Patents

Literature

542results about "Electric/magnetic roughness/irregularity measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Overlay alignment measurement of wafers

InactiveUS6079256AMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementControl systemEngineering

The present invention is a method and apparatus that uses a microscopic height variation positioned relative to a semiconductor device to scan a target on the device to produce an electrical signal representative of height variations of first and second periodic structures of the target in a selected path across the device, and a computing and control system to provide translation between the microscopic height variation detector and the target on the device in a selected path, and to calculate any offset between the first periodic structure and the second periodic structure of the target from the electrical signals from the microscopic height variation detector. The first periodic structure of the target is on a first layer of the device, and the second periodic structure, that complements the first periodic structure, is on a second layer of the device at a location that is adjacent the first periodic structure.

Owner:KLA INSTR

Pulsed eddy current sensor probes and inspection methods

A pulsed eddy current sensor probe includes a sensor array board. A number of sensors are arranged on the sensor array board and are operable to sense and generate output signals from the transient electromagnetic flux in a part being inspected. Each of the sensors has a differential output with a positive and a negative output. At least one drive coil is disposed adjacent to the sensors and is operable to transmit transient electromagnetic flux into the part. A first and a second multiplexer are arranged on the sensor array board and are operable to switch between the sensors. The first and second multiplexers are connected to the positive and negative outputs of the sensors, respectively.

Owner:GENERAL ELECTRIC CO

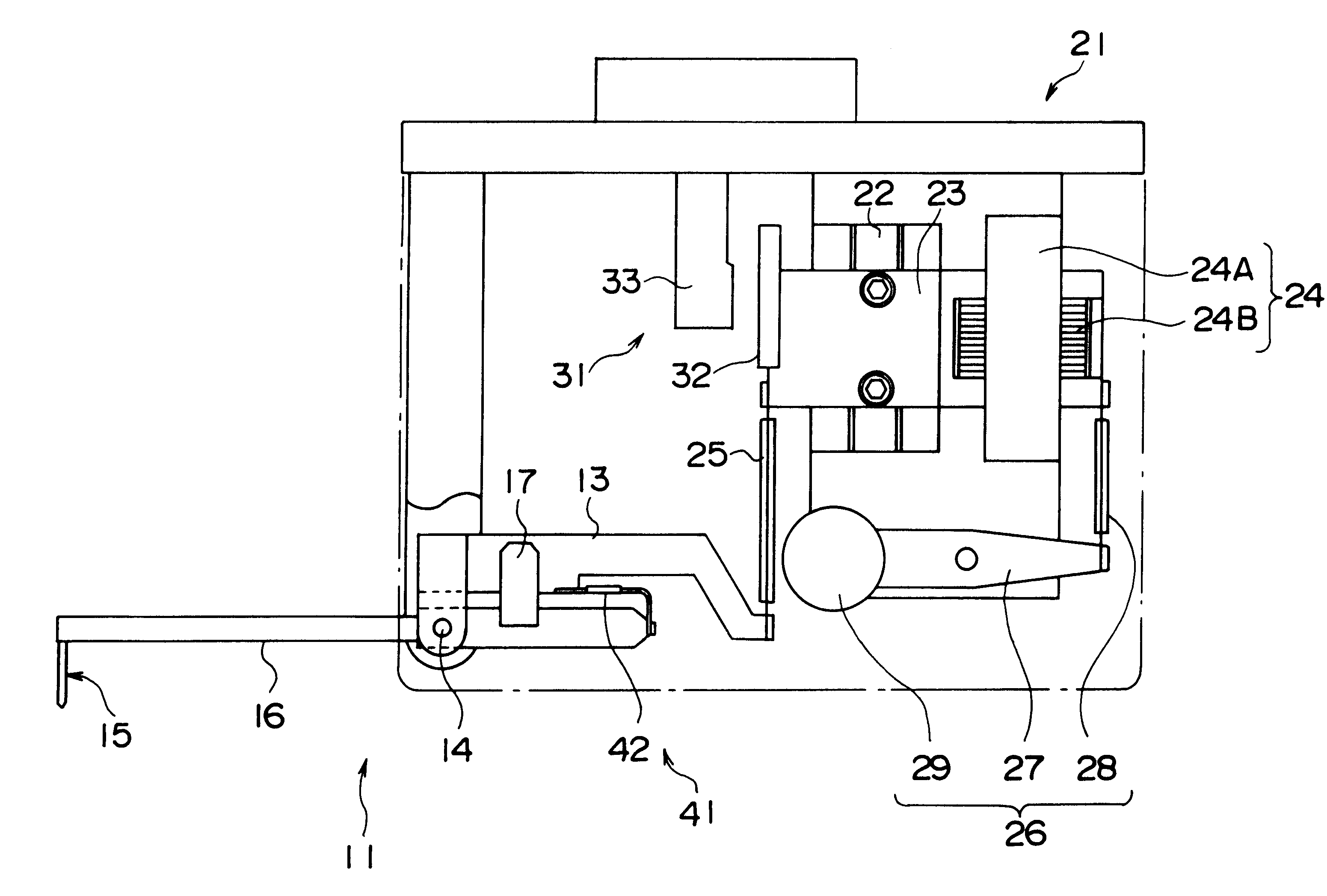

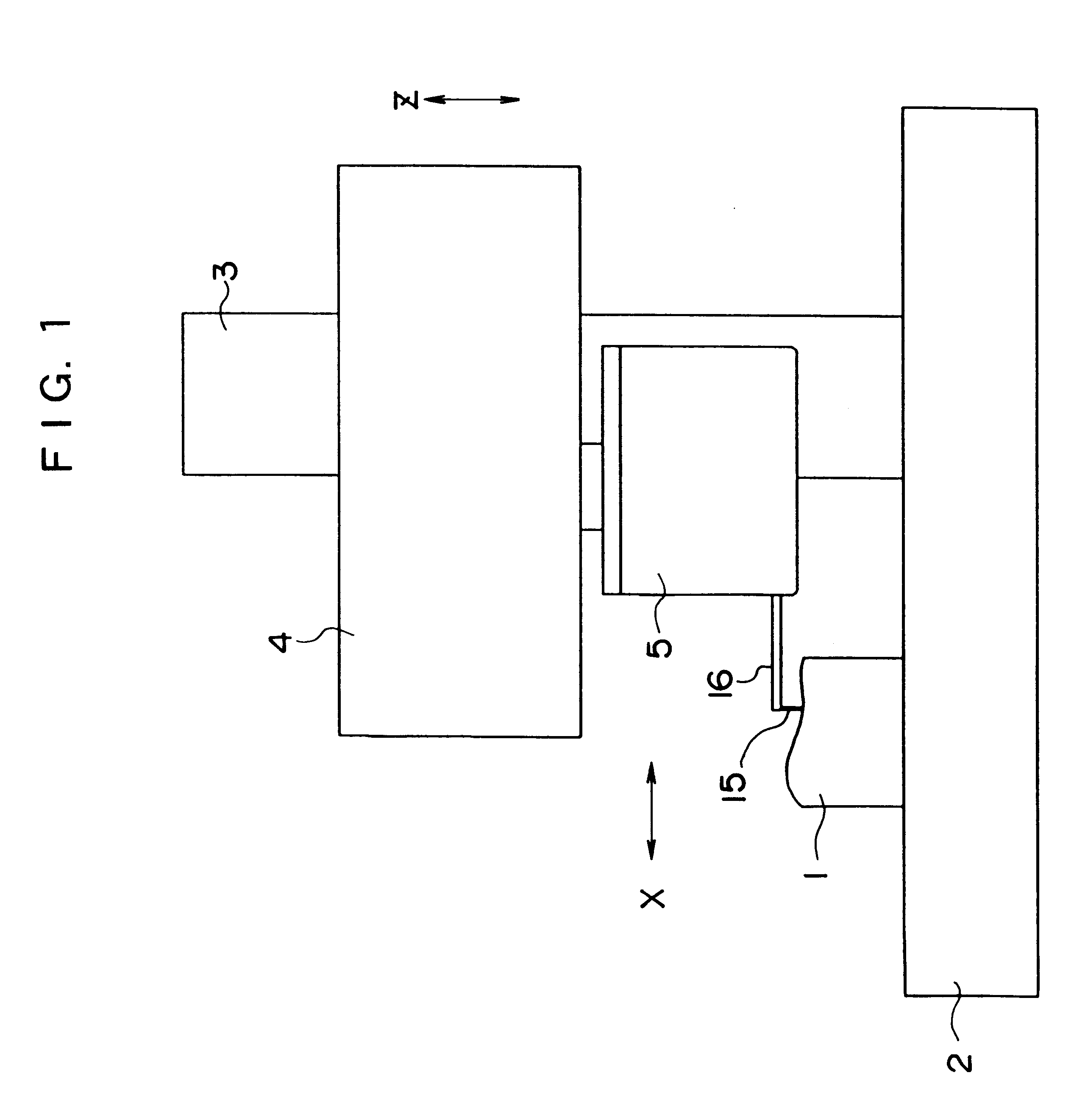

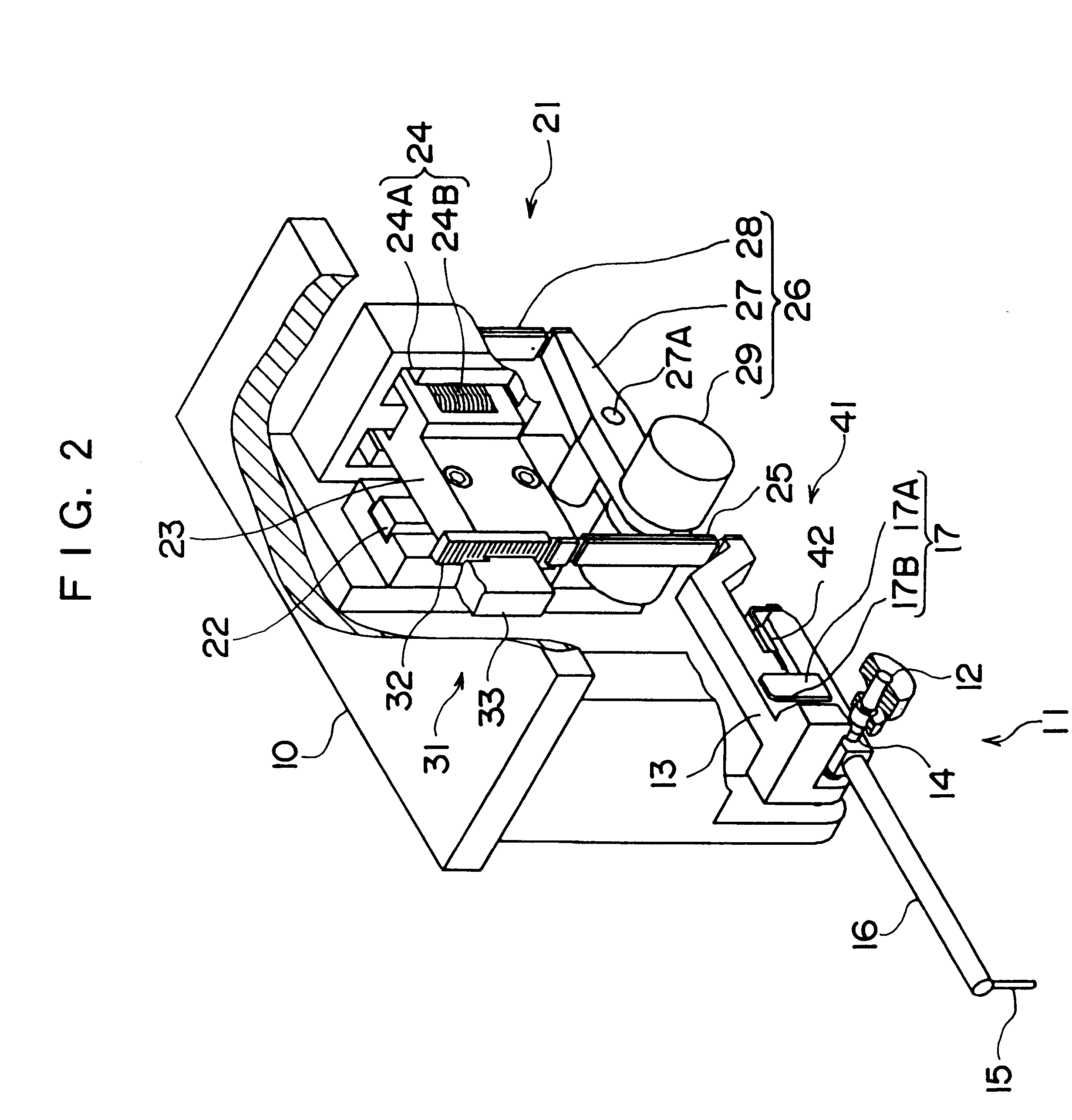

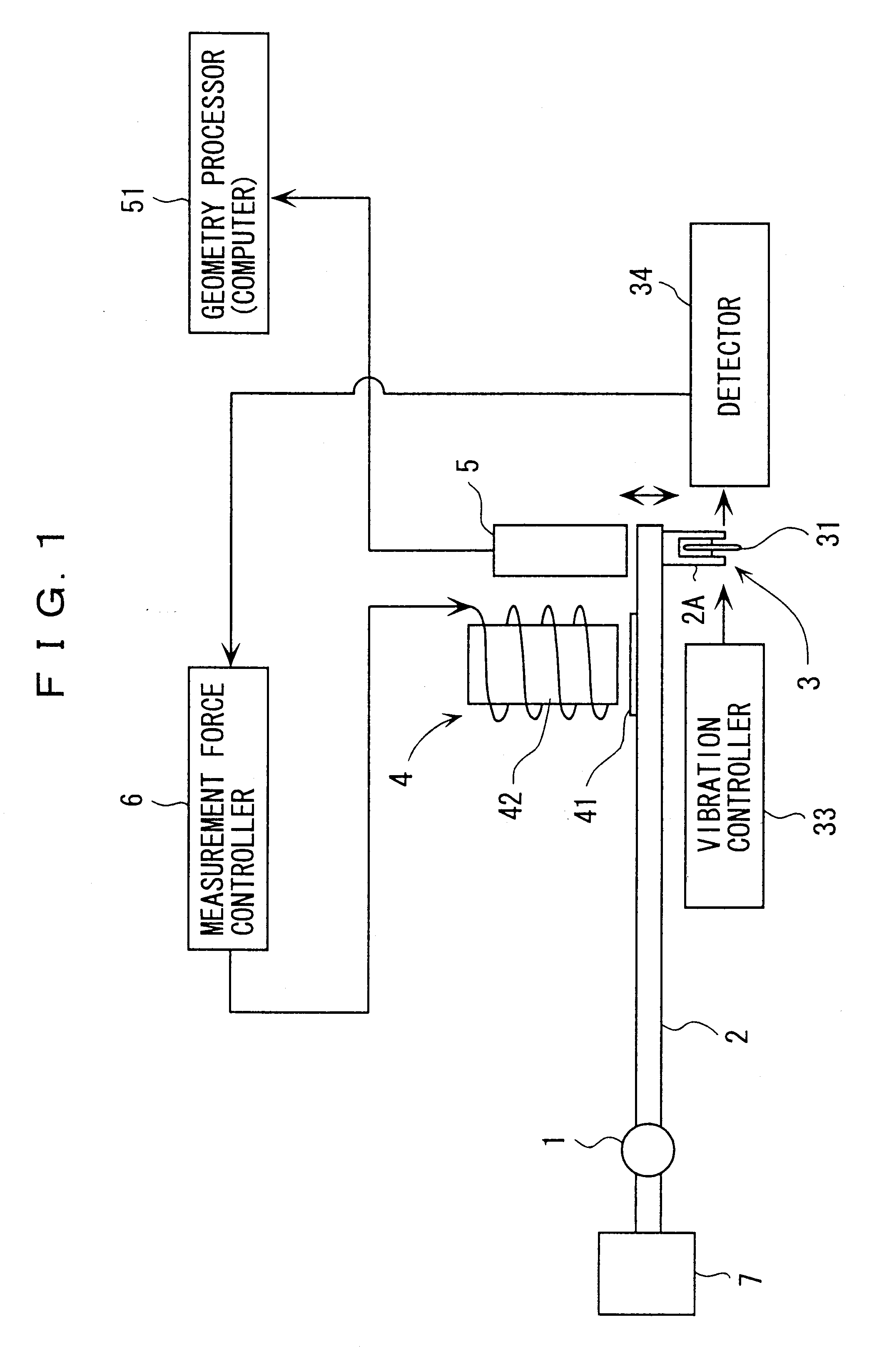

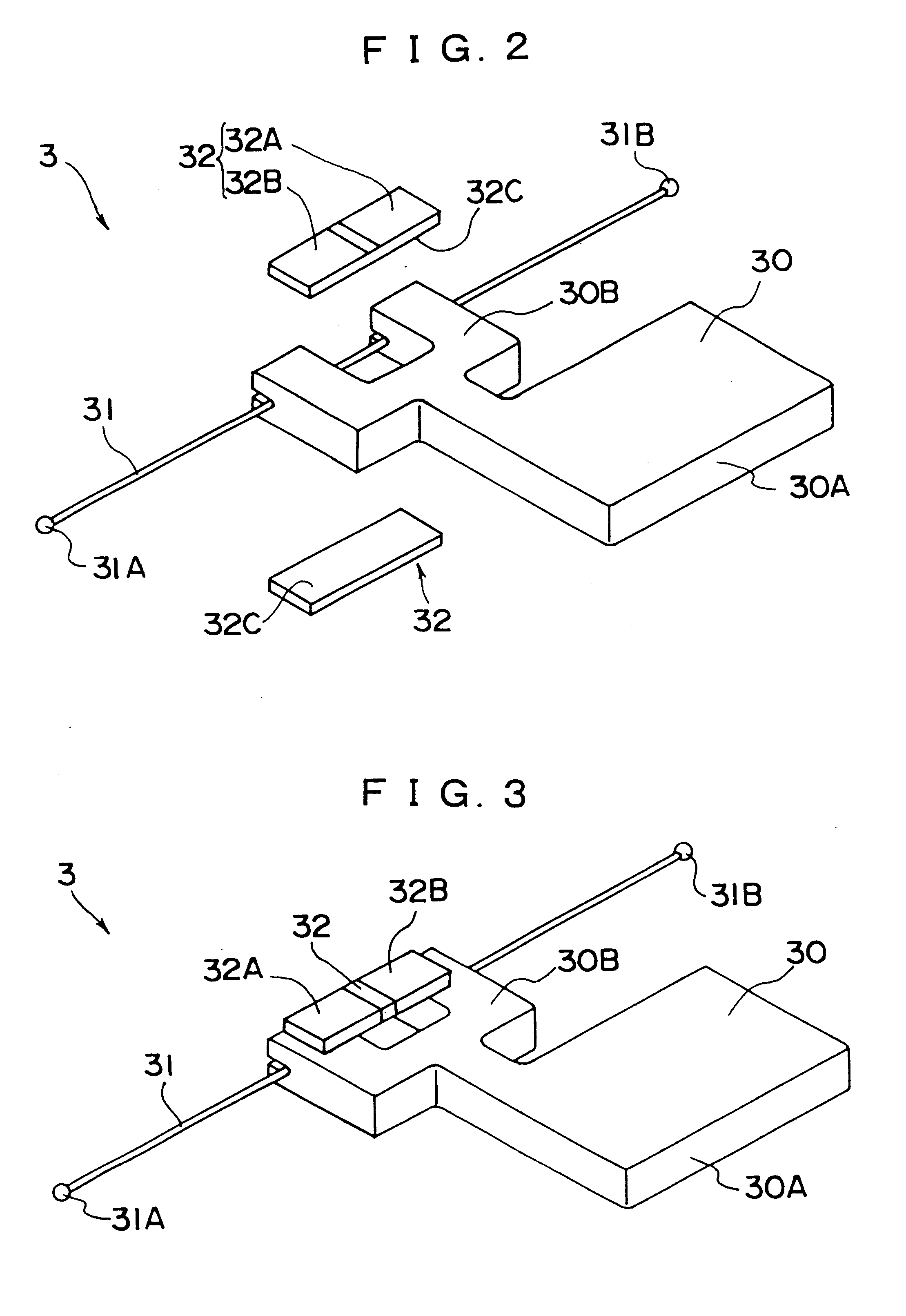

Surface-tracking measuring machine

InactiveUS6295866B1Accurate detectionReduce sensitivityCompasses with pivoted armsMechanical counters/curvatures measurementsResponsivityClassical mechanics

A surface-tracking measuring machine is provided, in which measurement range is enlarged while keeping a measuring force, responsivity, resolution thereof. For the object, the surface-tracking measuring machine has a frame (10), a probe (11) swingably supported by the frame (10) and having a tracer (15) at an end thereof, a measuring force controller (21) for controlling the measuring force applied to the probe, a displacement detector (31) for detecting a displacement of the probe, a measuring force detector (41) for detecting the measuring force applied to the probe, and a controller (51) for comparing a measuring force detected value detected by the measuring force detector and a previously commanded measuring force command value and to control the measuring force controller so that the measuring force detected value is equal to the measuring force command value.

