Patents

Literature

236 results about "Pulse detonation engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pulse detonation engine (PDE) is a type of propulsion system that uses detonation waves to combust the fuel and oxidizer mixture. The engine is pulsed because the mixture must be renewed in the combustion chamber between each detonation wave and the next. Theoretically, a PDE can operate from subsonic up to a hypersonic flight speed of roughly Mach 5. An ideal PDE design can have a thermodynamic efficiency higher than other designs like turbojets and turbofans because a detonation wave rapidly compresses the mixture and adds heat at constant volume. Consequently, moving parts like compressor spools are not necessarily required in the engine, which could significantly reduce overall weight and cost. PDEs have been considered for propulsion since 1940. Key issues for further development include fast and efficient mixing of the fuel and oxidizer, the prevention of autoignition, and integration with an inlet and nozzle.

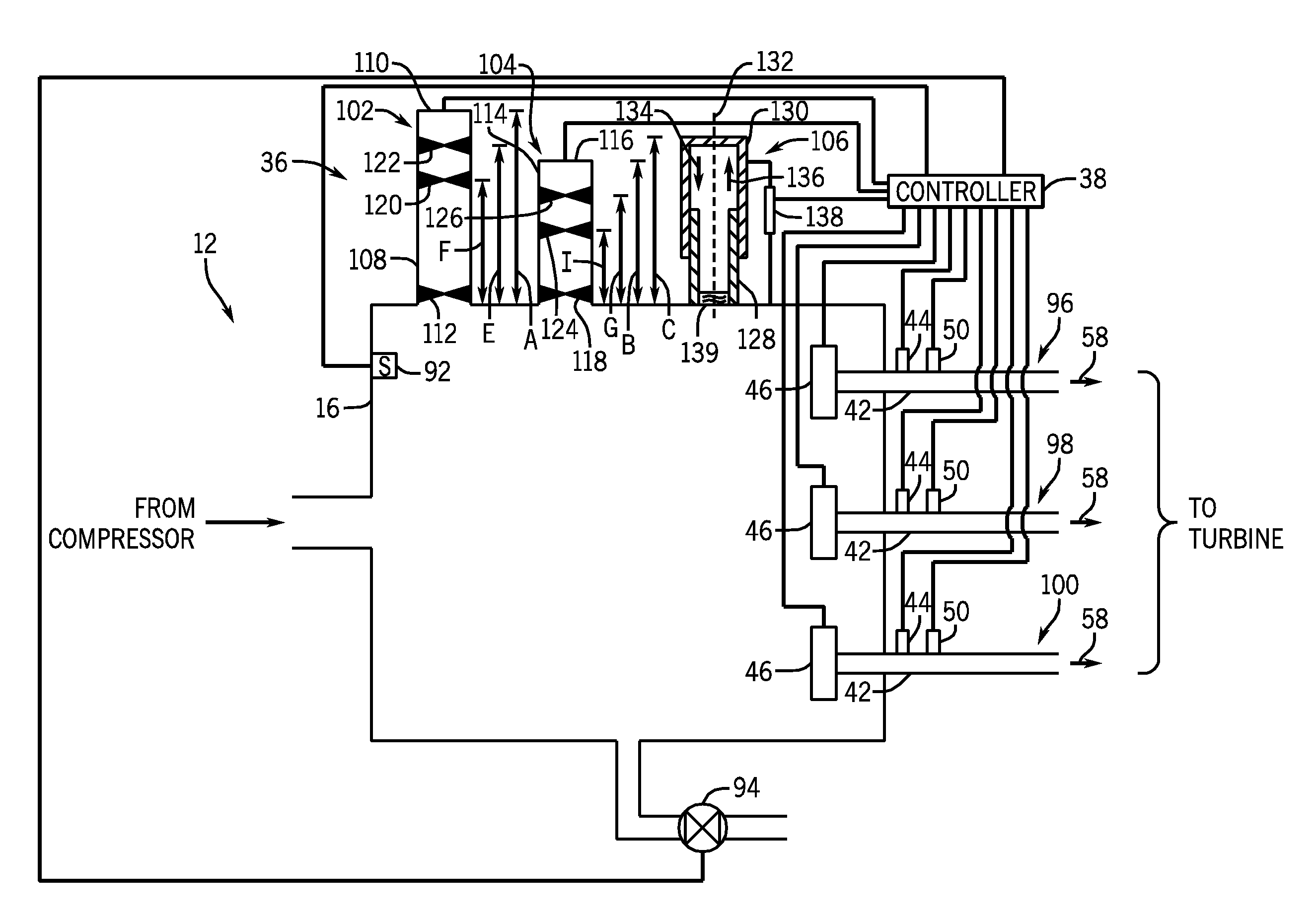

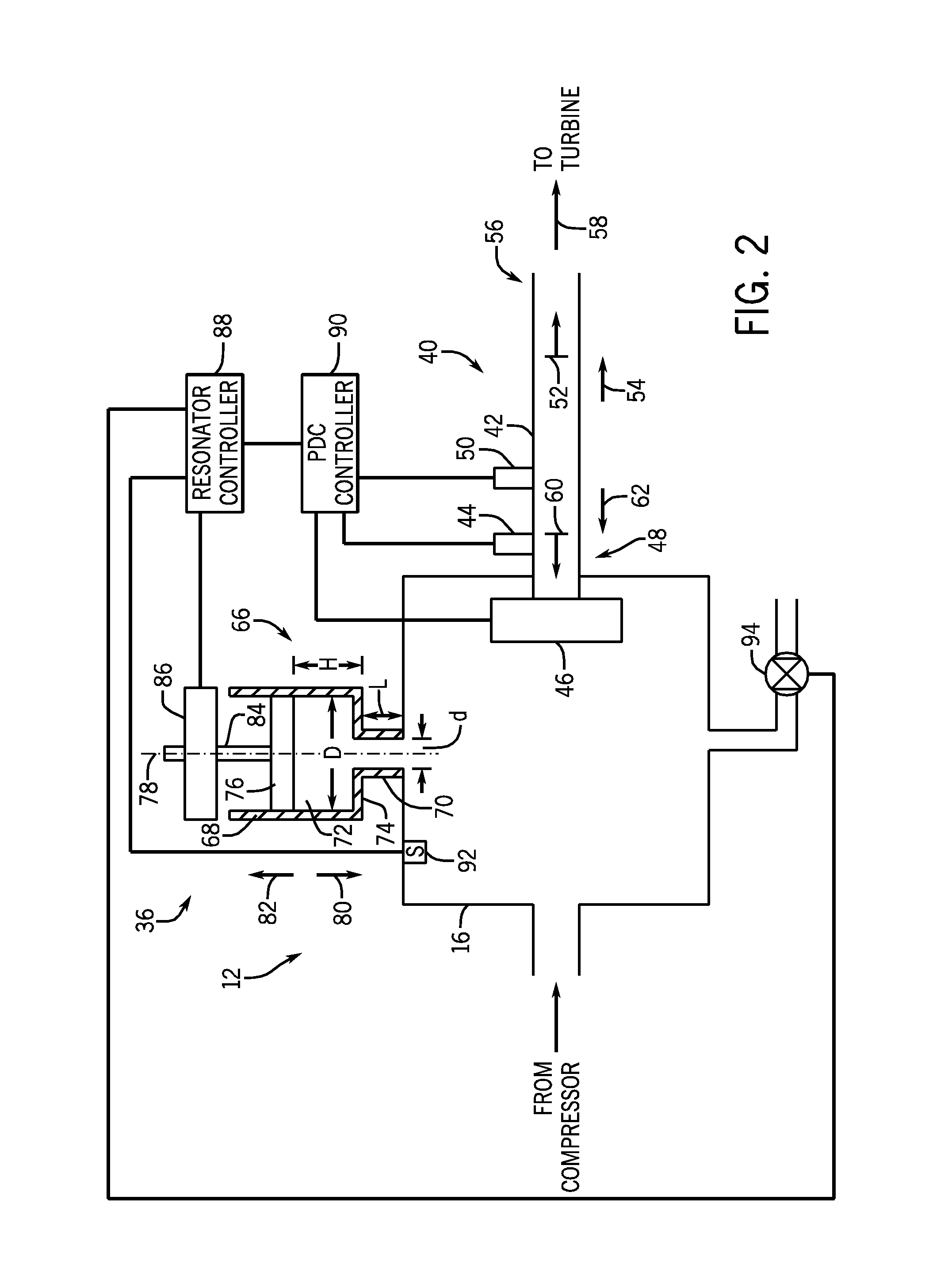

System and method for damping pressure oscillations within a pulse detonation engine

InactiveUS20120204534A1Continuous combustion chamberCosmonautic vehiclesOperating frequencyResonator

In one embodiment, a pulse detonation engine includes a resonator configured to fluidly couple to an air flow path upstream of a pulse detonation tube. The pulse detonation engine also includes a controller configured to receive signals indicative of an operating frequency of an air valve disposed at an upstream end of the pulse detonation tube, and to adjust a geometric configuration of the resonator in response to the signals.

Owner:GENERAL ELECTRIC CO

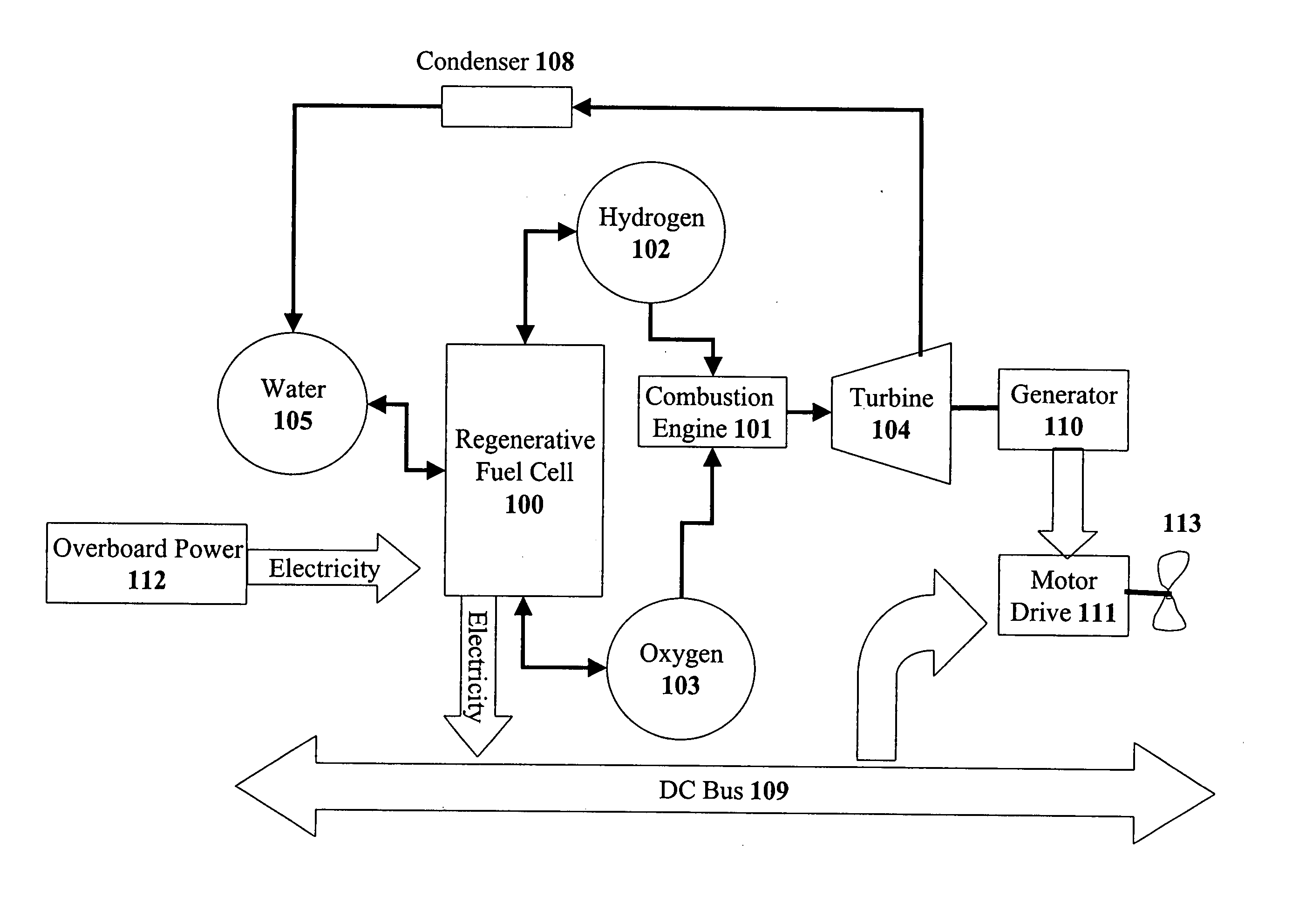

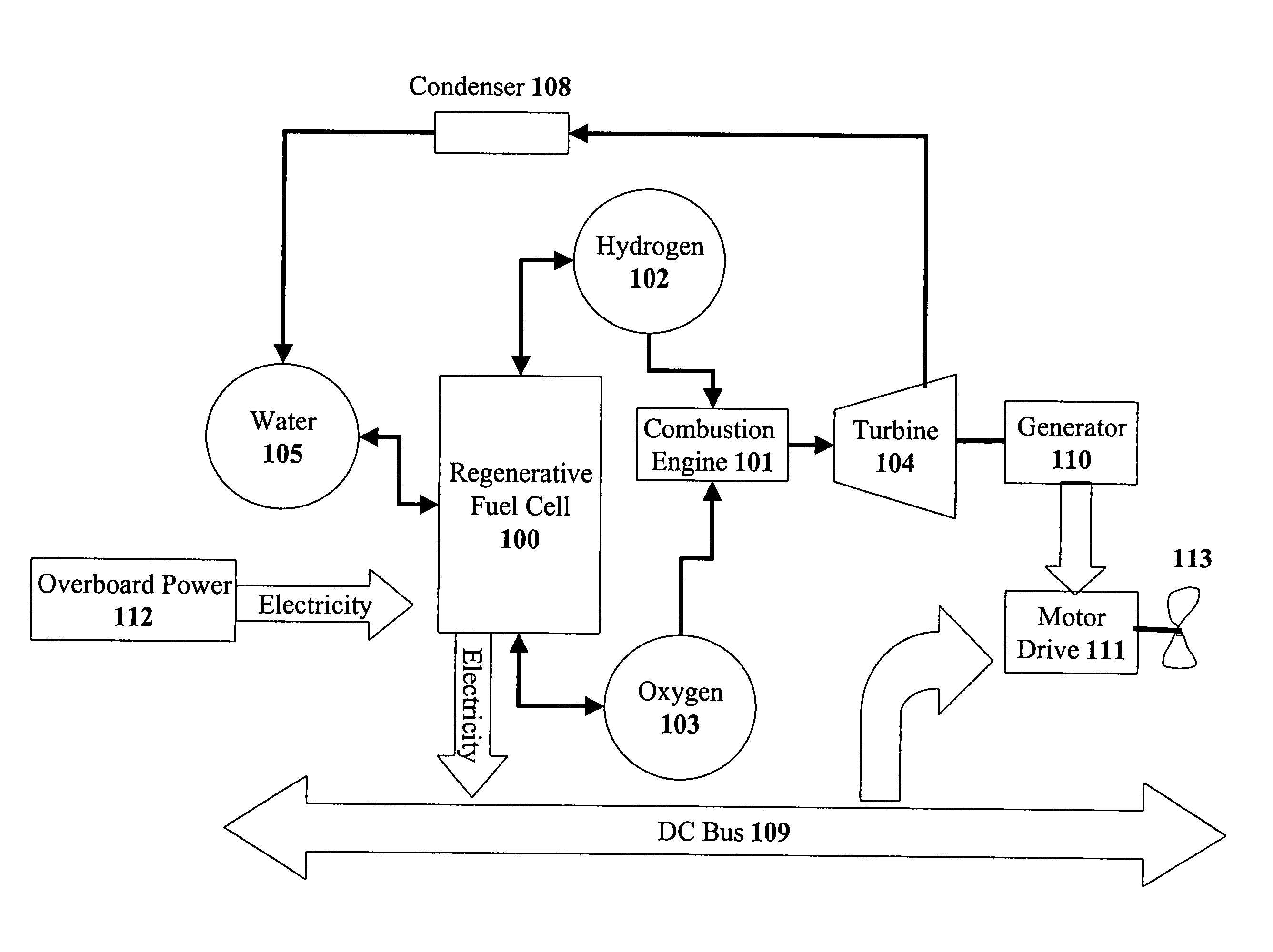

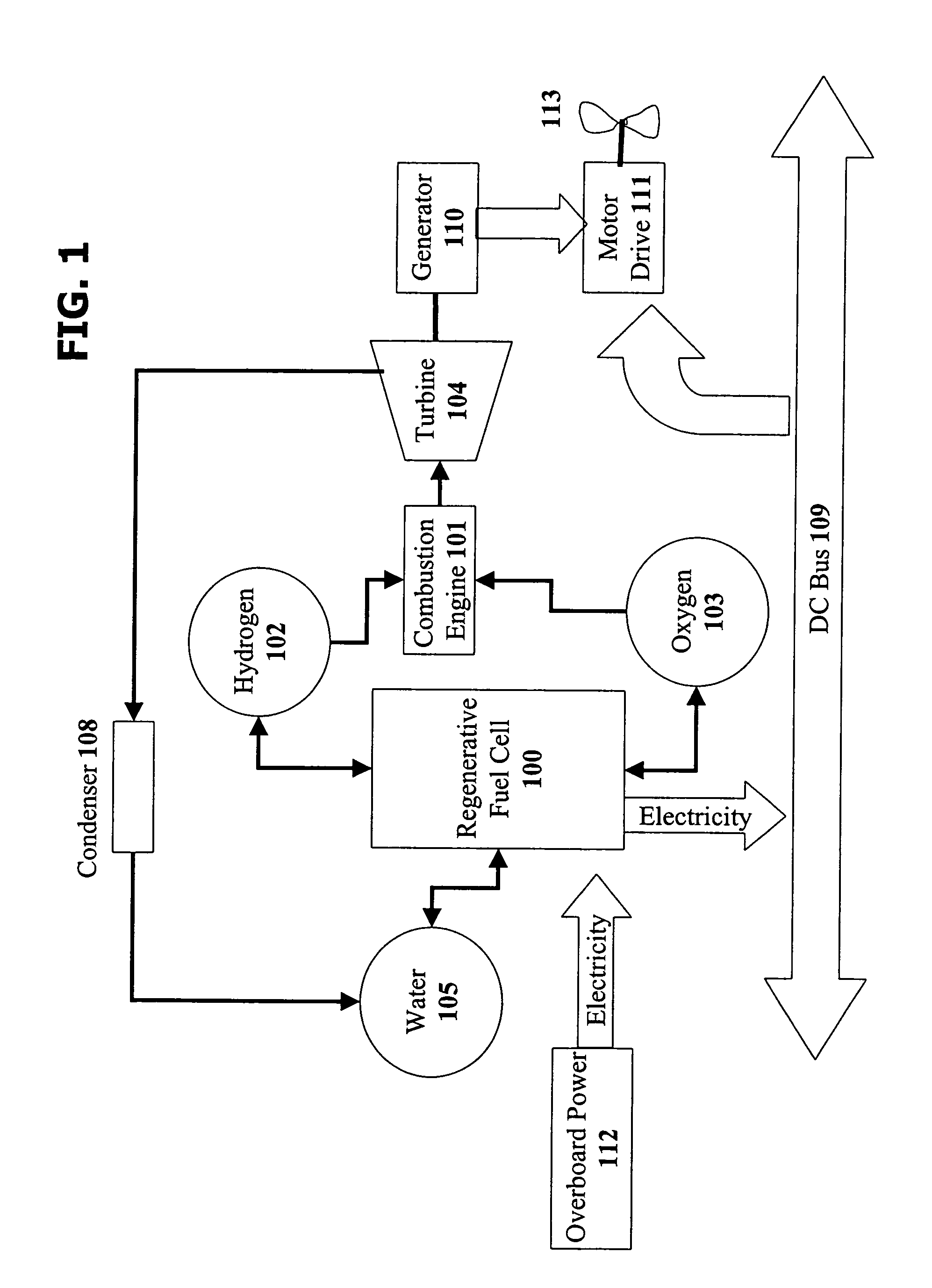

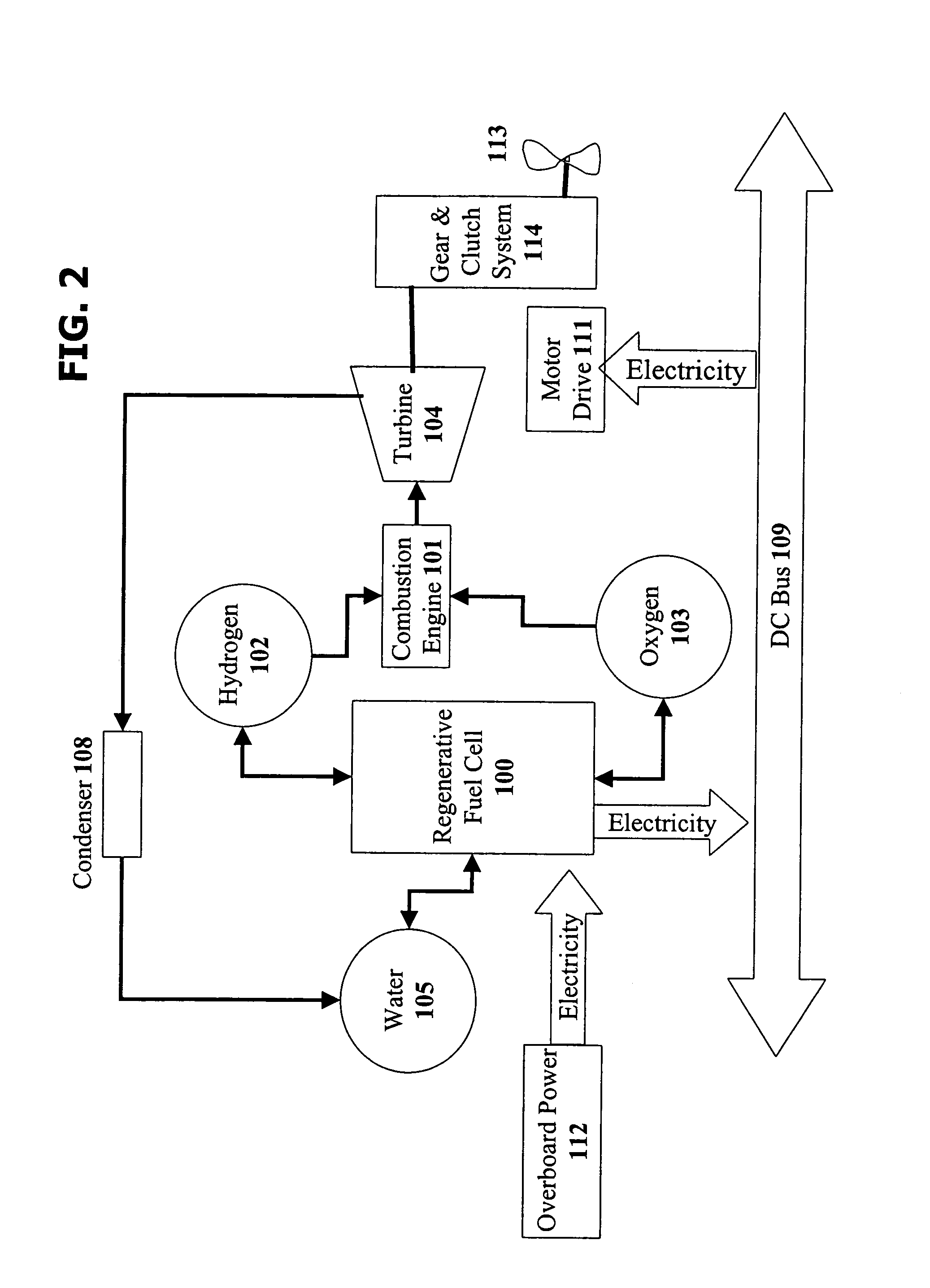

Power generation system using a combustion system and a fuel cell

ActiveUS20050252214A1Potentially more maneuverableReduce supplyReciprocating combination enginesRegenerative fuel cellsNuclear engineeringGas phase

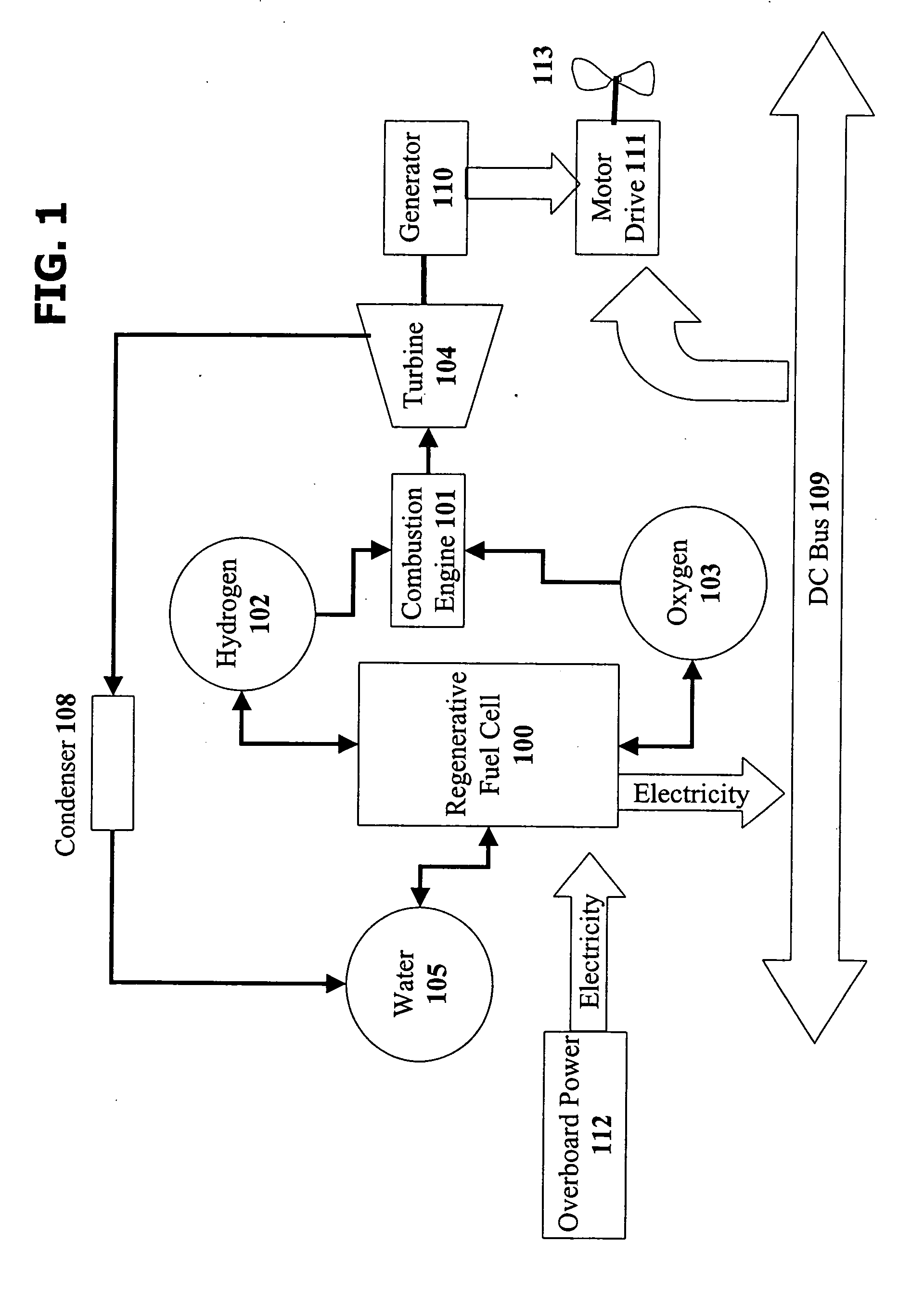

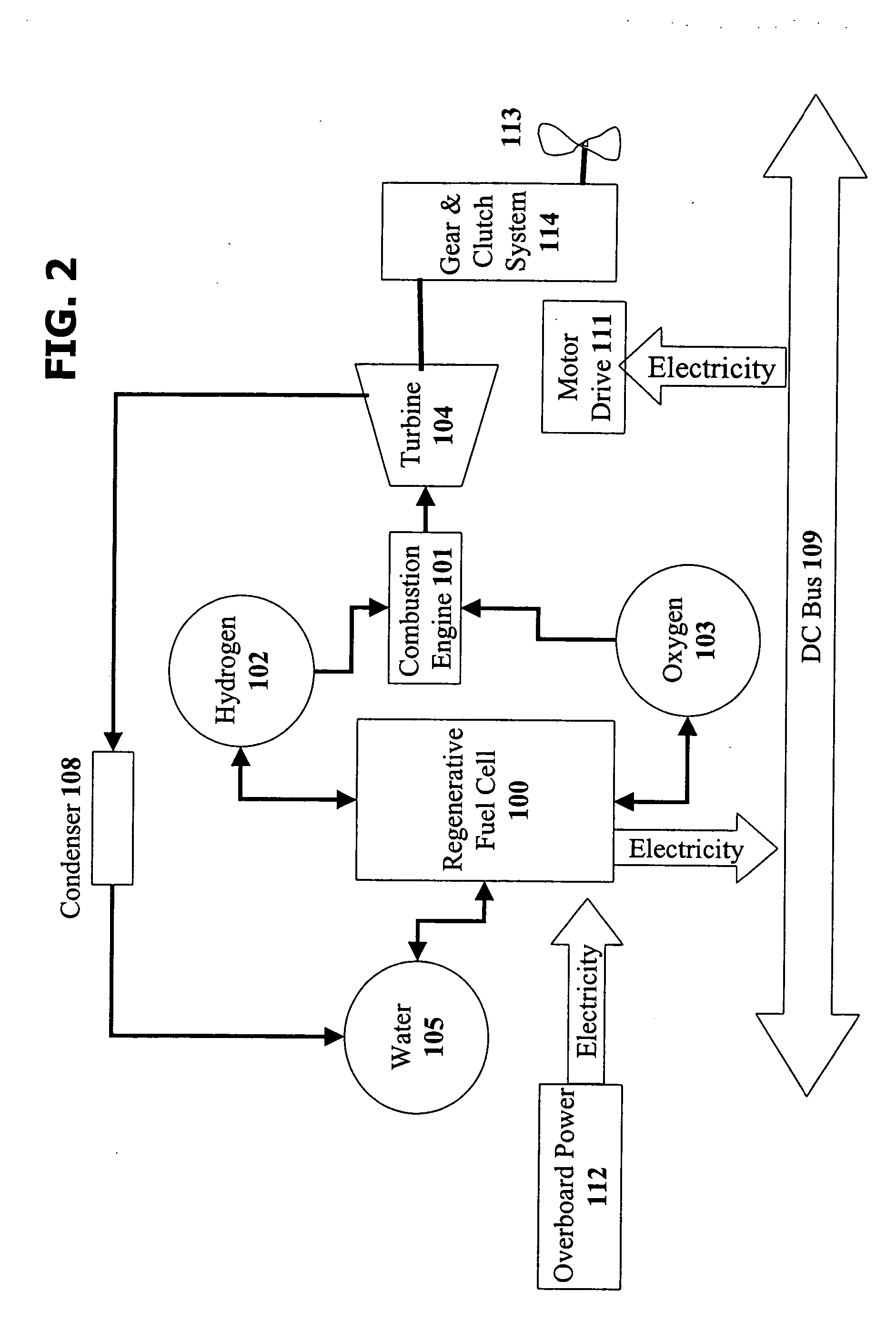

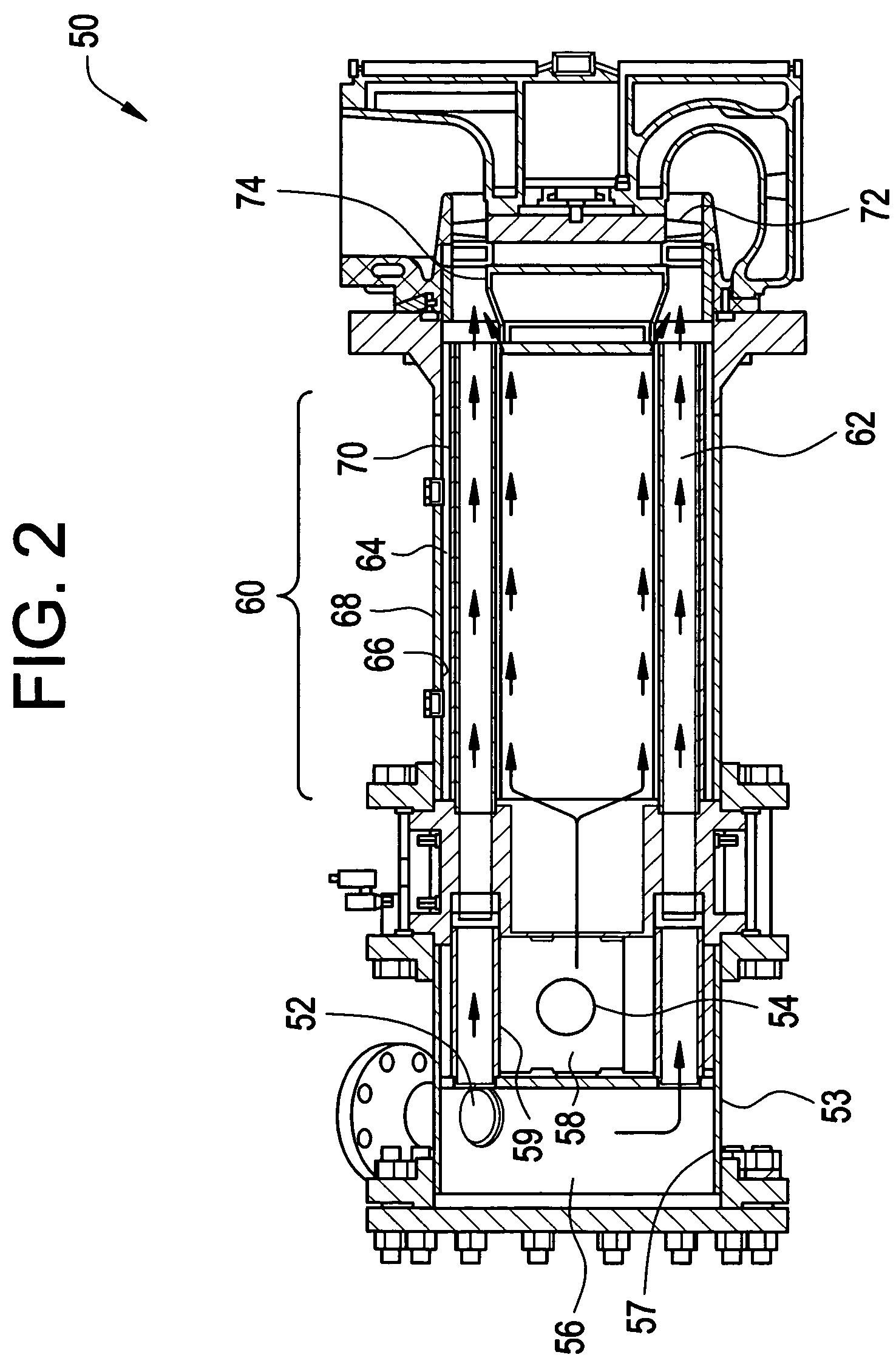

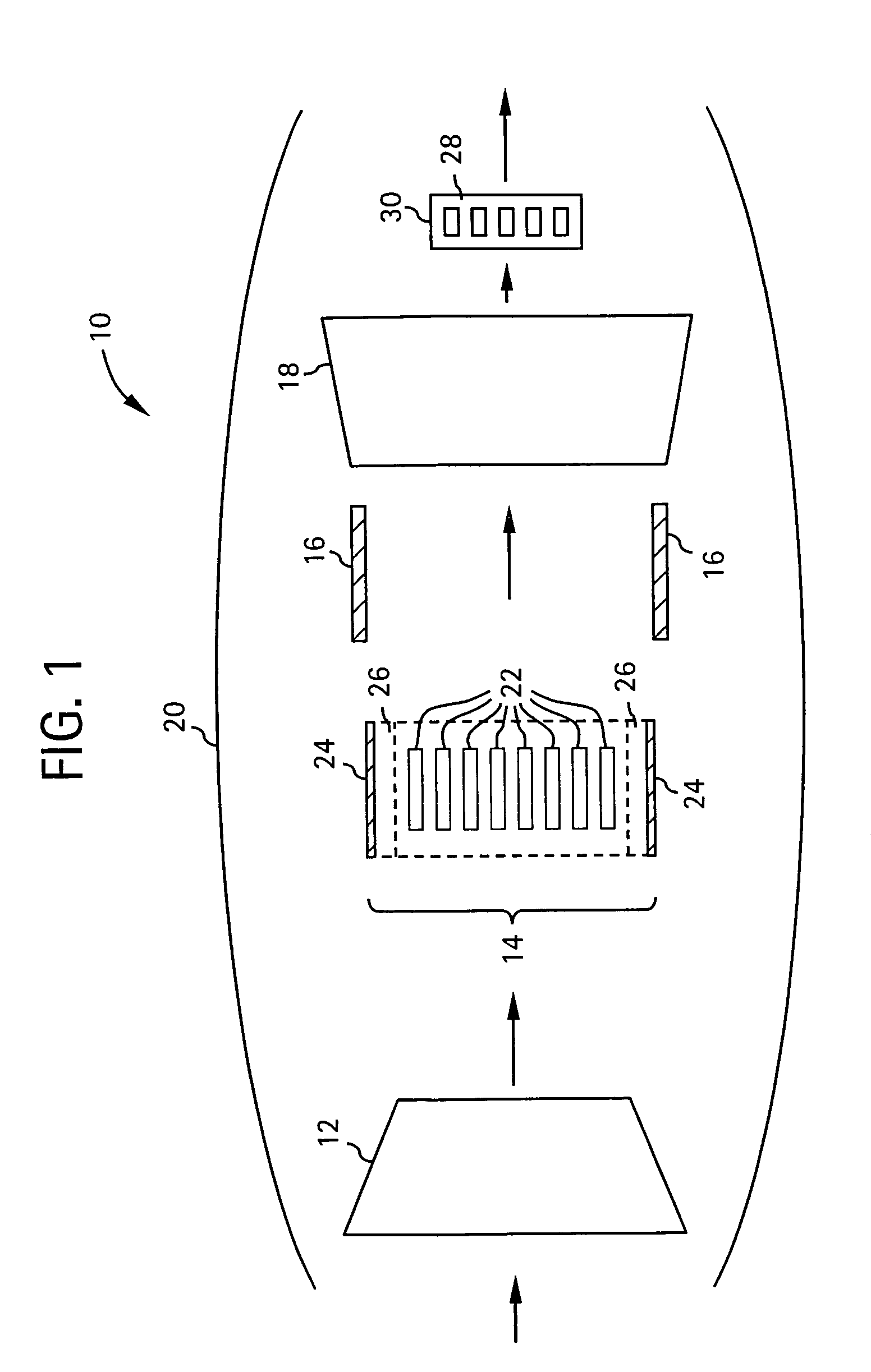

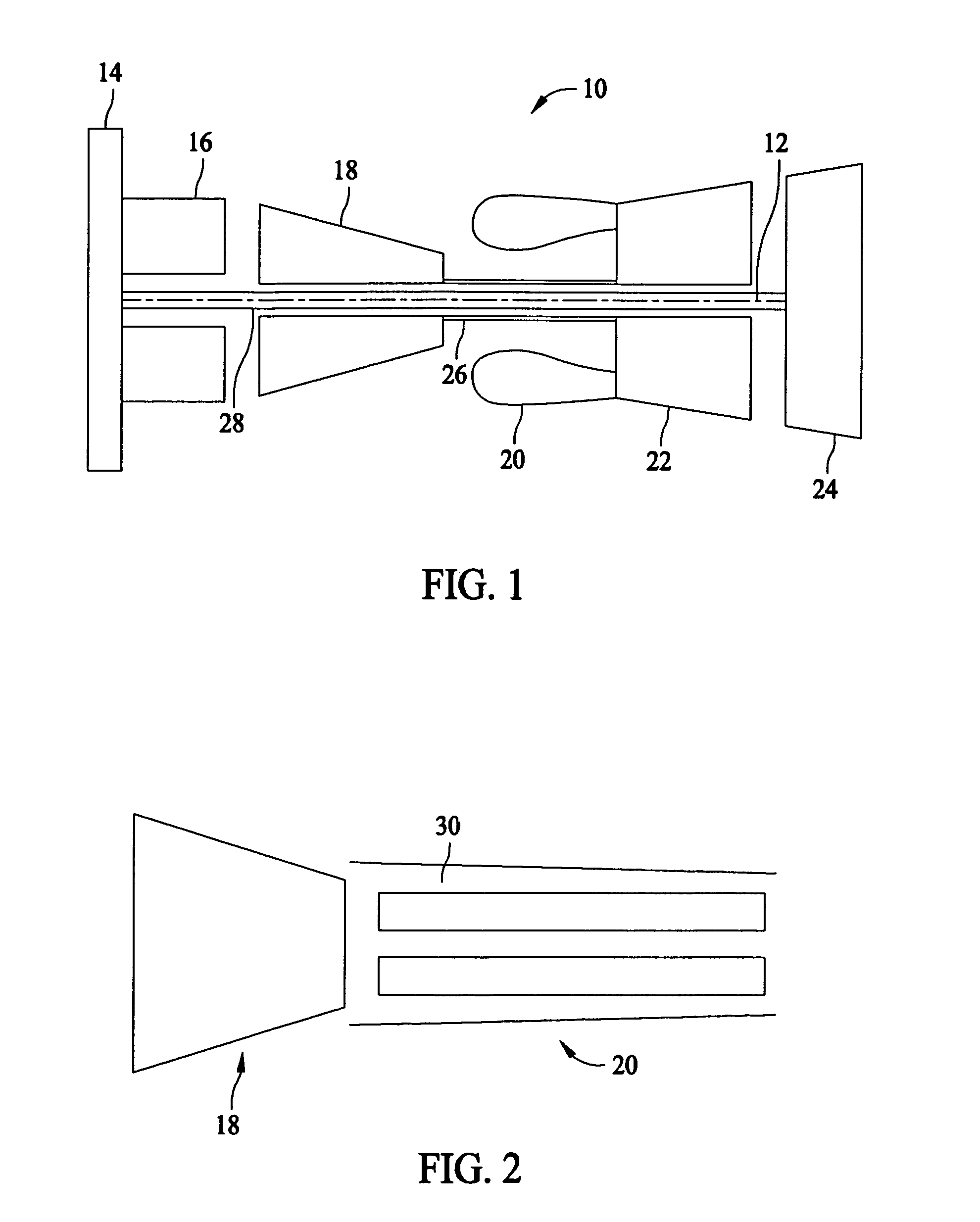

A regenerative fuel cell is combined with a combustion engine such as a Pulse Detonation Engine (PDE) to create a closed-loop power generation system. Stored hydrogen and oxygen are used by the regenerative fuel cell, and by the combustion engine, in which the reaction of the hydrogen and oxygen produces water in the gas phase (steam). The steam is used to generate work from a turbine shaft, which is used to drive a propulsion system for the marine vessel. After the steam passes through the turbine, the steam is cooled back to liquid water by a condenser, and stored with the water produced by the regenerative fuel cell. The stored water can be converted back into hydrogen and oxygen by using electrical power external to the closed-loop system. After regeneration of the water into hydrogen and oxygen, the closed-loop power system would be ready for operation again.

