Patents

Literature

44results about How to "Improve starting characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

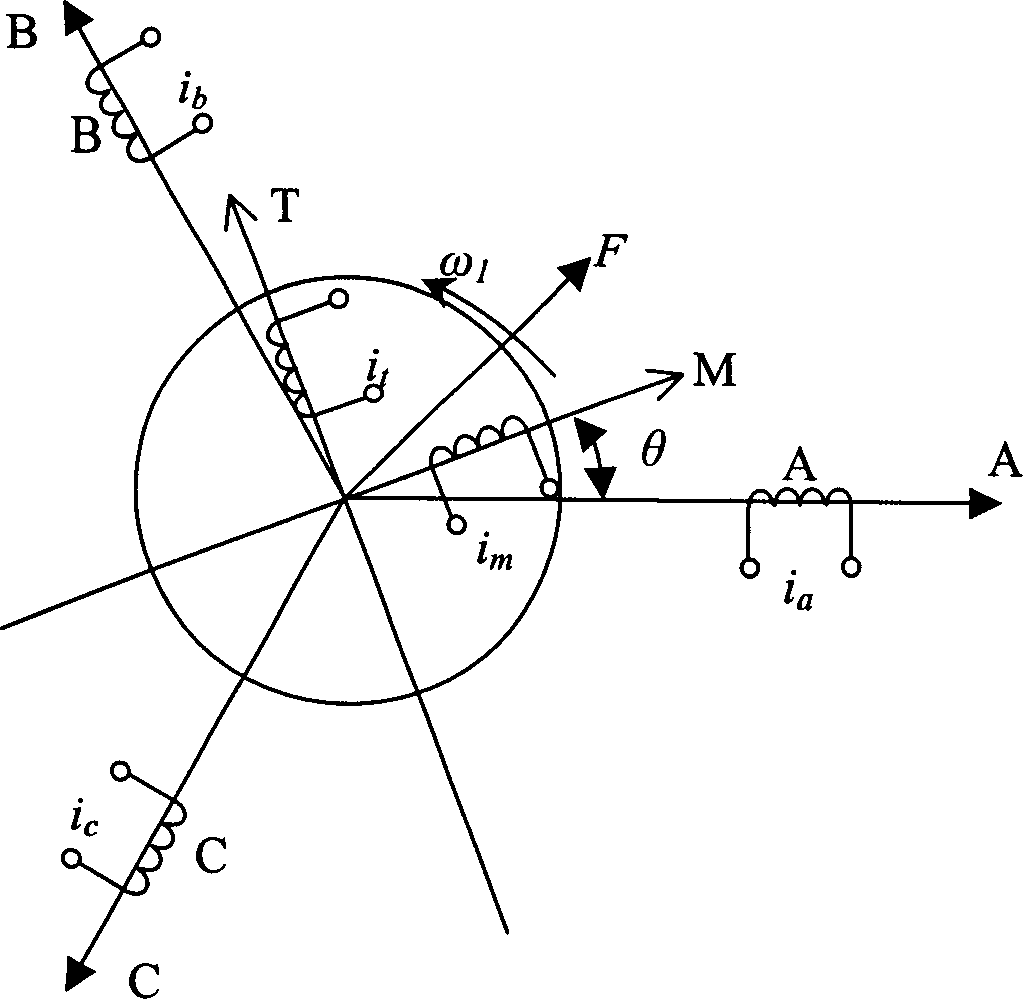

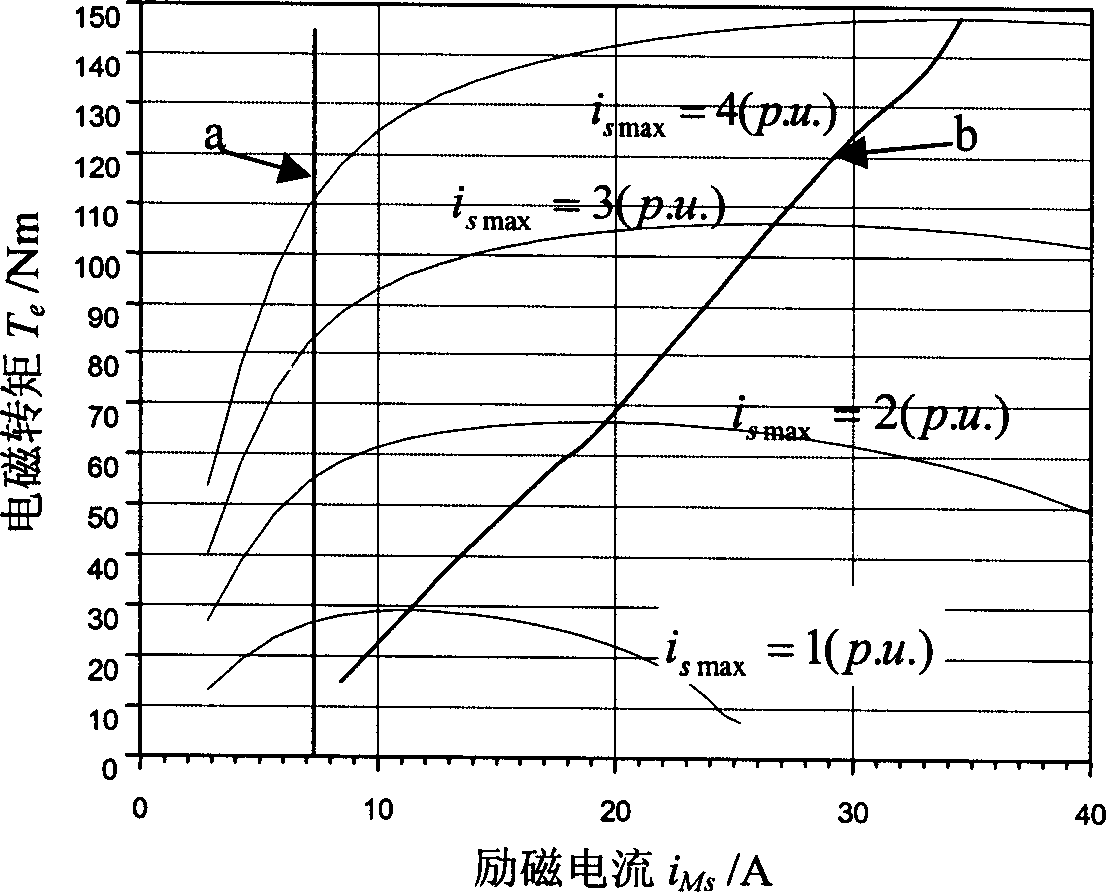

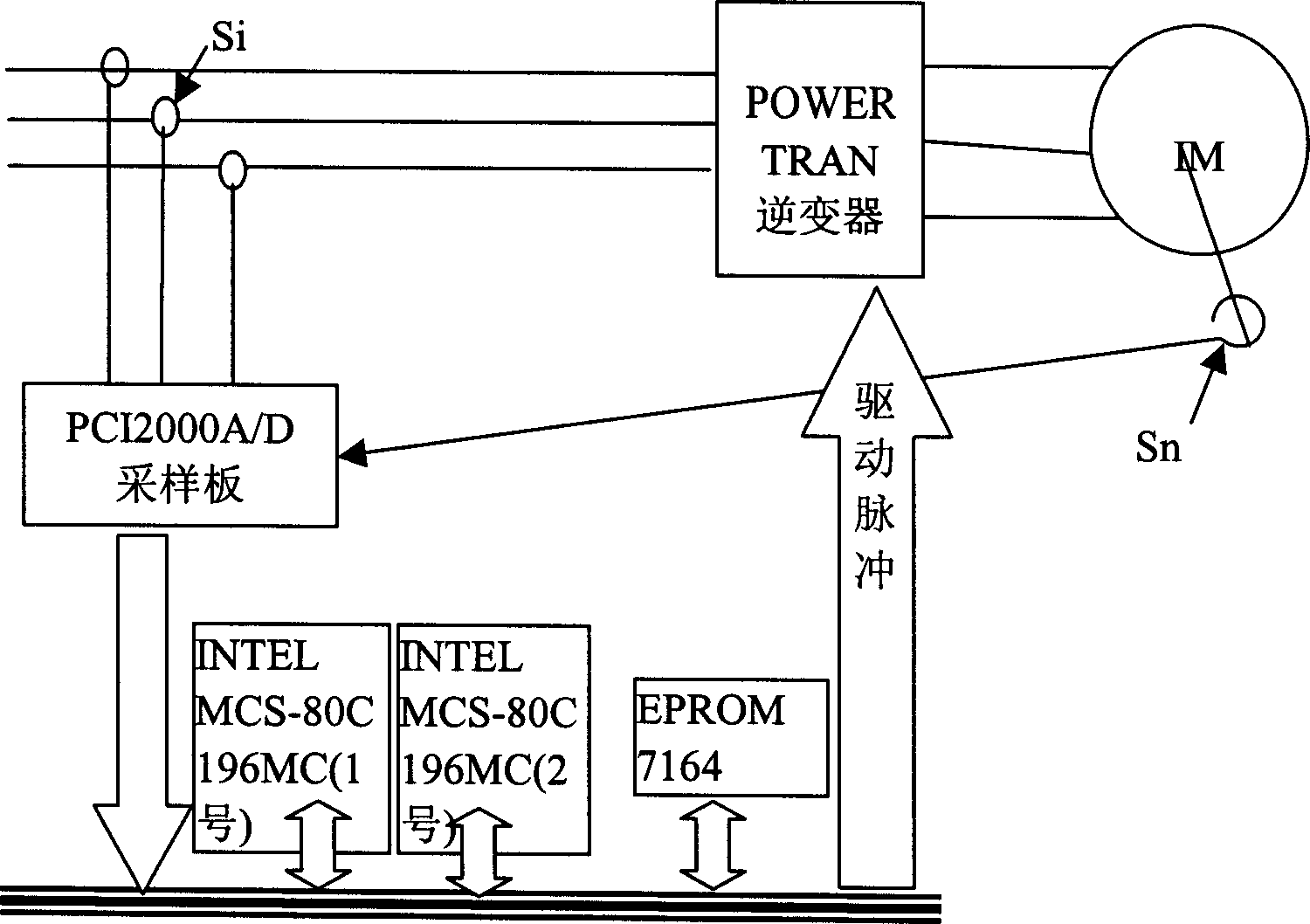

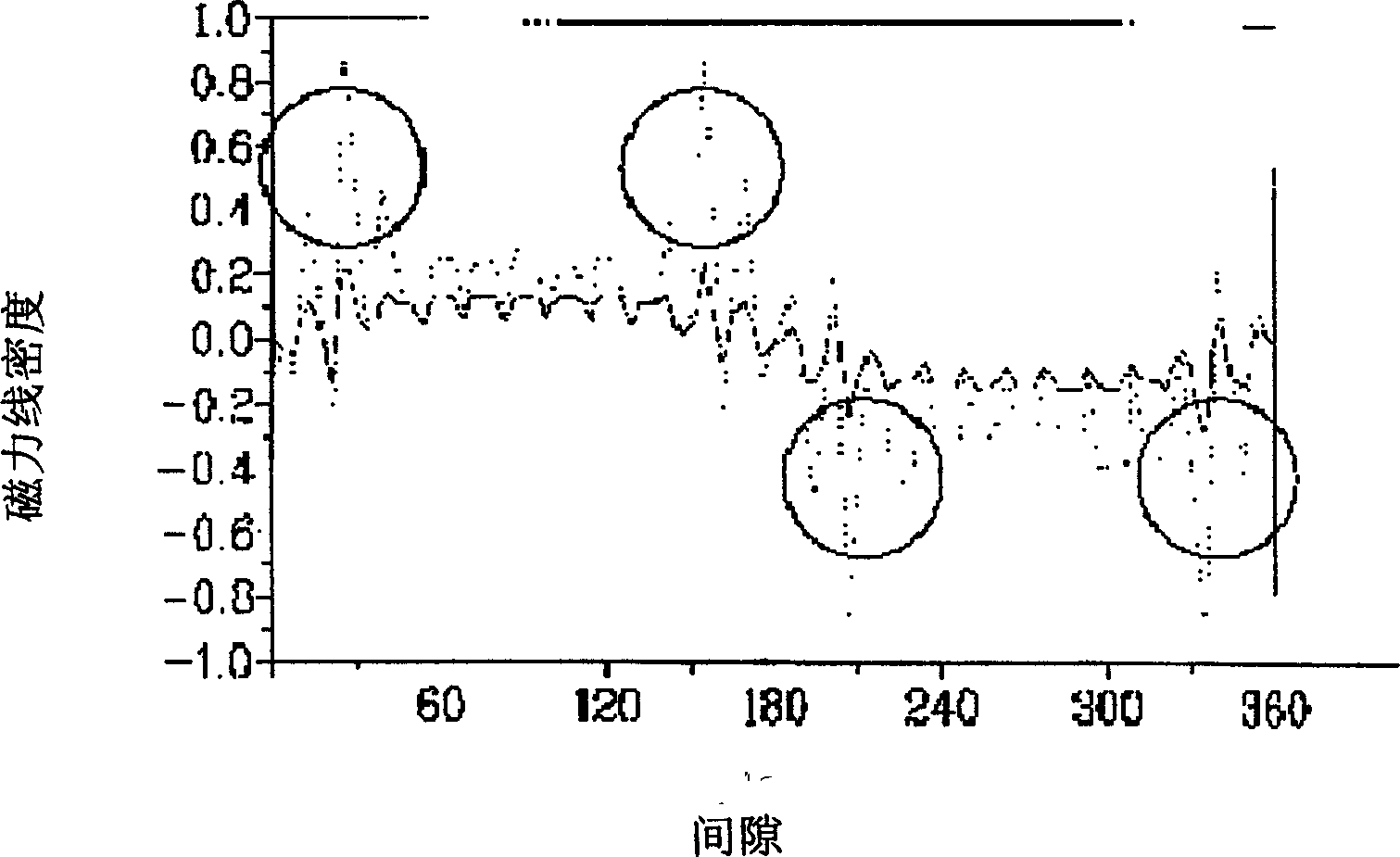

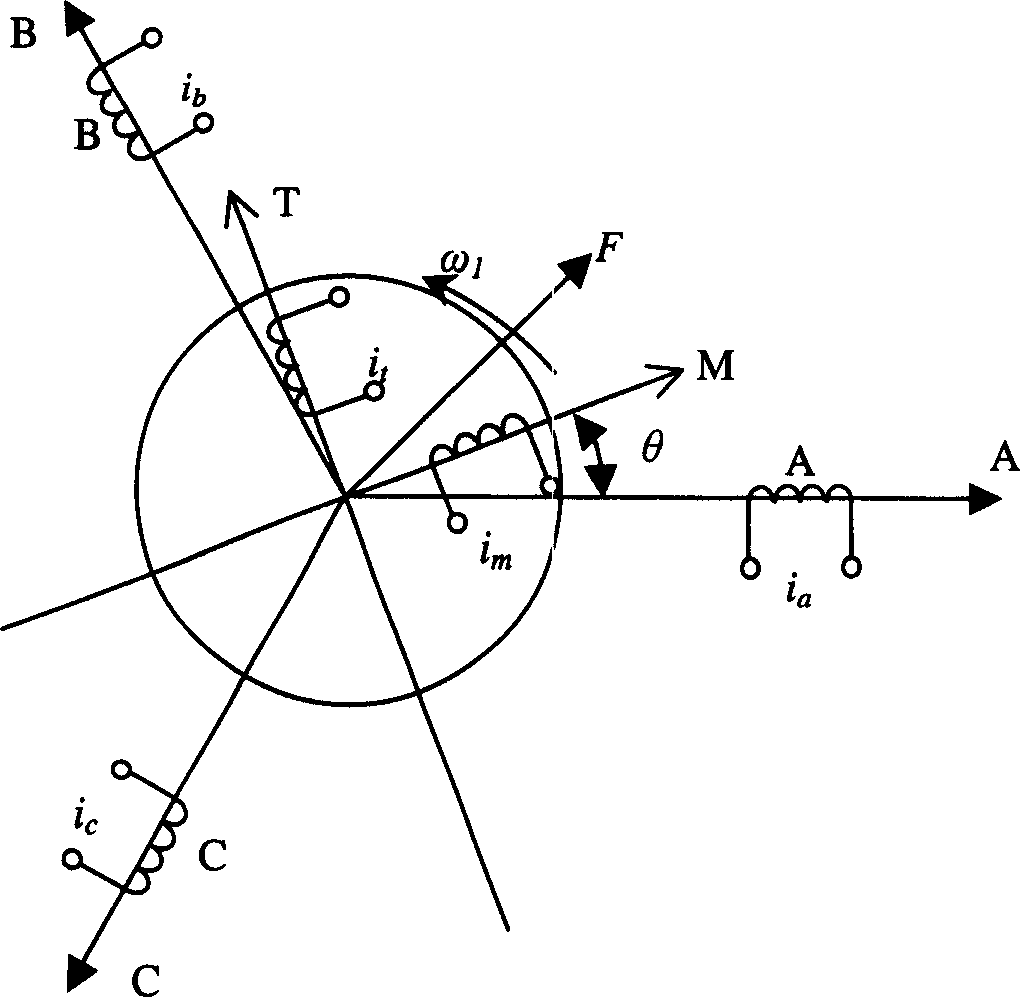

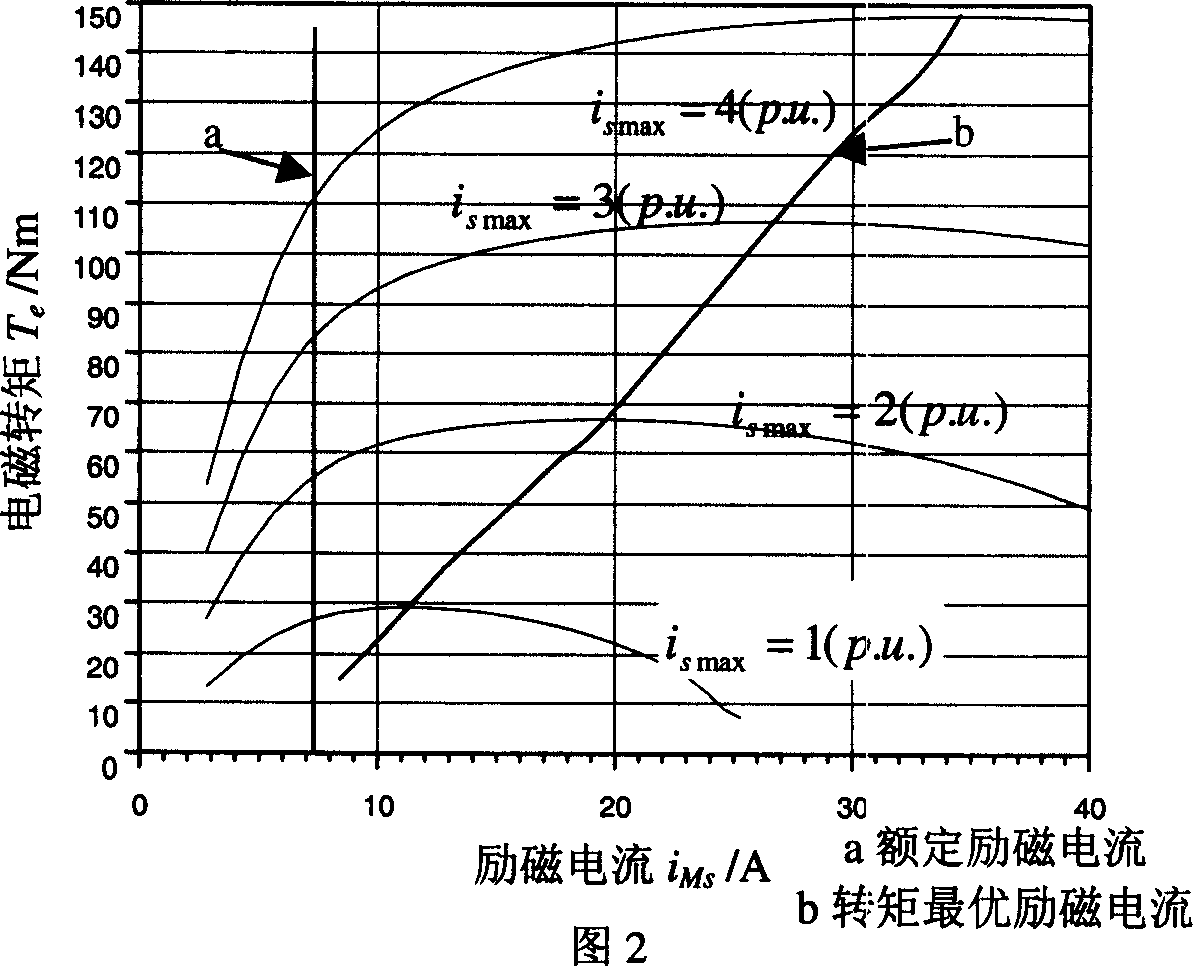

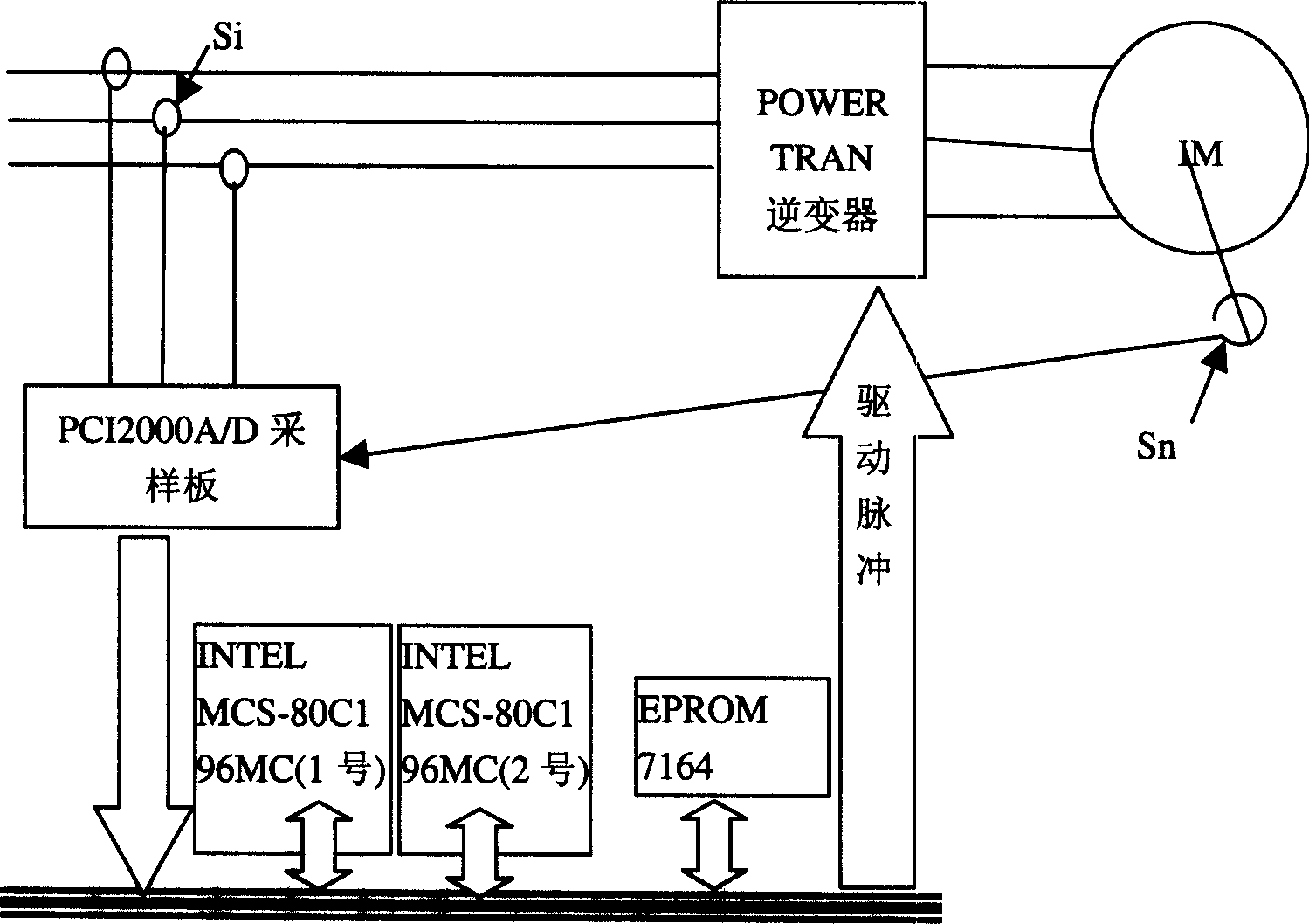

Asynchronous motor optimizing excitation control method based on magnetic-field saturated non-linear motor model

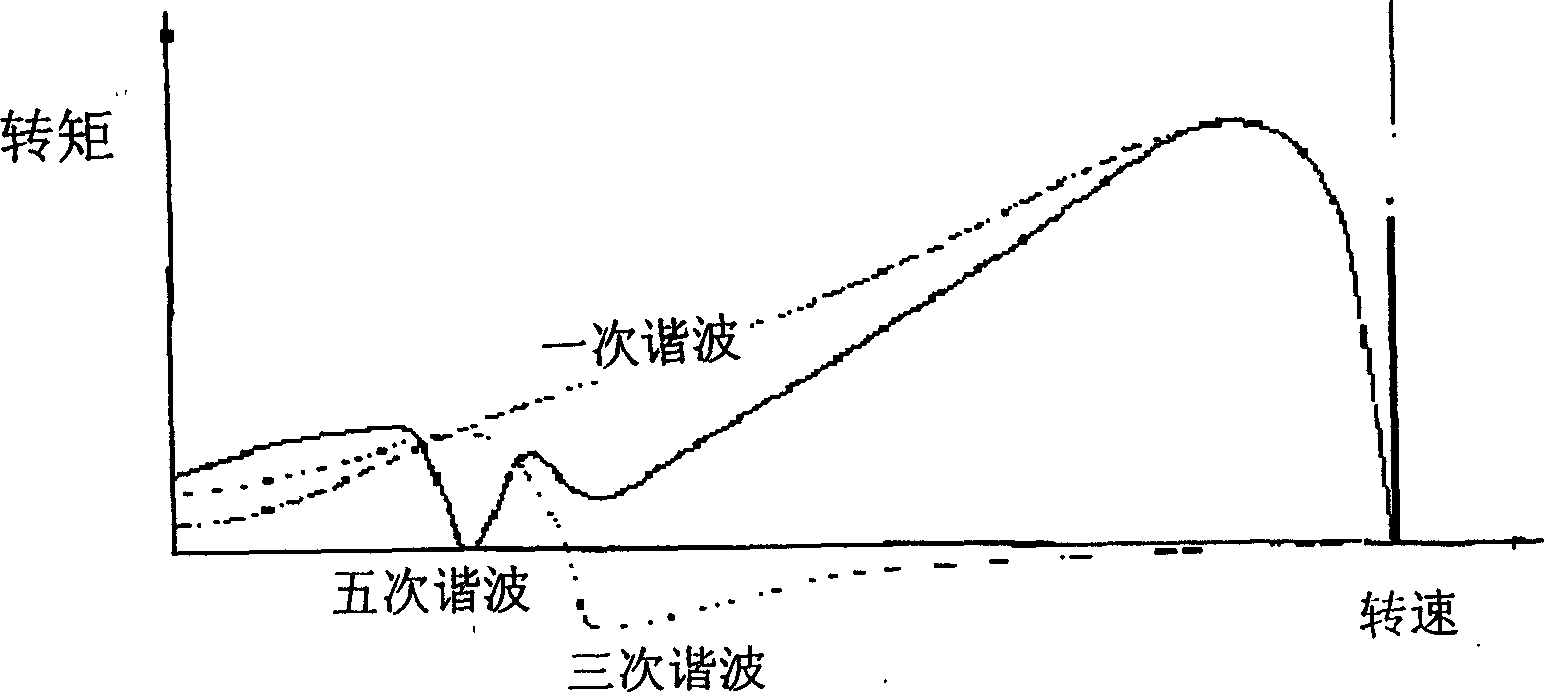

InactiveCN1404215AImprove performanceIncrease output torqueElectronic commutation motor controlVector control systemsMaximum torqueStator voltage

The present invention belongs to the field of asynchronous motor exciting speed-regulating technology and features the exciting speed-regulating method of optimizing stator-exciting current to regulate rotor magnetic linkage. It MT coordinate system, the finite element analysis to asynchronous motor magnetic field is performed to obtain the effect of saturated motor magnetic field on motor parameters and the stator and rotor magnetic linkage via solving non-linear equation. The magnetic linkage table is optimized to obtain optimized exciting table and maximum torque vs rotation speed table. By means of PI control method to obtain optimized exciting current and reference value of torque current, comparison to practical exciting current and torque current and PI regulation and voltage decoupling, final stator voltage in MT coordinate system is obtained for the control of the inverter.

