Patents

Literature

264 results about "Standard plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

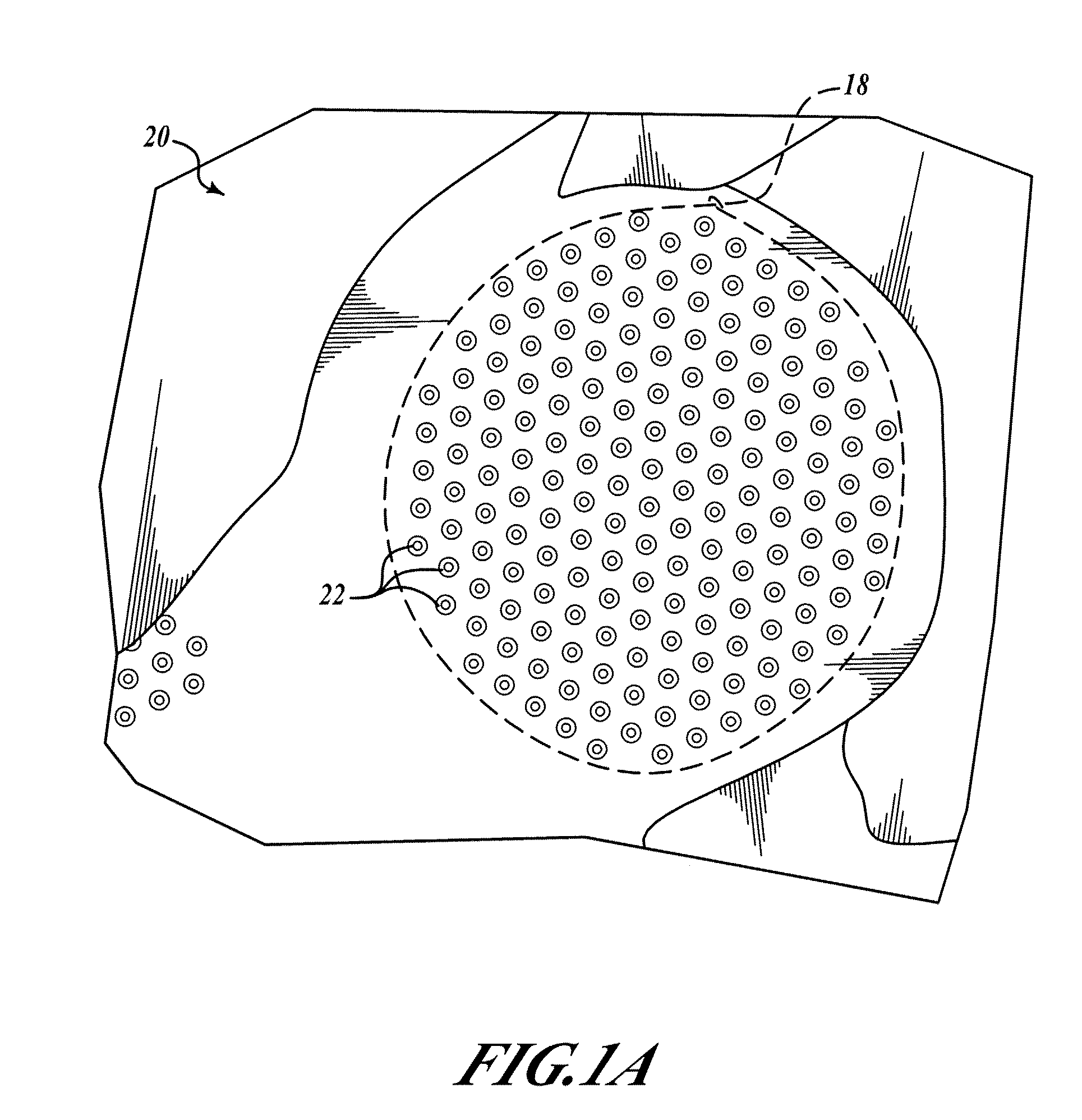

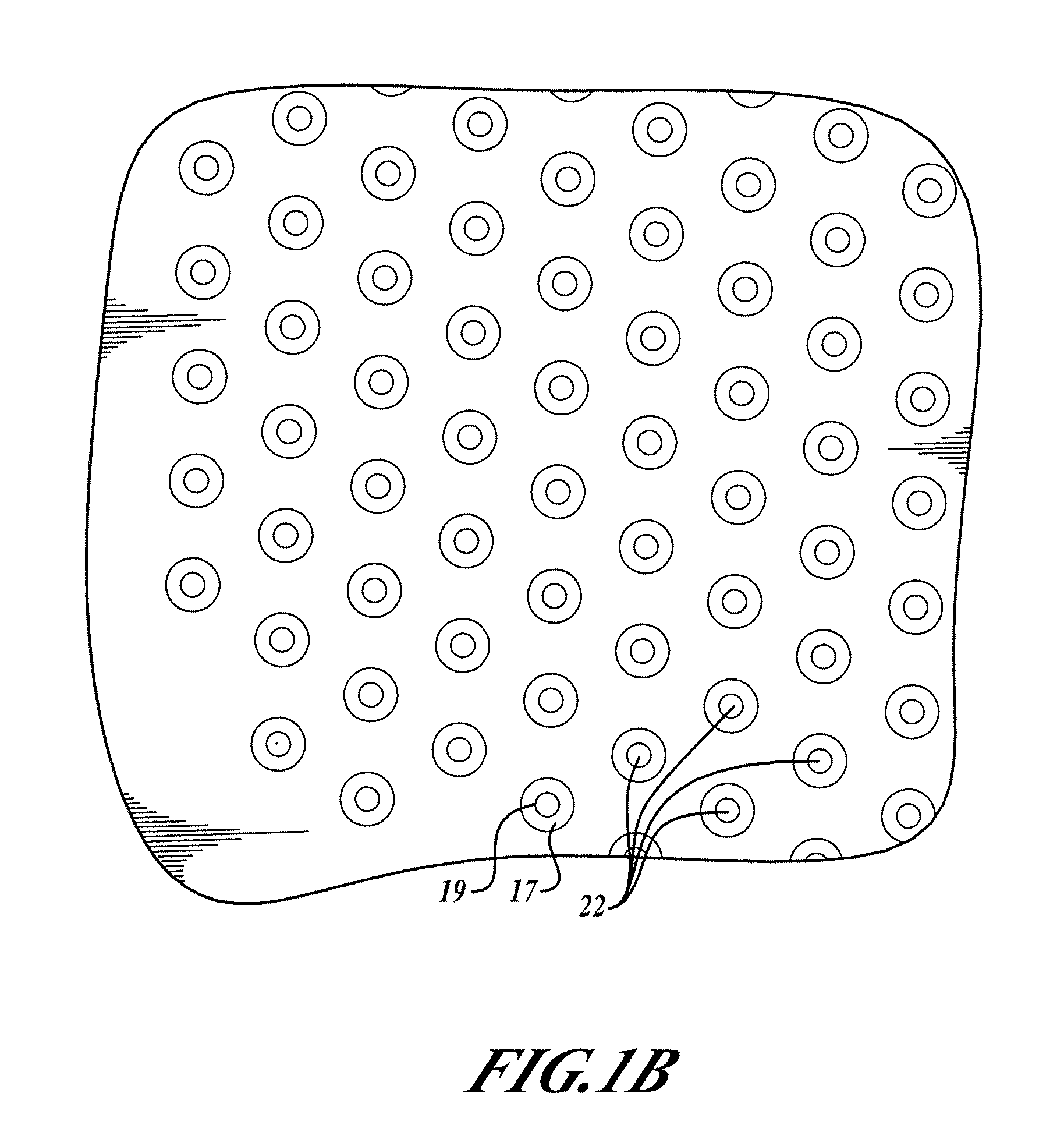

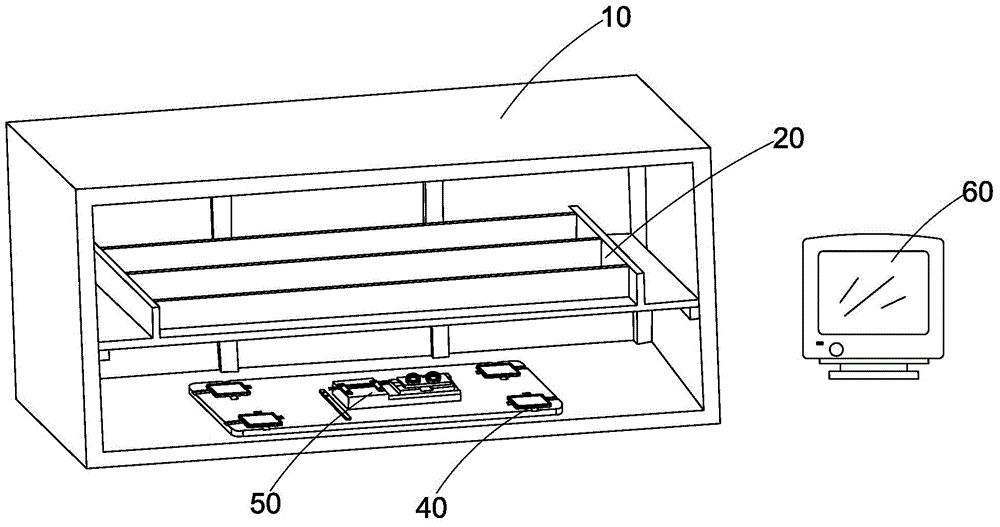

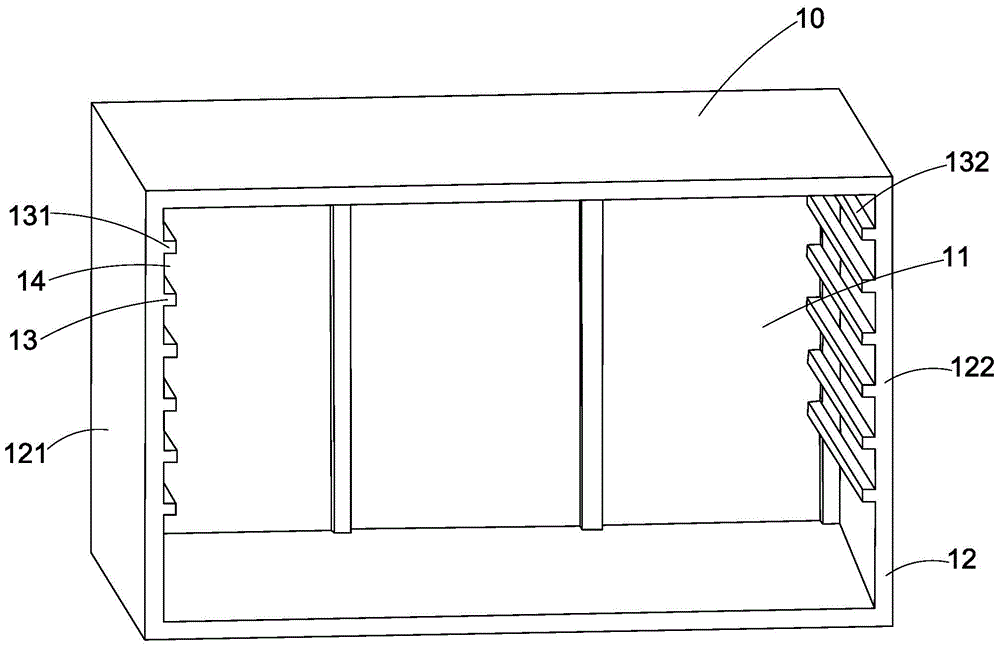

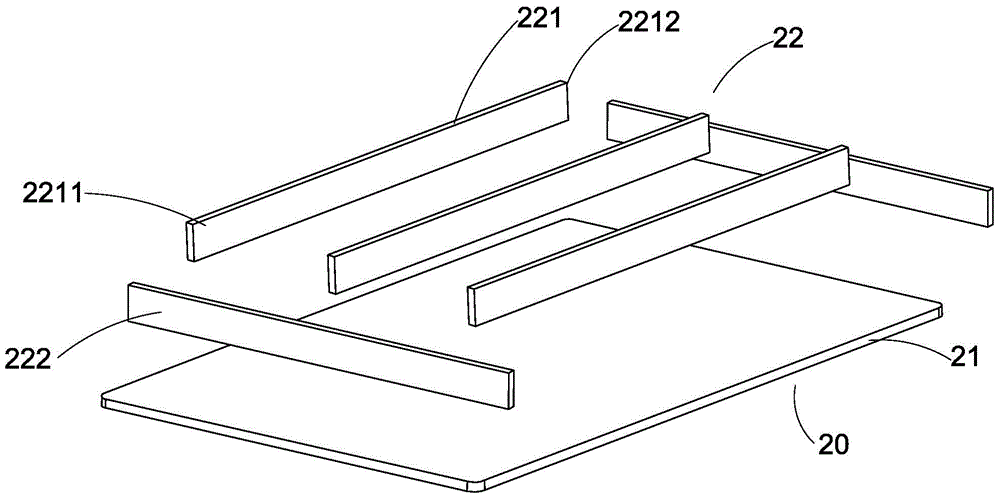

Device and method for quickly calibrating a variety of parameters of TOF depth camera

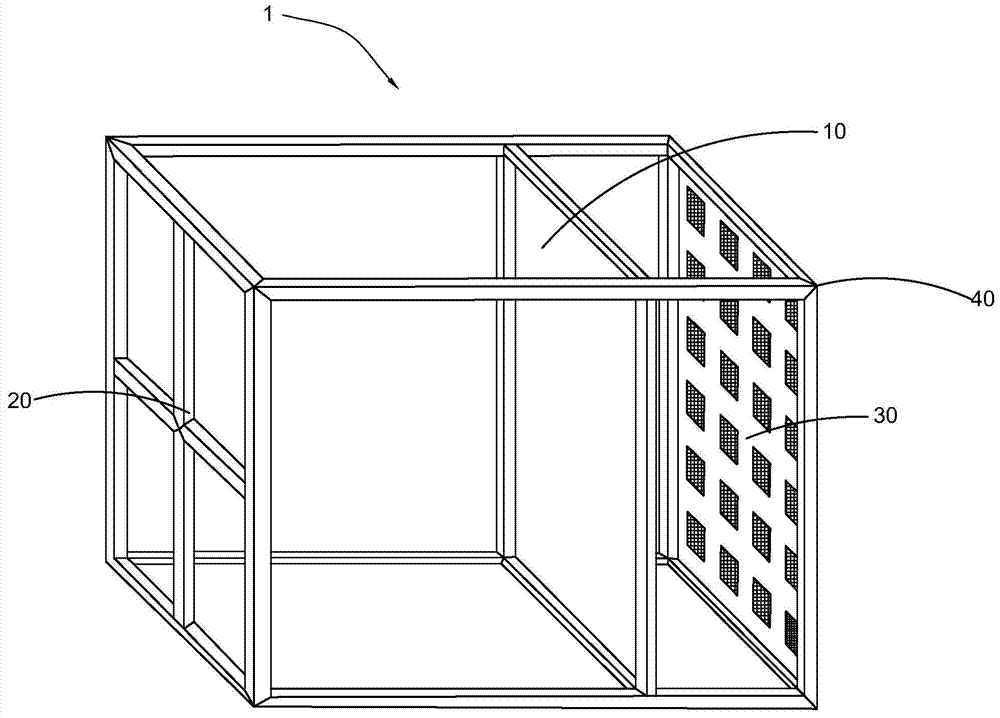

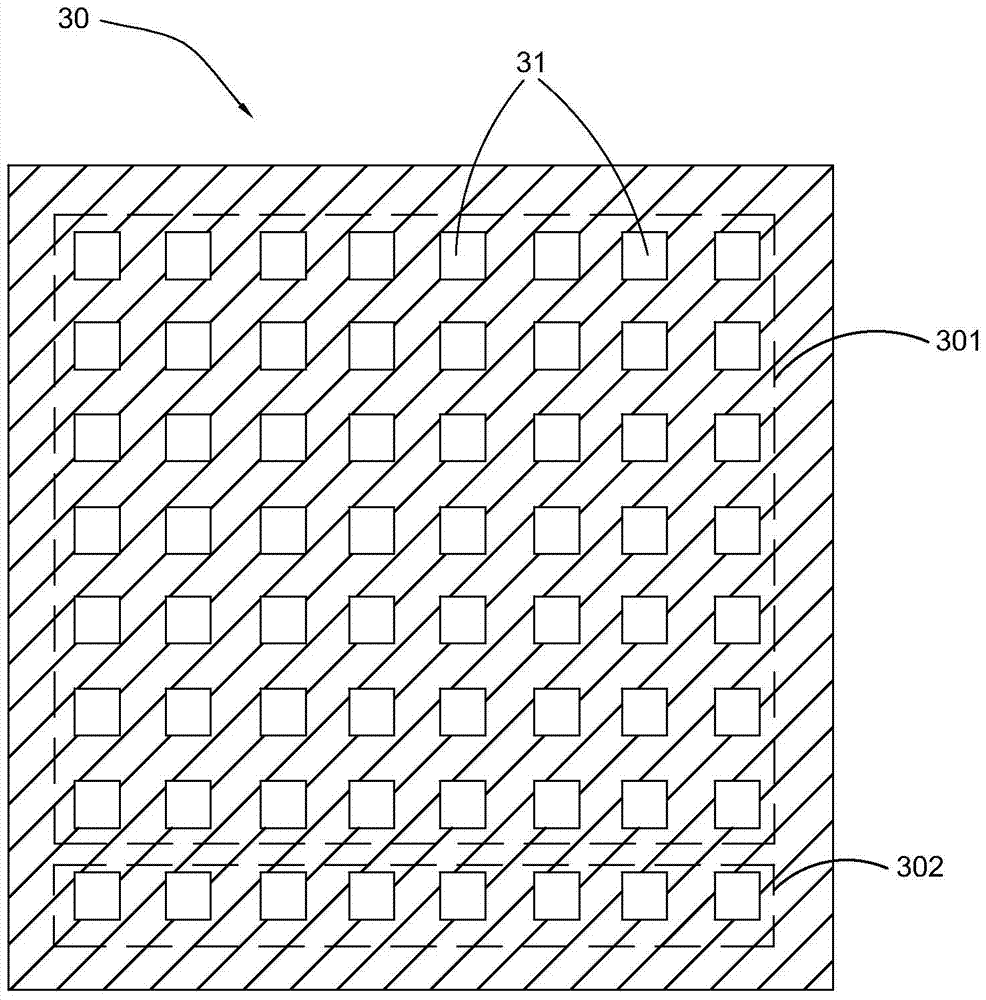

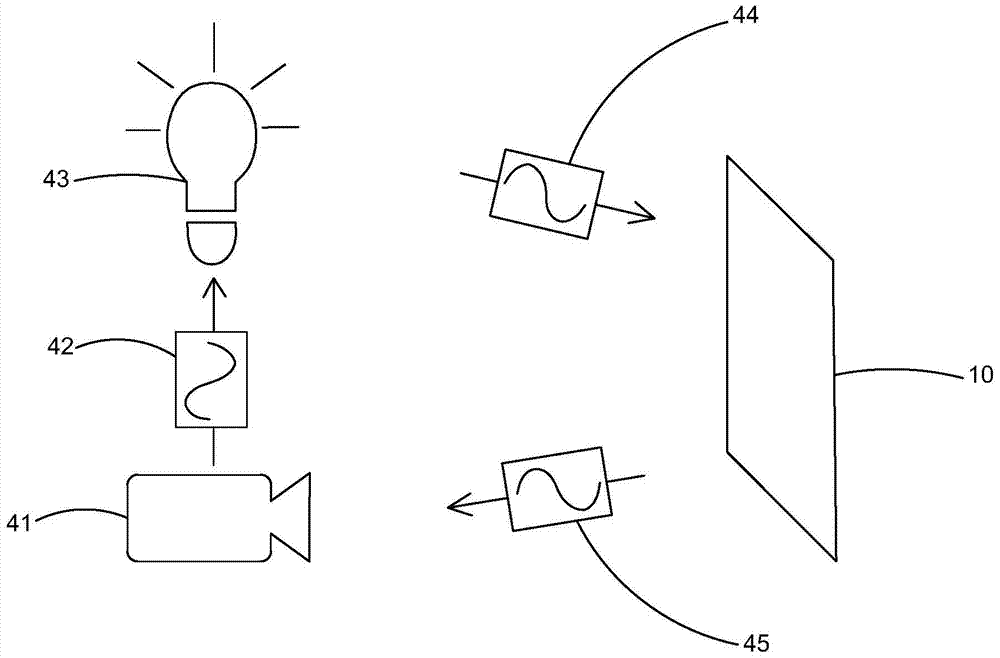

A device and a method for quickly calibrating a variety of parameters of a TOF (Time of Flight) depth camera are disclosed. The device comprises a calibration kit which is composed of a box body, a camera holder used for placing a TOF depth camera, an optical fiber calibration target, and a white calibration target. The optical fiber calibration target is provided with multiple light diffusion plates in uniform distribution. Each light diffusion plate is connected with a light guide fiber, and is used for calibrating the pixel offset of the TOF depth camera and calibrating error caused by integral time. The white calibration target is arranged between the camera holder and the optical fiber calibration target. The position of the camera holder relative to the white calibration target is fixed, and the position of the camera holder relative to the optical fiber calibration target is fixed. The calibration kit integrates planar markers used in camera internal parameter calibration and tools used in TOF depth camera calibration. Thus, a variety of parameters of the TOF depth camera can be calibrated quickly and effectively.

