Patents

Literature

64 results about "High turnover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This can happen for a variety of reasons, including job dissatisfaction, conflict with management or a toxic work environment. High turnover is simply an excessive occurrence of turnover, resulting in serious shortfalls in productivity and revenue, due to the need for constantly hiring and training new employees.

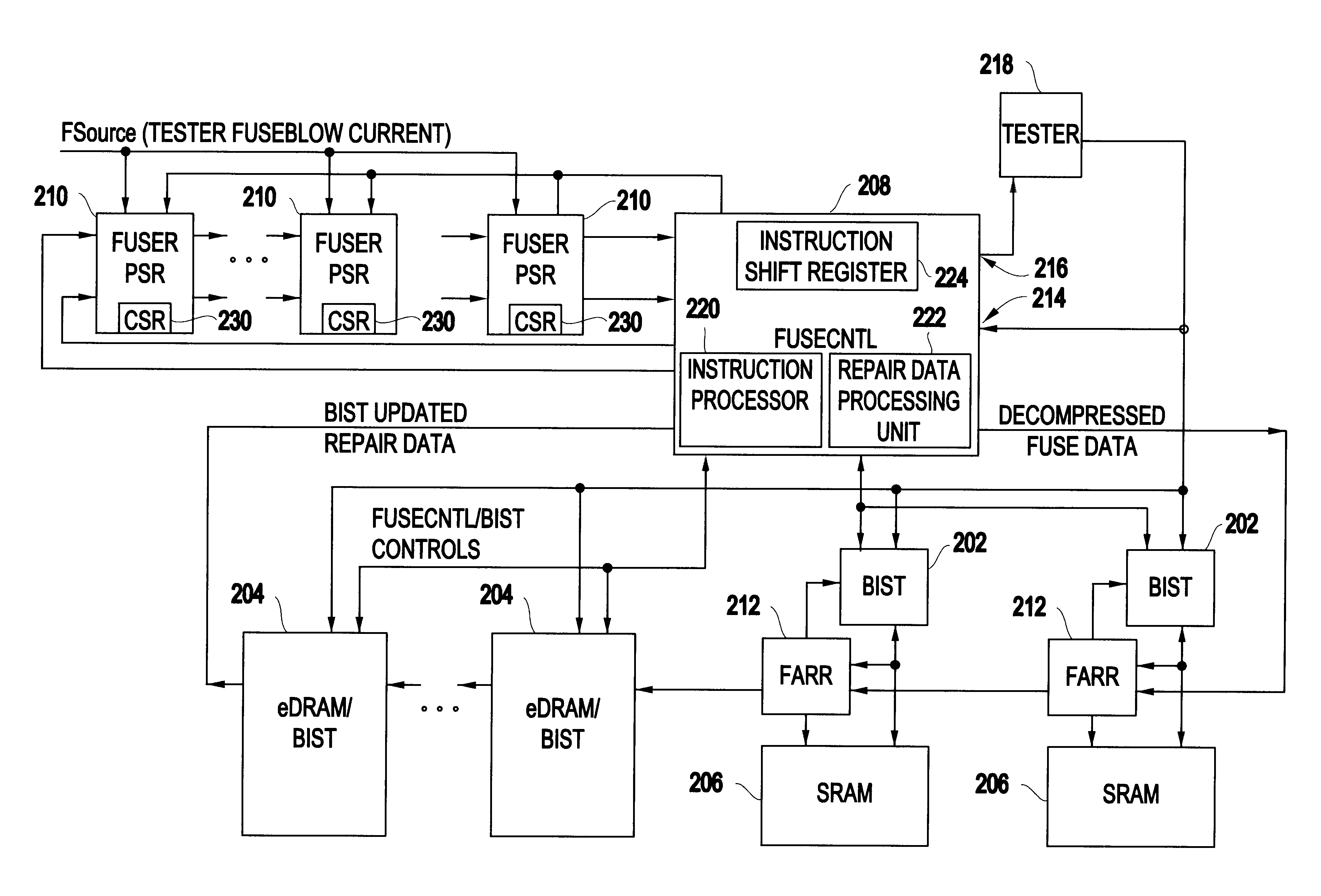

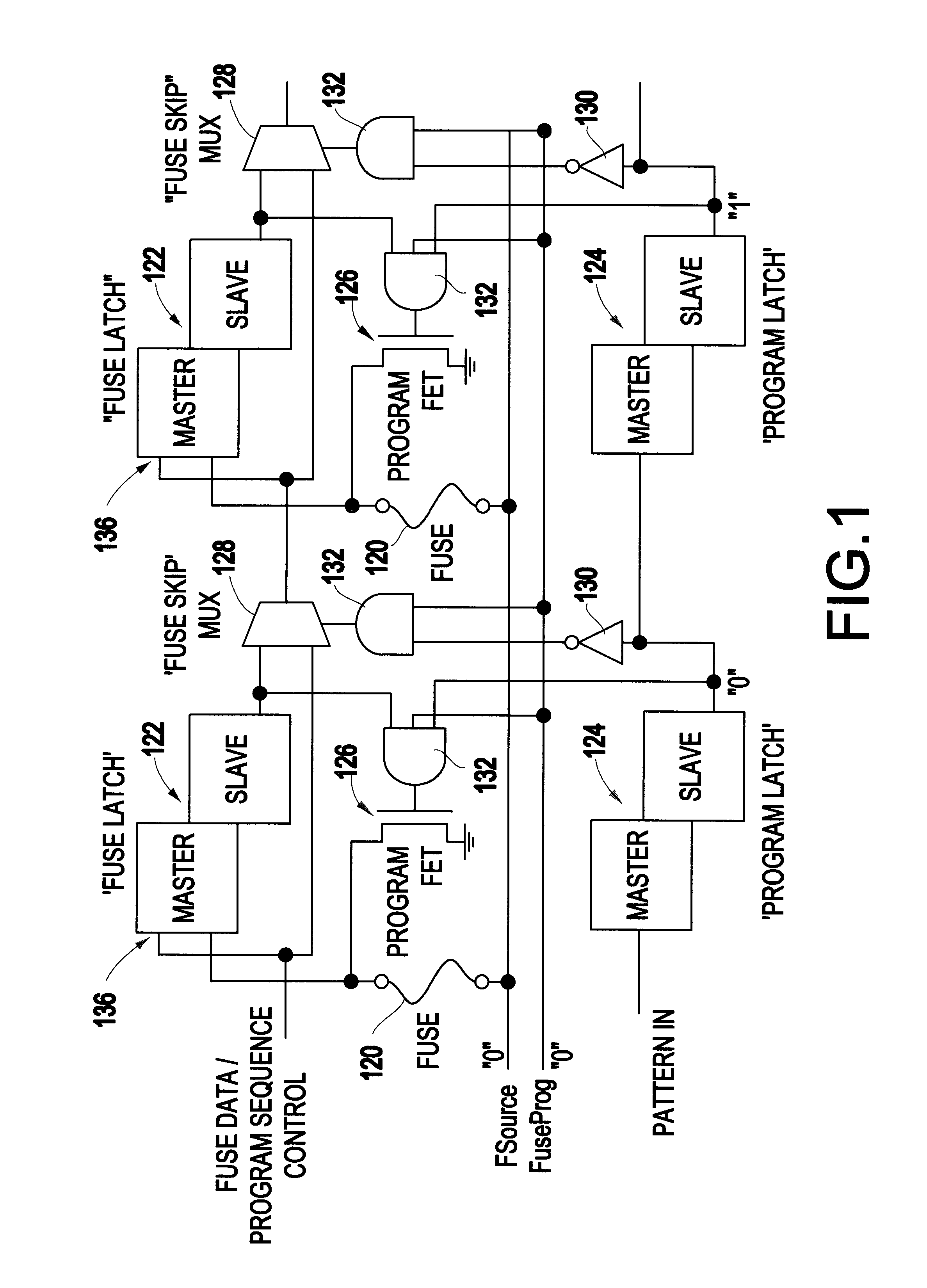

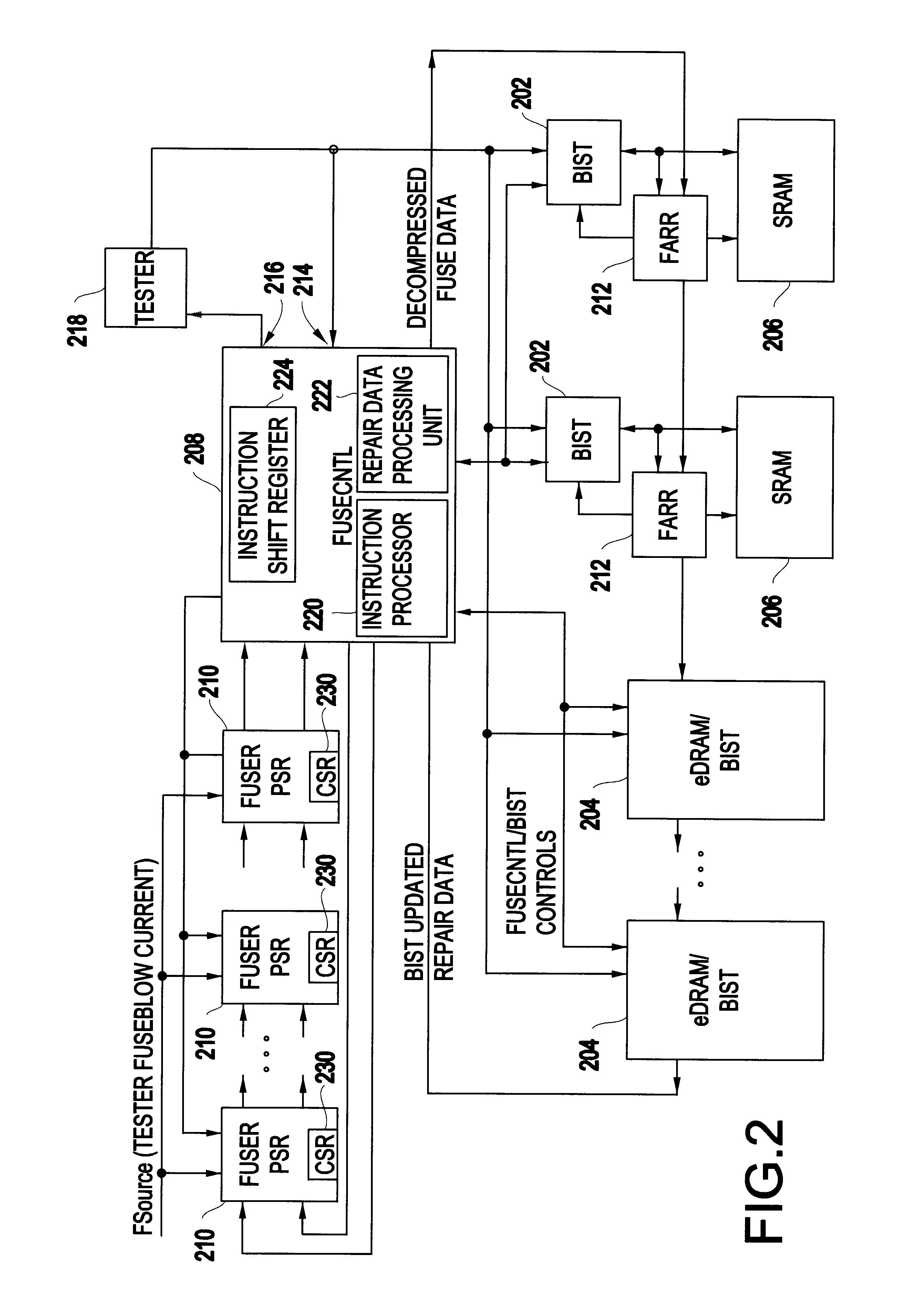

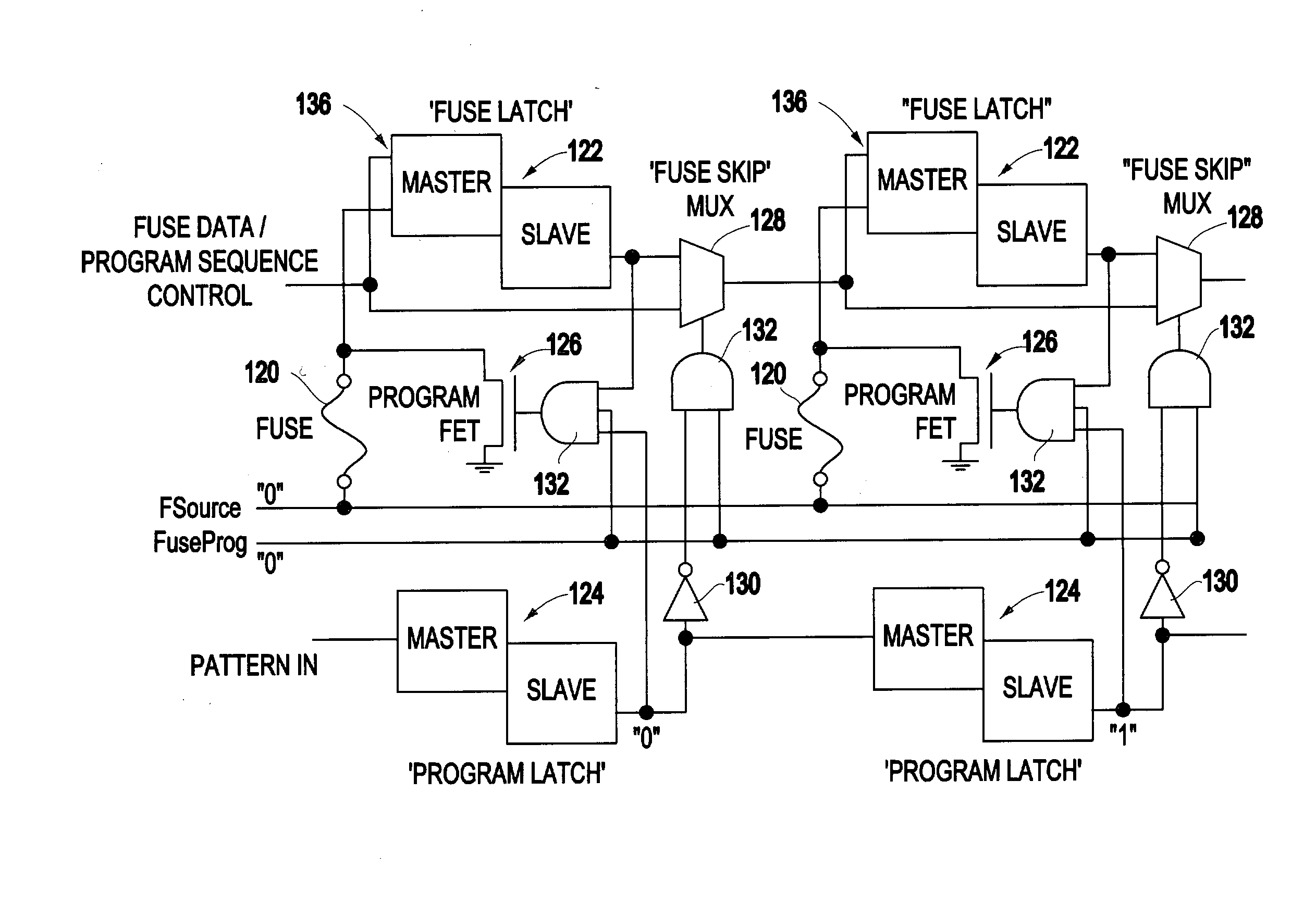

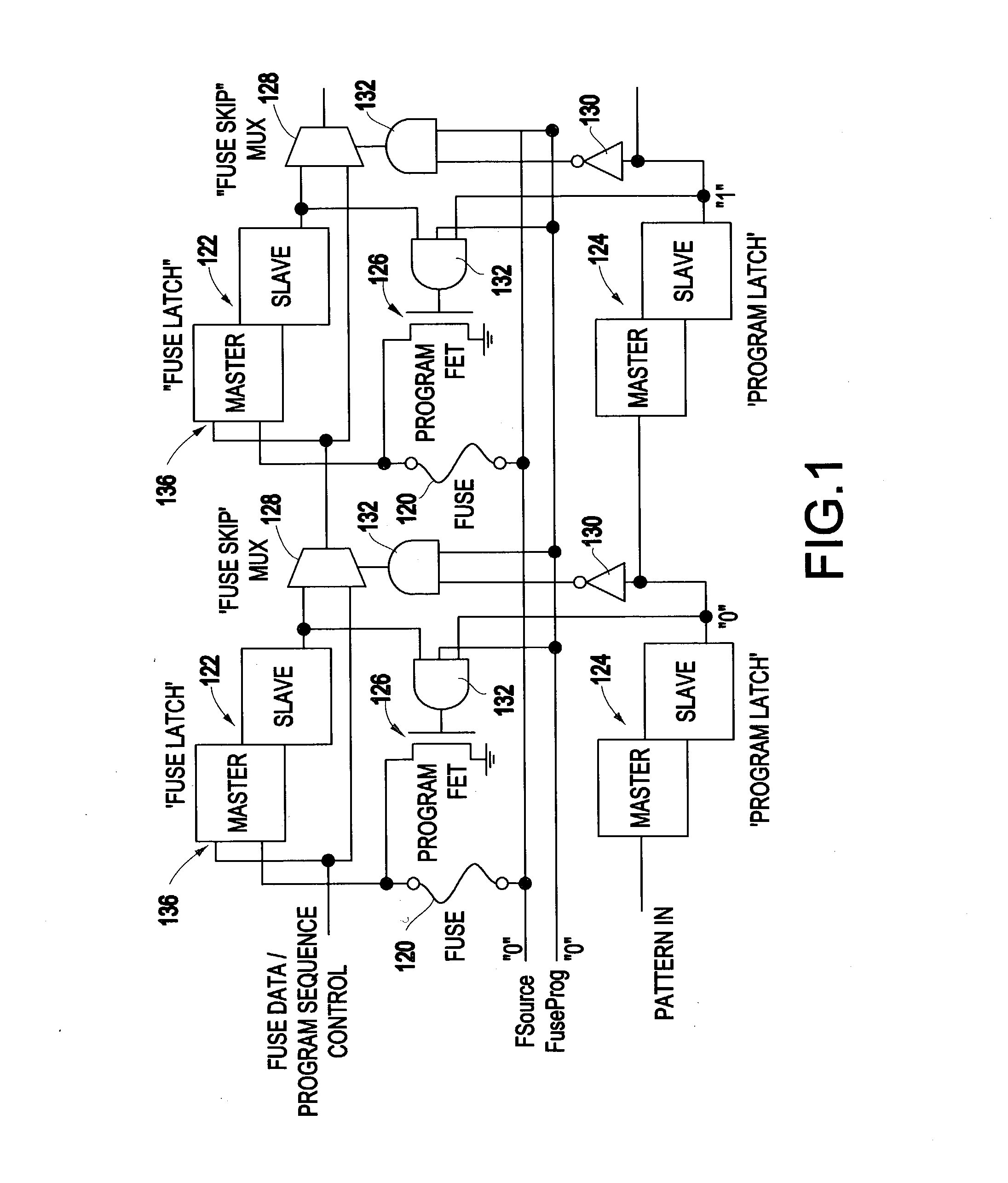

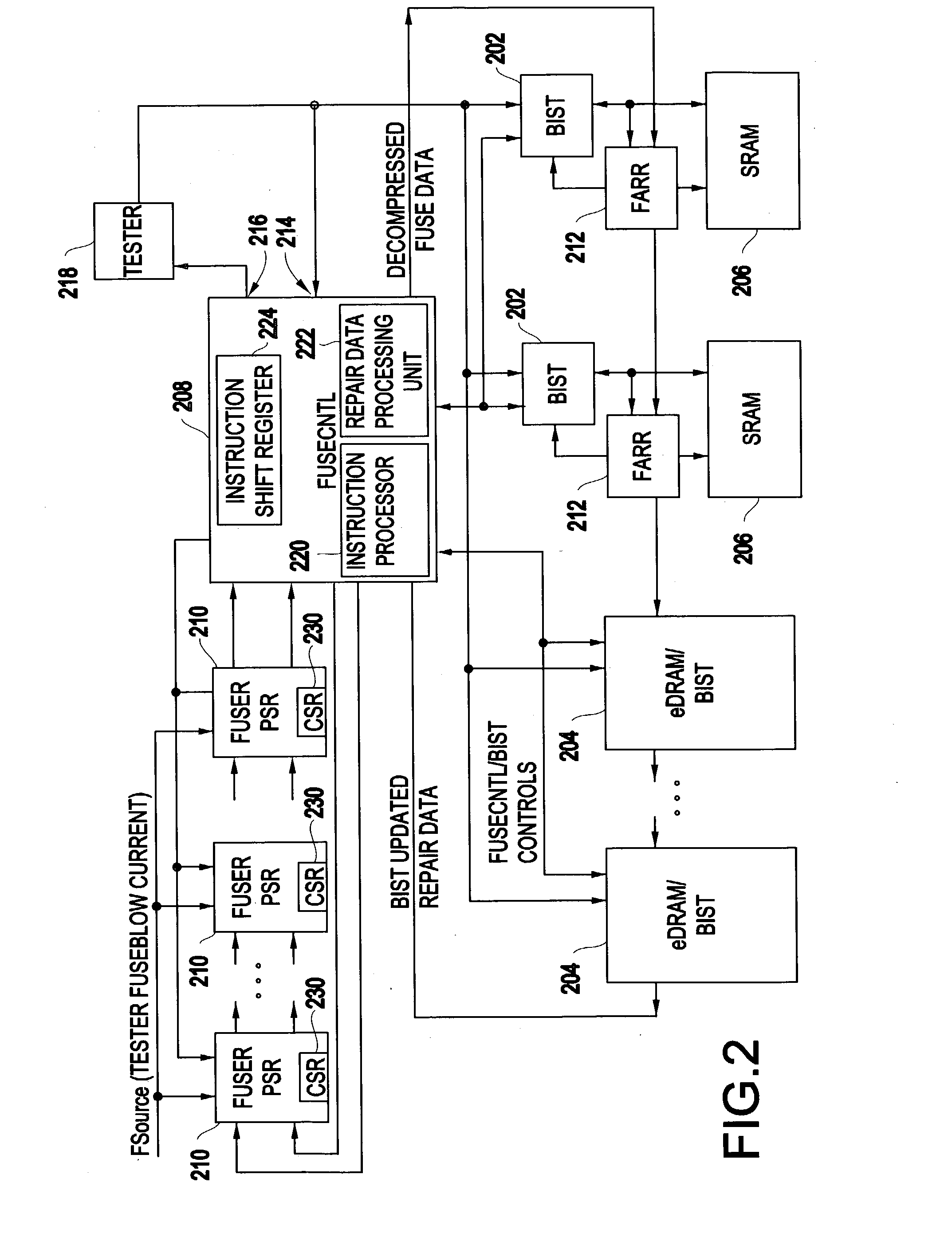

Method of electrically blowing fuses under control of an on-chip tester interface apparatus

A chip repair system designed for automated test equipment independent application on many unique very dense ASIC devices in a high turnover environment is disclosed. During test, the system will control on chip built-in self-test (BIST) engines collect and compress repair data, program fuses and finally decompress and reload the repair data for post fuse testing. In end use application this system decompresses and loads the repair data at power-up or at the request of the system.

