Patents

Literature

61results about "Compasses with pivoted arms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface-tracking measuring machine

InactiveUS6295866B1Accurate detectionReduce sensitivityCompasses with pivoted armsMechanical counters/curvatures measurementsResponsivityClassical mechanics

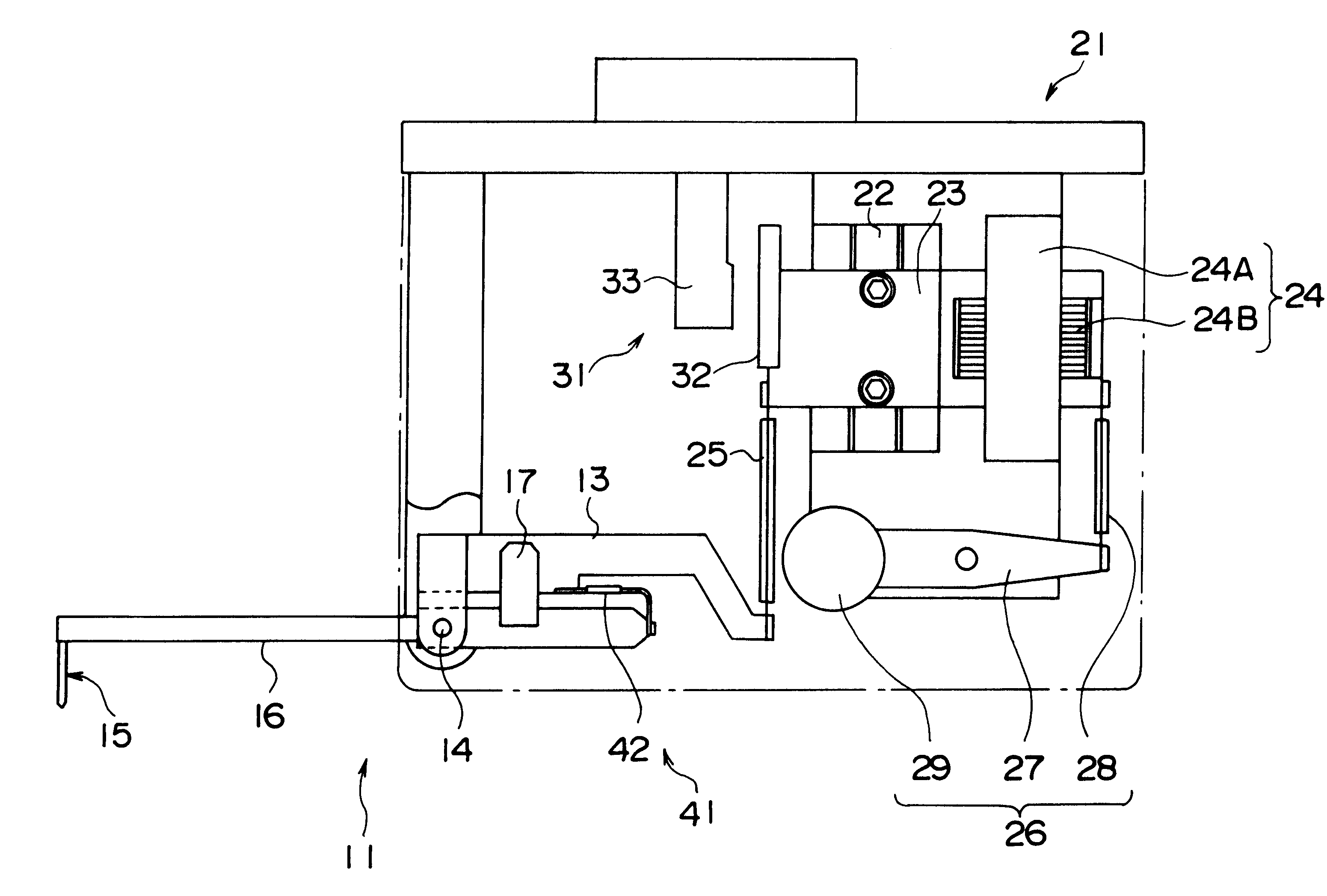

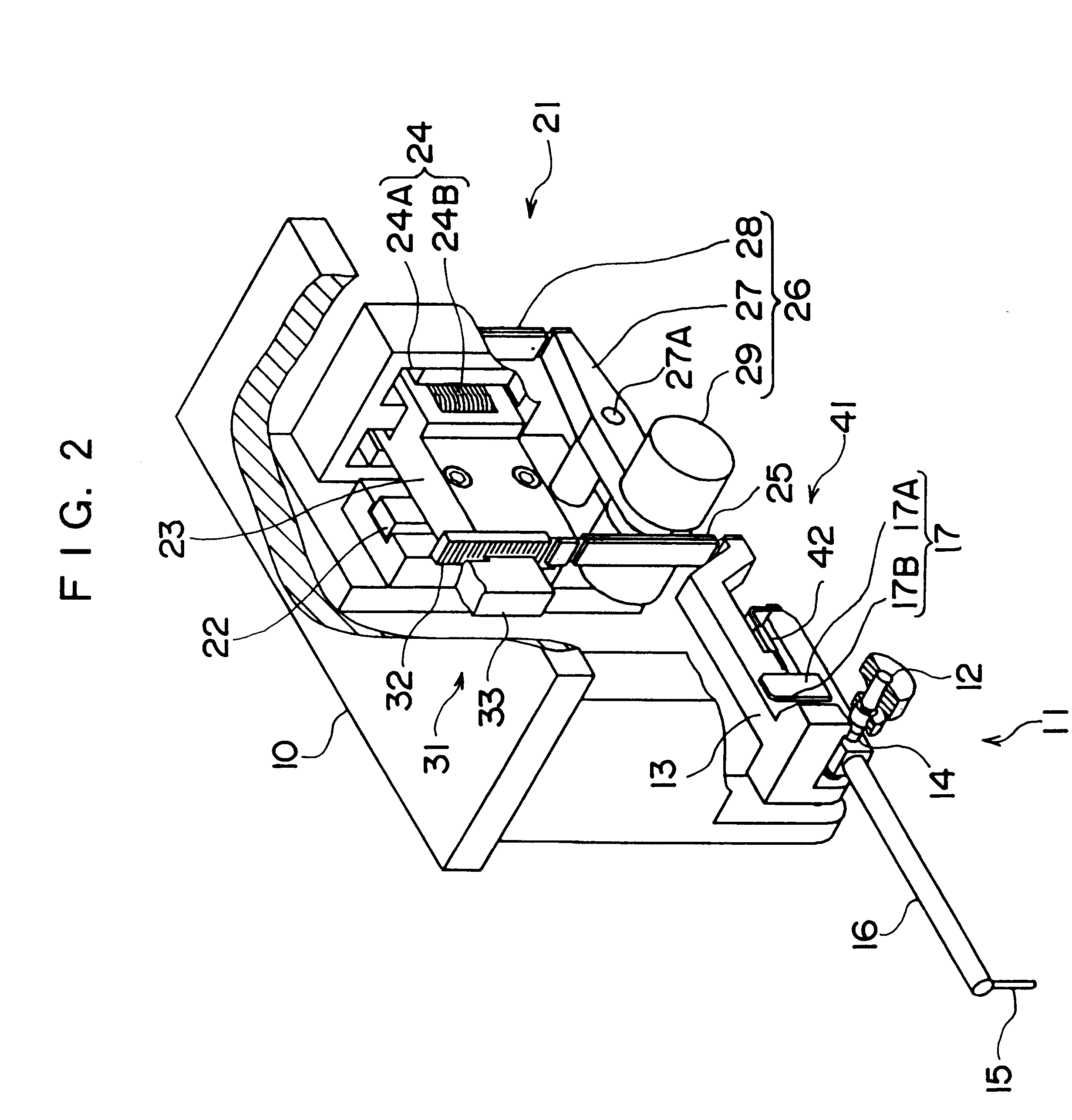

A surface-tracking measuring machine is provided, in which measurement range is enlarged while keeping a measuring force, responsivity, resolution thereof. For the object, the surface-tracking measuring machine has a frame (10), a probe (11) swingably supported by the frame (10) and having a tracer (15) at an end thereof, a measuring force controller (21) for controlling the measuring force applied to the probe, a displacement detector (31) for detecting a displacement of the probe, a measuring force detector (41) for detecting the measuring force applied to the probe, and a controller (51) for comparing a measuring force detected value detected by the measuring force detector and a previously commanded measuring force command value and to control the measuring force controller so that the measuring force detected value is equal to the measuring force command value.

Owner:MITUTOYO CORP

Use of magneto-resistive sensors for borehole logging

Owner:BAKER HUGHES INC

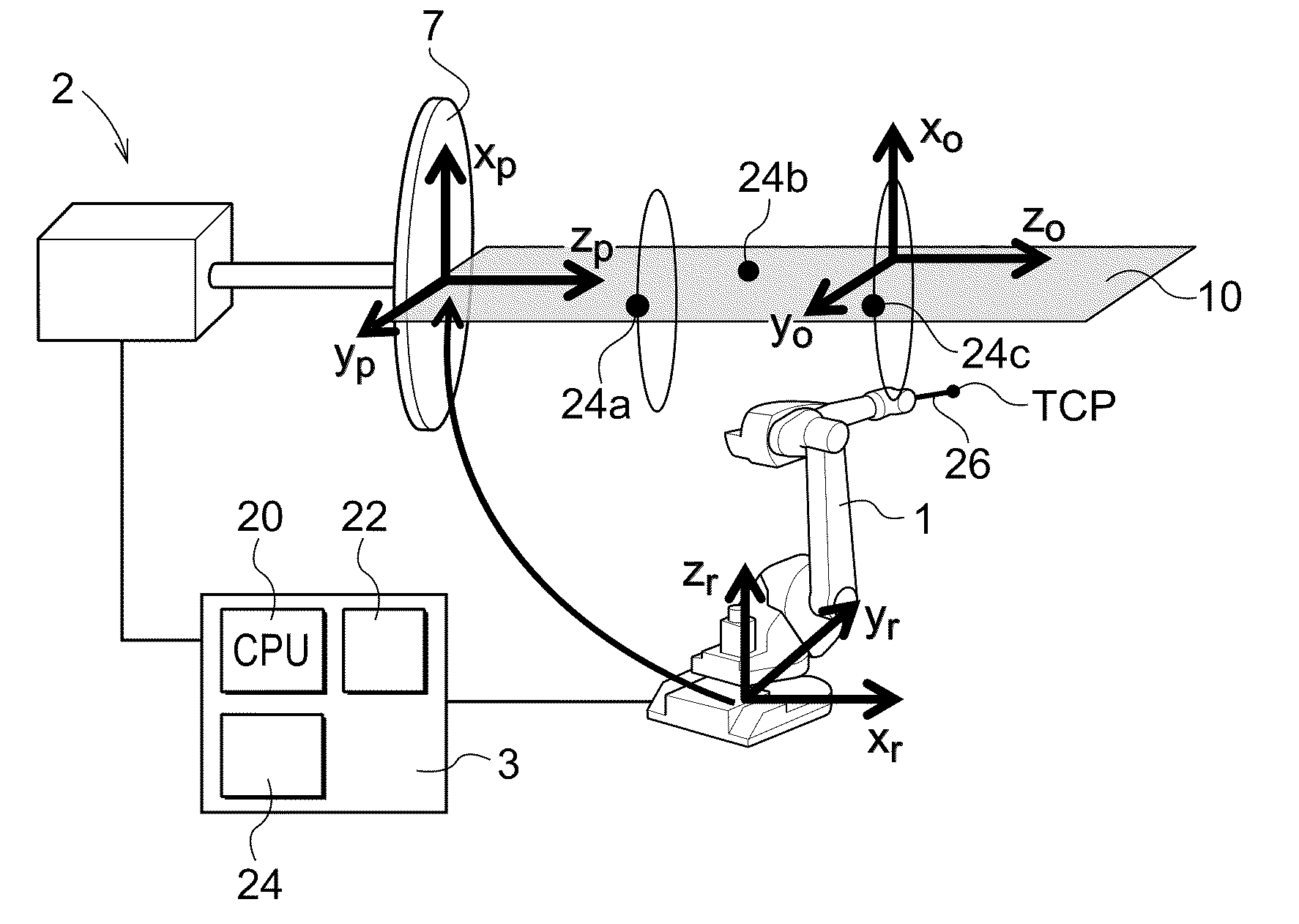

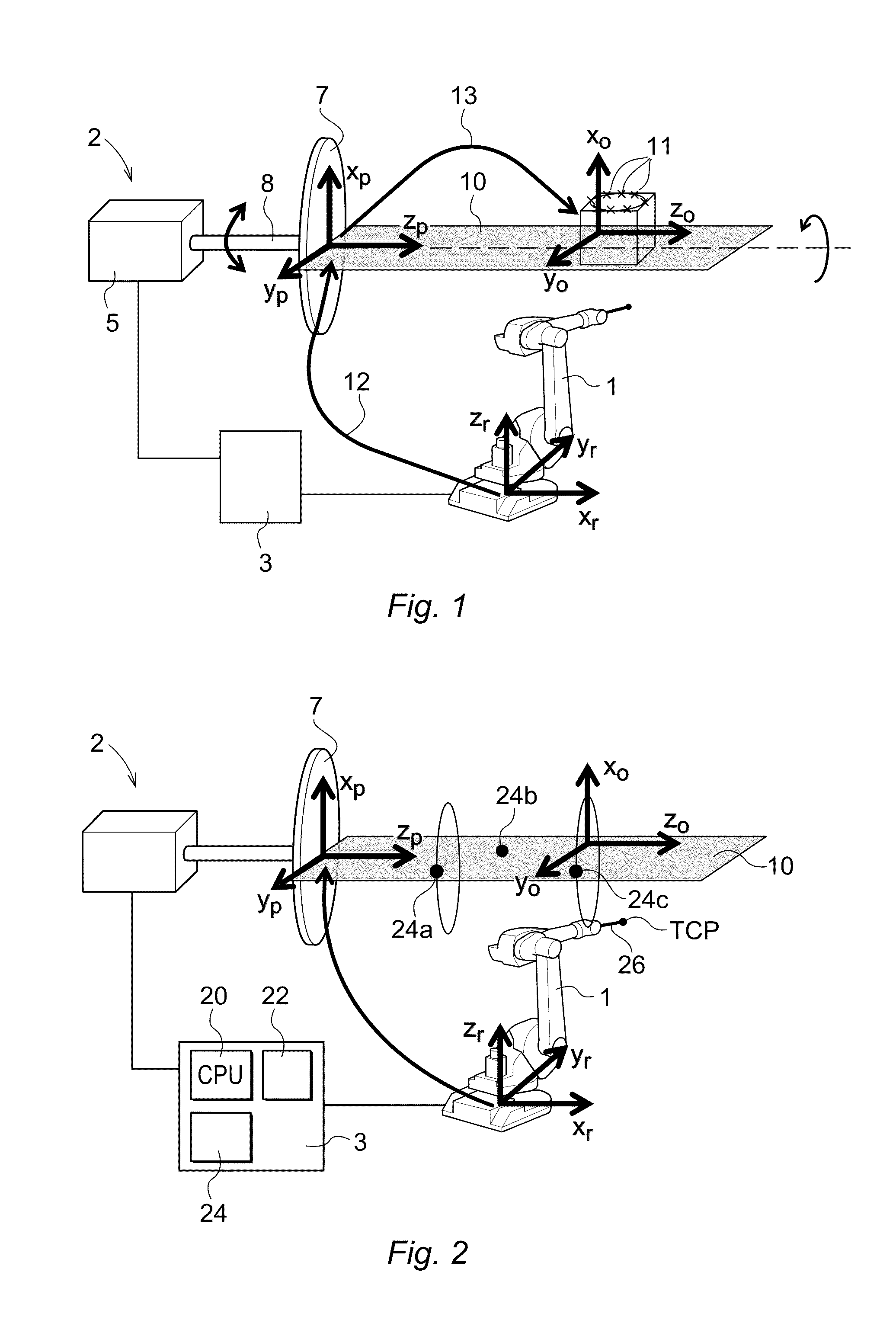

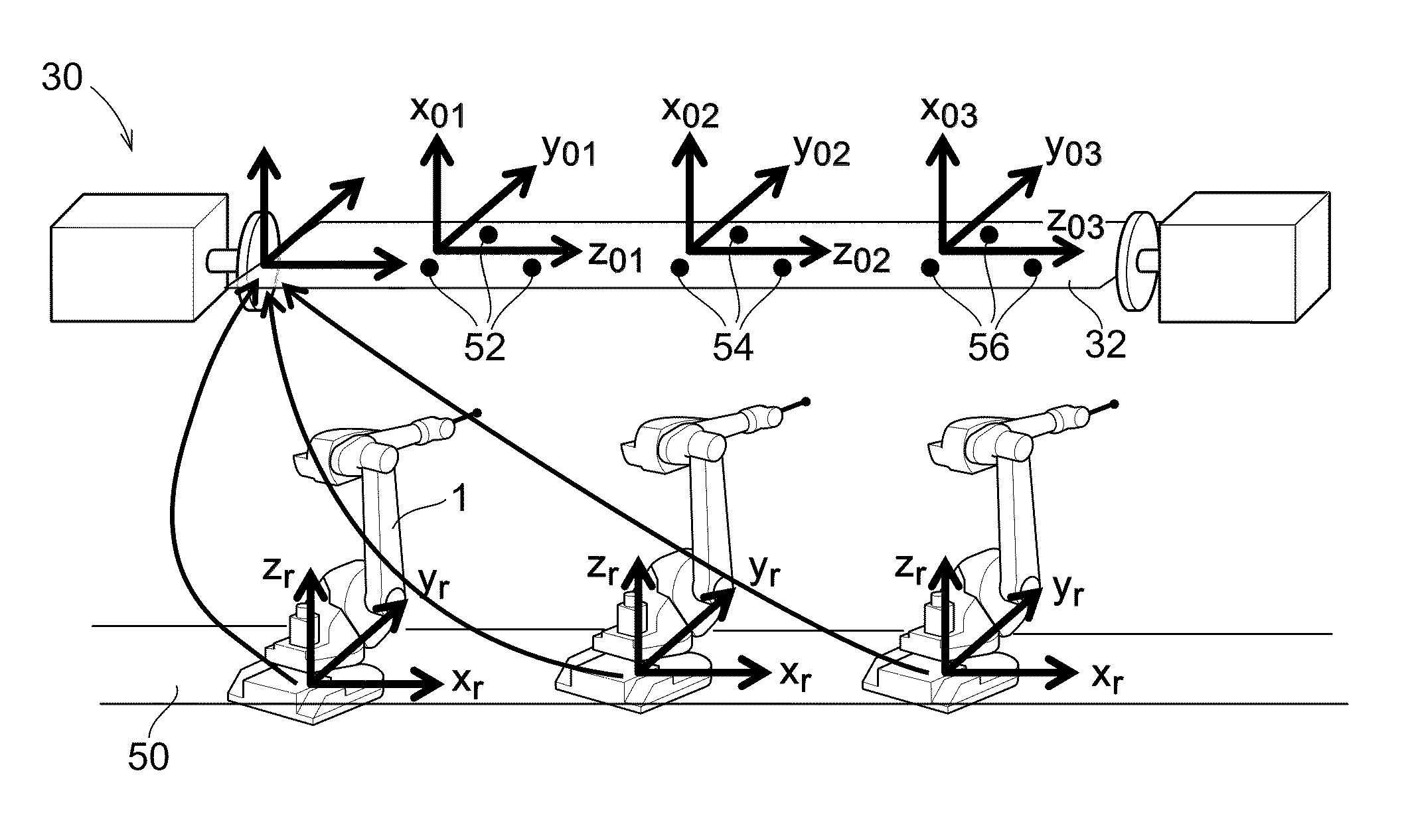

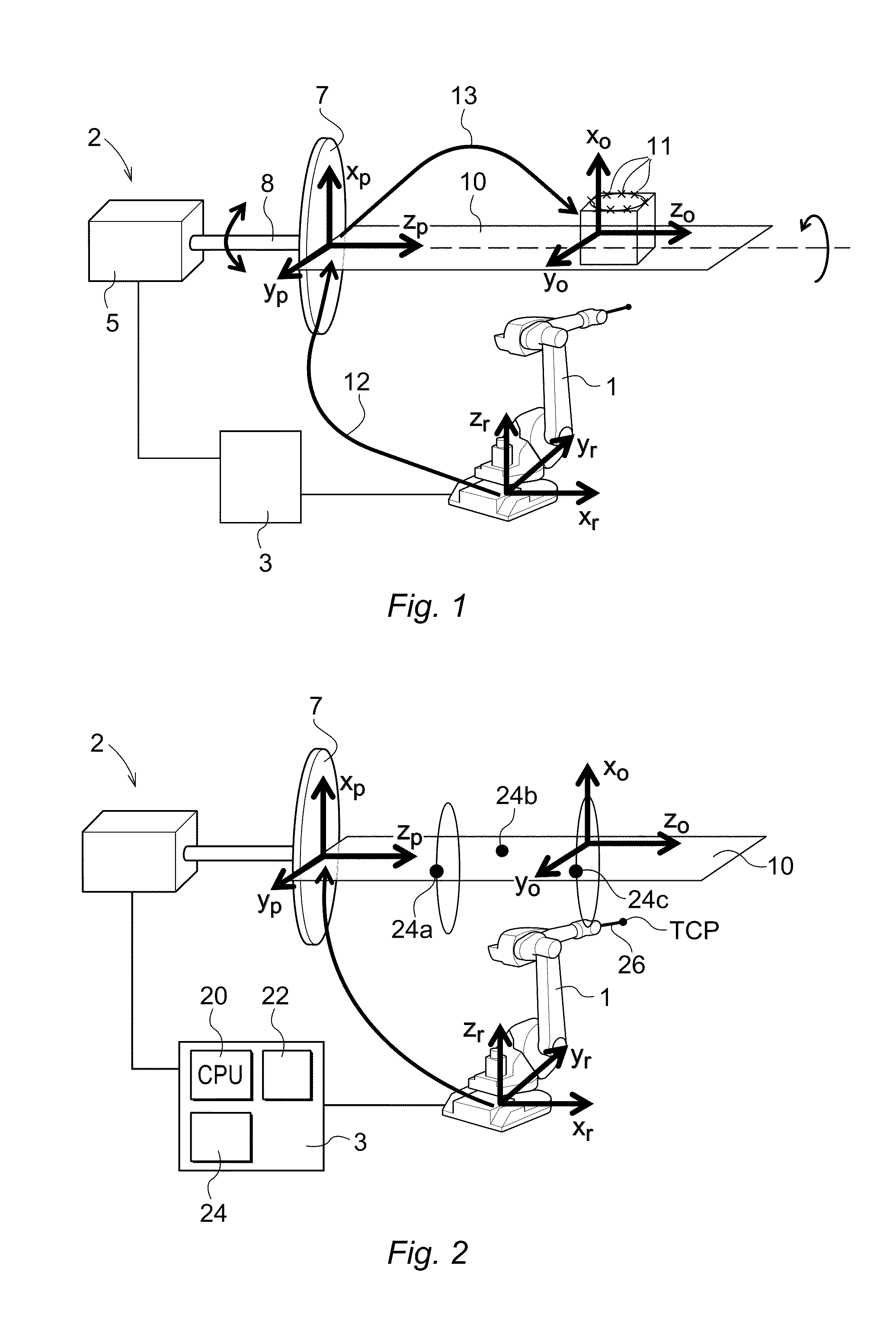

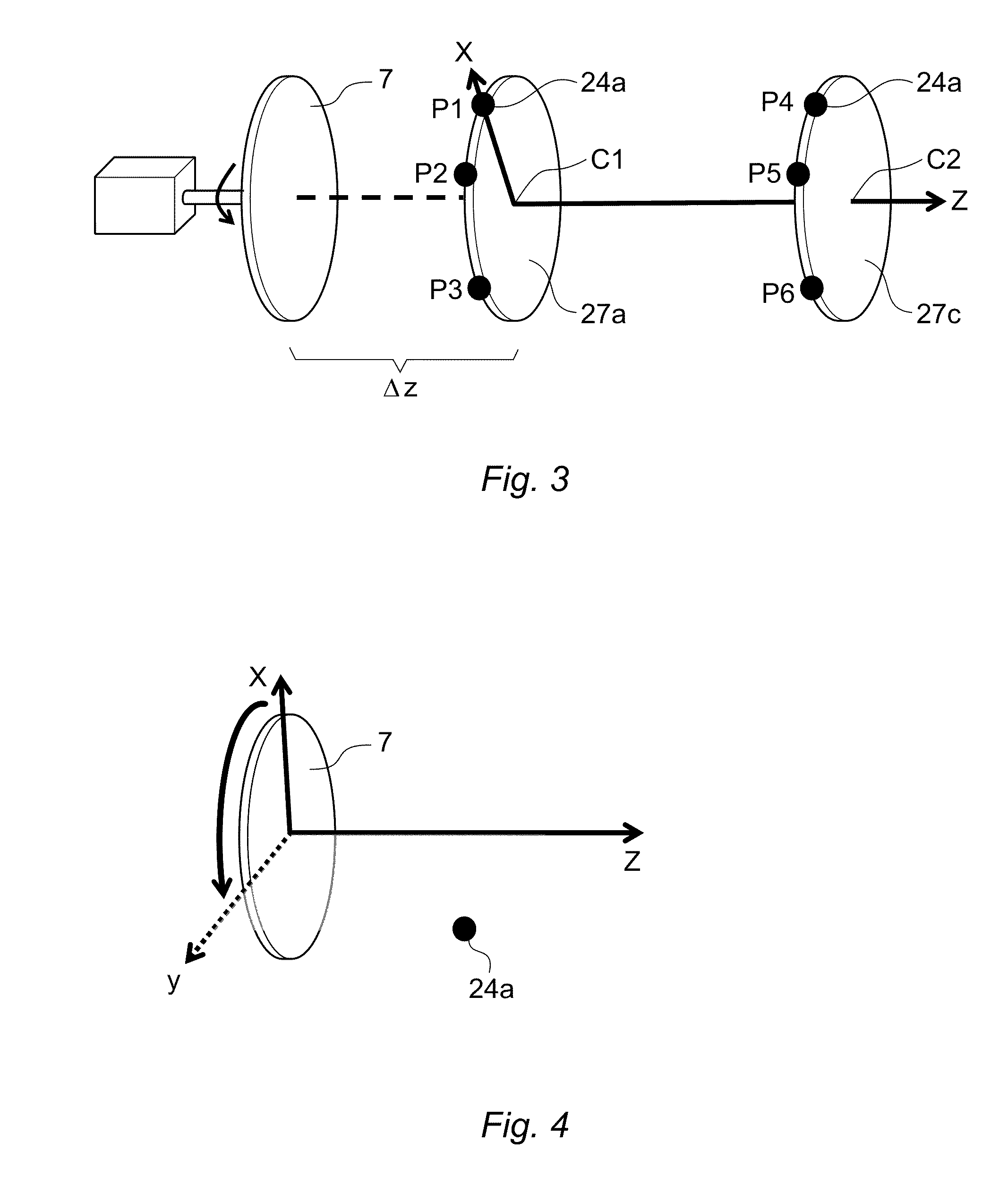

Method and an apparatus for calibration of an industrial robot system

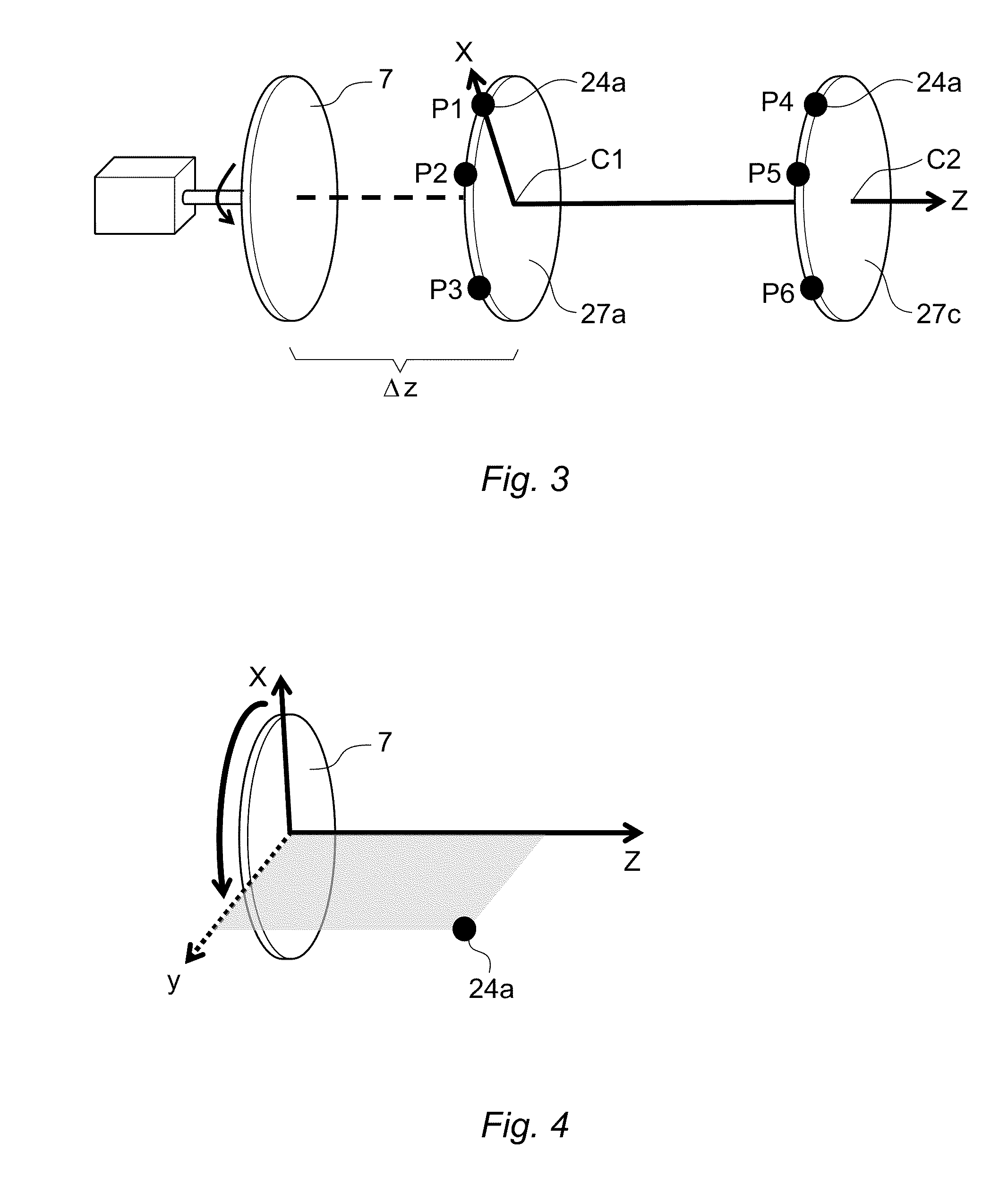

ActiveUS20110022216A1Easy CalibrationImprove accuracyProgramme-controlled manipulatorCompasses with pivoted armsRotational axisRobotic systems

The present invention relates to a method and an apparatus for calibration of an industrial robot system including at least one robot (1) having a robot coordinate system (xr1,yr1,zr1) and a positioner (2) having a positioner coordinate system (xp,yp,zp) and adapted to hold and change the orientation of a workpiece by rotating it about a rotational axis. Target points for the robot are programmed with respect to an object coordinate system (xo1,yo1,zo1). The apparatus comprising a robot controller (3), at least three calibration objects (24a-c) arranged on the positioner, and a calibration tool (26) held by the robot. The positions of the calibration objects are known in the object coordinate system. The robot controller is configured to determine the positions of the calibration objects with respect to the robot coordinate system, to determine the positions of a first (24a) and a second (24c) of said calibration objects for at least three different angles of the rotational axis of the positioner, to determine the direction of the rotational axis of the positioner in the robot coordinate system based on the determined positions of the first and second calibration objects for the three angles of the axis, and to determine the relation between the first object coordinate system and the positioner coordinate system by performing a best fit between the known and the determined positions of the calibration objects.

