Preparation method of cationic surfactant modified fly ash

A technology of surfactant and fly ash, which is applied in the field of preparation of modified fly ash, can solve the problems of reducing hydration heat, and the effect of bending resistance is not very good, and achieves changes in adsorption performance, low cost of industrialization, Handling simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

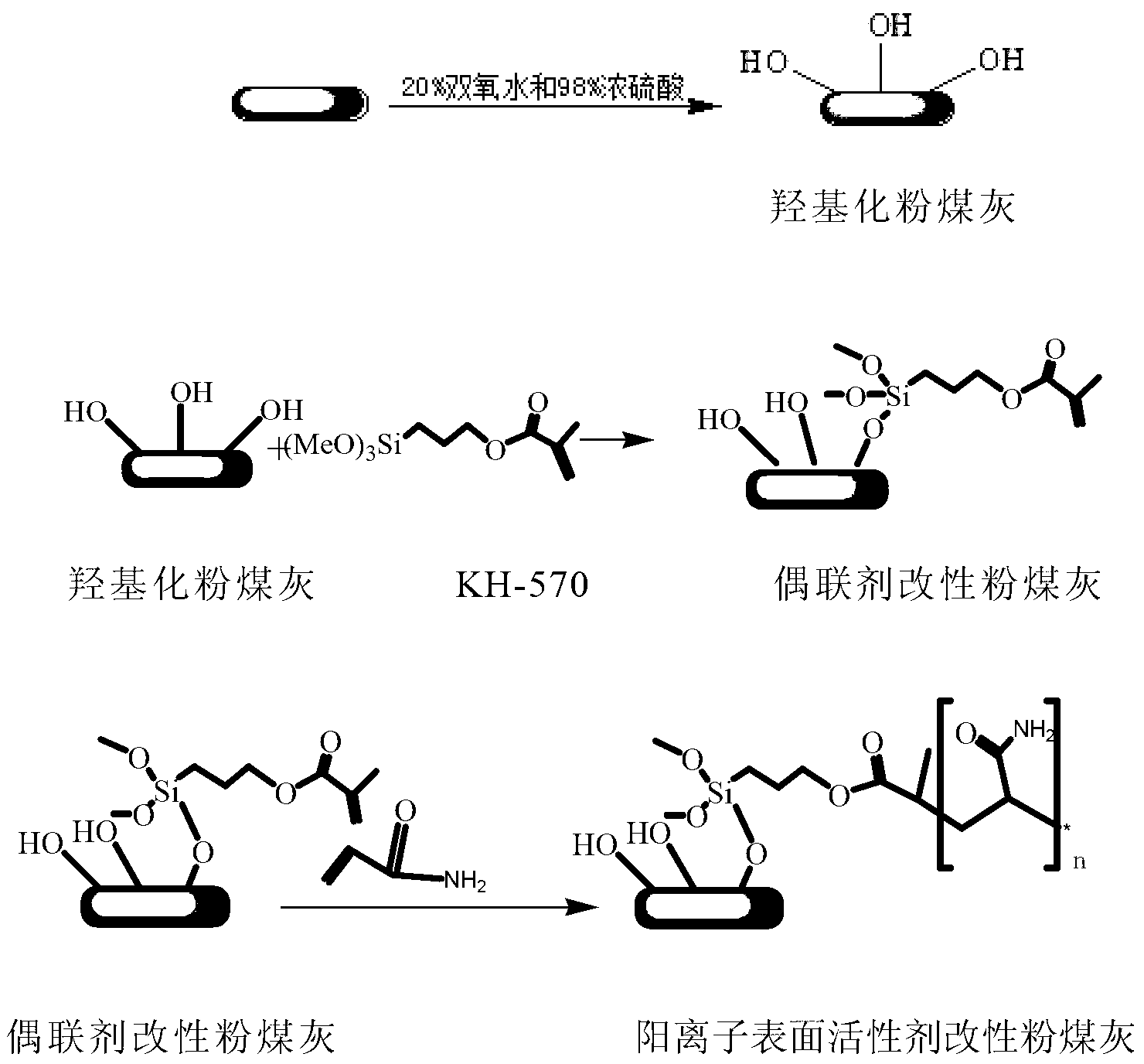

[0031] 1. Add water to 100g of fly ash and disperse evenly. After centrifugation, wash 3 times with absolute ethanol and dry, then add NaOH solution with a mass concentration of 30%, and reflux at 80°C for 24 hours. After the reaction, use a mass concentration of 10 % sulfuric acid solution to adjust the pH value to neutral, washed three times with absolute ethanol and vacuum dried to obtain the pretreated fly ash.

[0032] 2. Under ice-water bath conditions, slowly add 4ml of 20wt% hydrogen peroxide solution to 6ml of 98wt% sulfuric acid solution to obtain a mixed solution, while stirring while adding, then slowly add 10g of pretreated fly ash into the In the mixed solution, stir and react for 10 minutes, place it still until the gas generated is completely diffused and the mixed solution is cooled, then wash with double distilled water, dry under nitrogen protection to obtain hydroxylated fly ash.

[0033] 3. Add 2g of hydroxylated fly ash, 10mL of toluene, 2ml of KH-570 and...

Embodiment 2

[0036] 1. Add water to 100g of fly ash and disperse evenly. After centrifugation, wash 3 times with absolute ethanol and dry, then add NaOH solution with a mass concentration of 30%, and reflux at 80°C for 24 hours. After the reaction, use a mass concentration of 10 % sulfuric acid solution to adjust the pH value to neutral, washed three times with absolute ethanol and vacuum dried to obtain the pretreated fly ash.

[0037] 2. Under ice-water bath conditions, slowly add 8ml of 20wt% hydrogen peroxide solution to 12ml of 98wt% sulfuric acid solution to obtain a mixed solution, while stirring while adding, then slowly add 20g of pretreated fly ash into the In the mixed solution, stir and react for 10 minutes, place it still until the gas generated is completely diffused and the mixed solution is cooled, then wash with double distilled water, dry under nitrogen protection to obtain hydroxylated fly ash.

[0038] 3. Add 4g of hydroxylated fly ash, 20mL of toluene, 4ml of KH-570 an...

Embodiment 3

[0041] 1. Add water to 100g of fly ash and disperse evenly. After centrifugation, wash 3 times with absolute ethanol and dry, then add NaOH solution with a mass concentration of 30%, and reflux at 80°C for 24 hours. After the reaction, use a mass concentration of 10 % sulfuric acid solution to adjust the pH value to neutral, washed three times with absolute ethanol and vacuum dried to obtain the pretreated fly ash.

[0042] 2. Under ice-water bath conditions, slowly add 12ml of 20wt% hydrogen peroxide solution into 18ml of 98wt% sulfuric acid solution to obtain a mixed solution, while stirring while adding, then slowly add 30g of pretreated fly ash into the In the mixed solution, stir and react for 10 minutes, place it still until the gas generated is completely diffused and the mixed solution is cooled, then wash with double distilled water, dry under nitrogen protection to obtain hydroxylated fly ash.

[0043] 3. Add 6g of hydroxylated fly ash, 30mL of toluene, 3ml of KH-570...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com