Owner:MITUTOYO CORP

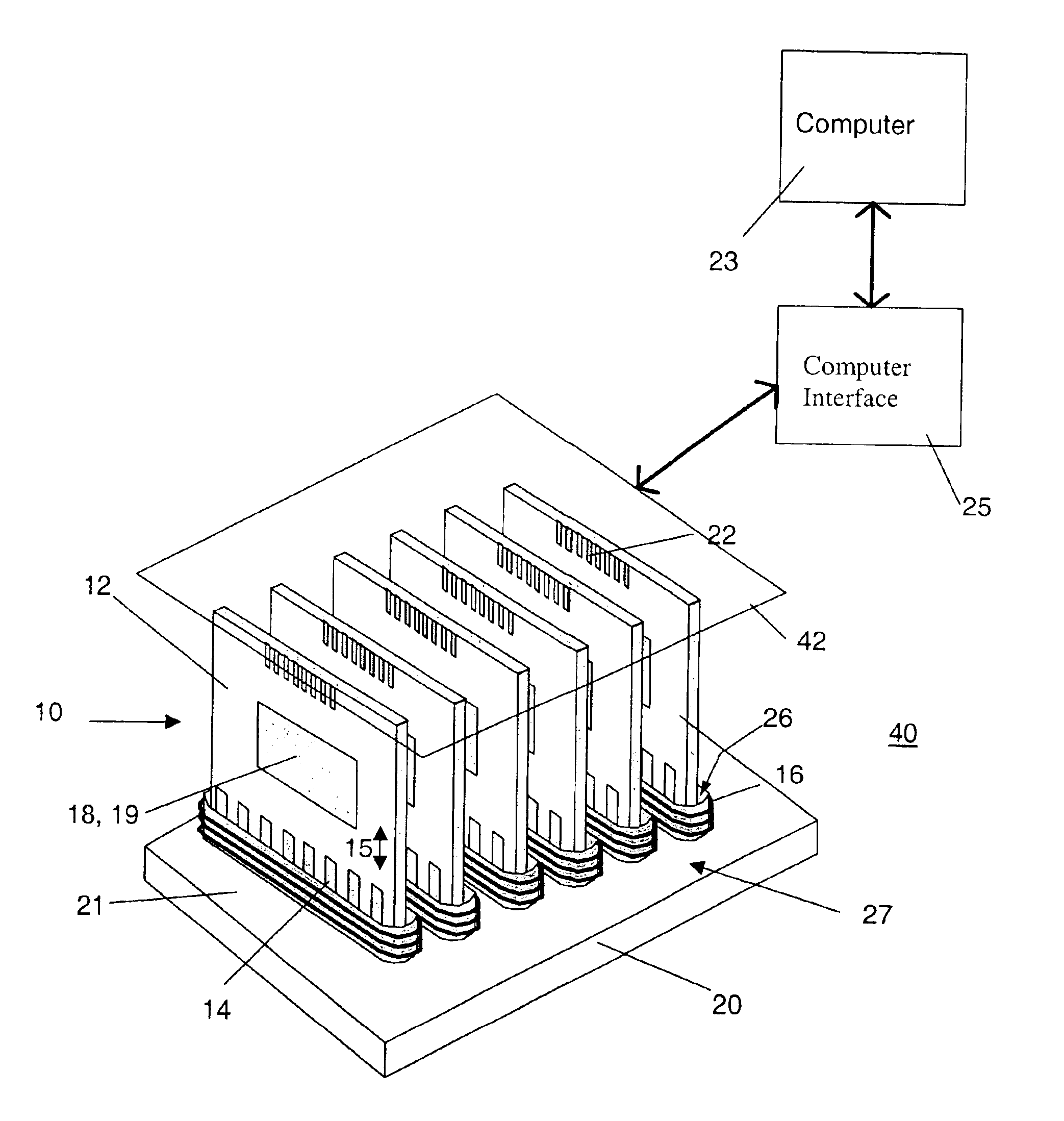

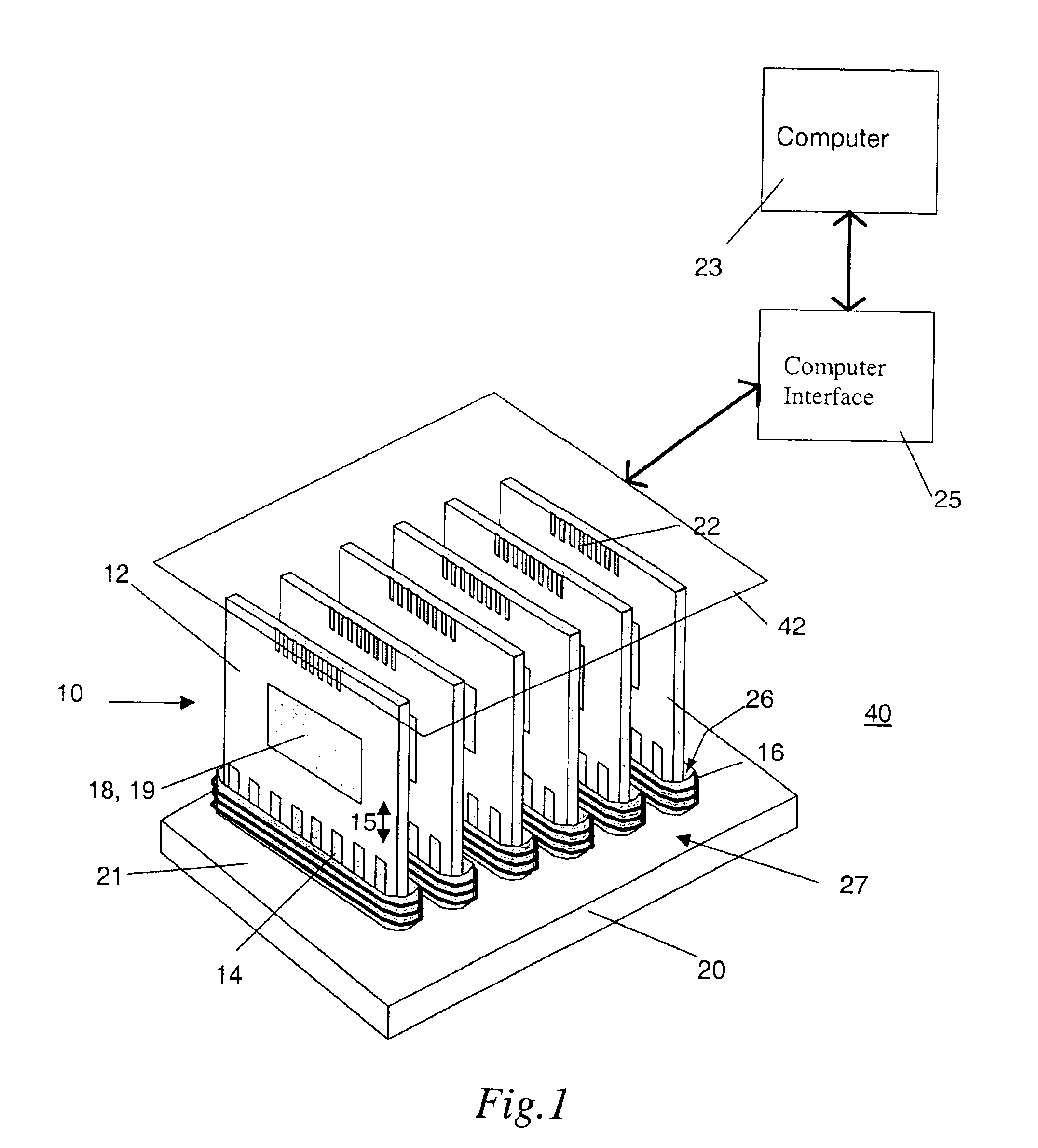

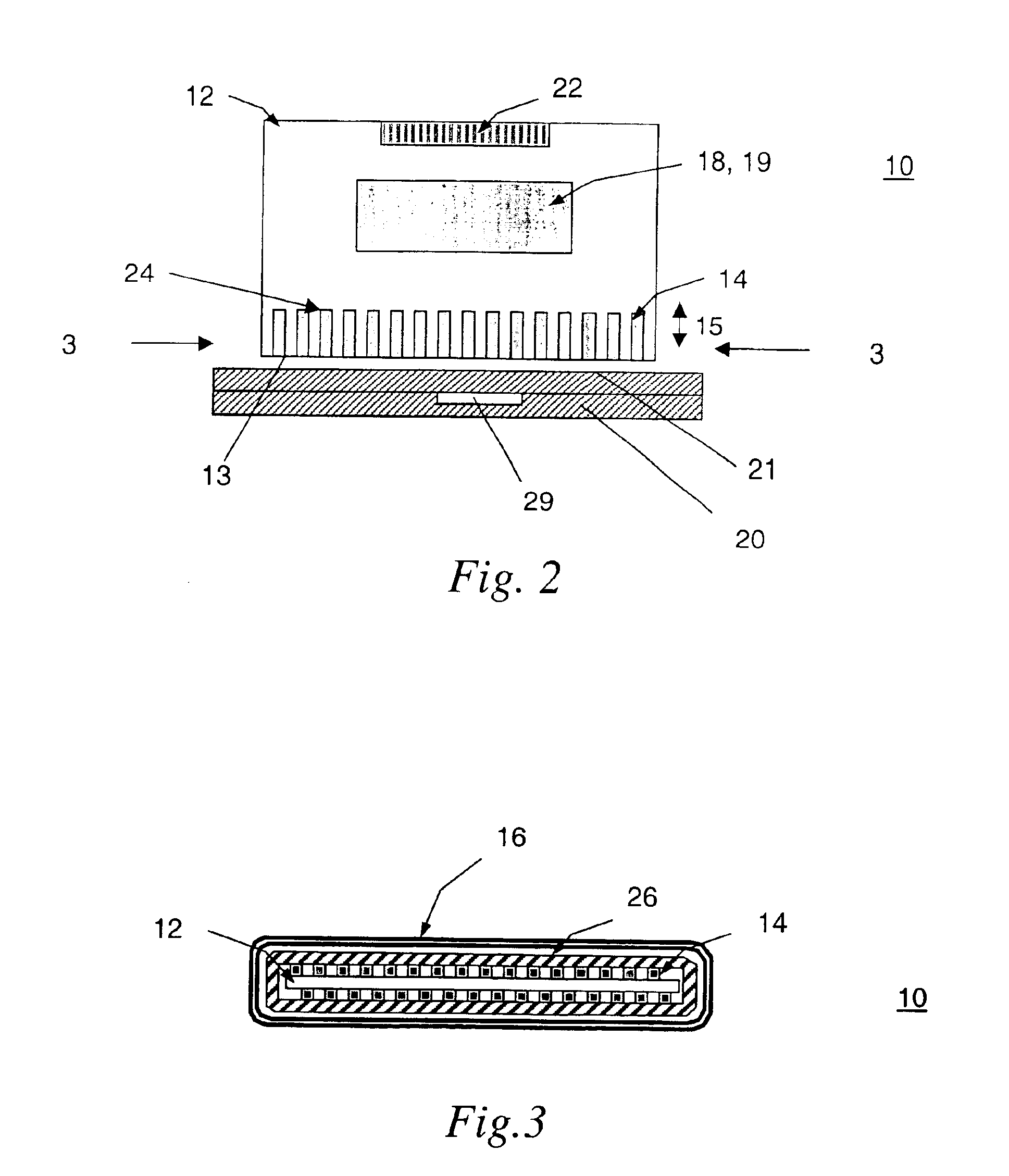

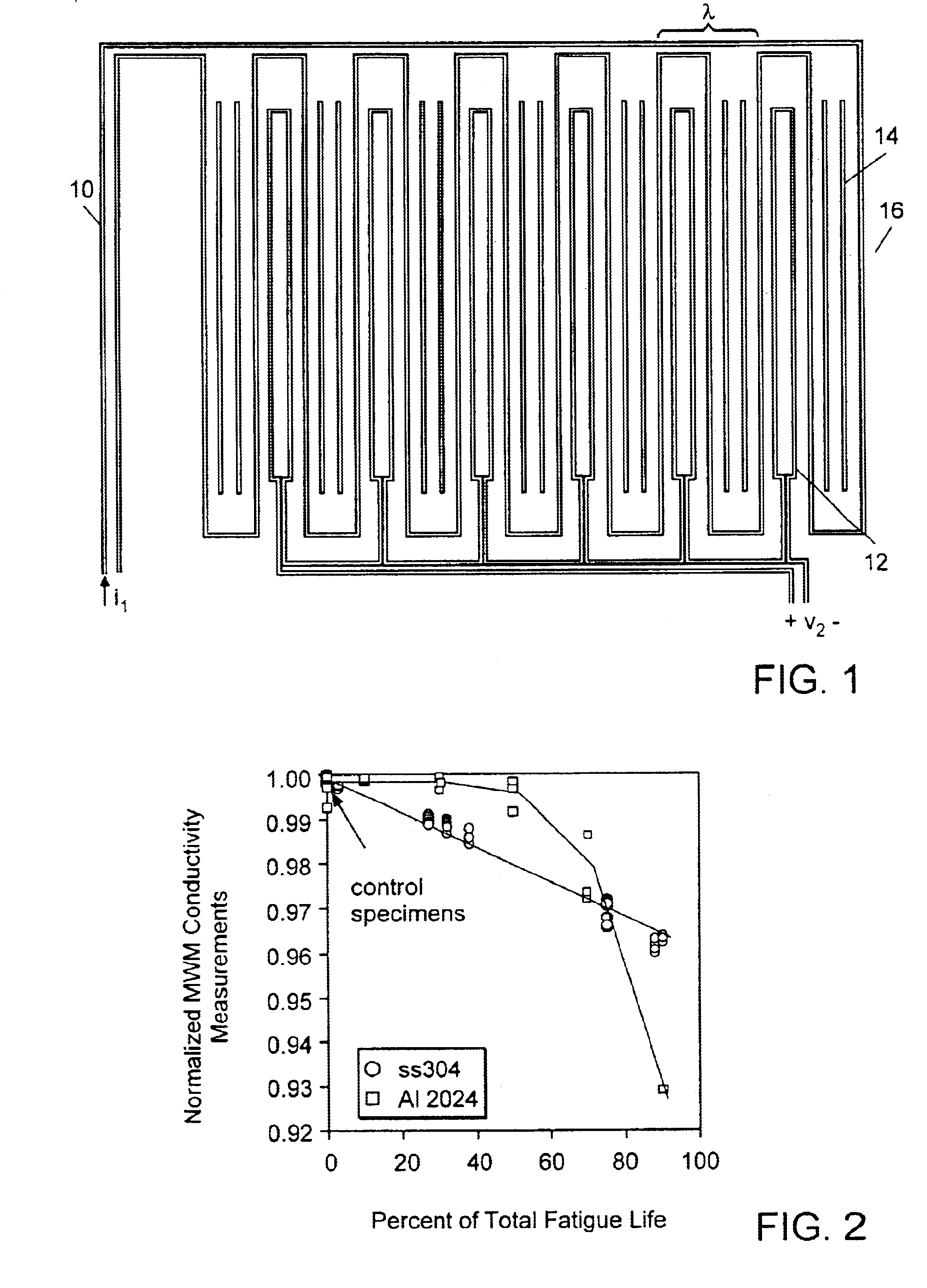

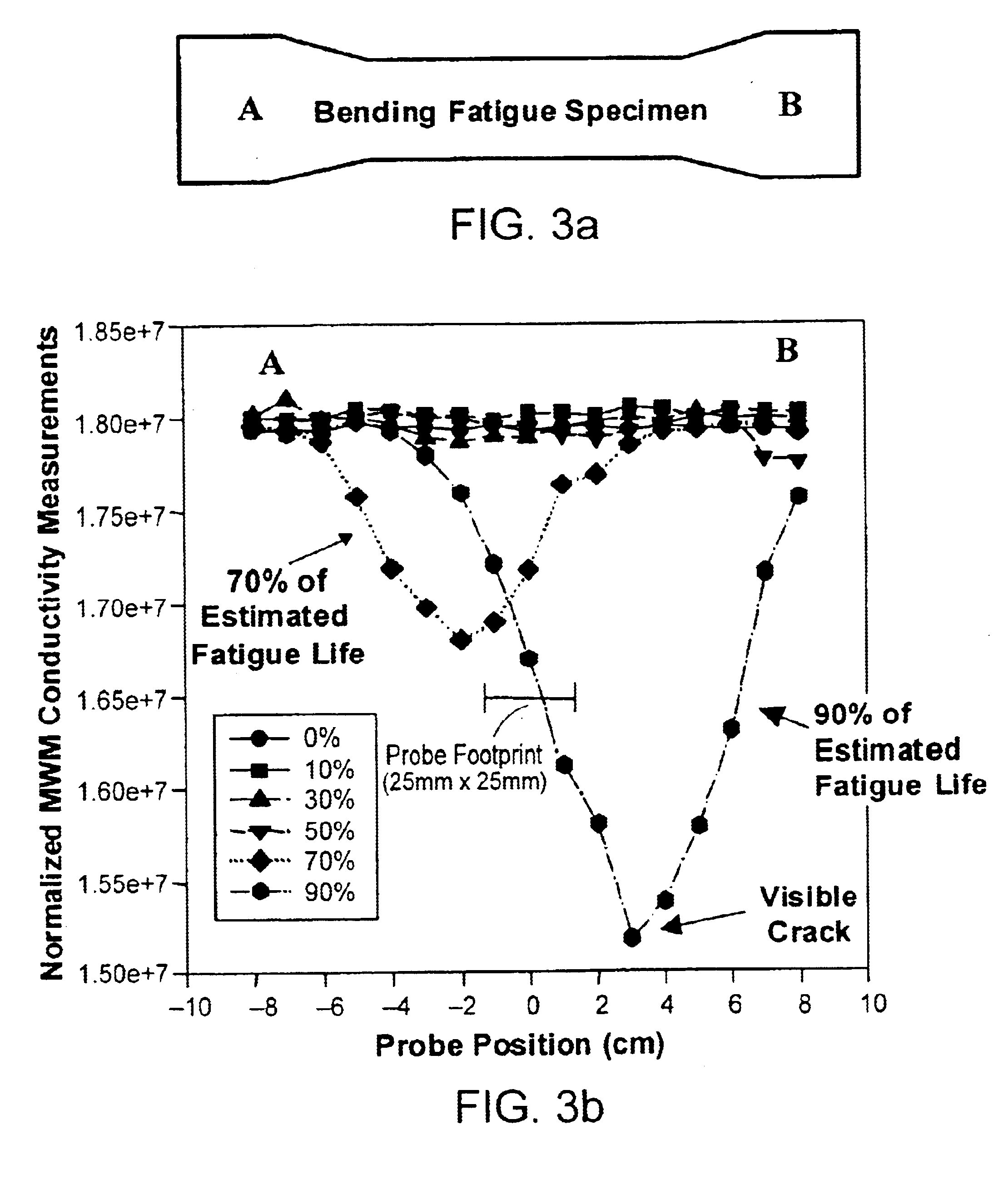

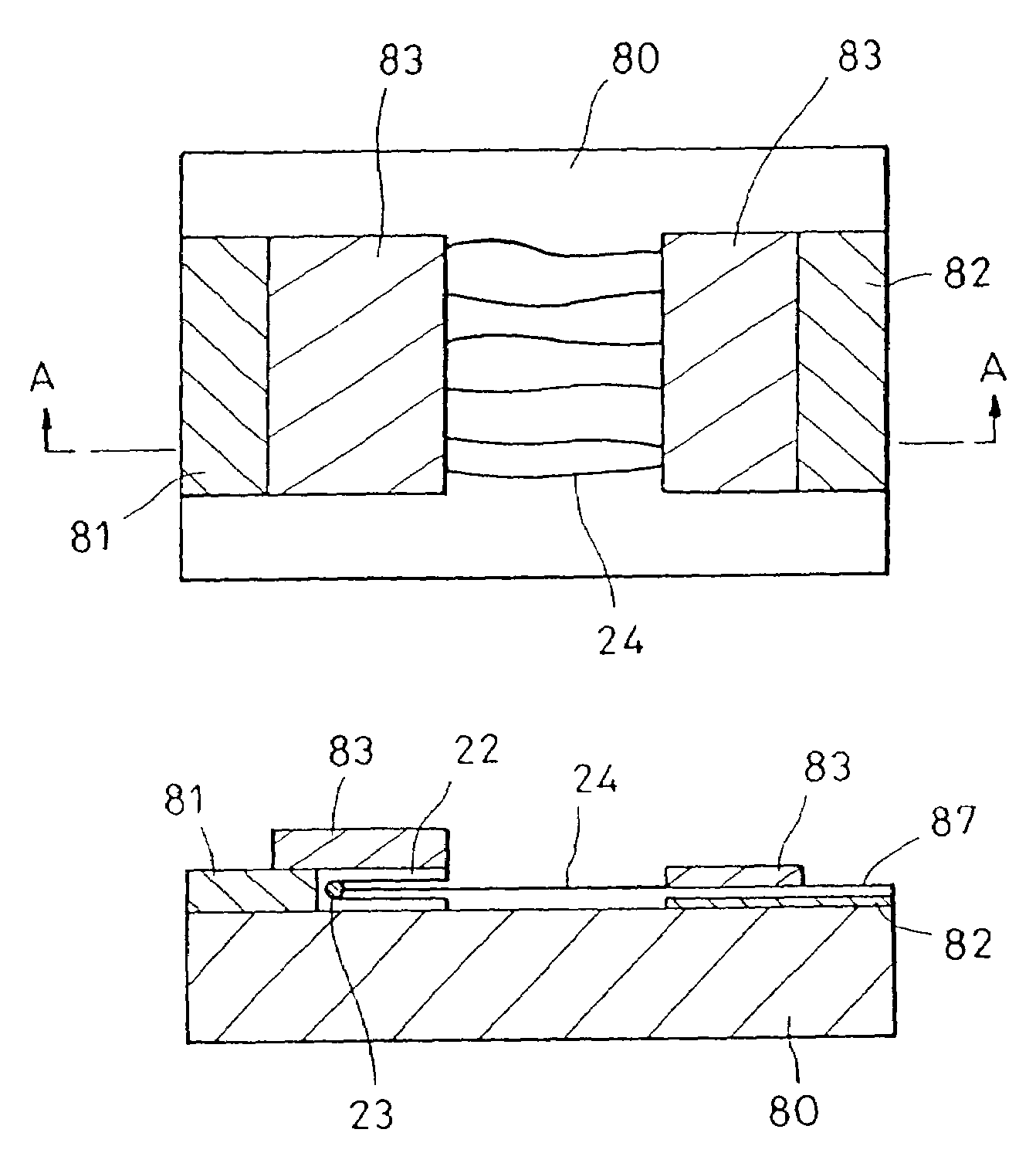

Surface mounted and scanning spatially periodic eddy-current sensor arrays

InactiveUS6952095B1Promote accurate modelingIncreased depth of sensitivityMagnetic property measurementsElectric/magnetic roughness/irregularity measurementsSurface mountingCurrent sensor

Inductive sensors measure the near surface properties of conducting and magnetic material. A sensor may have primary windings with parallel extended winding segments to impose a spatially periodic magnetic field in a test material. Those extended portions may be formed by adjacent portions of individual drive coils. Sensing elements provided every other half wavelength may be connected together in series while the sensing elements in adjacent half wavelengths are spatially offset. Certain sensors include circular segments which create a circularly symmetric magnetic field that is periodic in the radial direction. Such sensors are particularly adapted to surround fasteners to detect cracks and can be mounted beneath a fastener head. In another sensor, sensing windings are offset along the length of parallel winding segments to provide material measurements over different locations when the circuit is scanned over the test material. The distance from the sensing elements to the ends of the primary winding may be kept constant as the offset space in between sensing elements is varied. An image of the material properties can be provided as the sensor is scanned across the material.

Owner:JENTEK SENSORS

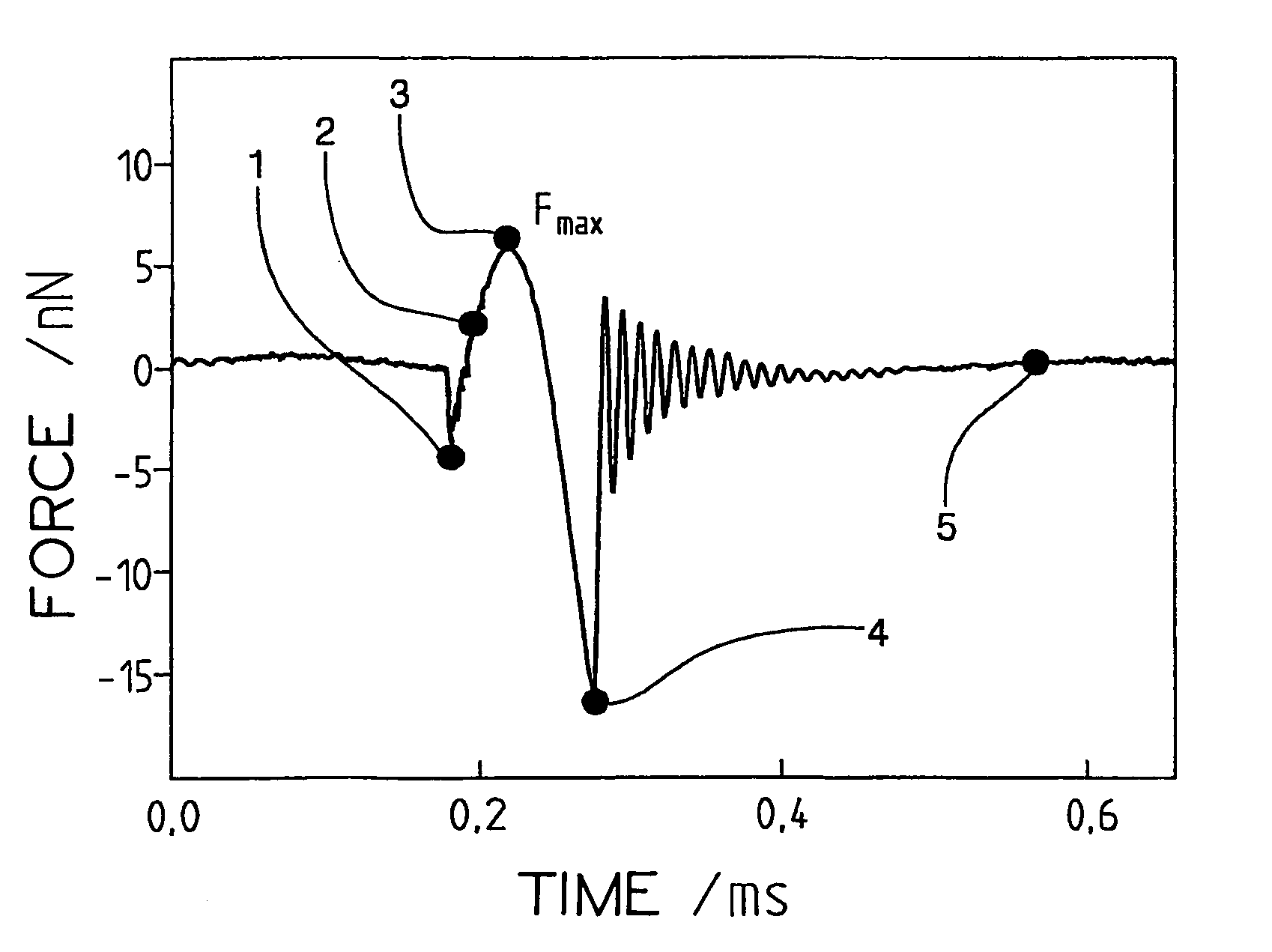

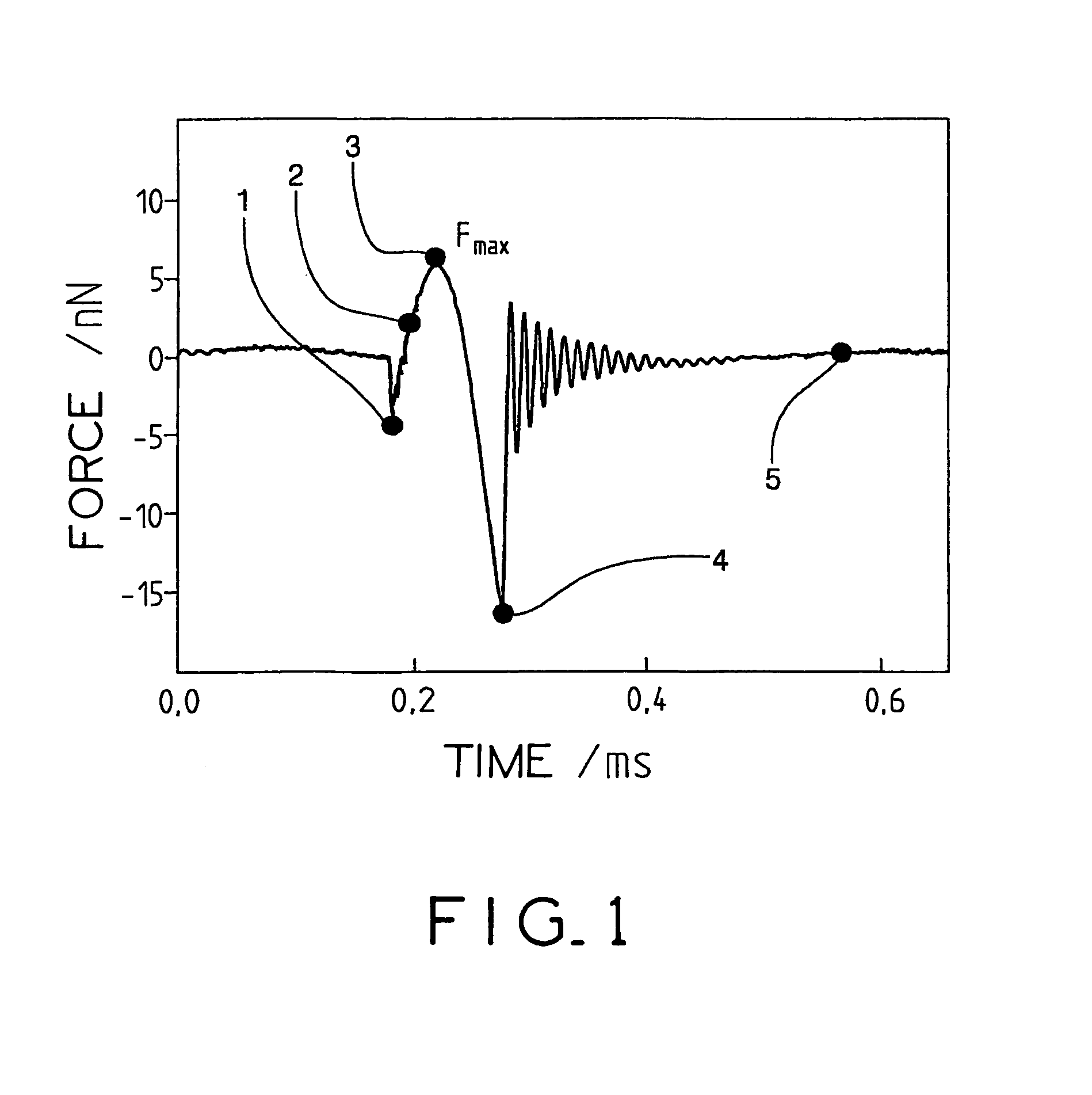

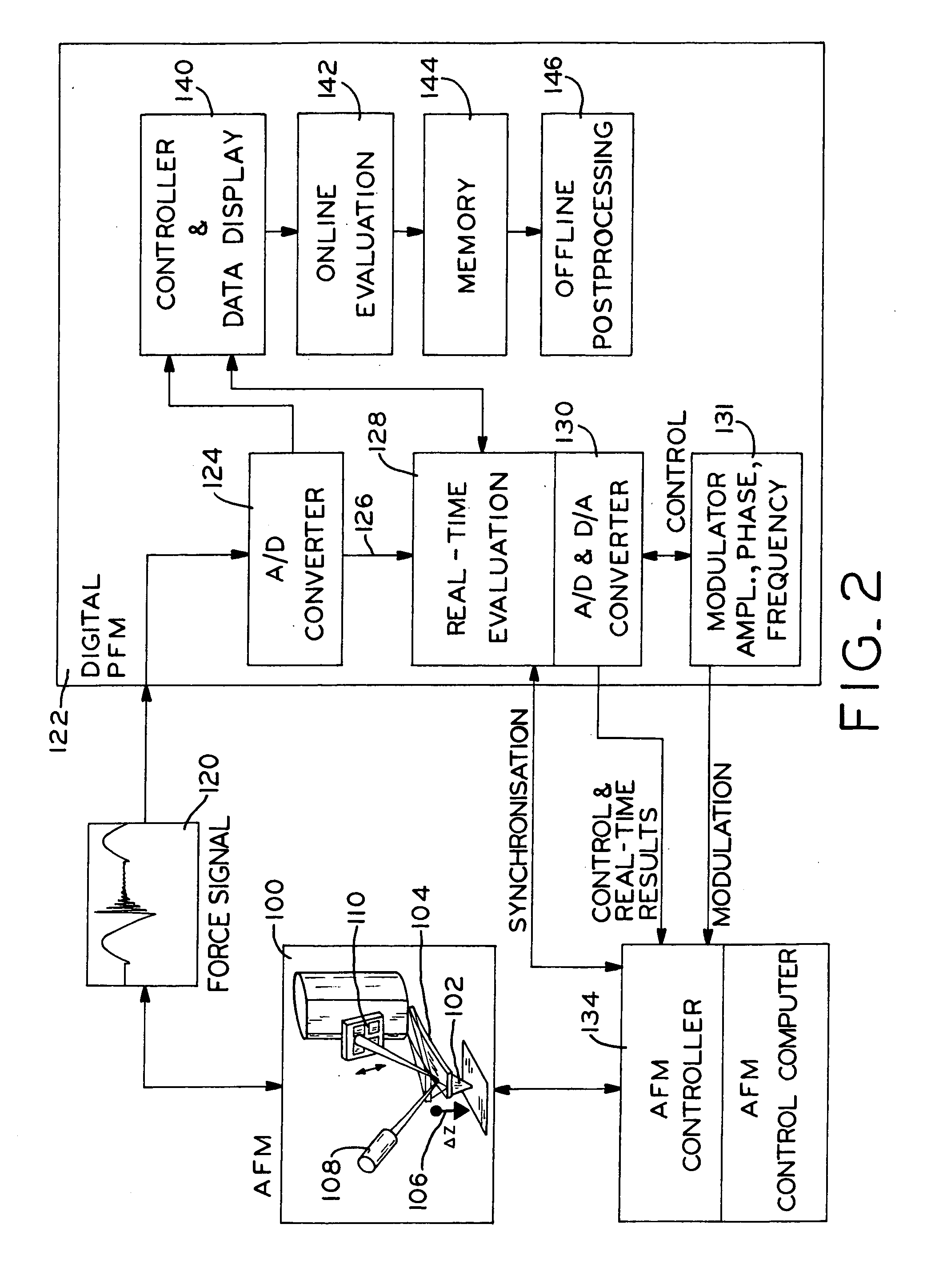

Scanning probe with digitized pulsed-force mode operation and real-time evaluation

InactiveUS7129486B2Short timeSolve the lack of precisionMaterial analysis using wave/particle radiationNanotechnologyData streamImage resolution

The invention relates to a method for creating the image of a sample surface to be analyzed, with a resolution which is better than 1 μm laterally in relation to the sample surface and better than 100 nm vertically in relation to said surface. According to the invention, the surface is scanned on a point-by-point basis by a scanning probe, the distance between the scanning probe and the sample surface at each scanning point being periodically modulated, in such a way that a force-time curve of the probe is produced for this point. The force-time curve is recorded at each scanning point, digitized using an A / D converter, evaluated online in real-time and stored, together with the entire data stream, in a first area of a memory device. One or several characteristic variables of the force-time curves are determined for each scanning point from the real-time evaluation results and the stored digitized force-time curves and an image of the sample surface is obtained from said characteristic variables of the scanning points.