Owner:ABB (SCHWEIZ) AG

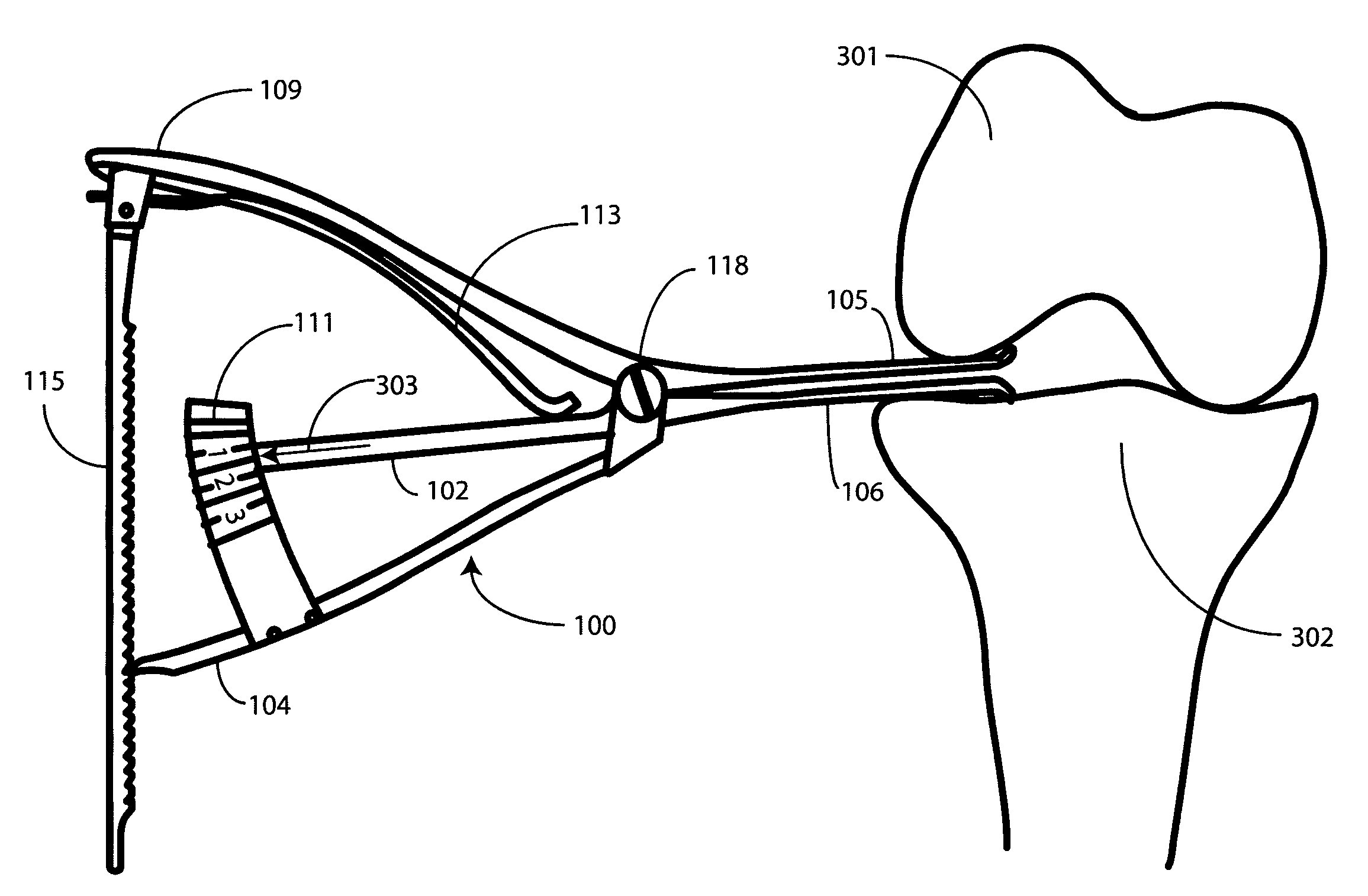

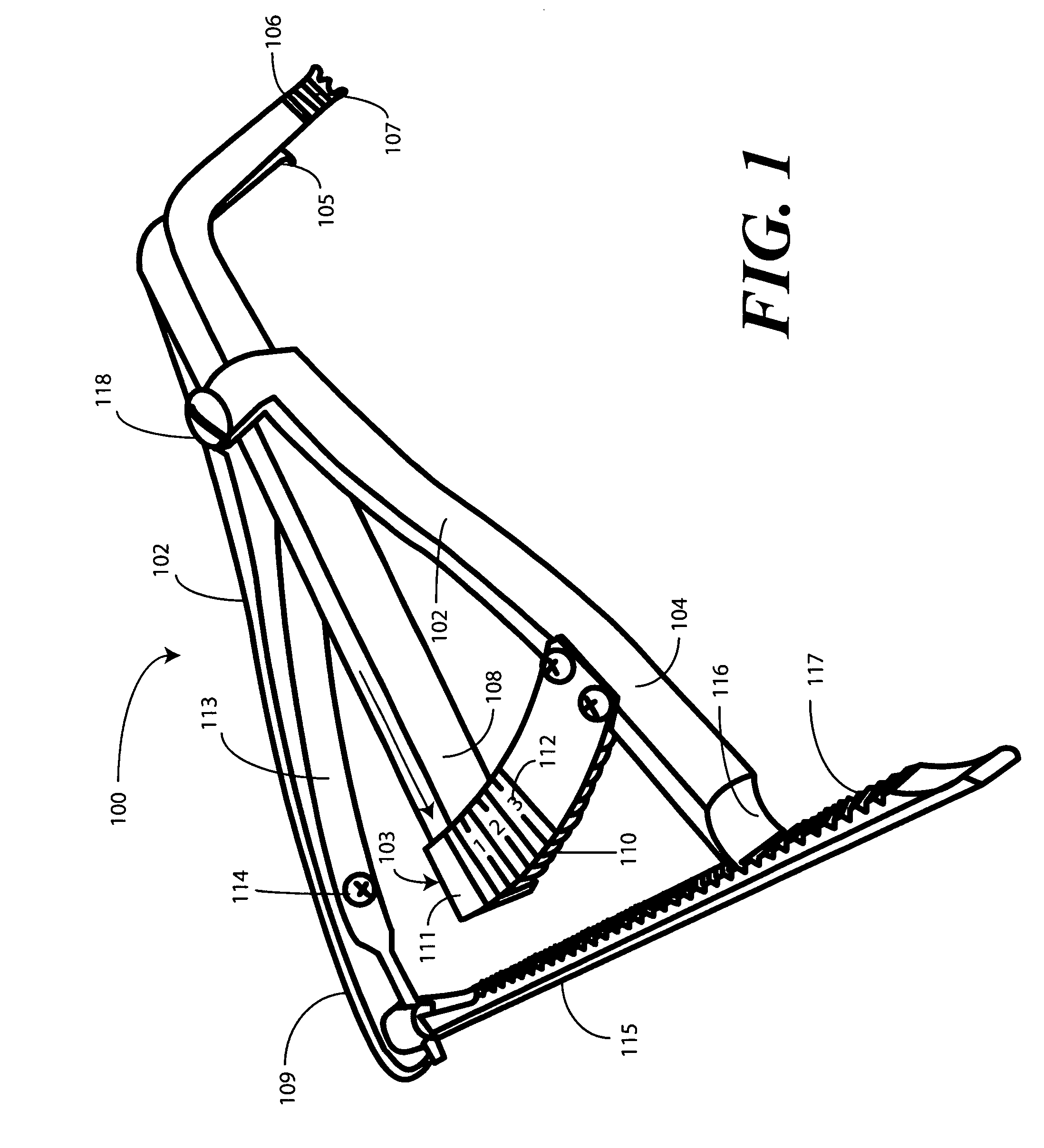

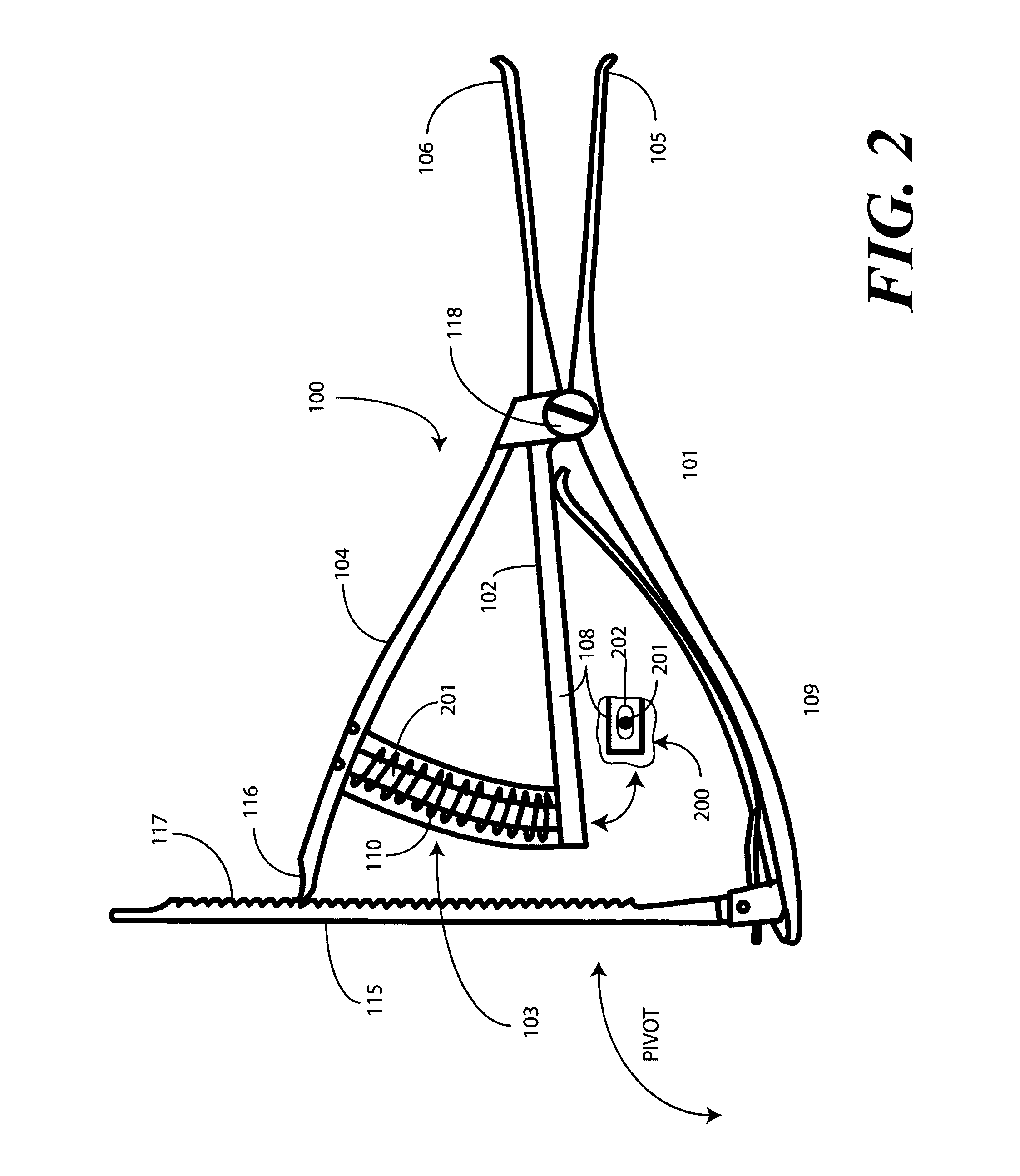

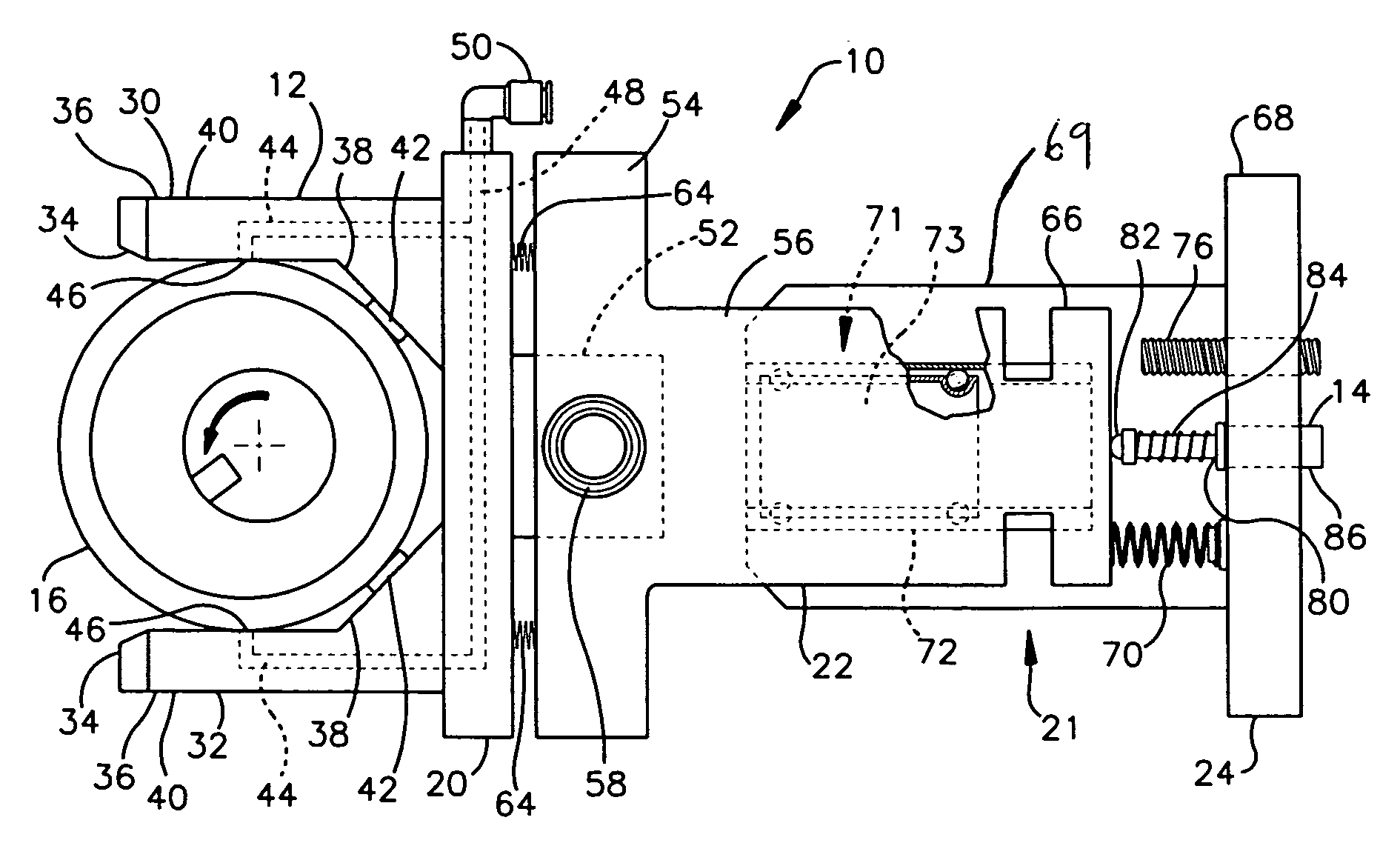

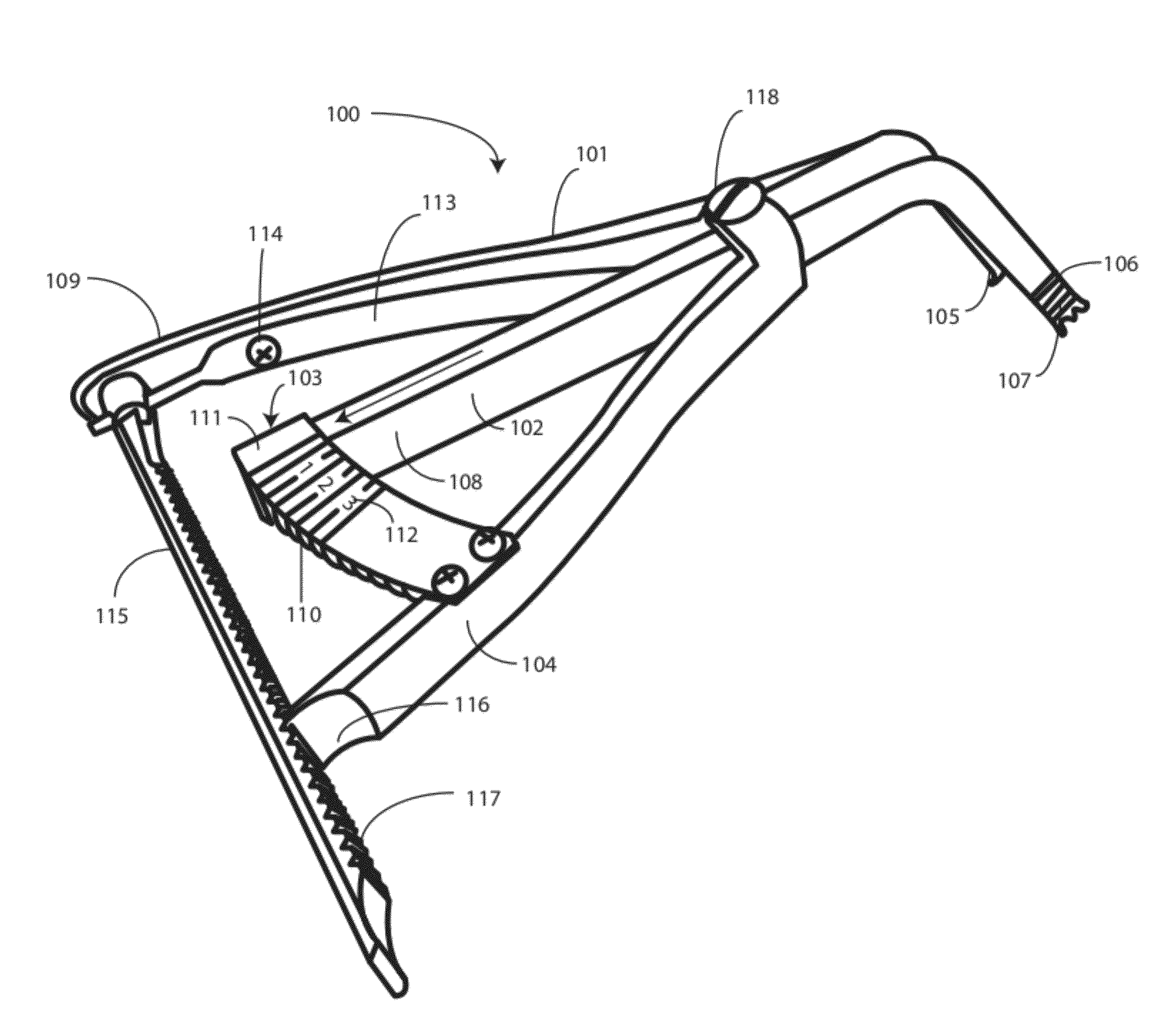

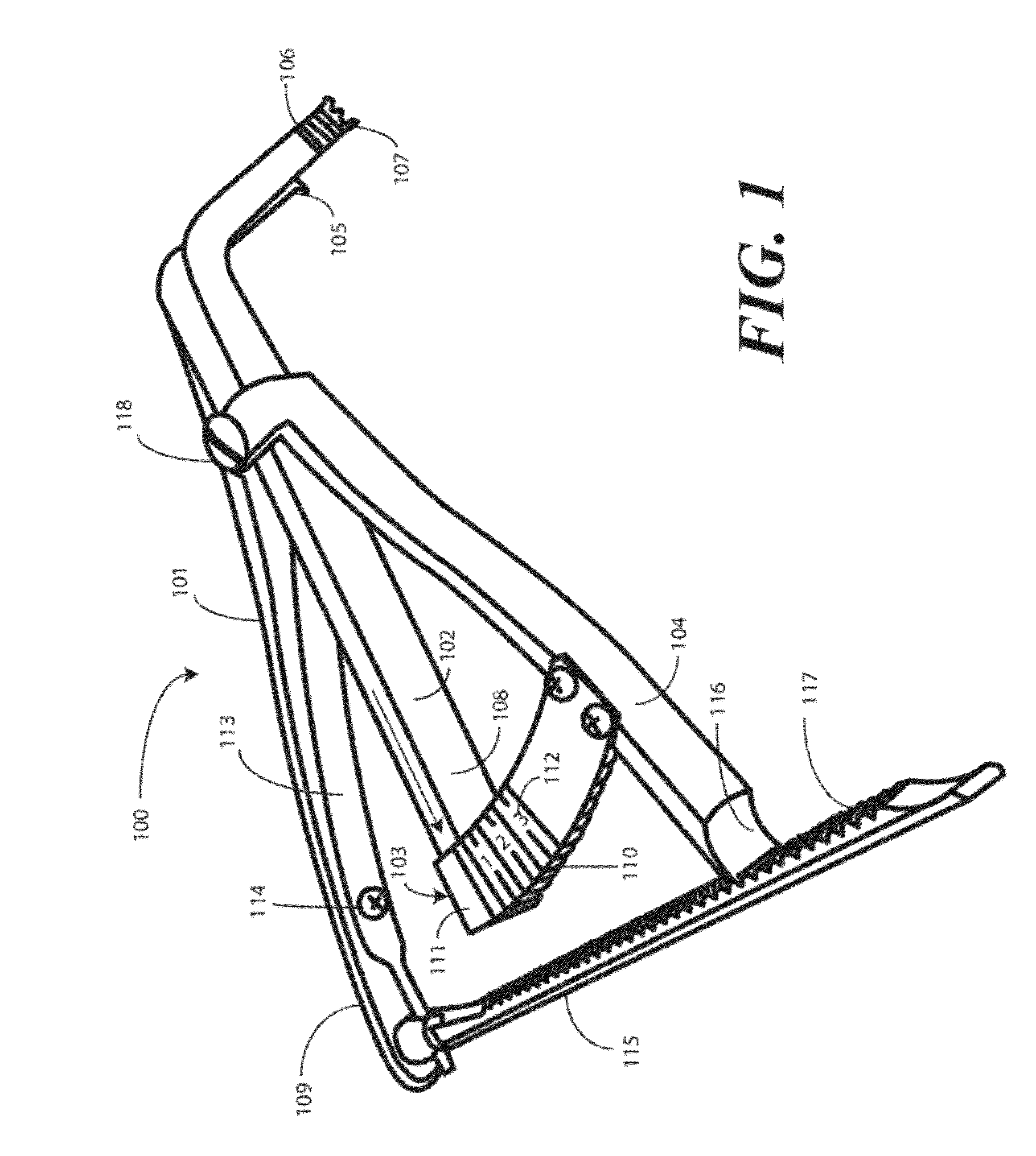

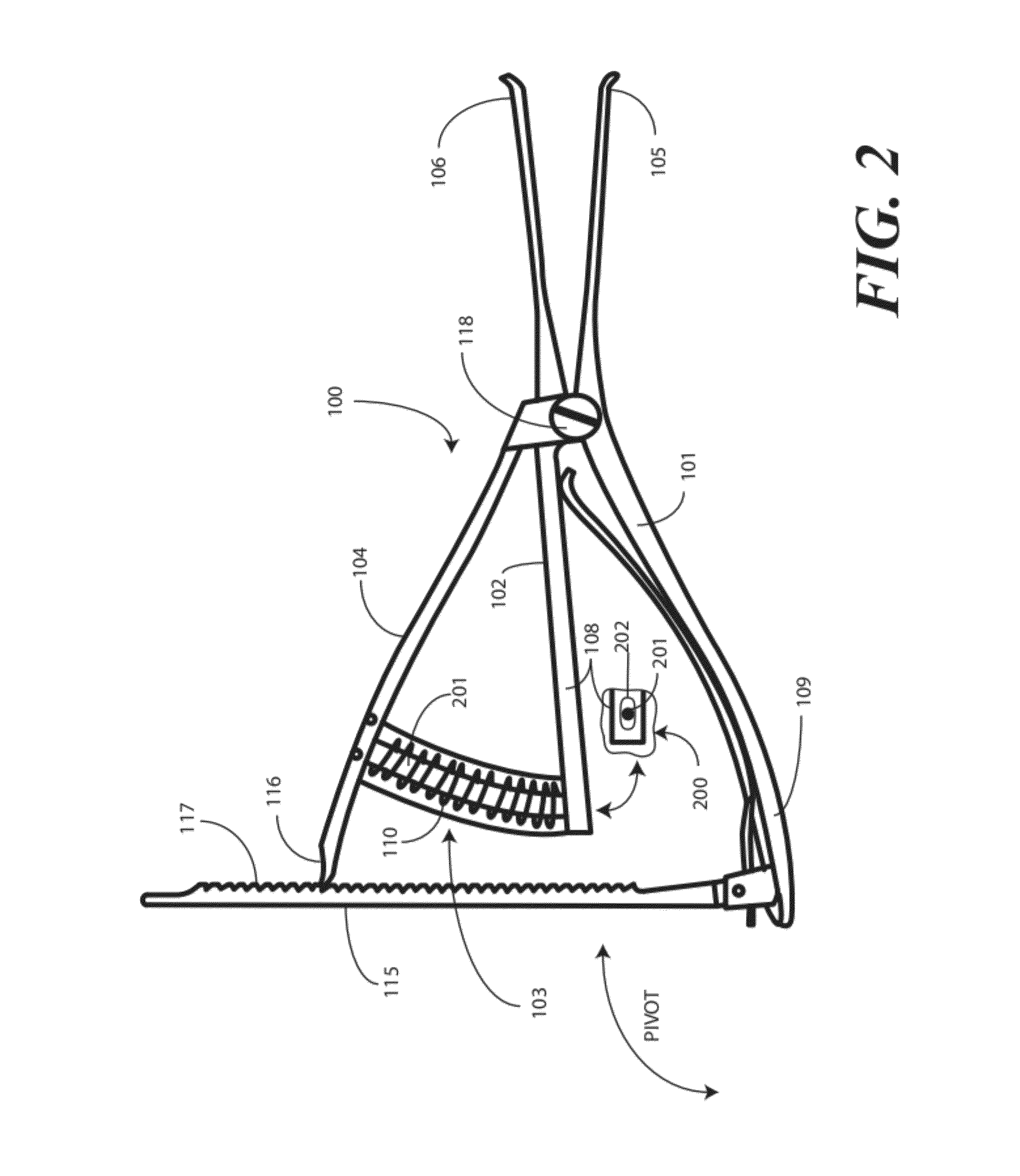

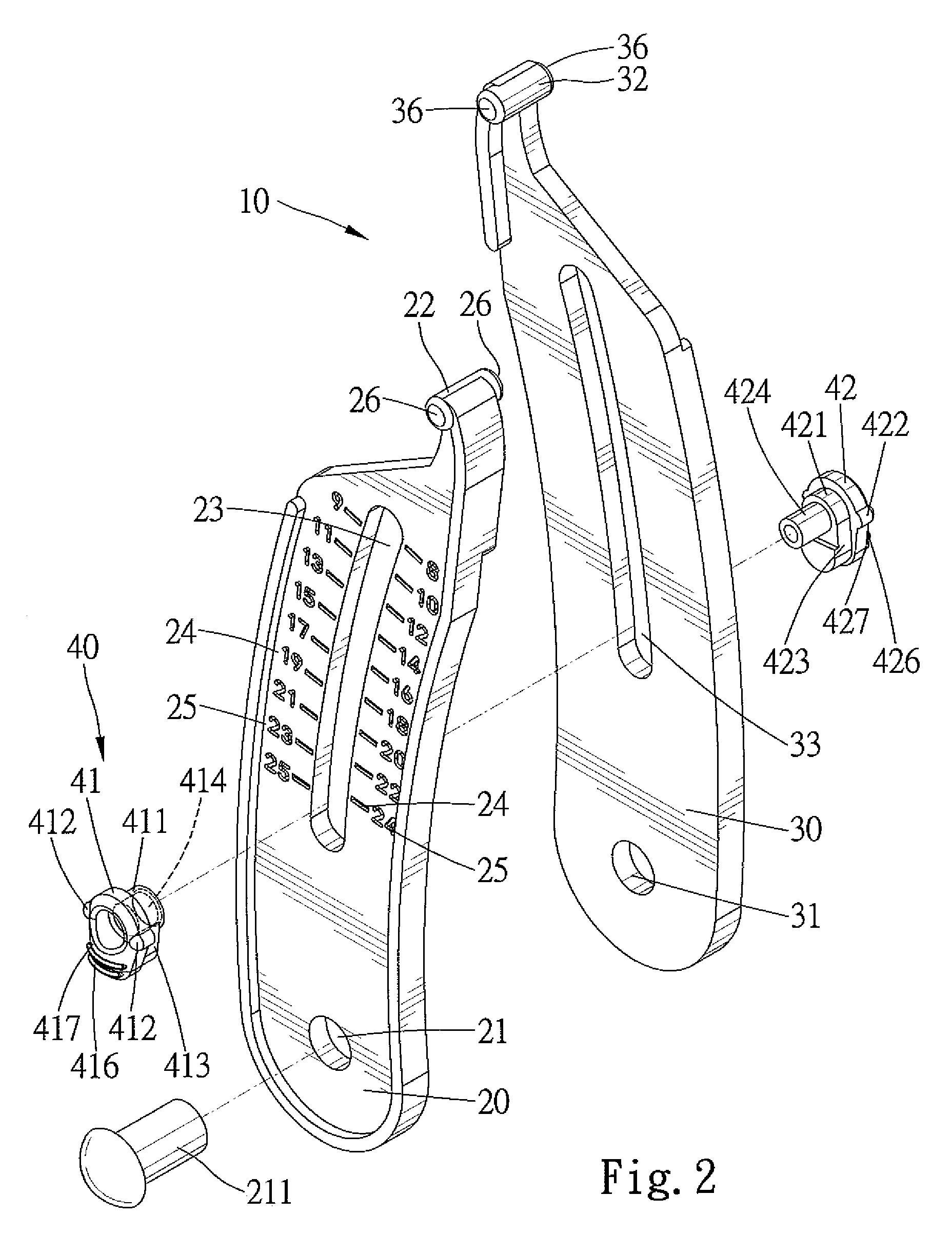

Femoral Tibial Spreader with Tensor Measurement

A femoral tibial spreader (100) for spreading adjacent bones includes a radial measurement gauge (111) for providing incidia corresponding to an amount of force being applied to the forward ends (105,106) of the femoral tibial spreader (100). The femoral tibial spreader (100) may be used, for example, to separate the femur (301) and tibia (302) during knee surgery. The radial measurement gauge (111) may be used to determine an amount of force being applied to the femur (301) and tibia (302), for example, by the medial and arterial ligaments. Two handle members (104,109) are squeezed together, which causes the forward ends (105,106) to open. A biasing member (110) allows a measurement extension (108) to pivot towards a handle member under tension, thereby providing a measurement of force applied by the ligaments.

Owner:INNOMED INC

Use of magneto-resistive sensors for borehole logging

Owner:BAKER HUGHES INC

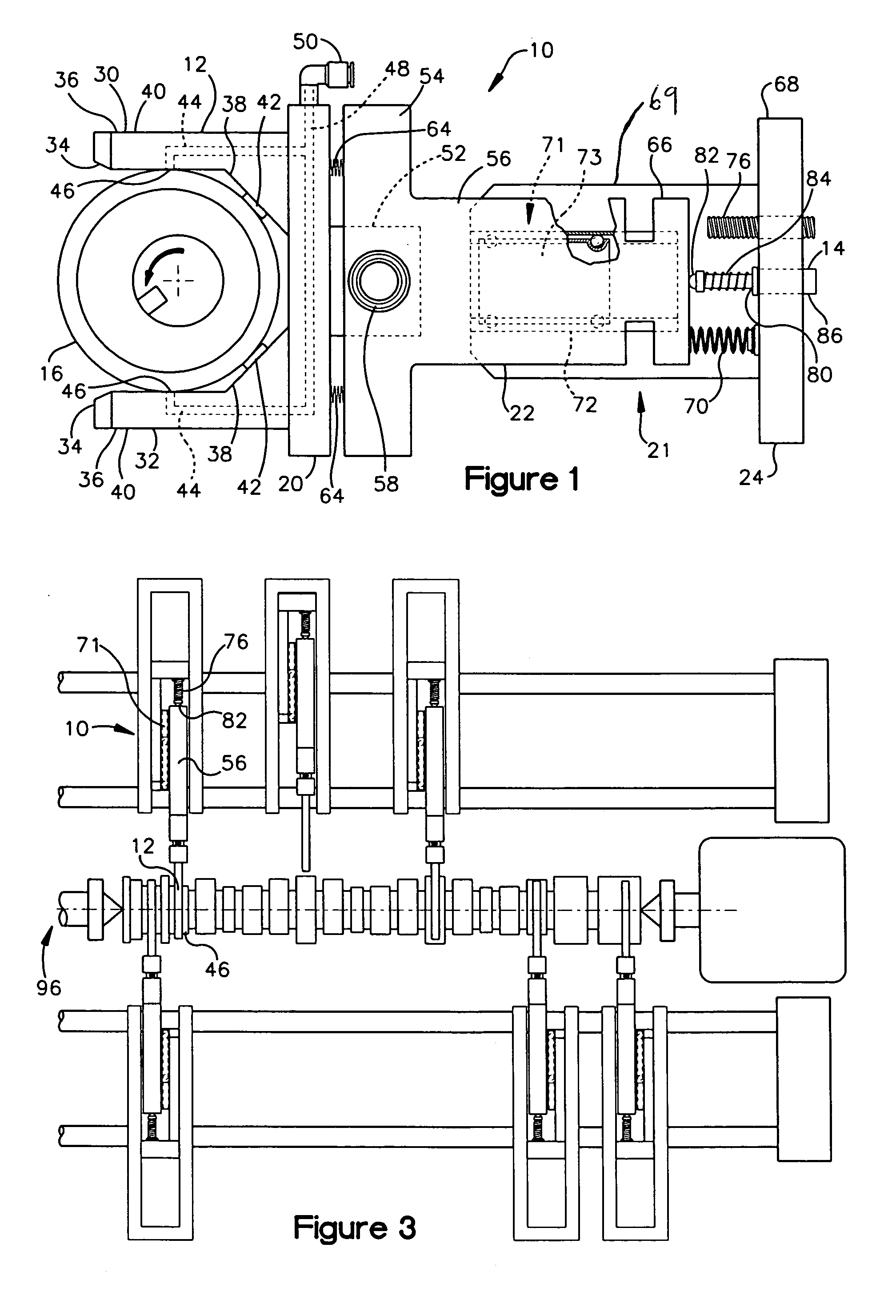

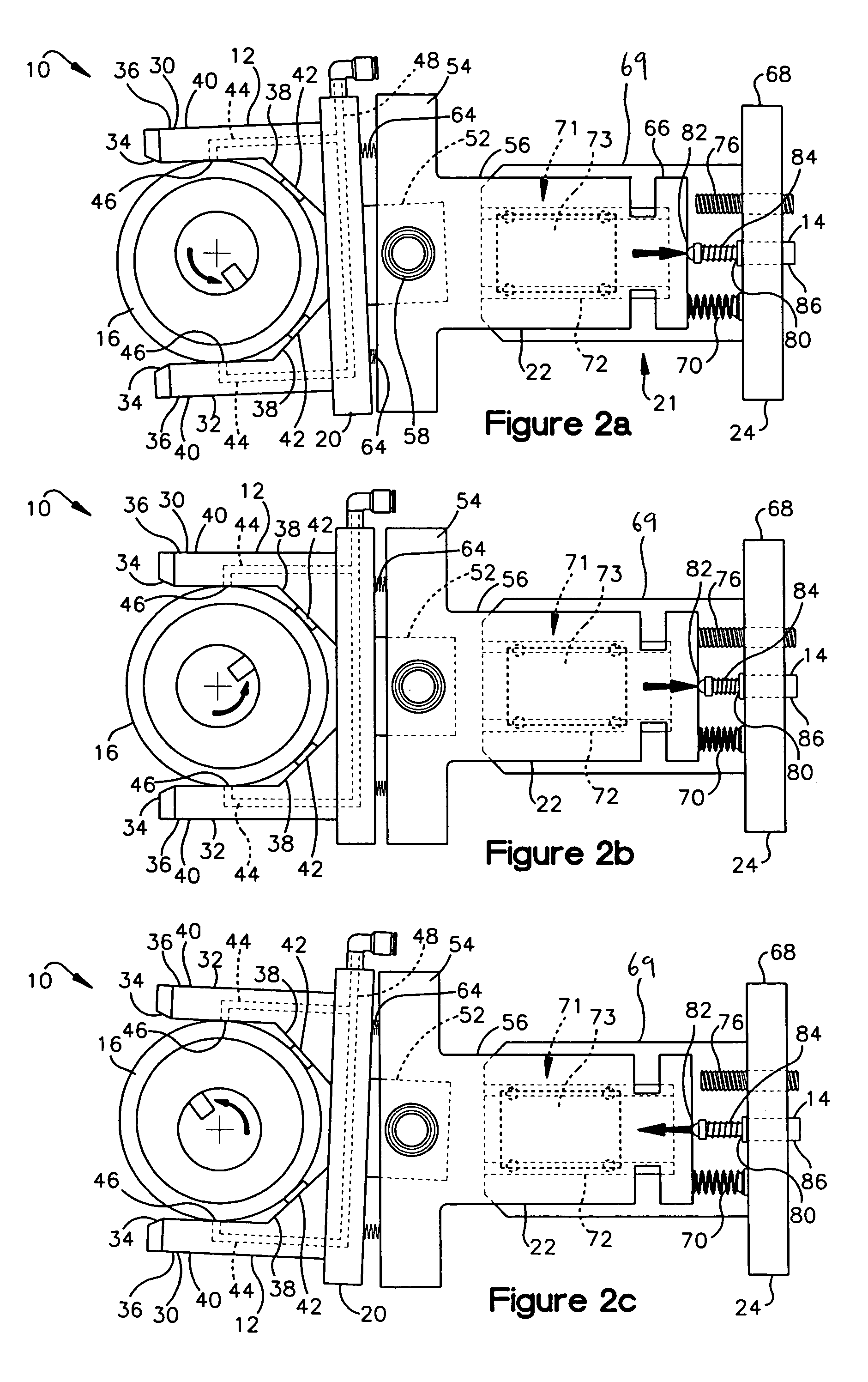

Gauge assembly for measuring diameter and total indicated runout

InactiveUS7197837B1Short timeOvercome disadvantagesCompasses with pivoted armsMechanical diameter measurementsLinear motionAerodynamic drag

The invention is directed to a gauge assembly that is used to measure parameters of camshaft journals or other objects with cylindrical surfaces. The gauge assembly includes two gauges, the first is an air snap gauge and the second a linear variable differential transducer. The air snap gauge is slidingly attached to the base and the second gauge is attached to a base as well. Air resistance measurements, taken through the air snap gauge provide a measure of diameter of the journal while relative linear motion between the base and air snap gauge, measured by the second gauge, provides a measure of journal runout relative to the center axis of the camshaft. Control logic is used to calculate other parameters such as runout of a journal relative to another journal on a common camshaft.

