Patents

Literature

816results about "Hydrocarbon by metathesis reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

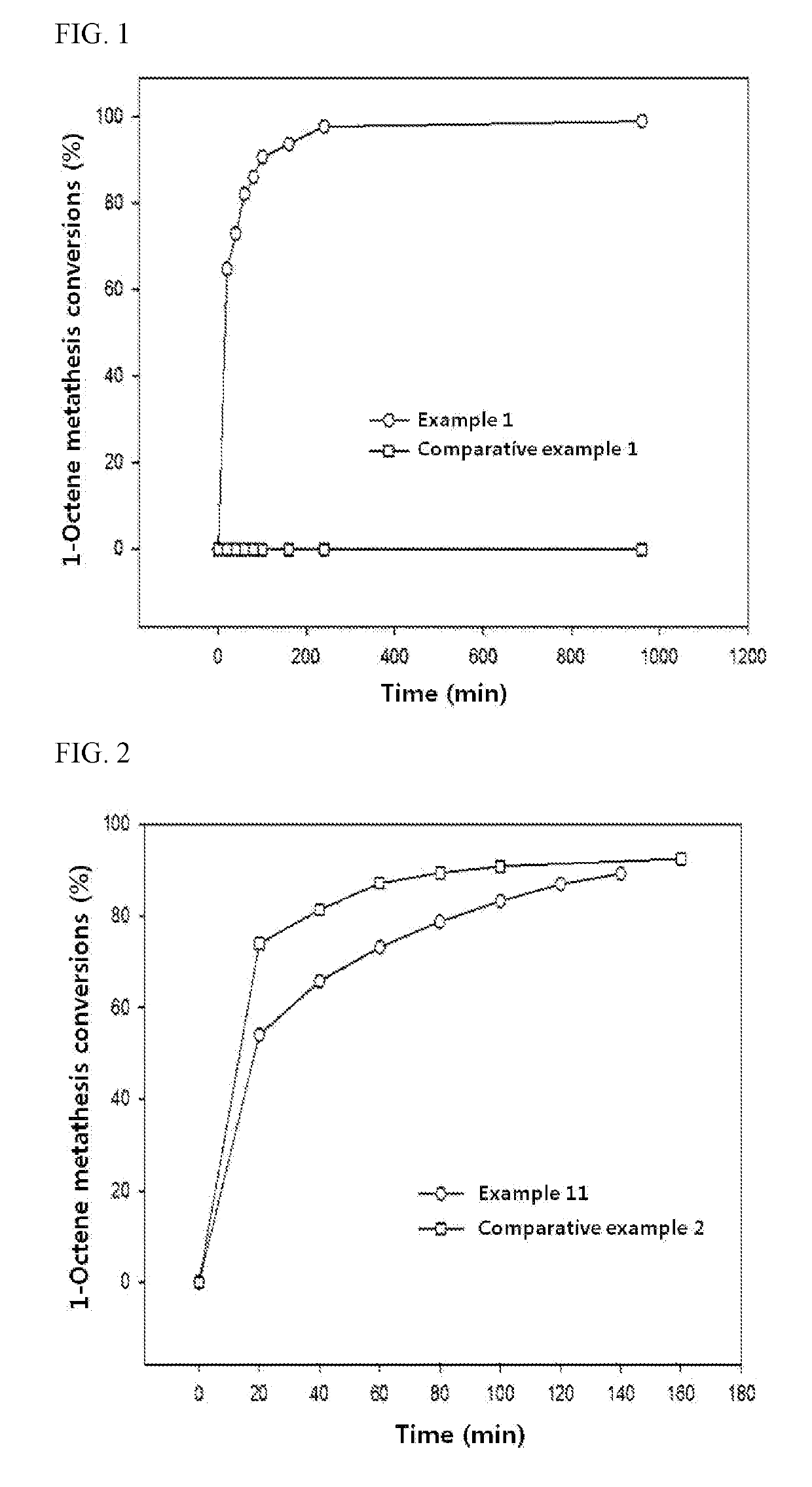

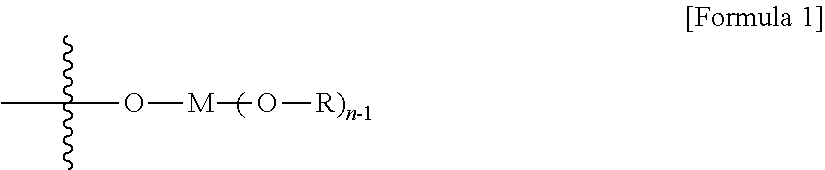

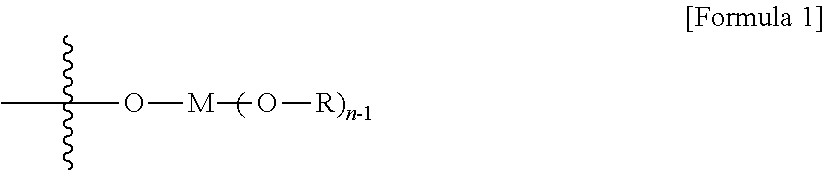

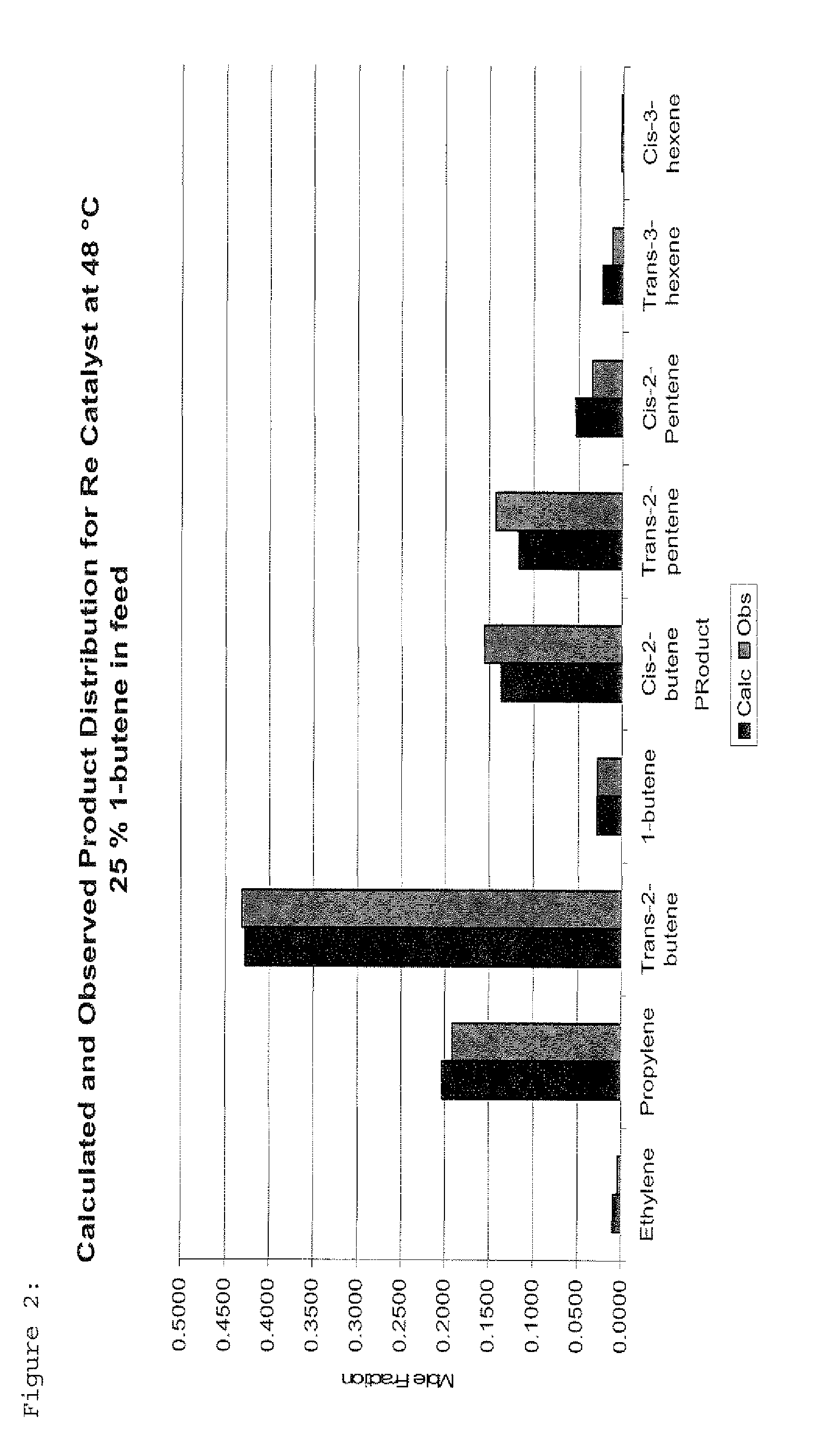

Olefin metathesis reaction catalyst and preparation method therefor

ActiveUS20190217277A1Separated/recovered readilyEasy to useMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumUnsaturated hydrocarbon

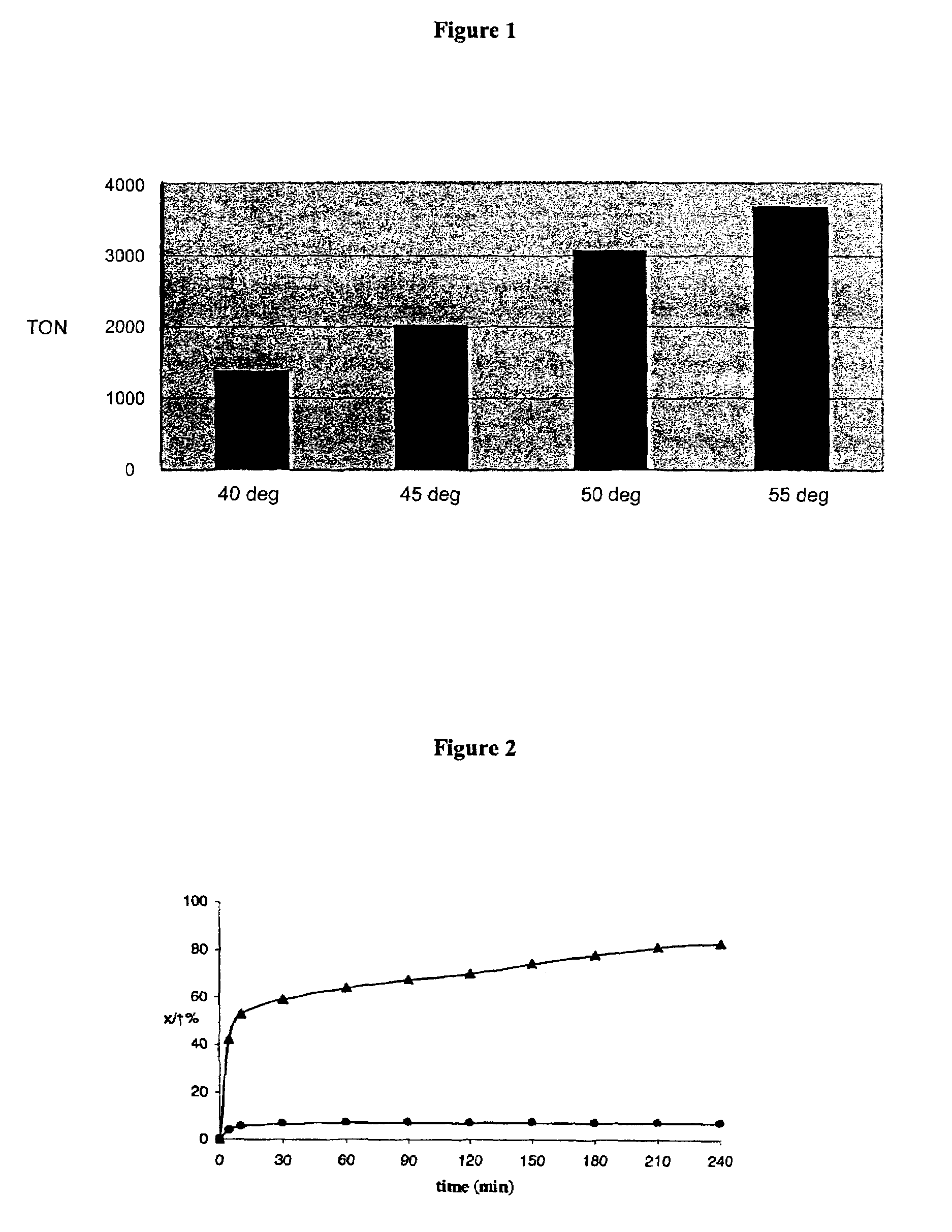

The present invention relates to an olefin metathesis reaction catalyst where rhenium (Re) oxide or molybdenum (Mo) oxide is supported, as a catalyst main component, on a surface-modified mesoporous silica or mesoporous alumina support, and a preparation method therefor. The olefin metathesis reaction catalyst of the present invention allows highly efficient metathesis of long-chain unsaturated hydrocarbons having at least eight carbons at a low temperature of 150° C. or lower. The catalyst can be separated readily from reaction solution, regenerated at a low temperature of 400° C. or lower by removing toxins accumulated on it during the metathesis reaction, and used repeatedly in metathesis reaction many times, thereby being made good use in commercial olefin metathesis processes.

Owner:KOREA RES INST OF CHEM TECH

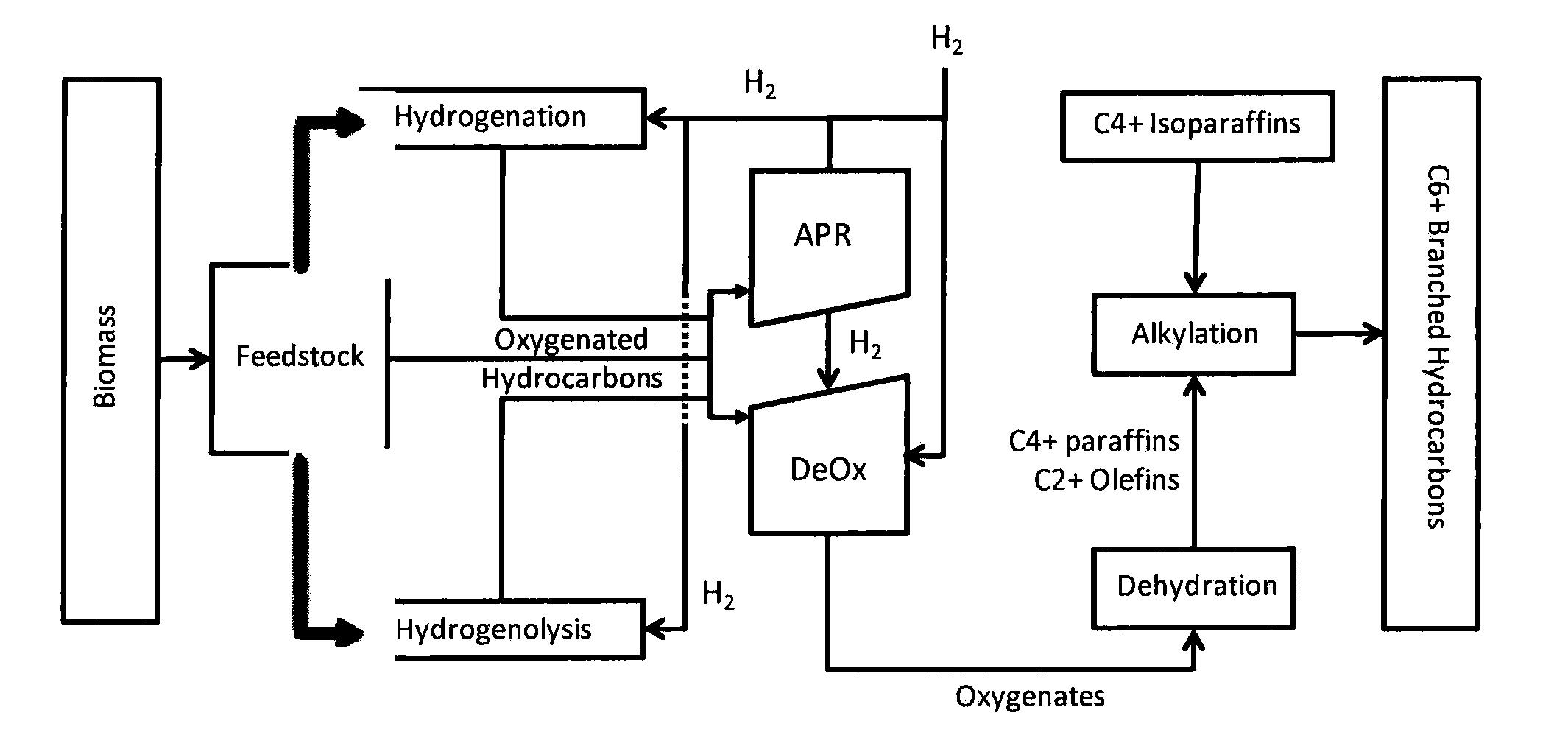

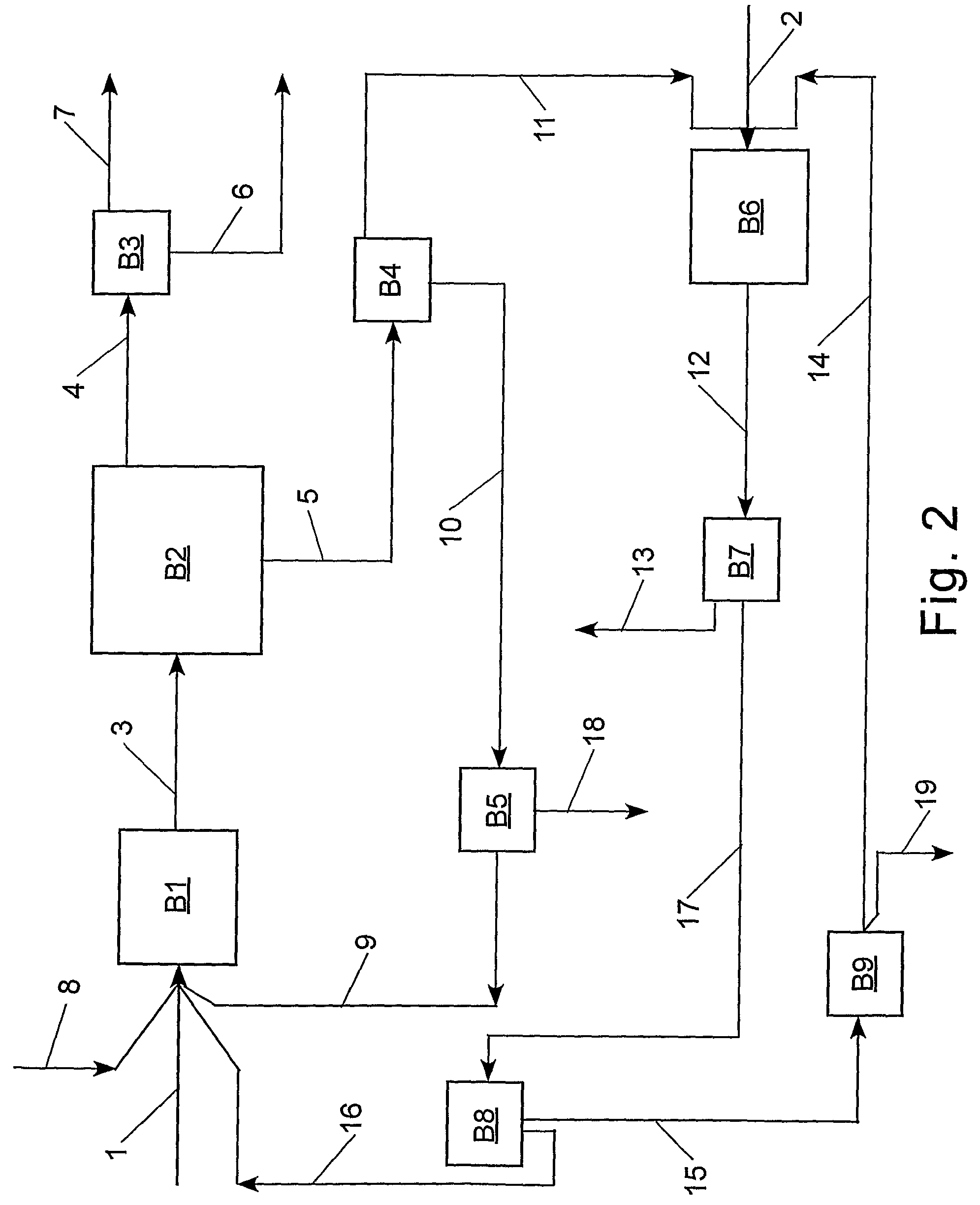

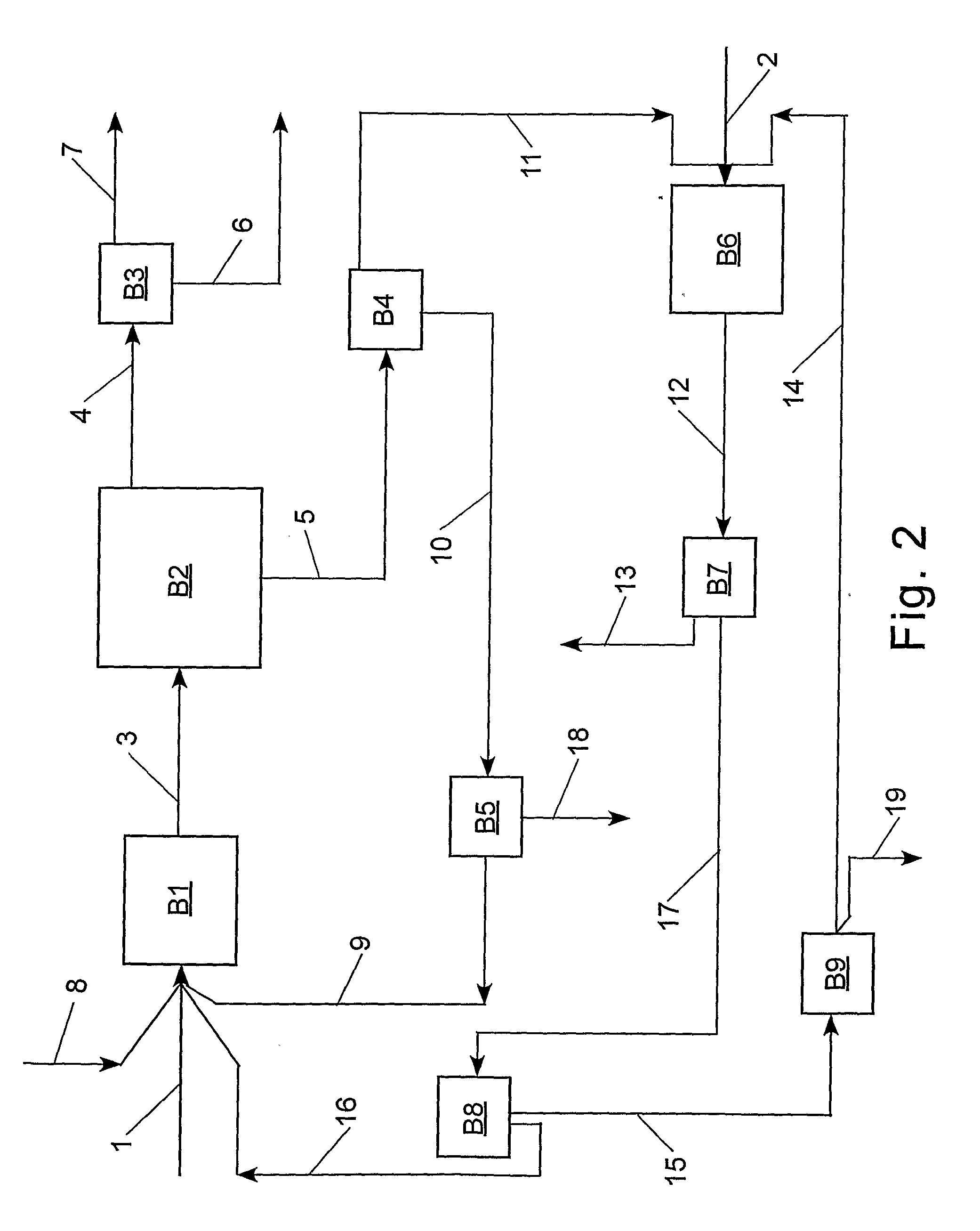

Synthesis of liquid fuels from biomass

ActiveUS20100076233A1Hydrocarbon by metathesis reactionLiquid hydrocarbon mixture productionFuranAlkane

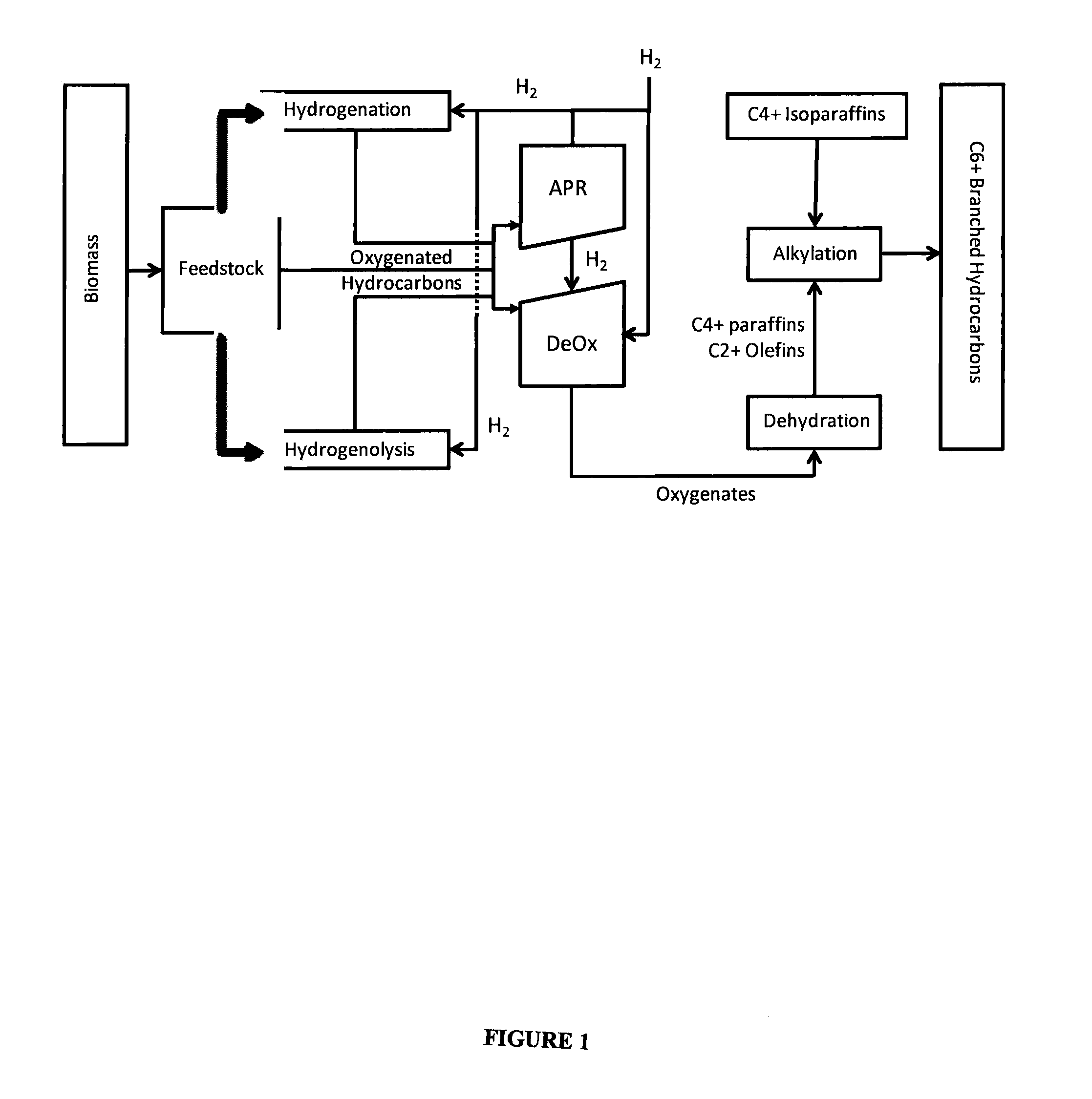

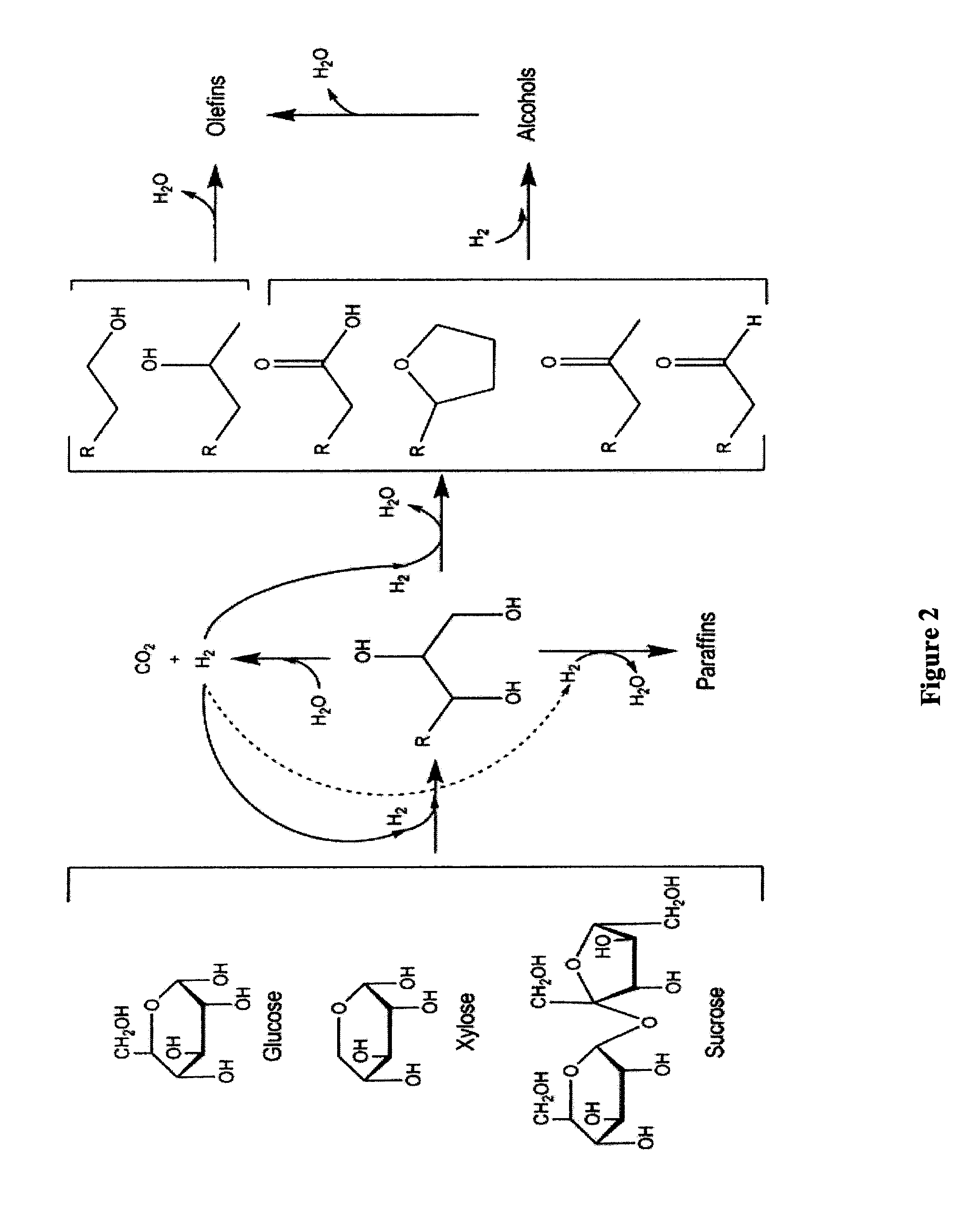

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to paraffins useful as liquid fuels. The process involves the conversion of water soluble oxygenated hydrocarbons to oxygenates, such as alcohols, furans, ketones, aldehydes, carboxylic acids, diols, triols, and / or other polyols, followed by the subsequent conversion of the oxygenates to paraffins by dehydration and alkylation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Chemical methods for treating a metathesis feedstock

