Wind power generation climbing hoisting crane

A technology of cranes and machine-drying, which is applied to cranes and other directions, and can solve problems such as heavy disassembly and loading, difficulty, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

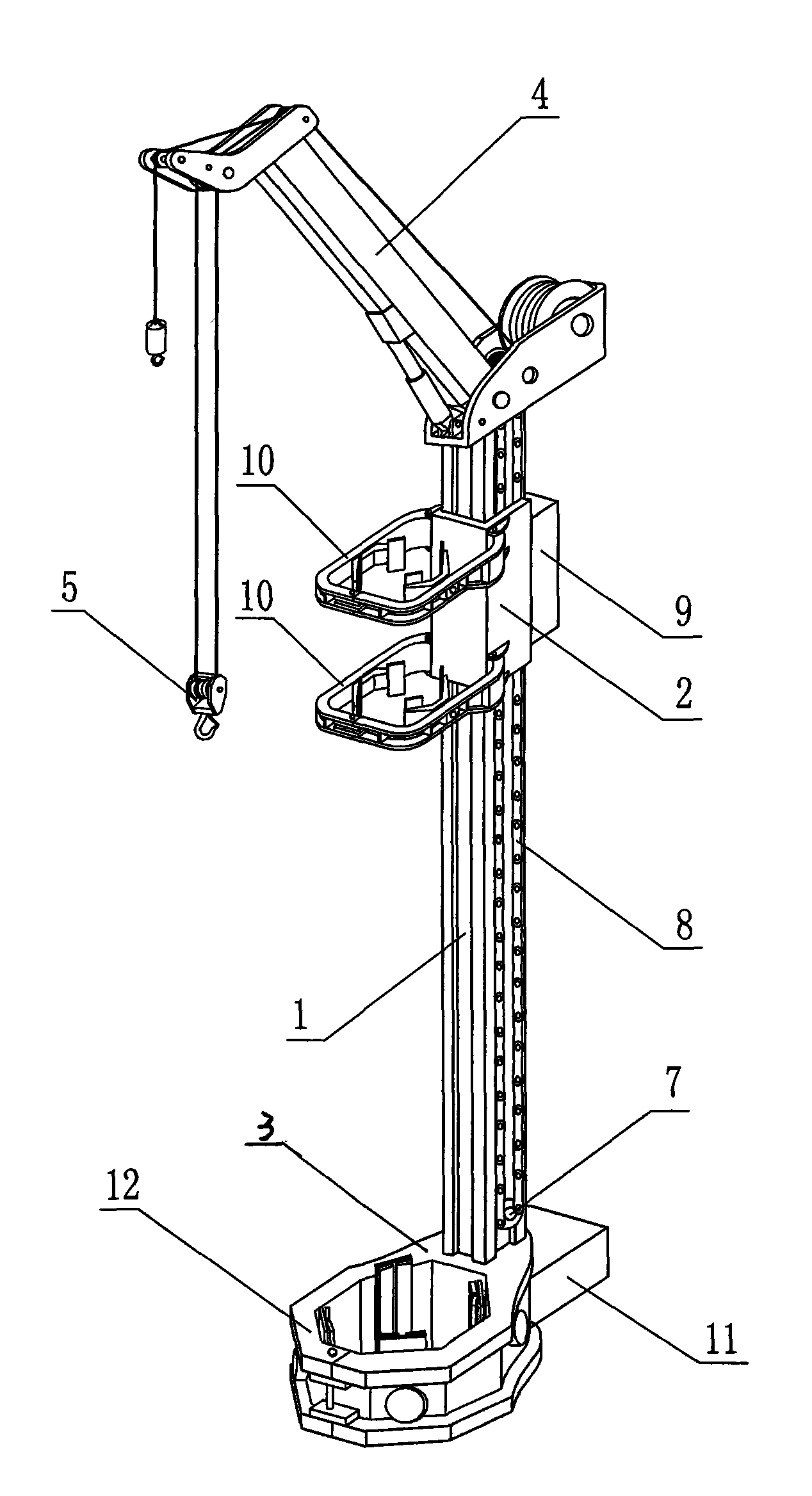

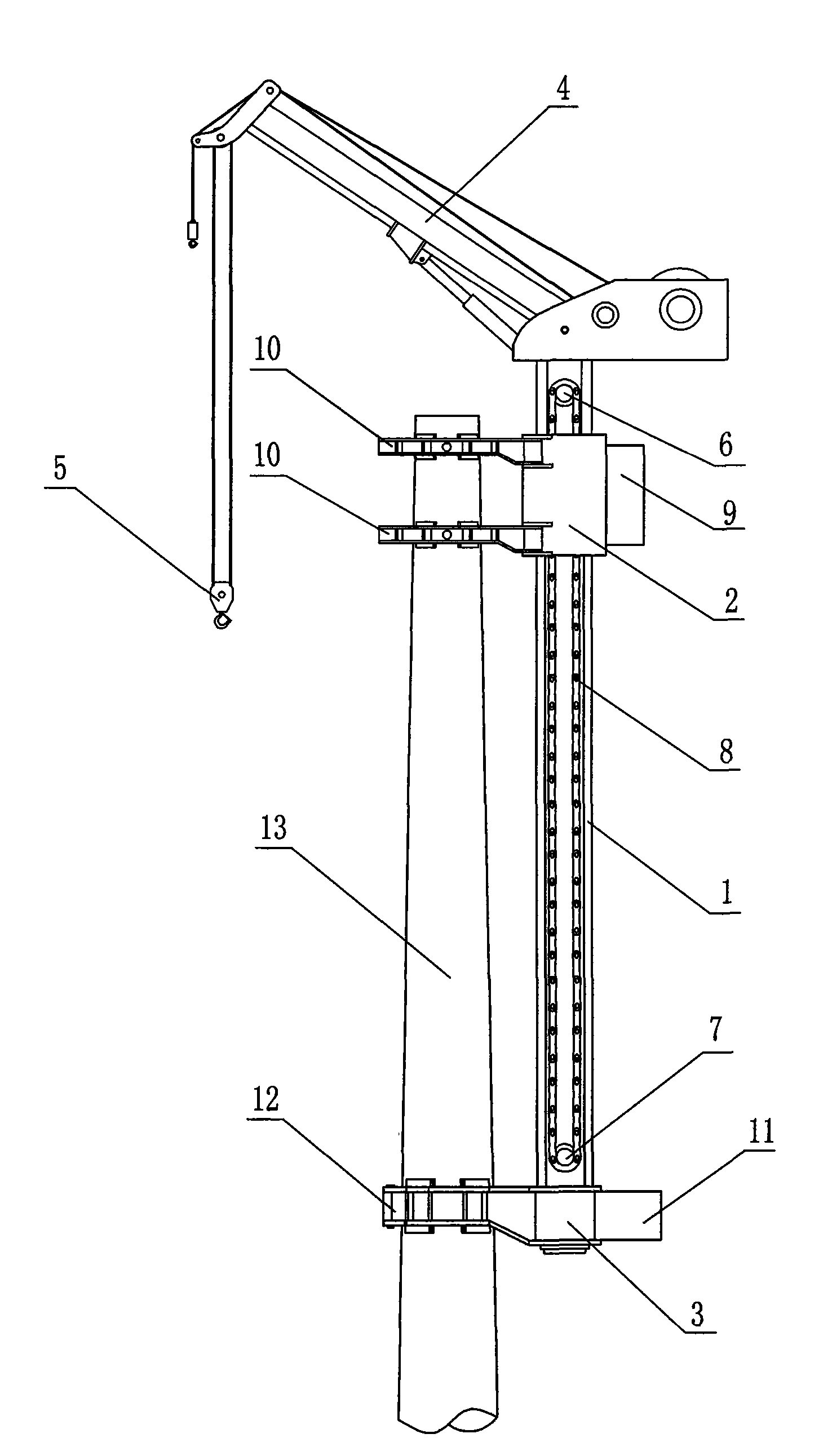

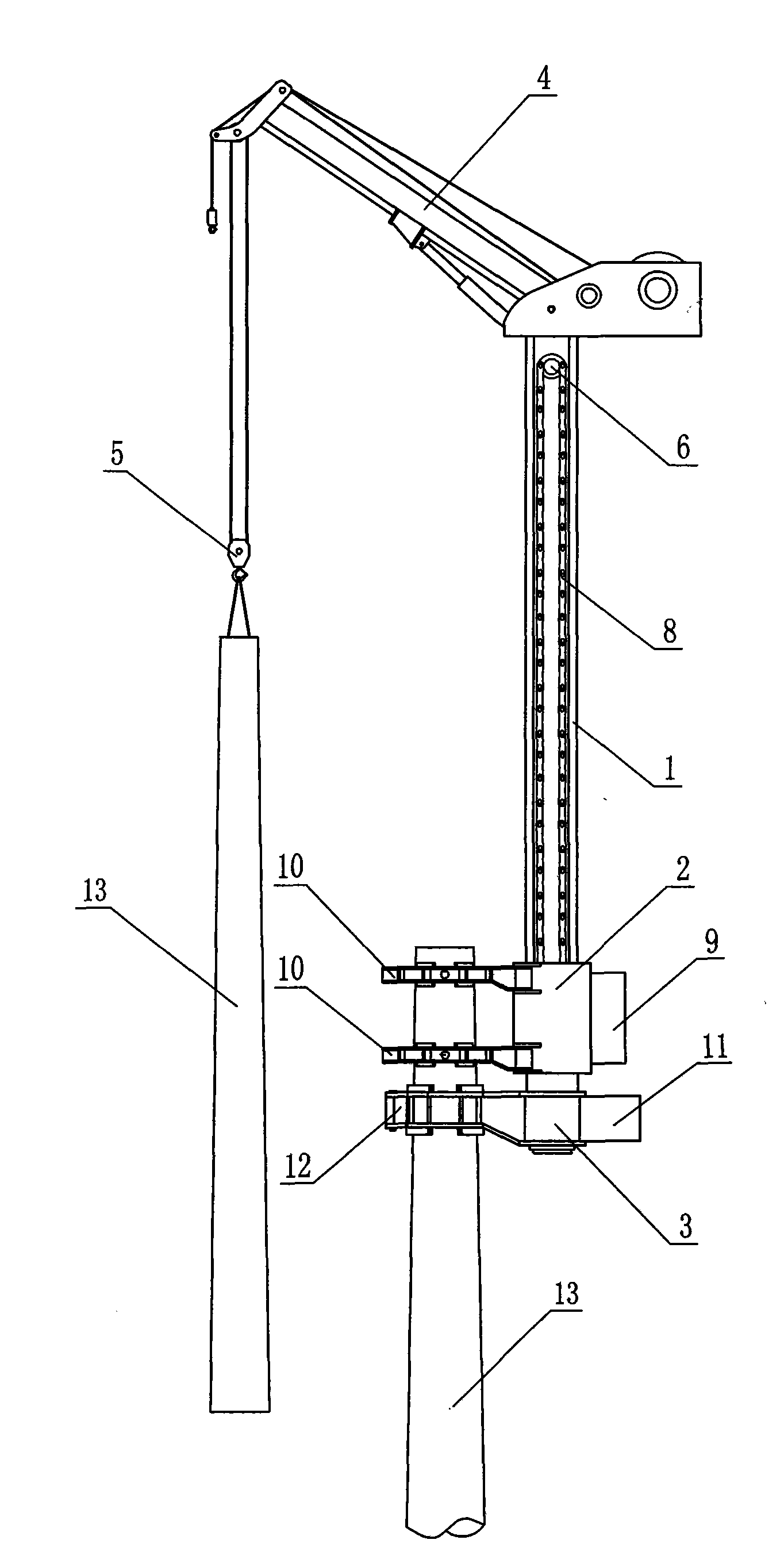

[0024] The wind power climbing hoisting crane is composed of a machine trunk 1, an upper clamp 2, a lower clamp 3, a hydraulic boom 4 and a pulley hook 5 connected by a hinge rope. The upper and lower ends of the cavity of the machine trunk 1 are installed The sprockets 6 and 7 are meshed and connected with the ring chain 8; the caliper body of the lower tong 3 is fixed on the lower end of the machine trunk 1, and the caliper body of the upper tong 2 is dynamically fitted on the outer wall of the machine trunk 1 and inserted into the body of the tongs. Seat has ratchet and chain 8 meshes; Upper holding tong 2 has the jaw 10 driven by hydraulic box 9, and lower holding tong 3 has the jaw 12 driven by hydraulic box 11.

[0025] Sprocket 6 and 7 are the main and passive wheels of each other.

[0026] The jaws 10, 12 of the upper holding tongs 2 and the lower holding tongs 3 are closed to each other and clamped tightly with the column 13.

[0027] The upper clamp 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com