Owner:MARVELL ASIA PTE LTD

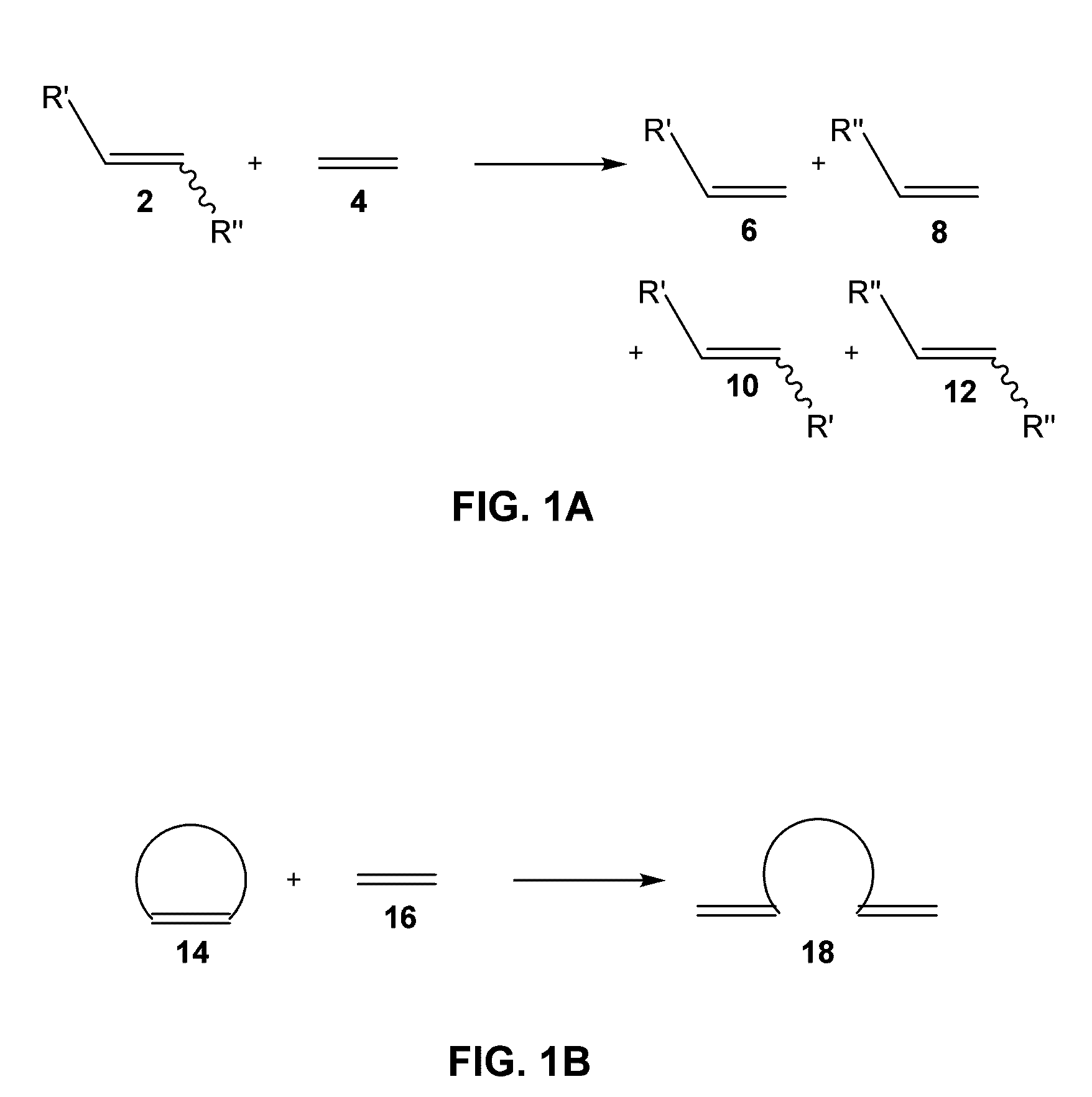

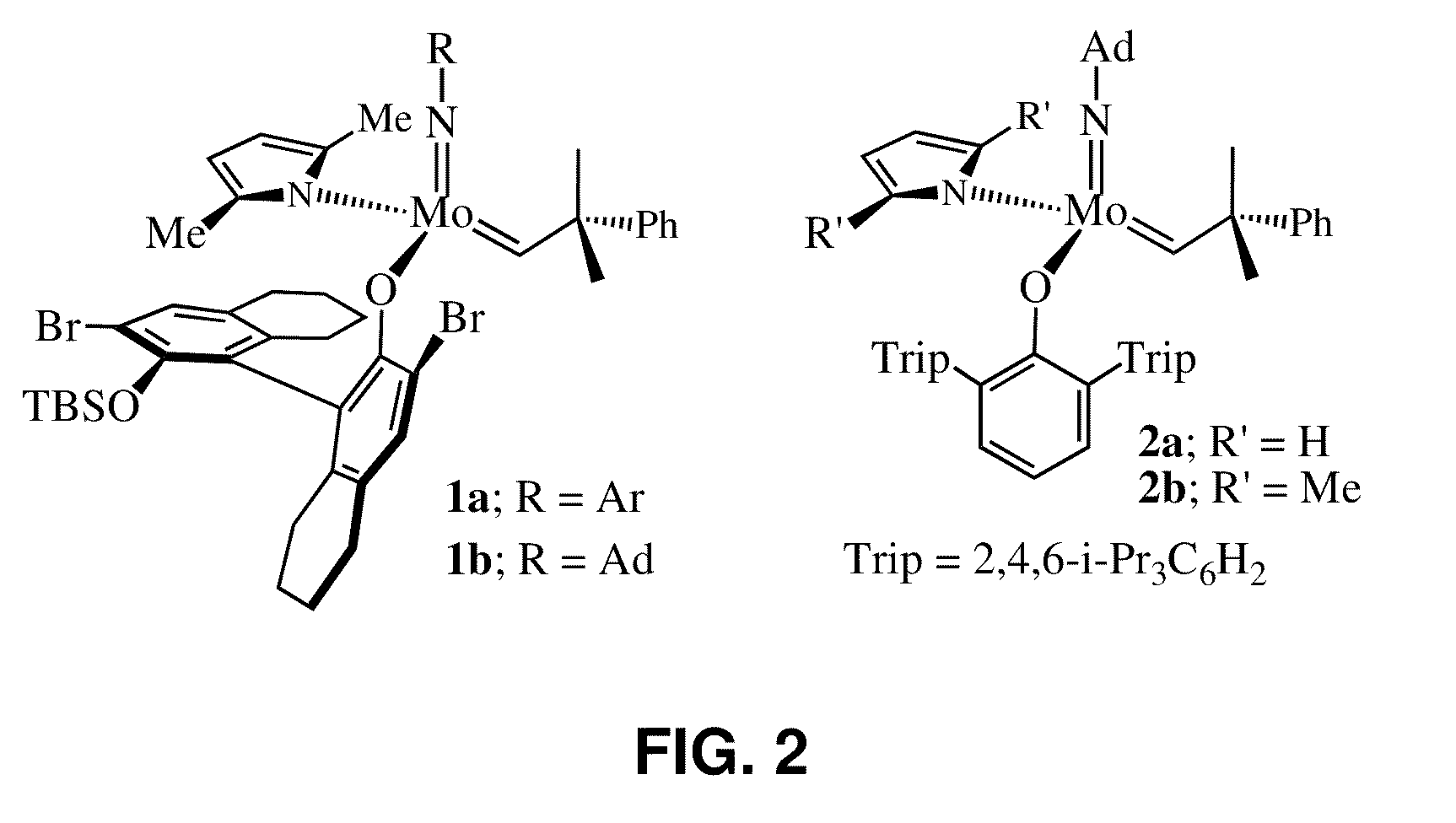

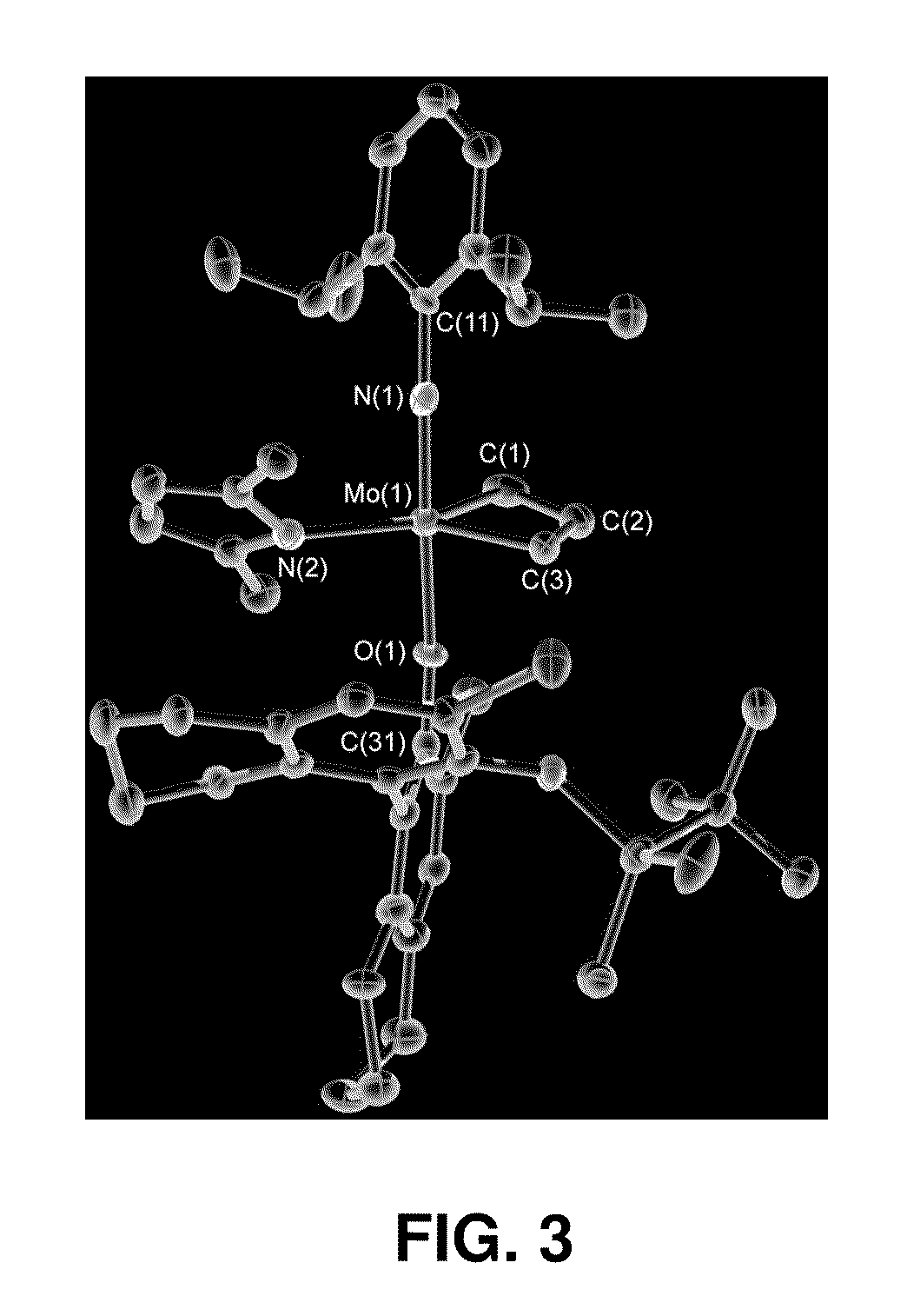

Catalysts and processes for the formation of terminal olefins by ethenolysis

ActiveUS20110015430A1Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHigh turnoverOrganic chemistry

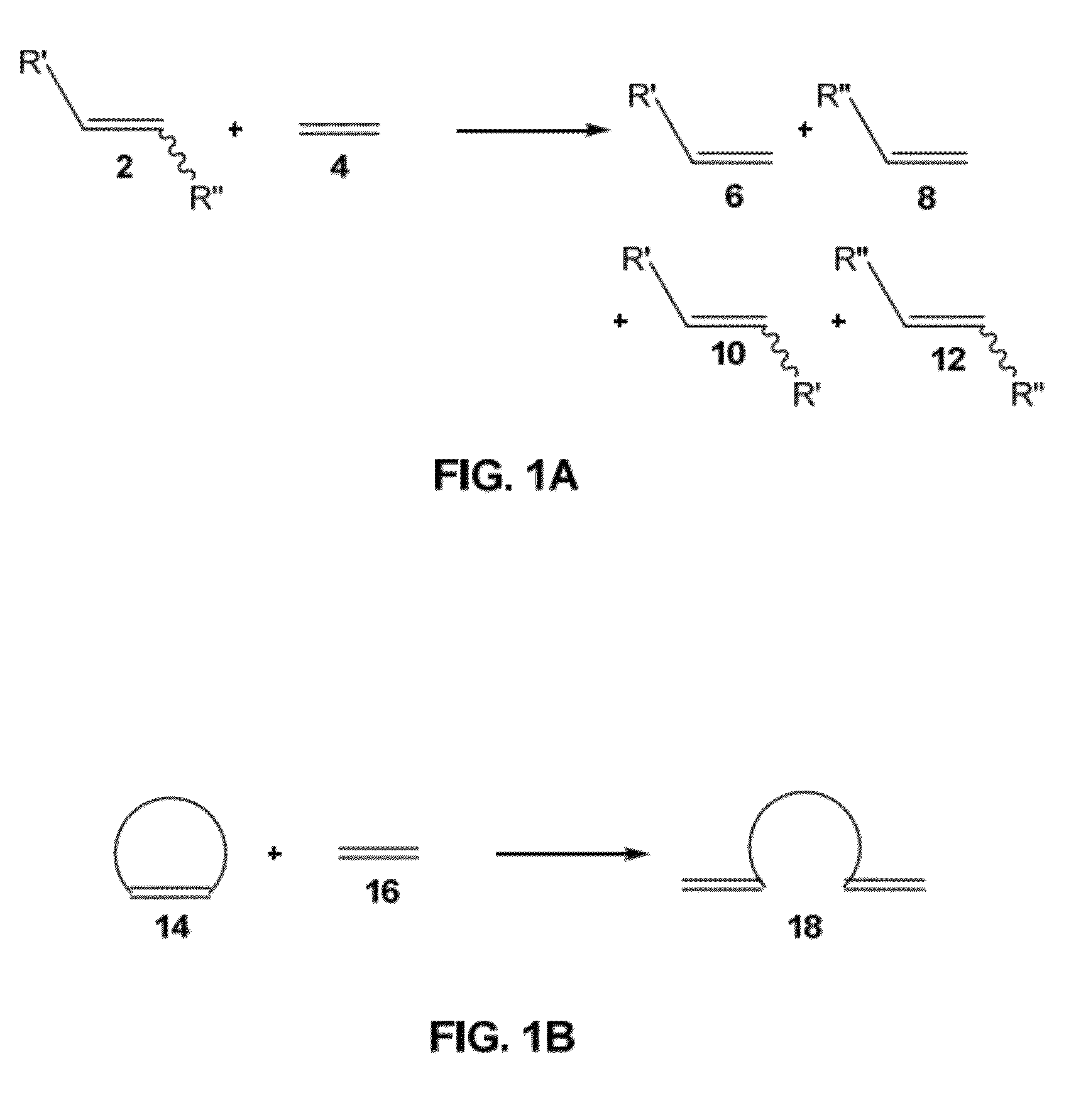

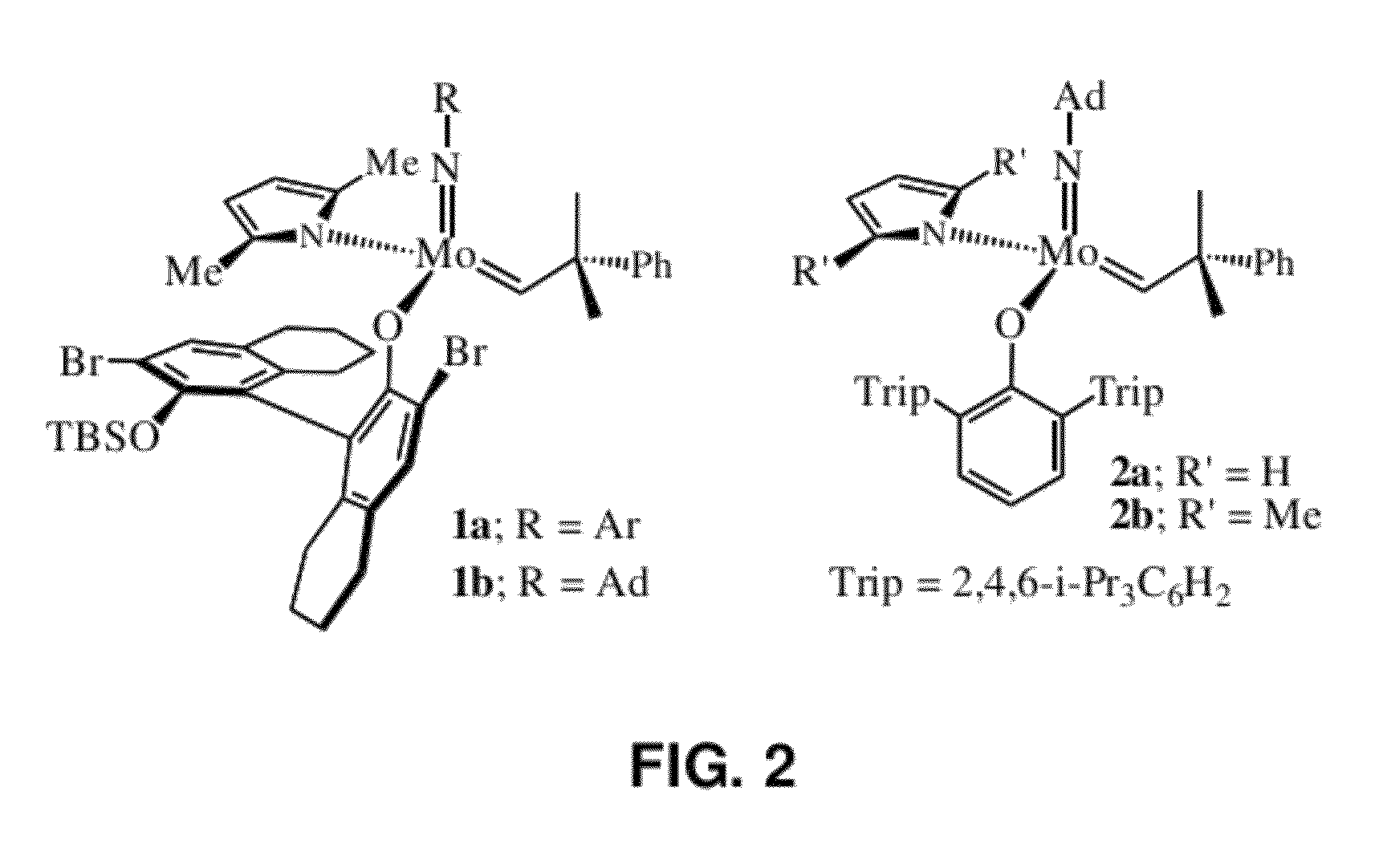

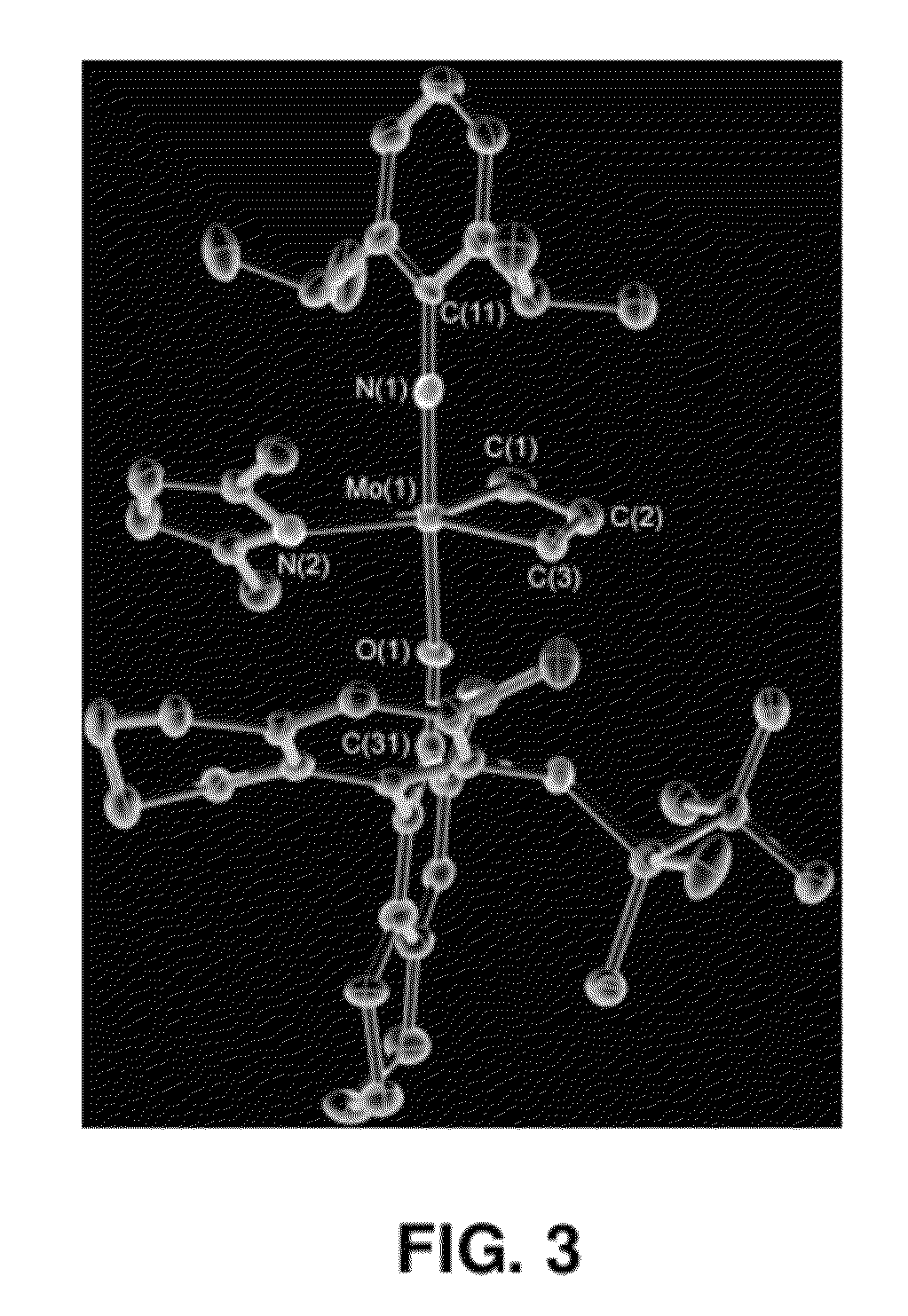

The present invention relates generally to catalysts and processes for the formation of terminal olefin(s) from internal olefin(s) via ethenolysis reactions. The ethenolysis reactions may proceed with high conversion, high turnover, and / or high selectivity.

Owner:BOSTON COLLEGE +1

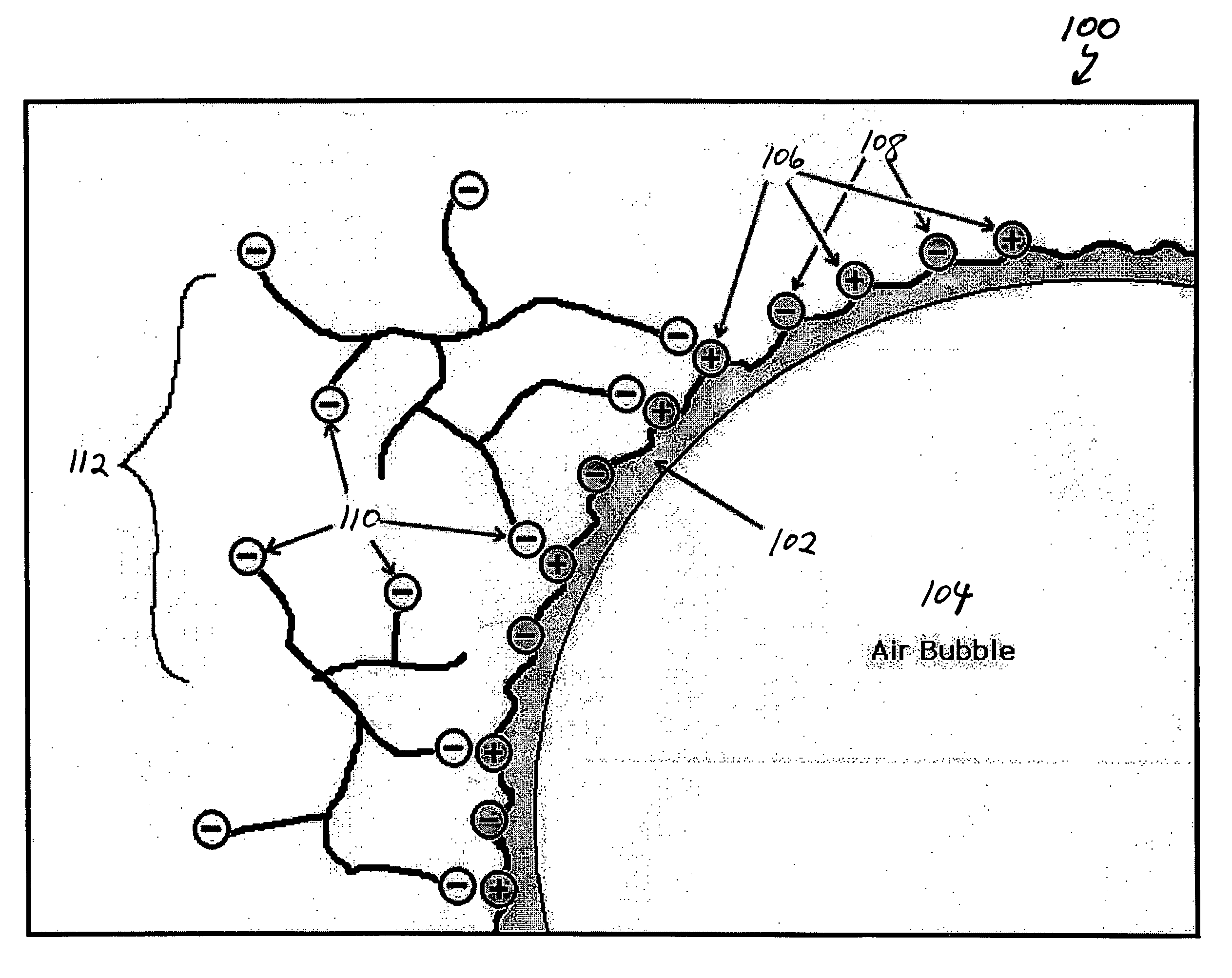

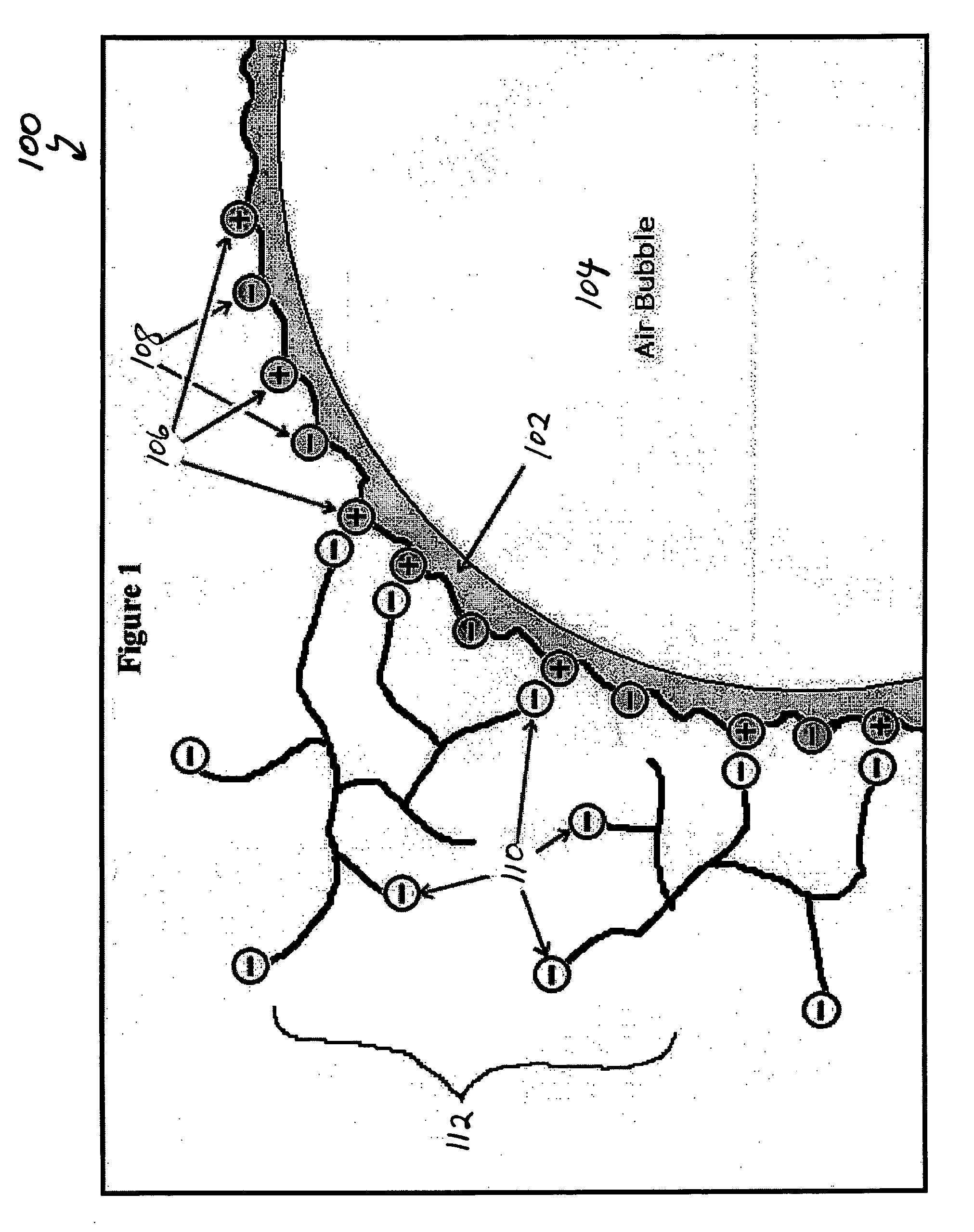

Stabilized edible foams

InactiveUS20070065555A1Improve stabilitySimple aeratingMilk preparationOther dairy technologyHigh turnoverAeration system

The invention relates to formulations for palatable foams with enhanced stability. In certain embodiments, the formulations include a base liquid (such as milk), a surfactant, a polysaccharide, and a polymer capable of molecular interaction with the polysaccharide. The formulations are versatile and can be adapted to create foams of various fat content, textures, and foam stabilities. The foams can be created with simple aeration systems such as disposable, pressurized canisters, as well as high-speed, bulk dispensation systems that are currently used in high turnover restaurants and convenience stores.