Owner:LOCKHEED MARTIN CORP

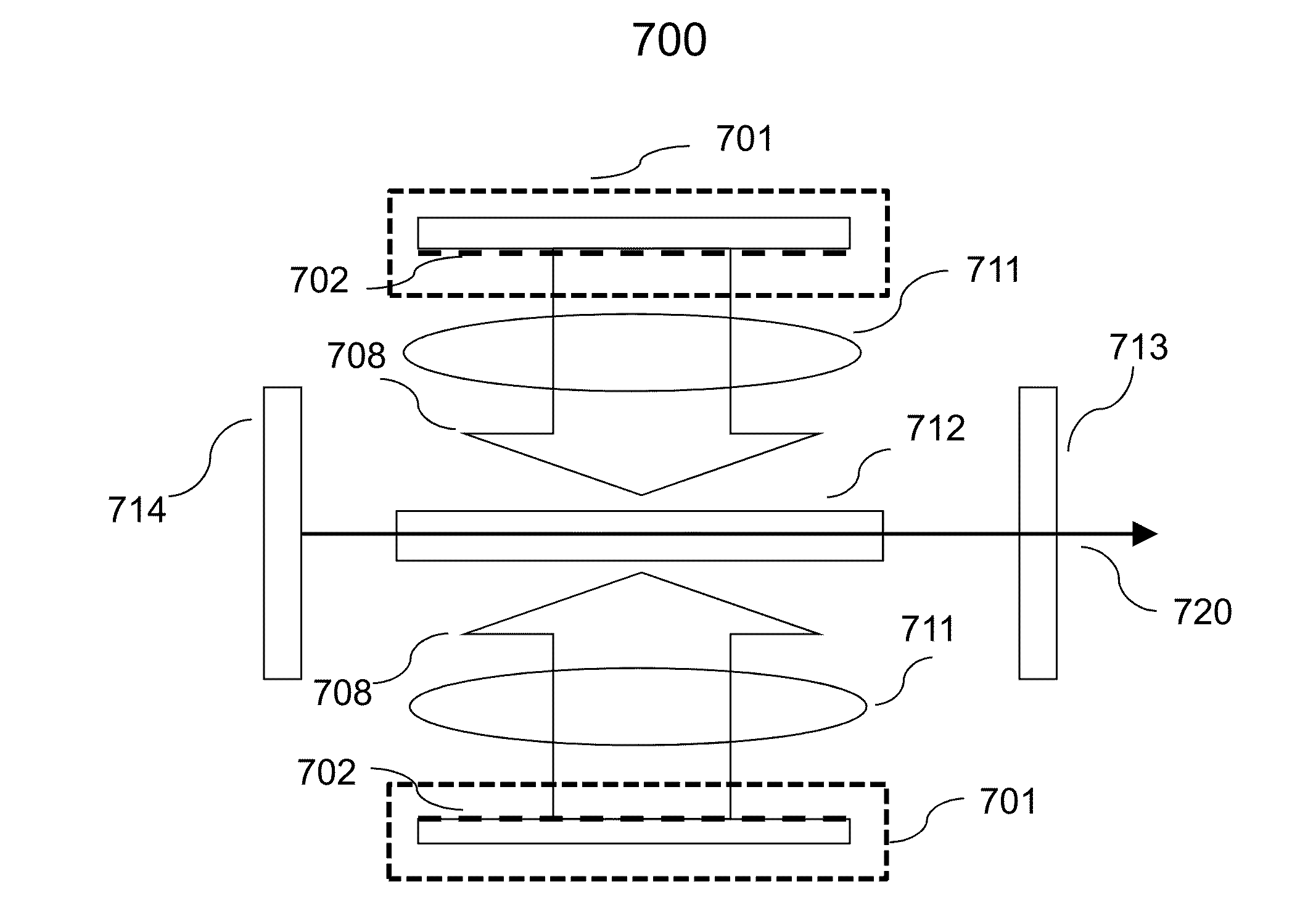

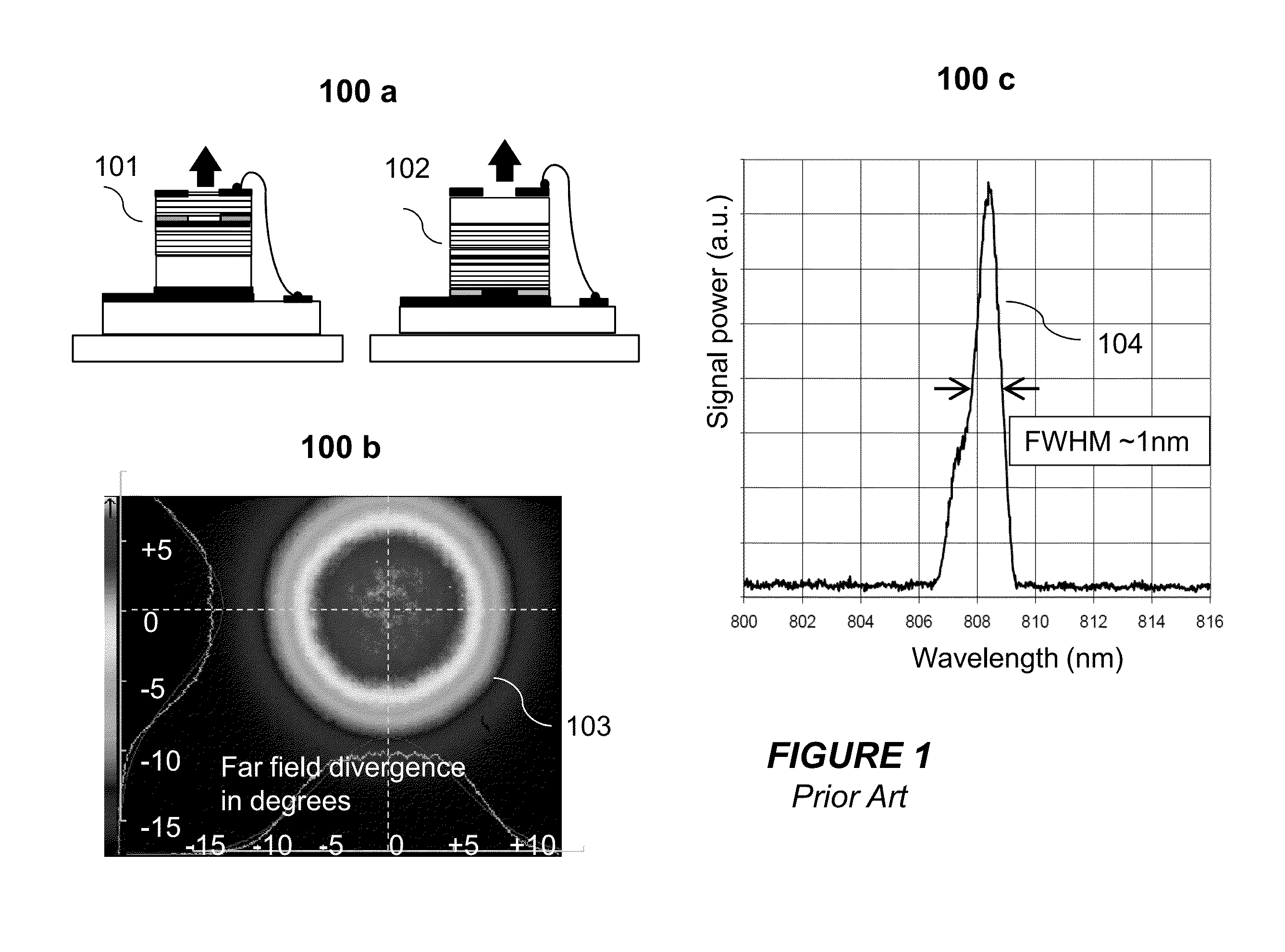

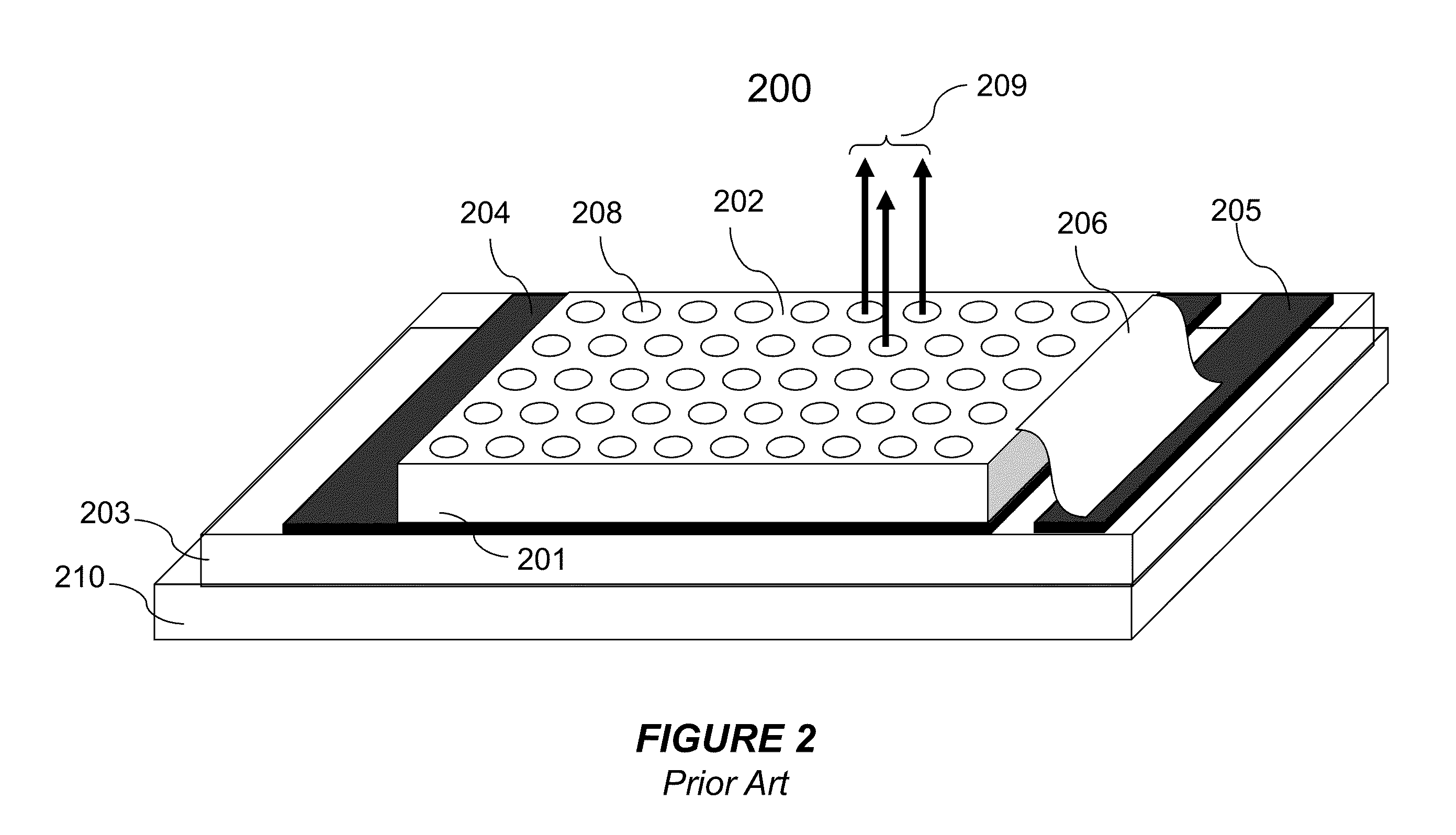

Optical Pump for High Power Laser

ActiveUS20130208753A1More powerReduce complexityLaser detailsSolid-state devicesHigh power lasersEngineering

Owner:PRINCETON OPTRONICS

Power generation system using a combustion system and a fuel cell

ActiveUS6978617B2Potentially more maneuverableReduce supplyReciprocating combination enginesFuel cell auxillariesGas phaseLiquid water

A regenerative fuel cell is combined with a combustion engine such as a Pulse Detonation Engine (PDE) to create a closed-loop power generation system. Stored hydrogen and oxygen are used by the regenerative fuel cell, and by the combustion engine, in which the reaction of the hydrogen and oxygen produces water in the gas phase (steam). The steam is used to generate work from a turbine shaft, which is used to drive a propulsion system for the marine vessel. After the steam passes through the turbine, the steam is cooled back to liquid water by a condenser, and stored with the water produced by the regenerative fuel cell. The stored water can be converted back into hydrogen and oxygen by using electrical power external to the closed-loop system. After regeneration of the water into hydrogen and oxygen, the closed-loop power system would be ready for operation again.

