Mixed C4 utilization method

A technology of mixing carbon four and mixing butene, which is applied in the direction of preparation of ether by addition of unsaturated compounds, organic chemistry, double decomposition reaction to hydrocarbon production, etc., can solve the problem of not being able to use effective raw materials such as ethylene and propylene, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

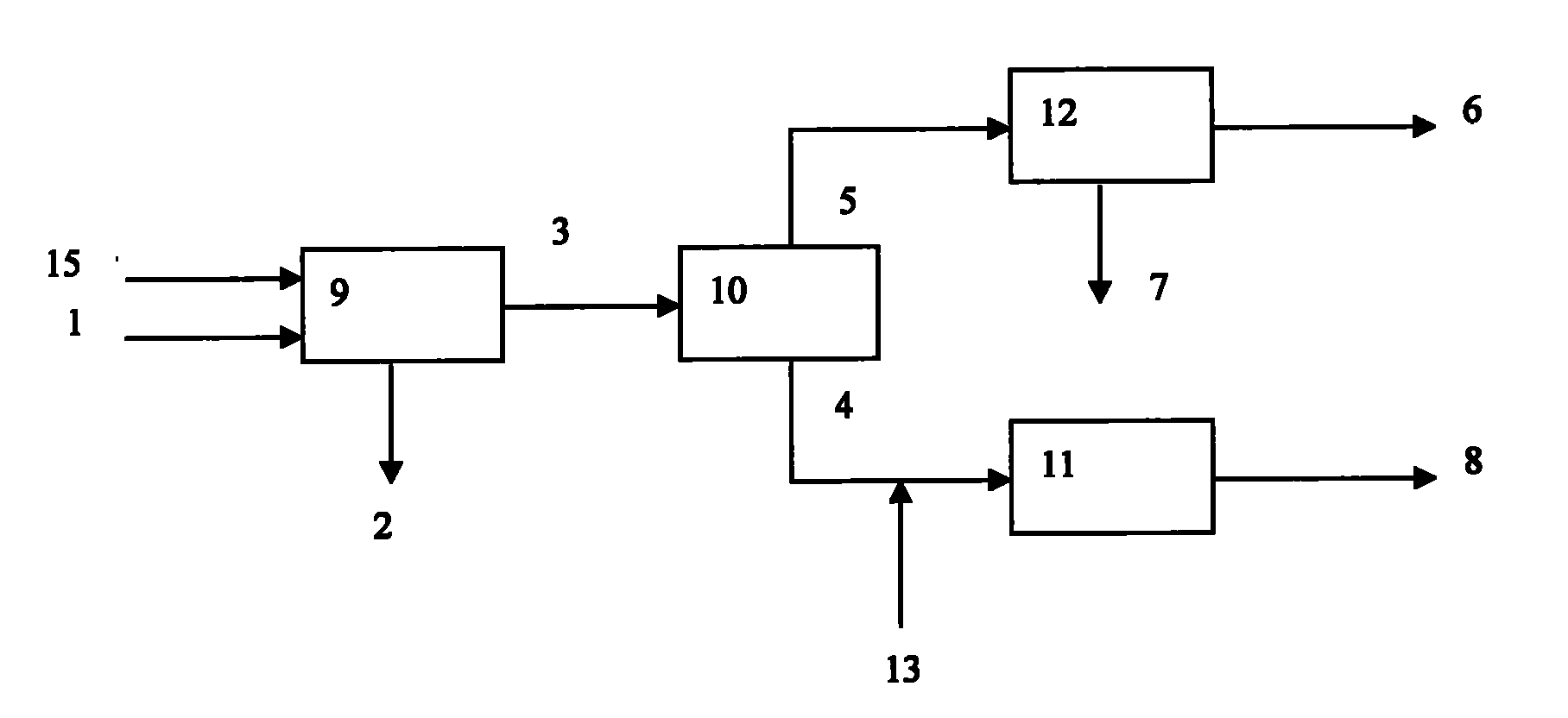

Embodiment 1

[0030] Composition (% by weight) is: butane 50%, isobutene 20%, n-butene 30% mixed carbon four 1 is introduced etherification unit, in cation exchange resin catalyst, cation exchange resin pore volume is 0.40ml / g, reaction temperature 58°C, reaction pressure 1.2MPa, reaction space velocity 7 hours -1 Catalyzed reaction with methanol to obtain MTBE product 2 and mixed carbon four 3 without isobutene under the condition of . The mixed carbon four 3 obtained in the etherification unit is introduced into the extraction unit 10, the solvent is acetonitrile, and the butane and butene are separated under the conditions of 45° C. at the top of the extraction column and 170° C. at the bottom of the extraction tower to obtain the mixed butane 5 and Mixed butene 4. Introduce the mixed butene 4 into the disproportionation propylene unit 11, using tungsten oxide as the catalyst, at 280-380°C, the reaction pressure is 1.0MPa, and the reaction space velocity is 0.5 hours -1 Under certain c...

