Patents

Literature

1069results about How to "Low cost of industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

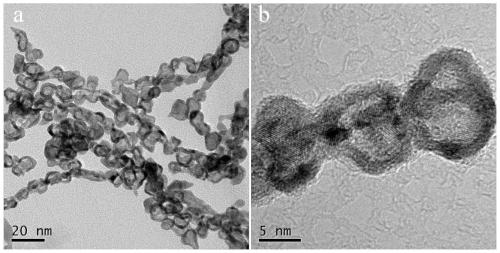

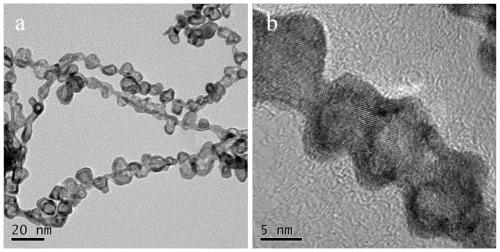

Microporous-mesoporous molecular sieve containing noble metal, preparation method and application to catalytic reduction of p-nitrophenol

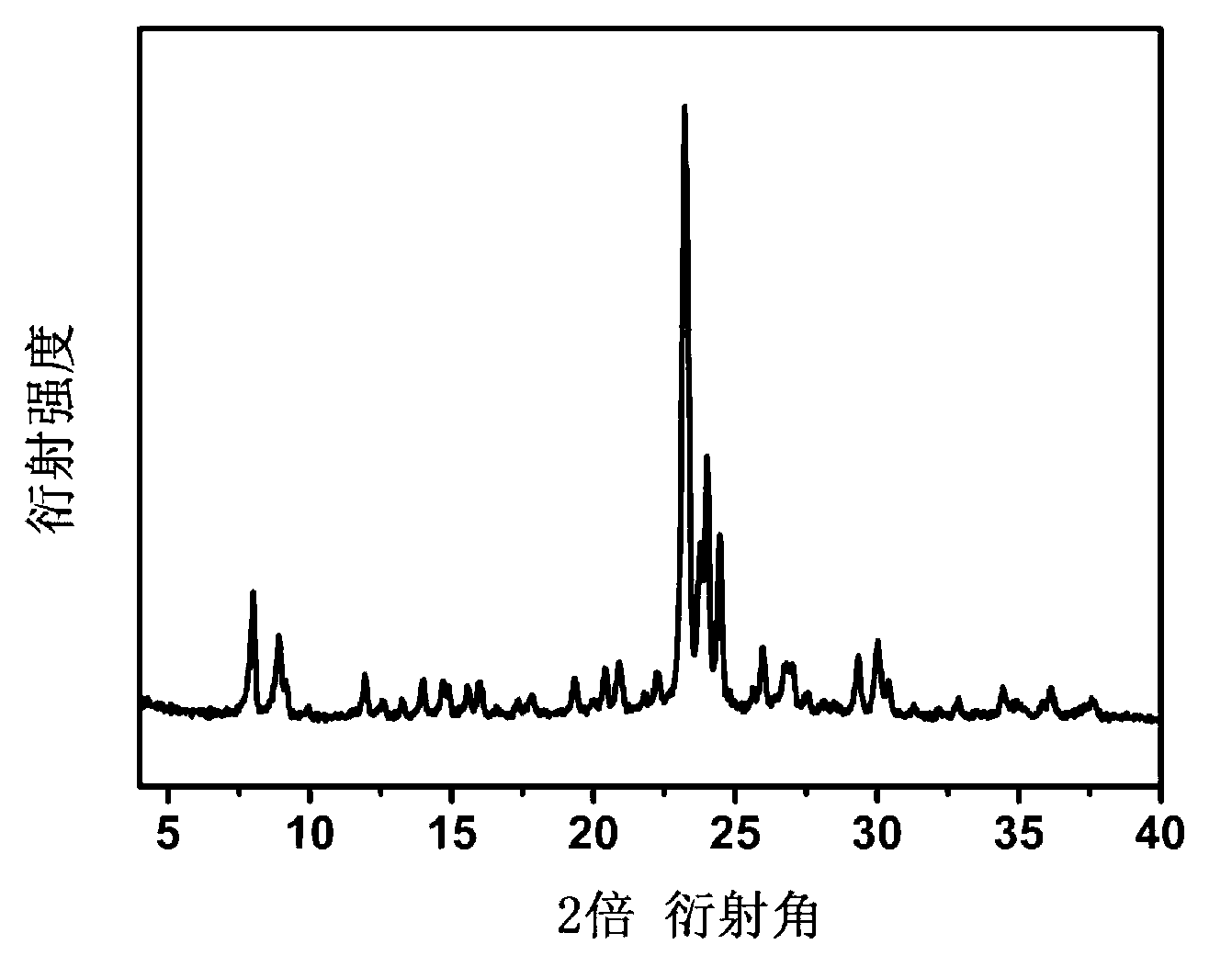

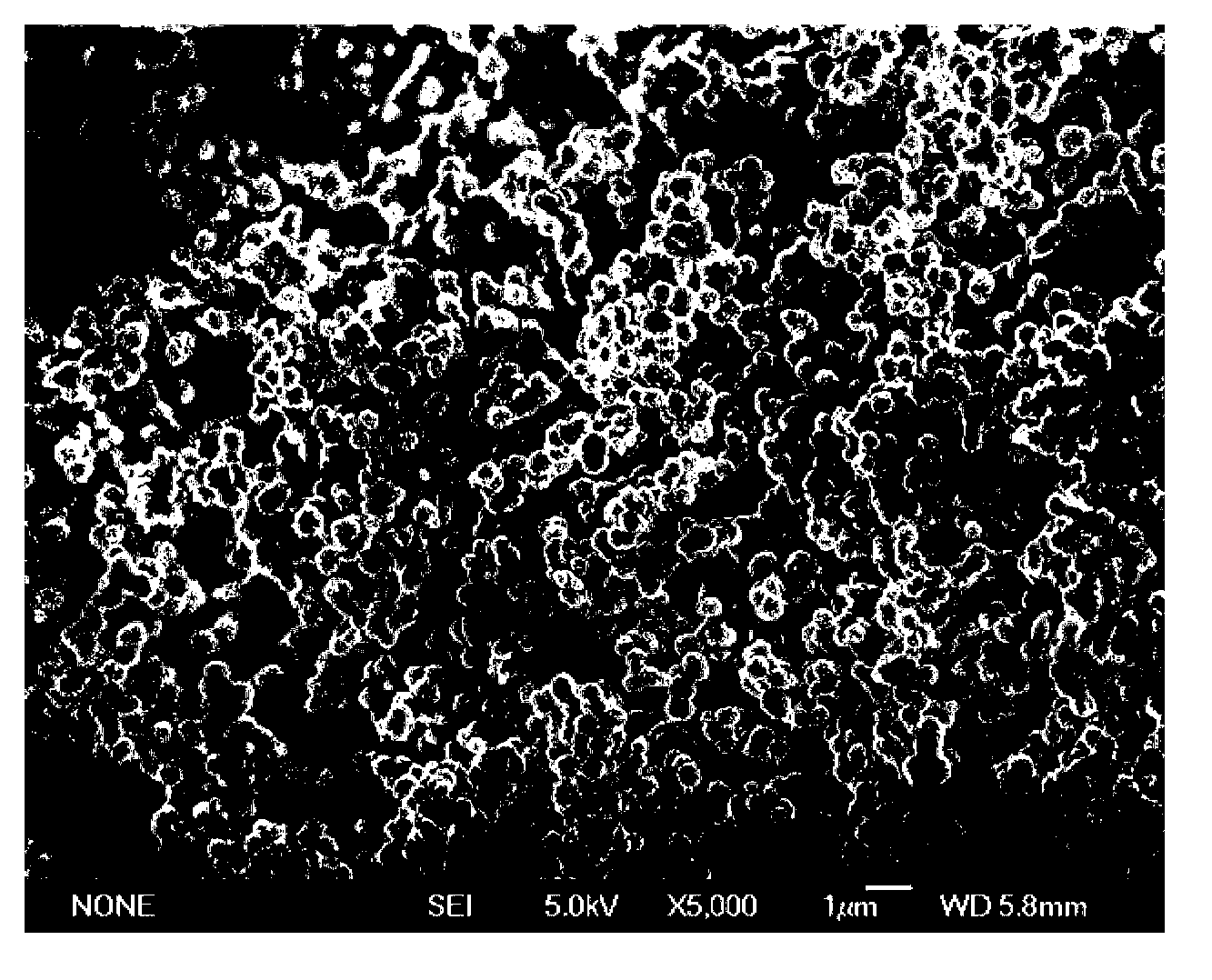

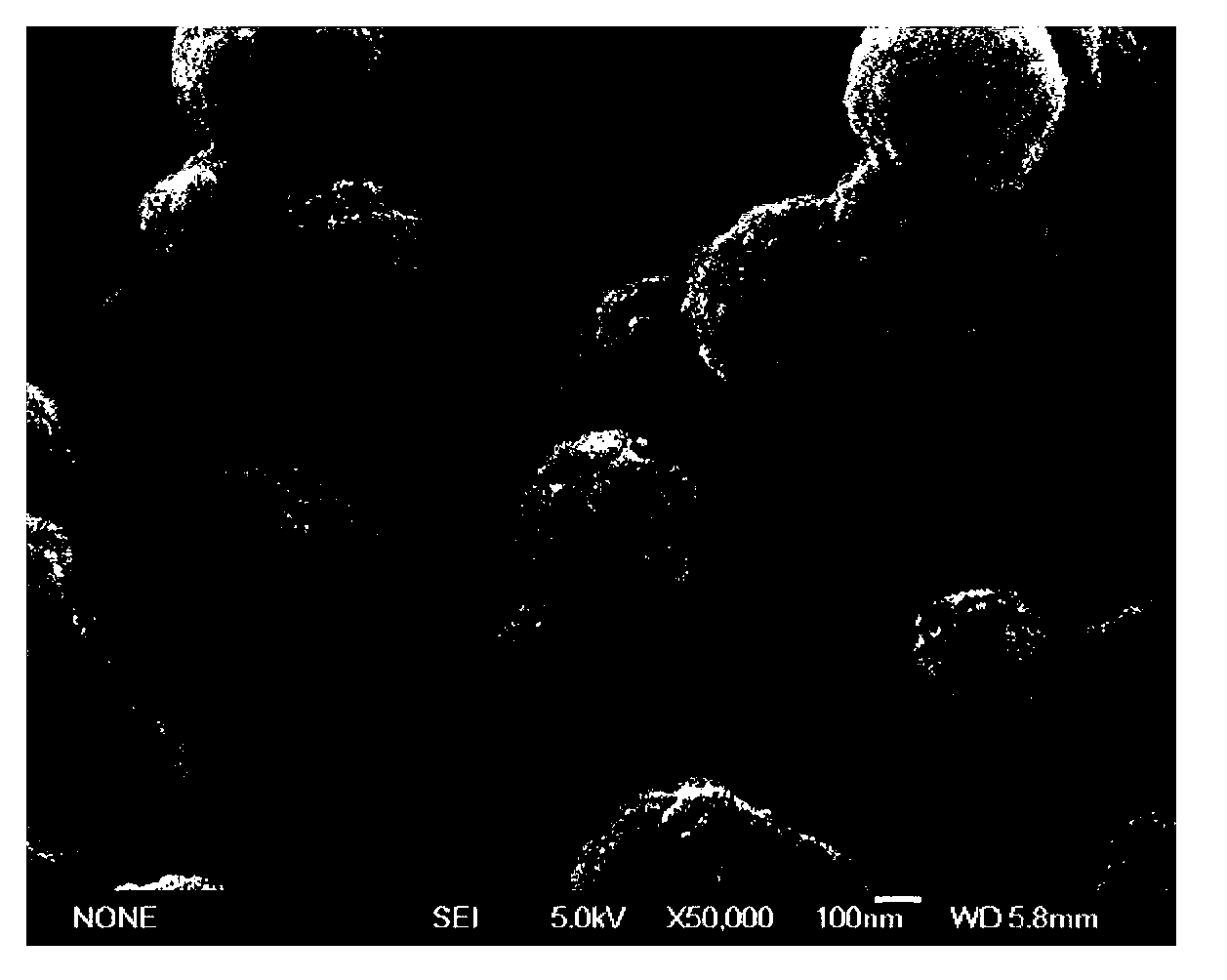

InactiveCN103011189AReduce pollutionLow cost of industrializationMolecular sieve catalystsOrganic compound preparationWater bathsDispersity

The invention belongs to the technical field of molecular sieve preparation, and particularly relates to an in-situ preparation method for a microporous-mesoporous molecular sieve containing noble metal. The in-situ preparation method comprises the steps as follows: adding a coupling pore-forming agent, a silicon source, an aluminum source or a titanium source, and an alkali source into a water solution of noble metal nano particles in sequence under the water bath condition; and ageing, drying, crystallizing, drying and carrying out high-temperature calcination to obtain the microporous-mesoporous molecular sieve containing the noble metal. The prepared microporous-mesoporous molecular sieve is provided with a hierarchical pore structure; the noble metal nano particles with high dispersity are covered in situ while a mesoporous structure is generated; and a synthetic method is convenient and simple, saves energy and reduces emission. A multifunctional catalyst prepared with the method integrates the advantages of the microporous channels of the molecular sieve, the transgranular meso pores and the intergranular meso pores of the molecular sieve and the noble metal nano particles, and is more suitable for catalytic reactions of sulfur-containing large molecules such as hydrogen desulfurization and the like.