ActiveUS20110160472A1Reduce starting peroxide valueFatty acid chemical modificationOrganic compound preparationChemical treatmentNatural oils

Owner:WILMAR TRADING PTE LTD

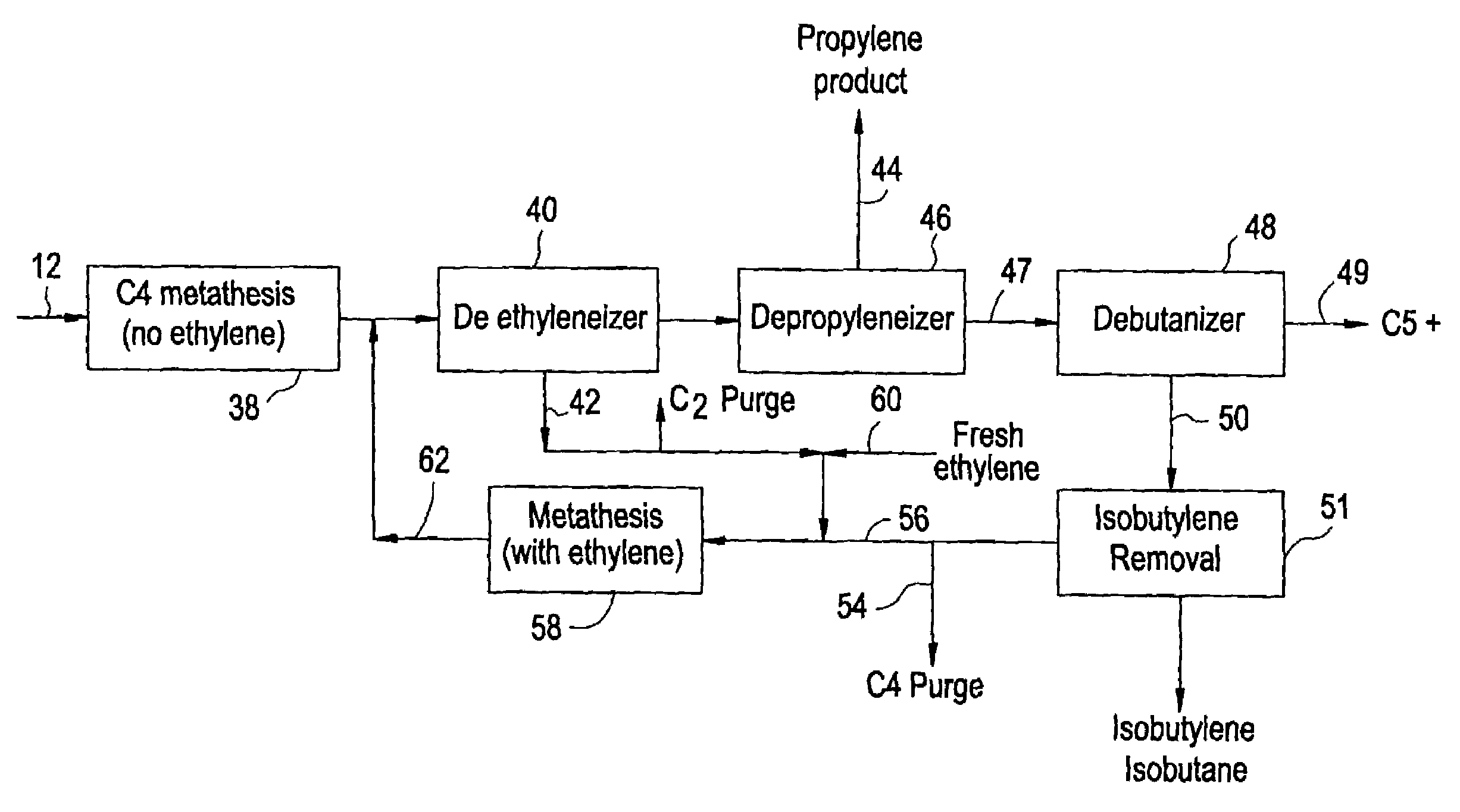

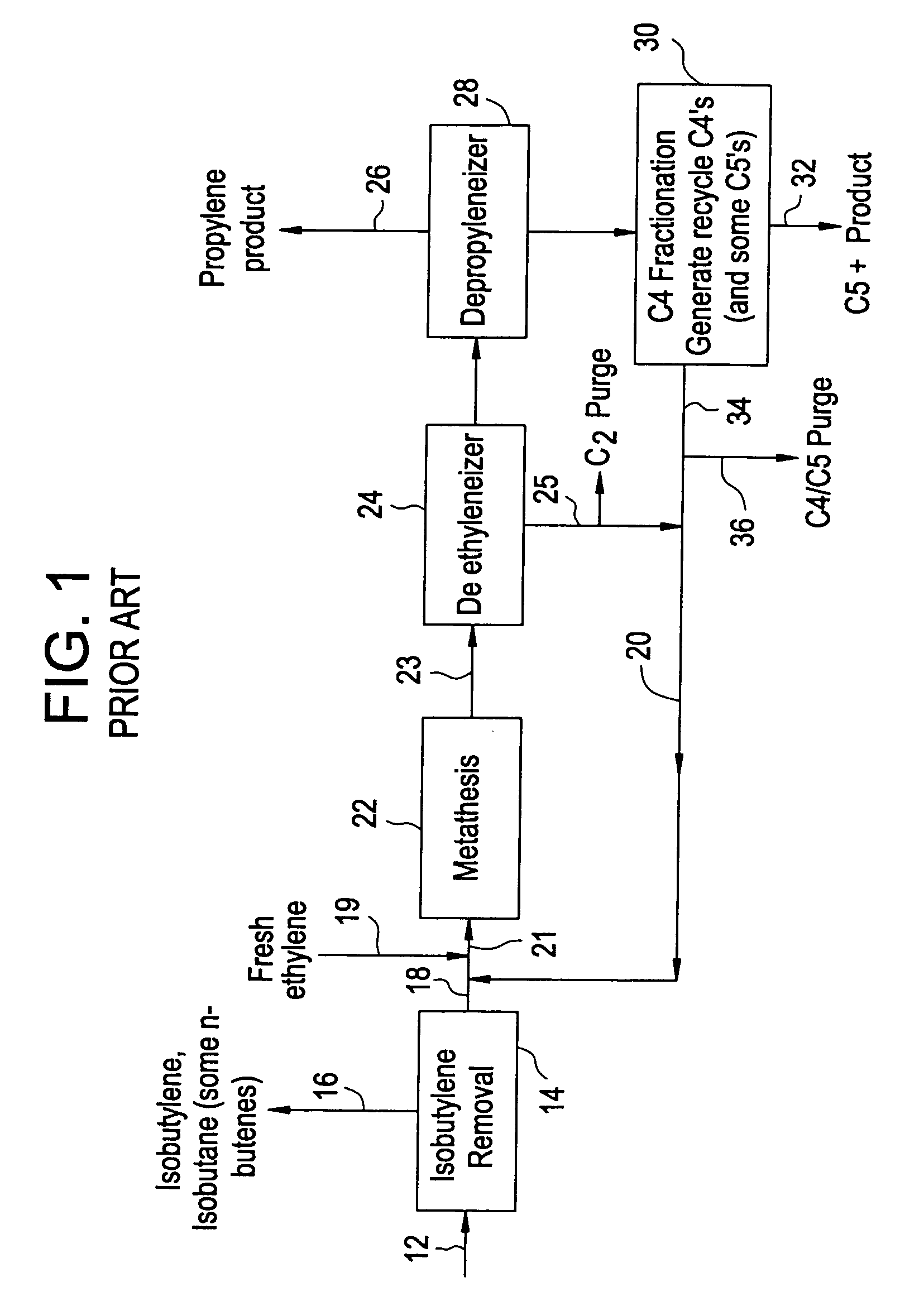

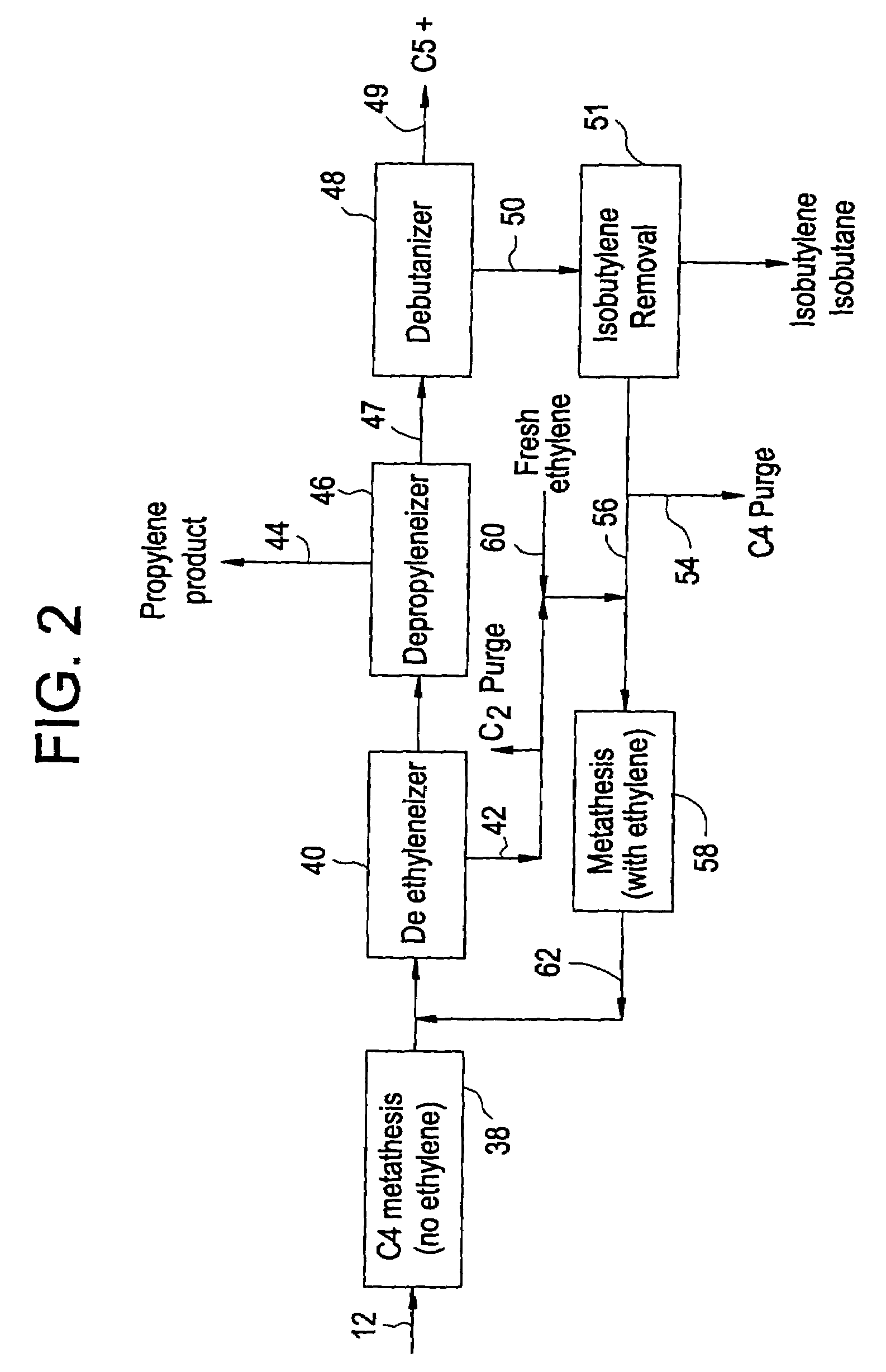

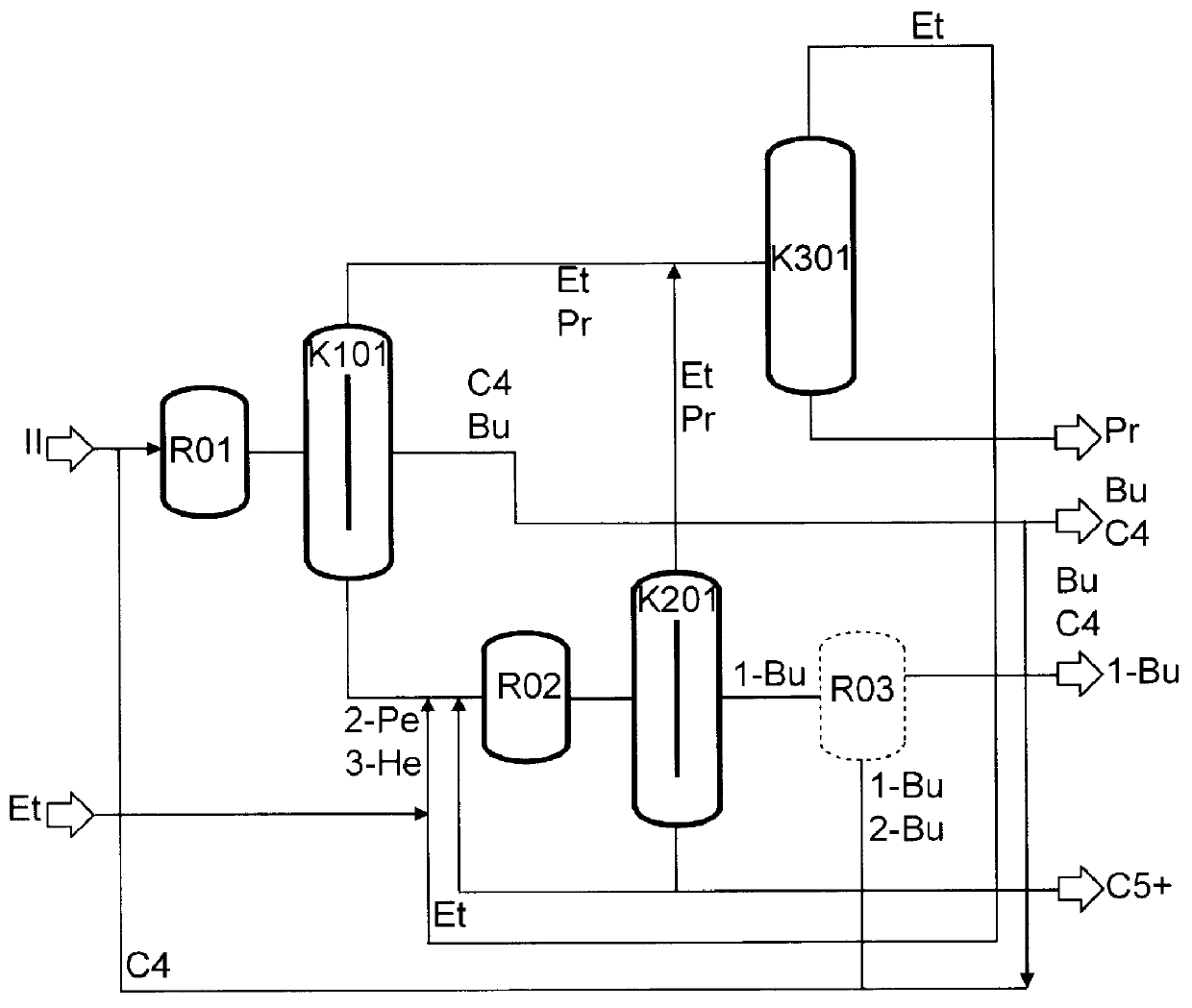

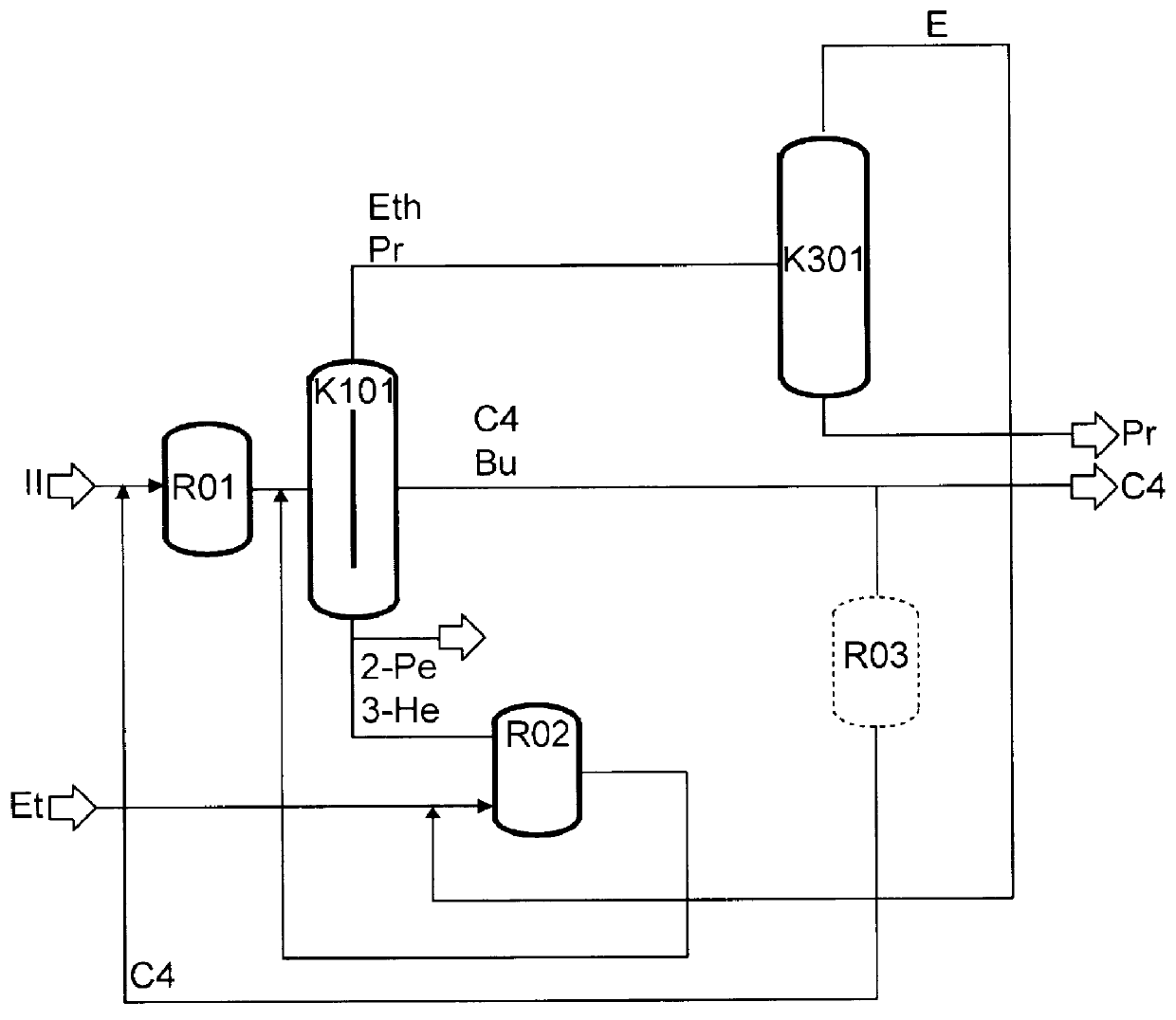

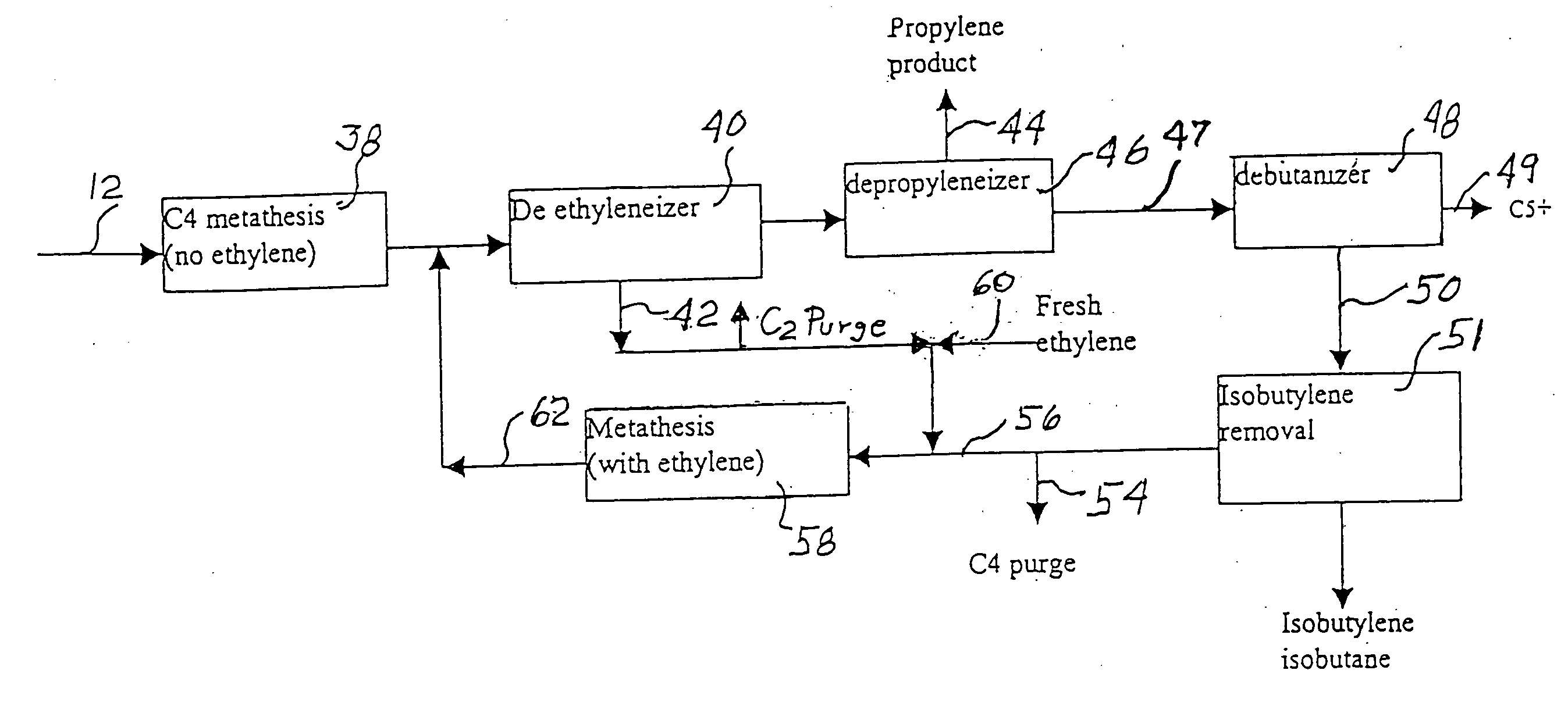

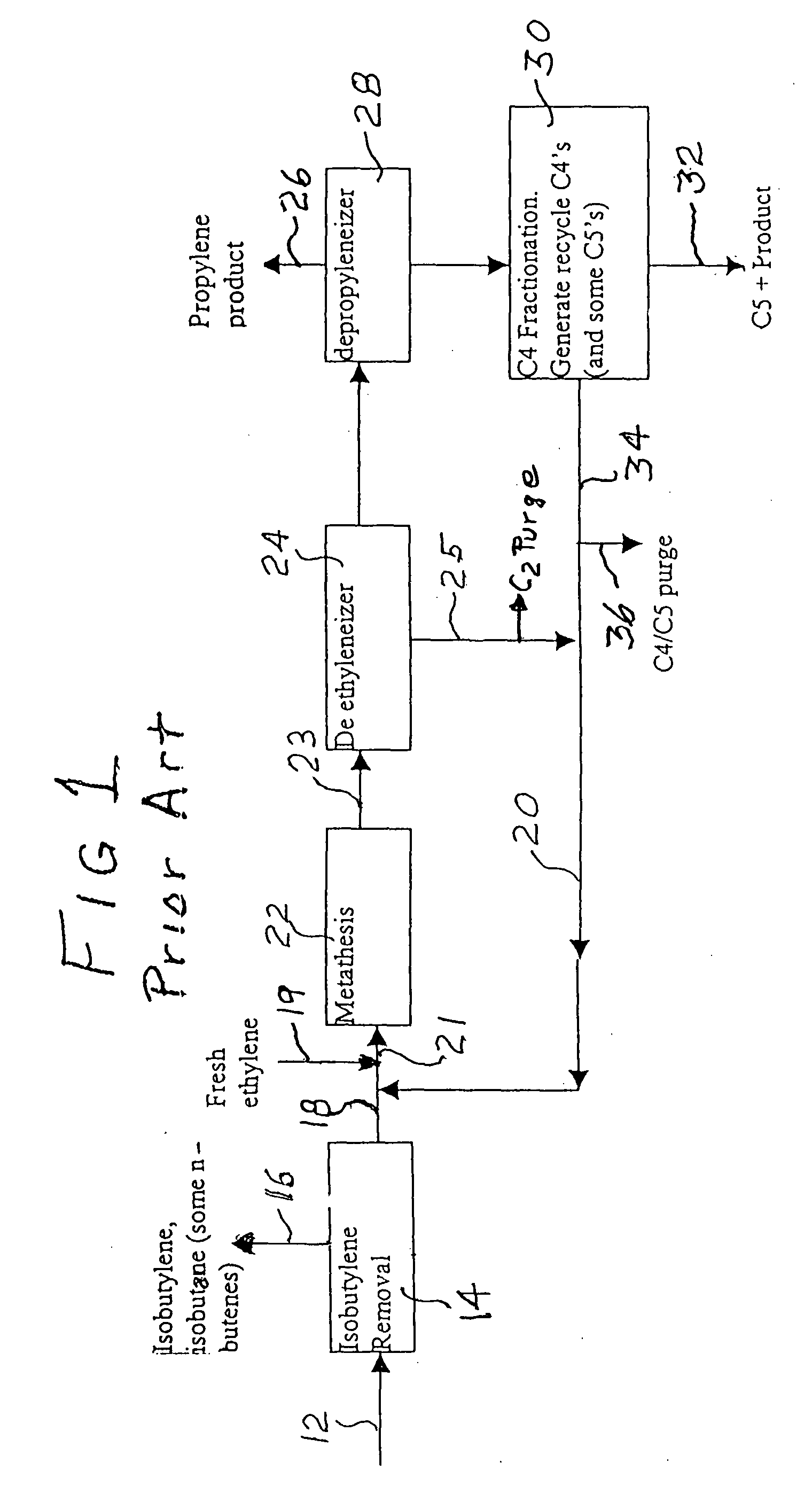

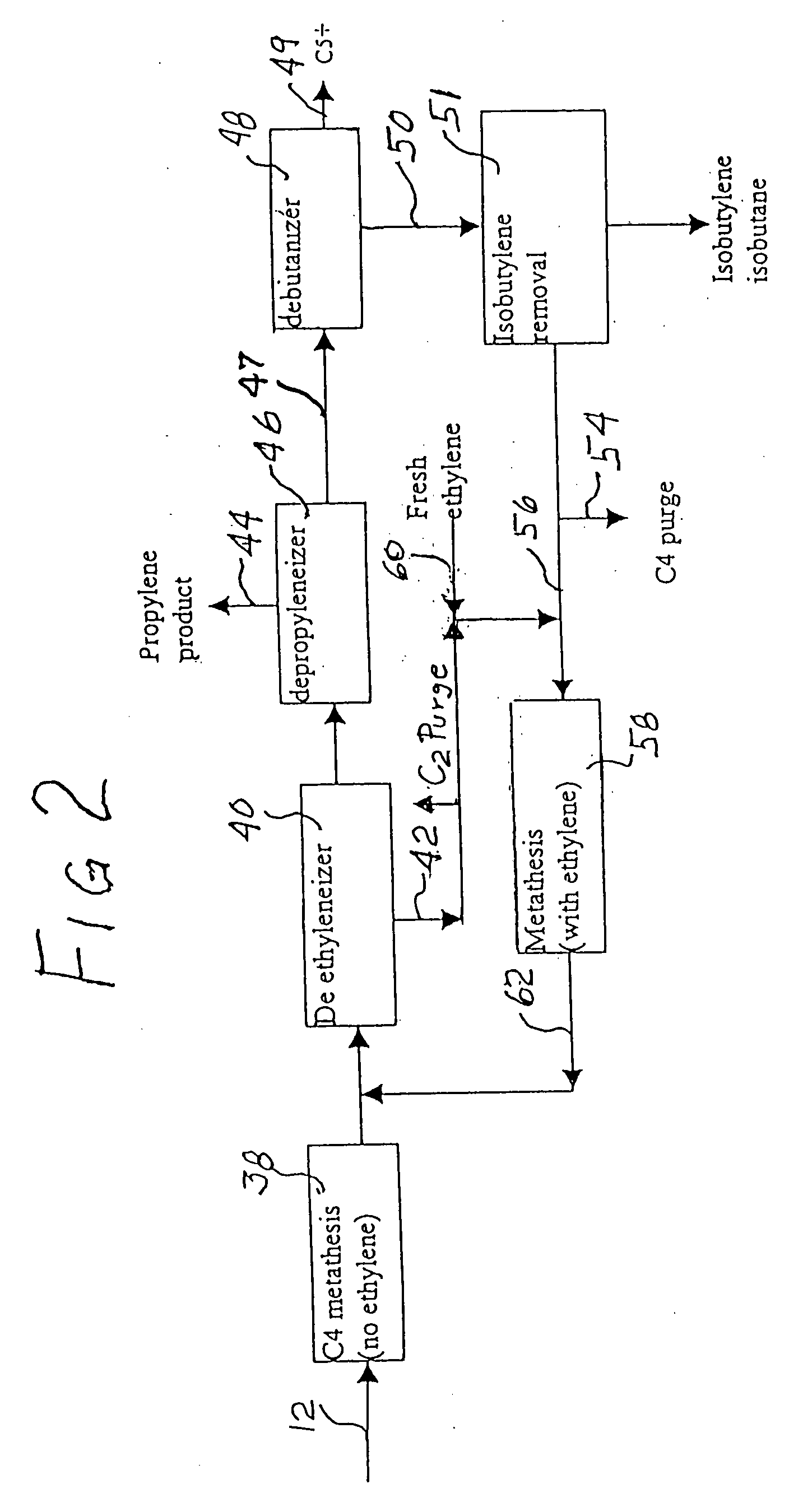

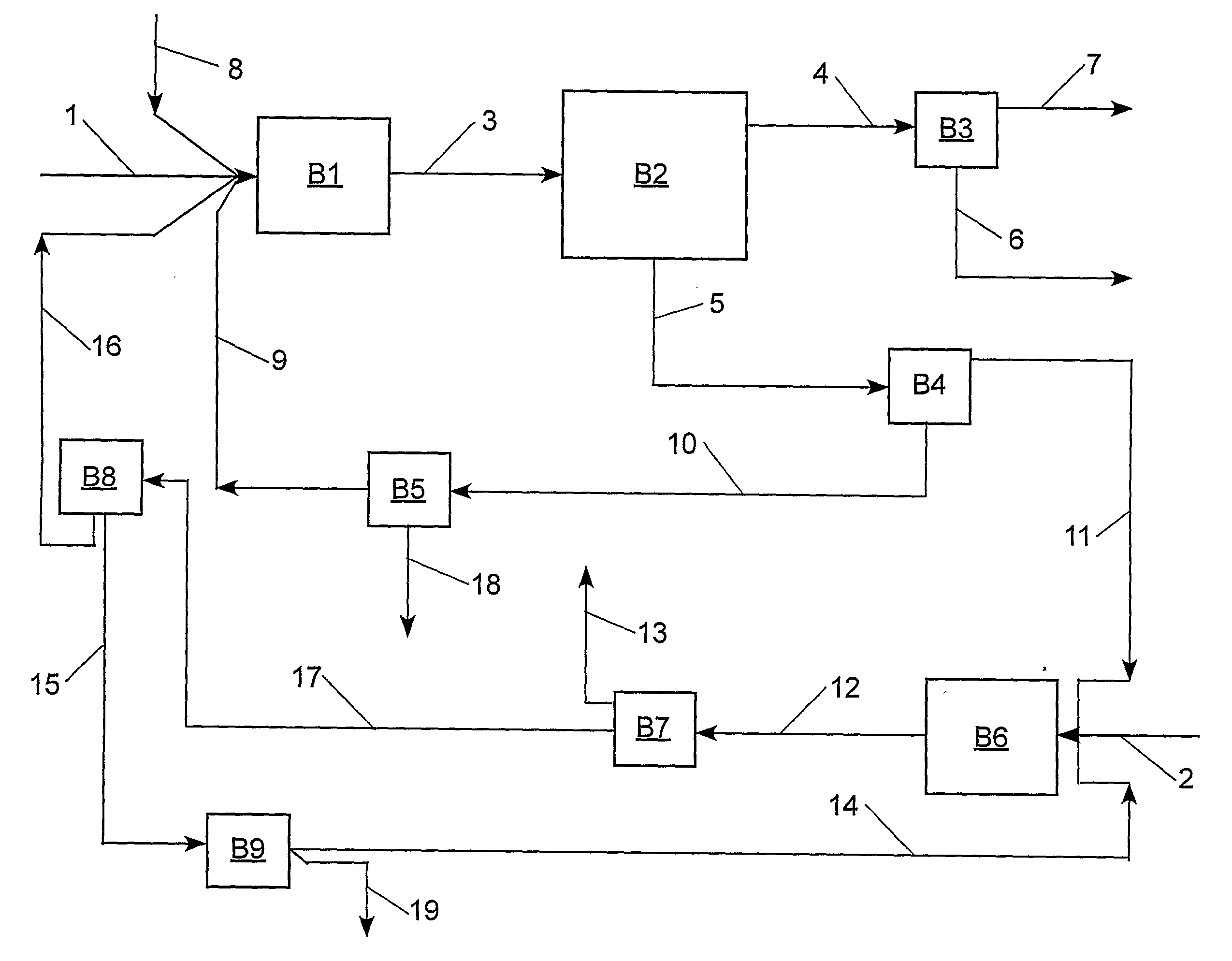

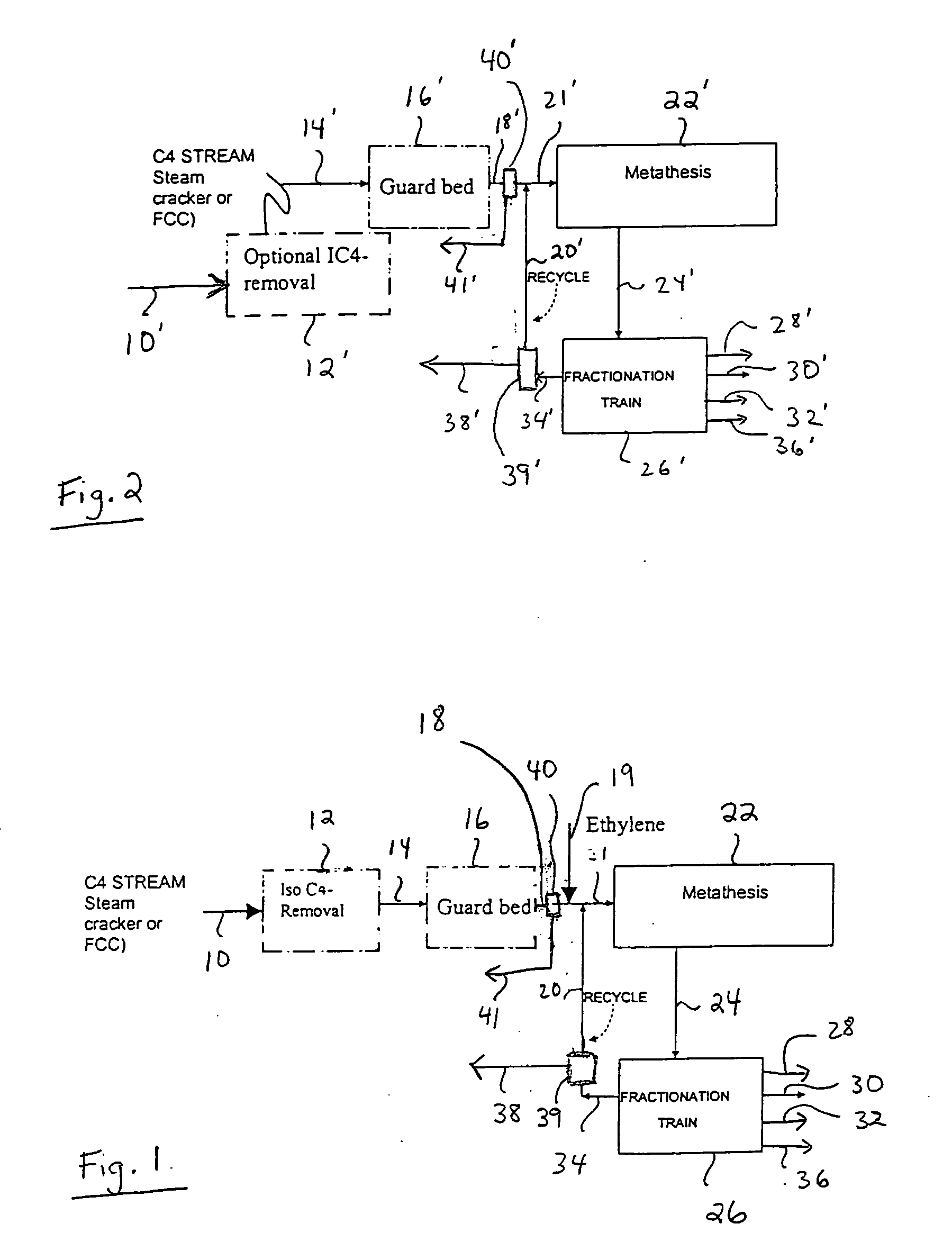

Processing C4 olefin streams for the maximum production of propylene

ActiveUS7214841B2Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

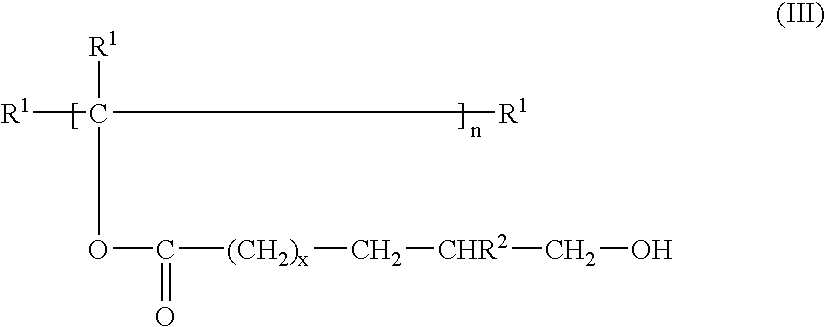

Integrate chemical processes for industrial utilization of seed oils

ActiveUS20050154221A1Easy to operateHigh olefin conversionFatty oils/acids recovery from wasteOxygen-containing compound preparationPolyesterAmino esters

Integrated processes of preparing industrial chemicals starting from seed oil feedstock compositions containing one or more unsaturated fatty acids or unsaturated fatty acid esters, which are essentially free of metathesis catalyst poisons, particularly hydroperoxides; metathesis of the feedstock composition with a lower olefin, such as ethylene, to form a reduced chain olefin, preferably, a reduced chain α-olefin, and a reduced chain unsaturated acid or ester, preferably, a reduced chain α,Ω-unsaturated acid or ester. The reduced chain unsaturated acid or ester may be (trans)esterified to form a polyester polyolefin, which may be epoxidized to form a polyester polyepoxide. The reduced chain unsaturated acid or ester may be hydroformylated with reduction to produce an α,Ω-hydroxy acid or α,Ω-hydroxy ester, which may be (trans)esterified with a polyol to form an α,Ωpolyester polyol. Alternatively, the reduced chain unsaturated acid or ester may be hydroformylated with reductive amination to produce an α,Ω-amino acid or α,Ω-amino ester, which may be (trans)esterified to form an α,Ωpolyester polyamine.

Owner:DOW GLOBAL TECH LLC

Preparation of olefins

