Patents

Literature

683results about "Ether preparation by compound addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

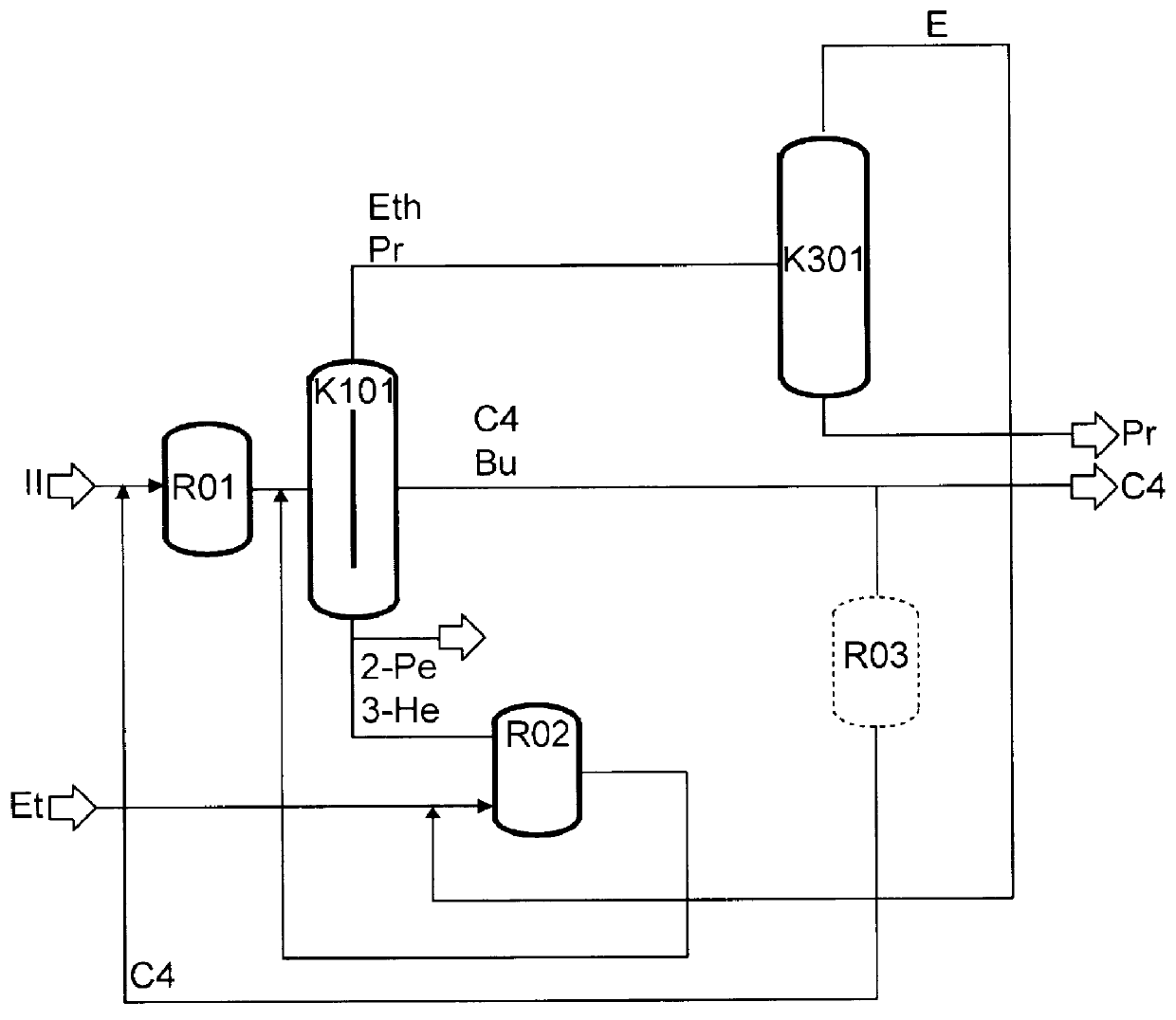

Preparation of olefins

The preparation of olefins from steam cracker or refinery C4 streams is carried out by selective hydrogenation of butadienes and acetylenic impurities in the steam cracker or refinery C4 stream, with simultaneous or subsequent, at least partial isomerization of 1-butene to 2-butene, followed by removal of i-butene from the C4 stream by reaction with an alcohol to form an ether, followed by removal of oxygen-containing impurities from the C4 stream using adsorber materials, followed by two-stage metathesis of the butenes in the C4 stream by conversion of 1-butene and 2-butene present in the C4 stream into propene and 2-pentene and subsequent reaction of the 2-pentene with ethene in the presence of a metathesis catalyst to form propene and 1-butene. Optionally, butadiene may be removed from the C4 stream by extractive distillation in a preliminary step.

Owner:BASF AG

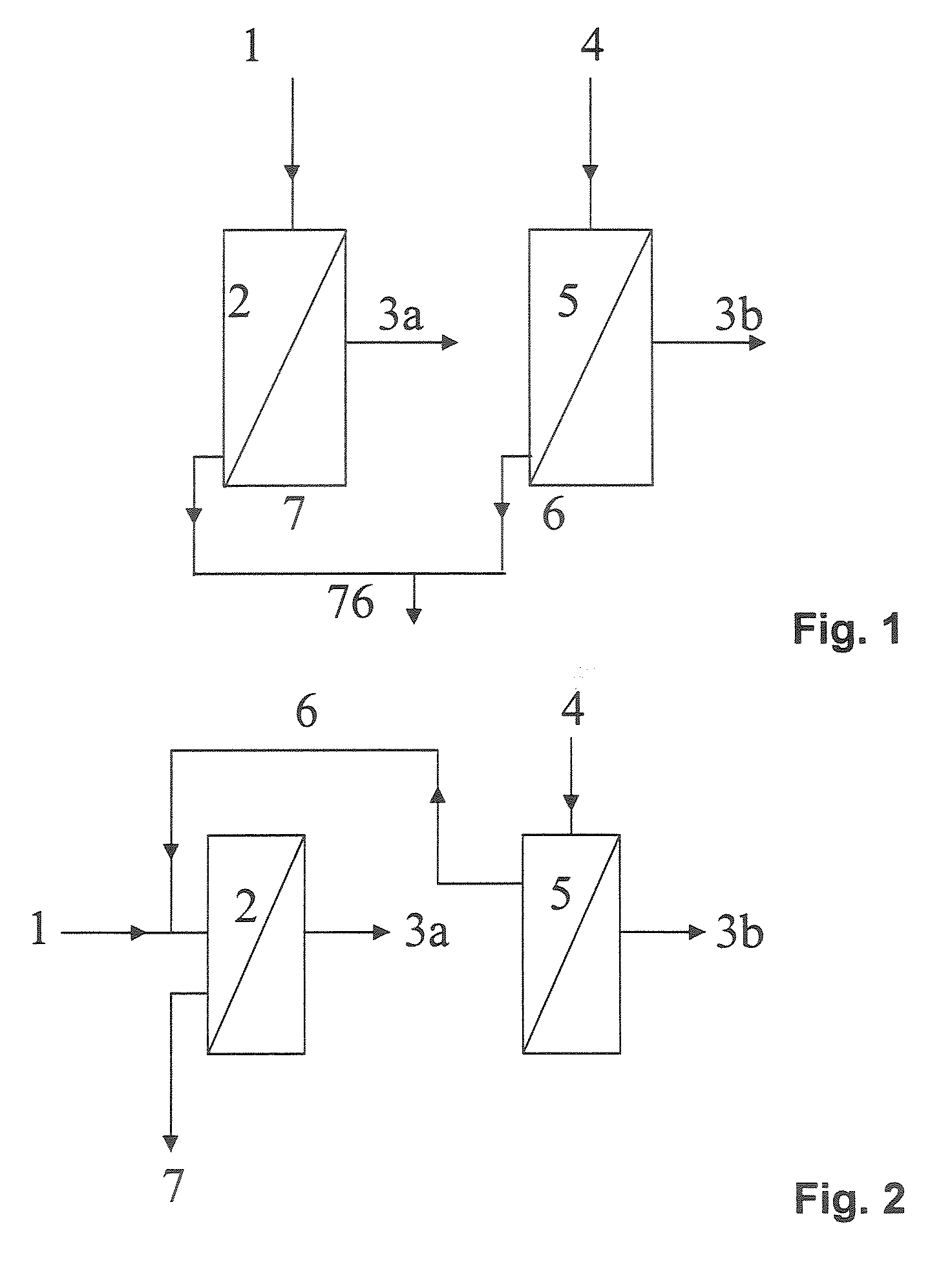

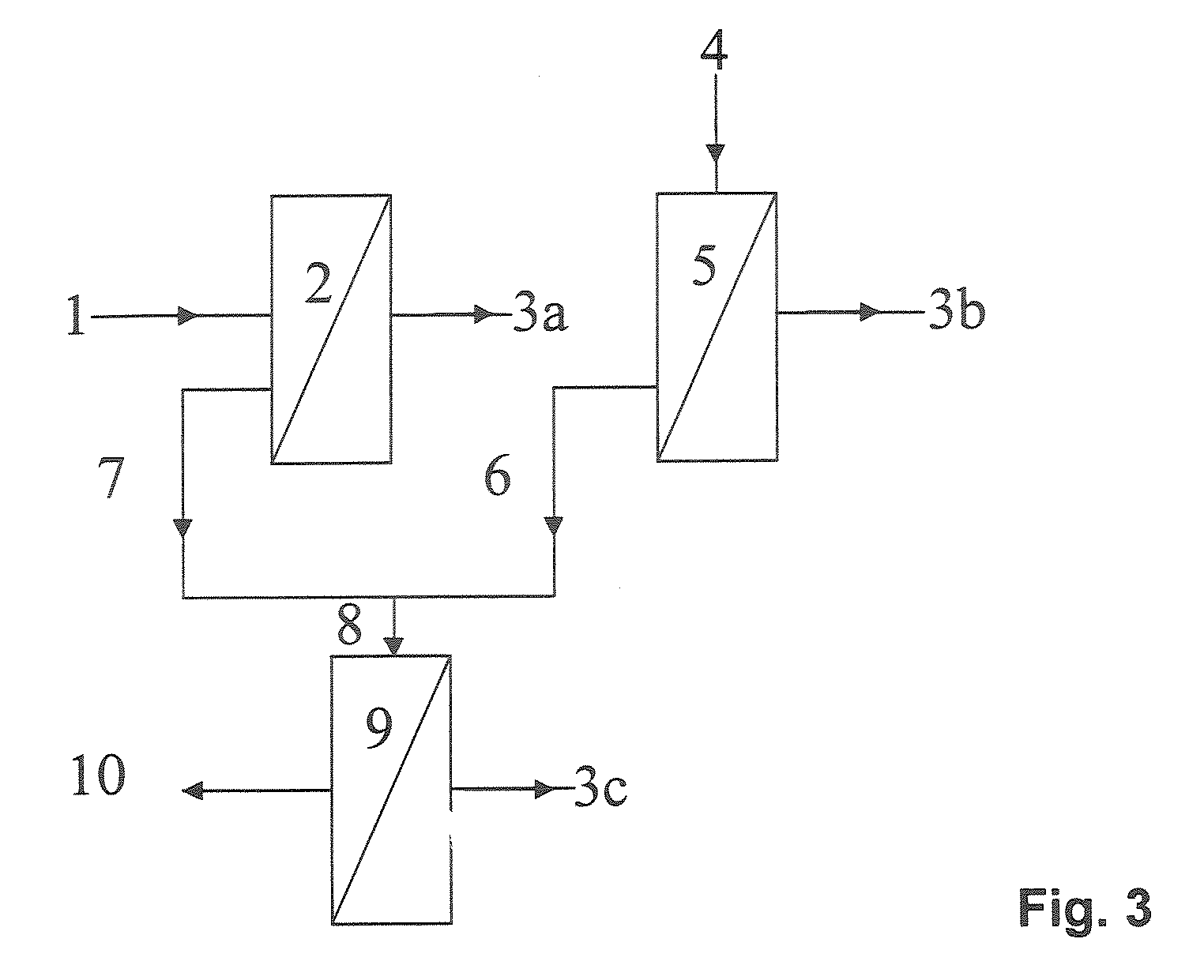

Process for dewatering ethanol

InactiveUS7399892B2Avoid disadvantagesSemi-permeable membranesMembranesEthyl tert-butyl etherWater content

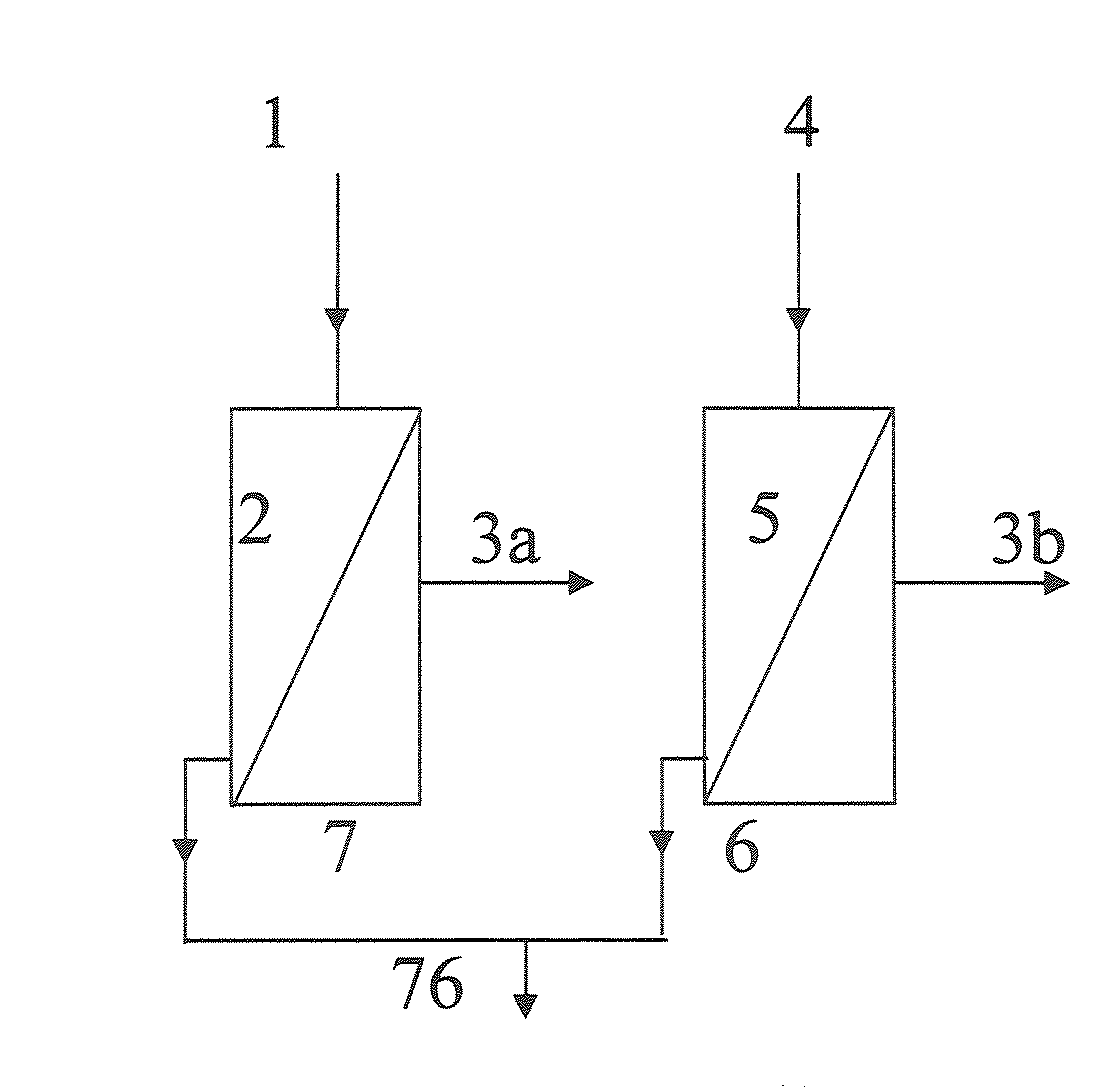

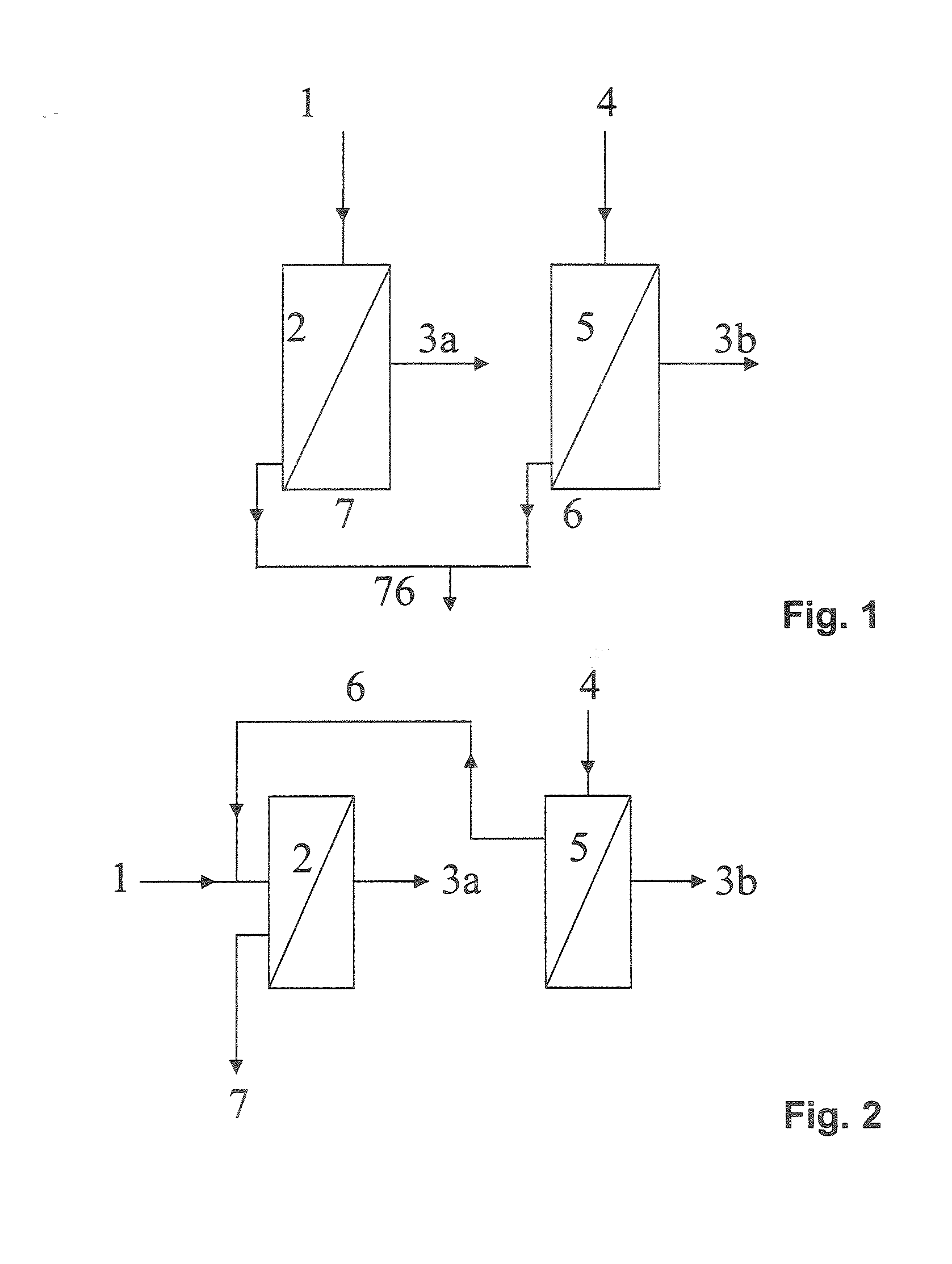

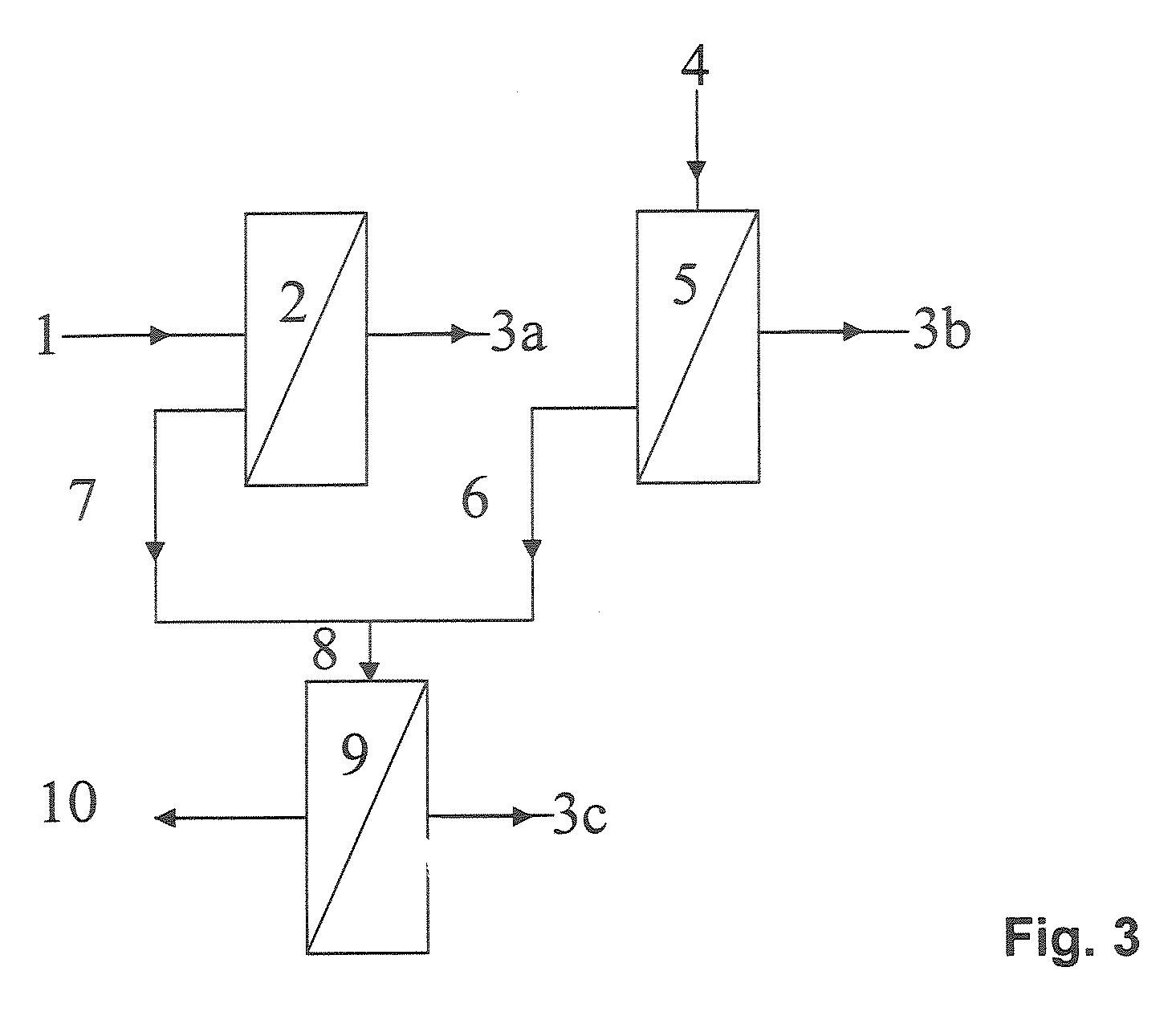

A process for preparing low-water ethanol from at least two streams of relatively water-rich ethanol that have a different water content by dewatering at membranes. The low-water ethanol can be used to prepare ethyl tert-butyl ether (ETBE).