Owner:JILIN UNIV

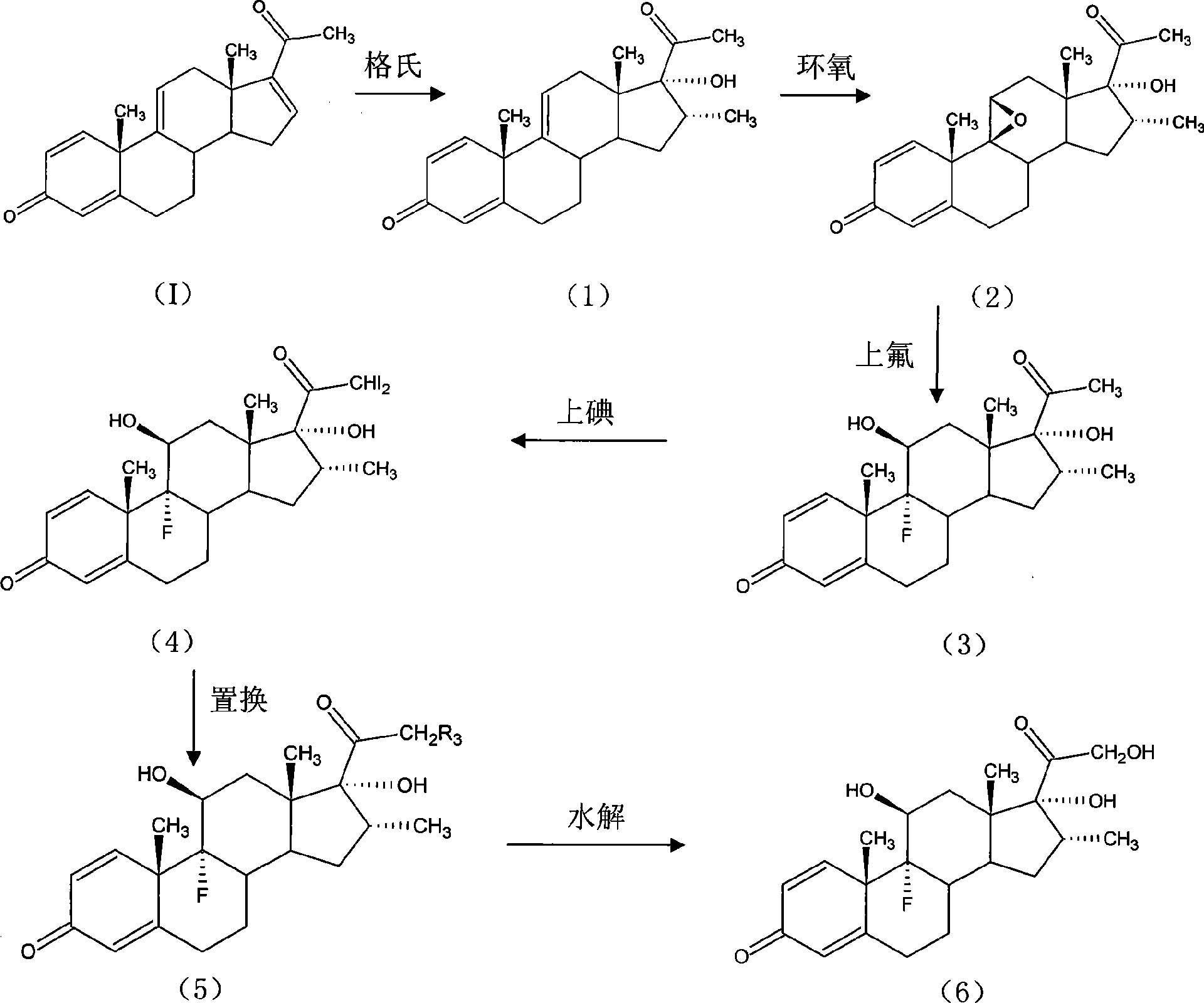

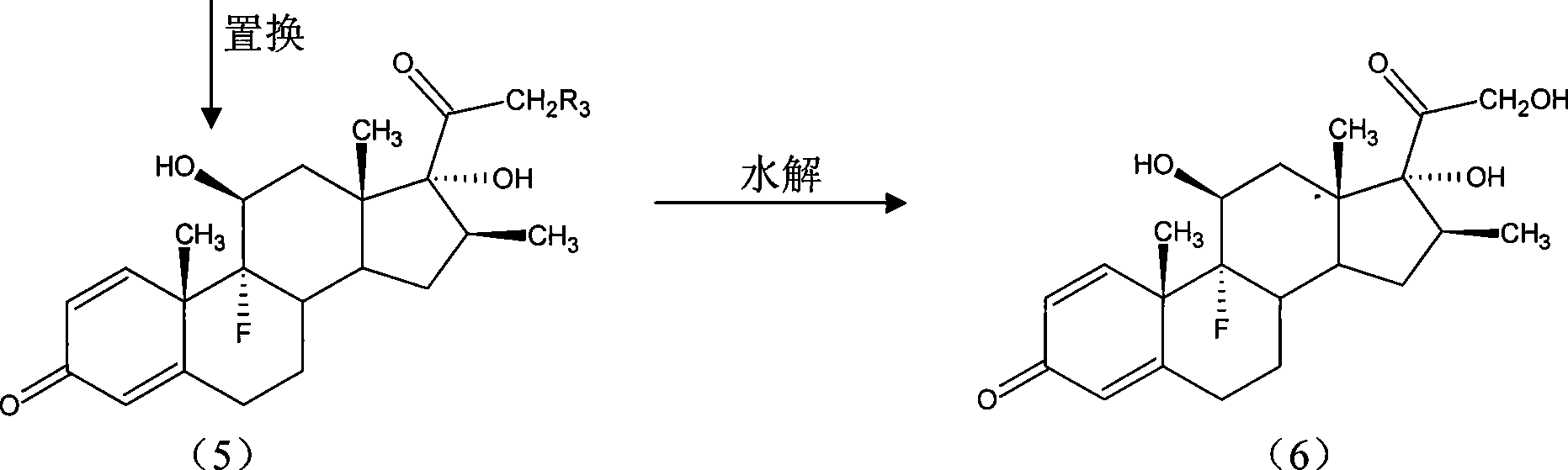

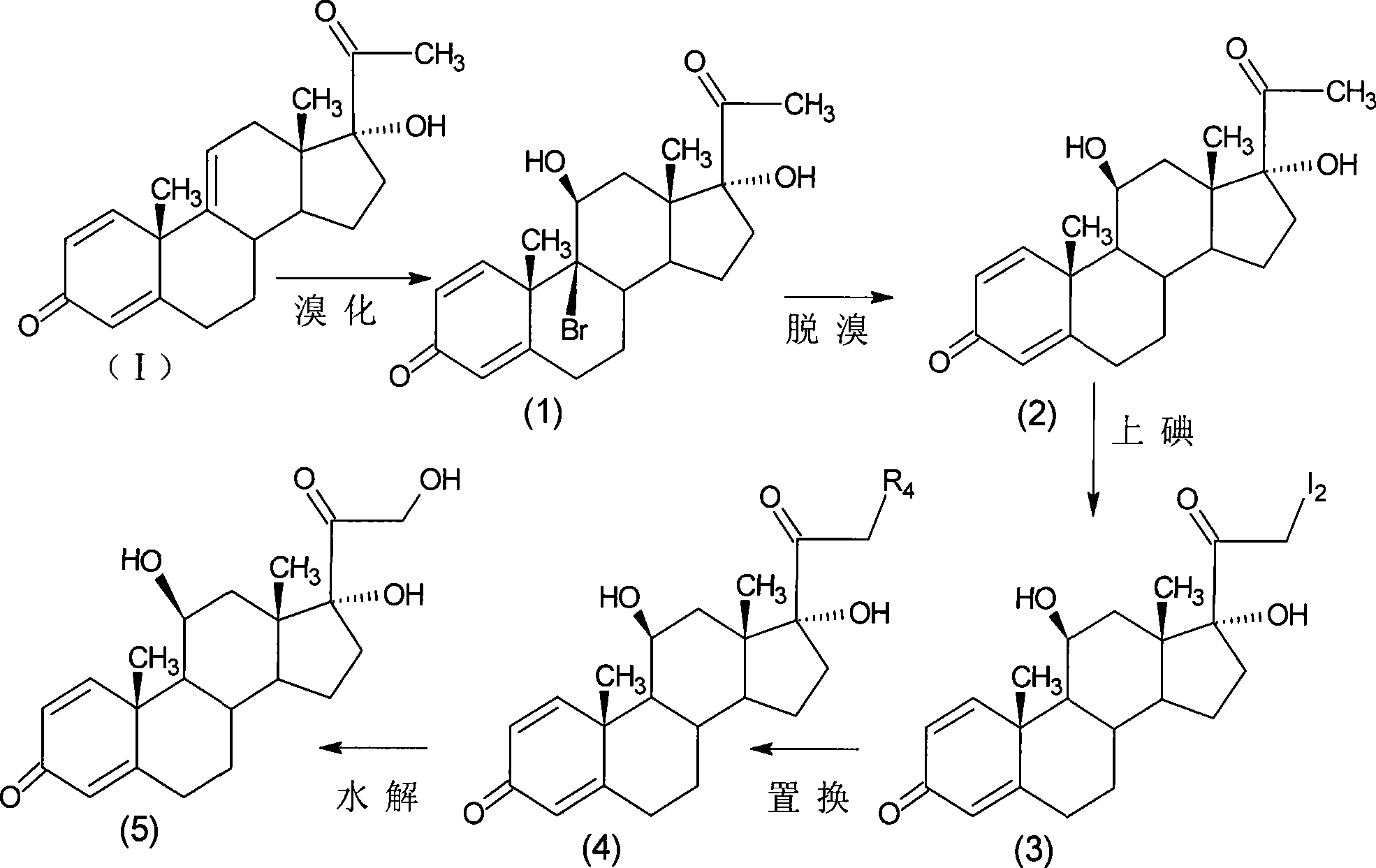

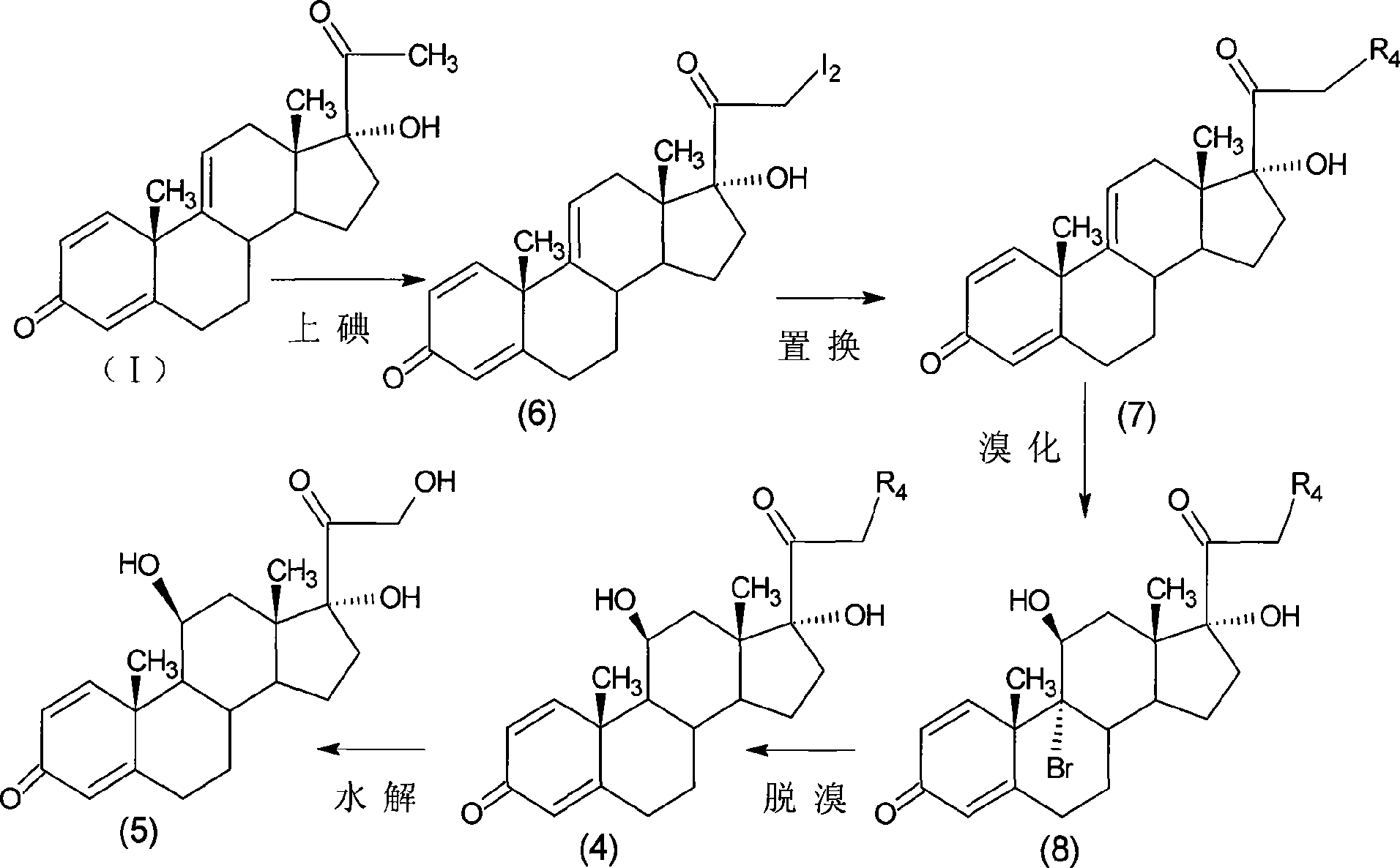

Method for preparing dexamethasone and series products thereof

The invention provides a completely new process route for synthesizing dexamethasone and series products thereof. The invention adopts 1, 4, 9, 16-tetraene-pregna-3, 20-diketone as the original material which is modified by 9, 11bits, 16, 17 bits and 21 bits so as to obtain the dexamethasone and the series products thereof such as dexamethasone acetate and dexamethasone sodium phosphate and the like. The process has the advantage that the invention adopts the existing intermediates of manufacturers as the original material; the route is simple; the materials are available; the use of expensive accessories is avoided; the yield and the cost are dramatically better than that of the prior methods used for synthesizing the dexamethasone and derivatives thereof; moreover, the adoption of the existing intermediates realizes the combined-line prodction of the betamethasone series products and the dexamethasone series products, thus greatly reducing the manufacturing cost and the industrial manufacturing condition.

Owner:TIANJIN TIANYAO PHARM CO LTD

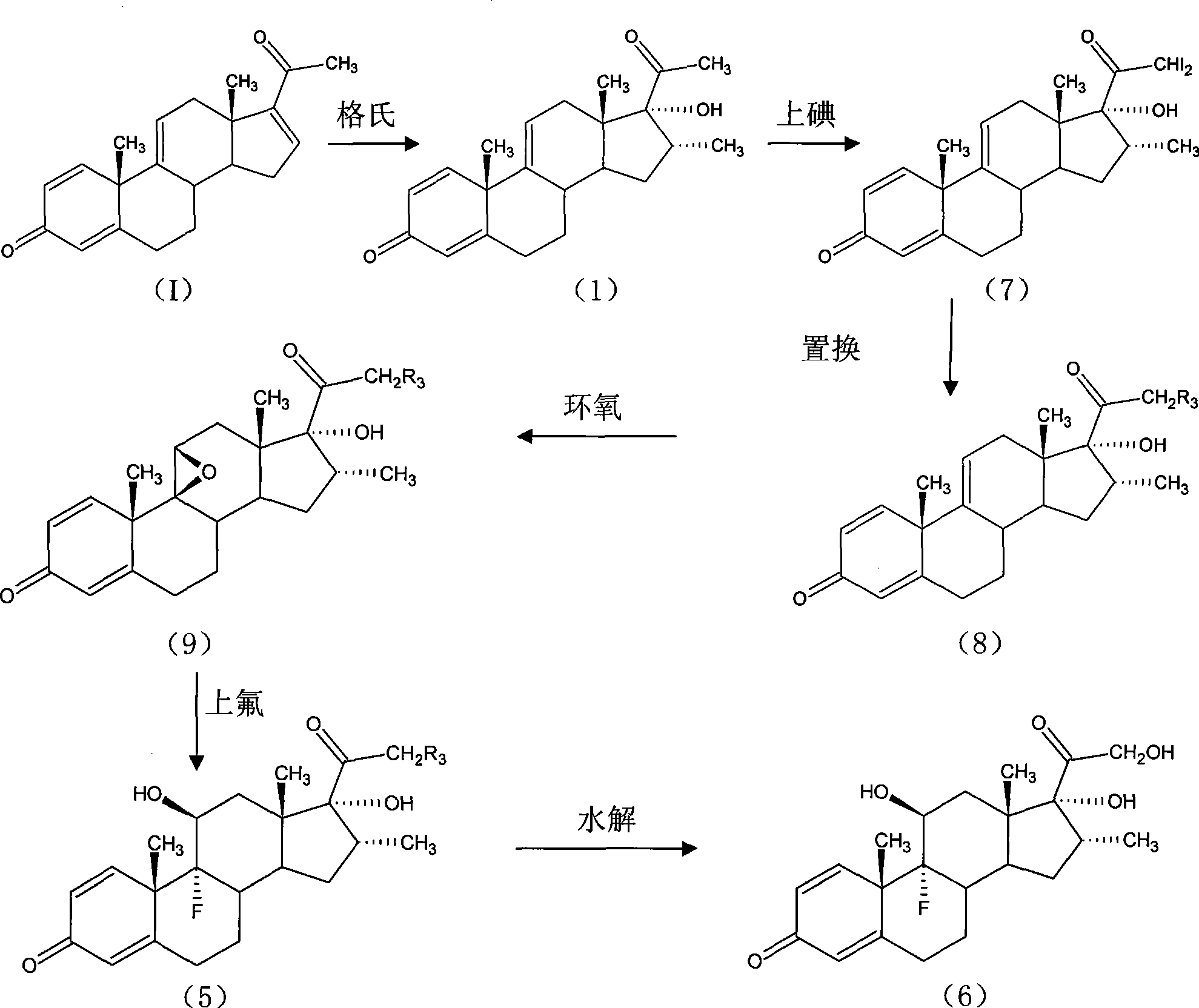

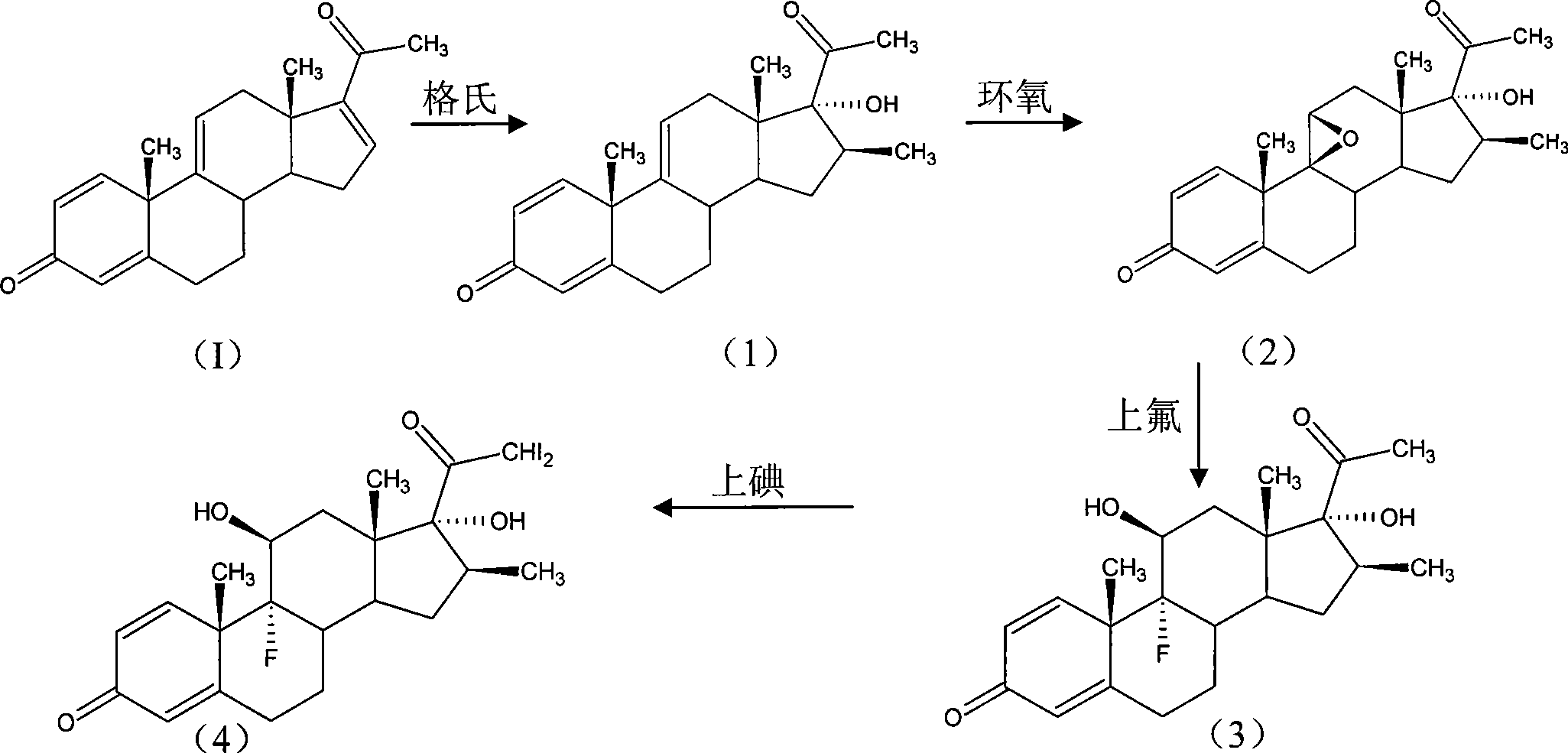

Method for preparing betamethasone and series products thereof

InactiveCN101397319ASimple lineRaw materials are easy to getSteroidsChemistryBetamethasone Sodium Phosphate

The invention provides a completely new process route for synthesizing betamethasone and series products thereof. The invention adopts 1, 4, 9, 16-tetraene-pregna-3, 20-diketone as the original material which is modified by 9, 11 bits, 16, 17 bits and 21 bits so as to obtain the betamethasone and the series products thereof such as betamethasone acetate and betamethasone sodium phosphate and the like. The process has the advantage that the invention adopts the existing intermediates of manufacturers as the original material; the route is simple; the materials are available; the use of expensive accessories is avoided; the yield and the cost are dramatically better than that of the prior methods used for synthesizing the betamethasone and derivatives thereof; moreover, the adoption of the existing intermediates realizes the combined-line production of the betamethasone series products and dexamethasone series products, thus greatly reducing the manufacturing cost and the industrial manufacturing condition.

Owner:TIANJIN TIANYAO PHARM CO LTD

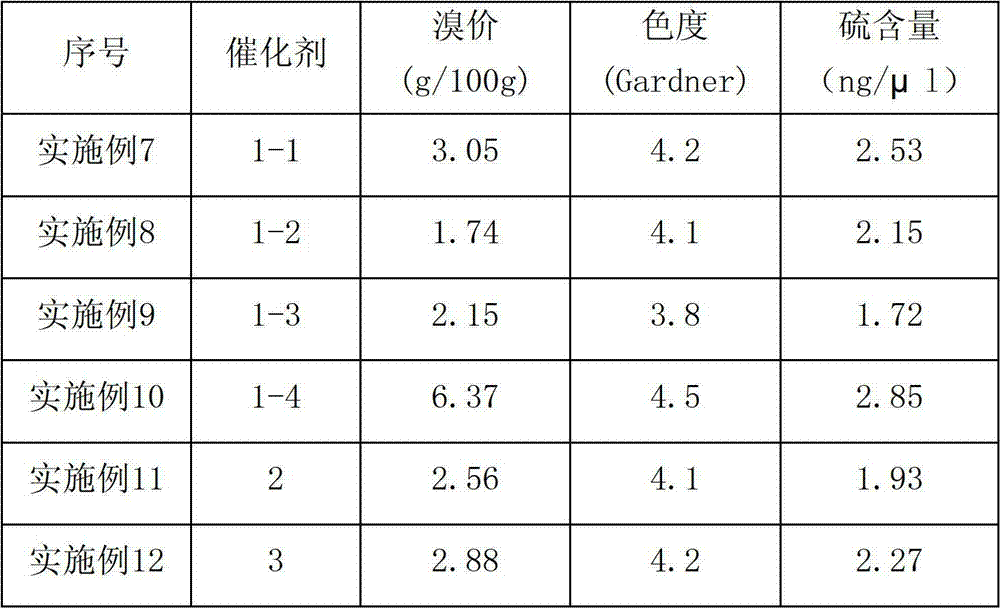

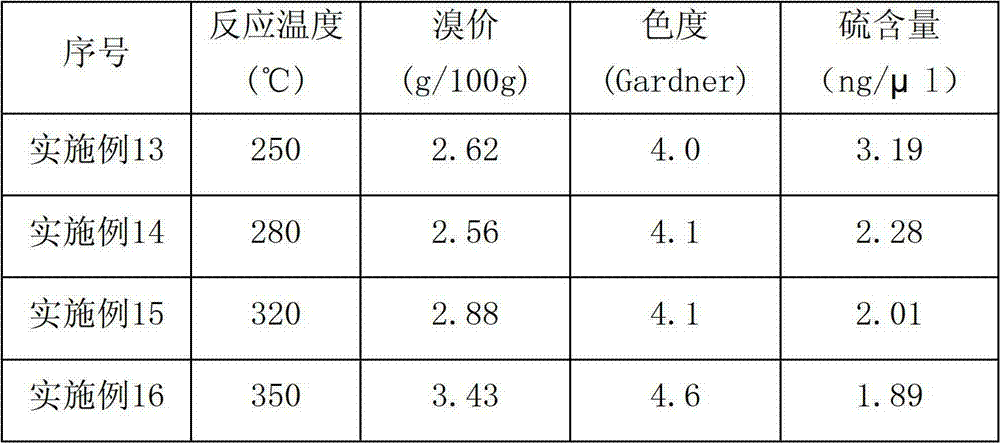

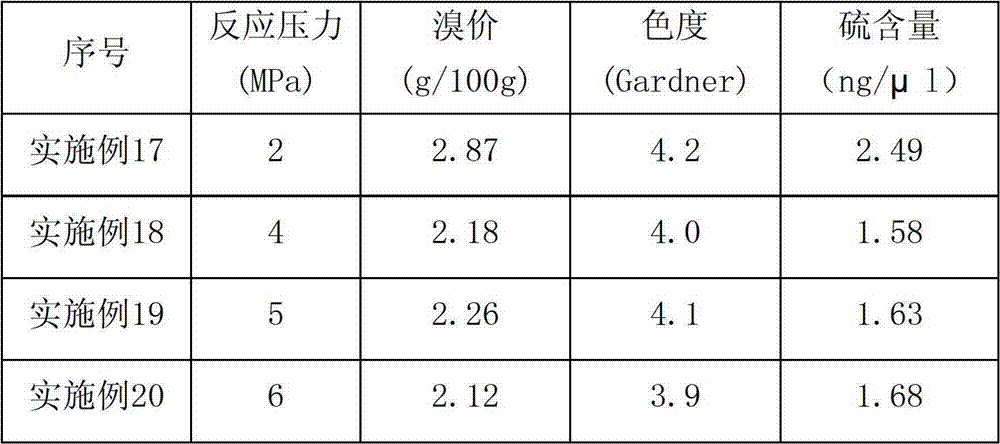

Preparation method for C9 hydrogenation petroleum resin

InactiveCN102924659AWide adaptabilityImprove performanceMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationSolvent

The invention relates to a preparation method for C9 hydrogenation petroleum resin. The C9 hydrogenation petroleum resin is dissolved in organic solvent, and the concentration of the C9 hydrogenation petroleum resin is 5wt %-30wt%. The C9 hydrogenation petroleum resin is filtered to remove undissolved substances, then subjected to a first section of hydrodesulfurization process and a second section of hydrogenation decoloration process, and finally subjected to the process of decompression rectification and solvent recovery to obtain C9 hydrogenation petroleum resin products. The preparation method adopts two-section hydrogenation, improves reaction activity, selectivity and impurity resistant capability, is wide in adaptability of C9 petroleum resin raw materials, and obtains C9 petroleum resin through adoption of thermal polymerization or catalytic polymerization. No matter impurity content in resin solution is high or low, particularly, when sulphur content is high in the resin solution, the two-step hydrogenation process can be carried out through the preparation method, and the C9 hydrogenation petroleum resin with high performance is obtained. Through the first section of hydrodesulfurization, hydrogenation noble metal catalyst in the second section is effectively protected. Service life of catalyst is greatly prolonged. Reaction pressure of the two-section hydrogenation is quite low, and industrial production cost is little.

