Patents

Literature

650 results about "Vernier scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vernier scale is a visual aid to take an accurate measurement reading between two graduation markings on a linear scale by using mechanical interpolation; thereby increasing resolution and reducing measurement uncertainty by using Vernier acuity to reduce human estimation error.

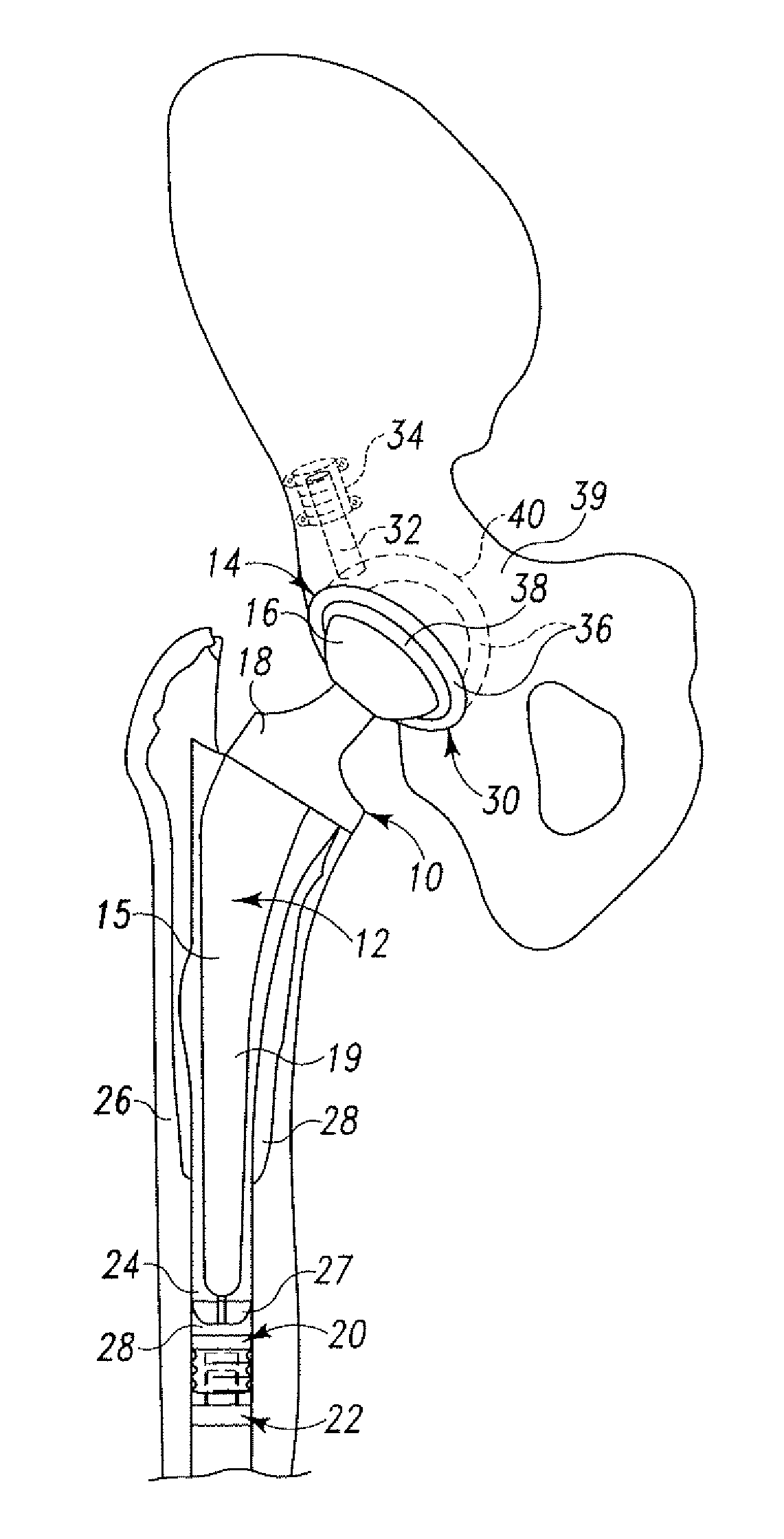

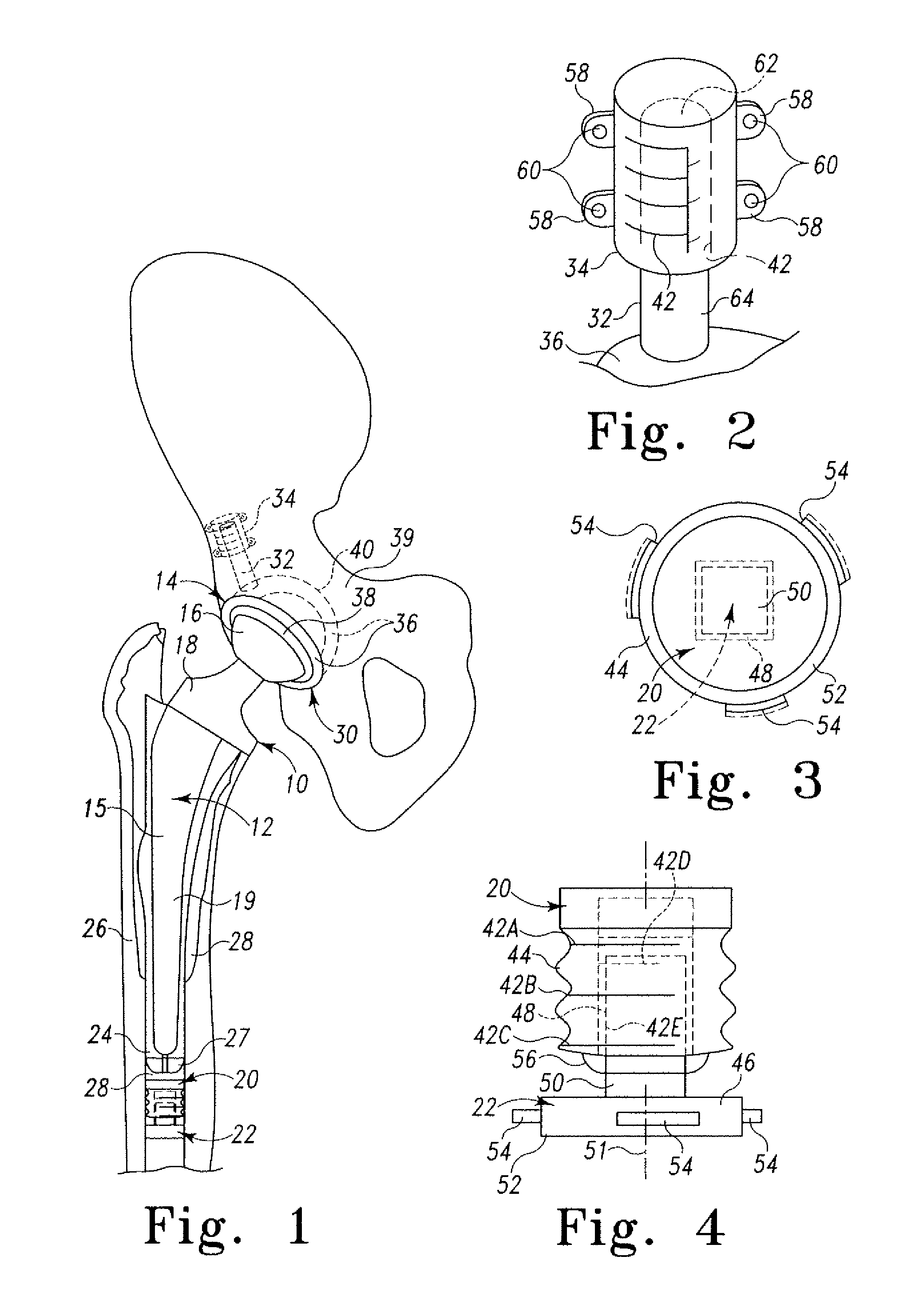

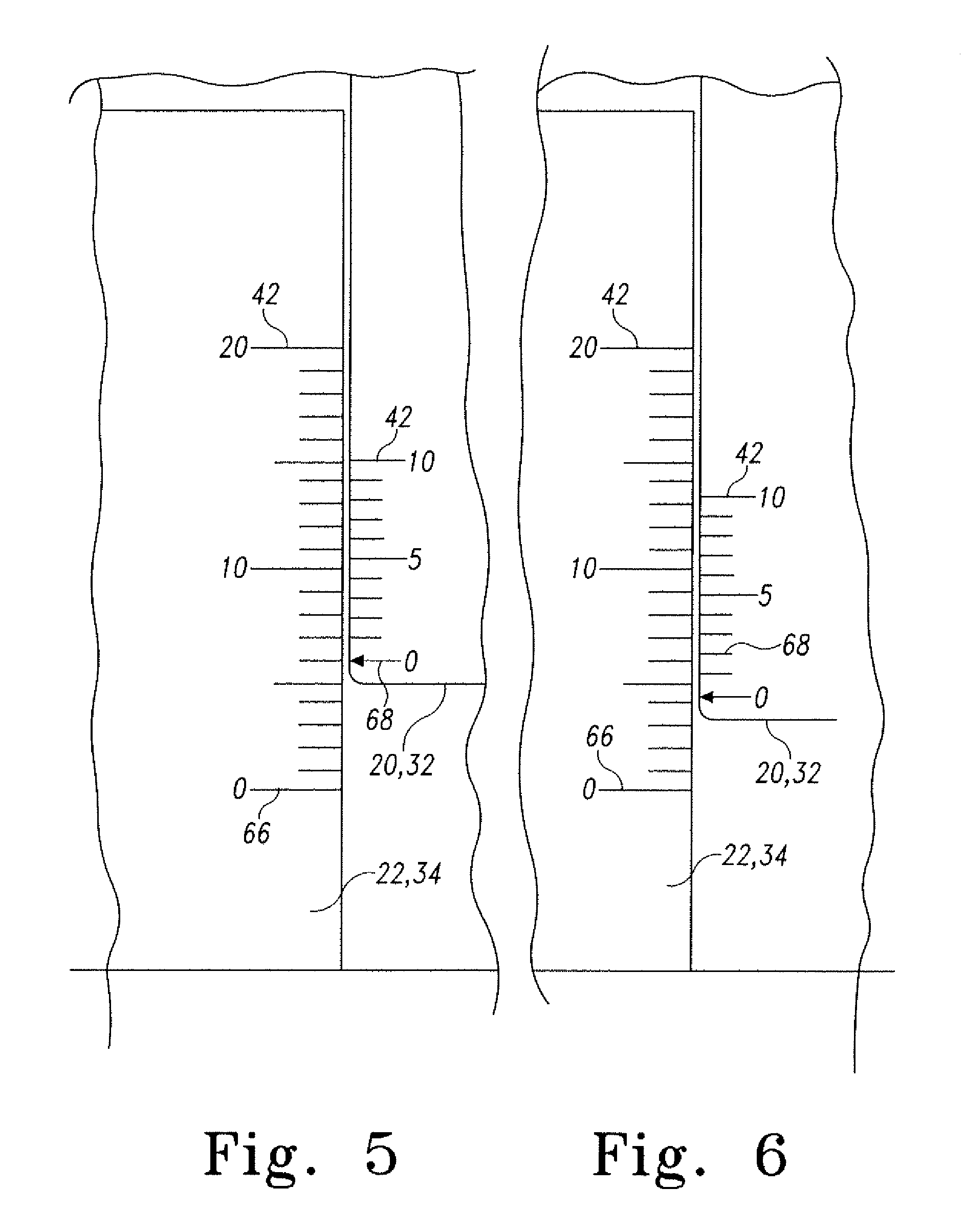

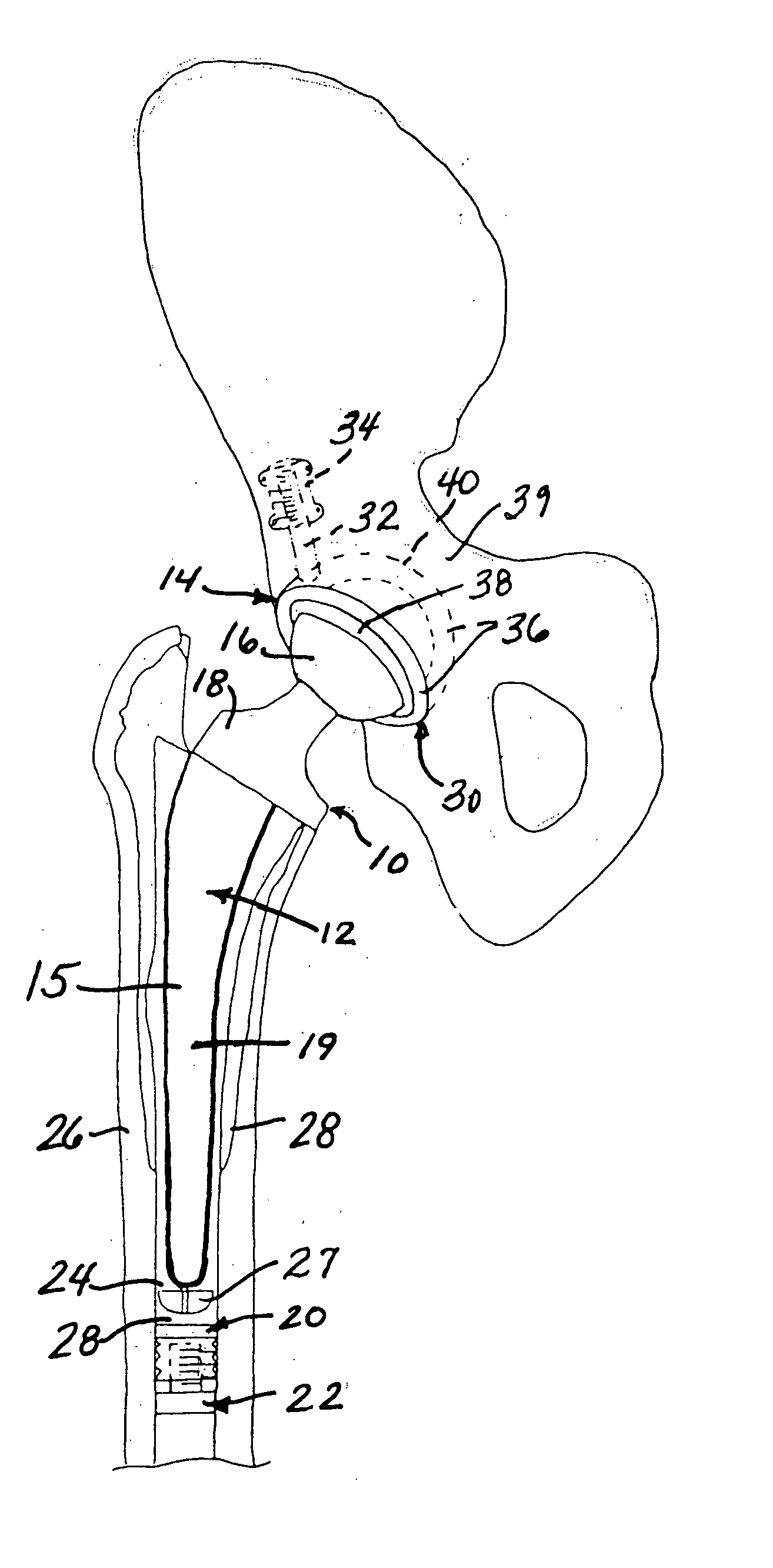

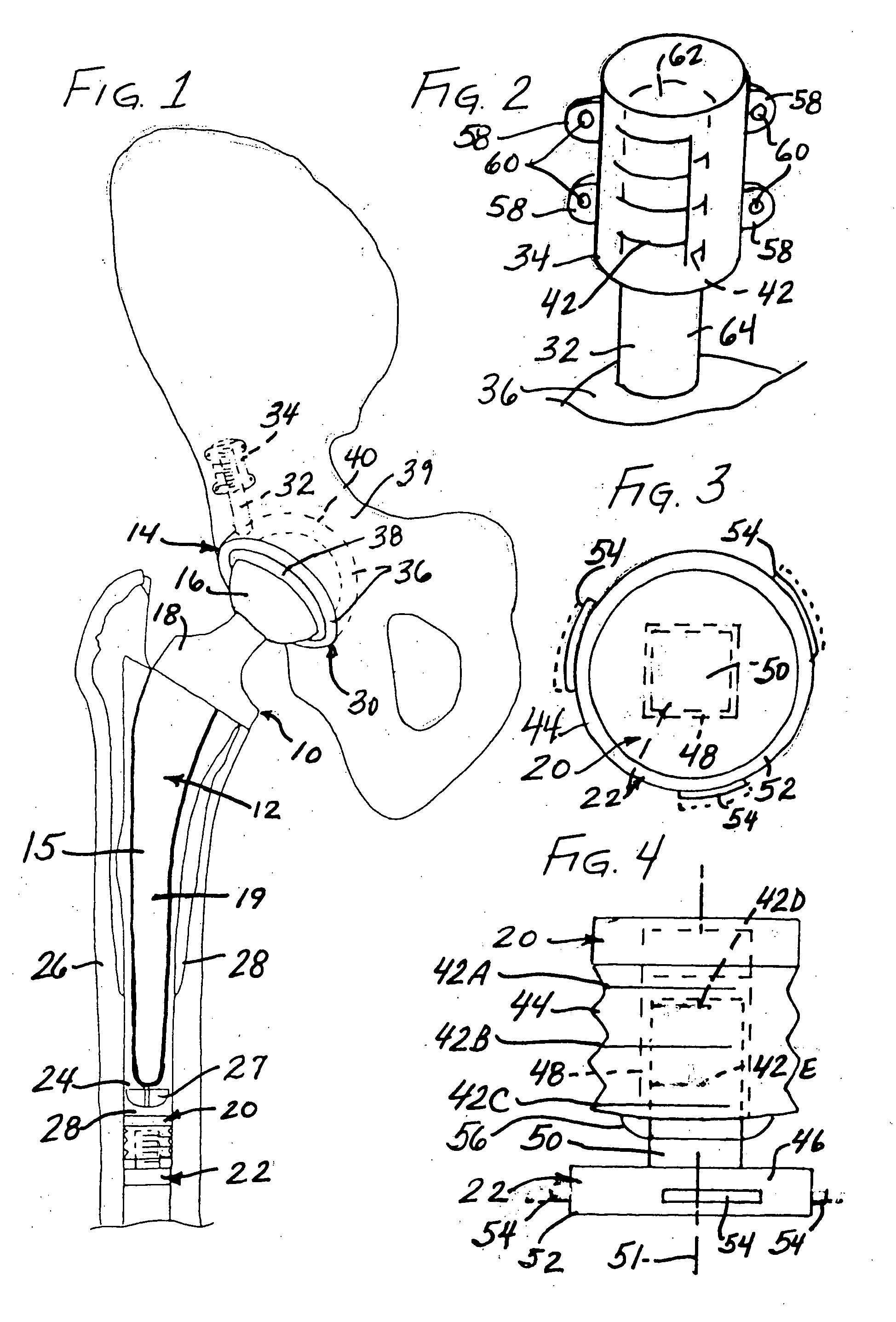

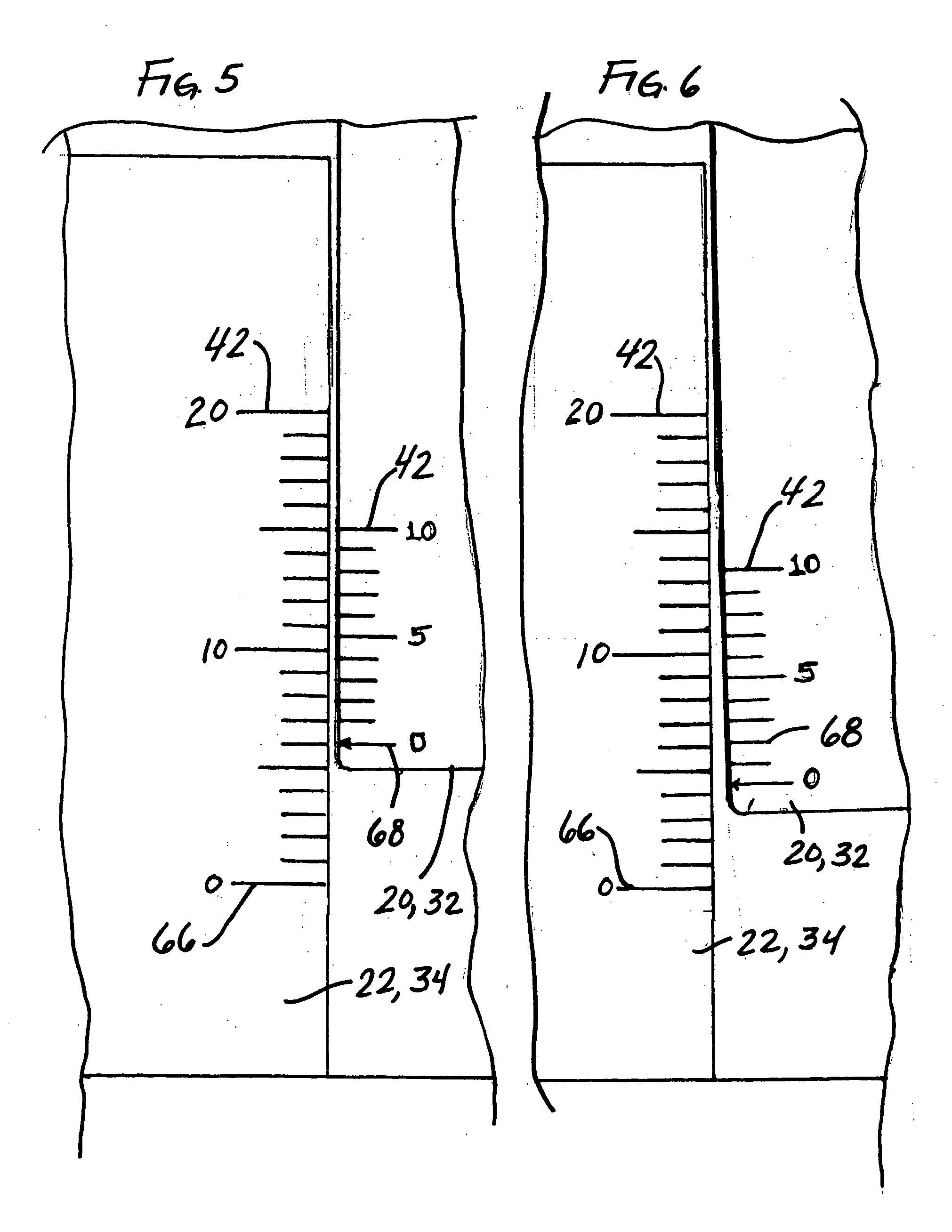

Implant system with migration measurement capacity

Owner:DEPUY PROD INC

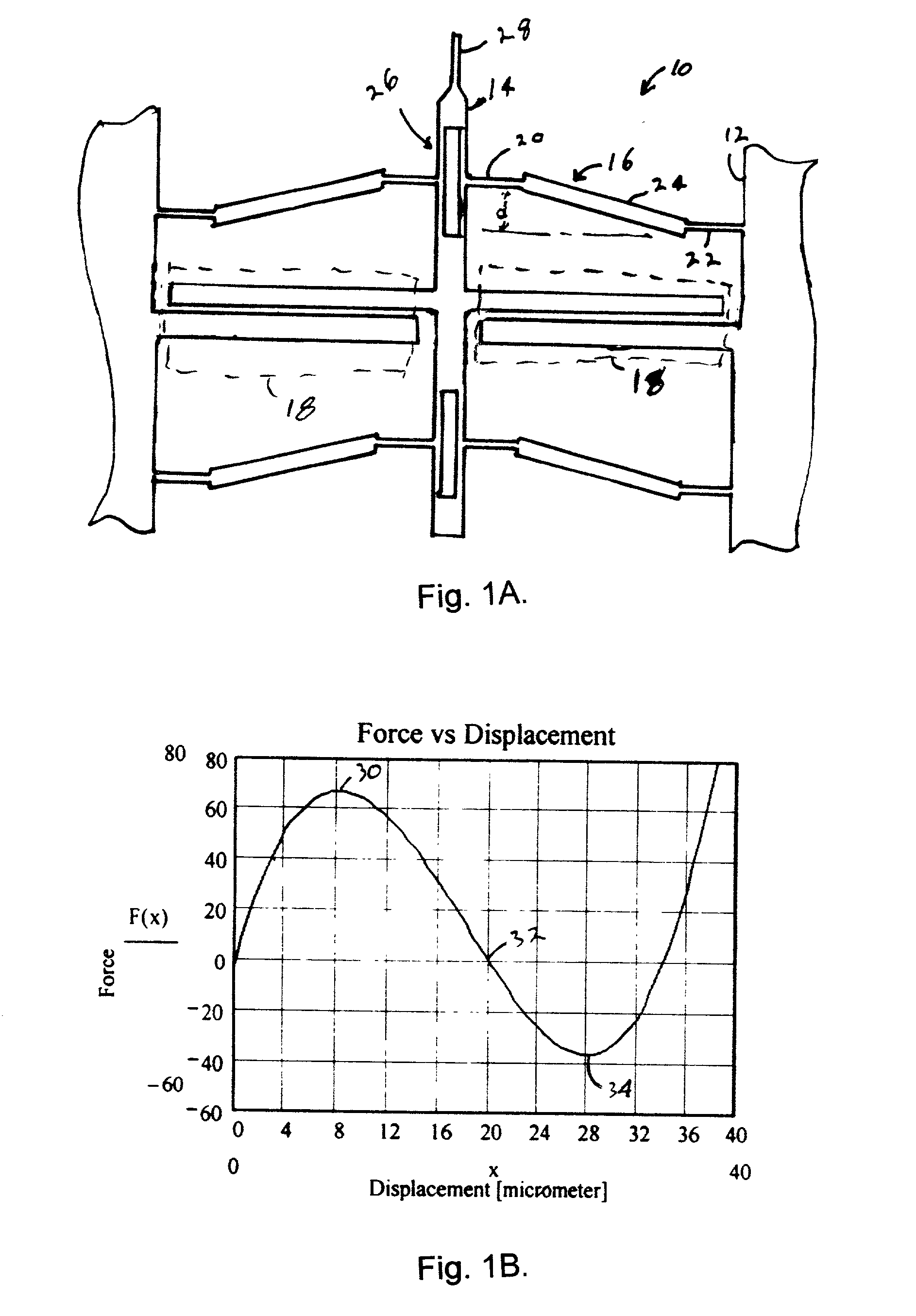

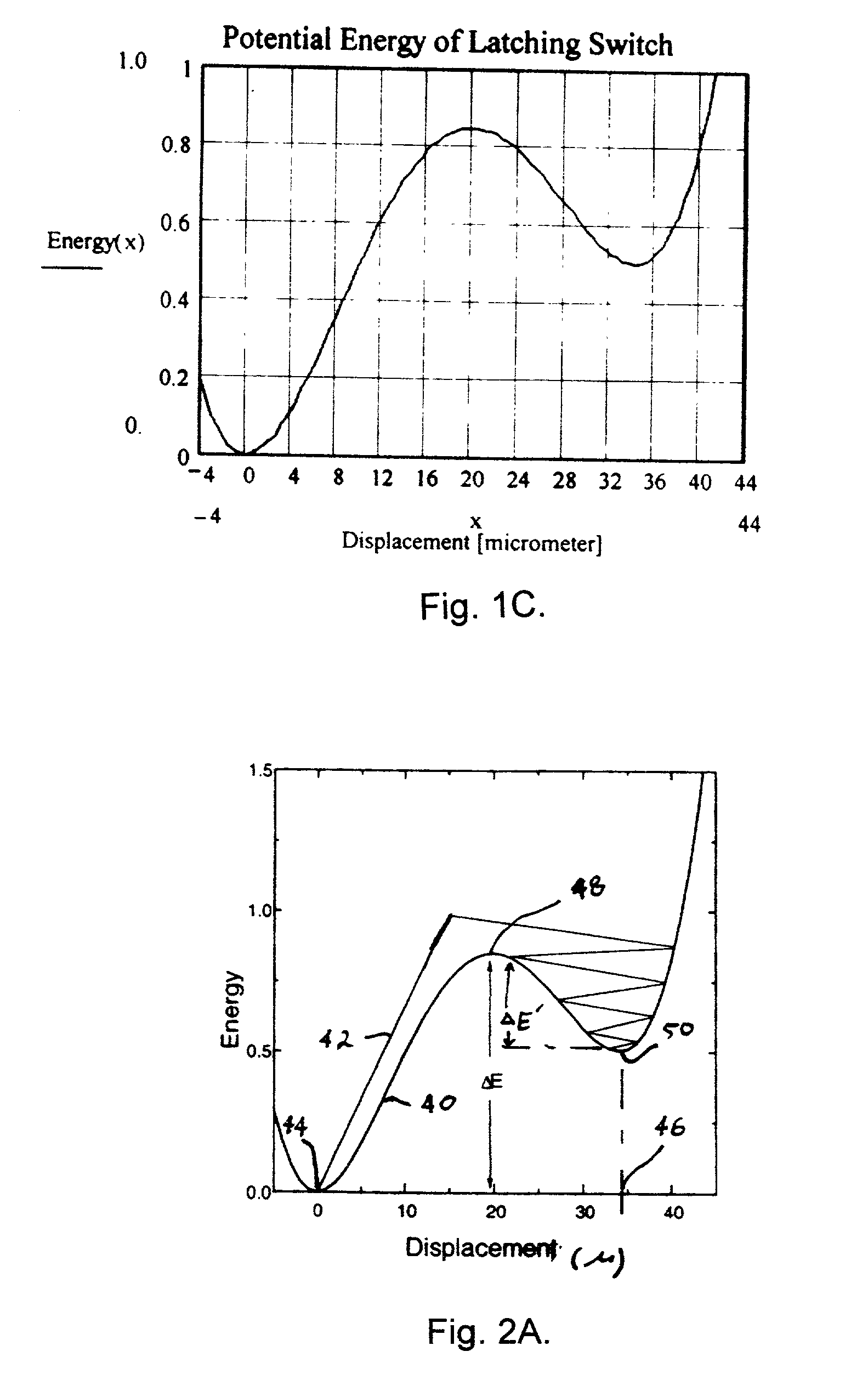

Bi-stable electrostatic comb drive with automatic braking

InactiveUS20020130586A1Increase motivationThe process is compact and efficientElectrostatic motorsElectrostrictive/piezoelectric relaysVernier scaleAutomatic braking

An electrostatic comb drive suitable for micro-electro-mechanical systems ("MEMS") application uses shaped fingers to achieve bi-directional actuation from a uni-polar actuation pulse. The finger shape also provides auto-braking of the movable member of the drive using a simple actuating pulse. In a further embodiment, an end stop inhibits overshoot and a back spring pushes the movable portion of the device back toward an operating position. In yet a further embodiment, a Vernier scale is provided on the movable portion of the drive relative to the fixed portion of the drive to indicate relative shift of these portions after the device is fabricated.