Owner:DURAFIZZ

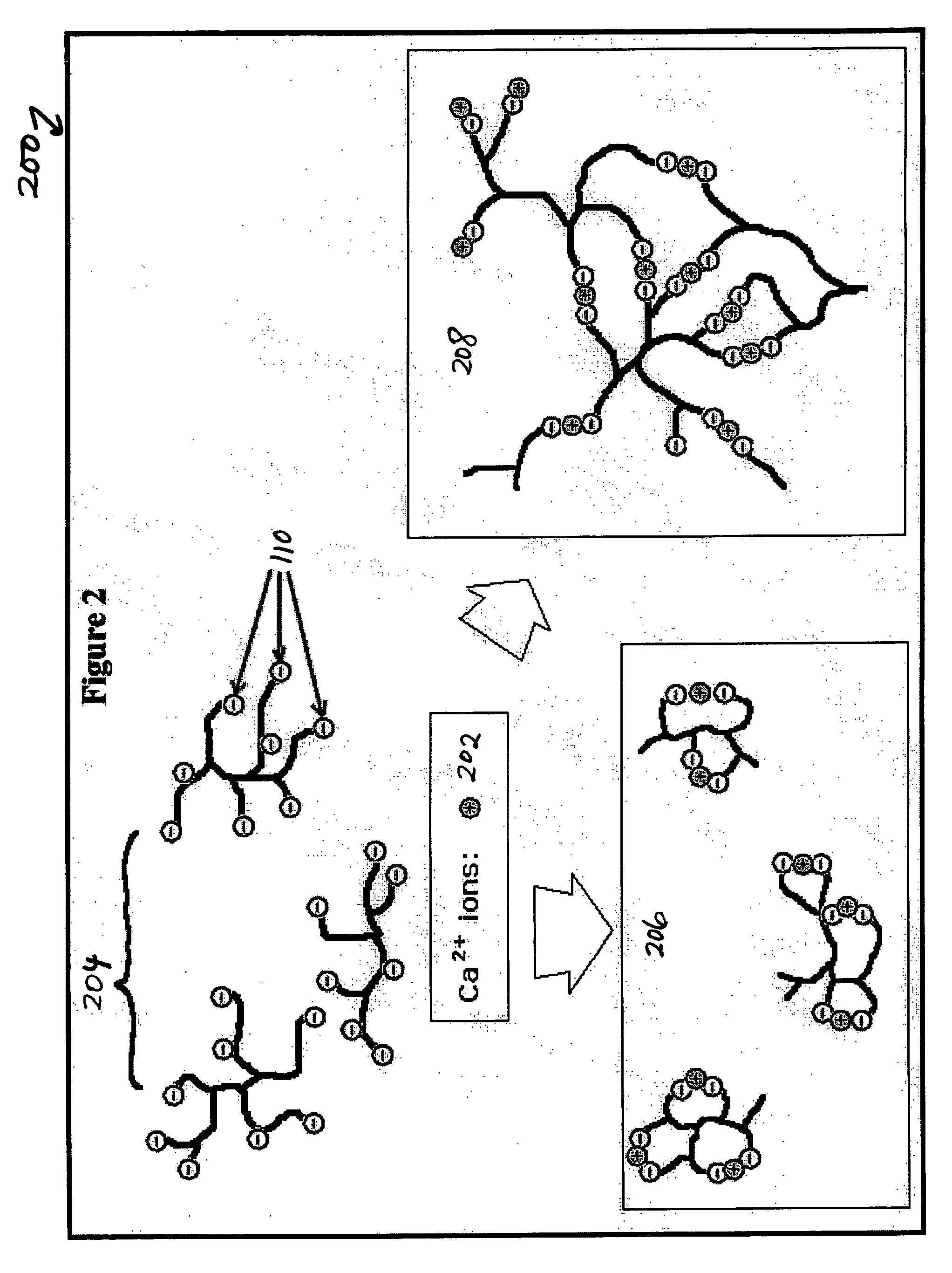

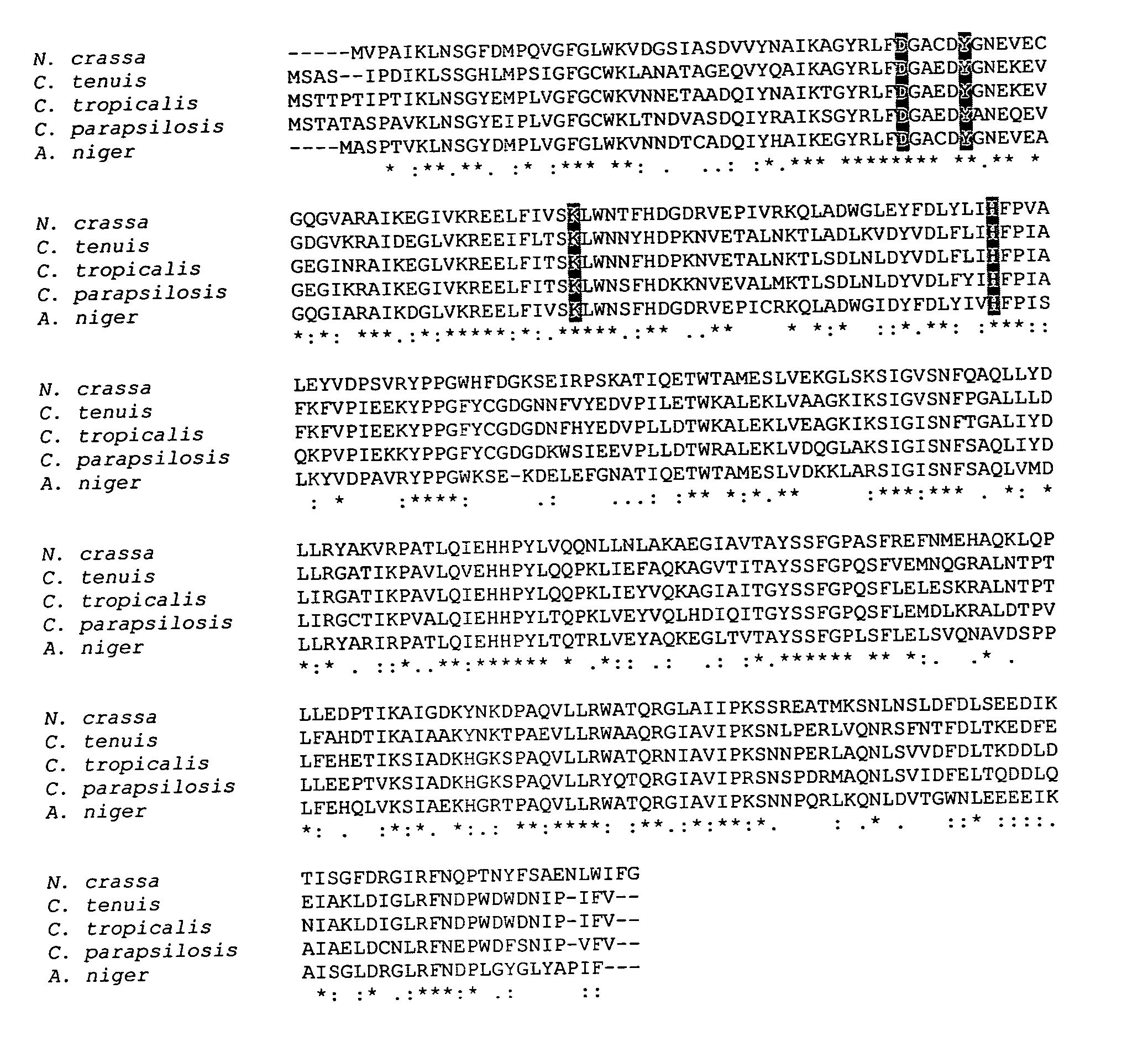

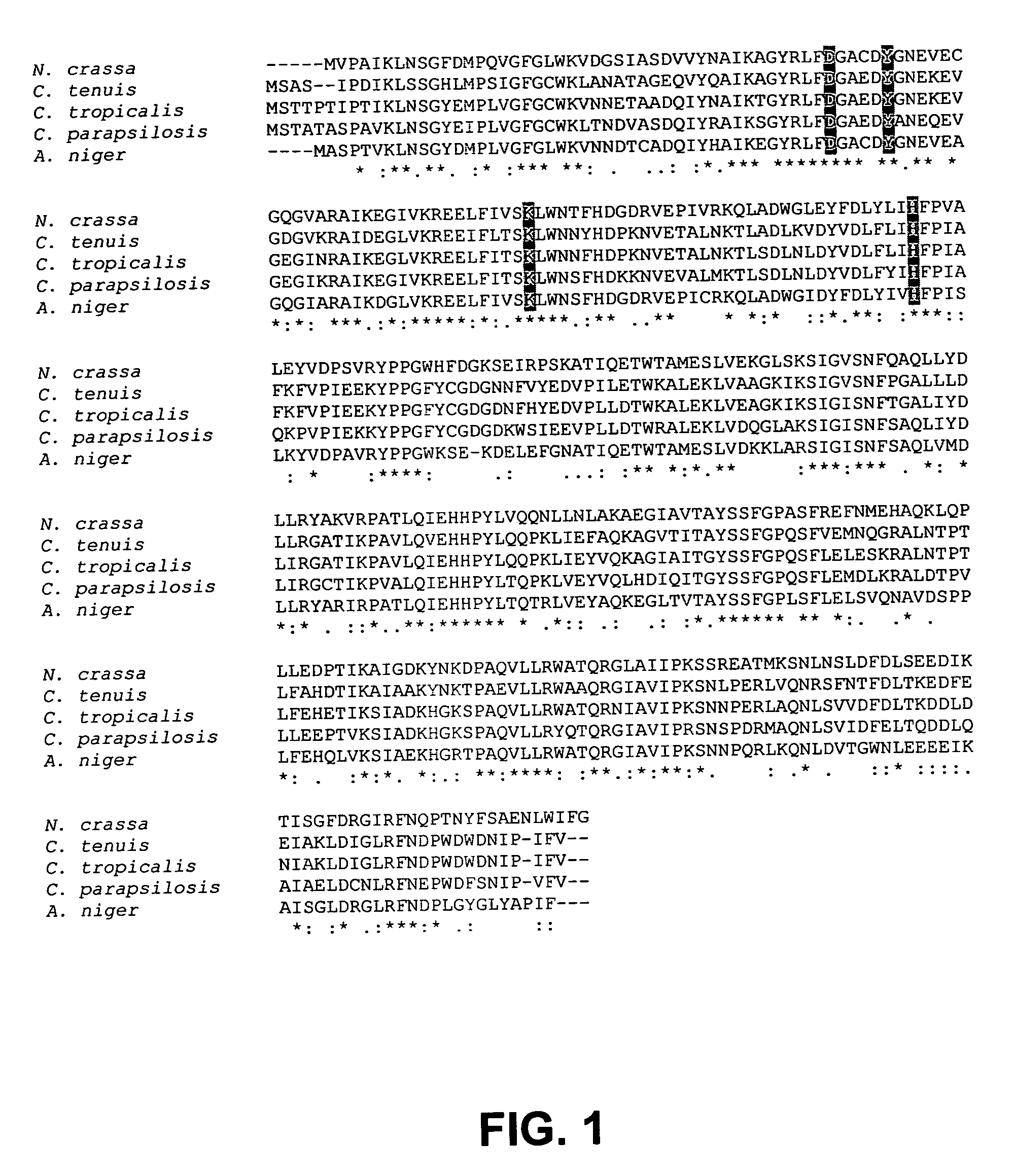

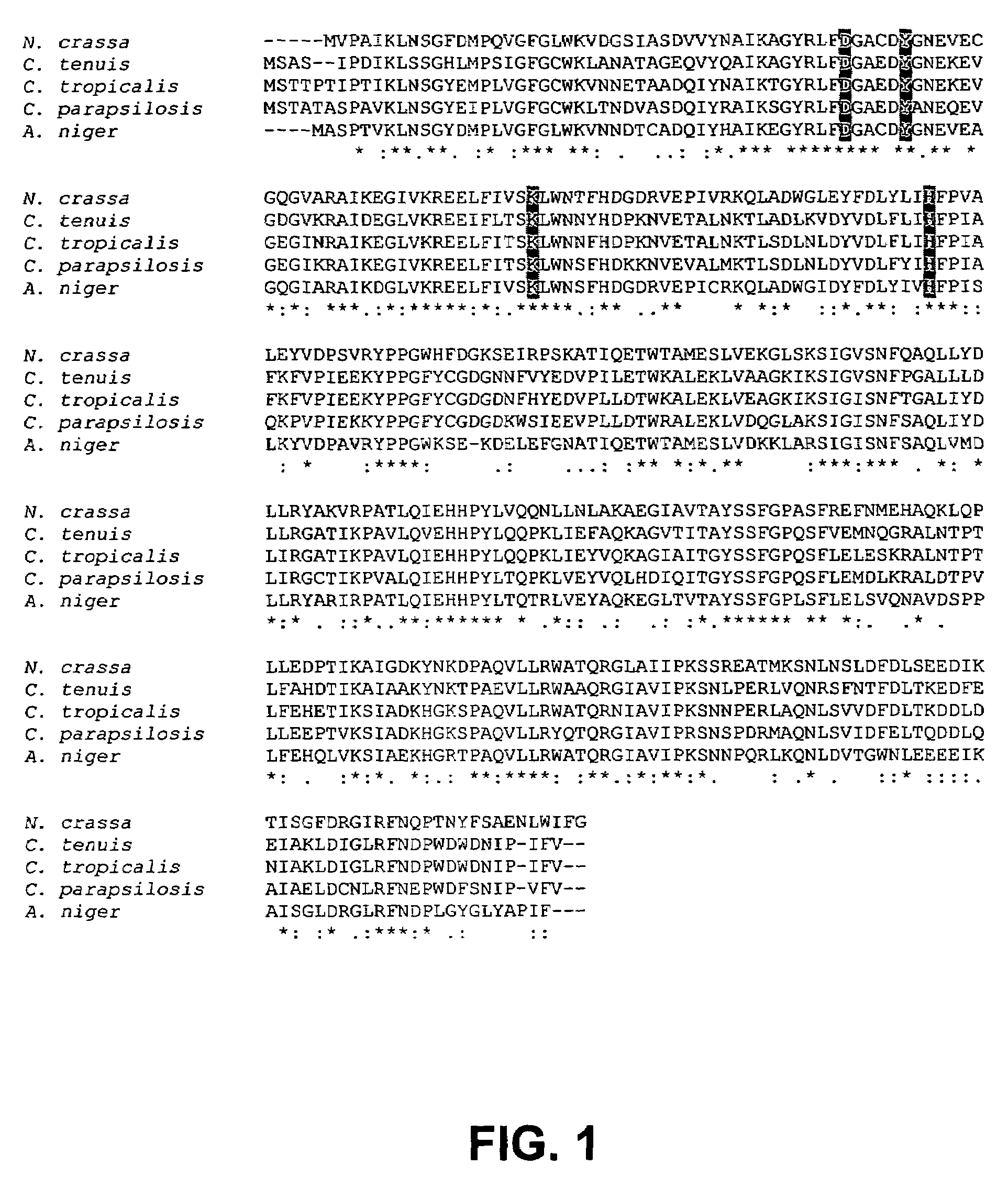

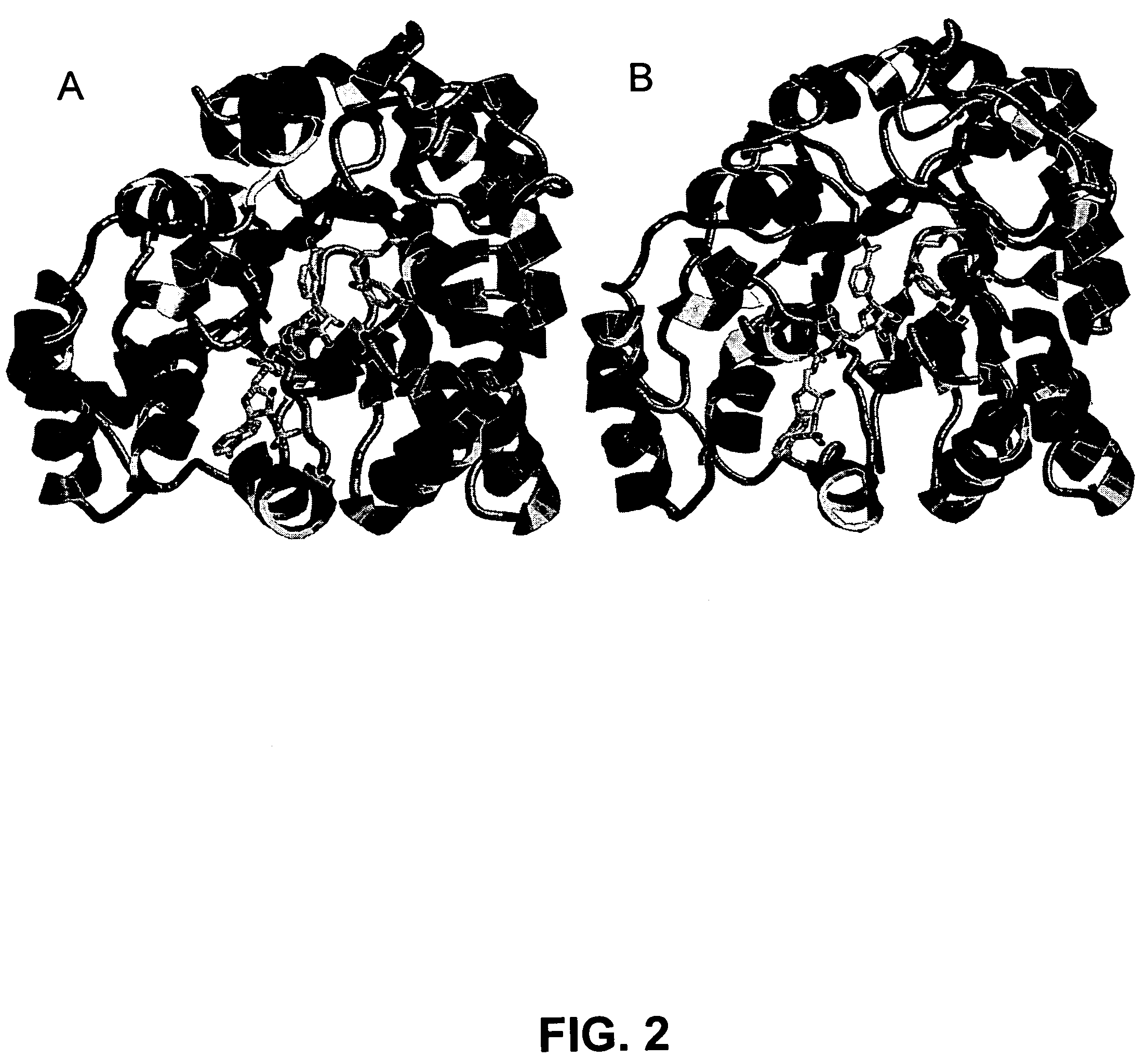

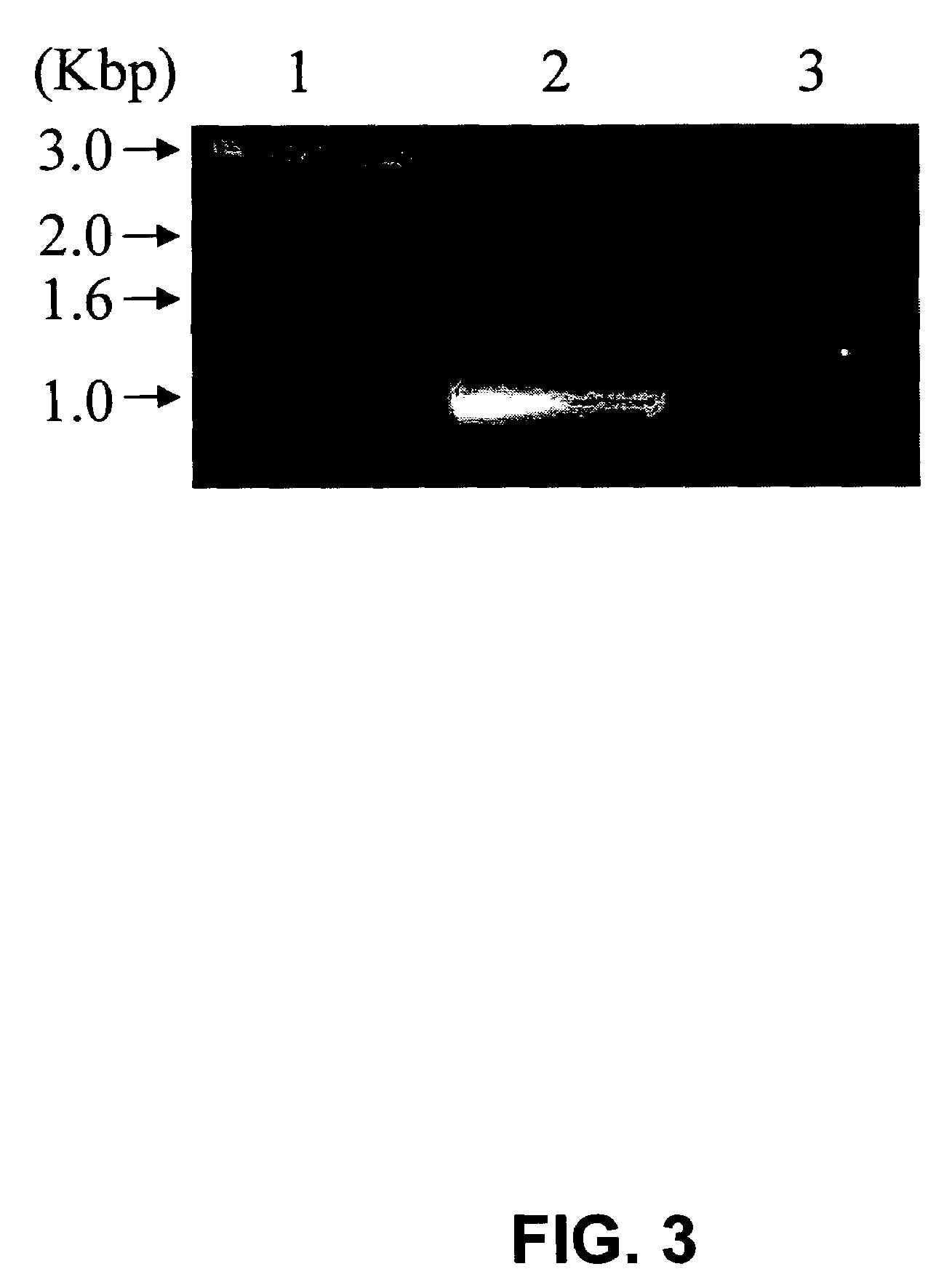

Highly active xylose reductase from neurospora crassa

ActiveUS20060035353A1High activityImprove efficiencyBacteriaSugar derivativesEscherichia coliHigh turnover

A new xylose reductase encoding gene from Neurspora crassa was heterologously expressed in E. coli as a His-tag fusion protein and subsequently purified in high yield. This xylose reductase was shown to have a high turnover rate and catalytic efficiency, high stability at room temperature, broad pH profile, and a preference of NADPH over NADH. This enzyme is utilized in production of xylitol and other sugar alcohols such as sorbitol and also in the metabolic enhancement of organisms used for fermentation of plant biomass into ethanol.

Owner:BIOTECH RES & DEV

Method of electrically blowing fuses under control of an on-chip tester interface apparatus

A chip repair system designed for automated test equipment independent application on many unique very dense ASIC devices in a high turnover environment is disclosed. During test, the system will control on chip built-in self-test (BIST) engines collect and compress repair data, program fuses and finally decompress and reload the repair data for post fuse testing. In end use application this system decompresses and loads the repair data at power-up or at the request of the system.

Owner:MARVELL ASIA PTE LTD

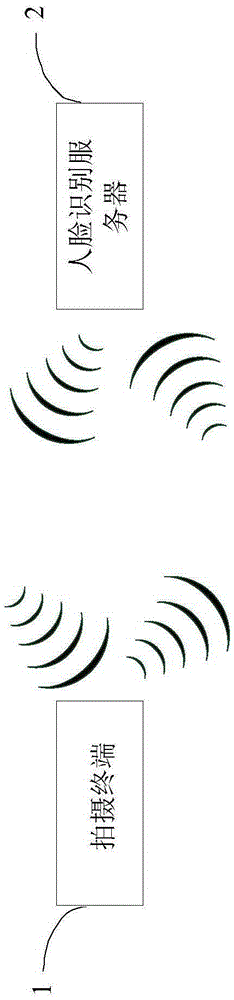

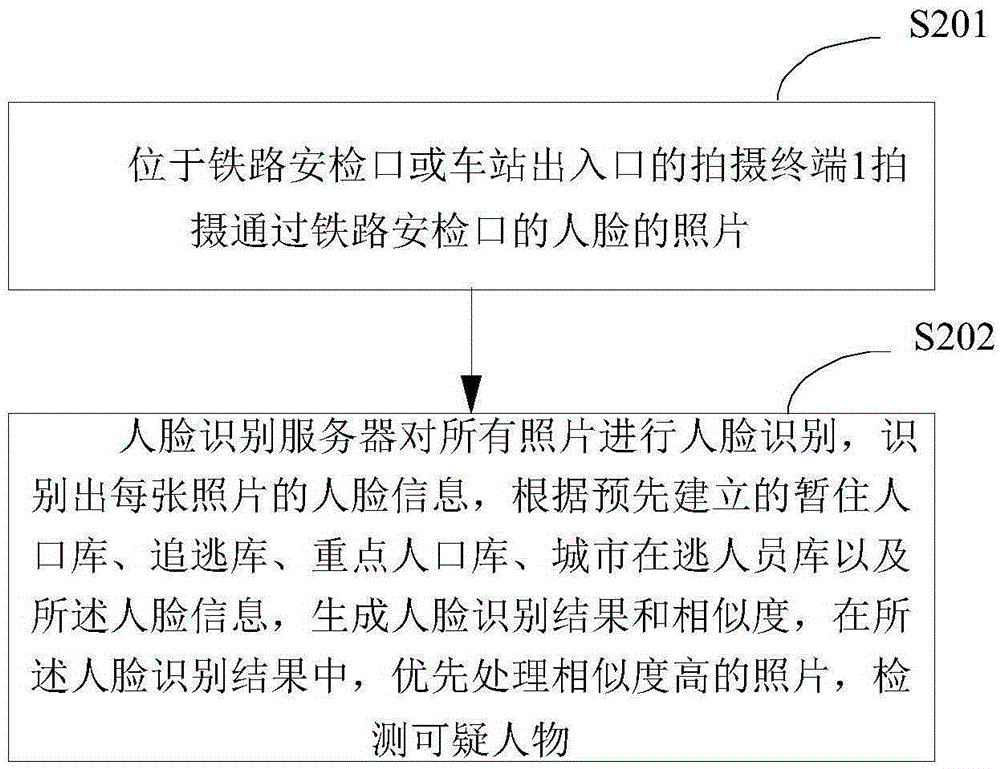

Face recognition system and recognition method based on railway security check

InactiveCN105426869AImprove securityImprove effectivenessCharacter and pattern recognitionHigh turnoverSecurity check

The invention is applicable in the field of image recognition, and provides a face recognition system and recognition method based on railway security check. The face recognition system based on railway security check comprises a shooting terminal positioned at a railway security checkpoint or a station entrance-exit and used for shooting photos of faces passing through the railway security checkpoint, and a face recognition server used for performing SHAPE / *MERGEFORMAT face recognition on all the photos to recognize face information of each photo, generating face recognition results and similarity according to a pre-built temporary resident population library, pursuit library, key population library, urban escaped criminal library and the face information and preferentially processing the photos with high similarity in the face recognition results to detect suspected persons. The system and the method have the advantages of improving the security and the validity of railway security check and being suitable for railway security checkpoints and station entrances-exits with high turnover.

Owner:CHONGQING KAIZE TECH

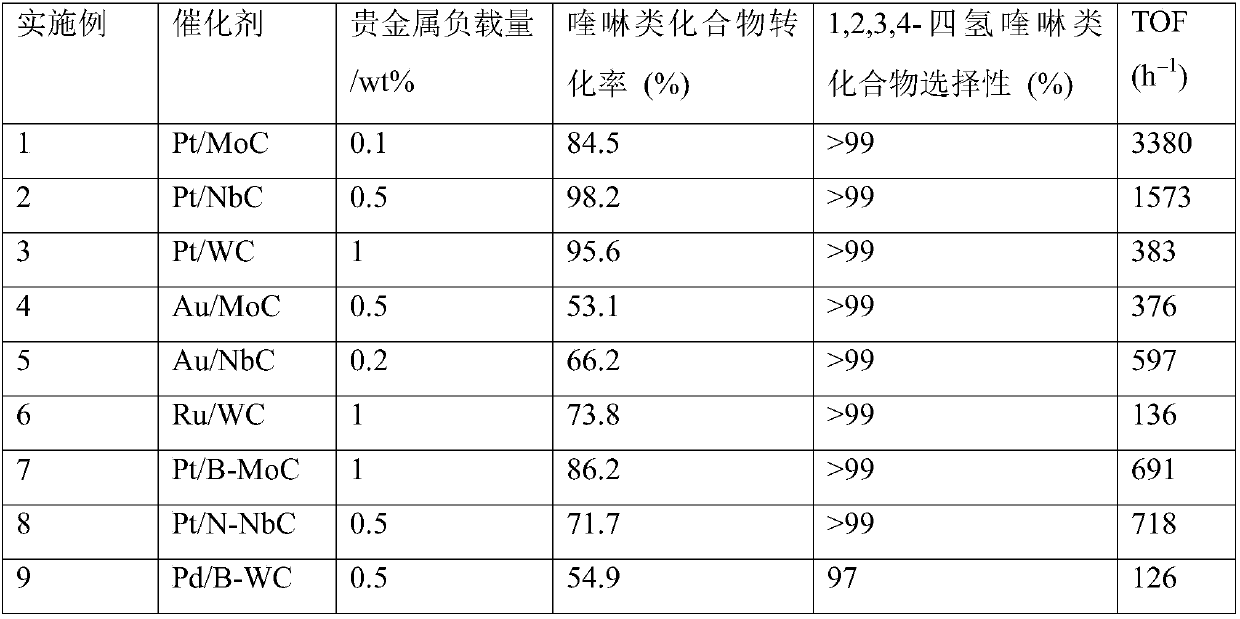

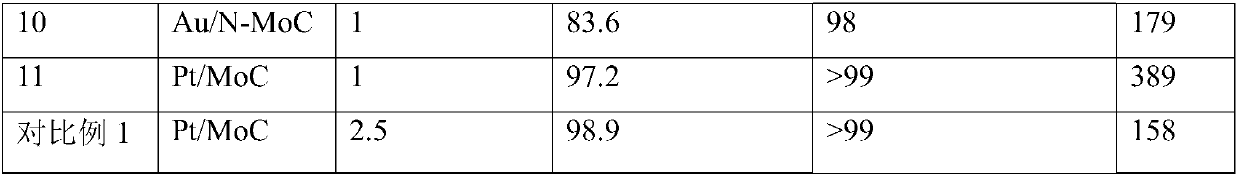

Catalyst for selective hydrogenation of quinoline compounds and preparation method of catalyst

ActiveCN107824209AGood choiceStrong metal-support interactionOrganic chemistryCatalyst activation/preparationHigh turnoverActive component

The invention relates to a catalyst for selective hydrogenation of quinoline compounds and a preparation method of the catalyst. The catalyst is prepared from a carrier and a noble metal active component loaded on the surface of the carrier, wherein the carrier is at least one of carbide MC, nitrogen-doped carbide N-MC and boron-doped carbide B-MC, and M is at least one of Mo, Nb and W; and the noble metal active component is at least one of Ru, Pd, Au and Pt, and the mass content of the noble metal active component is 0.1-2%. The prepared catalyst has high turnover frequency (TOF), and the quinoline compounds have better selectivity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Catalysts and processes for the formation of terminal olefins by ethenolysis

ActiveUS8222469B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHigh turnoverOrganic chemistry

The present invention relates generally to catalysts and processes for the formation of terminal olefin(s) from internal olefin(s) via ethenolysis reactions. The ethenolysis reactions may proceed with high conversion, high turnover, and / or high selectivity.

