Humic acid composite slow release fertilizer and producing method thereof

A slow-release fertilizer and humic acid technology, applied in organic fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of poor product appearance quality and internal quality slow-release properties, and achieve the improvement of seasonal utilization rate, soil fertility, and simplification. Effects of agricultural work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

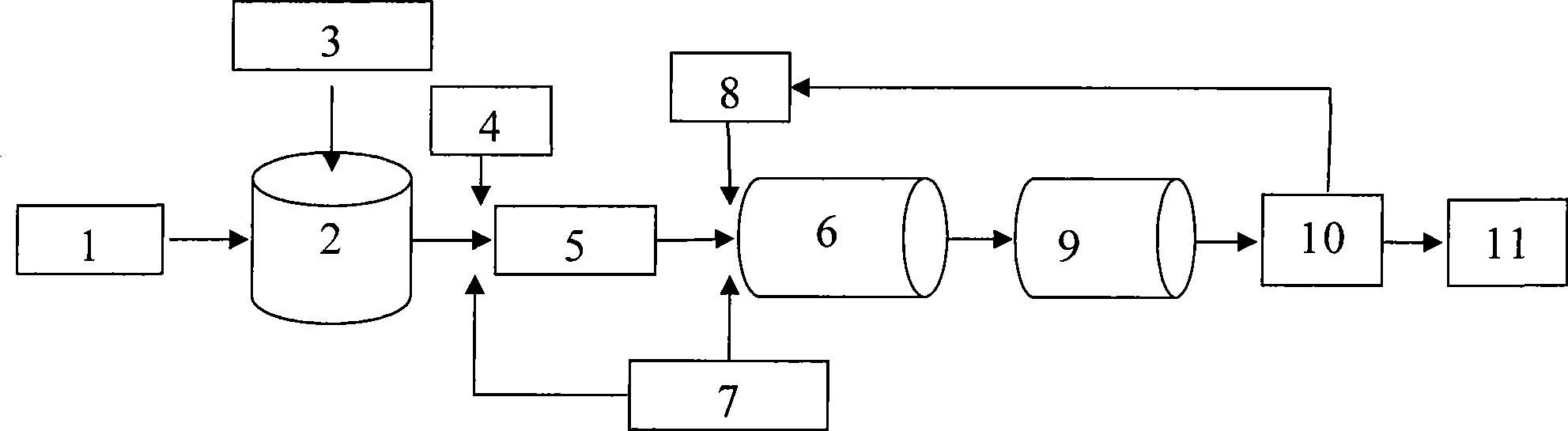

Method used

Image

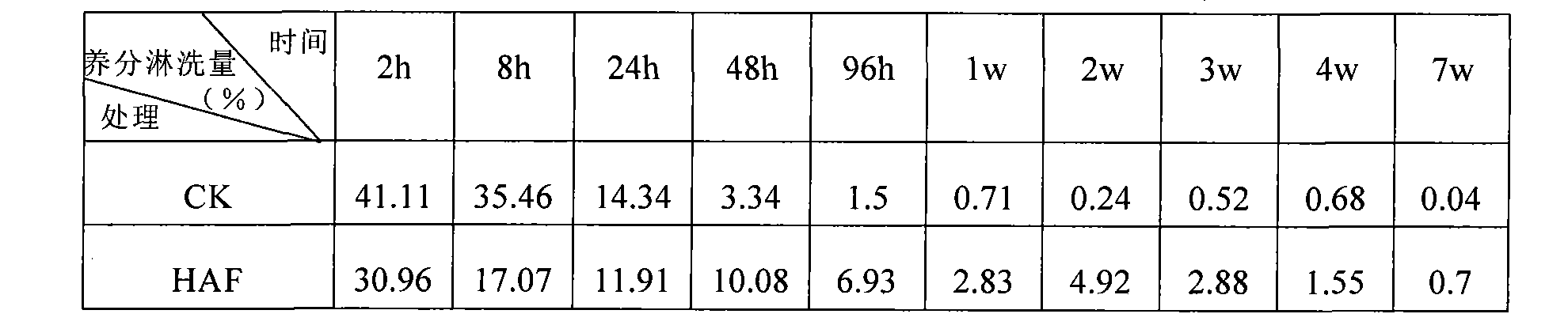

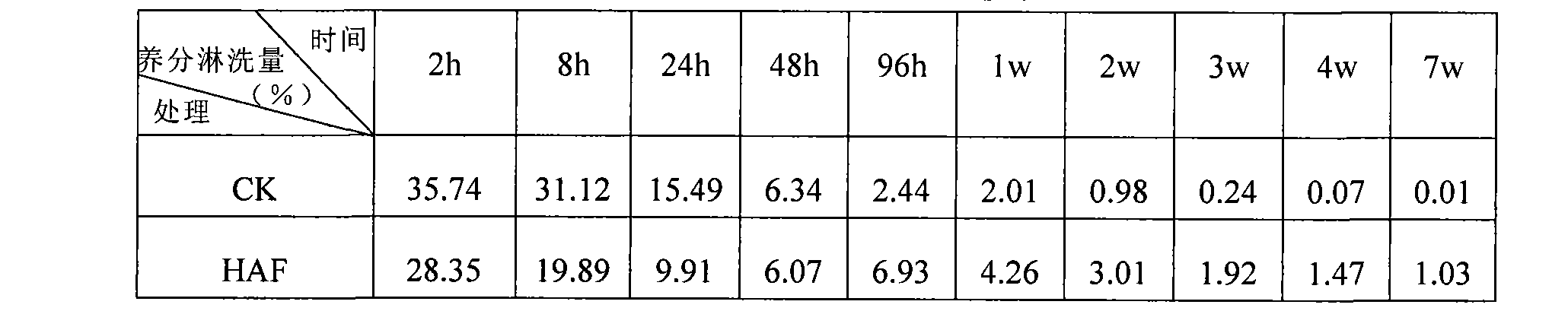

Examples

Embodiment 1

[0051] Weigh 100 parts by weight of dry, pulverized and sieved weathered coal of more than 80 meshes, add 25 parts by weight of ammonium bicarbonate and 20 parts by weight of water, stir evenly, compact into piles, cover with a layer of coal ash or plastic film, After standing for 3 days, the material was discharged to obtain the activated weathered coal. Then, add water to the activated weathered coal and mix to obtain the activated weathered coal slurry with a water content of 60%, then add respectively 20% ammonium sulfate, 10% potassium sulfate and 20% ammonium phosphate to make organic-inorganic composite slurry, stir and mix well, pass 8MPa, 150°C high-temperature steam into it, heat the organic-inorganic composite slurry to 60°C, and then use a high-pressure pump to compress air with 5.0MPa The slurry is atomized through the nozzle and directly sprayed into the 4.2m×22m drum of the spray granulation system (there are lifting boards on the walls around the drum, and ther...

Embodiment 2

