Patents

Literature

828results about "Ram jet engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

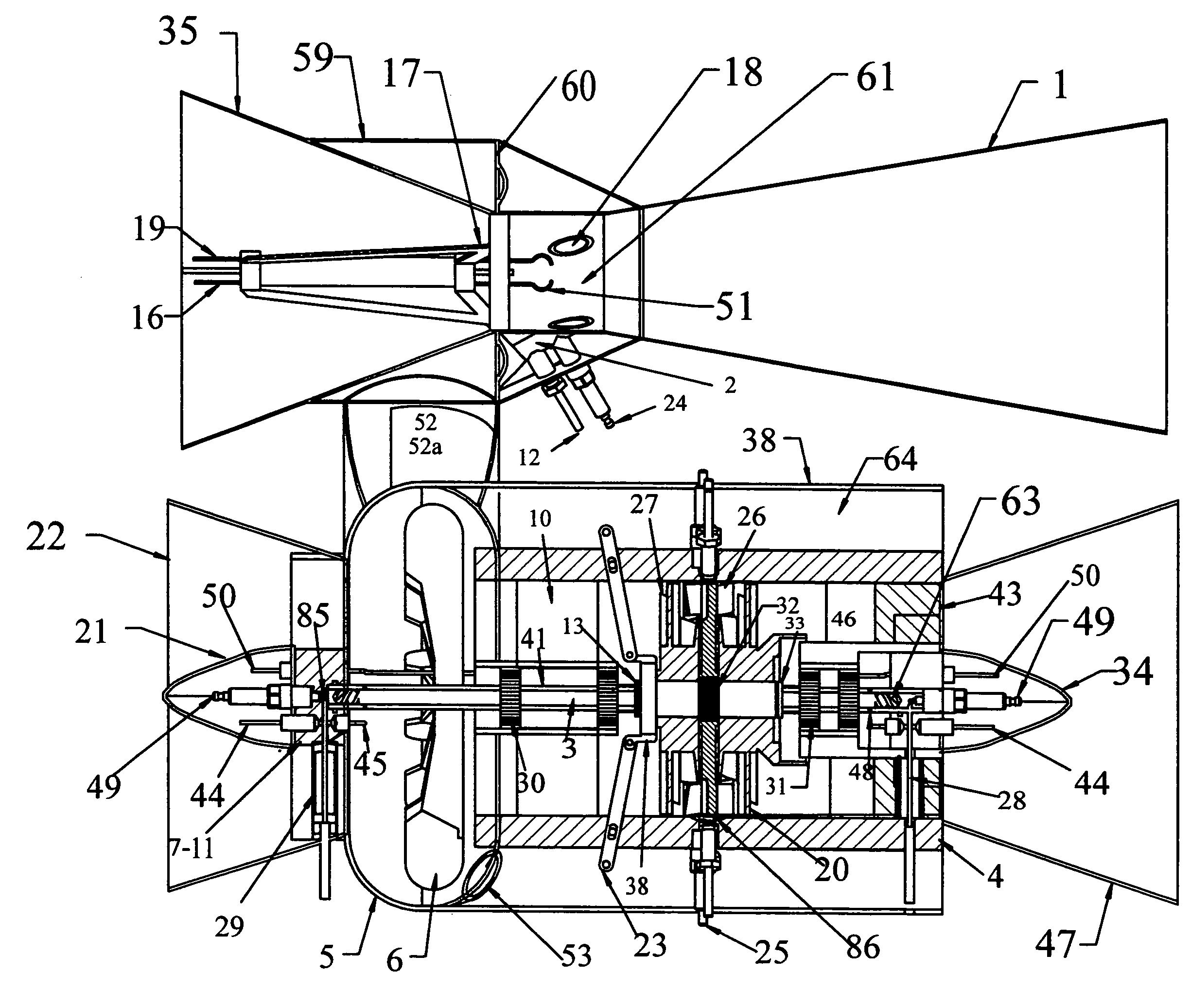

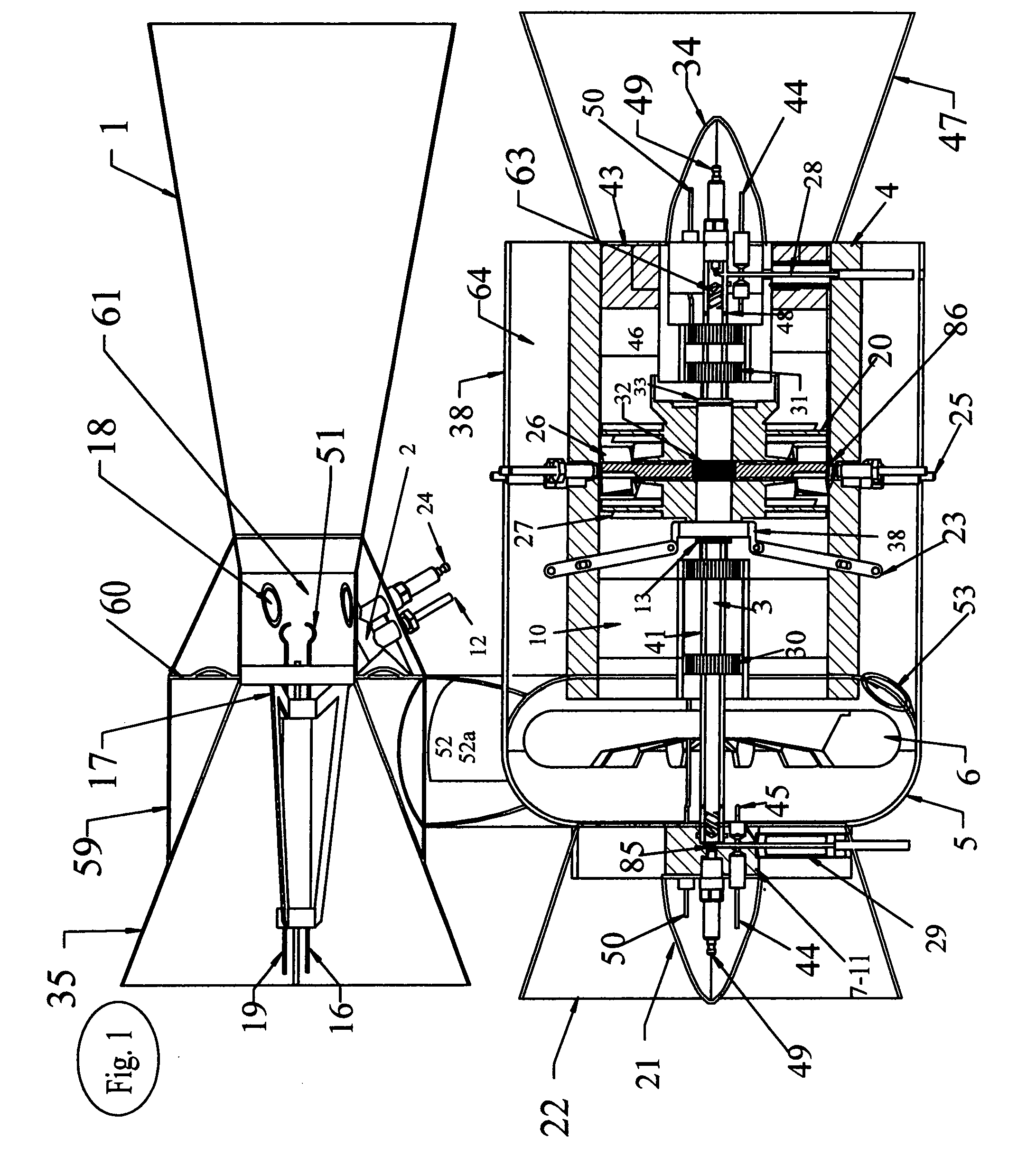

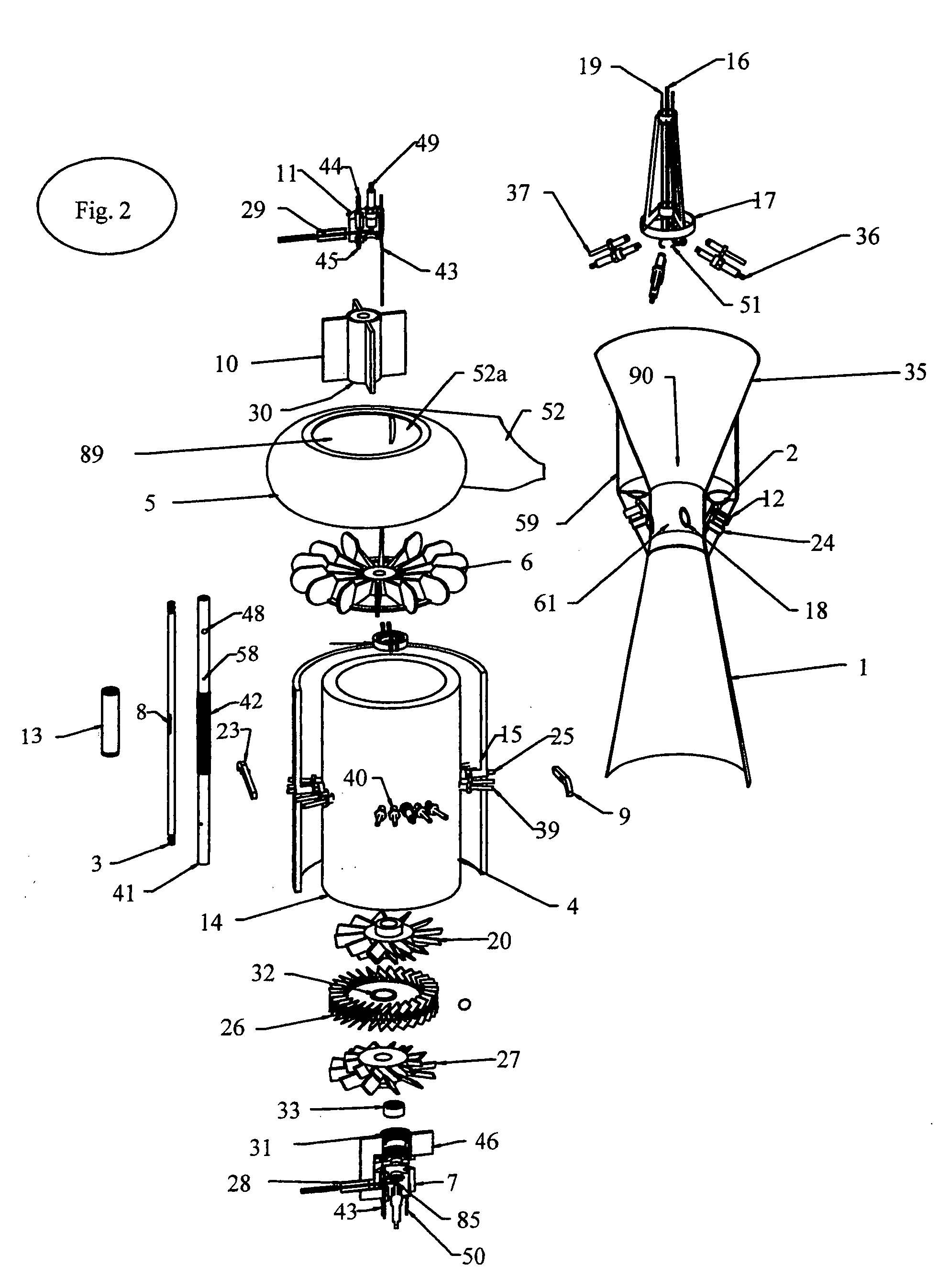

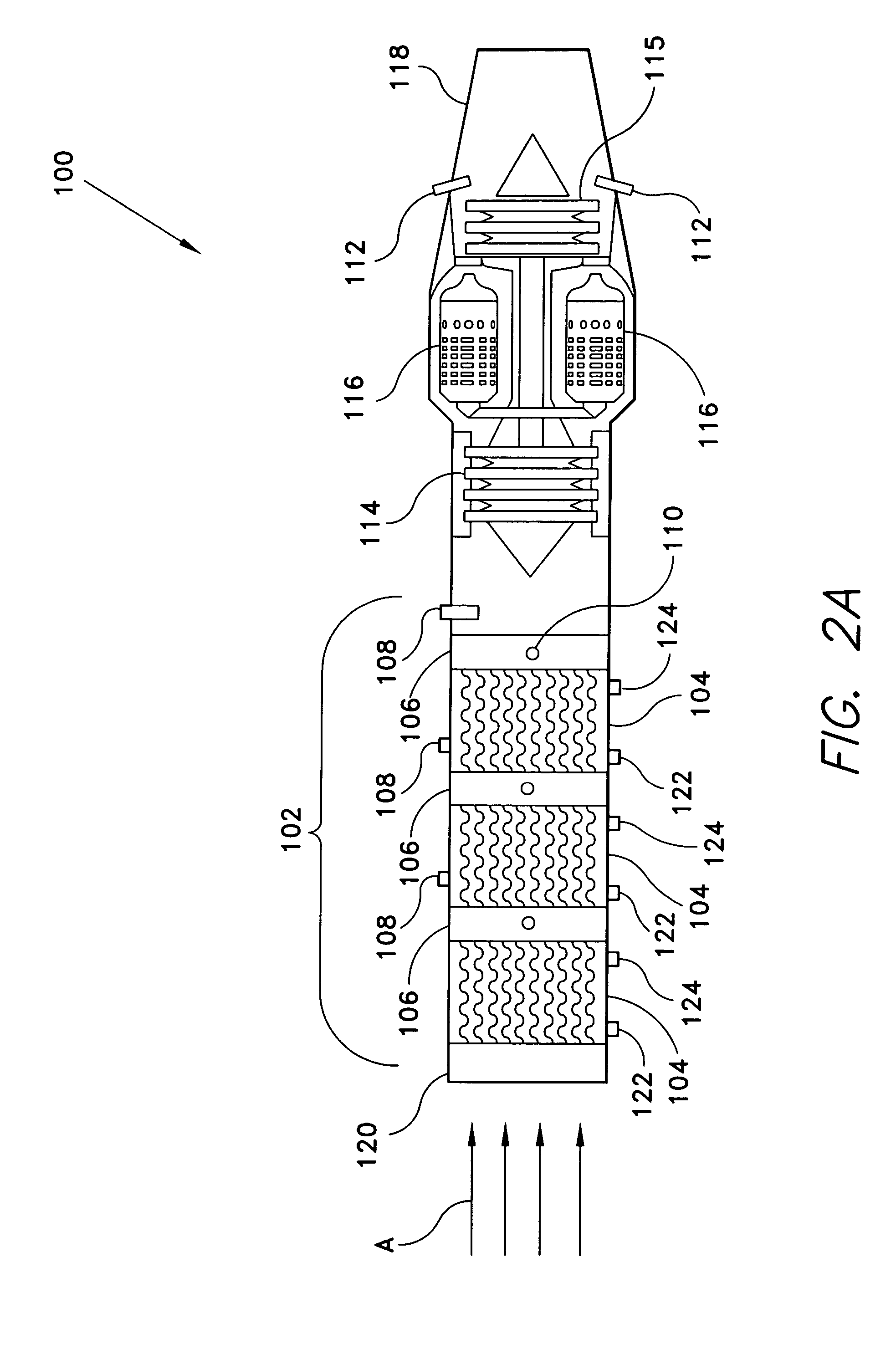

Methods of combining a series of more efficient aircraft engines into a unit, or modular units

InactiveUS20100251692A1More thermal capacityReduce environmental pollutionContinuous jet plantsRocket engine plantsRamjetFree-piston engine

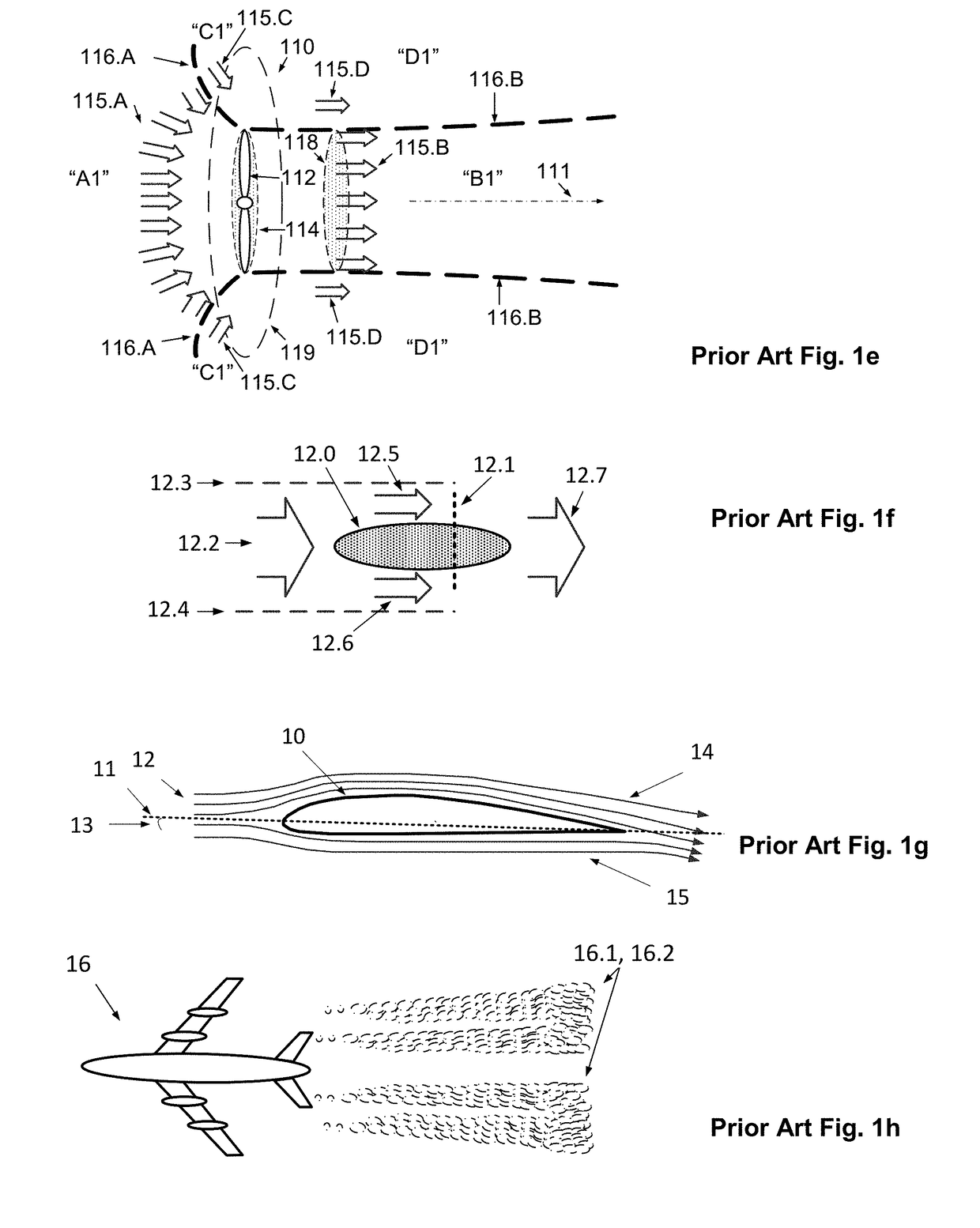

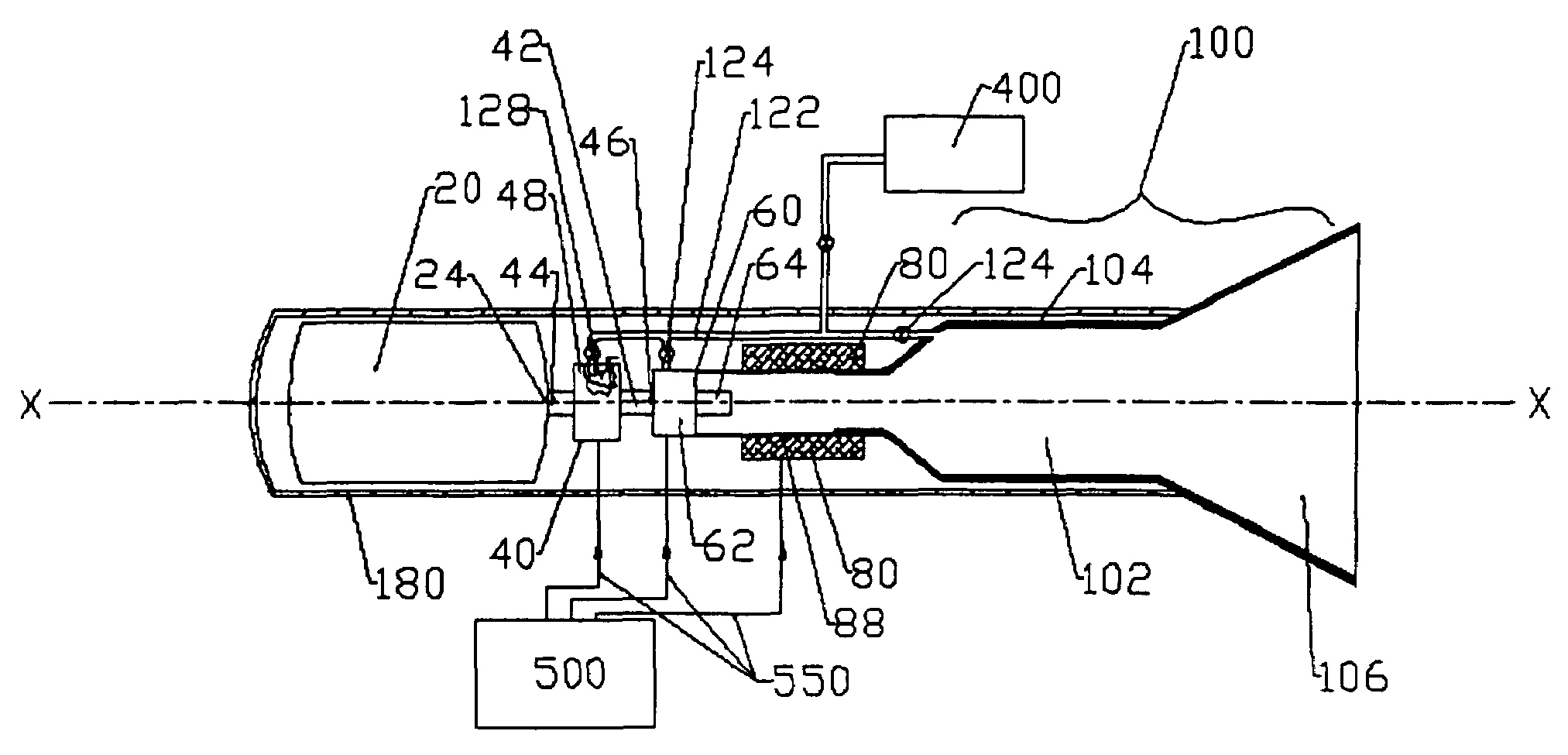

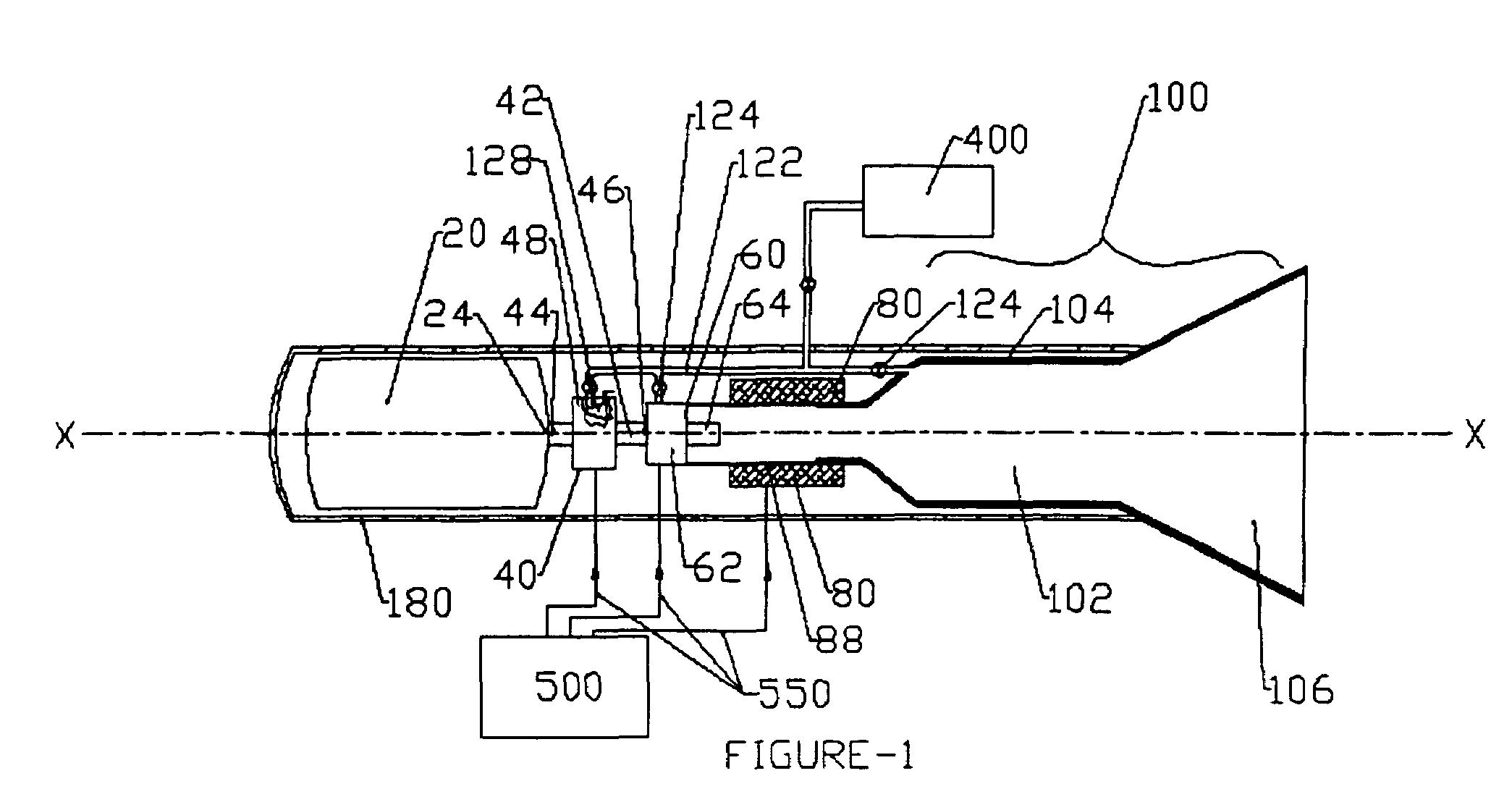

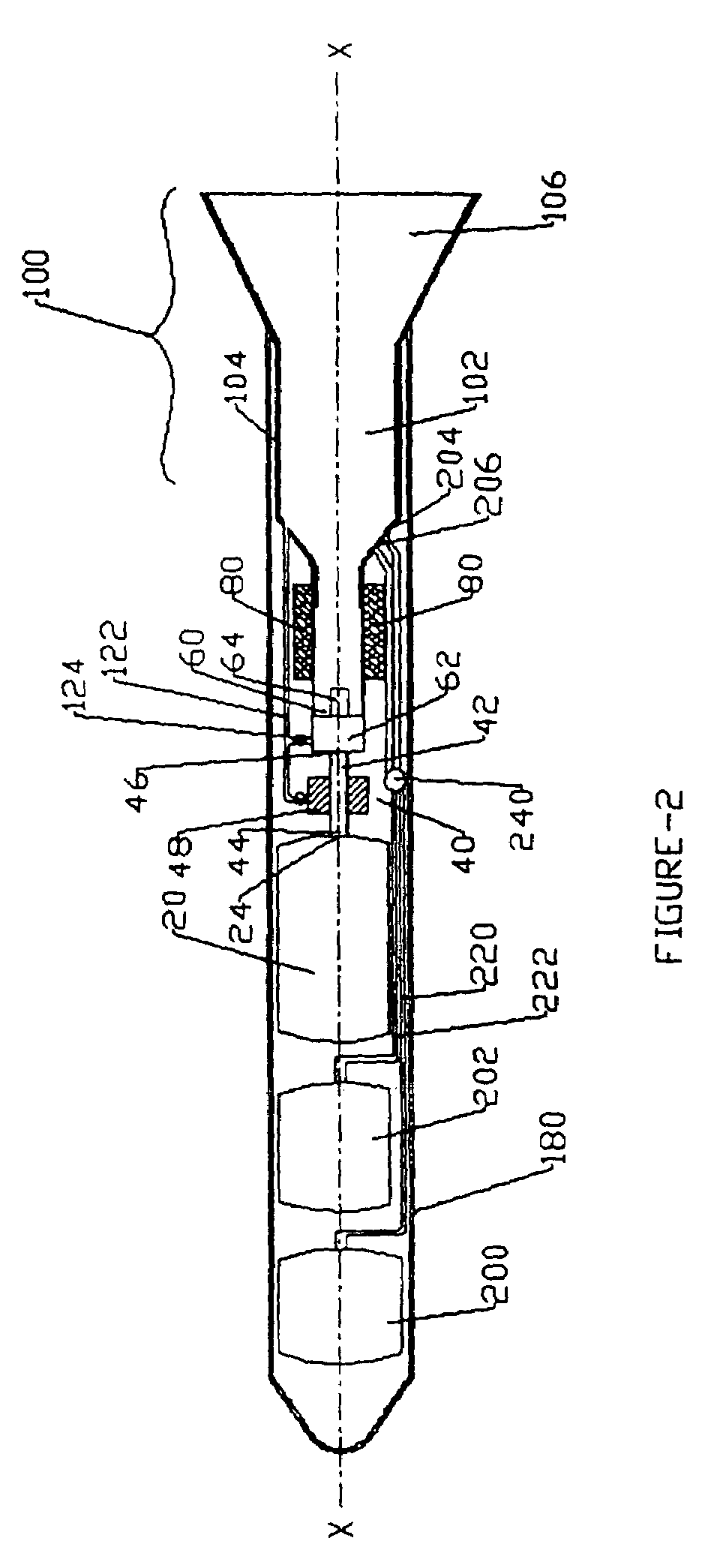

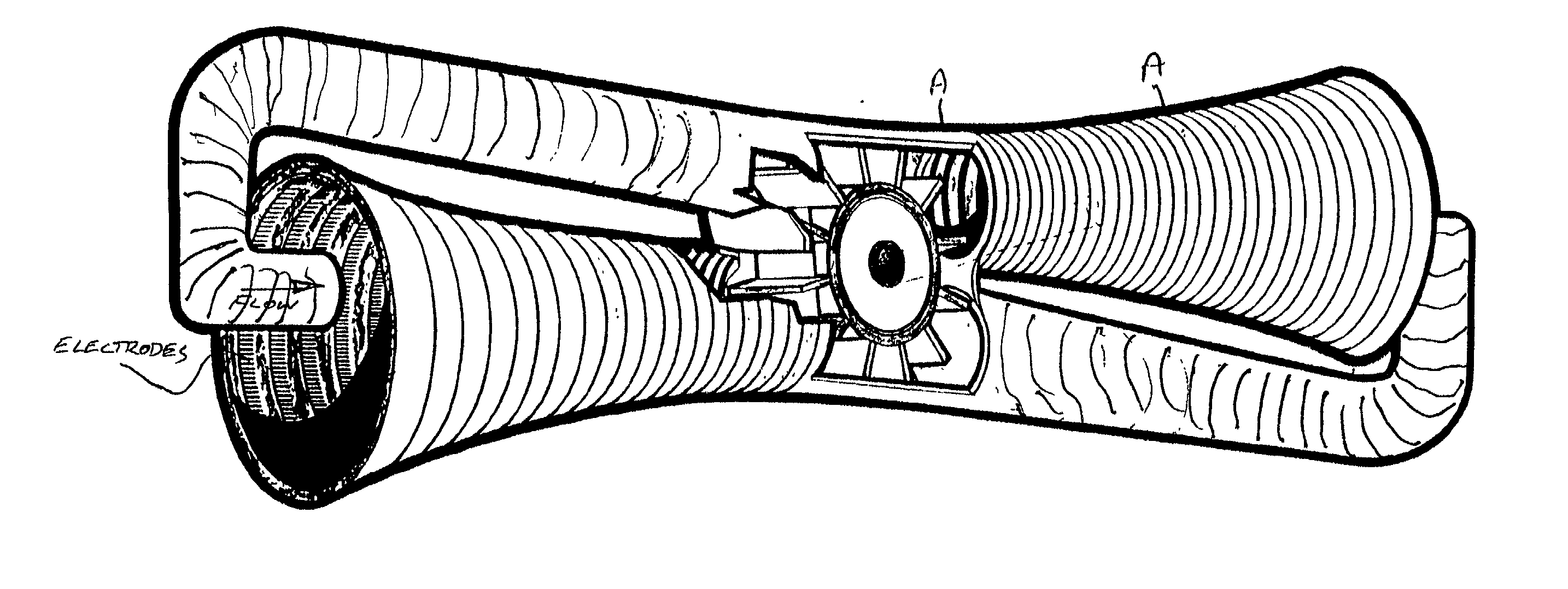

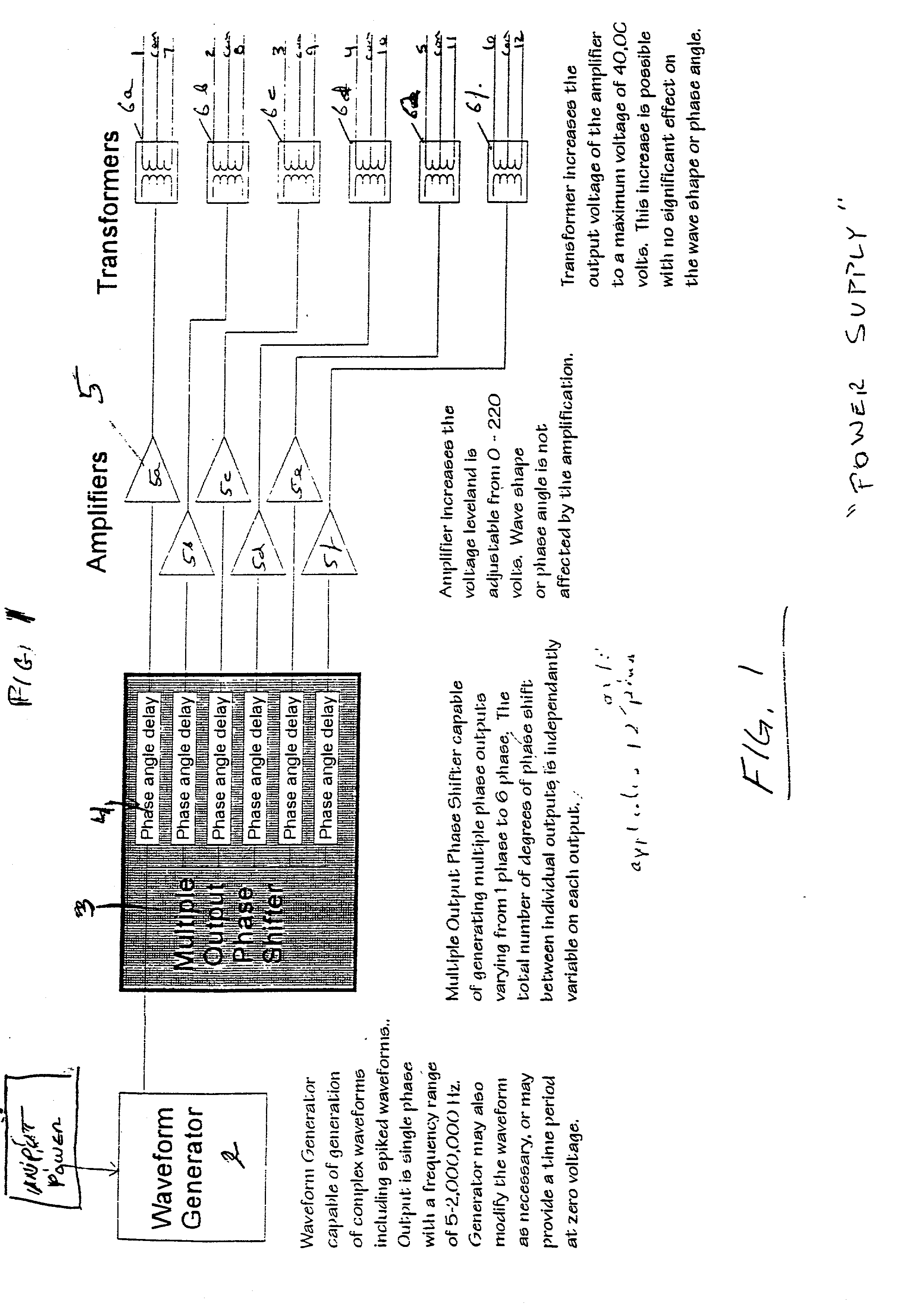

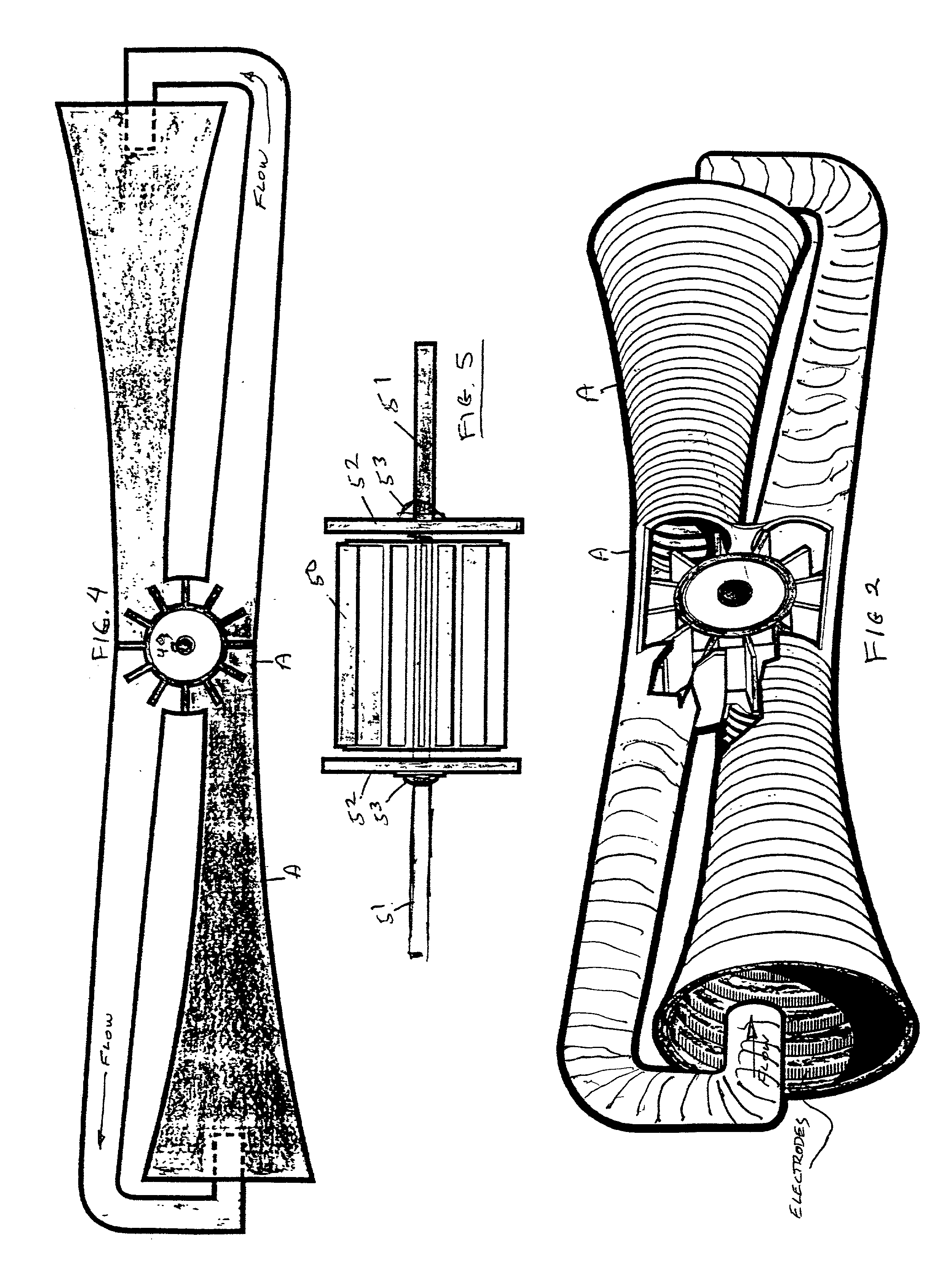

The present invention generally relates to units of engines and more particularly to units containing a unique combined-cycle (combustion-detonation) “counter-rotation, anti-gyration, gyroscopic,” turbine fan-jet / free-piston engine configuration for induced air supercharging and boosting the performance of novel Ramjet engines or Ramjet engine configurations by improving internal air-stream dynamics. These dynamics are the result of co-operative air stream intermixing through convergent, supercharge-attenuated, inducted, compressed, tuned, pre-heated ambient air. Achieved through the varying of the geometric structural form and the utilization of unique engines and air induction and propulsion conformations, aided with supplemental air, fuel, oxygen and optiomal water and electrolyte charging.