Owner:CHINA PETROLEUM & CHEM CORP

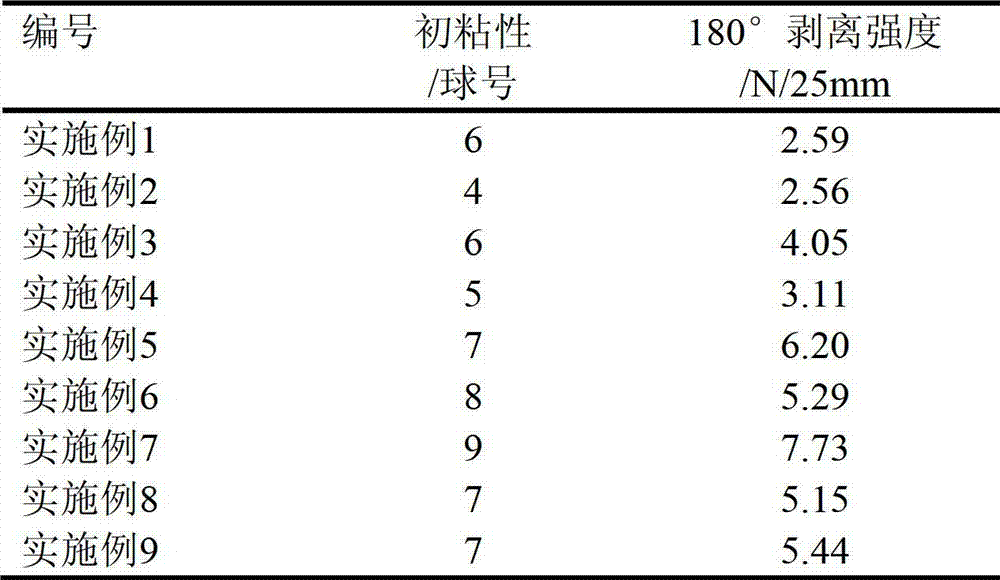

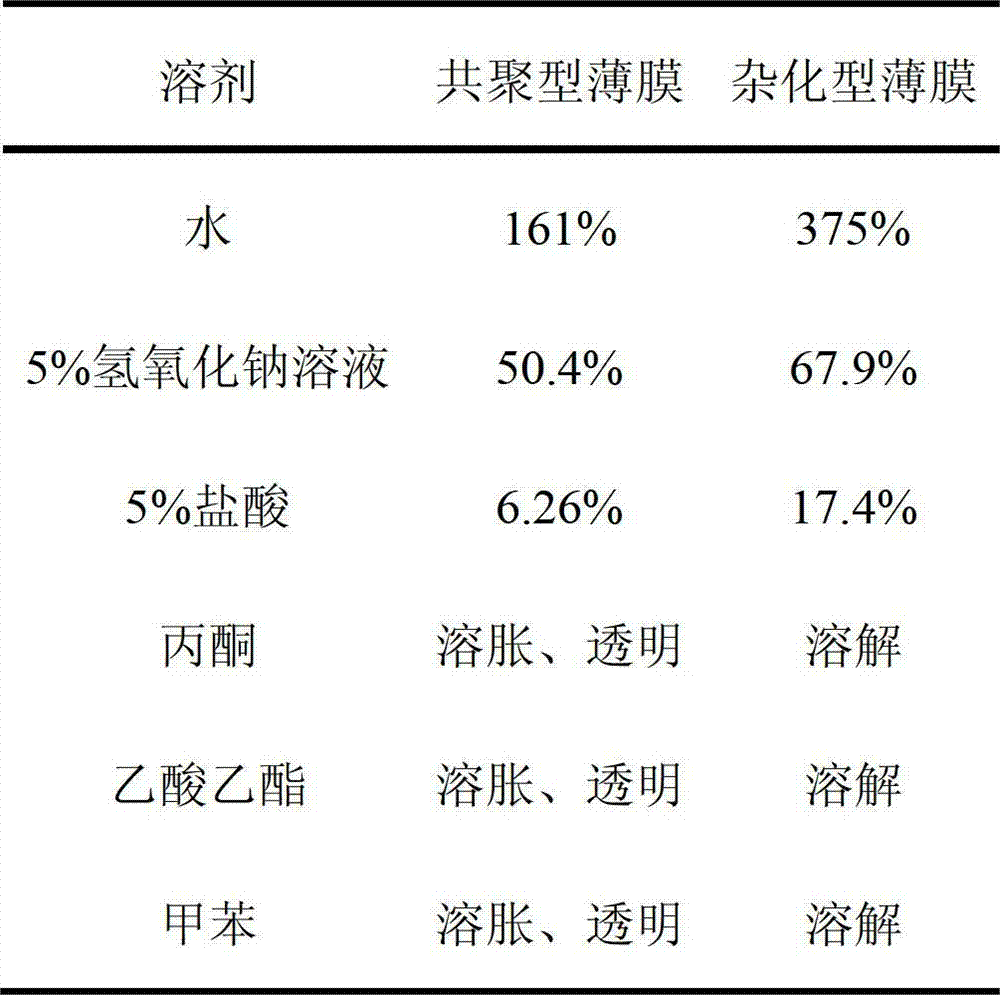

Method for preparing water-based urethane acrylate pressure-sensitive adhesive

The invention provides a method for preparing water-based urethane acrylate pressure-sensitive adhesive. According to the method, water-based urethane is chemically modified by using acrylate, and the water-based urethane and the acrylate are combined with each other in a chemical bond form, so that the synthesized water-based urethane acrylate pressure-sensitive adhesive has excellent performance of the water-based urethane and the acrylate. According to the water-based urethane acrylate pressure-sensitive adhesive, water-based urethane acrylate copolymerization emulsion and tackifying resin are used as main components. The method comprises the following steps of: firstly, reacting a hydroxy monomer, a hydrophilic chain extender and polyisocyanate which are used as main raw materials to generate polyurethane prepolymer, and adding a hydroxy-containing acrylate monomer to obtain hydroxy-terminated polyurethane prepolymer; secondly, adding a salt-forming agent to neutralize the hydroxy-terminated polyurethane prepolymer, and dispersing in water to obtain water-based polyurethane emulsion; and finally, properly polymerizing the water-based polyurethane emulsion and the acrylate to obtain the water-based urethane acrylate copolymerization emulsion, and adding the tackifying resin of different mass fractions, thereby obtaining water-based urethane acrylate pressure-sensitive adhesive emulsion.

Owner:JIANGSU HONGYUAN NEW MATERIAL TECH

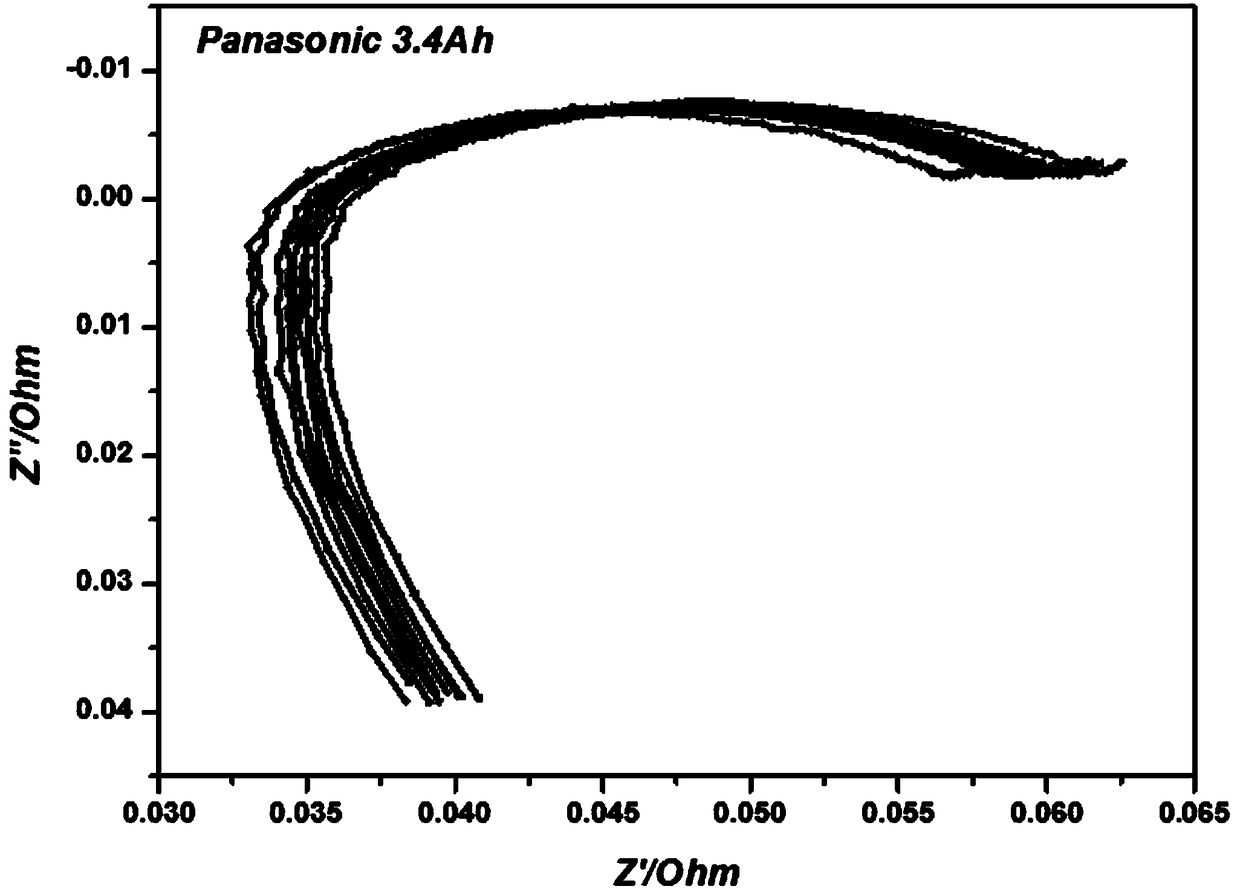

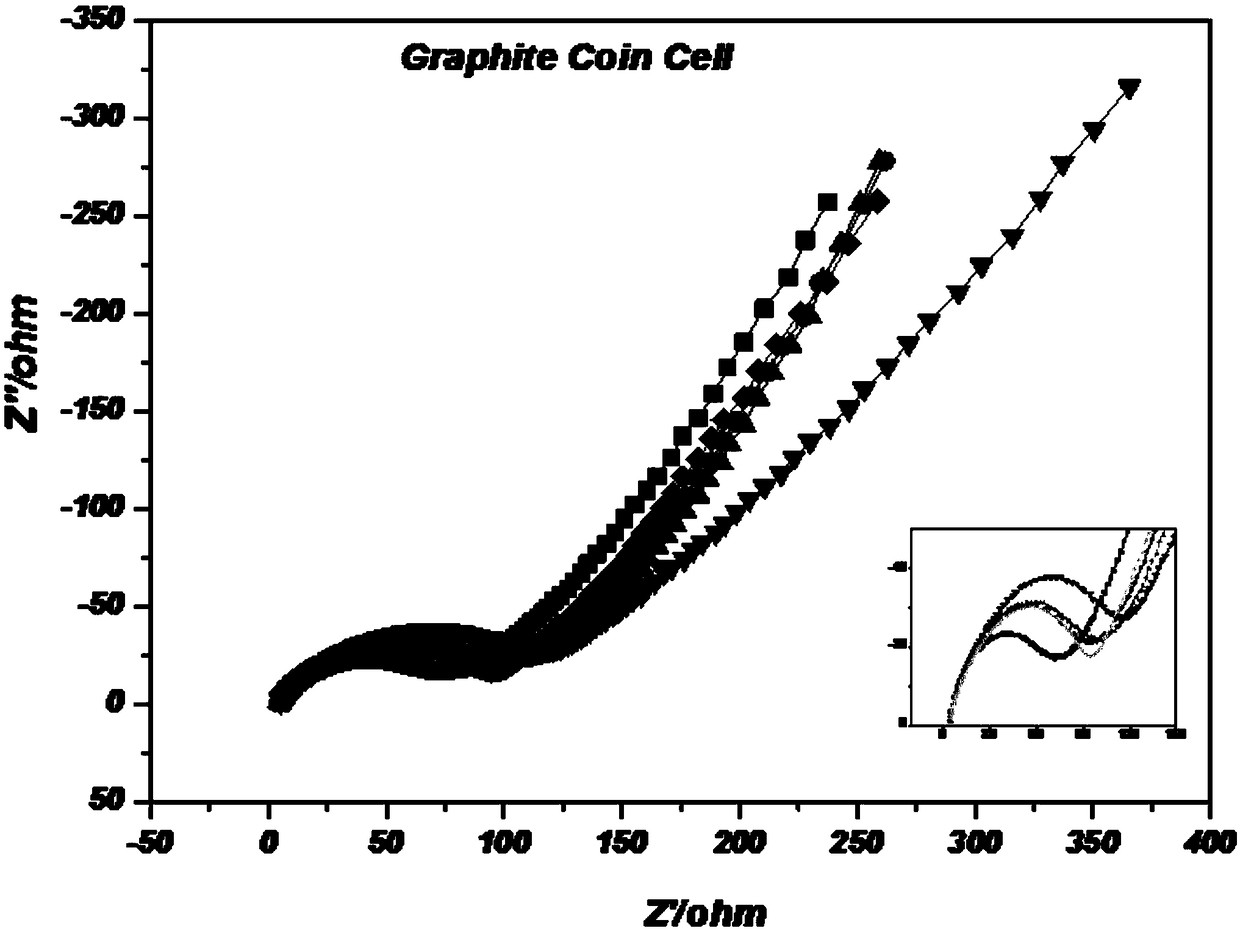

Method for quickly detecting consistency of batteries through AC impedance test

The invention discloses a method for quickly detecting the consistency of batteries through an AC impedance test, and the method comprises the following steps: (1), preparing ten or more batteries ofthe same type and same brand, and performing the parallel sample testing; (2), performing the AC impedance testing of the batteries which reach the specified voltage or capacity; (3), testing the DC internal resistance of the batteries through a DC discharge testing method; (4), finally performing the data processing according to the parallel sample data collection of the AC impedance of the batteries and the size calculation of the DC internal resistance, analyzing a coincidence pattern of Nyquist graphs, and performing the comprehensive evaluation of the consistency of the batteries. The method can obtain ohmic internal resistance, charge transfer internal resistance and diffusion internal resistance through the AC impedance test, wherein the ohmic internal resistance comprises the internal resistance of an electrode piece and made resistance caused by the technology. Through the comparison of the above internal resistance conditions, the method can obtain the statistical data of consistency for reference.

Owner:南京卡耐新能源技术发展有限公司 +4

Stain-resistant heat-insulation coating and preparation method thereof

InactiveCN104403465AImprove rigidityGood stain resistanceReflecting/signal paintsPhotopigmentCoating

The invention discloses a special electric stain-resistant heat insulation coating. The special electric stain-resistant heat insulation coating comprises the following components in parts by weight: 15-50 parts of a film formation emulsion, 5-30 parts of nano oxide powder, 10-20 parts of heat reflection pigment, 5-25 parts of hollow ceramic microbeads, 8-15 parts of a filler, 5-15 parts of additives and a proper amount of deionized water. The purposes of resisting stains and insulating heat can be achieved by introducing components such as nano oxide powder into the heat insulation coating. The invention also discloses a preparation method of the stain-resistant heat insulation coating. The preparation method of the stain-resistant heat insulation coating comprises the following steps: adding deionized water, part of the additives, the nano oxide powder, the hollow ceramic microbeads, the heat reflection pigment and filler into a grinder for grinding to obtain slurry; transferring the prepared slurry into a dispersing machine, adding the film formation emulsion and the rest of additives into the slurry, stirring and dispersing the slurry, filtering the slurry by a screen to obtain the stain-resistant heat insulation coating. The preparation method of the stain-resistant heat insulation coating is simple in process, easy to implement and simple and convenient to operate.

Owner:STATE GRID CORP OF CHINA +3

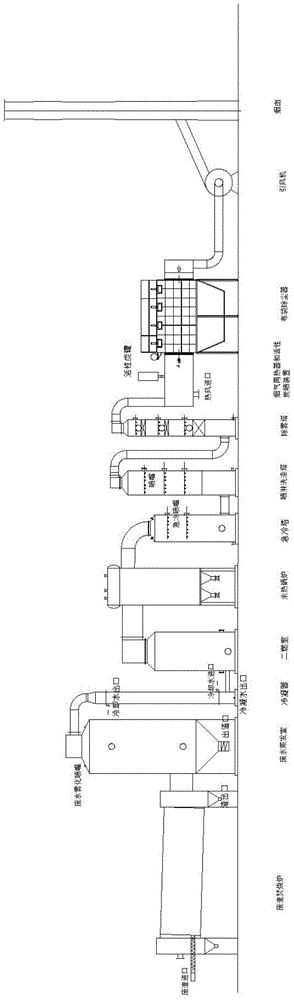

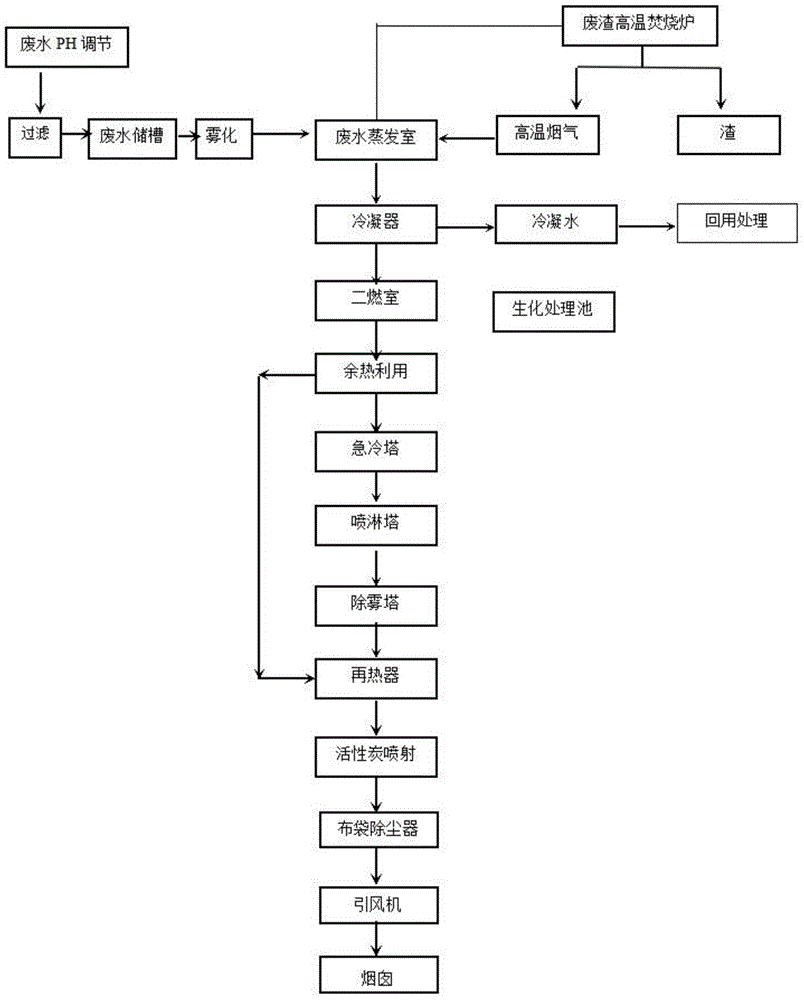

Method for treating high-concentration salty waste water and waste residue at low cost, and device thereof

ActiveCN105090997ATo achieve the purpose of initial dehydrationSave energyEmission preventionCombustion technology mitigationHigh concentrationWater vapor

The invention provides a method for treating high-concentration salty waste water and waste residue at low cost. The method is characterized by comprising a step 1 of mixing high-temperature smoke generated by burning of the waste residue with atomized waste water, and separating out water vapor smoke; a step 2 of separating out smoke through condensing of the water vapor smoke; a step 3 of subjecting the smoke to secondary burning, waste heat recovery, rapidly quenching treatment and purification treatment, and discharging the treated smoke. The method and the device thereof can simultaneously treat the waste residue and the waste water, and the treatment cost is low.

Owner:季栋梁

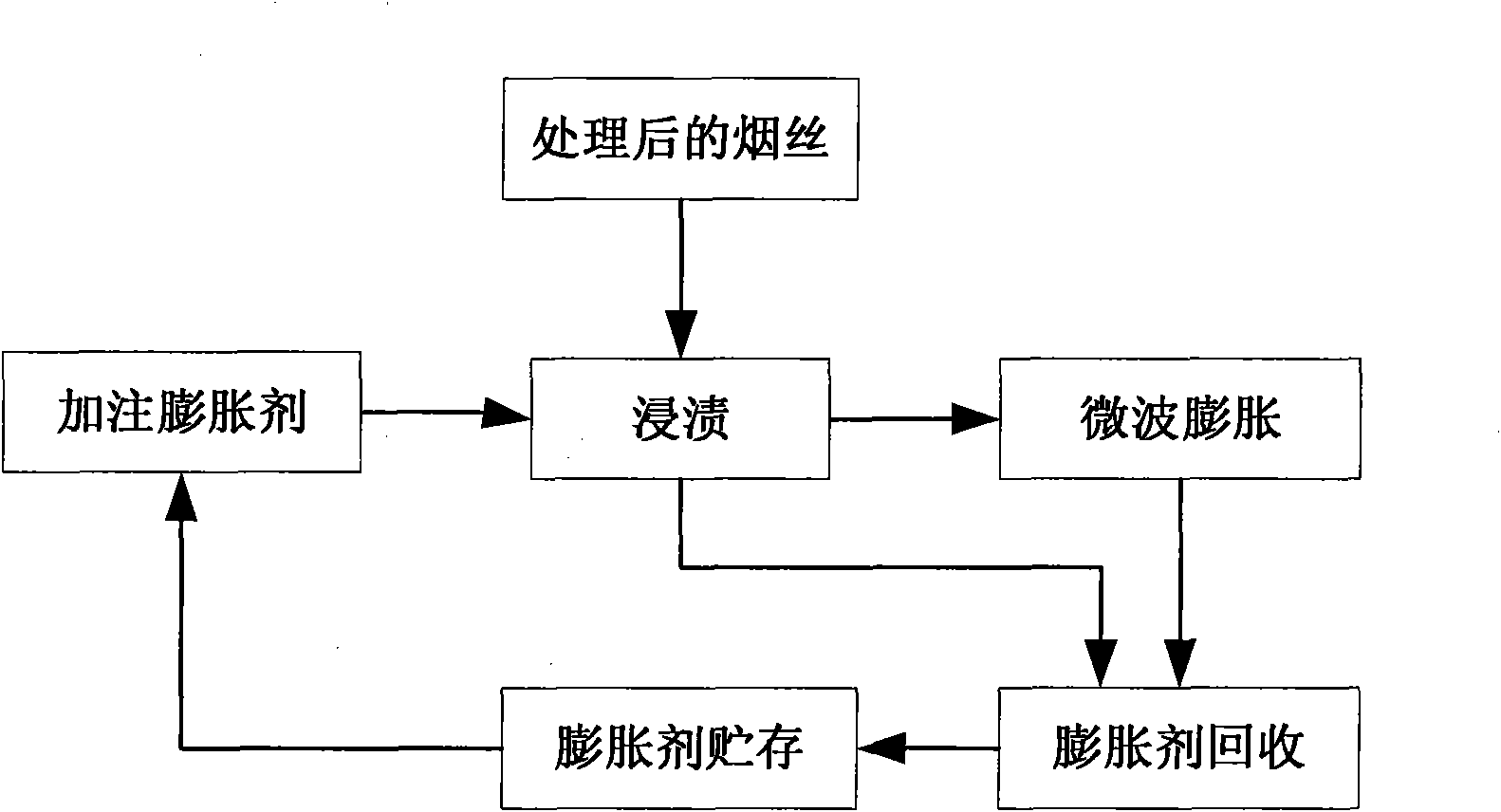

Method for continuous microwave expansion of cut tobacco

ActiveCN101617855AStable internal and external temperature changesNo damageTobacco preparationAlkaneMicrowave