Owner:BOSTON COLLEGE +1

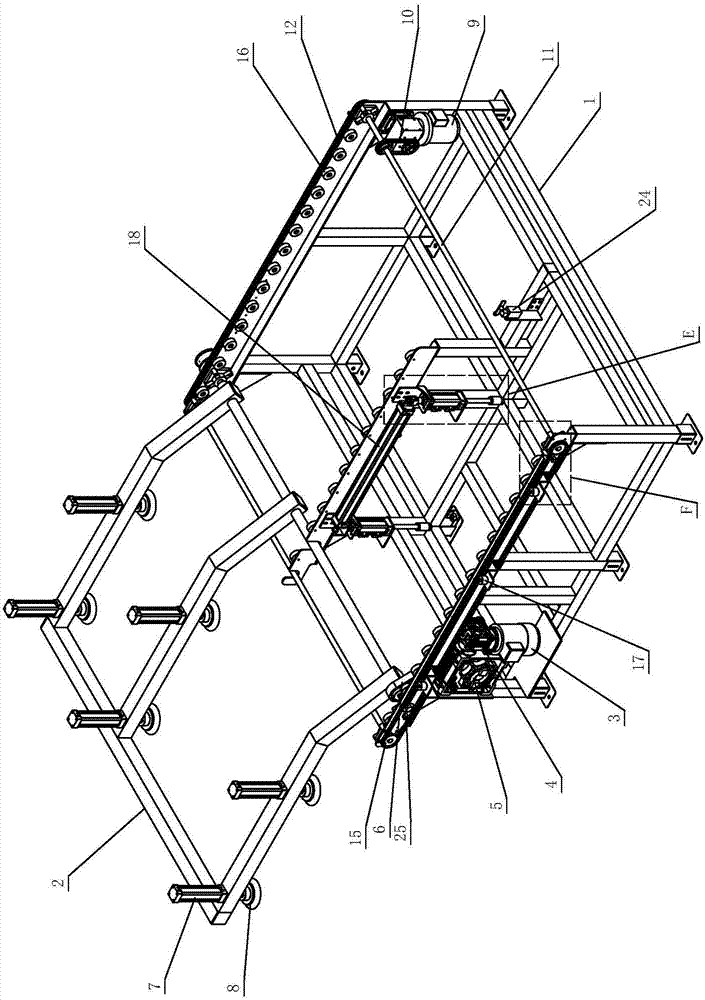

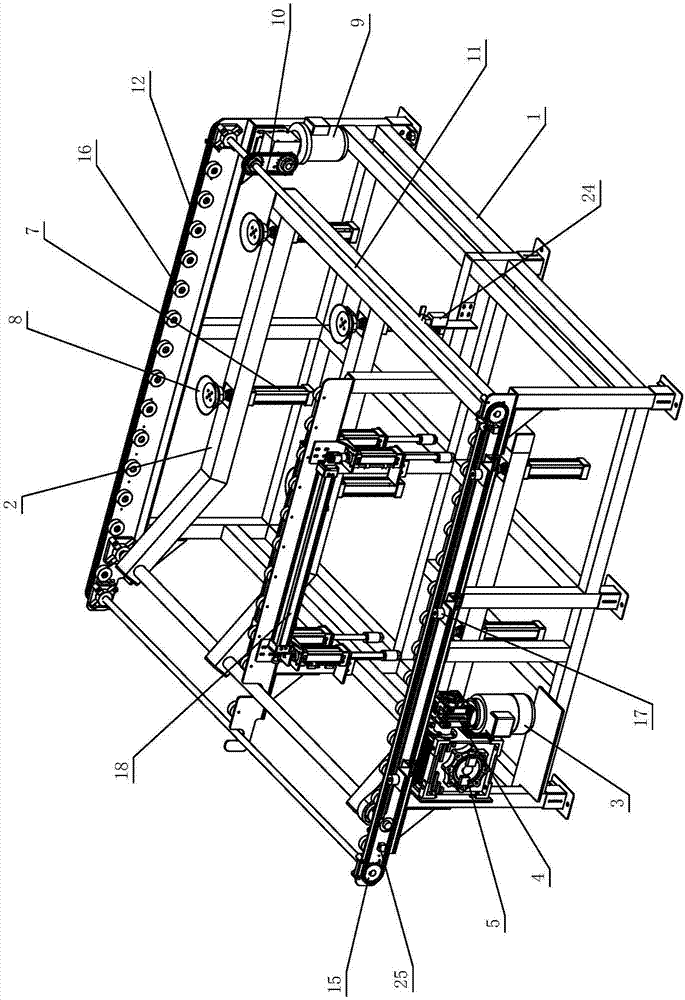

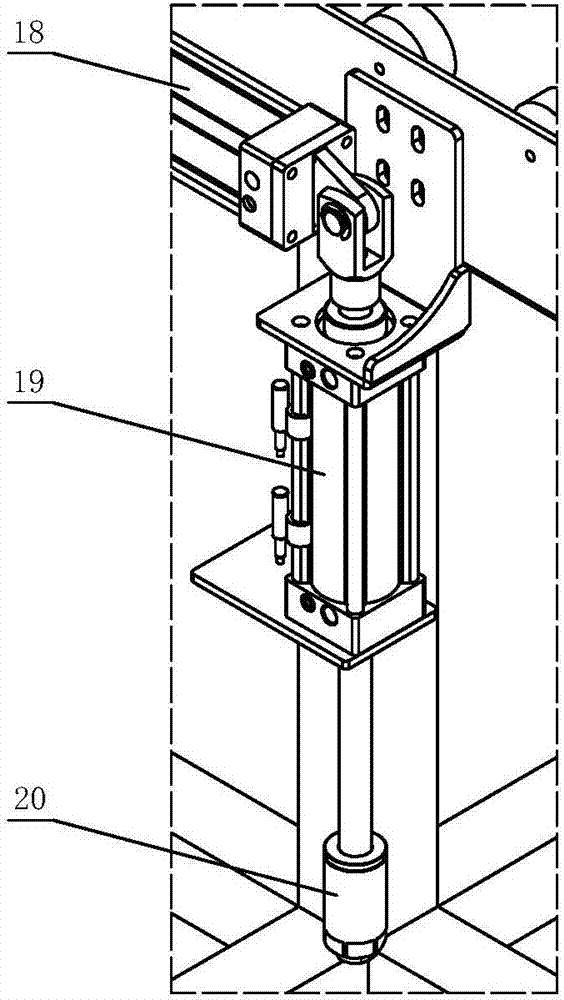

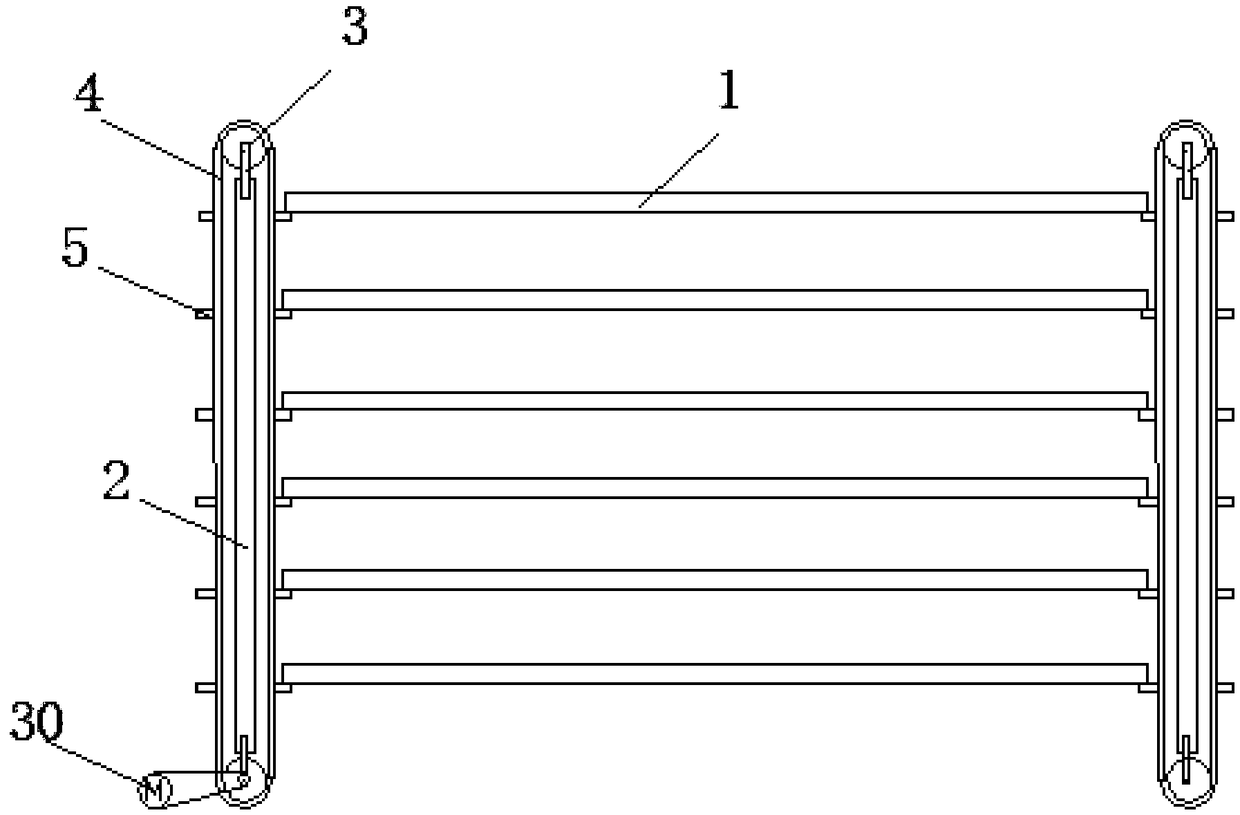

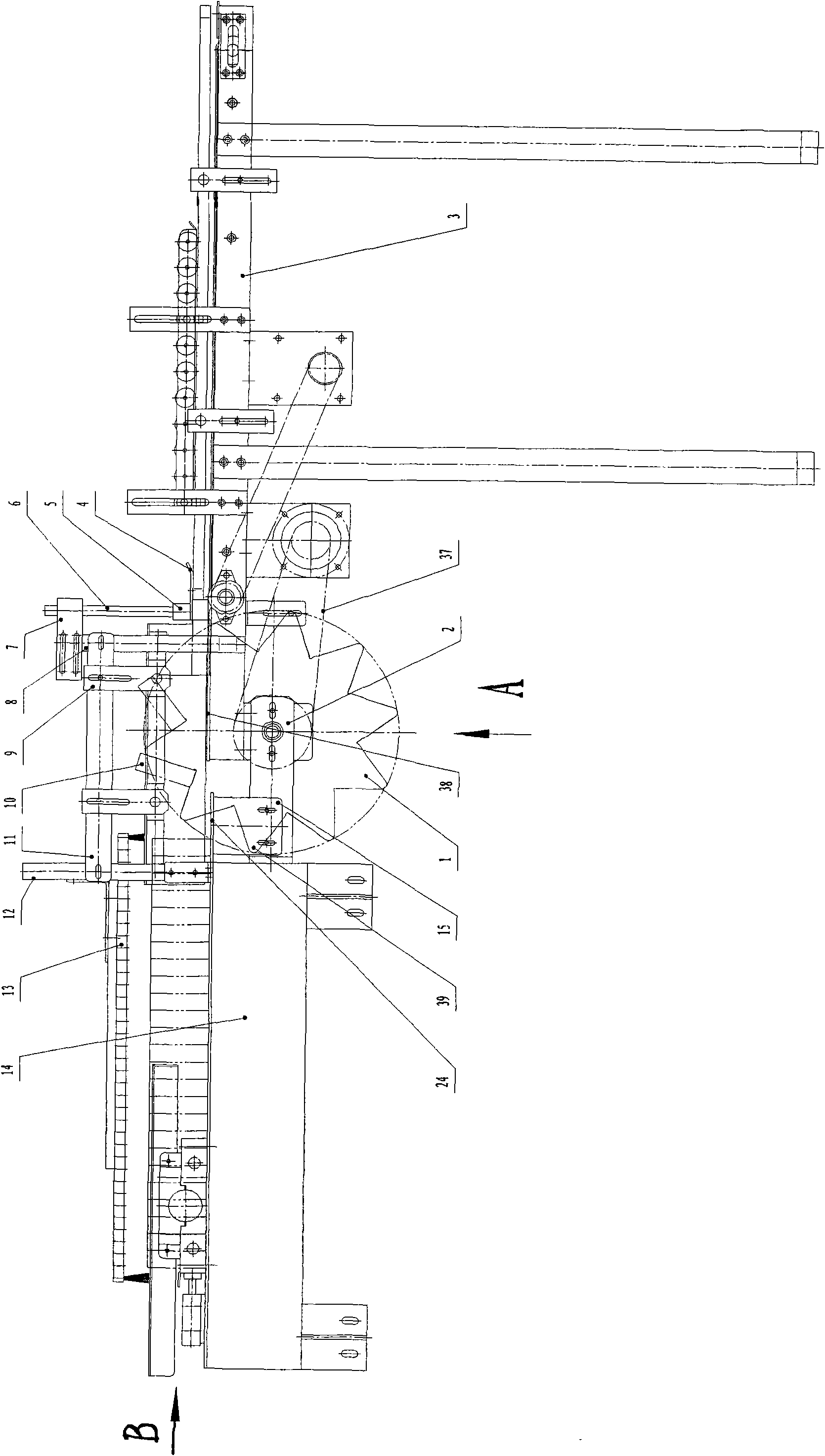

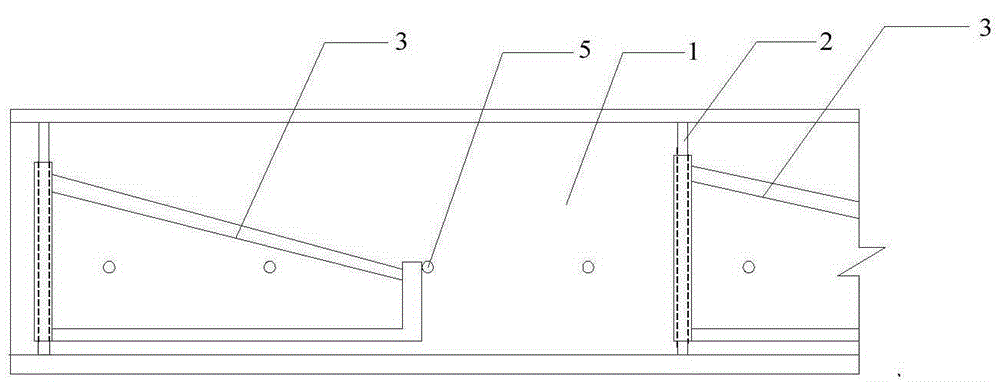

Plate overturning machine and numerical-control cutting production line thereof

PendingCN107954185ASimple structureReduce manufacturing costConveyorsConveyor partsHigh turnoverProduction line

A plate overturning machine comprises an equipment machine frame. An overturning mechanism and a conveying mechanism are arranged on the equipment machine frame. The overturning mechanism comprises anoverturning arm, one or more suction disk assemblies and an overturning drive assembly. One side of the overturning arm is rotationally connected with the equipment machine frame. The suction disk assemblies are assembled on the overturning arm. The overturning drive assembly is arranged on the equipment machine frame and drives the overturning arm to conduct reciprocating overturning between thecorresponding numerical-control cutting machine and the equipment machine frame where the overturning arm is located so that a plate-shaped workpiece on the numerical-control cutting machine can be overturned and placed on a feeding area of the equipment machine frame. The conveying mechanism is located in the feeding area of the equipment machine frame and comprises a conveying chain and a conveying drive assembly, wherein the conveying chain is provided with a stop block, the conveying drive assembly is arranged on the equipment machine frame and drives the conveying chain to operate, and the stop block moves along with the conveying chain and drives the plate-shaped workpiece in the feeding area to be conveyed in the direction of the corresponding numerical-control cutting machine. Theplate overturning machine has the advantages of being reliable and stable in performance, high in overturning efficiency, low in labor intensity and capable of achieving multi-machine combination.

Owner:FOSHAN HAOYANG WOODWORK MACHINERY MFR

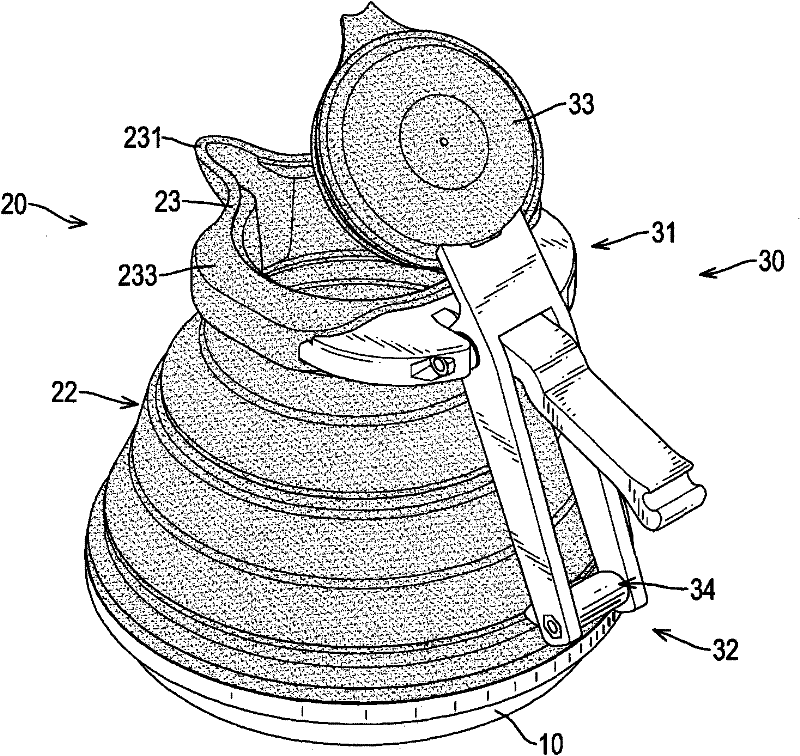

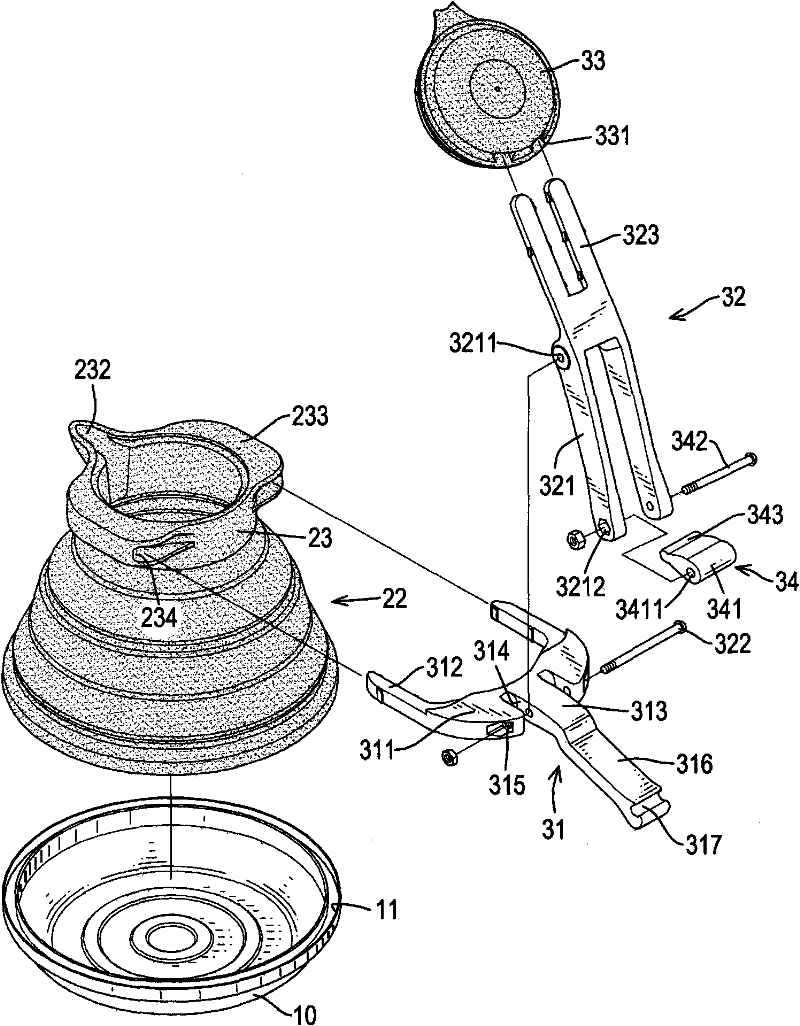

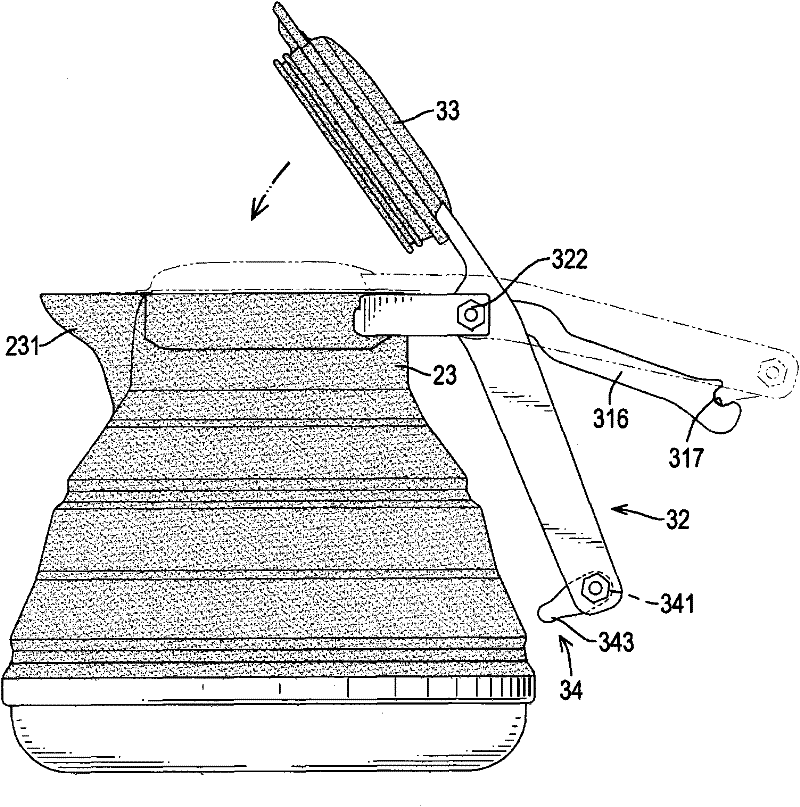

Foldable kettle and kettle body handle structure

ActiveCN102273926AReduce the overall heightReduce volumeWater-boiling vesselsHigh turnoverWater bottle

The invention relates to a folding kettle. A kettle bottom of a metal round basin body is combined with a telescopic kettle extending upwards; the top edge of the kettle bottom is upwards continuously combined with three turnover rings with diameters being narrow at the upper parts and wide at the lower parts in a turnover form; the top edge of the highest turnover ring is combined with a kettle neck; the middle of the front side of the kettle neck forwards extends to form a kettle mouth; and the periphery of the kettle neck is combined with an inserting handlebar with a handle at the rear side; therefore, when the folding kettle is used, the inside space of the folding kettle can be filled with water, and the kettle bottom is arranged on a heat source to be heated; and when the folding kettle is not used, each turnover rings can be folded, so that the telescopic kettle is folded to be flat and contained at the inner side of the kettle bottom, the defect that a common kettle occupies space is overcome by a structure with volume capable of being reduced, and the use effect that the folding kettle is very convenient to carry and fold is achieved.