Owner:KINDE SR RONALD AUGUST

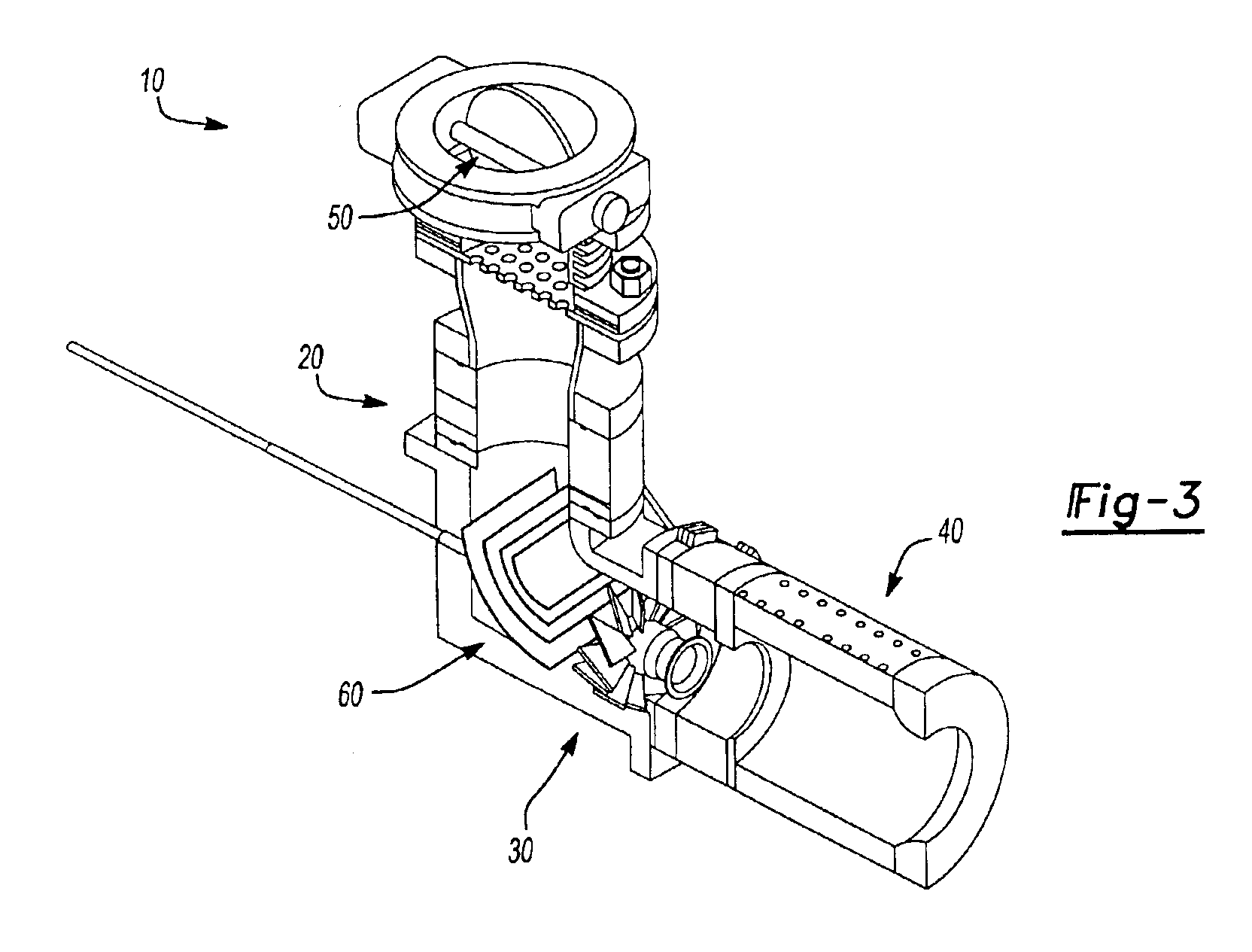

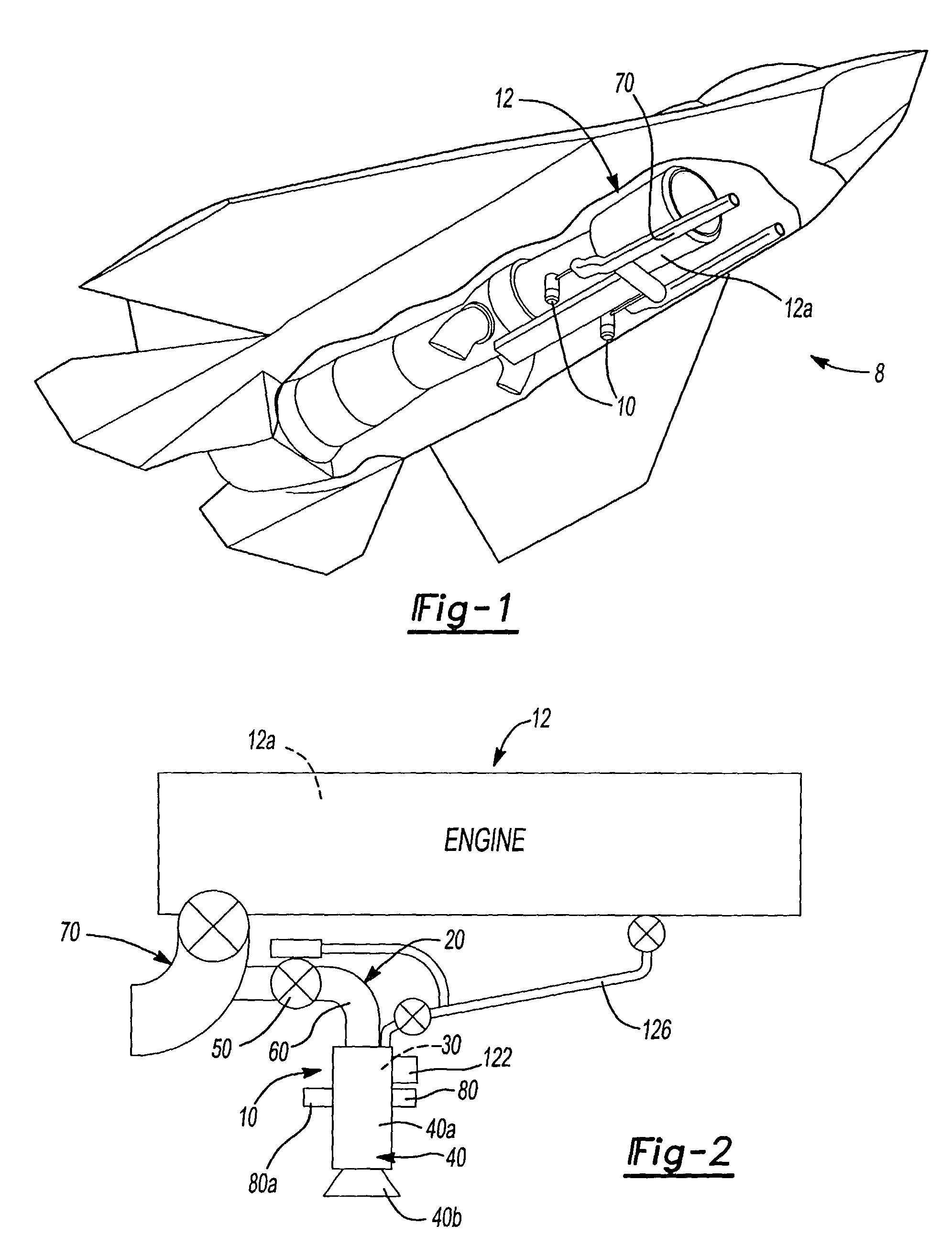

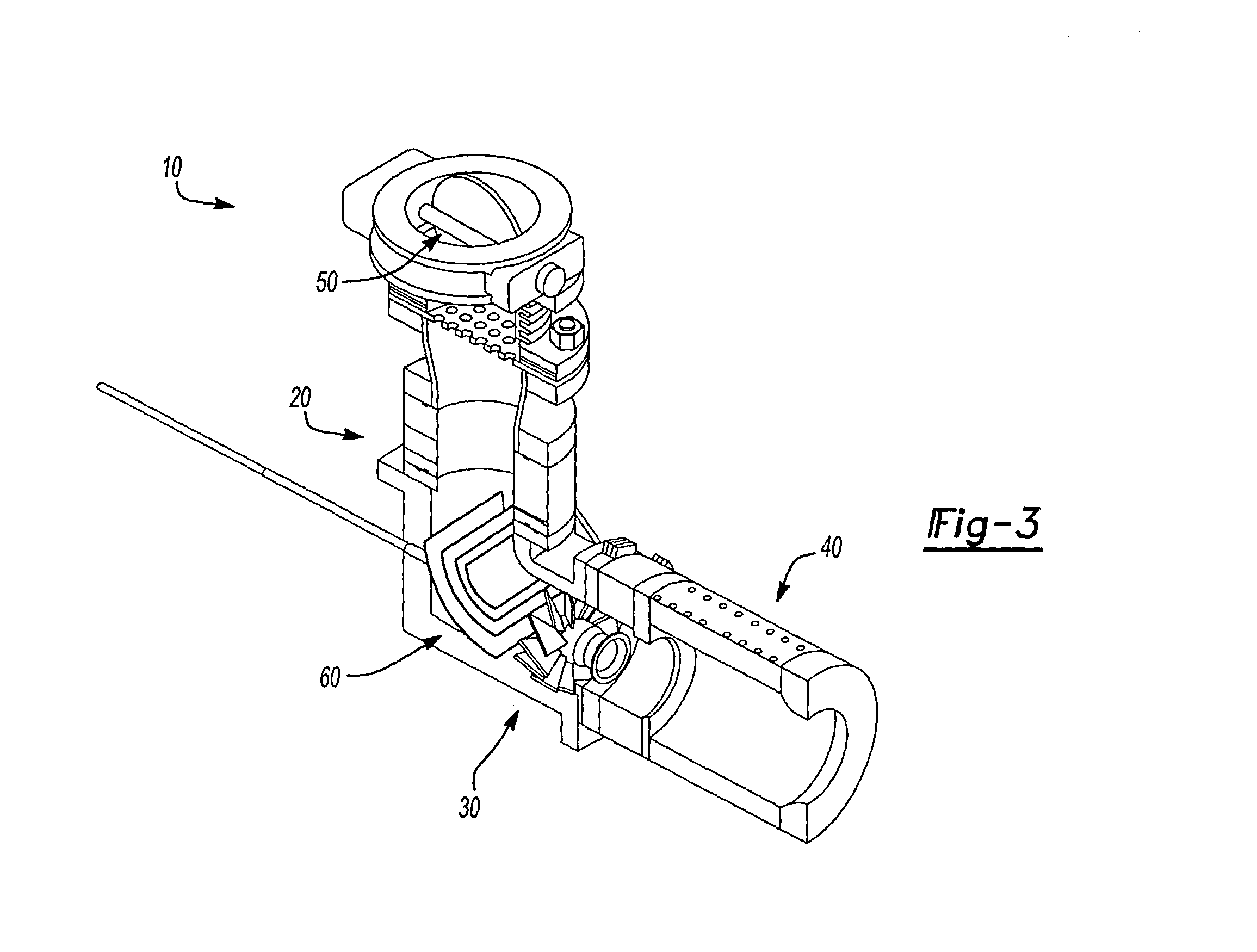

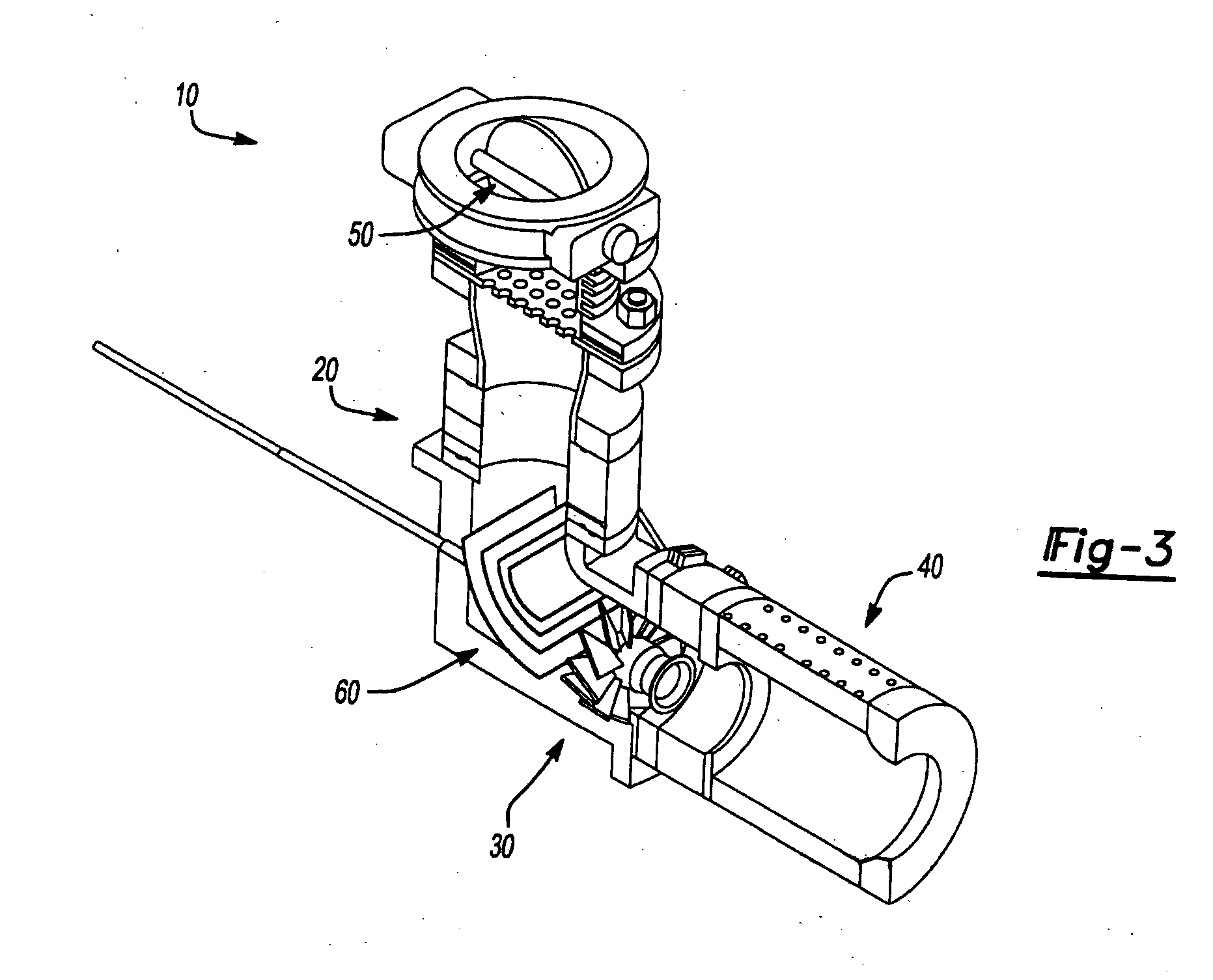

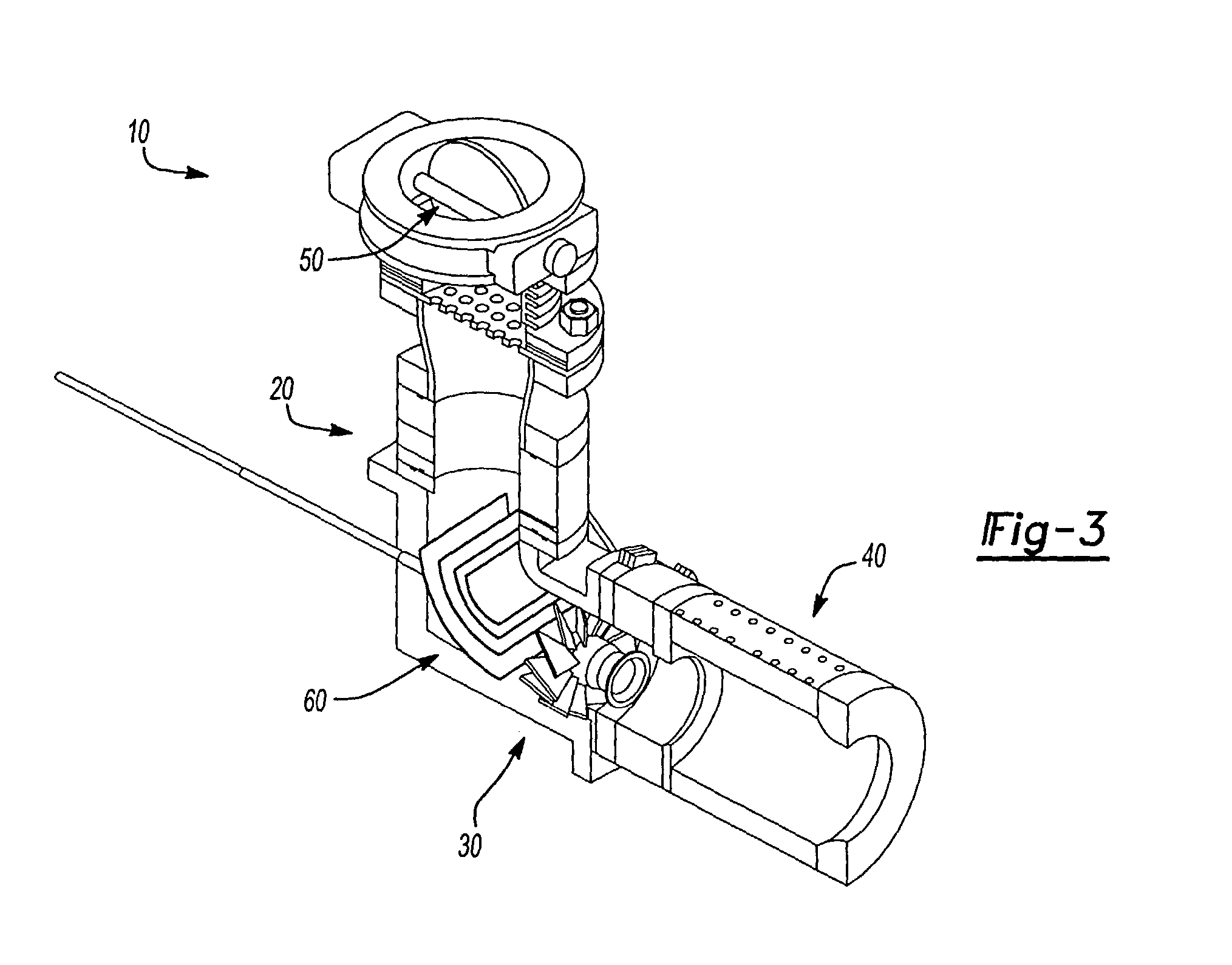

Compact swirl augmented afterburners for gas turbine engines

InactiveUS6895756B2Efficient flame propagationBurn quicklyTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityCombustion chamber

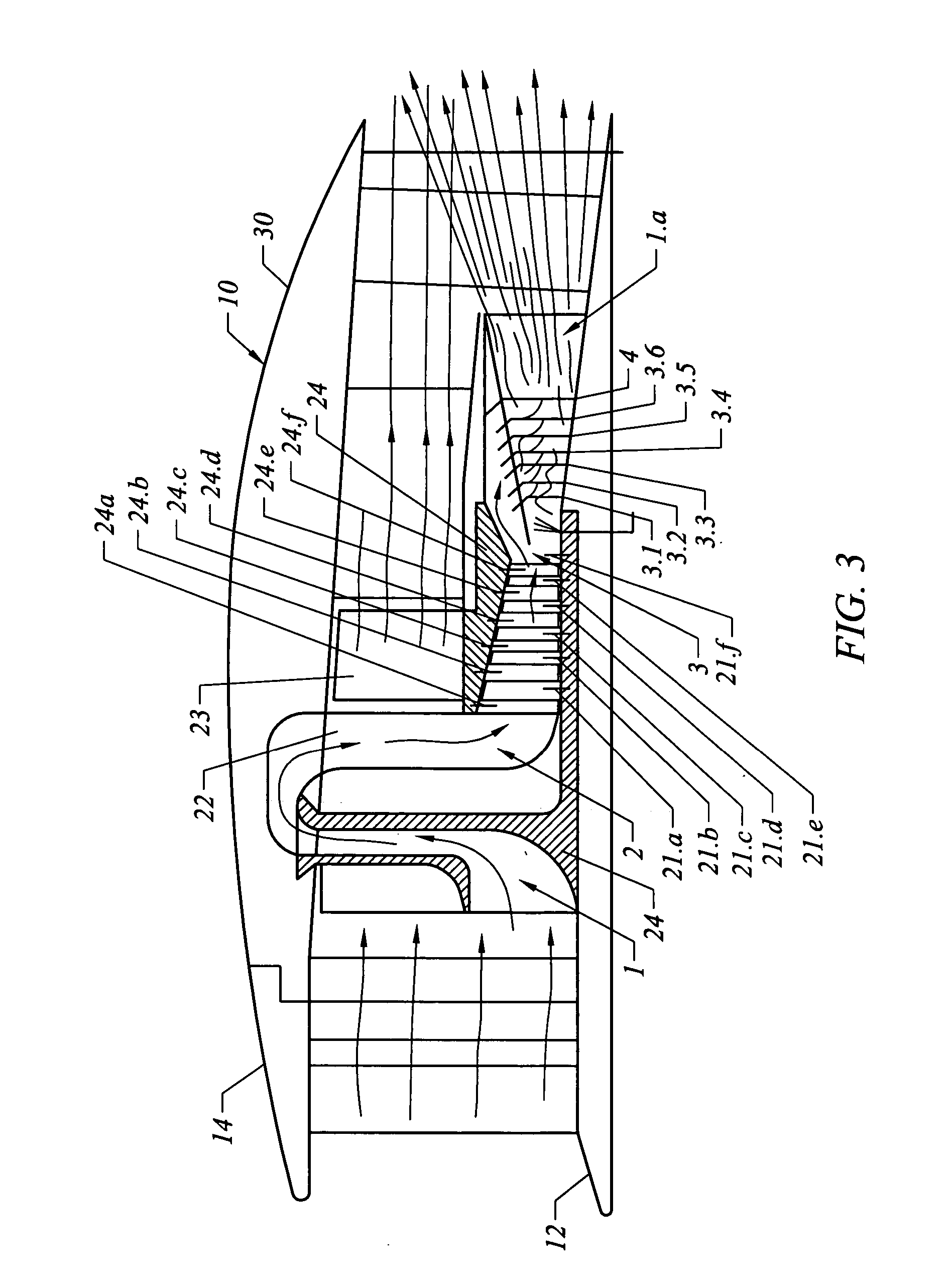

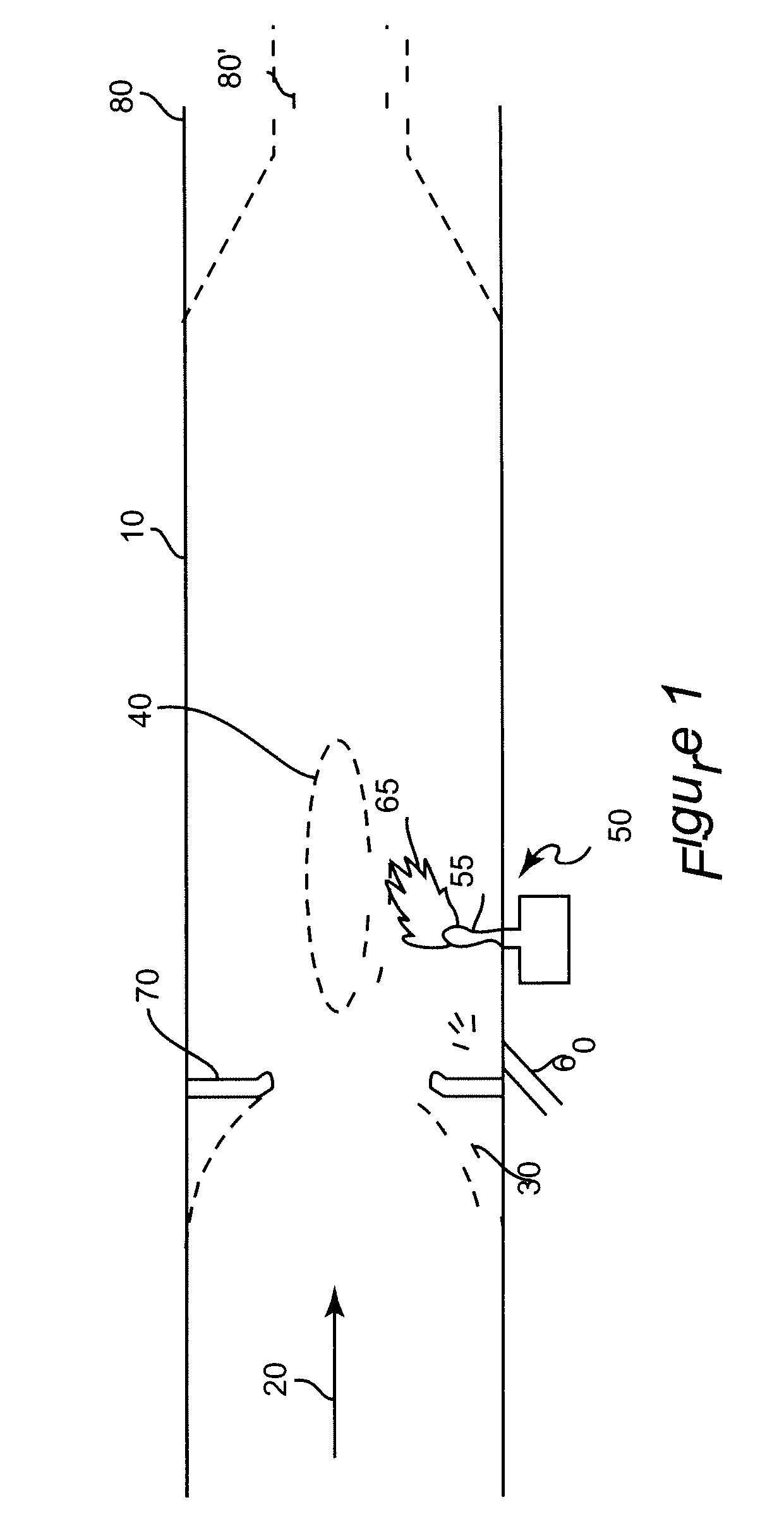

An afterburner apparatus that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and a central recirculation zone, which is positioned within the outer recirculation zone. These recirculation zones are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers. The recirculation zones accelerate flame propagation to allow afterburning to be completed in a relatively short length. Inherent with this swirl afterburner concept are design compactness, light weight, lower cost, smooth and efficient combustion, high thrust output, wide flammability limits, continuous operation at stoichiometric fuel / oxidizer mixture ratios, no combustion instabilities, and relatively low pressure losses.