Owner:LUMENTUM OPERATIONS LLC

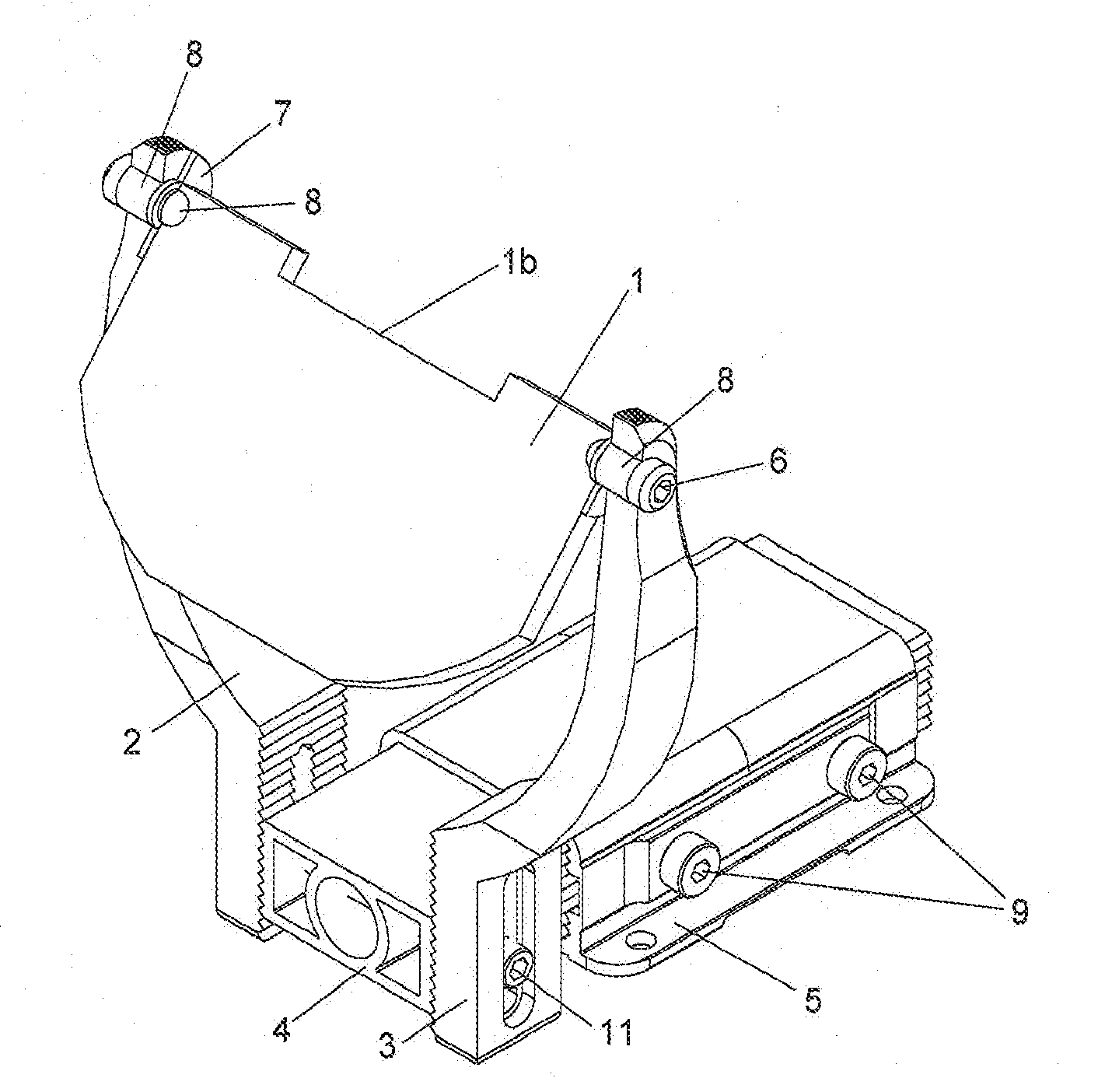

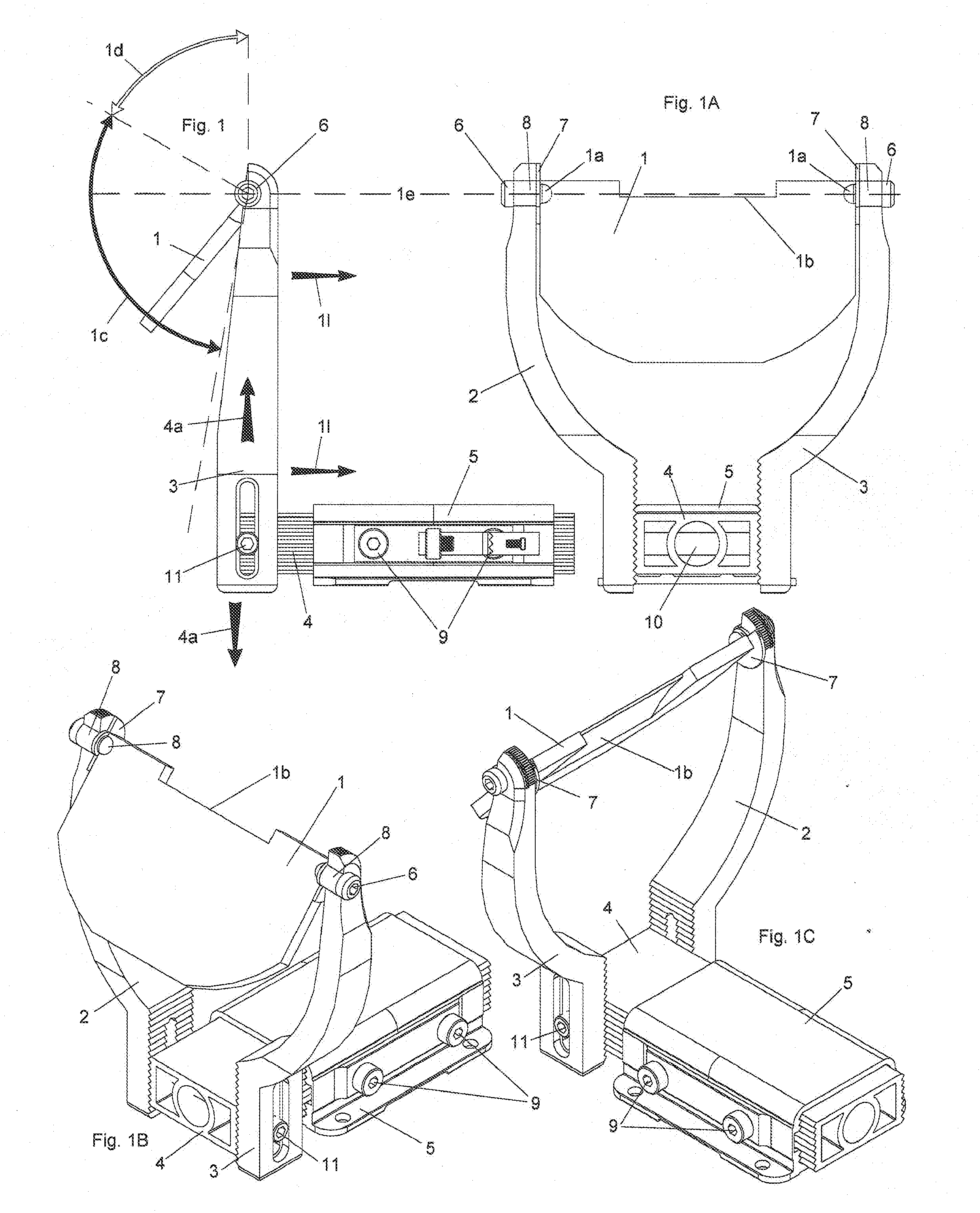

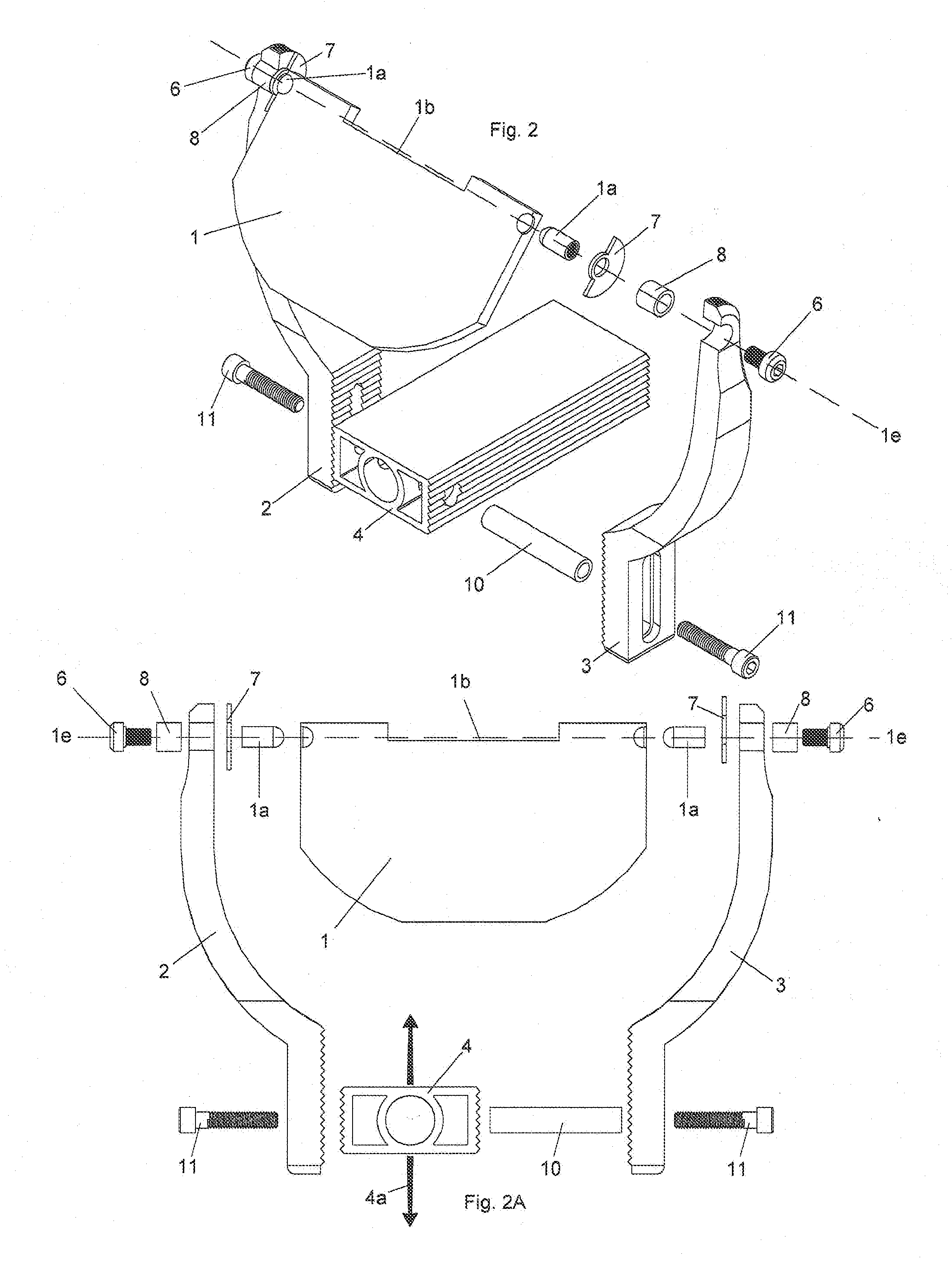

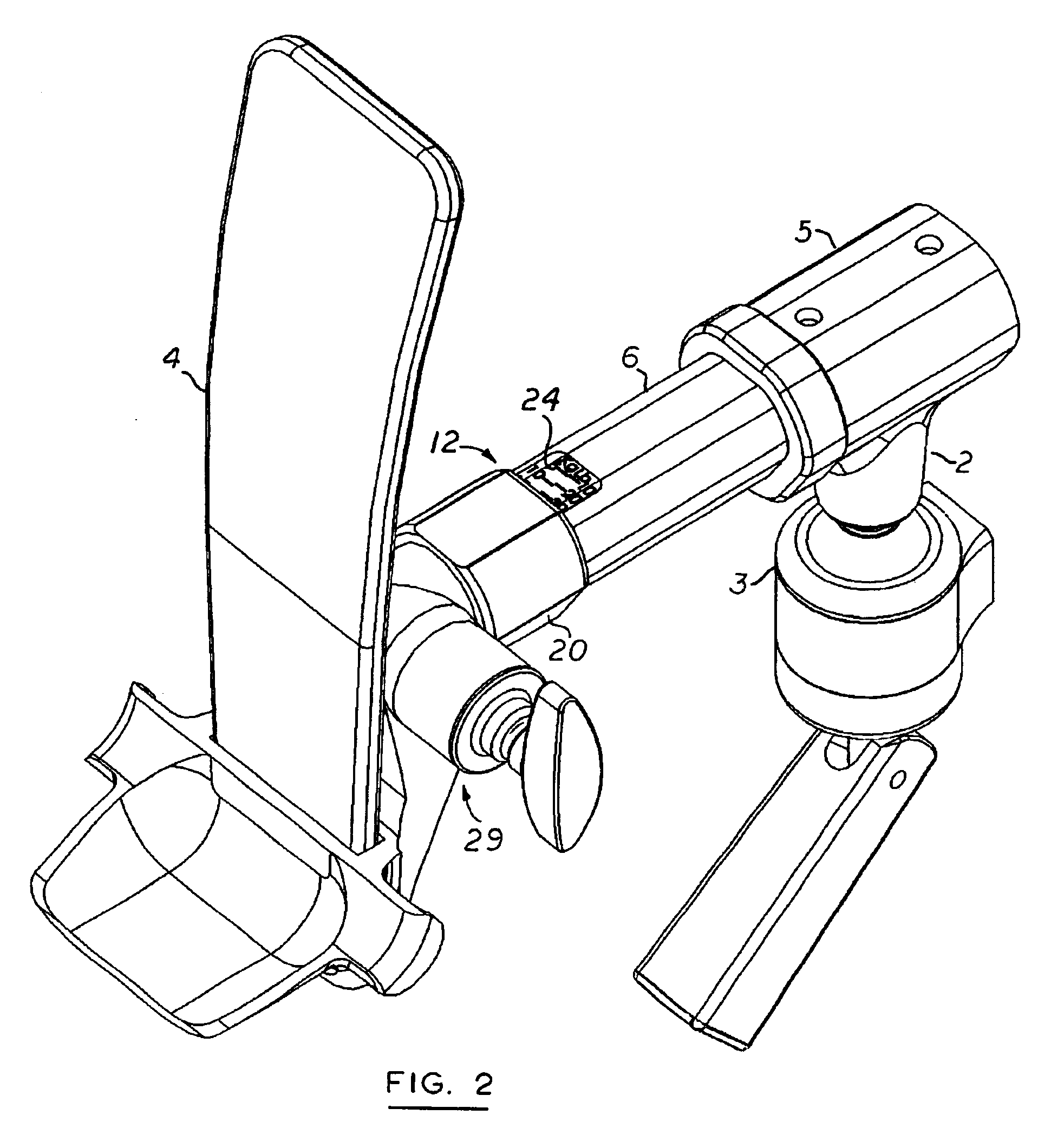

Adjustable Grinding Platform and Mounting Assembly

InactiveUS20120270479A1Accurately determineBelt grinding machinesGrinding feed controlVernier scaleEngineering

Owner:BATTY STUART

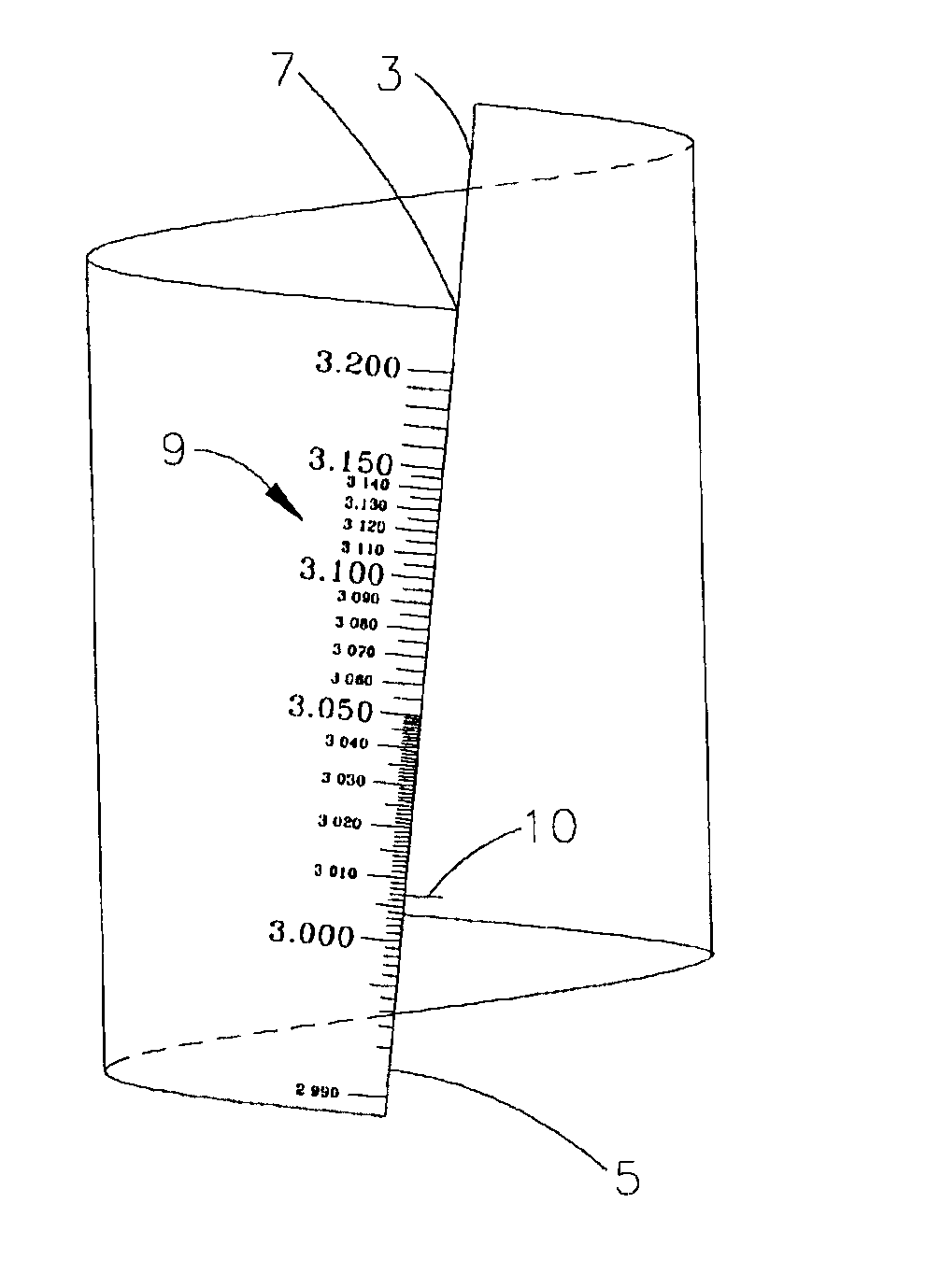

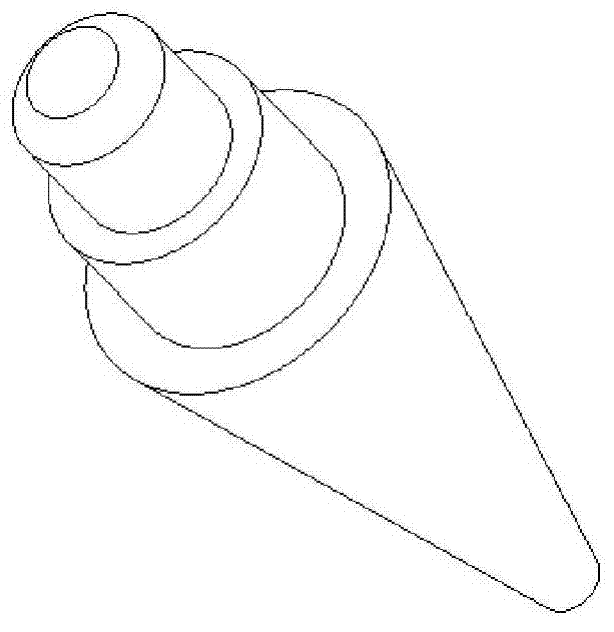

Helically formed cylinder of varying length and diameter

InactiveUS6904941B2Learn how to use it quicklyFast formingSleeve/socket jointsFluid pressure sealed jointsVernier scaleEngineering

A variable diameter cylinder made from a sheet having first and second edges that are opposite to each other and that slideably connect with each other to form a helical joint of a cylinder such that sliding the edges of the sheet along the joint varies a diameter and length of the cylinder. When marked with a scale, the cylinder acts as a measuring device that is both highly accurate and easy to use. A helical-based scale can be used alone, or a linear scale can be used in combination with a Vernier scale.

Owner:HOWARD DAVID W

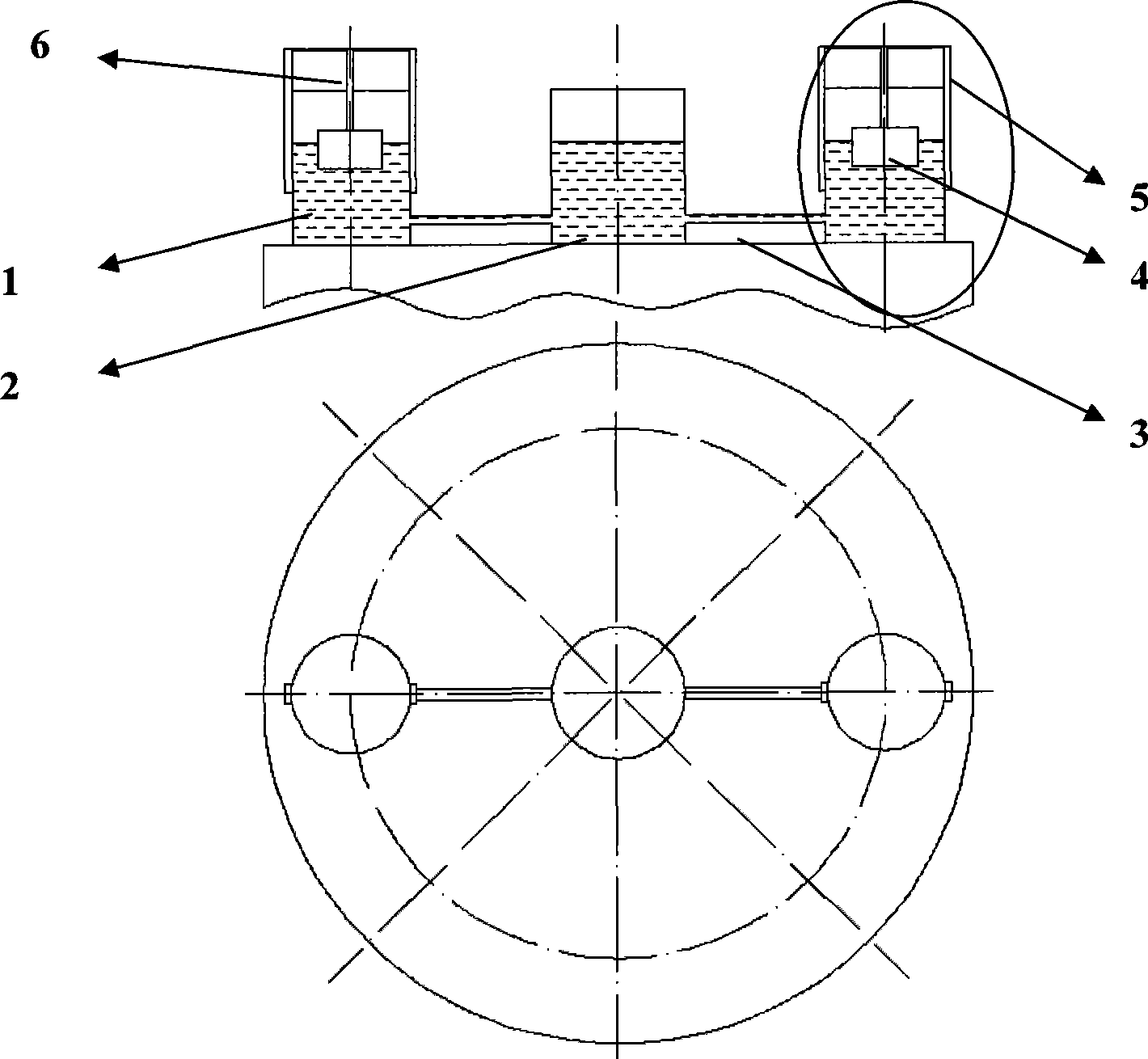

Implant system with migration measurement capacity

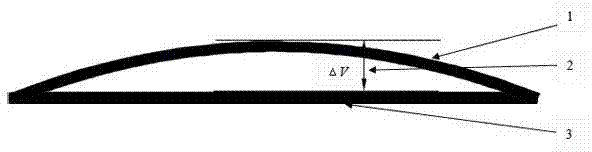

Position reference members are provided as part of an orthopaedic implant system. Both position reference members can be implanted on or in the same bone as the other parts of the implant. One of the position reference members is fixed to the bone and the other position reference member is movable with another part of the implant, such as a stem received in the intramedullary canal. The movable position reference member can move with respect to the fixed position reference member. At least one of the position reference members includes indicia such as a main scale or a vernier scale. Parts of the indicia and position reference members are radio-opaque and parts are radiolucent. Post-operative changes in the relative positions of the position reference members can be measured by radiography or fluoroscopy so that changes in the implant position can be monitored over time.