Owner:HONDA MOTOR CO LTD

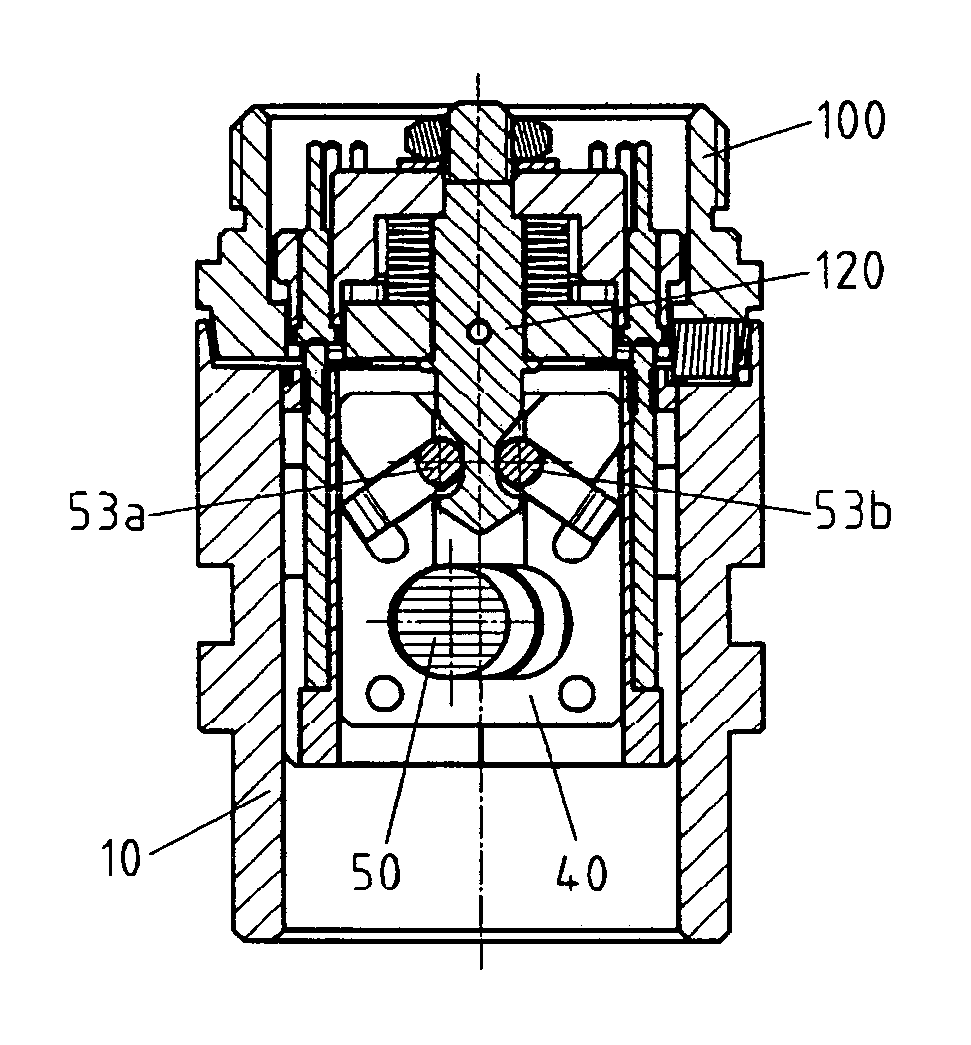

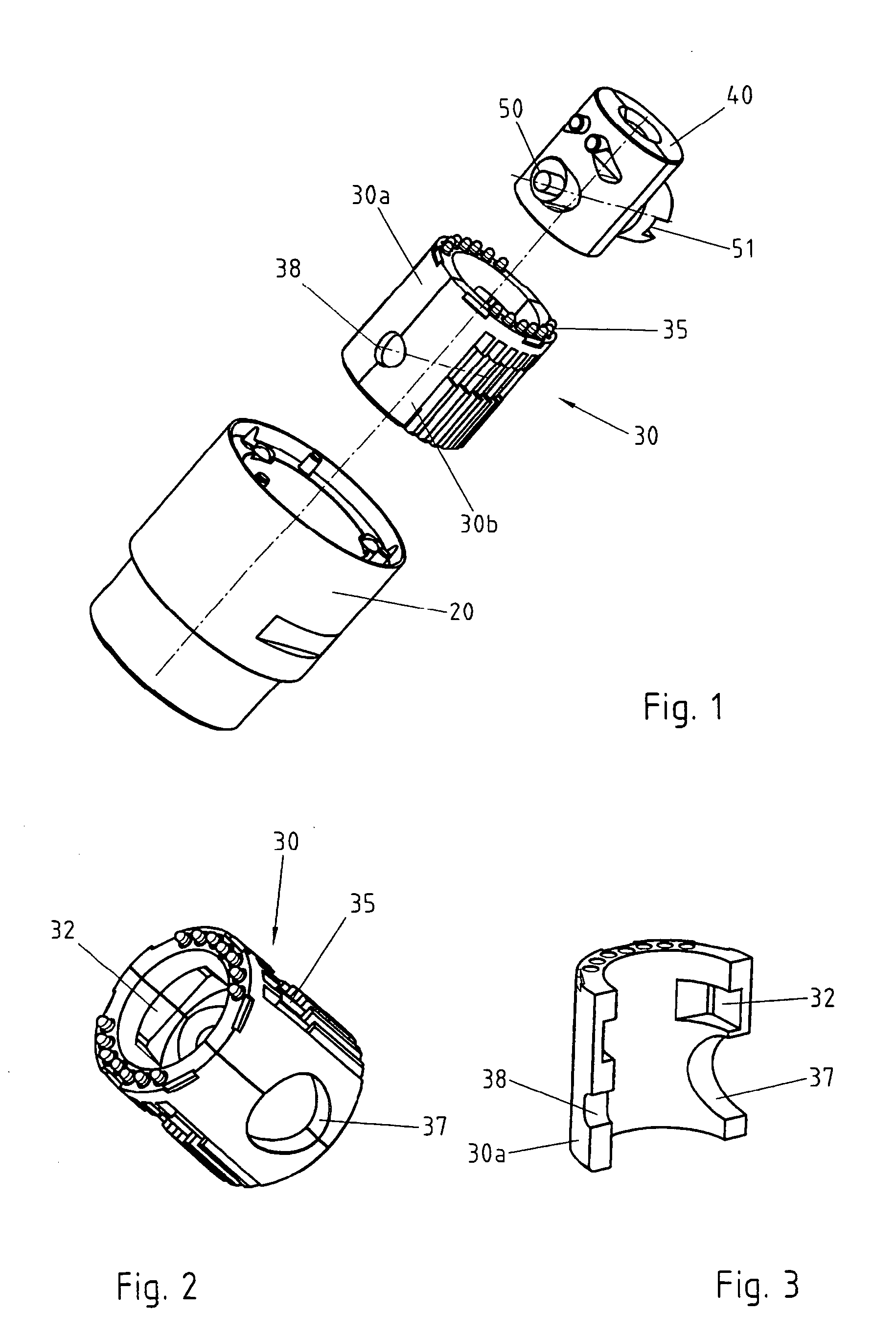

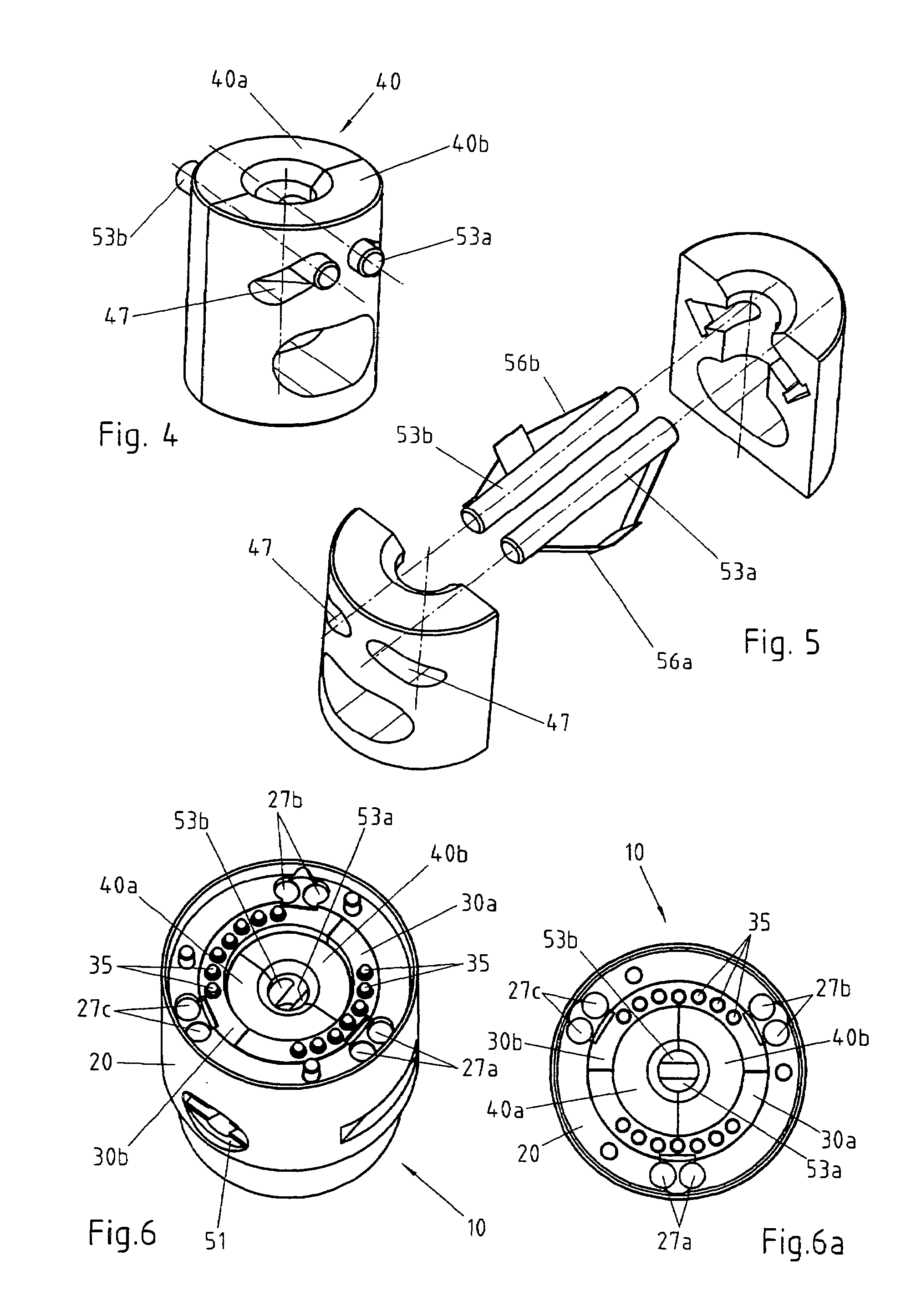

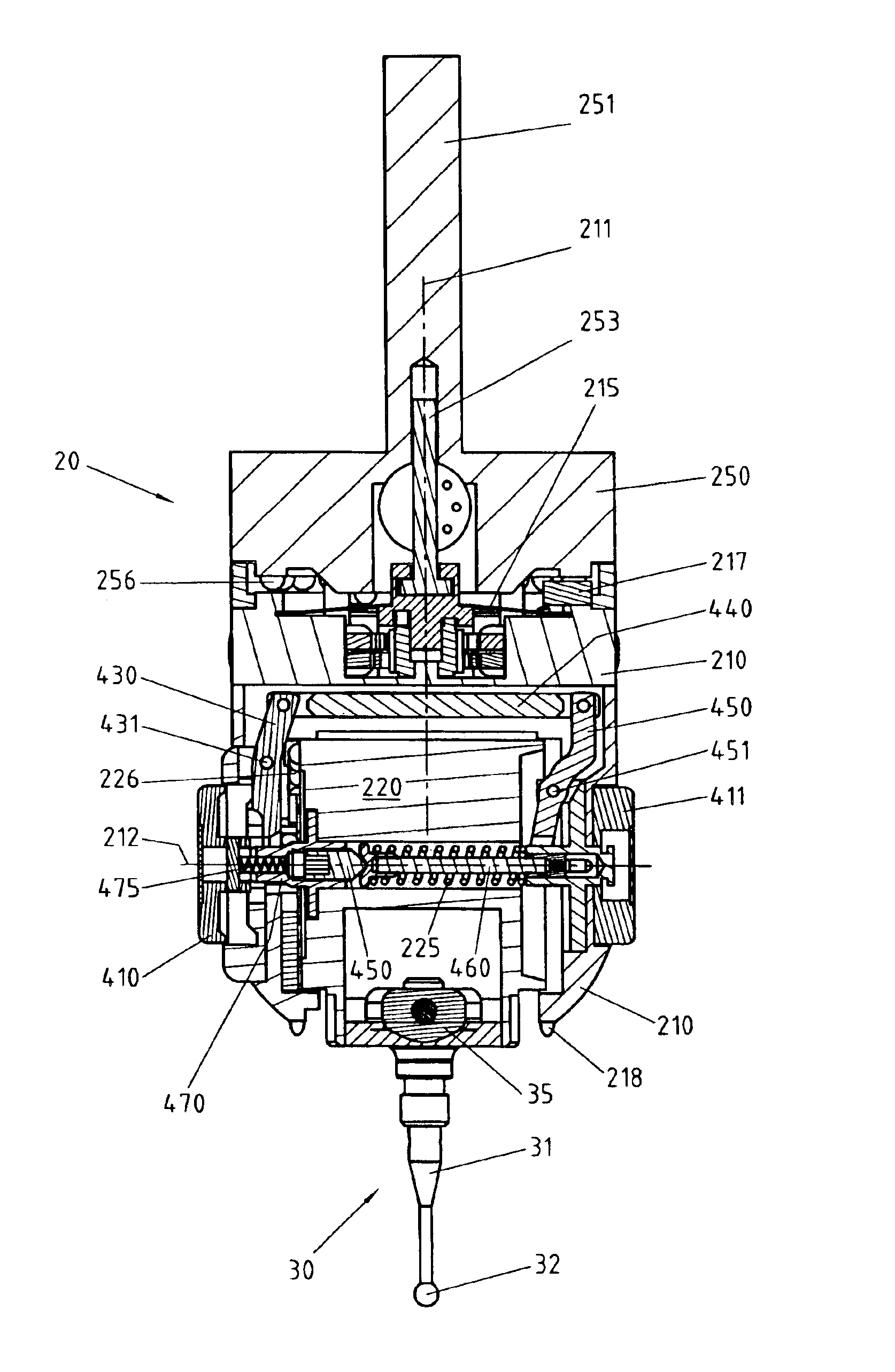

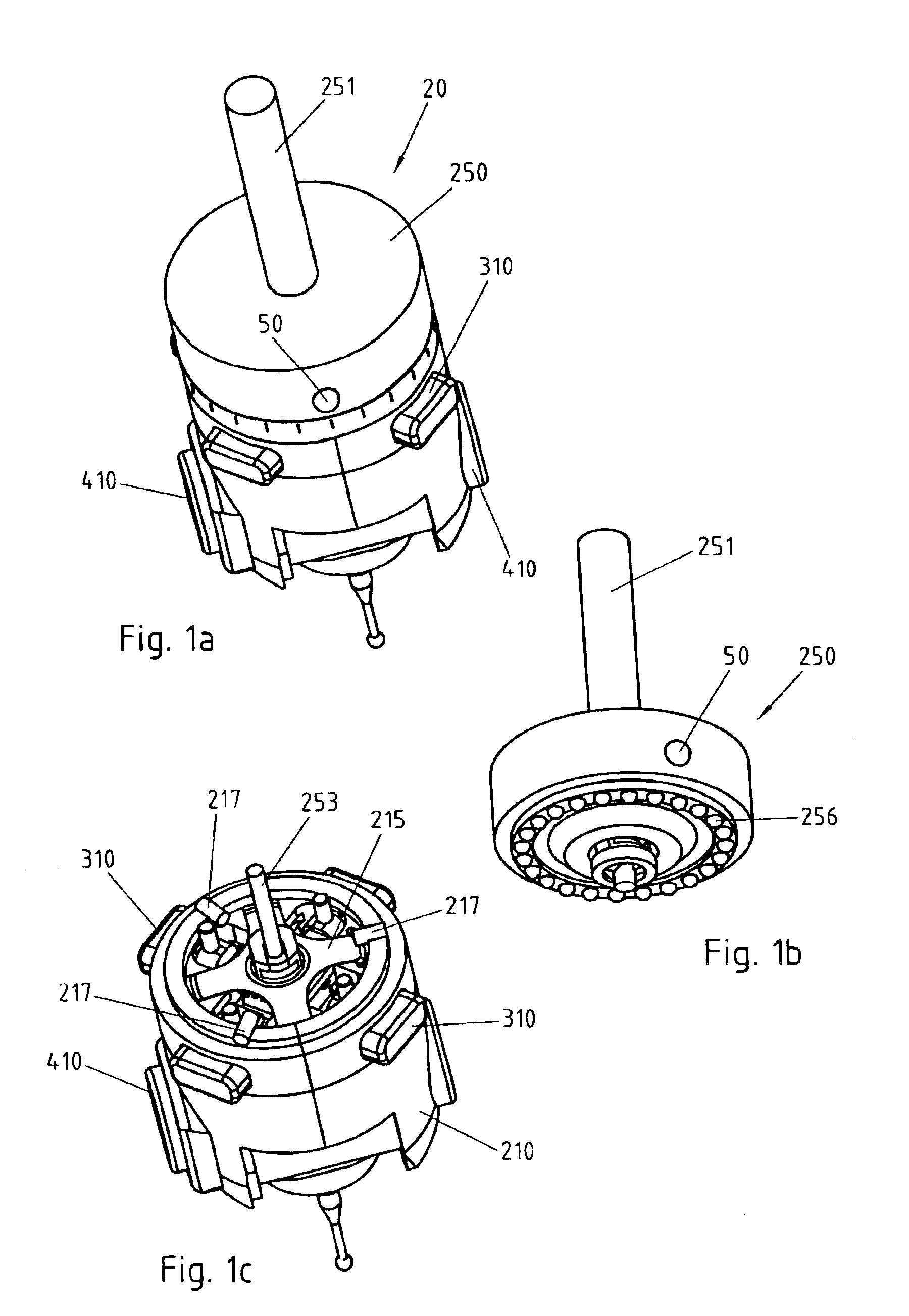

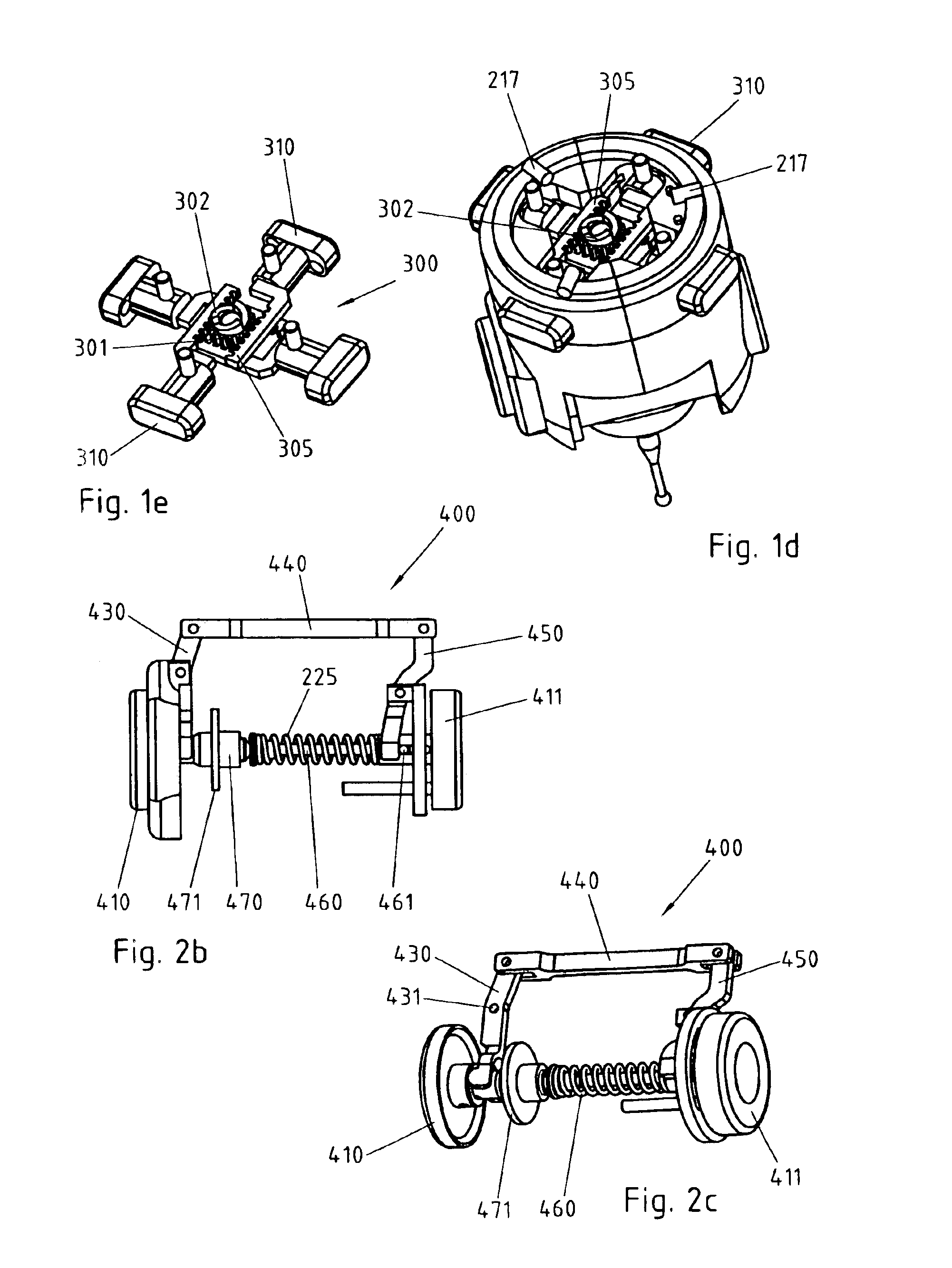

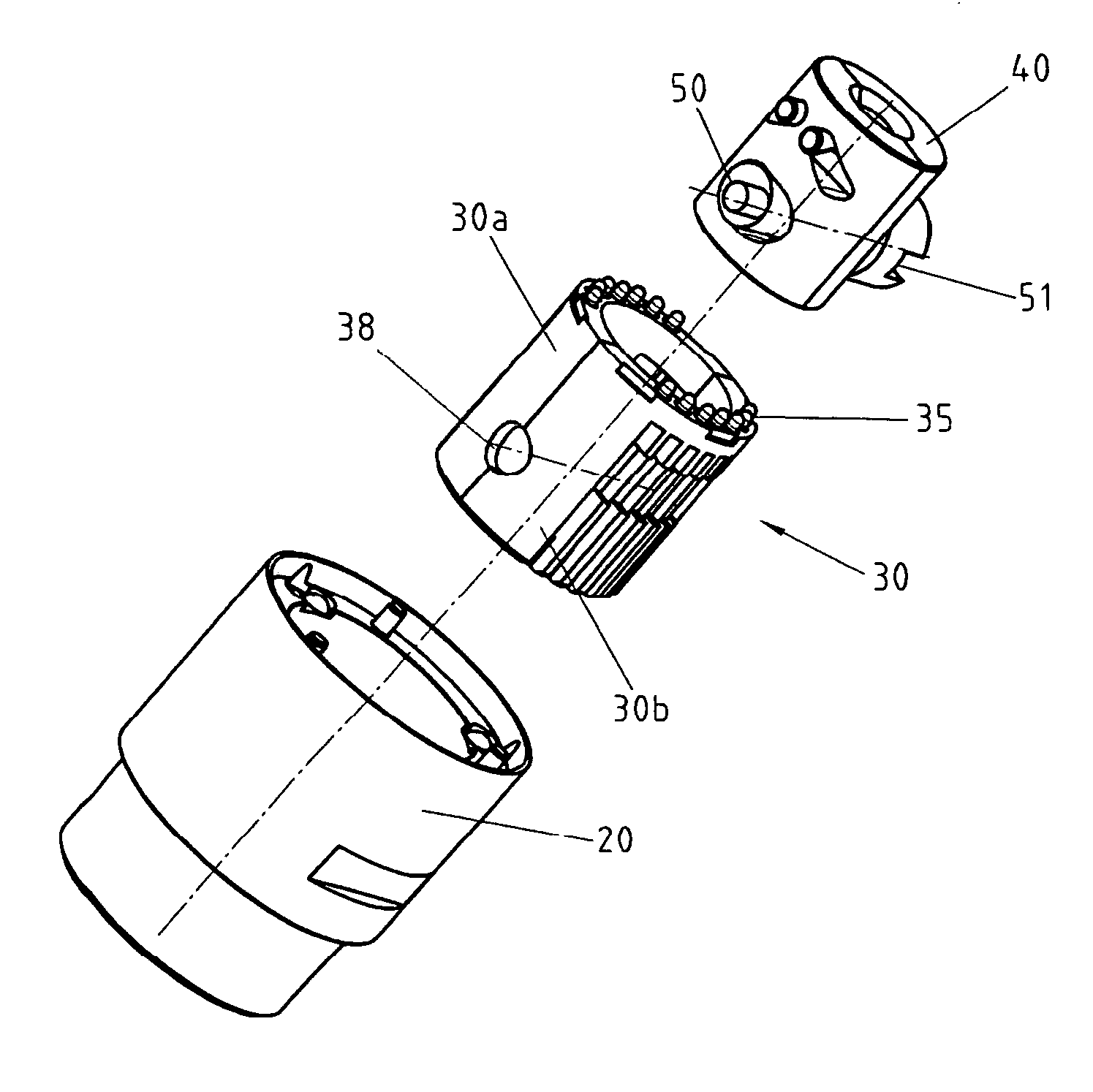

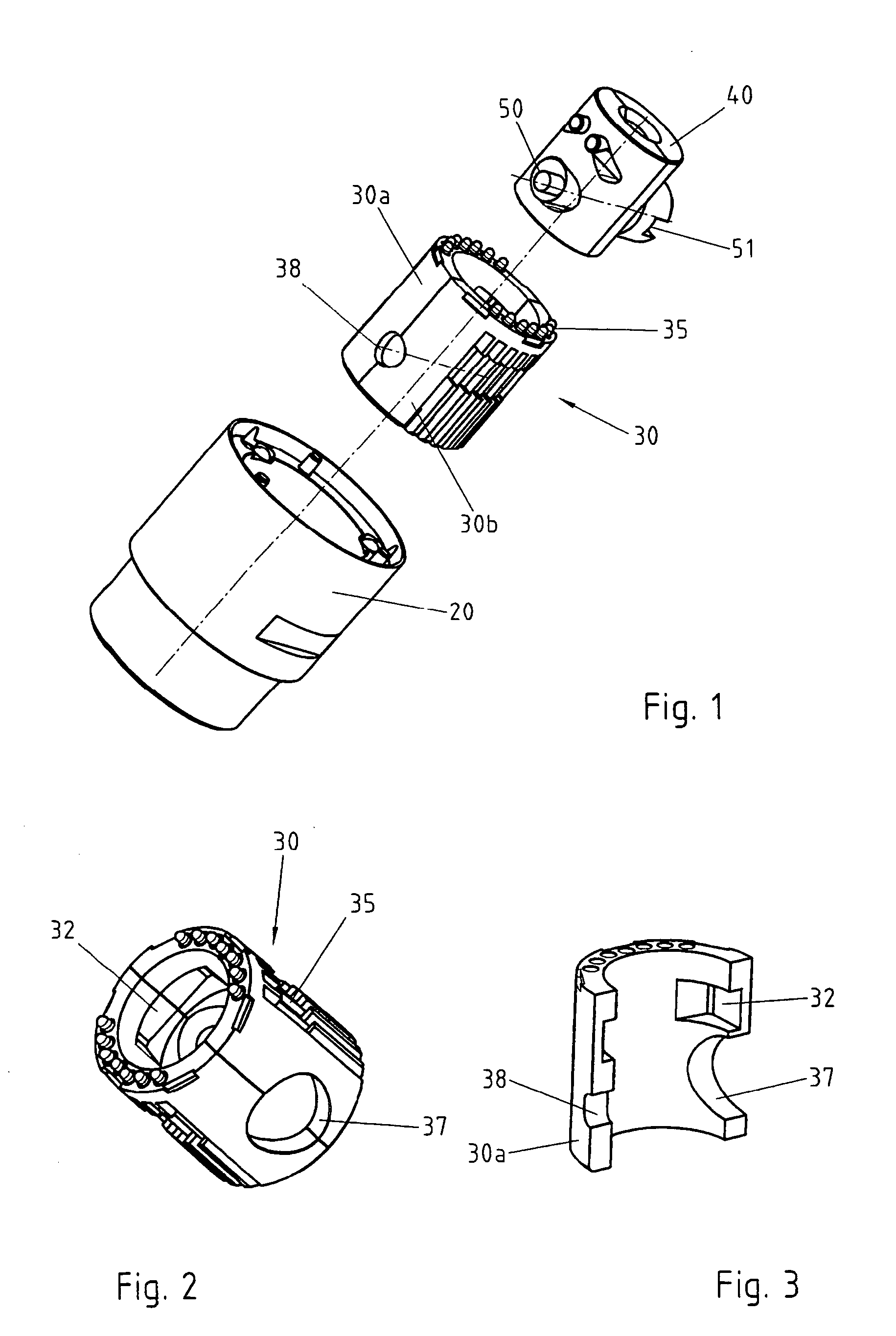

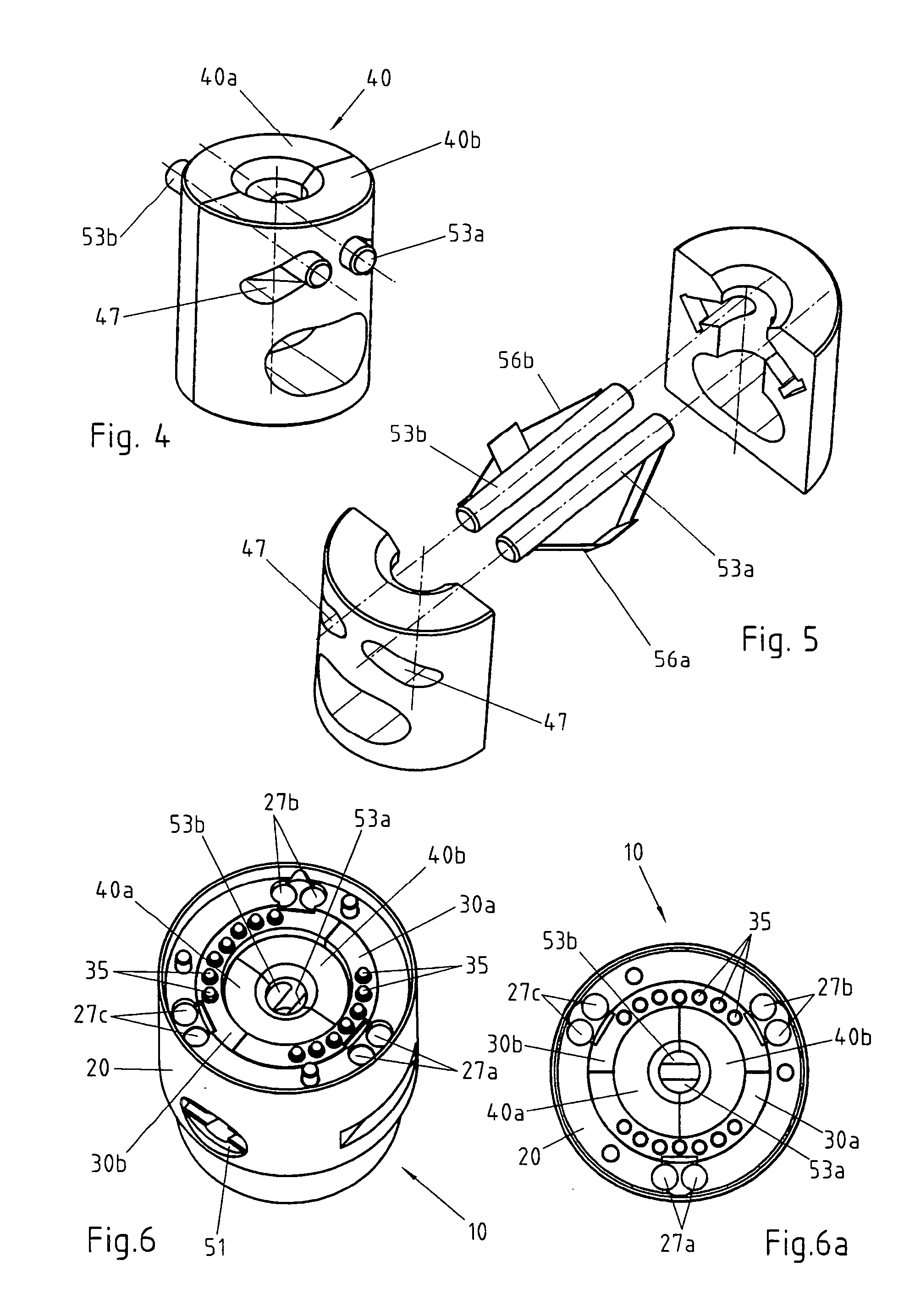

Tool-switching device

Tool-switching device for a machine for measuring coordinates wherein the tool is fastened on the tool-carrier and held by the action of elements exerting an axial force. The locking force is taken over symmetrically by the elements of a Boys connection, which increases the repeatability of the connection; in one embodiment, two pins or spheres are driven by a sliding bushing provided with two “V”-shaped slits or with two lateral gorges. In the subsequent embodiments, the pins are replaced by spheres, by levers or by a stirrup.

Owner:TESA SE

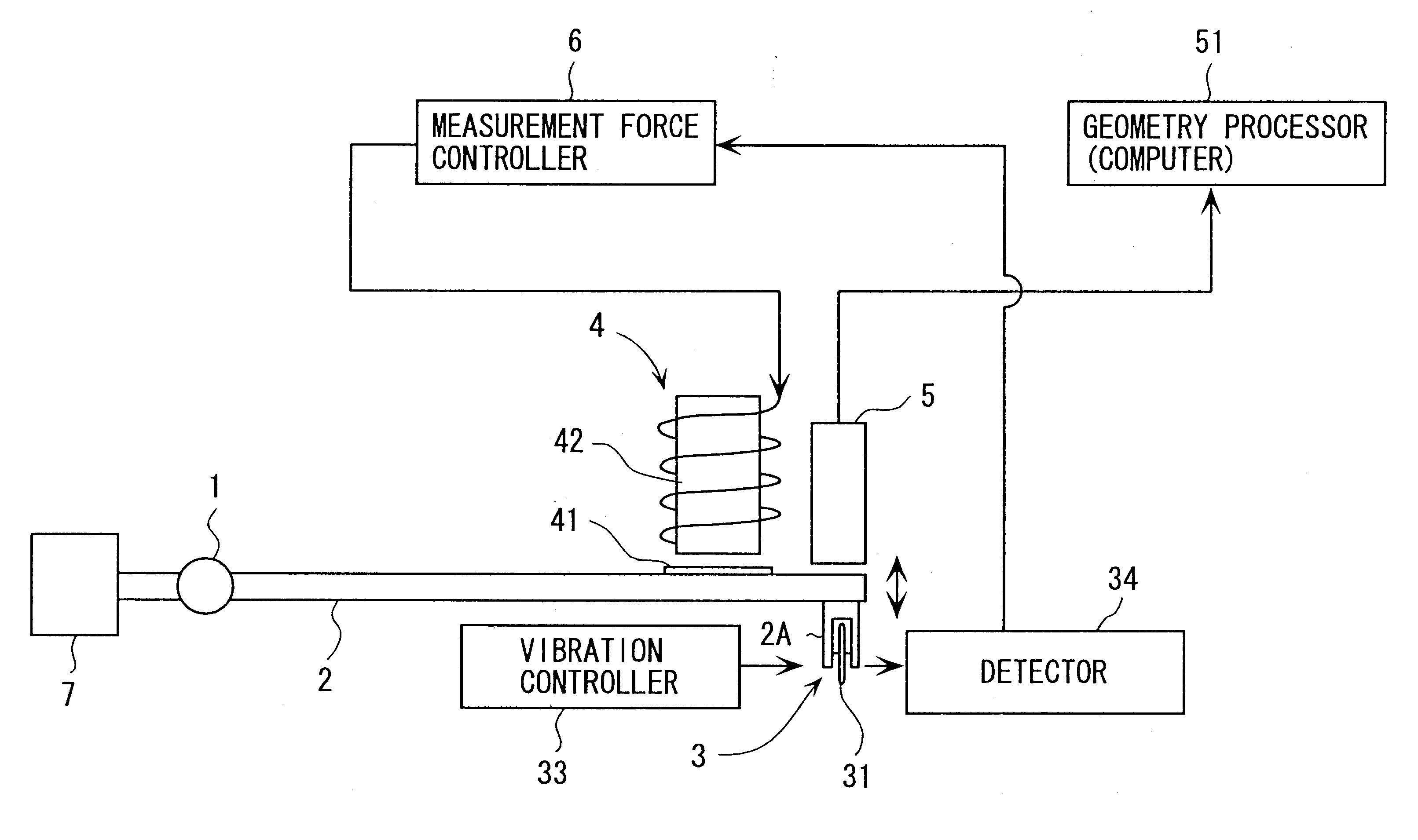

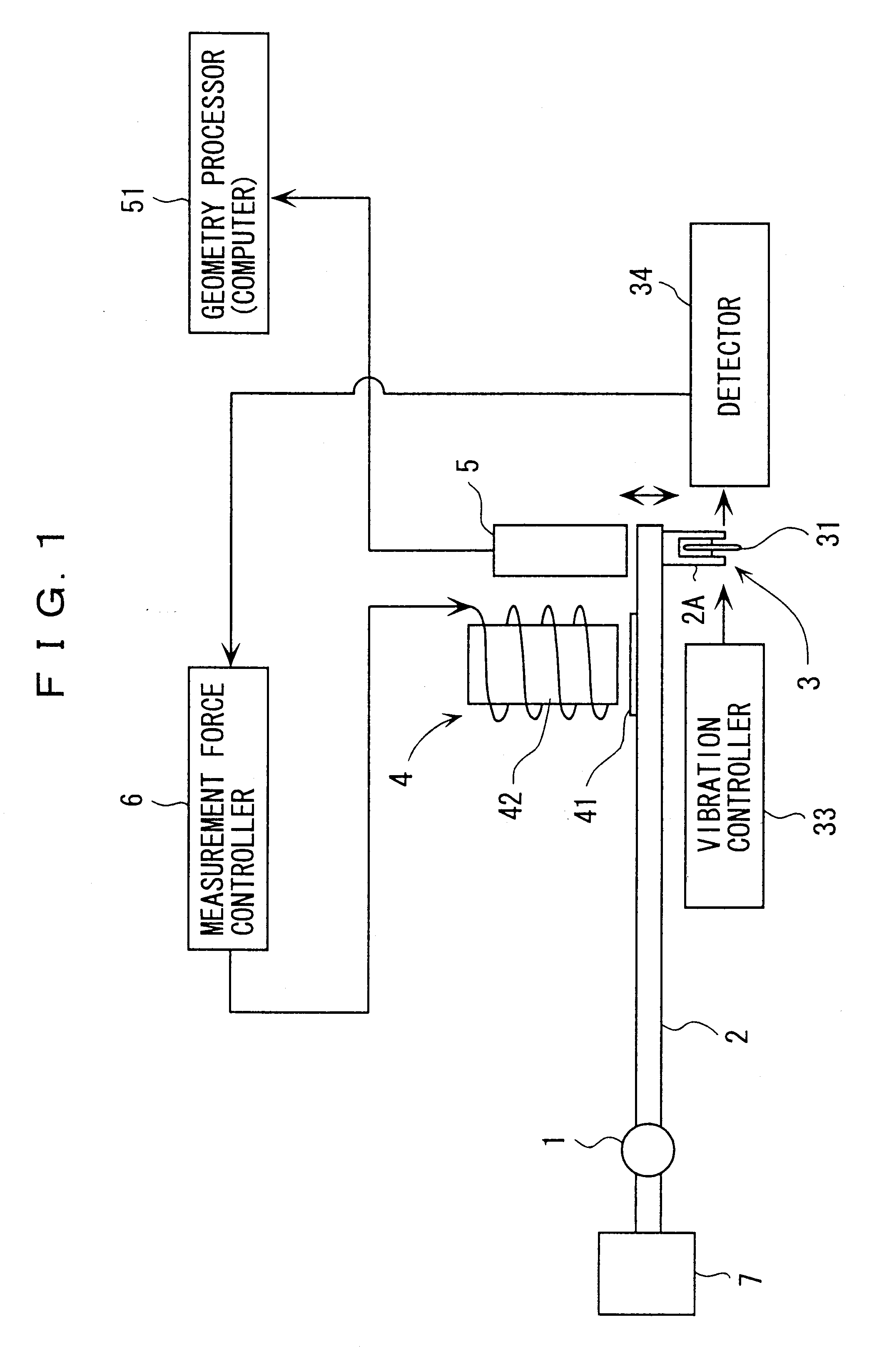

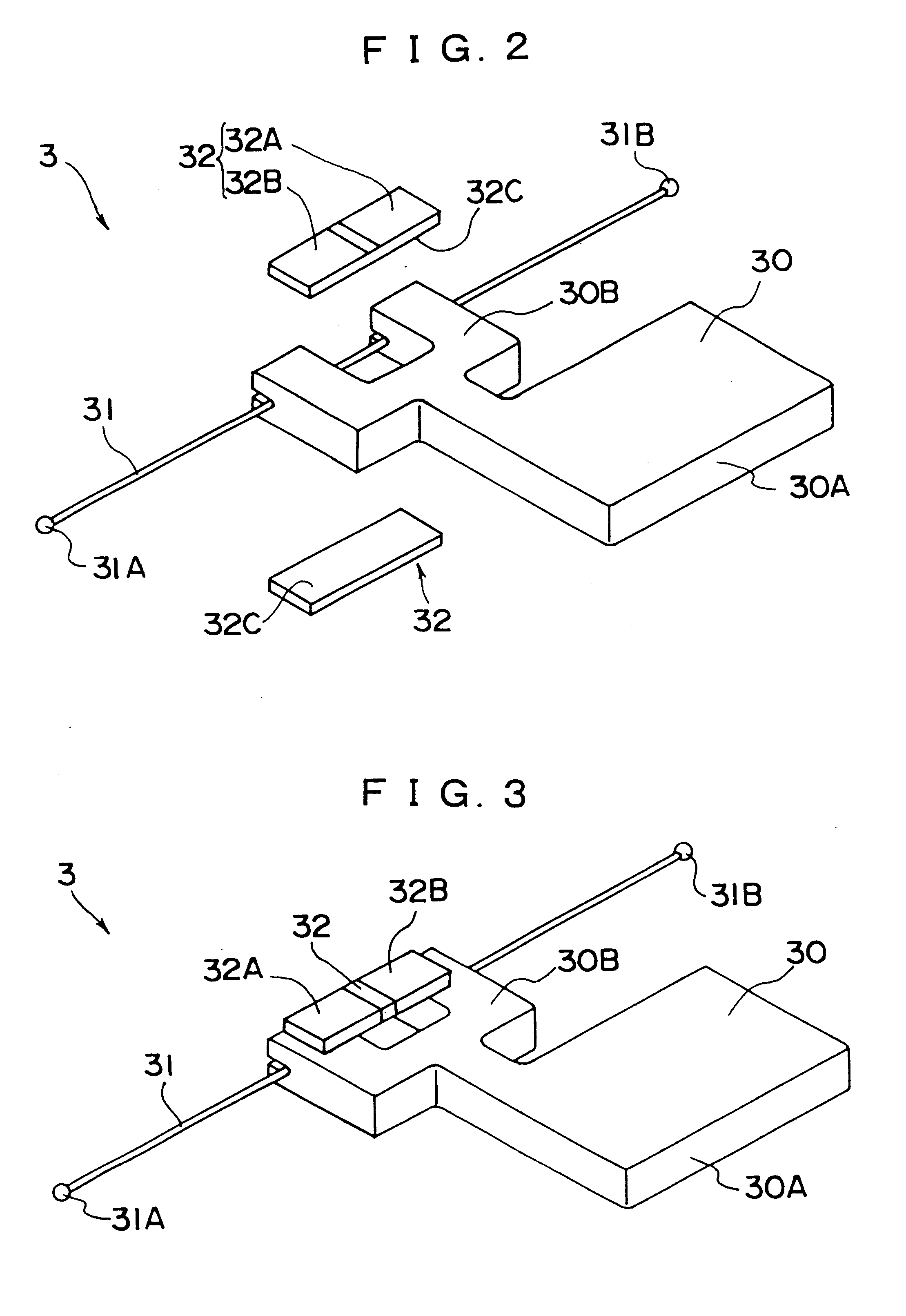

Micro-geometry measuring device

InactiveUS6314800B1Compasses with pivoted armsMechanical counters/curvatures measurementsMeasurement deviceState variation

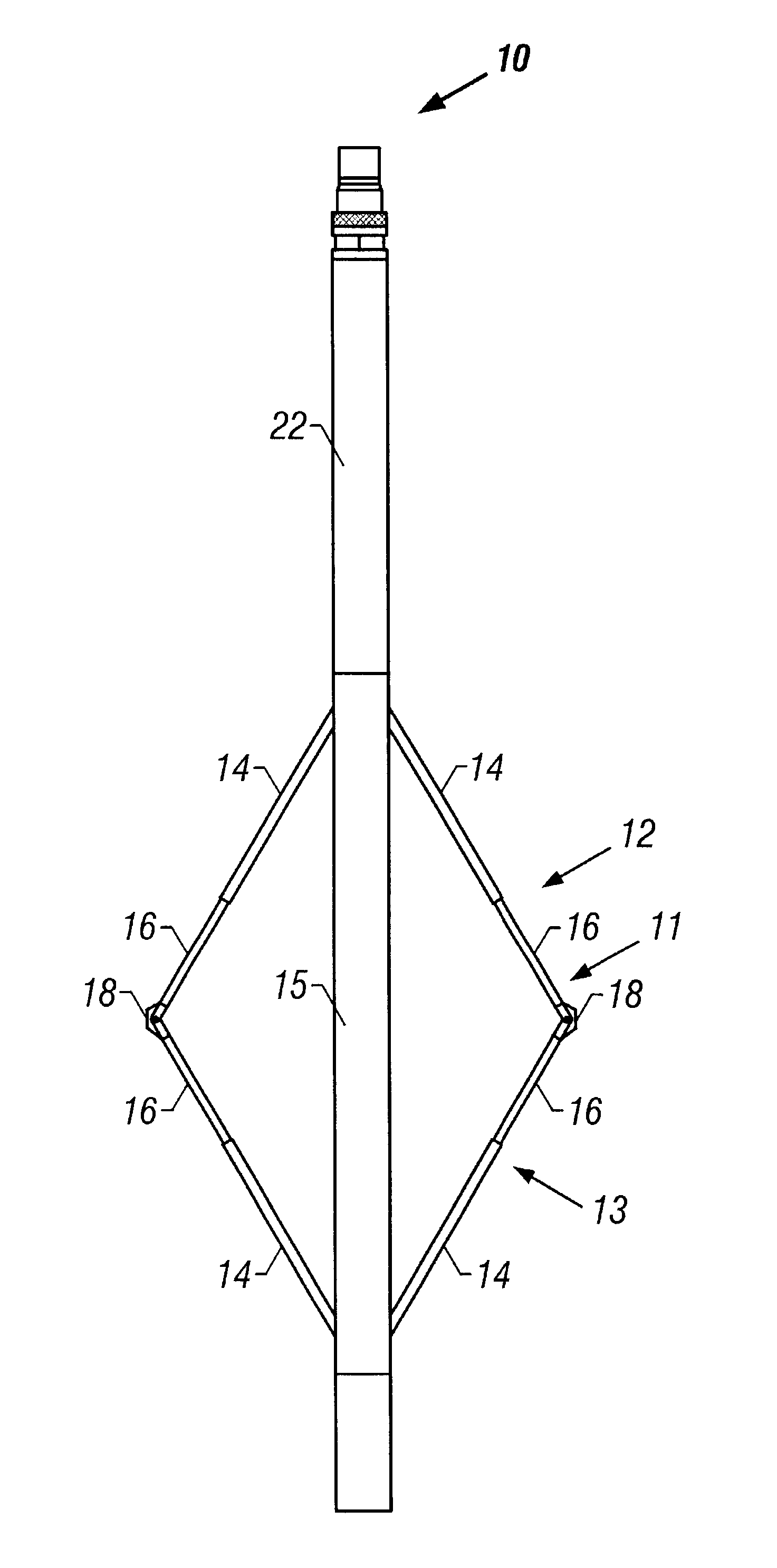

A micro-geometry measuring device capable of reducing measuring force thereof for avoiding damage on micro-geometry of workpiece surface and measuring at a high-speed is provided. The micro-geometry measuring device has a stylus mechanism having a stylus mechanism provided to an arm and having a stylus body, a measuring force adjusting mechanism for adjusting a measuring force working between the stylus body and the workpiece, a displacement sensor for detecting a position of the arm, and a measuring force controller for controlling the measuring force adjusting mechanism. The stylus mechanism includes a vibrator for resonantly vibrating the stylus body, and a detector for detecting vibration status changing when the stylus body touches the workpiece. The change in vibration of the stylus body vibrated by the vibrator is directly detected by the detector and a signal therefrom is fed back to the measuring force controller to keep constant measuring force working between the stylus body and the workpiece.

Owner:MITUTOYO CORP

Method and an apparatus for calibration of an industrial robot system

ActiveUS8457786B2Easy CalibrationImprove accuracyCompasses with pivoted armsComputer controlRotational axisRobotic systems

An industrial robot system has at least one robot (1) having a robot coordinate system (xr1, yr1, zr1) and a positioner (2) having a positioner coordinate system (xp, yp, zp) and adapted to hold and change orientation of a workpiece by rotating about a rotational axis. Target points for the robot are programmed with respect to an object coordinate system (xo1, yo1, zo1). A robot controller (3), at least three calibration objects (24a-c) arranged on the positioner, and a calibration tool (26) held by the robot are provided. The positions of the calibration objects are determined for at least three different angles of the rotational axis of the positioner, to determine the direction of the rotational axis of the positioner and relation between the object coordinate system and the positioner coordinate system by performing a best fit between known and determined positions of the calibration objects.