Owner:TSINGHUA UNIV

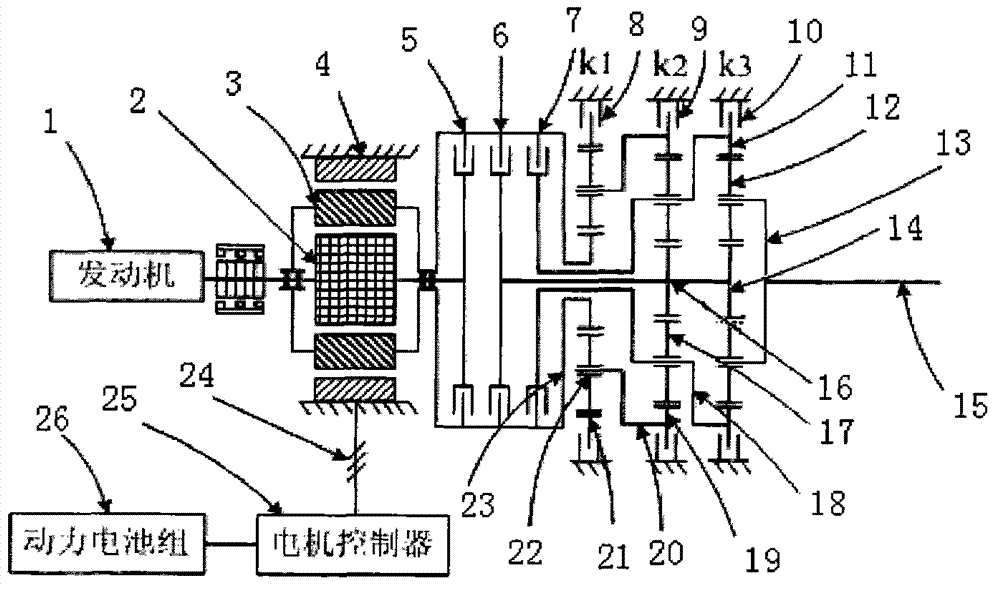

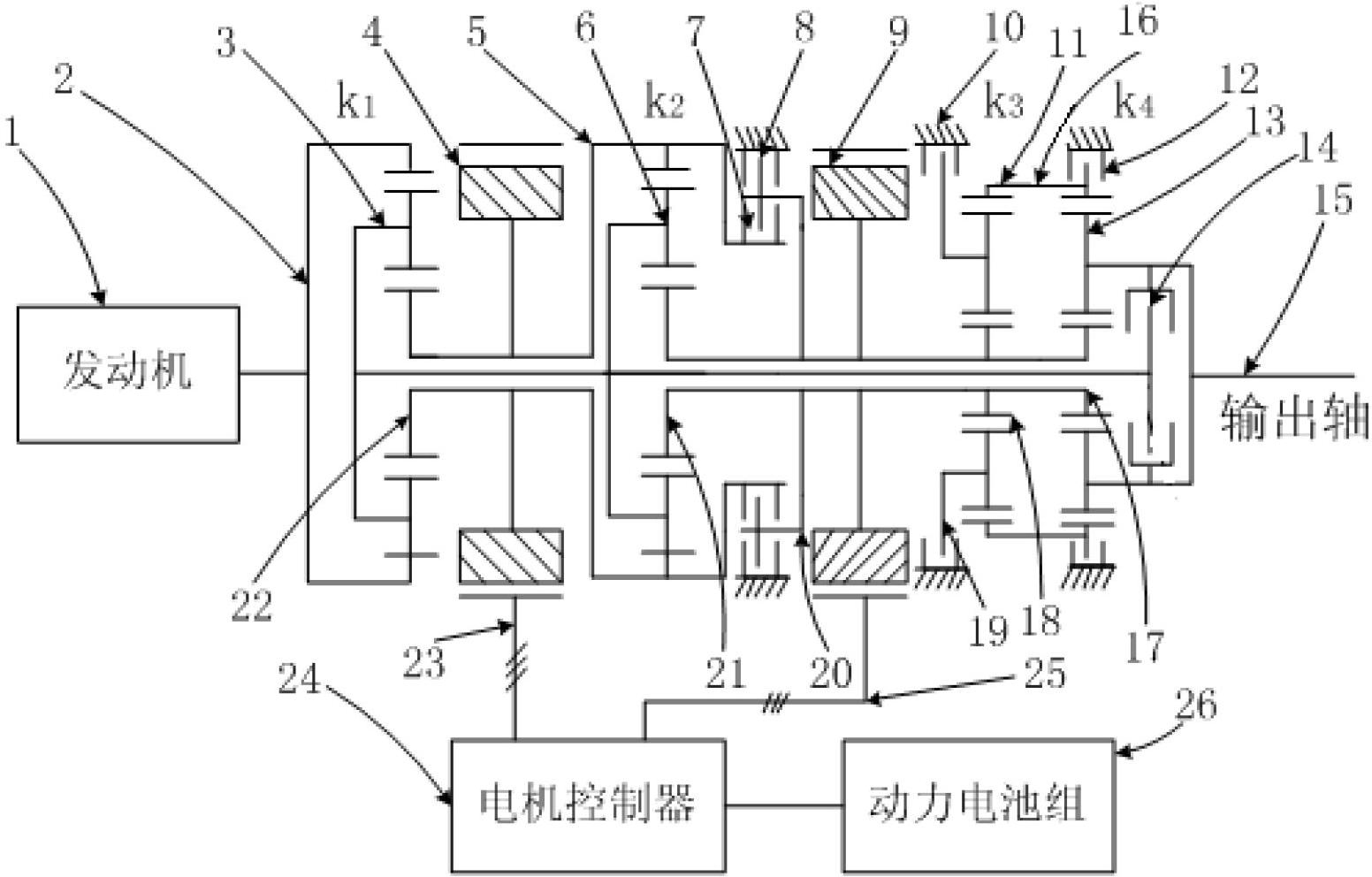

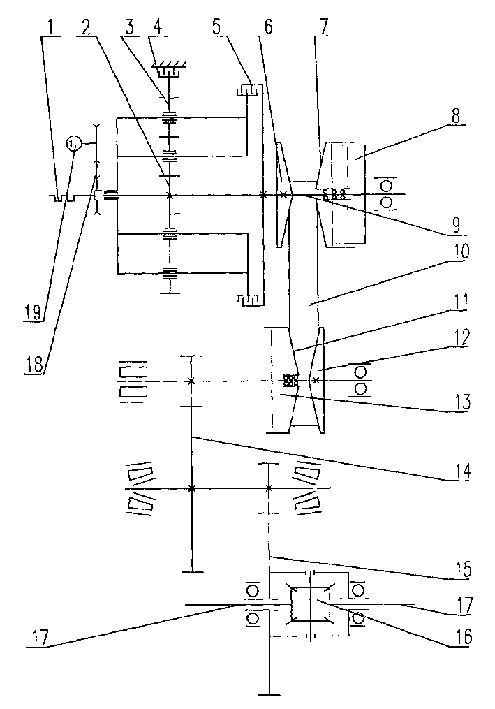

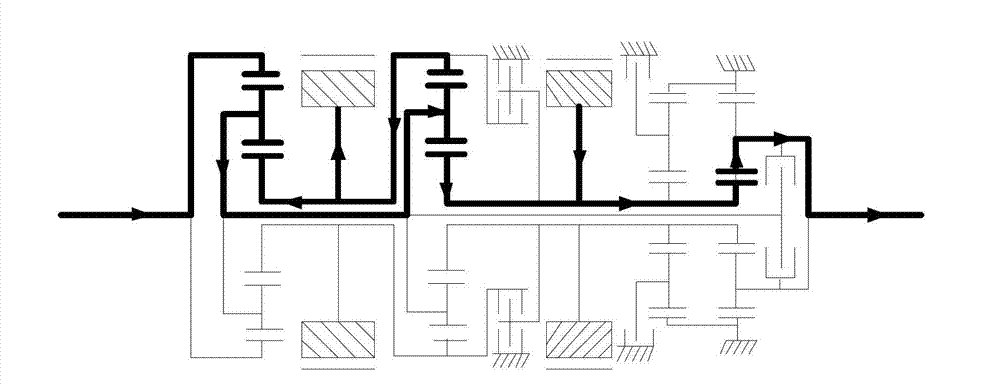

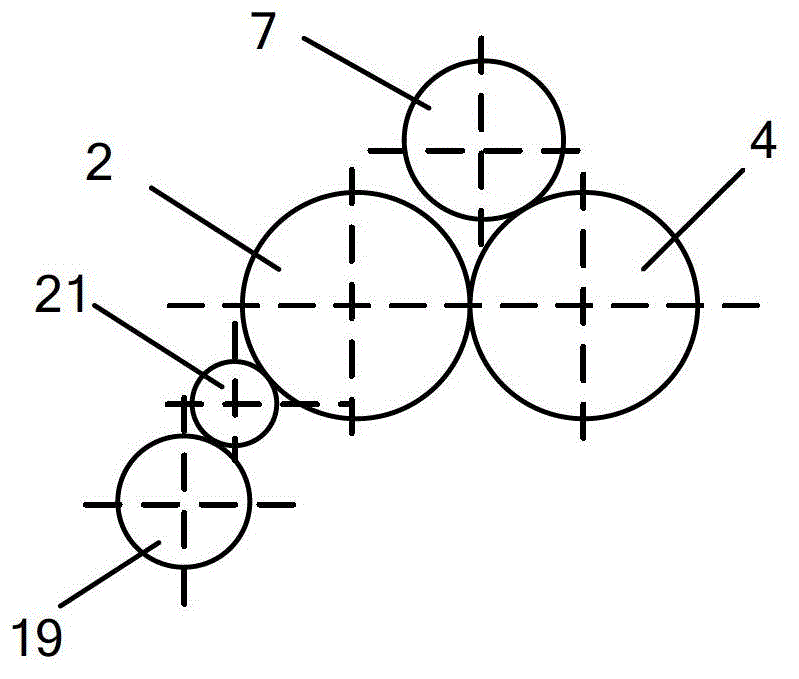

Electromechanical composite stepless transmission device for wheeled load-carrying vehicle with birotor motor

ActiveCN102815199ASimple structureLow costGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingPower batteryElectric machine

The invention belongs to the technical field of power transmission, relates to a composite stepless transmission device, and particularly relates to an electromechanical composite stepless transmission device for a wheeled load-carrying vehicle with a birotor motor. The electromechanical composite stepless transmission device comprises an engine, the birotor motor, a k1 planetary row, a k2 planetary row, a k3 planetary row, an output shaft, a birotor motor cable, a motor controller, a power battery pack and six control elements. An input shaft, the output shaft, the motor, a clutch, a brake and the planetary rows can be arranged coaxially to save space and improve power density. Only a two-layer sleeve shaft structure is needed, so that the electromechanical composite stepless transmission device is simple in structure and convenient in process. Power grade of the motor or the engine can be decreased by means of reasonable matching.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

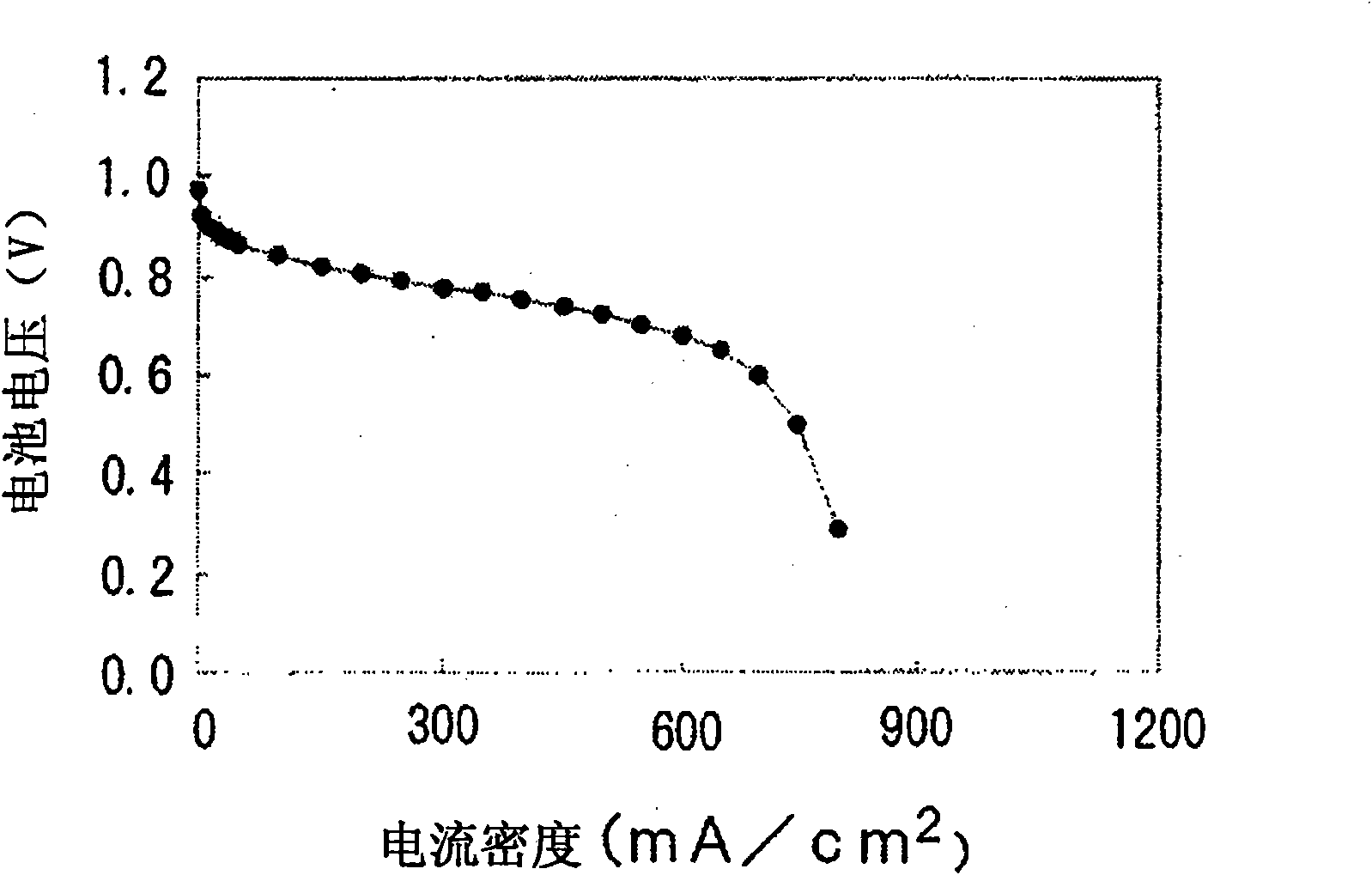

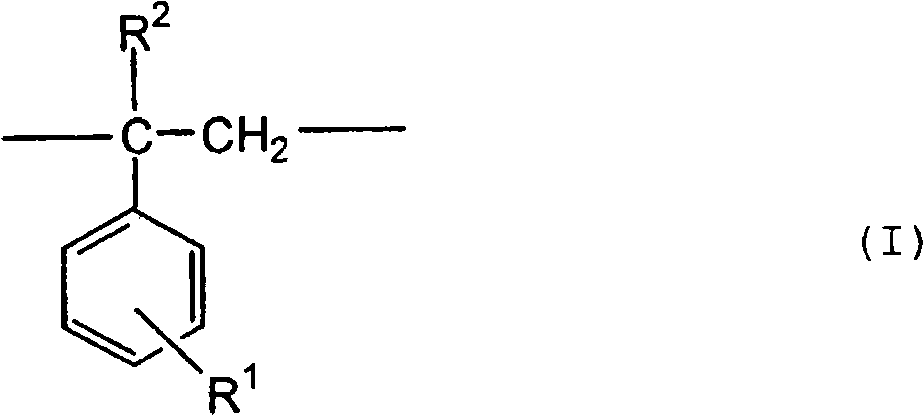

Polymer electrolyte, polymer electrolyte membrane, membrane-electrode assembly, and solid polymer fuel cell

InactiveCN101682048AGood formabilityIncreased durabilityNon-metal conductorsSemi-permeable membranesAlicyclic HydrocarbonsMechanical property

The invention discloses a polymer electrolyte which comprises, as the main component, a block / graft copolymer comprising, as constituent components, polymer blocks (A), (B) and (C) which cause phase-separation from one another, wherein the polymer block (A) comprises a vinyl compound unit as the main repeating unit and has an ion-conductive group, the polymer block (B) comprises a vinyl compound unit capable of forming a flexible phase as the main repeating unit and forms a flexible phase, and the polymer block (C) comprises a styrene derivative unit carrying an alicyclic hydrocarbon group having a polycyclic structure as the main repeating unit and forms a restrained phase; a membrane; a membrane-electrode assembly; and a solid polymer fuel cell. The polymer electrolyte has excellent durability and heat resistance, and shows little change in properties, such as the change in dimension between a dried state and a wet state, the change in mechanical properties and the change in methanolcross-over before and after the immersion in a methanol solution. The polymer electrolyte can be used stably in a solid polymer fuel cell during the long-term operation of the solid polymer fuel celland enables excellent start-up performance of the solid polymer fuel cell.

Owner:KURARAY CO LTD +1

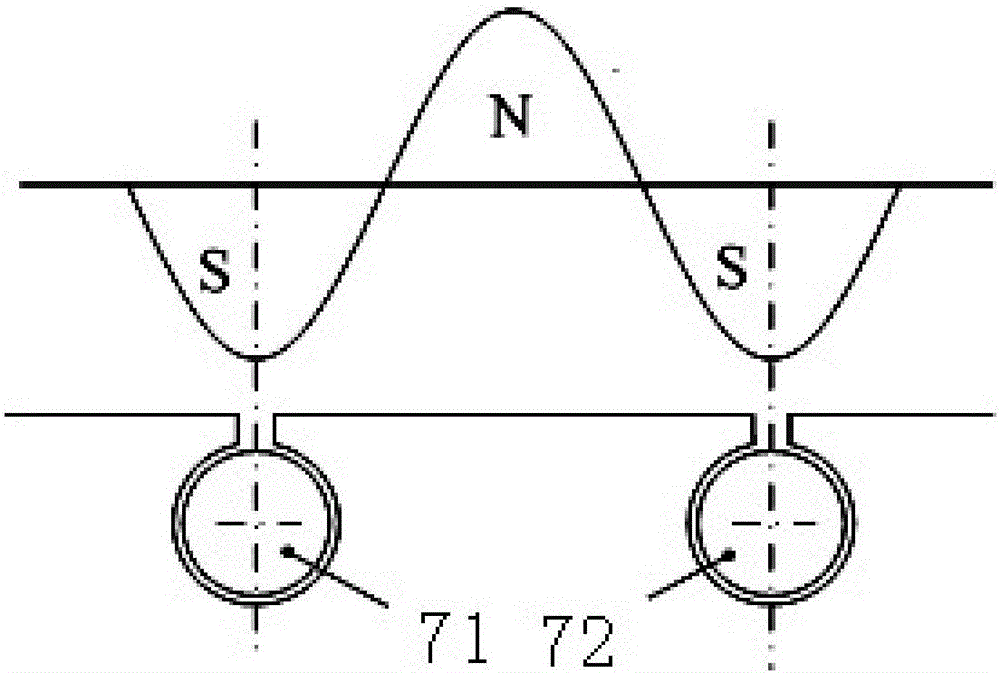

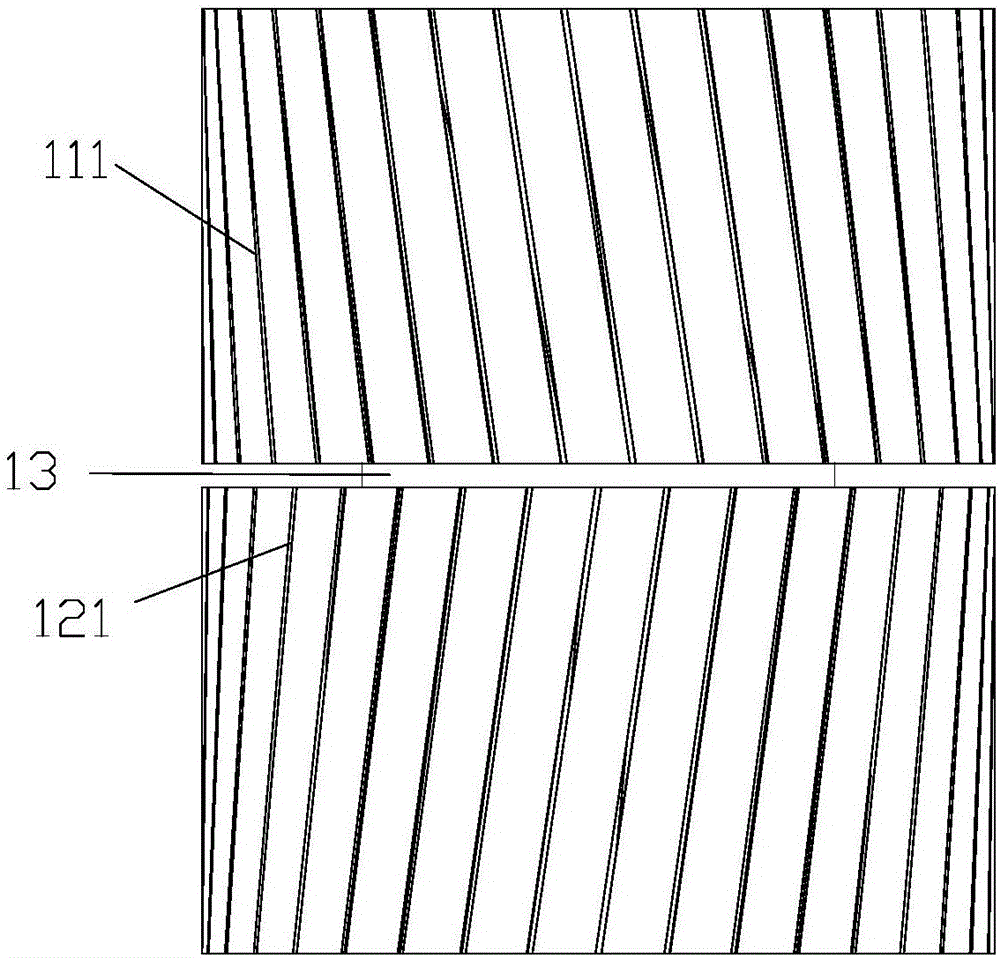

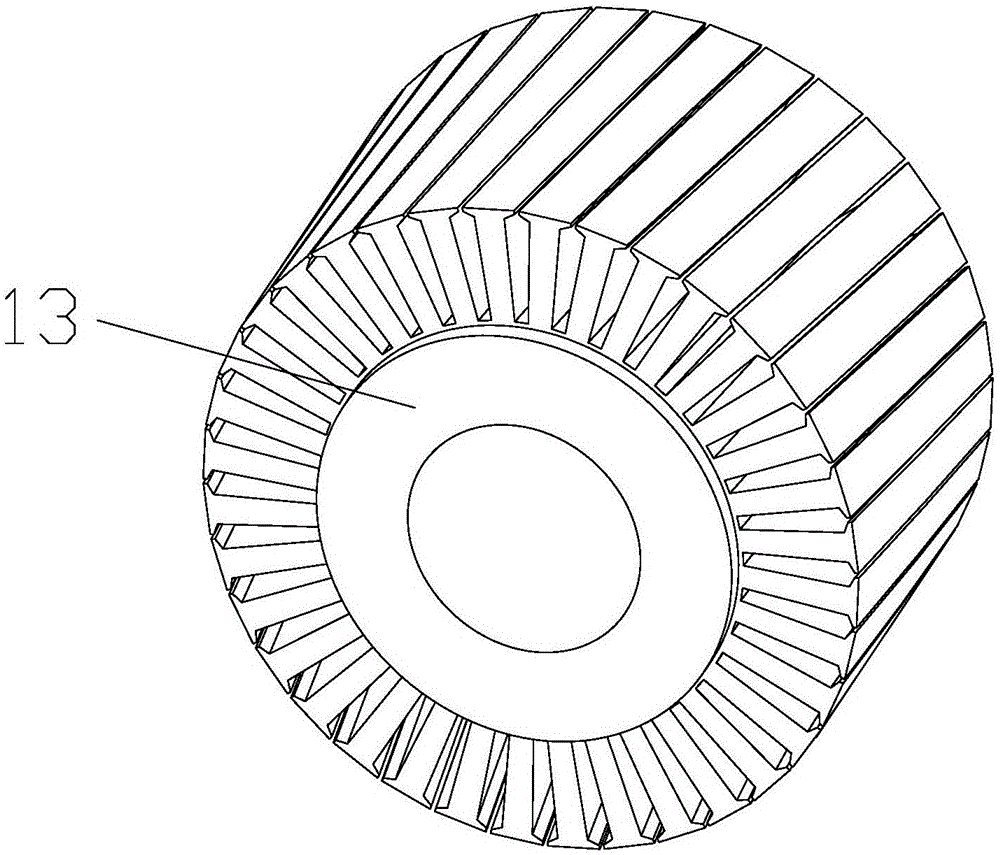

Double-skewed-slot rotor, and stator-rotor equal-slot matching structure based on rotor

PendingCN106849423ANormal startSynchronous additional torque reductionMagnetic circuit rotating partsStructure basedPhysics

The invention discloses a double-skewed-slot rotor, which relates to the technical field of motors. A slot number of the rotor is equal to that of a stator matched with the rotor. The double-skewed-slot rotor comprises a first rotor and a second rotor; a slot body of the first rotor and a corresponding slot body in the second rotor are twisted in opposite directions; skewed slot distances of the first rotor and the second rotor are both as follows: (shown in the description); skewed slot angles of the first rotor and the second rotor are both as follows: (shown in the description); Z1 is a slot number of the stator, p is a number of pole pairs of a motor, and Di1 is an inner diameter of the stator; and a staggered angle of the slot body of the first rotor and the corresponding slot body in the second rotor is as follows: (shown in the description), wherein Z2 is a slot number of the rotor. The invention also discloses a stator-rotor equal-slot matching structure based on the rotor. The double-skewed-slot rotor has the advantage that the limitation on the selection of the slot number of the stator and rotor of a traditional induction electric motor and the application of the equal-slot matching can be broken through.

Owner:HEFEI UNIV OF TECH

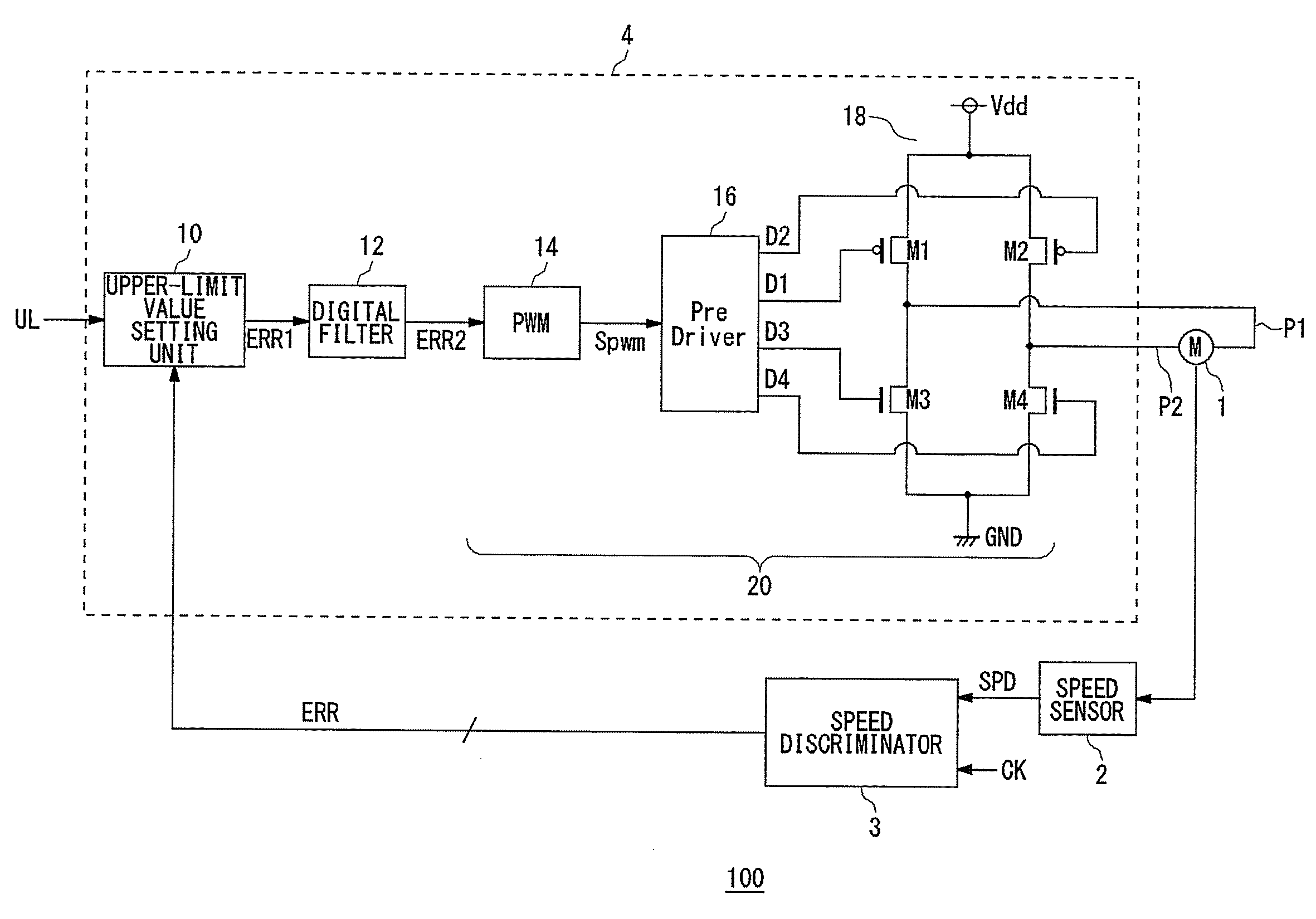

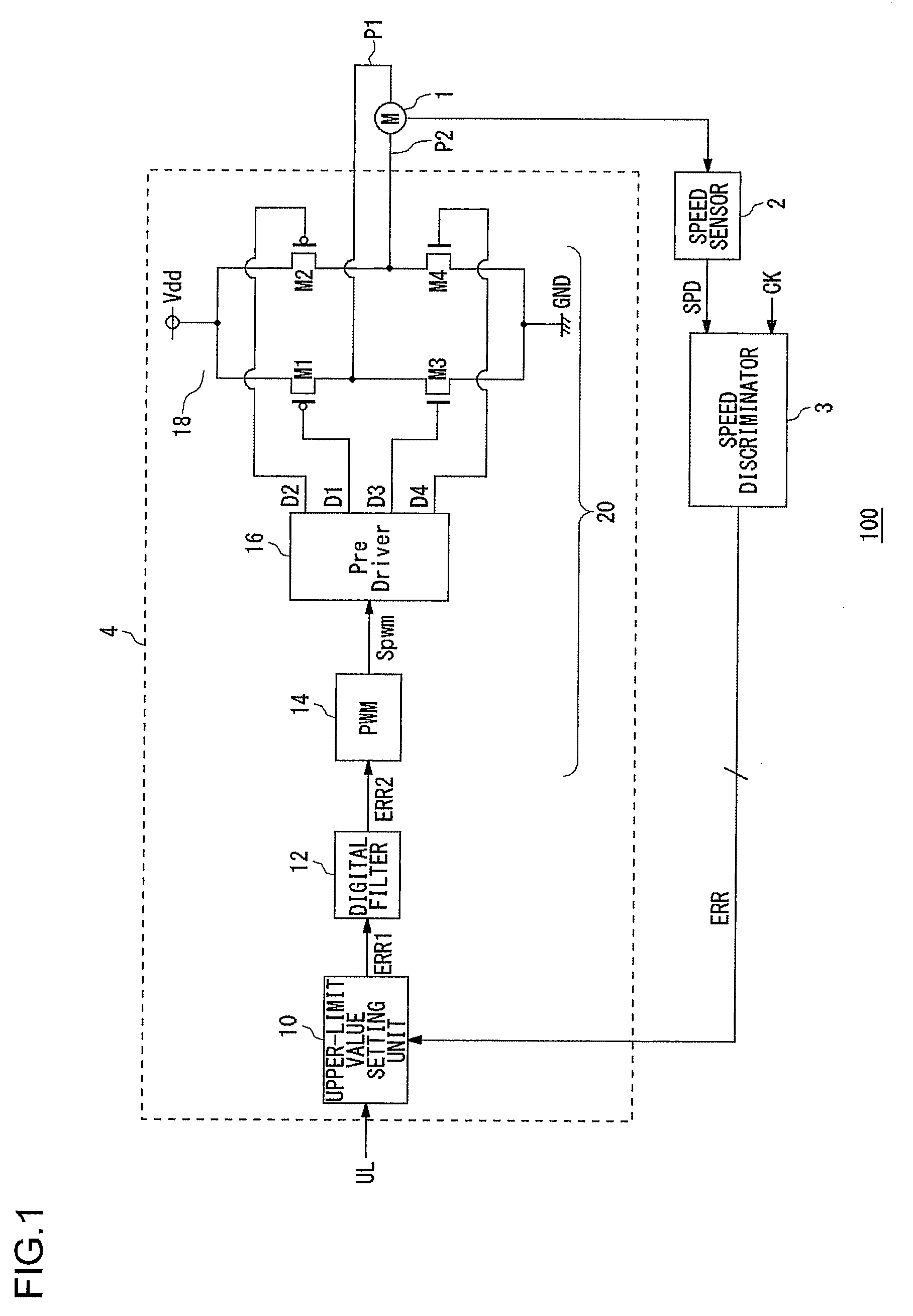

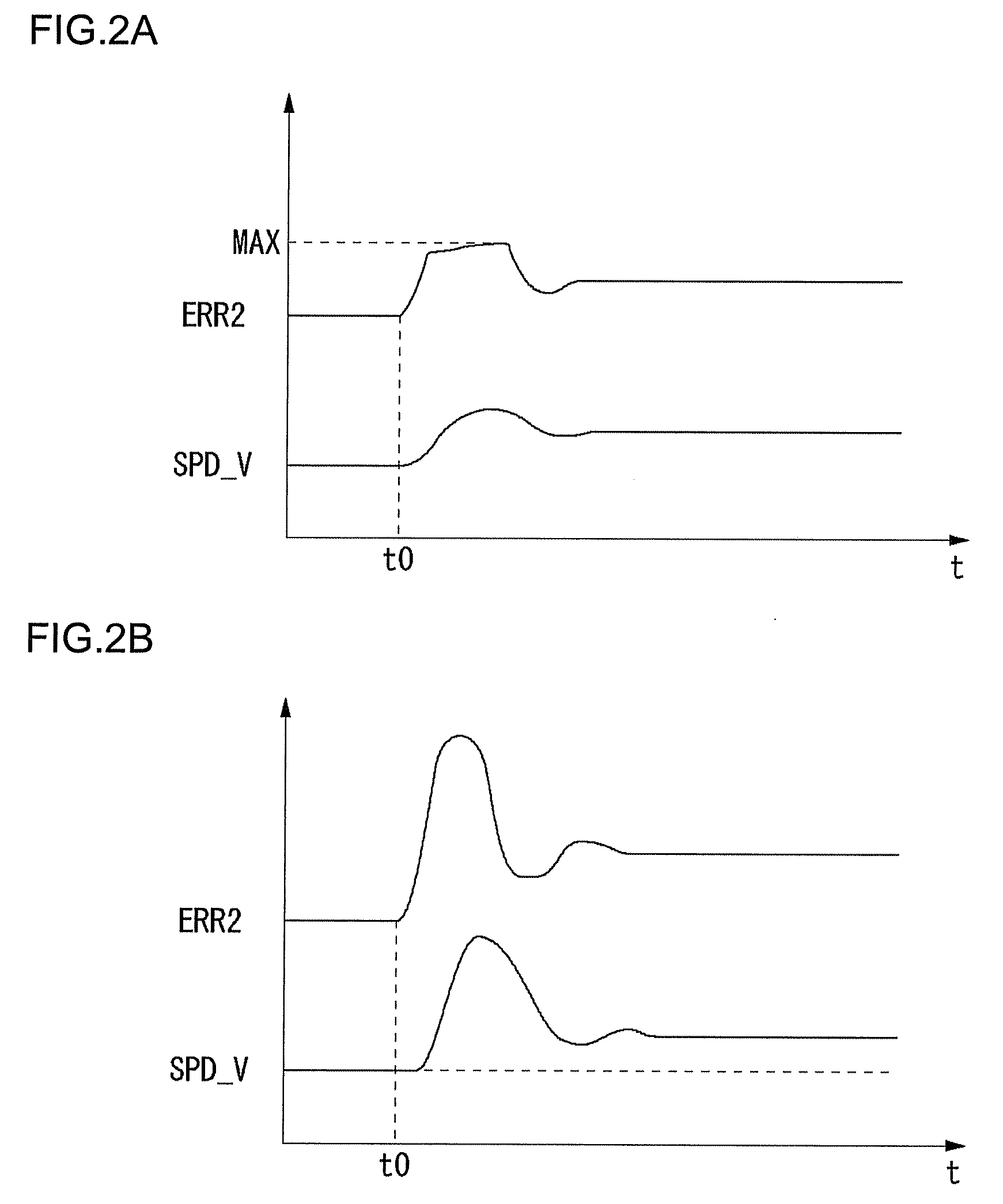

Motor driving circuit

ActiveUS20080247734A1Increase in circuit sizeImprove starting characteristicsElectric motor controlTemperatue controlMotor driveElectric machine