Owner:WITEC WISS INSTR & TECH

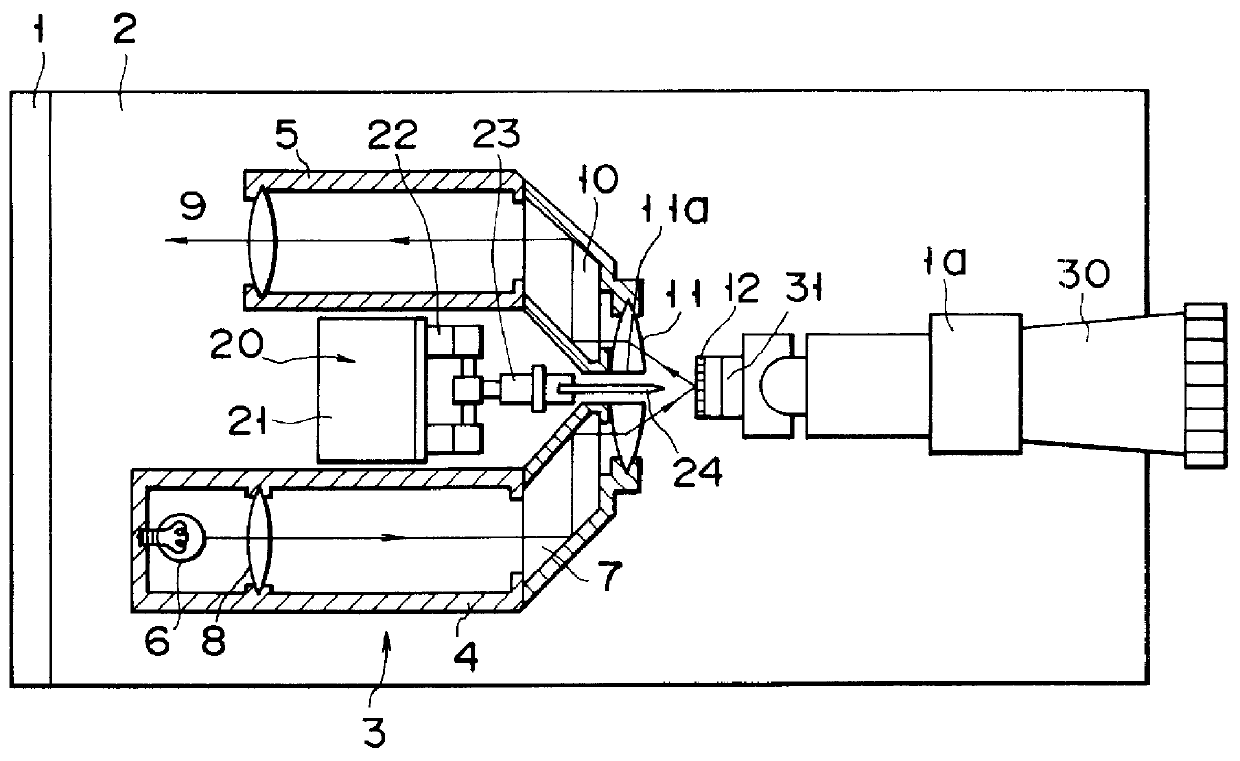

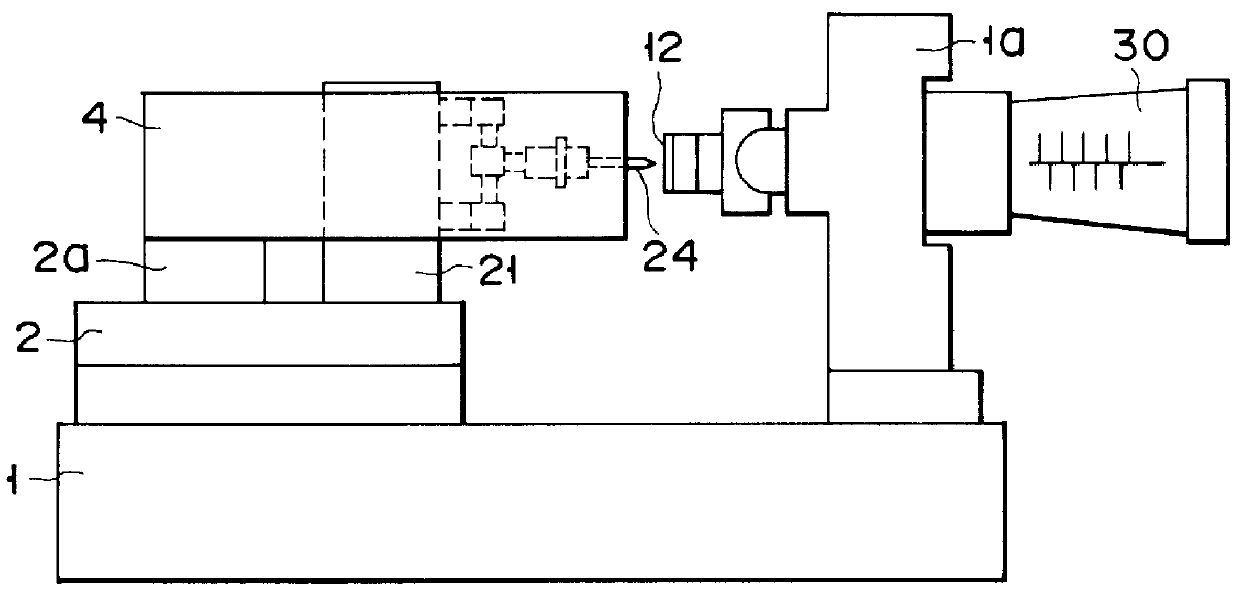

Scanning tunnel microscope

PCT No. PCT / JP88 / 00804 Sec. 371 Date Feb. 5, 1990 Sec. 102(e) Date Feb. 5, 1990 PCT Filed Aug. 12, 1988 PCT Pub. No. WO89 / 01603 PCT Pub. Date Feb. 23, 1989A scanning tunnel microscope is arranged by a combination of an optical microscope and a tunnel scanning unit. The scanning tunnel unit includes a probe held to be spaced apart from a sample placed on a sample table by a predetermined interval in an axial direction, and an actuator for axially moving the sample table and the probe to a tunnel region and relatively and three-dimensionally driving the sample table and the probe. An objective lens and the probe are arranged such that the axis of the probe of the scanning tunnel unit is aligned with an optical axis of the objective lens of the optical microscope. The sample and the probe are axially moved and brought into the tunnel region, and the sample is scanned in its surface direction while the sample and the probe are finely moved in the axial direction and a tunnel current is kept constant, thereby performing an STM observation of an observation surface of the sample. The objective lens of the optical microscope is axially moved to obtain an in-focus state, and the field of the STM observation surface is observed as an optical microscopic image through an eyepiece lens.

Owner:OLYMPUS OPTICAL CO LTD

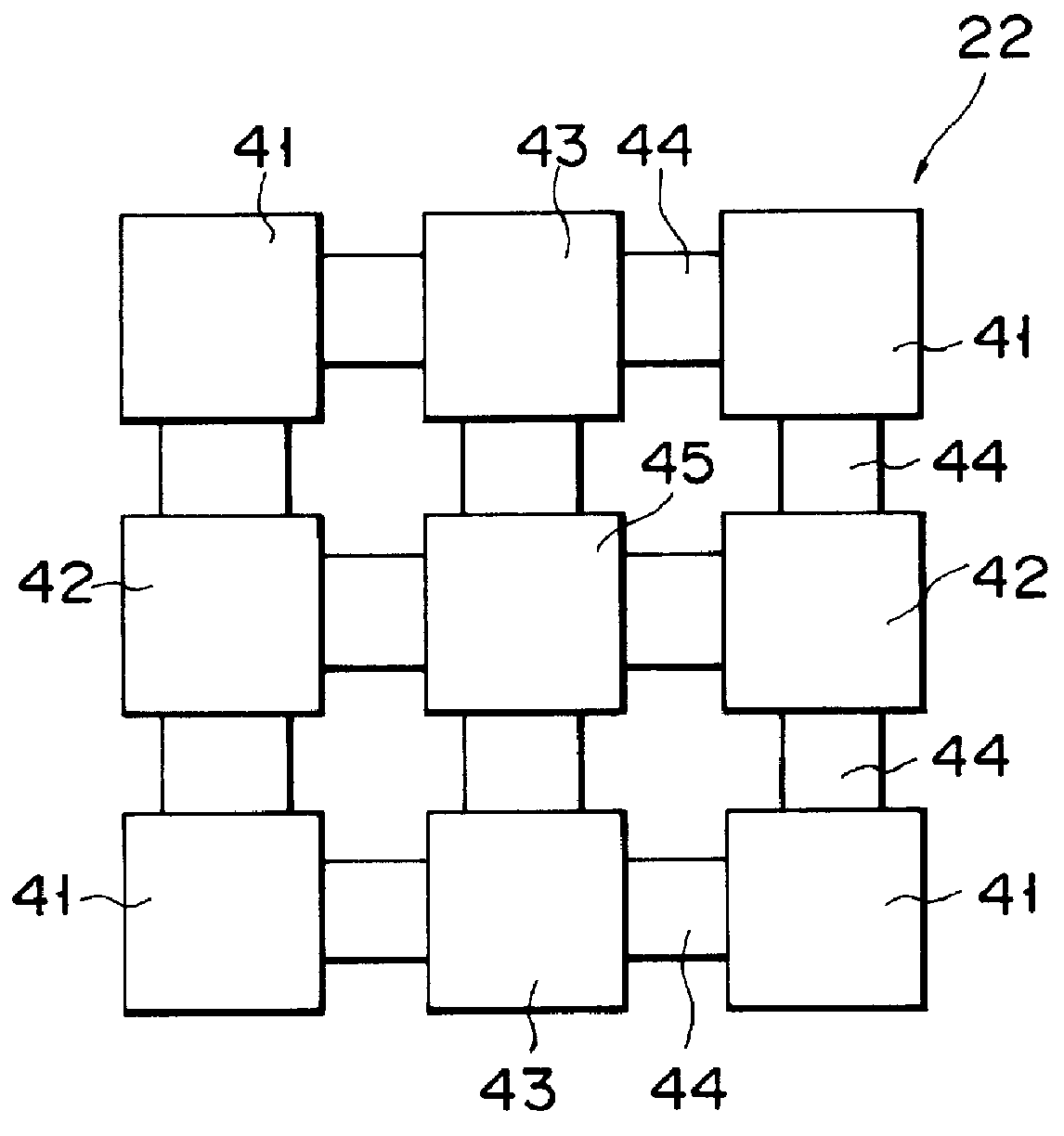

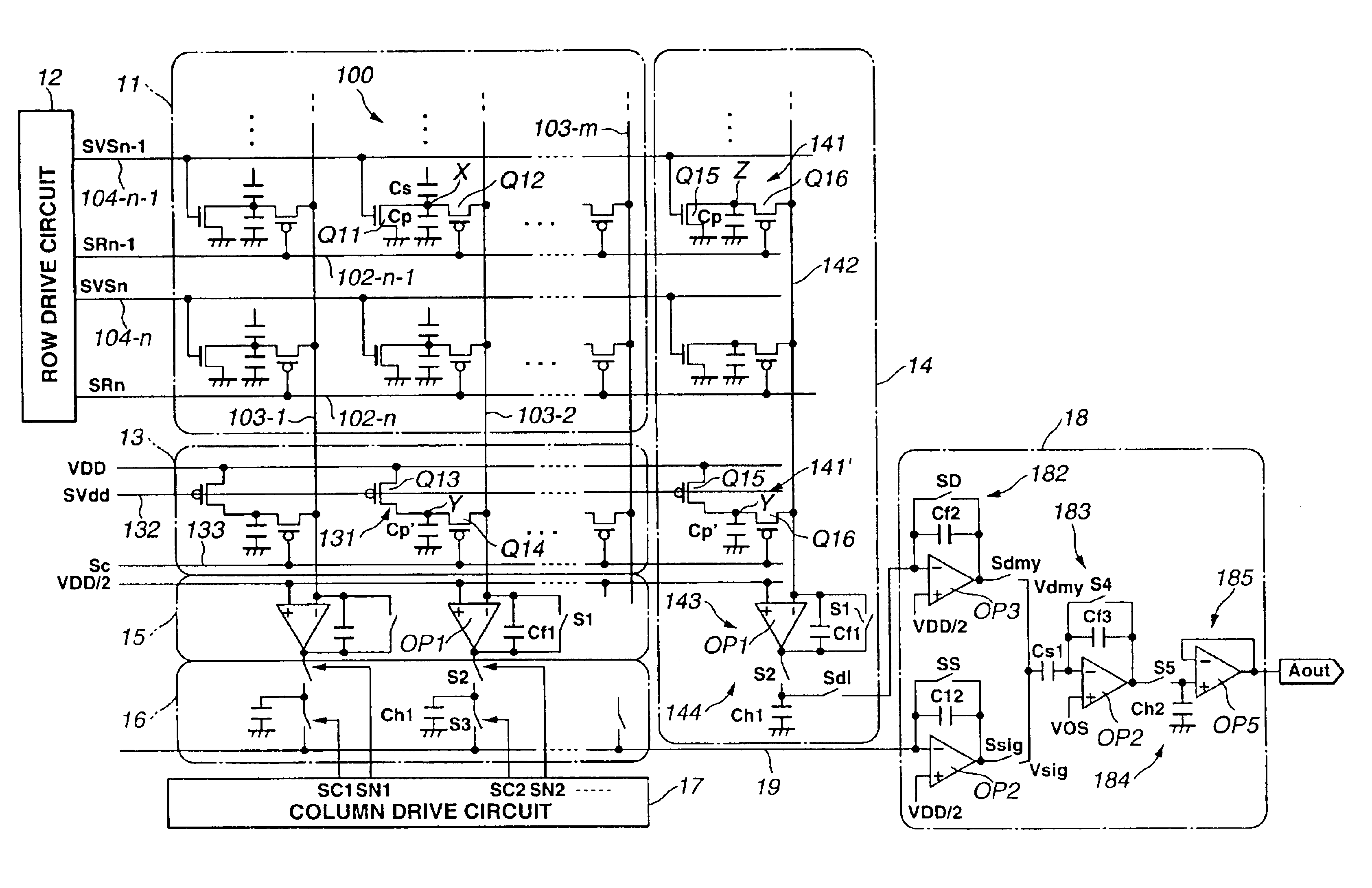

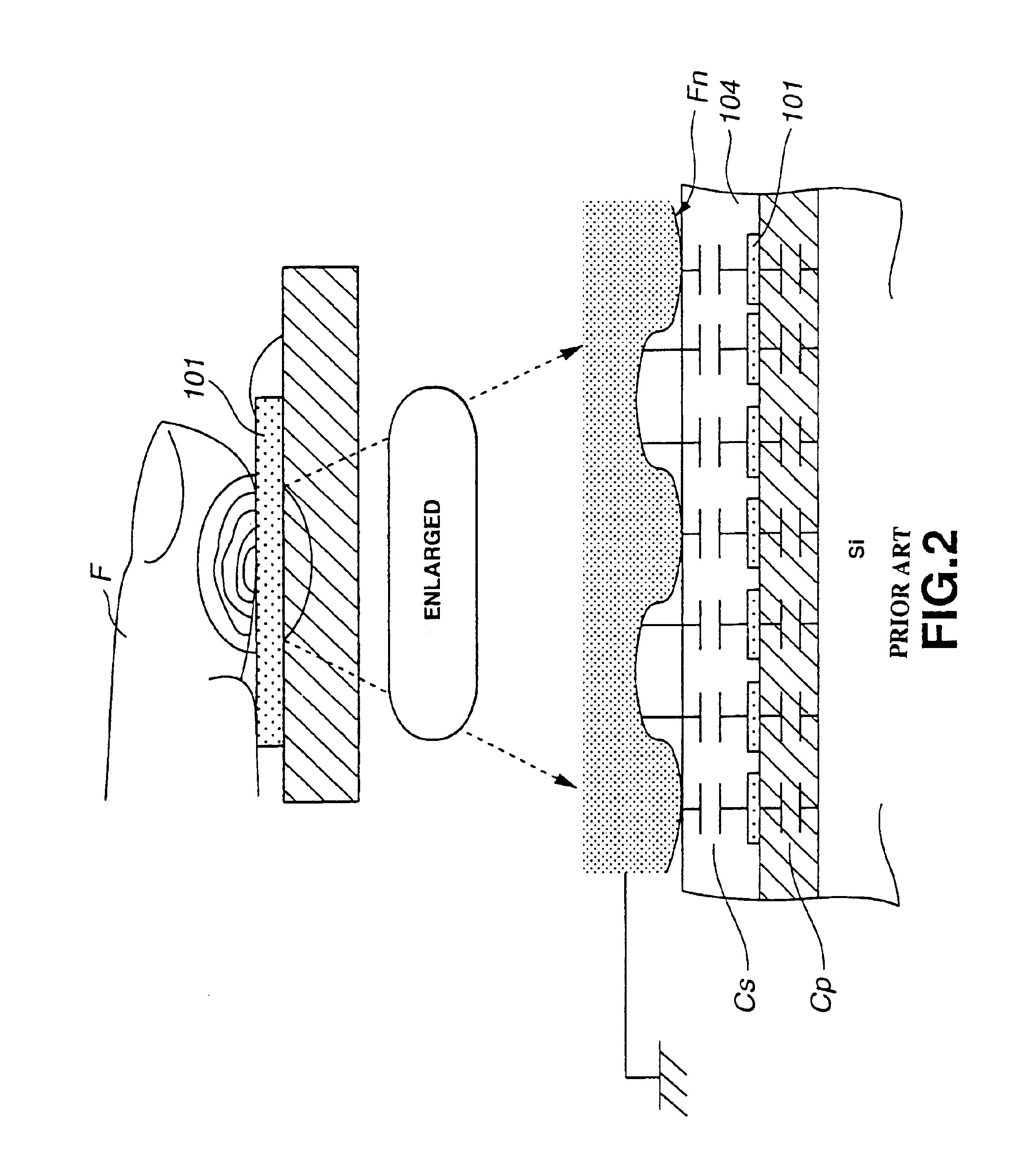

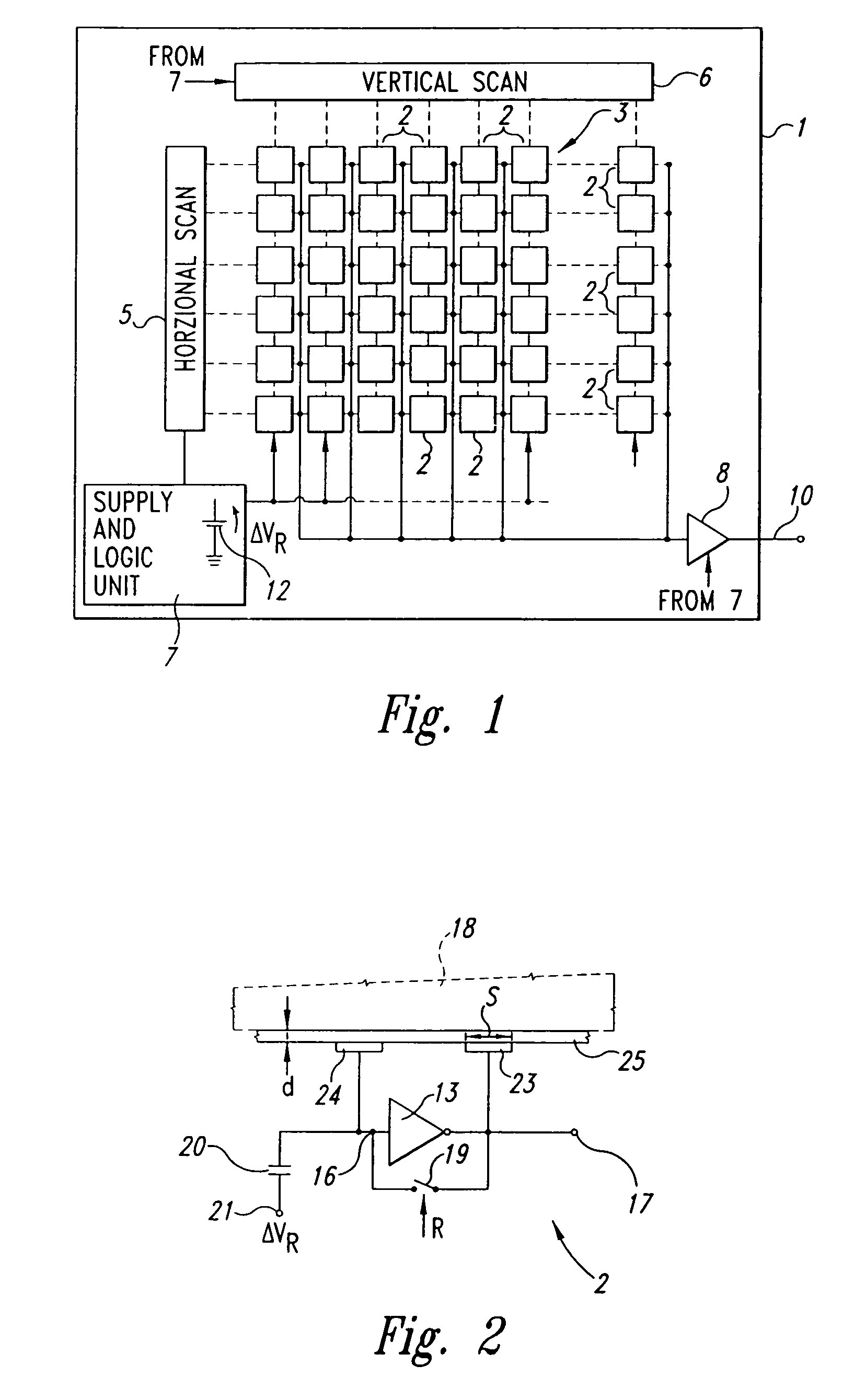

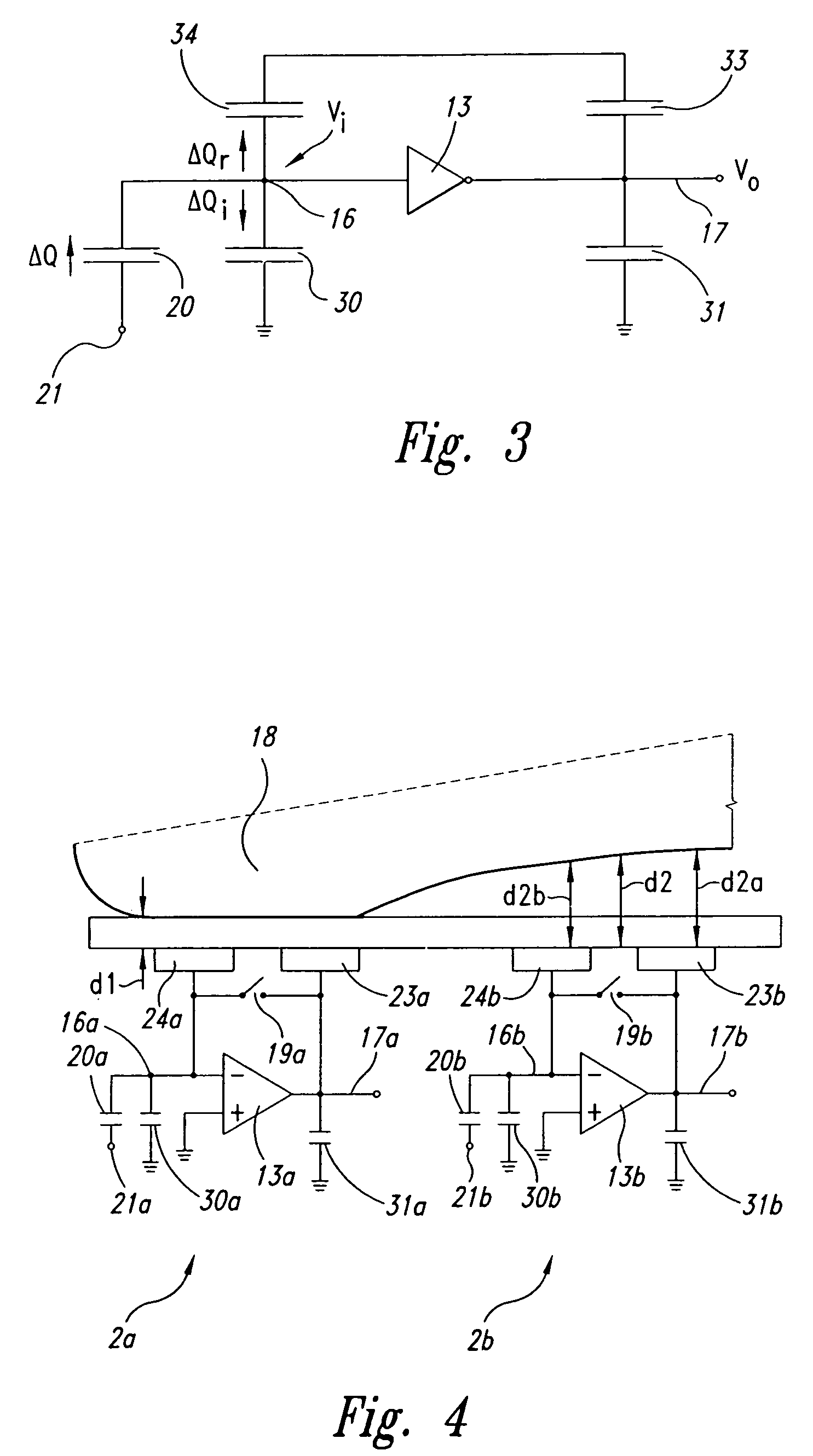

Electrostatic capacity detection apparatus and fingerprint crosscheck apparatus using the same

InactiveUS6937031B2Improve accuracyImprove controllabilityResistance/reactance/impedencePerson identificationSensor arrayParasitic capacitance

A capacitance sensor used as a fingerprint sensor is provided which includes, in addition to a sensor array (11) in which sensor cells (100) each with a sense electrode are disposed in the form of an array, a canceling dummy block (14) having, disposed in an area having no relation with any object under detection, one column of dummy cells (141) corresponding to each row in the sensor array (11) and each having a dummy electrode nearly identical in parasitic capacitance to the sense electrode of the sensor cell (100). Also, a differentiation output unit (183) is provided to differentiate between a sensed voltage Vsig sensed at the sensor array (11) by sensing circuit (13) and sensed voltage Vdmy sensed at the canceling dummy block (14), thereby eliminating the influence of a variation in parasitic capacitance Cp, caused by a production tolerance.