A method for continuous microwave expansion of cut tobacco comprises the following steps: impregnating the cut tobacco in an expanding agent; recycling the expanding agent in an impregnating device after impregnation; carrying out microwave expansion on the impregnated cut tobacco by a microwave dryer to obtain the expanded cut tobacco. The expanded cut tobacco comprises one or more than two components of ethanol with 4-12 carbon atoms, ketone with 4-12 carbon atoms, halogenether with 2-12 carbon atoms, alkane with 3-12 carbon atoms or alkane with 3-12 carbon atoms substituted by 2 halogen atoms. The filling value of the expanded cut tobacco reaches above 7.5, the cutting ratio is above 90%, the moisture content after expansion is 12-13%, the expansion of the cut tobacco is even without water damaged cut tobacco; the whole set of devices has low energy consumption and high automation, and continuous closed mass production can be carried out.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

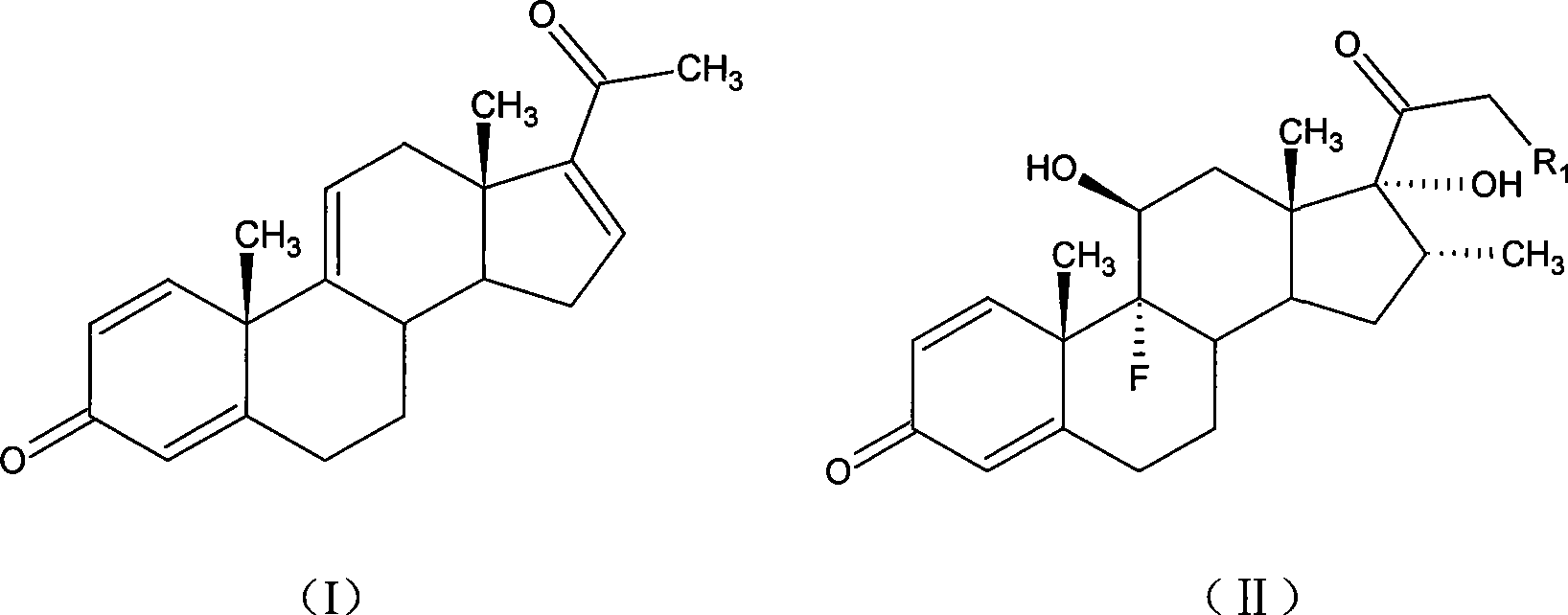

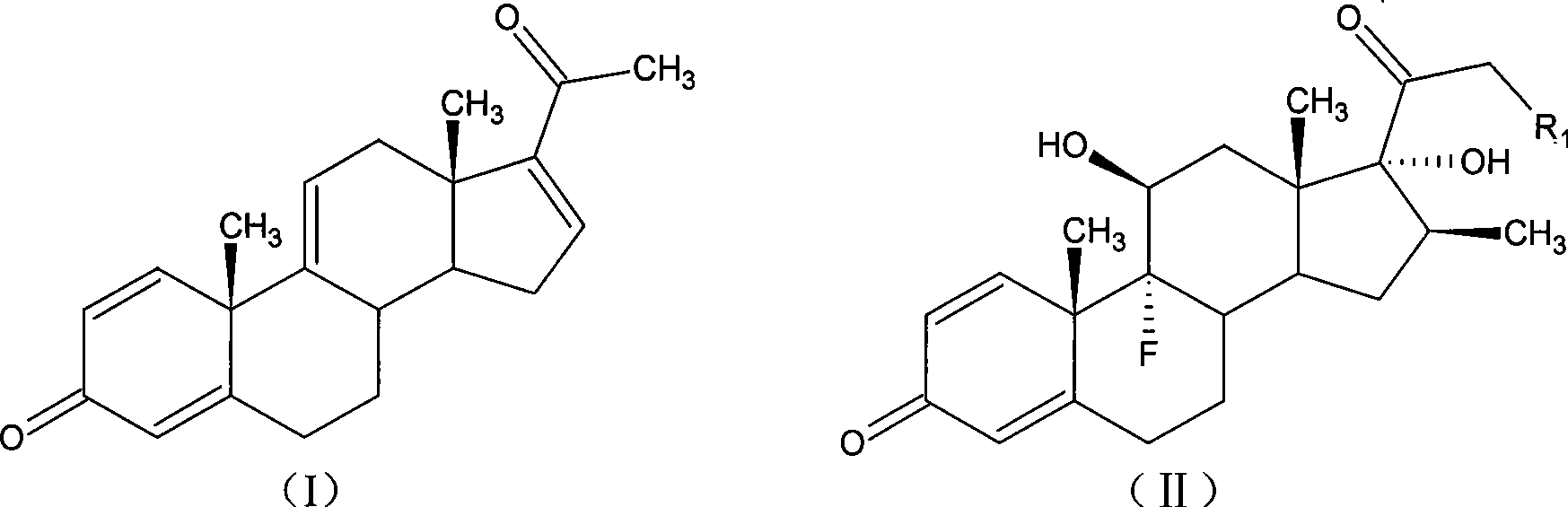

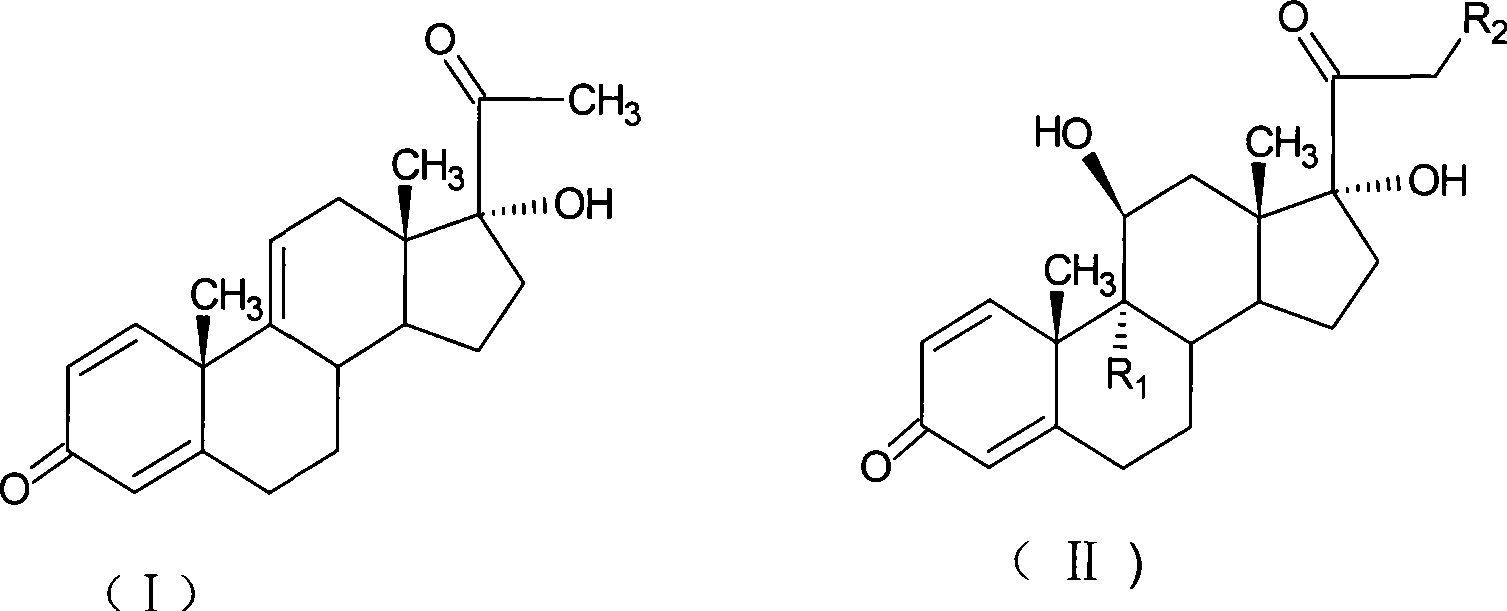

Preparation of metacortandralone and derivatives thereof

The invention relates to a preparation method of a steroid compound, in particular to the preparation for prednisolone and the derivative thereof, which takes 17-hydroxyl-1, 4, 9-triene- pregna-3, 20-diketone as the initiator and is improved by 9, 11th and 21st to obtain the prednisolone and the derivative thereof, such as prednisolone acetic ester, isoflupredone, and the like. The invention further provides the application of a compound (I) in the preparation of a compound (II). As the production process adopts the existing intermediate of the company as the initiator, the line is concise, the material is easy to obtain, expensive auxiliary materials are saved, and the yield and the cost are obviously superior to the historical synthetic method of the prednisolone and the derivative thereof; in addition, the adoption of the existing intermediate realizes the doubling production of the triamcinolone products and the prednisolone products, thus greatly reducing the production cost and industrial conditions. R1 is equal to H, F, Cl and Br; R2 is equal to H, OH and OCOR3, wherein, R3 is equal to the alkyl with less than 11carbon atoms.

Owner:TIANJIN PHARMA GROUP CORP

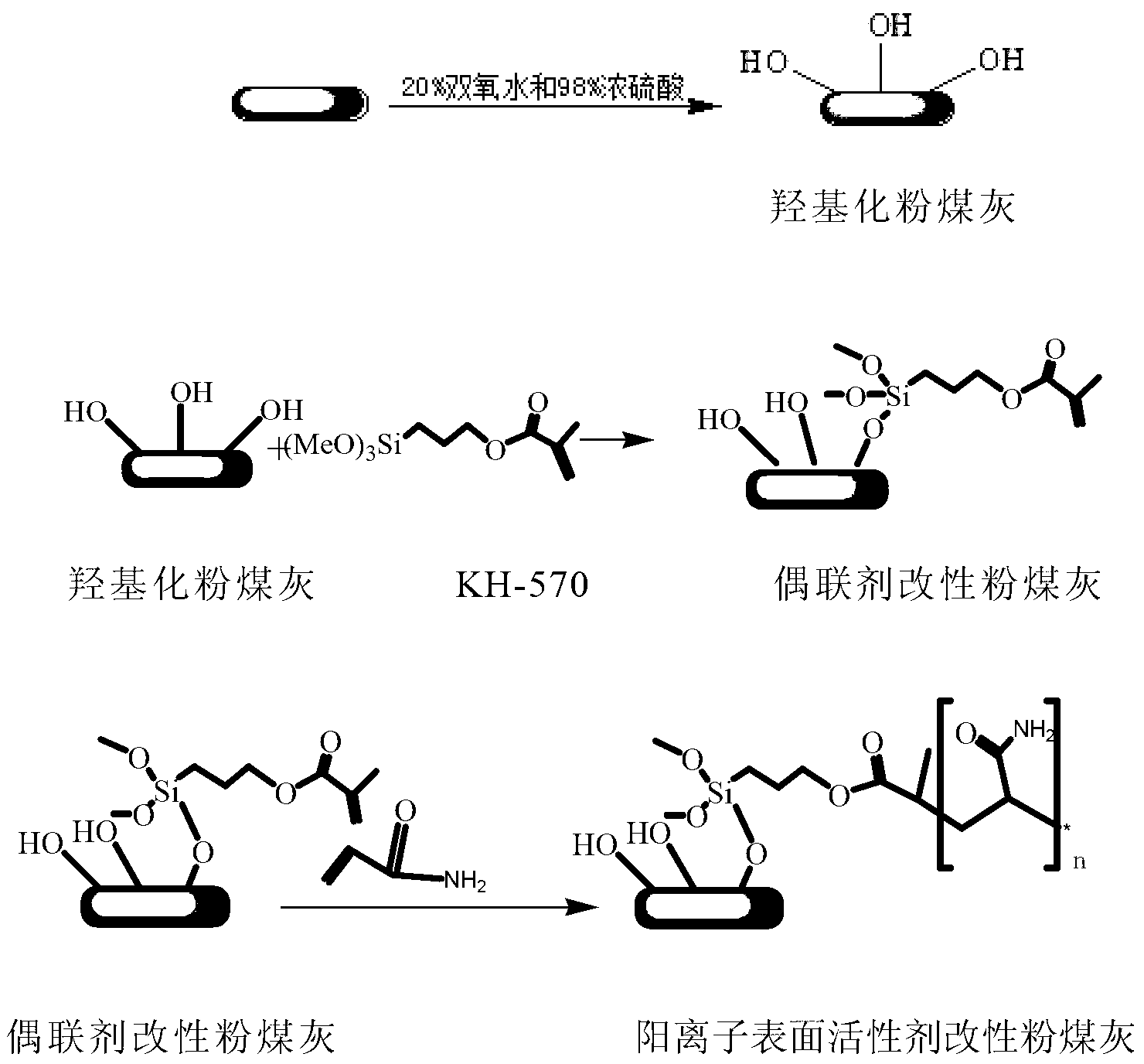

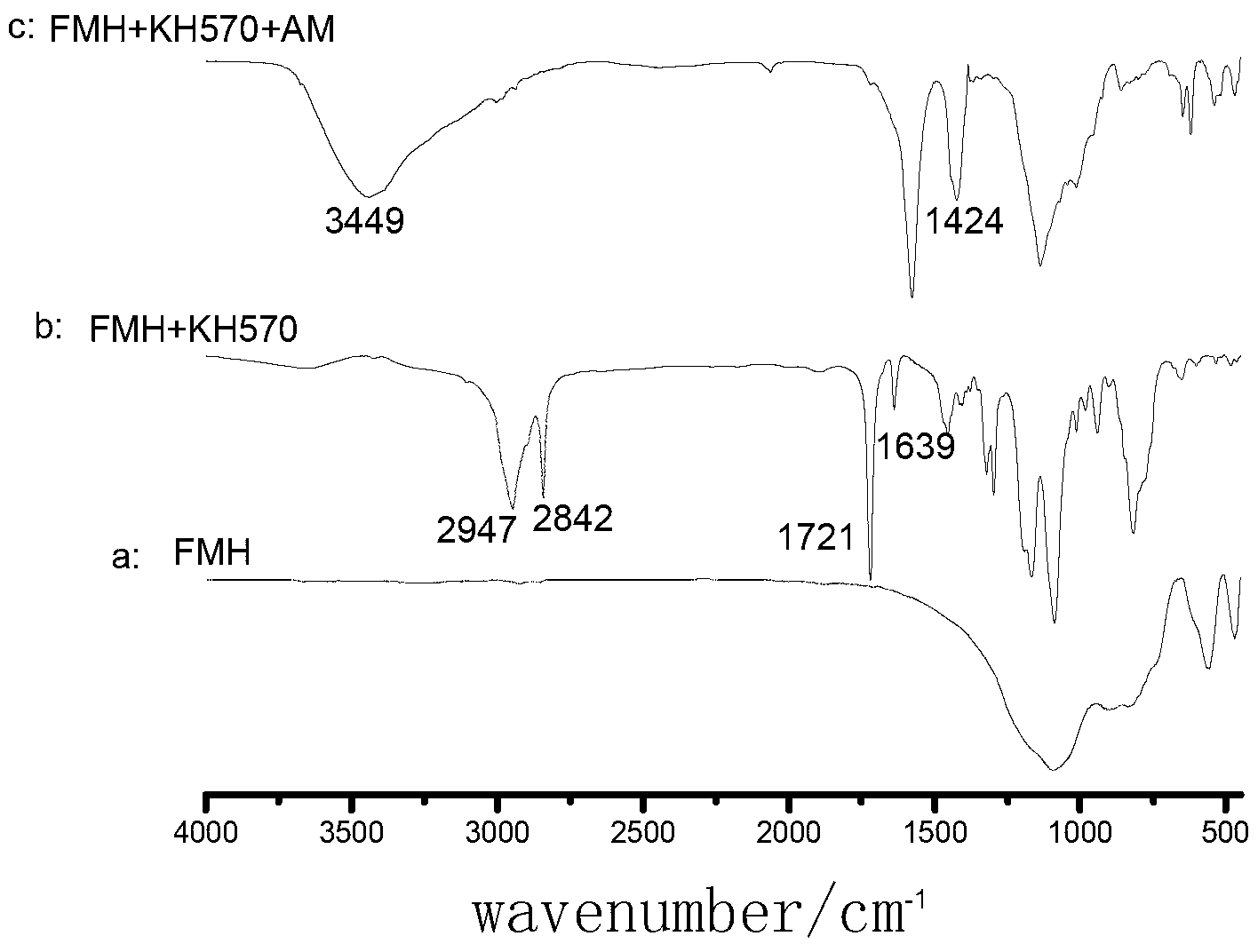

Preparation method of cationic surfactant modified fly ash

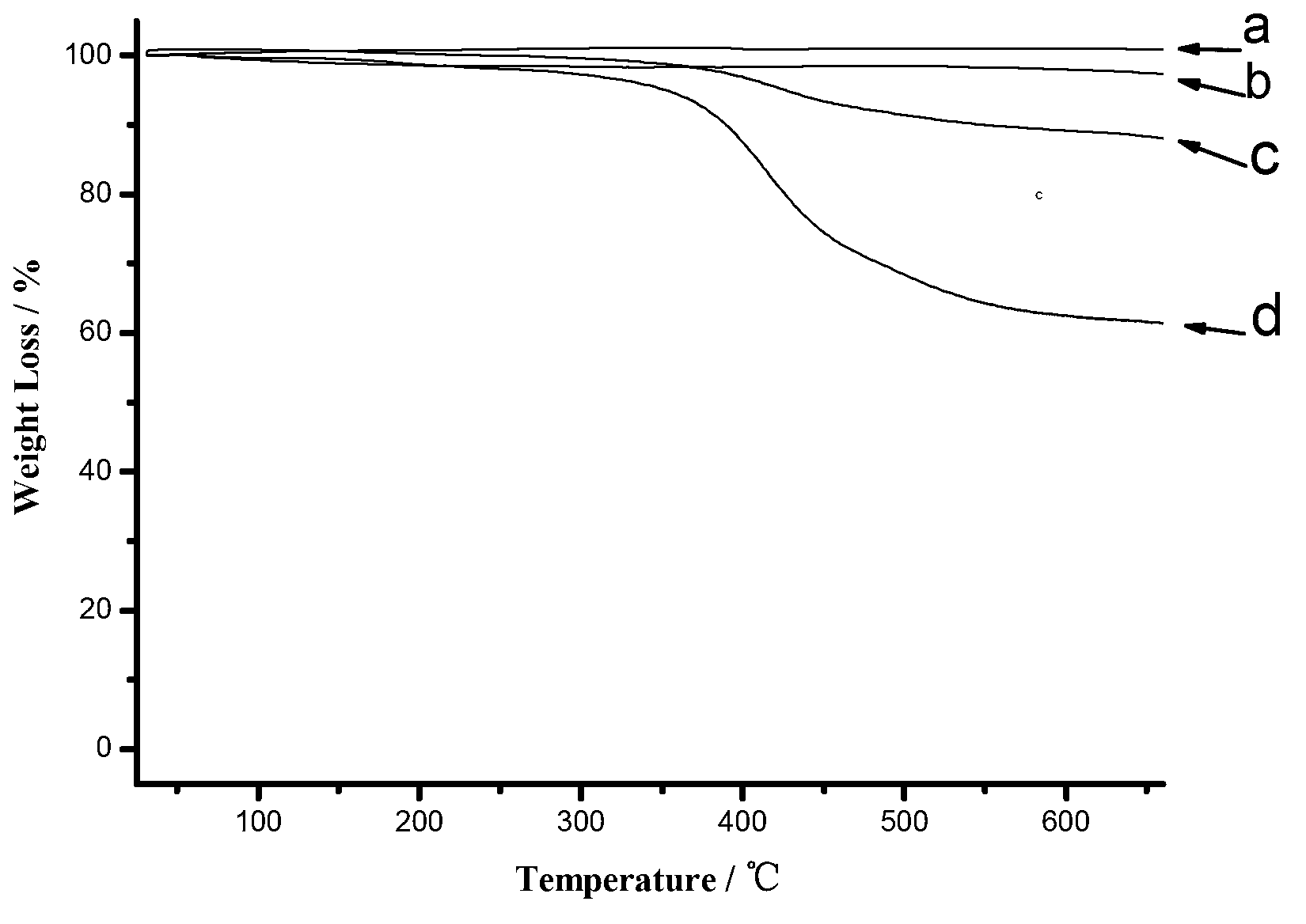

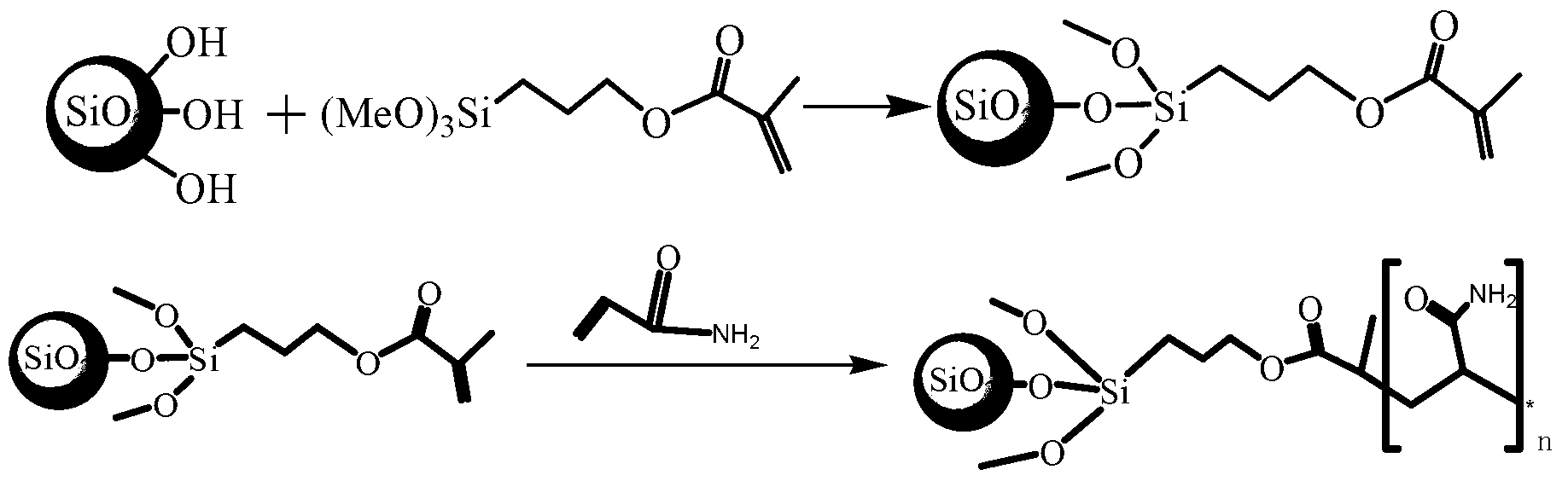

InactiveCN103304175AImprove adsorption capacityImprove flexural performanceAfter treatmentGraft reaction

The invention discloses a preparation method of cationic surfactant modified fly ash, which comprises the following steps of: firstly performing pretreatment and hydroxylation treatment on the surface of fly ash to obtain hydroxylated fly ash to obtain a grafting point; then modifying the fly ash by use of a coupling agent; and finally performing grafting reaction with a cationic surfactant polyacrylamide to obtain cationic surfactant modified fly ash. According to the preparation method disclosed by the invention, the polyacrylamide is grafted on the surface of the fly ash, and the adsorption property of the grafted fly ash is greatly changed; particularly the fly ash is applied to a cement-based composite material, and the fracture resistance of the cement-based composite material is obviously improved; and the preparation method disclosed by the invention has the advantages of low reaction temperature, mild conditions, simple after-treatment and low industrialization cost.