Owner:LOCKHEED MARTIN CORP

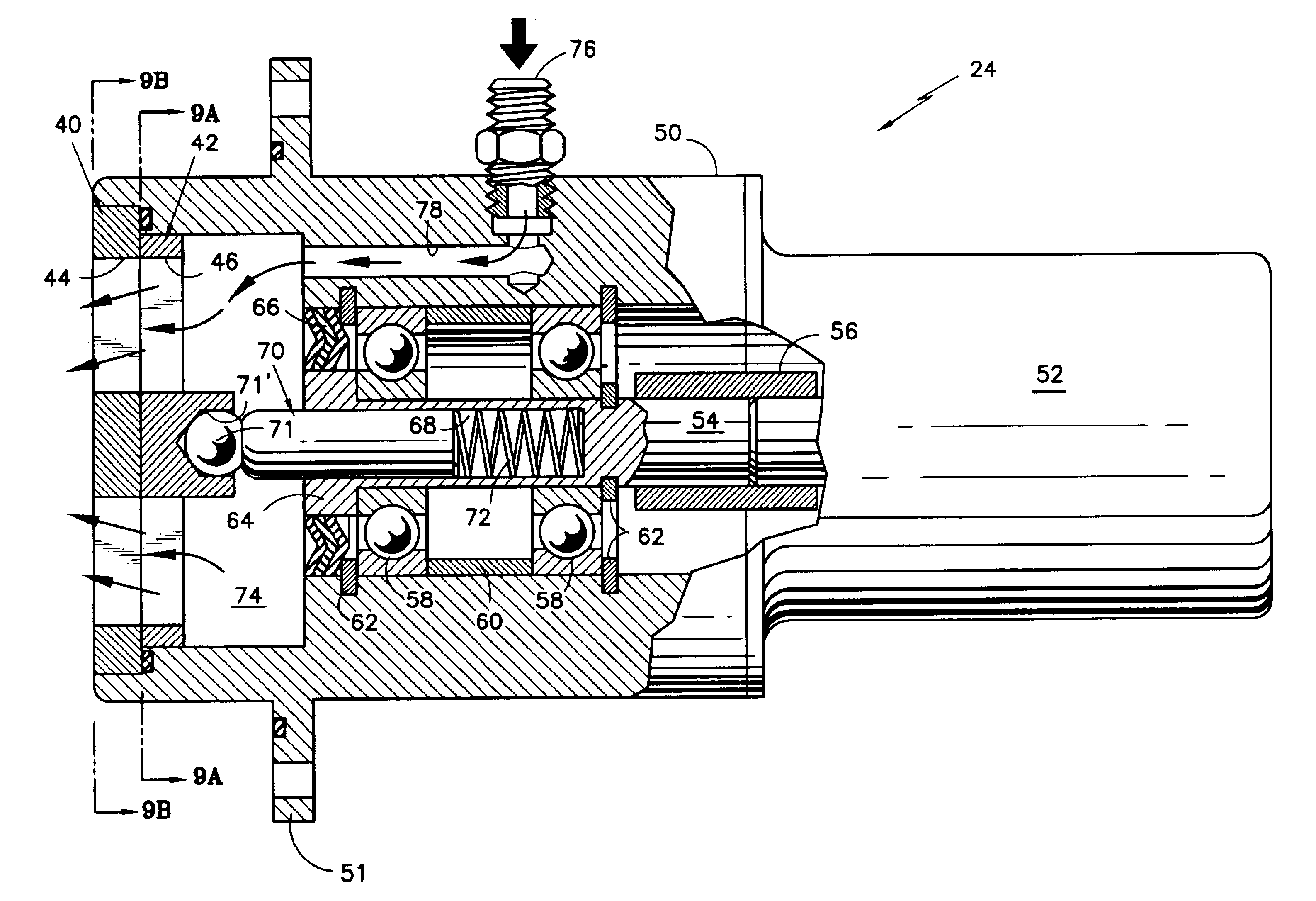

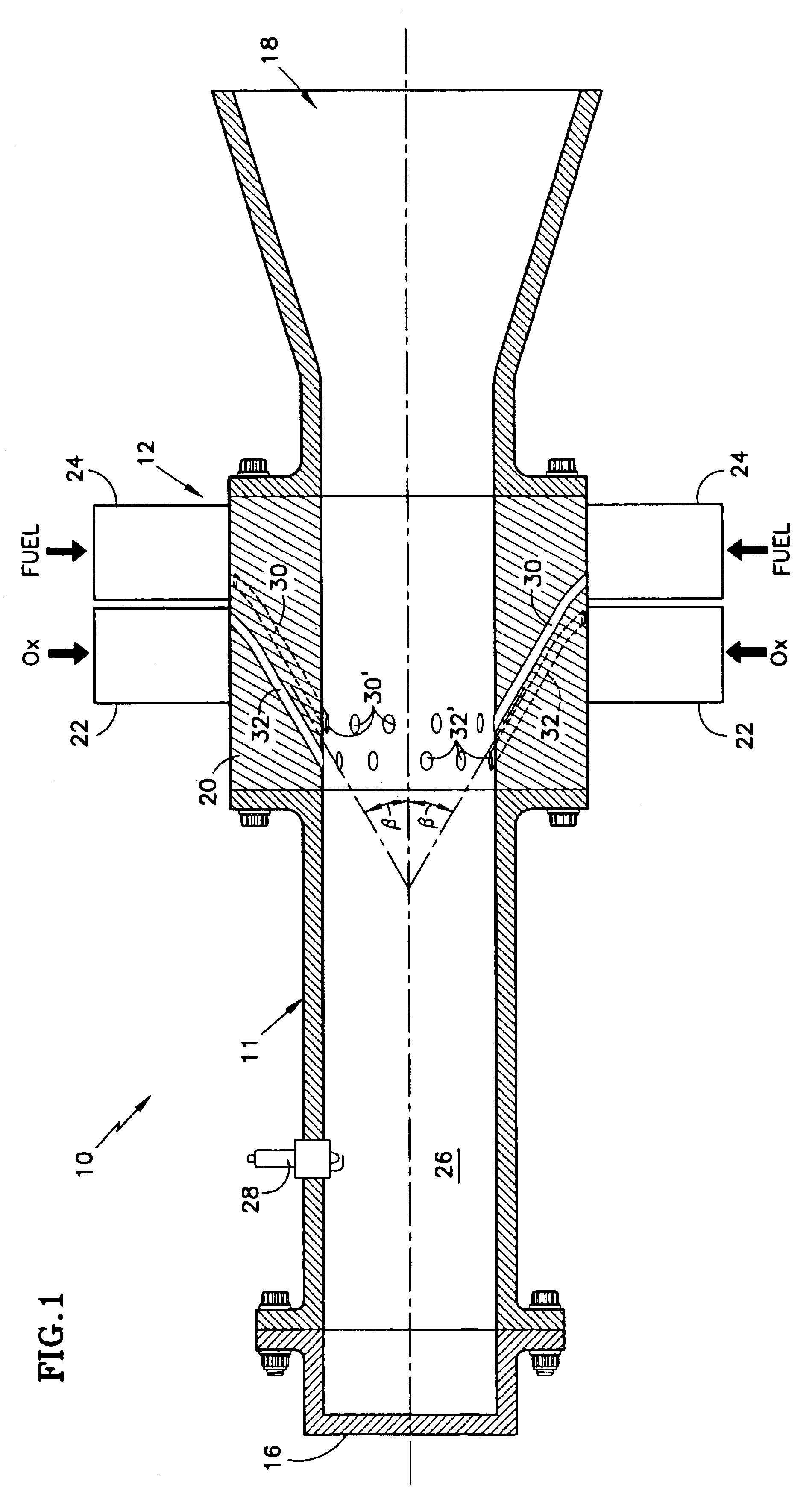

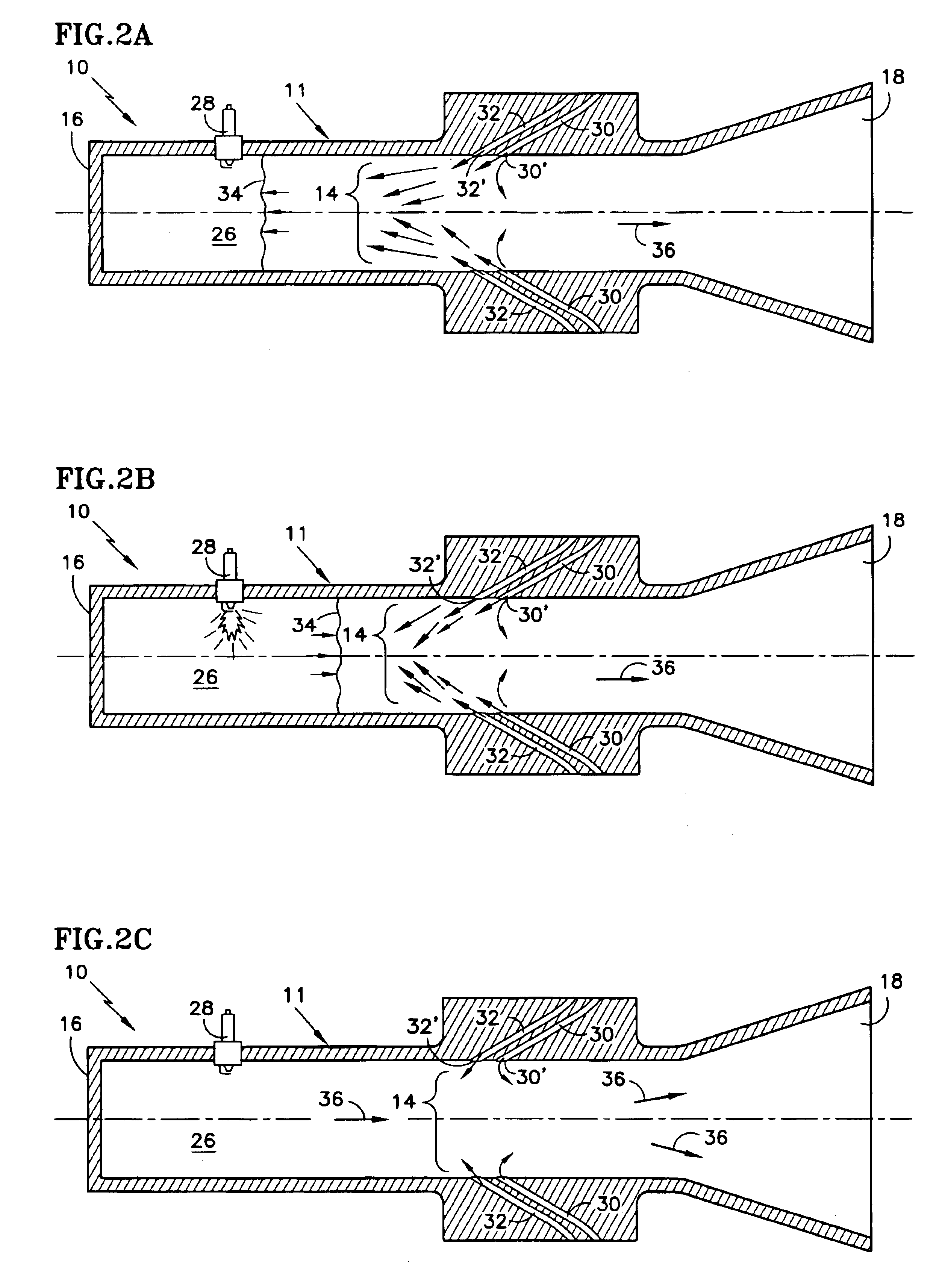

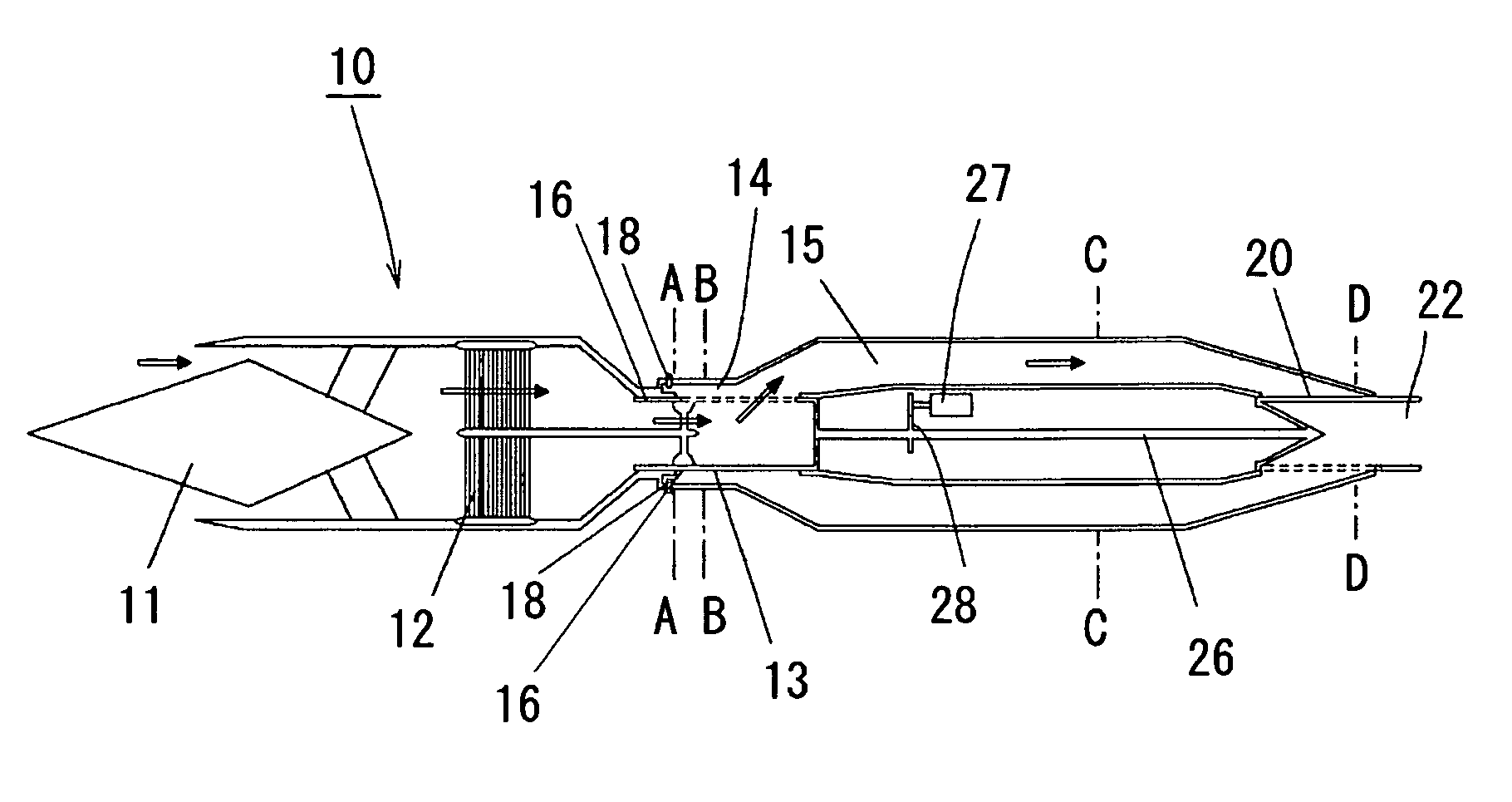

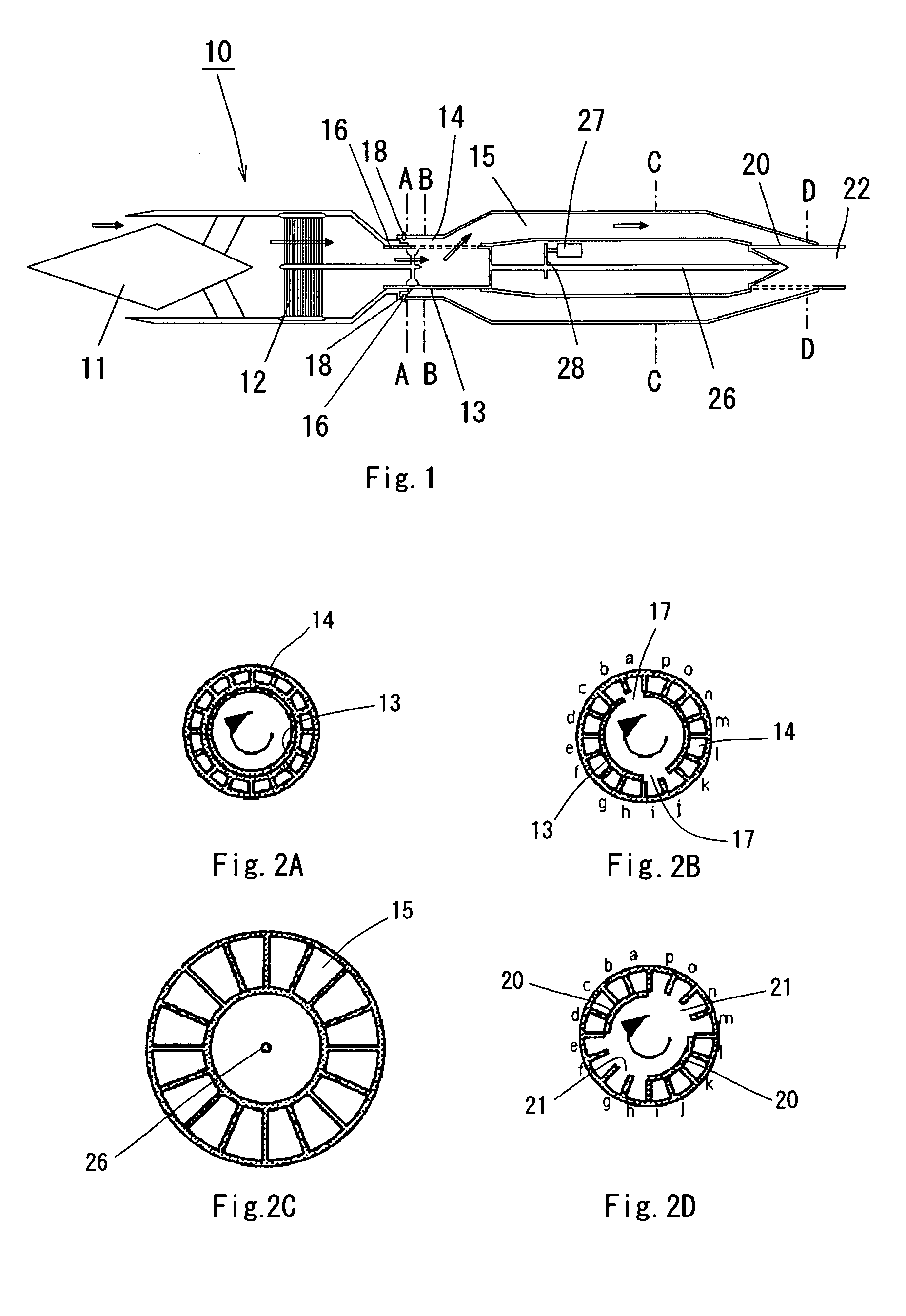

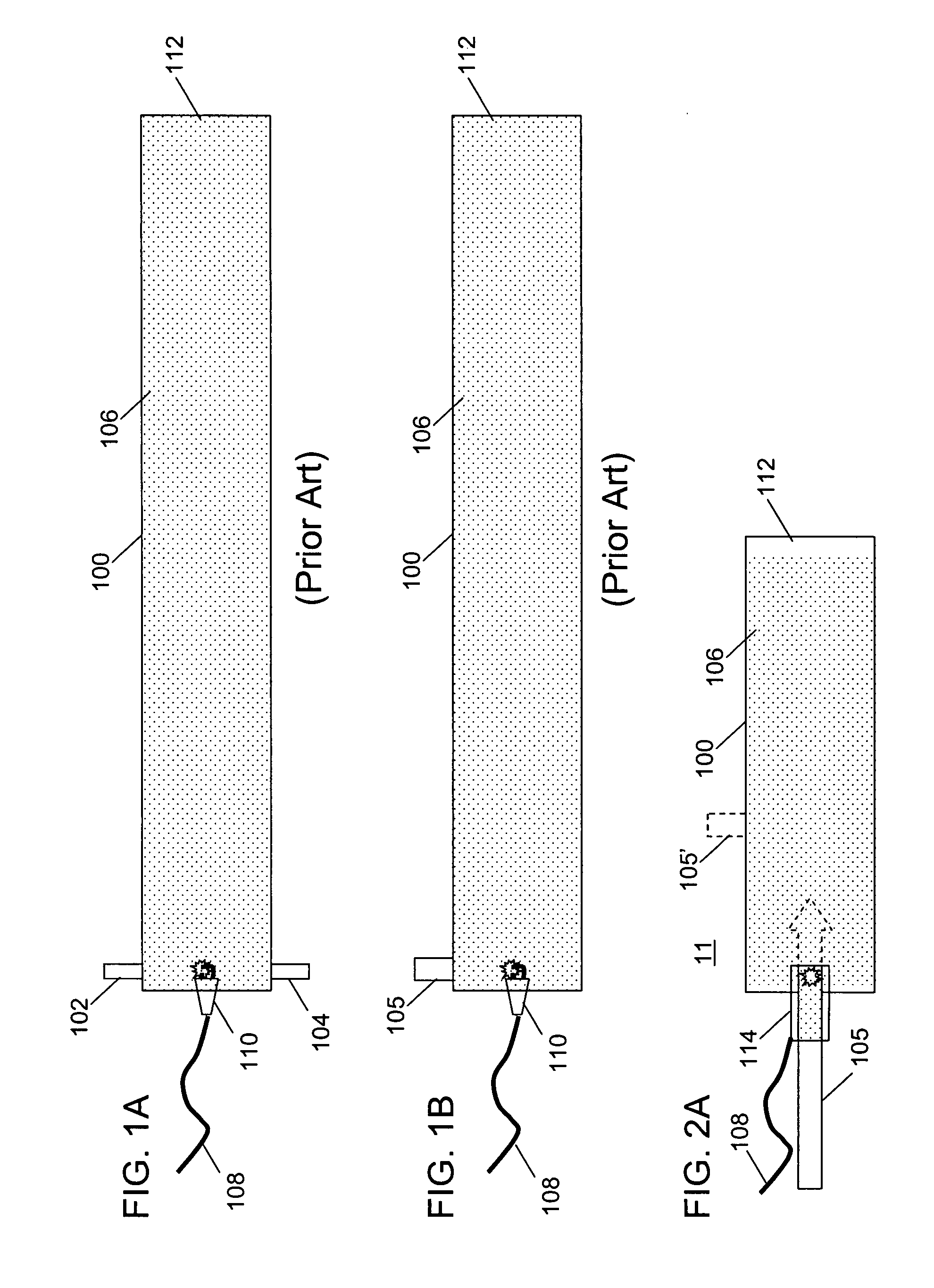

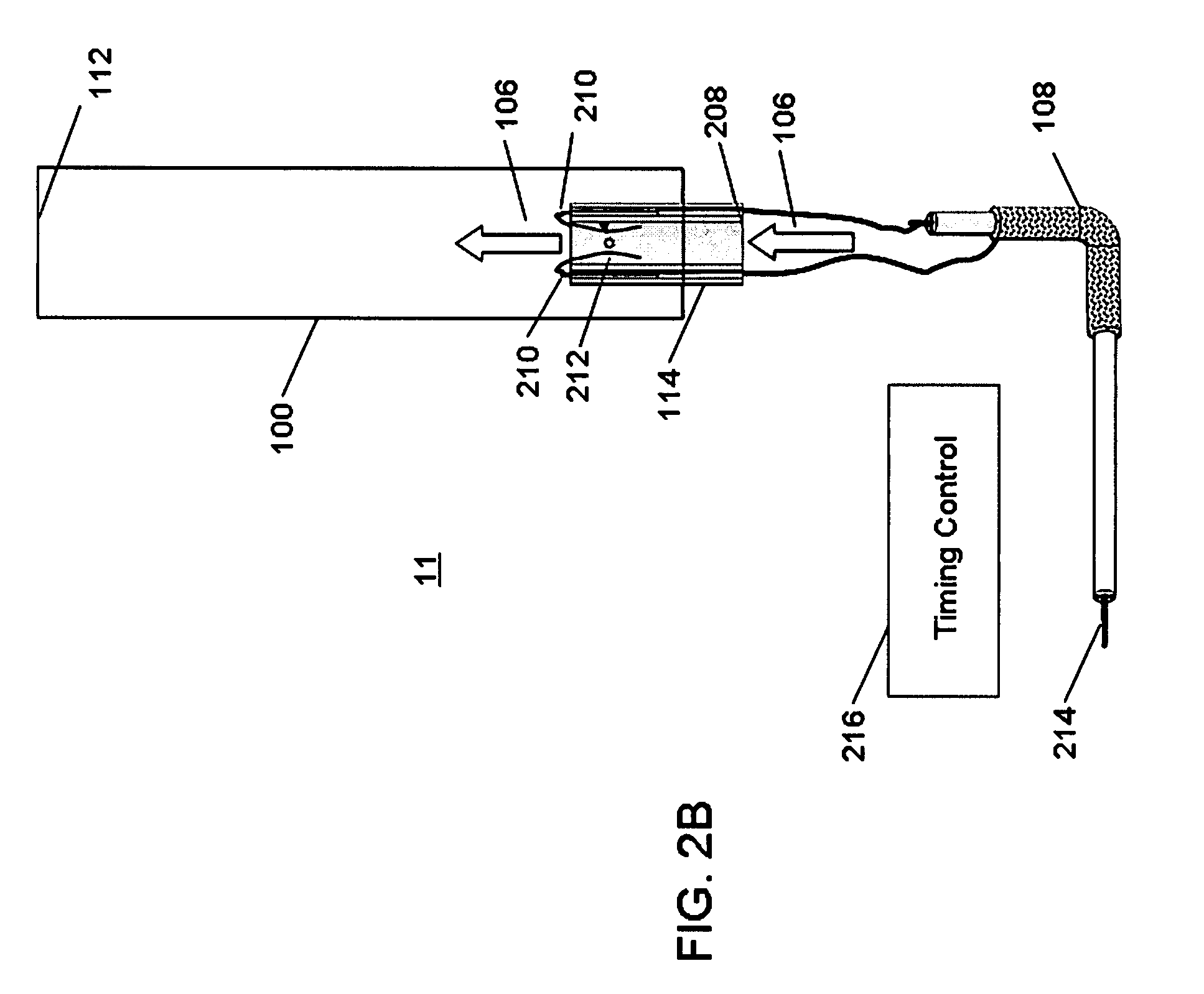

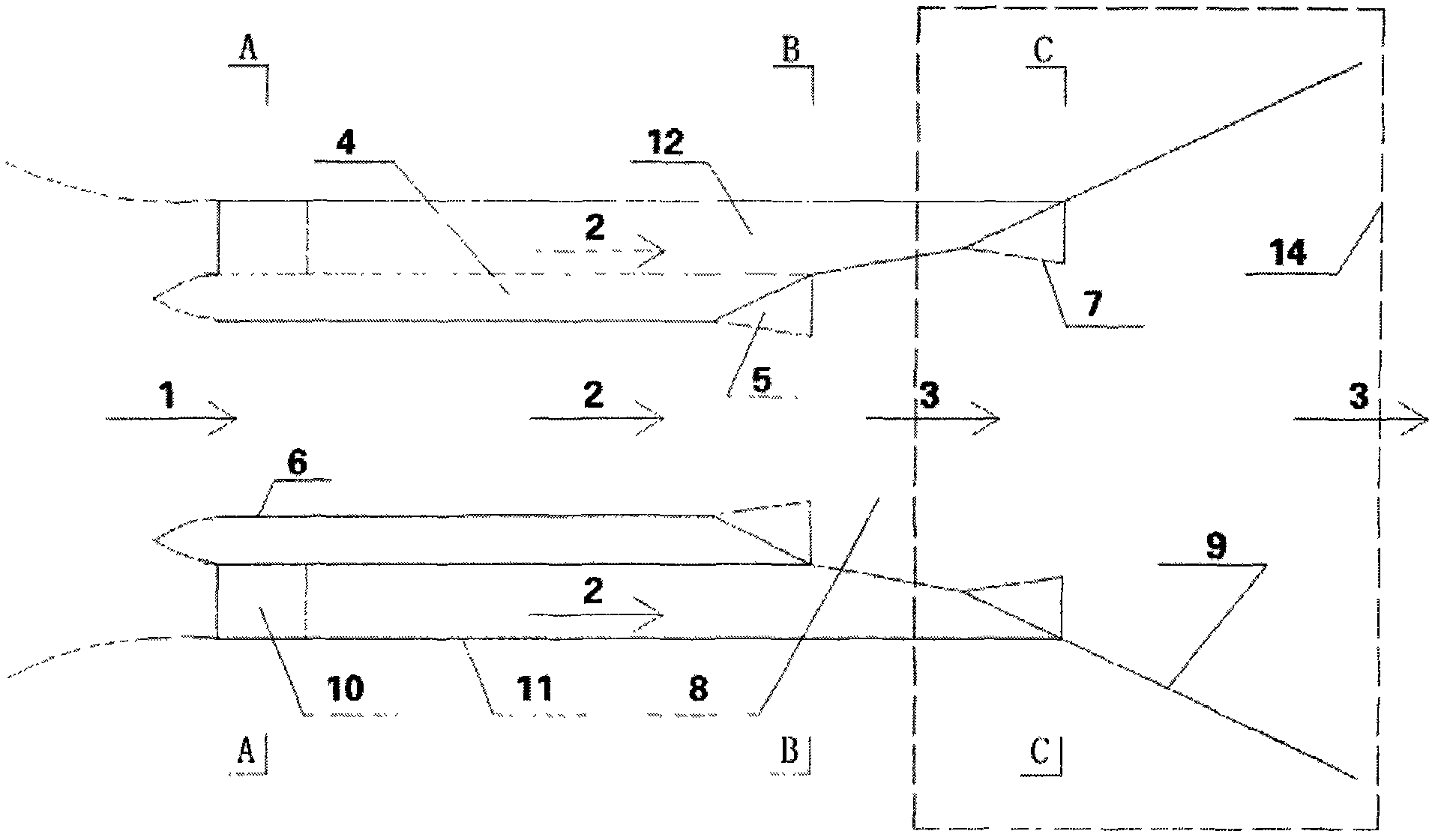

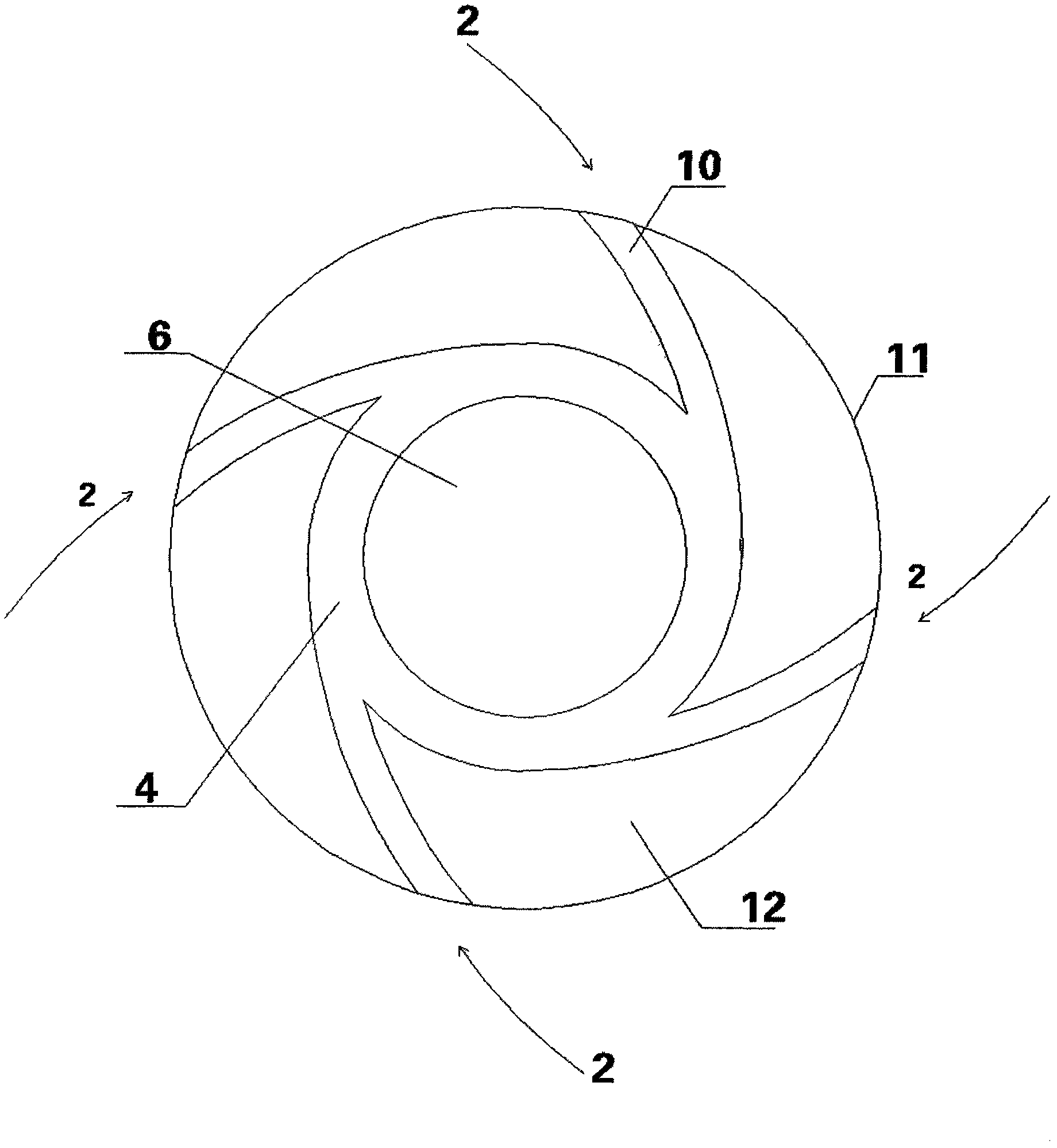

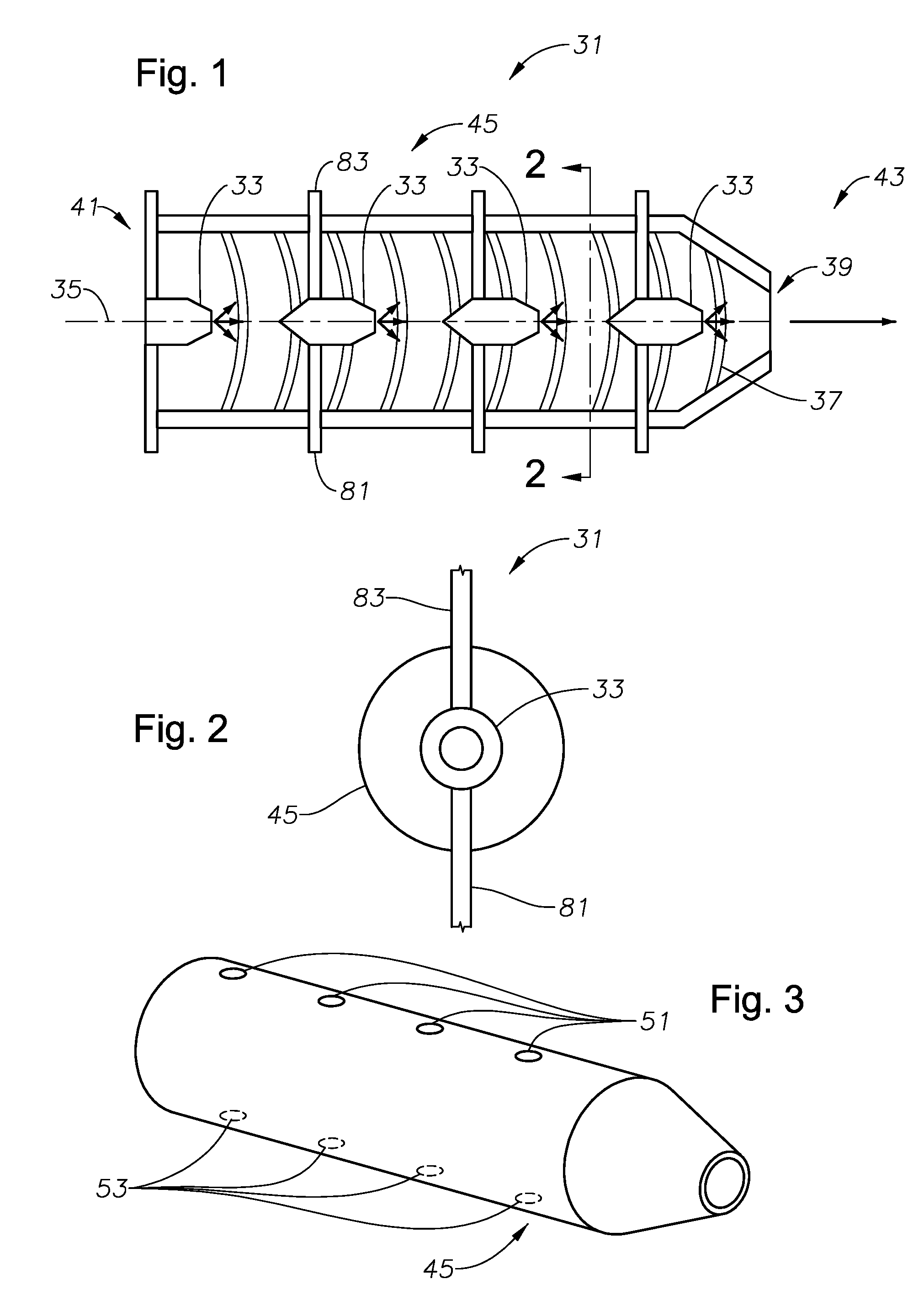

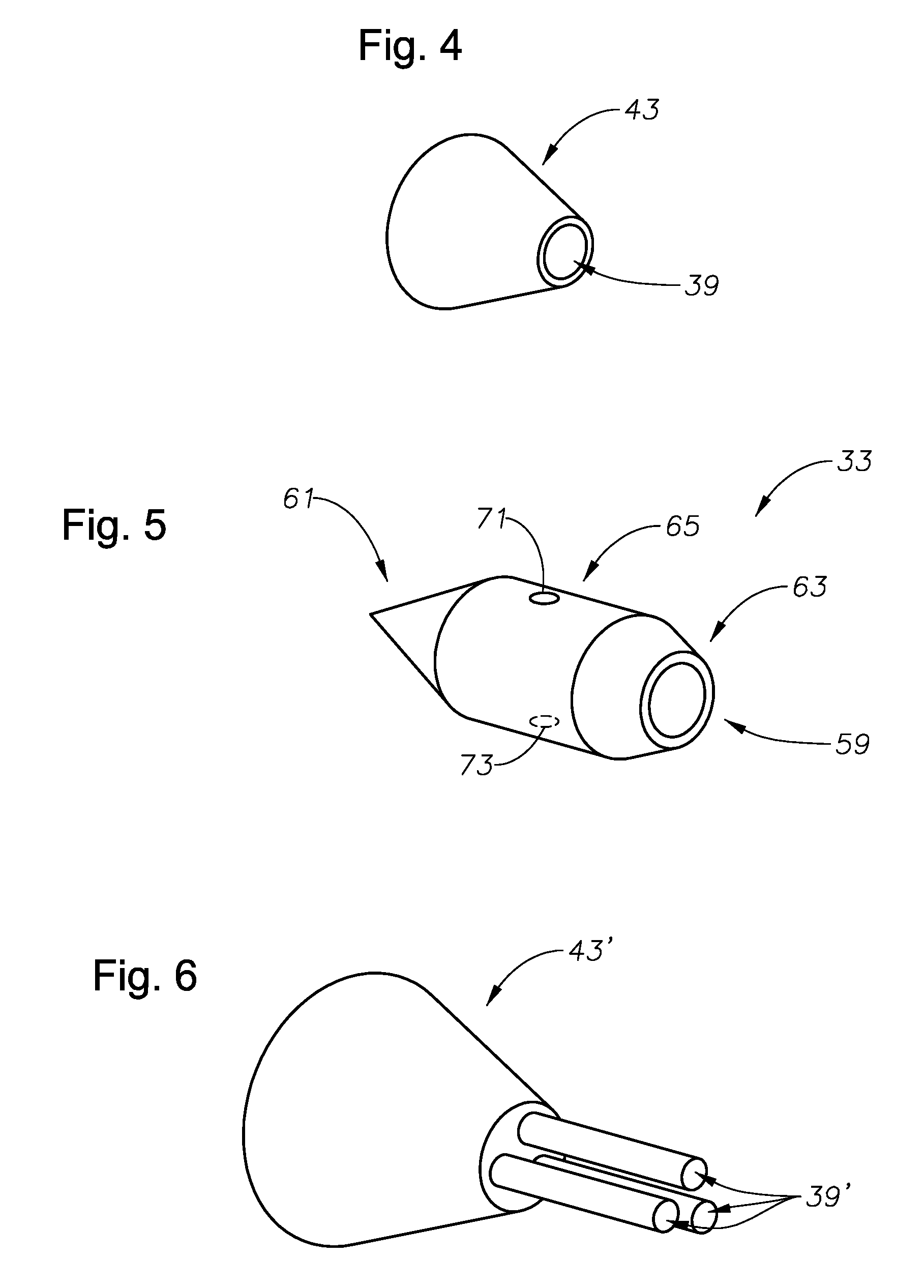

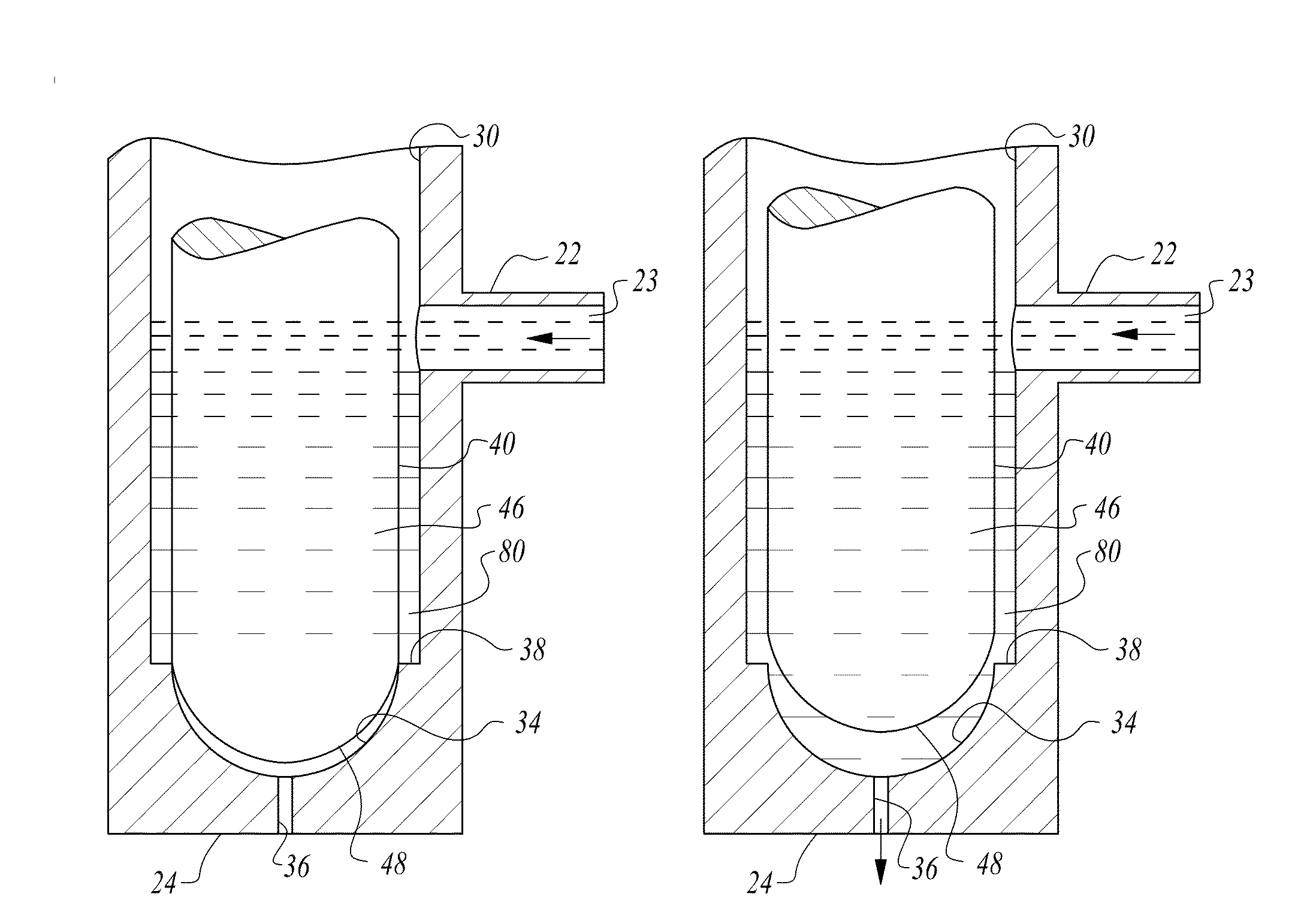

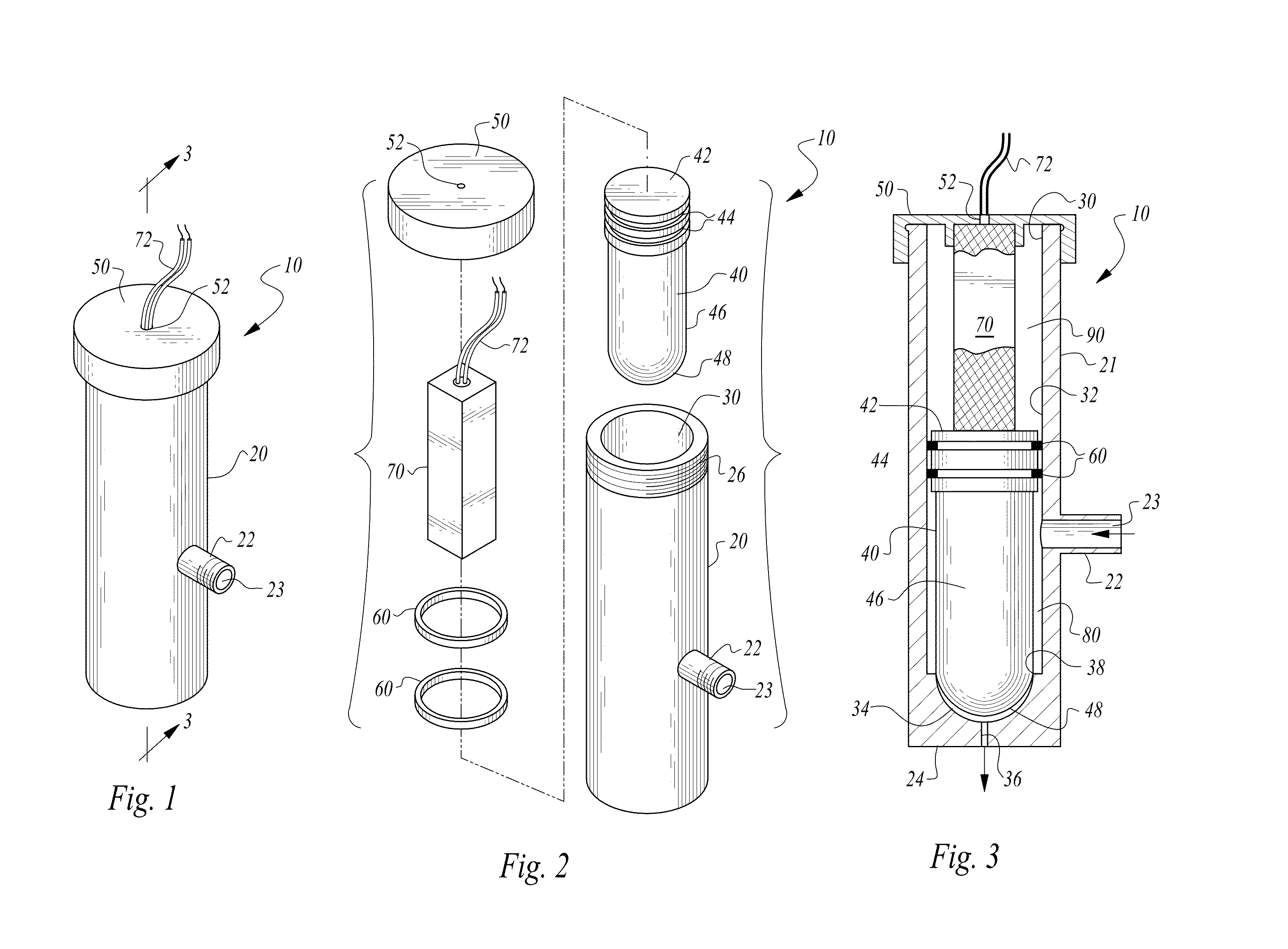

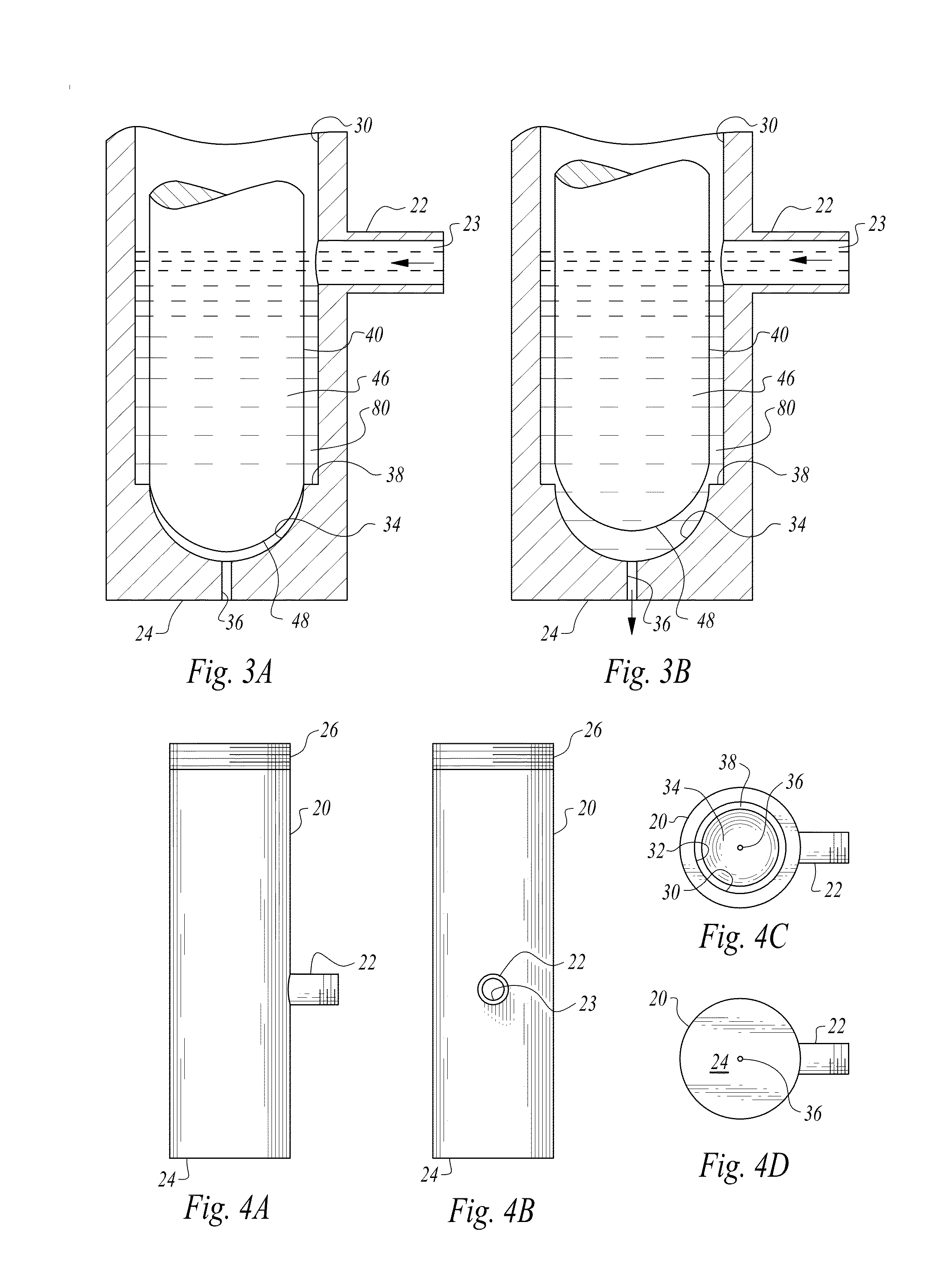

Pulse detonation engine having an aerodynamic valve

InactiveUS6883543B2Increase pressureSave pressurePulsating combustionCosmonautic vehiclesShock wavePropellant

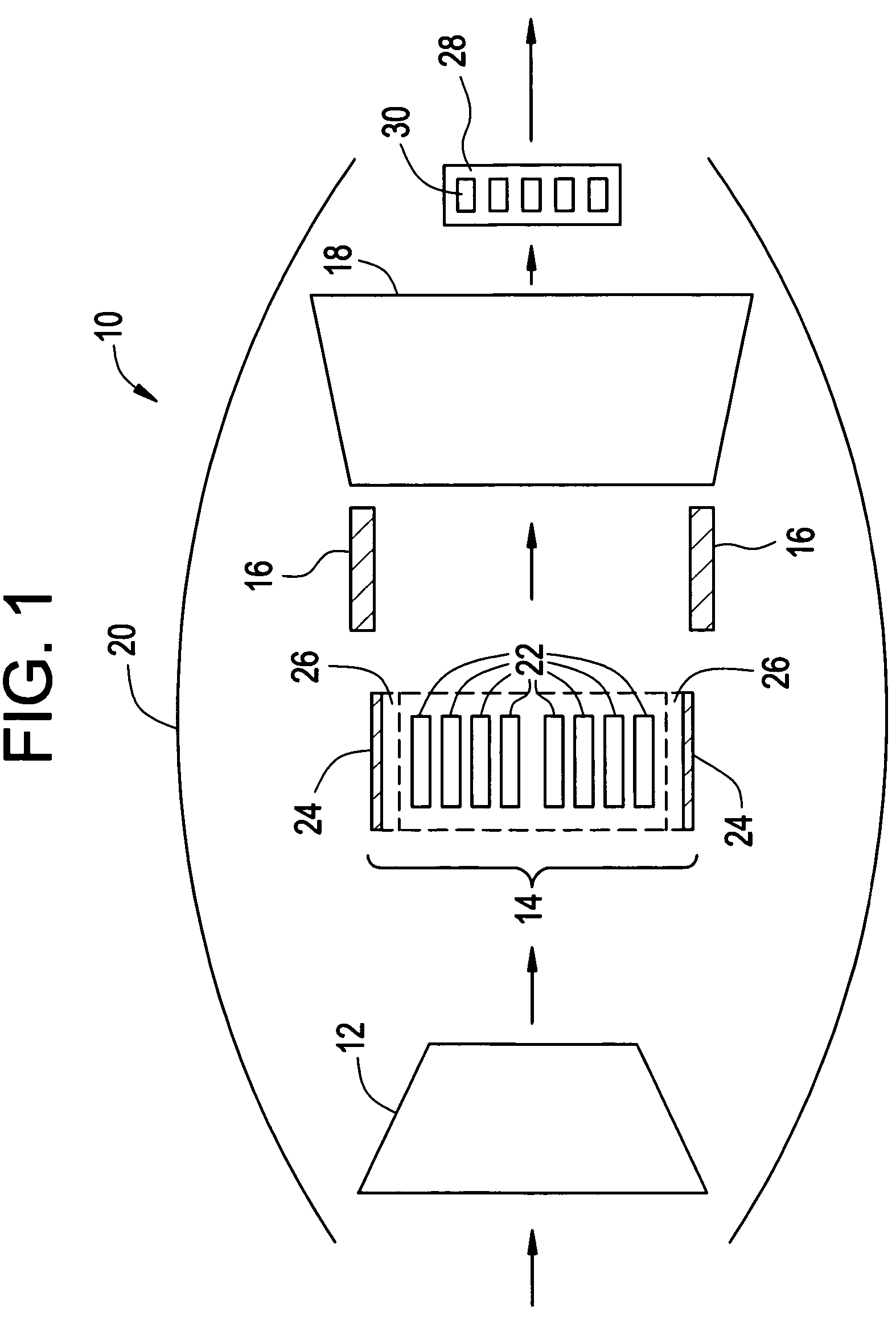

A pulse detonation engine (10) is provided with an aerovalve (14) for controlling the pressure of injected propellants (Ox, Fuel) in an open-ended detonation chamber (26). The propellants are injected at such pressure and velocity, and in a direction generally toward a forward thrust wall end (16) of the detonation chamber (26), an aerovalve (14) is formed which effectively inhibits or prevents egress of the propellant from the detonation chamber (26). A shock wave (34) formed by the injected propellant acts, after reflection by the thrust wall end (16) and in combination with the aerovalve (14), to compress and conserve, or increase, the pressure of the injected propellant. Carefully timed ignition (28) effects a detonation pulse under desired conditions of maintained, or increased, pressure. Termination of the propellant injection serves to “open” the aerovalve (14), and exhaust of the combusted propellants occurs to produce thrust. Alternate embodiments of propellant injection mechanisms (12, 112) provide pulse valves (24, 122, 124) each having a fixed slotted disk (40, 140, 240) and a rotating slotted disk (42, 142, 242) to provide the desired high speed valving of discrete pulses of propellant for injection.