Owner:ABB (SCHWEIZ) AG

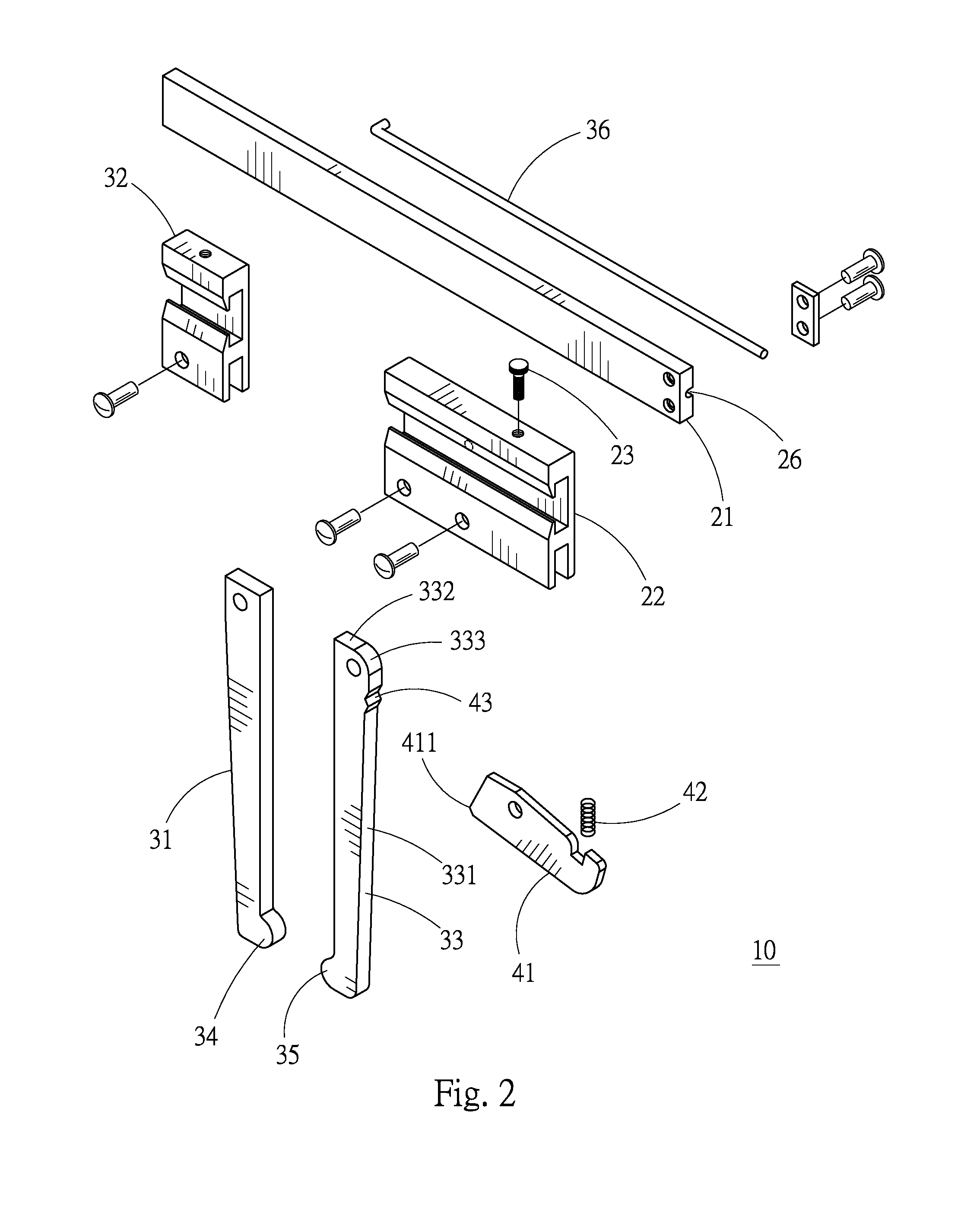

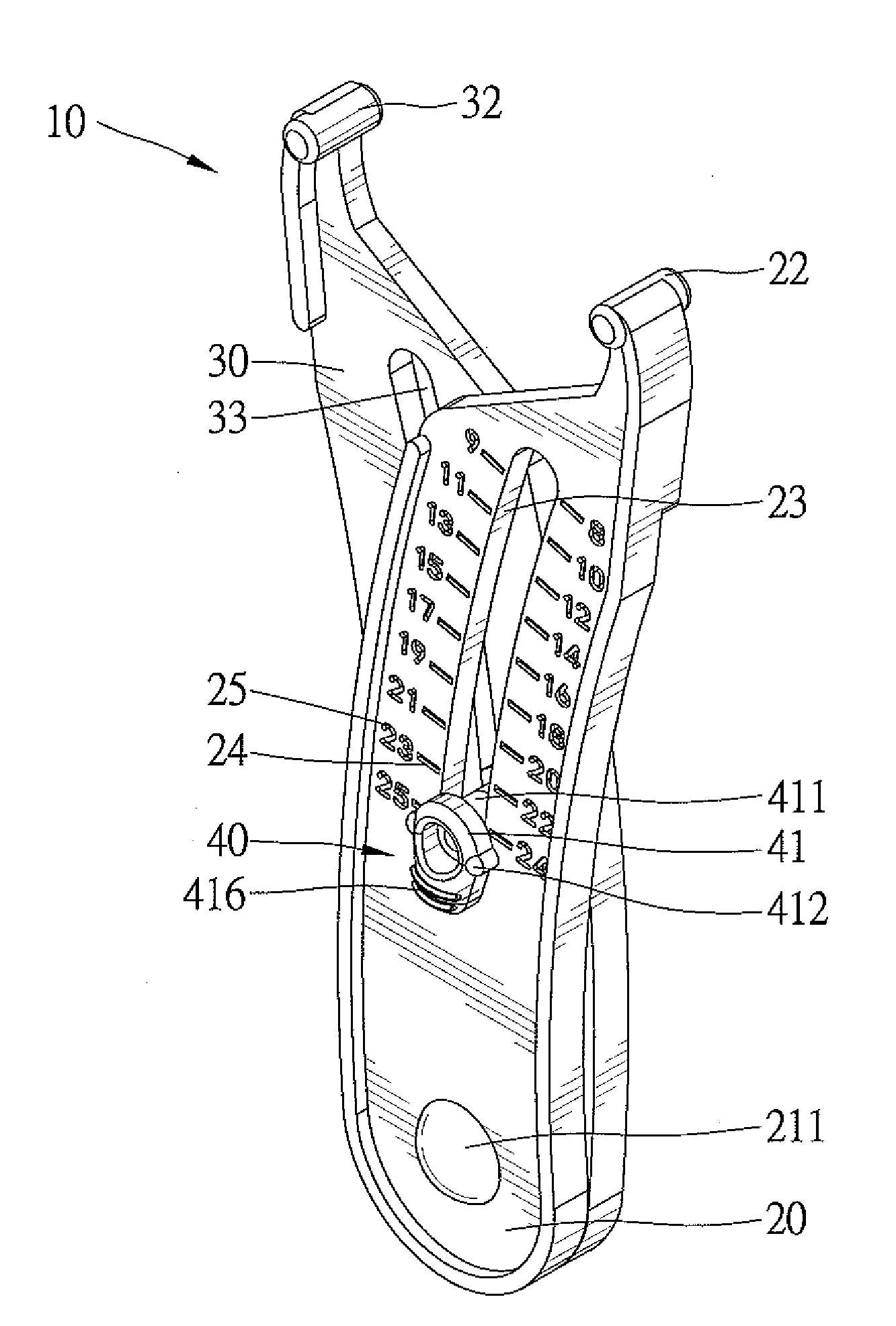

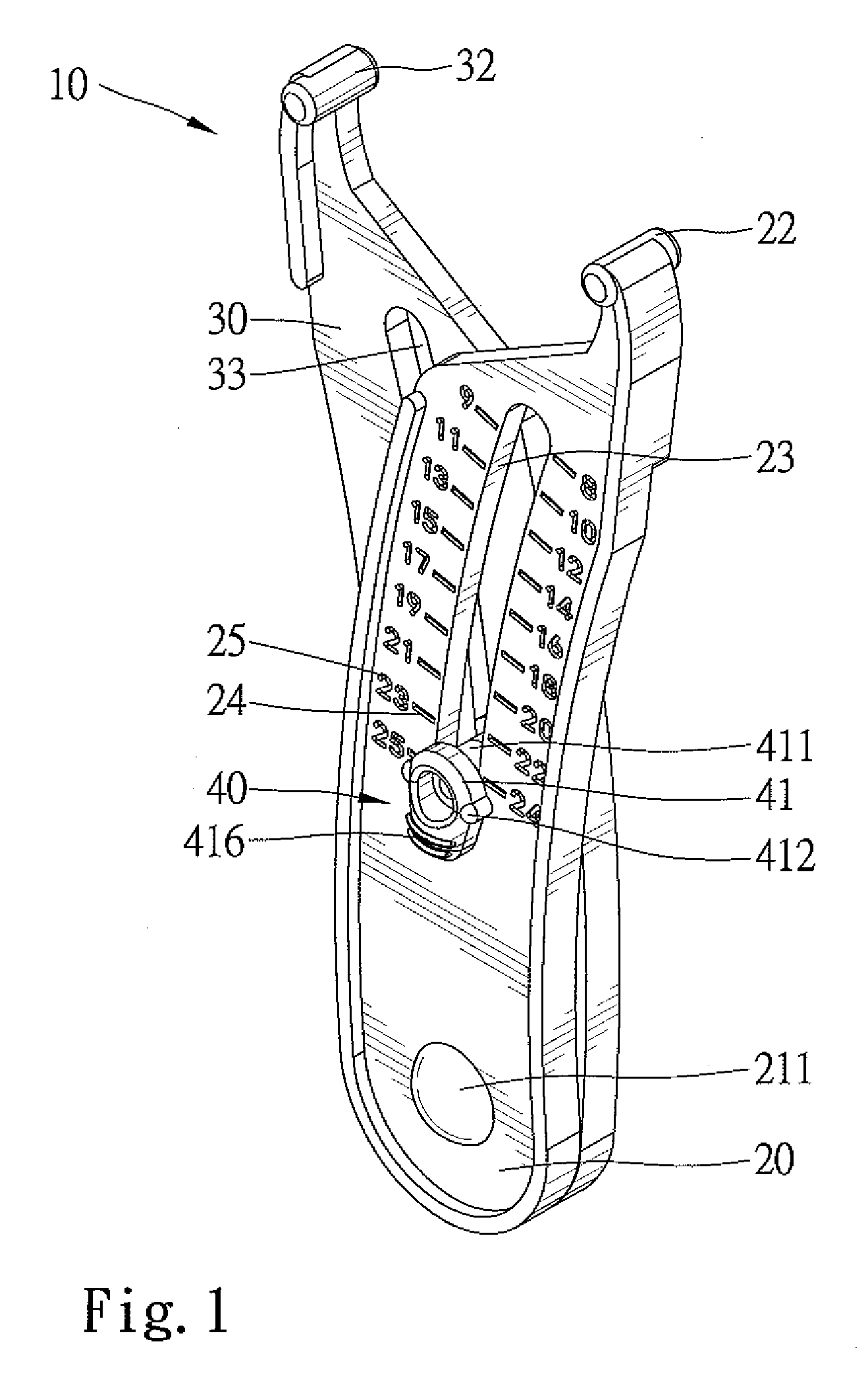

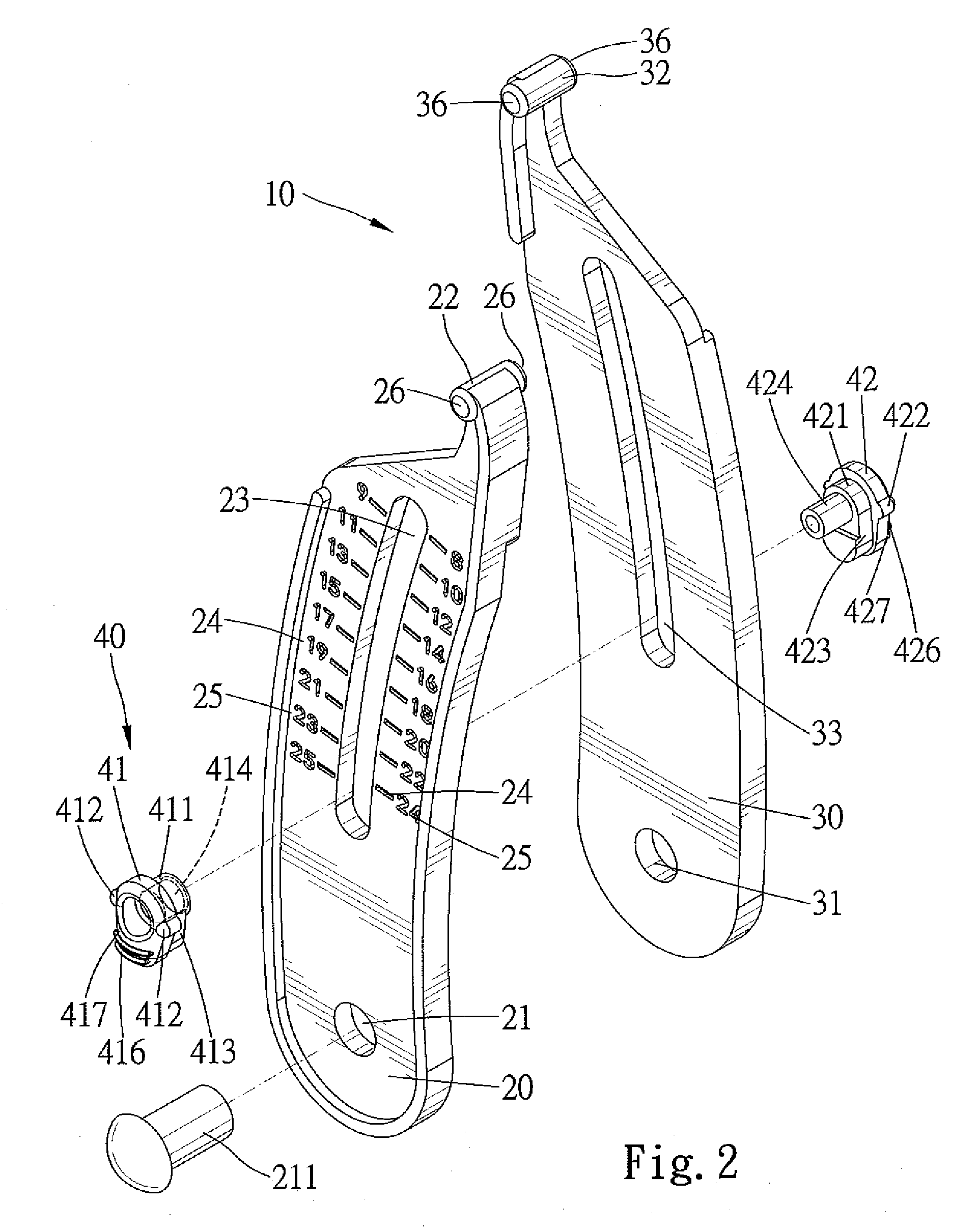

Femoral tibial spreader with tensor measurement

A femoral tibial spreader (100) for spreading adjacent bones includes a radial measurement gauge (111) for providing incidia corresponding to an amount of force being applied to the forward ends (105,106) of the femoral tibial spreader (100). The femoral tibial spreader (100) may be used, for example, to separate the femur (301) and tibia (302) during knee surgery. The radial measurement gauge (111) may be used to determine an amount of force being applied to the femur (301) and tibia (302), for example, by the medial and arterial ligaments. Two handle members (104,109) are squeezed together, which causes the forward ends (105,106) to open. A biasing member (110) allows a measurement extension (108) to pivot towards a handle member under tension, thereby providing a measurement of force applied by the ligaments.

Owner:INNOMED INC

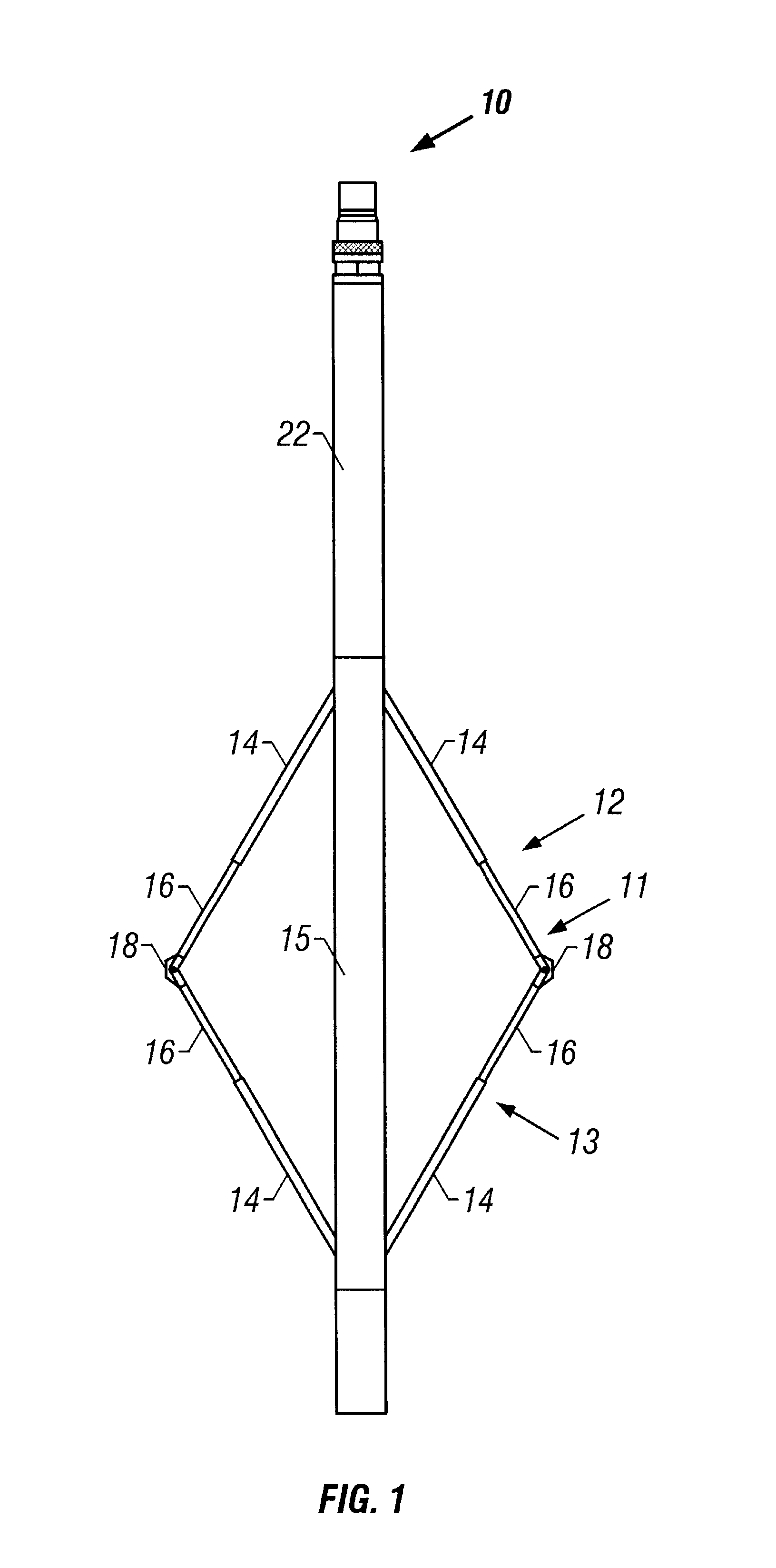

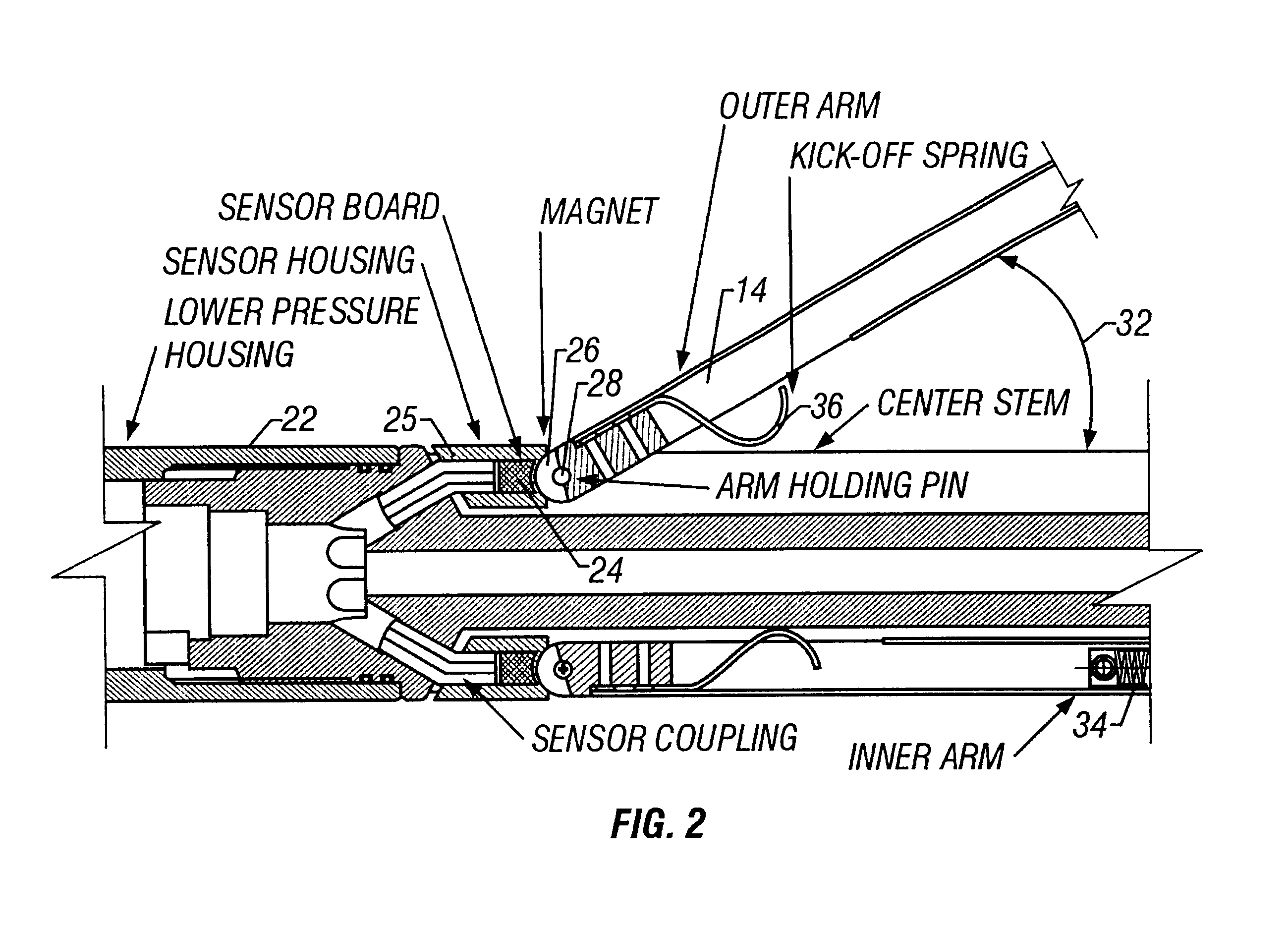

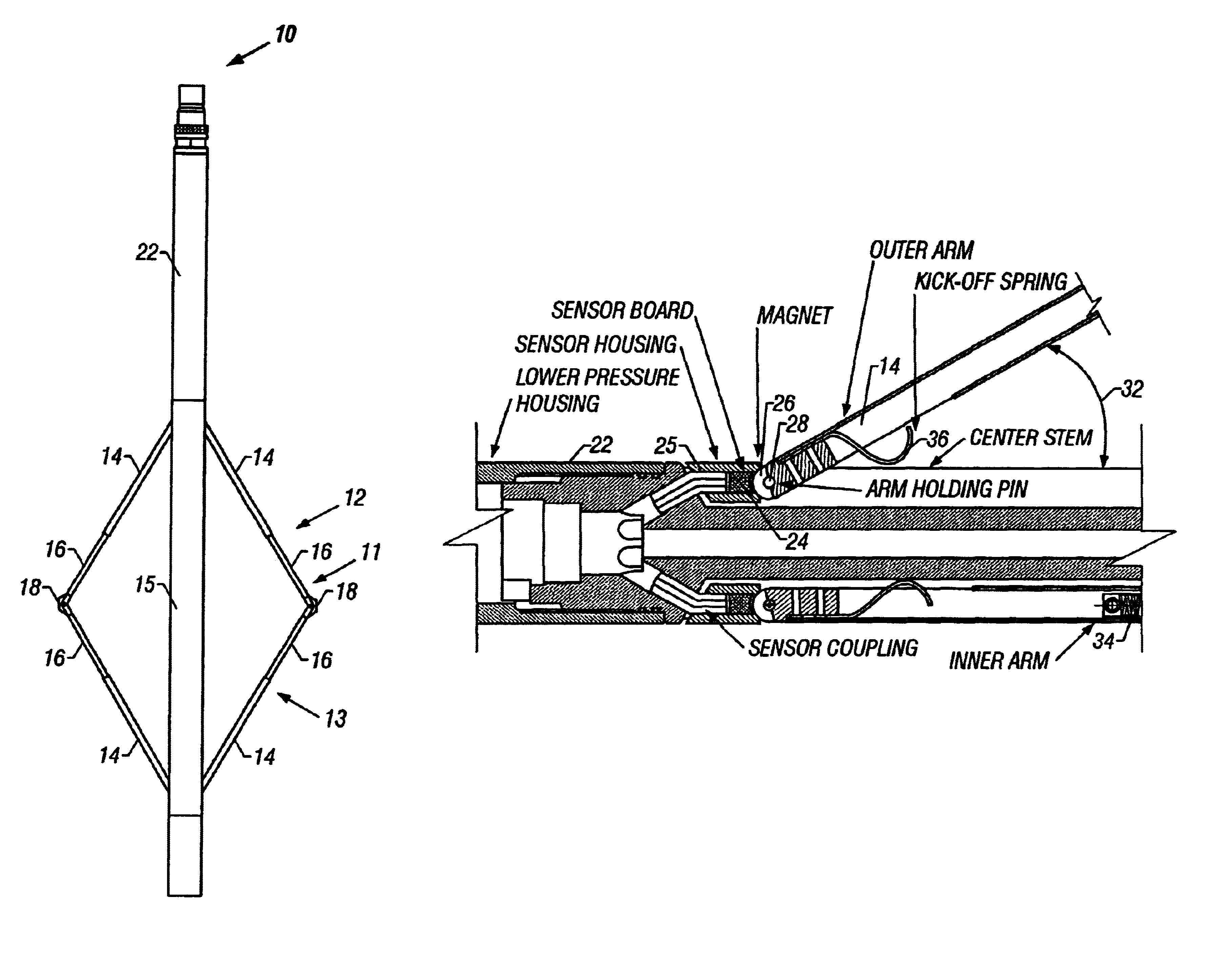

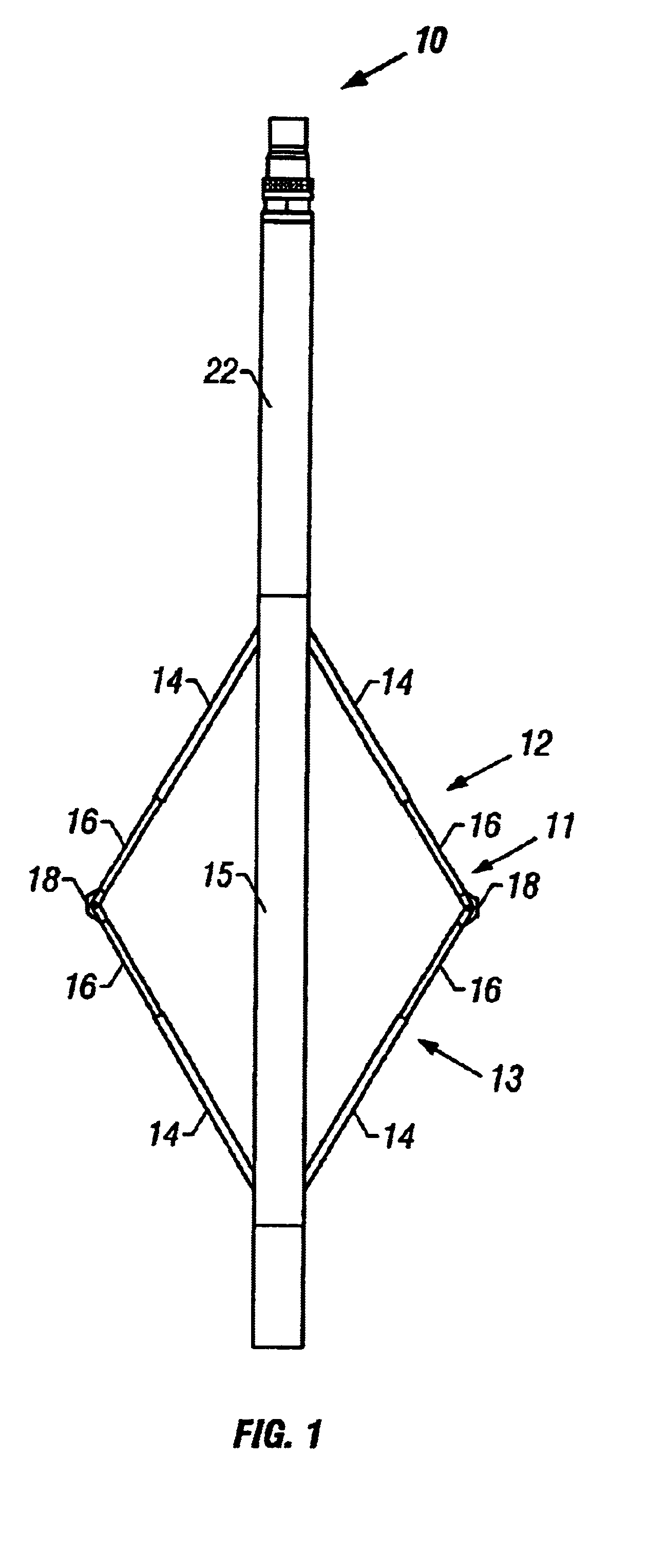

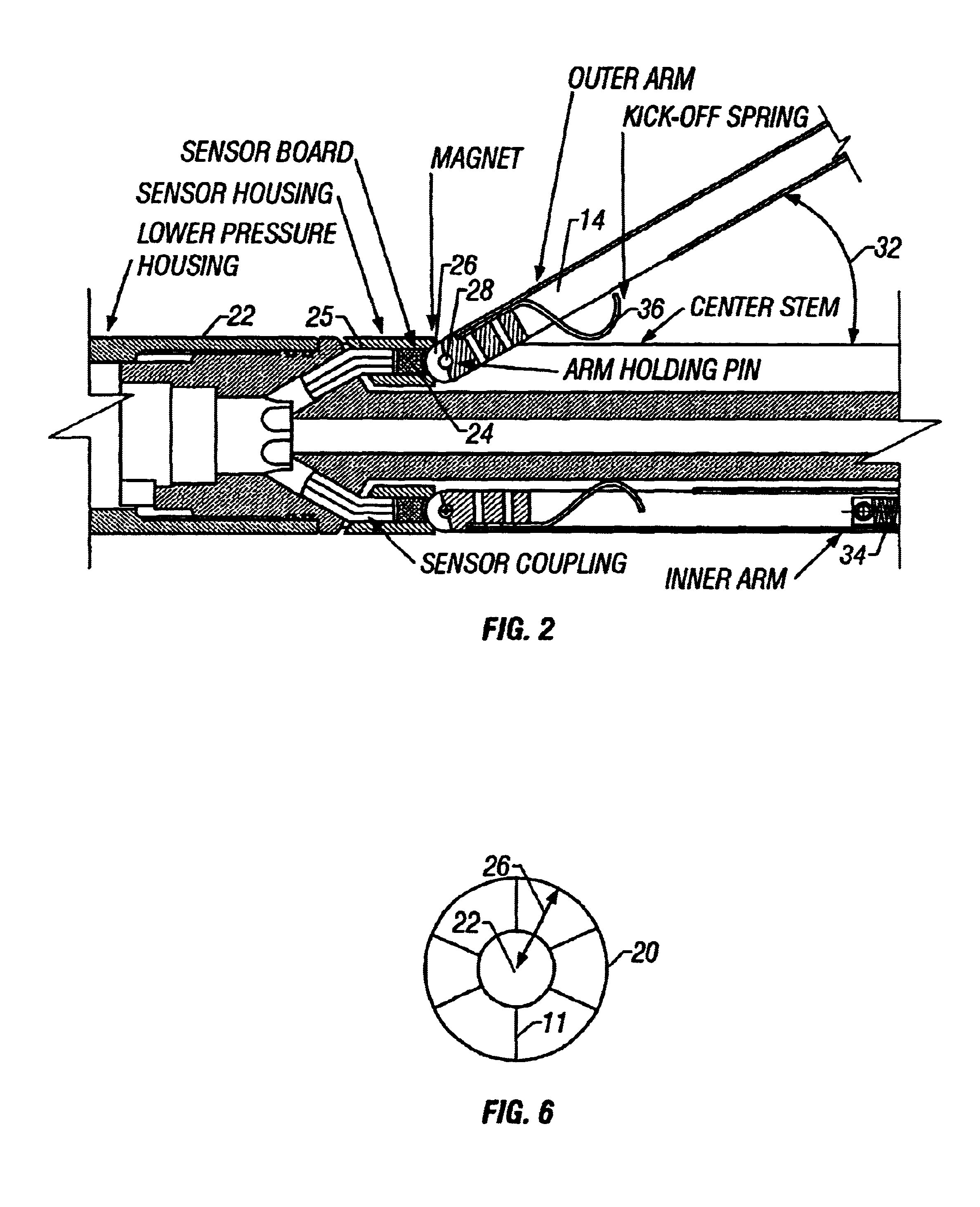

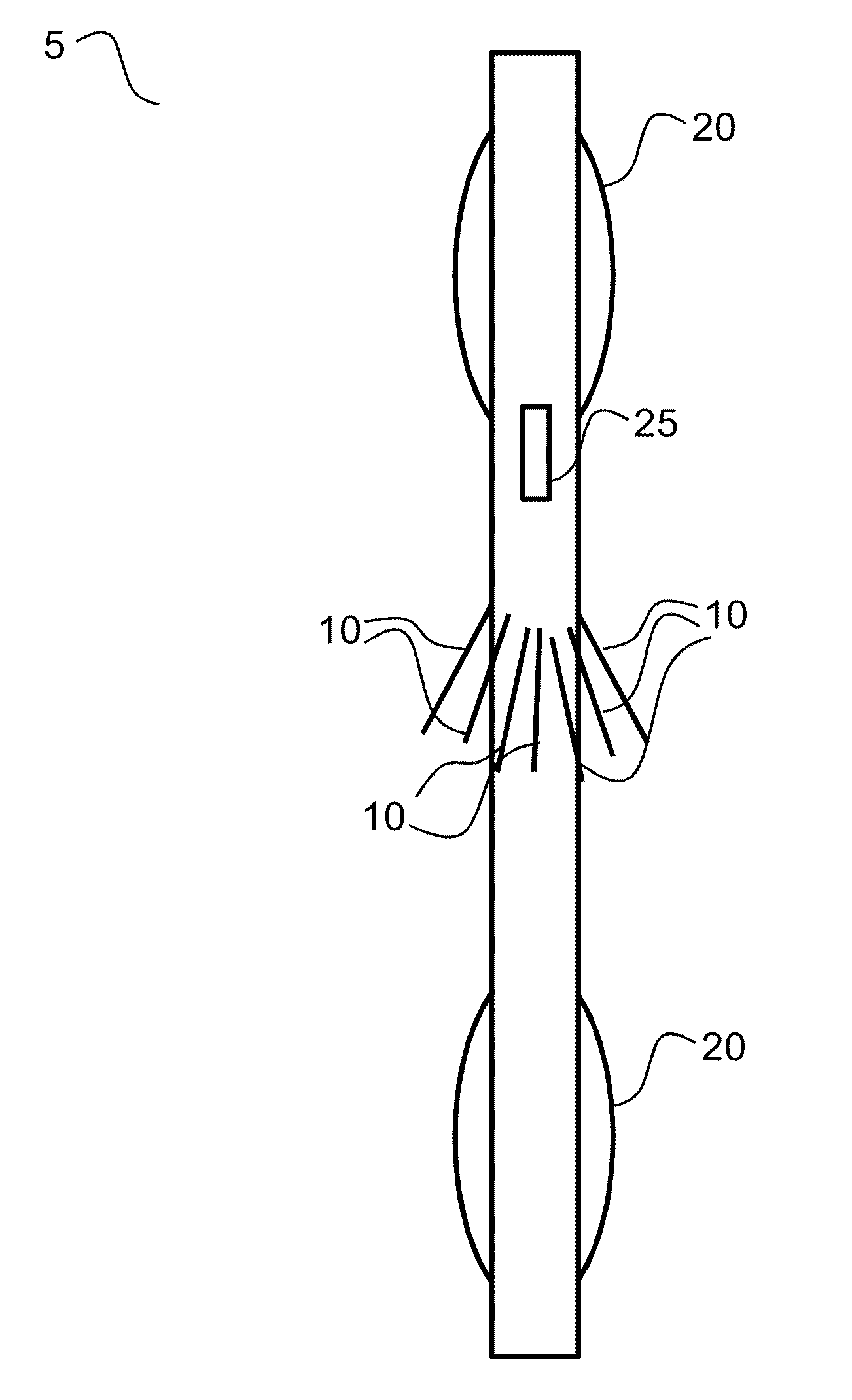

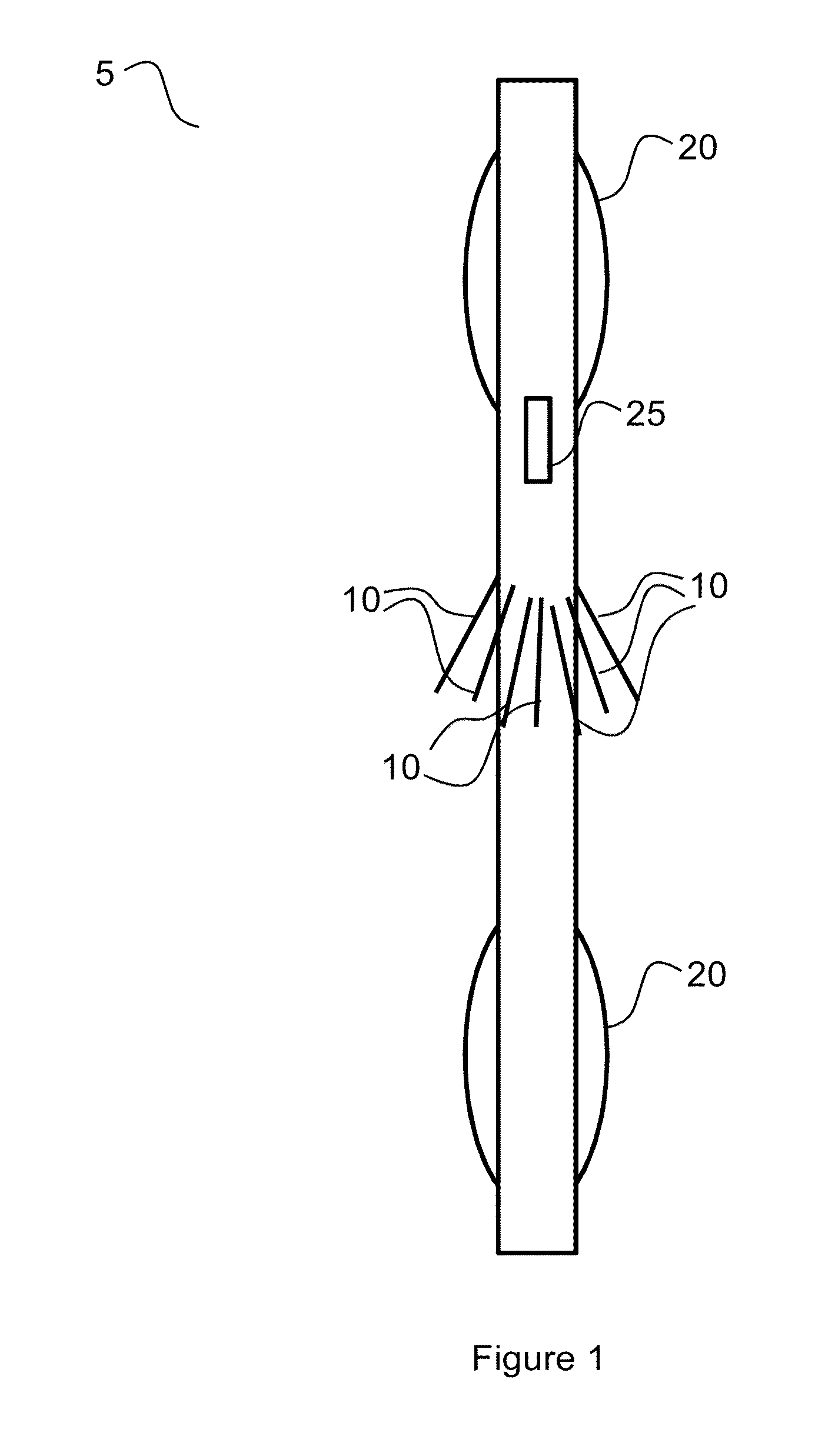

System and method for determining deformed pipe geometry

ActiveUS20150285607A1Raise the possibilitySurely and accurately determineFluid-tightness measurement by detecting dimension changeFeeler-pin gaugesMeasurement pointEngineering

A method and associated system for determining geometry of a deformed pipe or conduit or wellbore, the method comprising: collecting, determining and / or receiving measurement data indicative of a plurality of radii of the pipe or conduit using equipment centred in the pipe at two or more points a known distance from the measurement point but not at the measurement point itself; selecting a deformation type and / or deformation model; processing the measurement data to determine one or more geometrical properties of the pipe or conduit, the geometrical properties being indicative of, or associated with, one or more deformations, shapes or profiles of at least part of the pipe or conduit; and guiding and / or constraining at least a part of the processing of the measurement data using the selected deformation type or model and / or fitting the selected deformation model to the measurement data.

Owner:E V OFFSHORE

Adjustable probe

ActiveUS6854195B2Prevent movementKeep distanceCompasses with pivoted armsMechanical counters/curvatures measurementsMachine toolActuator

Touch-triggered probe comprising a fixed part, designed to be fastened onto a measuring machine or a machine tool, and a mobile contact feeler that can be oriented on two independent axes along a multiplicity of spatial directions. The two axes of the probe comprise each an actuator for unlocking and adjusting the axes.

Owner:HEXAGON TECH CENT GMBH

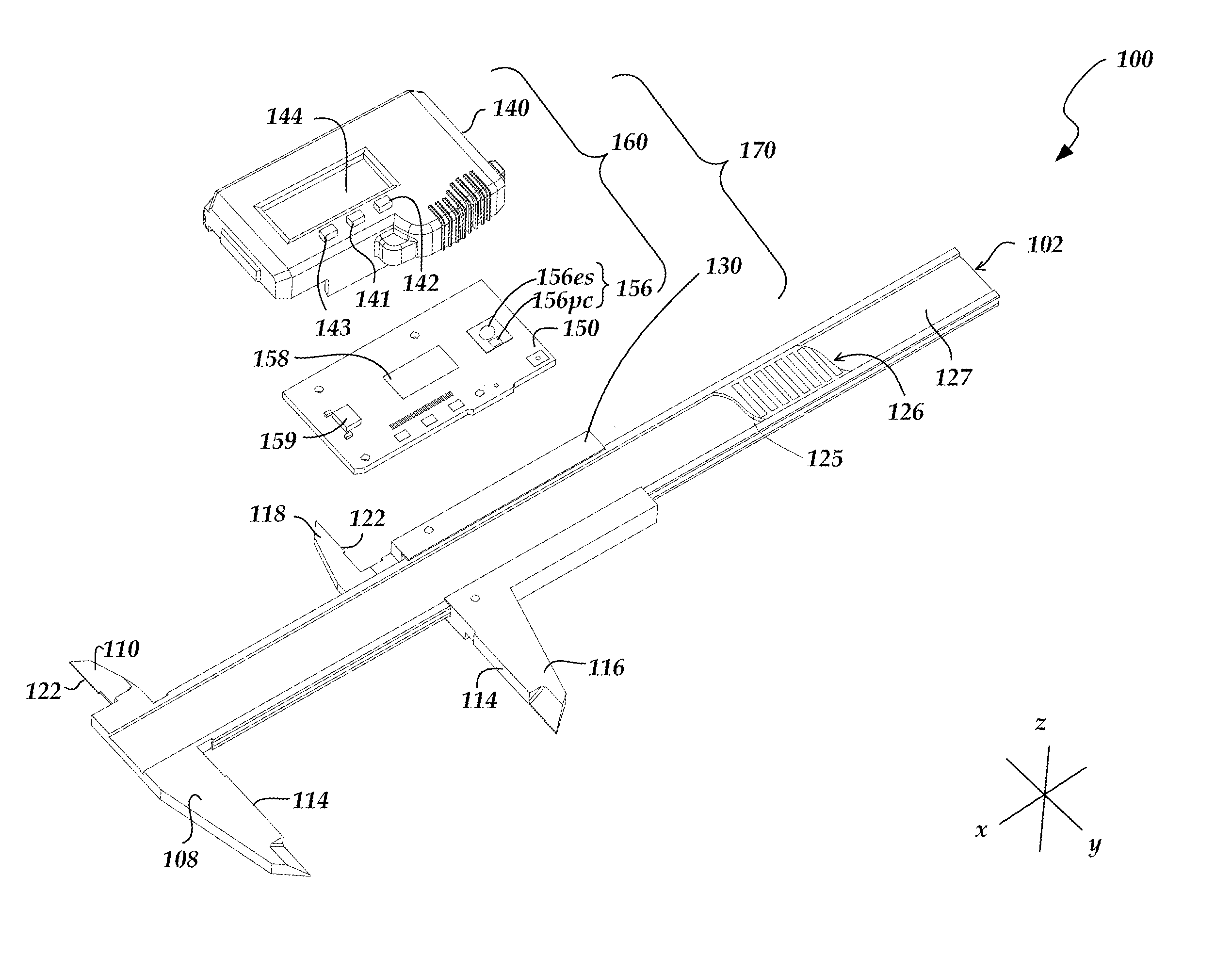

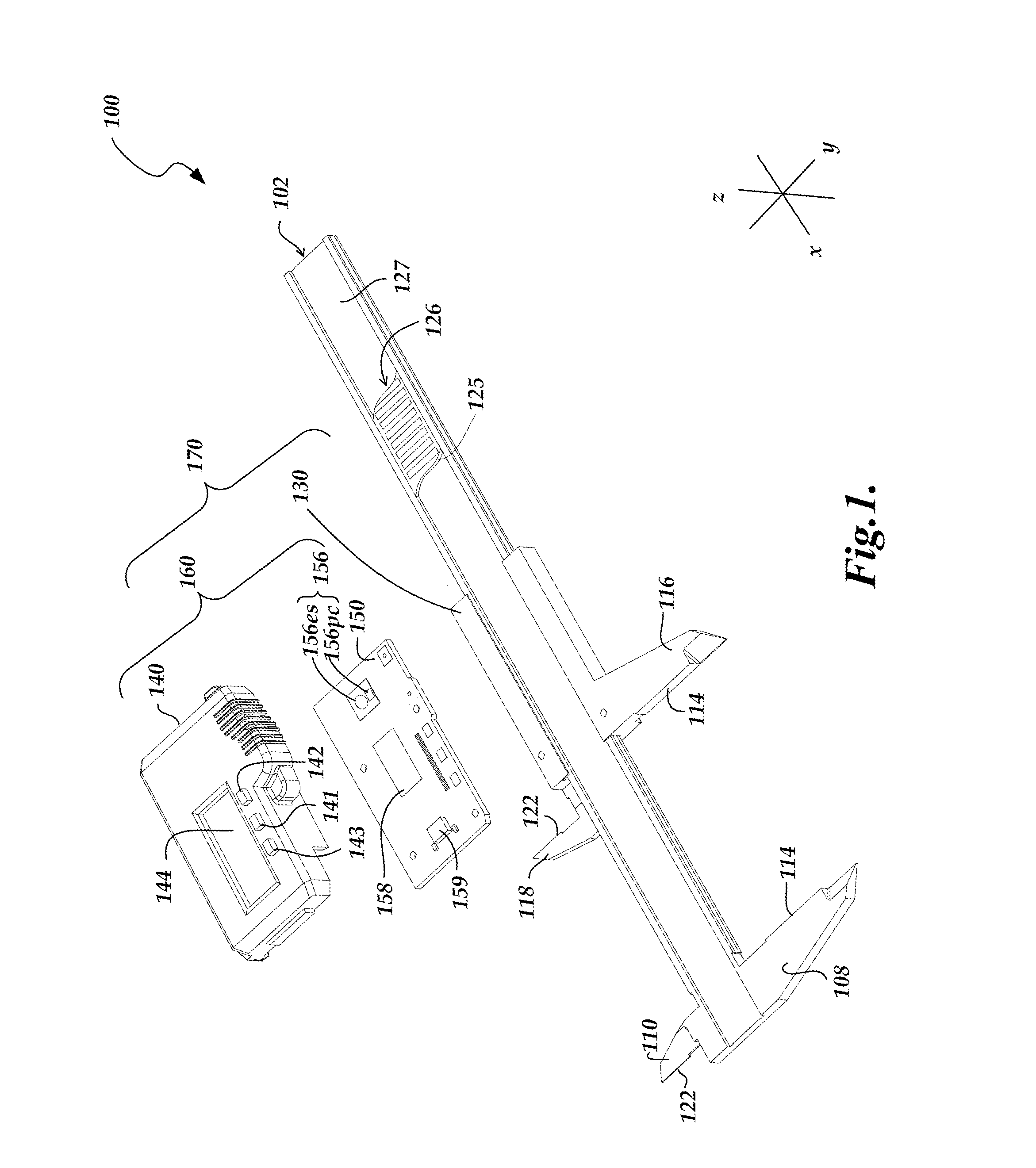

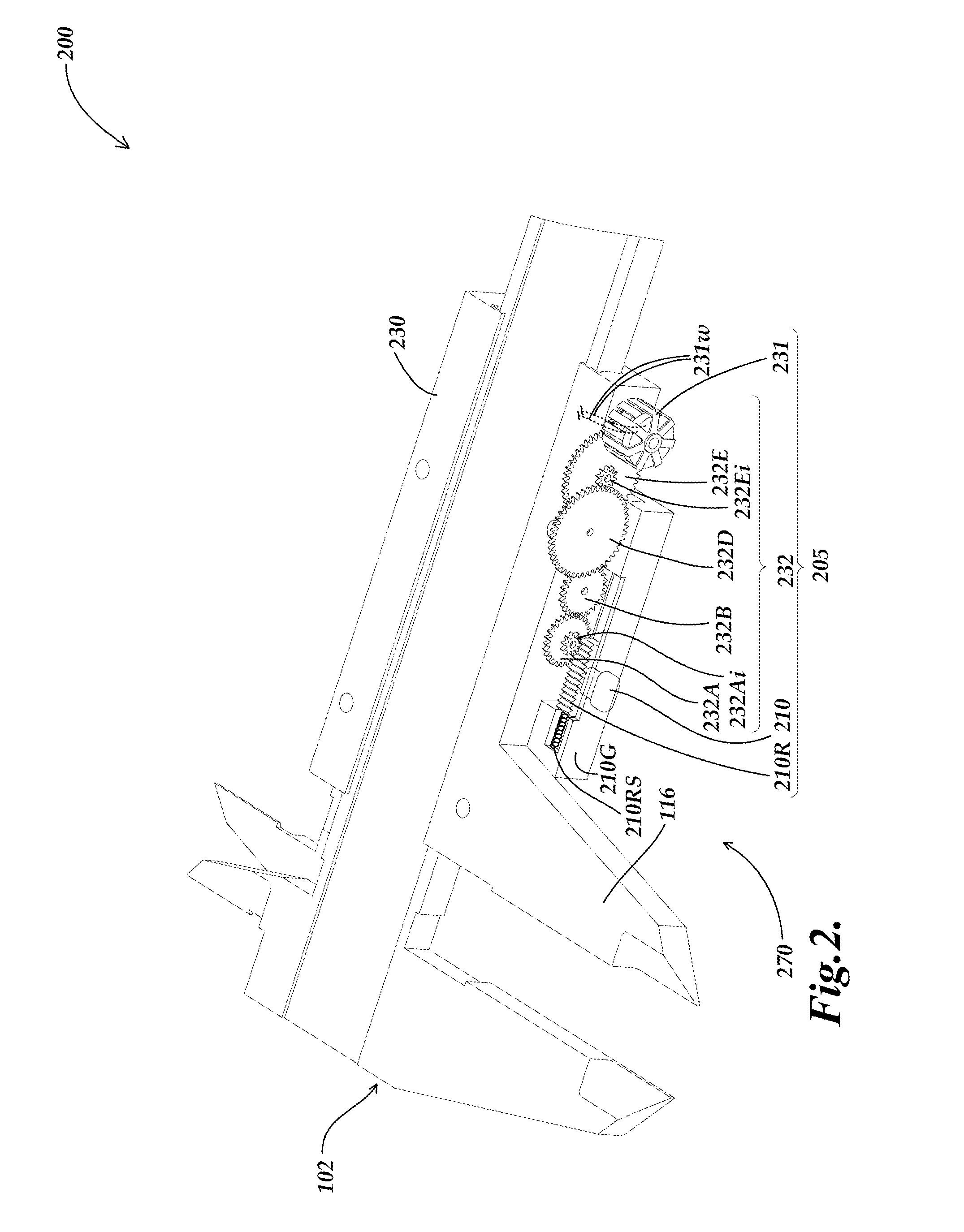

Electronic Caliper Configured to Generate Power for Measurement Operations

An electronic caliper generates power for measurement operations. The caliper comprises a scale member, a slider, a signal processing portion configured to measure a displacement between the scale member and slider, a power generating arrangement attached to the slider comprising a gear assembly configured to rotate in response to a force provided through a power generating handle to the gear assembly by a user moving the power generating handle relative to the gear assembly, and a power generator coupled to the gear assembly and configured to rotate in response to force provided by the rotating gear assembly and provide power to the signal processing portion. The power generating arrangement generates power as the user moves the power generating handle, and the power generating arrangement contributes a motion resistance force component of at most 20N as the user moves the power generating handle with a maximum manual acceleration.