The preparation of olefins from steam cracker or refinery C4 streams is carried out by selective hydrogenation of butadienes and acetylenic impurities in the steam cracker or refinery C4 stream, with simultaneous or subsequent, at least partial isomerization of 1-butene to 2-butene, followed by removal of i-butene from the C4 stream by reaction with an alcohol to form an ether, followed by removal of oxygen-containing impurities from the C4 stream using adsorber materials, followed by two-stage metathesis of the butenes in the C4 stream by conversion of 1-butene and 2-butene present in the C4 stream into propene and 2-pentene and subsequent reaction of the 2-pentene with ethene in the presence of a metathesis catalyst to form propene and 1-butene. Optionally, butadiene may be removed from the C4 stream by extractive distillation in a preliminary step.

Owner:BASF AG

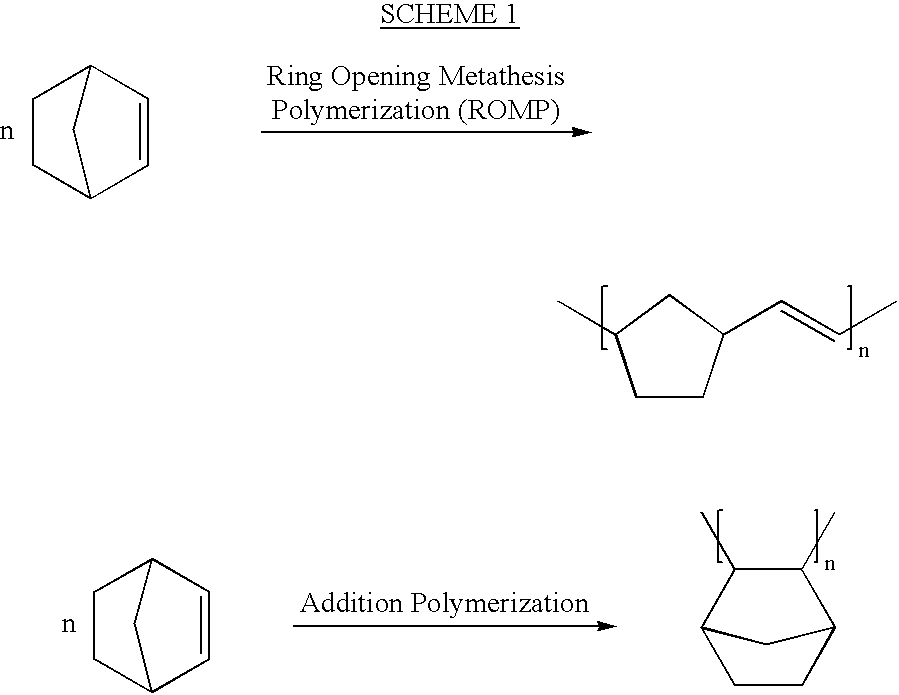

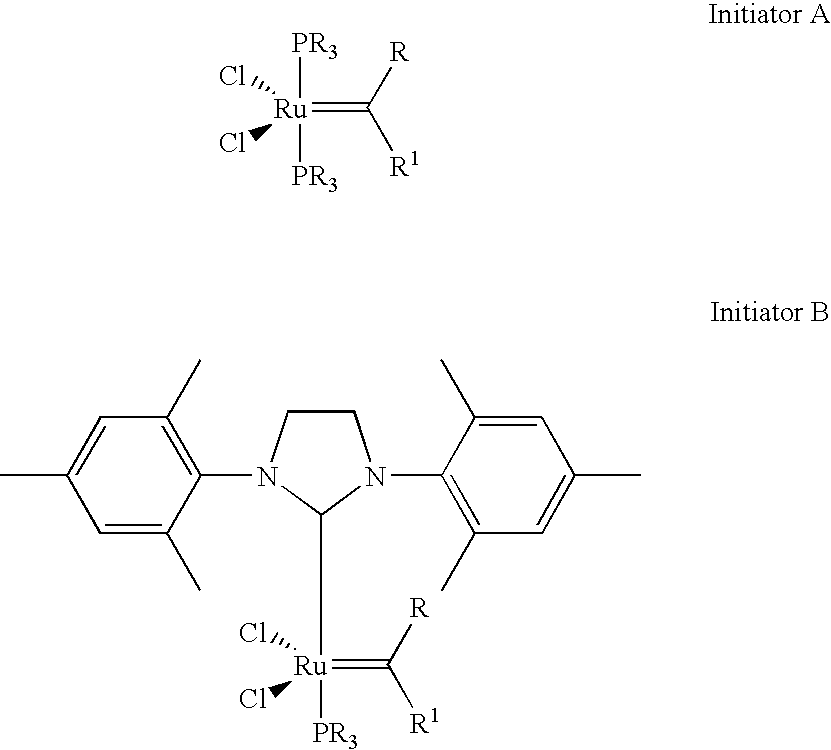

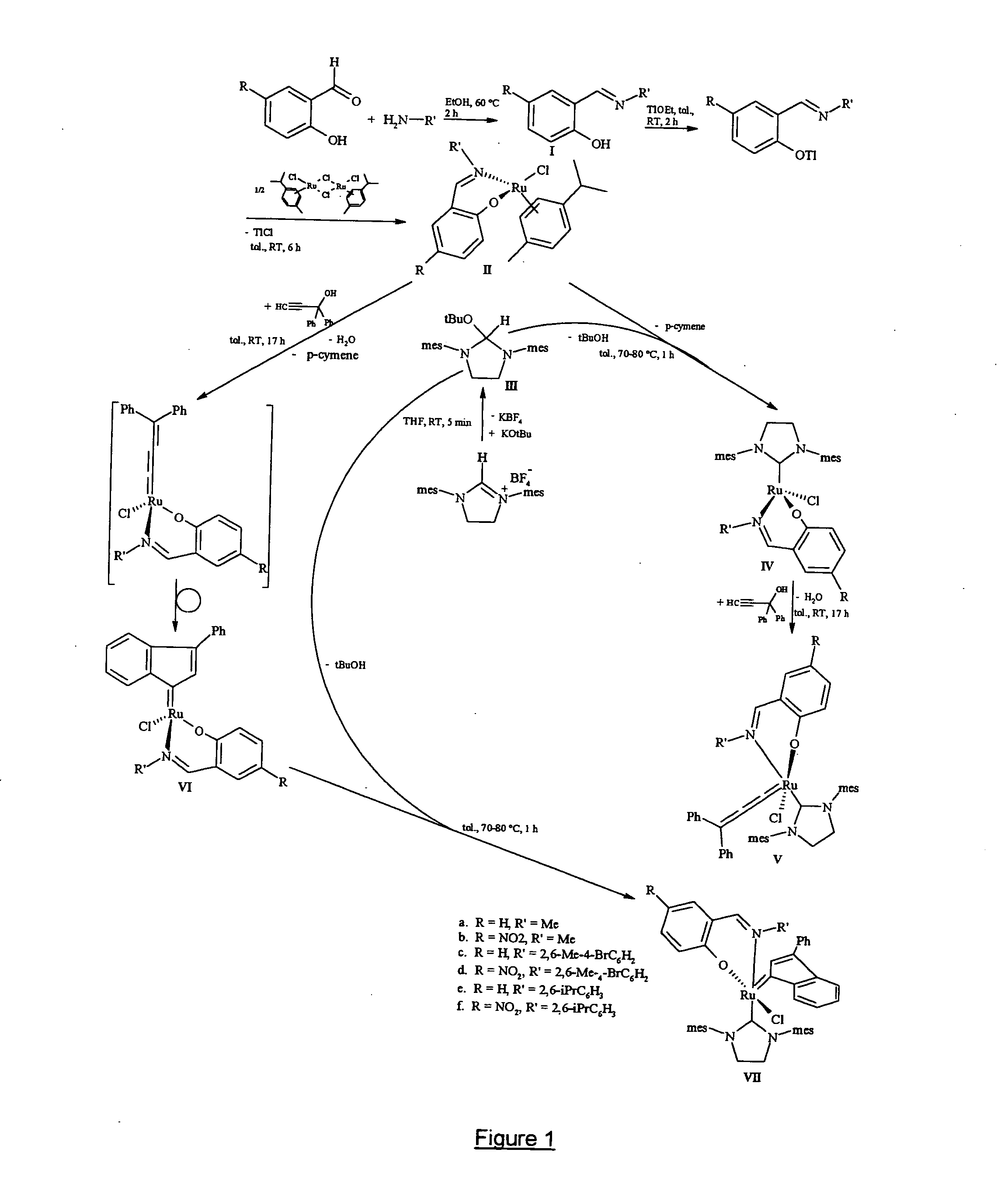

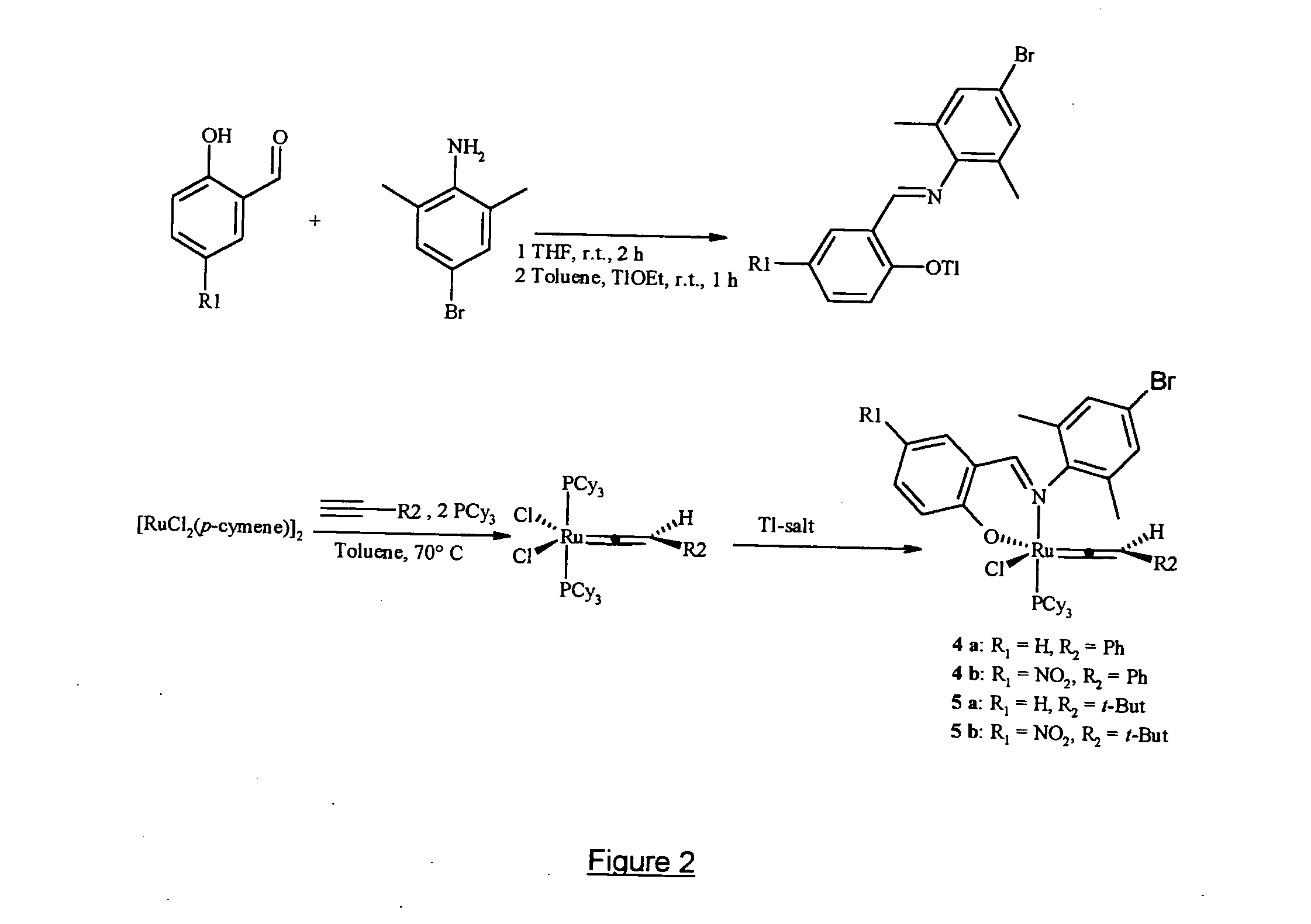

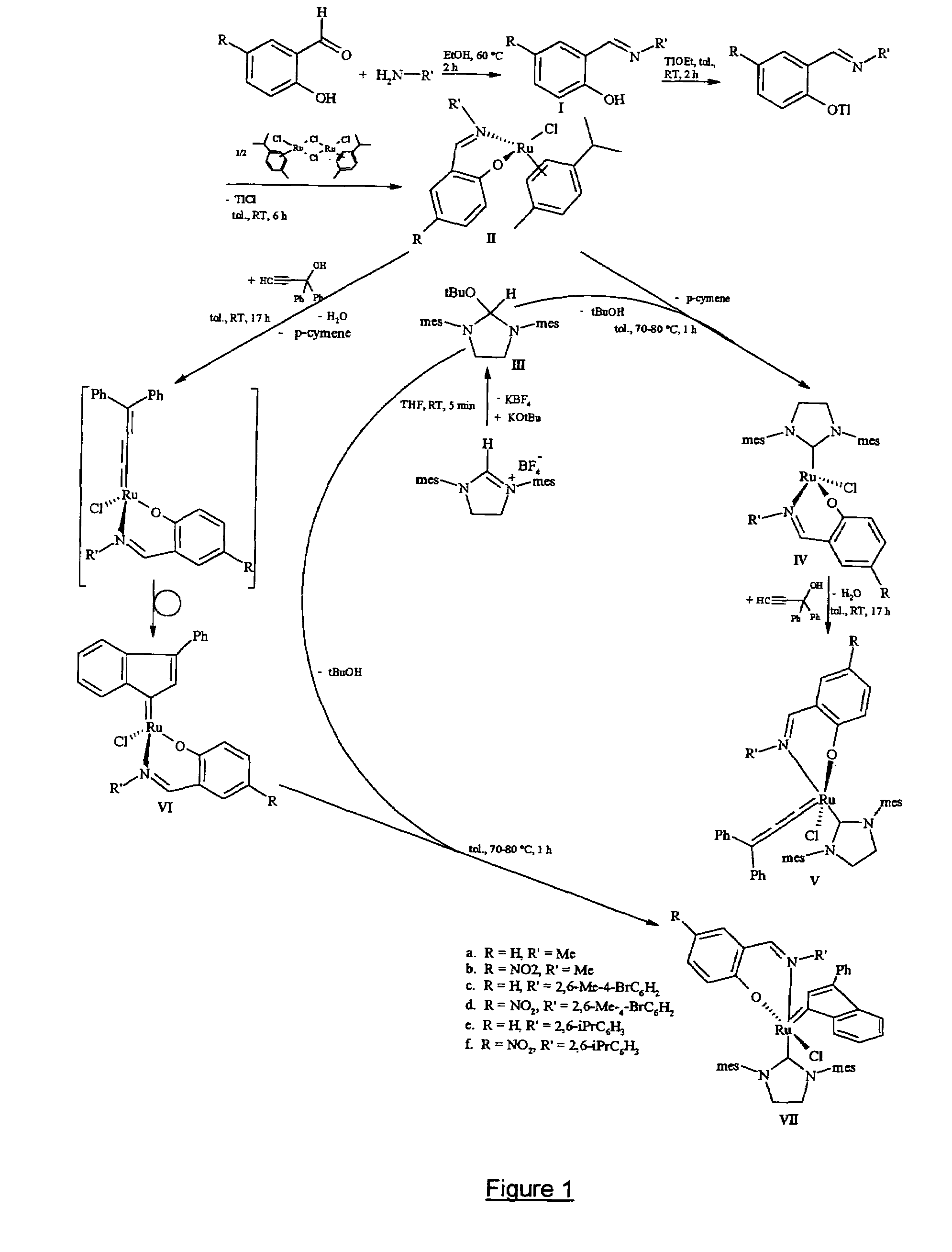

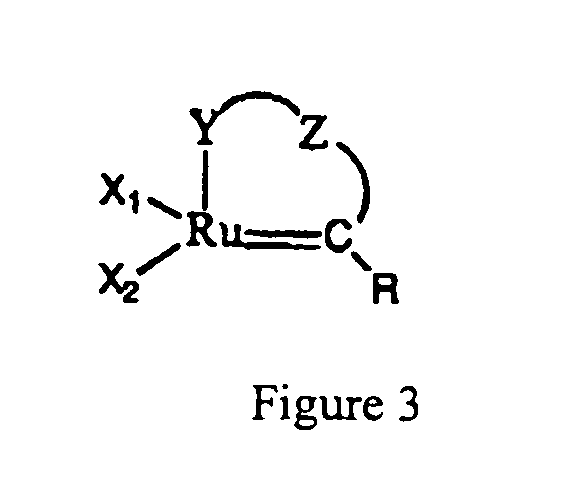

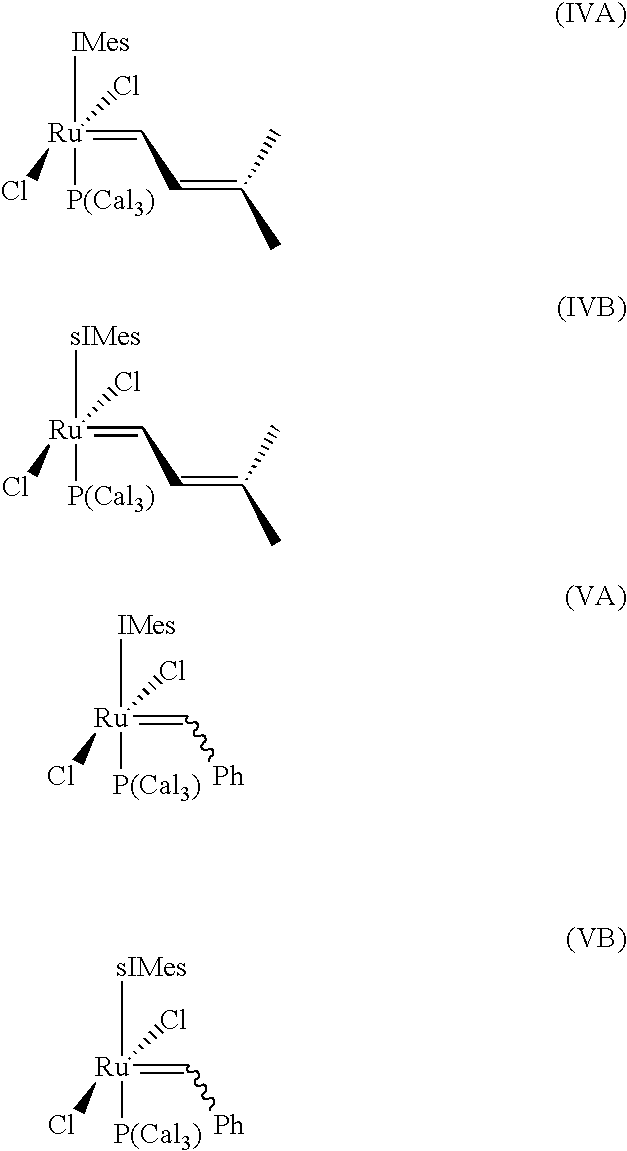

High activity metal carbene metathesis catalysts generated using a thermally activated N-heterocyclic carbene precursor

The invention provides a method for converting a less active or slower to initiate system to a higher activity system so that at the end of a polymerization the most active species is present in the system. The invention generally relates to a process for converting a less active or slower to initiate catalyst system to a higher activity catalyst system wherein the process comprises contacting a protected N-heterocyclic carbene with a metathesis catalyst and an olefin in the presence of energy. One of the benefits of the invention is that the amount of catalyst required is less than or lowered in the presence of the protected N-heterocyclic carbene as compared to the amount of catalyst required in the absence of the protected N-heterocyclic carbene. The protected N-heterocyclic carbene can be unsaturated or saturated. In addition, the invention describes novel ruthenium initiators and methods of making the same.