A motor driving circuit drives a motor on receipt of an error signal having a digital value corresponding to a deviation between a current rotation speed of the motor, which is the subject to be driven, and its target value. A digital filter eliminates a high-frequency component of the error signal. A driving unit controls an electric current flowing through the motor in accordance with the digital value of the error signal from which the high-frequency component is eliminated by the digital filter. An upper-limit value setting unit sets an upper limit value to the digital value of the error signal input to the digital filter. The upper-limit value setting unit is configured to be capable of changing the upper limit value in accordance with a setting signal from the outside.

Owner:ROHM CO LTD

Engine decompression system

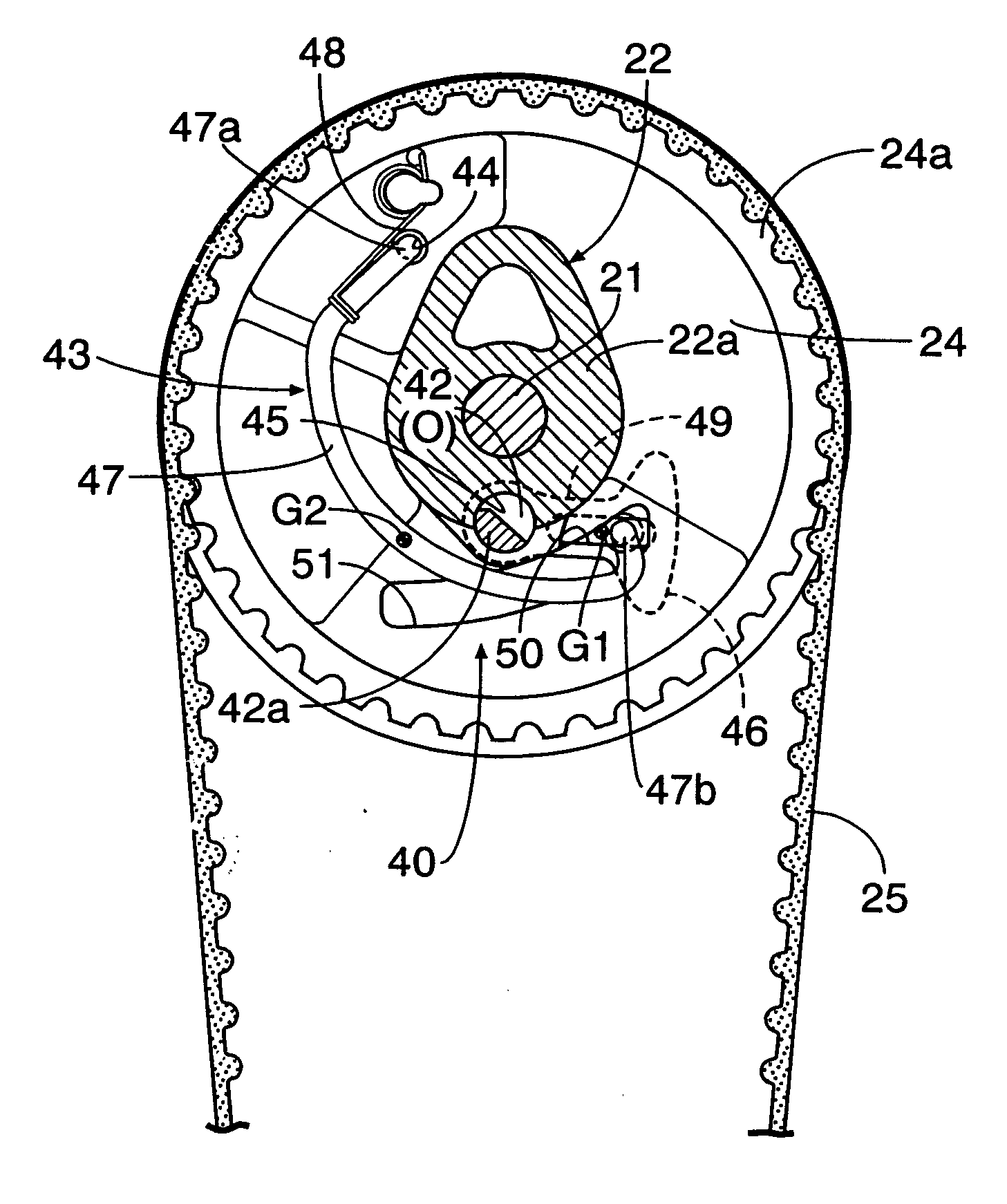

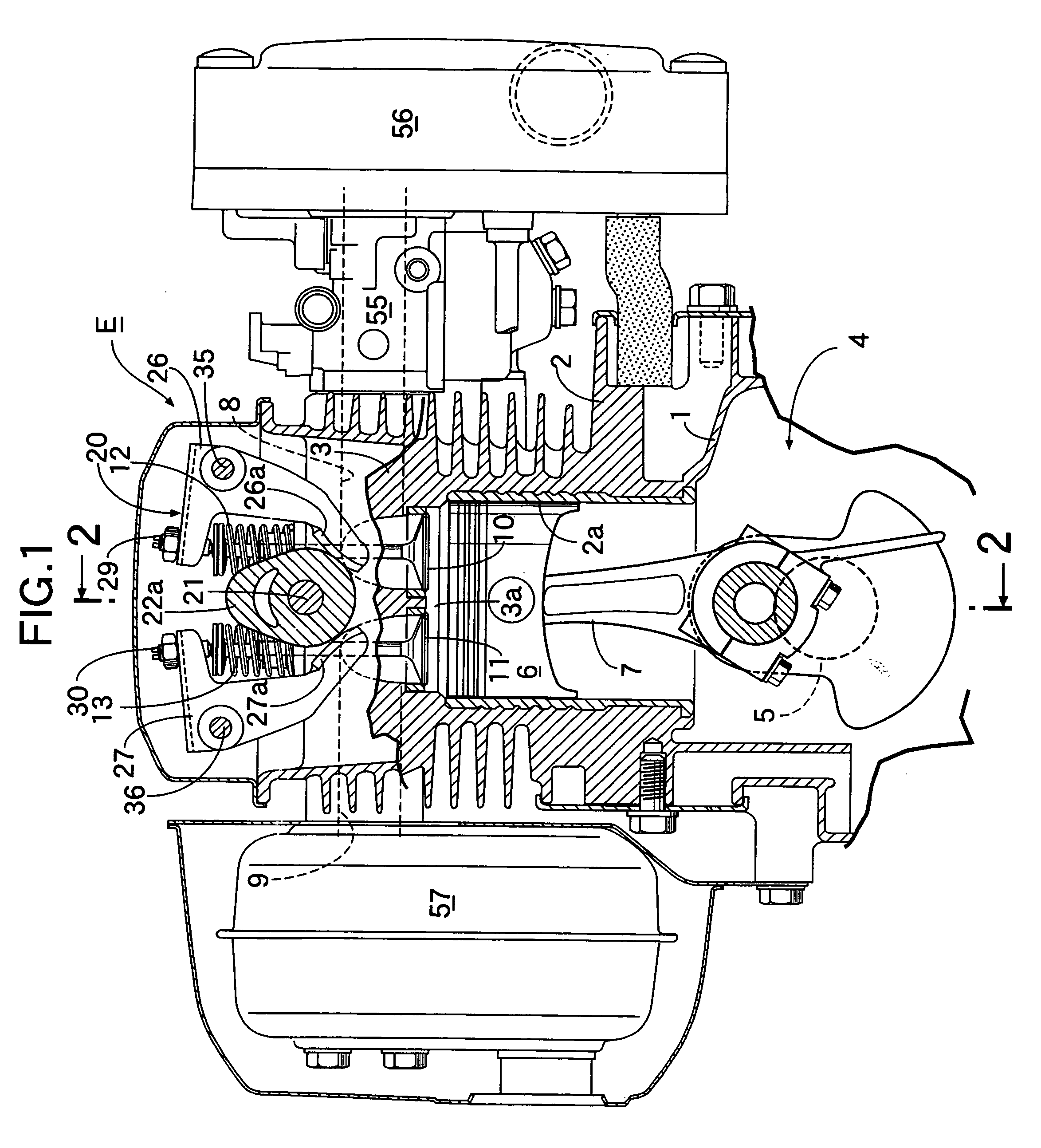

InactiveUS20060185638A1Improve starting characteristicsReduce pressureMuscle operated startersValve drivesCombustionEngineering

An engine decompression system that can secure a projecting height of a decompression cam from a base face of a valve operating cam to be relatively large in an engine starting rotational region, and maintain a state in which the projection height is decreased in a complete combustion rotational region of the engine. The decompression system includes a decompression cam shaft provided on a valve operating cam shaft or a rotating member integrally coupled thereto, the decompression cam shaft being capable of rotating between an operating position in which a decompression cam projects above a base face of a valve operating cam to slightly open engine valves during a compression stroke and a release position in which the decompression cam is withdrawn to allow the engine valves to close. A centrifugal mechanism connected to the decompression cam shaft maintains the decompression cam shaft at an operating position in a starting rotational region, and rotates the decompression cam shaft to the release position in a normal running region. The centrifugal mechanism is arranged so that, in a complete combustion rotational region between the starting rotational region and the normal running region, the decompression cam shaft is maintained at a middle position at which the projection height of the decompression cam is less than the projection height at the operating position.

Owner:HONDA MOTOR CO LTD

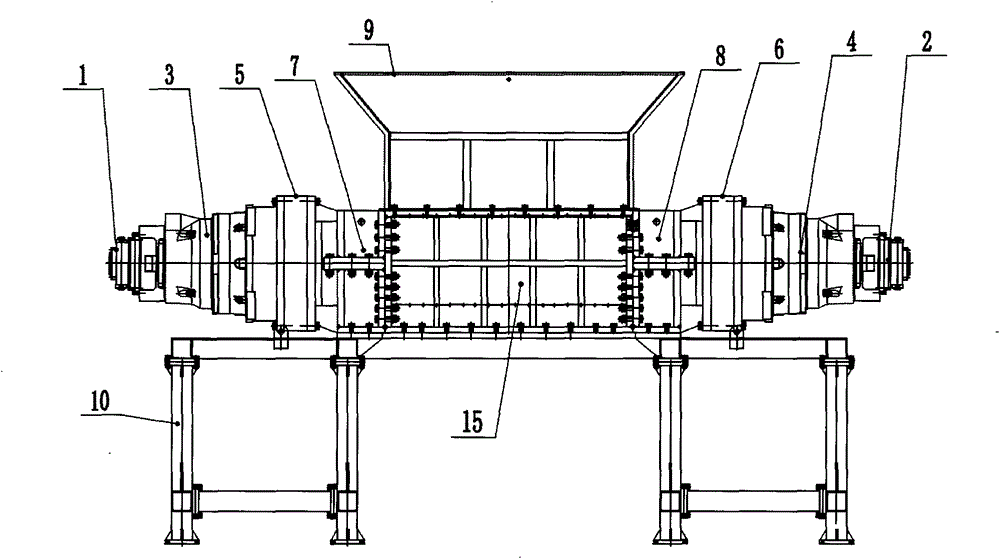

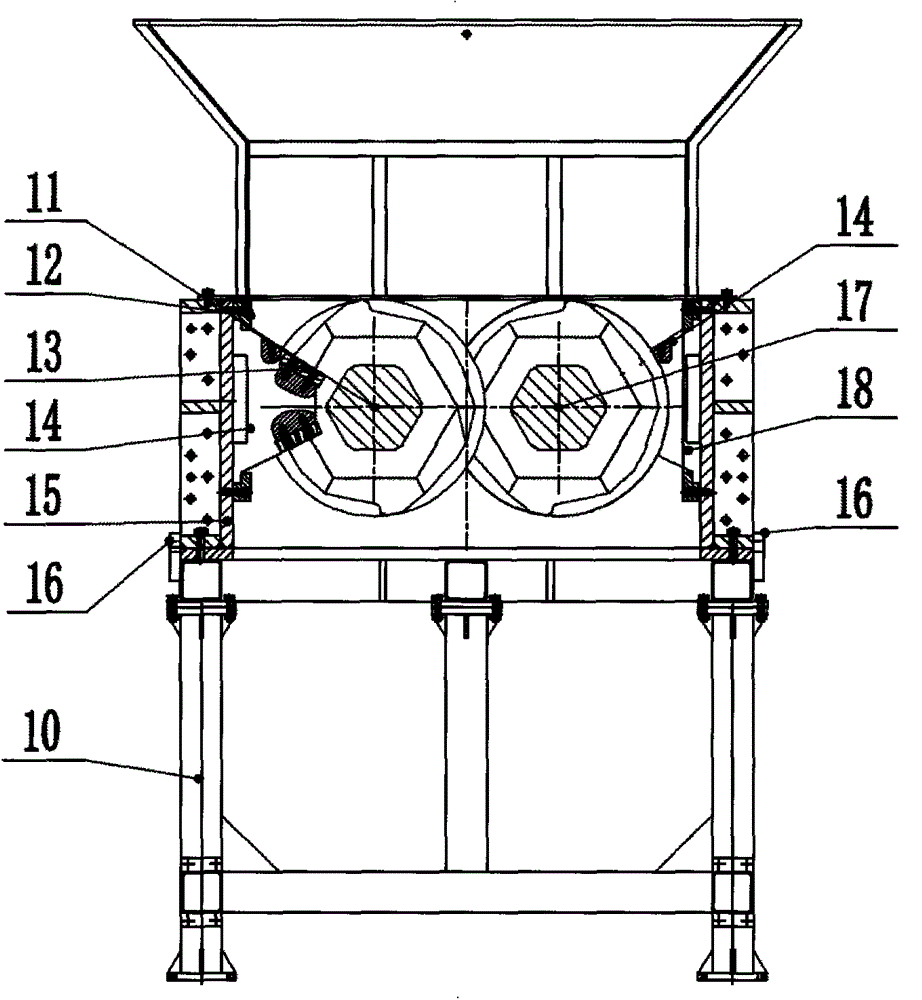

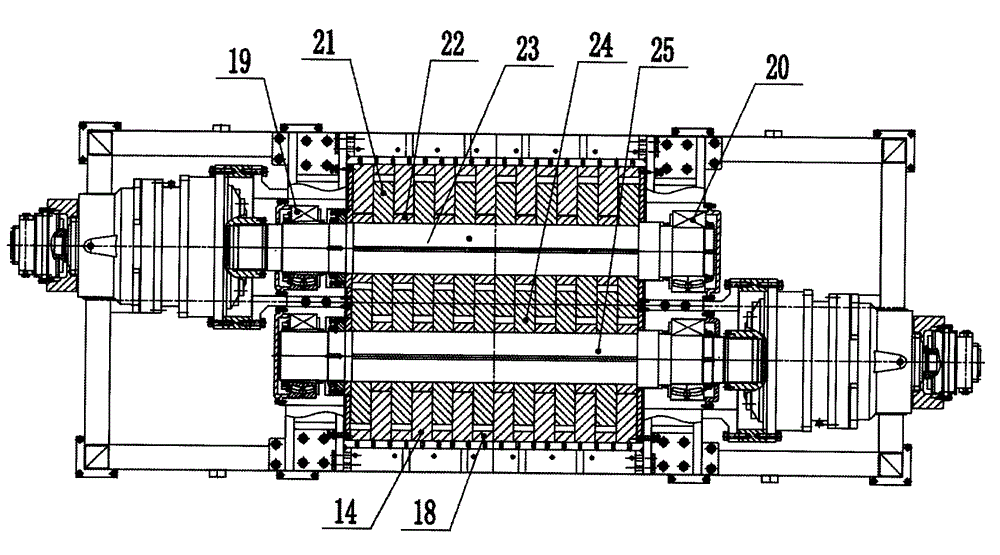

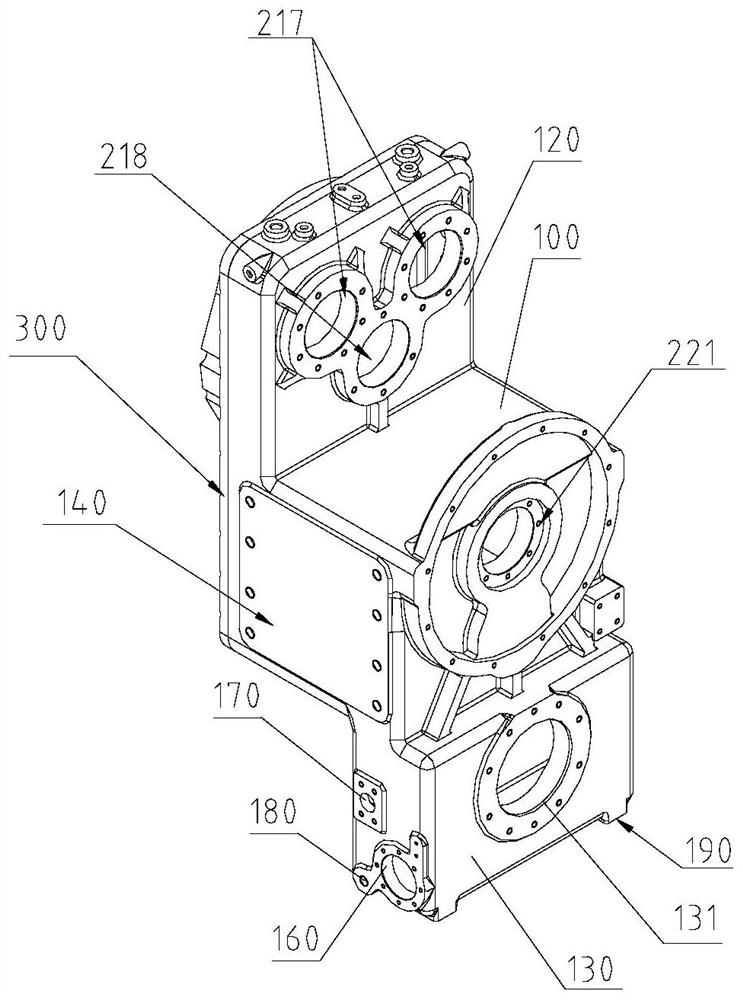

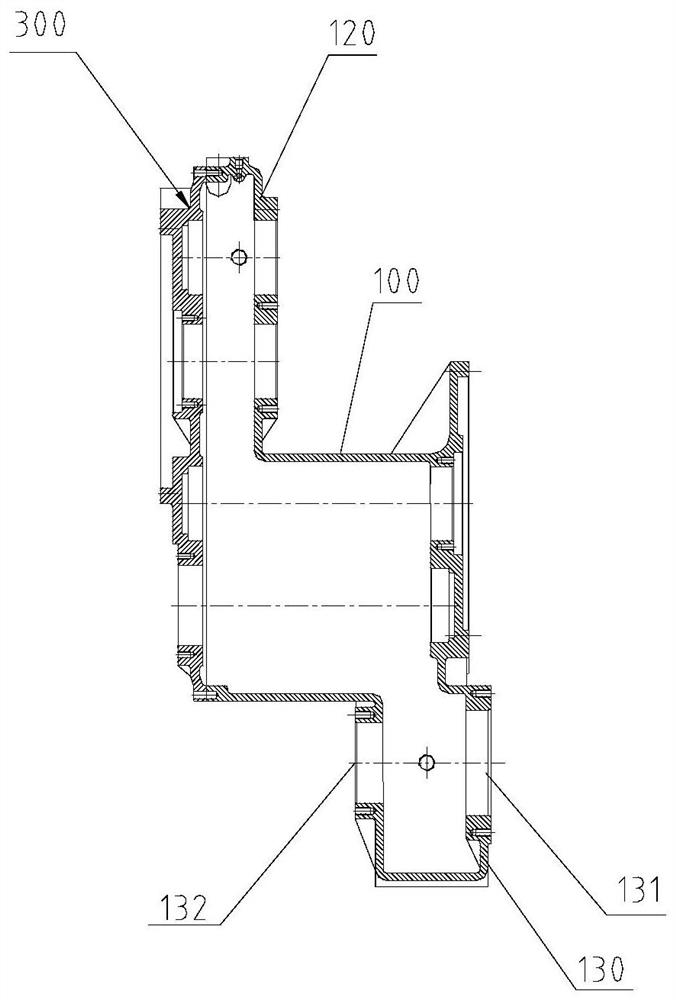

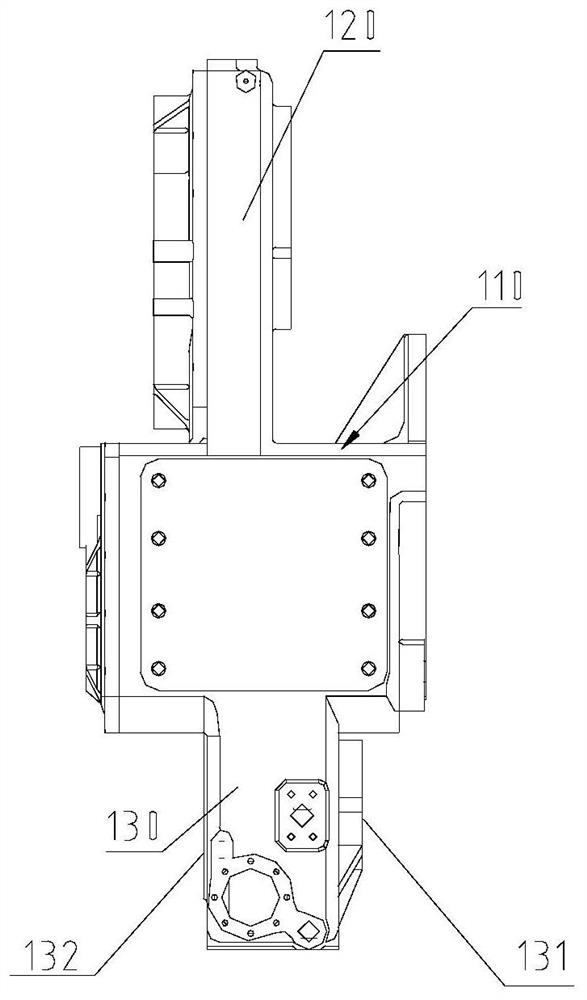

Heavy duty double-shaft scrap steel shredder

The present invention relates to a heavy duty double-shaft scrap steel shredder, which comprises a frame, a box, a material inlet hopper, a left hydraulic motor, a right hydraulic motor, a left speed reducer, a right speed reducer, a left connection flange, a right connection flange, a front cutter roller, a rear cutter roller, left bearing pedestals for arranging the front cutting roller and the right cutting roller, and right bearing pedestals for arranging the front cutting roller and the right cutting roller, wherein the box is arranged on the frame, the top portion of the box is provided with an opening, the material inlet hopper is arranged on the box opening on the top portion, the left side and the right side of the box are respectively provided with the front cutting roller left bearing pedestal, the front cutting roller right bearing pedestal, the rear cutting roller left bearing pedestal and the rear cutting roller right bearing pedestal, the front cutting roller right bearing pedestal is connected with the right flange, the rear cutting roller left bearing pedestal is connected with the left flange, the left speed reducer and the right speed reducer are respectively connected with the left hydraulic motor and the right hydraulic motor, the front cutter roller is arranged on the front cutting roller left bearing pedestal and the front cutting roller right bearing pedestal, the front cutter roller and the rear cutter roller are connected on the left speed reducer and the right speed reducer, and the front cutter roller and the rear cutter roller are provided with a front shaft cutter for shredding the material and a rear shaft cutter for shredding the material. The heavy duty double-shaft scrap steel shredder has advantages of low rotation speed, low noise, high torque, strong medium-thick steel plate shredding ability, low energy consumption, safety, reliability and the like, and can used for batch and mechanized scrap steel material treatment.