Owner:DEPUY PROD INC

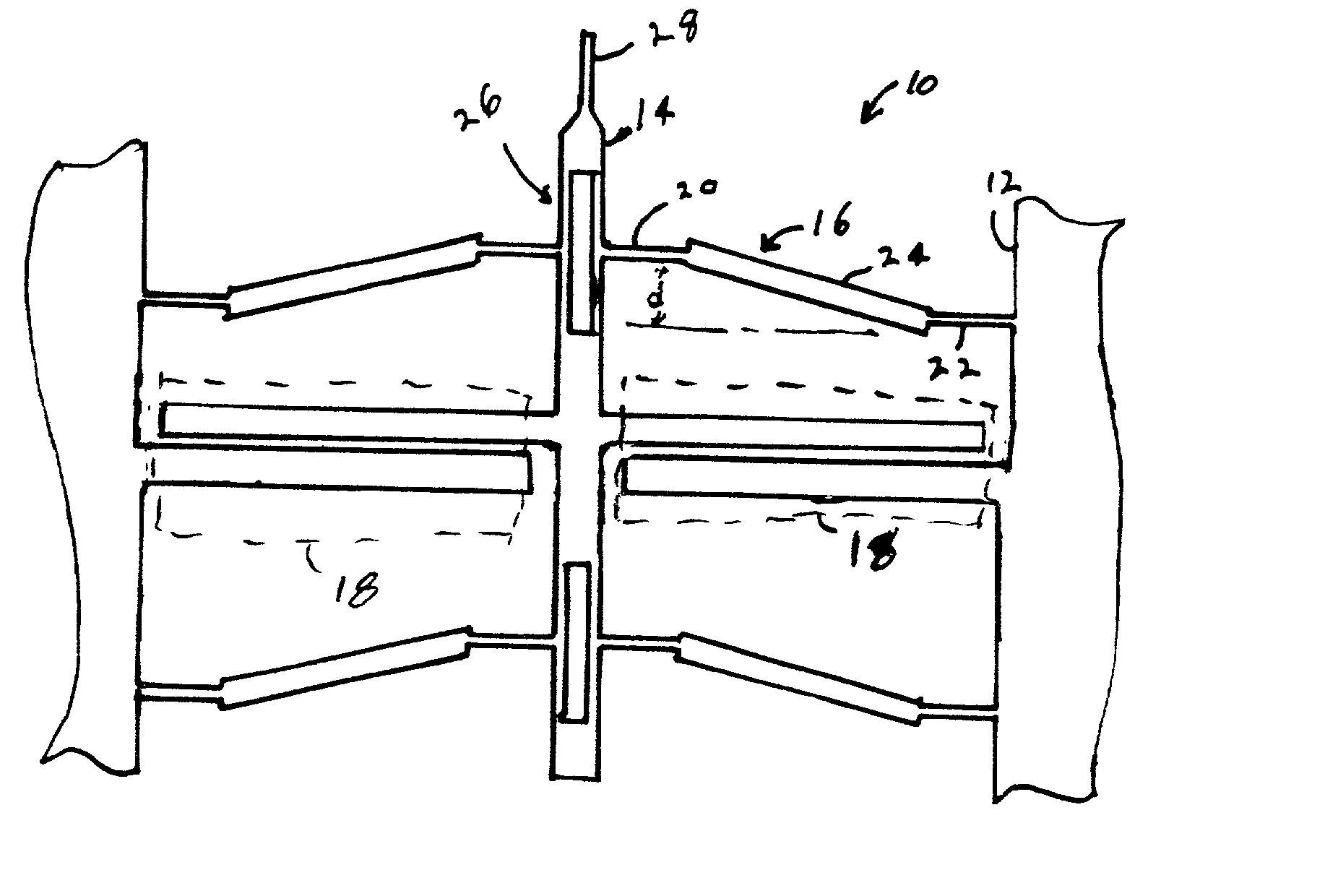

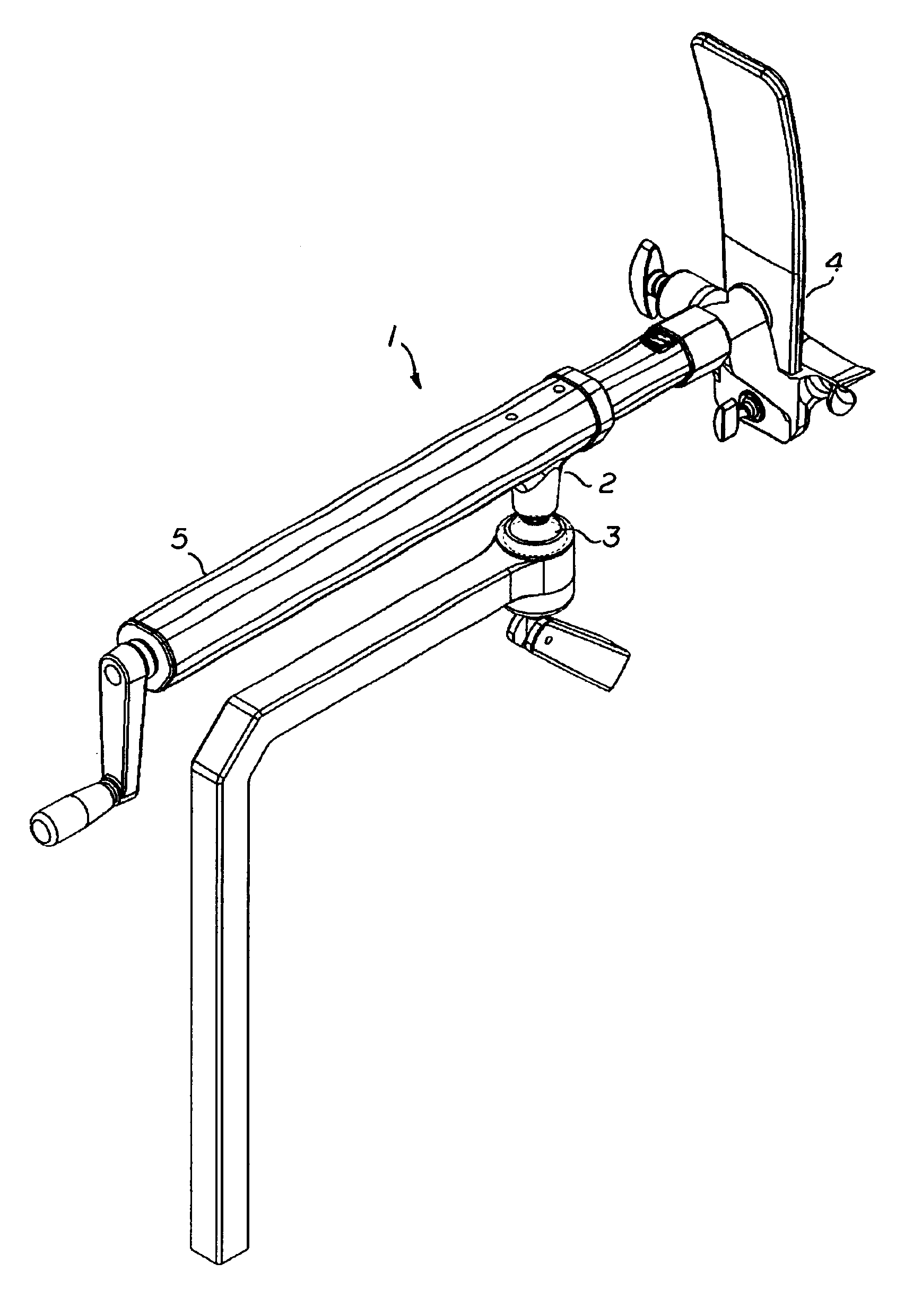

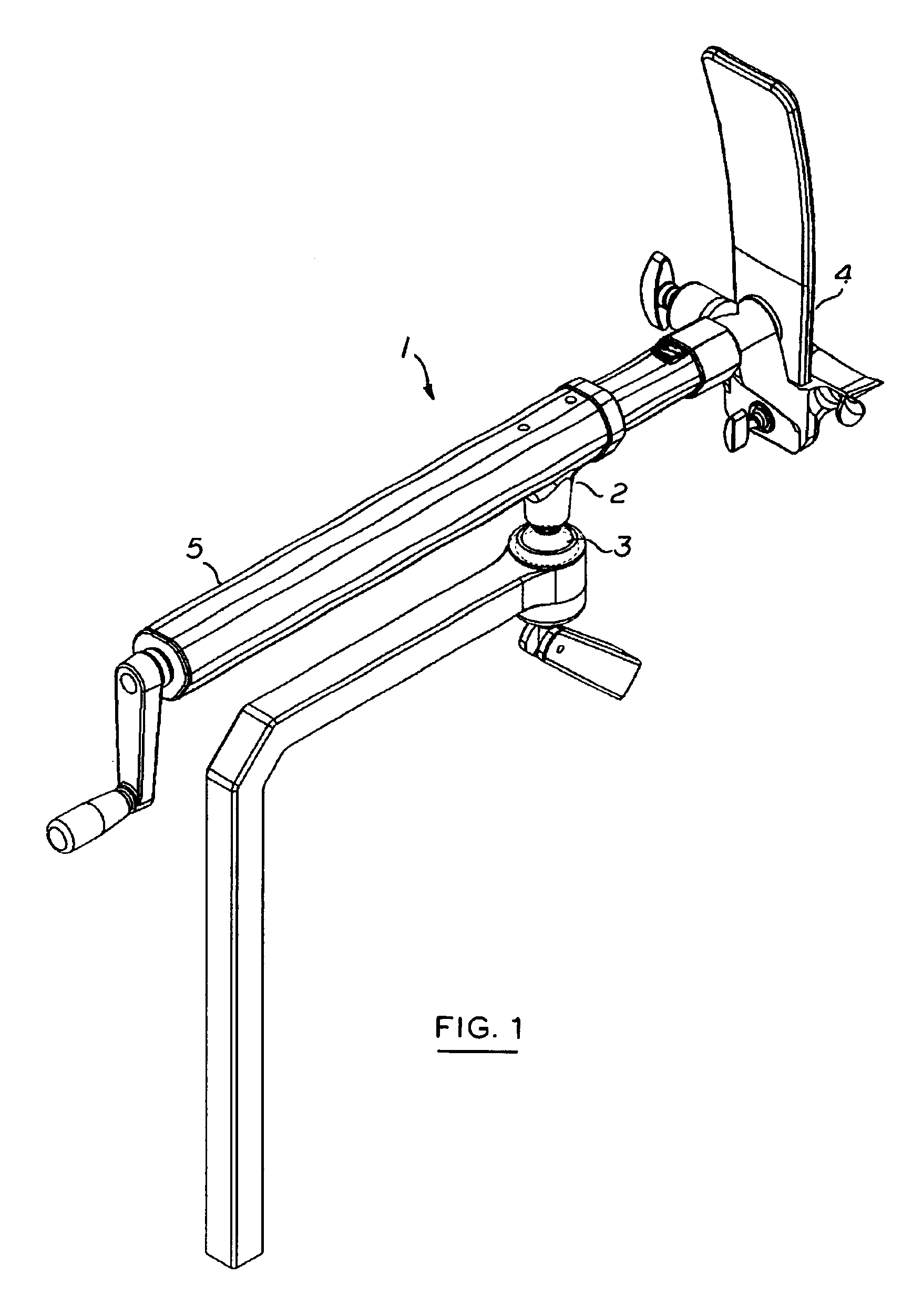

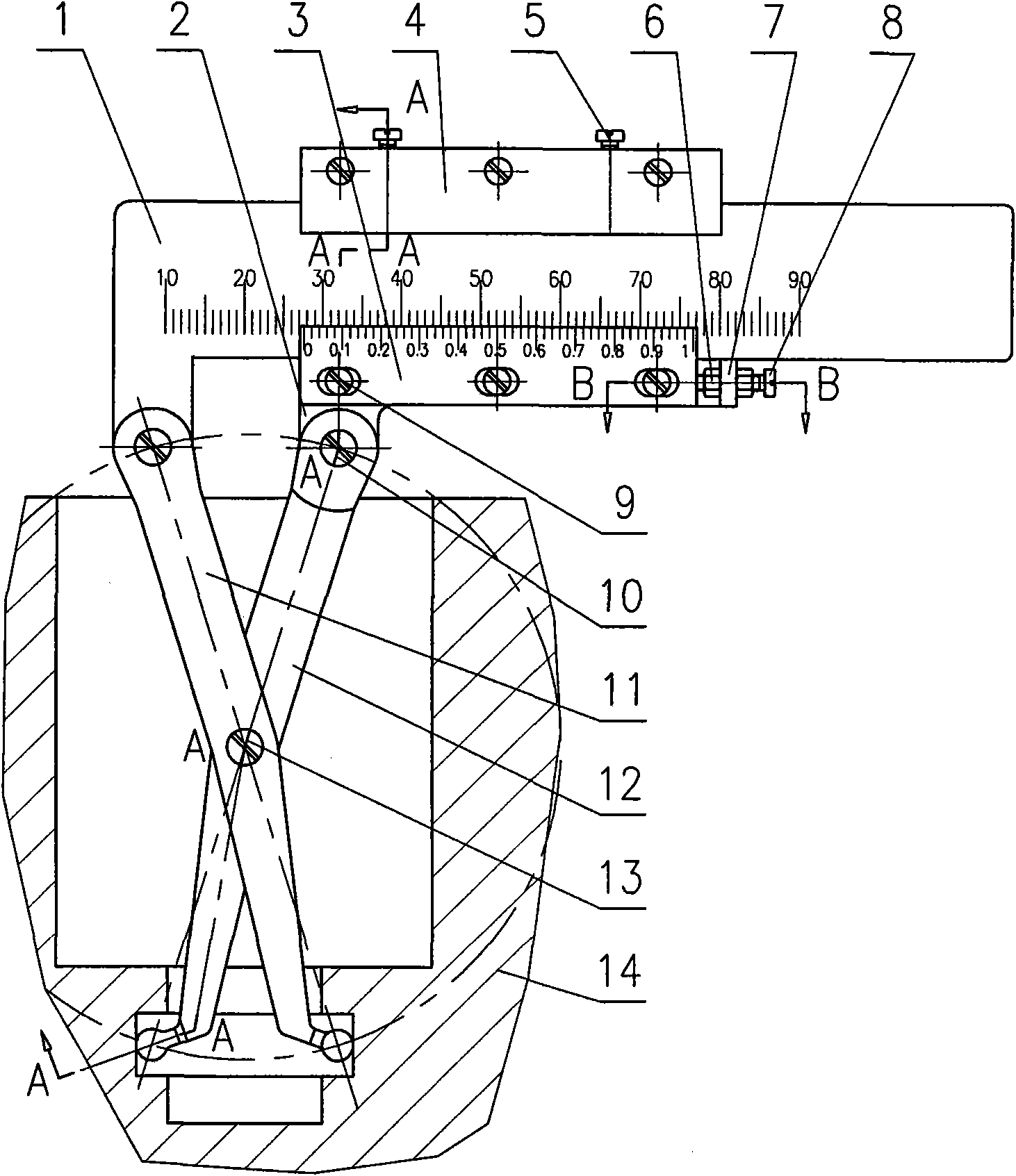

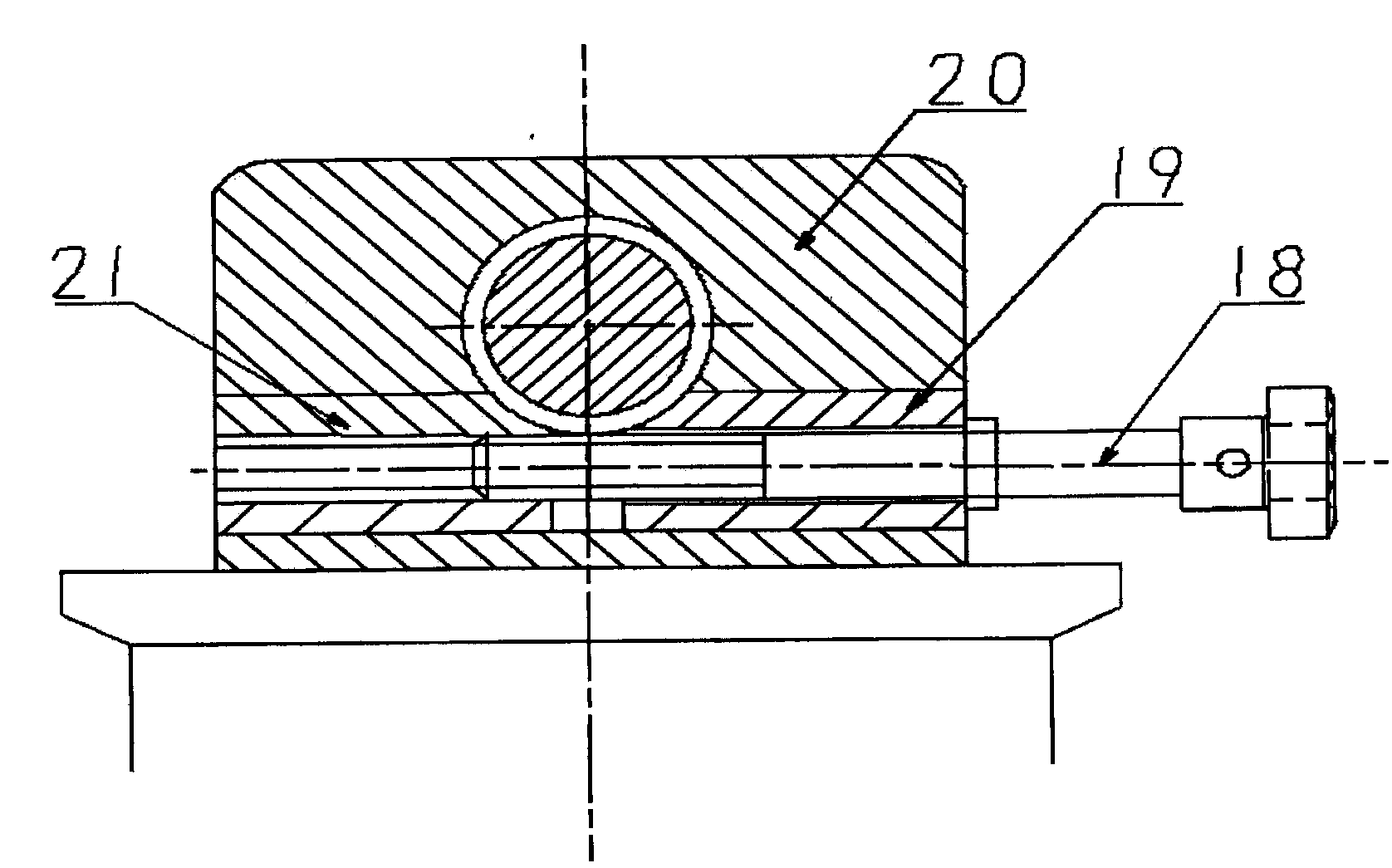

Orthopedic traction device

InactiveUS6895969B2Conveniently installedAccurately indicatedOperating chairsDiagnosticsVernier scaleCoil spring

An orthopedic traction apparatus includes in coaxial arrangement, a first tubular member anchored to a operating table or other stationary structure supporting a patient, and a second tubular member telescopically moving within the first one. A hand-crank and jack-screw mechanism is used to vary the position of the second member in relation to the first member. A tensiometer is provided at the distal end of the second member proximate a fixture adapted for attachment to a part of a patient's body. The tensiometer is based on a compressible, calibrated coil spring and is provided with a vernier scale for convenient and precise adjustment of the traction force. Alternately, the tensiometer uses a load-cell driving a digital read-out.

Owner:COMPOSITE MFG

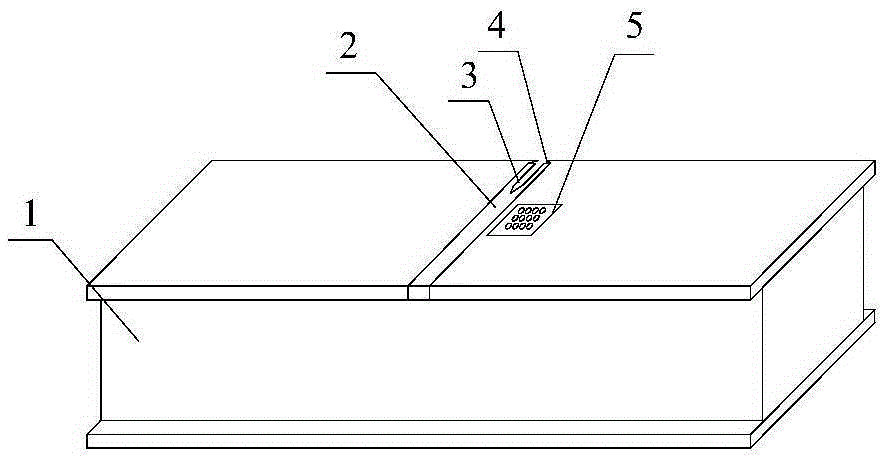

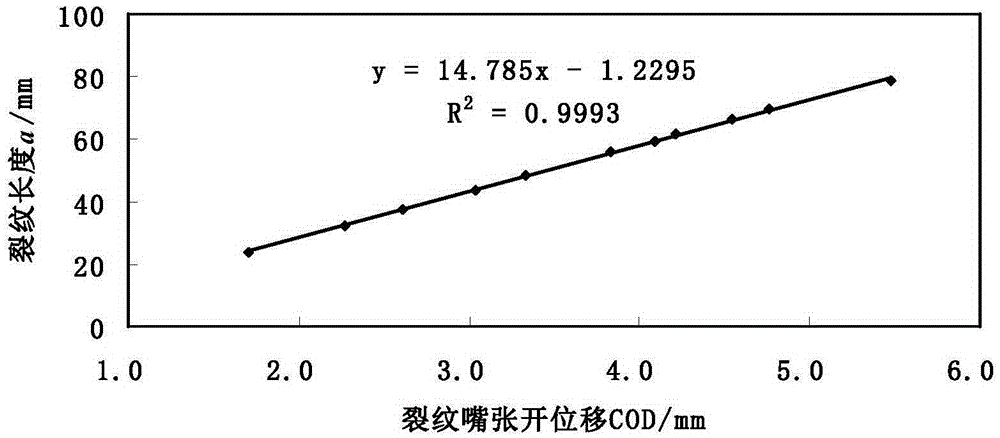

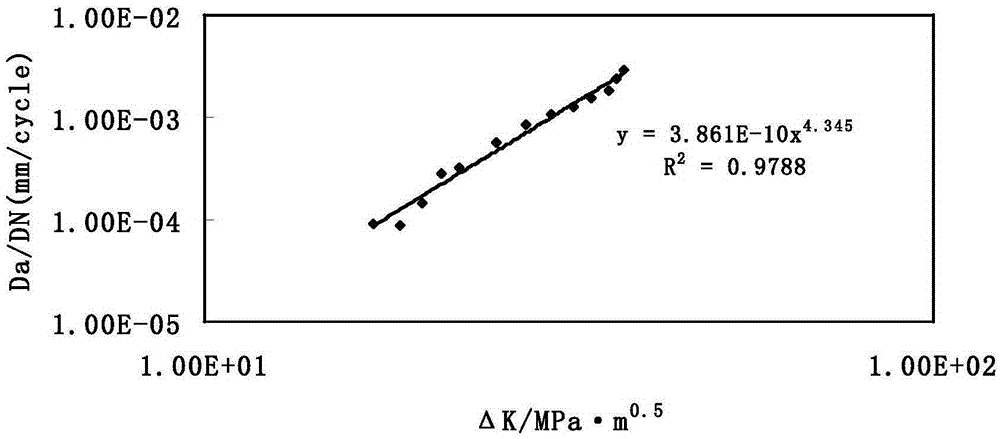

Fatigue crack propagation rate testing method of steel box girder

ActiveCN105352800AThe rate of expansion is real and reliableAffect accuracyMaterial strength using tensile/compressive forcesTest efficiencyVernier scale

The invention discloses a fatigue crack propagation rate testing method of a steel box girder. The fatigue crack propagation rate obtained by structure solid tests of the method is truer and more reliable than that obtained by the Paris equation obtained by present material tests for fatigue crack propagation. The Paris equation of the method is more instructive when being used for predicating residual life in a service period of a structure. When being used for measuring crack lengths, the method is different from conventional methods that shut down and measure with a vernier caliper. According to the method, a COD clip gauge is mounted to the front end of a mechanical gap of a steel box girder test piece, the linear relation between the COD clip gauge and the crack length a measured by the vernier caliper is calibrated through static load tests, the linear relation is applied to dynamic tests for the fatigue crack propagation rate and the real crack length a is measured directly through reading of the COD clip gauge, and therefore influences on accuracy of fatigue test results, which are caused by crack-tip plastic blunting caused by middle shutdown in dynamic fatigue tests, are avoided, time of shutting down tests and testing crack lengths is saved, and the test efficiency is increased.

Owner:武汉钢铁有限公司

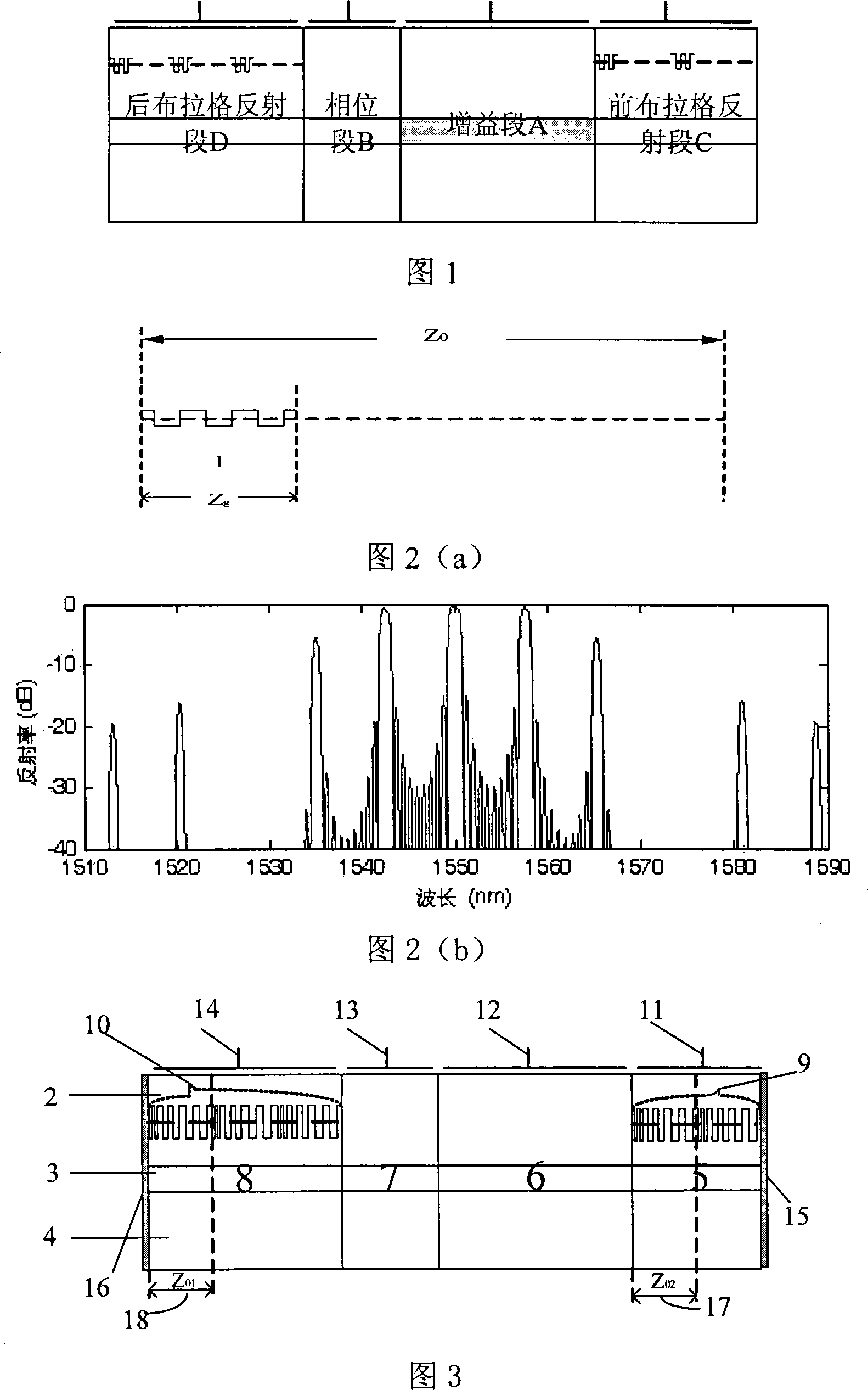

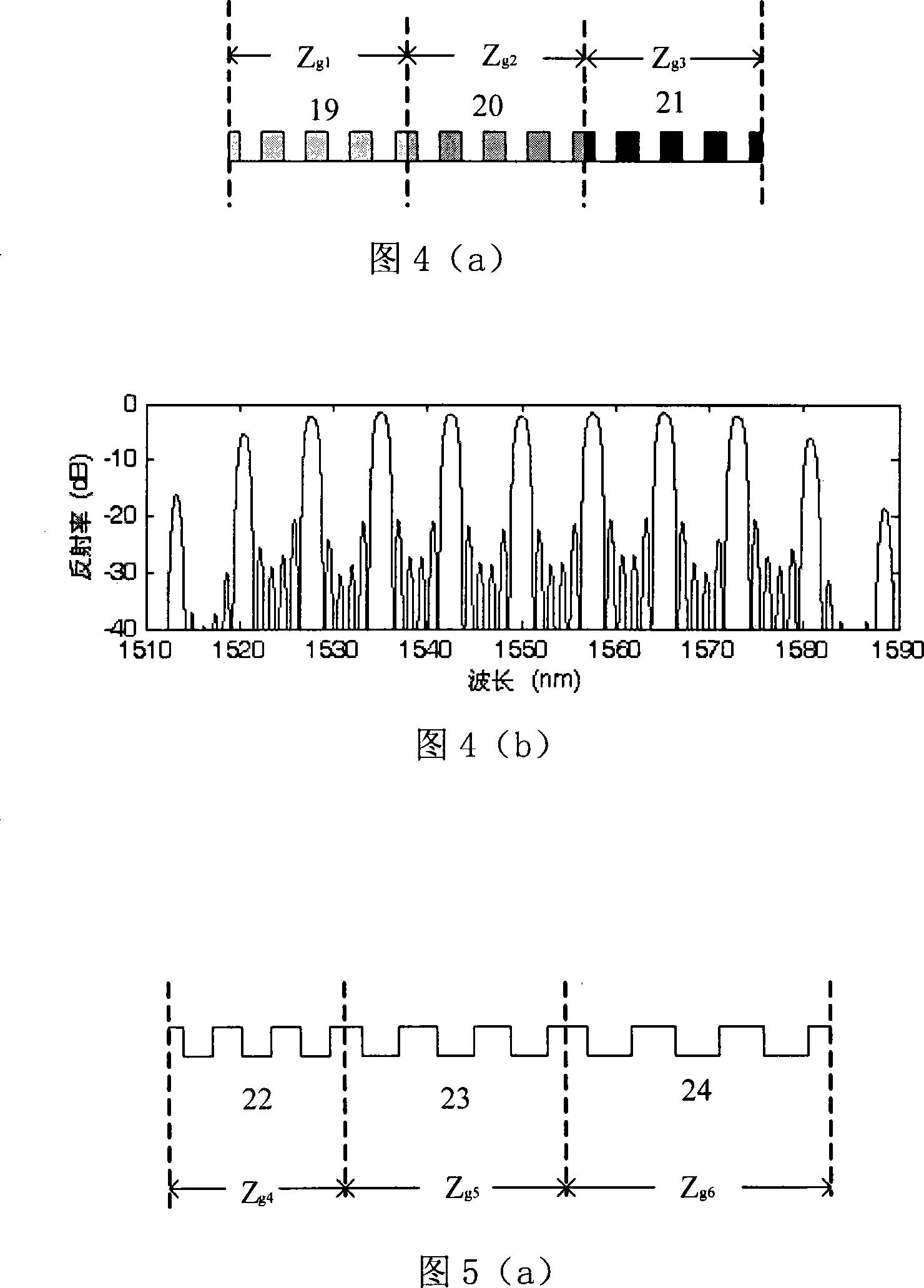

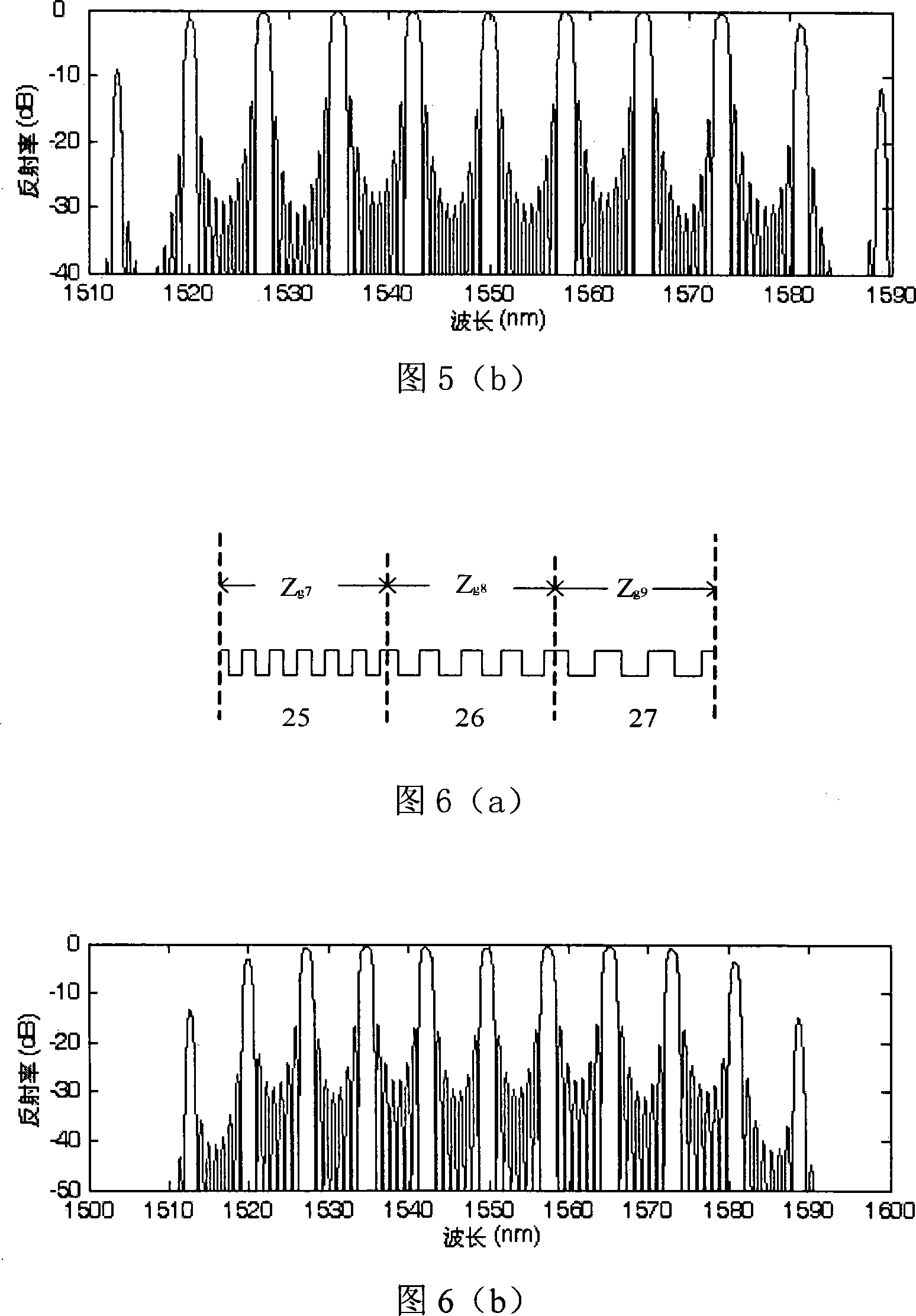

Tunable semiconductor laser

InactiveCN101022206AGood peak balanceImprove consistencyLaser detailsSemiconductor lasersGratingRefractive index

This invention discloses a tunable semiconductor laser, in which, two Prague reflection secions limit borders of a gain section at both ends, reflection sections of the front and back ends can be designed to Prague grating suitable for generating comb reflection peaks with even peak values in form, two Prague reflection sections of a laser can be designed to the form of various traces, phase shift and chirp of Prague grating and the theory of vernier caliper is used to change the refraction rate of the two reflection sections of the laser to realize quasi-continuous tune of broad spectrum.

Owner:HUAZHONG UNIV OF SCI & TECH

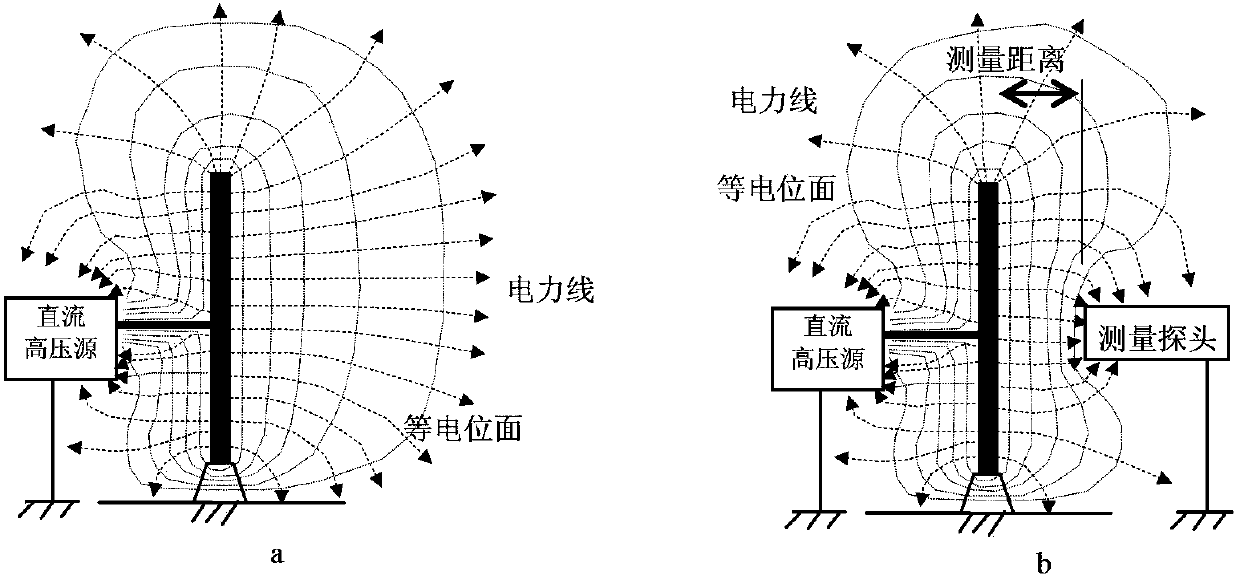

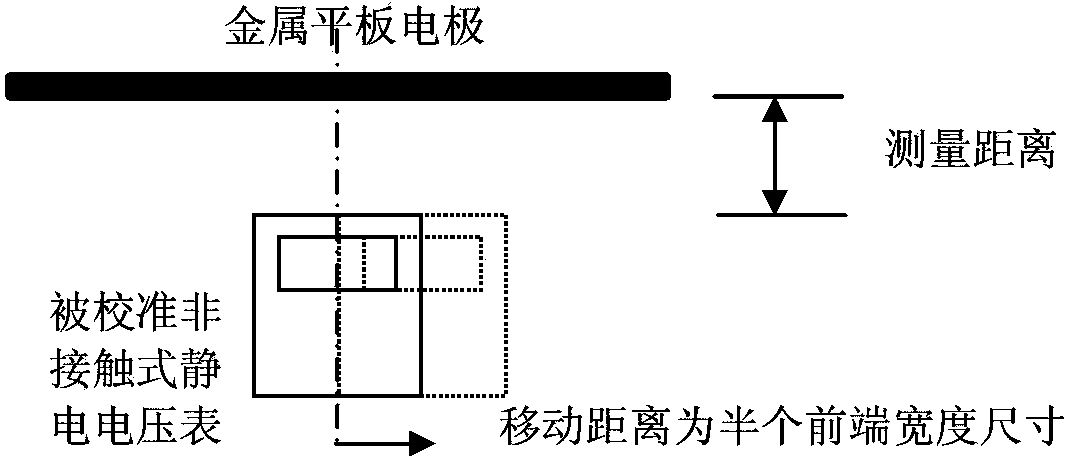

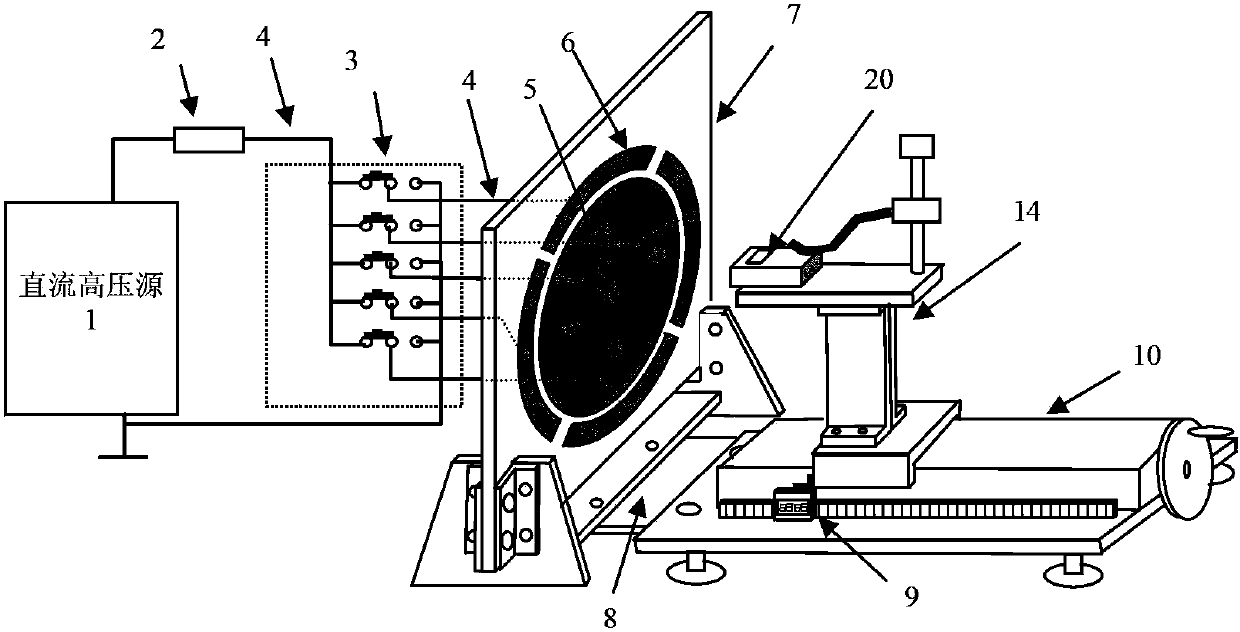

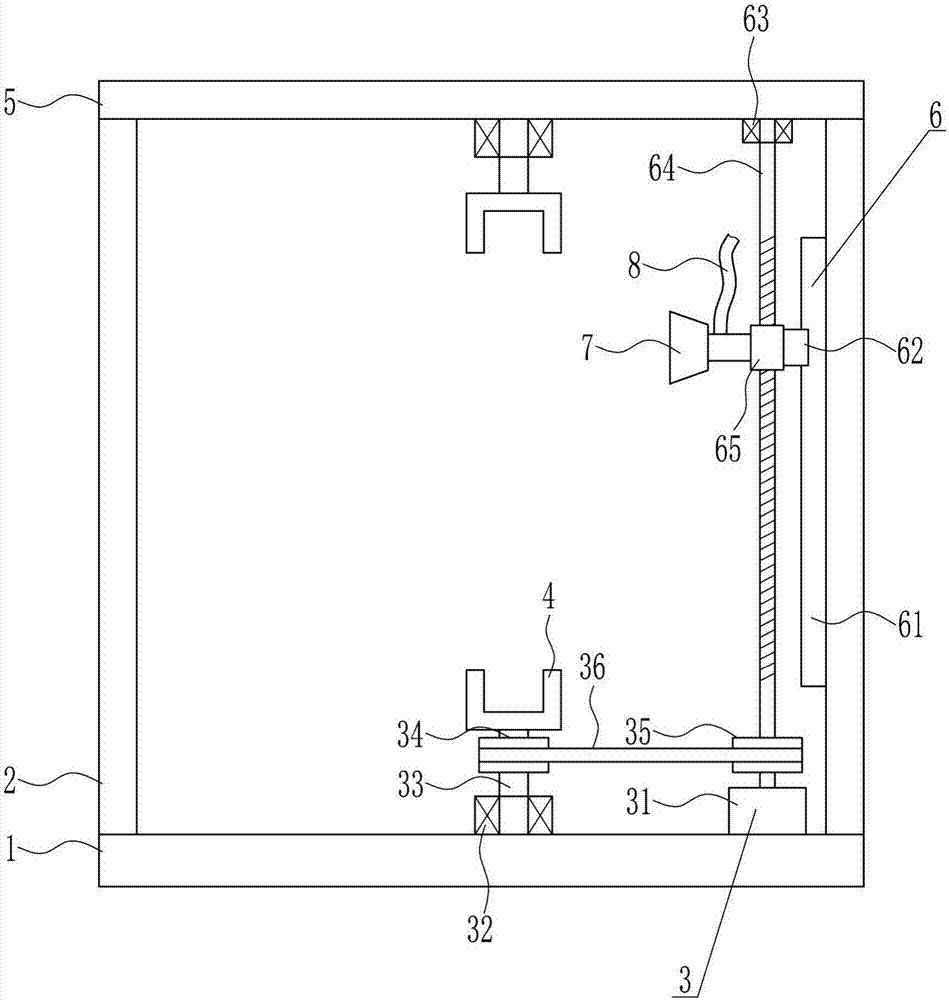

Device and method for calibrating non-contact type electrostatic voltmeter

The invention provides a device and method for calibrating a non-contact type electrostatic voltmeter. The method includes the steps that a direct-current high-voltage power supply and metal plate electrodes are utilized to acquire a standard static filed at local space near the centers of the electrodes, the voltage of the non-contact type electrostatic voltmeter can be traced to the direct-current voltage standard, and an experimental method that the edge effect is increased is adopted to test the edge effect of the metal plate electrodes. The risks that people get an electric shock are reduced through a glass flat plate support which bears the metal plate electrodes and through a protective resistor, and a perpendicular moving mechanism can adjust the test distance of a calibrated meter. A detachable vernier caliper is adopted, and therefore tracing is convenient to conduct.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