Owner:SONY CORP

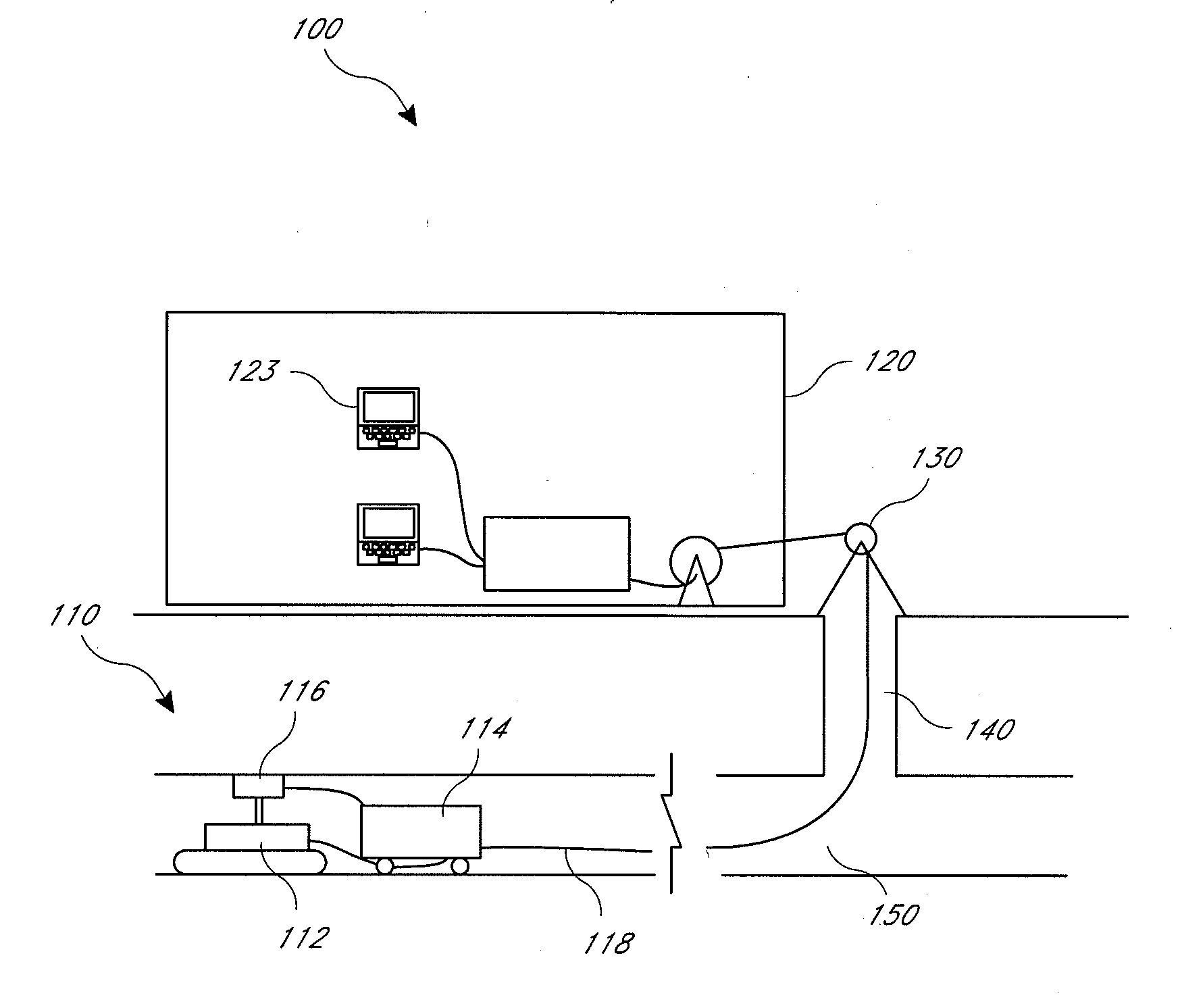

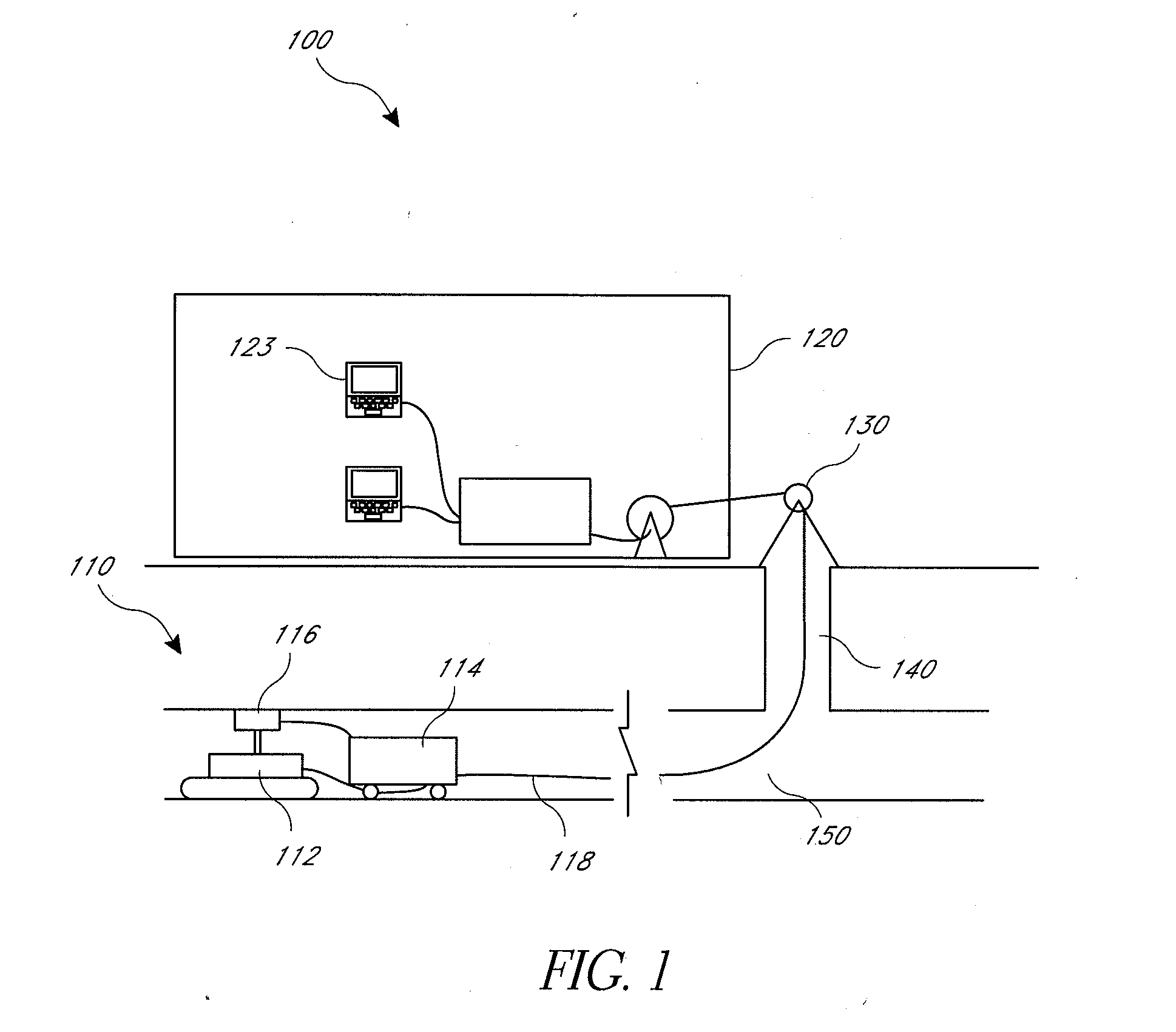

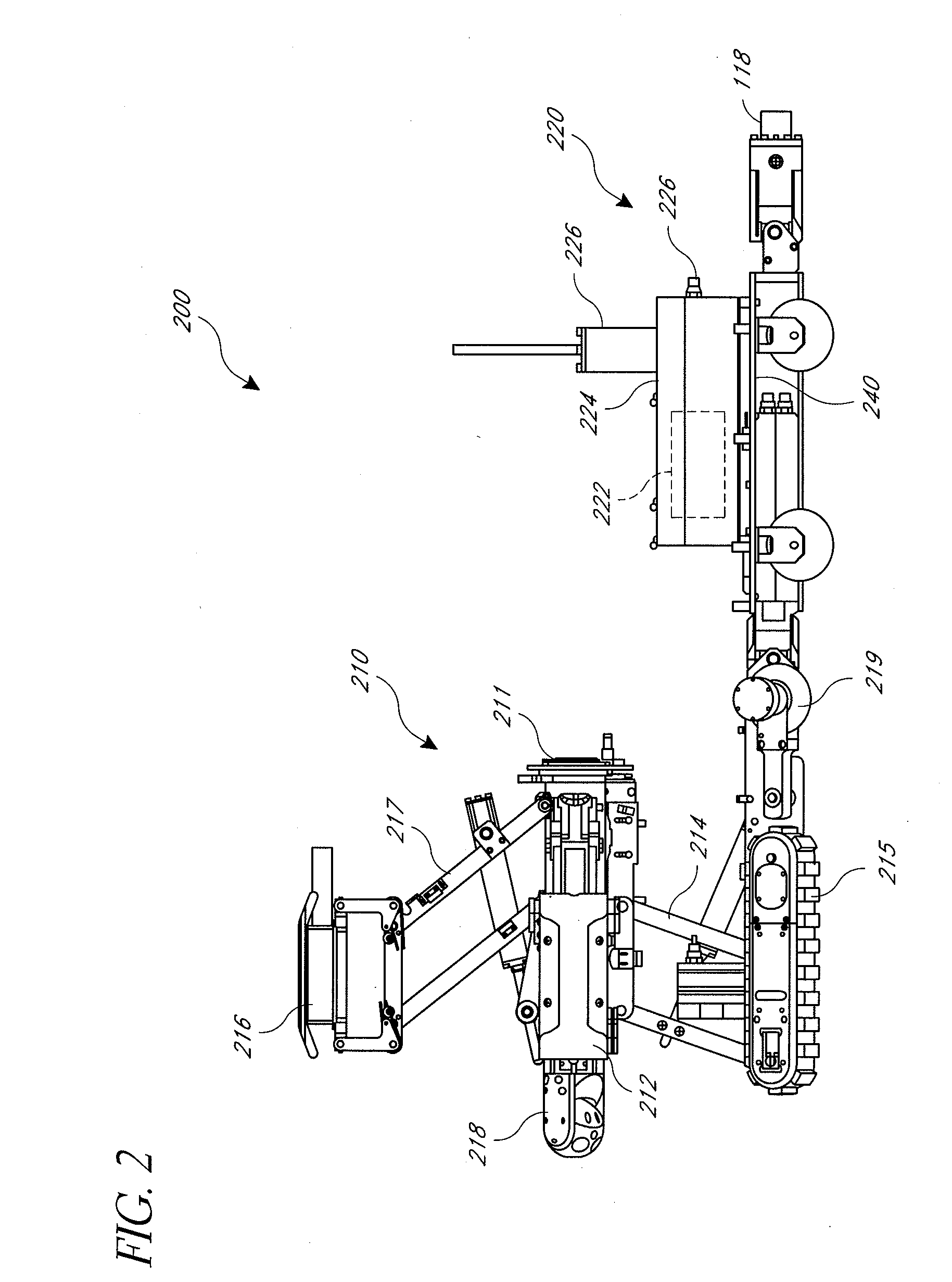

Apparatus and method for inspection of underground pipes

A system for inspecting an underground conduit from within comprises a data acquisition subsystem configured to be placed within the conduit and to move along at least a portion of the conduit to obtain data regarding the conduit. The system comprises a data storage subsystem configured to be placed within the conduit and to move along the conduit. The data storage subsystem receives and stores at least a portion of the data from the data acquisition subsystem for retrieval after the data acquisition subsystem has moved along the conduit.

Owner:SEWERVUE TECH CORP

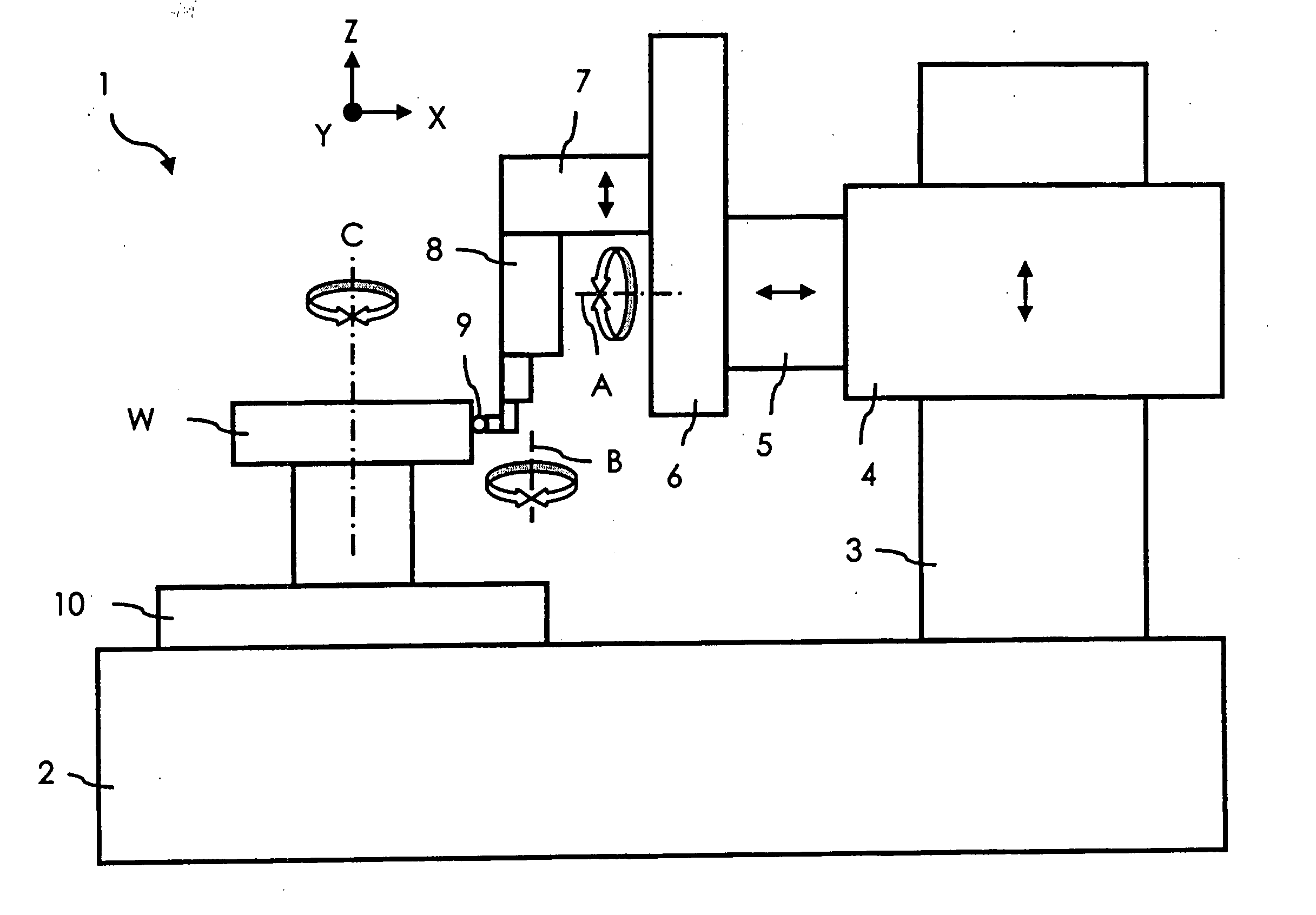

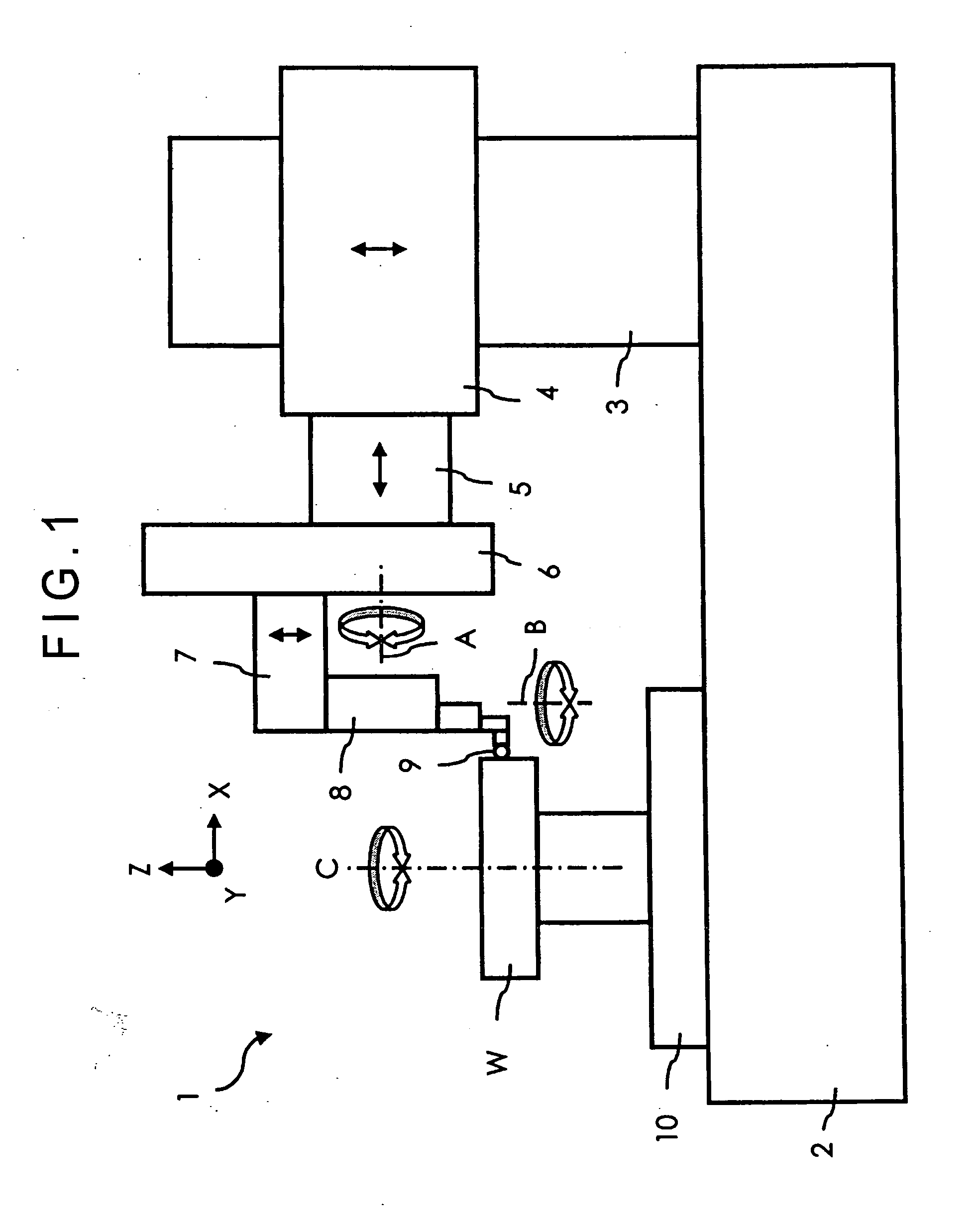

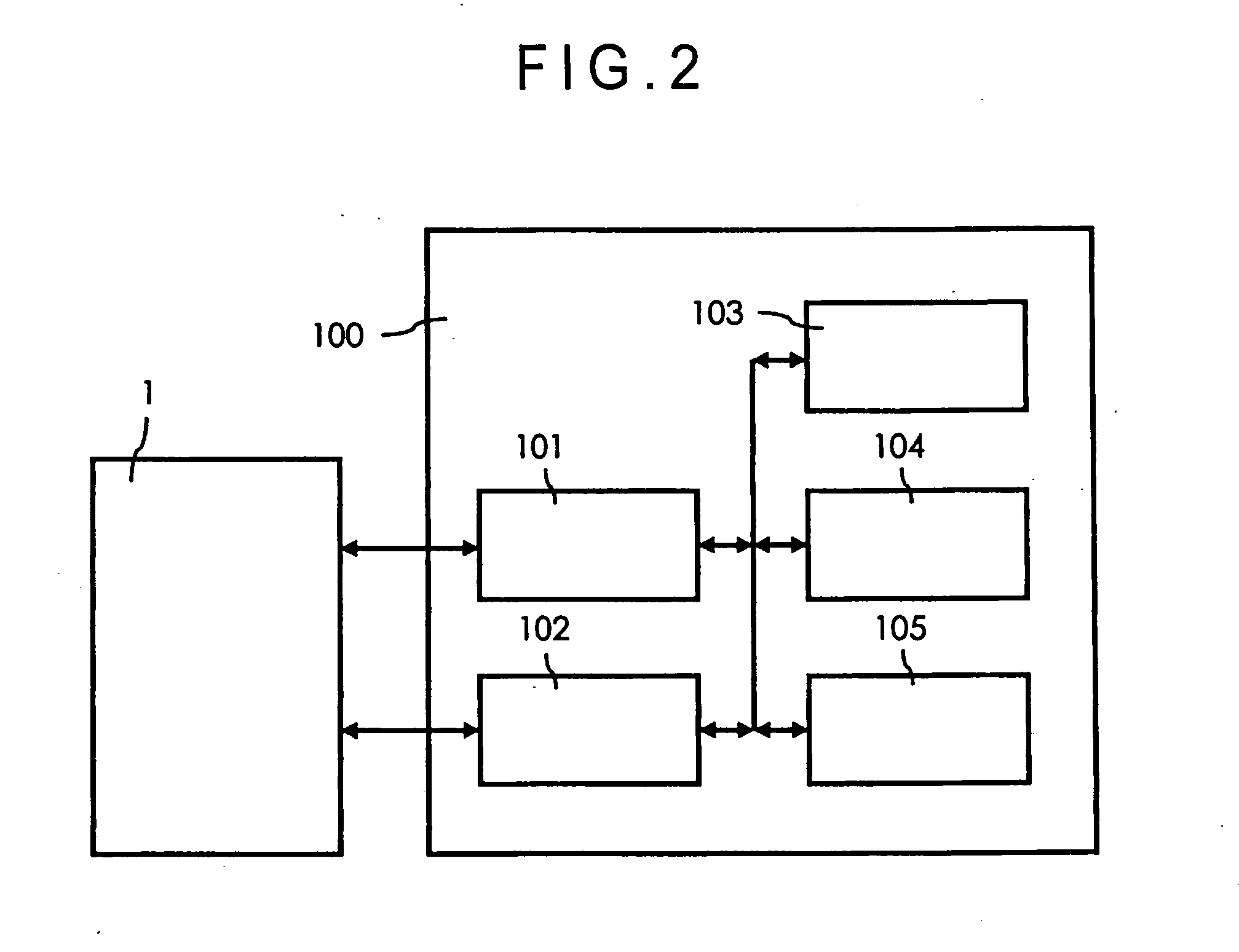

Width-measuring method and surface texture measuring instrument

ActiveUS20050132591A1Easy to measureSimple and accurate measurementMechanical counters/curvatures measurementsMechanical diameter measurementsMeasuring instrumentSurface roughness

A surface texture measuring instrument has a rotary table on which a workpiece is rotatably mounted, a Z-axis slider capable of moving in a Z-axis direction parallel to a rotation axis of the rotary table, an X-axis slider that is held by the Z-axis slider and is advanceable and retractable in an X-axis direction orthogonal to the rotation axis, a first arm that is held by the X-axis slider and is rotatable around a center line parallel to the X-axis, a second arm that is held by the first arm and is advanceable and retractable in a direction orthogonal to the X-axis, and a detector held by the second arm to measure a surface texture of the workpiece.

Owner:MITUTOYO CORP

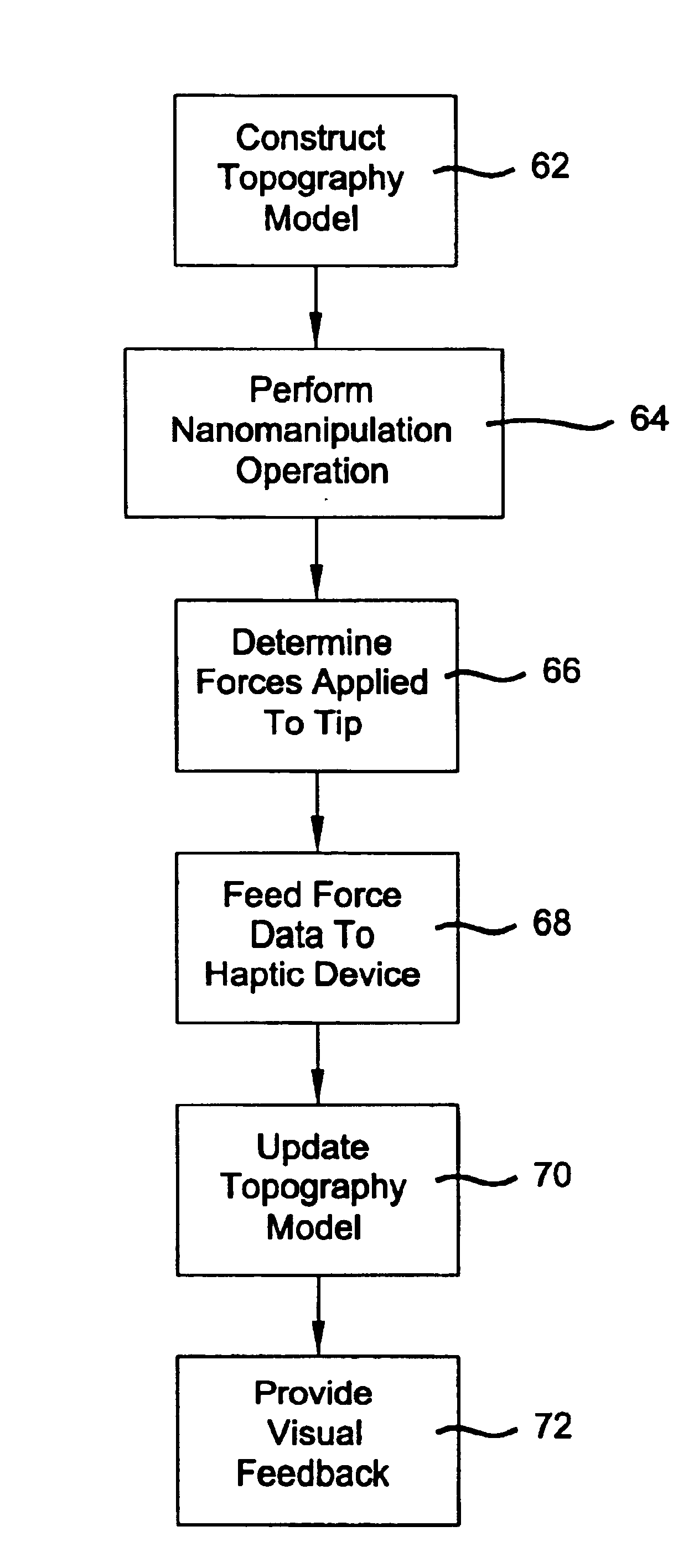

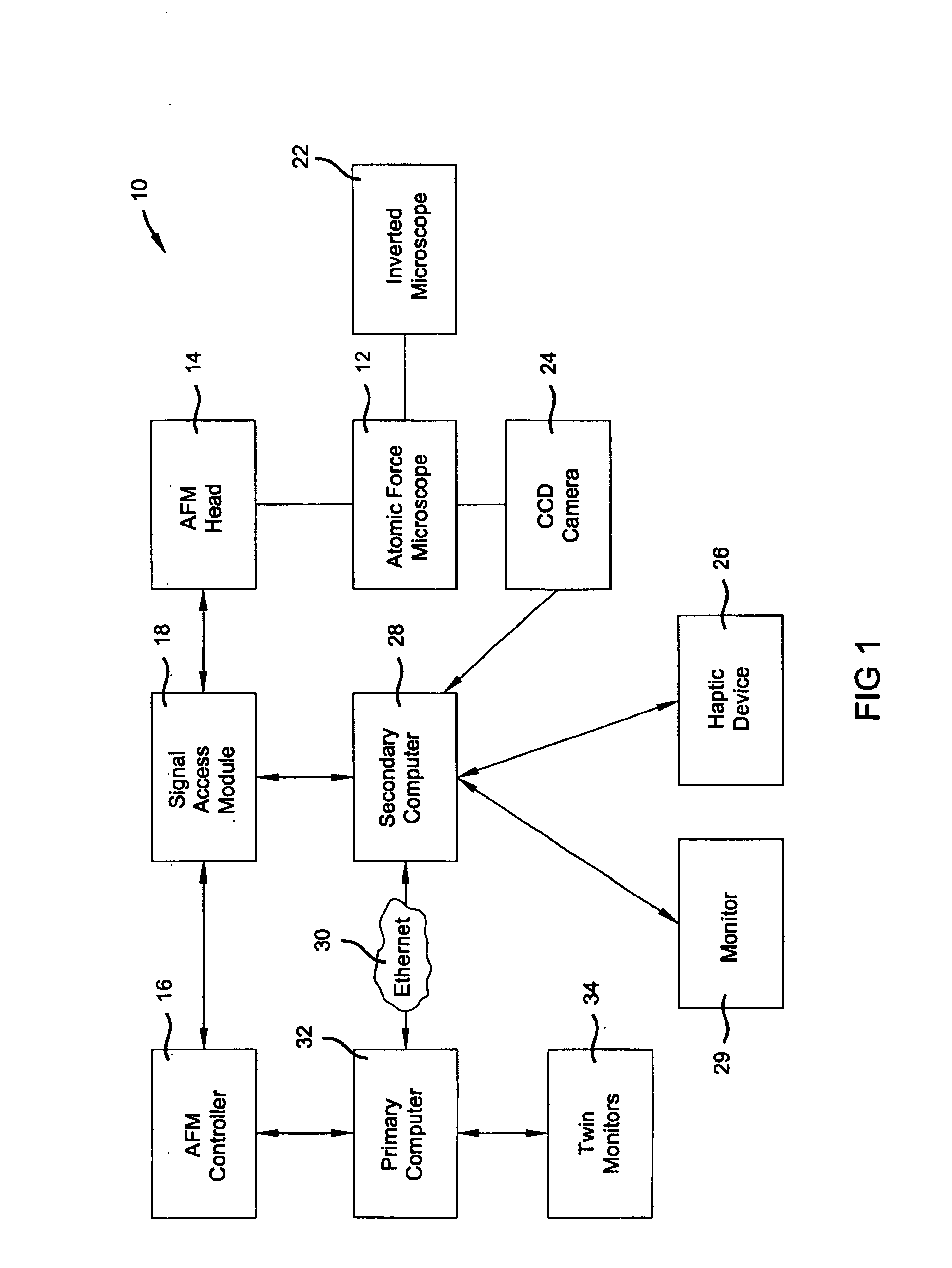

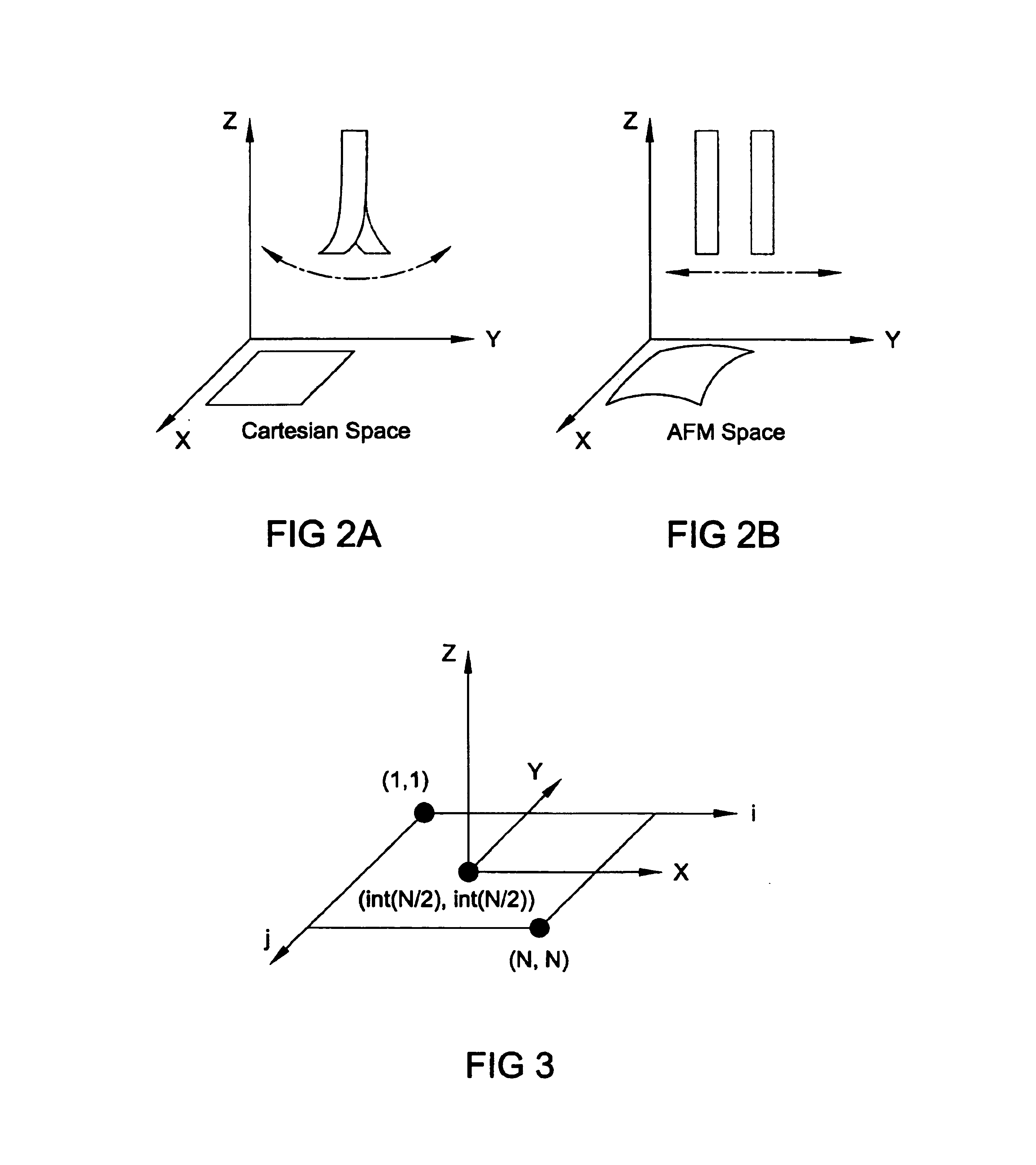

Augmenting reality system for real-time nanomanipulation using atomic force microscopy

An improved method is provided for performing nanomanipulations using an atomic force microscope. The method includes: performing a nanomanipulation operation on a sample surface using an atomic force microscope; determining force data for forces that are being applied to the tip of the cantilever during the nanomanipulation operation, where the force data is derived along at least two perpendicularly arranged axis; and updating a model which represents the topography of the sample surface using the force data.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

