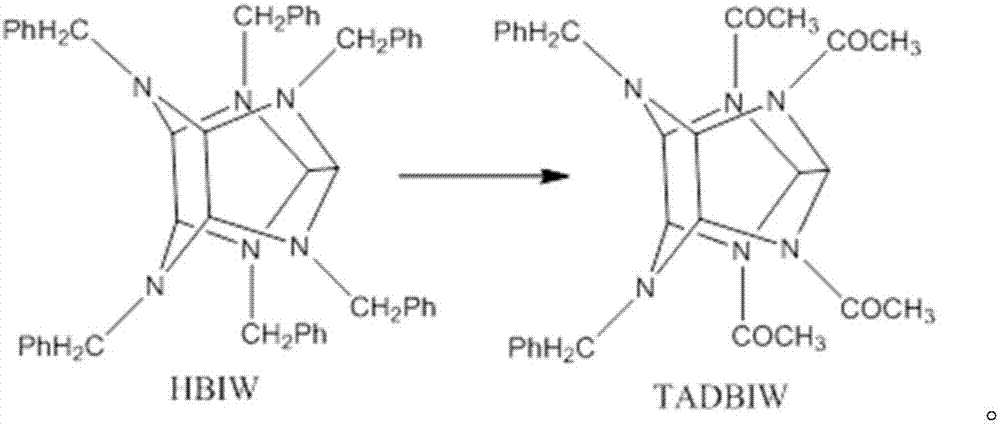

Application of palladium-based bimetallic catalyst in catalytic hydrogenolysis reaction of HBIW

A bimetallic catalyst, isowurtzitane catalyzing hydrogen technology, which is applied in the directions of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, organic chemistry, etc., can solve the problem of high production cost and achieve low production cost , Good application prospect, low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

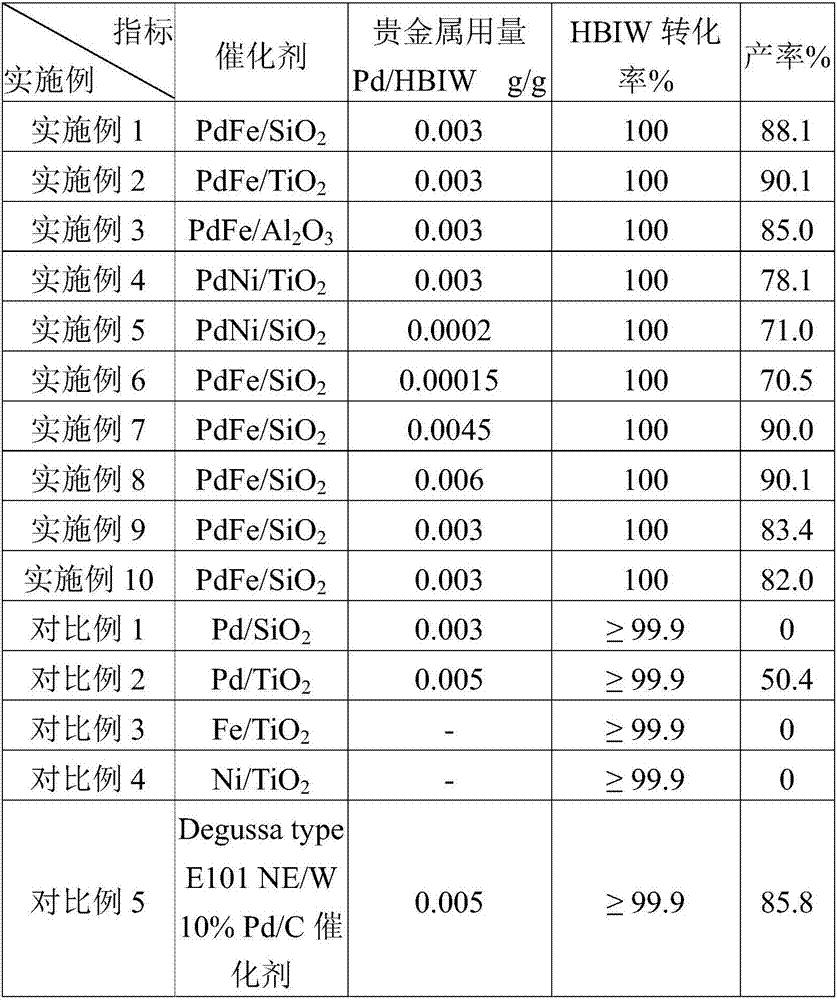

Embodiment 1

[0042] Preparation of palladium-based bimetallic catalyst:

[0043] Put the mixed solution of 10mg / mL chloropalladium acid and ferrous chloride into 200mL water, stir evenly, then add 1.0g of silicon oxide, stir for 1h, then add precipitant (sodium hydroxide), adjust the pH value to 13, in After mixing and reacting in a water bath at 60°C for 5h, add a reducing agent (sodium borohydride, the amount is 30 times the total molar amount of palladium and iron), stir for 0.5h, filter, wash, and vacuum dry at 60°C to obtain SiO 2 Supported Pd-Fe bimetallic catalyst, the molar ratio of palladium to iron is 1:1, and the total loading is 10%.

[0044] Hydrogenolytic debenzylation of hexabenzylhexaazaisowurtzitane (HBIW):

[0045] Put 1.0g of HBIW, 2.5mL of DMF, 1.5mL of acetic anhydride, 0.02mL of bromobenzene, and 0.05g of the above-mentioned catalyst into the reaction vessel, charge and discharge hydrogen, then charge the hydrogen to 4bar, react at 18°C for 4h, then raise the tempe...

Embodiment 2

[0047] In the preparation process of the palladium-based bimetallic catalyst of this embodiment, the carrier used is TiO 2 , other operations and parameters are the same as in Example 1.

[0048] The operation and parameters of the hydrogenolysis debenzylation reaction of hexabenzylhexaazaisowurtzitane (HBIW) in this example are the same as those in Example 1.

Embodiment 3

[0050] In the preparation process of the palladium-based bimetallic catalyst of this embodiment, the carrier adopted is Al 2 o 3 , other operations and parameters are the same as in Example 1.

[0051] The operation and parameters of the hydrogenolysis debenzylation reaction of hexabenzylhexaazaisowurtzitane (HBIW) in this example are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com