Owner:MITUTOYO CORP

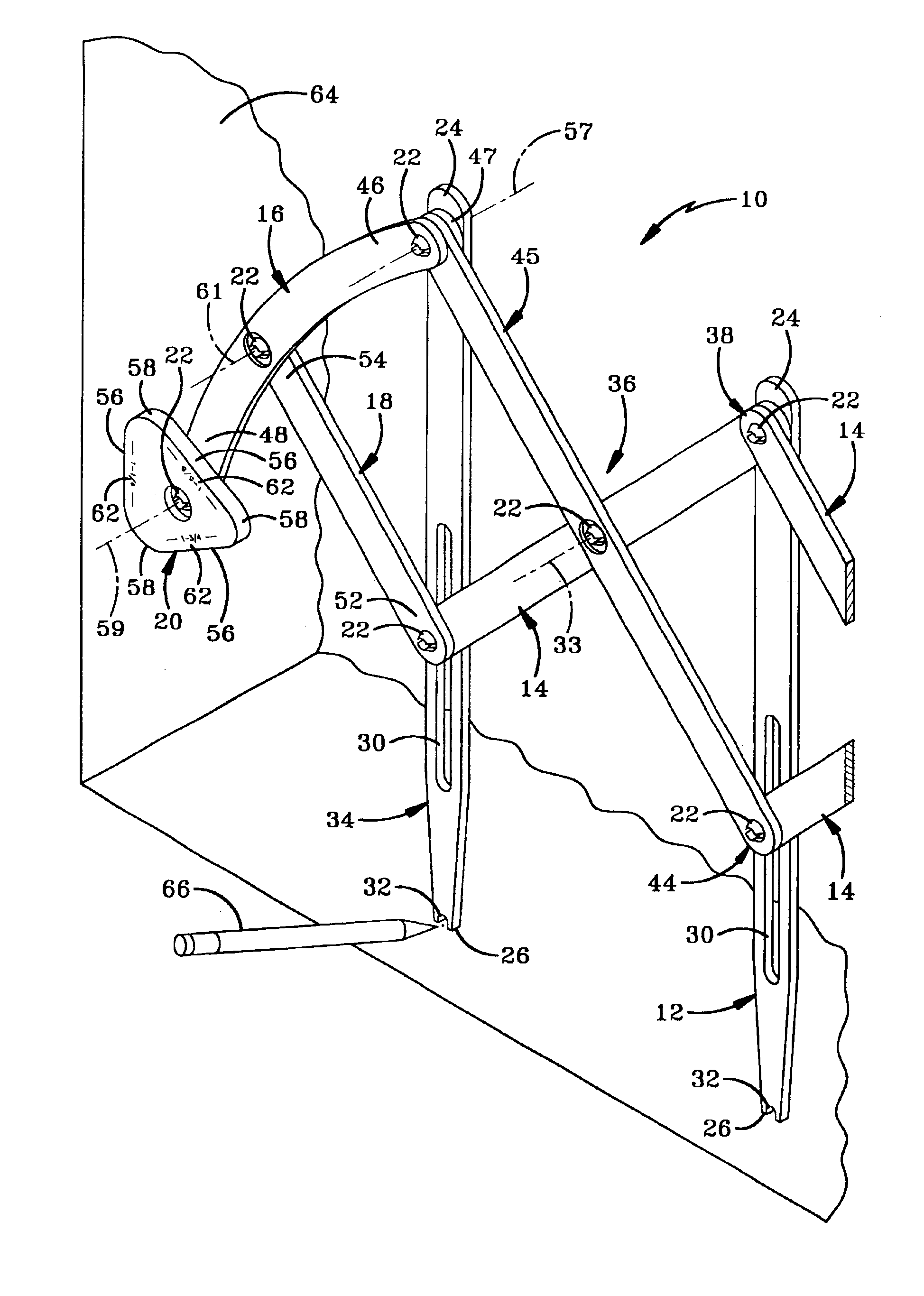

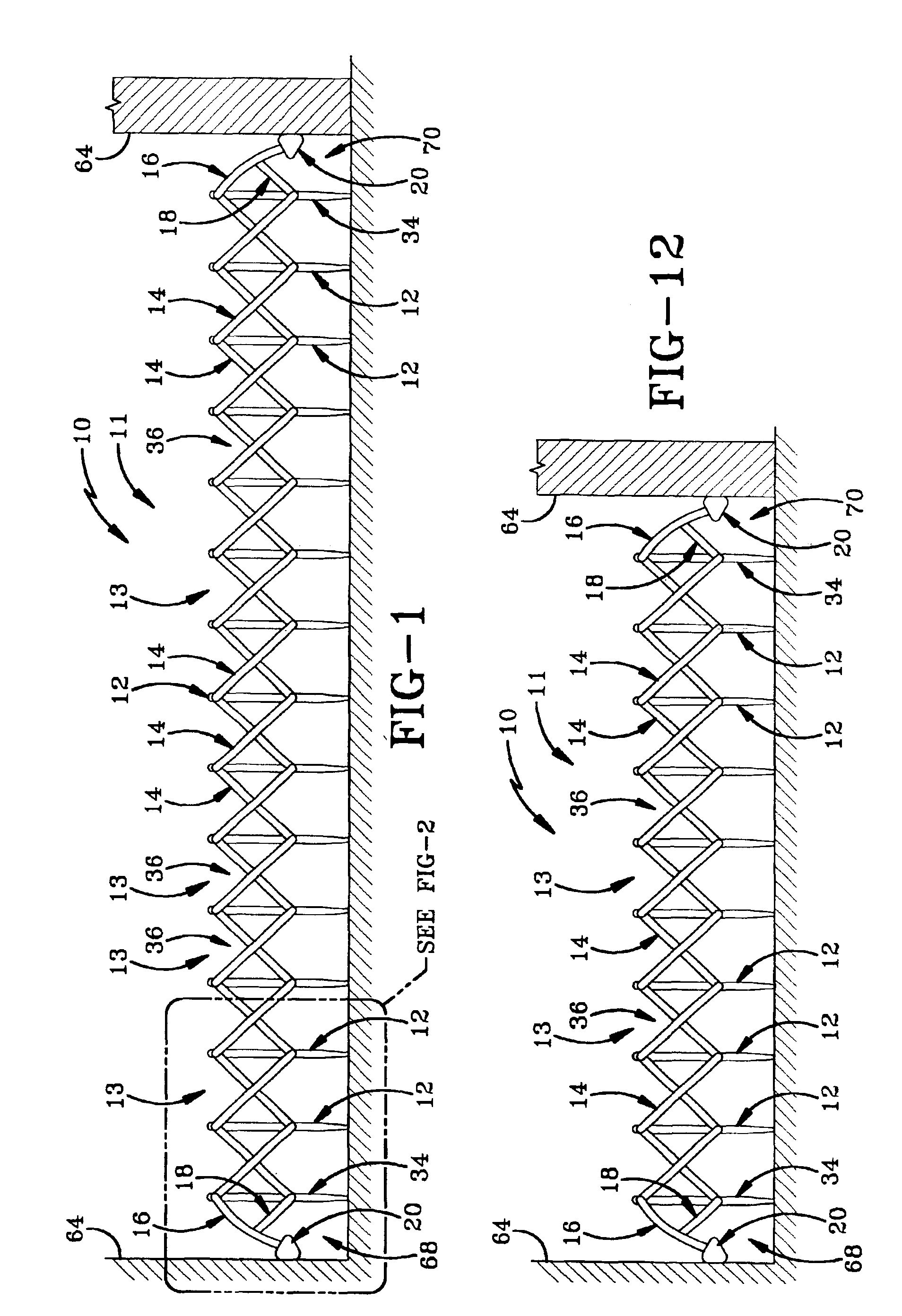

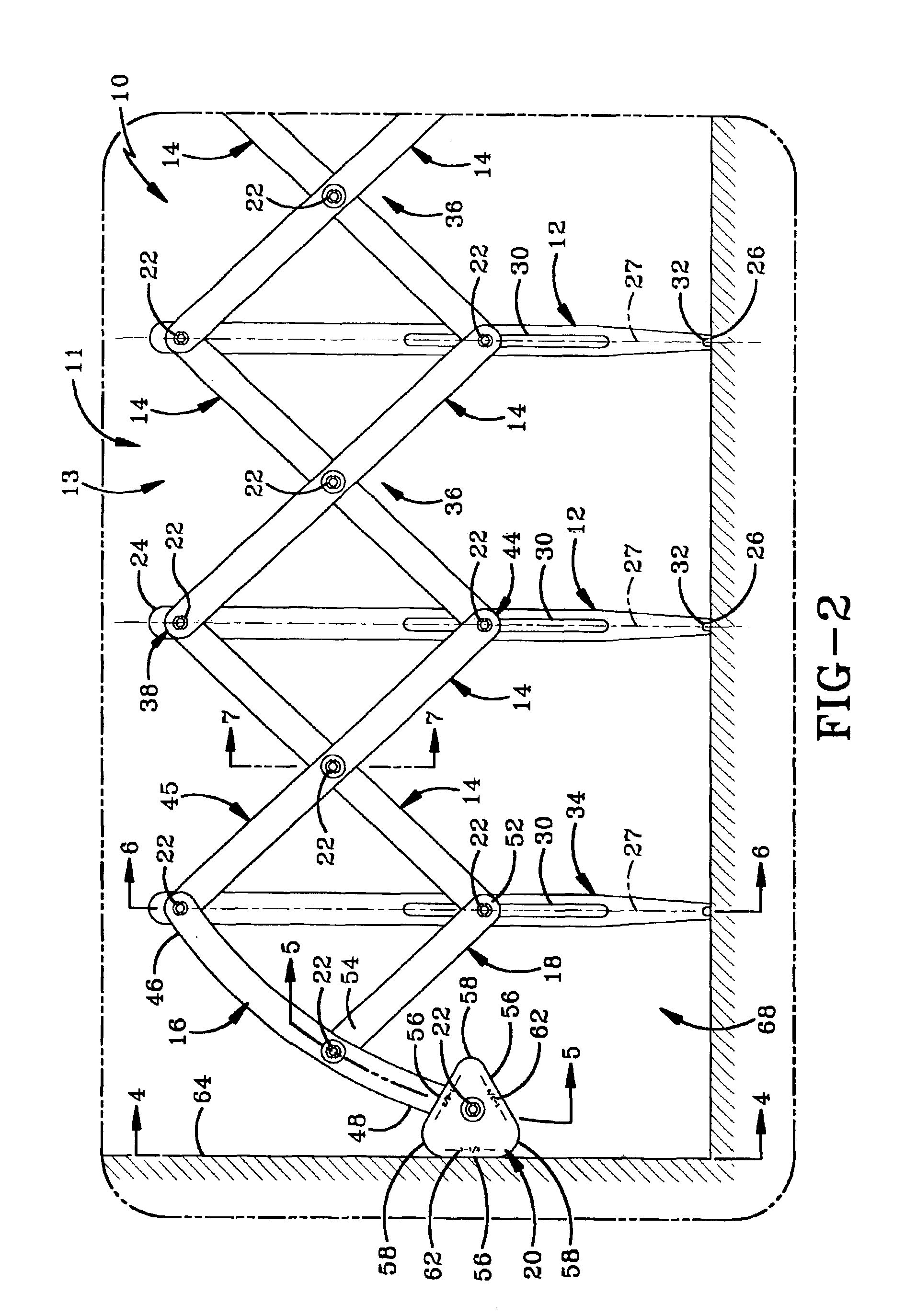

Adjustable baluster spacer tool

An adjustable spacer tool for spacing balusters includes an extendable pantograpic assembly having a first and second end and including evenly-spaced parallel uprights and X-shaped sets of cross-bars pivotally connected to one another. Each X-shaped set is pivotally connected to a pair of uprights adjacent upper ends thereof and pivotally and slidably connected to the uprights adjacent lower ends thereof. An arm, finger and cam extend outwardly from each end of the assembly to provide spacing between each end of the assembly and a desired surface for various sets of same-width balusters. Each arm is pivotally connected to one end of the assembly and to one end of the finger. The other end of the finger is pivotally and slidably connected to a respective end of the assembly. Each cam is pivotally connected to the arm distal the assembly. Removable connections permit adjustment of the overall length of the tool and replacement of parts.

Owner:L J SMITH INC

Tool-switching device

Tool-switching device for a machine for measuring coordinates wherein the tool is fastened on the tool-carrier and held by the action of elements exerting an axial force. The locking force is taken over symmetrically by the elements of a Boys connection, which increases the repeatability of the connection; in one embodiment, two pins or spheres are driven by a sliding bushing provided with two “V”-shaped slits or with two lateral gorges. In the subsequent embodiments, the pins are replaced by spheres, by levers or by a stirrup.

Owner:TESA SE

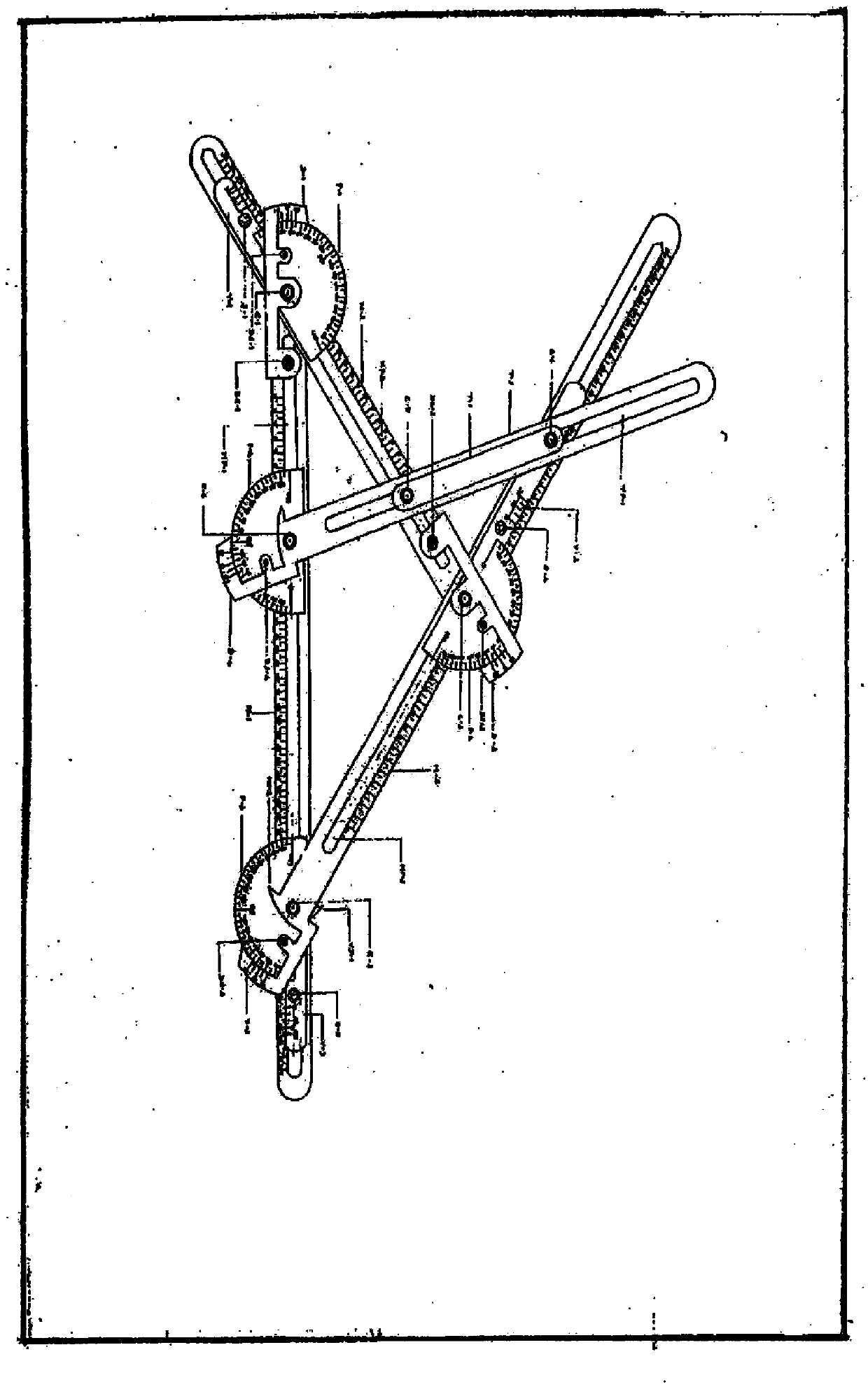

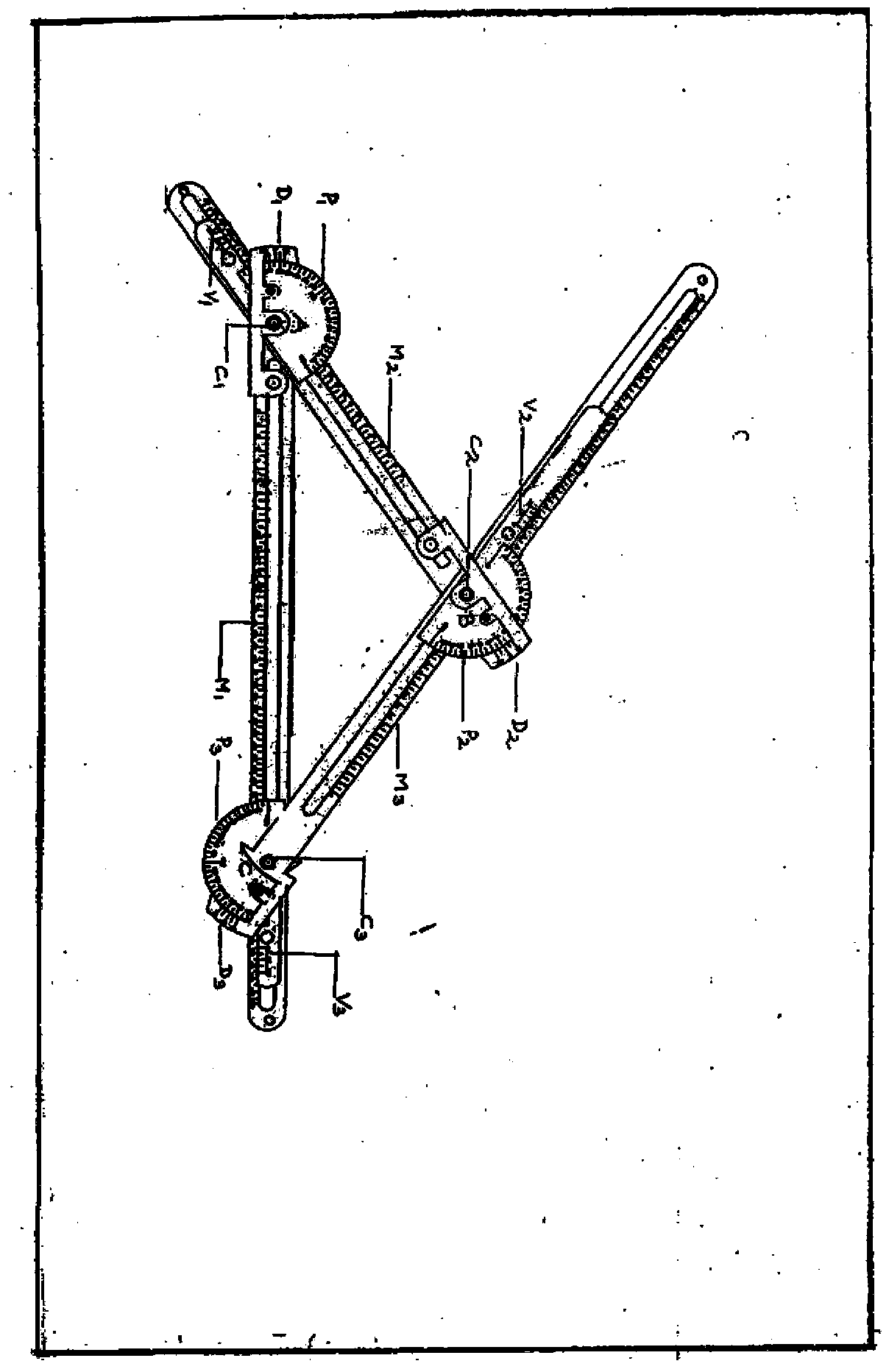

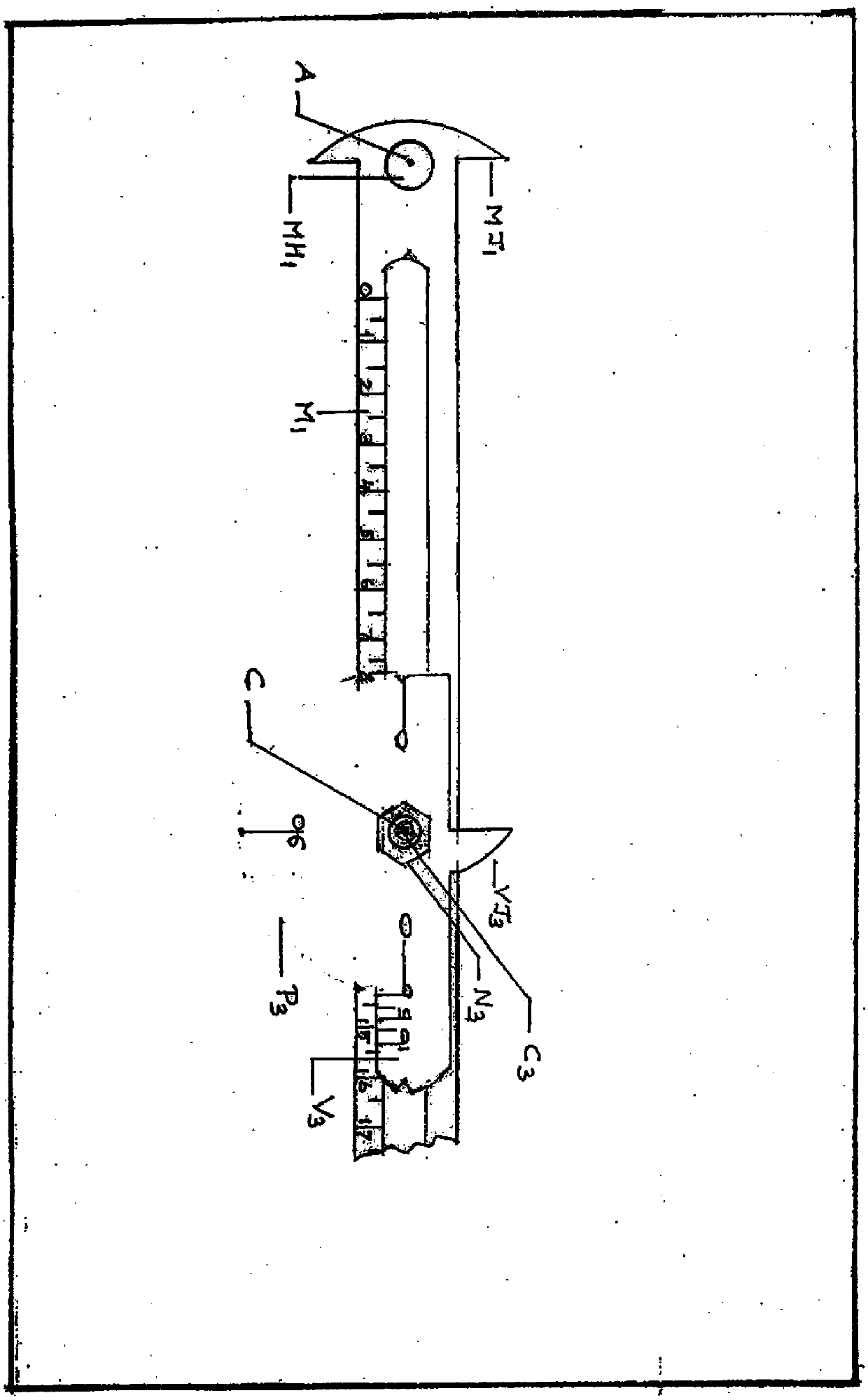

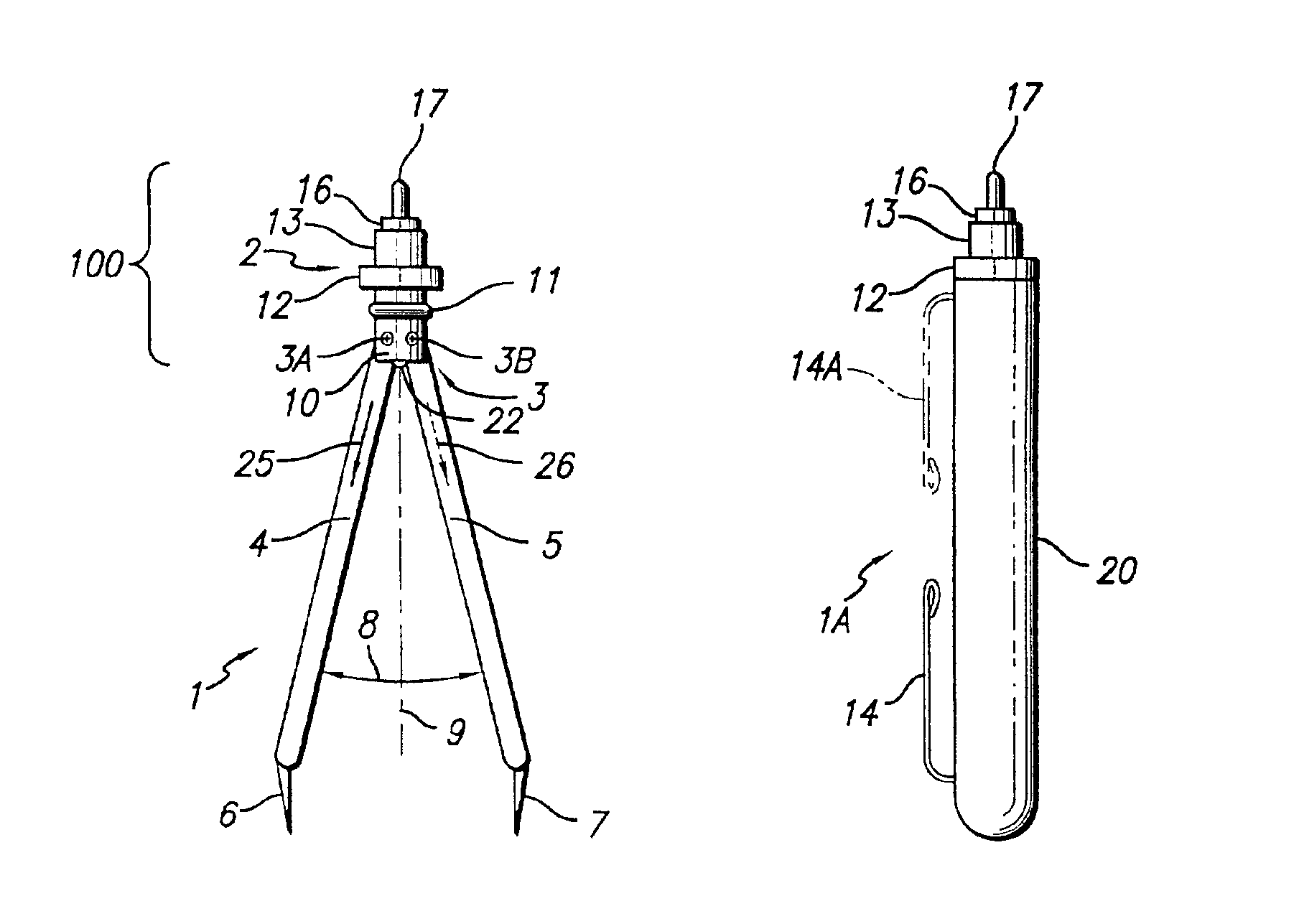

A multipupurpose instrument for triangle solutions, measurements and geometrical applications called triometer

The invention "Trio-meter"is a multipurpose instrument by using- "Multi-slotted link sliding assembly mechanism" - for triangle solutions including 'Pythagoras theorem' as a ready reckoner (Fig.II). Useful instrument with marker block attachment to draw and measure straight lines, lengths, arcs, semi circles, circles, bicircles, tricircles, parallelograms, rhombuses, trapezoids, parallel lines and triangles with fractional and accurate measurements easily and quickly (Fig. Ill to VIII). The novel instrument with trisector attachments, trisects an angle and multiplies an angle into double, triple & quadruple as well as reduces an angle in to two-third^ half, one third and quarter fractionally and accurately (Fig. IX). It comprises three slotted links with in-built main measuring scales, which are also working as sides of a triangle, three vernier calipers with three protractors and three indicators, assembled by centre pins, with all necessary attachments, parts and components (1 to 99) for complete operations and perfect functioning.