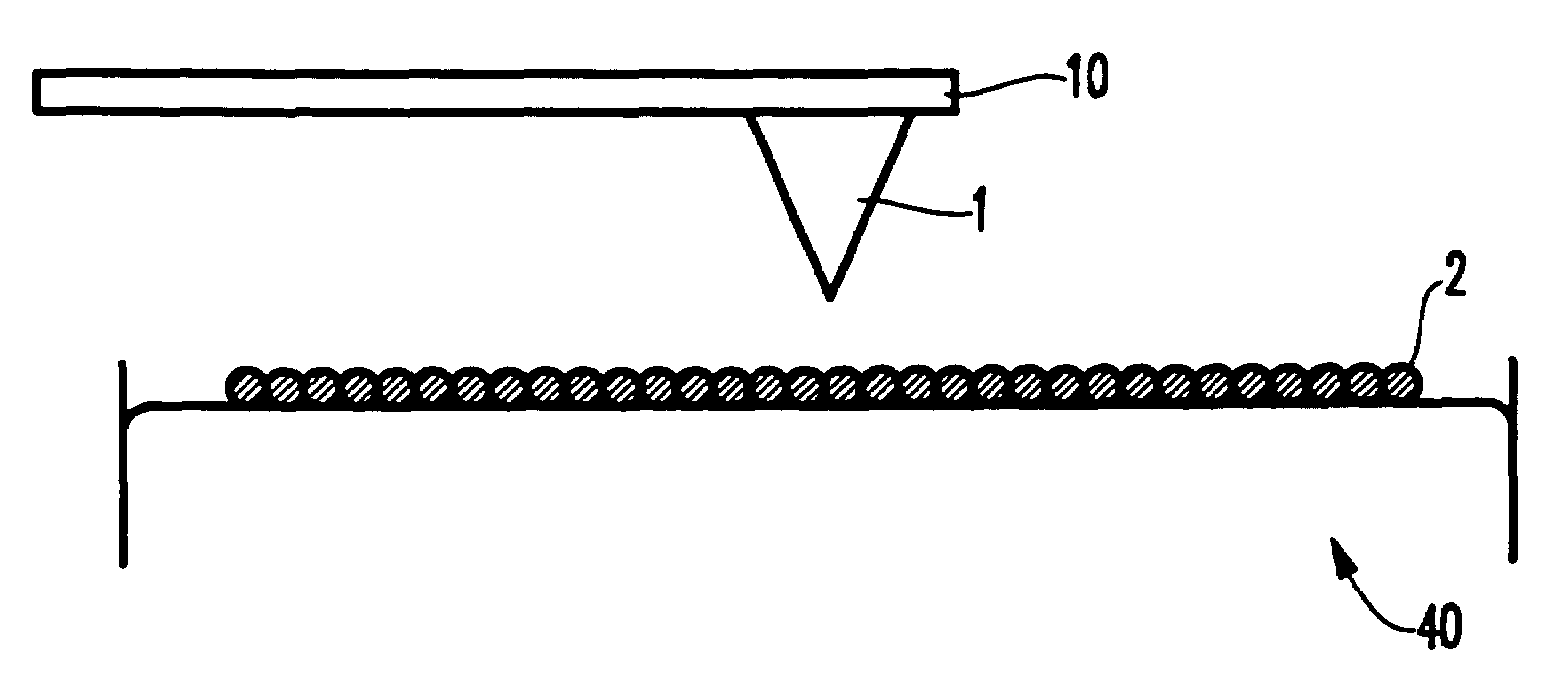

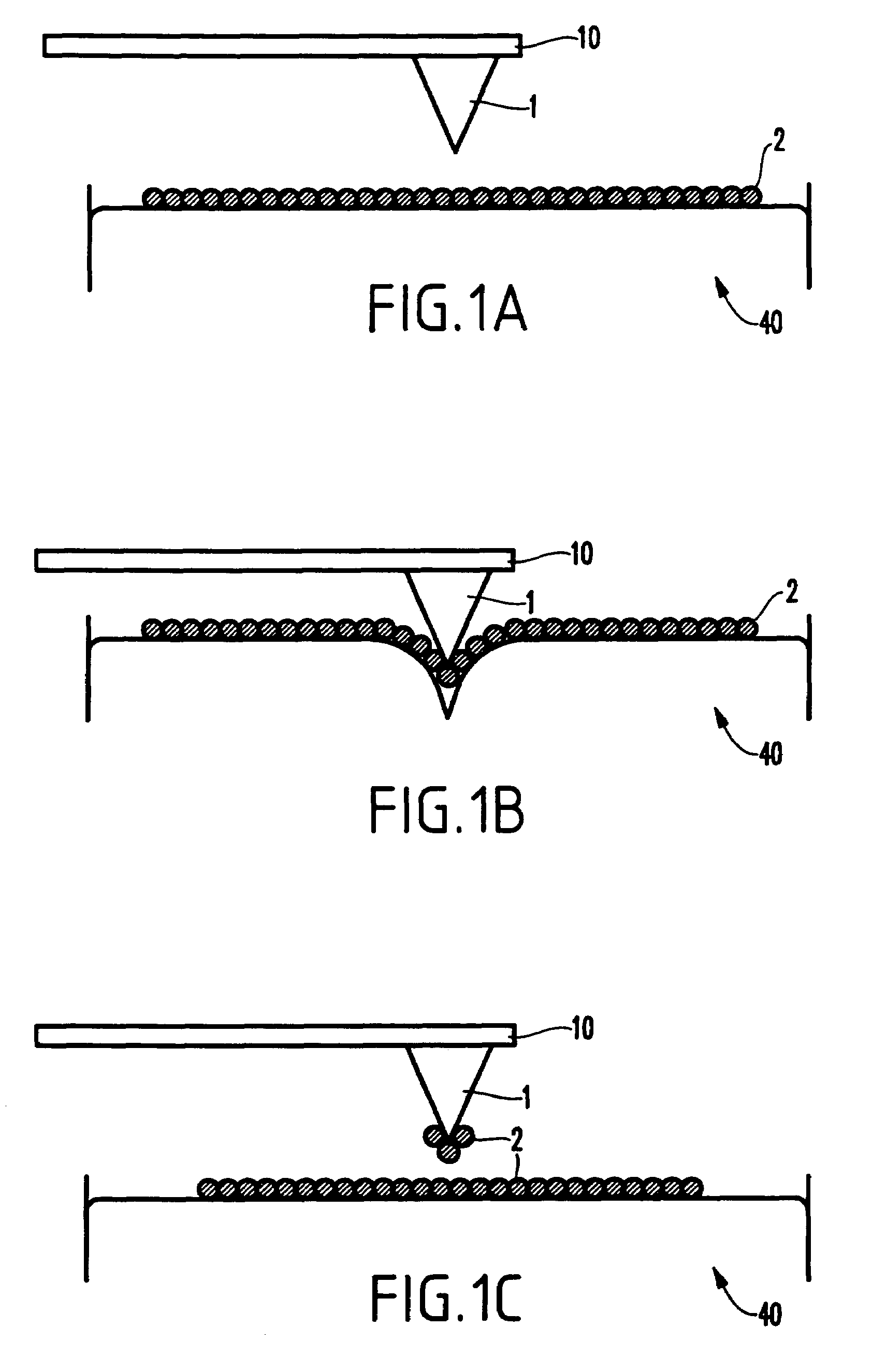

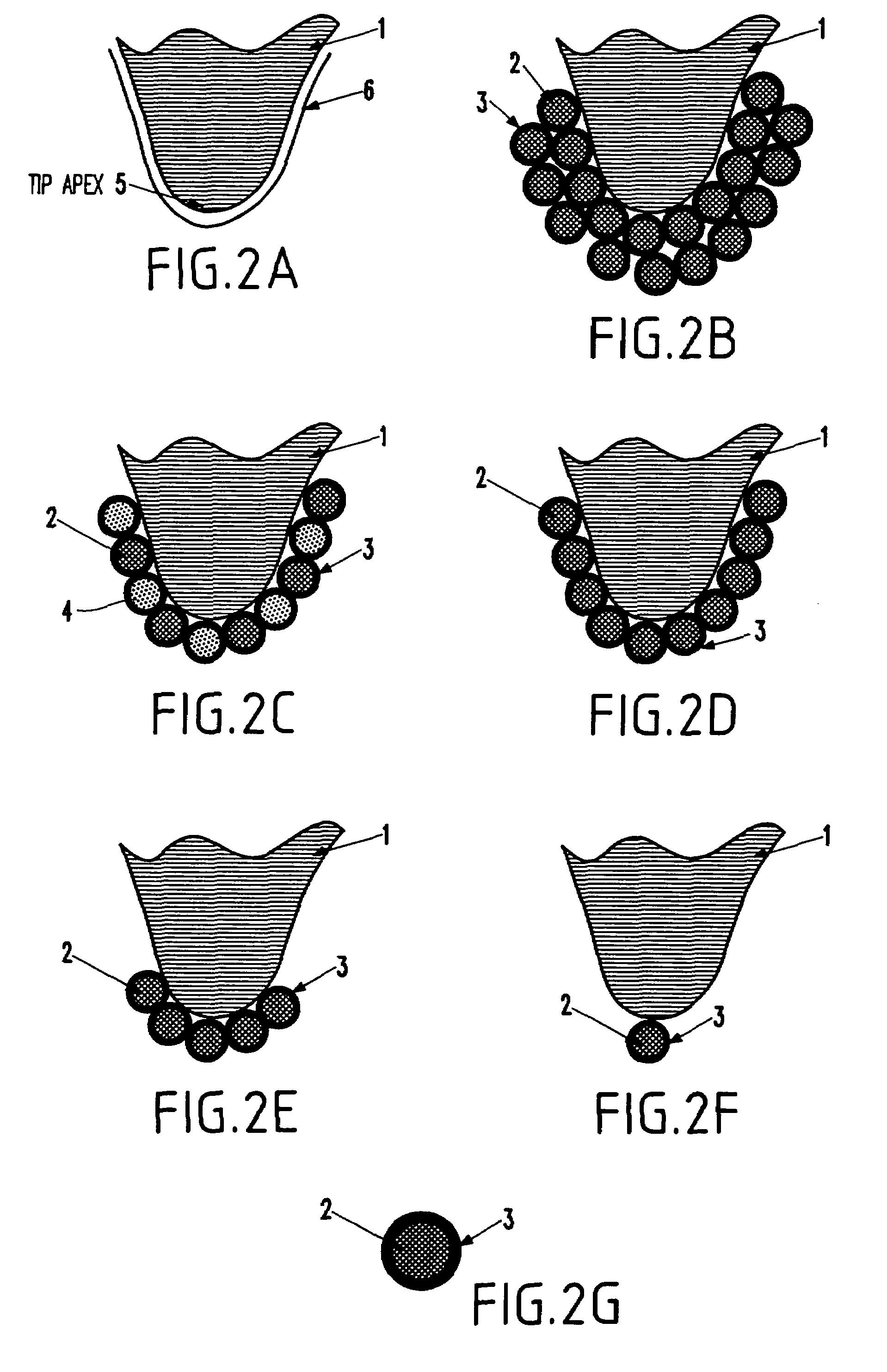

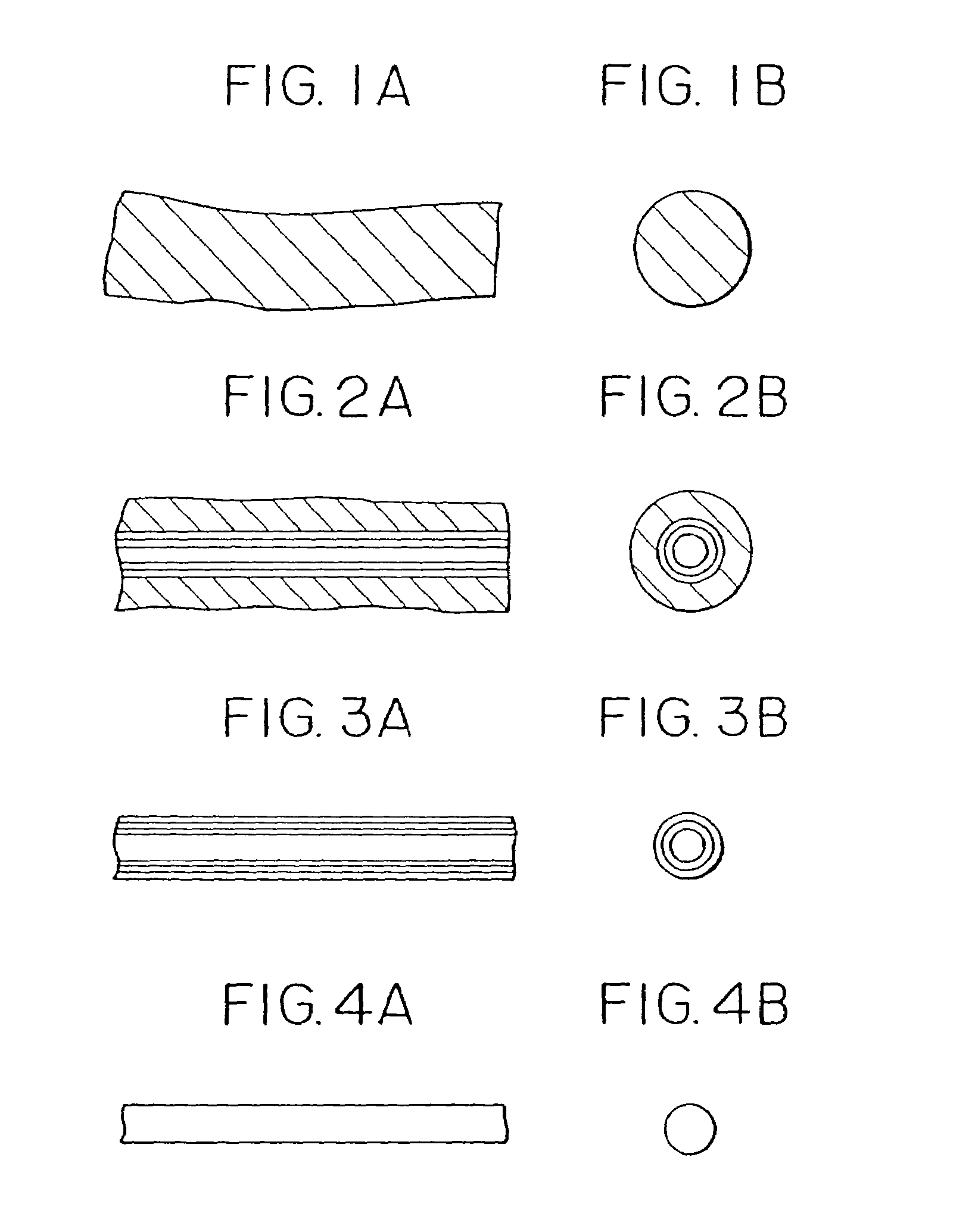

Scanning probe microscopy tips composed of nanoparticles and methods to form same

InactiveUS7282710B1Improve spatial resolutionImprove adhesionMaterial analysis using wave/particle radiationLayered productsChemical synthesisFluorescence

A structure and method for improving the spatial resolution of a scanning probe microscope (SPM) tip, which has been coated with a layer of chemically-synthesized nanoparticles. The nanoparticles are either single-species or heterogeneous, such that the single-species nanoparticles can be either ferromagnetic, paramagnetic, superparamagnetic, antiferromagnetic, ferrimagnetic, magneto-optic, ferroelectric, piezoelectric, superconducting, semiconducting, magnetically-doped semiconducting, insulating, fluorescent, or chemically catalytic. The layer of nanoparticles is at least two nanoparticles thick, or alternatively, is a single layer of nanoparticles thick, or alternatively, is a single layer of nanoparticles thick and covers only the tip apex portion of the tip, or alternatively, only a single nanoparticle is affixed to the tip apex. Alternatively, the layer of nanoparticles is transformed into an electrically-continuous magnetic film by annealing at a high temperature.

Owner:IBM CORP

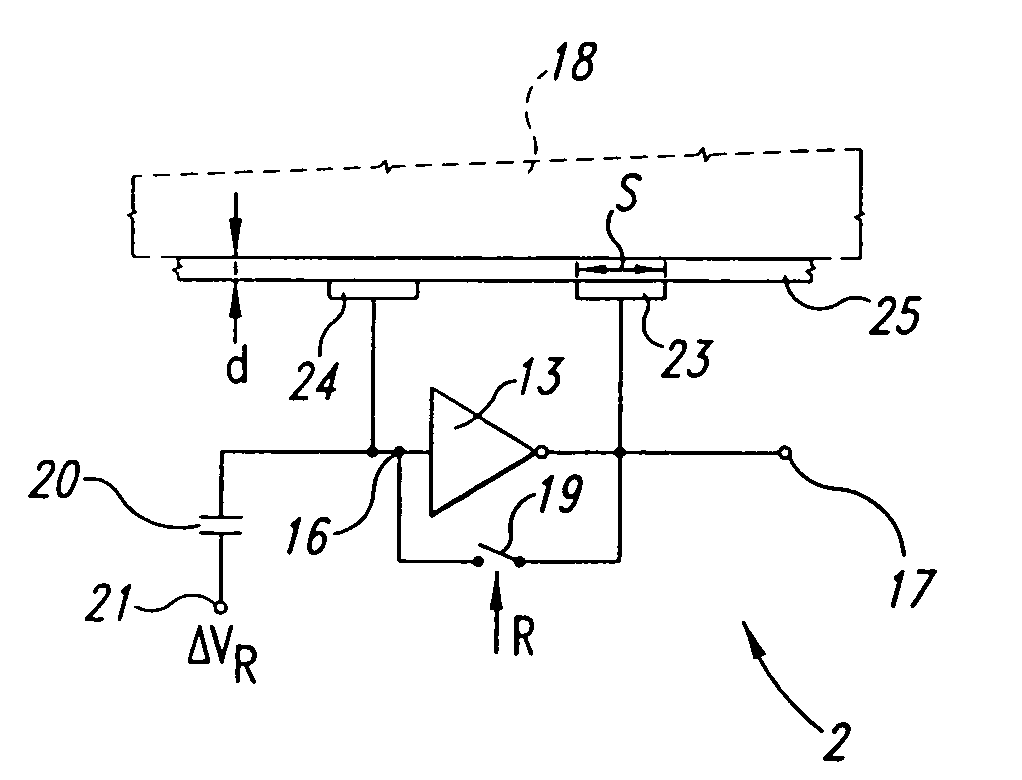

Capacitive distance sensor

InactiveUS6998855B2Prevent illegal useResistance/reactance/impedenceUsing electrical meansNegative feedbackSkin surface

A distance sensor has a capacitive element in turn having a first plate which is positioned facing a second plate whose distance is to be measured. In the case of fingerprinting, the second plate is defined directly by the skin surface of the finger being printed. The sensor includes an inverting amplifier, between the input and output of which the capacitive element is connected to form a negative feedback branch. By supplying an electric charge step to the input of the inverting amplifier, a voltage step directly proportional to the distance being measured is obtained at the output.

Owner:APPLE INC

Method of manufacturing an electronic device containing a carbon nanotube

InactiveUS6979244B2Improve directivityImprove performanceMaterial nanotechnologyNanoinformaticsCarbon nanotubeElectron

A method of manufacturing an electronic device in which a substrate with a pair of electrodes is provided and a carbon nanotube is formed or arranged to electrically connect the electrodes.

Owner:CANON KK

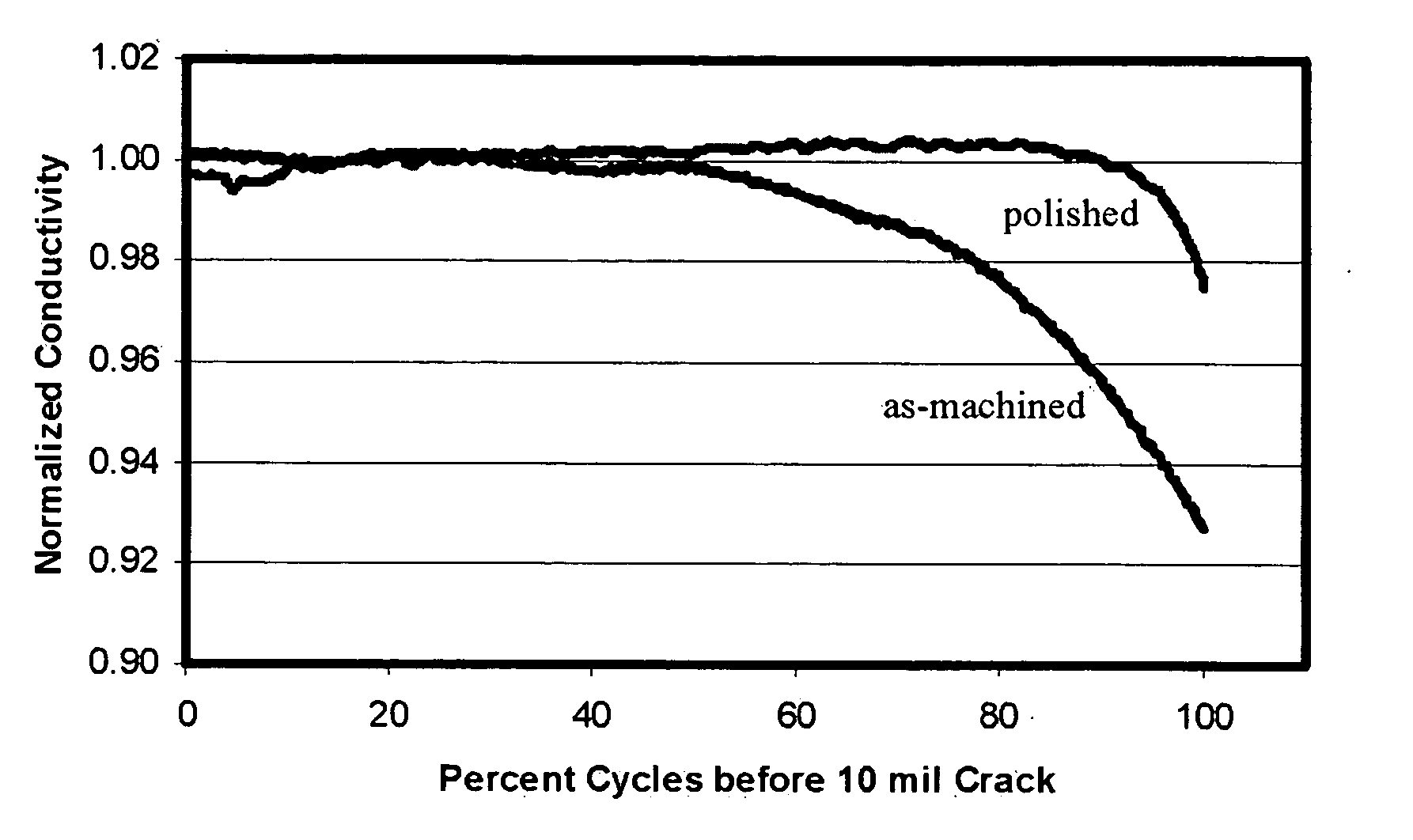

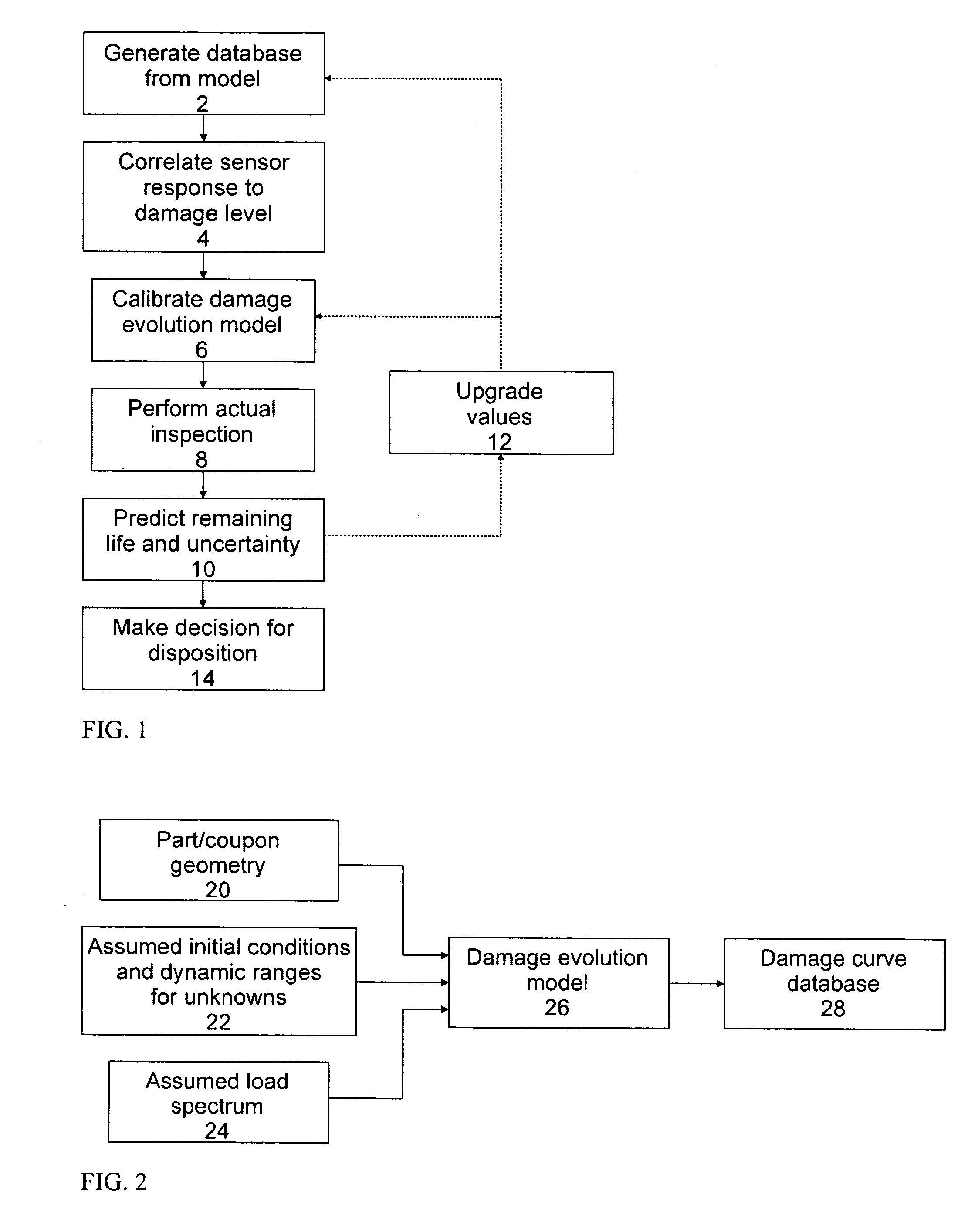

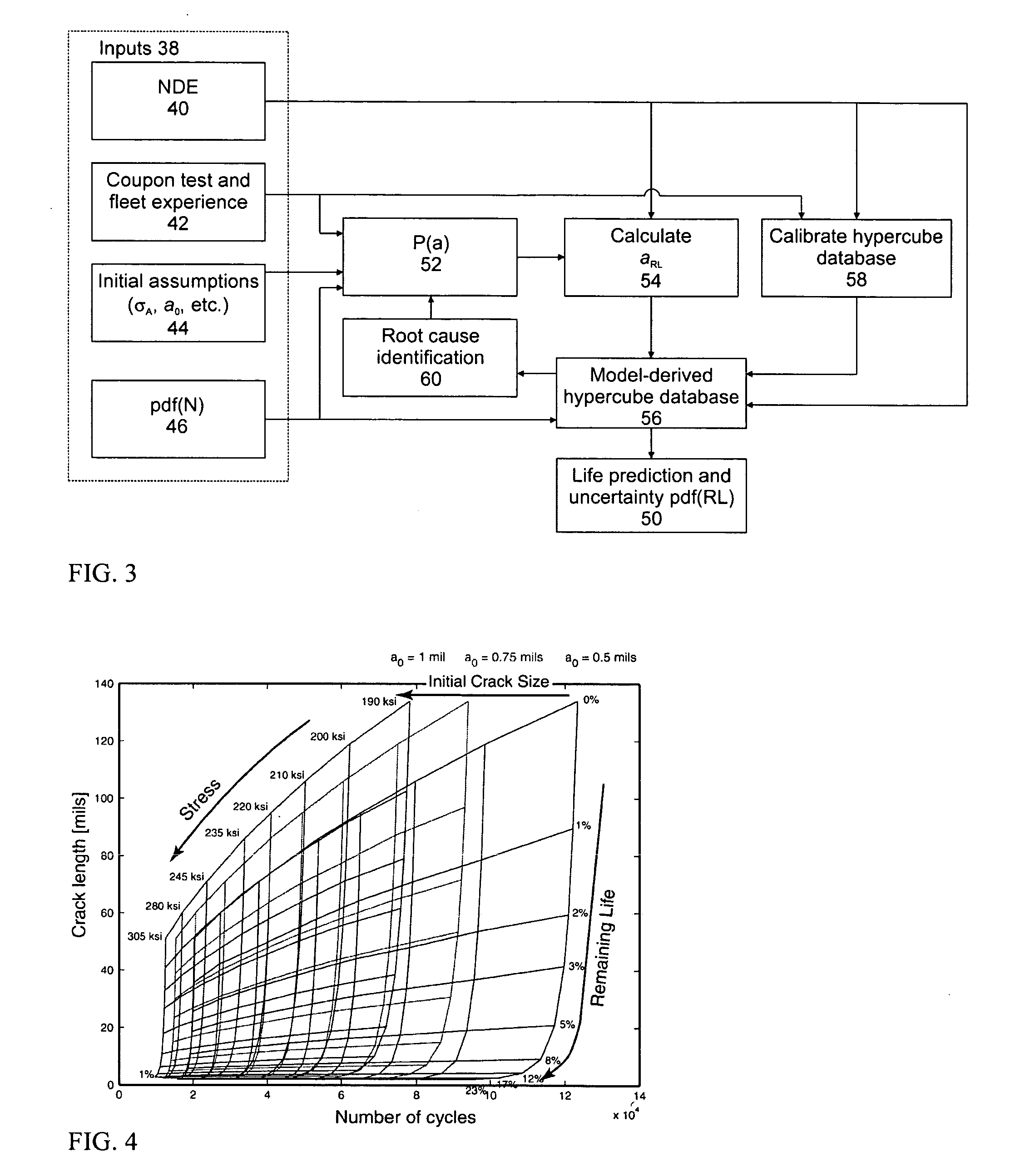

Remaining life prediction for individual components from sparse data

ActiveUS20070239407A1Effective calculationActive/predictive/anticipative controlElectric/magnetic roughness/irregularity measurementsRoot causeDecision taking

Predicting the remaining life of individual aircraft, fleets of aircraft, aircraft components and subpopulations of these components. This is accomplished through the use of precomputed databases of response that are generated from a model for the nonlinear system behavior prior to the time that decisions need to be made concerning the disposition of the system. The database is calibrated with a few data points, to account for unmodeled system variables, and then used with an input variable to predict future system behavior. These methods also permit identification of the root causes for observed system behavior. The use of the response databases also permits rapid estimations of uncertainty estimates for the system behavior, such as remaining life estimates, particularly, when subsets of an input variable distribution are passed through the database and scaled appropriately to construct the output distribution. A specific example is the prediction of remaining life for an aircraft component where the model calculates damage evolution, input variables are a crack size and the number of cycles, and the predicted parameters are the actual stress on the component and the remaining life.

