Combined set-shaped steel formwork and modeling method thereof

A technology for shaped steel and formwork, which is applied in the direction of formwork/formwork components, formwork/formwork/work frame, and connection parts of formwork/formwork/work frame, etc., which can solve the problems of lack of versatility, inconvenient operation, and large size. and other problems, to achieve the effect of flexible assembly, convenient disassembly and assembly, and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

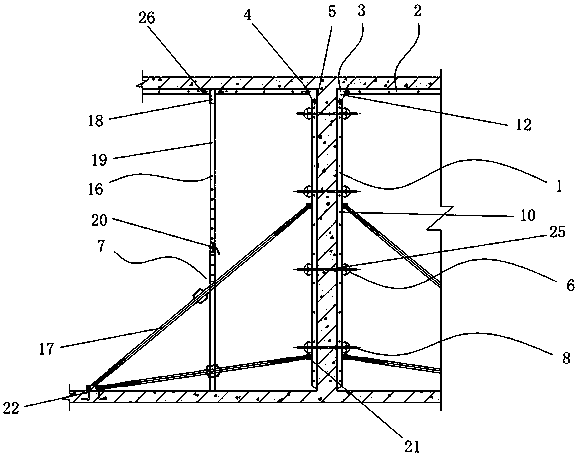

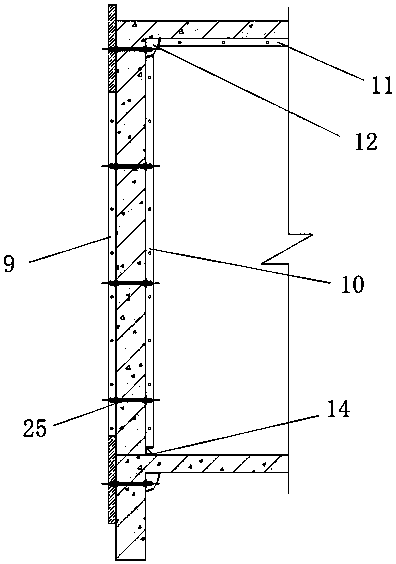

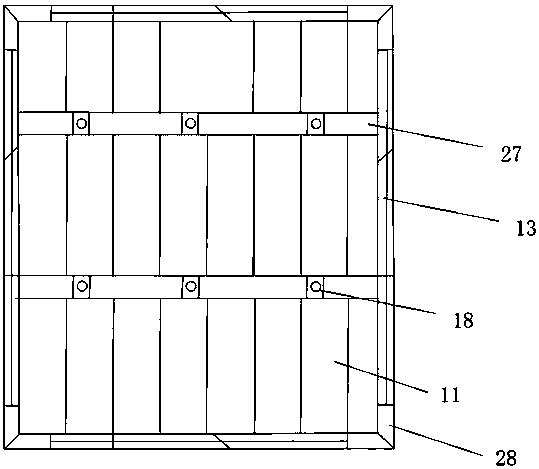

[0046] exist figure 1 , figure 2 , image 3 , Figure 4 In the shown embodiment, a combined shaped steel formwork includes:

[0047] Formwork assembly 1 is used to form the closed surface required for concrete structure construction and to ensure the building structure is formed when the concrete is poured; the formwork assembly 1 includes several single formworks, and the single formwork includes single standard boards 2 and single internal corners Part 3; the single standard plate 2 is provided with a standard plate bevel 4, and the single internal corner part 3 is provided with a female corner bevel 5;

[0048] Connecting component 6, is used for connecting single formwork into the connector of model;

[0049] The supporting component 7 is a stabilizer used to support the formwork component in concrete structure construction;

[0050] Fasteners 8 are used to shape the structure, width, and size of the formwork components.

[0051] The bevel 4 of the standard plate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com