Owner:GUANGZHOU 3E MACHINERY

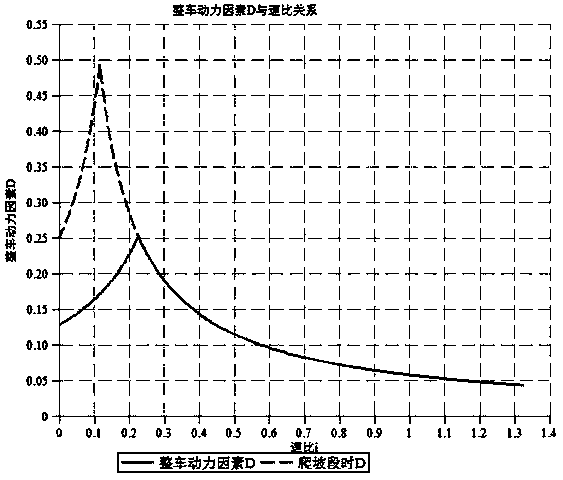

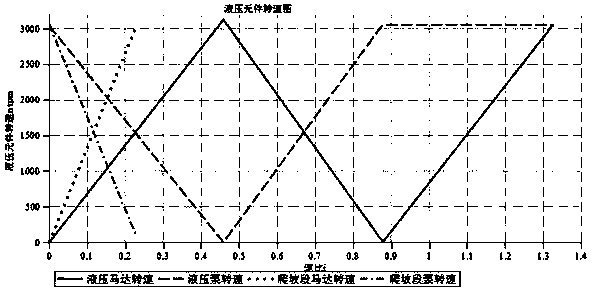

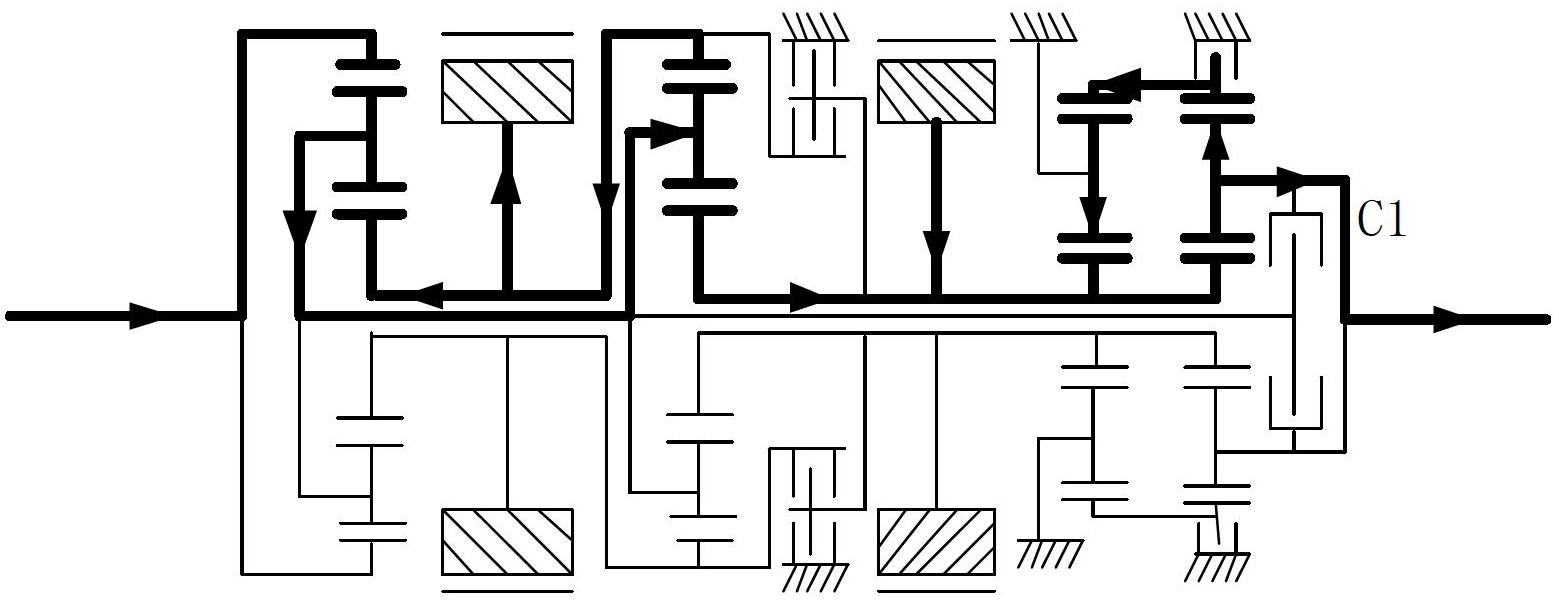

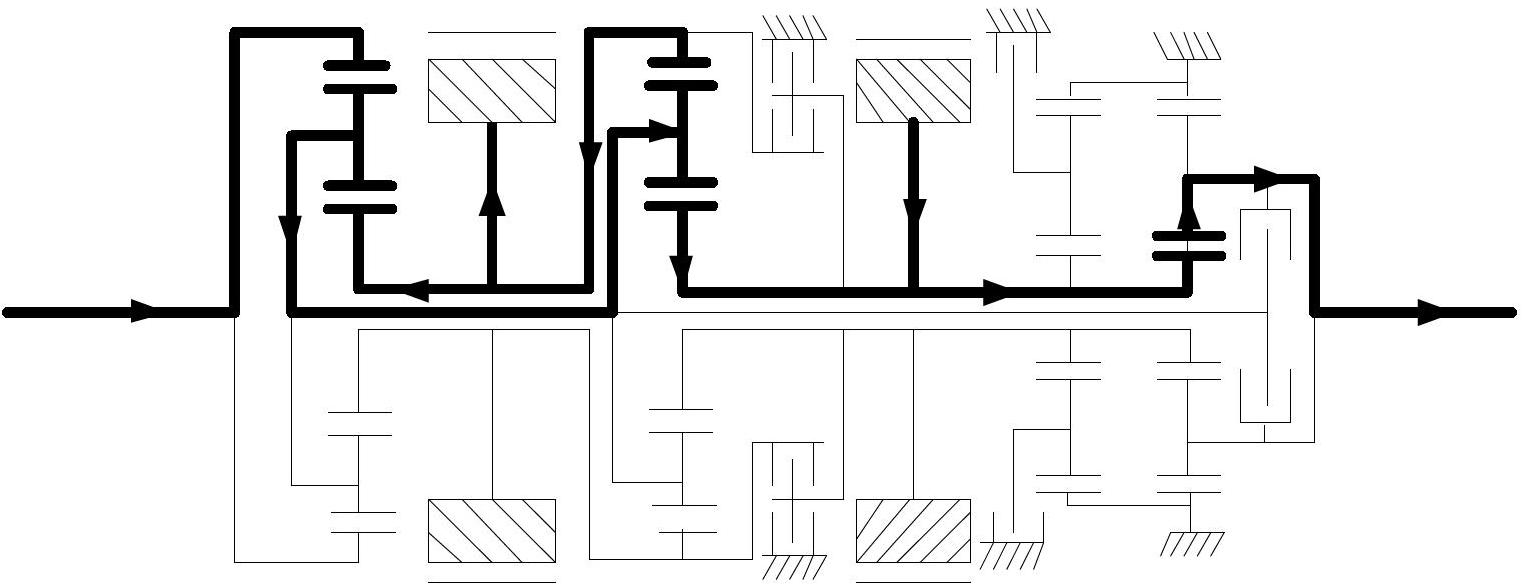

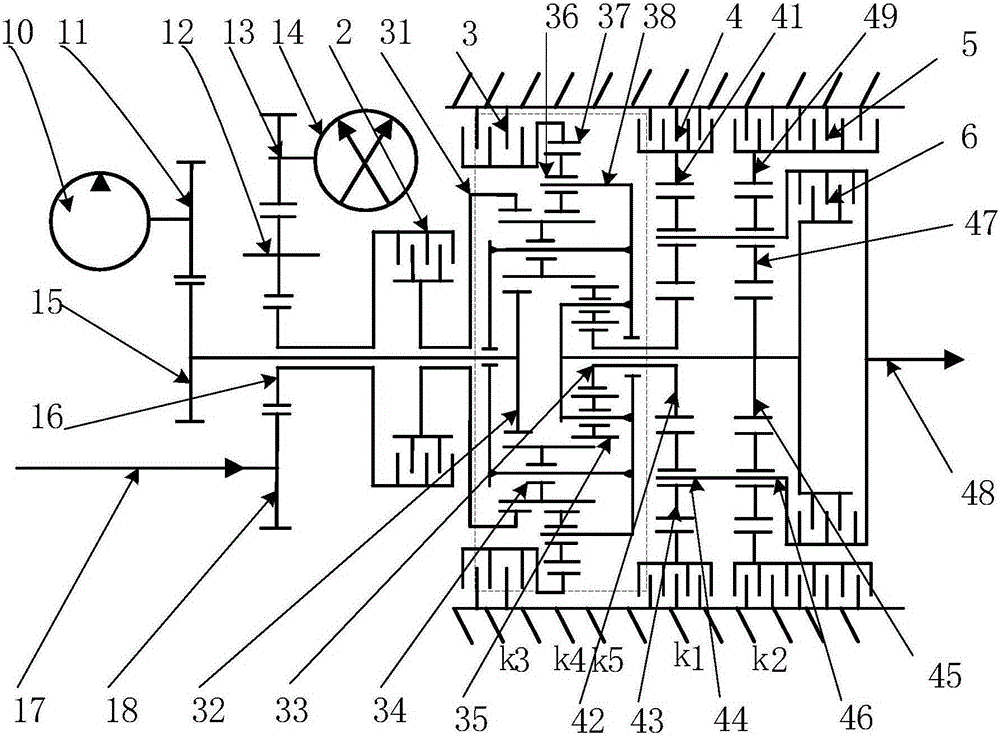

Four-segment hydraulic mechanical composite transmission device

ActiveCN103453104ASimple structureGreat tractionFluid gearingsElectric power transmissionHydraulic machinery

The invention belongs to the technical field of power transmission, in particular to a stepless transmission device. According to the technical scheme, a four-segment hydraulic mechanical composite transmission device comprises an input shaft, an output shaft, a planetary transmission component, a fixed shaft gear transmission component, a hydraulic speed regulating component, a segment-change operating component and an idler. One Lavina planetary mechanism is adopted as foundation, a multi-shaft fixed shaft gear and a synchronizer are utilized completely, three shunt modes of different-speed integrated torque, different-speed integrated speed and different-torque integrated speed are engaged reasonably, a four-segment continuous stepless speed change transmission structure, and the four-segment hydraulic mechanical composite transmission device has the advantages of simple structure, small size and the like; furthermore, by the aid of the four-segment hydraulic mechanical composite transmission device, purely mechanical transmission conditions of reverse gear and six fixed gears can be realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

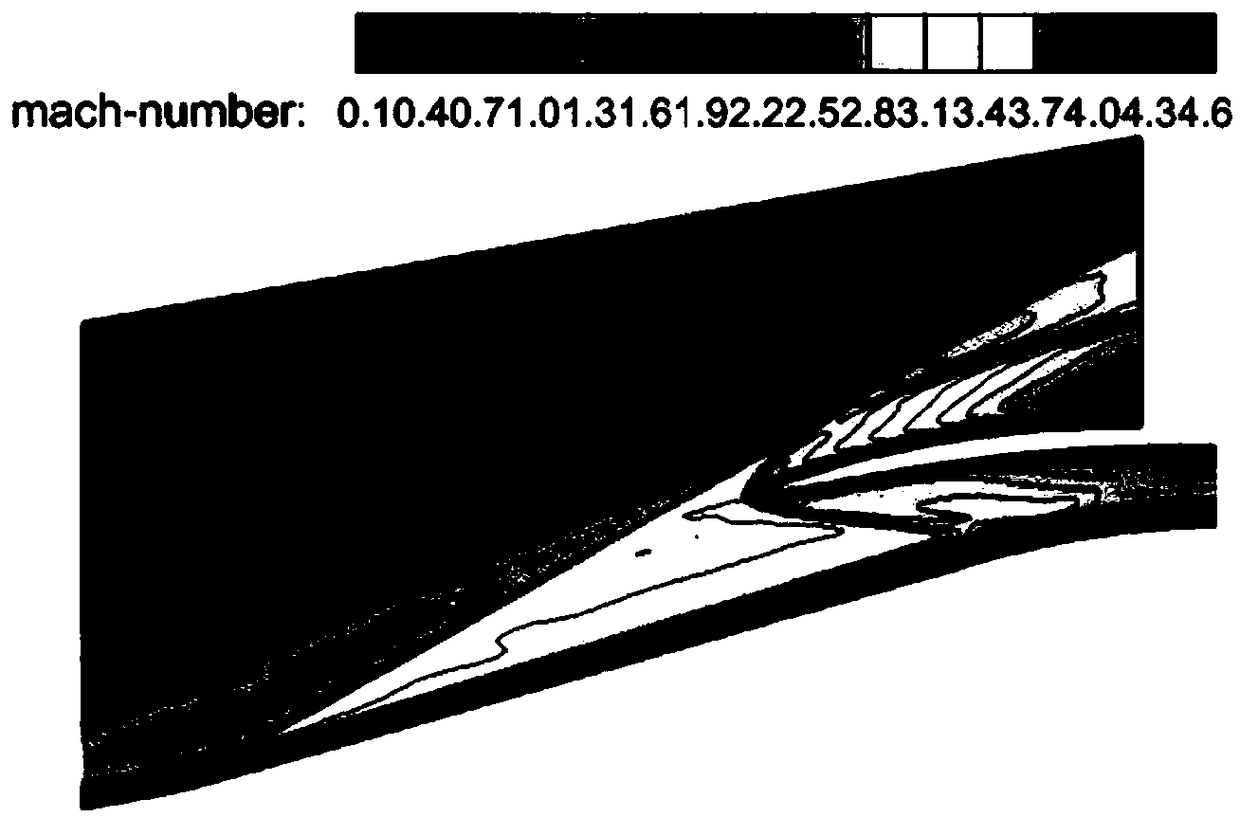

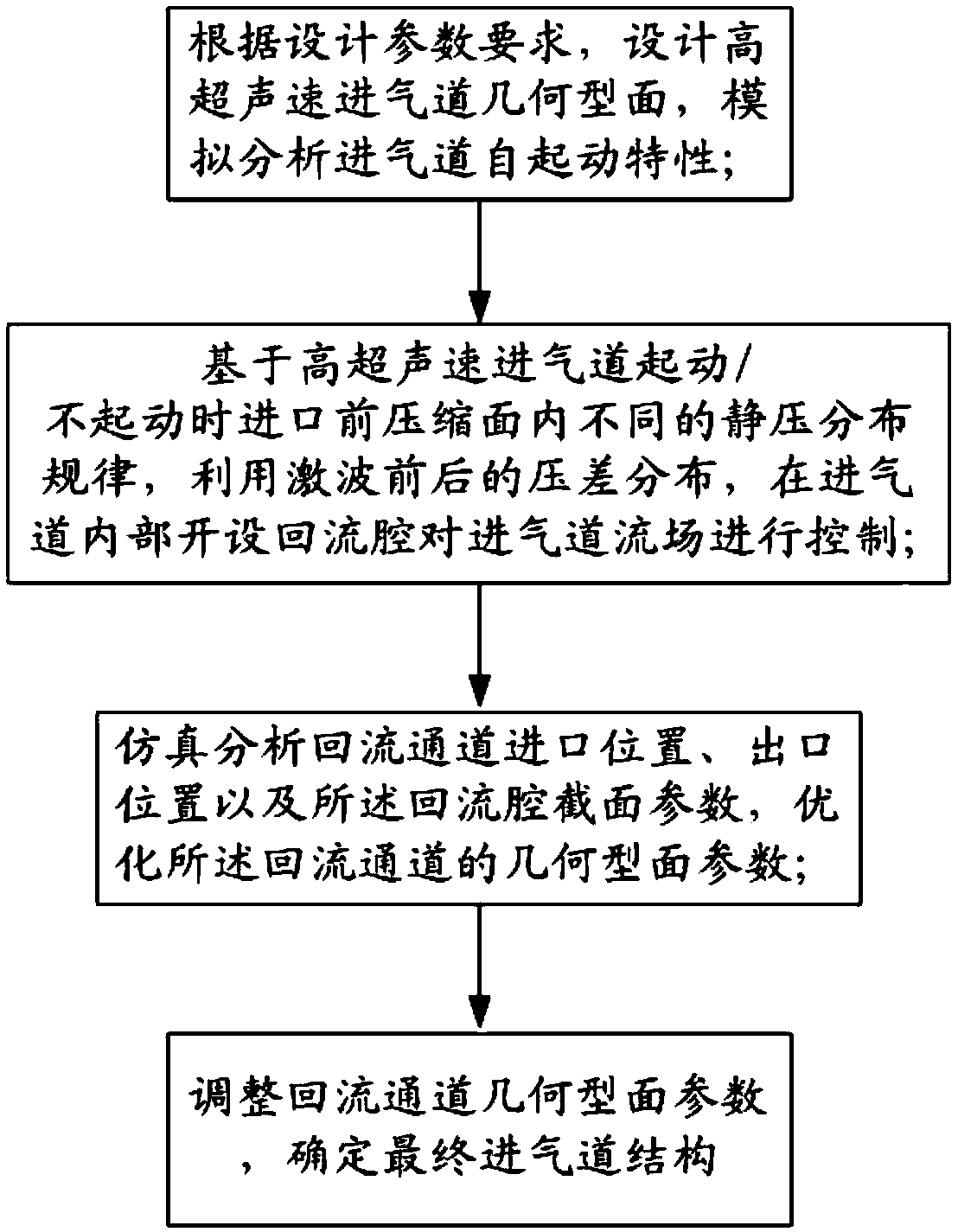

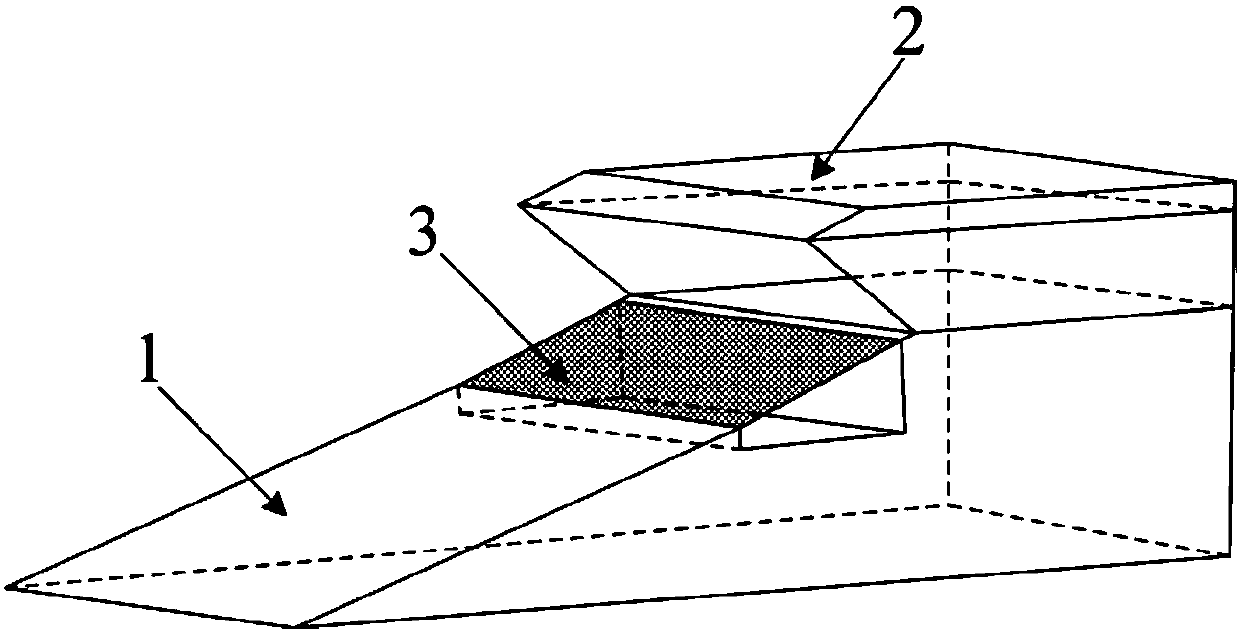

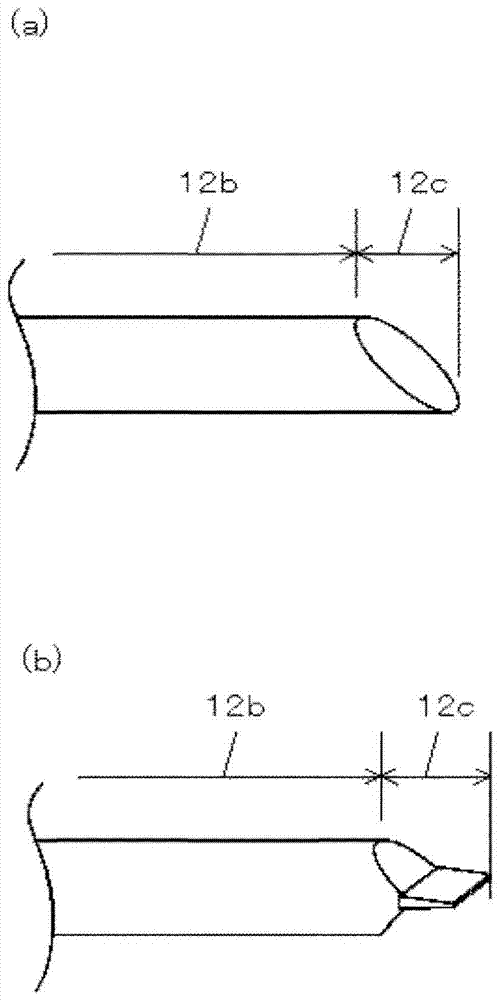

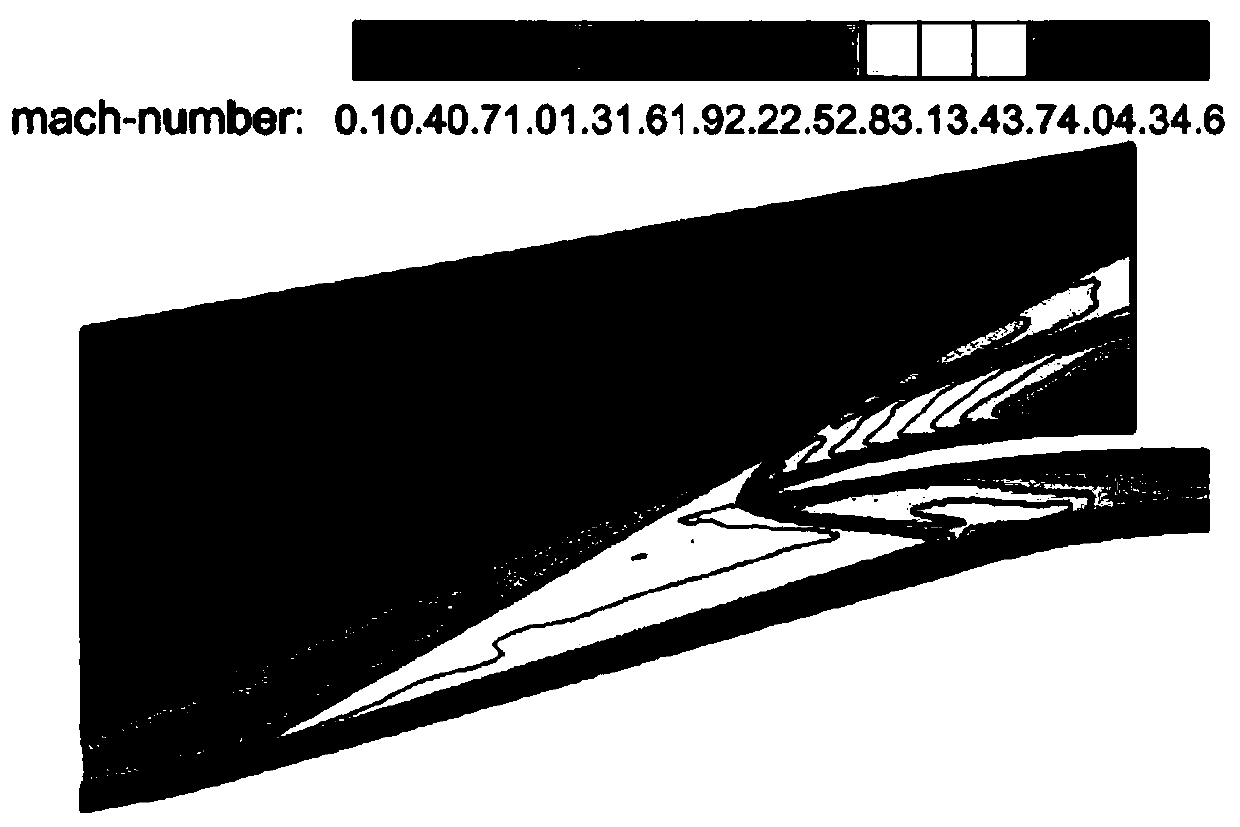

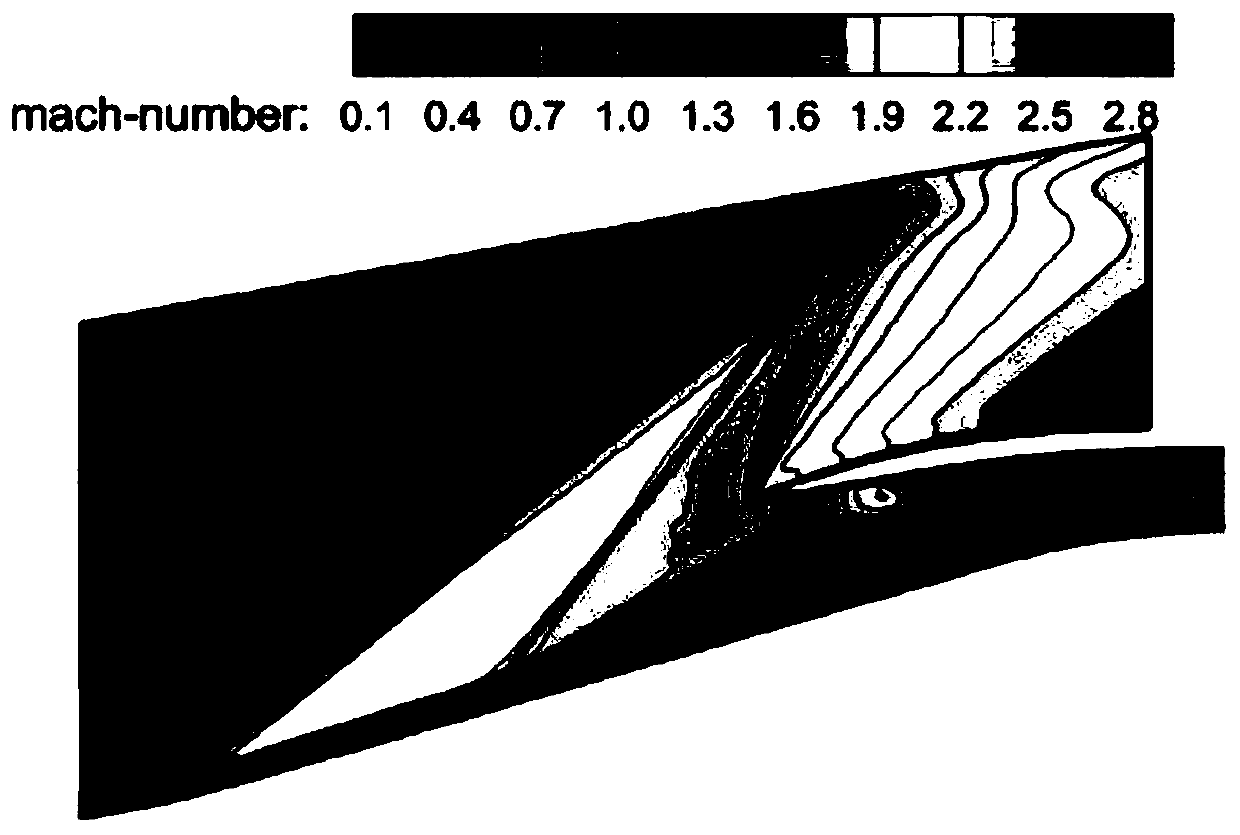

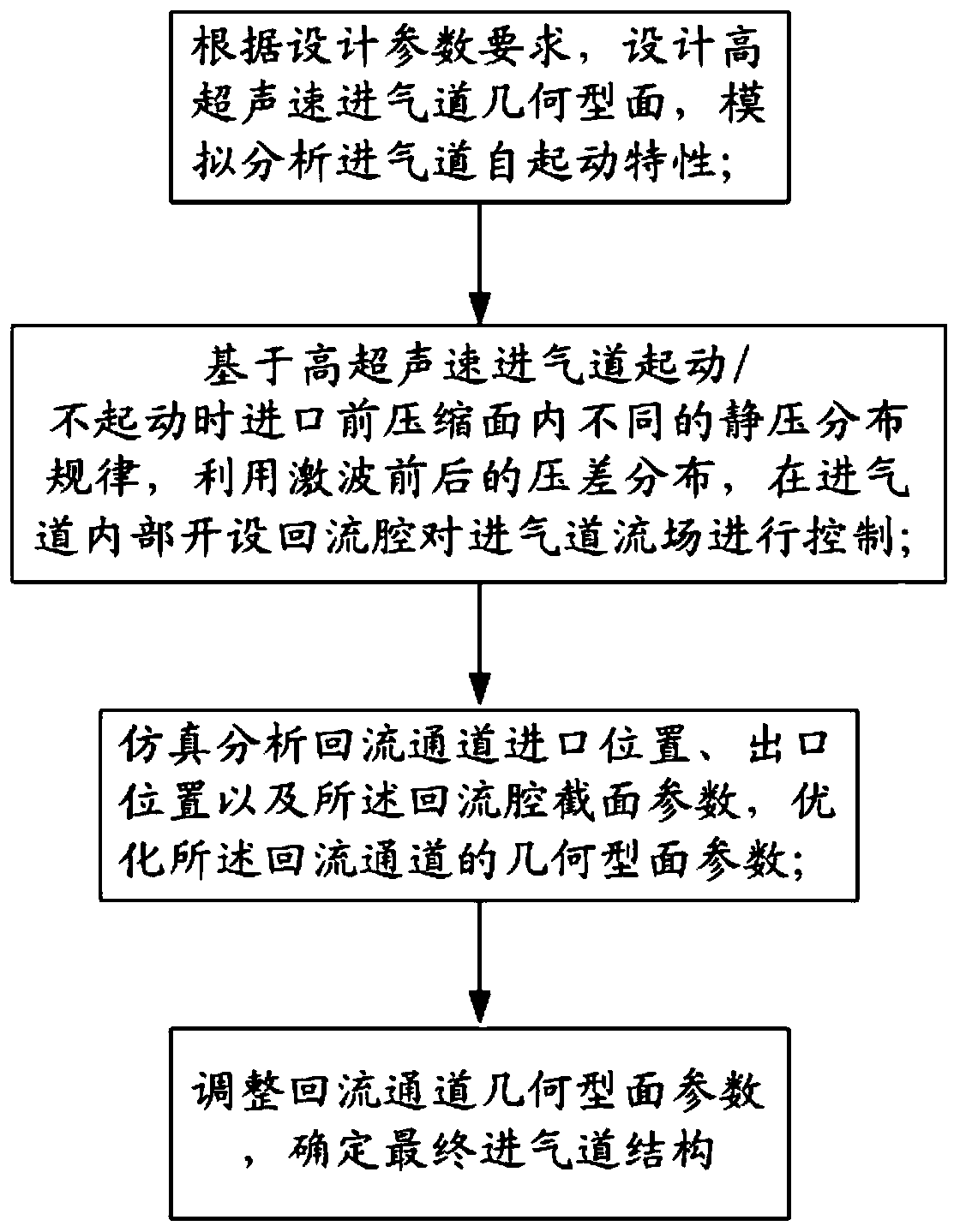

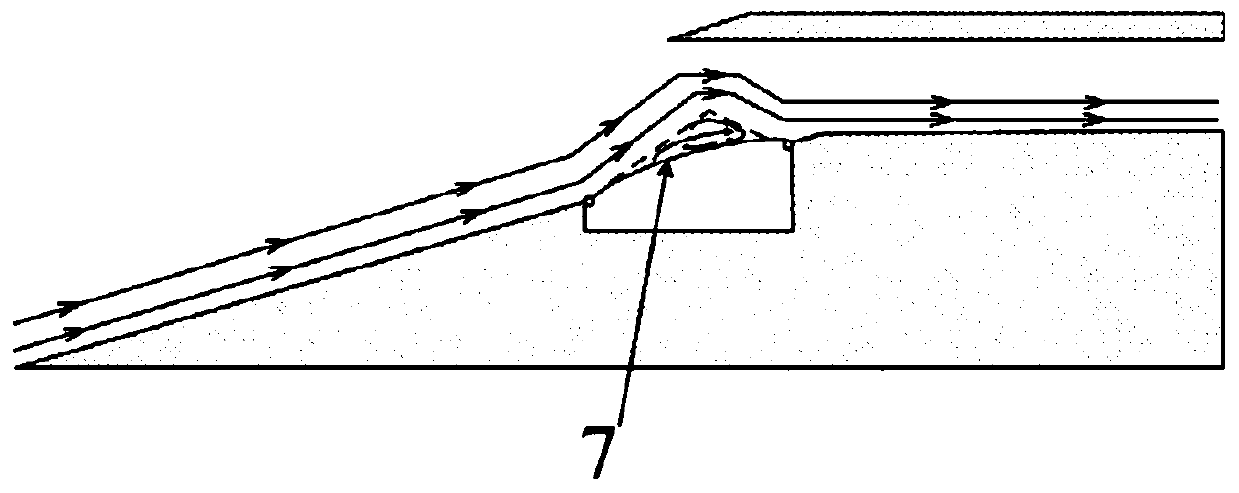

Closed type return flow channel flow field control method

ActiveCN109356723AImprove starting characteristicsReduce the starting Mach numberSustainable transportationEngine fuctionsShock waveAirway structure

The invention relates to a closed type return flow channel flow field control method. The closed type return flow channel flow field control method is characterized by comprising the following steps that a, according to design parameter requirements, a hypersonic air inlet duct geometric profile is designed, and the air inlet duct self-starting characteristics are simulated and analyzed; b, basedon different static pressure distribution laws in a compression surface before an inlet of a hypersonic air inlet duct during start / non-start, the pressure difference distribution before and after a shock wave is adopted, and a return flow cavity is formed in the air inlet duct to control a flow field of the air inlet duct; c, the inlet and outlet positions of a return flow channel and cross-sectional parameters of the return flow cavity are subjected to simulated analysis, and the geometric profile parameters of the return flow channel are optimized; and d, the geometric profile parameters ofthe return flow channel are adjusted to determine a final air inlet duct structure. The closed type return flow channel flow field control method can improve the starting ability of the hypersonic air inlet duct at a low Mach number and broadens the range of the working Mach number of the air inlet duct.