Owner:EVONIK OXENO GMBH (DE)

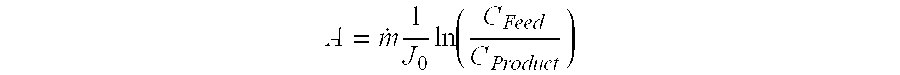

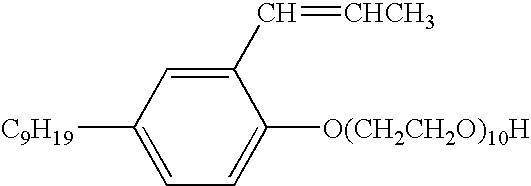

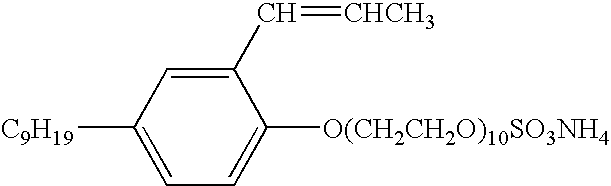

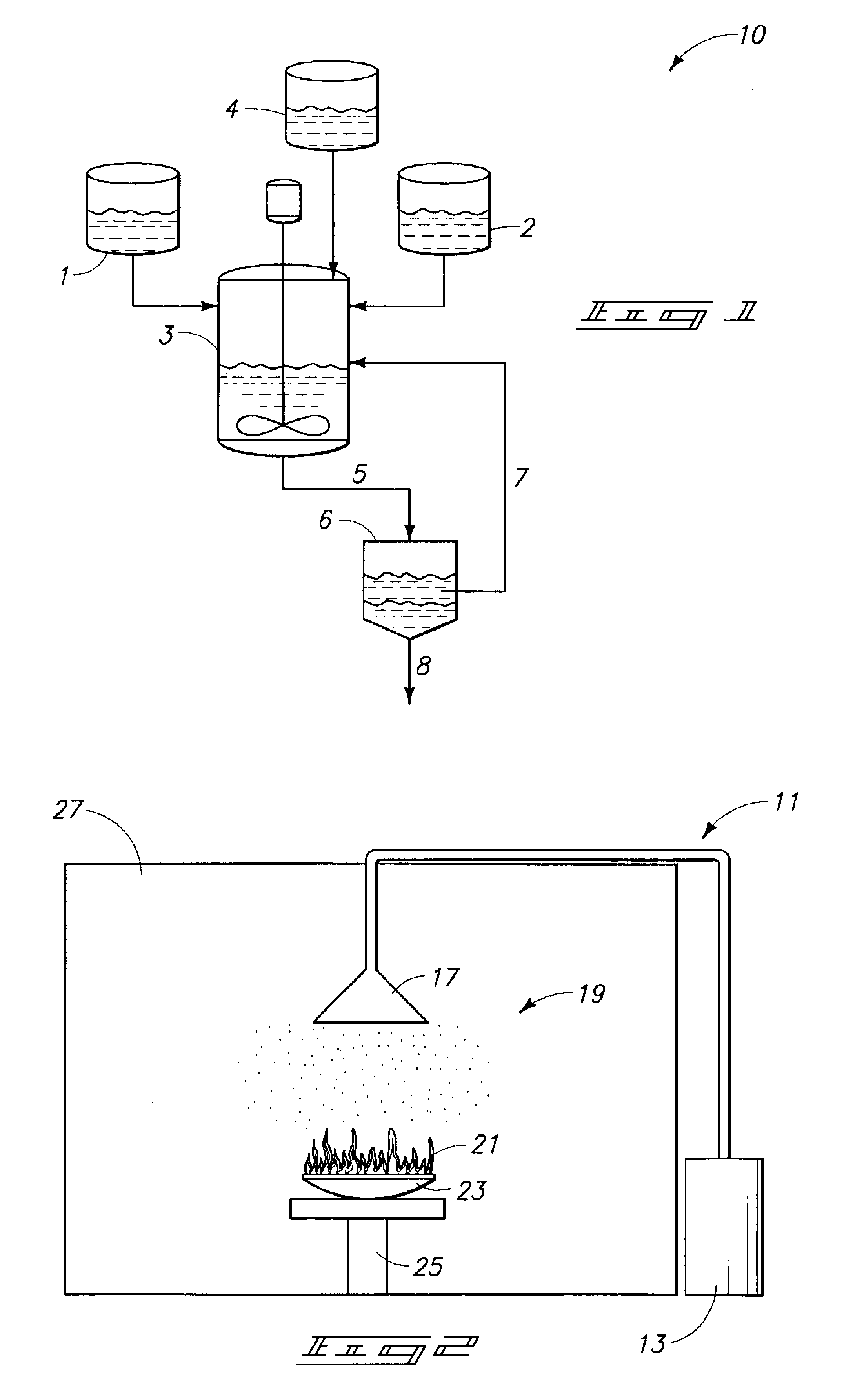

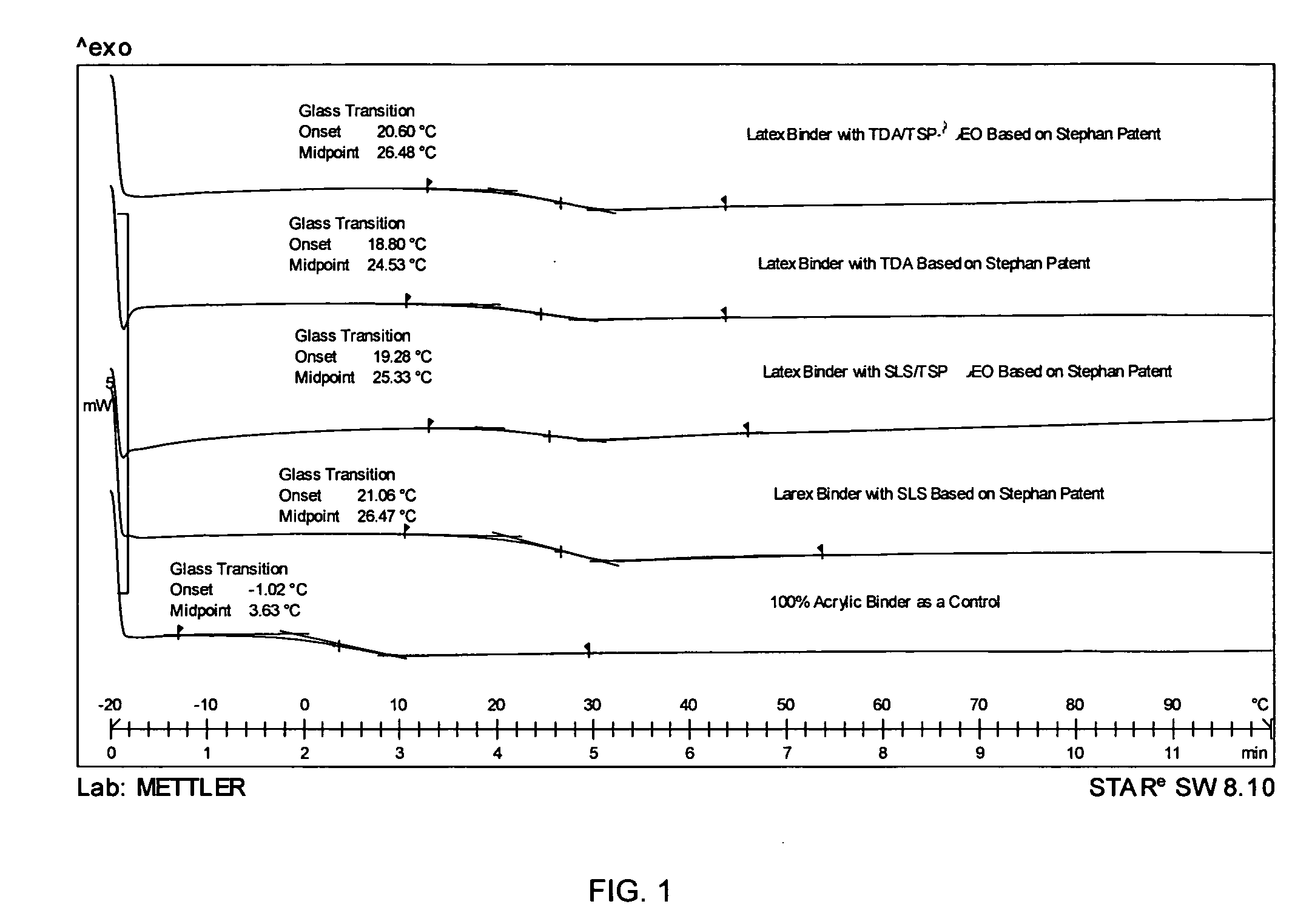

Low-VOC aqueous coating compositions with excellent freeze-thaw stability

InactiveUS6933415B2Improve freeze-thaw stabilityLow in VOCsOrganic compound preparationSpecial tyresFreezing thawingSURFACTANT BLEND

The present invention is an aqueous coating composition having excellent freeze-thaw stability and a low-VOC content. The aqueous coating composition of the invention includes at least one latex polymer derived from at least one monomer and at least one polymerizable alkoxylated surfactant, at least one pigment, and water. In accordance with the invention, less than 3.0% by weight of anti-freeze agents based on the total weight of the aqueous coating composition are used in the composition. The present invention also includes a method of preparing an aqueous coating composition such as a latex paint including the above components.

Owner:BASF AG

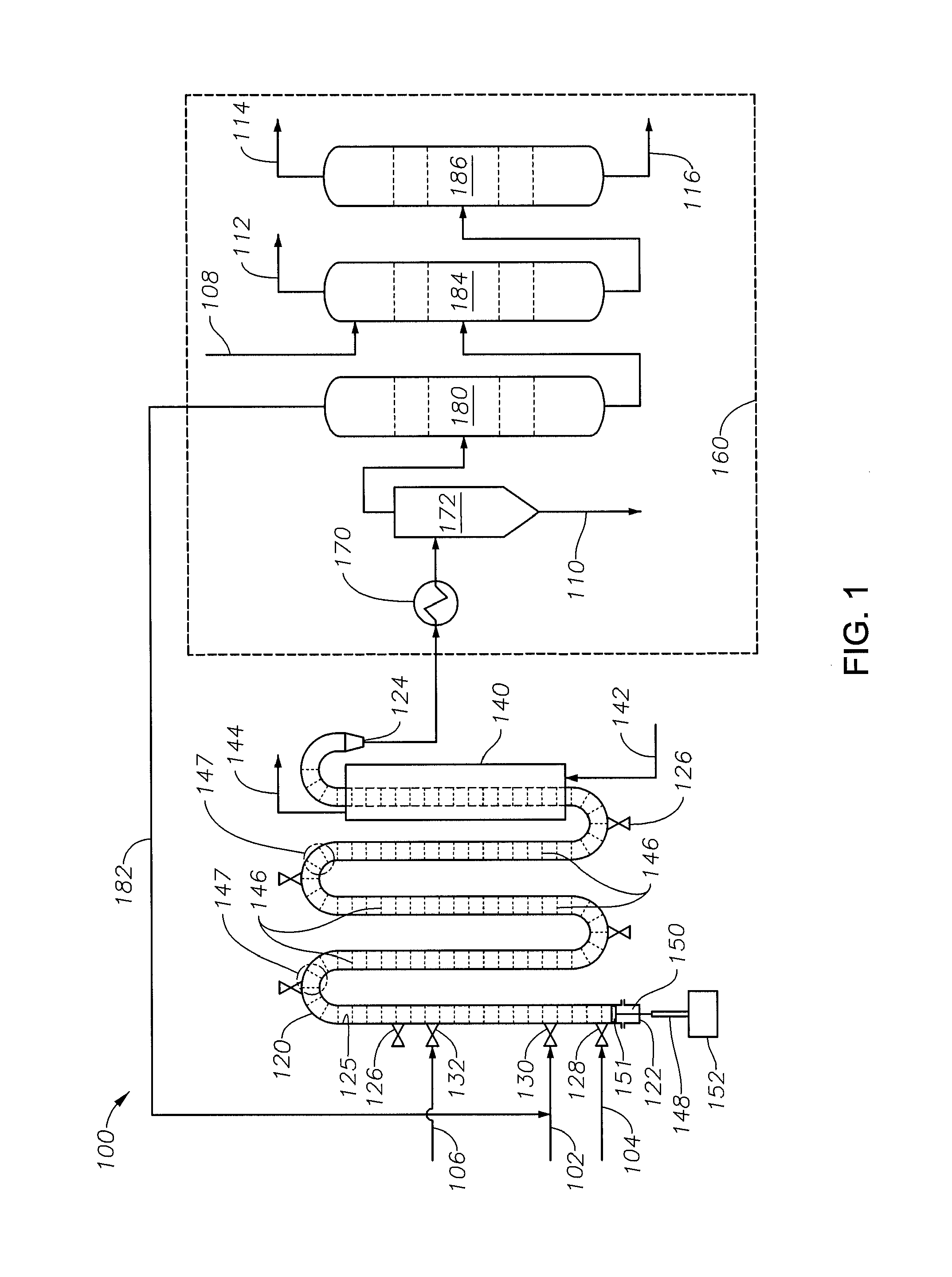

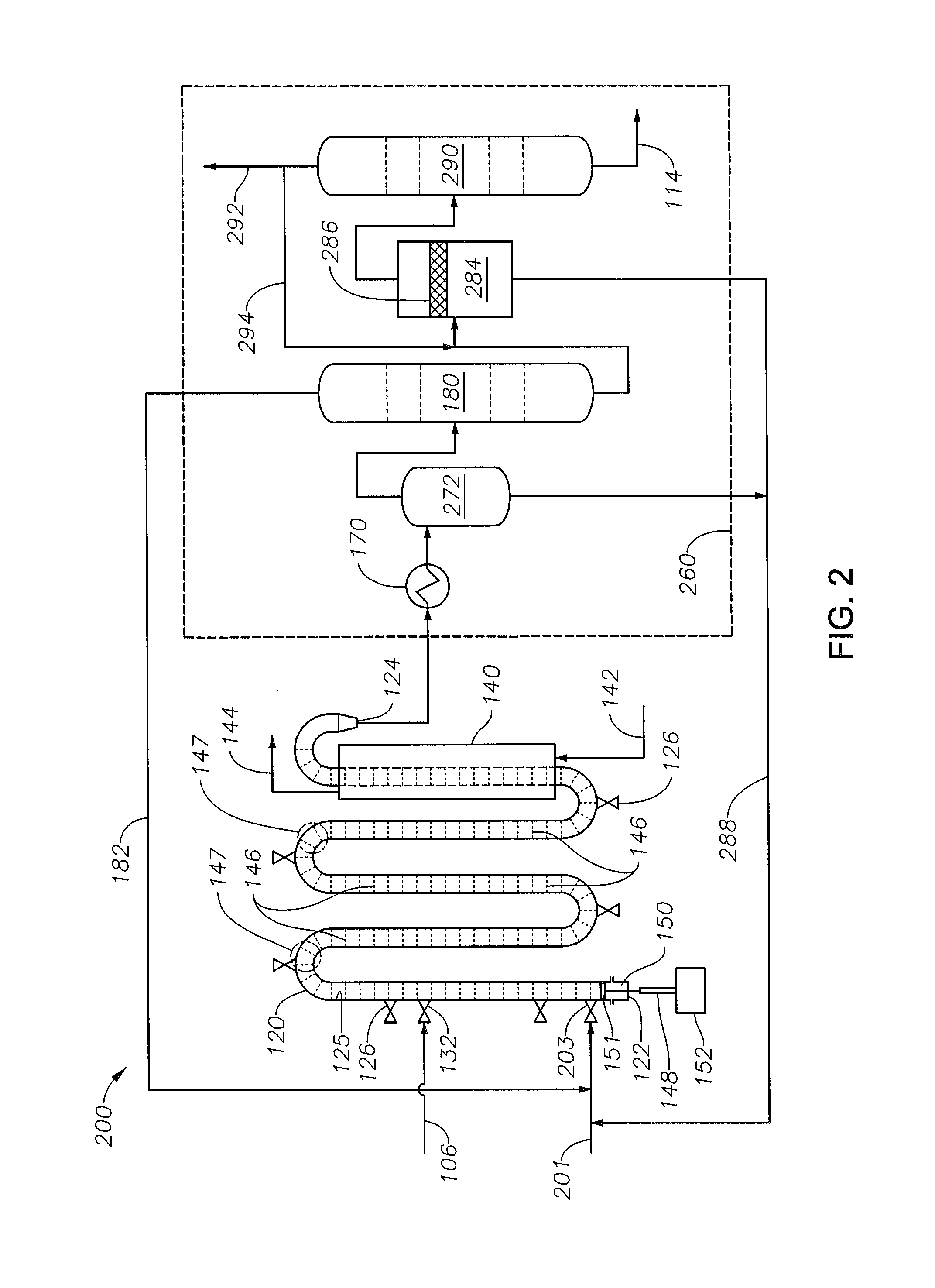

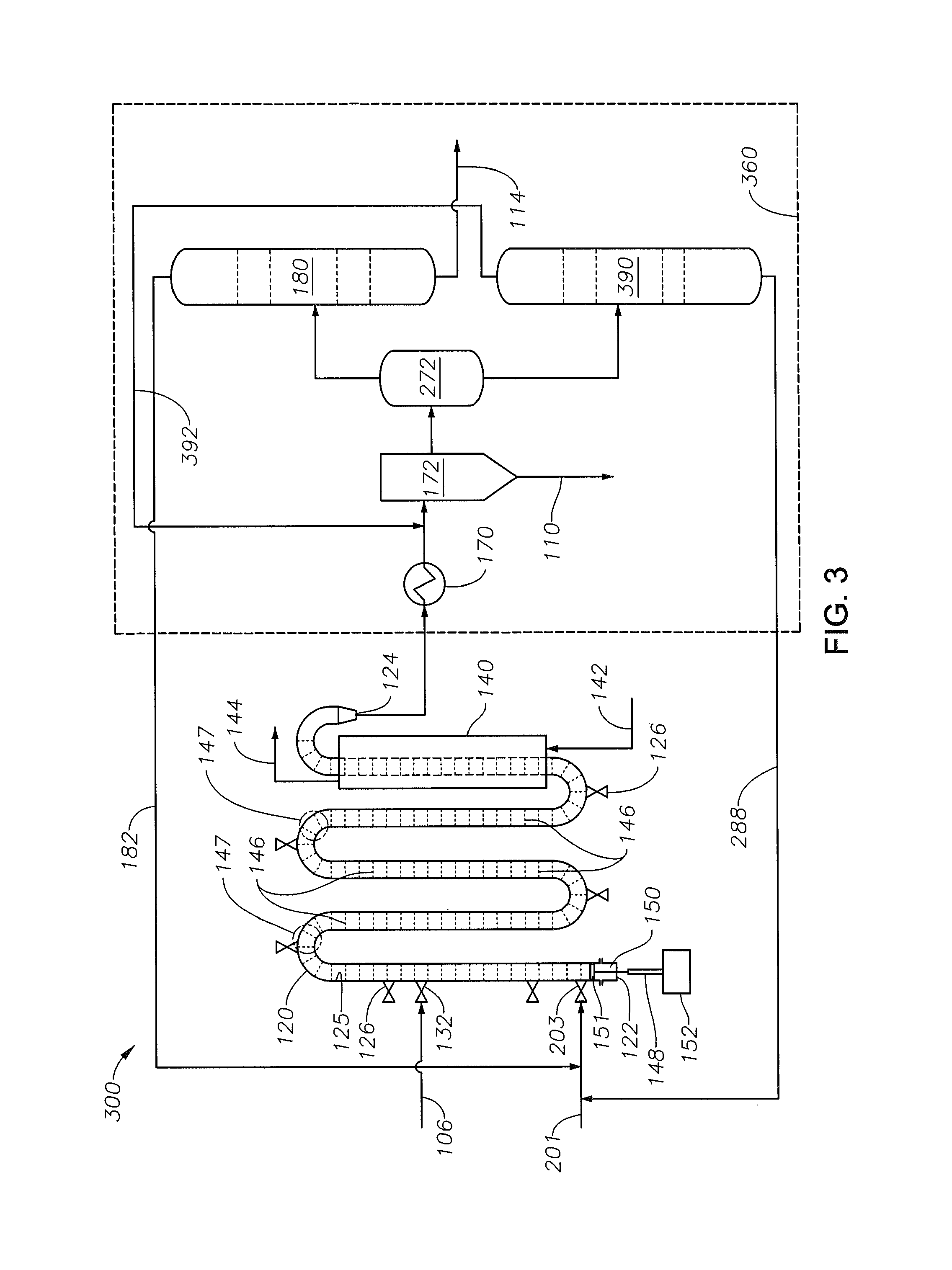

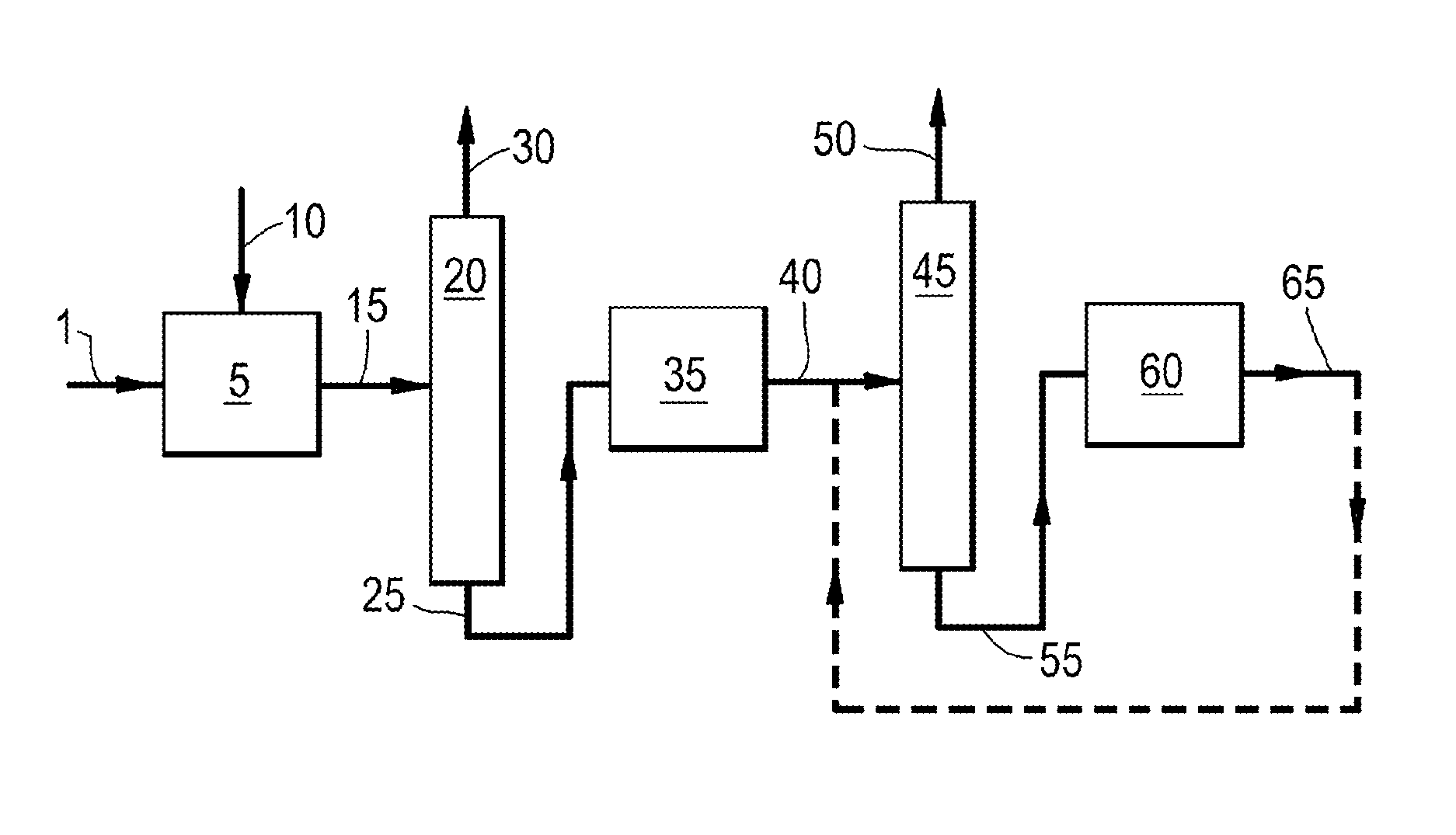

Olefin hydration process using oscillatory baffled reactor

ActiveUS9187388B2Well mixedIncrease surface area exposureChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsButeneInstability

A butanol production system and method of producing refined mixed butanols from water and mixed butenes. The system includes an internal baffle single pass reactor, a separation system and an exterior motion driver. The reactor has baffled cells. The separations system is operable to separately selectively separate water and mixed butenes from the crude product such that a refined mixed butanols is produced. The exterior motion driver is operable to induce unsteadiness in the fluid flow of the process fluid through the reactor. A method for producing refined mixed butanols includes introducing mixed butenes, water and a butene hydration catalyst into the reactor, operating the butanol production system such that the external motion driver induces unsteadiness in the process fluid flow and the reaction of mixed butenes and water occurs in the presence of the butene hydration catalyst such that mixed butanols form.