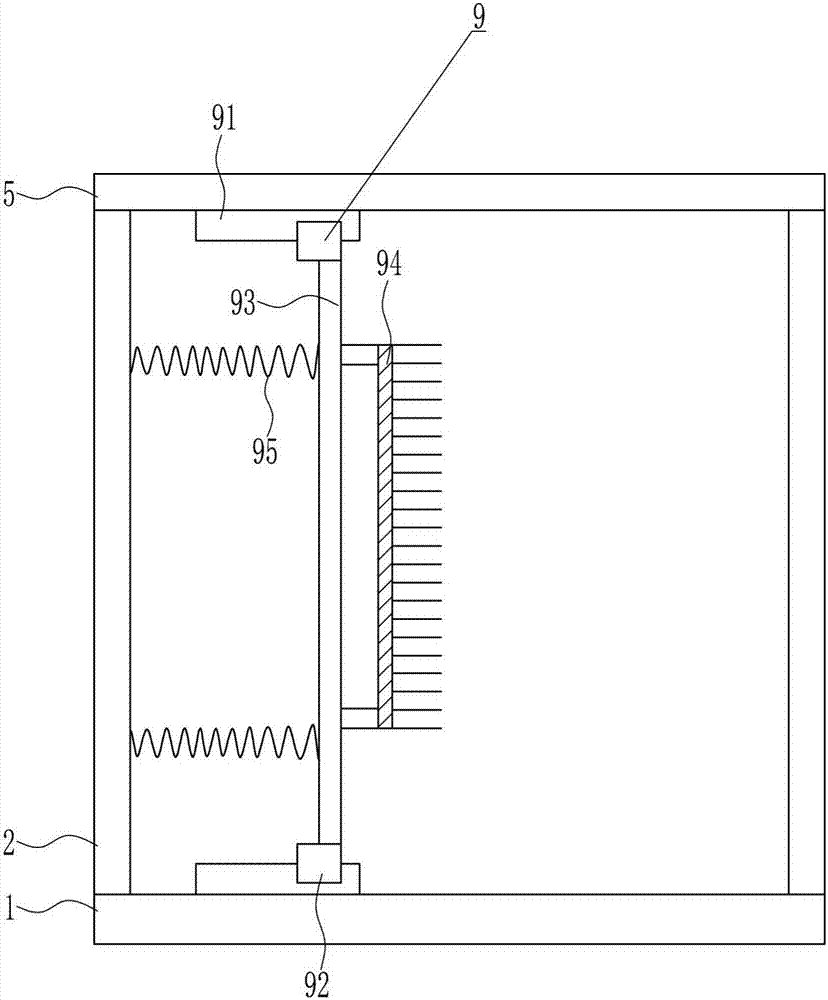

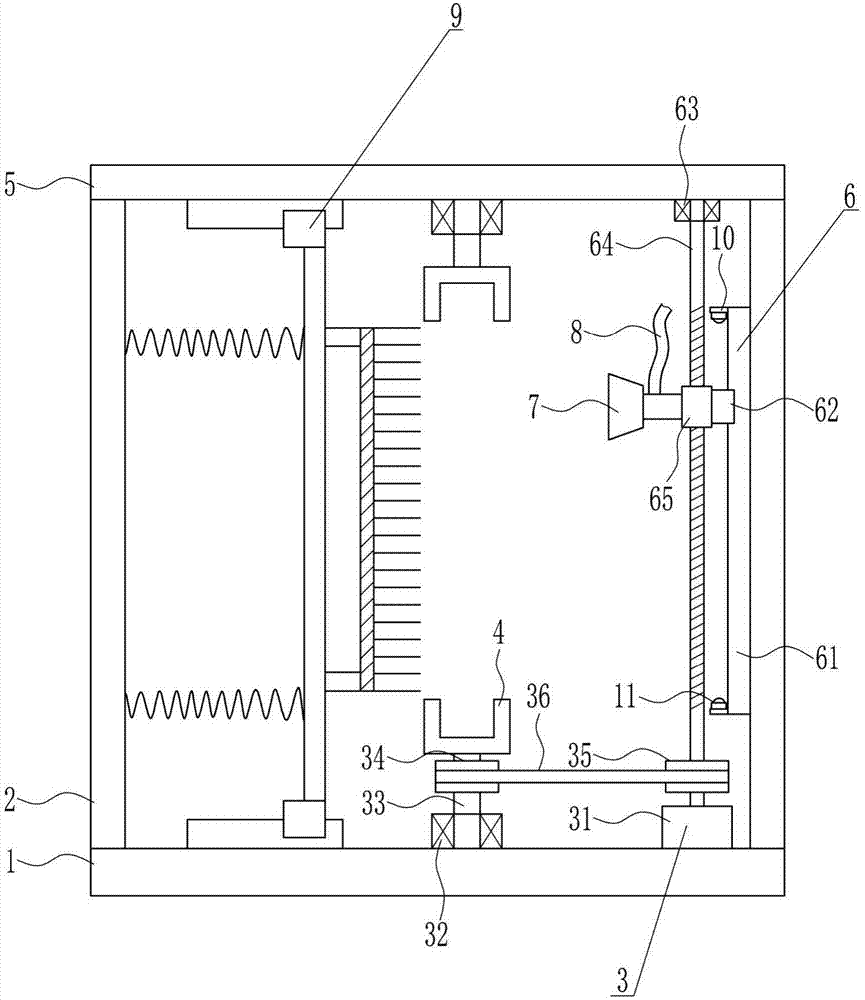

Efficient cleaning equipment for vernier calipers for detection equipment

InactiveCN107442495AComprehensive cleaningPerfect cleaningCleaning using toolsCleaning using liquidsVernier scaleSpray nozzle

The invention relates to cleaning equipment for vernier calipers, in particular to efficient cleaning equipment for vernier calipers for detection equipment. By the aid of the efficient cleaning equipment for the vernier calipers for the detection equipment, the vernier calipers can be thoroughly and comprehensively cleaned, the time and labor can be saved, and the efficient cleaning equipment is high in work efficiency. The efficient cleaning equipment for the vernier calipers for the detection equipment comprises a bottom plate and the like. Supports are symmetrically vertically mounted on the top of the bottom plate in bolted connection modes in the left-right directions, a top plate is horizontally mounted on the top of a space between the two supports by means of bolted connection, and a rotary device is arranged at the top of the bottom plate and the bottom of the top plate. The efficient cleaning equipment has the advantages that the vernier calipers can be driven by a first motor to rotate and simultaneously continuously move up and down with a spray nozzle, the efficient cleaning equipment is easy and convenient to operate, and excellent vernier caliper cleaning effects can be realized by the efficient cleaning equipment; the vernier calipers can be thoroughly and comprehensively cleaned by the aid of the efficient cleaning equipment, the time and the labor can be saved by the aid of the efficient cleaning equipment, and the efficient cleaning equipment is high in work efficiency.

Owner:邵林芳

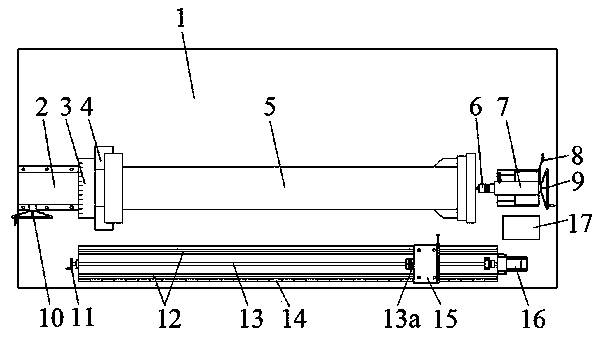

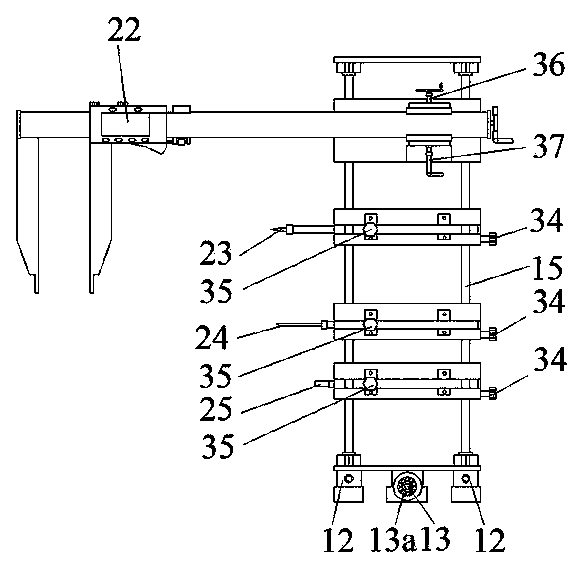

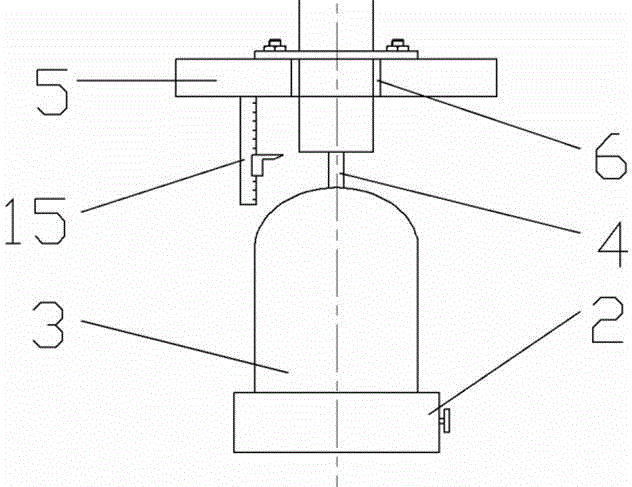

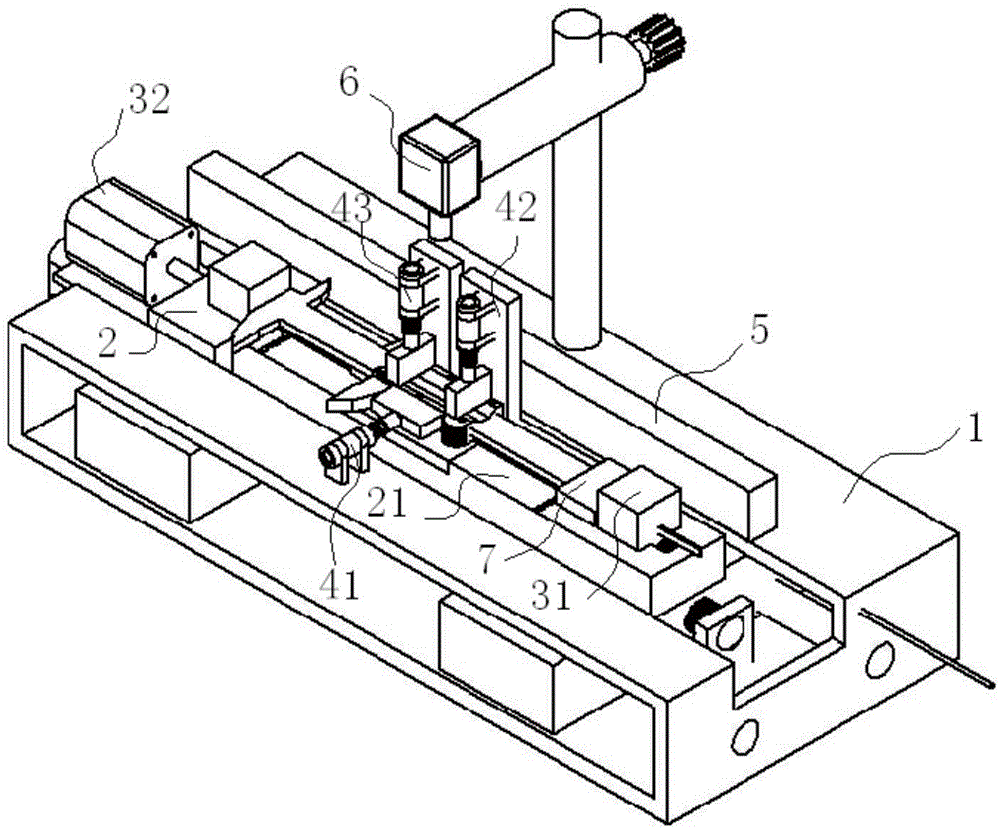

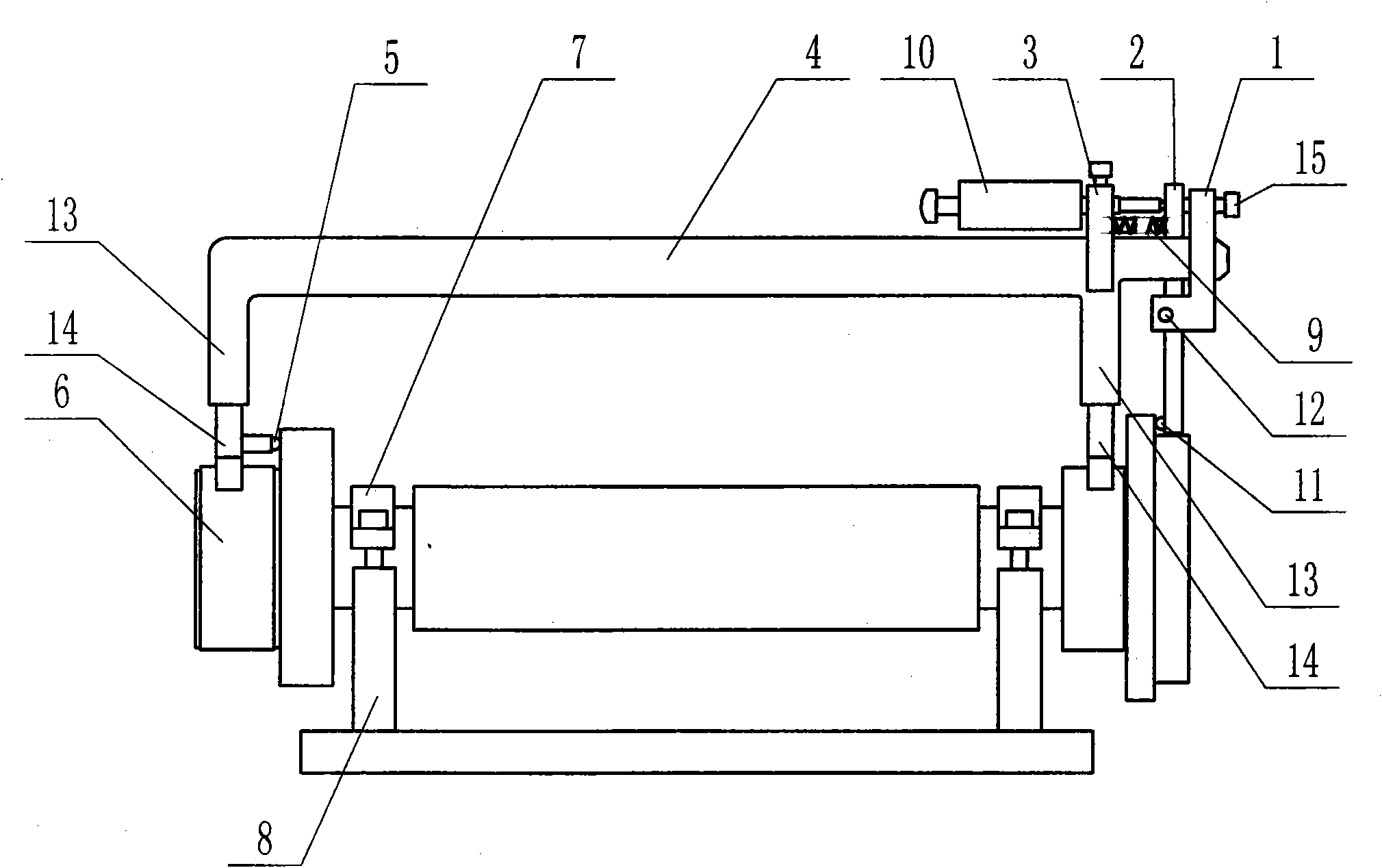

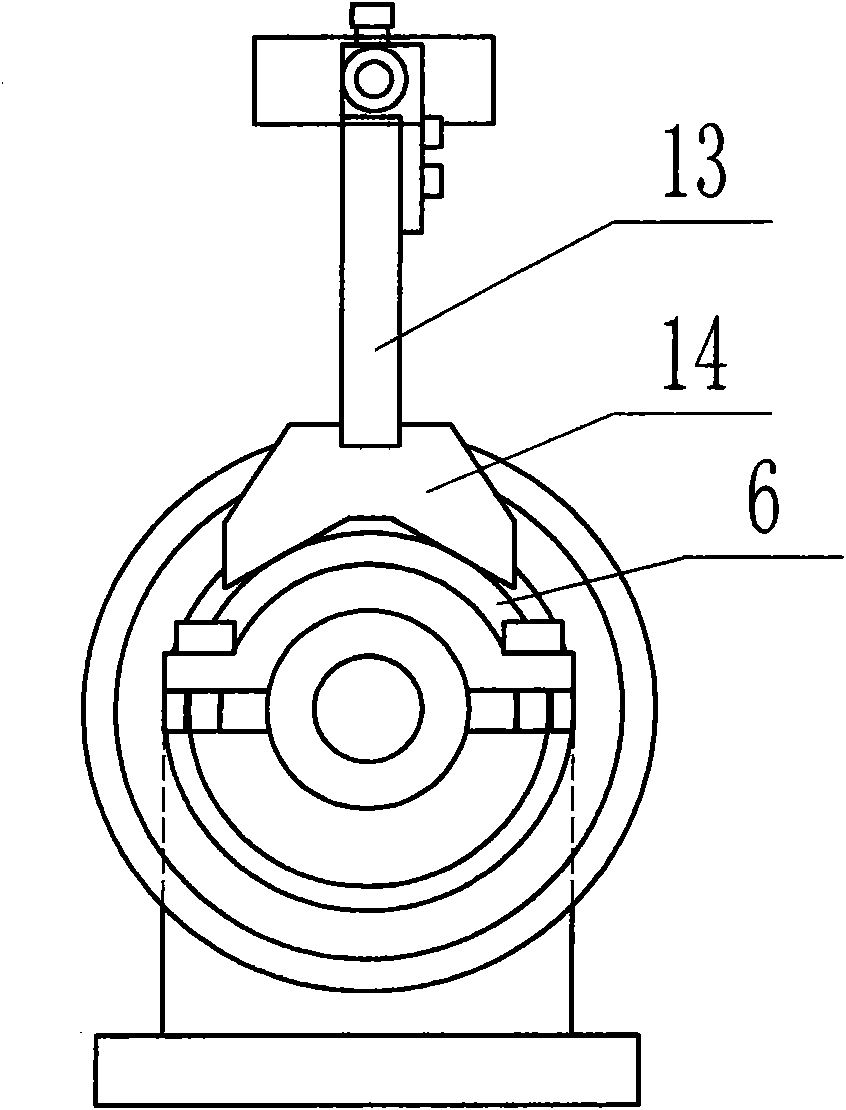

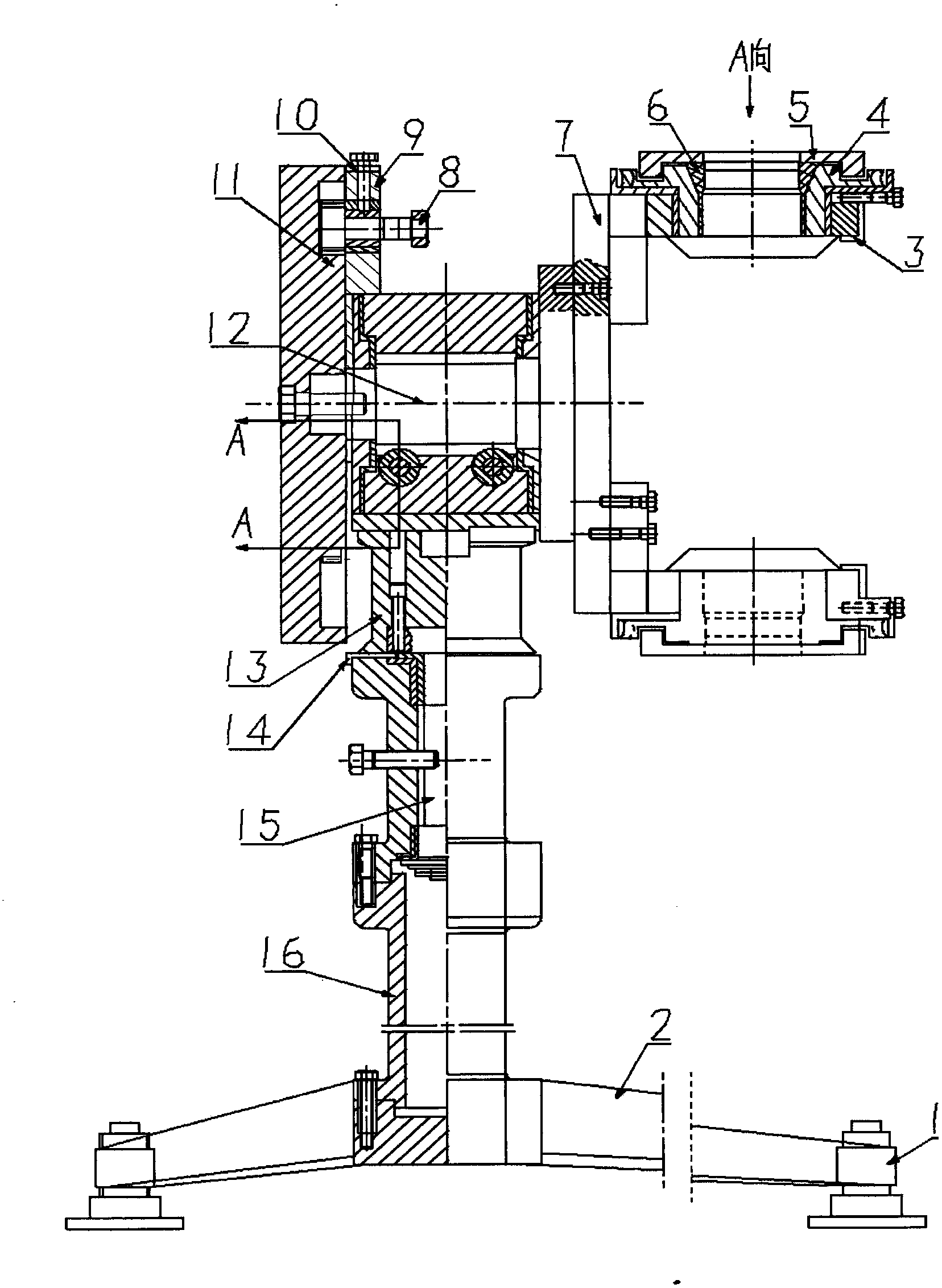

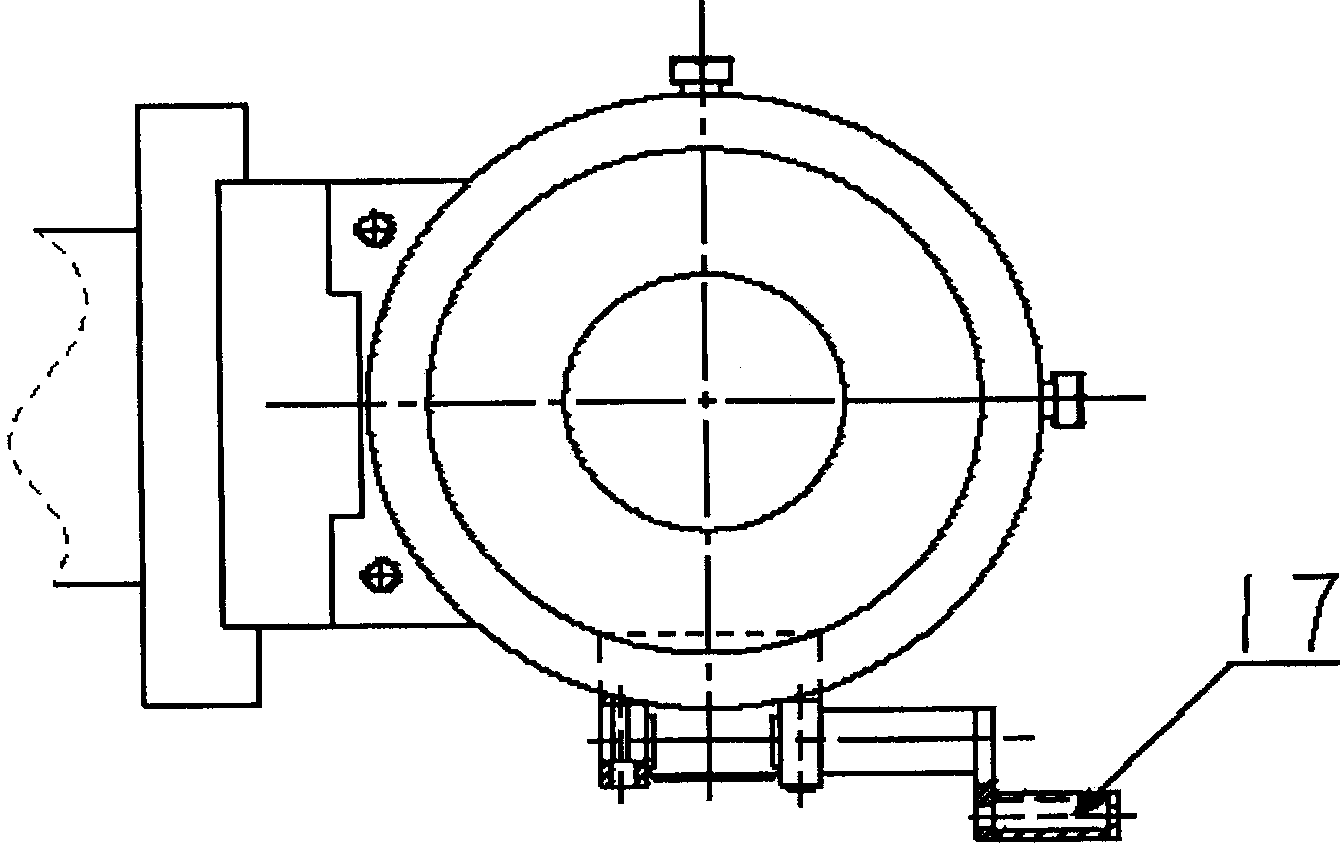

Pipeline geometric size measuring machine

InactiveCN103453823AHigh working reliabilityEasy to operateMechanical counters/curvatures measurementsMechanical diameter measurementsVernier scaleMarking out

The invention discloses a pipeline geometric size measuring machine and belongs to the technical field of measuring equipment. The pipeline geometric size measuring machine comprises a pipeline clamping device, a measuring device and a control box, and the pipeline clamping device, the measuring device and the control box are arranged on an operating platform. The pipeline clamping device is used for supporting a pipeline to be measured through a spindle box mechanism and a tail bracket mechanism. The measuring device is provided with two guide rails on the operating platform, the two guide rails are parallel to the axis of the pipeline clamping device, a measuring framework is driven by a measuring framework driving mechanism to move on the guide rails, and a vernier caliper clamp, an LVDT displacement meter clamp, a hatching pen clamp and a thickness gauge clamp are arranged on the measuring framework. When the pipeline geometric size measuring machine works, the position of the pipeline to be measured and the position of the measuring framework are adjusted electrically or manually, the geometric size of each portion of the pipeline to be measured is measured, or, marking-out is carried out. The pipeline geometric size measuring machine can complete the four operations of marking-out calibration of the pipeline, diameter measurement on any section, thickness measurement on any portion and ellipticity measurement on pipeline sections comprehensively. The pipeline geometric size measuring machine is high in working reliability and convenient to operate, and can improve locating accuracy, enhance measuring effects and improve work efficiency.

Owner:DALIAN UNIV OF TECH

Level vernier caliper

InactiveCN101581561AEasy to measureQuick measurementSlide gaugesMechanical diameter measurementsVernier scaleLong axis

The invention discloses a level vernier caliper which is characterized in that the level vernier caliper comprises an upper arm and a lower arm which pass through a middle pore and are connected together by a major axis; the upper arm and the lower arm pass through a hole at one end and are connected at the lower ends of a main scale and an auxiliary scale by a minor axis; the main scale and a pad are arranged in a corresponding groove of the auxiliary scale; a structure for regulating a groove clearance of the main scale in the auxiliary scale is provided; a vernier and a pressure pad are arranged on the top of the notch of the auxiliary scale; a structure for adjusting and locking the exact position of the vernier on the auxiliary scale is provided. The main scale is provided with a plurality of scribed lines in increments of 1mm within limits; and the auxiliary scale is provided with 51 scribed lines in increments of 0.98mm; in a plane where a measuring round ball center passing through the upper arm and the lower arm is perpendicular to the major axis, the axel centers of the two minor axes arranged on the main scale and the auxiliary scale and the measuring round ball center passing through the upper arm and the lower arm are on a circle taking the axle center of the major axis as the center of the circle and are symmetry for the axle center of the major axis; the connecting line of the axel centers of the two minor axes is parallel to the movement direction of the auxiliary scale opposite to the main scale. The level vernier caliper can conveniently and quickly measure the diameter of a pinhole at the bottom of a micropore of mechanical spare parts or the diameter of an annular groove of the pinhole.