Owner:CALIFORNIA INST OF TECH +1

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

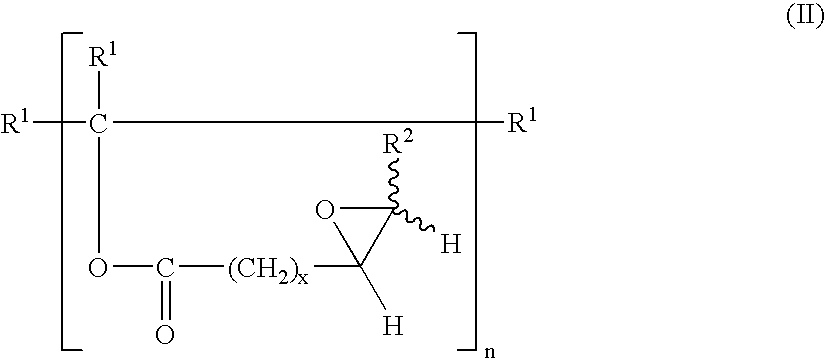

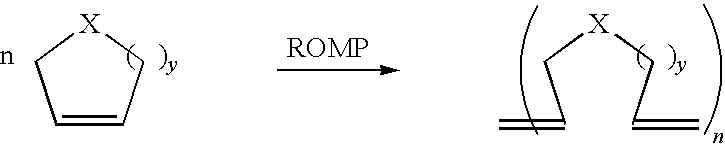

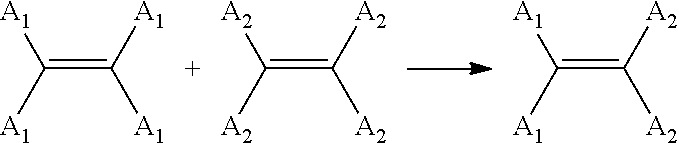

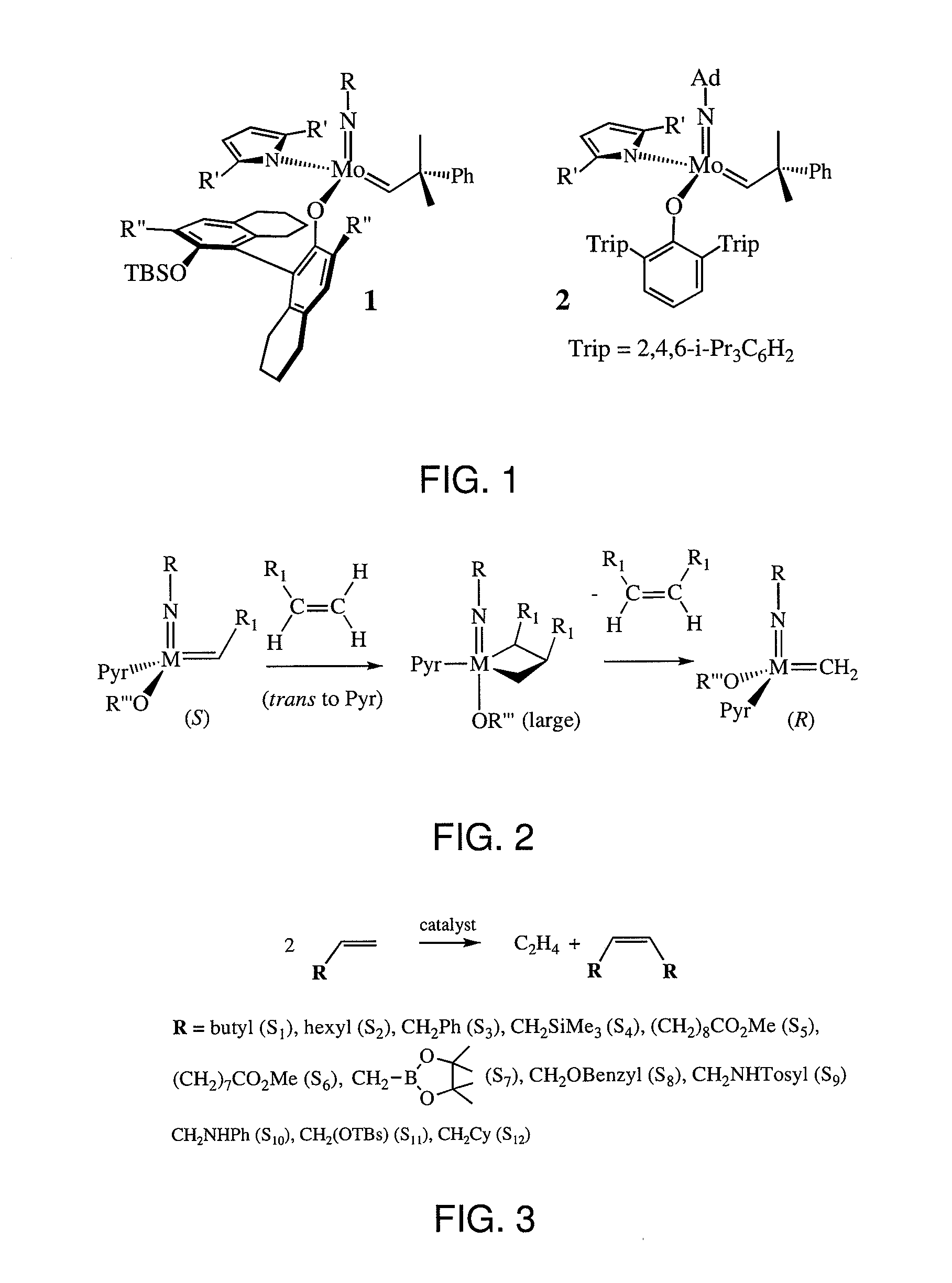

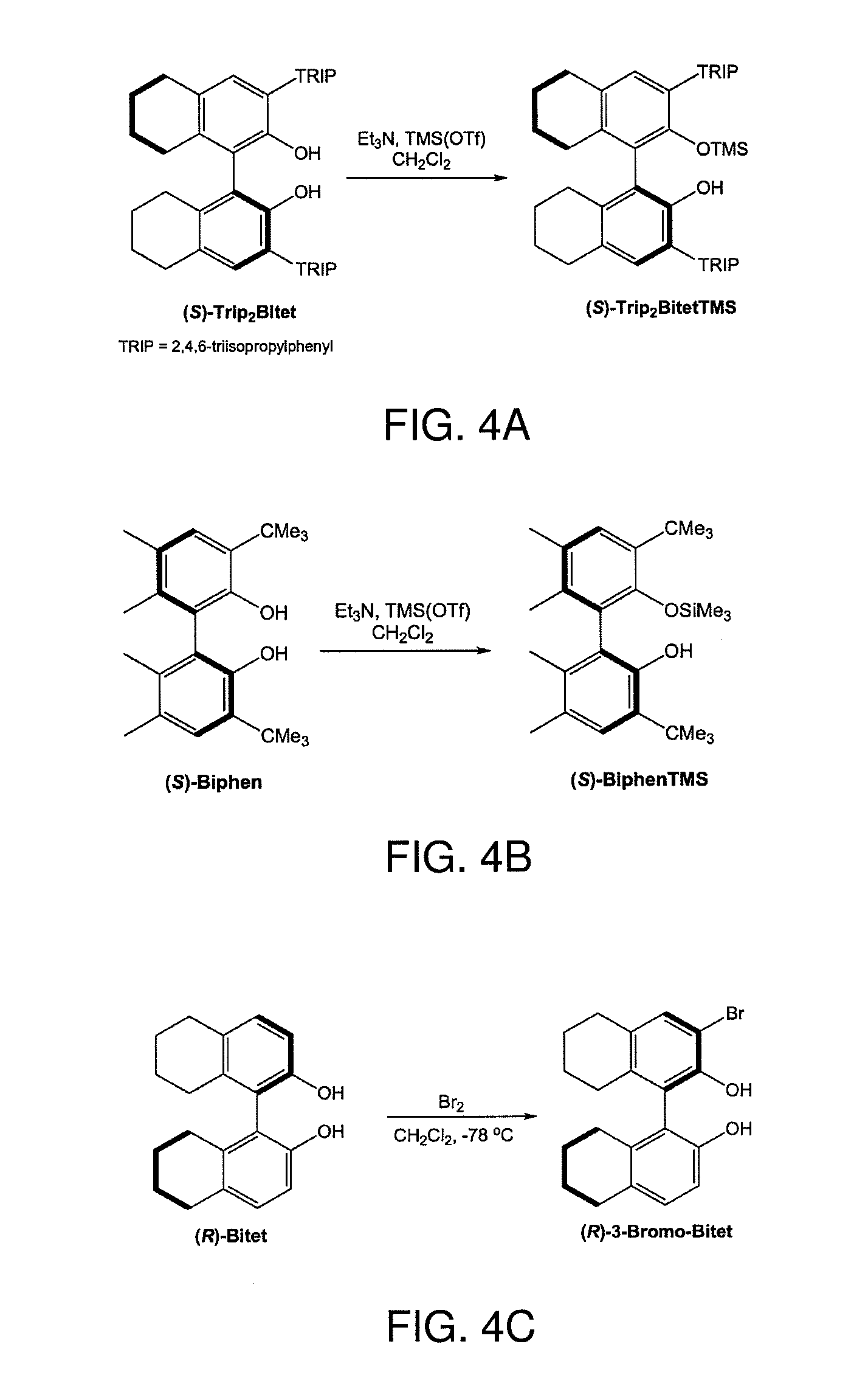

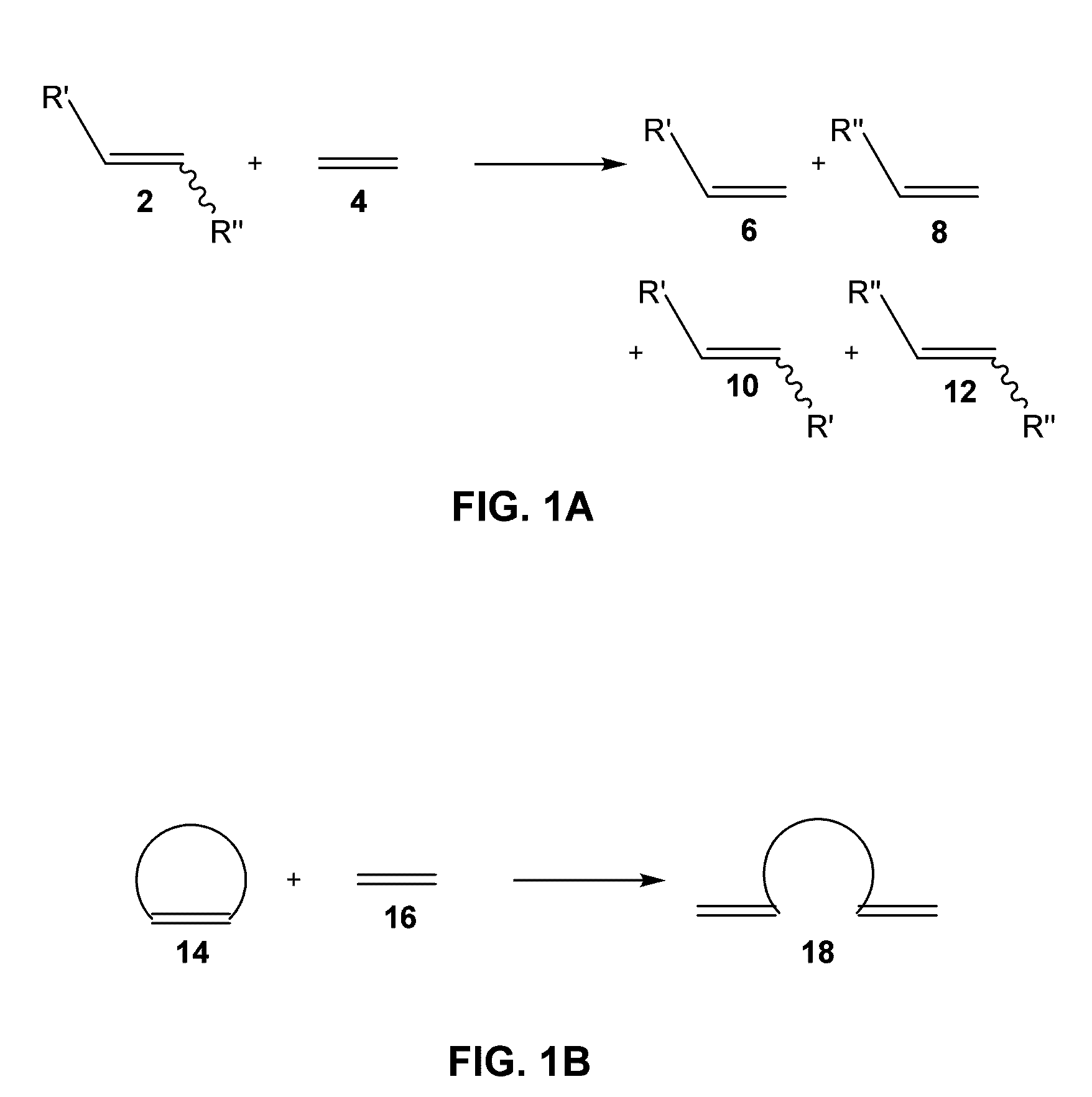

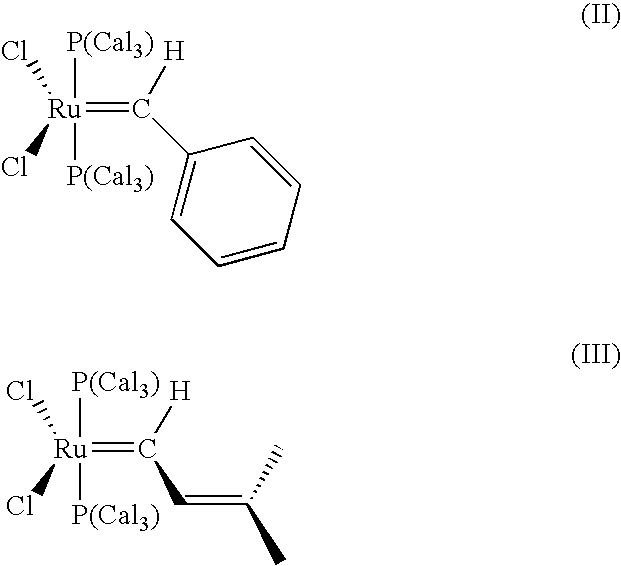

Synthesis of terminal alkenes from internal alkenes and ethylene via olefin metathesis

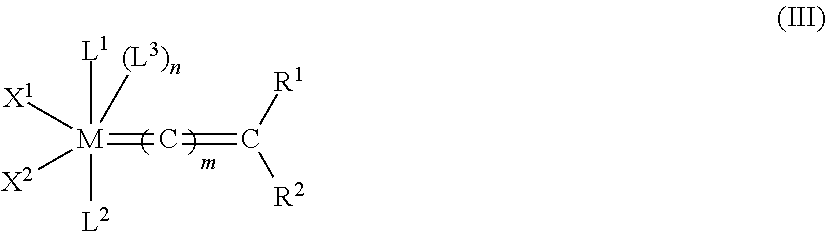

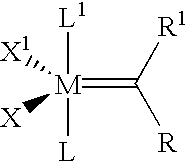

This invention relates generally to olefin metathesis, and more particularly relates to the synthesis of terminal alkenes from internal alkenes using a cross-metathesis reaction catalyzed by a selected olefin metathesis catalyst. In one embodiment of the invention, for example, a method is provided for synthesizing a terminal olefin, the method comprising contacting an olefinic substrate comprised of at least one internal olefin with ethylene, in the presence of a metathesis catalyst, wherein the catalyst is present in an amount that is less than about 1000 ppm relative to the olefinic substrate, and wherein the metathesis catalyst has the structure of formula (II) wherein the various substituents are as defined herein. The invention has utility, for example, in the fields of catalysis, organic synthesis, and industrial chemistry.

Owner:MATERIA

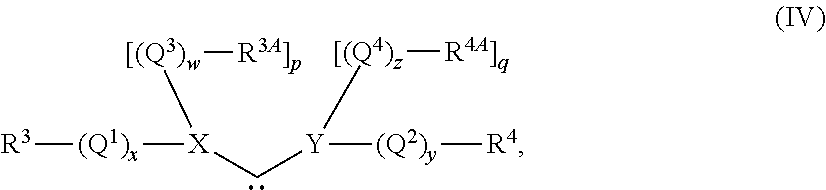

Use of a phosphorus containing ligand and a cyclic organic ligand in a transition metal compound

ActiveUS7671224B2Ruthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsChemical compoundDouble bond

According to the present invention there is provided a compound in the form of a transition metal compound including a transition metal, a phosphorus containing ligand, and a cyclic organic ligand. The phosphorus containing ligand is a heterocyclic organic compound with a ligating phosphorus atom which ligates with the transition metal, and which ligating phosphorus atom is an atom in the heterocyclic ring structure of the heterocyclic organic compound. The cyclic organic ligand is a cyclic organic compound with a ligating carbon atom in the cyclic ring structure of the cyclic organic compound which ligates with the transition metal by means of a double bound. The invention also relates to a method preparing such a compound and a metathesis reaction wherein such a compound is used as a catalyst.

