Patents

Literature

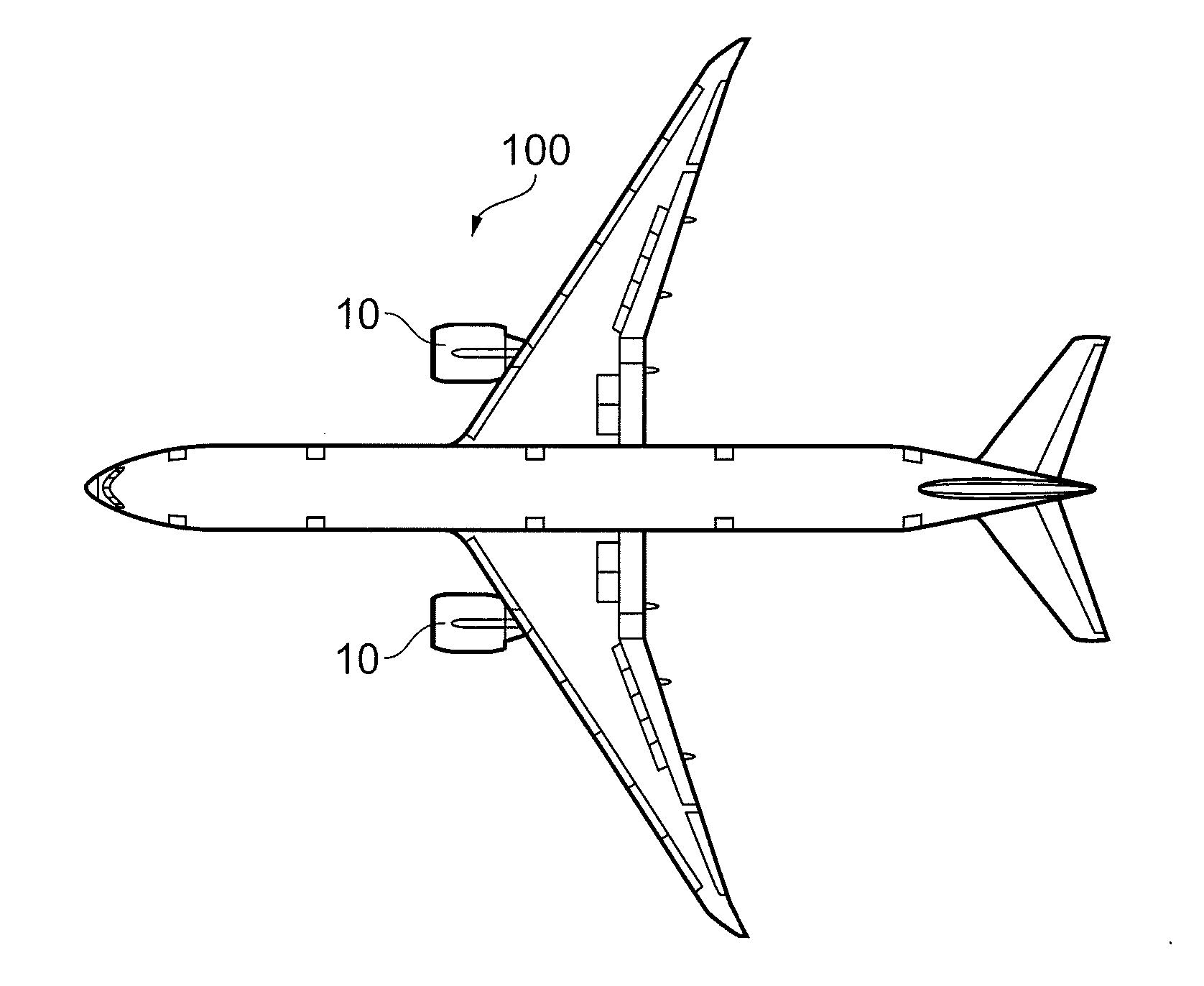

1916 results about "Engine room" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

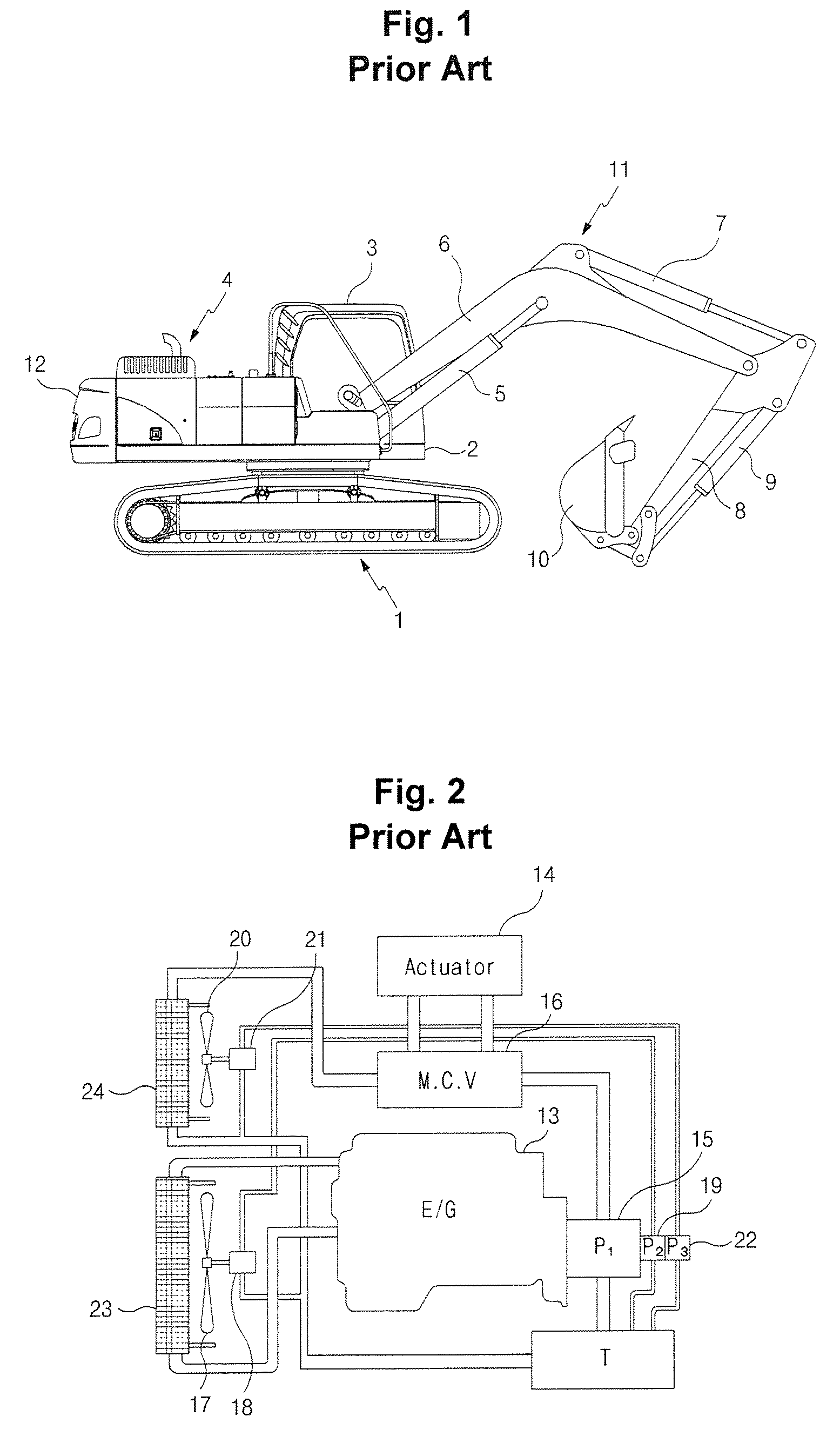

On a ship, the engine room or ER is the propulsion machinery spaces of the vessel. To increase a vessel's safety and chances of surviving damage, the machinery necessary for operations may be segregated into various spaces. The engine room is generally the largest physical compartment of the machinery space. It houses the vessel's prime mover, usually some variations of a heat engine - diesel engine, gas or steam turbine, or some combination of these (such as CODAG; see Marine propulsion). On some ships, the machinery space may comprise more than one engine room, such as forward and aft, or port or starboard engine rooms, or may be simply numbered.

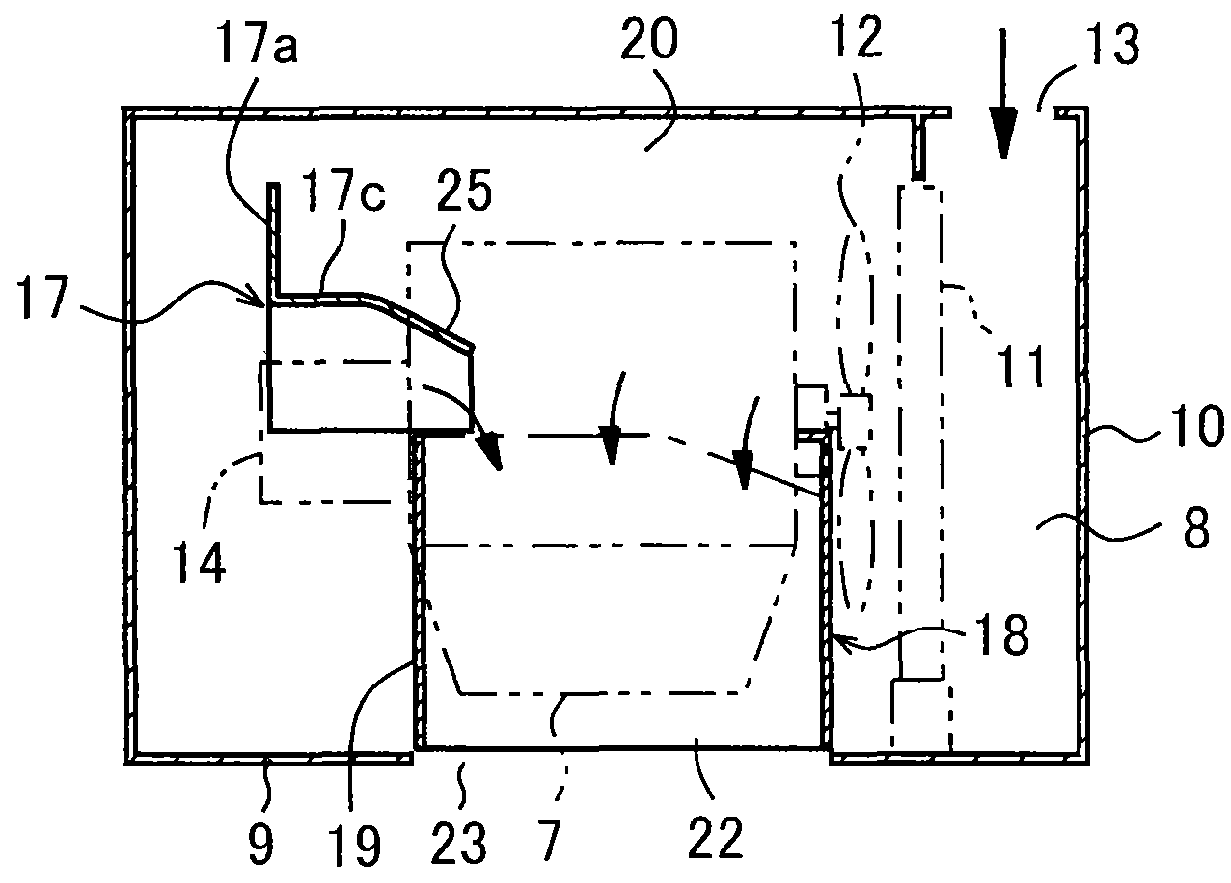

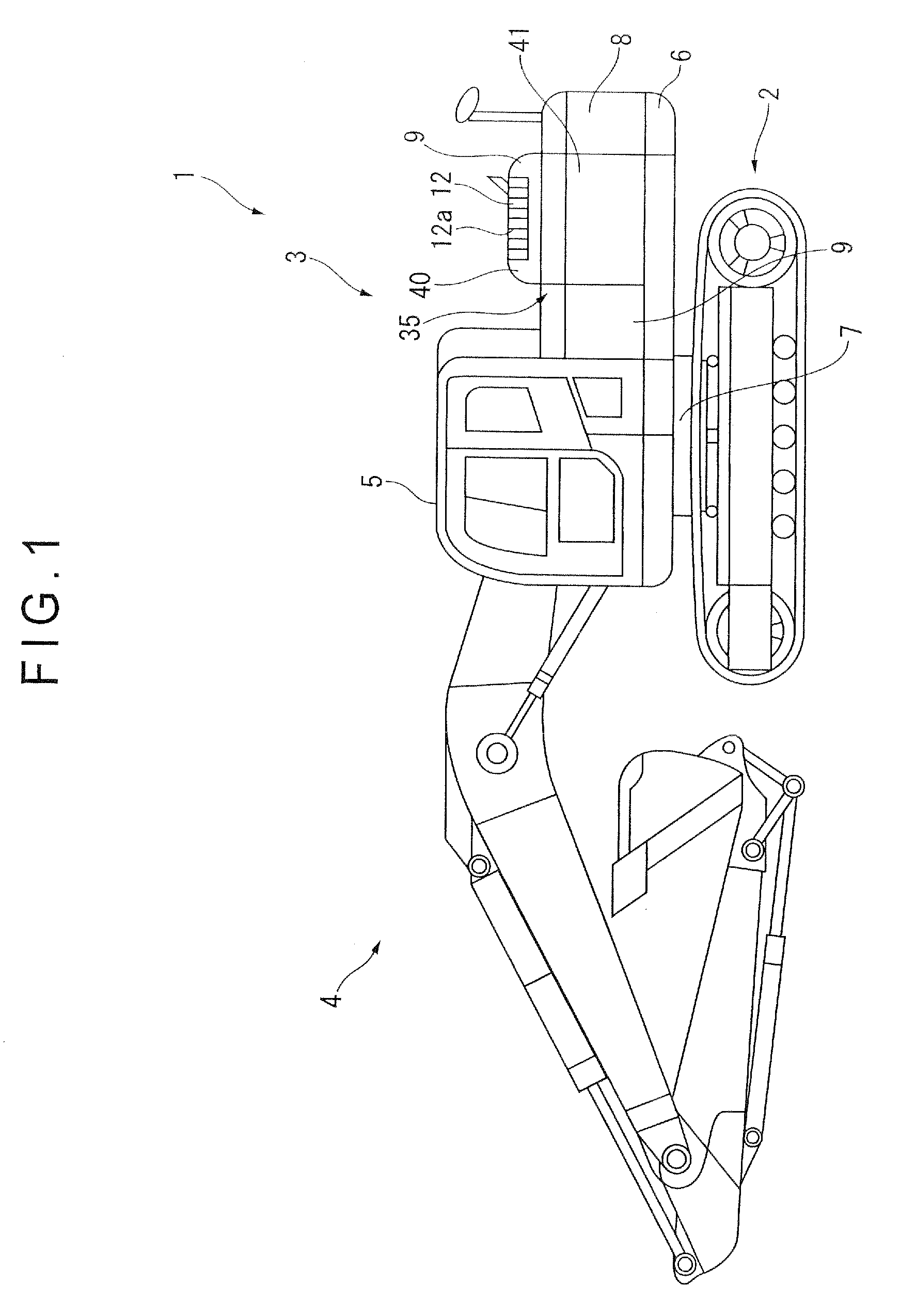

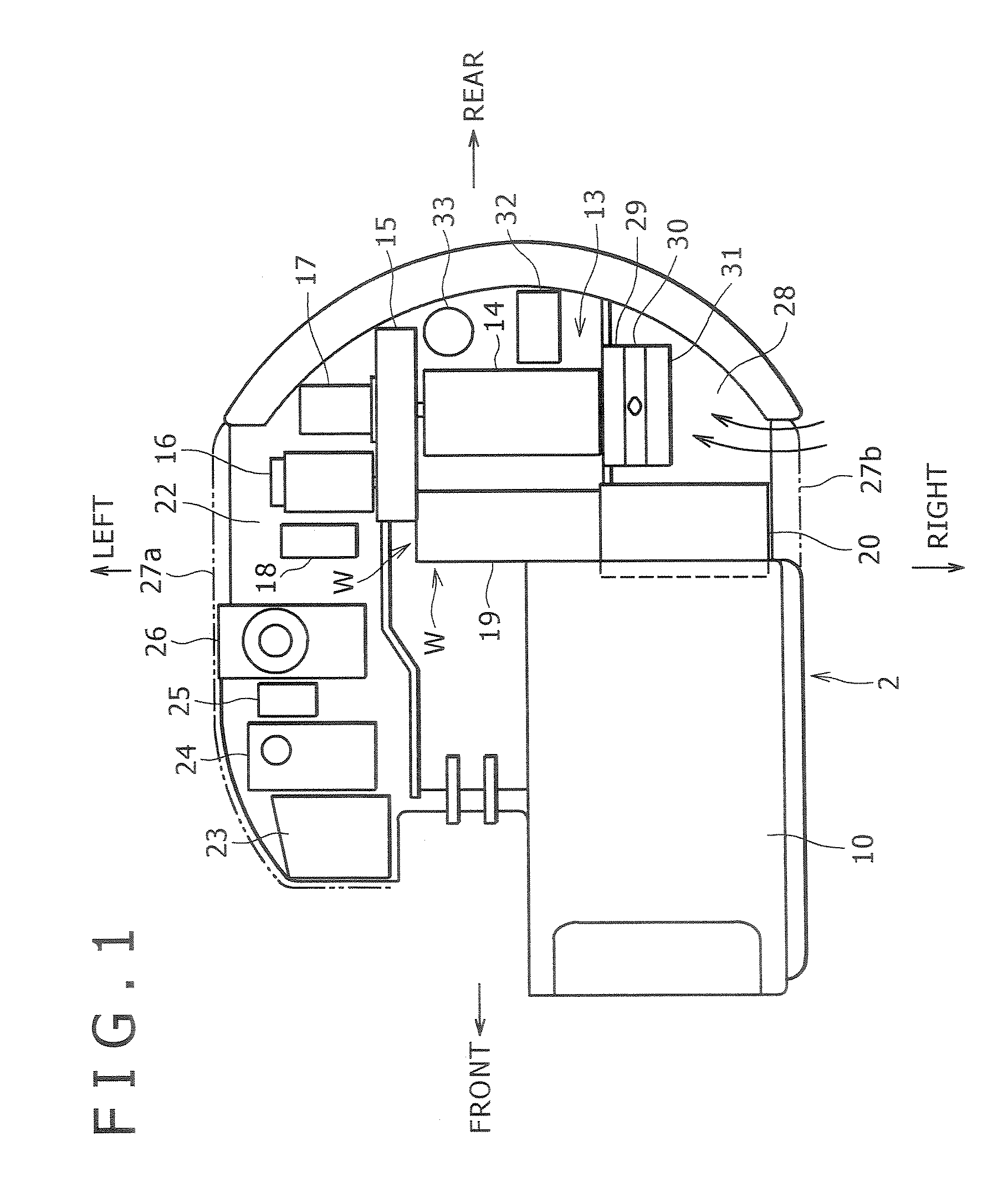

Engine room for construction equipment

InactiveUS8196555B2Reduce noiseAvoid componentsCoolant flow controlExhaust apparatusInhalationAtmospheric air

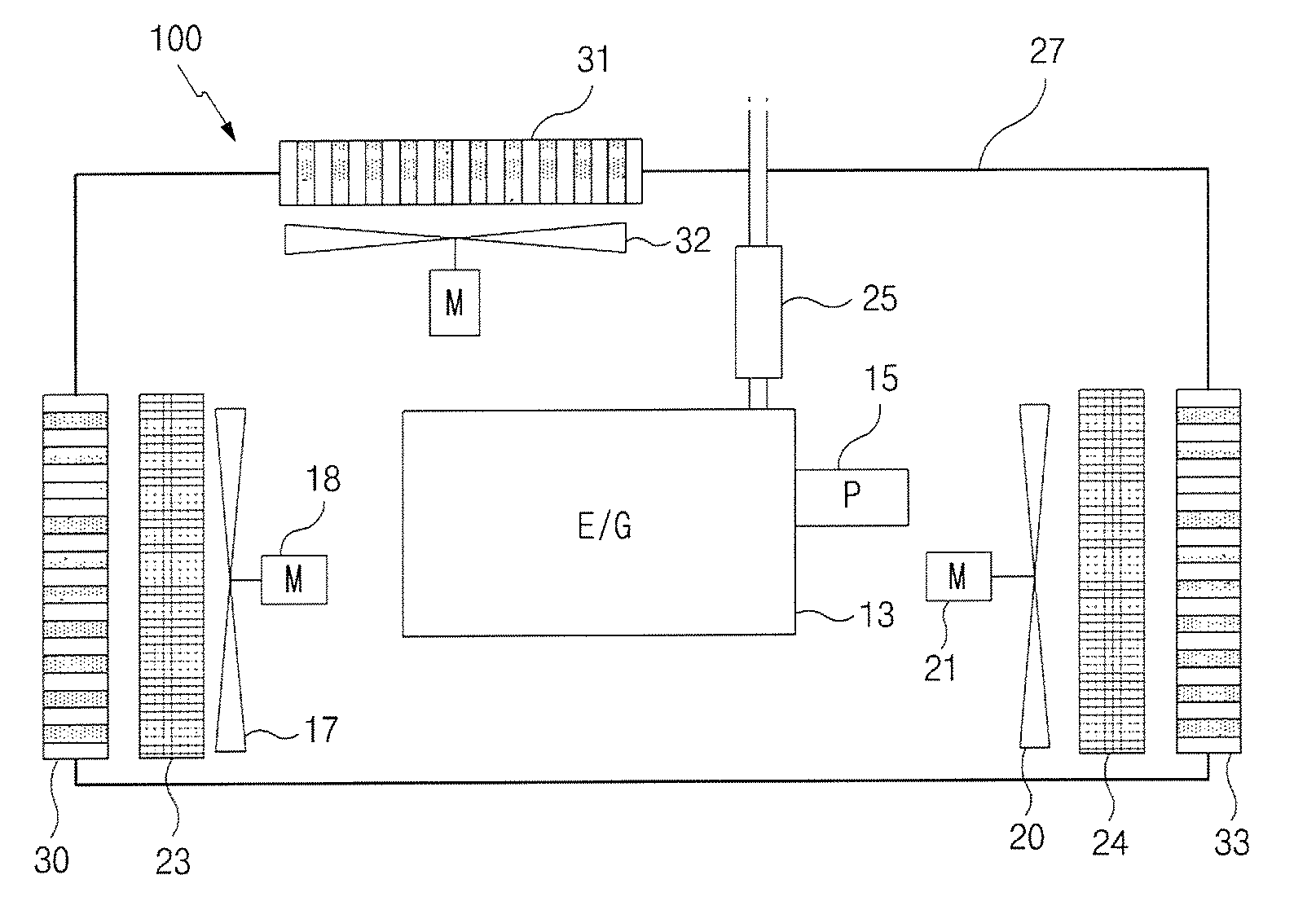

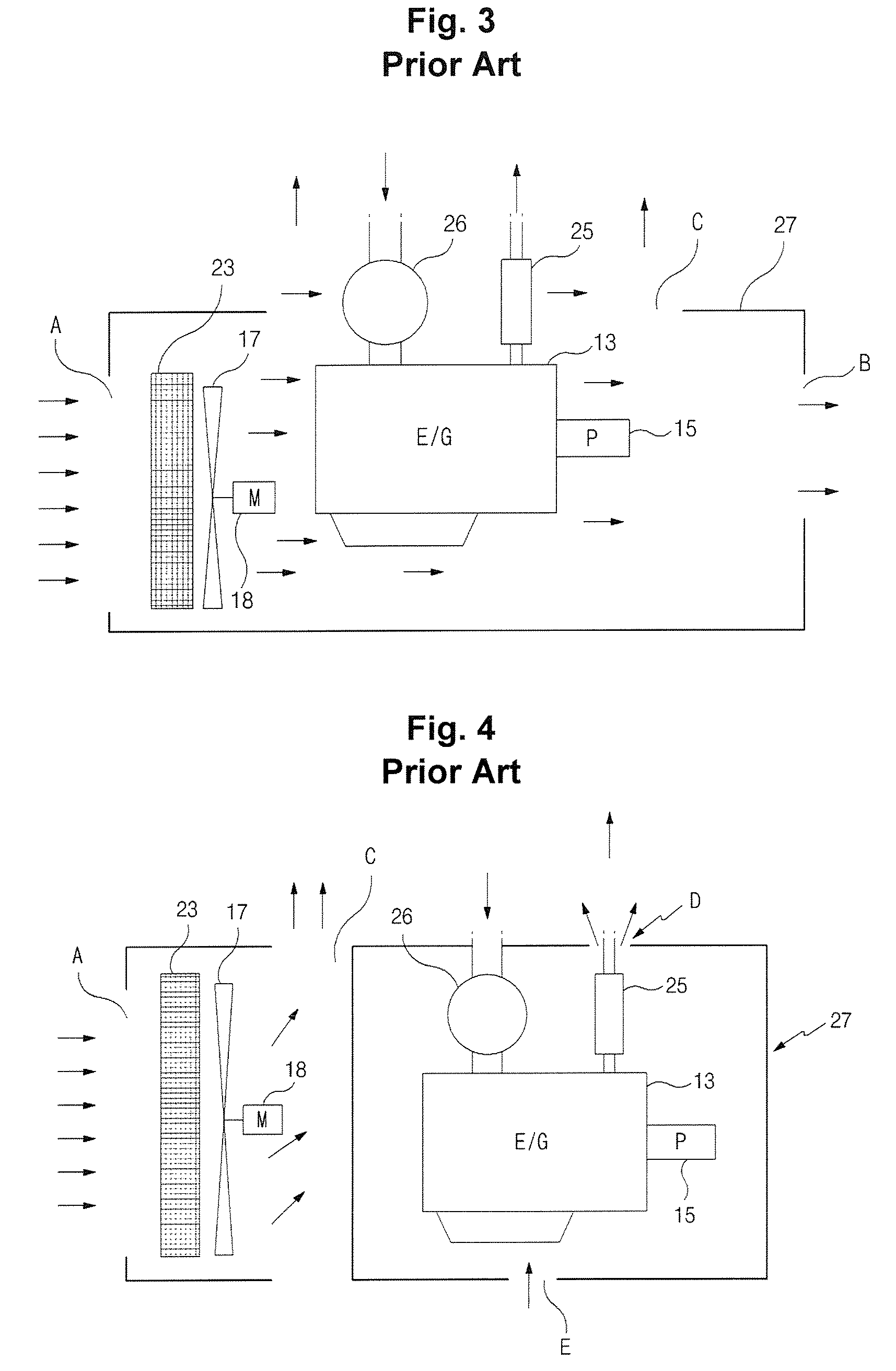

An engine room for construction equipment is provided, which can minimize emission of noise generated in an engine room due to driving of an engine and a ventilating fan to an outside of the engine room by absorbing the noise through a noise trap, and can improve the cooling performance of corresponding components by smoothing inhalation / discharge of an external air to / from the airtight engine room. The engine room for construction equipment includes a radiator cooling water for cooling the engine, a muffler discharging an exhaust gas from an engine to the atmosphere, a first noise trap installed in an inlet port to absorb noise generated in the engine room and emitted to an outside, a second noise trap installed in an outlet port to absorb the noise generated in the engine room and emitted to the outside, a radiator fan inhaling the external air through the first noise trap and making the inhaled external air pass through the radiator and the circumference of the engine, a discharge fan discharging the air in the engine room to the outside through the second noise trap, and an outer wall forming an airtight space for accommodating therein the engine, the muffler, the radiator fan, the hydraulic pump, and the discharge fan that generate the noise.

Owner:VOLVO CONSTR EQUIP HLDG SWEDEN AB

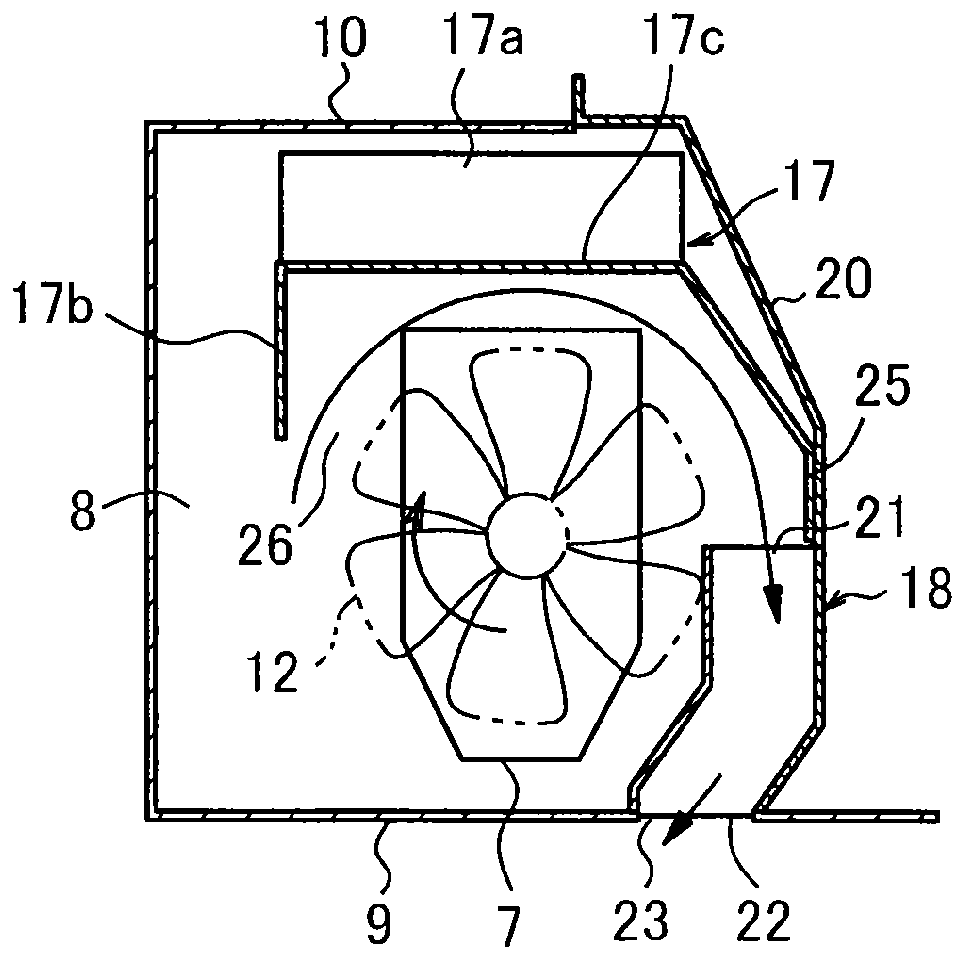

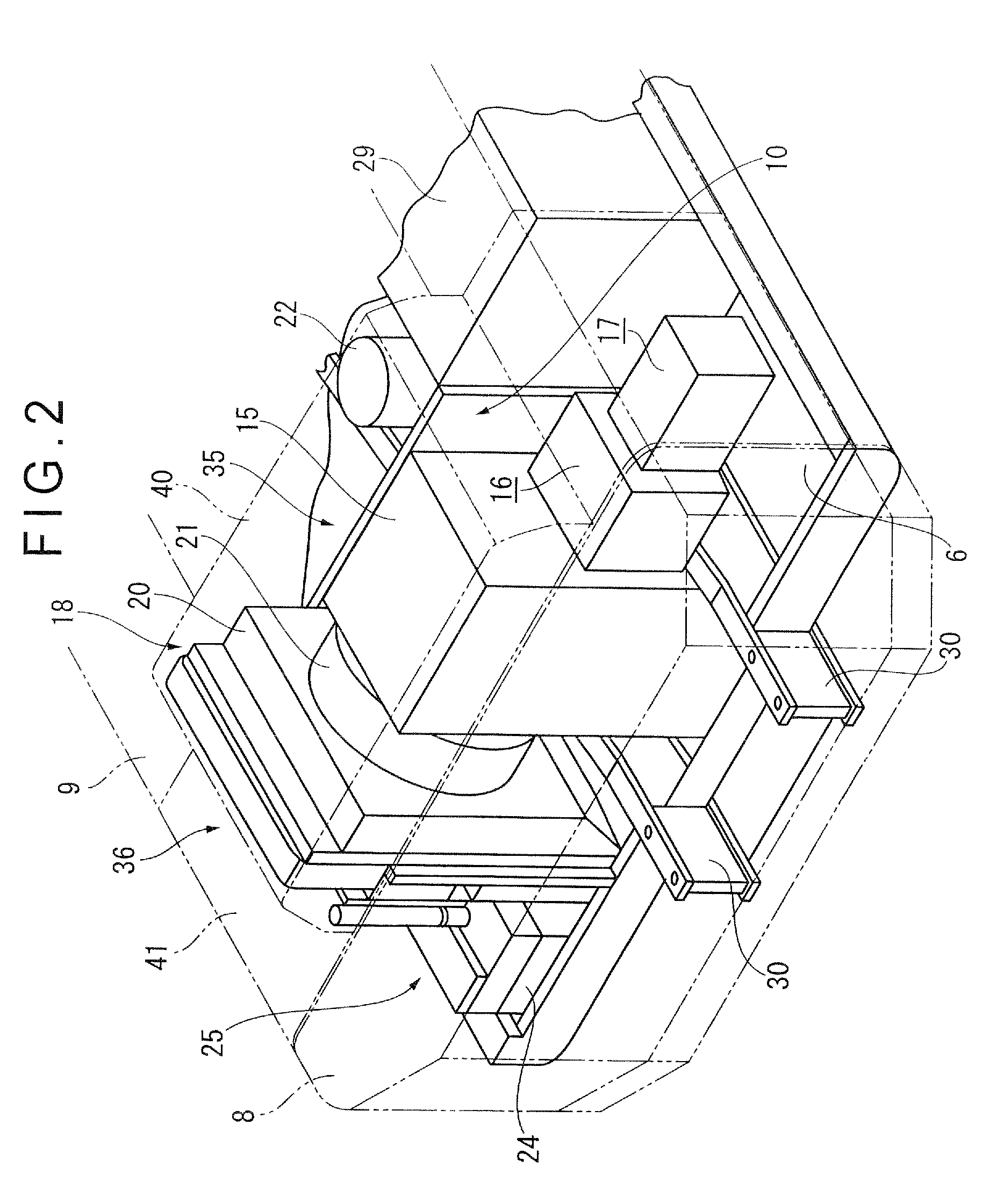

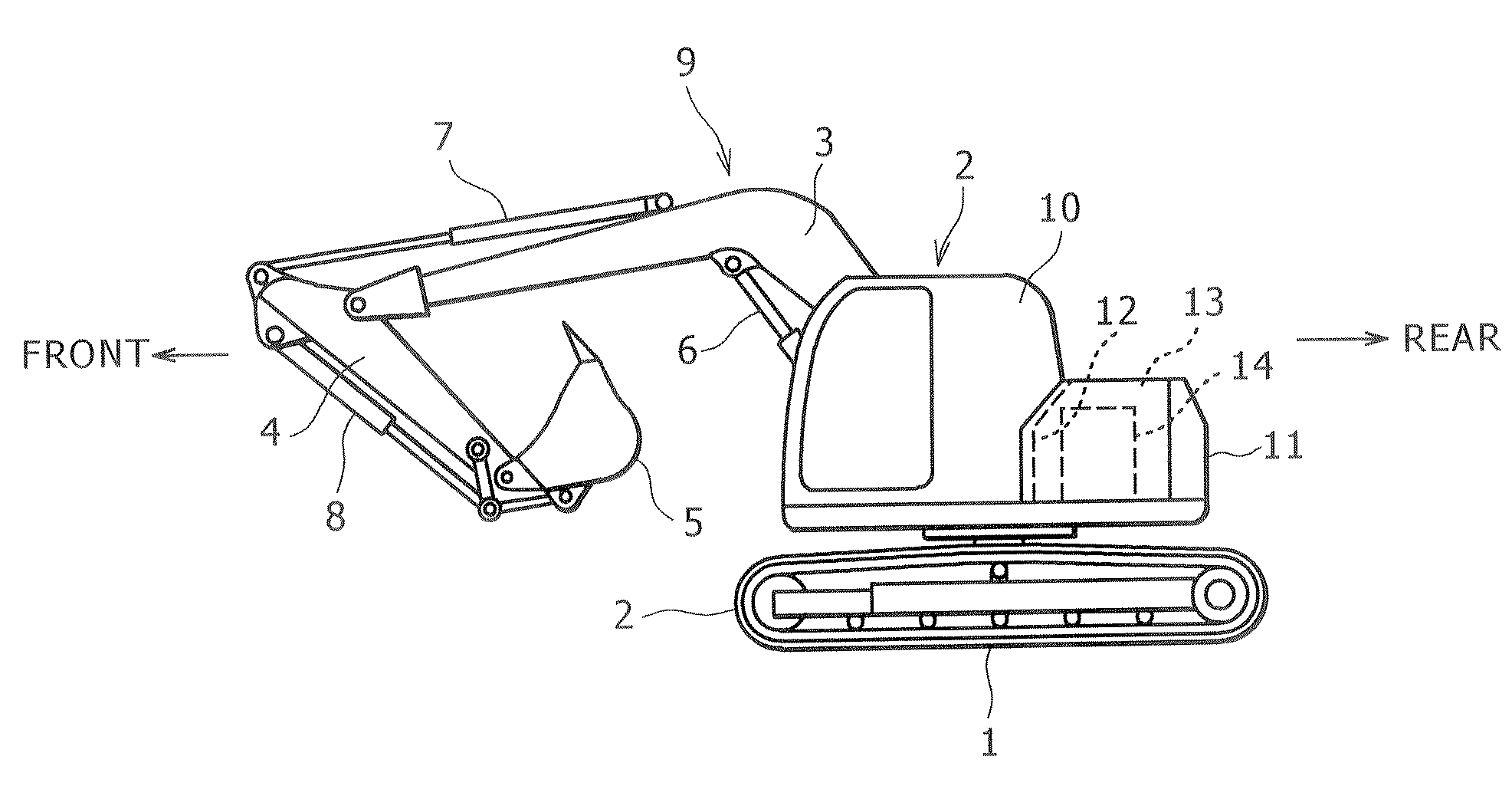

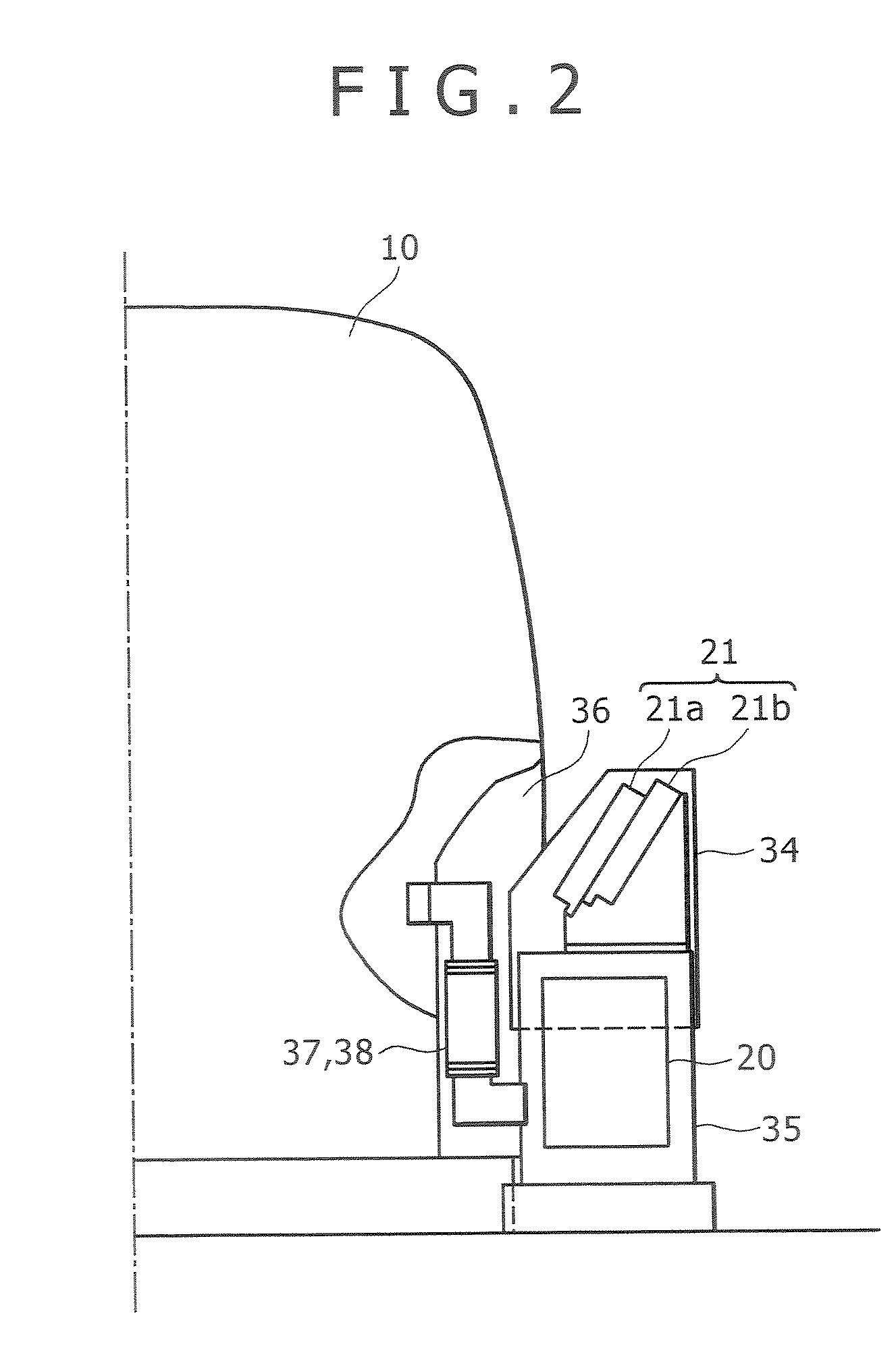

Construction machine

ActiveUS9376786B2Efficient collectionImprove exhaust efficiencyAir coolingSoil-shifting machines/dredgersEngineeringEngine room

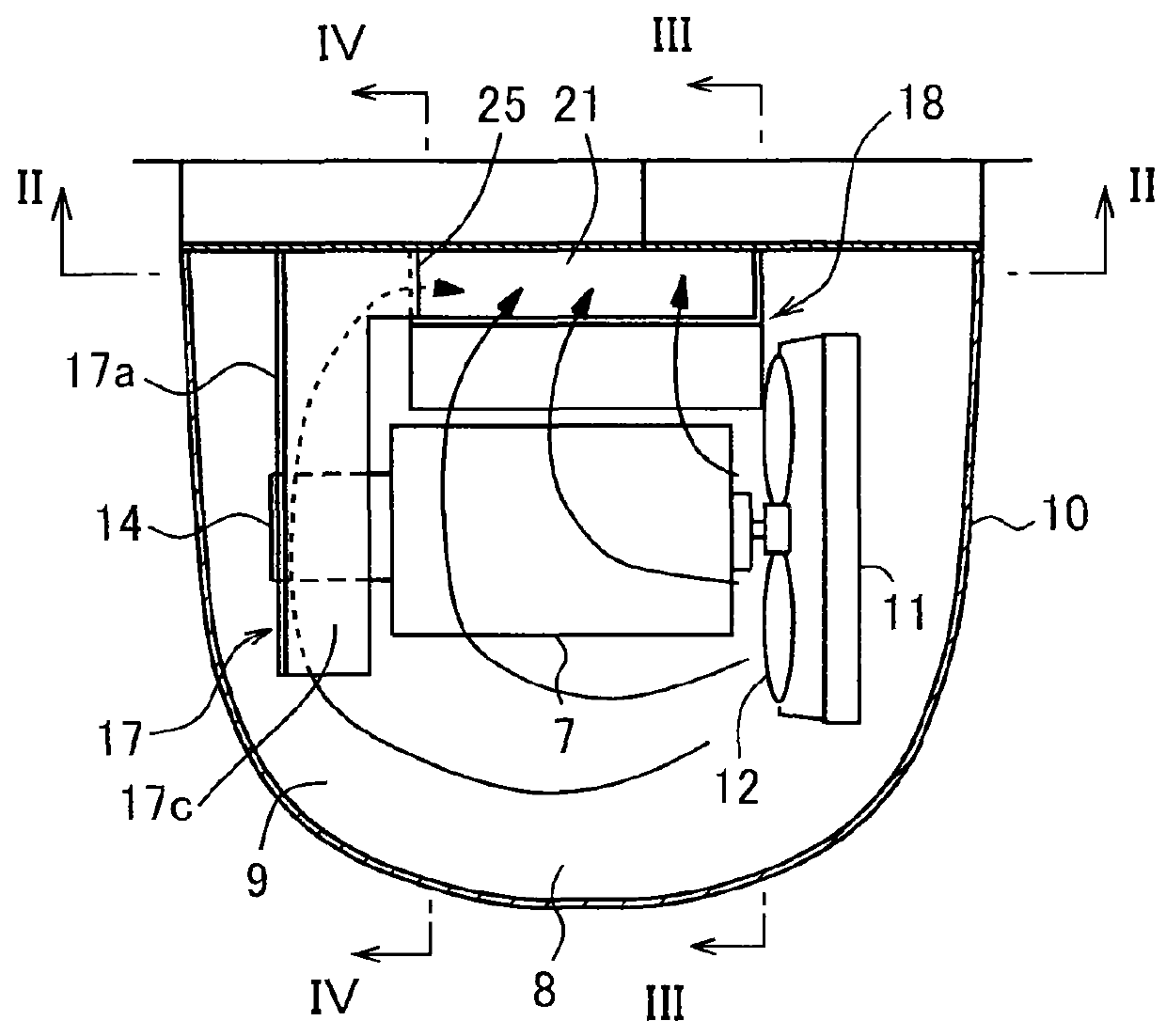

In a construction machine having an engine room and capable of efficiently collecting air flowing in the engine room, a heat exchanger provided at a first side of the engine, and a fan provided at the first side and rotating to generate around the engine a flow of cooling air, further includes an exhaust duct extending in a fan axial direction parallel with a rotation axis of the fan along the engine. The exhaust duct guides the flow of the air to collect the air flowing downstream of the fan in the fan axial direction, in a region extending in the fan axial direction, and discharges the air to an outside of the engine room.