Owner:BEIJING SPACE TECH RES & TEST CENT

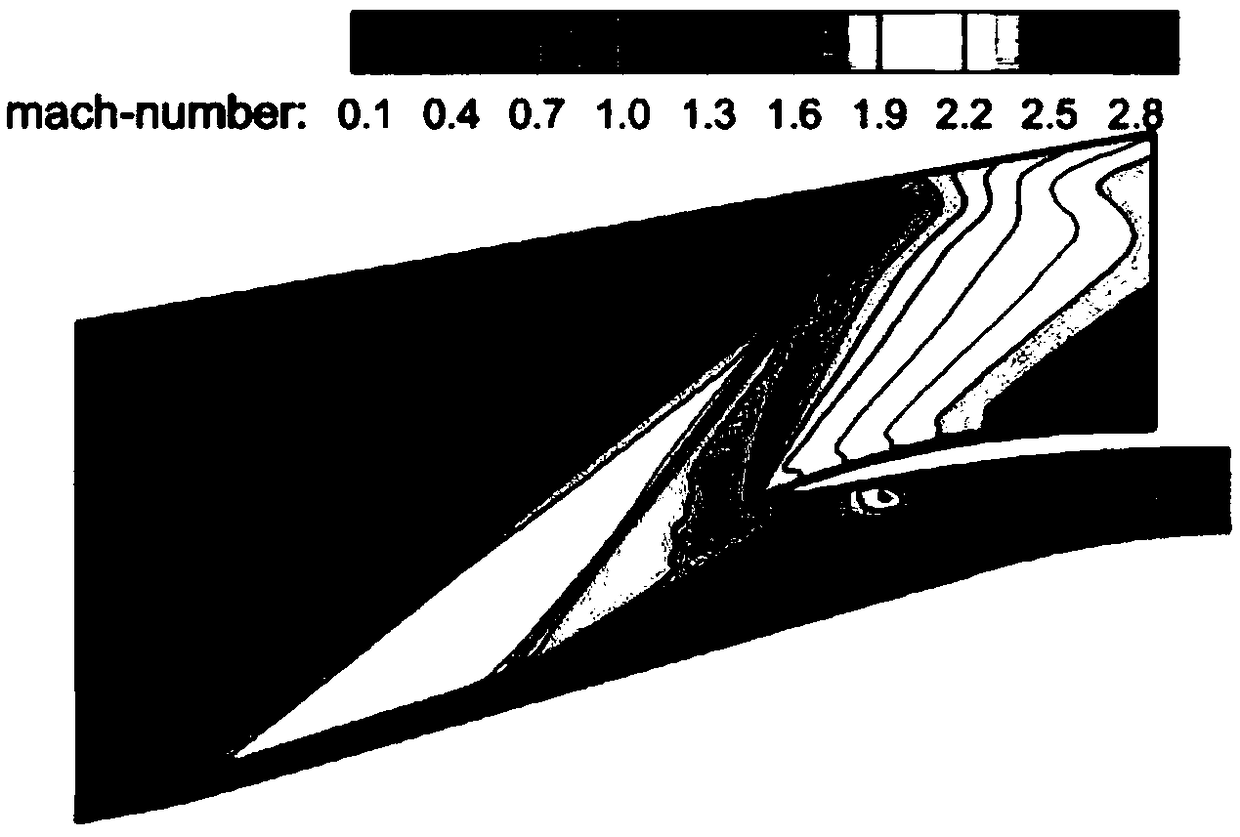

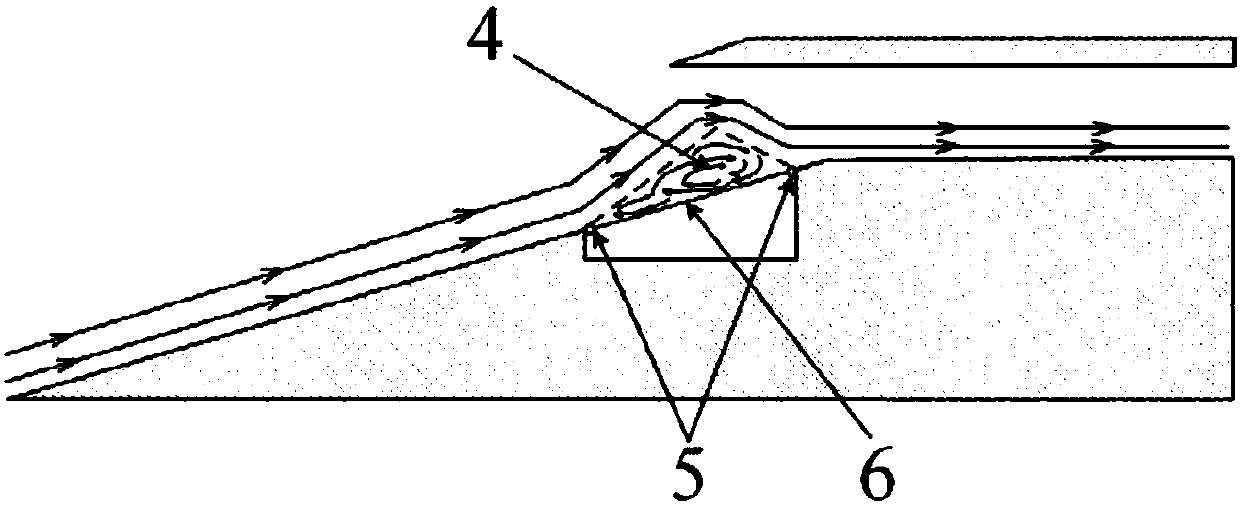

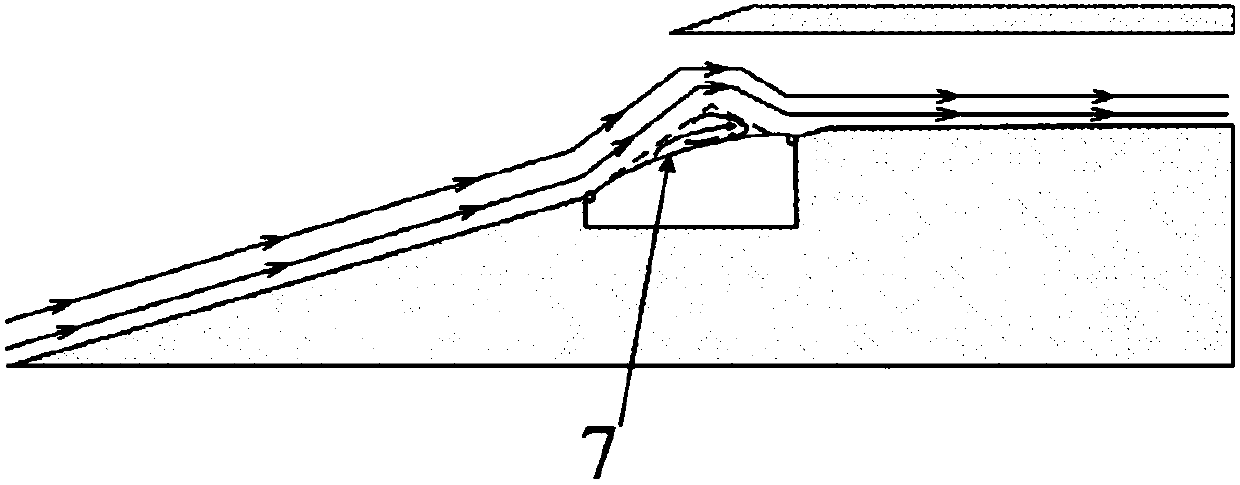

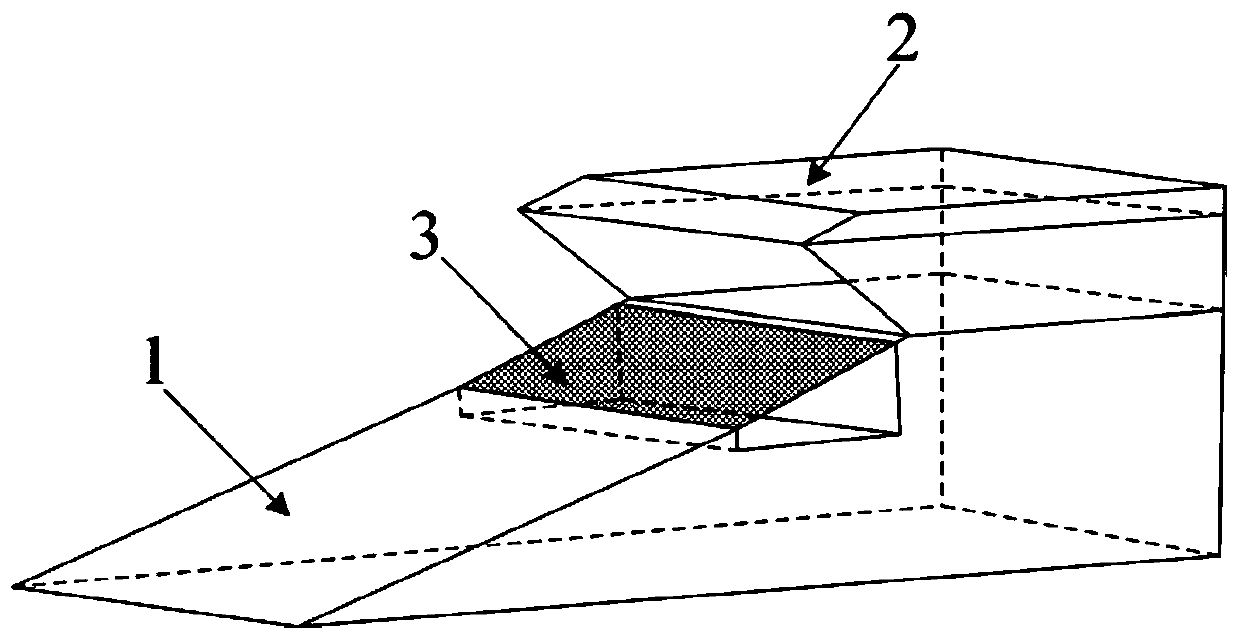

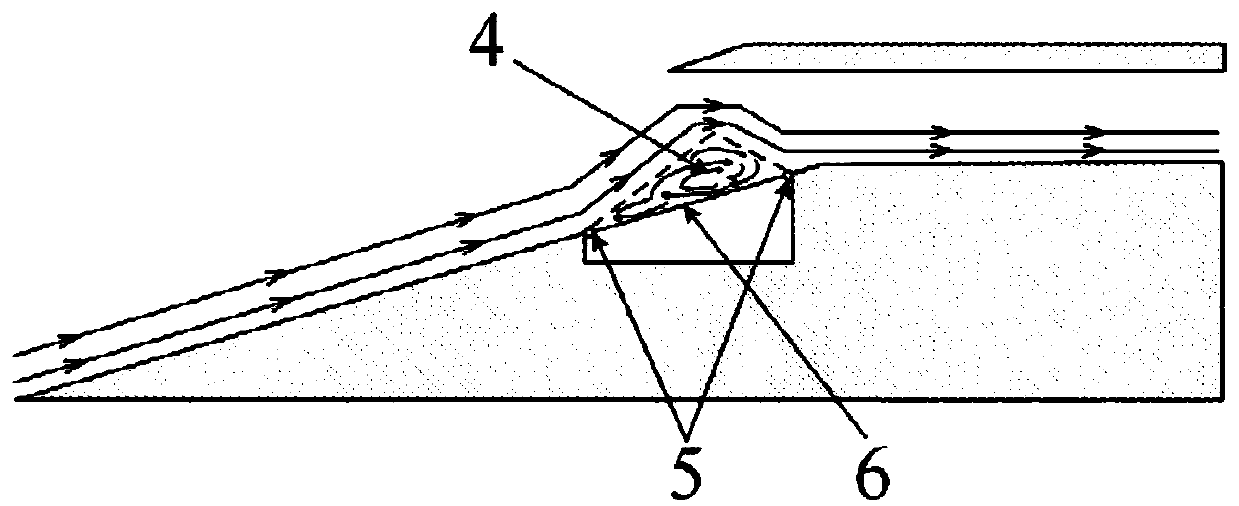

Flow control method capable of improving starting performance of inlet by use of flexible wall surface

ActiveCN107701314AImprove starting characteristicsSimple structureGas turbine plantsRam jet enginesRamjetEngineering

The invention discloses a flow control method capable of improving starting performance of an inlet by use of a flexible wall surface and relates to a ramjet engine inlet. Type selection of a flexiblematerial is determined according to fluidity pressure oscillation frequency and amplitude when the inlet is not started; the size of the flexible wall surface is determined according to the size of an air flow separation area at the compression section inlet when the inlet is not started; the initial mounting position of the flexible wall surface is determined according to the initial position ofthe air flow separation area. When the inlet is not started, fluidity pressure is periodically oscillated, the flexible wall surface is driven to produce tiny oscillation, so that the oscillation flow field energy is transferred and dissipated toward the flexible wall surface, flow field oscillation is inhibited, and the purpose of improving the starting characteristic of the supersonic speed inlet is achieved. The flow field oscillation is inhibited through oscillation of the flexible wall surface with the flow field, and the starting characteristic of the supersonic speed inlet can be improved; the structure is simple, the control effect is remarkable, and the engineering application potential is high.

Owner:XIAMEN UNIV

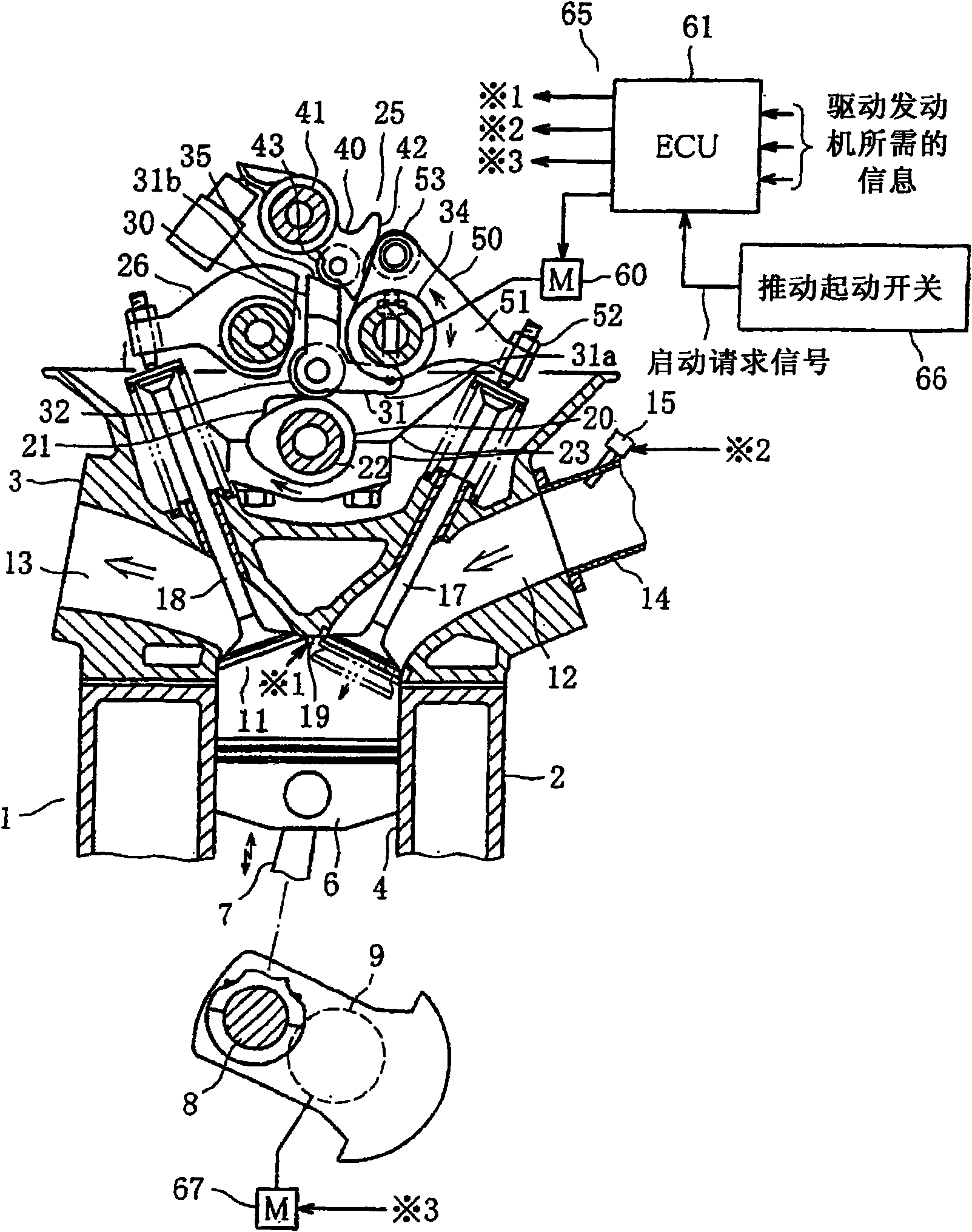

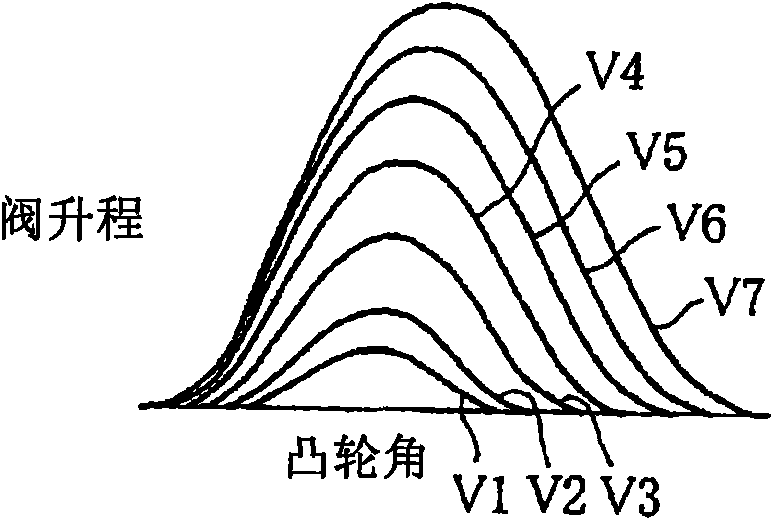

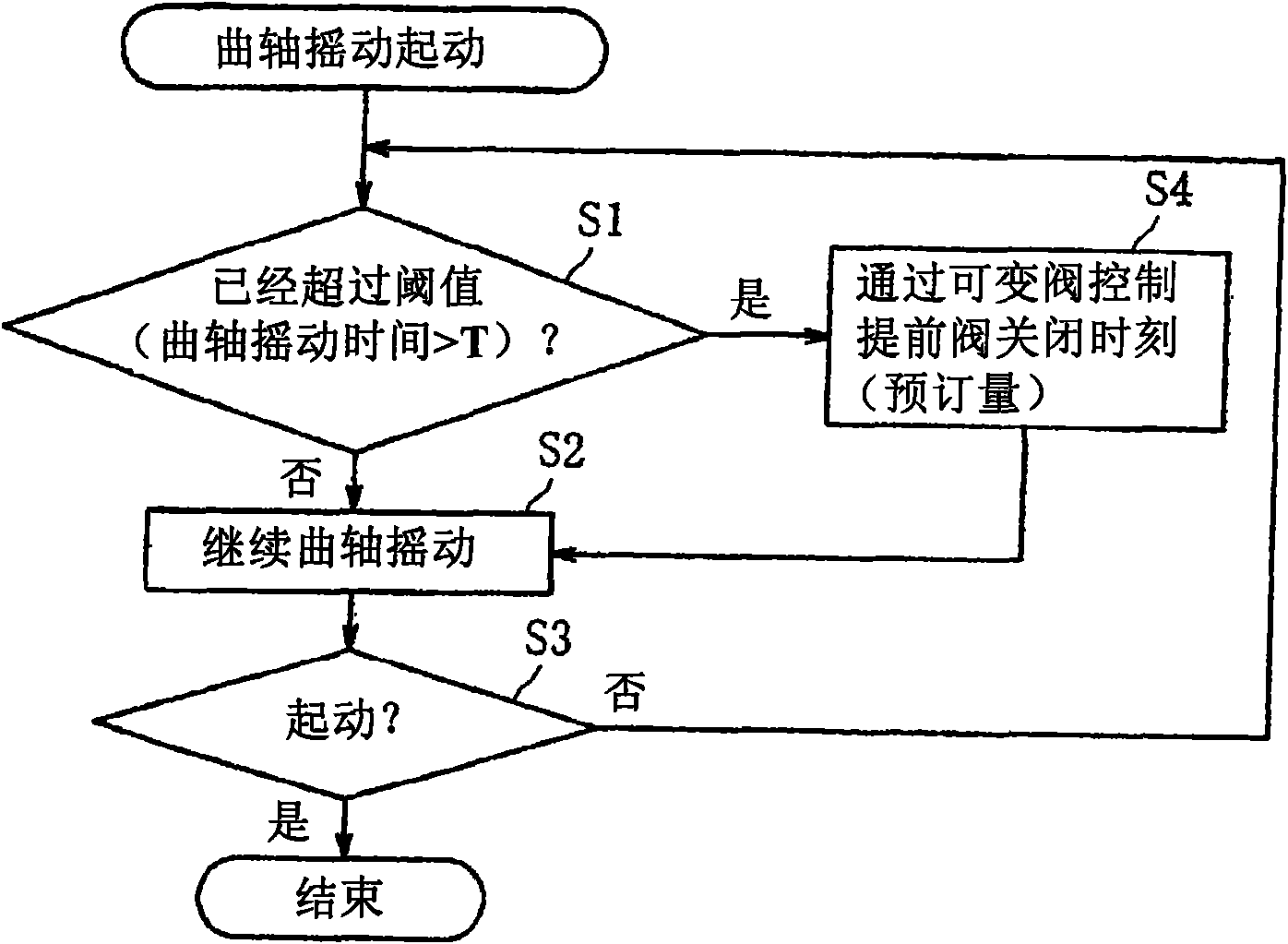

Start control device of internal combustion engine

ActiveCN101619678AImprove starting characteristicsReliable startElectrical controlInternal combustion piston enginesExternal combustion engineInlet valve

A start control device of an internal combustion engine, the start control device includes: a starting unit, which cranks the internal combustion engine to start the internal combustion engine while opening and closing an intake valve; a variable valve mechanism, which can change a closing timing of the intake valve; and a control unit, which controls the variable valve mechanism so as to advancethe closing timing of the intake valve while the starting unit cranks.

Owner:MITSUBISHI MOTORS CORP

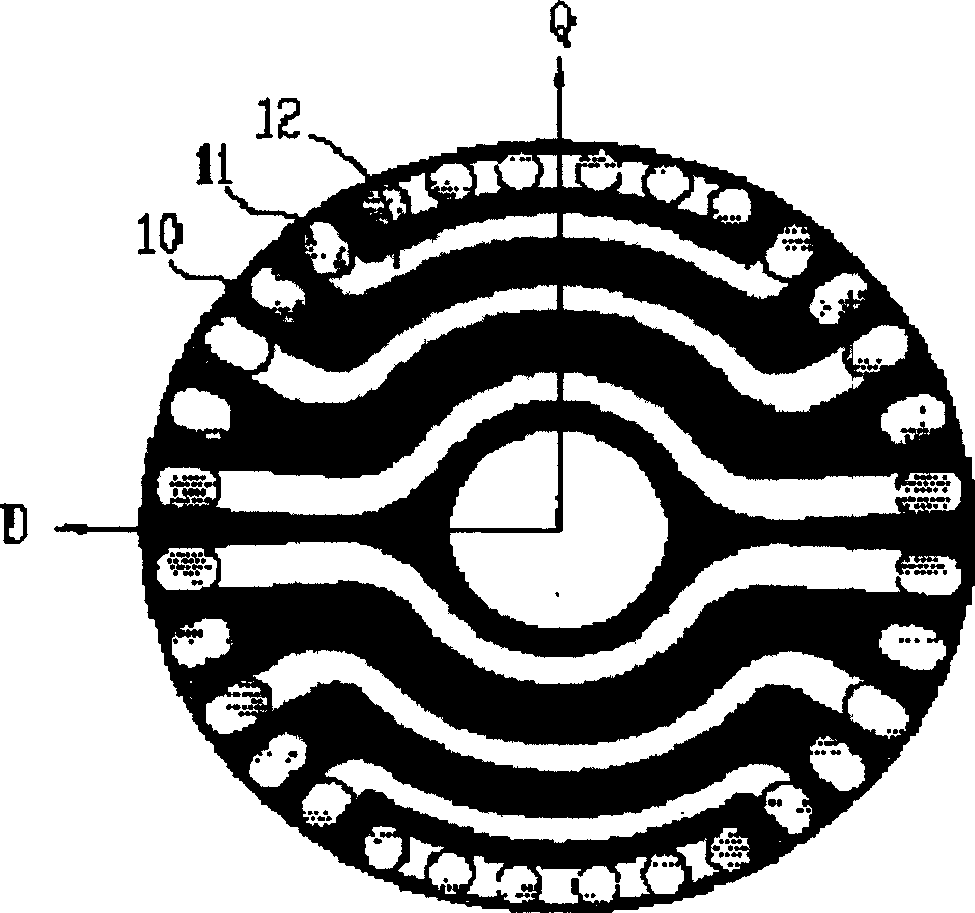

Rotor of synchronous magneto resistance motor

InactiveCN1533011AImprove starting characteristicsImprove trustworthinessMagnetic circuit rotating partsSynchronous motorsMagnetic lineEngineering

This invention discloses a rotor of a synchronous reluctance machine including a core, several conducting rods inserted into the outer cycle of the core in uniform space and several blocking plates plugging into the core divided into two symmetrical groups around the shaft-center. The said conducting rods includes: the conducting rods inserting into the outer cycle of the core and connecting with the ends of the blocking plates and deep-inserting rods inserting but not connecting with their ends, the outer surfaces of the rods are just aligned with the peripheral face of the core and the deep-inserting rods deep in the peripheral face of the core forming a certain distance between the two outer surfaces.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

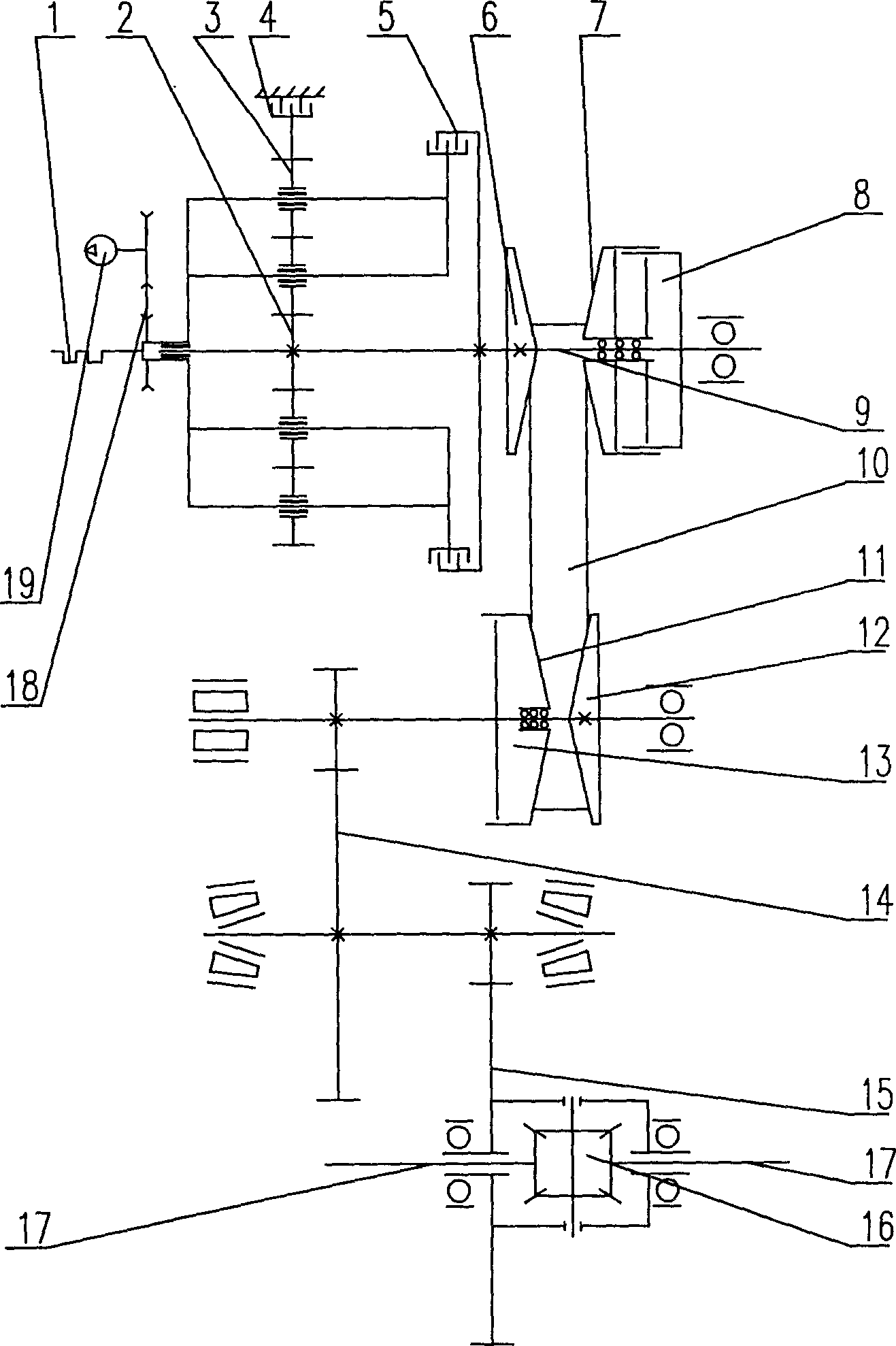

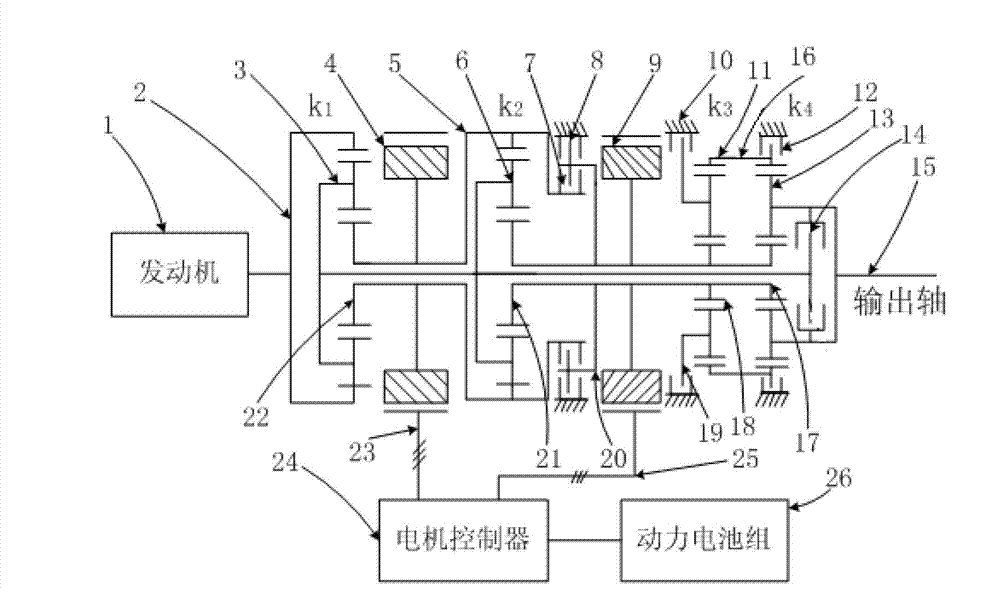

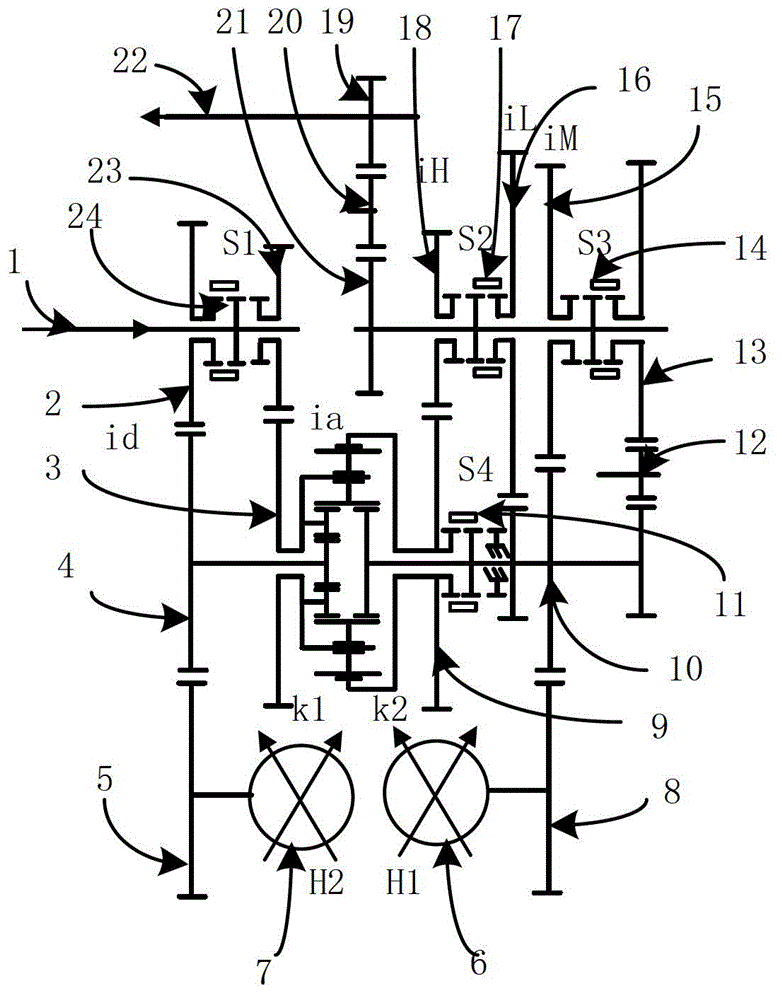

Three-section-type electromechanical composite stepless transmission device for wheel-type load-carrying vehicle