Owner:HEFEI UNIV OF TECH

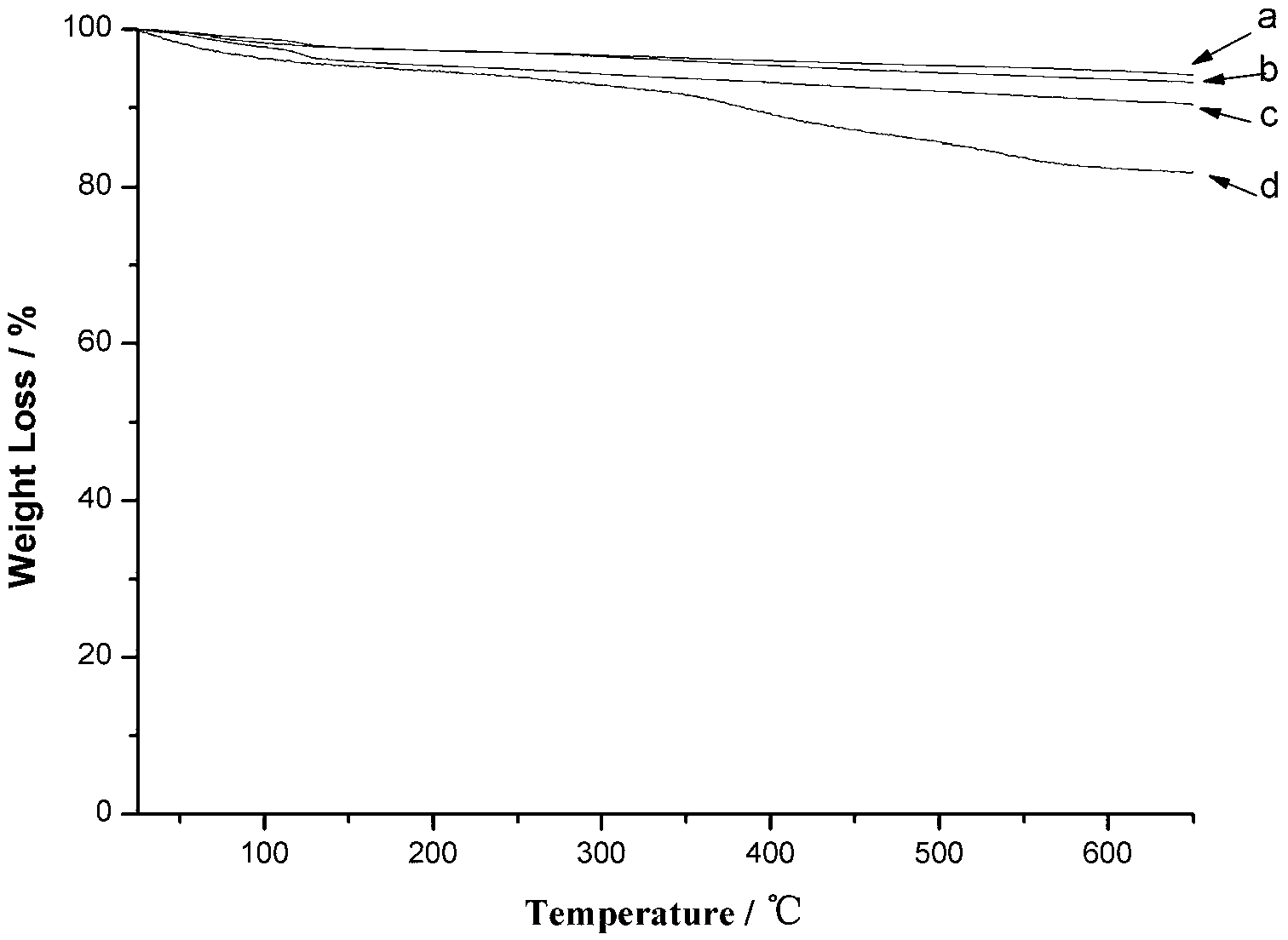

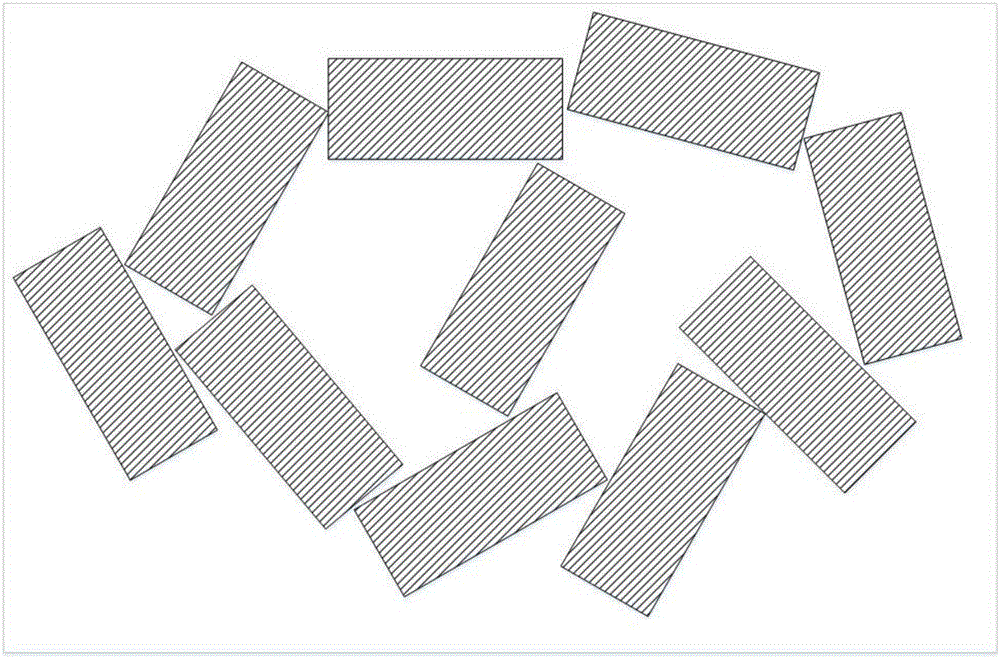

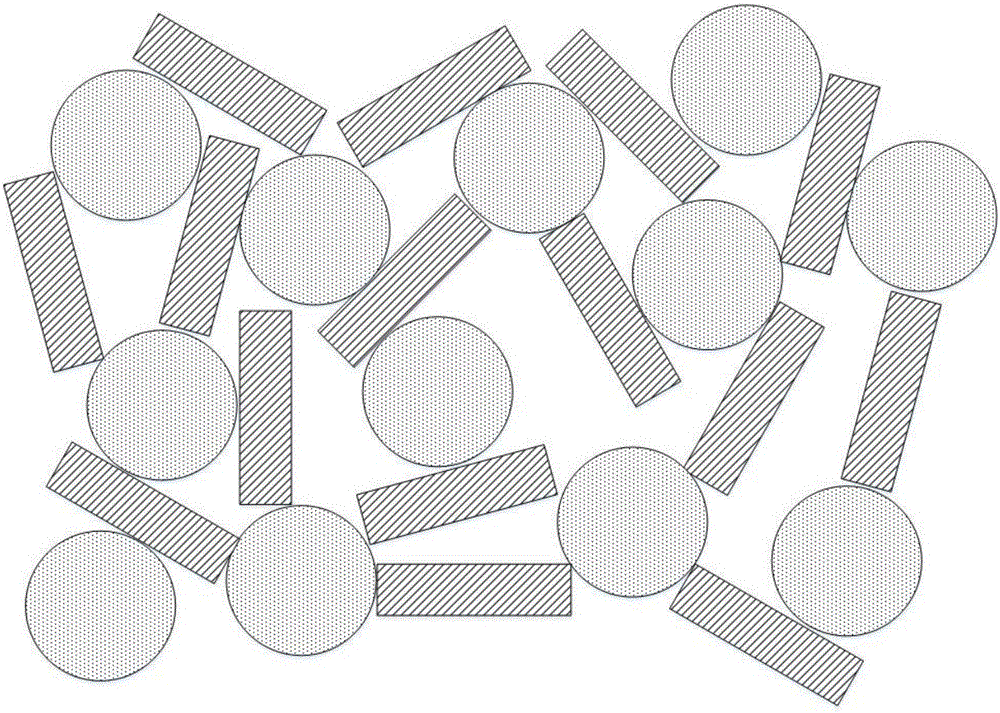

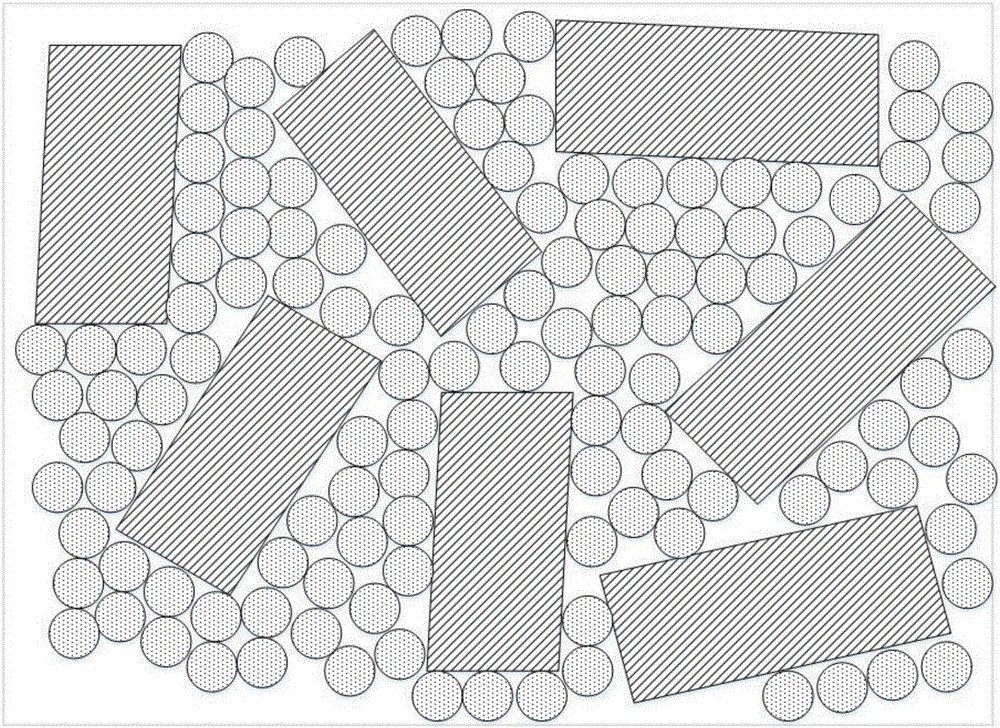

Low-filling high-heat-conductivity organic-inorganic compound

The invention discloses a low-filling high-heat-conductivity organic-inorganic compound which comprises, by weight, 50-1000 parts of organic component serving as a heat-radiating matrix, 100-400 parts of flaky inorganic matter serving as a first heat-conducting filler and 10-800 parts of non-flaky inorganic matter serving as a second heat-conducting filler.A heat-conducting network of two dimension / three dimension and two dimension / one dimension is formed in the organic heat-radiating matrix by compounding the inorganic heat-conducting fillers various in shape, so that the low-filling high-heat-conductivity organic-inorganic compound has high heat conductivity and good storage stability.