Owner:陈焕春

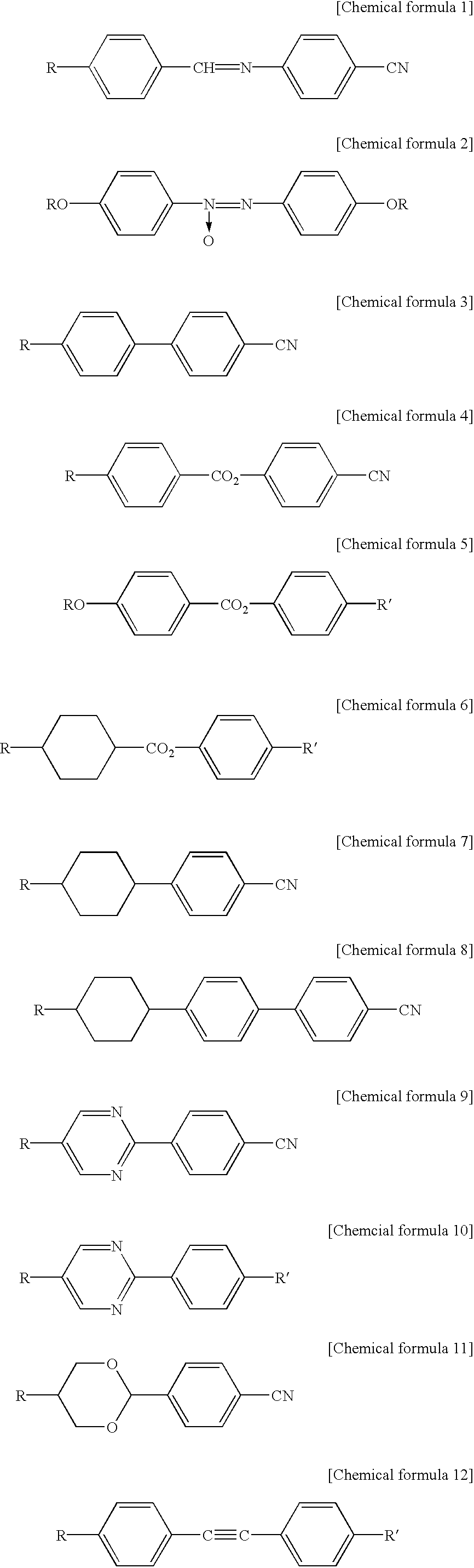

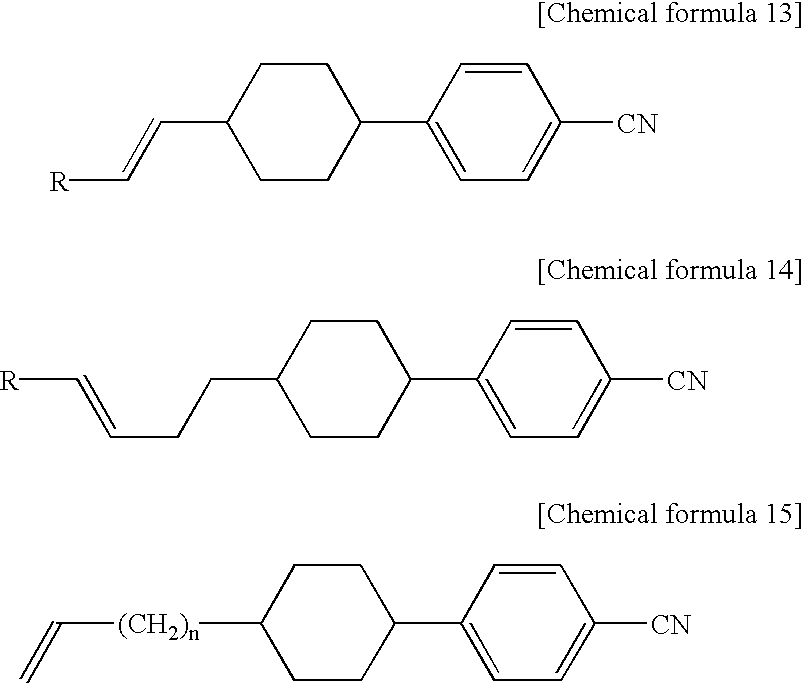

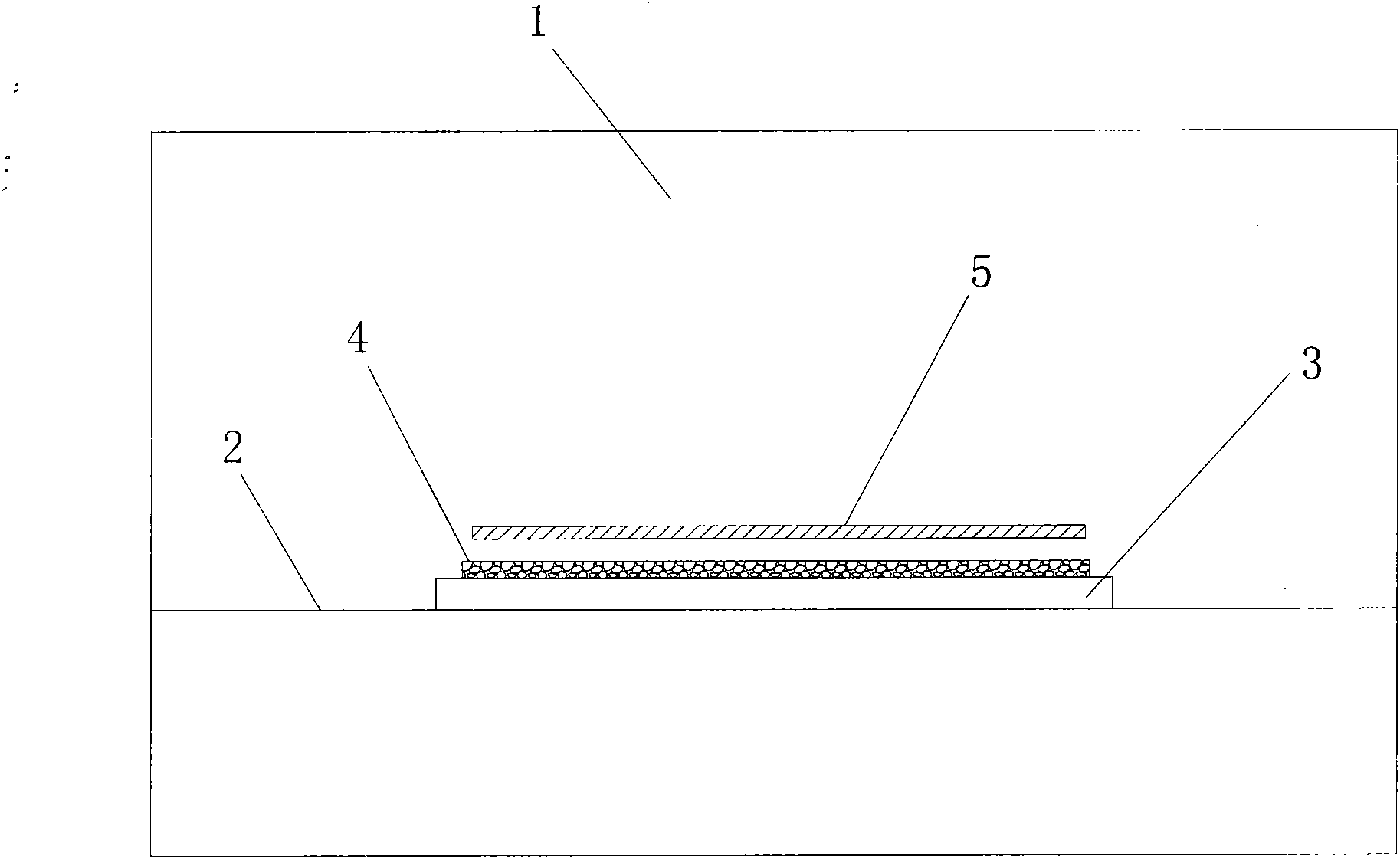

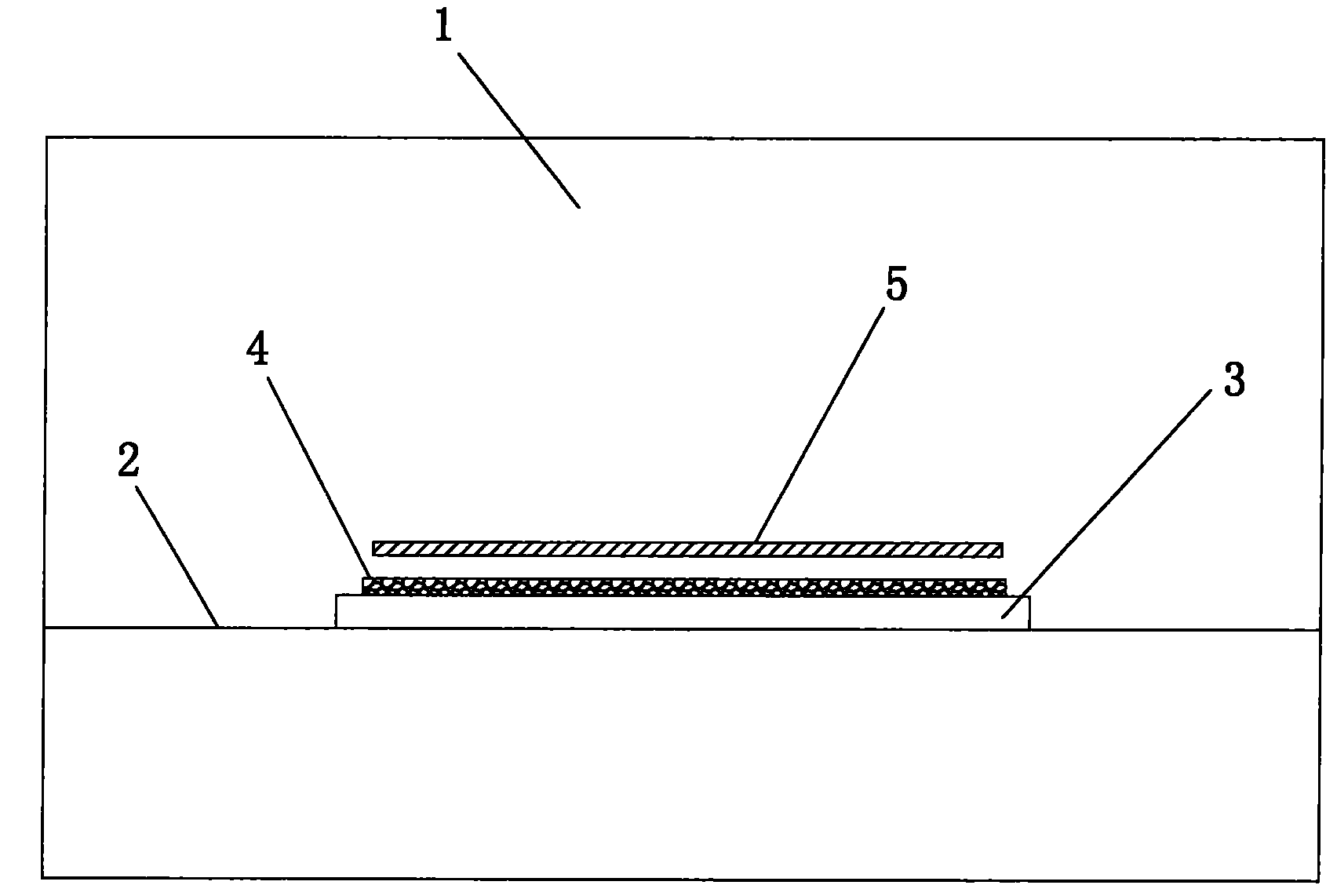

Liquid crystal display and method for producing the same

The invention provides a liquid crystal display having high reliability, which is excellent in terms of optical characteristics, heat resistance, and shock resistance, wherein a liquid crystal display consisting of a cholesteric liquid crystal, a chiral nematic liquid crystal or a liquid crystal 1 layer, being a combination thereof, which is roughly pillar-like and polygonal in section or has a roughly pillar-like form enclosed by a closed curve, and divided by said polymer network into areas whose minimum diameter measured by vernier calipers is 5 mum and whose maximum diameter measured by vernier calipers is 100 mum, is obtained by polymer networks 4 formed by polymerization of monomer, so that sufficient reflection can be obtained from the liquid crystal 1 without being optical scattering. Although the perpendicular array of the helical axes of liquid crystal 1 is slightly disordered by a polymer network 4 with respect to the plane of a pair of ITO 2a, 2b and substrates 3a,3b, wherein since almost all light entering from the substrata 3a side is reflected backwards (substrate 3a side) by Bragg's reflection, it is possible to decrease the visual angle dependency in comparison with a prior art liquid crystal display not containing any polymer constituents, and networks 4 which have been greatly established form intensive pillars (macromolcular resin walls), thereby improving the shock resistance properties.

Owner:NANOX

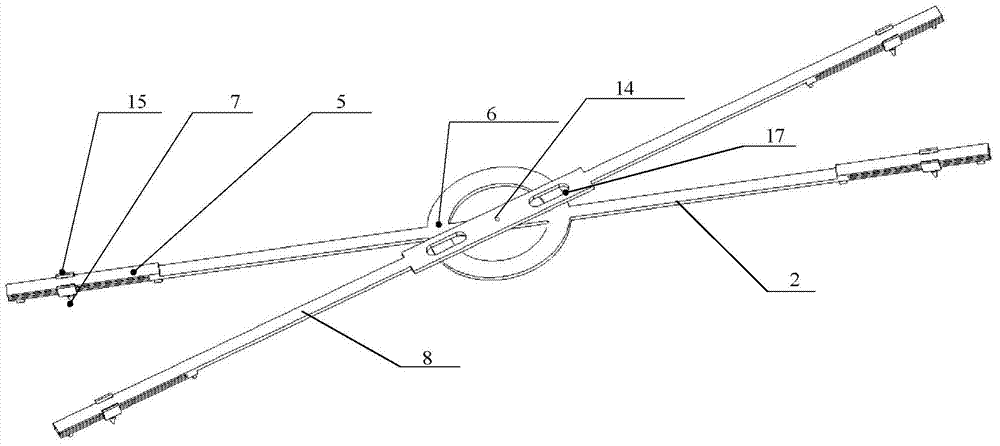

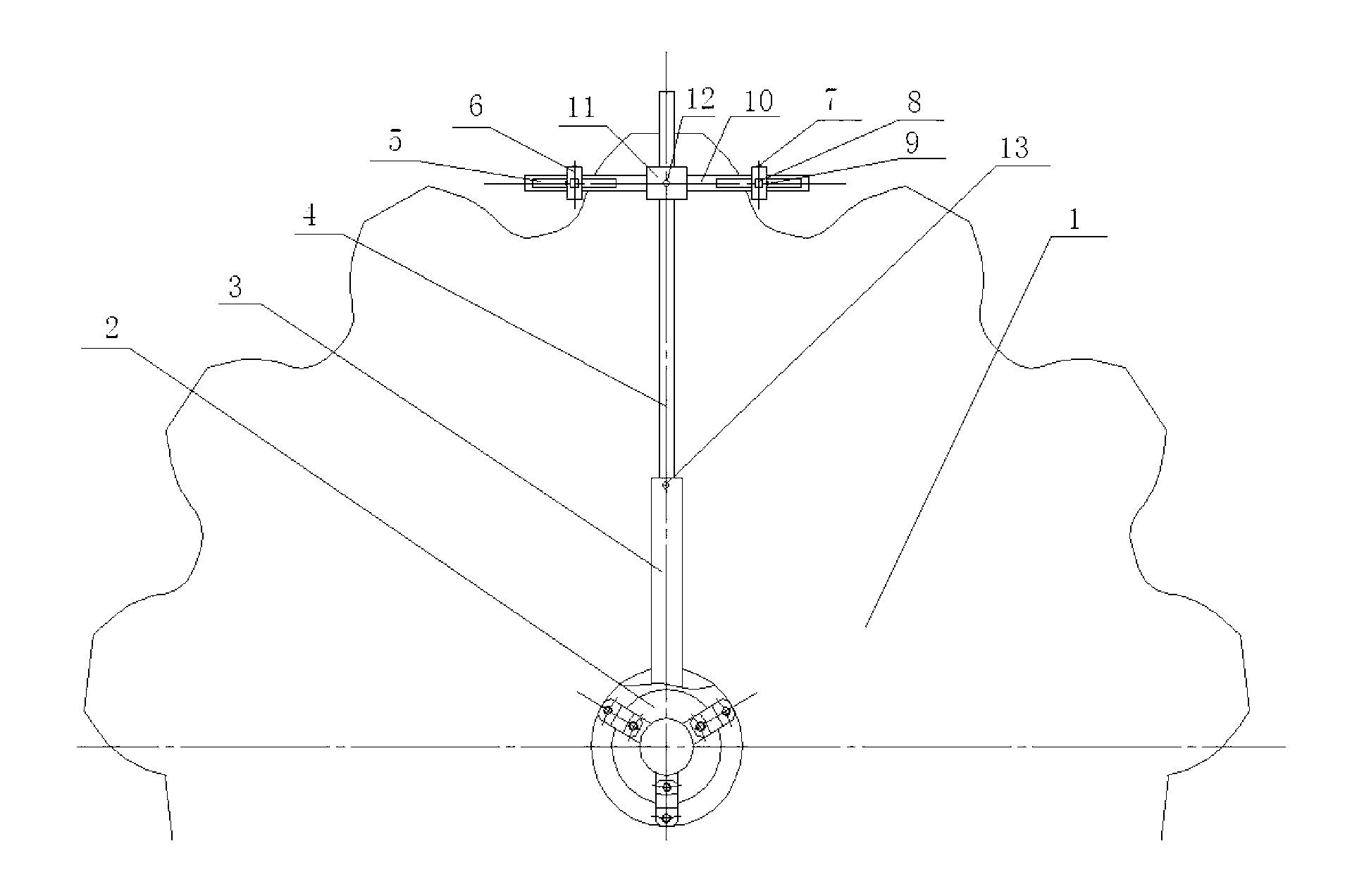

Flange multi-parameter integrated measuring method and device

ActiveCN103542791AHigh precisionImprove measurement efficiencyAngles/taper measurementsMechanical counters/curvatures measurementsVernier scaleMeasurement device

The invention provides a flange multi-parameter integrated measuring device comprising an upper ruler, a lower ruler, a rotary device, a sliding device and a slider. Two sides of the upper ruler and the lower ruler are provided with scale values, the middle of the lower ruler is provided with an angle-measuring indexing plate, and the middle of the upper ruler is provided with a portion indexing plate corresponding to the angle-measuring indexing plate; the upper ruler and the lower ruler are arranged in a crossed manner, and the rotary device is arranged at the center of the cross point of the upper ruler and the lower ruler and is connected to the upper ruler and the lower ruler; the sliding device is flexibly connected to the ruler range of the upper ruler and the lower ruler whose two sides are provided with the scale values and is provided with vernier scales; the slider is connected with the sliding device and provided with scale values. The invention further provides a corresponding measuring method. The device has the advantages of simple structure, convenience for usage, high measuring efficiency and high measuring accuracy.

Owner:SHANGHAI INST OF SATELLITE EQUIP

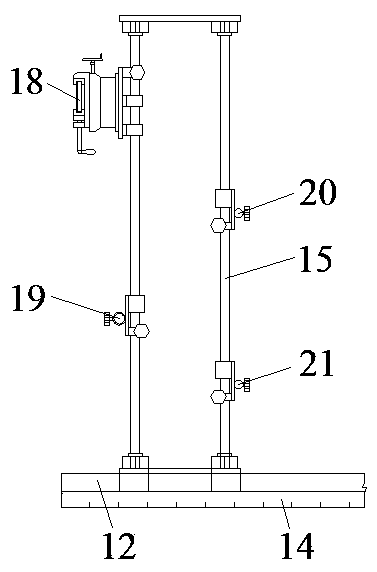

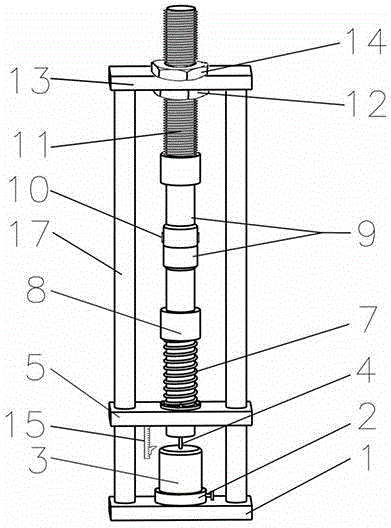

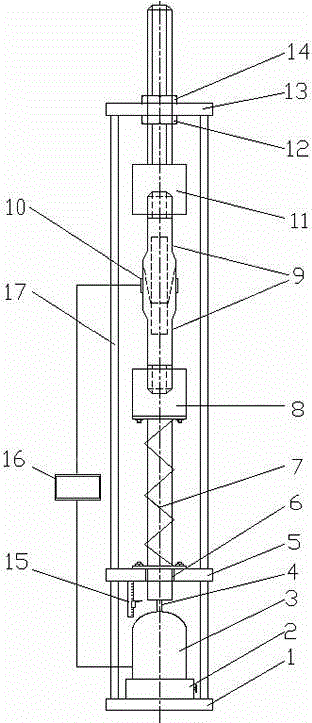

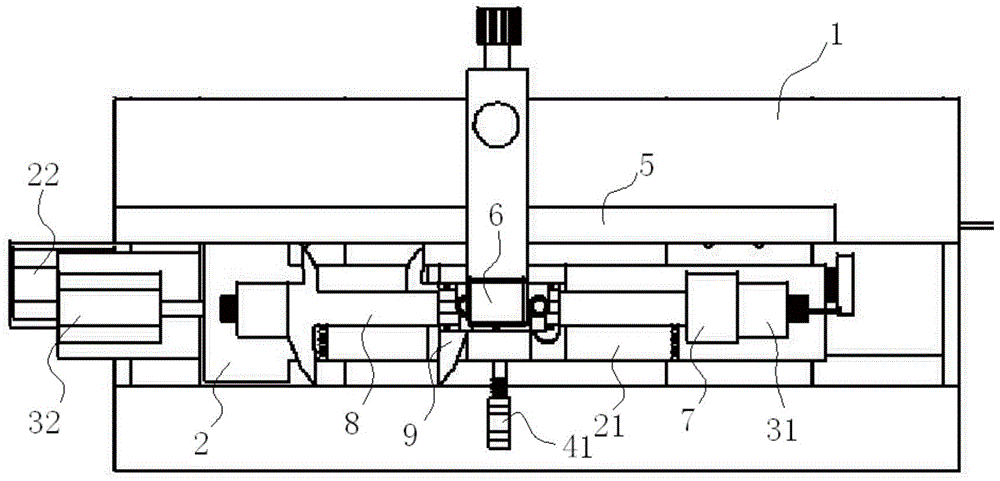

Simulative testing device and method of drilling tool thread dynamic fatigue

InactiveCN104677584ADoes not affect deliverySimple structureVibration testingTest fixtureData recording

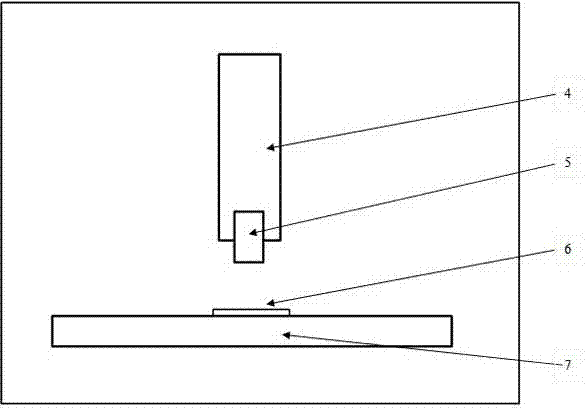

The invention relates to a simulative testing device and method of drilling tool thread dynamic fatigues in the technical field of petroleum and natural gas drilling engineering. The device comprises a base, a fine adjustment lifting device, a vibration exciter, a sliding bearing, a lower connection column, a vernier calliper, an upper connection column, a spring, a tensile nut, a compressive nut, a strain gauge and a measurement and control host. In the method, two parts including a static load module and a dynamic load module are adopted, wherein a static load is simulated by utilizing a spring mechanism; and a dynamic load is simulated by using a vibration excitation mechanism. By adopting the technical scheme, static tensile and compressive loads can be applied to a testing tubular column; dynamic excitation in different forms can also be applied; real-time monitoring and data recording of strain, exciting force and excitation frequency can be realized; and the device is simple in structure and convenient to use.