Owner:UMICORE AG & CO KG

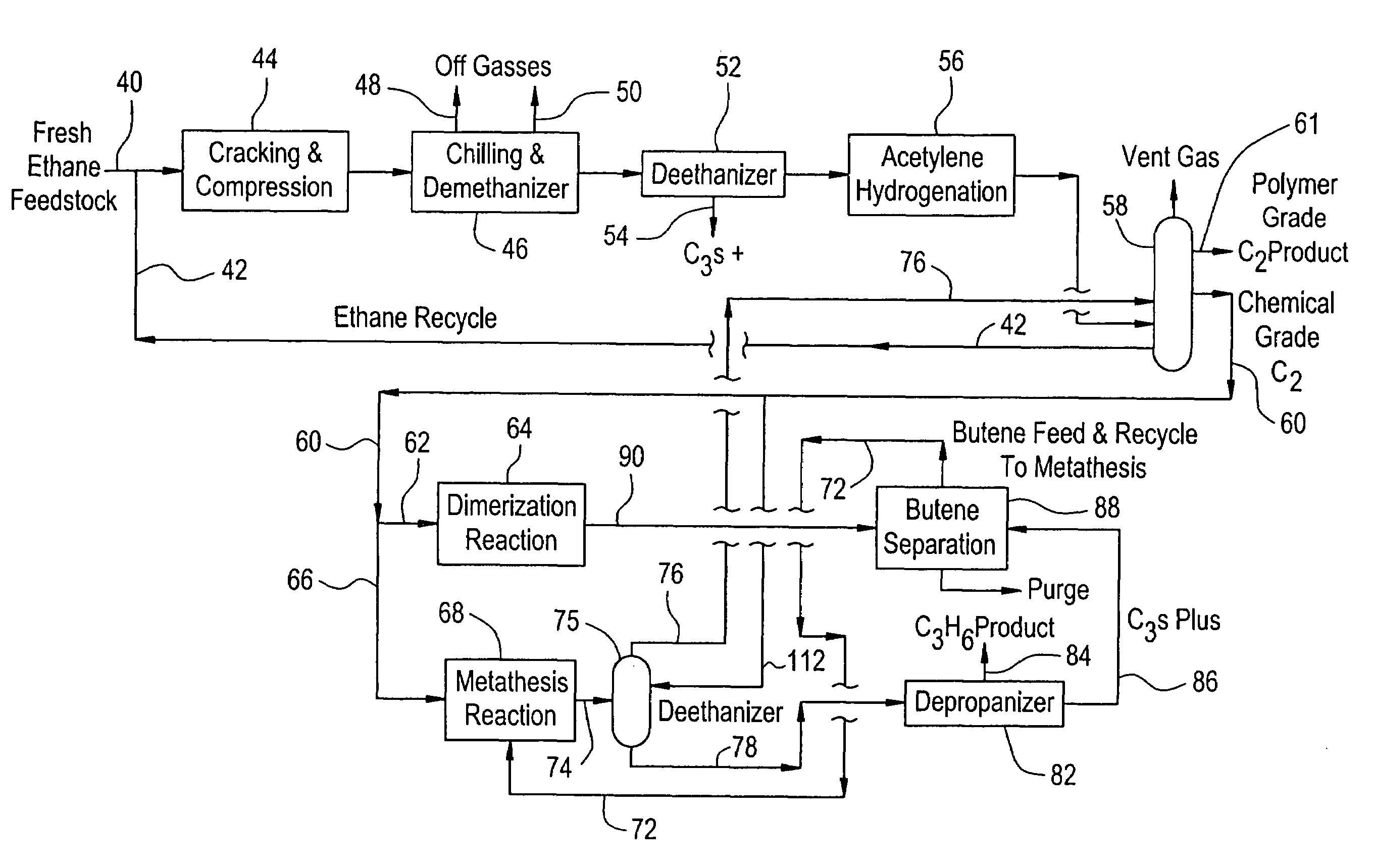

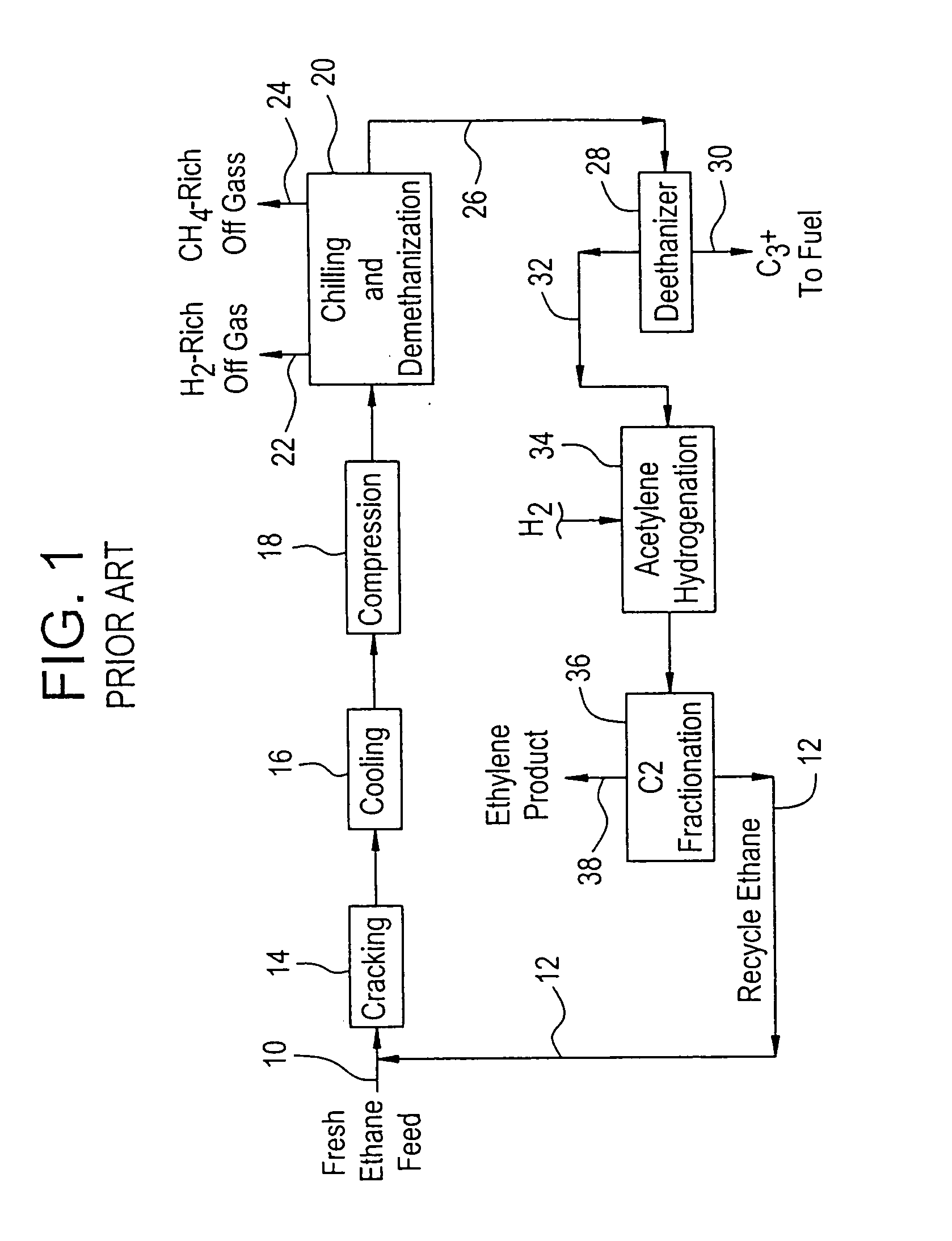

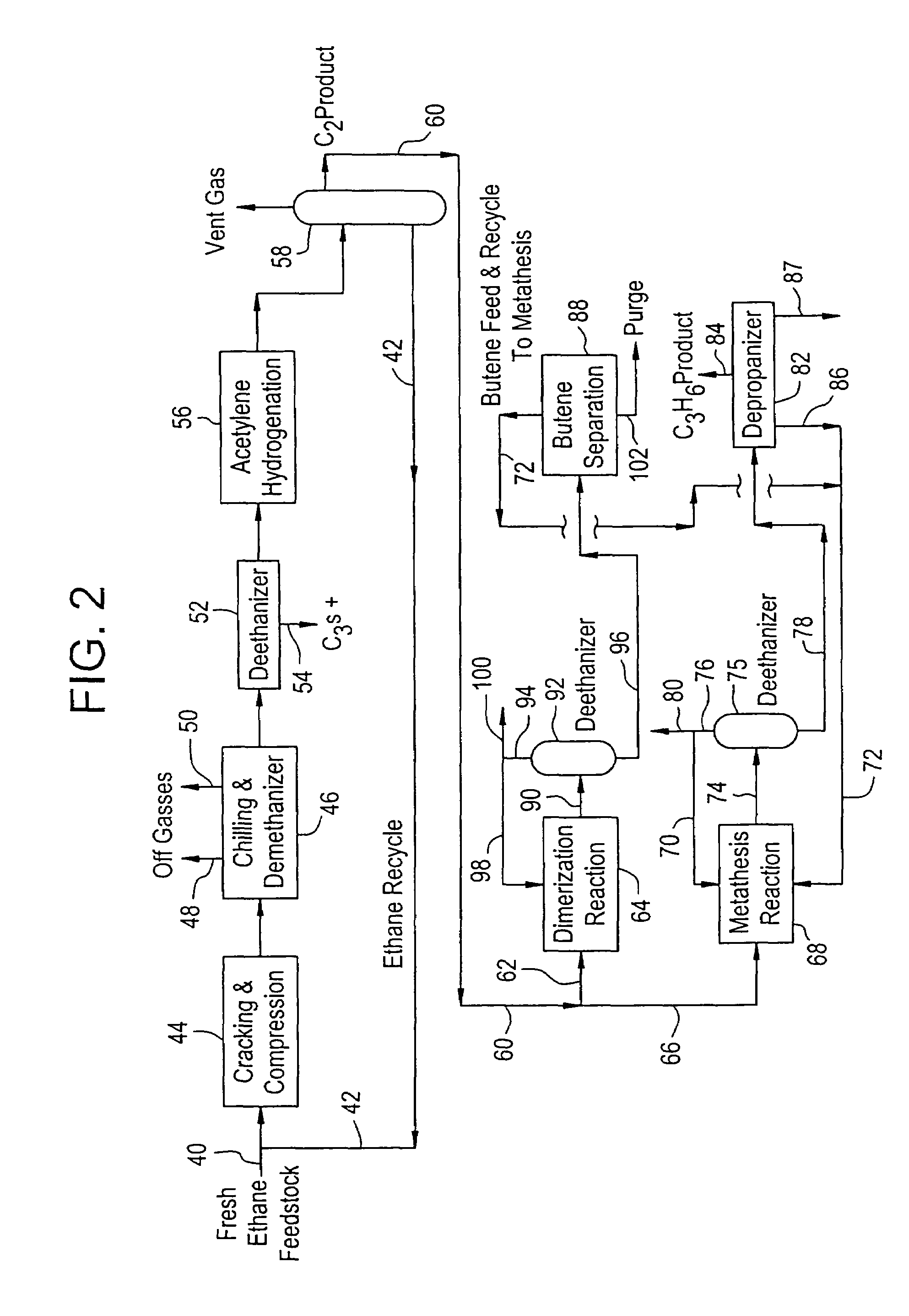

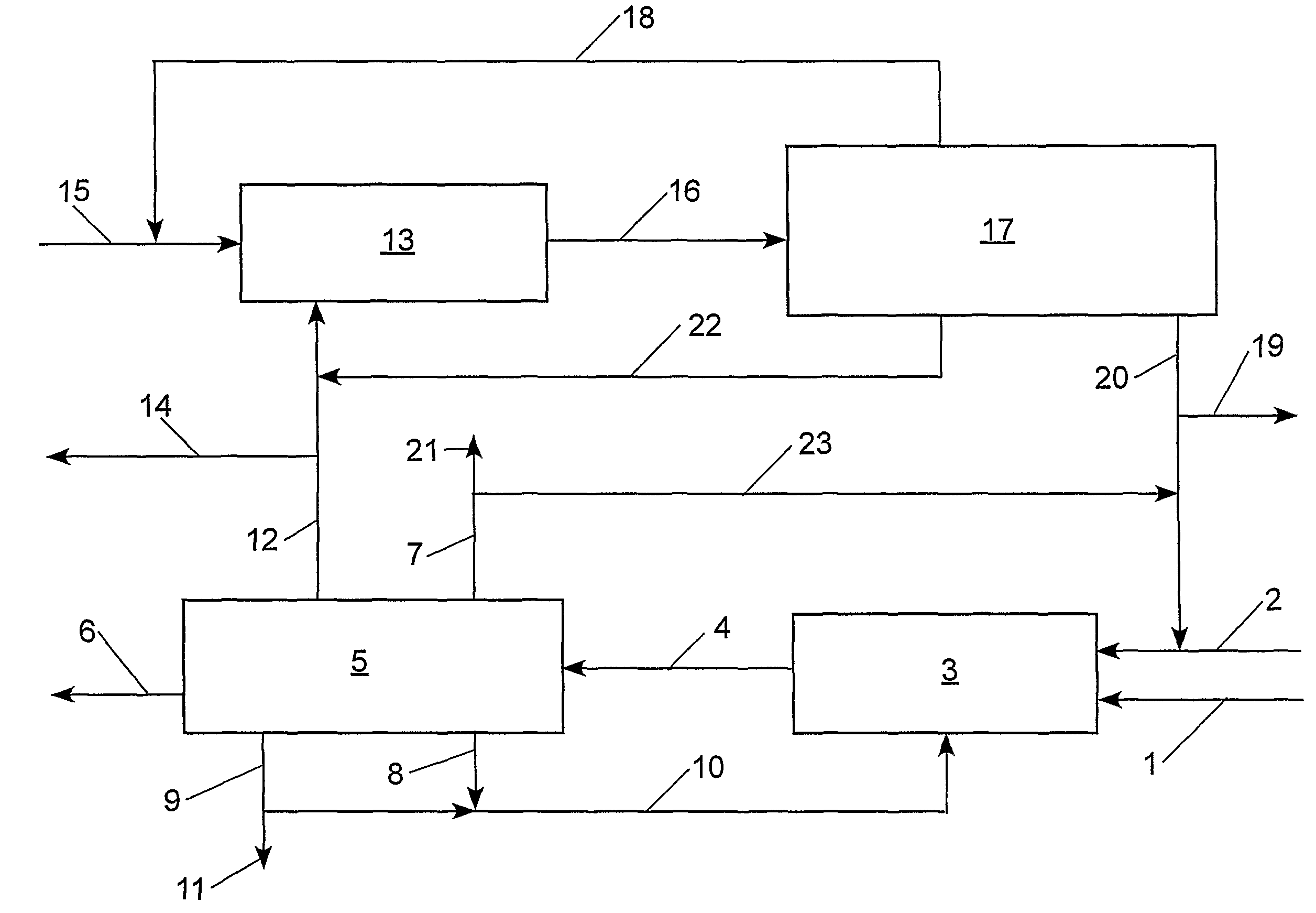

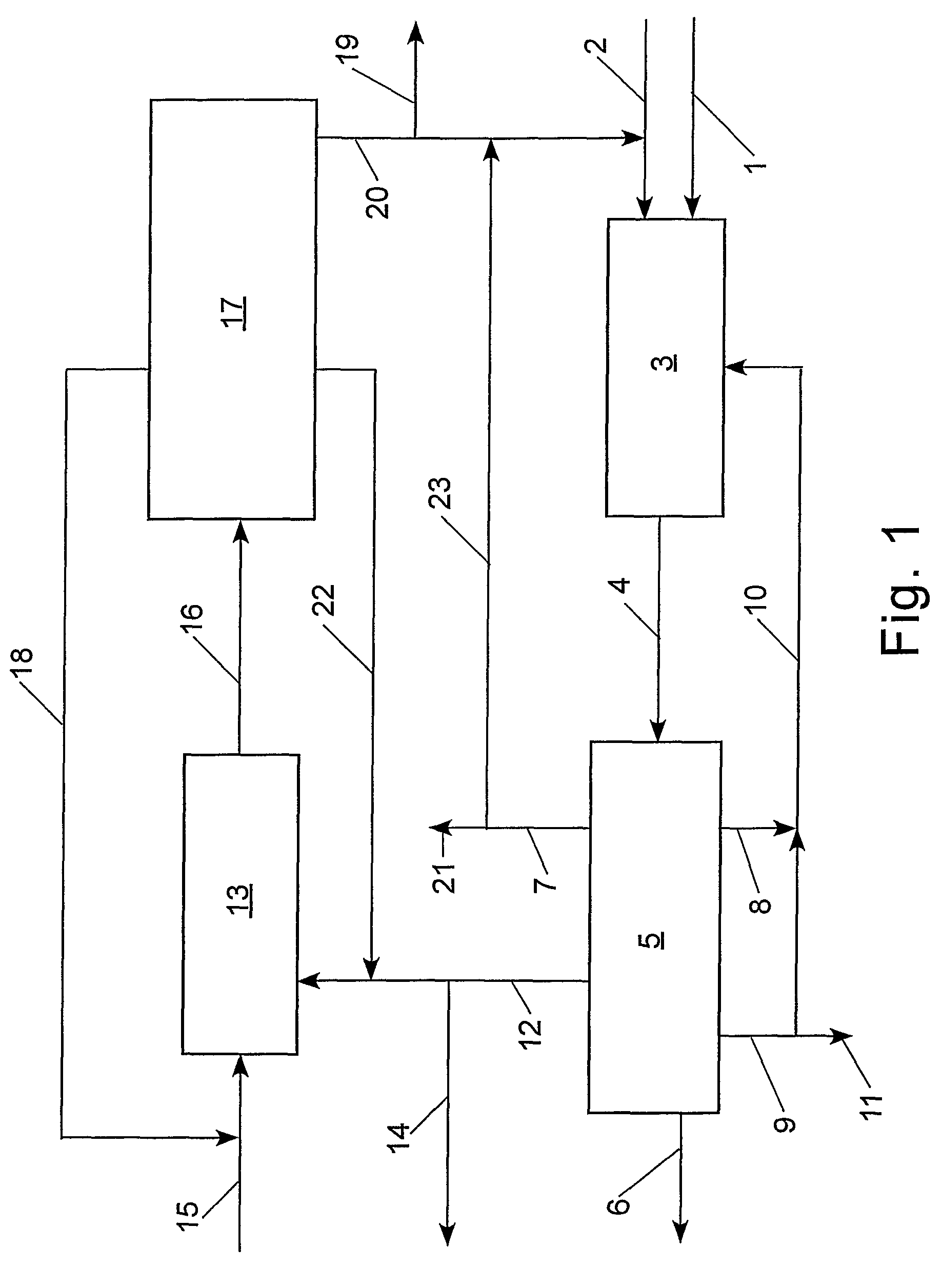

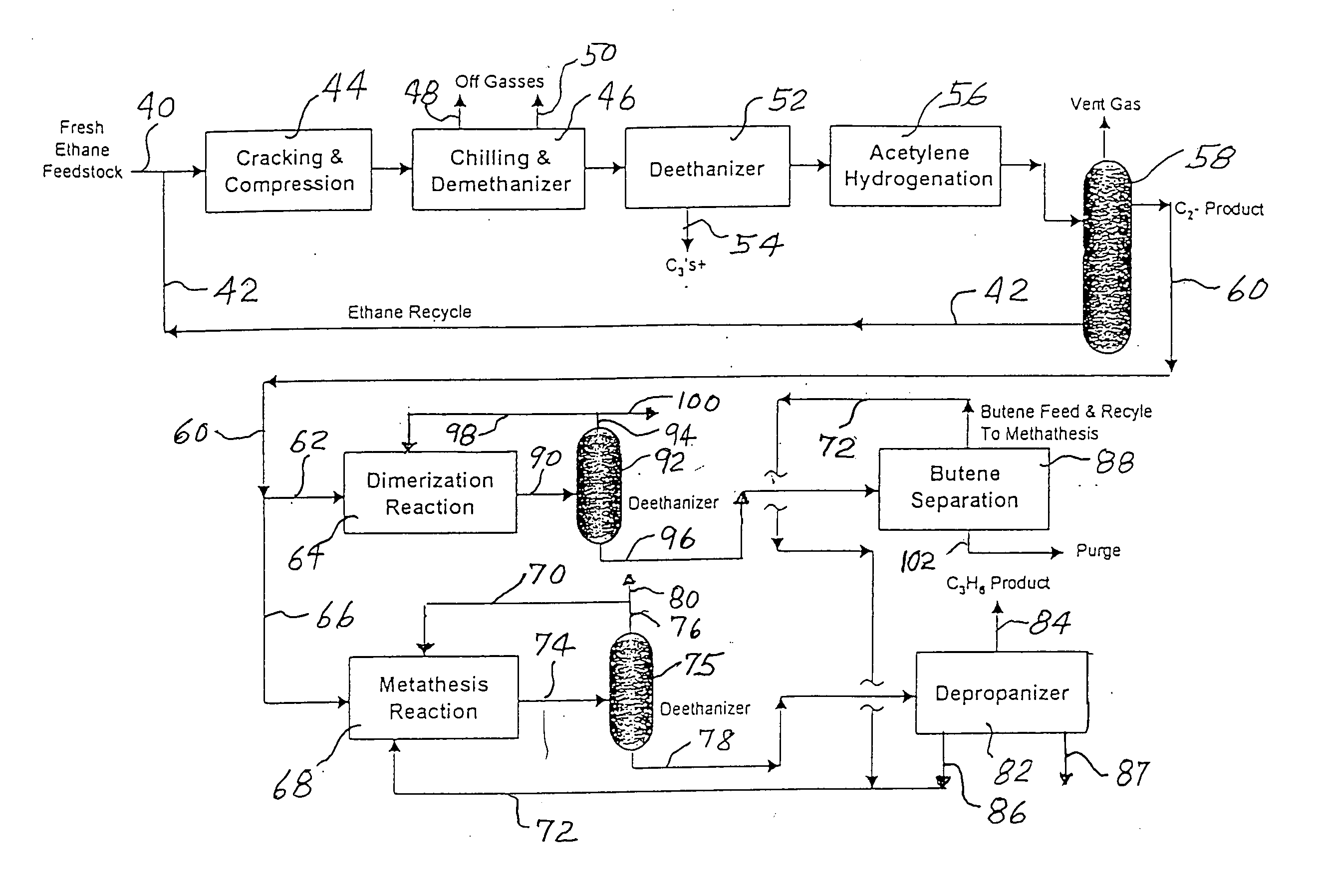

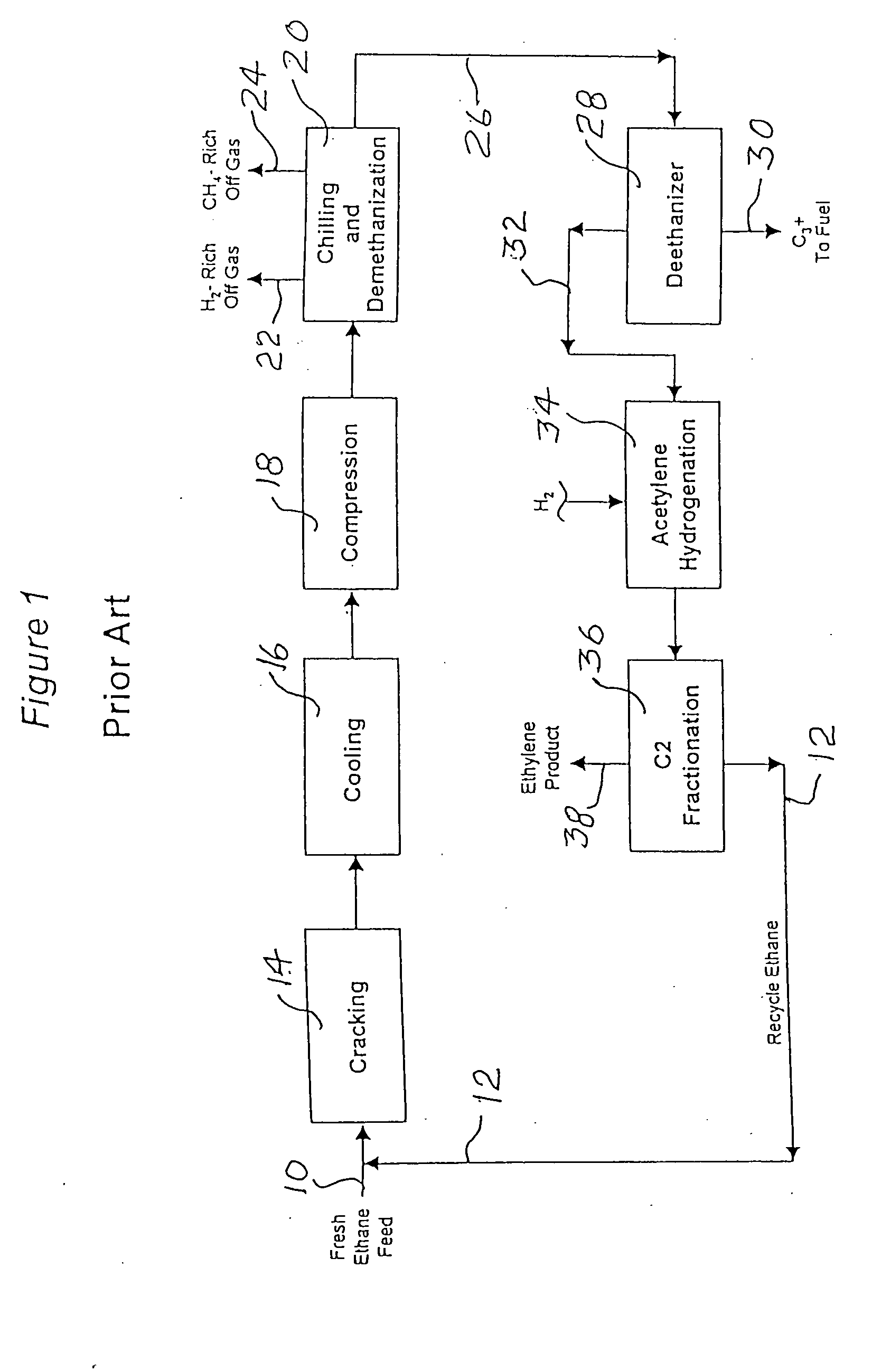

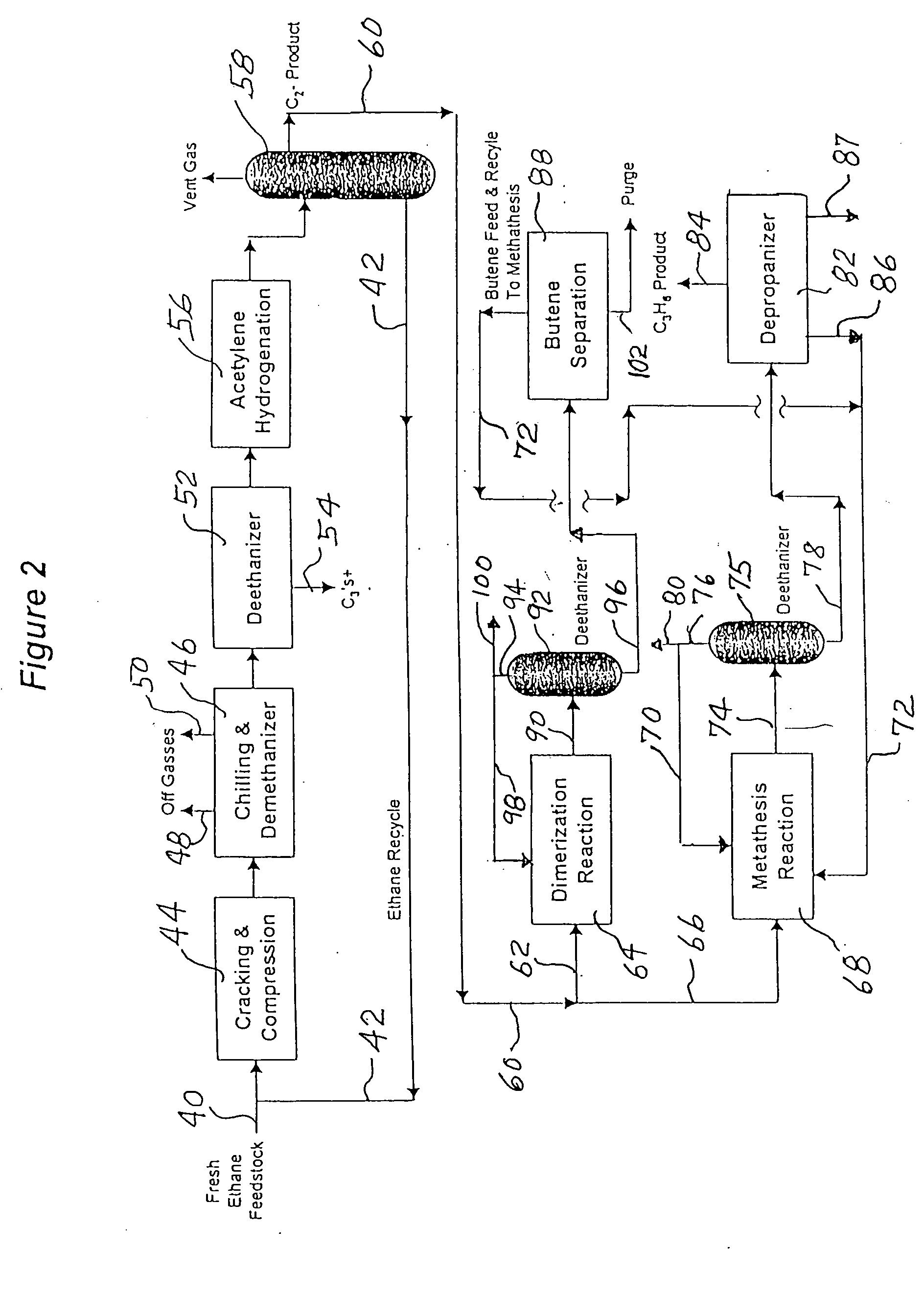

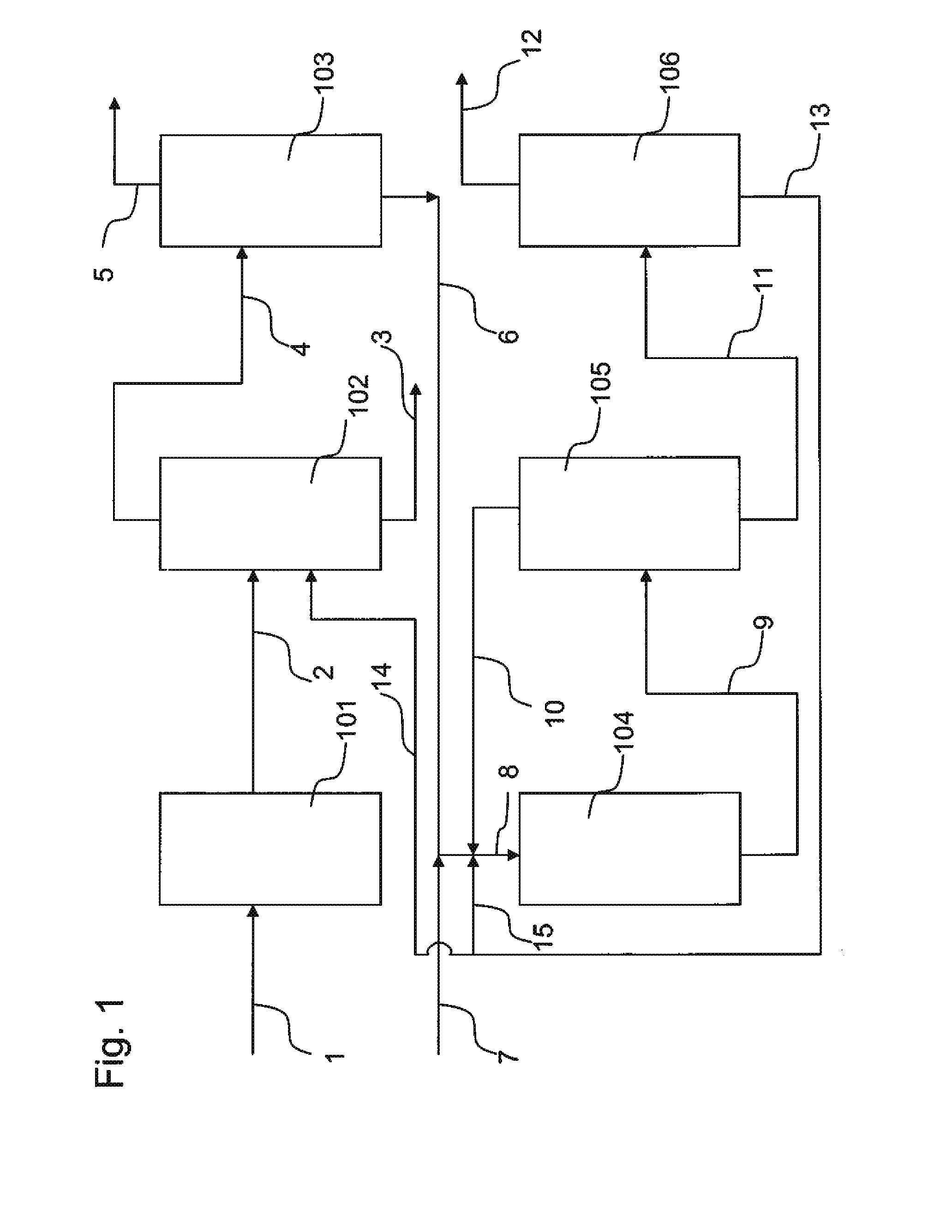

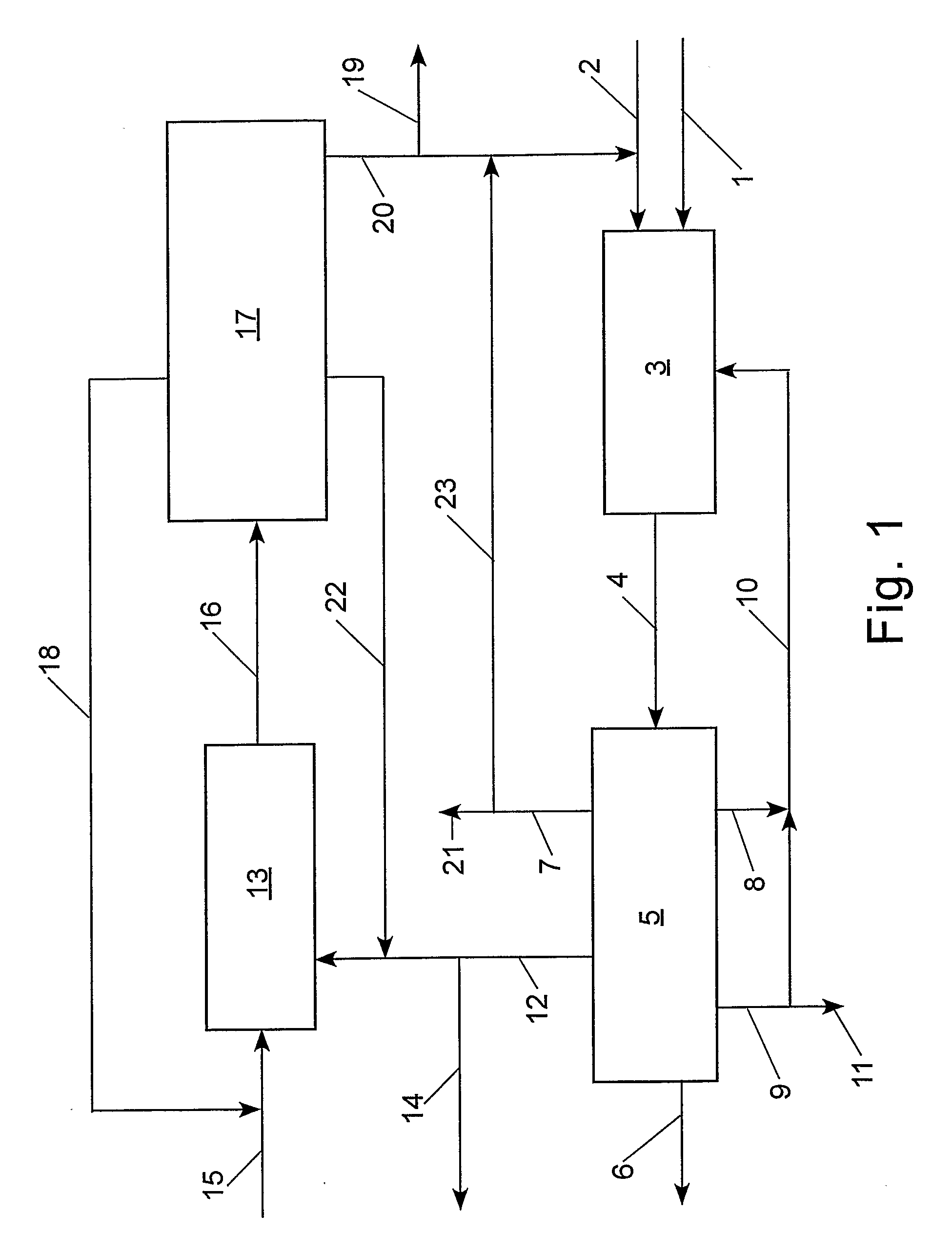

Production of propylene from steam cracking of hydrocarbons, particularly ethane

ActiveUS7223895B2Thermal non-catalytic crackingHydrocarbons from unsaturated hydrocarbon additionButenePolymer science

An ethane or other hydrocarbon feedstock is steam cracked to produce an ethylene stream which is processed in an ethylene plant recovery section to separate an ethane recycle and a polymer grade or chemical grade ethylene product stream. A portion of the ethylene product stream may then be reacted by dimerization to produce a butene stream. These formed butenes and / or butenes recovered from other sources and another portion of the ethylene product stream are reacted by metathesis to produce a propylene stream which is deethanized and separated from heavier hydrocarbons to produce the propylene product. The butene product stream may also be deethanized and is separated from heavier hydrocarbons. The overhead from the metathesis section deethanizer may be recycled to the ethylene plant recovery section. The reflux for the metathesis section deethanizer may be generated from the overhead or may be a portion of the ethylene product stream.