Owner:UNITED TECH CORP

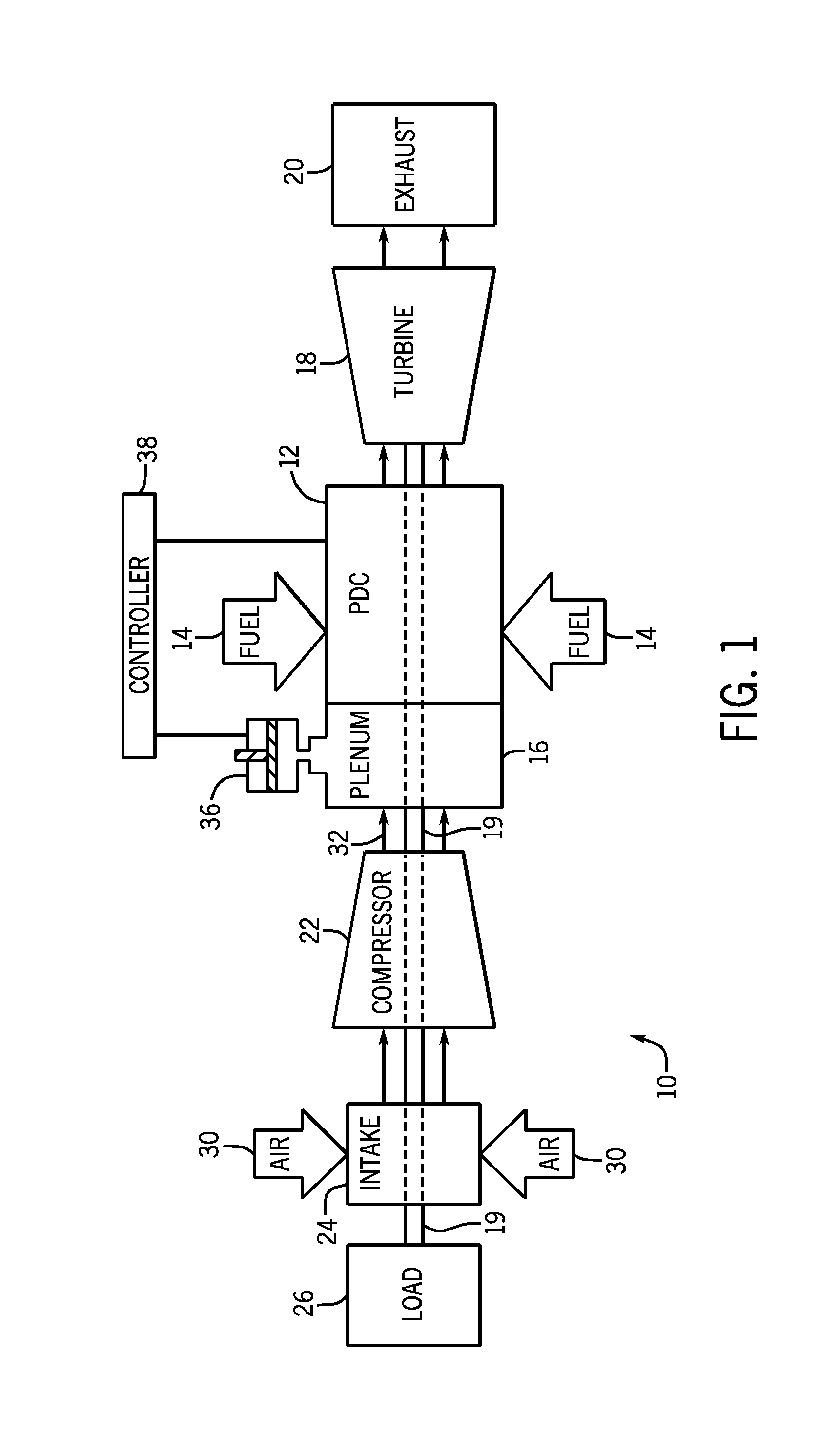

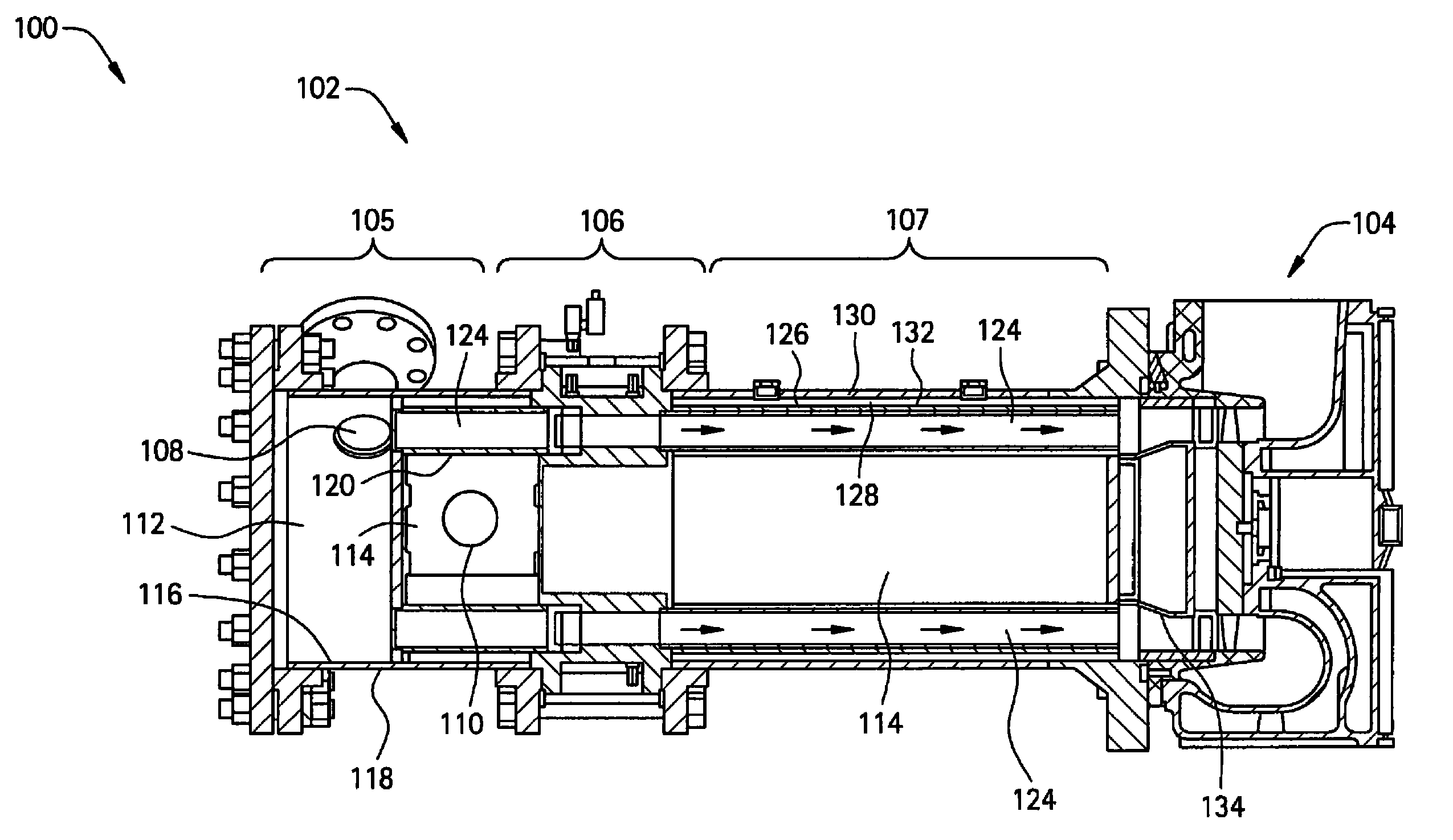

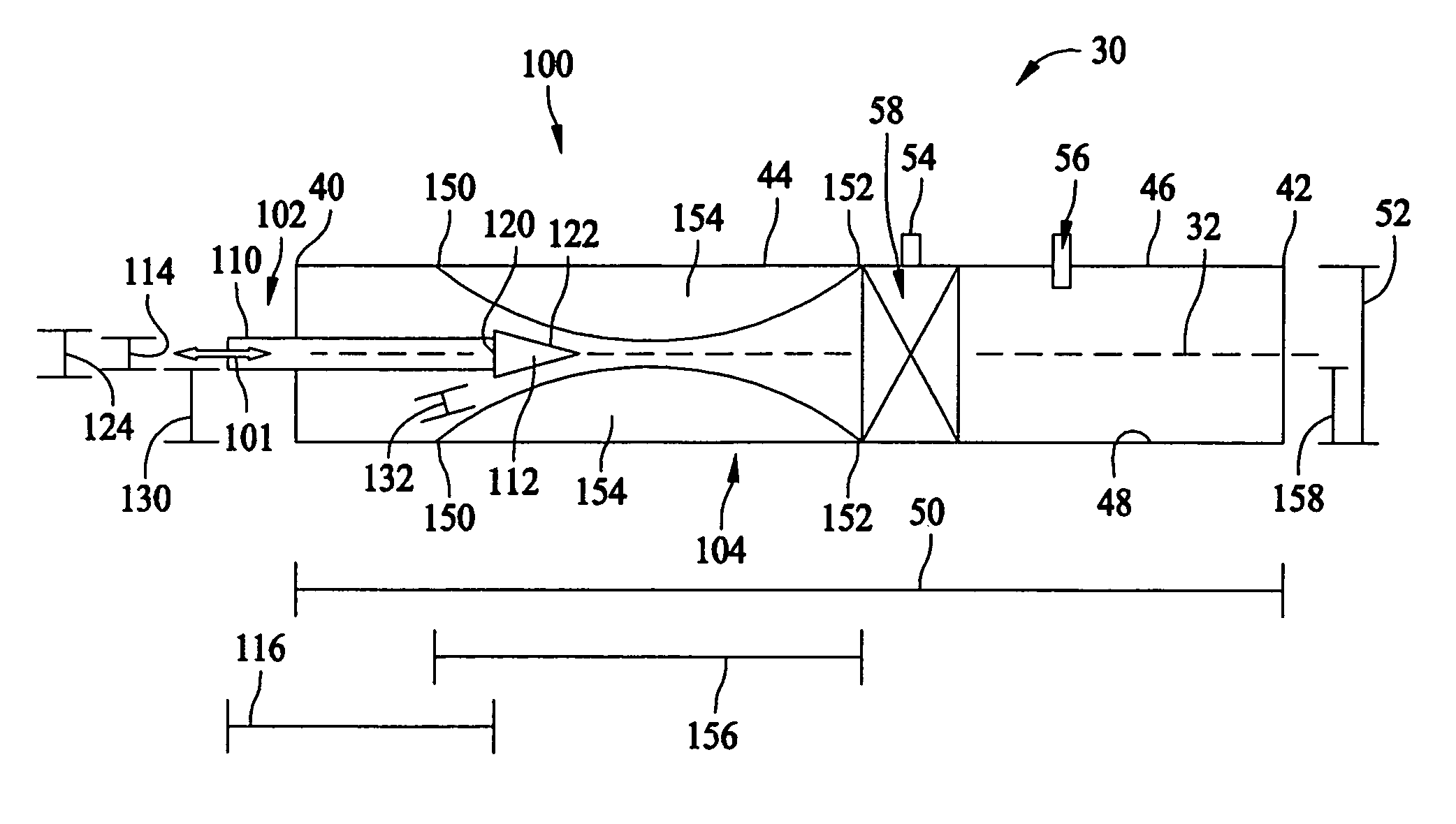

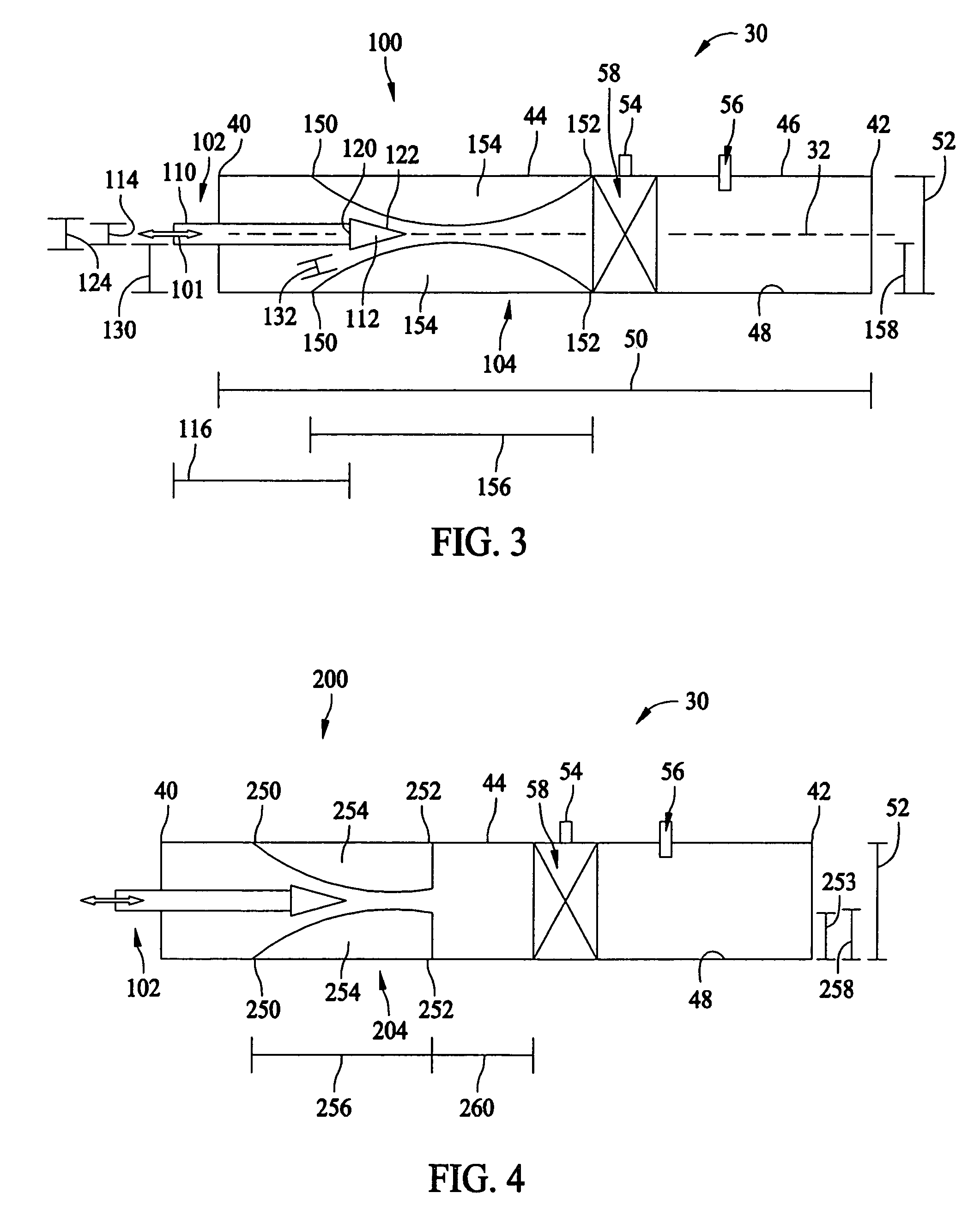

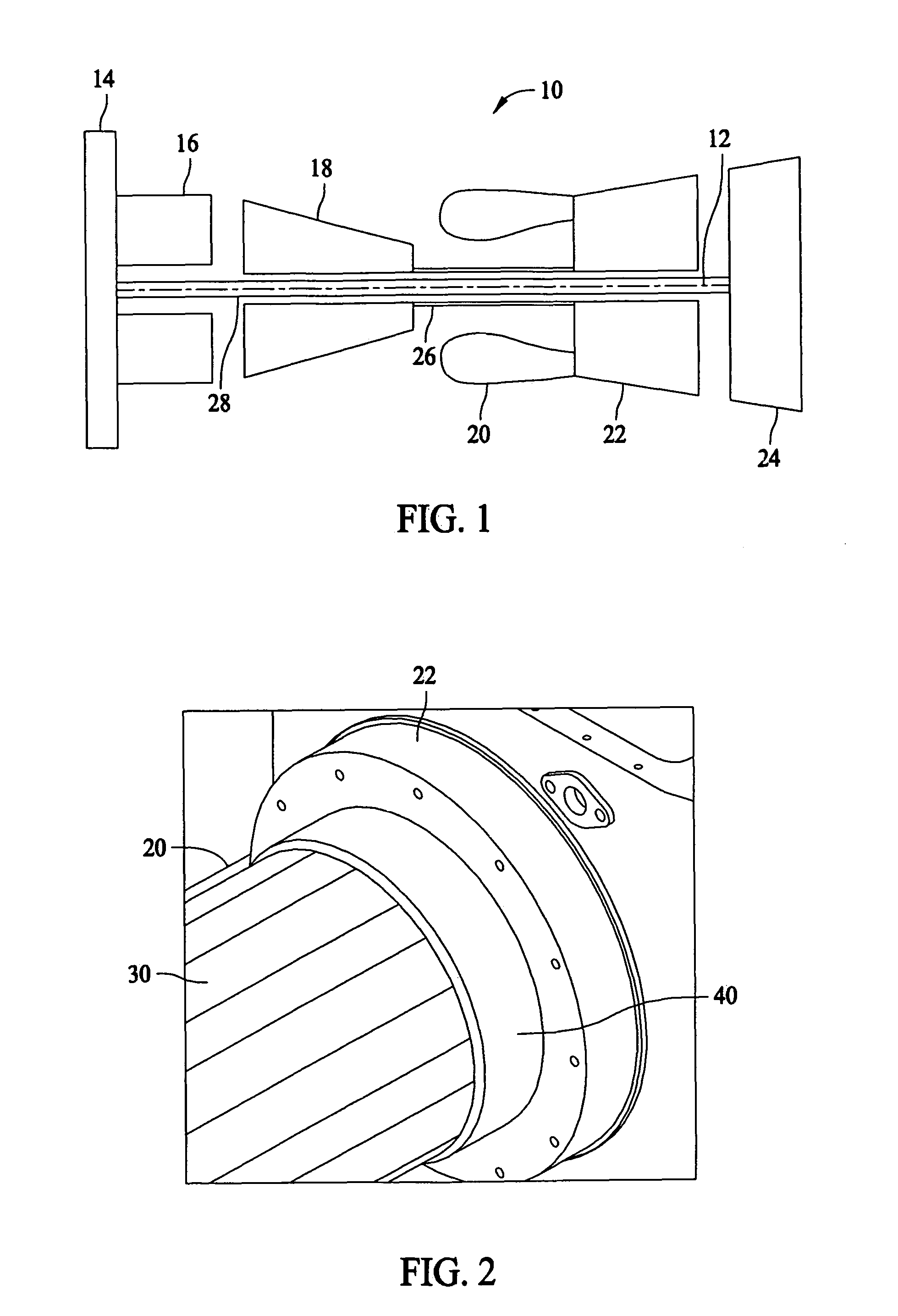

Pulse detonation engines and components thereof

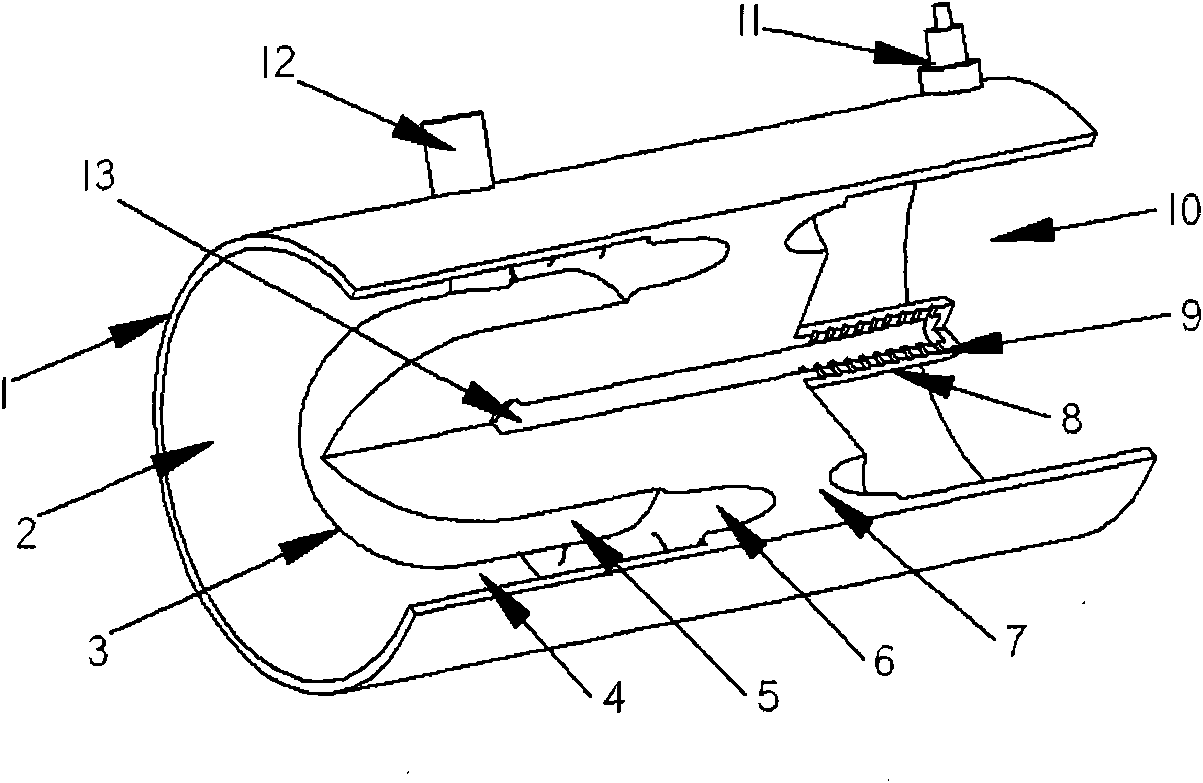

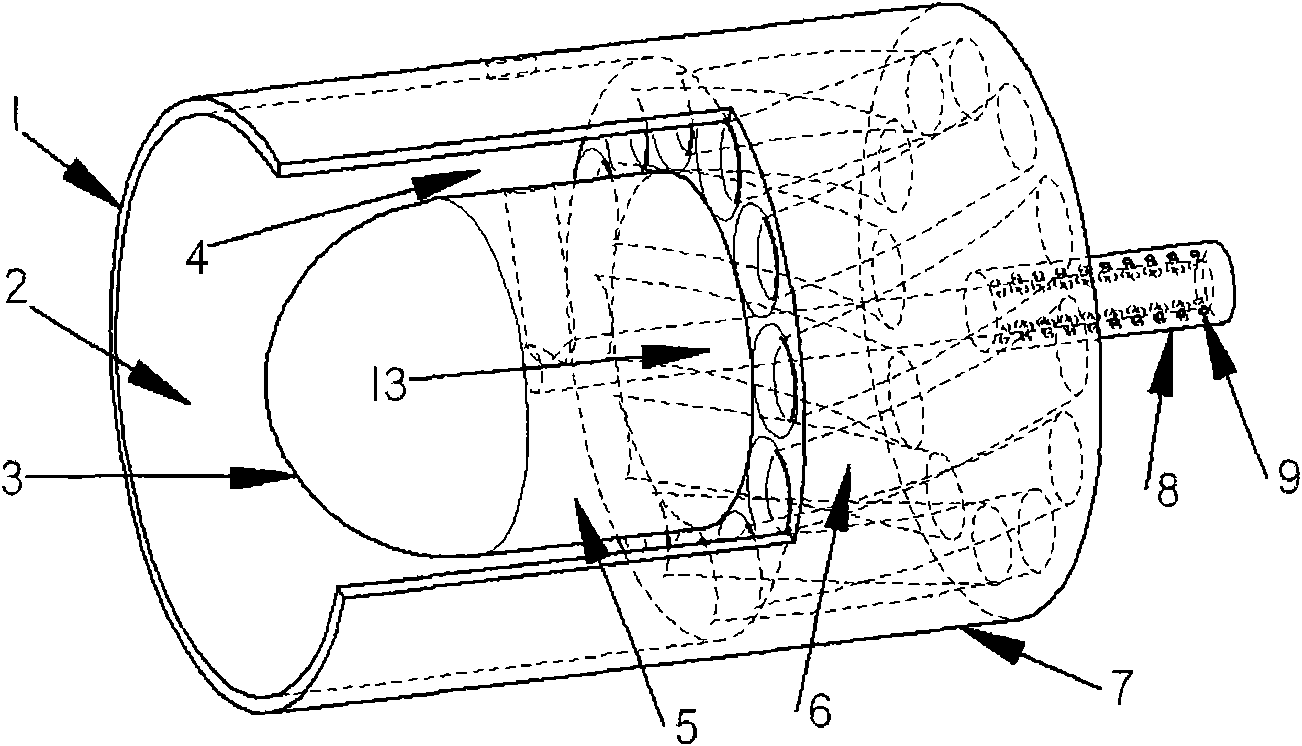

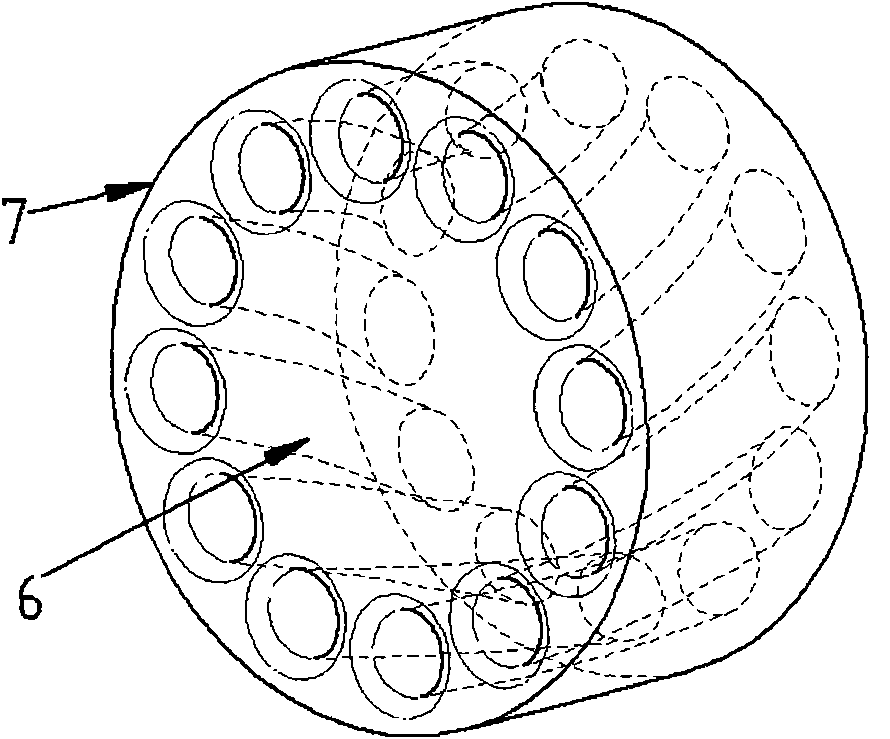

A pulse detonation engine comprises a primary air inlet; a primary air plenum located in fluid communication with the primary air inlet; a secondary air inlet; a secondary air plenum located in fluid communication with the secondary air inlet, wherein the secondary air plenum is substantially isolated from the primary air plenum; a pulse detonation combustor comprising a pulse detonation chamber, wherein the pulse detonation chamber is located downstream of and in fluid communication with the primary air plenum; a coaxial liner surrounding the pulse detonation combustor defining a cooling plenum, wherein the cooling plenum is in fluid communication with the secondary air plenum; an axial turbine assembly located downstream of and in fluid communication with the pulse detonation combustor and the cooling plenum; and a housing encasing the primary air plenum, the secondary air plenum, the pulse detonation combustor, the coaxial liner, and the axial turbine assembly.

Owner:GENERAL ELECTRIC CO

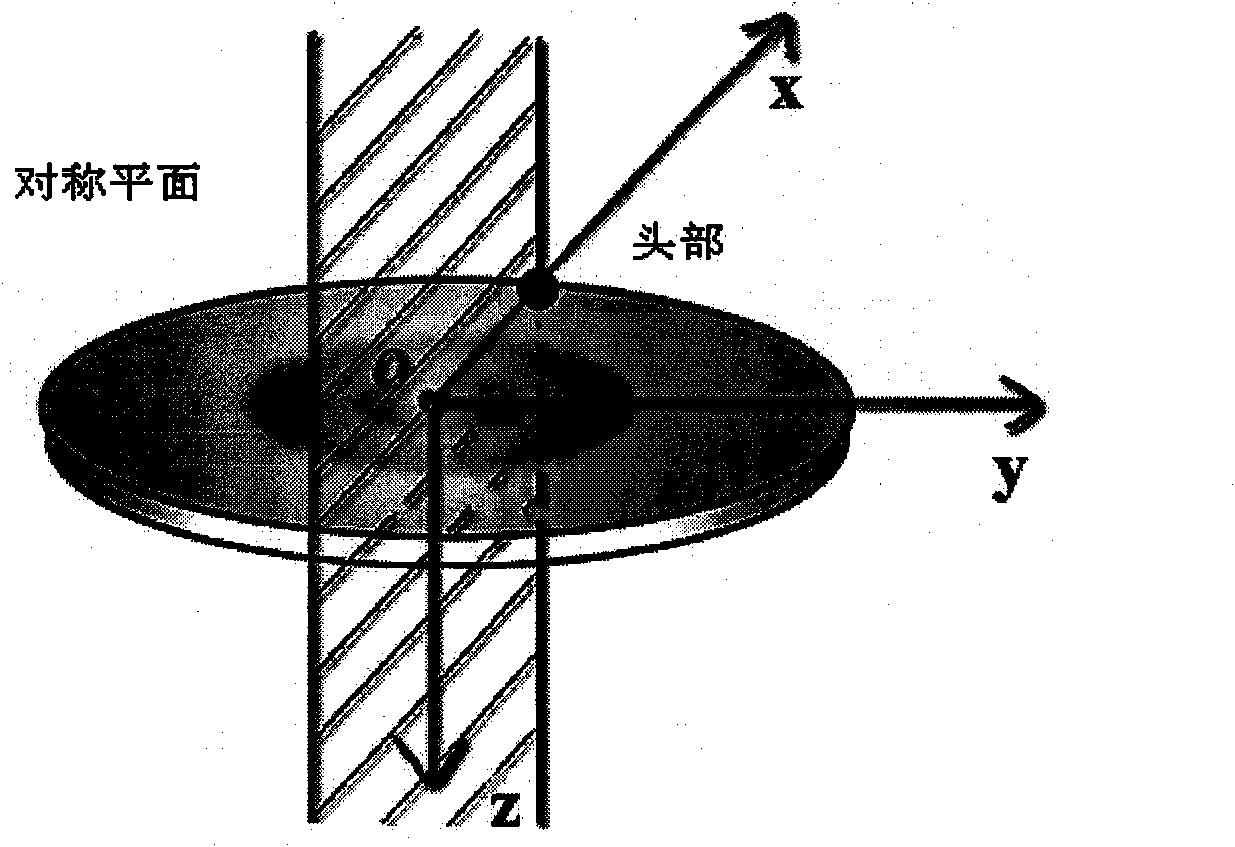

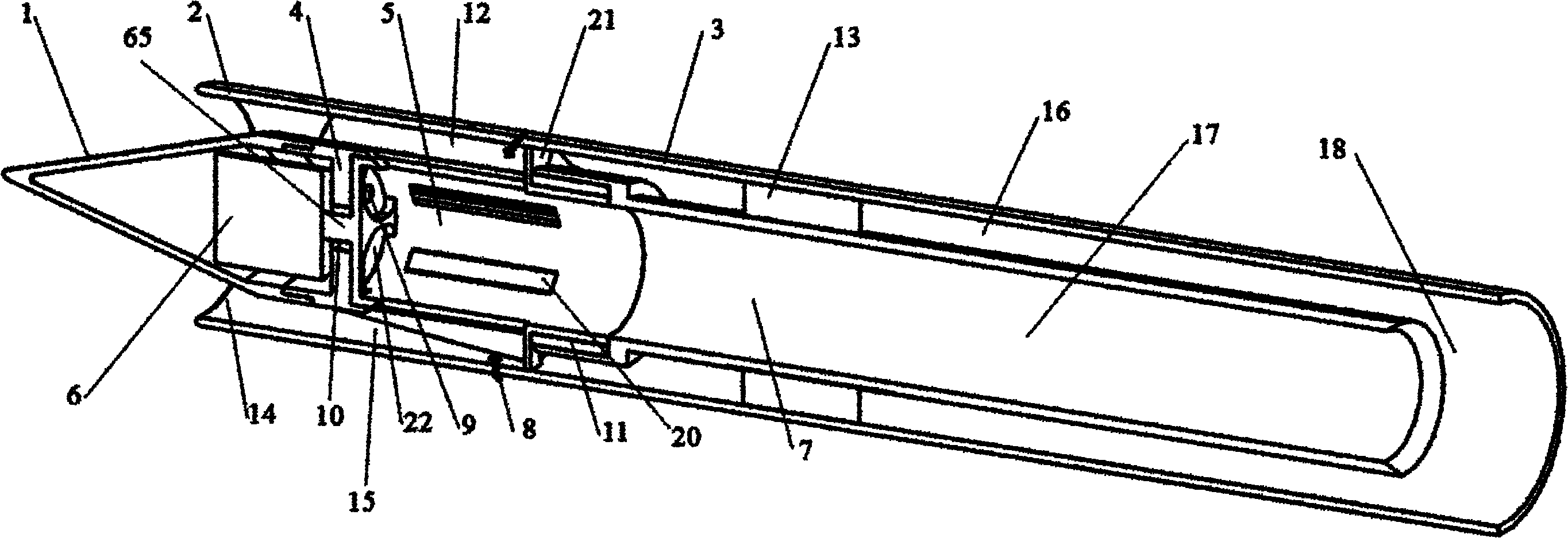

Method for simulating six degrees of freedom movement of spinning aircraft

InactiveCN101625571AEasy to controlSolid theoretical foundationSimulator controlVehicle position/course/altitude controlAviationRunge–Kutta method

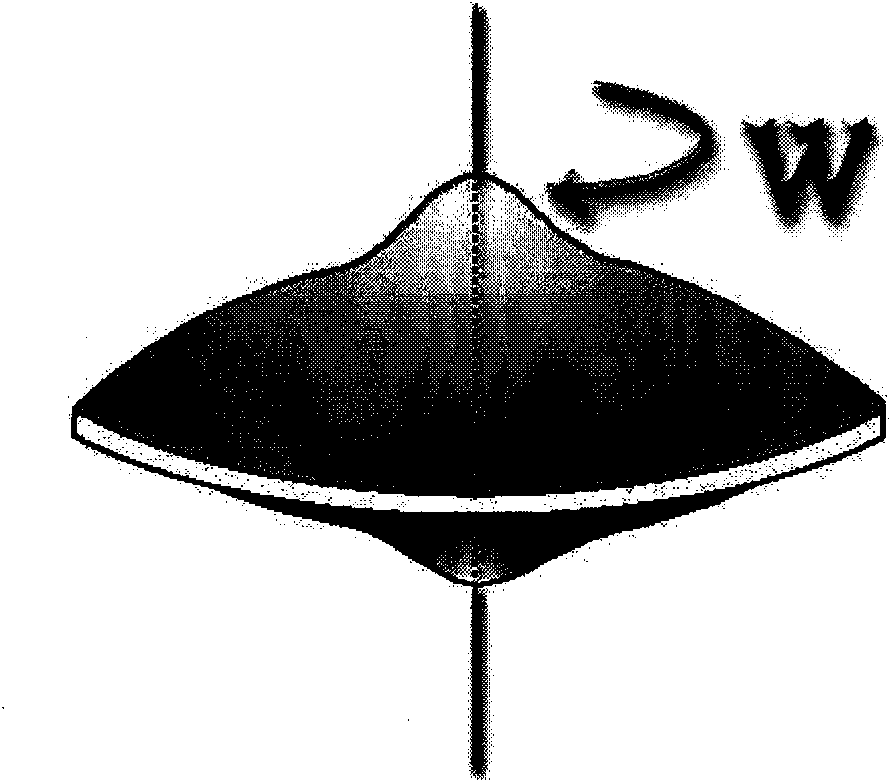

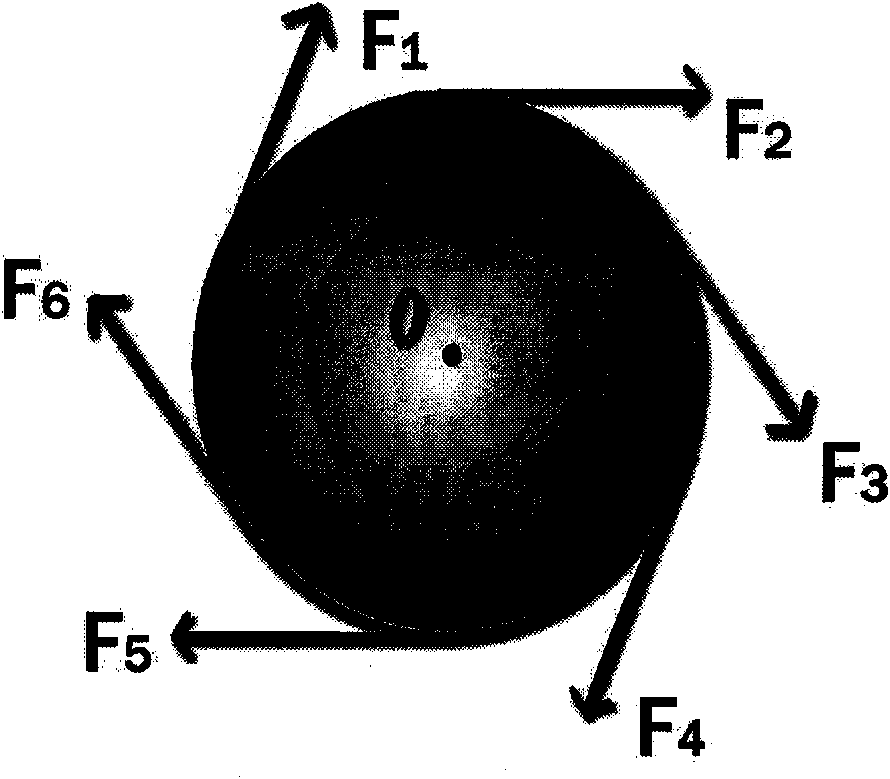

The invention belongs to the technical field of aerospace modelling and discloses a method for building the six degrees of freedom movement model of a spinning aircraft. During spinning, the special geometric configuration of an aircraft and air mutually act to provide elevating force for the aircraft, and the aircraft skilfully combines a pulsed detonation engine to provide thrust. Based on classical aerodynamics theorem of momentum and theorem of moment of momentum, a nonlinear mathematical simultaneous differential equation which can descript the center of mass motion and the center of mass surrounding motion is deduced. According to known engine thrust, the track of spatial movement of the aircraft is solved with the Runge-Kutta method; according to the track of spatial movement, the corresponding thrust of the engine is solved with a difference method; the two different methods can obtain the same result, i.e. the correctness of the movement model algorithm built by the invention is proved. The invention has the effect and benefits that the invention can realize the control of flexible space movement of the spinning aircraft, and has important application value in various application fields.