Owner:ANHUI UNIVERSITY

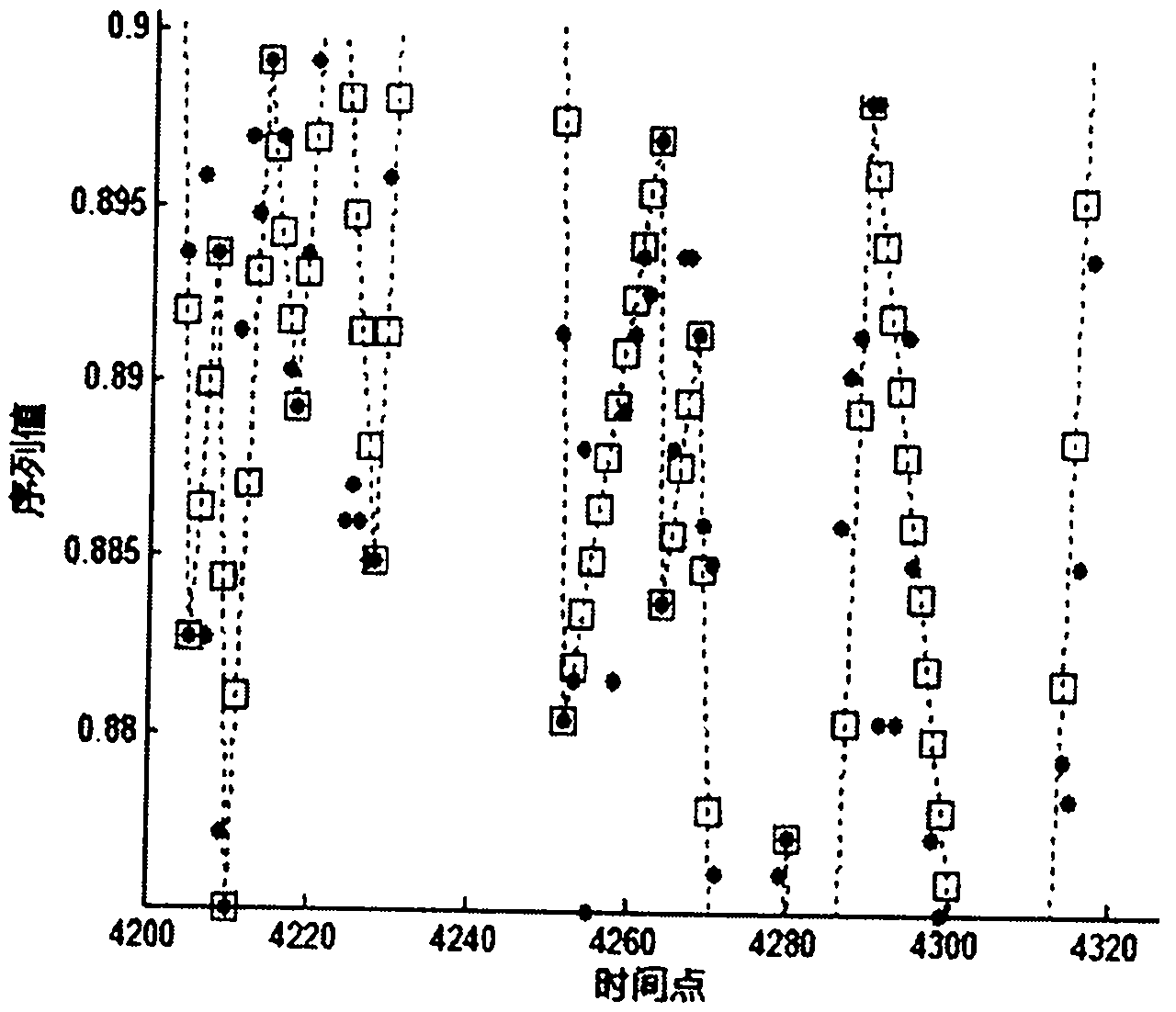

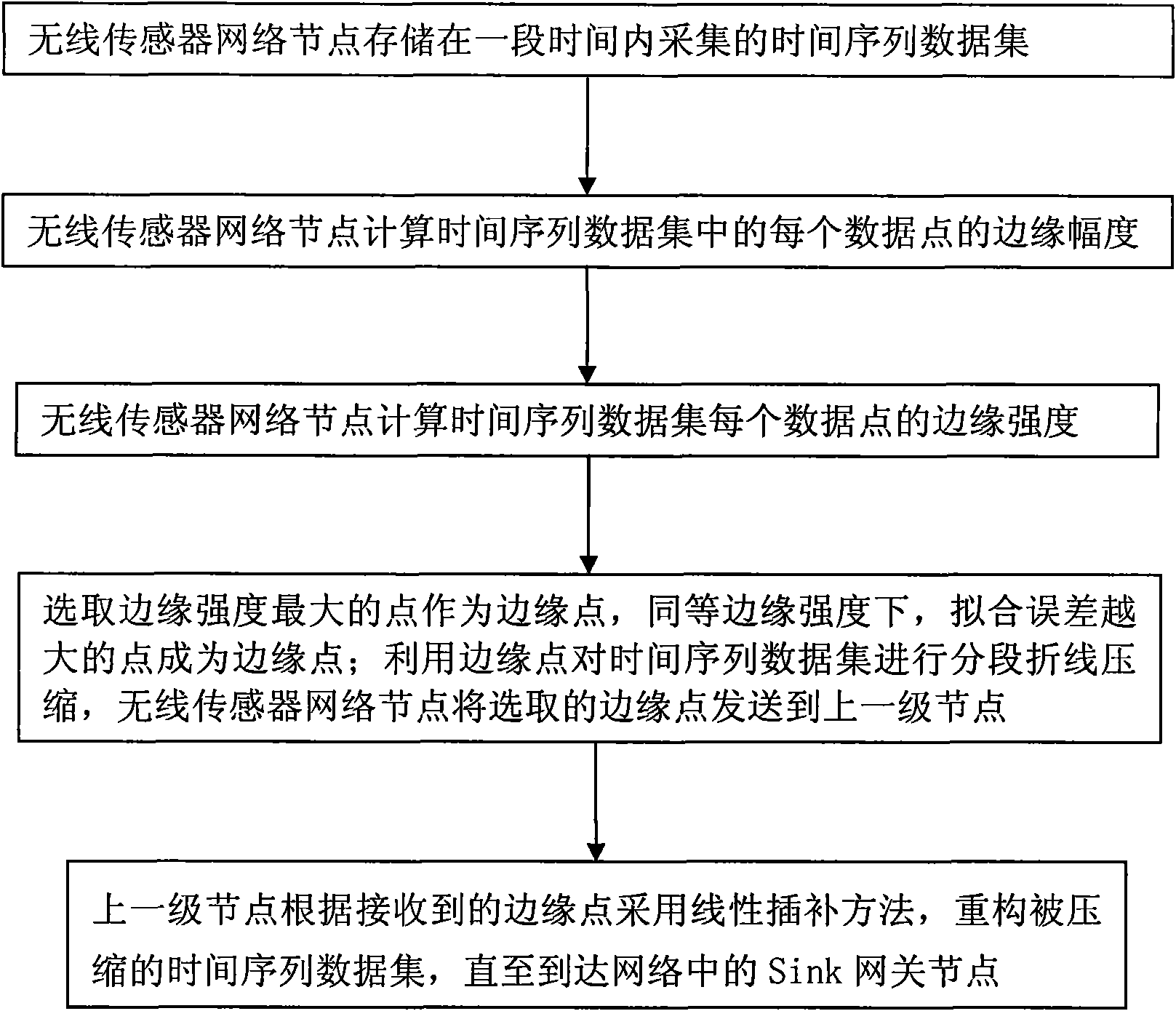

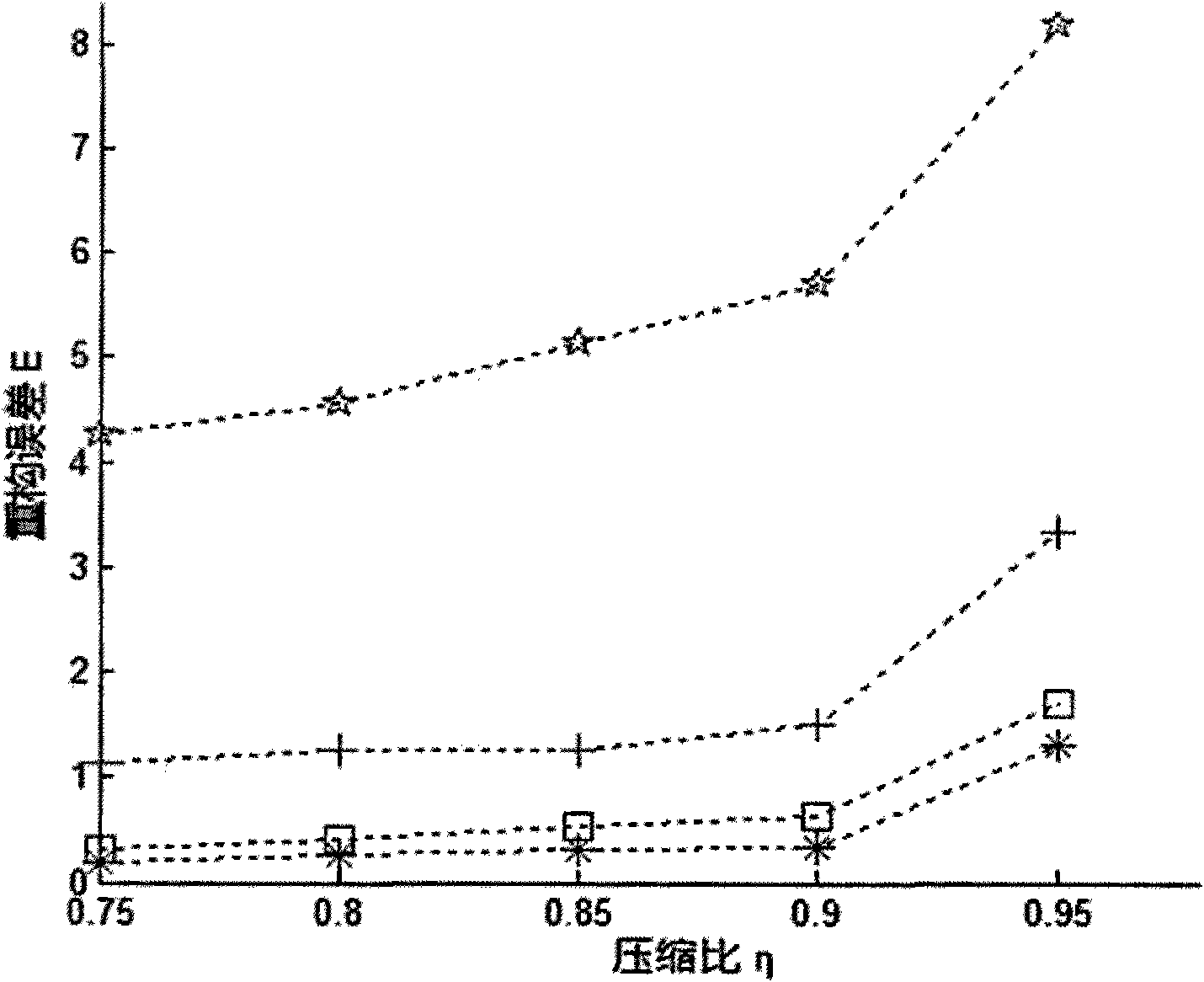

Data compression method of wireless sensor network nodes based on non-threshold

InactiveCN101925091AExtend the life cycleReduce energy consumptionEnergy efficient ICTNetwork traffic/resource managementData compressionLine sensor

The invention relates to the technical field of data compression of wireless sensor network nodes, in particular relating to a data compression method of wireless sensor network nodes based on non-threshold. The method in the invention can perform effective segmental broken line compression on time series data streams collected by the wireless sensor network nodes in a period of time under the premise of ensuring the data compression ratio or data reconstruction precision required by users, thus lowering energy consumption of the sensor nodes and delaying the network life cycle. As the invention is based on the characteristic of the non-threshold, users can perform effective compression on data without possessing any future knowledge about a monitored object, thus being applicable to compression of various time series data with different fluctuation characteristics and being widely used for compression of data of the wireless sensor network nodes needing long-term monitoring.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

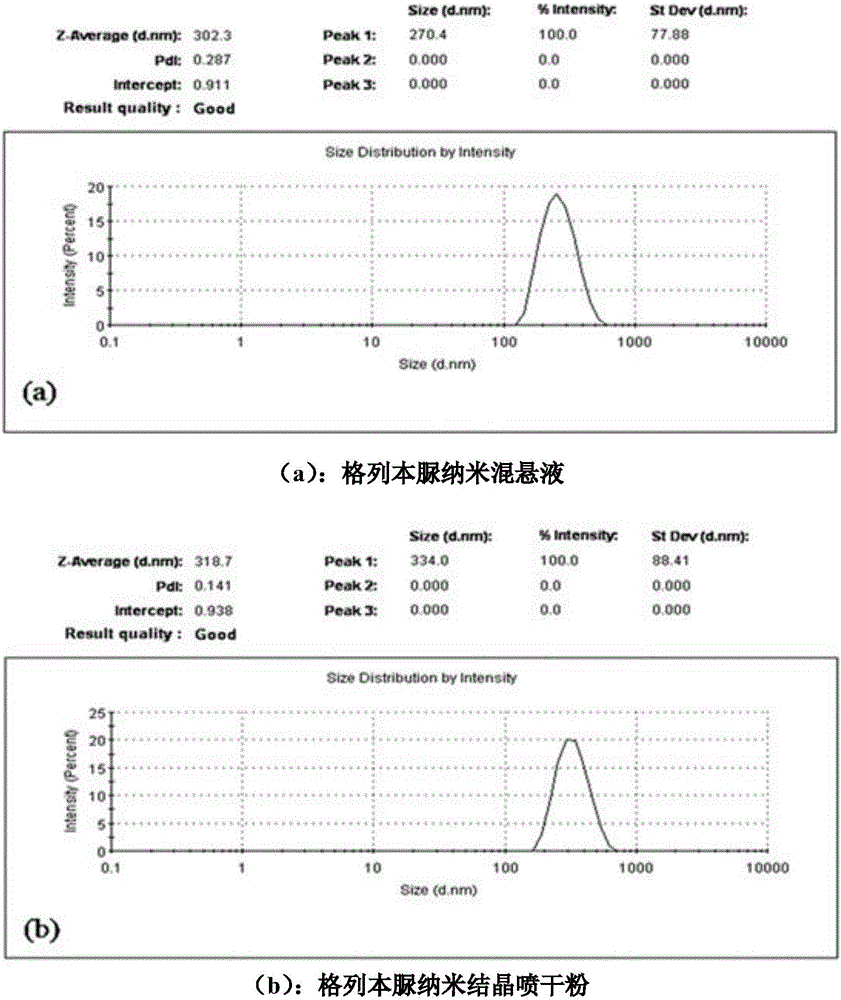

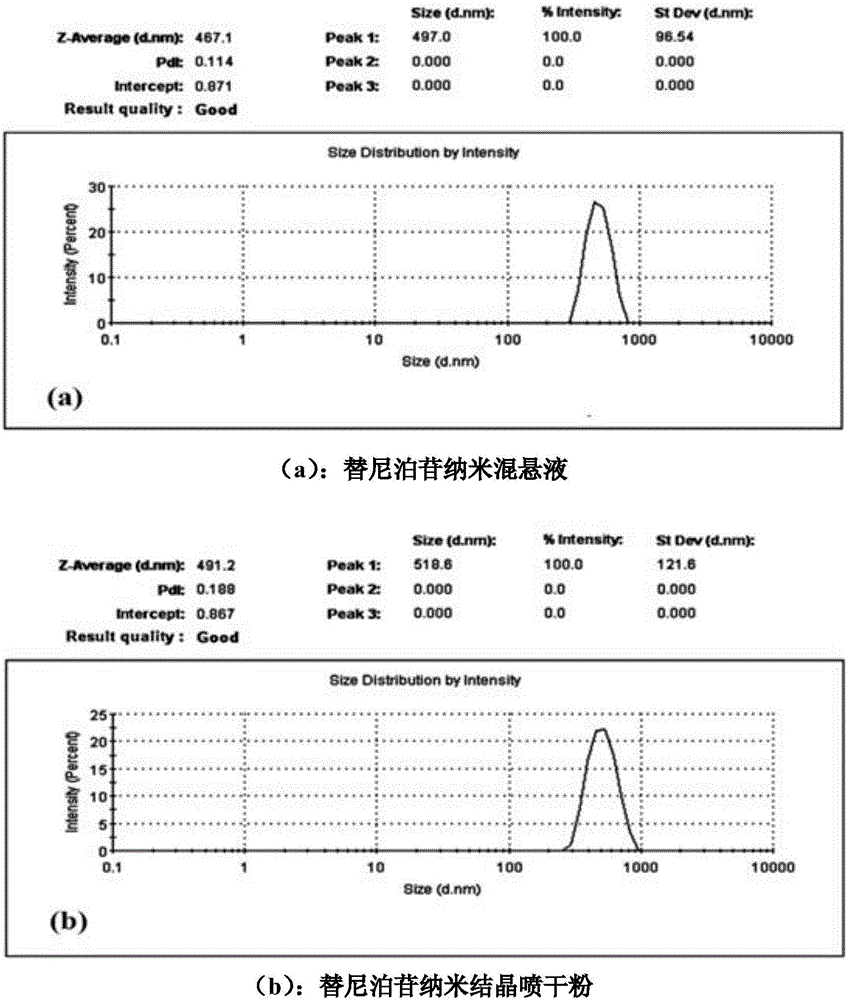

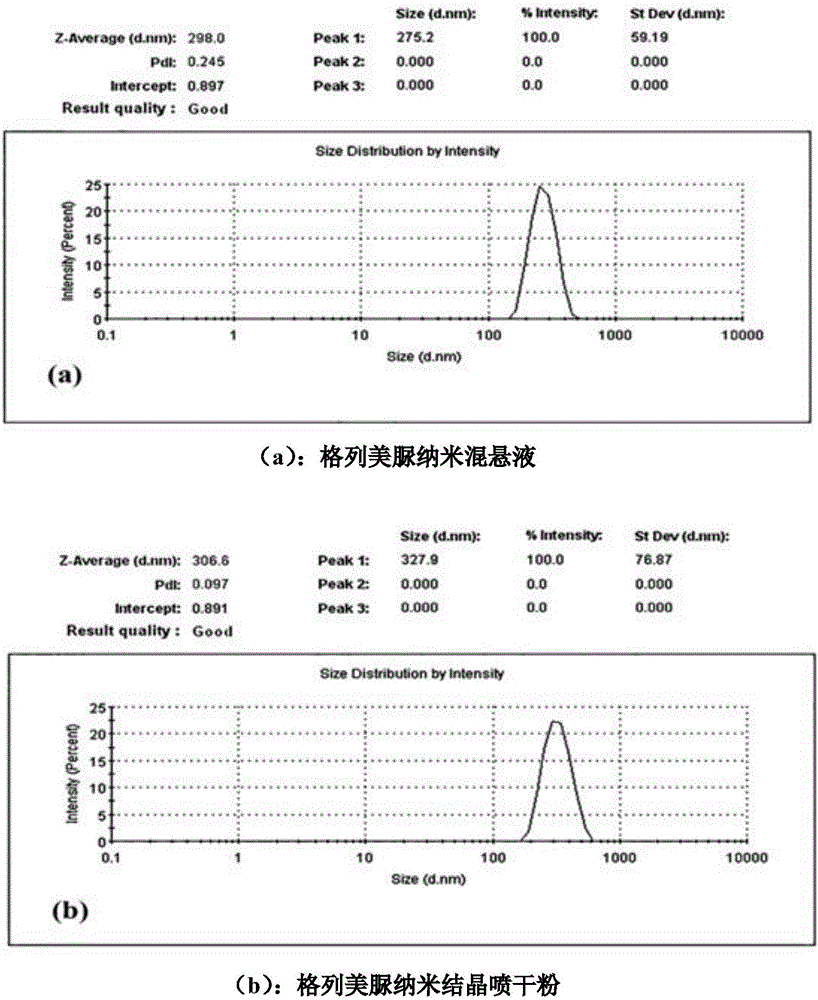

A treating method for a nanometer suspension solidification process

ActiveCN105902496AInhibit aggregationGuaranteed Particle SizePowder deliverySulfonylurea active ingredientsPharmaceutical formulationSURFACTANT BLEND

The invention discloses a treating method for a nanometer suspension solidification process, and belongs to the field of medicine preparations. The nanometer suspension comprises a medicine, a stabilizing agent and water. The method includes adding a surfactant into the medicine nanometer suspension before solidification, and solidifying. Before solidification of the nanometer suspension, 0.01-10% (w / v) of the surfactant is added to inhibit particle aggregation in the solidification process and to maintain the particle size, thus preparing nanometer crystal powder uniform in particle size distribution and easy in redispersion. The method reduces the using amount of a conventional solidification protective agent, and even can fully replace the conventional protective agent, thus increasing the medicine content in the nanometer crystal powder, reducing the cost of auxiliary materials and improving medicine taking compliance.

Owner:SHENYANG PHARMA UNIVERSITY

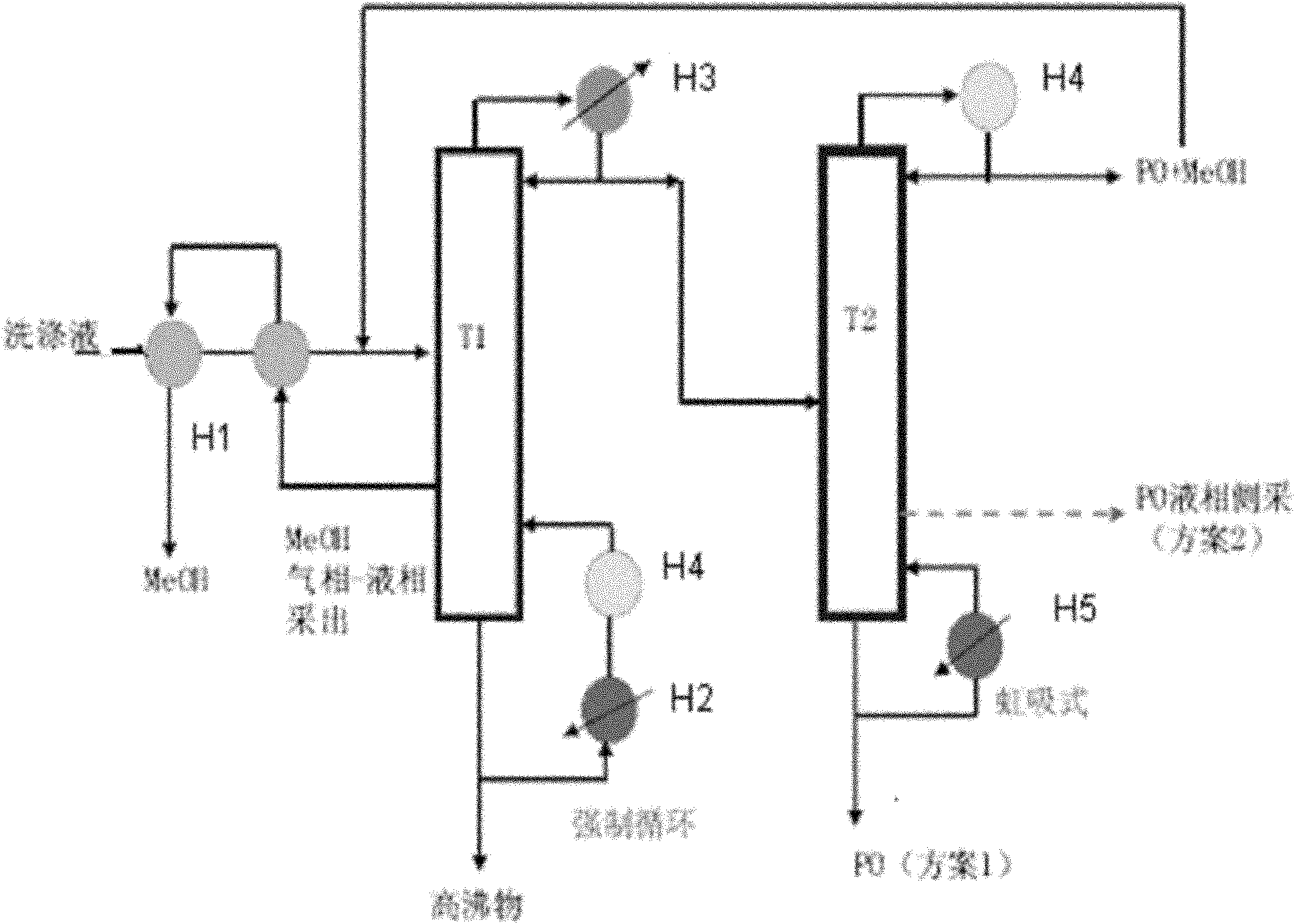

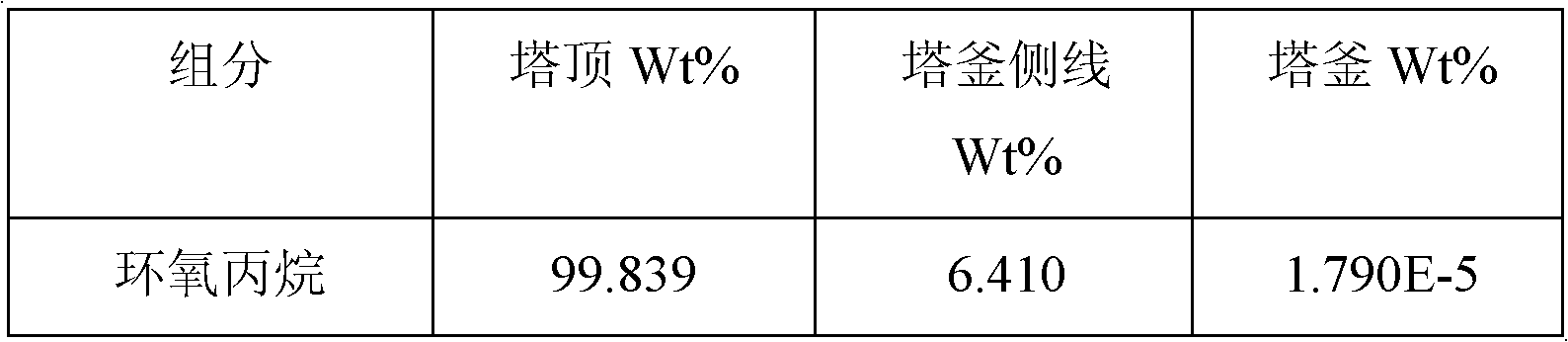

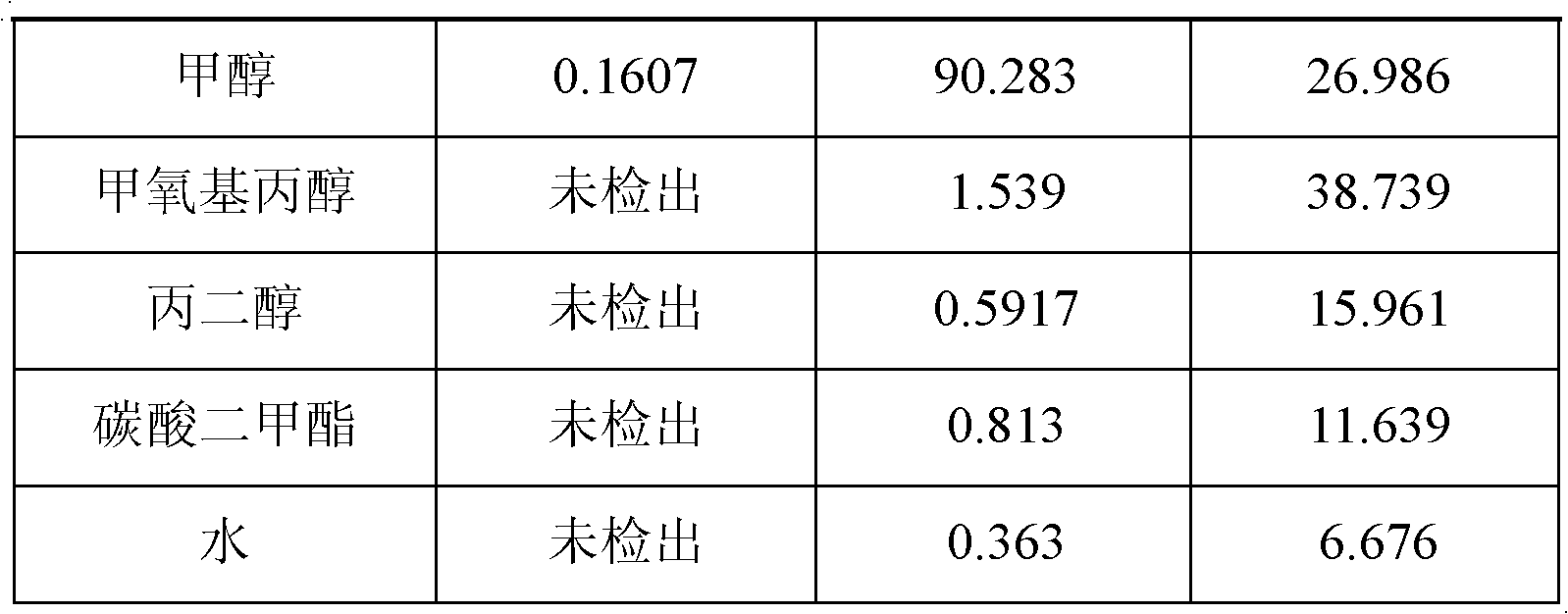

Method for separating out and purifying epoxypropane and methyl alcohol

ActiveCN102093316AReduce the temperatureReduce generationOrganic compound preparationHydroxy compound preparationAlcoholHigh pressure

The invention discloses a method for separating out and purifying epoxypropane and methyl alcohol. The method comprises the following steps: 1) rectifying washing mother liquor which contains the epoxypropane and methyl alcohol and is used for producing aliphatic polycarbonate in a first rectifying tower so as to obtain tower top material containing crude epoxypropane from the tower top of the first rectifying tower and obtain the methyl alcohol from a tower plate at the tower kettle side line of the first rectifying tower; and 2) rectifying the tower top material containing the crude epoxypropane in a second rectifying tower so as to obtain the epoxypropane from the tower plate of the tower kettle or tower kettle side line of the second rectifying tower. In the invention, a double-tower efficient rectification mode is adopted, namely, vacuum or normal pressure rectification is used in the first tower, and high pressure rectification is used in the second tower, thereby extremely effectively separating out two target substances epoxypropane and methyl alcohol, obtaining high-purity epoxypropane and methyl alcohol materials, reducing by-products and fully utilizing material energy,and the industrial process reaches the requirement of green chemistry.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A continuous extraction method of effective ingredients from fruitbodies of Cordyceps militaris

InactiveCN101007025AHigh purityNo pollution in the processBulk chemical productionPlant ingredientsAdditive ingredientBULK ACTIVE INGREDIENT

The invention disclosed a way to successively extract active ingredients from carpohole of north aweto. The invention adopts super critical CO2 to extract sterin substances, precipitating with alcohol to get nucleoside substances with cordycepin and Cordyceps polyose, separating with normal phase low pressure gel silica chromatography to get crude cordycipin, preparative reversed-phase high-performance liquid chromatography to get cordycepin crystal with high purity. The invention can not only successively extract sterin substances and Cordyceps polyose (CM-1) from the carpohole of north aweto, it can also get the cordycepin metamer; it is not applicable to small experiments but also applicable to industrial production. Since the producers can extract many substances by one treatment of carpohole, the invention can not only decrease the industrial cost but also make the biggest economic returns.

