Patents

Literature

598 results about "Reactions stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing arene selectivity by enhancing methanol aromatizatian and process for preparation of catalyst thereof

ActiveCN101550051AImprove methodHigh yieldMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveFixed bed

The invention relates to a process for preparing arene selectivity by enhancing methanol aromatizatian. The process uses methanol as raw material, compositely modifies HZSM-5 molecular sieve catalyst by active ions like Ga, Zn, Cu, Cr and Ag for catalyzing methanol aromatizatian, employs the fixed bed continuous process or the floating bed continuous process, wherein the reaction pressure is 0.1-3.5MPa; the reaction temperature is 380-500 DEG C; the space velocity of raw material liquid is 0.1-10.0 h; and N2 space velocity is 120-800 h. The advantages of the invention lie in collocation combination of mixing ion modification, and arene selectivity reaches to 70%.

Owner:TIANJI COAL CHEM IND GROUP +1

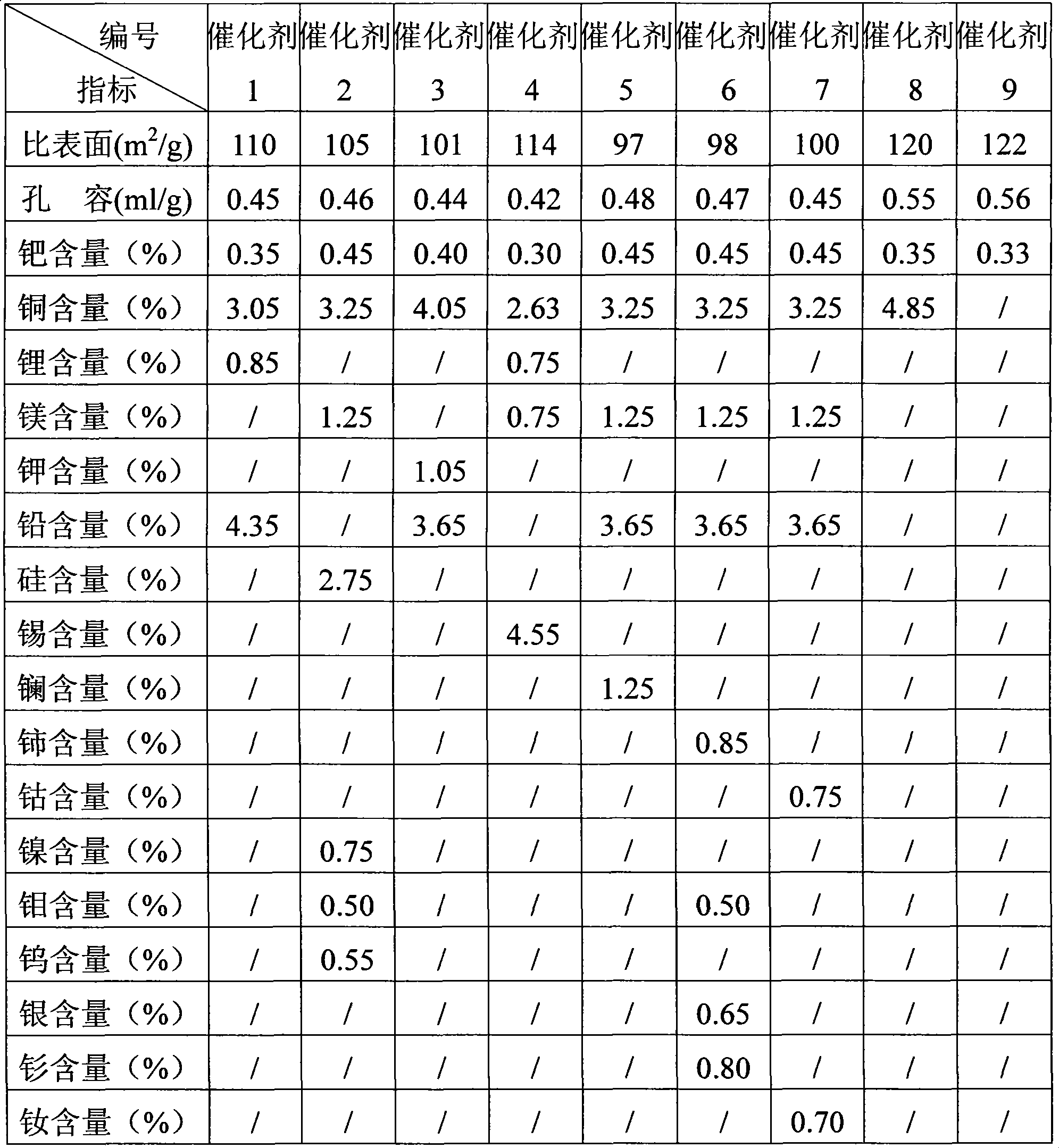

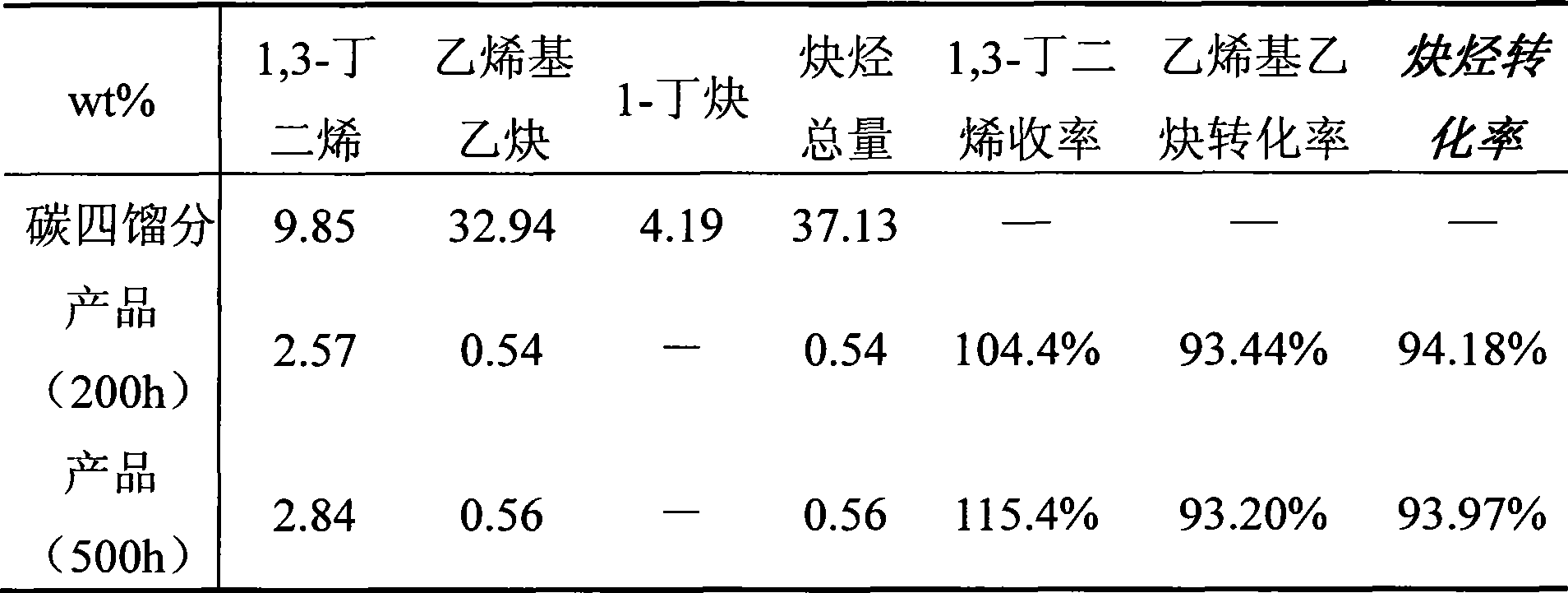

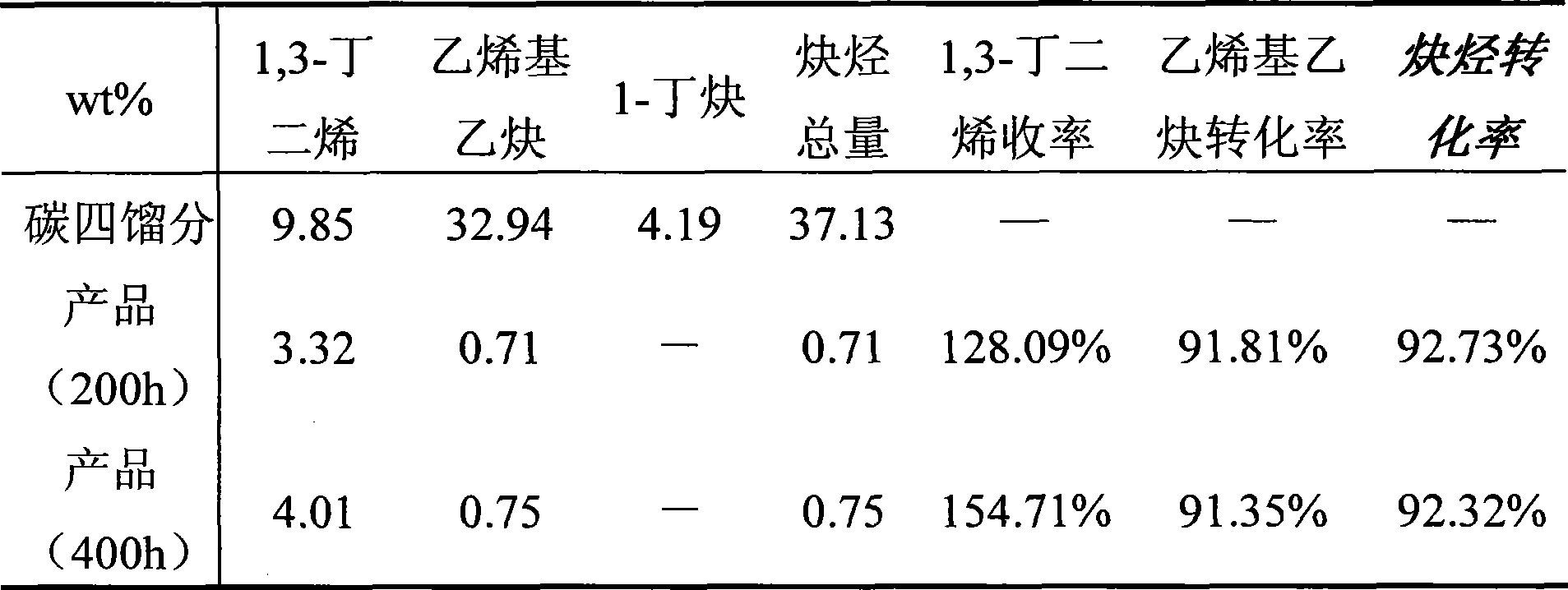

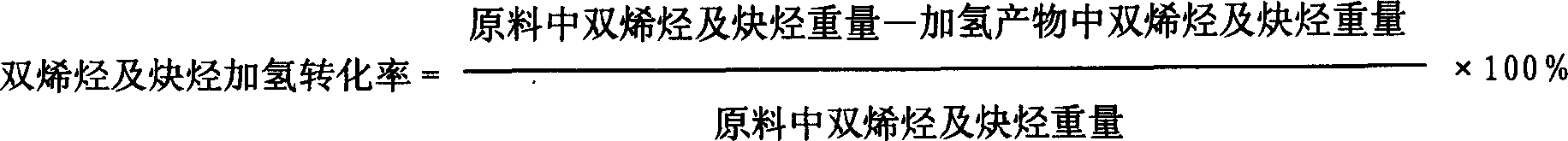

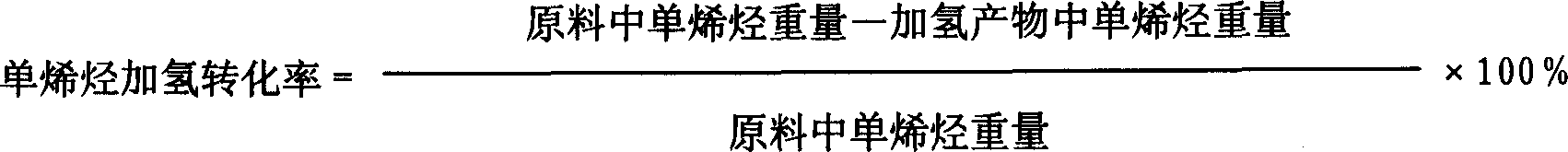

Acetylene hydrocarbon selective hydrogenation method

ActiveCN101434508AGood hydrogenation effectImprove hydrogenation activityHydrocarbon by hydrogenationHydrocarbon purification/separationButadiene DioxideUnsaturated hydrocarbon

The invention relates to a selective hydrogenation method of high unsaturated hydrocarbons in C4 fractions, which is characterized in that salvage stores which are rich in acetylene hydrocarbon and prepared by extracting butadiene are used as the material, and a fixed bed reactor is adopted to obtain 1, 3-budiene by selective hydrogenation under the existence of a catalyst. The adopted process conditions are as follows: the reaction temperature is between 30 DEG C and 90 DEG C, the reaction pressure is between 1.0 MPa and 4.0 MPa and the liquid space velocity is 7 to 20h<-1>. The catalyst is preferably a palladium system catalyst with alumina as a carrier, the specific surface is 50 to 150m<2> / g and the specific pore volume is 0.25 to 1.0ml / g. The method has remarkable good effects on reducing waste of resources and improving economic benefits by effectively utilizing the salvage stores rich in acetylene hydrocarbon and prepared by extracting butadiene.

Owner:PETROCHINA CO LTD

Titanium dioxide nanopowder manufacturing process

Owner:EI DU PONT DE NEMOURS & CO

Method of converting ethanol to base stock for diesel fuel

ActiveUS20070287873A1Moderate acidityPhysical/chemical process catalystsHydrocarbon from oxygen organic compoundsGas phaseBase oil

A method of converting ethanol to a diesel fuel base stock comprises: a reaction stage (a) of contacting the ethanol with an acid catalyst, amorphous or structured, predominantly mesoporous, for example at a temperature of 300° C. to 500° C., at a pressure of 2 to 10 MPa and at a WHSV of 0.2 to 4 h−1, producing a gas phase, an organic liquid phase and an aqueous liquid phase, and a stage (b) of separating said gas phase, said organic liquid phase and said aqueous liquid phase at a pressure close to the reaction pressure. The method can involve recycling at least part of the gas phase separated in stage (b) to stage (a), and hydrogenating at least part of the organic liquid phase separated in stage (b).

