Two-stage gasification method and gasification device for fuels with wide size distribution

A technology of a gasification device and a feeding device, which is applied to the gasification of granular/powdered fuel, the production of combustible gas, and the mitigation of combined combustion, etc. The effect of flexible raw material throughput, flexible fuel throughput, and reduced processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described below with reference to specific examples, which are only for the purpose of illustrating the present invention, and do not limit the scope of the present invention in any way.

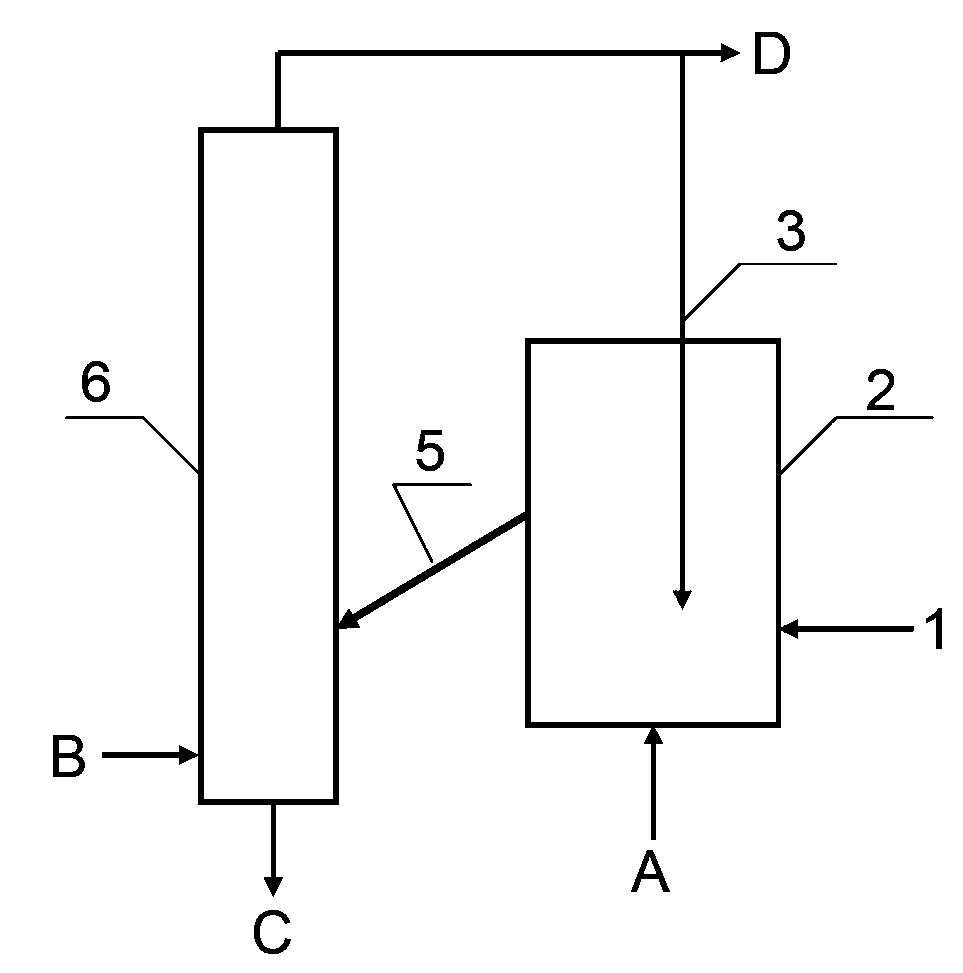

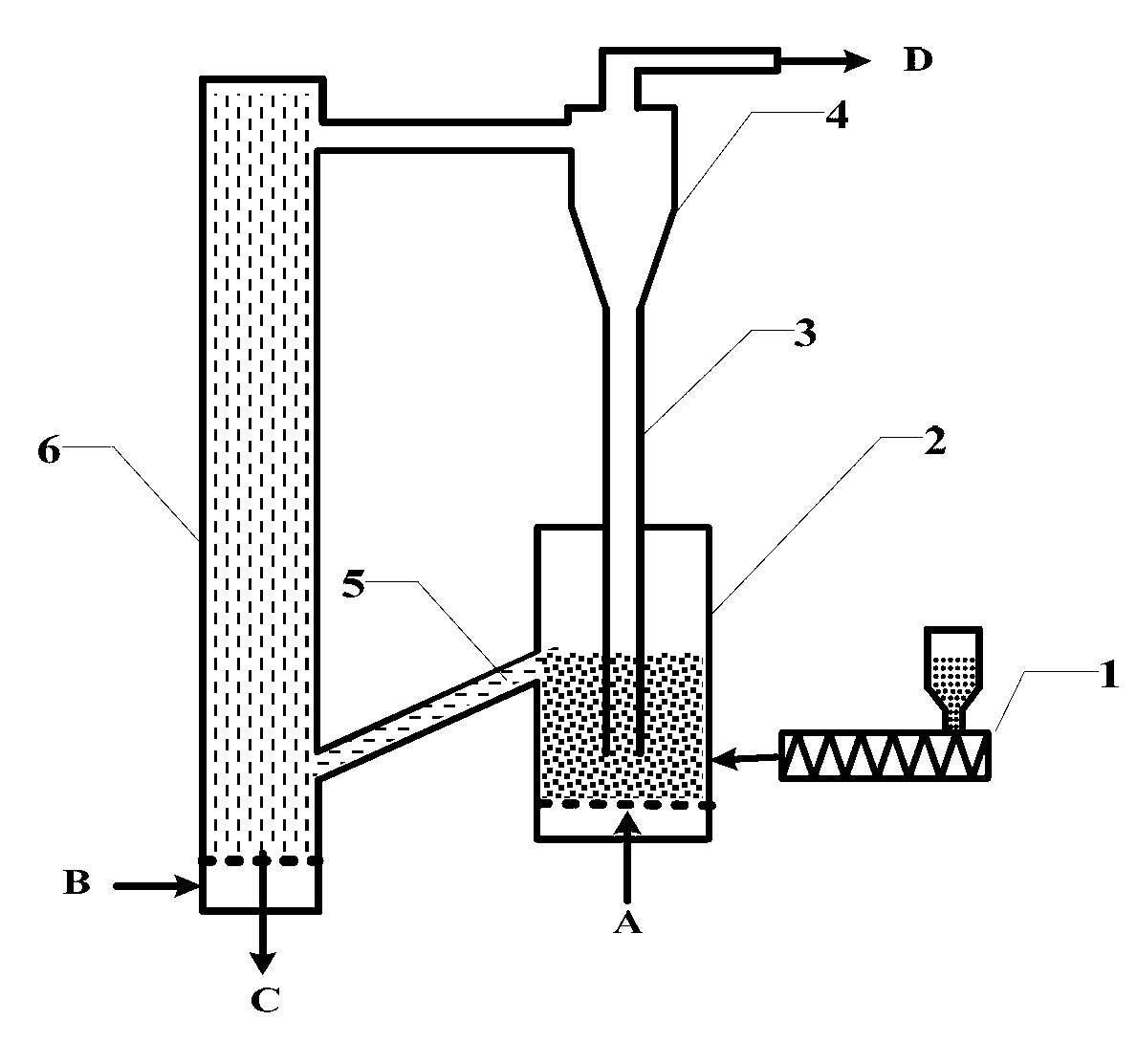

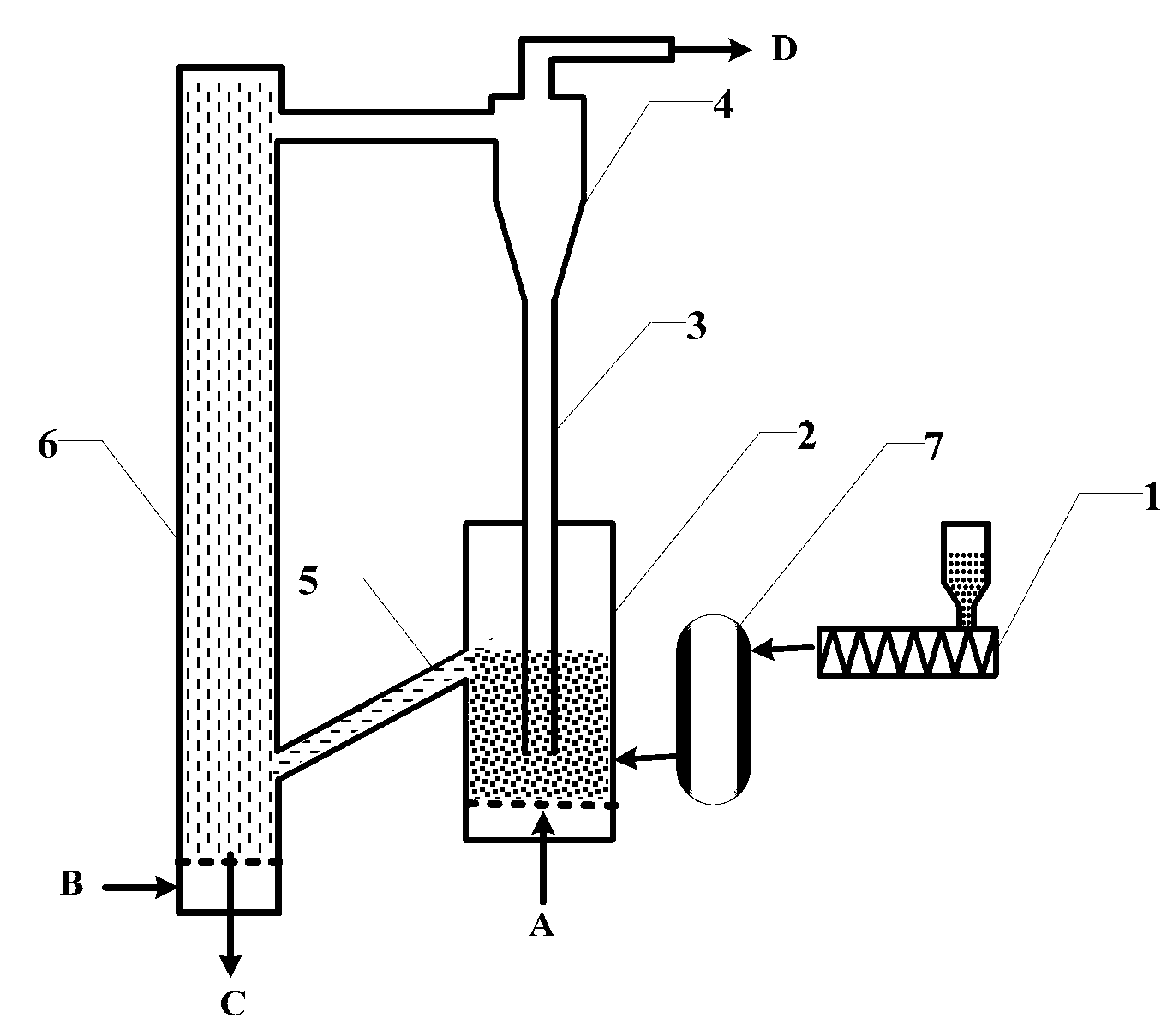

[0042] The two-stage gasification method for wide particle size distribution solid fuel of the present invention comprises the following steps:

[0043] 1) The fuel is fed into the fluidized bed pyrolyzer through the feeding device, and the gasifying agent is added into the fluidized bed pyrolyzer at the same time, and the fuel is dried / heated under the heating of the semi-coke of the pyrolyzer and the gasifying agent Decomposition or partial gasification to generate solid products containing semi-coke and gas products containing pyrolysis gas, tar or water vapor;

[0044] 2) Send the solid and gas products generated in step 1 into the entrained bed gasifier together, and at the same time add gasification agent into the entrained bed gasifier to complete the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com