Owner:THE BOEING CO +1

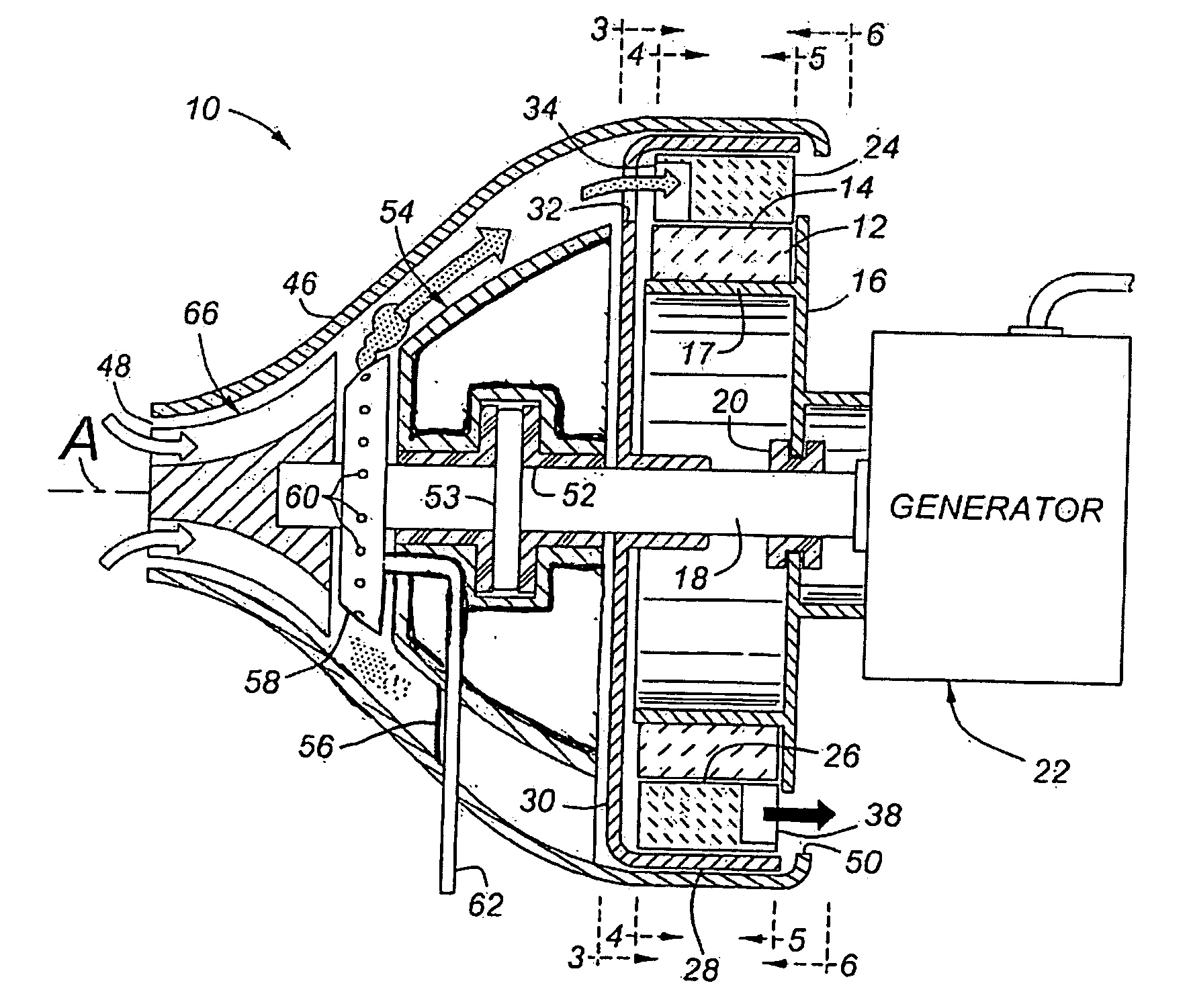

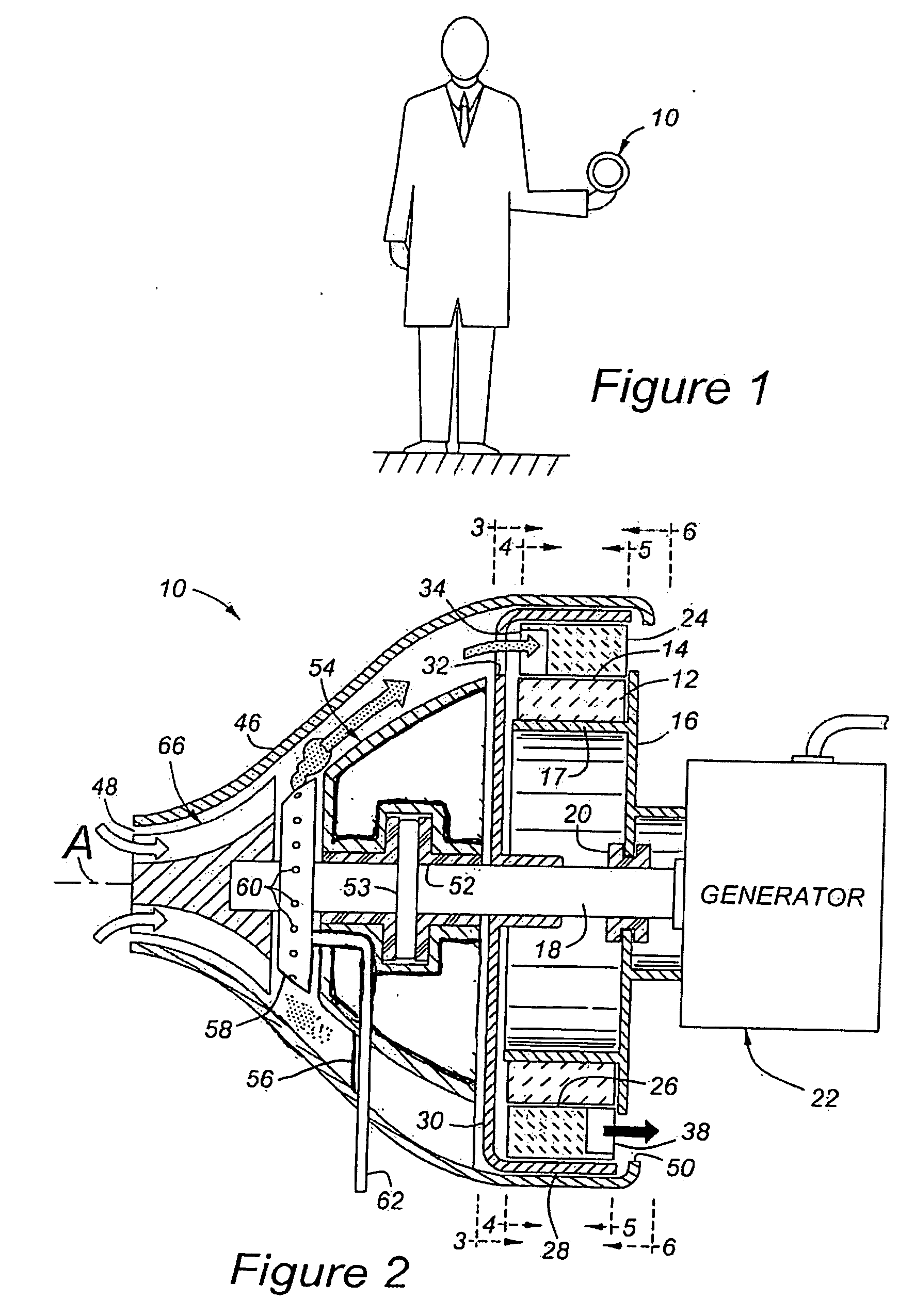

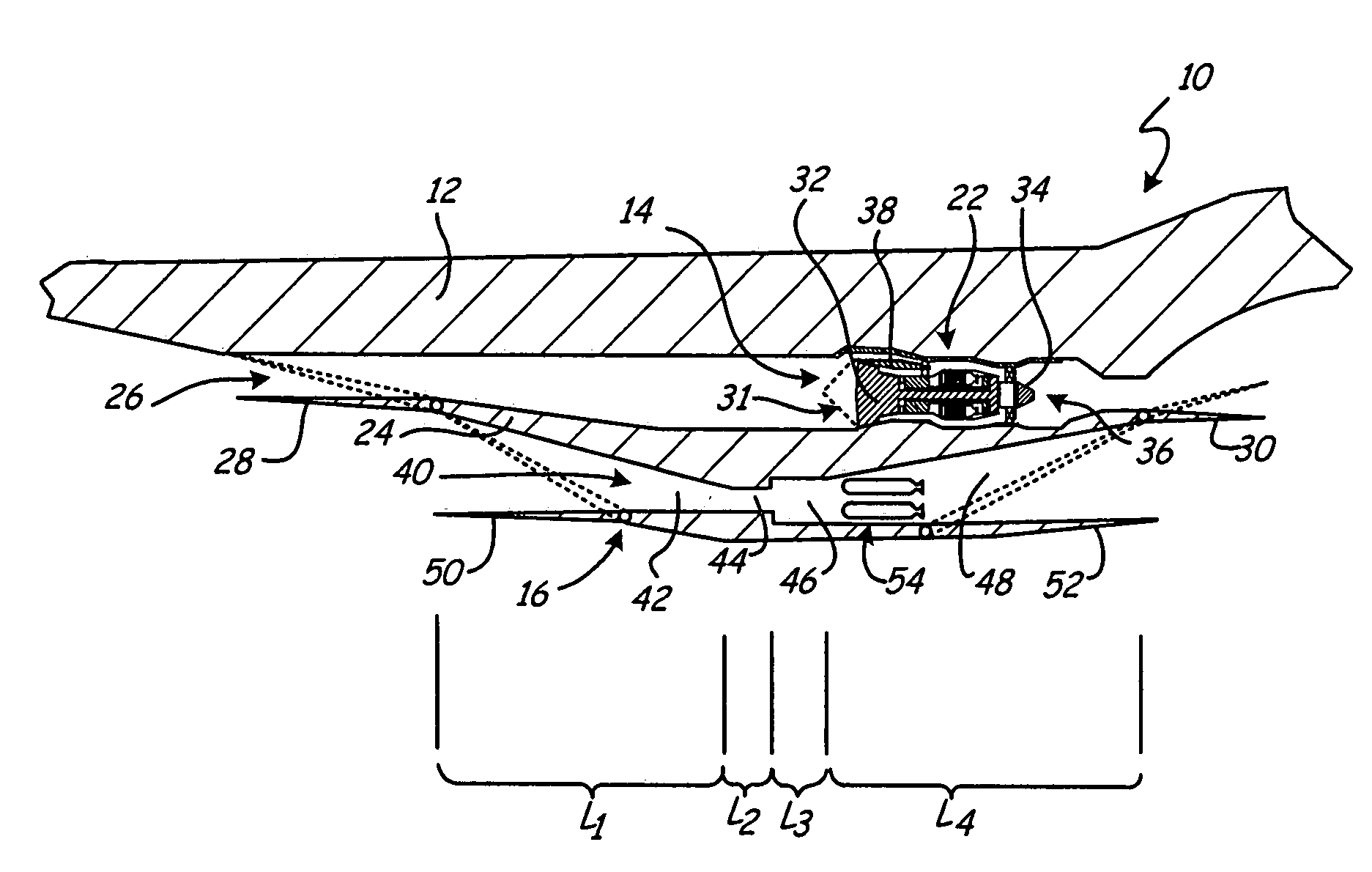

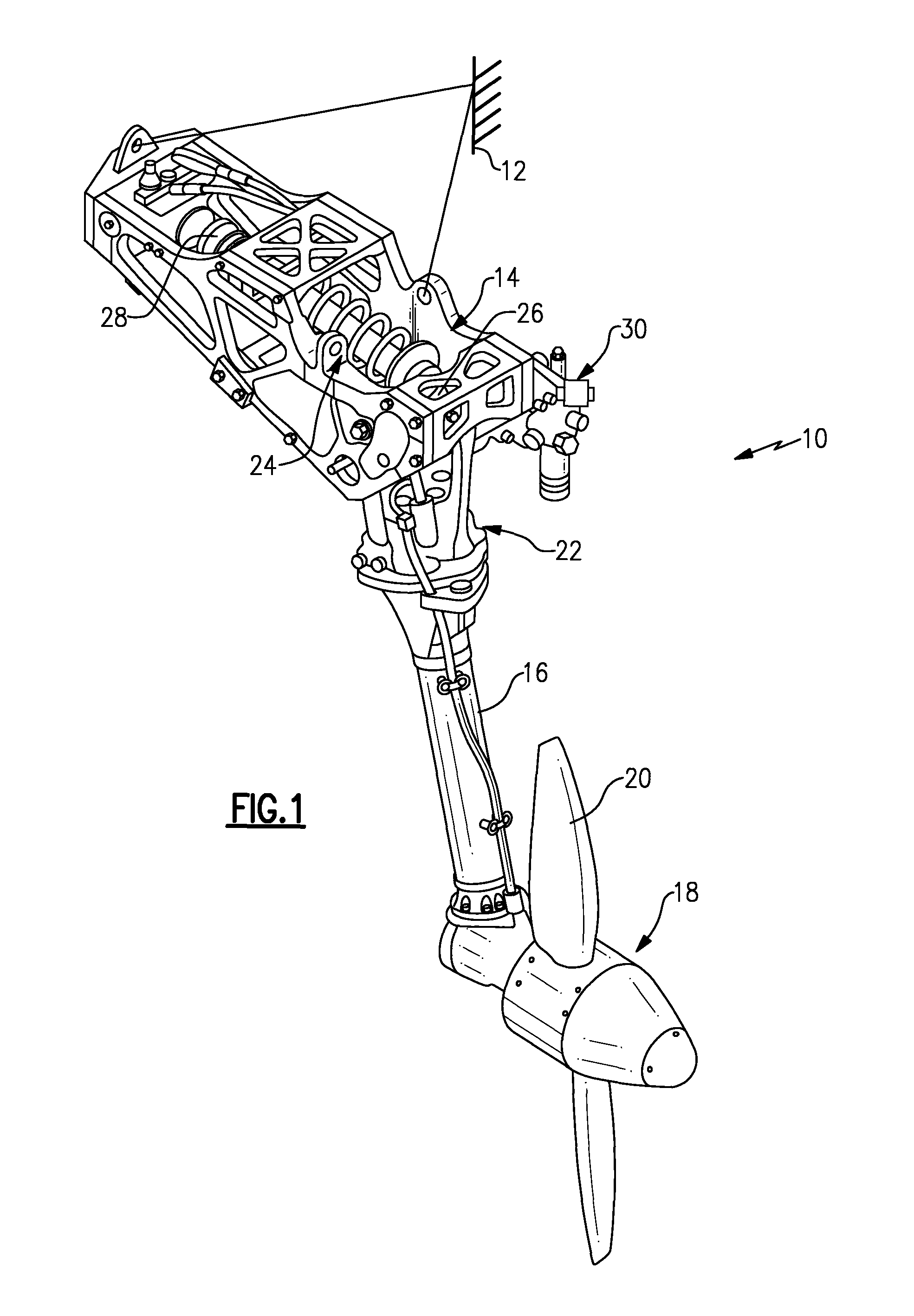

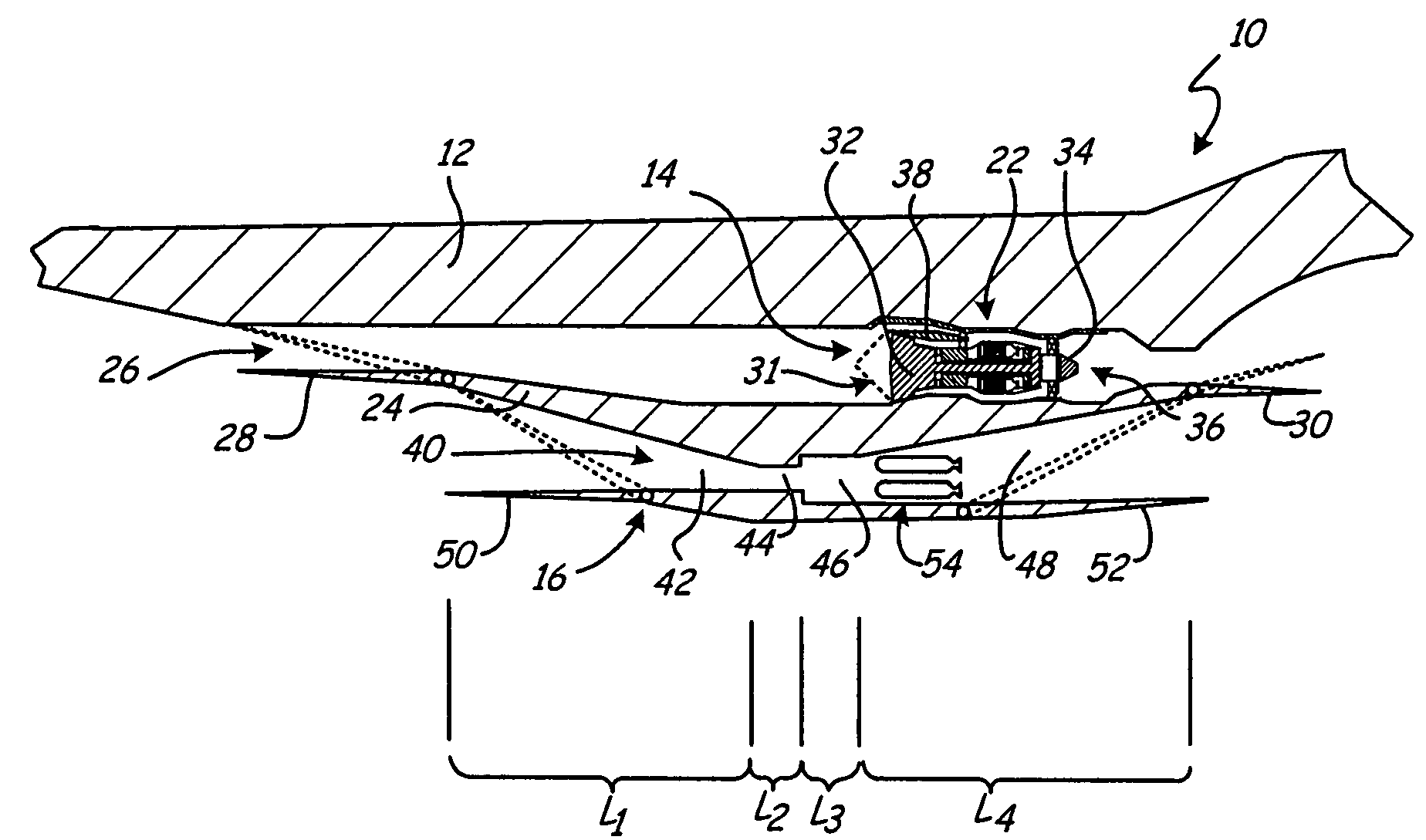

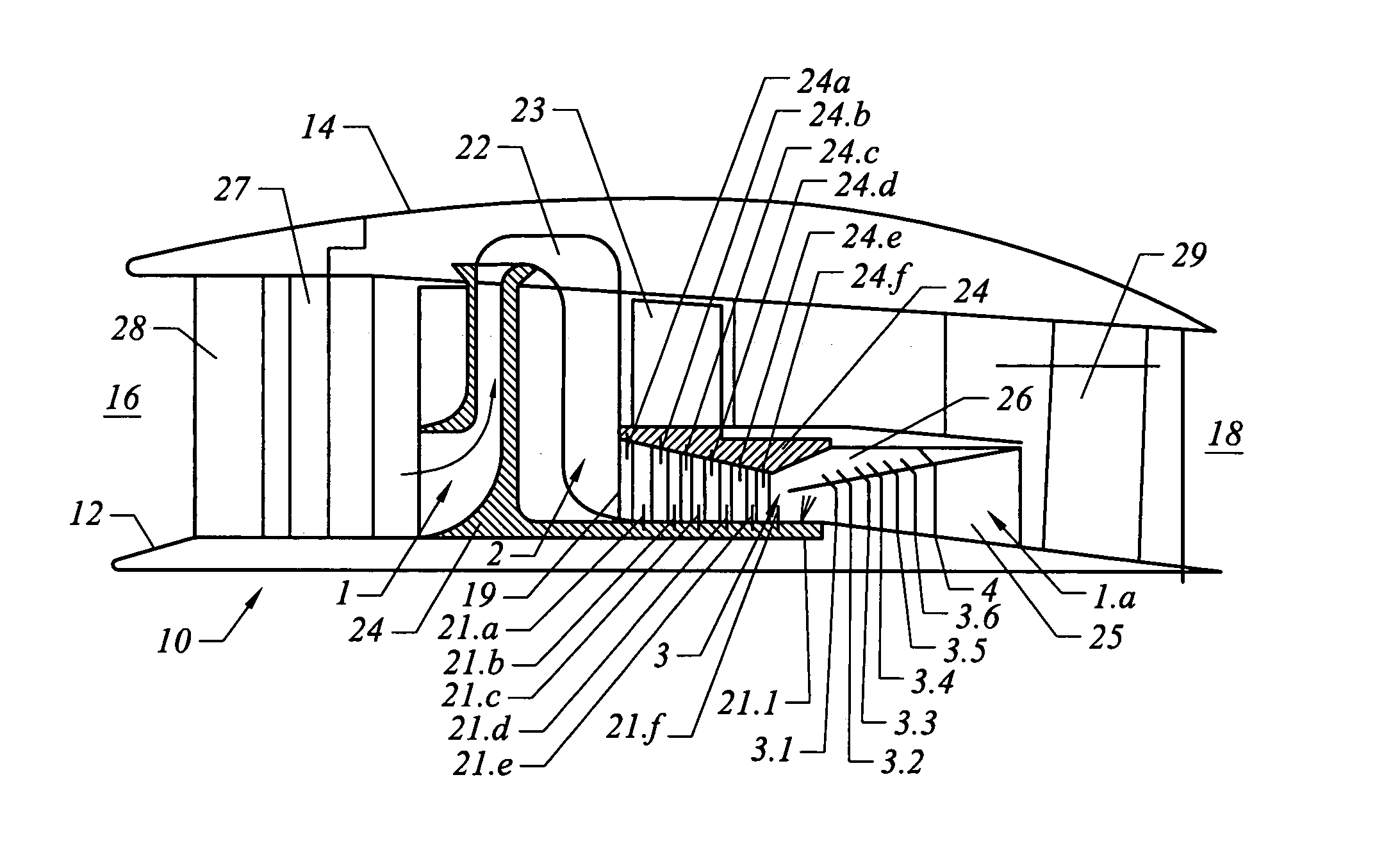

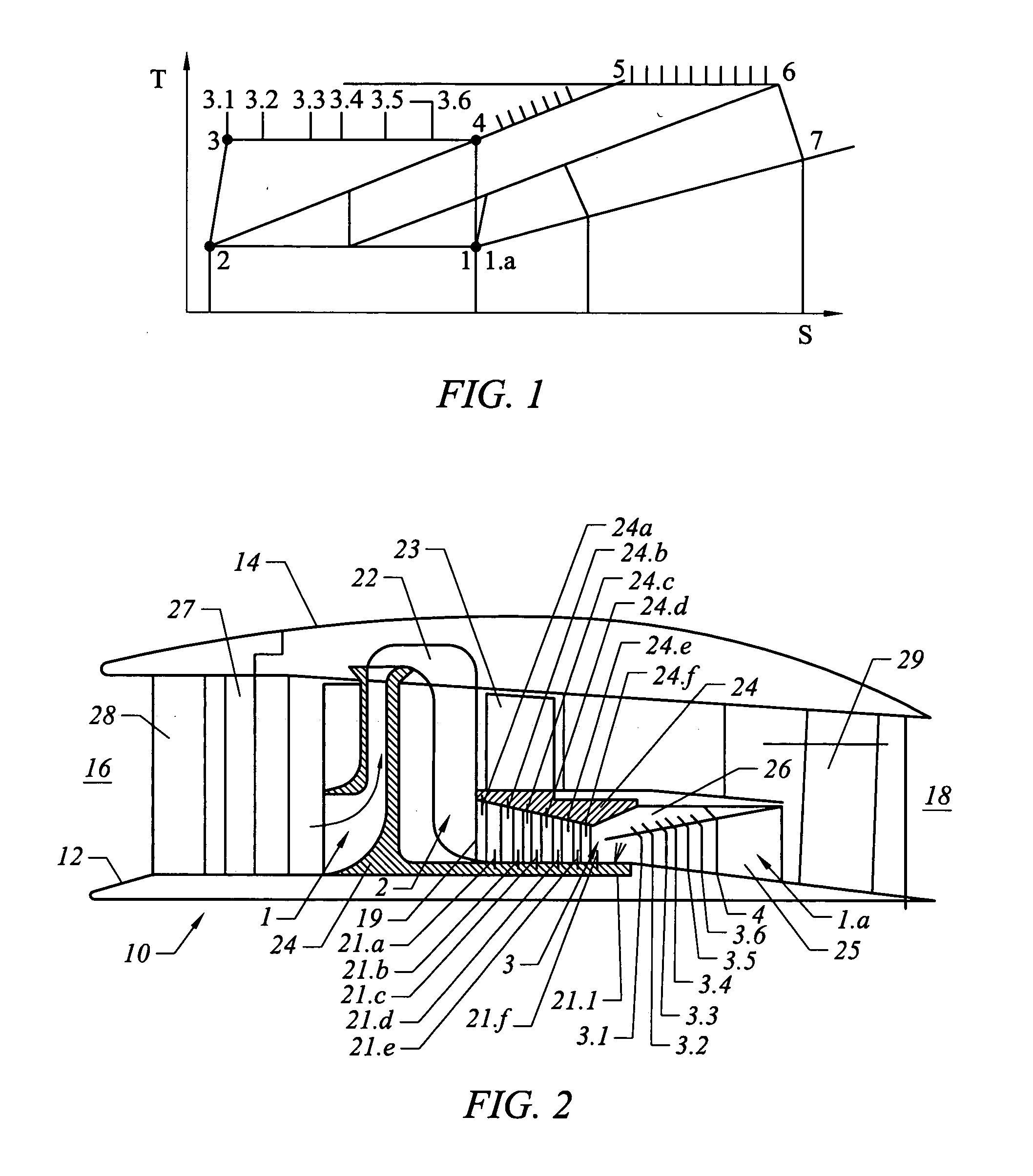

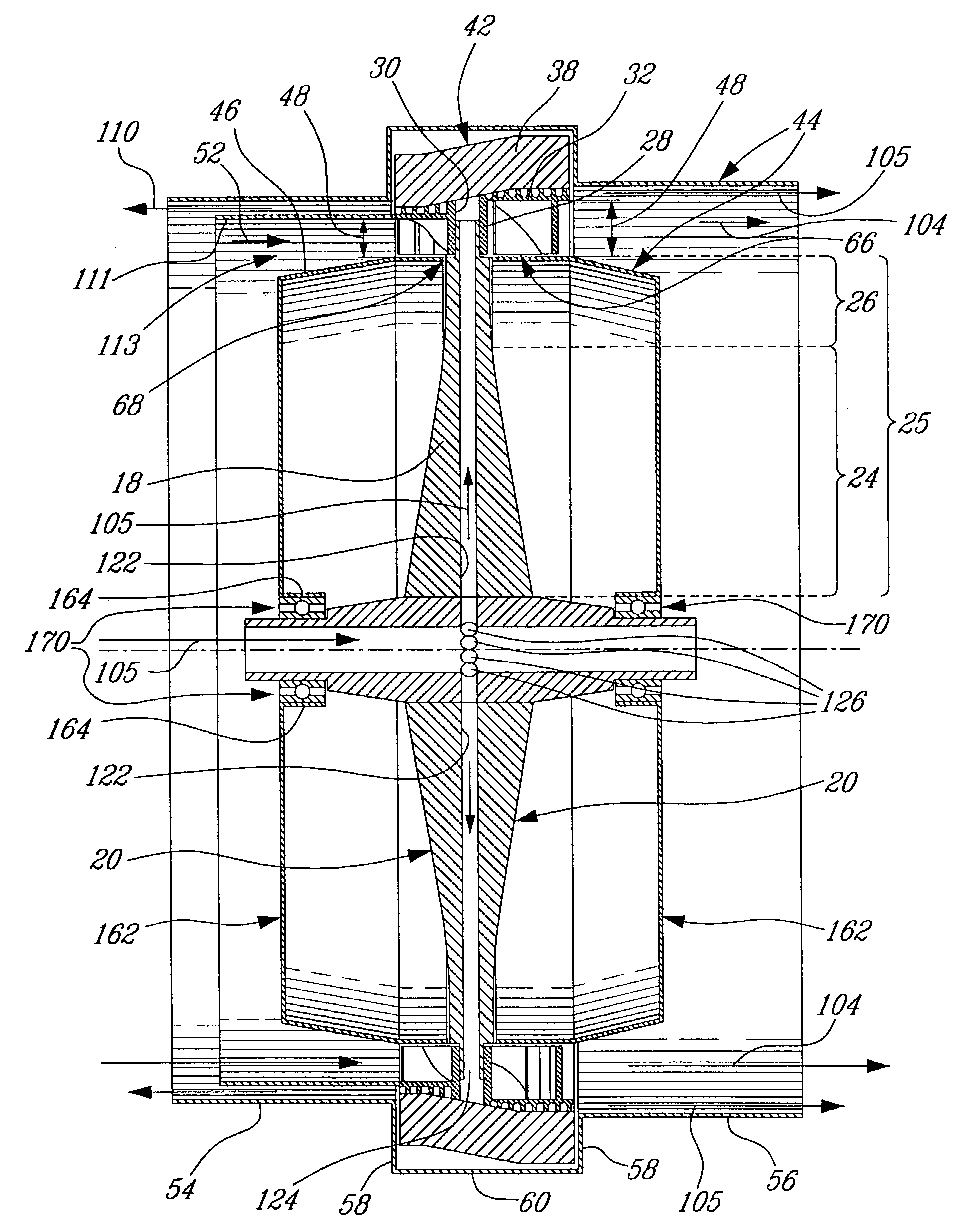

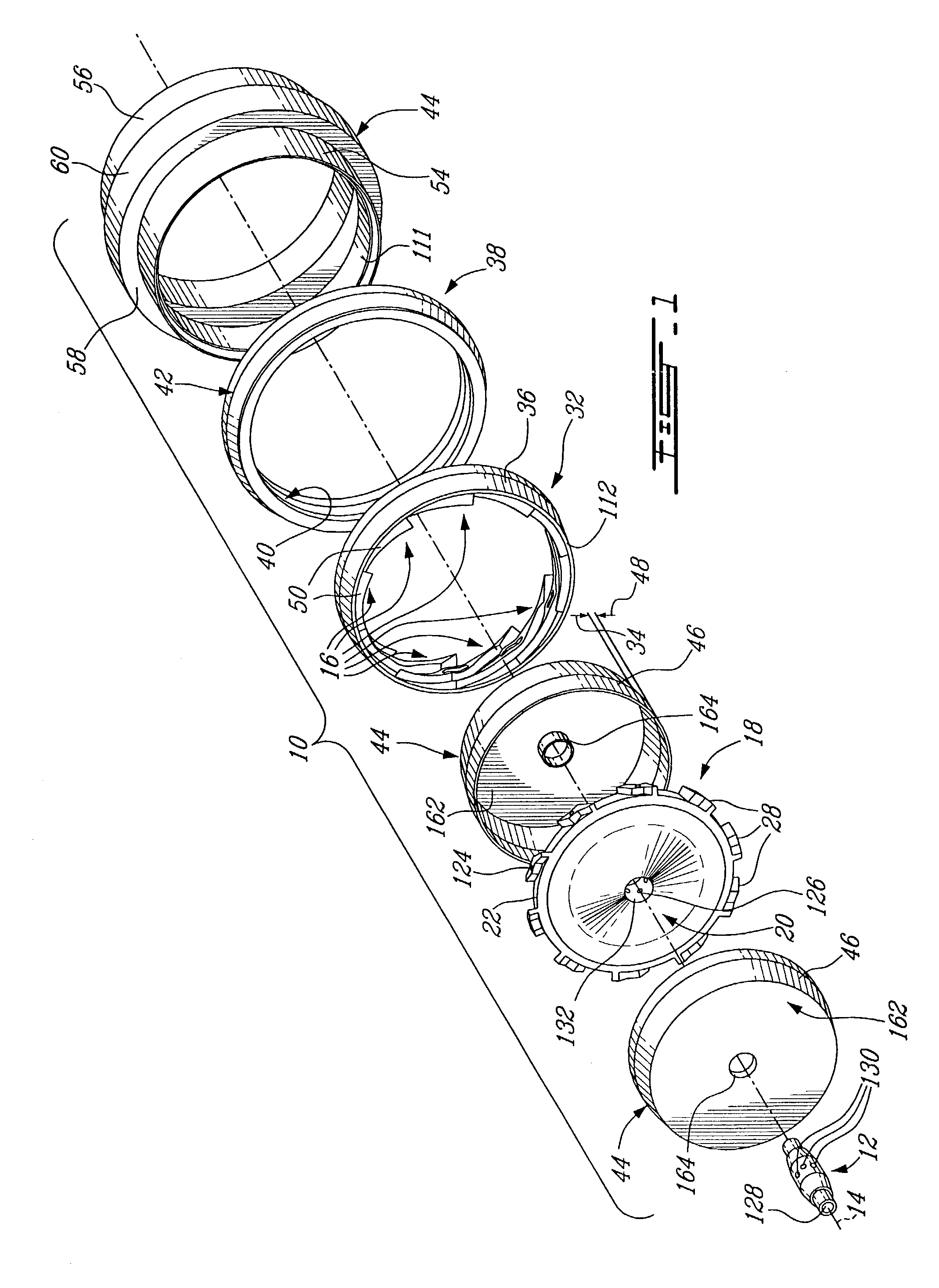

Rotary ramjet turbo-generator

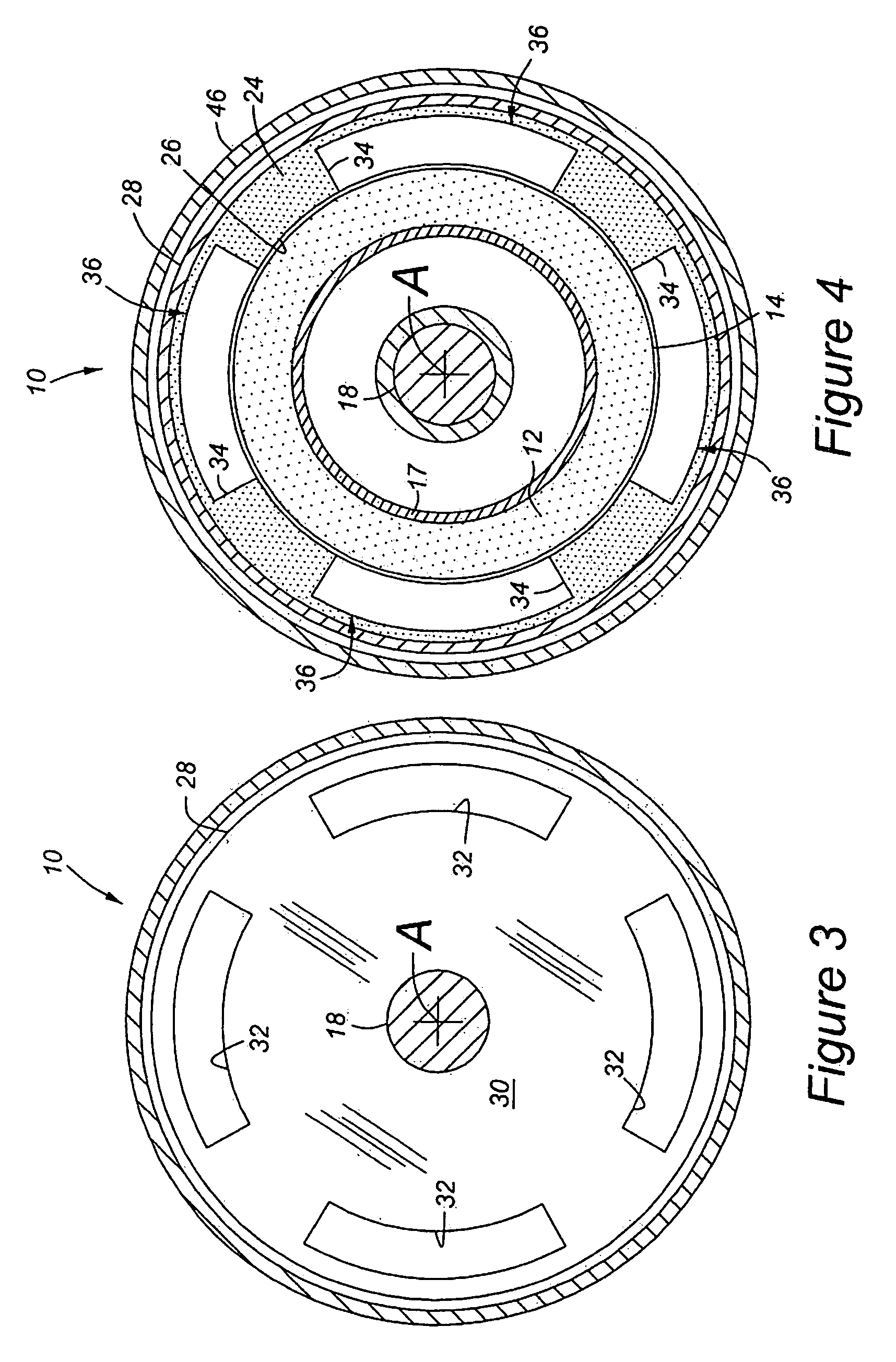

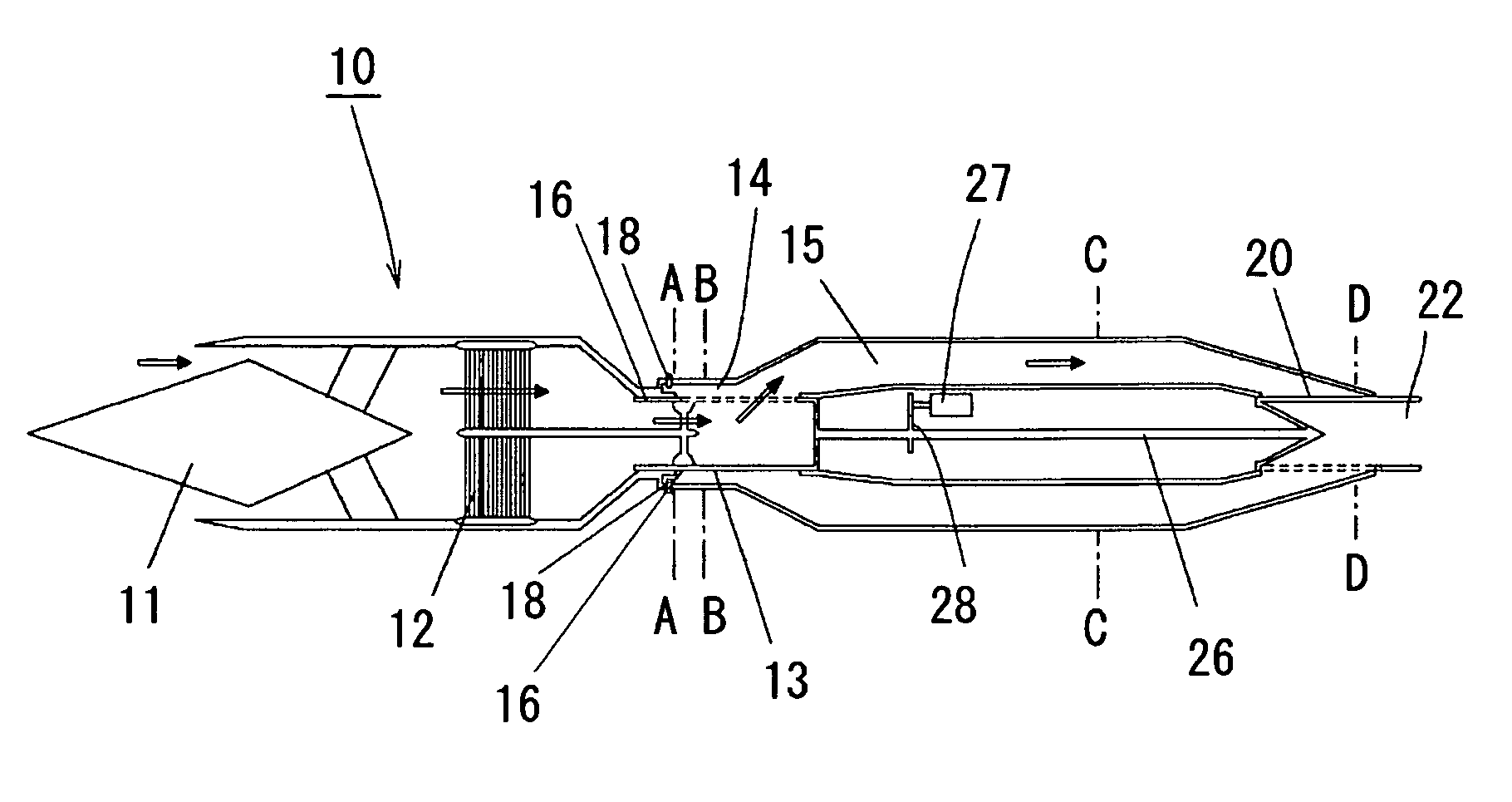

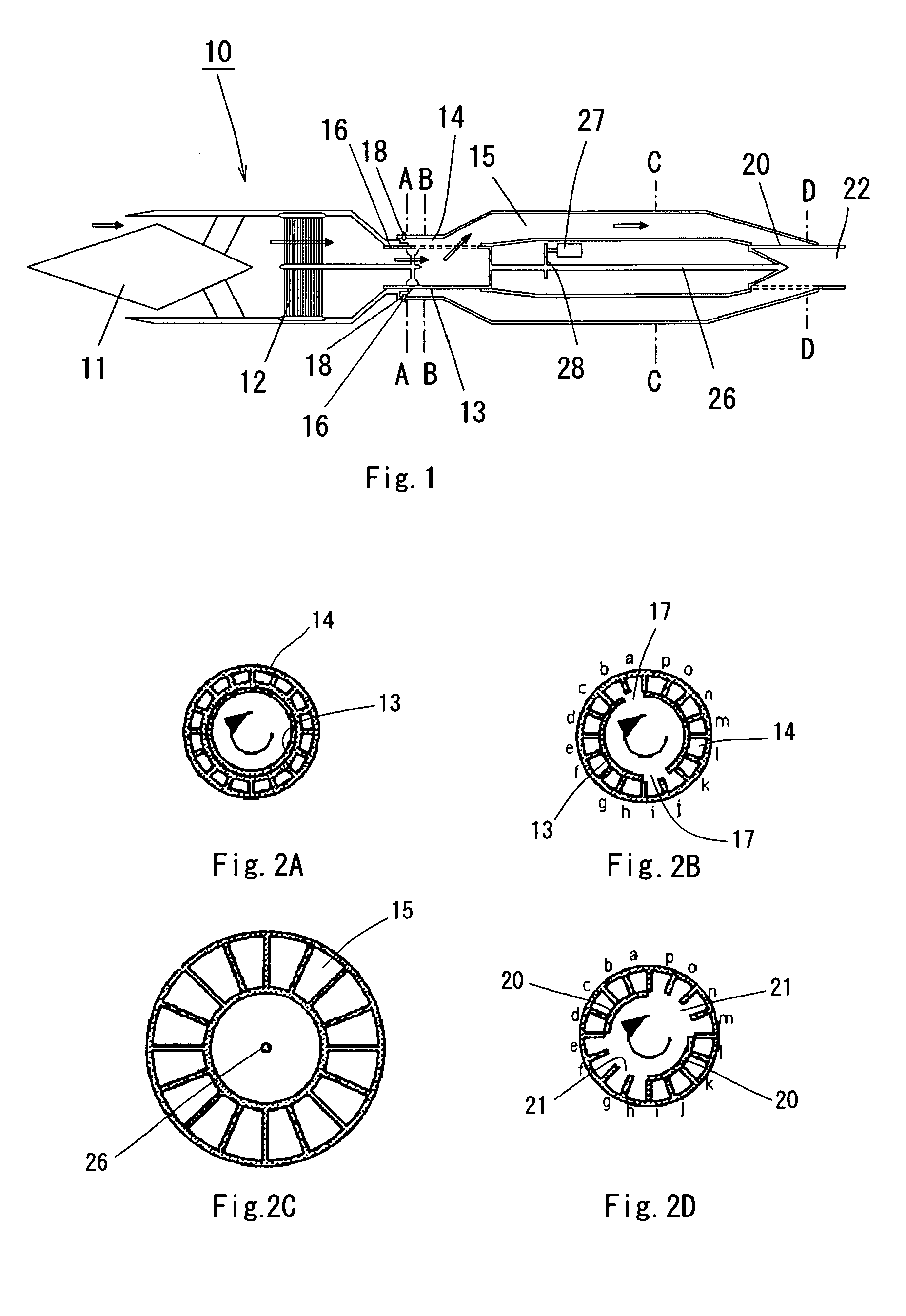

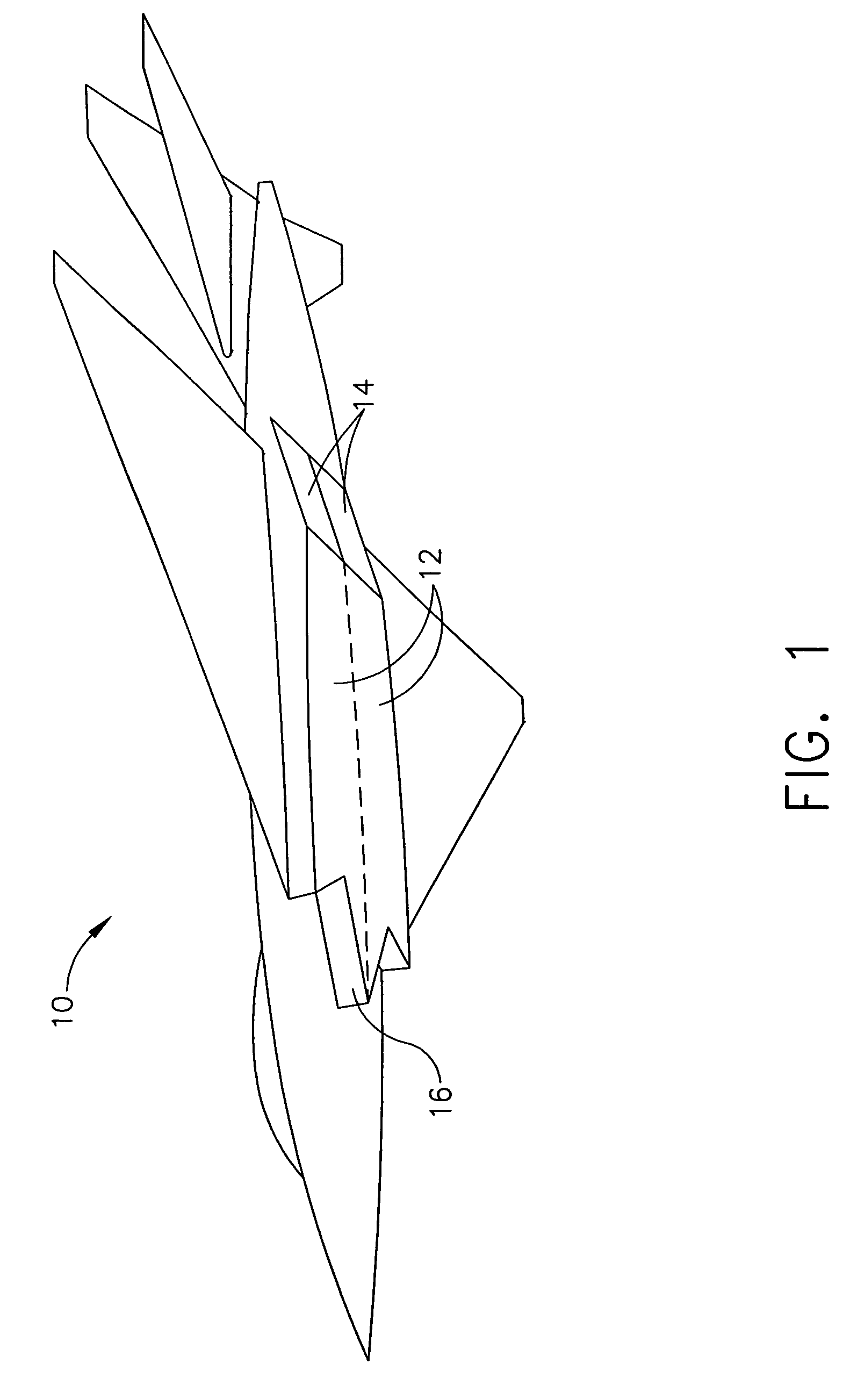

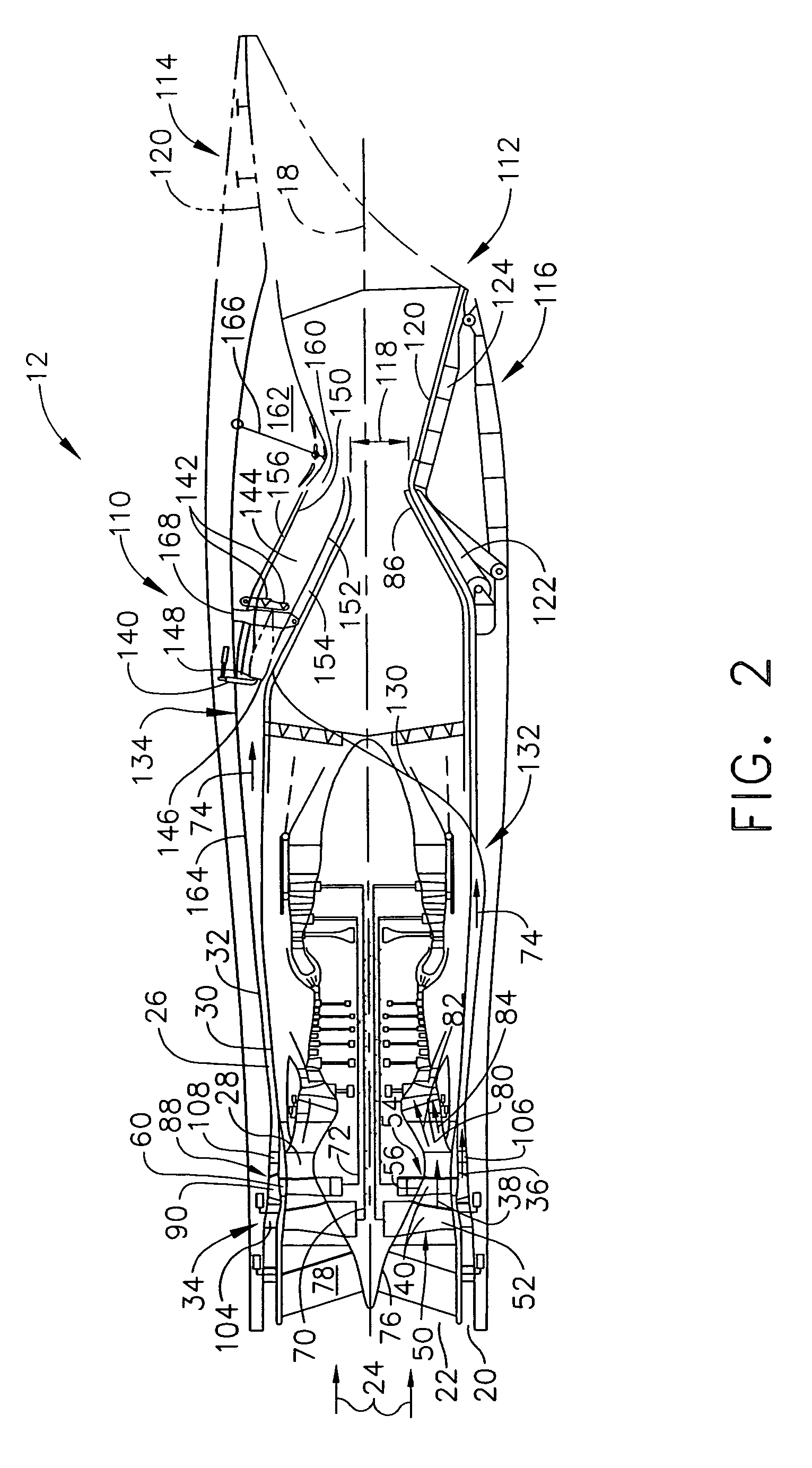

ActiveUS20070056290A1MiniaturizationHigh thermal efficiencyEngine manufactureEfficient propulsion technologiesBrayton cycleElectricity

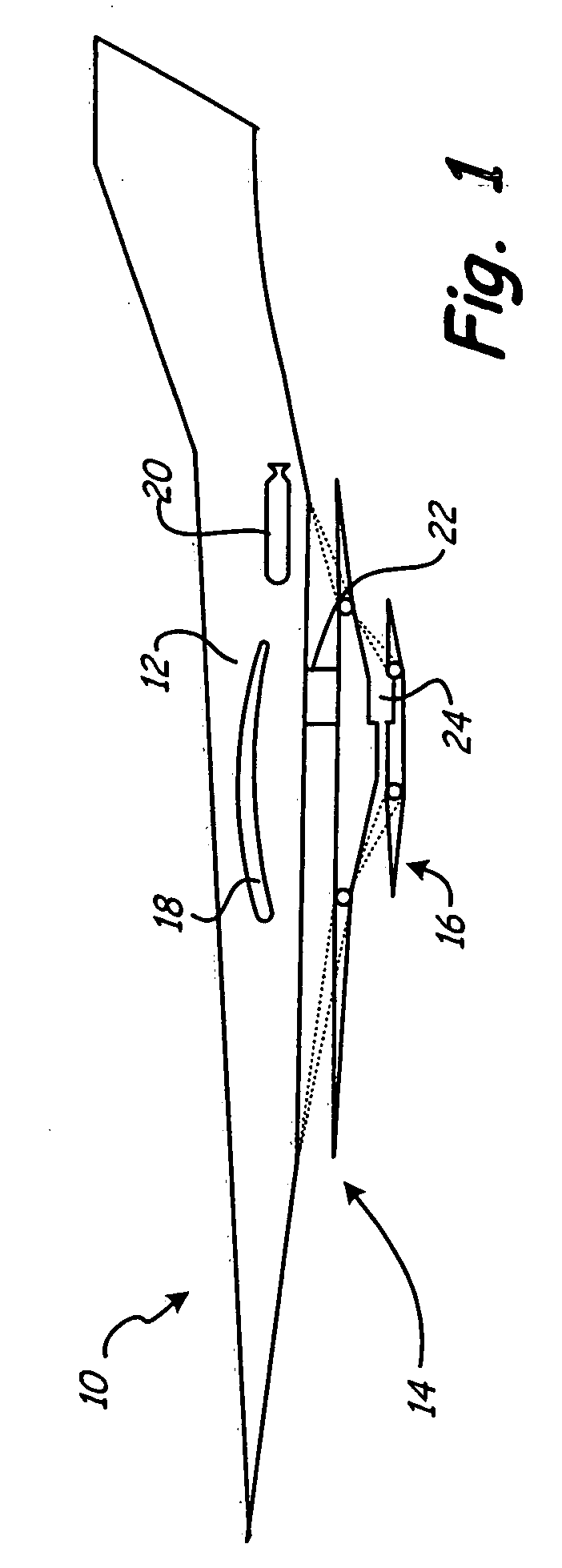

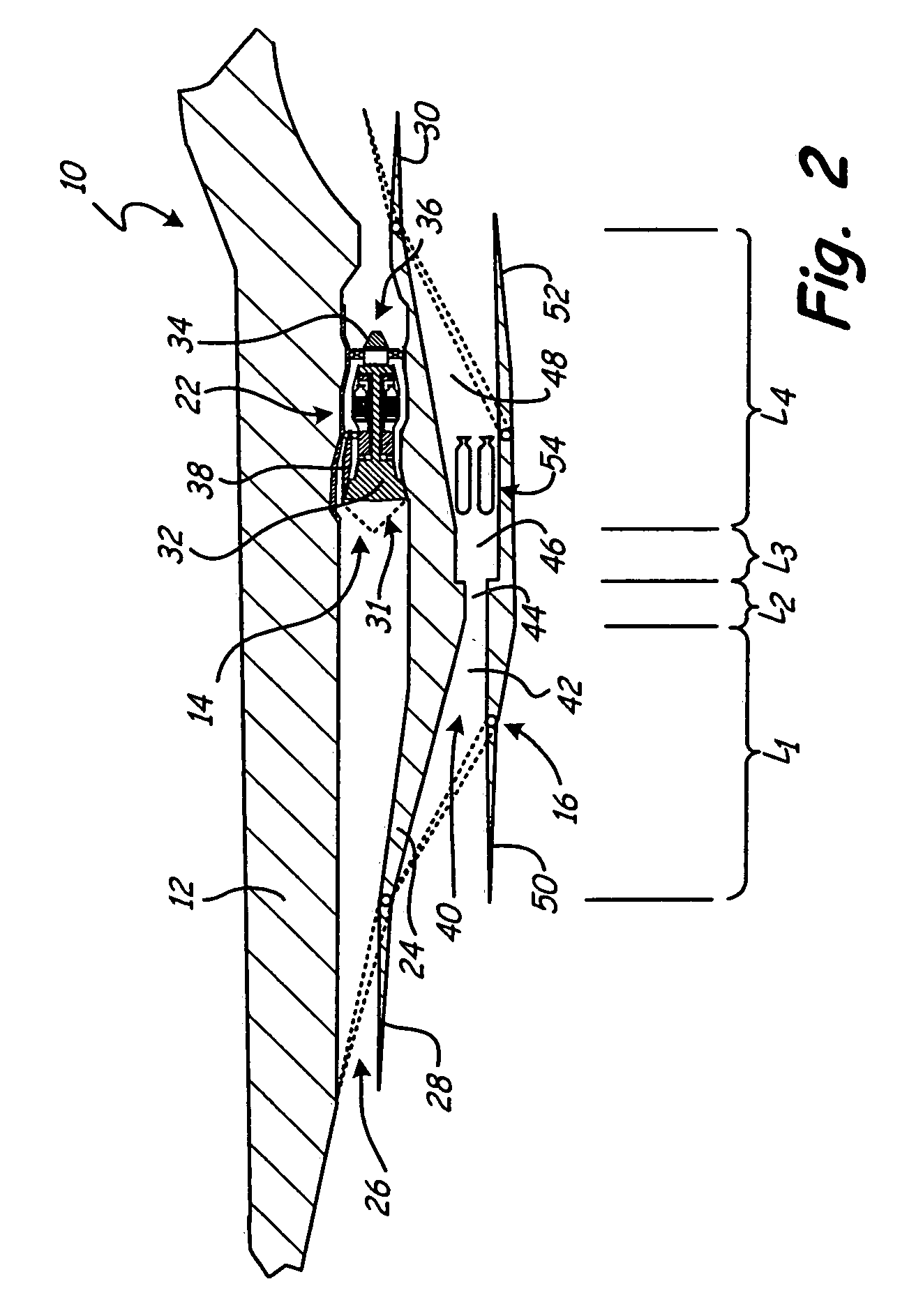

A Brayton-cycle rotary ramjet engine (10) operated within the confines of a helically elongated pass-through duct formed between a preferably stationary radially outward surface (14) and an outer rotating flow channel (36). The flow channel (36) is contoured between its inlet (34) and outlet (38) to include a supersonic diffuser (40), a combustor (42) and an expansion nozzle (44). Gaseous fuel, or liquid fuel atomized by a fuel slinger (58) within a housing (46), or solid fuel in the form of fine particulates, is inter-mixed with an oxidizer prior to being directed to the flow channel inlets (34). The air and fuel are combusted in the flow channels (36) and exhausted through the rear of the housing (46). A generator (22) can be coupled to a power shaft (18) to convert net shaft power into electricity. Preferably, the rotor (24) and stator (12) are fabricated from a ceramic or other high-temperature material so that combustor exit temperatures (T3) can be operated at highly efficient levels.