Owner:INST FR DU PETROLE

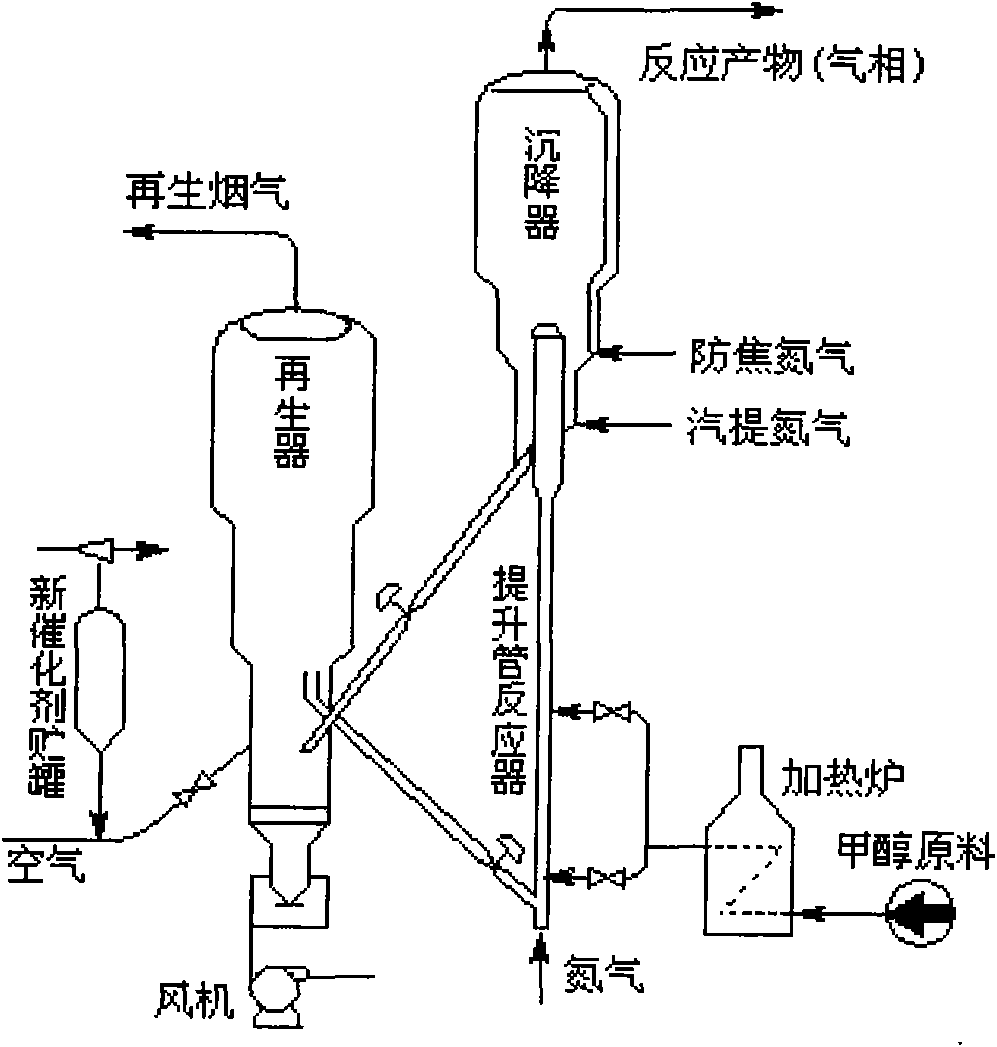

Method for preparing olefin by conversion of methanol

ActiveCN1704390AHigh selectivityImprove catalytic performanceHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveReaction temperature

The invention relates to a method for preparing olefin by conversion of methanol by using Zn-SAPO-34 molecular sieve and bonding agent as the catalyst for alkene production through methanol converstion, and employing a reaction temperature of 300-500 deg. C, a reaction pressure of atmospheric pressure, methanol weight space velocity of 1.0-10hr-1, the prepared low carbon alkene can be used in the industrial production of alkene from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesizing process for obtaining lithium difluoro-oxalato-borate and lithium tetrafluoroborate

InactiveCN101648963AImprove performanceSimple processGroup 3/13 element organic compoundsBoron halogen compoundsOrganic solventPhysical chemistry

The invention discloses a synthesizing process for simultaneously obtaining lithium difluoro-oxalato-borate and lithium tetrafluoroborate with favorable performance, which comprises the following steps: (1) leading a fluorine-contained compound, a boron-contained compound, a lithium-contained compound and an oxalate-contained compound to react in a reaction medium at the reaction pressure of 0.1-1MPa and the temperature of 0-100 DEG C, wherein the molar ratio of lithium element, fluorine element, boron element and oxalate ion is (2-3):(5-6):6:2:1; generating reaction liquid containing the lithium difluoro-oxalato-borate and the lithium tetrafluoroborate; (2) carrying out initial separation on the lithium difluoro-oxalato-borate and the lithium tetrafluoroborate in the reaction liquid and then carrying out further extraction separation by an organic solvent which can extract the lithium difluoro-oxalato-borate or the lithium tetrafluoroborate; and (3) respectively carrying out recrystallization and vacuum drying to obtain the battery-grade lithium difluoro-oxalato-borate and the lithium tetrafluoroborate. The invention is suitable for industrially producing two lithium salts which have favorable performance and are used for a lithium ion battery.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