Owner:NINGBO SUNNY OPOTECH CO LTD

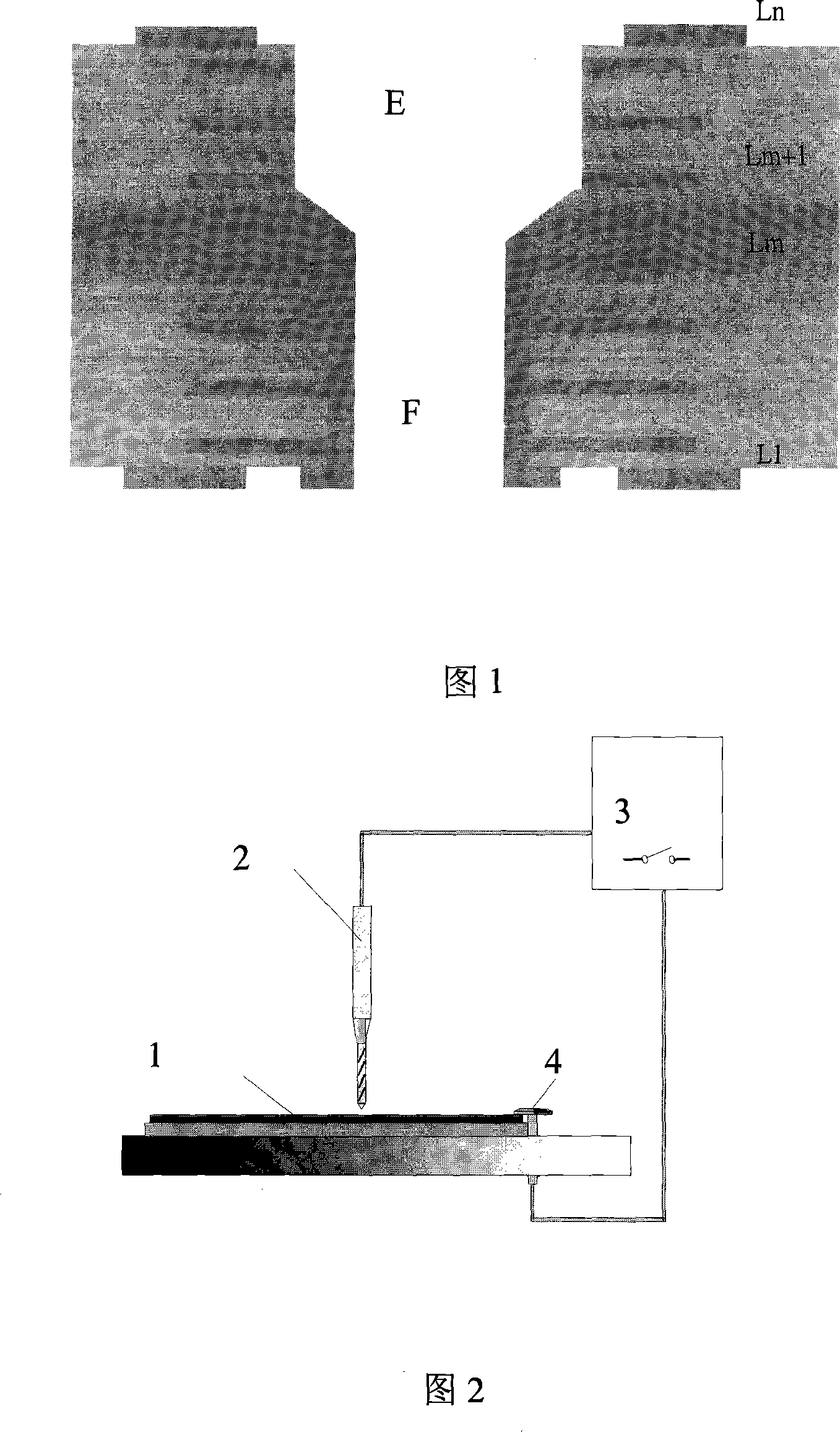

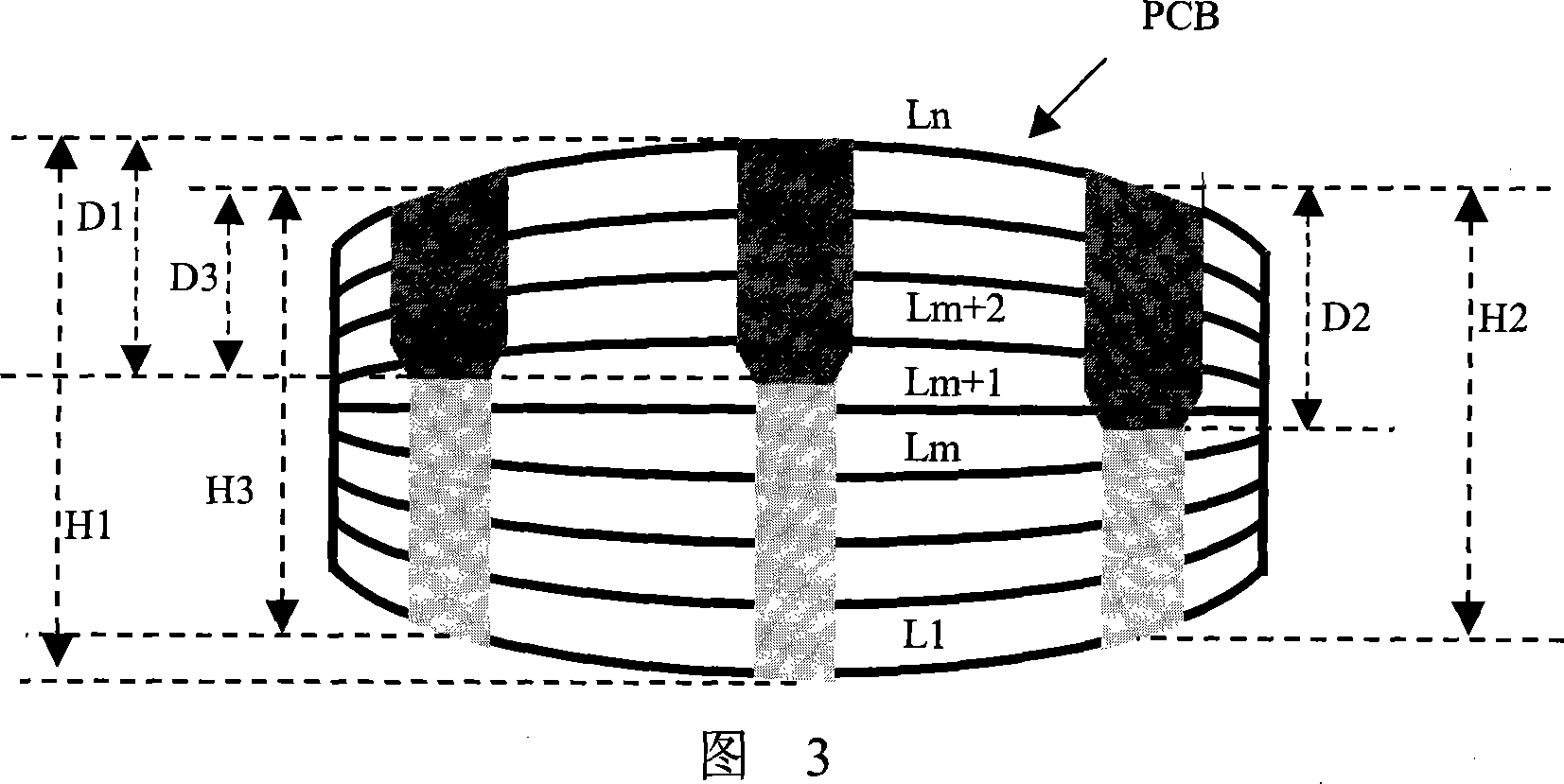

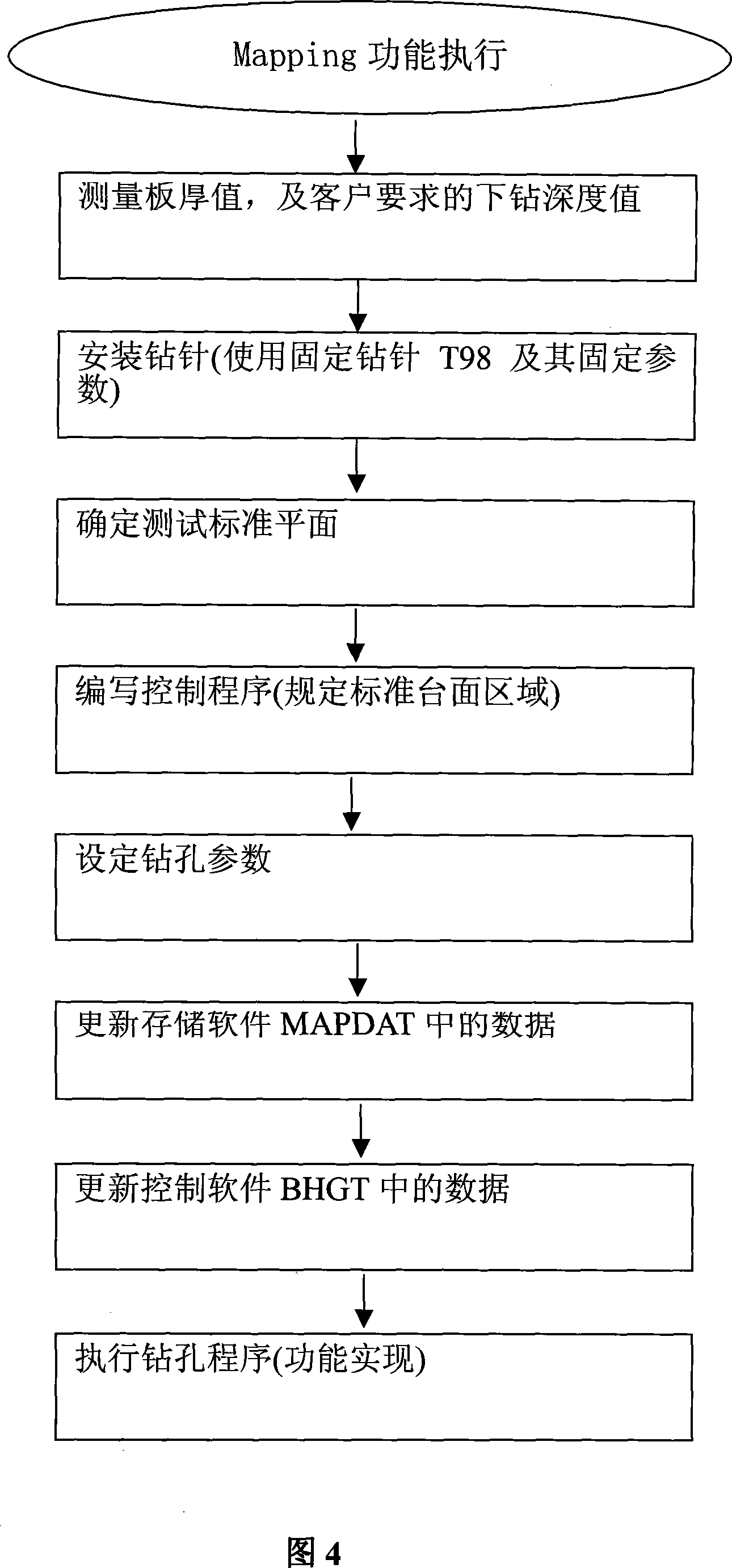

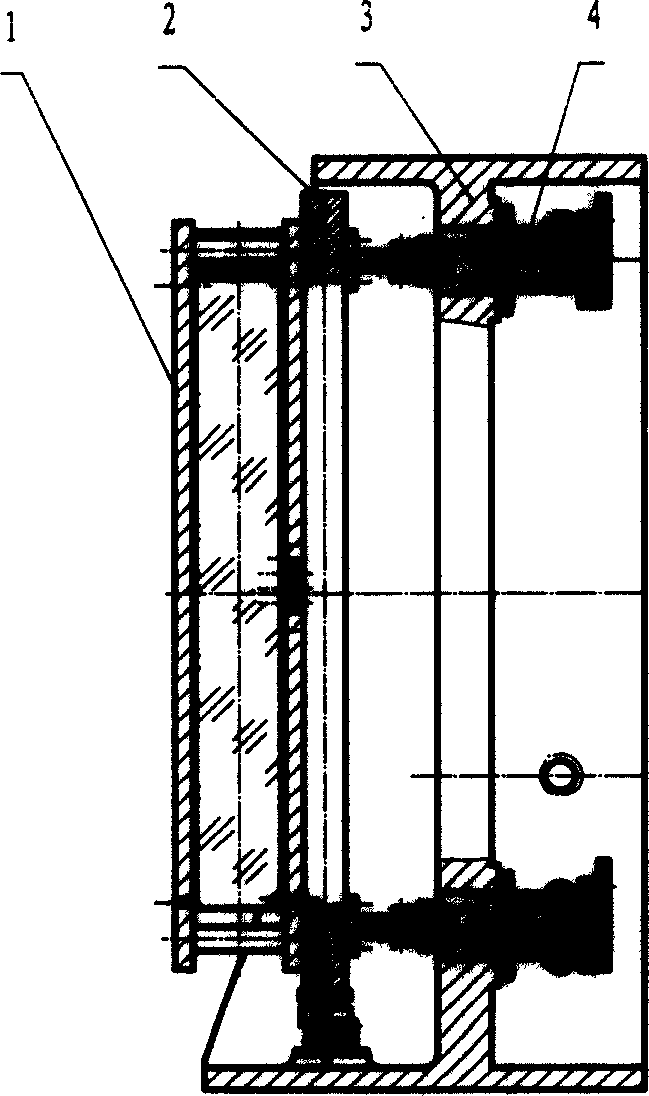

Method for deep drilling print circuit board

ActiveCN101094562AHigh control precisionEffects of reduced precisionConductive material mechanical removalStandard planeEngineering

The method comprises: setting the plane contacting with the PCB as a standard plane; recording the actual location height Hn of each point on PCB, and saving it into the storage software of the machine; selecting a target layer, setting a standard drilling depth D1 and standard plate thickness H1; the drilling depths of other points are Dn=D1*Hn / H1+ compensation value; according to the drilling depth Dn of each points, re-setting the parameters in the drilling program, and renewing each parameter in the storage software in machine; finally, according to Dn value, modifying the program-controlled instruction.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

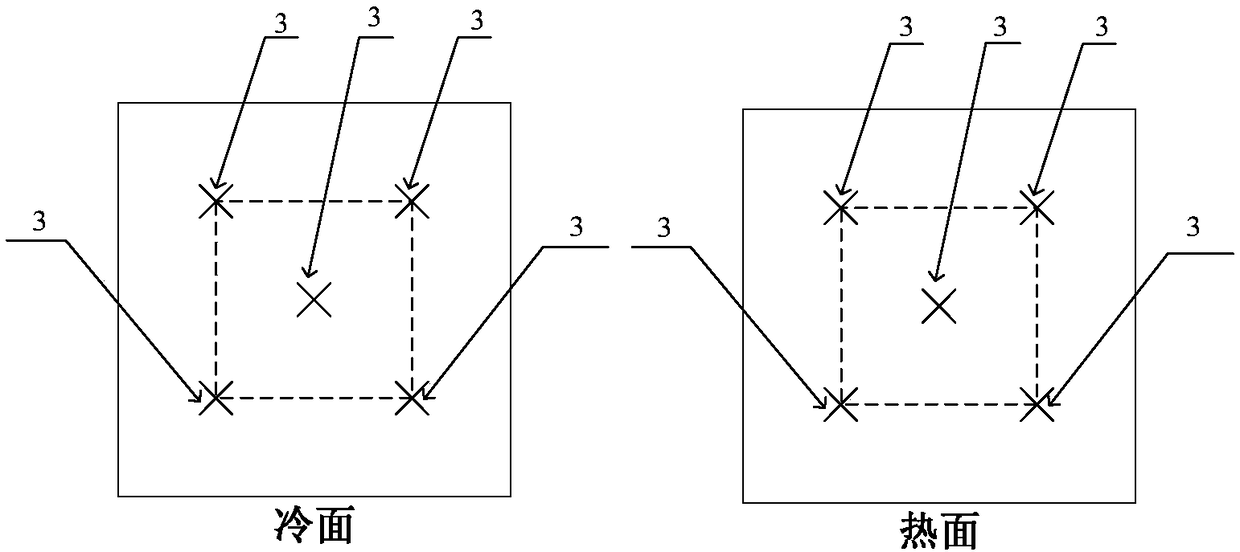

Heat resistance heat flow meter calibration method and implementation device thereof

The invention discloses a heat resistance heat flow meter calibration method and an implementation device thereof. The implementation device comprises a heat insulating plate, a hot plate, a cold plate, a heat conductivity coefficient standard plate and a heat resistance heat flow meter, wherein the hot plate, the heat conductivity coefficient standard plate and the heat resistance heat flow meter are successively arranged between the heat insulating plate and the cold plate, and the two sides of the heat conductivity coefficient standard plate are respectively provided with a temperature sensor. The heat flux of the heat conductivity coefficient standard plate is obtained through measuring the thickness of the heat conductivity coefficient standard plate and the temperature difference of the two sides of the heat conductivity coefficient standard plate, according to an equal principle of the heat conductivity coefficient standard plate and the heat flux through the heat resistance heat flow meter and the output potential of the heat resistance heat flow meter, and a sensitivity ratio of the heat resistance heat flow meter is obtained. The heat resistance heat flow meter calibration method and the implementation device thereof provided by the invention have the advantages that the design is reasonable, the structure is simple, and the implementation device is suitable for the heat resistance heat flow meter calibration method utilizing an axial heat conduction principle.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

Large caliber standard plate precison regulation stand

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

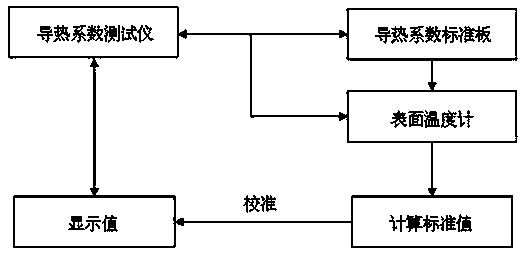

Detection and measurement method for heat conduction coefficient tester

The invention discloses a detection and measurement method for a heat conduction coefficient tester. The measurement is implemented through a heat conduction coefficient standard plate and a surface thermometer. The measurement method comprises the steps of error measurement, temperature uniformity measurement, linear error measurement, repetitiveness measurement and working surface planeness measurement. Due to the mode, the detection and measurement method for the heat conduction coefficient tester has the advantages that the heat conduction coefficient standard plate and the surface thermometer are used for precisely measuring the measurement accuracy of the heat conduction coefficient tester; five performance key indexes, including the measurement error, the temperature uniformity, the linear error, the repetitiveness and the working surface planeness of the heat conduction coefficient tester are provided according to a theory of a protective hot surface method heat conduction coefficient tester, and a calculation method for corresponding performance parameters is also provided, so that the calibration of the heat conduction coefficient tester is realized.

Owner:苏州市计量测试研究所

Pencil, pencil processing method and pencil groove milling machine for machining pencil

ActiveCN104589842AImprove skid resistanceHigh strengthWriting connectorsNon-propelling pencilsEngineeringFace structure

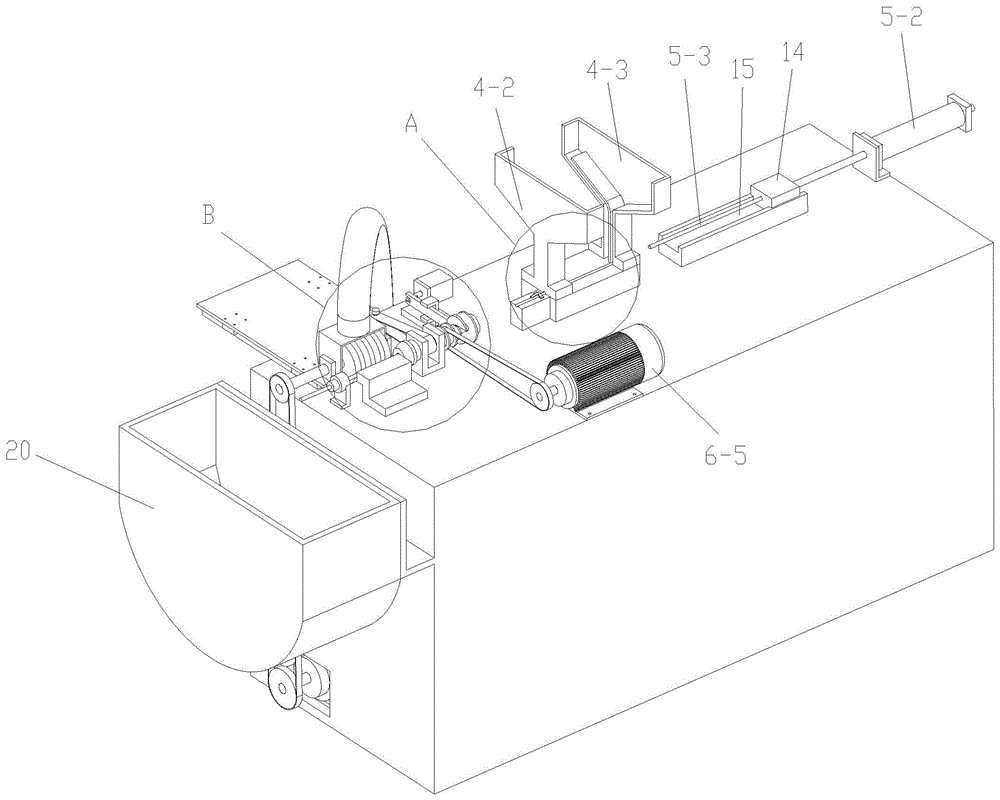

An antiskid pencil comprises a pen rod, a set of annular grooves arranged at a spaced mode are formed in the outer surface of the pen rod, and the annular grooves are of a concave arc-face structure. A method for machining the antiskid pencil includes the first step that a proper plate is selected, and the thickness of the plate is 120% that of a standard plate; the second step that a groove is planed in the plate, and a pencil core is placed in the machined groove; the third step that the plate is cut and is machined into pencil blank; the fourth step that a set of annular grooves are simultaneously ground in the outer surface of the pencil blank through a pencil groove milling machine; the fifth step the surface of the pencil is painted. The pencil groove milling machine used for machining the pencil includes a rack, a blanking mechanism used for containing pencils and allowing the pencils to fall down one by one is arranged on the rack, the bottom end of the blanking mechanism is connected with a feed mechanism in a matched mode, the feed mechanism is connected with a clamping mechanism used for locating the pencils, and the clamping mechanism is provided with a groove milling mechanism used for milling grooves in the pencils in a matched mode.

Owner:浙江艾特佳文化用品有限公司

Novel foamed wood-plastic template for building and production process of template

The invention discloses a novel foamed wood-plastic template for building and a production process of the template, and belongs to the technical field of manufacturing building templates. The novel foamed wood-plastic template for building solves the problem of poor foaming effect of the building templates. The novel foamed wood-plastic template for building is composed of a main material, a stabilizing system, a lubricating system and a foaming system; the production process comprises the steps of adding the raw materials to a hot mixing pot for mixed heating, cooling and then sending to a host for plasticizing and foaming, carrying out open water-cooled skinning of the product through a die lip water channel, and adjusting a setting table and the temperature of a water cooler to set and cool the extruded material, and performing longitudinal / transverse cutting on the set product under the traction of a traction engine to obtain the standard plate-like novel foamed wood-plastic template for building. The production process of the novel foamed wood-plastic template for building is mainly used for the production and manufacture of the building templates.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

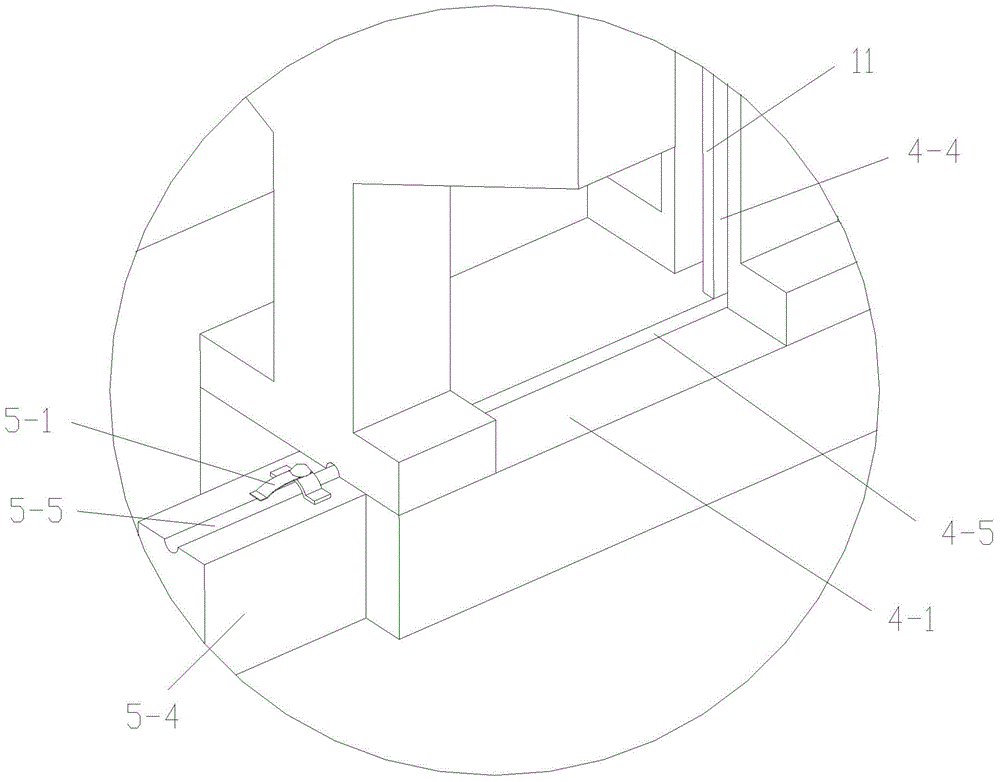

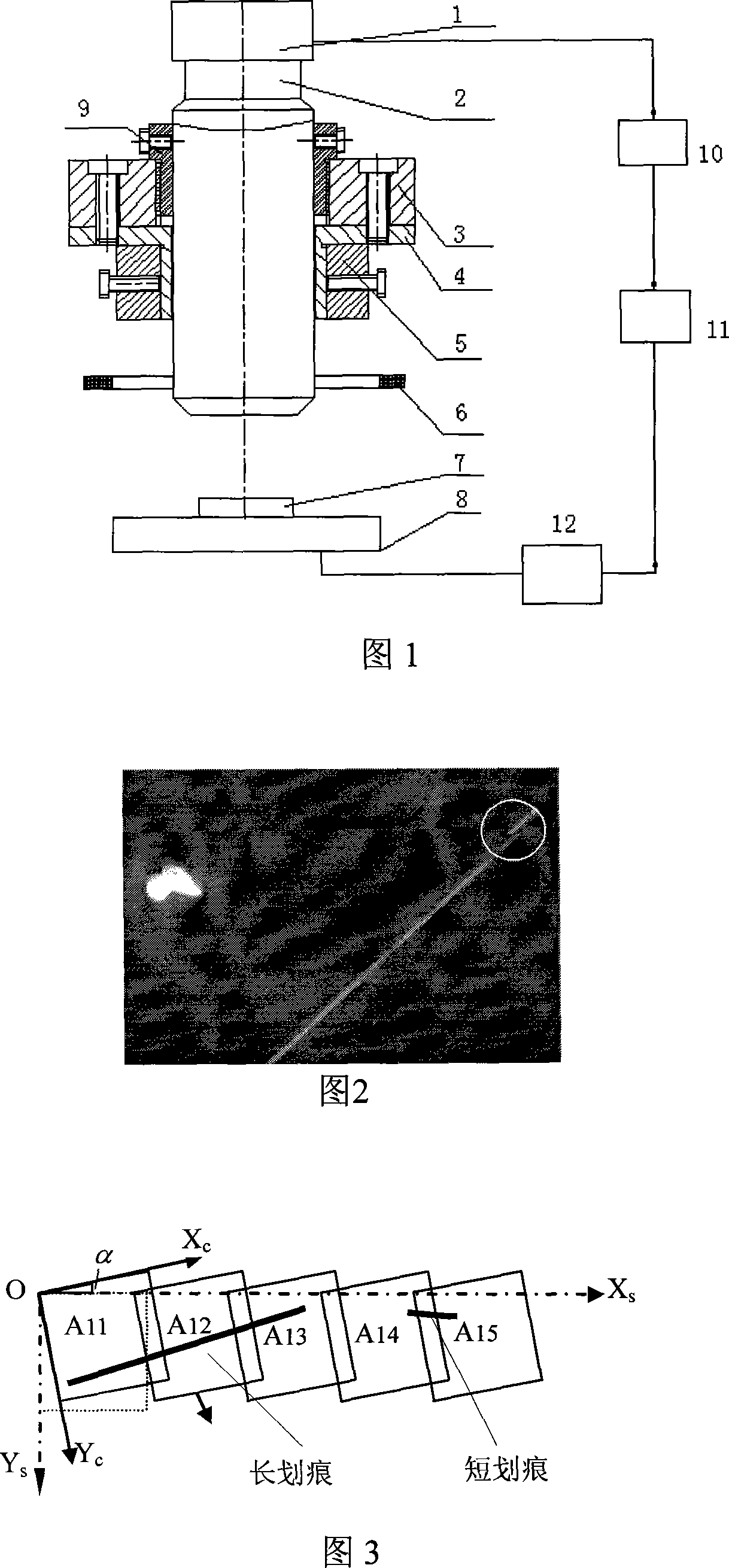

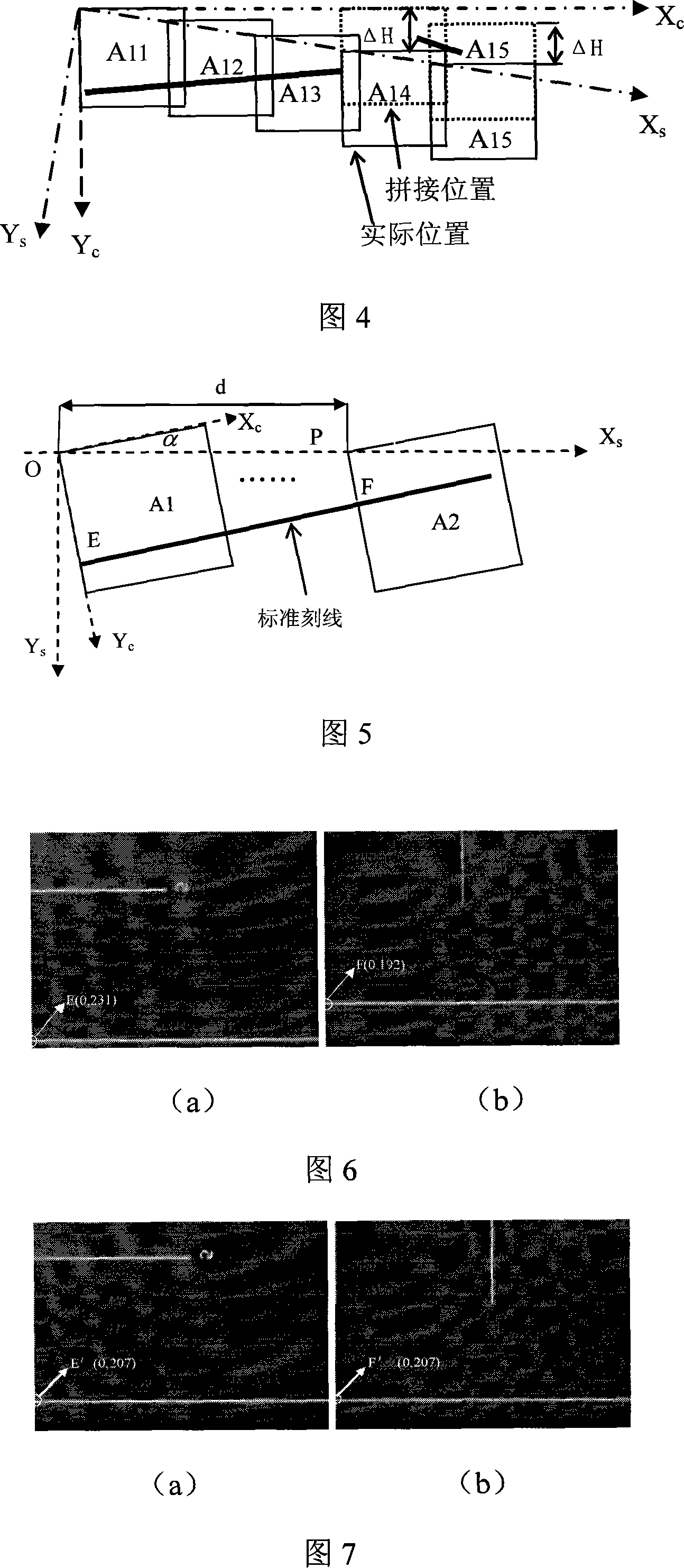

Object image coordinate error regulation device and method when spicing surface flaw detecting image