Owner:ABB LUMMUS GLOBAL INC

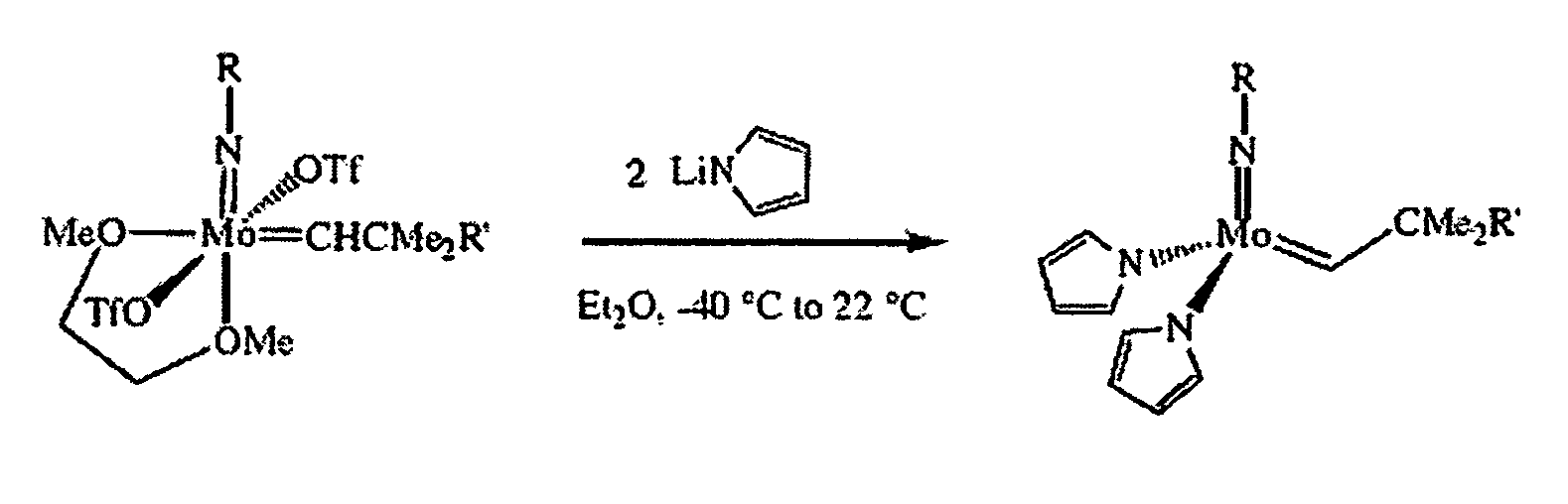

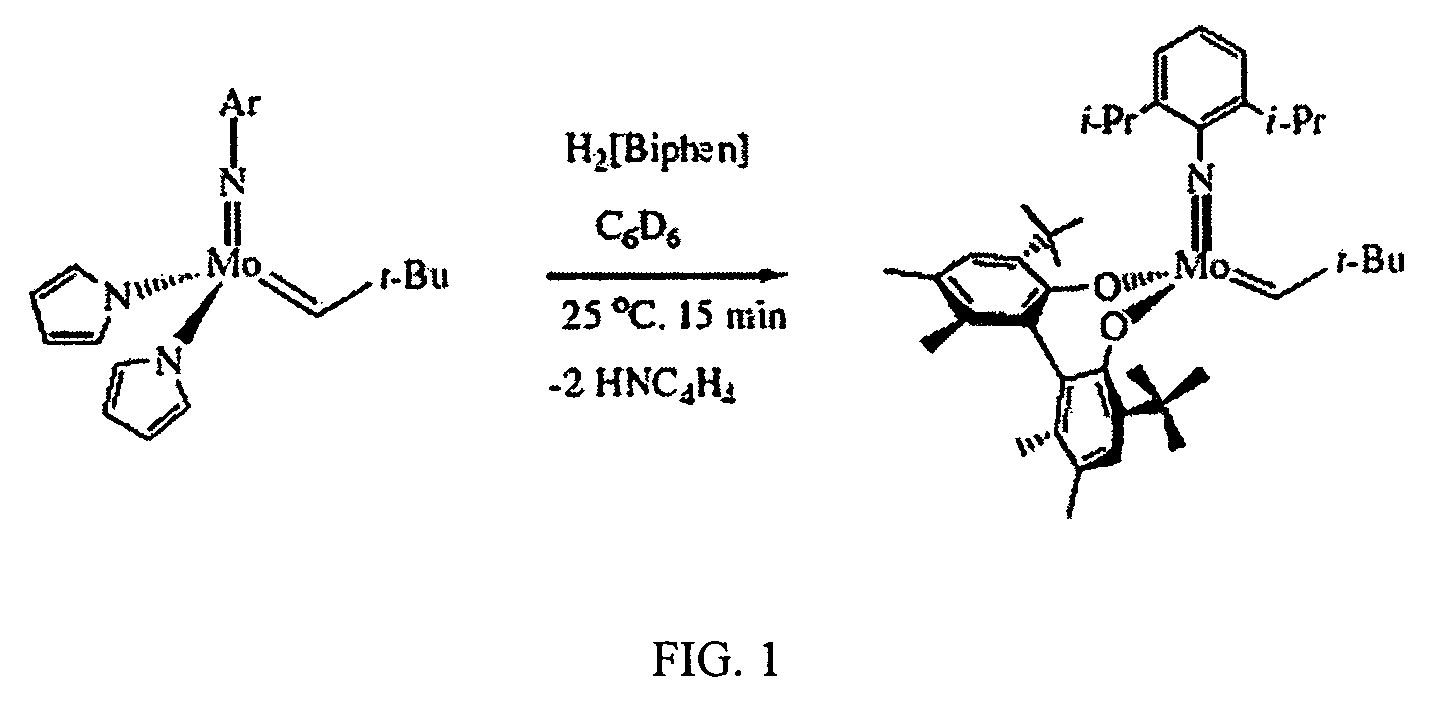

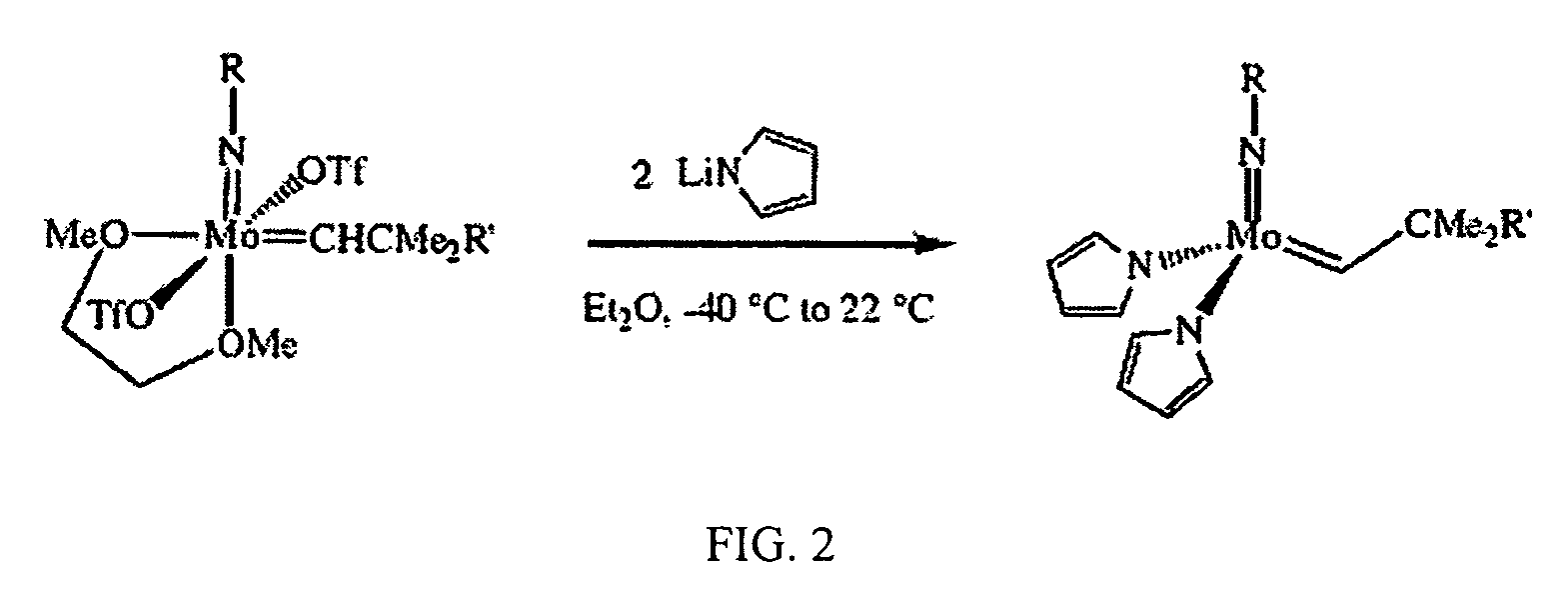

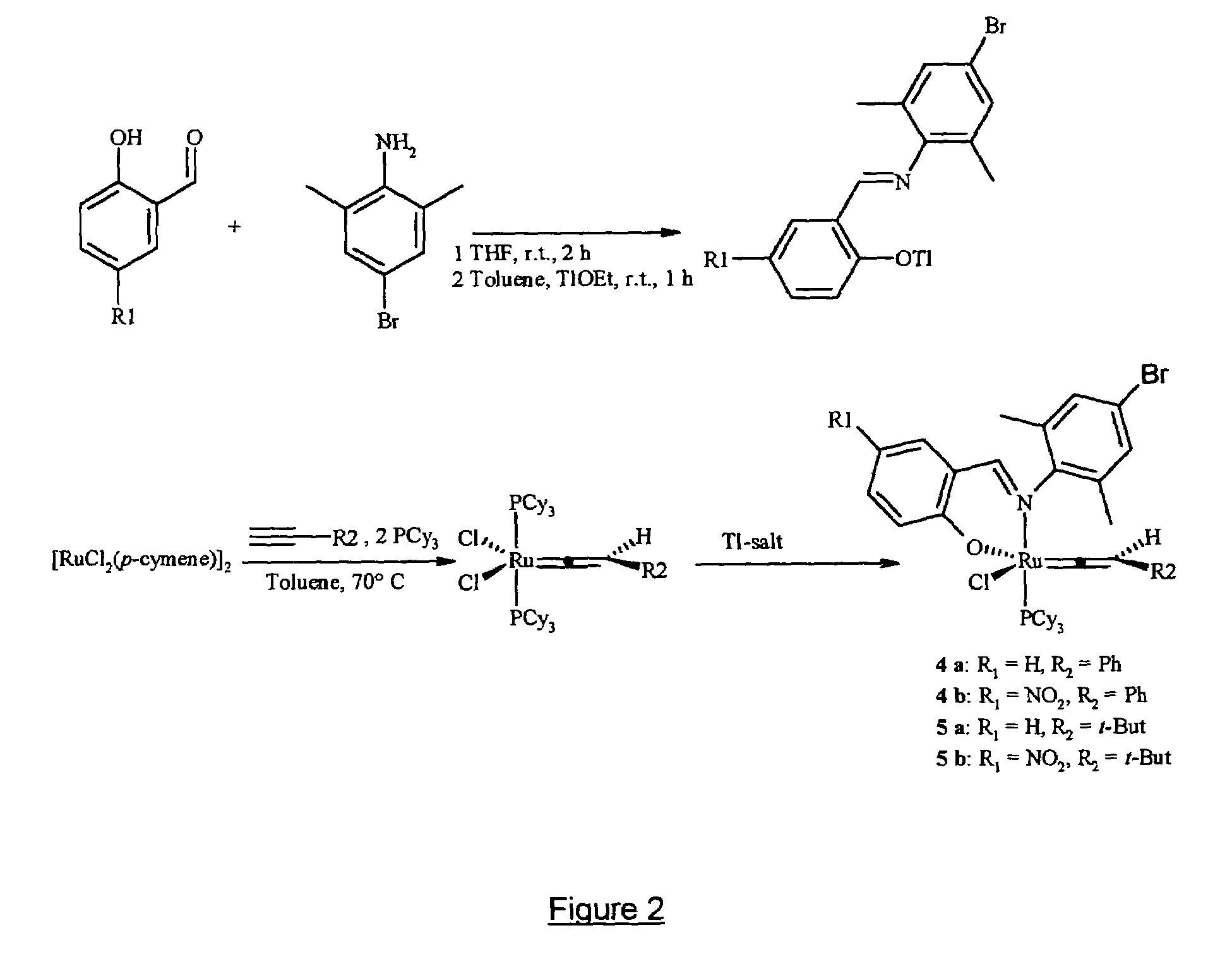

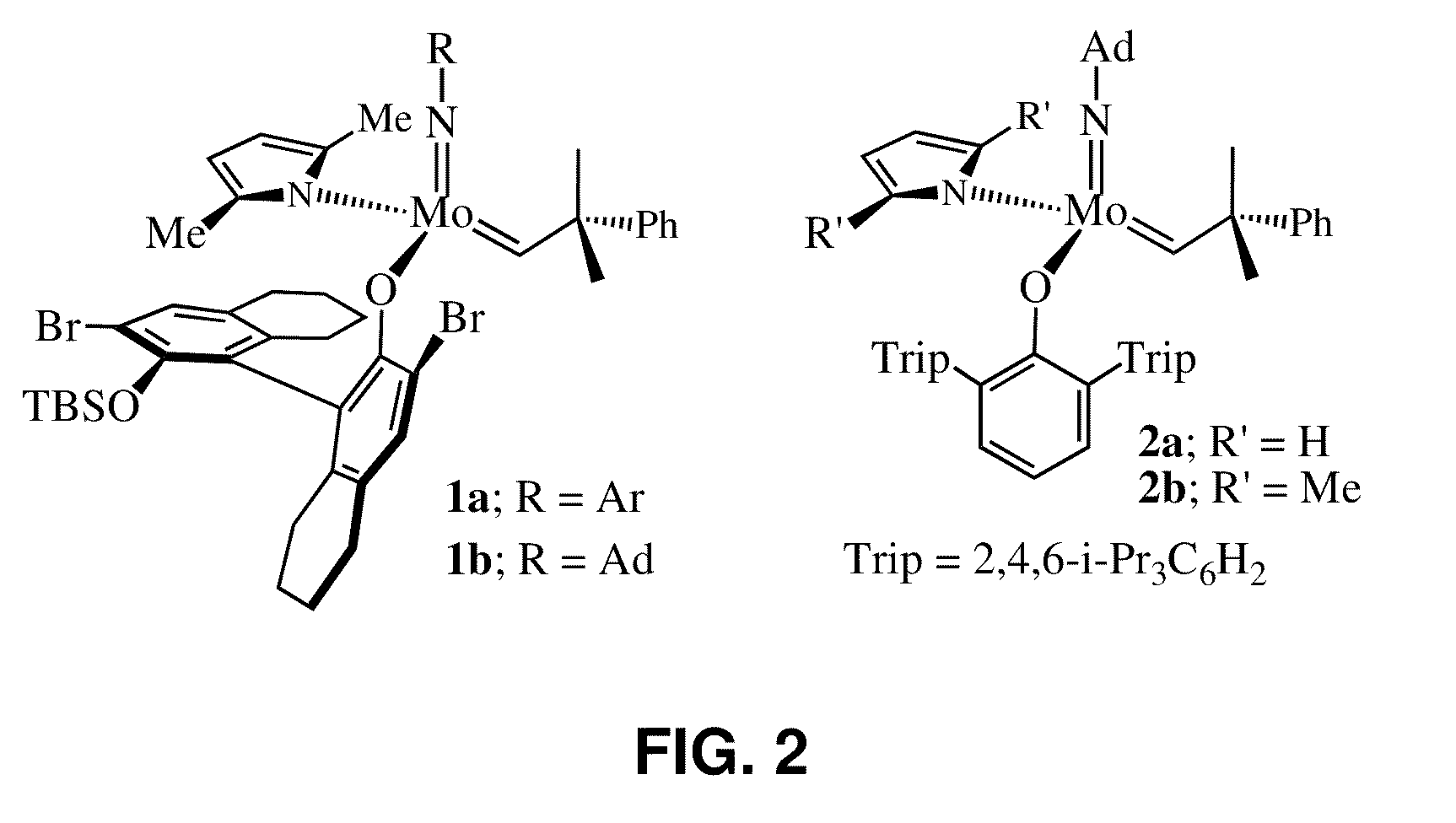

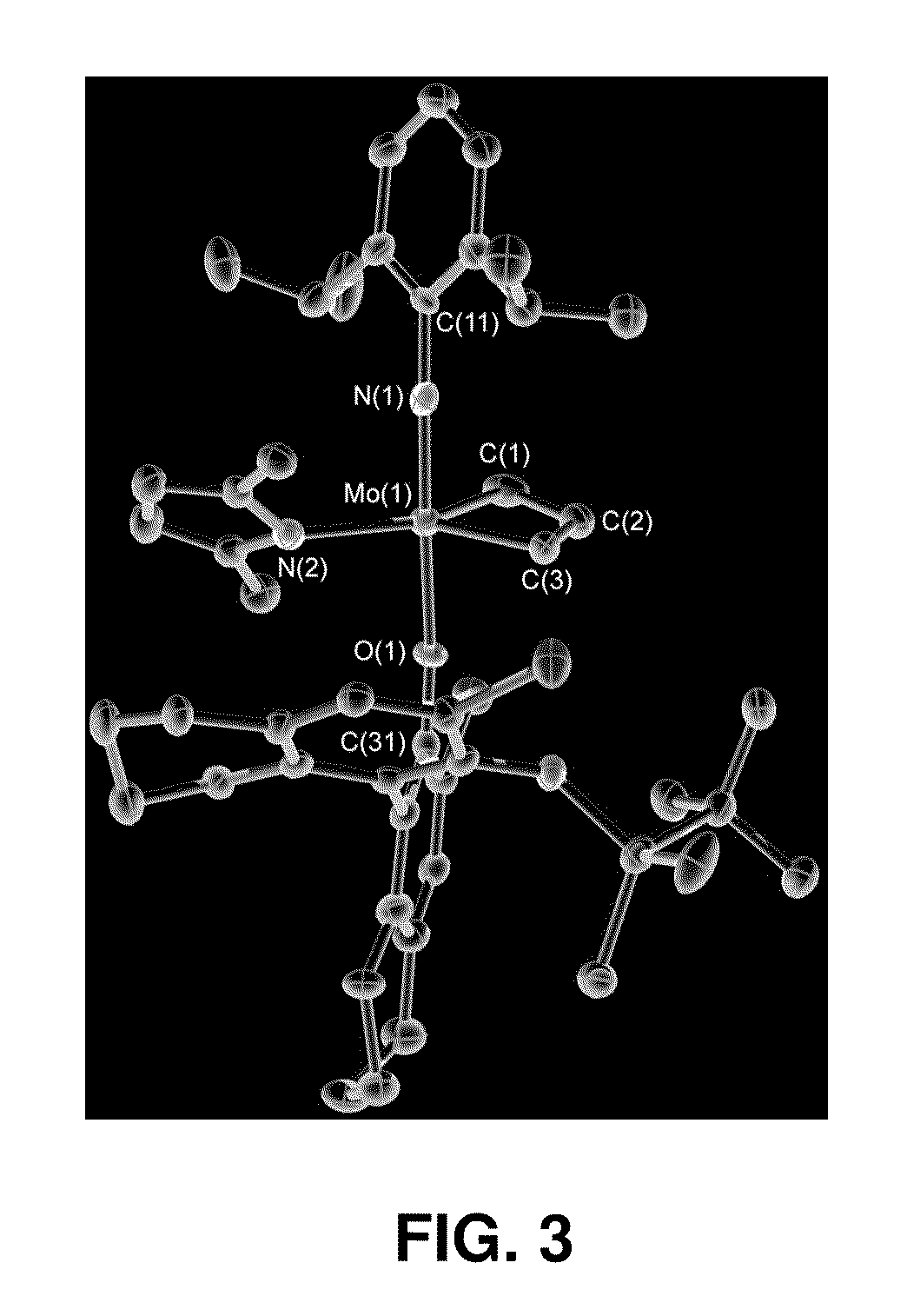

Olefin metathesis catalysts and related methods

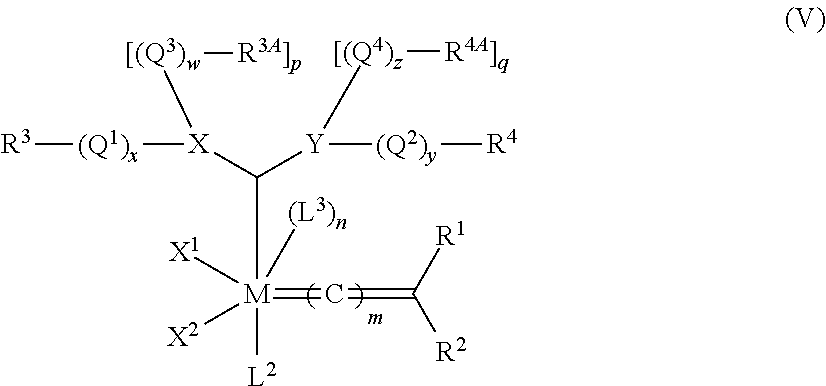

ActiveUS7932397B2Group 5/15 element organic compoundsGroup 8/9/10/18 element organic compoundsChemical reactionAlkene

The present invention provides methods for the synthesis of catalysts and precursors thereof. Methods of the invention may comprise combining a catalyst precursor and at least one ligand to generate a catalytically active species, often under mild conditions and in high yields. In some cases, a wide variety of catalysts may be synthesized from a single catalyst precursor. Methods of the invention may also include the preparation of catalysts which, under reaction conditions known in the art, may have been difficult or impossible to prepare and / or isolate due to, for example, steric crowding at the metal center. The present invention also provides catalyst compositions, and precursors thereof, which may be useful in various chemical reactions including olefin metathesis. In some cases, methods of the invention may reduce the number of synthetic and purification steps required to produce catalysts and / or other reaction products, as well as reducing time, cost, and waste production.

Owner:MASSACHUSETTS INST OF TECH

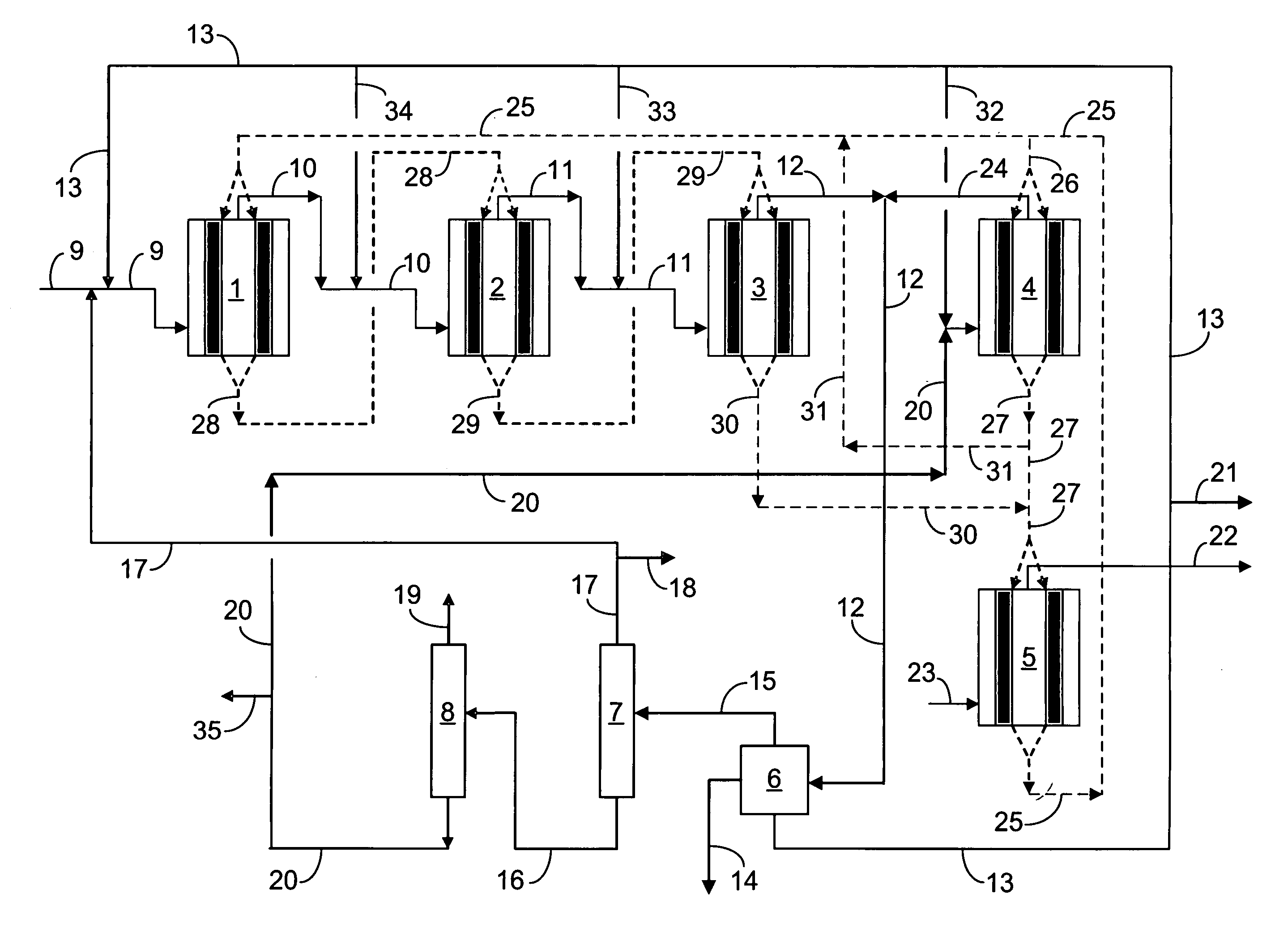

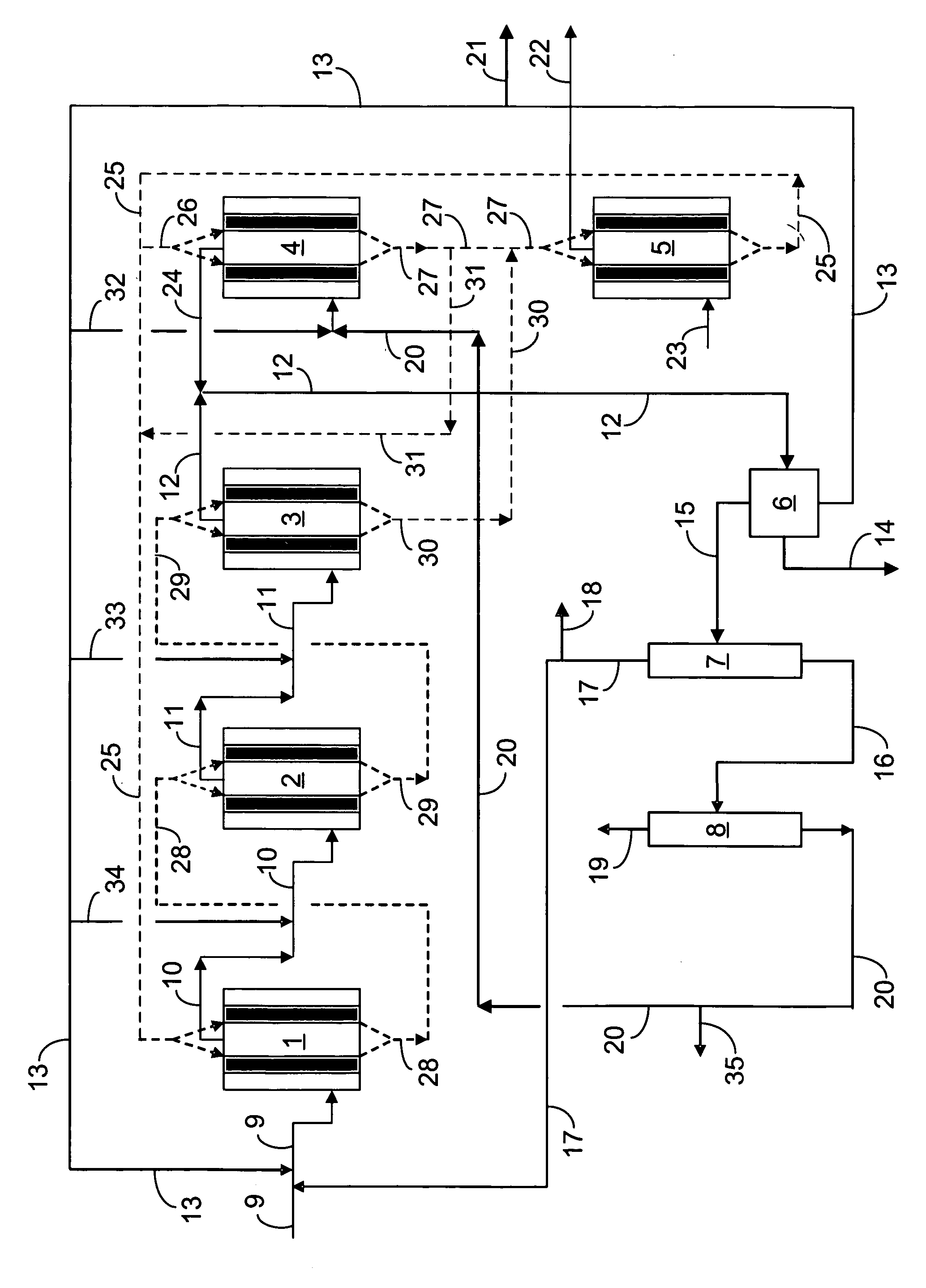

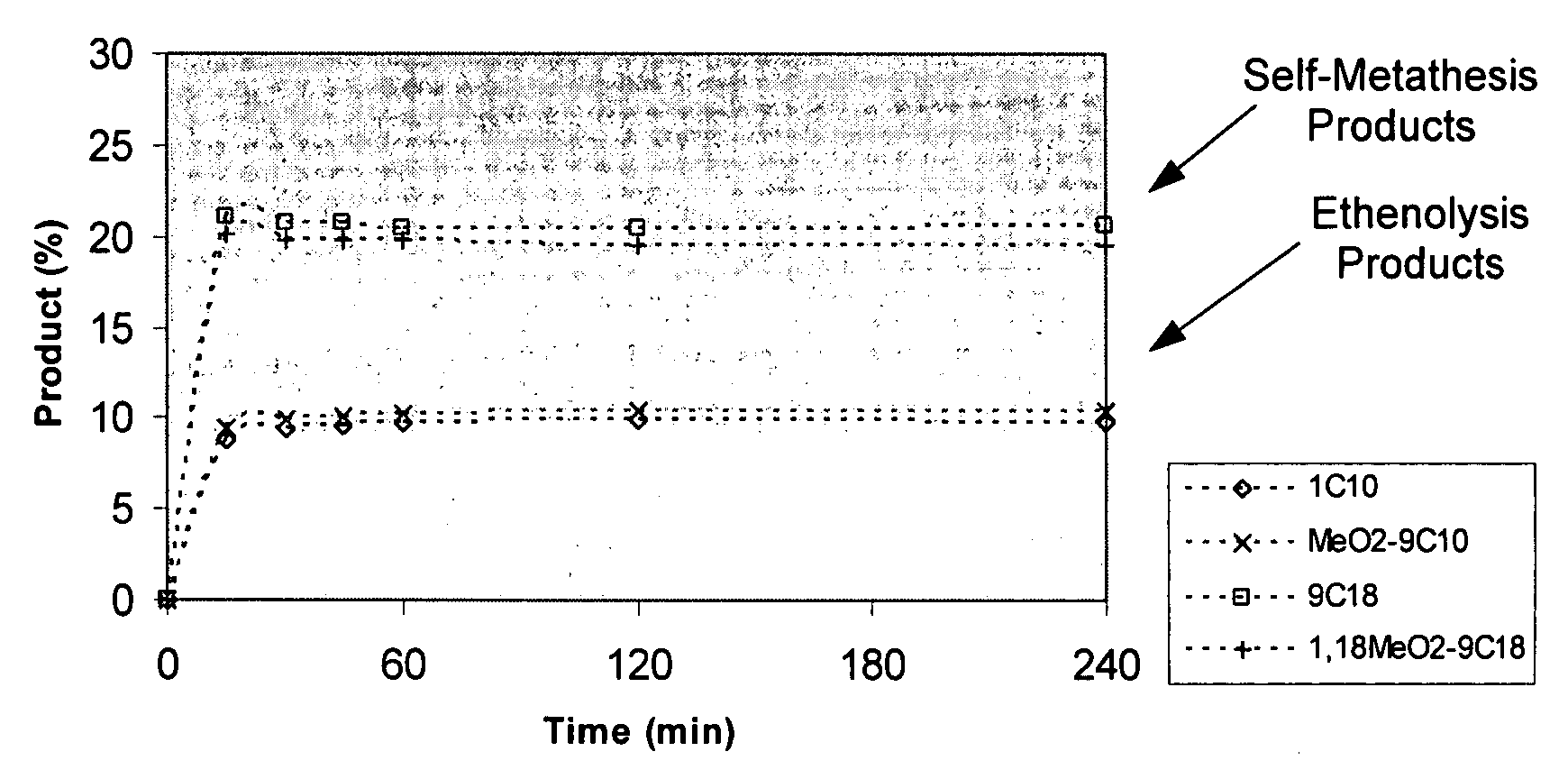

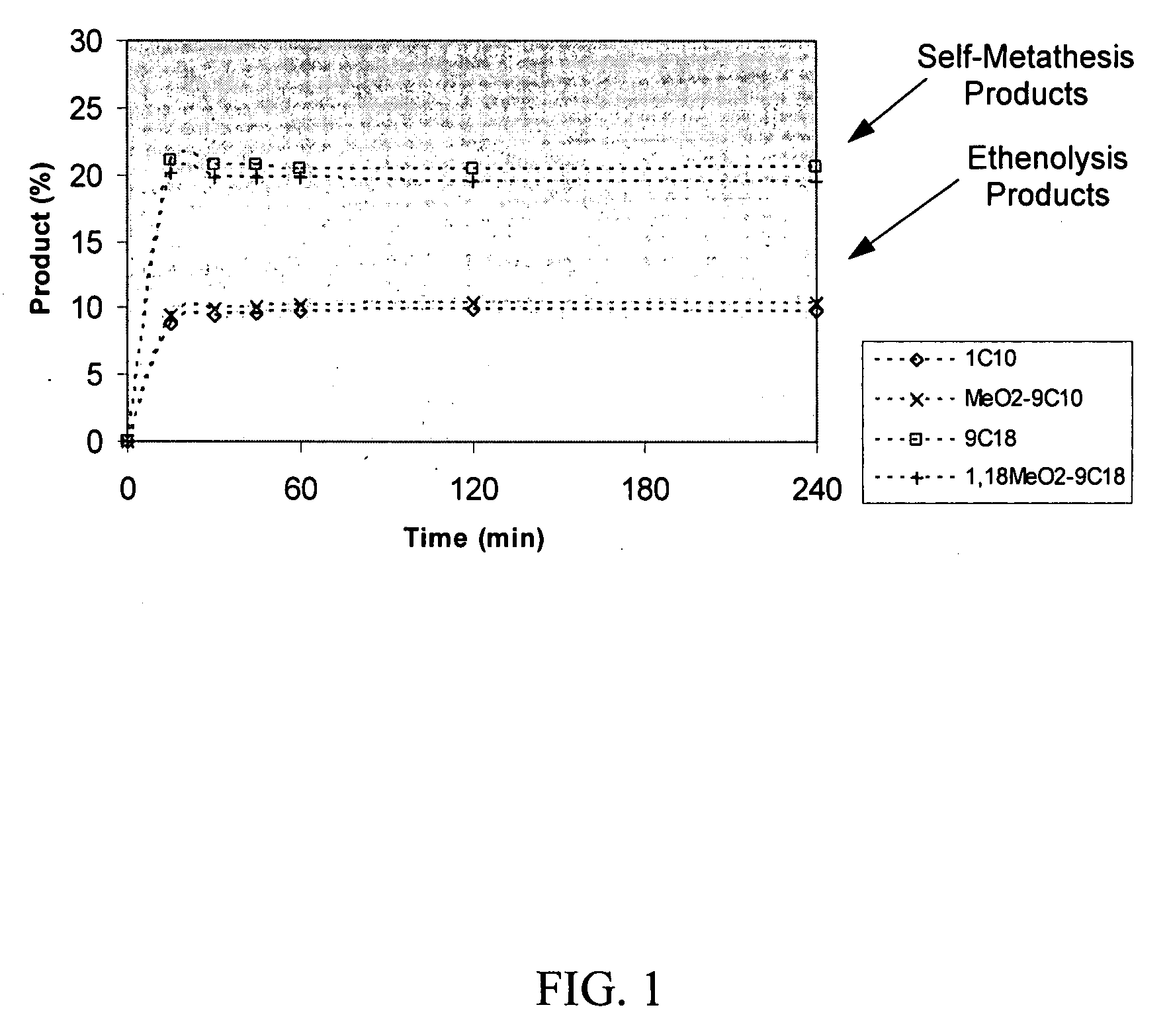

Metathesis process for preparing an alpha, omega-functionalized olefin

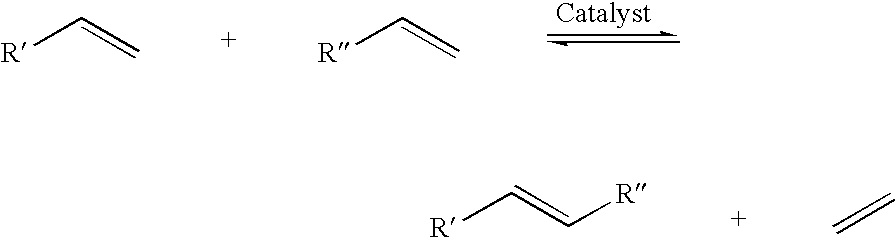

InactiveUS7812185B2Shorten the lengthImprove turnover rateOrganic compound preparationCarboxylic acid esters preparationReaction zoneAlpha-olefin

A cross-metathesis process for preparing an α,ω-functionalized olefin, such as methyl 9-decenoate, and an α-olefin having three or more carbon atoms, such as 1-decene. The process involves contacting in a first reaction zone an α-functionalized internal olefin, such as methyl oleate, and an α-olefinic monomer having three or more carbon atoms, such as 1-decene, with a first metathesis catalyst to prepare an effluent stream containing the α,ω-functionalized olefin, such as methyl 9-decenoate, an unfunctionalized internal olefin, such as 9-octadecene, unconverted reactant olefins, and optionally, an α,ω-difunctionalized internal olefinic dimer, such as dimethyl 9-octadecen-1,18-dioate; separating said effluent streams; then contacting in a second reaction zone the unfunctionalized internal olefin with ethylene in the presence of a second metathesis catalyst to obtain a second product effluent containing the α-olefinic monomer having three or more carbon atoms; and cycling a portion of the α-olefinic monomer stream(s) to the first zone.