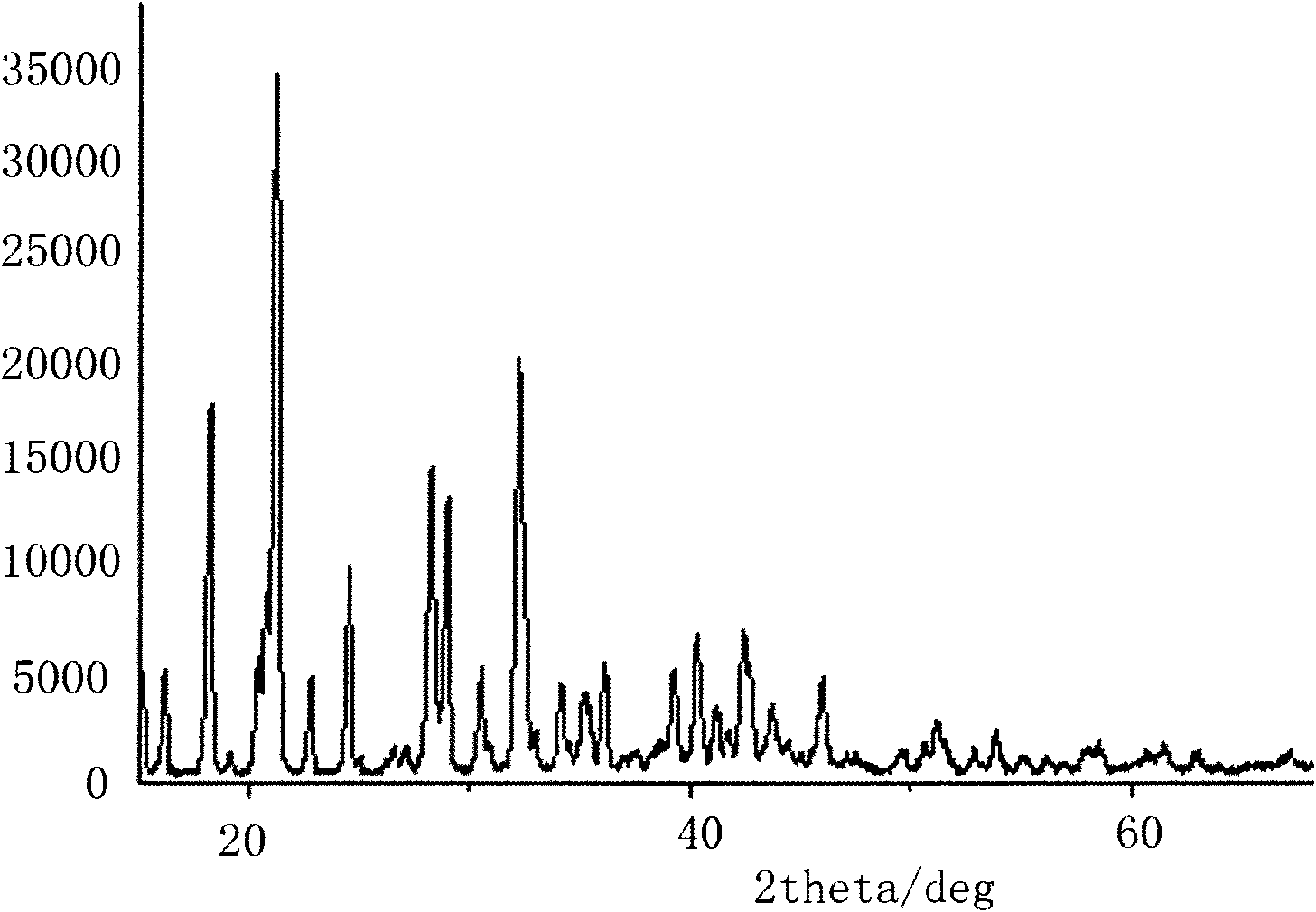

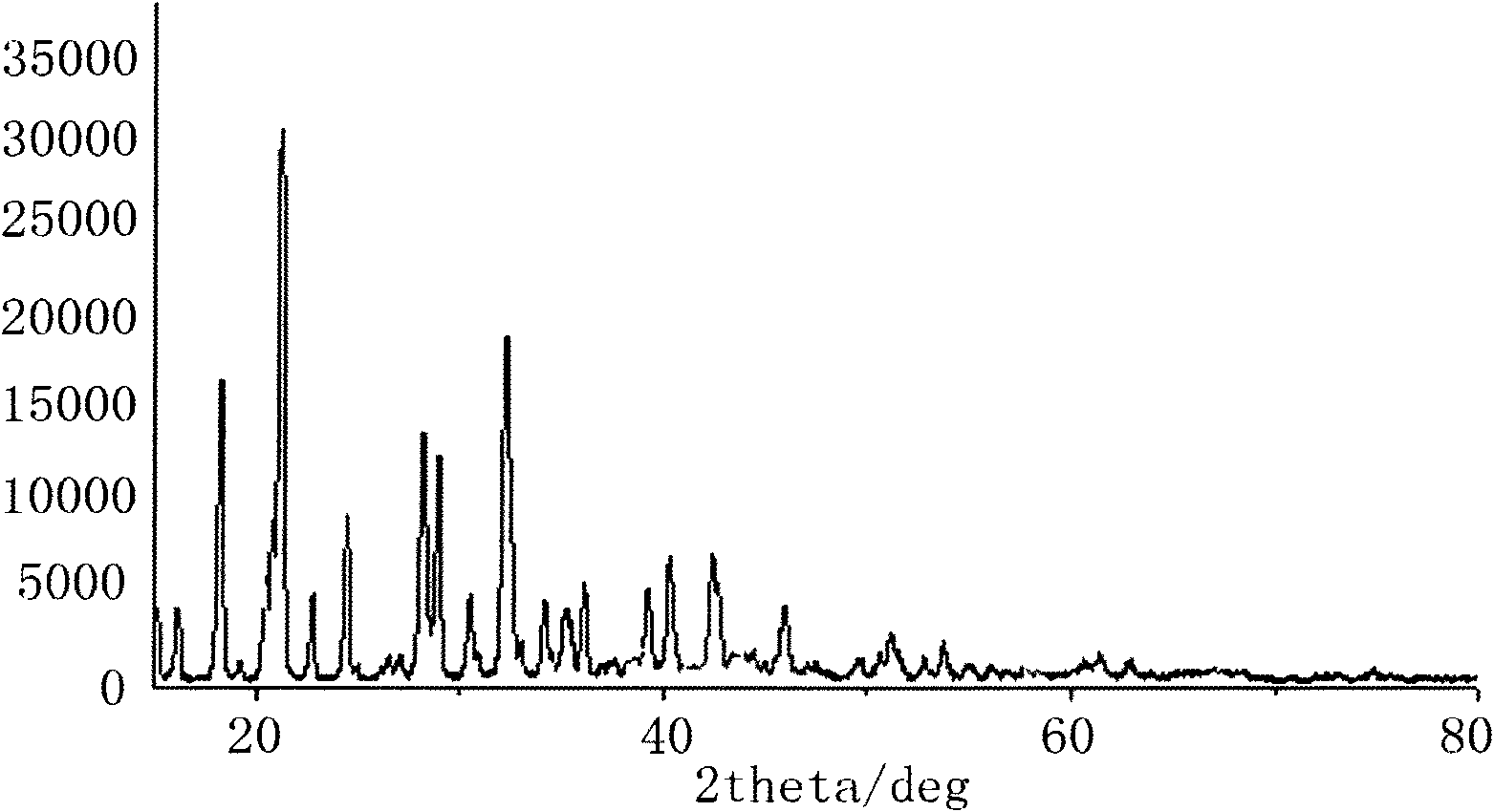

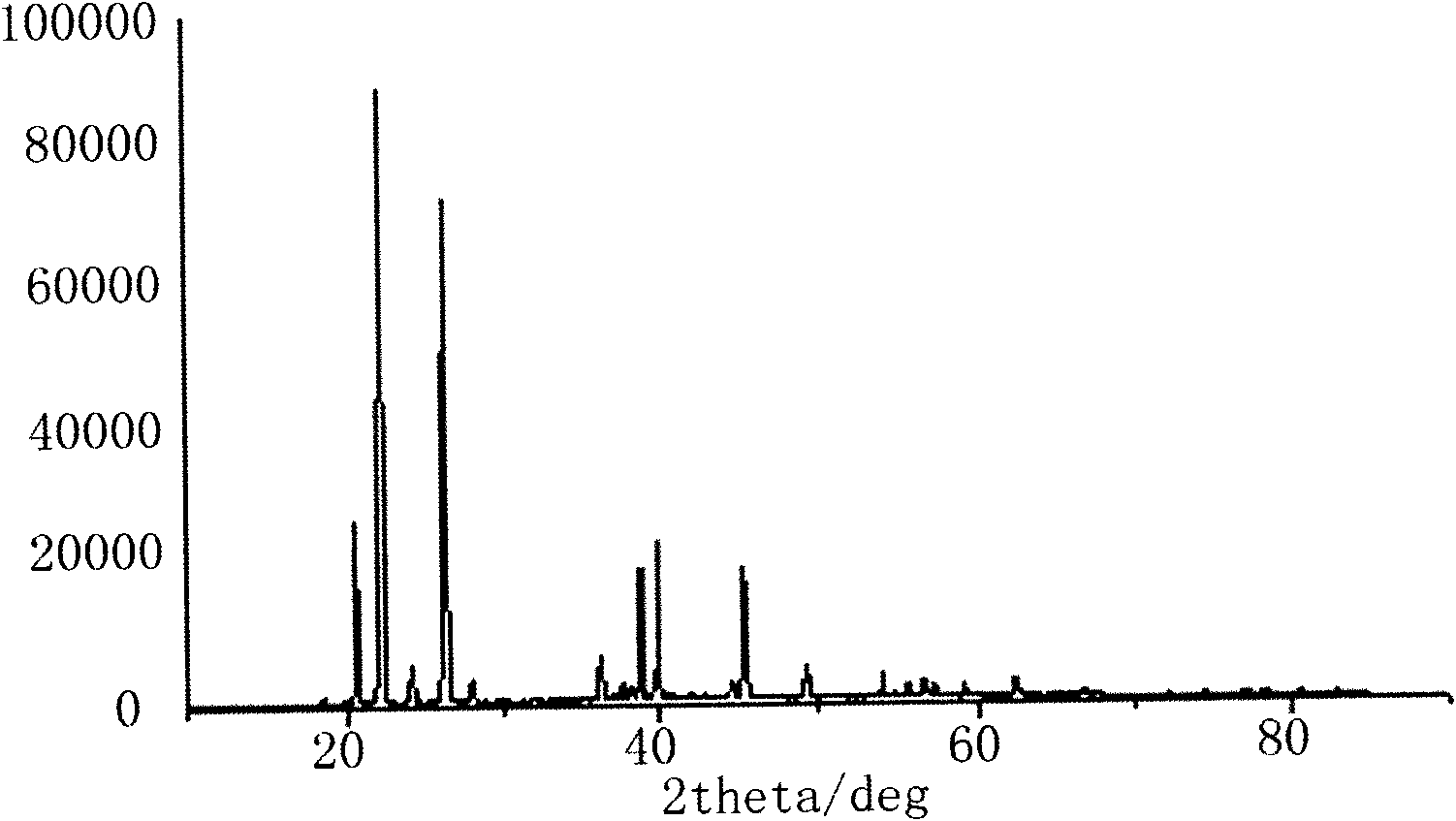

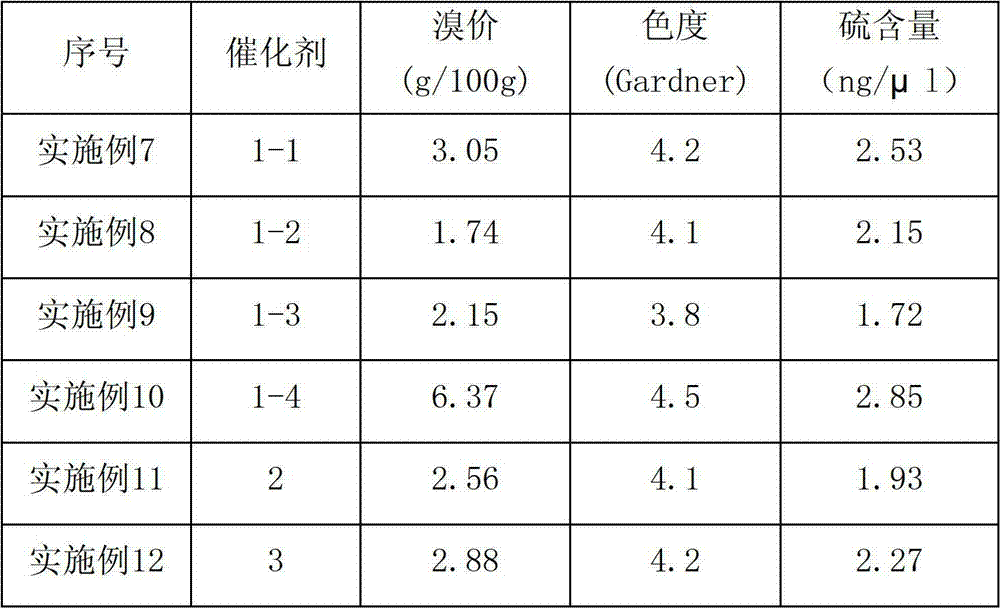

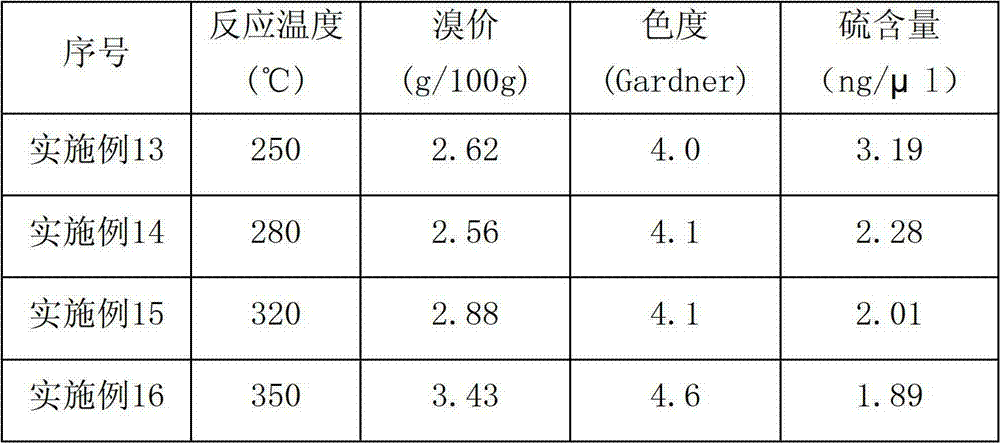

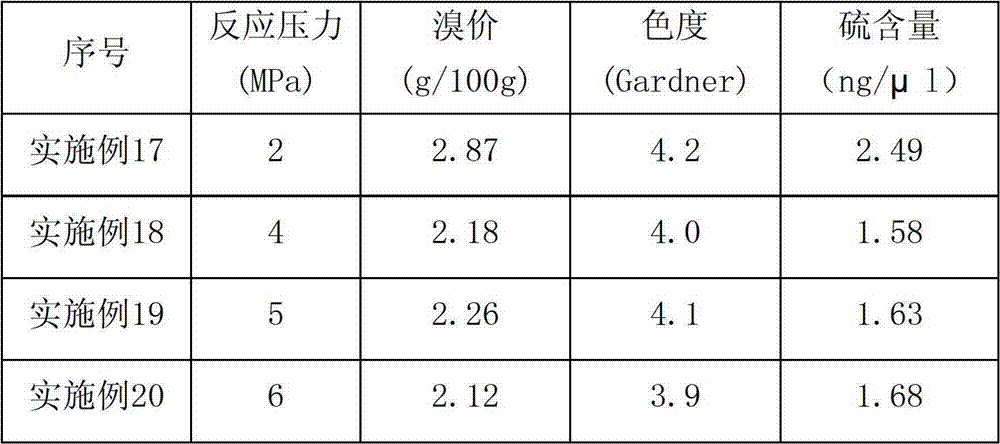

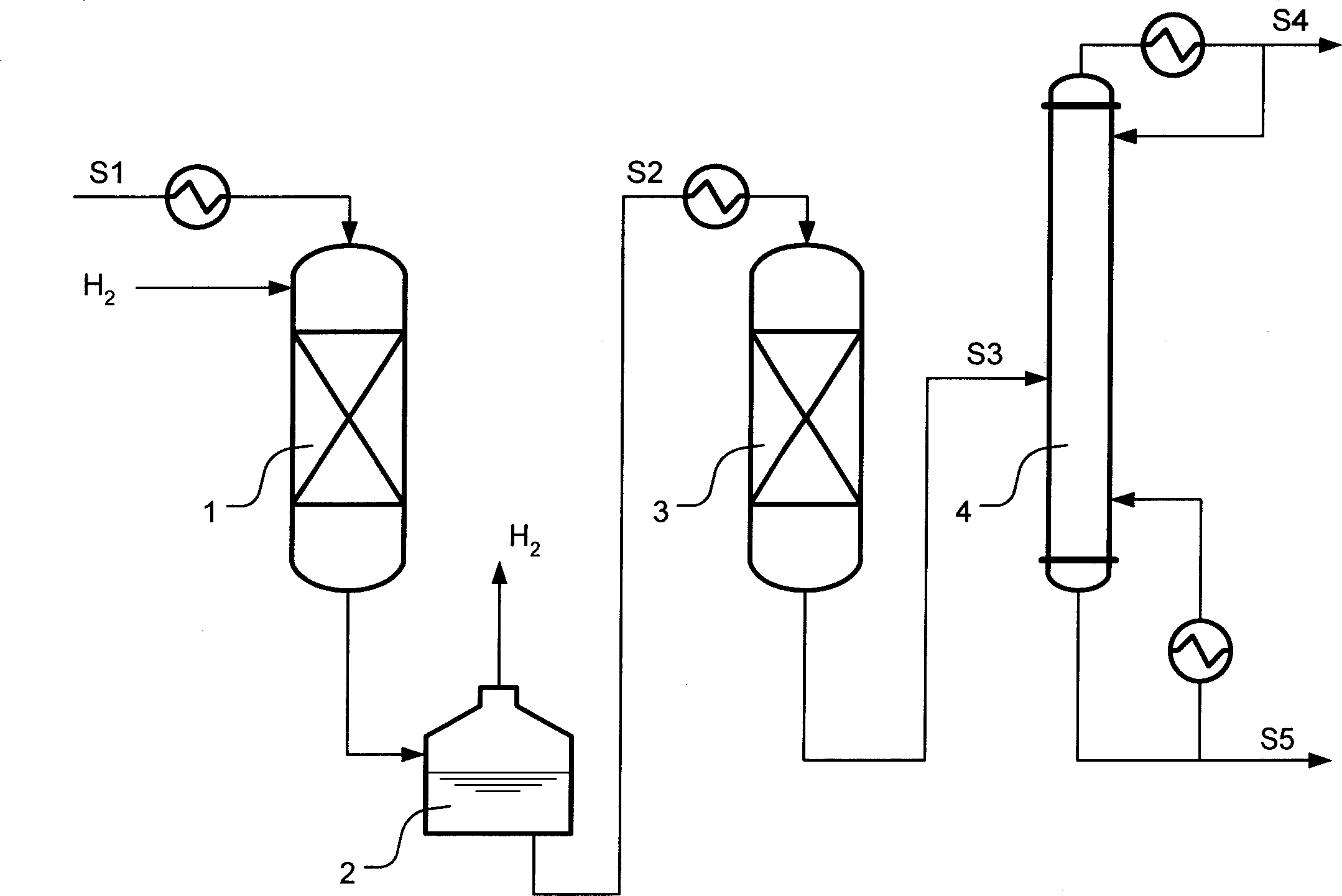

Preparation method for C9 hydrogenation petroleum resin

InactiveCN102924659AWide adaptabilityImprove performanceMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationSolvent

The invention relates to a preparation method for C9 hydrogenation petroleum resin. The C9 hydrogenation petroleum resin is dissolved in organic solvent, and the concentration of the C9 hydrogenation petroleum resin is 5wt %-30wt%. The C9 hydrogenation petroleum resin is filtered to remove undissolved substances, then subjected to a first section of hydrodesulfurization process and a second section of hydrogenation decoloration process, and finally subjected to the process of decompression rectification and solvent recovery to obtain C9 hydrogenation petroleum resin products. The preparation method adopts two-section hydrogenation, improves reaction activity, selectivity and impurity resistant capability, is wide in adaptability of C9 petroleum resin raw materials, and obtains C9 petroleum resin through adoption of thermal polymerization or catalytic polymerization. No matter impurity content in resin solution is high or low, particularly, when sulphur content is high in the resin solution, the two-step hydrogenation process can be carried out through the preparation method, and the C9 hydrogenation petroleum resin with high performance is obtained. Through the first section of hydrodesulfurization, hydrogenation noble metal catalyst in the second section is effectively protected. Service life of catalyst is greatly prolonged. Reaction pressure of the two-section hydrogenation is quite low, and industrial production cost is little.

Owner:CHINA PETROLEUM & CHEM CORP

Process of catalytically cracking C4 and above olefin to produce propylene

The present invention relates to the process of catalytically cracking C4 and above olefin to produce propylene, and aims at raising product propylene selectivity and yield. The present invention adopts ZSM type molecular sieve catalyst carrying alkali earth metal, and the reaction material C4 and above olefin produces cracking reaction to produce propylene under the conditions of 400-600 deg.c temperature, 0-0.15 MPa reaction pressure and 10-50 / hr liquid phase space velocity. The present invention may be used in the industrial production of catalytically cracking C4 and above olefin to produce propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

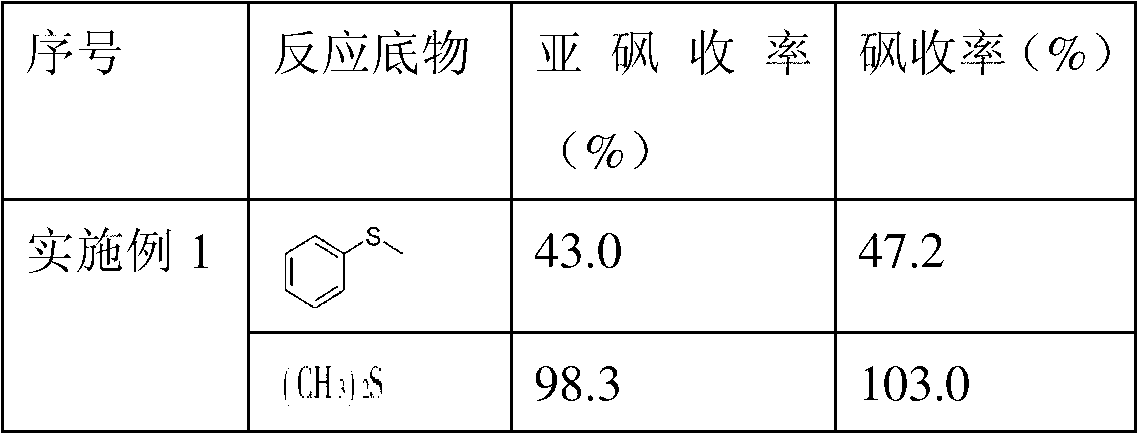

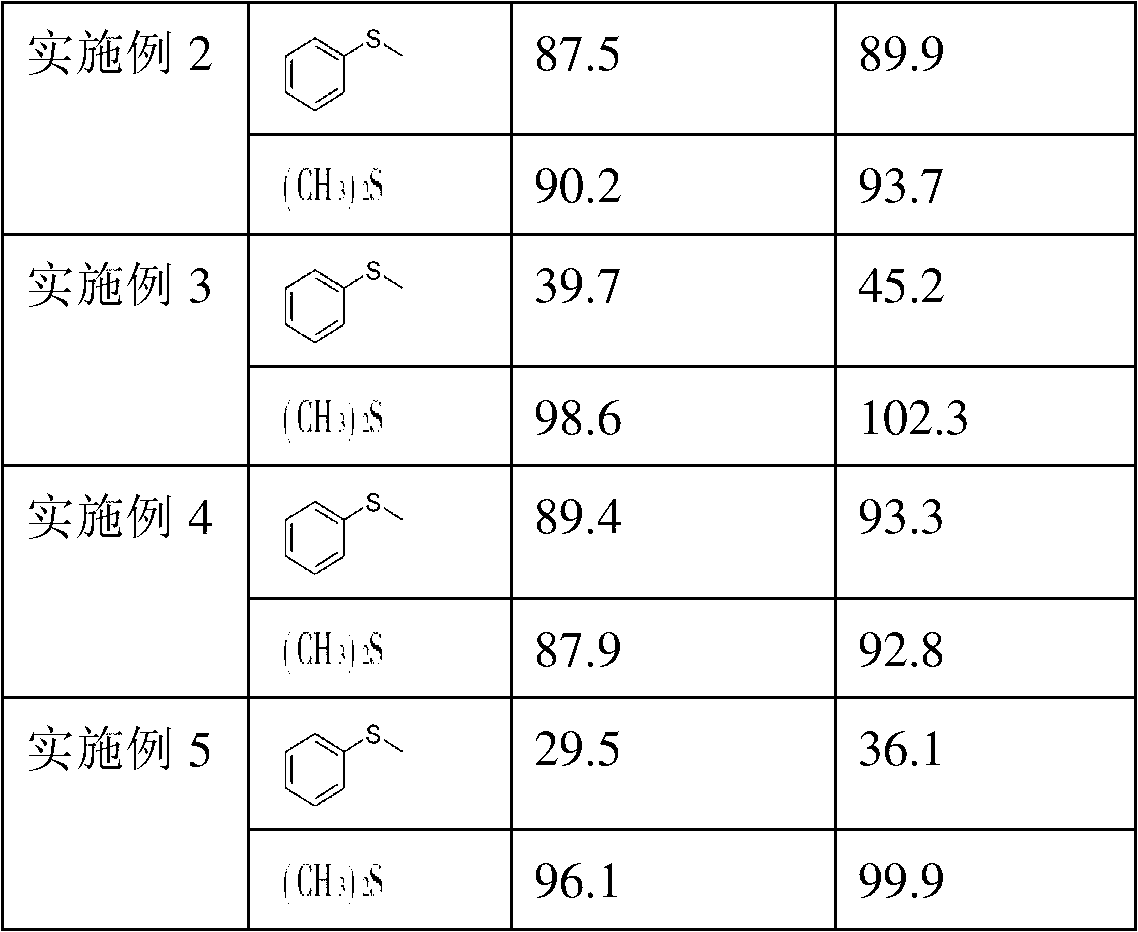

Preparation method for sulfoxide and sulphone

InactiveCN102838516AImprove conversion rateGood choiceOrganic chemistryMolecular sieve catalystsFixed bedReaction temperature

The invention discloses a preparation method for sulfoxide and sulphone. The preparation method comprises the following steps: conducting contact reaction on thioether and hydrogen peroxide, and catalyst in a fixed bed reactor, wherein the mole ratio of thioether and hydrogen peroxide is 1:0-1.5, the space velocity of the reaction system is 5-100, the reaction temperature ranges from normal temperature to 100 DEG C, the reaction pressure is 0.1-1.0 MPa, and the catalyst is obtained from one or more titaniferous molecular sieve raw powder or formed titaniferous molecular sieve. The method has the advantages of convenient operation, mild reaction conditions, easy separation, high product yield and the like, and the utilization rate of oxidant hydrogen peroxide can be greatly improved.