Owner:DALIAN UNIV OF TECH

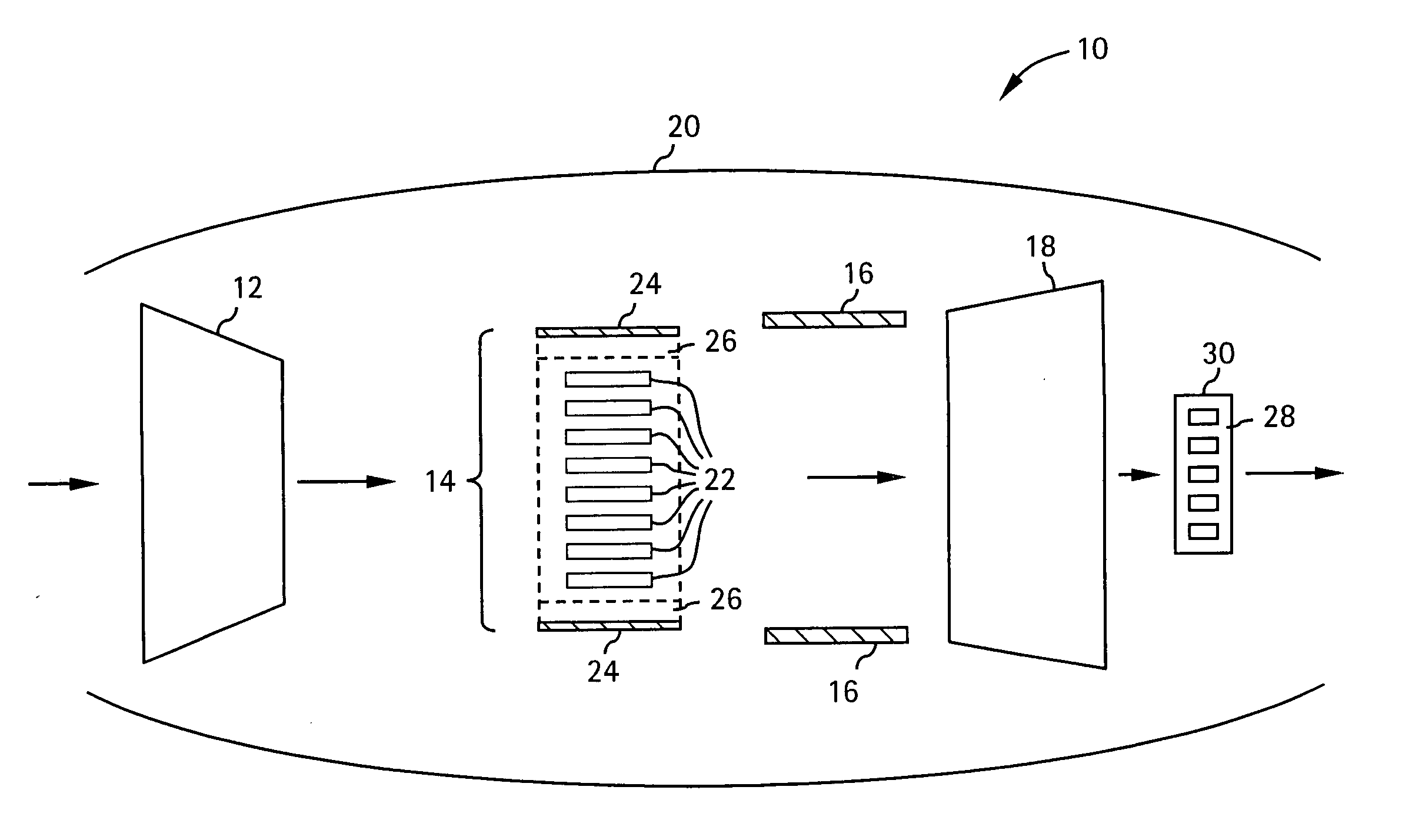

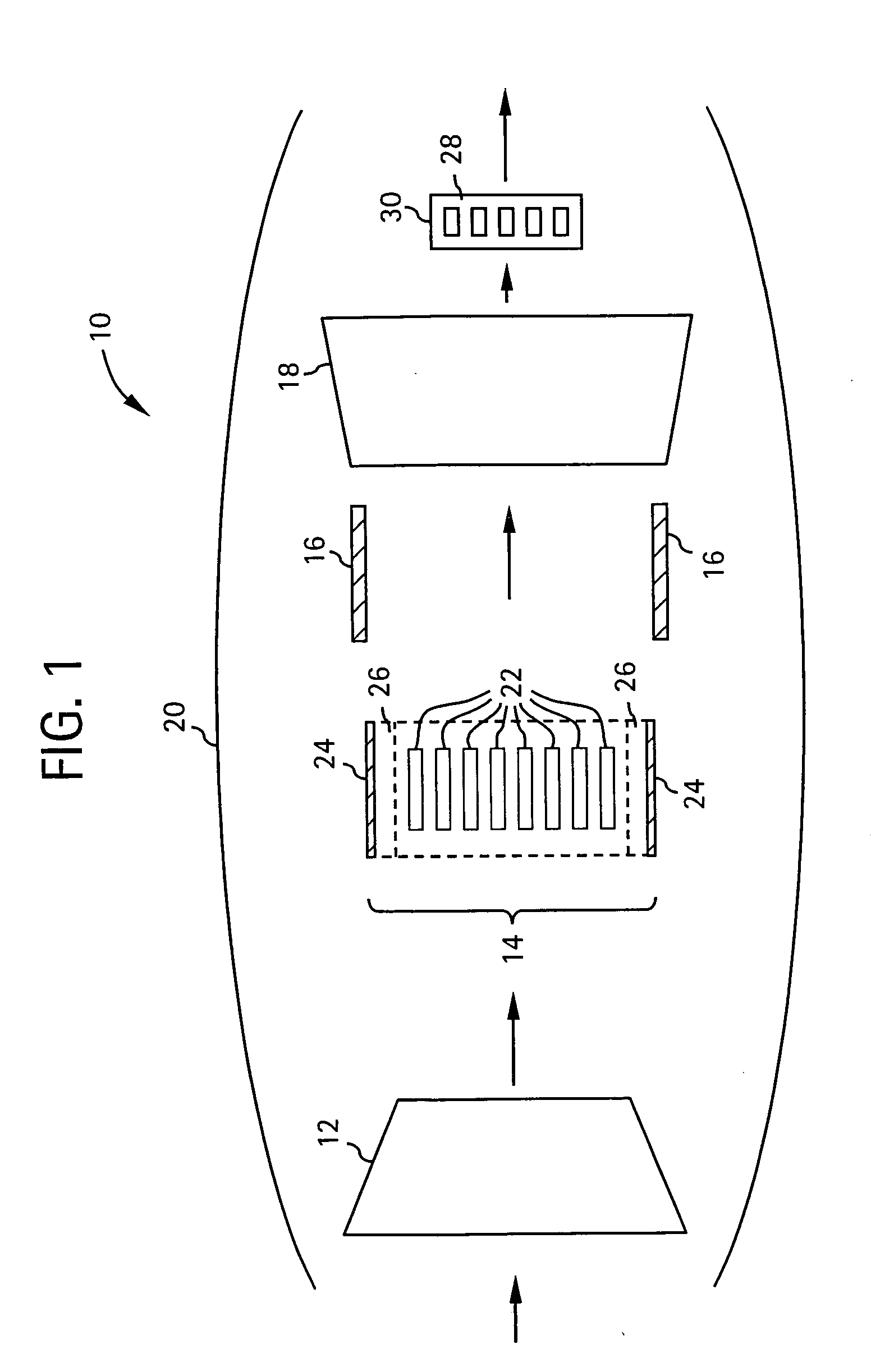

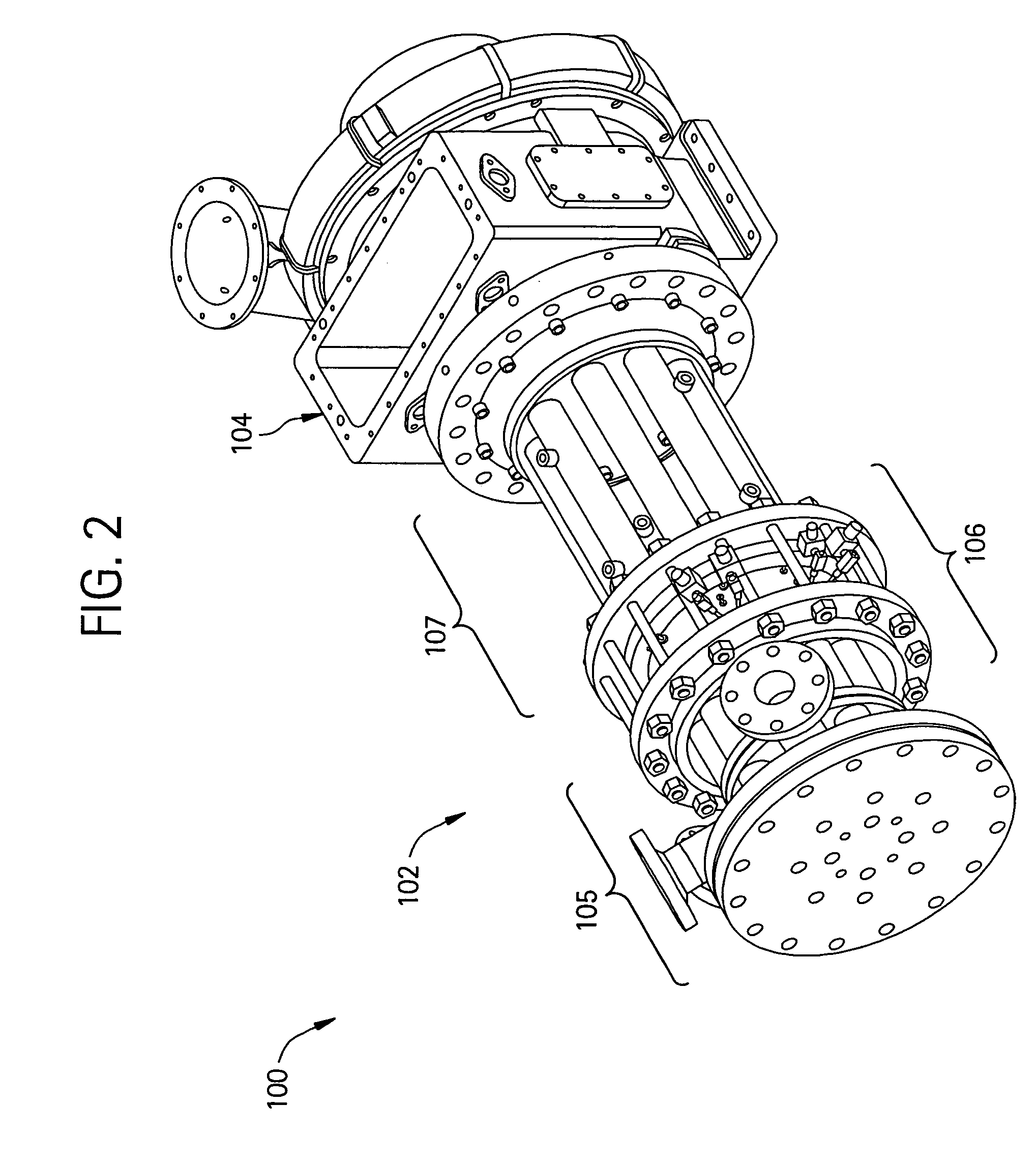

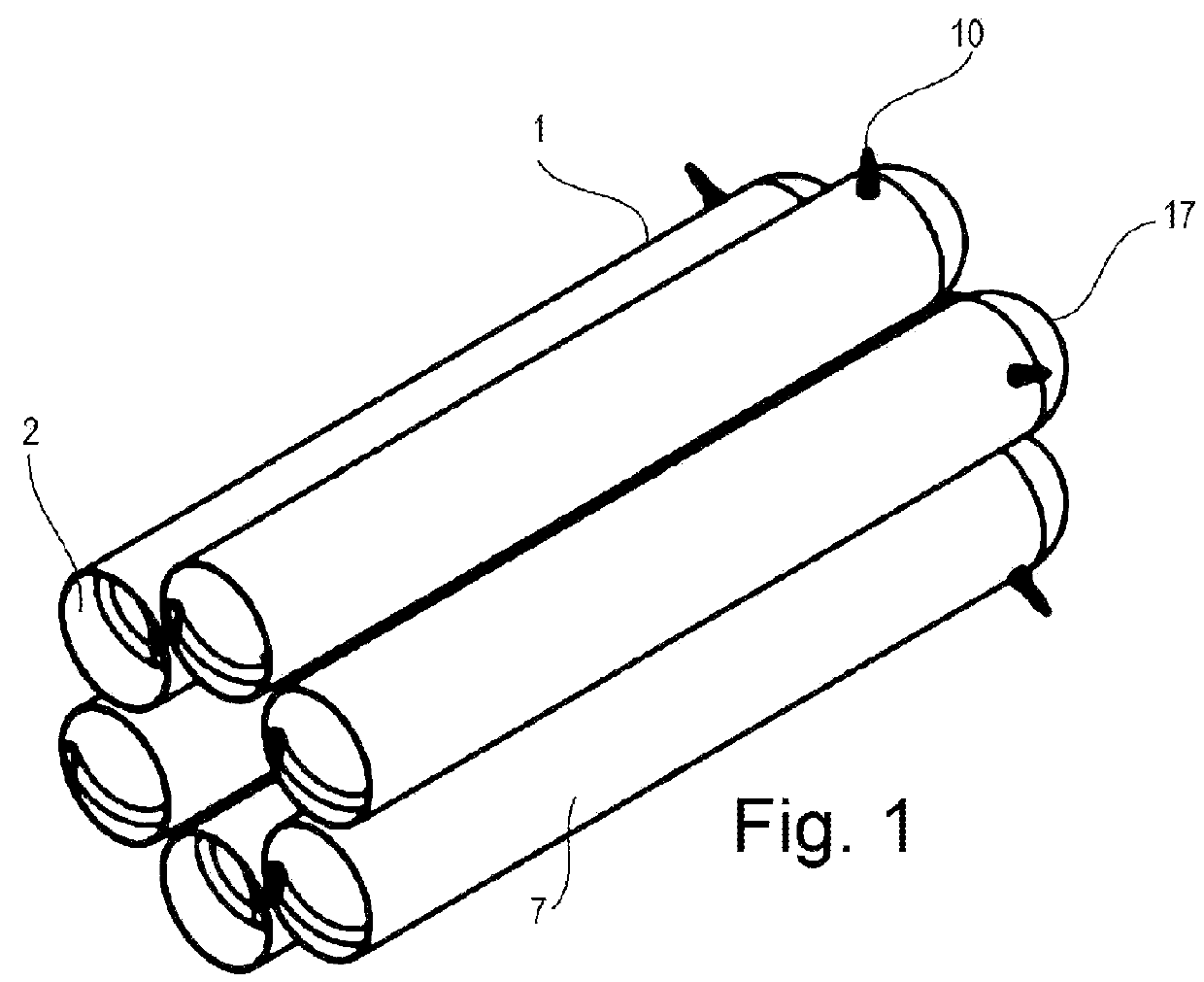

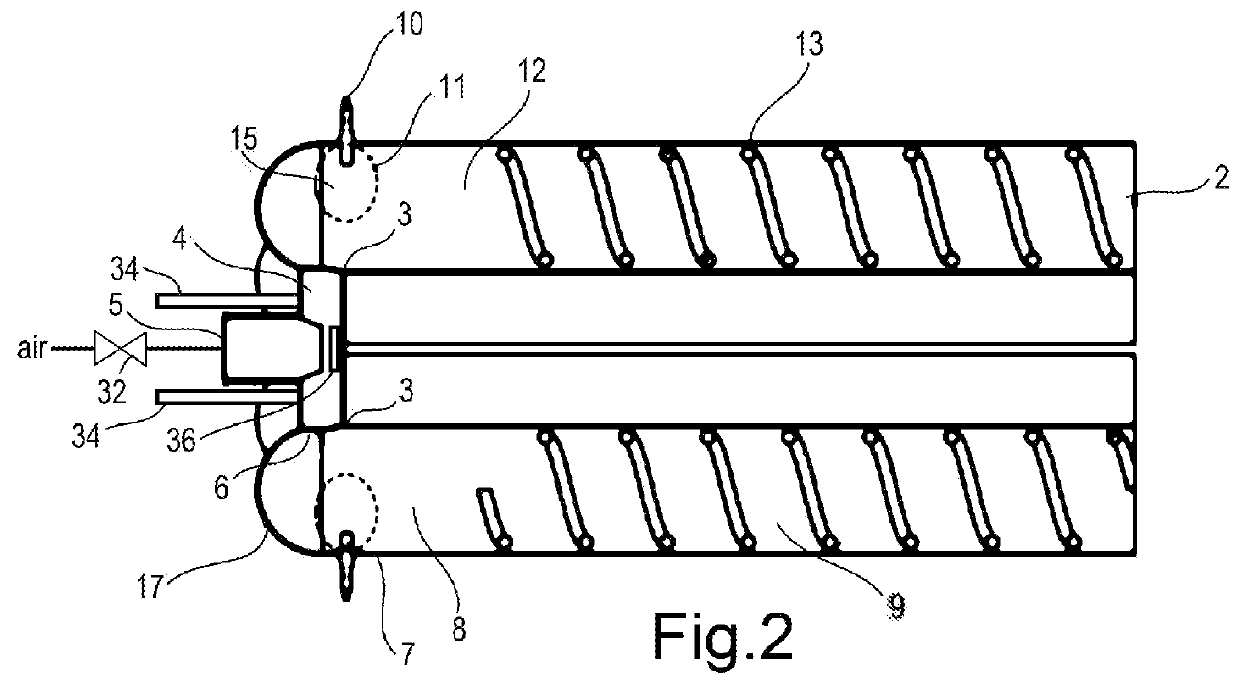

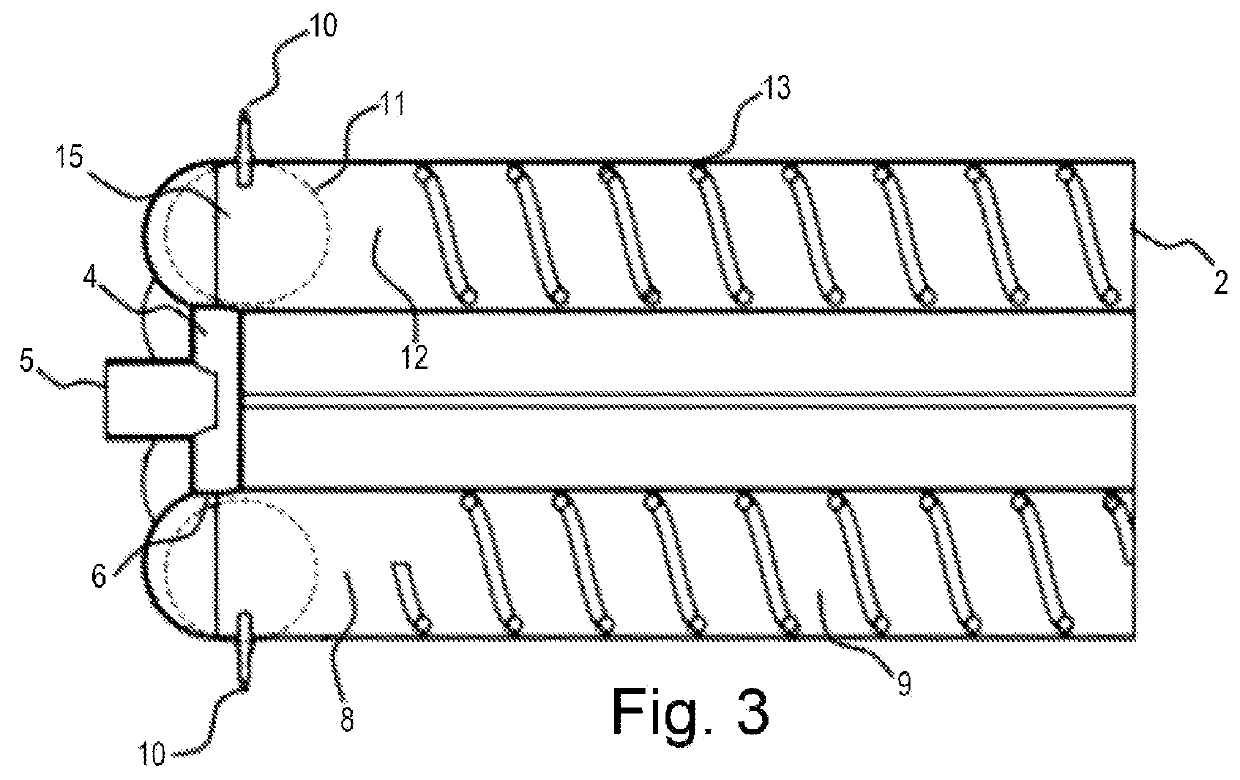

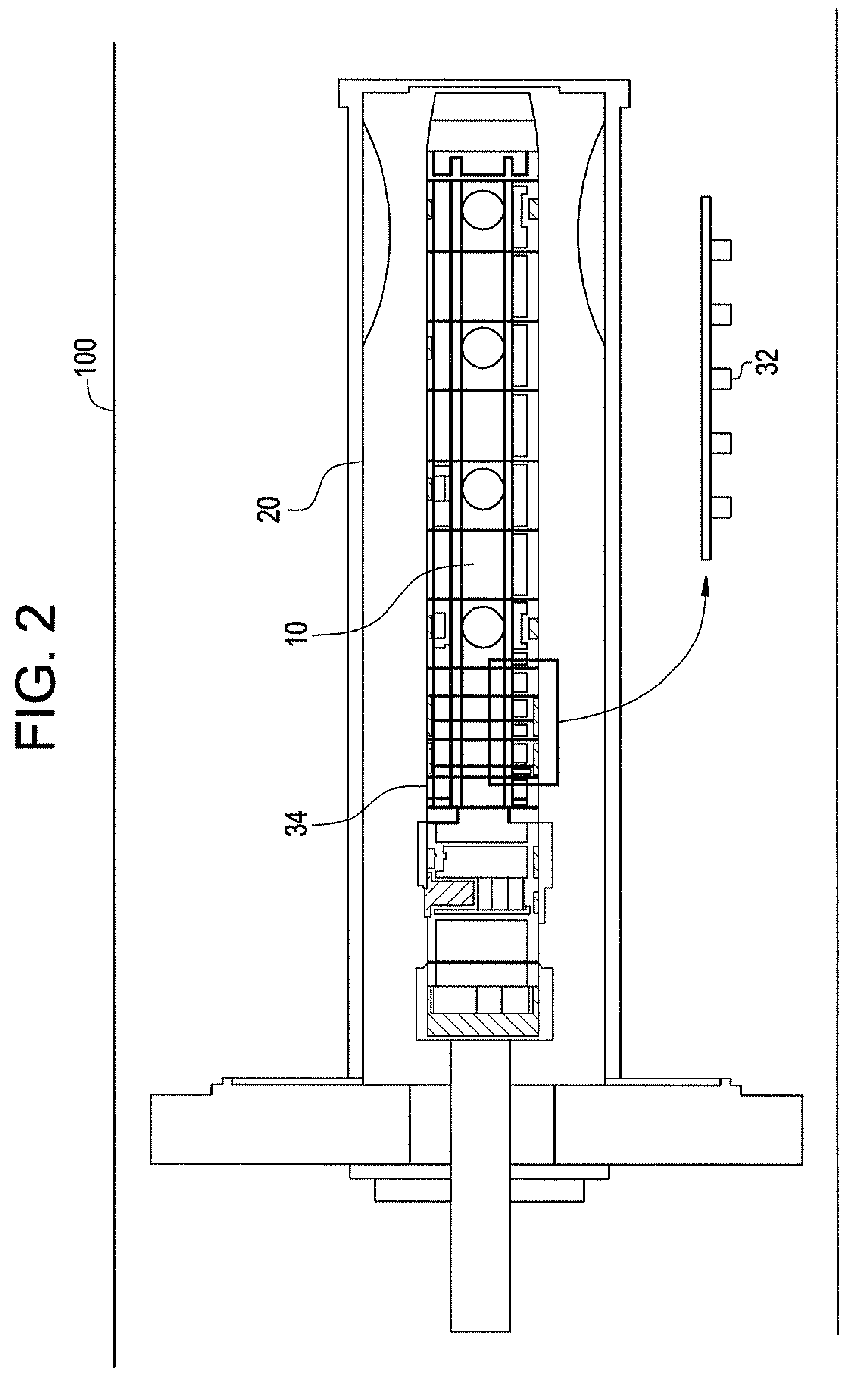

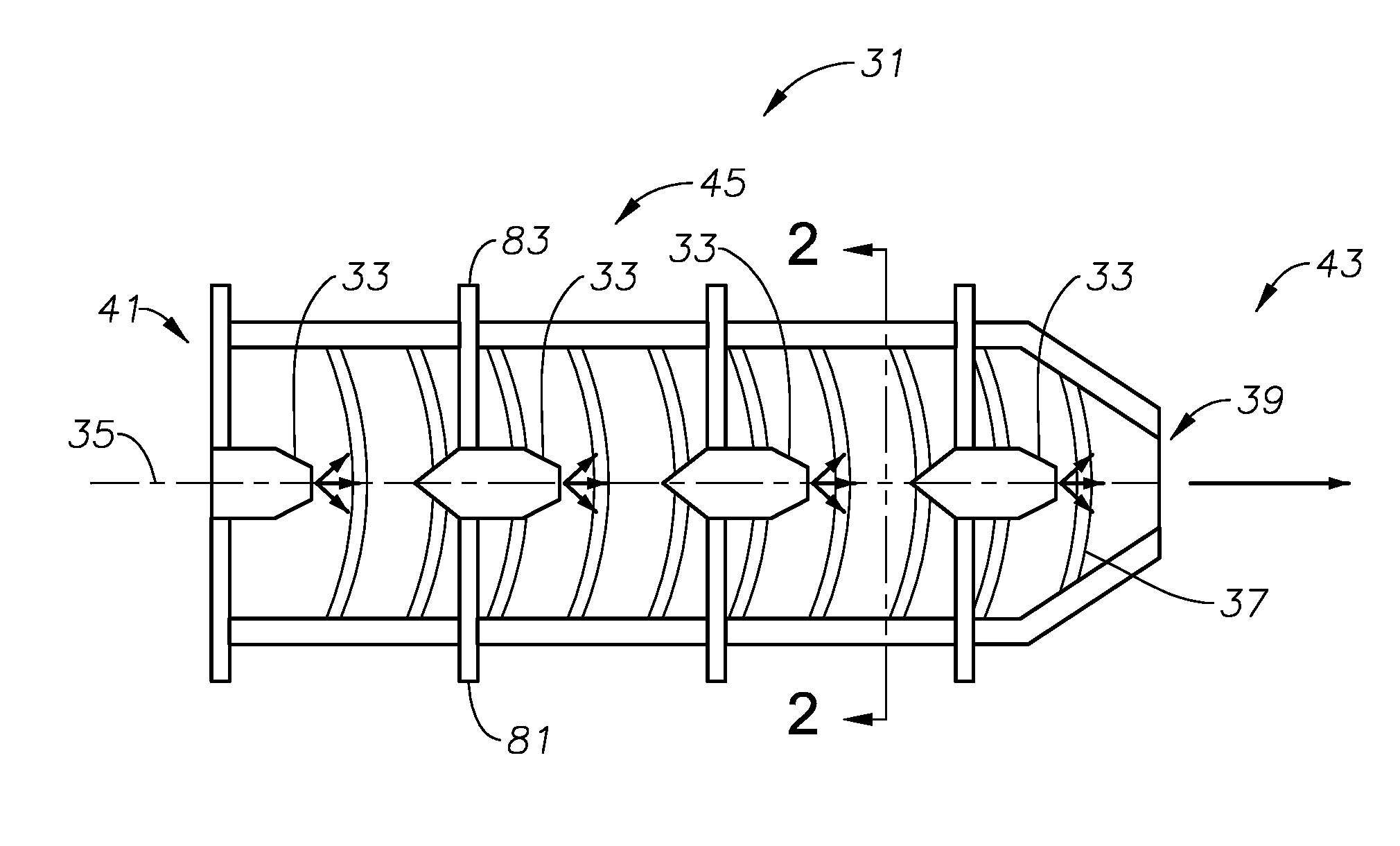

Multiple tube pulse detonation engine turbine apparatus and system

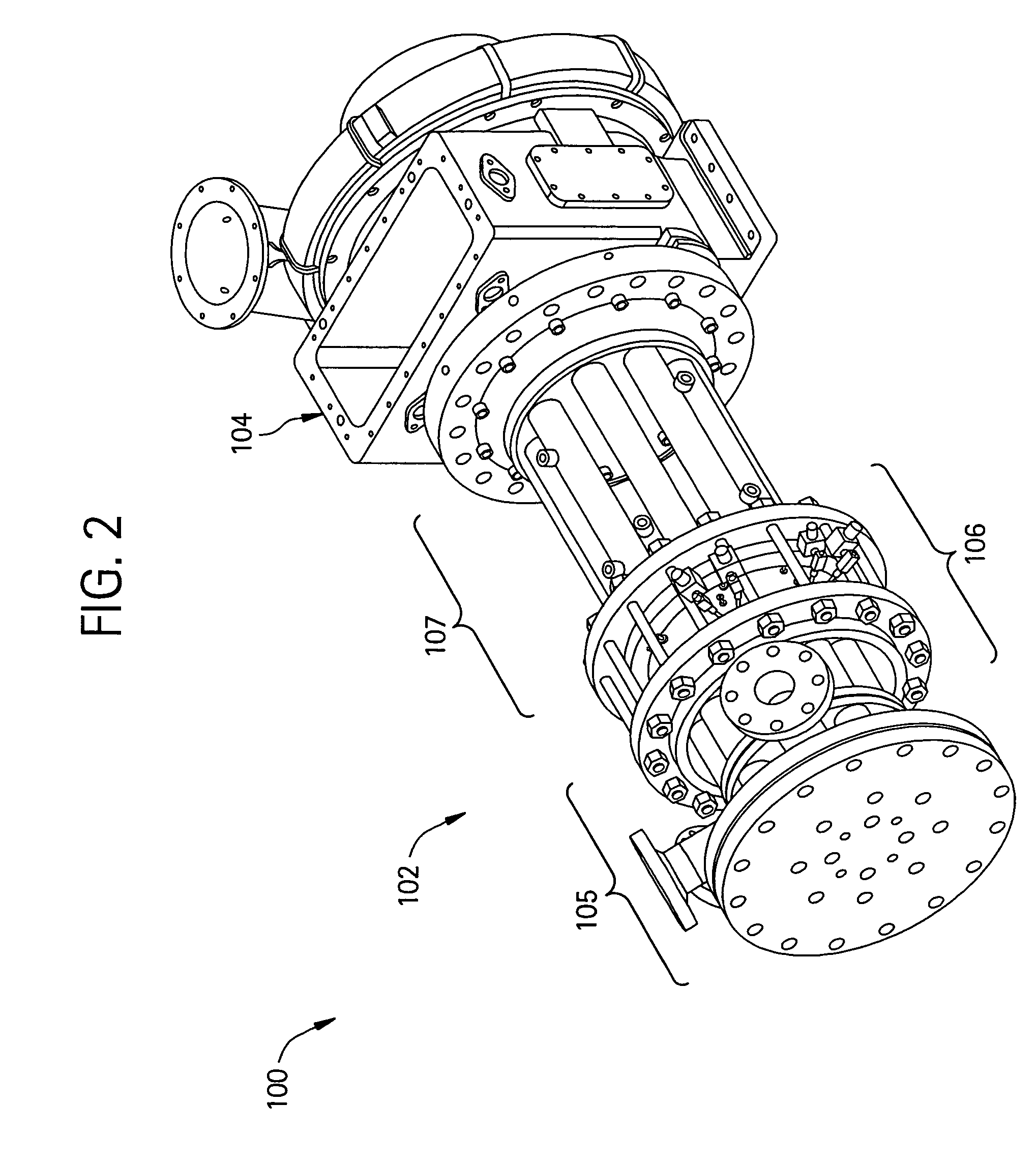

ActiveUS20070180811A1Facilitate fuel injectionEasy to igniteGas turbine plantsExplosive combustion chamberCombustorEngineering

A pulse detonation combustor (PDC) assembly includes an upstream chamber forming an inlet plenum, a downstream chamber including a downstream portion of at least one PDC tube, and an integrated PDC head coupled to the upstream chamber and the downstream chamber. The integrated PDC head is configured to facilitate fuel injection and ignition within the PDC tube. The PDC tube includes an inner seal surface and an outer seal surface configured to mate with the inner seal surface, wherein the inner seal surface includes an elevated section thereon that engages with the outer seal surface such that the PDC tube is free to partially pivot about a longitudinal axis thereof.

Owner:GENERAL ELECTRIC CO

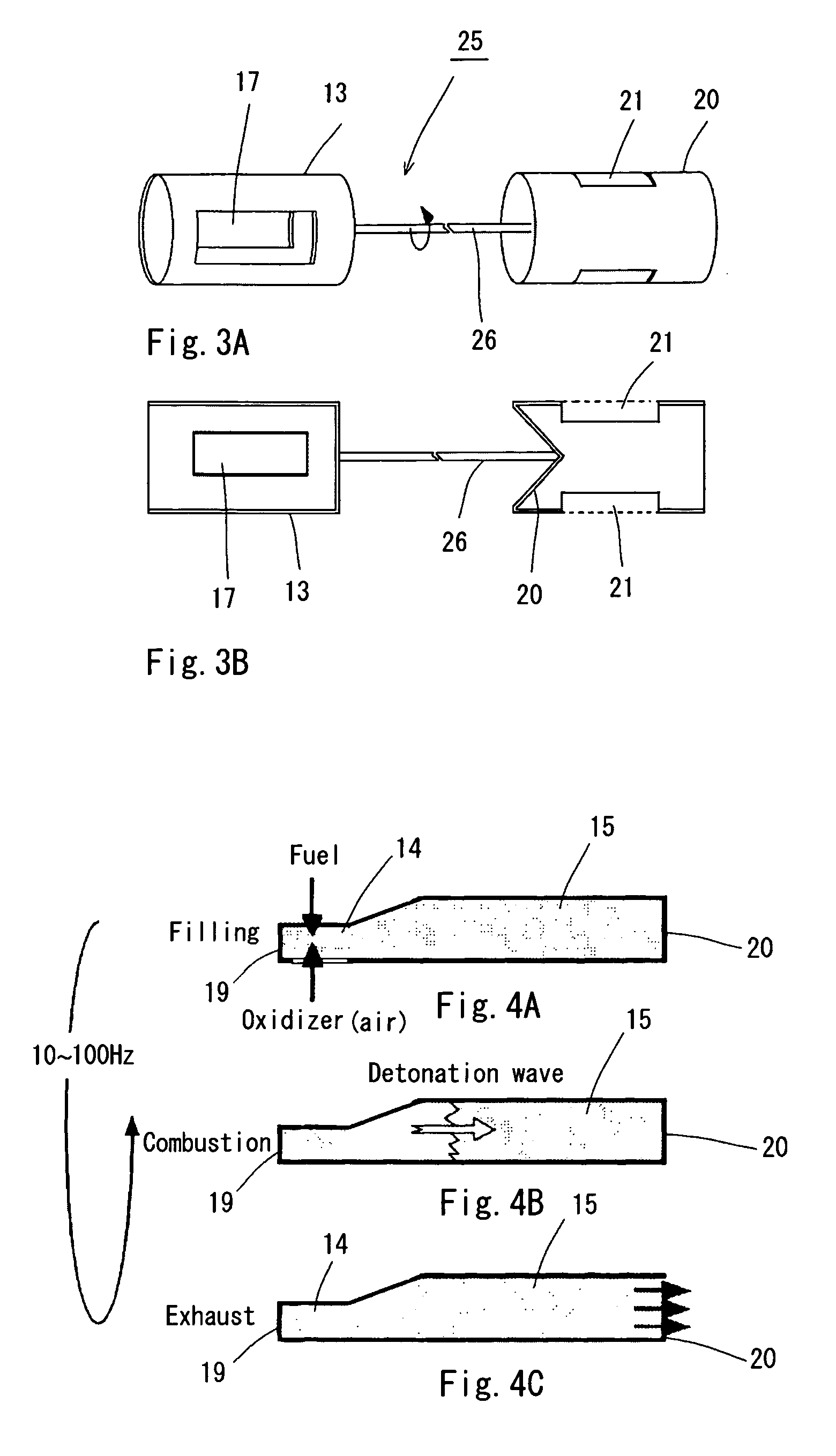

Pulse detonation engine and valve

InactiveUS20050183413A1Accurate timingIncrease air densityPulsating combustionTurbine/propulsion fuel heatingCombustion chamberCombustor

Pressure and density of a gaseous mixture are increased in the process of introducing the gaseous mixture into the combustor of an air-breathing pulse detonation engine employing atmospheric oxygen as an oxidizer. The exit valve 20 able to be opened and closed is provided at the outlet of the combustor 15, an air cooler 12 is provided in the exit of the intake, and density is increased by exchange of heat of the air received at the intake with a coolant in the air cooler 12. Furthermore, by closing the exit valve 20 provided in the outlet of the combustor during the process of loading the gaseous mixture, transition to the detonation process is possible without expansion of the high-pressure high density air obtained by ram-compression at the intake.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

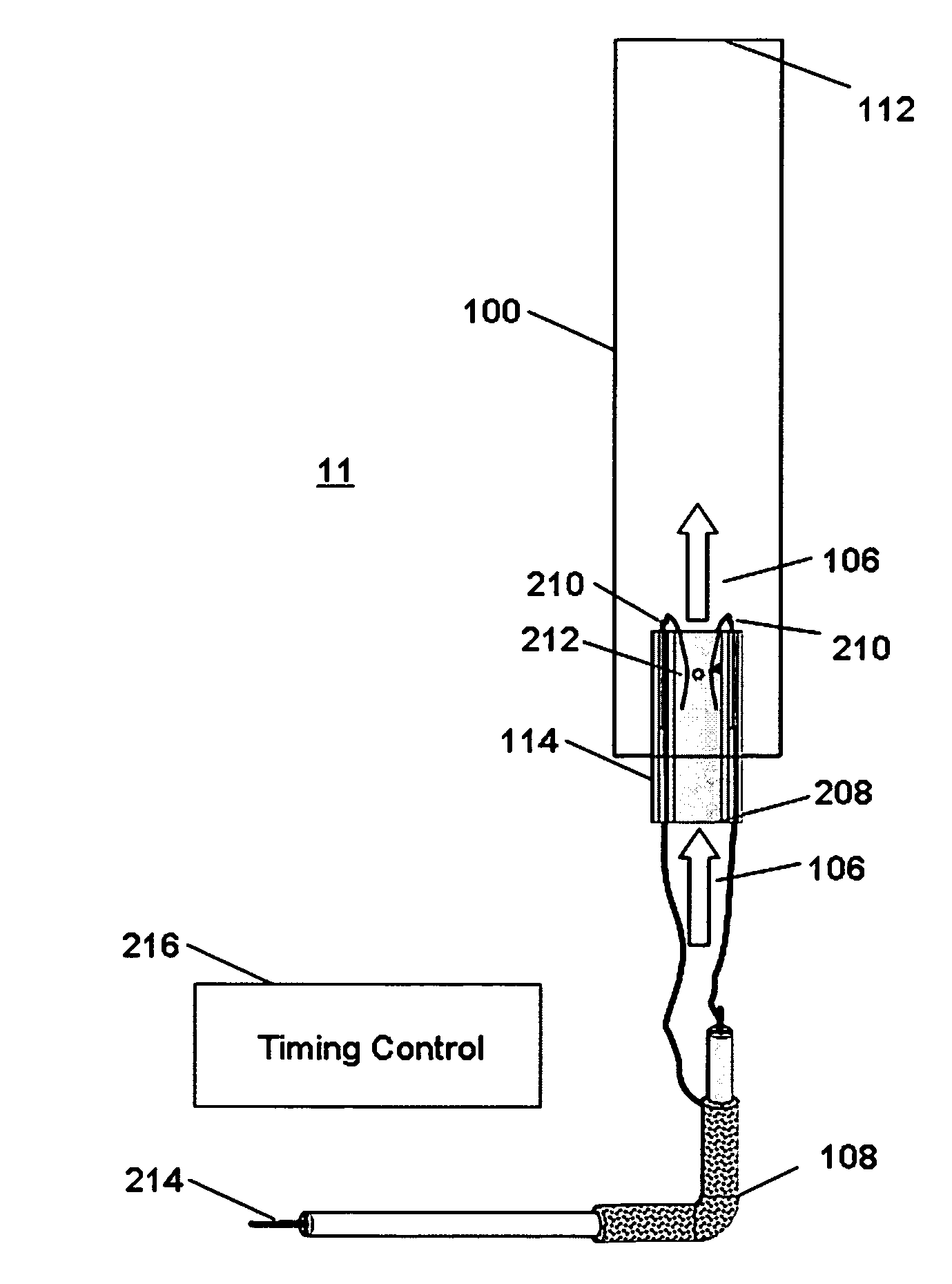

System and method for ignition of a gaseous or dispersed fuel-oxidant mixture

An improved system and method for ignition of a gaseous or dispersive fuel-oxidant mixture is provided where a gaseous or dispersive fuel-oxidant mixture is supplied to a detonator tube having a fill point and an open end and an igniter placed at an ignition point within the detonator tube is ignited while the gaseous or dispersive fuel-oxidant mixture is flowing through the detonator tube. A detonation impulse is produced at the ignition point that propagates to the open end of said detonator tube where it can be supplied to a detonation tube having an open end, to an internal combustion engine, a combustion chamber, and to a pulse detonation engine.

Owner:SOUNDBLAST TECH

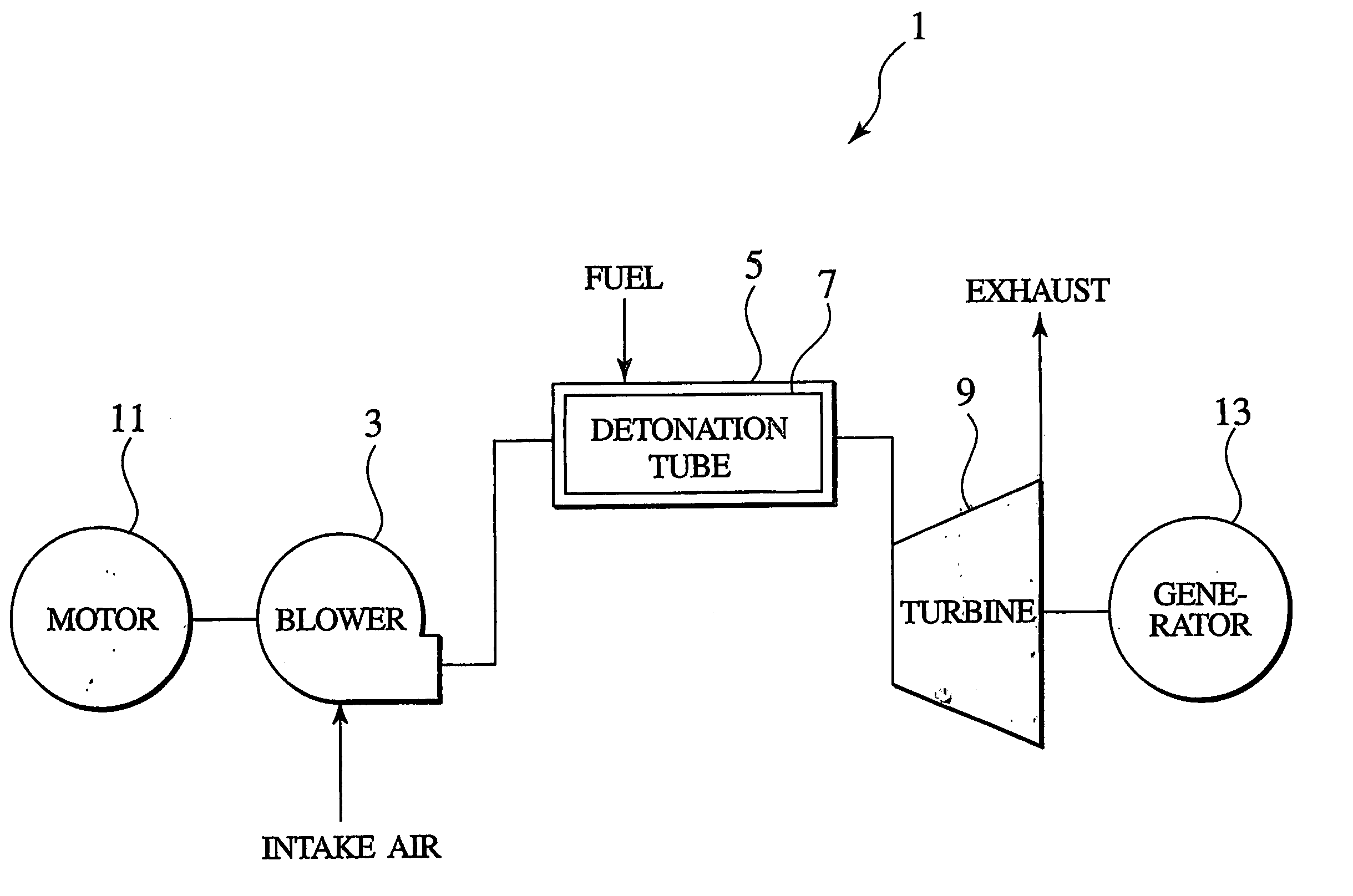

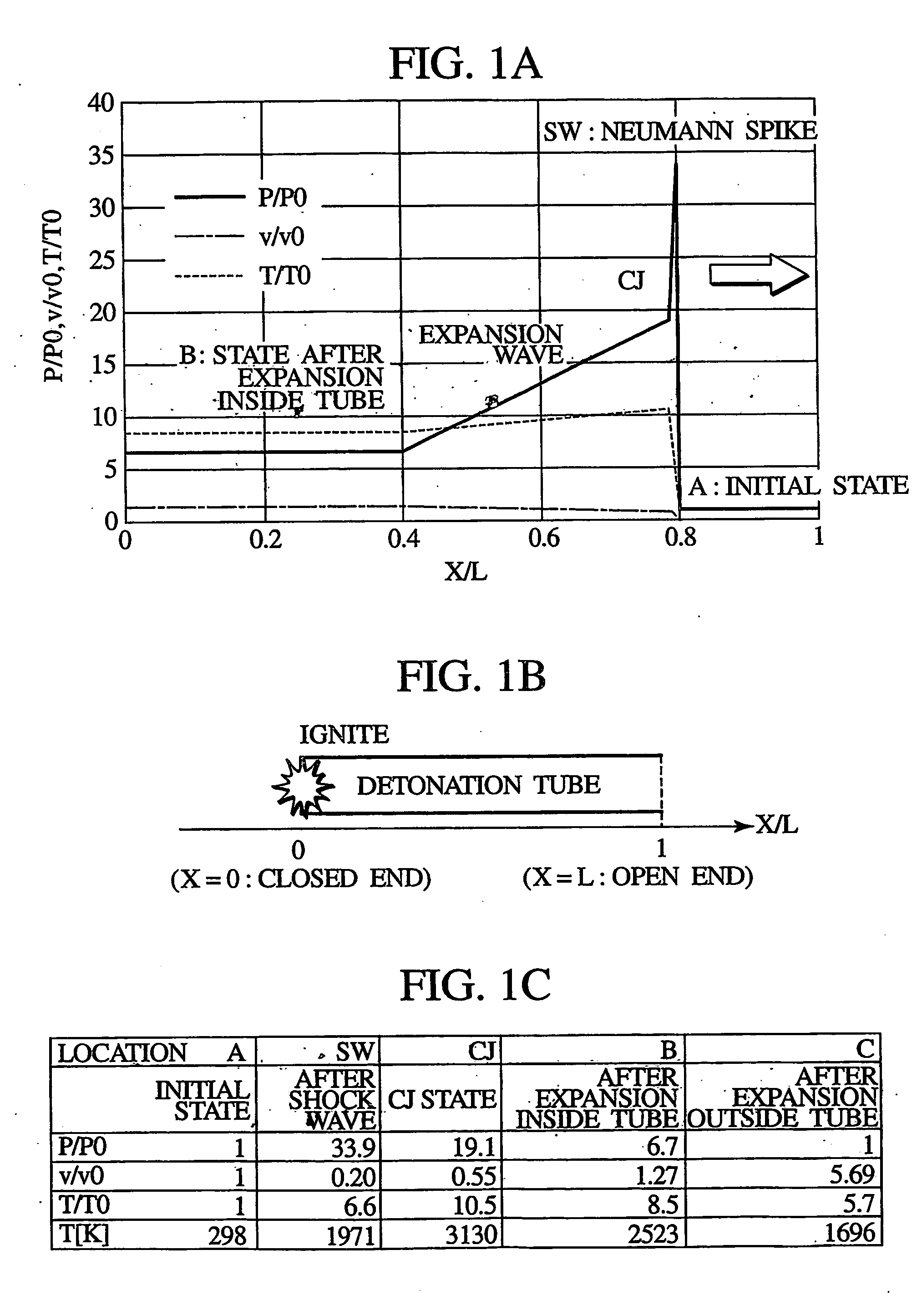

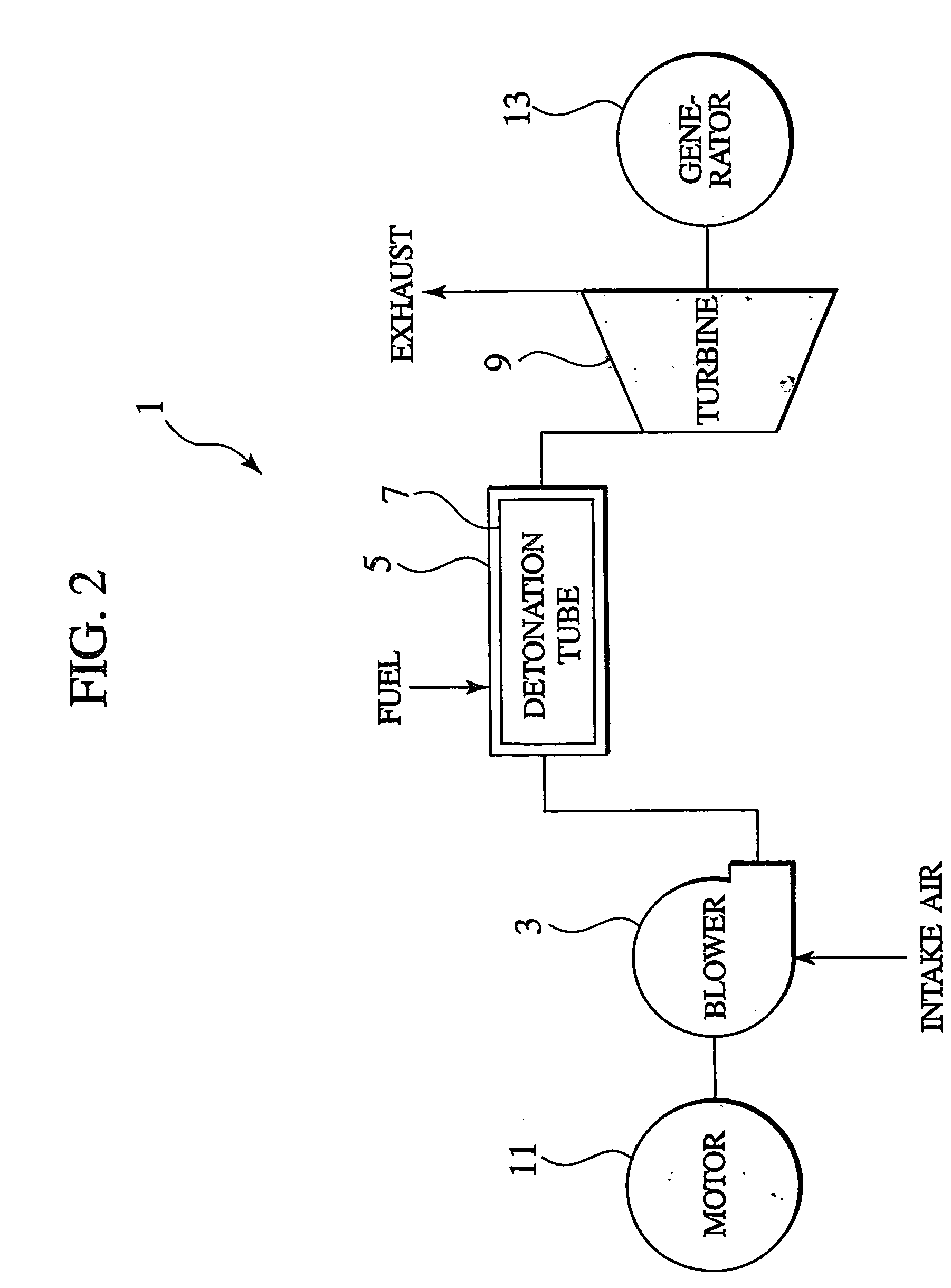

Pulse detonation engine system for driving turbine

ActiveUS20050210879A1Turbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustionTurbine

A pulse detonation engine system (1) for driving a turbine is comprises a detonation generator section (5) including a detonation tube (7) having a tubular hollow section for permitting detonation to be generated therein during combustion stage of a mixture gas combined with a gas and a fuel, a gas supply section (17) for feeding the gas into the tubular hollow section of the detonation tube (7) at given time intervals, a fuel valve (19) for feeding the fuel into the tubular hollow section of the detonation tube (7) at the given time intervals, and an ignition plug (15) for igniting the mixture gas in the tubular hollow section of the detonation tube (7), and a pulse detonation driven turbine (9) driven directly or indirectly by energy of detonations that are intermittently generated in the tubular hollow section of the detonation tube (7).

Owner:IHI CORP

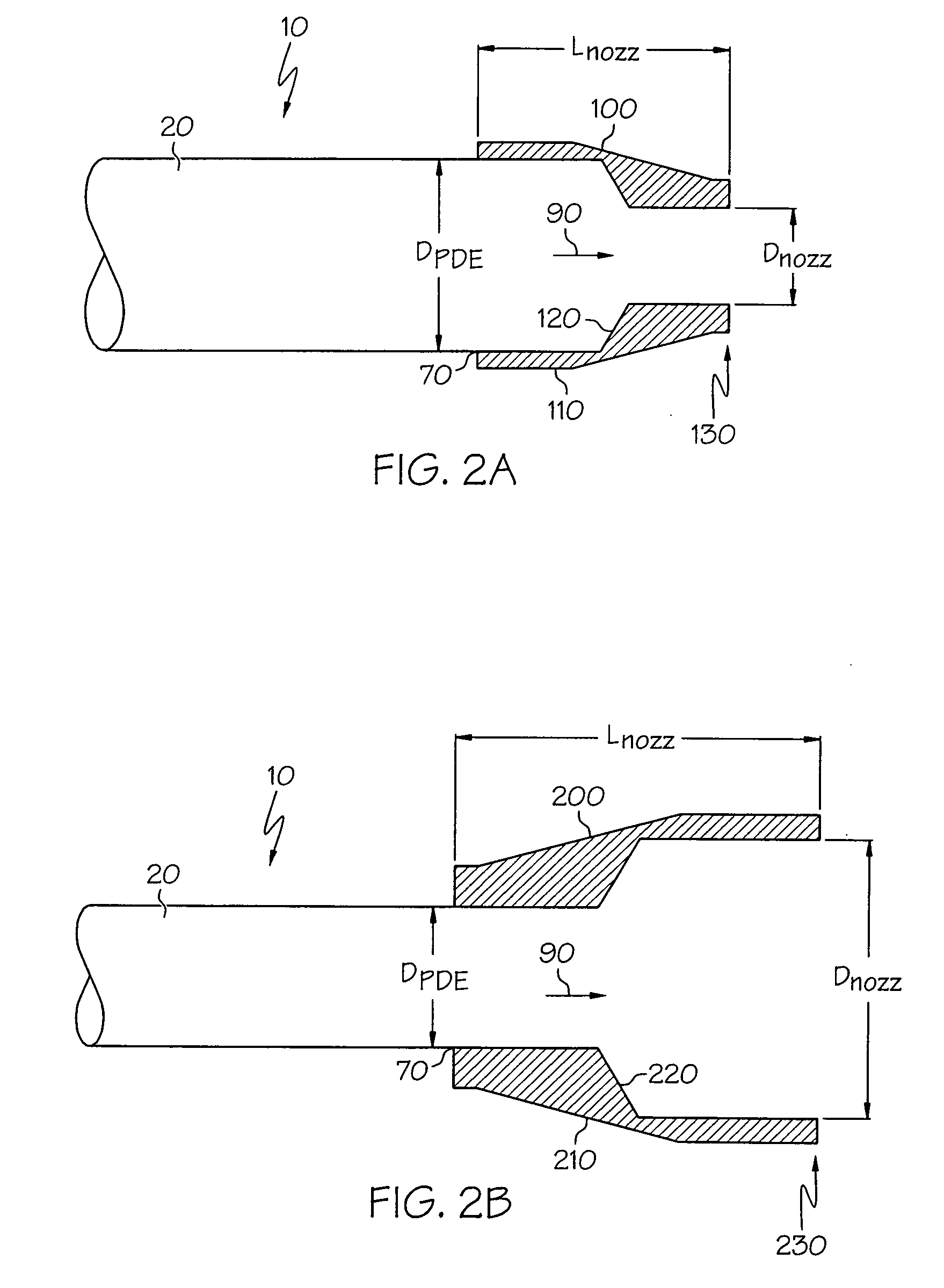

Performance improvements for pulse detonation engines

InactiveUS20090320446A1Reduce noiseImprove performanceEngine manufactureEngine fuctionsEquivalence ratioNoise reduction

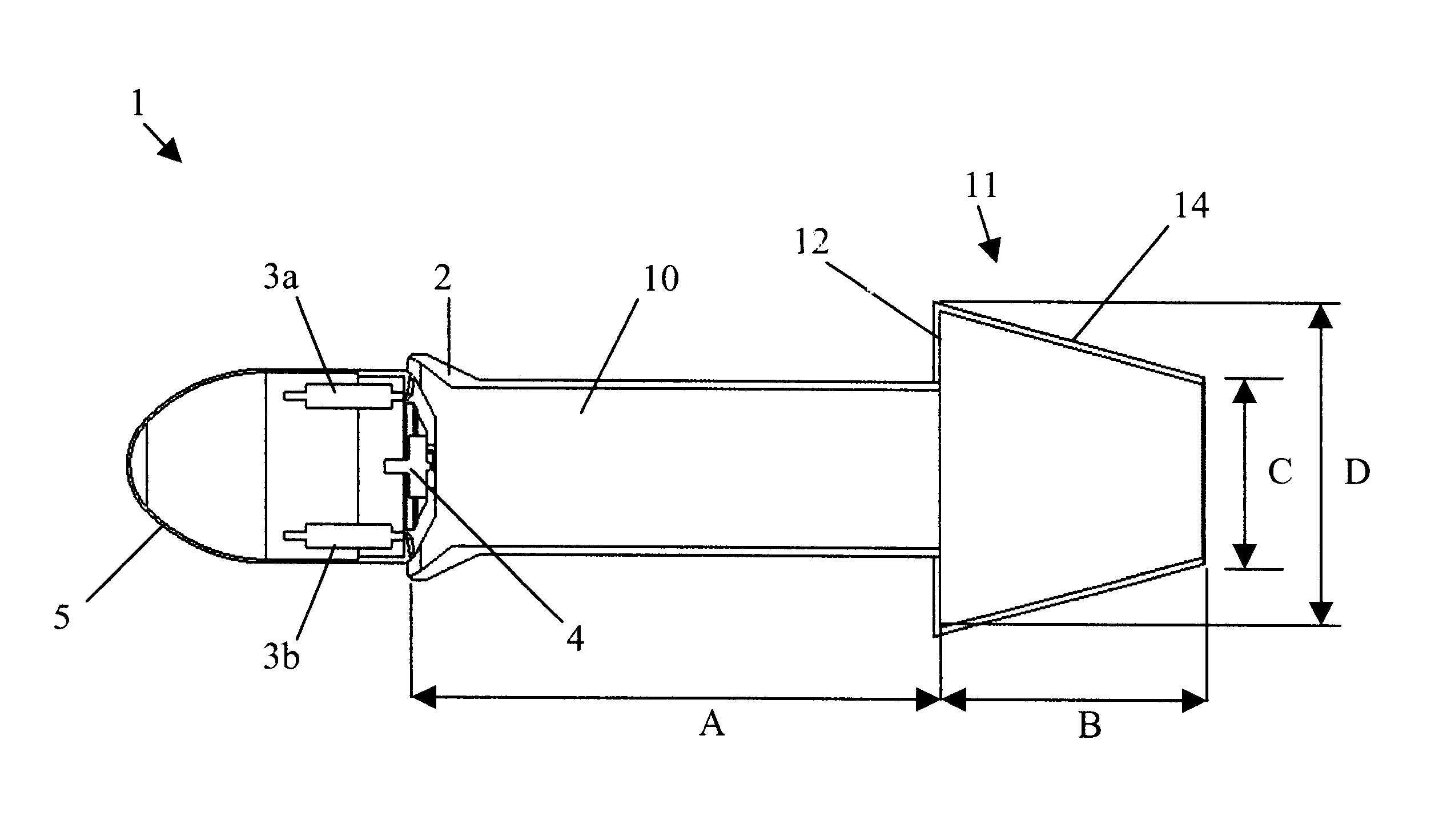

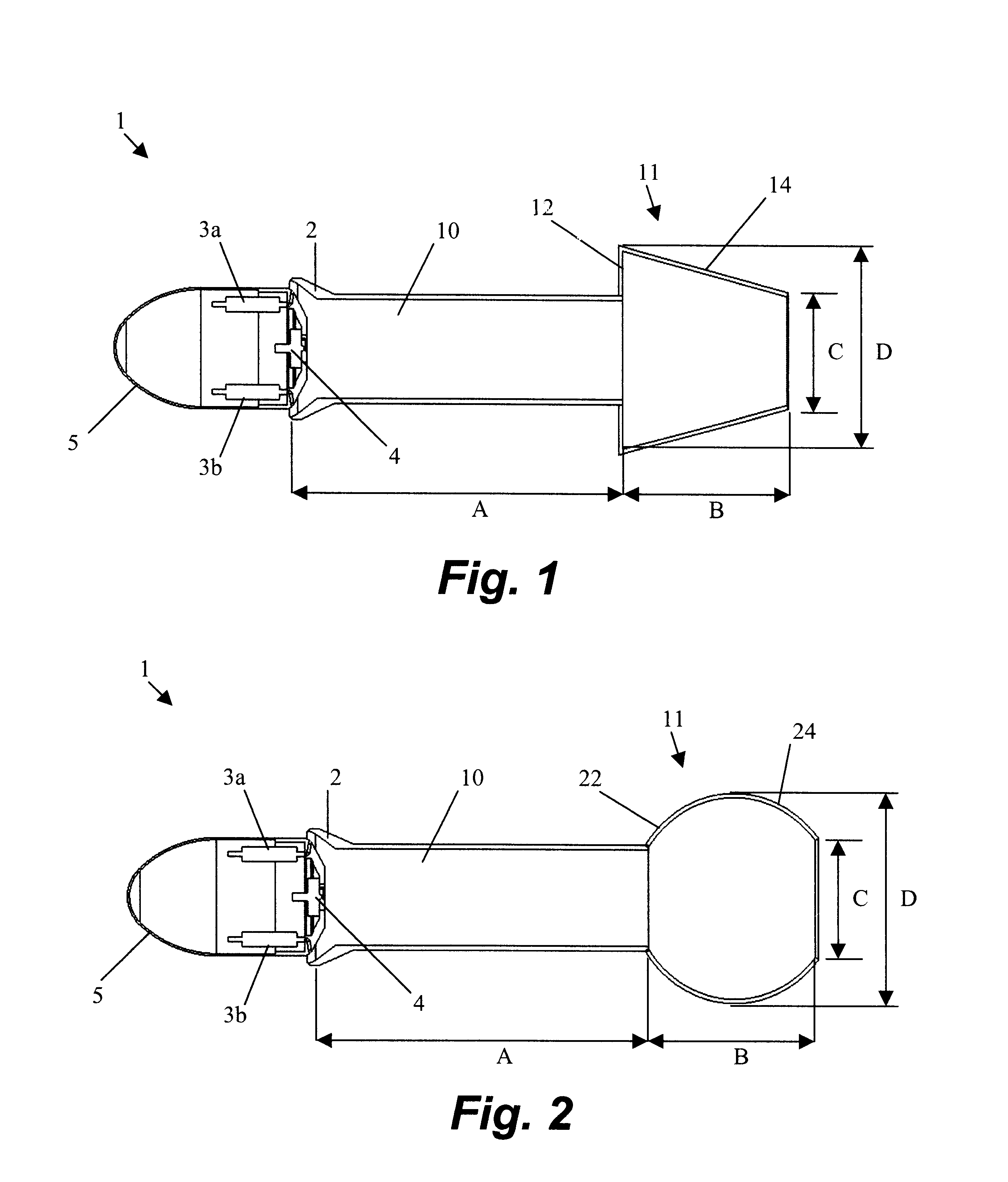

A device and method for improving the performance of a pulse detonation engine. The device includes at least one of an exhaust structure and an ejector. The exhaust structure can be configured as a straight, converging or diverging nozzle device, and connected to the engine to control the flow of a primary fluid produced during a detonation reaction. The ejector is fluidly coupled to the engine, using the movement of the primary fluid to promote entrainment of a secondary fluid that can be mixed with the primary fluid. The secondary fluid can be used to increase the mass flow of the primary fluid to increase thrust, as well as be used to cool engine components. Device positioning, sizing, shaping and integration with other engine operating parameters, such as fill fraction, choice of fuel and equivalence ratio, can be used to improve engine performance. In addition to thrust augmentation and enhanced cooling, the disclosed device can be used for engine noise reduction.