Owner:JENTEK SENSORS

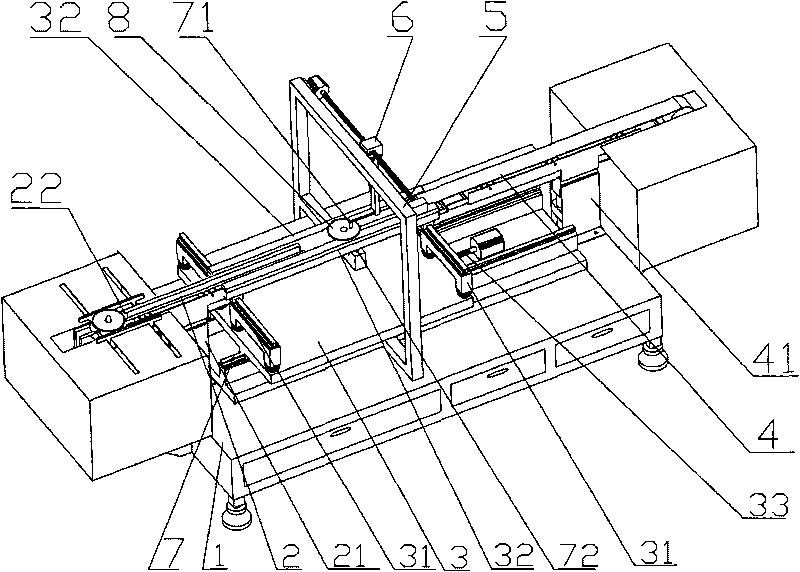

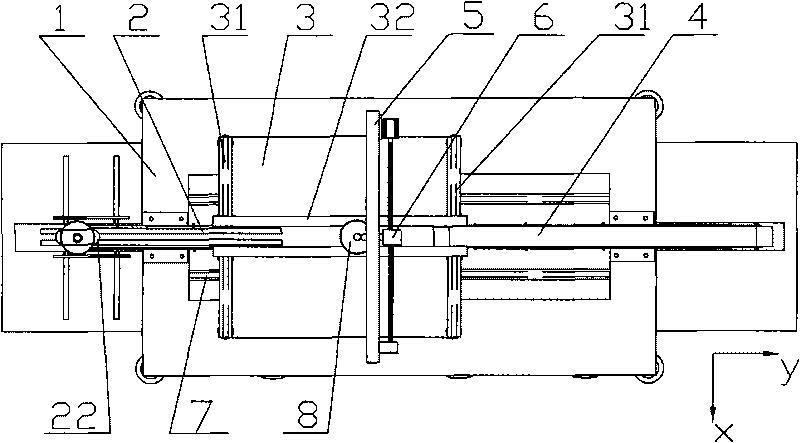

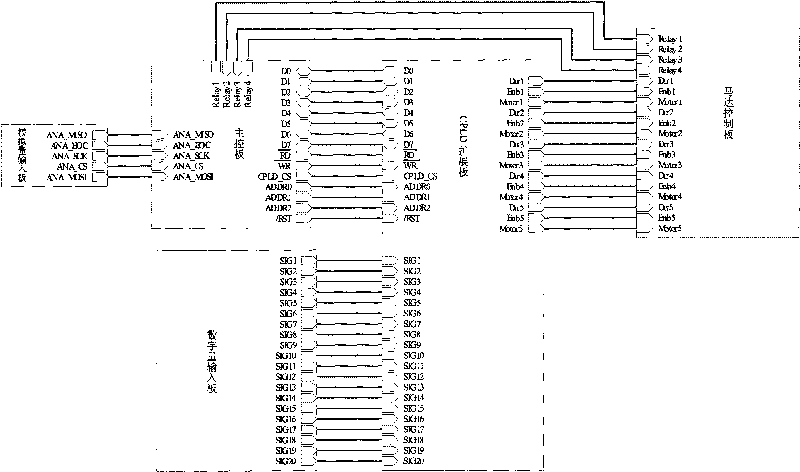

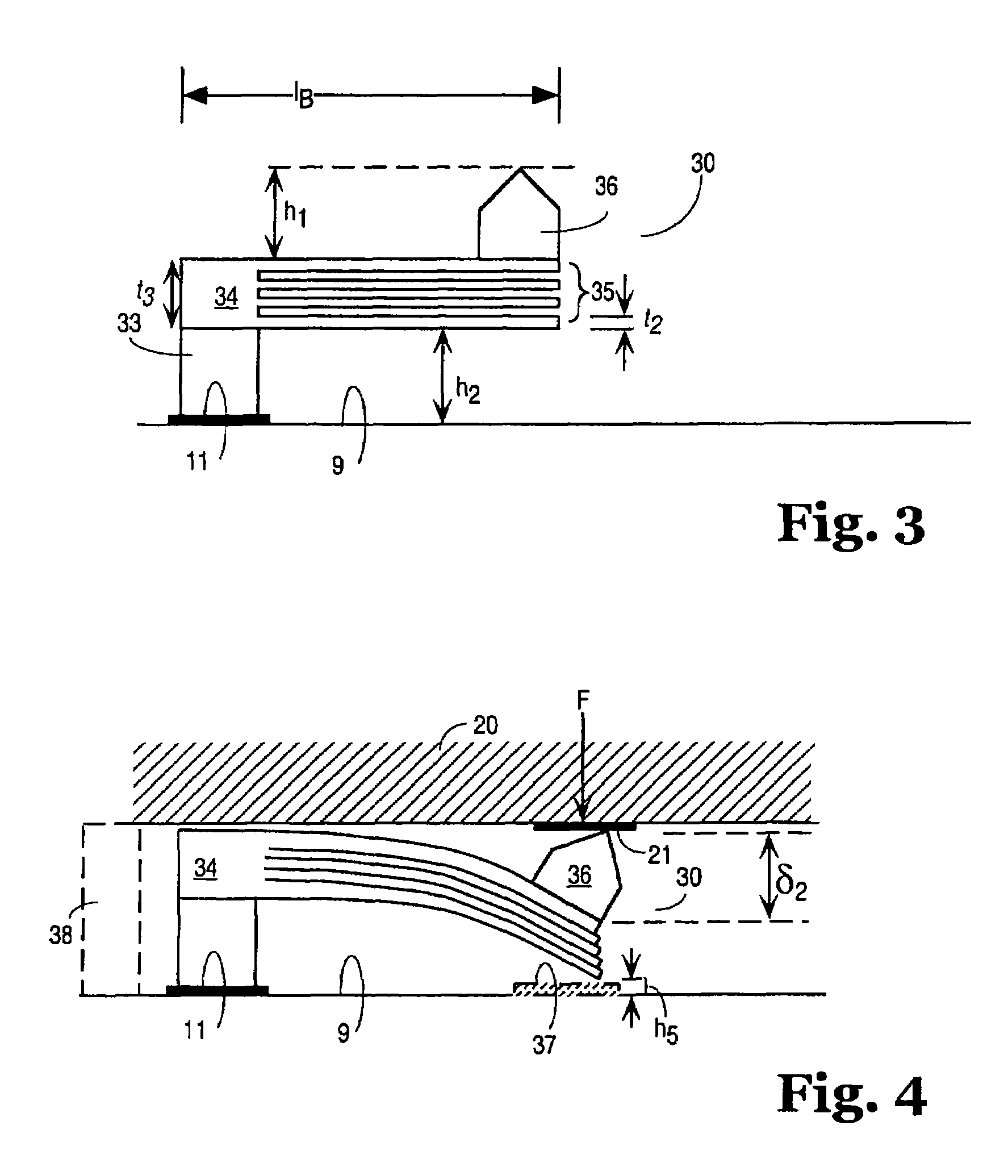

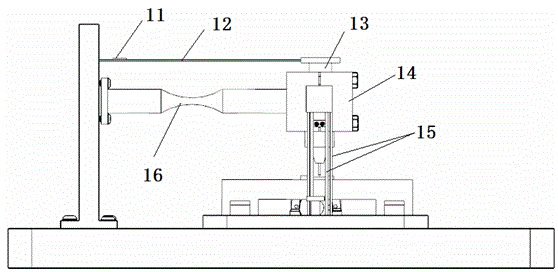

Automatic test device of flatness and thickness of metal sheet

InactiveCN101726243AGuaranteed correctnessRealize coordinated and continuous operationElectric/magnetic roughness/irregularity measurementsElectrical/magnetic thickness measurementsTest efficiencyAutomatic test equipment

The invention relates to an automatic test device of the flatness and thickness of a metal sheet, which comprises a machine frame, a feeding mechanism, a test platform and a discharging mechanism. The machine frame and the test platform are connected through a Y-directional track. The test platform comprises a test frame, guide rails, a test cross beam, a cantilever fixing frame, a cantilever, an upper test probe, a lower test probe, a Y-directional ball screw mechanism and a measuring circuit. The automatic test device has the following beneficial effects that: the test is accurate; the test efficiency and the test precision are improved because the probes always cover the effective test range of a saw blade; mechanical and electrical integration technology is fully used, the structure is simple, the operation and maintenance are convenient, and the application in the field of the test of the flatness and thickness of other metals can be realized with a little improvement, and the promotion and use are easy; and an eddy induction principle is used to realize the test of the flatness and the thickness of the metal sheet, the interference of water and other non-metal impurities on the saw blade is eliminated effectively, precise positioning of the saw blade is not required in test, the price is low, and the operation is simple.

Owner:WUHAN TEXTILE UNIV

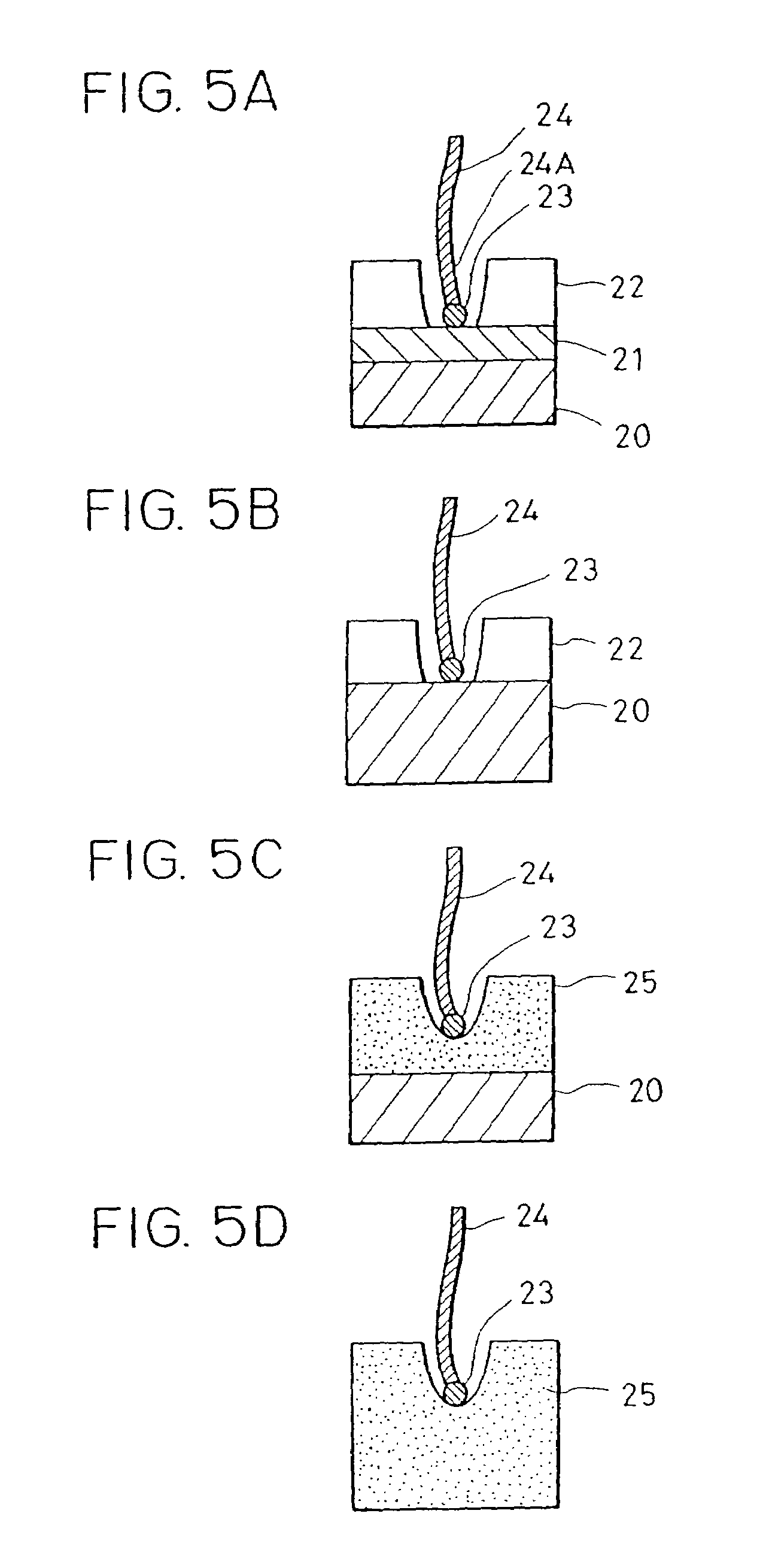

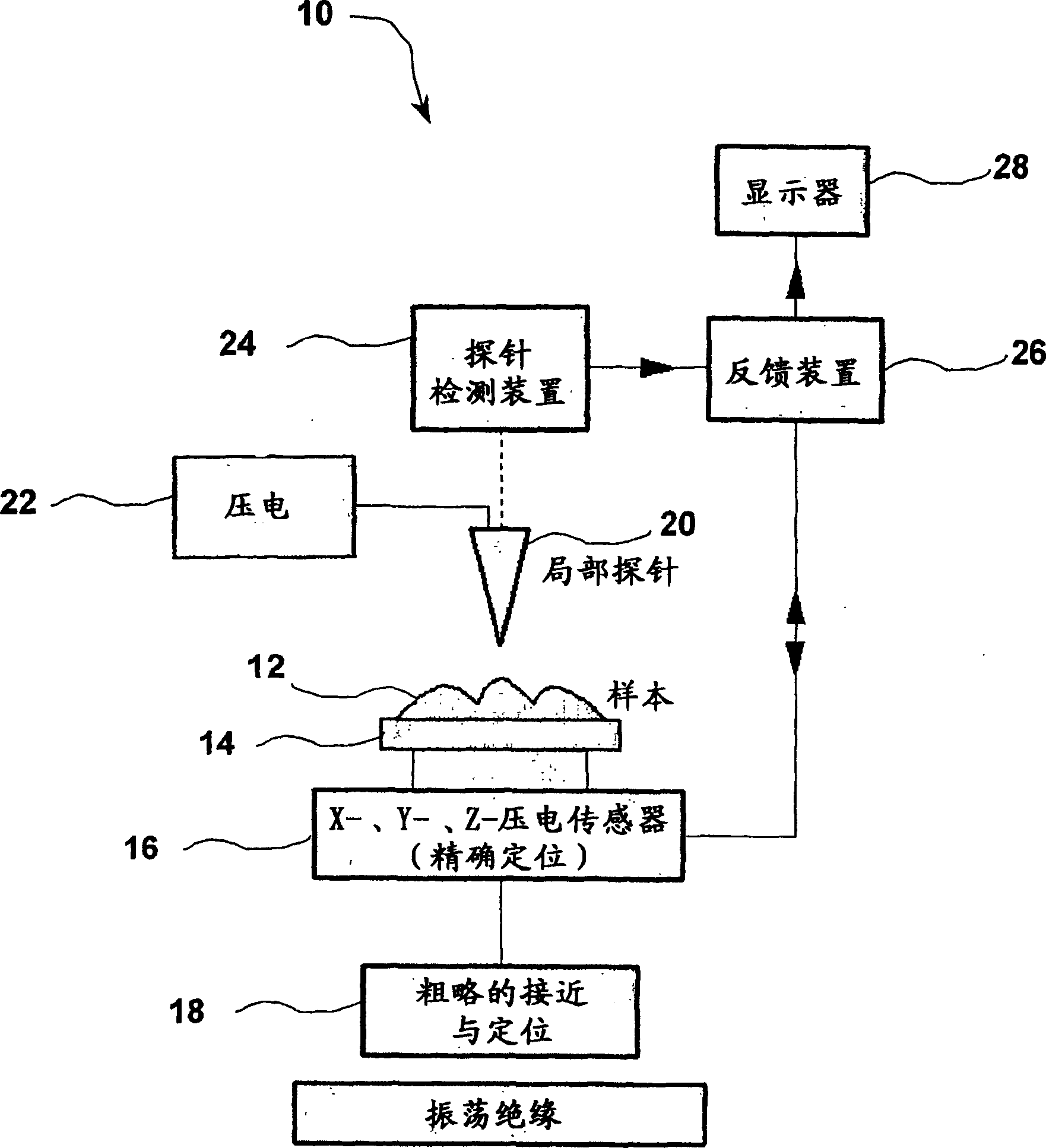

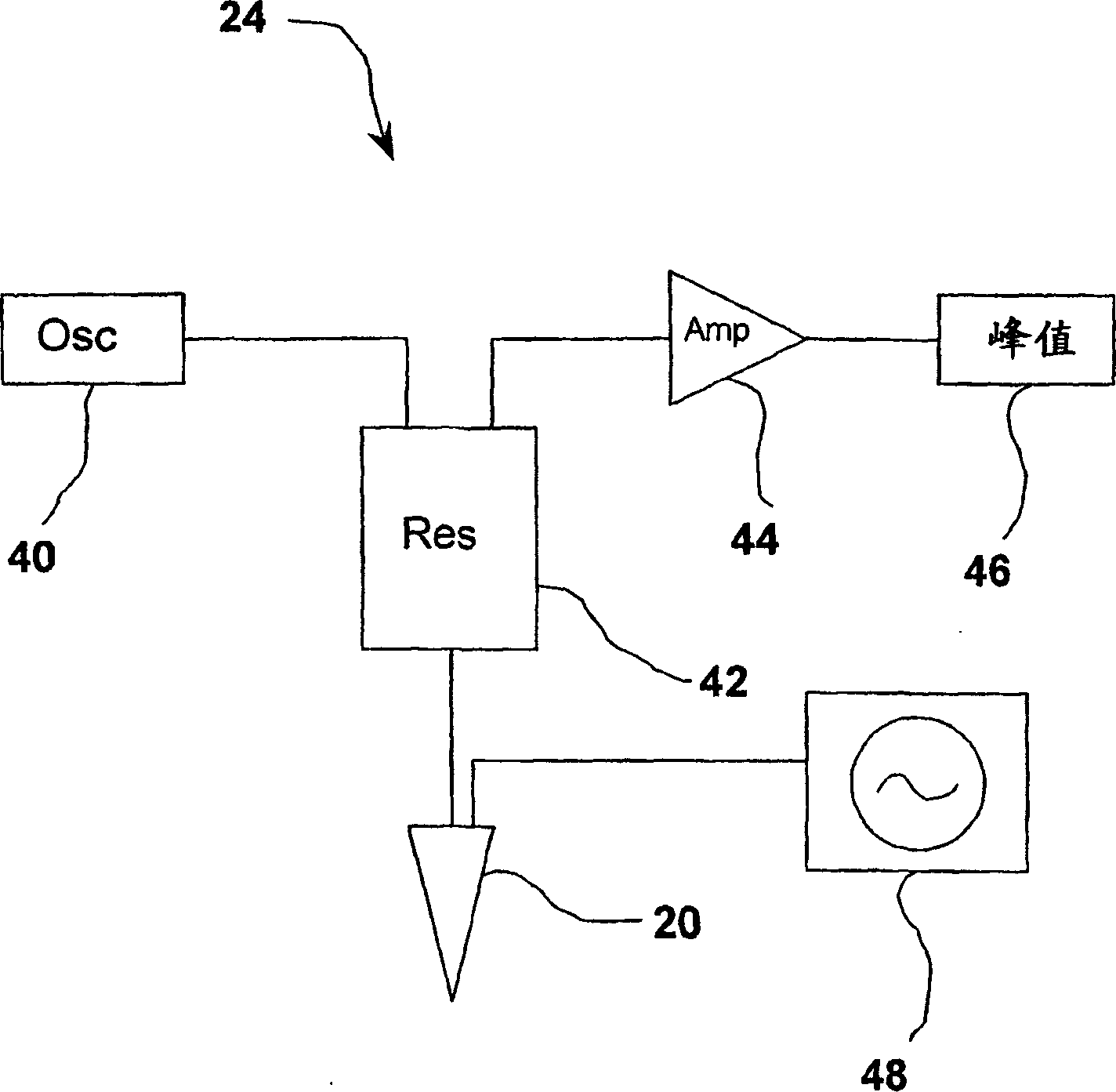

Scanning probe microscope

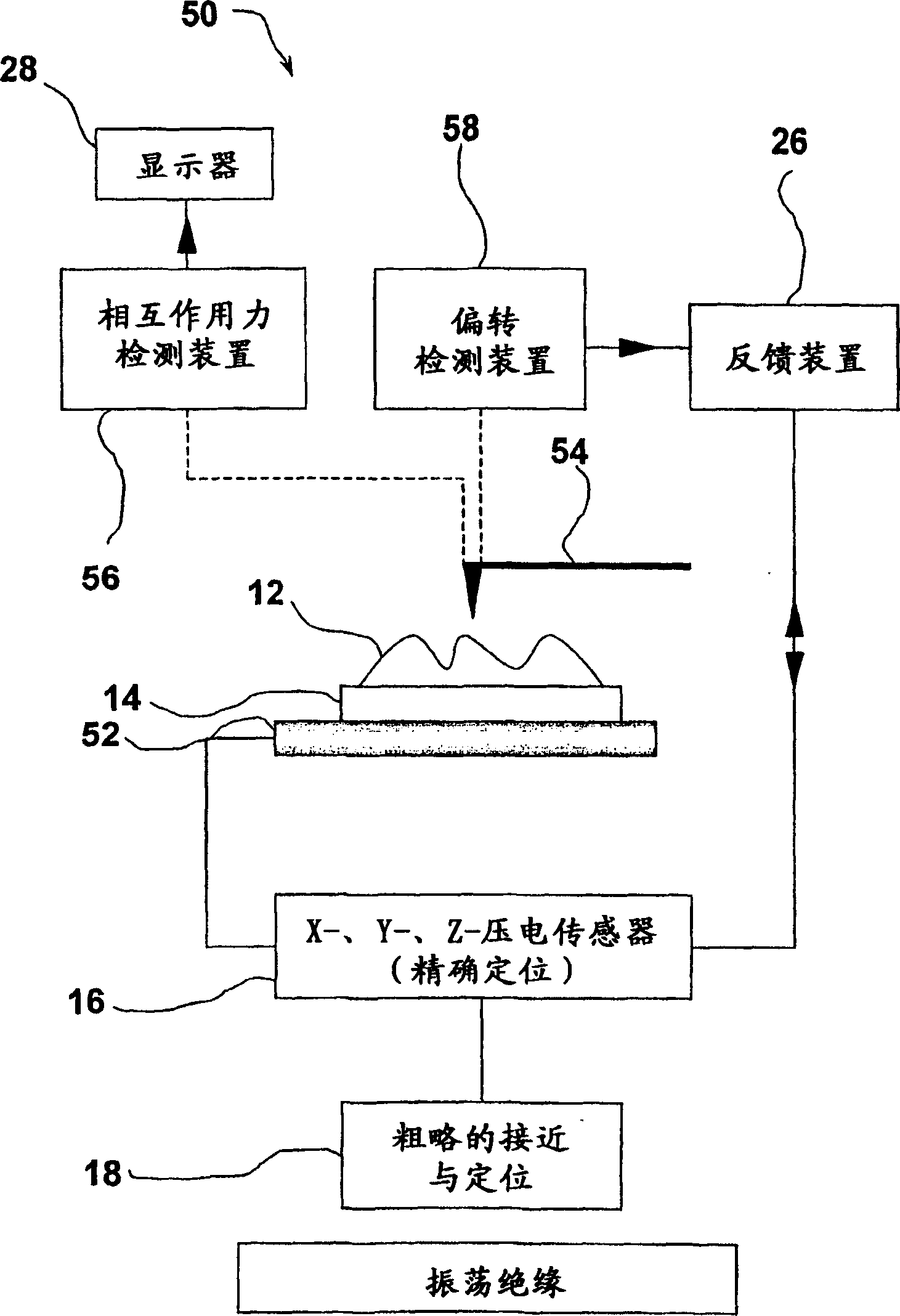

InactiveCN1672011ANanotechnologyElectric/magnetic roughness/irregularity measurementsAtomic force microscopyScanning probe microscopy

A scanning probe microscope detects or induces changes in a probe-sample interaction. In imaging mode, the probe 54 is brought into a contact distance of the sample 12 and the strength of the interaction measured as the probe 54 and sample surface are scanned relative to each other. Image collection is rapidly performed by carrying out a relative translation of the sample 12 and probe 54 whilst one or other is oscillated at or near its resonant frequency. In a preferred embodiment the interaction is monitored by means of capacitance developed at an interface between a metallic probe and the sample. In lithographic mode, an atomic force microscope is adapted to write information to a sample surface.