Owner:宁夏富诚生物科技有限公司

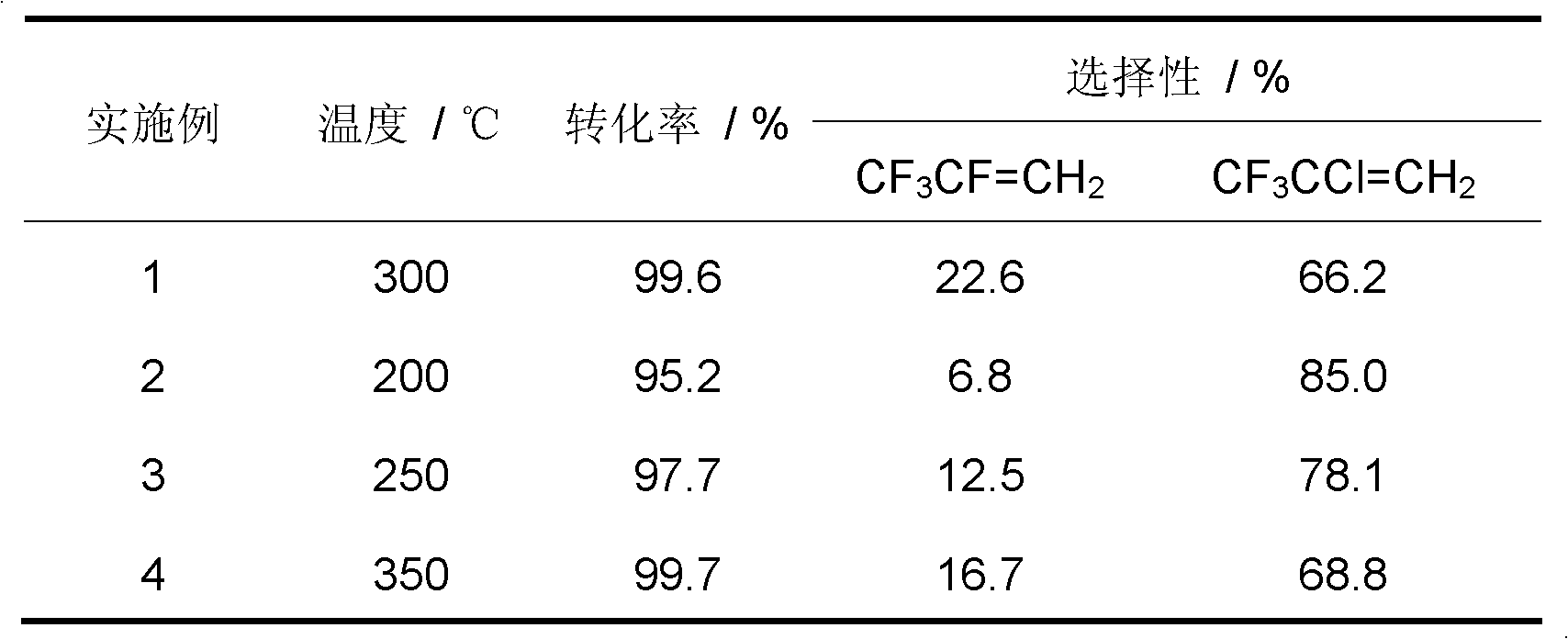

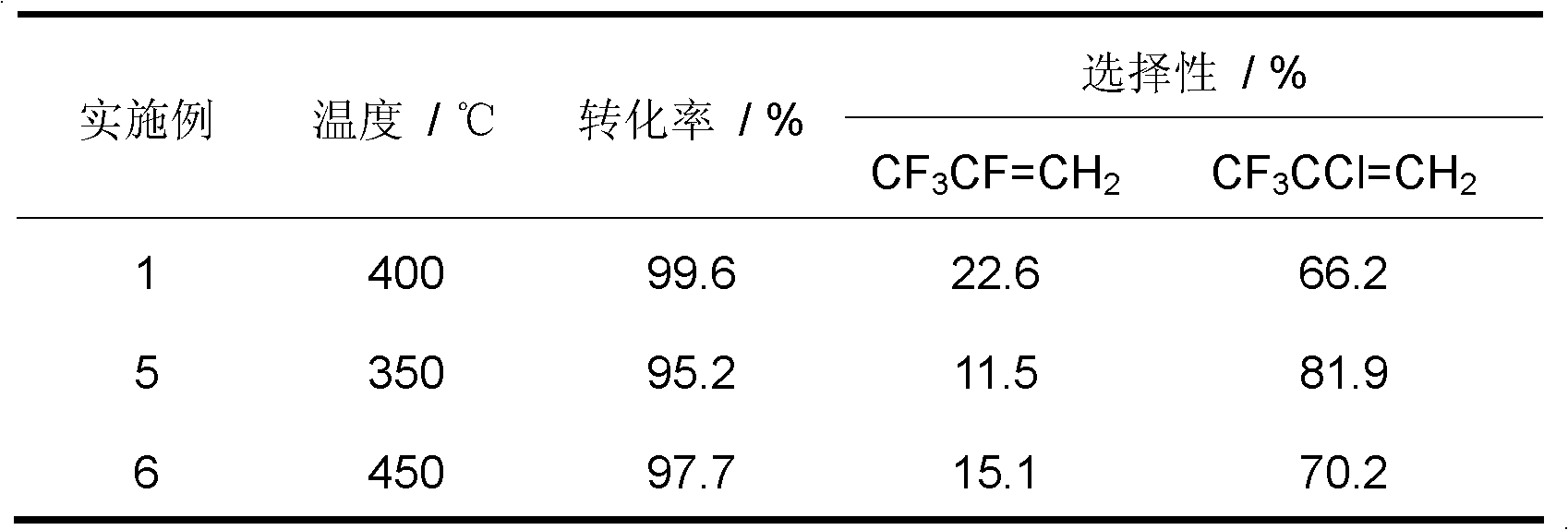

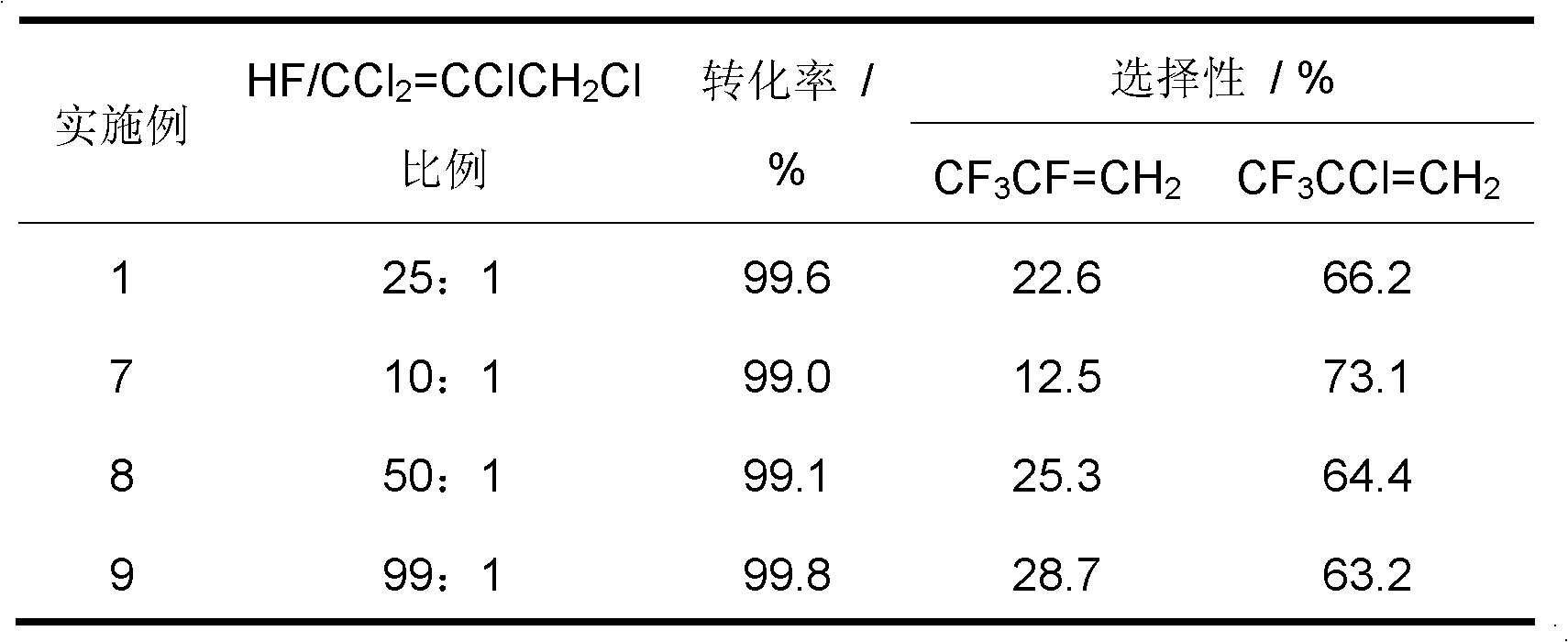

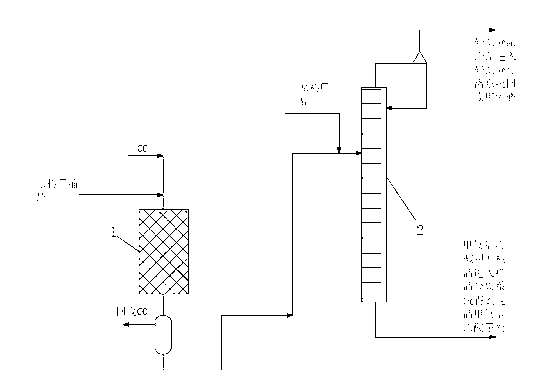

Method for preparing 2,3,3,3-tetrafluoropropene

InactiveCN102351637AMild reaction conditionsSimple processPreparation by hydrogen halide split-offHydrogen fluorideVapor phase

The invention discloses a method for preparing 2,3,3,3-tetrafluoropropene. The method comprises the following steps of: loading Cr2O3 catalyst in a reactor; introducing preheated hydrogen fluoride and 1,1,2,3-tetrafluoropropene gas into the reactor, and performing vapor phase catalytic fluorination to synthesize 2,3,3,3-tetrafluoropropene, wherein a molar ratio of the hydrogen fluoride to the 1,1,2,3-tetrafluoropropene is (10-99):1, the catalyst is equally divided into two sections, the upper-section catalyst in the reaction has the temperature of between 200 and 350DEG C, the lower-section catalyst has the temperature of between 350 and 450DEG C, the reaction velocity is 250-2,000h<-1>, and the reaction pressure is normal pressure; and introducing obtained effluent into a rectifying tower, and performing deacidification and rectification treatment on the 2,3,3,3-tetrafluoropropene to obtain the final product. The method has the advantages of mild reaction conditions, simple process, and optimum distribution of energy and resources.

Owner:ZHEJIANG NORMAL UNIVERSITY

Continuous synthesis method for methyl methoxyacetate

InactiveCN102701977ANo emissionsEasy to operatePreparation by carbon monoxide or formate reactionChemical recyclingMethyl methoxyacetateWastewater

The invention relates to a synthesis method for methyl methoxyacetate, in particular to a continuous synthesis method for the methyl methoxyacetate. The continuous synthesis method is characterized in that: methylal and CO are used as raw materials; carbonylation reaction is performed in a carbonylation reactor in which a catalyst is filled to obtain a methyl-glycolate-containing methyl methoxyacetate rough product; then a series of separation is performed to obtain a pure product of the methyl methoxyacetate; and the methylal is recovered from a separated light component byproduct and is returned to the carbonylation reactor to realize a continuous synthesis process, wherein the purity of the methylal and the molar ratio of the methylal to the CO are any values, and the reaction pressure in the carbonylation reactor is greater than or equal to normal pressure. According to the method, the production efficiency can be effectively increased, the production process can be simplified, the emission of waste residue and wastewater in a production process can bee reduced, and the aims of continuous production and reduction of the production cost are achieved.

Owner:东莞市同舟化工有限公司

Catalyst for synthesizing benzaldehyde and benzyl alcohol from toluol, the preparation process and application thereof

InactiveCN1485131AEasy to separateEase of usePreparation by oxidation reactionsCarbonyl compound preparation by oxidationAlkaline earth metalBenzaldehyde

A catalyst of synthesizing benzaldehyde and benzyl alcohol by methylbenzene, its manufacturing method and application. The active component is zirconium, or transit metals, alkaline metal, alkaline-earth metals, metals of IIIAíóIVA and VA Group in the Periodic Table. The method comprises solving a zirconium compound or a zirconium compound and a compound of an element as the active component, adding a precipitator; drying, burning, pulverizing to particles. In reactions, a gas containing oxygen is the oxygen source, such as oxygen and air, an organic solution wouldn't be used. The catalyzing reaction is 180-195 degree C, the pressure is 0.8-1.2Mpa. when the conversion rate of methylbenzene is 13.0úÑ, the total selectivity of benzaldehyde and benzyl alcohol is 86.6úÑ. In the method, the catalyst is easy to be separated and could be recyclable, the reaction condition is mild.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for preparing propylene and ethylene by catalytic cracking of olefin

ActiveCN1704389AHigh reactivityGood hydrothermal stabilityHydrocarbon by hydrocarbon crackingRare earthReaction temperature

The invention relates to a process for preparing propylene and ethylene by catalytic cracking of olefin through using C4-C8 olefin as raw material, using M-ZSM-5 molecular sieve containing rare earth metals or their oxides as the catalyst for the reactive main body, and employing a reaction temperature of 450-650 deg. C, reaction pressure 0-0.2 MPa, liquid hourly space velocity of 0.5-150h-1, the invention can be applied into the industrial production of propylene through olefin pyrolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene by ethanol dehydration

ActiveCN101121624AReduce carbon deposition rateExtended service lifeMolecular sieve catalystsHydrocarbonsDegree CelsiusReaction temperature

The present invention relates to a preparation method of ethylene using the dehydration of ethanol, which is to solve the problem in the prior technology that: the reaction temperature is higher; the hollow speed is lower and the energy consumption is higher. The present invention uses ethanol as the raw material and water as the thinner; under the condition that the reaction temperature is 200- 400 Celsius system, the reaction pressure calculated by a pressure meter is 0-2MPa and the reaction weight hollow speed is 0.1-10 hours, the raw material is contacted with ZSM molecule screen catalyzer to produce a ethylene flow; thereinto the molar ratio between water and ethanol is 0-10: 1. The technical scheme can solve the problem greatly, which can be used in the industrial production of ethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene glycol

ActiveCN101475443AImprove technical effectOrganic compound preparationHydroxy compound preparationOxalateHydrogen

The invention relates to a method for producing glycol, which mainly solves the problem that catalysts in the prior art are poor in stability and short in regeneration period. By adopting a technical proposal of taking oxalate as raw material, taking polar or nonpolar solvent as thinner and allowing the raw material to be in contact with and react with a copper-bearing catalyst so as to form glycol-containing effluent at a temperature between 120 and 300 DEG C, at a weight space velocity between 0.01 and 10 hours, with the hydrogen / ester molar ratio of 5-300:1, under the reaction pressure between 0.1 and 10.0 MPa, under the condition that the mass fraction of the oxalate is between 0.1 and 100 percent, the method solves the problem well, and can be used in the industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing pentane from light C5 distillate

InactiveCN1699309AHigh economic valueImprove qualityHydrocarbon by hydrogenationDistillation purification/separationParticulatesDistillation

Disclosed is a process for preparing pentane from light C5 distillate which comprises the steps of, subjecting light C5 distillate to hydrogenation reaction through catalyst fixed bed, the reaction pressure being 1.0-3.0 MPa, the reaction temperature being 15-35 deg. C, the mol ratio of hydrogen and total amount of unsaturated hydrocarbons in the C5 distillate being 1-5, the liquid hourly space velocity of the material being 1.0-5.0hr-1, the catalyst being loading type using Ni as active component, and using the mixture of Al2O3 and SiO2 as the carrier, passing particulate clay fixed bed at 150-170 deg. C so as to remove the residual unsaturated hydrocarbons, the liquid hourly space velocity of the material being 1.0-5.0hr-1, then removing light distillate through distillation segregation, the tower still temperature being 90-100 deg. C, the tower top temperature being 55-60 deg. C, the absolute pressure in the tower being 0.50-0.60 MPa, the reflux ratio being 2.5-3.5.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD +1

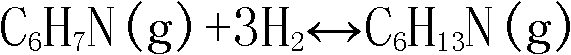

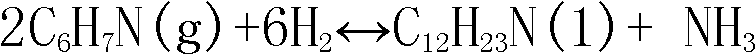

Method for synthesizing cyclohexylamine with aniline by means of gas-phase catalytic hydrogenation

ActiveCN102633649AExtended service lifeHigh yieldOrganic compound preparationAmino compound preparationGas phaseFixed bed

The invention discloses a method for synthesizing cyclohexylamine with aniline by means of gas-phase catalytic hydrogenation, which includes the steps: 1) mixing fresh hydrogen with circulating hydrogen; 2) mixing mixed hydrogen with the aniline according to the molar ratio of 15:1-19:1 in an aniline evaporator to enable vaporization of the aniline; 3) carrying out a hydrogenation reaction of vaporized mixed gas in a fixed bed hydrogenation reactor prefilled with cobalt-ruthenium catalyst or nickel-ruthenium catalyst at the reaction temperature of 165-179 DEG C and under the reaction pressureof 0.2-0.3MPa; and 4) materials which are subjected to the hydrogenation reaction enter a separator by means of heat exchange, condensation and cooling, performing gas separation to obtain crude cyclohexylamine, and then rectifying so that a cyclohexylamine product is prepared. By the aid of the method, production cost is effectively reduced, product yield is increased, and the service life of the catalyst is prolonged.