Owner:DOW GLOBAL TECH LLC

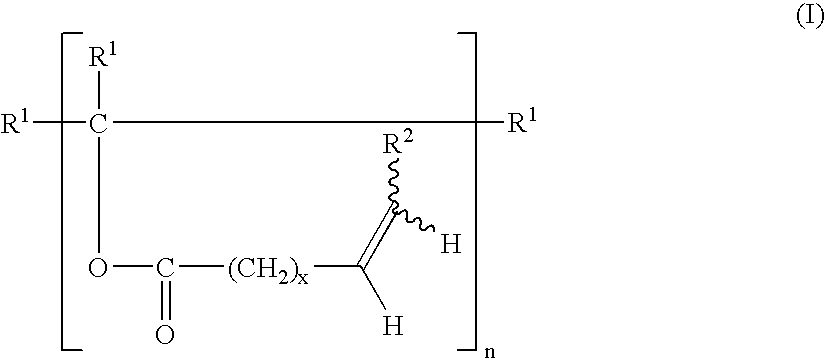

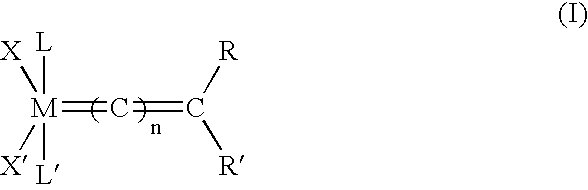

Catalytic compositions for the metathesis of unsaturated fatty bodies with olefins and metathesis methods using catalytic compositions

InactiveUS20100022789A1High conversion levelSignificant selectivityFatty acid chemical modificationOrganic compound preparationPtru catalystUnsaturated fat

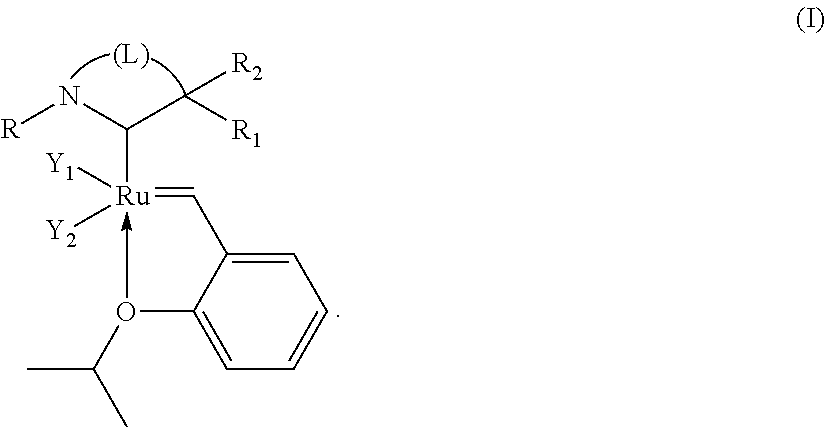

Catalytic compositions useful for carrying out the metathesis of unsaturated fatty bodies, in particular unsaturated fatty bodies comprising oleic acid or oleic acid esters, contain a ruthenium-based catalyst which can be isolated and which has the formula (I) below:

Owner:RHODIA OPERATIONS SAS +1

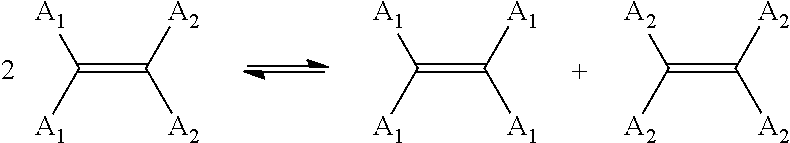

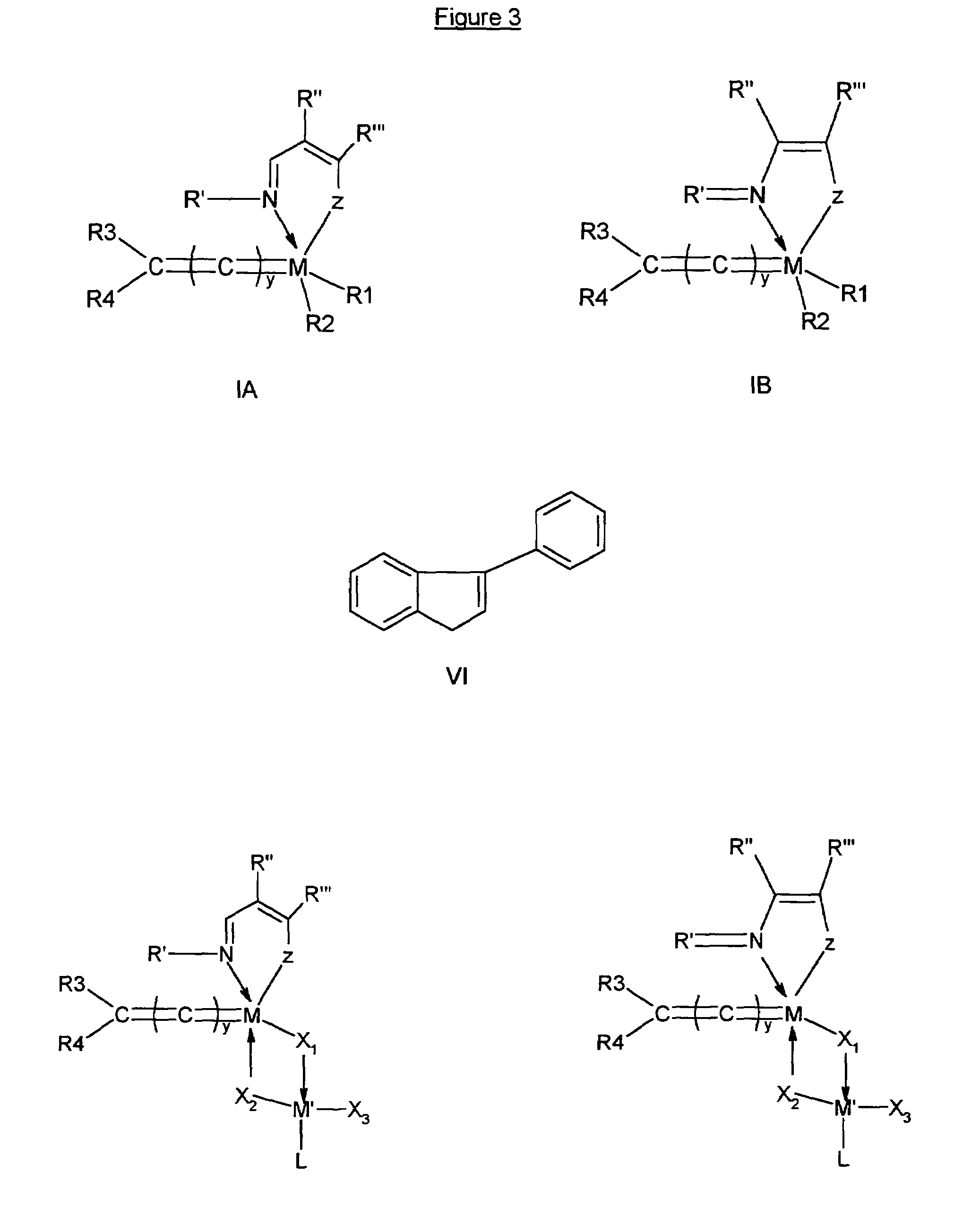

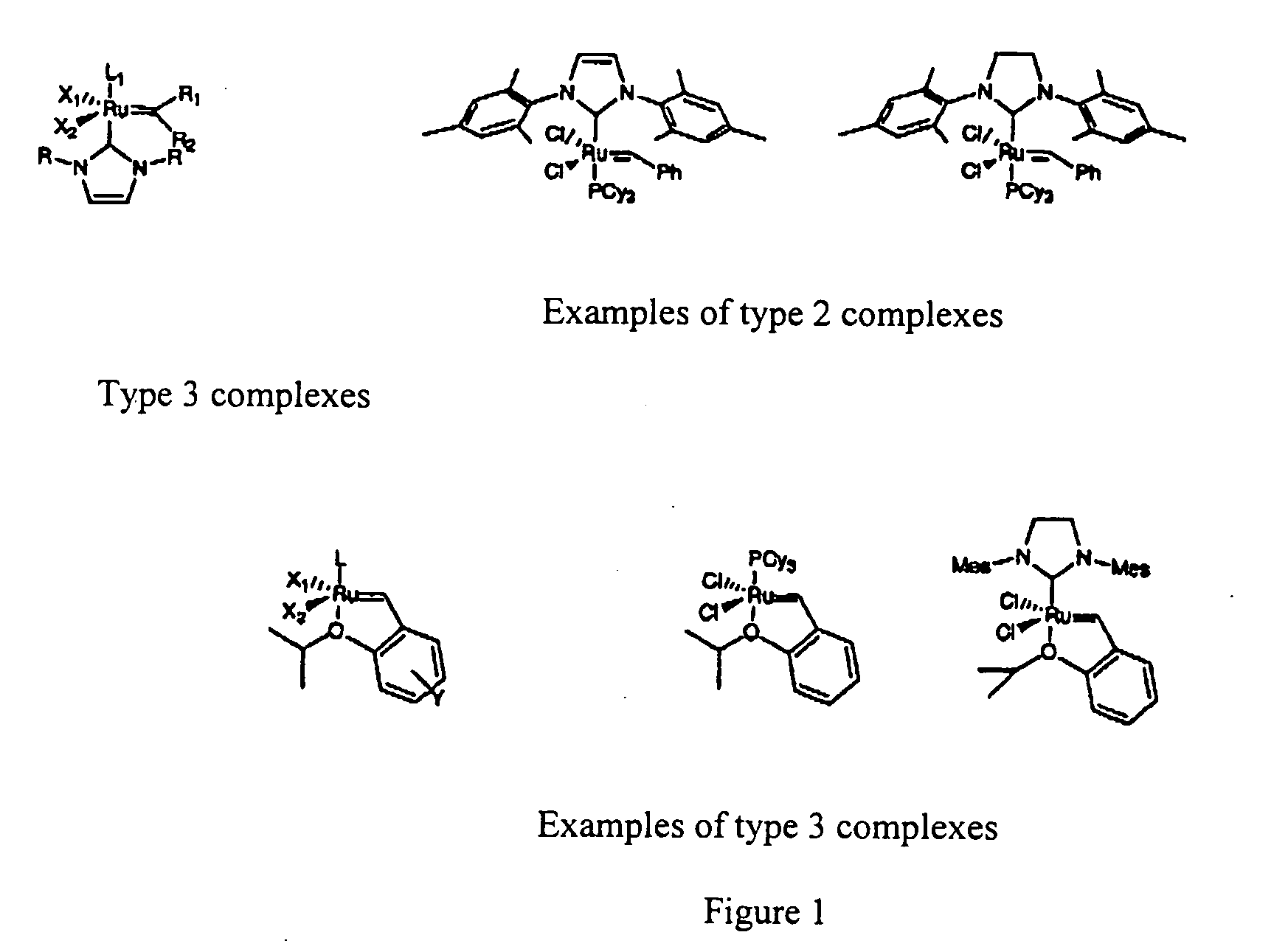

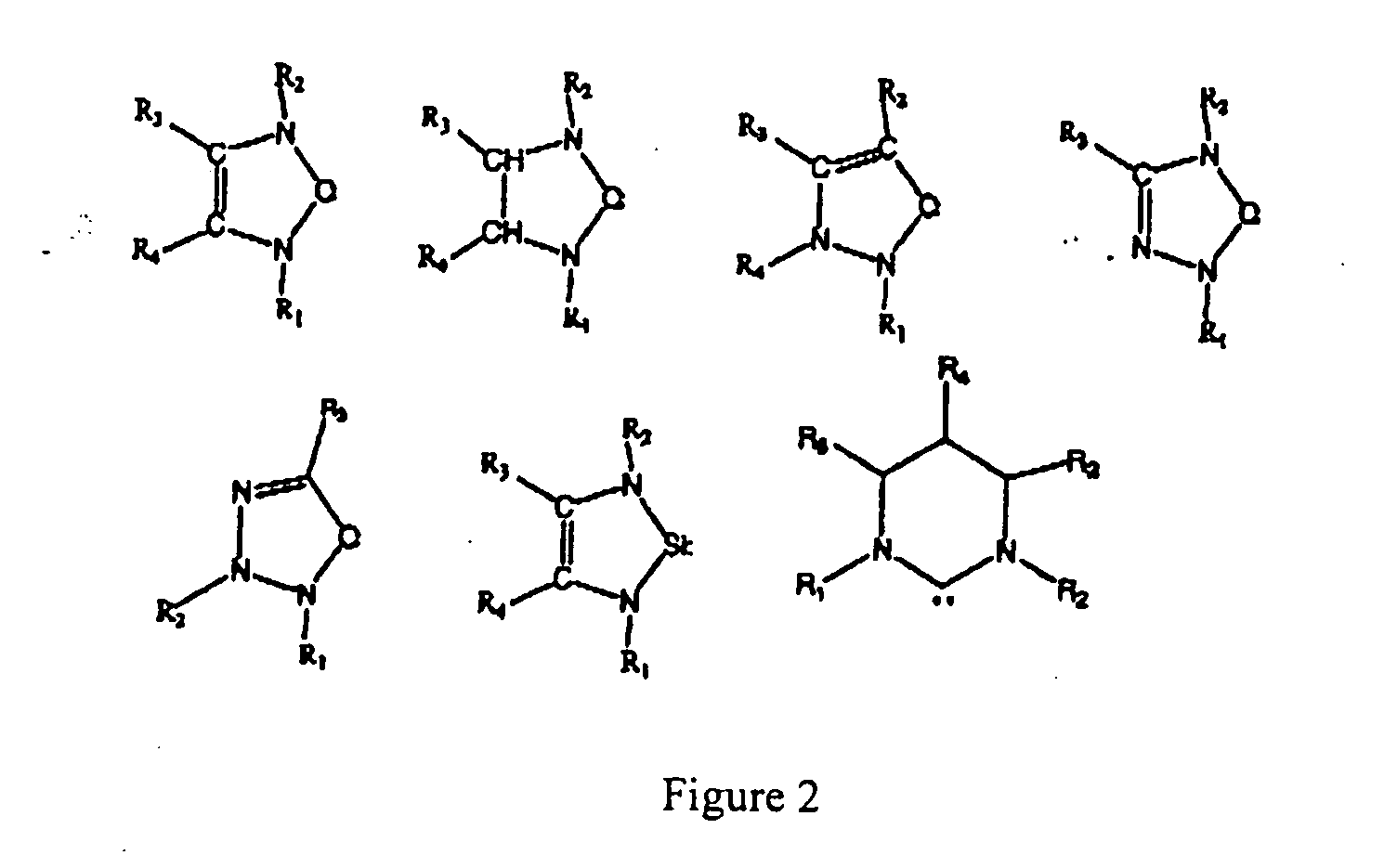

Metal complexes useful in metathesis and other reactions

InactiveUS20050043541A1Group 5/15 element organic compoundsOrganic chemistry methodsFuranHigh activity

This invention provides metal complexes being useful as catalyst components in metathesis reactions and in reactions involving the transfer of an atom or group to an ethylenically or acetylenically unsaturated compound or another reactive substrate and, with respect to a sub-class thereof, for the polymerisation of α-olefins and optionally conjugated dienes, with high activity at moderate tempera-tures. It also provides methods for obtaining polymers with very narrow molecular weight distribution by means of a living reaction. It also provides methods for making said metal complexes and novel intermediates involved in such methods. It further provides derivatives of said metal complexes which are suitable for covalent bonding to a carrier, the product of such covalent bonding being useful as a supported catalyst for heterogeneous catalytic reactions. It also provides a direct one-step synthesis of pyrrole, furan and thiophene compounds from diallyl compounds.

Owner:RIMTEC CORP

Production of propylene from steam cracking of hydrocarbons, particularly ethane

ActiveUS20050107650A1Improved and economical methodThermal non-catalytic crackingHydrocarbons from unsaturated hydrocarbon additionButenePolymer science

An ethane or other hydrocarbon feedstock is steam cracked to produce an ethylene stream which is processed in an ethylene plant recovery section to separate an ethane recycle and a polymer grade or chemical grade ethylene product stream. A portion of the ethylene product stream may then be reacted by dimerization to produce a butene stream. These formed butenes and / or butenes recovered from other sources and another portion of the ethylene product stream are reacted by metathesis to produce a propylene stream which is deethanized and separated from heavier hydrocarbons to produce the propylene product. The butene product stream may also be deethanized and is separated from heavier hydrocarbons. The overhead from the metathesis section deethanizer may be recycled to the ethylene plant recovery section. The reflux for the metathesis section deethanizer may be generated from the overhead or may be a portion of the ethylene product stream.

Owner:ABB LUMMUS GLOBAL INC

Metal complexes useful in metathesis and other reactions

This invention provides metal complexes being useful as catalyst components in metathesis reactions and in reactions involving the transfer of an atom or group to an ethylenically or acetylenically unsaturated compound or another reactive substrate and, with respect to a sub-class thereof, for the polymerisation of α-olefins and optionally conjugated dienes, with high activity at moderate tempera-tures. It also provides methods for obtaining polymers with very narrow molecular weight distribution by means of a living reaction. It also provides methods for making said metal complexes and novel intermediates involved in such methods. It further provides derivatives of said metal complexes which are suitable for covalent bonding to a carrier, the product of such covalent bonding being useful as a supported catalyst for heterogeneous catalytic reactions. It also provides a direct one-step synthesis of pyrrole, furan and thiophene compounds from diallyl compounds.

Owner:RIMTEC CORP

Olefin metathesis catalysts and related methods

ActiveUS20080119678A1Group 5/15 element organic compoundsGroup 8/9/10/18 element organic compoundsChemical reactionAlkene

The present invention provides methods for the synthesis of catalysts and precursors thereof. Methods of the invention may comprise combining a catalyst precursor and at least one ligand to generate a catalytically active species, often under mild conditions and in high yields. In some cases, a wide variety of catalysts may be synthesized from a single catalyst precursor. Methods of the invention may also include the preparation of catalysts which, under reaction conditions known in the art, may have been difficult or impossible to prepare and / or isolate due to, for example, steric crowding at the metal center. The present invention also provides catalyst compositions, and precursors thereof, which may be useful in various chemical reactions including olefin metathesis. In some cases, methods of the invention may reduce the number of synthetic and purification steps required to produce catalysts and / or other reaction products, as well as reducing time, cost, and waste production.

Owner:MASSACHUSETTS INST OF TECH

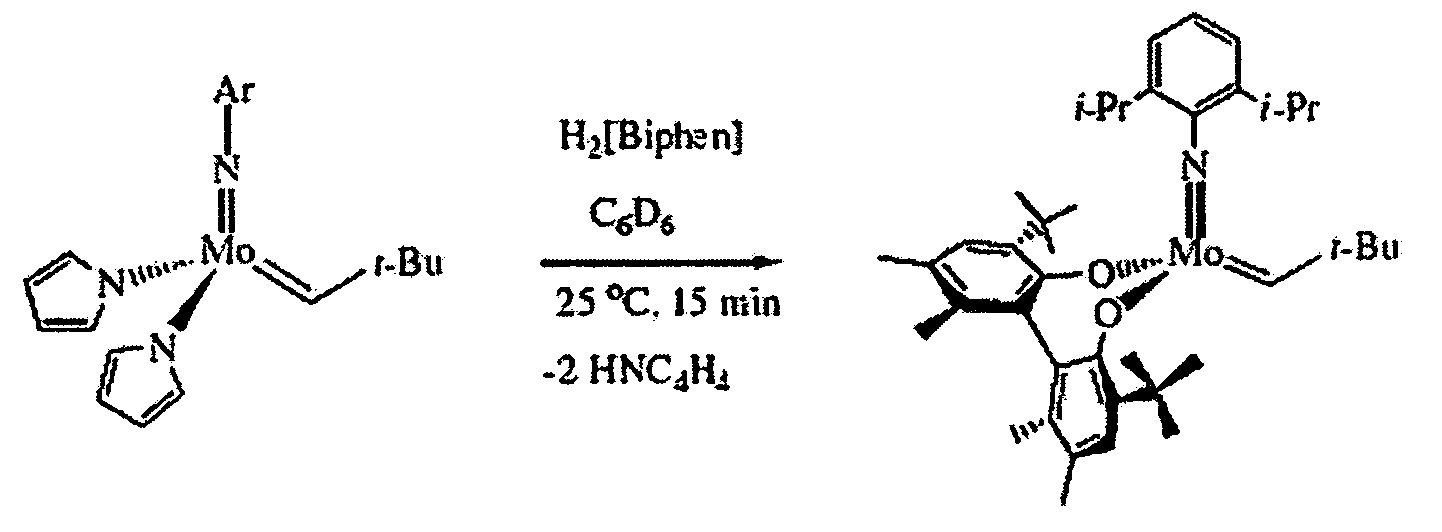

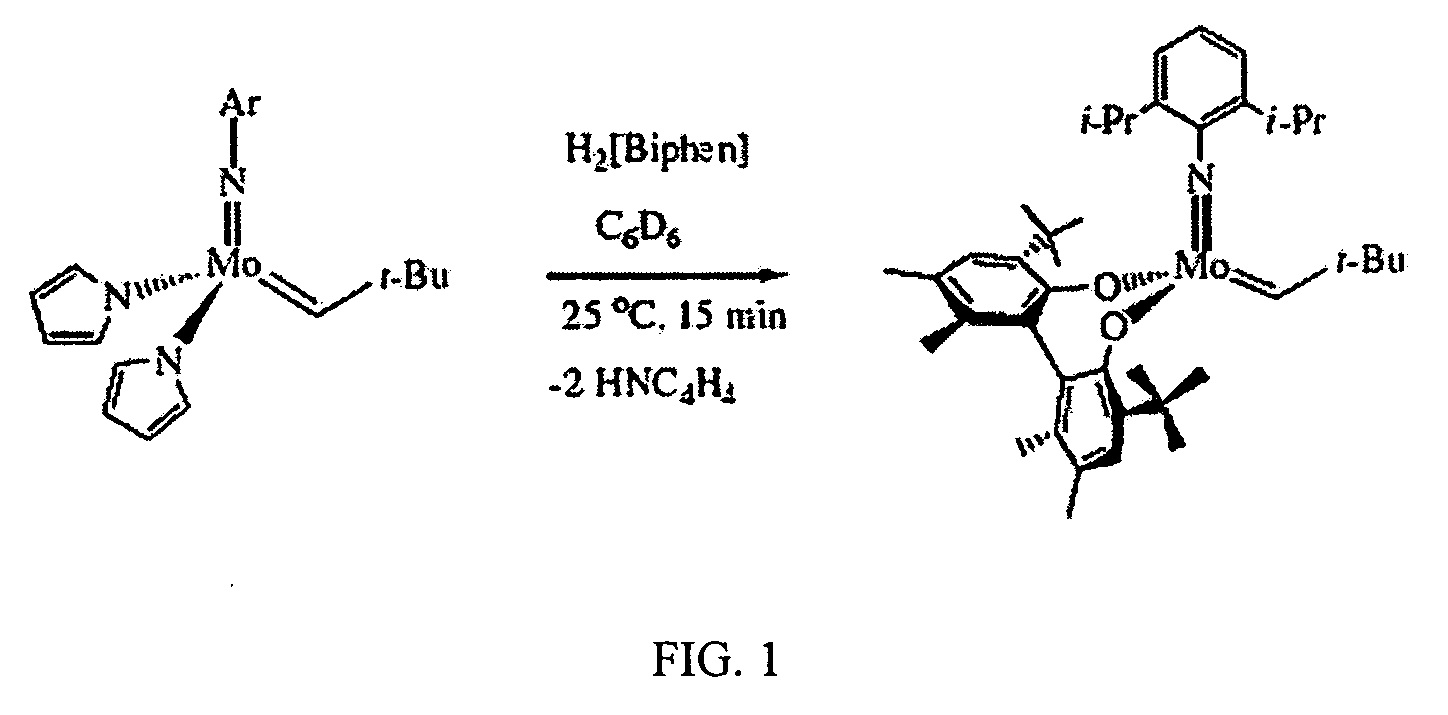

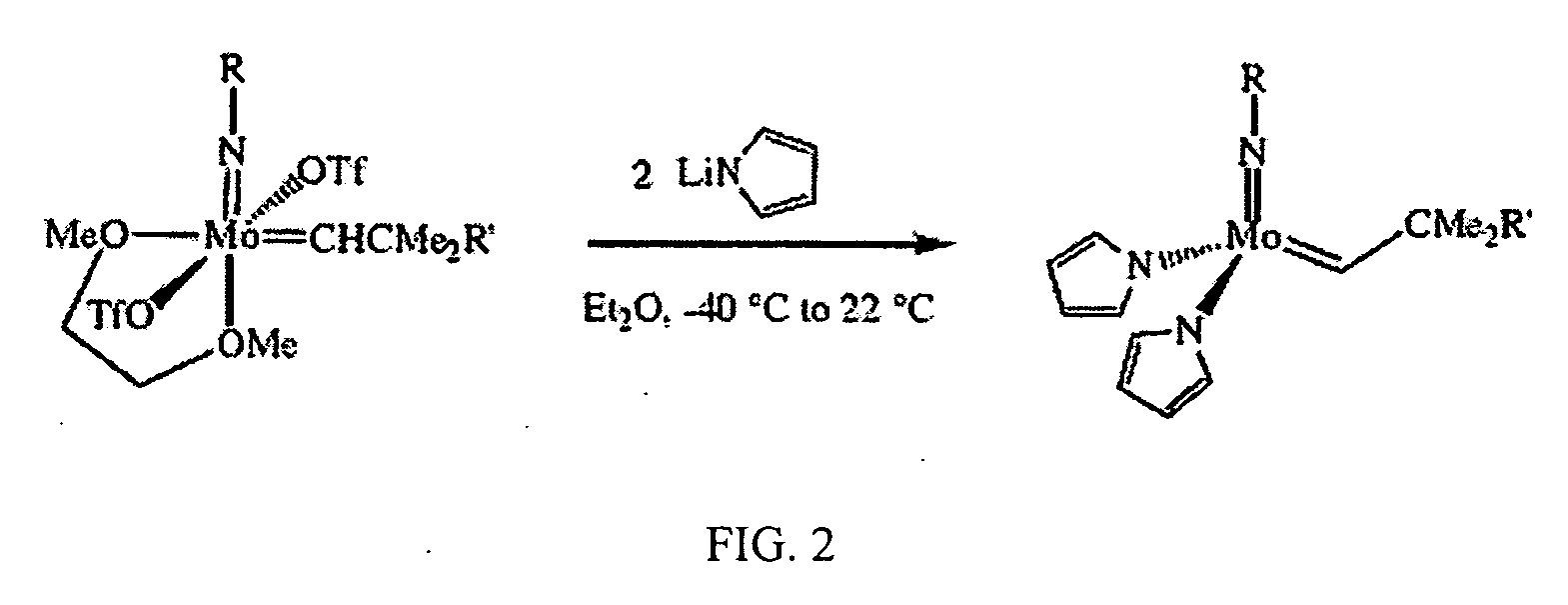

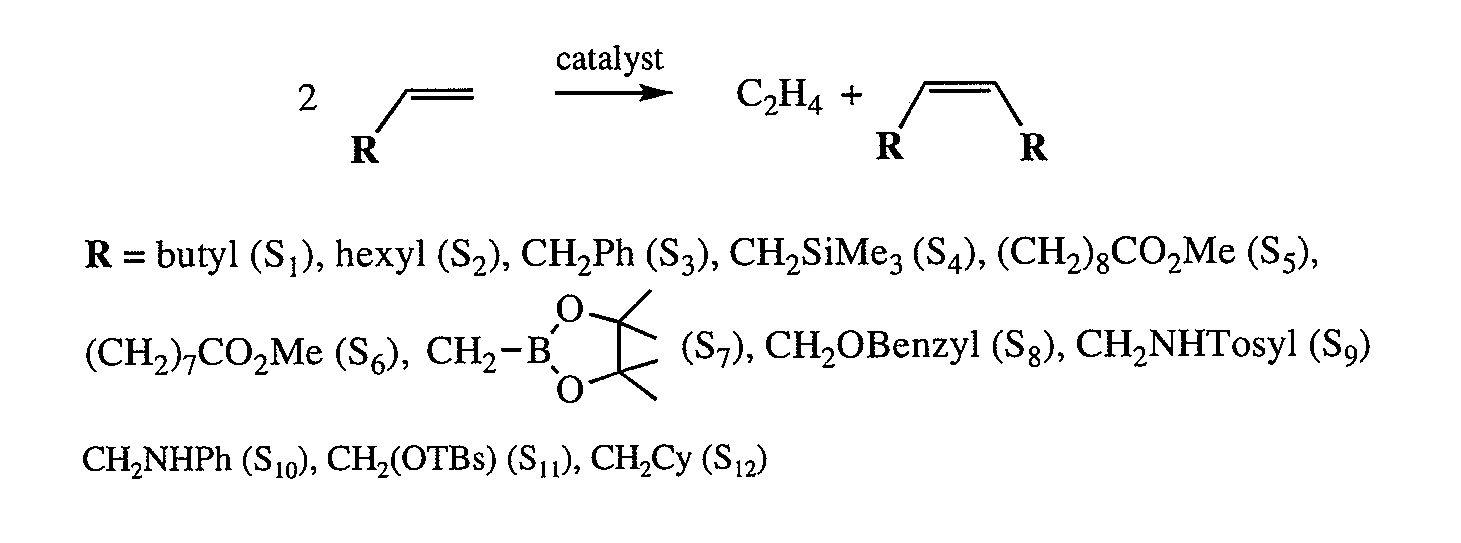

Highly z-selective olefins metathesis

ActiveUS20110077421A1Organic chemistry methodsCarboxylic acid esters preparationOrganic chemistryOlefin metathesis

Owner:MASSACHUSETTS INST OF TECH +1

Processing C4 olefin streams for the maximum production of propylene

ActiveUS20050014981A1Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

Catalysts and processes for the formation of terminal olefins by ethenolysis

ActiveUS20110015430A1Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHigh turnoverOrganic chemistry

The present invention relates generally to catalysts and processes for the formation of terminal olefin(s) from internal olefin(s) via ethenolysis reactions. The ethenolysis reactions may proceed with high conversion, high turnover, and / or high selectivity.

Owner:BOSTON COLLEGE +1

Method of Producing Propylene Containing Biomass-Origin Carbon

InactiveUS20080312485A1Quality improvementSwitch-over frequencyMolecular sieve catalystsBiofuelsButeneDecomposition

Ethanol obtained from ordinary biomass resources contains many impurities other than water and these impurities themselves or their decomposition products contaminate ethylene when the ethylene is produced by a dehydration reaction, whereby the activity of metathesis catalyst is adversely affected. A method for producing propylene of the present invention is characterized in that the ethanol obtained from biomass is converted to ethylene by a dehydration reaction, the ethylene is separated from the generated water, the separated ethylene is purified by adsorption in an adsorption tower filled with an adsorbent, and then a metathesis reaction is carried out along with a raw material containing n-butene. With the present invention, propylene having biomass-derived carbon and reduced-environmental burden can be efficiently produced without lowering the catalysis activity.