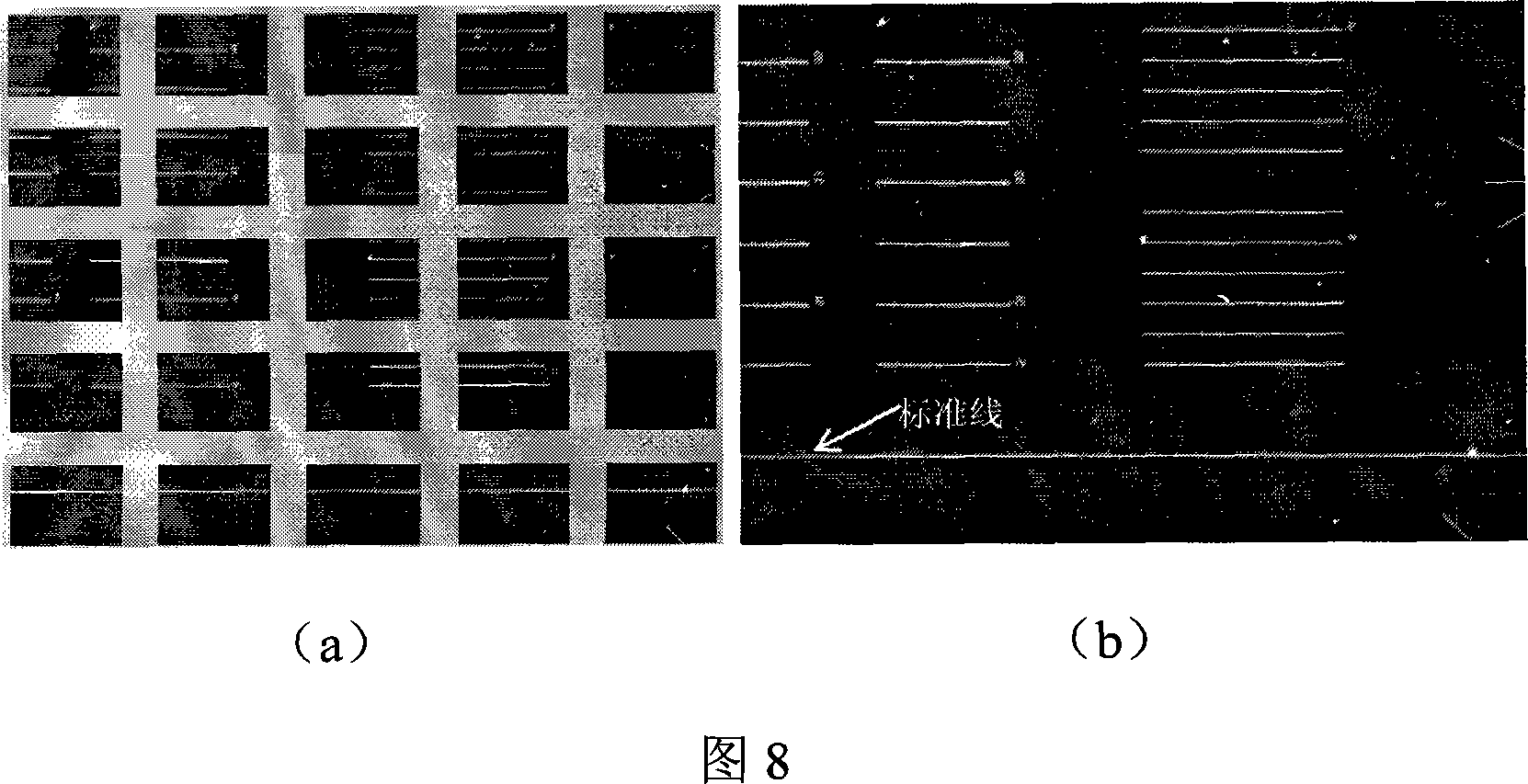

ActiveCN101086482AAccurate defect parameter evaluationAccurate splicingMaterial analysis by optical meansSpecial data processing applicationsImage processing softwareDigital image

The invention relates to the coordinate error adjustment device and method in the jointing of surface default testing image. It joints the image of hundreds of caliber image using digital image treatment. It proposes the way of determination of the maximum angular tolerance alpha max, based on the tested caliber component dimension, viewing filed size and caliber number NXN aiming at the whole caliber jointing error, CCD coordinate and scanning track coordinate included angle alpha .It designs the angular adjustment structure to realize the consistence adjustment of the CCD coordinate system and the scanned track coordinate system. It uses the standard mark line standard plate, XY scanning system and special image processing software combination to realize the specific adjustment method with the included angle of two coordinates less than alpha max, ensures the right joint caliber to achieve the default degree and position accuracy.

Owner:ZHEJIANG UNIV

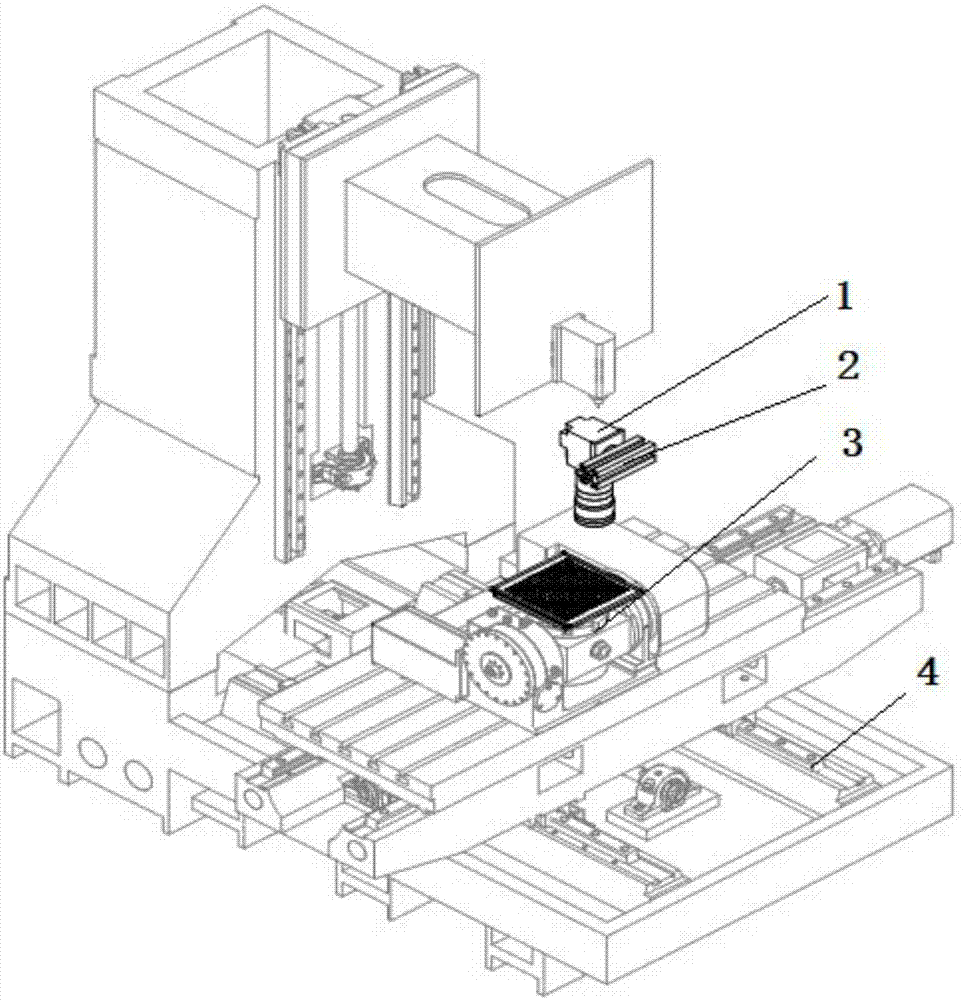

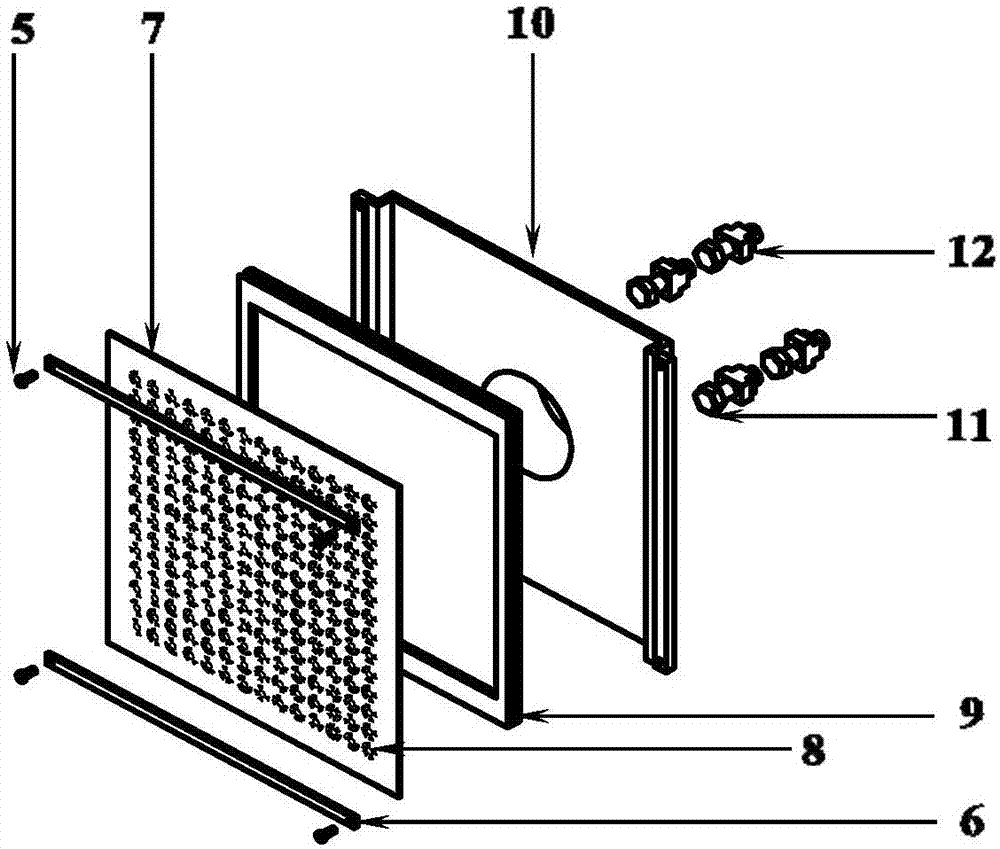

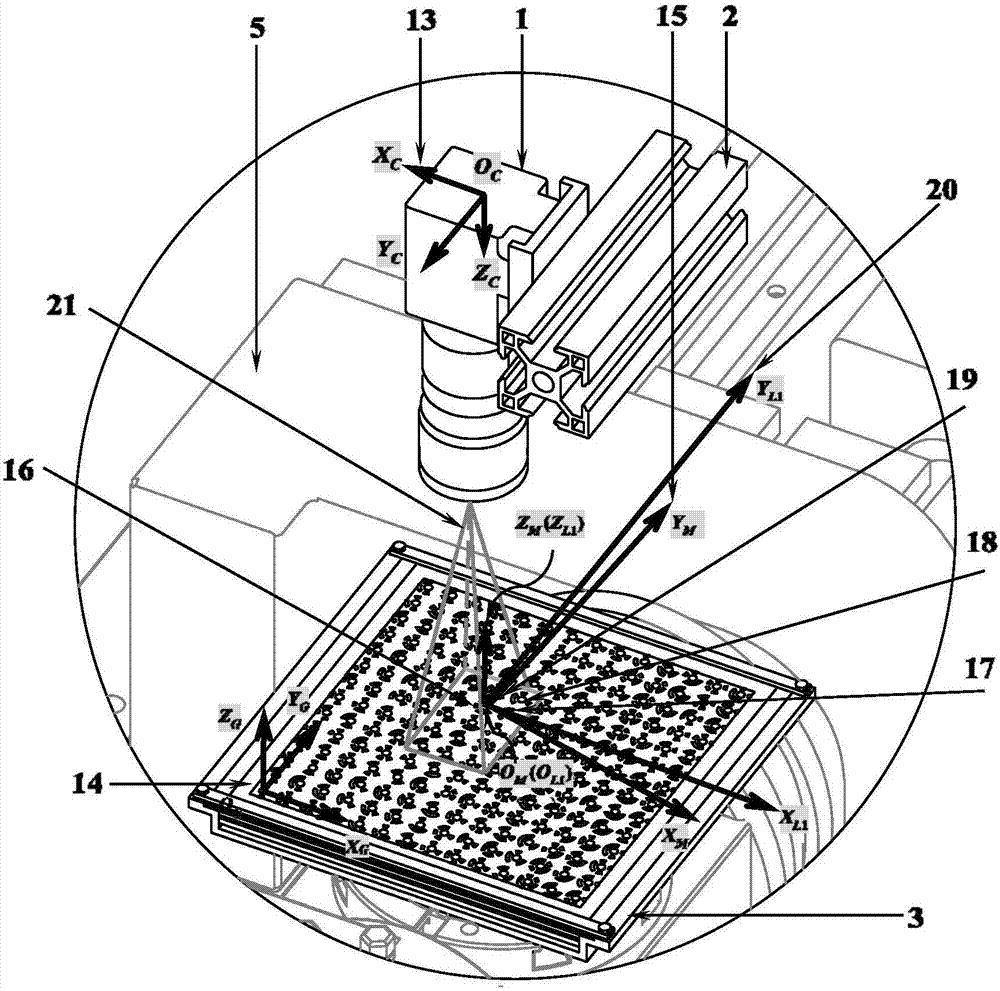

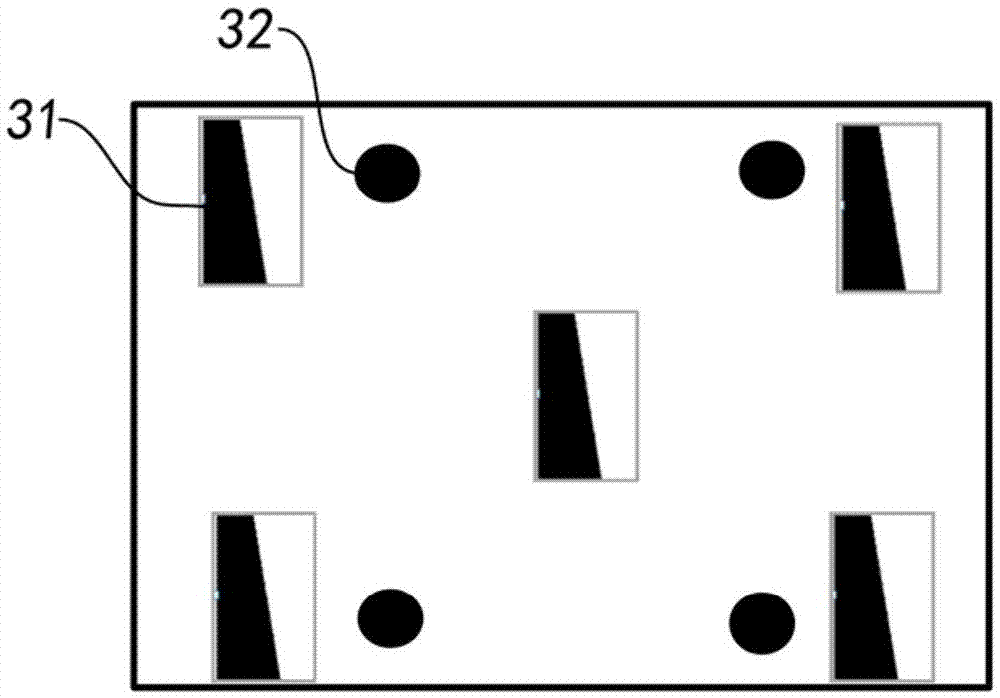

High-dynamic wide-range any contour error monocular six-dimensional measurement method of numerical control machine tool

ActiveCN107971831AImprove interpolation speedExtended interpolation feed rate rangeMeasurement/indication equipmentsCoded elementContour error

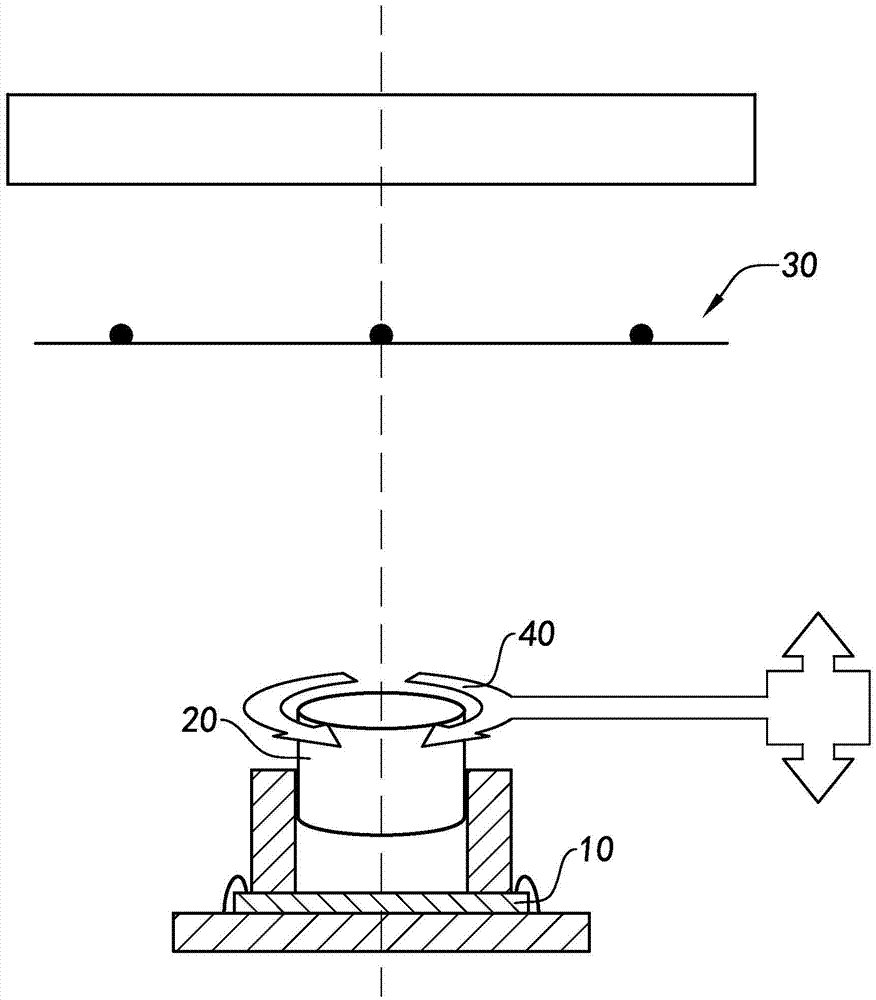

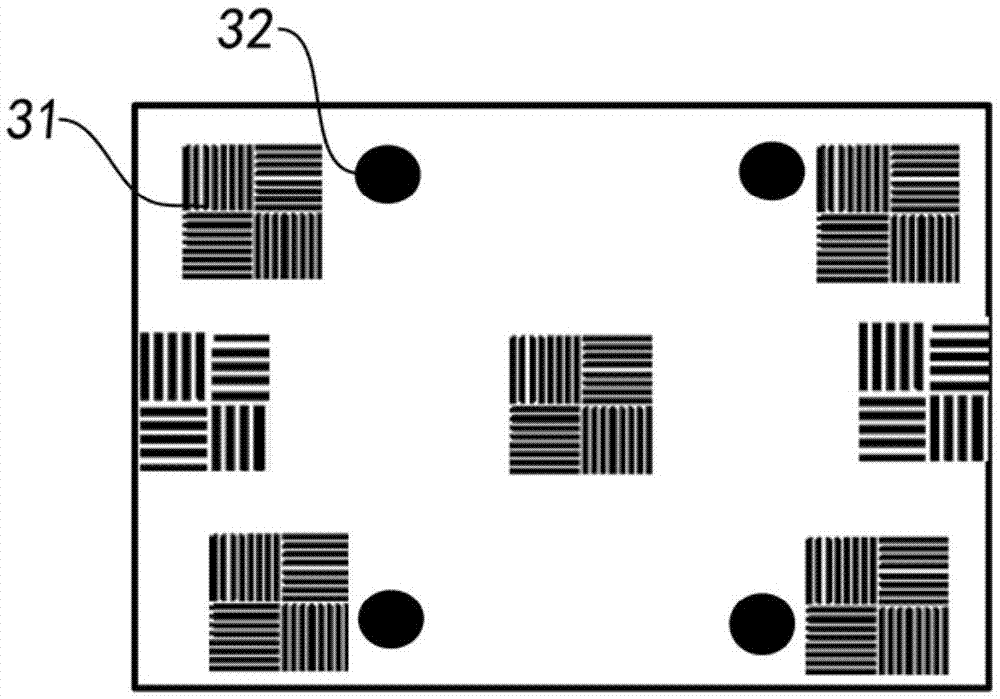

The invention discloses a high-dynamic wide-range any contour error monocular six-dimensional measurement method of a numerical control machine tool, belongs to the field of machine tool dynamic errordetection, and relates to a high-dynamic any wide-range contour error six-dimensional measurement method of a numerical control machine tool. In the high-dynamic any wide-range contour error six-dimensional measurement method, the monocular vision measurement technology cooperates with short-time stroboscopic illumination and a prior standard plate. In the method, a measurement tool and a measurement system are designed, and the monocular vision pose algorithm is combined with priori knowledge to increase the dimensionality and range of the machine tool interpolation contour capable of beingmeasured by vision. Through combination with the error distribution principle, a small measurement view field is utilized for improving the view field measurement precision of coding elements; the method is adopted for carrying out traversal shooting on each frame of image, and the actual six-dimensional motion contour of the machine tool can be obtained; and through comparison with the nominal motion contour of the machine tool, six-dimensional errors generated by the interpolation contour of the numerical control machine tool can be resolved. By means of the method, the monocular vision posealgorithm is combined with a datum conversion method, and the dimensionality of the machine tool interpolation contour measured by vision is improved; and wide-range any contour error six-dimensionalmeasurement of the numerical control machine tool in the small view field is achieved.