Owner:SAUDI ARABIAN OIL CO

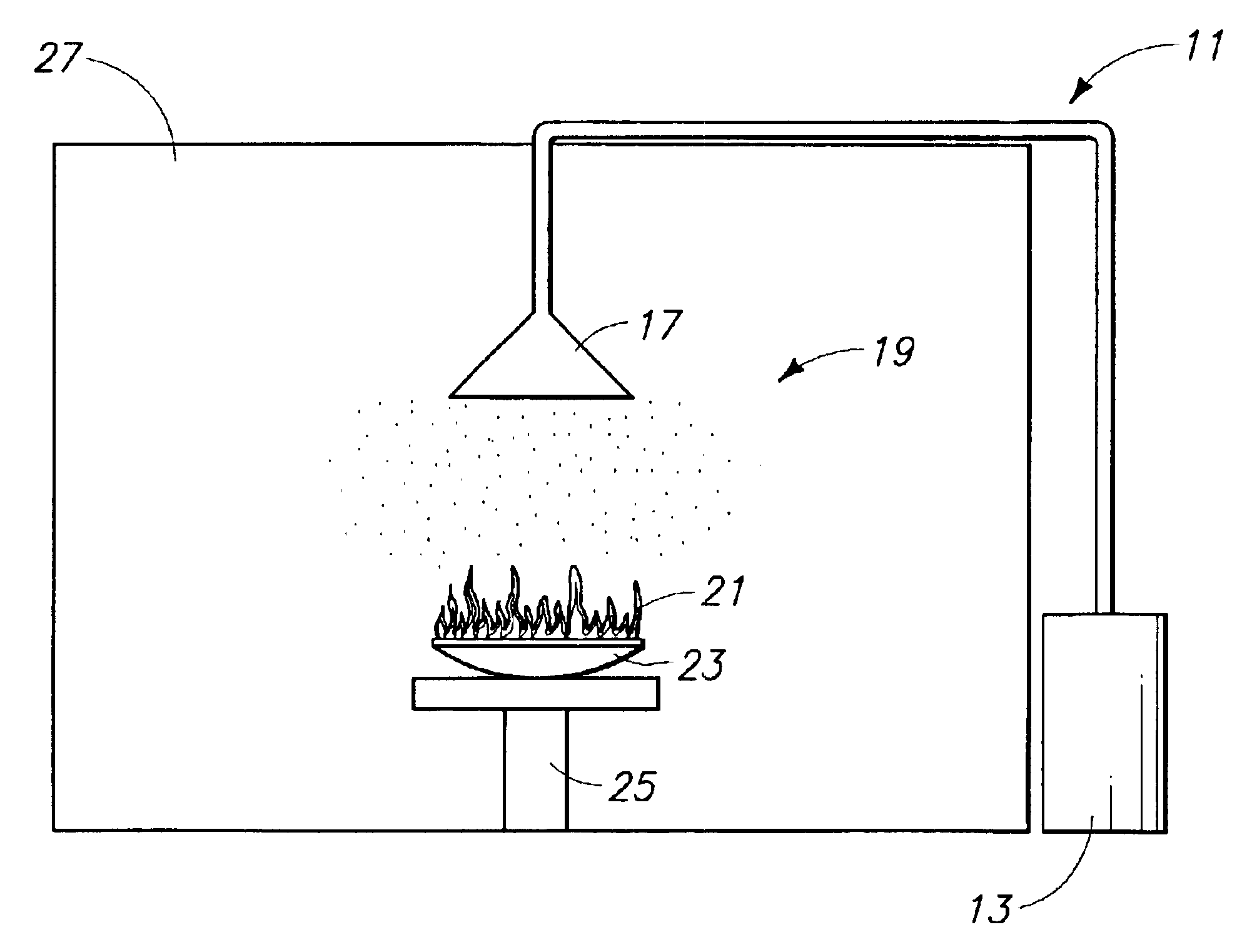

Methods for preparing ethers, ether compositions, fluoroether fire extinguishing systems, mixtures and methods

Highly fluorinated, saturated, and unsaturated fluoroethers are efficient, economical, non-ozone-depleting fire extinguishing agents used alone or in blends with other fire extinguishing agents in total flooding and portable systems. Methods for producing ethers, halogenated ether intermediates, and fluoroethers are disclosed. Novel fluoroether compositions are disclosed. Fluoroether extinguishing mixtures, methods, and systems are disclosed.

Owner:PCBU SERVICES INC

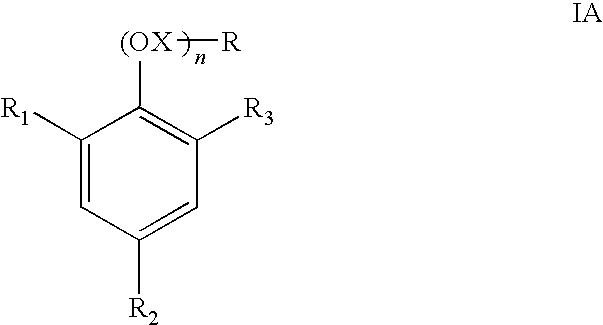

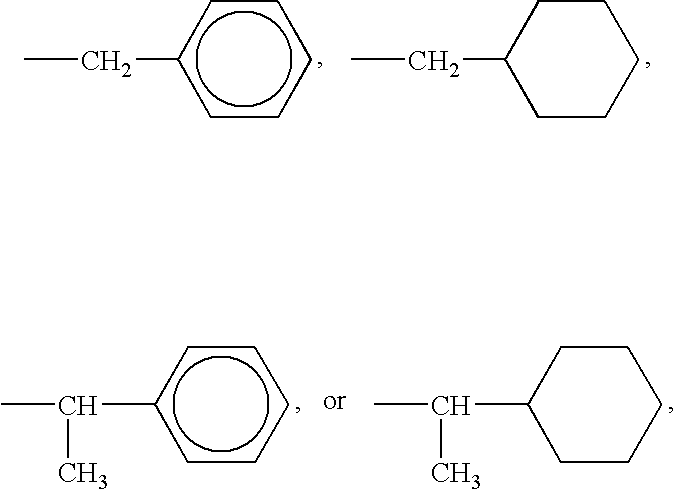

Latex binders, aqueous coatings and paints having freeze-thaw ability and methods for using same

ActiveUS20090186968A1Promote recoveryImprove freeze-thaw stabilityPlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsFreezing thawingPolymer chemistry

Disclosed are latex polymers and an aqueous coating compositions having excellent freeze-thaw stability, open time, stain resistance, low temperature film formation, foam resistance, block resistance, adhesion, water sensitivity and a low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributylphenol. Also provided is an aqueous coating composition including at least one latex polymer, at least one pigment, water and at least one freeze-thaw additive. Typically, the freeze-thaw additive in an amount greater than about 1.3% by weight of the polymer, typically in an amount greater than about 2% by weight of the polymer, in an amount greater than about 4% by weight of the polymer, in an amount greater than about 7.5% by weight of the polymer, in an amount greater than about 10% by weight of the polymer or in an amount greater than about 20% by weight of the polymer.

Owner:RHODIA OPERATIONS SAS

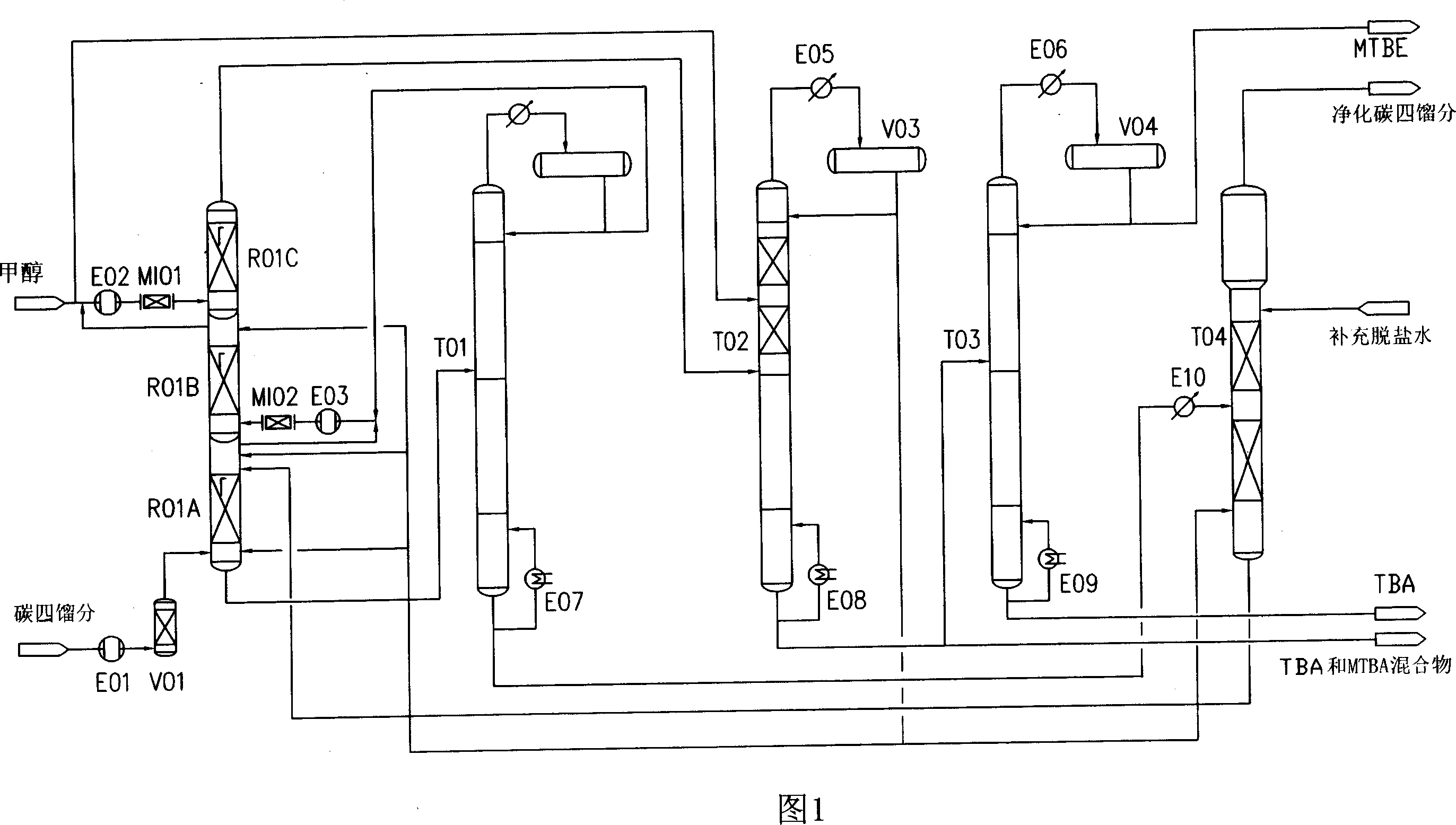

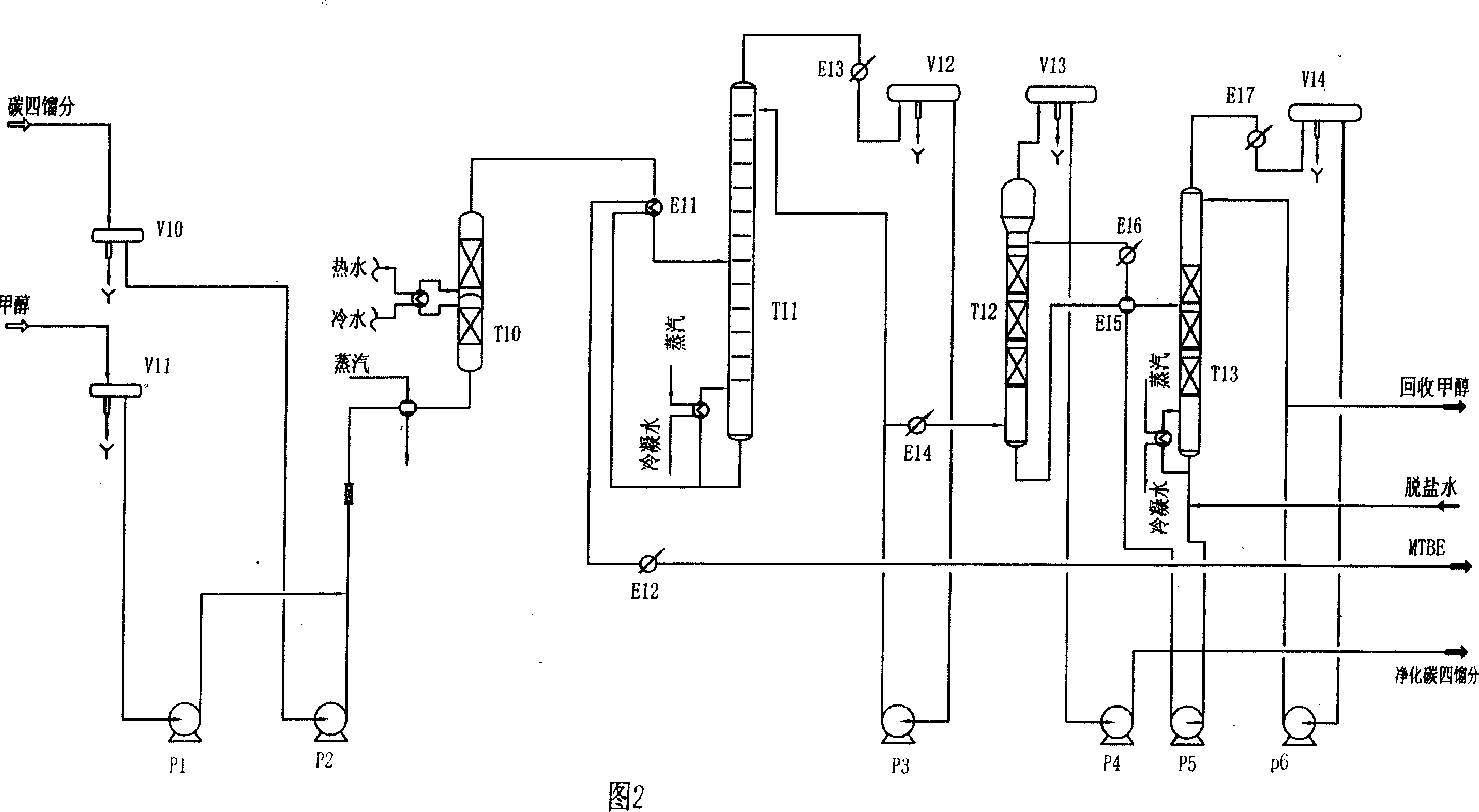

Phrcess of coproducing methyl tert-butyl ether and tert-butyl alcohol

InactiveCN101020622ASave energyLess investmentPreparation by hydroxy group additionEther preparation by compound additionMethanol waterMethyl t-butyl ether

The present invention relates to process of co-producing methyl tert-butyl ether and tert-butyl alcohol with isobutene and methanol in C4 fraction. The present invention features that two kinds of product are produced in an identical equipment with reduced investment, and that separation is completed through several reactions, resulting in simplified equipment and facilitated separation.

Owner:西安道特石化工程有限公司

Solvents containing cycloakyl alkyl ethers and process for production of the ethers

InactiveUS20050065060A1Moderate boiling pointPromote decompositionSurface-active detergent compositionsDetergent mixture composition preparationAlcoholChemical reaction

The present inventions are (A) a solvent comprising at least one cycloalkyl alkyl ether (1) represented by the general formula: R1-O-R2 (wherein R1 is cyclopentyl or the like; and R2 is C1-10 alkyl or the like); (B) a method of preparations the ethers (1) characterized by reacting an alicyclic olefin with an alcohol in the presence of an acid ion-exchange resin having a water content of 5 wt % or less. The solvent is useful as cleaning solvent for electronic components, precision machinery components or the like, reaction solvent using various chemical reactions, extraction solvent for extracting objective organic substances, solvent or remover for electronic and electrical materials, and so on. The process enables industrially advantageous production of the objective cycloalkyl alkyl ethers (1).

Owner:ZEON CORP

Oligomerization of isobutene in N-butenic hydrocarbon streams

InactiveUS7161053B2Efficient preparationOrganic chemistry methodsOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon mixturesProton

Isobutene in isobutenic hydrocarbon mixtures is oligomerized over a solid acidic ion exchange resin, said acidic ion exchange resin containing, for example, sulfonic acid groups, some of whose protons have been exchanged for metal ions.

Owner:EVONIK DEGUSSA GMBH

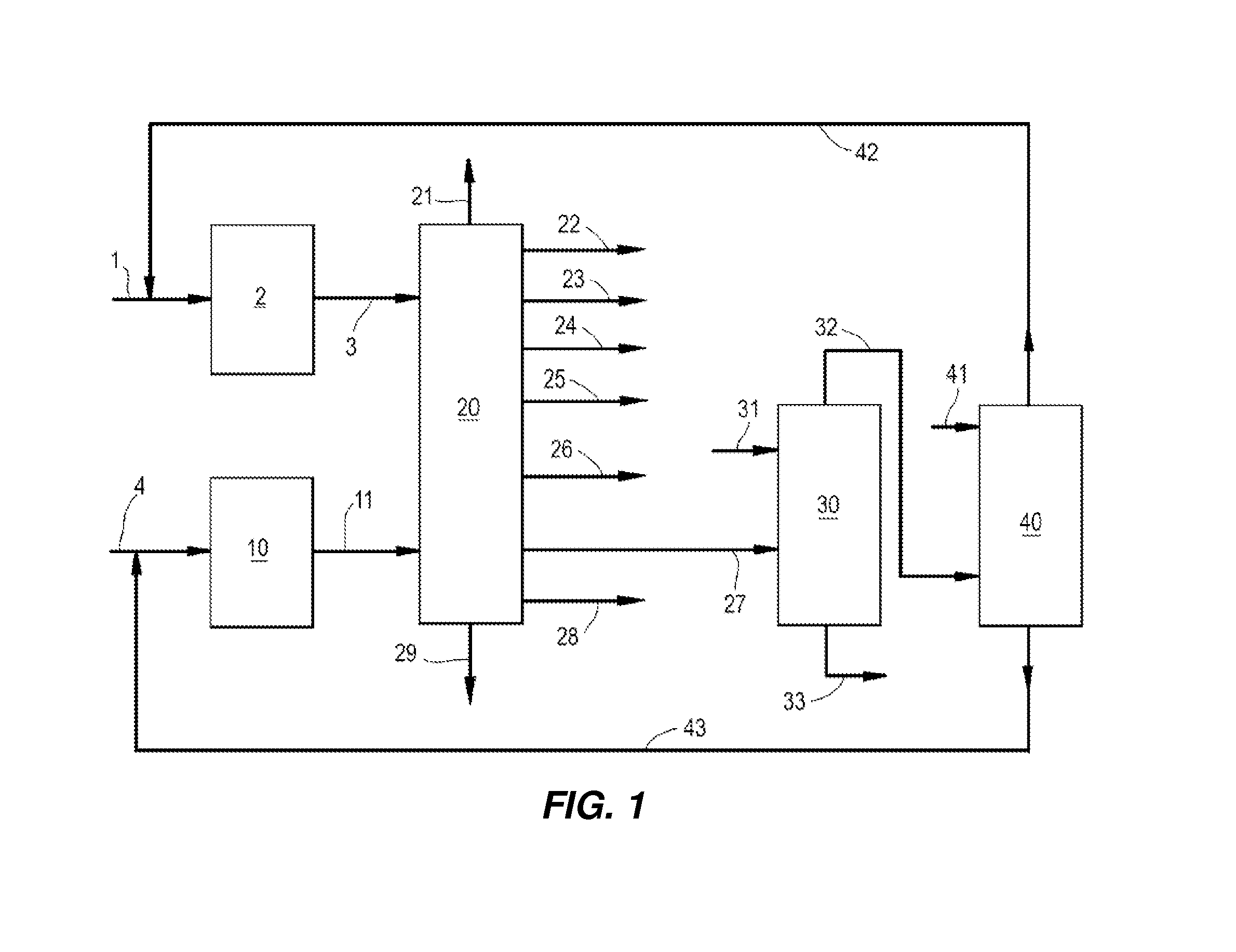

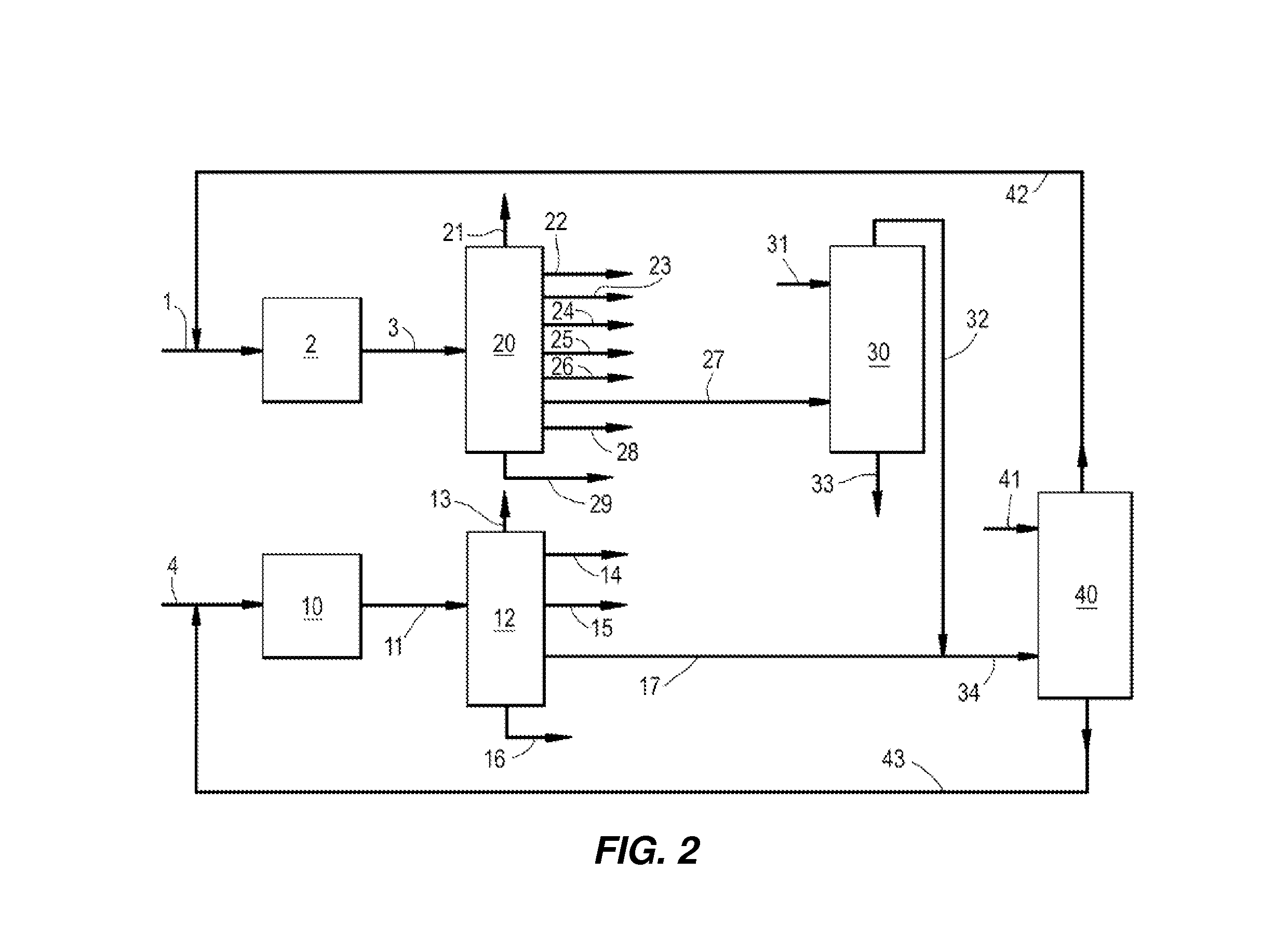

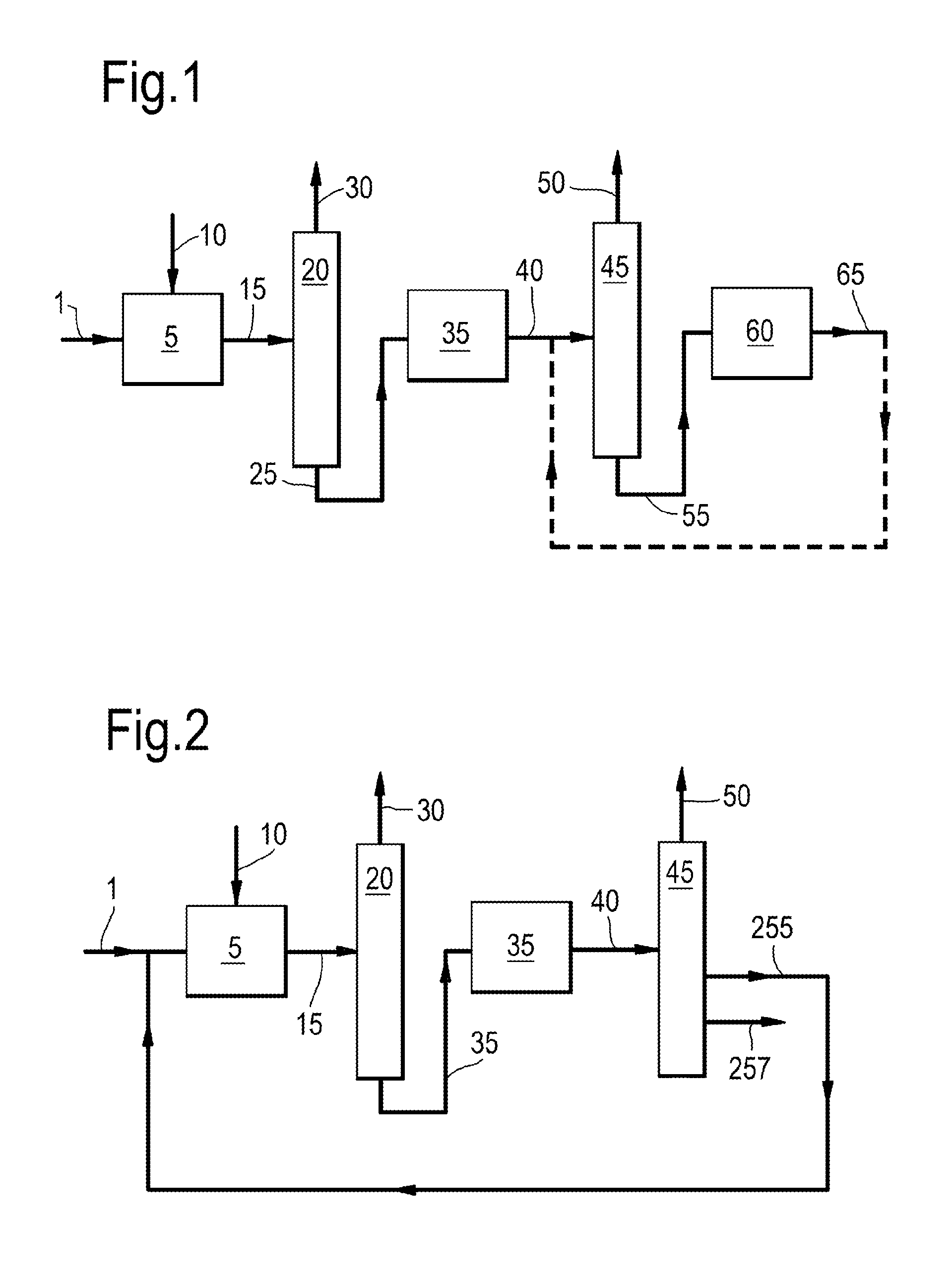

Process for olefin etherification

The invention relates to processes for the etherification of olefins with alcohols. According to one aspect, a heterogeneous etherification catalyst is used under conditions that permit limiting the contact time between the desired product and the catalyst, thereby mitigation reverse reactions. According to a second aspect, a recycling process is used that significantly increases the yield of desired product.

