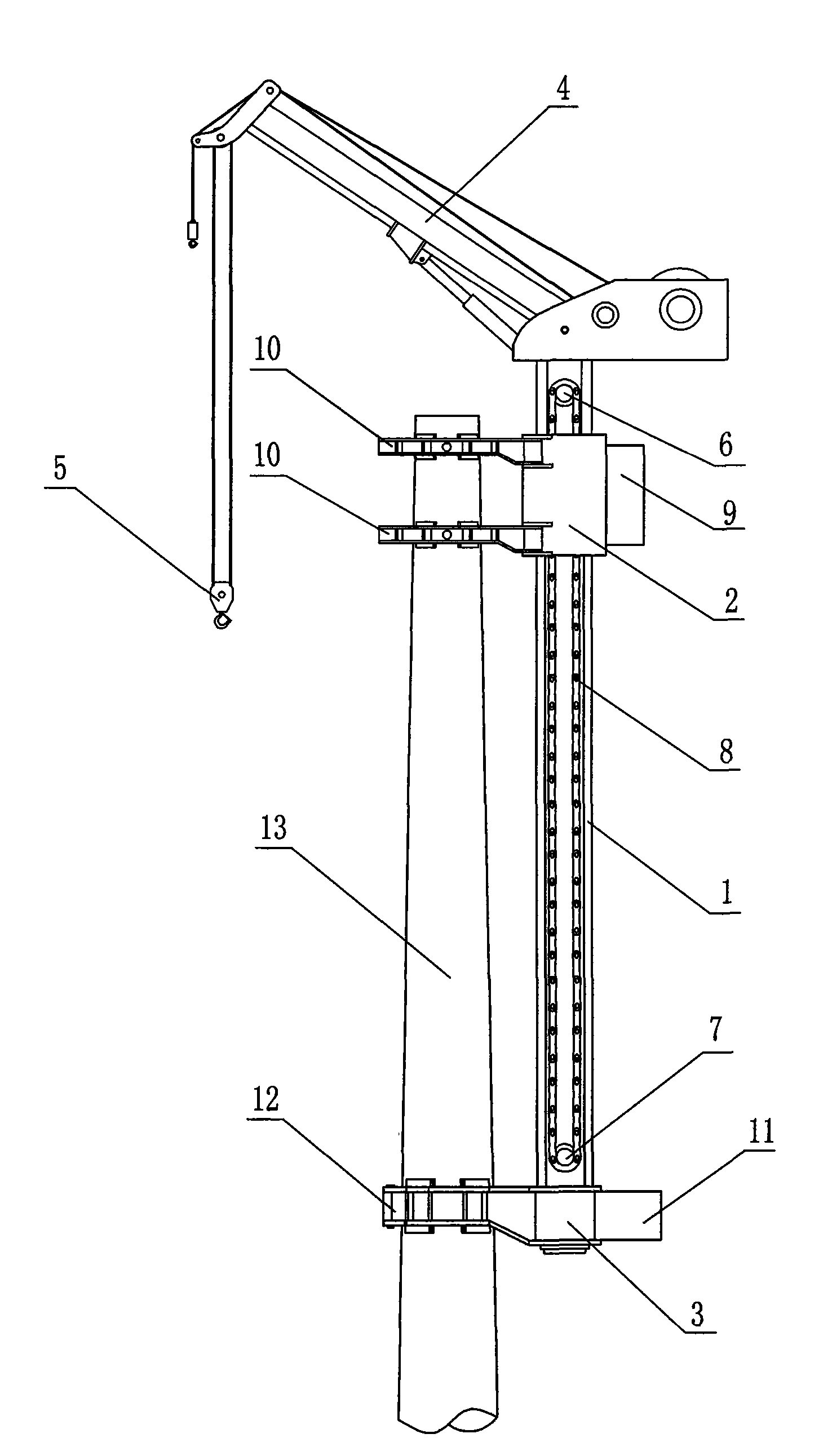

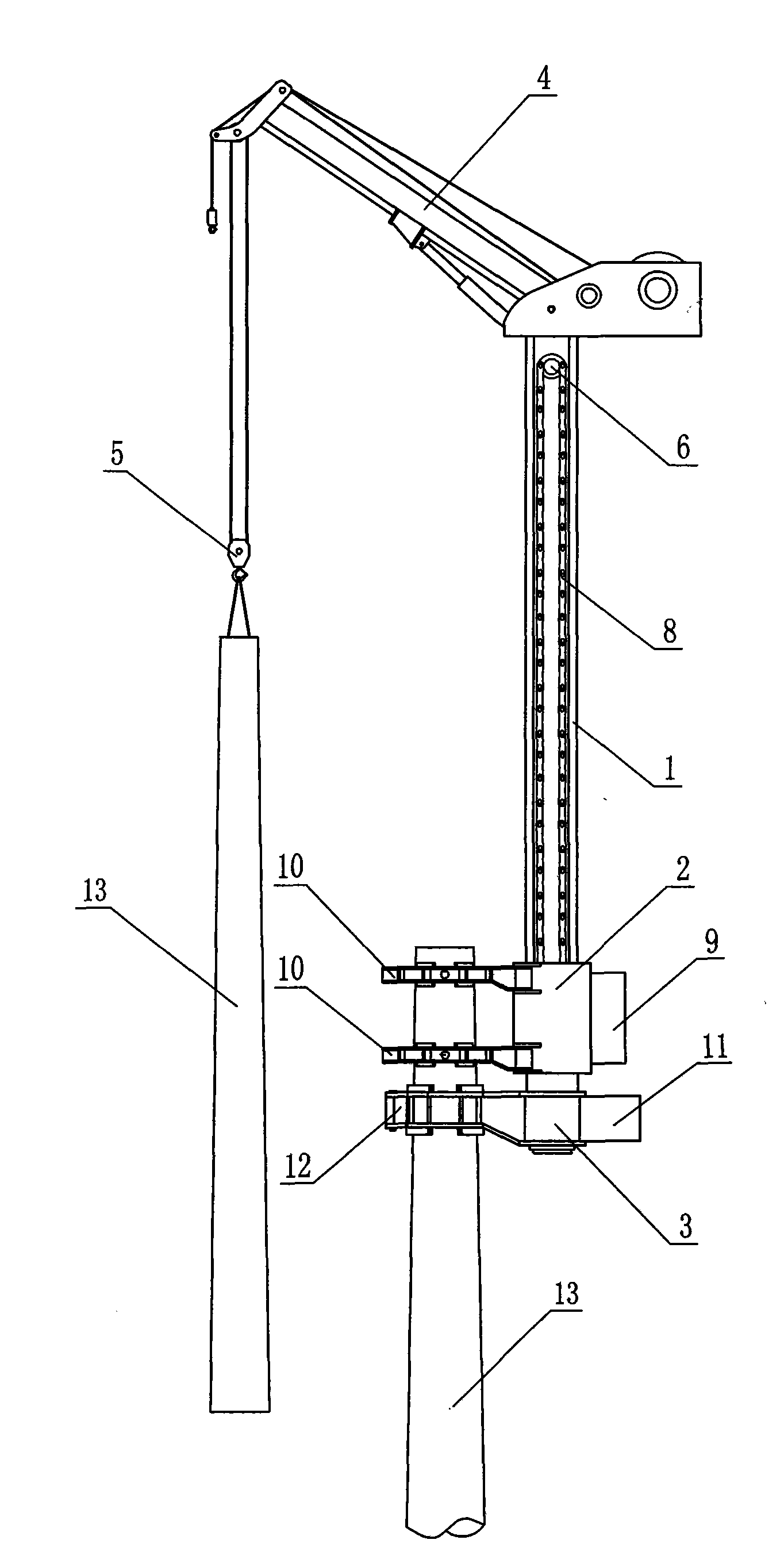

Wind power generation climbing hoisting crane

The invention relates to a wind power generation climbing hoisting crane, which belongs to hoisting machinery and consists of a machine stem, an upper holding clamp, a lower holding clamp, a hydraulic boom and a pulley hook connected with a hinging rope, wherein the upper end and the lower end in a cavity of the machine stem are provided with chain wheels which are in meshed connection by using a ring chain. The clamp body of the lower holding clamp is fixed at the lower end of the machine stem, and the clamp body of the upper holding clamp is sleeved on the outer wall of the machine stem through movable fit and an inner seat of the clamp body is provided with a ratchet to mesh the chain; and the upper holding clamp is provided with a jaw driven by a hydraulic tank, and the lower holding clamp is provided with a jaw driven by the hydraulic tank. The wind power generation climbing hoisting crane can be widely applied to large-sized wind generating sets such as the hoisting of the parts of a tower tube, an engine room, a wind wheel hub and the like, is applicable to hoisting operations of high altitude and superaltitude heavy equipment, is not limited by the maximum lifting height and fields, can perform hoisting operations on flat grounds, hillsides and sea surface, is electromechanically integrated with high automation degree, can be controlled on the ground, has light weight, is convenient for assembly and disassembly, transition and transportation, and has high operational efficiency.