Owner:KOBELCO CONSTR MASCH CO LTD

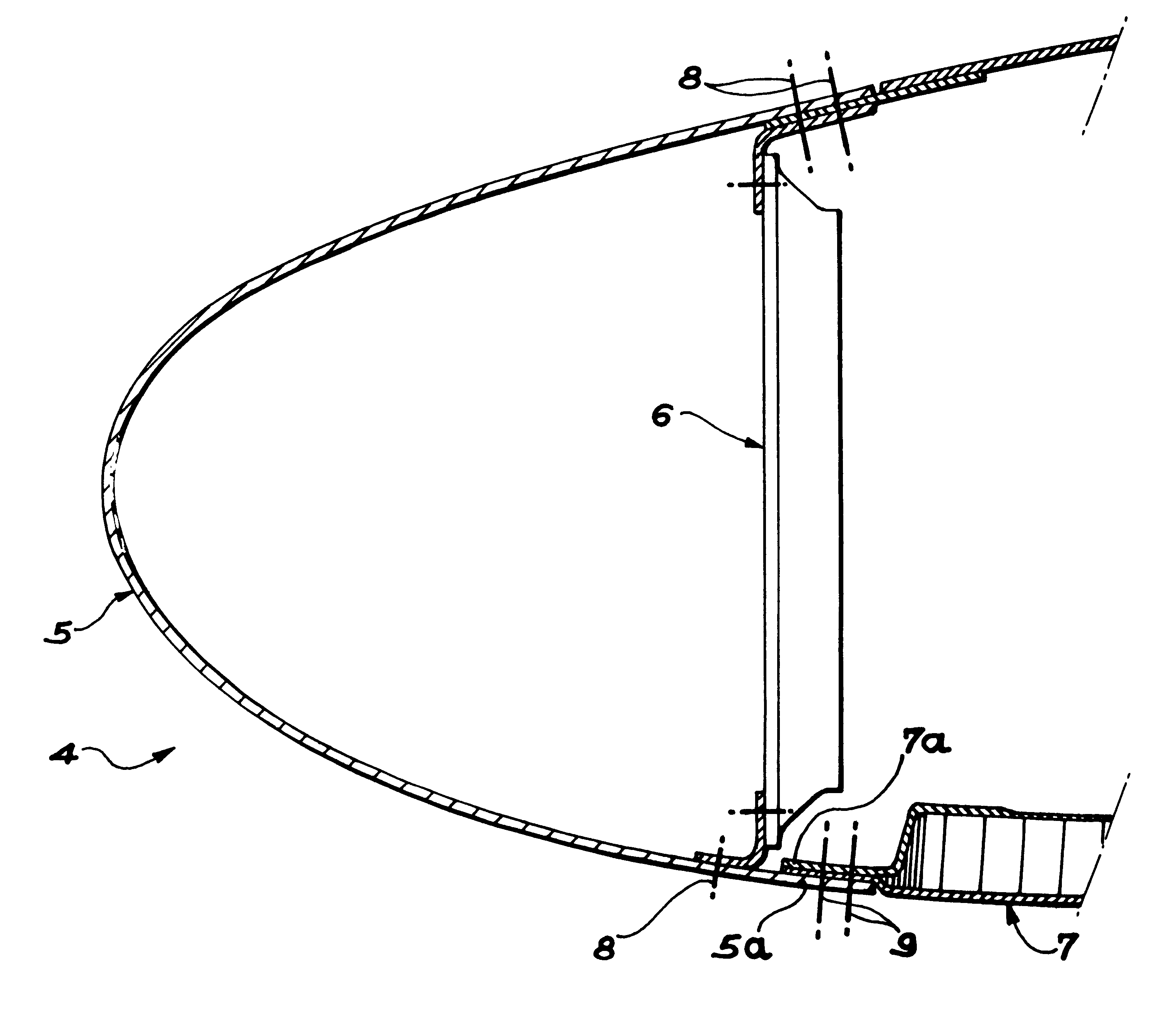

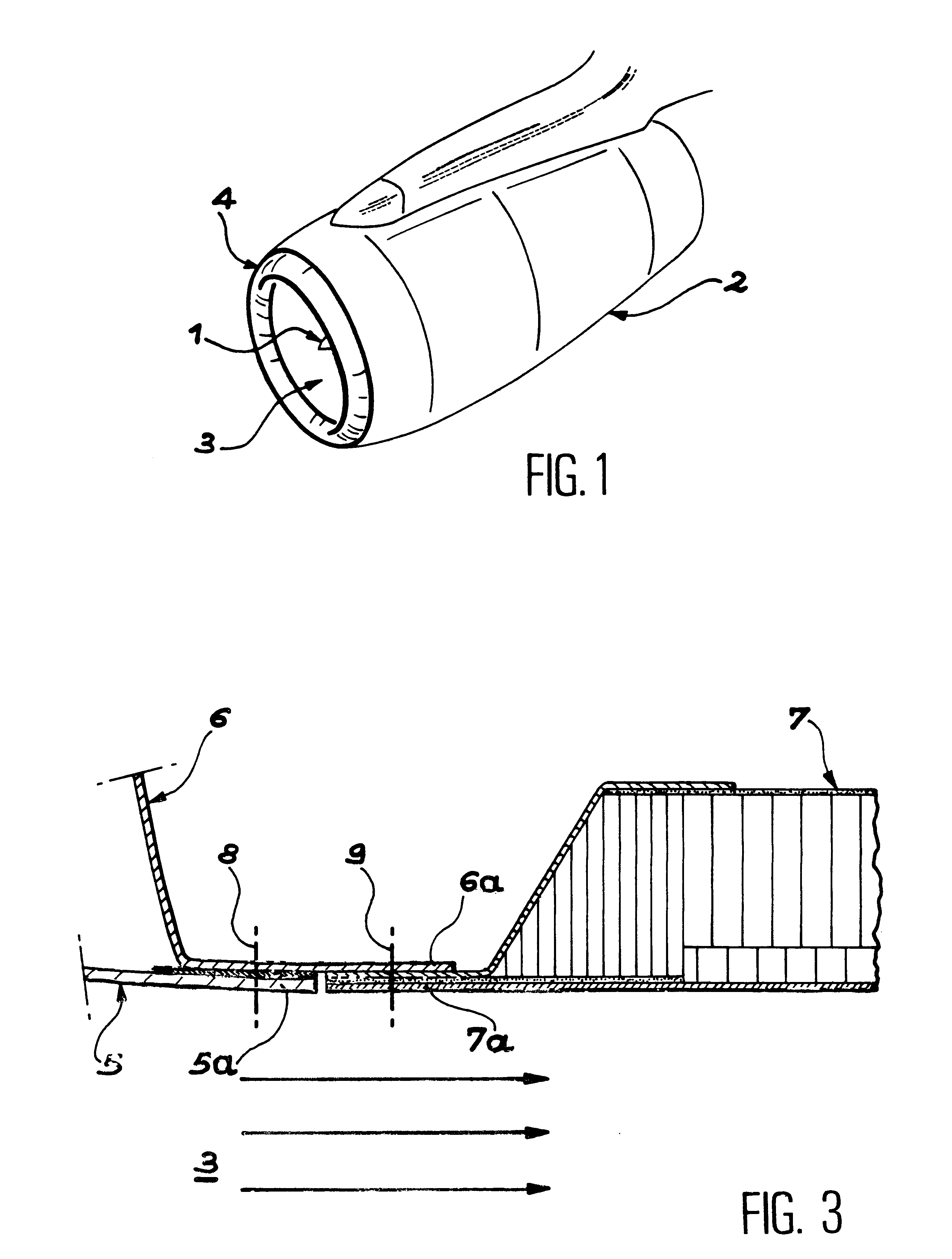

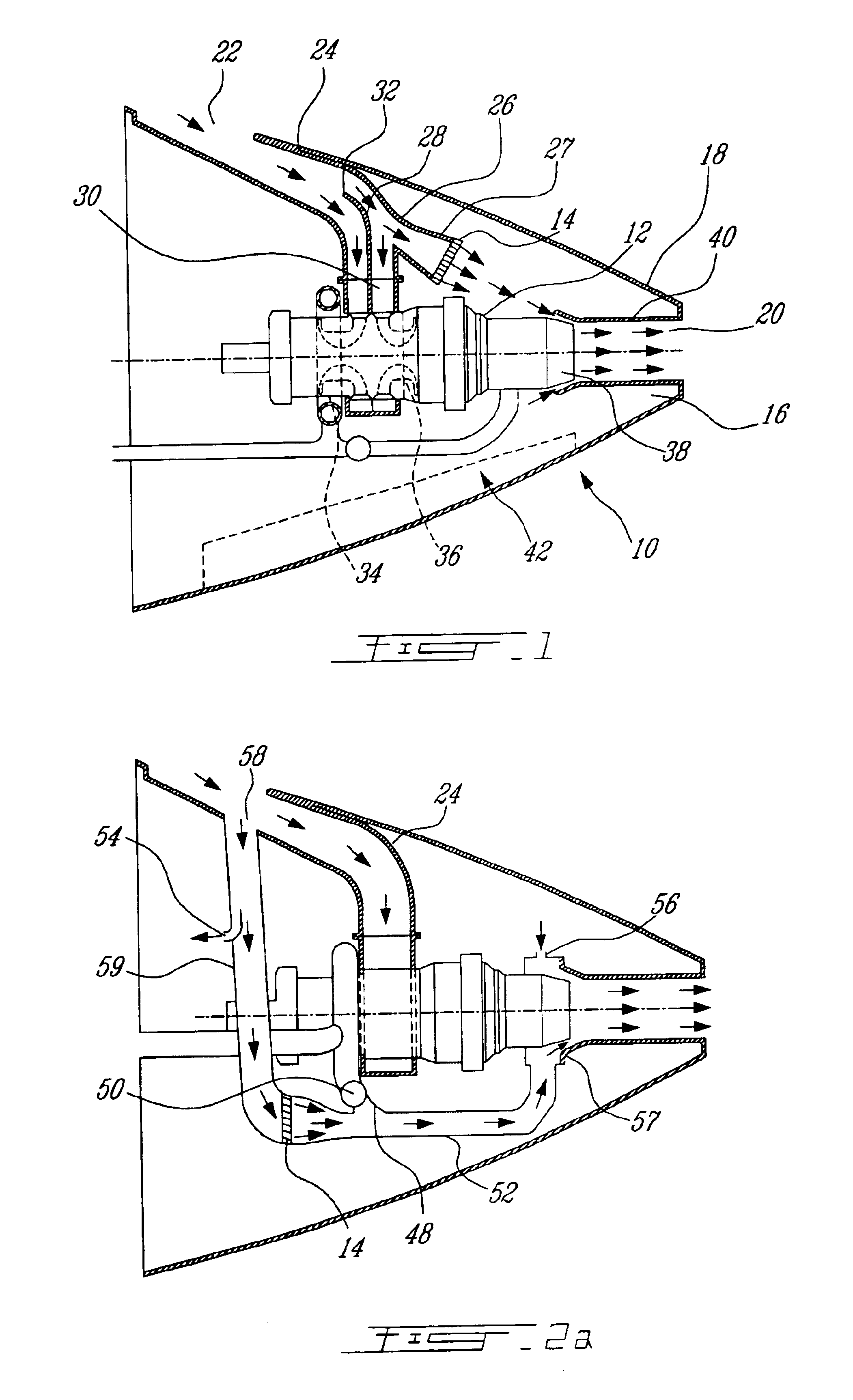

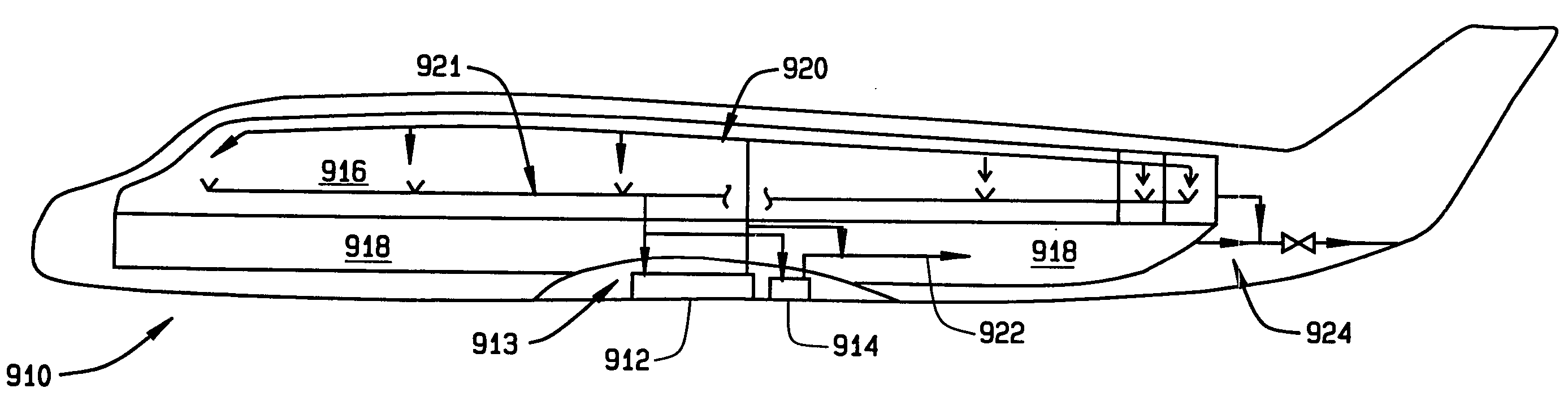

Air intake structure for aircraft engine

InactiveUS6328258B1Aircraft power plant componentsEfficient propulsion technologiesAirplaneEngine room

Owner:AEROSPATIALE MATRA

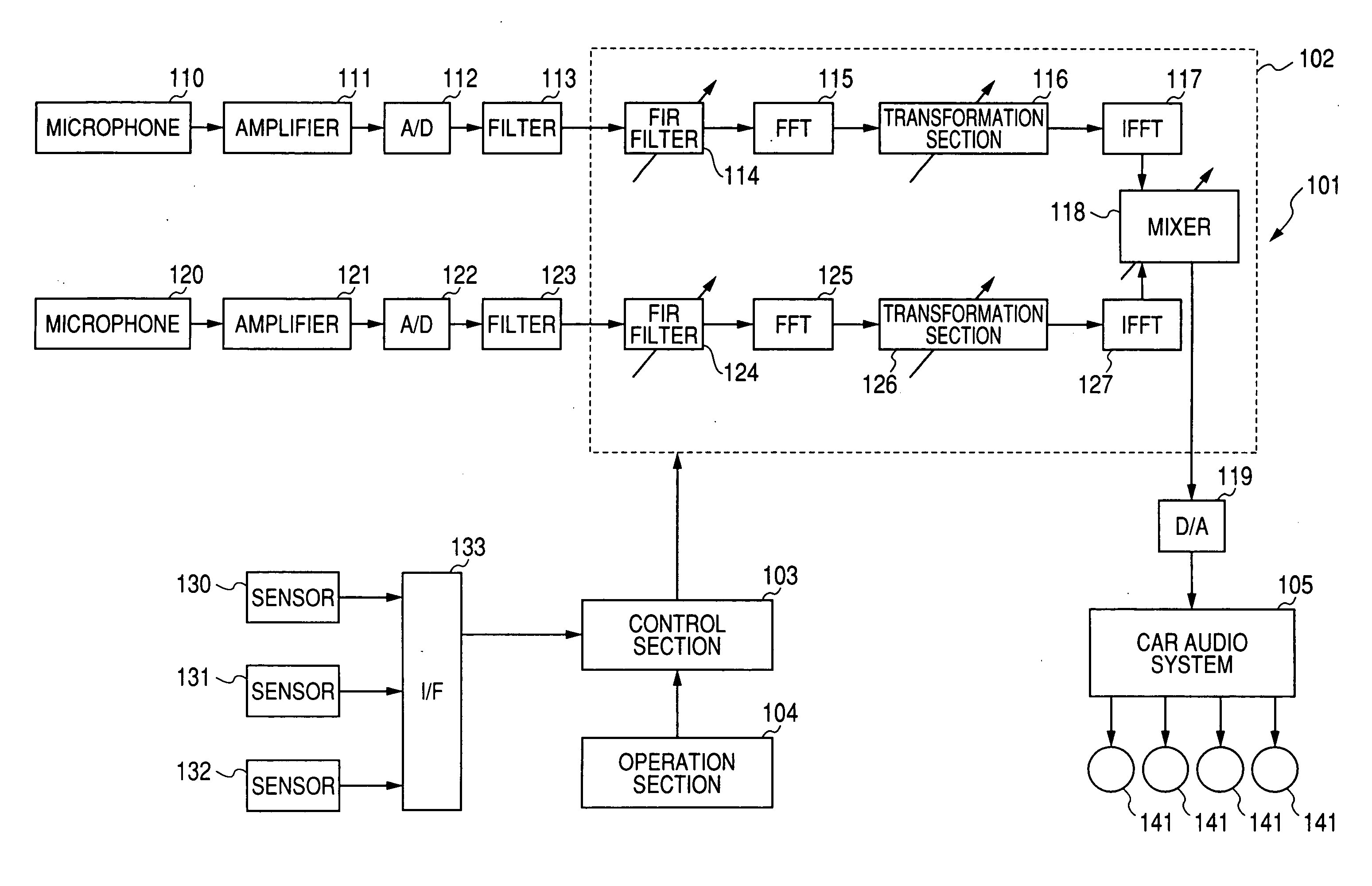

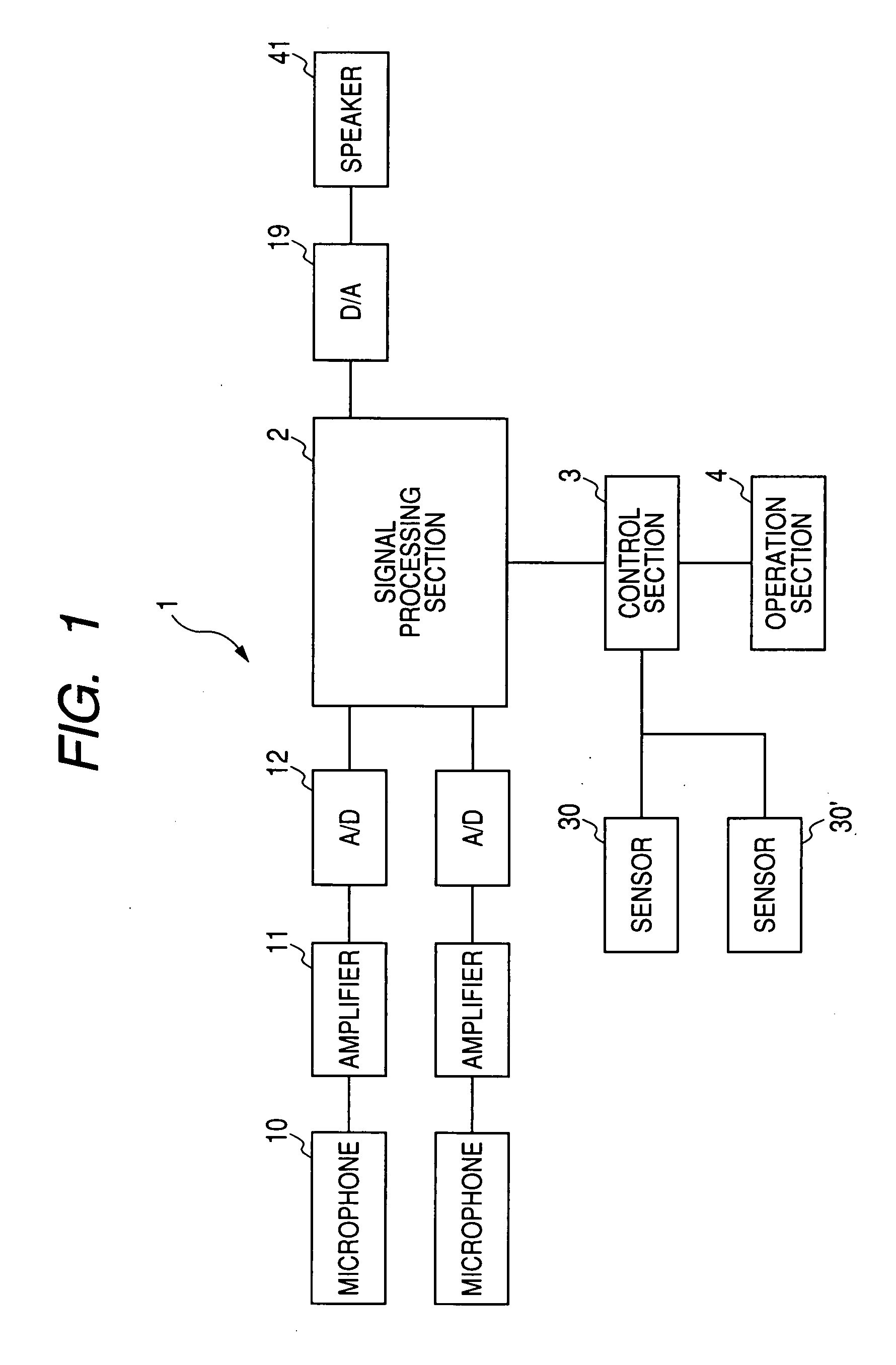

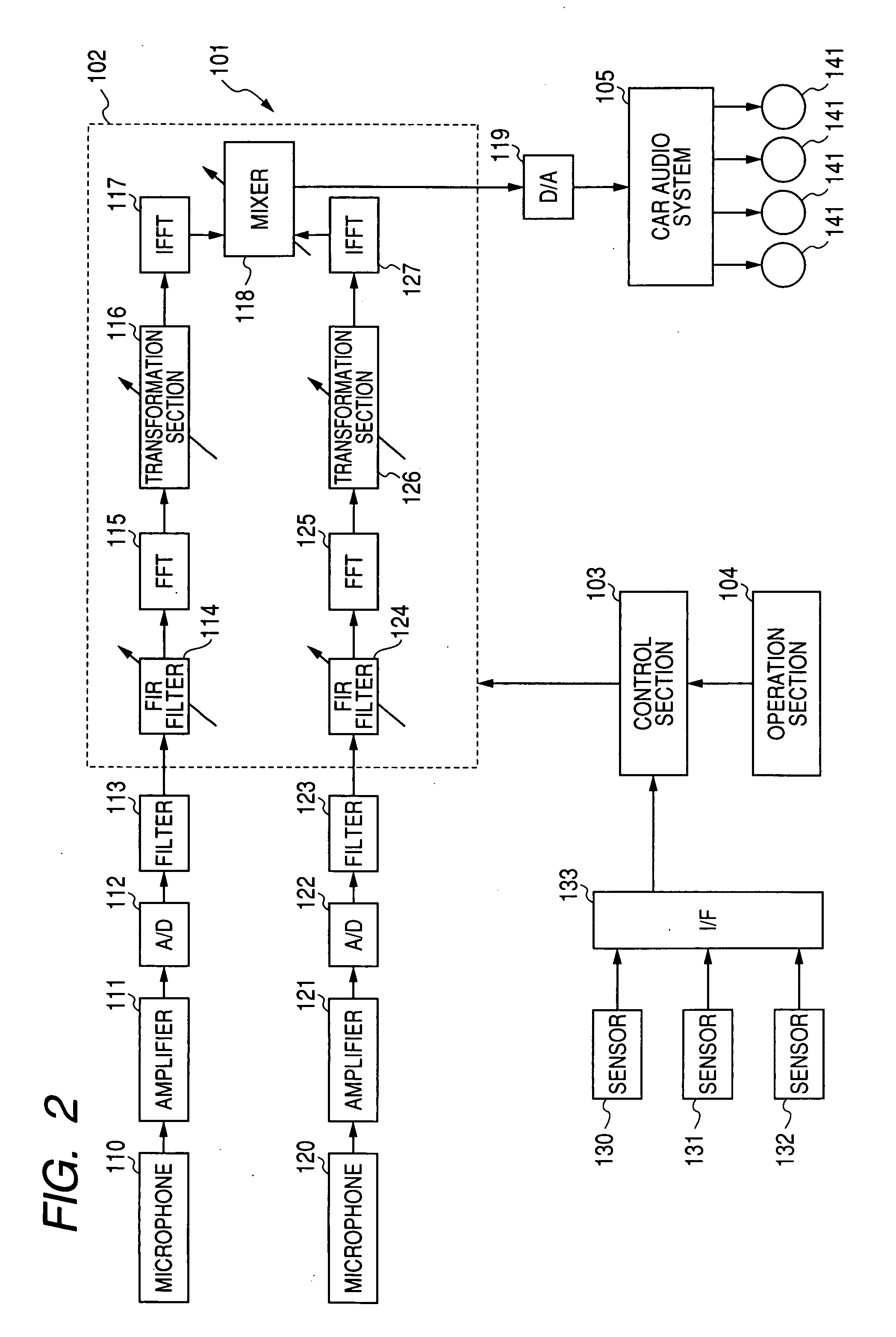

Engine Sound Processing System

Microphones are provided at an air inlet of the engine and a vehicle-cabin-side wall surface of an engine room, and engine sounds are picked up. The engine sound is processed by a signal processing section, and the processed engine sound is output from a speaker provided in a vehicle cabin. The signal processing section is provided with a filter which simulates a sound insulation characteristic of the vehicle cabin and a transformation section for processing the engine sound according to driving condition. A spectrum transformation characteristic of the transformation section is determined according to values detected by a vehicle speed sensor, an engine speed sensor, and an accelerator depression sensor, and a spectrum of the engine sound is transformed by means of specification of the spectrum transformation characteristic, thereby enhancing an engine sound.

Owner:YAMAHA CORP

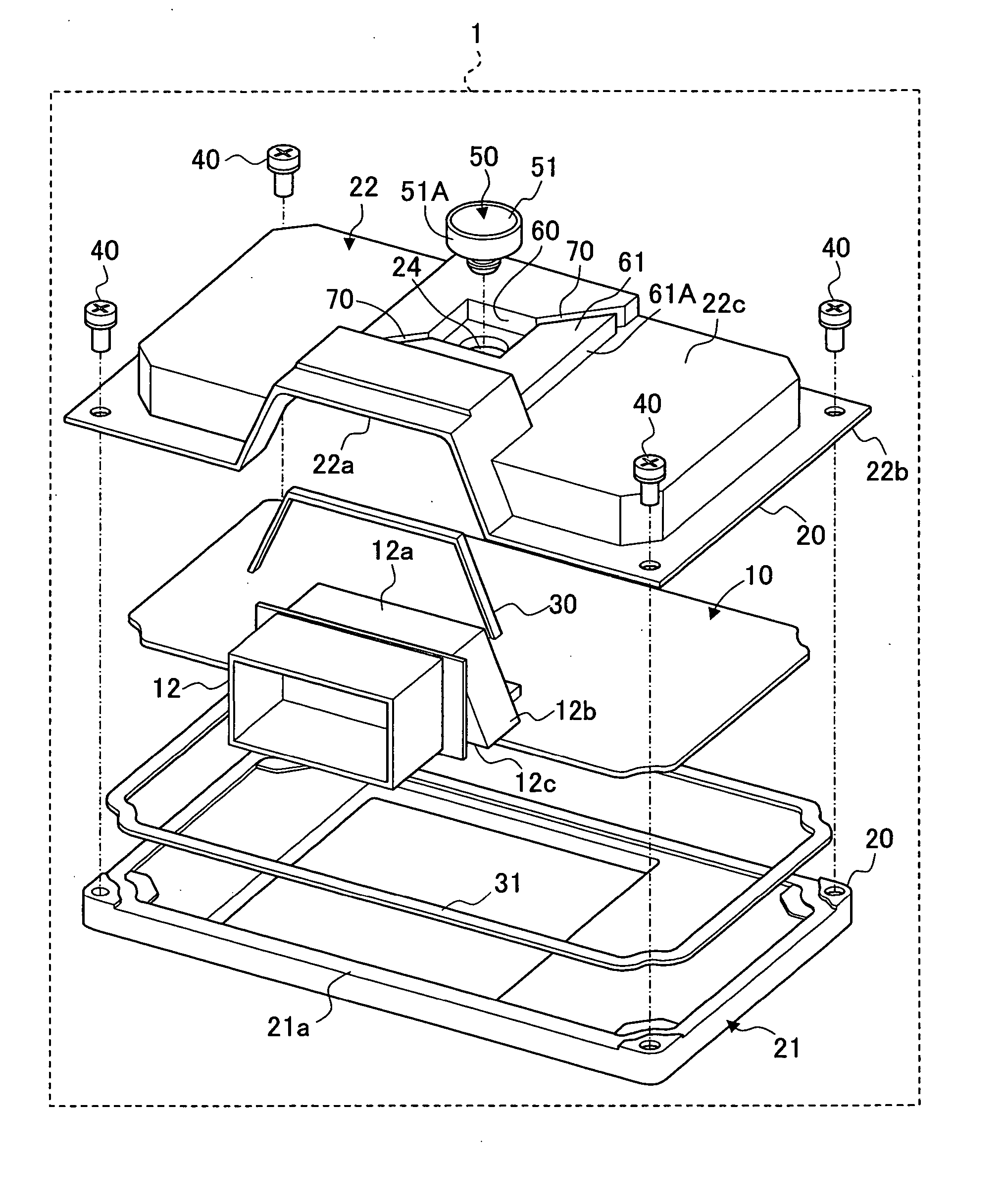

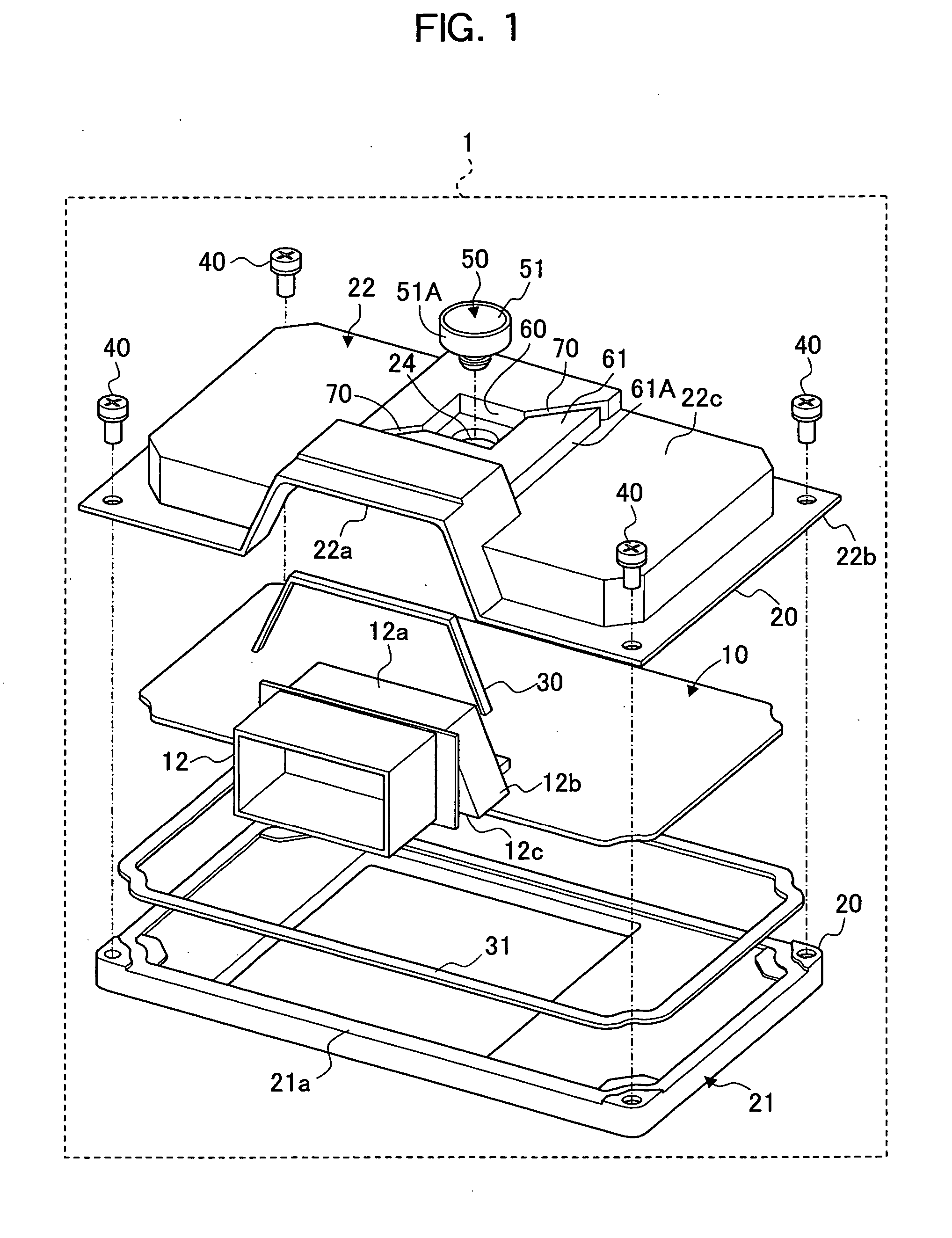

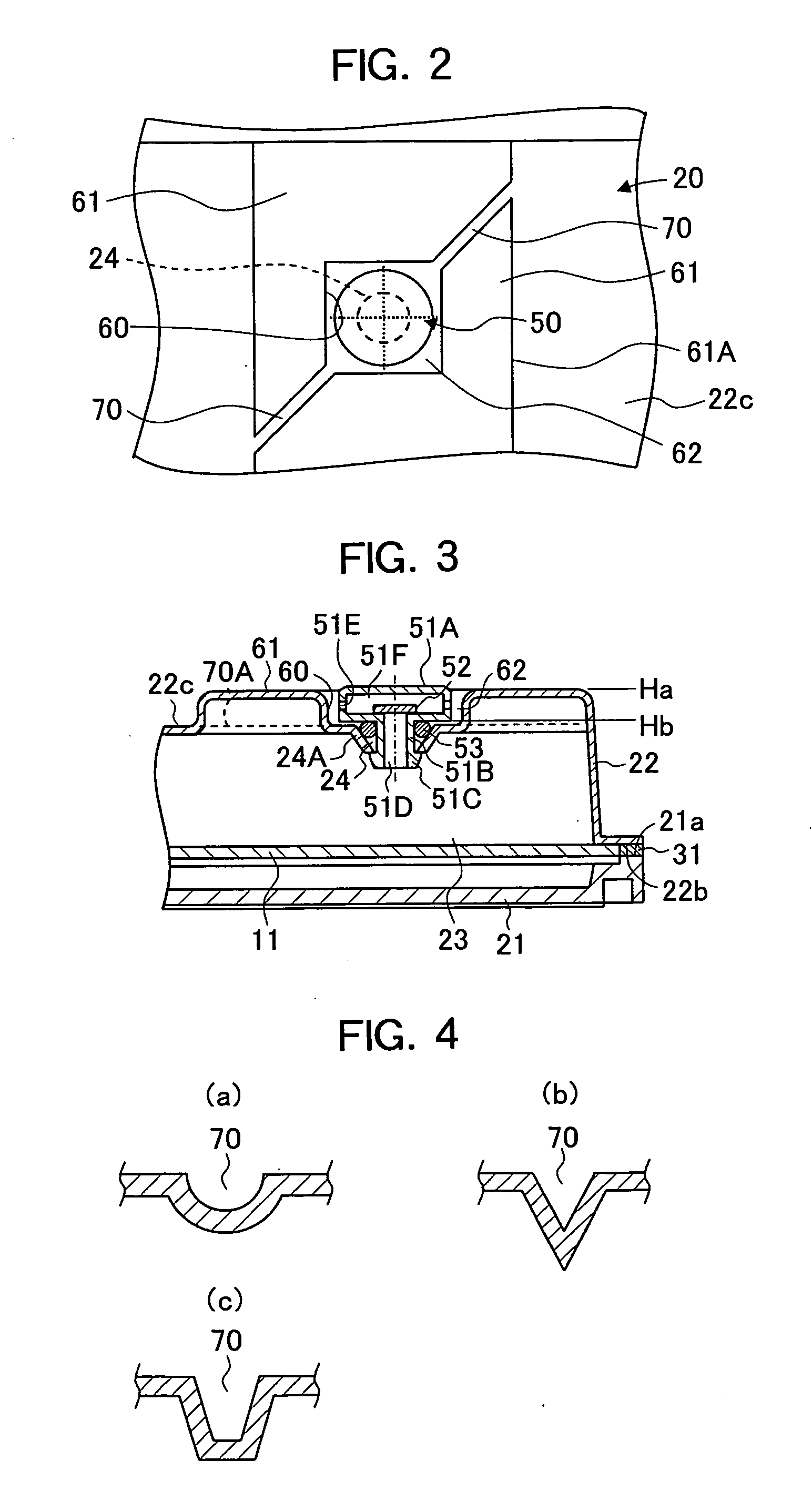

Electronic control unit and waterproof case

ActiveUS20070109730A1Good flexibilityDirect contact guaranteeSubstation/switching arrangement detailsThin material handlingPhysical medicine and rehabilitationEngineering

The mounting direction, posture, or location of an electronic control unit provided with a respiratory filter in a waterproof case is not restricted in an engine room or the like. Raised protective walls that surround the portion at which the respiratory filter is arranged are provided, and at least two concave portions for drainage that each extend through different positions of the protective walls are provided.