Owner:DOW GLOBAL TECH LLC

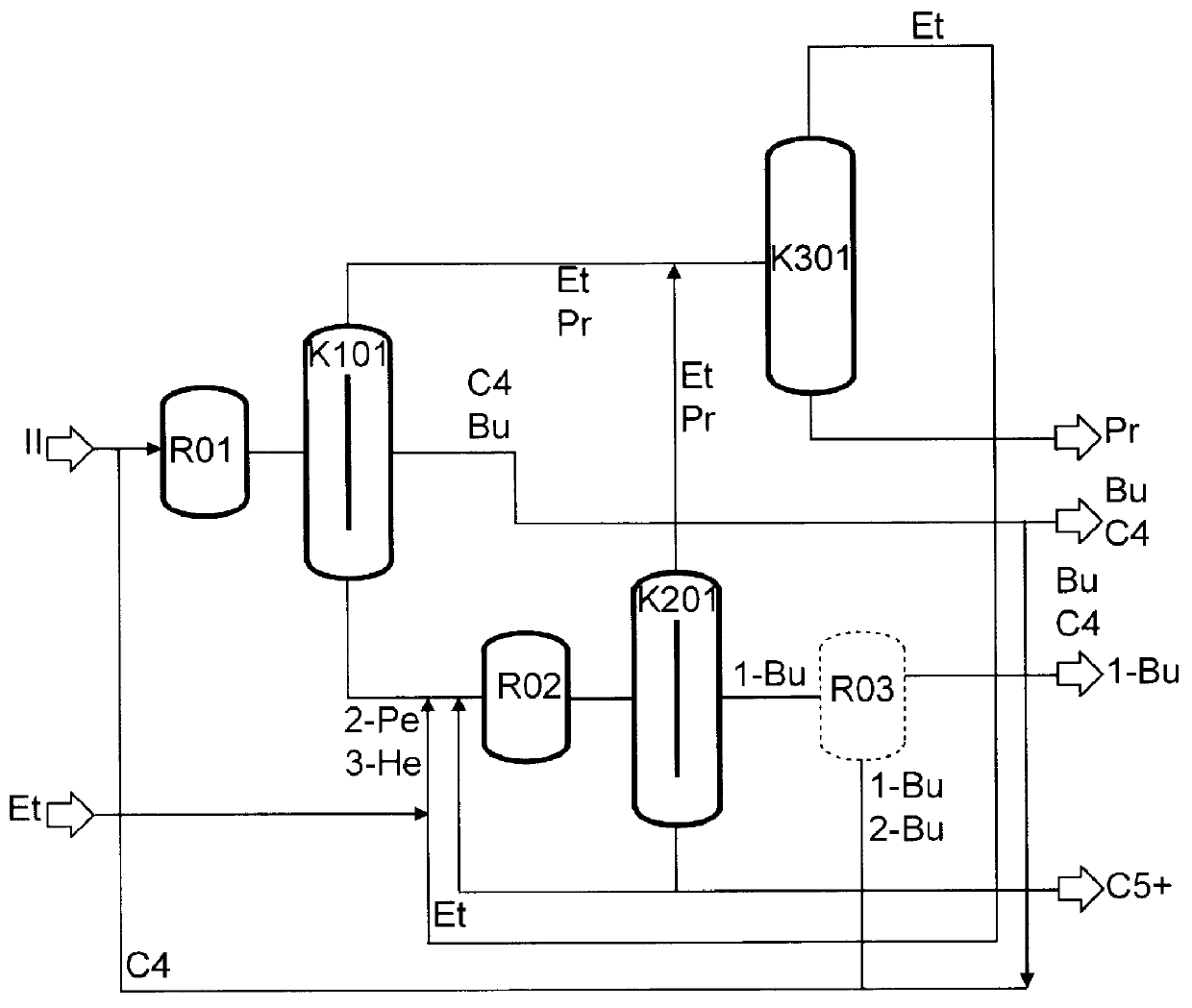

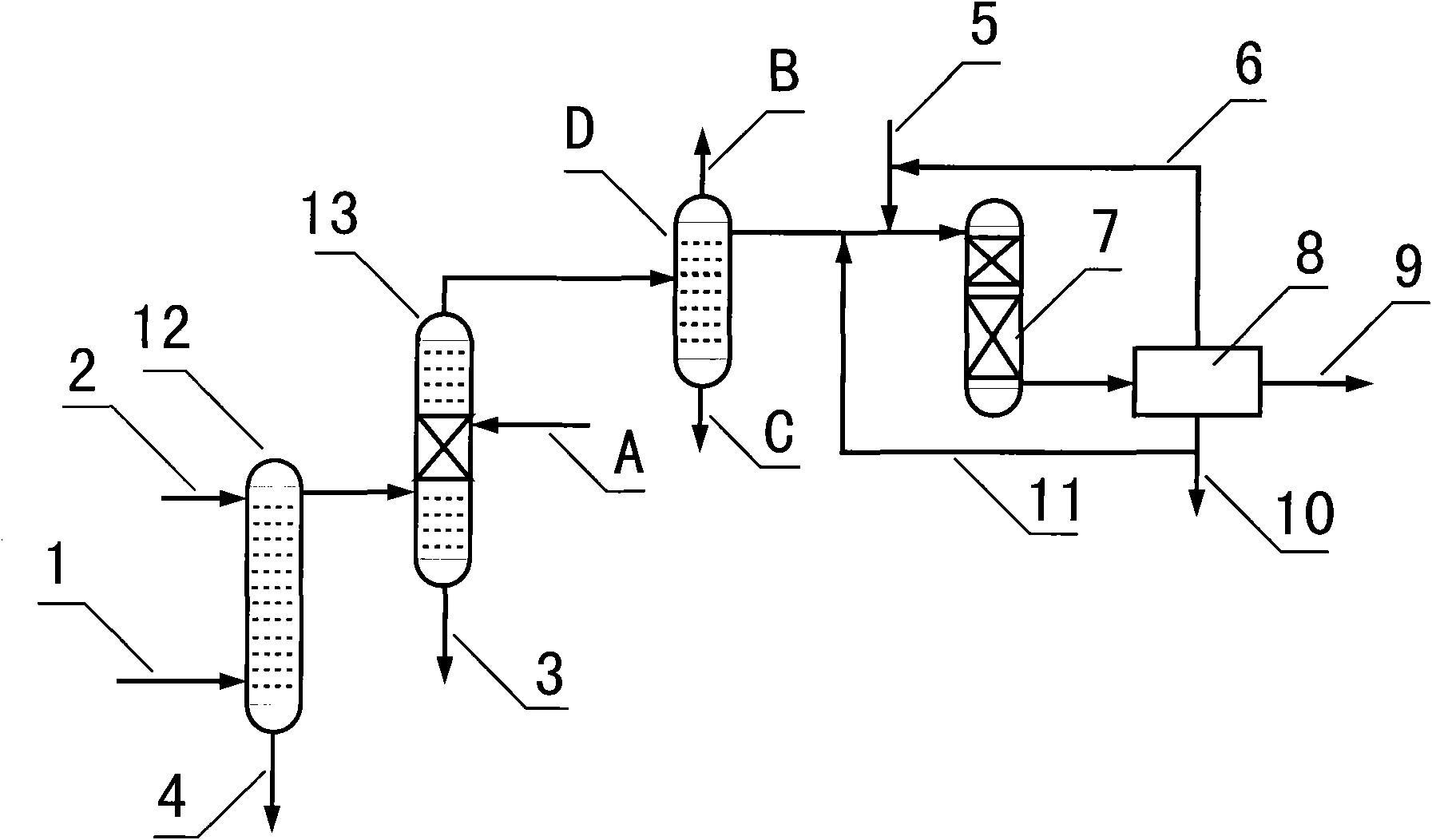

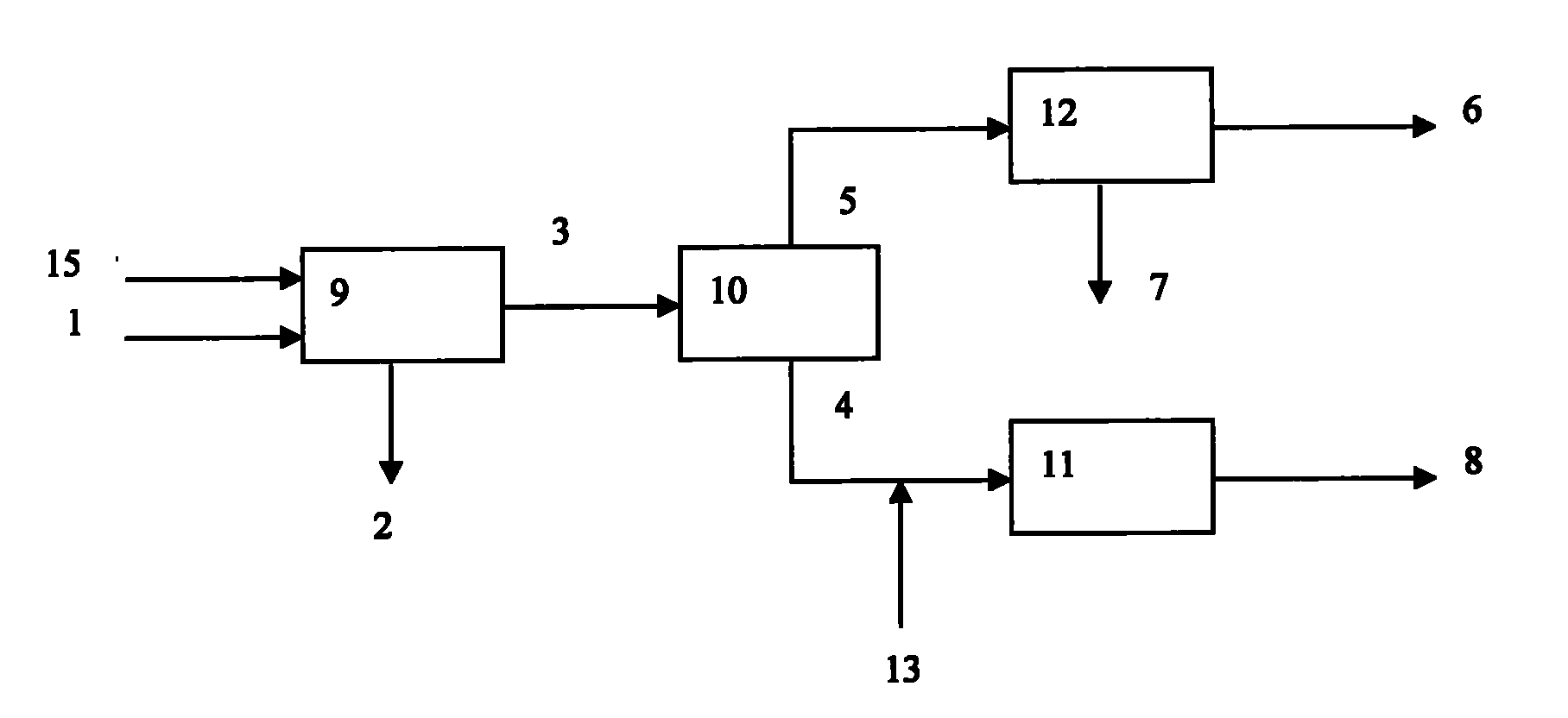

Comprehensive use method of mixed C-4

ActiveCN101555197AIncrease valueImprove technical effectHydrocarbon by metathesis reactionEther preparation by compound additionAlcoholBiochemical engineering

The invention relates to a comprehensive use method of mixed C-4, which mainly aims at solving the problem that the comprehensive utilization ratio of mixed C-4 by-products generated by a steam cracking device and an FCC device is low in the prior art. The method comprises the following steps: (1) adopting an extract technology to obtain butadiene through separation; (2) adopting an etherificationtechnology to synthesize MTBE by using isobutene remained in the C-4 undergoing the extraction in the first step; (3) separating water, ether and alcohol in the C-4 undergoing the etherification in the second step by adopting a refining and separating technology; (4) producing propylene through the disproportionating reaction between the mixed C-4 which is purified in the third step and ethyleneby adopting an olefine disproportionation technology; and (5) cyclically taking the mixed C-4 which is left after the reaction in the fourth step as the raw material of a cracking furnace. Such a technical scheme better solves the problem and can be used in the industrial production for increasing the propylene production and the comprehensive value of the mixed C-4.