Owner:RGT UNIV OF MICHIGAN

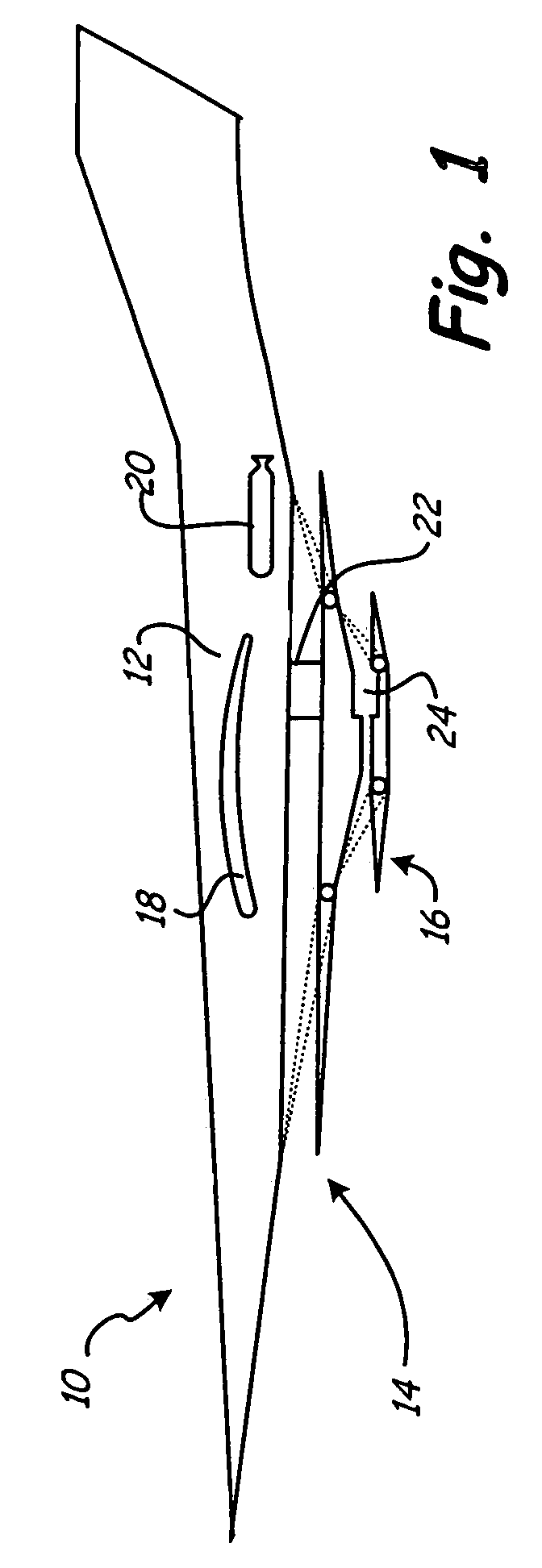

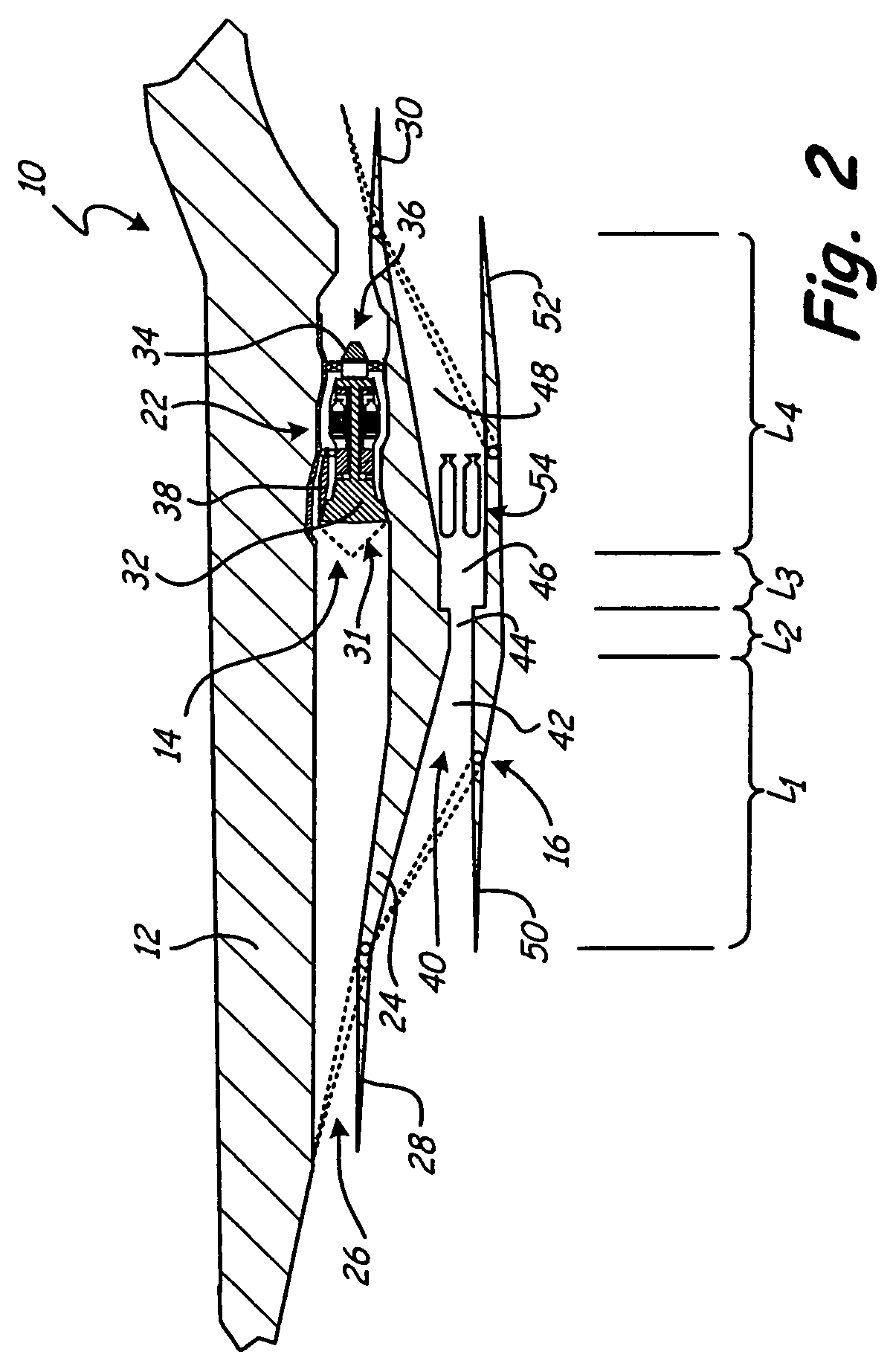

Low shock strength propulsion system

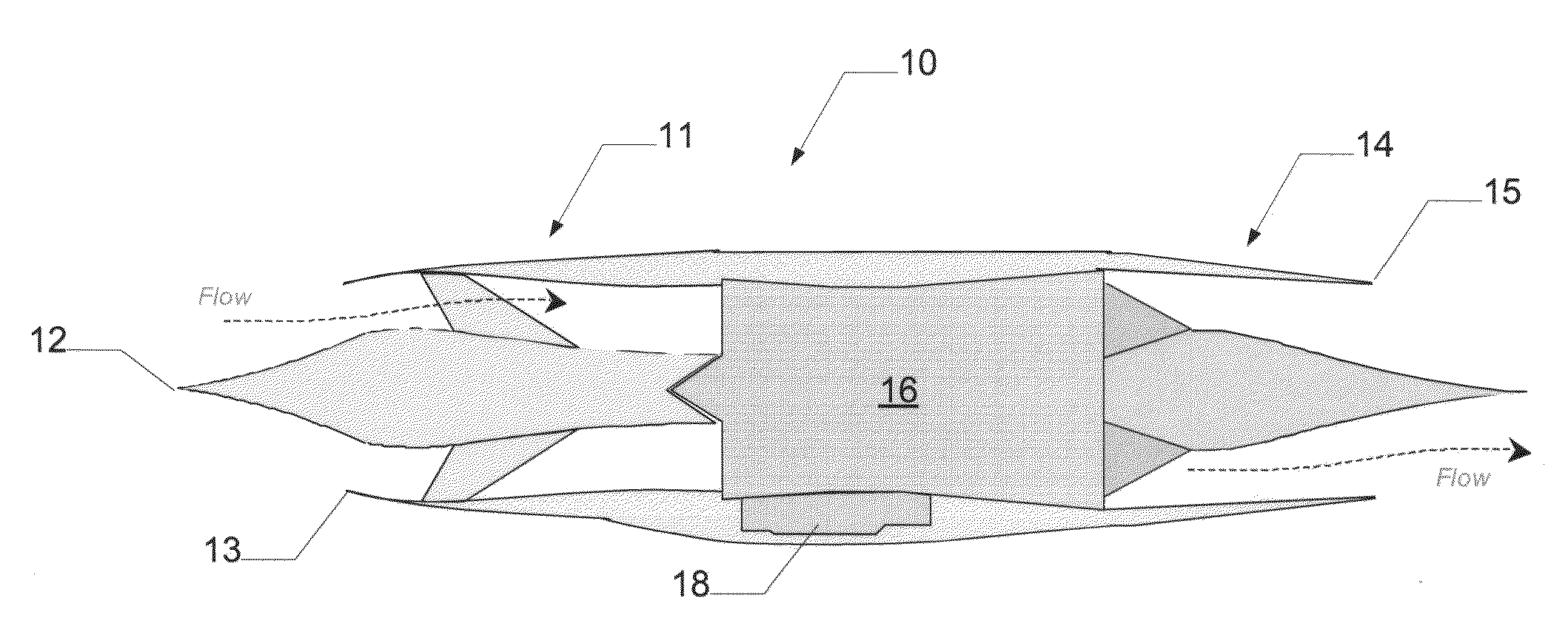

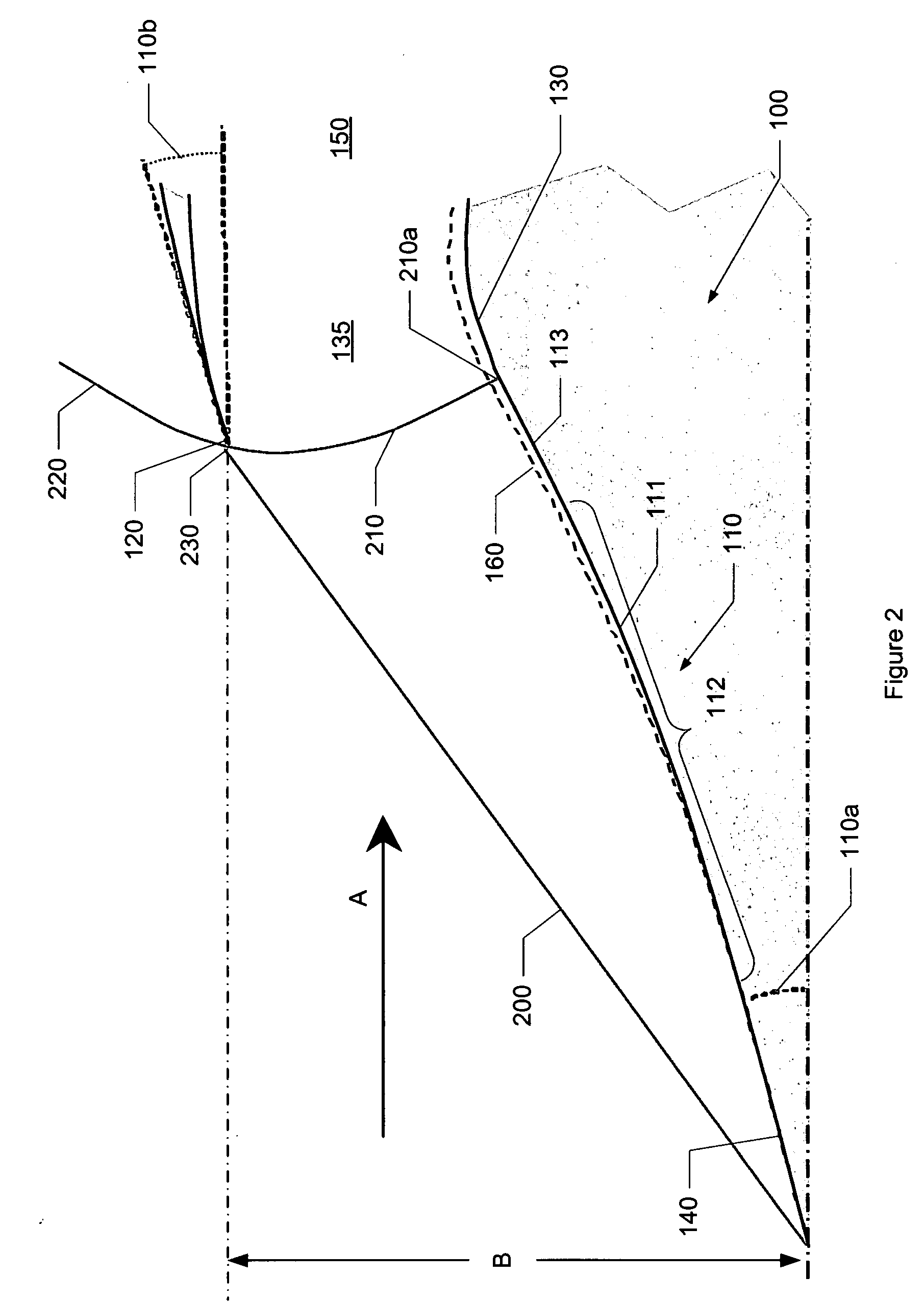

Embodiments of the invention relate to a supersonic nacelle design employing a bypass flow path internal to the nacelle and around the engine. By shaping the nacelle, embodiments of the invention may function to reduce sonic boom strength, cowl drag, and / or airframe interference drag. Embodiments of the invention may also function to improve total pressure recovery and / or total thrust of the primary flow path through the engine.

Owner:GULFSTREAM AEROSPACE CORP

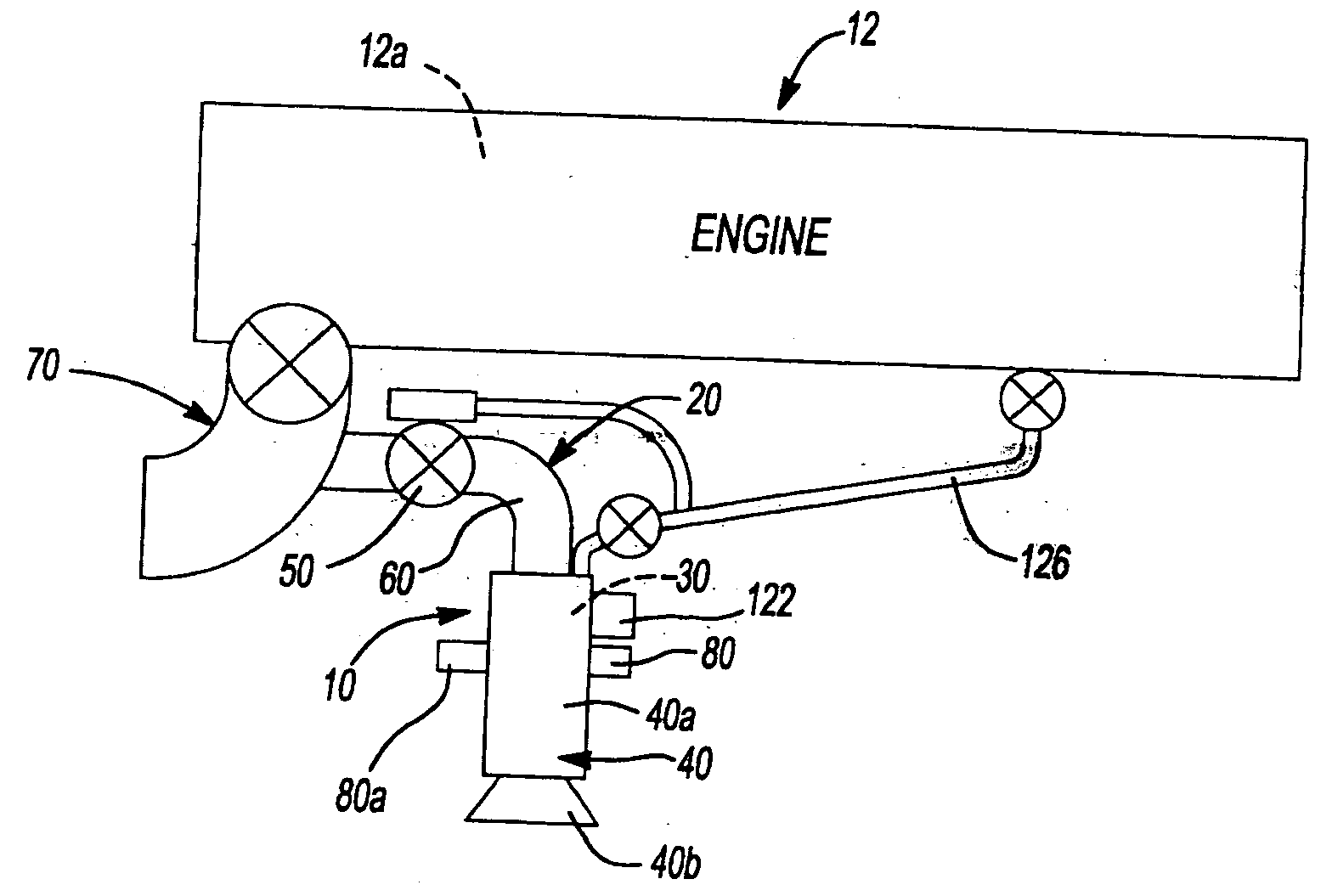

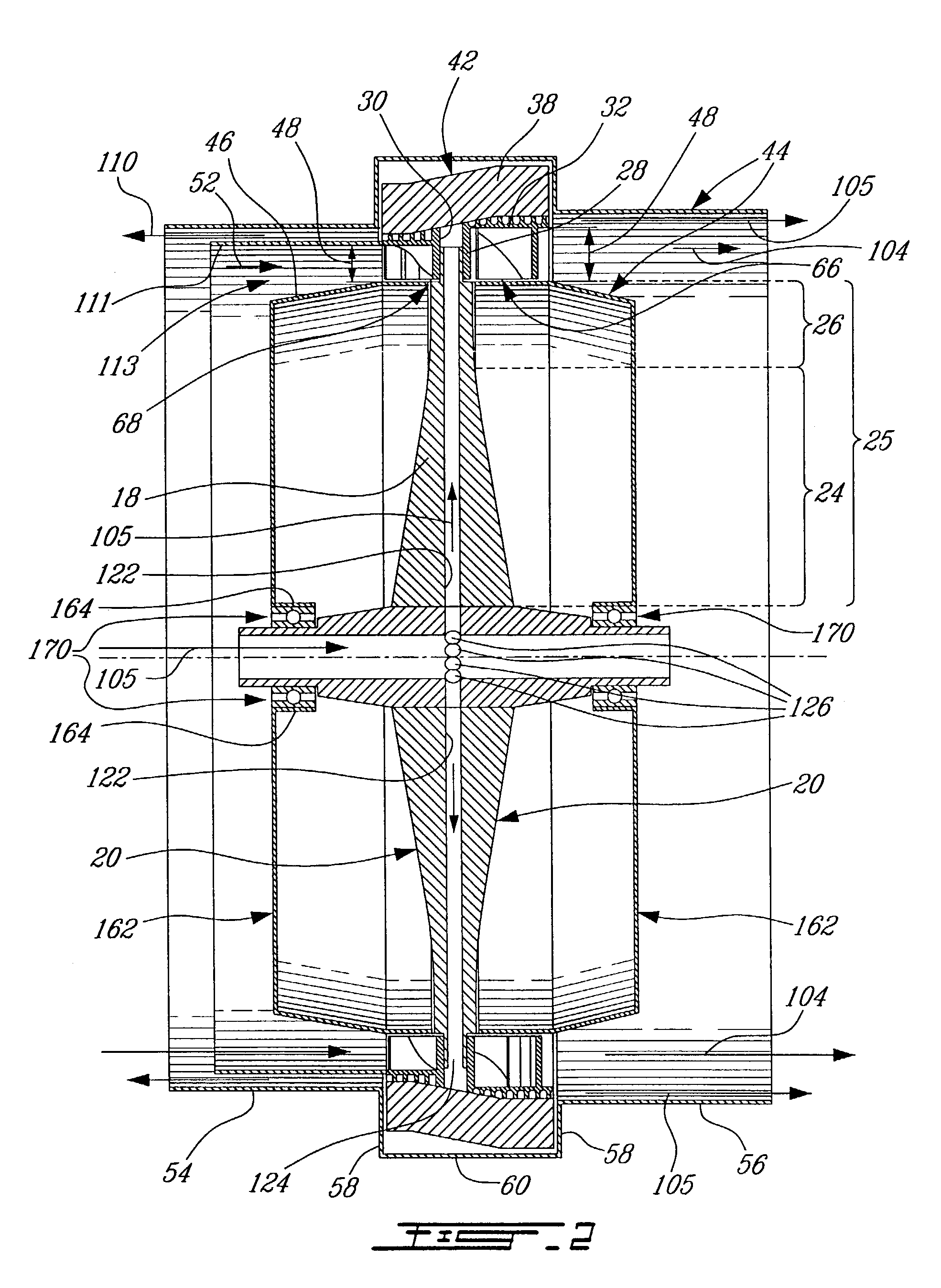

Combined cycle engines incorporating swirl augmented combustion for reduced volume and weight and improved performance

InactiveUS6907724B2Shorten the lengthFast atomizationContinuous combustion chamberJet type power plantsRamjetFlame propagation

A combined-cycle engine having at least one core engine and at least one ramjet engine. The ramjet utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and an inner central recirculation zone, both of which are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers, which accelerate flame propagation throughout the core flowfield. The swirl generator provides smooth combustion with no instabilities and minimum total pressure losses and enables significant reductions in the L / D ratio of the combustor. Other benefits include simplicity, reliability, wide flammability limits, high combustion efficiency and high specific thrust performance.

