Plate processing method and system

A processing method and technology of a processing system, which are applied in image data processing, data processing applications, electrical digital data processing, etc., can solve the problems of low recognition rate, low recognition accuracy, and low processing efficiency of small plates, and achieve accurate High, high recognition efficiency, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

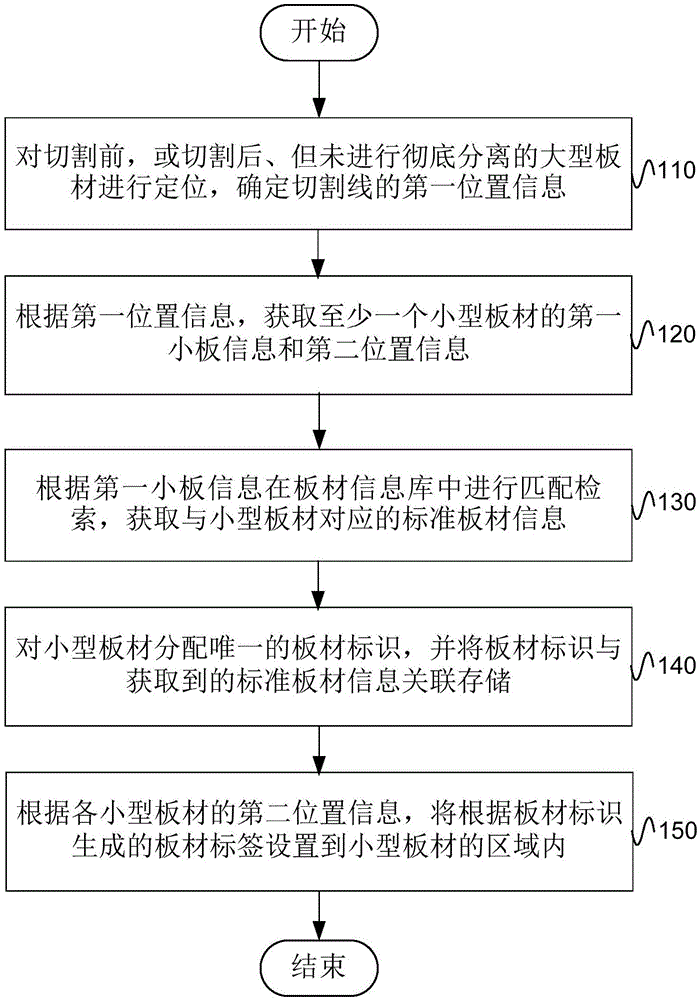

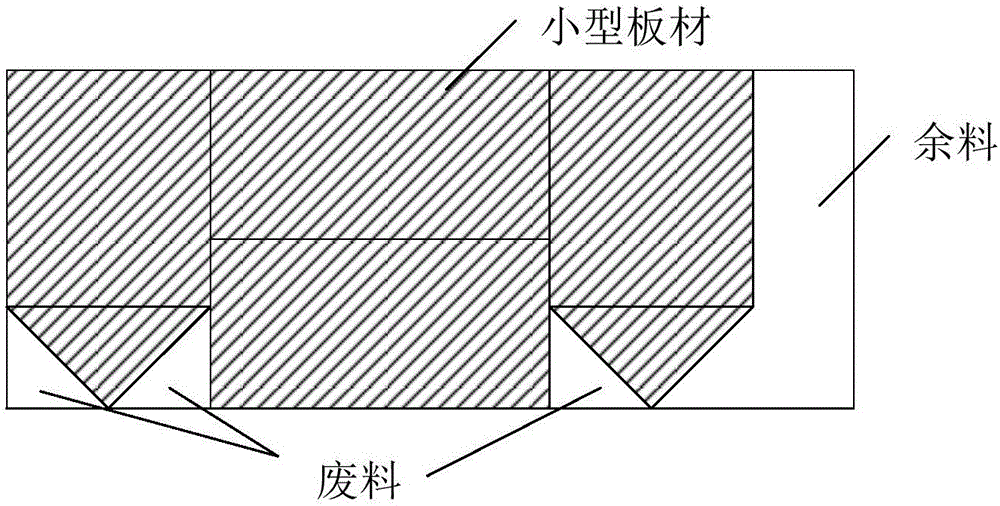

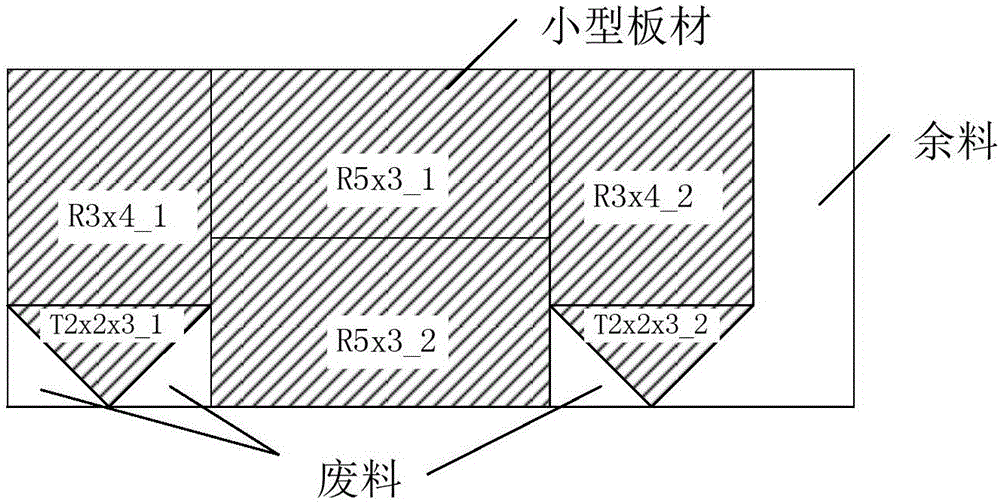

[0022] figure 1 It is a flow chart of the processing method of boards provided by the embodiment of the present invention. The execution subject of this method may be a system with functions of positioning identification, data information retrieval and matching, and label printing, and this system is applied to the processing line of furniture boards. It is used to process large plates before or after cutting. It is explained here that the large plate referred to in the present invention refers to the whole plate targeted by the cutting process; the small plate refers to the local single plate corresponding to each cutting area after cutting. like figure 1 As shown, the processing method of the plate comprises steps as follows:

[0023] S110. Position the large plate before cutting or after cutting but not completely separated, and determine the first position information of the cutting line of the large plate on the large plate.

[0024] In the existing plate processing pr...

Embodiment 2

[0057] Figure 4 Another method flow chart of the processing method of the plate provided by the embodiment of the present invention, the method can be regarded as figure 1 A specific implementation of the shown method embodiment. Such as Figure 4 As shown, the processing method of the above-mentioned plates comprises steps as follows:

[0058] S410. Position the large plate before cutting or after cutting but not completely separated, and determine the first position information of the cutting line of the large plate on the large plate. Step S410 is similar to the aforementioned step S110.

[0059] Specifically, in order to accurately describe the position information of the cutting line on the large plate, the large plate can be placed on the plate carrying platform, and the plate carrying platform corresponds to the preset reference coordinate system.

[0060] The coordinate system itself has a fixed position coordinate datum, which is used to measure the coordinate in...

Embodiment 3

[0100] Figure 8 A structural schematic diagram of the plate processing system provided by the embodiment of the present invention can be used to perform such as figure 1 The method steps shown. Such as Figure 8 As shown, the plate processing system includes: a positioning module 810, an information acquisition module 820, a background server 830 and a label processing device 840, and the server 830 is connected to the information acquisition module 820 and the label processing device 840 respectively, wherein the server 830 is provided with Plate information library 831, matching retrieval module 832 and plate identification distribution module 833, wherein:

[0101] The positioning module 810 is used to locate the large plate before cutting or after cutting but not completely separated, and determine the first position information of the cutting line of the large plate on the large plate; the information acquisition module 820 is used for according to the first One posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com