Owner:CHINA PETROLEUM & CHEM CORP +1

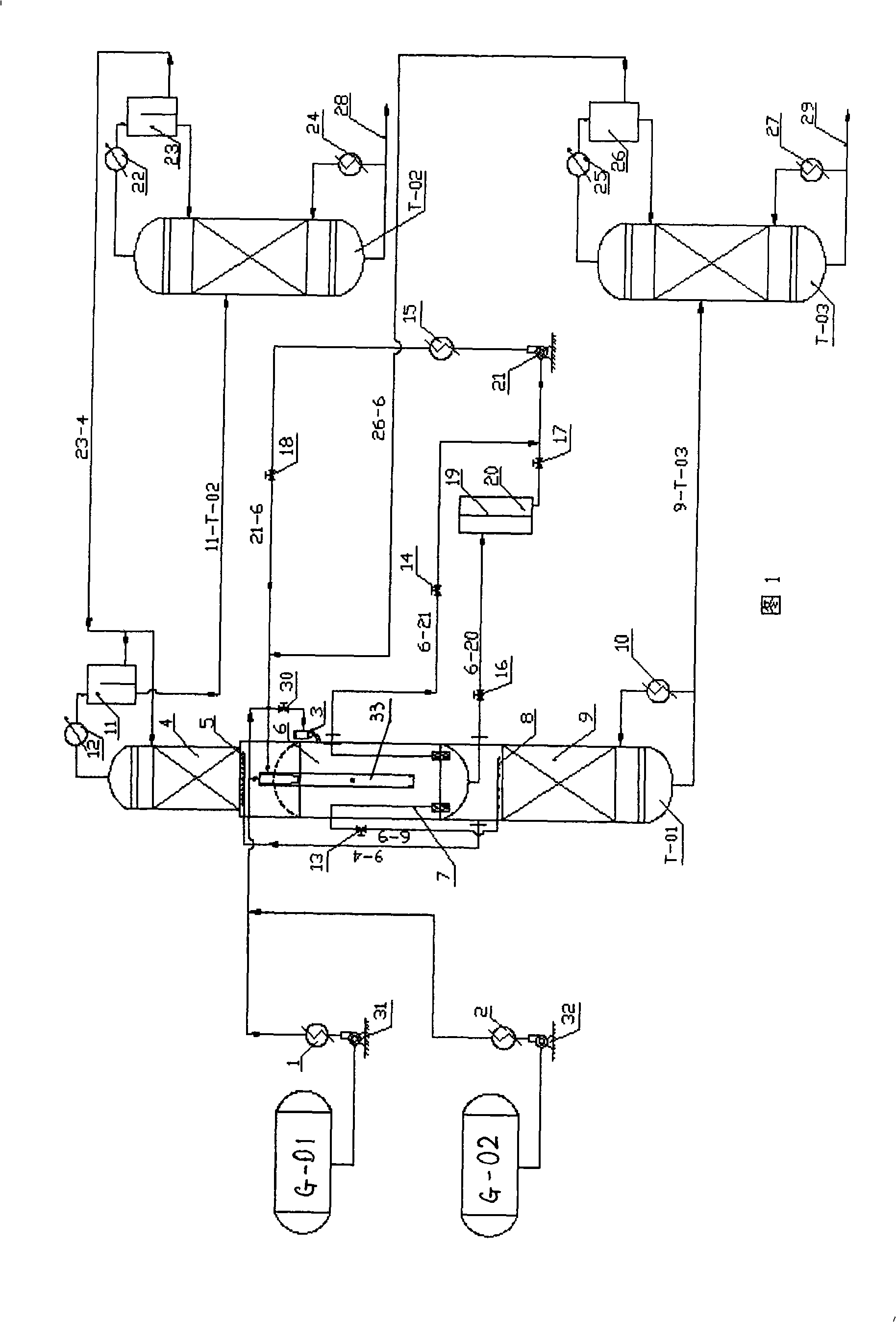

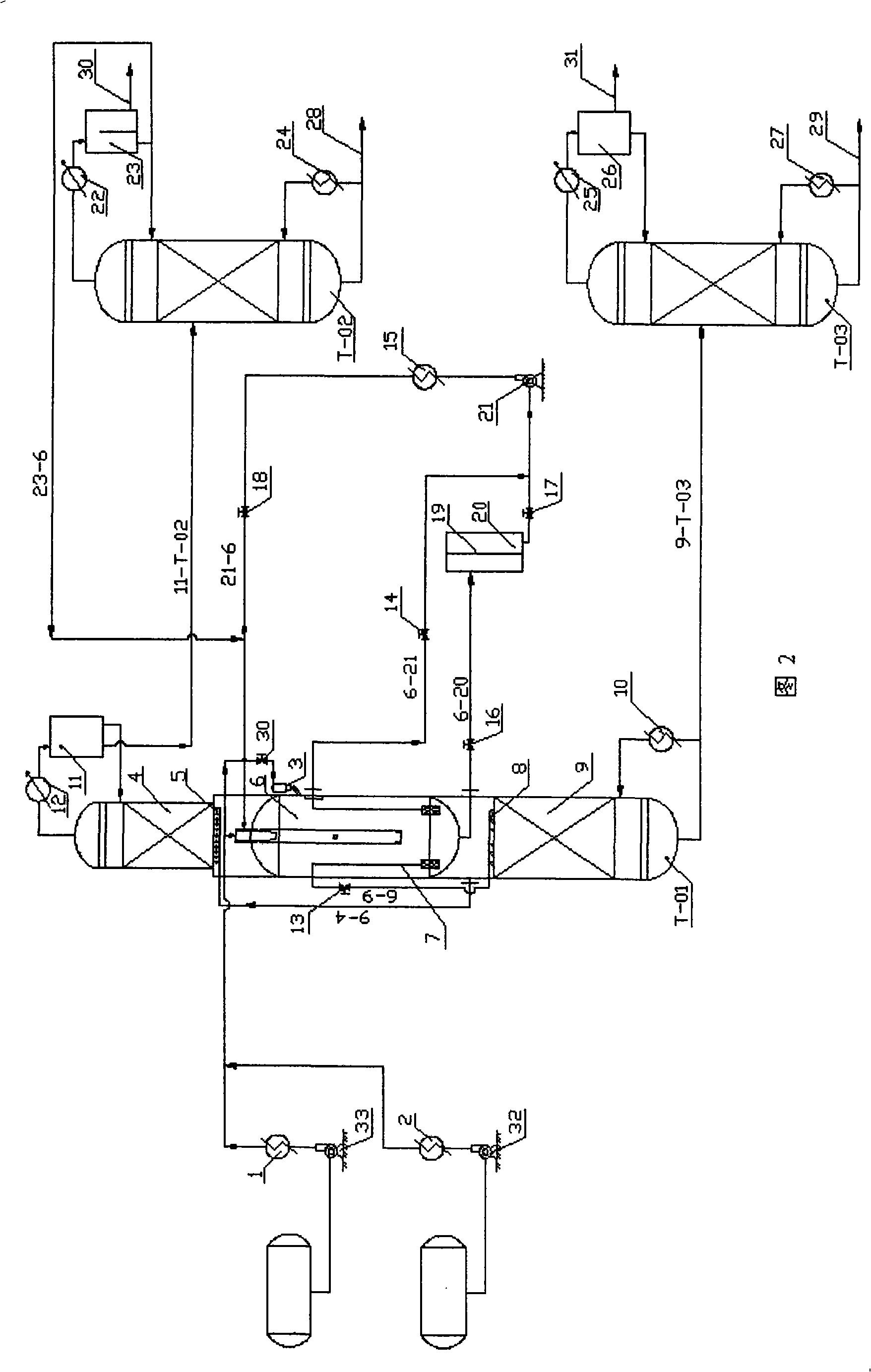

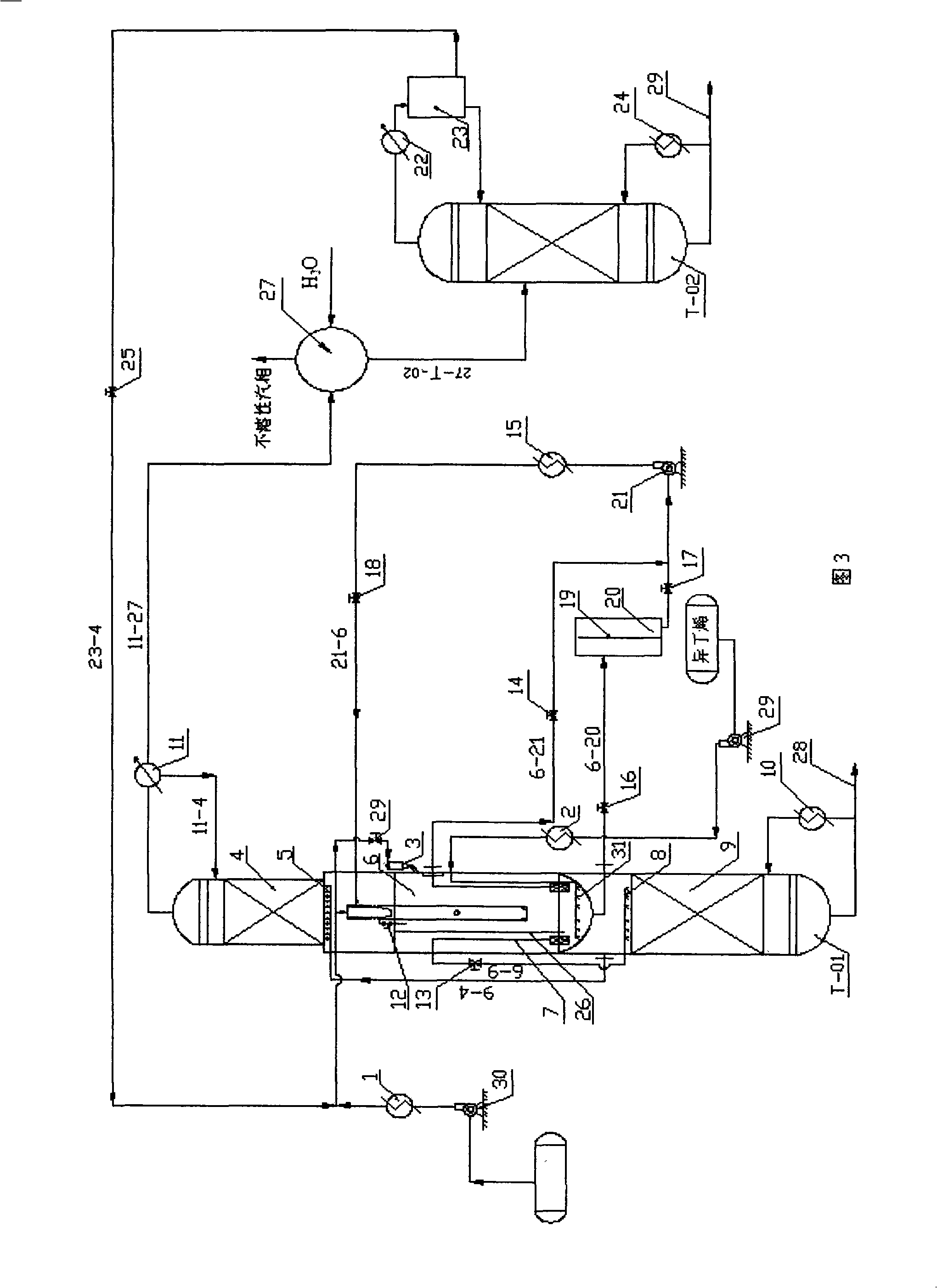

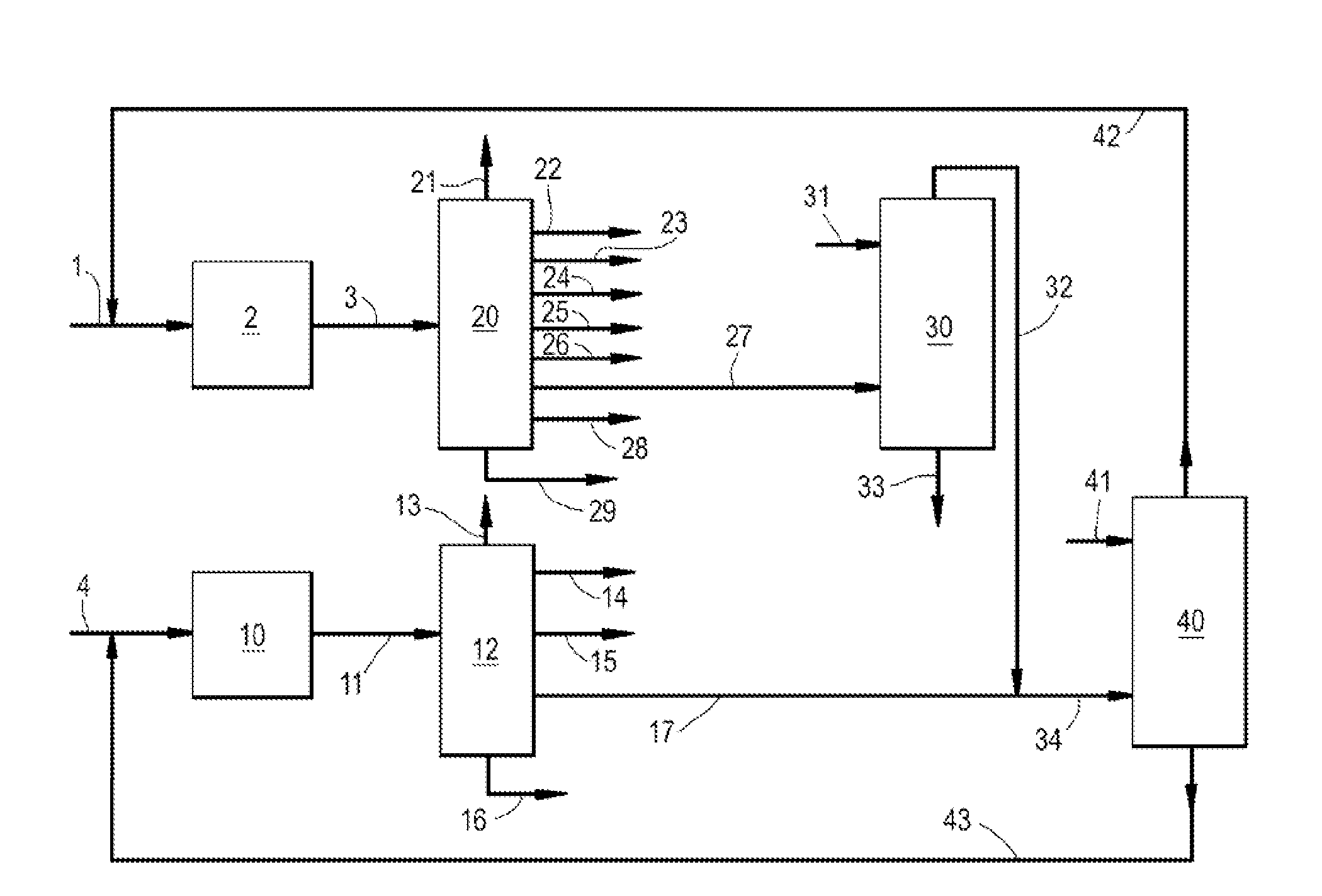

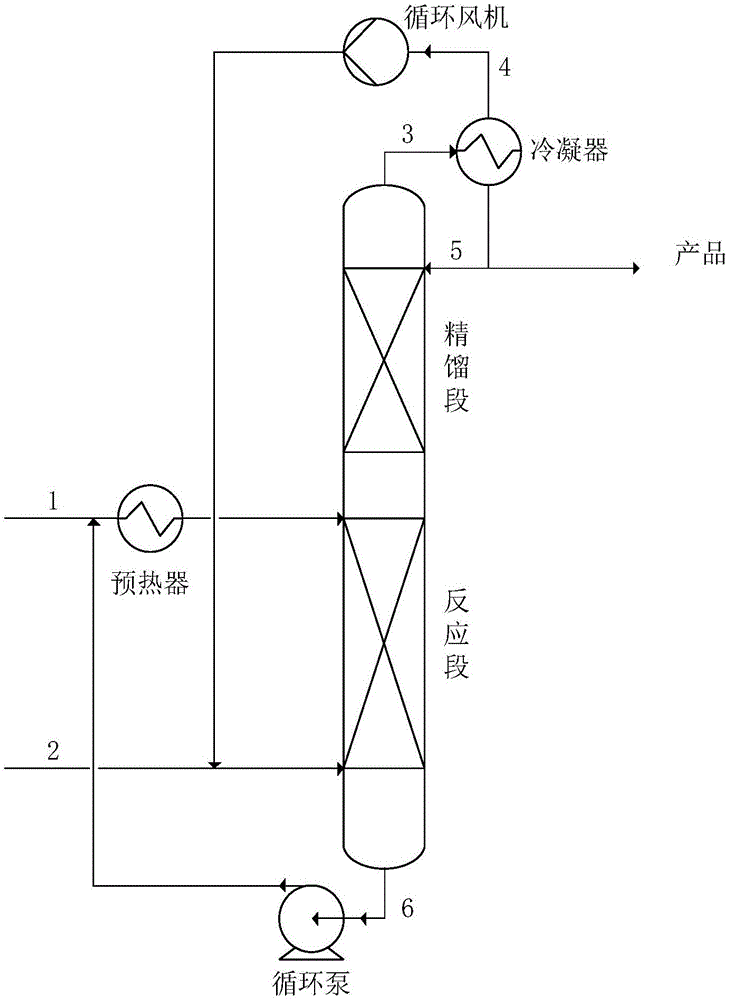

Catalytic reaction, rectification integrated technique and special-purpose equipment

InactiveCN101254444AIncrease production capacityHigh reaction conversion rateOrganic compound preparationCarboxylic acid esters preparationAlcoholEther

A catalytic reaction / rectification integrated process is provided, which includes: reaction raw materials are pre-heated and then mixed with catalysts; the resulting mixture is fed into a jet mixing reaction section 6 of a catalytic reaction / rectification integrated tower through a feed port, wherein the jet mixing reaction section 6 is a kettle-like reactor in the middle of the catalytic reaction / rectification integrated tower T-01; after the reaction raw materials are pressurized by a centrifugal pump, a subsonic or transonic jet mixer 33 inside the jet mixing reaction section 6 jets the reaction raw materials at a high speed into the jet mixing reaction section 6 and performs high-efficiency mixing of solid and liquid phases inside the jet mixing reaction section 6, thereby enhancing the heat and the mass transfer efficiencies during the process; the reaction mixture is directly separated and purified inside the catalytic reaction / rectification integrated tower. Therefore, the catalytic reaction / rectification integrated process has high conversion rate and production capacity and low energy consumption and production cost. The process is used for esterification, alcohol synthesis from alkenes and water, and the ether synthesis from alkenes and alcohols. A special catalytic reaction / rectification integrated tower is also provided.