Owner:张世宇

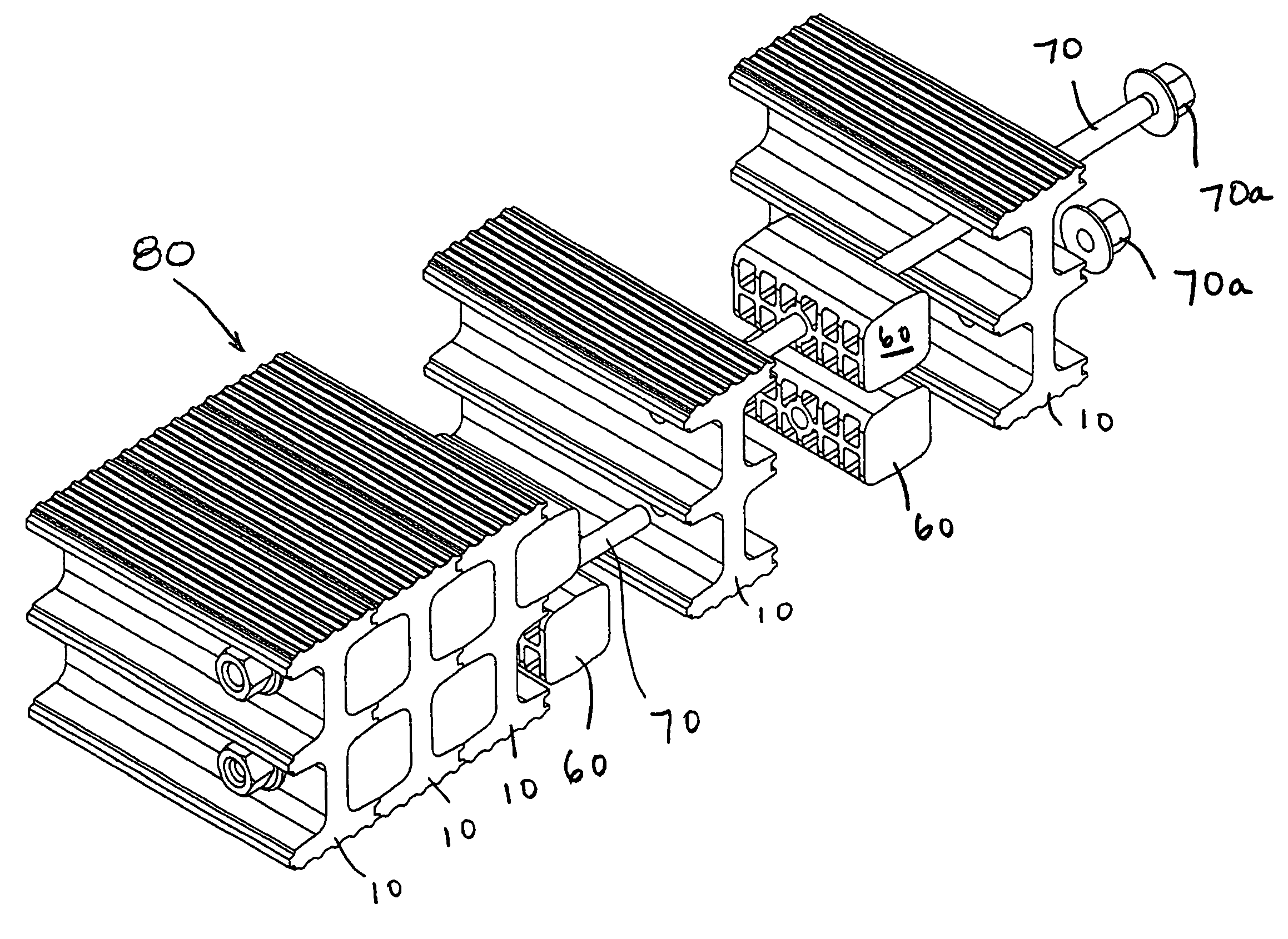

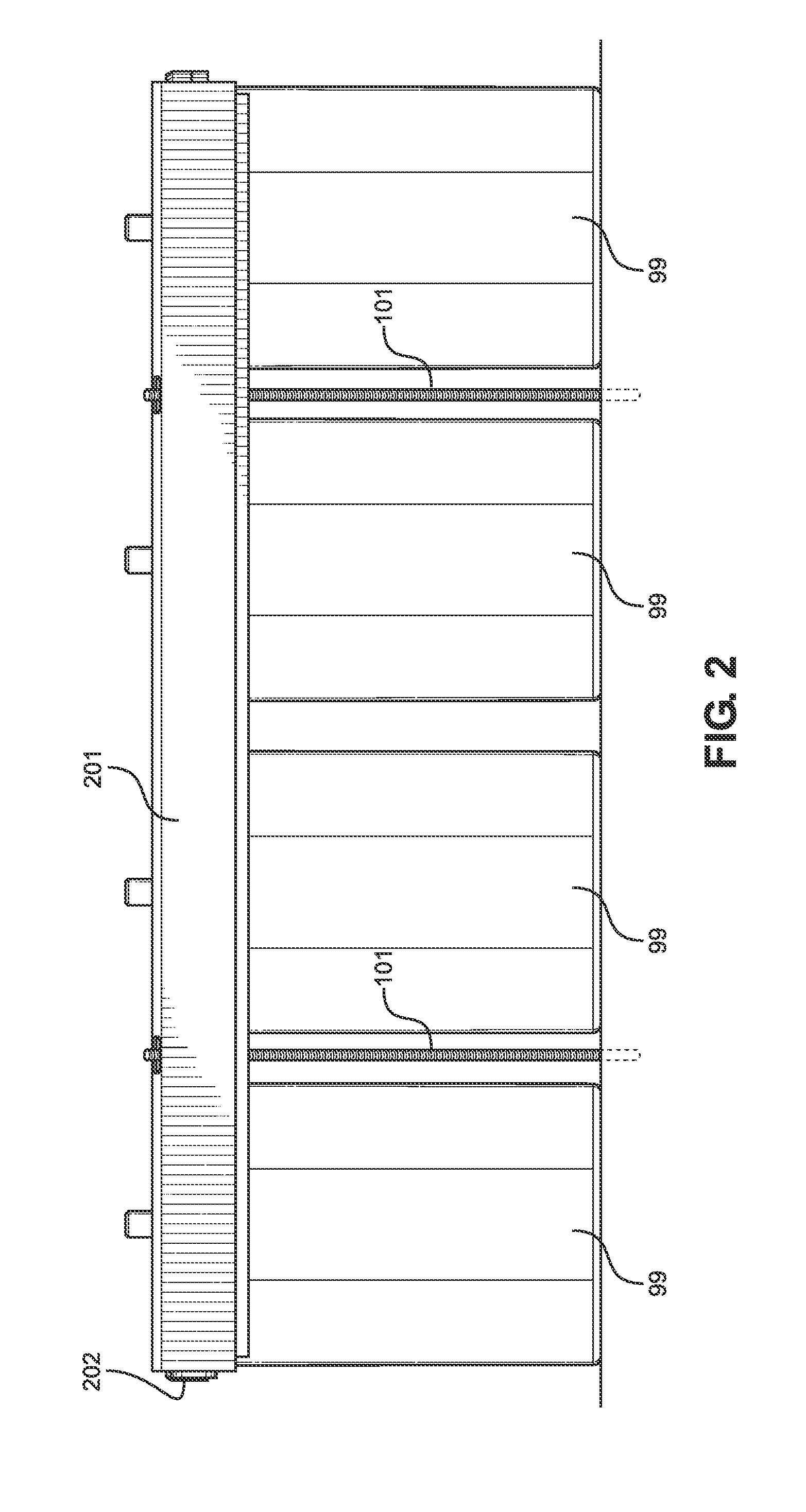

Mat assembly for heavy equipment transit and support

A mat assembly particularly suited for heavy equipment transit and support, such as roadway construction and the like. The mat assembly is made up of a number of structural members preferably having a “double I-beam” cross-sectional shape. Each I-beam has spaced apart flanges with edges preferably formed in tongue and groove profiles. When butted together, the tongue and grooves of adjacent I-beams mesh. Filler blocks are disposed in the cavities between the webs of the I-beams. Tension members extending through the webs and filler blocks tie multiple I-beams together to form the mat assembly. Preferably, both the I-beams and filler blocks are formed of a plastic material, via extrusion or other molding methods. The resulting mat is capable of bearing very high loads yet is decay resistant.