InactiveCN102661369AImprove powerRealize stepless speed changeToothed gearingsPower batteryElectric machine

The invention belongs to the technical field of power transmission, and relates to an stepless transmission device, and in particular relates to a three-section-type electromechanical composite stepless transmission device for a wheel-type load-carrying vehicle, which comprises an engine, a k1 planet line, a k2 planet line, a k3 planet line, a k4 planet line, a motor a, a cable of the motor a, a motor, a braking construction member of the motor b, a cable of the motor b, a clutch a, a clutch b, a brake a, a brake b, a brake c, an energy and power output shaft, a motor controller and a power battery pack. Two planet lines are utilized for constructing two kinds of flow dividing modes, additionally, two planet lines are utilized to construct two different speed reduction ratios, and a three-section-type electromechanical composite stepless transmission device is formed by utilizing the switching mode of clutches or brakes, the stepless speed variation in a lager range is realized, and the structure is simple; and a differential exchange moment flow dividing mode is adopted for a starting stage, the three-section-type electromechanical composite stepless transmission device for the wheel-type load-carrying vehicle has zero-speed output and better starting property, clutches are not required to be started, and the starting performance is good.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

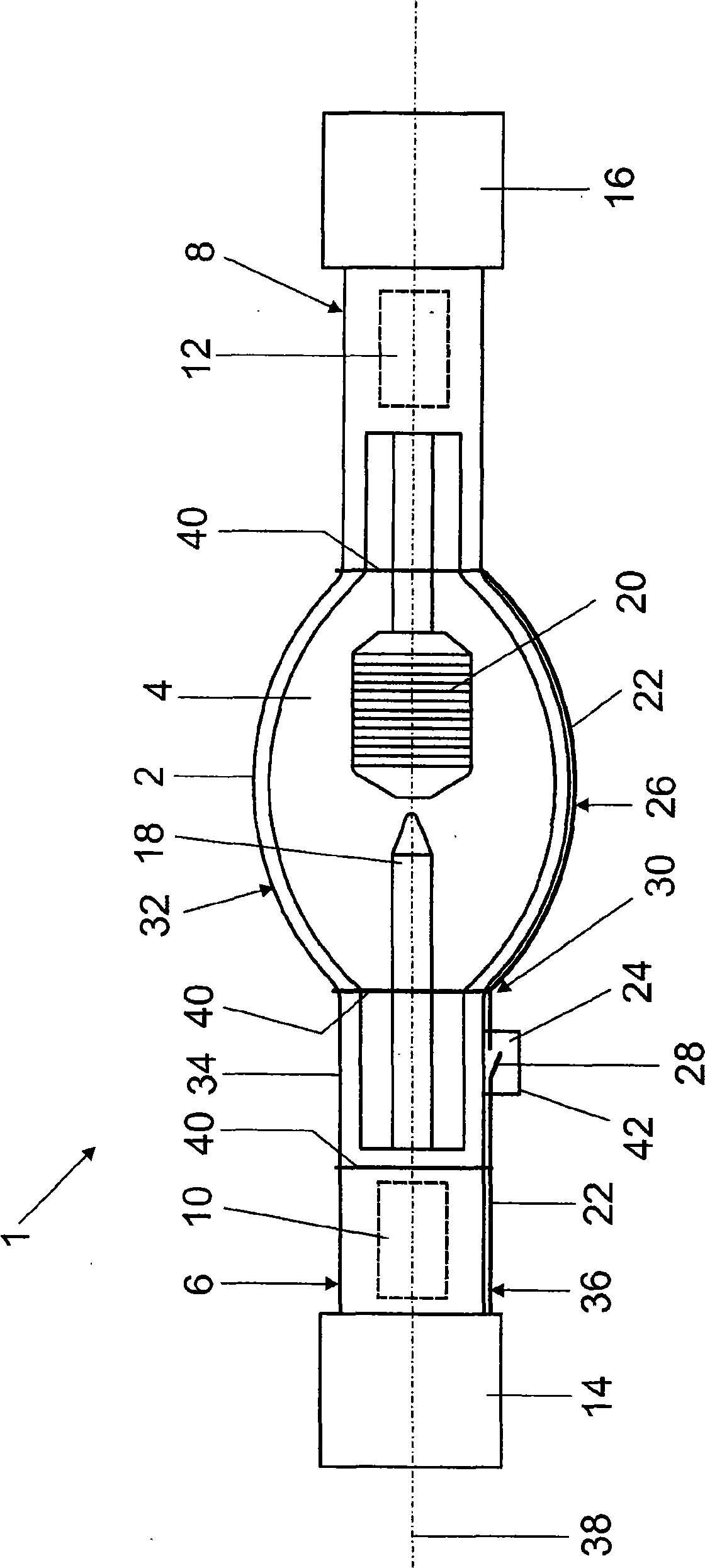

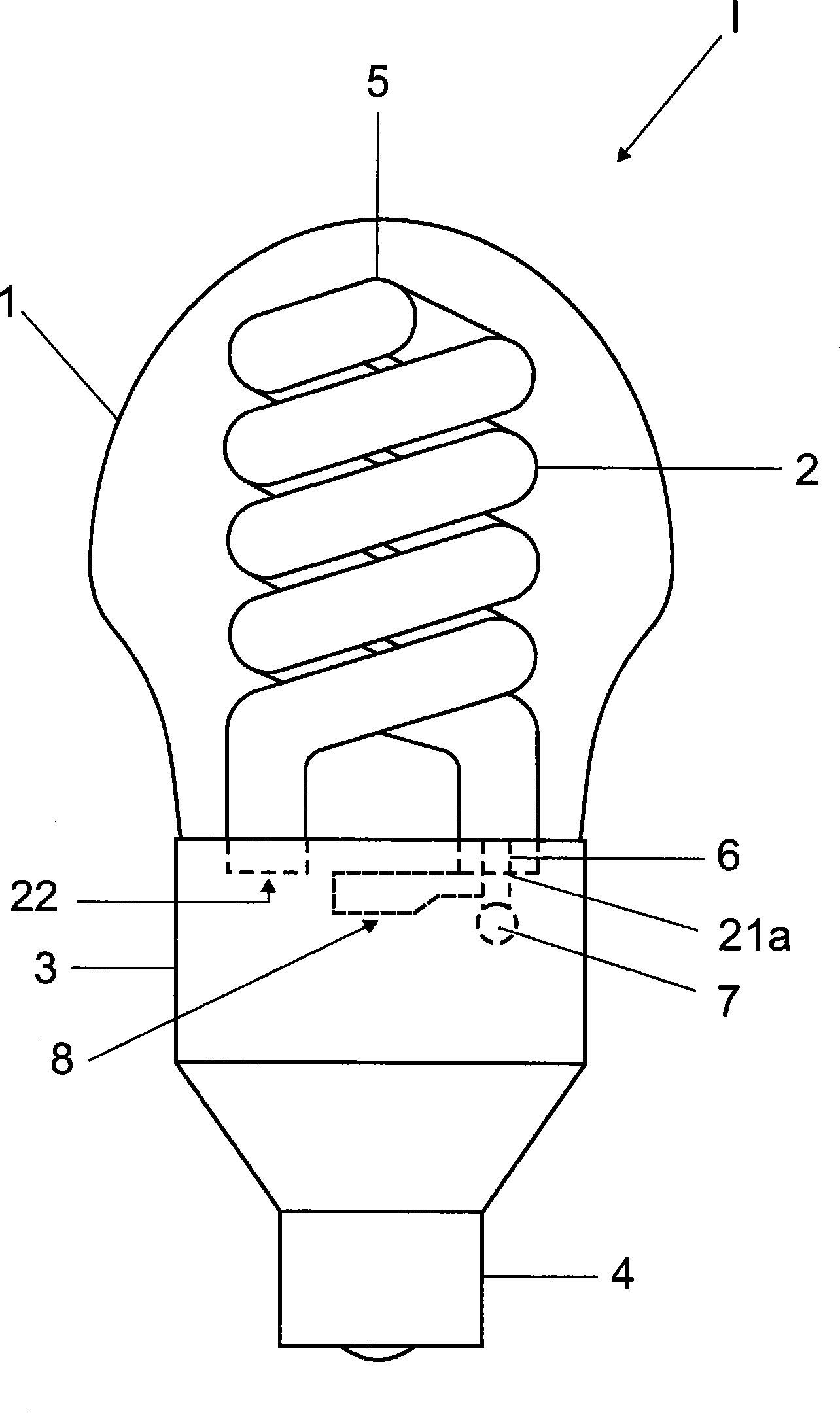

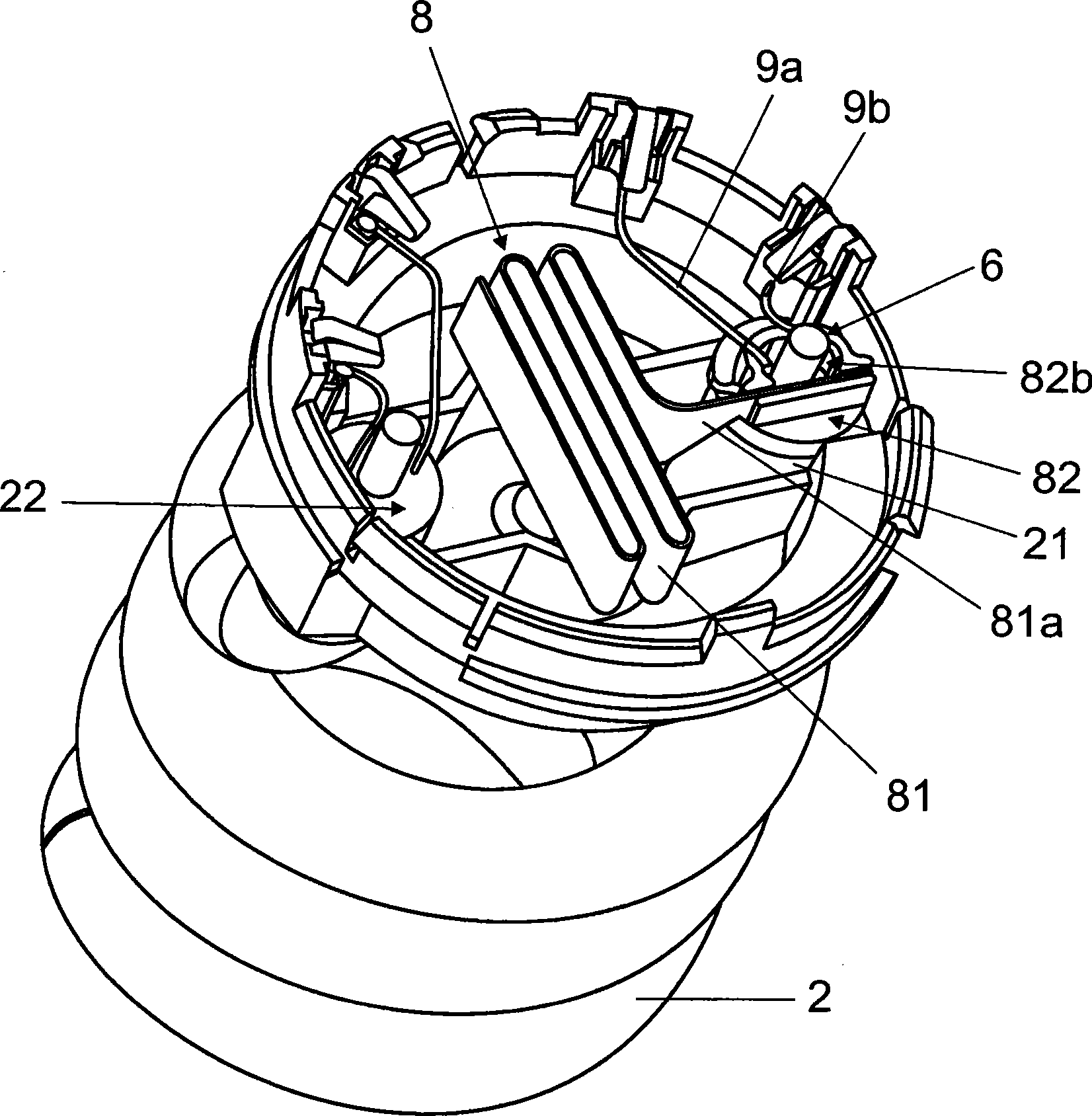

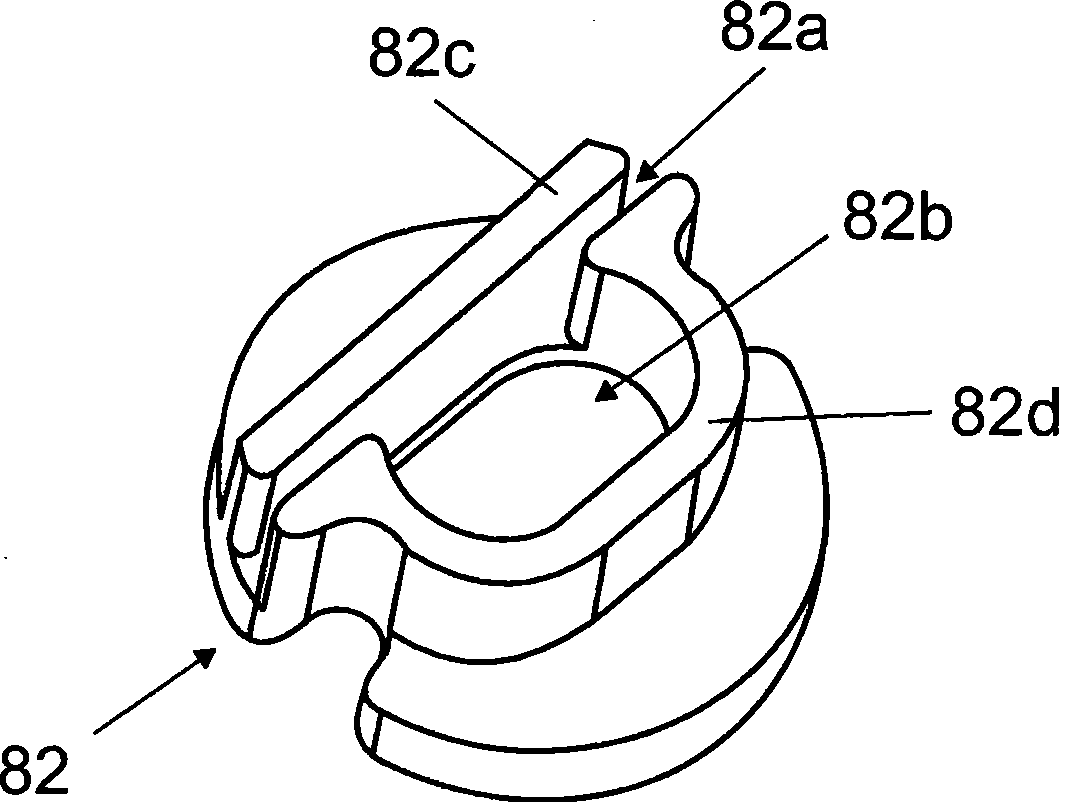

Discharge lamp with an auxiliary ignition element

InactiveCN101490801AIgnition feature improvementsCompact structureHigh-pressure discharge lampsGas discharge lamp detailsThermodynamicsConductive coating

Disclosed is a discharge lamp, in particular a high pressure discharge lamp, with at least one discharge vessel and at least one ignition assisting element, preferably an ignition assisting wire or an electrically conducting coating of the discharge vessel, which element can be electrically connected to a power feed to the discharge lamp and which extends at least in some sections along the discharge vessel, wherein a device is provided for interrupting the electrical connection between at least one partial section of the ignition assisting element and the power feed in the operating state of the discharge lamp. Additionally disclosed are an ignition assisting device and a method for operating a discharge lamp of this kind.

Owner:OSRAM GMBH

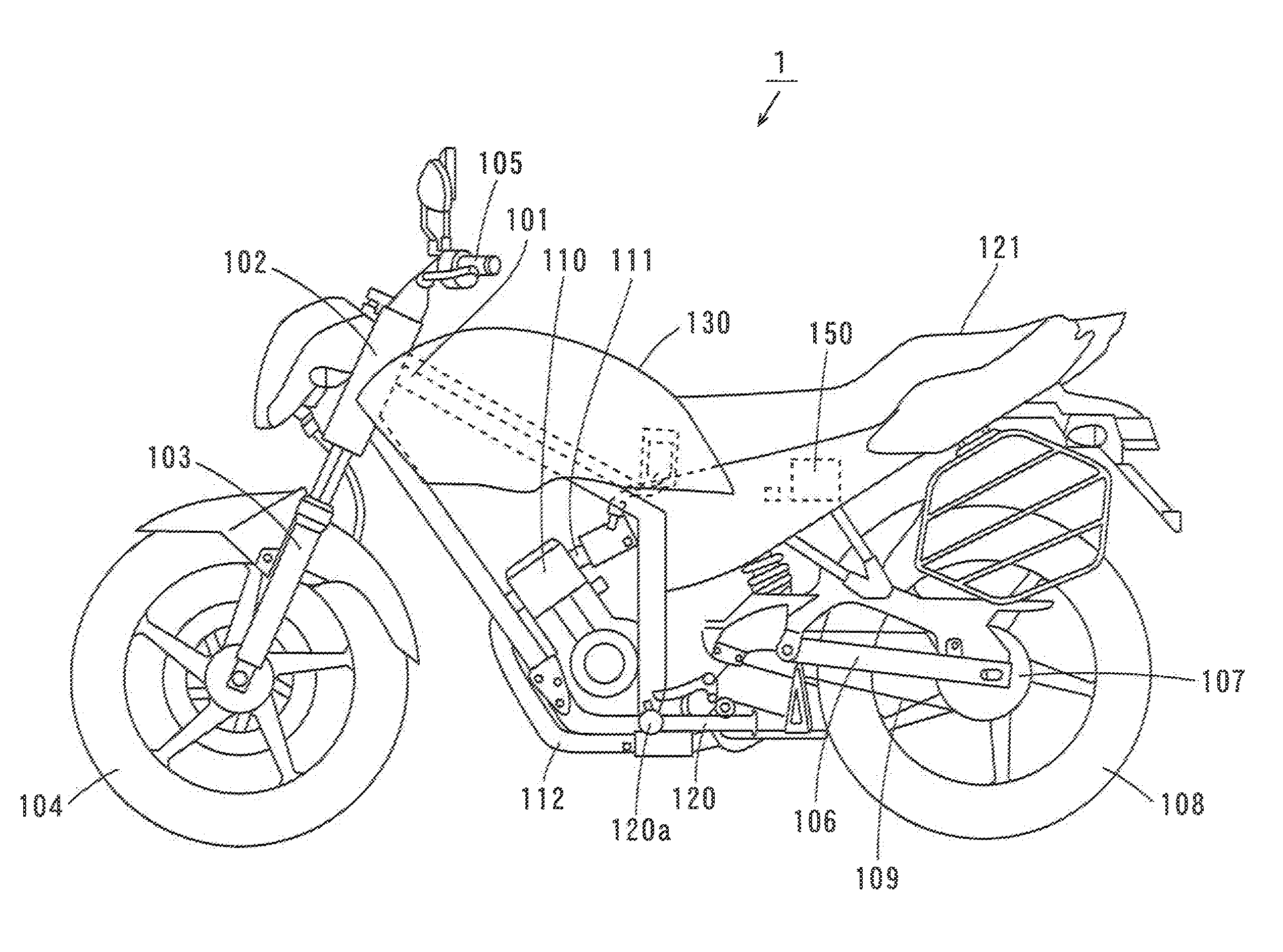

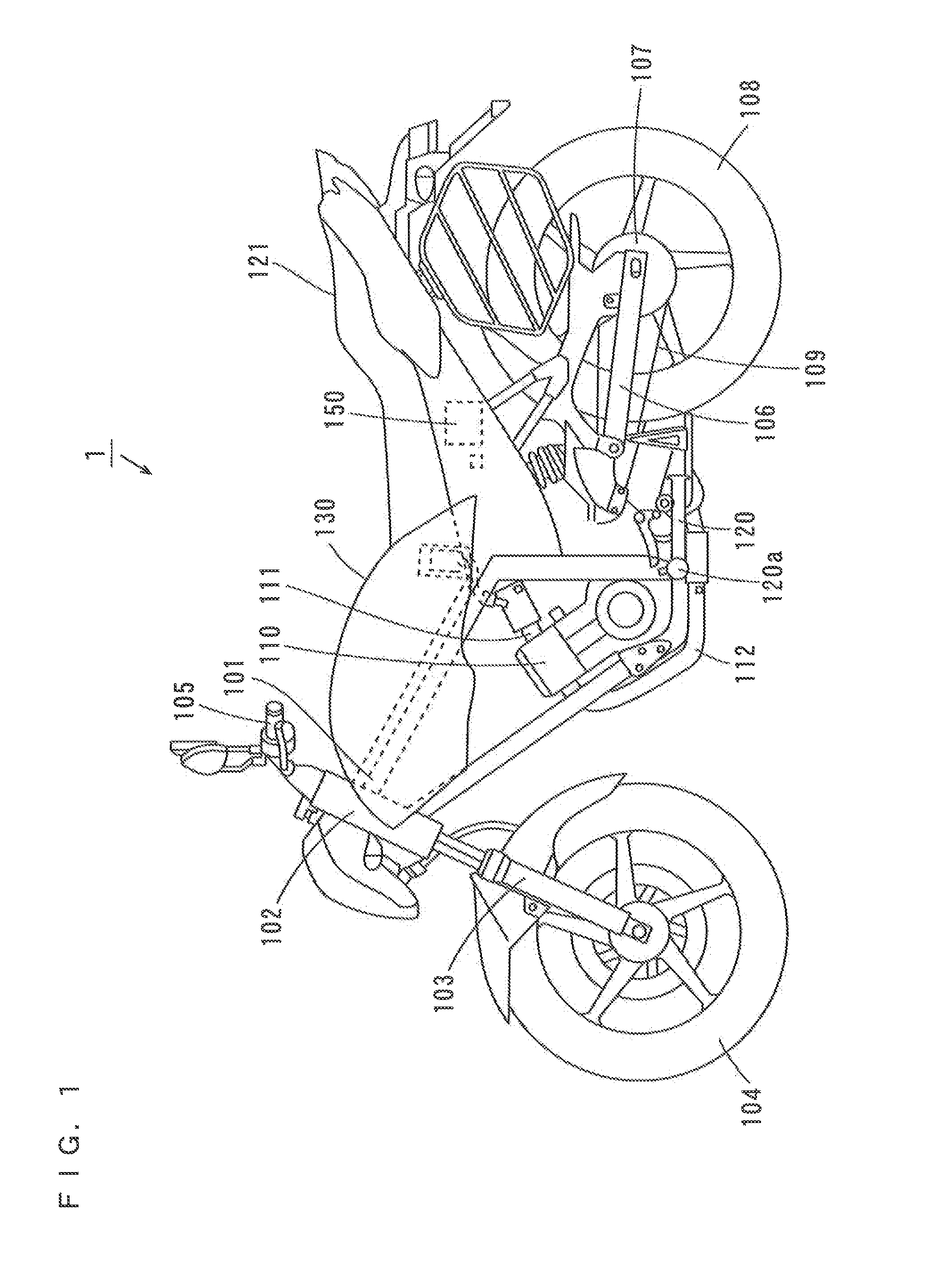

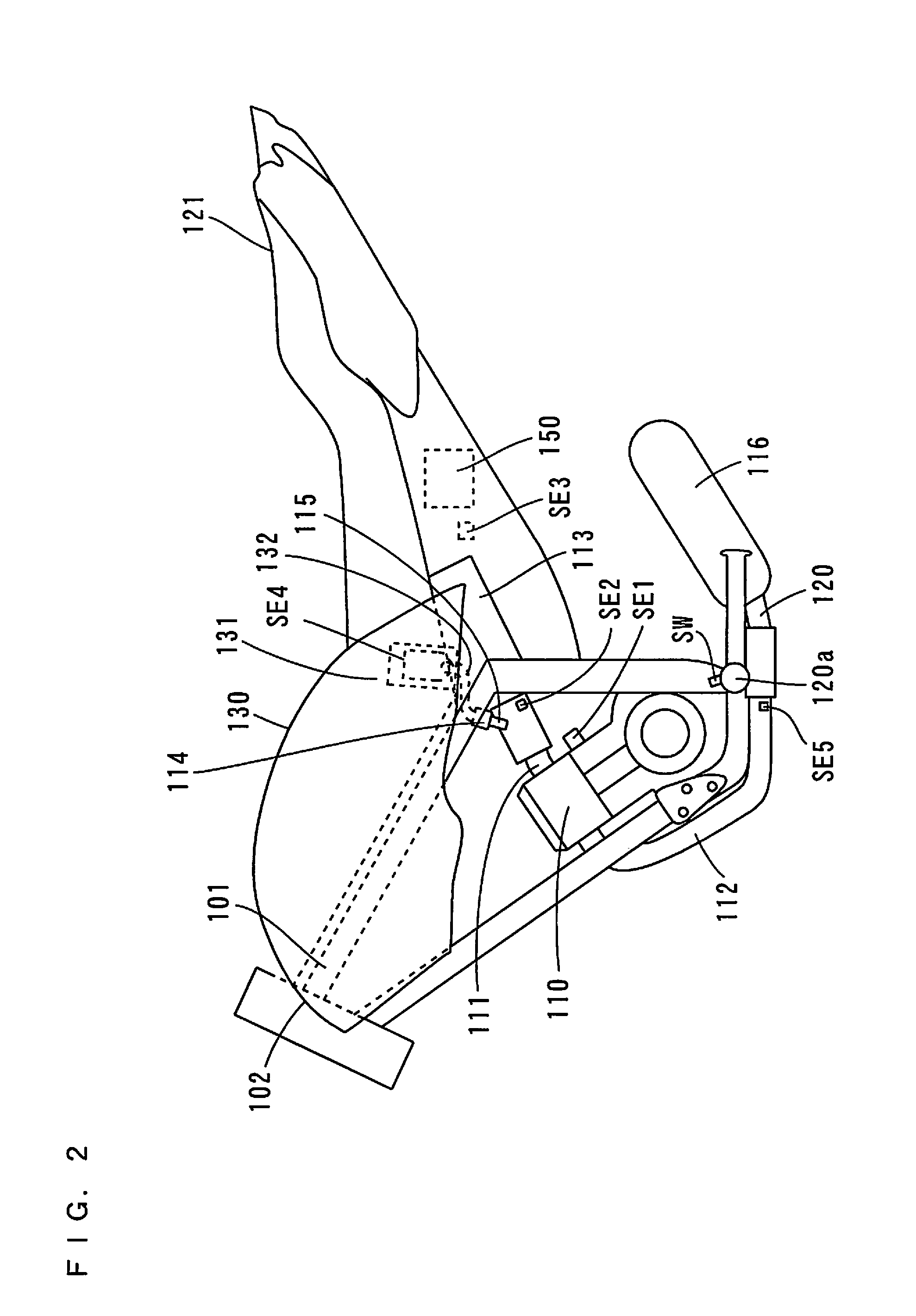

Motorcycle

ActiveUS20130191009A1Avoid overall overheatingImprove starting characteristicsElectrical controlInternal combustion piston enginesEngineeringElectrical and Electronics engineering

A motorcycle includes a CPU (Central Processing Unit) of an ECU (Electronic Control Unit) that drives a fuel heating device when a fuel heating condition is satisfied and the result of a fuel heating prohibition determination process indicates that heating is permitted. On the other hand, the CPU does not drive the fuel heating device when the fuel heating condition is not satisfied or when the result of the fuel heating prohibition determination process indicates that heating is prohibited. In the fuel heating prohibition determination process, the CPU determines a tilted state of the motorcycle, and prohibits or permits heating of fuel in a fuel pipe by the fuel heating device based on a detection result of the tilted state.