Owner:NANJING UNIV

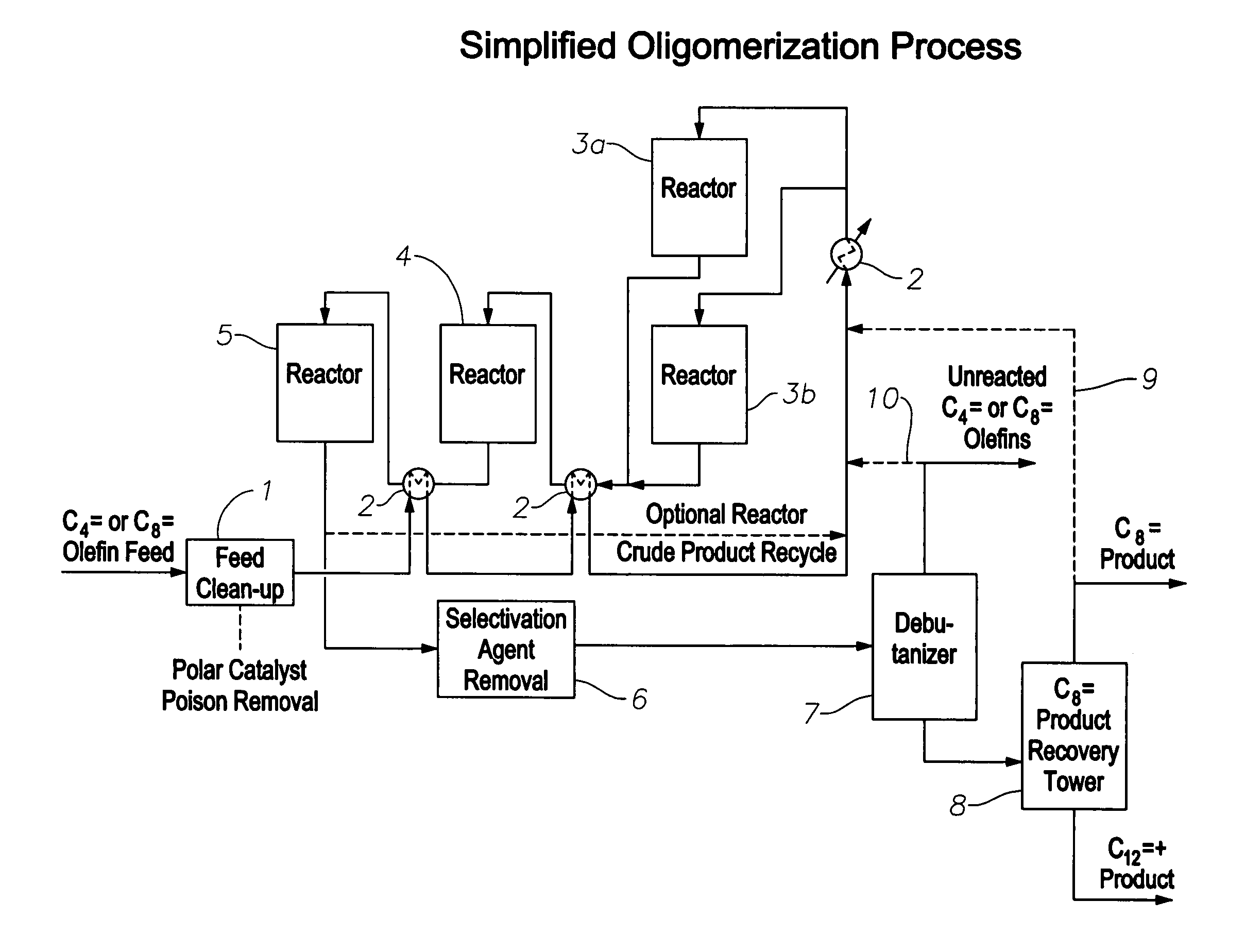

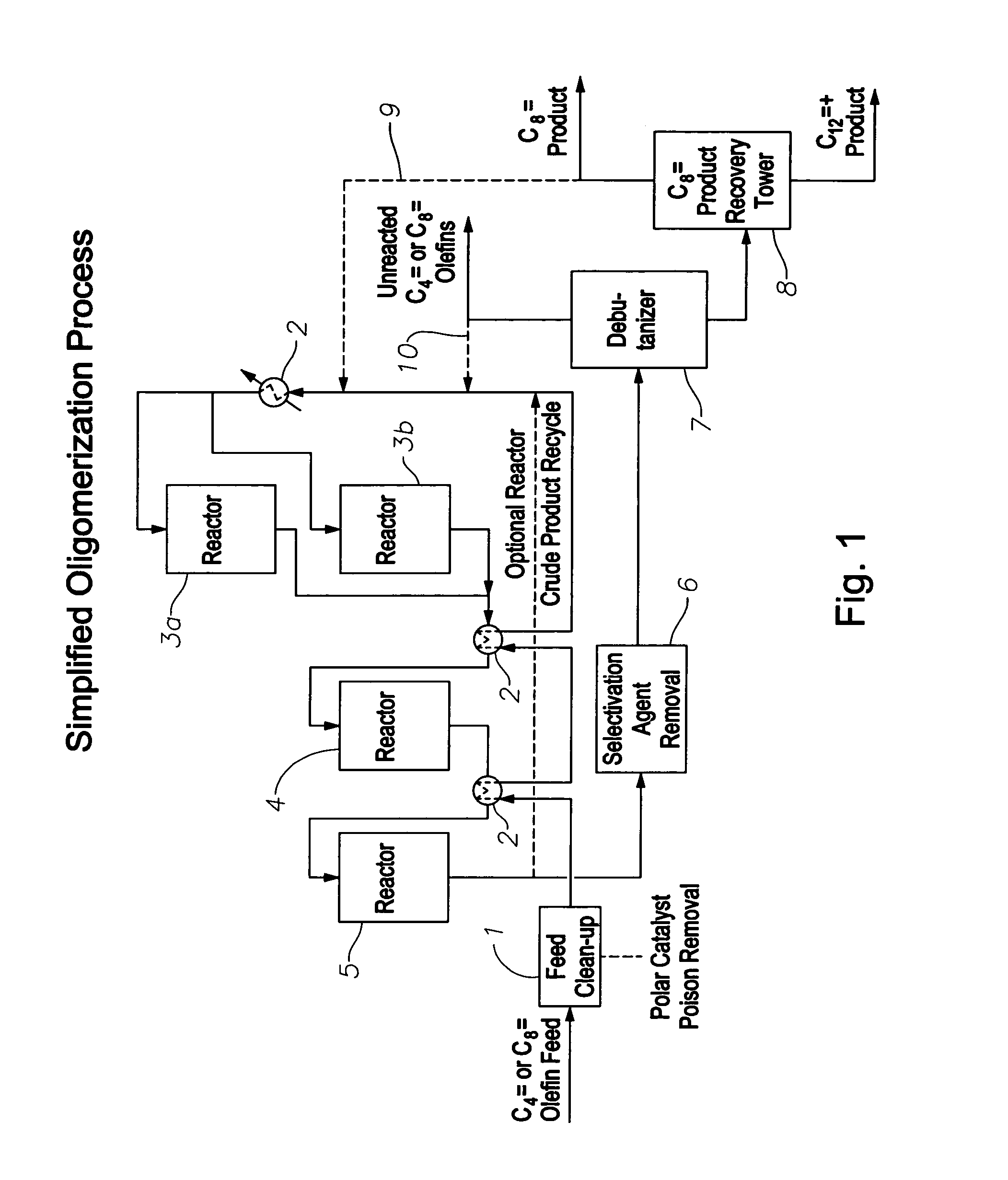

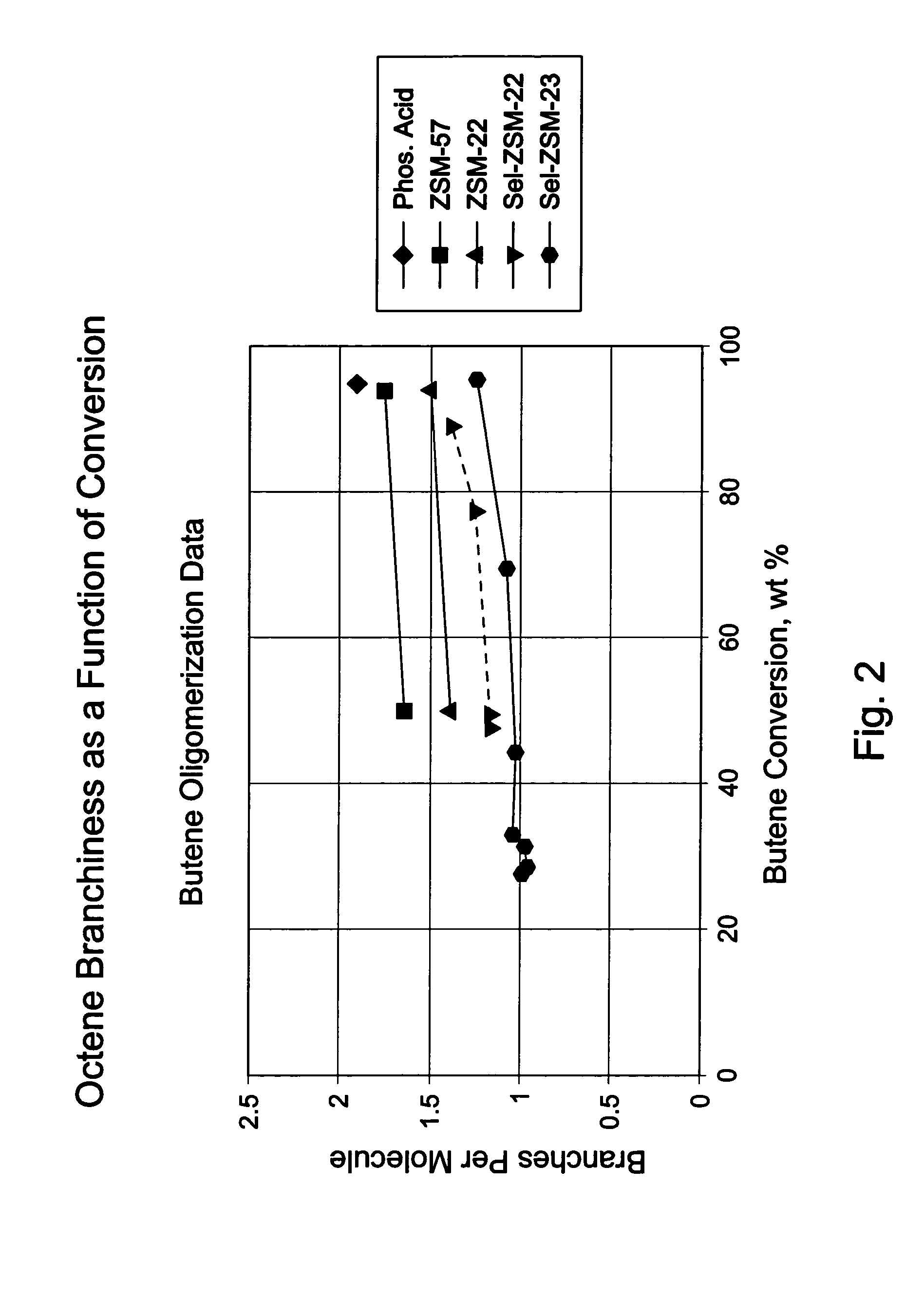

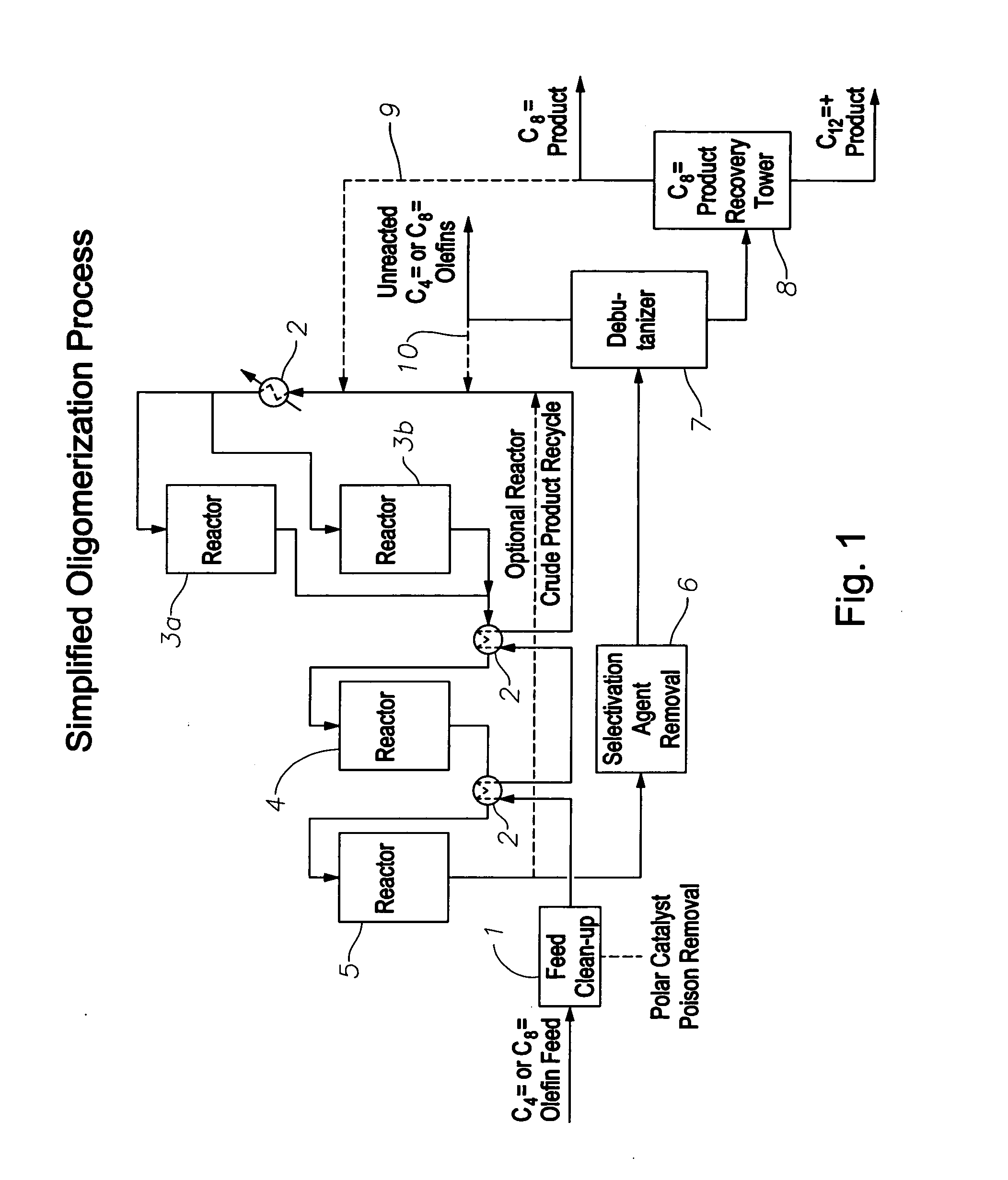

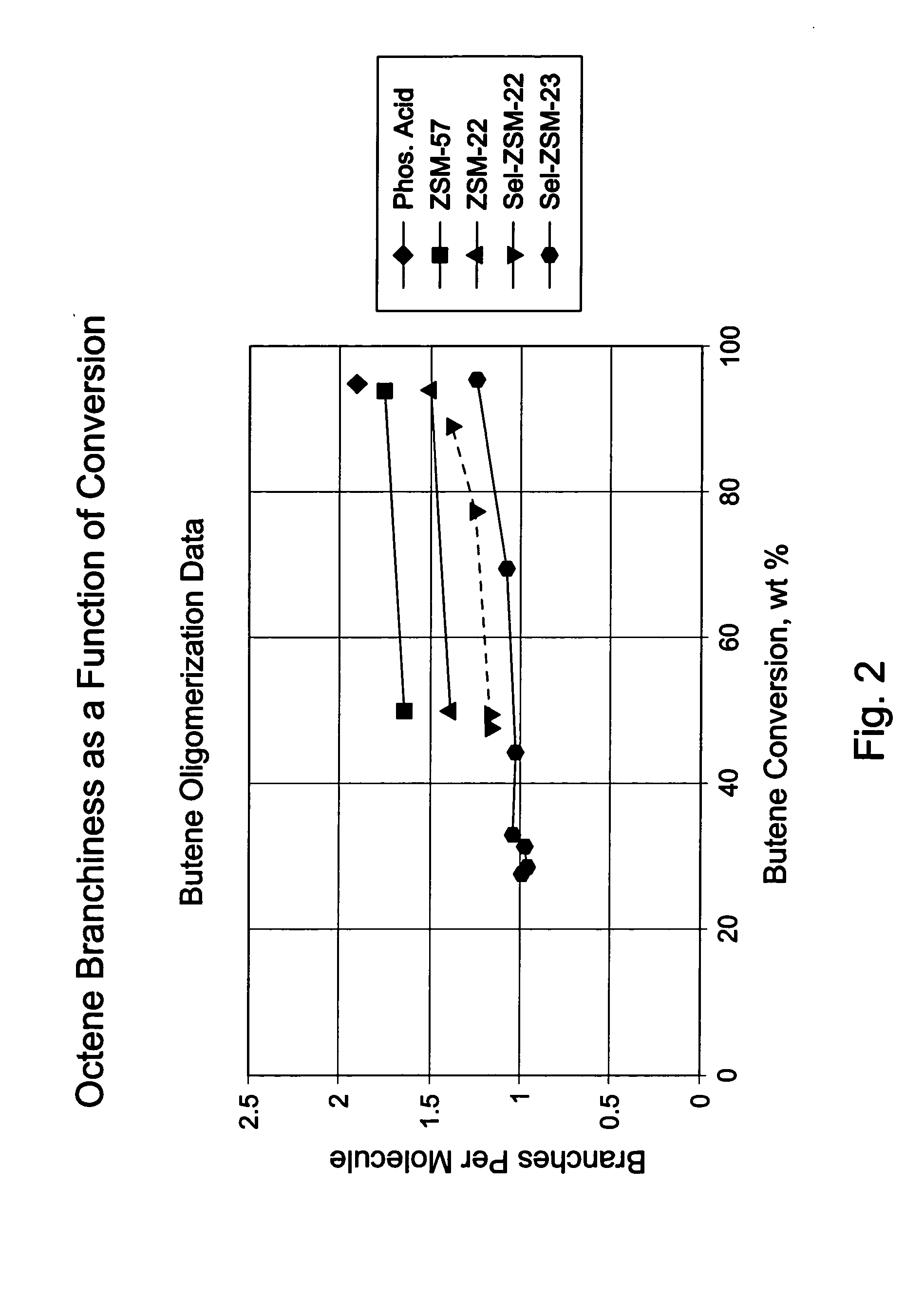

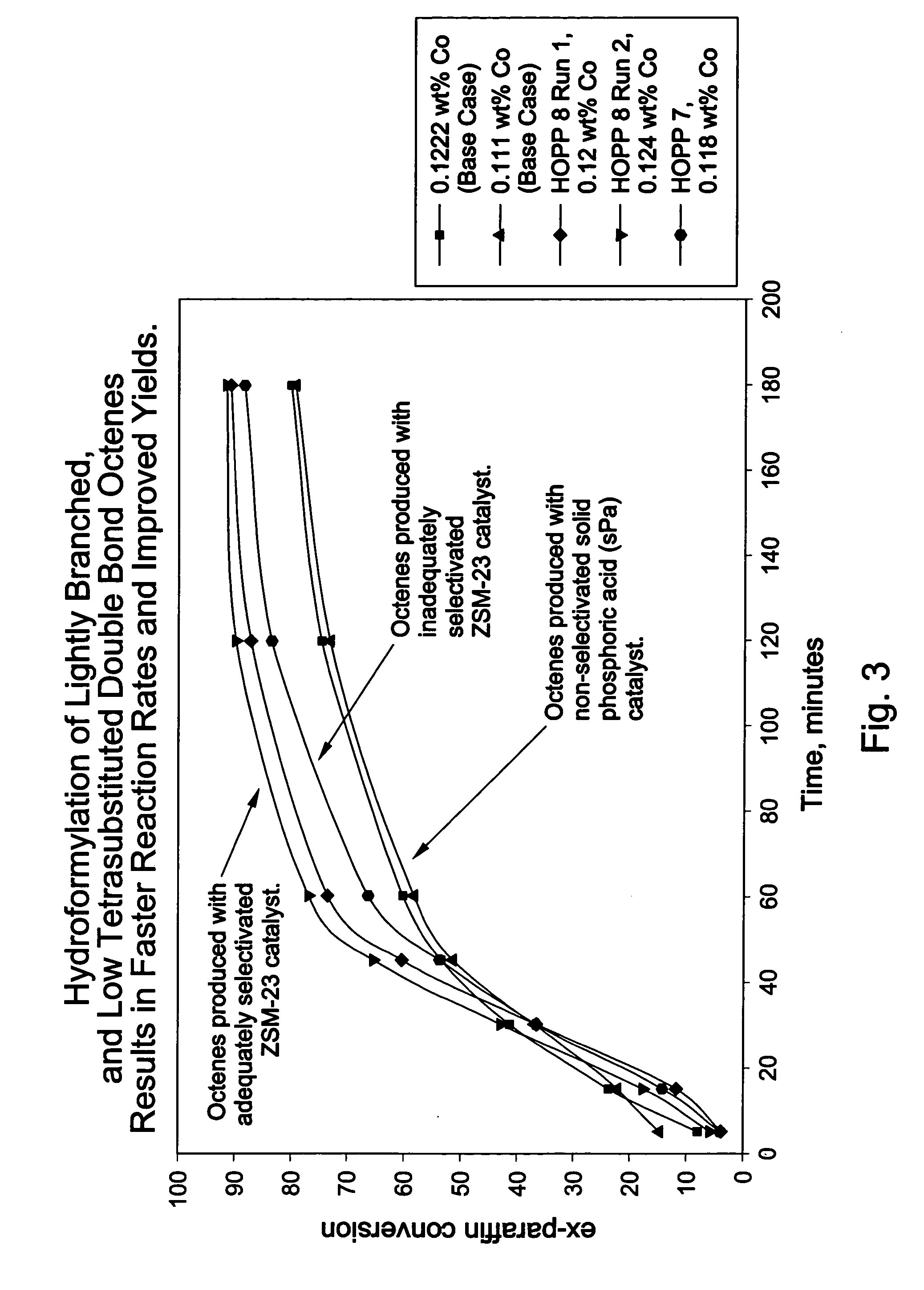

Oligomerization of olefins

ActiveUS7425662B2Increased branchingImprove linearityHydrocarbon by dehydrogenationCarboxylic acid esters preparationButeneMolecular sieve

A selectivated molecular sieve, e.g., ZSM-22 or ZSM-23, is used as olefin oligomerization catalyst to provide product, e.g., octenes and dodecenes from butene, having a low degree of branching and hindered double bonds.