Owner:UNITED TECH CORP +1

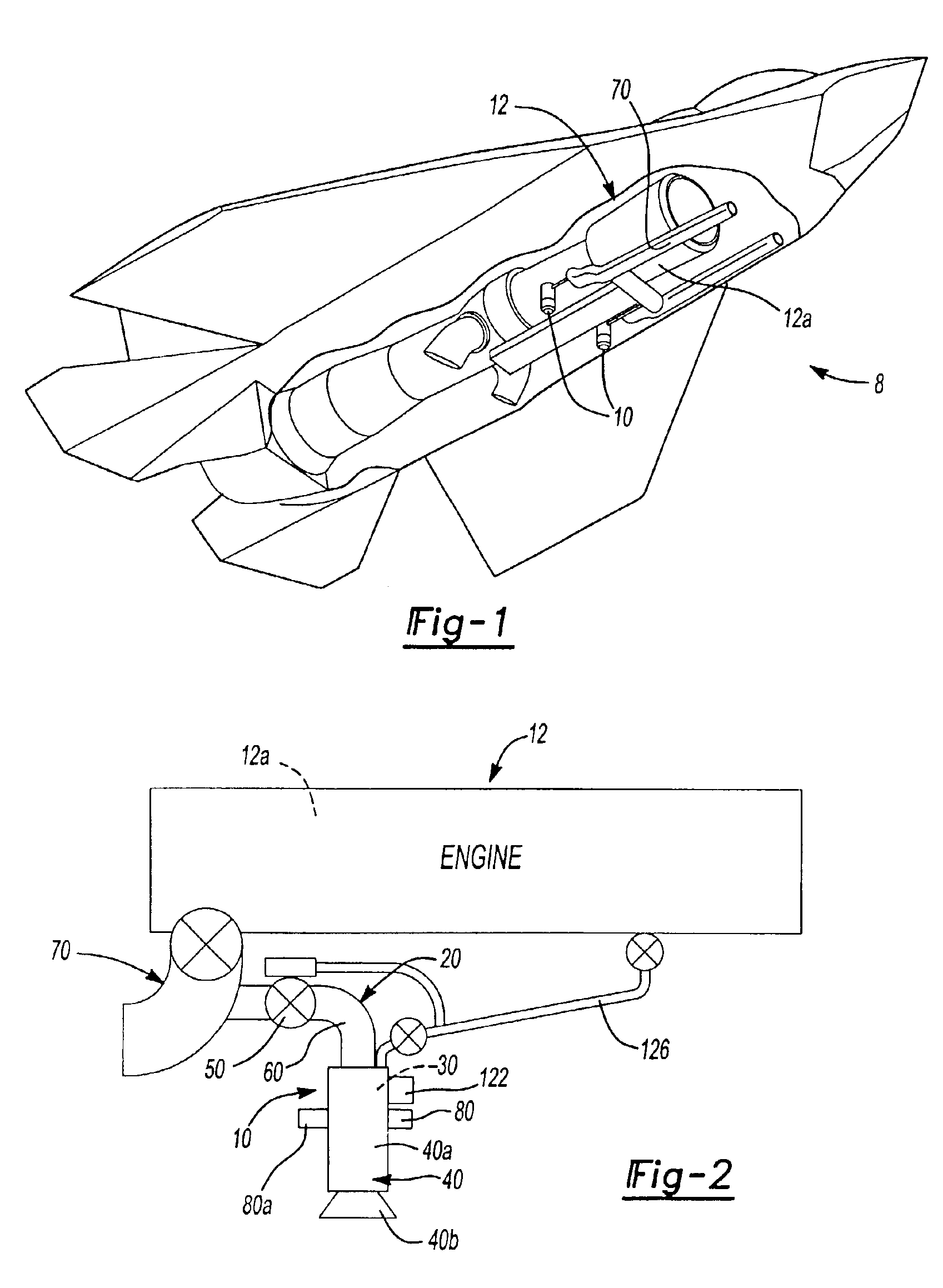

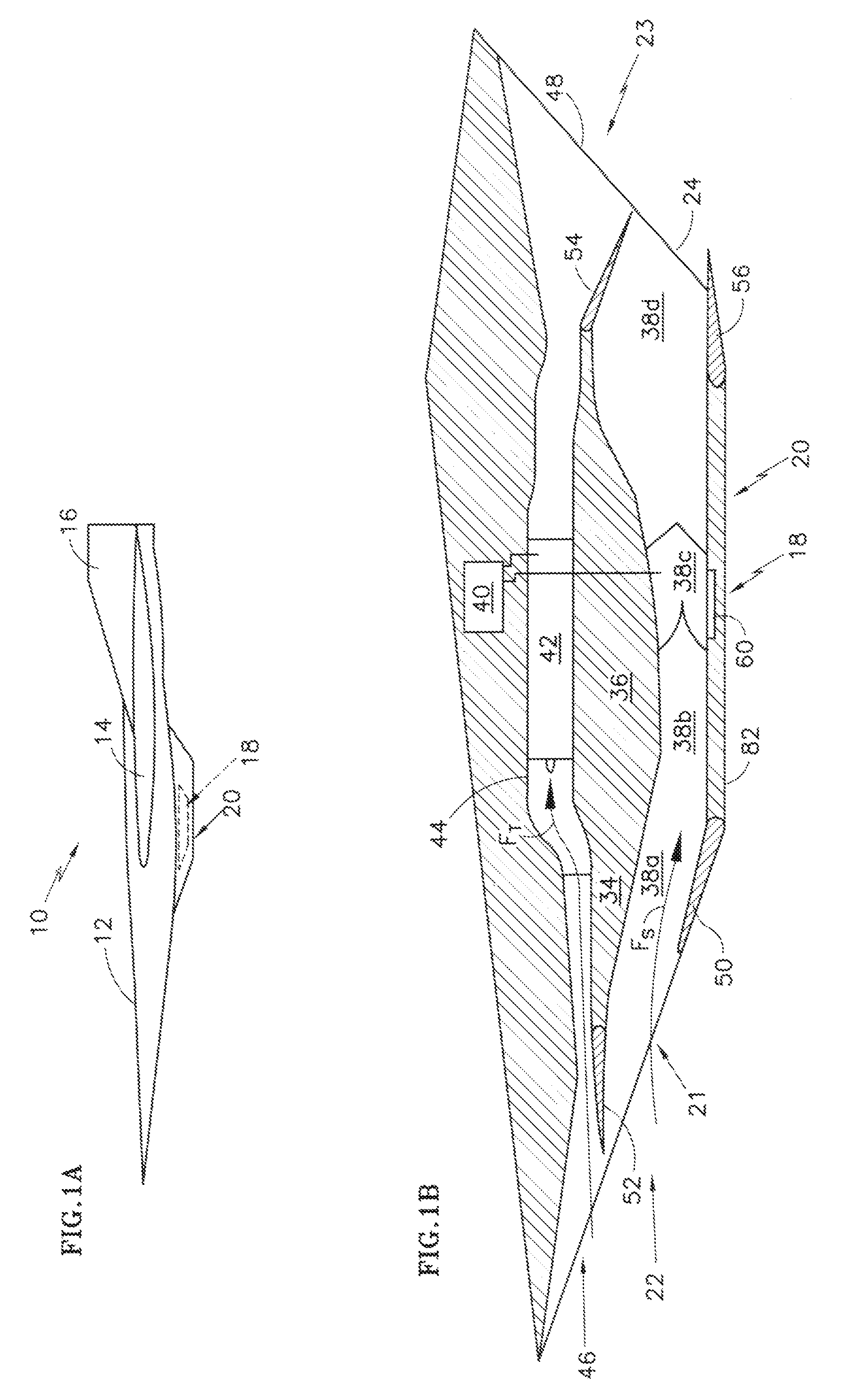

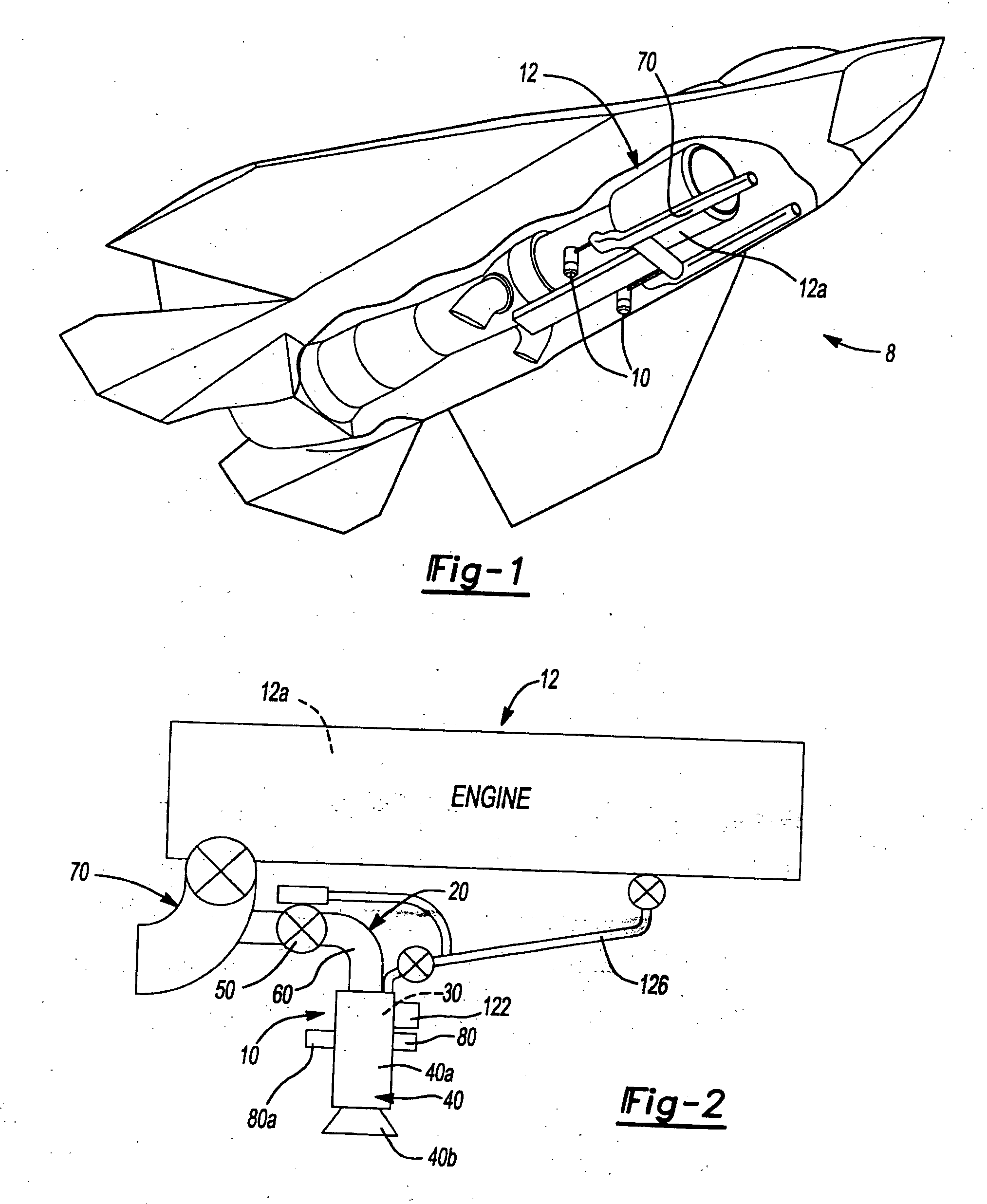

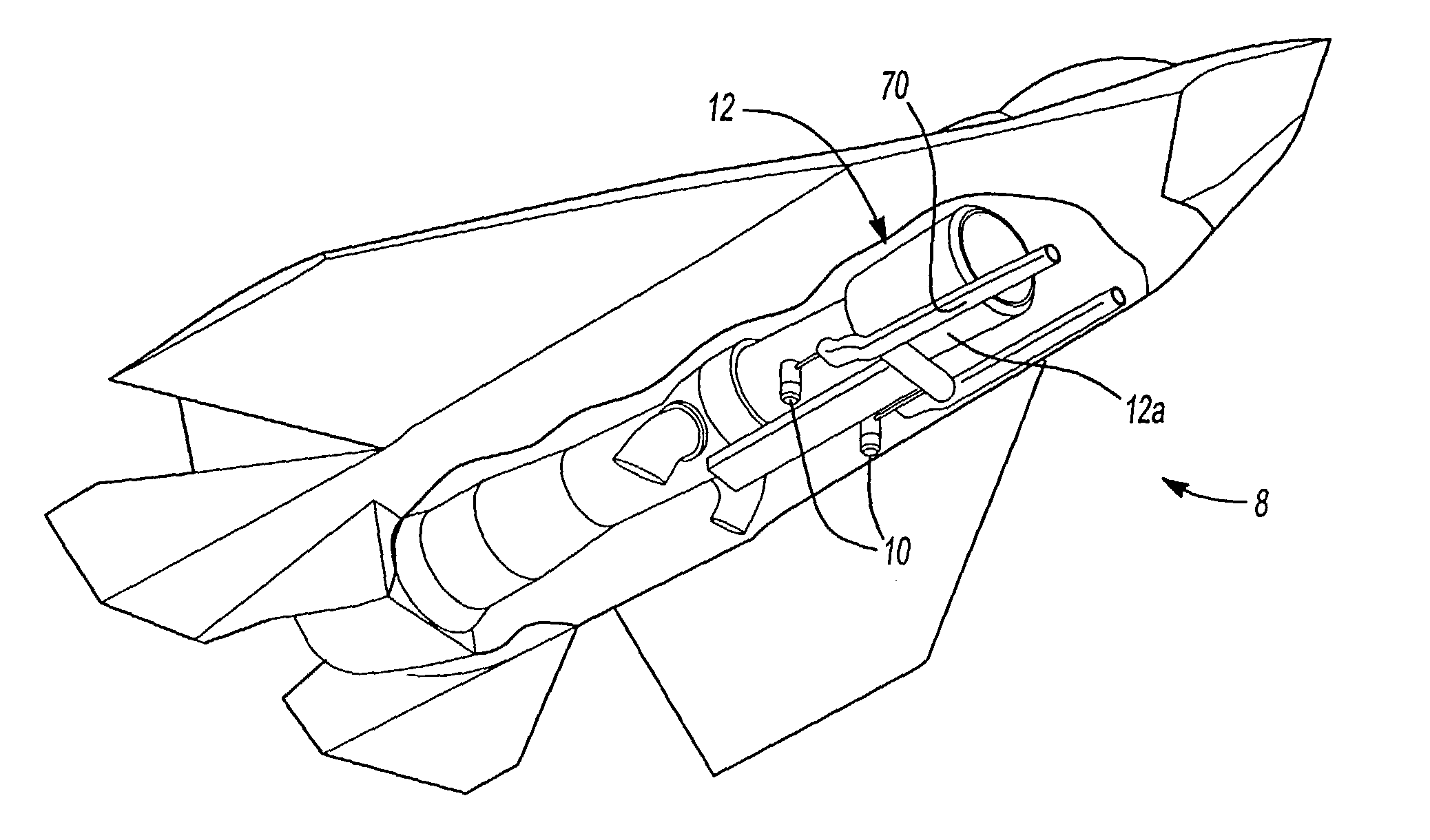

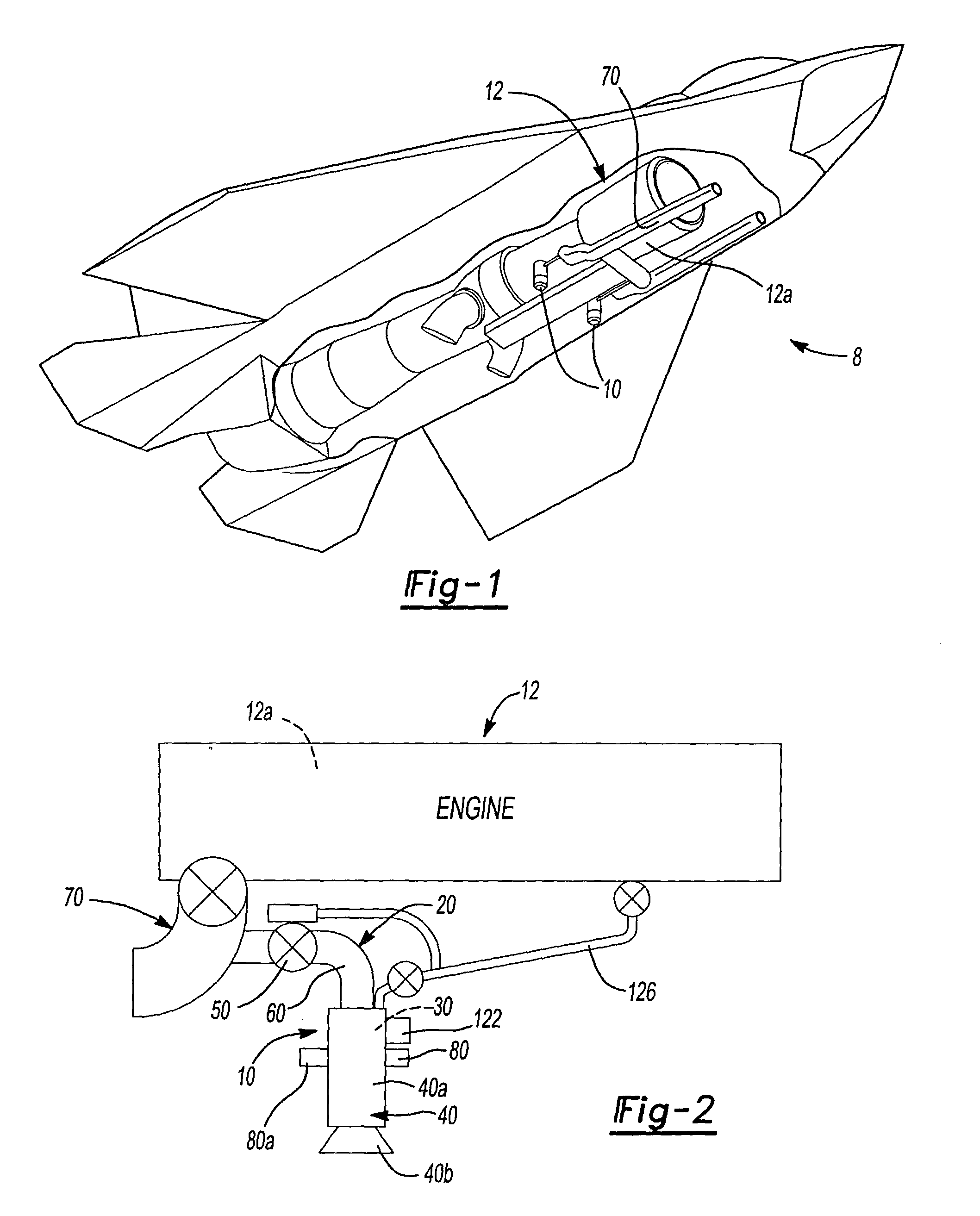

Single-stage hypersonic vehicle featuring advanced swirl combustion

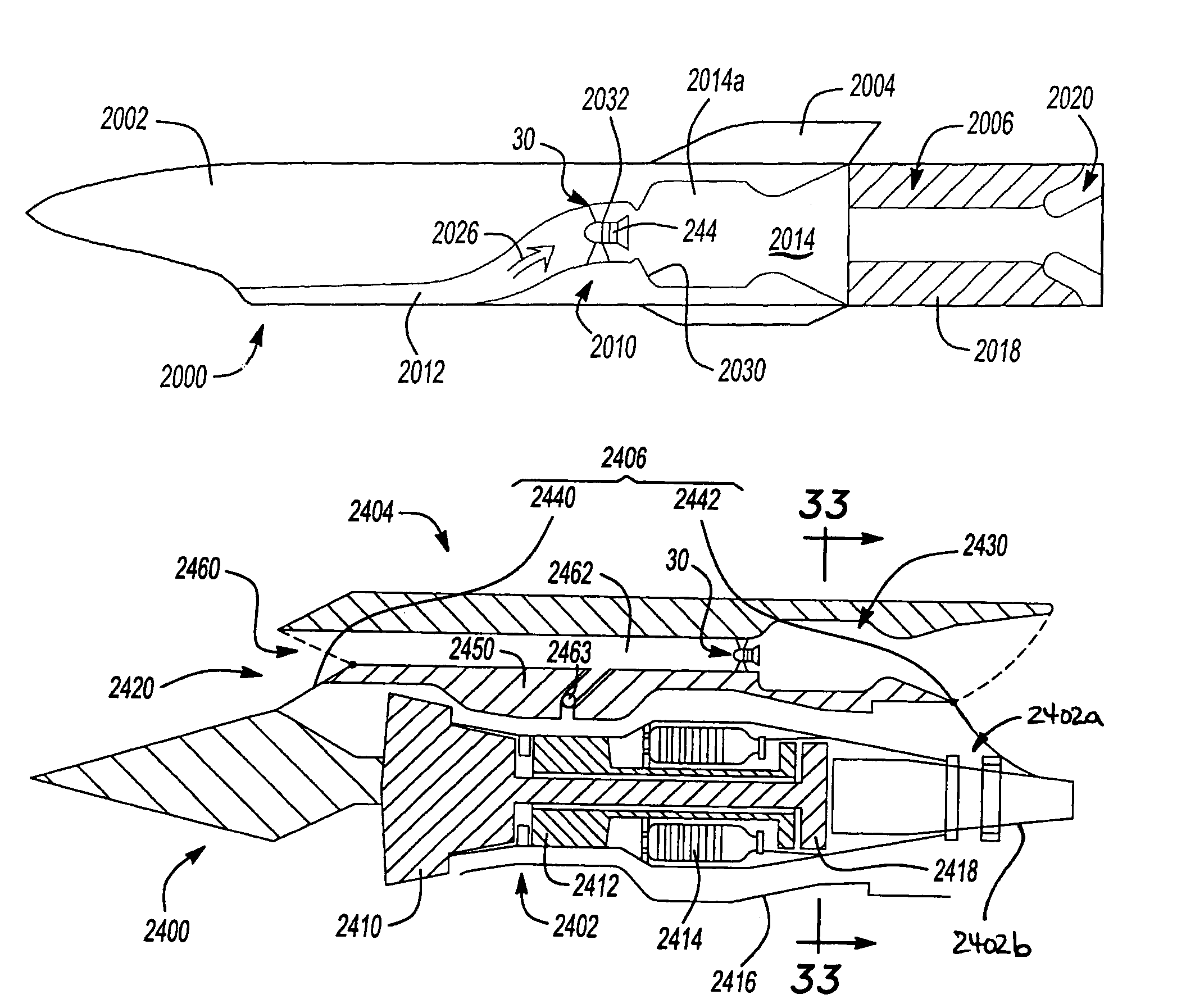

InactiveUS20080283677A1Reduce complexityShorten the lengthAircraft navigation controlPower plant exhaust arrangementsRamjetLow speed

A single-stage hypersonic vehicle is comprised of a low-speed and a high-speed propulsion system. The low-speed propulsion system propels the single-stage vehicle to a threshold velocity, after which the high-speed propulsion system then takes over. The low-speed propulsion system includes a combined-cycle engine featuring a swirl generator that is integrated into a turbojet engine to provide a compact turbojet and swirl afterburner-ramjet propulsion system. The high-speed propulsion system includes a hypersonic engine that is operable at the threshold takeover velocity and beyond. In various embodiments, the high-speed propulsion system comprises a scramjet, rocket, or scramjet / rocket engine depending requirements. Benefits of the swirl generator design include its ability to rapidly and efficiently atomize, vaporize, mix and burn the fuel and oxidizer for the low speed propulsion system, significantly reduce length, weight, cooling requirements and complexity for both propulsion systems, while maintaining high propulsion performance and reducing propulsion and launch costs.

Owner:UNITED TECH CORP

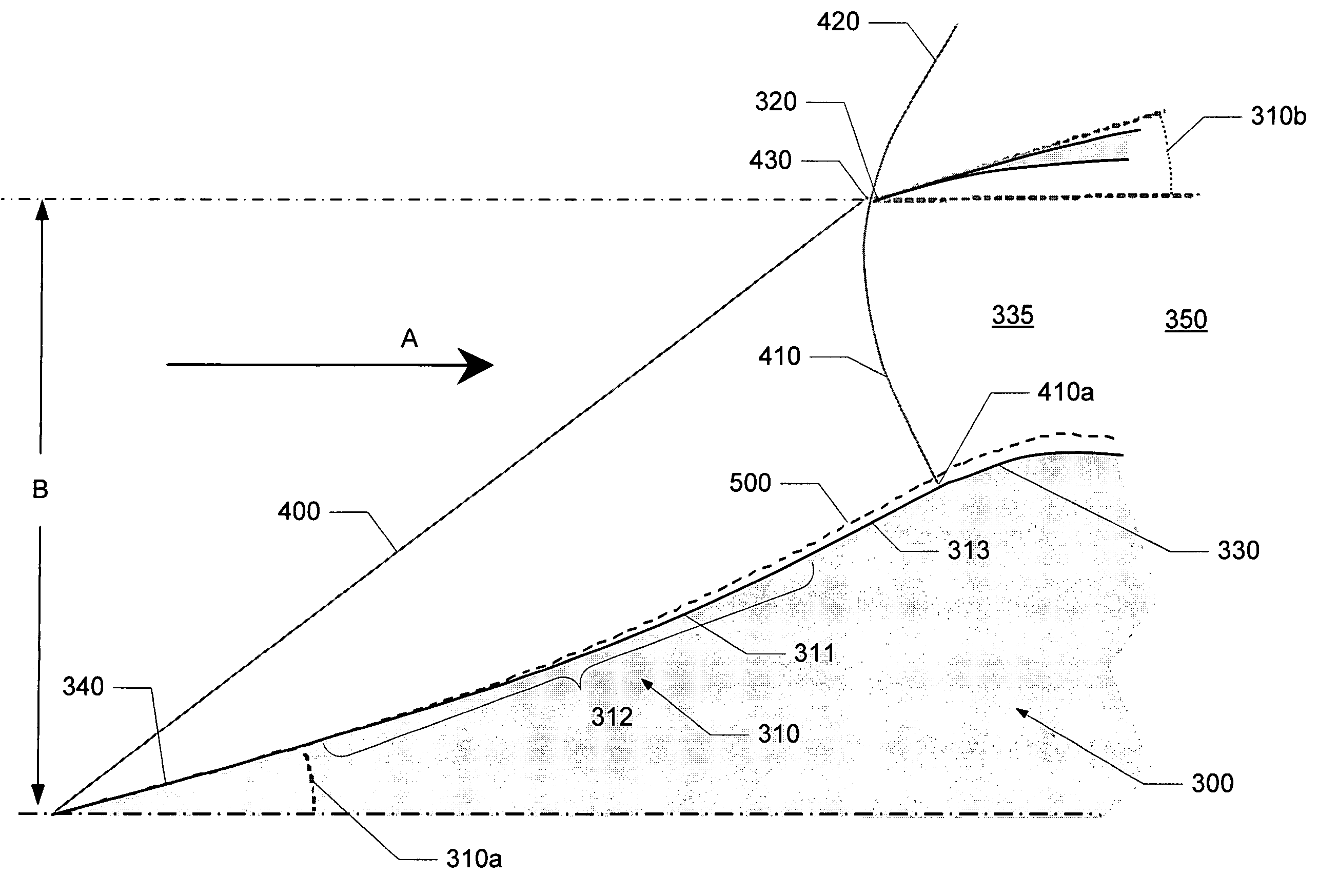

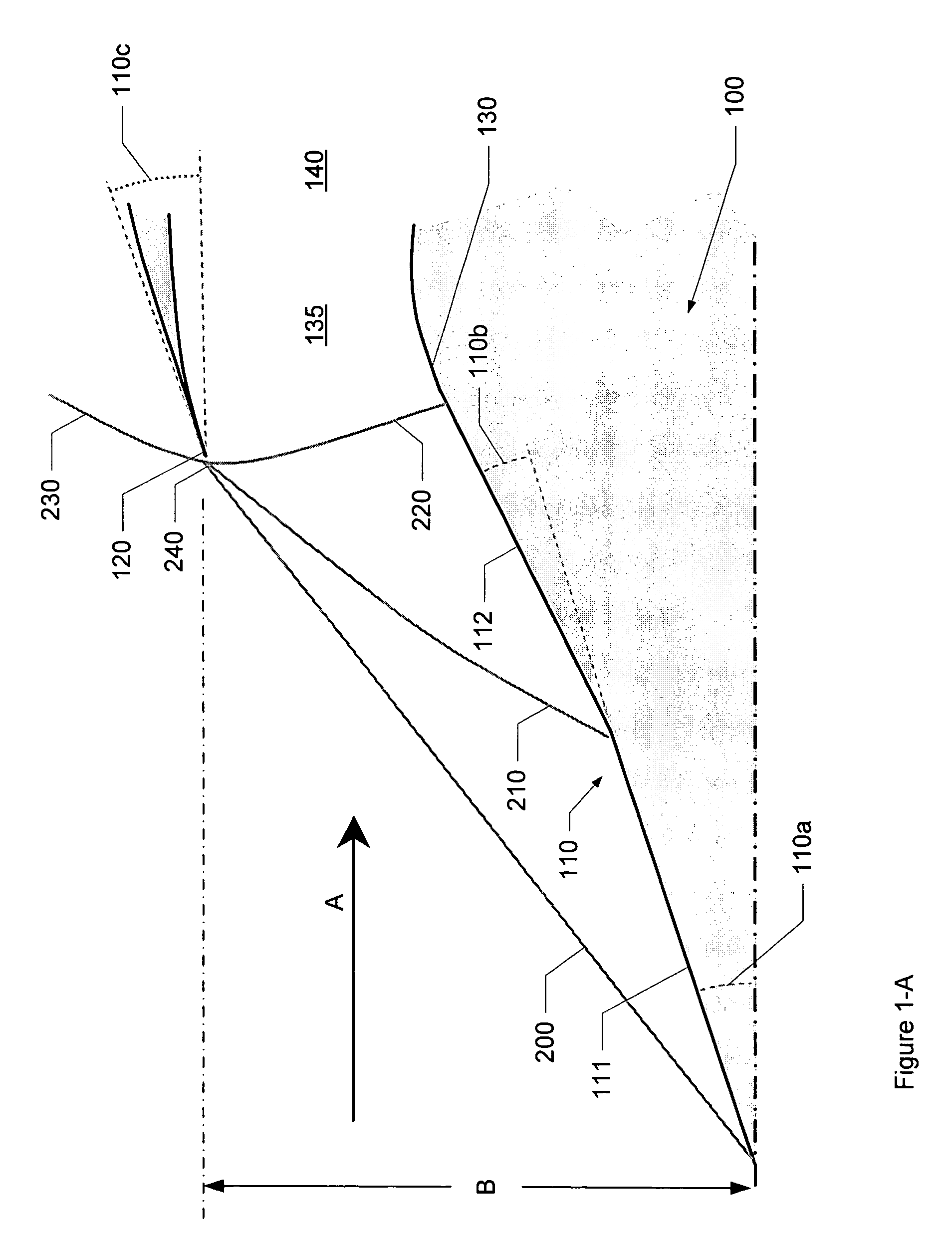

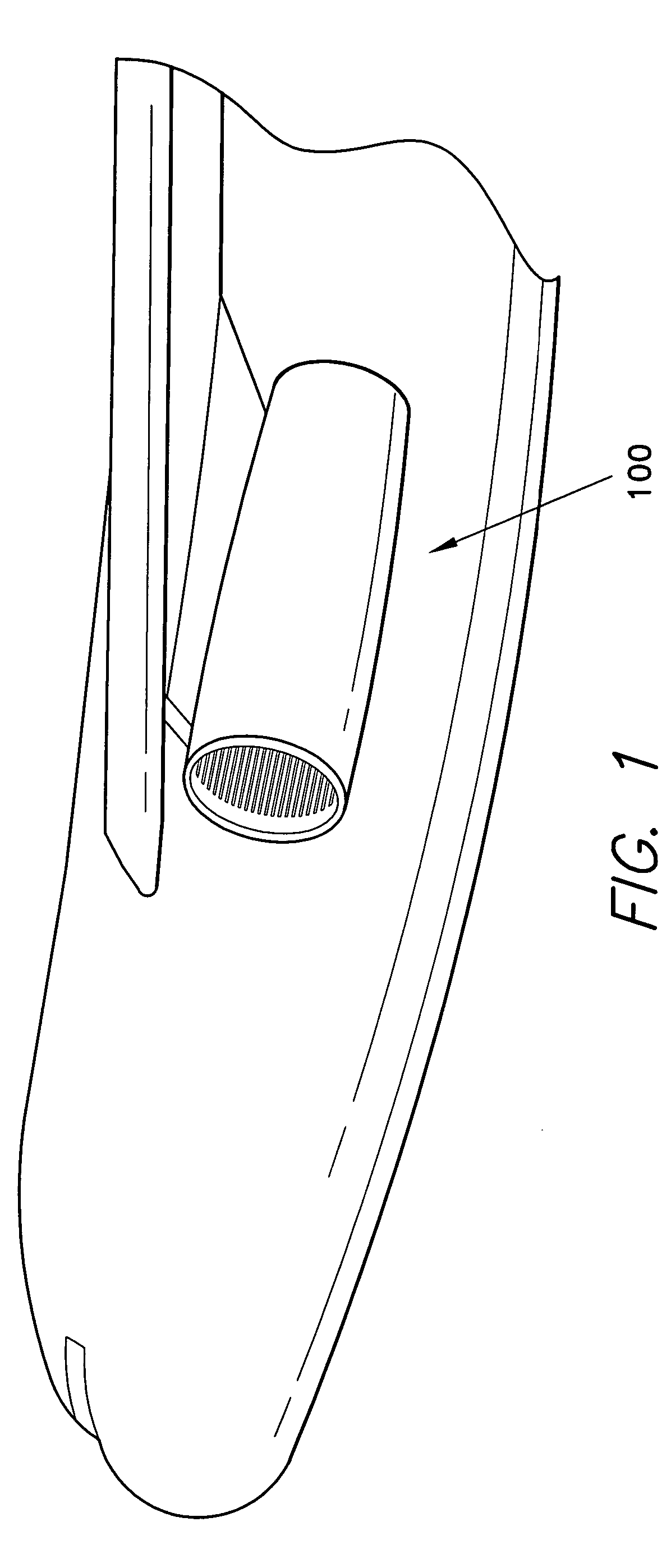

Low shock strength inlet

ActiveUS20090107557A1Power plant exhaust arrangementsAircraft power plant componentsNacelleUltimate tensile strength

Embodiments of the invention relate to a supersonic inlet having a cowl lip configured to capture the conic shock and exhibit a zero or substantially zero cowl angle. The inlet may be configured to employ a relaxed isentropic compression surface and an internal bypass. The nacelle bypass may prevent flow distortions, introduced by the capture of the conic shock, from reaching the turbomachinery, thereby allowing the cowl angle to be reduced to zero or substantially zero. Such a cowl angle may reduce the inlet's contribution to the overall sonic boom signature for a supersonic aircraft while allowing for an increase in engine pressure recovery and a subsequent improvement in generated thrust by the engine.