Owner:NEWPARK MATS & INTEGRATED SERVICES

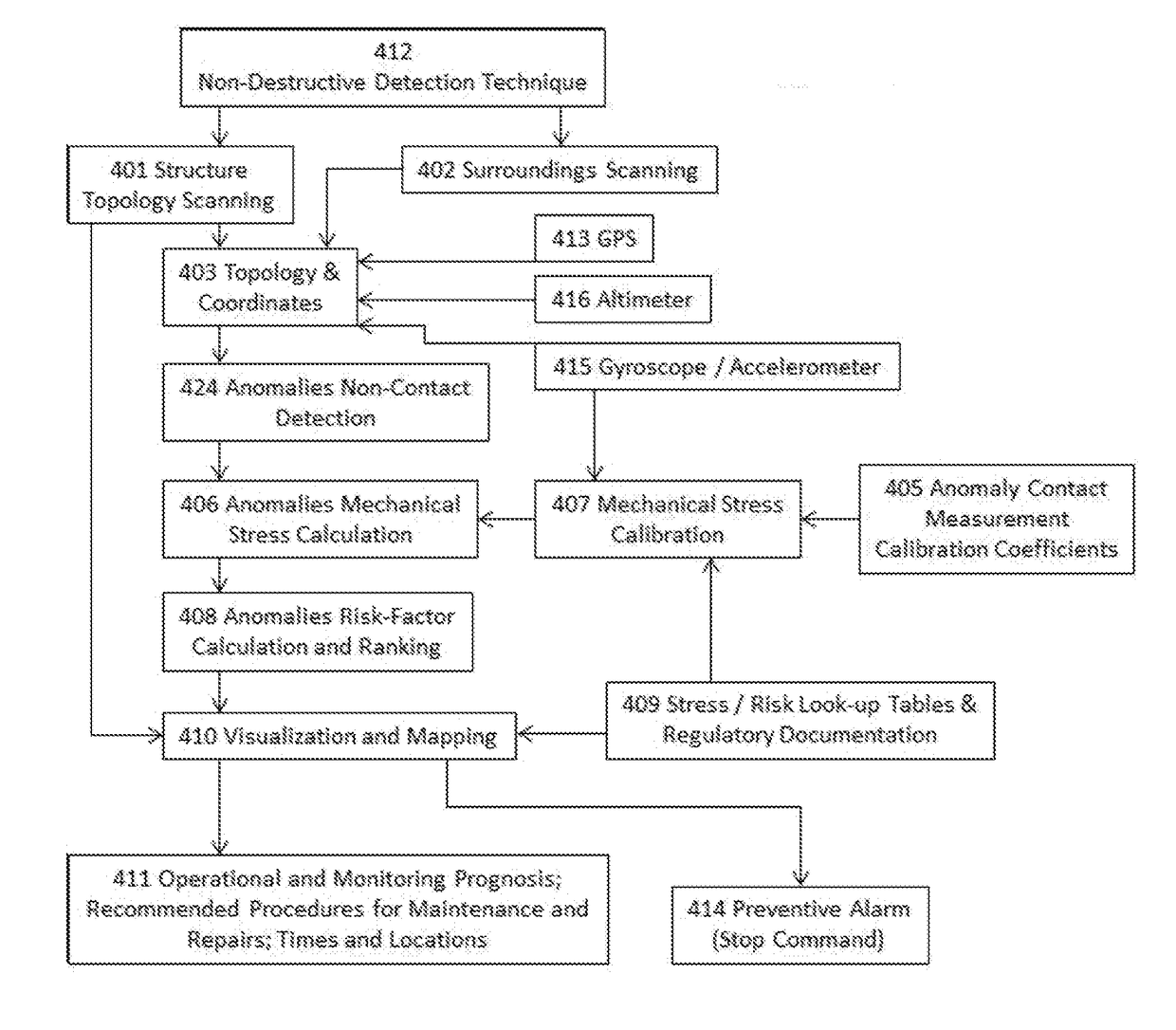

Non-destructive system and method for detecting structural defects

ActiveUS20170122909A1Stable positionImprove accuracyForce measurement by measuring magnetic property varationUnmanned aerial vehiclesEngineeringHeavy duty

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device can determine the position of the defect or stress including depth information. The device includes registration means that optimized for use with metallic structures of various types, shapes, and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in roiled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs, bridges, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

Reinforced ground cover mats

The invention is directed to reinforced ground cover mats which can be used to facilitate the passage of heavy equipment and vehicles on wet or disturbed ground. The ground cover mats are comprised of boards contained within a metal frame. A structural support in the form of an I-beam encases the boards and frame on one side, and a tubular member such as a pipe on the other side, thereby increasing the strength at the middle of the mat ends. Further, the tubular member can be modified at its ends to facilitate insertion of a sling and stacking of adjacent mats. The mat also comprises means for lifting, including passages through which chains or cable may be threaded, lifting shackle assemblies or pear link assemblies.