Owner:YAMAHA MOTOR CO LTD

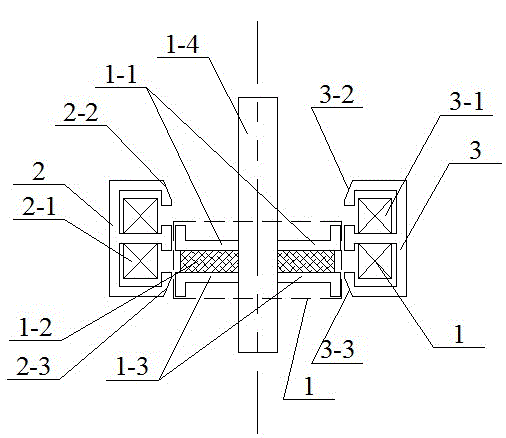

High efficiency bistable electromagnetic clutch

ActiveCN103148120AImprove starting characteristicsGuaranteed uptimeOther washing machinesMagnetically actuated clutchesPower flowElectromagnetic clutch

The invention relates to a high efficiency bistable electromagnetic clutch, and relates to the technical field of driving. The high efficiency bistable electromagnetic clutch solves the problem of the existing clutch in the structure and in the energization manner that enough starting force can be generated by applying larger electric current and the acting force generated in the process is too large after starting and is several dozens of times of starting force. A chamfer angle is formed between the right end surface of an upper magnetic conducting column of a first stator and the upper end surface of the upper magnetic conducting column of the first stator, and a chamber angle is formed between the right end surface of a lower magnetic conducting column of the first stator and the lower end surface of the lower magnetic conducting column of the fist stator; a chamber angle is formed between the left end surface of an upper magnetic conducting column of a second stator and the upper end surface of the upper magnetic conducting column of the second stator, and a chamber angle is formed between the left end surface of a lower magnetic conducting column of a second stator and the lower end surface of the lower magnetic conducting column of the second stator. The clutch is suitable for bistable electromagnetic clutch systems with general precision requirements, and is used for direct driving control of brushless direct current motors and bistable electromagnetic clutches.

Owner:HARBIN INST OF TECH

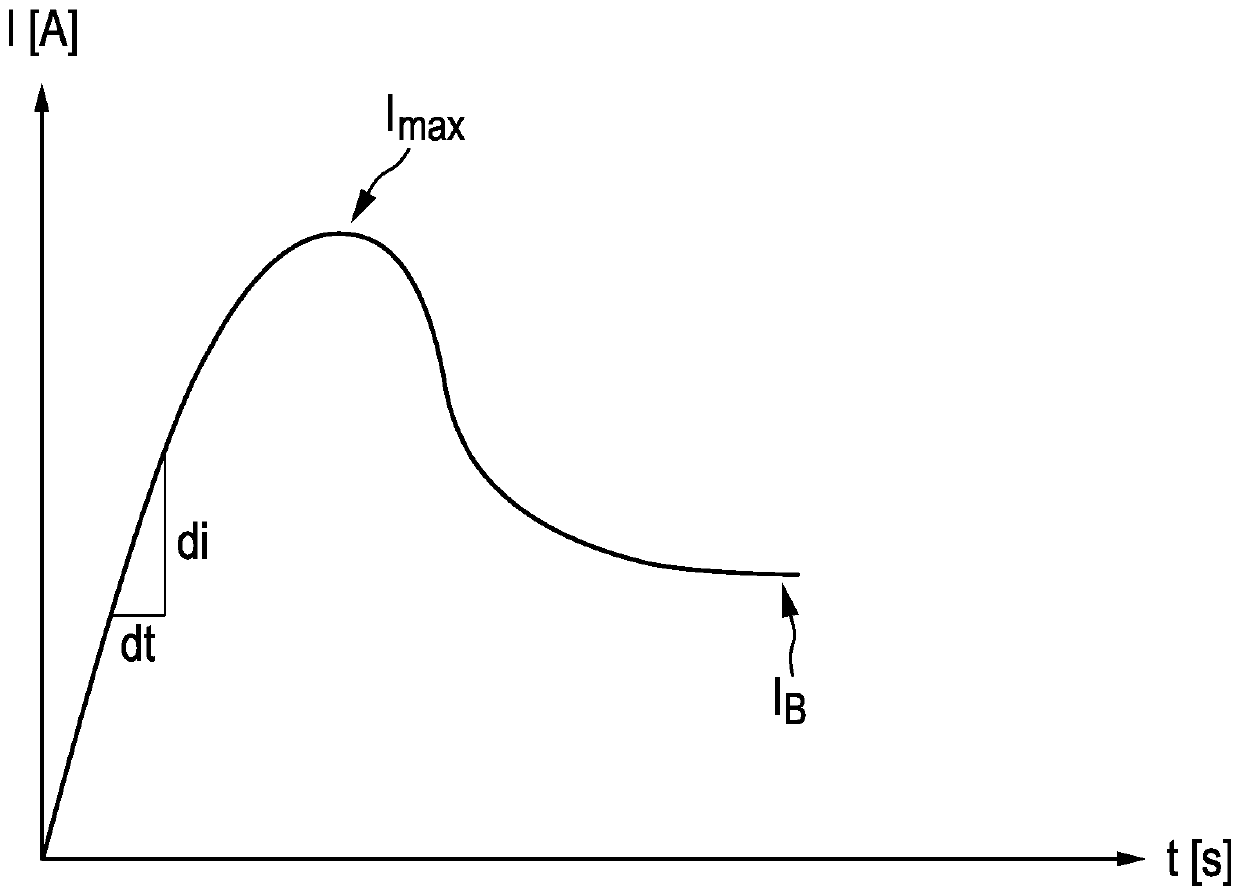

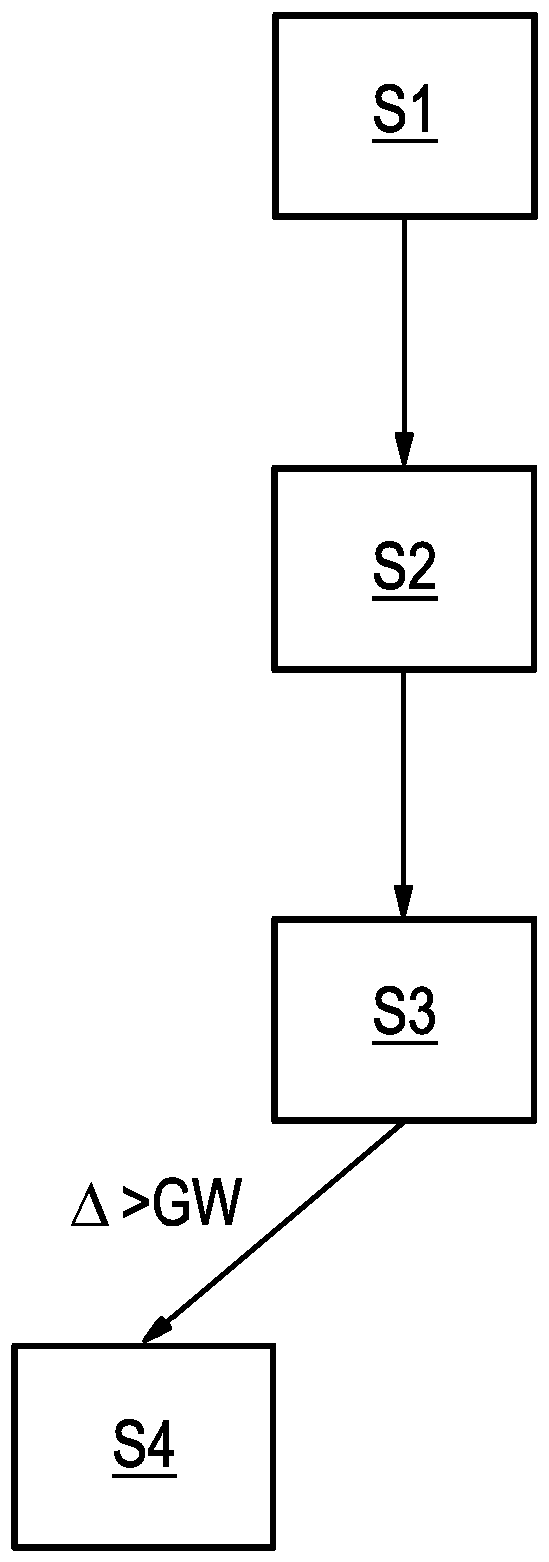

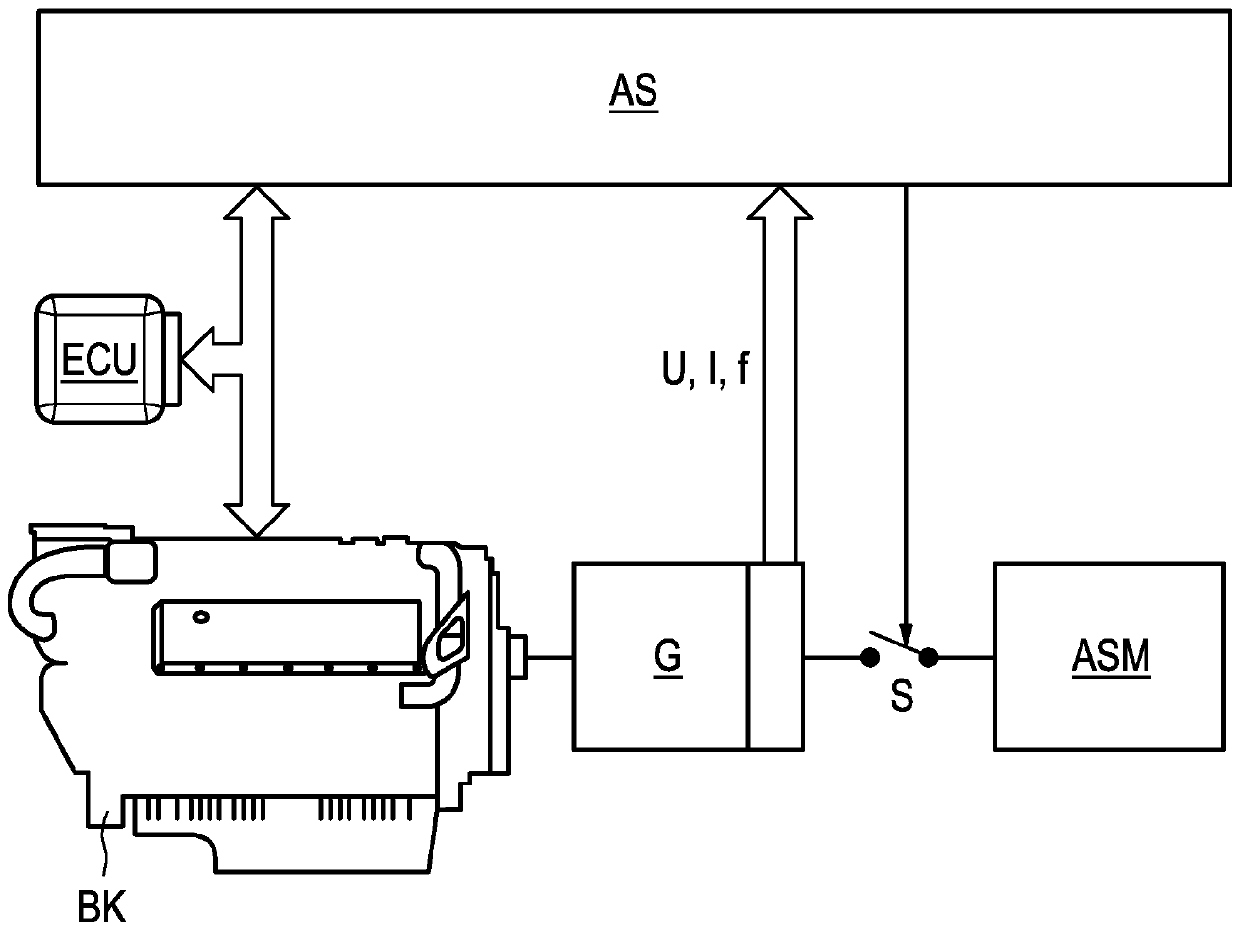

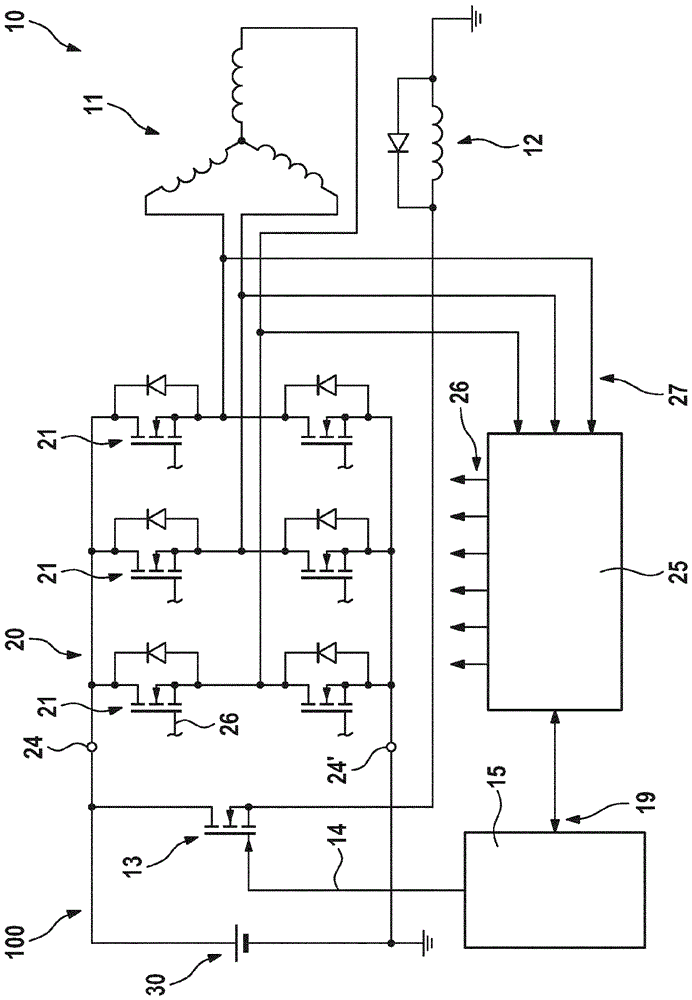

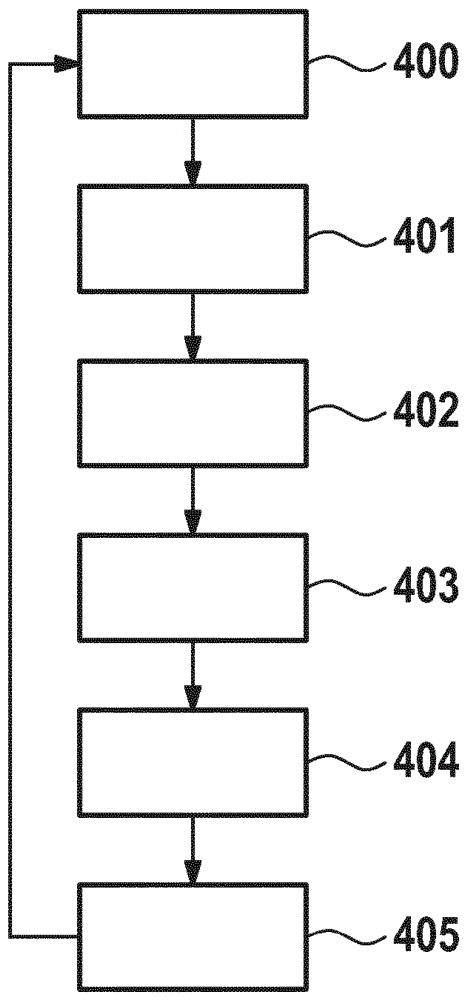

Method for the open-loop and closed-loop control of an internal combustion engine with a generator and asynchronous machine, open-loop and closed-loop control unit, and internal combustion engine

ActiveCN111556923AIncreased fuelImproved load switching capabilityElectrical controlSpeed sensing governorsLoop controlEngineering

The invention relates to a method for the open-loop and closed-loop control of an internal combustion engine (BK), in particular a diesel engine or gas engine, with a generator (G) and asynchronous machine (ASM), comprising the following steps: detecting at least one electrical characteristic variable of the generator, wherein the electrical characteristic variable is selected from current (I), voltage (U) or frequency (f); determining a characteristic variable change in the electrical characteristic variable of the generator in a predetermined time interval; comparing the change in characteristic variable with a first threshold value; and in the event that the change in characteristic variable is greater than the first threshold value, changing from a standard speed control of the internal combustion engine to a feed-forward control.

Owner:ROLLS ROYCE SOLUTIONS GMBH

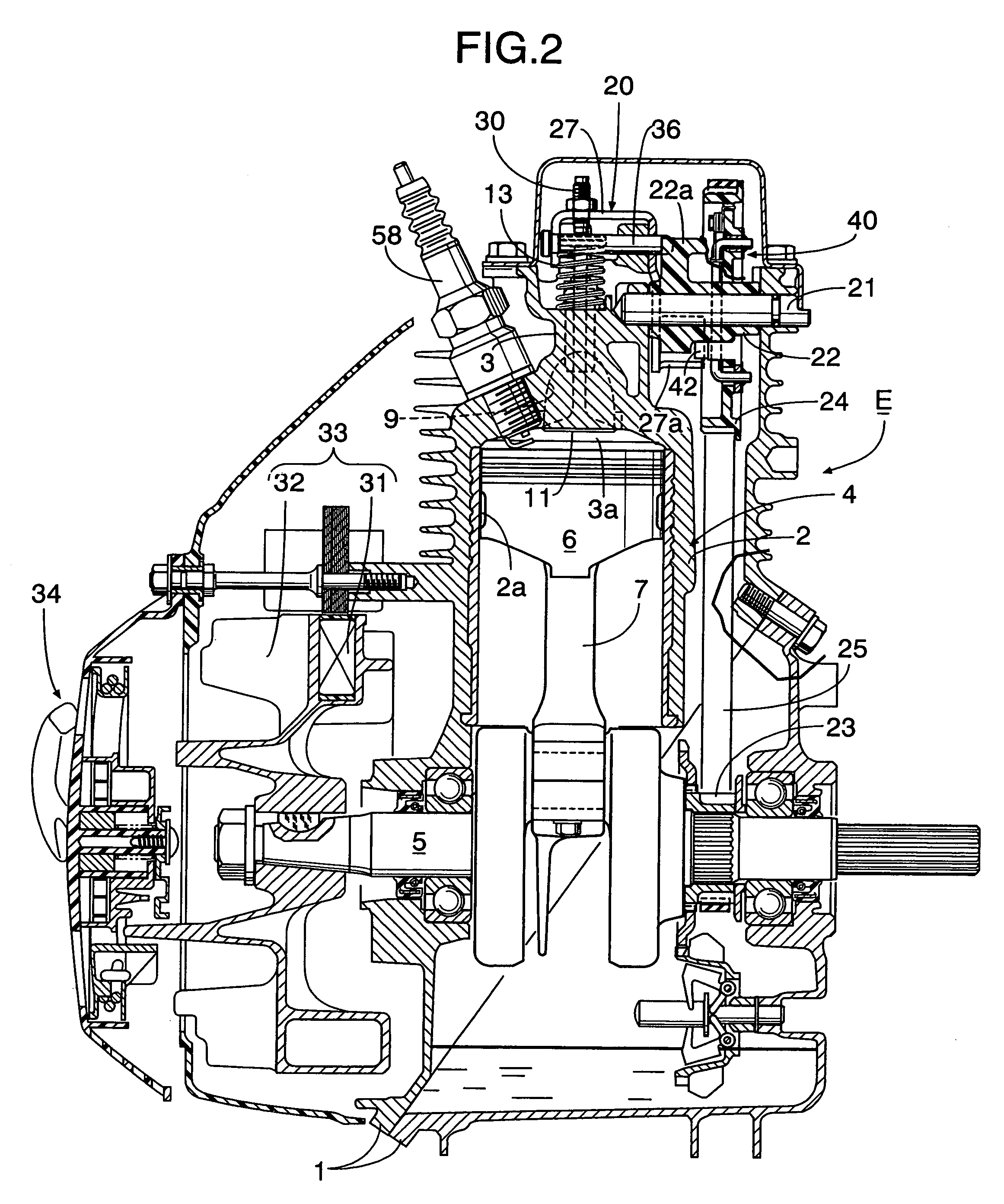

Stepless speed change gearing device

InactiveCN1181275CImprove starting characteristicsDrive chain shortGearing controlFluid gearingsCar drivingTransmission belt

The stepless variable drive mainly includes reverse brake and forward gear clutch which are placed in the gear shifting box, driving cone disk wheel, driven cond disk wheel and metal driving strap component, in which the driving and driven cone disk wheels are respectively formed from a fixed cone disk and axially-movable cond disk which are oppositely arranged. It is characterized by that the input portion of forward gear clutch is coupled with output shaft of engine, the output portino of forward gear clutch is coupled with driving cone disk wheel, the fixed cone disk of the driving cone disk wheel is set at one side of forward gear clutch, and the forward gear clutch is a wet friction clutch in which the pressure can be progressively applied by chip microprocessor controlled hydraulic system according to set control curve instead of main clutch function in car driving chain.

Owner:刘冰

Three-section-type electromechanical composite stepless transmission device for wheel-type load-carrying vehicle

InactiveCN102661369BImprove powerRealize stepless speed changeToothed gearingsPower batteryElectric machine

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

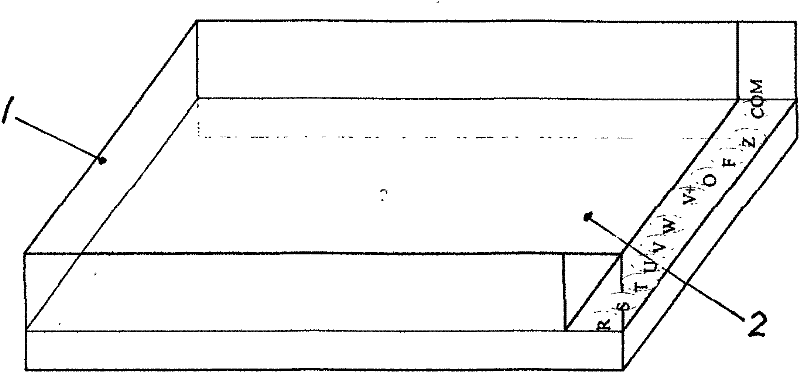

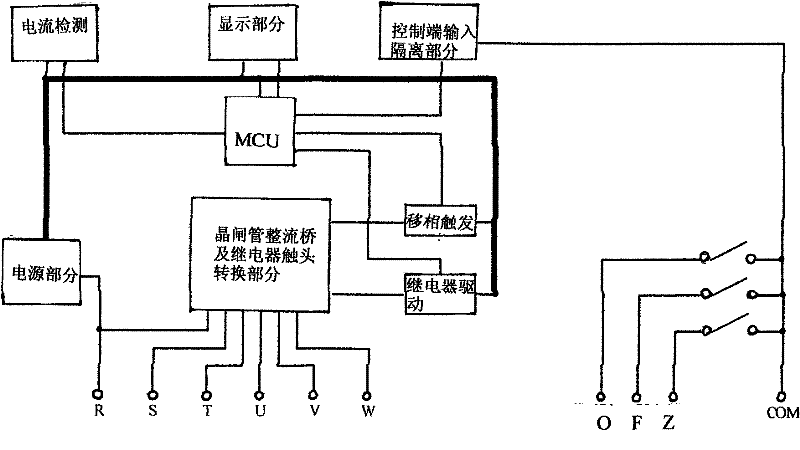

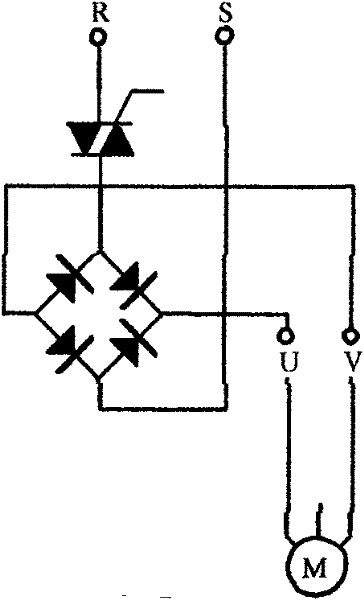

Forward and reversal rotation soft-starting braking controller for alternating current motor

InactiveCN102684569ALow costAdd control functionAc motor stoppersPolyphase induction motor starterMicrocontrollerPhase shifted

The invention relates to the technical field of motor controlling, relates to a forward and reversal rotation soft-starting braking controller for an alternating current motor and aims to solve the problems of impact current and abrasion of mechanic transmission components caused by the fact that the forward and reversal rotation and braking of existing alternating current motors are required to be respectively controlled and directly started. The controller comprises a casing and a circuit board, a microcontroller is arranged in the circuit board, a phase shift trigger circuit in the circuit board is controlled by the microcontroller and connected with a trigger electrode of a thyristor, a cathode of the thyristor is connected with a power input terminal, an anode of the thyristor is connected with a minisize large current relay contact and a rectifier bridge, a relay drive chip in the circuit board is controlled by the microcontroller and connected with a minisize large current relay coil, the minisize large current relay contact is respectively connected with the thyristor or the rectifier bridge and an output terminal, and the microcontroller in the circuit board is respectively connected with a digital tube display circuit, a current detecting circuit and a command input isolation circuit which is connected with a control terminal. The forward and reversal rotation soft-starting braking controller for the alternating current motor has the advantage of integrating functions and advantages of motor forward and reversal rotation, an electronic soft starter and an electronic brake.

Owner:刘志涛

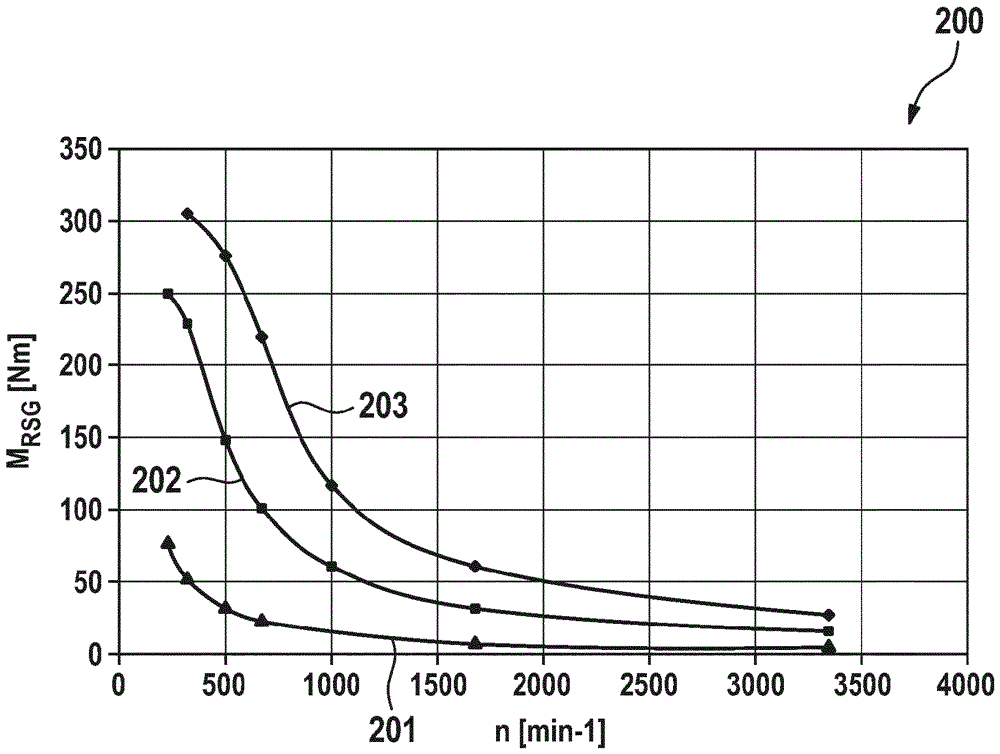

Method for regulating the actual torque delivered by an electric machine in a motor vehicle to the nominal torque

ActiveCN103347728BBest torque supportRealize the boost functionHybrid vehiclesAC motor controlElectric machineControl theory

The invention relates to a method for adjusting an actual torque delivered by an electric motor in a motor vehicle to a target torque, wherein the electric motor comprises a stator winding (11), a rotor winding (12), a field rheostat (15) associated with the rotor winding (12), and a power converter (20) which is connected downstream of the stator winding (11) and has actuatable switch elements (21), wherein the actual torque is adjusted to the target torque in that a commutation angle is set by deliberately actuating the switch elements (21) and / or in that a current is deliberately set by the stator winding (12).