Owner:SHANGHAI ELITE AGRI SCI TECH GROUP +1

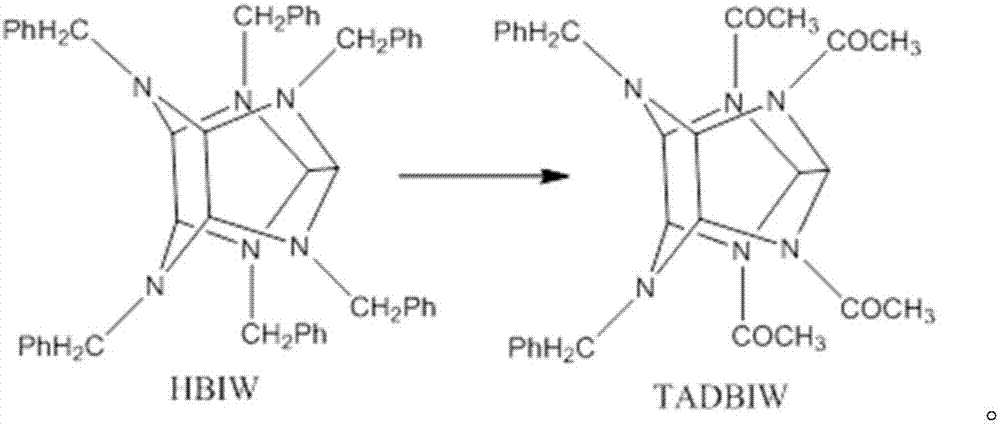

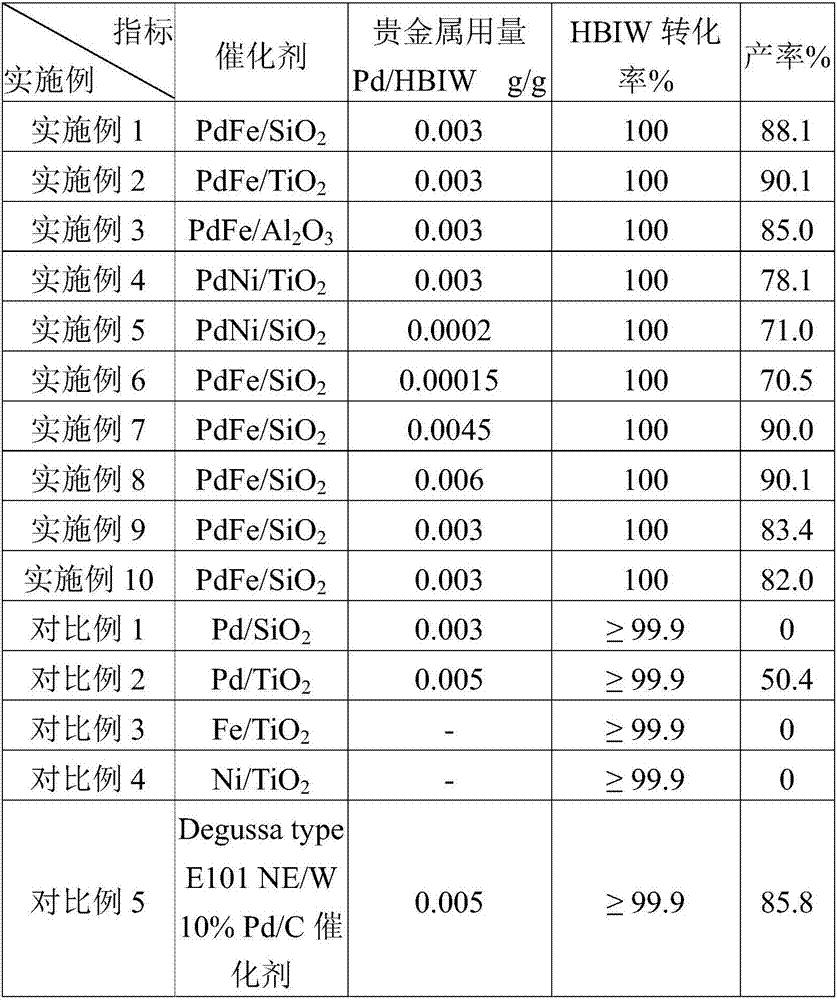

Application of palladium-based bimetallic catalyst in catalytic hydrogenolysis reaction of HBIW

ActiveCN106946894ARaw materials are easy to getLow in palladiumOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPalladiumHigh selectivity

The invention discloses an application of a palladium-based bimetallic catalyst in the catalytic hydrogenolysis reaction of HBIW. The HBIW is an intermediate hexabenzylhexaazaisowurtzitane in the synthesis process of an energetic material CL-20. The palladium-based bimetallic catalyst is prepared through substituting precious metal with cheap transition metal and adopting oxide as a carrier, and has high catalytic reaction activity, high yield, high selectivity and high stability in the catalytic hydrogenolysis debenzylation reaction of the HBIW; and the palladium-based bimetallic catalyst has the advantages of easily available raw materials, low content of the precious metal palladium, low production cost, simple process, effective reduction of the industrial production cost, and very good application prospect.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Nano flame-retardant coating

InactiveCN103540243AGood synergyLow cost of industrializationFireproof paintsAnti-corrosive paintsSodium BentoniteTalc

The invention discloses a composite type nano flame-retardant coating comprising the following raw materials in parts by weight: 22-25 parts of titanium pigment, 10-25 parts of talc powder, 10-15 parts of calcium carbonate, 5-8 parts of mica powder, 5-8 parts of bentonite, 2-8 parts of kaolin, 7-11 parts of a thickening agent solution, 1.0-1.4 parts of a dispersant, 33-40 parts of polyacrylic ester emulsion of which the mass percent is 50%, 0.05-0.2 part of an anti-mildew agent, 0.05-0.2 part of a defoaming agent, 2.1-3.1 parts of propanediol, 1-3 parts of ethanediol, 7-11 parts of purified water, 0.02 part of an initiator, 0.6 part of a leveling agent, 25 parts of a modified ammonia type curing agent, and the balance of a nano flame-retardant composite.

Owner:苏州瑞邦塑胶有限公司

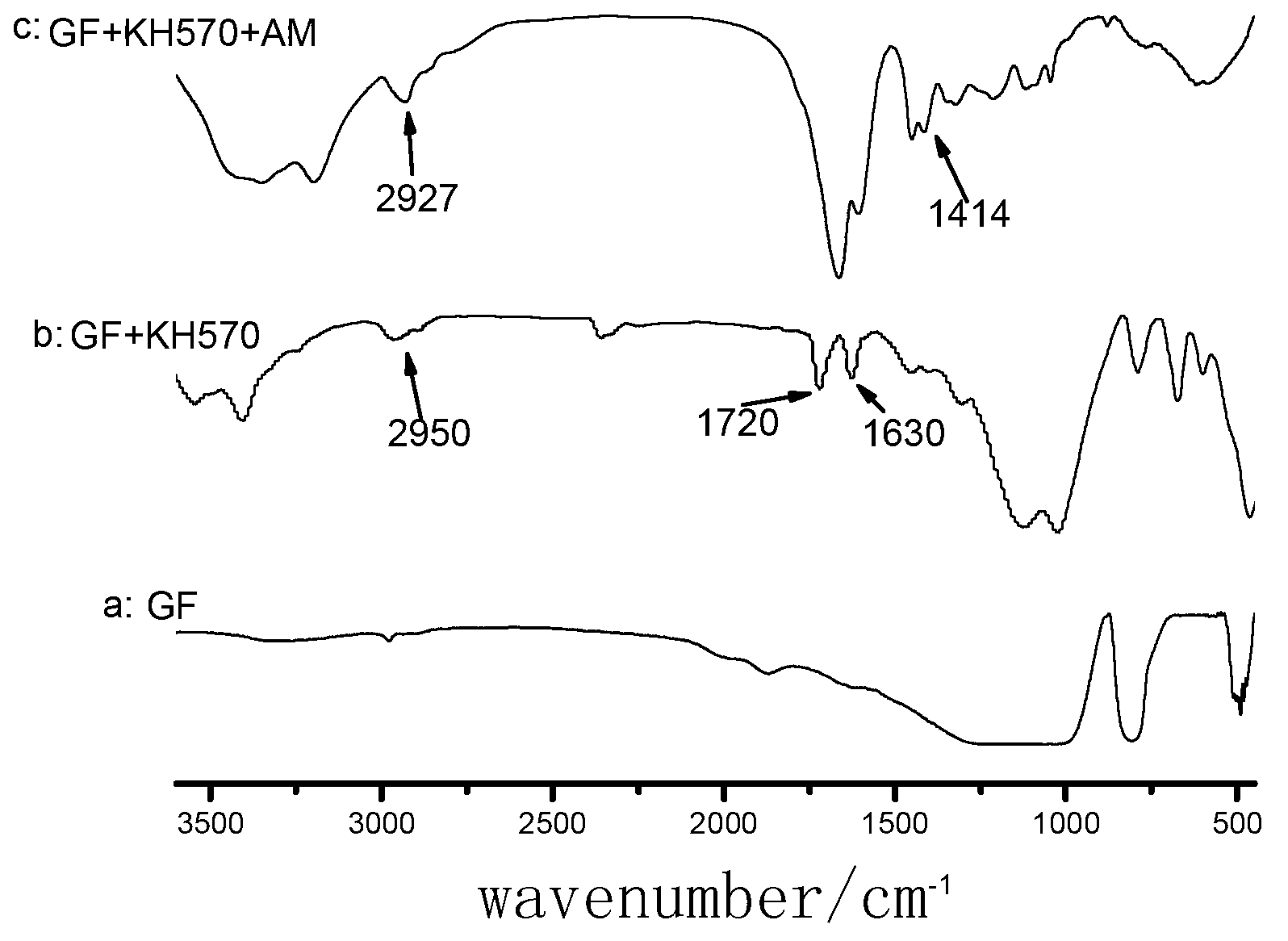

Preparation method of modified silicon powder

The invention discloses a preparation method of modified silicon powder. The preparation method comprises the following steps of: firstly, performing hydroxylation treatment on the surface of silicon powder to obtain hydroxylated silicon powder; then modifying the hydroxylated silicon powder by using a coupling agent to obtain coupling agent modified silicon powder; and finally, performing graft polymerization on the coupling agent modified silicon powder and acrylamide through a graft polymerization reaction to obtain polyacrylamide grafted silicon powder (modified silicon powder). According to the modified silicon powder, the acrylamide is grafted on the surface of the silicon powder, so that the tenacity of a cement-based composite material is improved, the dosages of water and cement of the composite material are reduced, and the rupture strength is obviously improved and can completely meet requirements for the rupture strength of a high-performance cement-based composite material; and because the modified silicon powder has surface hydrophilic groups, the modified silicon powder has good dispersity, and the problem of agglomeration of a mineral admixture can be well solved. The preparation method is low in reaction temperature, mild in condition, simple in after-treatment and low in industrialization cost.

Owner:HEFEI UNIV OF TECH

High-sublevel multi-layer mining method of ultrathin copper ore body

InactiveCN102086765ALow cost of industrializationThe pit rate is reducedUnderground miningTunnel/mines ventillationResource protectionCopper mine

The invention discloses a high-sublevel multi-layer mining method of an ultrathin copper mine body. Mining channels are reclaimed to be connected with an upper middle section and a lower middle section based on the high-sublevel that the altitude difference of the middle section of the ore body is 50 meters, wherein, the thickness of the ore body bed is 0.4-1m, and the inclined angle of the ore body is above 25 degrees; the ore blocks between the middle sections are divided into extraction ore blocks with 50 meters square; a layered communication channel with small specification the altitude difference of which is 13-17m is reclaimed between the mining channels; the extraction ore blocks between the mining channel are divided into three extraction units; the ores mined by each extraction unit is centralized to the mining channel uniformly; and the ores are sent out from a trench after being transported to a transportation road. The method disclosed by the invention has the advantages that the copper ore resource mining recovery rate is effectively improved, cost is low, land is saved, unification of the resource protection and the environment protection is realized, and use is safe.

Owner:DAYAO GUIHUA COPPER SMELTING YONGREN ZHIJU BRANCH

Efficient polycarboxylic acid water reducing agent with additional modified celluloses

InactiveCN105985052AGood dispersionReduce bleedingSolid waste managementPolyacrylamideSodium hydroxide

The invention discloses an efficient polycarboxylic acid water reducing agent with modified celluloses. The efficient polycarboxylic acid water reducing agent comprises, by weight, 240-250 parts of methyl-2-buten polyoxyethylene ether, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persulfate, 0.53-0.55 part of thioglycolic acid, 13-14 parts of lignin, an appropriate quantity of sodium hydroxide solution with the concentration of 10 wt%, an appropriate quantity of deionized water, 26-28 parts of graphene oxide, 5-7 parts of waste liquid from sugar factories, 7-8 parts of hydroxypropyl methyl celluloses, 2-3 parts of polyacrylamide, 3-4 parts of calcium chloride, 2-3 parts of triethanolamine, 5-6 parts of carbon black, 19-22 parts of building brick residues and 1-1.2 parts of silane coupling agents kh550. The efficient polycarboxylic acid water reducing agent has the advantages that components such as the hydroxypropyl methyl celluloses, the polyacrylamide and the carbon black are added into the efficient polycarboxylic acid water reducing agent in preparation procedures by the aid of a series of treatment processes, accordingly, the flowability and the frost resistance of concrete can be improved, and the dispersion resistance of products in water further can be improved.

Owner:ANHUI XINRUN NEW MATERIALS

Filter element for filtration and manufacturing method thereof

InactiveCN101766989AWide variety of sourcesDoes not change physical and chemical propertiesOther chemical processesWater/sewage treatment by sorptionAdhesiveFiltration

The invention relates to a filter element, in particular to a filter element for filtration and a manufacturing method thereof. In the preparation process of the filter element, various raw materials are weighed according to percentage by weight in a formula, adding materials according to specified steps and then mixing and stirring evenly, extruding or punching for shaping in a preset mould, drying the water in the model at a certain temperature for sizing, namely forming the porous filter element with specified shape. The filter element of the invention utilizes various non-toxic and harmless raw materials with absorption characteristics, is formed by bonding water-borne adhesive, has the characteristics that the usage of a filter material in unit volume is large, the adsorption efficiency is high, the finished filter element after adsorption and saturation can regenerate under the condition of high temperature while the original physicochemical property of the filter element is not changed, the surface of the filter element after being jammed by absorbing and stopping sundries can be polished by sand paper and reused, and the like; in addition, the cost for manufacturing the water-borne adhesive is low and the raw materials are safe and environmental friendly.

Owner:张顺

Method for plating copper on stainless steel

The invention discloses a method for plating copper on a decorative stainless steel plate. The method comprises the following steps of: carrying out chemical oil removal on a stainless steel material and then putting the stainless steel material into a pre-plating solution containing iron, nickel and chromium cations to carry out pulse electroplating to obtain a grey iron-nickel-chromium compound film witch a certain thickness; and finally, enabling the grey iron-nickel-chromium compound film to enter an acidic copper sulfate solution to carry out direct-current copper electroplating. Compared with a conventional stainless steel electroplating method, the method provided by the invention has the advantages that steps of etching, removing hung ash, electrolyzing and activating, pre-plating the nickel and the like are reduced; industrial flows are obviously reduced and seem to be simple; the production efficiency is improved and the industrial production cost is reduced; meanwhile, a lot of strong acids are not needed so that an industrial operation environment is obviously improved and the environmental pollution is reduced; and an oxidized film on the surface of stainless steel does not need to be etched in advance in the process disclosed by the invention so that the method has the very great adaptability to the stainless steel materials with different chemical components.