Owner:UNIVERSITY OF CINCINNATI

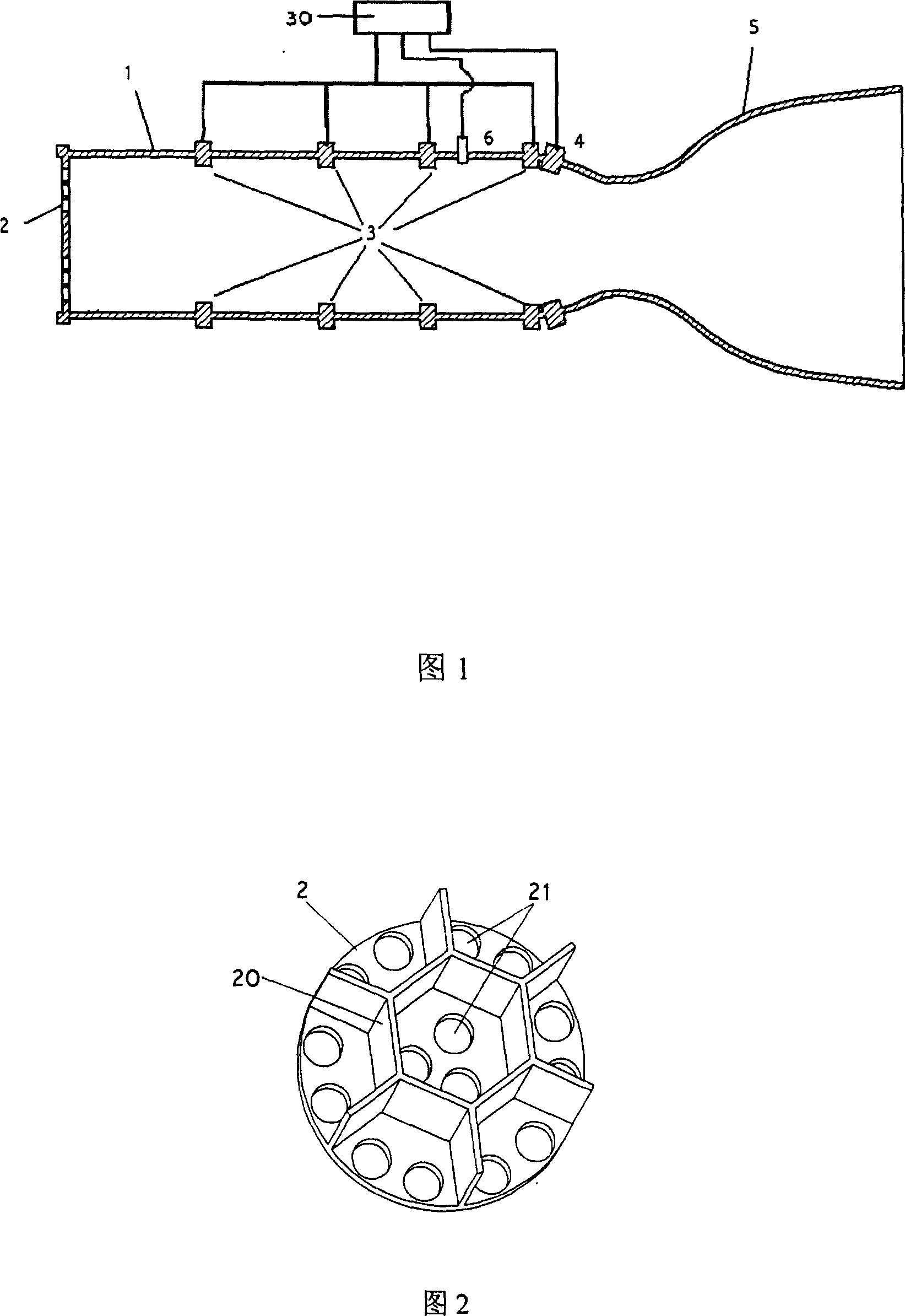

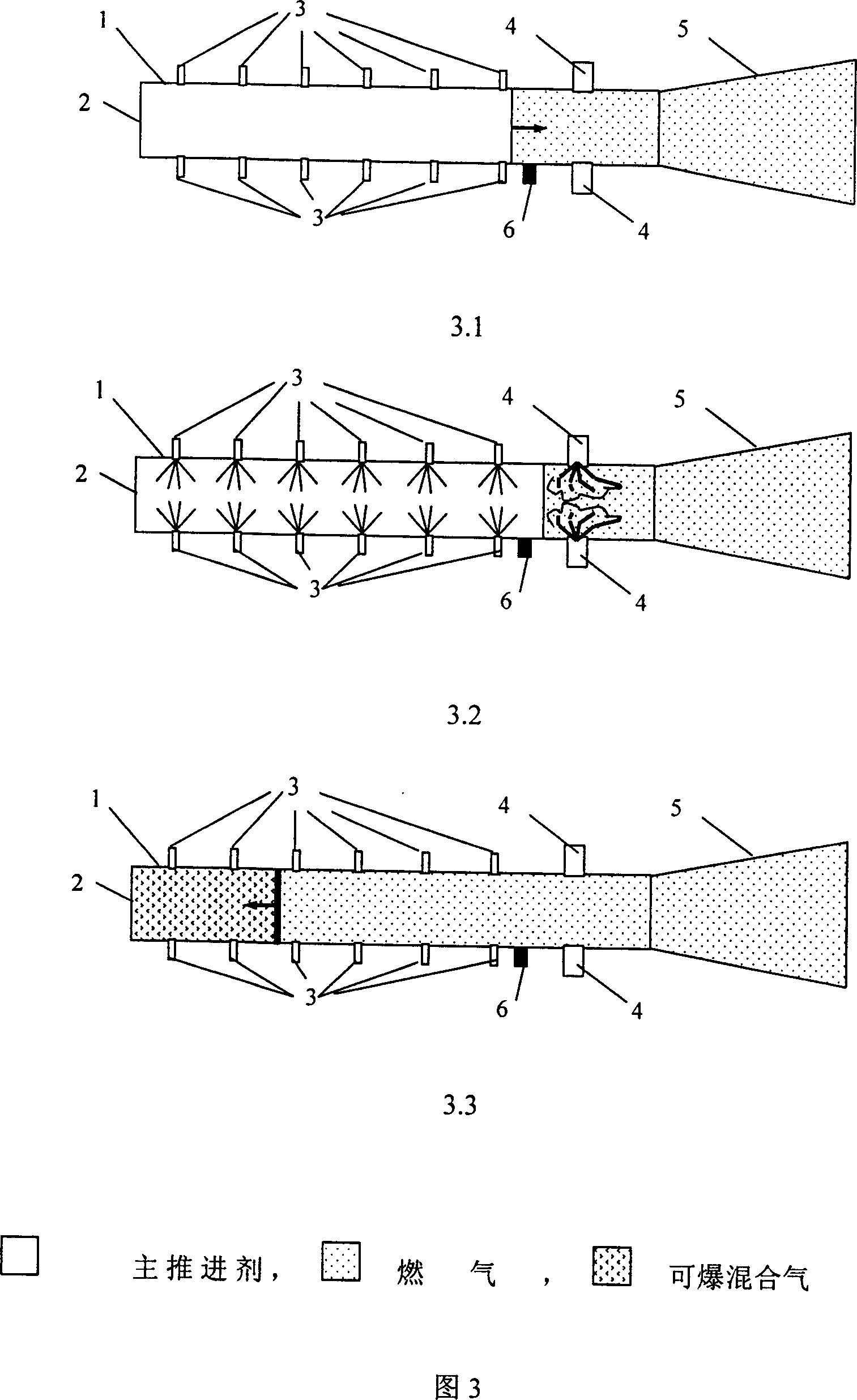

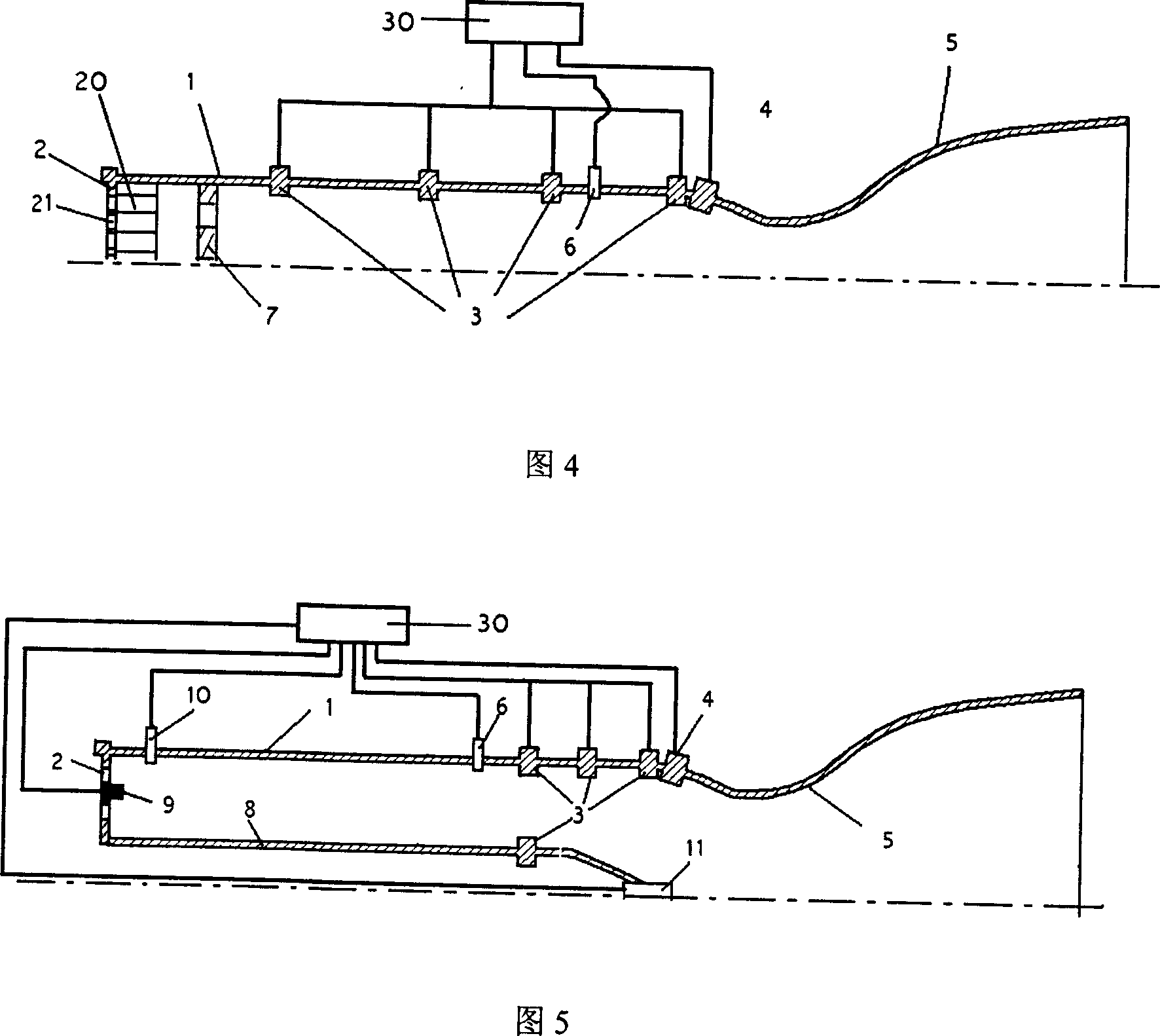

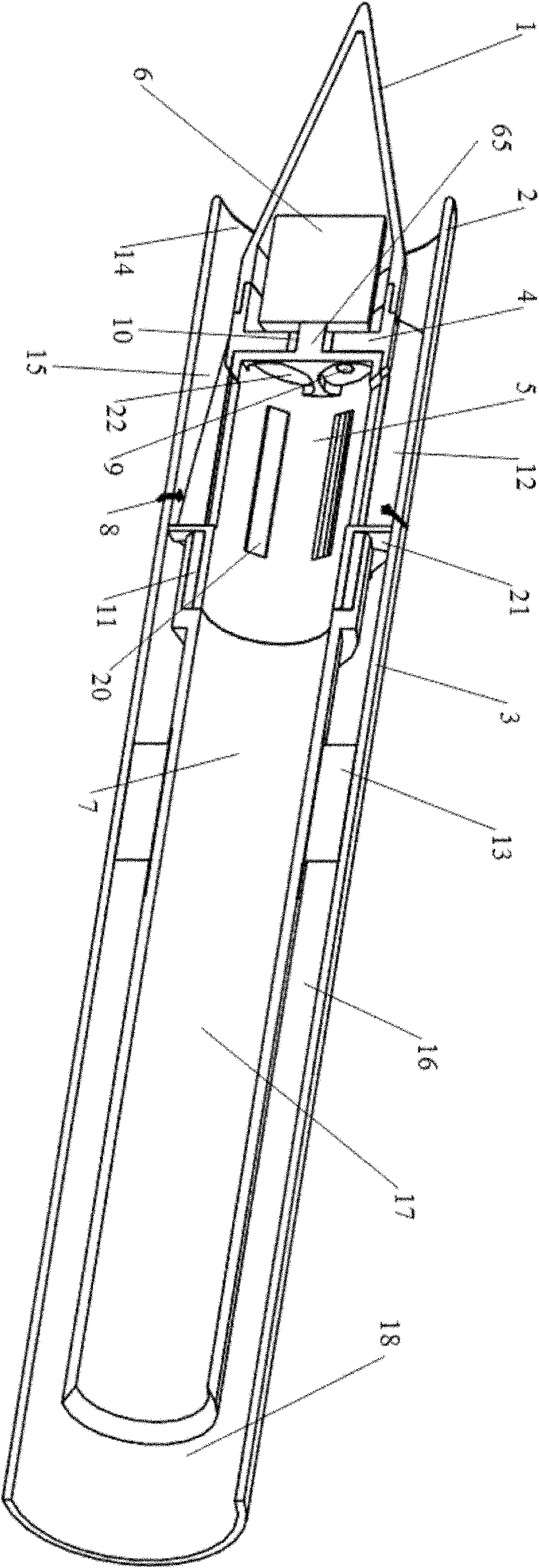

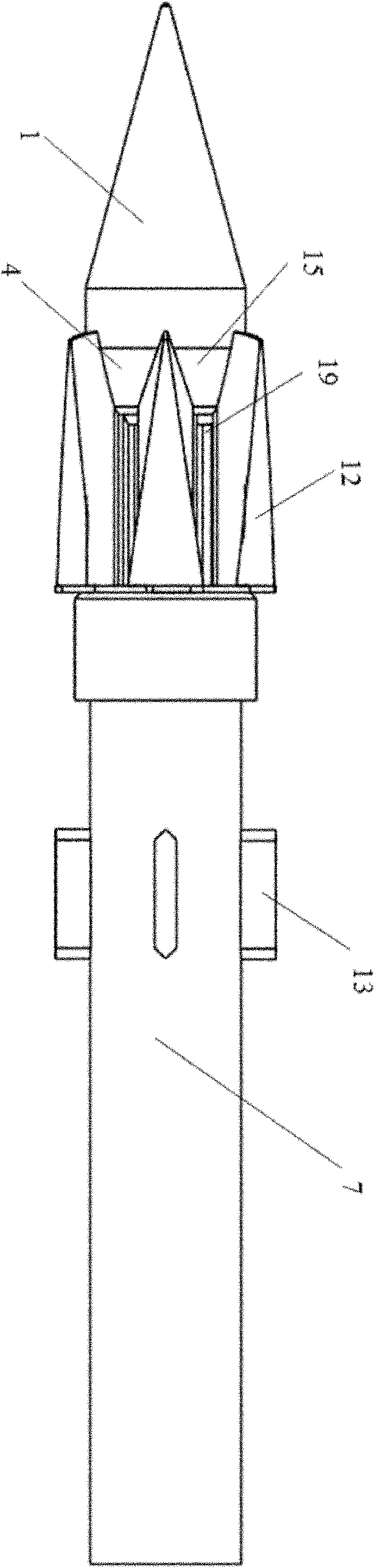

High-frequency pulse pinking engine and control method thereof

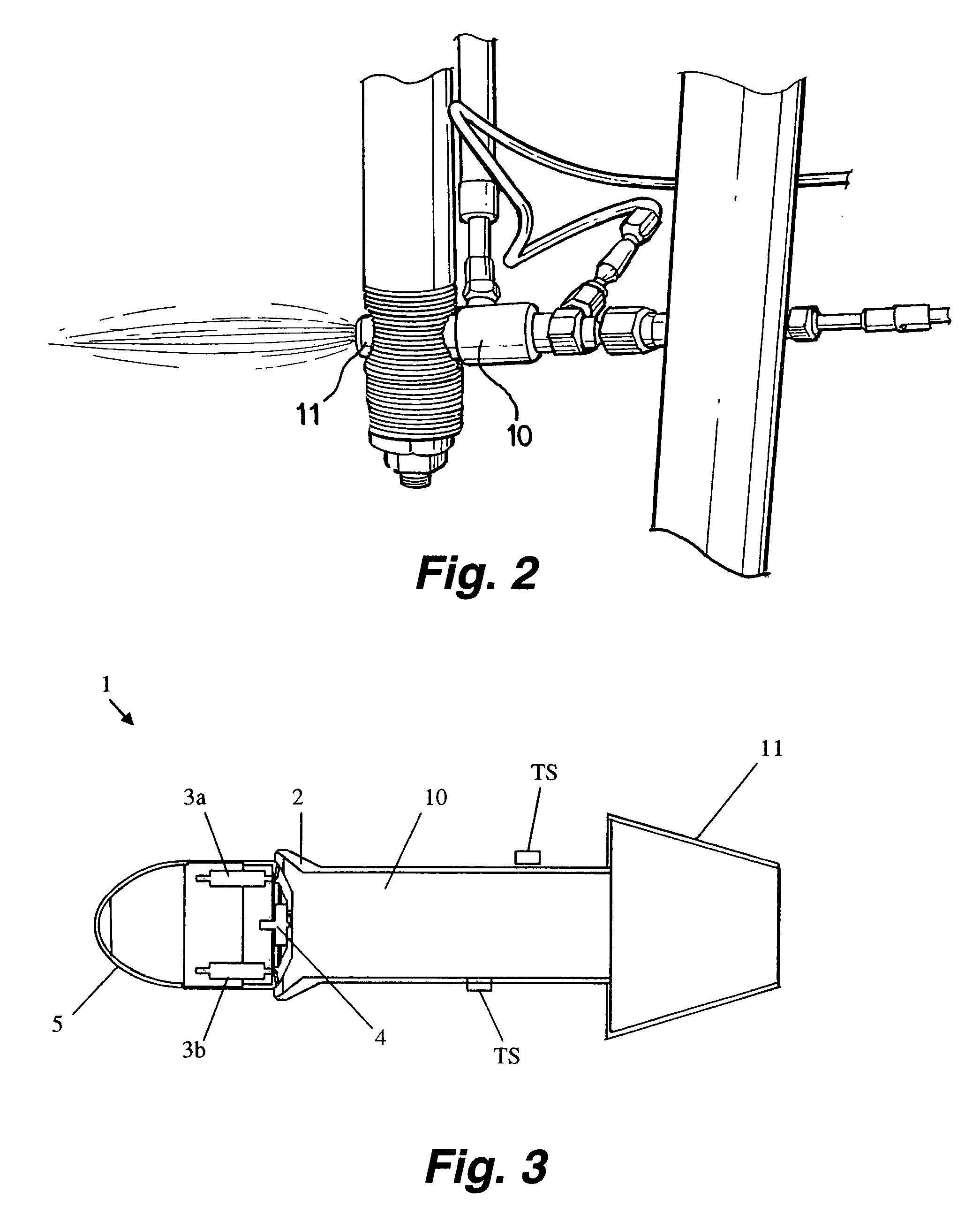

InactiveCN101012786AIncrease working frequencyHigh energy and high working frequencyRocket engine plantsCombustion chamberHigh energy

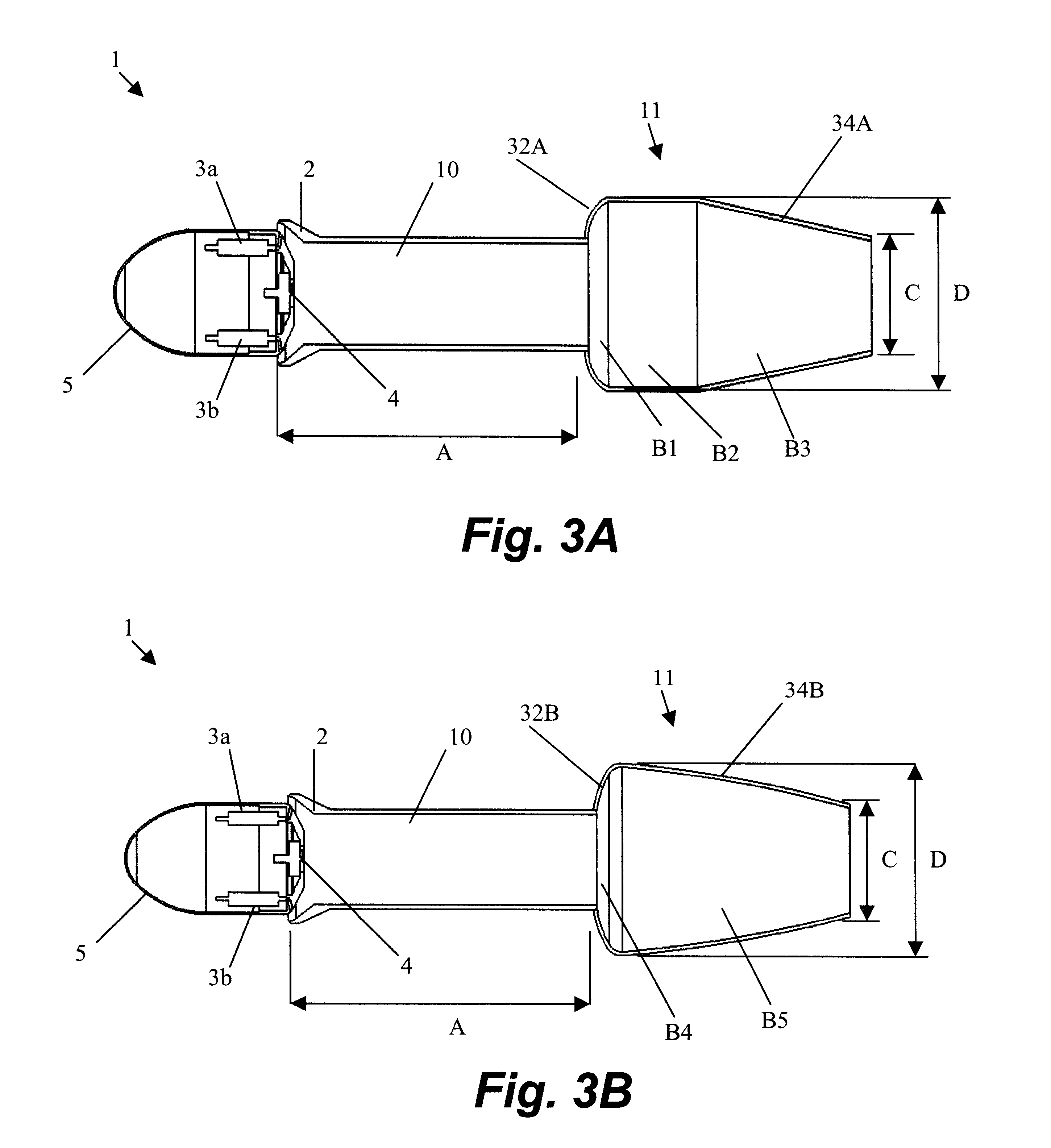

The invention relates to a pulse detonation engine with high frequency and the control method. The engine comprises combustor shell 1, jet panel of main propellant 2, nozzle of side secondary propellant 3, detonation assistant nozzle 4, jet pipe 5, post sensor 6 and control cell 30. The main propellant can be jetted out from the jet panel of main propellant 2 in high pressure and high speed. When the interface of main propellant and high-temperature fired gas spreads to the downstream of combustor, the secondary propellant is jetted in from the nozzle 3 and hypersensitivity detonation mixed gas is jetted from the detonation assistant nozzle 4 to detonate; the detonation wave is formed upwards to spread and then the high-temperature gas in combustor expands outward rapidly; when the pressure in combustor is decreased to the jetting total pressure of main propellant, the main propellant is jetted again. According to it the invention obtains the pulse detonation engine with very high working frequency and full development for detonation wave, which does not depend on the pulse firing system with high energy and high frequency and the isolating gas system. The gas drainage noise can be decreased in a large scale.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Multiple tube pulse detonation engine turbine apparatus and system

Owner:GENERAL ELECTRIC CO

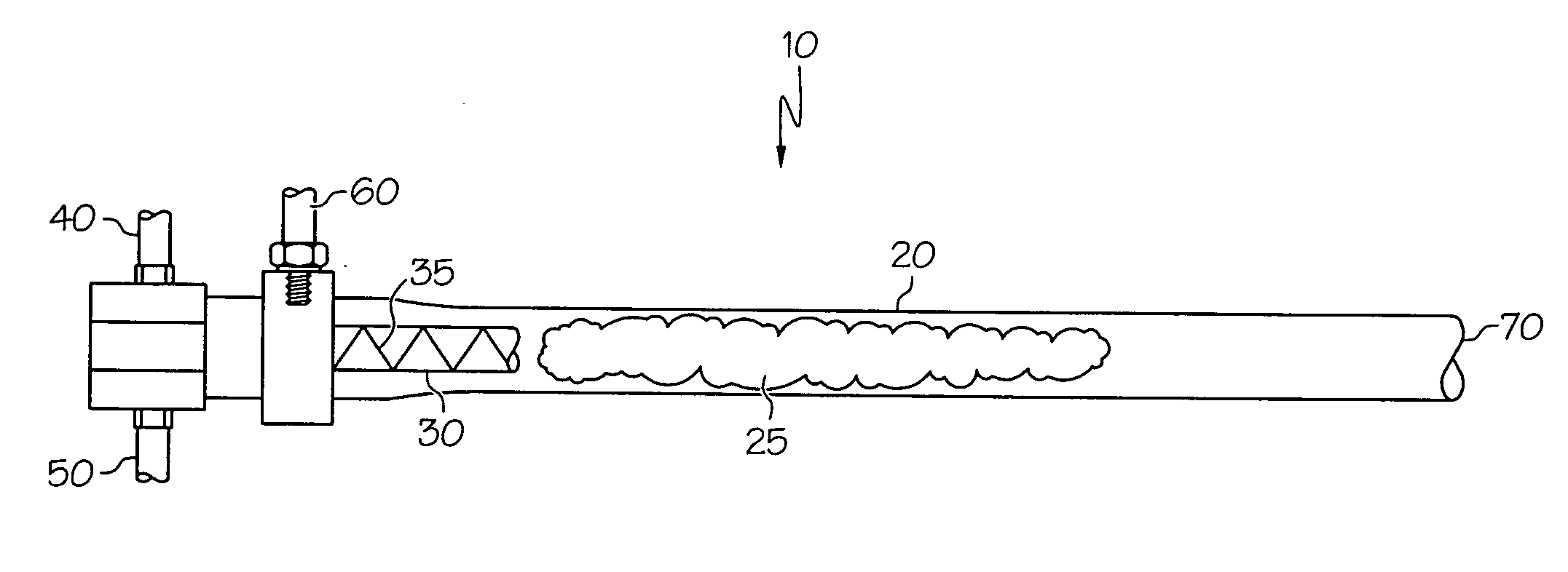

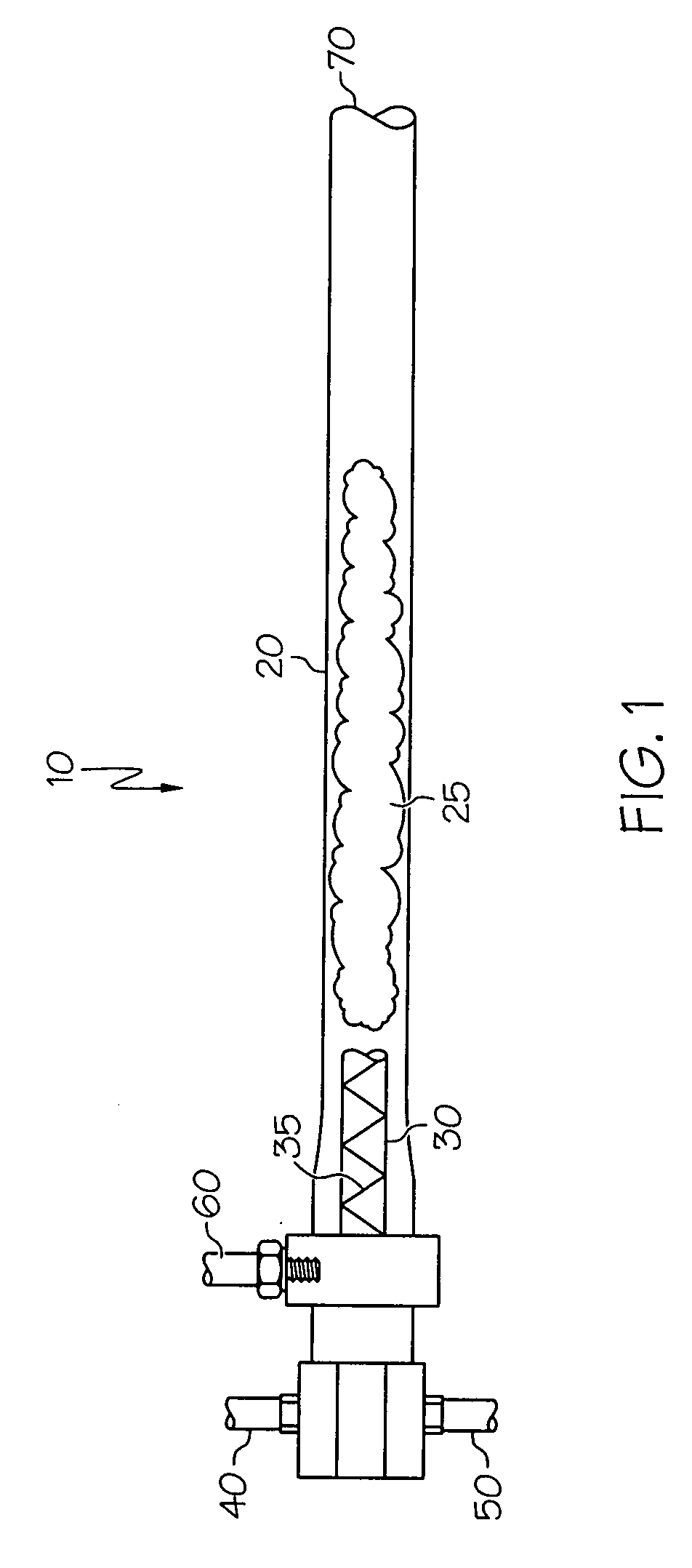

Method and apparatus for improving the efficiency of pulsed detonation engines

InactiveUS6662550B2Improve efficiencyShort and more compactTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionPulse detonation engineNozzle

A pulsed detonation engine having improved efficiency has a detonation chamber for receiving a detonable mixture, an igniter for igniting the detonable mixture, and an outlet for discharging detonation products. A diverging-converging nozzle is provided at the outlet of the detonation chamber. The geometry of the diverging-converging nozzle is selected to enable a relatively short nozzle to significantly improve efficiency of the pulsed detonation engine.

Owner:LEIDOS

Methods and apparatus for controlling air flow within a pulse detonation engine

ActiveUS7980056B2Turbine/propulsion fuel supply systemsTurbine/propulsion engine coolingStream flowAirflow

A flow control device for use with a pulse detonation chamber including an inlet coupled in flow communication with a source of compressed air. The inlet extends at least partially into the chamber to facilitate controlling air flow into the chamber. The device also includes a body portion extending downstream from and circumferentially around the inlet, wherein the body portion is positioned in flow communication with the inlet.

Owner:GENERAL ELECTRIC CO

Multitube valveless pulse detonation engine

ActiveUS9359973B2Minimizes back pressureReduce impactPulsating combustionGas turbine plantsShock waveEngineering

Disclosed herein is a valveless multitube pulse detonation engine including: a plurality of detonation tubes, wherein each detonation tube comprises an independent discharge outlet, and the plurality of detonation tubes interconnected at a common air / fuel mixture intake port. In the disclosed engine, an air and fuel mixture is detonated in the detonation tubes simultaneously, and the common air / fuel mixture intake port minimizes back-pressure caused by detonating the air / fuel mixture by directing multiple reverse shock waves into one another and effectively using the back-pressures as reacting surfaces for one another and effectively reducing the effect of back flowing shock waves moving towards upstream. The detonation tubes may be non-linear, and may have independent discharges. The independent discharges may be coupled to an adapter nozzle terminating in a combined exhaust outlet.

Owner:EXPONENTIAL TECHNOLOGY

Pulsed detonation engines manufactured from materials having low thermal stability

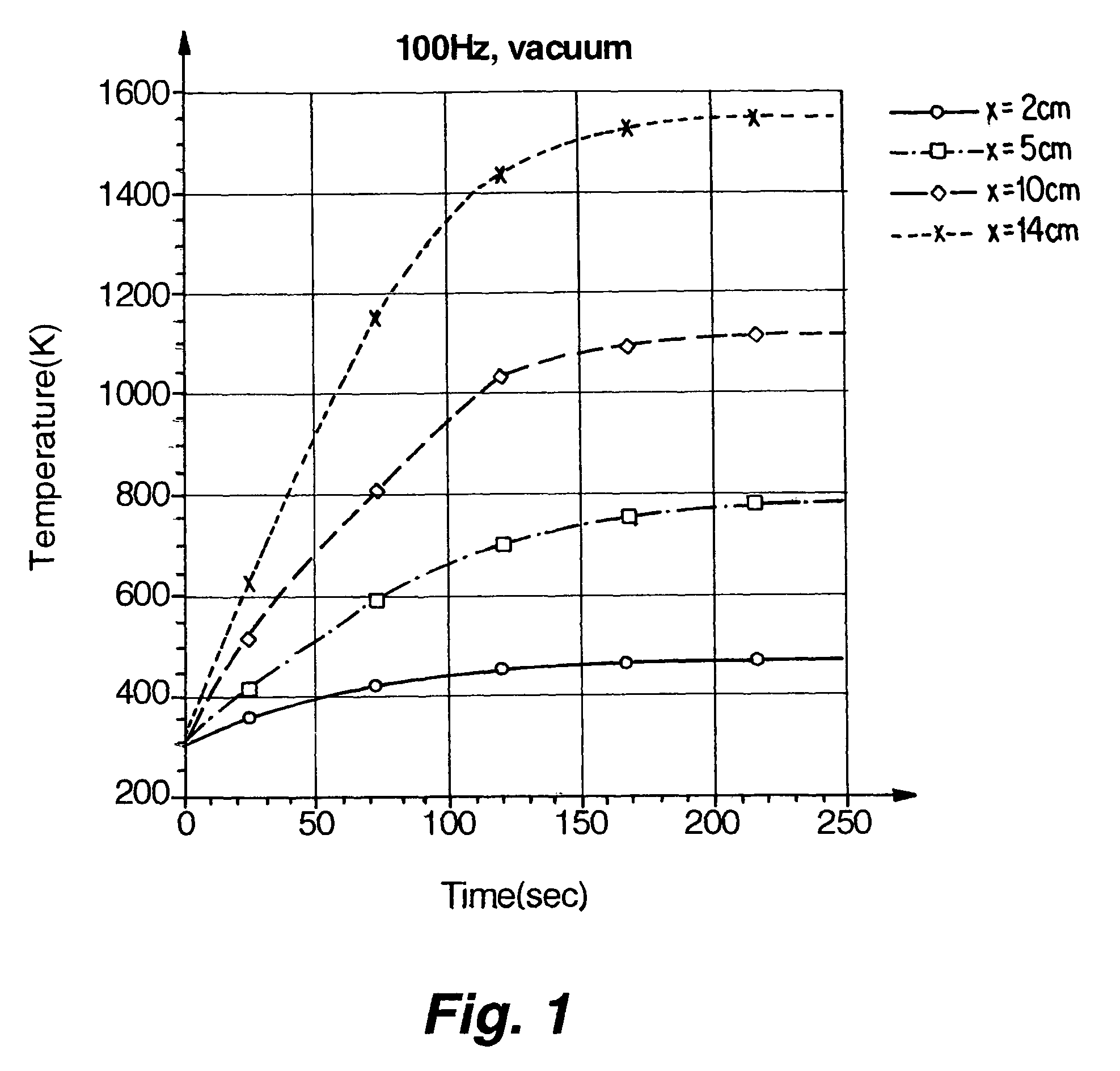

ActiveUS7735311B2Solve the stability is not highPromotes relative motionAircraft navigation controlAircraft power plantsEngineeringThermal stability

Pulsed detonation engines (PDEs), or various components thereof, such as the detonation chamber and / or nozzle, can be economically constructed from materials having low thermal stability, such as plastics, composites, and light metals. During operation, the intermittent injection and detonation of reactants produces a motive force (e.g., thrust) over relatively short intervals useful in orbit control and the like. The relatively short intervals of operation prevent temperatures of the PDE components from reaching temperatures that would result in their dimensional failure.