Owner:RICCO ENG INT

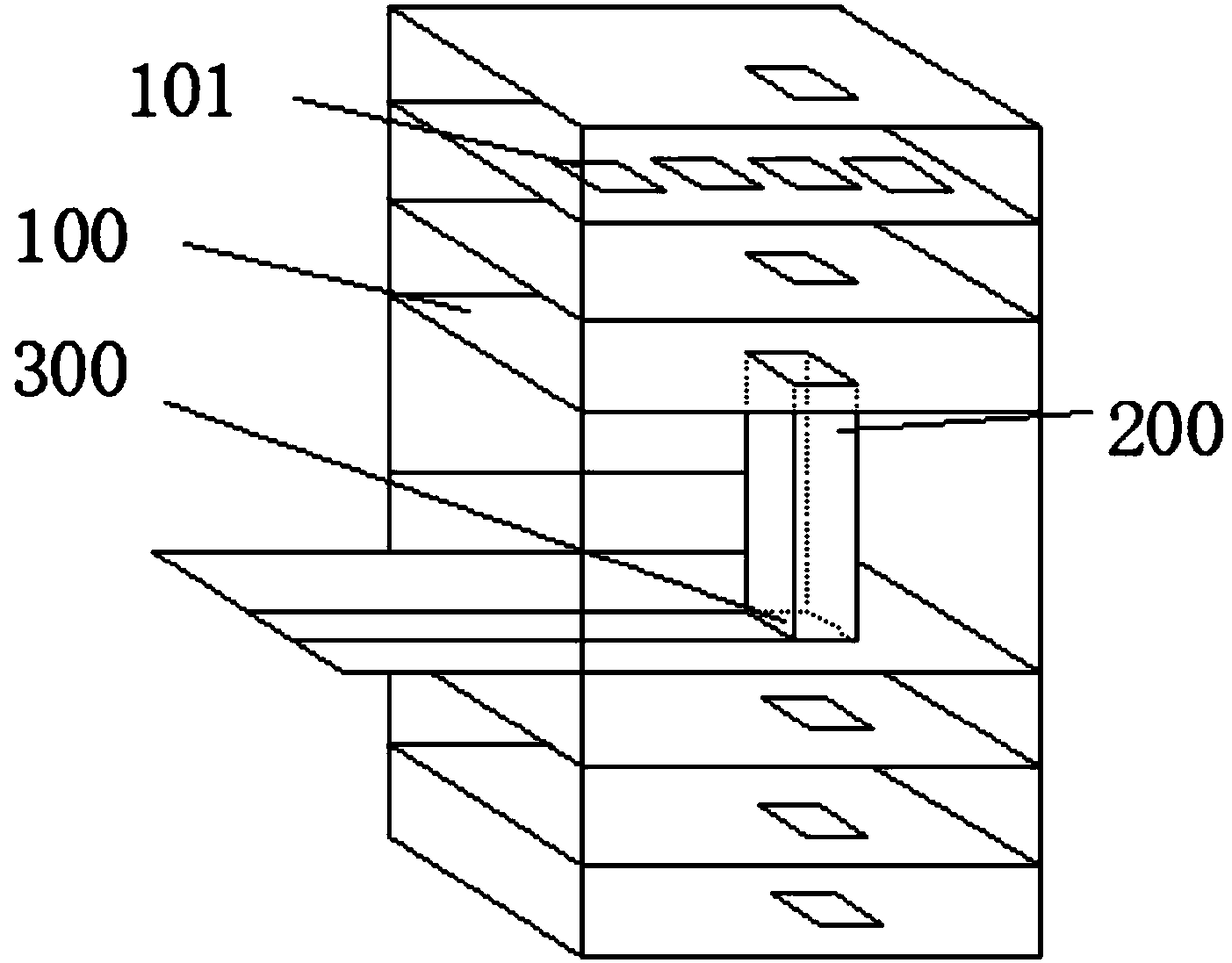

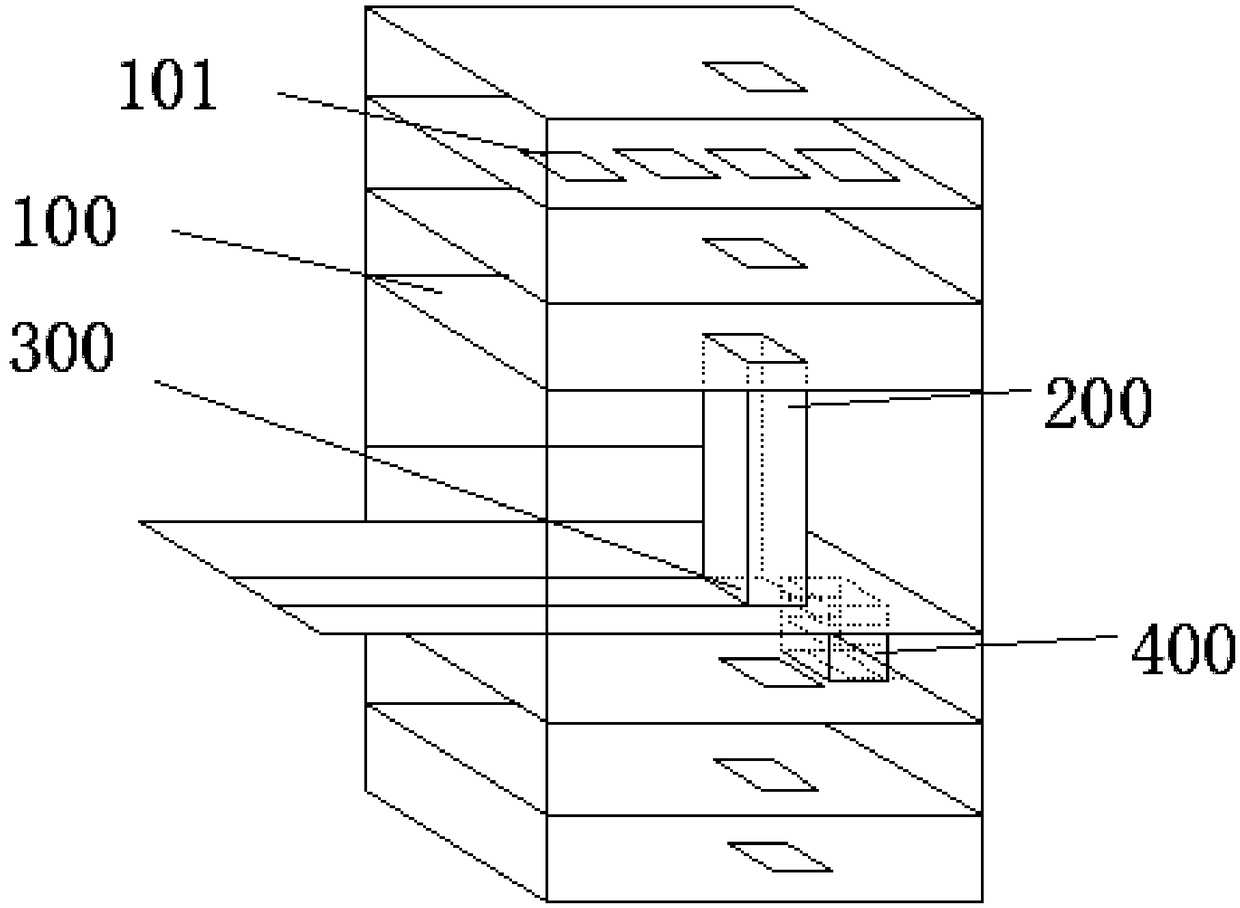

Three-dimensional logistics storage turnover system

PendingCN109110363AImprove space utilizationImprove turnover efficiencyStorage devicesHigh turnoverLogistics management

The invention discloses a three-dimensional logistics storage turnover system and belongs to the technical field of storage equipment. The system comprises one or more storage layers, an elevator, a driving system and a doorway; each storage layer is provided with one or more berths; the elevator penetrates through the one or more storage layers and moves up and down among the one or more storagelayers; the driving system is used for driving cargoes to move from the elevator to the one or more berths and move from the one or more berths into the elevator and is used for driving the cargoes tobe moved among the berths; and the doorway communicates with the elevator and is used for storing the cargoes when depositing and taking out the cargoes. The system adopts the three-dimensional design, the space is utilized sufficiently, the cargoes are stored and taken automatically, and the system has the higher turnover efficiency.

Owner:青岛华通石川岛停车装备有限责任公司

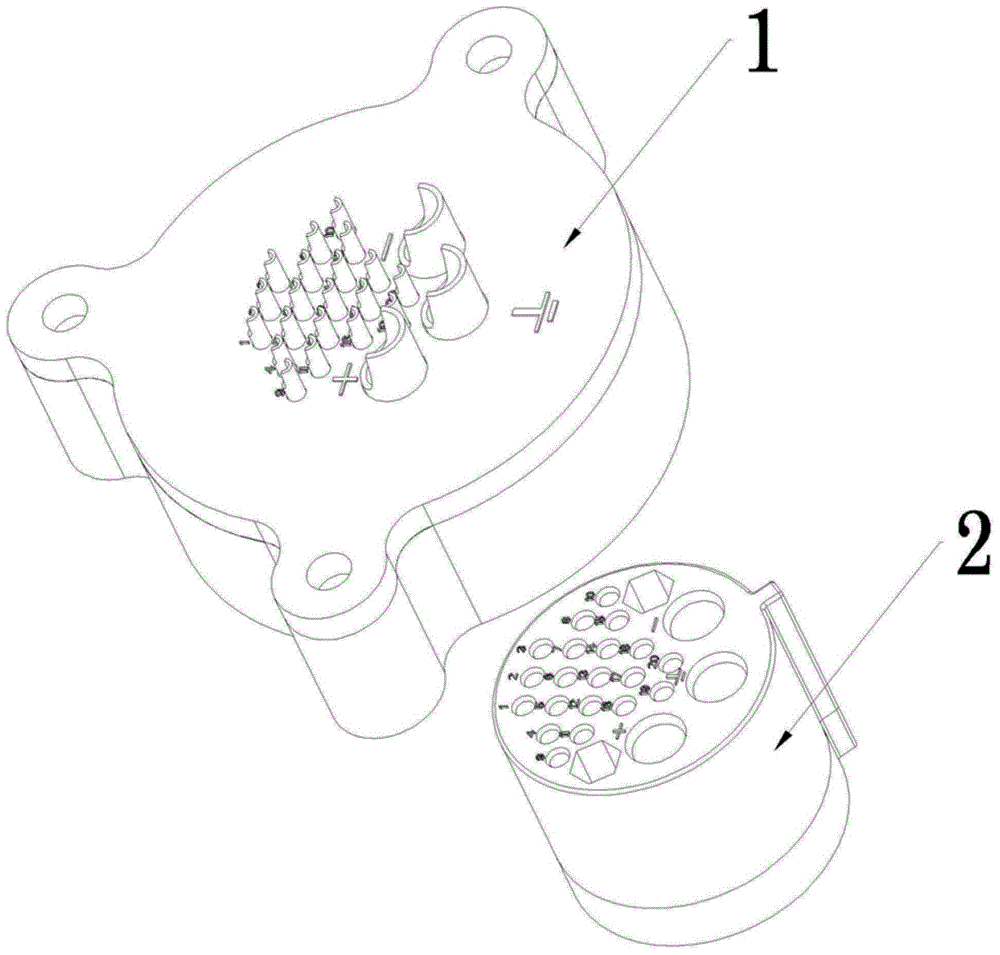

Ultra-high turnover led panel signal connector

InactiveCN103560369AReasonable layoutEasy installation and maintenanceSecuring/insulating coupling contact membersCoupling contact membersHigh turnoverElectrical and Electronics engineering

The invention relates to an ultra-high turnover led panel signal connector which comprises a lower triangular connector body and an upper triangular connector body. The lower triangular connector body and the upper triangular connector body are fixed to form a whole through a screw. The lower triangular connector body comprises a connector female base upper cover, a connector female base lower cover, a power source male copper pin and a signal male copper pin. The connector female base upper cover and the connector female base lower cover are respectively provided with three power source wire plugging holes formed in an arc-shaped mode, twenty signal pin holes and three screw holes distributed in a triangular mode, wherein the power source wire plugging holes, the signal pin holes and the screw holes of the connector female base upper cover are meshed with and correspond to the power source wire plugging holes, the signal pin holes and the screw holes of the connector female base lower cover in position. The upper triangular connector body comprises a power source female base copper pin, a signal female copper pin, a connector male base upper cover and a connector male base lower cover. The connector male base upper cover and the connector male base lower cover are both provided with power source pin plugging holes and signal pin holes, wherein the power source pin holes and the signal pin holes are meshed with and correspond to the connector female base lower cover in position. The ultra-high turnover led panel signal connector has the advantages that modification is conducted on an existing led panel heightened connector to form the connector, power source signals are distributed through the copper pins, the power source copper pins and the signal copper pins are reasonable in layout and installation and maintenance are convenient and fast.

Owner:福建国能光电科技有限公司

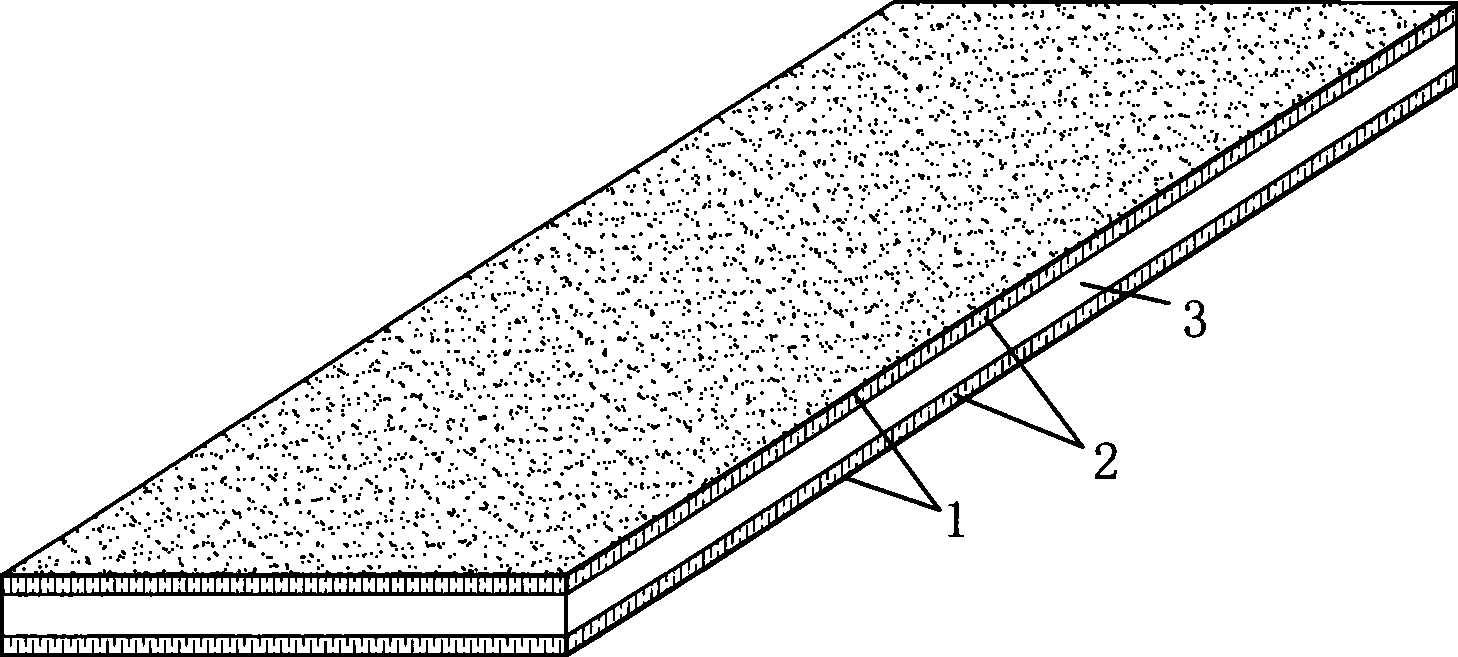

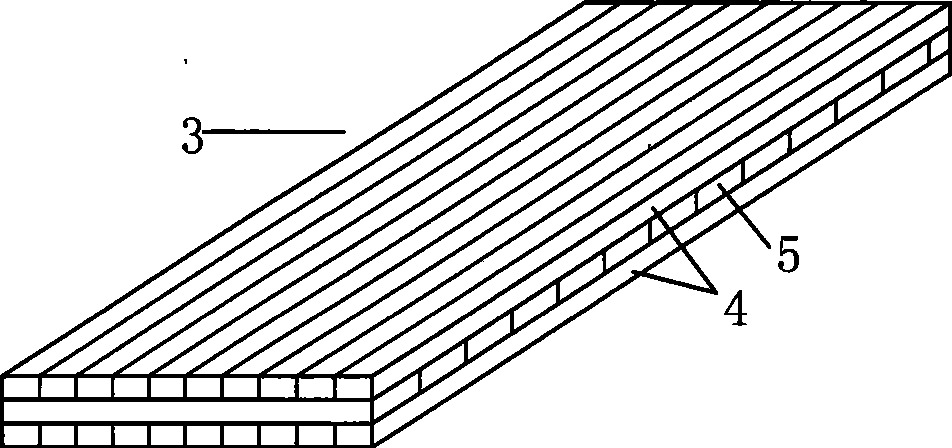

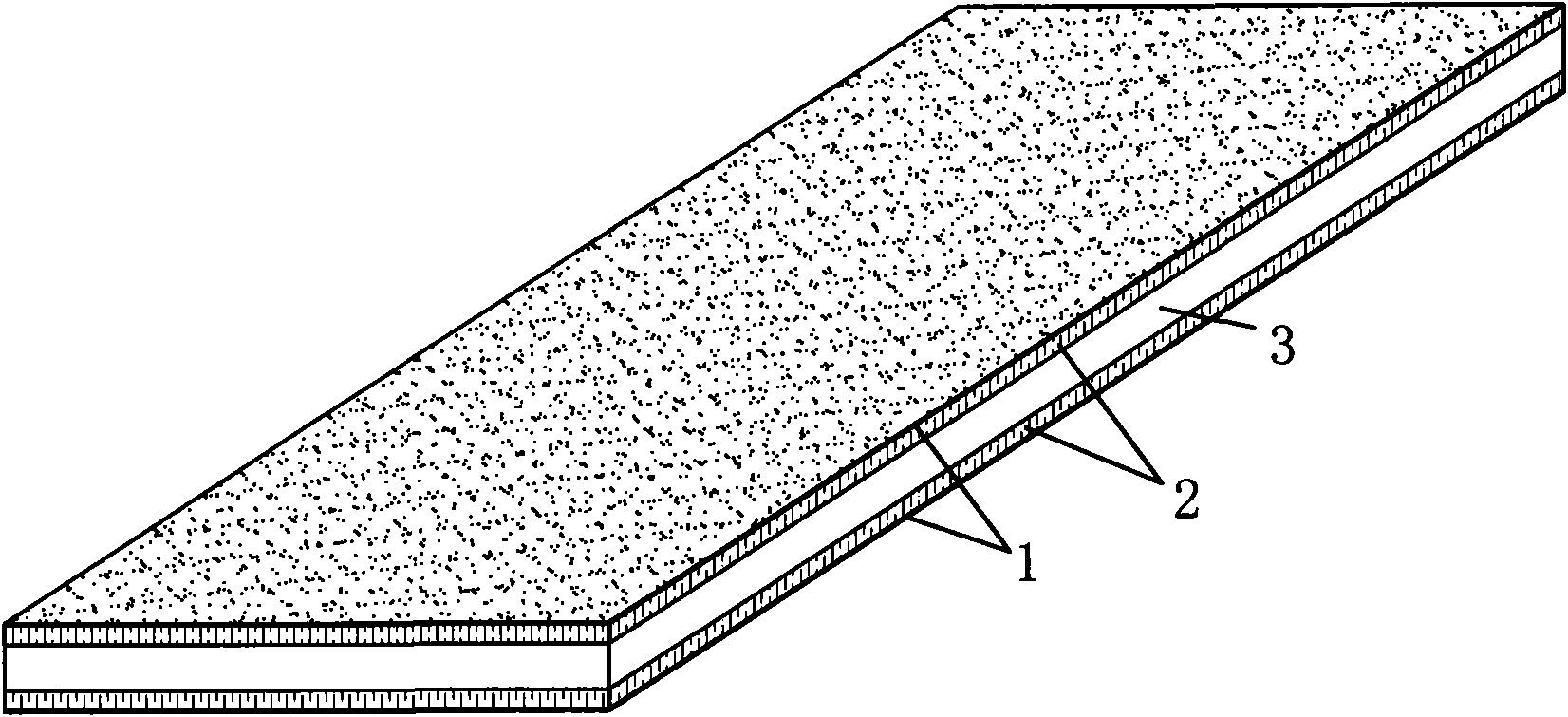

High-strength plywood for building shutter panel

InactiveCN101498171AEasy to assemble and disassembleHigh turnoverSynthetic resin layered productsWood layered productsHigh turnoverWeather resistance

The invention provides a veneer which is used for fair-faced concrete building template and has the advantages of lightness, high strength, convenient disassembly and assembly, easy cutting, high cost performance, weather resistance, corrosion prevention, strong durability, easy demoulding, high turnover frequency and being suitable for industrial production. The veneer consists of a covering film, a panel and a core plate; the covering film is prepared from a resin pressed film; the panel is prepared by gluing a gum dipping fiber reinforced composite material; and the core plate is a three-layer structural plate. The invention is mainly used for panels in building template systems, particularly for panels of fair-faced concrete templates.