Owner:SHANDONG WEIJIAO GRP

Production of 3,3,3-trifluoro-propene

InactiveCN101074185AExtend your lifeLow reaction temperaturePreparation by halogen replacementHydrogen fluorideGas phase

Production of 3,3,3-trifluopene is carried out by taking hydrogen fluoride and 1,1,1,3-tetrachloropane as raw materials, jetting 1,1,1,3-tetrachloropane liquid into overheat hydrogen fluoride gas at 120-230 degree, entering mixed gas of HF and 1,1,1,3-tetrachloropane into reactor in proportion of 5-25:1 mol at 230-300 degree, 500h-1-3500h-1 and 0MPa-0.6MPa and gas-phase fluorizating to obtain final product. It can decrease olefin hydrocarbon impurities and high-polymer content effectively and extend fluorizating catalyst life.

Owner:XIAN MODERN CHEM RES INST +1

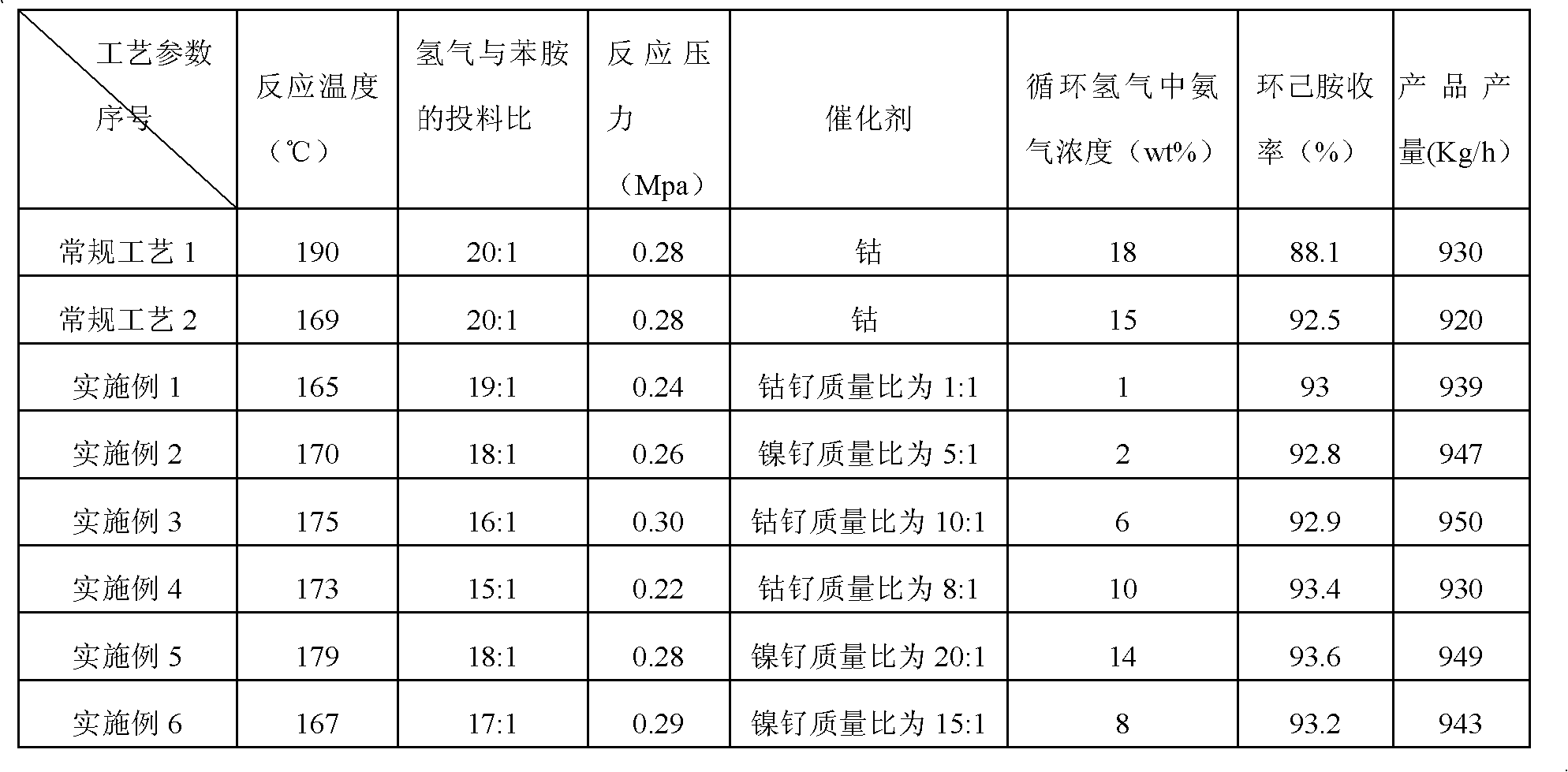

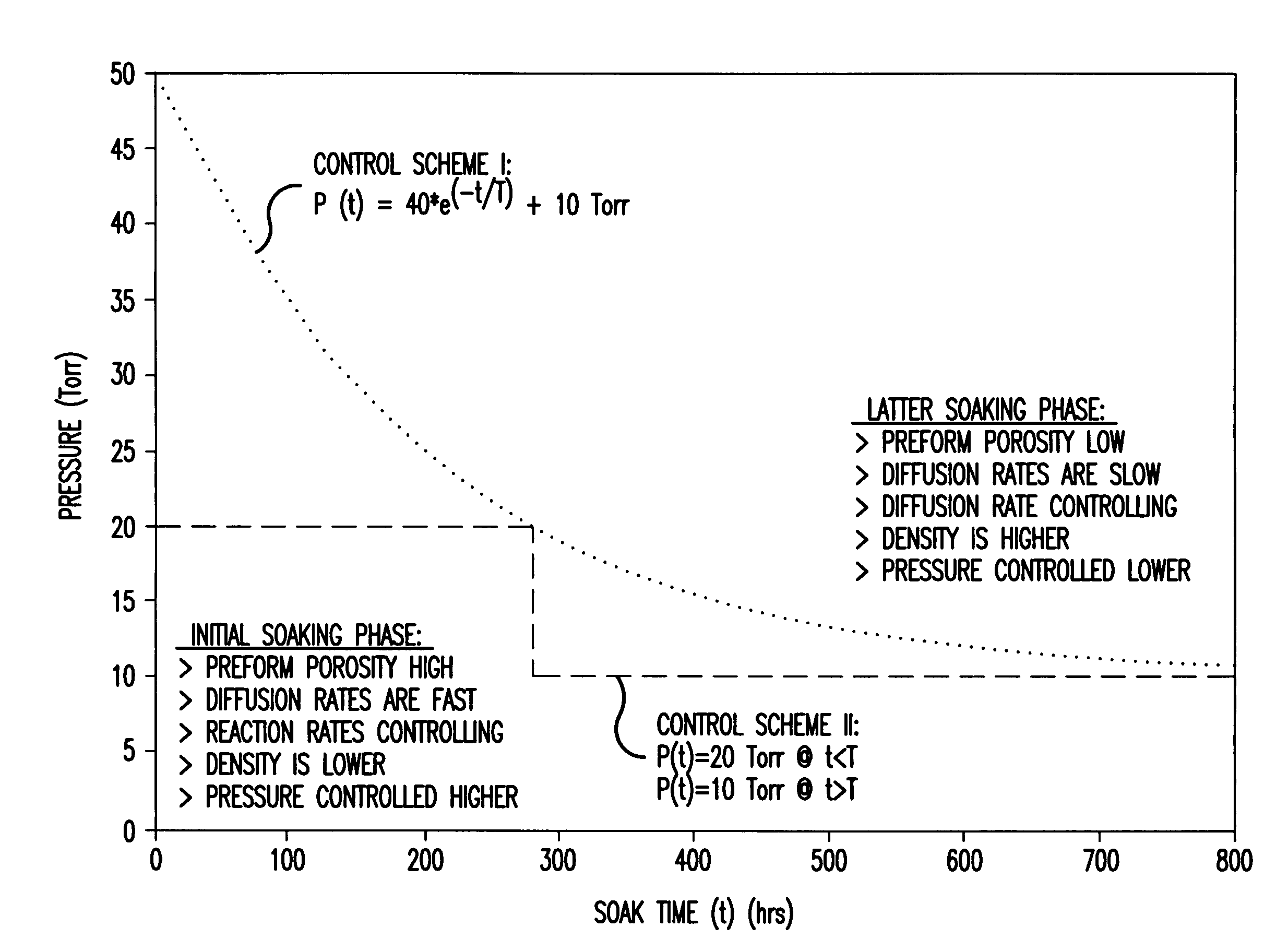

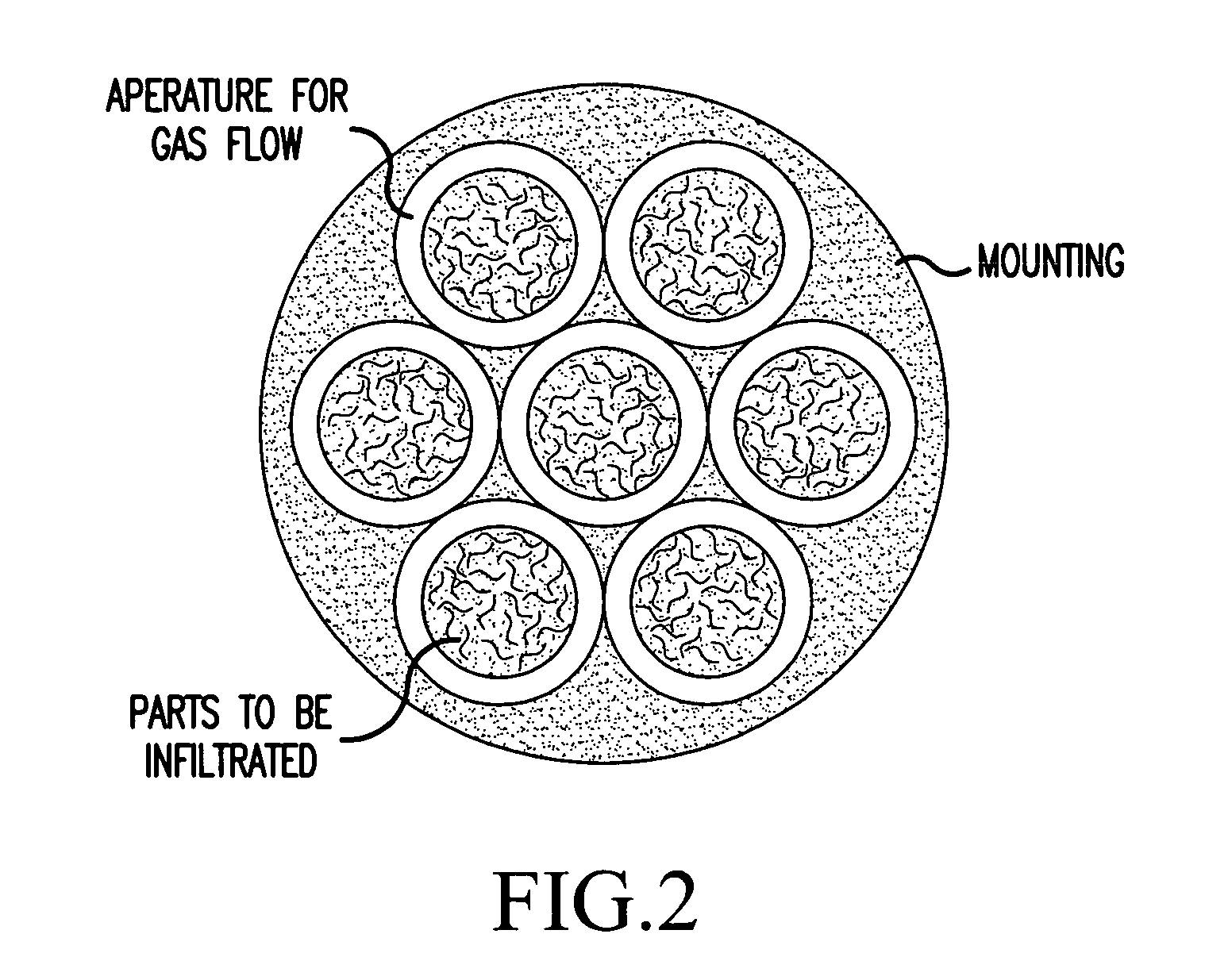

Pressure swing CVI/CVD

InactiveUS20080124462A1Increase ratingsReduce in quantityChemical vapor deposition coatingCarbon fibersPorous carbon

Method of chemical vapor infiltration of a deposable carbon material into a porous carbon fiber preform in order to densify the carbon fiber preform. The method includes the steps of: situating the porous carbon fiber preform in the reaction zone; providing a linear flow of a reactant gas comprising deposable carbon material in the reaction zone at an initial reaction pressure of at most 50 torr to produce deposition of the deposable carbon material into the preform; and adjusting the pressure of the gas to reaction pressures lower than said initial reaction pressure while deposable carbon material continues to be deposited into the porous carbon fiber preform. This method enables attainment of a target increased density in a carbon fiber preform much more quickly than known processes. A programmed pressure swing throughout the CVI / CVD run may be set in order to provide a linear increase in density. Alternatively, step changes in pressure during the course of the densification process may be made to enhance the rate of densification. This method reduces the number of cycles and the required intermediate machining steps necessary to densify preforms.