Owner:SOUTHWEST PETROLEUM UNIV

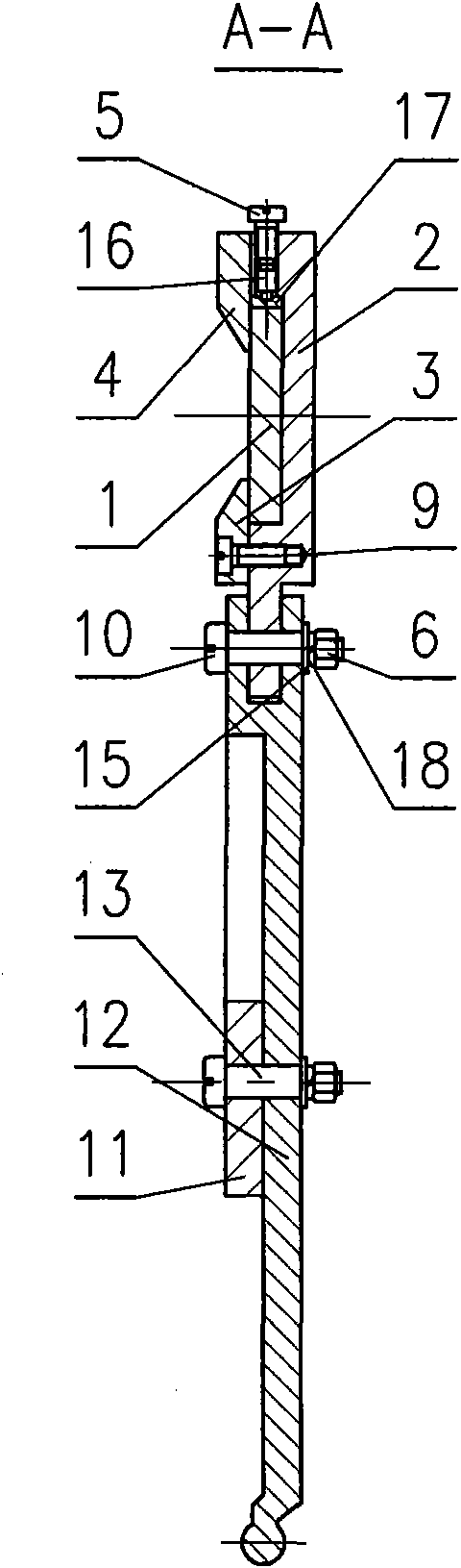

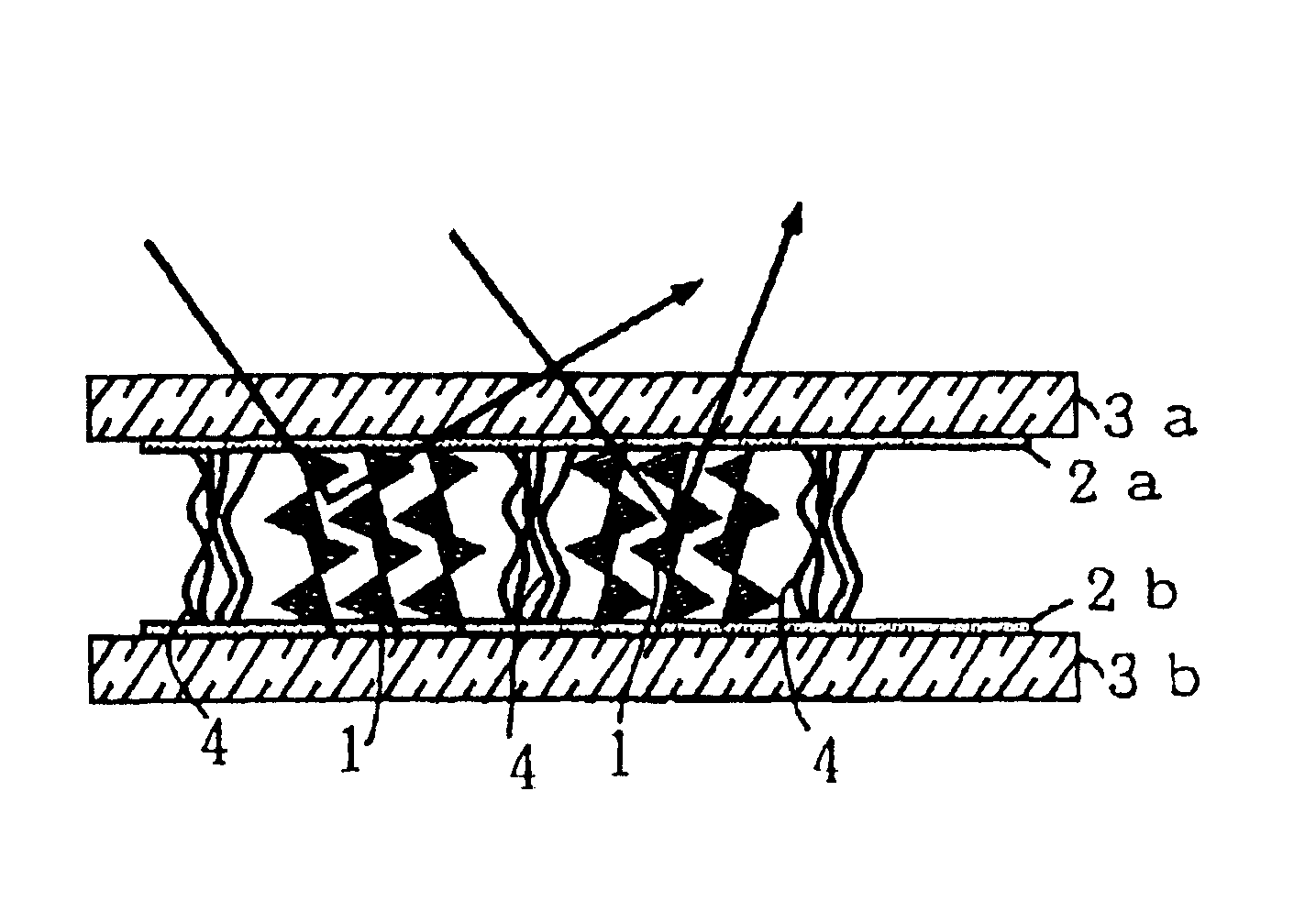

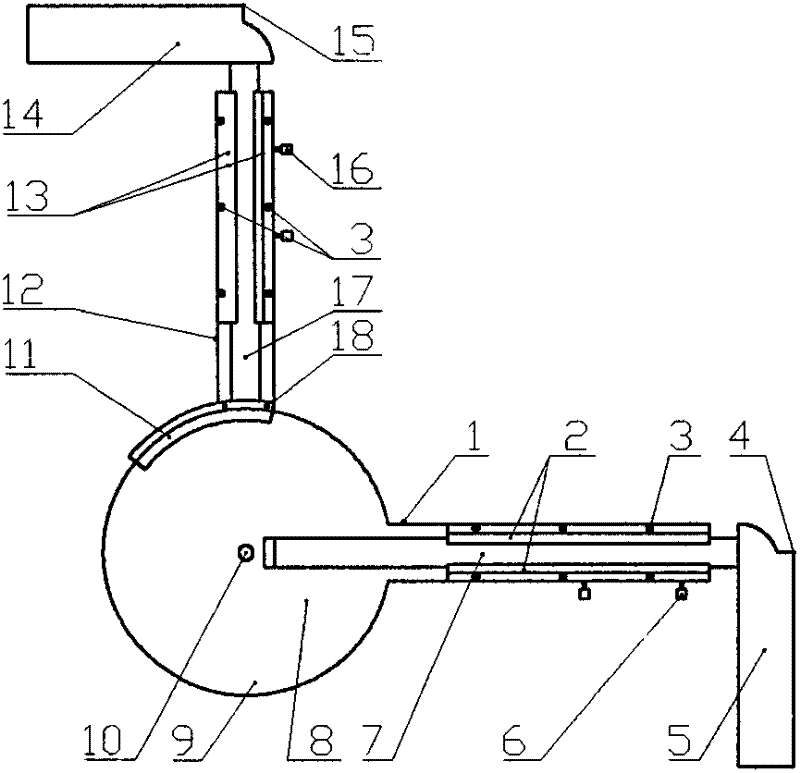

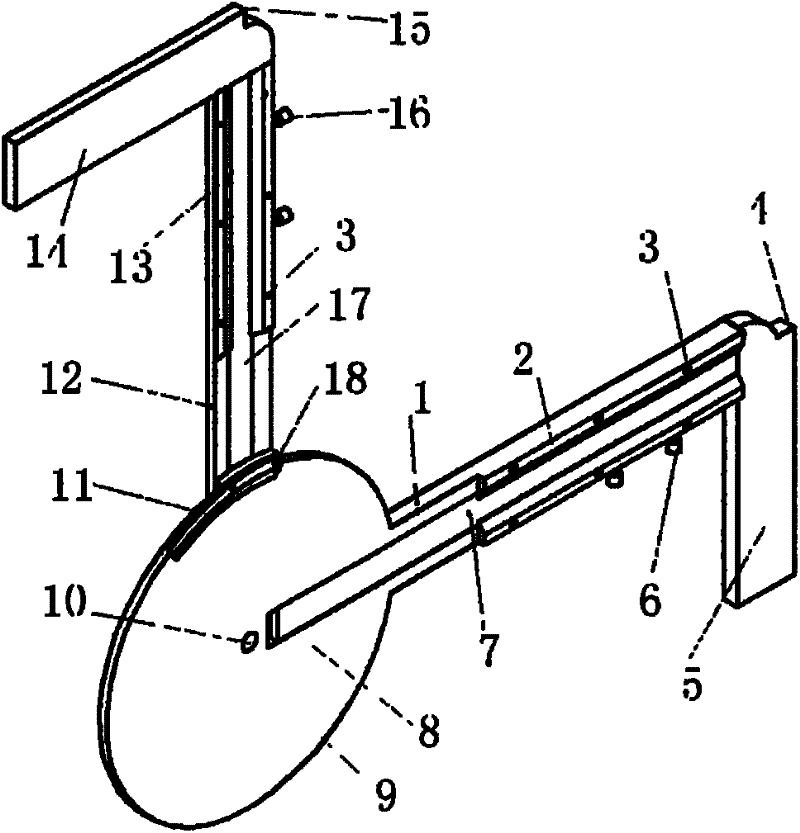

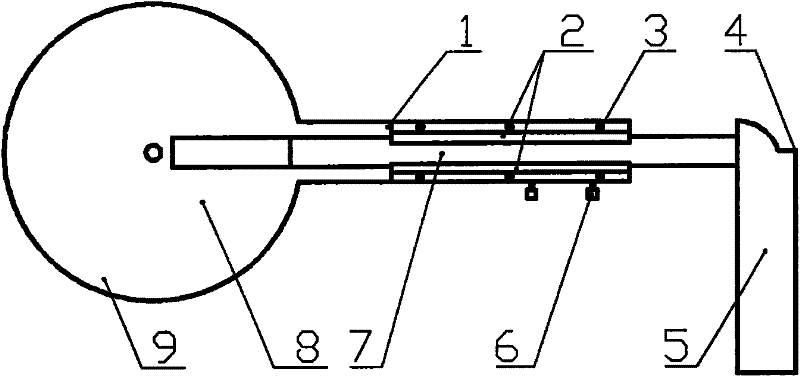

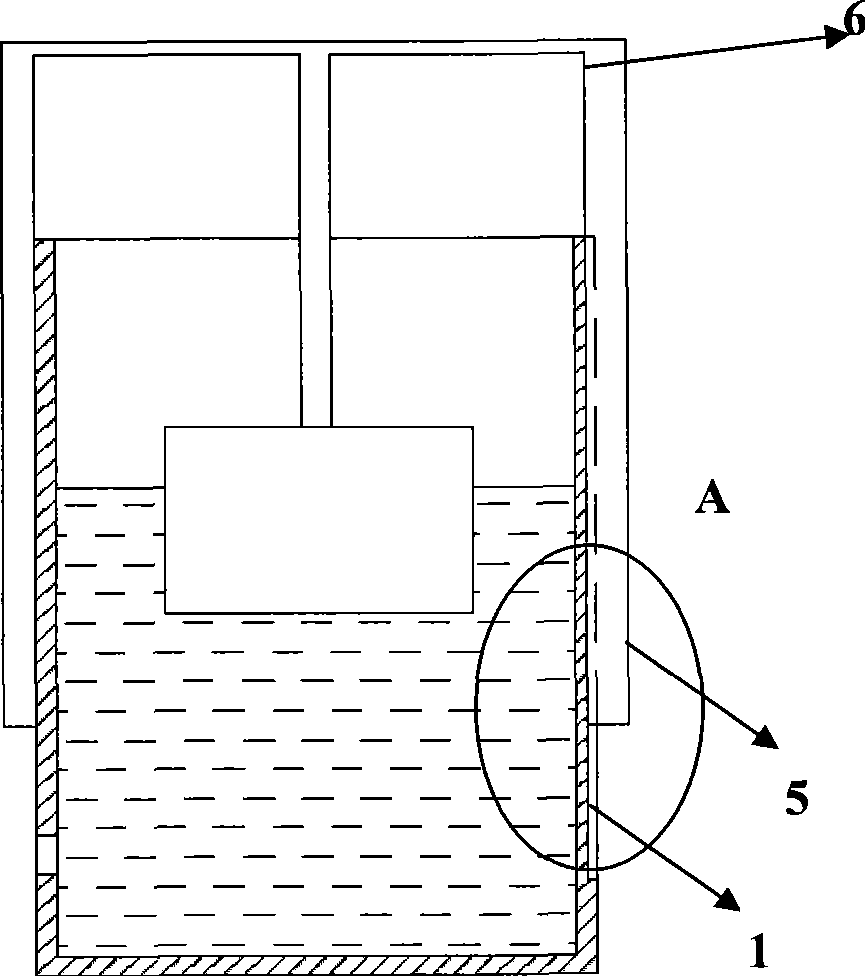

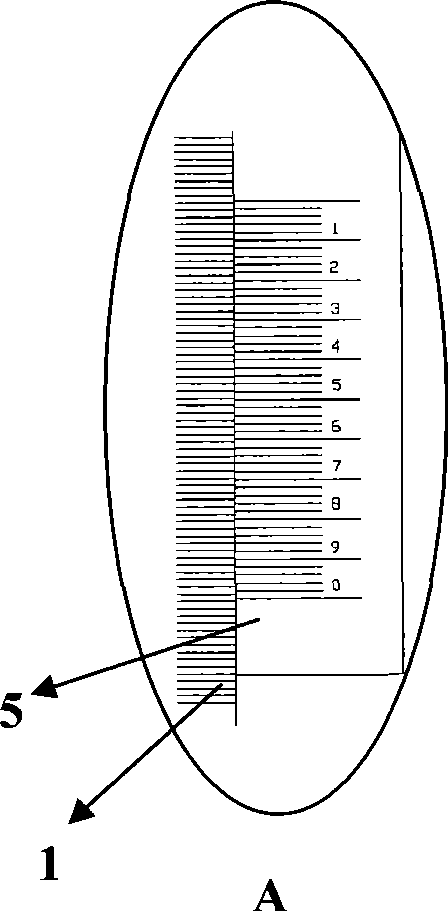

Vernier scale for measuring bending radius and bending angle of numerically-controlled bending pipe

InactiveCN102338613AAccurate measurementRealize measurementAngles/taper measurementsVernier scaleEngineering

The invention discloses a vernier scale for measuring the bending radius and bending angle of a numerically-controlled bending pipe. The vernier scale comprises a main scale, an angle scale and an auxiliary scale, wherein the angle scale is disk-like; the main scale and the auxiliary scale are strip-shaped; a main scale holder which extends in the radial direction is arranged on a disk body of the angle scale; an angle vernier scale is arc-shaped; the main scale is arranged on a disk surface of the angle scale through the main scale holder; the lower end of the auxiliary scale is connected to the center of the angle scale through a connection pin shaft and can freely rotate; the angle vernier scale is fixed on a scale body of the auxiliary scale; an inner arc-shaped edge of the angle vernier scale is in fit with a disk edge of the angle main scale; and central lines, in the length direction, of the main scale and the auxiliary scale respectively pass through the center of a circle of the angle scale. The invention has the advantages that: the bending radius and the bending angle of the numerically-controlled bending pipe can be accurately and effectively measured; a measurement value can be accurate to 0.02 mm; the measurement accuracy of the bending angle can be 0.02 DEG; and the vernier scale has the characteristics of simple structure, low manufacturing cost, easiness in assembly and operation and convenience for subsequent calculation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Vernier caliper calibrating device

The invention discloses a vernier caliper calibrating device. The calibrating device comprises a base, and further comprises a movable platform, a first clamp, a second clamp, an image acquisition device and a grating scale, wherein the movable platform is arranged on the base in a sliding manner; the first clamp is arranged on the movable platform, and is used for fixing the body of the vernier caliper; the second clamp is fixedly arranged on the base, and is used for fixing the vernier of the vernier caliper; the image acquisition device is fixedly arranged on the base, and is used for acquiring the scale images of the vernier caliper; the grating scale comprises an indicative grating and a scale grating; the indicative grating is fixed on the base; the scale grating is fixed on the movable platform. The calibrating device takes the grating scale with high precision to replace a standard gauge block for calibrating as calibrating standard; the precision of the vernier caliper calibrating device is improved; the whole calibrating process can be operated automatically; manual labor is saved; the calibrating efficiency is improved.

Owner:CHINA JILIANG UNIV

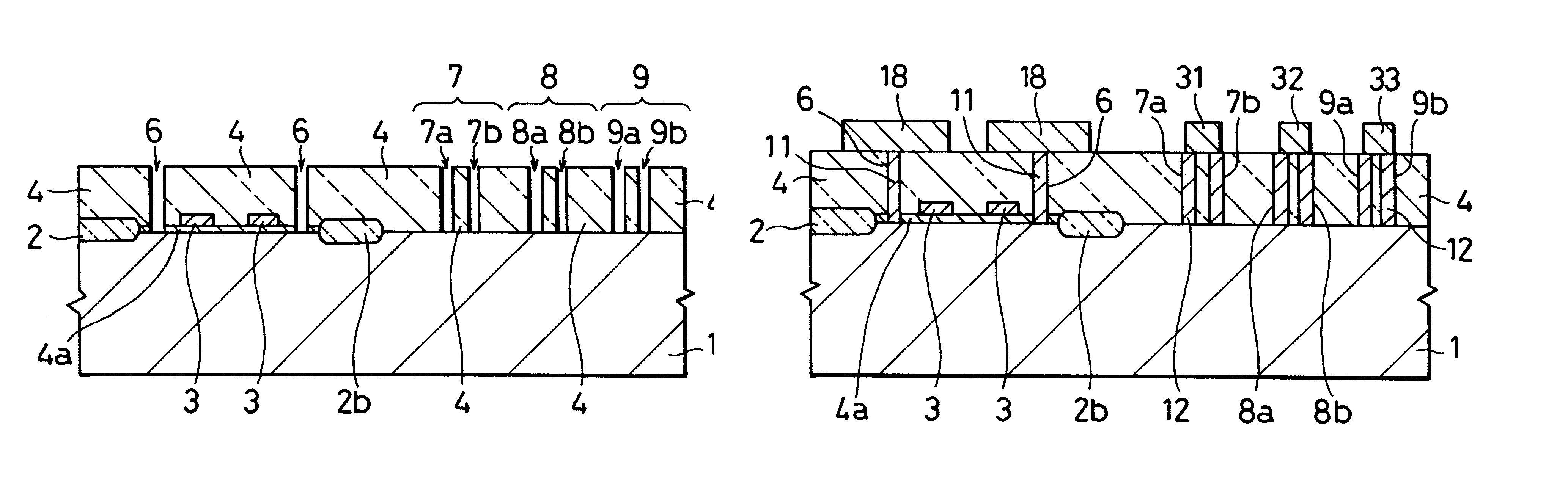

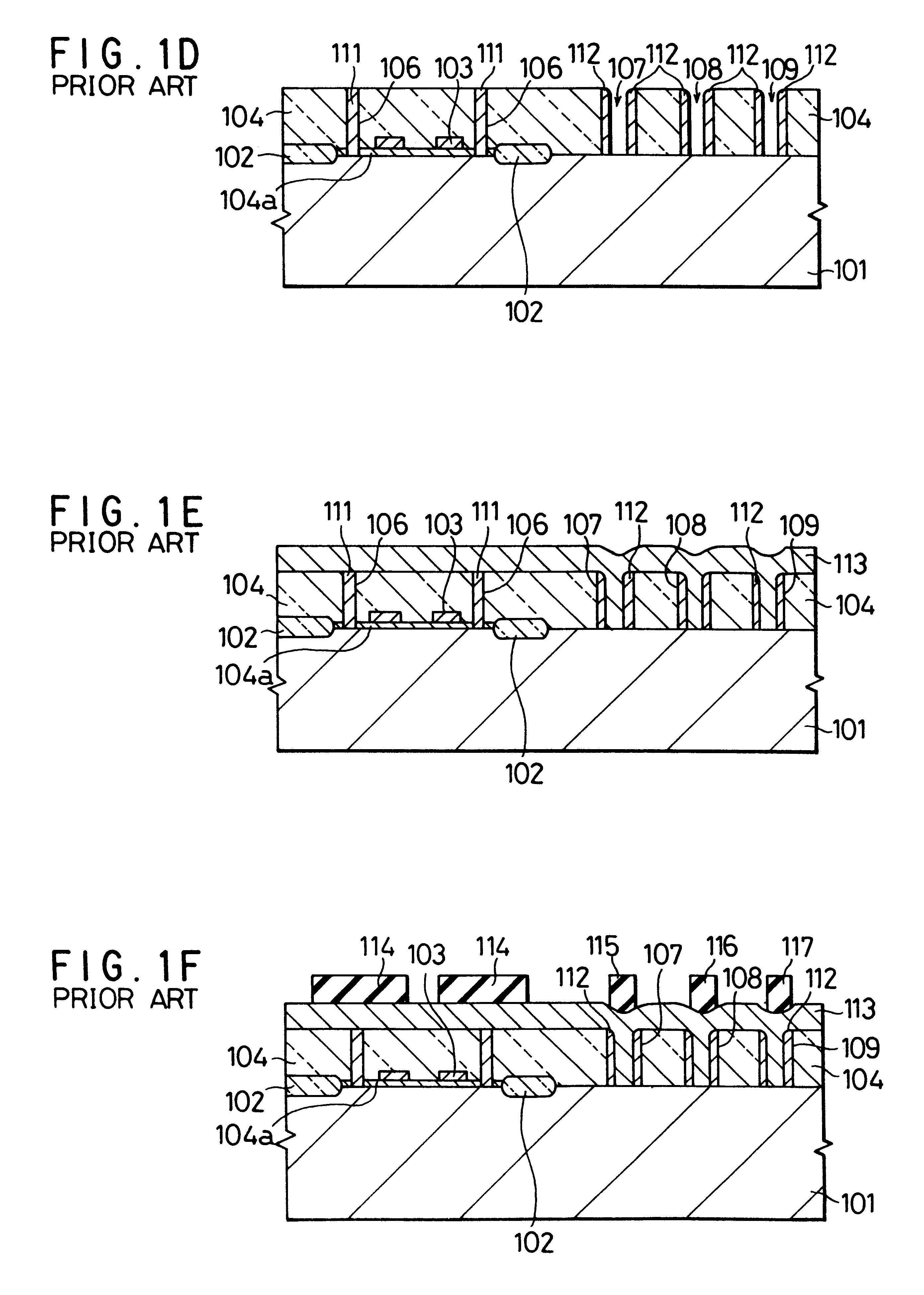

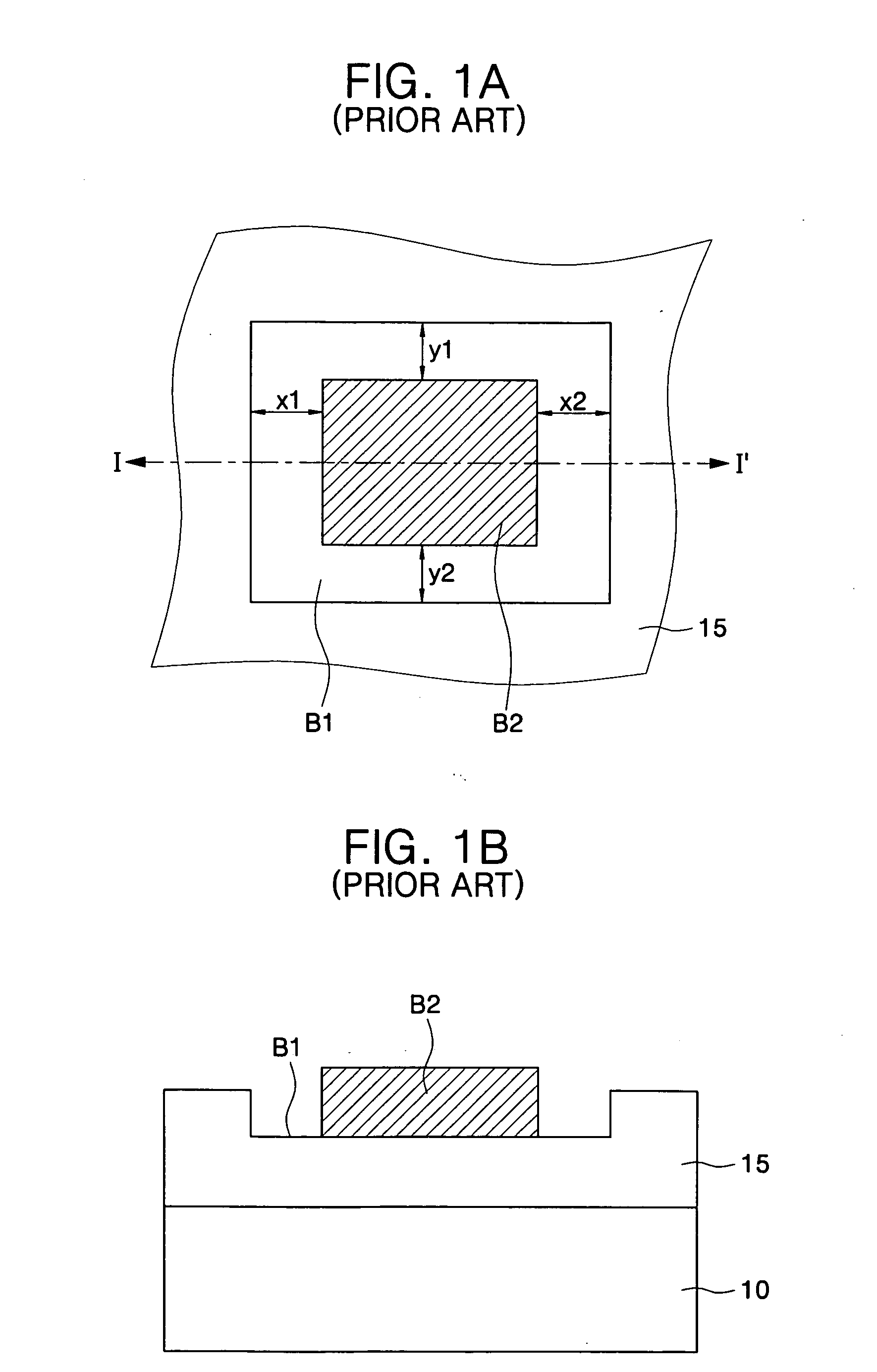

Fabrication method for semiconductor device utilizing parallel alignment slits

InactiveUS6316328B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsLithographic artistVernier scale

A fabrication method for a semiconductor device is provided, which is able to increase pattern-to pattern lithography overlay accuracy. After a first layer made of a first material is formed, first and second slits serving as a first alignment mark are formed in the first layer. The first and second slits are spaced with a specific distance and are approximately parallel to each other. Each of the first and second slits is filled with a second material. Then, a second layer made of a third material is formed on the first layer. Subsequently, a mask is formed on the second layer. The mask has a first pattern serving as a second alignment mark. The second alignment mark is overlapped with the first and second slits serving as the first alignment mark. Preferably, the first alignment mark provides the main scale of a caliper, and the second alignment mark provides the vernier scale of the caliper.

Owner:NEC ELECTRONICS CORP

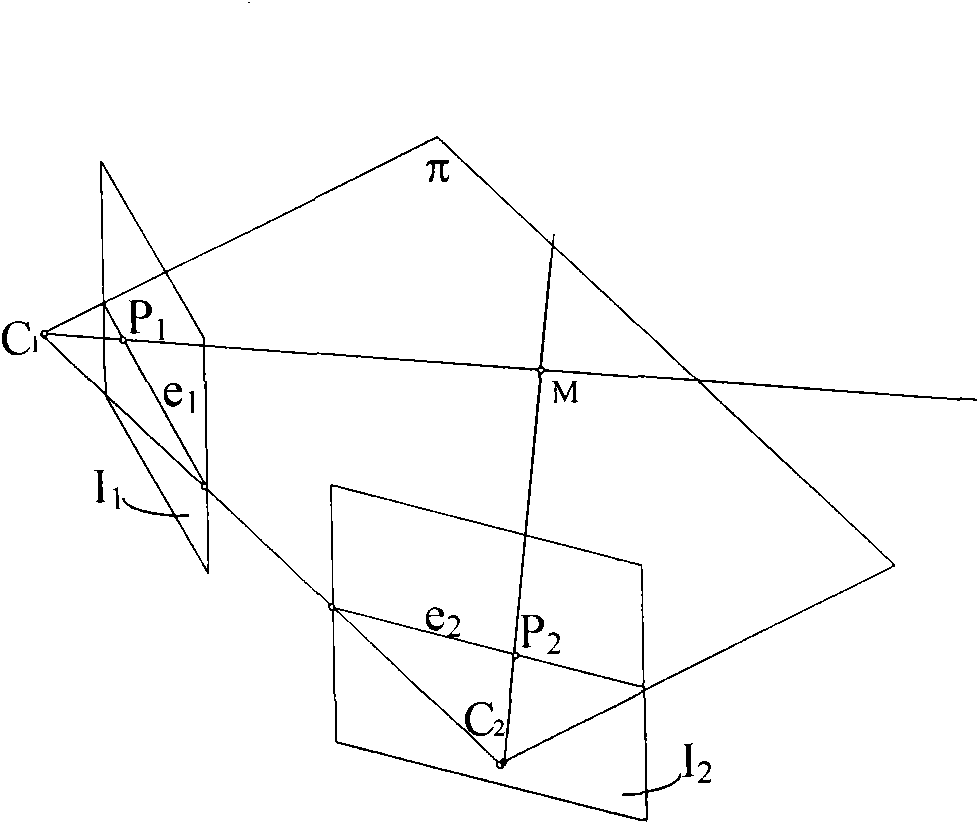

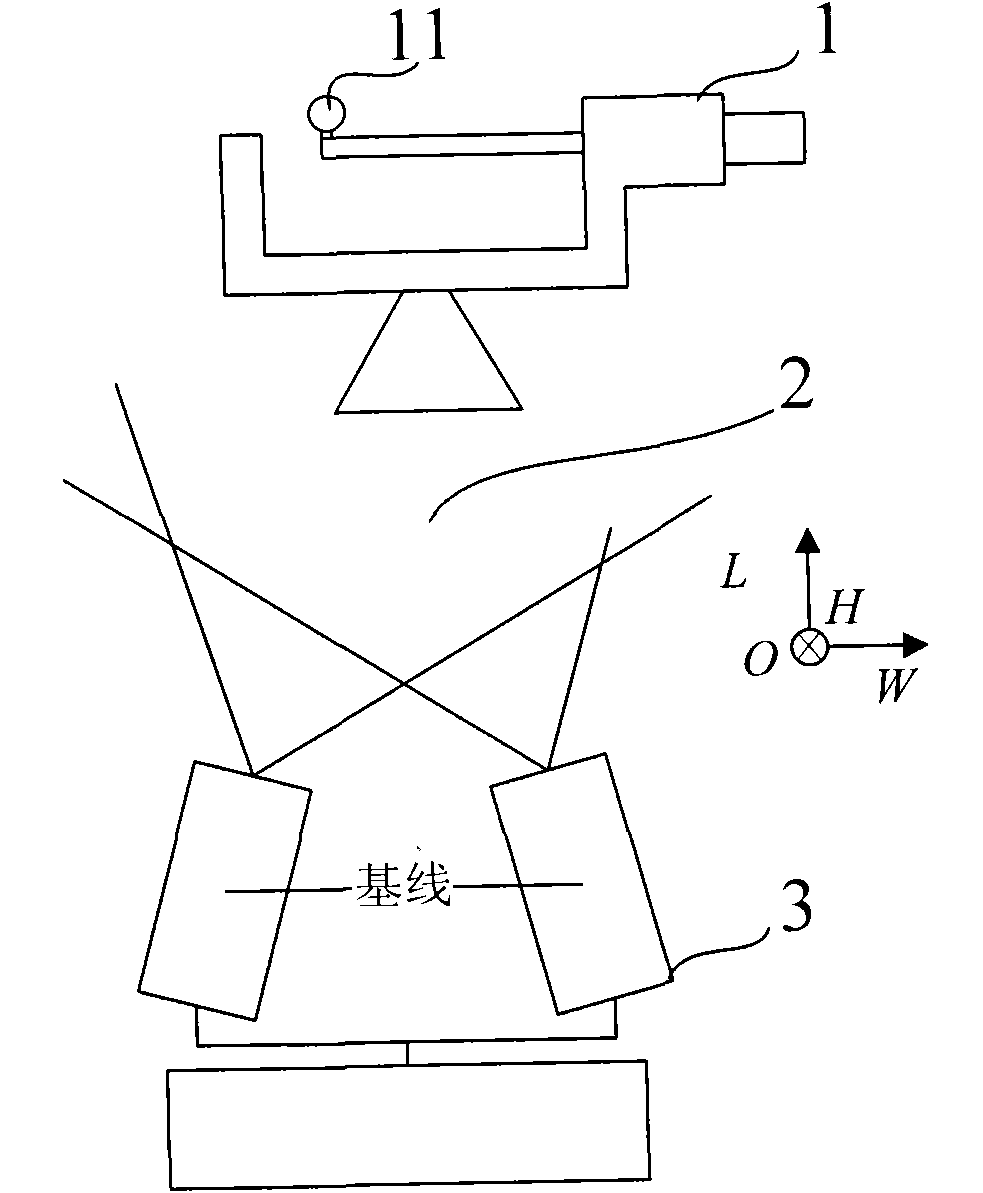

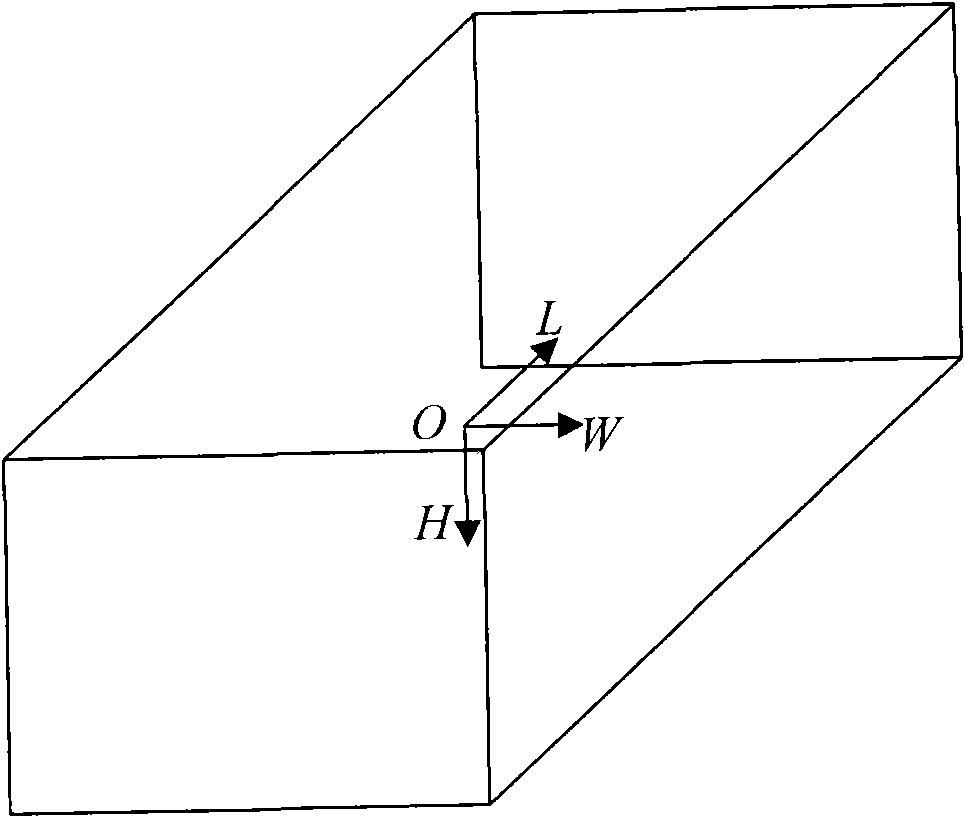

Method for measuring and calculating binocular vision displacement measurement errors and measuring system

The invention provides a method for measuring and calculating binocular vision displacement measurement errors and a measuring system based on a standard measuring tool (a screw micrometer or a vernier caliper). The method comprises the following steps of: arranging a marker on a meter head of the standard measuring tool; parallelly arranging the standard measuring tool in three coordinate axis directions in a three-dimensional coordinate system of a stereo space respectively, regulating the standard measuring tool to move the marker together with the meter heads in the three coordinate axis directions respectively and acquiring actual values of displacement of the marker; and calculating an arithmetic mean value of absolute values of the difference between the actual values and measured values of the displacement to acquire the displacement measurement errors in the three coordinate axis directions respectively, and calculating the displacement measurement errors in the three coordinate axis directions to acquire errors in an entire measurement range. The system comprises the standard measuring tool (the screw micrometer or the vernier caliper) and a binocular vision measurement device.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

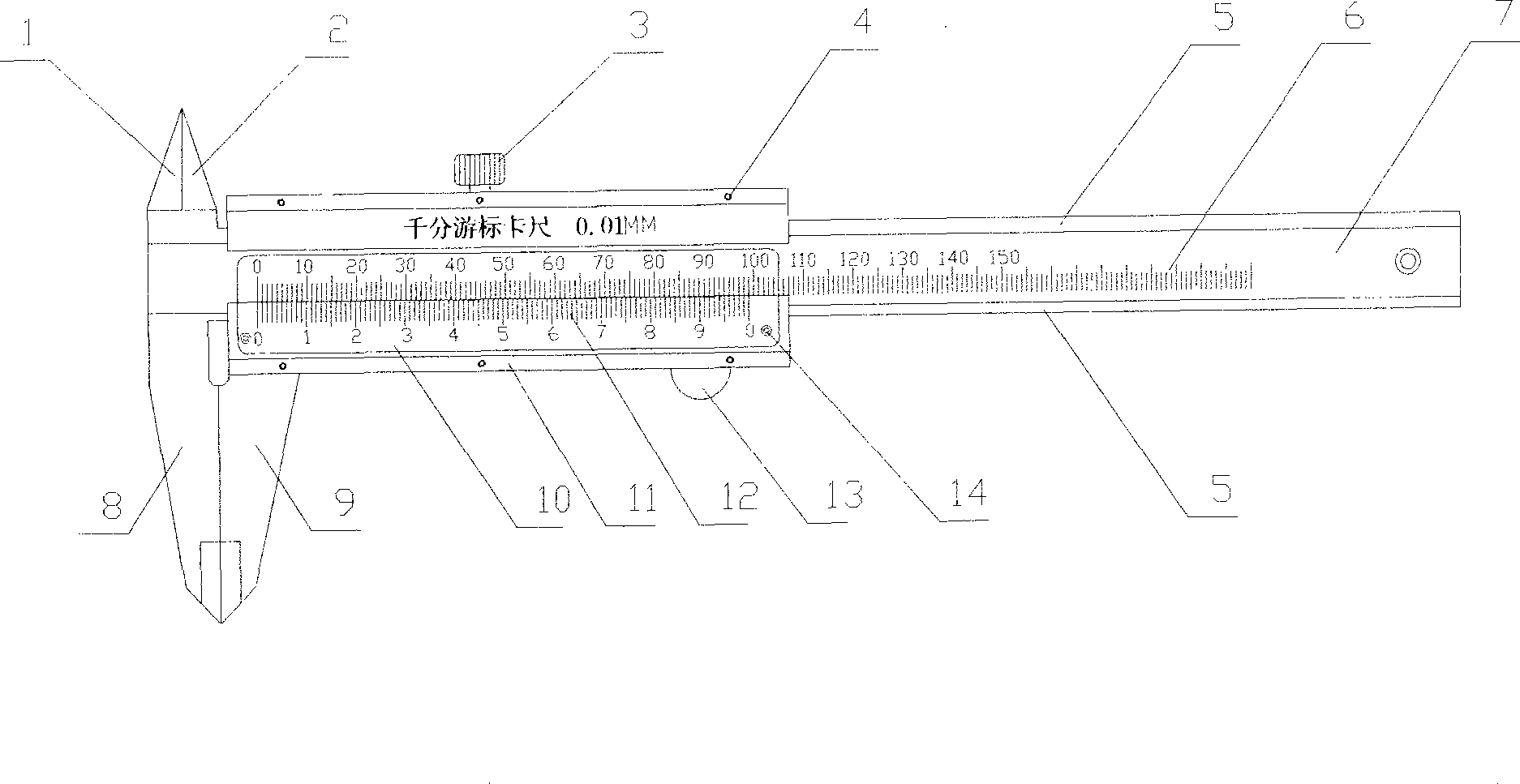

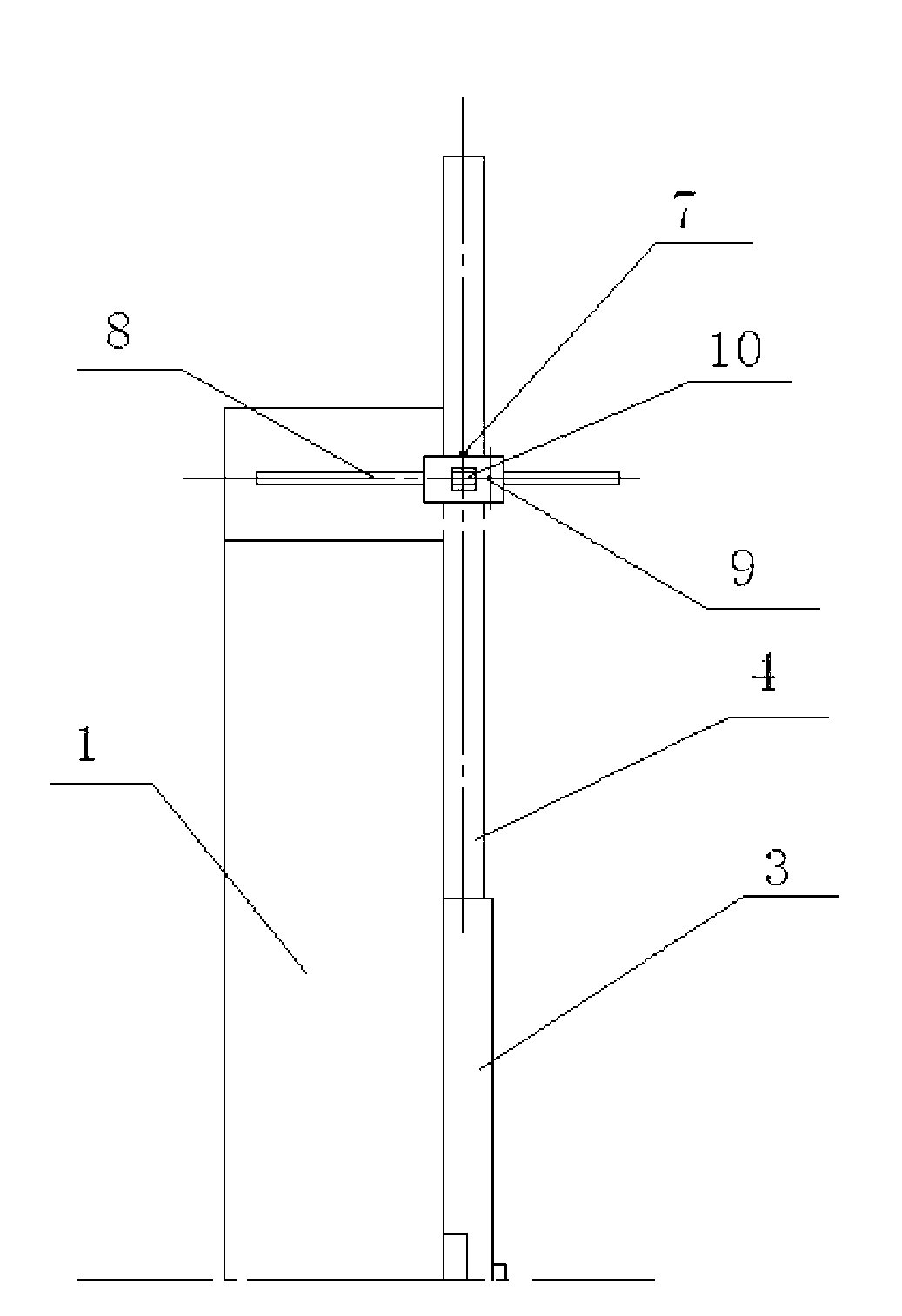

Micrometer vernier caliper

The invention discloses the function and the schematic diagram of a micrometer vernier caliper with the accuracy being 0.01 mm. The micrometer vernier caliper structurally comprises a main scale 7, an adding tape 11, a magnifying glass lens 10, a main scale outer diameter measuring end wall 8, an adding tape outer diameter measuring end wall 9, a main scale graduation 6, an adding tape graduation 12, a main scale inner diameter measuring end wall 1, an adding tape inner diameter measuring end wall 2, an adding tape anti-displacement fastening screw 3, an adding tape retaining screw 4, a chute 5, an adding tape propelling sheave 13 and a magnifying glass lens retaining screw 14. The invention has the advantages that the accuracy is very accurate; the use is convenient and durable; the popularization and the application are easy; and the market prospect is wide.