Owner:DALIAN UNIV OF TECH

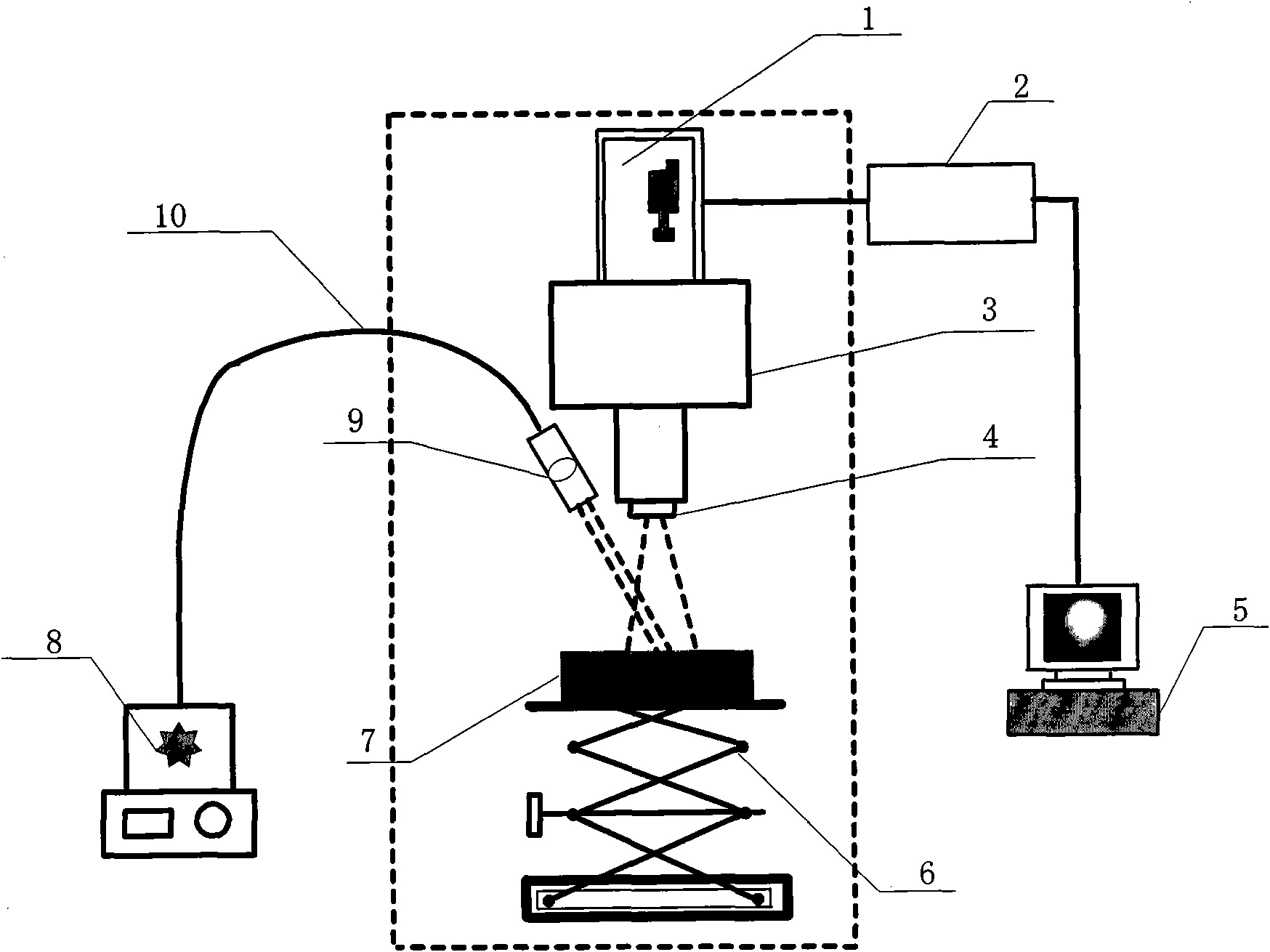

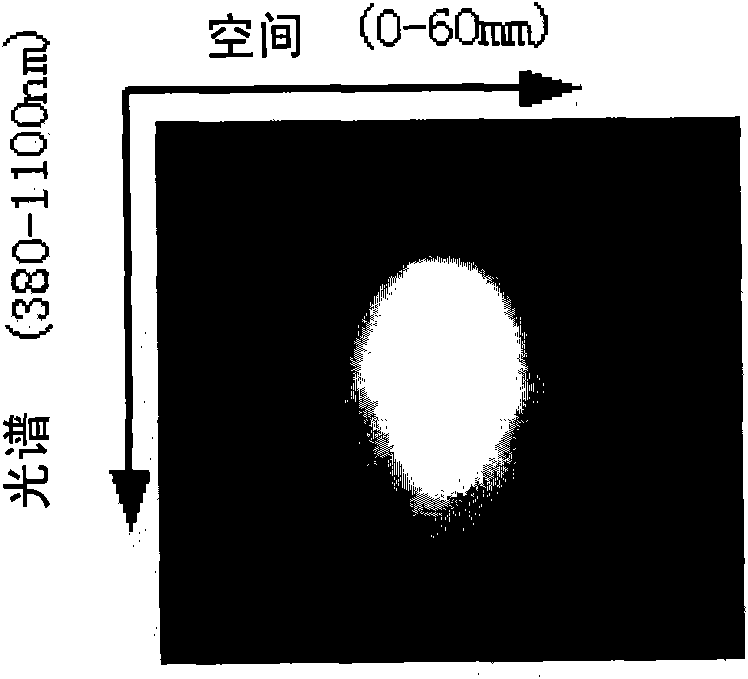

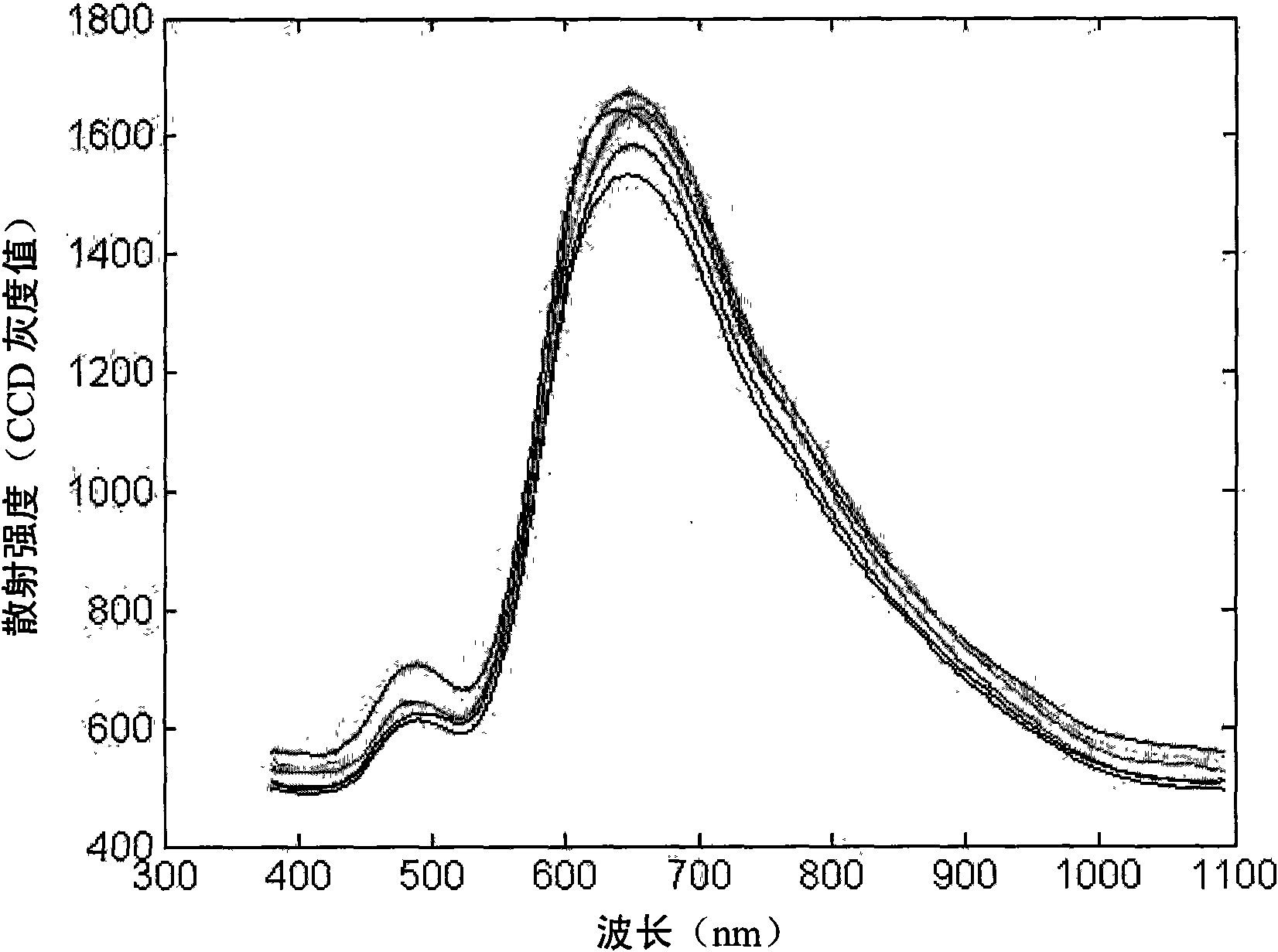

Non-destructive inspection method of total amount of meat bacteria

InactiveCN101806703AImprove safety and qualityGood for healthMicrobiological testing/measurementIndividual particle analysisColony countingPollution

The invention discloses a non-destructive inspection method of total amount of meat bacteria, comprising the following steps: S1, obtaining an original reflection spectrum image Rs of a sample to be detected and storing the image; S2, detecting the TVC of the sample as standard reference data with a standard plate colony counting method according to National Standard; S3, obtaining a relative reflection spectrum image R of the sample according to the FORMULA that R=(Rs-Rd) / (Rr-Rd), wherein Rd is a black image when an image obtaining system works with dark current, and Rr is a reflection spectrum image of a standard reference whiteboard; S4, correcting the image with an SNV method; S5, choosing a second-order differential spectrum for the image R after being corrected, and selecting the best wavelength representing the TVC of the sample to be detected with a step-by-step regression method; S6, extracting the data and TVC detection result of the second-order differential spectrum relative to the best wavelength, and dividing the data and TVC detection result into two sets respectively as correction set data and validation set data; S7, establishing an LS-SVM data model, and detecting the value of the TVC of the sample to be detected. The method is human-oriented and advanced with quick and pollution-free detection process so that our country is in line with developed countries in the field of food quality and safety.

Owner:CHINA AGRI UNIV

Method for rapid detection of residual amount of sulfanilamide in food

ActiveCN103760141AAchieving High Sensitivity DetectionReduce distractionsFluorescence/phosphorescenceFluorescamineSulfanilamide

The invention discloses a method for rapid detection of the residual mount of sulfanilamide in food. The method comprises the following steps: firstly enabling the sulfanilamide and fluorescamine to perform derivation reaction, further enriching derivative products by using cloud point extraction, adding a sample enrichment and a standard plate prepared from a sulfanilamide standard product on a thin layer silica gel plate, comparing the fluorescence intensities of the two under an ultraviolet lamp to judge the concentration range of the fluorescamine in a sample, and determining the residual amount of the sulfanilamide in the food, wherein a detection limit of the method is 0.08 micron g / mL. The method disclosed by the invention has the advantages of simplicity in operation, small using amount of organic solvent, high detection sensitivity, short detection time, strong specificity and capability of realizing effective separation from interfering substances, is a simple, convenient, fast and accurate analytical method, does not need large-scale instruments, only needs to configure small-scale instruments and equipment, and further has extensive application prospects.

Owner:KUNMING UNIV OF SCI & TECH

Verticality detecting equipment and detecting method for product

The invention discloses verticality detecting equipment and a detecting method for a product. The detecting equipment comprises a light source, an image detecting instrument and a display screen, wherein the display screen is connected with the image detecting instrument, and the light source is positioned below the image detecting instrument; a light transmitting mechanism comprising a pedestal, a supporting plate and a standard plate is arranged between the light source and the image detecting instrument; the supporting plate is fixedly arranged on the pedestal; the standard plate is fixedly arranged on the supporting plate; a testing hole is formed on the standard plate and is provided with at least two adjacent vertical faces which are vertical to the upper surface of the supporting plate; two vertical faces are respectively the first vertical face and the second vertical face which are vertical to each other; the supporting plate below the testing hole is formed to be a positioning platform for positioning a product; a rectangular light transmitting hole is formed on the positioning plate; and an inner side face of the rectangular light transmitting hole is positioned on the same plane with the first vertical face or the second vertical face. The verticality detecting equipment and the detecting method have high detecting efficiency, and can be applied to implementing batch detection.

Owner:NINGBO YUNSHENG +4

High strength composite expansion pearlite building material

The present invention relates to a kind of building material. Magnesia, inorganic salts, expansion pearlite and water in certain proportion are mixed into slurry, and the slurry is molded in prefabricated mold into standard plate or block or in-situ cast into building in required shape. The mold is formed through the steps of compounding slurry, casting, curing in mold, curing outside mold and other steps. The building material of the present invention has relatively high compression strength and impact strength other than the light weight and good heat insulating performance, and is especially suitable for use as well material and floor heat insulating material.

Owner:张树荣

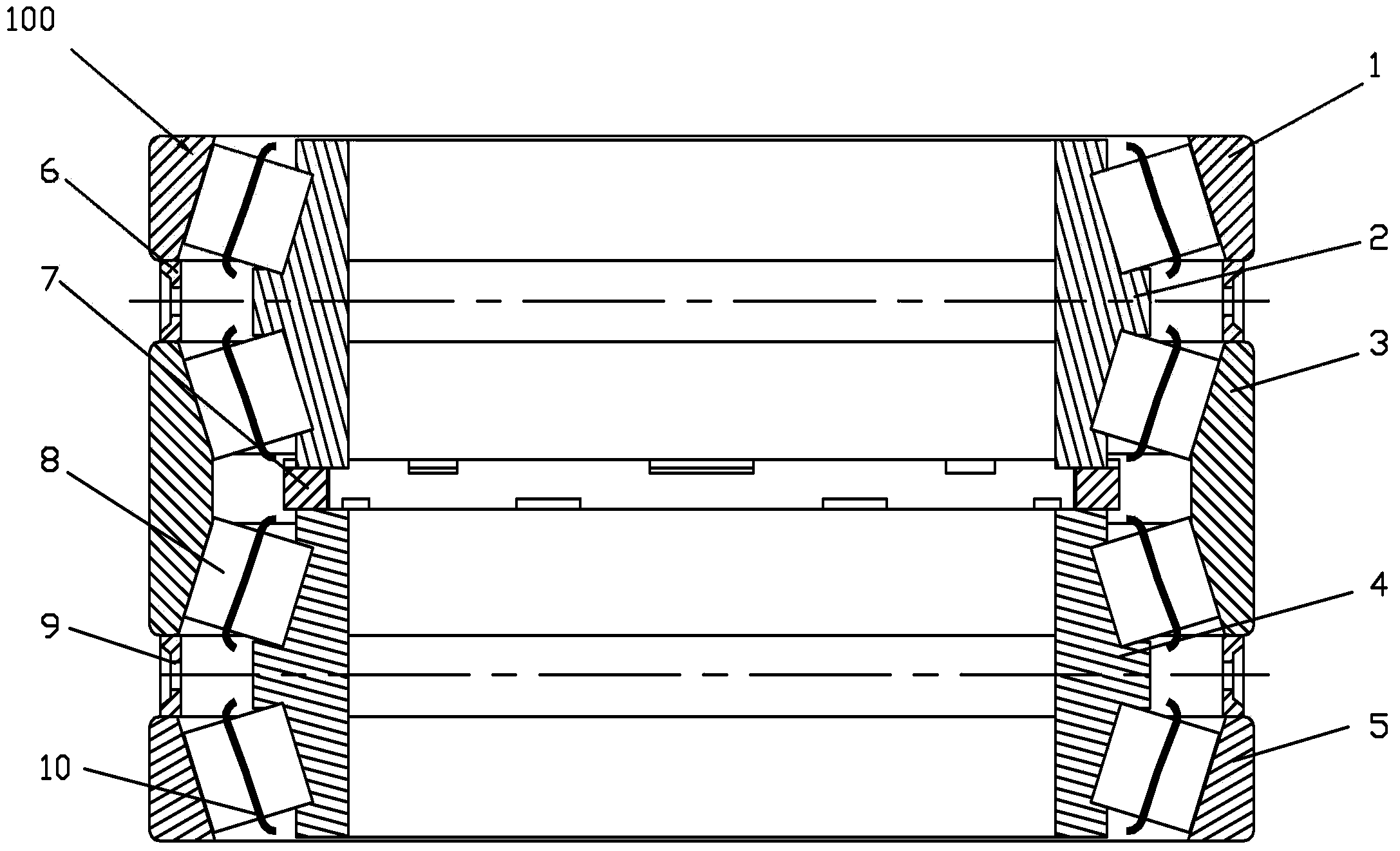

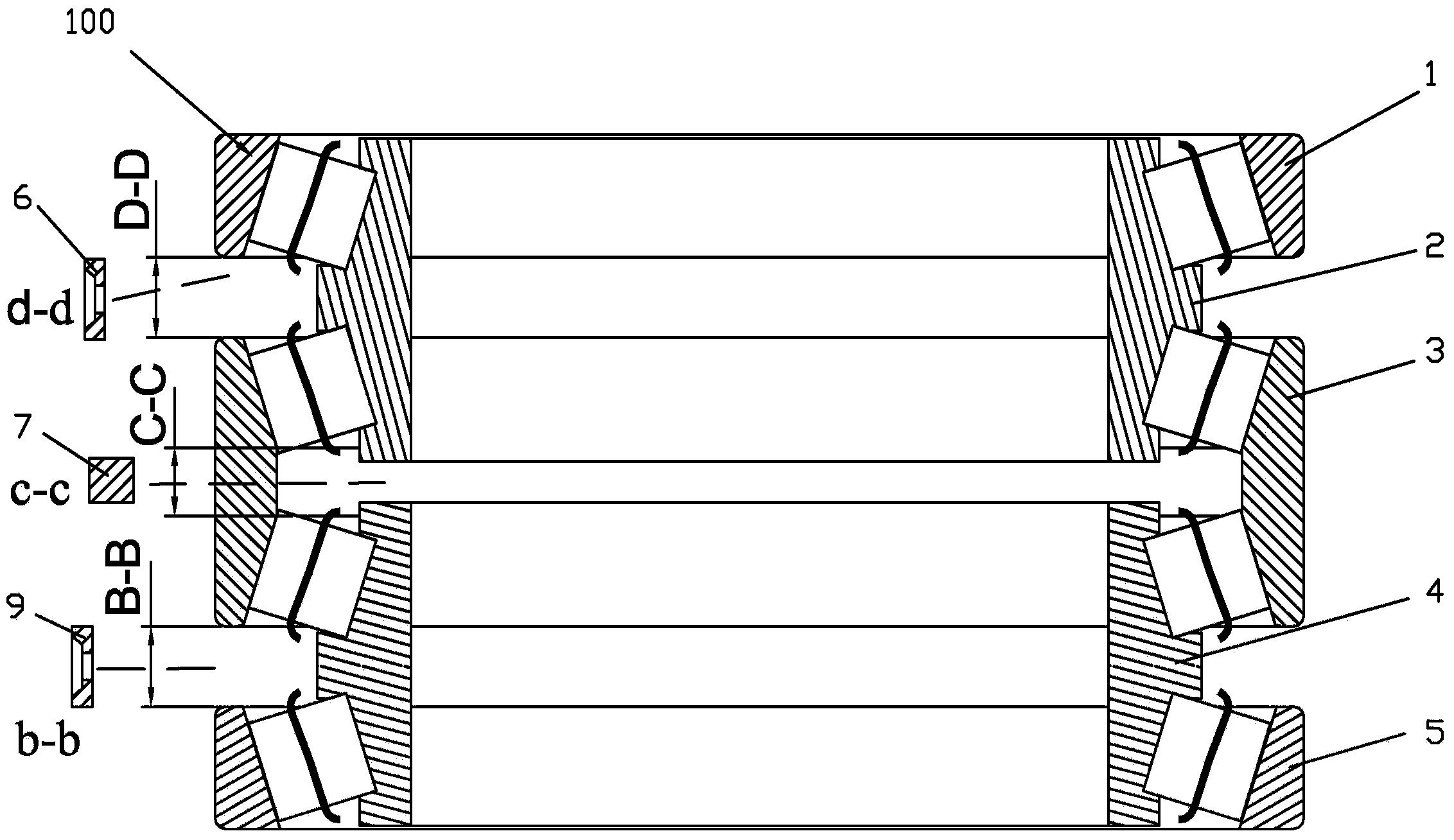

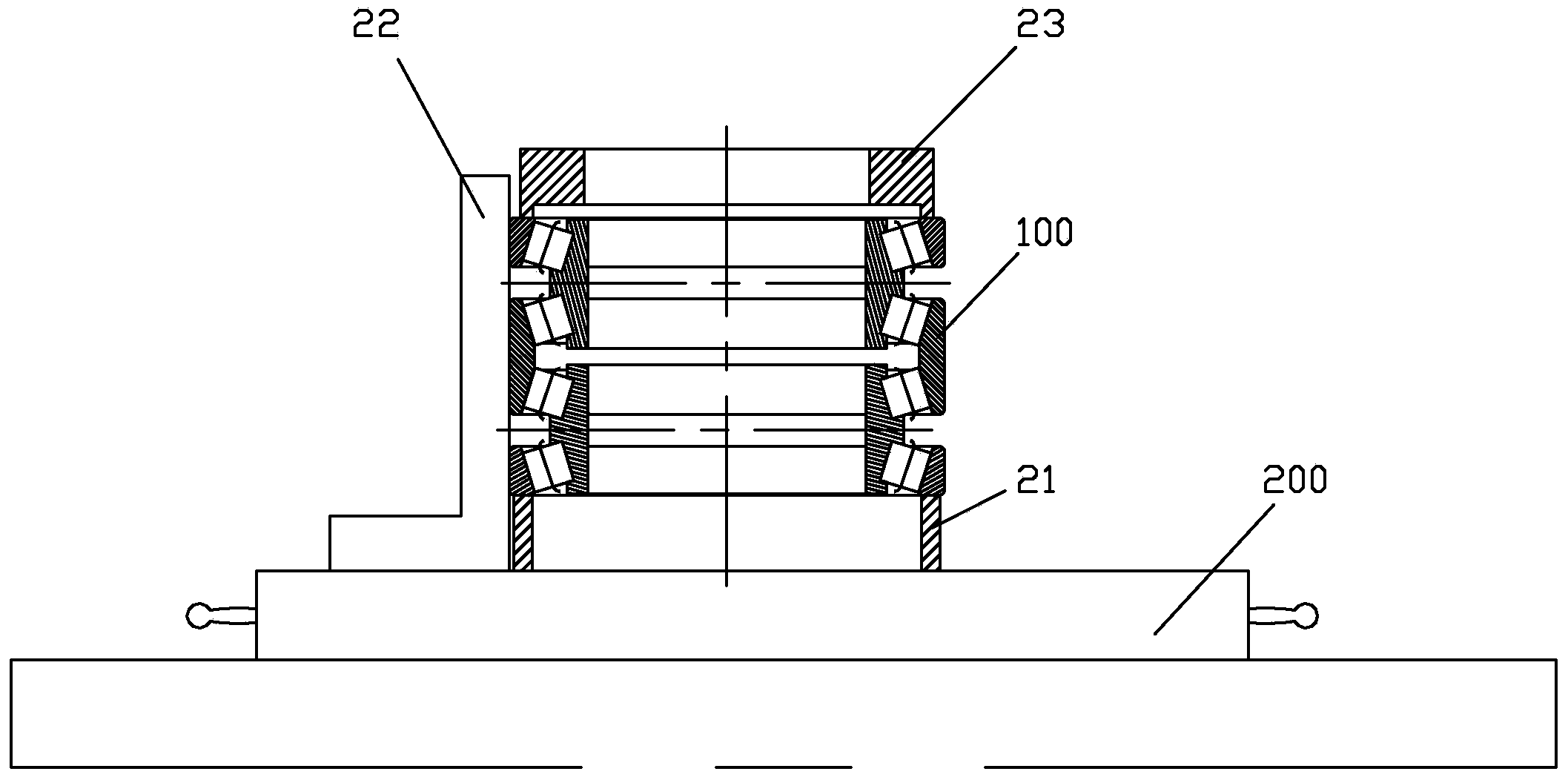

Method for adjusting working clearances of antifriction bearings of rolling device of seamless steel tube cold rolling mill

ActiveCN103722018AReasonable workmanshipSimple and fast operationRolling equipment maintainenceMetal rolling arrangementsObservational errorVernier scale

The invention provides a method for adjusting working clearances of antifriction bearings of a rolling device of a seamless steel tube cold rolling mill. According to the method, a standard plate, a 90-degree angle square, a bottom gasket, a top weight, a vernier caliper, a gauge and a filler gauge are adopted to form measurement tools. The standard plate serves as the measuring basis, the 90-degree angle square serves as a vertical check tool, the bottom gasket is used for supporting the end face of a lower side outer ring of a lower side bearing, and the top weight is pressed on the end face of an upper side outer ring. Three axial distances of the bearings are measured one by one from bottom to top through the vernier caliper or the gauge, the antifriction bearings are arranged upside down, and then distances between the bearing outer rings are measured one by one from bottom to top again. Measurement errors can be corrected through four measuring points and two times of measurement, the thickness of a spacer can be determined through computation, and the working clearances can be adjusted quickly and accurately.