Owner:HONEYWELL INT INC

Selective hydrogenation method for phenylacetylene in the presence of phenylethylene

ActiveCN101475438AMolecular sieve catalystsHydrocarbon by hydrogenationLoss rateReaction temperature

The invention relates to a method for selective hydrogenation of phenylacetylene in the presence of styrene, which mainly solves the problem of high loss rate of the styrene in the prior art. The method adopts a technical proposal that hydrocarbon fractions containing the phenylacetylene are taken as raw materials, the raw materials are contacted with carbonic oxide catalyst under the condition that the reaction temperature is between 15 and 100 DEG C, the weight space velocity is between 0.01 and 100 h, the mol ratio of hydrogen to the phenylacetylene is 1-30:1, and the reaction pressure is between -0.08 and 5.0 MPa, the phenylacetylene in reaction effluent is hydrogenated into styrene, wherein carbon content in the carbonic oxide catalyst is between 0.02 and 8 in percentage by weight. The method better solves the problem, and can be applied in industrial production for removing the phenylacetylene by hydrogenation in the presence of the styrene.

Owner:CHINA PETROLEUM & CHEM CORP +1

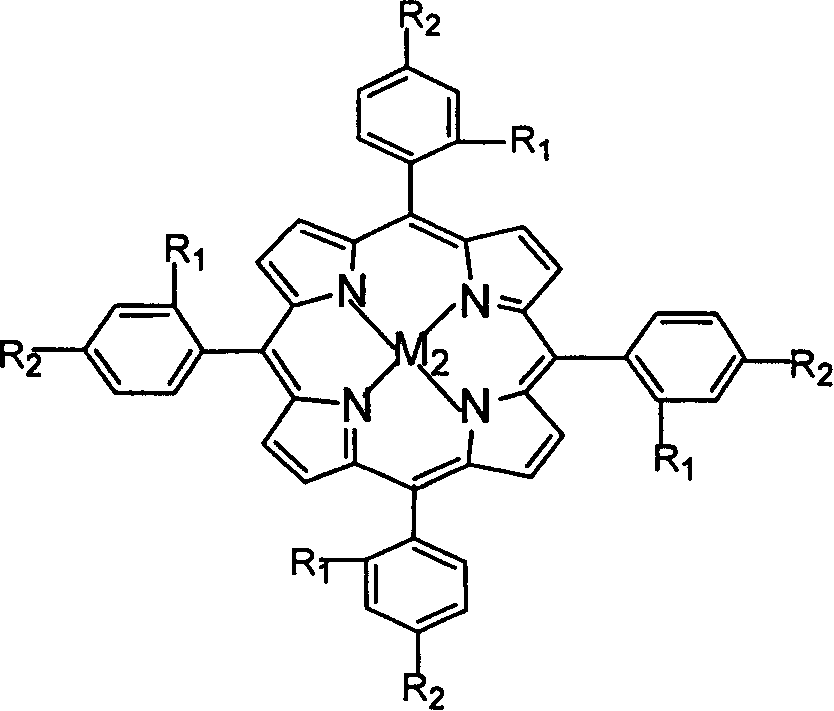

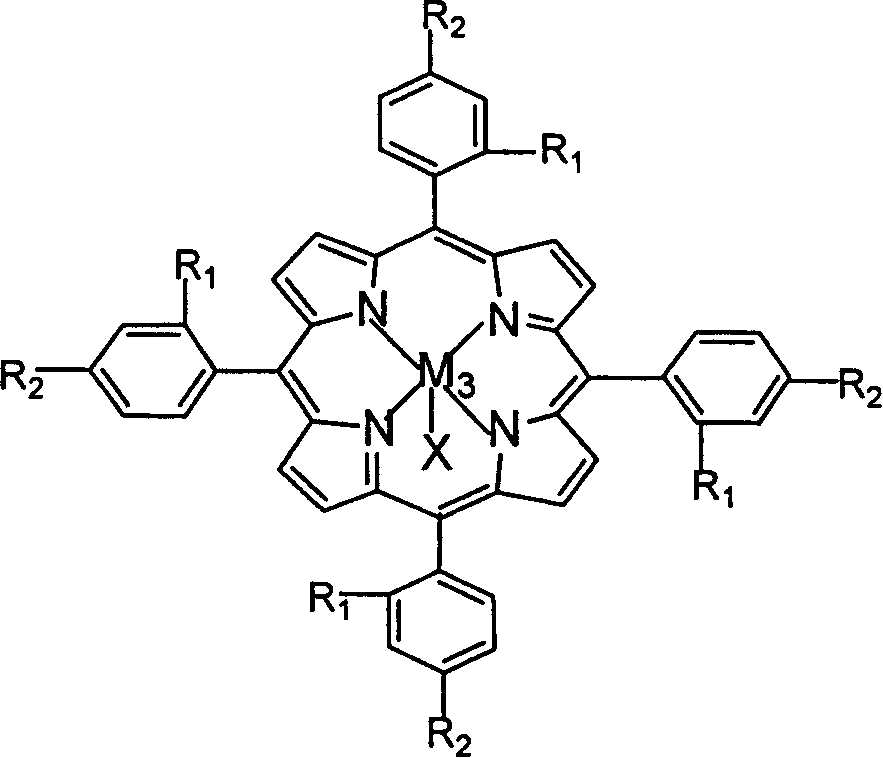

Catalyst used for catalytic synthesizing dimethyl carbonate directly from methanol and carbon dioxide and preparation and using method thereof

The invention discloses a direct catalytic synthesis catalyst to prepare dimethyl carbonate from methanol and carbon dioxide and the preparation and application methods of the catalyst. The catalyst of the invention consists of transitional metal soluble salt, promoter and carrier, with the weight ration from 0.01to 0.5: 0.01to 0.1:1. The preparation method is that: (1) the carrier is impregnated into the transition metal soluble salt solution; (2) the promoter is added into the solution, which is stirred in room temperature, ultrasonically dispersed and stored stationarily in room temperature; (3) the solution is dried, sintered, reduced and activated to produce catalyst. The application method is that: the catalyst is put in high pressure reactor or micro reaction device with the temperature of the catalyst bed controlled between 90 degrees centigrade to 140 degrees centigrade and the reaction pressure between 0.6 to 3.0MPa. The catalyst is applicable in direct catalytic synthesis to prepare dimethyl carbonate from methanol and carbon dioxide. The raw material sources are rich, the cost is low, the preparation method is simple and the operation is easy. The catalyst is easily separated from the products, the reaction conditions are mild and the catalyst can be used repeatedly. The catalyst has high activity and selectivity.

Owner:SUN YAT SEN UNIV

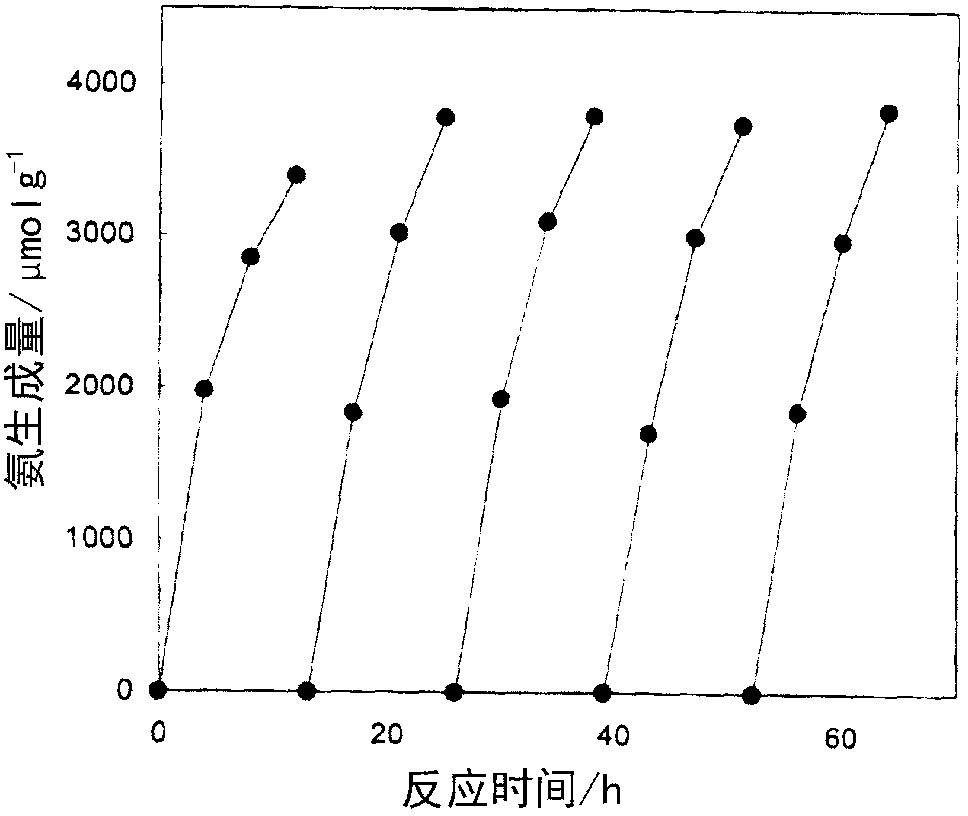

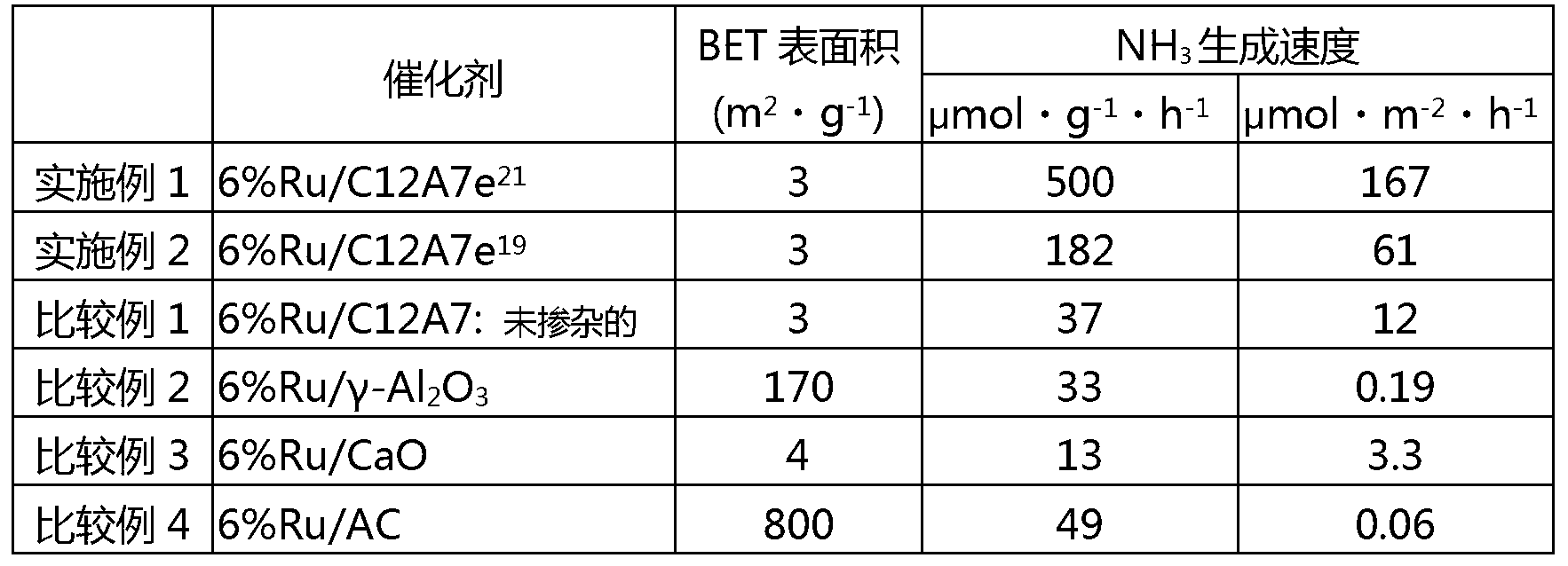

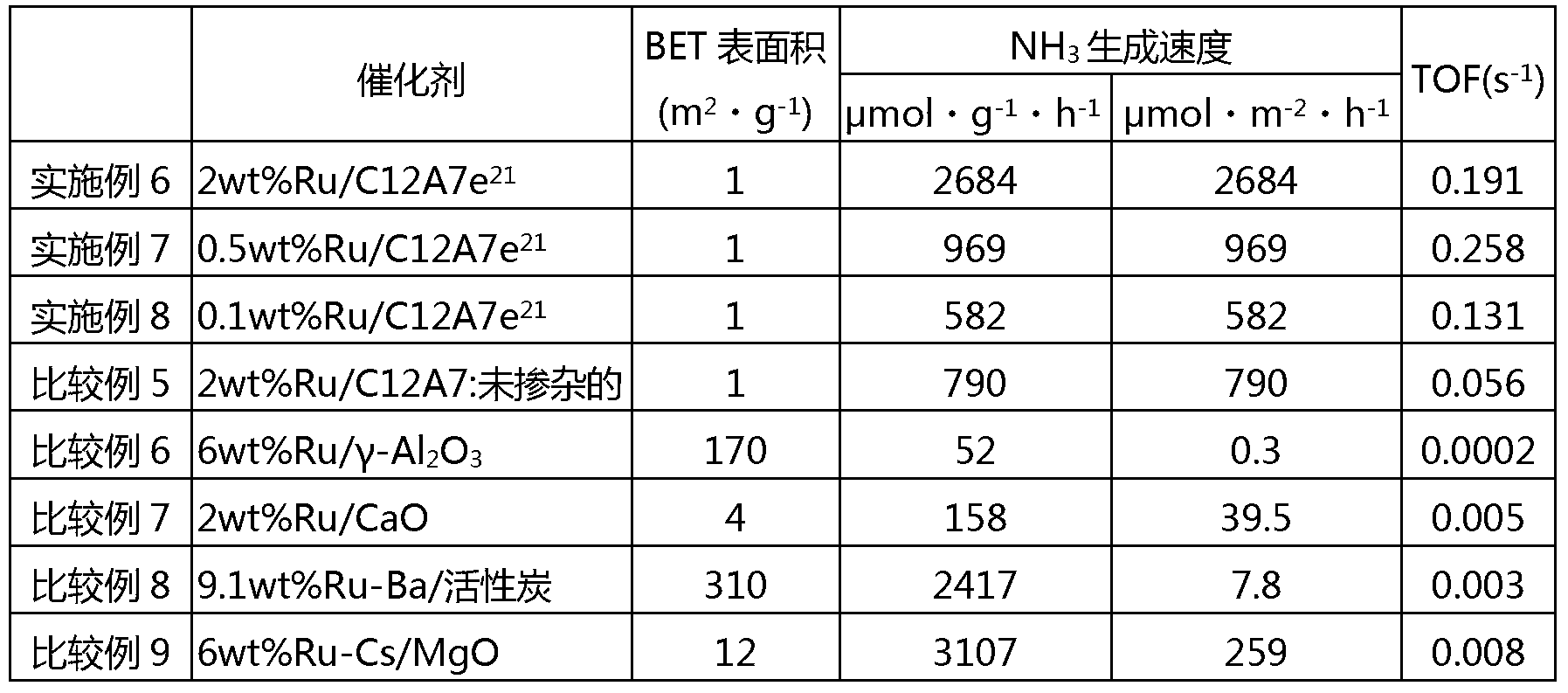

Ammonia synthesis catalyst and ammonia synthesis method

ActiveCN103237599AReduce energy consumptionEasy to manufactureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPorous mediumElectron donor

The present invention provides a catalyst substance that is stable and performs well in the synthesis of ammonia, one of the most important chemical substances for fertilizer ingredients and the like. The catalyst substance exhibits catalytic activity under mild synthesis conditions not requiring high pressure, and is also advantageous from a resource perspective. Further provided is a method for producing the same. This catalyst comprises a supported metal catalyst having a mayenite compound, containing a conduction electron of 1015 cm-3 or more, as a carrier for the ammonia synthesis catalyst. The mayenite compound used as the carrier may take any shape, including that of powder, a porous medium, a solid sintered body, a thin-film, or a solid single crystal. Use of this catalyst makes a realization that the electron donor ability toward a transition metal can be large, and the ammonia synthesis by reacting the starting material nitrogen and hydrogen on the catalyst under low reactive pressure between 10kPa and the 30MPa level at a reactive temperature between 100 and 600 DEG C can be promoted.