Owner:EXXONMOBIL CHEM PAT INC

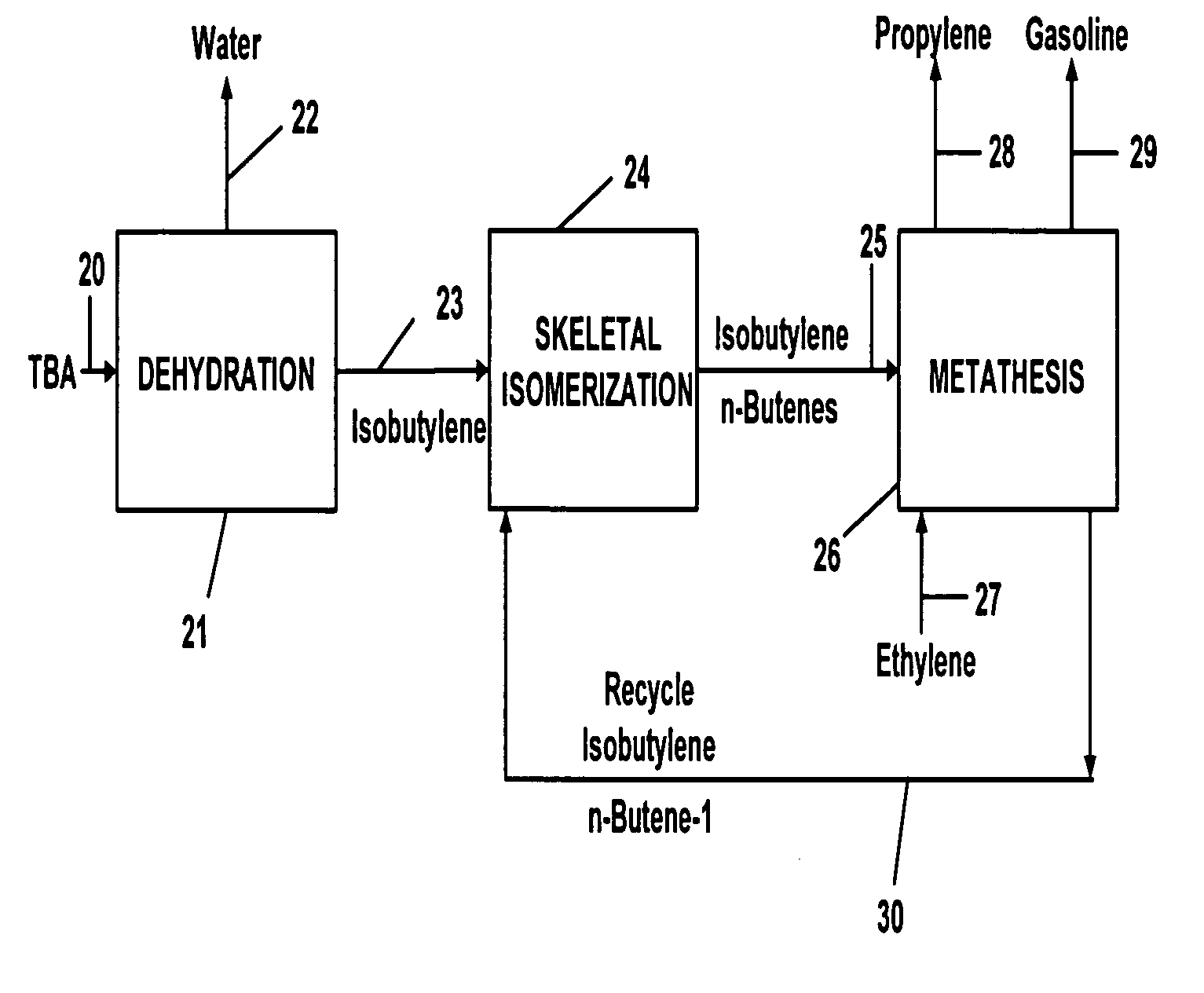

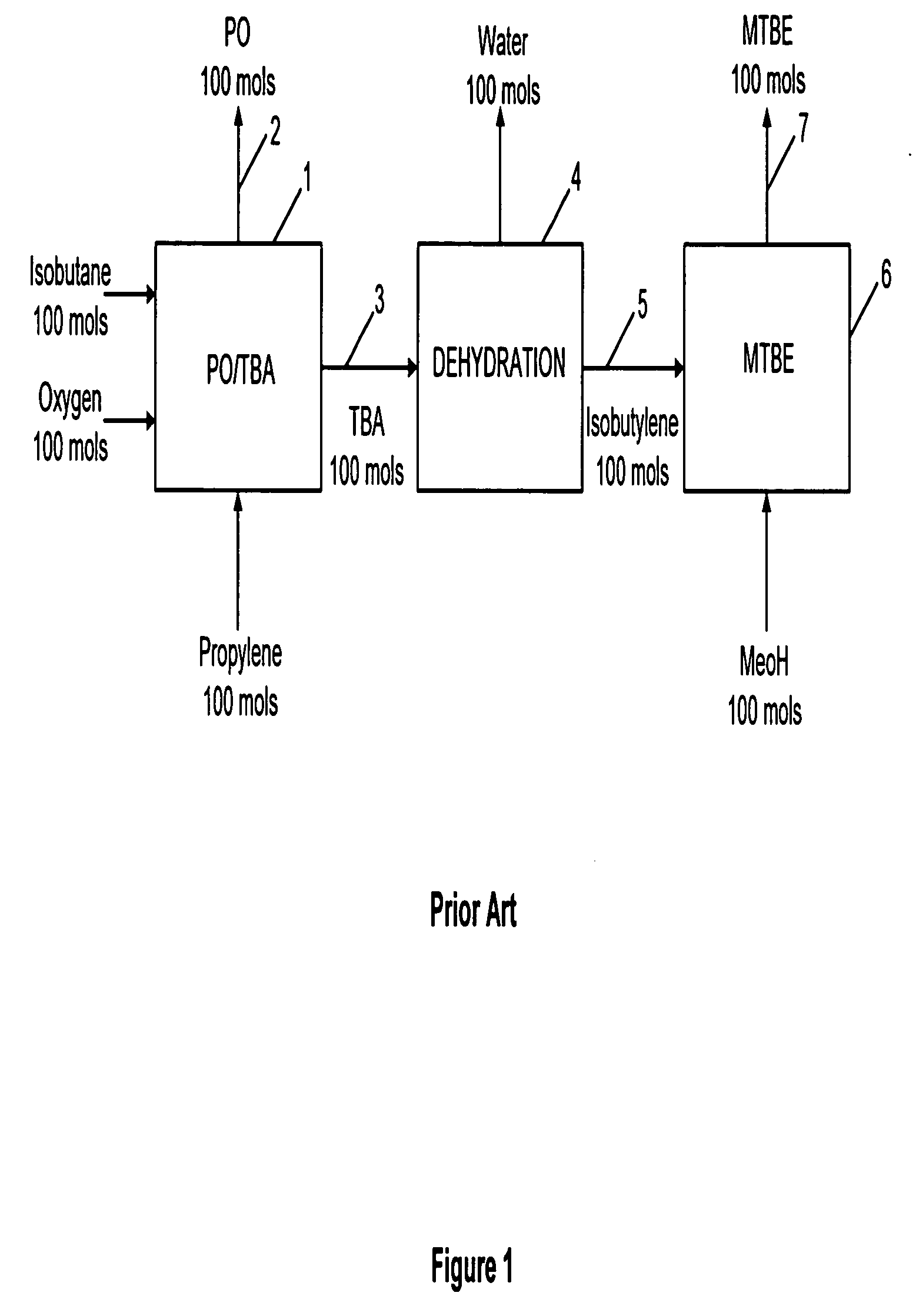

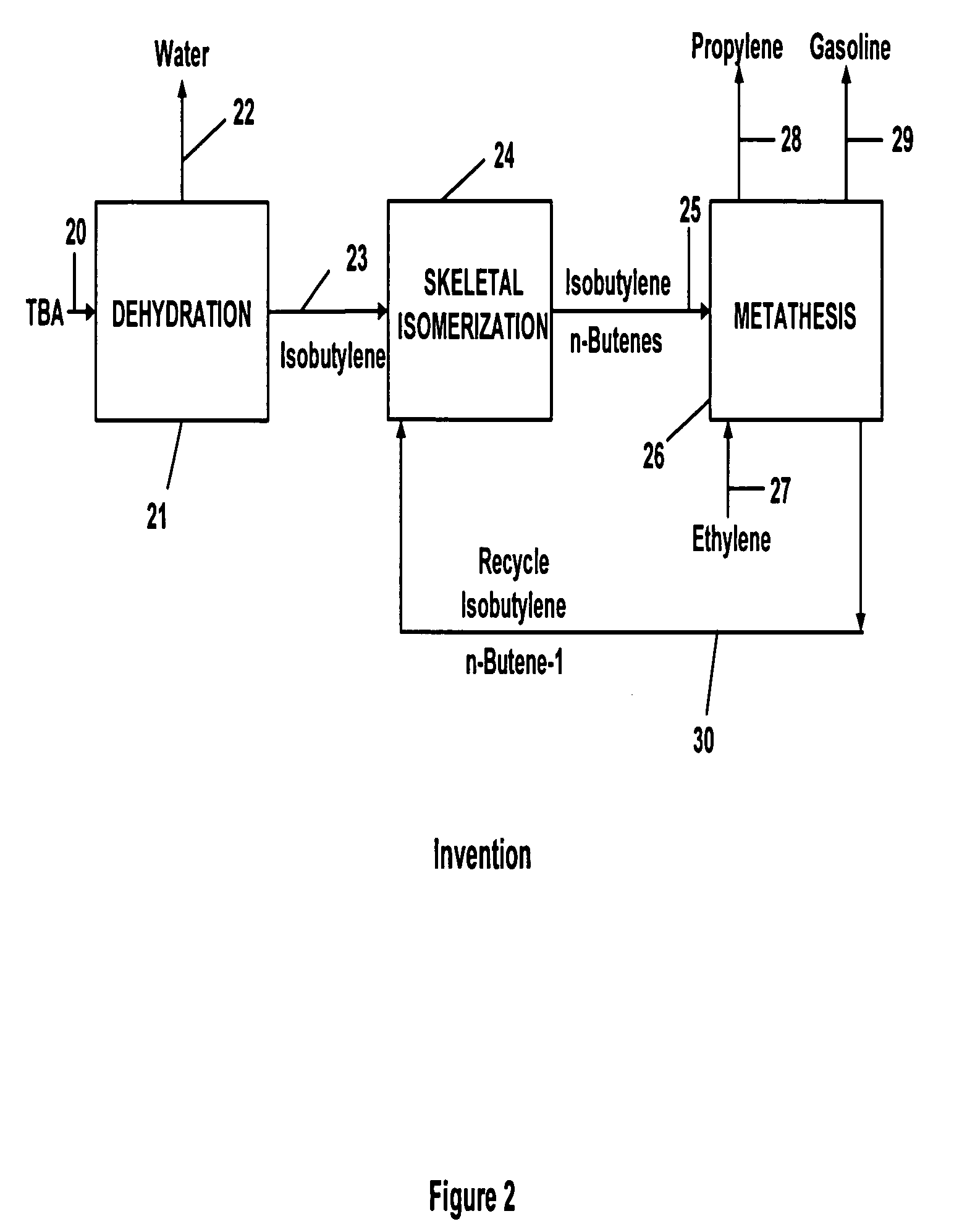

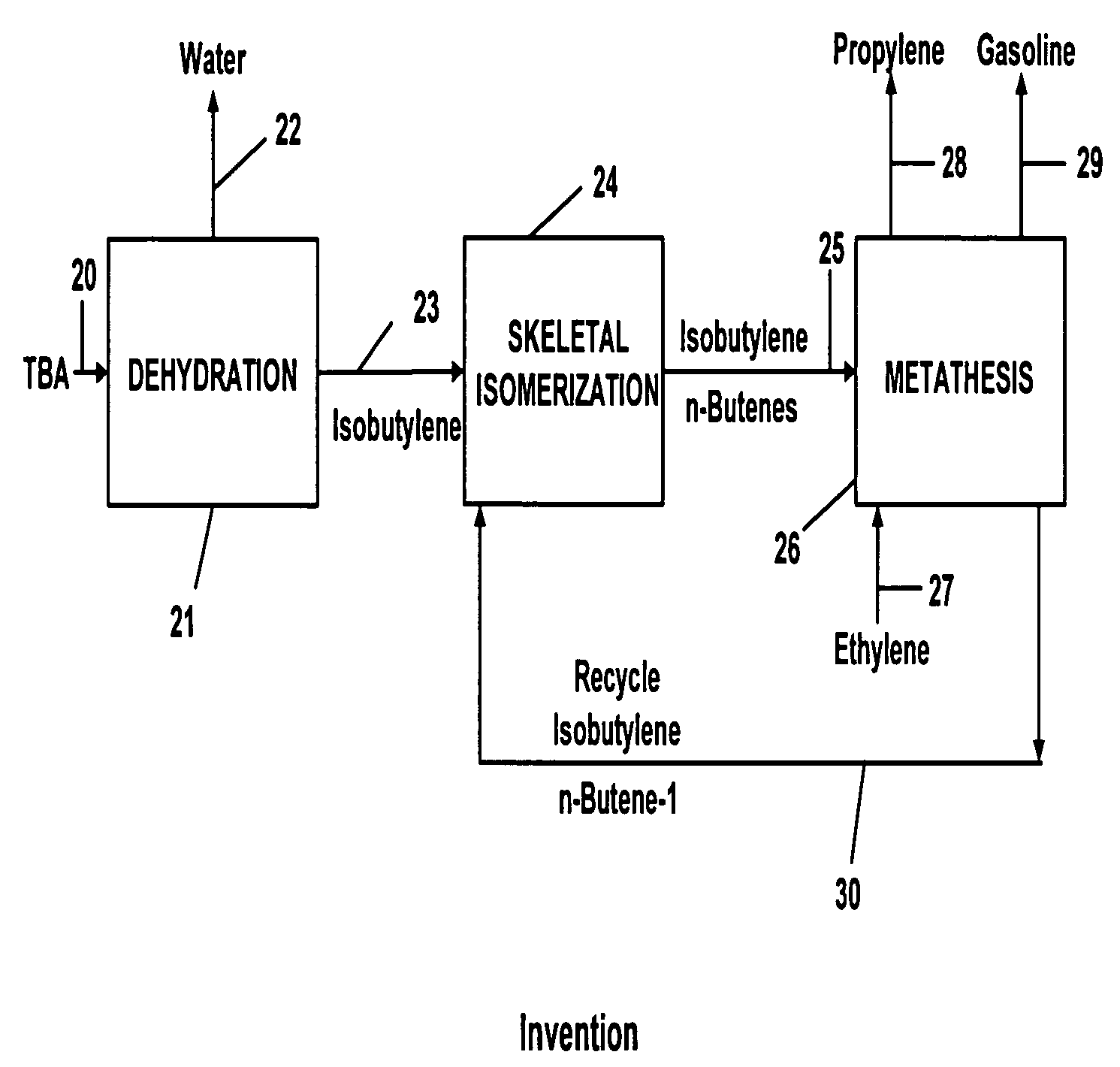

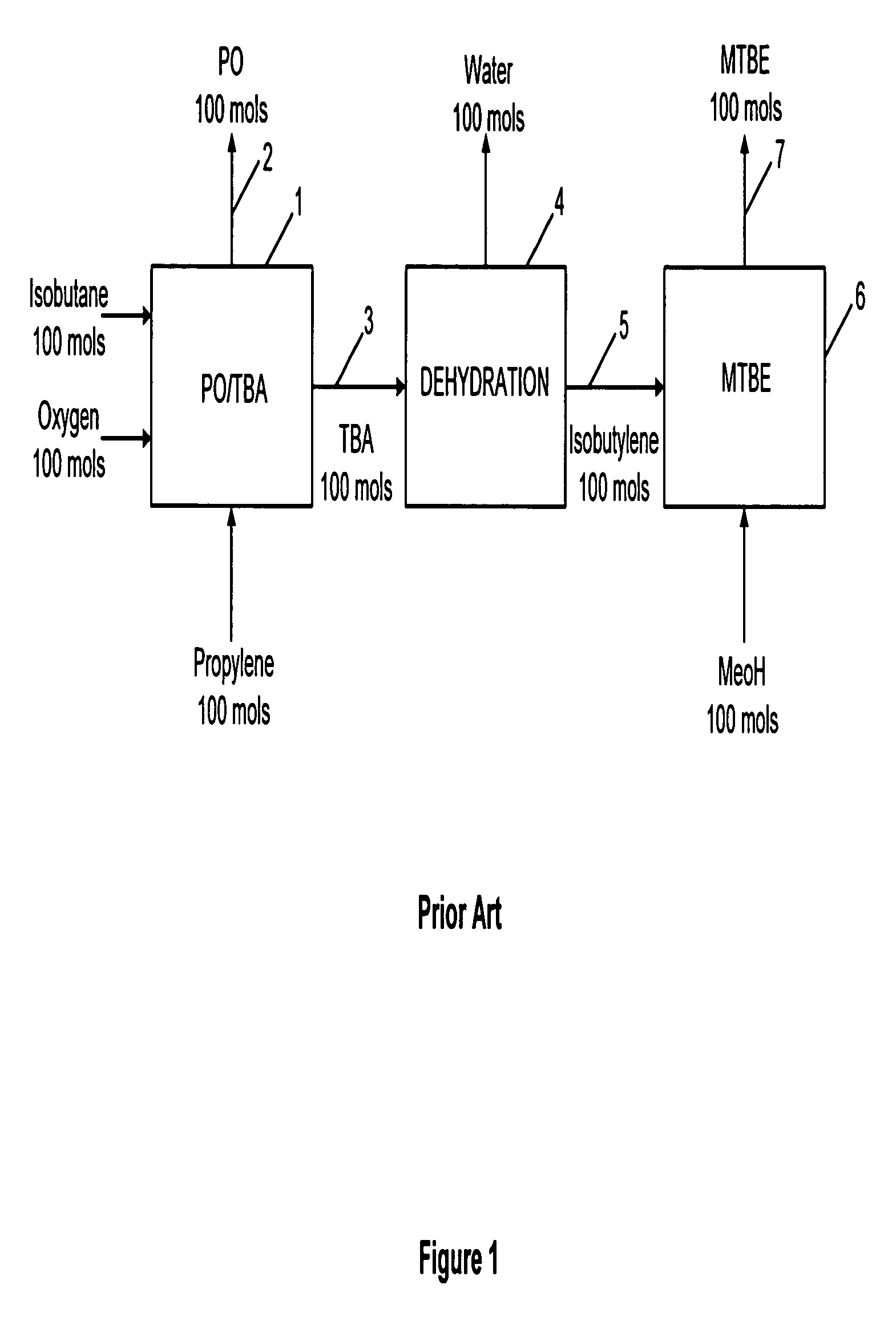

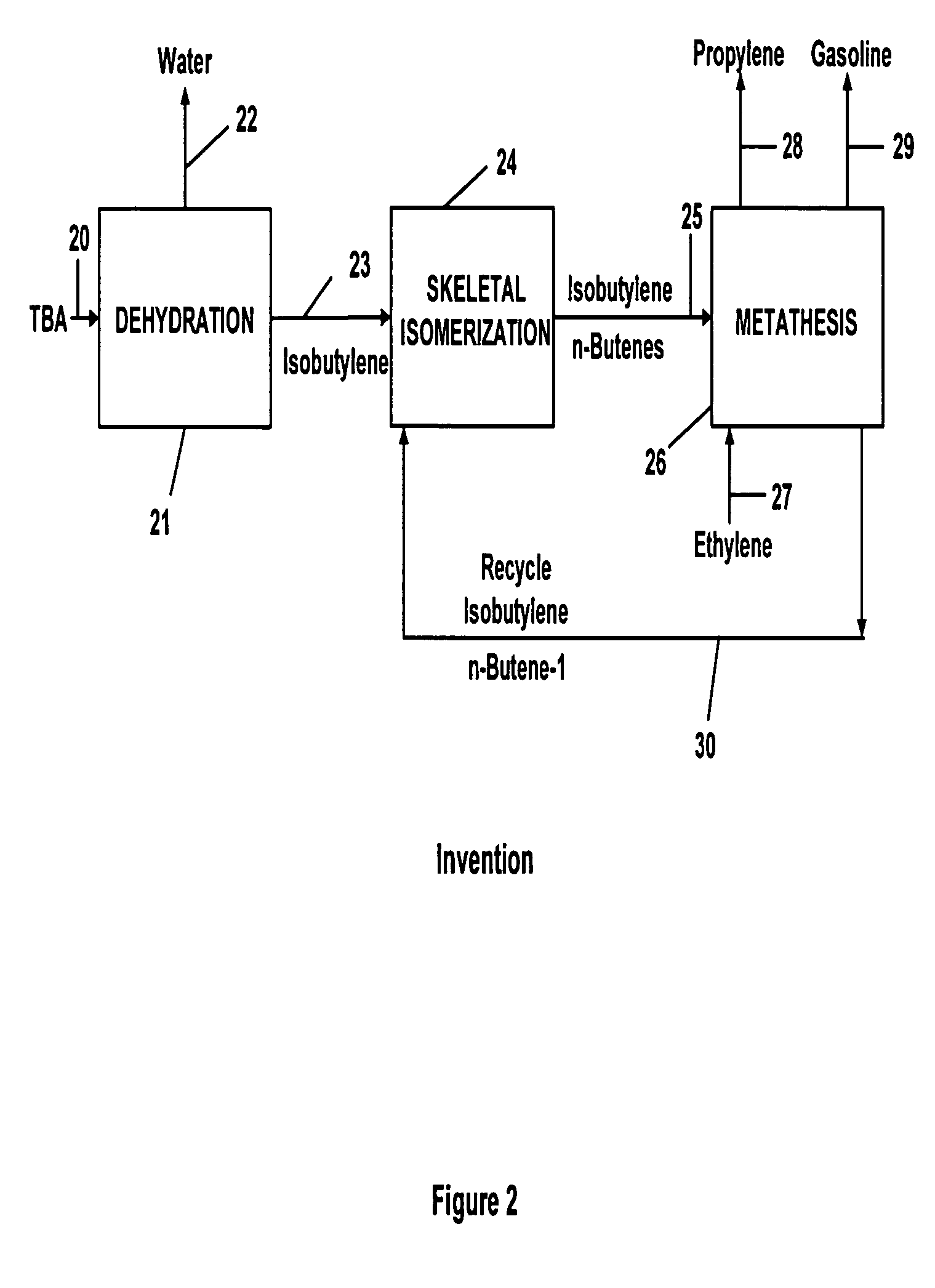

Propylene production

InactiveUS20050250969A1Versatile product mixHydrocarbon by isomerisationPreparation by oxidation reactionsIsomerizationGasoline

A method for forming propylene wherein ethylene is employed as a primary feed material in a combination of steps comprising dehydration, skeletal isomerization, and metathesis to form a versatile product mix that can contain one or more of propylene, gasoline, MTBE, and propylene oxide.

Owner:EQUSR CHEM LP

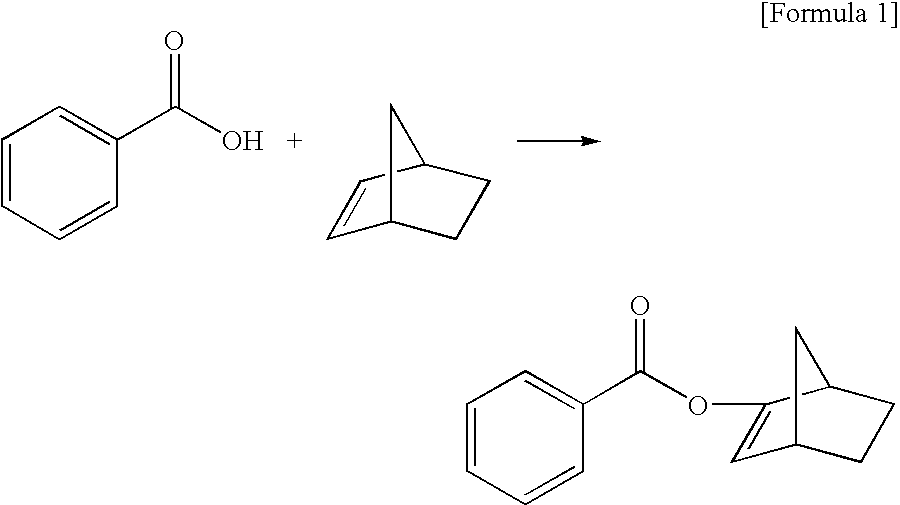

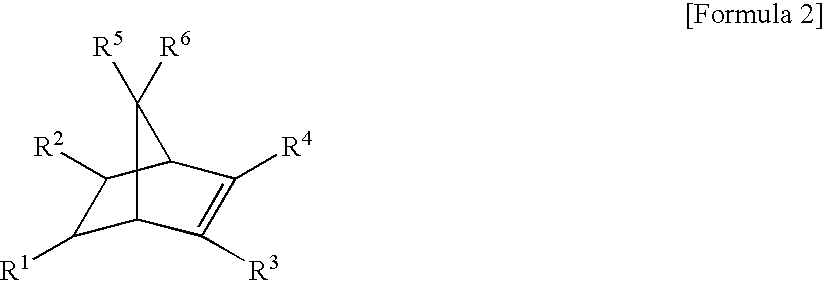

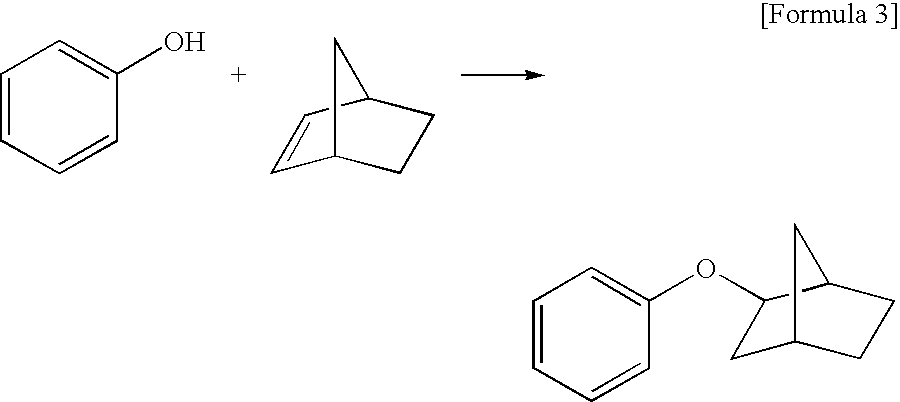

Process for Production of Carboxylic Acid Ester or Ether Compound

InactiveUS20090012324A1Easy to operateEconomical to useOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholNickel compounds

Disclosed is a process for production of a carboxylic acid ester from a carboxylic acid and an olefin or production of an ether compound from an alcohol and an olefin at low cost and with high yield in an industrially advantageous manner. The process comprises the step of reacting a carboxylic acid with an olefin to yield a corresponding carboxylic acid ester or reacting an alcohol with an olefin to yield a corresponding ether compound. In the process, a catalyst comprising a combination of (i) at least one metal compound selected from an iron compound, a cobalt compound and a nickel compound and (ii) an acidic compound is used.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Process for preparing lower olefins

InactiveUS20130172627A1Thermal non-catalytic crackingLiquid hydrocarbon mixture productionMolecular sieveExtractive distillation

The invention is a process for preparing lower olefins comprising: a) steam cracking a paraffinic feedstock to obtain a cracker effluent comprising olefins and saturated and unsaturated C4 hydrocarbons; b) contacting an oxygenate feedstock with a molecular sieve-comprising catalyst, at a temperature in the range of from 350 to 1000° C. to obtain an oxygenate conversion effluent comprising olefins and saturated and unsaturated C4 hydrocarbons; c) subjecting the cracker effluent and the oxygenate conversion effluent to one or more separation steps such that an olefin product stream comprising ethylene and / or propylene, and a stream comprising saturated and unsaturated C4 hydrocarbons are obtained; and d) subjecting part of the stream comprising C4 hydrocarbons from both the cracker effluent and the oxygenate conversion effluent to extractive distillation to obtain a stream enriched in unsaturated C4 hydrocarbons and a stream enriched in saturated C4 hydrocarbons.

Owner:SHELL OIL CO

Preparation method of hydrofluoroether

ActiveCN103254041AMild reaction conditionsEasy to operateEther preparation by compound additionHydrofluoroetherReactions stress

The invention discloses a preparation method of hydrofluoroether. The preparation method comprises the following steps of: mixing a solvent, a catalyst, olefin and alcohol to have reaction, wherein the mole ratio of the solvent to the alcohol is (1-6):1, the mole ratio of the catalyst to the alcohol is (0.01-0.15):1, the mass ratio of the olefin to the alcohol is (0.5-5):1, the reaction temperature is 20-60 DEG C, the reaction pressure is 0.05-0.6MPa, and the reaction time is 0.5-3 hours; and rectifying after the reaction is accomplished, so as to obtain a hydrofluoroether product. The preparation method has the advantages that the reaction condition is gentle, the operation is simple, products are easy to separate, and less wastewater, waste gas and waste residue are discharged.

Owner:JUHUA GROUP TECH CENT

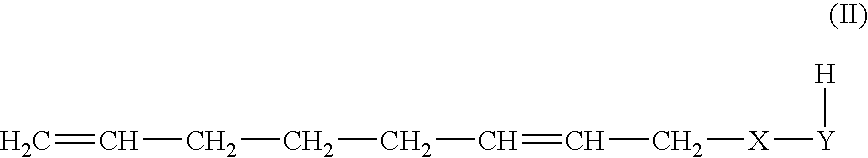

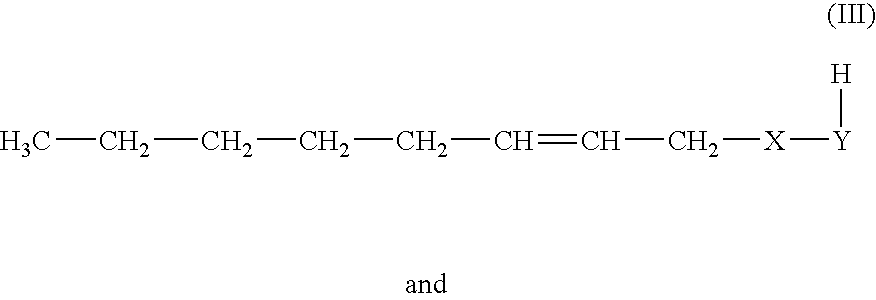

Method for producing 1-octene

InactiveUS7030286B2High purityHigh yieldOrganic compound preparationOrganic chemistry methods1-OcteneOctene

The invention relates to a process for preparing 1-octene by reacting 1,3-butadiene with a telogen of the formula H—X—Y—H, where X is O, N, S or P and Y is C, N or Si and X and Y bear, depending on their valence, further substituents, in the presence of a telomerization catalyst to form a telomer of the formula H2C═CH—CH2—CH2—CH2—CH═CH—CH2—X—Y—H, partially hydrogenating the telomer to form a 1-substituted 2-octene of the formula H3C—CH2—CH2—CH2—CH2—CH═CH—CH2—X—Y—H and dissociating the 1-substituted 2-octene to give 1-octene.

Owner:OXENO OLEFINCHEMIE GMBH

Propylene production

InactiveUS6977318B2Versatile product mixHydrocarbon by isomerisationPreparation by oxidation reactionsIsomerizationGasoline

Owner:EQUSR CHEM LP

Process for preparing ethylene and/or propylene and an iso-olefin-depleted c4 olefinic product

InactiveUS20130237714A1Reduce concentrationHigh selectivityOxygen-containing compound preparationPreparation by oxidation reactionsMolecular sieveAlkene

The present invention provides a process for preparing ethylene and / or propylene and an iso-olefin-depleted C4 olefinic product, comprising the steps of:a) providing a C4 hydrocarbon stream, comprising normal olefins and iso-olefins;b) subjecting the C4 hydrocarbon stream to an etherification process with methanol and / or ethanol wherein at least part of the iso-olefins are converted with methanol and / or ethanol to an tert-alkyl ether, and retrieving an etherification product stream;c) separating at least part of the etherification product stream into at least an ether-enriched stream and a first iso-olefin-depleted C4 olefinic product;d) converting at least part of the tert-alkyl ether in the ether-enriched stream to ethylene and / or propylene by contacting least part of the ether-enriched stream with a molecular sieve-comprising catalyst at a temperature in the range of from 350 to 1000° C. and retrieving a second olefinic product comprising ethylene and / or propylene.

Owner:SHELL OIL CO

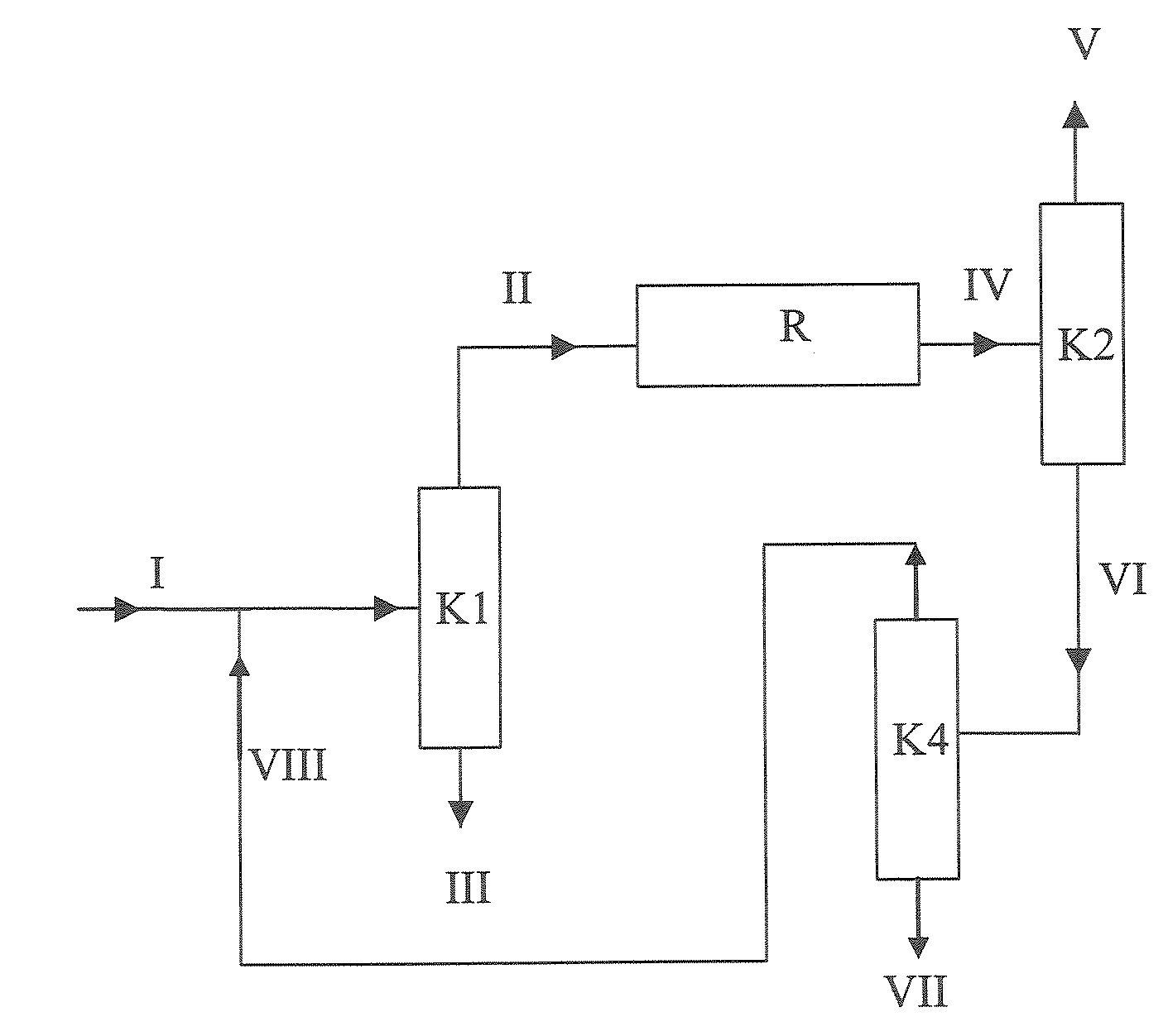

Process for the dissociation of mtbe

ActiveUS20080058575A1Improved and simplifiedWork-up of the bottom products obtainedEther separation/purificationOrganic compound preparationGas phaseBoiling point

Isobutene is prepared by dissociation of MTBE in the gas phase, by a) fractional distillation of an MTBE-containing stream comprising feed MTBE (I) and a recycle stream (VIII) to give an MTBE-containing overhead stream (II) and a bottom stream (III) having a boiling point higher than MTBE, b) catalytic dissociation of the overhead stream (II) obtained in step a) to give a dissociation product (IV), c) separation by distillation of the dissociation product (IV) obtained in step b) into an overhead stream (V) comprising more than 90% by mass of isobutene and a bottom stream (VI) comprising diisobutene, MTBE and more than 50% of the methanol present in the dissociation product (IV), d) fractional distillation of the bottom stream obtained in step c) under conditions under which the methanol is obtained as bottom product (VII) and more than 99% of the MTBE is obtained in the overhead product (VIII), and e) recirculation of the overhead product (VIII) to step a).

Owner:EVONIK OPERATIONS GMBH

Novel alkyl perfluoroalkene ethers

InactiveUS20110282104A1Organic compound preparationNon-surface-active detergent compositionsEtherMedicinal chemistry

Owner:EI DU PONT DE NEMOURS & CO

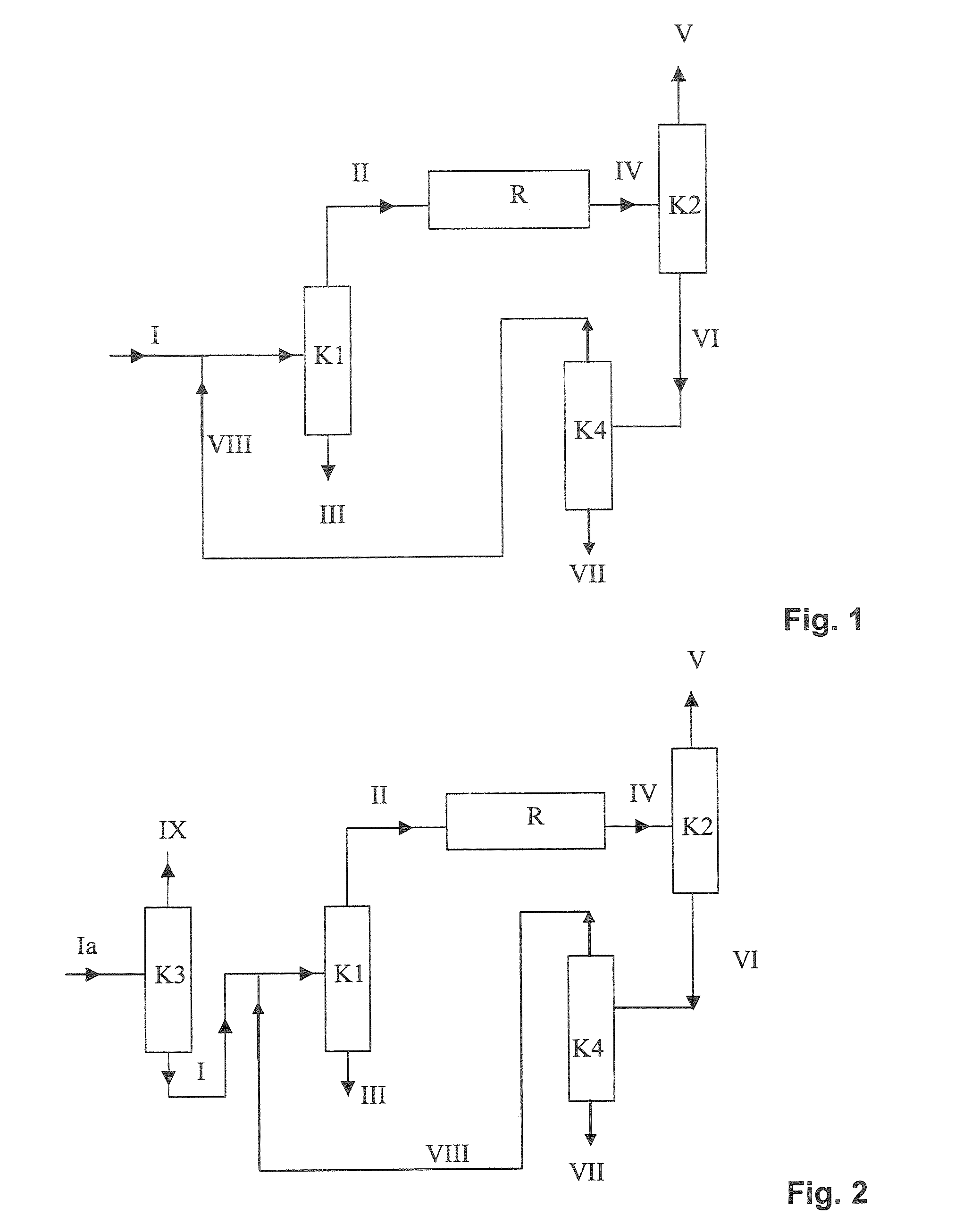

Process for preparing ethylene and/or propylene

InactiveUS8754277B2Reduce the amount requiredConveniently separatedOxygen-containing compound preparationOrganic compound preparationMolecular sieveAlkene

The present invention provides a process for preparing ethylene and / or propylene, comprising the steps of providing a hydrocarbon stream, comprising C4+ normal olefins and C4+ iso-olefins; converting C4+ isoolefins to tert-alkyl ether and separating the ethers from the hydrocarbon stream; isomersing the C4+ normal olefins to iso-olefins and converting C4+ isoolefins to tert-alkyl ether and separating the ethers from the hydrocarbon stream; converting the obtained tert-alkyl ether to ethylene and propylene by contacting the tert-alkyl ether with a molecular sieve-comprising catalyst and retrieving an olefinic product.

