High efficiency bistable electromagnetic clutch

An electromagnetic clutch and bistable technology, applied in the field of drive, can solve problems such as excessive size, difficult control, mechanical impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

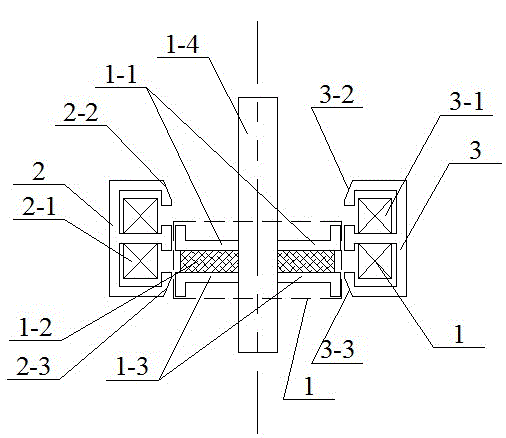

[0008] Specific implementation mode one: as figure 1 As shown, it is composed of a mover 1, a first stator 2, and a second stator 3;

[0009] The mover 1 is composed of an upper disc-shaped magnetizer 1-1, a disc-shaped permanent magnet 1-2, a lower disc-shaped magnetizer 1-3, and a central axis 1-4; the upper disc-shaped magnetizer 1- The lower end face of 1 connects the upper end face of disc-shaped permanent magnet 1-2, and the lower end face of disc-shaped permanent magnet 1-2 connects the upper end face of lower disc-shaped magnetizer 1-3; Last disc-shaped magnetizer 1- The center hole of 1, the center hole of the disc-shaped permanent magnet 1-2, and the center hole of the lower disc-shaped magnetizer 1-3 are all socketed on the central axis 1-4; the first stator 2 and the second stator 3 Both are E-type magnetic conductors, the first stator 2 is inlaid with a first coil 2-1, and the middle magnetic column of the second stator 3 is inlaid with a second coil 3-1; the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com