Owner:MAXXIMAT

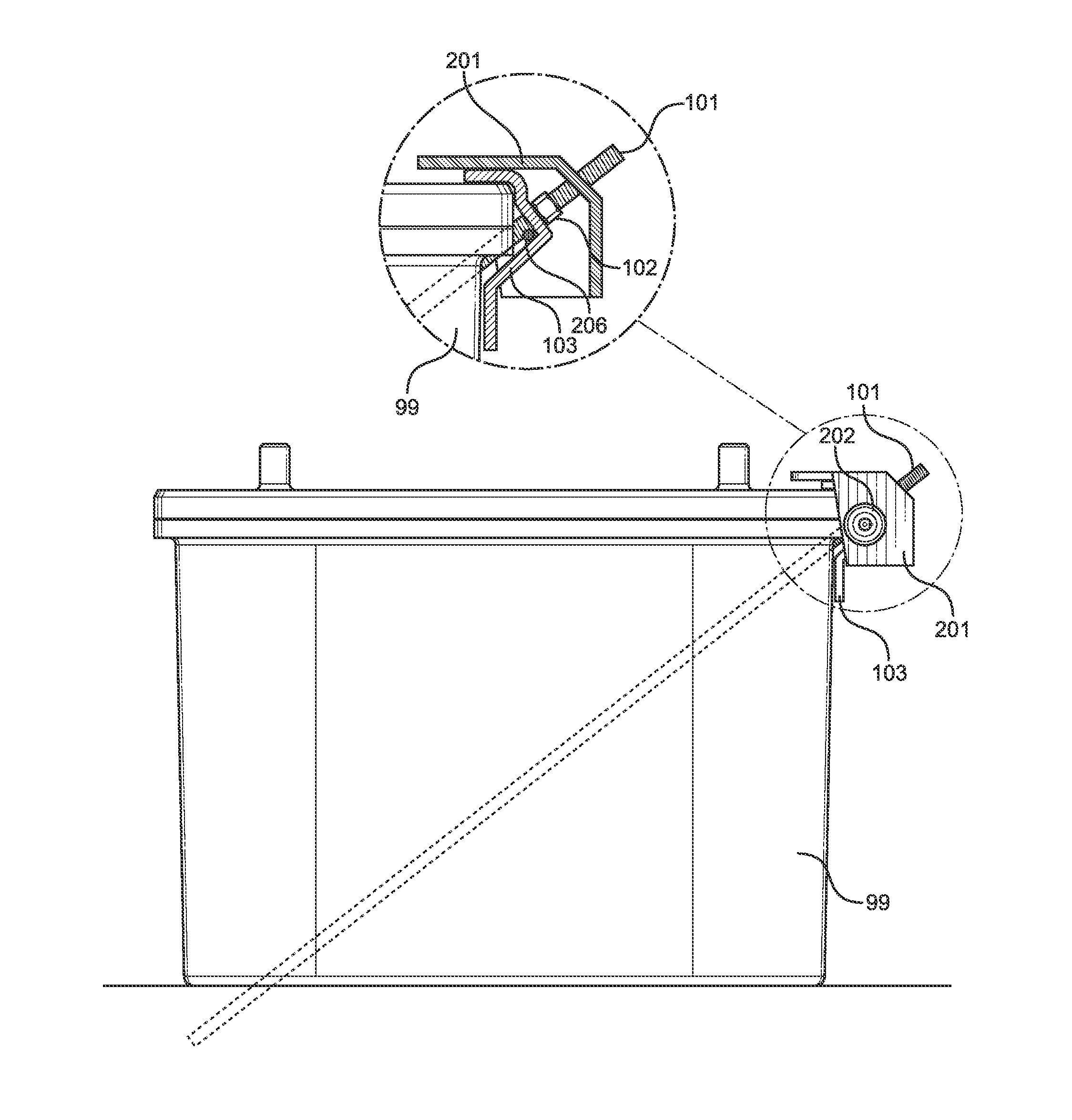

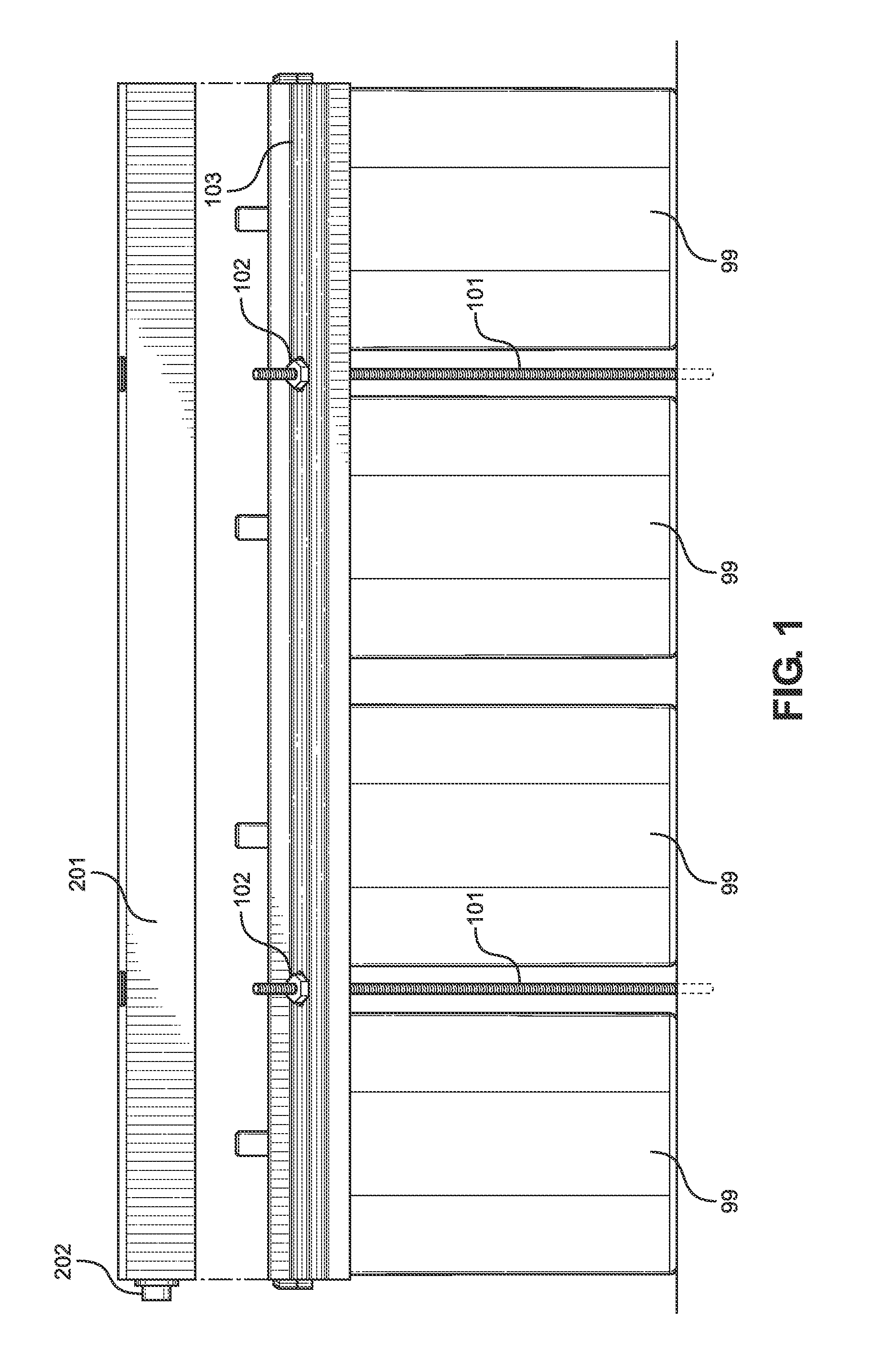

Commercial motor vehicle and heavy equipment battery locking device and system for use

InactiveUS20150089981A1Fit tightlyVehicle locksLocks for portable objectsMobile vehicleElectrical battery

The present invention relates to a commercial motor vehicle and heavy equipment battery locking device, methods of producing the same, and methods of utilizing the same. In particular, the present invention relates to a lockable device that covers the hold-down nut(s), hold-down bolt(s), and / or hold-doom bracket(s) that secure a battery to a commercial motor vehicle or heavy equipment so that the battery cannot be stolen as well as a system for production and use.