Owner:宝武特种冶金有限公司

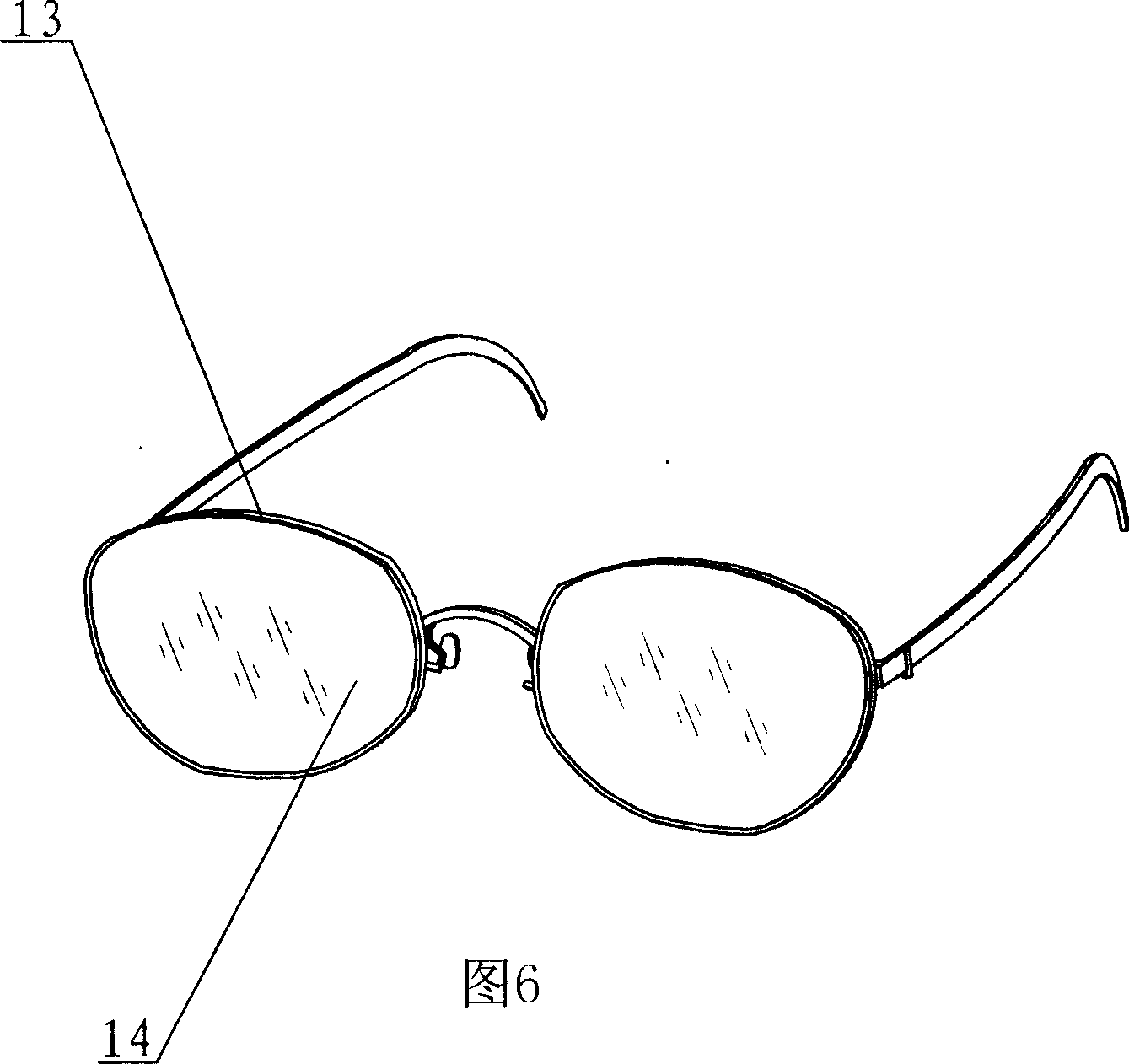

Detector for detecting binocular vision unequal images

Owner:SCHOOL OF OPHTHALMOLOGY & OPTOMETRY WENZHOU MEDICAL COLLEGE

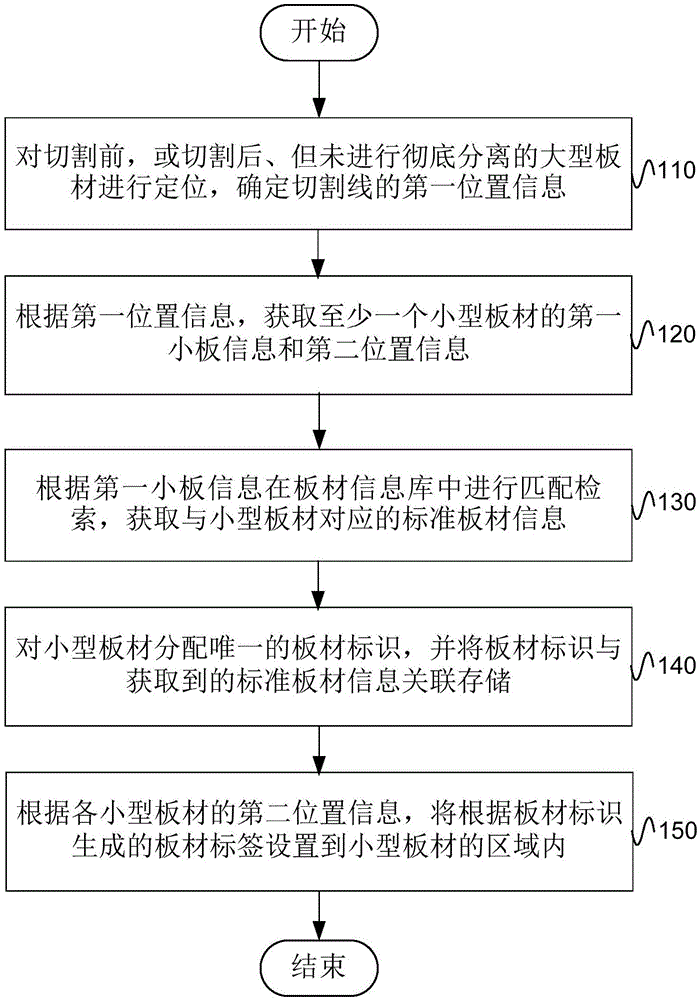

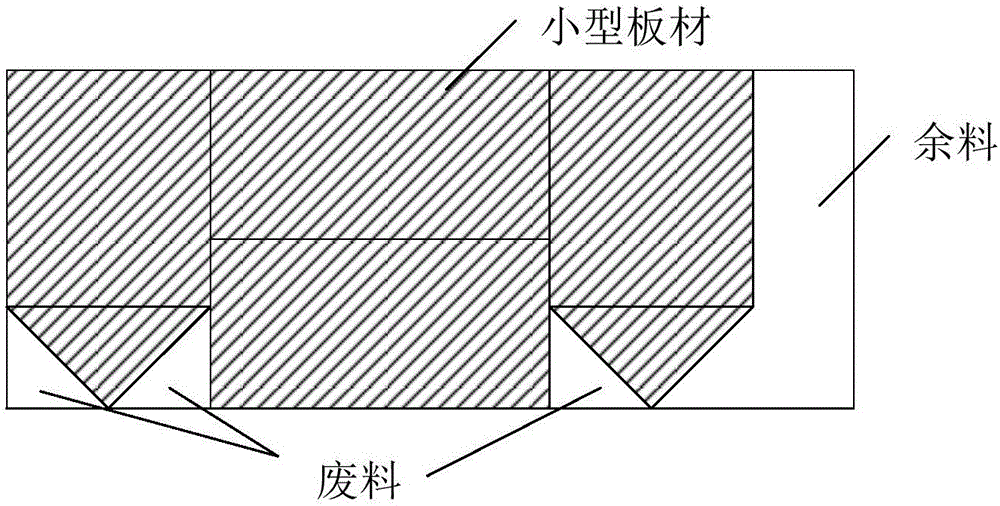

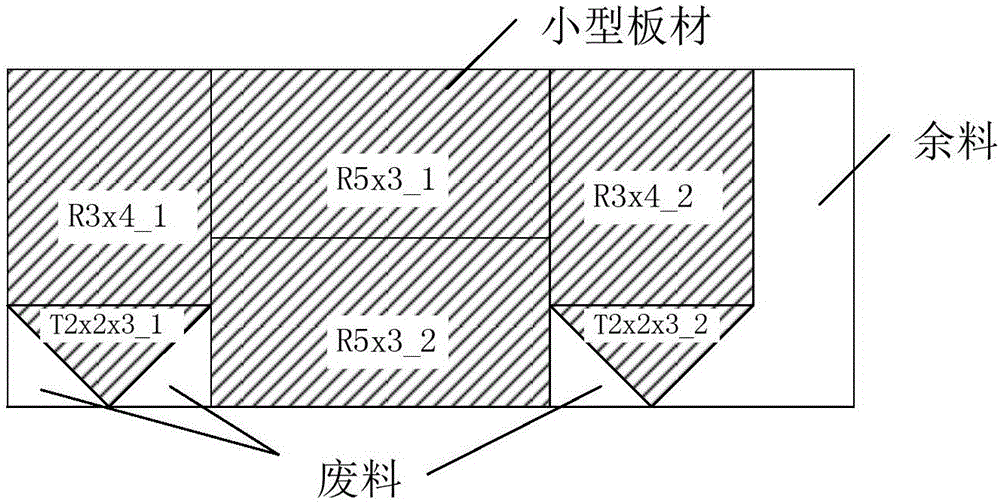

Plate processing method and system

ActiveCN106503151AQuick identificationImprove recognition efficiencyImage enhancementImage analysisInformation repositoryComputer science

The embodiment of the invention discloses a plate processing method and a plate processing system. The method comprises the following steps of positioning a large plate not separated completely before cutting or after cutting, and determining first position information of a cutting line on the large plate; acquiring first small plate information and second position information of at least one small plate according to the first position information; performing matching retrieval in a plate information base according to the first small information and acquiring one piece of standard plate information corresponding to the small plate; distributing a unique plate identifier for the small plate and performing associative storage on the plate identifier and the acquired standard plate information; and setting plate tags generated according to the plate identifier into the area of the small plates according to the second position information of each small plate. According to the scheme of the embodiment of the invention, the plate tag of the small plate is set after the large plate is positioned, so that the problems of low identification rate, low identification accuracy and low processing efficiency of the small plates in the prior art are solved.

Owner:北京源著智能科技有限公司

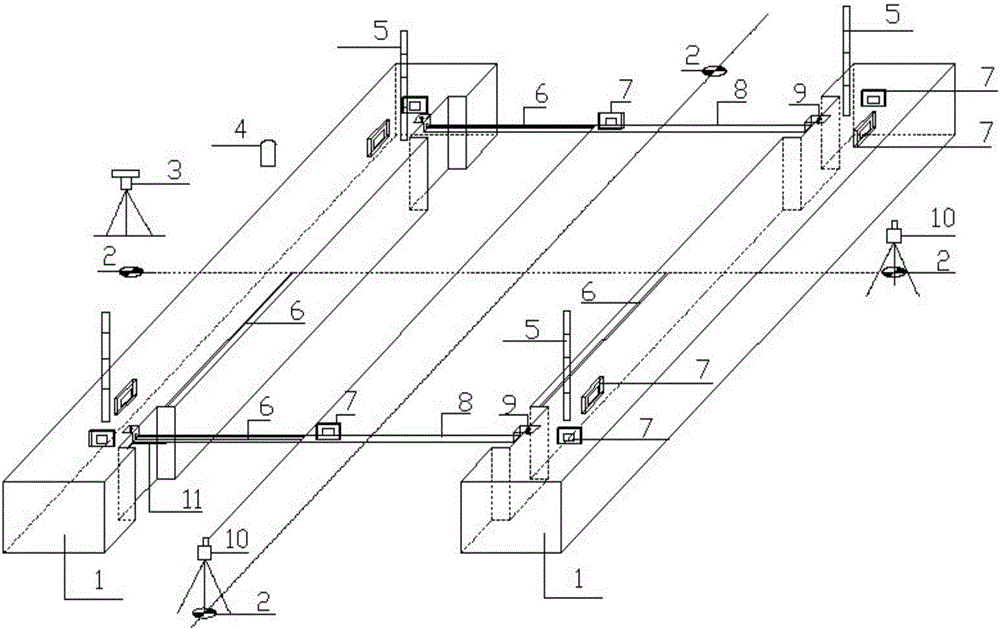

Accurate installation measuring method for rolling mill bases

InactiveCN105798067AHigh measurement accuracySpeed up the installation processMetal rolling stand detailsMeasuring devicesTheodoliteMicrometer

Disclosed is an accurate installation measuring method for rolling mill bases. The accurate installation measuring method includes the following steps that (1) two transverse center line center standard plates and two longitudinal center line center standard plates are buried around the rolling mill bases in advance; (2) elevation datum points are buried around the rolling mill bases in advance; (3) horizontal brackets are placed on the two bases on the inlet side and the outlet side of a rolling mill correspondingly, and inside micrometers are placed on the horizontal brackets; (4) theodolites are used to cooperate with the inside micrometers placed on the horizontal brackets so as to measure the longitudinal and transverse center lines of the rolling mill bases; (5) a precise level is used to cooperate with indium light rulers for elevation measurement of the rolling mill bases; (6) frame level meters are adopted to measure levelness of the rolling mill bases; and (7) measurement of degree of parallelism of the rolling mill bases is performed. By means of the accurate installation measuring method for the rolling mill bases, the measuring accuracy of the center lines, elevation, levelness and degree of parallelism of the rolling mill bases can be greatly improved, the measuring speed is high, the equipment installation progress can be greatly improved, and therefore, the construction cost is greatly reduced.

Owner:MCC TIANGONG GROUP

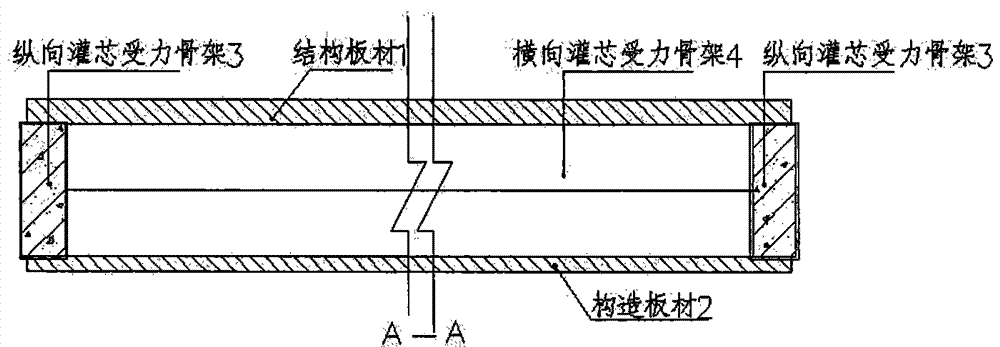

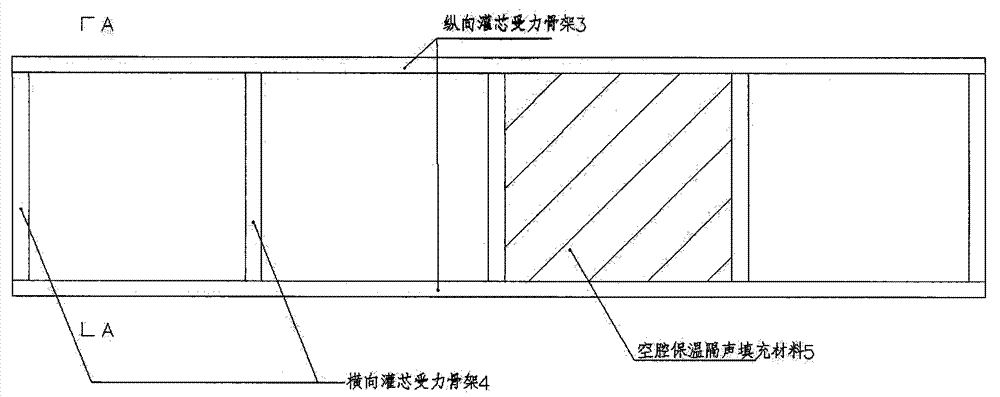

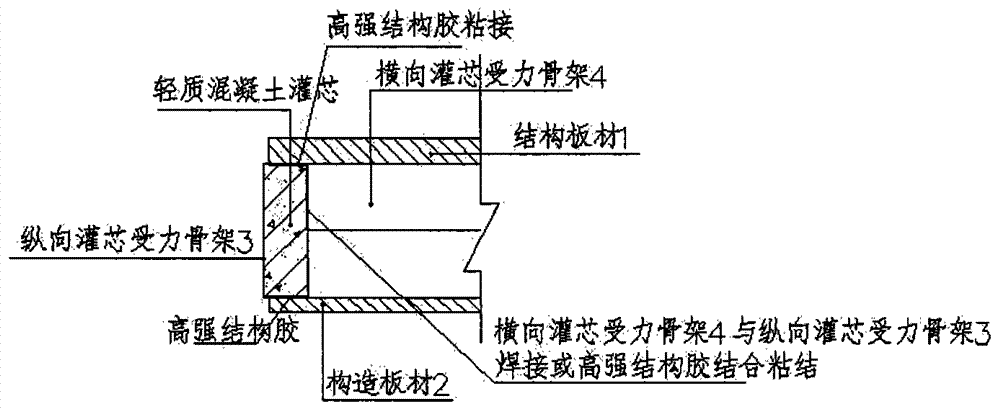

Novel fabricated light framework plate

The invention is a novel fabricated light framework plate, and relates to a fabricated framework plate with light weight, which is mainly applied to the fields of inner and outer wall plates and roof panels of various types of steel structure engineering. The novel fabricated light framework plate which is easily, conveniently and rapidly manufactured according to the standard industrialized production, is provided with two to a plurality of structure stress core filling frameworks which are filled with gel materials and are configured longitudinally according to different plate widths, plate spans and load requirements, and then a plurality of horizontal structure stressed core filling frameworks are pulled and connected horizontally so as to form a sealed stressed framework; then the upper part and the lower part of the framework are bonded with commercially available standard plates by high-intensity building structure glue; certain pressure is applied to the plate surface to cure so as to form a finished product; the plate is of a hollow grid structure, and is provided with an immobile air layer, insulates sound and preserves temperature, and saves materials; the manufacture method through a dry method is simple in process and rapid without consuming a great amount of water and electricity; the novel fabricated light framework plate is less in device investment, and large-scale industrial production is easy to carry out.

Owner:汪超

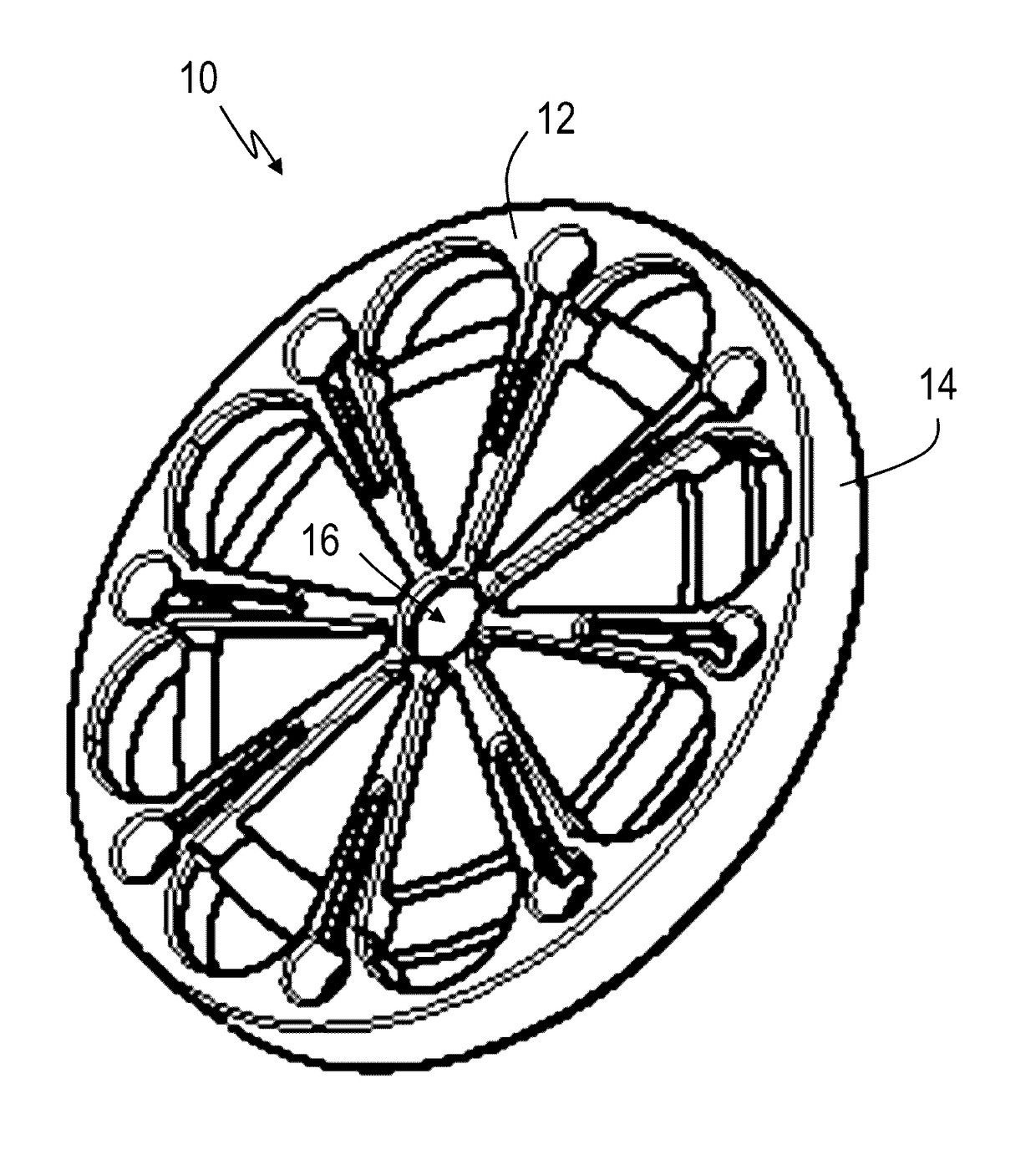

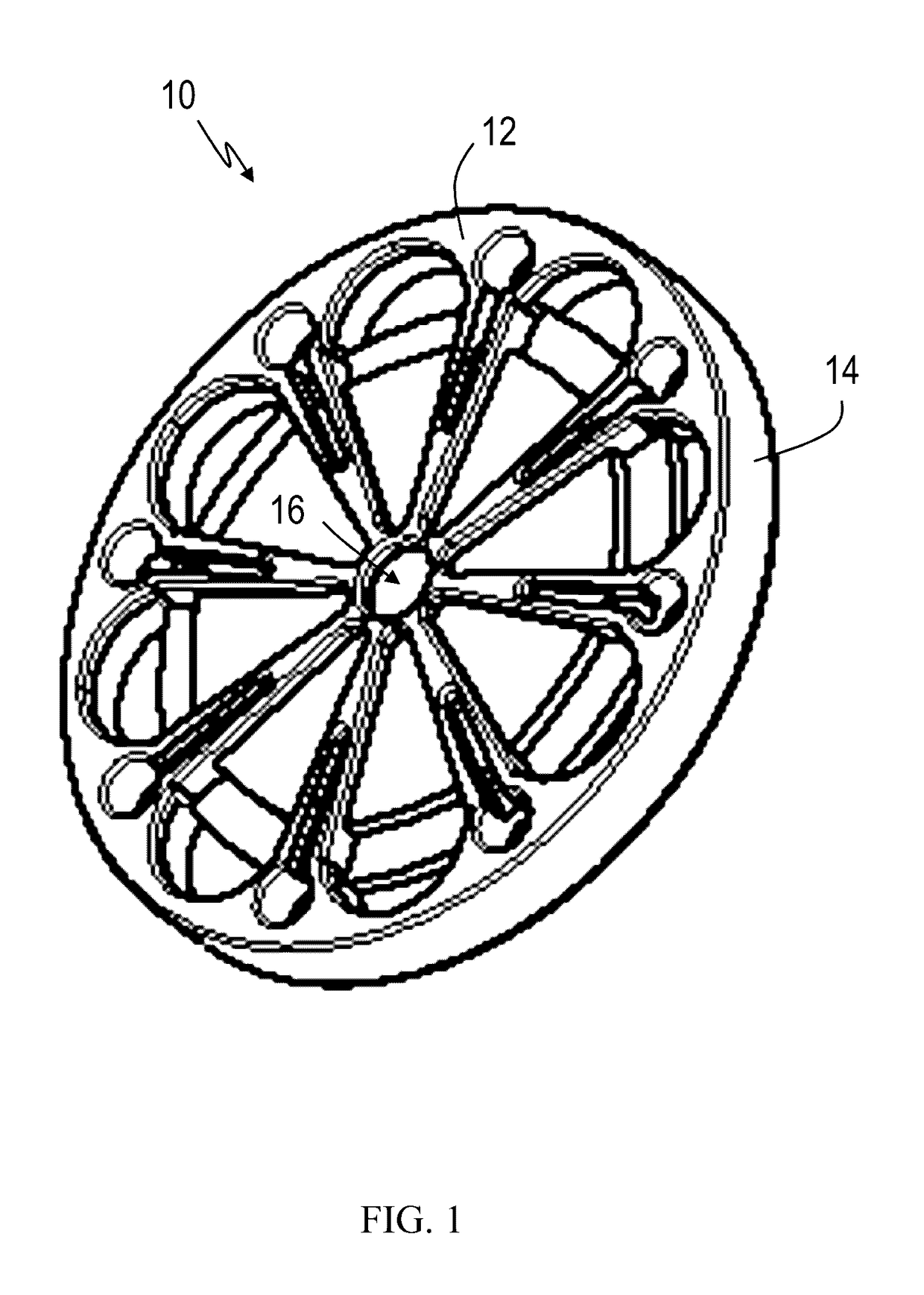

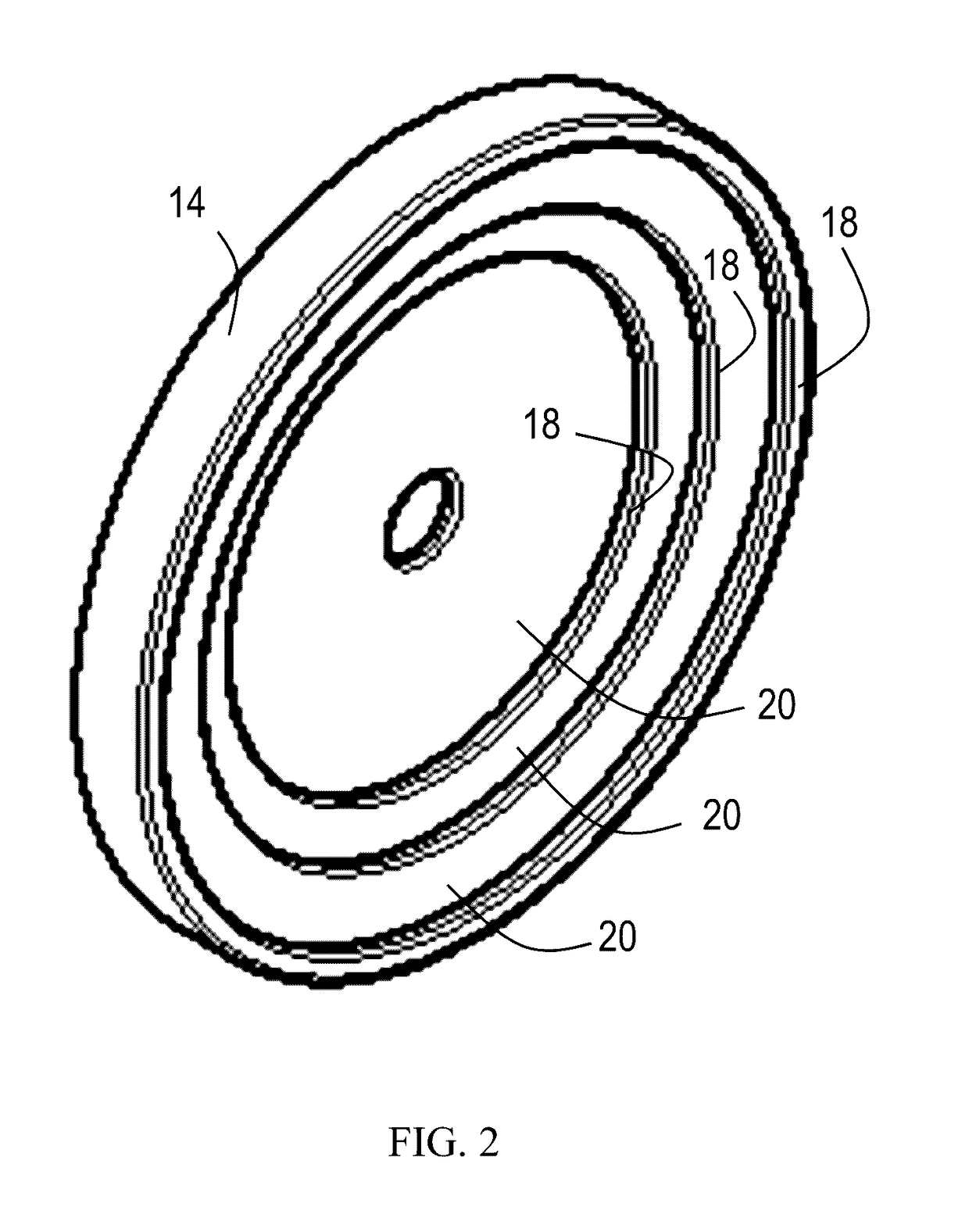

Spacer for barbells and weighted plates

A spacer that is preferably made from high density polyethylene and has a diameter that is larger than a standard plate for a barbell. The spacer has a central hole dimensioned to accept a standard barbell and, when placed onto a barbell, will space the barbell apart from the ground a sufficient distance that a user can easily add or more plates from the barbell without having the lift the barbell. The spacer provides a more efficient way to add or remove weights from a barbell that is on the ground (e.g., when a user is performing deadlifts, snatches, and power cleans, etc.). The spacer may be placed on a barbell similarly to a regular weight plate, preferably before any other weight is added.