Owner:GULFSTREAM AEROSPACE CORP

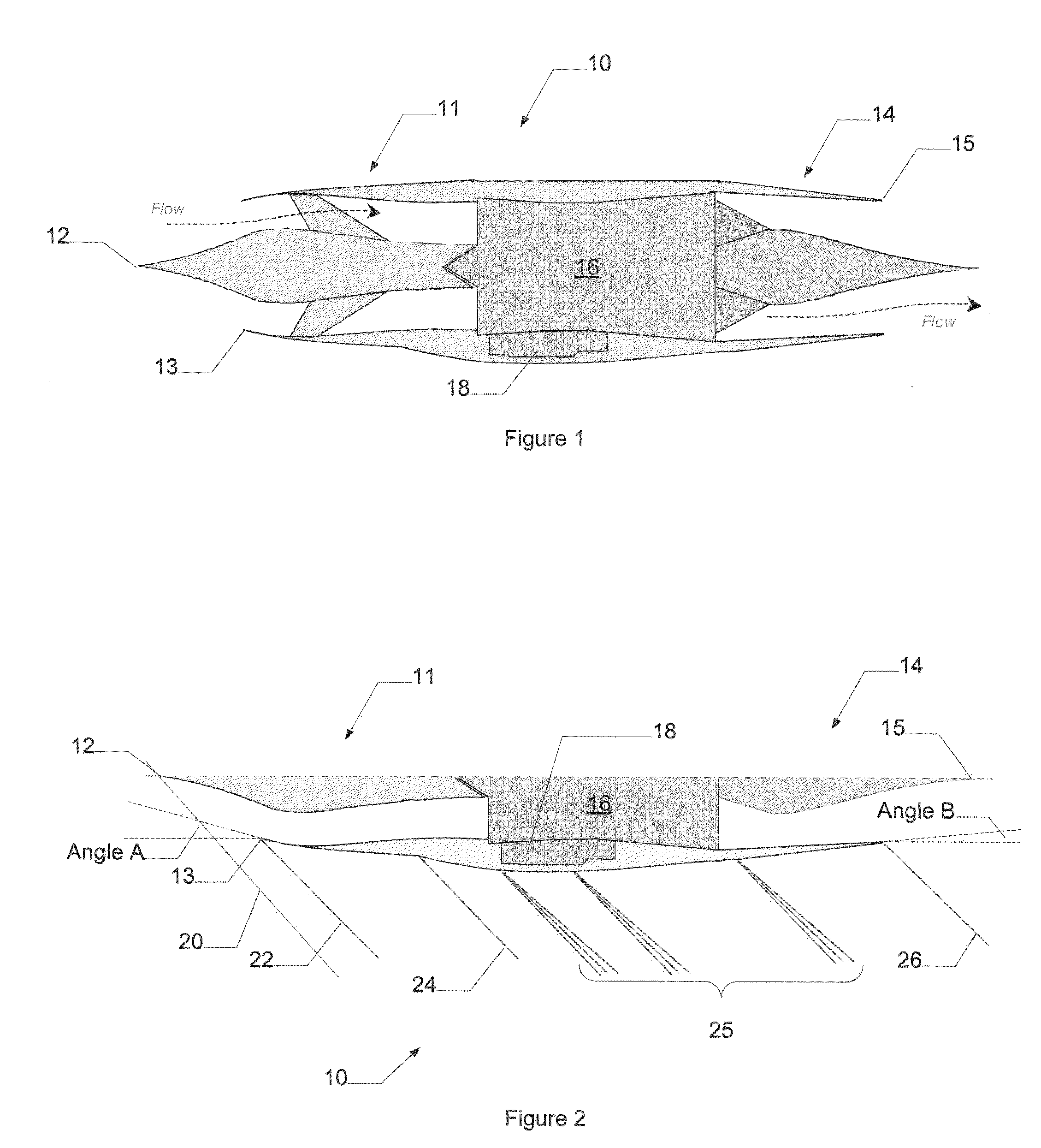

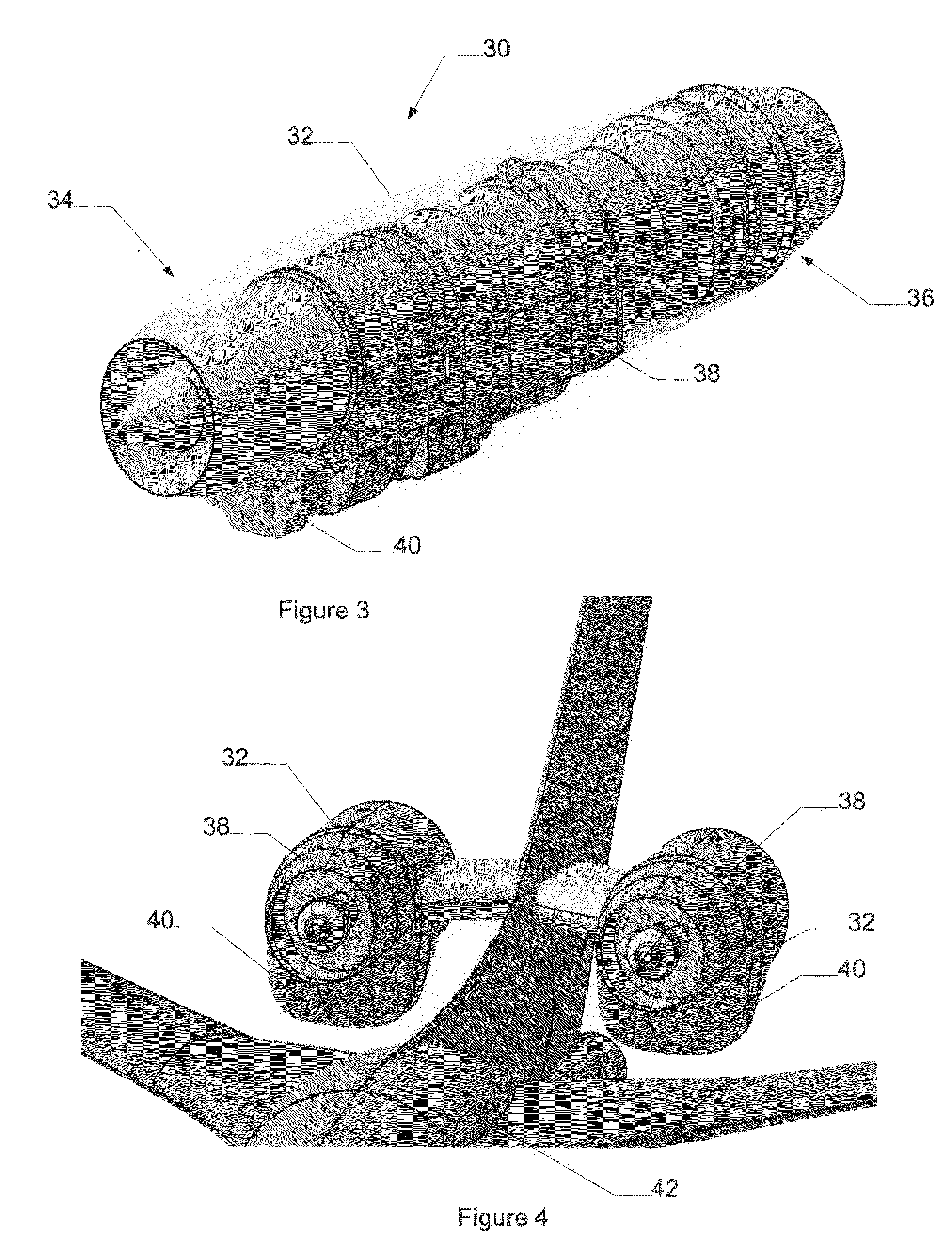

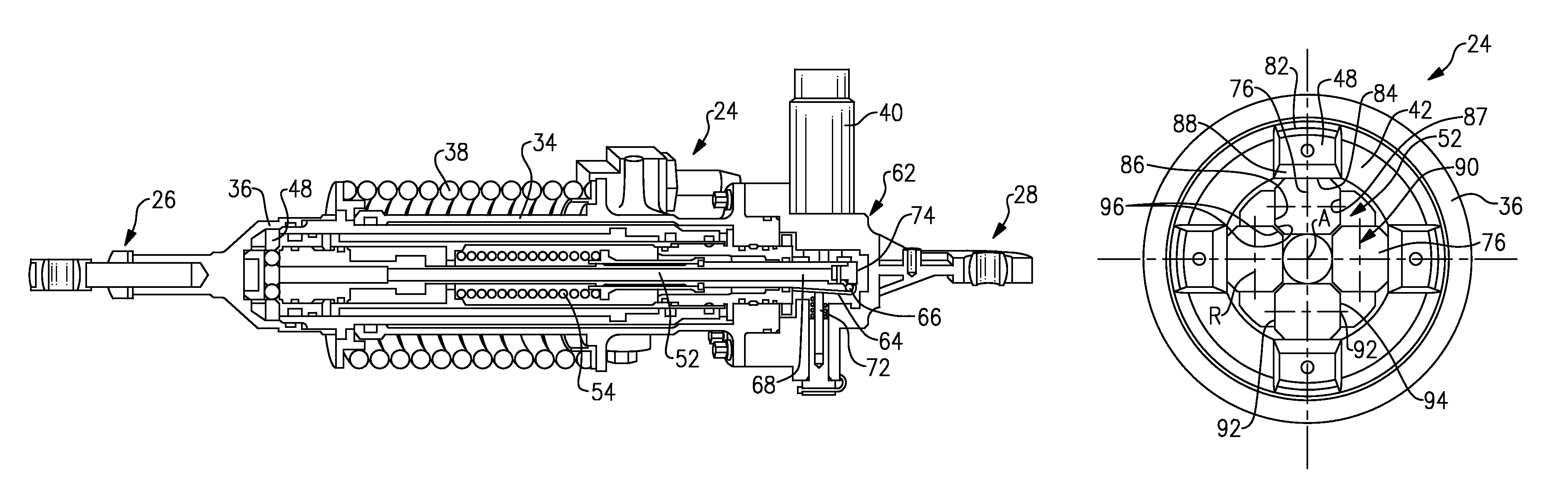

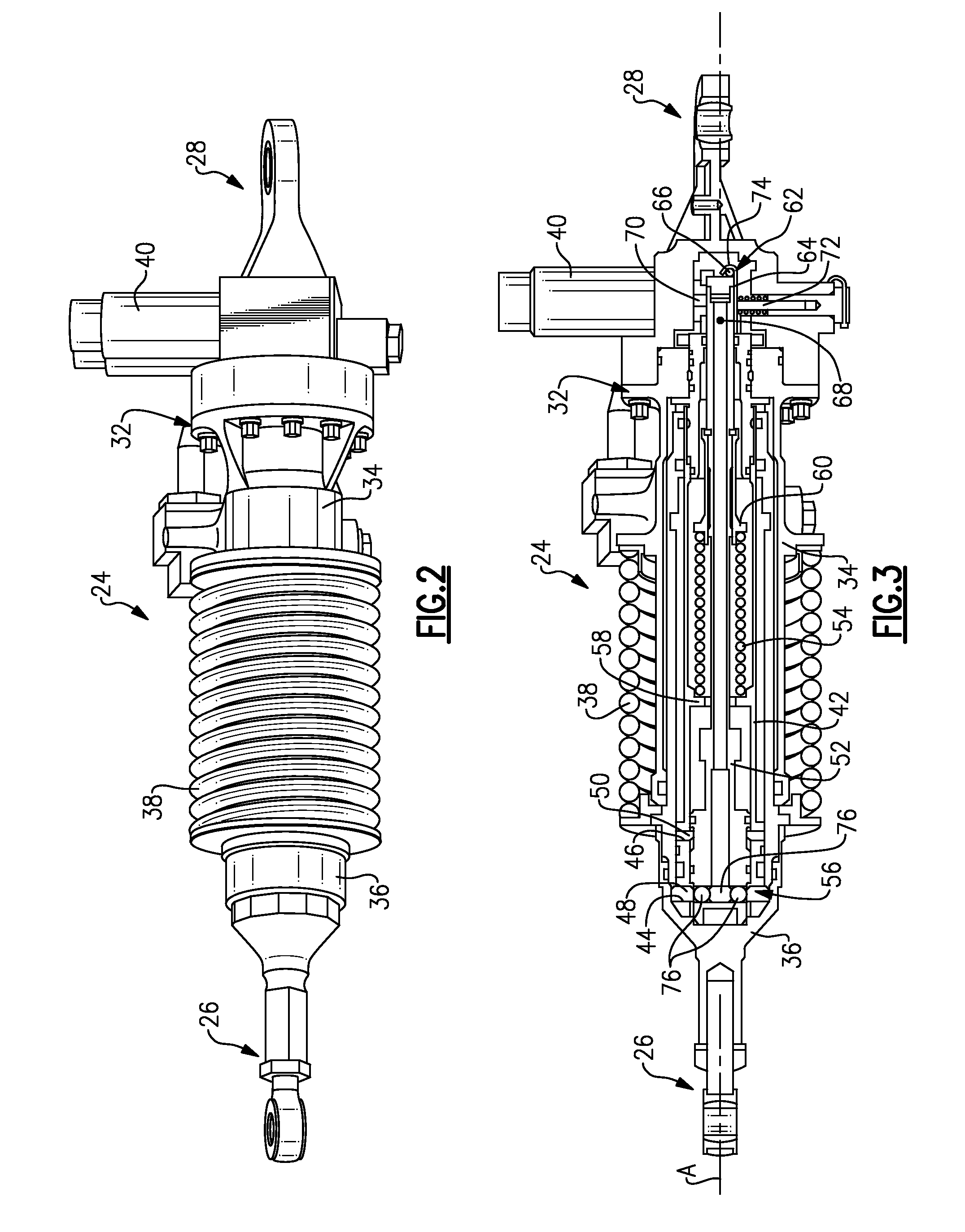

Ram air turbine deployment actuator

An actuator for a ram air turbine system includes a lock bolt having a multiple circumferentially arranged lateral supports. A piston rod supports multiple up-lock wedges. Multiple rollers are supported by the lateral supports with chamfers on the rollers engaging one another and are configured to radially support the up-lock wedges in a retracted position.

Owner:HAMILTON SUNDSTRAND CORP

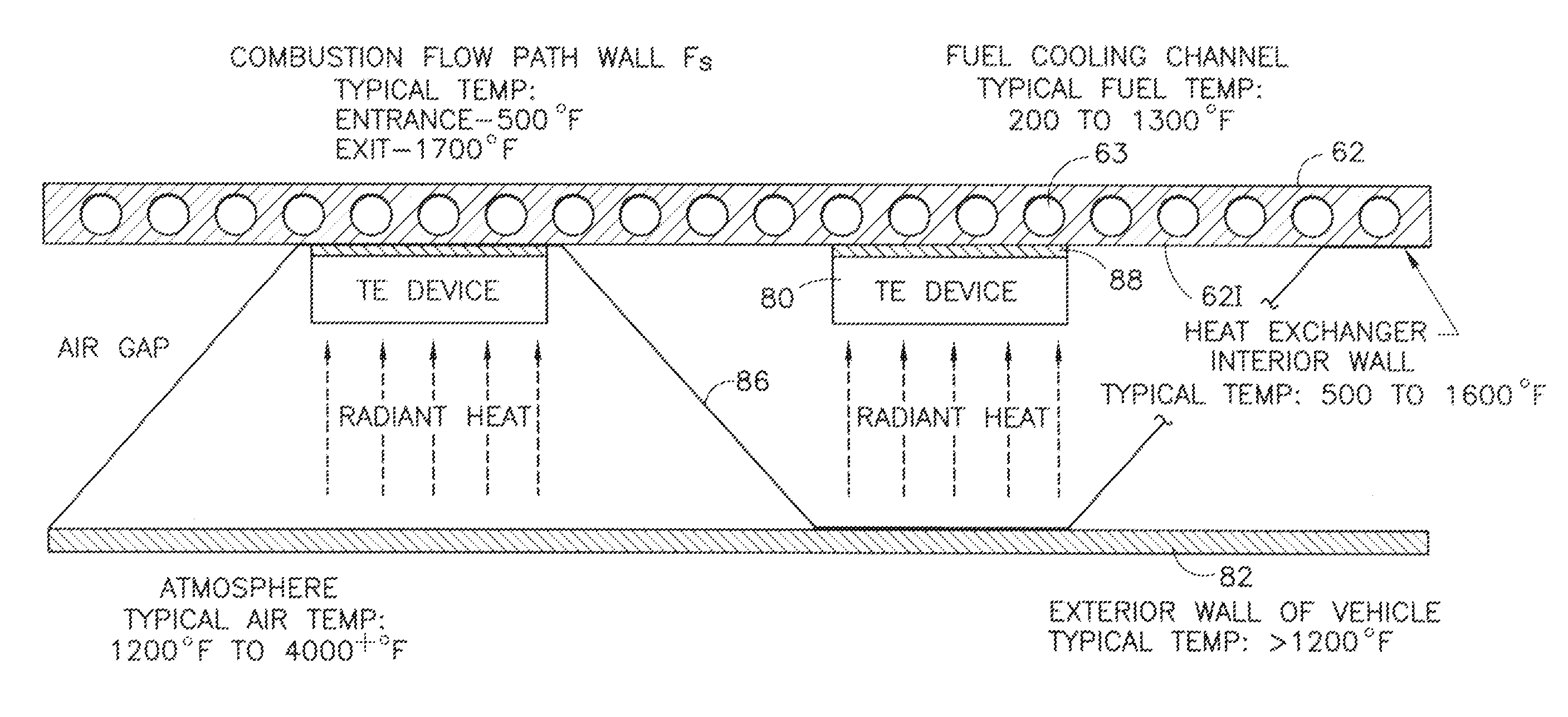

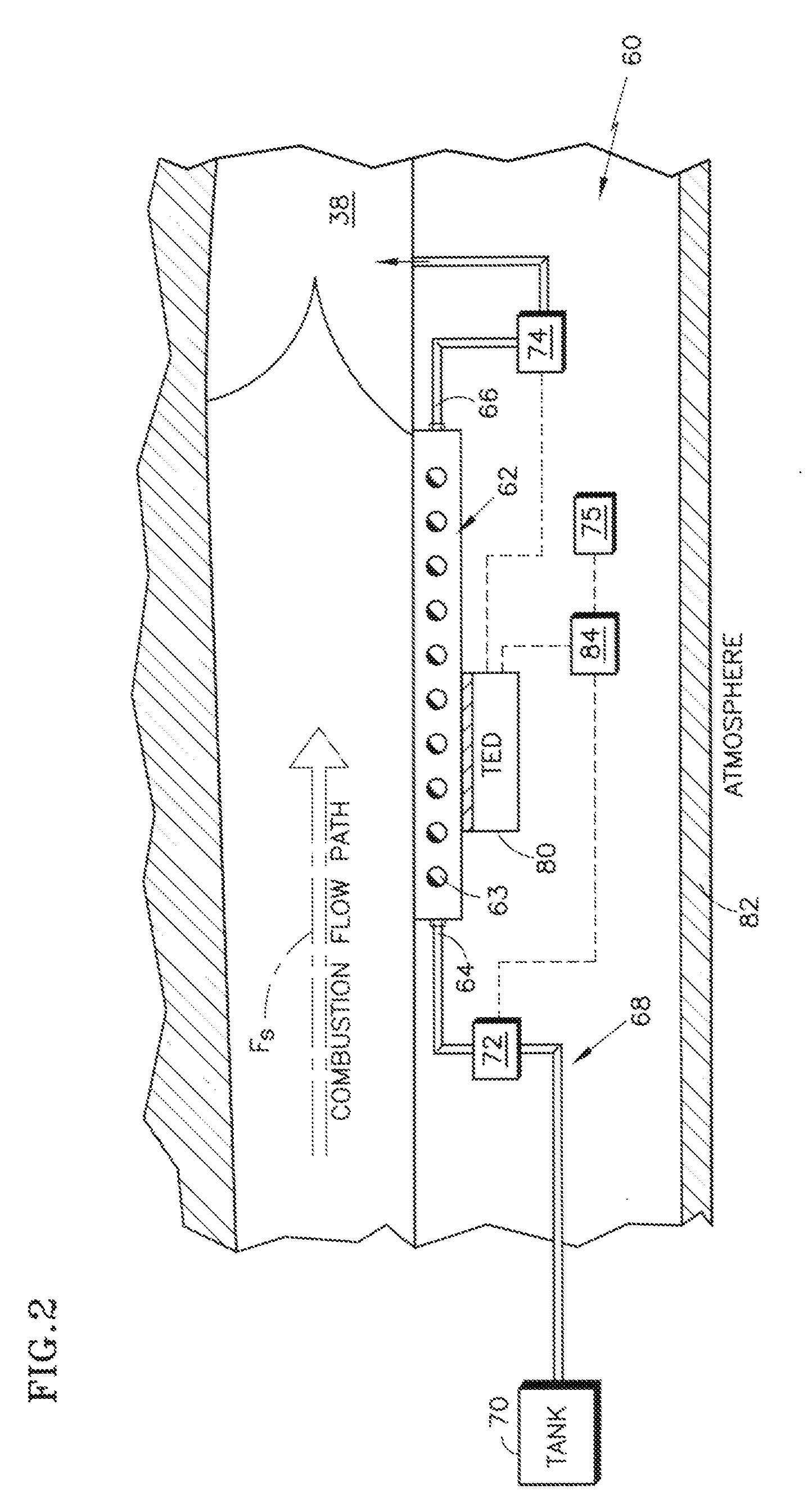

Flowpath heat exchanger for thermal management and power generation within a hypersonic vehicle

InactiveUS20090151321A1Maximize thermal gradientStress minimizationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal energyPlate heat exchanger

An electrical power generation system incorporates thermoelectric devices (TE Devices) for electrical power generation adjacent a flow path heat exchanger (HEX) adjacent to a vehicle flowpath structure such as a scramjet flow path to take advantage of the waste heat, high thermal gradients, and available, unused volume. A thermally conductive material communicates thermal energy from a vehicle external skin structure to the TE Device while a thermally conductive compliant material allows the TE Device to “float” with minimal mechanical stress.

Owner:AEROJET ROCKETDYNE OF DE

Single-stage hypersonic vehicle featuring advanced swirl combustion

InactiveUS7762077B2Reduce complexityShorten the lengthPower plant exhaust arrangementsEfficient propulsion technologiesRamjetLow speed

A single-stage hypersonic vehicle is comprised of a low-speed and a high-speed propulsion system. The low-speed propulsion system propels the single-stage vehicle to a threshold velocity, after which the high-speed propulsion system then takes over. The low-speed propulsion system includes a combined-cycle engine featuring a swirl generator that is integrated into a turbojet engine to provide a compact turbojet and swirl afterburner-ramjet propulsion system. The high-speed propulsion system includes a hypersonic engine that is operable at the threshold takeover velocity and beyond. In various embodiments, the high-speed propulsion system comprises a scramjet, rocket, or scramjet / rocket engine depending requirements. Benefits of the swirl generator design include its ability to rapidly and efficiently atomize, vaporize, mix and burn the fuel and oxidizer for the low speed propulsion system, significantly reduce length, weight, cooling requirements and complexity for both propulsion systems, while maintaining high propulsion performance and reducing propulsion and launch costs.

Owner:UNITED TECH CORP

Turbo rocket with real carnot cycle

InactiveUS20050138914A1Improve efficiencyReduce supplyEngine fuctionsBlade accessoriesCombustion chamberCarnot cycle

Engine embodiments primarily designed for aircraft propulsion and power generation incorporating the Carnot cycle for efficient combustion with typical embodiments including air compressors having one or more stages with isothermal compression and including combustion and expansion chambers having in part isothermal expansion before final adiabatic expansion.

Owner:PAUL MARIUS

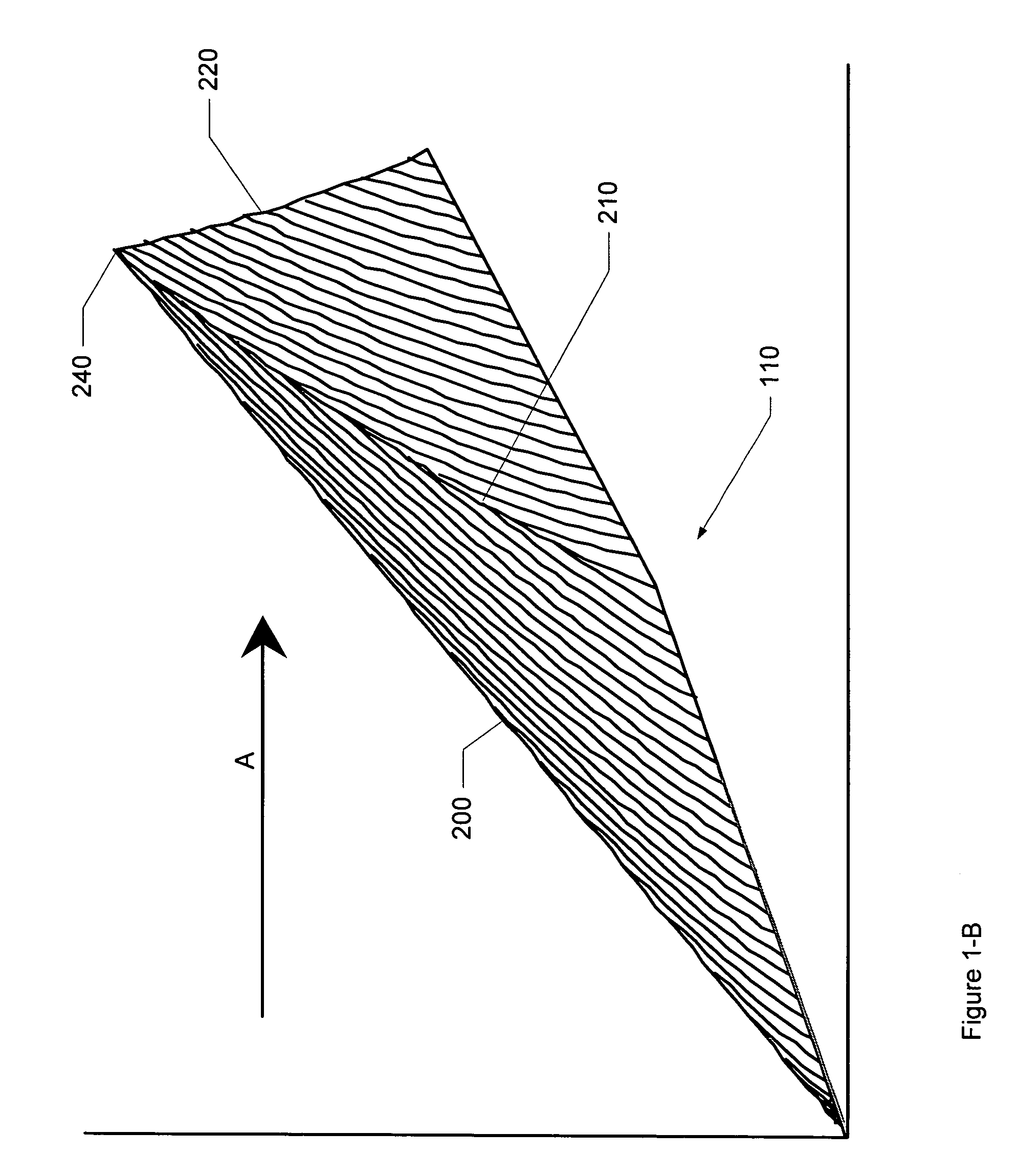

Isentropic compression inlet for supersonic aircraft

ActiveUS20080271787A1Improve performanceInherent shock stabilityCosmonautic vehiclesEngine manufactureEngineeringAirplane

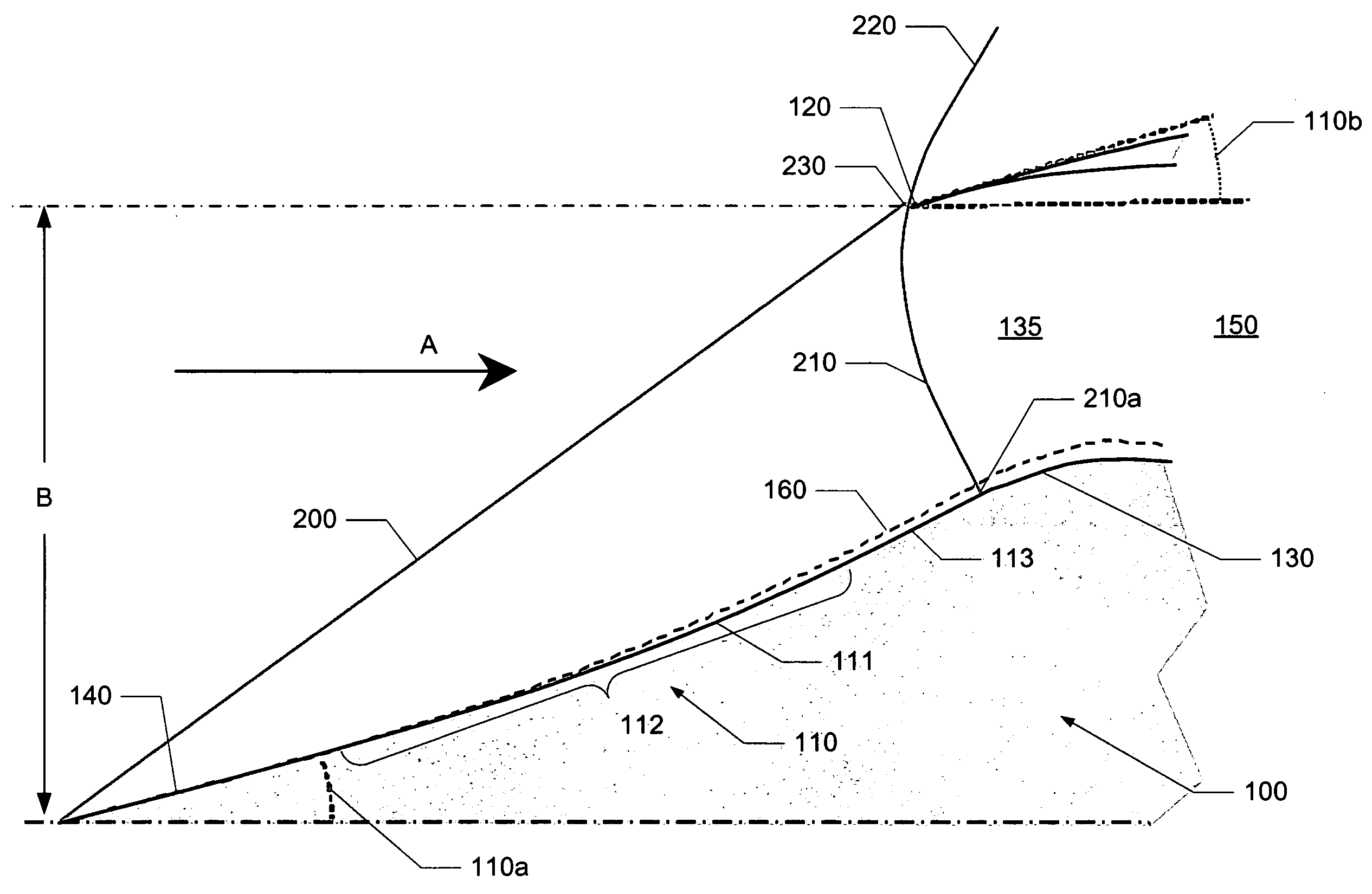

Embodiments of the invention relate to a supersonic inlet employing relaxed isentropic compression to improve net propulsive force by shaping the compression surface of the inlet. Relaxed isentropic compression shaping of the inlet compression surface functions to reduce cowl lip surface angles, thereby improving inlet drag characteristics and interference drag characteristics. Using supersonic inlets in accordance with the invention also demonstrated reductions in peak sonic boom overpressure while maintaining performance.

Owner:GULFSTREAM AEROSPACE CORP

Compact swirl augmented afterburners for gas turbine engines

InactiveUS20060230764A1Promotes rapid and efficient atomization and mixingBurn quicklyTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityFlame propagation

An afterburner apparatus that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel and an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and a central recirculation zone, which is positioned within the outer recirculation zone. These recirculation zones are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers. The recirculation zones accelerate flame propagation to allow afterburning to be completed in a relatively short length. Inherent with this swirl afterburner concept are design compactness, light weight, lower cost, smooth and efficient combustion, high thrust output, wide flammability limits, continuous operation at stoichiometric fuel / oxidizer mixture ratios, no combustion instabilities, and relatively low pressure losses.

Owner:UNITED TECH CORP

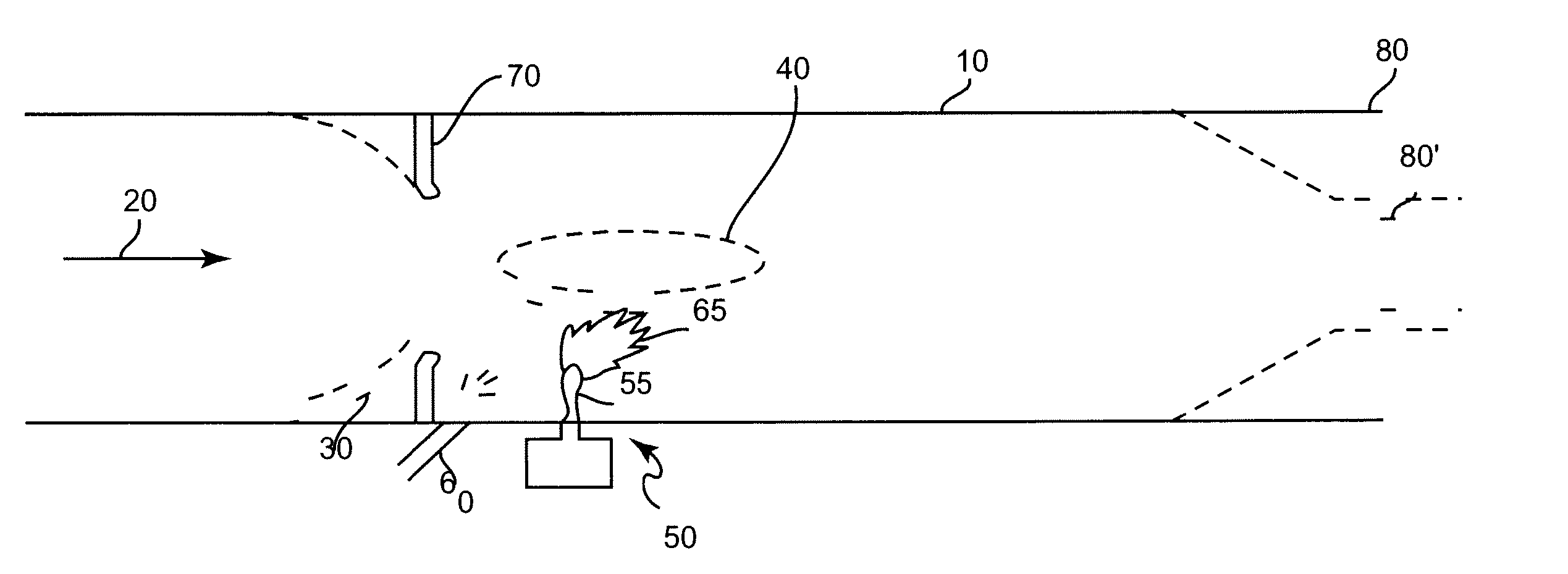

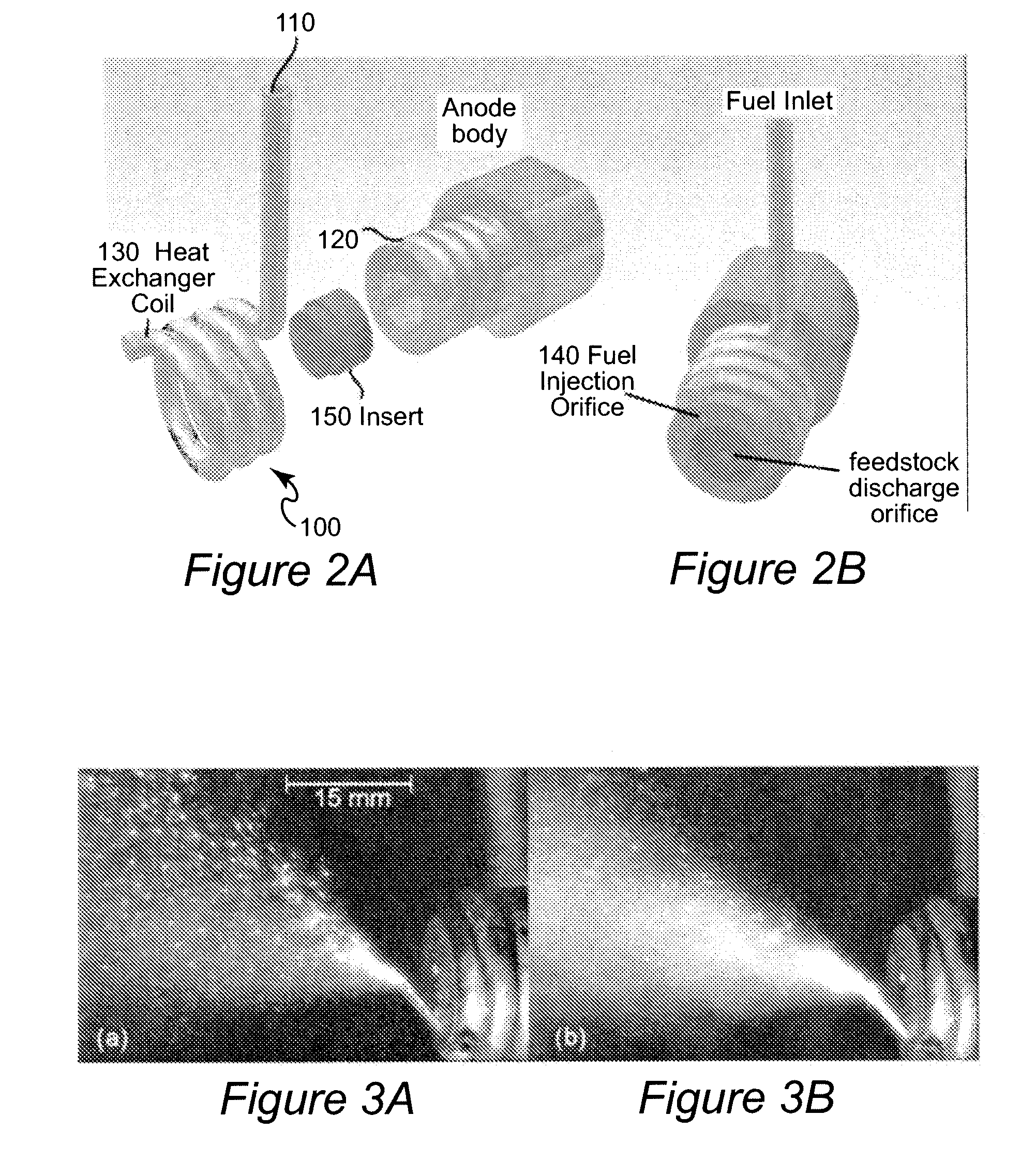

Improved Plasma Torch for Ignition, Flameholding and Enhancement of Combustion in High Speed Flows

InactiveUS20070044449A1Improves fuel mixingEnhances combustion reactionContinuous combustion chamberGas turbine plantsCombustionNitrogen

Preheating of fuel and injection into a plasma torch plume fro adjacent the plasma torch plume provides for only ignition with reduced delay but improved fuel-air mixing and fuel atomization as well as combustion reaction enhancement. Heat exchange also reduced erosion of the anode of the plasma torch. Fuel mixing atomization, fuel mixture distribution enhancement and combustion reaction enhancement are improved by unsteady plasma torch energization, integral formation of the heat exchanger, fuel injection nozzle and plasma torch anode in a more compact, low-profile arrangement which is not intrusive on a highspeed air flow with which the invention is particularly effective and further enhanced by use of nitrogen as a feedstock material and inclusion of high pressure gases in the fuel to cause effervescence during injection.

Owner:VIRGINIA TECH INTPROP INC

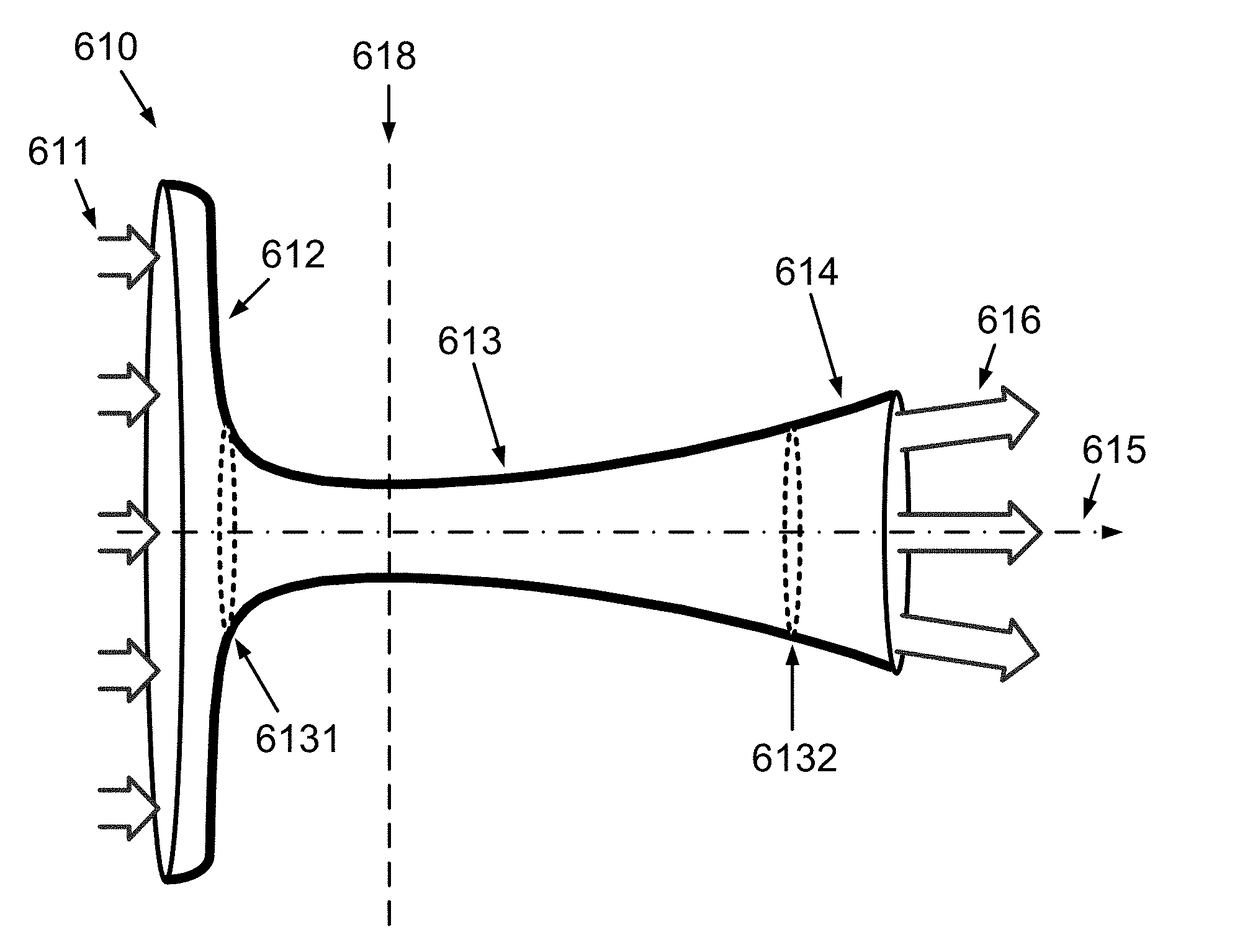

Generalized Jet-Effect

The invention provides a method for computational fluid dynamics and apparatuses making enable an efficient implementation and use of an enhanced jet-effect, either the Coanda-jet-effect, the hydrophobic jet-effect, or the waving-jet-effect, triggered by specifically shaped corpuses and tunnels. The method is based on the approaches of the kinetic theory of matter, thermodynamics, and continuum mechanics, providing generalized equations of fluid motion. The method is applicable for slow-flowing as well as fast-flowing real compressible-extendable fluids and enables optimal design of convergent-divergent nozzles, providing for the most efficient jet-thrust. The method can be applied to airfoil shape optimization for bodies flying separately and in a multi-stage cascaded sequence. The method enables apparatuses for electricity harvesting from the fluid heat-energy, providing a positive net-efficiency. The method enables efficient water-harvesting from air. The method enables generators for practical-expedient power harvesting using constructive interference of waves due to the waving jet-effect.