Owner:张繁荣

Heat contractibility rate measuring method for furniture thermoplastic plastic edge sealing stripes

ActiveCN101957332AThe determination method is simpleSimple test equipment usedMaterial thermal coefficient of expansionThermoplasticVernier scale

The invention discloses a heat contractibility rate measuring method for furniture thermoplastic plastic edge sealing stripes. The heat contractibility rate measuring method comprises the following steps of: preparing a circulating air oven, a test desk, a timer, a glass plate and talcum powder; preparing a sample and measuring the length L1; placing the test desk in the circulating air oven, and placing the glass plate on the test desk and uniformly spreading the talcum powder; adjusting the temperature of the circulating air oven to 60 to 70 DEG C, and placing the sample on the talcum powder; timing by utilizing the timer, taking out the sample after 4 hours, horizontally placing the sample for cooling at the room temperature, and measuring the length L2; and calculating the heat contractibility rate according to a formula. The invention adopts simple devices comprising the circulating air oven, the test desk, a slide calliper, the glass plate and the talcum powder. The temperature is controlled by the circulating air oven, i.e. the heat contractibility rate of edge sealing stripe products can be directly measured. The measuring method is simple and visual, the measuring result comes from practical per se, and the heat contractibility rate of the furniture edge sealing stripe products before and after edge sealing can be conveniently measured, thus the measuring result is more accurate.

Owner:东莞市华富立装饰建材有限公司

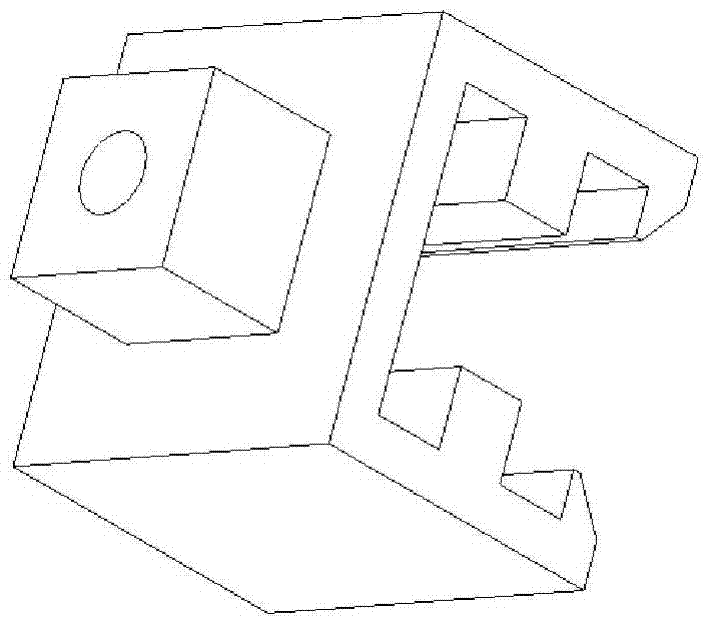

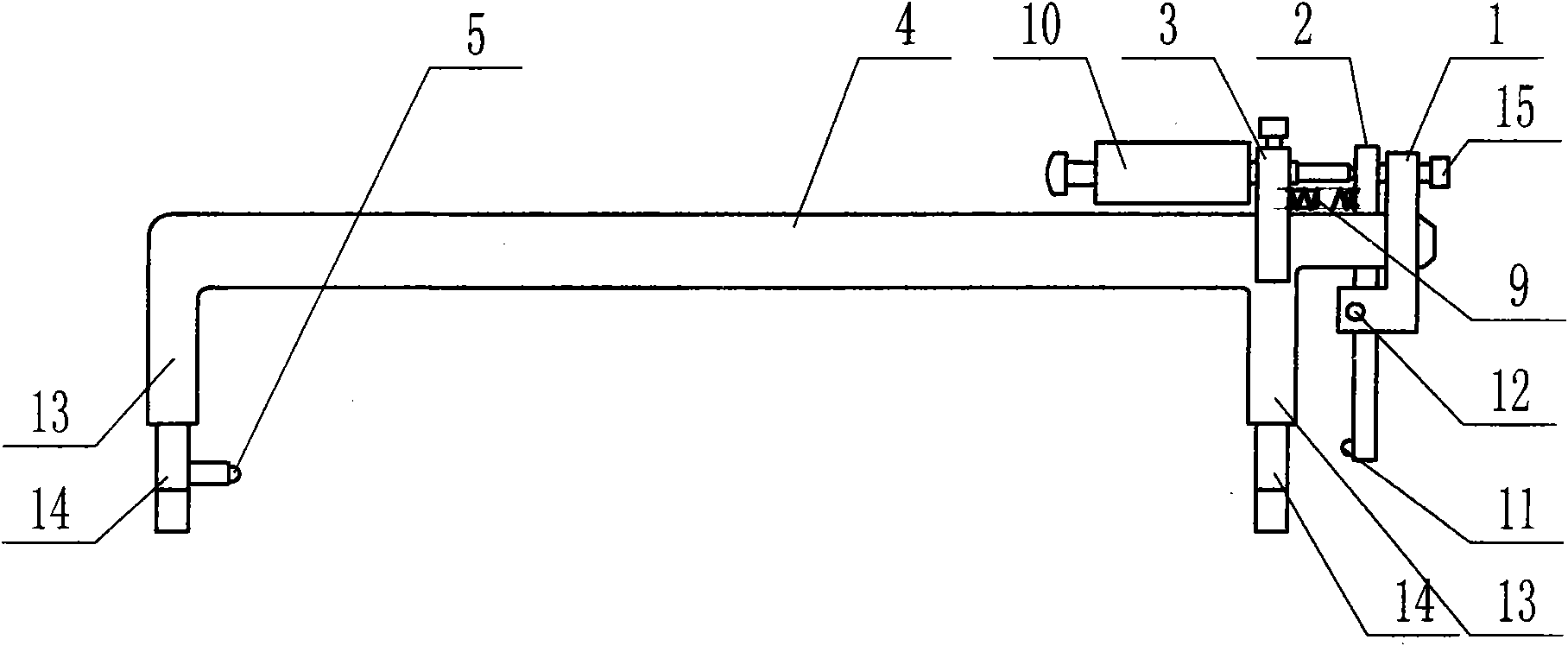

Check tool for measuring axial length of crank shaft and application thereof

ActiveCN101776429AAccurate measurement of axial lengthEasy to measure onlineMechanical measuring arrangementsVernier scaleEngineering

The invention discloses a check tool for measuring the axial length of a crank shaft and the application thereof. The check tool is characterized in that both ends of a measuring frame are respectively provided with downwards vertical measuring arms, the end heads of the measuring arms are respectively provided with positioning blocks, a positioning measure head is arranged on one positioning block, the other end of the measuring frame is provided with a measuring measure head opposite to the positioning measure head, the measuring measure head is arranged on one end of a lever, and the other end of the lever is in contact with a dial indicator. The invention also discloses a method for applying the check tool to the axial length detection of the crank shaft and the online axial length detection method of the crank shaft in the processing station of a machine tool. The check tool has high measuring precision, can be used for accurate measurement on occasions with two measuring points which have unequal heights and can not be accurately measured by vernier calipers, can also conveniently realizes the on-line measurement of the crank shaft in the processing station of a machine tool and avoid rapidly advanced grinding wheels colliding with workpieces to scrap the crank shaft.

Owner:桂林福达曲轴有限公司

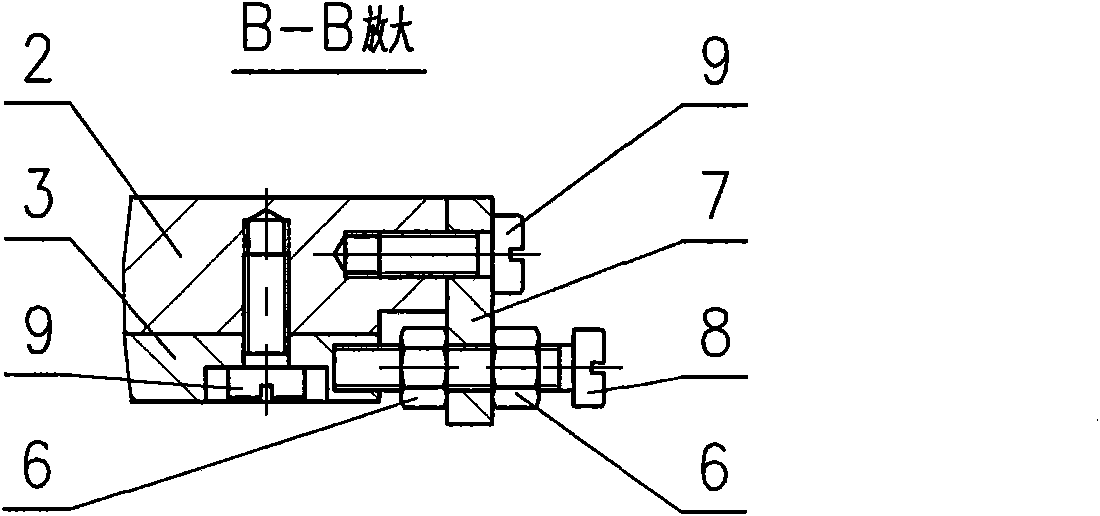

Clinometer calibration stand

ActiveCN103994780AHigh measurement accuracyGuaranteed measurement accuracyIncline measurementVernier scaleDrive shaft

The invention relates to a clinometer calibration stand. Adjustable landing legs are arranged at the bottom of a three-leg support frame, an upright column is arranged on the three-leg support frame, a mandrel is coaxially arranged in the axial center of the upright column, a rotary table is arranged above the mandrel, and a Y-axis vernier angle caliper is arranged at the periphery of the rotary table; a square supporting seat is connected to and positioned above the rotary table, a transmission shaft penetrates through the square supporting seat to be connected with a rotating disc large gear, a gear supporting seat of an adjusting small gear is arranged above the square supporting seat, the adjusting small gear is meshed with the rotating disc large gear, and an X-axis vernier angle caliper is arranged on the gear supporting seat; a U-shaped connecting frame is arranged at the other side of the transmission shaft, and a Z-axis vernier angle caliper is erected on the U-shaped connecting frame. The clinometer calibration stand disclosed by the invention can be used for accurately calibrating the angles of three coordinate axes by being provided with a three-circumference adjustable rotating mechanism and carries out micro-adjustment through the vernier scale of each coordinate axis, thereby enhancing the measurement accuracy, guaranteeing the convenience for adjustment and ensuring the measurement accuracy of a clinometer.

Owner:SHENYANG AIRCRAFT CORP

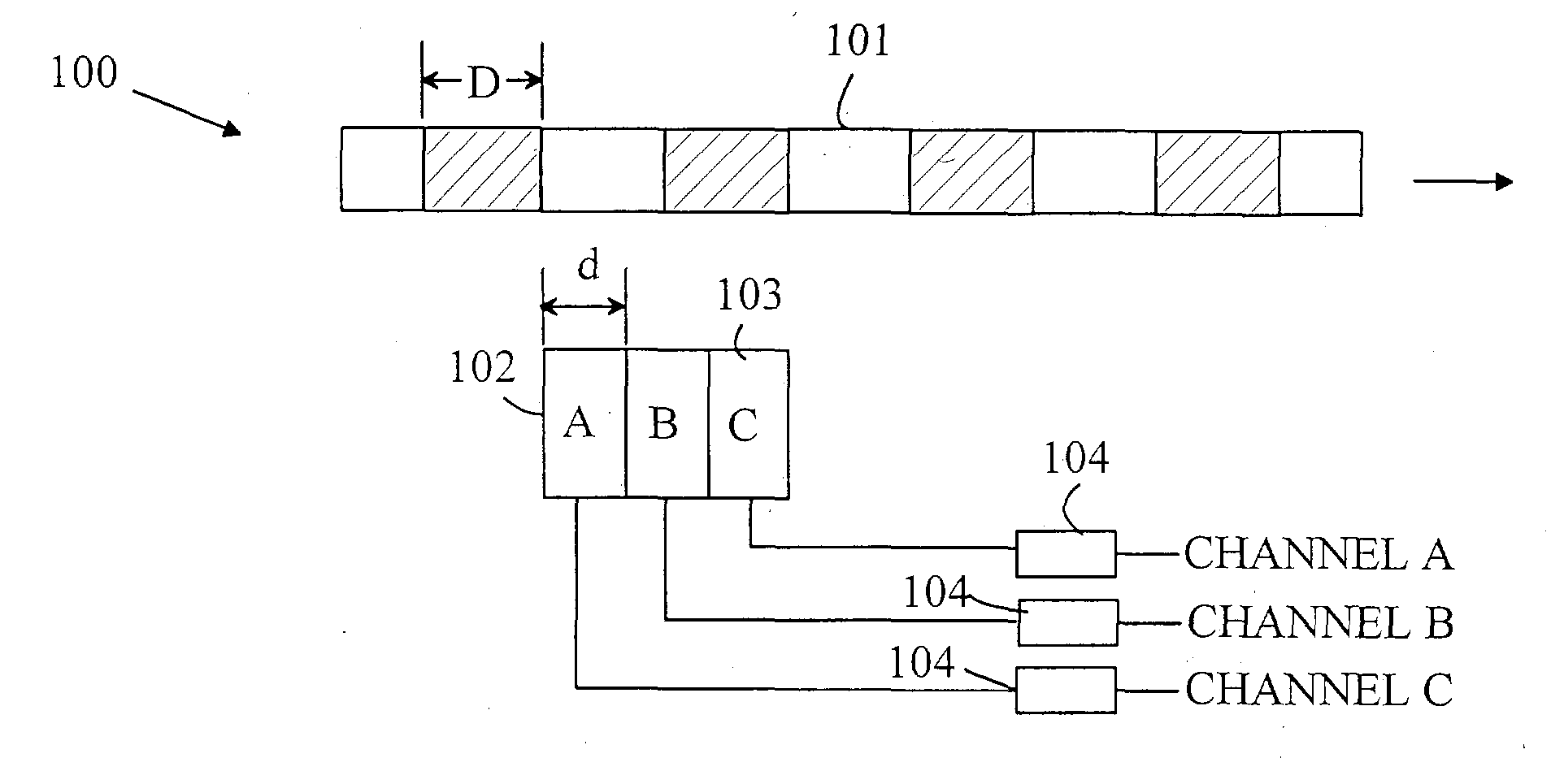

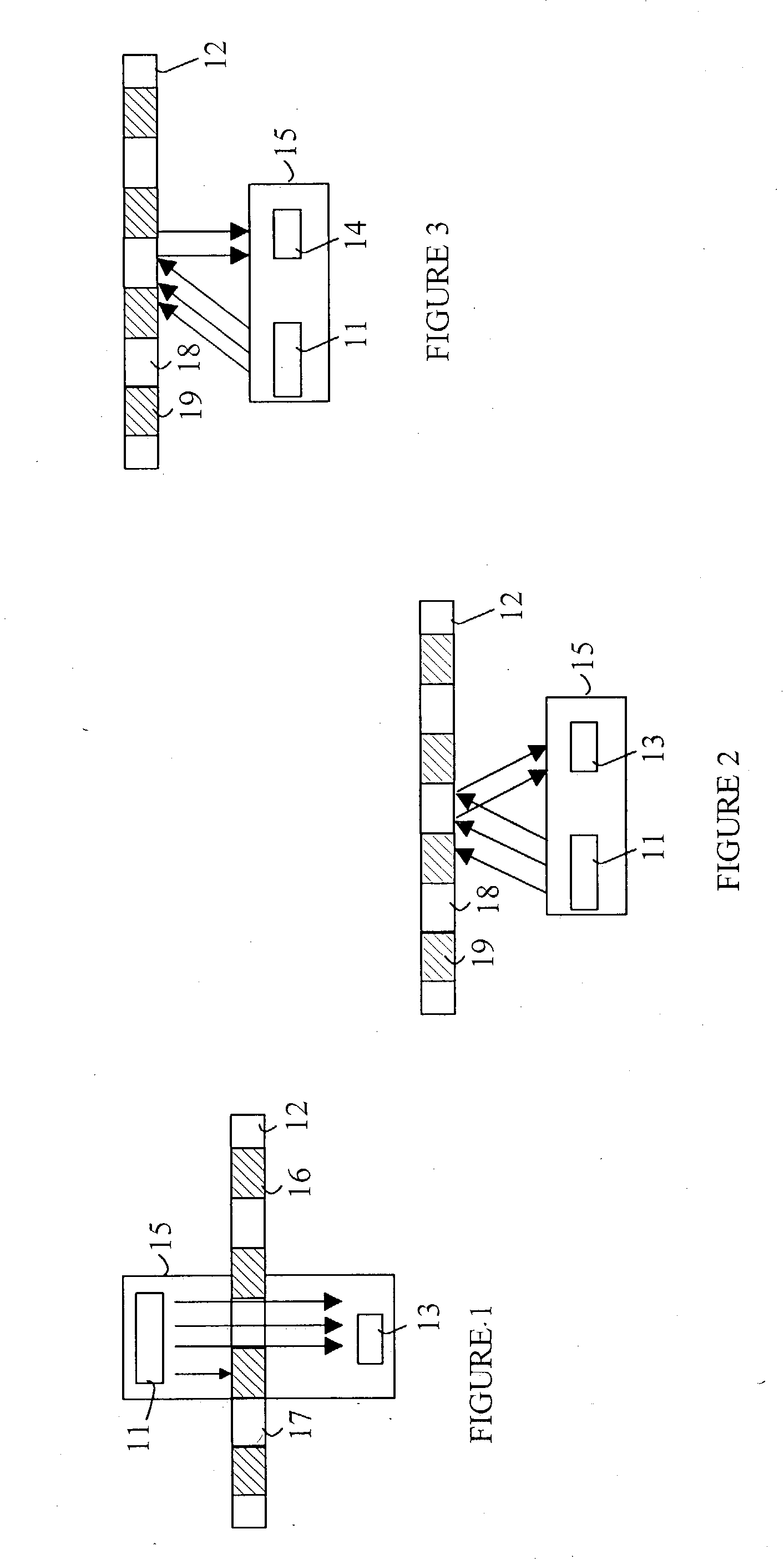

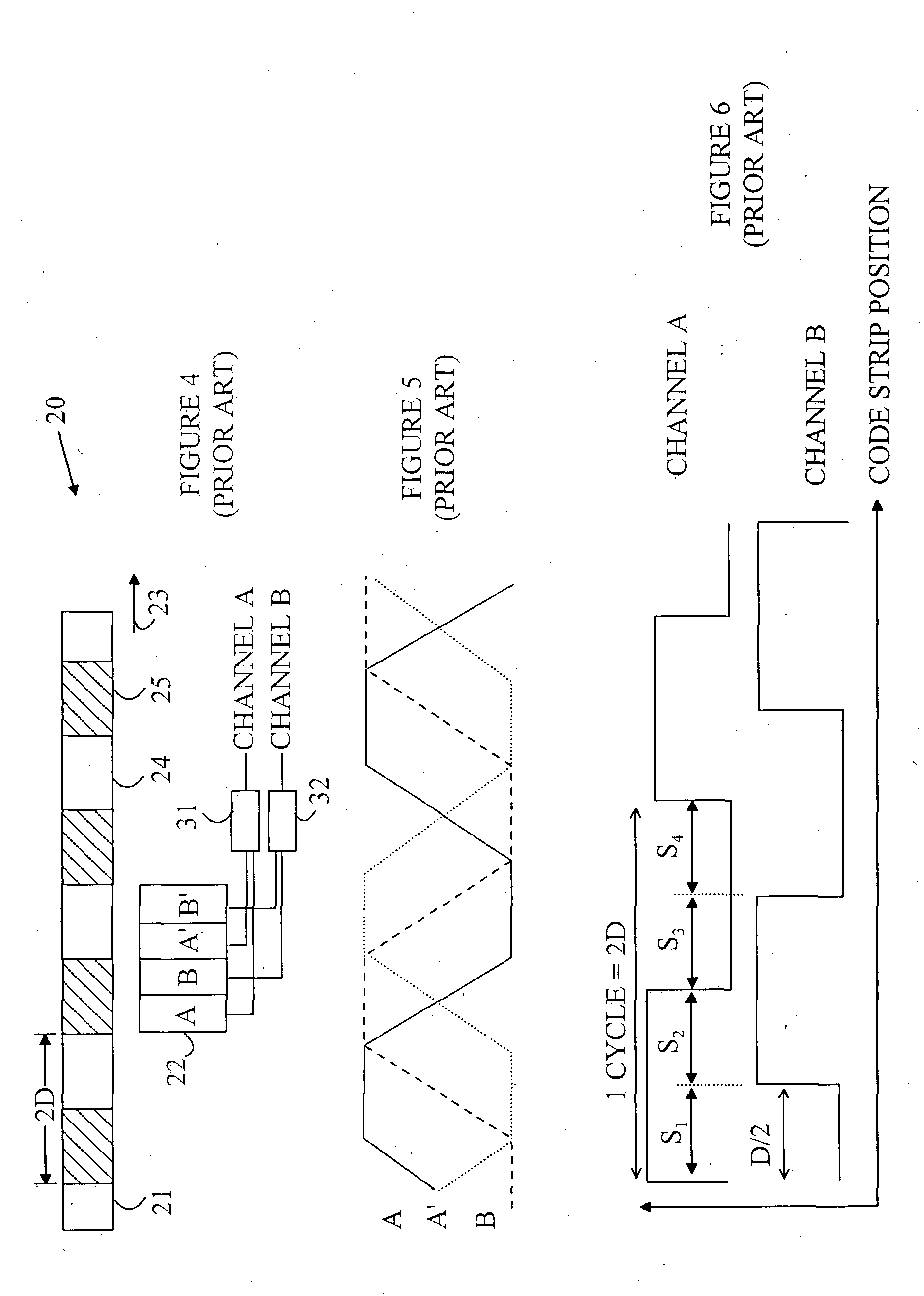

Vernier-scaled high-resolution encoder

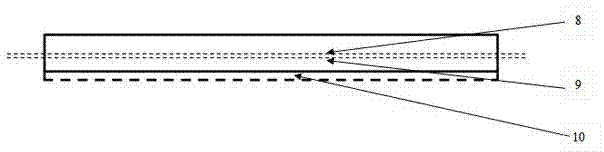

InactiveUS20050006571A1Material analysis by optical meansConverting sensor output opticallyVernier scaleDetector circuits

An encoder having a first array of n photodetectors and a code strip imaging system where n>2 is disclosed. Each photodetector is characterized by a width d. The code strip imaging system generates an image of a code strip on the first array. The image includes alternating dark and light stripes of width D. The dark stripes have a lower luminosity than the white stripes. The widths of the photodetectors and stripes in the image are chosen such that nd=(n−1)D, the code strip image moving in a first direction with respect to the first array, wherein the distances d and D are measured in a direction parallel to the first direction. Detector circuits convert the outputs from the photodetectors to logic signals that define a state for the encoder that repetitively cycles through 2n values when the code strip image moves a distance of 2D.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