Owner:LEIDOS +1

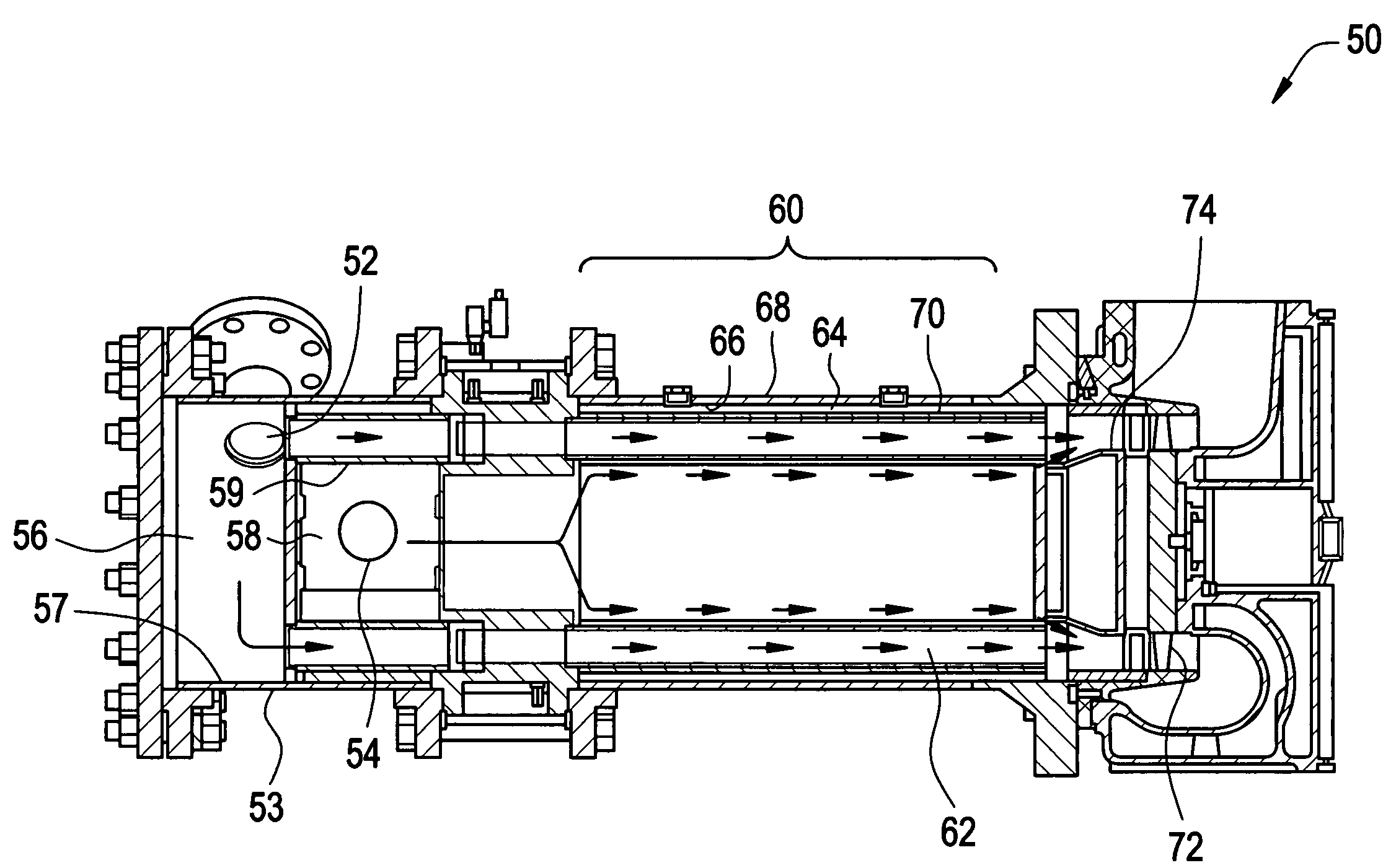

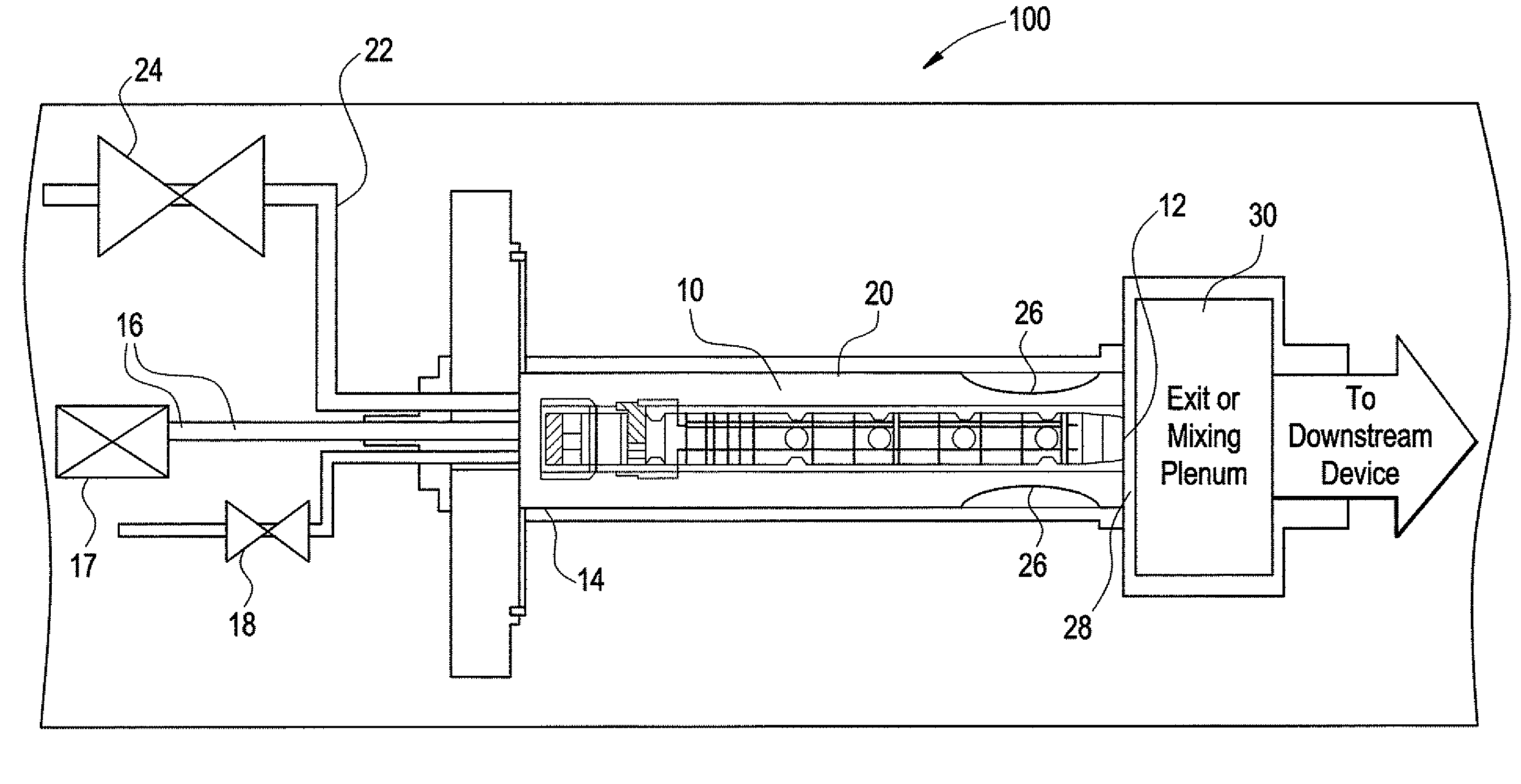

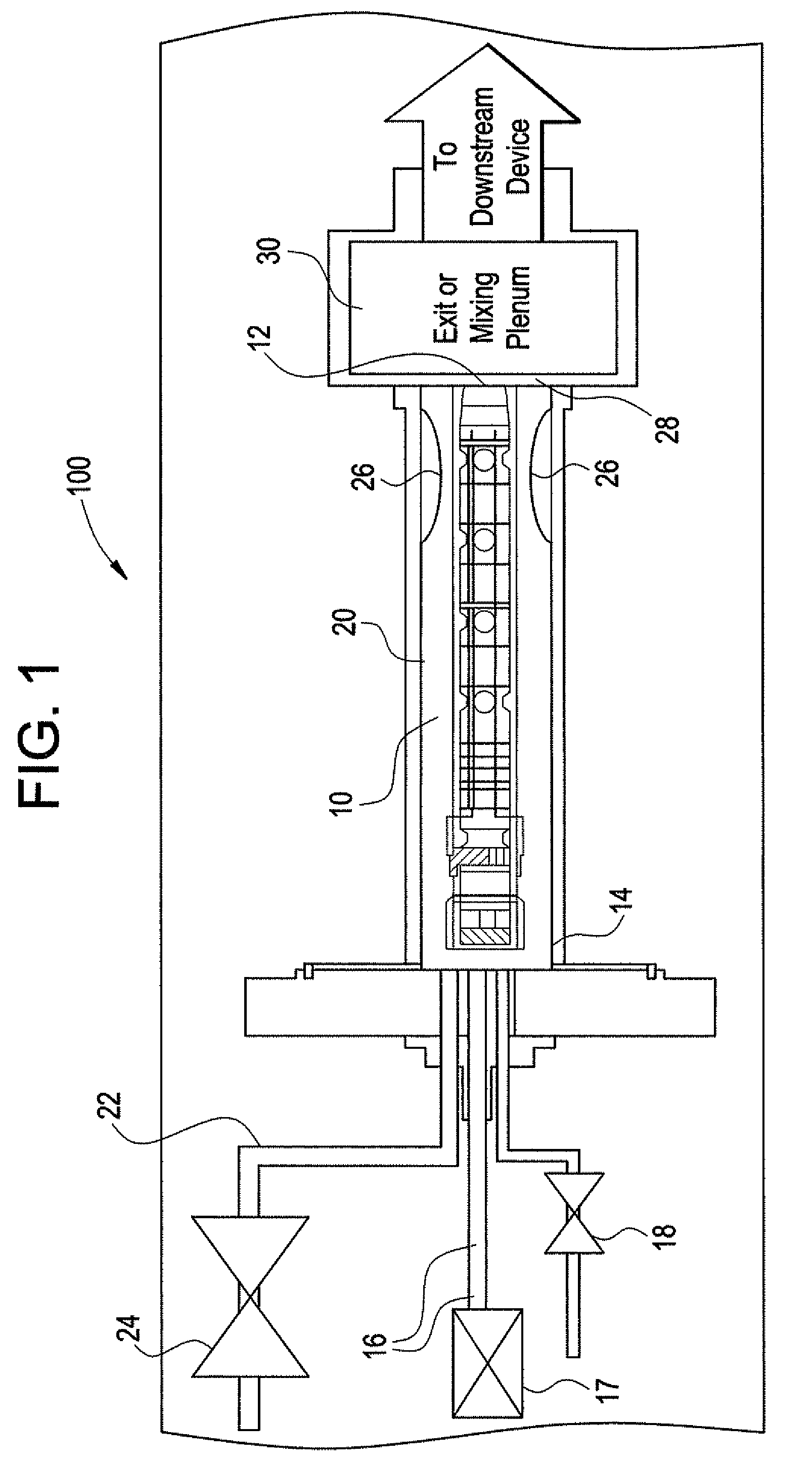

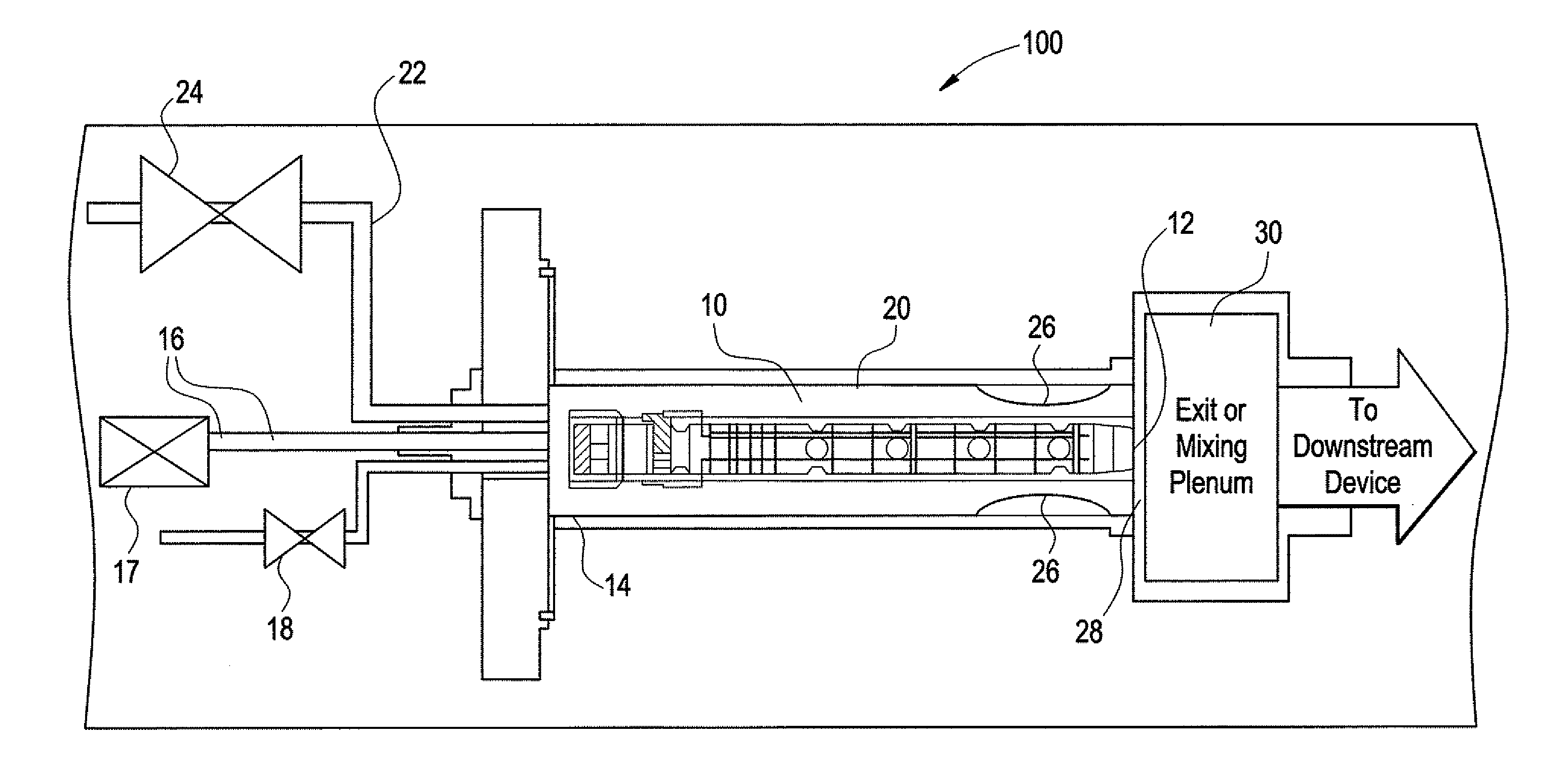

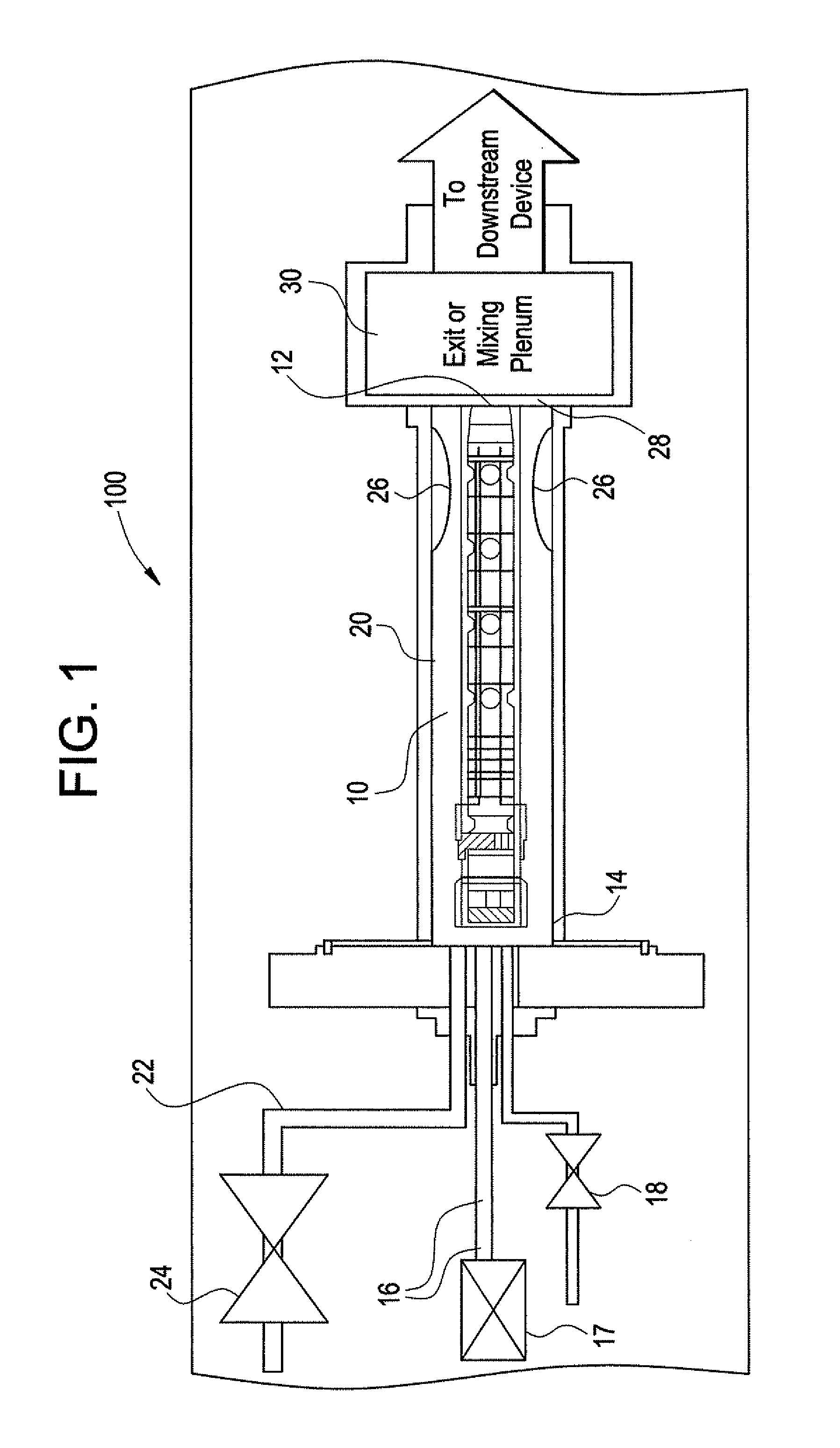

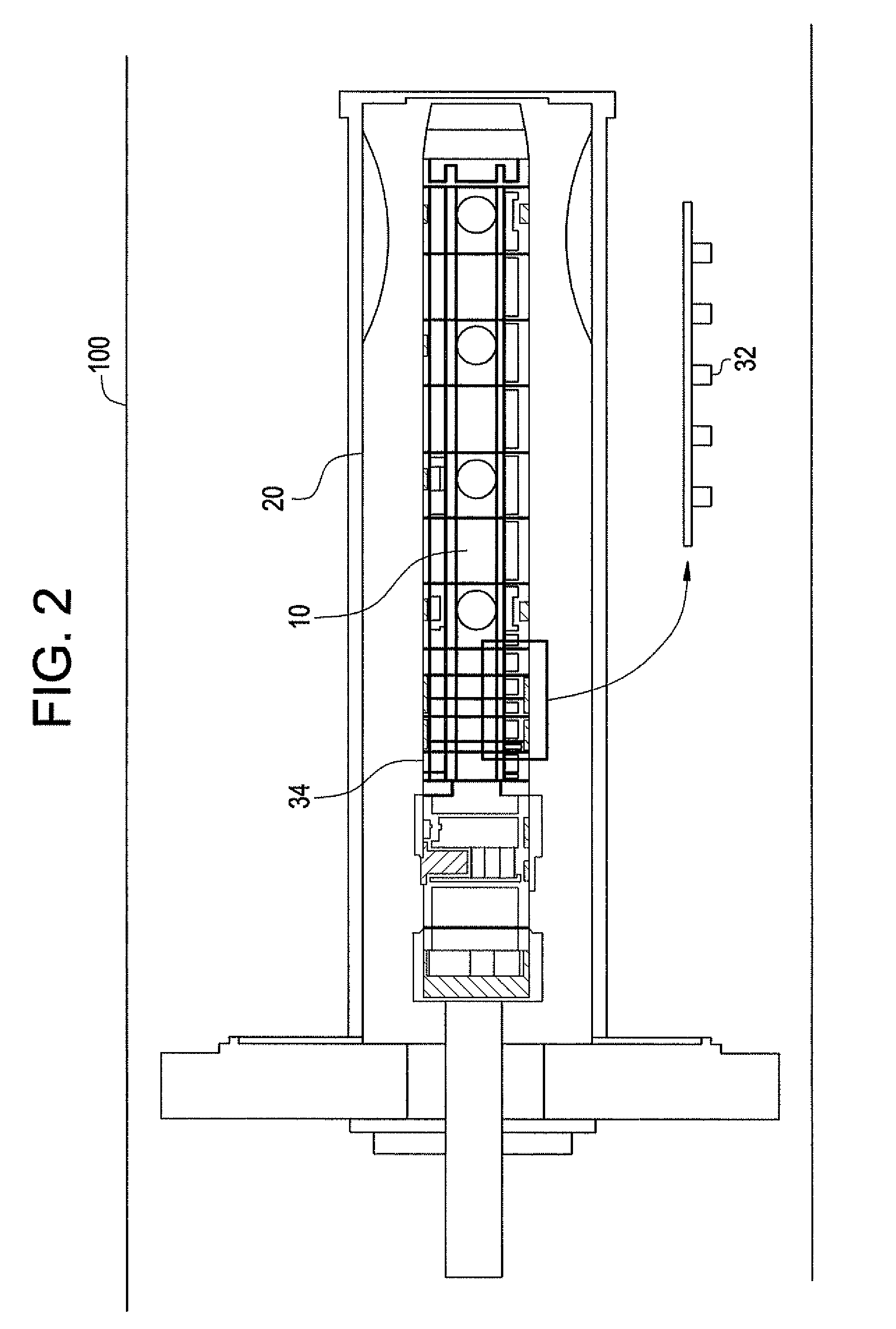

Pulse detonation engine bypass and cooling flow with downstream mixing volume

InactiveUS7841167B2Preventing back flow (and the associated shock lossesWell mixedGas turbine plantsIntermittent jet plantsCombustorTurbine

An engine contains at least one pulse detonation combustor which is surrounded by a bypass flow air duct, through which bypass air flow is directed. The bypass air duct contains at least one converging-diverging structure to dampen or choke the upstream propagation of shock waves from the pulse detonation combustor through the bypass flow air duct. The bypass air also serves to cool the outer surfaces of the pulse detonation combustor. The bypass air flow is controlled in tandem with the heat release from the PDC to provide the appropriate amount of thermal energy to a downstream energy conversion device, such as a turbine. A mixing plenum is positioned downstream of the pulse detonation combustor and bypass flow air duct.

Owner:GENERAL ELECTRIC CO

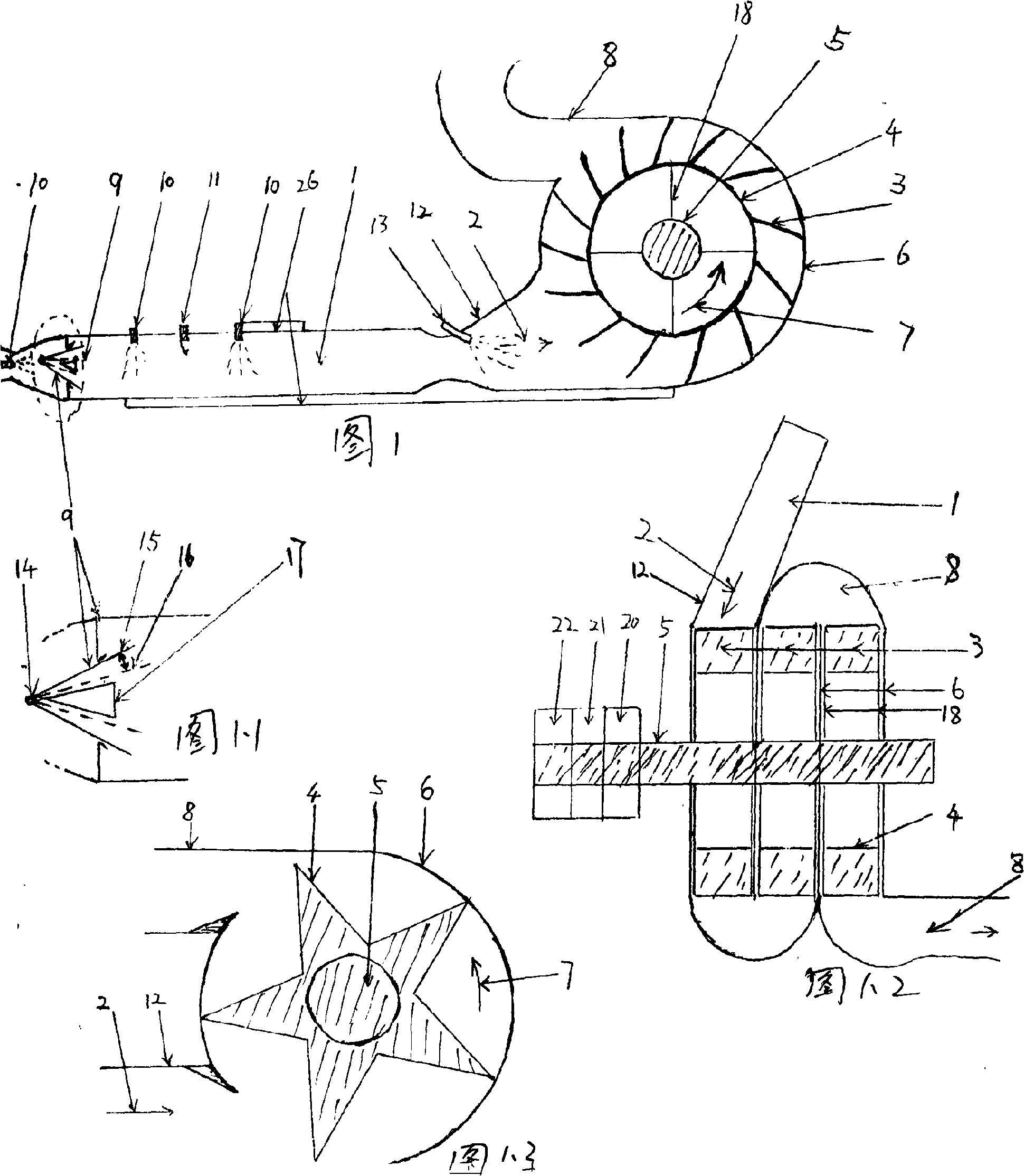

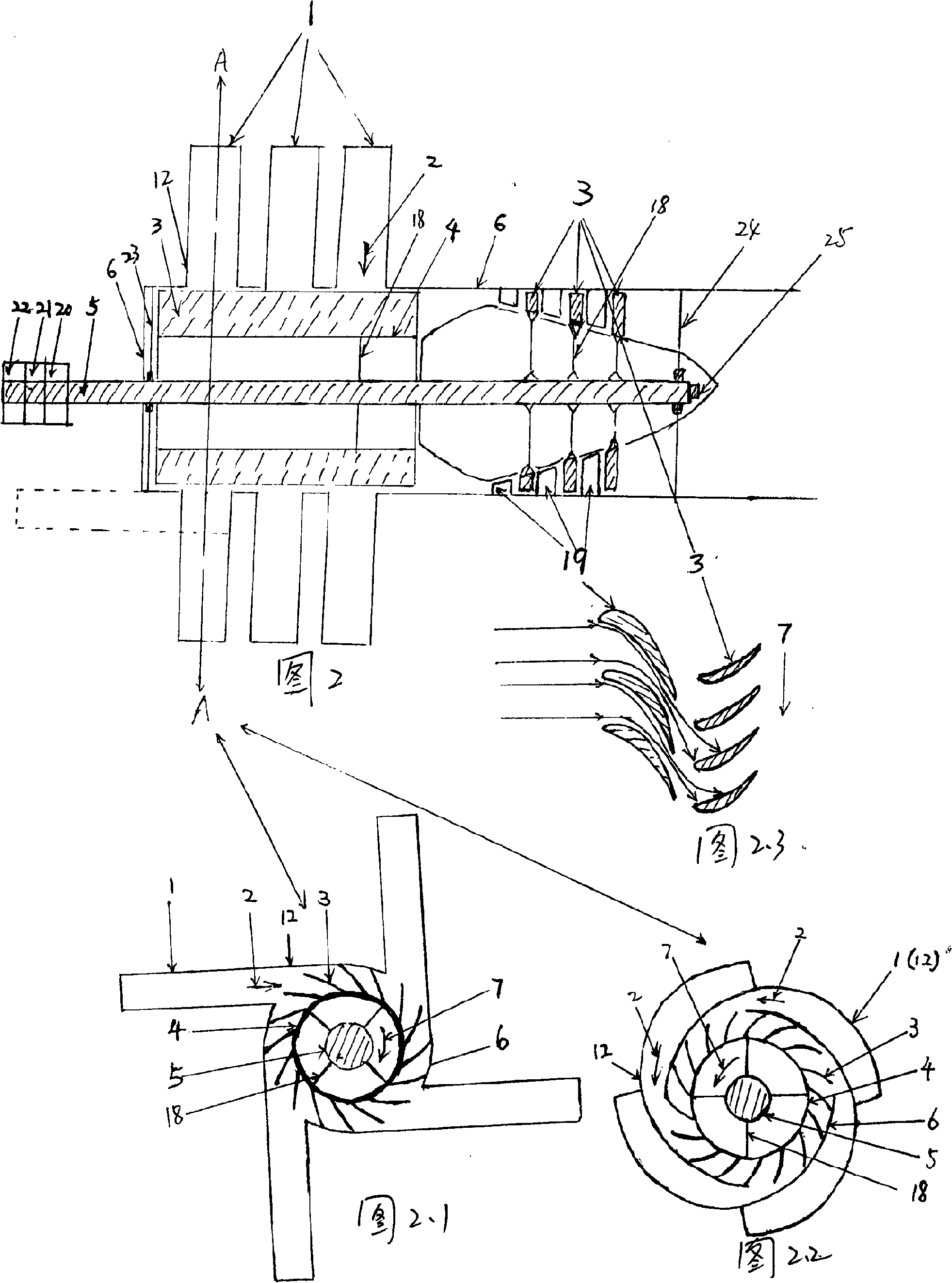

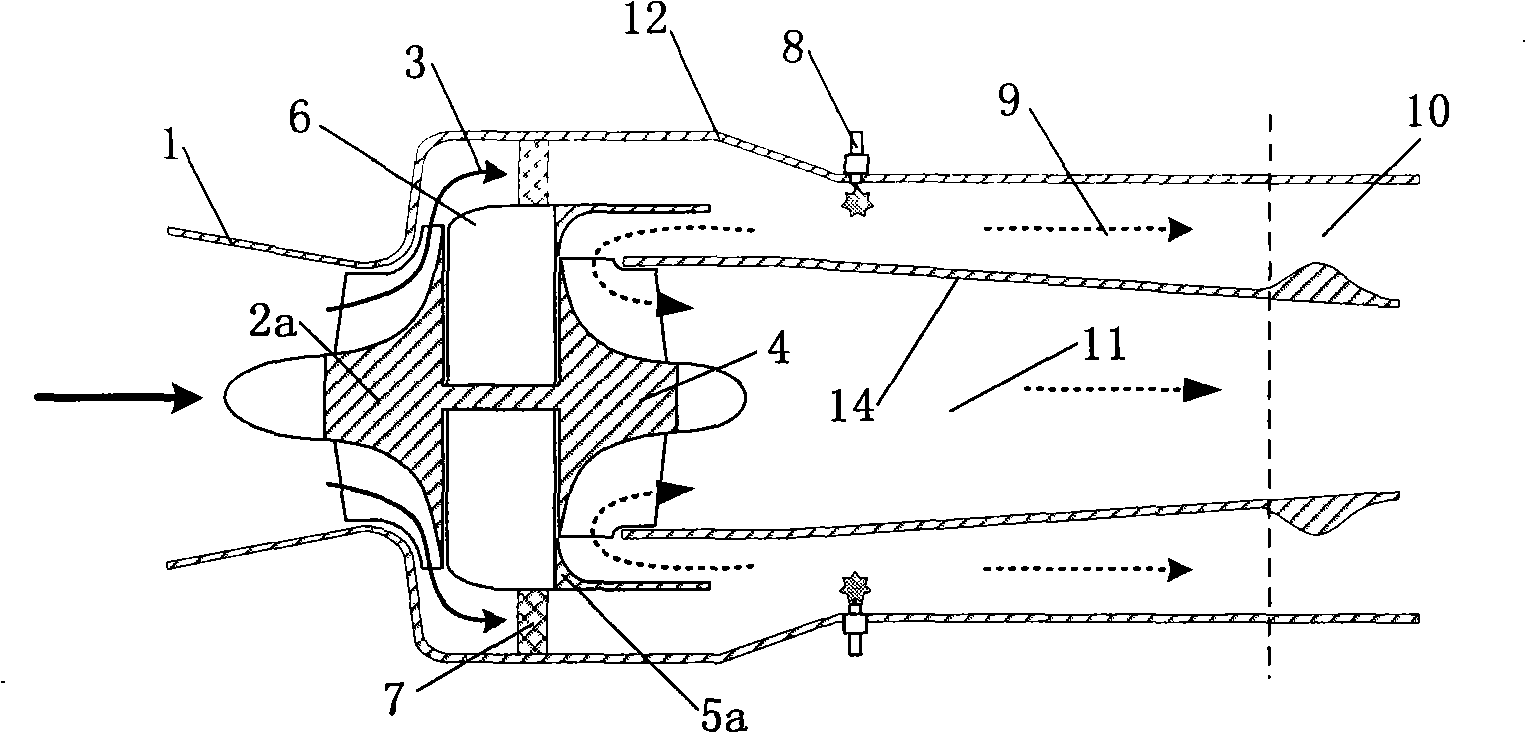

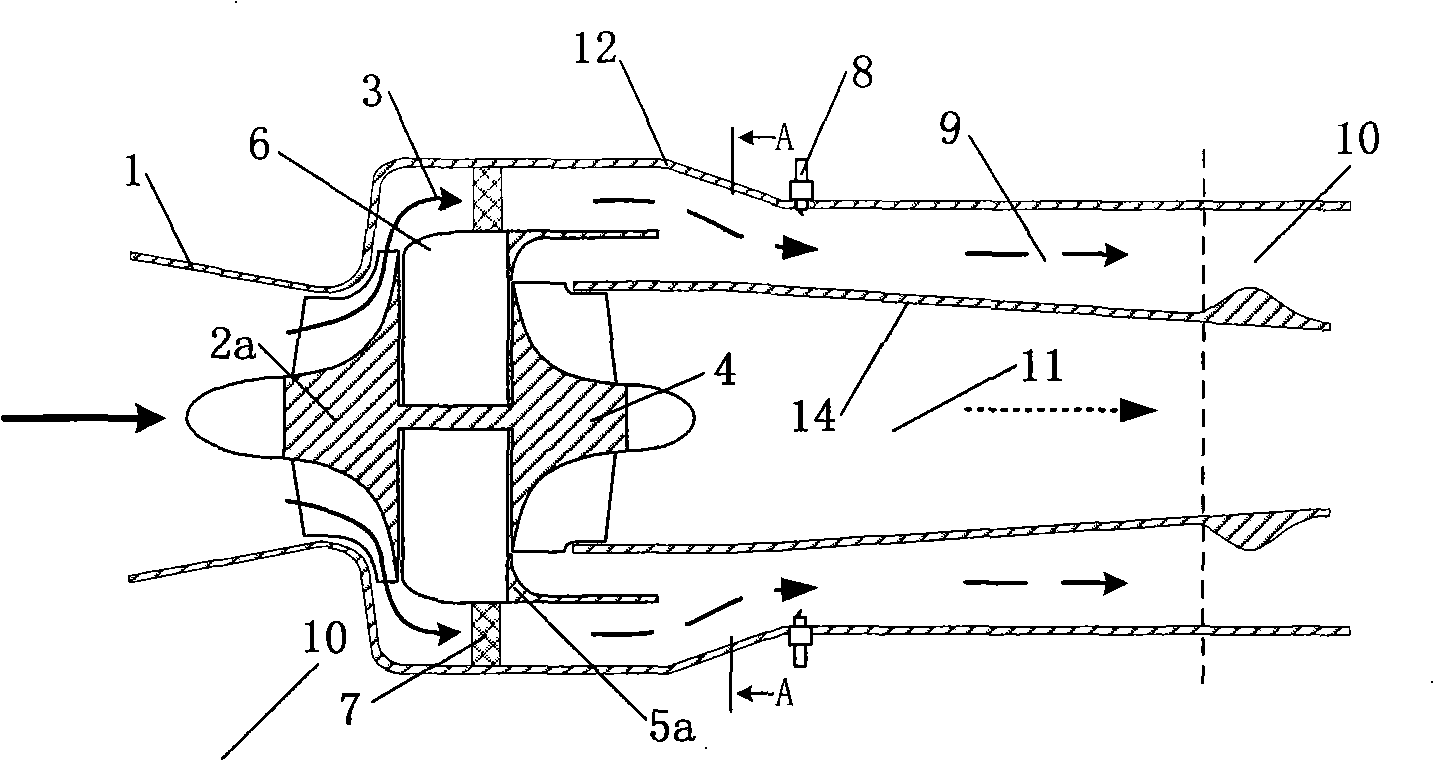

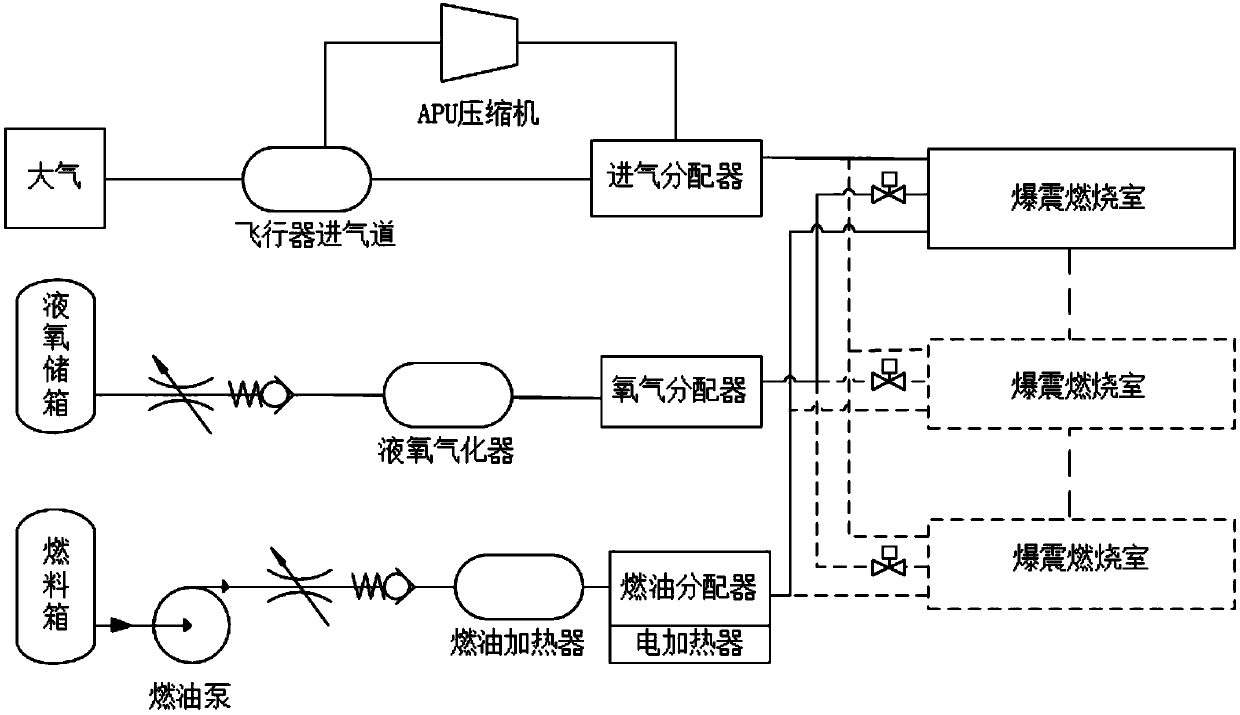

Air-breathing rotary detonation wave injection and multimode ram detonation coupled circulating propulsion system

The invention provides an air-breathing rotary detonation wave injection and multimode ram detonation coupled circulating propulsion system, and particularly relates to a ram detonation engine applied to a space plane power system. The propulsion system has an injection mode (Ma=0-2), a direct shock mode (Ma=2-6) and an oblique shock mode (Ma=6-12) during the detonation process. An annular-phase detonation wave control system of the propulsion system is capable of controlling different modes of a detonation combustion chamber and regulation and switching among the different modes and full propulsion vector regulation of a tail pipe. Propulsion of the propulsion system is increased and can be controlled simultaneously by controlling the detonation flow field through the detonation wave. Rotary detonation thermal circulation and ram power circulation are coupled into the ram detonation power circulation propulsion system structurally and functionally.