Owner:SOLITON HLDG CORP DELAWARE CORP

Propulsion from combustion of solid propellant pellet-projectiles

InactiveUS7194852B1High volume loadAbility to throttleGas turbine plantsContinuous jet plantsRamjetCombustion chamber

Owner:KRISHNAN VINU B

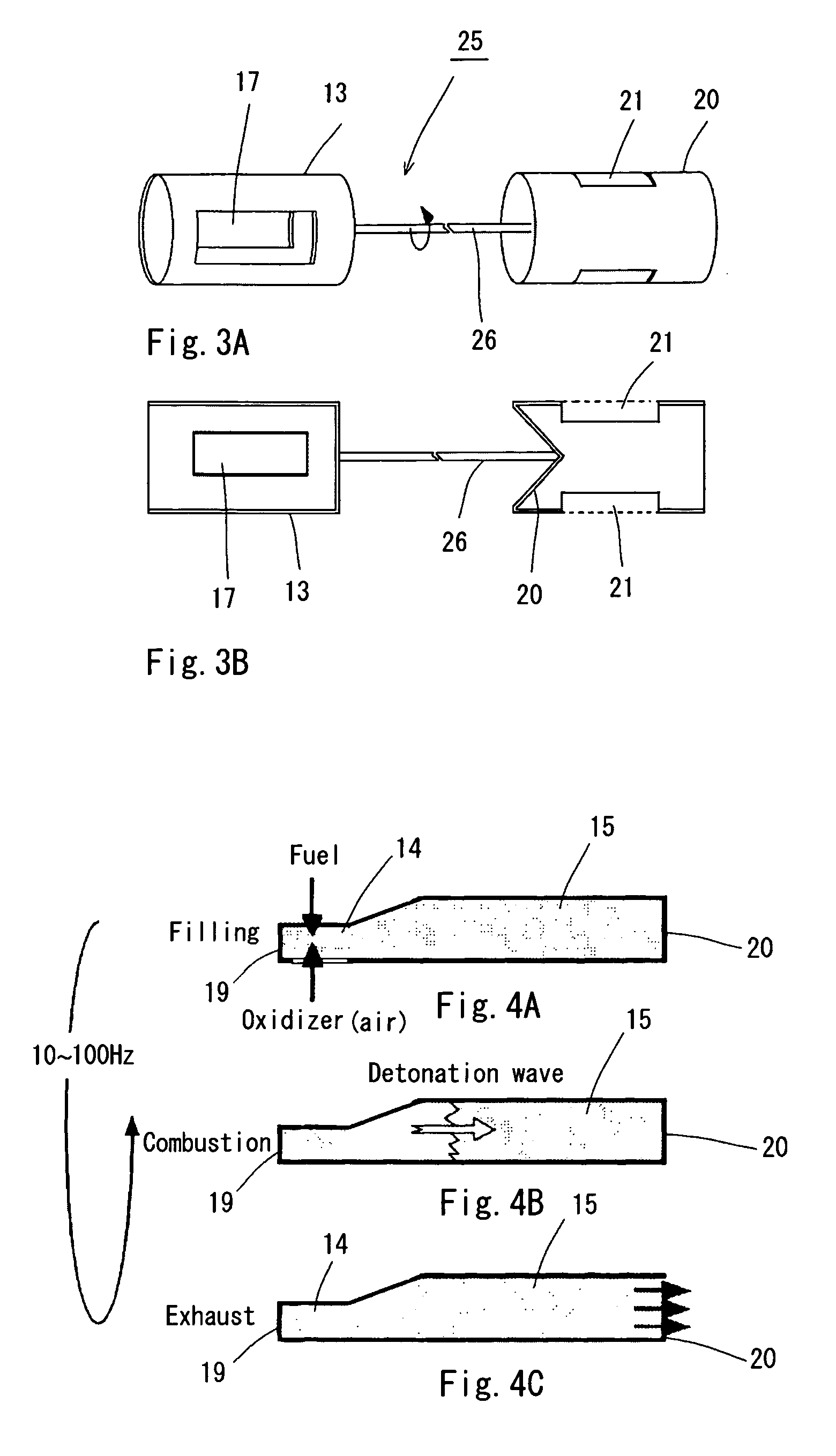

Pulse detonation engine and valve

InactiveUS20050183413A1Accurate timingIncrease air densityPulsating combustionTurbine/propulsion fuel heatingCombustion chamberCombustor

Pressure and density of a gaseous mixture are increased in the process of introducing the gaseous mixture into the combustor of an air-breathing pulse detonation engine employing atmospheric oxygen as an oxidizer. The exit valve 20 able to be opened and closed is provided at the outlet of the combustor 15, an air cooler 12 is provided in the exit of the intake, and density is increased by exchange of heat of the air received at the intake with a coolant in the air cooler 12. Furthermore, by closing the exit valve 20 provided in the outlet of the combustor during the process of loading the gaseous mixture, transition to the detonation process is possible without expansion of the high-pressure high density air obtained by ram-compression at the intake.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Jet aircraft electrical energy production system

InactiveUS20050034464A1Improve efficiencyEasy extractionGas turbine plantsAir/fuel supply for combustionJet engineGas turbines

The jet aircraft electrical energy production system produces electrical energy by ionizing airflow through a ram or gas turbine jet engine. The ionized particles in the airflow may also be separated, liquefied, stored for future utilization.

Owner:GONZALEZ E H

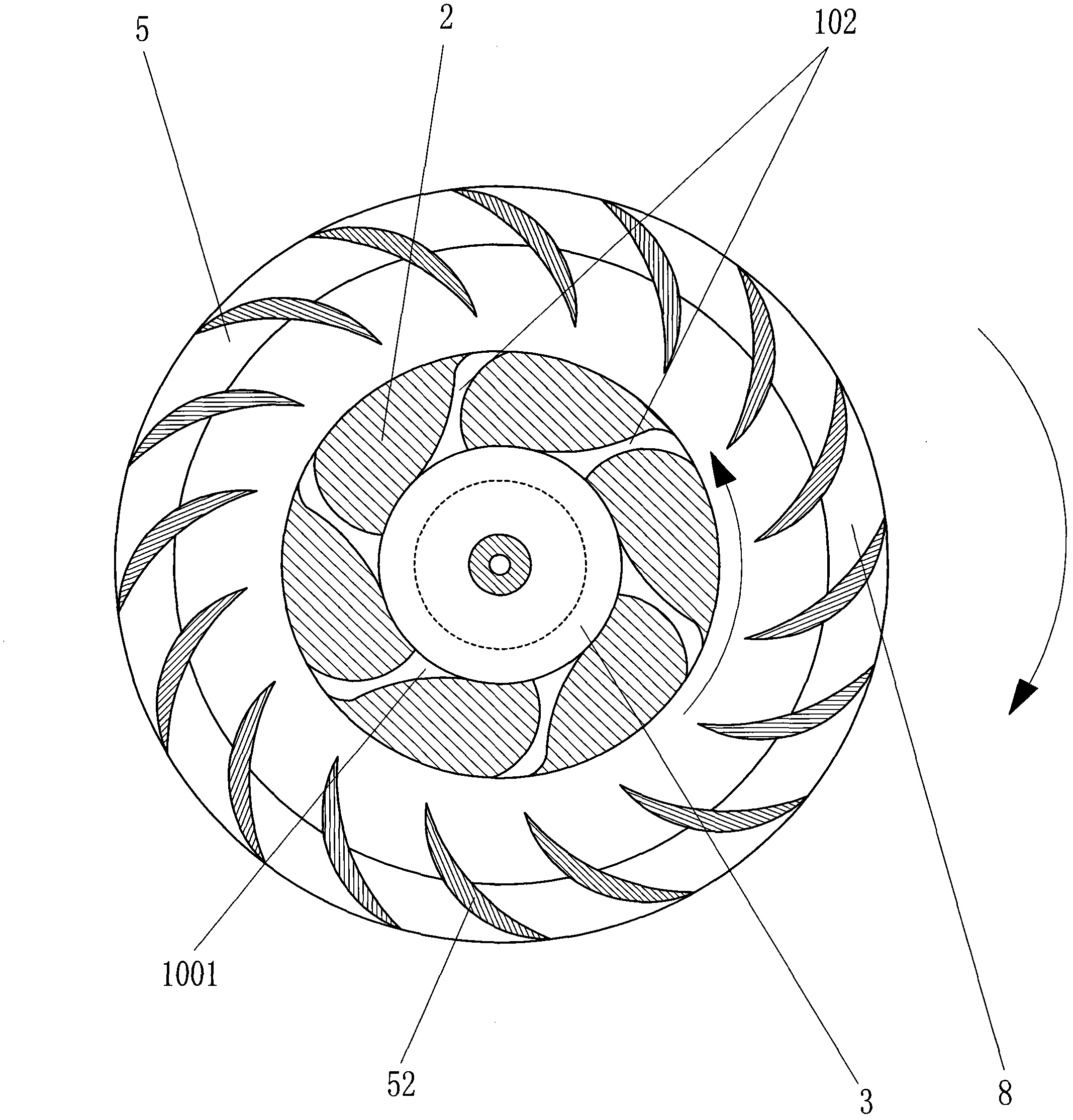

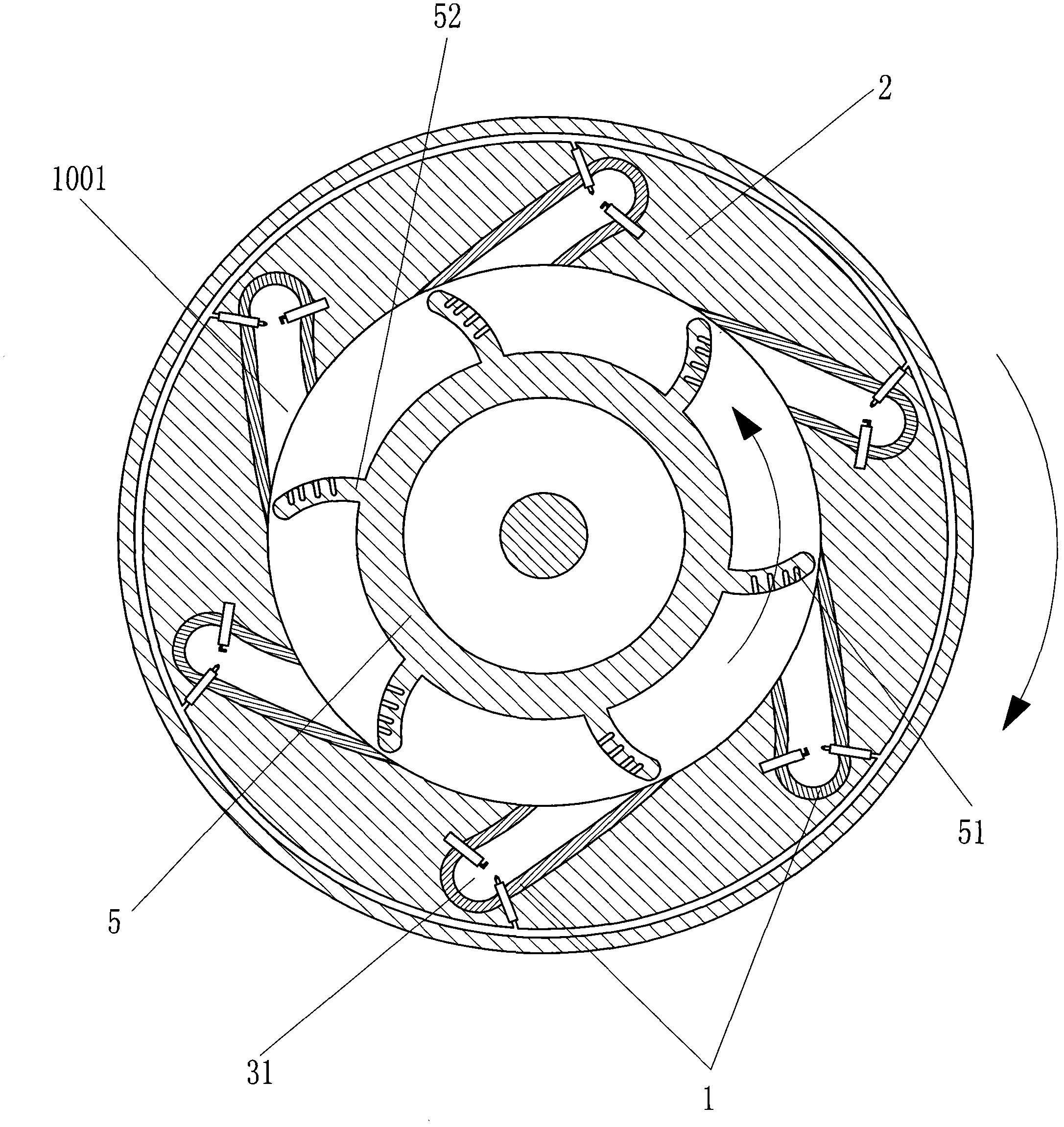

Rotary ramjet engine

An engine for providing rotary power about an output shaft with a high power-to-weight ratio includes a plurality of flow guiding blades mounted on the inner surface of an annular thruster base. The flow guiding blades cooperate with the peripheral surface of a rotor for forming a plurality of ramjet-like thrusters. The configuration of the flow guiding blades allows for optimization of the number of thrusters. The centrifugal forces generated by the rotating components is compensated by an annular reinforcement wall made with high strength materials allowing for downsizing of the rotor and associated components.

Owner:SCOPRA SCI & GENIE SEC

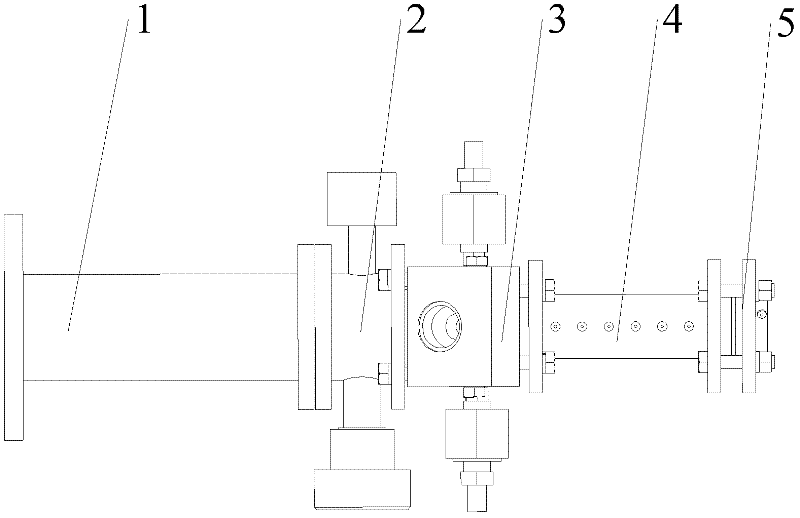

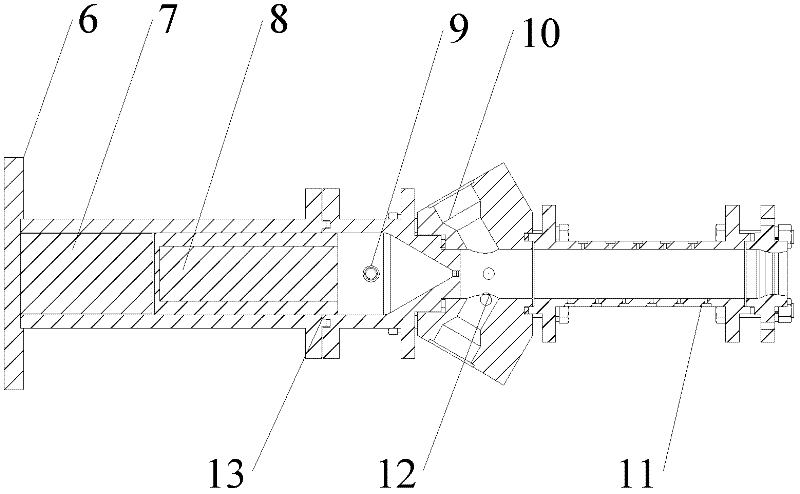

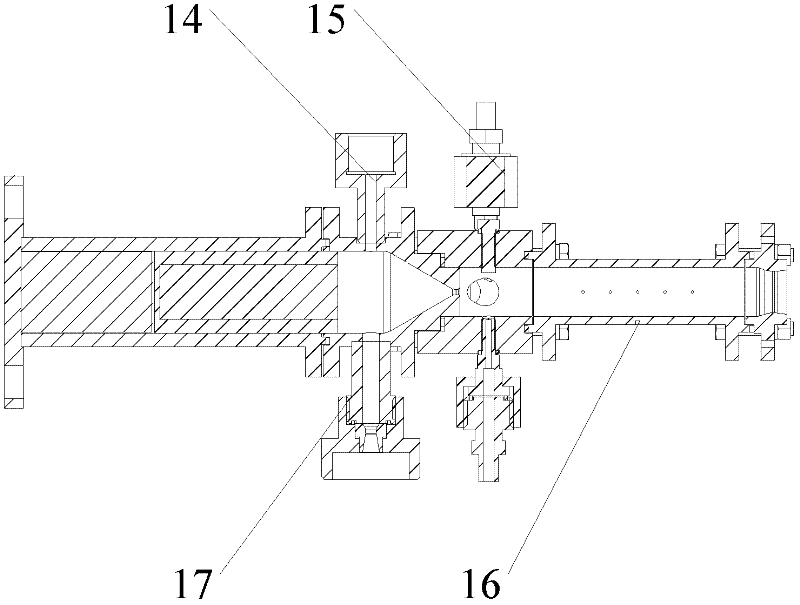

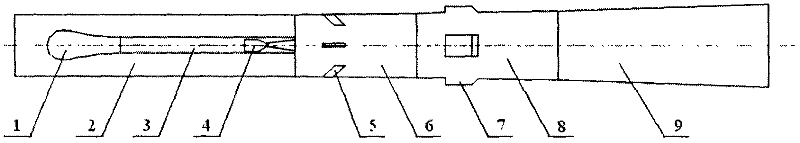

Solid-liquid hybrid rocket ramjet for test

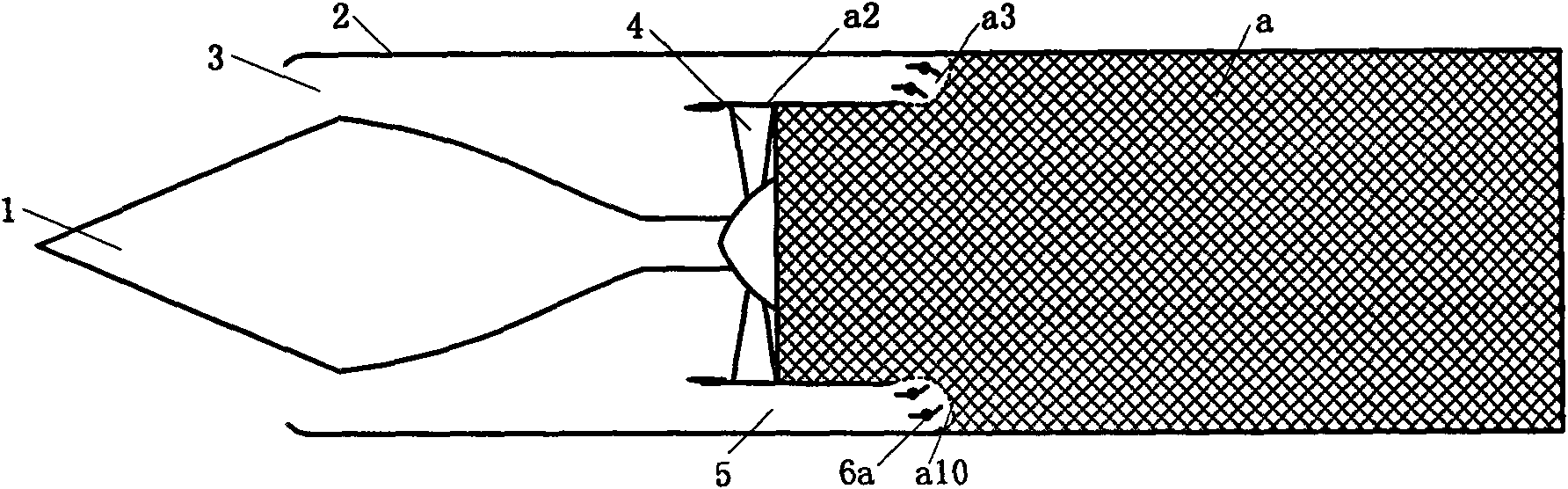

InactiveCN102400814AImprove efficiencyImprove stabilityRocket engine plantsRam jet enginesRamjetCombustion chamber

The invention discloses a solid-liquid hybrid rocket ramjet for test, which comprises a combustion chamber of a fuel gas generator, a spray pipe of the fuel gas generator, the head of a secondary combustion chamber, the body of the secondary combustion chamber and a tail spray pipe, wherein the combustion chamber of the fuel gas generator, the spray pipe of the fuel gas generator, the head of thesecondary combustion chamber, the body of the secondary combustion chamber and the tail spray pipe are sequentially connected with one another in series by a plurality of flanges; and the flange at the head of the combustion chamber of the fuel gas generator is fixedly connected with a thrust frame. The ramjet adopts an in-series detachable layout, so that each component and part can be conveniently detached and changed, the adjusting requirement of each parameter of the ramjet during test can be met, and the working condition under various structural parameter combination and various operating modes of the solid-liquid hybrid rocket ramjet can be conveniently simulated. A plurality of groups of important measure points are arranged and preset for the ramjet, so that each main parameter required by the test of the solid-liquid hybrid rocket ramjet can be directly or indirectly obtained.

Owner:BEIHANG UNIV

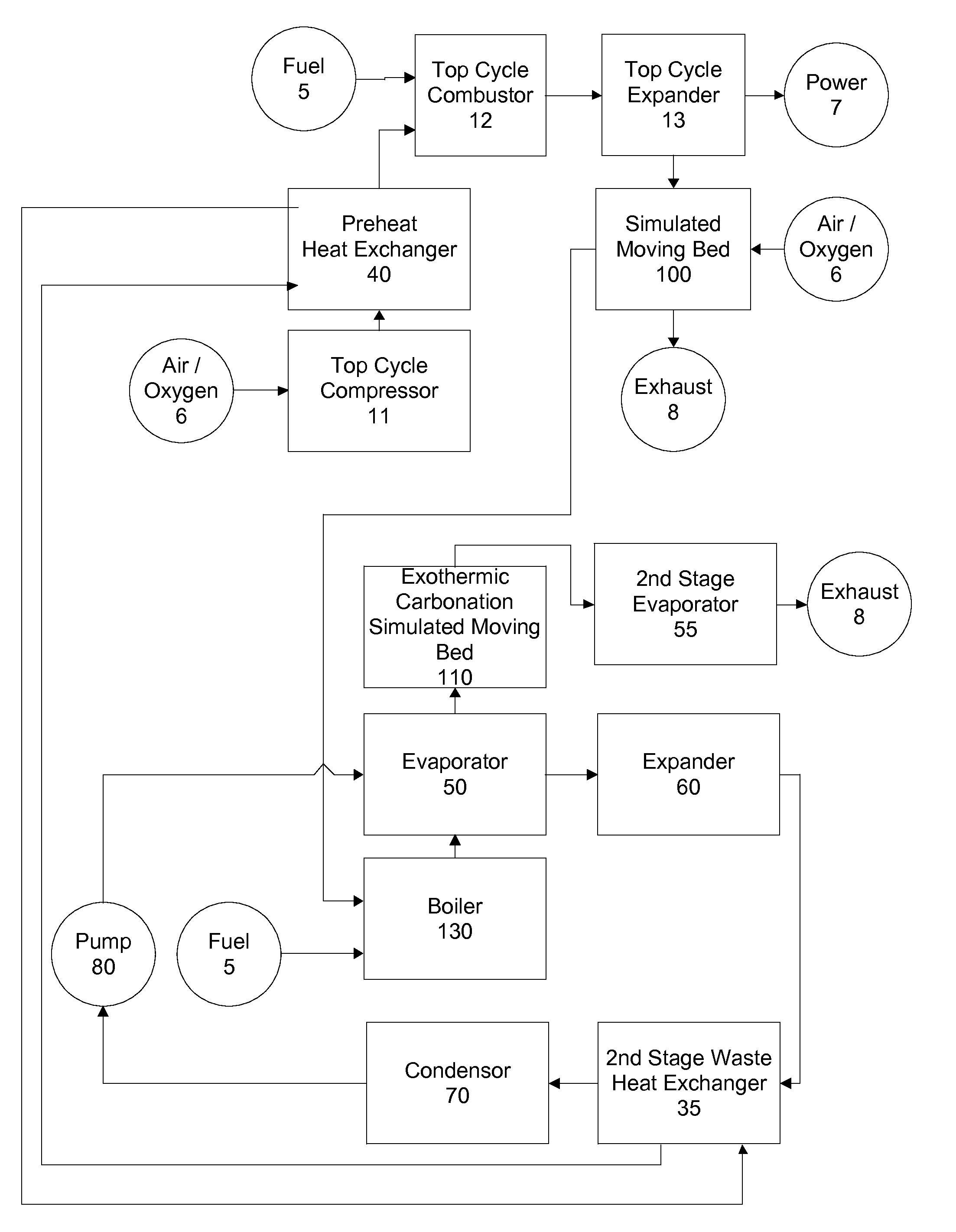

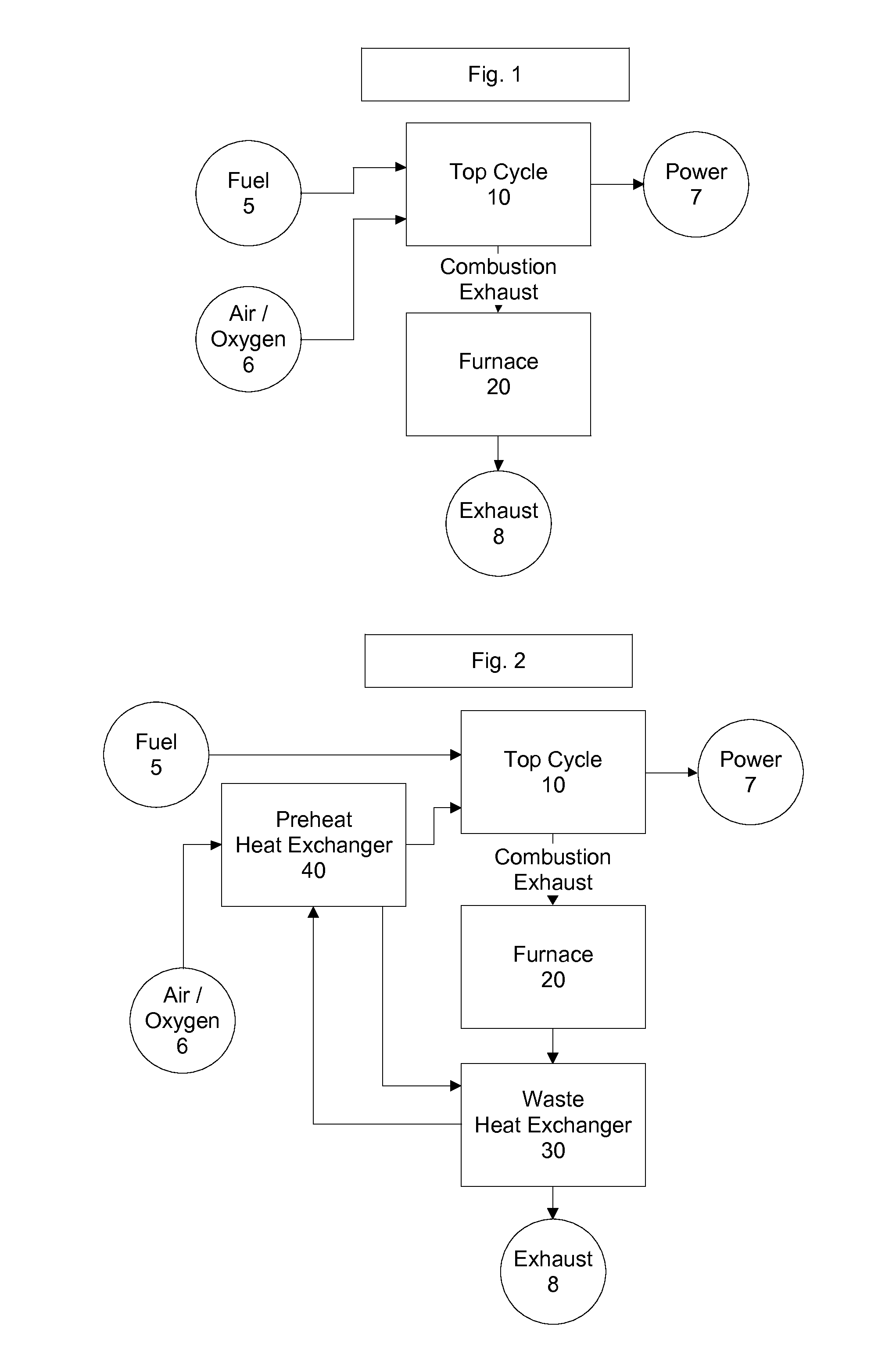

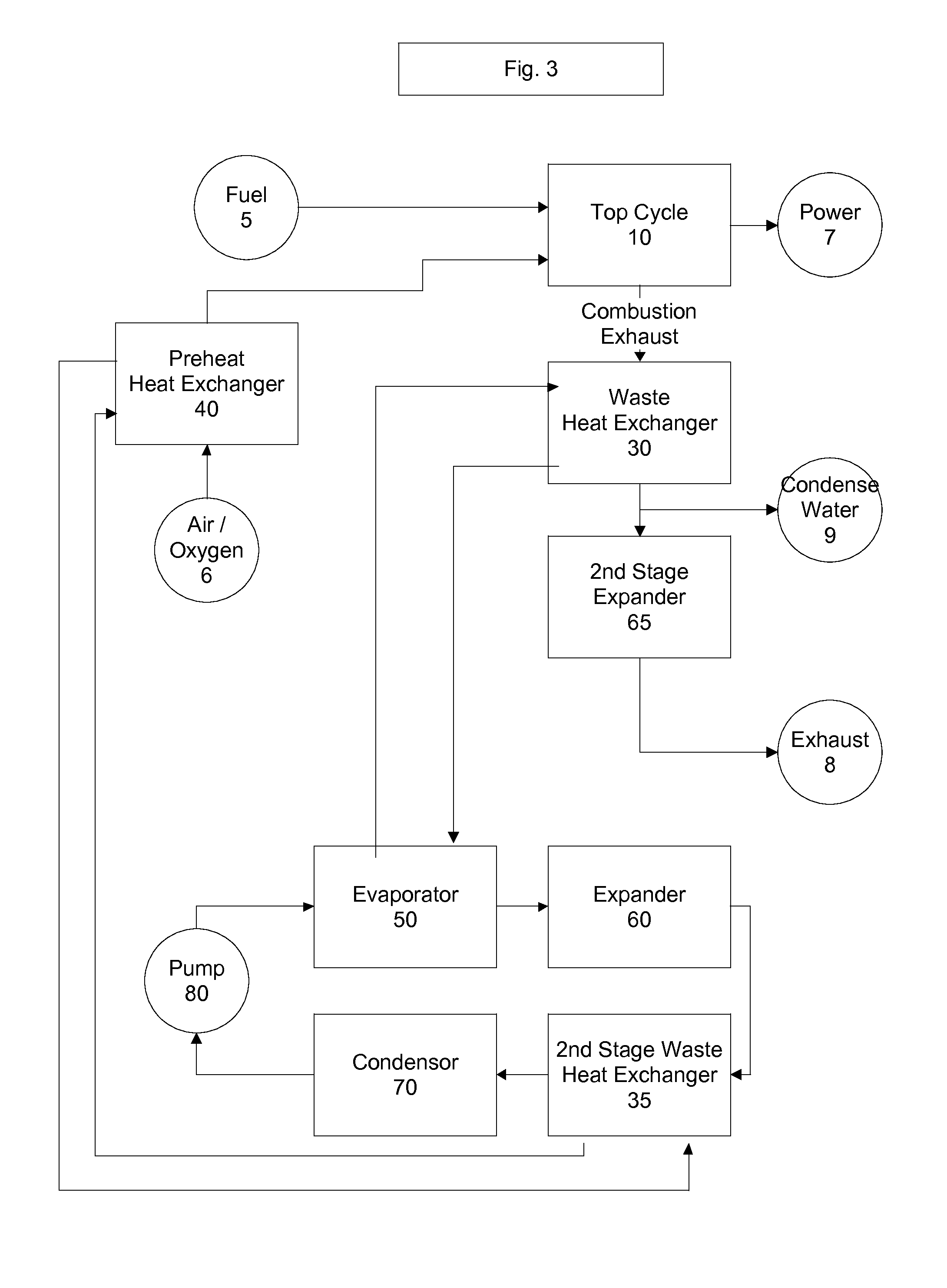

Top cycle power generation with high radiant and emissivity exhaust

The present invention generally relates to power generation methods and secondary processes requiring high radiant and emissivity homogeneous combustion to maximize production output. In one embodiment, the present invention relates to a top cycle power generator with combustion exhaust modified to have radiant flux in excess of 500 kW per square meter and emissivity greater than 0.90, and supercritical CO2 power generating cycle to maximize exergy efficiency.