Owner:R·K·斯瓦密 +4

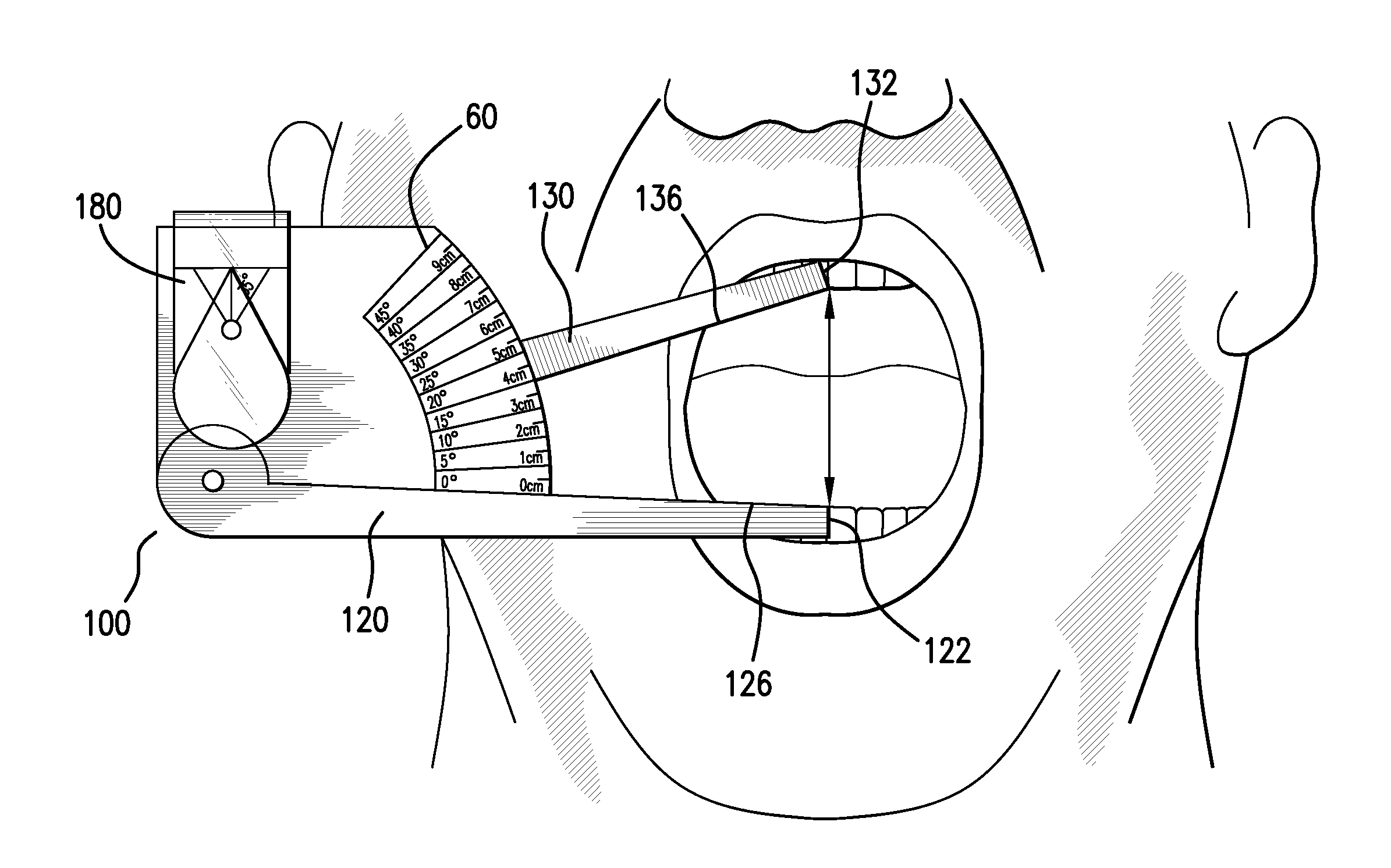

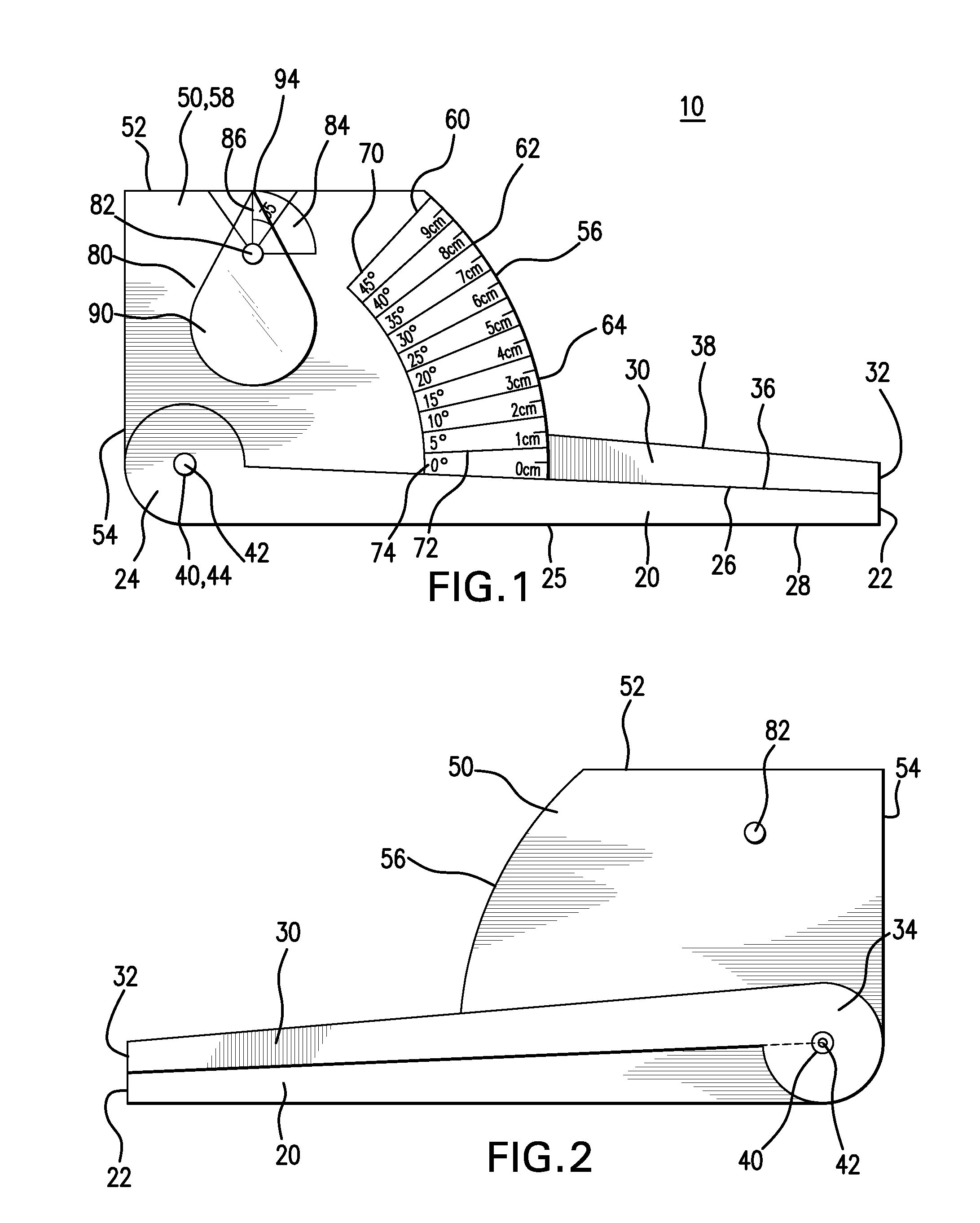

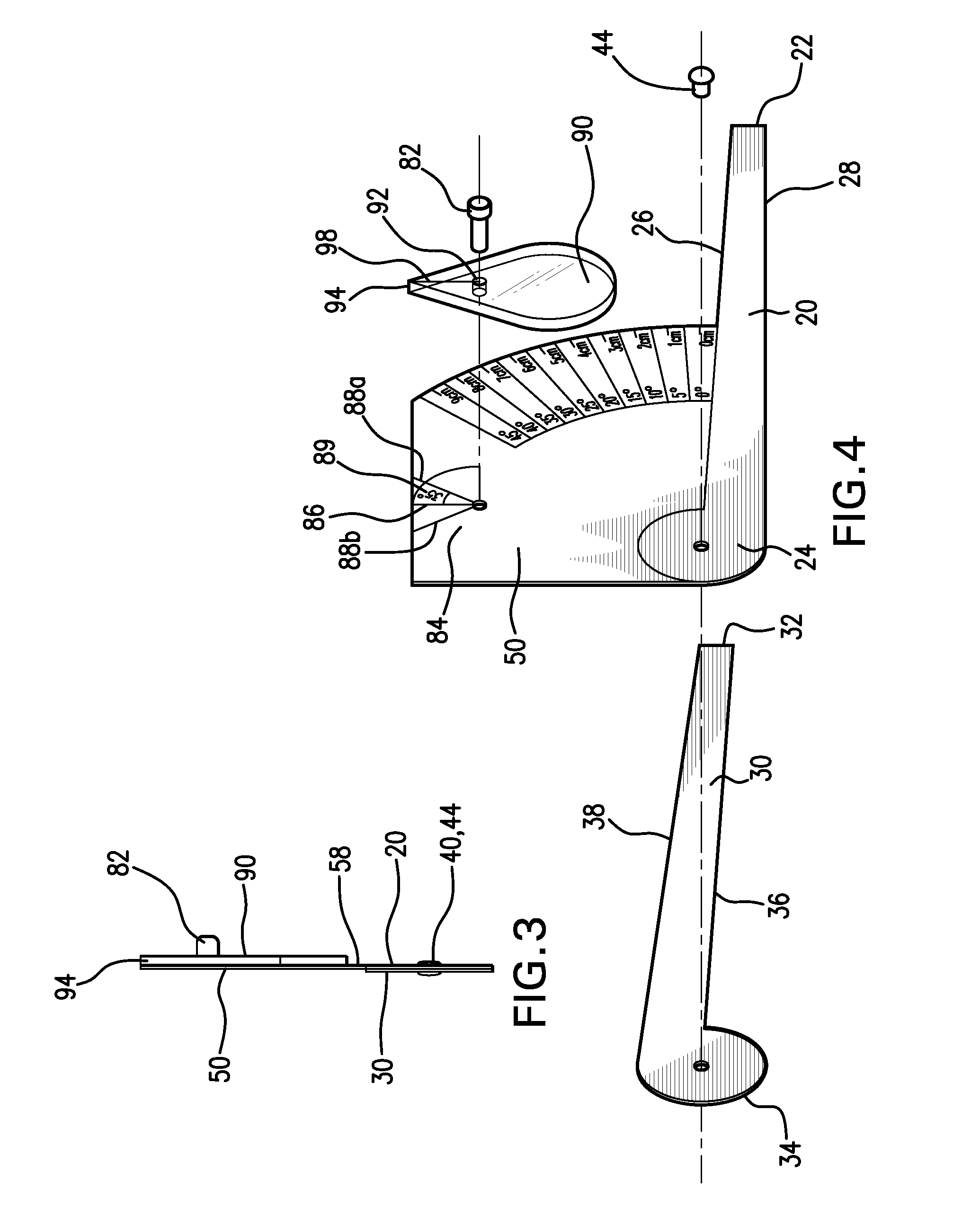

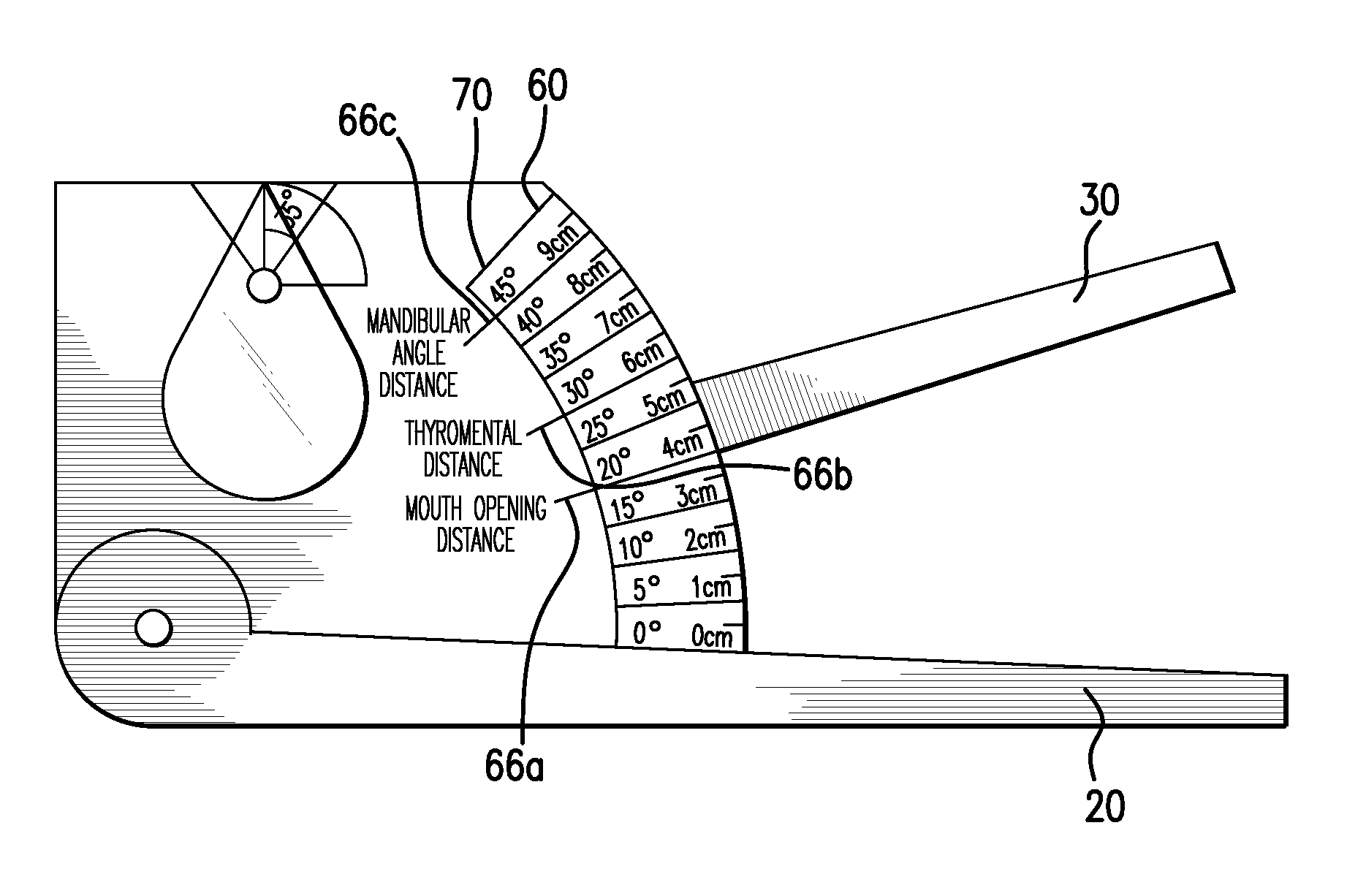

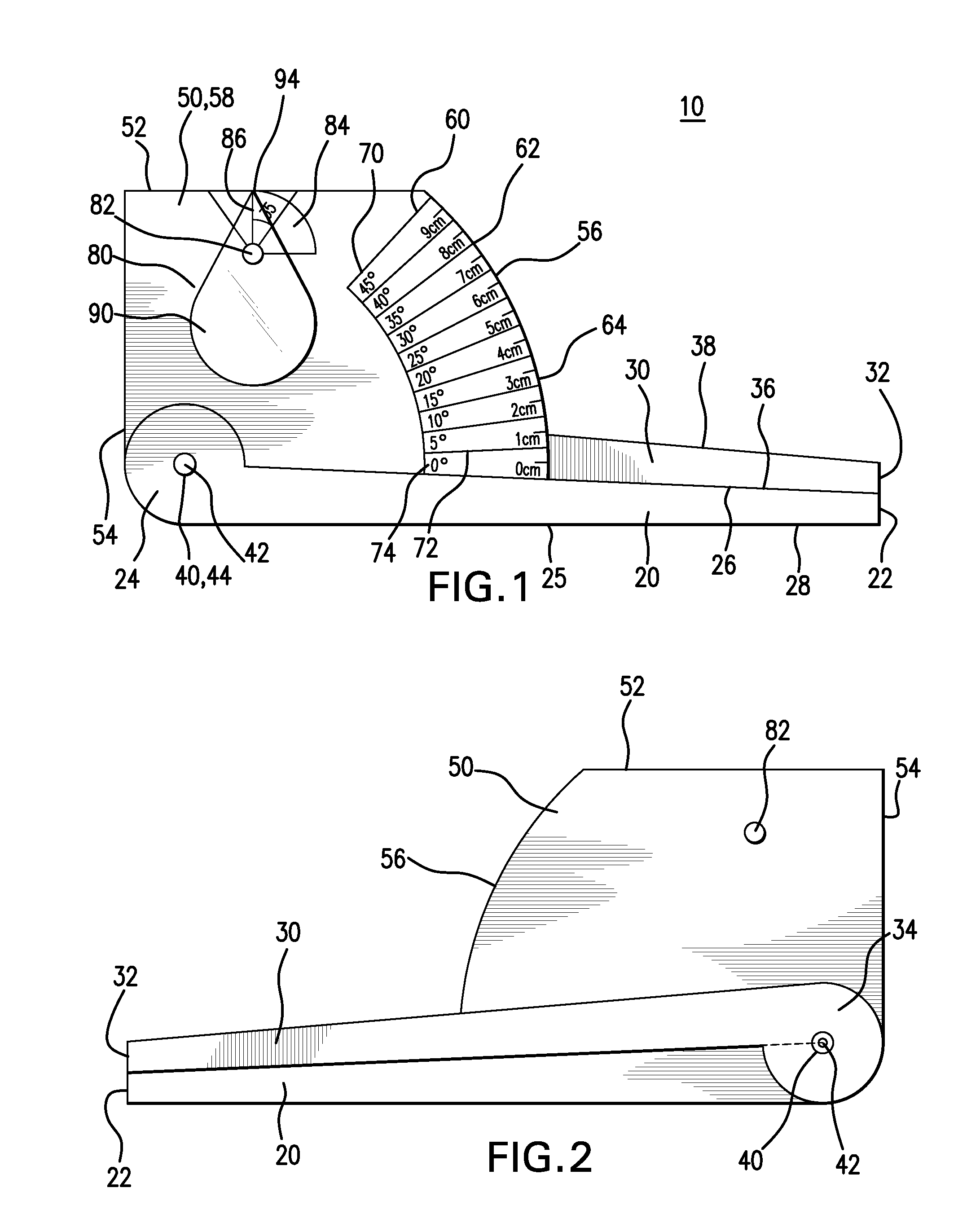

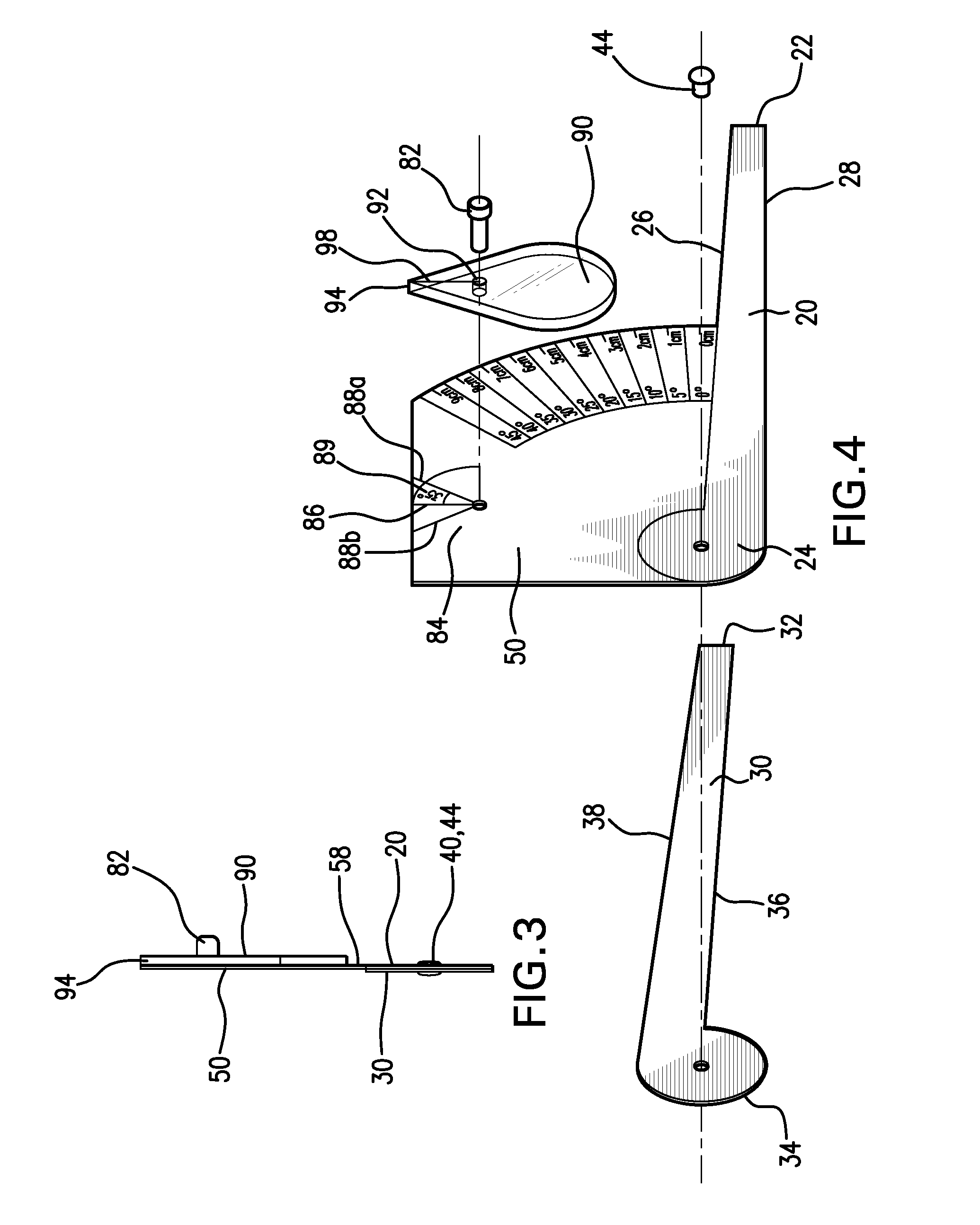

Multifunctional airway evaluator for orotracheal intubation

Owner:UNIQUE SURGICAL INNOVATIONS

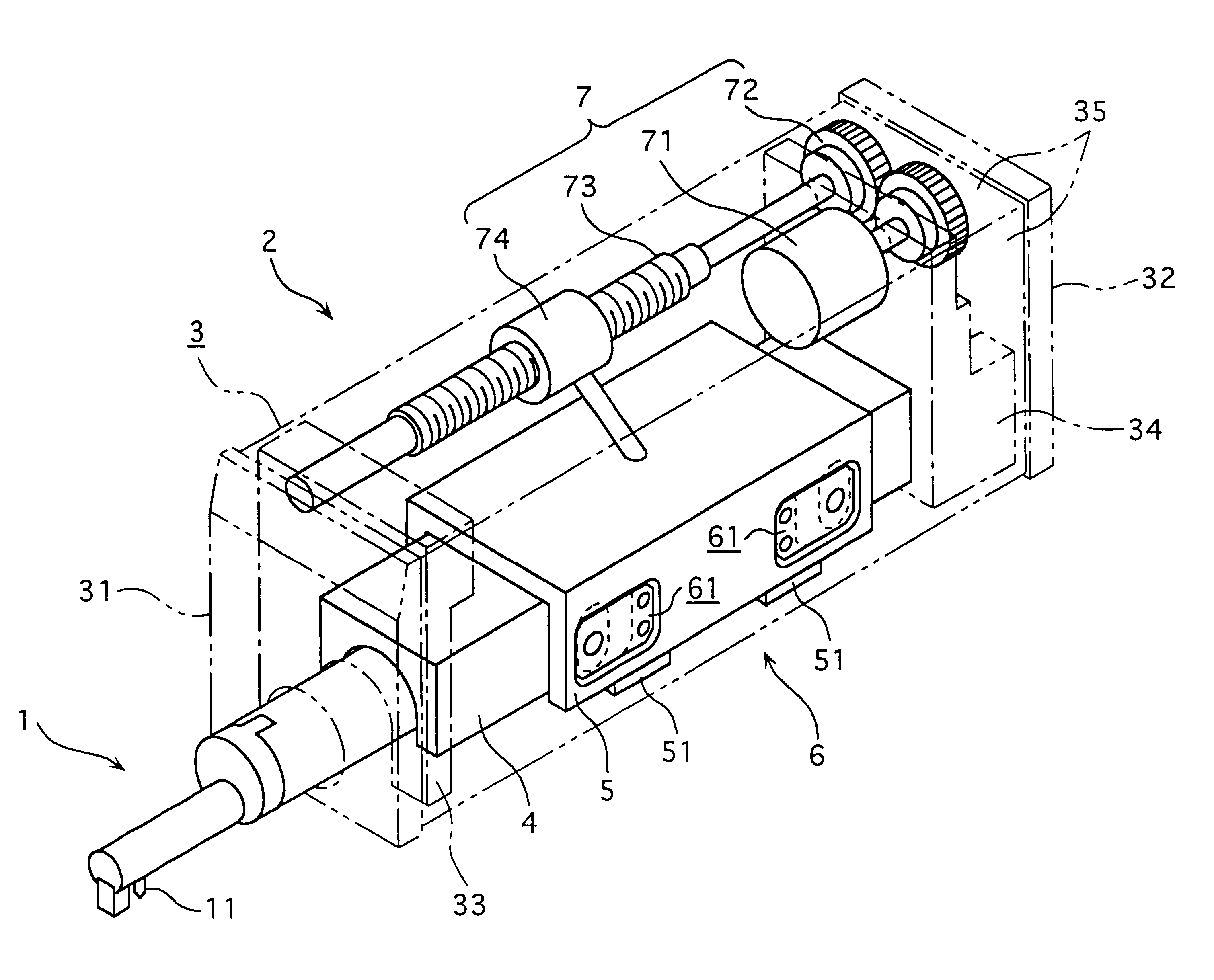

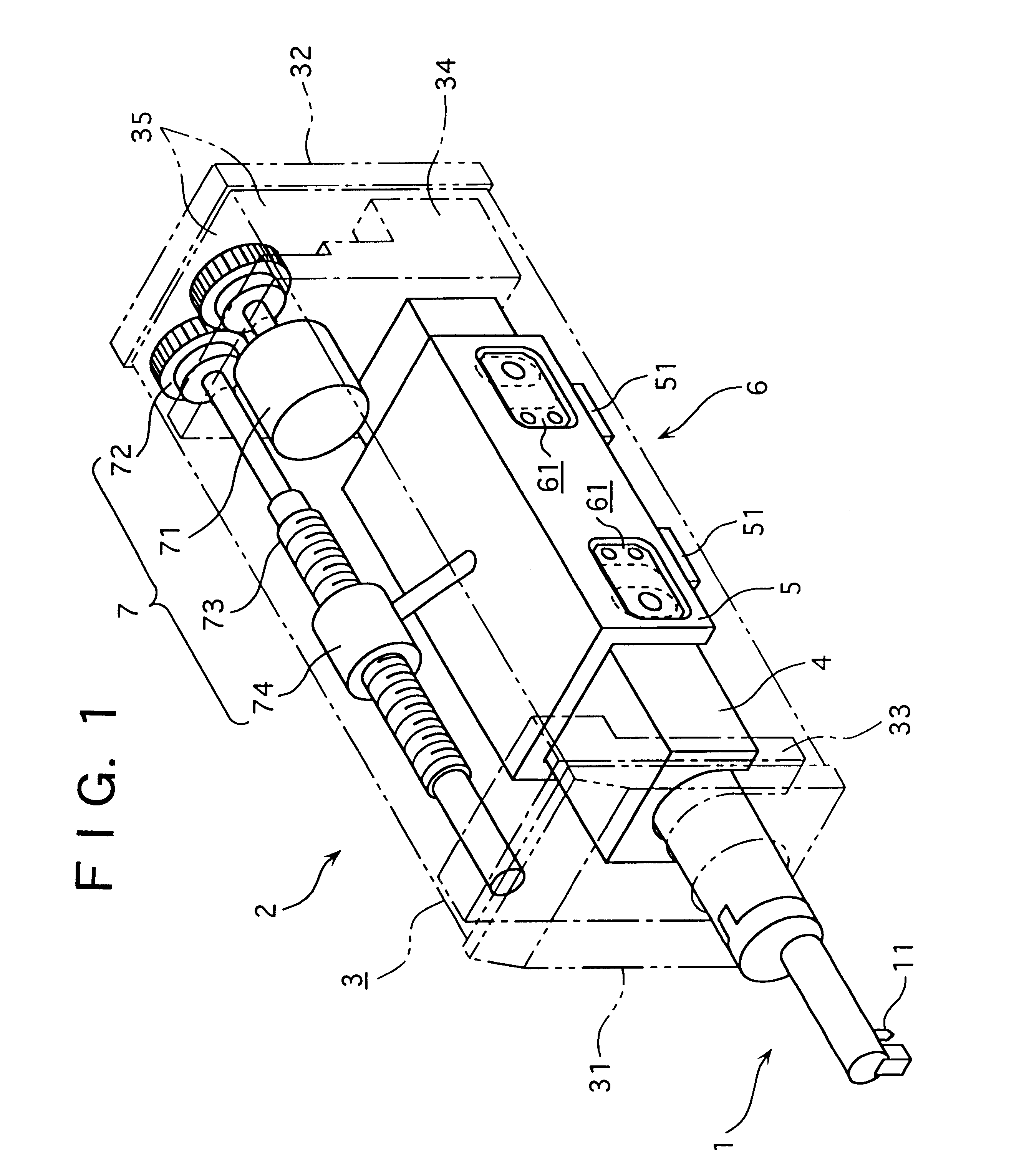

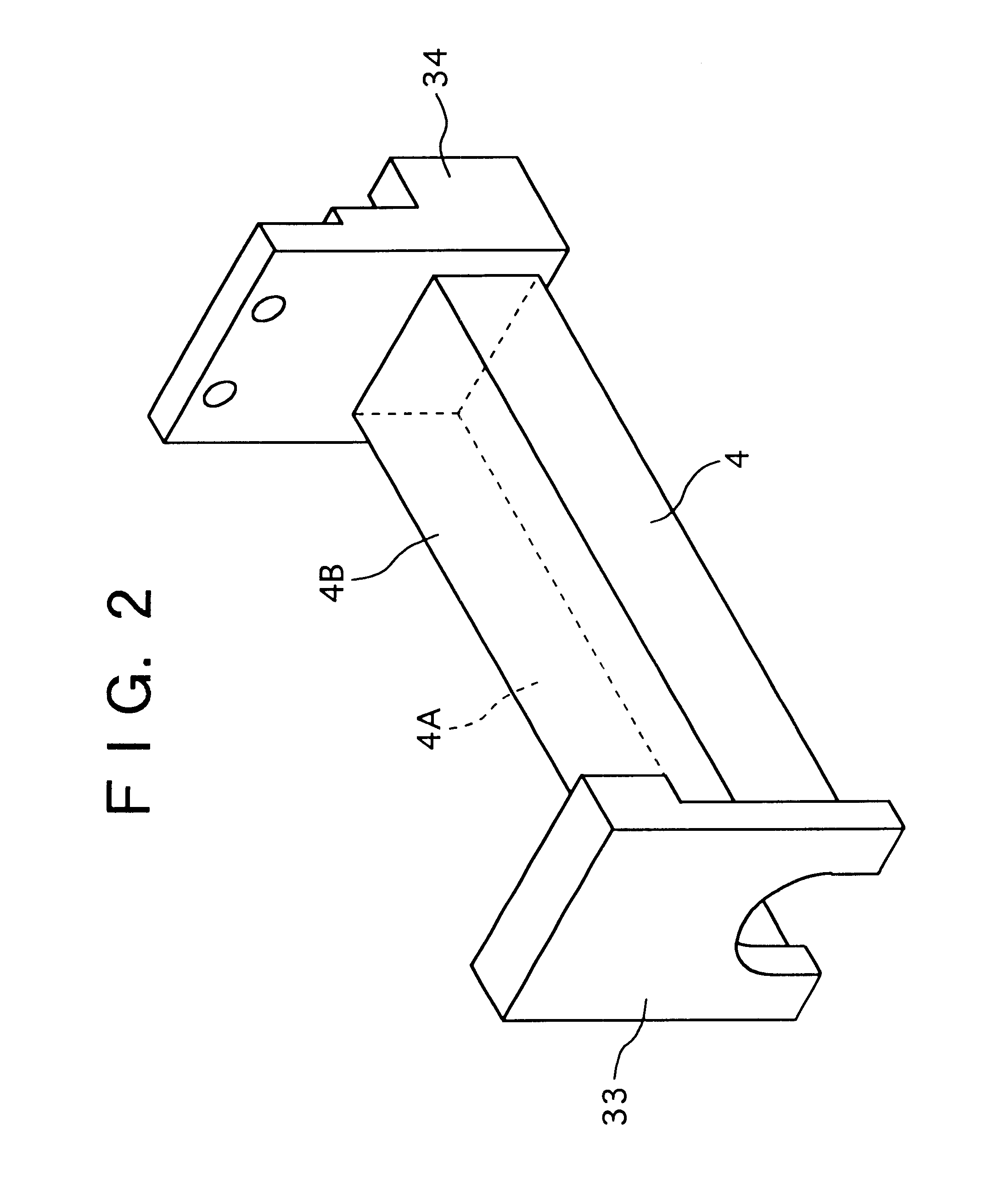

Drive unit

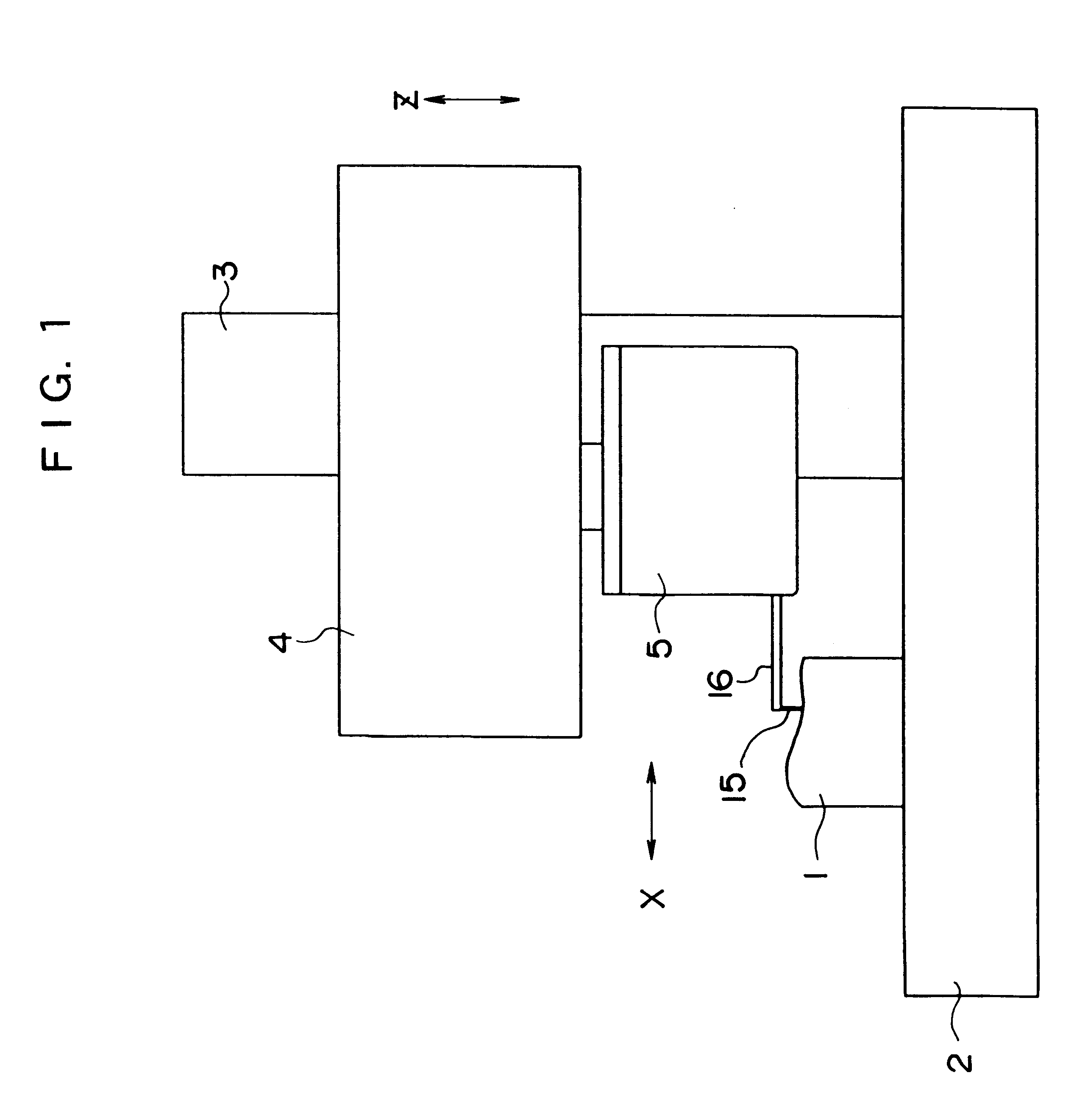

A slider holding a measuring tool moves along an approximately reverse U-shaped guide rail provided in parallel with a moving direction of the measuring tool without being rotated. Accordingly, a cross section of the guide rail can be enlarged without increasing the size of the entirety of a drive unit. As a result, high rigidity can be obtained while reducing the size and weight of the drive unit as compared to a conventional arrangement having two shafts. Further, linearity of the slider and the measuring tool moving along a reference surface of the guide rail can be attained with high accuracy. Further, since a pre-load means for biasing the slider toward a guide rail is provided, a position or orientation of the slider and the measuring tool can be stabilized, thus securely repeating movement of the measuring tool.

Owner:MITUTOYO CORP

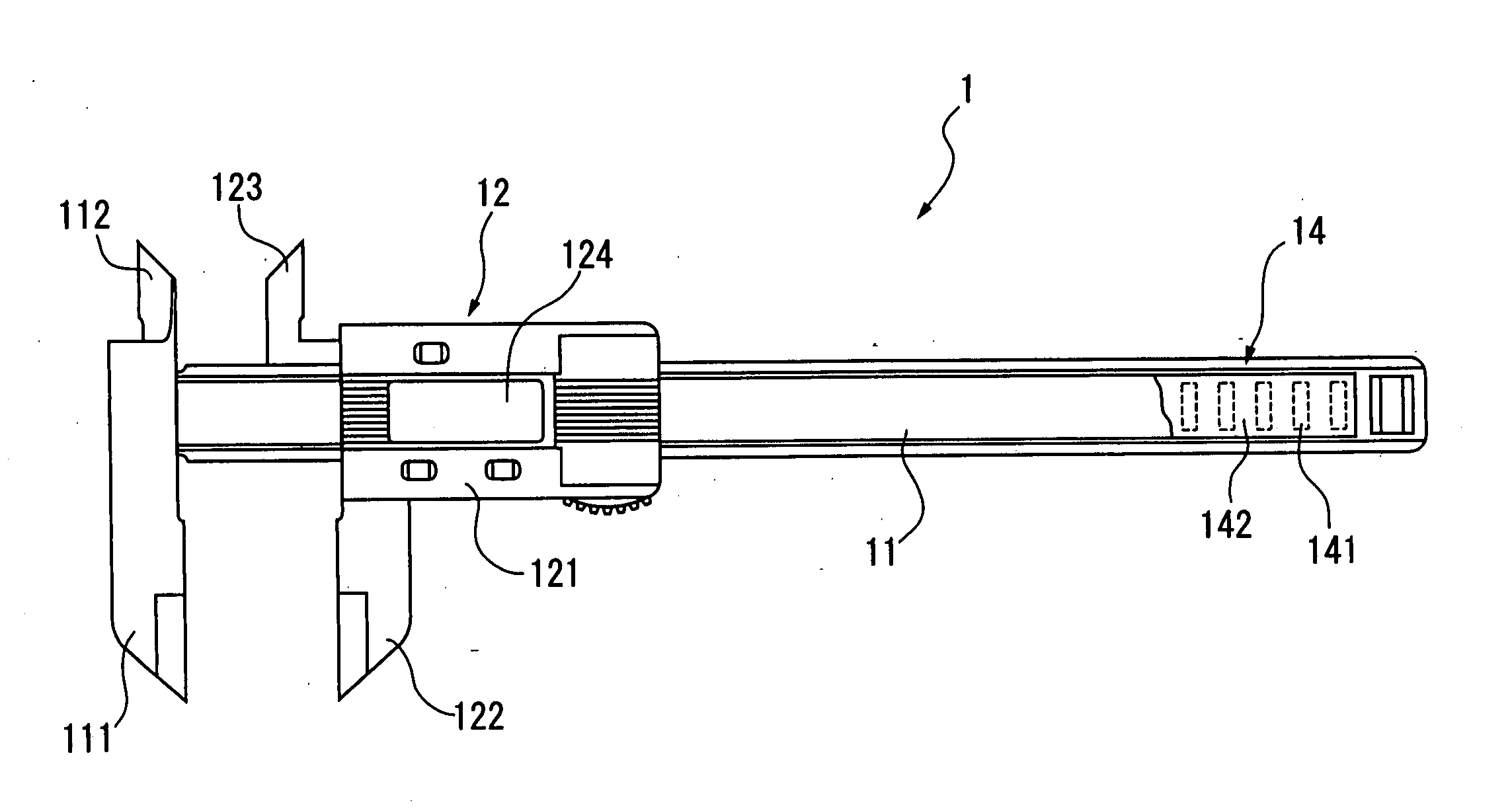

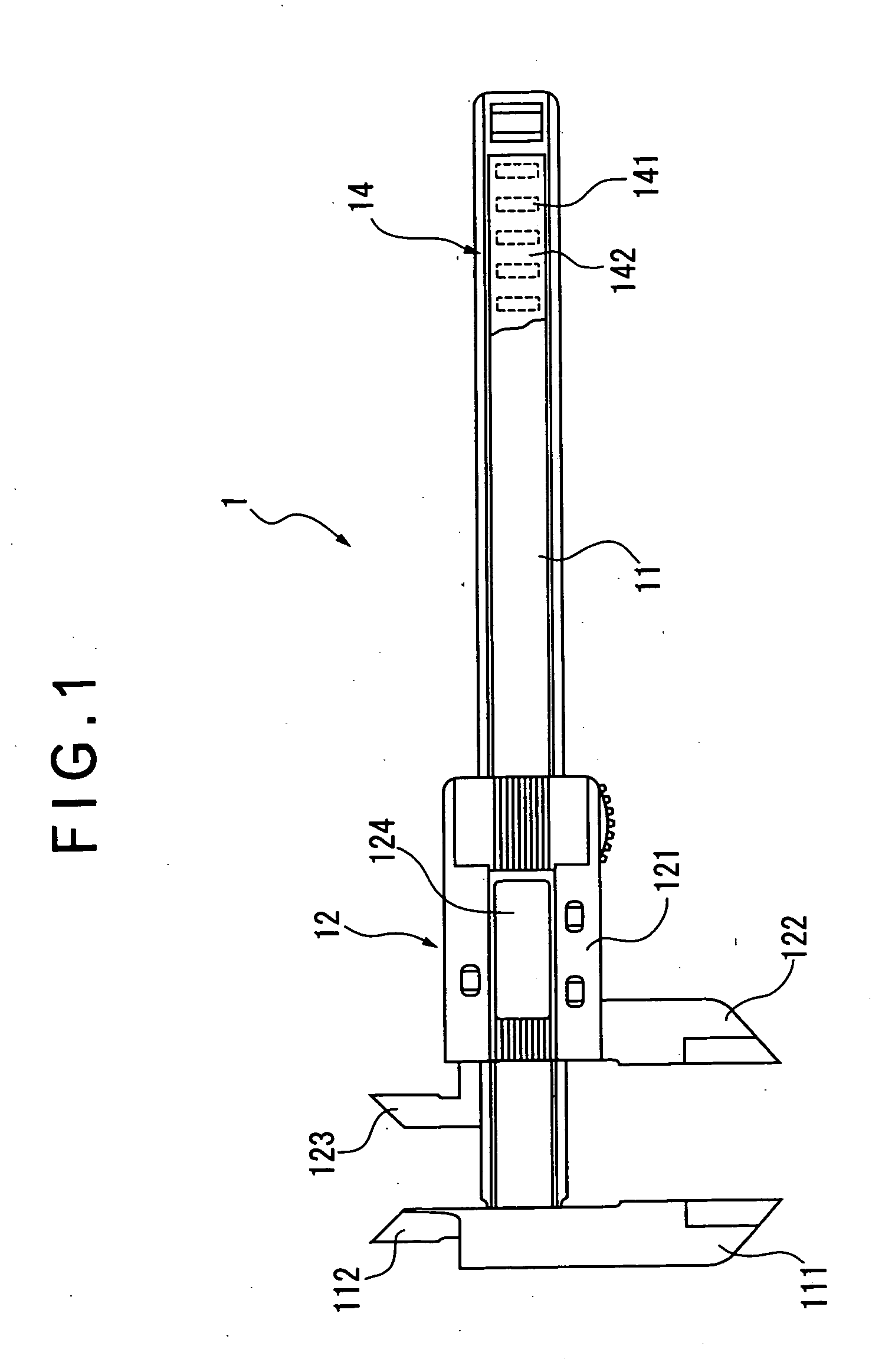

Measuring tool, encoder and producing method of encoder

InactiveUS20050081400A1Improve performanceEasy to produceCompasses with pivoted armsMaterial nanotechnologyCarbon nanofiberEngineering

Components of a measuring tool such as a main beam (11) and a slider (12) of a caliper gauge (1) are formed by a synthetic resin containing carbon nanofiber and an electro-conductive electrode (15) is formed on the surface of the main beam (11) at a predetermined pitch, so that a production process can be simplified, rigidity of the components can be enhanced, linear expansion coefficient can be reduced, and anti-frictional properties can be improved, thus enhancing durability while improving measurement accuracy.