Owner:HITACHI ASTEMO LTD

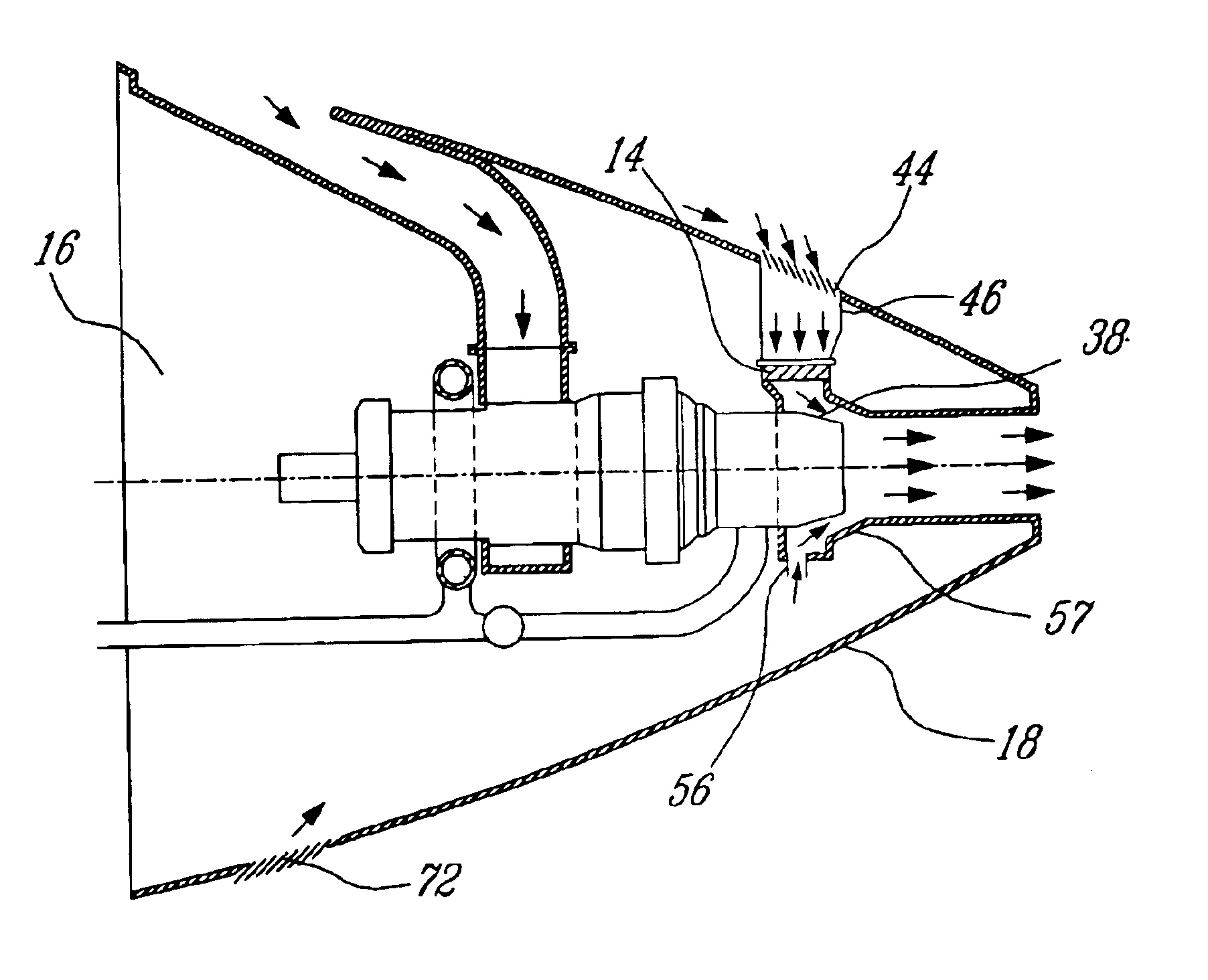

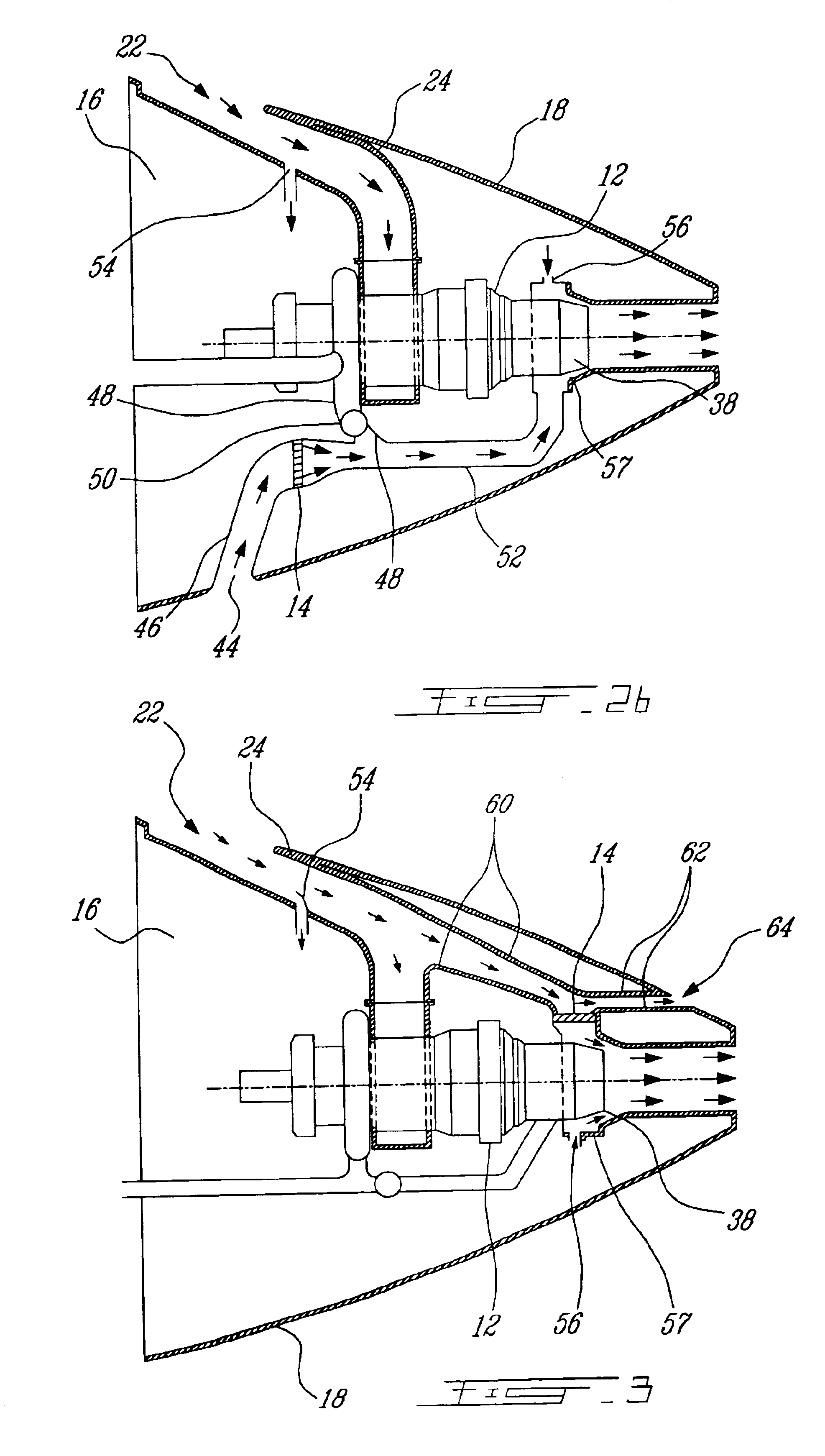

Passive cooling system for auxiliary power unit installation

InactiveUS6942181B2Improve cooling effectEnhanced cooling airflowPower plant cooling arrangmentsAir-treating devicesAuxiliary power unitOil cooling

A passive cooling system for an auxiliary power unit (APU) installation on an aircraft is provided. The system is for an auxiliary power unit having at least a compressor portion of a gas turbine engine and an oil cooler contained separately within a nacelle. The system includes the auxiliary power unit housed within the nacelle of the aircraft, an engine exhaust opening defined in the aft portion of the nacelle and communicating with the gas turbine engine, at least a first air inlet duct communicating with a second opening defined in said nacelle and with said compressor portion and the oil cooler is located within a second duct communicating with an opening other than the engine exhaust opening of said nacelle and with the engine exhaust opening. Exterior cooling air and engine exhaust ejected through said engine exhaust opening entrain cooling air through said second duct to said oil cooler, and thus provide engine oil cooling. An exhaust eductor is also provided.

Owner:PRATT & WHITNEY CANADA CORP

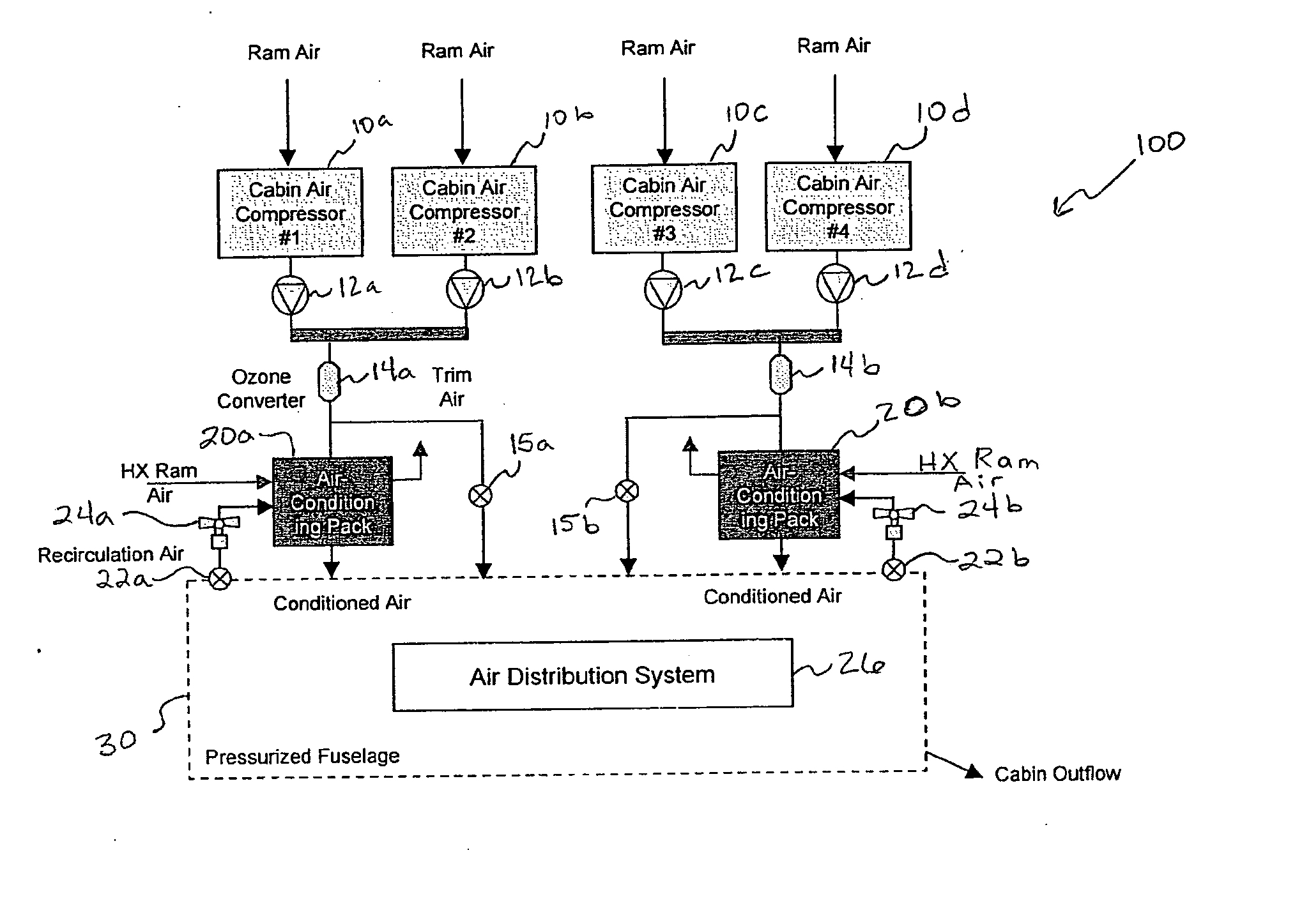

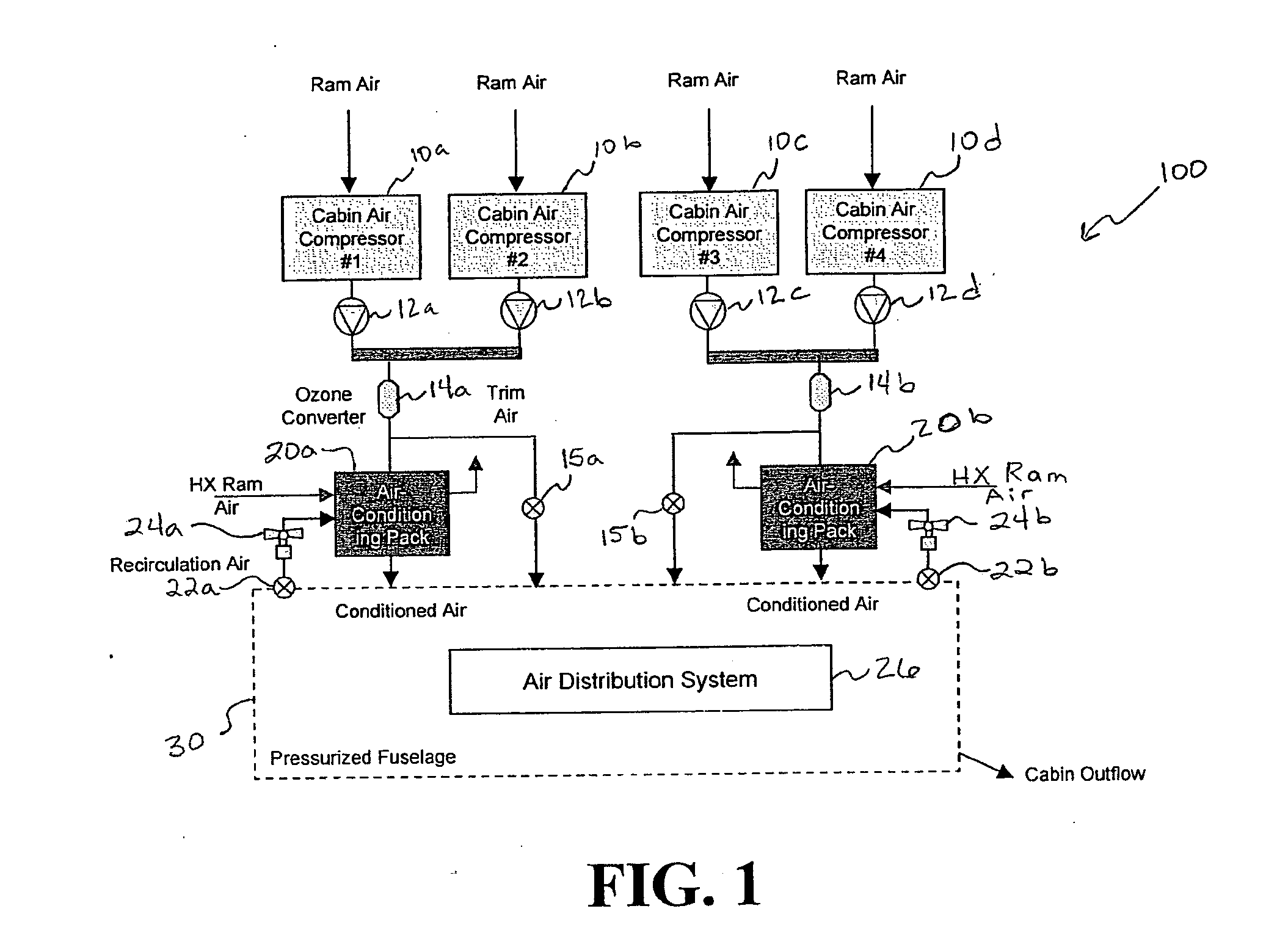

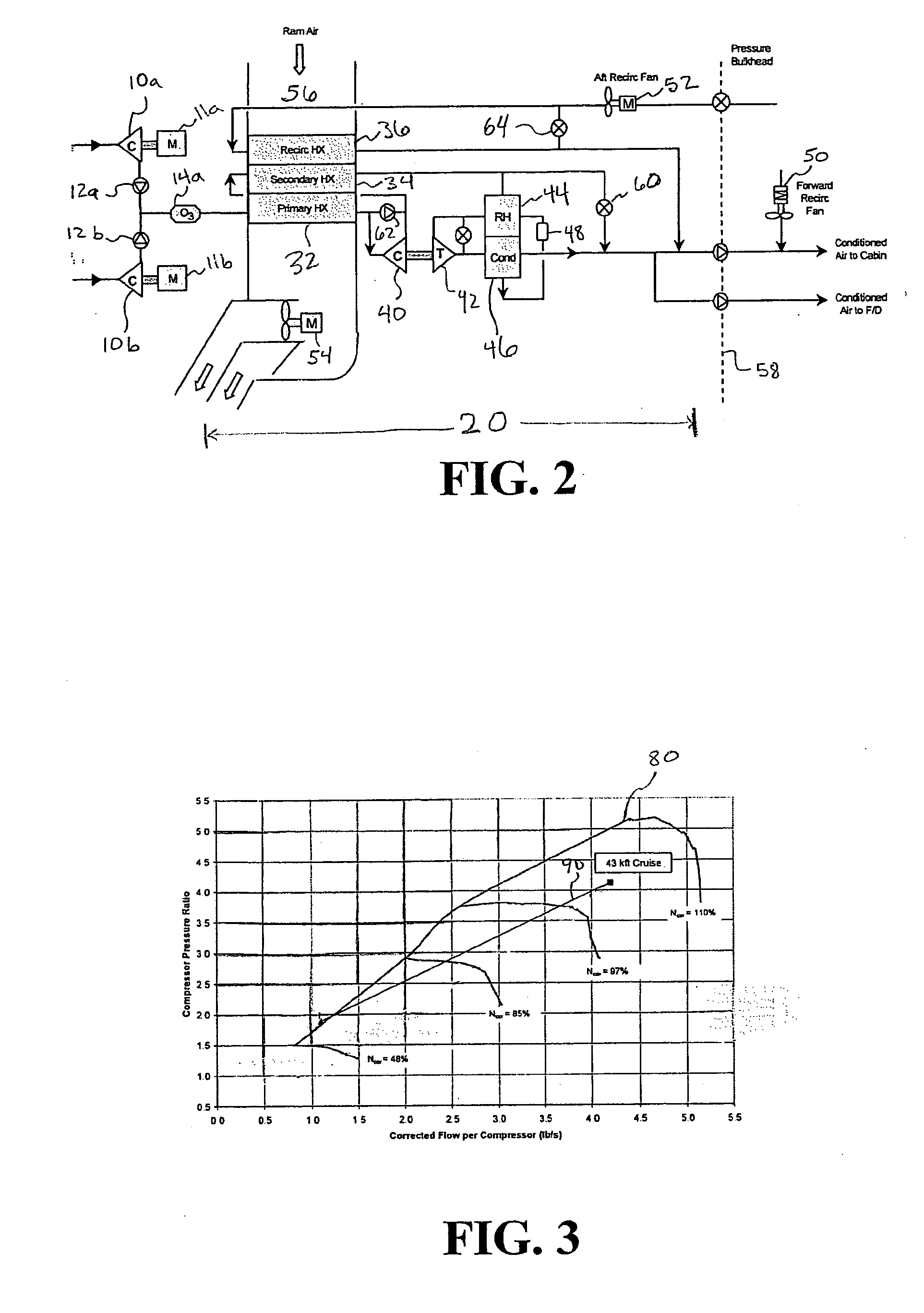

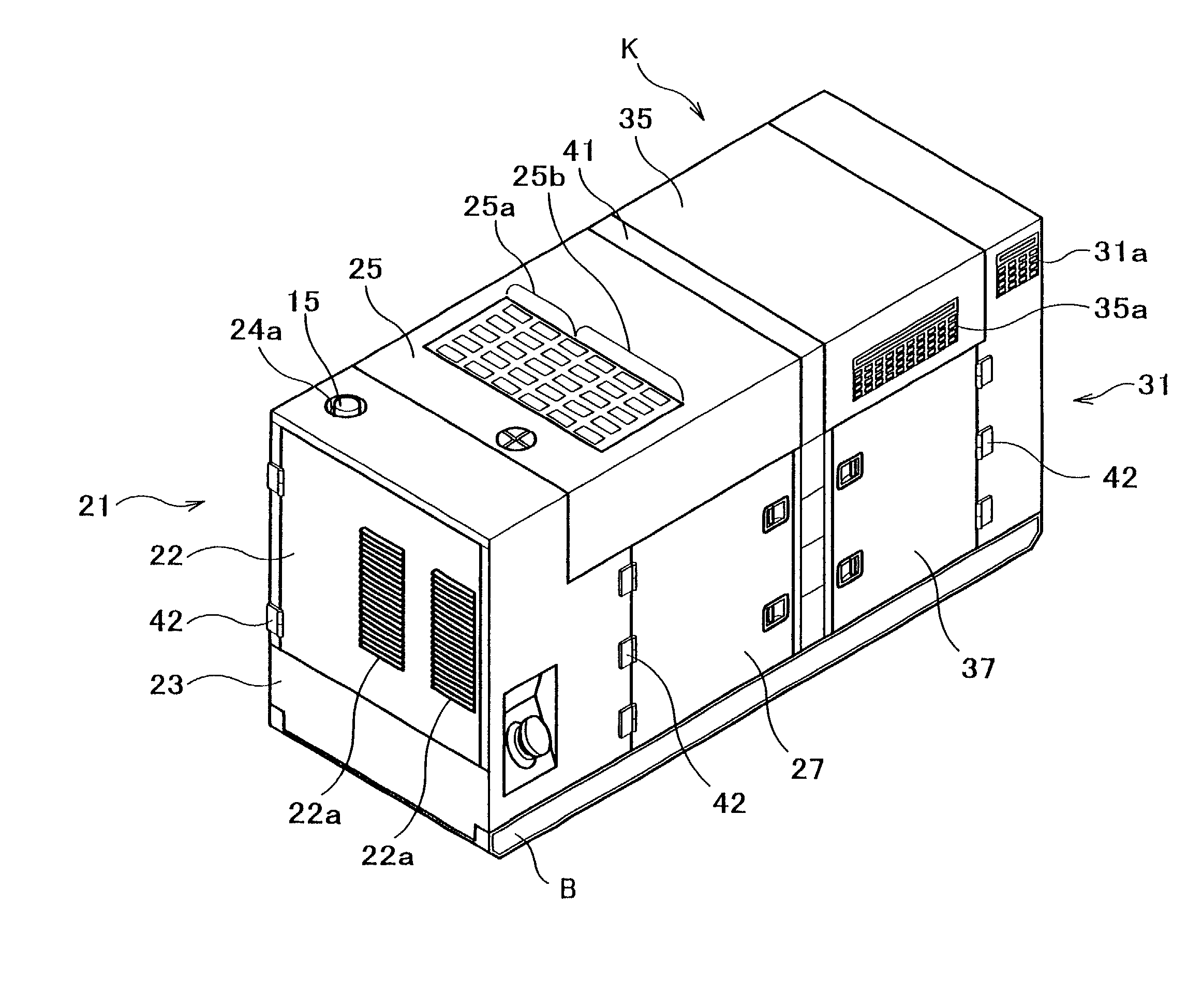

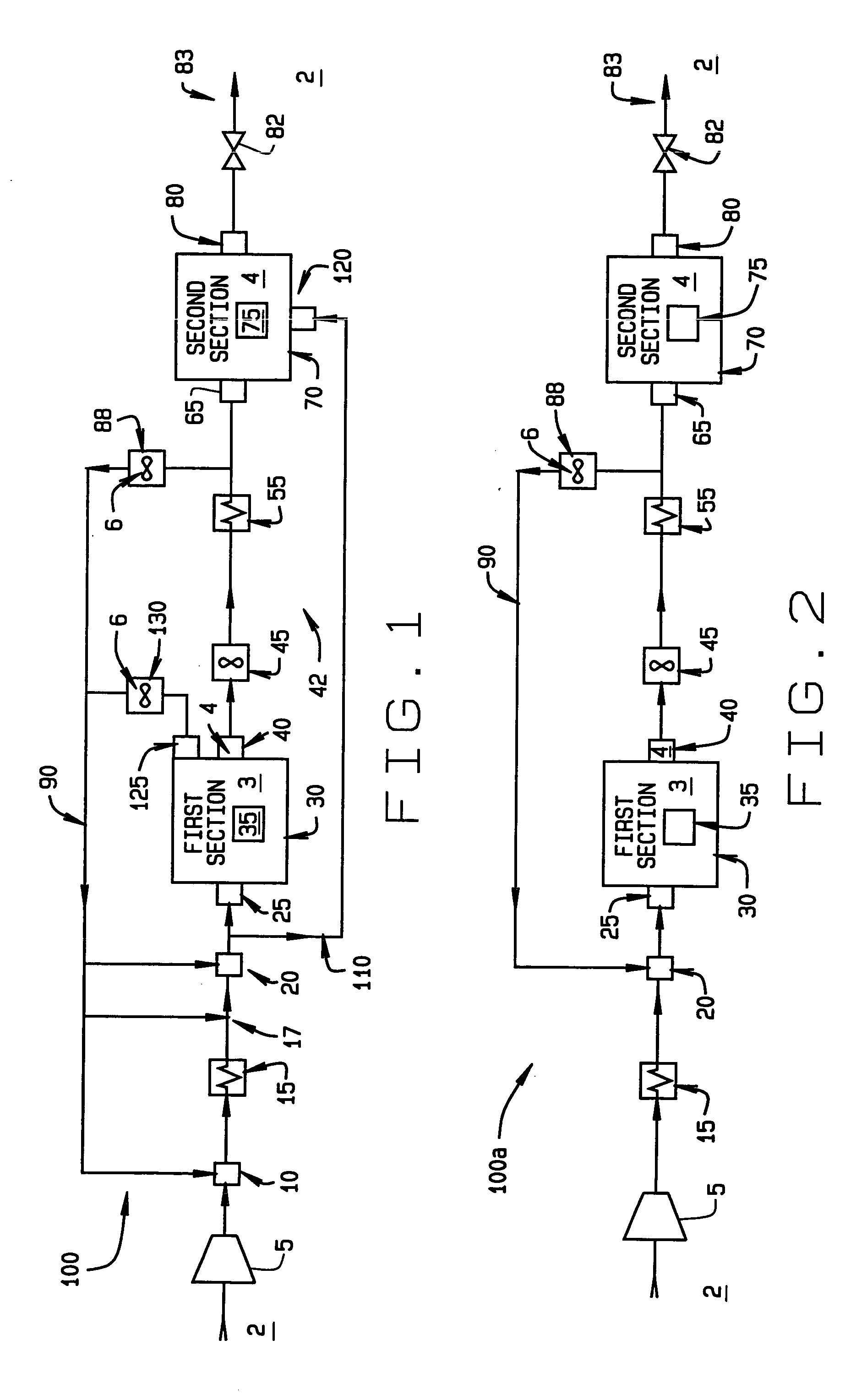

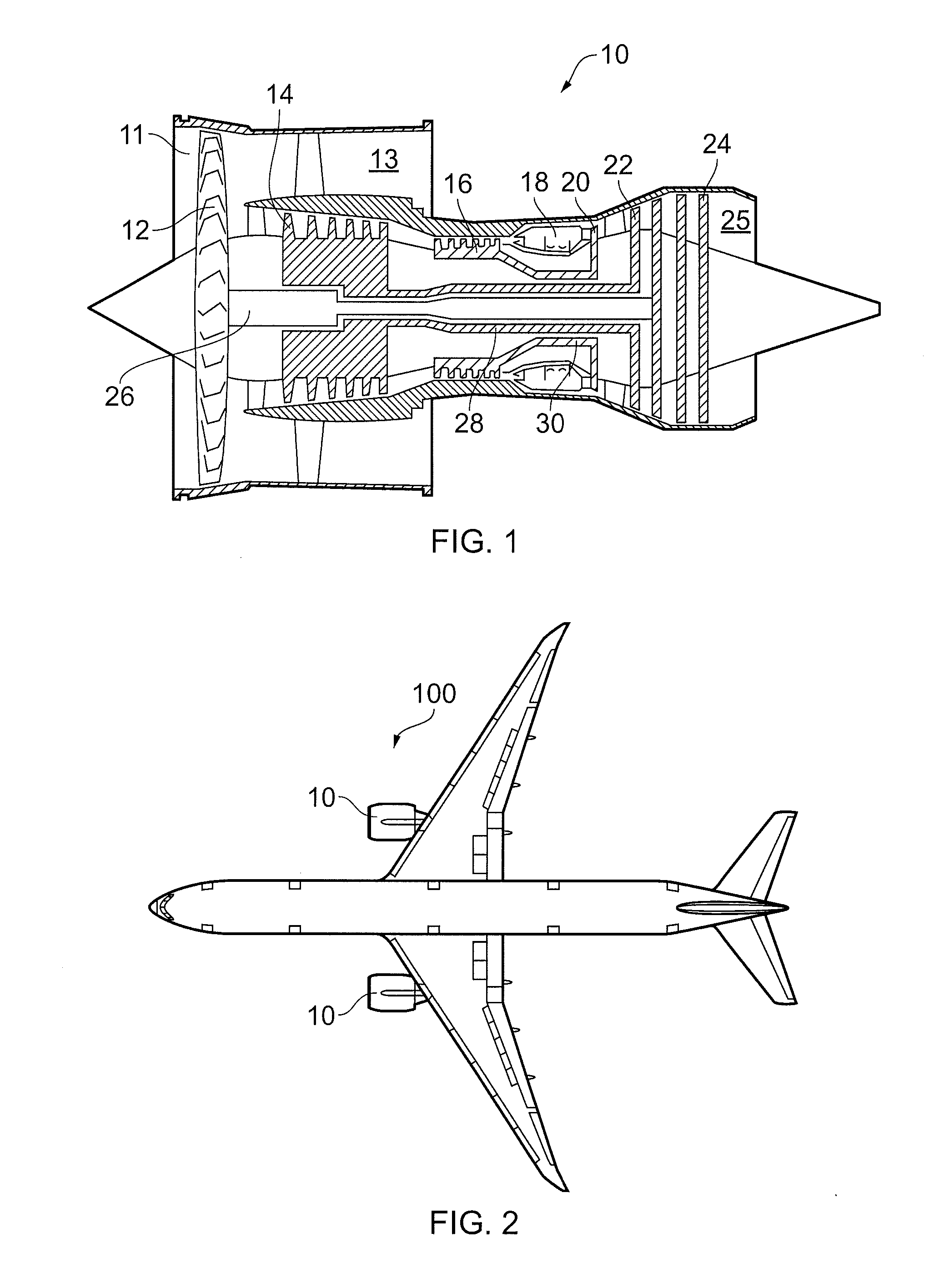

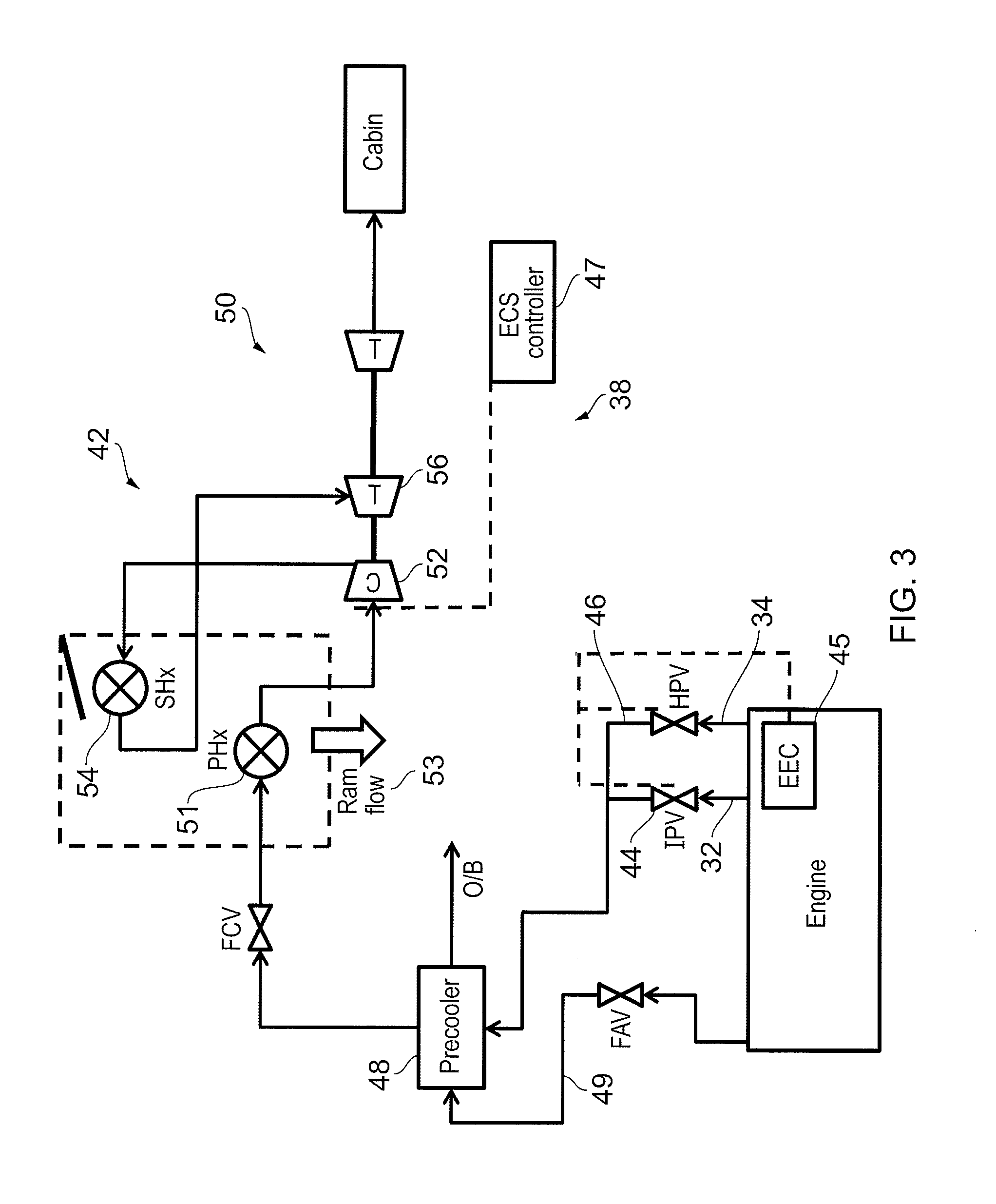

Low energy electric air cycle with portal shroud cabin air compressor

InactiveUS20070113579A1Domestic cooling apparatusAir-treatment apparatus arrangementsAir cycleElectricity

An environmental control system for an aircraft cabin includes a plurality of electrically-driven ported shroud cabin air compressors, each cabin air compressor compressing ram air received from the aircraft exterior, a heat exchange circuit comprising a primary heat exchanger receiving airflow from at least one of the cabin air compressors, and the secondary heat exchanger supplying airflow to the aircraft cabin, and an air cycle machine comprising a compressor adapted to receive airflow from the primary heat exchanger and supply compressed air to the secondary heat exchanger. The environmental control system may further comprise an air recirculation system, having an aft recirculation fan adapted to receive a portion of recirculation air from the aircraft cabin, and a recirculation heat exchanger, disposed in the heat exchange circuit in series with the primary and secondary heat exchangers, and adapted to receive airflow from the aft recirculation fan.