Owner:HOLLINGSHEAD DAVID

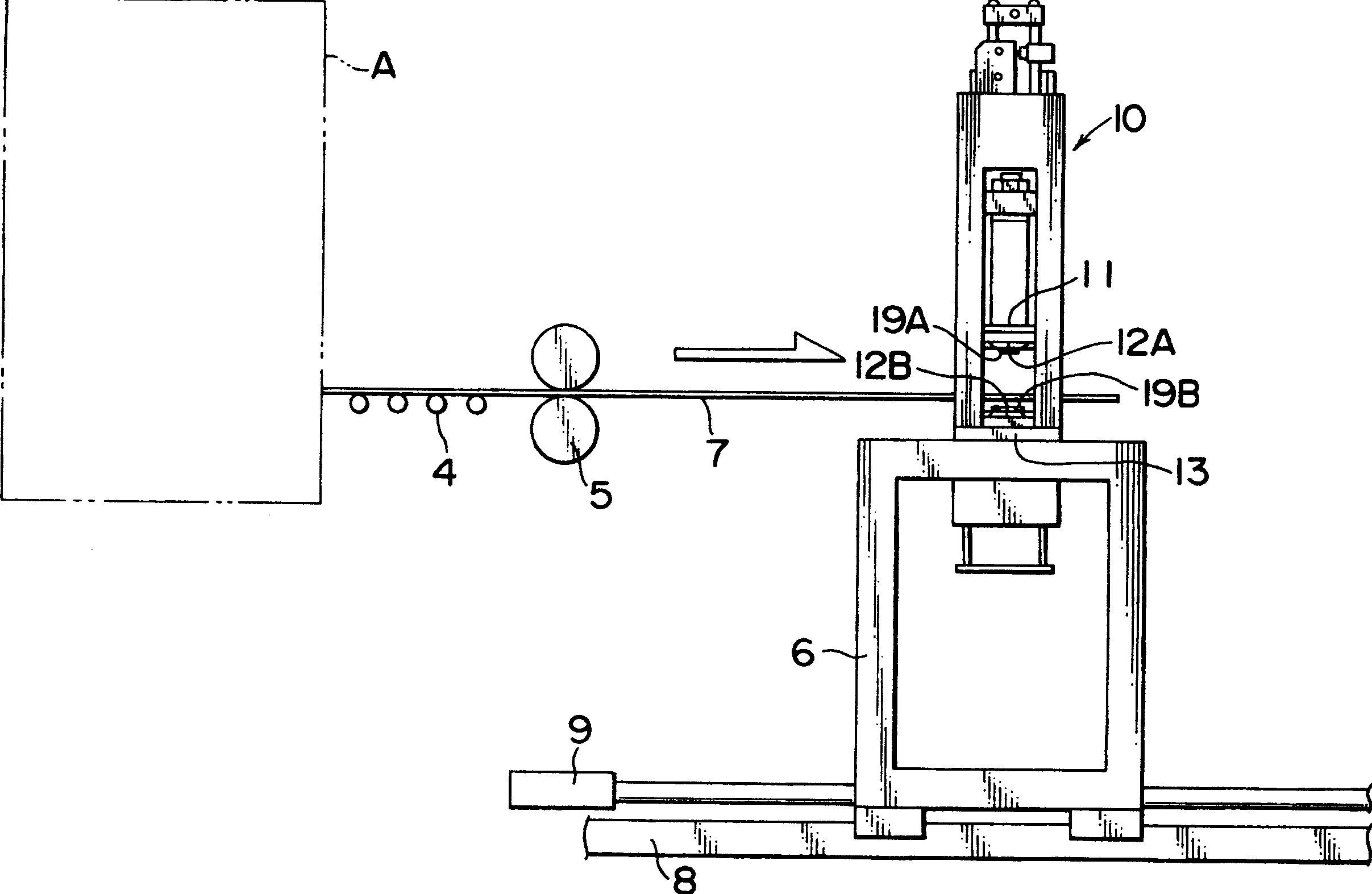

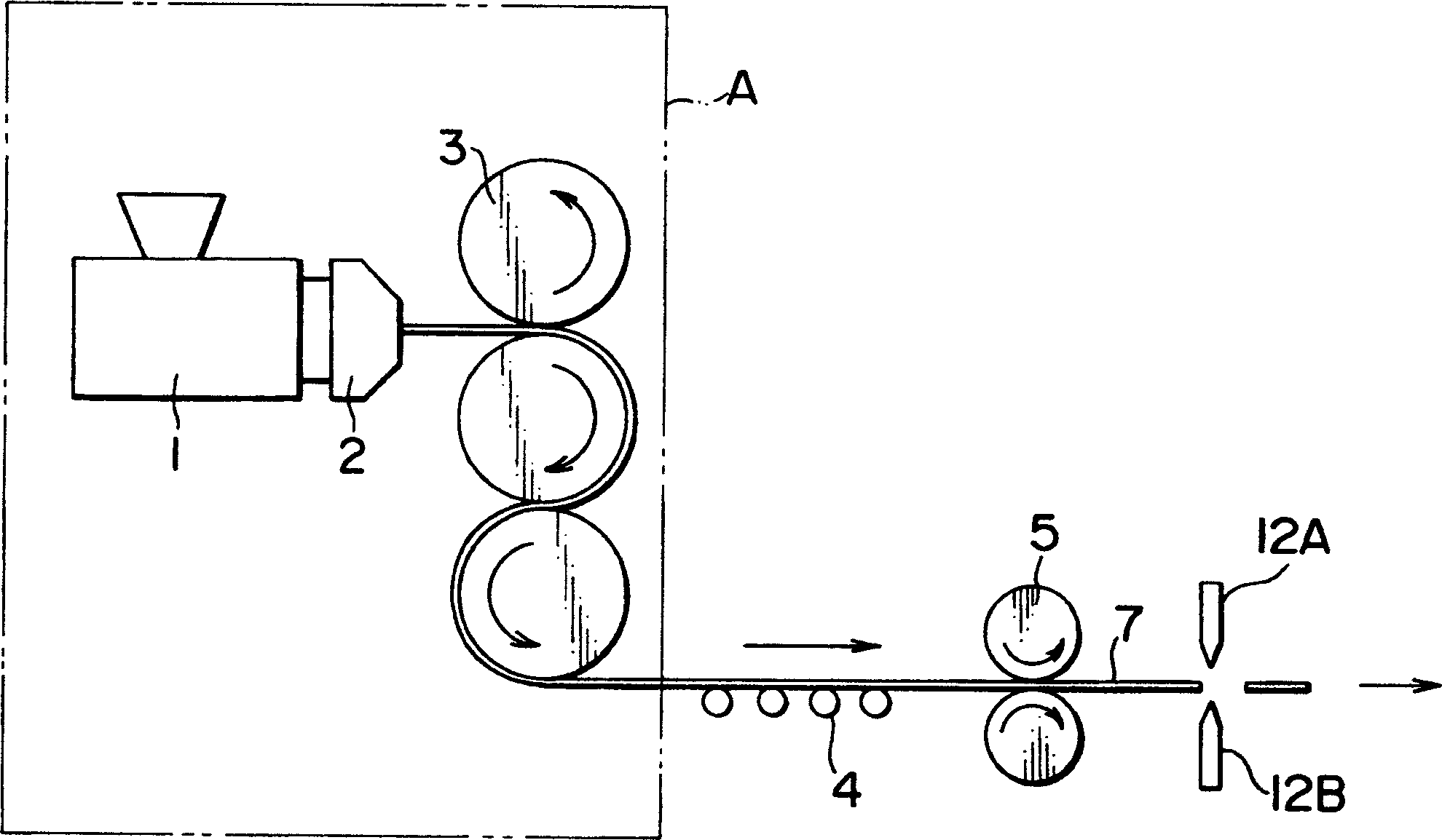

Cutting machine and manufacturing system for fixed size sheet

InactiveCN1757493AShort cutting timeImprove cutting accuracyMetal working apparatusElastic componentAcrylic resin

The invention provides a cutting machine capable of cutting rigid synthetic resin plate at high quality, in particular to the wide and thin rigid synthetic resin plate made from rubber and added with little acrylic resin or the like and provides a cutting machine capable of cutting out standard plate without chip from continuously flowing rigid synthetic resin plate. The cutting machine (10) comprises opposite an upper blade (12A) and a lower blade (12B), wherein two side faces of each blade are with elastic components (19A, 19B) protruded than the blades, while the elastic components can clamp rigid synthetic resin plate (7) when in cutting, the elastic components arranged on two side faces of the upper or lower blade are composed of an elastic portion near the blade and an elastic portion far from the blade, while the rigidity of the elastic portion near the blade is higher than the elastic portion far from the blade.

Owner:SUMITOMO CHEM CO LTD

Method for calibrating heat flow meter method conductometer based on guarded hot plate method

ActiveCN108152325AAvoid inaccurate measurementsAvoid repeat purchasesMaterial heat developmentHeat flowMaterials science

The invention discloses a method for calibrating a heat flow meter method conductometer based on a guarded hot plate method, and belongs to the field of calibration of thermal conductivity measuring apparatus. The method disclosed by the invention is characterized in that a guarded hot plate method conductometer is used for measuring a thermal conductivity value of a thermal conductivity standardplate, the thermal conductivity standard plate is assigned with a value at the corresponding temperature, and then the thermal conductivity standard plate assigned with the value is put into a heat flow meter method conductometer to be calibrated to perform a calibration procedure, thereby obtaining calibration factors of the heat flow meter method conductometer at the corresponding test temperature. Thus, the defect that a heat flow meter method conductometer with a fixed structure needs to be disassembled to solely calibrate heat flow meter parts is avoided, and meanwhilefurthermore, the problem of inaccurate apparatus measurement indirectly caused by disassembling the conductometer is avoided.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

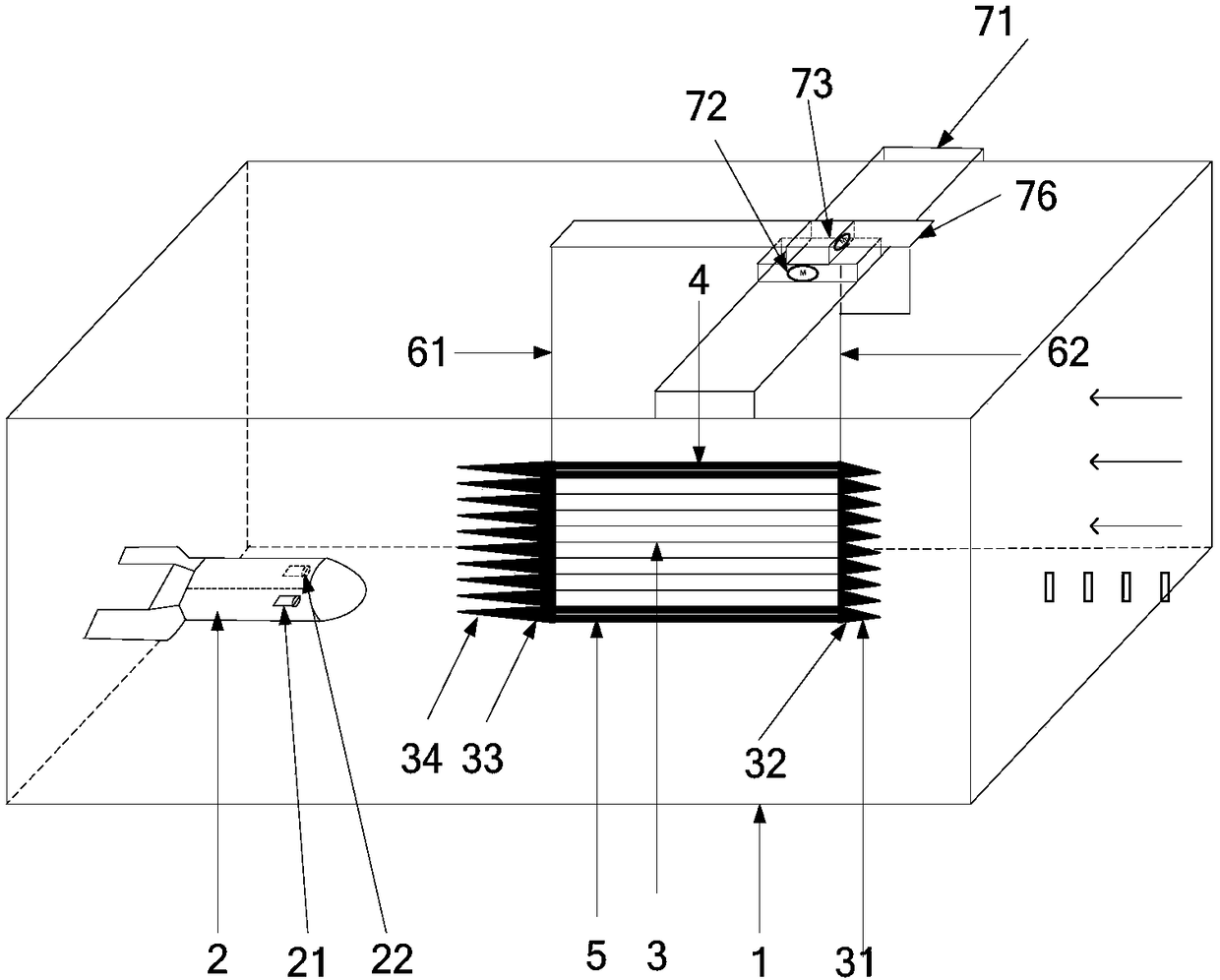

Calibration device and method for acoustic wave scattering region of Doppler current meter

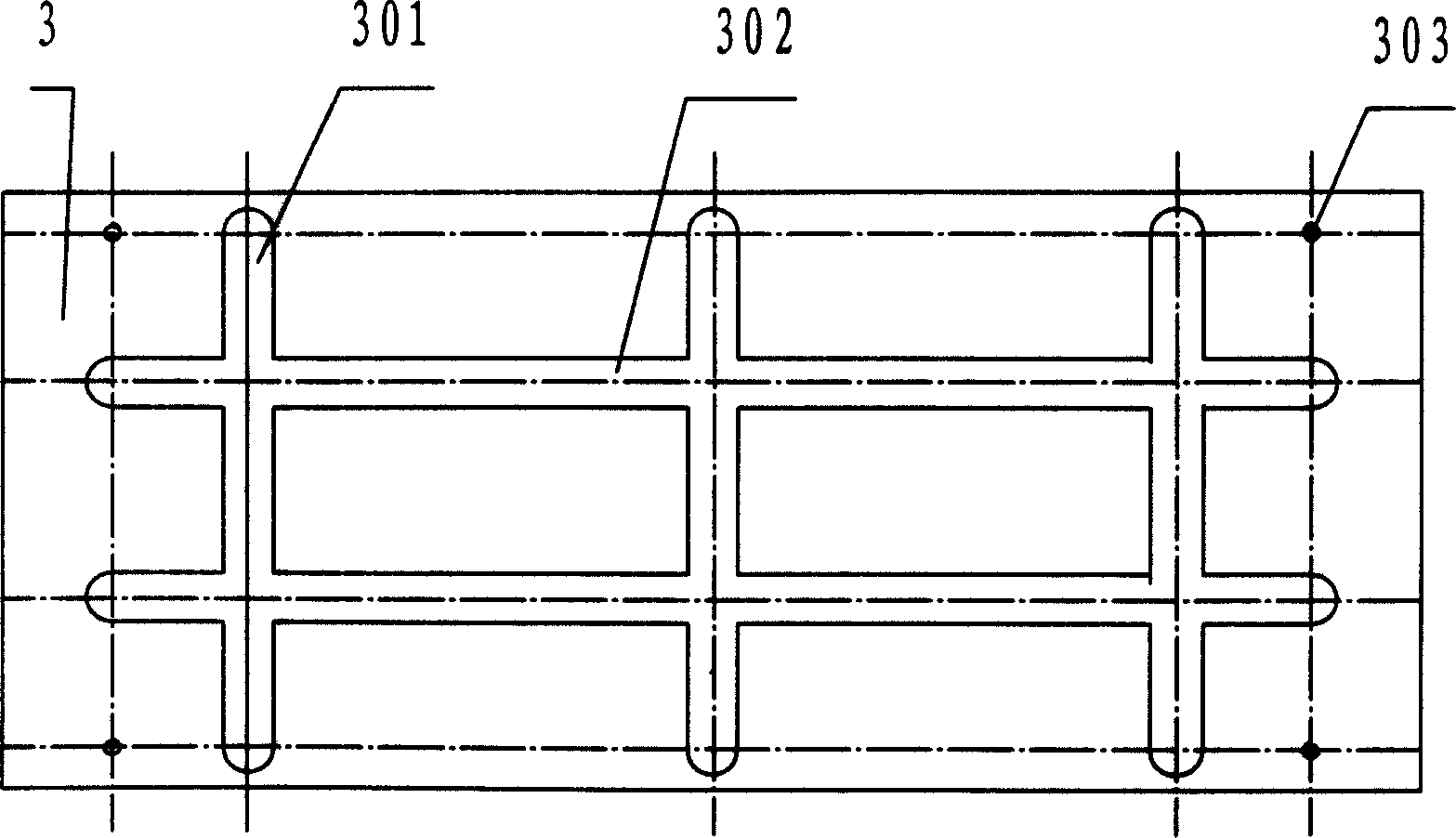

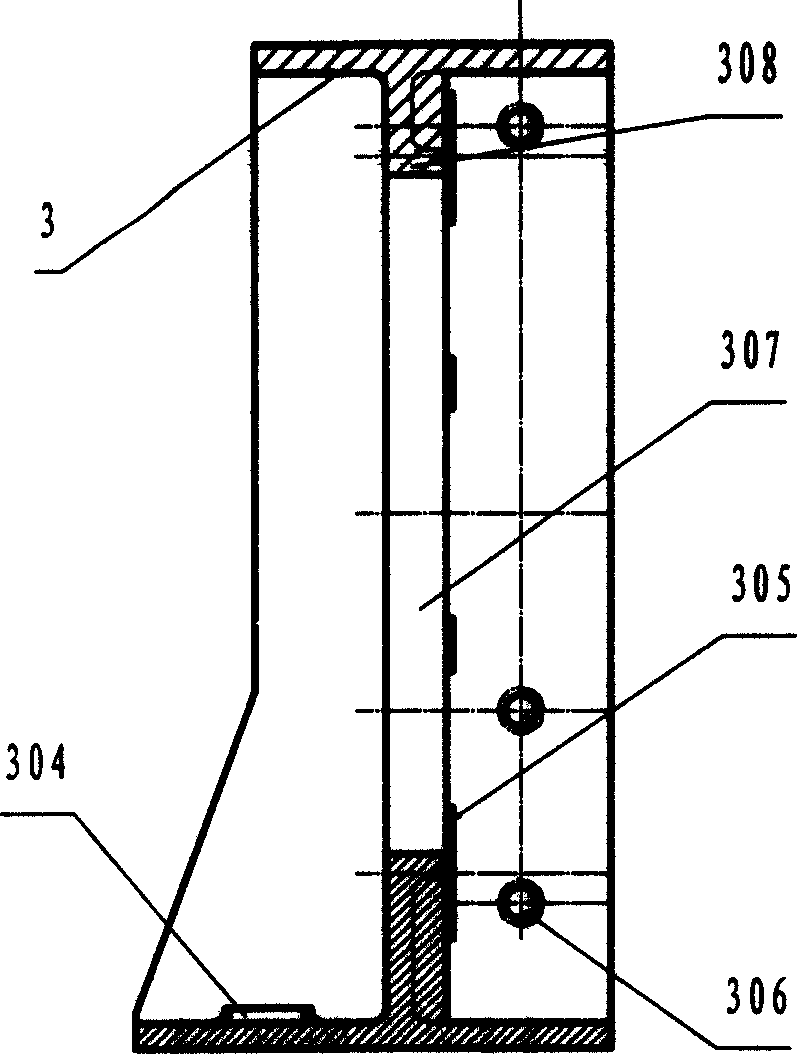

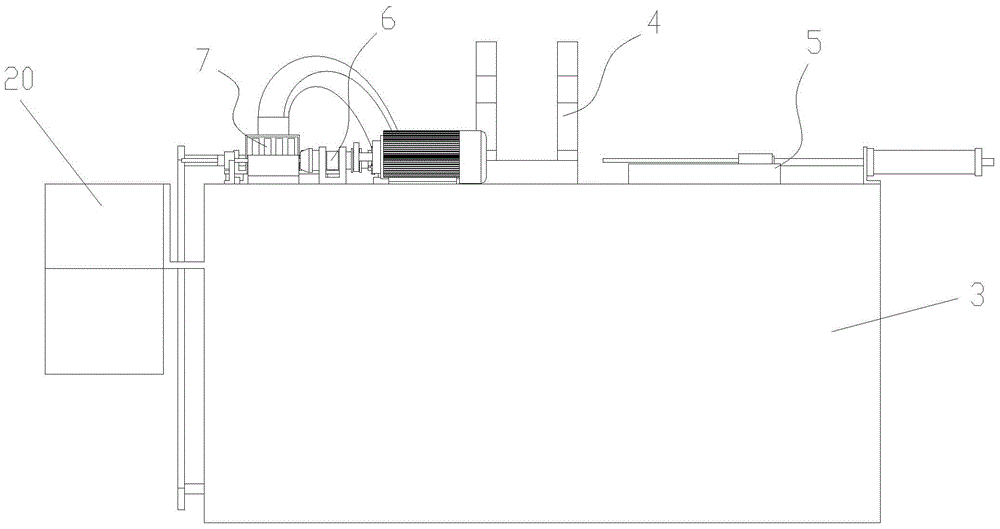

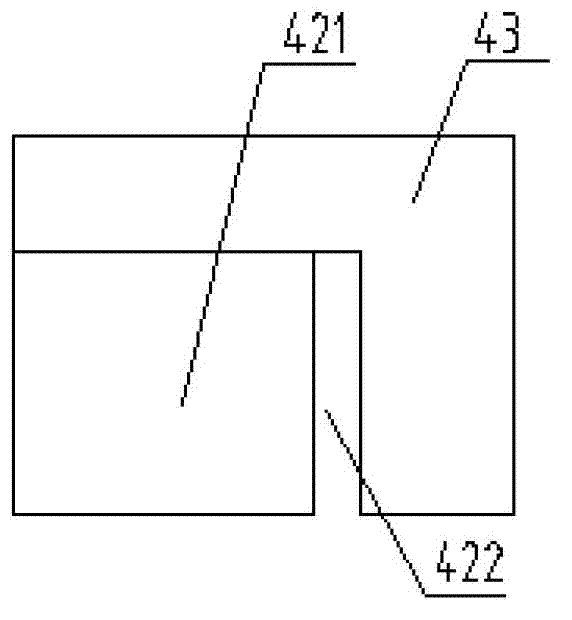

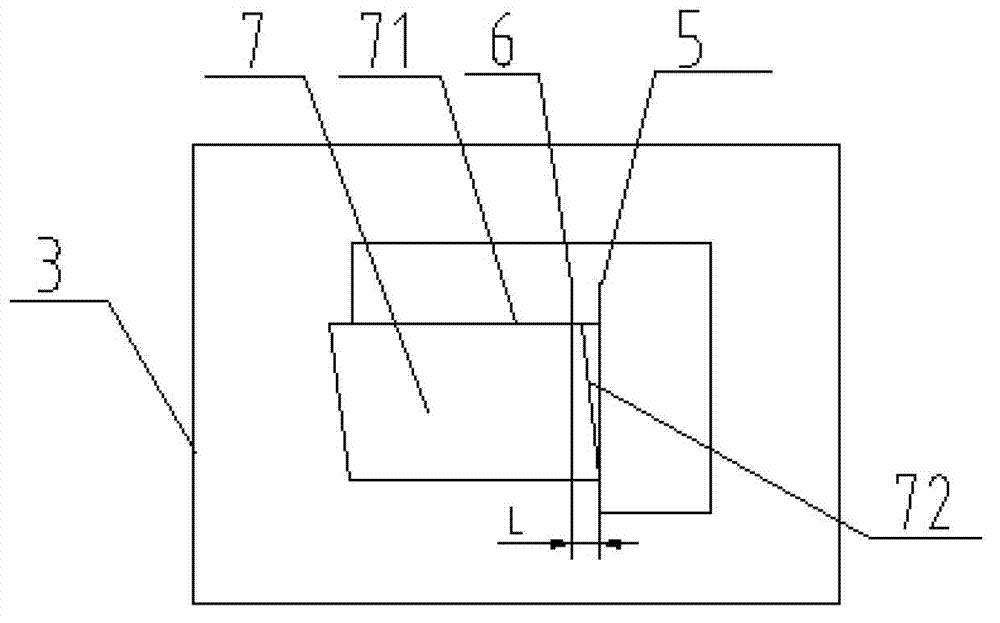

ActiveCN108303570AAvoid enteringHigh precisionTesting/calibration of speed/acceleration/shock measurement devicesCurrent meterCircular cone