Owner:MITSUI CHEM INC

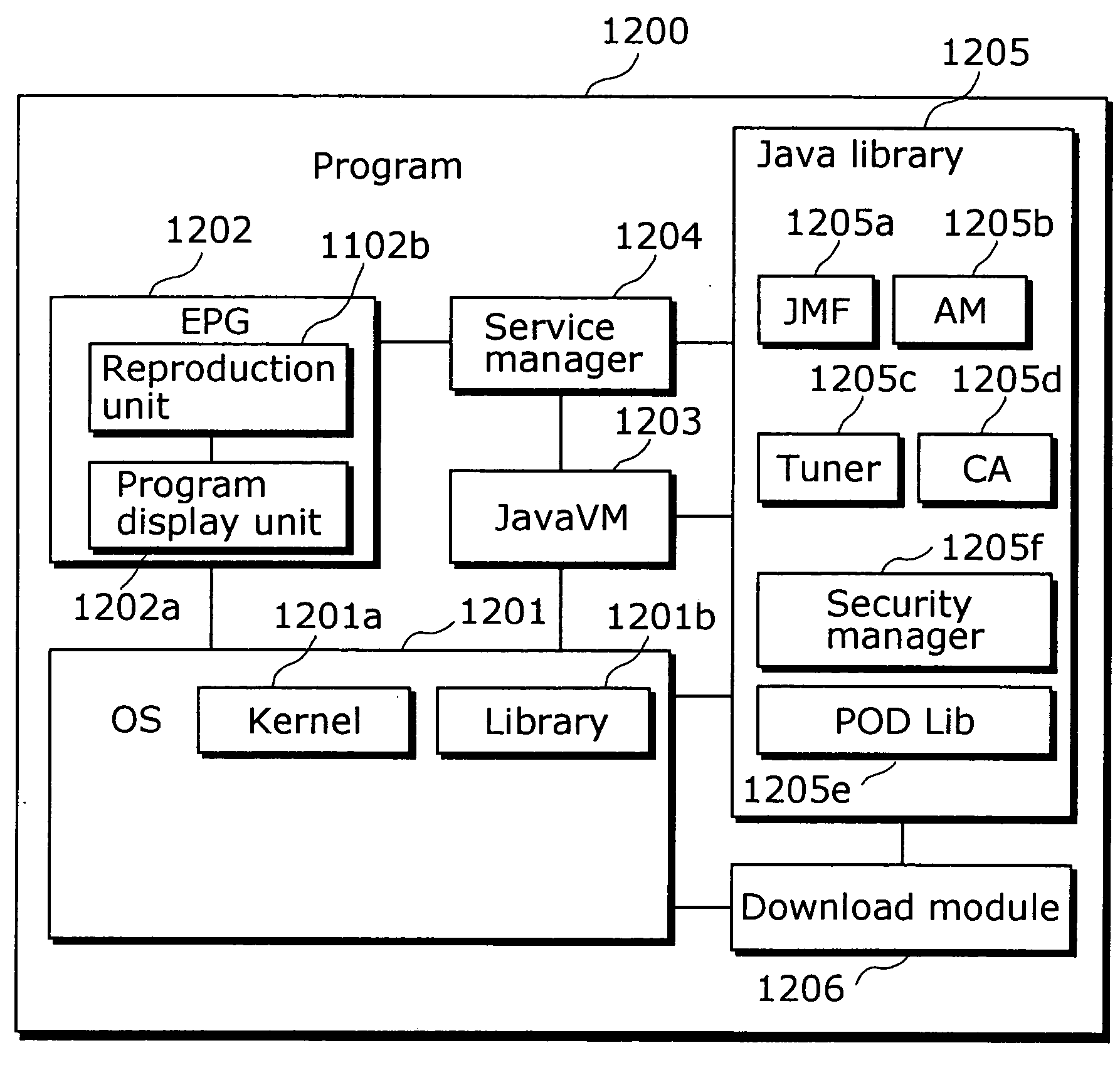

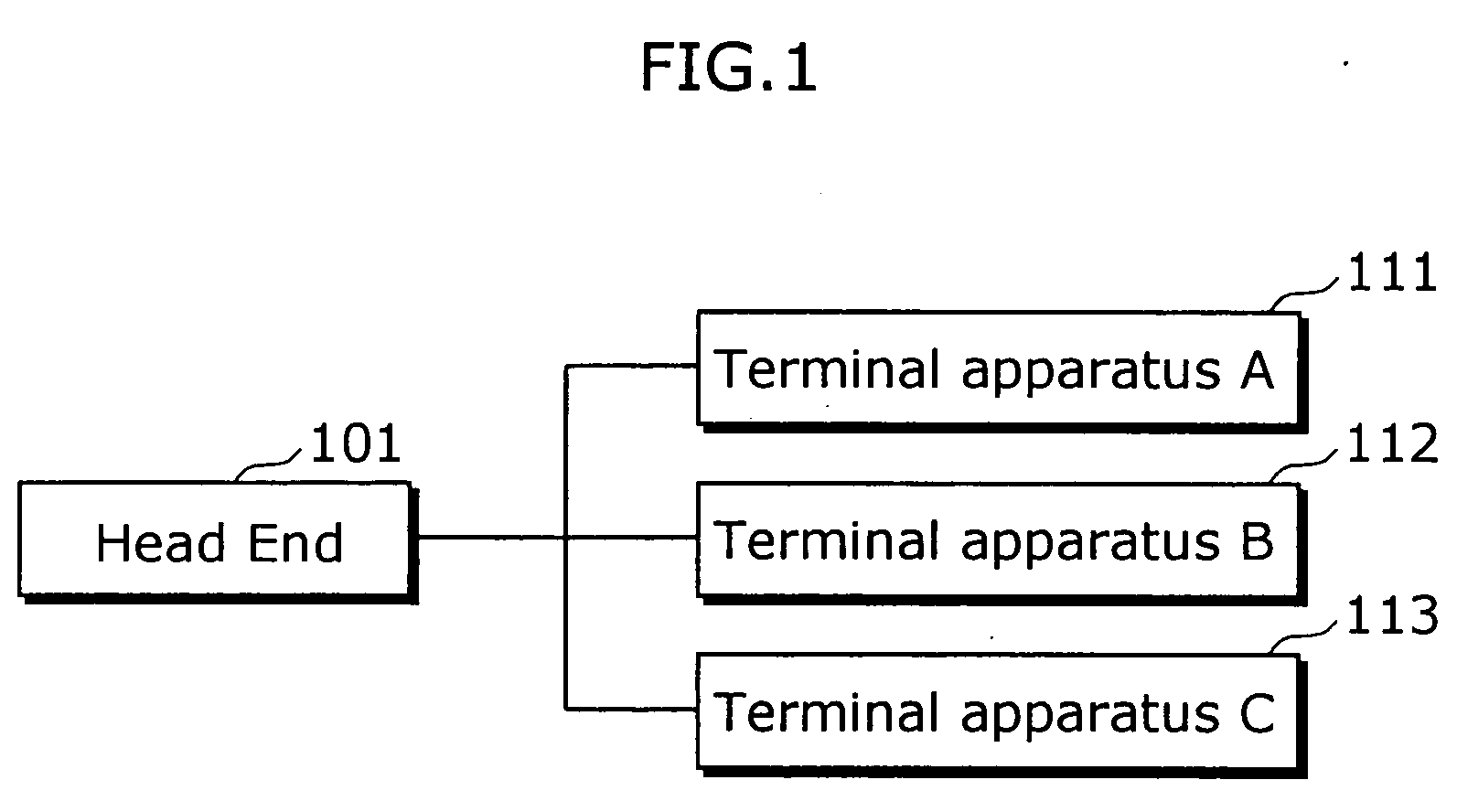

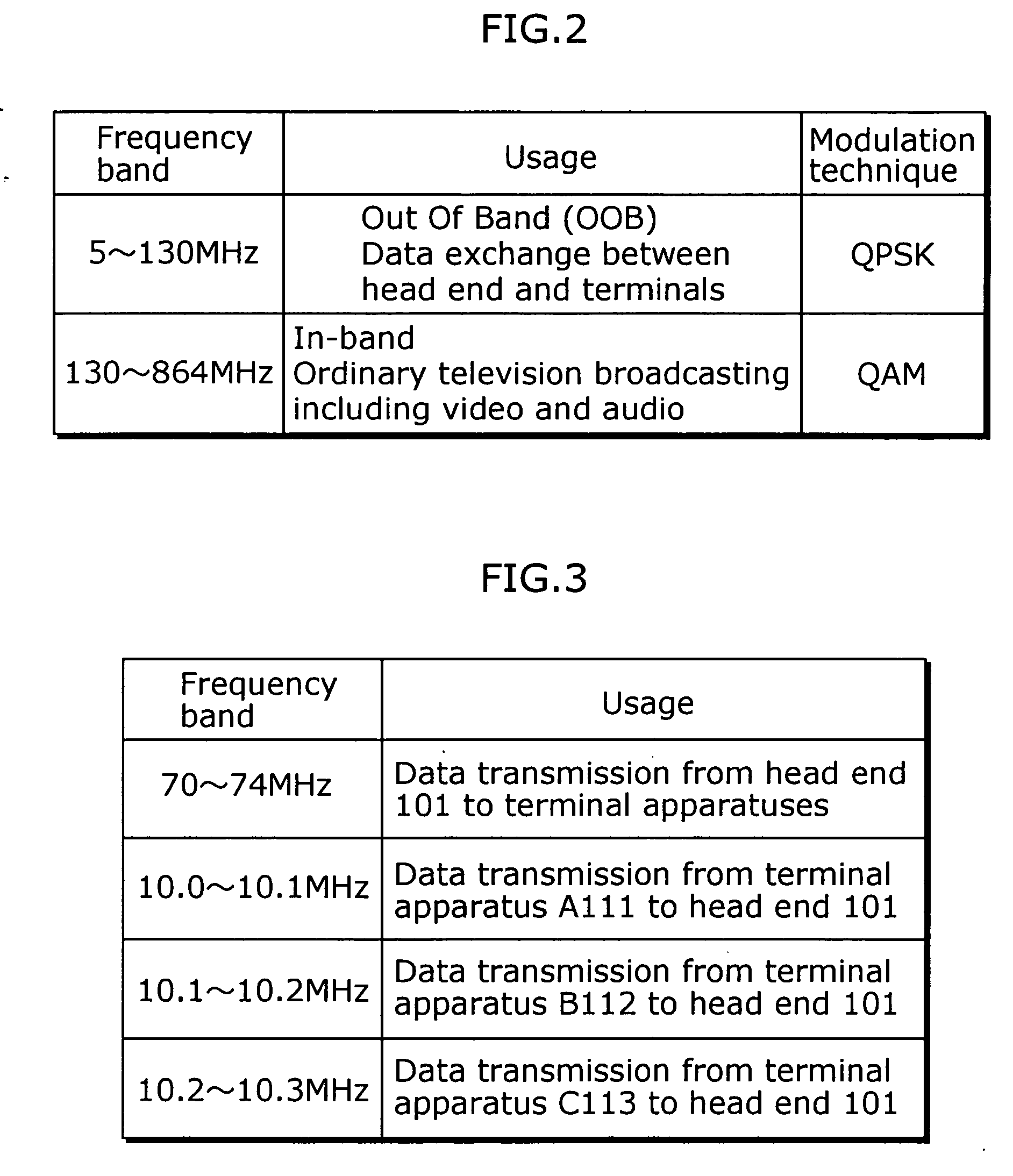

Authenticated program execution method

InactiveUS20050138397A1Guaranteed reputationImprove responsivenessUnauthorized memory use protectionHardware monitoringBiological activationAuthentication

According to a conventional technique, in the case where a program is stored into a non-volatile memory once and then activated, authentication of the program is performed immediately before such activation. However, calculations such as decryption of encrypted values are required before the activation of the program starts, which causes the problem that responsiveness is decreased in proportion to the time required for calculations. In order to solve this problem, authentication of a program is performed immediately before such program is stored, so that no authentication is performed or only a part of the authentication is performed to verify the validity of certificates at program activation time.

Owner:PANASONIC CORP

Process for co-producing olefins and esters by ethenolysis of unsaturated fats in non-aqueous ionic liquids

A process is described in which an unsaturated fat is reacted with ethylene in a metathesis reaction in the presence of at least one non-aqueous ionic liquid to produce both an olefinic fraction and a composition of monoalcohol or polyol esters. Particular application to an oleic sunflower seed oil, an oleic rapeseed oil or to a mixture of monoalcohol esters of said oils, the process producing both an olefinic fraction and a monoalcohol or glycerol esters composition generally having more than half of its chains constituted by unsaturated C10 chains.

Owner:INST FR DU PETROLE

Ruthenium metathesis catalyst and method for producing olefin reaction product by metathesis reaction using the same

InactiveUS6175047B1Easy to prepareHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsCarbon–carbon bondReducing agent

The invention has an object of safely and simply preparing a large amount of a ruthenium metathesis catalyst, which is used as a catalyst for a carbon-carbon bond formation using, particularly, a metathesis reaction. The metathesis catalyst has the following complex composition (A) or (B). The composition (A) includes RuX12(arene)(PR1R2R3) and R4CHX22, R5C=CH or R4CHX2 and a reducing agent, wherein X1 and X2 respectively are a halogen atom; arene is a hydrocarbon having a benzene ring; R1, R2 and R3, which may be the same or different, respectively are an alkyl group having 1-8 carbon atoms, a cycloalkyl group having 3-8 carbon atoms or an optionally substituted aryl group, wherein the substituent group is an alkyl group having 1-8 carbon atoms, an alkoxy group having 1-8 carbon atoms, an alkylamino group having 1-8 carbon atoms or a halogen atom; R4 is an alkyl group which has 1-8 carbon atoms and may have an ether bond or an ester bond, an optionally subsituted aryl group, wherein the substituent group is a halogen atom or a hydroxyl group; or cycloalkyl group having 3-8 carbon atoms; and R5 is an optionally substituted alkyl group which has 1-8 carbon atoms and may have an ether bond or an ester bond, wherein the substituent group is a halogen atom or a hydroxyl group, an aryl group or a cycloalkyl group having 3-8 carbon atoms. The composition B includes [RuX12(arene)]2, PR1R2R3, R5C=CH or R4CHX2 and a reducing agent, wherein X1, arene, R1, R2, R3, R4 and R5 are the same as defined above.

Owner:TAKASAGO INTERNATIONAL CORPORATION

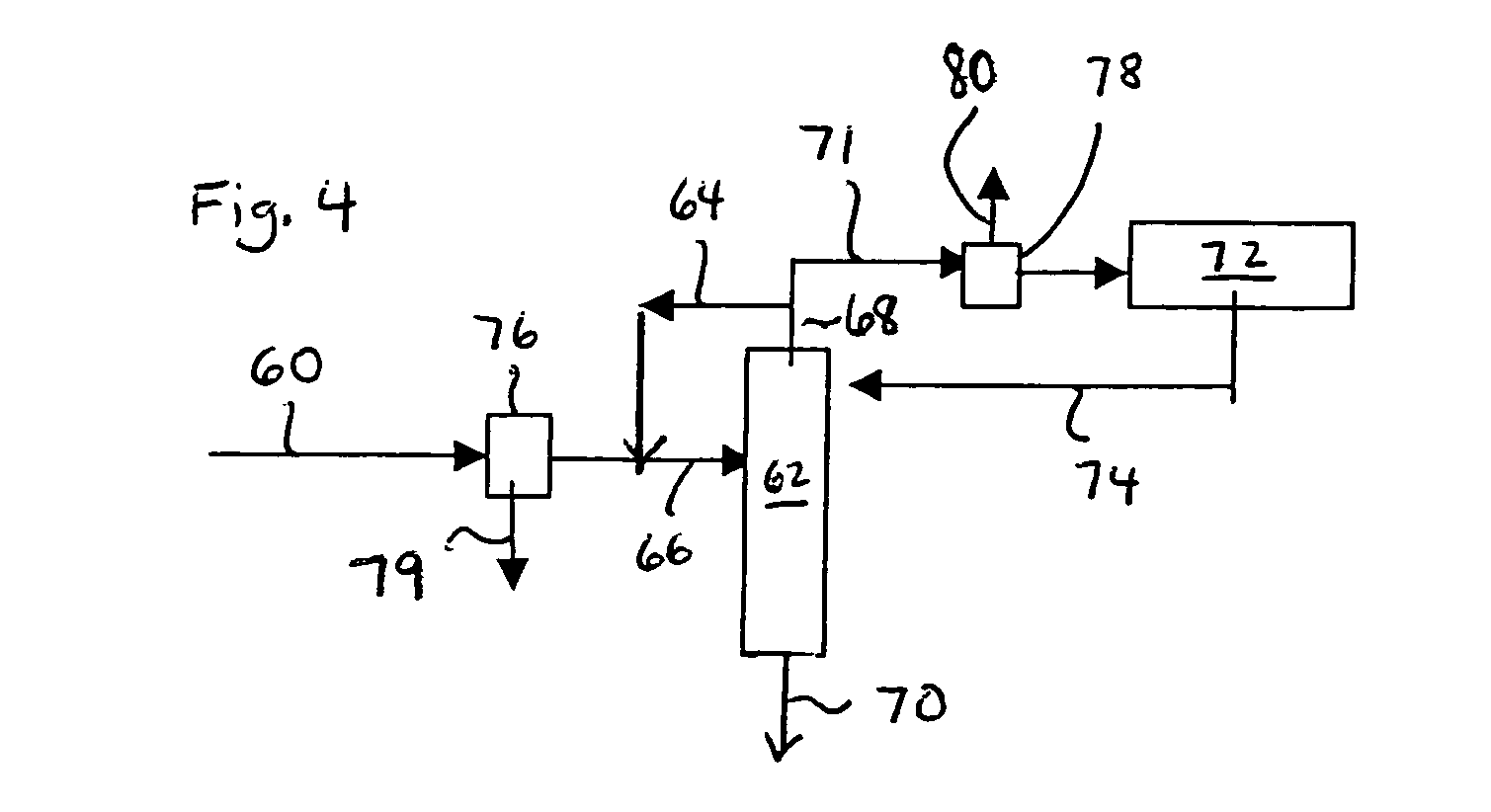

Production of 1-Butene and Propylene From Ethylene

ActiveUS20120095275A1Reduce the amount requiredIncrease productionHydrocarbon by isomerisationHydrocarbons from unsaturated hydrocarbon additionEthylenePropene

A process for producing propylene and 1-butene is disclosed. The process comprises dimerizing ethylene in the presence of a dimerization catalyst to produce a dimerization mixture comprising 1-butene and 2-butenes. The dimerization mixture is distilled to produce a 1-butene stream containing 1-butene and ethylene, a 2-butenes stream, and a heavy stream. The 2-butenes stream is reacted with ethylene in the presence of a metathesis catalyst to produce a metathesis mixture comprising propylene, ethylene, and 2-butenes. Propylene is separated from the metathesis mixture.

Owner:EQUSR CHEM LP +1

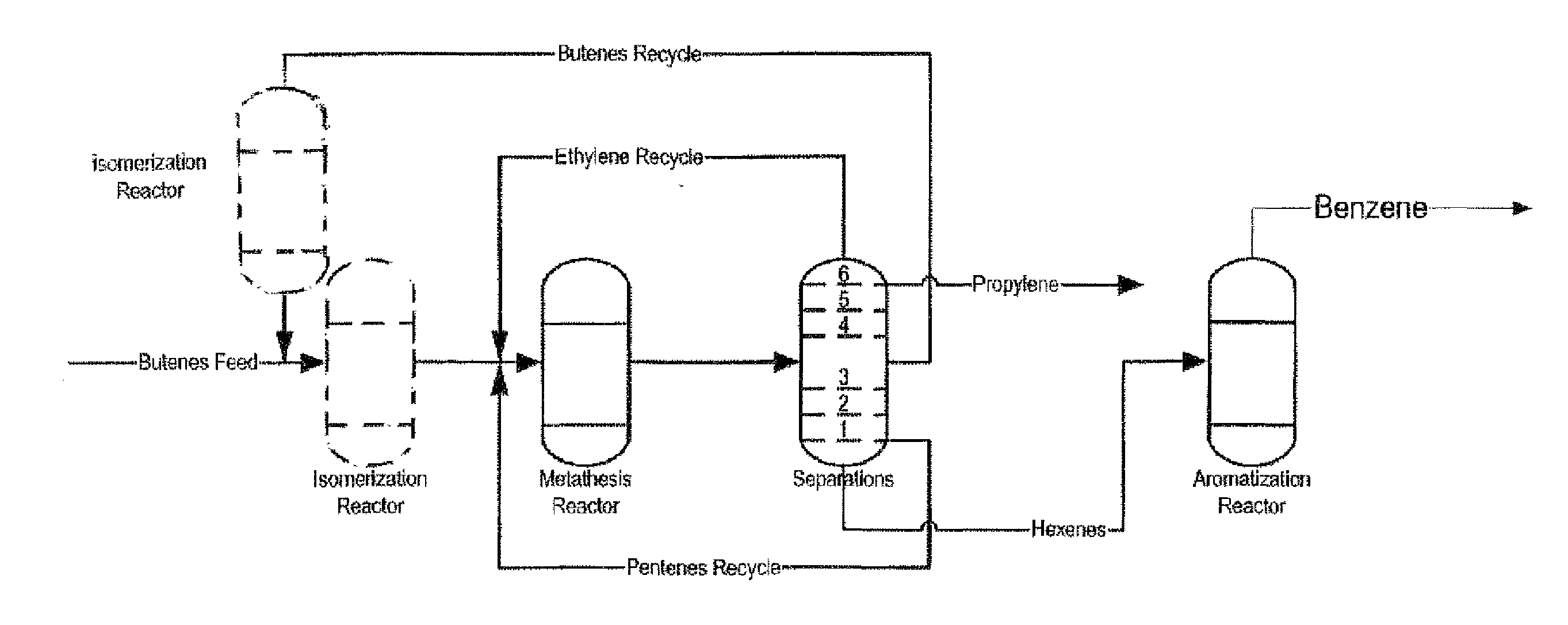

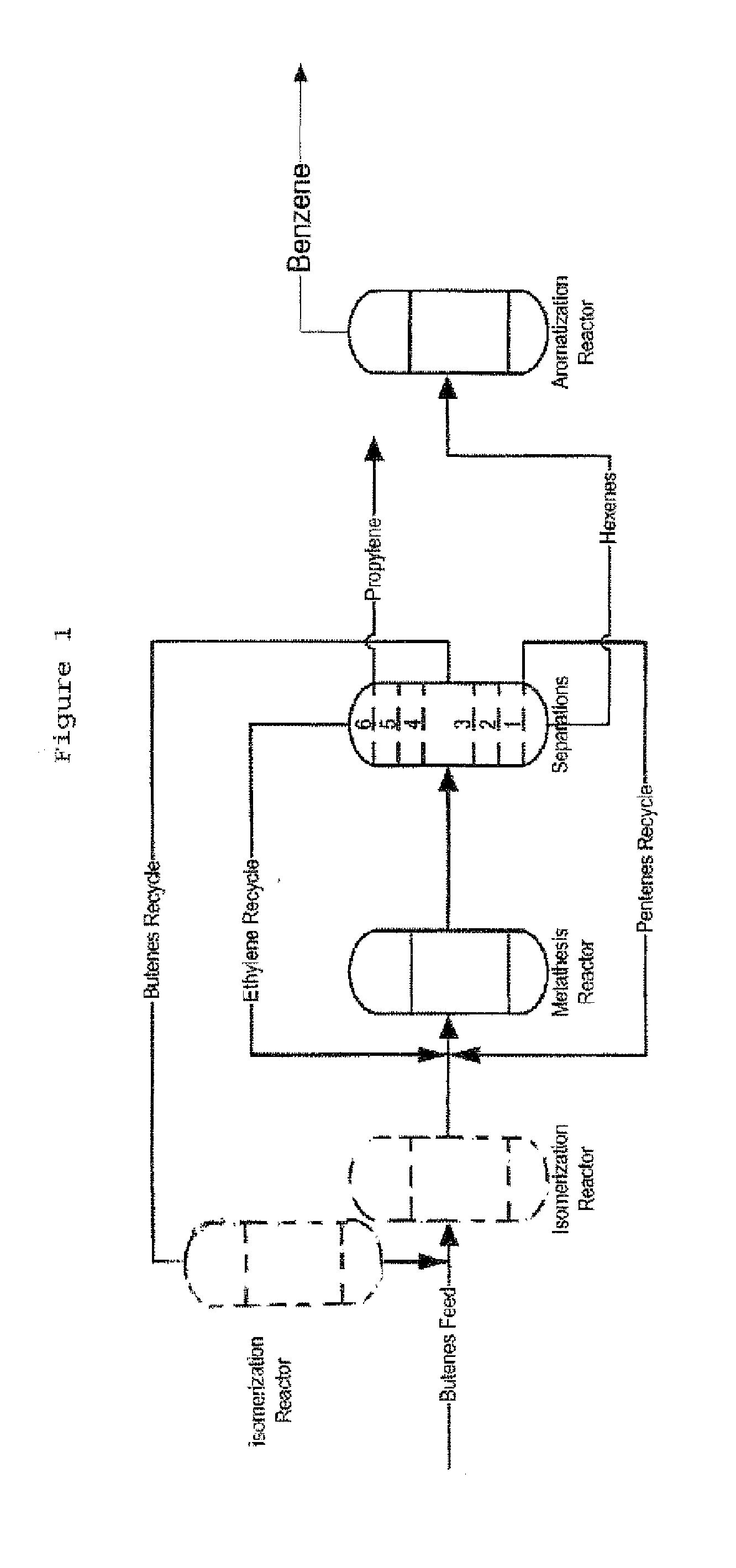

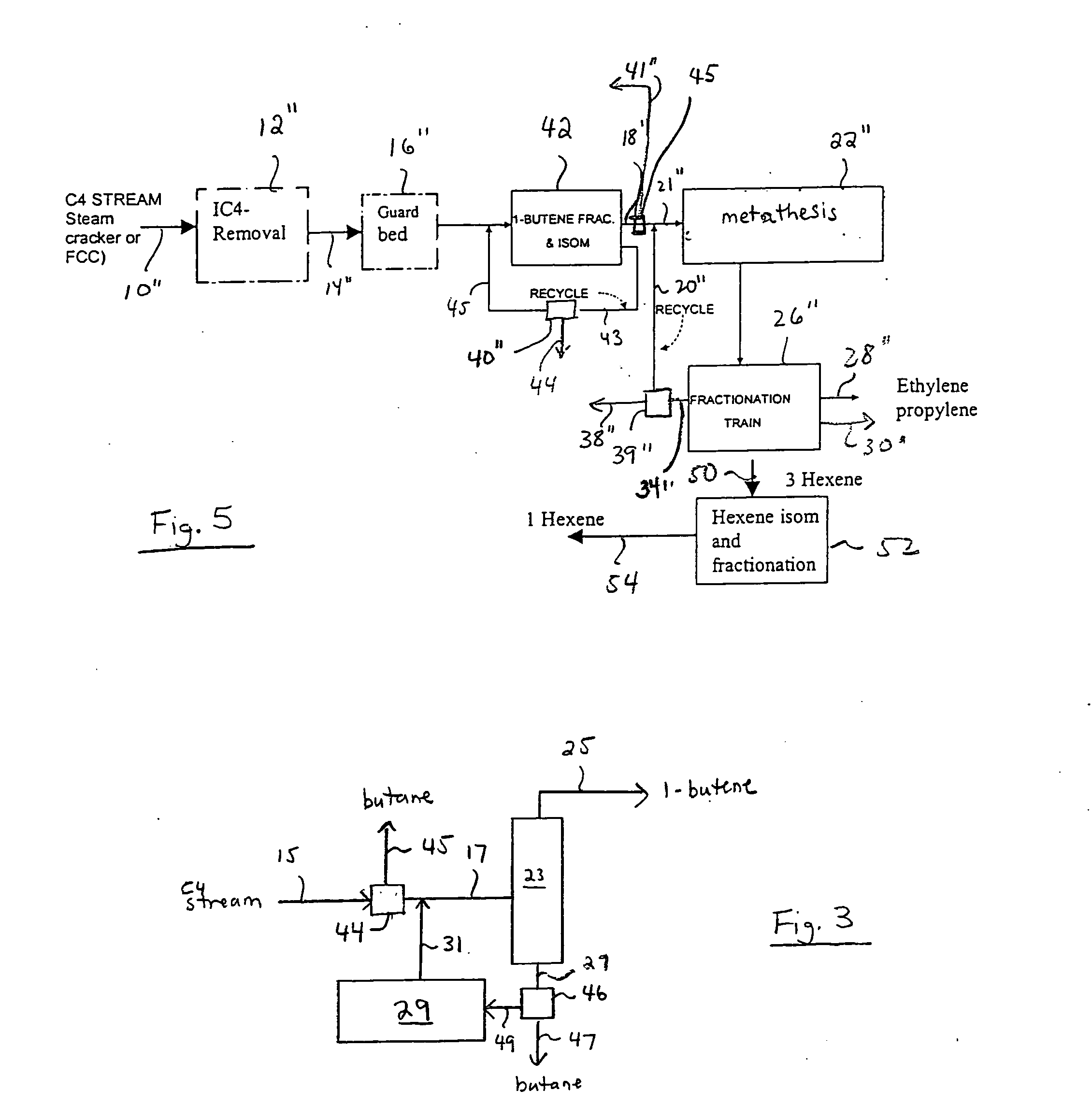

Process for Producing Propylene and Aromatics from Butenes by Metathesis and Aromatization

InactiveUS20110263917A1Molecular sieve catalystDistillation purification/separationIsomerizationOctene

The invention is for a process for producing propylene and hexene (along with ethylene, pentenes, product butenes, heptenes and octenes) by metathesis from butenes (iso-, 1- and cis and trans 2-) and pentenes and then aromatizing the hexenes (along with higher olefins, such as heptenes and octenes) to benzene (along with toluene, xylenes, ethylbenzene and styrene). Since the desired products of the metathesis reaction are propylene and hexene, the feed to the metathesis reaction has a molar ratio for 1-butene:2-butene which favors production of propylene and 3-hexene with the concentration of hexenes and higher olefins in the metathesis product being up to 30 mole %. An isomerization reactor may be used to obtain the desired molar ratio of 1-butene:2-butene for the feed composition into the metathesis reactor. After the metathesis reaction, of hexene and higher olefins are separated for aromatization to benzene and other aromatics.

Owner:SAUDI BASIC IND CORP SA

Metathesis Process For Preparing An Alpha, Omega-Functionalized Olefin

InactiveUS20080228017A1Shorten the lengthImprove turnover rateOrganic compound preparationCarboxylic acid esters preparationReaction zoneAlpha-olefin

A cross-metathesis process for preparing an α,ω-functionalized olefin, such as methyl 9-decenoate, and an α-olefin having three or more carbon atoms, such as 1-decene. The process involves contacting in a first reaction zone an α-functionalized internal olefin, such as methyl oleate, and an α-olefinic monomer having three or more carbon atoms, such as 1-decene, with a first metathesis catalyst to prepare an effluent stream containing the α,ω-functionalized olefin, such as methyl 9-decenoate, an unfunctionalized internal olefin, such as 9-octadecene, unconverted reactant olefins, and optionally, an α,ω-difunctionalized internal olefinic dimer, such as dimethyl 9-octadecen-1,18-dioate; separating said effluent streams; then contacting in a second reaction zone the unfunctionalized internal olefin with ethylene in the presence of a second metathesis catalyst to obtain a second product effluent containing the α-olefinic monomer having three or more carbon atoms; and cycling a portion of the α-olefinic monomer stream(s) to the first zone.

Owner:DOW GLOBAL TECH LLC

Impurity reduction in Olefin metathesis reactions

InactiveUS7507854B2Reduced responseIncrease productionOrganic compound preparationCarboxylic acid esters preparationAcetic acidBenzoic acid

The present invention relates to the use of isomerization inhibitors in olefin metathesis reactions. The inhibitors are low molecular weight organic acids such as formic acid, acetic acid, benzoic acid, and the like.

Owner:MATERIA

Butane removal in C4 upgrading processes

InactiveUS20060047176A1High efficiency and low costHydrocarbon by isomerisationChemical industryButeneAlkane

Disclosed herein is a process for producing a selected butene, comprising obtaining a C4 feed stream comprising C4 paraffins and C4 olefins, splitting the C4 feed stream to form a first stream comprising a first butene and a second stream comprising a second butene, isomerizing at least a part of the second stream to convert a portion of the second butene to the first butene, and recycling at least some of the isomerized part of the second steam to the splitting step, wherein a portion of at least one of the C4 feed stream and the second stream is passed through a facilitated transport membrane to remove butanes, forming at least one purge stream comprising butanes. A process for the conversion of C4 olefins, comprising obtaining a C4 feed stream comprising C4 paraffins and C4 olefins, including 1-butene and 2-butene, and reacting the C4 feed stream in a metathesis reactor to form a second stream is also disclosed. The second stream is fractionated to form one or more product streams and a recycle stream primarily containing C4 olefins and C4 paraffins. The recycle stream and / or the C4 feed stream is passed through a facilitated transport membrane to remove butanes, forming at least one purge stream.

Owner:ABB LUMMUS GLOBAL INC

Popular searches

Hydrocarbon preparation catalysts Catalyst activation/preparation Catalytic reactions Metal/metal-oxides/metal-hydroxide catalysts Bulk chemical production Treatment with hydrotreatment processes Hydrogen/synthetic gas production Hydrocarbon from saturated and unsaturated hydrocarbon addition Hydrocarbon oils treatment products Refining to eliminate hetero atoms

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com