Owner:HONEYWELL INT INC

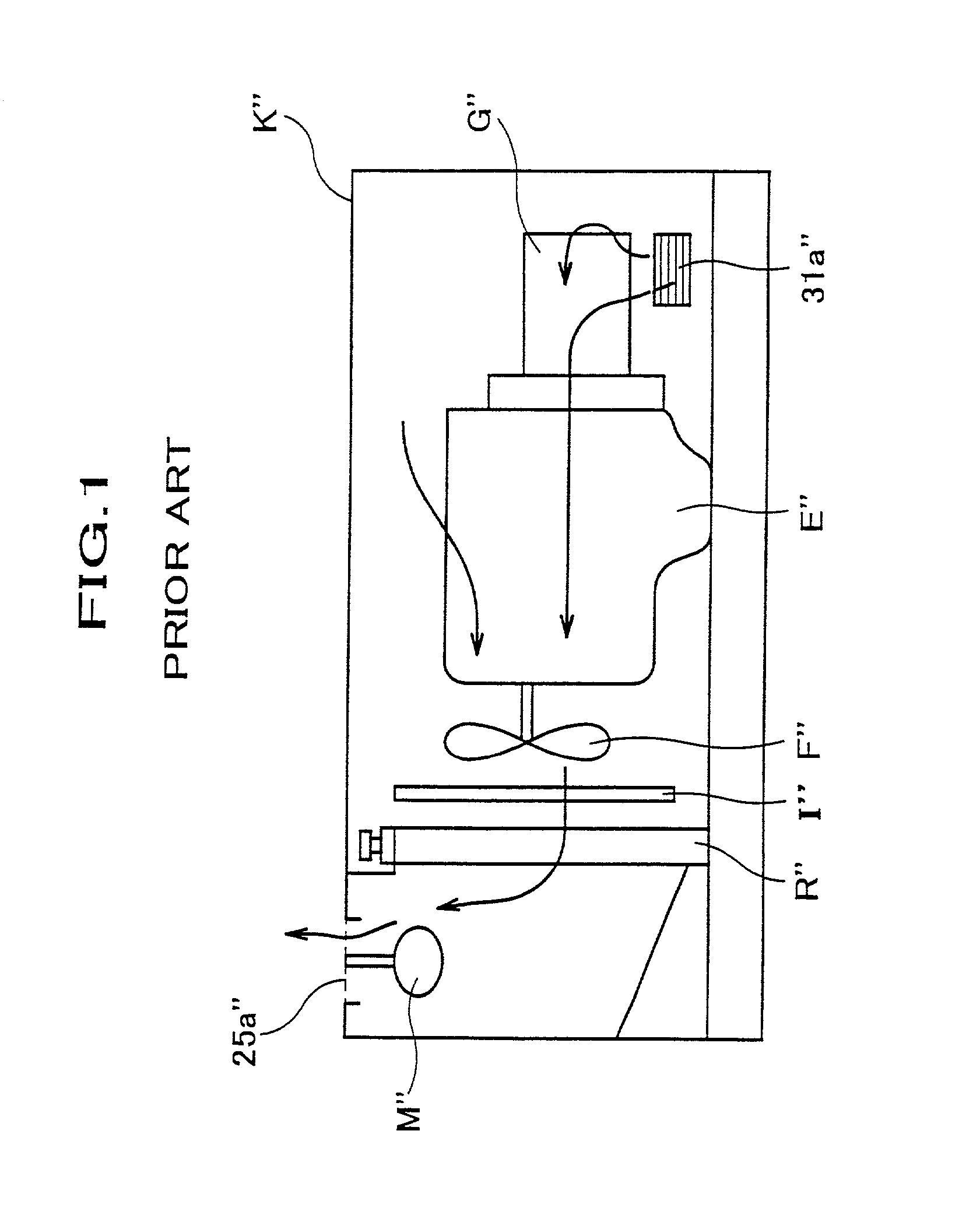

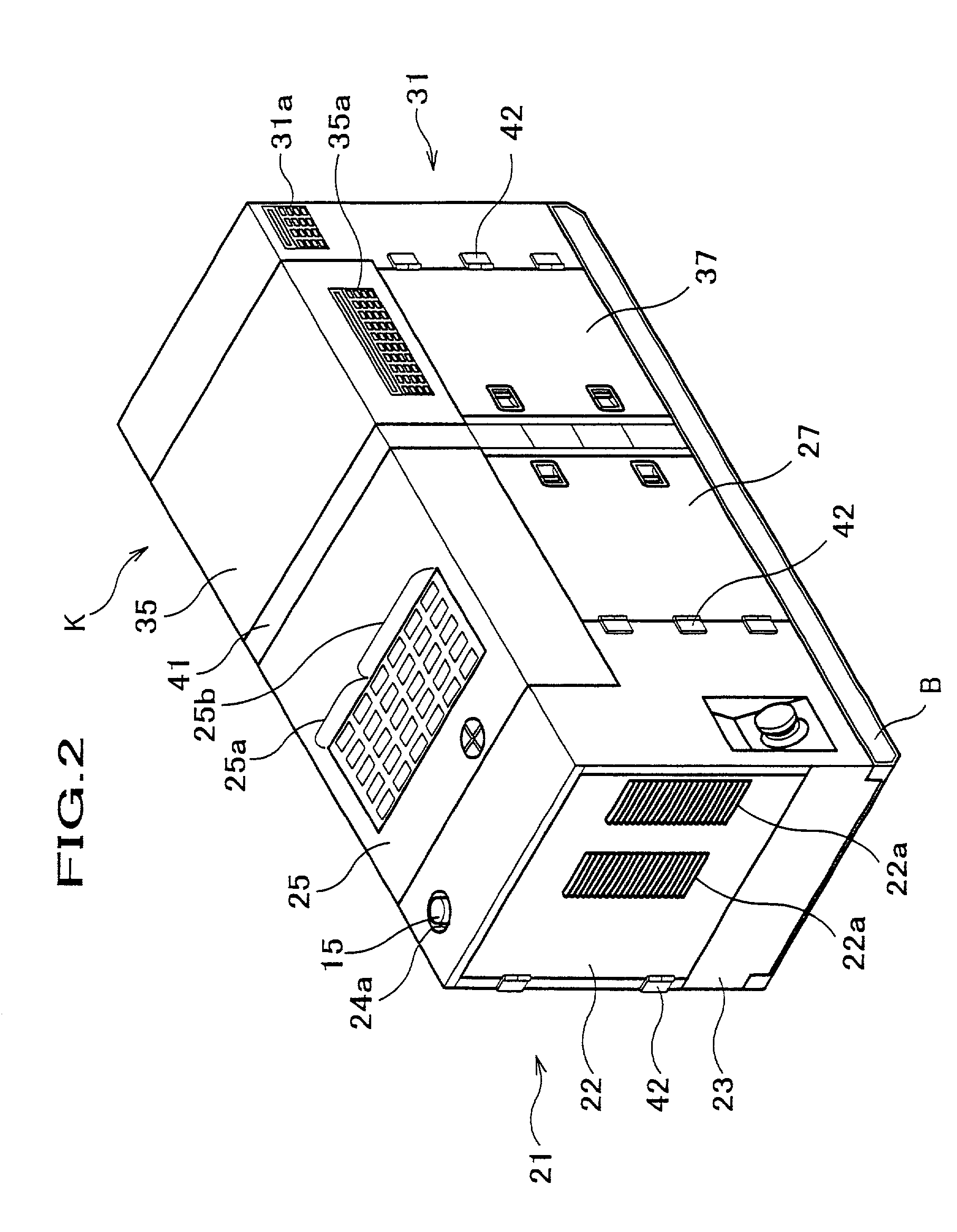

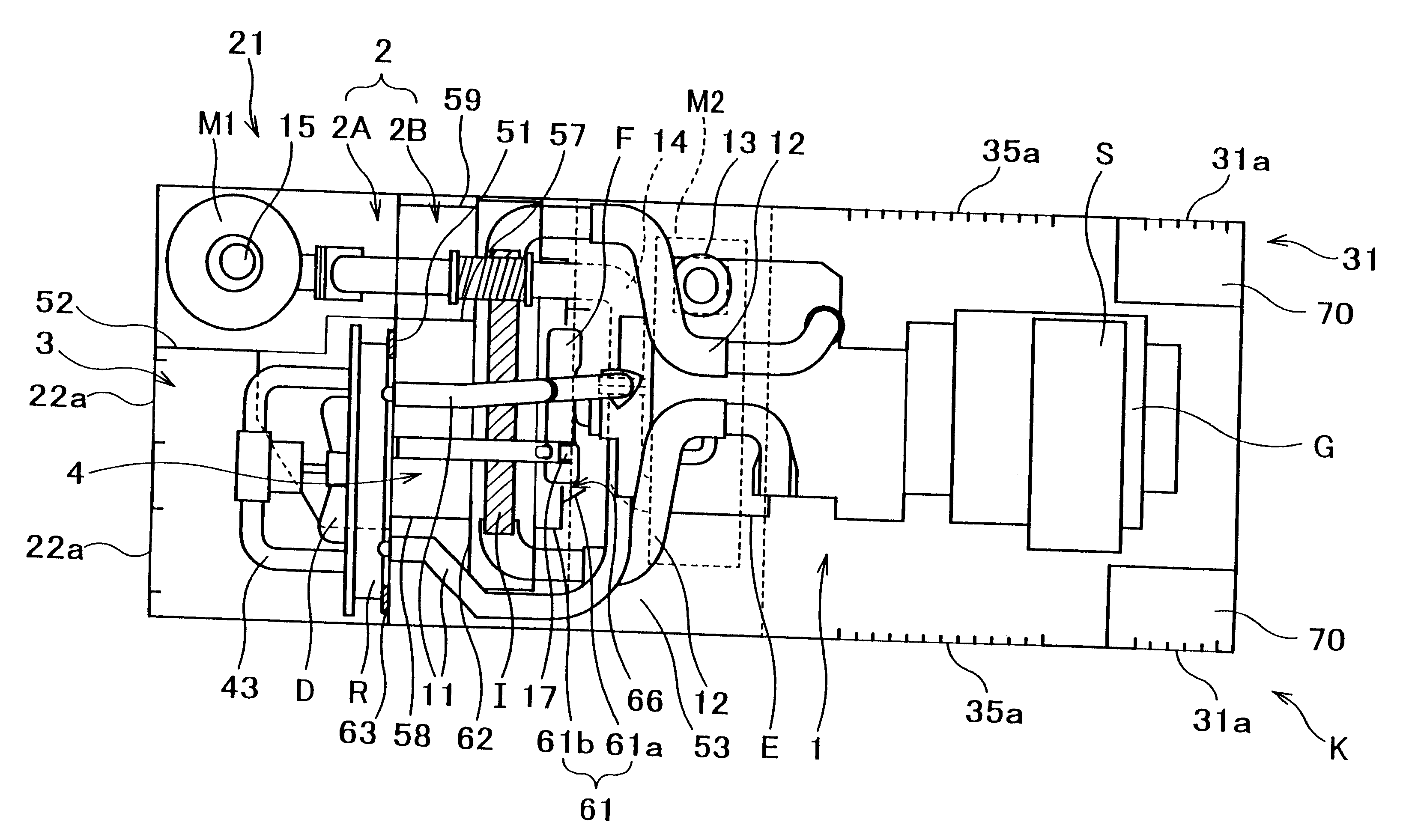

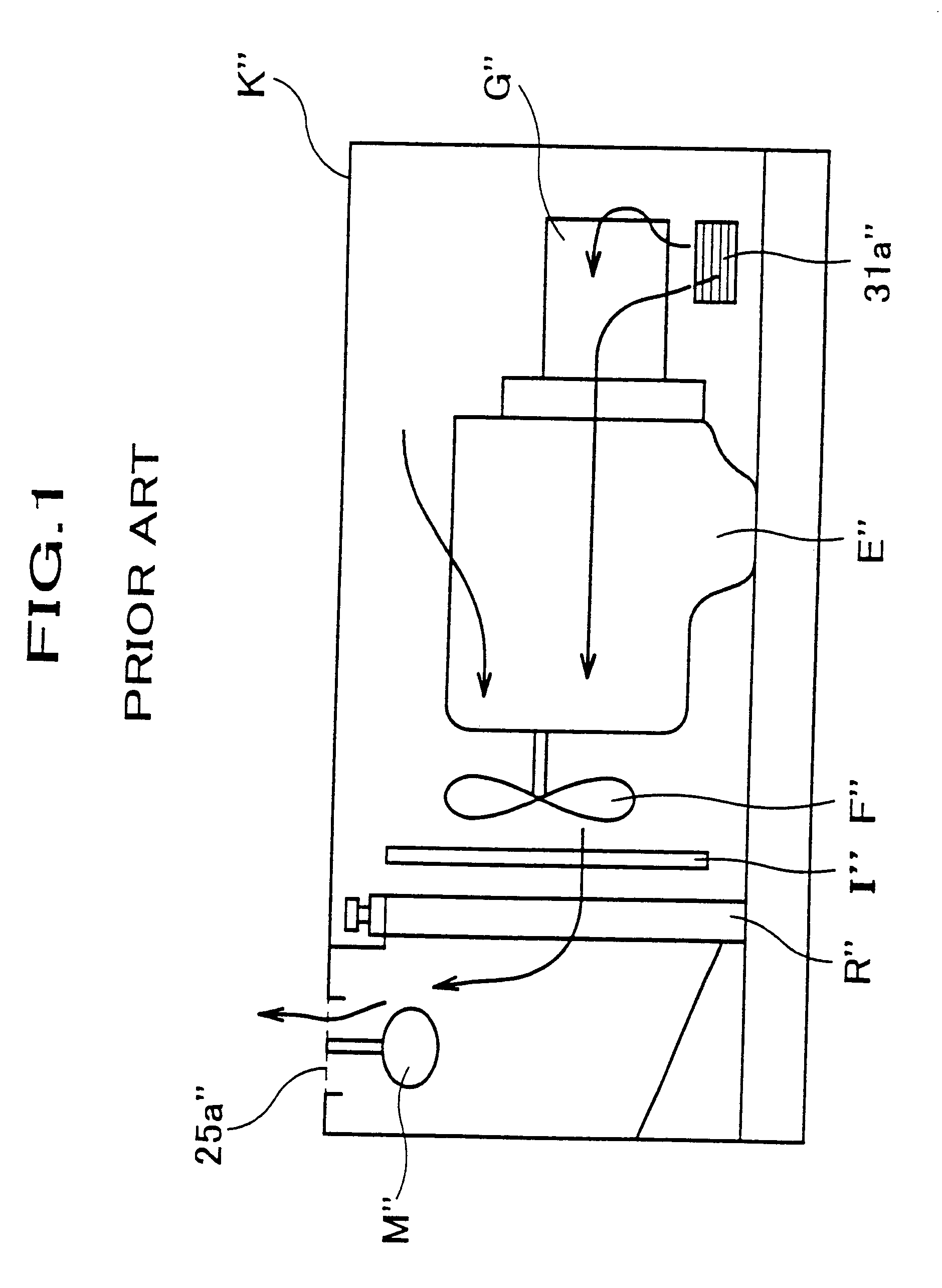

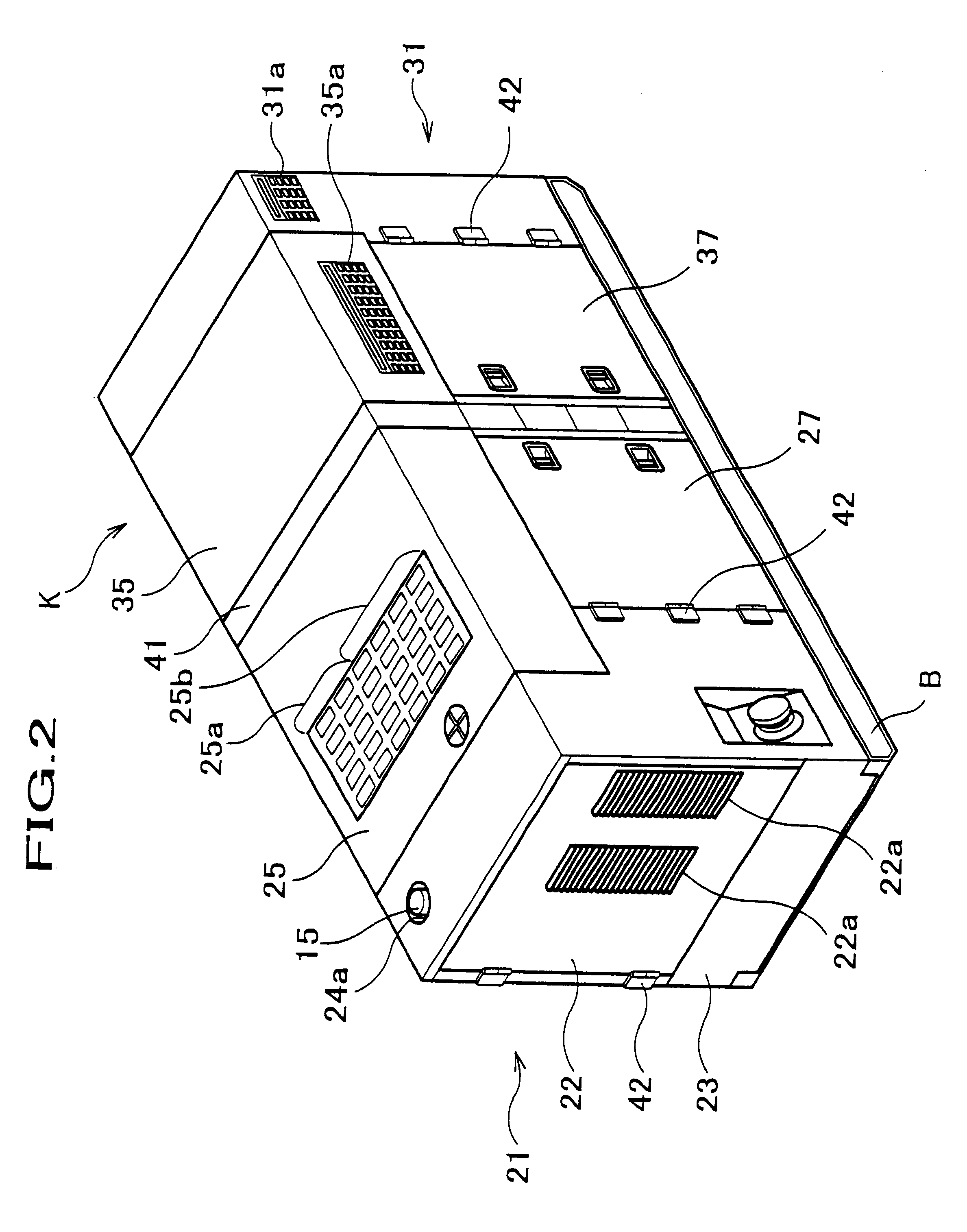

Soundproof type engine driven work machine

InactiveUS20020000342A1Small sizeImprove cooling efficiencySoil-shifting machines/dredgersMachines/enginesEngineeringMuffler

The soundproof casing is divided to an engine room 1, a muffler room 2 and a radiator room 3. The engine room 1 includes the engine E and a work machine unit (generator unit G). The muffler room 2 includes mufflers M1, M2. The radiator room includes a radiator R. An electric fan D is provided between an air intake aperture 22a and the radiator. The radiator room and the muffler room are communicated. An air flow duct 4 to communicate the engine room and the muffler room is provided. An engine fan F is provided just opposite to an entrance of the air flow duct. An inter-cooler I is provided in the air flow duct. The soundproof type engine driven work machine including aforementioned apparatuses is offered to improve the cooling efficiency as well as reducing unfavorable noise.

Owner:DENYO LMTD

High efficiency aircraft cabin air supply cooling system

ActiveUS20050051668A1Save energyReduce needDomestic cooling apparatusAir-treatment apparatus arrangementsFlight vehicleThermal management system

A thermal management system for an aircraft is provided. The aircraft includes a primary air conditioning system which compresses and cools outside air to create inside air. The inside air pressurizes the internal volume of the aircraft and ventilates a first object in the internal volume. An exhaust exhausts a portion of the inside air to allow more outside air to be drawn into the aircraft. A cooler cools a coolant which in turn controls temperature of at least two objects in the internal volume.

Owner:THE BOEING CO

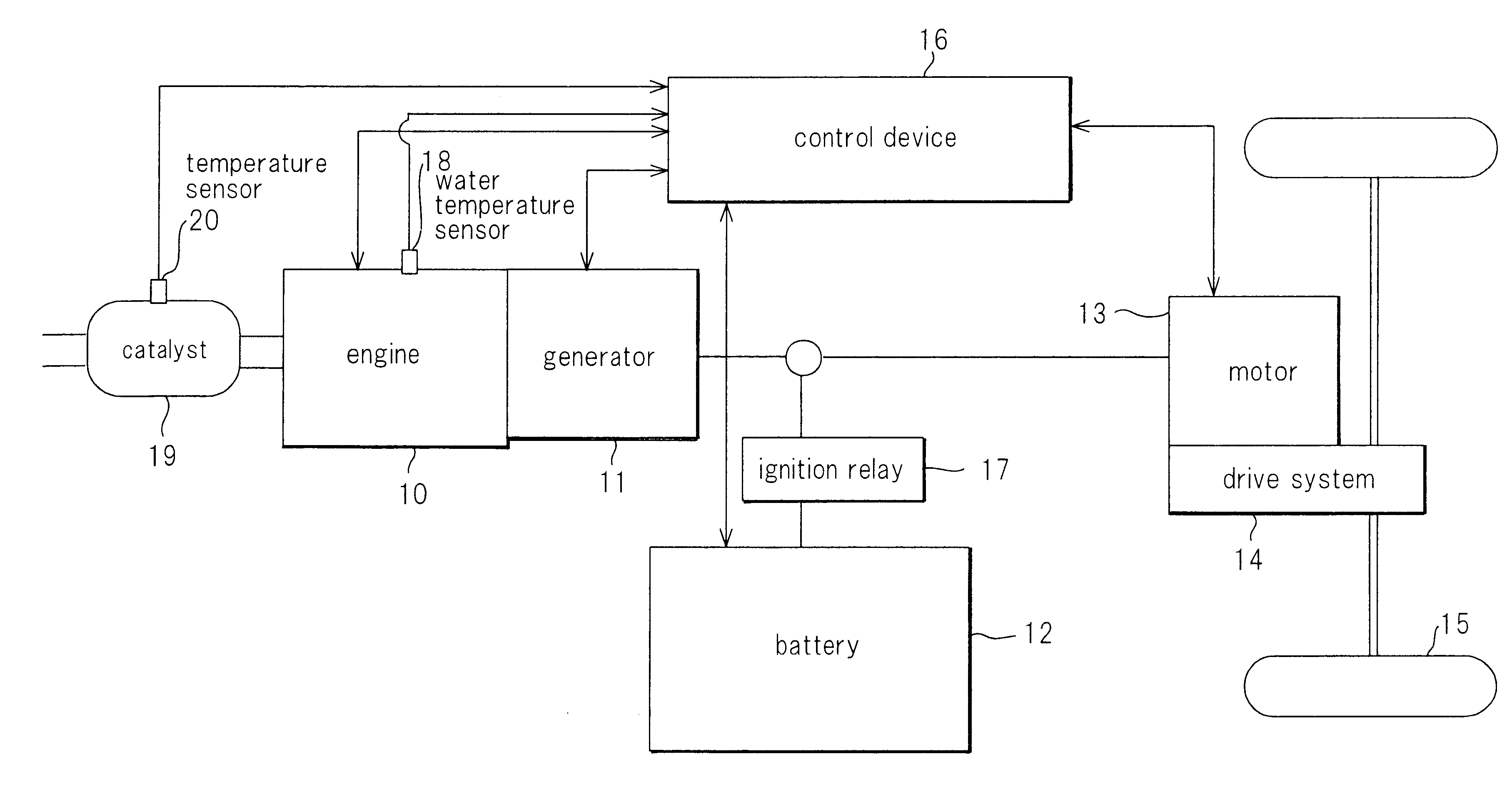

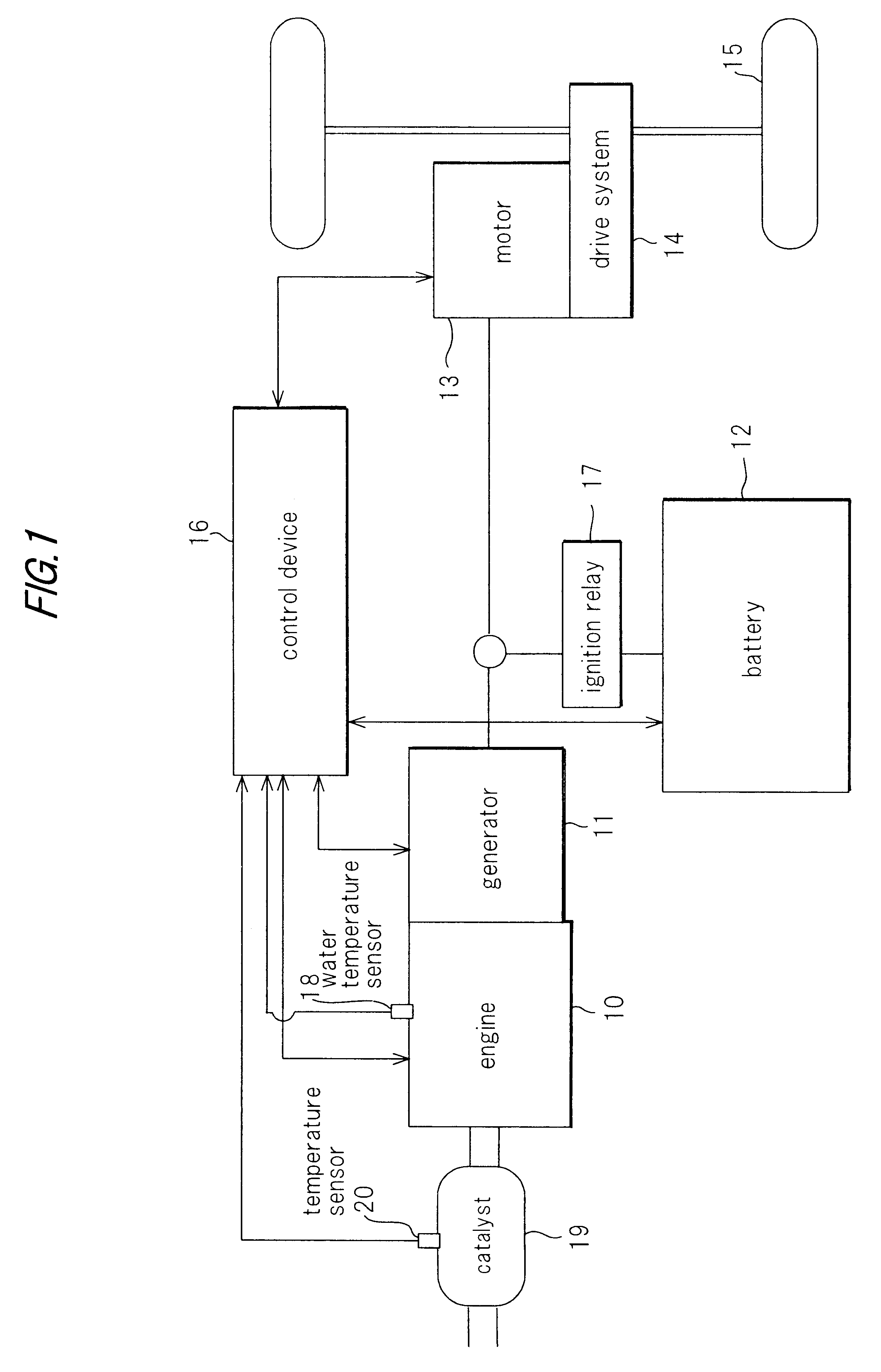

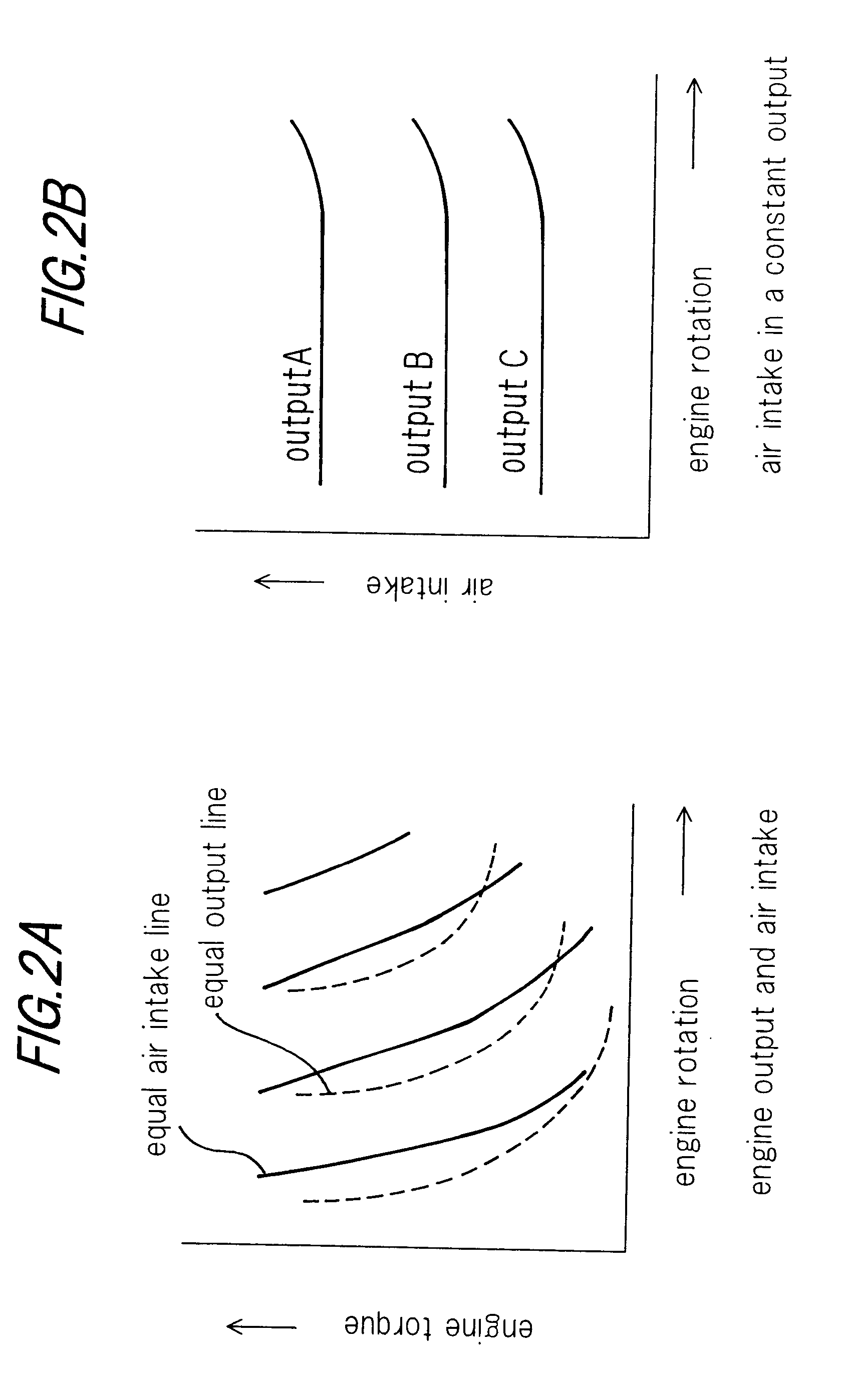

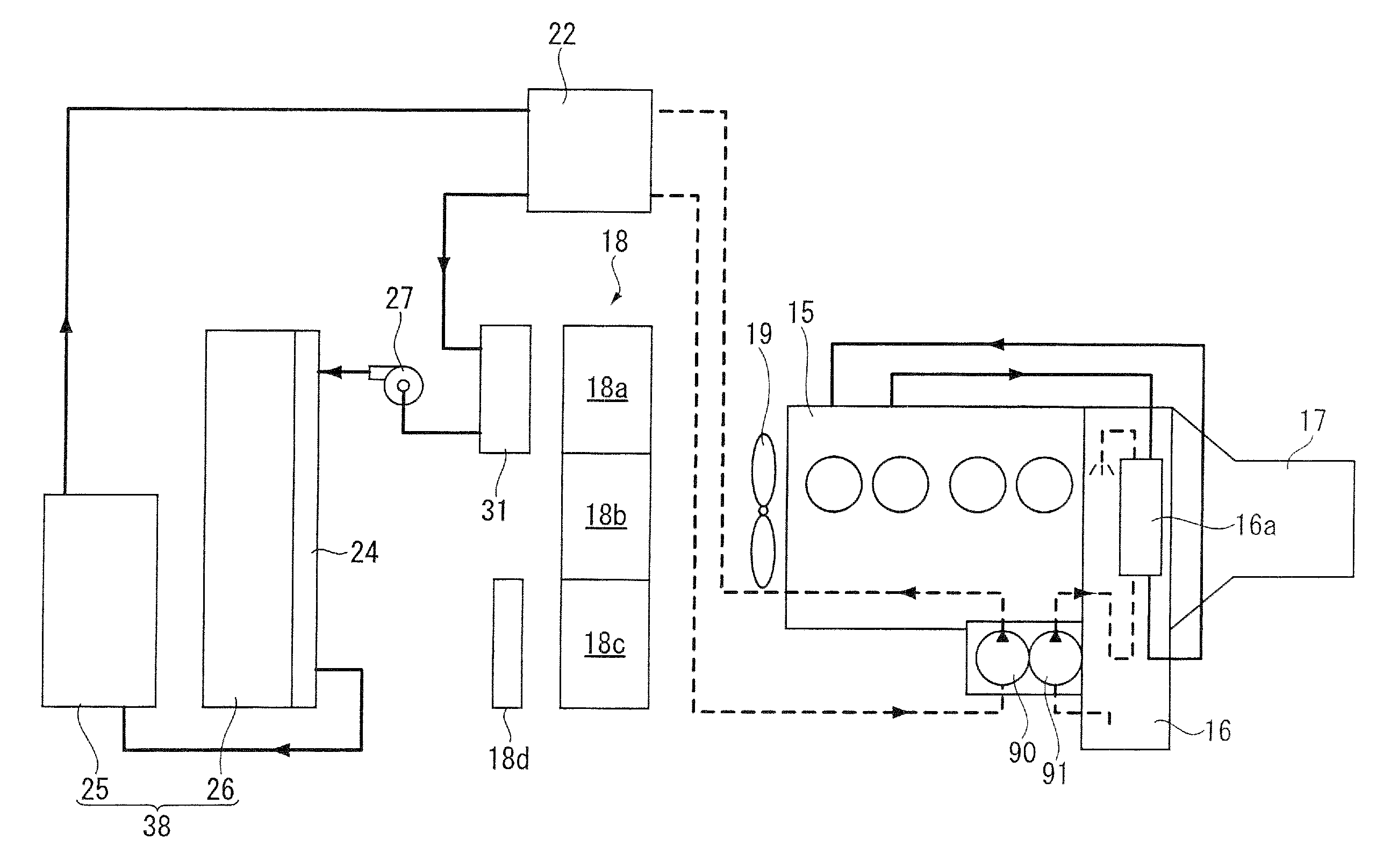

Generator control device for an electrical automobile

An engine is activated to drive a generator when an electrical output is required. The required electrical output (PO) is searched and the necessary engine output is calculated. The basic driving point (NO, TO) which obtains maximum fuel efficiency is set at that output (S101-S105). The load of the generator is controlled so as to reach the set basic driving point. When the catalyst temperature is lower than a set value, while maintaining the required electrical output, the basic driving point is varied to a driving point (Ncold, Tcold) which will raise the exhaust gas temperature (S106-108). Furthermore when the temperature of the peripheral engine components in the engine room is higher than a set value, while maintaining the required electrical output, the driving point is varied to a driving point (Nheat, Theat) which will lower the exhaust gas temperature (S109-S111). Hence while maintaining the electrical output, it is possible satisfy each component temperature condition. Therefore while maintaining drivability, fuel efficiency performance, lowering exhaust gas emissions and component deterioration can suppressed.

Owner:NISSAN MOTOR CO LTD

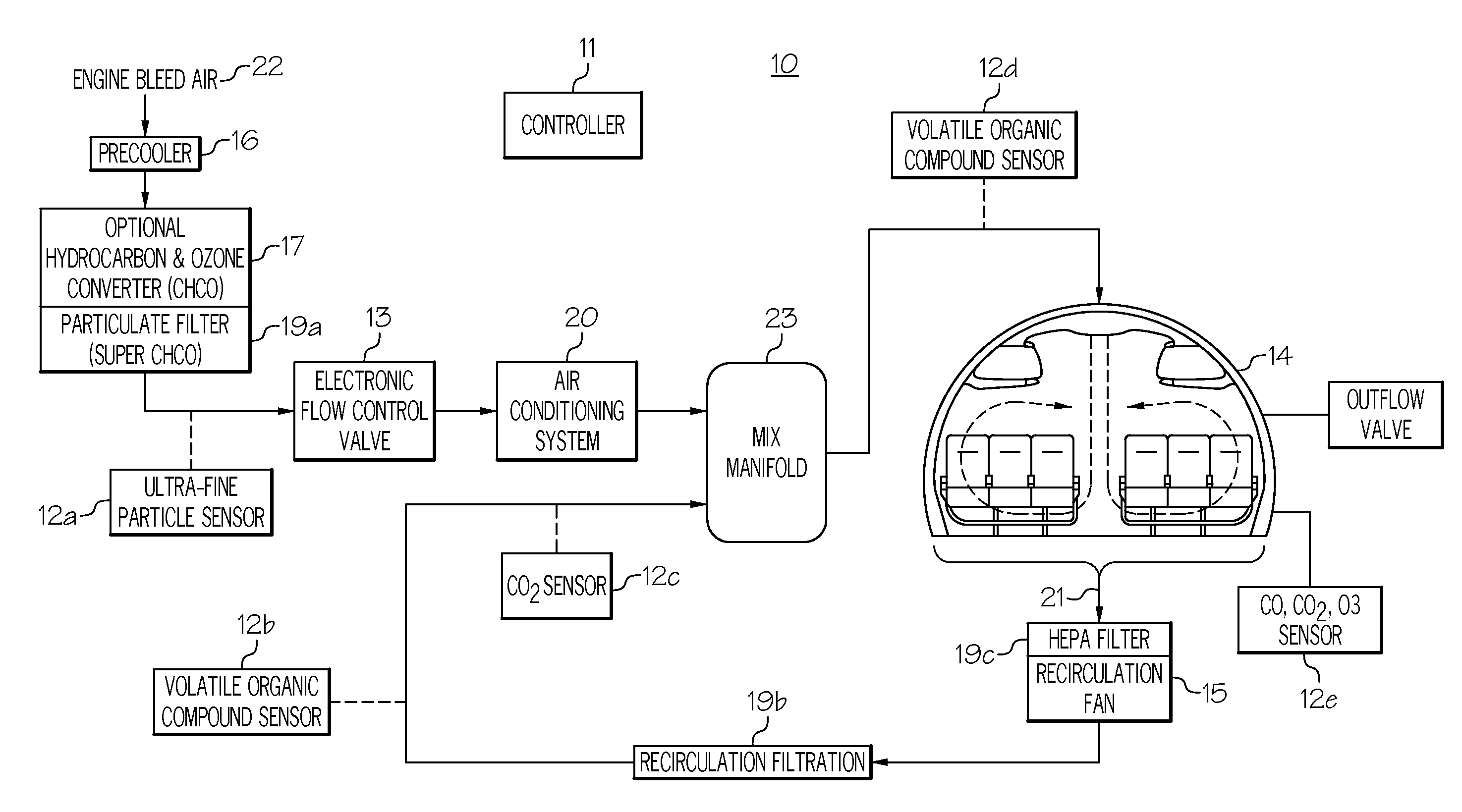

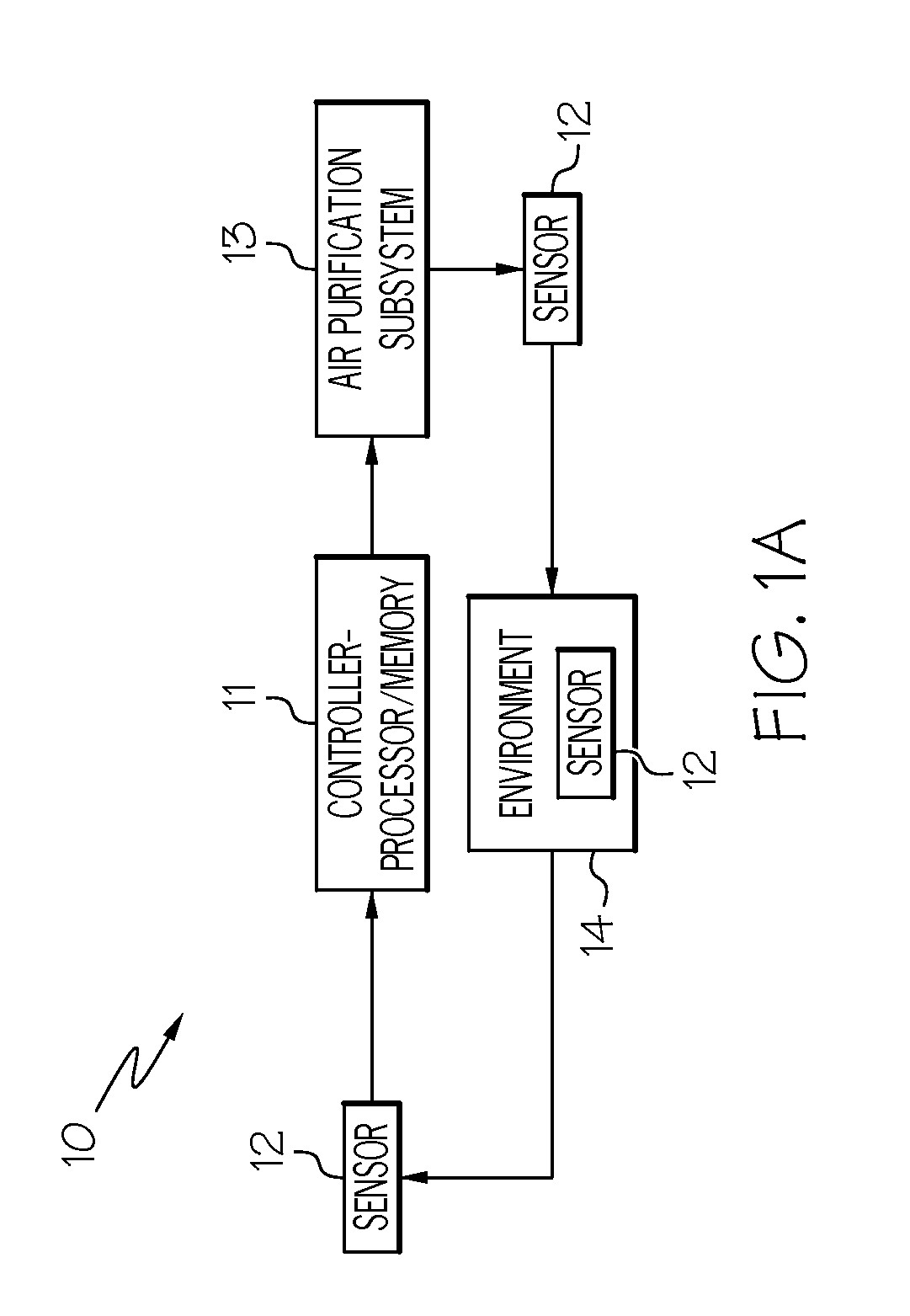

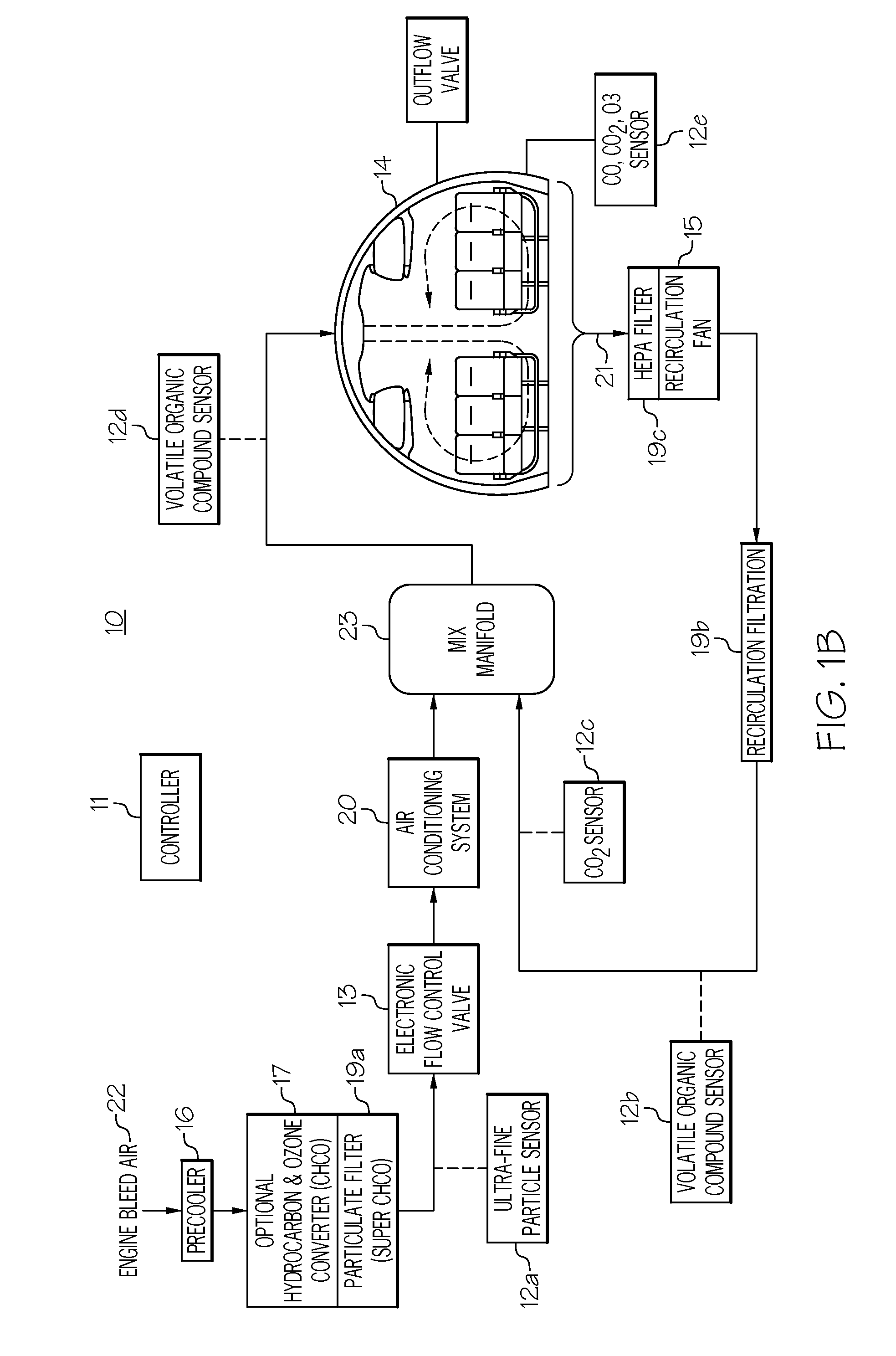

Aircraft environmental control system that optimizes the proportion of outside air from engines, apu's, ground air sources and the recirculated cabin air to maintain occupant comfort and maximize fuel economy

ActiveUS20160214723A1Air-treatment apparatus arrangementsEnergy efficient board measuresControl systemEnvironmental control system

An Environmental Control System includes sensors, an air purification subsystem, and a controller in communication with the sensors and air purification subsystem. The sensors detect contaminants in outside air supplied through engine and APU bleeds or other air sources including ground supplies and electric compressors, contaminants in recirculated air, particulates in outside air, carbon dioxide in recirculated air, temperature in an environment, and pressure in an environment. These sensed parameters are compared against thresholds. Based on the comparisons, changes to the outside air and / or recirculated air are made.