Owner:NANJING UNIV OF TECH

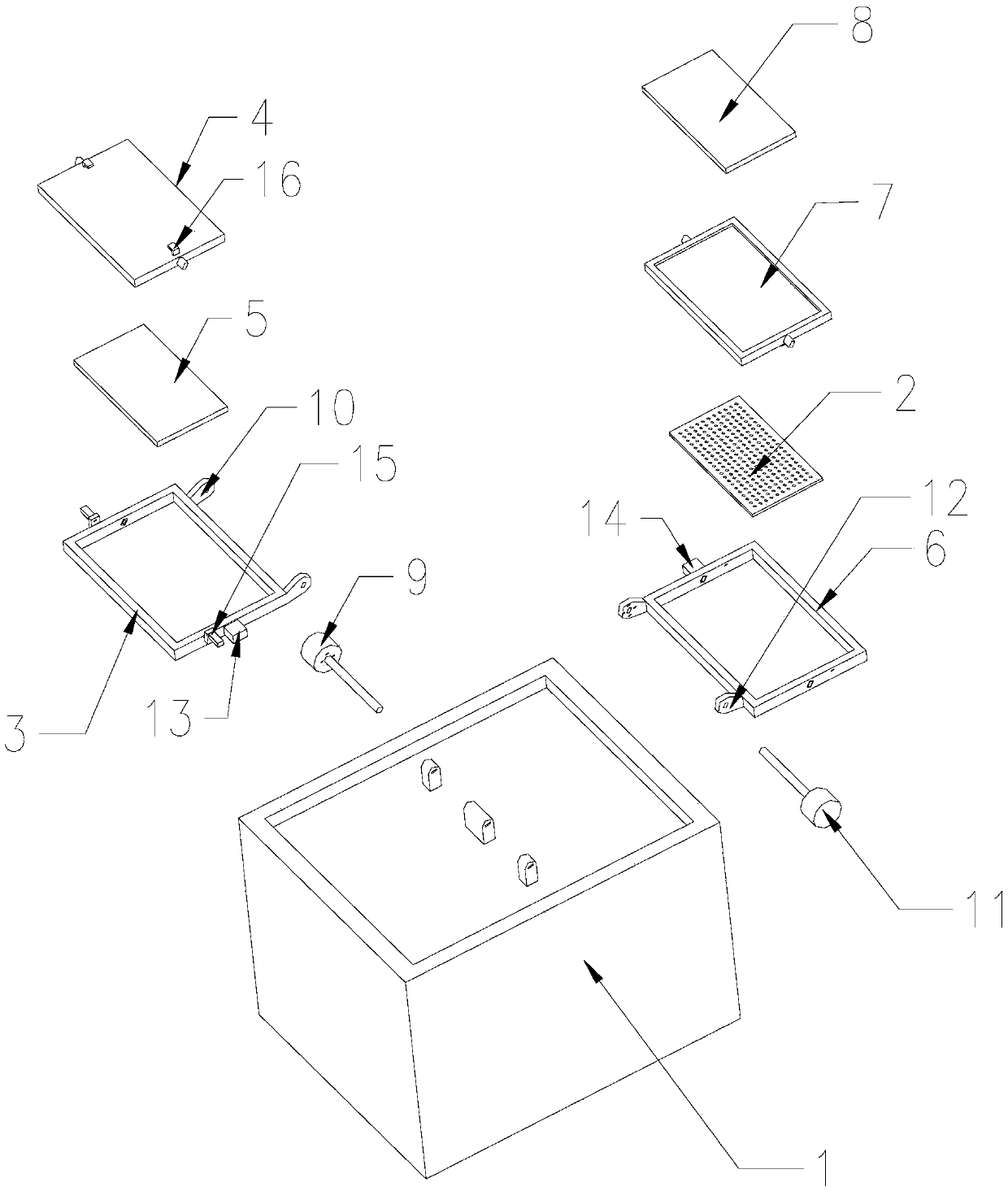

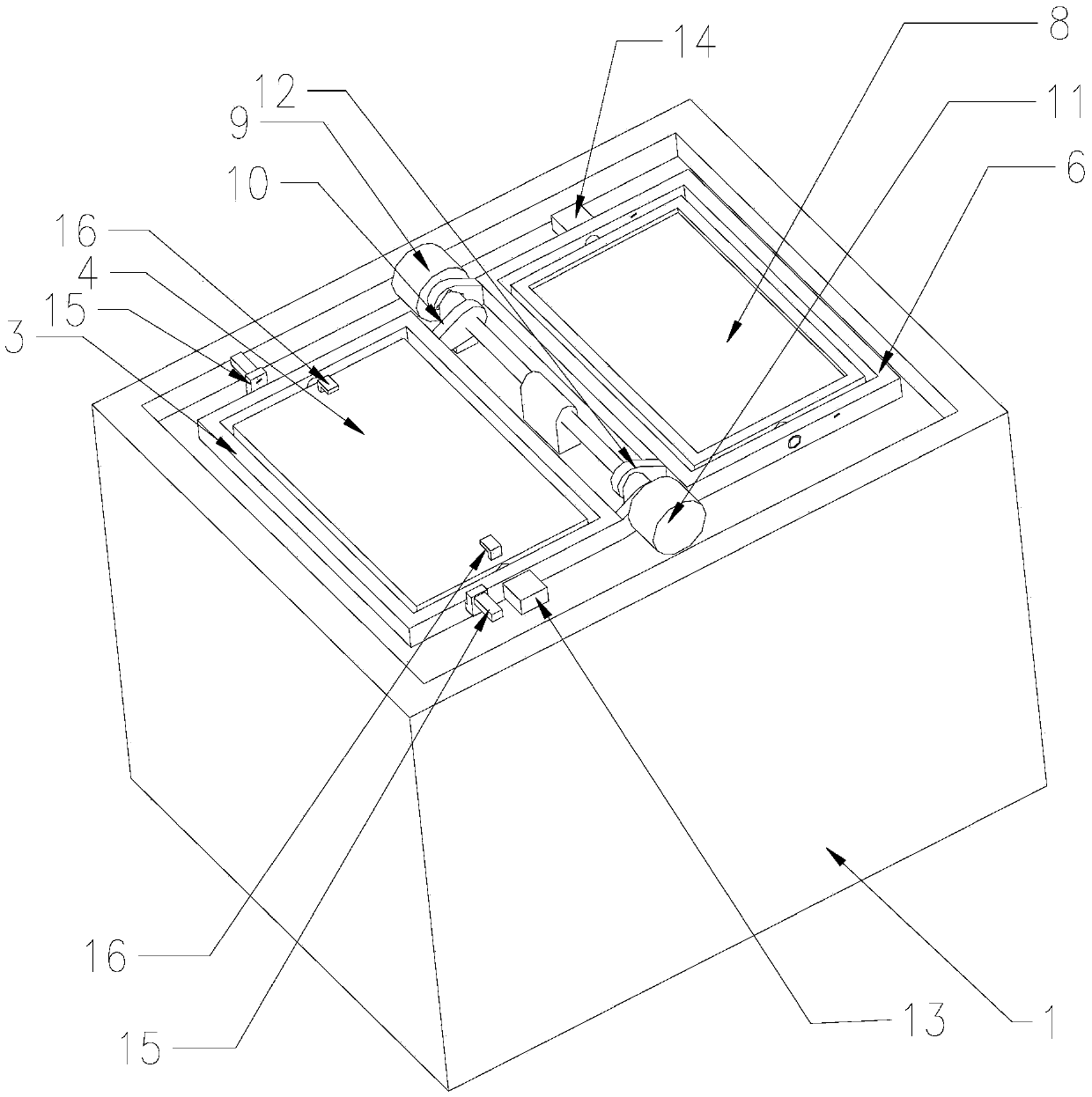

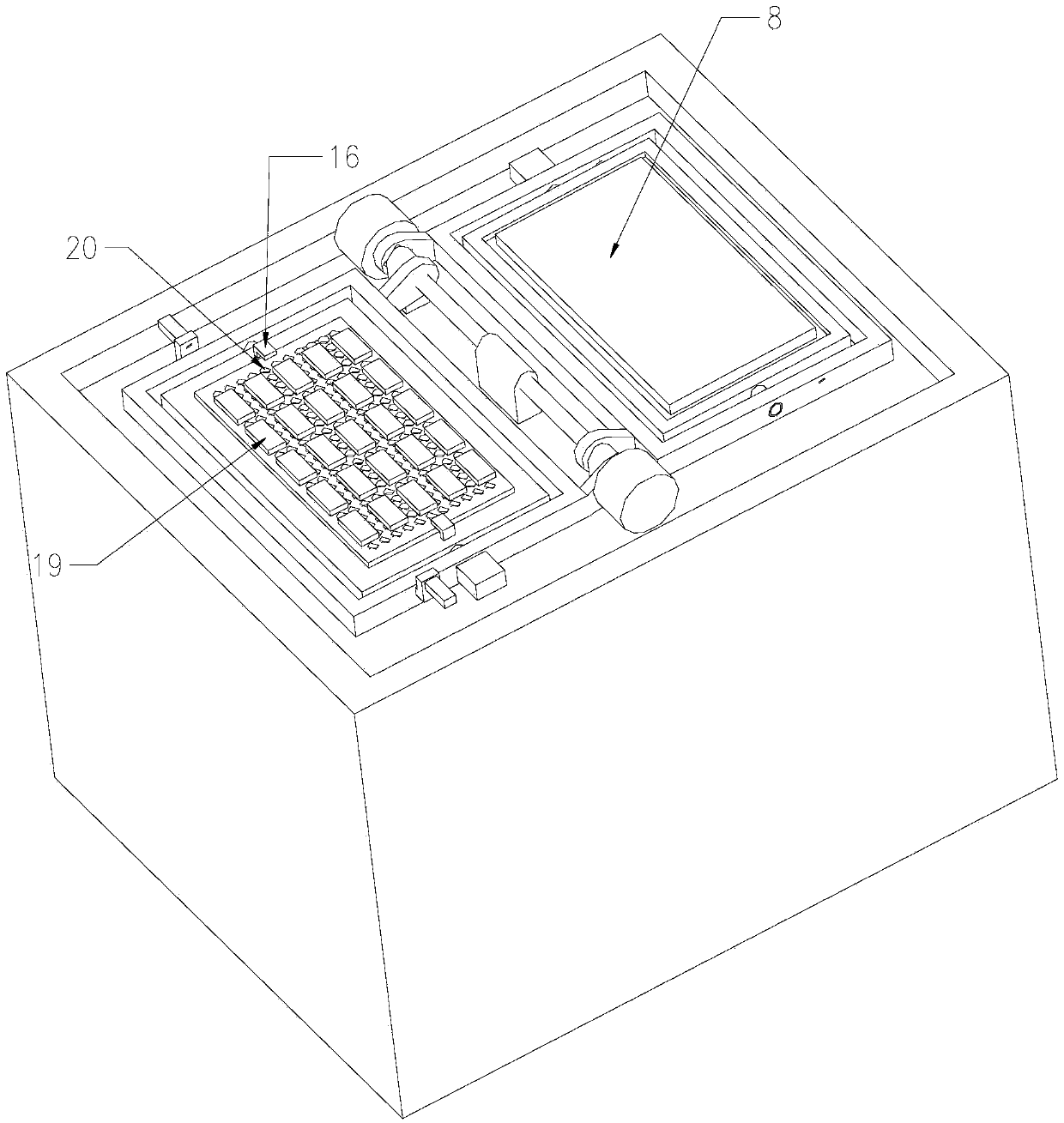

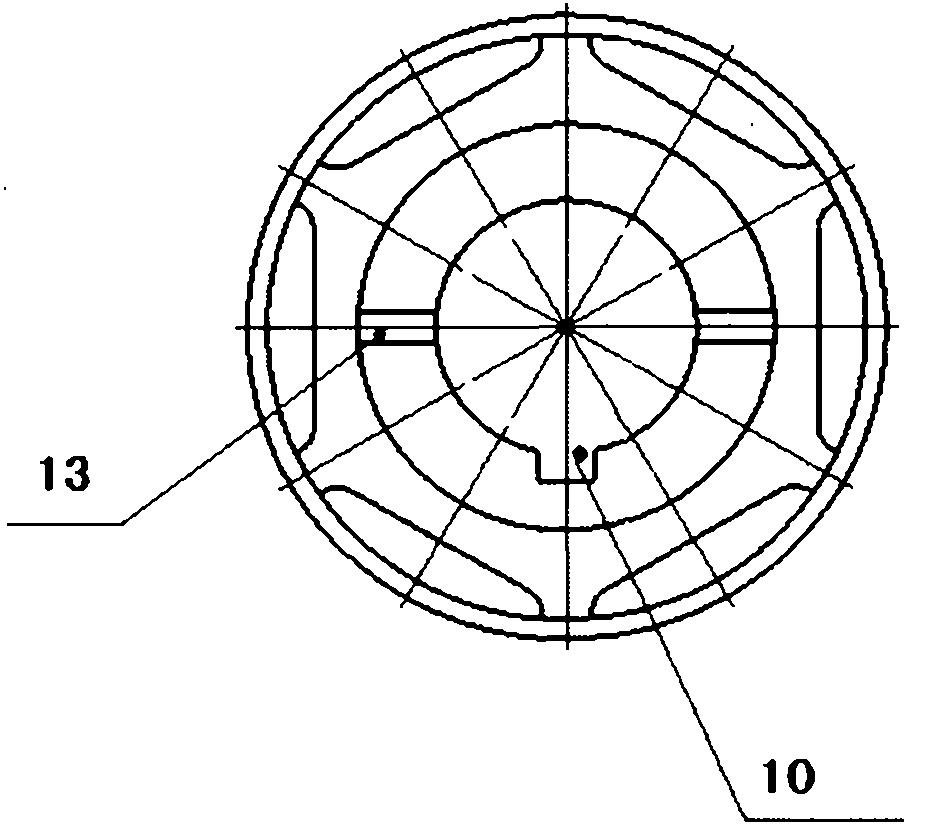

Automatic turnover device of magnetic steel product and turnover method thereof

The invention discloses an automatic turnover device of a magnetic steel product and a turnover method thereof. The automatic turnover device of the magnetic steel product comprises a frame, a first plate turning mechanism, a second plate turning mechanism, a first rotating mechanism for driving the first plate turning mechanism to overturn, a second rotating mechanism for driving the second plate turning mechanism to overturn, a third rotating mechanism, a fourth rotating mechanism, a turnover net plate and a plate turning locking mechanism; the turnover of the magnetic steel product on the net plate can be realized through controlling the first rotating mechanism, the second rotating mechanism, the third rotating mechanism and the fourth rotating mechanism; because of effects of a first sponge plate in the first plate turning mechanism and a second sponge plate in the second plate turning mechanism, the magnetic steel product cannot be deviated in multiple turnover process, and cannot generate collision; and the automatic turnover device of the magnetic steel product has the advantages of realization of turnover automation of the magnetic steel product, high turnover efficiency, capability of preventing staff from working under bad environments for a long time and guarantee of health of the staff.

Owner:NINGBO YUNSHENG +2

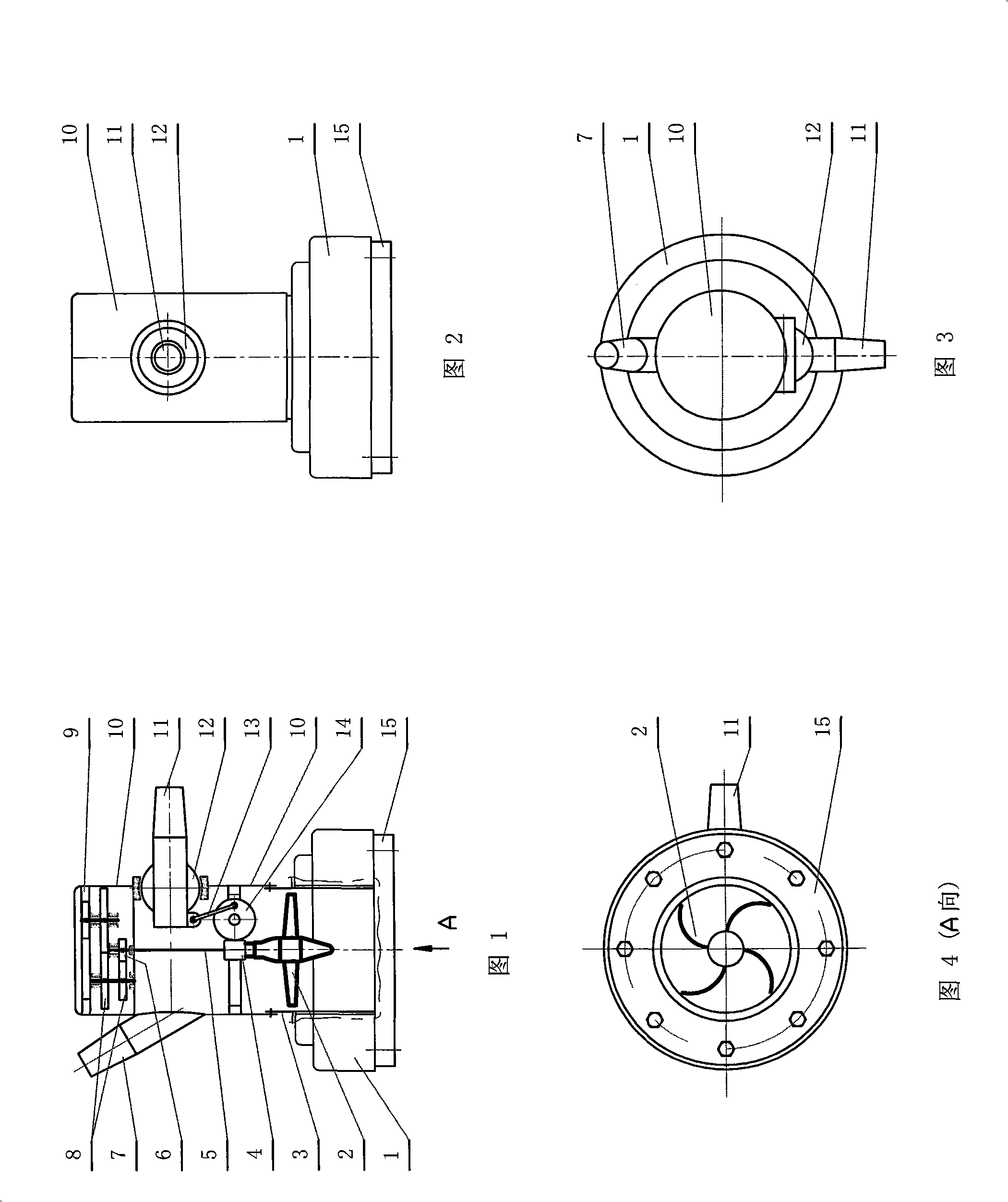

Oil rotating spray all-directional blending sweeper

ActiveCN101301594AReduce lossHigh turnover utilizationFlow mixersHollow article cleaningHigh turnoverTurbine

The present invention relates to an oil product rotating-spray omnidirectional concoction cleaner, a rotary internal sleeve is provided on a base having a flange disk outside the cleaner, a reduction gearbox is provided on the top of the inner chamber of a revolving drum fixed in the internal sleeve, the primary gears of which are arranged on the upper part of the principal axis, the axial flow turbine is arranged on the lower part of the principal axis; a worm is arranged on the lower part of the principal axis, the worm wheel meshed with the worm is arranged on the mandril in the middle of the inner chamber of the revolving drum; a fixed nozzle communicating the inner chamber is arranged on one side of the revolving drum , a spherical hinge is arranged on the other side, the big end of a swaying nozzle communicating with the inner chamber of the revolving drum inserts the spherical hinge; the two ends of the connecting rod are articulated with the eccentric shaft of the worm wheel and the big end of the swing nozzle respectively. The present invention forms vortex diffusion by nozzle spraying reelingly and rolling up and down driven by fluid, has no dead angle region, high concoction efficiency, short time and high turnover utilization of the storage tin; furthermore, the jet current out of the nozzle impacts the alluvium on the bottom of the tin to clear off the siltation to realize the cleaning function.

Owner:江西省仁达实业有限责任公司

Plywood for panel of as-cast-finish concrete building template

InactiveCN101575909AEasy to assemble and disassembleHigh turnoverForming/stuttering elementsHigh turnoverWeather resistance

The invention provides a plywood for a panel of an as-cast-finish concrete building template having the advantages of light weight, high strength, easy cutting, high cost performance, weathering resistance, corrosion resistance, good durability, easy demoulding, high turnover frequency, and the suitability for industrialized production. The plywood consists of a covering film, a panel and a core plate, wherein the covering film is prepared by pressing resin; the panel is prepared by gluing a veneer of gum dipping wood or gum dipping fiber reinforced composite material; and the core plate is a common plywood, composite plywood or hybrid plywood. The plywood is mainly applied to the panel in a building template system, particularly the panel of the as-cast-finish concrete building template.

Owner:NANJING UNIV OF TECH

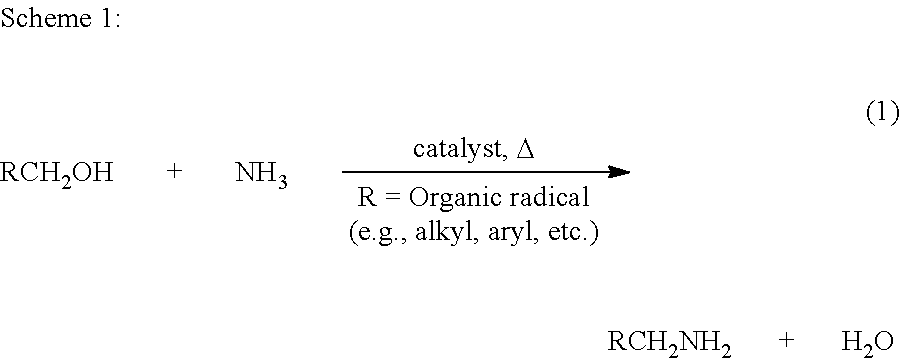

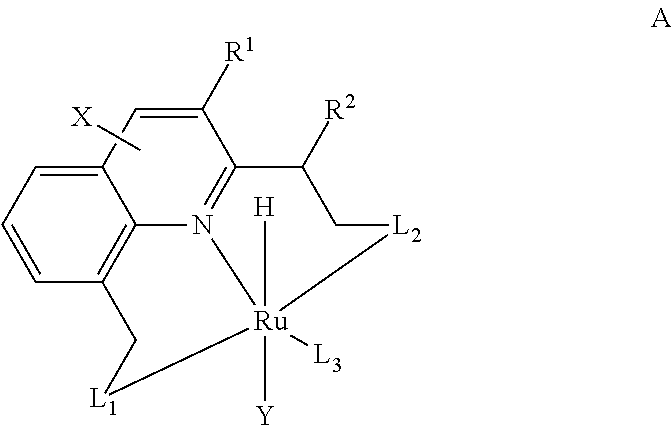

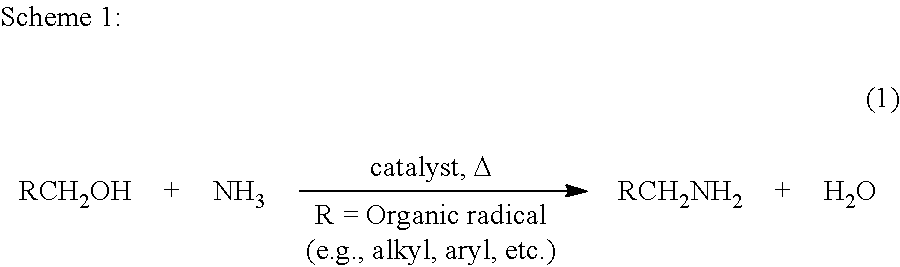

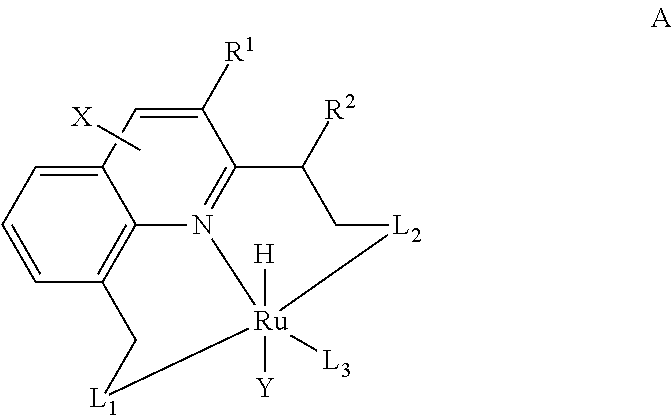

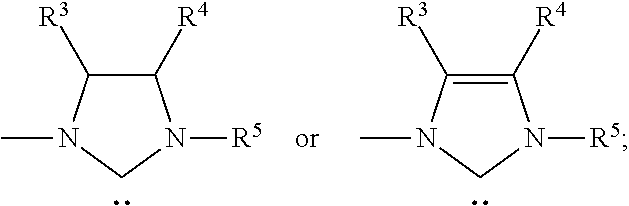

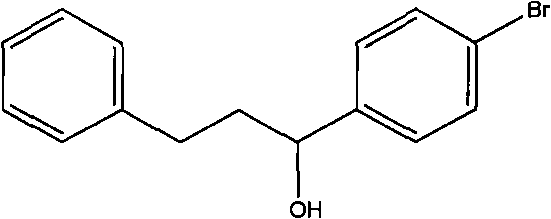

Process for preparing amines from alcohols and ammonia

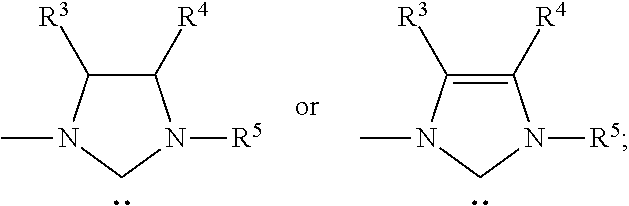

ActiveUS20110152525A1Good atom economyHighly economicalRuthenium organic compoundsOrganic compound preparationHigh turnoverAlcohol

The present invention provides novel ruthenium based catalysts, and a process for preparing amines, by reacting a primary alcohol and ammonia in the presence of such catalysts, to generate the amine and water. According to the process of the invention, primary alcohols react directly with ammonia to produce primary amines and water in high yields and high turnover numbers. This reaction is catalyzed by novel ruthenium complexes, which are preferably composed of quinolinyl or acridinyl based pincer ligands.

Owner:YEDA RES & DEV CO LTD

Highly active xylose reductase from Neurospora crassa

ActiveUS7381553B2High activityImprove efficiencySugar derivativesBacteriaEscherichia coliHeterologous

A new xylose reductase encoding gene from Neurspora crassa was heterologously expressed in E. coli as a His-tag fusion protein and subsequently purified in high yield. This xylose reductase was shown to have a high turnover rate and catalytic efficiency, high stability at room temperature, broad pH profile, and a preference of NADPH over NADH. This enzyme is utilized in production of xylitol and other sugar alcohols such as sorbitol and also in the metabolic enhancement of organisms used for fermentation of plant biomass into ethanol.

Owner:BIOTECH RES & DEV

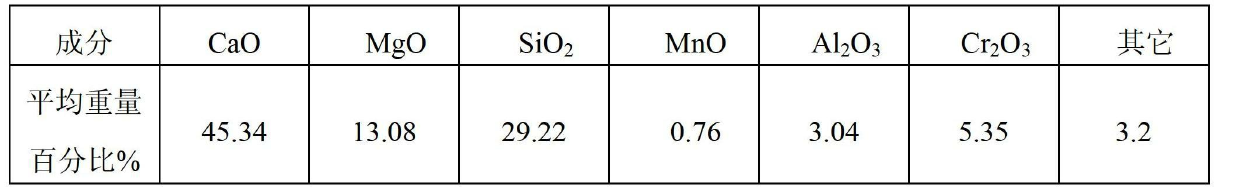

Process for cooling stainless steel slag by wet method

InactiveCN102676712AReduce transportationSave the link of carbon steel slag pad tankHigh turnoverFilling materials

The invention discloses a process for cooling stainless steel slag by a wet method. The process comprises the following steps of: cooling naturally for 20 to 24 hours on a cooling station after electric furnace mother solution slag is conveyed from a field; spraying for cooling for 4 to 6 hours, and controlling a slag surface, so that water is not accumulated on the slag surface; standing for 3 to 4 hours, when the maximum temperature of the walls of slag tanks is lower than 120 DEG C and the temperature of an inner core of the steel slag is lower than 300 DEG C, turning the slag over in a slag box, keeping dried in the slag box, and paving by using the massive slag; crushing the turned massive steel slag, wherein massive materials of which the diameter is smaller than 200 millimeters are taken as tank filling materials; transferring the tank filling materials into empty slag tanks to fill up the tank, wherein 3 to 5 tons of tank filling materials are added into each empty slag tank; and conveying the filled slag tanks to a slagging point and receiving the slag, and conveying the received slag to a slag field. The process has the advantages of separating the stainless steel slag from carbon steel slag, along with high cooling speed, high turnover efficiency of the slag tank, a few intermediate link and the like while the problem of tank adhesion is solved.

Owner:BAOSTEEL DEV CO LTD

Process for preparing amines from alcohols and ammonia

ActiveUS8586742B2Good atom economyHighly economicalRuthenium organic compoundsOrganic compound preparationHigh turnoverAlcohol

The present invention provides novel ruthenium based catalysts, and a process for preparing amines, by reacting a primary alcohol and ammonia in the presence of such catalysts, to generate the amine and water. According to the process of the invention, primary alcohols react directly with ammonia to produce primary amines and water in high yields and high turnover numbers. This reaction is catalyzed by novel ruthenium complexes, which are preferably composed of quinolinyl or acridinyl based pincer ligands.

Owner:YEDA RES & DEV CO LTD

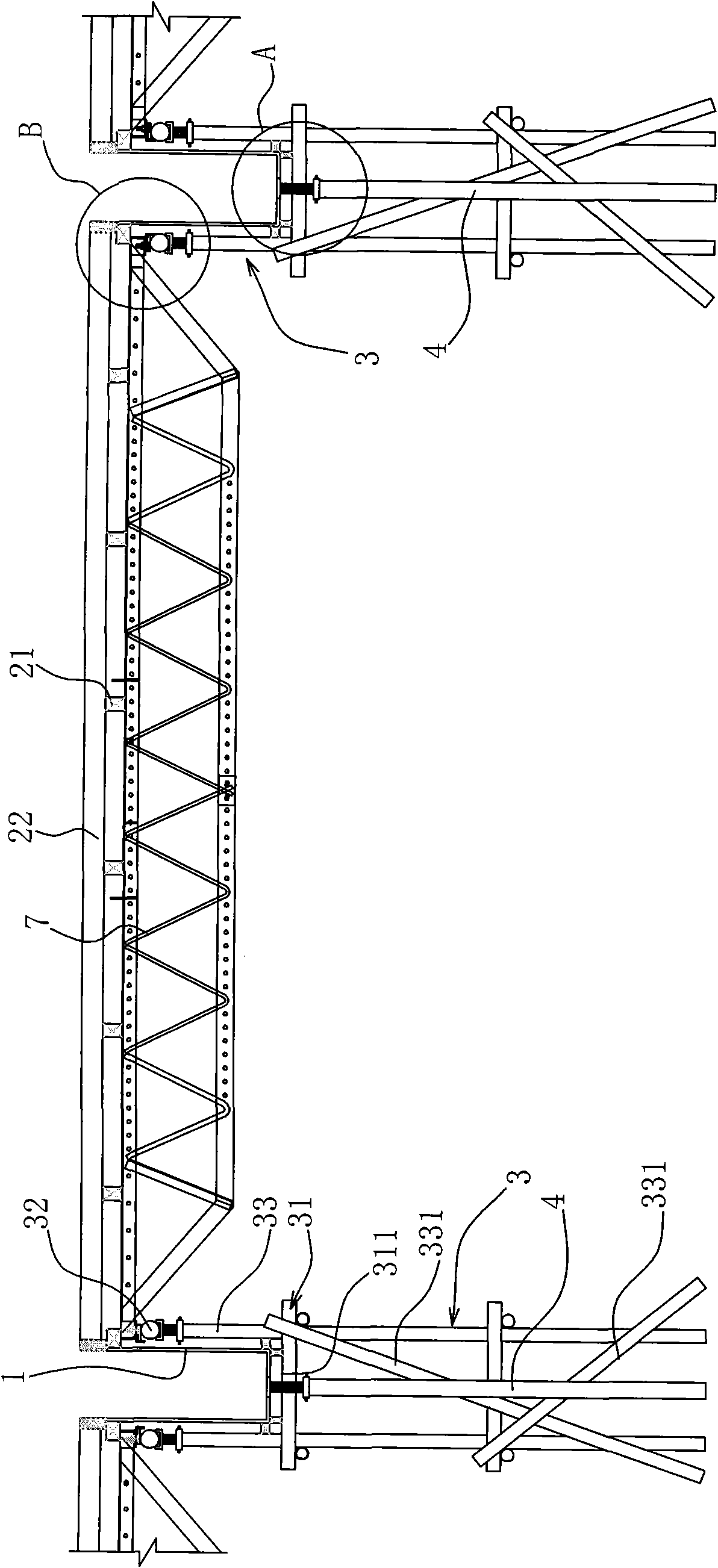

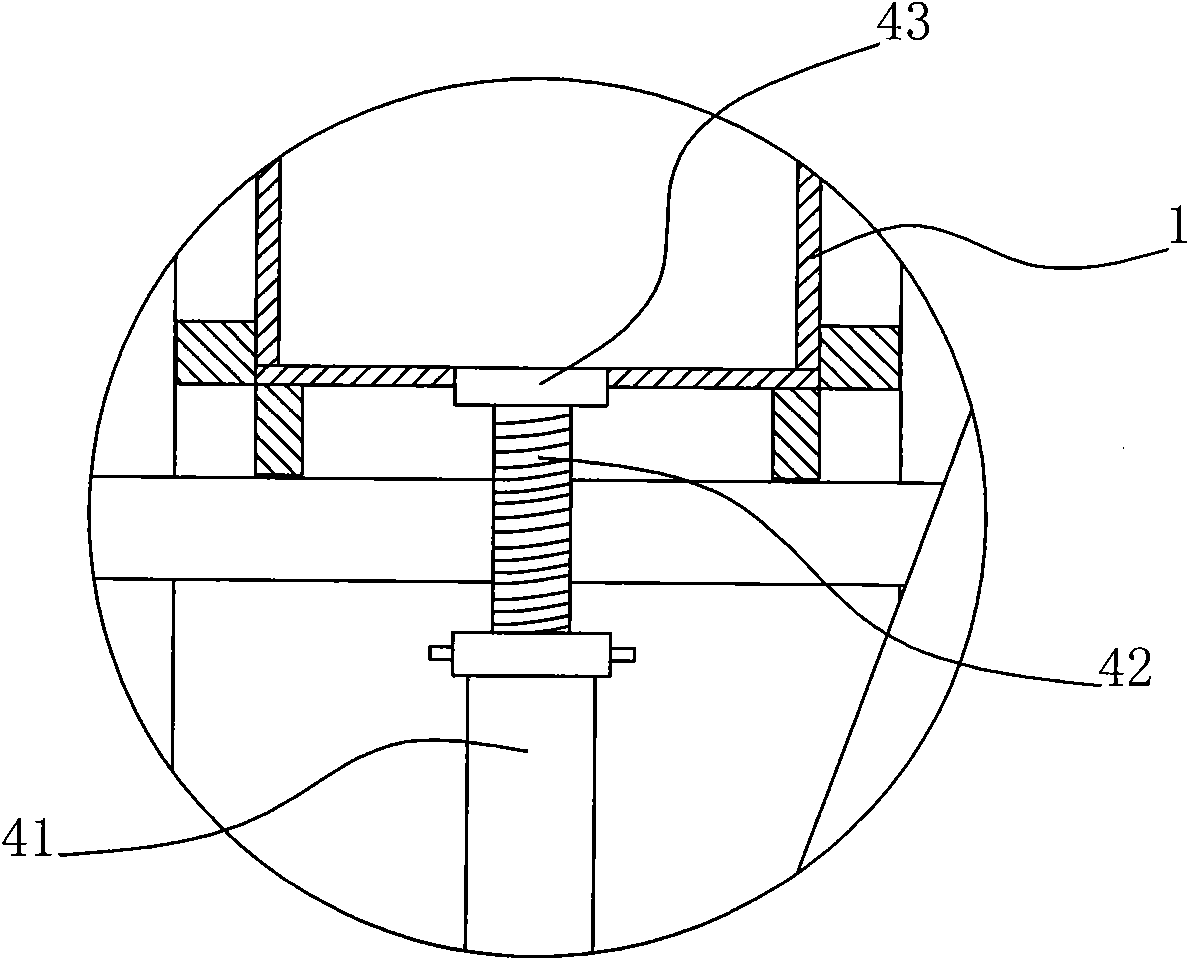

Combined set-shaped steel formwork and modeling method thereof

InactiveCN110273539AGenerate accuratelyRealize the establishmentGeometric CADForms/shuttering/falseworksHigh turnoverEngineering

The invention discloses a combined set-shaped steel formwork. The combined set-shaped steel formwork comprises a formwork assembly, connecting assemblies, a supporting assembly and fasteners, wherein the formwork assembly is used for forming a closed surface required for the construction of a concrete structure and ensuring a plate piece for forming of a building structure during concrete pouring; the formwork assembly comprises a plurality of single formwork bodies, and the single formwork bodies comprise single standard plates and single internal corner pieces; the single standard plates are provided with standard plate bevel angles, and the single internal corner pieces are provided with internal corner piece bevel angles; the connecting assemblies are used for connecting the single formwork bodies into a connector of a model; the supporting assembly is a stabilizer used for supporting the formwork assembly during the construction of the concrete structure; and the fasteners are members used for shaping the structure, width and size modeled by the formwork assembly. The invention further discloses a method for modeling using the combined set-shaped steel formwork. The combined set-shaped steel formwork and the modeling method have the advantages of light weight, high turnover usage rate, recyclability, high work efficiency, flexible assembly, high versatility, high machining precision, accurate forming size, uniform corner angles, flat and smooth surface and wide application range.