Owner:TOKYO INST OF TECH +1

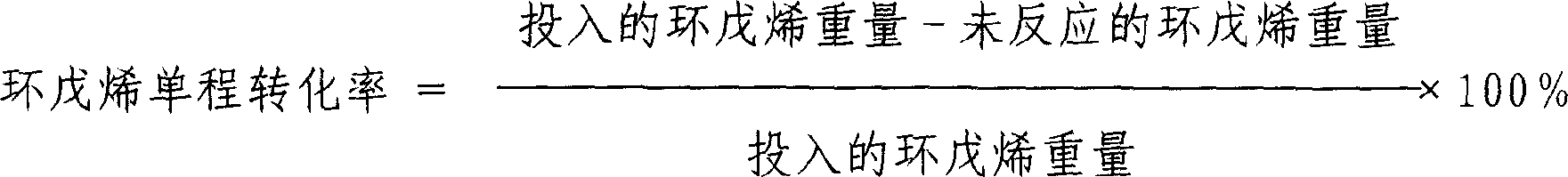

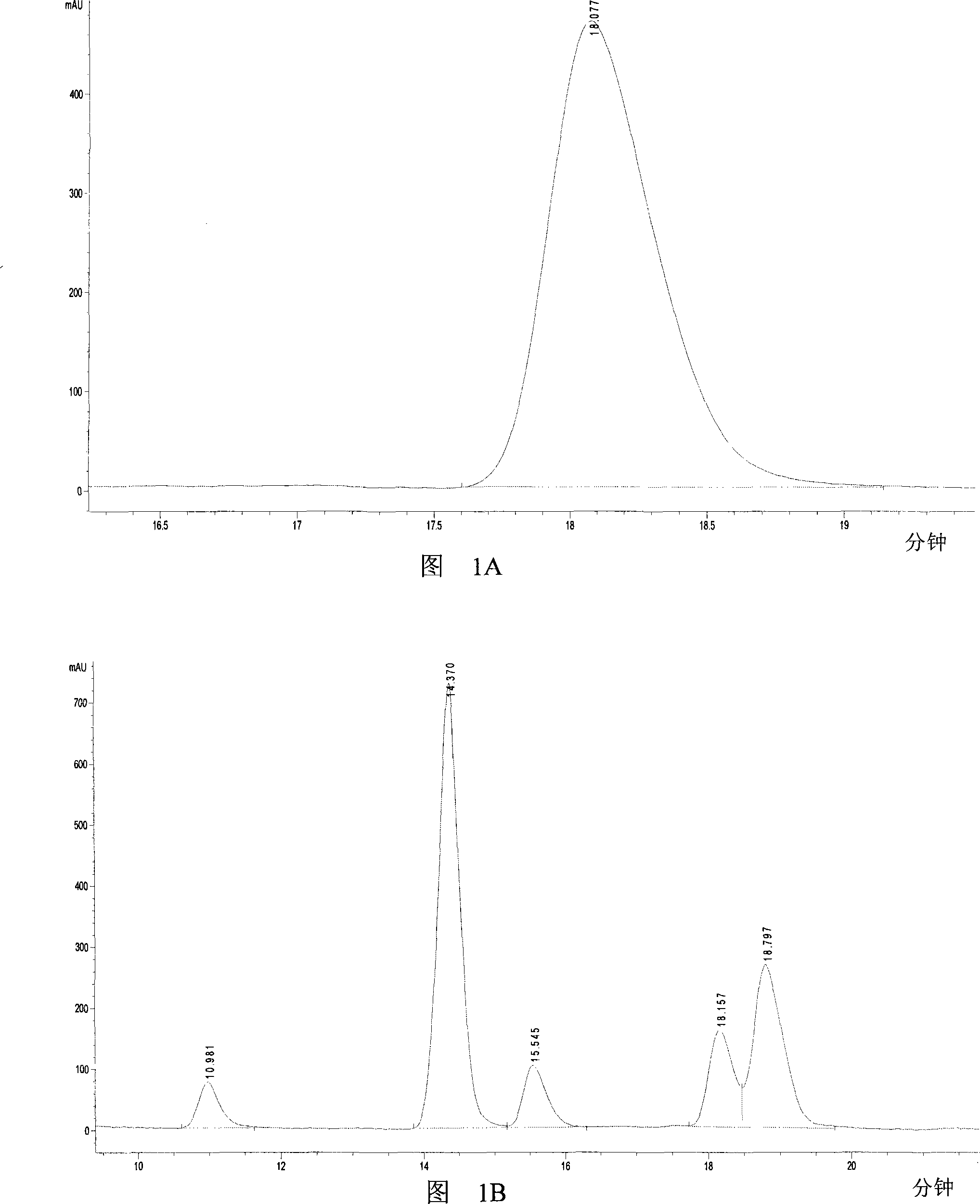

Cyclopentanol preparing and refining method

ActiveCN1676504AEasy to refineHigh selectivityOrganic compound preparationPreparation by hydroxy group additionHydration reactionCyclopentene

This invention is a making and refining method of cyclopentanol, which includes: 1) the materials comprises cyclopentene, phenylic acid solvent, water activator continuously pass through catalyst fixed bed to carry out hydration reaction, and the volume space velocity is 2-15hr to the power -1, the mole ratio of cyclopentene and water is 0.8-5.0, the weight ratio of phenylic acid and cycloamylene is 0.5-1.0. the intensity of activator is 0.01-0.2wt%, the reaction temperature is 130-180deg.C, the reaction pressure is 1.0-3.0MPa, the catalyst is strong acid cation exchange resin with sulfo group anchored on the surface, and the activating solvent is trialkylamine; 2)the reacted materials cool to house temperature and demix into oil phase and aqueous phase, the oil phase materials through continuous distilling separation procedure get non-reacting cycloamylene, refined cyclopentanol and phenylic acid full of solvent. The strong points of this invention are that the conversion of cyclopentene and selectivity of cyclopentanol are high, and the refining of cyclopentanol is simple and low energy consumption.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Method for synthesizing lactic acid by using glycerol

ActiveCN101225041ASolution to short lifeNo churnOrganic compound preparationCarboxylic compound preparationSynthesis methodsReaction temperature

The invention discloses a synthesis method of lactic acid by using glycerol, which is characterized in that the glycerol is adopted as the material; the lactic acid is obtained via reaction under the alkaline condition with the reaction pressure of 1 to 15 atm, the reaction temperature of 20 to 140 DEG C, the reaction time of 0.5 to 48 h and the catalyst and the oxidant existing; and when the synthesis method of lactic acid is adopted, the glycerol can be partially converted into the lactic acid with conversion rate of the glycerol being 12% to 70%, selectivity of the lactic acid being 33% to 81% and yield of the lactic acid being 9.7% to 32%. The synthesis method of lactic acid by using glycerol has the advantages that high reaction temperature is not needed, and the reaction can be conducted under the condition of normal temperature or close to normal temperature, thus a large amount of energy is saved; the reaction is conducted under the condition of atmospheric pressure or close to atmospheric pressure with the oxygen existing, thus requirement to equipments is low and investment is small; and the reaction system is simple which is beneficial to industrialization, and the catalyst has long service life without loss.

Owner:PEKING UNIV

Preparation of biodegradable block copolyester

The invention belongs to the technical field of macromolecular materials, and in particular relates to a preparation method for biodegradable blocked copolyester. The preparation method comprises the following steps: carrying out esterification reaction between adipate and 1,4 butanediol in the presence of catalyst, wherein the reaction time is 3 to 5h, nitrogen is adopted for protection, the reaction pressure is between 0.1 and 0.8MPa and the reaction temperature is between 130 and 180 DEG C during a first stage; and the reaction time is 1.5 to 5h, the reaction pressure is between 0.3 and 0.6MPa and the reaction temperature is between 150 and 200 DEG C during a second stage so as to generate polybutylene adipate; and carrying out ester exchange reaction of dimethyl terephthalate (DMT) and 1,4 butanediol in the presence of catalyst, wherein the nitrogen is adopted for protection, the reaction time is 2 to 5h, the reaction pressure is between 0.1 and 0.7MPa and the reaction temperature is between 150 and 170 DEG C so as to generate polybutylene terephthalate (pbt); and mixing both prepolymers and carrying out melt copolycondensation reaction under negative pressure, wherein the vacuum degree is controlled to be between 0 and 200Pa, the reaction temperature is between 210 and 260 DEG C and the reaction time is 3 to 8h. The preparation method carries out esterification reaction and ester exchange reaction, and the esterification reaction has two stages so as to effectively reduce secondary reaction of 1,4 butanediol. A prepared product has a characteristic viscosity number above 1.2dl / g, a melting point controlled between 100 and 140 DEG C, a tensile strength between 18 and 37MPa and a breaking elongation ratio from 800 to 1,500 percent.