Owner:HONEYWELL INT INC

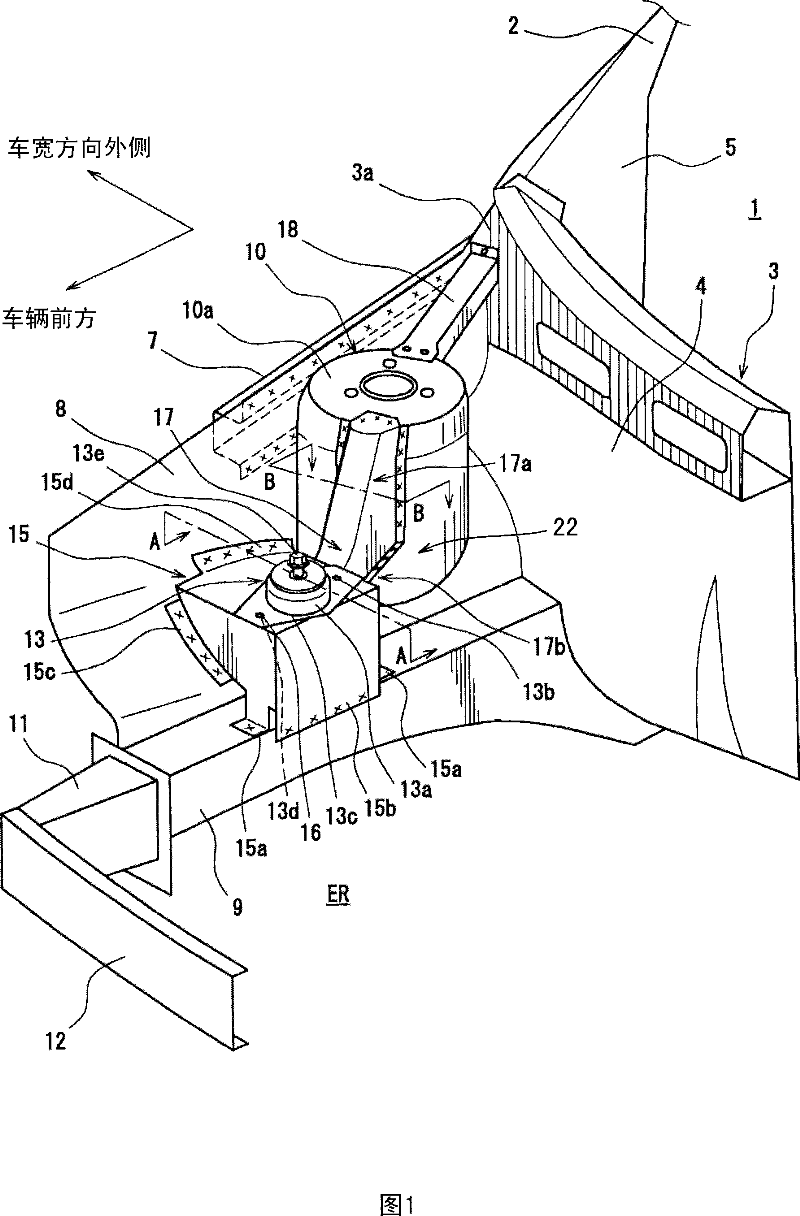

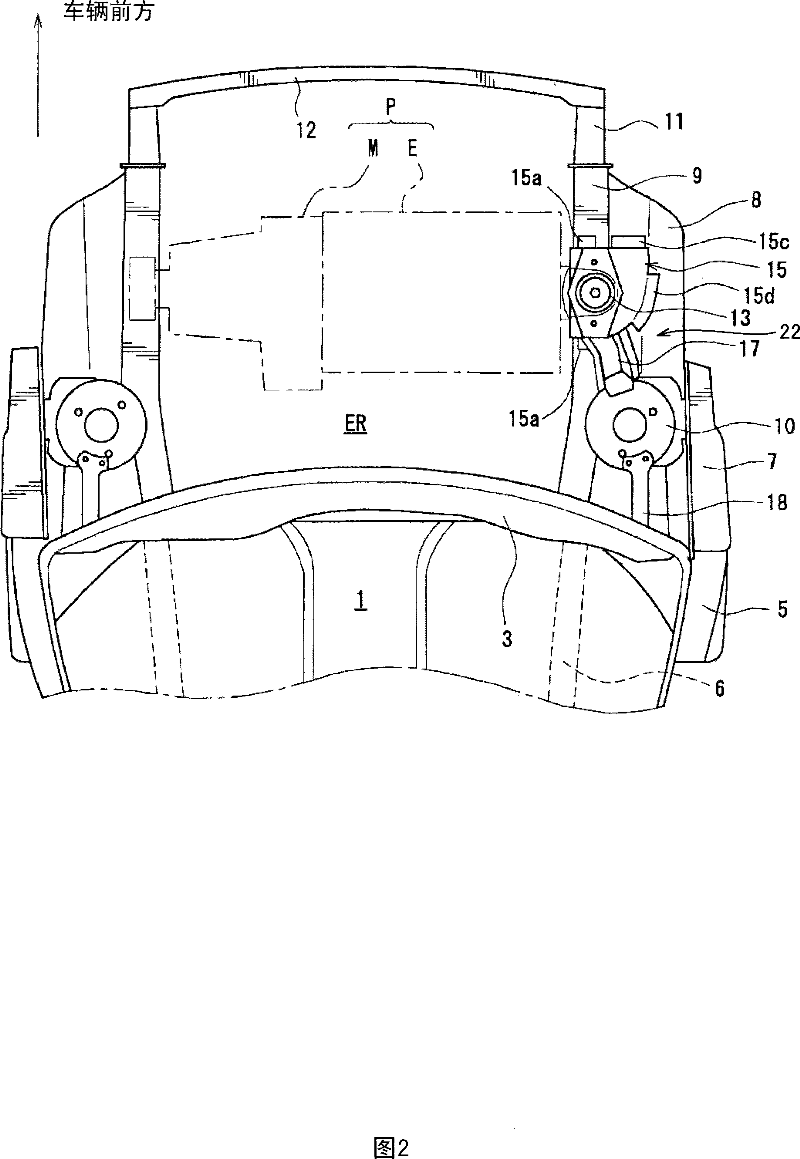

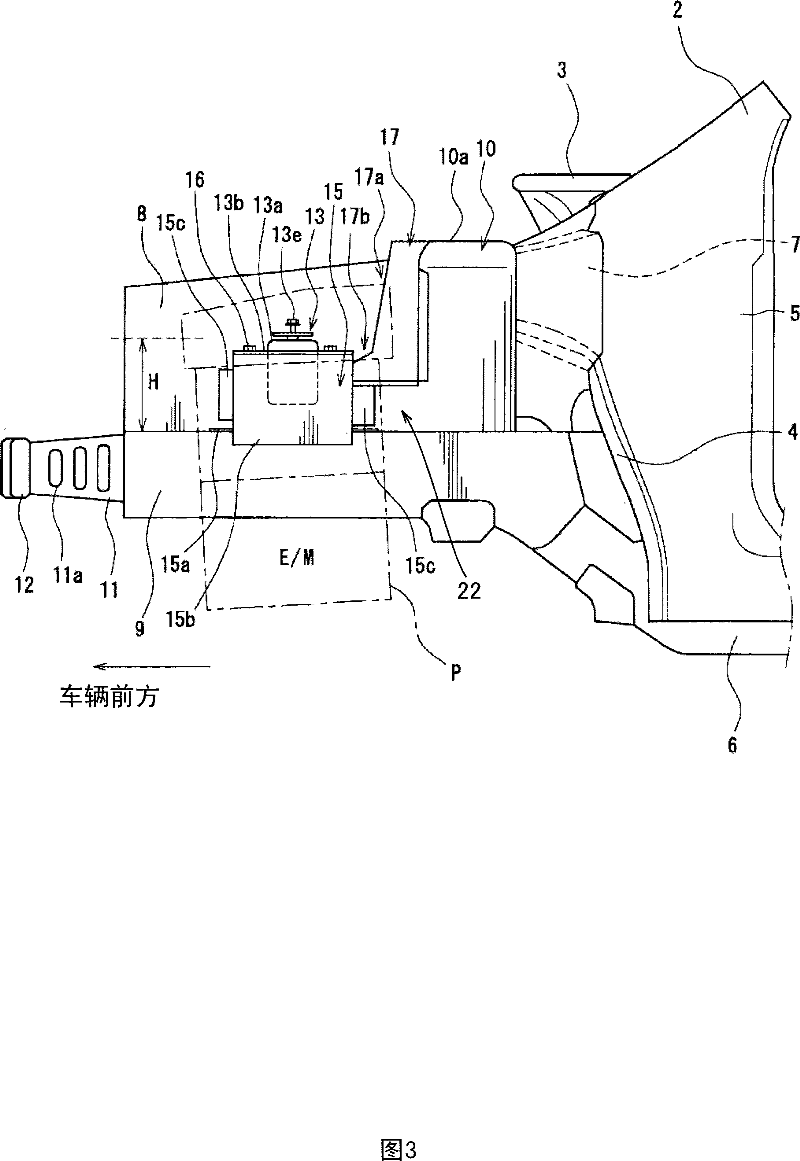

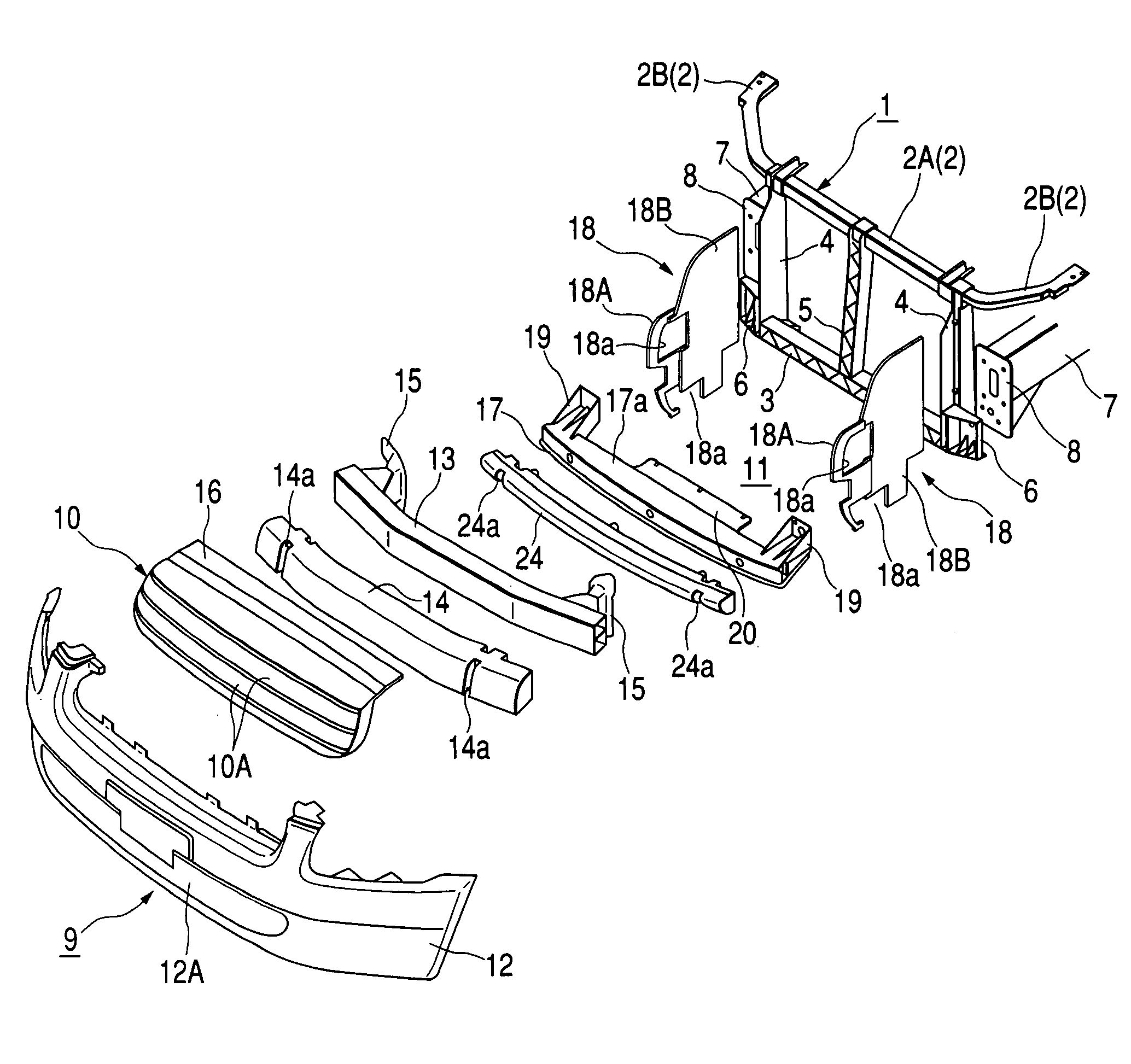

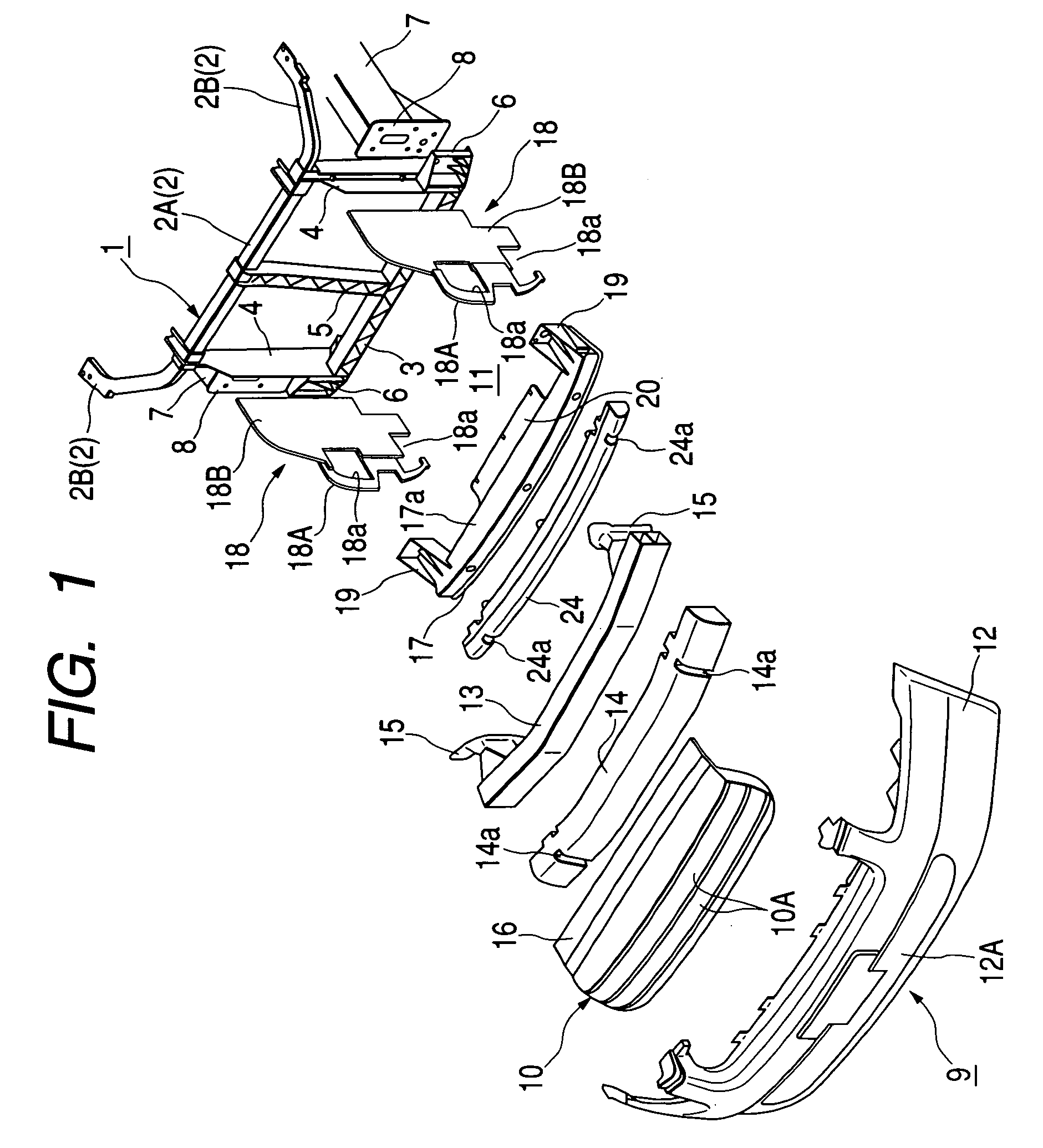

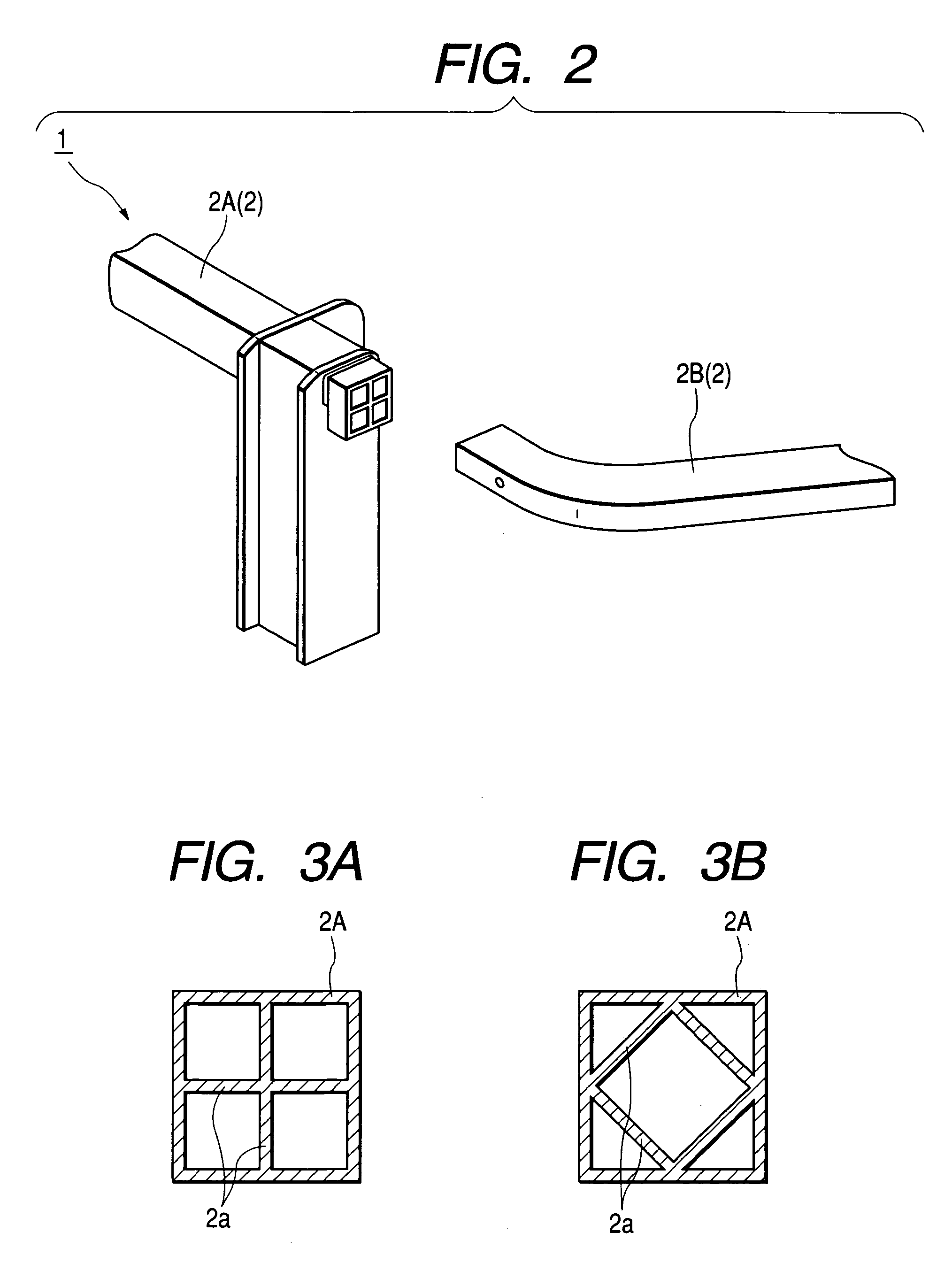

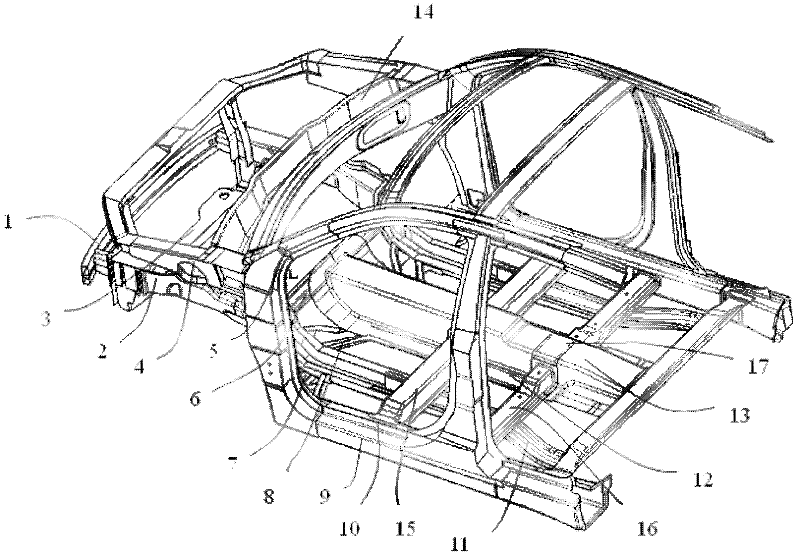

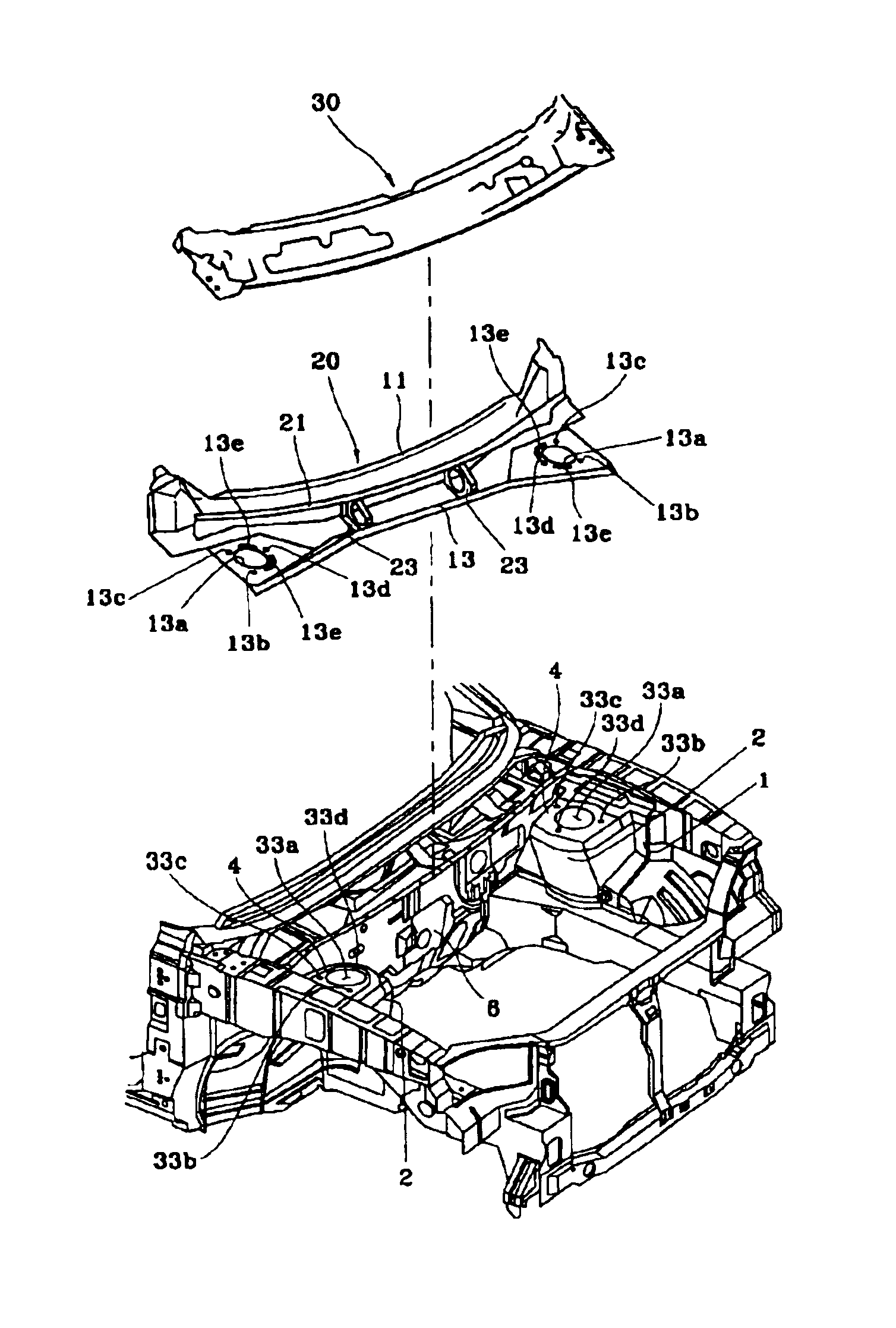

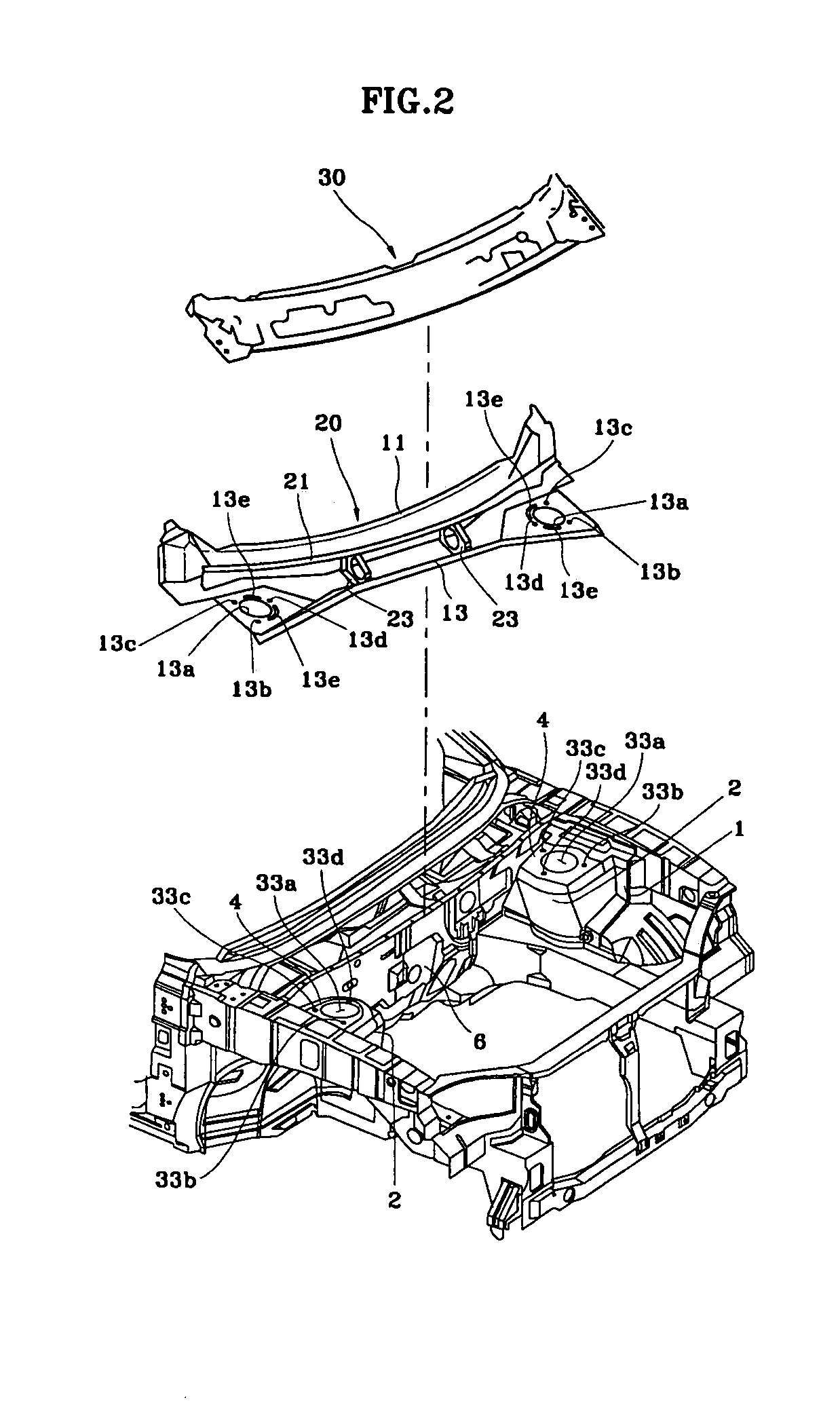

Vehicle front body structure

InactiveCN101037118AImprove the delivery effectImprove impact absorption performanceSuperstructure subunitsSuspension towerAxial compression

The present inventive vehicle front body structure, comprises a front side frame provided so as to project forward from a dash panel; an apron member provided so as to project substantially forward at a location that is outside the vehicle width direction of the front side frame; a suspension tower portion provided so as to at least partly protrude in an engine room for at least partly accommodating a front suspension vibration damper therein, the suspension tower portion being engaged with the apron member and the front side frame; an engine mount provided at the front side frame in front of the suspension tower portion so as to support a side portion of a power plant; and a first connecting member provided so as to straightly interconnect an upper portion of the suspension tower portion and a portion of the front side frame that is located in front of the engine mount, the member being disposed so as to overlap with the engine mount in a top view. The present invention provide a front structure of vehicle body for transmitting a collision load working on a front side frame to an upper portion of a vehicle body which is capable of absorbing the energy caused by the axial compression of the front side frame by suppressing any upward bend of the front side frame by reliably dispersing the collision load to the upper portion of the vehicle body while arranging an engine mount on the front side frame.

Owner:MAZDA MOTOR CORP

Structure of front portion of vehicle body

InactiveUS7114587B2Improve heating efficiencyImprove cooling efficiencyVehicle seatsSuperstructure subunitsEngineeringEngine room

A portion between a front end of an air guide plates, which forms an air duct portion, and the front exterior member of the vehicle is sealed by a seal portion. Therefore, hot air leaking from inside of an engine room, is positively prevented from being drawn into the air duct portion after it flows around the front end of the air guide plate.

Owner:CALSONIC KANSEI CORP

Hybrid working vehicle

ActiveUS20090199553A1Storage can be shortenedReduce power lossFluid couplingsElectric propulsion mountingEngineeringCooling fluid

An engine room is divided into a left room and a right room by a cooling unit. An intake chamber is disposed at a left side and an engine and the like are disposed at a right side. A cooling heat sink is provided on a side of the intake chamber, and a storage and a controller for controlling hybrid electronic devices are formed in this order in a cooling heat sink. Further, a cooling pump for supplying cooling liquid to the cooling heat sink is provided in the intake chamber. A radiator for cooling the cooling liquid is provided in front of the cooling unit.

Owner:KOMATSU LTD

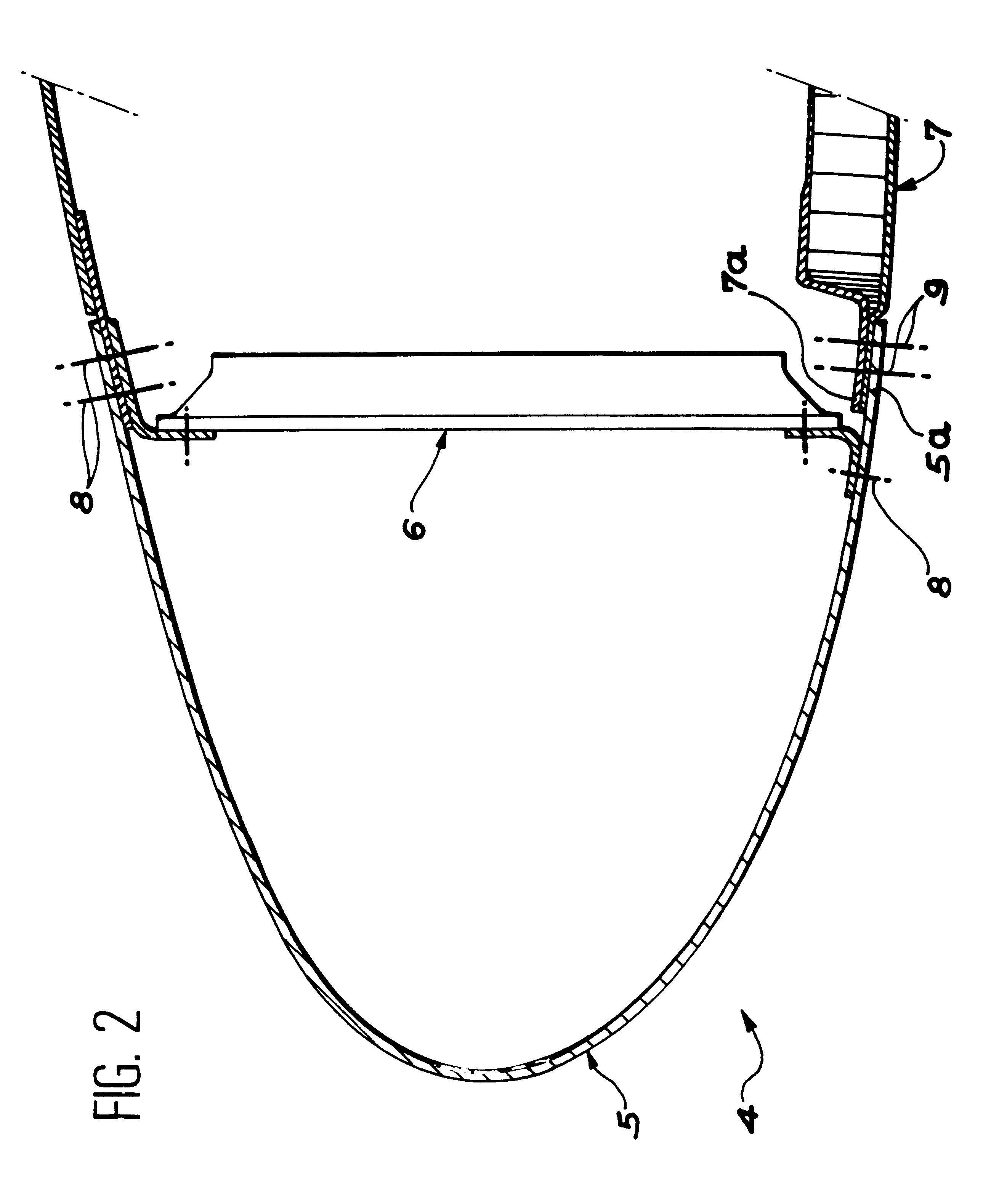

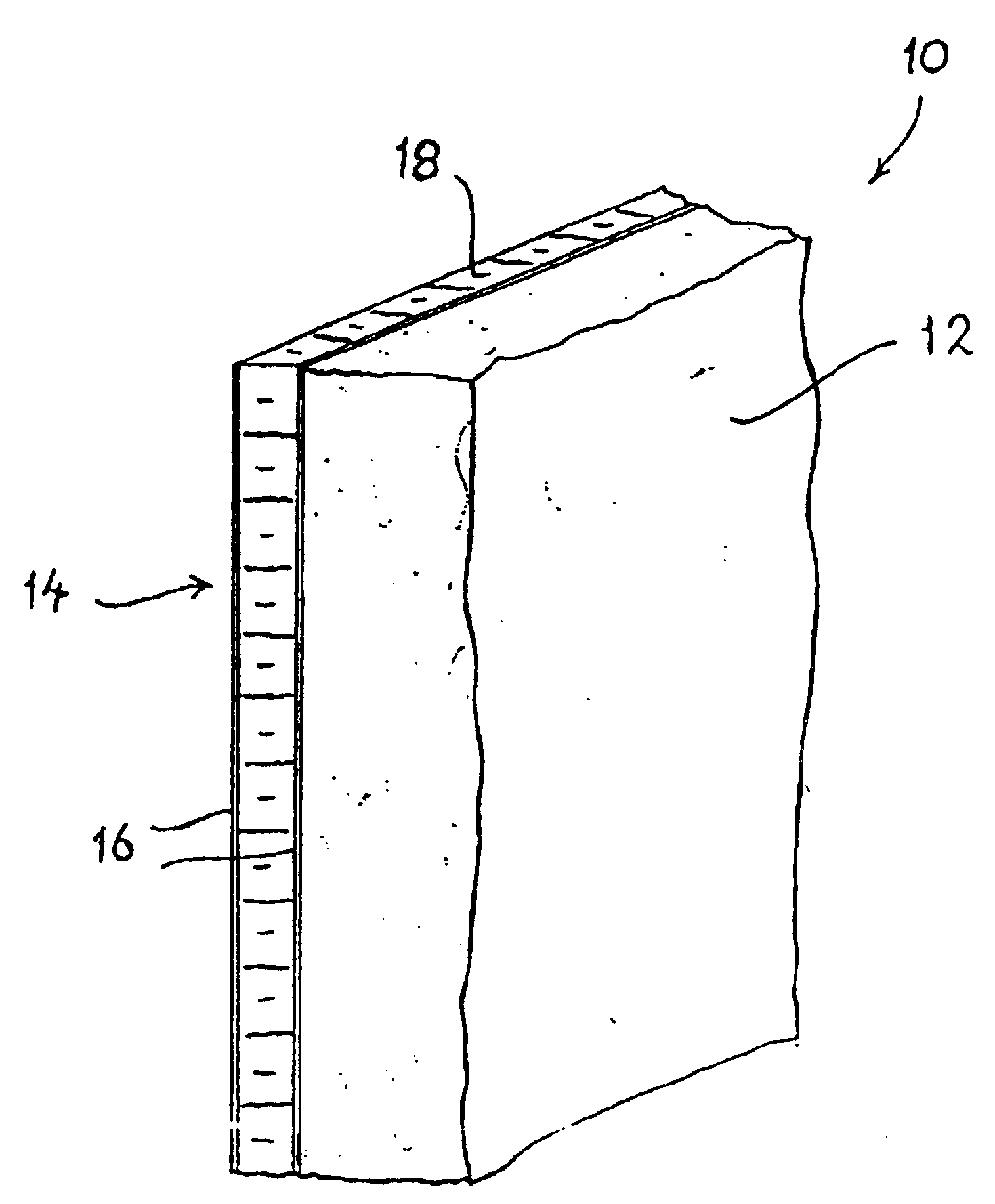

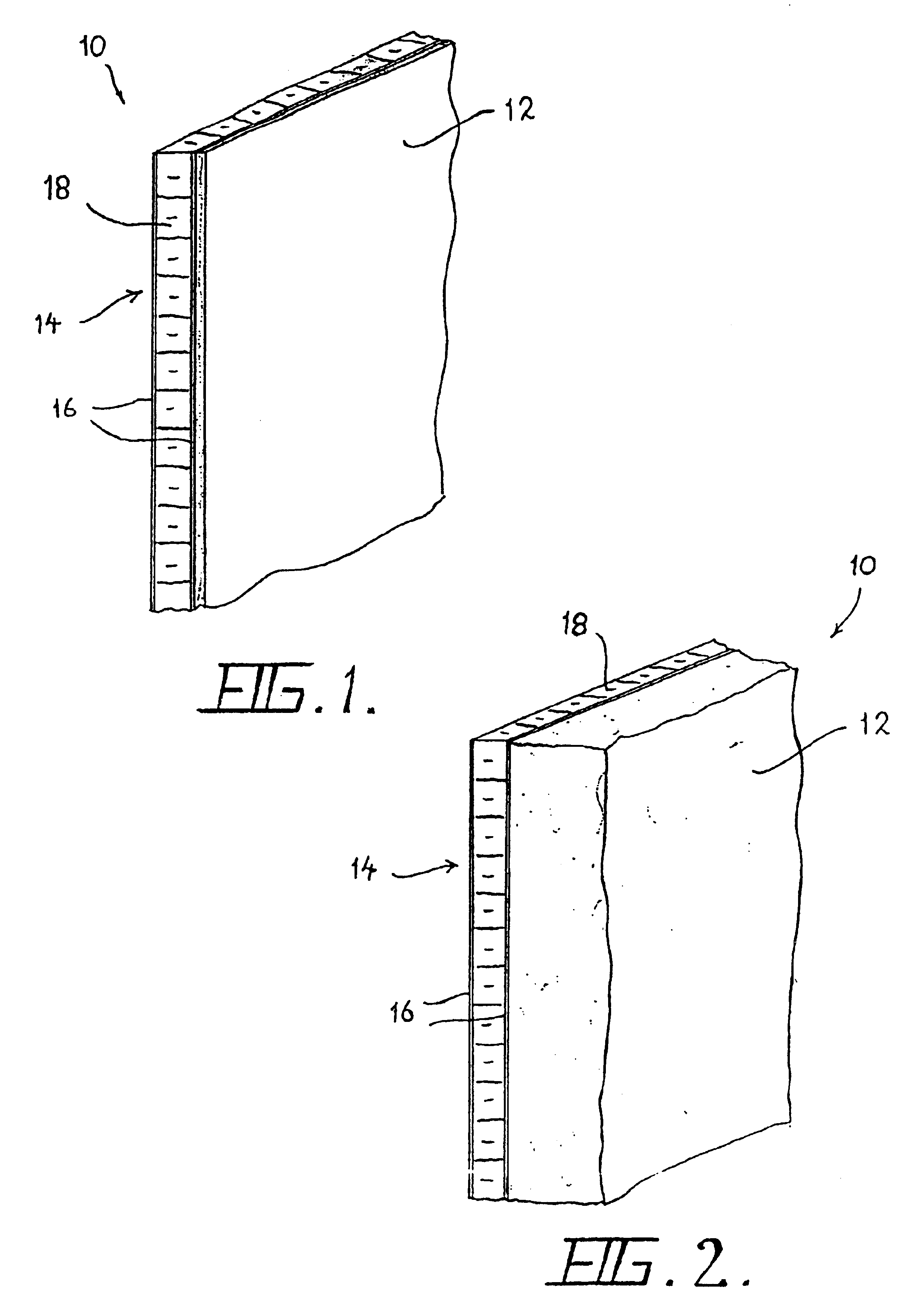

Fire barrier panel

A fire barrier panel of the kind suitable for lining car decks and engine rooms of high speed aluminum ferries is described. The panel (10) includes a relatively thin layer of inorganic insulating material (12) adhered to a lightweight support structure (14). The layer of inorganic insulating material may be an intumescent material made from mineral fibers. The decribed lightweight support structure (14) is a honeycomb panel having a honeycomb core (18) of non-combustible aluminum foil provided with two face skins made of glass reinforced plastics resin material (16). This construction of the honeycomb panel (14) is lightweight and has high stiffness and rigidity suitable for stiffening and supporting the insulating material into a rigid panel. The layer of intumescent material (12) supported on the panel expands when exposed to high temperatures to form a thick fire insulating barrier panel. Because the panels are self-supporting, and therefore support structures, installation costs are much lower than for prior art fire insulation systems.