Owner:INFINITESIMA

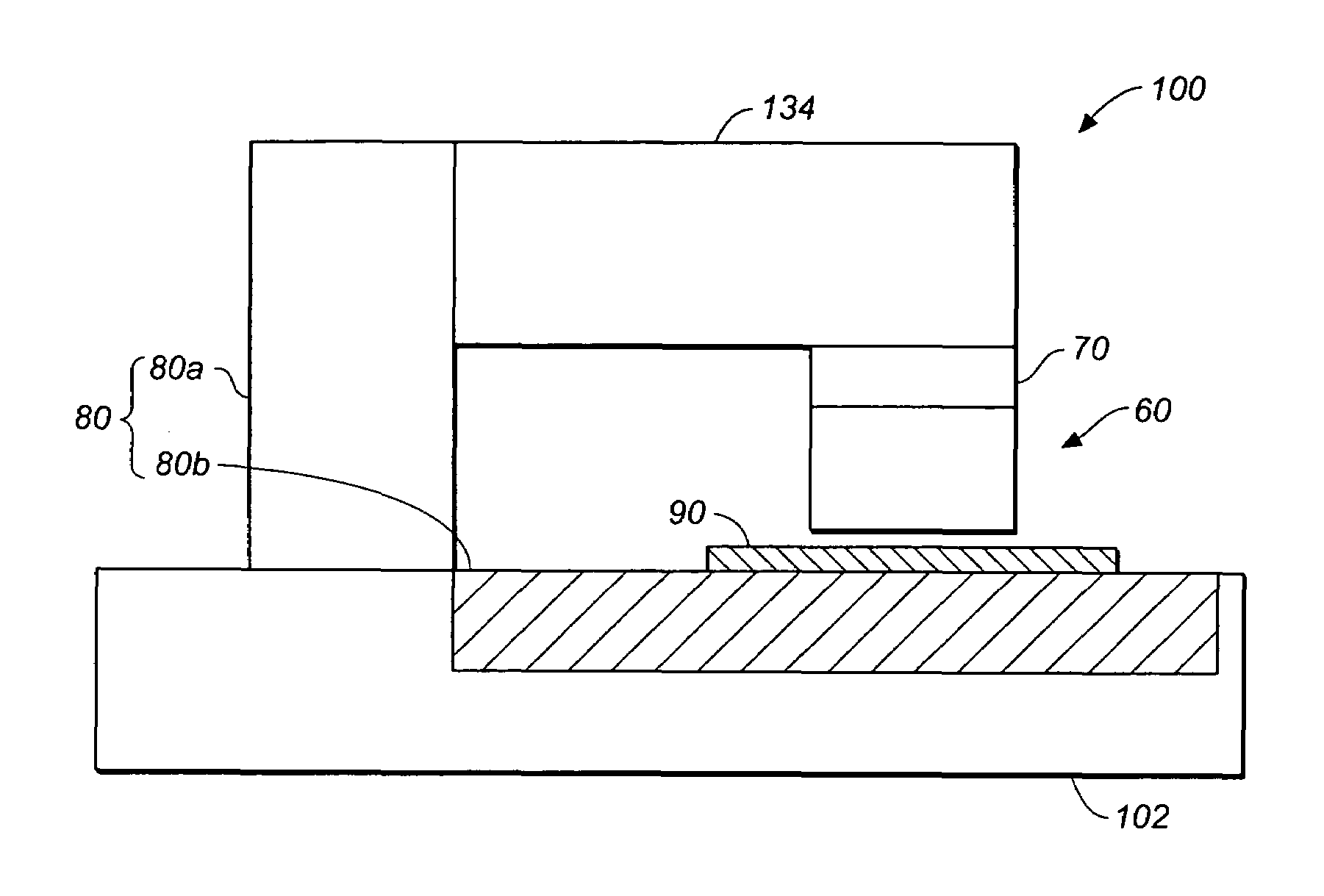

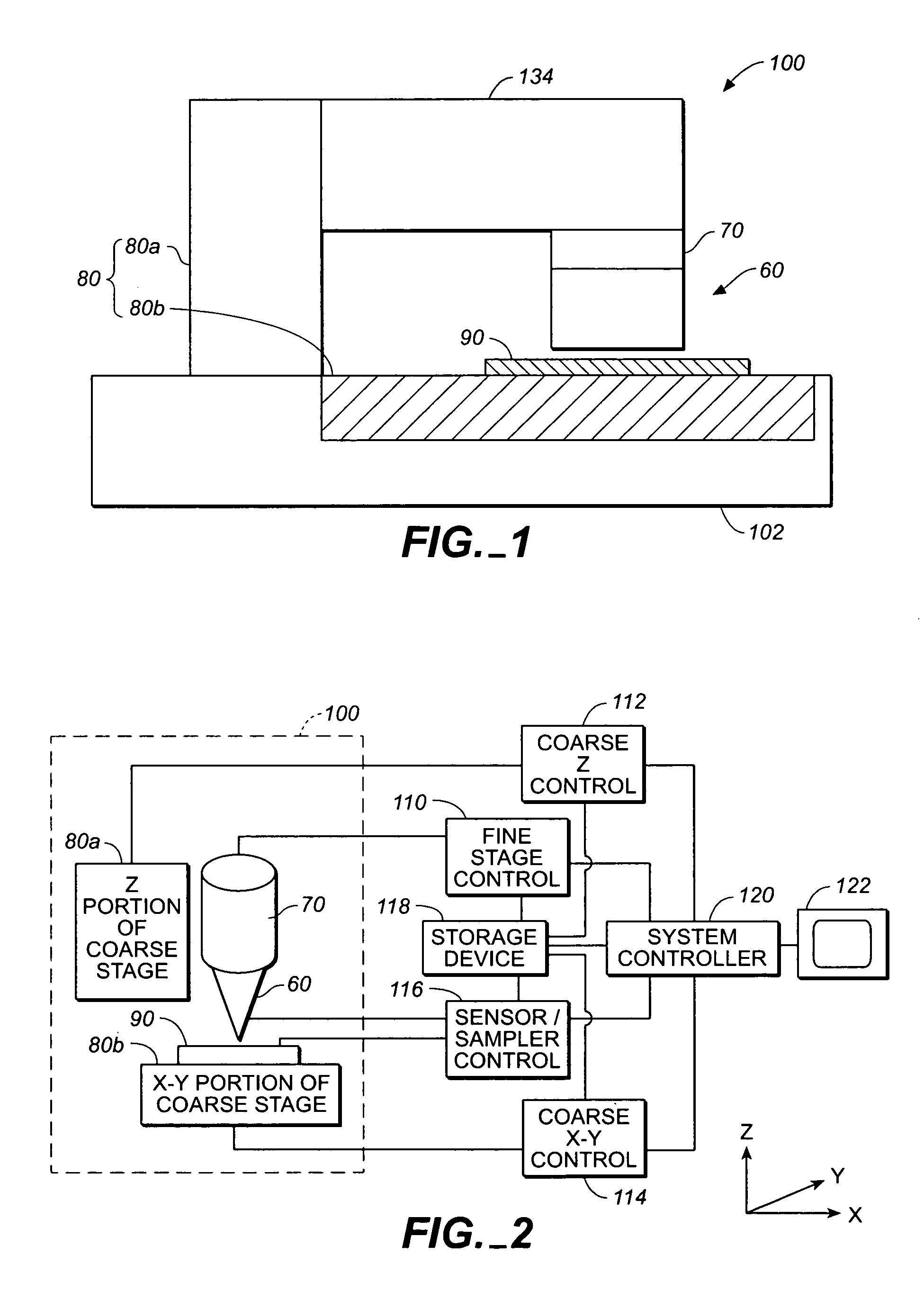

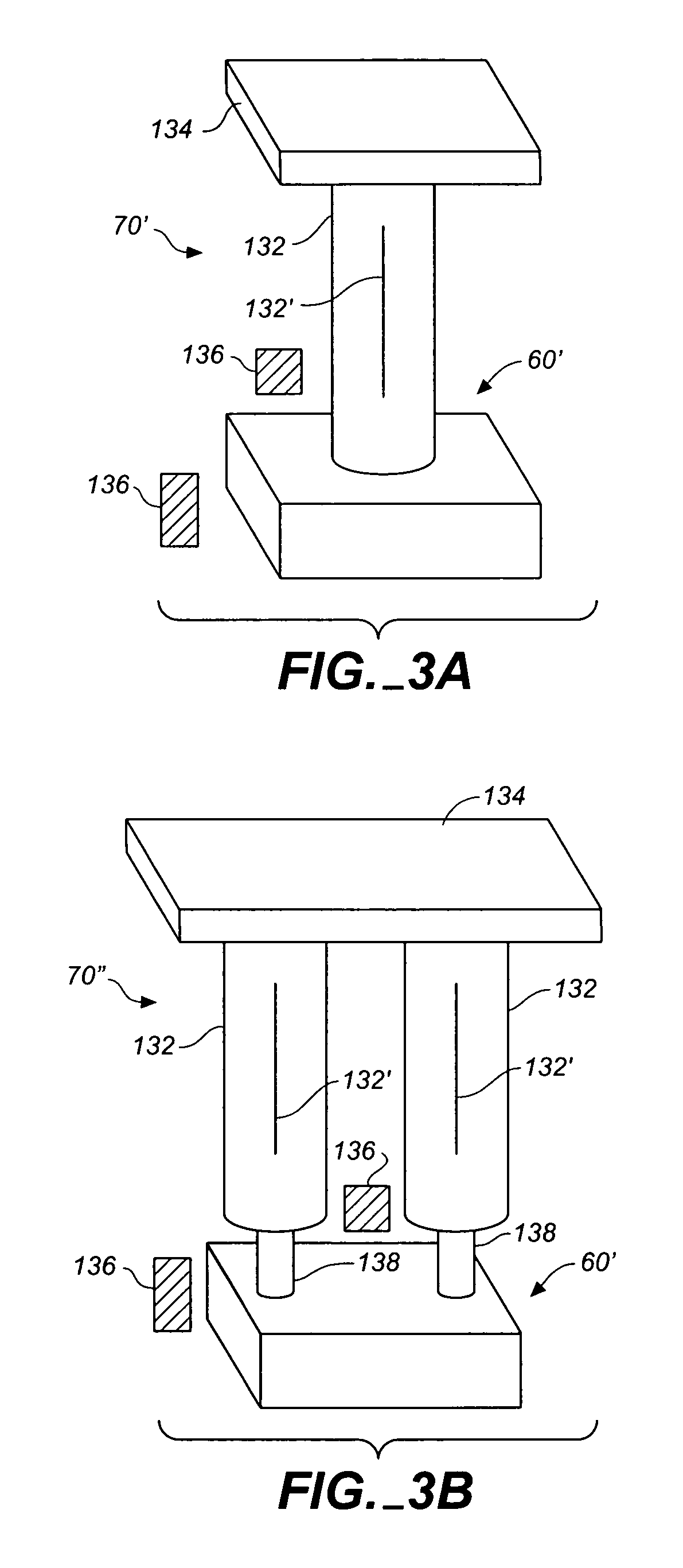

Dual stage instrument for scanning a specimen

Owner:KLA CORP

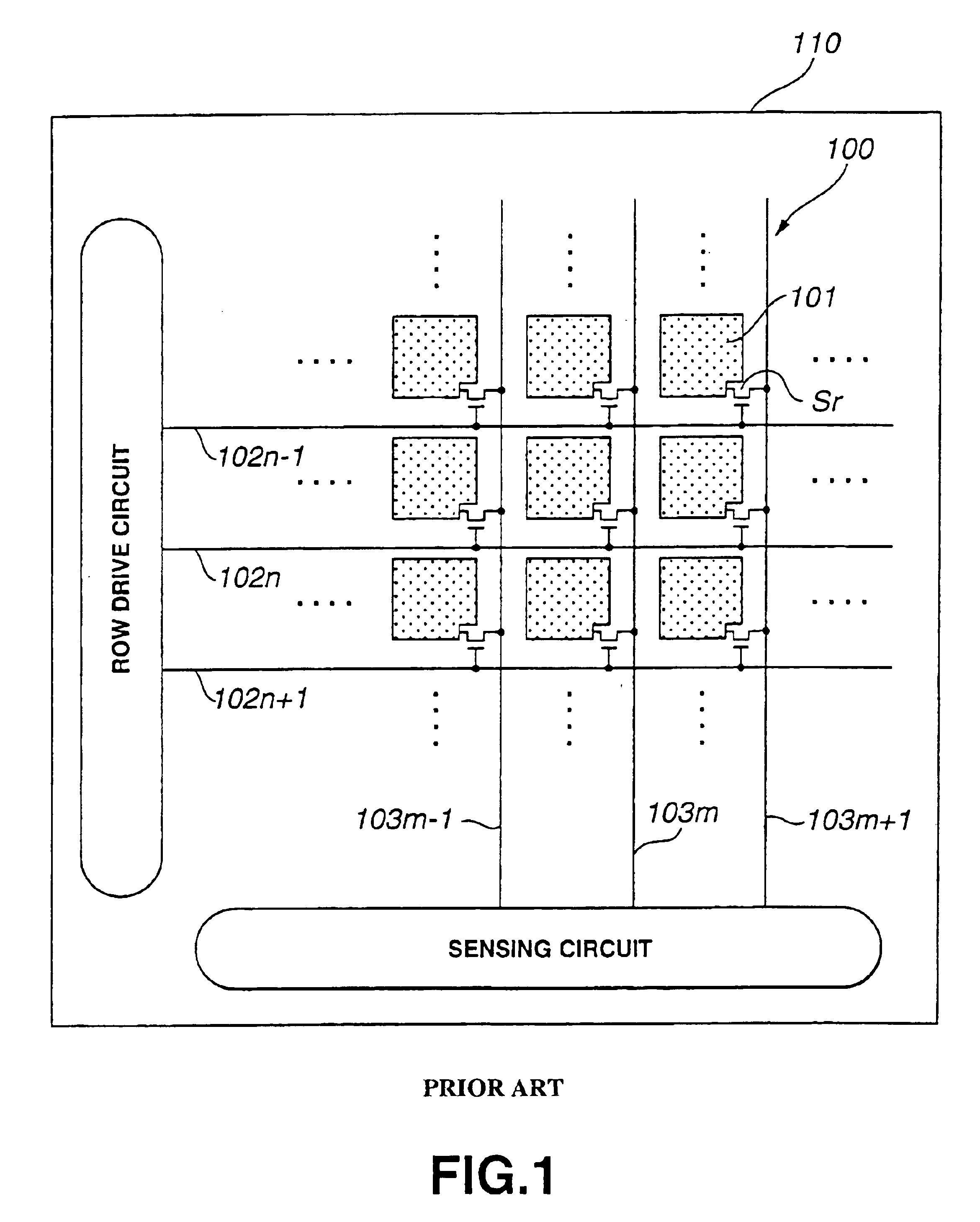

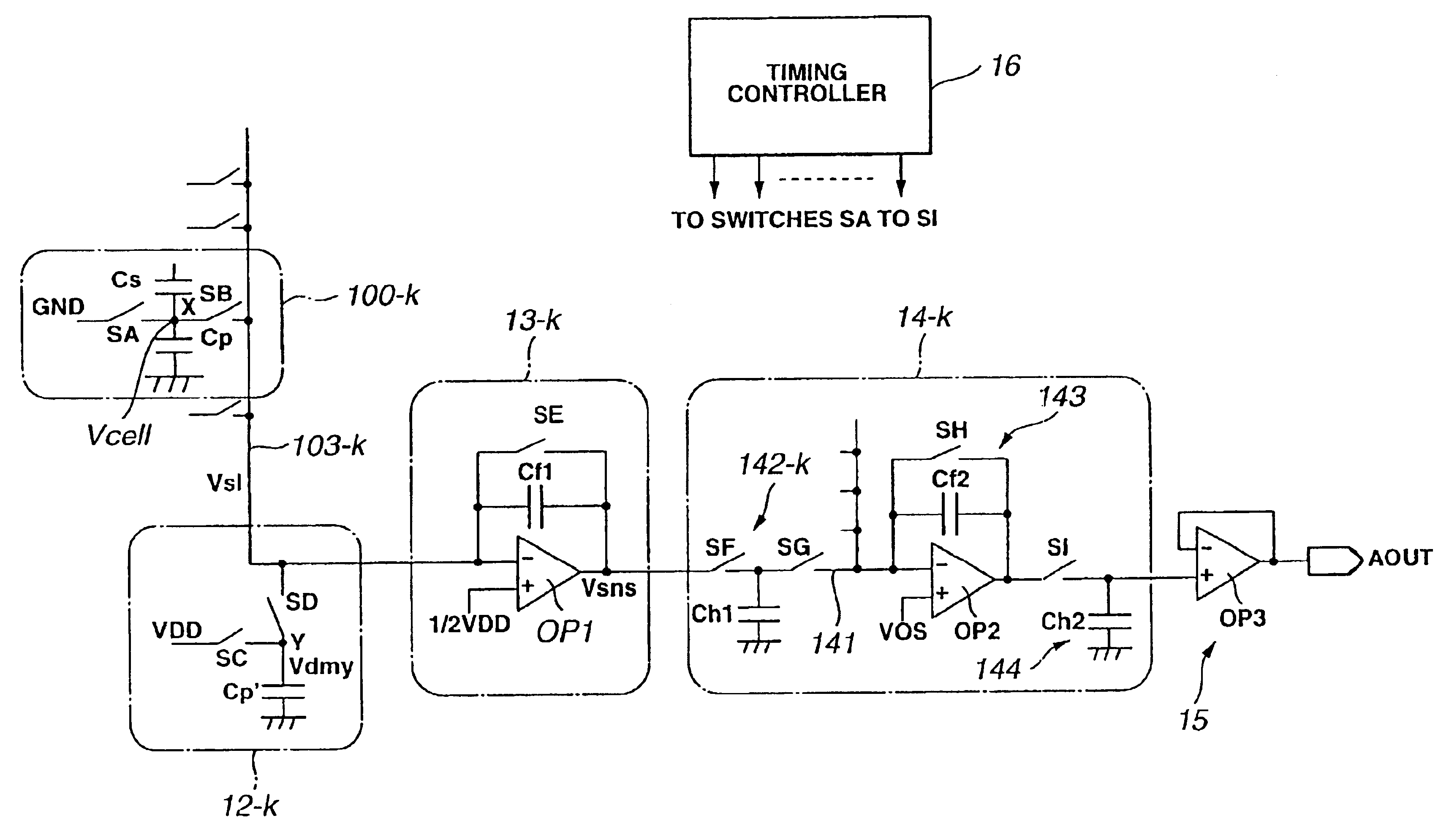

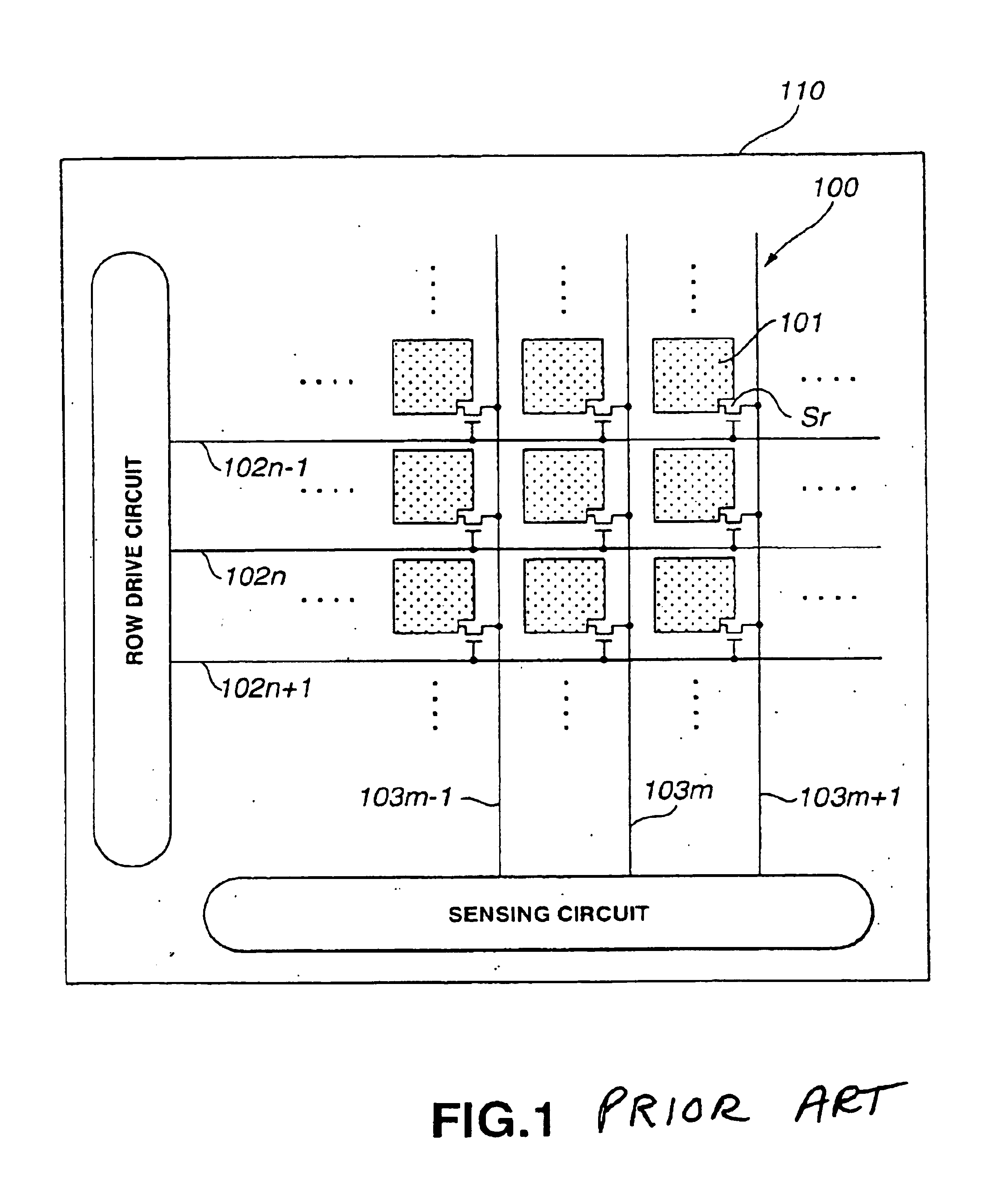

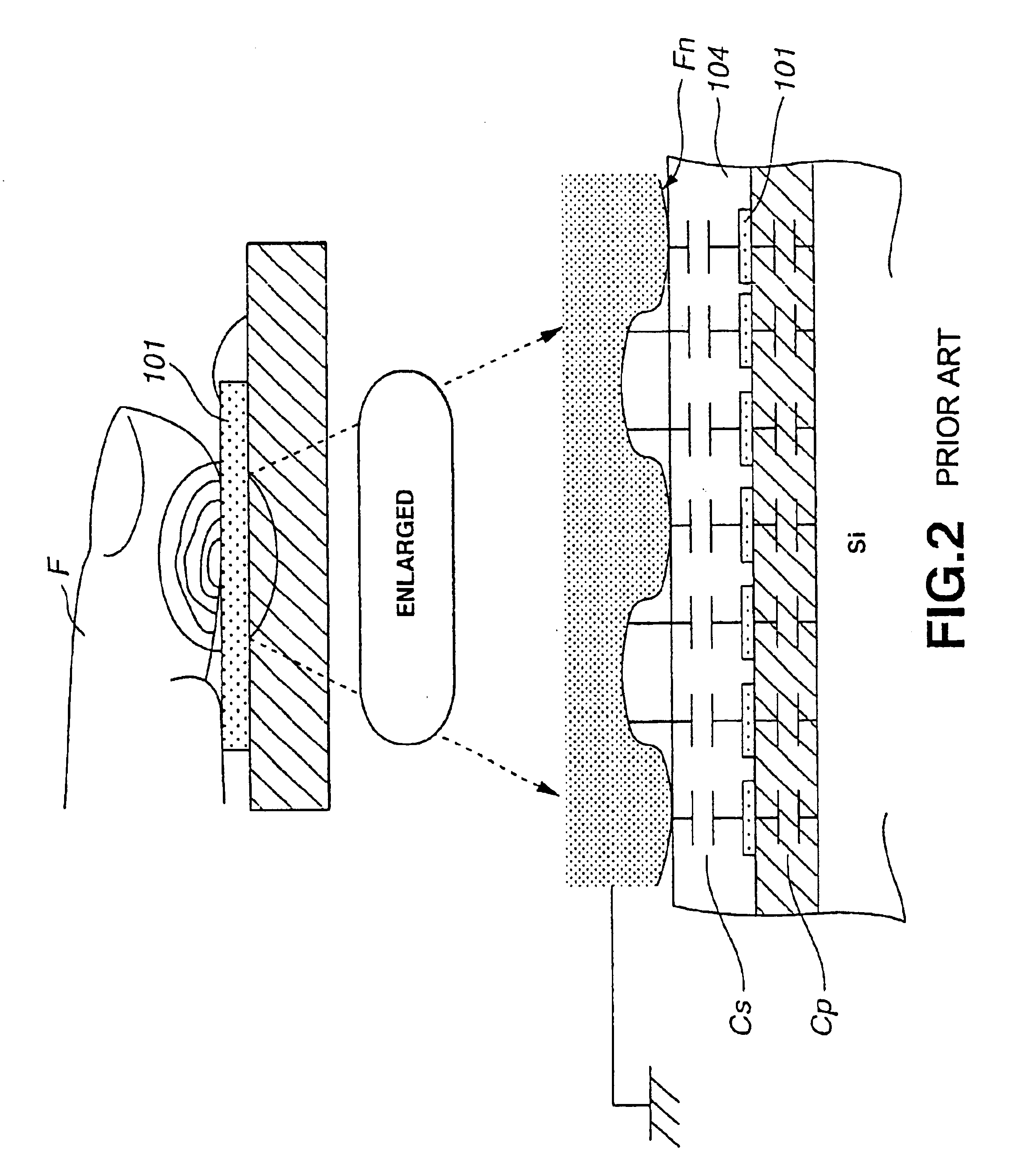

Electrostatic capacitance sensor and fingerprint collator comprising it

InactiveUS6882164B2High sensitivityIncreased durabilityResistance/reactance/impedencePerson identificationEngineeringCapacitance transducer

A capacitance sensor usable as a fingerprint sensor is provided in which a timing controller (16) provides such a switching control as to first cause a switch (SA) in a sensor cell (100-k) to turn on to set the potential at a sense electrode to a reference potential and then a switch SB to turn on after the switch (SA) is turned off, whereby charge is stored from the sensor cell (100-k) into a reference capacitance Cf1 of a sensing circuit (13-k), the sensitivity of sensing the capacitance is raised by increasing the number of times the charge storage is repeated and only signal components are extracted by reducing noise components by averaging.

Owner:SONY CORP

Electrostatic force detector with cantilever for an electrostatic force microscope

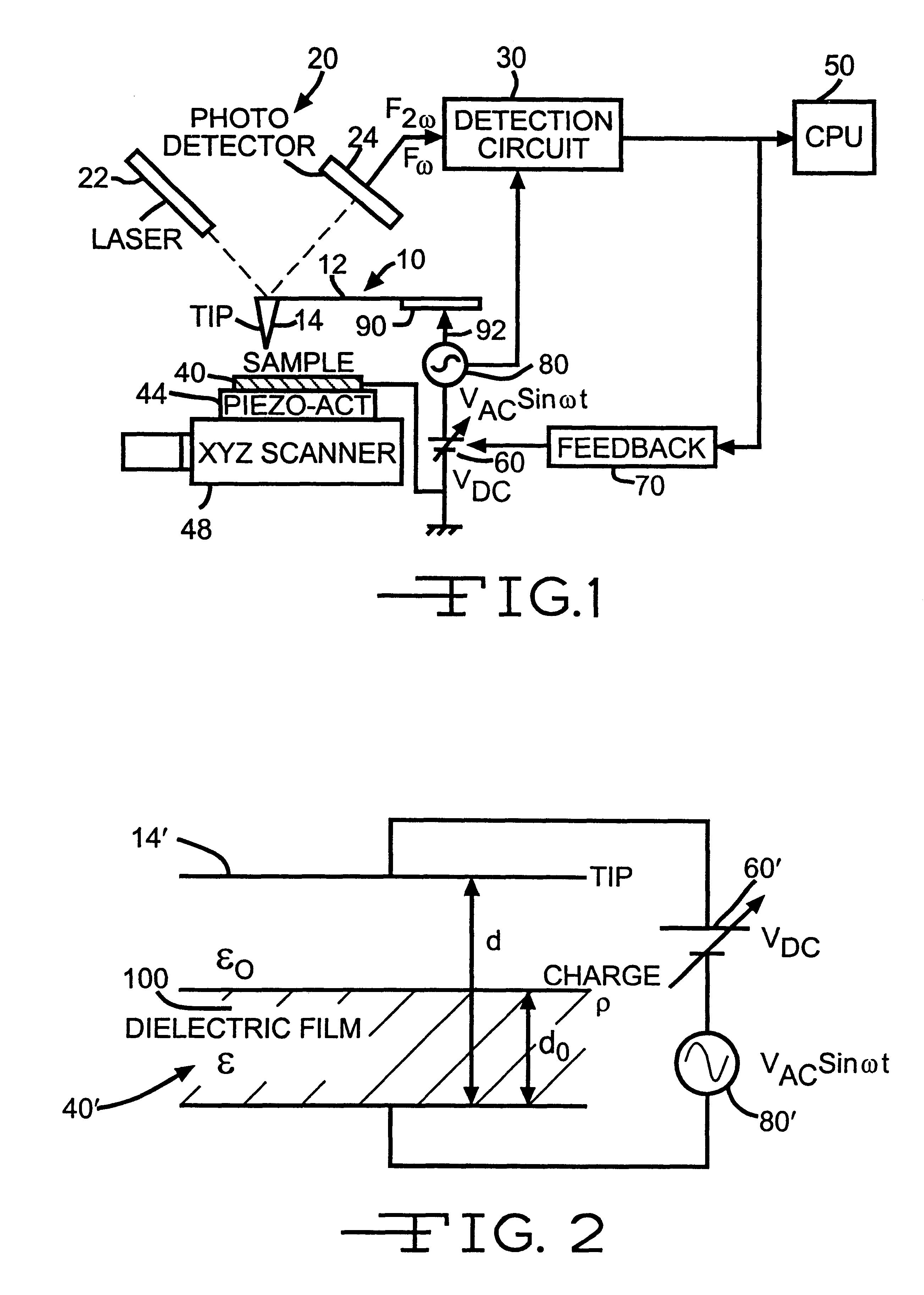

InactiveUS6507197B1Reduce errorsSimultaneous measurementNanotechMaterial analysis by electric/magnetic meansParallel plateImage resolution

An electrostatic force microscope wherein electrostatic force applied to the detector is determined through obtaining the field distribution on several different shaped detectors with the calculation of the voltage distribution near the detector with the Finite Element Method to direct the measurement of the absolute charge amount on surface under test so that one can define the differences between the analysis and the results from the parallel plate model. Of interest is how large the error in the charge detection occurs in conjunction with thickness change of dielectric materials to be tested. There is provided a detector with cantilever which has proper shape for the spatial resolution of 10mu made out of nickel foil for an electrostatic force microscope and the electrostatic force which appeared on it has been calculated.

