Pulse knock rotor spindle engine

A technology of pulse detonation and engine, which is applied in the direction of engine components, engine cooling, machine/engine, etc. It can solve the problems of large noise and single use, and achieve the effect of wide application and overcoming huge noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

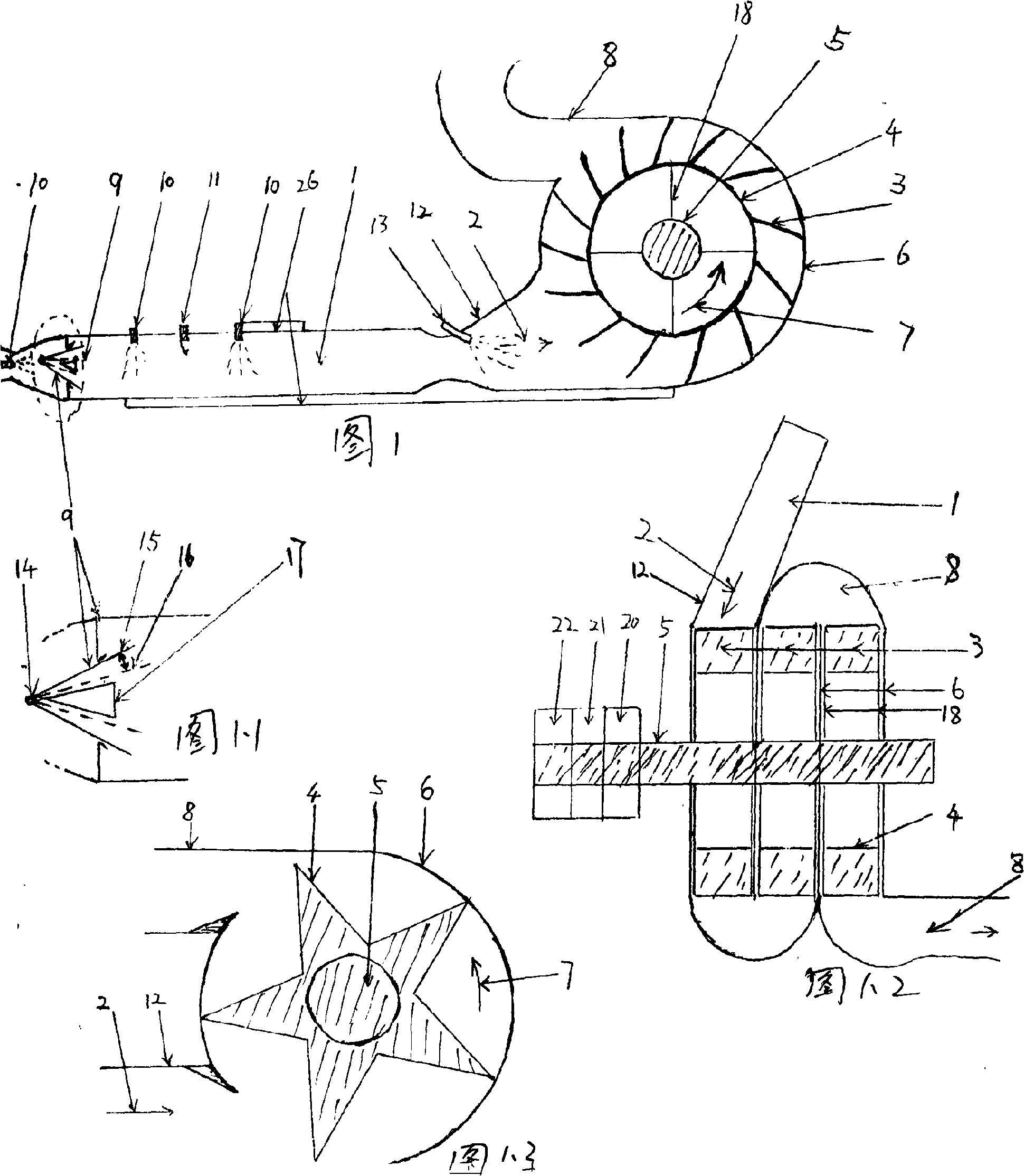

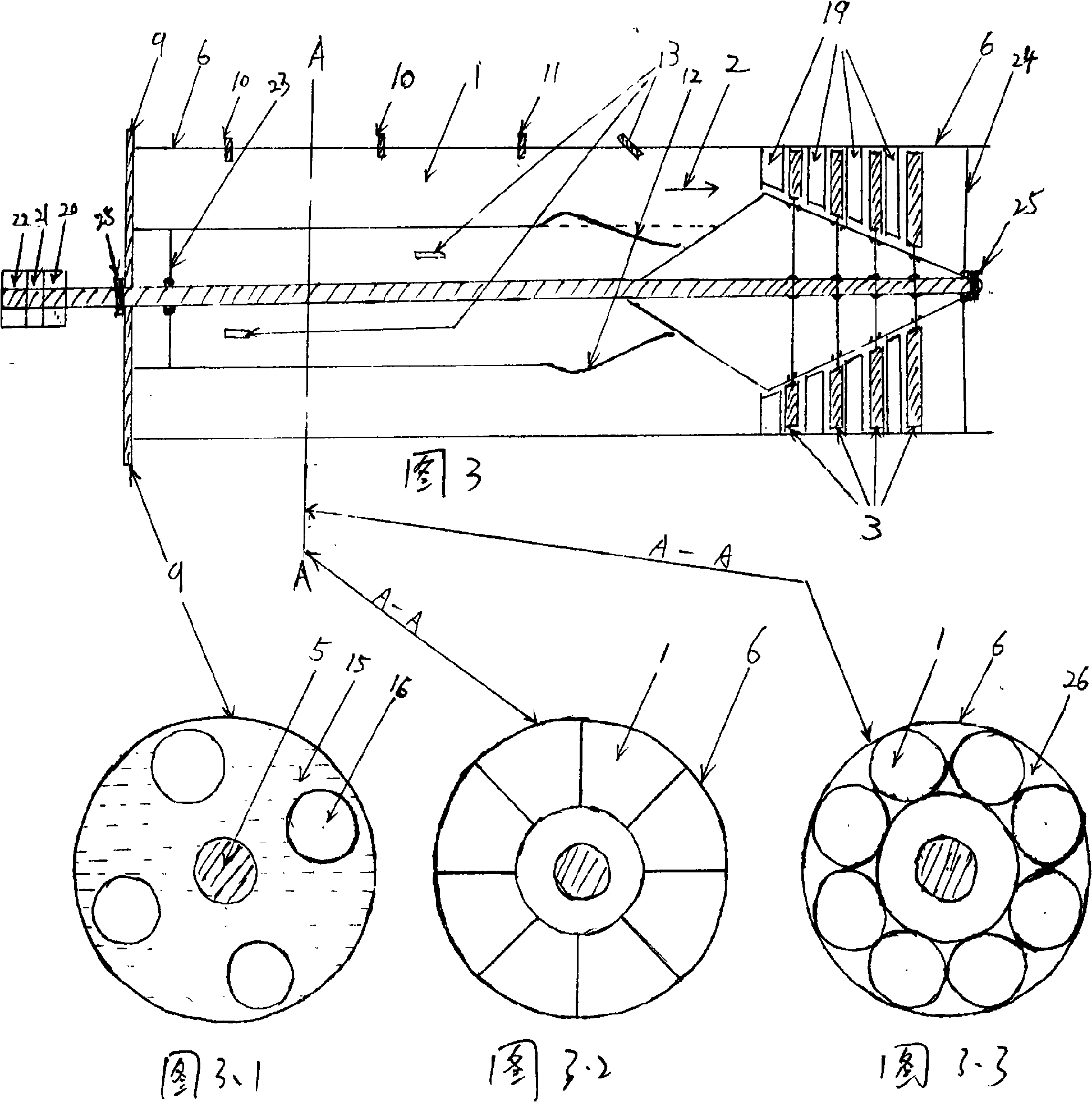

[0033] Embodiment 1: a pulse detonation rotor shaft engine with only one pulse detonation engine: (such as accompanying drawing 1, accompanying drawing 1.2) is mainly driven by a pulse detonation engine 1 with an intake valve 9 and a three-stage impeller rotor 4 An output shaft 5 and other components, the working process is that the air in the pulse detonation engine 1 is mixed with the fuel injected by the fuel nozzle 10, the igniter 11 ignites the pulse detonation engine 1 to work, and the propellant gas 2 generated passes through the propellant gas ejection port 12 Completely enter the casing 6 connected with it, there is a water nozzle 13 in the propelling gas ejection port 12, and the sprayed atomized water can absorb the heat energy in the high-temperature and high-pressure propelling gas 2 and turn it into water vapor to increase the propelling gas 2, the rest of the water can continue to evaporate in the casing 6 to cool down the engine, and the boosted propellant gas 2...

Embodiment 2

[0034] Embodiment 2: a kind of pulse detonation rotary shaft engine that uses hydrogen and oxygen work completely: (as accompanying drawing 1) original structure in the specific embodiment 1 is unchanged, just makes the pulse detonation engine 1 on its basis The upstream of the intake valve 9 is airtightly connected (not shown) with the hydrogen supply pipe, the gas supply regulation system, and the hydrogen cylinder, and the upstream of the nozzle 10 is airtightly connected (not shown) with the oxygen supply pipe, the gas supply regulation system, and the oxygen cylinder. And make the hydrogen / oxygen=2 / 1 (molar ratio) that enters the pulse detonation engine 1 by the gas supply regulating system, all the other work processes are identical with the concrete embodiment 1. Make pulse detonation engine 1 become the pulse detonation rocket engine (PDRE) that uses hydrogen, oxygen fuel by air-breathing pulse detonation engine (PDE) like this, make pulse detonation rotorshaft engine o...