Owner:XINJIANG SUZHONG CONSTR ENG

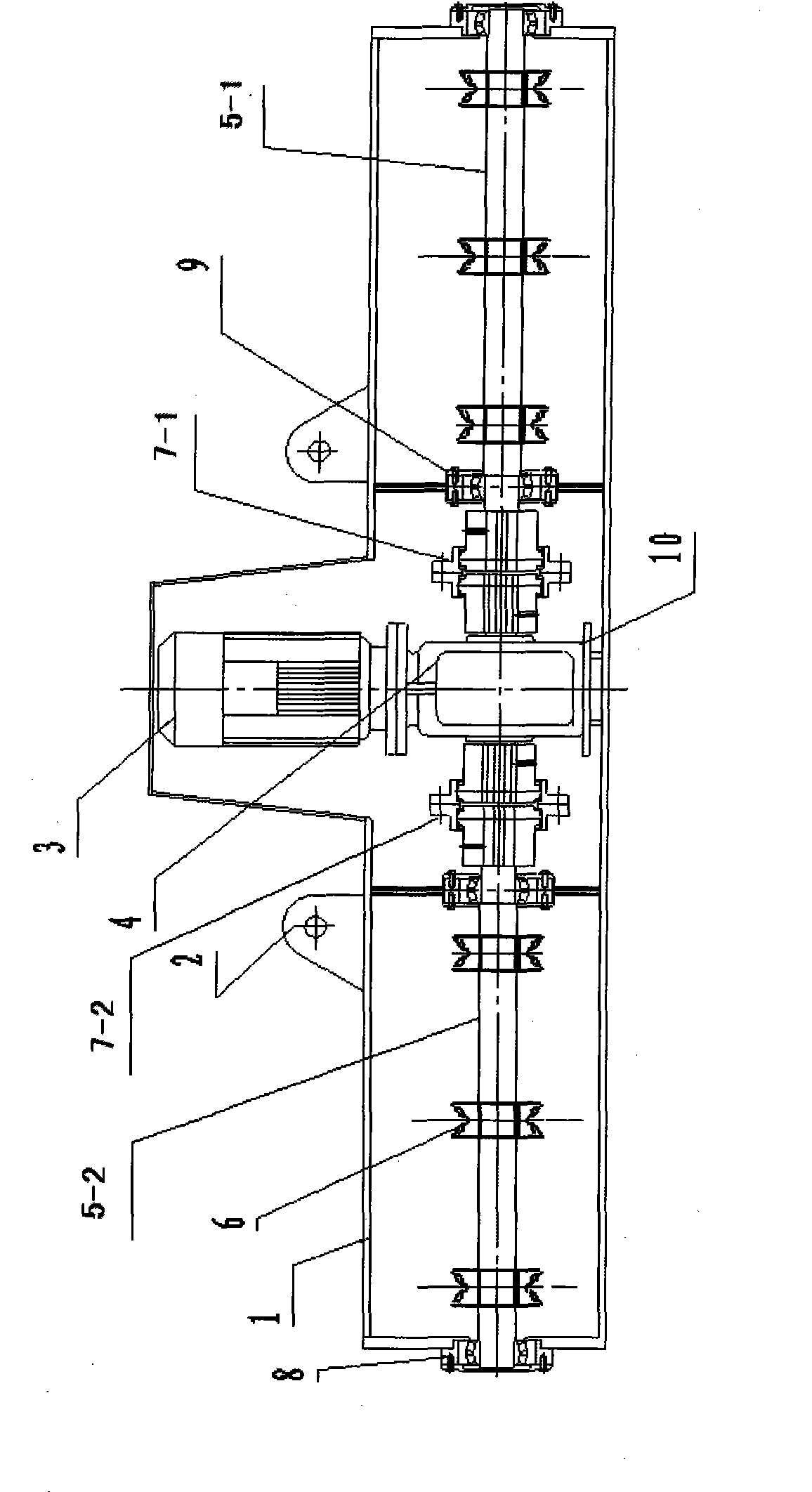

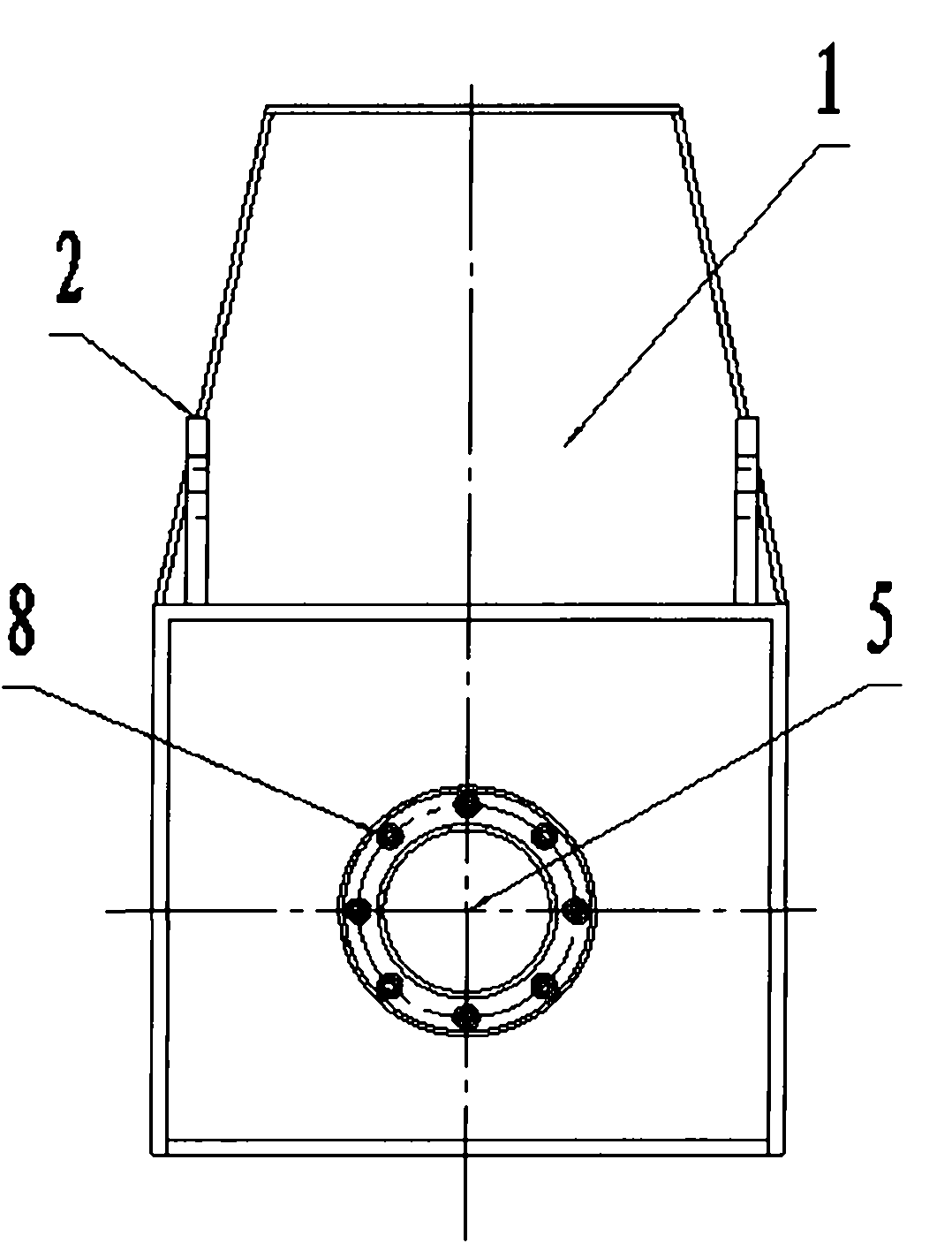

Electric box turnover device

InactiveCN101961780AReduce labor intensityCompact structureMould handling equipmentsHigh turnoverCoupling

The invention relates to an electric box turnover device. Lifting lugs are symmetrically arranged on the top of an outer shell. The device is characterized in that: the shell has a convex framework with an opening; a bracket is arranged between front and back walls; a speed reducer is arranged on the bracket; a turnover motor is connected with the speed reducer and arranged above the speed reducer and in a groove of the shell; the two sides of the speed reducer are symmetrically connected with transmission shafts through couplings; the other end of each transmission shaft is supported on the side wall of the shell through a bearing; each transmission shaft is provided with a plurality of link chain sprockets; the transmission shafts and the link chain sprockets are fixed through keys and keyways; slots and slot grooves are formed on the link chain sprockets at equal intervals; and the widths of the slots and the slot grooves are respectively matched with the width and thickness of the link chain sprockets. The electric box turnover device can realize the controlled motion and stop 360-degree forward and reverse continuous or joggle electric turnover of a sand box, has low rotating speed and high turnover efficiency, stably operates and can be used for the turnover and close of the sand box, the inclined spraying of a flow coating sand box, the turnover of a casting mold and a tool and the turnover of large castings during processing.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

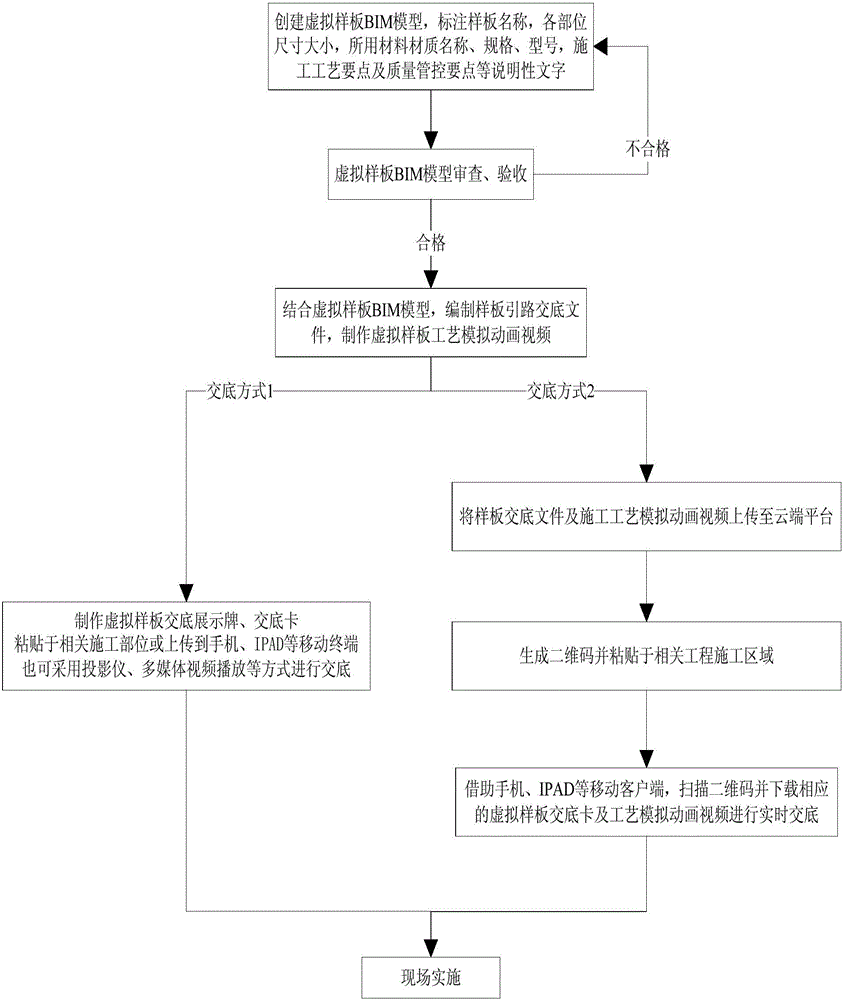

Virtual template leading quality control method based on BIM technology

InactiveCN106296026ASimple operation processImprove efficiencyResourcesHigh turnoverResource consumption

The invention discloses a virtual template leading quality control method based on a BIM technology. The virtual template leading quality control method comprises the following steps: a, creating a virtual template BIM model; b, carrying out examination and acceptance on the virtual template BIM model; c, compiling a template leading disclosure document by combining with the virtual template BIM model, and making a virtual template process simulated animation; d, carrying out technical disclosure; and f, carrying out site implementation according to a disclosure content. According to the virtual template leading quality control method disclosed by the invention, the template leading quality control with a virtual template to replace a real template is realized; the mentioned template leading quality control method has the characteristics of simple operation process, high efficiency, small resource investment, low comprehensive cost, high turnover rate and low resource consumption; the problem of the resource consumption due to real quality template making is solved fundamentally; and a new way is created for introduction of an engineering quality template.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

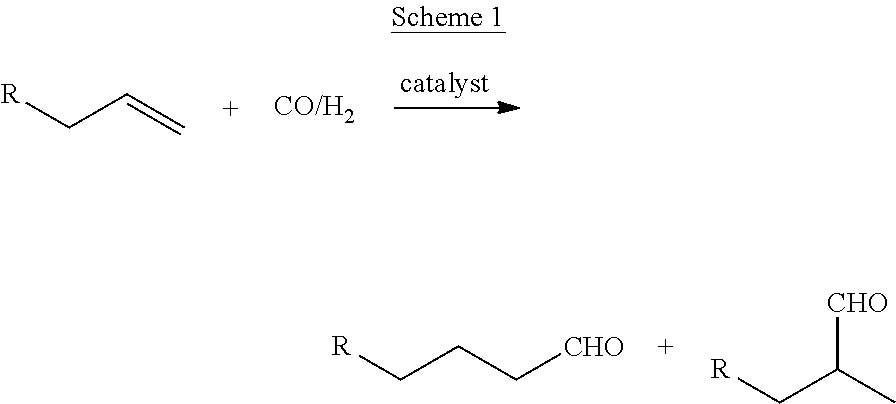

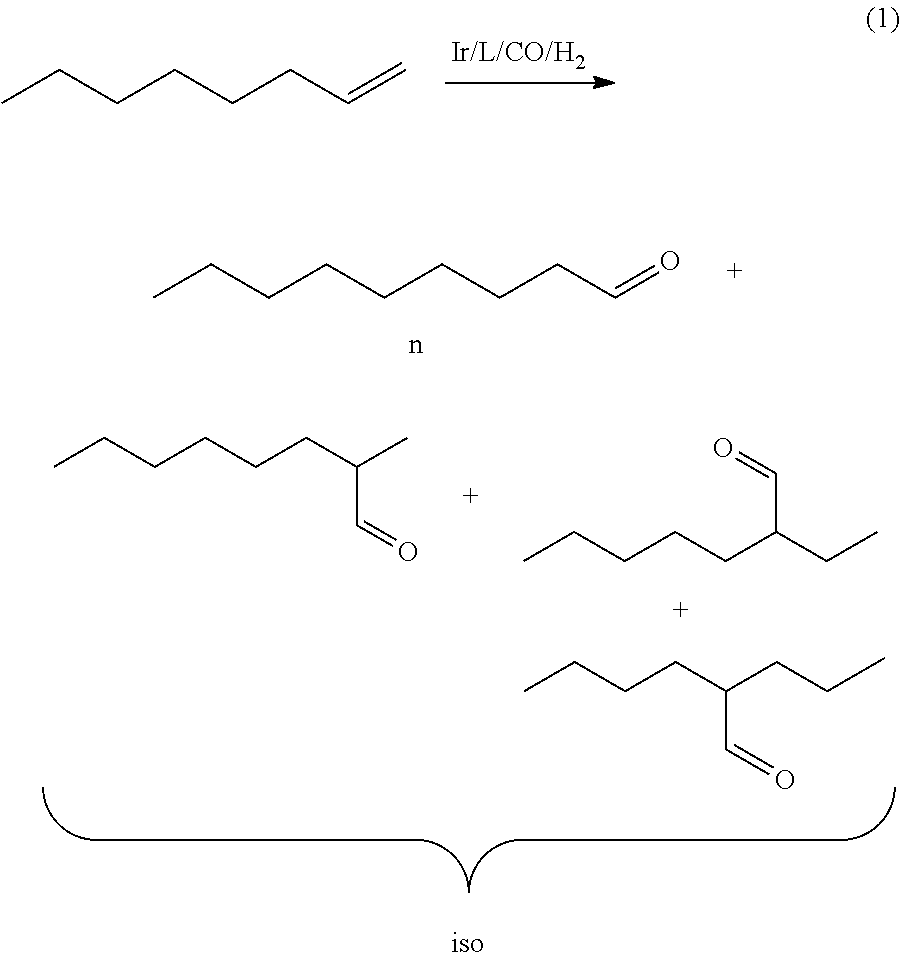

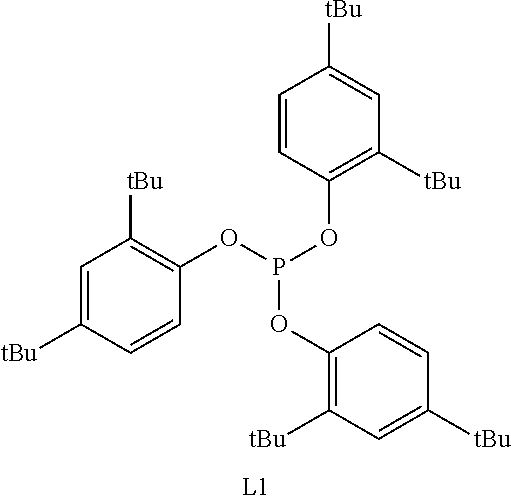

Method for hydroformylation of unsaturated compounds

InactiveUS8927776B2High activityHigh yieldOrganic compound preparationCarbonyl compound preparation by oxidationHigh turnoverSyngas

Owner:EVONIK DEGUSSA GMBH

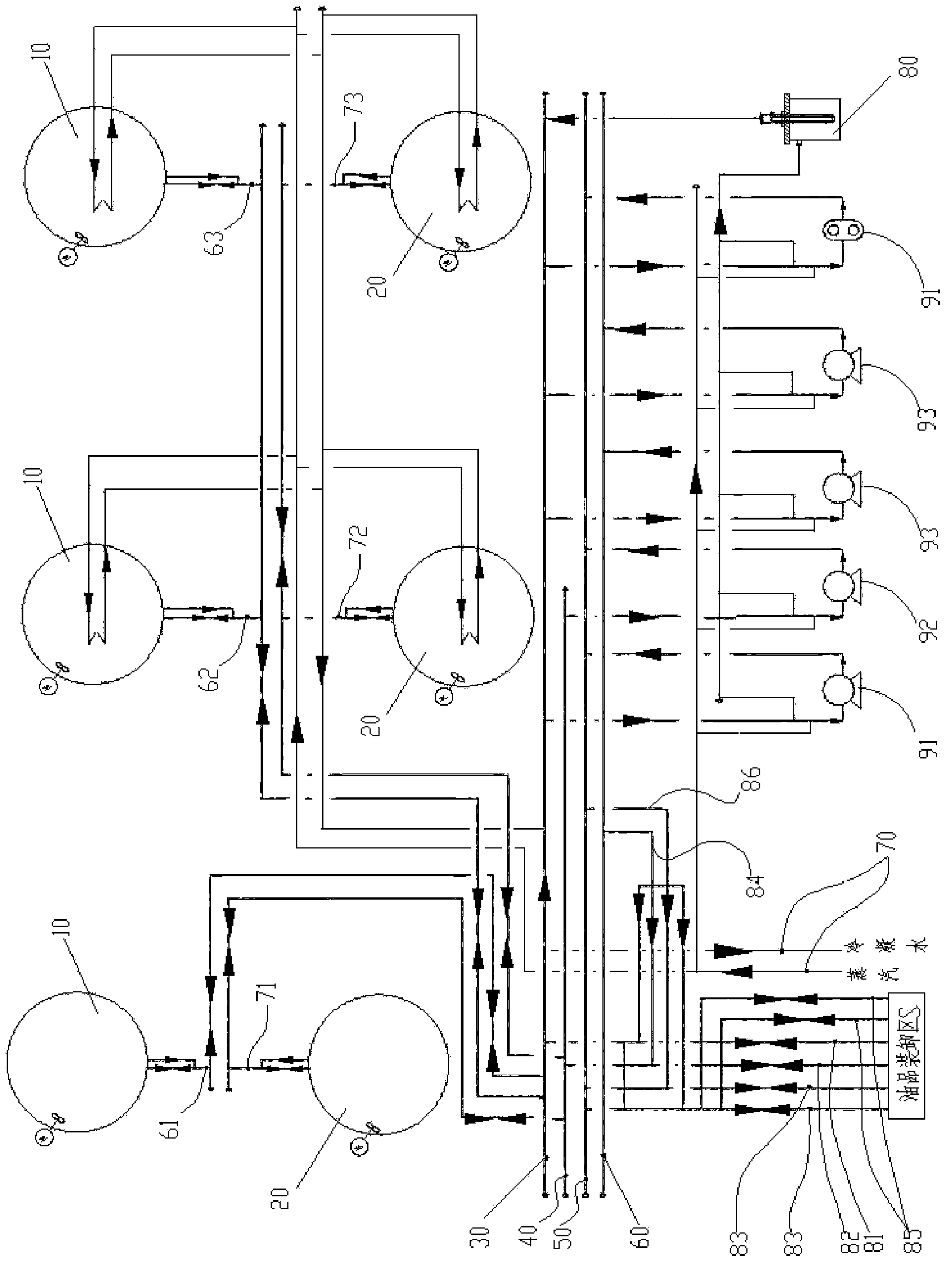

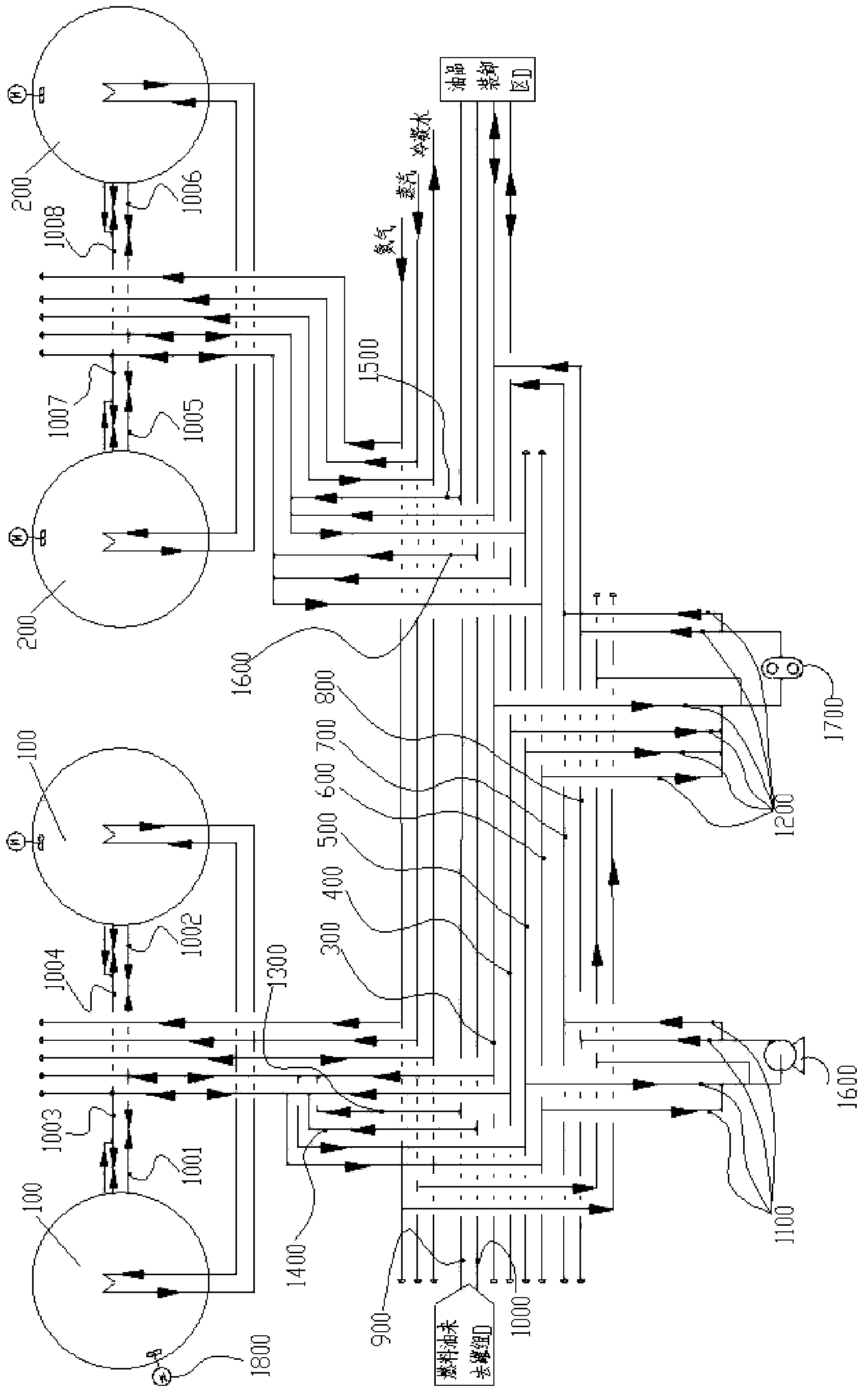

Petroleum conveying system applicable to large petroleum reserve depot

The invention relates to design of petroleum depot technological systems, in particular to a petroleum conveying system applicable to a large petroleum reserve depot. The petroleum conveying system is a single-pipe process technological system or a double-pipe procedure technological system, thus, a single-pipe technological process can be adopted in terms of large petroleum reserve depots with low turnover frequency and a double-pipe technological process device can be adopted in terms of large petroleum reserve depots with high turnover frequency. Under the condition that oil discharging of the large petroleum reserve depots is not affected, the problems of diseconomy and complicated operation of a multiple-pipe technological process are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