[0053] Weigh 100 parts by weight of dry, pulverized and sieved weathered coal of more than 80 meshes, add 25 parts by weight of ammonium bicarbonate and 20 parts by weight of water, stir evenly, compact into piles, cover with a layer of coal ash or plastic film, After standing for 3 days, the material was discharged to obtain the activated weathered coal. Then, add water to the activated weathered coal and mix to obtain a slurry with a water content of 60%, and then meter and add 20% ammonium sulfate, 15% potassium chloride and 15% ammonium phosphate in parts by weight according to the nutrient ratio , to make an organic-inorganic composite slurry, stir and mix well, pass 8MPa, 150°C high-temperature steam into it, heat the organic-inorganic composite slurry to 60°C, and then use a high-pressure pump to directly blow the slurry with 5.0MPa compressed air Spray into the 4.2m×22m drum of the spray granulation system (there are lifting boards on the wall around the drum, and ther...

Embodiment 3

[0055] Weigh 100 parts by weight of dry, pulverized and sieved weathered coal of more than 80 meshes, add 25 parts by weight of ammonium bicarbonate and 20 parts by weight of water, stir evenly, compact into piles, cover with a layer of coal ash or plastic film, After standing for 3 days, the material was discharged to obtain the activated weathered coal. Then, add water to the activated weathered coal and mix to obtain a slurry with a water content of 60%, and then add 10% calcium nitrate, 10% potassium chloride, and 10% potassium sulfate in parts by weight according to the nutrient ratio and 15% ammonium phosphate to make an organic-inorganic composite slurry, stir and mix well, pass in pressurized high-temperature steam (8Pa, 150°C) to heat to 60°C, pass in 25kg of air to compress and atomize through a high-pressure pump (5Pa), Spray directly into the 4.2m×22m drum of the spray granulation system (there are lifting boards on the surrounding walls of the drum, and there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com