Owner:ASHMERE HLDG

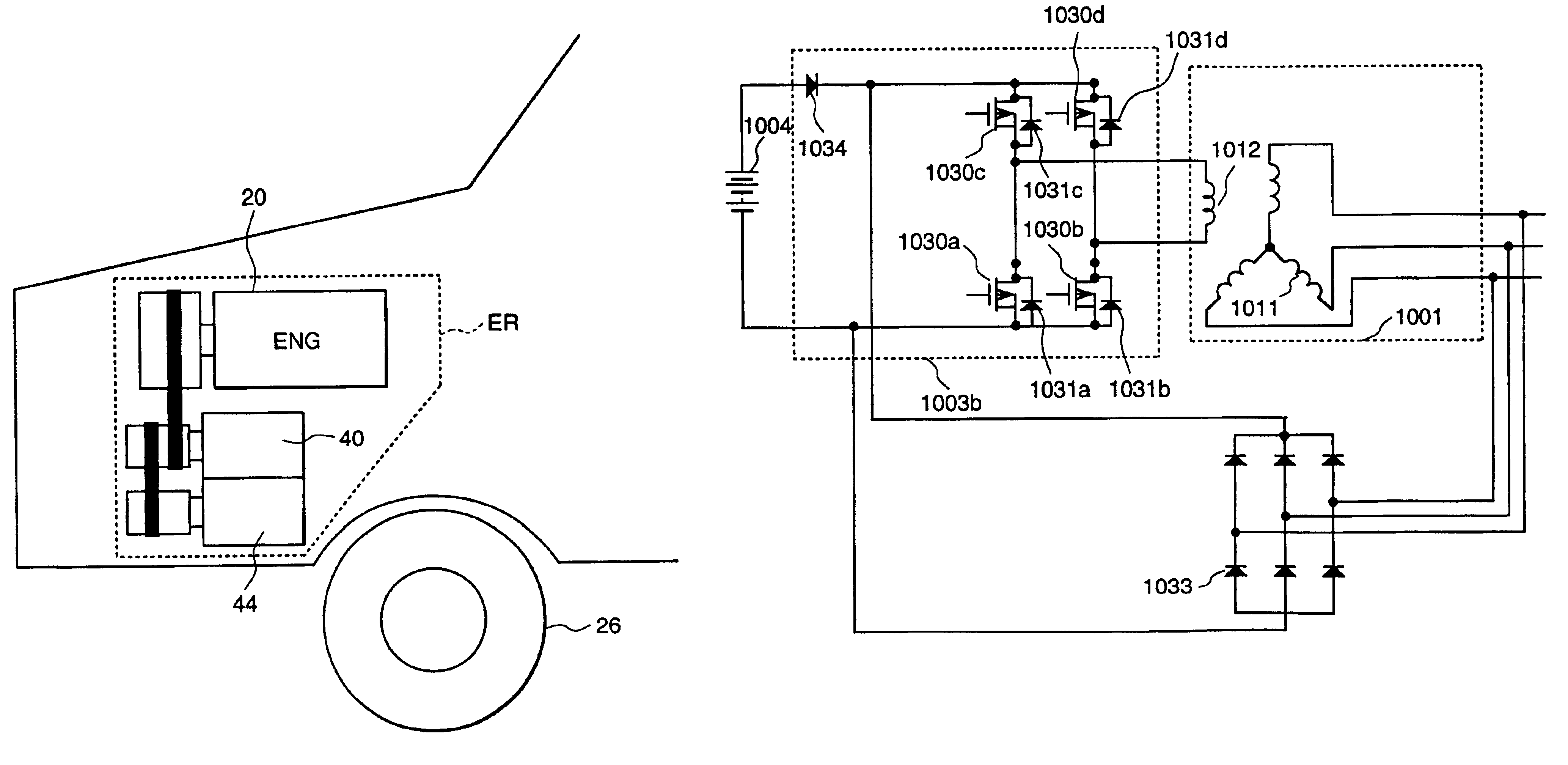

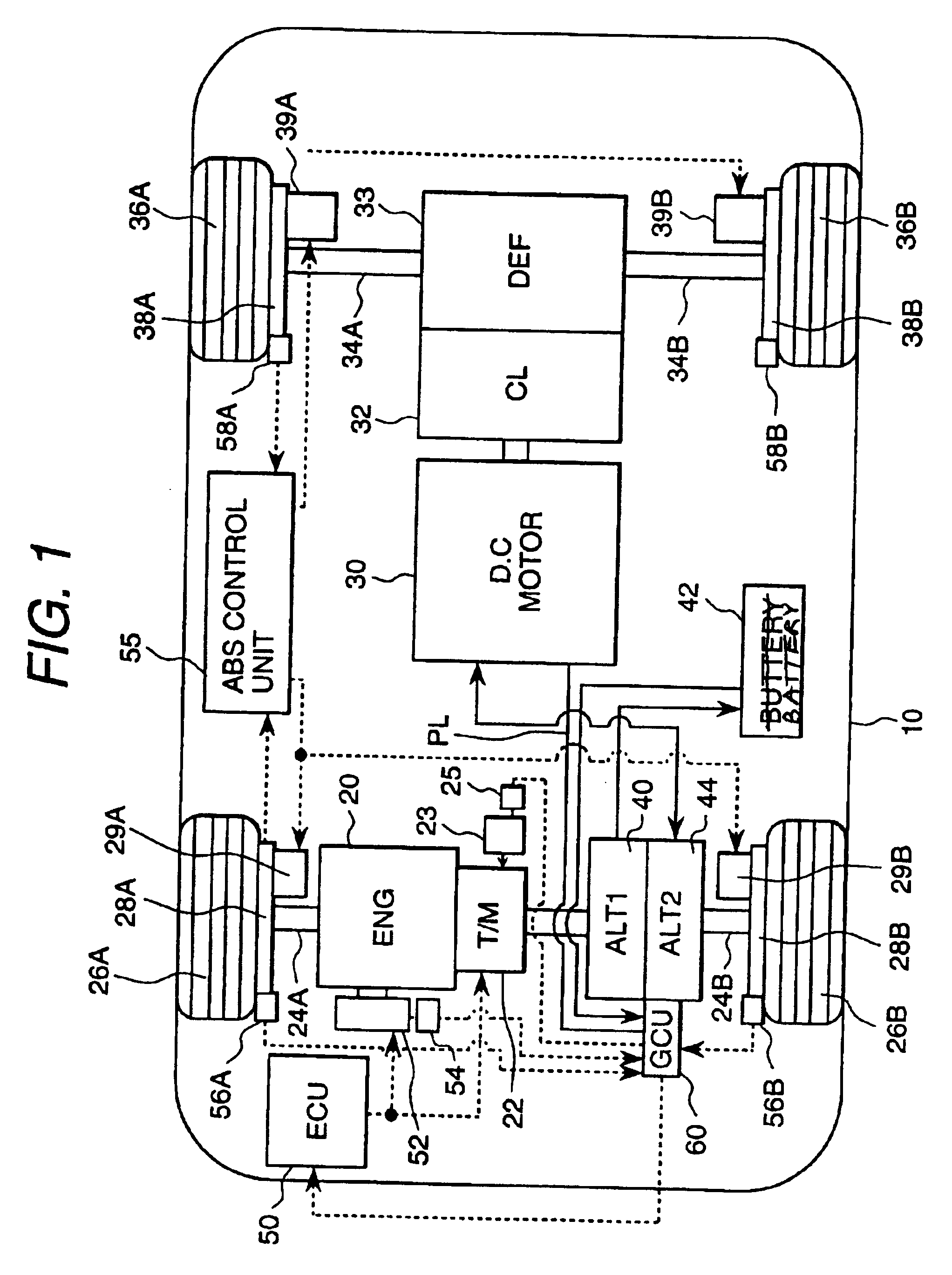

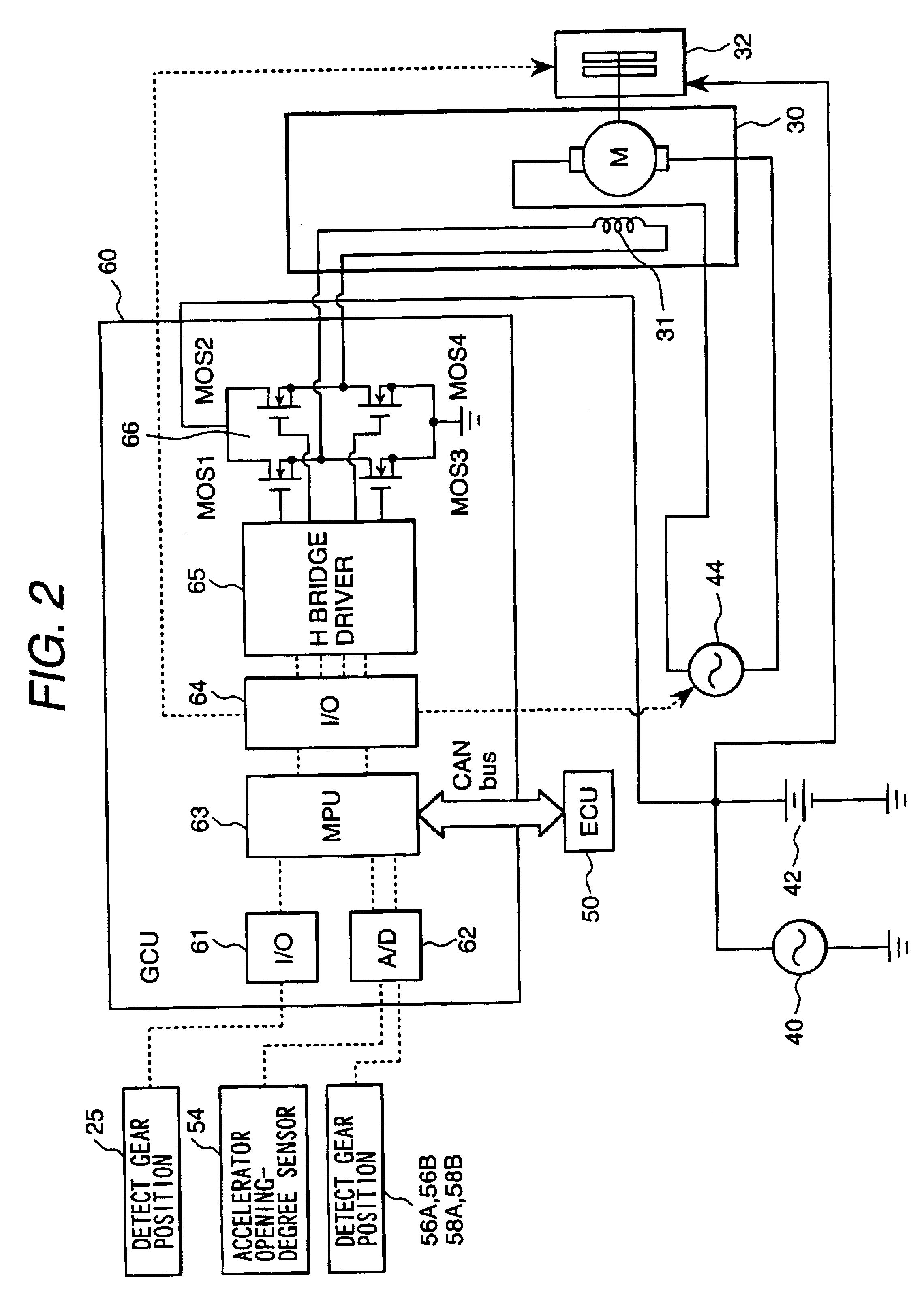

Electric generating system for automobiles and its control method

InactiveUS6965173B2Easy to installMounting of the vehicle driving apparatus is facilitatedEngine controllersElectric motor startersMotor driveVehicle driving

The present invention provides a vehicle driving apparatus capable of being mounted easily even in a narrow space such as under-floor of the vehicle. The vehicle driving apparatus comprises a first and a second generators driven by an engine for driving front wheels, and a motor driven by receiving a power supply from the second generator to drive rear wheels, the first and second generators being installed in the vicinity of an engine within an engine room, the motor being arranged in the vicinity of a differential gear with which a reduction mechanism is integrated and is positioned substantially in a central part of the rear wheels.

Owner:NISSAN MOTOR CO LTD UNDIVIDED 50 INTEREST

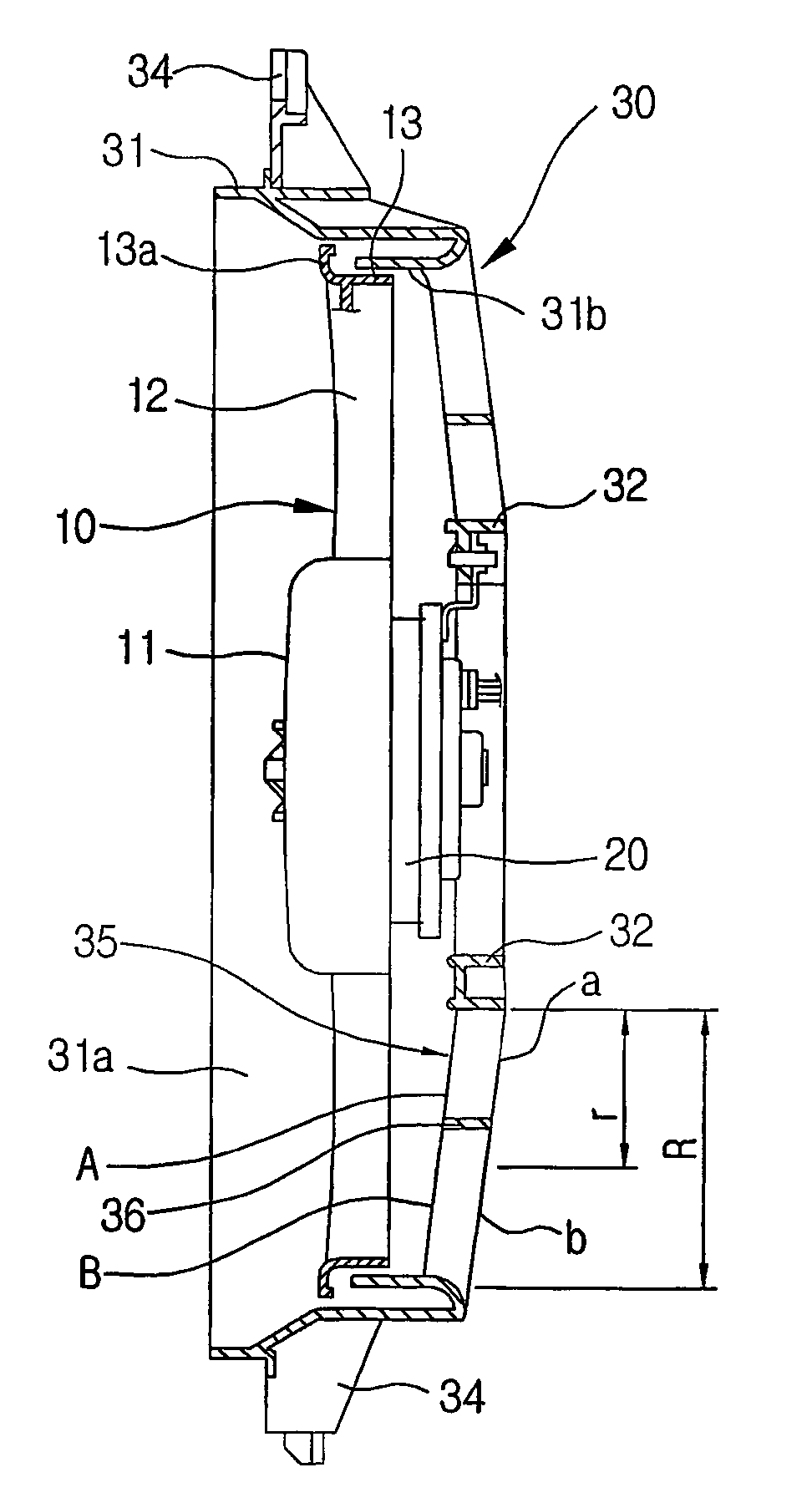

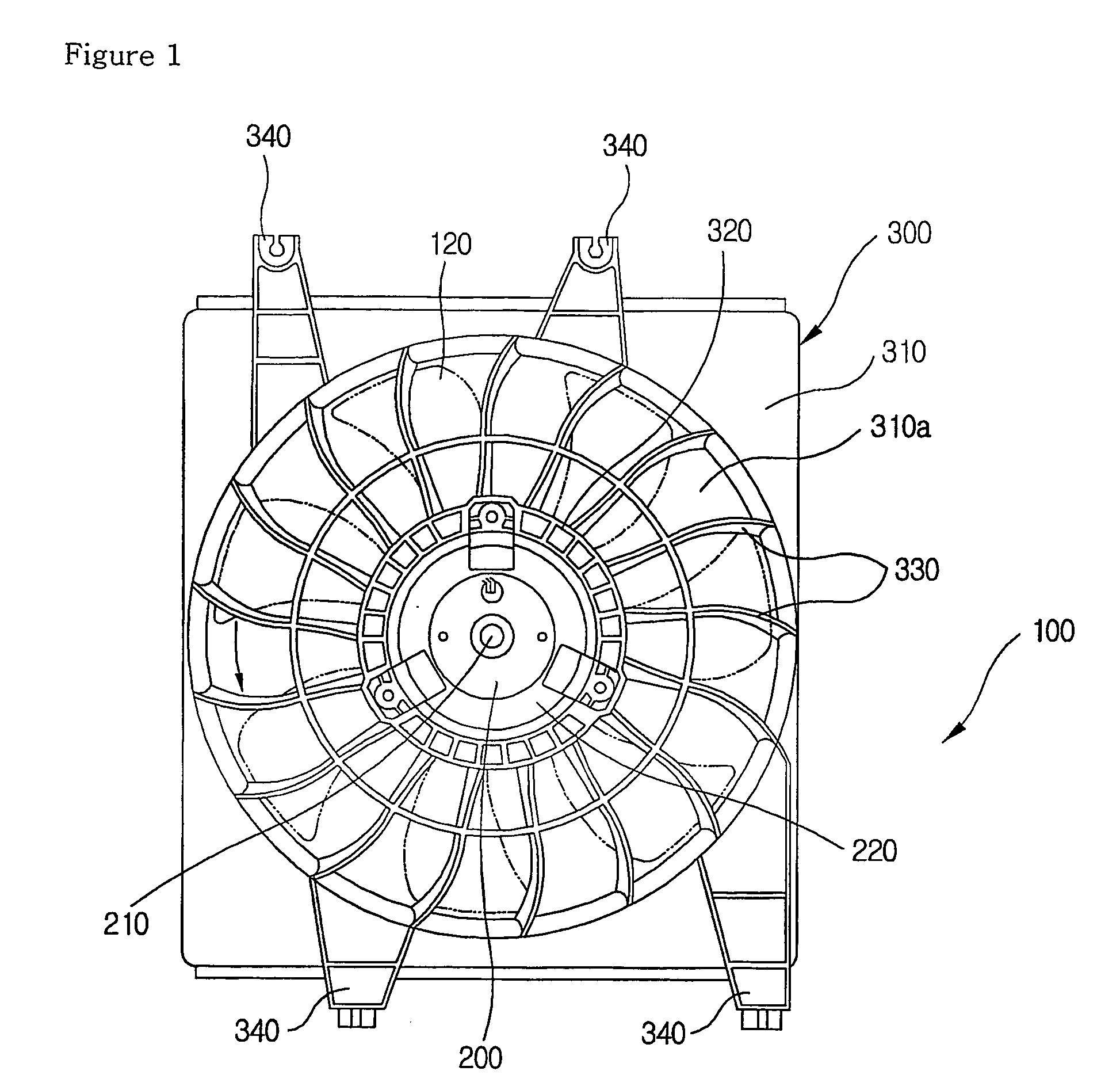

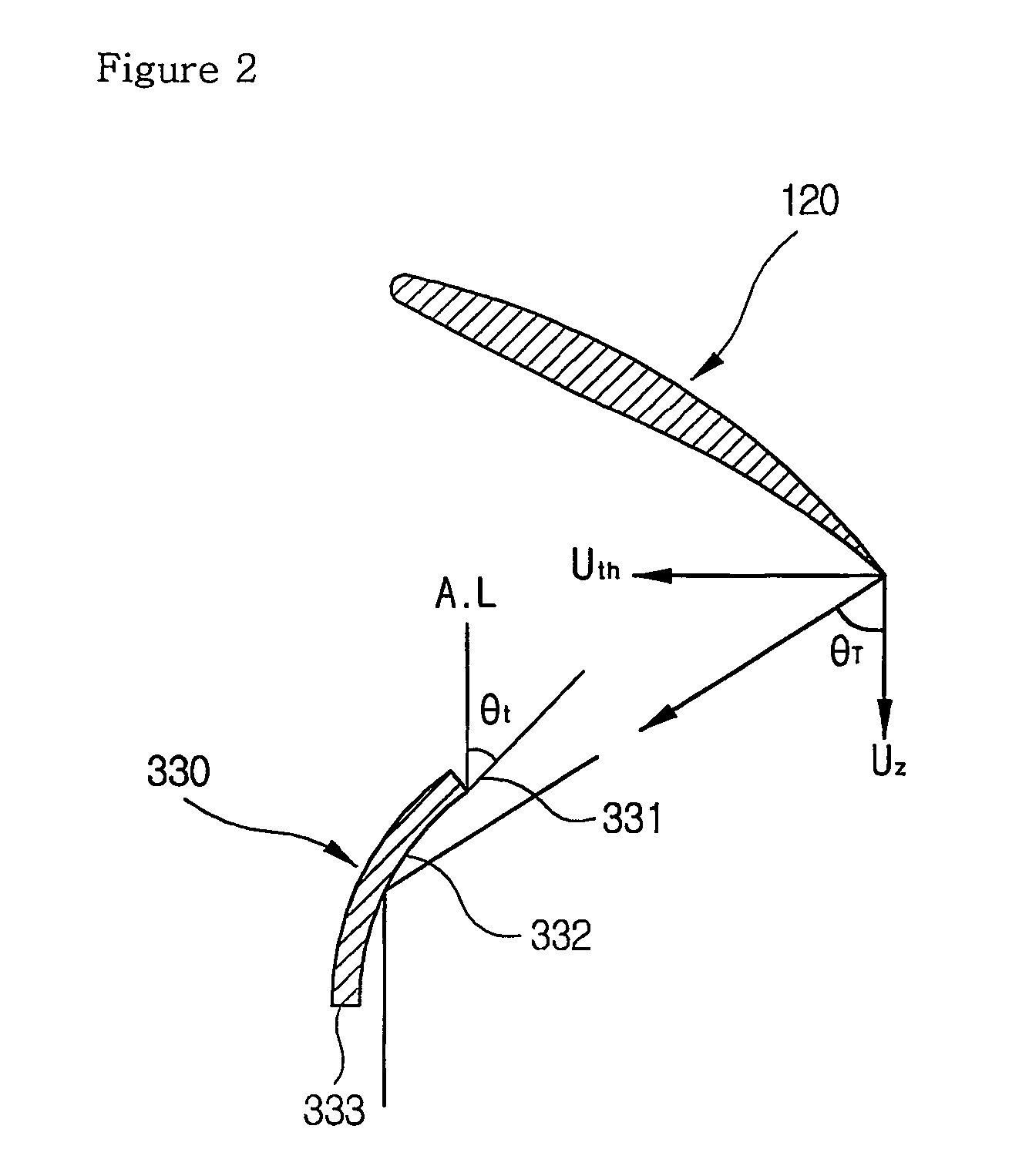

Guide blade of axial-flow fan shroud

ActiveUS20060147304A1Improve blowing efficiencyImprove air conditioning performanceEngine manufacturePump componentsLeading edgeEngineering

The present invention discloses guide blades of an axial flow fan shroud for guiding the air blown by an axial flow fan in an axial direction, and more particularly, to a guide blade structure capable of preventing the backflow of high temperature heat from an engine room toward a condenser. A guide blade 35 of an axial flow fan shroud 30 comprises: a leading edge 37 for introducing the air blown by an axial flow fan 10 including a number of blades 12; a trailing edge 39 extended from the leading edge 37 to downstream; and an air flow guide surface 38 for guiding the blown air between the leading and trailing edges 37 and 39, wherein if a first outlet area a is defined by at a radius r from a root in the total length R of an angle of projection Aout of the guide blade 35 and a second outlet area b is defined by the remainder, the angle of projection Aout increases as approaching a tip with respect to an axial line in the second outlet area b.

Owner:HANON SYST

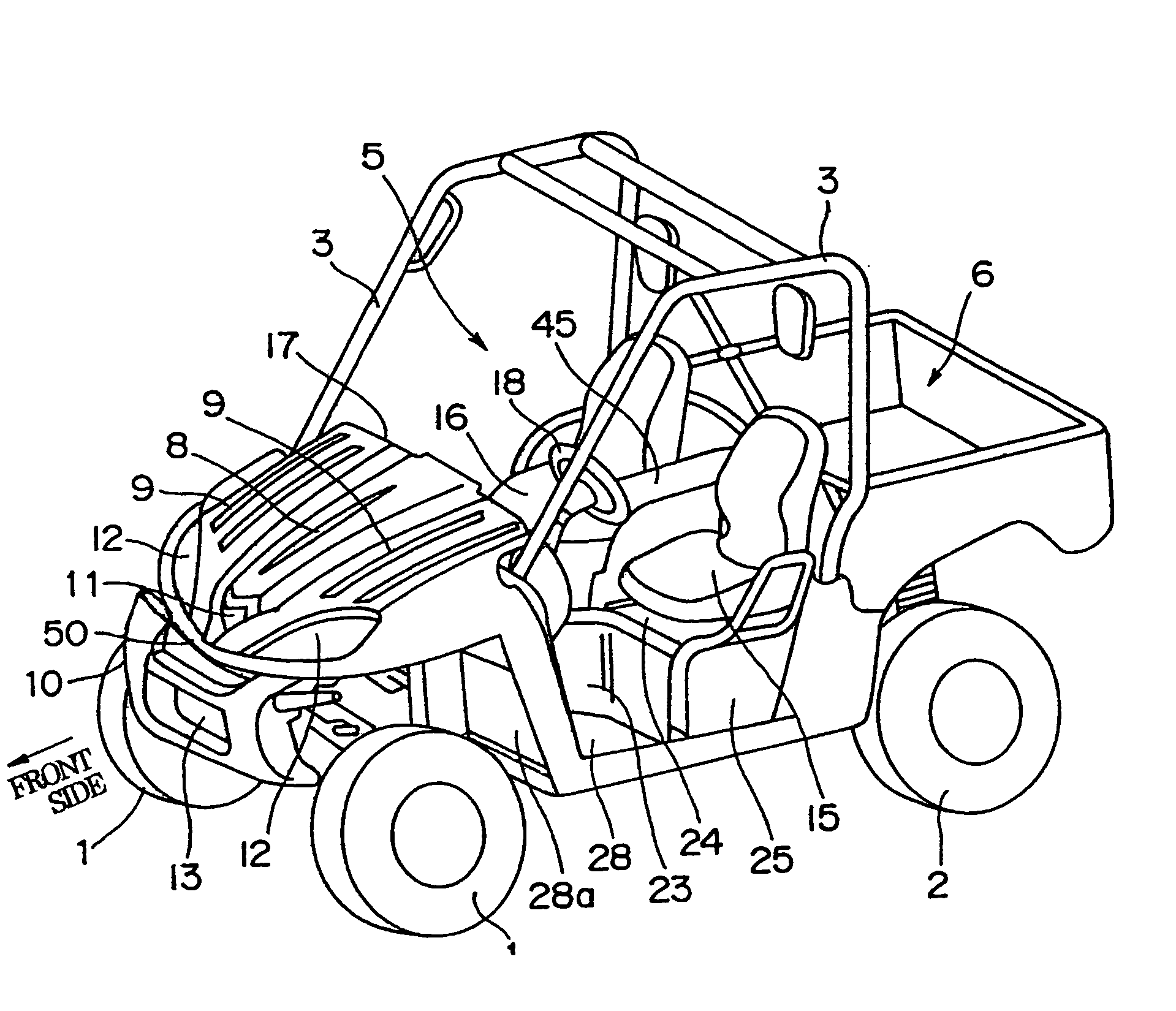

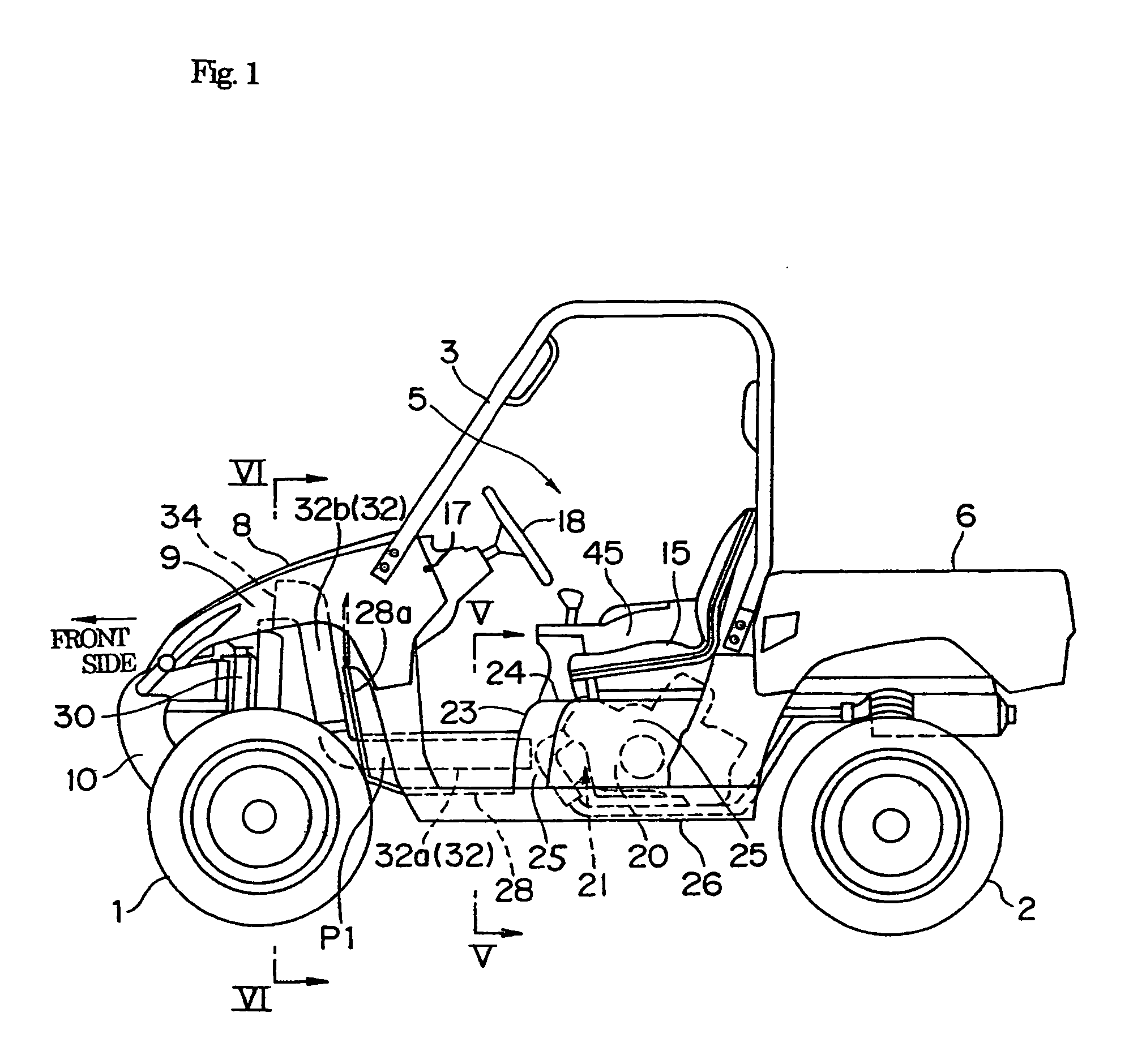

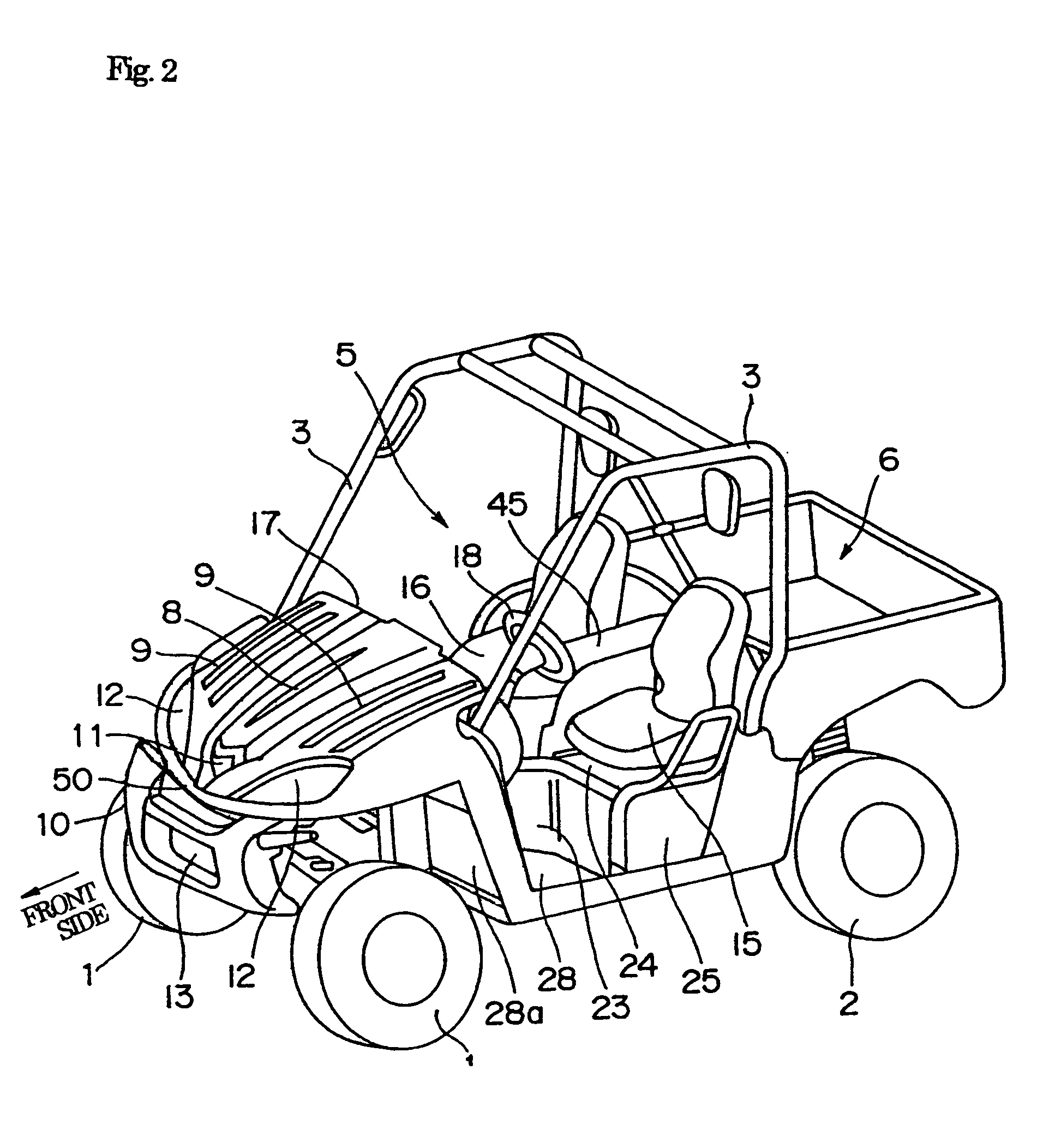

Four wheeled utility vehicle

InactiveUS20080289896A1Efficient introductionAvoid noiseUnderstructuresPropulsion coolingEngineeringSurface cover