Owner:MITUTOYO CORP

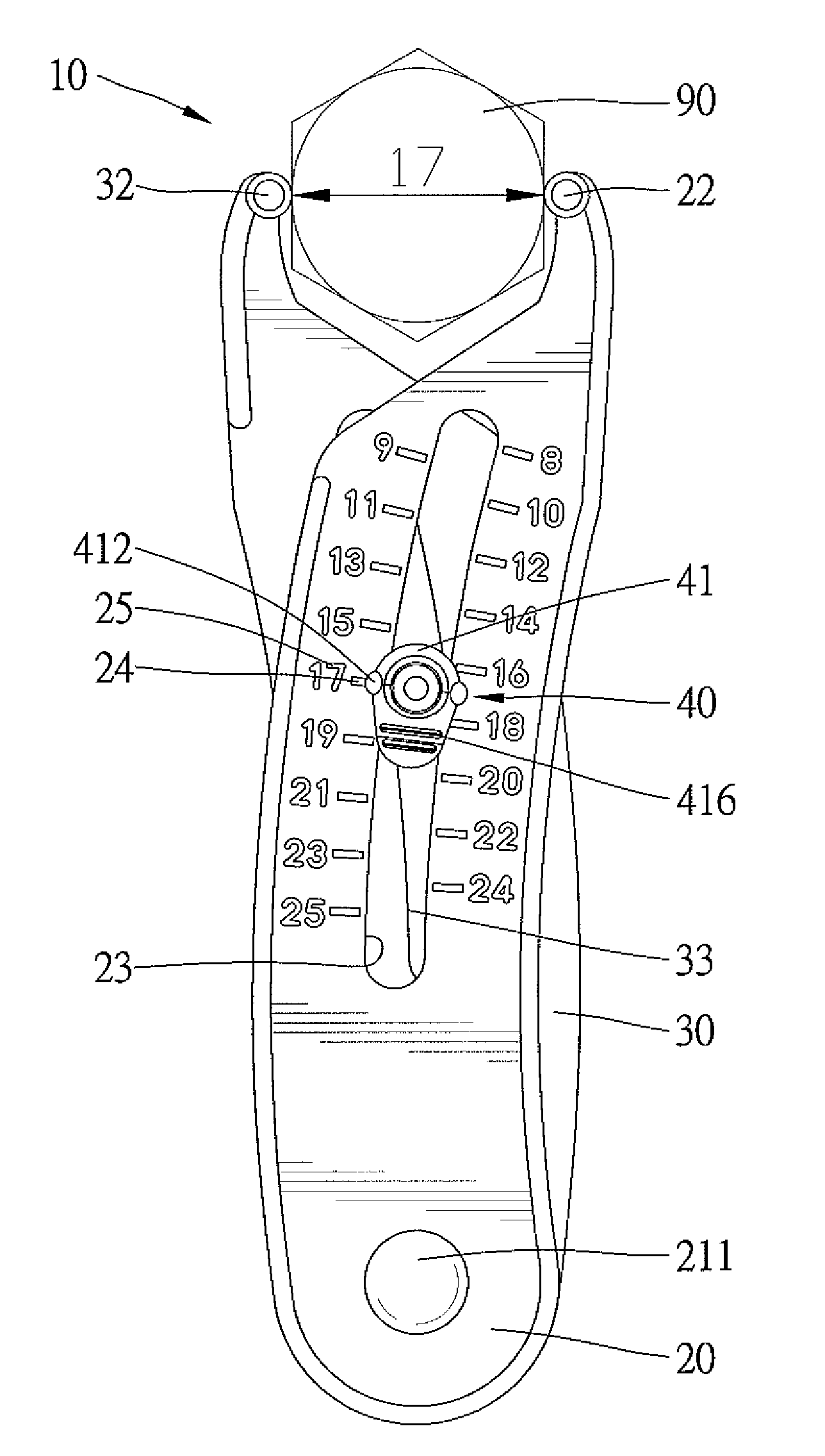

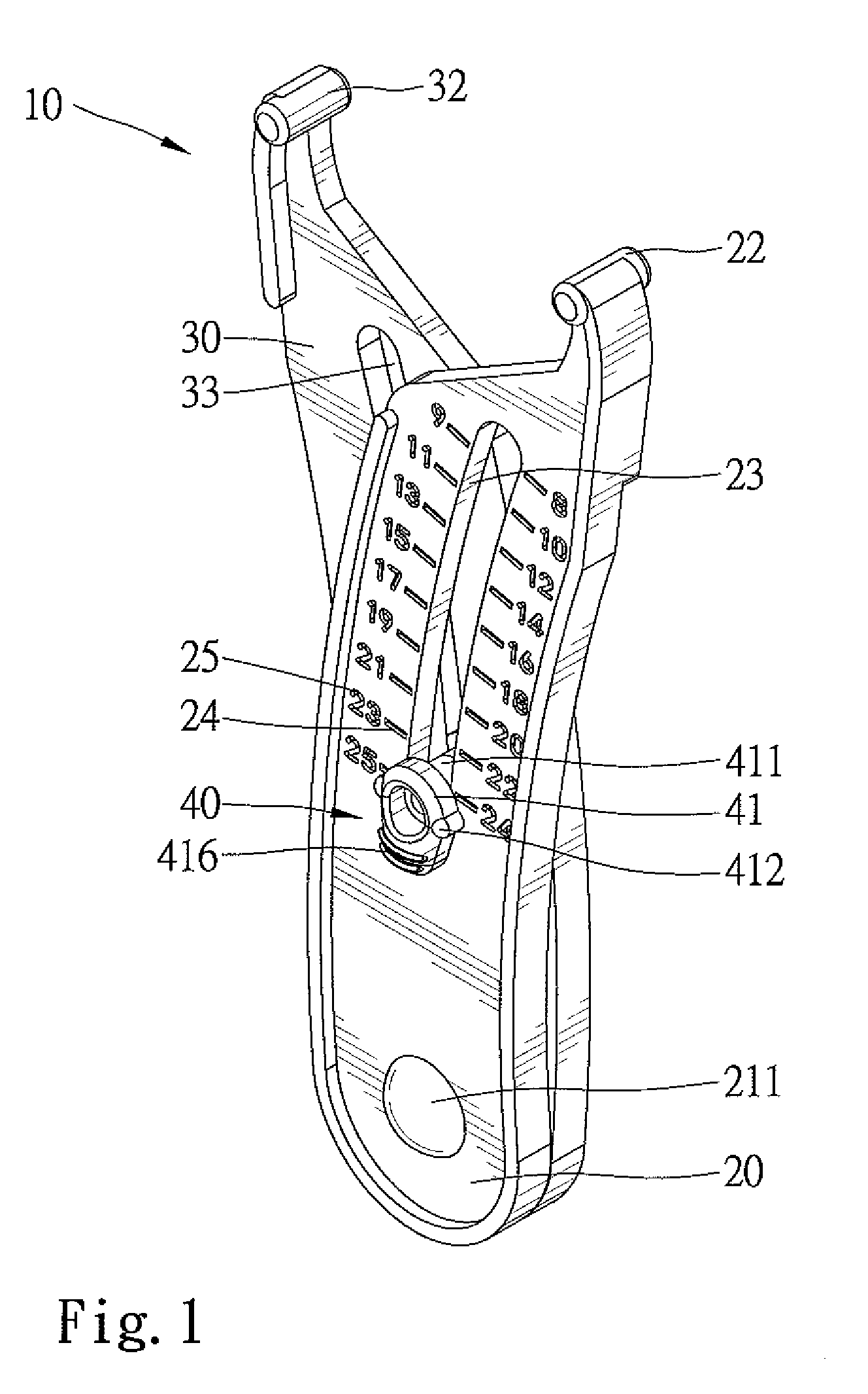

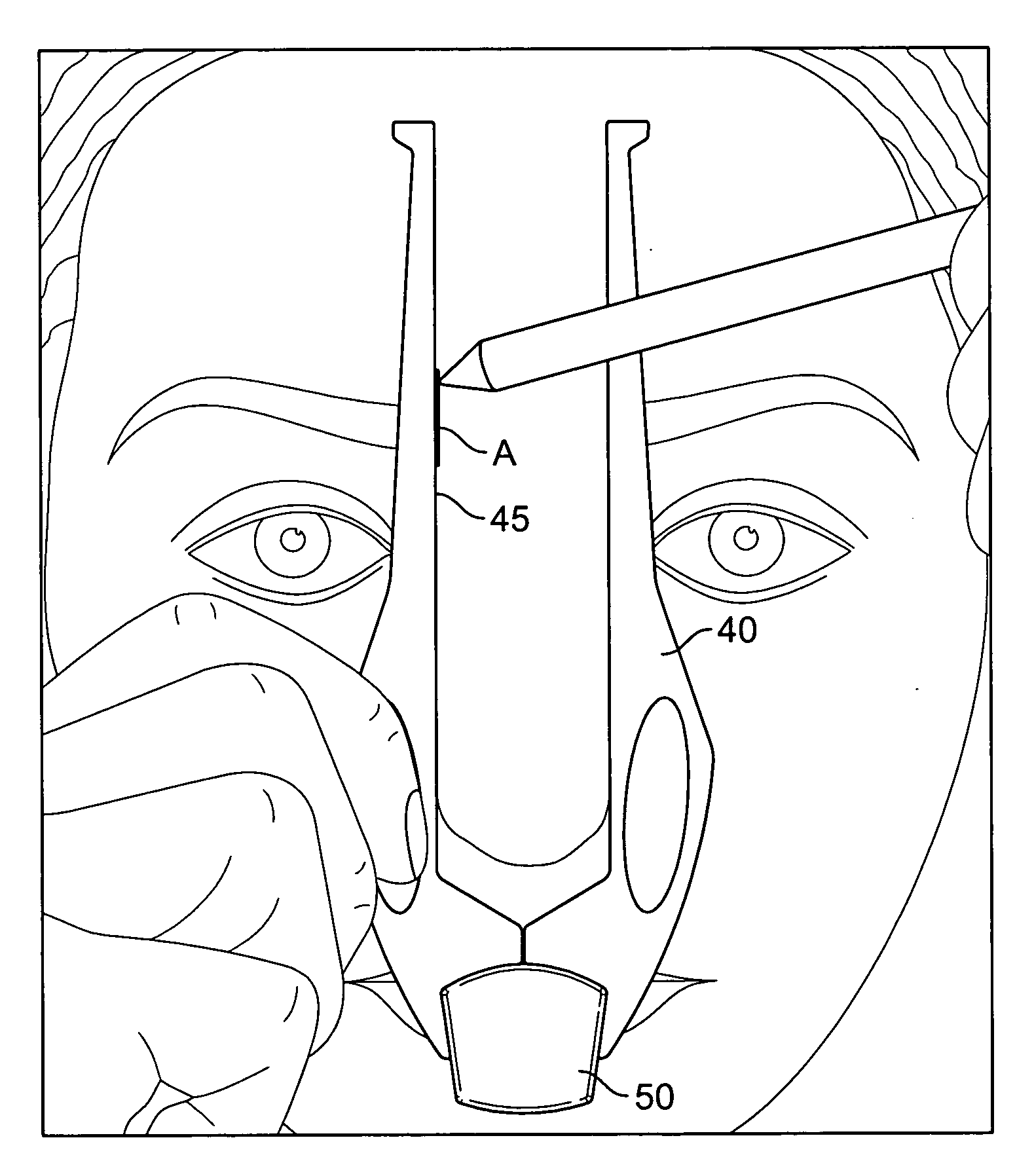

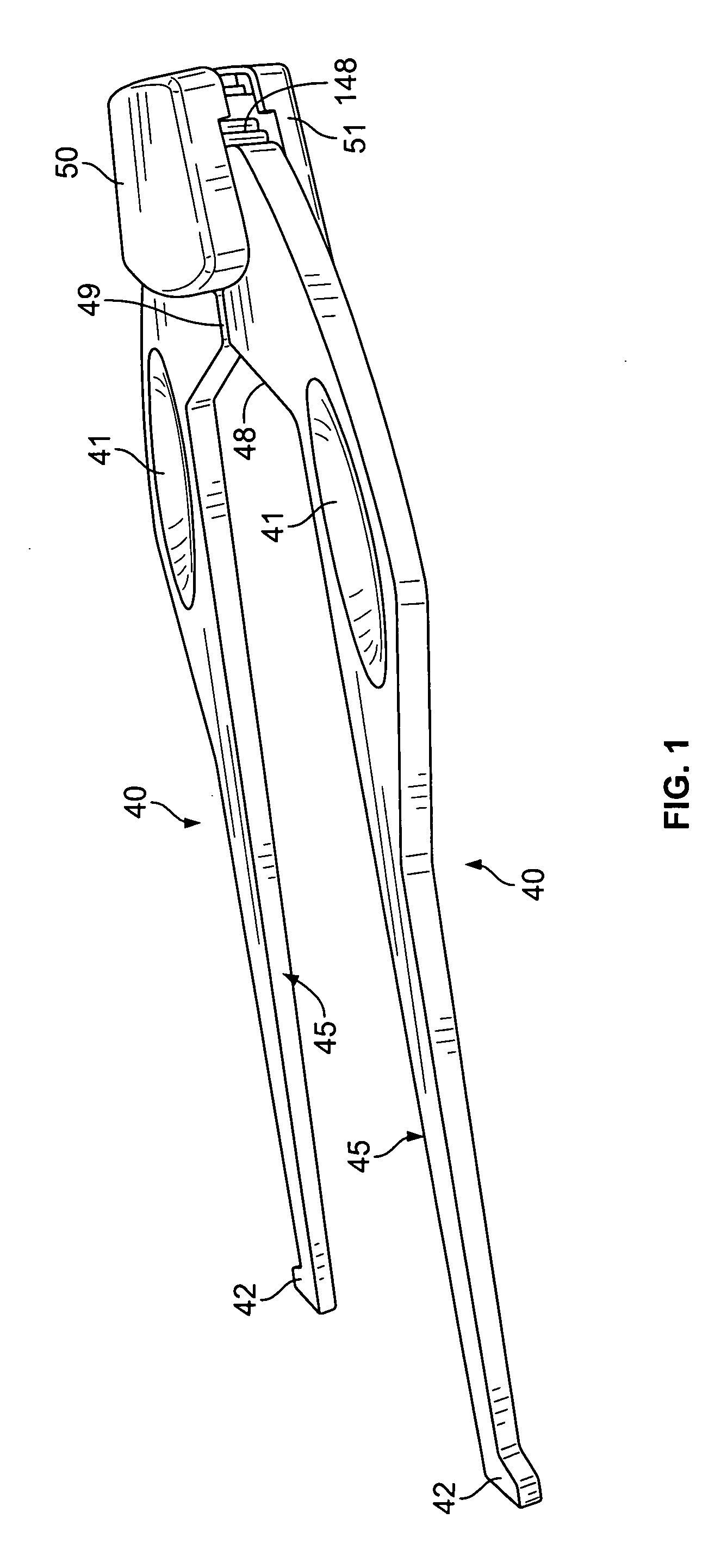

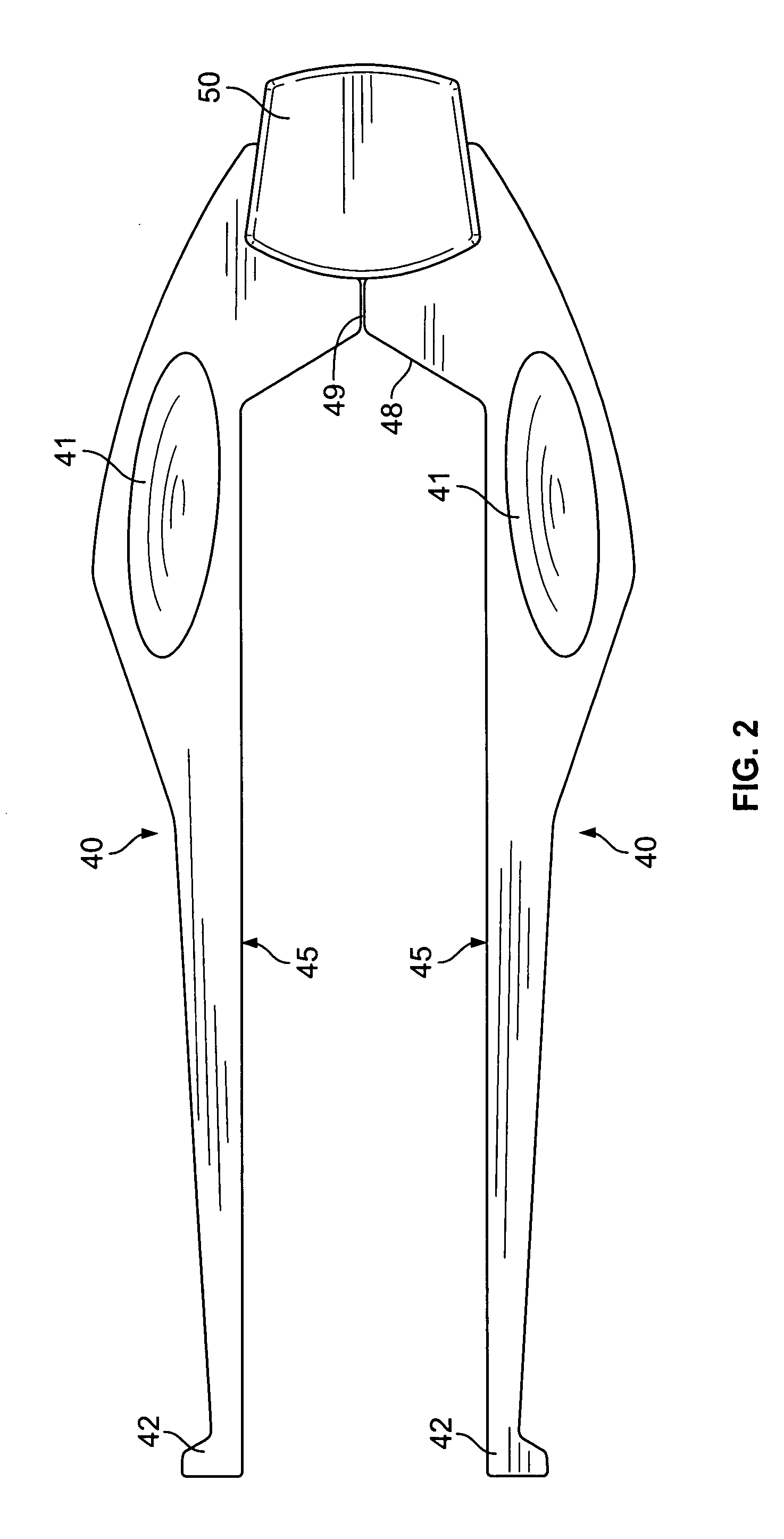

Multifunctional Airway Evaluator For Orotracheal Intubation

A multifunctional airway evaluator for oratracheal intubation includes first and second connected elongated arms, movable relative to each other about a pivot axis, a planar plate connected to the first arm and extending upwardly therefrom, and a gravity-operated angular indicator attached to the planar plate. The plate includes a distance scale on its front face, and the distance scale includes a plurality of spaced apart grade lines aligned radially with the pivotal axis and distance parameters associated with the grade lines, each of the distance parameters indicating a distance between the distal ends of the first and second arms when the arms are in a relative position. The gravity-operated angular indicator includes an axial pin disposed perpendicular to the planar plate, a rotating disk pivotally attached to and rotatable around the axial pin by gravity, and one or more angular measurement marker provided adjacent the rotating disk.

Owner:UNIQUE SURGICAL INNOVATIONS

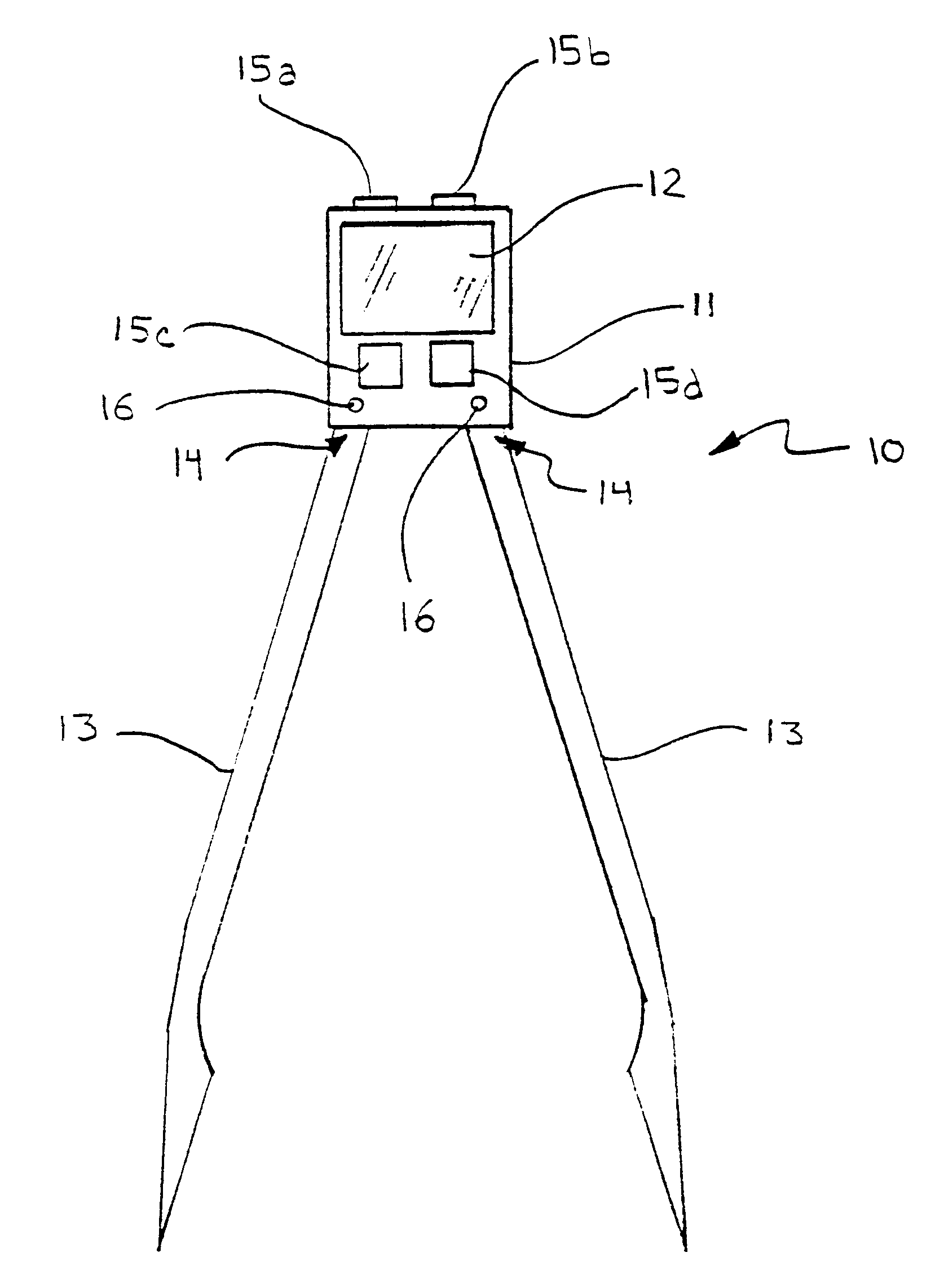

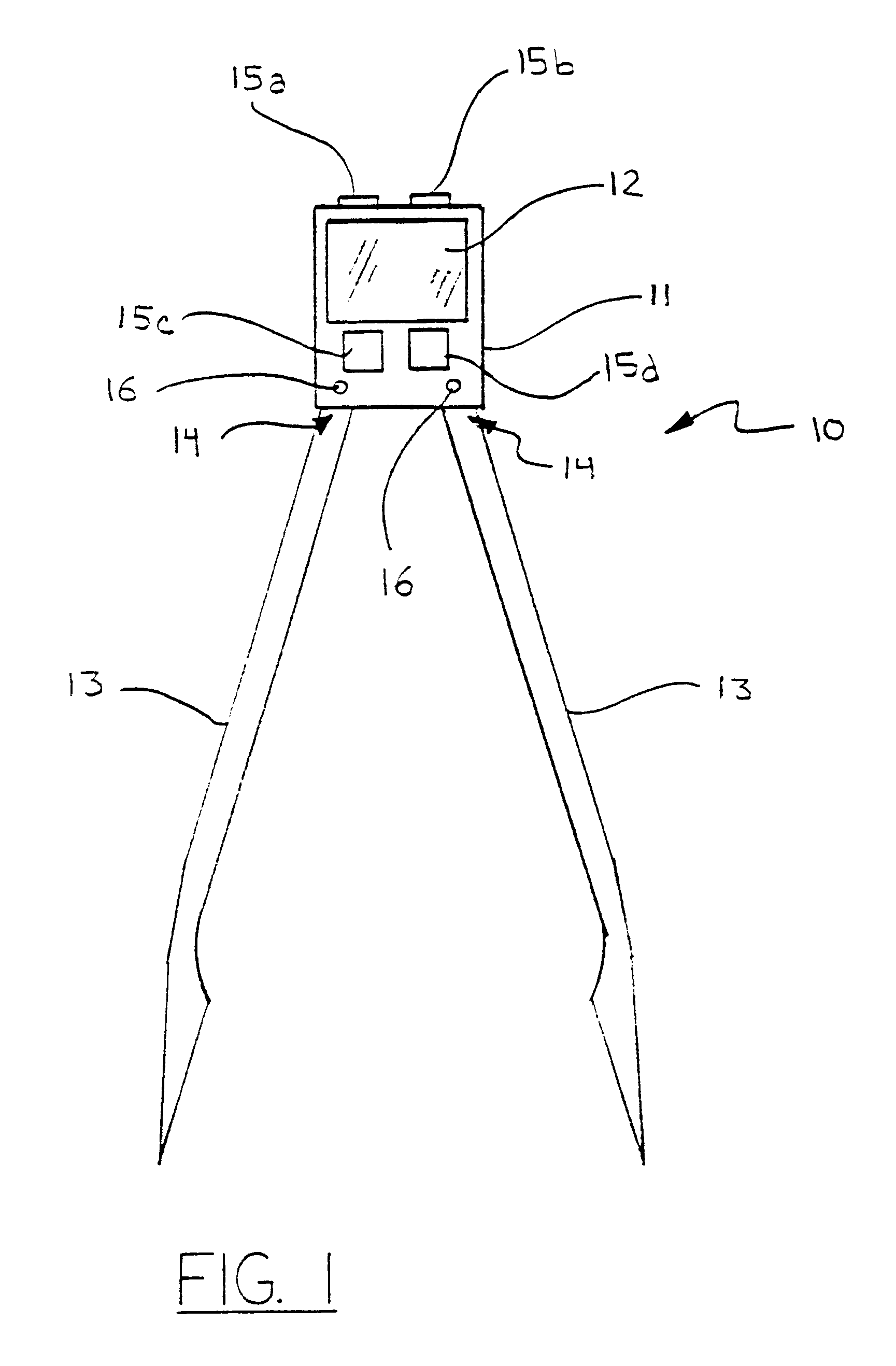

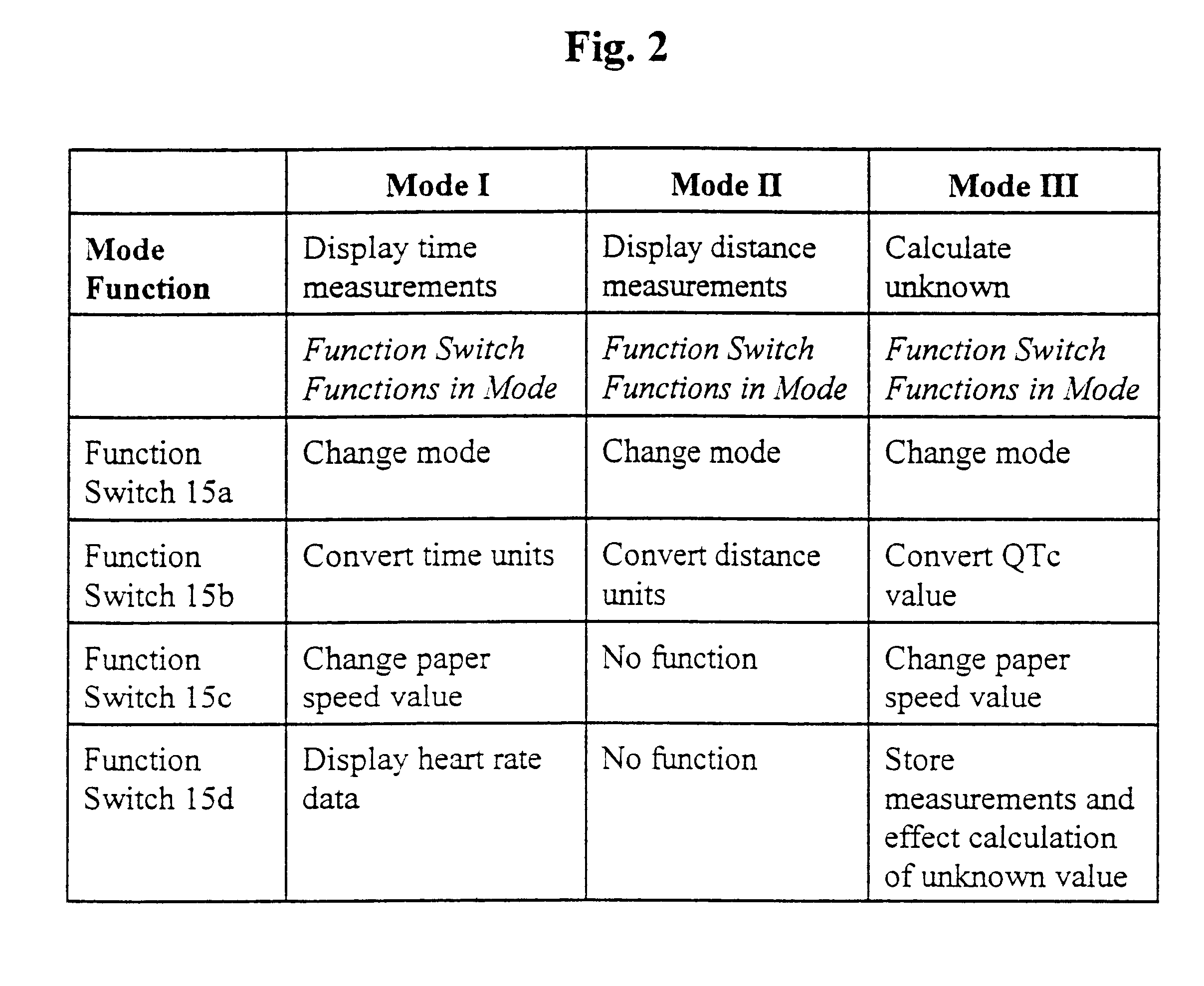

Electrocardiogram compass

The specification discloses a compass for obtaining measurements from an electrocardiogram tracing, the comprising a compass body, a display screen, compass legs pivotally connected to the body, and a computer operatively coupled to the display screen. The relative movement of the compass legs is translated into electronic signal information. The computer is adapted to receive the electronic signal information, and is further operative to convert the electronic signal information into physiological information to be displayed on the display screen. A power source powers the computer and display screen.

Owner:MAHER KEVIN

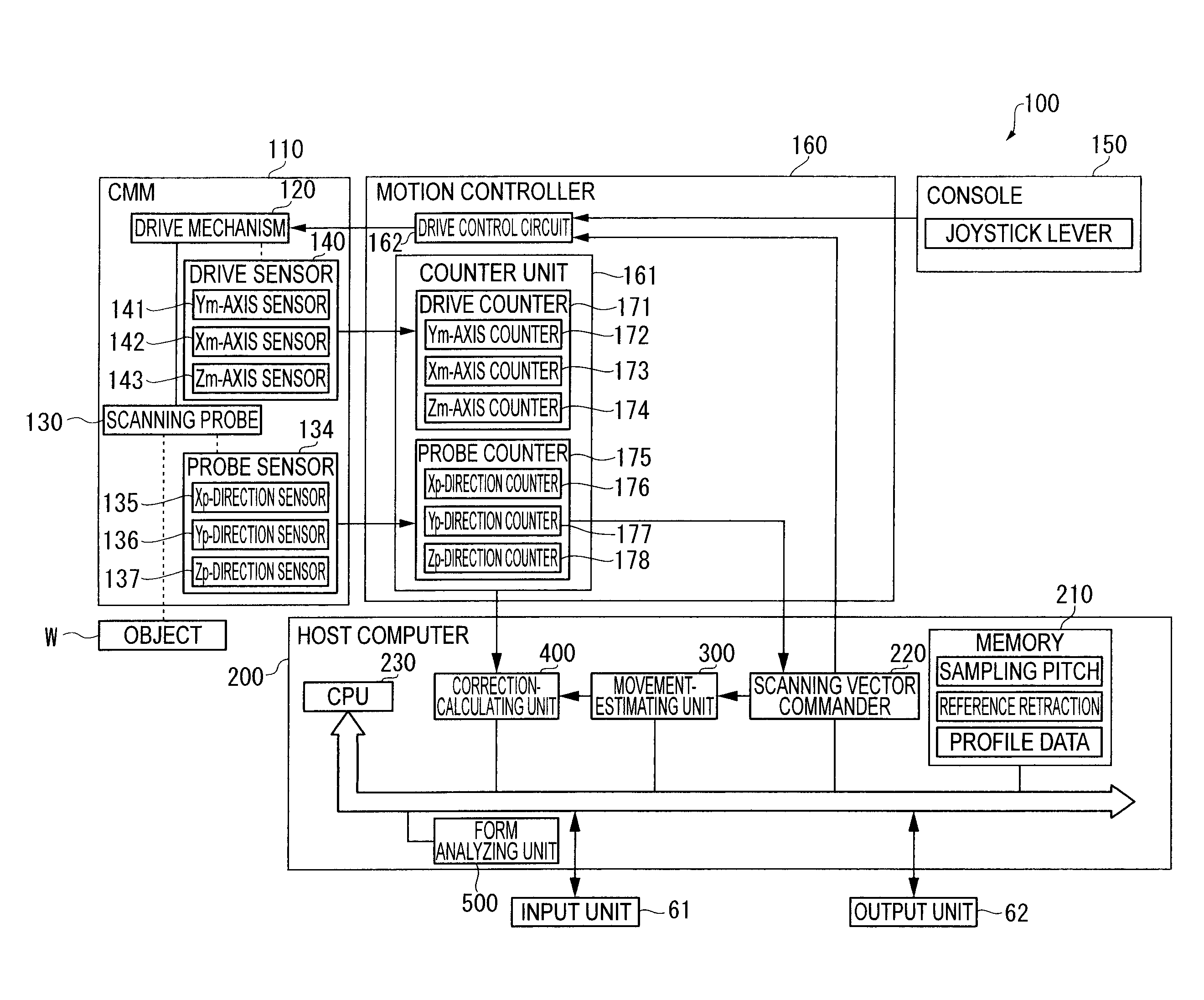

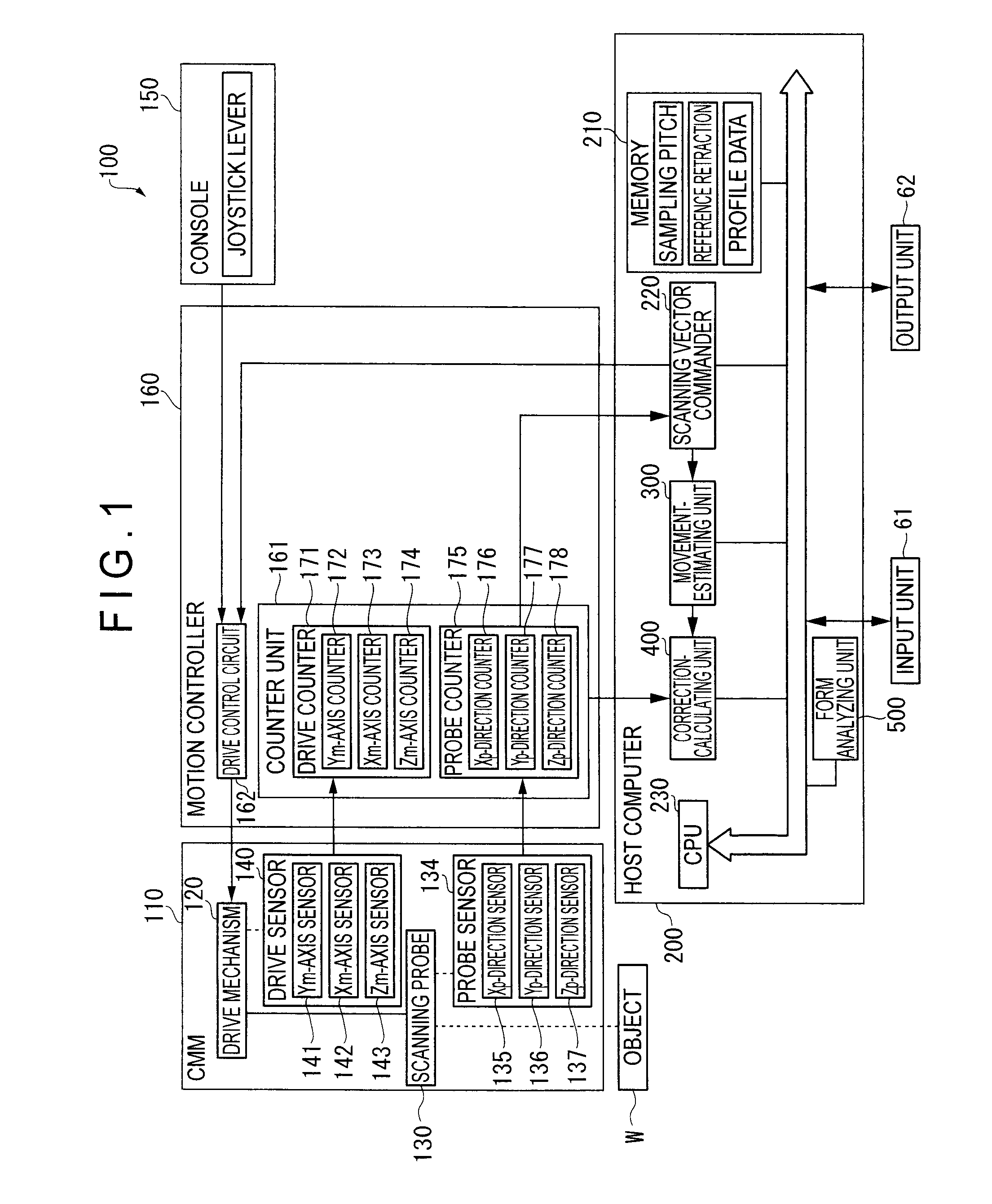

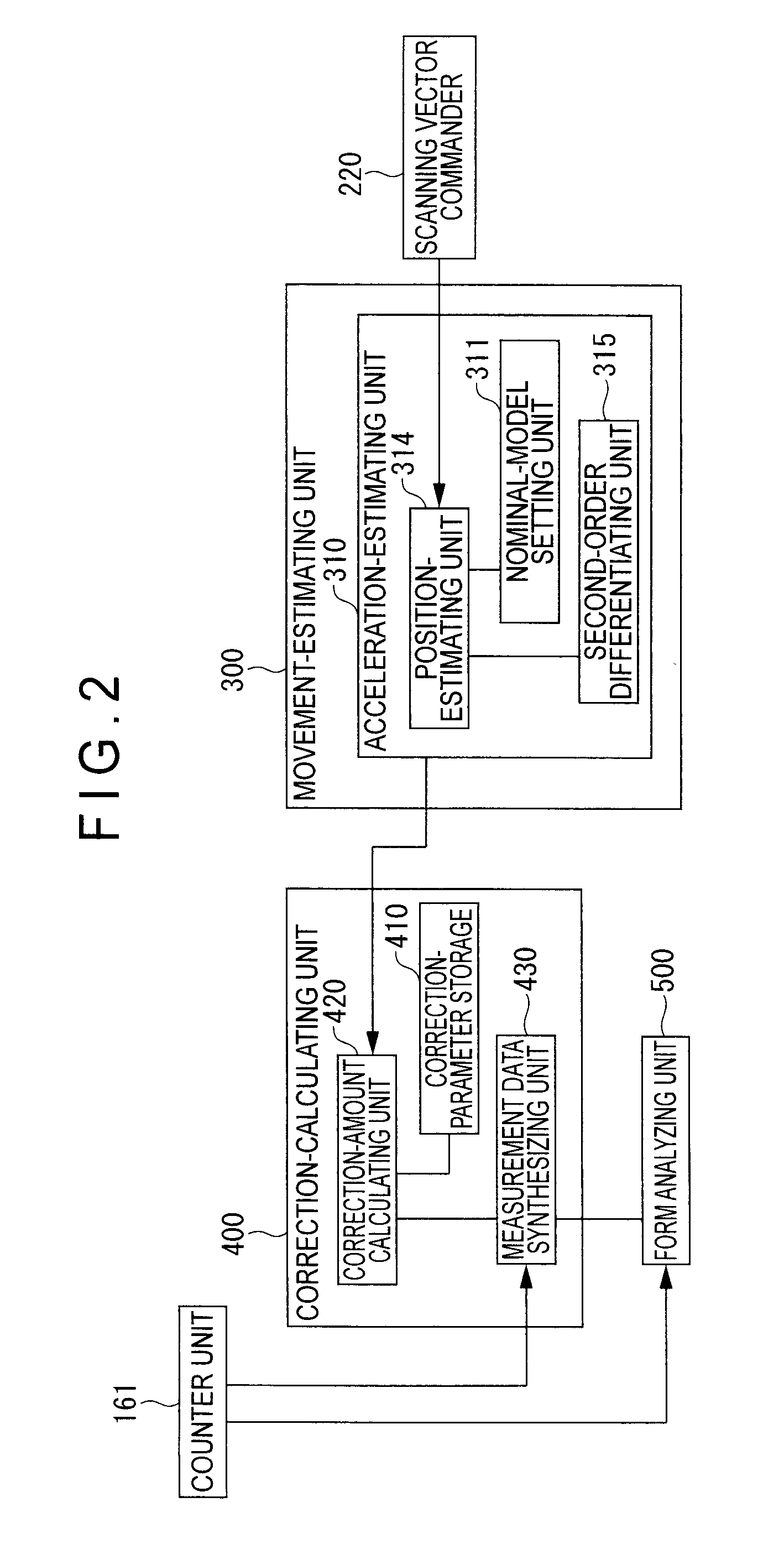

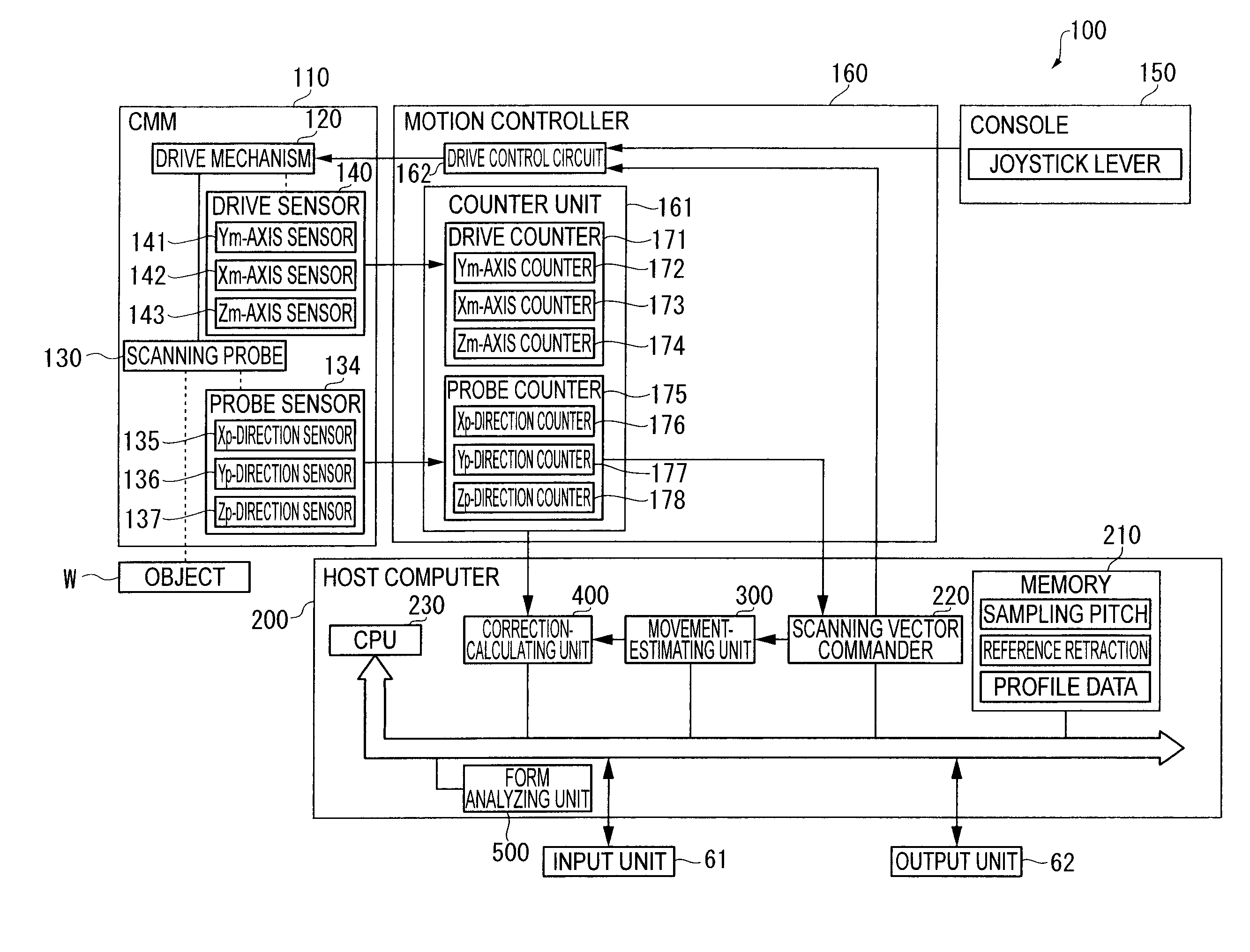

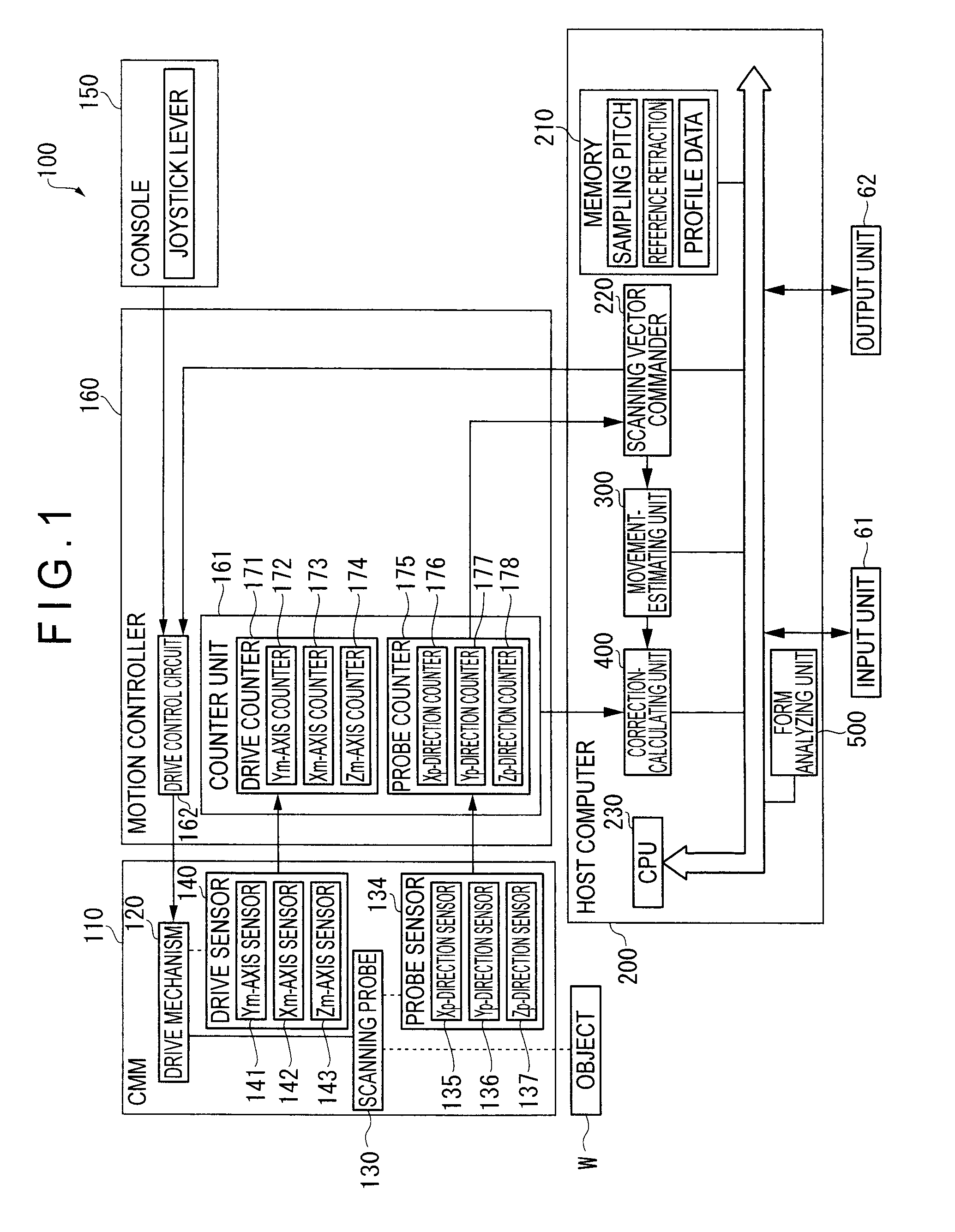

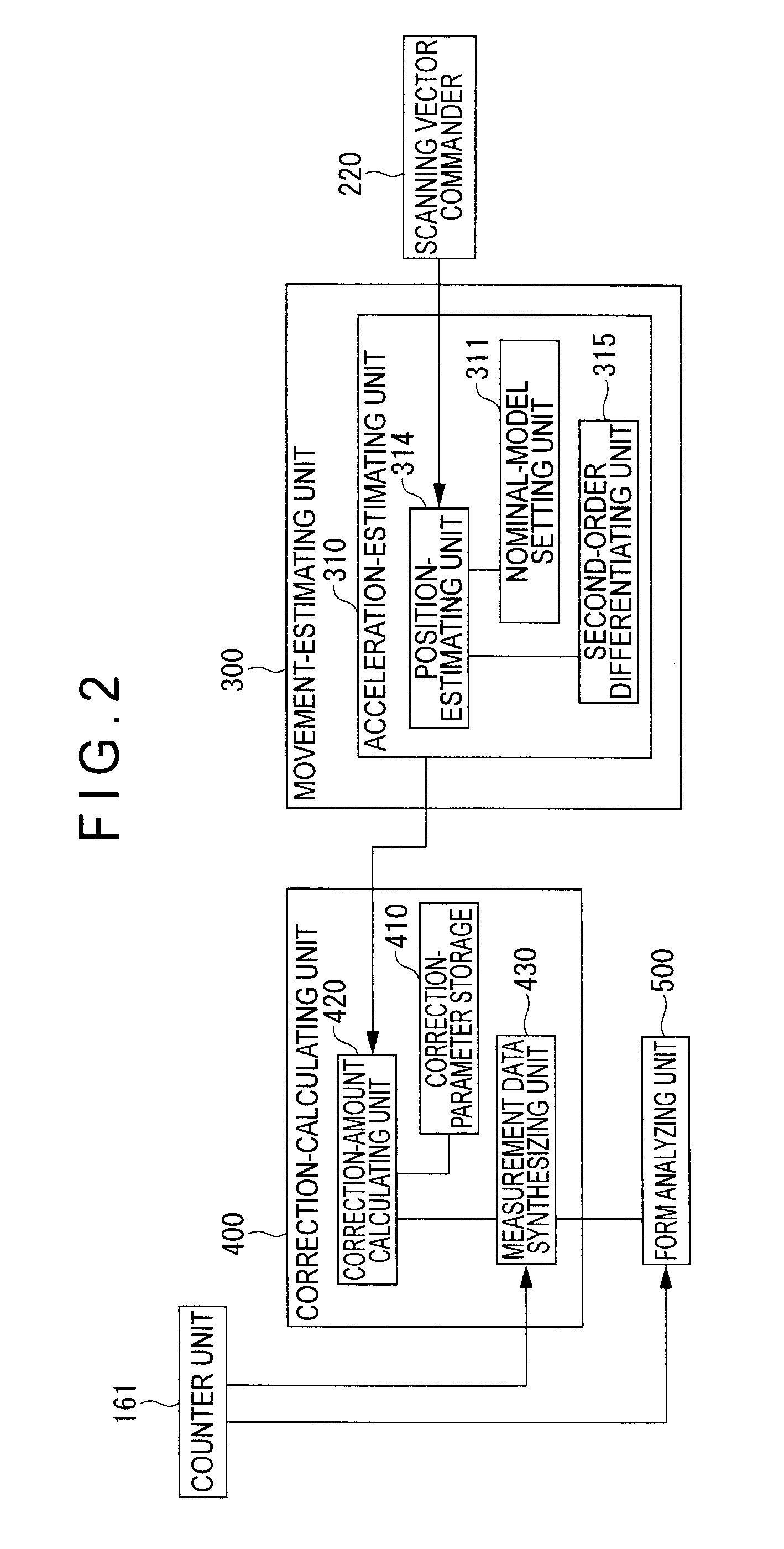

Surface texture measuring instrument

ActiveUS20090037128A1Erroneous outputAccurate calculationDigital data processing detailsTemperatue controlObservational errorMeasuring instrument

A surface texture measuring instrument includes: a movement-estimating unit for estimating a movement condition of a drive mechanism based on a scanning vector command issued by a scanning vector commander to calculate an estimated operation state quantity; and a correction-calculating unit for correcting a detection value of a drive sensor in accordance with the estimated operation state quantity calculated by the movement-estimating unit. The movement-estimating unit includes: a nominal-model setting unit in which a nominal model representing signal transfer function of the scanning vector command from the issuance of the scanning vector command to a reflection on a movement position of the scanning probe is stored. The correction-calculating unit includes a correction-amount calculating unit that calculates a correction amount for correcting a measurement error generated on account of deformation during the drive of the drive mechanism based on the estimated operation state quantity; and a measurement data synthesizing unit that synthesizes the detection value of the drive sensor and a detection sensor and the correction amount calculated by the correction-amount calculating unit to acquire a measurement data.