Owner:MILES AHEAD INNOVATIONS

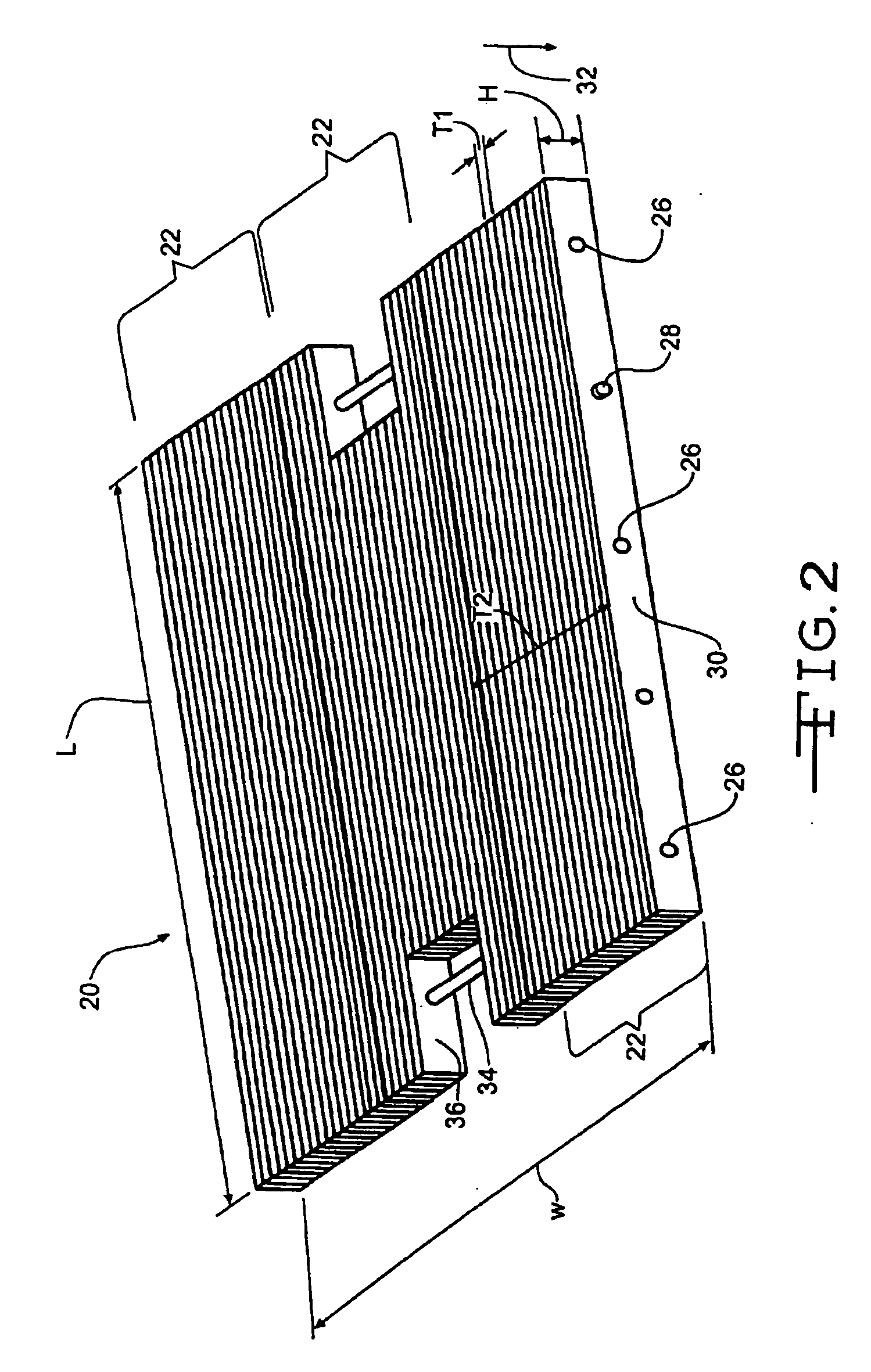

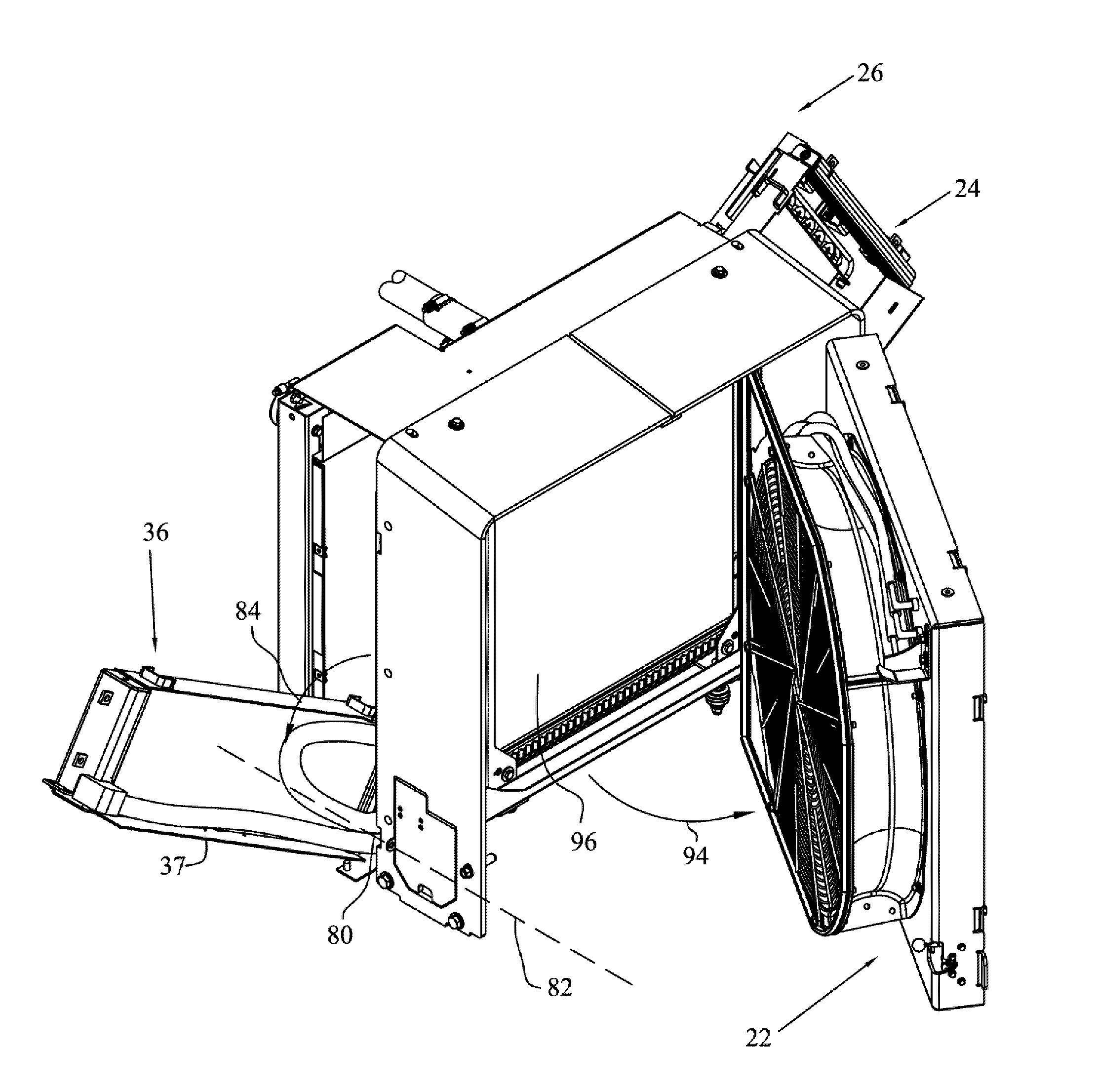

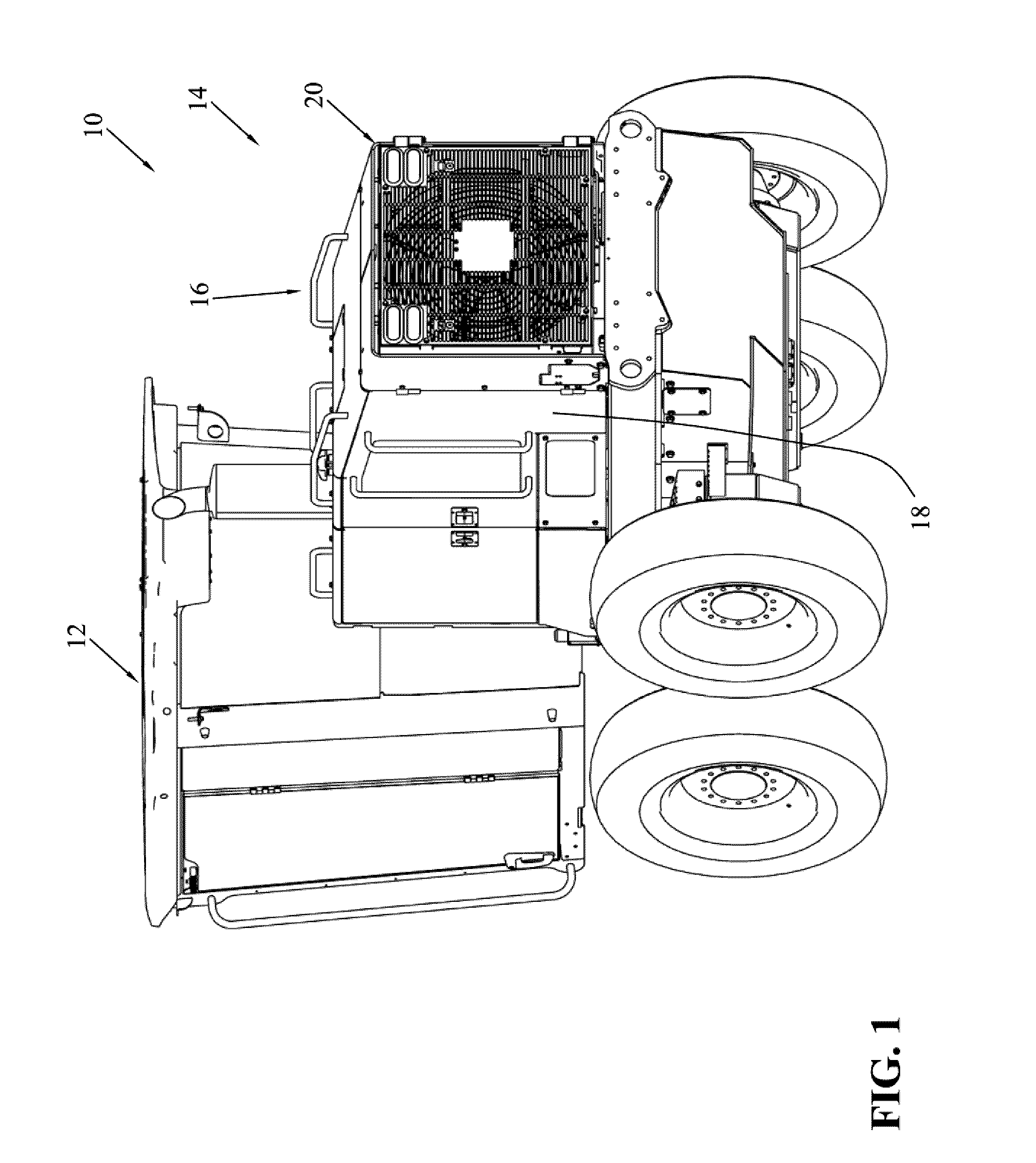

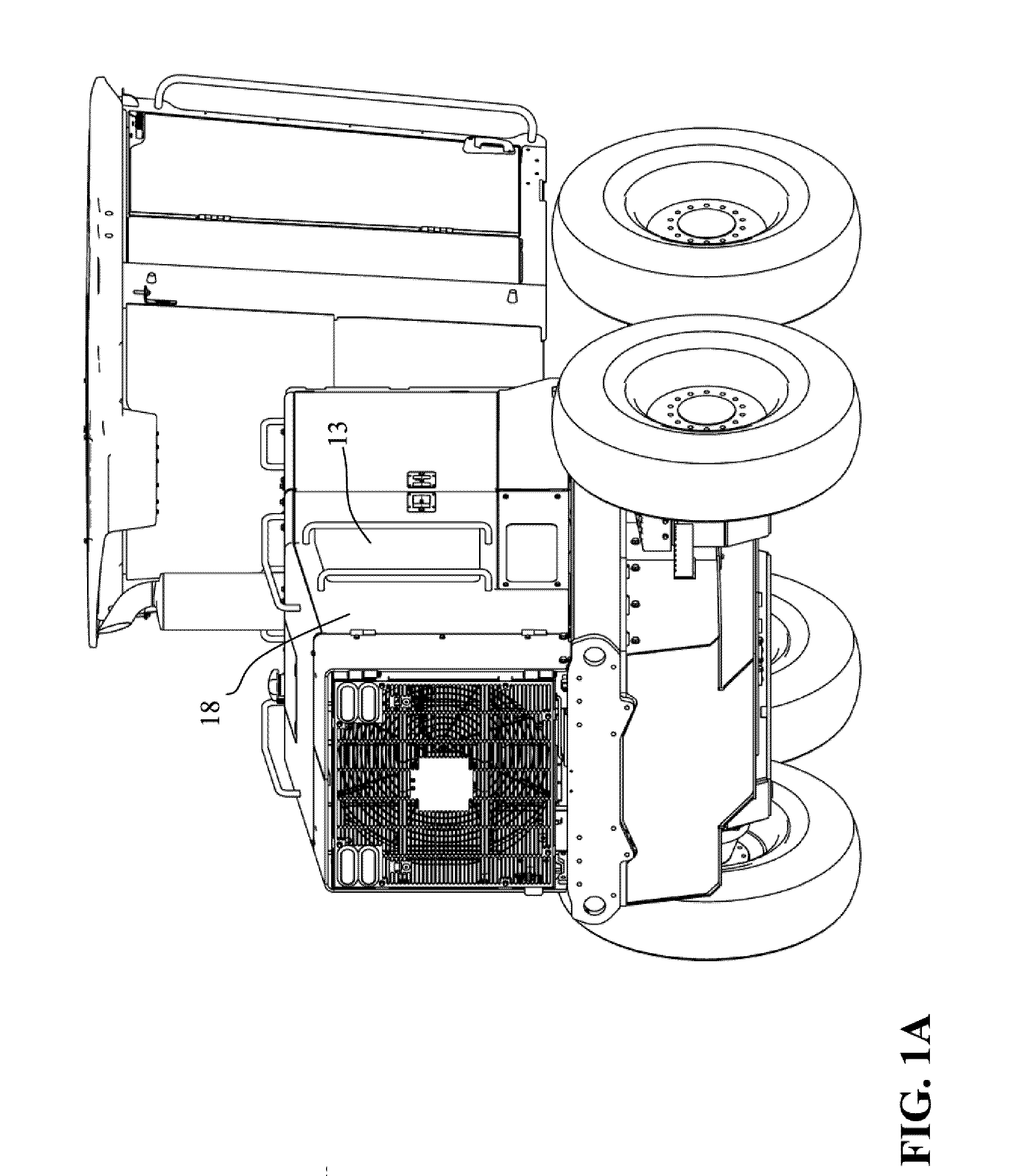

Stacked Heat Exchanger System with Swing-Out Heat Exchangers

A heat exchanger system for use with heavy equipment including a heat exchanger rotatable about a horizontal axis out of a frame.