Owner:董国光

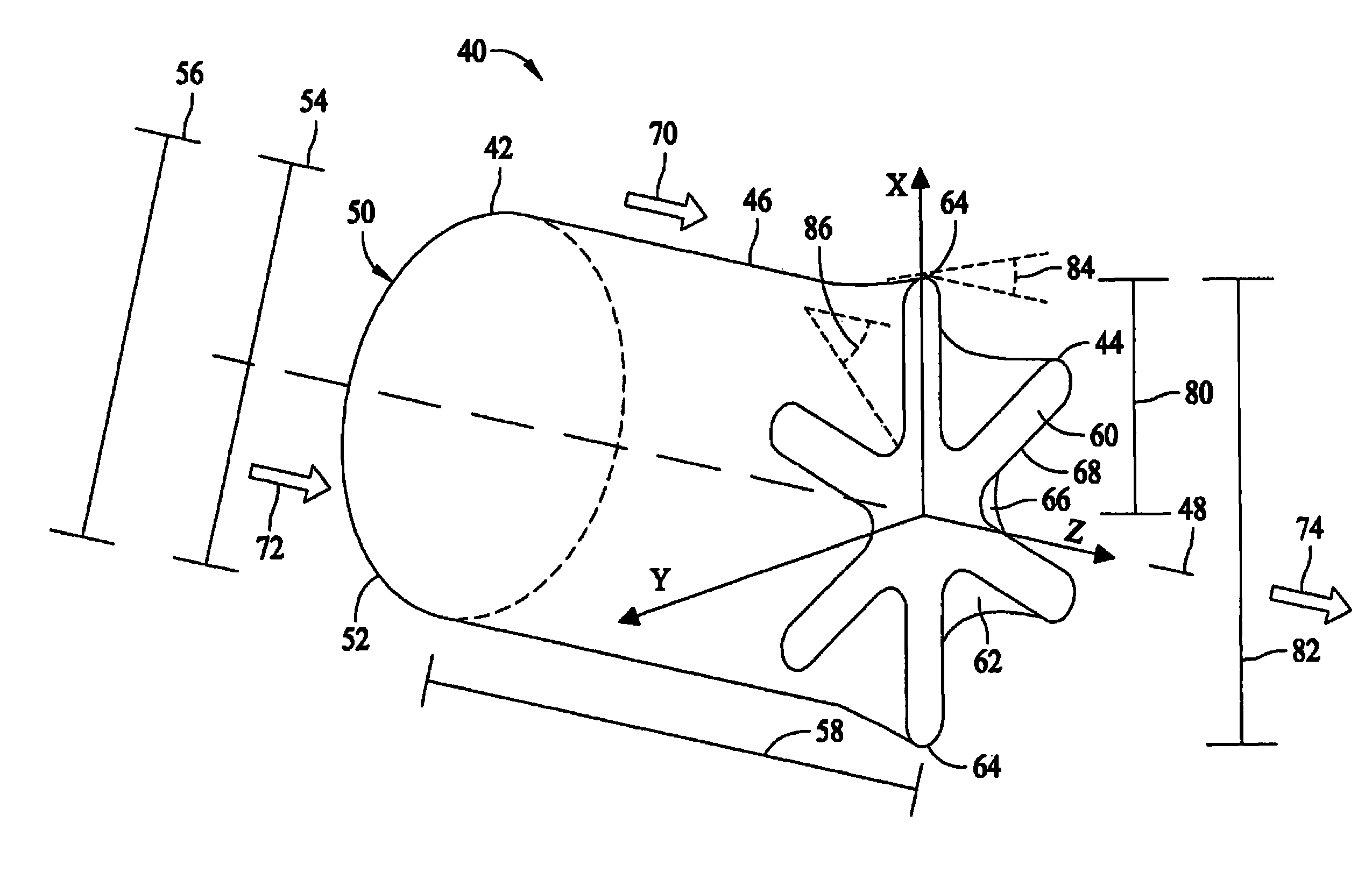

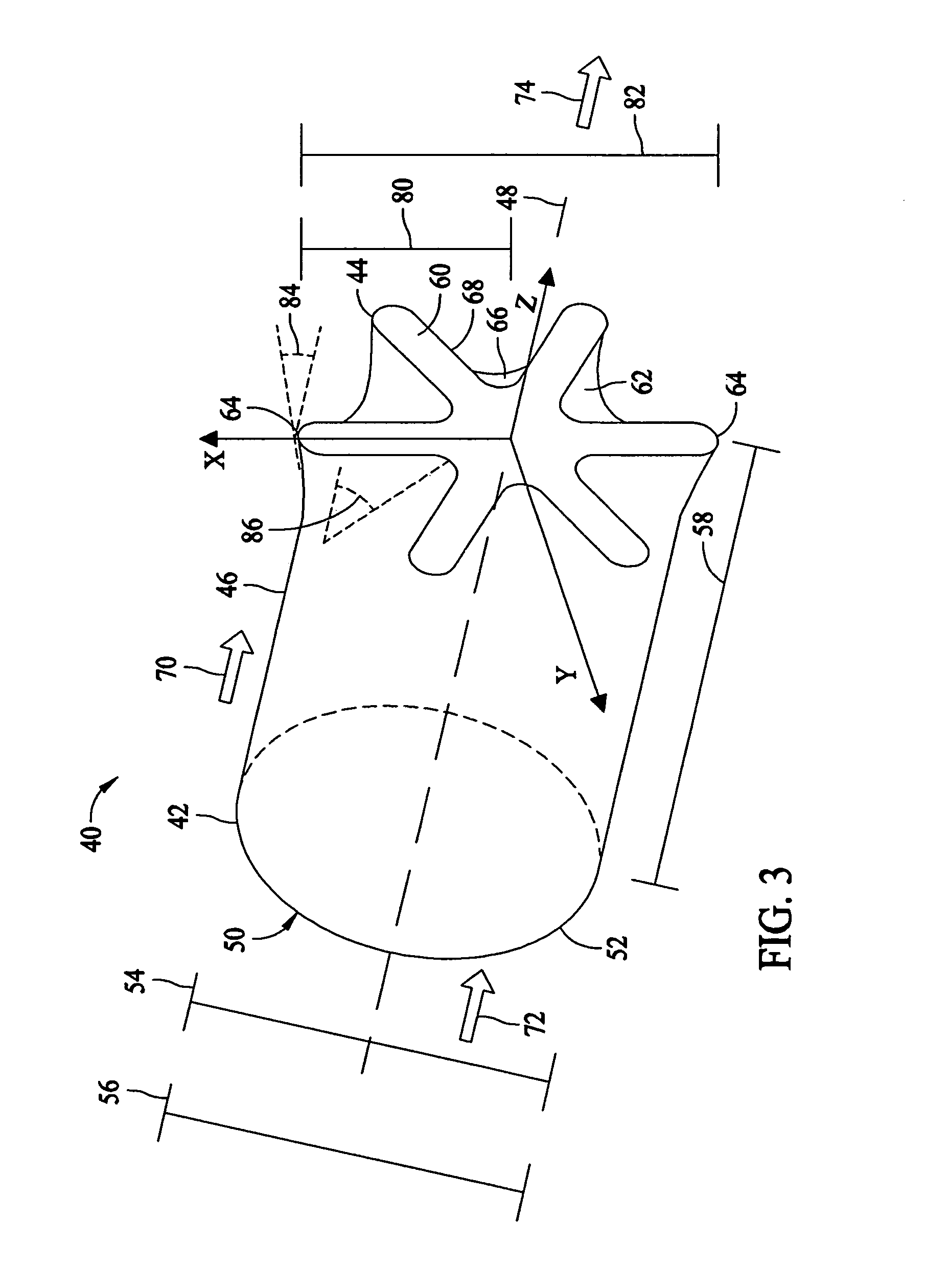

Methods and apparatus for operating a pulse detonation engine

ActiveUS7836682B2Increase air circulationSpeed up the flowGas turbine plantsJet propulsion plantsCombustorEngineering

A method for operating a pulse detonation engine, wherein the method includes channeling air flow from a pulse detonation combustor into a flow mixer having an inlet portion, an outlet portion, and a body portion extending therebetween. The method also includes channeling ambient air past the flow mixer and mixing the air flow discharged from the pulse detonation combustor with the ambient air flow such that a combined flow is generated from the flow mixer that has less flow variations than the air flow discharged from the pulse detonation combustor.

Owner:GENERAL ELECTRIC CO

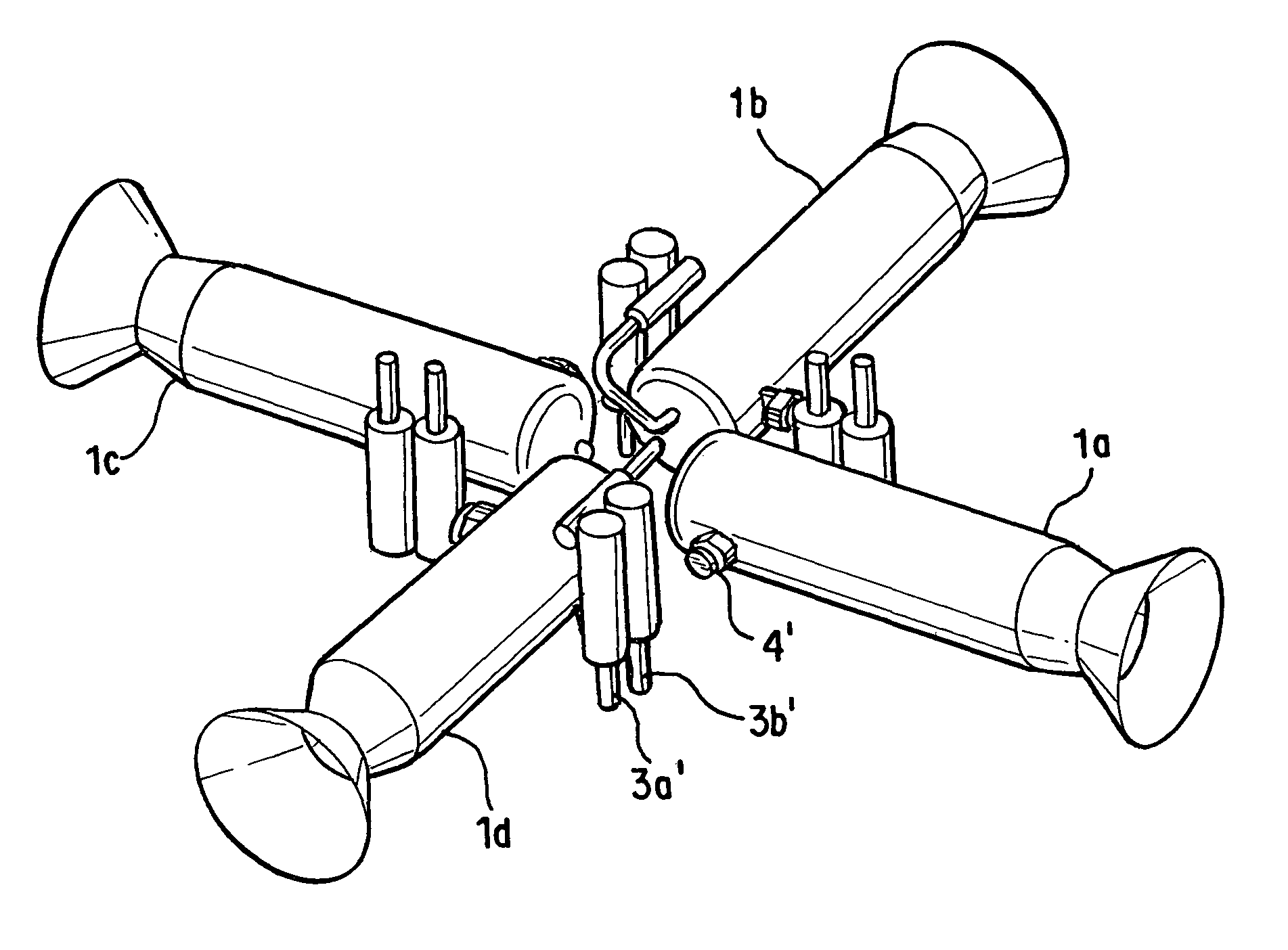

Pulse detonation/deflagration apparatus and related methods for enhancing DDT wave production

ActiveUS8205433B2Easy to implementEnhancing deflagration to detonation wave productionCosmonautic vehiclesEngine manufactureCombustion chamberEngineering

Pulse detonation / deflagration apparatus for providing enhanced pressure wave operating frequency and / or magnitude, and methods of increasing the frequency or the magnitude of deflagration to detonation waves, are provided. A pulse detonation / deflagration apparatus can include a main / outer pulse detonation / deflagration actuator / engine (PDA / E) with multiple smaller internal combustion chambers or tubes positioned inside the cavity of the main / outer PDA / E with each performing the function of individual PDA / Es. The output pressure waves created by the internal PDA / Es can be utilized for propulsion or for controlling large scale flows, where needed.

Owner:LOCKHEED MARTIN CORP

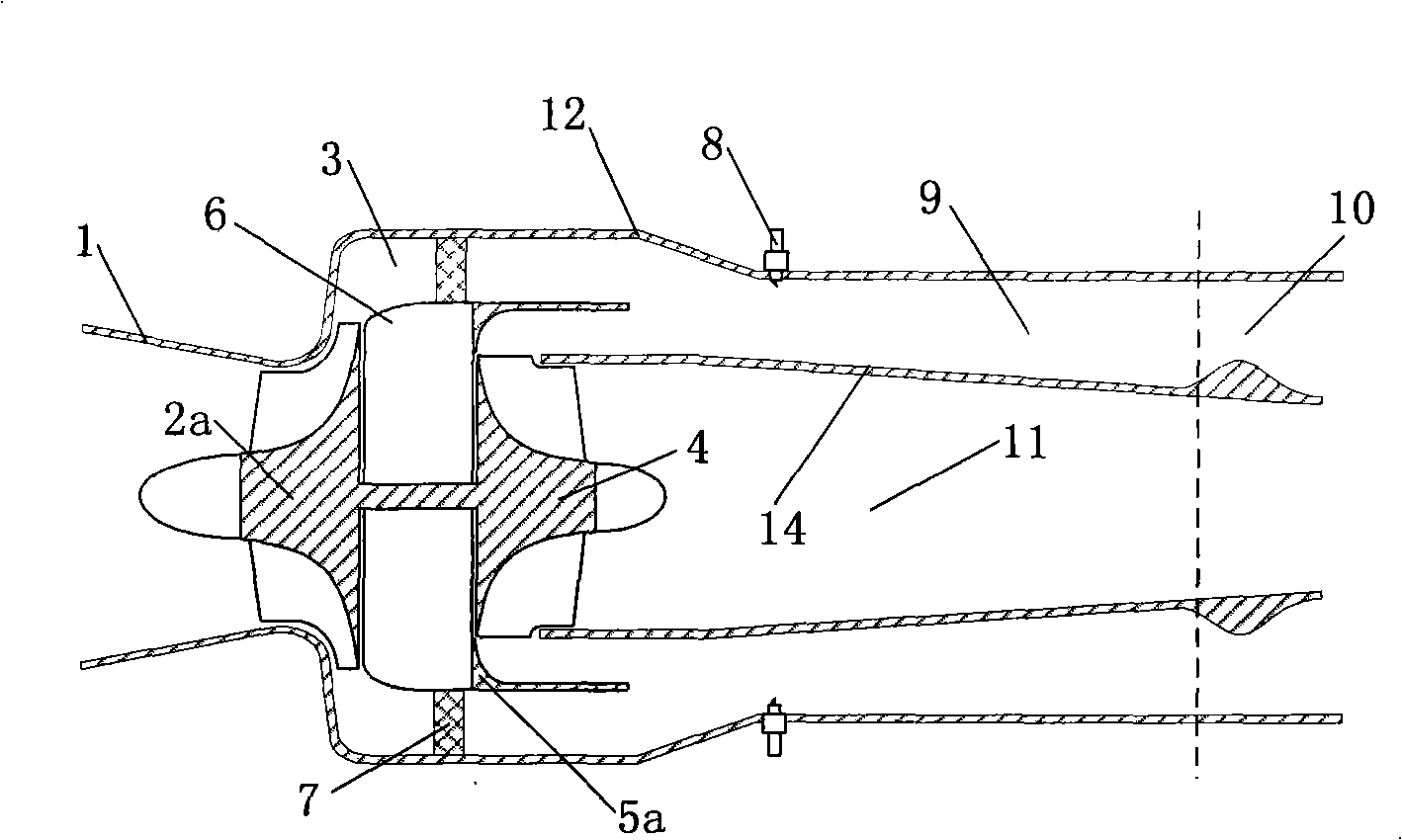

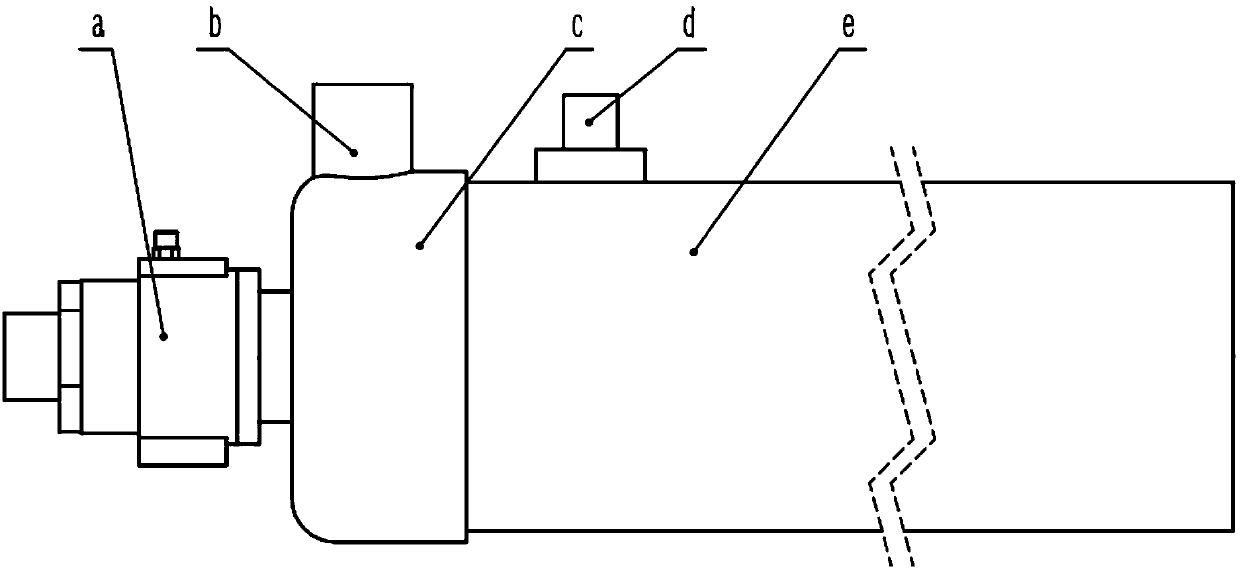

Single-tube rotary valve type double-bypass pulse detonation engine

The invention provides a single-tube rotary valve type double-bypass pulse detonation engine. In the detonation engine, air inlets are repeatedly opened and closed through circumferential rotation of a barrel type valve, and then the rotary valve type single-tube detonation engine is realized. The invention not only has the advantages of simple structure, light weight and small volume, but also avoids the technical problems of coordination, control, coupling interference, and the like among a plurality of detonation tubes. The double-bypass design is also adopted by the detonation engine, captured air flow is switched between the inner bypass and the outer bypass, therefore, the periodic blockage of the air flow in the air inlet is avoided, a low flow resistance is kept, and the ejection effect of inner bypass high-speed air flow to outer bypass air flow is utilized for realizing additional push effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Pulse detonation engine bypass and cooling flow with downstream mixing volume

InactiveUS20080115480A1Well mixedEasy to operateGas turbine plantsIntermittent jet plantsCombustorStream flow

An engine contains at least one pulse detonation combustor which is surrounded by a bypass flow air duct, through which bypass air flow is directed. The bypass air duct contains at least one converging-diverging structure to dampen or choke the upstream propagation of shock waves from the pulse detonation combustor through the bypass flow air duct. The bypass air also serves to cool the outer surfaces of the pulse detonation combustor. The bypass air flow is controlled in tandem with the heat release from the PDC to provide the appropriate amount of thermal energy to a downstream energy conversion device, such as a turbine. A mixing plenum is positioned downstream of the pulse detonation combustor and bypass flow air duct.

Owner:GENERAL ELECTRIC CO

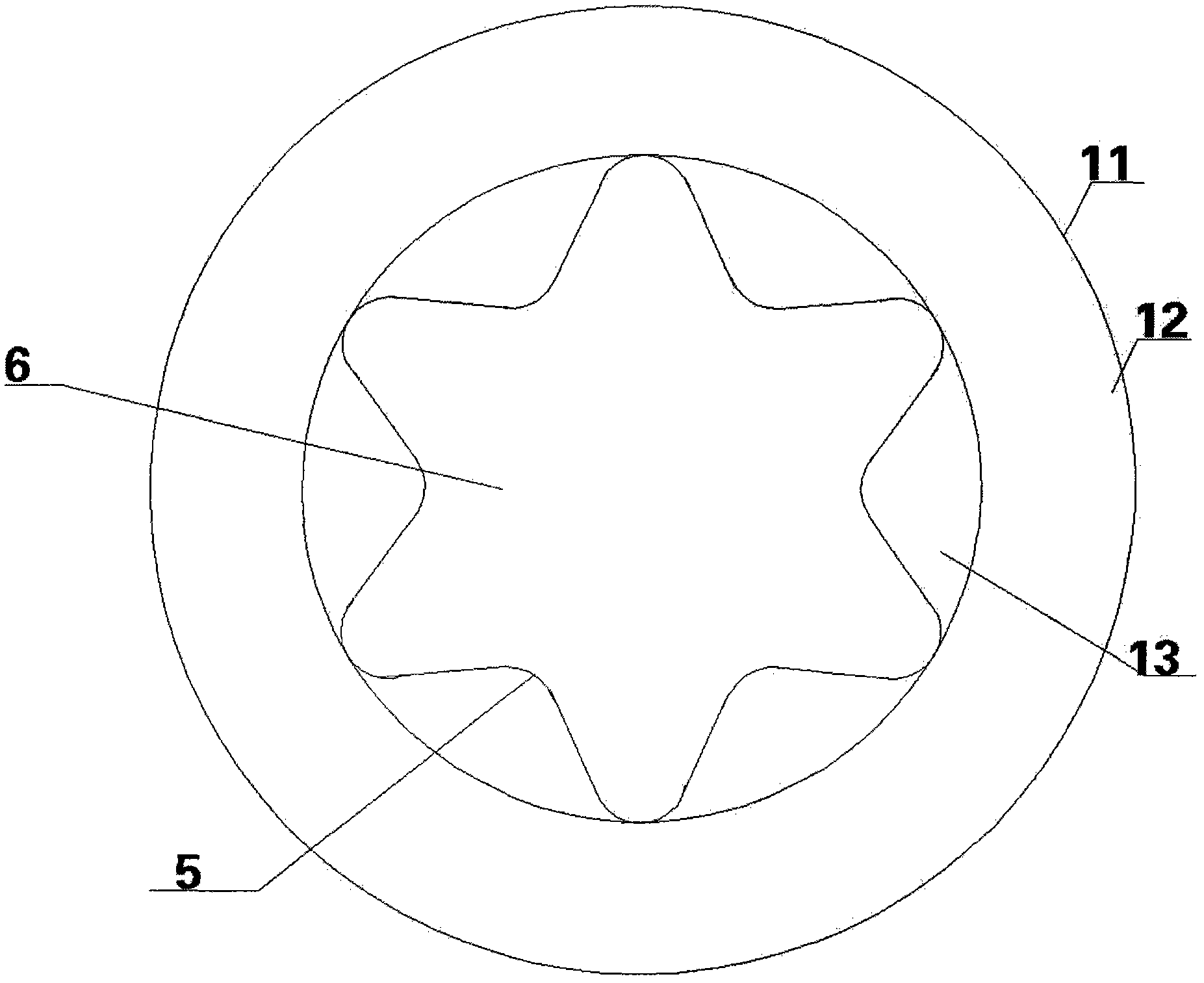

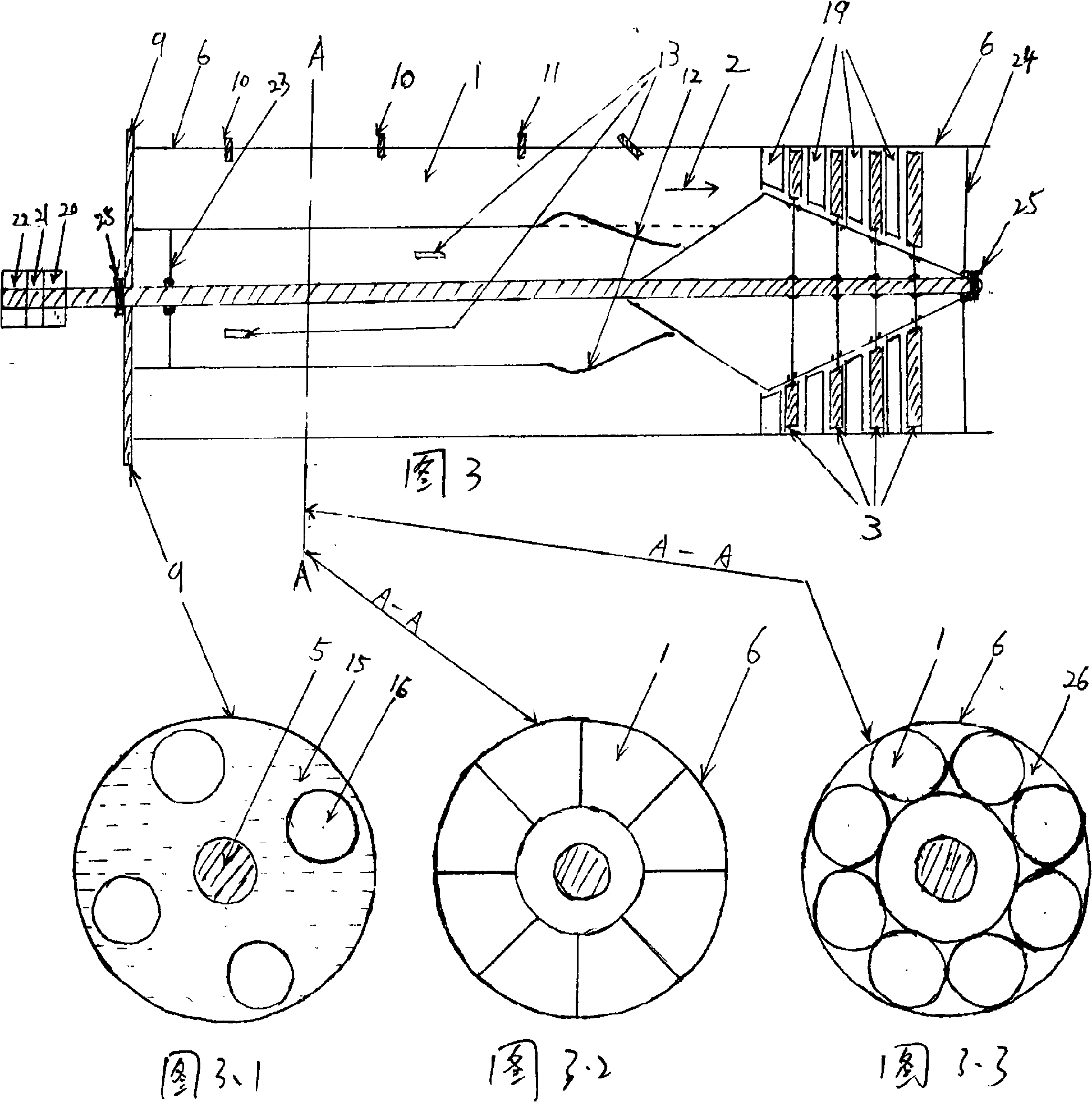

Air inlet of air-breathing pulse detonation engine

The invention discloses an air inlet of an air-breathing pulse detonation engine. The housing of the engine constitutes the circular air inlet, wherein an inlet cone is arranged on the medial axis at the rear end of the air inlet; a cylindrical structure at the rear part of the inlet cone and the housing of the engine constitute a ring-shaped channel; the air flow is fed into a special-shaped channel having a special-shaped structure via the ring-shaped channel; the special-shaped channel is evenly distributed on the circumference of the air inlet with the distance between the central symmetrical curve of the special-shaped channel and the medial axis of the engine remaining unchanged but deviating along the circumference; a fuel channel is arranged on the medial axis of the inlet cone, and the two ends of the fuel channel are connected with the fuel inlet and a fuel injection lever located on the medial axis outside the rear end of the cylindrical structure; the fuel injection lever is particularly a hollow oil tube with one end thereof being closed; a plurality of fuel injection holes are formed on the lateral surface of the fuel injection lever; the housing of the engine and the rear end surface of the cylindrical structure constitute a mixing chamber; and an igniter is located on the lateral wall of the mixing chamber. The invention can improve the atomization and evaporation of the fuel and reduce the impact of reversed fuel on the air inlet.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pulse knock rotor spindle engine

InactiveCN101338702AIncrease useSingle purposeTurbine/propulsion engine coolingGas turbine plantsHigh pressureSubmarine

The present invention relates to a pulse detonation rotor shaft engine. In the technical proposal, the pulse detonation rotor shaft engine mainly consists of a pulse detonation engine, a rotor and an output shaft; propulsive gas with the high temperature and high pressure expansion of pulse which is ejected when the pulse detonation engine works is used as a power source to push the rotor to rotate; the rotor drives the output shaft to rotate; a pulse detonation rotor shaft engine uses the output shaft to output most energy produced by the pulse detonation engine by outputting torsion continuously; the output shaft drives various kinds of loads to work. The pulse detonation rotor shaft engine has the beneficial effects as follows: firstly, the pulse detonation rotor shaft engine can be used as a shaft engine to be widely applied in various kinds of dynamic systems, such as ship, submarine, tank, tractor, automobile, train, and the like and has wide purposes; secondly, the pulse detonation rotor shaft engine overcomes the disadvantage of the large noise of the prior pulse detonation engine; thirdly, compared with a piston type engine, the pulse detonation rotor shaft engine has the obvious advantages of simple structure, low cost, high reliability, long service life, light weight, less fraction resistance loss, etc.

Owner:RUGAO HUAYANG ALUMINUM PROD

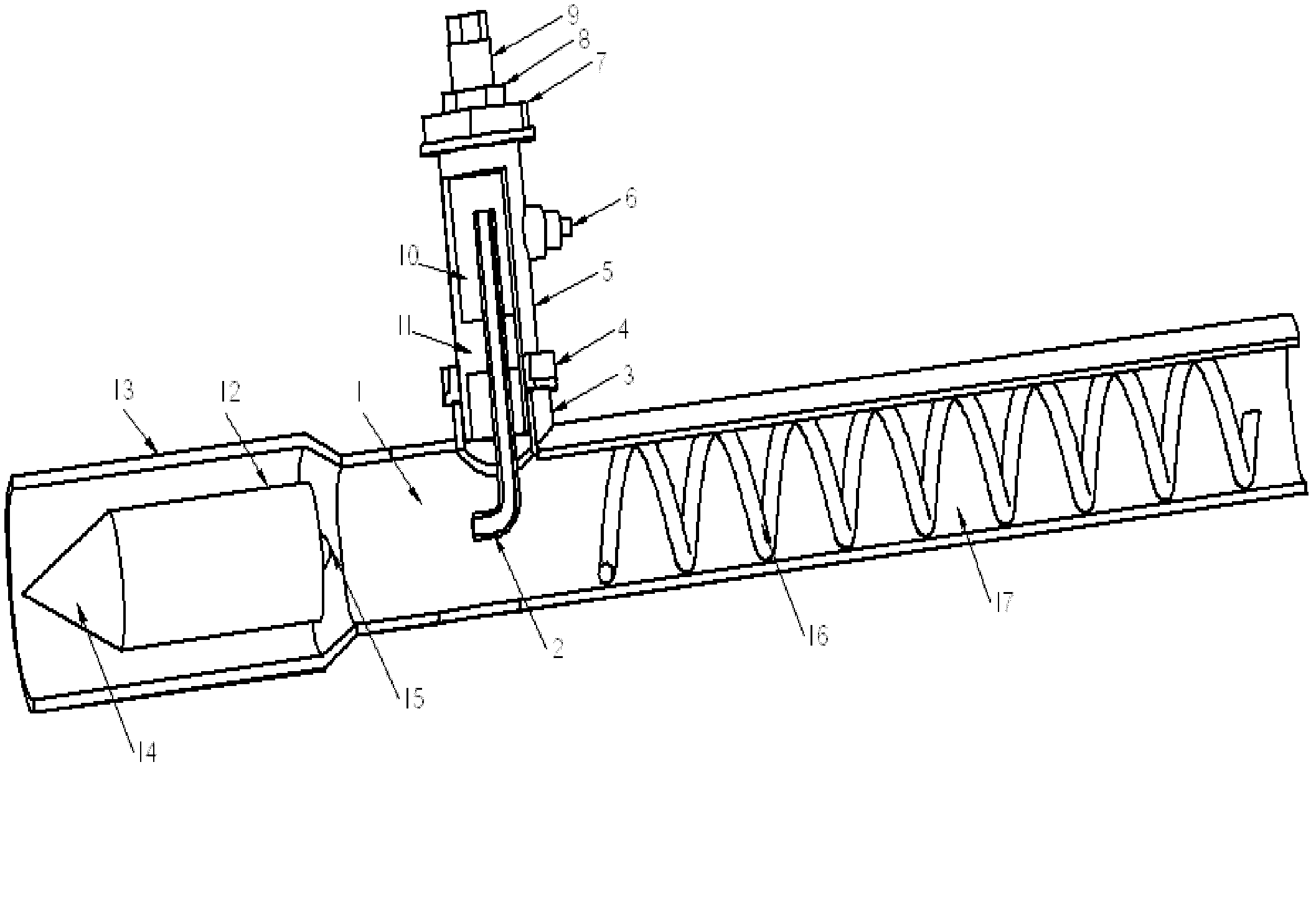

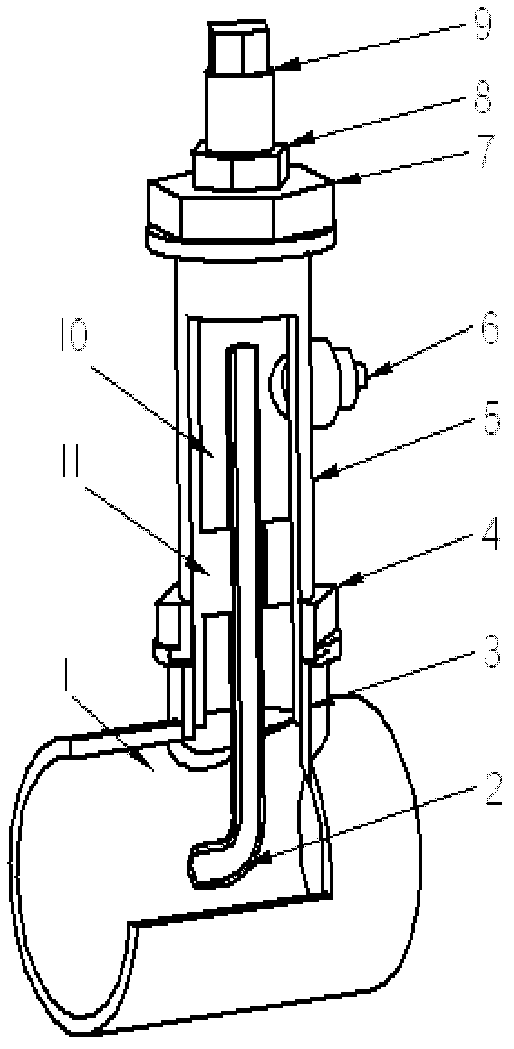

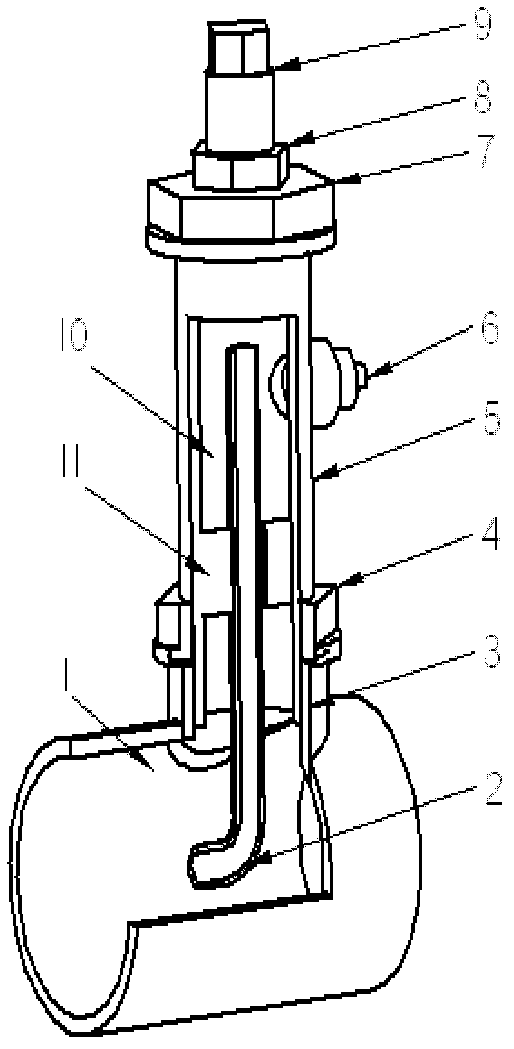

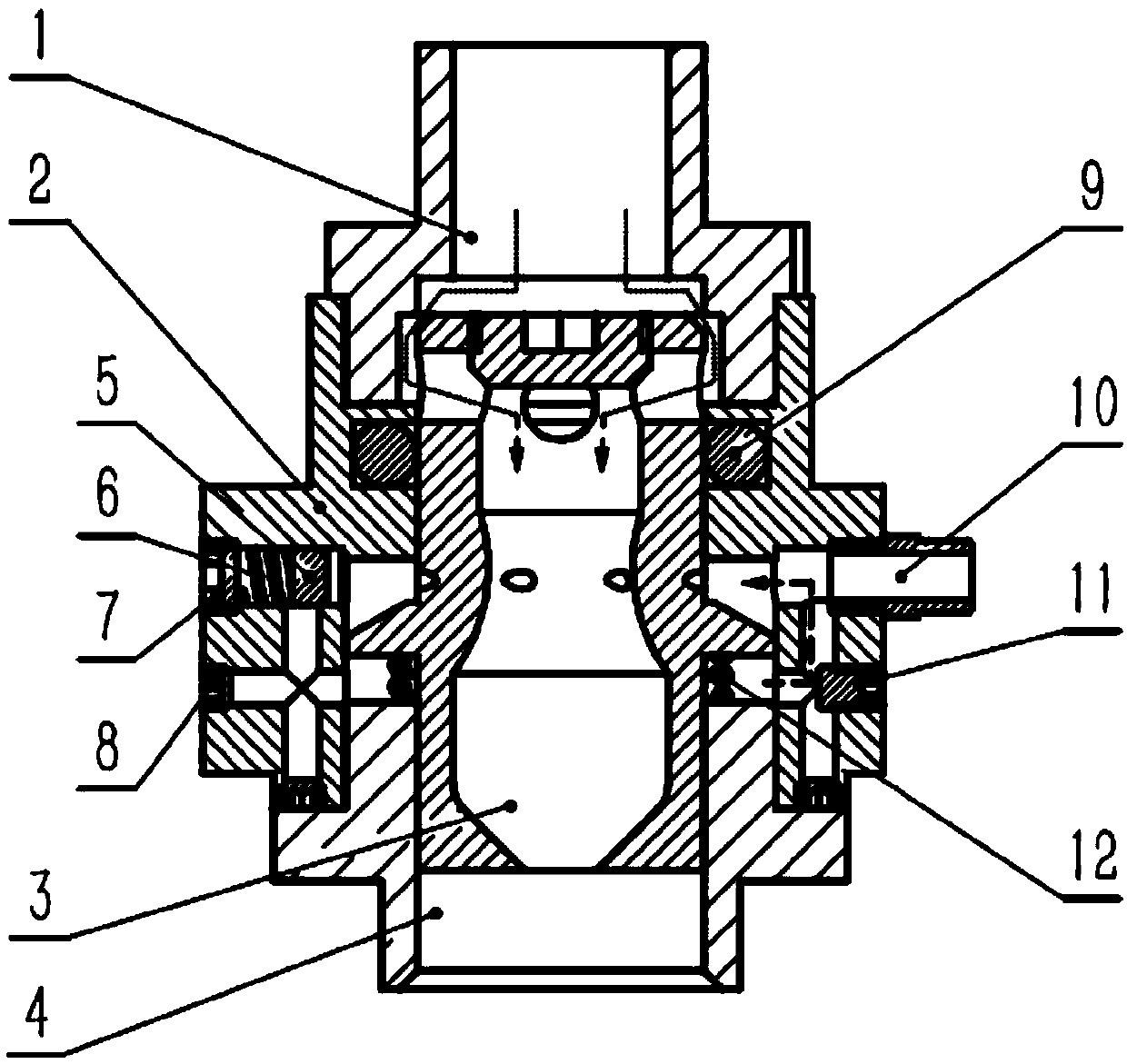

Jet ignition device of pulse detonation engine

InactiveCN102619643AIncrease working frequencyImprove convenienceIntermittent jet plantsRocket engine plantsDraining tubeDeflagration to detonation transition

The invention relates to a jet ignition device of a pulse detonation engine, which is characterized in that a jet tube is fixedly connected with a mixing chamber through a sealing clamp nut, an adjusting plug is mounted at the top end of the jet tube through a sealing nut and a clamping nut; a drain tube is arranged in a jet chamber inside the jet tube and is connected with the jet tube through a fixing rib, and the lower end of the drain tube extends into the mixing chamber; and an ignition seat is arranged on one side of the jet tube and is located at one end of an outlet of the drain tube. Compared with the time and the distance for generating detonation waves by normal ignition devices, the time and the distance for generating the detonation waves by the jet ignition device are shorter, accordingly the DDT (deflagration to detonation transition) time and distance is shortened. In this case, length of a detonation chamber can be further shortened so as to improve working frequency of the pulse detonation engine. After the detonation chamber is shortened, exhausting burden in the pulse detonation engine is reduced, so that expansion wave-beams generated from the outlet of the pulse detonation engine can catch up with pressure waves transmitted before, pressure disturbance in an air-inlet passage is reduced, and working stability of the pulse detonation engine is enhanced while better propulsive performance is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Turbine combined pulse detonation engine

The invention discloses a turbine combined pulse detonation engine (PDE). An air inlet device is positioned at the front tip of an engine shell; a gas compressor is positioned at the lower reaches of the air inlet device and is coaxial with the air inlet device; the gas compressor is coaxial with a radial turbine; a flow-guide casing is a smooth transition case between the gas compressor and the radial turbine; a guider is positioned between the flow-guide casing and the radial turbine; an inlet valve is positioned between the flow-guide casing and the inner wall of the engine shell; a diffusion cushion chamber ranges from the lower reaches of the gas compressor to the upper reaches of the inlet valve; a multi-tube detonation chamber is positioned at the lower reaches of the inlet valve; the outer annular wall surface of the multi-tube detonation chamber is part of the engine shell and the inner annular wall surface forms an inner annular wall; an inner flow passage is positioned at the lower reaches of the radial turbine; an ignition system is an ignition device of the multi-tube detonation chamber and the exit of the multi-tube detonation chamber is connected with a nozzle. The PDE is no longer than the length corresponding to the maximum external profile diameter of the gas compressor, thus greatly reducing coupling of detonation circulation and turbine operation, having high working frequency and conducing to power extraction.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pulse Detonation Engine with Variable Control Piezoelectric Fuel Injector

InactiveUS20130081376A1Improve operationImprove inflight stabilityIntermittent jet plantsEngine controlFuel typeStreamflow

A pulse detonation engine including one or more fuel injectors comprising one or more piezoelectric driving stacks wherein a flow control member of each injector is driven directly by the one or more piezoelectric stacks without additional amplification means or interposing elements while a flow area of the nozzle is variably adjustable to deliver controlled flow rates in a desired flow profile to improve engine performance and reduce emissions. The pulse detonation engine configured to support variable mission and operational requirements including delivery of required thrust using specific fuel types and with power and performance of the pulse detonation engine variably adaptable. The fuel injectors associated with the pulse detonation engine configure to deliver specified flow rates with minimal linear movement of the flow control member. The injector and drive electronics configured to deliver higher frequency operation and response with increased operational stability.

Owner:WEIDLINGER ASSOCIATES

Novel fuel injection system for self-adaptive pulse detonation engine

InactiveCN109252980AJet adaptiveInjection implementationTurbine/propulsion fuel valvesIntermittent jet plantsInjection pressureCombustion chamber

The invention discloses a device for self-adaptive fuel injection into a combustion chamber of a pulse detonation engine, and provides a fuel injection system applicable to the self-adaptive pulse detonation engine. The system mainly comprises an oxidant supply system, a fuel supply system and an injection valve. By periodic pressure fluctuation in a pulse detonation combustion chamber, self-adaptive periodic on and off of a fuel supply passage can be realized, and periodic detonation combustion in the pulse detonation combustion chamber can be realized. By adoption of the fuel injection device, high injection pressure can be adopted for acquiring great atomizing effects; by fuel liquid crushing and mixing action of oxygen, fuel atomization is enhanced. By fuel supply delaying, fuel chamber entering time of a fuel slightly lags behind that of air, air entering the fuel chamber easily serves as isolation air to realize isolation between a high-temperature combustion product and a newlyfilled explosive mixture, an isolation gas system required by a current self-adaptive pulse detonation engine is not needed, and a system structure is simplified.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com