Method for adjusting working clearances of antifriction bearings of rolling device of seamless steel tube cold rolling mill

A technology of seamless steel pipe and roll device, which is applied in the direction of keeping roll equipment in an effective state, metal rolling, manufacturing tools, etc., can solve the problems of inconvenient use of measuring tools, inconvenient manual handling, and high labor intensity, so as to achieve easy implementation and reduce The effect of tool investment and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

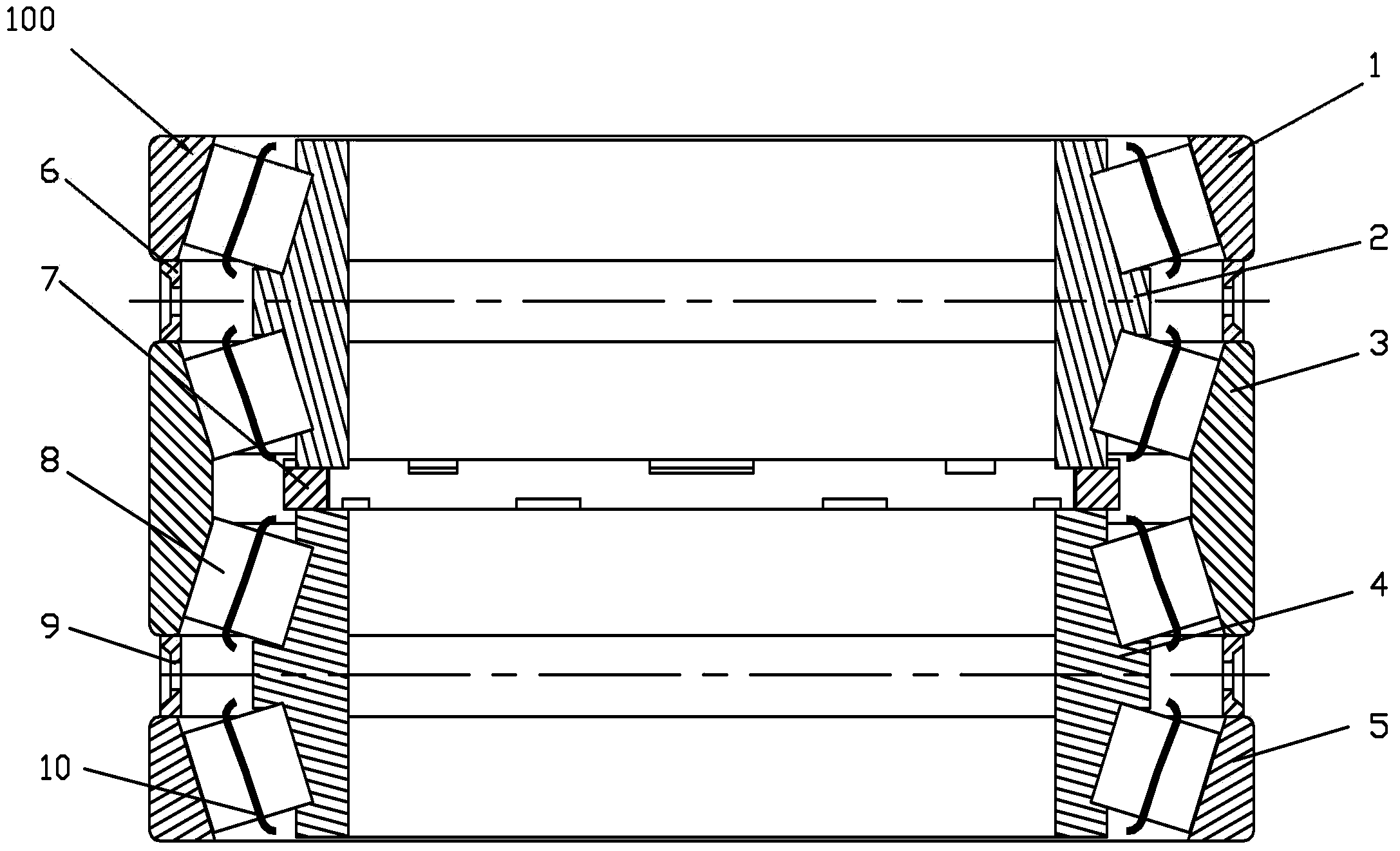

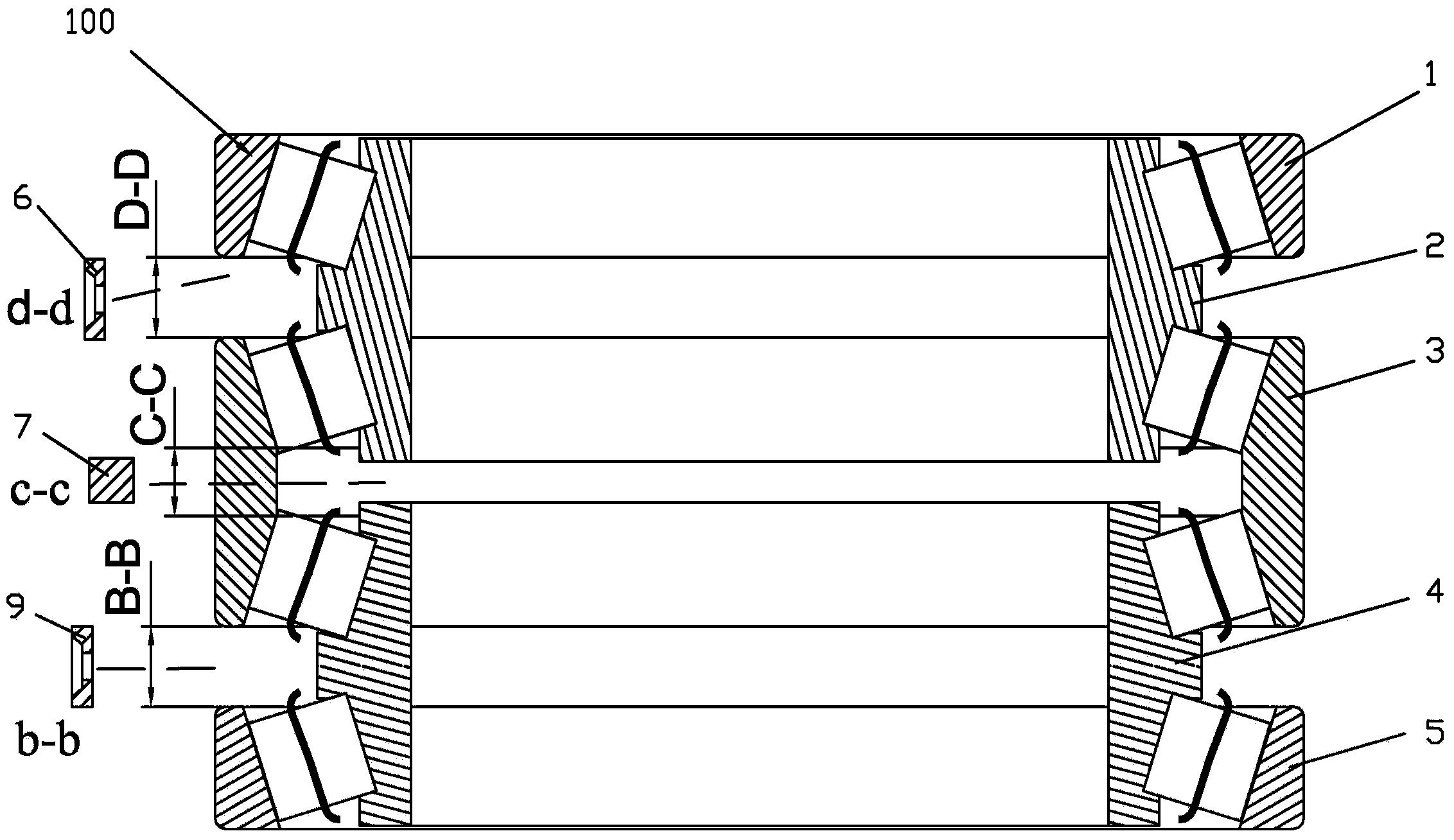

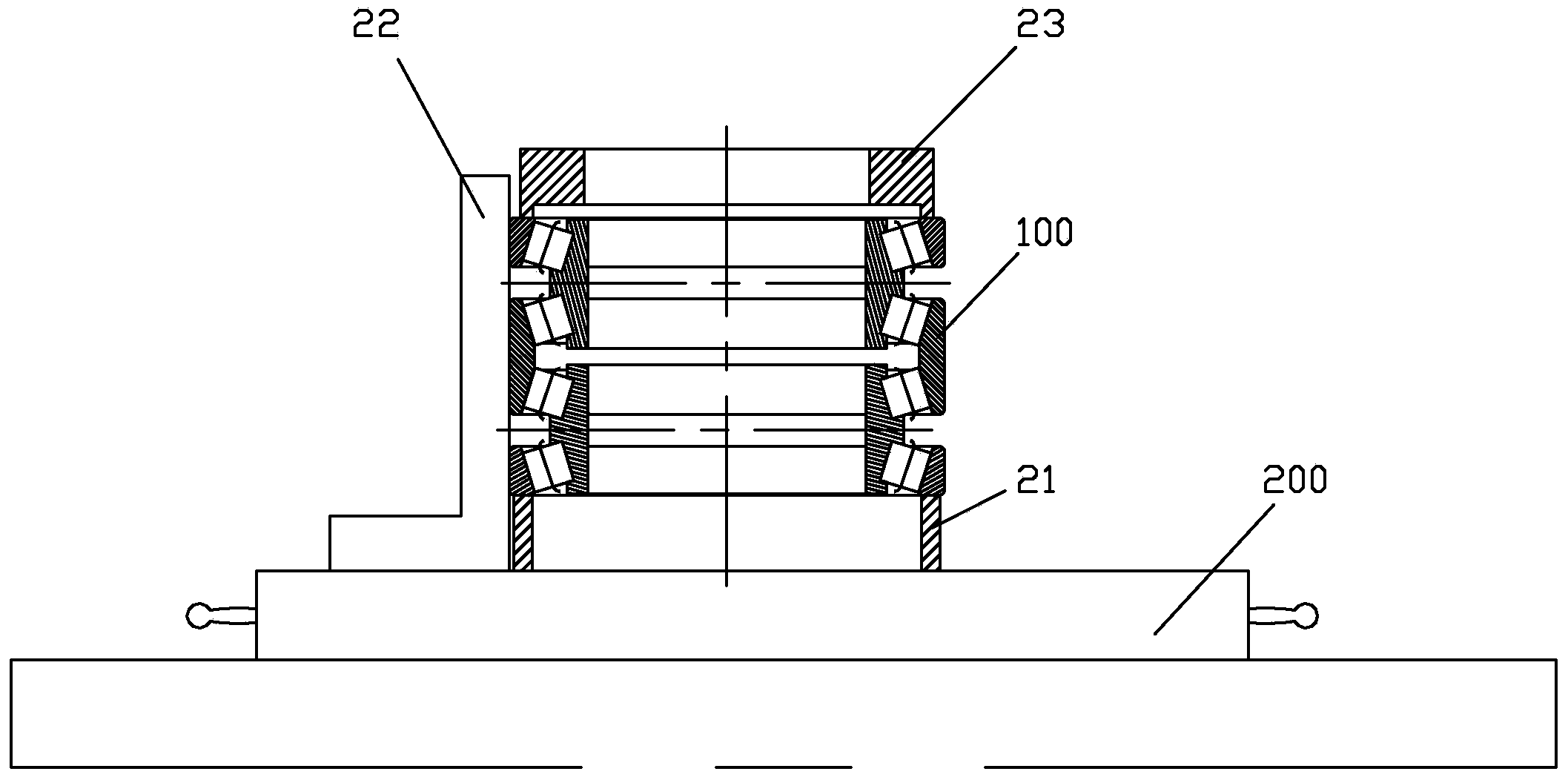

[0117] Taking the 380652 (77752) column tapered roller bearing (new product) of LG-80 cold rolling mill as an example, the assembly process is as follows:

[0118] Step 1) Bearing preparation: bearing cleaning, wiping, inspection;

[0119] Step 2) Measure bearing clearance:

[0120] 1) Place the bearing: place the bottom washer flat on the standard flat plate, place the lower outer ring of the bearing vertically on the bottom washer, and then place the lower inner ring (including the cage and rolling elements), the middle outer ring of the bearing at one time Ring, spacer ring, upper inner ring (including cage and rolling elements), upper outer ring, placed vertically;

[0121] 2) Adjust the verticality of the bearing 1: Place two sets of 90-degree angle rulers on the standard flat plate, and use the vertical plane to fit the circumferential surfaces of the upper, middle and lower outer rings of the bearing to achieve the purpose of correcting the verticality of the bearing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com