Owner:KAWASAKI HEAVY IND LTD

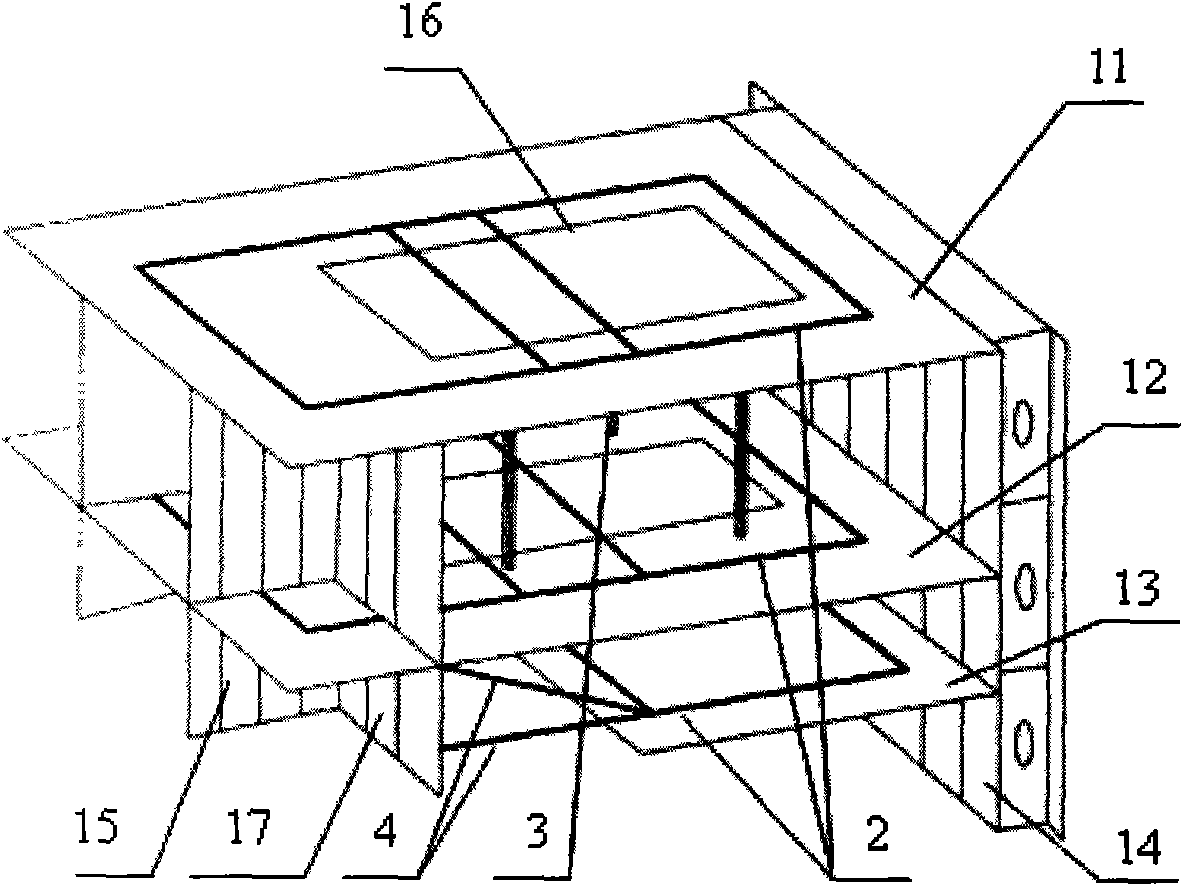

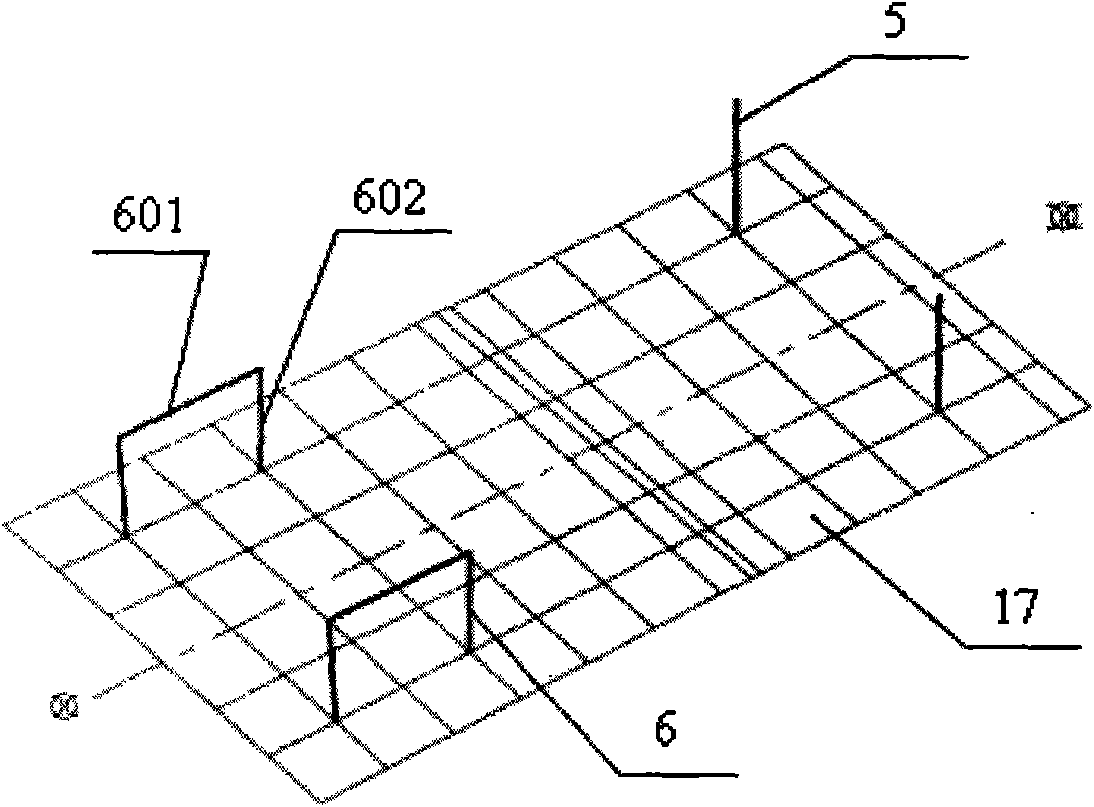

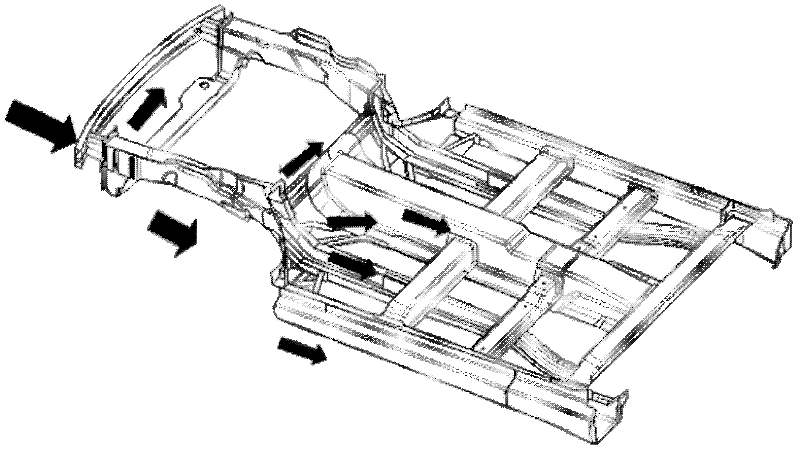

Method for assembling and lifting engine room section

ActiveCN101570234AAvoid Intersection WorkReduce intensive constructionVessel partsWelding apparatusMarine engineeringEngine room

The invention belongs to the field of construction of ship sections and particularly discloses a method for assembling and lifting an engine room section. The method comprises the following assemblingsteps: (1) each section strengthening; (2) plane base jig manufacture and lining: a positioning support is arranged on a base jig; (3) subsection assembly: a transverse bulkhead subsection and a suspending deck platform subsection are positioned according to a line and the positioning support on the plane base jig, and other subsections are sequentially lifted, positioned and welded after welding; (4) subsection strengthening after assembly; and (5) finished engine room section measurement. By assembling thirteen subsections into one section, the invention obviously improves the carrying speed, ensures the installation integrity of a subsection structure, can assemble various outfits and accessories in place in advance, prevents the vertical crossing operation among different work types and relieves a state of uneven labor force distribution.

Owner:JIANGNAN SHIPYARD GRP CO LTD

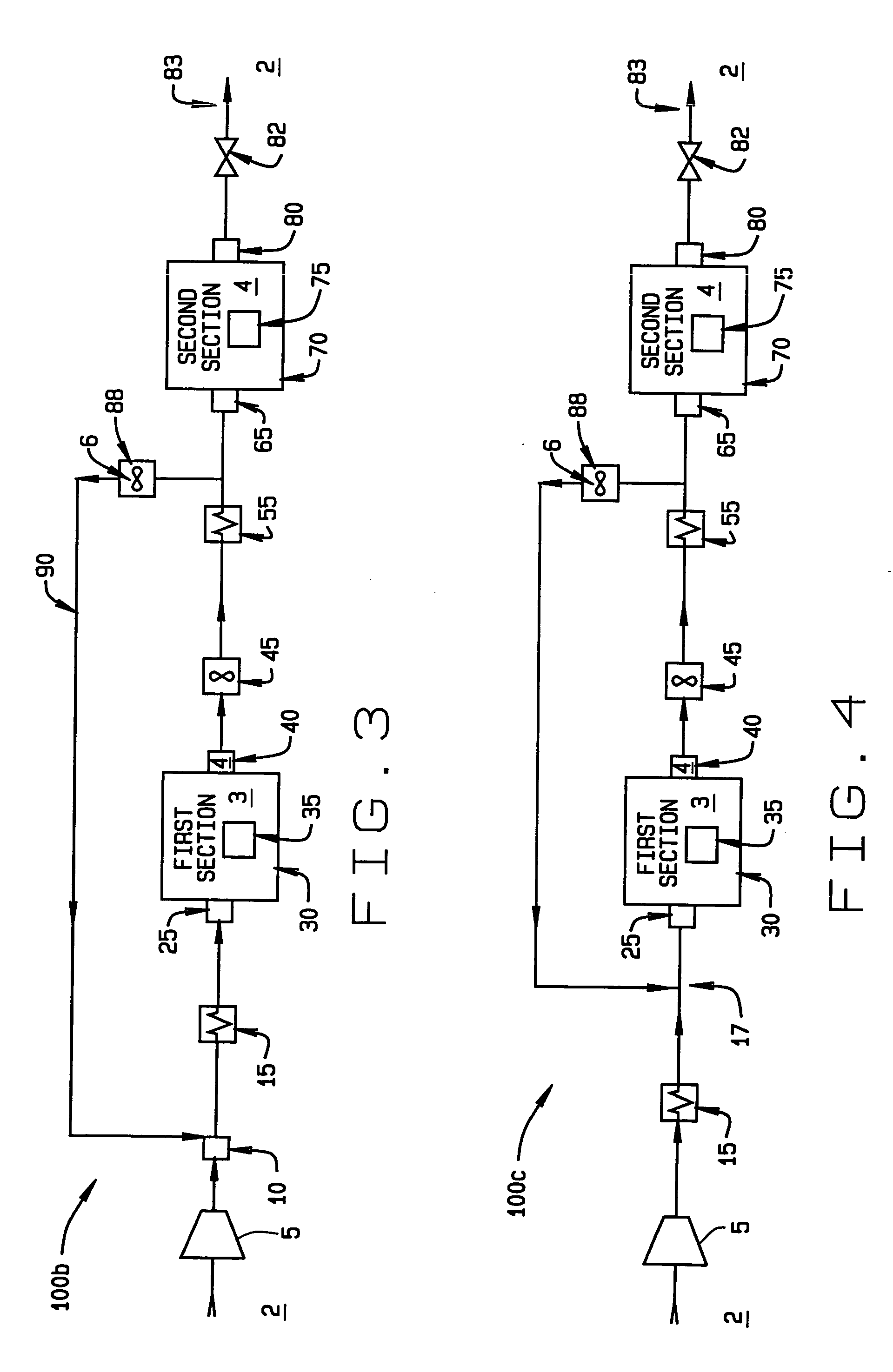

Pneumatic system for an aircraft

InactiveUS20150107261A1Easy to operateReduce total pressure lossAir-treating devicesPower installationsAir cycle machineControl system

A bleed air system for an aircraft has a gas turbine engine and operating method. The system includes an environmental control system (ECS) for providing cabin airflow to the aircraft, including operating modes such as first and second air cycle machine operating modes and heat exchanger operating modes. The ECS includes first, second and third bleed ports each configured to provide engine bleed air from gas turbine engine compressors to the ECS. The ECS includes a bleed air system sensor arrangement configured to sense one or more bleed air system conditions, an environmental control system controller that selects an environmental control system operating mode that provides required cabin air flow and temperature at an optimal specific fuel consumption of the gas turbine engine at the sensed system conditions, and a bleed port valve controller which determines an operating pressure required to operate the environmental control system in the selected mode.

Owner:ROLLS ROYCE PLC

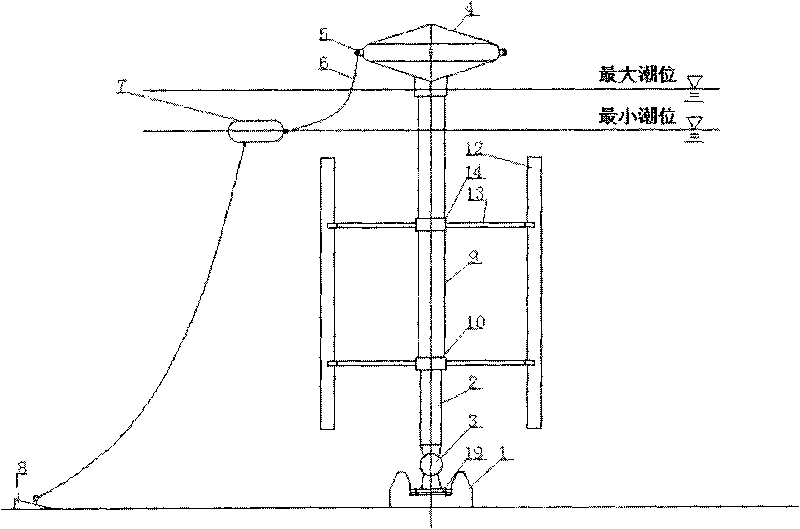

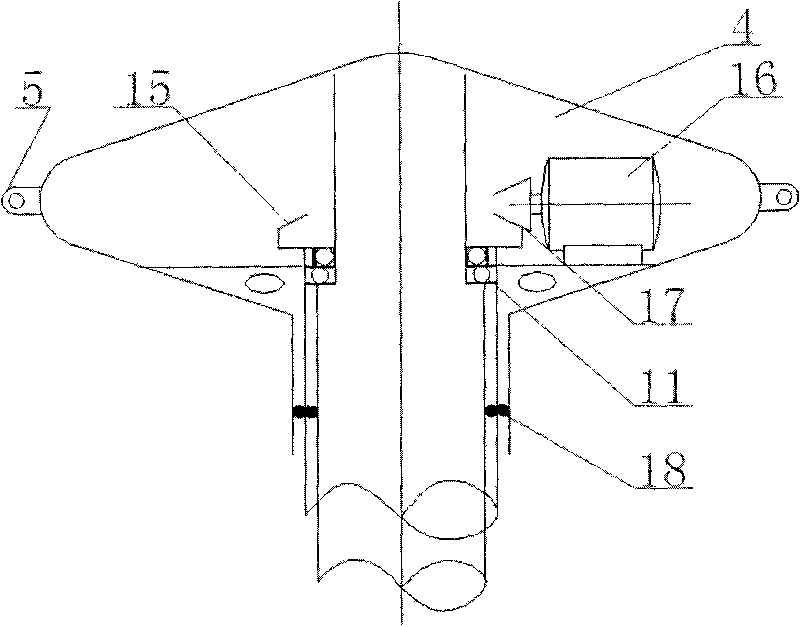

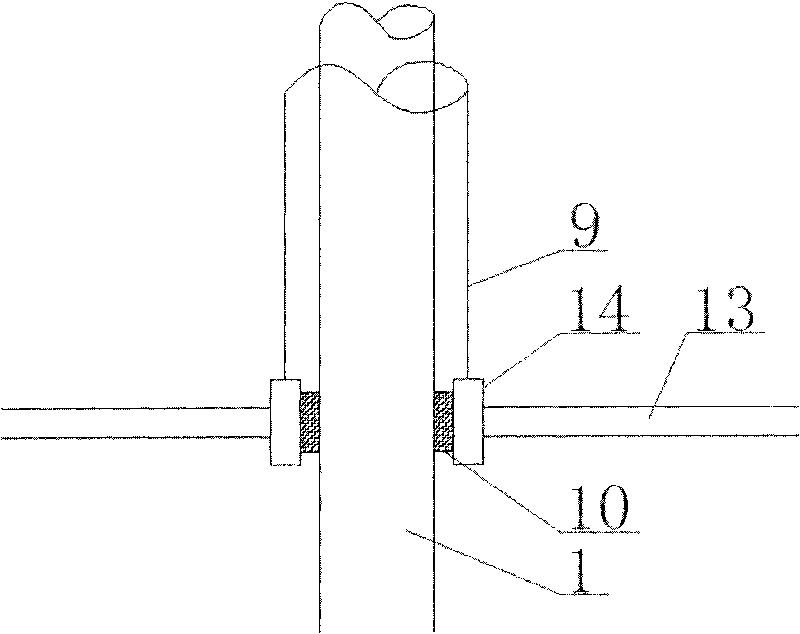

High-power vertical shaft tidal generating set

InactiveCN101705904AStructural solutionMachines/enginesEngine componentsSocial benefitsWater turbine

The invention provides a high-power vertical shaft tidal generating set. A gravity type pylon base (1) is connected with a pylon (2) through a universal ball hinge (3); an engine room (4) is arranged at the top end of the pylon; the periphery of the engine room is distributed with ropes (6) used by anchor chain plate holes (5) for connecting a floating bucket (7) and an anchor chain on an anchor (8); a water turbine spindle (9) is sleeved on the pylon, and both ends of the water turbine spindle are provided with bearings; water turbine blades (12) are uniformly distributed and fixed on a shaft hub (14) of the spindle through a spoke (13); an umbrella-shaped gear (15) on the spindle is engaged with a small umbrella-shaped gear (17) on a shaft of a generator (16) in the engine room; sealing shaft sleeves (18) are additionally arranged at the upper end of the spindle, on the lower wall of the engine room and on the pylon; and the base and the universal ball hinge are connected through a flange plate (19). The high-power vertical shaft tidal generating set provides clean renewable energy sources required by production and life for coastal areas, numerous islands and remote areas and particularly for residents on islands which cannot be covered by the national grid, and has positive social benefit.

Owner:HARBIN ENG UNIV

Soundproof type engine driven work machine

InactiveUS6491133B2Small sizeImprove cooling efficiencyCasingsSoil-shifting machines/dredgersEngineeringSoundproofing

The soundproof casing is divided to an engine room (1), a muffler room (2) and a radiator room (3). The engine room (1) includes the engine E and a work machine unit (generator unit G). The muffler room (2) includes mufflers M1, M2. The radiator room includes a radiator R. An electric fan D is provided between an air intake aperture (22a) and the radiator. The radiator room and the muffler room are communicated. An air flow duct (4) to communicate the engine room and the muffler room is provided. An engine fan F is provided just opposite to an entrance of the air flow duct. An inter-cooler I is provided in the air flow duct. The soundproof type engine driven work machine including aforementioned apparatuses is offered to improve the cooling efficiency as well as reducing unfavorable noise.

Owner:DENYO LMTD

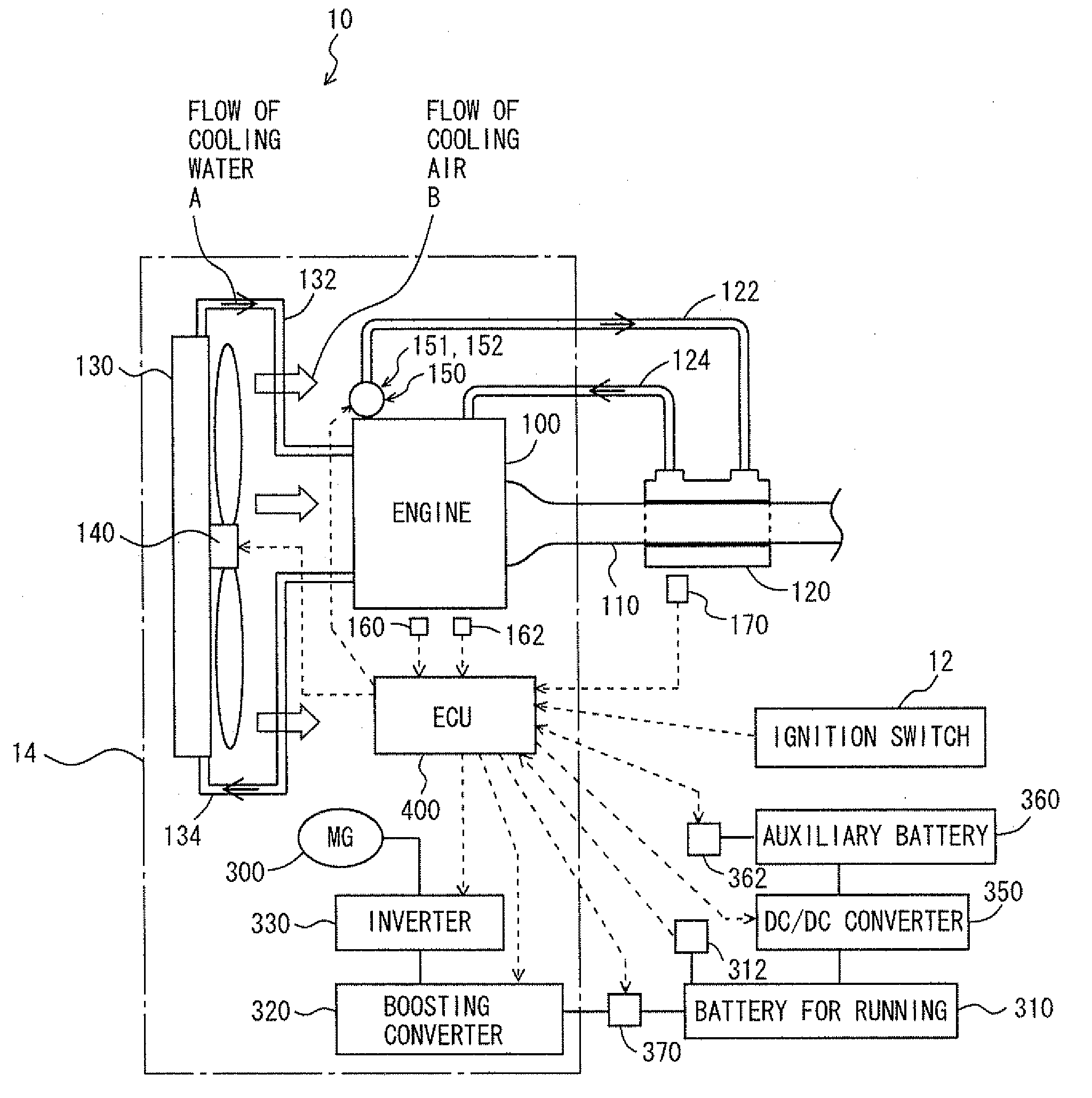

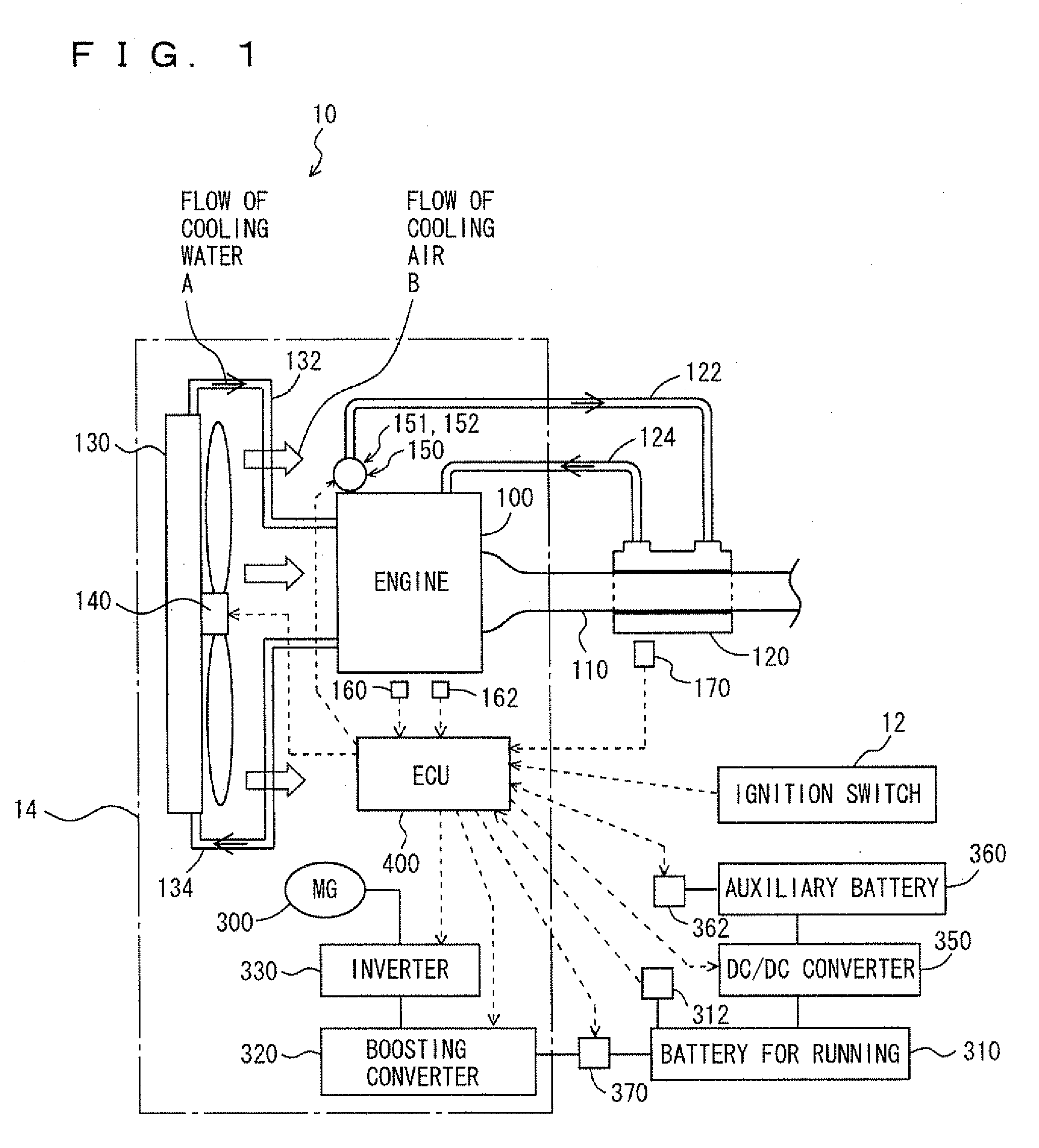

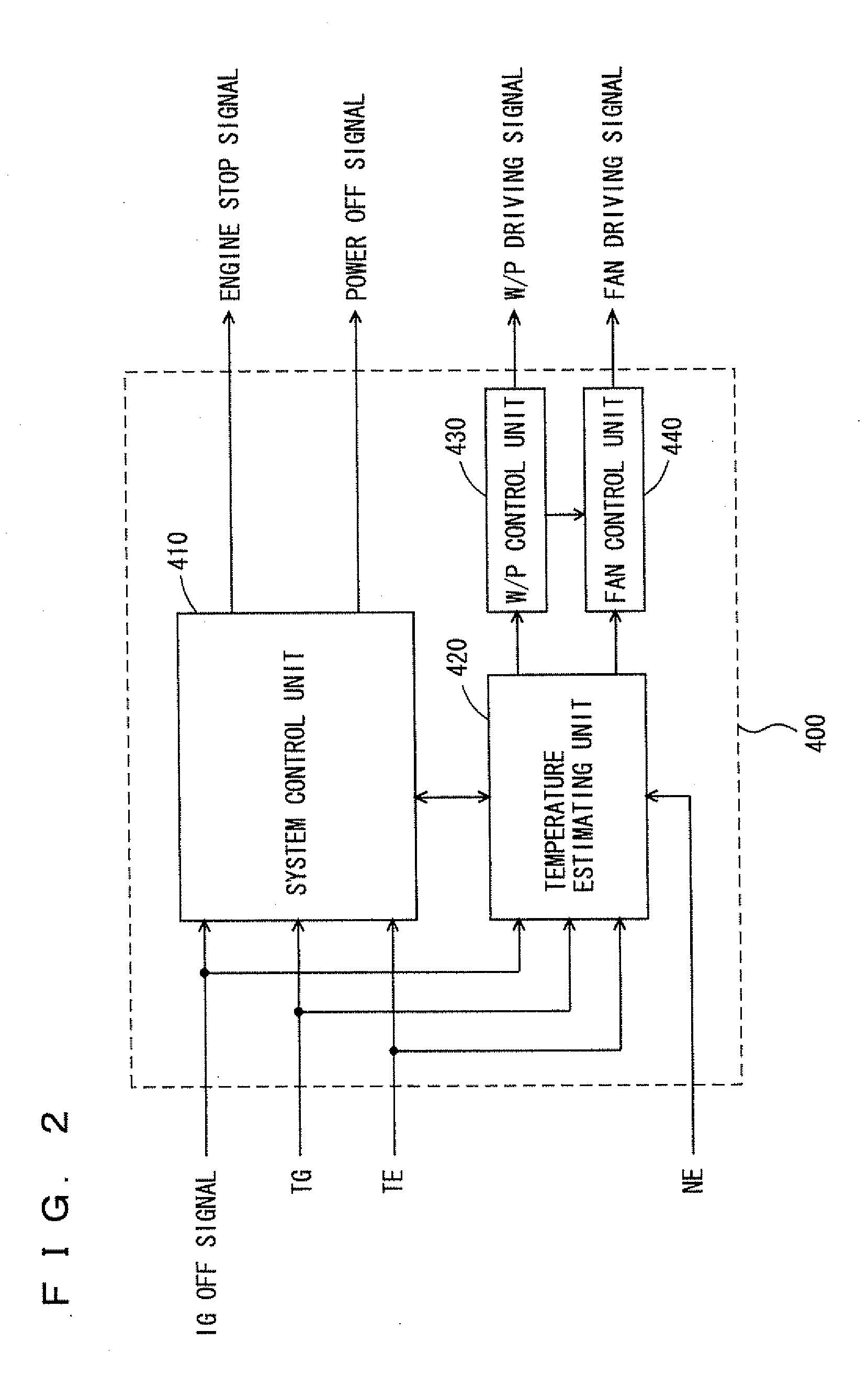

Vehicle cooling controller and cooling control method

ActiveUS20100236502A1Improve starting characteristicsFavorably warmedCoolant flow controlInternal combustion piston enginesCoolantEngine room

A drive component for driving an electric water pump for causing engine coolant to flow is mounted in an engine compartment. When the ignition is off and the temperature of a exhaust heat recovery device is above a temperature, an ECU estimates a peak temperature in the engine compartment after the stop of the engine. When the peak temperature is above a temperature, the ECU stops the engine and drives the electric water pump and an electric fan for cooling the drive component for driving the electric water pump.

Owner:TOYOTA JIDOSHA KK

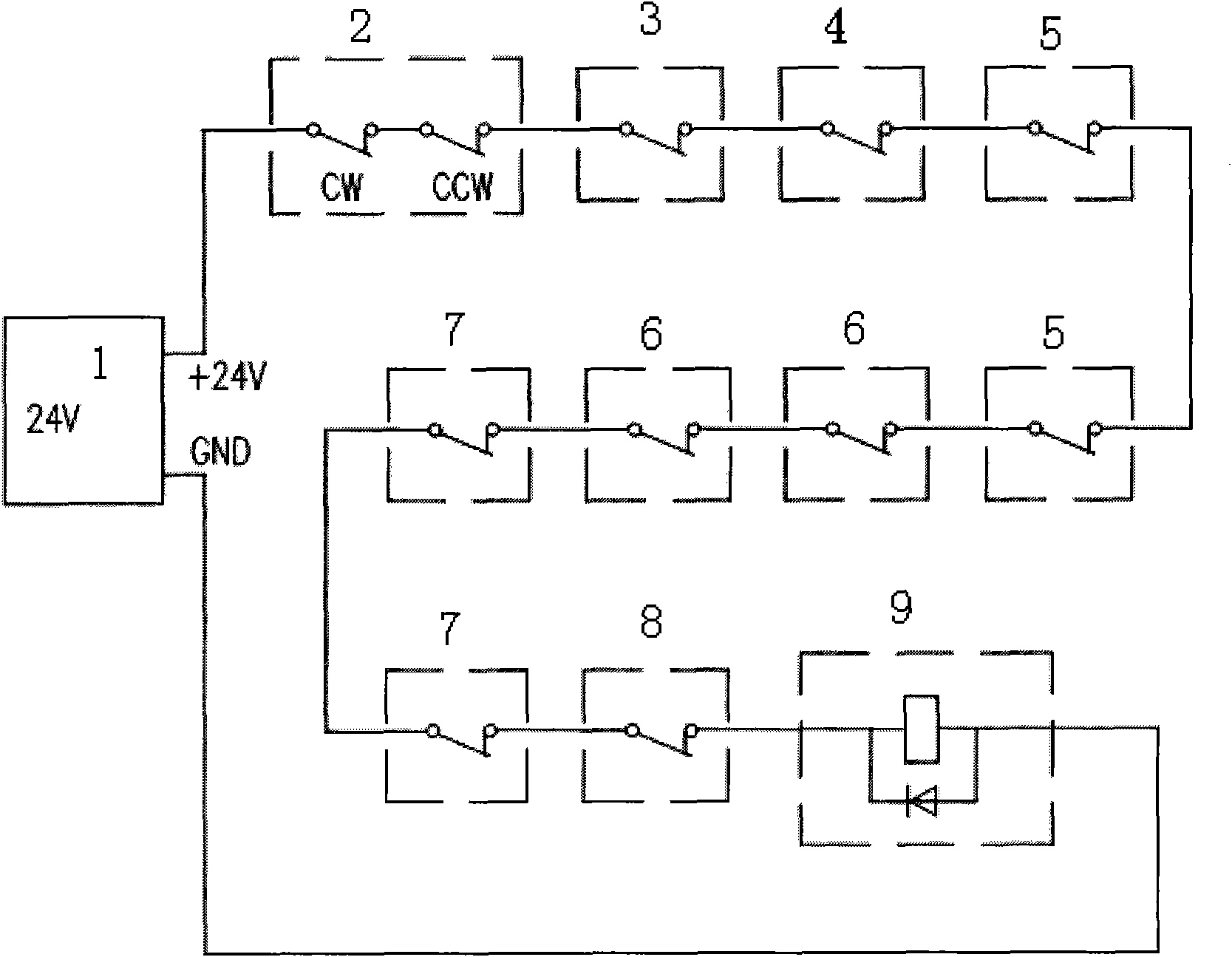

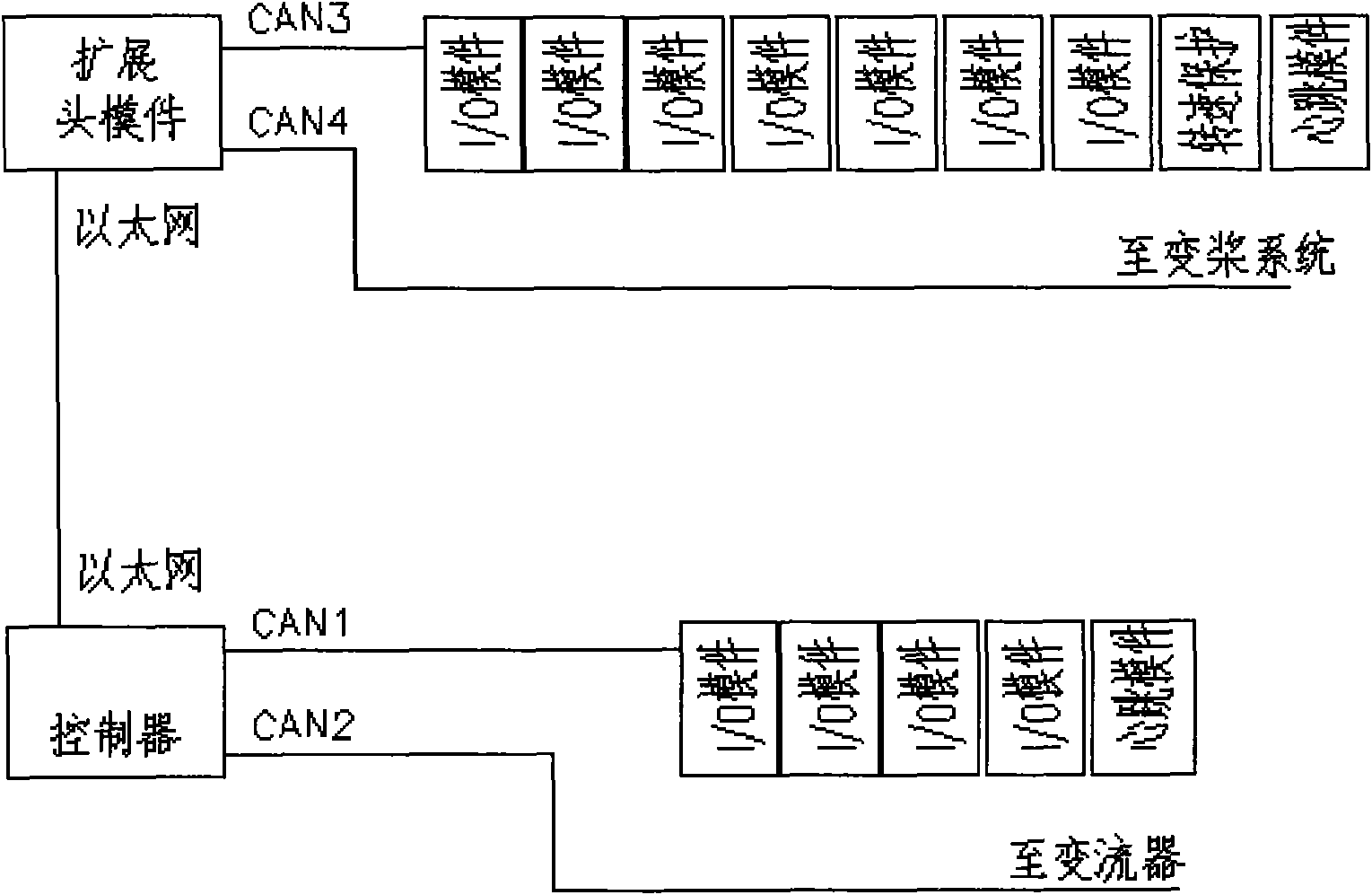

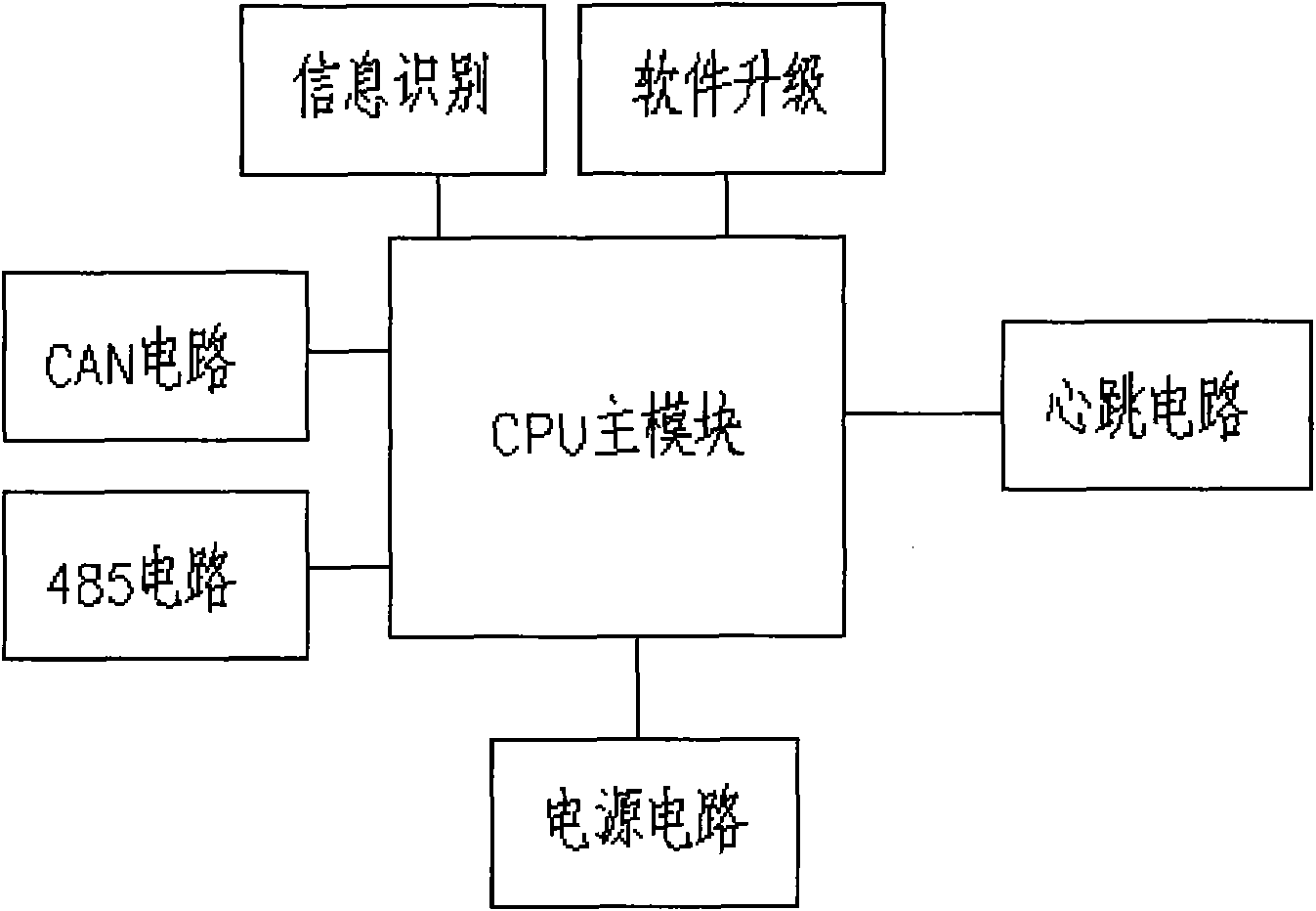

Stand-by safety chain monitoring and protecting device for wind power generation control system

InactiveCN101776042AImprove protectionReduce connectionsWind motor controlMachines/enginesActive safetyControl system

The invention discloses a stand-by safety chain monitoring and protecting device for a wind power generation control system, comprising a power supply, a cable-twisting switch, an engine-room vibration protection switch, a grid protection switch, a converter protection switch, an engine room and tower support emergent stop button, a distributed heartbeat signal monitoring switch, a rotary speed protection switch and a safety chain relay, wherein the power supply generates power signals and is respectively connected in series with the cable-twisting switch, the engine-room vibration protection switch, the grid protection switch, the converter protection switch, the engine room and the tower support emergent stop button, the distributed heartbeat signal monitoring switch, the rotary speed protection switch and the safety chain relay. The monitoring and protecting device adopts an active safety design, runs independent of a PLC system and monitors relevant signals at real time; and when incidents endangering the safety of a machine set occur, the monitoring and protecting device actively controls a pitch system to realize full feathering, thereby achieving the safe shut-down of the machine set.