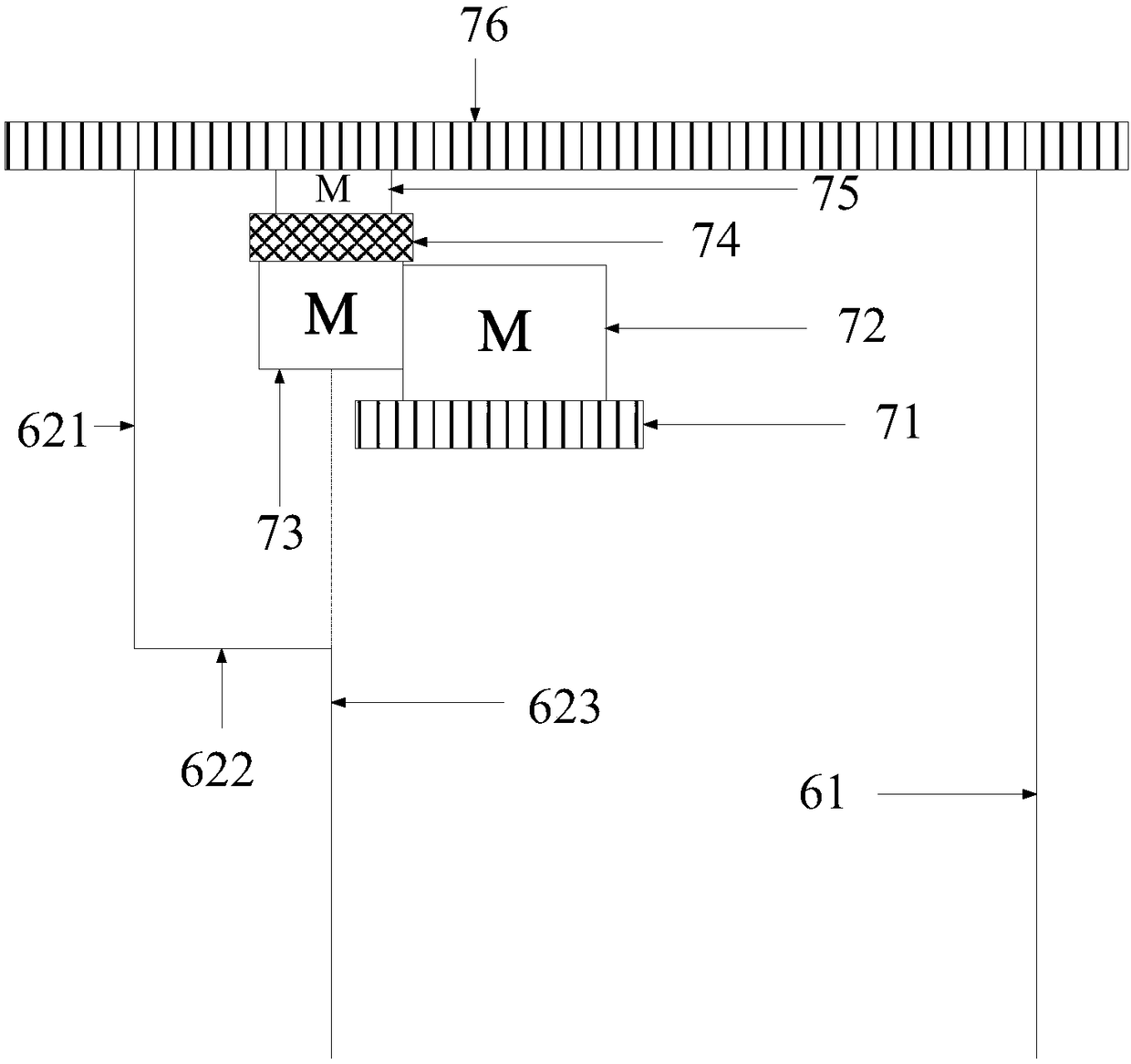

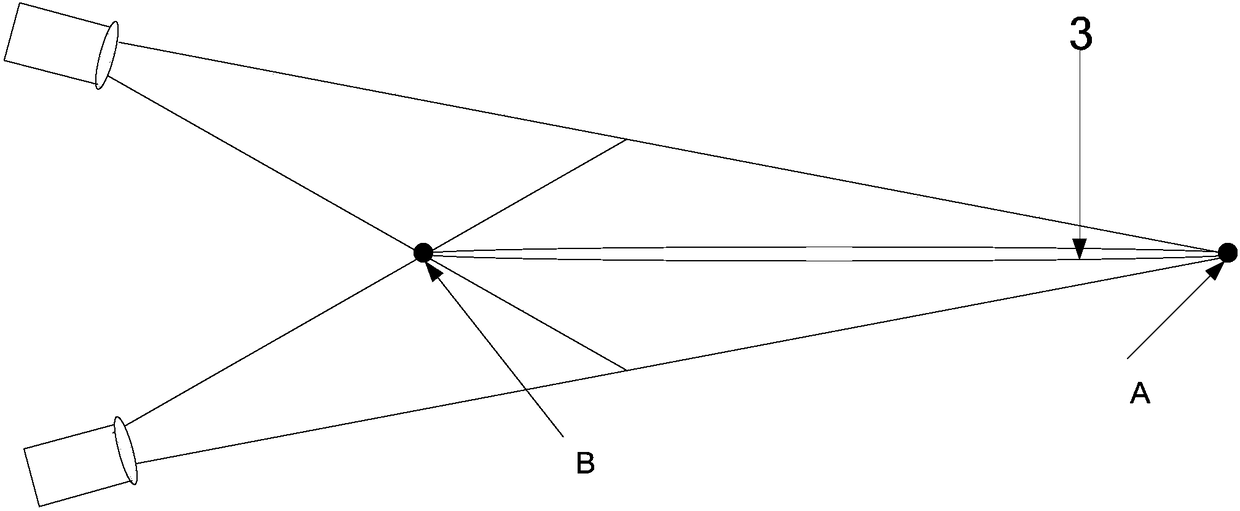

The invention relates to a calibration device and method for a sound wave scattering region of a Doppler current meter. The device comprises a standard plate (3), an upper damper (4), a lower damper (5), a first connecting rod (61), a second connecting rod (62) and a moving mechanism. The standard plate (3) is formed by connecting the round tubes to each other. One end of each of the round tubes is provided with a long cone (34), and the other end is provided with a short cone (31). The moving mechanism includes a first guide rail (71), a first linear stepping motor (72), a rotary stepping motor (73), a turntable (74), a second linear stepping motor (75) and a second guide rail (76). The first connecting rod (61) is a straight rod, the second connecting rod (62) includes an upper verticalrod (621), a horizontal rod (622) and a lower vertical rod (623), and the axis of the lower vertical rod (623) and the rotation axis of the rotary stepping motor (73) are in the same straight line. The effective acoustic scattering region of the Doppler current meter can be accurately calibrated.

Owner:HARBIN ENG UNIV

Camera shooting module focusing method based on chromatic aberration

The invention discloses a camera shooting module focusing method based on chromatic aberration. The focusing method comprises the steps of firstly providing a defocusing amount in each test view field and a monotonic function of imaging quality based on chromatic aberration of a camera shooting module in an optical axis direction, and then shooting and analyzing an image of at least one first test pattern of a standard plate by using the camera shooting module to acquire the chromatic aberration of the camera shooting module in the optical axis direction, and acquiring the defocusing amount of the camera shooting module in each test view field based on the chromatic aberration; subsequently, the needed moving amount of an optical lens of the camera shooting module relative to a light sensitive chip can be judged, and thus focusing of the camera shooting module is completed after the position of the optical lens relative to the light sensitive chip is adjusted.

Owner:NINGBO SUNNY OPOTECH CO LTD

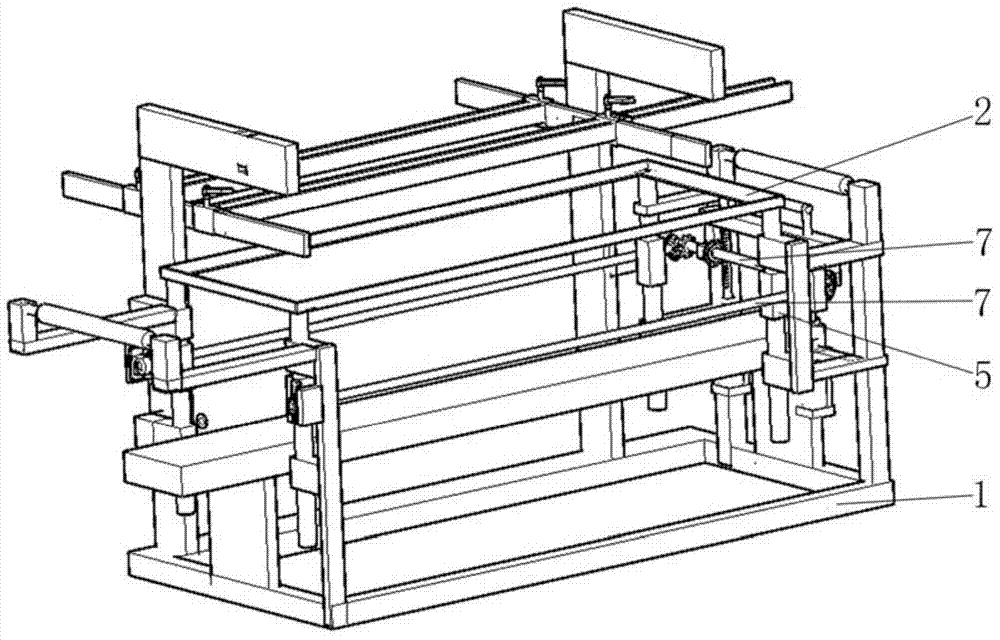

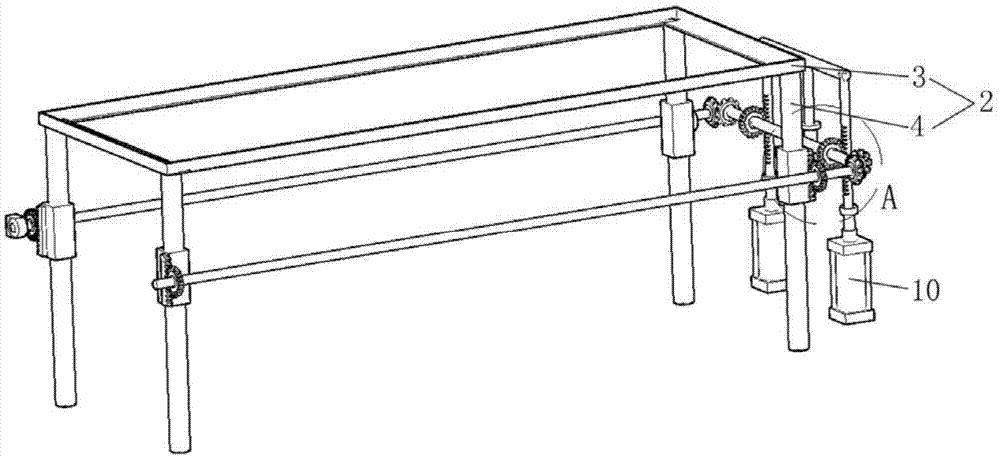

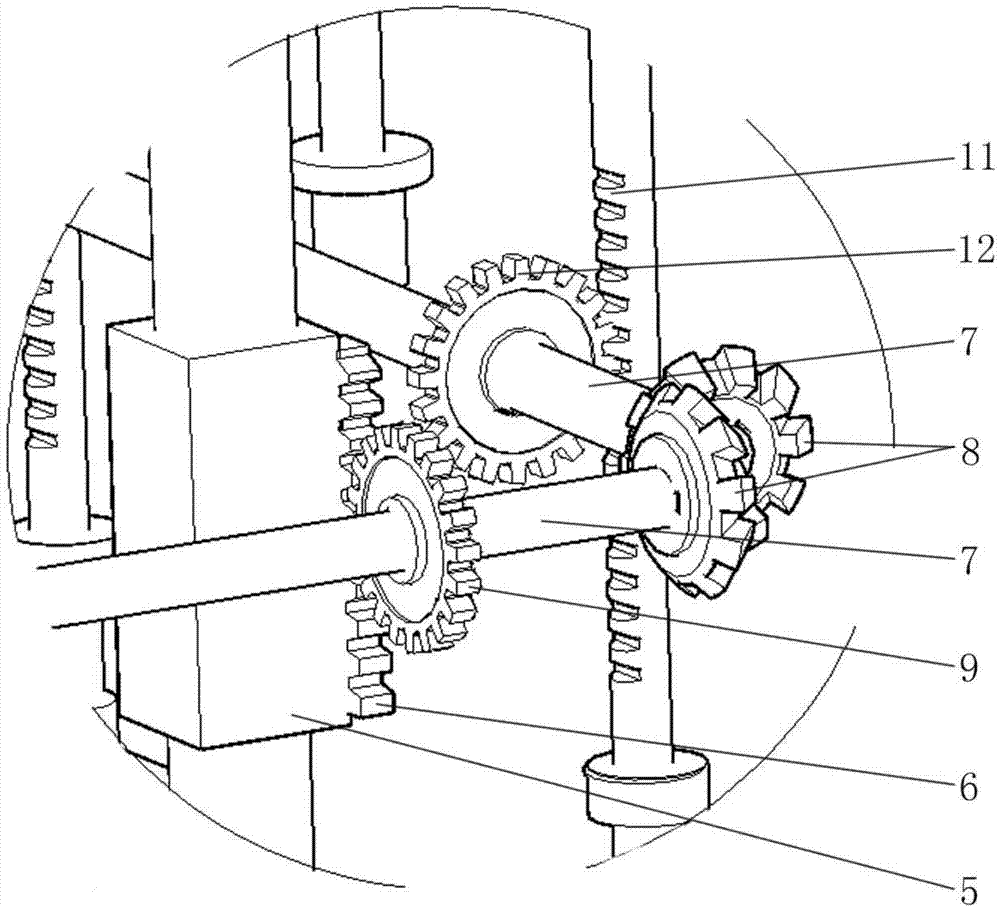

Novel hole drilling machine for processing plate materials and hole drilling method

InactiveCN104842408ASimple structureEasy to operateDrilling machinesEngineeringUltimate tensile strength

The invention discloses a novel hole drilling machine for processing plate materials. A carrying platform capable of ascending and descending relative to a machine frame is arranged on the hole drilling machine; plate materials to be processed are carried by the carrying platform. The hole drilling machine provided by the invention has the advantages that the structure is simple; the operation is convenient; the ascending or the descending of the carrying platform is utilized, and lateral side holes and front side holes of the plate materials can be directly processed; the plate material turning by production personnel is not needed; the positioning of the plate materials is not only limited on one standard plate; the use flexibility is greatly improved; the number of machine loading operation times of the plate materials is reduced; the damage to the plate materials during the operation is reduced; the work intensity of operators is greatly reduced; the hole drilling efficiency of the plate materials, particularly the plates for furniture is greatly improved, and the speed is three times or more than three times of that of an ordinary drill bar with the same drill bit group number. The invention also discloses a method using the hole drilling machine to process the plate materials.

Owner:何有港

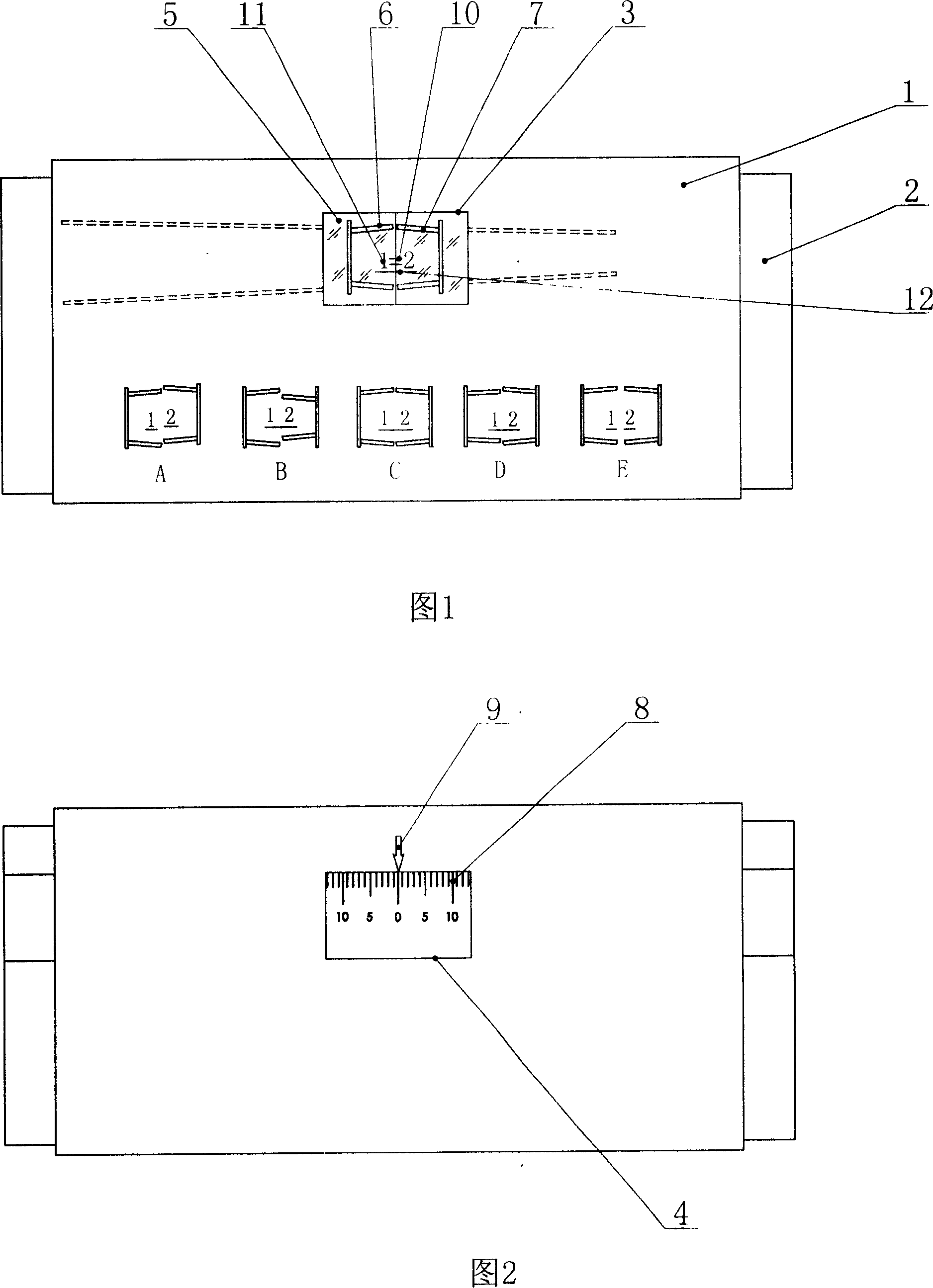

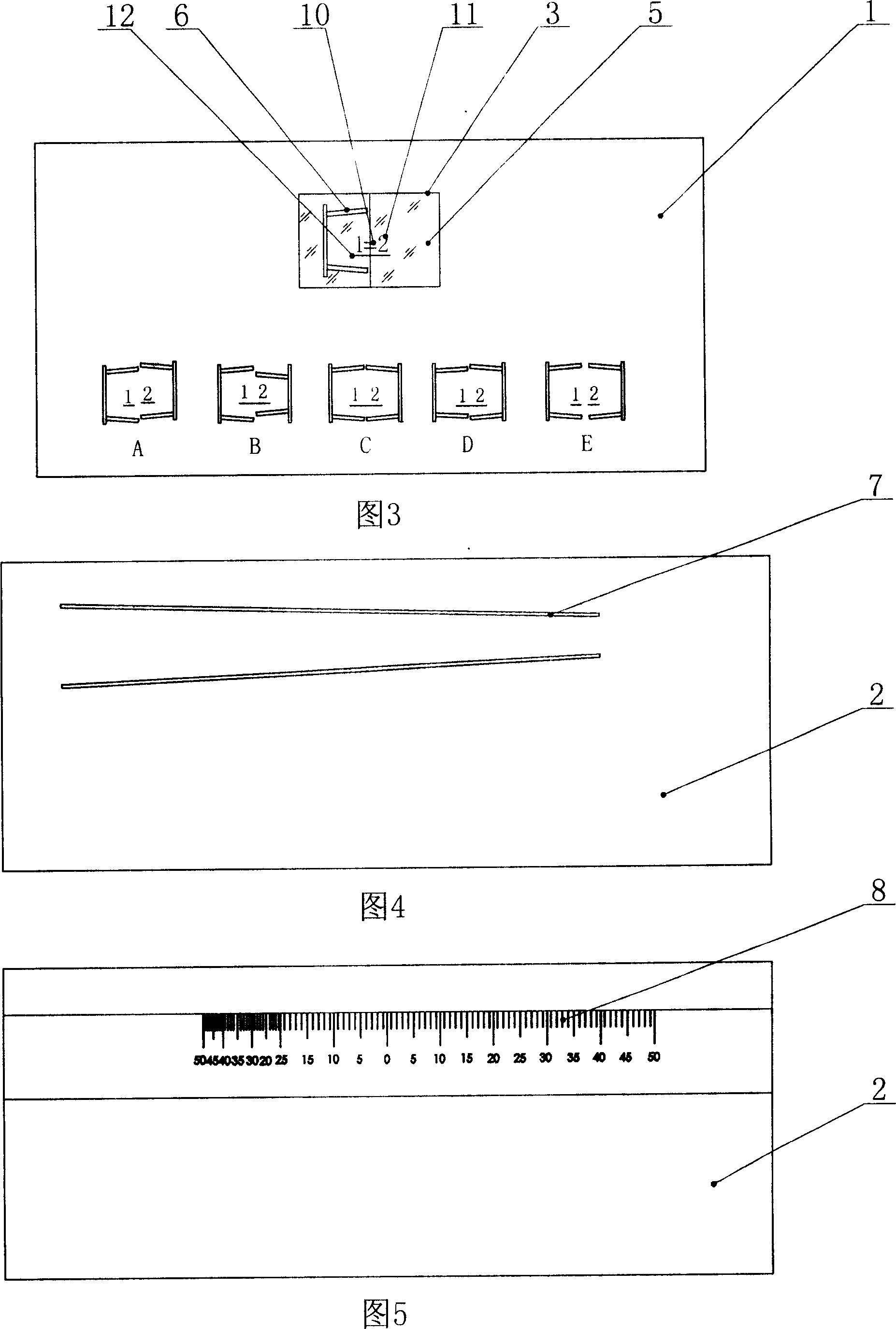

Linear array CCD camera alignment adjustment method

The invention discloses a linear array CCD camera alignment adjustment method, relating to the visual sense system camera calibration technology field. The linear array CCD camera alignment adjustment method adopts a calibration plate drawn with a vertical line group and an oblique line group to finish calibration adjustment of a linear array CCD camera by adjustment software of the linear array CCD camera. The linear array CCD camera alignment adjustment method not only determines a specific position of a scanning line and determines whether scanning line is horizontal, but also realizes the facts that the focal length adjustment of the linear array camera does not need extra hardware support, the cost is reduced, a mobile standard plate is not needed to realize fast and effective calibration and operation is flexible.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

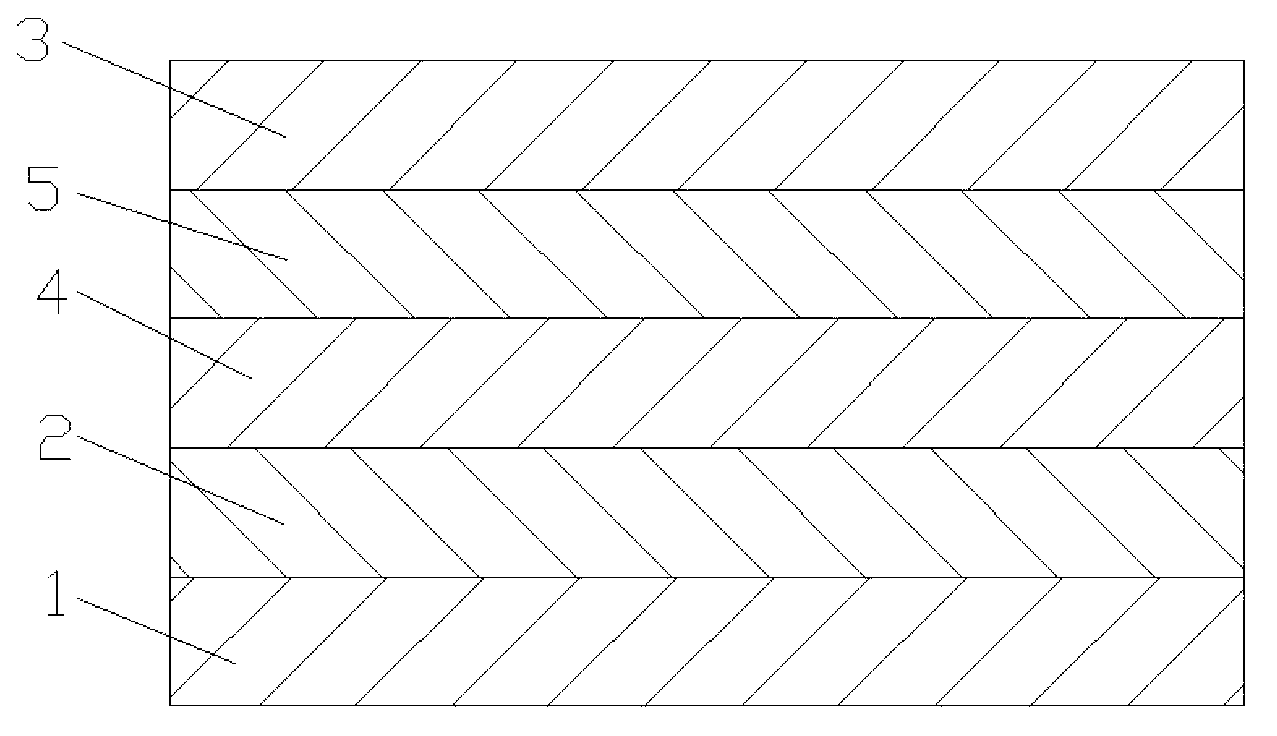

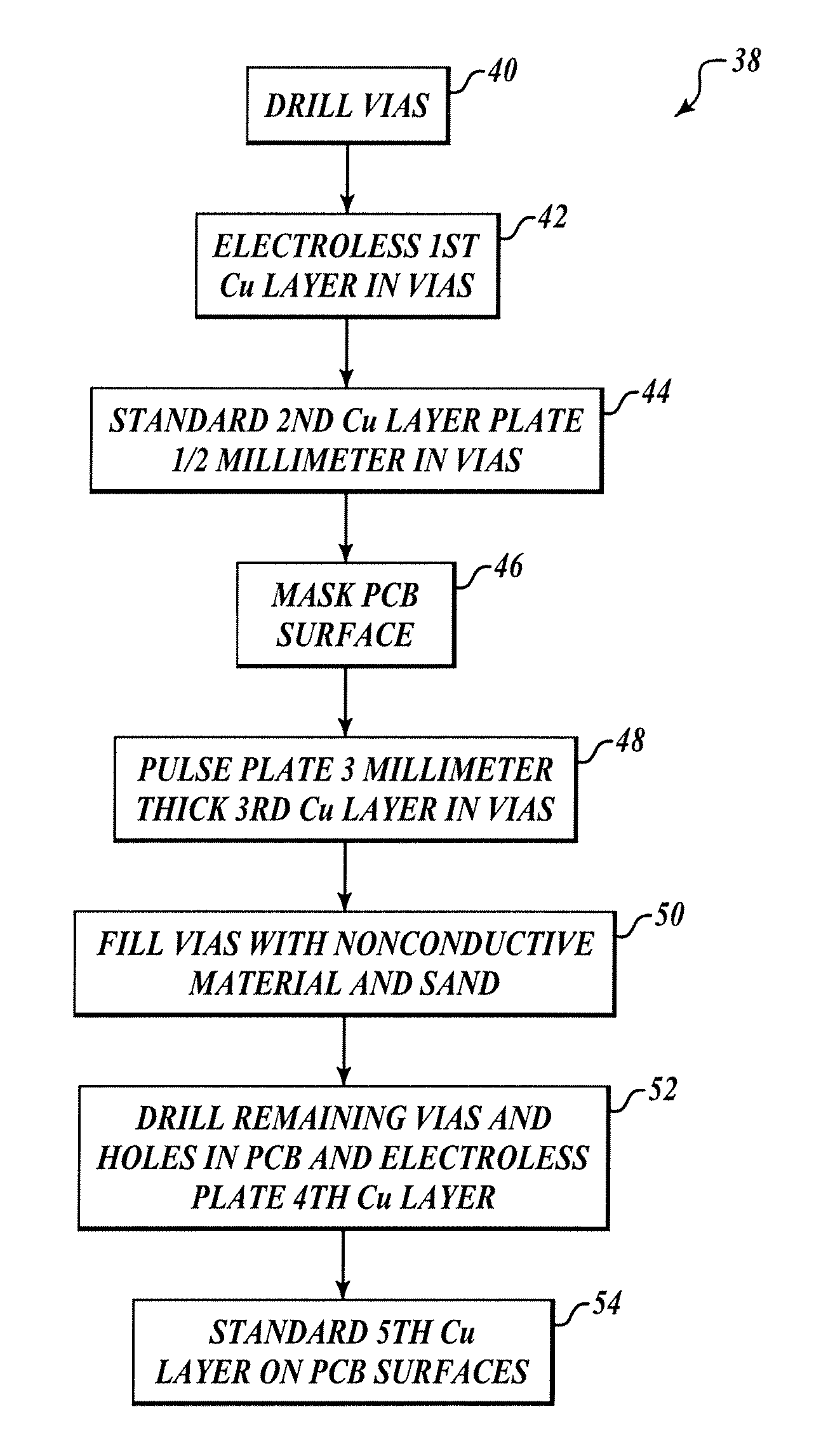

Method for providing an efficient thermal transfer through a printed circuit board

InactiveUS8112884B2Printed circuit aspectsConductive pattern formationSurface mountingConductive materials

A method of heat sinking a surface mount device (SMD) component. In an example method through holes are formed in a printed circuit board (PCB), a first copper layer is electroless plated in the holes, a second copper layer is standard plated in the holes and surrounding surfaces of the PCB, a third copper layer is masked and pulse plated in the holes, the holes are filled with non-conductive material and then is sanded flush with the second copper layer. A fourth copper layer electroless plated on the PCB over the area of the holes, a fifth copper layer (or pad) plated on the PCB over the area of the holes, and a surface mount device is attached to the fifth copper layer.