Owner:DEERE & CO

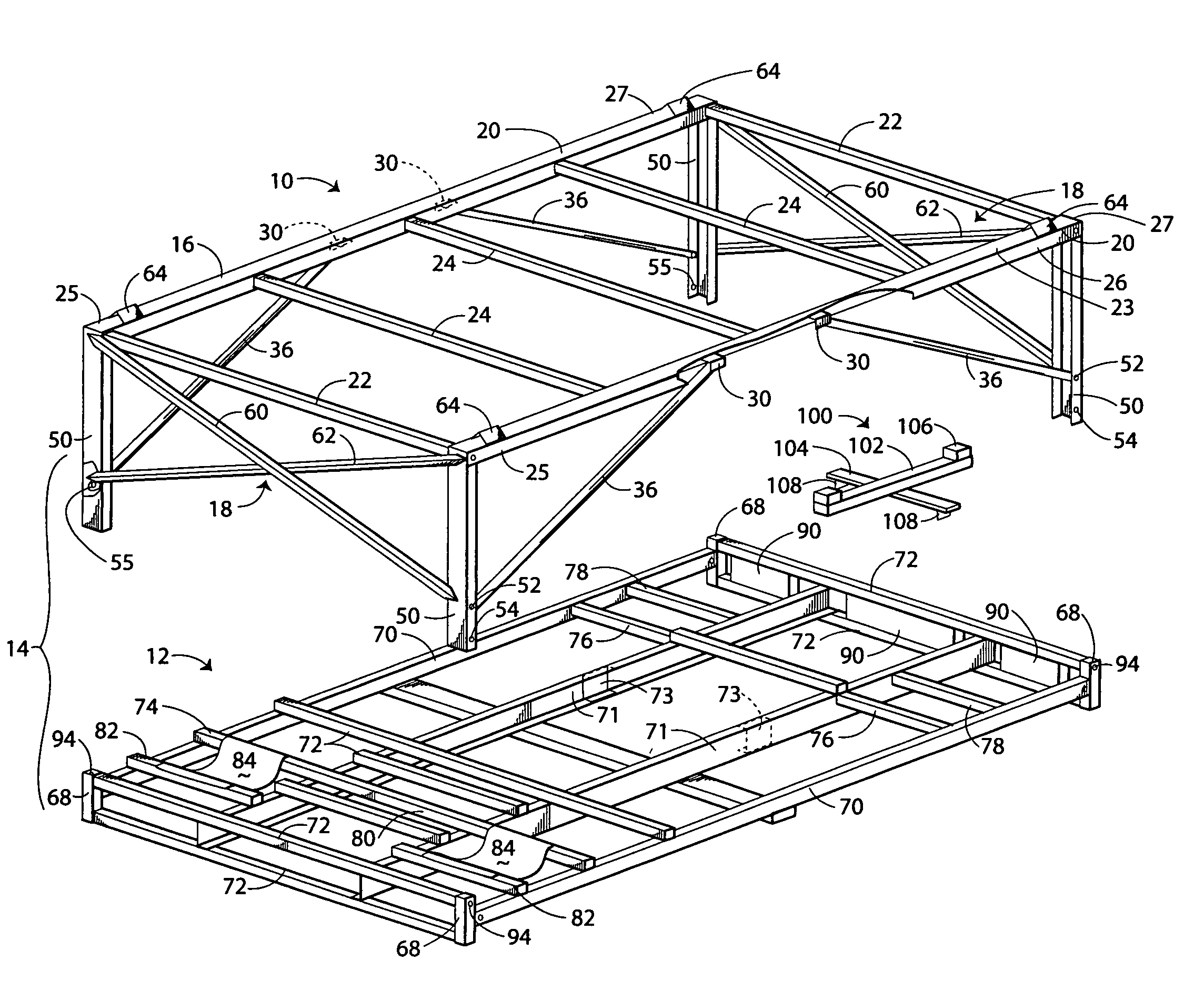

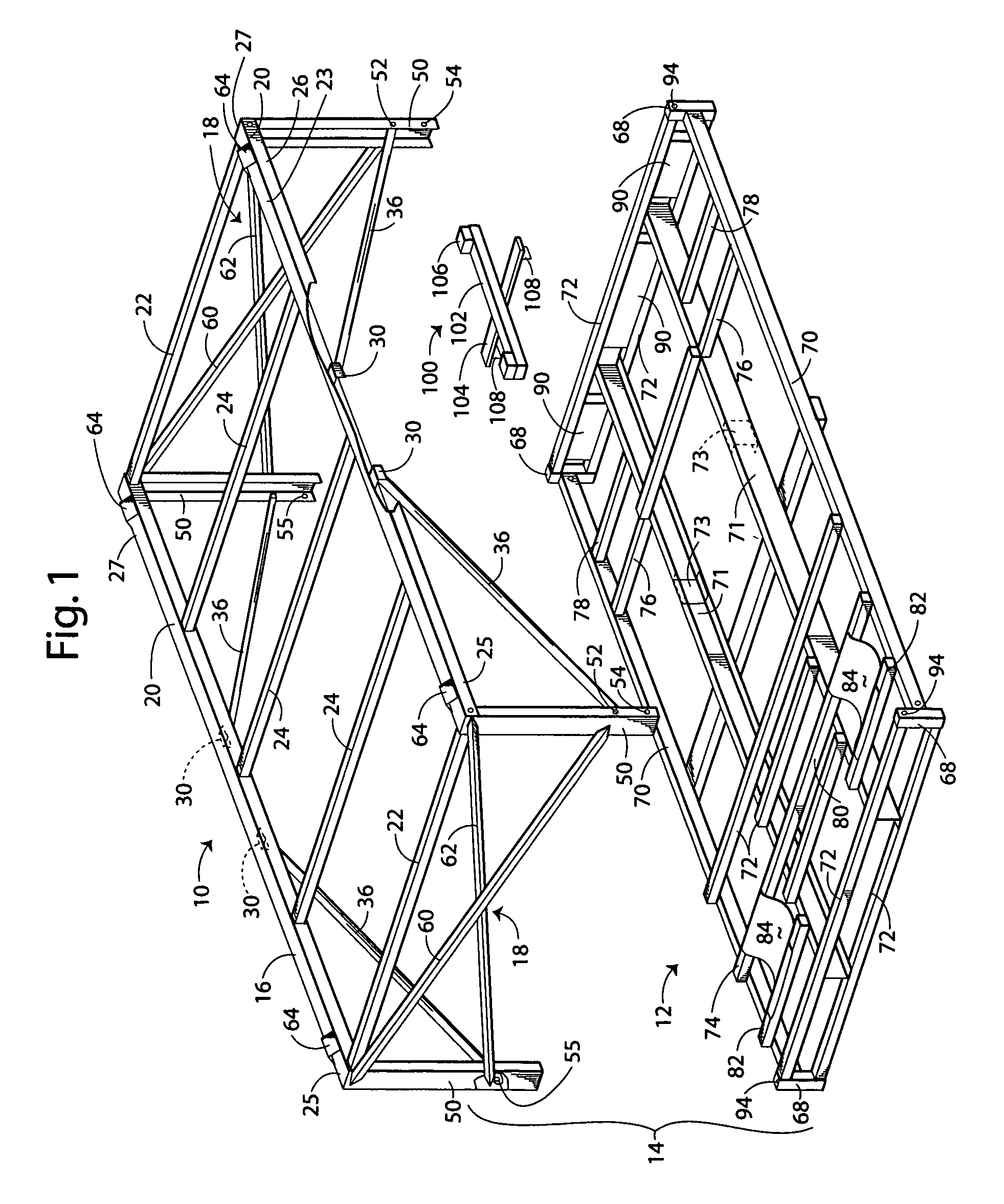

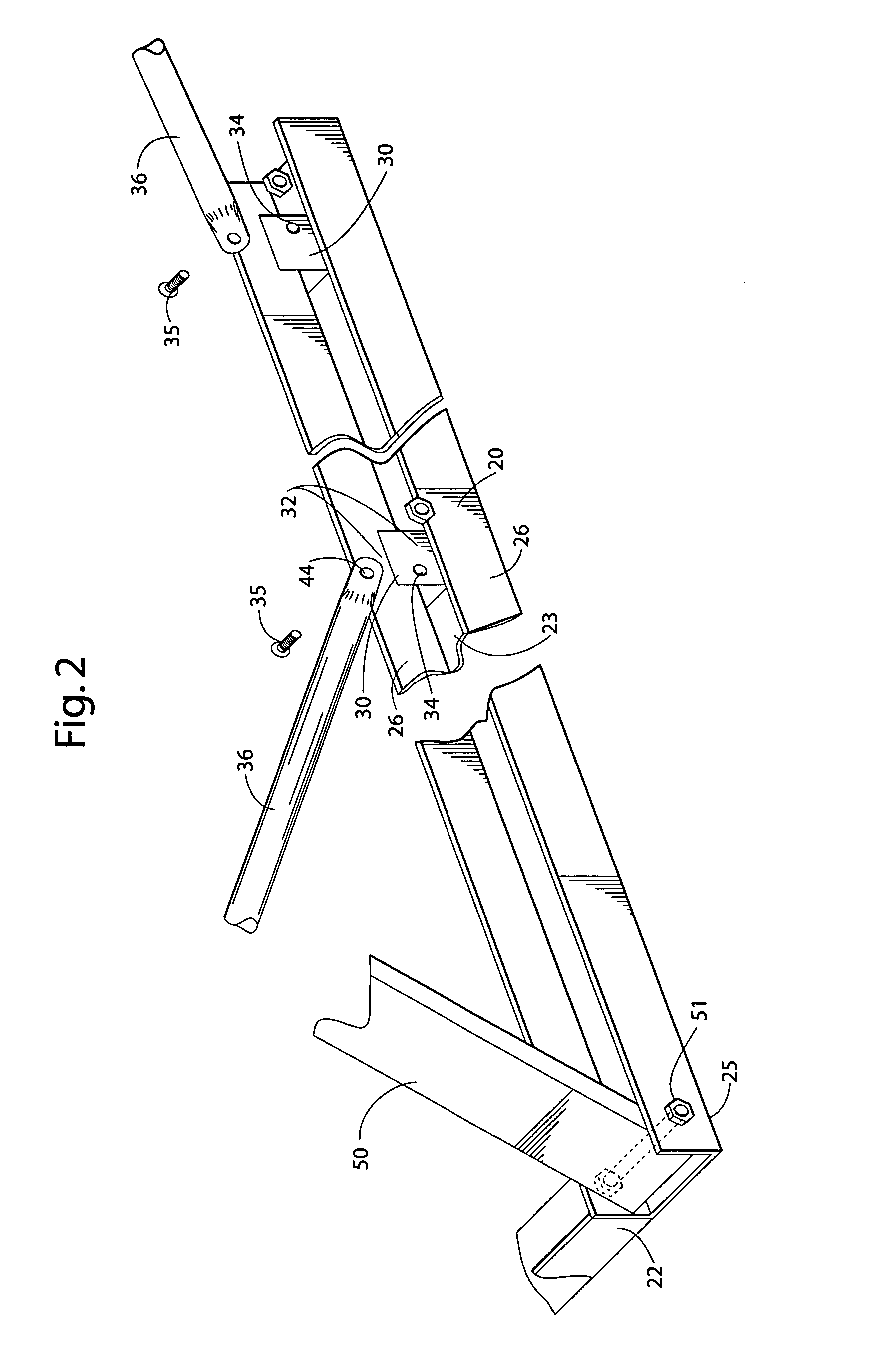

Top and foldable end frame assembly for pallet container

A top and end frame assembly (10) attachable to a pallet (12) for packing, shipping, and storing heavy articles, with a pair of stringers (20) made with open-sided U-shaped channels and connected together by transverse members (22, 24). Two pairs of opposing corner posts (50) each formed of an open-sided U-shaped channel pivotally attach at respective opposing distal ends of the stringers (20). Each corner post (50) moves between a folded position with the corner posts received in the respective stringer for shipping in a knocked-down position and an extended position for attaching to a pallet for a frame container. Two pairs of opposing side diagonal members (36) pivotally attach to a respective one of the stringers and move between a received position within the stringer and a diagonal position for pinning at an opposing end to a respective one of the corner posts. The corner posts being pivoted to the extended position attach at distal ends to the pallet (12) for containing heavy equipment.

