Four-stage hydromechanical compound transmission

A technology of hydraulic machinery and composite transmission, applied in transmission, fluid transmission, mechanical equipment, etc., can solve the problems of complex system structure, unfavorable system volume and weight, etc., to reduce noise, improve overall efficiency, and improve fuel economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

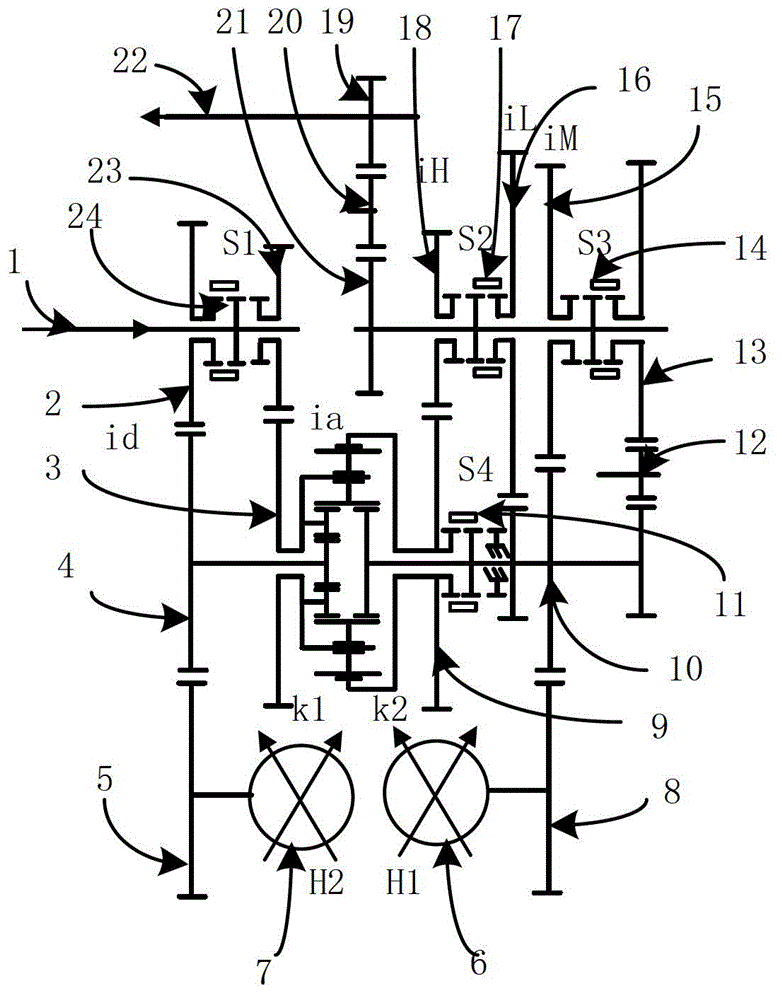

[0026] See attached figure 1 , a four-stage hydromechanical compound transmission device, which includes an input shaft, an output shaft, a planetary transmission part, a fixed shaft gear transmission part, a hydraulic speed regulating part, a section change operation part, an idler A and an idler B idler; in,

[0027] The planetary transmission part is a Lavina planetary mechanism;

[0028] The segment changing operation components include: synchronizer S1, synchronizer S2, synchronizer S3, synchronizer S4;

[0029] The hydraulic speed regulating components include: speed regulating element H1 and speed regulating element H2;

[0030] Fixed shaft gear transmission components include: fixed shaft gear A, fixed shaft gear B, fixed shaft gear C, fixed shaft gear D, fixed shaft gear E, fixed shaft gear F, fixed shaft gear G, fixed shaft gear H, fixed shaft gear I, fixed shaft gear J, fixed shaft gear K and fixed shaft gear L;

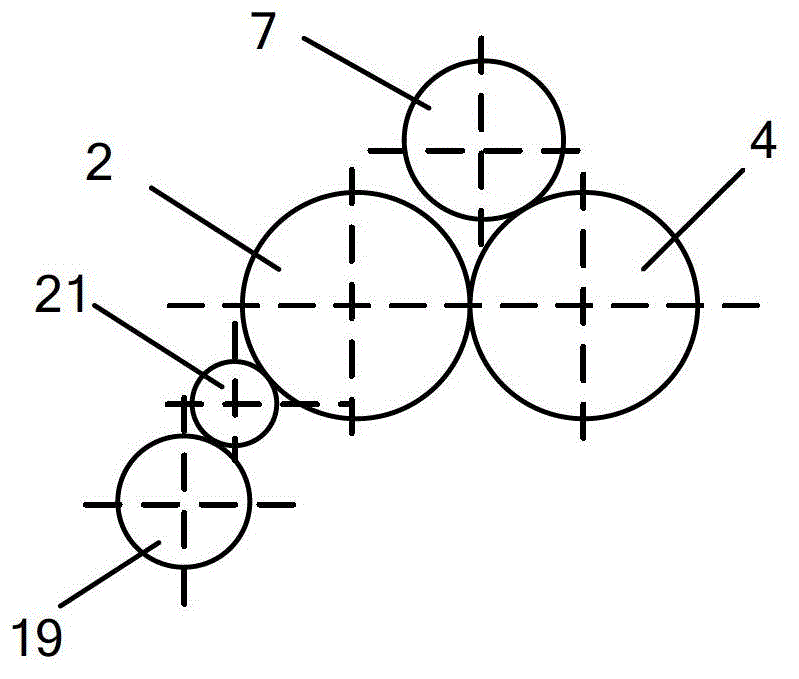

[0031] See attached figure 2 , the overall con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com