Embodiment 3

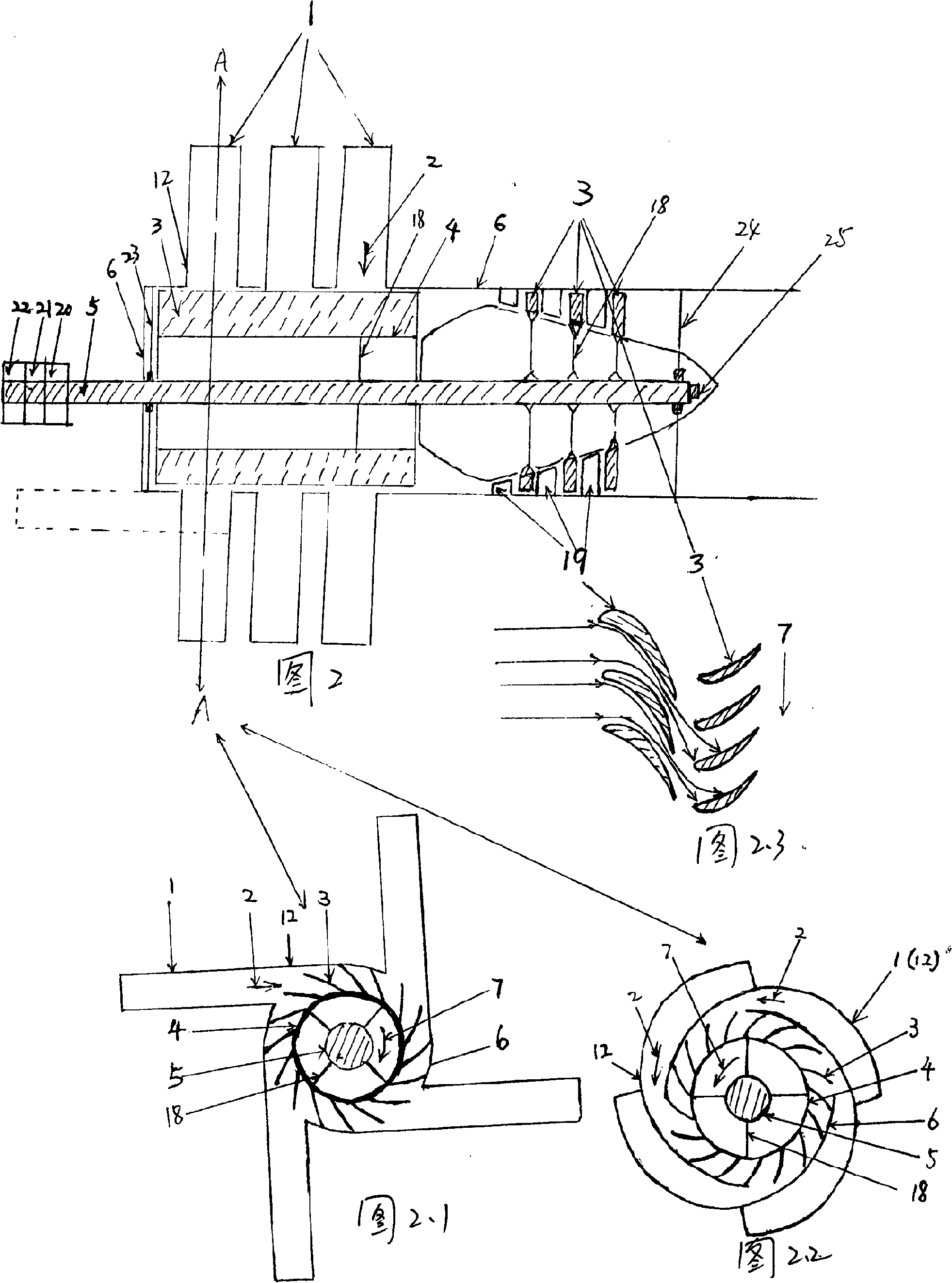

[0035] Embodiment 3: (as accompanying drawing 2) the impeller that is driven by a plurality of pulse detonation engines, turbine composite rotor type pulse detonation rotor shaft engine: its work process is that 12 intake valve type pulse detonation engines 1 work hours The generated propellant gas 2 enters the same engine housing 6 connected to it through each propellant gas outlet 12 after being boosted by water spraying, and jointly tangentially pushes the impeller blades 3 to rotate the impeller rotor 4 and drive the output shaft 5 to rotate At this time, the direction of the propelling gas 2 has been changed by the impeller blades 3, and then the turbine blades 3 of the downstream turbine rotor 4 are pushed again to make the turbine rotor 4 rotate. The front of the turbine blades 3 of each stage of turbine rotor 4 is fixed on the inner wall of the casing 6 The air-guiding stator blade 19 on the top has a total of 1-stage impeller rotor and 3-stage turbine rotor in this fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com