Preparation method for C9 hydrogenation petroleum resin

A hydrogenated petroleum resin and petroleum resin technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem that catalyst life cannot meet industrial requirements, insolubility Solve problems such as increased sol content, high sulfur and nitrogen content, and achieve the effects of improving impurity resistance, catalyst life, and low reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

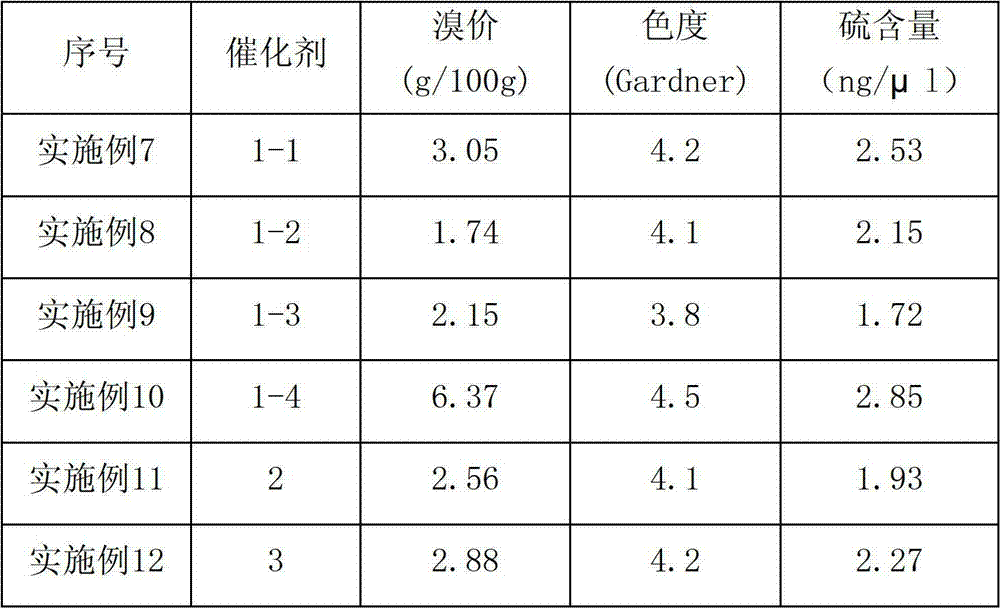

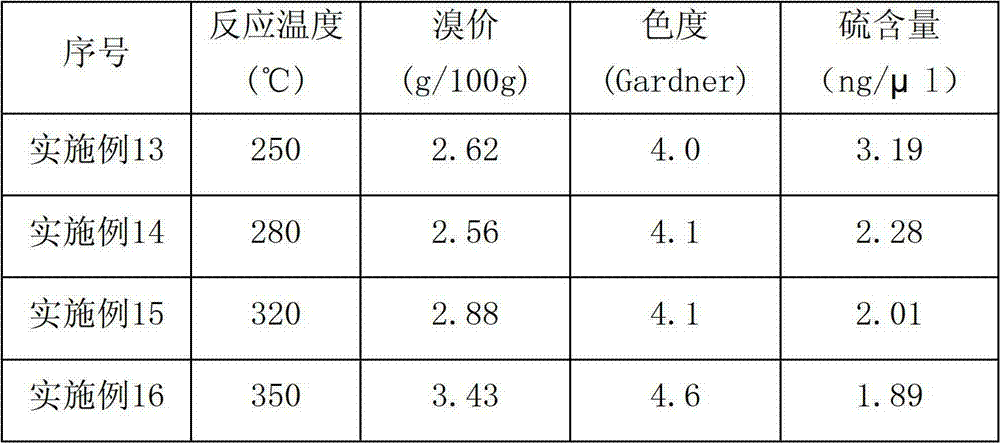

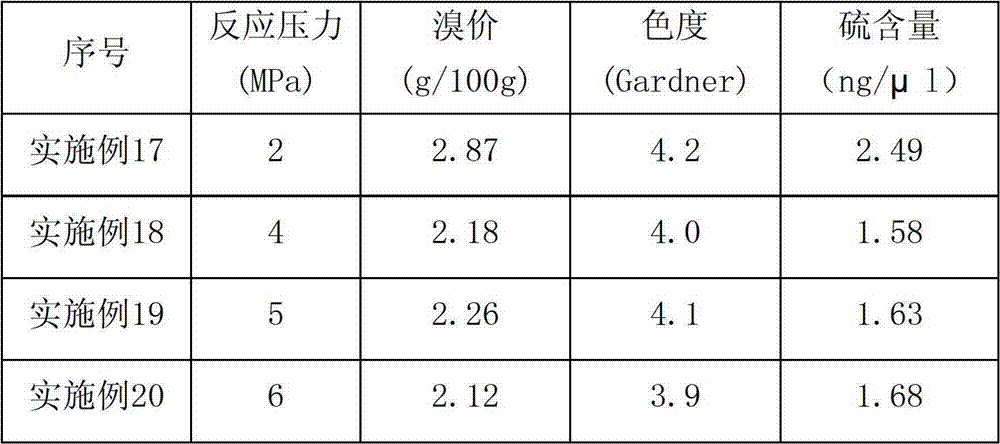

Examples

Embodiment 1

[0043] Weigh 500g of pseudo-boehmite, 200g of aluminum hydroxide, 300g of diatomaceous earth and 100g of polyethylene glycol powder, mix well, add 270g of 6% dilute nitric acid aqueous solution for kneading, age at room temperature for 30 minutes, and shape it on an extruder for 3 strips, dried at 120°C for 24 hours, then calcined at 800°C for 2 hours to obtain a catalyst carrier, crushed and sieved to obtain 10-20 mesh particles. Use a predetermined amount of nickel nitrate solution to impregnate 10-20 mesh particles to prepare four kinds of catalysts with different nickel contents, then dry at 120°C, and roast at 420°C for 4 hours to obtain the first-stage hydrodesulfurization catalyst precursor in the method of the present invention . Fill 10ml into the reactor before use, and reduce with hydrogen at 400°C for 3 hours. Catalyst compositions and physicochemical parameters with different nickel contents are listed in Table 2 below.

[0044] Table 2. Hydrodesulfurization ...

Embodiment 2

[0047] Weigh 800g of pseudo-boehmite, 100g of aluminum hydroxide, 100g of diatomaceous earth and 50g of polyethylene glycol powder, mix uniformly, and prepare a first-stage hydrodesulfurization catalyst with a nickel content of 30% according to the preparation method of Example 1. Body, its specific surface area is 143m 2 / g, the pore volume is 0.52ml / g. Fill 10ml into the reactor before use, and reduce with hydrogen at 400°C for 3 hours. Catalyst is marked as 2 # .

Embodiment 3

[0049] Weigh 200g of pseudo-boehmite, 400g of aluminum hydroxide, 400g of diatomaceous earth and 80g of polyethylene glycol powder, mix uniformly, and prepare a first-stage hydrodesulfurization catalyst with a nickel content of 30% according to the preparation method of Example 1. Body, whose specific surface area is 120m 2 / g, the pore volume is 0.54ml / g. Fill 10ml into the reactor before use, and reduce with hydrogen at 400°C for 3 hours. Catalyst is marked as 3 # .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com