Owner:HONEYWELL INT INC

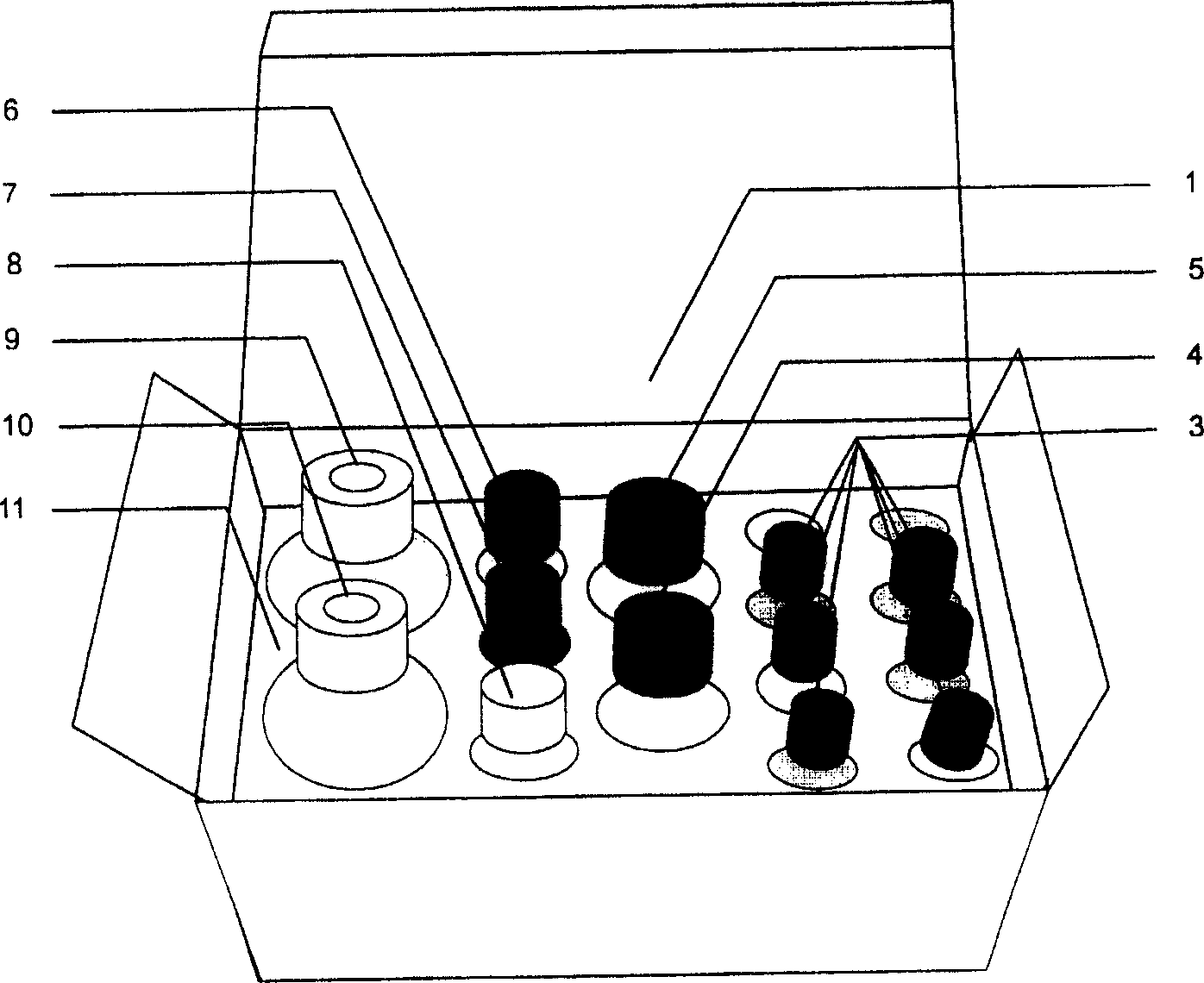

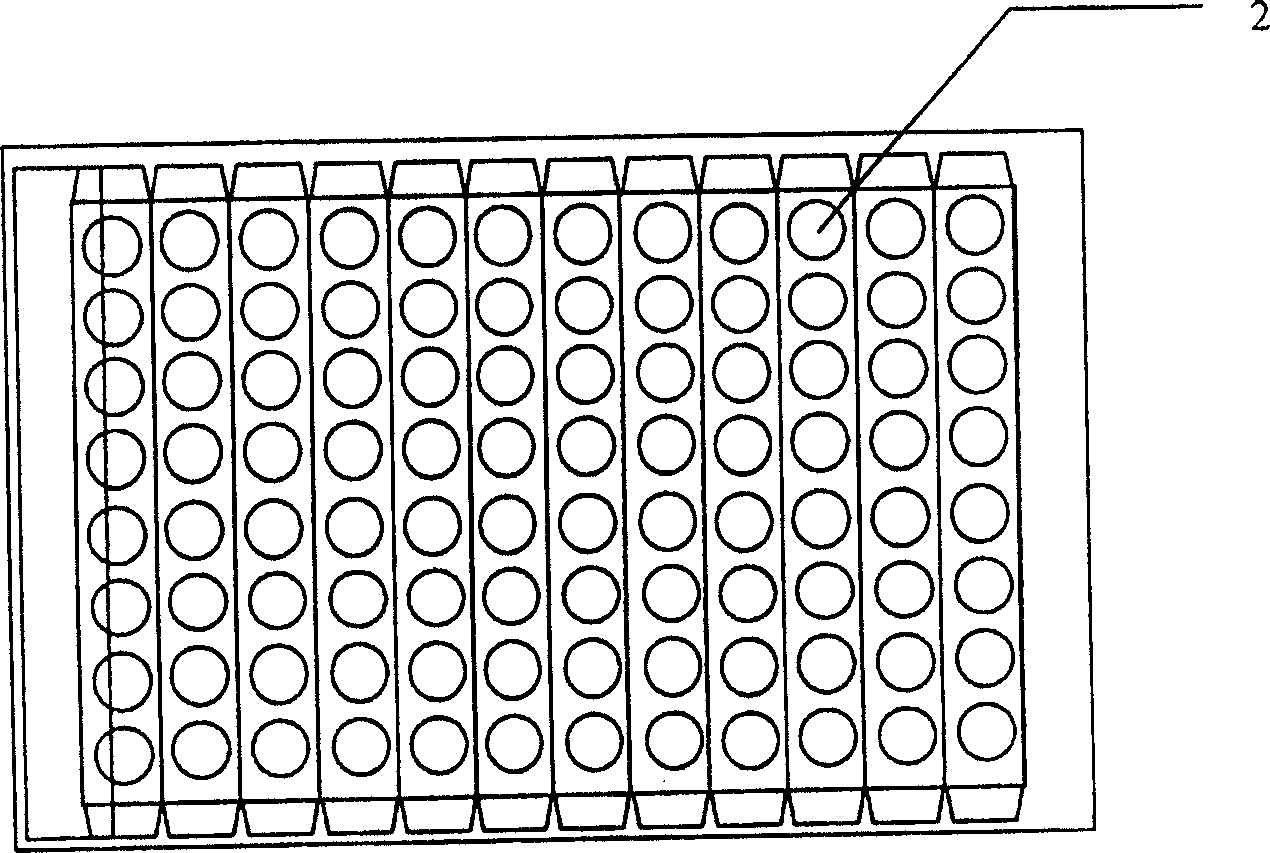

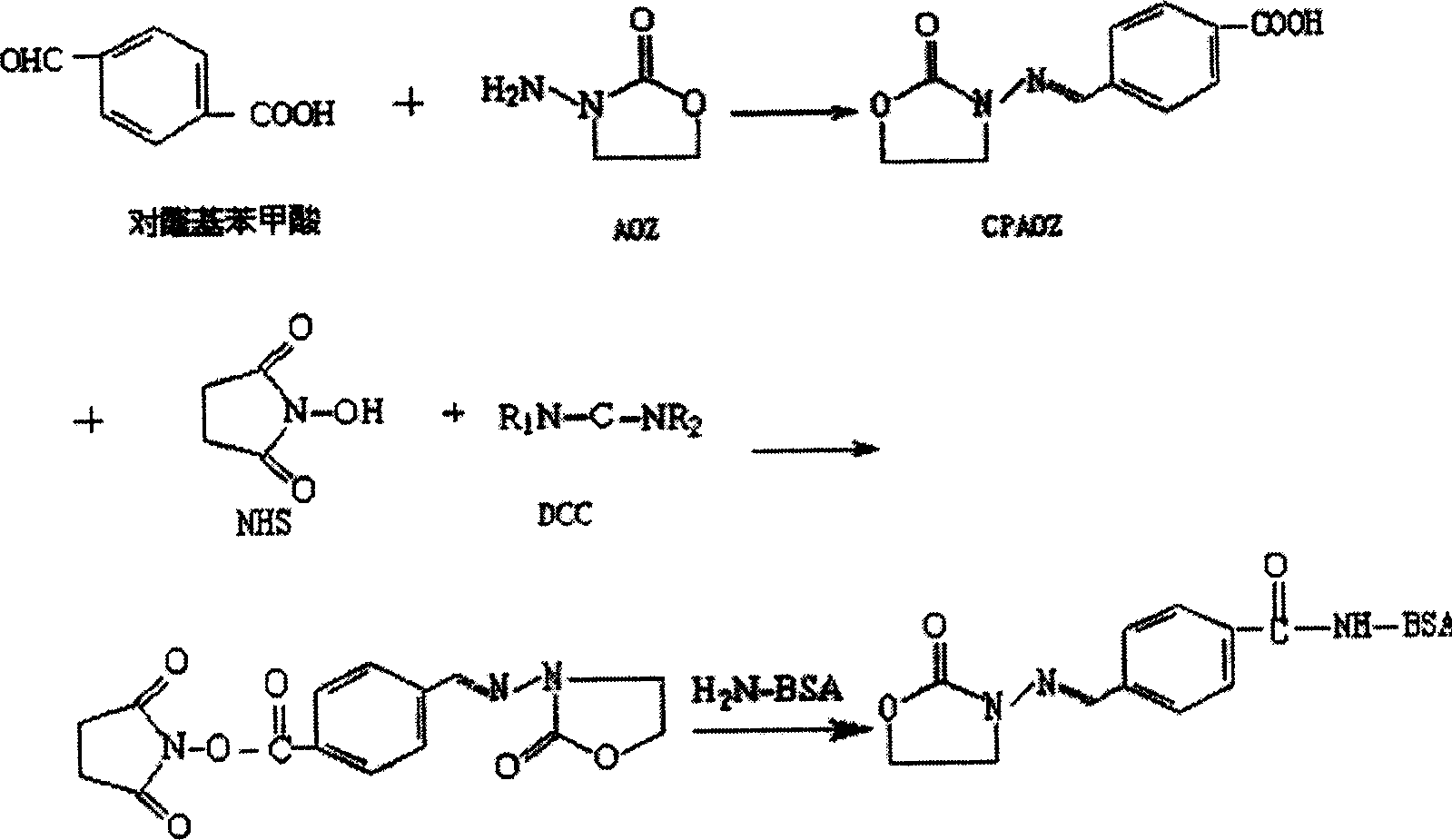

An enzyme linked immuno-detection kit suitable for furazolidone retention analysis and application

The invention discloses an enzyme immune detecting agent box suit for analyzing the surplus furazolidone and its application in the field of chemo immunology analyzing technology. The agent box is mainly formed by a 3-amido-2-AOZ peculiarity antibody, a AOZ standard solution which comprises AOZ and the ferment standard plate of the egg albumin complex. The sample releases AOZ after alcaine hydrolysis, then the benzaldehyde derivatizes over the night, MAX column purifies, it adopts indirect contest ELISA method to detect the animal structure such as liver and the AOZ surplus in muscle. The core technology comprises: artificial antibody synthesis, antibody preparing, ELISA method establishing, and ELISA agent box adjustment.

Owner:HUAZHONG AGRI UNIV

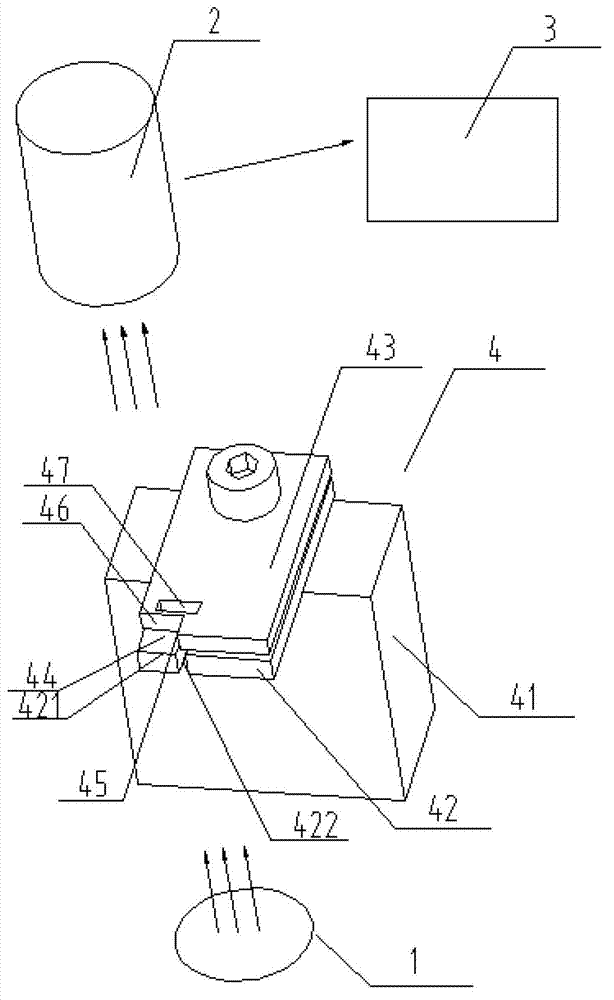

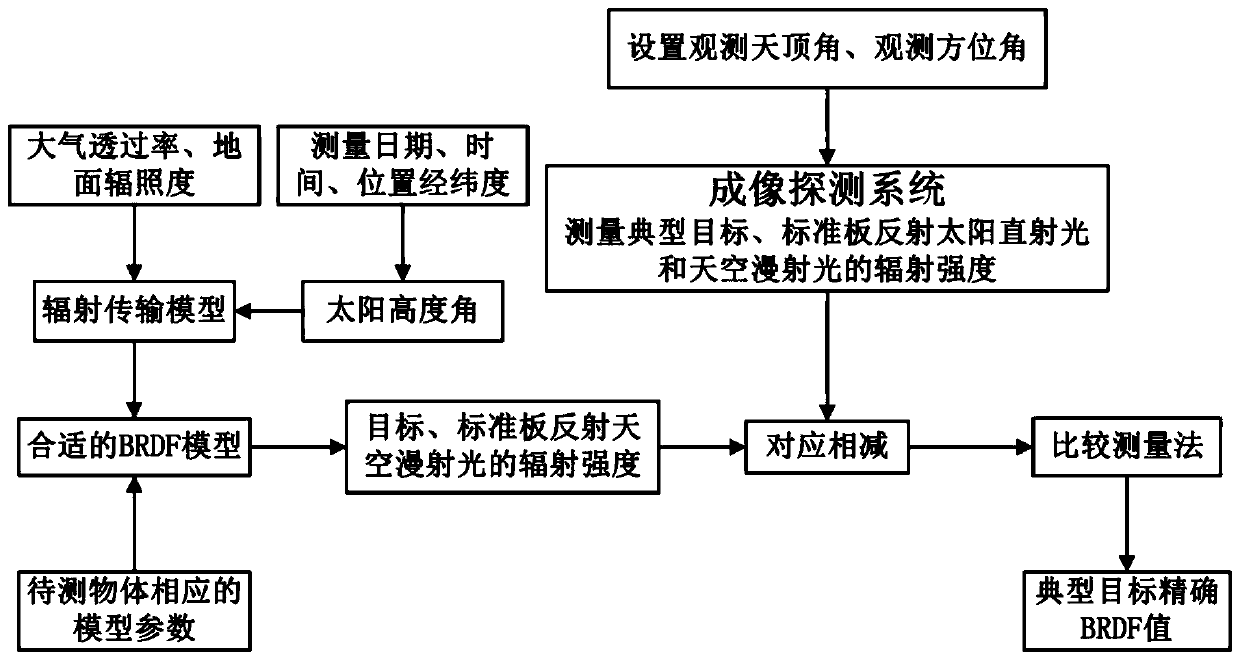

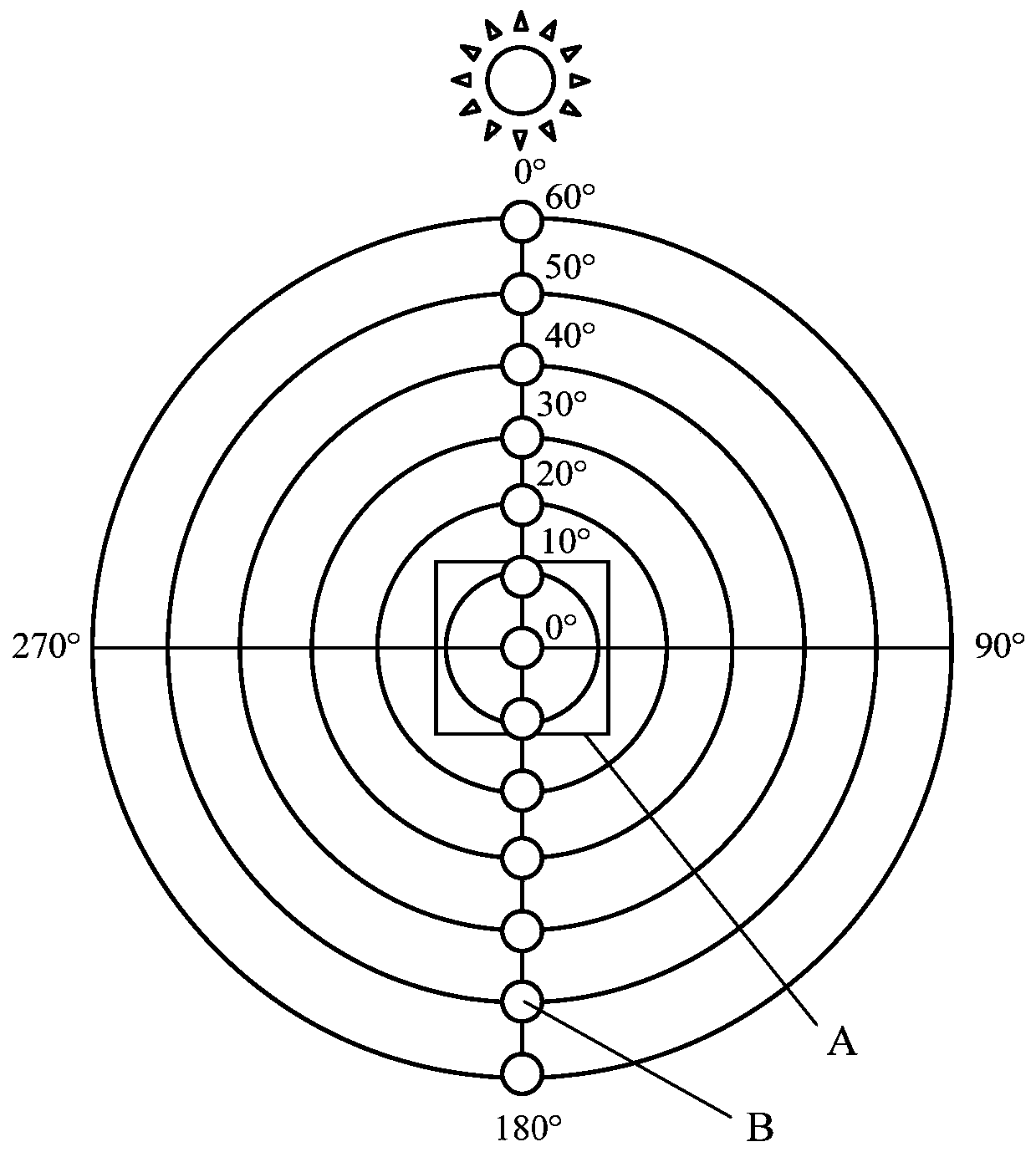

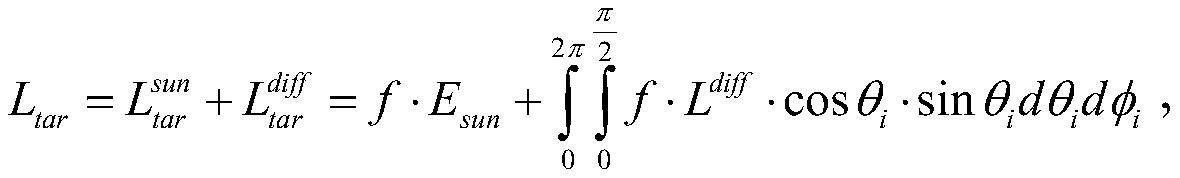

Bidirectional reflection distribution function measurement method for typical target in field environment

ActiveCN109932341AReduce the impactHigh measurement accuracyScattering properties measurementsLight irradiationSky

The invention relates to a bidirectional reflection distribution function measurement method for typical target in a field environment. The method includes the following steps that: an imaging detection system is adopted to measure the natural light irradiation reflection radiation intensities of a typical target to be tested and a standard plate under different observational geometric conditionsin a field environment; the sky diffused light reflection radiation intensities of the typical target to be tested and the standard plate in the field environment are calculated on the basis of an atmospheric radiation transmission model; the sun direct light reflection radiation intensities of the typical target to be tested and the standard plate are correspondingly obtained according to the natural light irradiation reflection radiation intensities and the sky diffused light reflection radiation intensities; and the bidirectional reflectance ratio of the typical target to be tested is calculated according to a comparative measurement method, and the BRDF (bidirectional reflectance distribution function) value of the typical target to be tested is obtained according to a relationship between the bidirectional reflectance ratio and the bidirectional reflectance distribution function model. With the bidirectional reflection distribution function measurement method for the typical target in the field environment of the invention adopted, the influence of sky diffused light on the measurement of the BRDF value of the typical target can be effectively reduced, and therefore, the measurement accuracy of the BRDF of the typical target under different climatic conditions can be improved.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

Mobile phone camera module distortion test method

The invention aims at providing a mobile phone camera module distortion test method. The method comprises the steps of adjusting parameters of a camera module to the optimum and adjusting a mobile phone to an automatic mode; placing the mobile phone to face a distortion test square standard plate and enabling an optical axis center of the mobile phone camera module to face the center of the distortion test square standard plate; enabling the mobile phone to face the distortion test square standard plate and enabling the optical axis center of the mobile phone camera module to face the center of the distortion test square standard plate; carrying out photographing; and calculating a distortion value through IMATEST software. The method is simple and easy to operate and is fast and effective; the distortion values can be measured for many times; the time is reduced; and the detection guarantee for production of the camera is provided.

Owner:芜湖赋兴光电有限公司

Method and system for focusing multi-camera module based on near-infrared environment

The invention relates to a method and a system for focusing a multi-camera module based on a near-infrared environment. The focusing method comprises the steps that infrared light arrives at a test standard plate and gets into each camera of the multi-camera module after being reflected; a focusing operation is carried out on the cameras through a focusing hand wheel; image information acquired by each camera is sent to an analysis center to process, and whether a next step of the focusing operation is carried out continuously or not is judged according to a processing result or the multi-camera module is judged to be unqualified. The method provided by the invention not only can greatly reduce the manufacturing cost of test equipment and simplify the focusing mode, but also reduces the damage probability of a test line by being matched with a special focusing tool. Meanwhile, the production probability is improved, and the matching difference between two lenses can be eliminated by being matched with software.

Owner:NINGBO SUNNY OPOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com