Owner:SHELL OIL CO

Process for preparing hydrofluoroethers

InactiveUS6023002AFurther reactionAchieve efficiencyOrganic compound preparationEther preparation by compound additionEtherHydrofluoroether

Owner:3M INNOVATIVE PROPERTIES CO

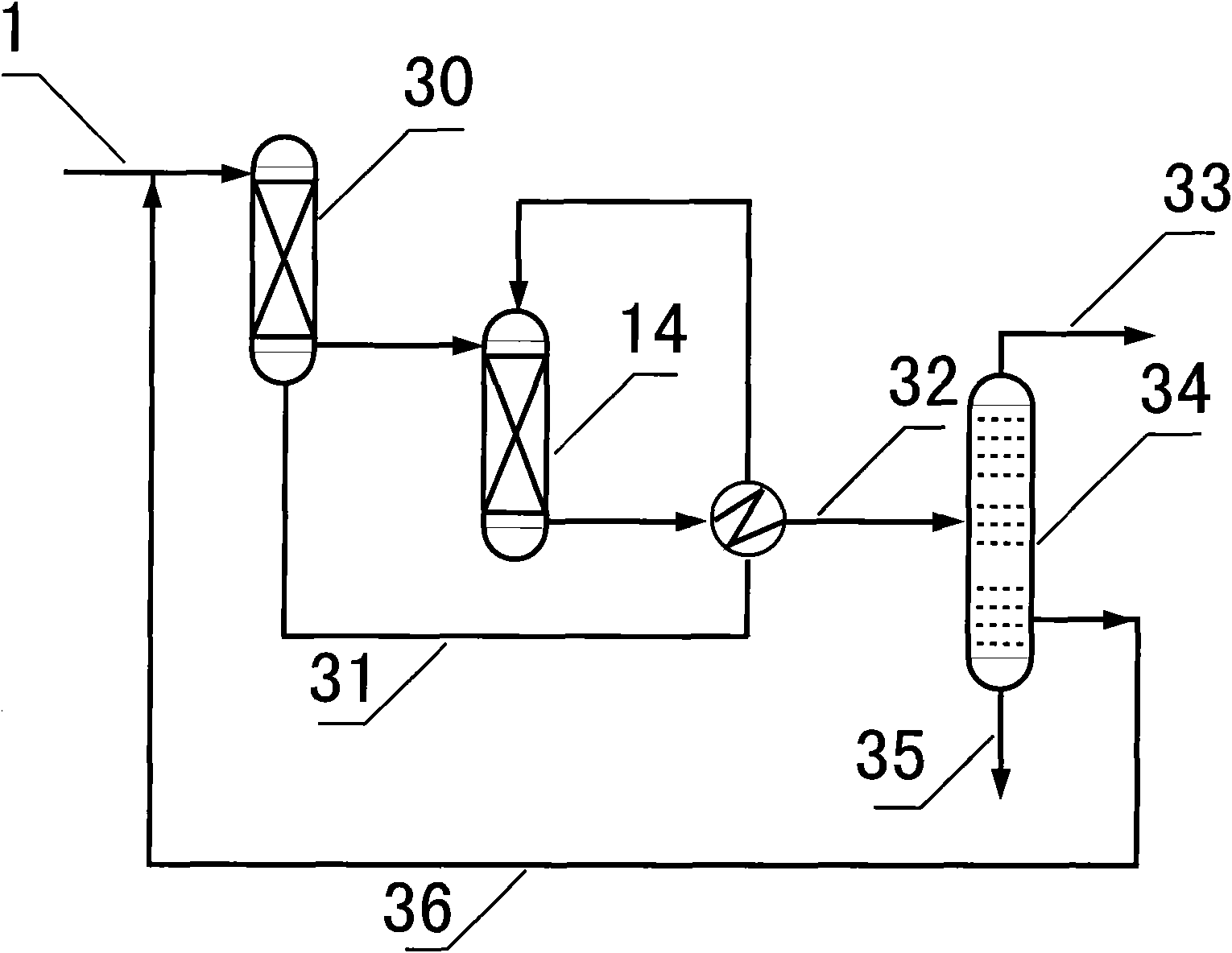

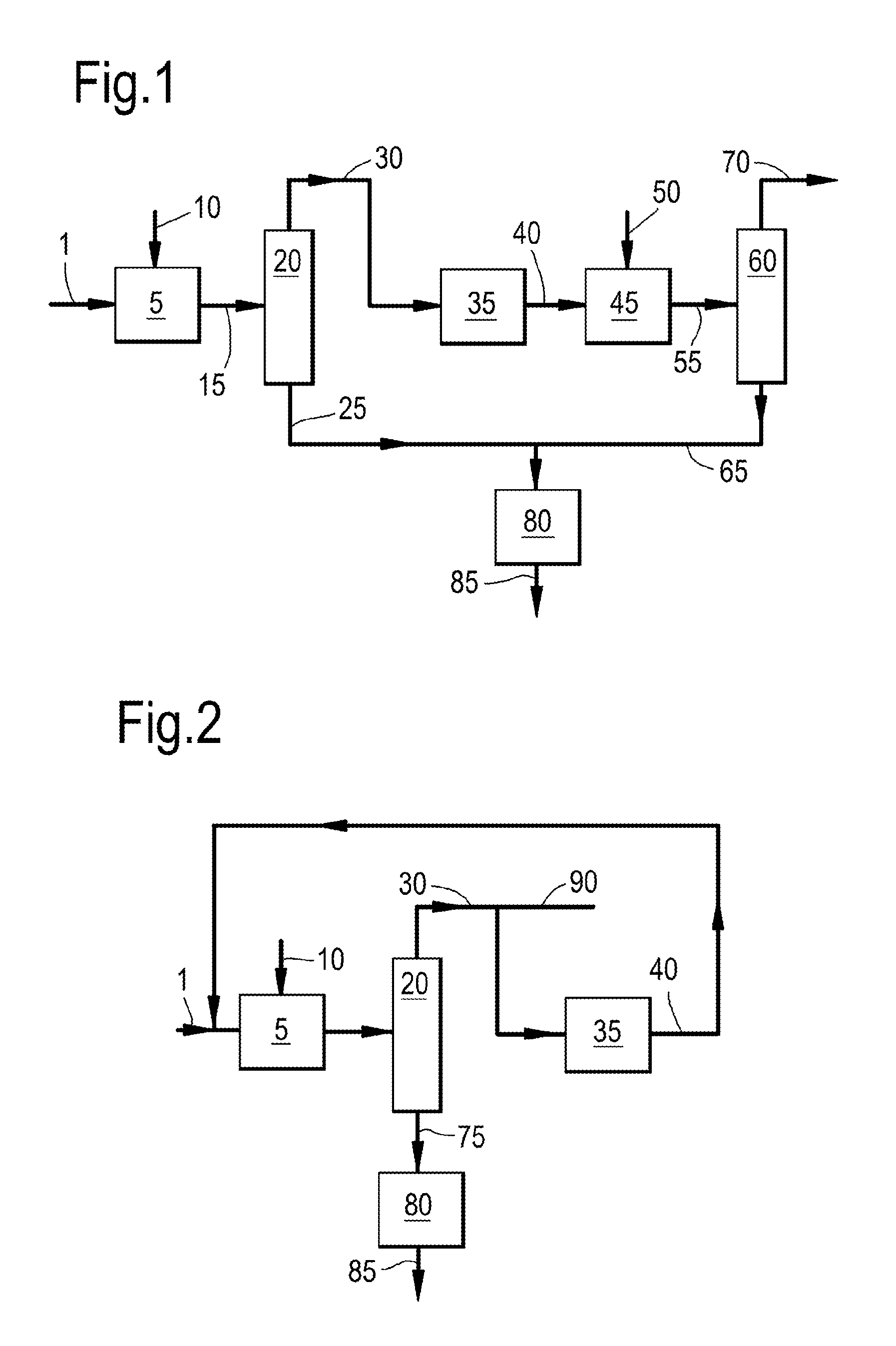

Method for preparing diol mono-tert-butyl ether

ActiveCN106397137APromote generationSuppress generationEther separation/purificationEther preparation by compound additionEtherDiol

The present invention relates to a method for preparing diol mono-tert-butyl ether. According to the method, isobutene gas and liquid-phase diol are introduced into the catalyst bed layer in the middle portion of a reactor, the generated diol mono-tert-butyl ether is instantly distilled from the bed layer under the gas stripping effect of the isobutene gas so as to avoid the generation of ethylene glycol di-tert-butyl ether due to the continuous reaction between the diol mono-tert-butyl ether and the isobutene, the diol mono-tert-butyl ether is separated on the upper portion of the reactor, the separated diol mono-tert-butyl ether is condensed on the tower top, the condensed diol mono-tert-butyl ether is extracted from the tower top or the side line, and the unreacted isobutylene and the unreacted diol are respectively extracted from the tower top and the tower bottom and then are recycled to the inlet. With the process of the present invention, the generation of the diol di-tert-butyl ether can be inhibited, such that the problems that the azeotropy of the diol di-tert-butyl ether and the diol mono-tert-butyl ether causes high separation energy consumption, high investment, and the like can be avoided.

Owner:WANHUA CHEM GRP CO LTD

Oligomerization of olefins

ActiveUS20050182284A1Improve linearityIncreased branchingHydrocarbon by dehydrogenationCarboxylic acid esters preparationMolecular sieveButene

A selectivated molecular sieve, e.g., ZSM-22 or ZSM-23, is used as olefin oligomerization catalyst to provide product, e.g., octenes and dodecenes from butene, having a low degree of branching and hindered double bonds.

Owner:EXXONMOBIL CHEM PAT INC

Process for dewatering ethanol

InactiveUS20070173670A1Avoid disadvantagesSemi-permeable membranesMembranesEthyl tert-butyl etherWater content

A process for preparing low-water ethanol from at least two streams of relatively water-rich ethanol that have a different water content by dewatering at membranes. The low-water ethanol can be used to prepare ethyl tert-butyl ether (ETBE).

Owner:EVONIK OXENO GMBH (DE)

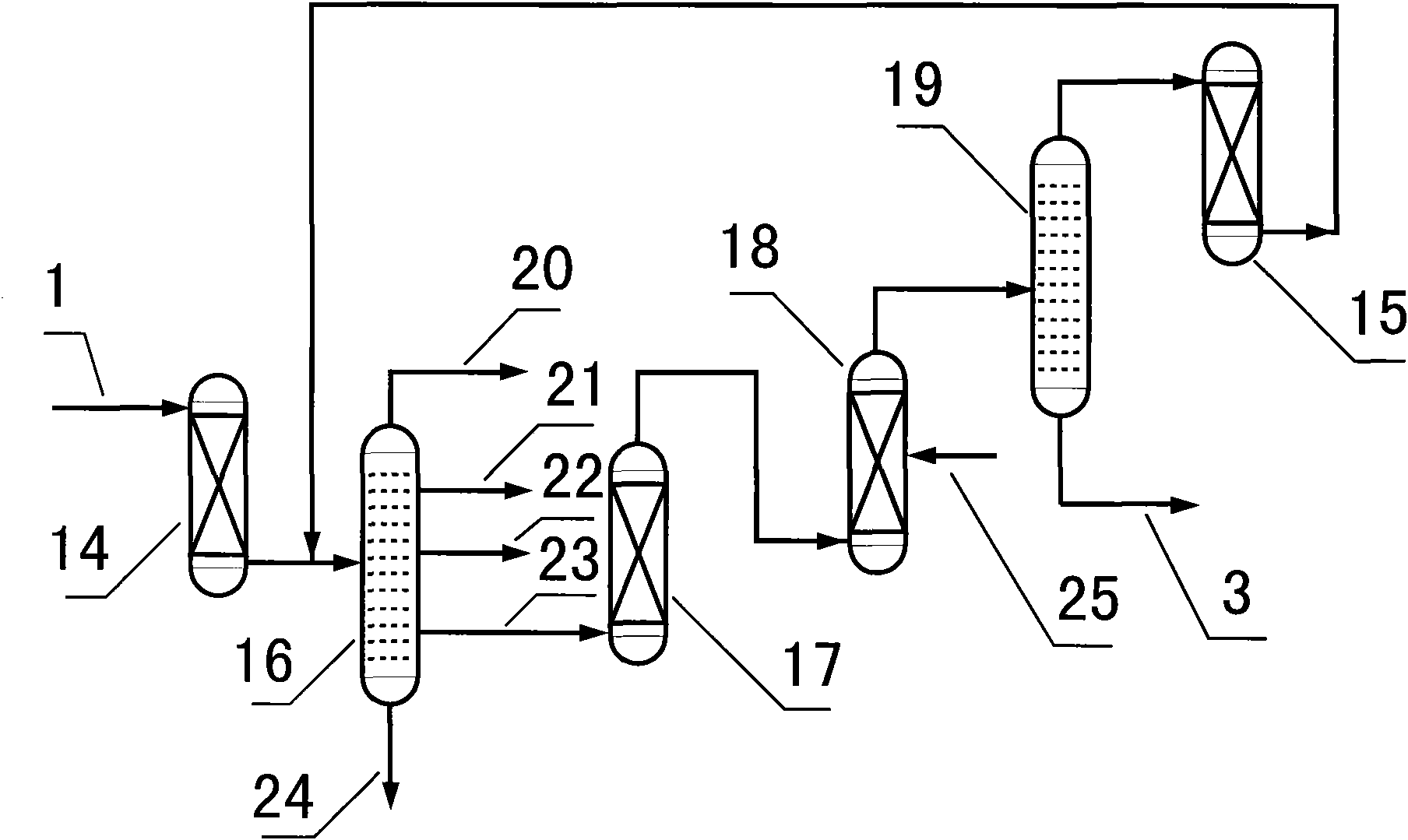

Mixed C4 utilization method

InactiveCN102372608AHigh yieldIncrease profitHydrocarbon by metathesis reactionEther preparation by compound additionAromatic hydrocarbonIon-exchange resin

The invention discloses a mixed C4 utilization method which comprises the following steps of: performing an etherification reaction between mixed C4 and methanol in the presence of cation exchange resin to generate MTBE and isobutene-free mixed C4, allowing the isobutene-free mixed C4 to enter into an extraction tower for extraction to obtain mixed butanes and mixed butylene, and allowing the mixed butane to perform a catalytic reaction in the presence of a modified shape-selective zeolite catalyst to generate propane and aromatic hydrocarbon. The mixed butylene is used as the raw material for the production of propylene. The mixed C4 is fully utilized, thus raising the yield of ethene and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

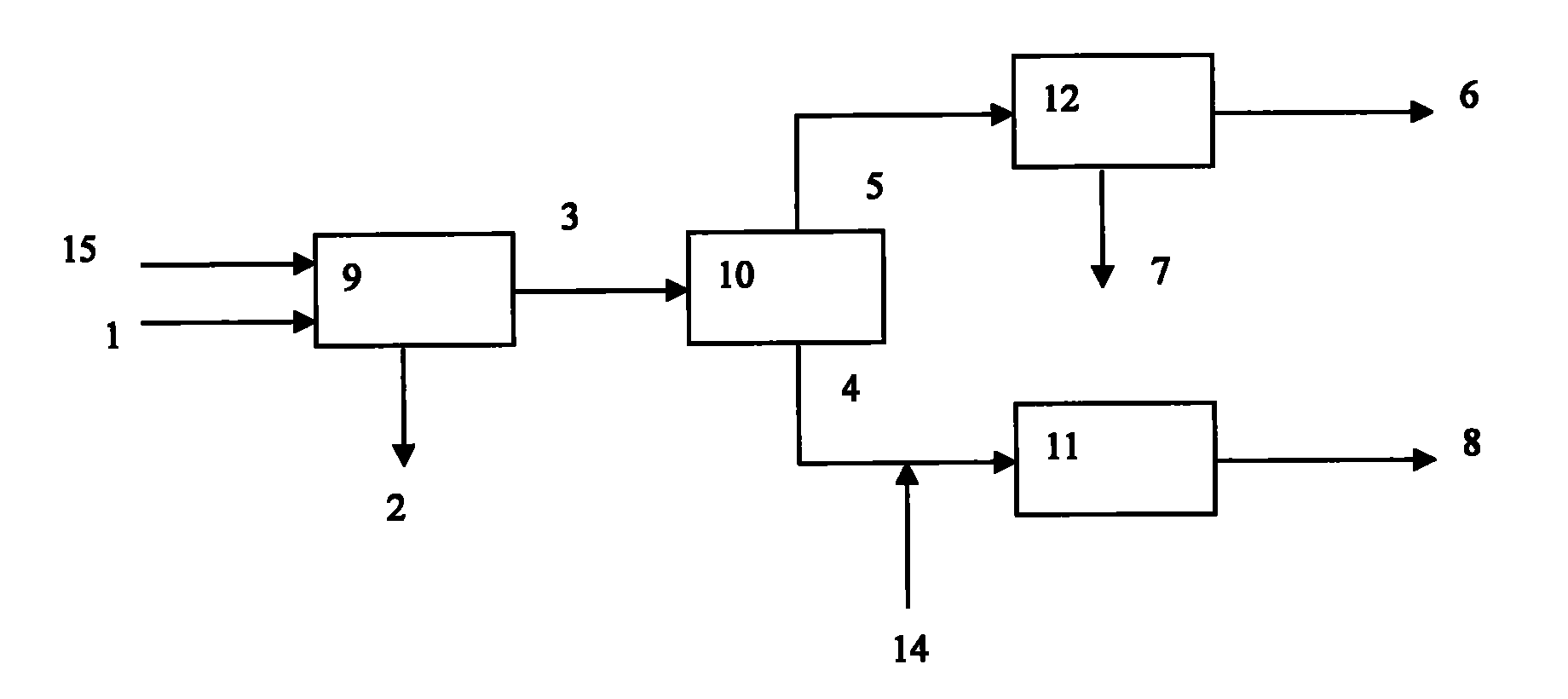

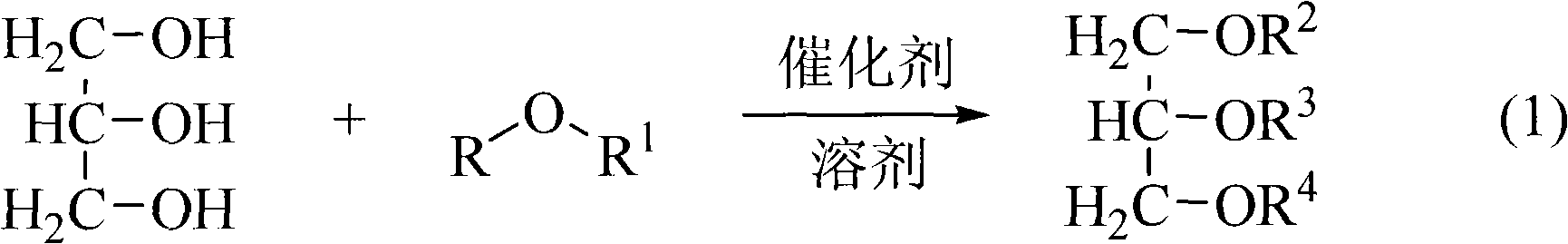

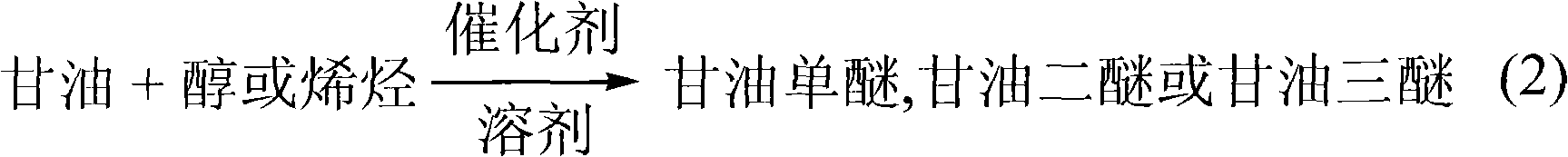

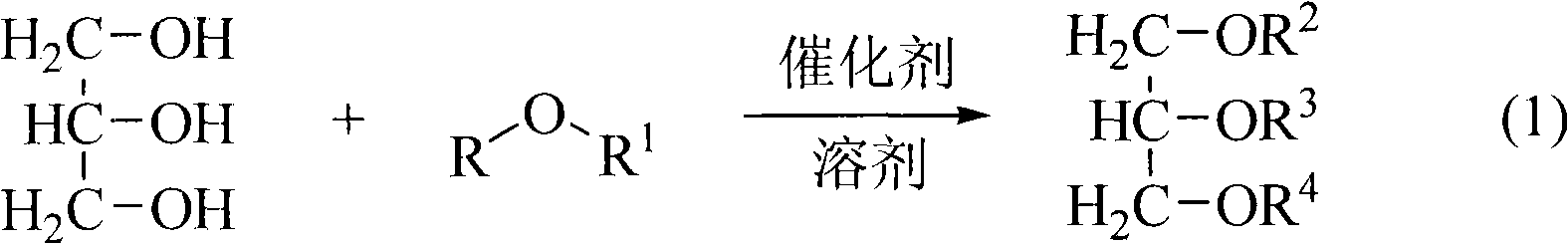

Method for preparing glycerin ether from glycerol

InactiveCN101624334AHigh yieldEther preparation by compound additionBulk chemical productionAlcoholTert butyl

The invention relates to a method for preparing glycerin ether from glycerol. The glycerol reacts with ether, alcohol or olefinic hydrocarbon in the existence of a catalyst to obtain di-tert-butyl glycerin ether, tri-tert-butyl glycerin ether and other glycerin ethers which can be used as diesel fuel additives, antibacterial agents, flavoring agents, humectants, emulsifying agents and surfactants at a high yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

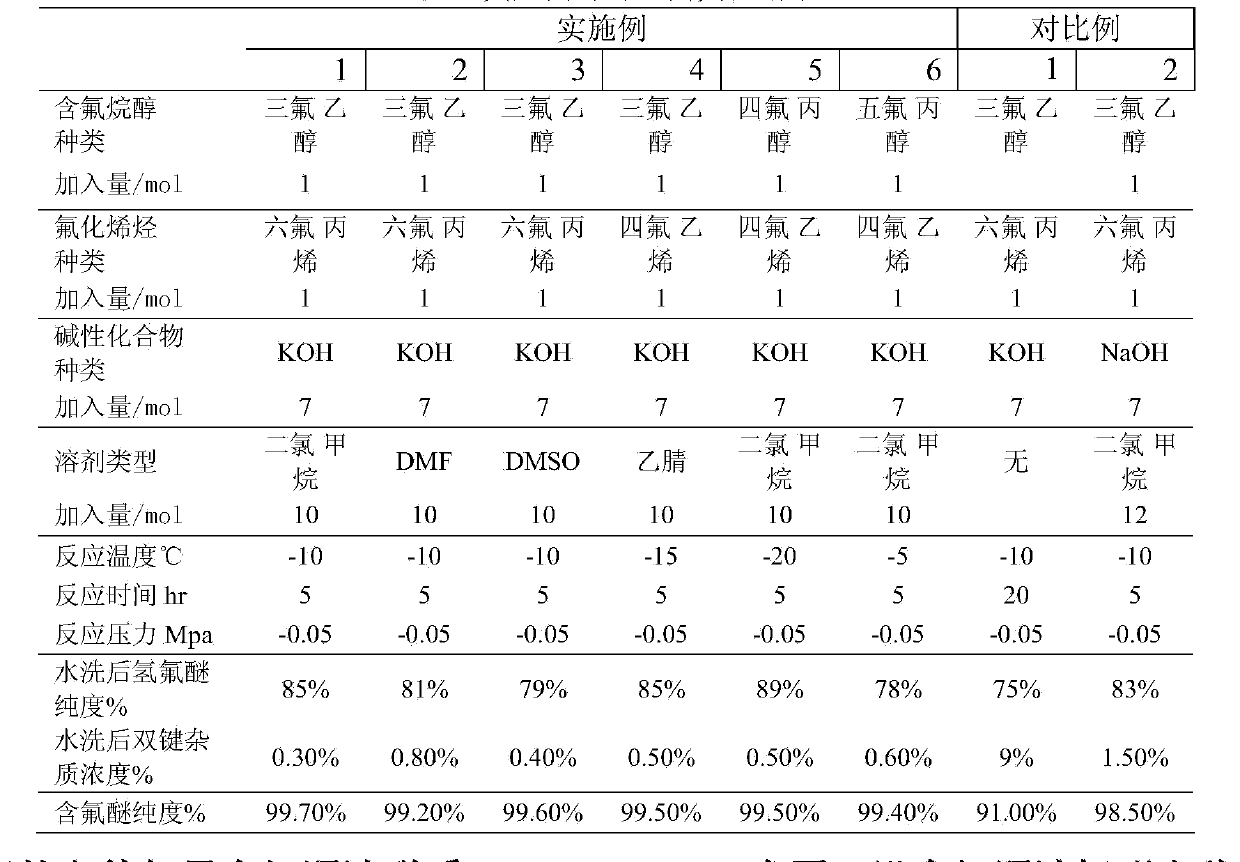

Preparation method of hydrofluoroether

InactiveCN103739450AInhibitionEasy to purifyEther preparation by compound additionReaction temperatureDouble bond

The invention relates to a preparation method of hydrofluoroether. The preparation method comprises the following steps: (1), dissolving an alkali compound in fluorine-containing alkanol, adding a solvent, adding fluorinated olefin, and heating and stirring for reaction to obtain a mixed solution; (2), washing the mixed solution obtained in the step (1) by using water, standing for demixing, collecting an organic phase solution of a lower layer, and rectifying to obtain a hydrofluoroether product. According to the preparation method, the generation of double-bond impurities can be inhibited, and a reaction product from which a target product is easily purified can be obtained; the reaction temperature and the reaction pressure are relatively mild, the safety coefficient is high, and more satisfactory reaction speed can be obtained; the solvent is easily recycled, the cost is lowered, and a plurality of wastes are prevented from polluting the environment.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com