Owner:MITUTOYO CORP

Caliper

Owner:YANG JEN YUNG

Caliper

ActiveUS20090056160A1Accurate size measurementEasy to operateCompasses with pivoted armsBallastwayCalipersEngineering

Owner:HU BOBBY

Surface texture measuring instrument

ActiveUS7715999B2Accurate calculationTemperatue controlDigital data processing detailsObservational errorMeasuring instrument

A surface texture measuring instrument includes: a movement-estimating unit for estimating a movement condition of a drive mechanism based on a scanning vector command issued by a scanning vector commander to calculate an estimated operation state quantity; and a correction-calculating unit for correcting a detection value of a drive sensor in accordance with the estimated operation state quantity calculated by the movement-estimating unit. The movement-estimating unit includes: a nominal-model setting unit in which a nominal model representing signal transfer function of the scanning vector command from the issuance of the scanning vector command to a reflection on a movement position of the scanning probe is stored. The correction-calculating unit includes a correction-amount calculating unit that calculates a correction amount for correcting a measurement error generated on account of deformation during the drive of the drive mechanism based on the estimated operation state quantity; and a measurement data synthesizing unit that synthesizes the detection value of the drive sensor and a detection sensor and the correction amount calculated by the correction-amount calculating unit to acquire a measurement data.

Owner:MITUTOYO CORP

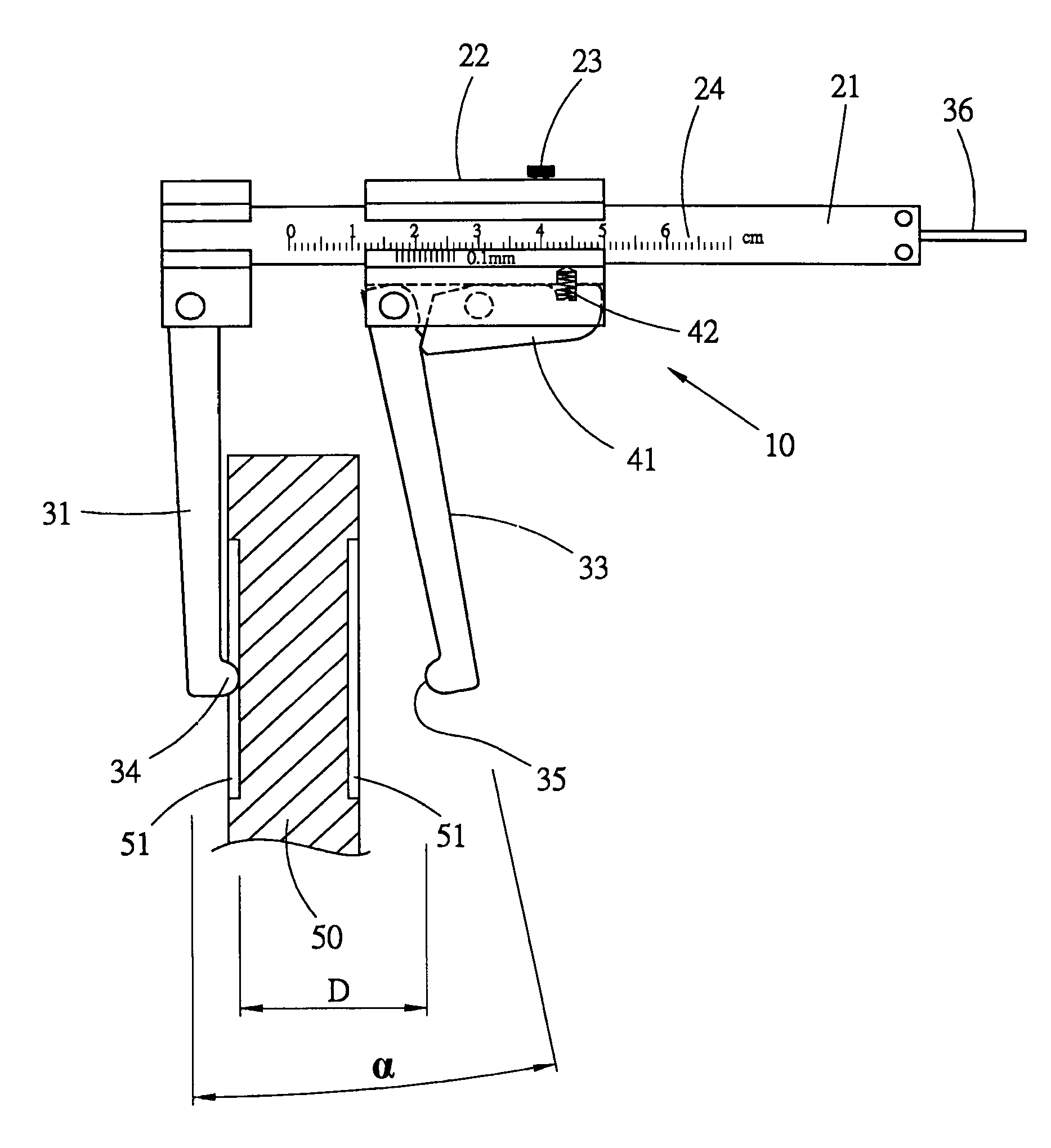

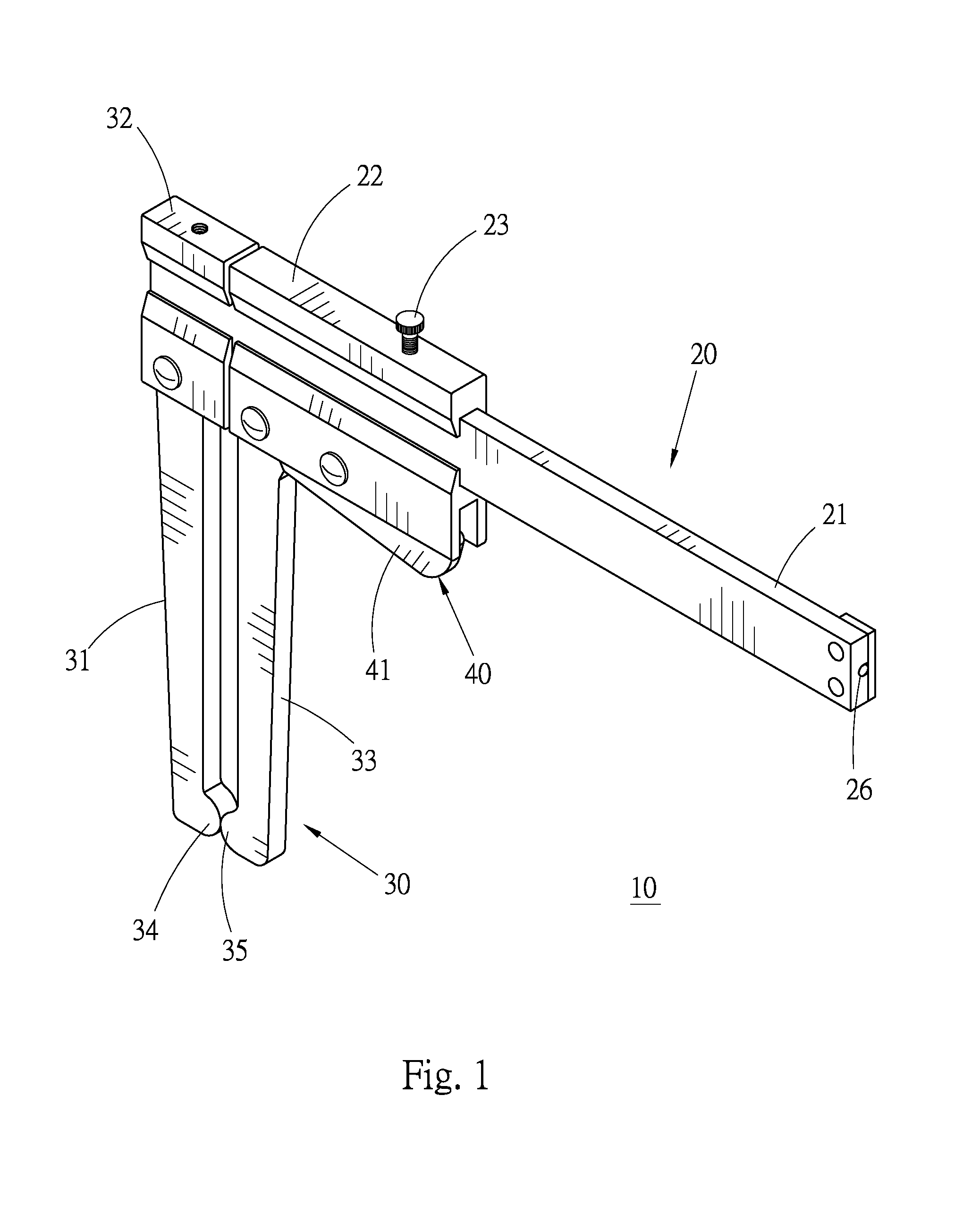

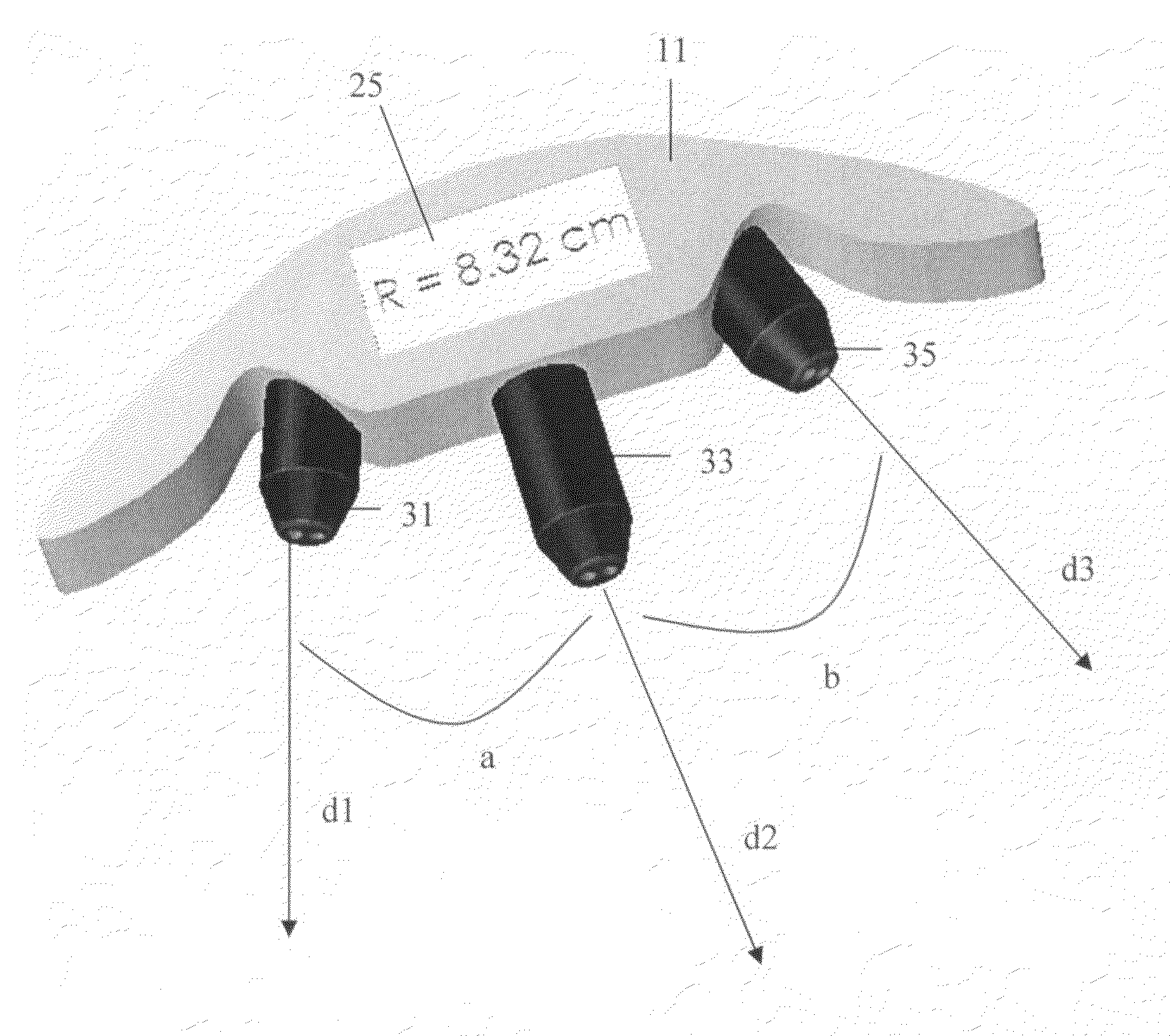

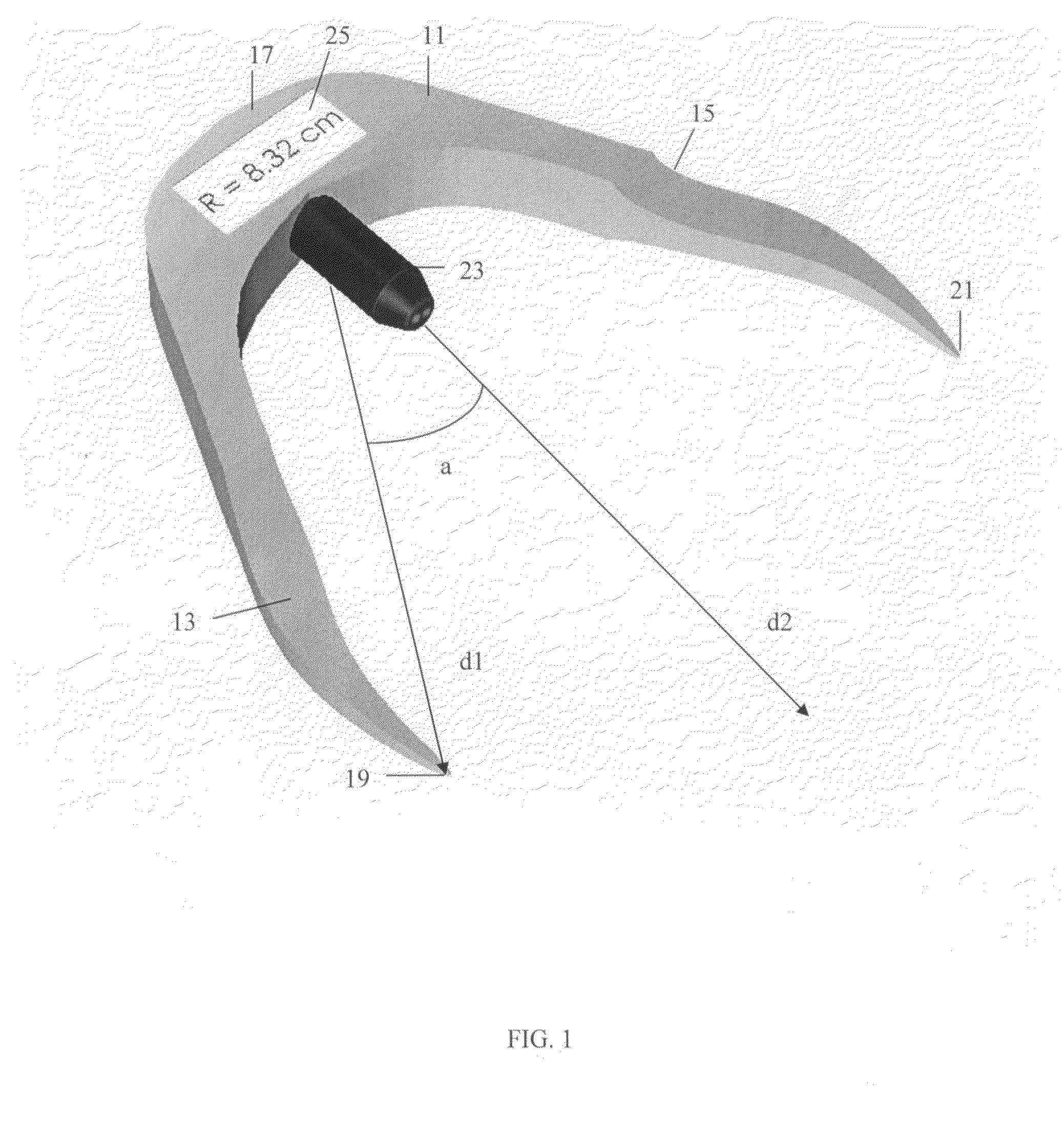

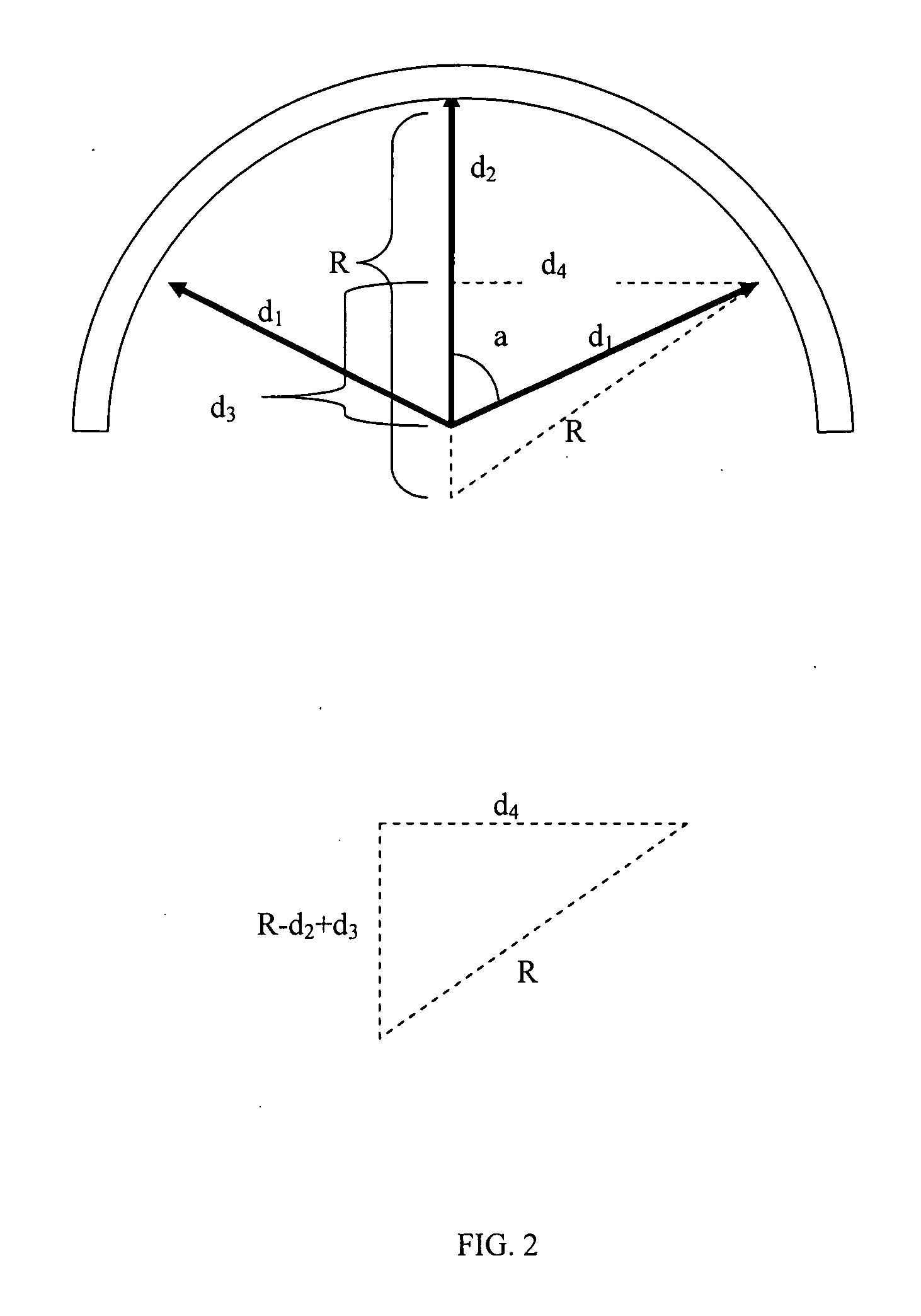

Surface curvature measurement tool

ActiveUS20080289205A1Improve sensitivity and accuracyIncrease rangeCompasses with pivoted armsOptical rangefindersDisplay deviceLinear encoder

A device for measuring the radius of curvature of a surface comprises a main body that is held above the surface being measured; and a non-contact sensor mounted to the main body that measures a distance between the surface being measured and the sensor, the device calculating the radius of curvature of the surface based on the measured distance. The device can further include a display mounted to the main body that displays the calculated radius of curvature. The non-contact sensor can be, for example, an acoustical distance sensor or an optical distance sensor. In one embodiment, the device includes two arms extending from the main body of the device and being substantially symmetric about the non-contact sensor, the arms terminating in contact points that make contact with the surface being measured. In another embodiment, the device includes three non-contact sensors mounted to the main body, each measuring a distance between the surface being measured and the respective sensor, the device calculating the radius of curvature of the surface based on the measured distances. In yet another aspect of the invention, a radius of curvature measuring device has an adjustable arm that is movable with respect to a main body and a linear encoder associated with the adjustable arm for measuring a distance from the surface of interest.

Owner:SURE SHOT MEDICAL DEVICE

Caliper

ActiveUS7509754B2Accurate measurementEasy to operateCompasses with pivoted armsBallastwayEngineeringCalipers

Owner:HU BOBBY

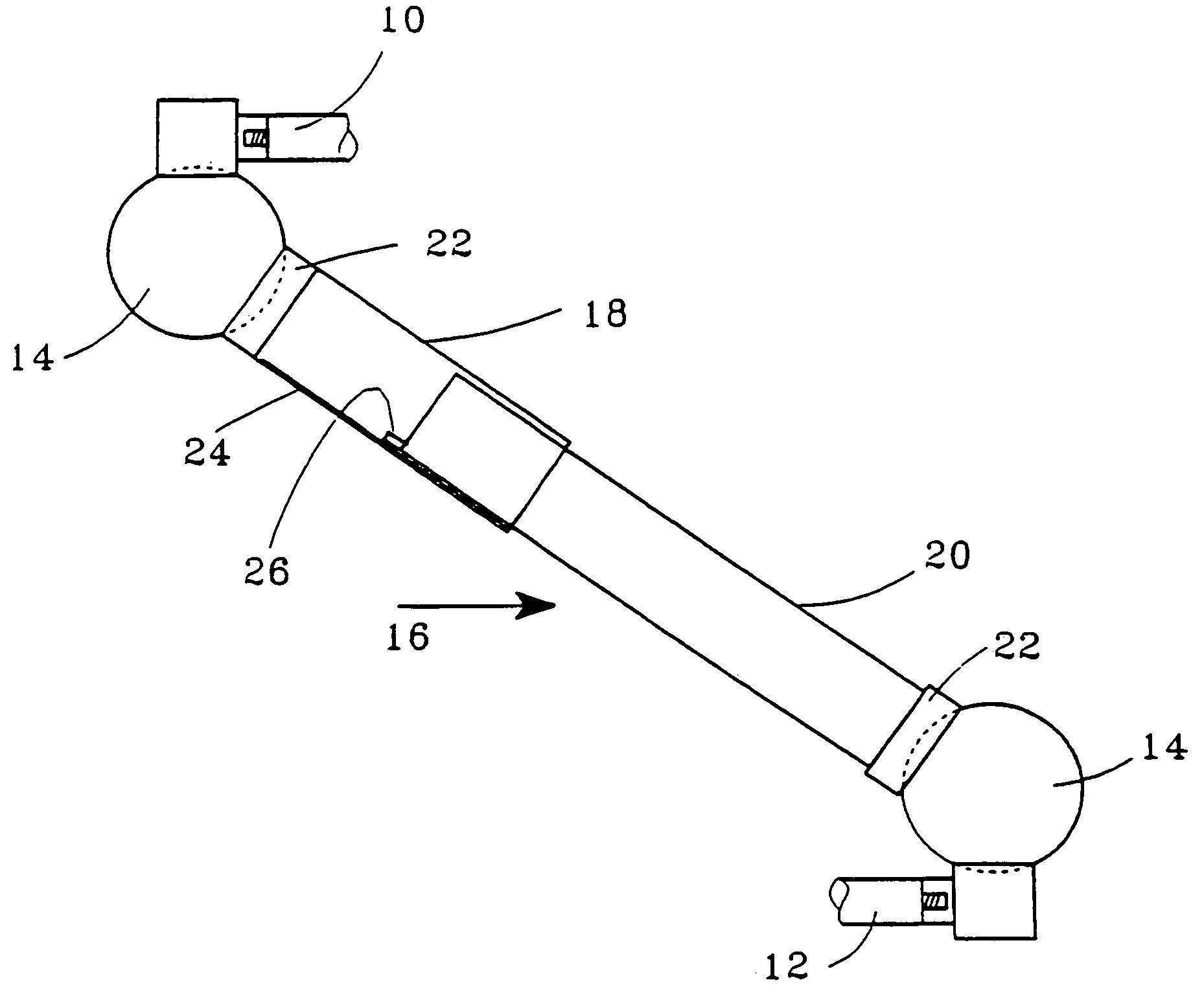

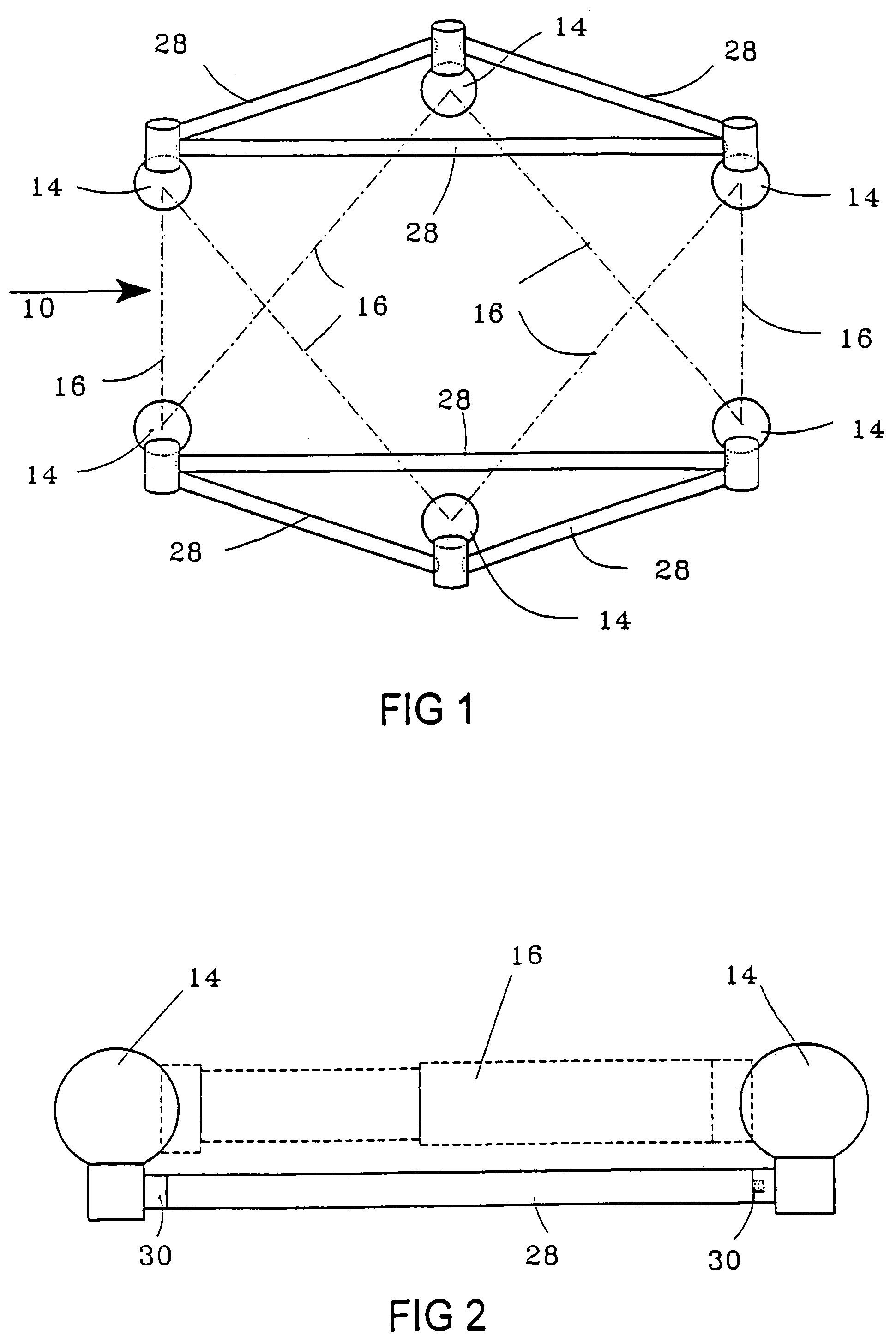

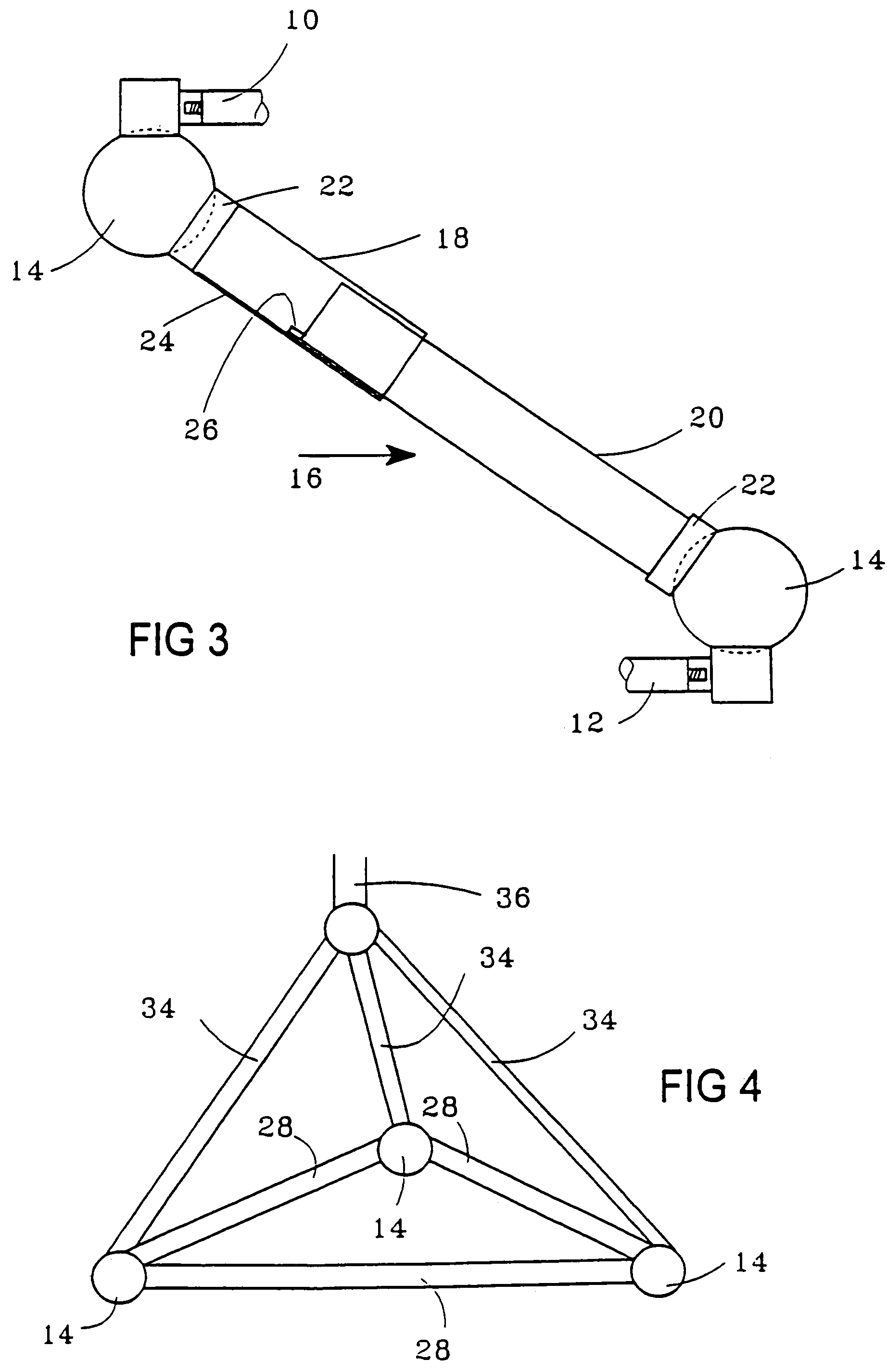

Performing measurement or calibration on positioning machines

A machine having a pair of spaced structures, a plurality of ball and socket joints spaced apart on each structure, and six struts interconnecting the structures. Each strut engages with a respective ball and socket joint on each of the structures, and defines a variable distance between the centers of the ball and socket joints to which the strut is connected. At least one of the ball and socket joints to which the strut is connected has a plurality of the struts connected thereto, the ball and socket joint having a socket on each respective strut, co-operating with a sphere, the sockets having three engagement elements biased into engagement with the sphere.

Owner:RENISHAW PLC

Brow tool

Owner:PLAIN NATALIE

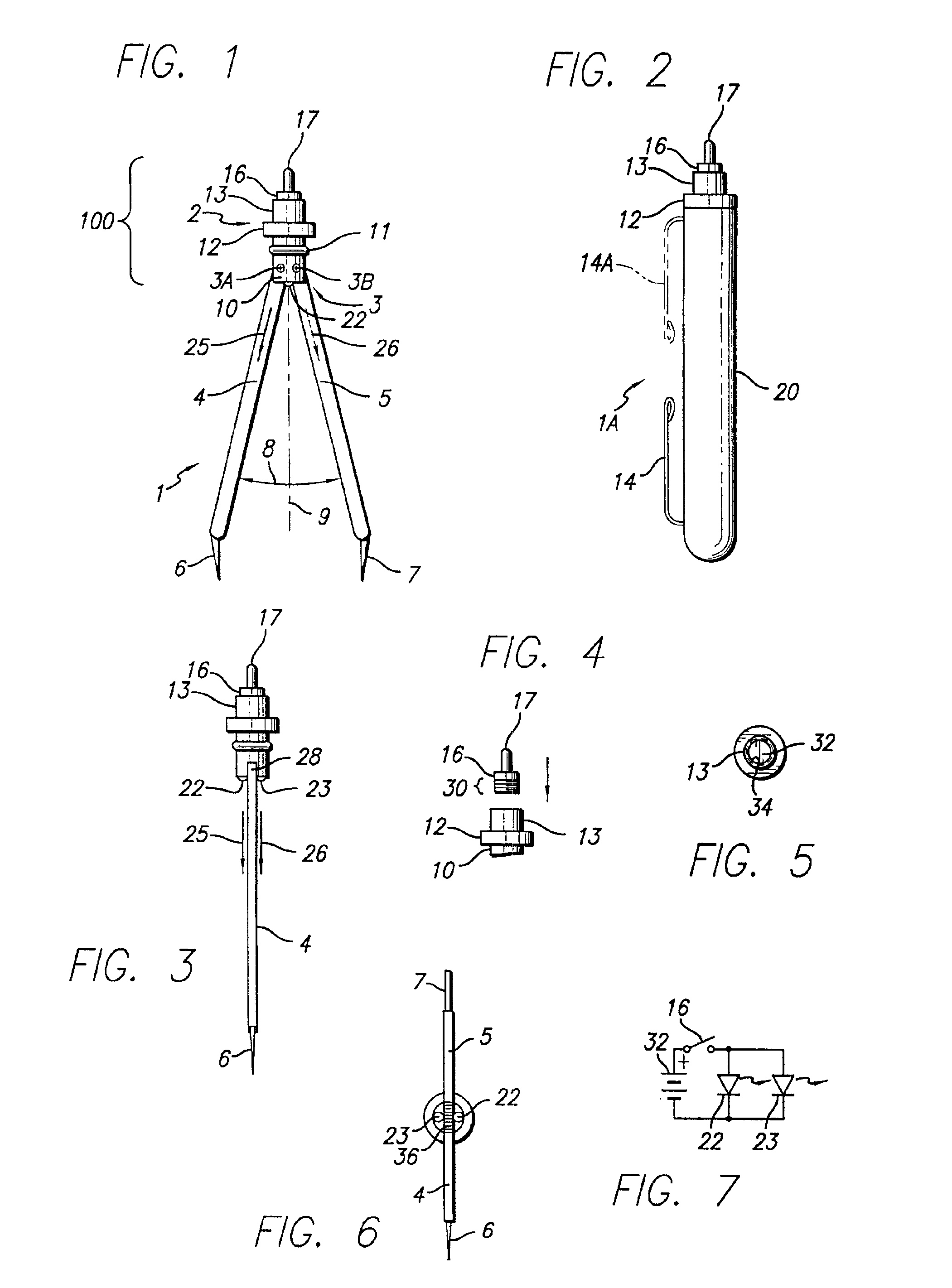

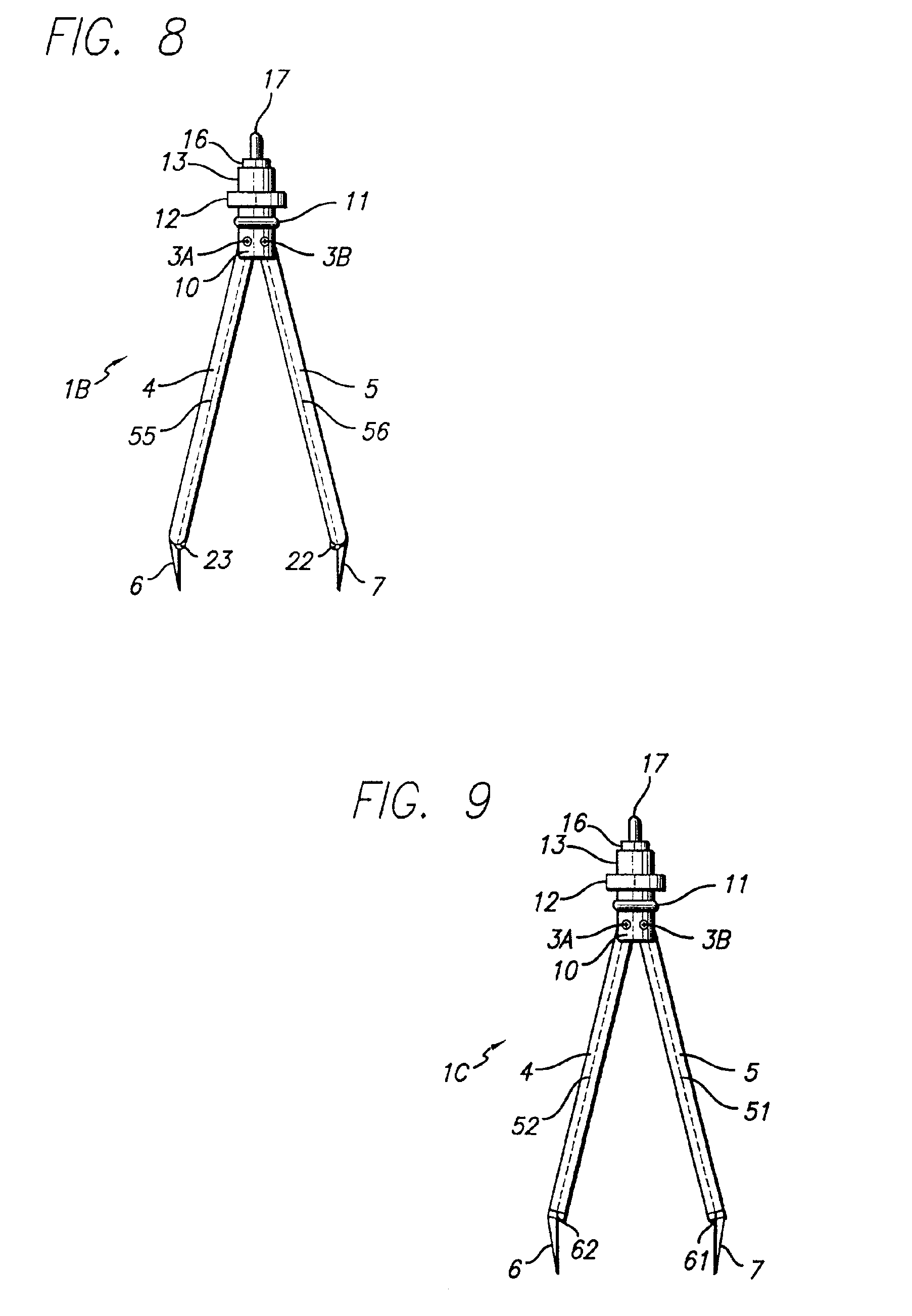

Illuminated caliper instrument

InactiveUS6877242B2Sufficient lightingCompasses with pivoted armsLighting elementsNight visionCalipers

An illuminated caliper device includes a caliper assembly having first and second caliper legs each having a pointed tip and a pivot end. A pivot support and first and second pivot elements pivotally connects the pivot ends of the first and second caliper legs to the pivot support. A battery housing attached to the pivot support contains a battery. First and second light emitting diodes are coupled by a switch mounted on the battery housing to first and second terminals of the battery and produced light that is directed to areas of the surface to be measured by pointed tips of the legs. The intensity and color of light emitted by the first light emitting diode are such as to sufficiently illuminate the surface under low ambient illumination conditions without disrupting acquired night vision of a user.

Owner:MACKIN ROBERT A +1

Popular searches

Electric/magnetic contours/curvatures measurements Electric/magnetic roughness/irregularity measurements Point coordinate measurements Mechanical roughness/irregularity measurements Electrical/magnetic diameter measurements Simulator control Special data processing applications Programme total factory control Fracture Invalid friendly devices

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com