Owner:ROBERT BOSCH GMBH

Power box for electric wheel type engineering machinery

PendingCN113074229AMeet independent driveWide stepless speed regulation rangeGearing controlFluid gearingsTransfer caseElectric machinery

Owner:TIANJIN ENG MACHINERY INST

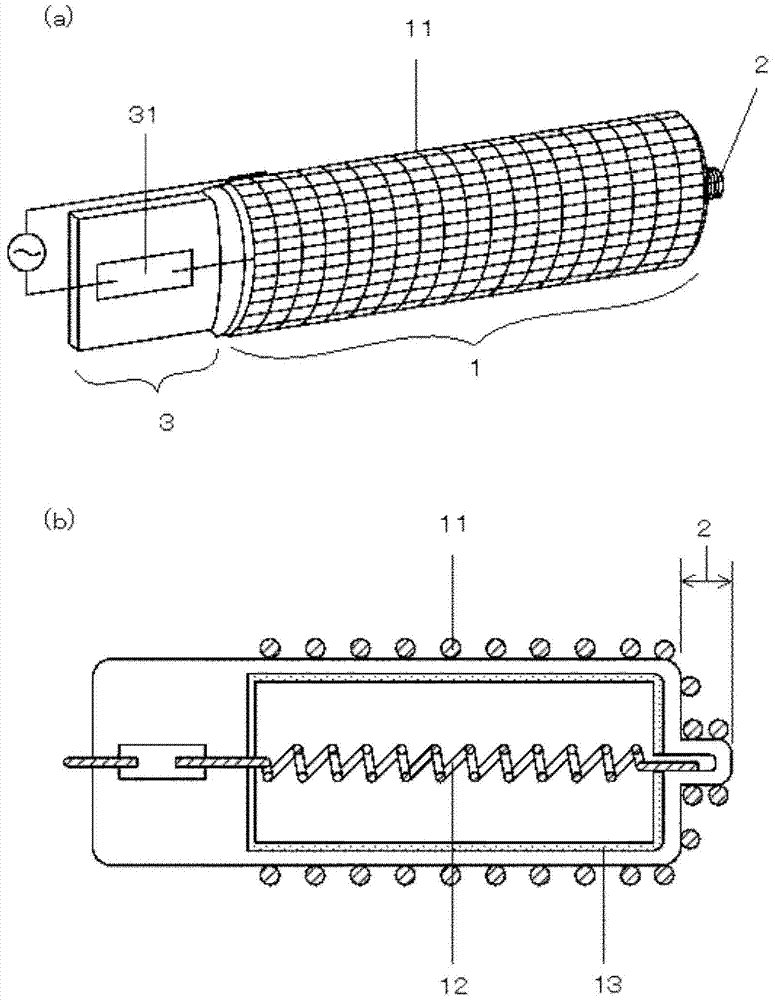

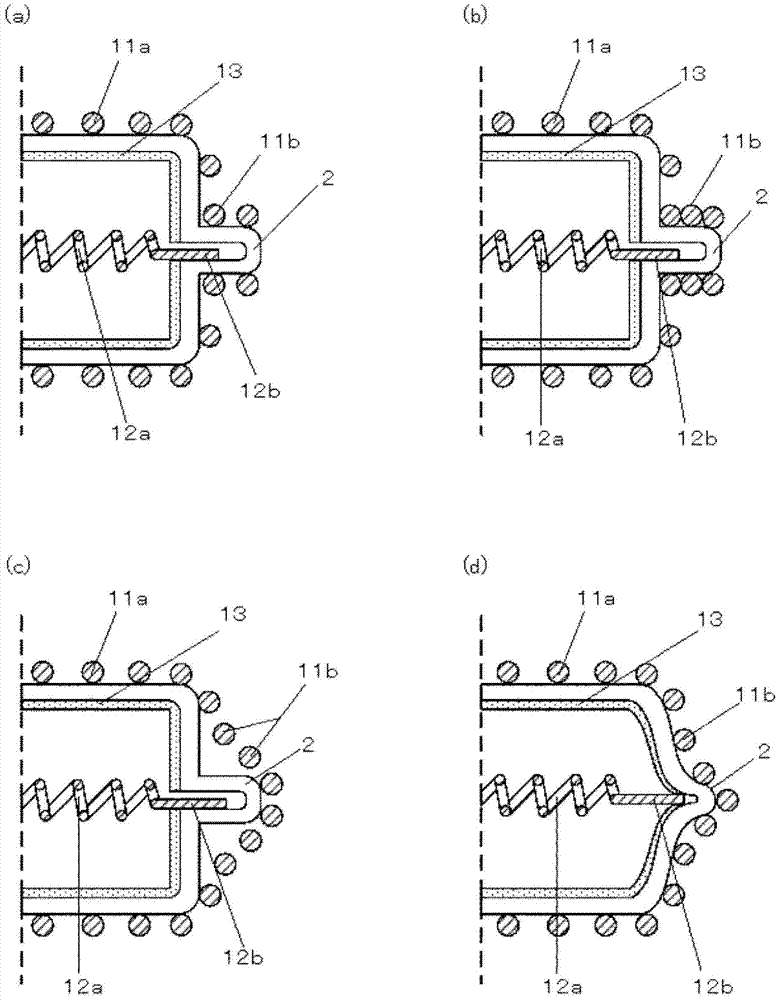

excimer lamp

ActiveCN103972040BAchieve sterilizationImprove starting characteristicsGas discharge lamp detailsPhosphorUltraviolet lights

The present invention provides an excimer lamp which radiates ultraviolet rays by inducing excimer to discharge in a discharge container, can suppress generation of ozone and radiate ultraviolet light useful for sterilization and plays a superior starting characteristic. The excimer lamp is provided with a long size discharge container, an end head part formed by protruding from one end part of the discharge container, and a seal part formed at the other end part of the discharge container. An internal electrode arranged in the discharge container and an external electrode arranged out of the discharge container are used as a pair of electrodes, excimer illuminating gas is sealed in the discharge container. The excimer lamp is characterized in that a phosphor enabling the ultraviolet rays to light is arranged on the inner wall of the discharge container; the internal electrode extends along a tube axis of the discharge container; one end of the internal electrode is guided in the end head part; the other end of the internal electrode is embedded in the seal part; and the external electrode extends continuously from the discharge container and is arranged at the end head part.

Owner:USHIO DENKI KK

Flow Field Control Method of Closed Backflow Channel

ActiveCN109356723BImprove starting characteristicsReduce the starting Mach numberSustainable transportationEngine fuctionsShock waveAirway structure

The invention relates to a closed type return flow channel flow field control method. The closed type return flow channel flow field control method is characterized by comprising the following steps that a, according to design parameter requirements, a hypersonic air inlet duct geometric profile is designed, and the air inlet duct self-starting characteristics are simulated and analyzed; b, basedon different static pressure distribution laws in a compression surface before an inlet of a hypersonic air inlet duct during start / non-start, the pressure difference distribution before and after a shock wave is adopted, and a return flow cavity is formed in the air inlet duct to control a flow field of the air inlet duct; c, the inlet and outlet positions of a return flow channel and cross-sectional parameters of the return flow cavity are subjected to simulated analysis, and the geometric profile parameters of the return flow channel are optimized; and d, the geometric profile parameters ofthe return flow channel are adjusted to determine a final air inlet duct structure. The closed type return flow channel flow field control method can improve the starting ability of the hypersonic air inlet duct at a low Mach number and broadens the range of the working Mach number of the air inlet duct.

Owner:BEIJING SPACE TECH RES & TEST CENT

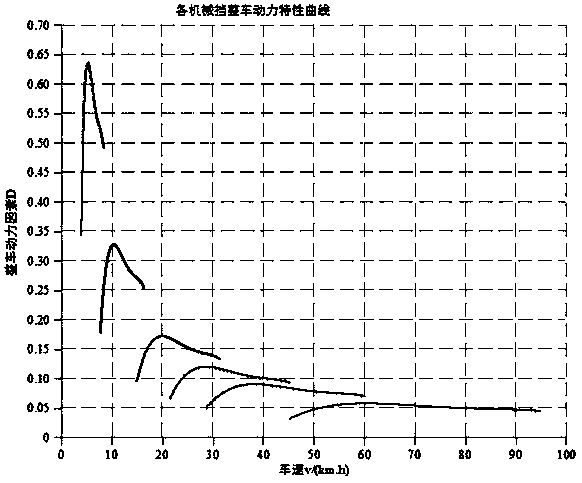

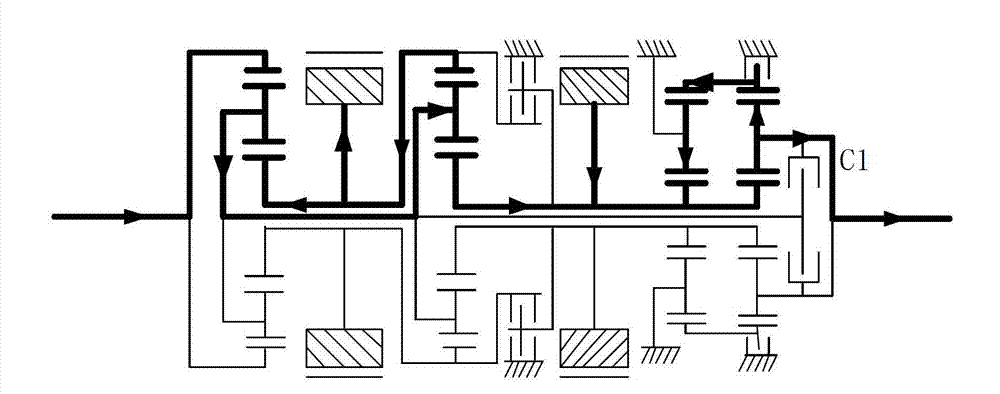

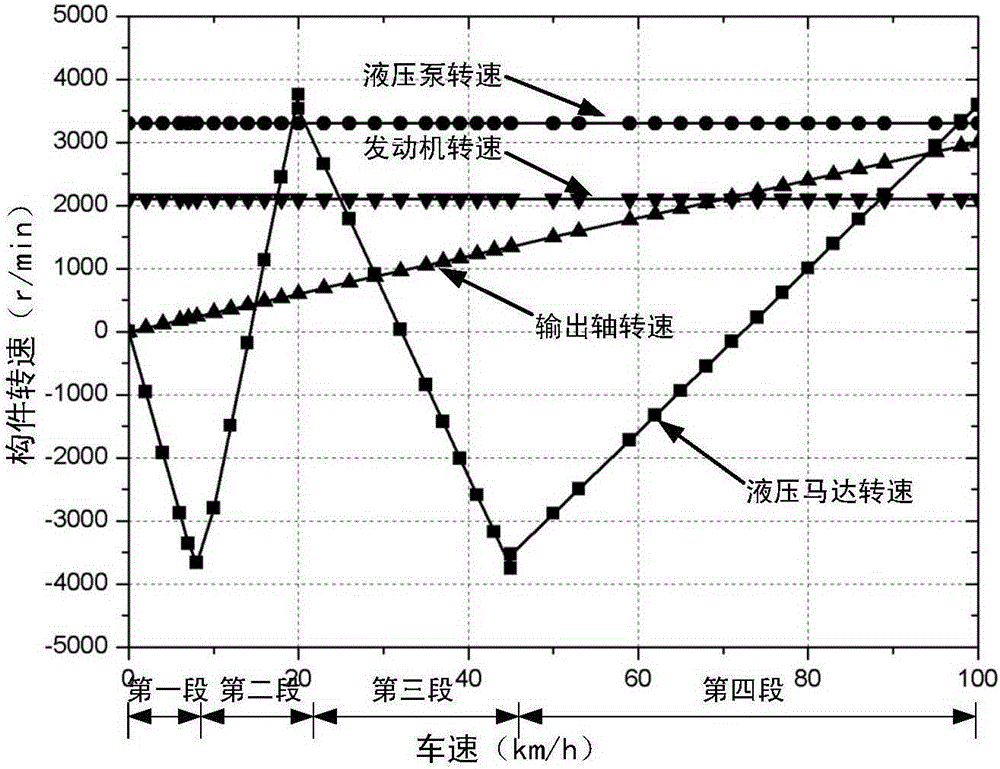

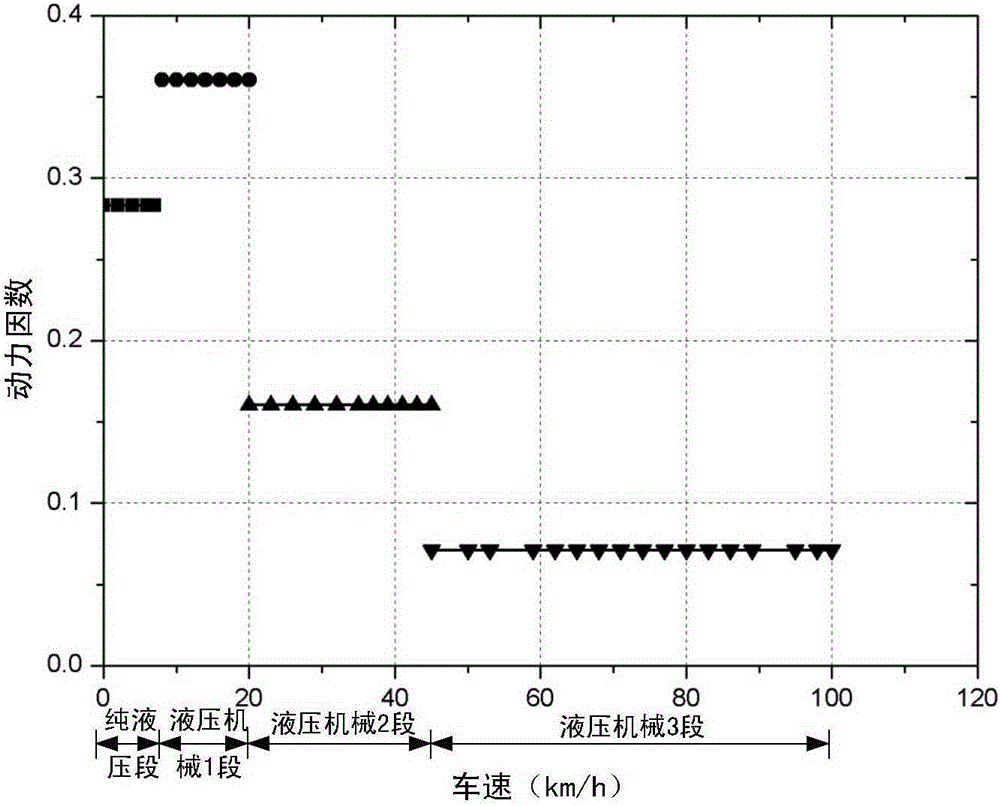

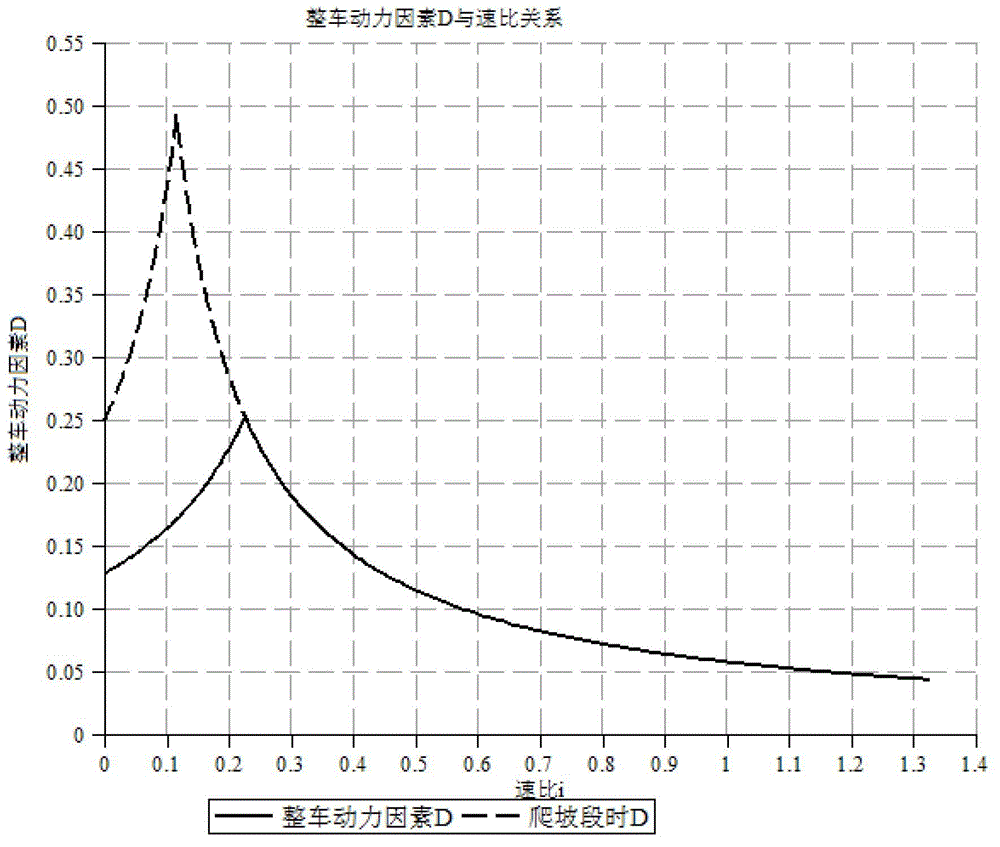

Equal-proportional four-stage hydraulic-mechanical compound stepless transmission

ActiveCN103591247BImprove transmission efficiencyImprove starting characteristicsTransmission elementsFluid gearingsHydraulic pumpHydraulic machinery

The invention belongs to the technical field of vehicle transmission, and particularly relates to an equal-proportion four-section-type hydraulic mechanical composite stepless transmission device. According to the technical scheme, the equal-proportion four-section-type hydraulic mechanical composite stepless transmission device is composed of a frontward and backward convergence planet mechanism formed by a planet bar k3, a planet bar k4, a planet bar k5 and a gear ring (37) of a hydraulic-section planet bar, a three-gear speed changing mechanism composed of a planet bar k1 and a planet bar k2, a transmission device body, an engine input transmission shaft and a hydraulic pump / motor. According to the principle of continuous section changing, one hydraulic section and three hydraulic mechanical sections are formed, and two mechanical gears can be formed. The equal-proportion four-section-type hydraulic mechanical composite stepless transmission device has the advantages of realizing continuous stepless speed changing, being good in starting characteristic and being high in transmission efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Four-stage hydromechanical compound transmission

ActiveCN103453104BSimple structureGreat tractionFluid gearingsElectric power transmissionHydraulic machinery

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A Flow Control Method Using Flexible Wall Surface to Improve Inlet Starting Performance

ActiveCN107701314BImprove starting performanceSignificant comprehensive unsteady control effectGas turbine plantsRam jet enginesRamjetEngineering

The invention discloses a flow control method capable of improving starting performance of an inlet by use of a flexible wall surface and relates to a ramjet engine inlet. Type selection of a flexiblematerial is determined according to fluidity pressure oscillation frequency and amplitude when the inlet is not started; the size of the flexible wall surface is determined according to the size of an air flow separation area at the compression section inlet when the inlet is not started; the initial mounting position of the flexible wall surface is determined according to the initial position ofthe air flow separation area. When the inlet is not started, fluidity pressure is periodically oscillated, the flexible wall surface is driven to produce tiny oscillation, so that the oscillation flow field energy is transferred and dissipated toward the flexible wall surface, flow field oscillation is inhibited, and the purpose of improving the starting characteristic of the supersonic speed inlet is achieved. The flow field oscillation is inhibited through oscillation of the flexible wall surface with the flow field, and the starting characteristic of the supersonic speed inlet can be improved; the structure is simple, the control effect is remarkable, and the engineering application potential is high.

Owner:XIAMEN UNIV

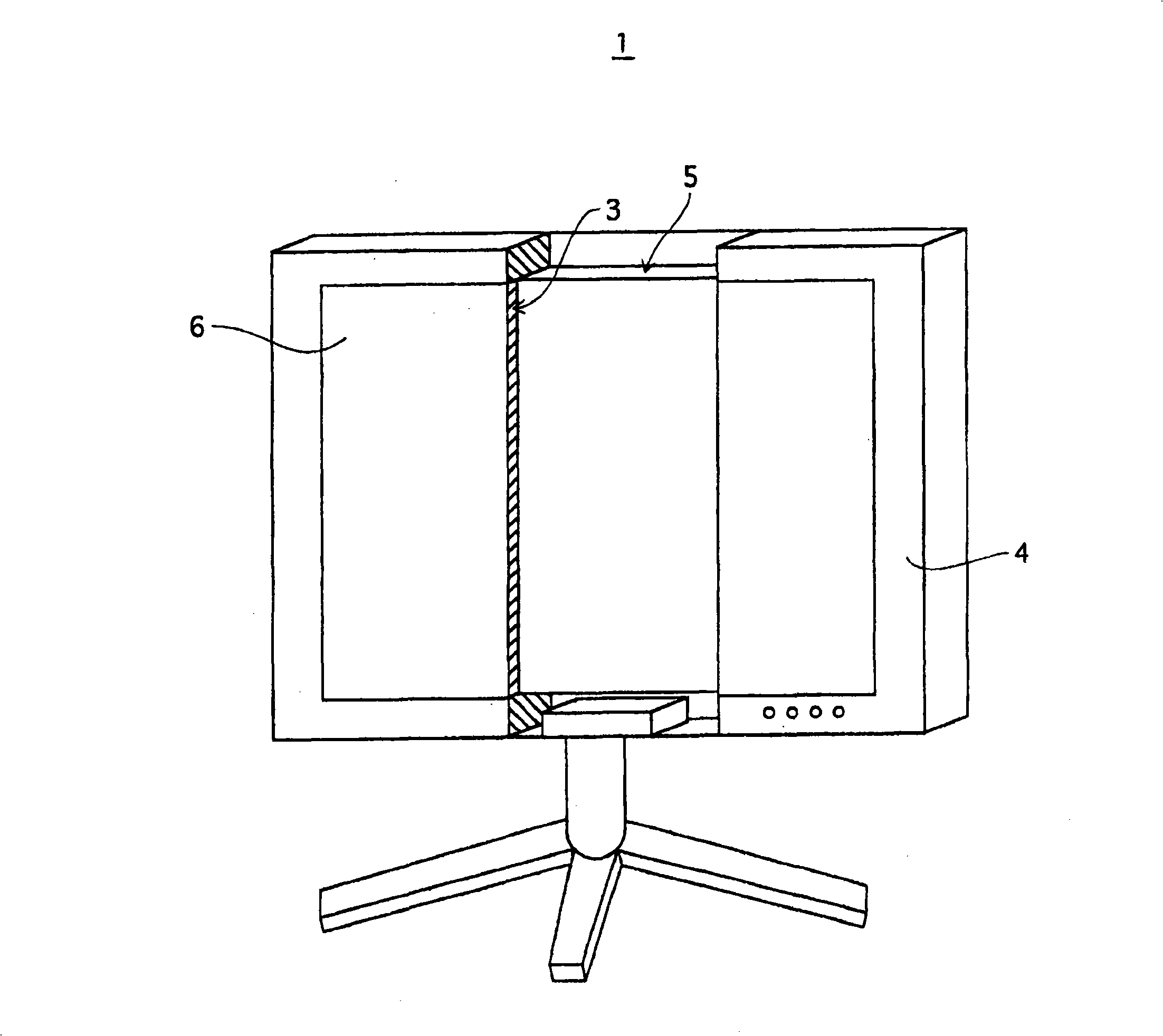

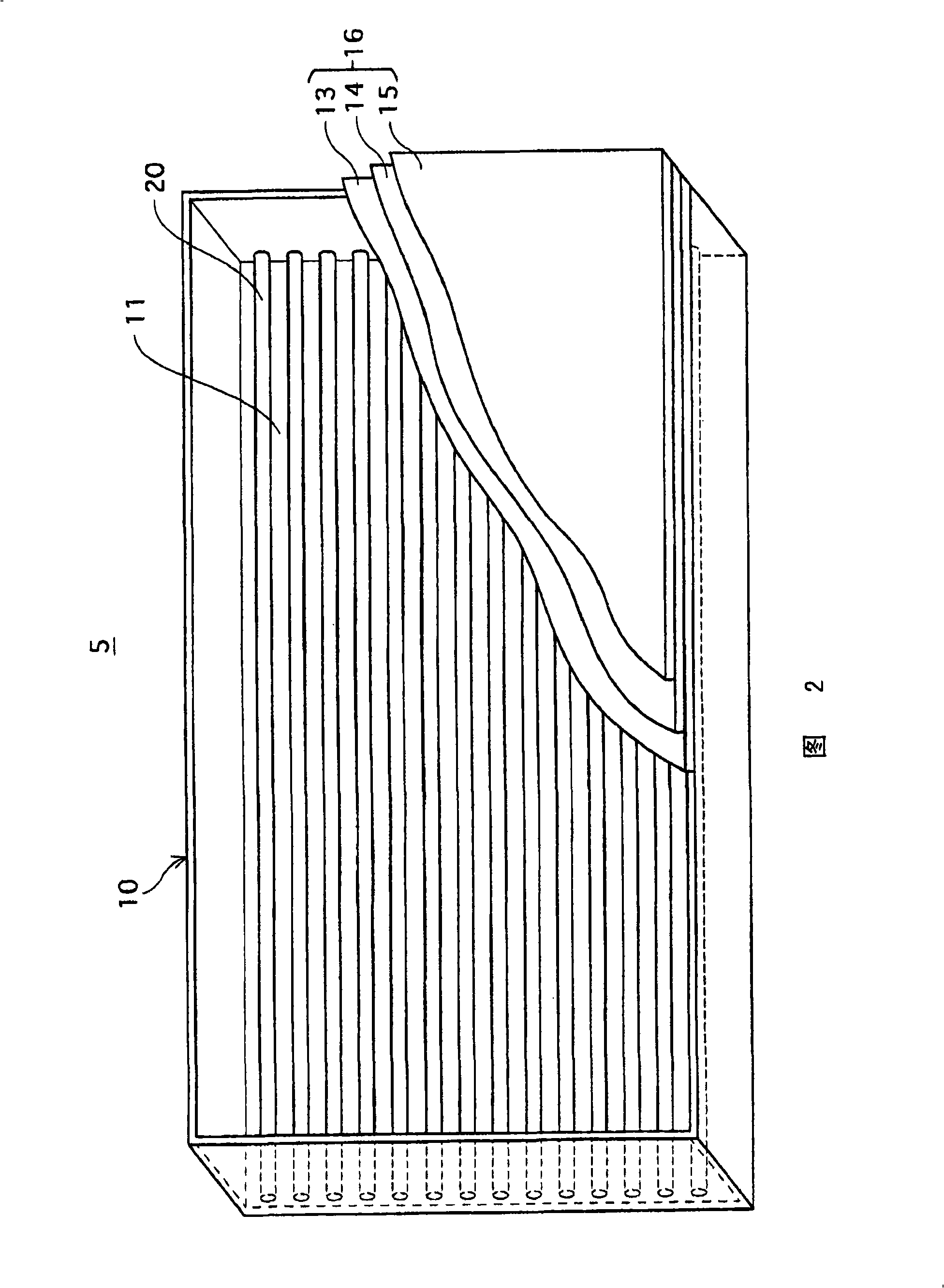

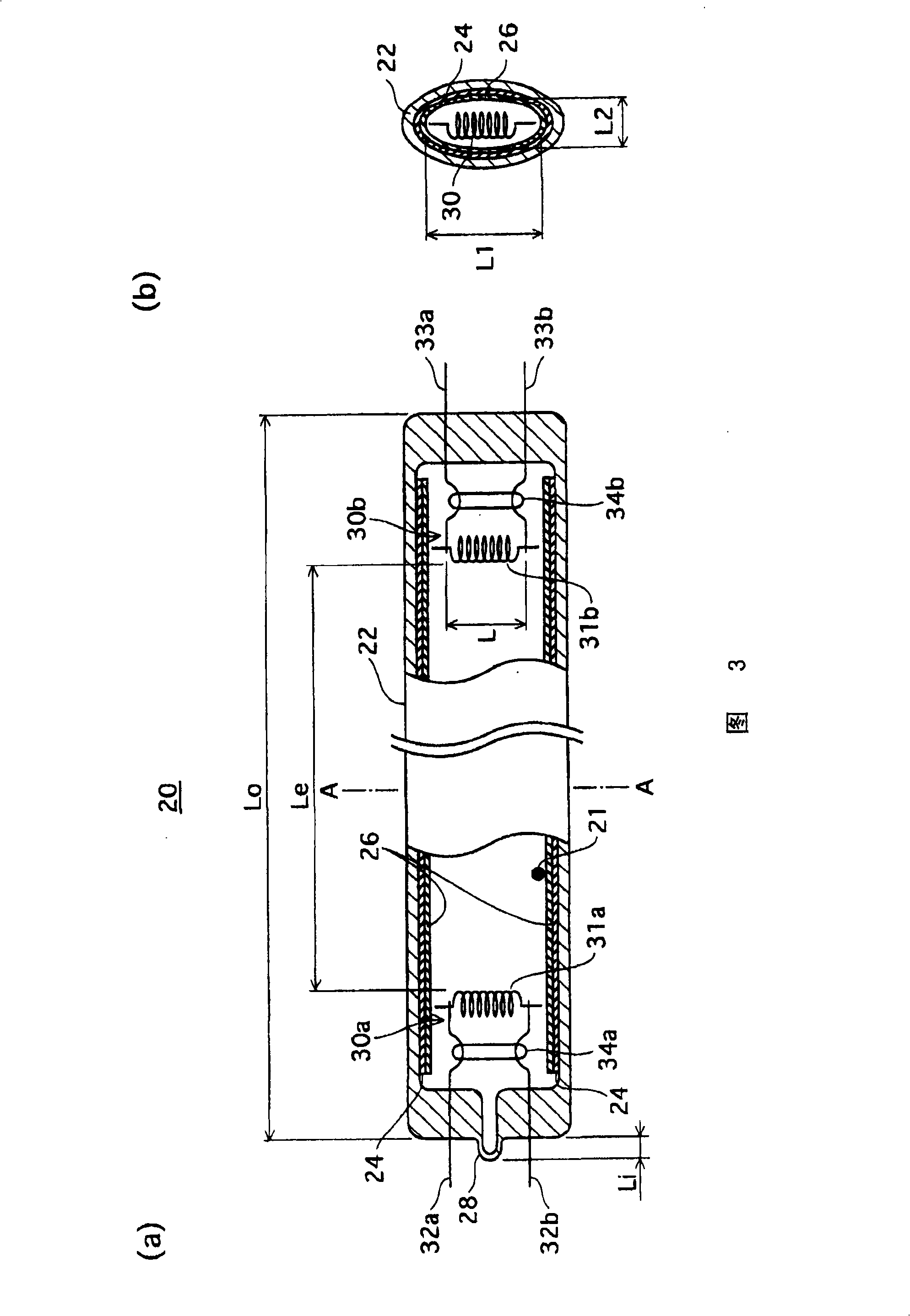

Hot cathode discharge lamp, lamp unit and display

InactiveCN101263576AHigh partial pressure ratioSolution to short lifeElongate light sourcesElectric lightingOptoelectronicsLight source

Disclosed is a hot cathode discharge lamp (20) comprising a glass bulb (22) whose cross section perpendicular to the tube axis has a flattened shape, and electrode coils (31a, 31b) arranged within the glass bulb (22) so that the axes thereof are aligned along the major diameter of the flattened shape. The length L of the electrode coils (31a, 31b) in the axis direction satisfies the following relation: L2 < L < L1, with L1 being the major inner diameter of the flattened shape of the glass bulb (22)and L2 being the minor inner diameter thereof. Also disclosed is a backlight unit (5) comprising the hot cathode discharge lamp (20) as a light source.

Owner:PANASONIC CORP

Discharge lamp, in particular low pressure discharge lamp

InactiveCN101501815AEasy temperature controlImprove cooling effectLow-pressure discharge lampsGas discharge lamp detailsEngineeringLow-pressure discharge

Owner:OSRAM GMBH

Asynchronous motor optimizing excitation control method based on magnetic-field saturated non-linear motor model

InactiveCN1206800CImprove performanceIncrease output torqueElectronic commutation motor controlVector control systemsMaximum torqueStator voltage

The present invention belongs to the field of asynchronous motor exciting speed-regulating technology and features the exciting speed-regulating method of optimizing stator-exciting current to regulate rotor magnetic linkage. It MT coordinate system, the finite element analysis to asynchronous motor magnetic field is performed to obtain the effect of saturated motor magnetic field on motor parameters and the stator and rotor magnetic linkage via solving non-linear equation. The magnetic linkage table is optimized to obtain optimized exciting table and maximum torque vs rotation speed table. By means of PI control method to obtain optimized exciting current and reference value of torque current, comparison to practical exciting current and torque current and PI regulation and voltage decoupling, final stator voltage in MT coordinate system is obtained for the control of the inverter.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com