Owner:TONGJI UNIV

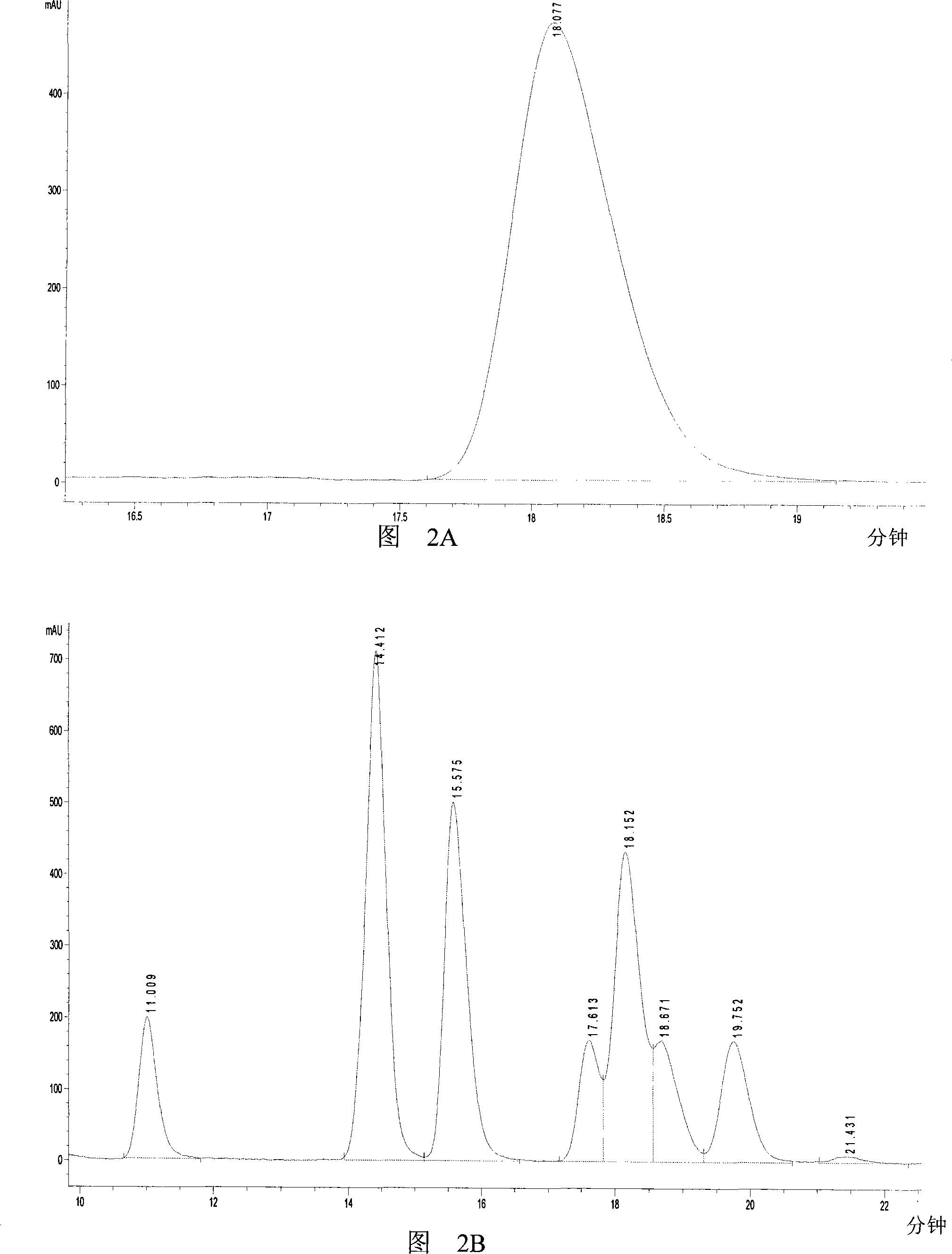

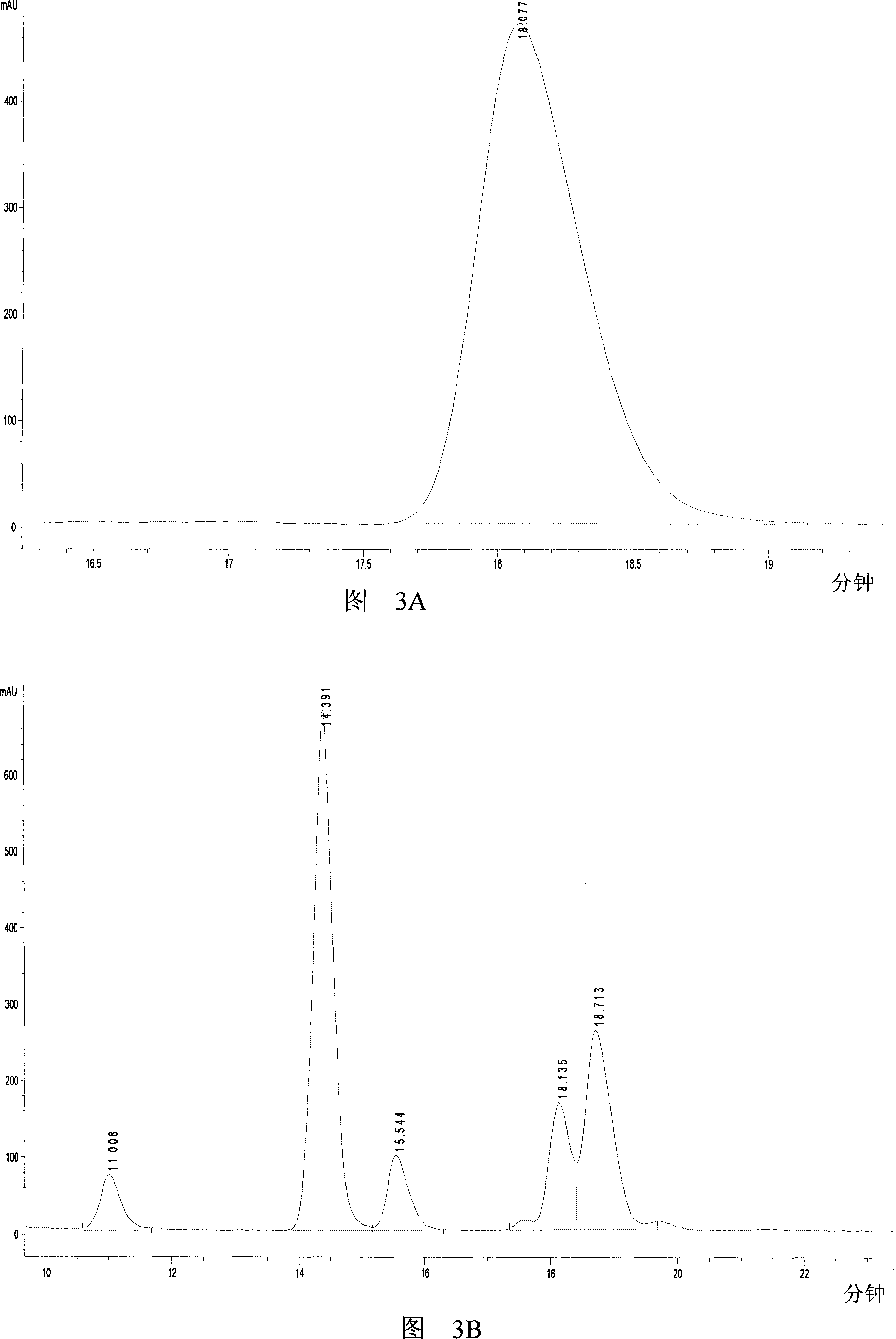

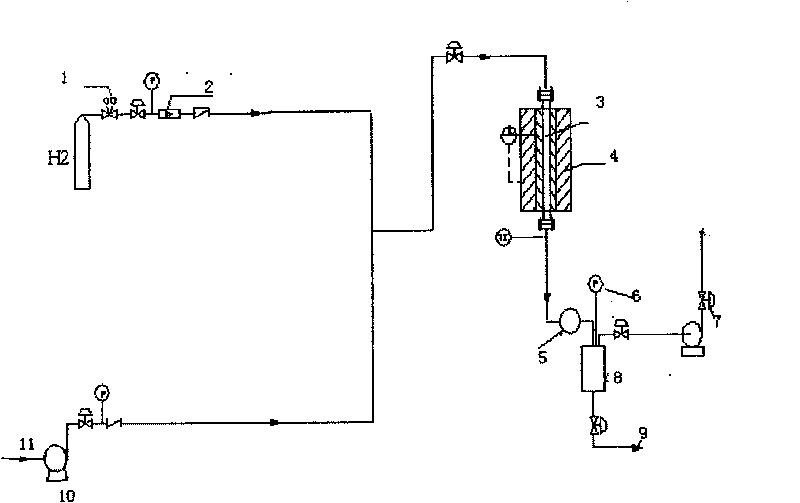

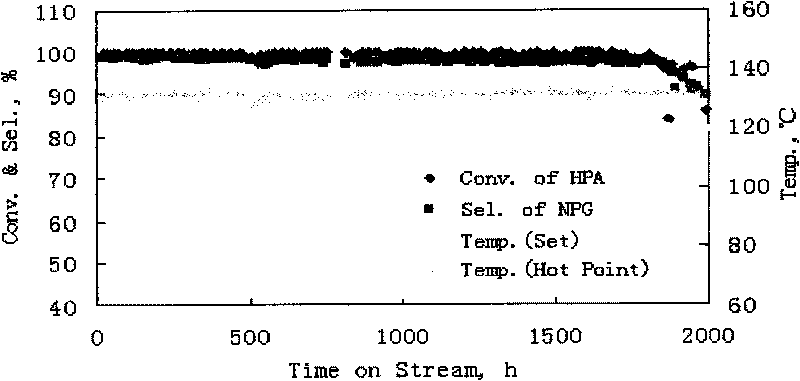

Method for preparing neopentylene glycol

InactiveCN101735015ALarge amount of processingOrganic compound preparationHydroxy compound preparationOrganic solventHydrogenation reaction

The invention provides a method for preparing neopentylene glycol. In the method, in the presence of an organic solvent, hydroxyl pivalaldehyde(HPA) serving as a starting raw material undergoes a hydrogenation reaction in the presence of a copper-based catalyst to form the neopentylene glycol(NPG), wherein the reaction pressure is 1 to 5MPa, the reaction temperature is between 100 and 140 DEG C, a molar ratio of the hydrogen gas to the hydroxyl pivalaldehyde is 1-20:1, and the used organic solvent is saturated fatty alcohol or a mixture thereof. The conversion rate of the HPA in the raw material is over 99.5 percent, the selectivity of the generated NPG is over 97 percent, and the catalyst lifetime is over 2,000 hours.

Owner:SHANGHAI HUAYI ACRYLIC-ACID CO LTD

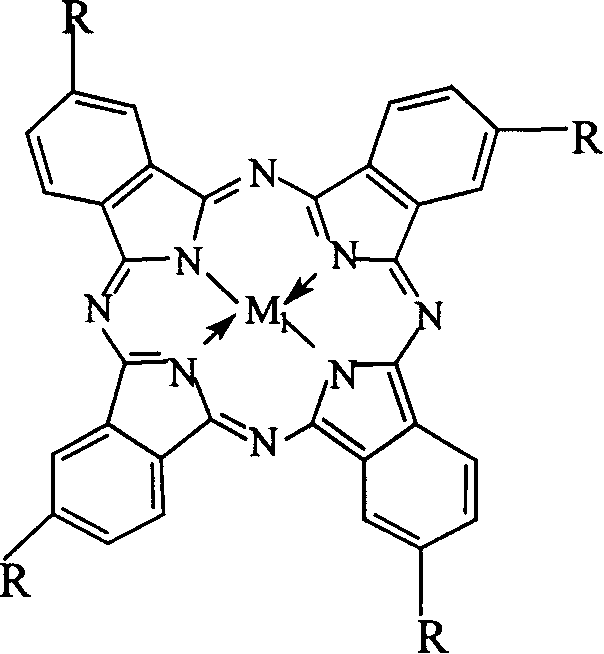

Method of preparing adipinic acid using bionic catalytic oxggen to oxidize cyclohexane

InactiveCN1231449CReduce dosageHigh catalytic activityOrganic compound preparationCarboxylic compound preparationRecyclable catalystEnzyme structure

Owner:BEIJING UNIV OF TECH

Preparation method of hydrofluoroether

ActiveCN103254041AMild reaction conditionsEasy to operateEther preparation by compound additionHydrofluoroetherReactions stress

The invention discloses a preparation method of hydrofluoroether. The preparation method comprises the following steps of: mixing a solvent, a catalyst, olefin and alcohol to have reaction, wherein the mole ratio of the solvent to the alcohol is (1-6):1, the mole ratio of the catalyst to the alcohol is (0.01-0.15):1, the mass ratio of the olefin to the alcohol is (0.5-5):1, the reaction temperature is 20-60 DEG C, the reaction pressure is 0.05-0.6MPa, and the reaction time is 0.5-3 hours; and rectifying after the reaction is accomplished, so as to obtain a hydrofluoroether product. The preparation method has the advantages that the reaction condition is gentle, the operation is simple, products are easy to separate, and less wastewater, waste gas and waste residue are discharged.

Owner:JUHUA GROUP TECH CENT

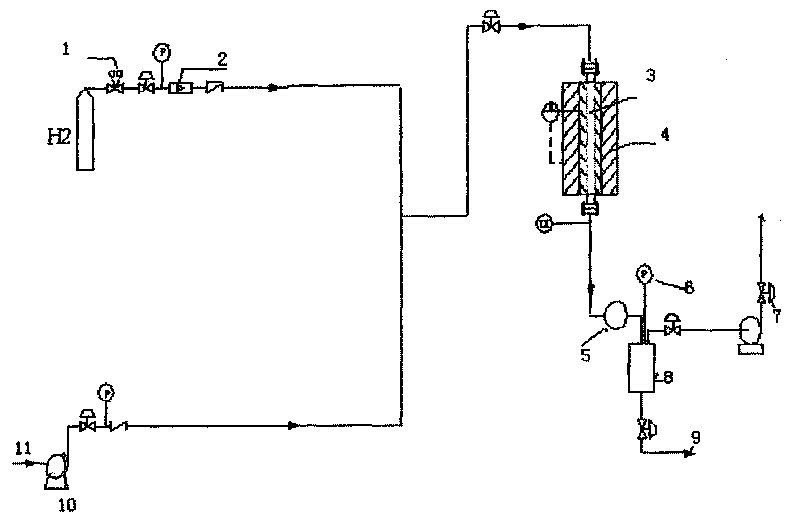

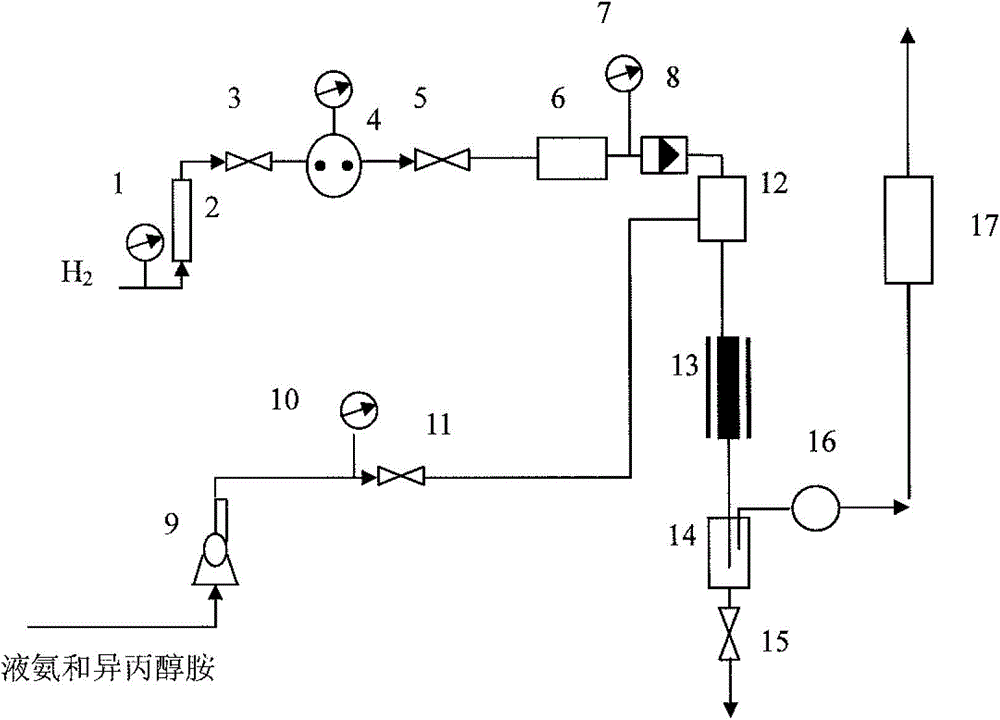

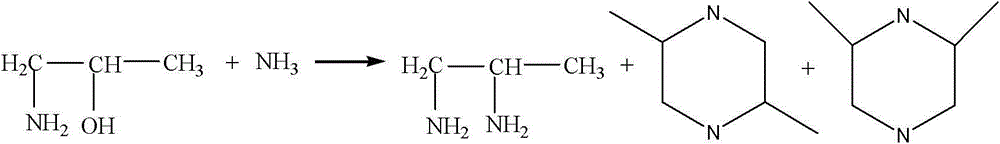

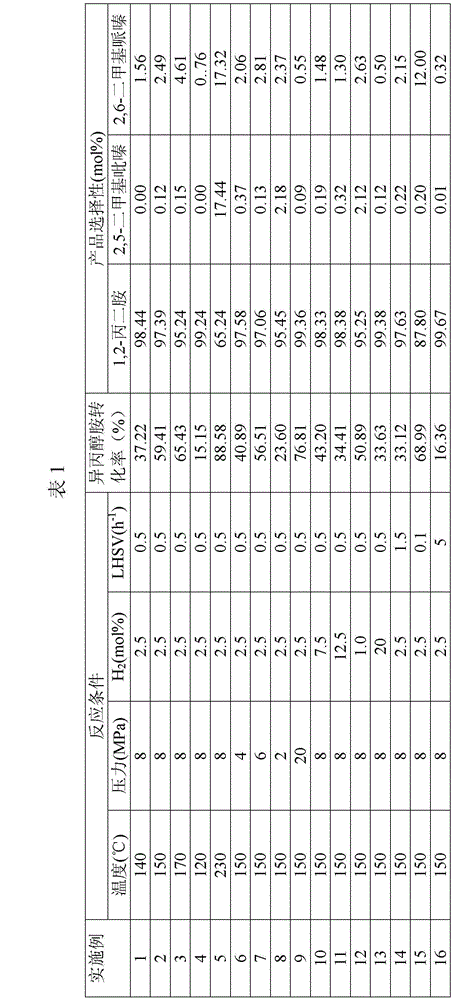

A method of preparing 1,2-diaminopropane from isopropanolamine and liquid ammonia and a device thereof

ActiveCN104693037AHigh selectivityLow one-time investment costOrganic compound preparationAmino compound preparationHydrogenPropylenimine

The invention relates to a method of preparing 1,2-diaminopropane from isopropanolamine and liquid ammonia. The method includes mixing the isopropanolamine and the liquid ammonia according to a certain ratio, pumping the mixture into a reactor and reacting under existence of a catalyst and hydrogen. The method adopts the novel catalyst which is excellent in catalytic performance and prone to long-term operation. The method allows production of a diaminopropane product by hydroamination of the isopropanolamine to be achieved under a low reaction pressure. By adjustment of reaction conditions, composition of products can be regulated flexibly and selectivity of a target product is improved. A reaction process is simple. One-time investment of production devices and a production cost are reduced. Separation of a reaction product from the catalyst is simple. The method is prone to large-scale continuous industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

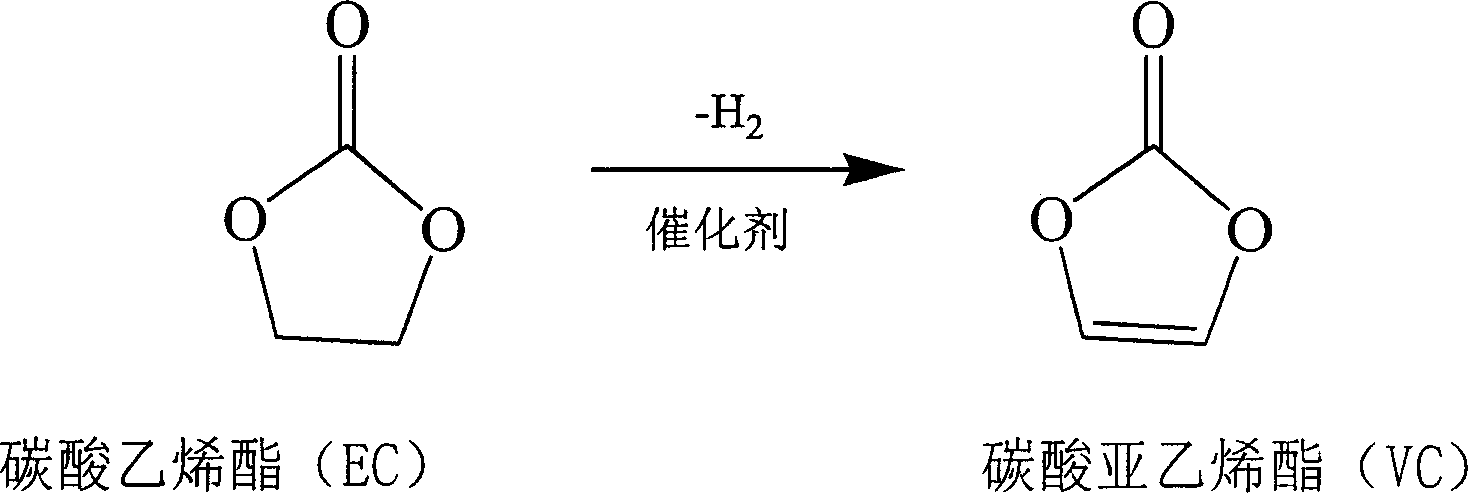

Process for synthesizing vinylene carbonate

A method for synthesing vinylene carbonate, employing fixed bed reactor, adding catalyst, employing nitrogen, argon gas or hydrogen as diluting gas and protecting gas, the reaction temperature is 200-600 Deg C, the velocity of feeding is 1-100 g / h mlcat, the reaction pressure is 0.1-10 Mpa, getting the vinylene carbonate through vinyl carbonate catalytic dehydrogenation. The invention is characterized by the higher selectivity of reaction product, less side product, simple operation, no corrosion and pollution in reacting course.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com