Embodiment 2

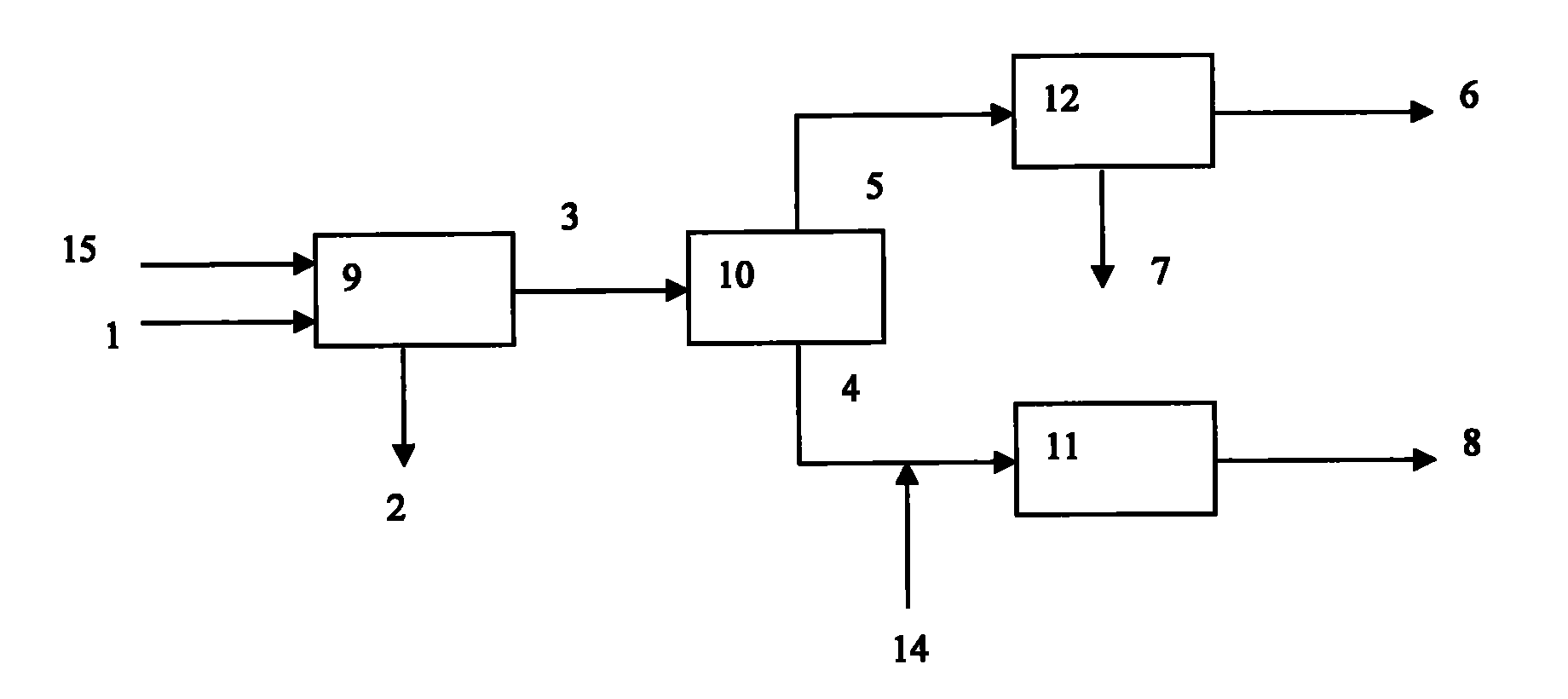

[0034] according to figure 2 As shown, the composition (weight %) is: butane 55%, isobutene 20%, n-butene 25% mixed carbon four 1 is introduced into the etherification unit 9, in the macroporous cation exchange resin catalyst, the cation exchange resin pore volume is 0.42 ml / g, reaction temperature 62°C, reaction pressure 1.1MPa, reaction space velocity 9 hours -1Catalyzed reaction with methanol to obtain MTBE product 2 and mixed carbon four 3 without isobutene under the condition of . The mixed carbon four 3 obtained by the etherification unit is introduced into the extraction unit 10, the solvent is acetonitrile, and the butane and butene are separated under the condition of 45°C at the top of the extraction tower and 170°C at the bottom of the extraction tower to obtain mixed butane 5 and mixed Butene 4. Introduce the mixed butene 4 into the disproportionation propylene unit 11, using tungsten oxide as the catalyst, at 280-380°C, the reaction pressure is 1.5MPa, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com