Owner:UNIVERSAL FOREST PRODUCTS

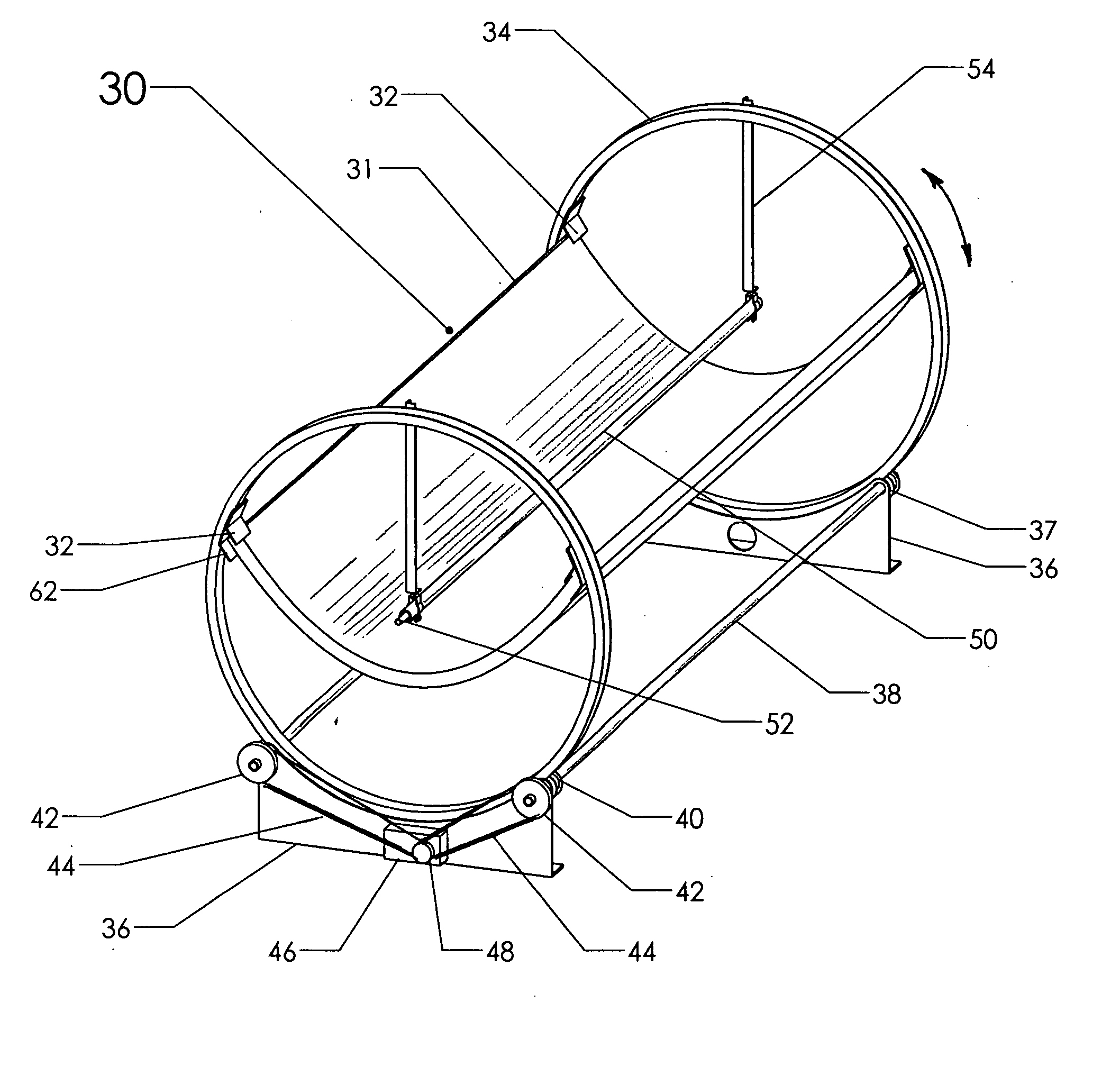

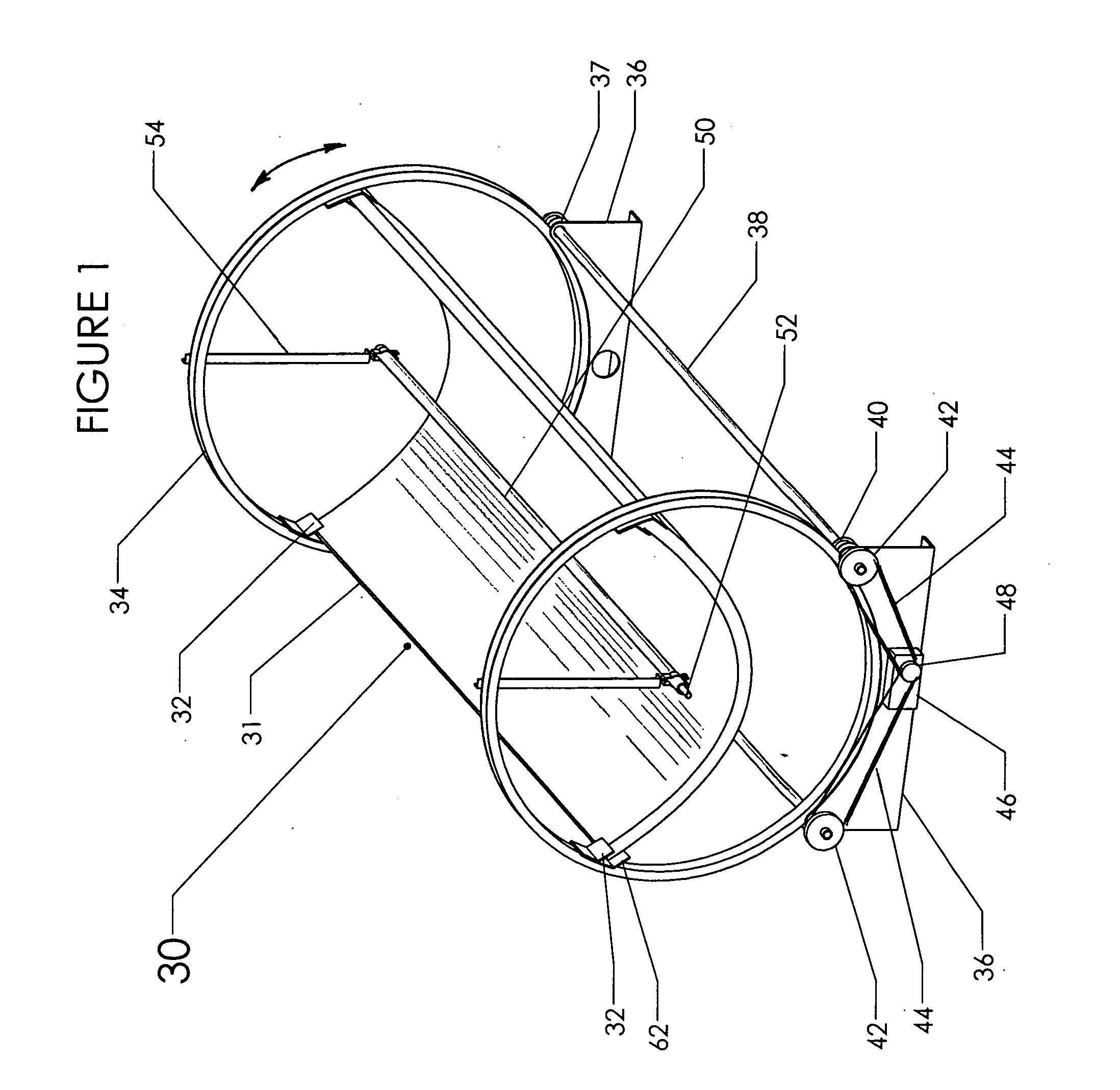

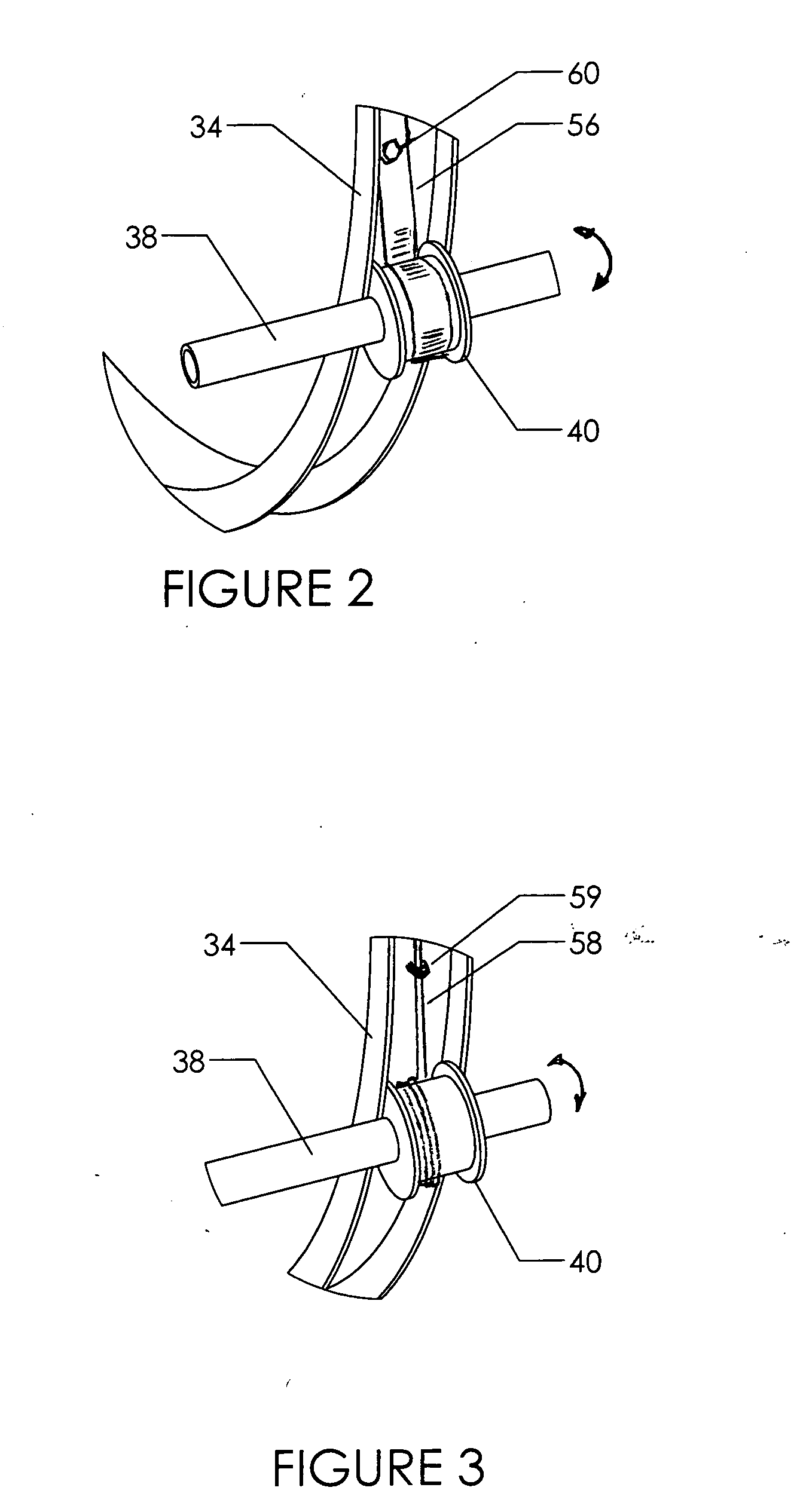

Low Cost Fixed Focal Point Parabolic Trough

InactiveUS20110100358A1Reduce quality problemsImprove rigiditySolar heating energySolar heat devicesEngineeringHeavy equipment

In accordance with one embodiment, a parabolic trough system is disclosed to capture solar heat. It has low mass, high rigidity and precise robust rotational control. The trough does not require massive supports, since it use a “sandwich structure” where the core is lightweight urethane foam and the skin is made of aluminum sheet. The inside skin also functions as the parabolic reflector. The shape minimizes wind loads by centering the receiver in the parabola and by making the center of focus the center of rotation.The system can be rapidly built in the field since there are few parts. Assembly does not require heavy equipment. Support posts are used on both sides of the trough to minimize the anchoring requirements in wind loads.The trough bodies are rotated in a rotational control mechanism that uses circumscribing rings to support a continuous row of troughs that can sustain 120 mile per hour winds. Optical performance is improved with the drive ring design. The structure is continuous and torque is uniformly applied to each ring through two spools supported on drive tubes. A cable is wrapped around each spool as well as around the top part of the ring. As the spools rotate, they pull the cable and rotate the rings and troughs with precision and strength. The spools and cables also restrain the system under high wind loads.

Owner:PERISHO RANDAL JEROME

Safe moving and withdrawing method of complex-structured thick coal seam fully mechanized heavy equipment

ActiveCN102094675AGuarantee support safetySafe and quick removalUnderground transportAnchoring boltsFully developedYard

The invention discloses a safe moving and withdrawing method of complex-structured thick coal seam fully mechanized heavy equipment. A moving and withdrawing route comprises a moving and withdrawing transport route through an assisted transport gate road, i.e. from a working face to the assisted transport gate road to an assisted transport gate road roundabout channel to an assisted transport tunnel to an auxiliary adit to a stock yard, and a moving and withdrawing transport route through a belt gate road, i.e. from the working face to the belt gate rod to a return airway to the assisted transport tunnel to the stock yard; and a reasonable mining-stopping supporting method and a roof supporting method during the period of moving and withdrawing are simultaneously combined. By virtue of the moving and withdrawing method, maximum effectiveness of labor force and equipment resources are fully developed, long-distance comprehensive transportation of the thick coal seam fully mechanized heavy equipment is realized, and safe and fast moving and withdrawing of facilities in the working surface is ensured.

Owner:DATONG COAL MINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com