Owner:GURIN MICHAEL

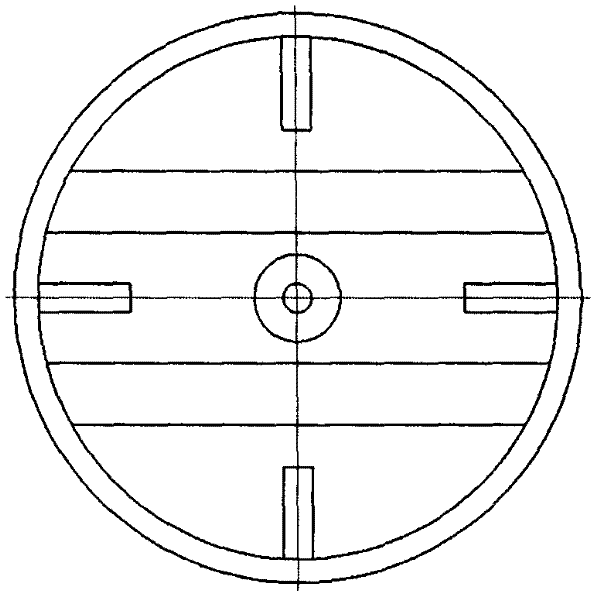

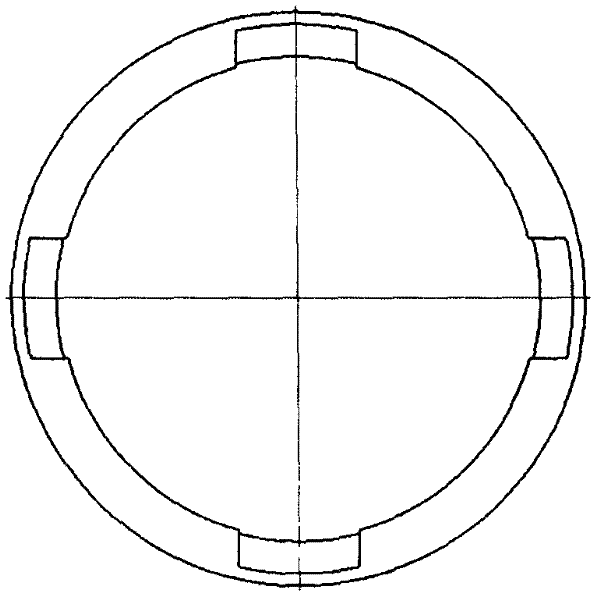

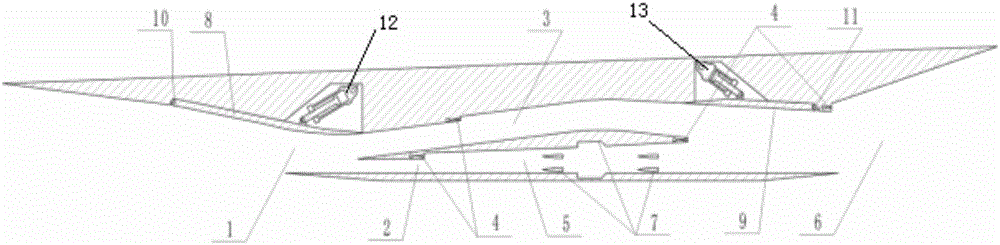

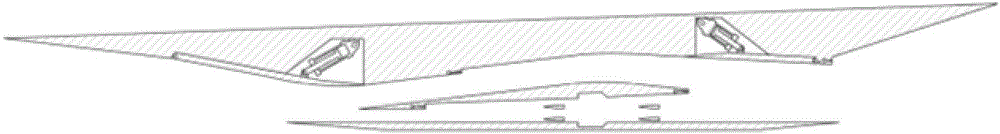

Center rocket type bimodal ramjet with circular structure

InactiveCN102374071AWork lessExpand the lower limitRocket engine plantsRam jet enginesRamjetCombustion chamber

The invention discloses a center rocket type bimodal ramjet with a circular structure. in the bimodal ramjet, a circular-structured combustion chamber is adopted, a center rocket is installed in a separation section, and the high-temperature fuel-rich gas of the center rocket can be used as an effective ignition source and a flame stabilization source; a small support plate group is used to inject secondary fuel so as to perform secondary burning together with incoming flow air tissue. The injection of the secondary fuel is stepwise carried out along the axial direction of the engine, wherein the support plate directly performs injection in a primary combustion chamber, a concave cavity performs forward injection in a secondary combustion chamber, and the support plate performs injection in the secondary combustion chamber as well after the support plate is installed. The engine provided by the invention has simple structure, is easy to process, safe and reliable to operate, is more suitable for application of the bimodal ramjet with larges size structure in an actual project.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

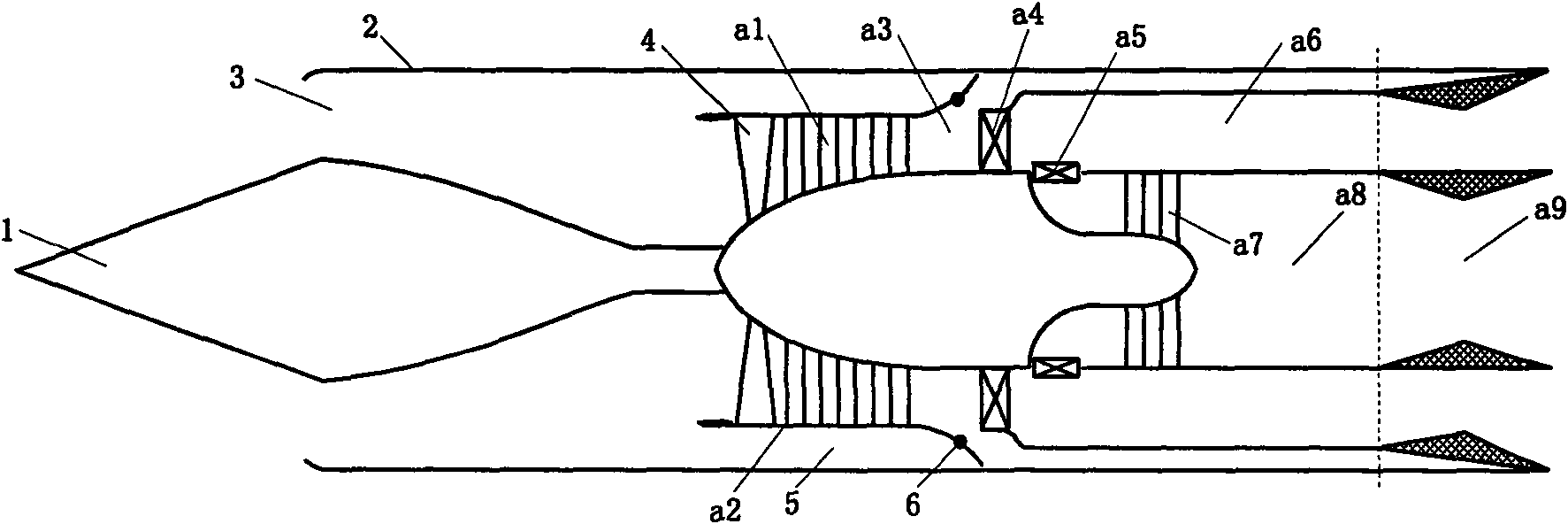

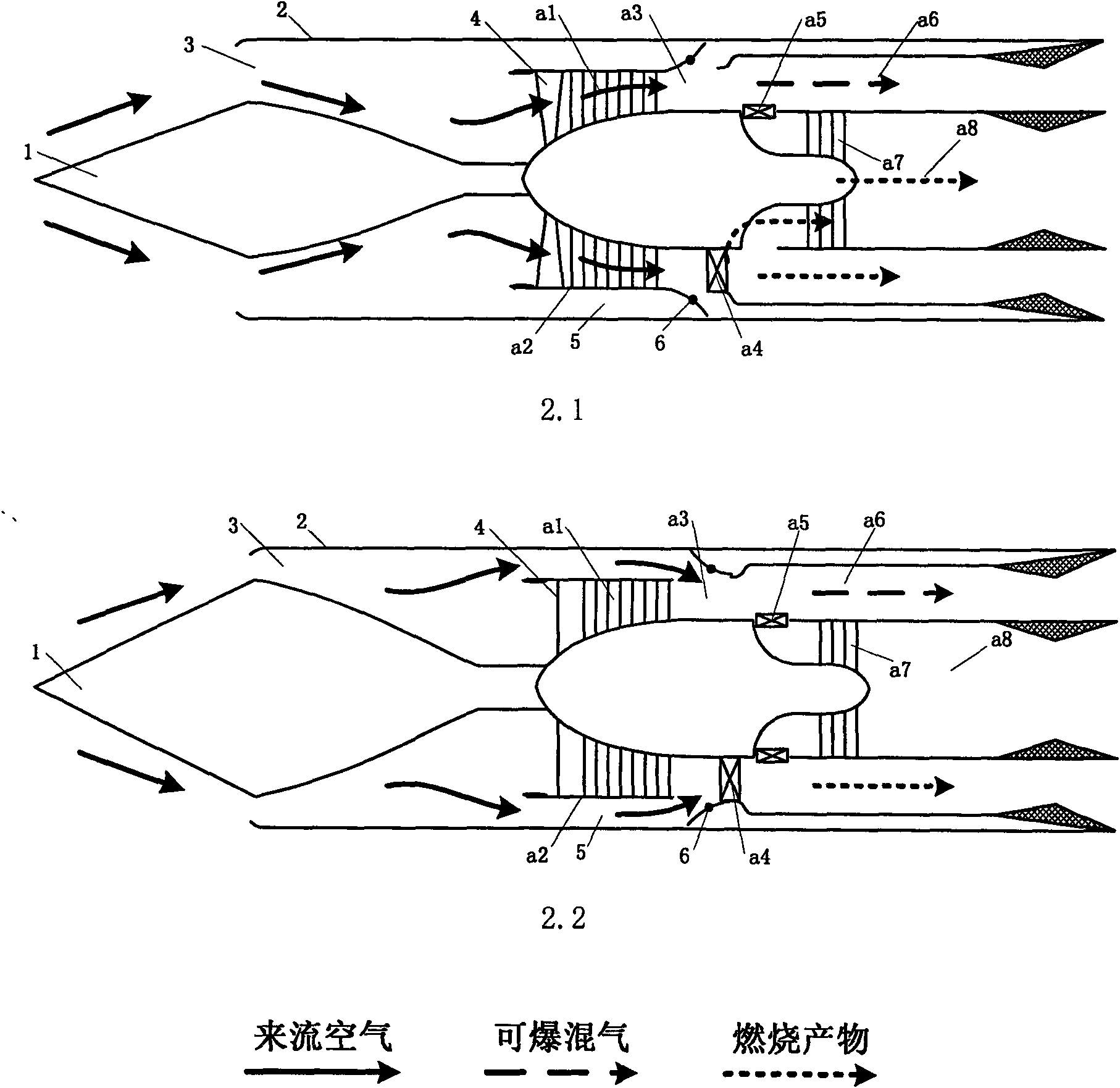

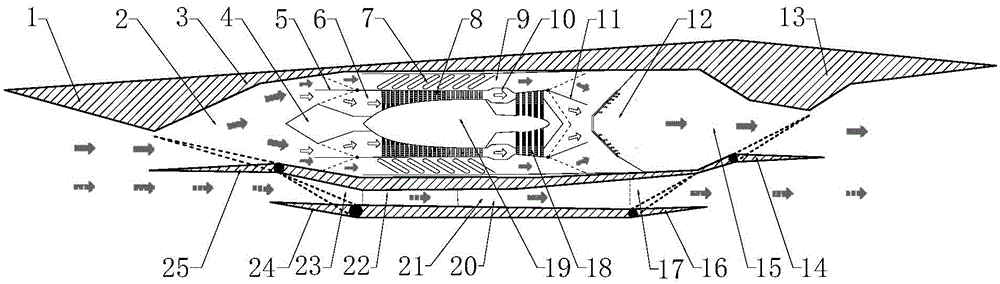

Turboramjet combined engine based on knocking combustion

InactiveCN102155331ASolve sizeSolve the weight problemRam jet enginesComposite engine plantsAirflowCombustion

The invention discloses a turboramjet combined engine based on knocking combustion. Along the air flow direction, an adjustable central conical body is positioned at the forefront end of the combined engine, and surrounds into an adjustable air intake channel with a shell; the downstream of the adjustable central conical body is connected with an air intake device of a preposed turbine combined pulsation knocking engine; the upstream of an air pressing machine of the preposed turbine combined pulsation knocking engine is provided with an adjustable inlet guiding blade; an engine shell of the preposed turbine combined pulsation knocking engine surrounds into an annular air duct with the shell; and an adjustable plate is positioned at an expanding pressure buffer chamber between the air duct and the preposed turbine combined pulsation knocking engine. By the turboramjet combined engine based on knocking combustion provided by the invention, the problems of long size, great weight, complex structure, many components, and the like of a complete machine are solved, and simultaneously the propulsive performance of the turboramjet combined engine based on the knocking combustion is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

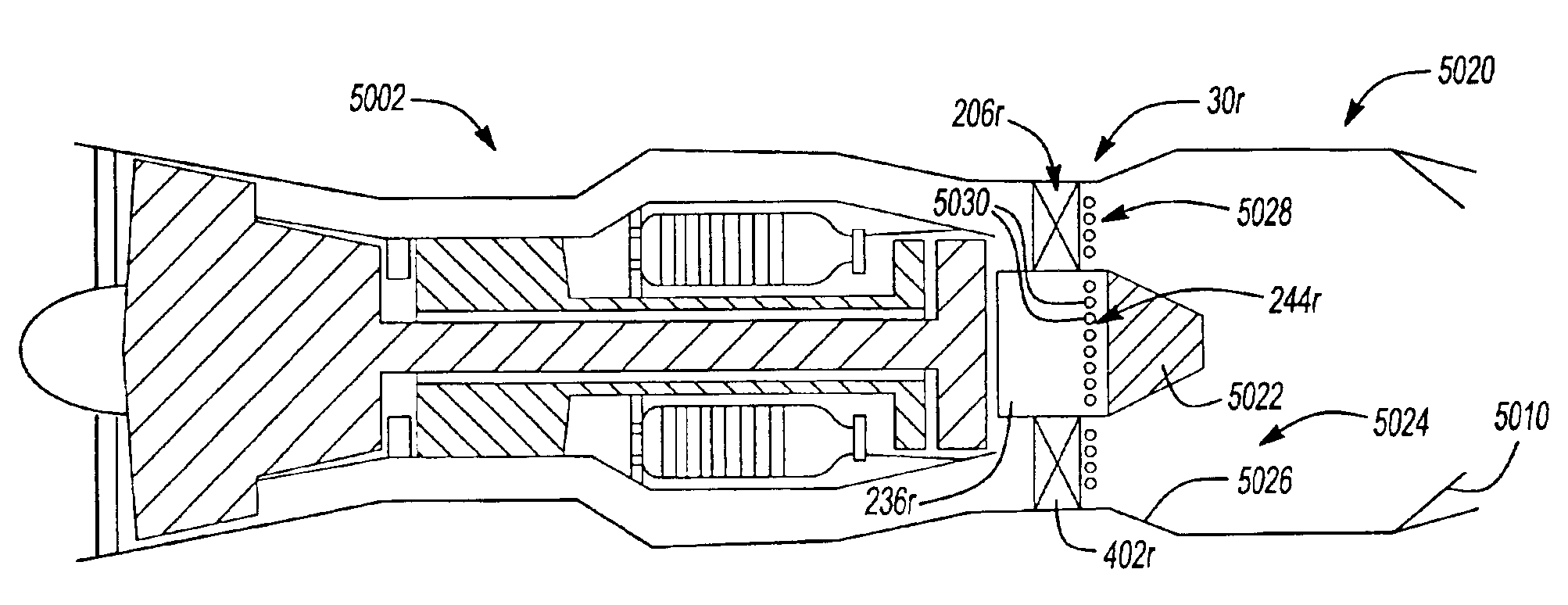

Combined cycle engines incorporating swirl augmented combustion for reduced volume and weight and improved performance

InactiveUS20050081508A1Rapid fuel atomizationVaporization fastContinuous combustion chamberJet type power plantsRamjetFlame propagation

A combined-cycle engine having at least one core engine and at least one ramjet engine. The ramjet utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and an inner central recirculation zone, both of which are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers, which accelerate flame propagation throughout the core flowfield. The swirl generator provides smooth combustion with no instabilities and minimum total pressure losses and enables significant reductions in the L / D ratio of the combustor. Other benefits include simplicity, reliability, wide flammability limits, high combustion efficiency and high specific thrust performance.

Owner:UNITED TECH CORP +1

Co-probe power generation system

InactiveUS20020050719A1Minimize captureMinimize total lossWorking fluid for enginesEfficient propulsion technologiesSurface layerCorona discharge

A fluid moving system that includes a multiplicity of electrode elements mounted in spaced relationships to one another adjacent along a surface. The electrode elements produce charged particles by a corona-type discharge. The electrode elements are also used for delivering progressively changing electric potentials along the smooth surface in order to create an electric potential field for propelling charged particles from one electrode element toward the next and thereby inducing a surface layer fluid flow over the surface. A switching mechanism for reversing the direction of the corona discharge and the direction of the moving charged particles is also incorporated into the system in order to reinforce and accelerate the flow.

Owner:CADDELL ROBERT I +1

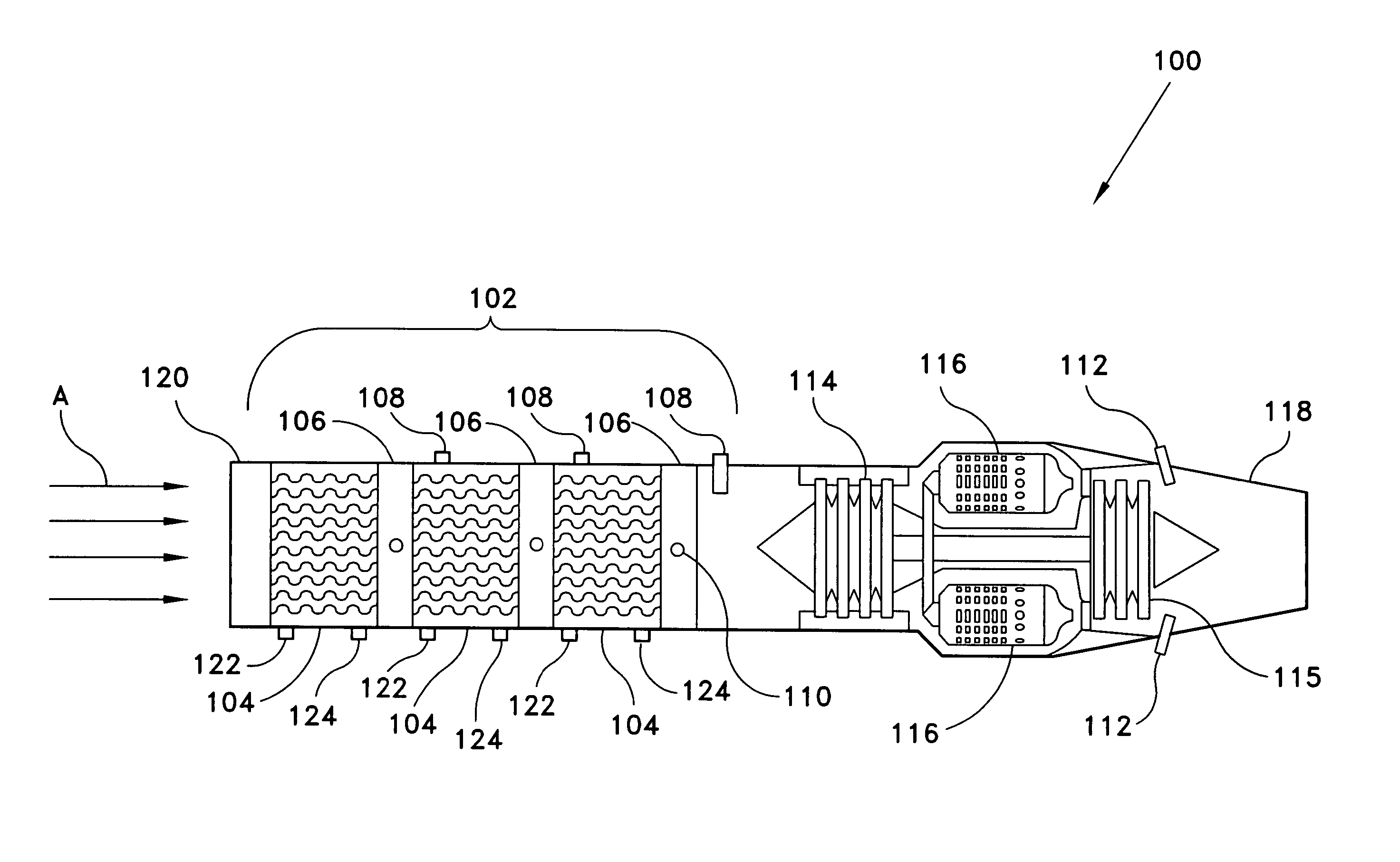

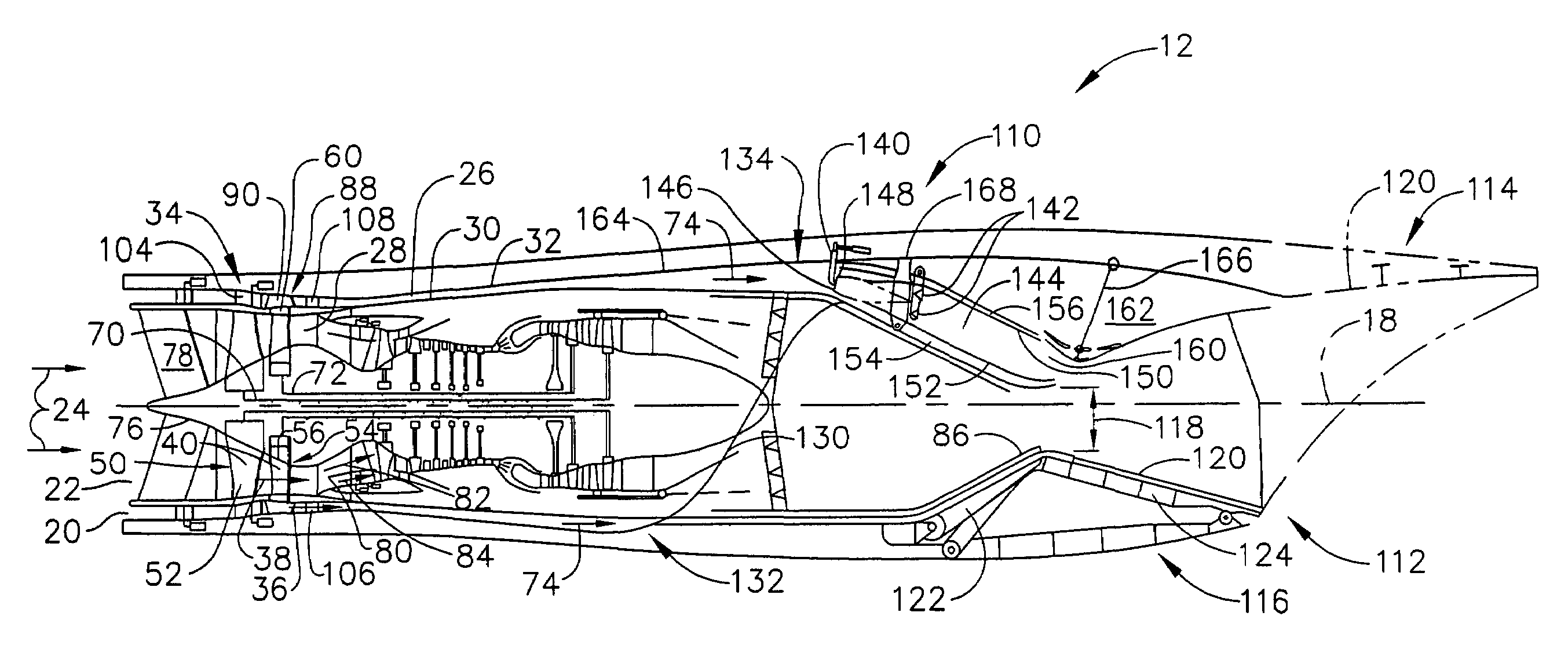

Methods and apparatus for assembling a gas turbine engine

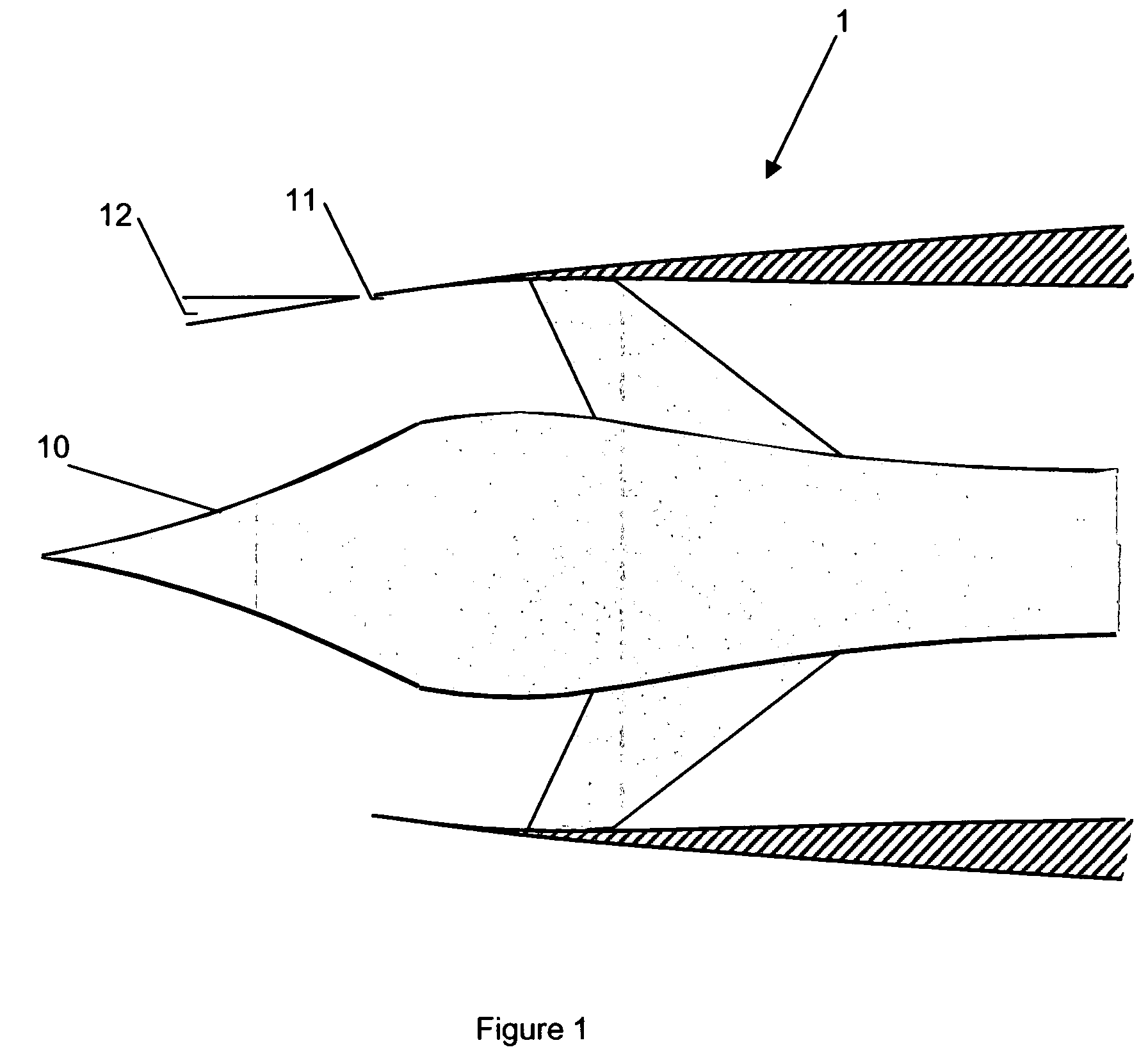

A method for assembling a gas turbine engine includes providing a core engine, and providing a flade system including a flade stream augmentor positioned within a flade duct. The method also includes channeling airflow through the core engine to produce engine thrust, channeling airflow through the flade duct to produce engine thrust, and igniting a portion of the airflow channeled through the flade duct using the flade stream augmentor to increase the amount of thrust produced by the flade system.

Owner:GENERAL ELECTRIC CO

Double-channel variable geometry rocket base combined cycle engine

InactiveCN106150757AImprove adhesionMeet power needsGas turbine plantsRam jet enginesHigh-speed flightAirflow

The invention discloses a dual-channel variable-geometry rocket-based combined cycle engine, which adopts a dual-channel structure and realizes good work in a wide flight range through a partitioned combustion mode; the dual channels work simultaneously in a low-speed flight state to complete ejection mode and sub-stage The work in the low-speed section of the combustion mode; in the high-speed flight state, it is converted to the high-speed channel to work alone, and completes the work of the high-speed section of the sub-combustion mode and the super-combustion mode. The variable geometry method that the top pressure plate rotates around the rotating shaft is used to realize the adjustment of the small shrinkage ratio in the low-speed flight state and the large shrinkage ratio in the high-speed flight state, and meet the air capture and airflow compression requirements under different flight Mach numbers in a wide range of the engine. The binary mixed pressure inlet is adopted, the top pressure plate and the side plate of the inlet have good adhesion, and the mechanical dynamic seal is easy to realize, which is suitable for engineering applications; it meets the power requirements of different working modes of the aircraft. The top pressure plate and the conversion plate are respectively connected to the rotating shaft of the double fulcrum structure, the structure is rigid, and the high temperature sealing is easy to realize.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

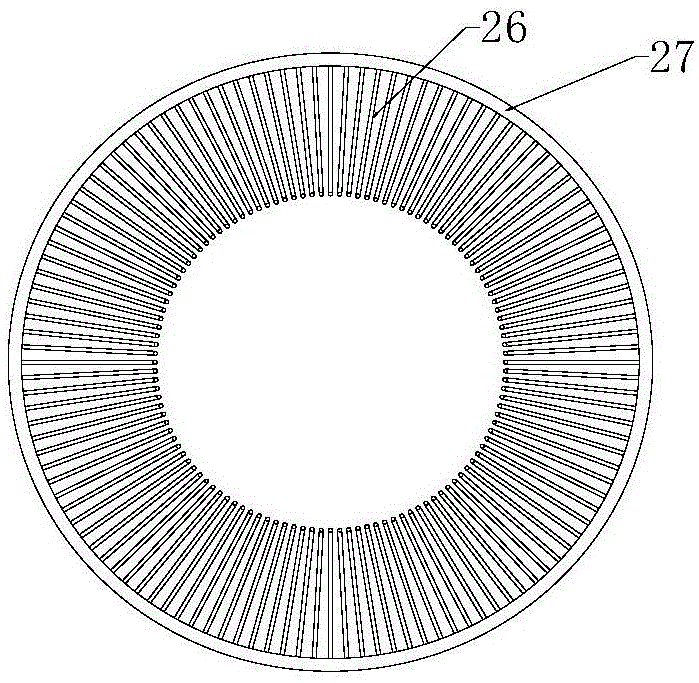

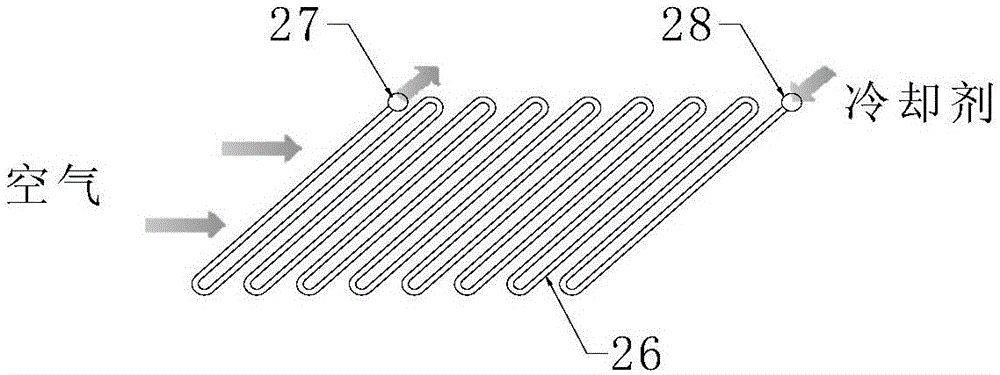

Pre-cooling air-breathing type variable cycle engine

InactiveCN105156227ALower airflow temperatureReduce the temperatureTurbine/propulsion engine coolingGas turbine plantsRamjetCombustion chamber

The invention discloses a pre-cooling air-breathing type variable cycle engine and relates to the reusable pre-cooling air-breathing type variable cycle engine applied to aeronautics and astronautics devices. The engine mainly consists of a pre-cooler, a turbine engine, a super combustion chamber and a super combustion ramjet engine, wherein the pre-cooler and the super combustion chamber form a subsonic combustion ramjet engine; a turbine subsonic combustion ramjet engine is connected with the super combustion ramjet engine in parallel; working states of the turbine subsonic combustion ramjet engine and the super combustion ramjet engine are selected by adjusting a switching adjusting device, so that the working modal of the whole engine is controlled. The pre-cooler can reduce an inlet gas flow temperature of a super combustion chamber, can increase the efficiency of the super combustion chamber, can expand the working range of a subsonic combustion punching modal, and can make up insufficient thrust force when turbine subsonic combustion ramjet engine is transferred to the super consumption ramjet engine, so that the pre-cooling air-breathing type variable cycle engine has the advantage that the transfer class of a combined engine is stably transferred.

Owner:TSINGHUA UNIV

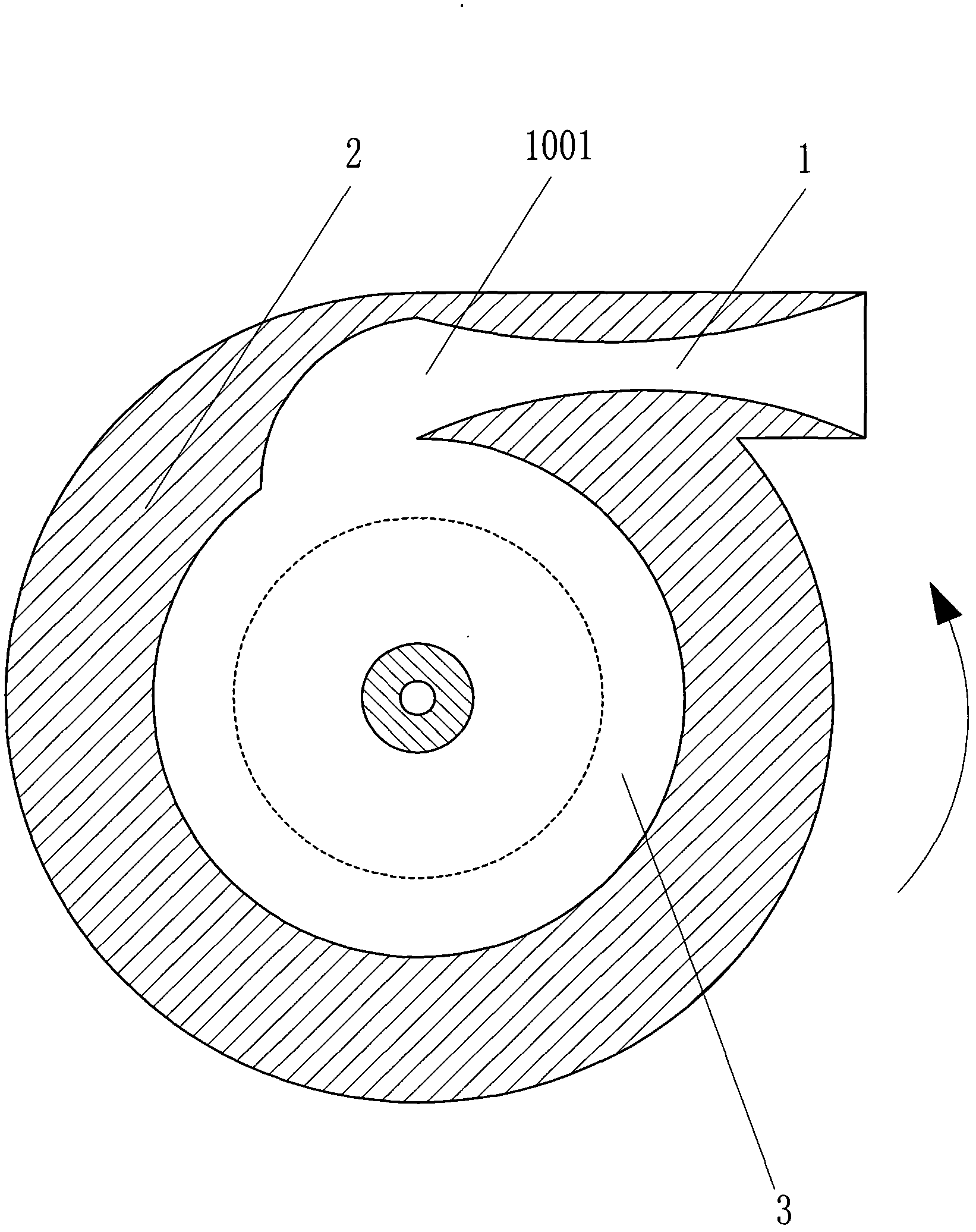

supersonic rotary engine

InactiveCN102278233ASimple structureReduce manufacturing costNon-positive displacement enginesRocket engine plantsRotary engineHigh pressure

The invention discloses a supersonic rotor engine, which comprises a supersonic jet channel (1), a rotating structure body (2) and a high pressure working medium source (3), wherein the supersonic jet channel (1) is formed on the rotating structure body (2); a working medium inlet (1001) of the supersonic jet channel (1) is communicated with the high pressure working medium source (3); the loading capacity of the high pressure working medium source (3) is higher than 2MPa; the jet of the supersonic jet channel (1) is generally oriented by a tangent line of rotating circumferential of the rotating structure body (2); and the rotating structure body (2) externally outputs power. The supersonic rotor engine has a simple structure, low manufacturing cost and high reliability, and greatly improves the efficiency of conventional engines.

Owner:靳北彪

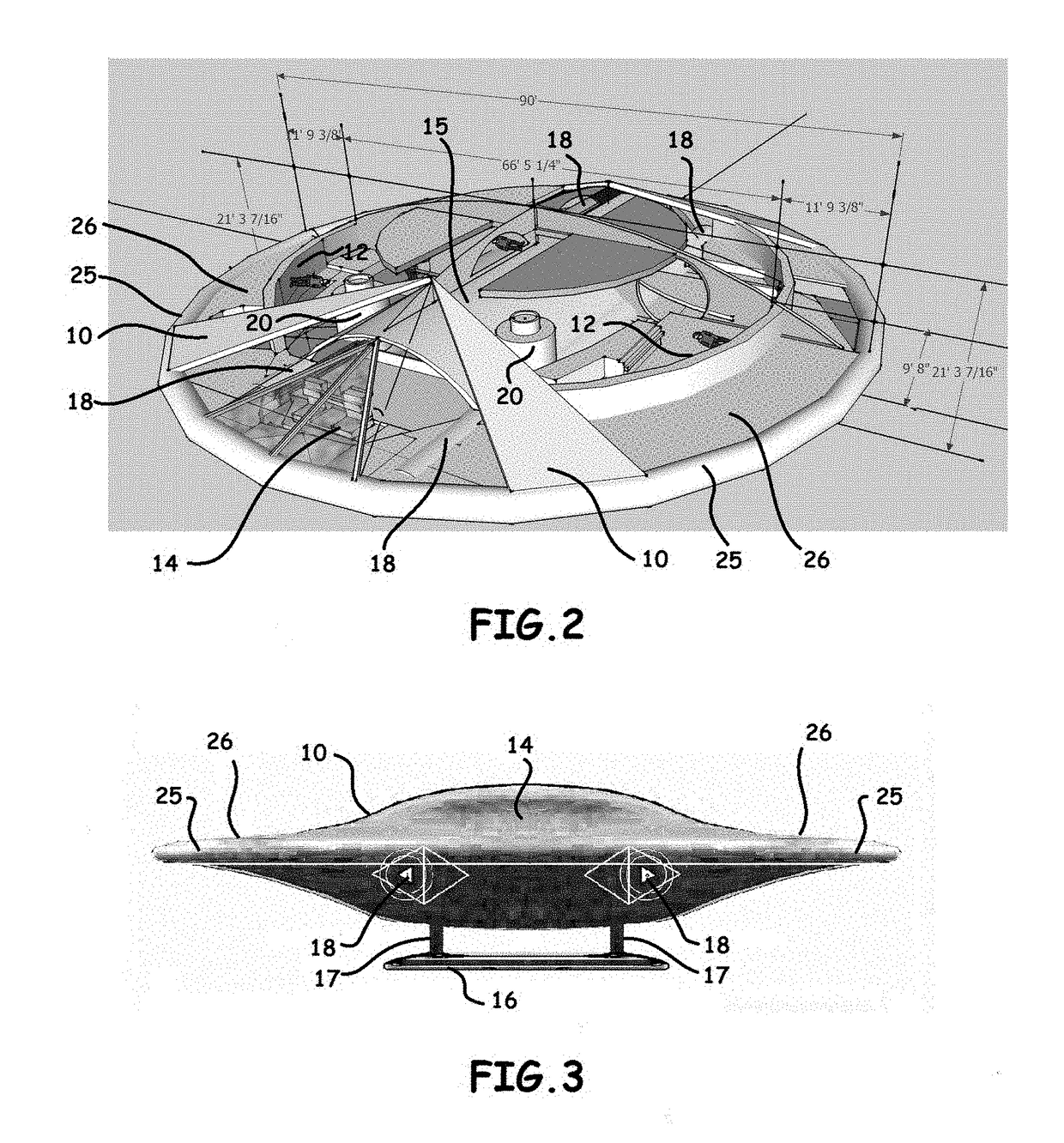

Centripetal aerodynamic platform spacecraft

ActiveUS20170190446A1Reducing required liquid oxygenReducing booster tank capacity weightCosmonautic environmental control arrangementLaunch systemsGravitationSpacecraft

An aerodynamic platform or spacecraft including a habitable 1G centripetal force rotating gravity producing interior corridor within an aerodynamic shell and an aerodynamic drone booster launch system with reentry and reuse capability.

Owner:WILLIAMS SR LAWRENCE ELLIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com