Owner:红木枋家居科技(湖州)有限公司

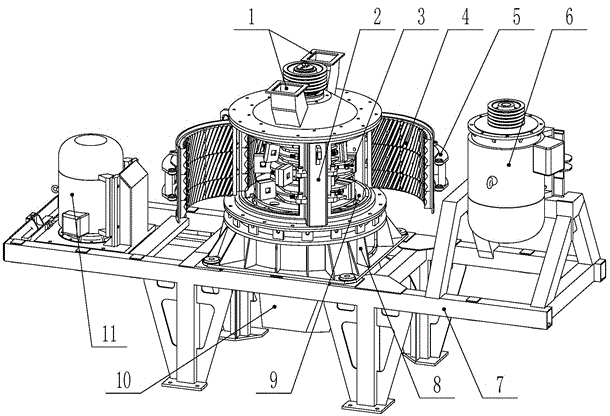

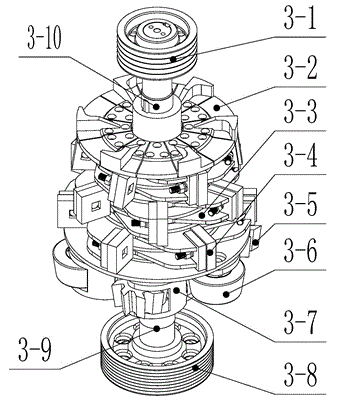

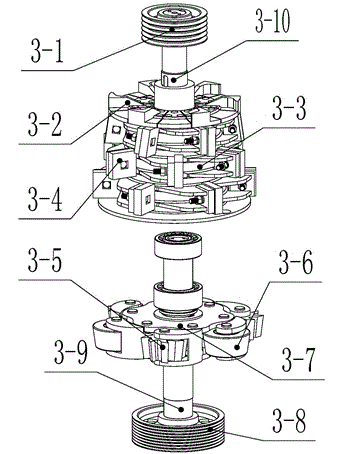

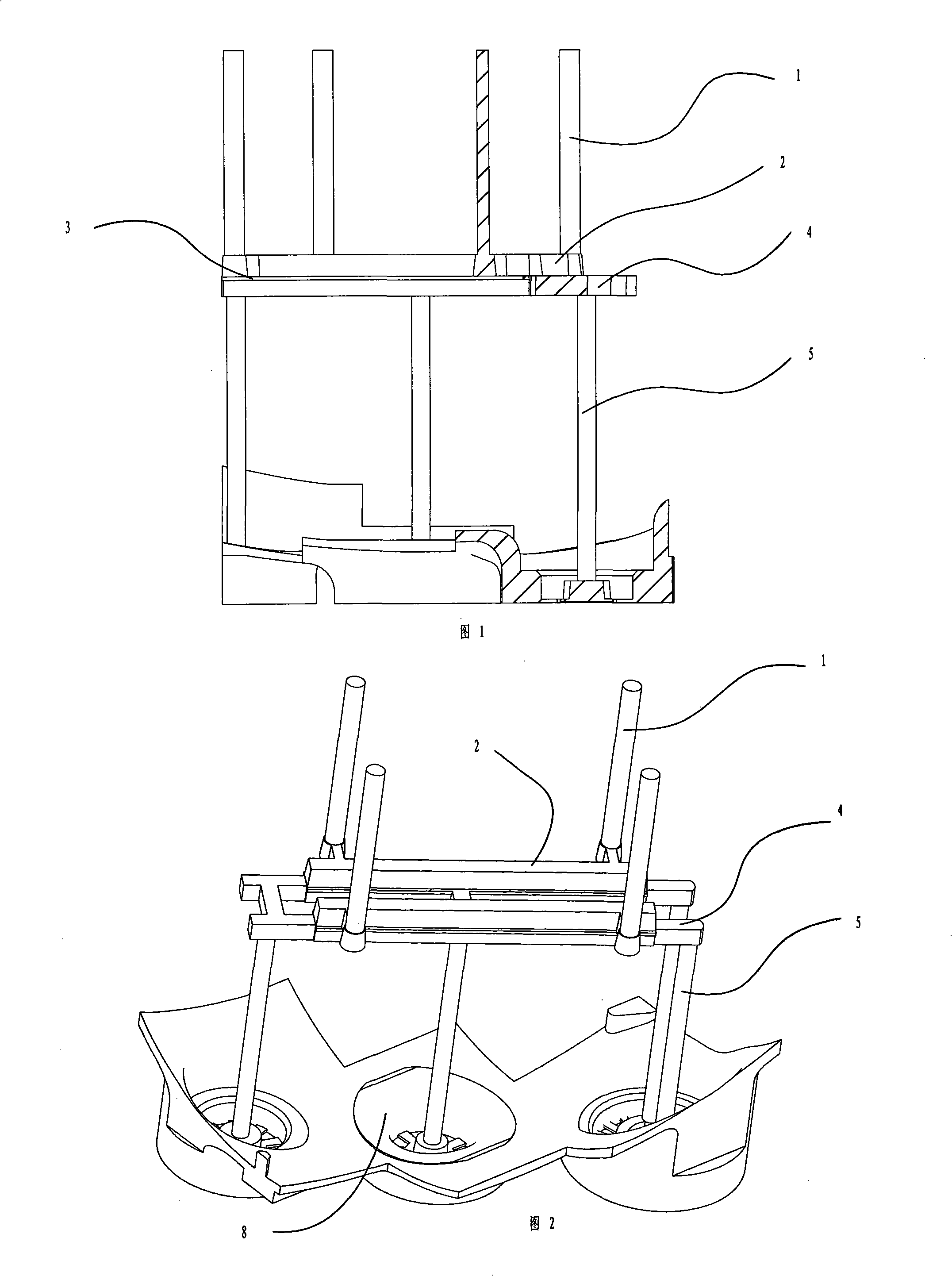

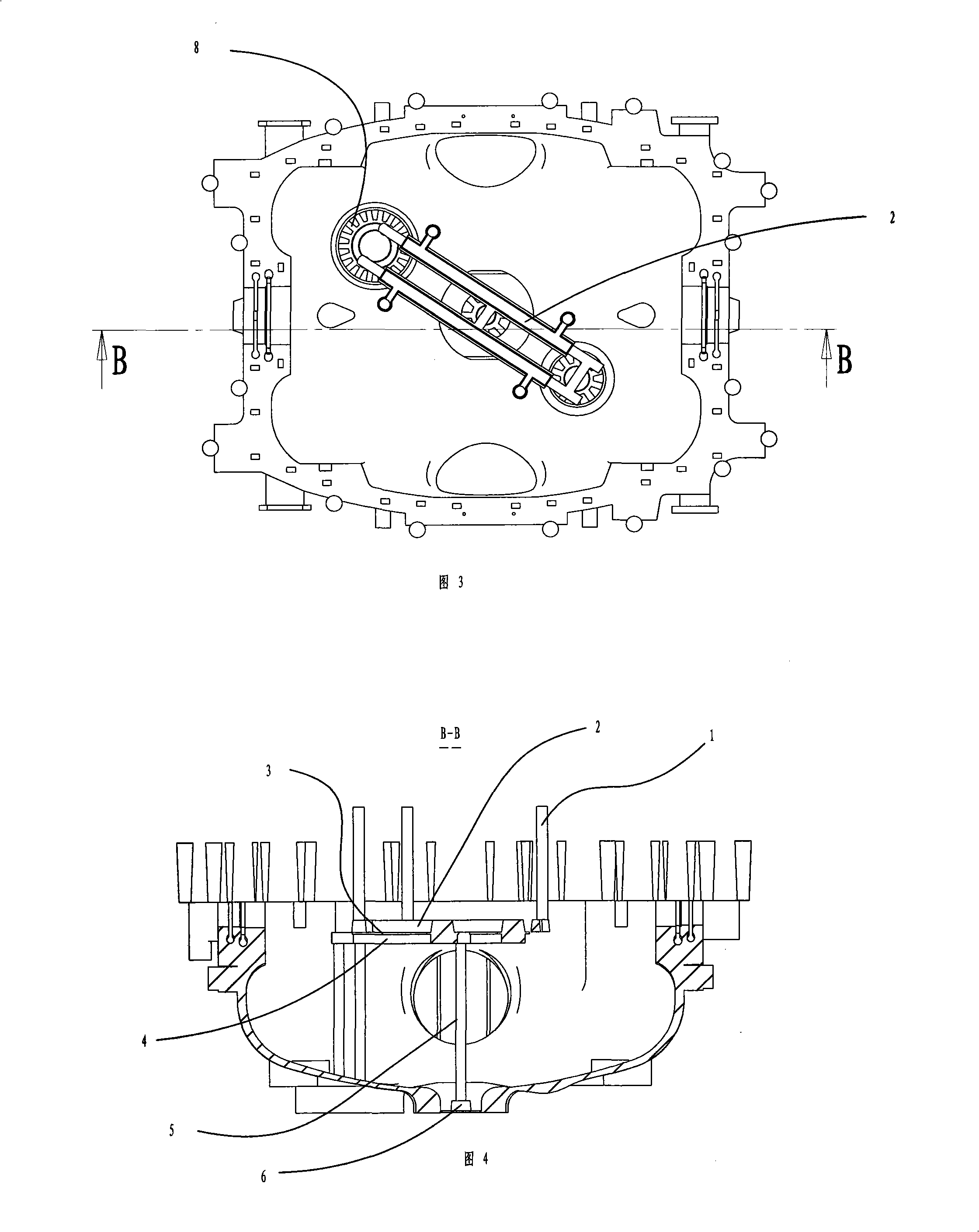

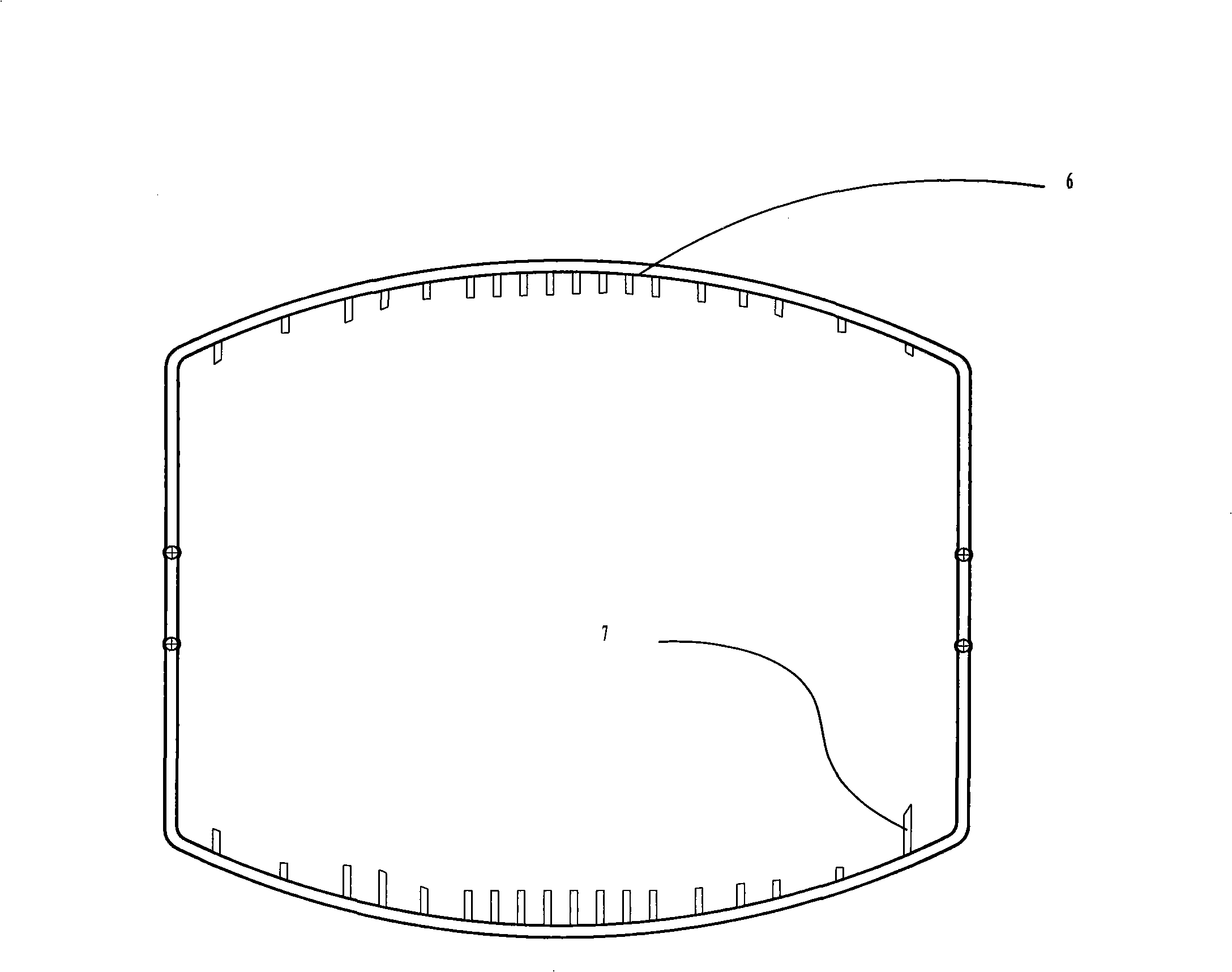

Vertical combined crushing and grinding machine

The invention provides a vertical combined crushing and grinding machine. The vertical combined crushing and grinding machine comprises an integral support, a grinding cavity seat, a cylinder body, a vertical rotor body, a spiral impact plate, a discharge hopper, charge hoppers, a turnover door, a grinding cavity wall lining plate, an electromotor, a crushing mechanism and a grinding mechanism. The vertical combined crushing and grinding machine enables the material crushing and grinding processes to be realized by one machine, is compact in structure and small in occupied area, saves the process, and improves the efficiency. Materials are impacted and crushed at high speed by a hammer head on a tower-shaped hammer seat in a spiral through crushing cavity, are thrown to the turnover door, are rebounded to the hammer head on the tower-shaped hammer seat, and are crushed repeatedly in the way, so as to guarantee relatively sufficient crushing. A centrifugal rotation roller acts on a grinding cavity wall lining plate, the materials are ground and crushed to 1mm below, and the qualified materials discharged from the discharge hopper finally are uniform in granularity and high in crushing ratio. In addition, the crushing and grinding cavity of the through combined crushing and grinding machine of the design is difficult to block, is smooth in material discharge and is long in service life, and the industrial cost is reduced.

Owner:四川皇龙智能破碎技术股份有限公司

Method for extracting luteolin from peanut roots, stems, leaves and shells

The invention relates to a method for extracting luteolin from peanut roots, stems, leaves and shells, comprising the following steps: washing materials comprising peanut roots, stems, leaves and shells, removing impurities in the peanut roots, stems, leaves and shells, and grinding the peanut roots, stems, leaves and shells subject to impurity removal; extracting by using 75% ethanol, filtering, decoloring, and concentrating at reduced pressure; precipitating by using hot water, filtering, heating filtrate, and concentrating at reduced pressure; absorbing by using KLFC-150 macroporous resin, and eluting by using 75% ethanol; concentrating elution solution at reduced pressureto obtain crude luteolin; dissolving the crude luteolin in ethanol, adding water to dilute the crude luteolin, recovering the ethanol, concentrating, crystallizing, and recrystallizing to obtain the high-purity luteolin product. The operation process is mainly characterized in that the peanut roots, stems, leaves and shells are used as extraction raw materials and are low-cost sustainable resources, the 75% ethanol is used as extraction solvent and eluent, and the product contains no toxic solvent and other residue, is safe and environmentally friendly and is low in production cost and high in yield.

Owner:彭国平

Novel almoxicillin sodium and clavulanate potassium compound powder preparation for injection and technology for preparing same

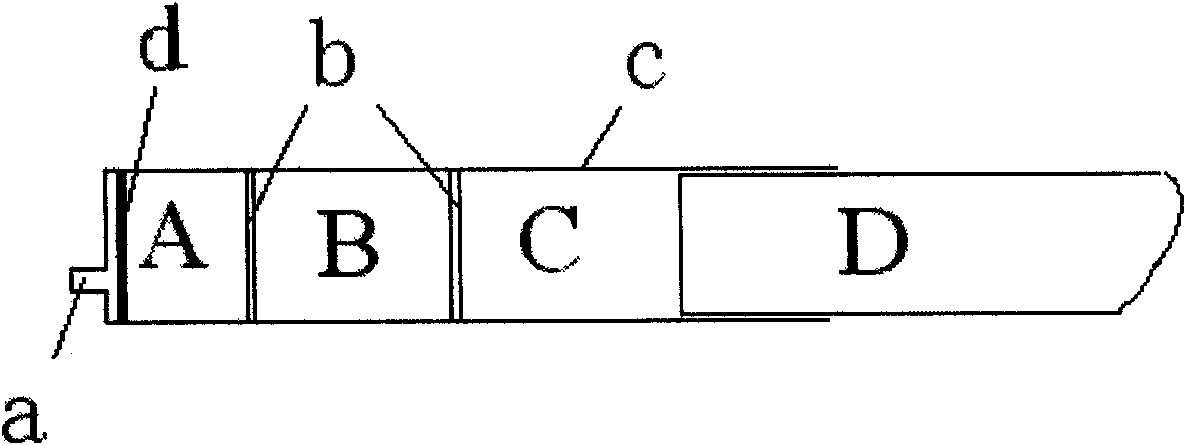

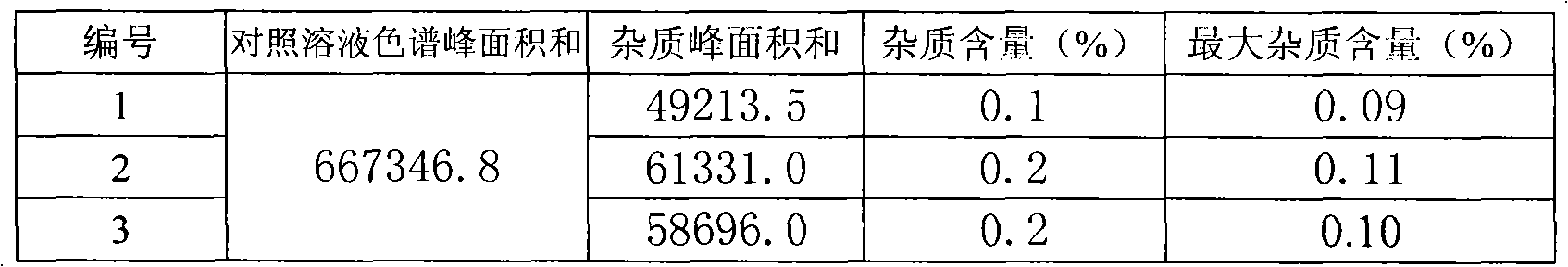

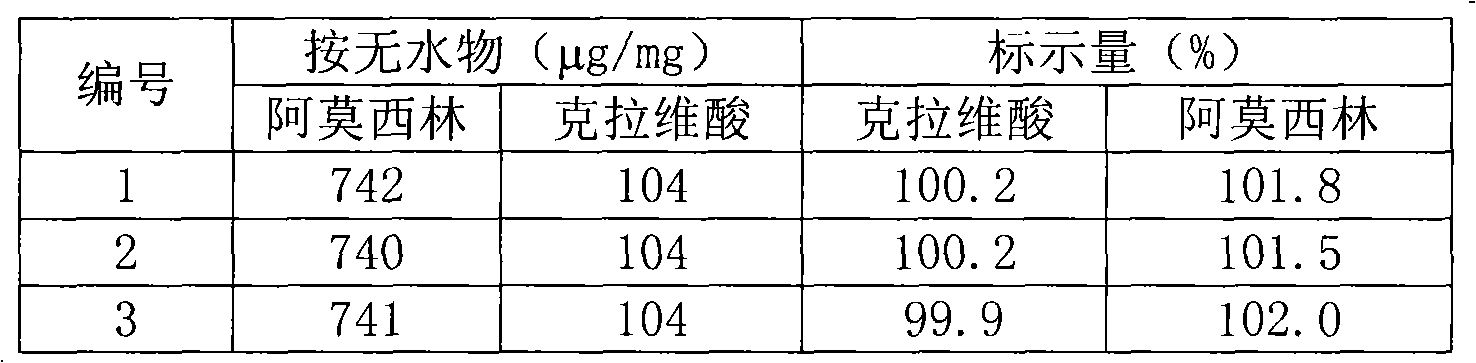

ActiveCN101647779ALong validity periodLow cost of industrializationAntibacterial agentsPowder deliveryChemistryInjector

The almoxicillin sodium and clavulanate potassium is widely and clinically used due to good curing effect and safety. The formulations of the almoxicillin sodium and clavulanate potassium are mainly oral preparations in different ratios; because of the advantages of quick response and the like, the injection preparation is deeply and clinically welcomed, but only the 5:1 injection preparation is available in the market at present; and because the clavulanate potassium ratio in the preparation is high, the penicillin anaphylaxis and the high-potassium disease are easily caused, and the preparation is relatively high in price. Because the preparation has the defects of higher process requirements, poor preparation stability, easy decoloring and degradation, and necessary storage and transport at a low temperature, the circulation and use of the medicaments are inconvenient. By changing the ratio of the almoxicillin sodium to the clavulanate potassium and improving the preparation process, the safety of the drugs is improved, the cost of the drugs is lowered and the stability of the drug preparations is improved under a condition of ensuring the curing effect; and simultaneously, because of using a special disposable injector, the conventional complex steps of dissolving and mixing are saved.

Owner:XIANGBEI WELMAN PHARMA CO LTD

Medium-pressure heavy-section outer-cylinder iron casting gating system of steam turbine

The invention discloses a gating system of a large-section iron casting for an medium pressure external cylinder in a steam turbine; the gating system comprises a weighing ladle, a sprue, a runner and an ingate, the runner consists of an upper runner and a lower runner, a refractory ceramic filter is arranged between the upper runner and the lower runner, the minimum sectional area ratio of the sprue, the runner, a transition sprue, a transition runner and the ingate is 1.2:1.34:1:1.07:1.24; the sprue, the upper runner and the lower runner are arranged at the middle part of the casting, and the ingate of an ingate is arranged at the inner wall of an axle hole of the casting; and the gating system of the structure mainly plays a role in buffering, decompressing and steady entry of melted iron, the molding sand in the scour cast is avoided, the casting is heated evenly, with the advantages of being not easy to be mingled with impurities, carry sand, produce air gaps and cracks.

Owner:RIYUE HEAVY IND

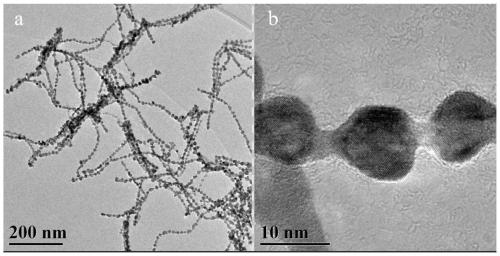

One-dimensional porous platinum-containing alloy nanowire catalyst and preparation method thereof

InactiveCN111509236AReduce usageLow cost of industrializationCell electrodesNanotechnologyPtru catalystNanowire

The invention belongs to the field of electrocatalysis, and particularly relates to a one-dimensional porous low-platinum nanowire catalyst capable of being applied to oxygen reduction reactions in various energy conversion technologies, and a preparation method thereof. The preparation method comprises the following steps: dissolving a platinum metal salt and a salt of another one or more transition metals in a solvent, adding a surfactant and a reducing agent, and reacting at a certain temperature to prepare a platinum alloy nanowire with one-dimensional structural morphology; and then preparing the one-dimensional porous platinum-containing alloy nanowire by adopting an acid corrosion mode. The catalyst has a one-dimensional nanowire and a porous structure, has relatively high oxygen reduction catalytic activity and stability, and can be applied to oxygen reduction catalysts in various energy conversion devices. The method has the characteristics of high yield, simple synthesis process, high catalytic activity and the like, is suitable for large-scale industrial production, and has important significance for promoting the commercialization process of various energy conversion devices.

Owner:HUAZHONG UNIV OF SCI & TECH

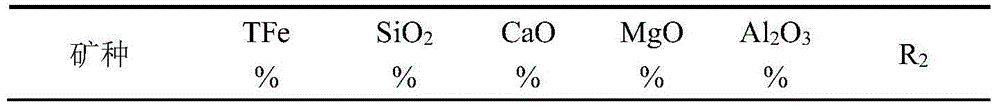

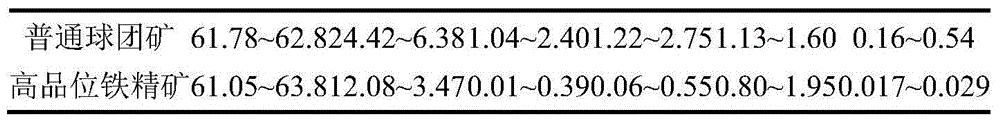

Blast furnace iron-making raw material and blast furnace iron-making method

InactiveCN104531923ASteady and straightLow cost of industrializationBlast furnace detailsLow magnesiumBlast furnace

The invention provides a high-aluminum low-magnesium blast furnace iron-making raw material and a method for high-aluminum low-magnesium blast furnace iron-making by using the high-aluminum low-magnesium blast furnace iron-making raw material. The high-aluminum low-magnesium blast furnace iron-making raw material consists of high-aluminum low-magnesium sintered ore, pellet ore and raw ore; the blast furnace material is free of magnesium-containing ore; the high-aluminum low-magnesium sintered ore is prepared from a mixture of high-aluminum low-magnesium iron ore powder and auxiliary sintering materials in a sintering way; the pellet ore is ordinary pellet ore; the raw ore is high-grade iron ore concentrate. In the blast furnace iron-making process, the high-aluminum low-magnesium sintered ore and the ordinary pellet ore together with reasonably added raw ore are adopted, and appropriate blast furnace operation mechanisms are selected, so that the coal gas flow can be reasonably distributed in the blast furnace iron-making process, the blast furnace slag is good in property, the slag iron can be smoothly discharged, stable and smooth operation of a blast furnace is maintained, and the pig iron making cost is lowered.

Owner:SHANDONG IRON & STEEL CO LTD

Iron oxyhydroxide modified active carbon desulfurizer as well as preparation method thereof

InactiveCN103521195AEasy to handleEfficient desulfurizationOther chemical processesActivated carbonLignin sulfate

The invention relates to an iron oxyhydroxide modified active carbon desulfurizer which is prepared from the following raw materials in parts by weight: 120-130 parts of active carbon, 12-14 parts of iron oxyhydroxide, 4-5 parts of lignin sulfate, 4-5 parts of polyvinyl alcohol, 8-10 parts of modified attapulgite and an appropriate amount of water. According to the iron oxyhydroxide modified active carbon desulfurizer disclosed by the invention, the iron oxyhydroxide is used to efficiently desulfurate and dechlorinate, and the desulfuration effect is long in lasting time. The lignin sulfate is further used, so that raw materials such as active carbon can be uniformly dispersed in water. Therefore, the desulfurizer has a better water treatment effect, free from toxic substances and low in production cost, and can be repeatedly and recycled, thereby not only saving the industrial cost, but also laying a foundation for industrial application.

Owner:BENGBU PIONEER FILTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com