Accurate installation measuring method for rolling mill bases

An accurate measurement and rolling mill technology, applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc., can solve the problem of reducing the accuracy of measurement, and achieve the goal of improving measurement accuracy, improving installation progress, and saving construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

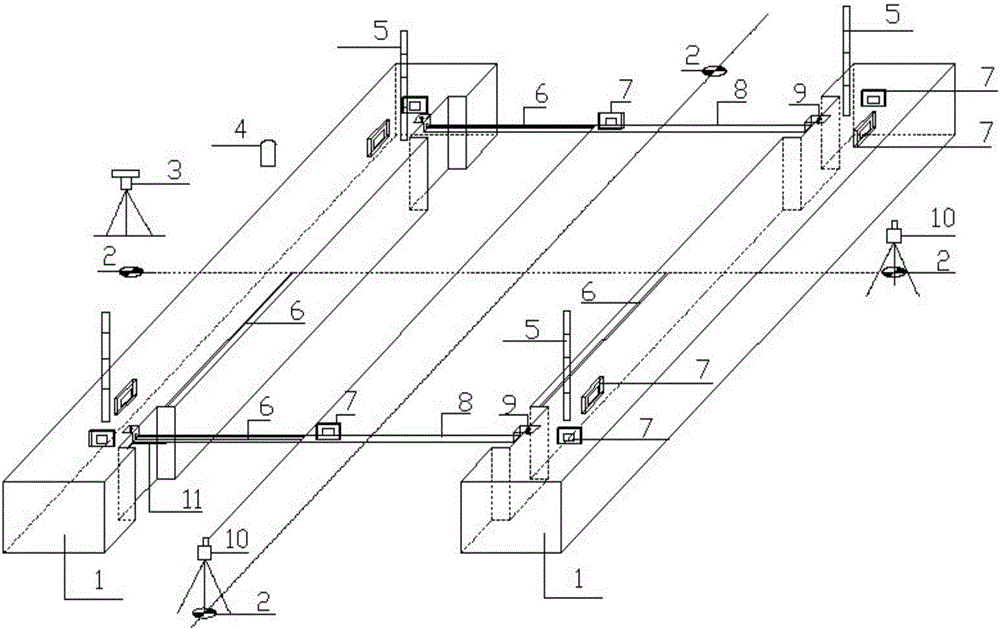

[0017] As shown in the figure: Part No. 1 is the base of the rolling mill to be installed, and each rolling mill is composed of two bases on the entrance and exit sides. The center target plate 2 is measured and set by the total station, and the target plate buried around the rolling mill base in advance is the benchmark basis for the center line and parallelism measurement of the rolling mill base. The precision level 3 is a measuring instrument used to measure the levelness of the rolling mill base. The elevation reference point 4 is measured and set by the total station, and the reference points buried around the rolling mill base in advance are the basis for the elevation measurement of the rolling mill base. The indium ruler 5 is a measuring tool for measuring the height of the rolling mill base with a precision level. The inner diameter micrometer 6 cooperates with the theodolite to measure the center line and parallelism of the rolling mill base. The frame level meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com