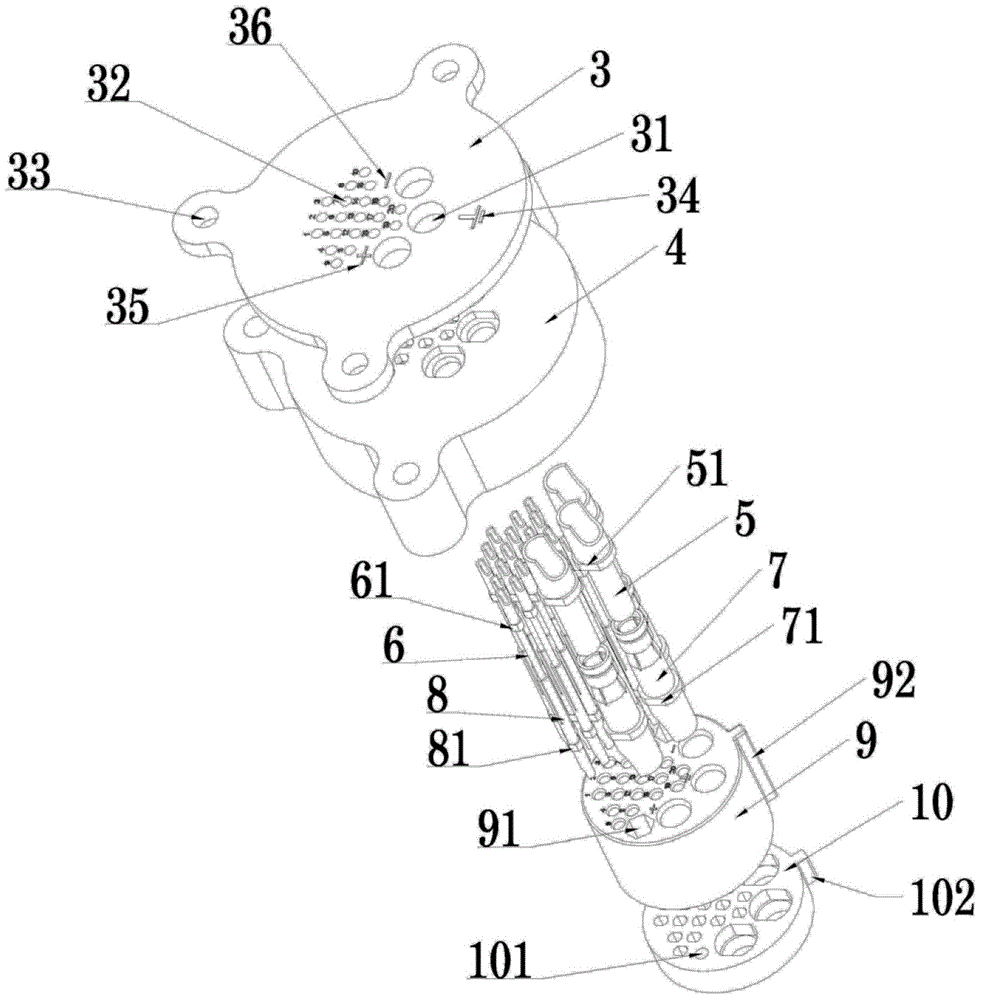

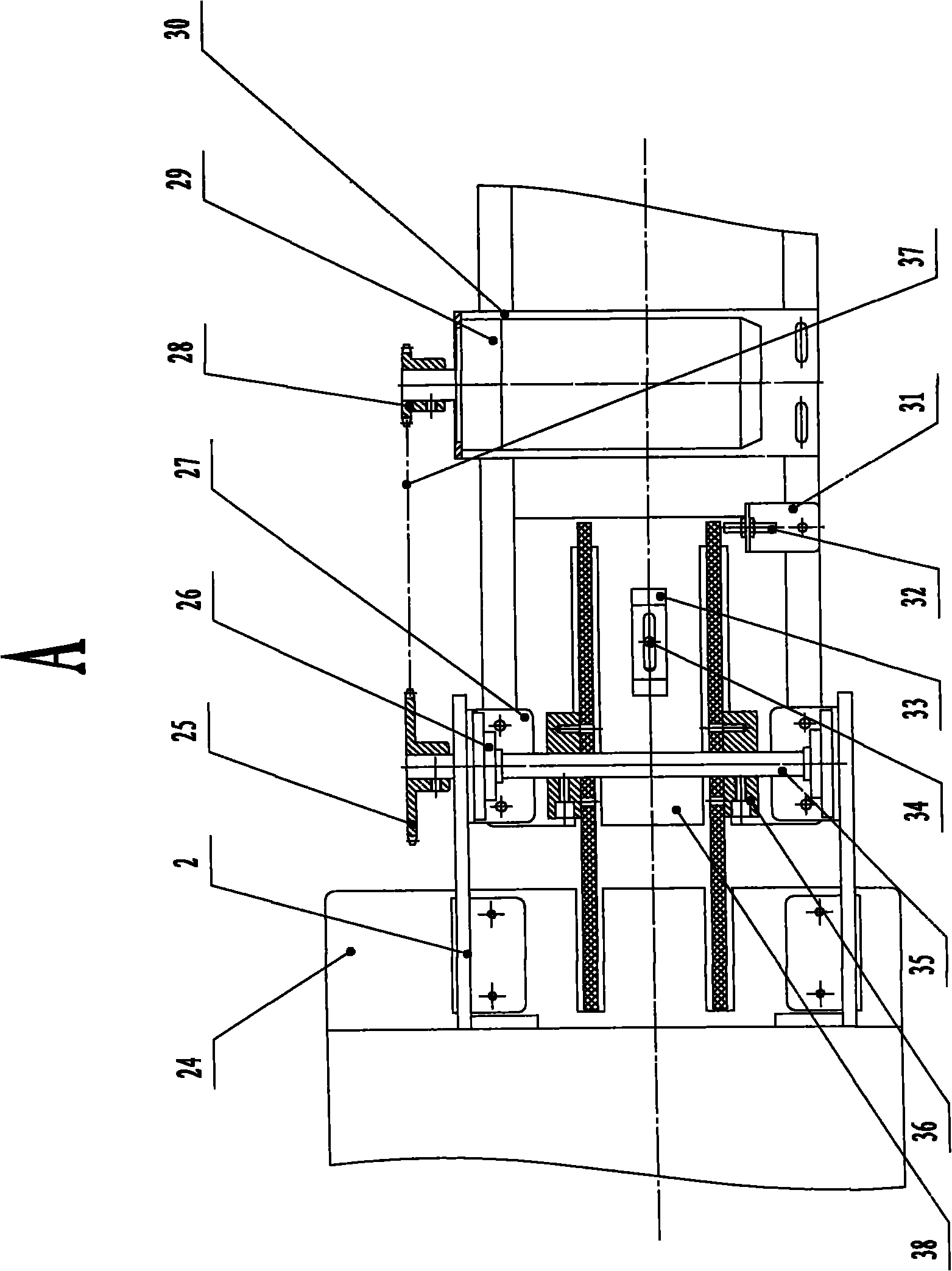

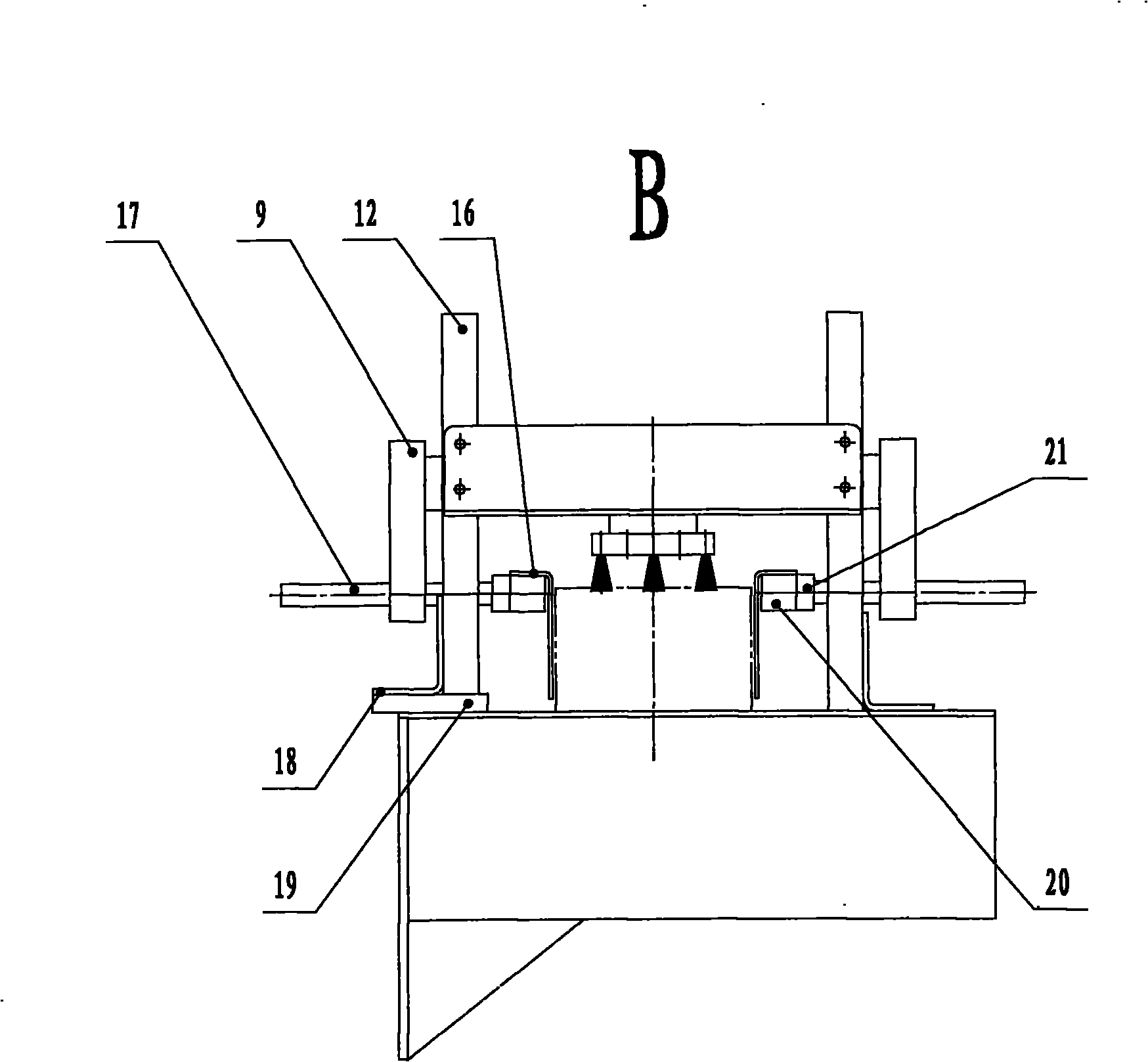

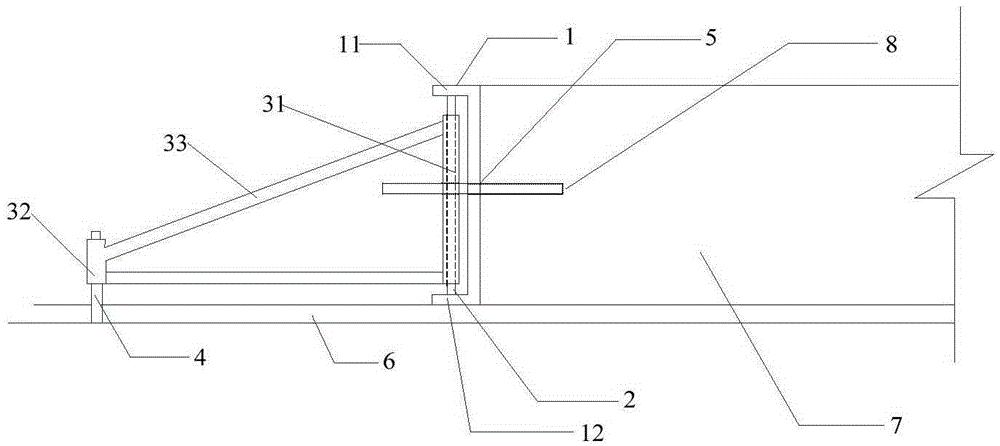

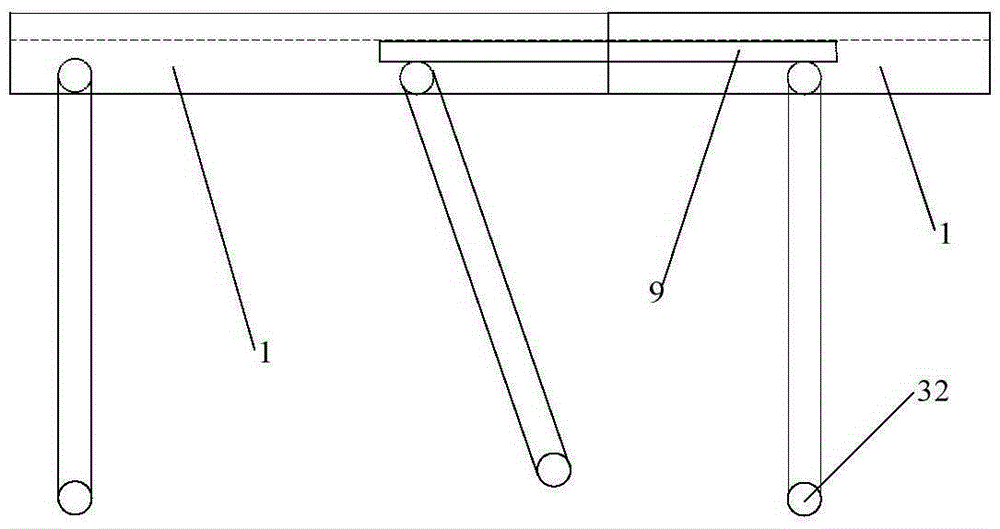

Packaging box turnover mechanism

The invention discloses a packaging box turnover mechanism. The packaging box turnover mechanism comprises an input platform (38) and a front supporting plate (24), wherein a rotating wheel (1) is arranged between the input platform and the front supporting plate; a rotating wheel support (36) is arranged on the two sides of the rotating wheel; a rotating wheel mandrel (35) penetrates the rotating wheel (1) and the rotating wheel support (36); the rotating wheel mandrel is connected with a motor (29) through a transmission component; and a stalling proximity switch (32) and an in-place proximity switch (34) are arranged on the input platform (38) and adjacent to the rotating wheel (1). A single packaging box is conveyed to the front end of the input platform through the packaging box conveying mechanism under a flat state so as to enter a corner of the rotating wheel, is rotated by the rotating wheel to change an angle, and is naturally conveyed to a code box mechanism in an upright state to be collected and converged. The packaging box turnover mechanism does not cause abrasion to a complex membrane layer on the surface of the packaging box, can maintain the original appearance quality of the packaging box, has high turnover working efficiency, and completely meets requirements of high-end customers.

Owner:瑞安市华东包装机械有限公司

Concrete side mold and mold support method thereof

InactiveCN105239495AEasy to install and storeImprove construction efficiencyRoads maintainenceFlooringHigh turnoverEngineering

The invention provides a concrete side mold, including a side formwork. The side formwork is rotatably connected with a plurality of supporting frames; and one end of the supporting frame forms a fixed part fixed on a basis structure, and the other end of the supporting frame forms a rotating part rotating on the side formwork. A mold support method of the concrete side mold includes the following steps: properly placing the position of the concrete side mold; fixing the concrete side mold on the basis structure; pouring concrete; removing the mold after construction; and rotatably abutting the rotating parts to the side formwork for storage. The concrete side mold of the invention has the advantages of convenient installation and storage, high construction efficiency, high turnover frequency, stable and reliable system, and improvement of the construction quality.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

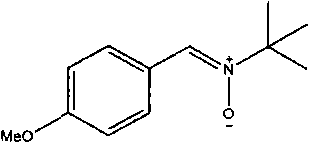

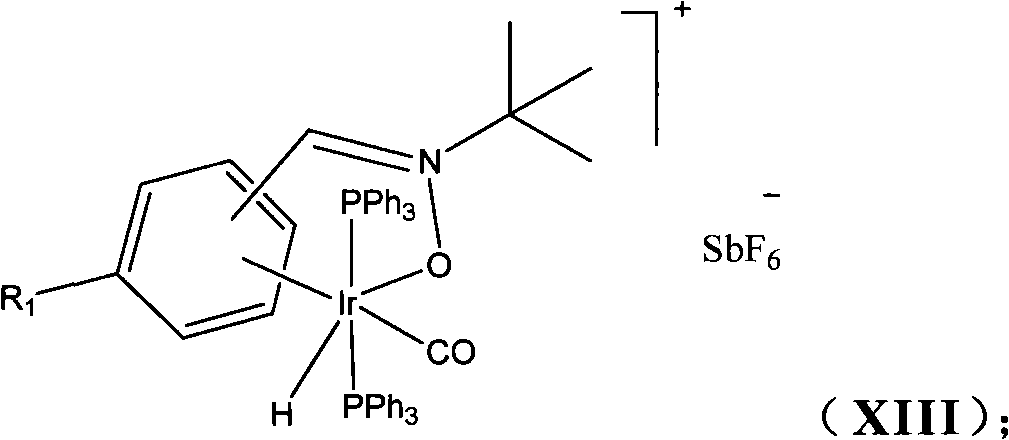

Novel nitrone ligand, organic metal iridium catalyst and preparation method and application thereof

ActiveCN101851176AImprove catalytic performanceLower reaction barrierOrganic compound preparationOrganic chemistry methodsIridiumHigh turnover

The invention discloses an organic compound, which is characterized in that: the compound has the structure of a formula (I): RAn (I); A has a nitrone ligand with the structure of a formula (II); n is 1 or 2; R is selected from one of the following aryl groups: phenyl group or naphthyl group, and R is substituted by one or more of the following groups: hydrogen, nitro group, trifluoromethyl group, halogen, methyl group, methoxy group, hydroxy group, phenyl group, phenolic group and isopropyl group. The compound can be synthesized into a series of catalysts with high catalytic activity and a high turnover rate, various easy-obtained, economic substituted Alpha-phenethyl alcohol compound and phenethyl alcohol compound can be catalyzed under mild conditions to react to prepare various alcohol compounds, the reaction can obtain a high reaction yield in a short reaction time, meanwhile, almost no byproducts are produced, and therefore the reaction is environment-friendly green catalytic reaction and atomic economic catalytic reaction.

Owner:JIANGSU SINOCOMPOUND CATALYST

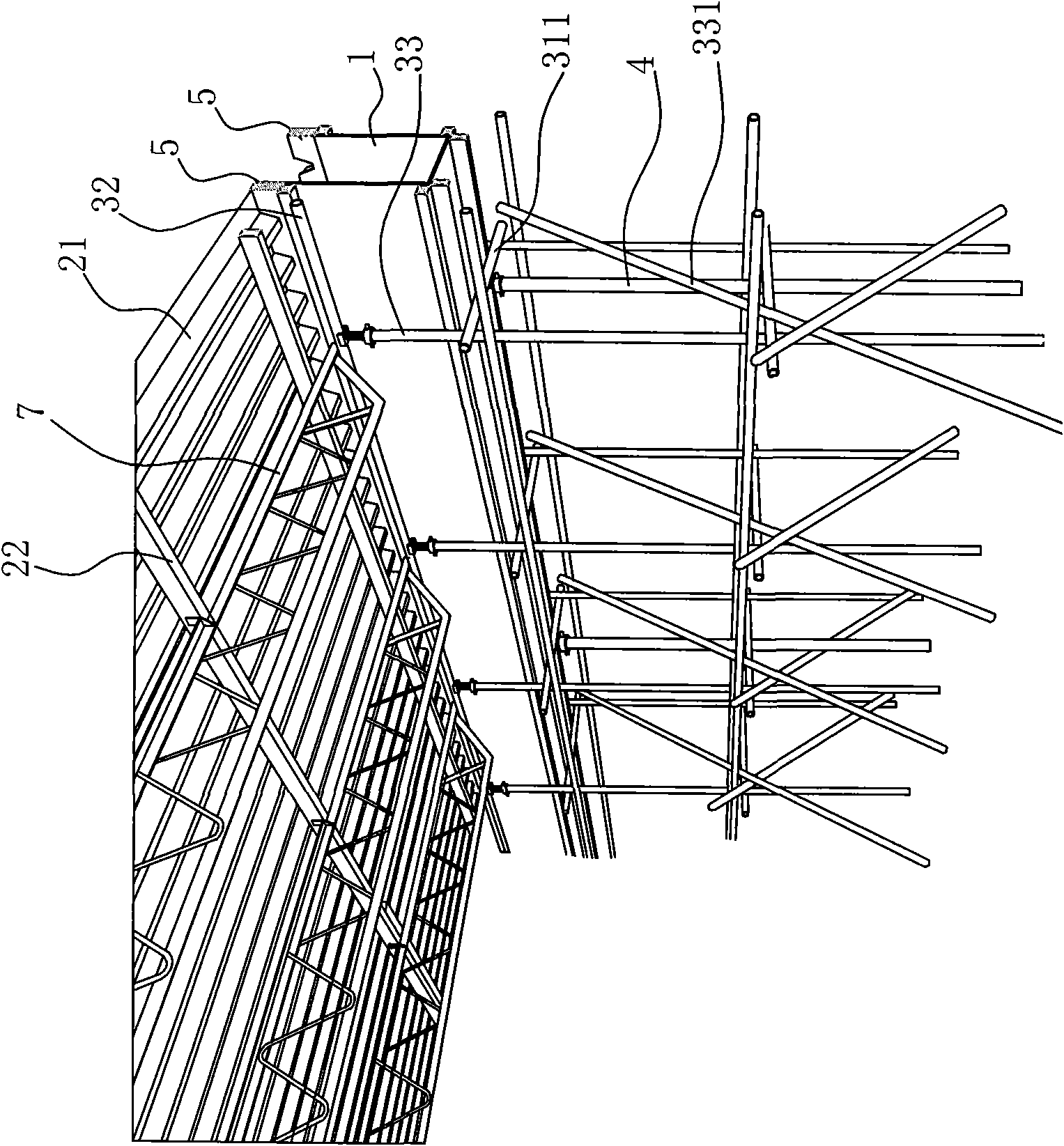

Hanging cable guiding device and method

ActiveCN102852092AFast constructionHigh turnoverBridge structural detailsBridge erection/assemblyHigh turnoverArchitectural engineering

The invention relates to the technical field of bridge construction and in particular relates to a hanging cable guiding device and method. The device comprises threaded sleeves, a strand rope, high-strength bolts, a steel wire rope and high-strength screws, wherein the strand rope comprises seven steel strands. The device is characterized in that one steel strand is respectively arranged at each of two ends of the strand rope: the steel strand at the left end is sleeved into the first threaded sleeve; the end of the steel strand at the left end is provided with a first pier head; the steel strand at the right end penetrates through the second high-strength bolt; the end of the steel strand at the right end is provided with a second pier head; the second high-strength bolt is screwed in the second threaded sleeve; the steel wire rope of a winch penetrates in the second threaded sleeve; and the second threaded sleeve and the steel wire rope are fixed by adopting the high-strength screws. The device disclosed by the invention combines the advantages of various traditional hanging cable guiding devices, has the characteristics of rapid construction speed, high turnover number, safety and reliability and has certain development and application value.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

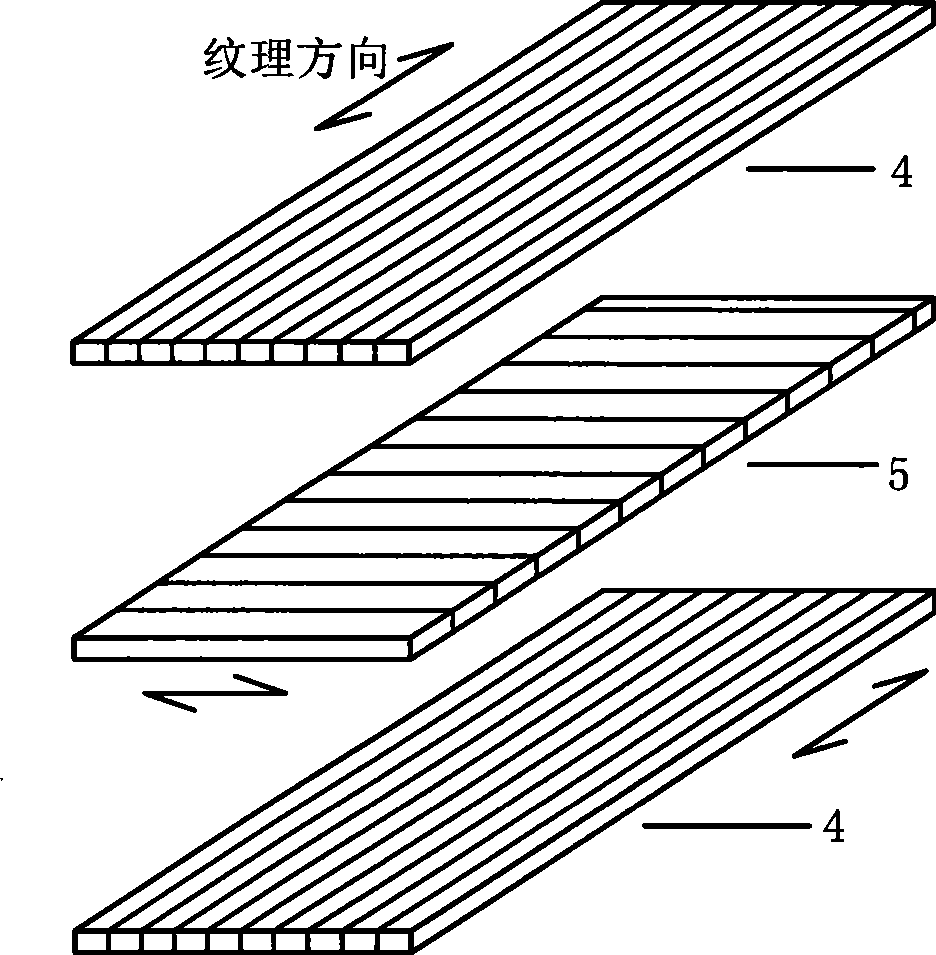

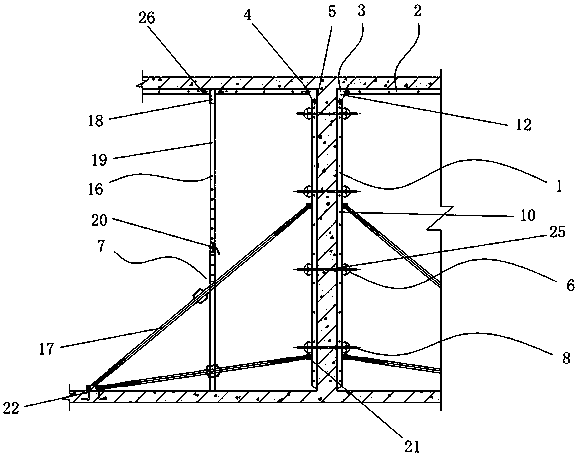

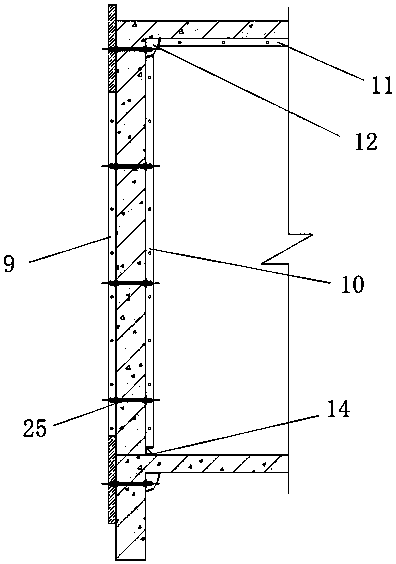

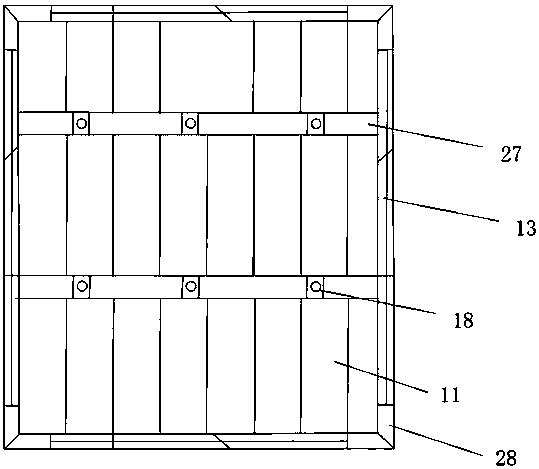

Long-slab-span cast-in-situ beam ribbed floor early-dismantling template formwork system

ActiveCN102418417AEasy constructionEasy to achieve early demolitionForms/shuttering/falseworksFalseworkHigh turnover

The invention discloses a long-slab-span cast-in-situ beam ribbed floor early-dismantling template formwork system. The system comprises a beam template, a ribbed floor template, a truss, a bracket and an under-beam adjustable supporting column, wherein the under-beam adjustable supporting column is dismantled after the bracket, the truss, the beam template and the ribbed floor template; the bracket comprises an under-beam template bracket, a placement rod and a rod supporting column; the ribbed floor template comprises a compression type steel template and a grille; the ribbed floor template is laid on the truss; the end part of the compression type steel template is positioned on the top of the beam template; and a plug is arranged between the end part of the compression type steel template and the top of the beam template. In the system, the adopted floor template is the compression type steel template, the compression type steel template is laid on the grille, the grille is laid on the truss, the truss stretches over the beam template, a supporting scaffold is not required to be arranged at the bottom of the floor, and dead weight of an upper layer floor is not transferred to a lower layer floor; and thus, the floor template is easy to construct, early dismantling can be easily realized, and the compression type steel template has high turnover frequency and is low in cost.

Owner:杨峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com