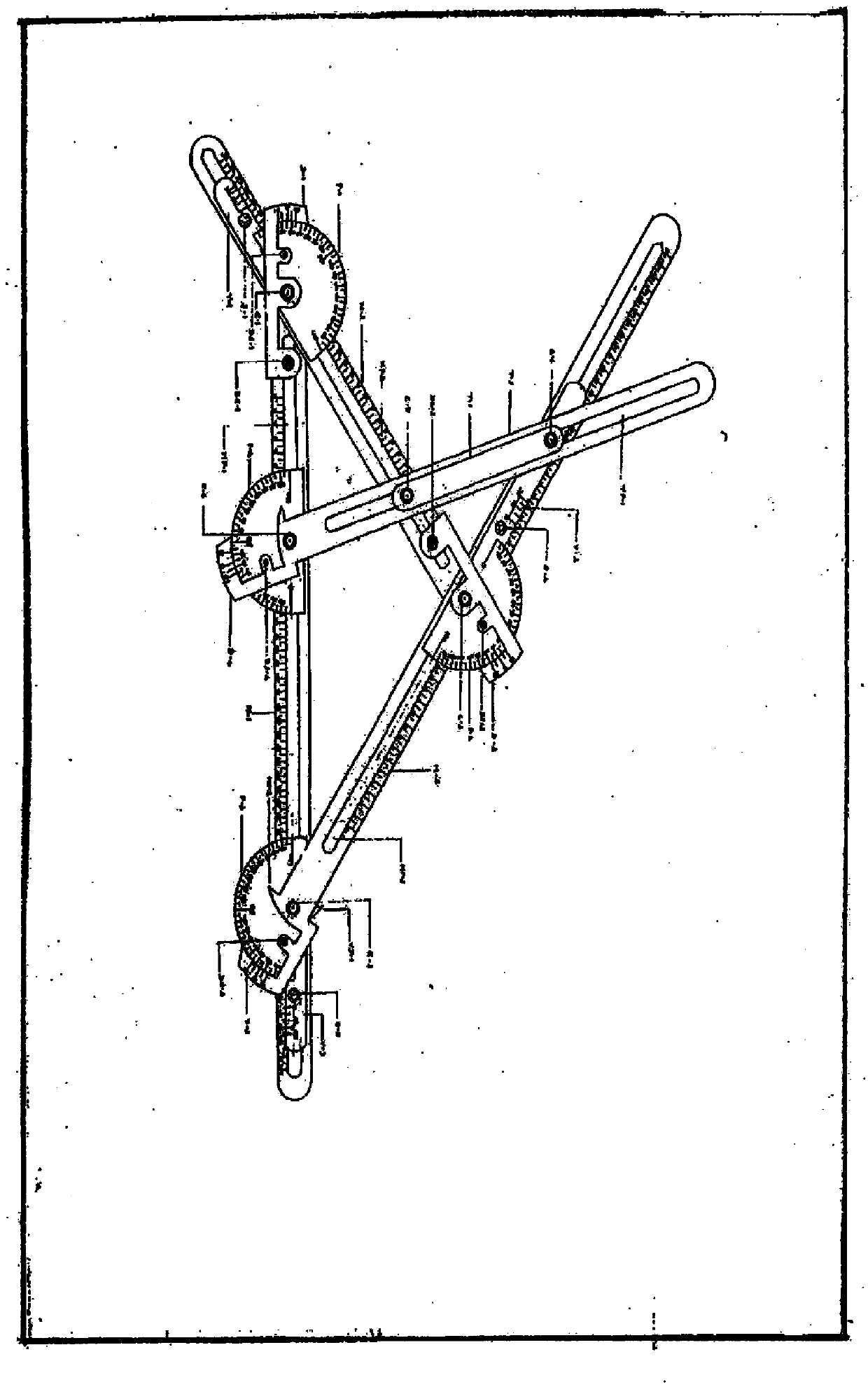

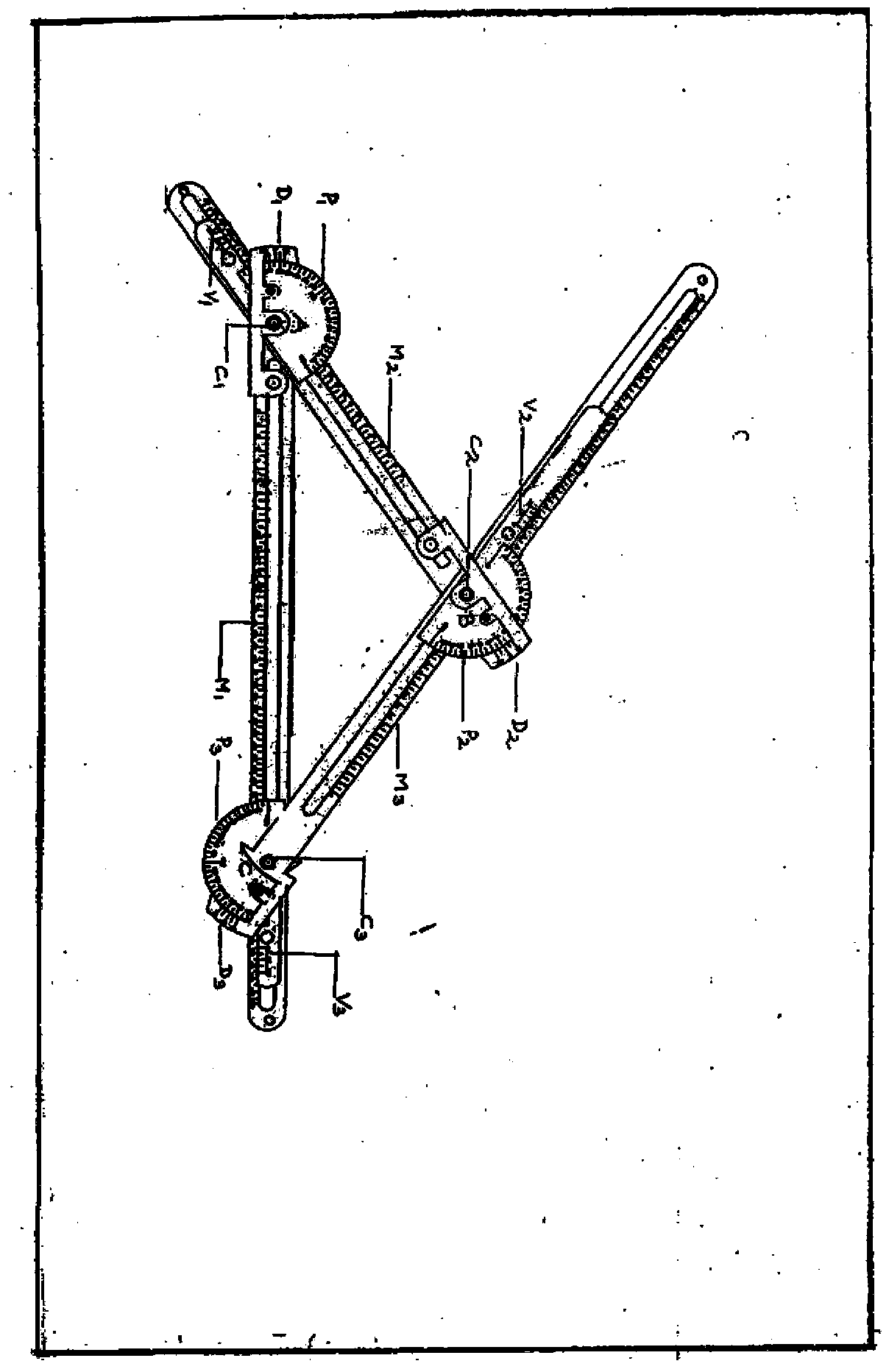

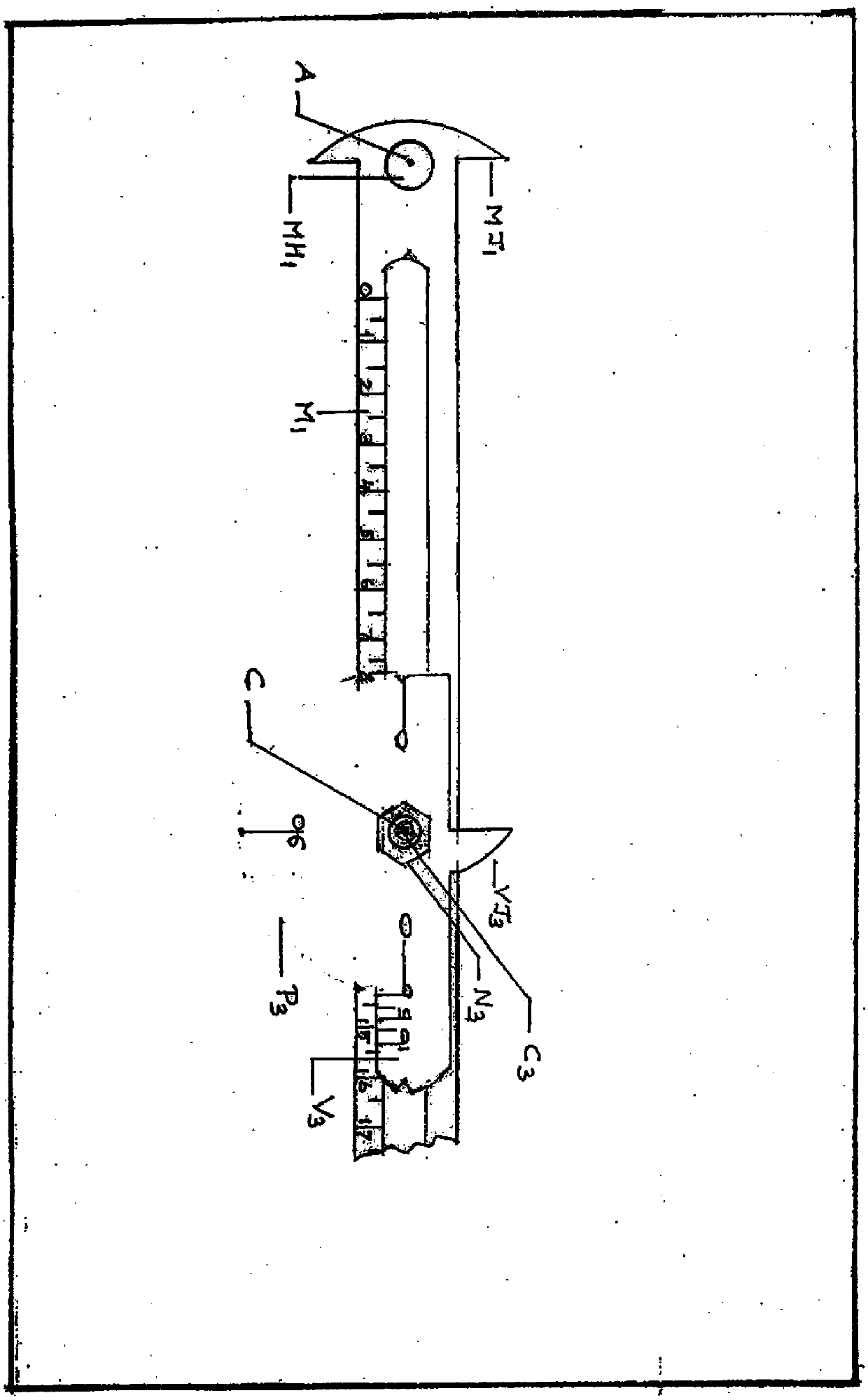

A multipupurpose instrument for triangle solutions, measurements and geometrical applications called triometer

The invention "Trio-meter"is a multipurpose instrument by using- "Multi-slotted link sliding assembly mechanism" - for triangle solutions including 'Pythagoras theorem' as a ready reckoner (Fig.II). Useful instrument with marker block attachment to draw and measure straight lines, lengths, arcs, semi circles, circles, bicircles, tricircles, parallelograms, rhombuses, trapezoids, parallel lines and triangles with fractional and accurate measurements easily and quickly (Fig. Ill to VIII). The novel instrument with trisector attachments, trisects an angle and multiplies an angle into double, triple & quadruple as well as reduces an angle in to two-third^ half, one third and quarter fractionally and accurately (Fig. IX). It comprises three slotted links with in-built main measuring scales, which are also working as sides of a triangle, three vernier calipers with three protractors and three indicators, assembled by centre pins, with all necessary attachments, parts and components (1 to 99) for complete operations and perfect functioning.

Owner:R·K·斯瓦密 +4

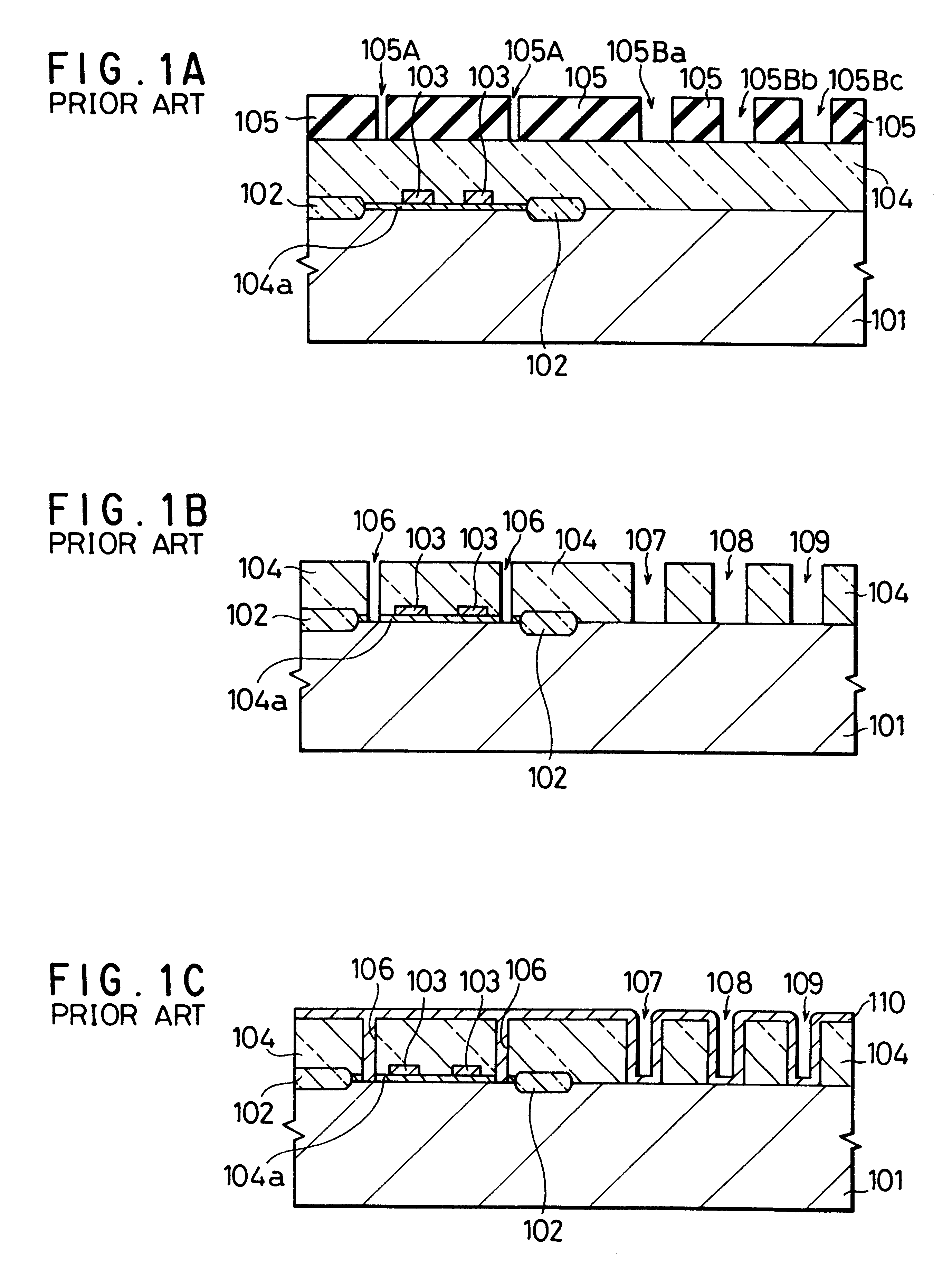

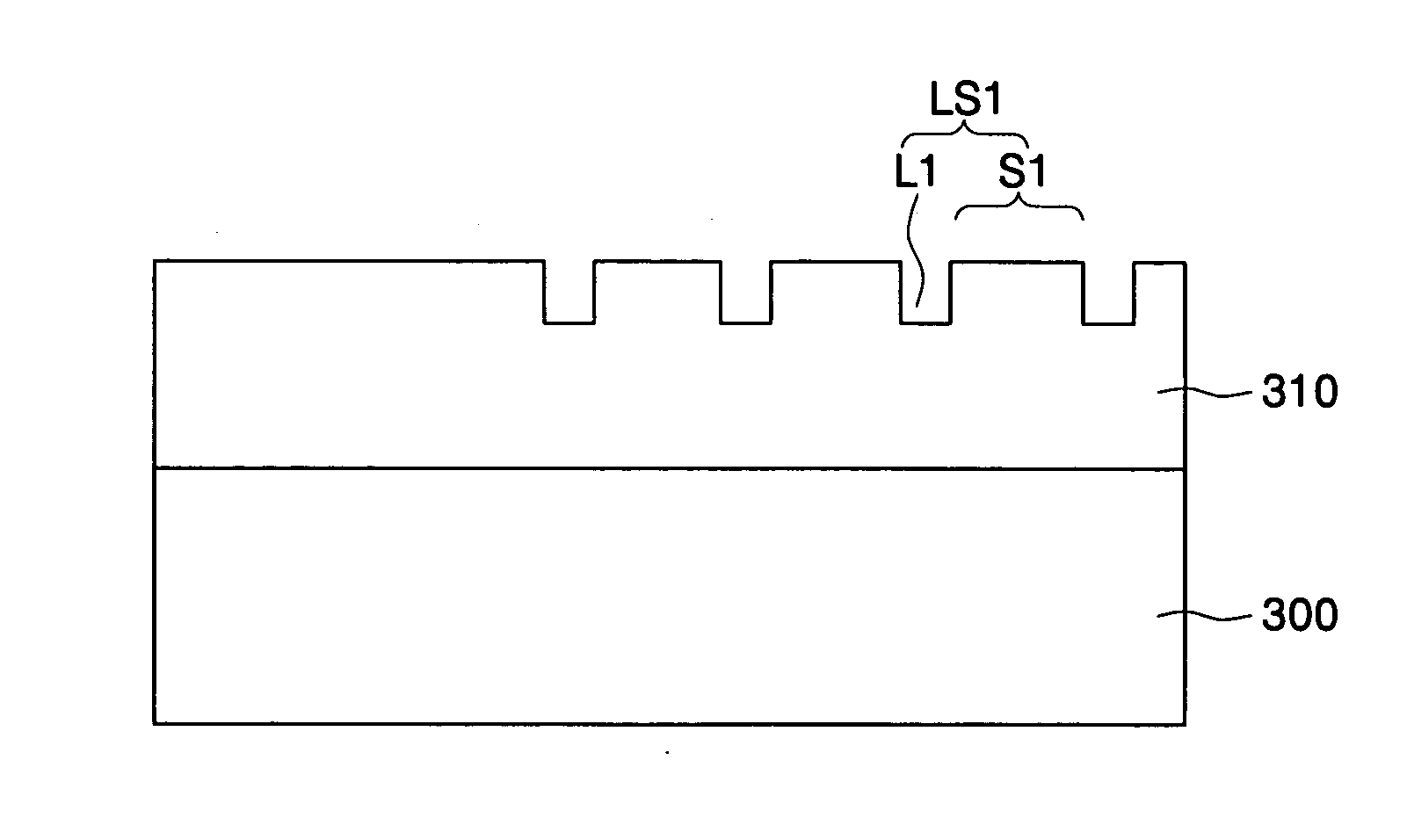

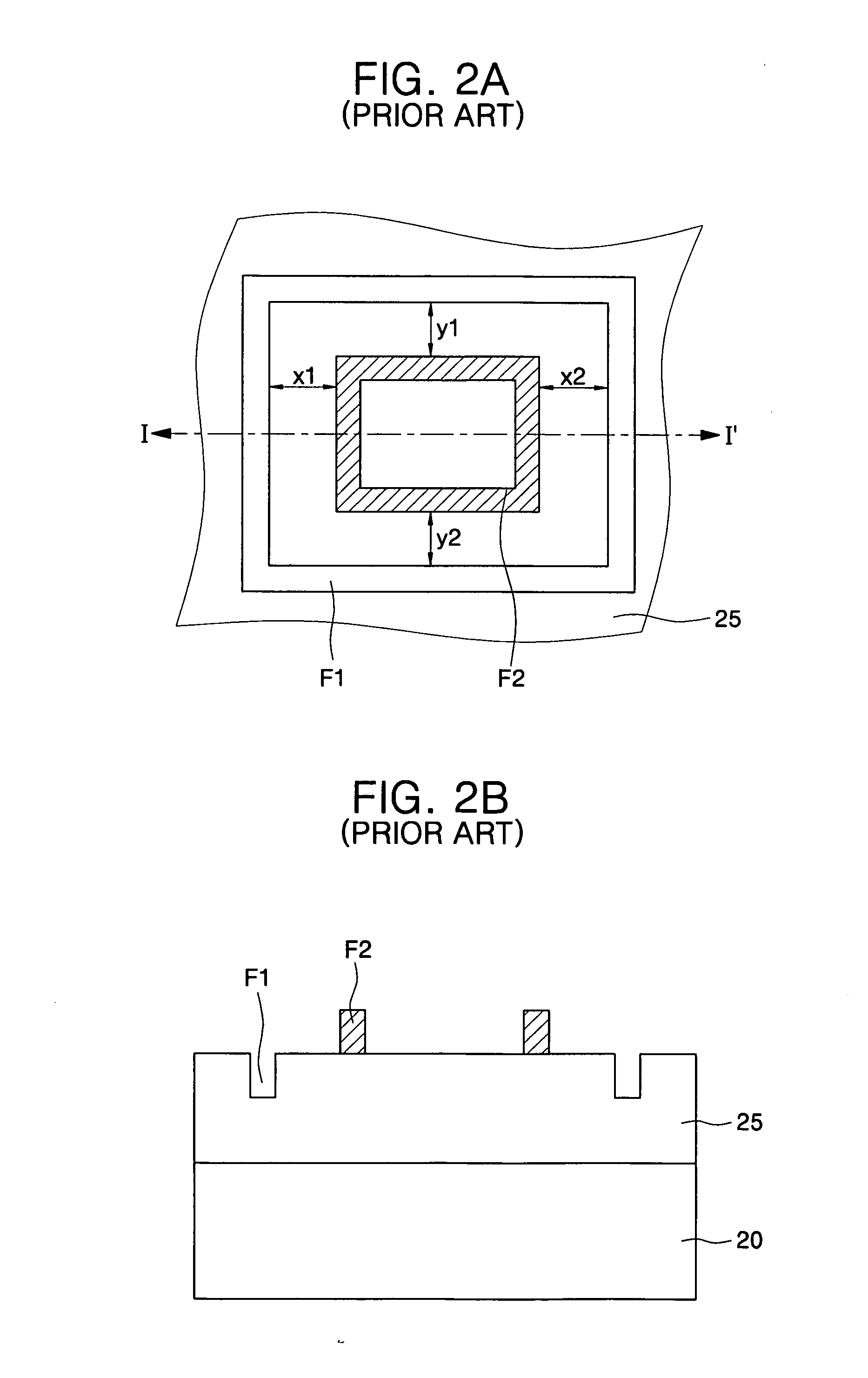

Semiconductor device having overlay measurement mark and method of fabricating the same

ActiveUS20060131576A1Avoid failureReduce ranging errorSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsVernier scaleDevice material

There are provided a semiconductor device having an overlay measurement mark, and a method of fabricating the same. The semiconductor device includes a scribe line region disposed on a semiconductor substrate. A first main scale layer having a first group of line and space patterns and a second group of line and space patterns is disposed on the scribe line region. Line-shaped second main scale patterns are disposed on space regions of the first group of the line and space patterns. Line-shaped vernier scale patterns are disposed on space regions of the second group of the line and space patterns. In the method, a first main scale layer having a first group of line and space patterns and a second group of line and space patterns is formed on a semiconductor substrate. Line-shaped second main scale patterns are formed on space regions of the first group of the line and space patterns. Line-shaped vernier scale patterns are formed on space regions of the second group of the line and space patterns.

Owner:SAMSUNG ELECTRONICS CO LTD

Method and device for detecting wear of tooth surface of large involute spur gear

InactiveCN103292673ASimple structureEasy to operateMechanical counters/curvatures measurementsVernier scaleEngineering

The invention discloses a method and a device for detecting wear of a tooth surface of a large involute spur gear. The method and the device are used for efficiently detecting the degree of wear of the large gear. The method includes fixing the detected gear; placing a three-jaw chuck in a shaft hole of the detected gear; respectively reading indicated values of the position of a positioning slider on a primary positioning scale and a secondary positioning scale from the first positioning scale and the secondary positioning scale and denoting the sum of two read numbers as Y; directly reading the expansion distance of a measuring jaw on the measuring jaw and denoting a value of the expansion distance of the measuring jaw as X; measuring the distance from the tip of the measuring jaw to the center line of the detected gear, simultaneously reading a value of the distance on a measuring scale and a vernier scale and denoting the value as Z which is a measured wear extent of the detected gear. The measuring device comprises the three-jaw chuck, the primary positioning scale, the secondary positioning scale, the positioning slider, the measuring scale, the vernier scale and the measuring jaw. The method and the device have the advantages that the method and the device are applied to detecting large gears, and the difficult problem that large gears cannot be detected by large quantities of precision gear detectors is solved.

Owner:UNIV OF SCI & TECH LIAONING

Milling residual stress measuring method based on deflection changes and inverse method

The invention discloses a milling residual stress measuring method based on deflection changes and an inverse method. Corrosion delamination is carried out on a stress layer for multiple times, the thickness of a material layer removed through corrosion each time is measured by a vernier caliper, a part is scanned on a machine tool by using a laser displacement sensor to measure the change of the deflection of the part after the corrosion of each time, the change of the bending moment generated by the stress layer is obtained according to the change of the position of the neutral layer in the part, the residual stress value is calculated forwards in an inverse mode by combining the changes of measured deflection, and lastly the stress values of all the stress layers before the self-balance of the stress are obtained. The milling residual stress measuring method based on the deflection changes and the inverse method is simple in operation and reliable in result, and the used equipment is low in price.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

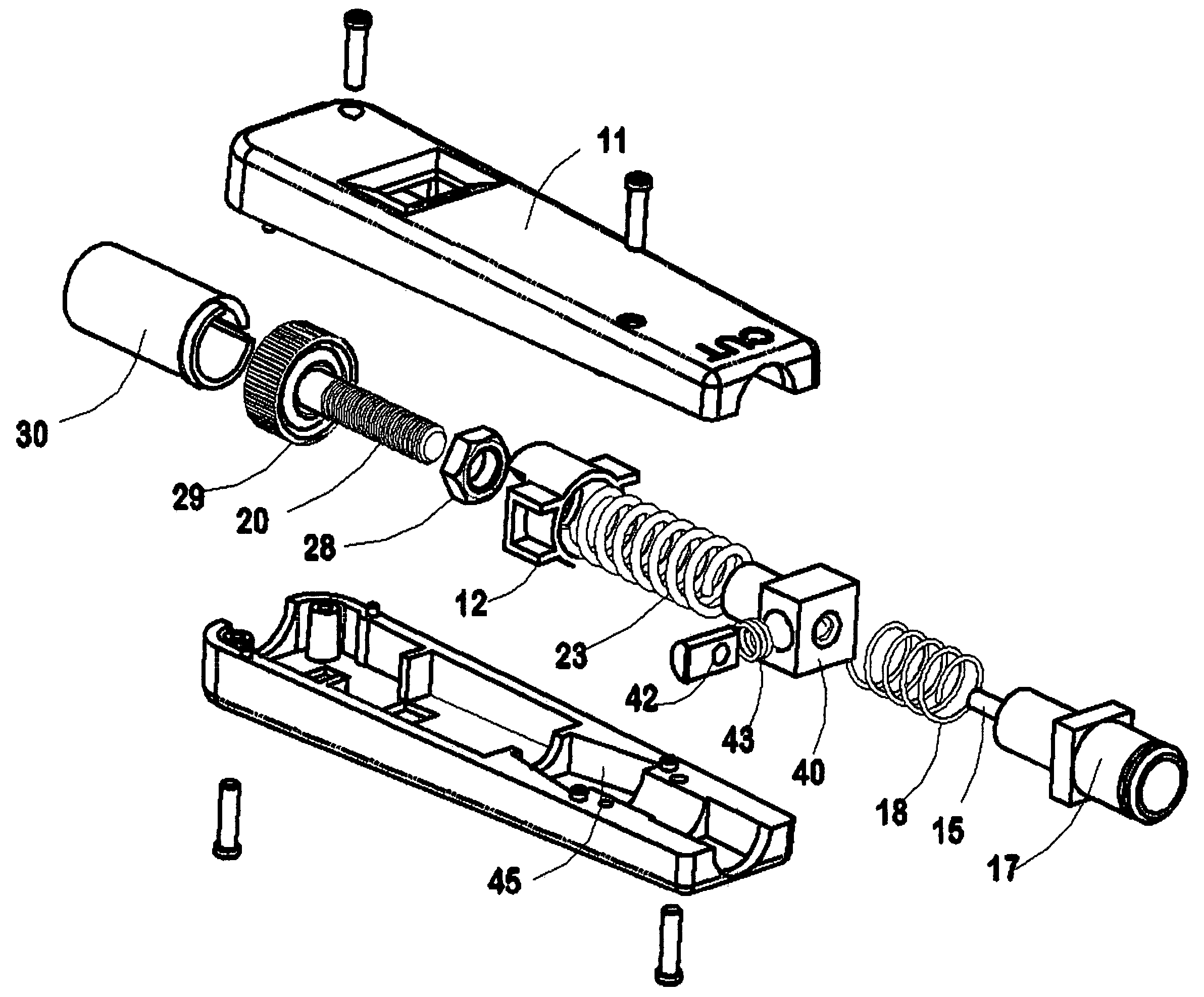

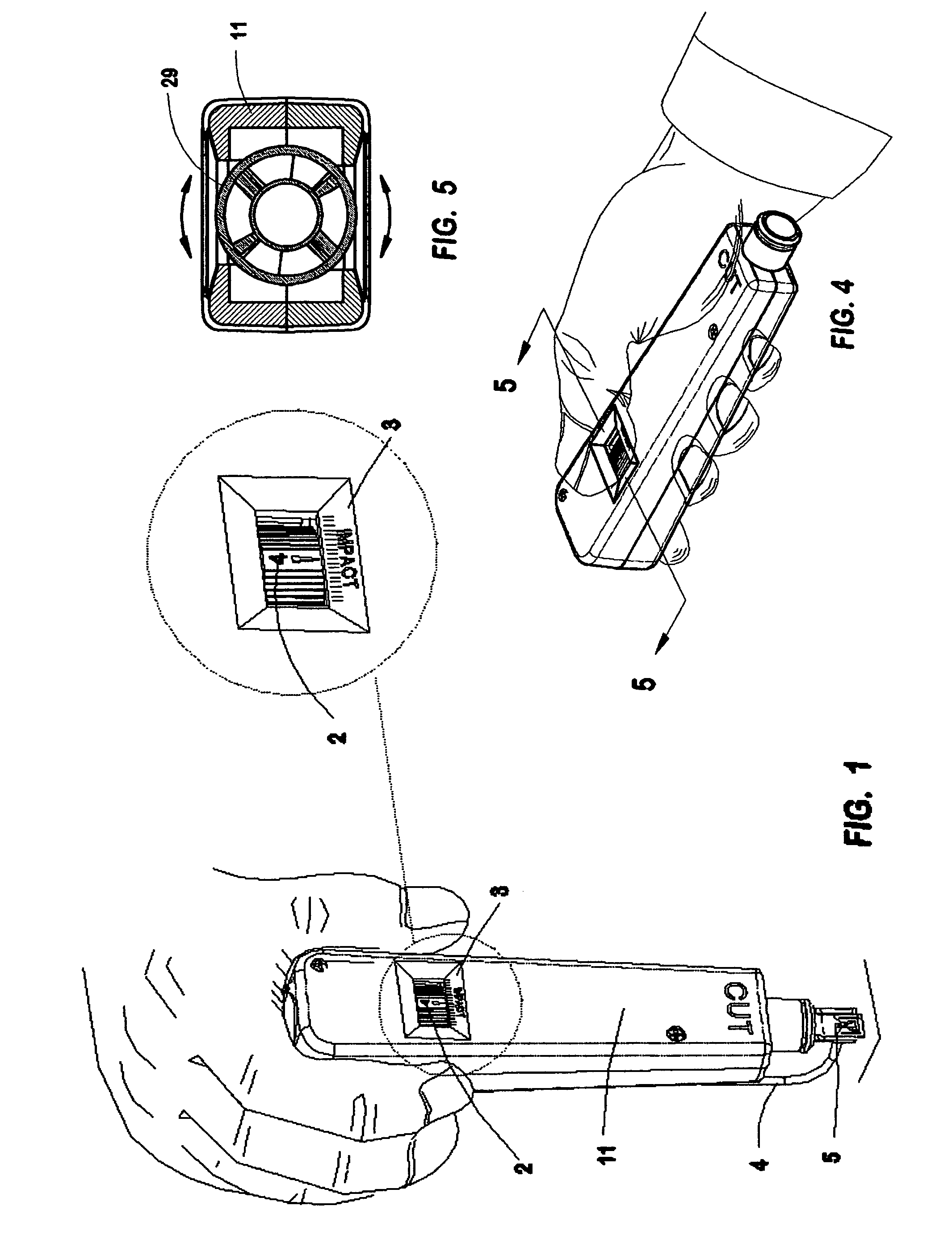

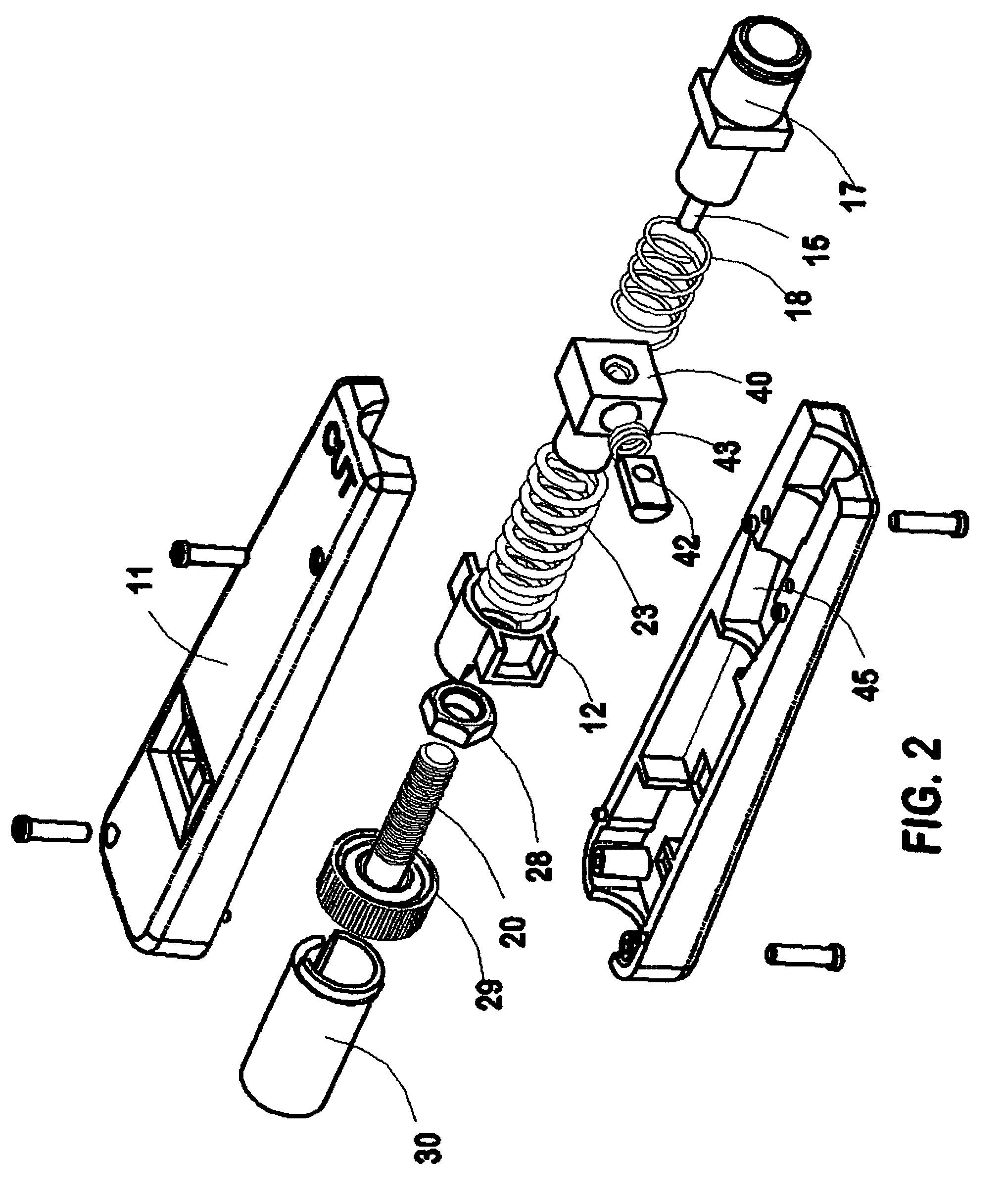

Optical selectable force impact tool

InactiveUS7621040B2Easy to adjustReadily accessible and visibleLine/current collector detailsOther manufacturing equipments/toolsVernier scaleEngineering

An user-friendly impact tool for wire end termination in which the pre-set compression of a main drive spring is adjusted by hand with an adjustment screw having a knurled knob that is both visible and hand-accessible through an opening in the housing wall, and also having a vernier scale formed partly on the outer housing wall surface and partly on the knurled knob itself to correctly indicate the pre-load adjustment position of the drive spring.

Owner:SULLSTAR TECH

Measuring device and method for large-dimension slewing platform slide rail flatness

The invention relates to a device and a method for measuring the planeness of guide rails of a large-size revolving platform in the technical field of measurement. The device comprises movable measuring cups, reference measuring cups, conduits, buoys, calipers and connecting rods, wherein a liquid is filled in the measuring cups; the movable measuring cups and the reference measuring cups in various places are connected with each other through the conduits; the buoys are floated on the liquid level of the movable measuring cups; the calipers are connected with the buoys through the connecting rods; and scales on the calipers and scales of the measuring cups form vernier calipers. The movable measuring cups are placed in specified positions on the circumference of the revolving platform, and the planeness of the guide rails which are arranged on adjusting shims is guaranteed by comparison of the measured value of the 'vernier calipers' in the various places and adjustment of the height of the adjusting shims on the specified positions; and the measurement precision of the planeness reaches 0.02 millimeter and is improved by a magnitude order. The invention is suitable for measuring the planeness of the large platform and has the advantages of strong universality, low price, high measurement precision and easy realization.

Owner:SHANGHAI JIAO TONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com