Owner:NANJING SCIYON AUTOMATION GRP

Construction machine

InactiveUS7388301B2Efficient layoutImprove cooling effectGas pressure propulsion mountingPropulsion using engine-driven generatorsHydraulic pumpEngine power

An inverter / converter as a kind of hybrid unit is composed of a body and a casing covering the body and is disposed in an engine room. An air intake port and an air discharge port each provided with a fan are formed in the casing to configure an internal air cooling device for introducing air present outside the engine room into the casing, allowing the air to flow through the interior of the casing and then discharging it from the air discharge port. A power divider for distributing engine power to a hydraulic pump and a generator-motor is disposed on one of right and left sides of an engine in a rear portion of an upper rotating body. Further, an electric power storage device and the inverter / converter are disposed right and left in parallel behind a cabin and in front of the engine, and a partition wall which defines the engine room is configured by casings of the electric power storage device, the inverter / converter and the power divider.

Owner:KOBELCO CONSTR MASCH CO LTD

Front body framework structure of automobile

ActiveCN102358349AAbsorb in timeReasonable dispersionMonocoque constructionsAbsorbed energyEngineering

The invention discloses a front body framework structure of an automobile. The front body framework structure of the automobile comprises an automobile body A post, a front protective cross beam, a front engine room framework assembly and a front floor framework assembly, wherein the front engine room framework assembly comprises a front engine room longitudinal beam, and a plurality of longitudinal beams and cross beams, which are connected with the front engine room longitudinal beam and are used for dispersing and transferring collision energy; and the front floor framework assembly comprises a front floor longitudinal beam, a lower door sill, and a plurality of longitudinal beams and cross beams, which are connected with the front floor longitudinal beam and the lower door sill and are used for dispersing and transferring collision energy. Through the technical scheme, a plurality of structural beams are welded to form a closed annular body framework structure; the plurality of longitudinal beams and cross beams are used for absorbing and transferring the collision impact load, so that the front part is deformed and absorbs energy sufficiently; the number of impact energy transfer passages is large; the energy is reasonably dispersed; the energy is absorbed in time; the invasion amount of a front baffle plate is small; the deformation of the floor and a middle passage is small; the deformation of a cab is reduced; and thus, the damage to a passenger in the collision, and the maintenance cost of the automobile are reduced.

Owner:CHERY AUTOMOBILE CO LTD

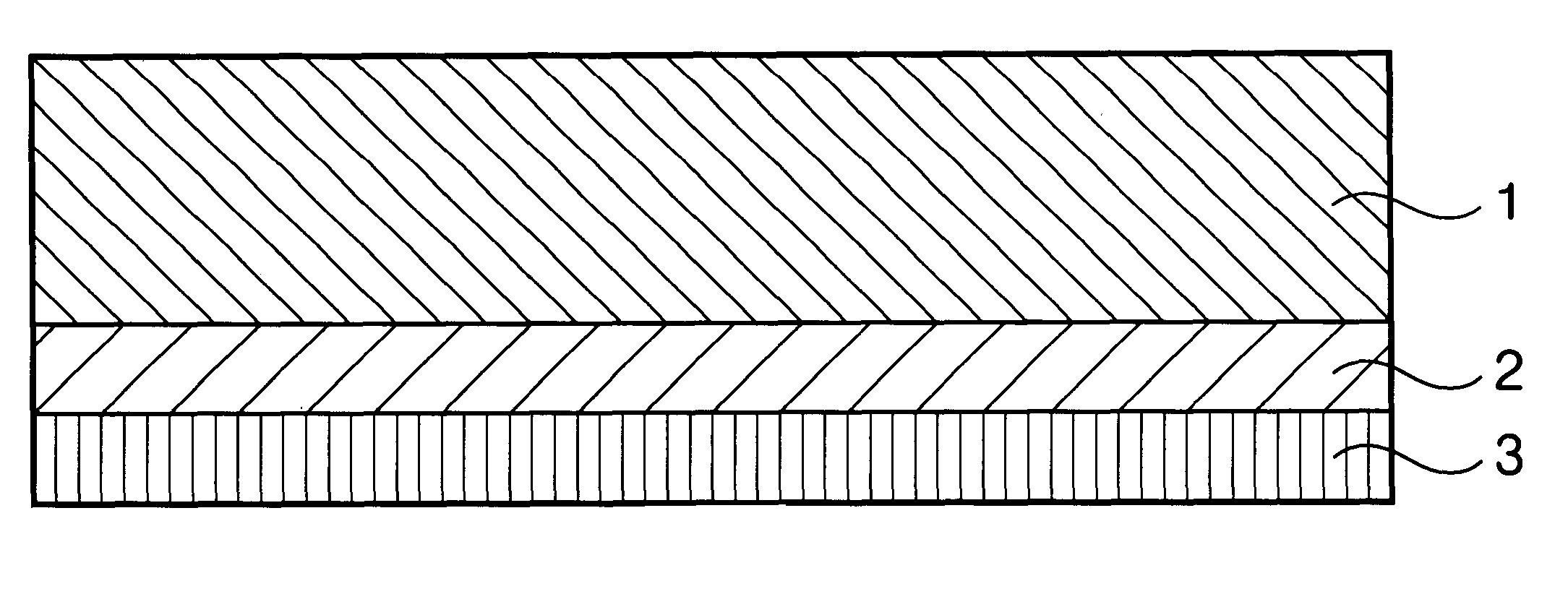

Copper foil for printed wiring board having excellent chemical resistance and heat resistance

InactiveUS6329074B1Bond strength is sufficientHigh bonding strengthInsulating substrate metal adhesion improvementChromatisationAcrylic resinAlloy

This invention provides a copper foil for a printed wiring board, which comprises a copper foil, an alloy layer (A) comprising copper, zinc, tin and nickel which is formed on a surface of the copper foil, said surface to be brought into contact with a substrate for a printed wiring board, and a chromate layer which is formed on a surface of the alloy layer (A,. The copper foil for a printed wiring board has the following features: even if a printed wiring board is produced using a long-term stored copper foil, the interface between the copper foil and the substrate is only slightly corroded with chemicals; even if the copper foil contacts a varnish containing an organic acid, e.g., a varnish for an acrylic resin, in the formation of a copper-clad laminate, the bond strength is sufficient. Even if a printed circuit board made by using the copper foil is placed in a high temperature environment, e.g., in an engine room of an automobile, for a long period of time, blistering of the copper circuit from the substrate due to deterioration of the interface between the copper circuit and the substrate does not take place.

Owner:MITSUI MINING & SMELTING CO LTD

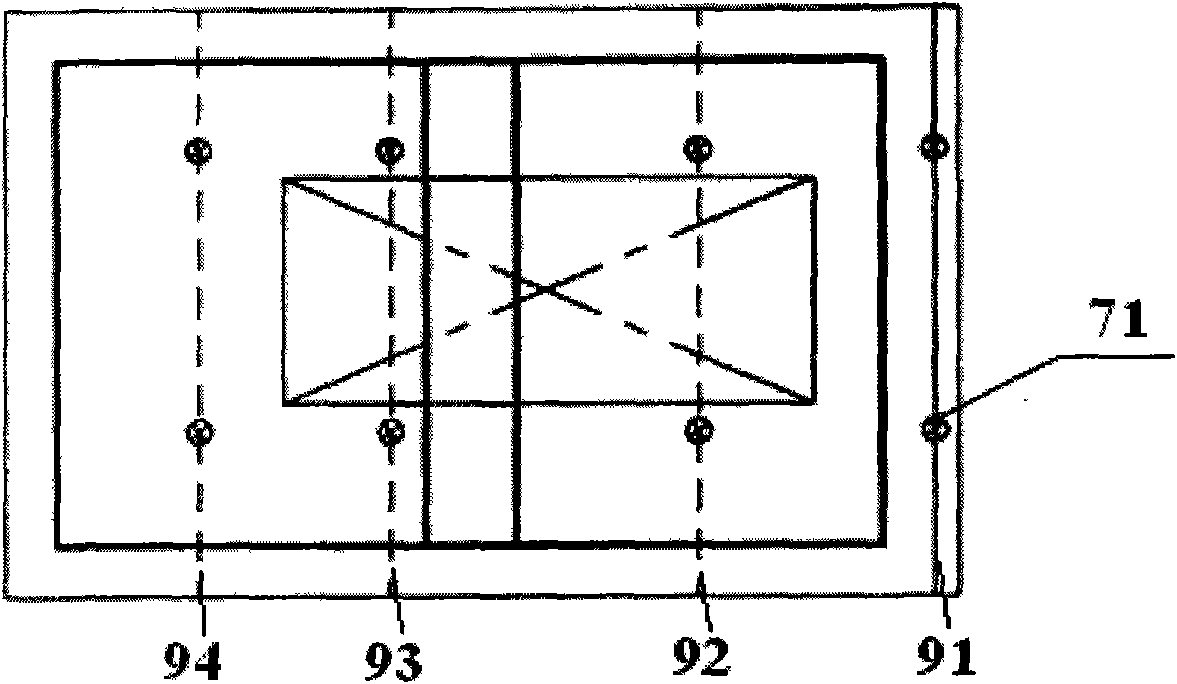

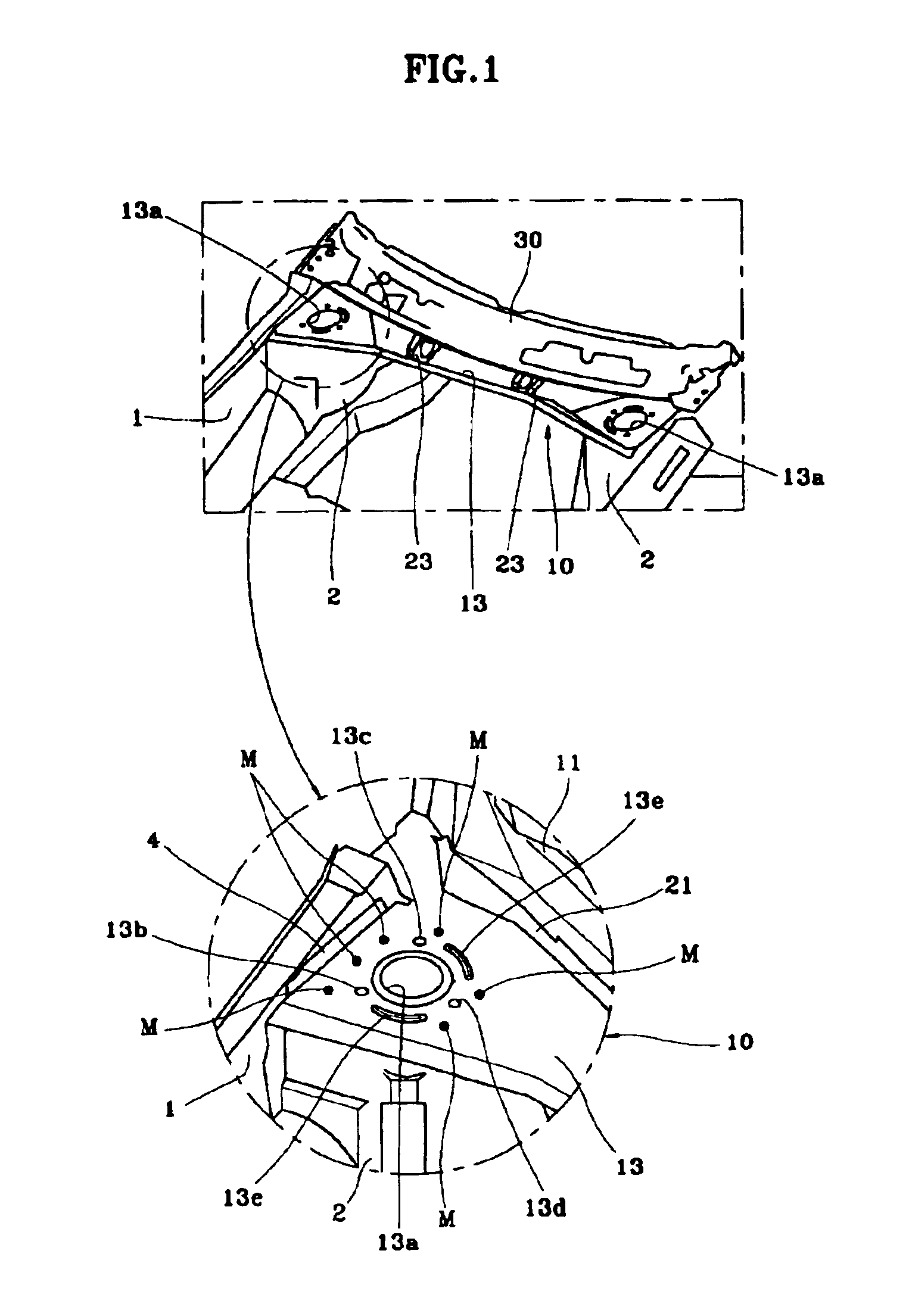

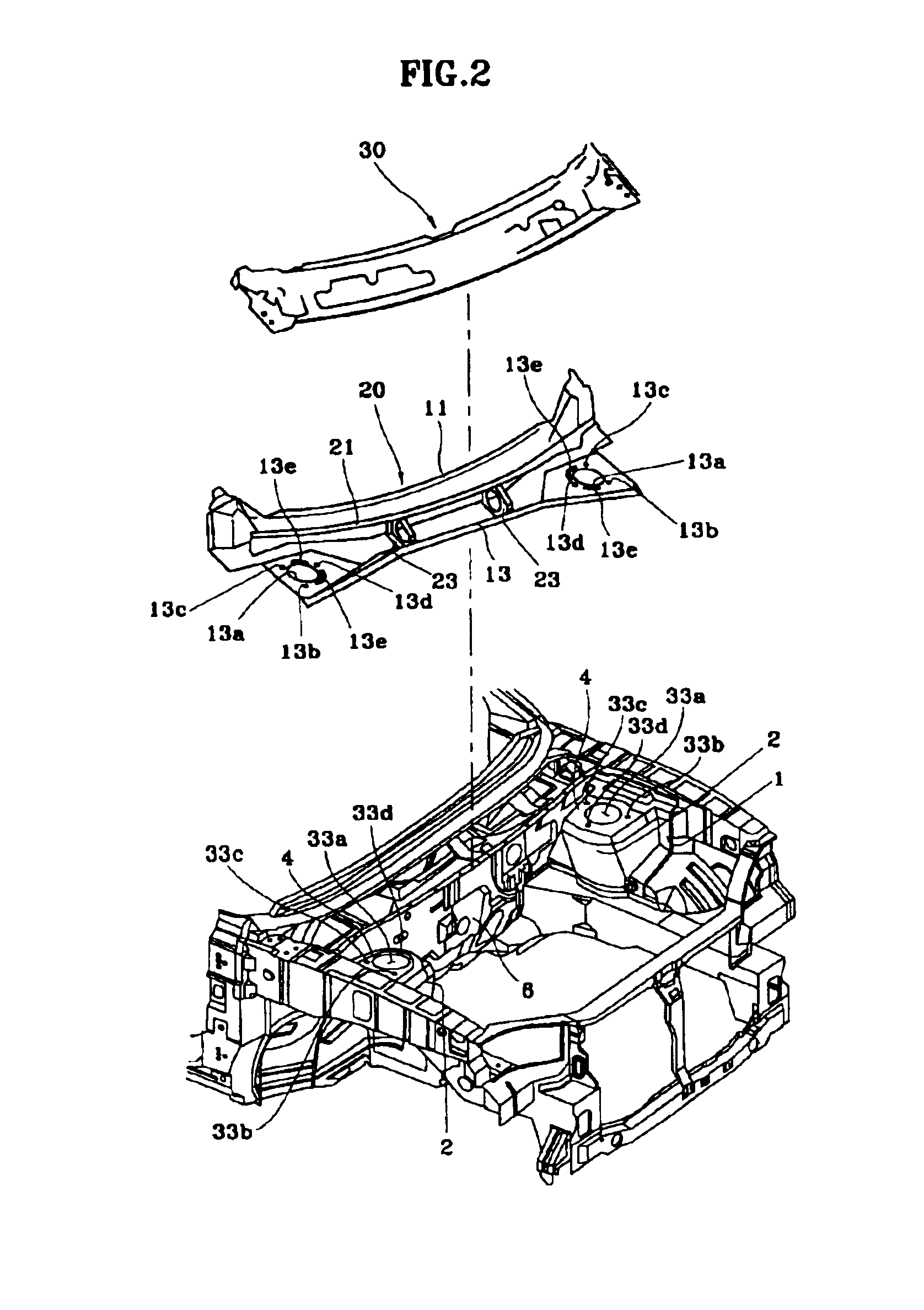

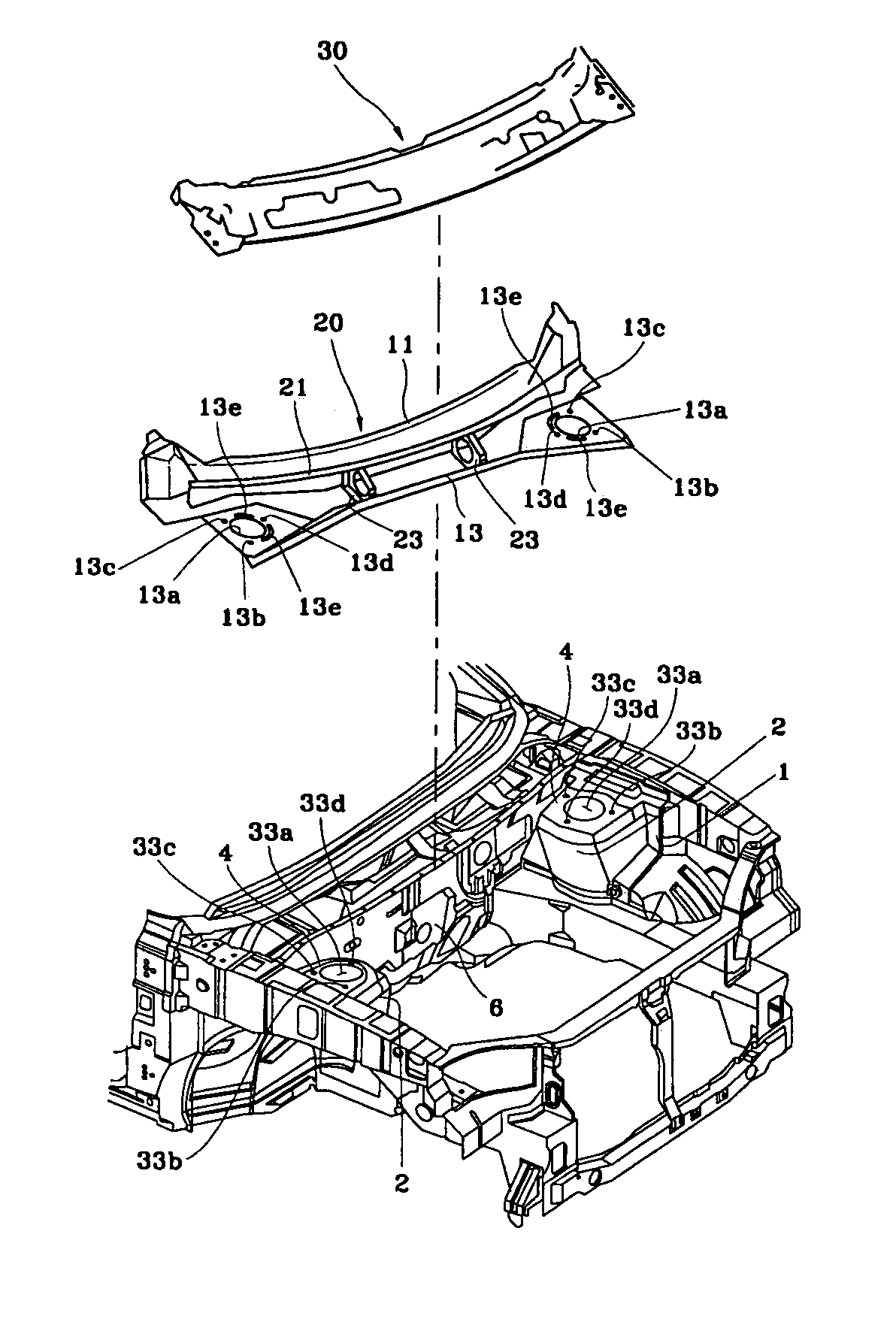

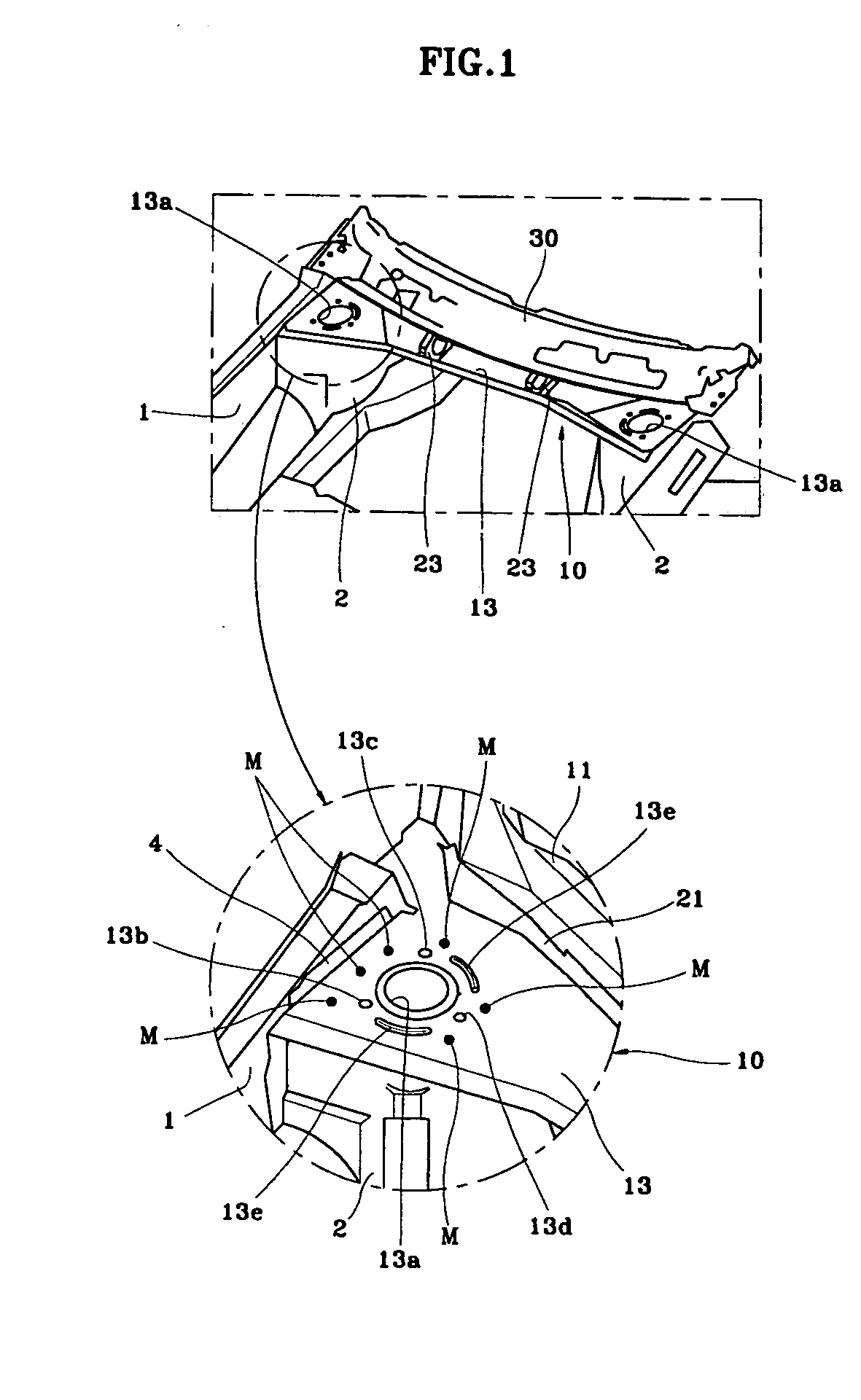

Upper mounting part structure of front strut assembly

InactiveUS6921126B2Improve rigidityMinimizing resonance generatedVehicle seatsSuperstructure subunitsResonanceShock absorber

An upper mounting part of a front strut assembly adapted to reinforce the rigidity of the periphery of a frontal mounting hole, rear mounting hole, and central mounting hole by a lower cowl panel mounted for integrally welding to the shock absorber housing upper panel placed at both sides of the engine room, and a lower cowl reinforcing means welded onto the lower cowl panel is disclosed. The structure minimizes resonance generated by the load transmitted from the outside of the vehicle, reduces driving noise and improves the vehicle ride and steering.

Owner:HYUNDAI MOTOR CO LTD

Upper mounting part structure of front strut assembly

InactiveUS20050067858A1Improve rigidityMinimize resonanceSuperstructure subunitsVehicle cleaningResonanceLoad generation

An upper mounting part of a front strut assembly adapted to reinforce the rigidity of the periphery of a frontal mounting hole, rear mounting hole, and central mounting hole by a lower cowl panel mounted for integrally welding to the shock absorber housing upper panel placed at both sides of the engine room, and a lower cowl reinforcing means welded onto the lower cowl panel is disclosed. The structure minimizes resonance generated by the load transmitted from the outside of the vehicle, reduces driving noise and improves the vehicle ride and steering.

Owner:HYUNDAI MOTOR CO LTD

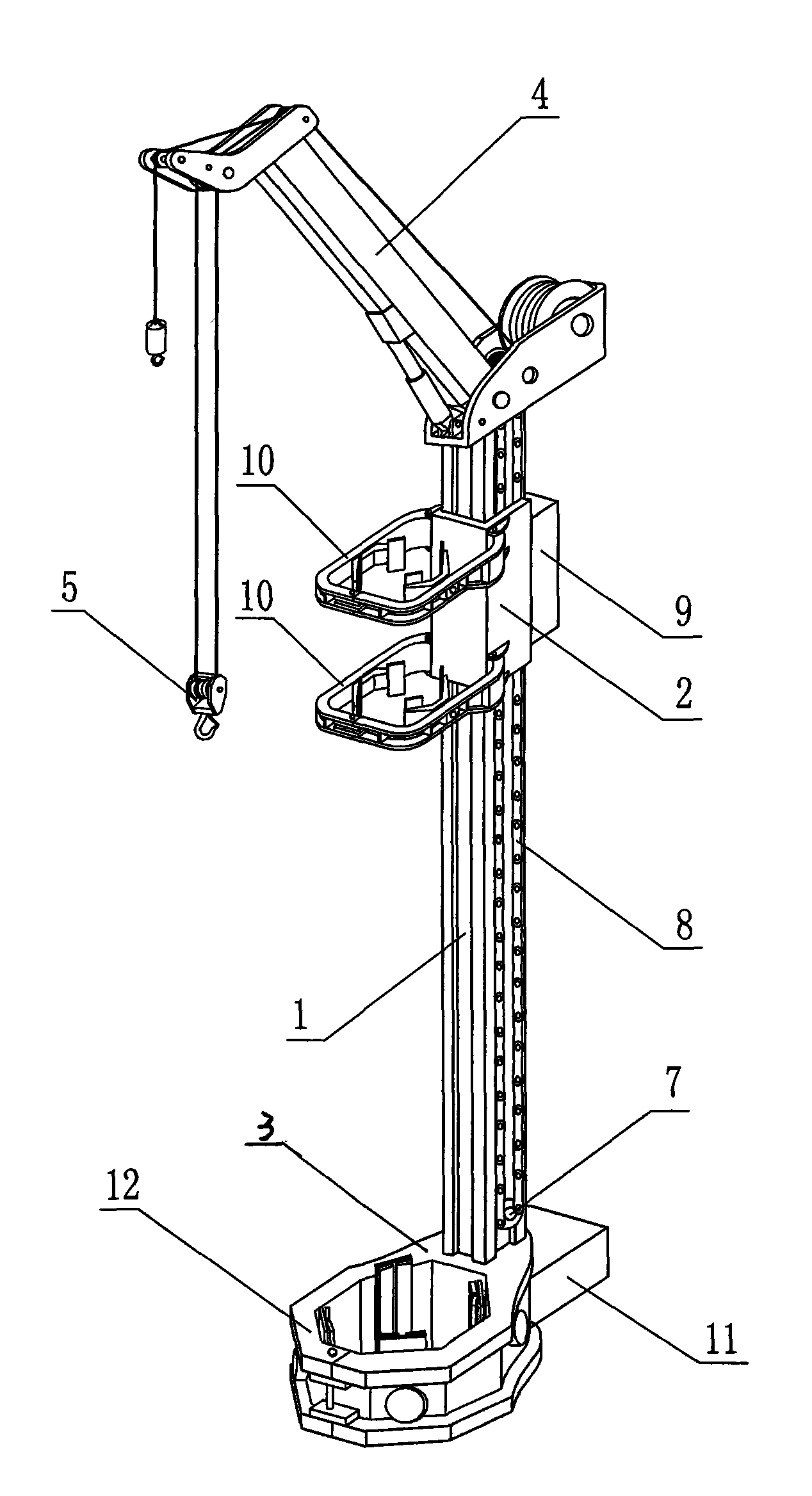

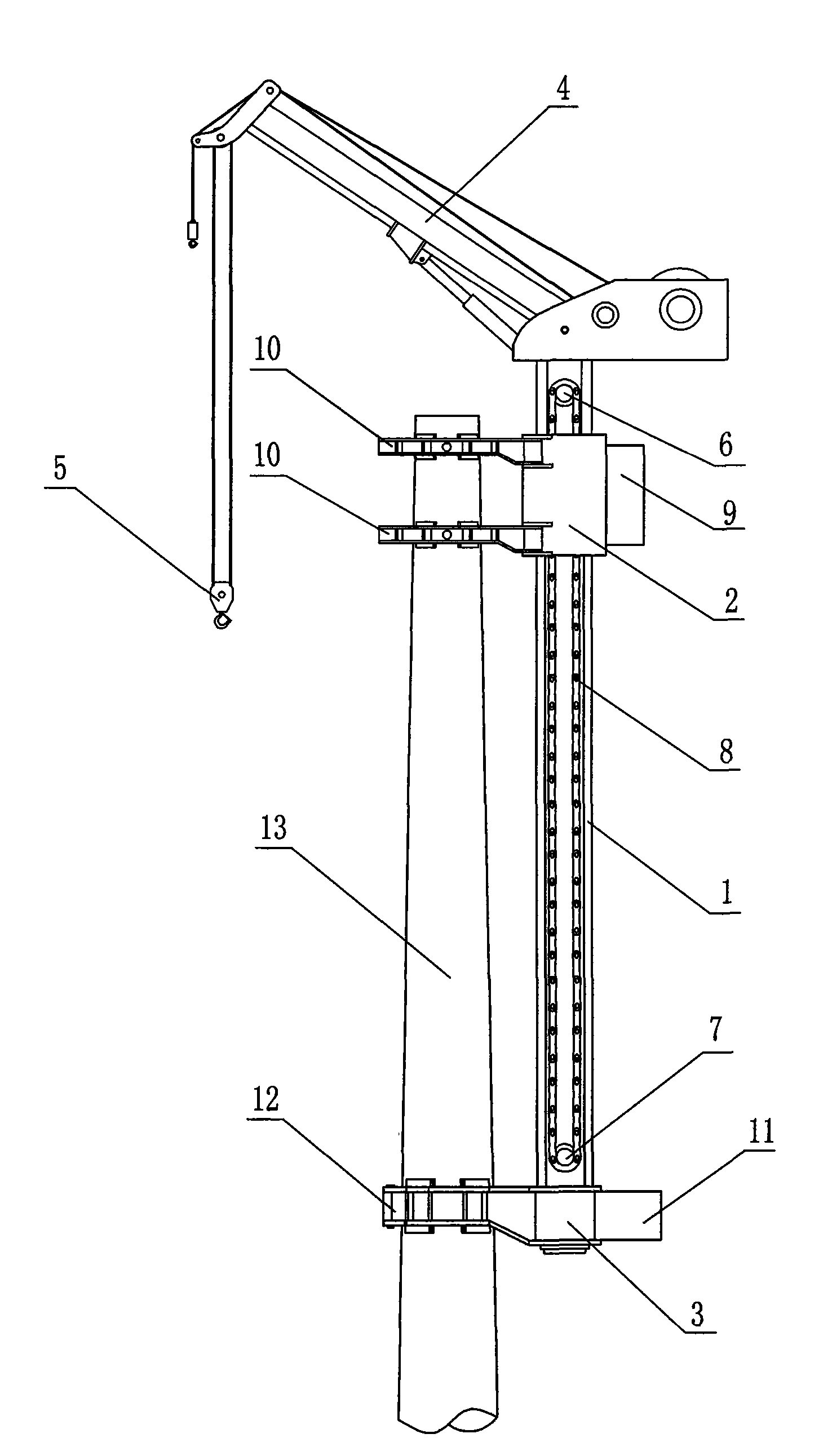

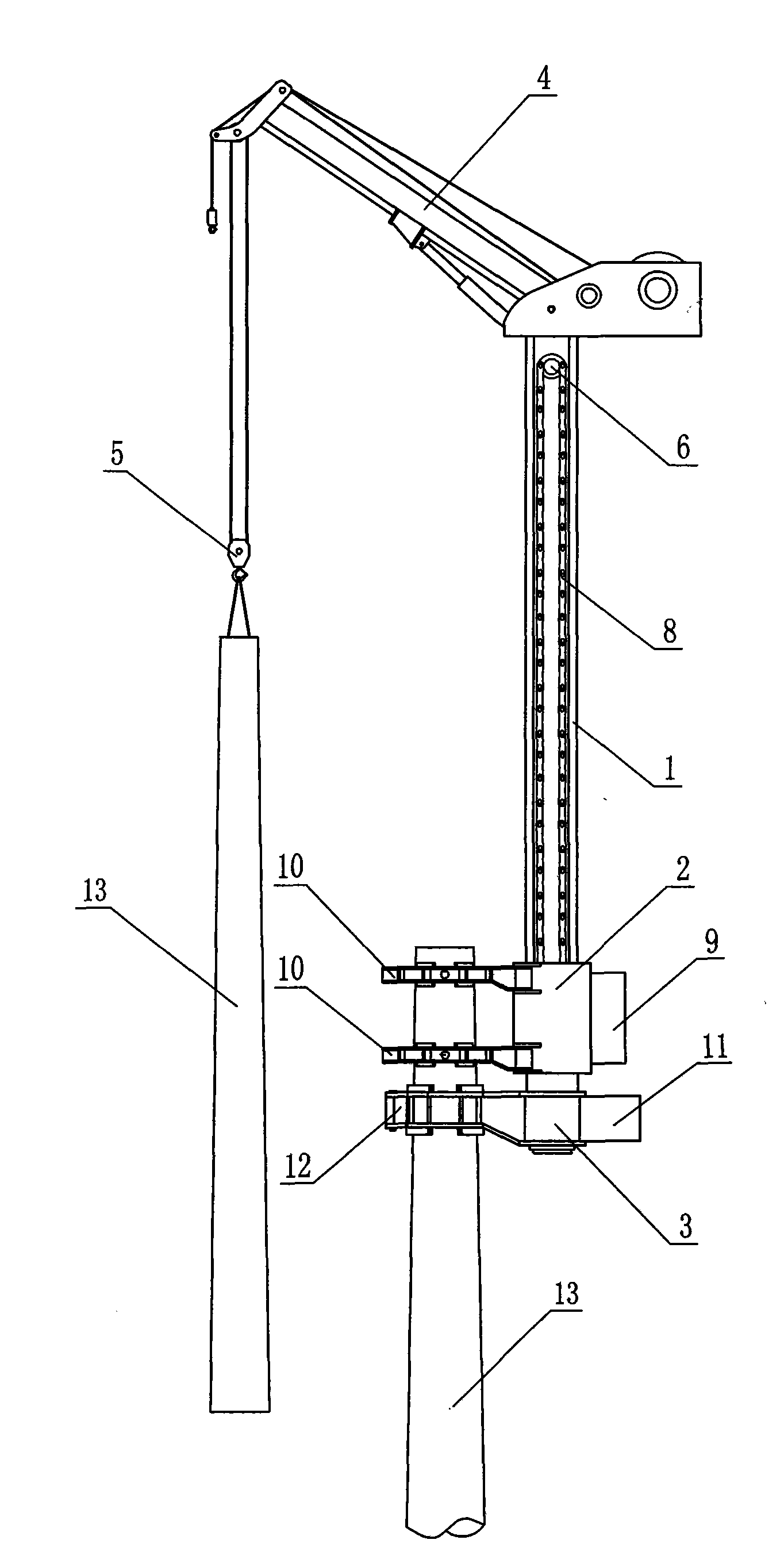

Wind power generation climbing hoisting crane

The invention relates to a wind power generation climbing hoisting crane, which belongs to hoisting machinery and consists of a machine stem, an upper holding clamp, a lower holding clamp, a hydraulic boom and a pulley hook connected with a hinging rope, wherein the upper end and the lower end in a cavity of the machine stem are provided with chain wheels which are in meshed connection by using a ring chain. The clamp body of the lower holding clamp is fixed at the lower end of the machine stem, and the clamp body of the upper holding clamp is sleeved on the outer wall of the machine stem through movable fit and an inner seat of the clamp body is provided with a ratchet to mesh the chain; and the upper holding clamp is provided with a jaw driven by a hydraulic tank, and the lower holding clamp is provided with a jaw driven by the hydraulic tank. The wind power generation climbing hoisting crane can be widely applied to large-sized wind generating sets such as the hoisting of the parts of a tower tube, an engine room, a wind wheel hub and the like, is applicable to hoisting operations of high altitude and superaltitude heavy equipment, is not limited by the maximum lifting height and fields, can perform hoisting operations on flat grounds, hillsides and sea surface, is electromechanically integrated with high automation degree, can be controlled on the ground, has light weight, is convenient for assembly and disassembly, transition and transportation, and has high operational efficiency.

Owner:张世宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com