Owner:TREK BICYCLE CORPORATION

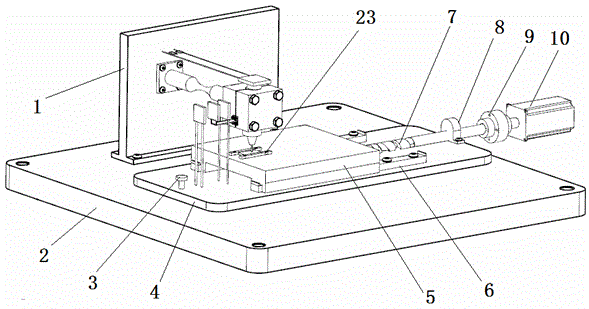

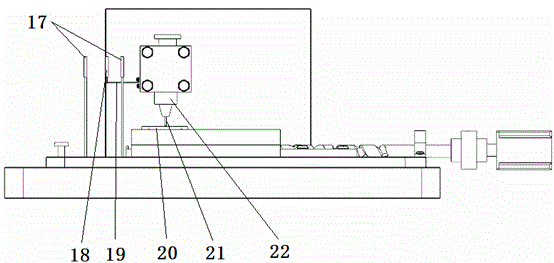

Measuring apparatus for measuring bearing and its part surface appearance

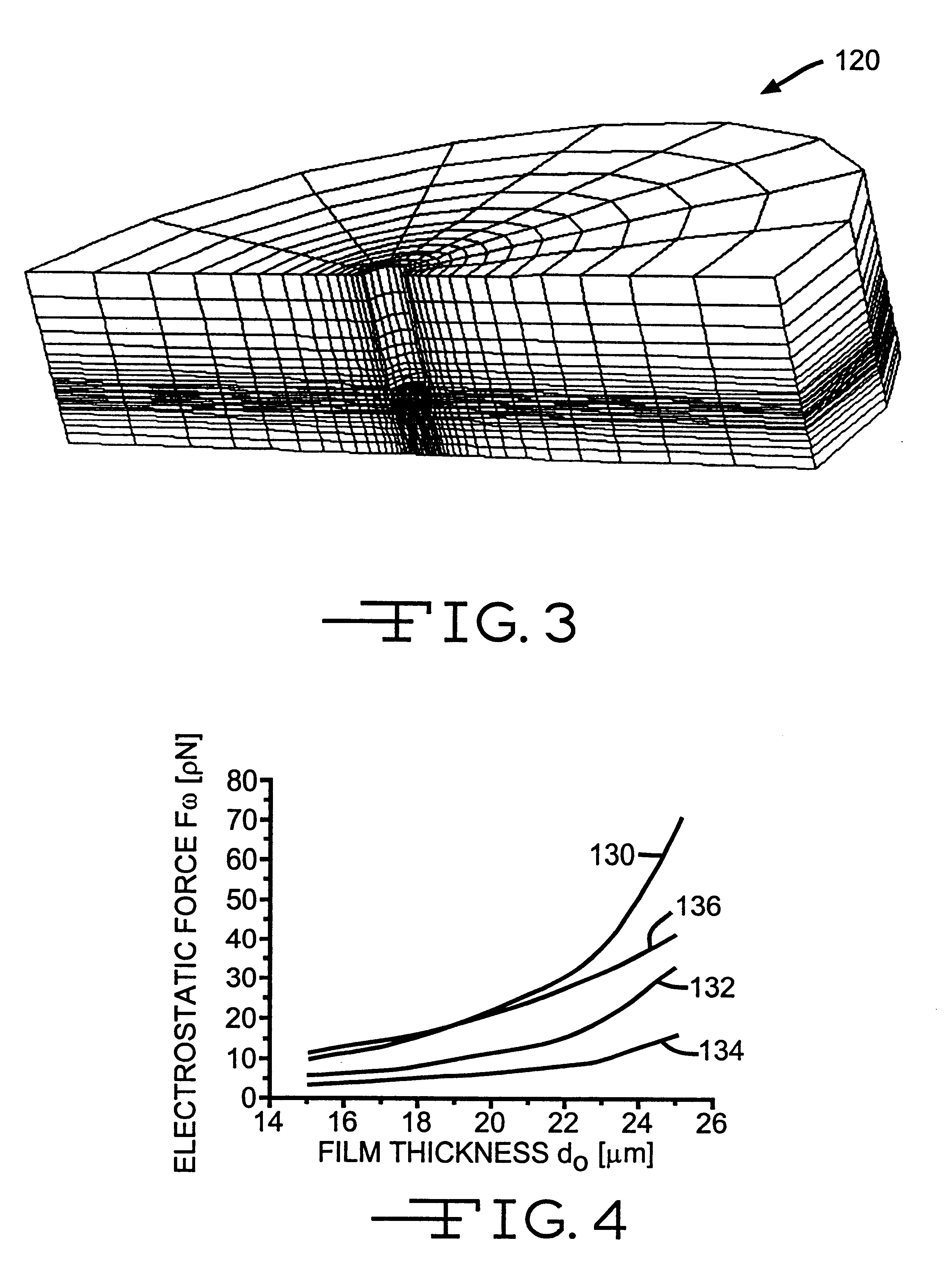

InactiveCN101216281ASatisfy high-precision testing requirementsRealize high-precision measurementUsing electrical meansElectric/magnetic contours/curvatures measurementsGratingEngineering

A measuring apparatus for measuring surface topography of bearing and other parts comprises a pedestal (1), an absolute encoder (2), a ball screw (3), an X-axis sliding guide track device (4), an X-axis limit switch (5), an X-axis signal collection grating (6), a driving box supporting plate (7), a sensor driving box (8), an upright guide track (9), a Z-axis motor (10), a Z-axis manual adjusting knob (11), an X-axis motor (12), an X-axis belt wheel and cog belt (13), an inductive sensor device (14), a sensor coupling rod (15), a multi-dimensional workbench (16) and an electrical system. The invention can measure more than 100 parameters, including profile, waviness, roughness, peak height, valley deepness, total height, average deviation, gradient, slope, bearing length ratio and others; provides detection reference for users to perform various technical analyses to the workpiece to be measured; and can add certain measurement parameter at any time according to the requirement of users.

Owner:LUOYANG BEARING SCI & TECH CO LTD

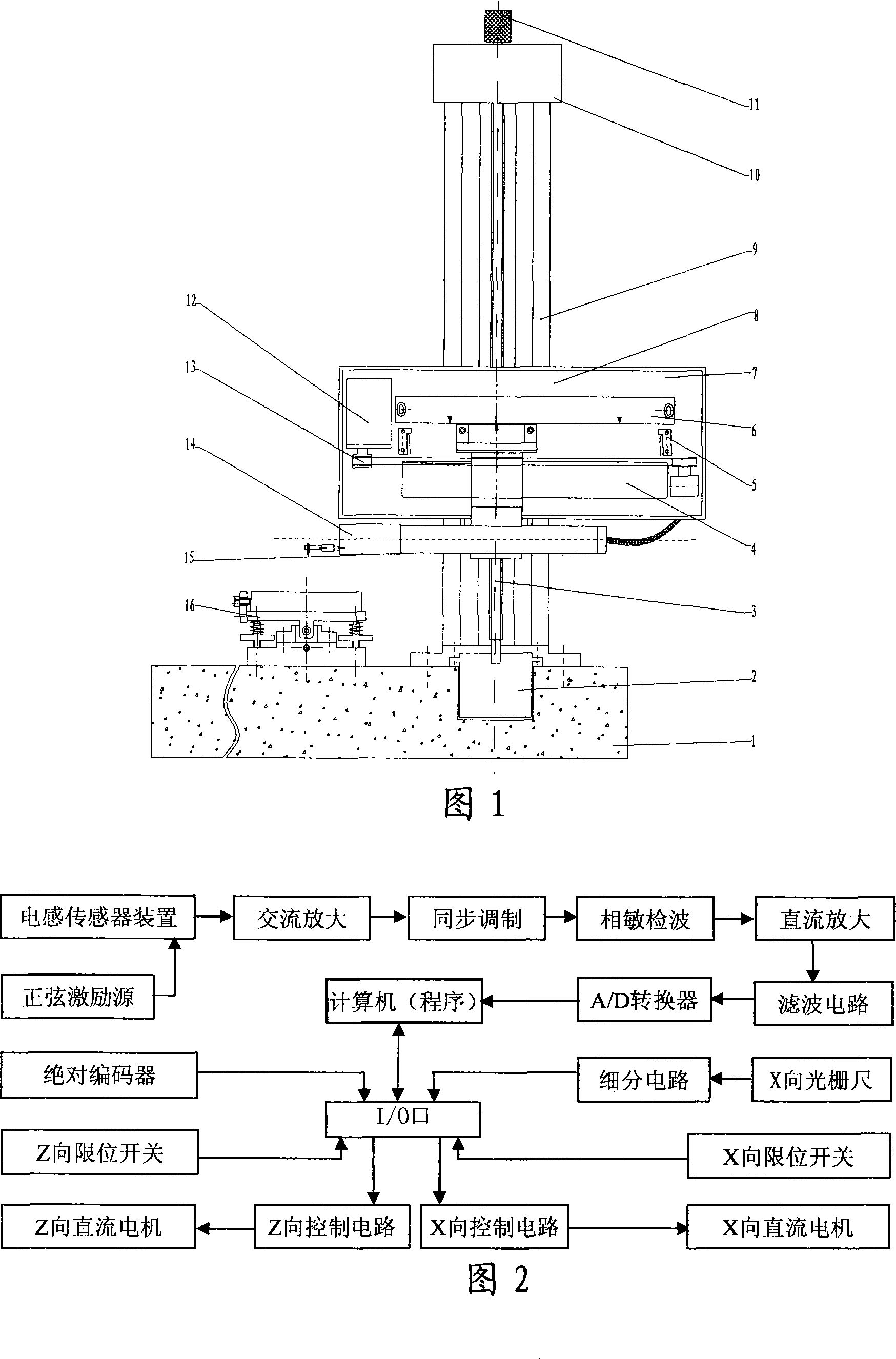

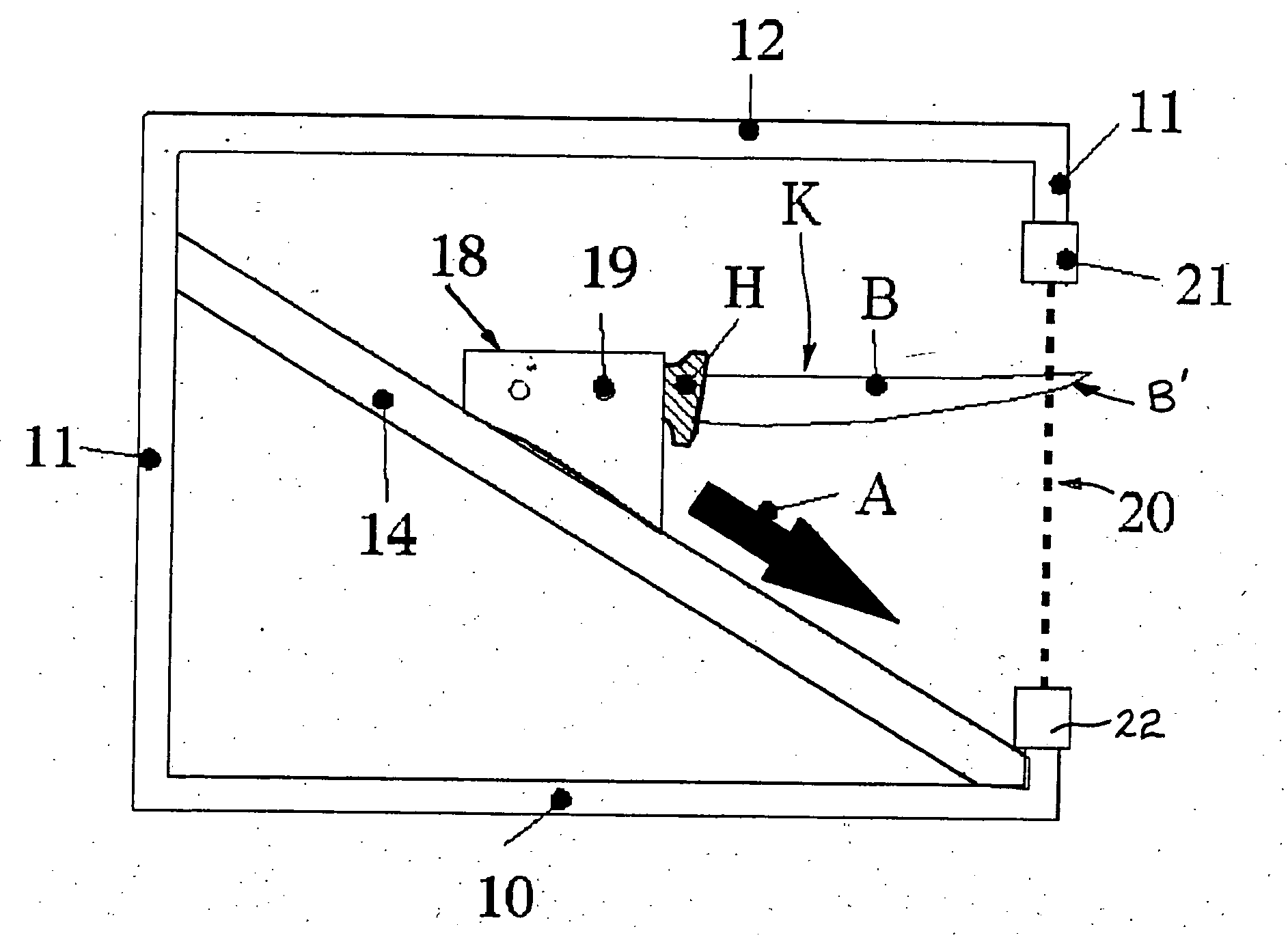

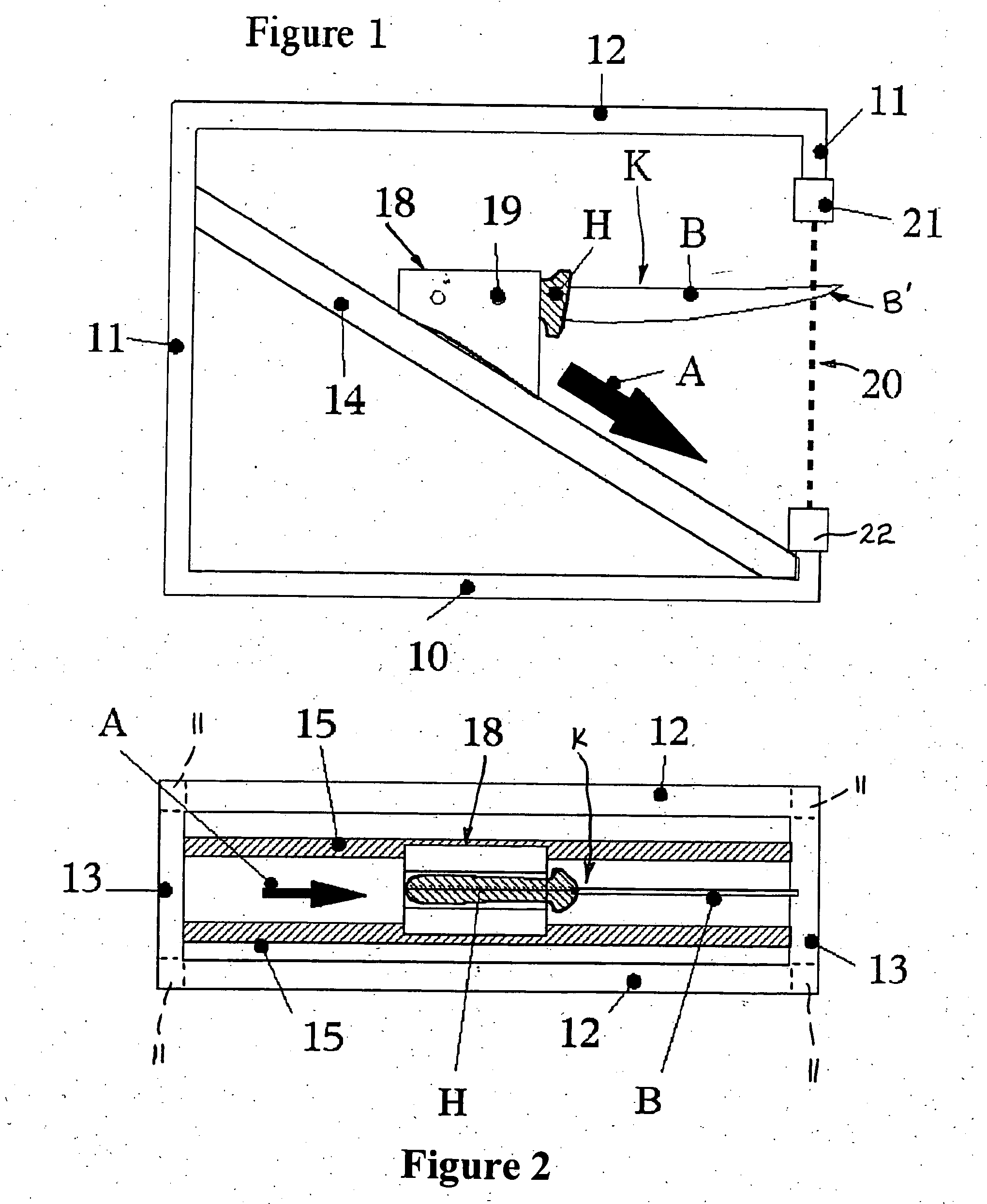

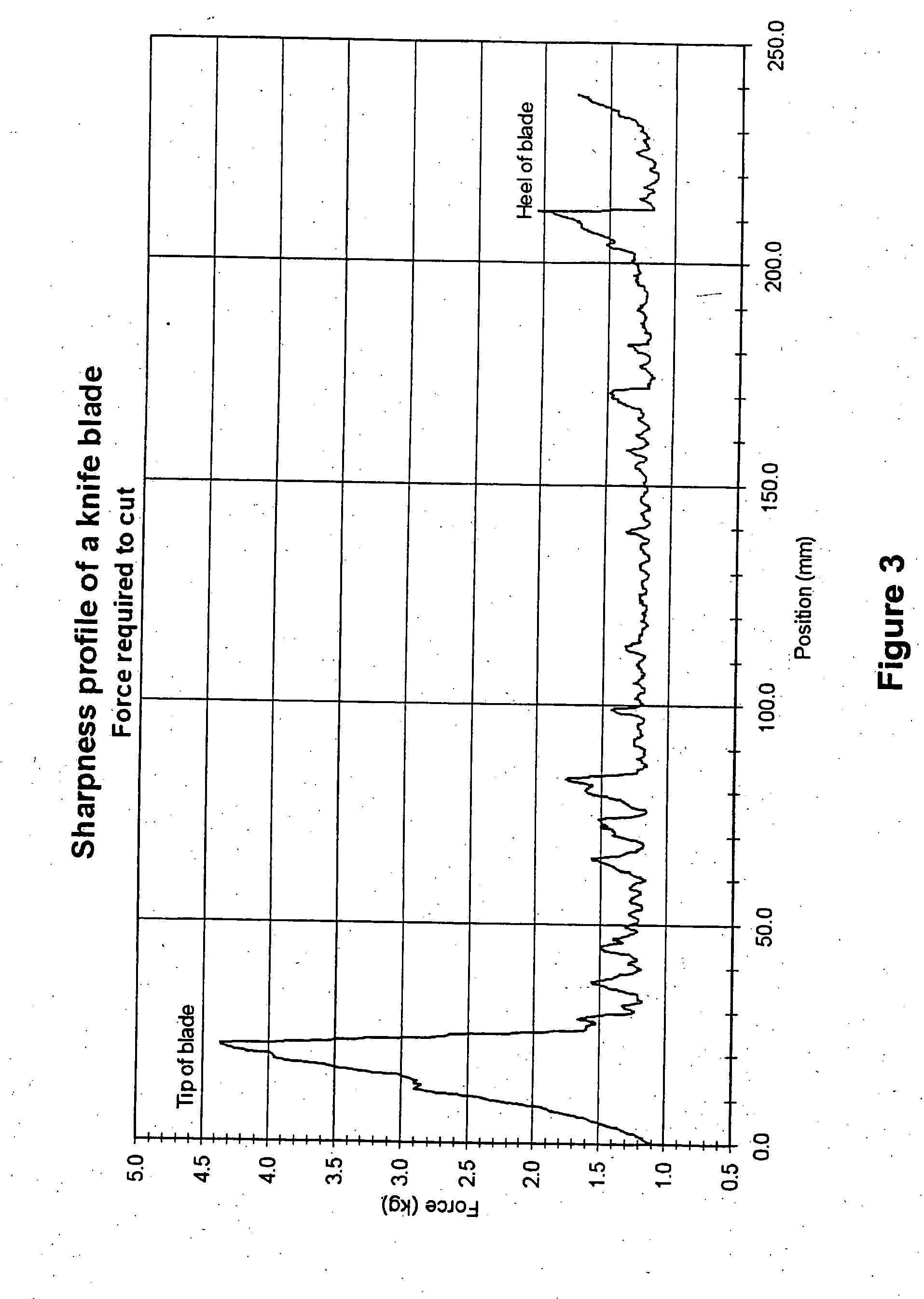

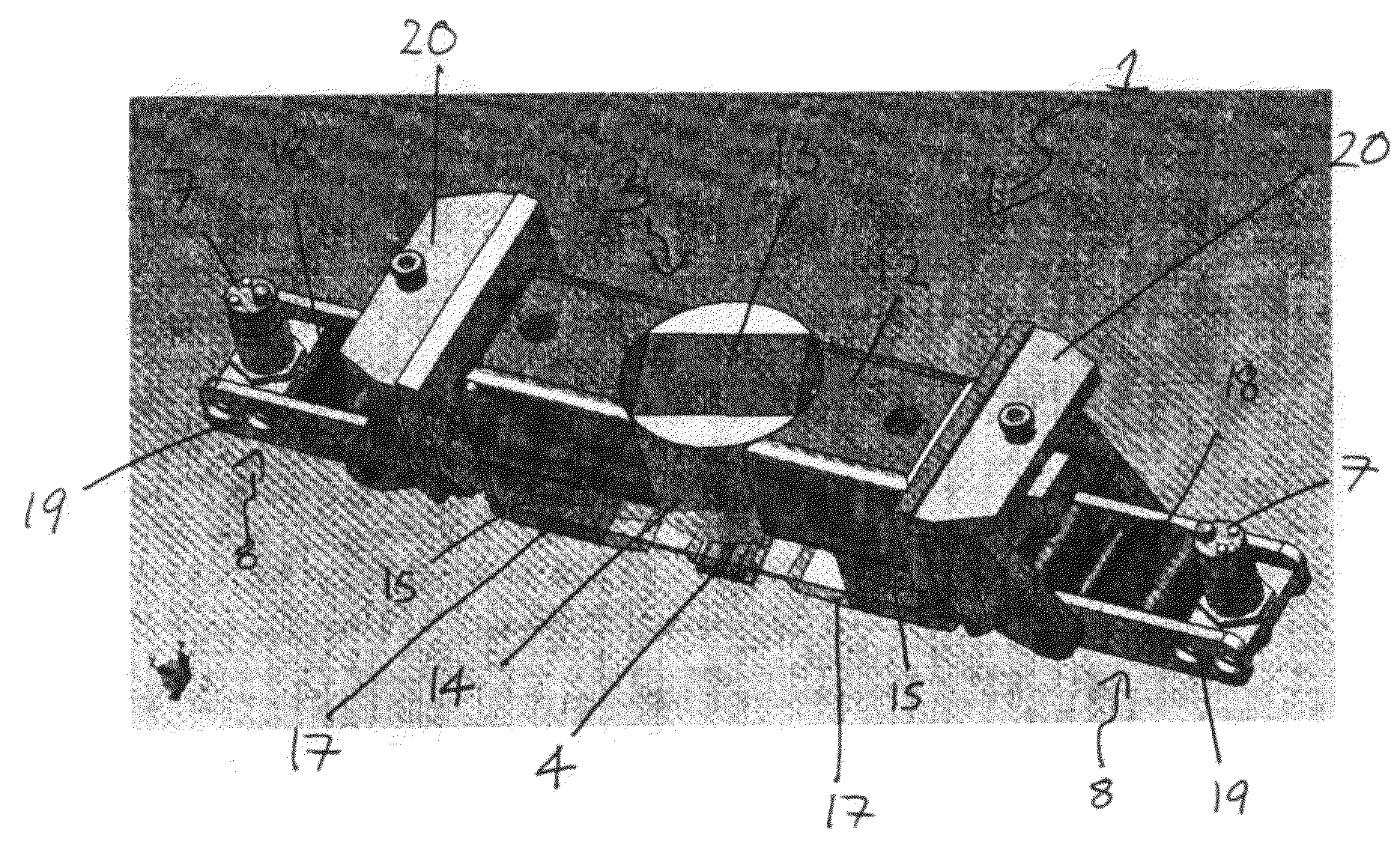

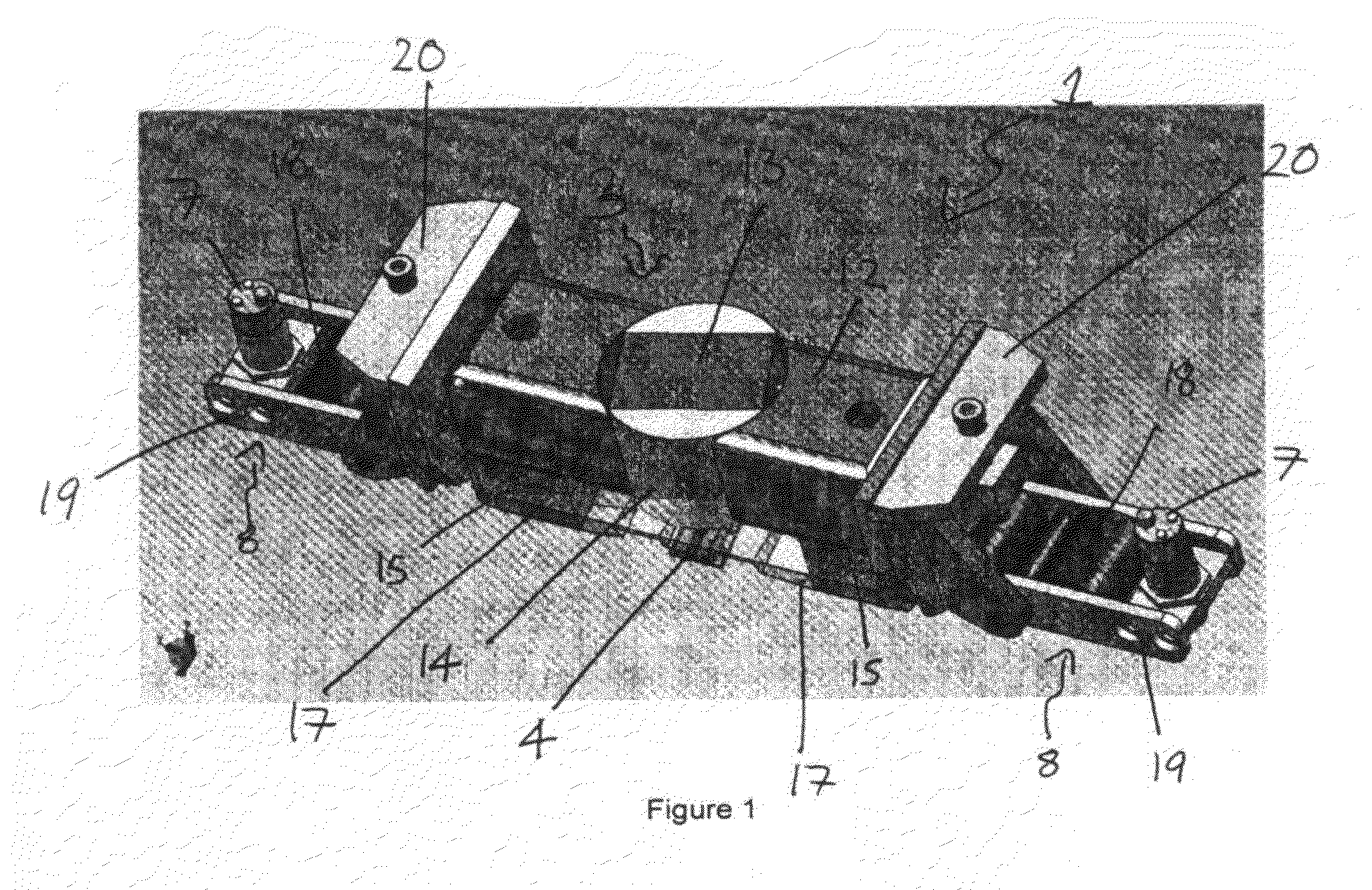

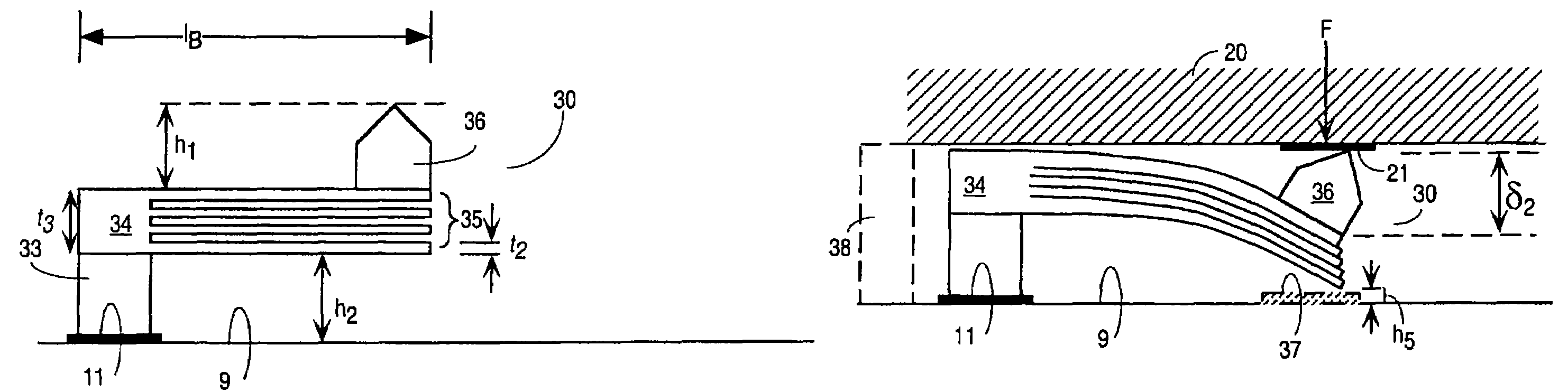

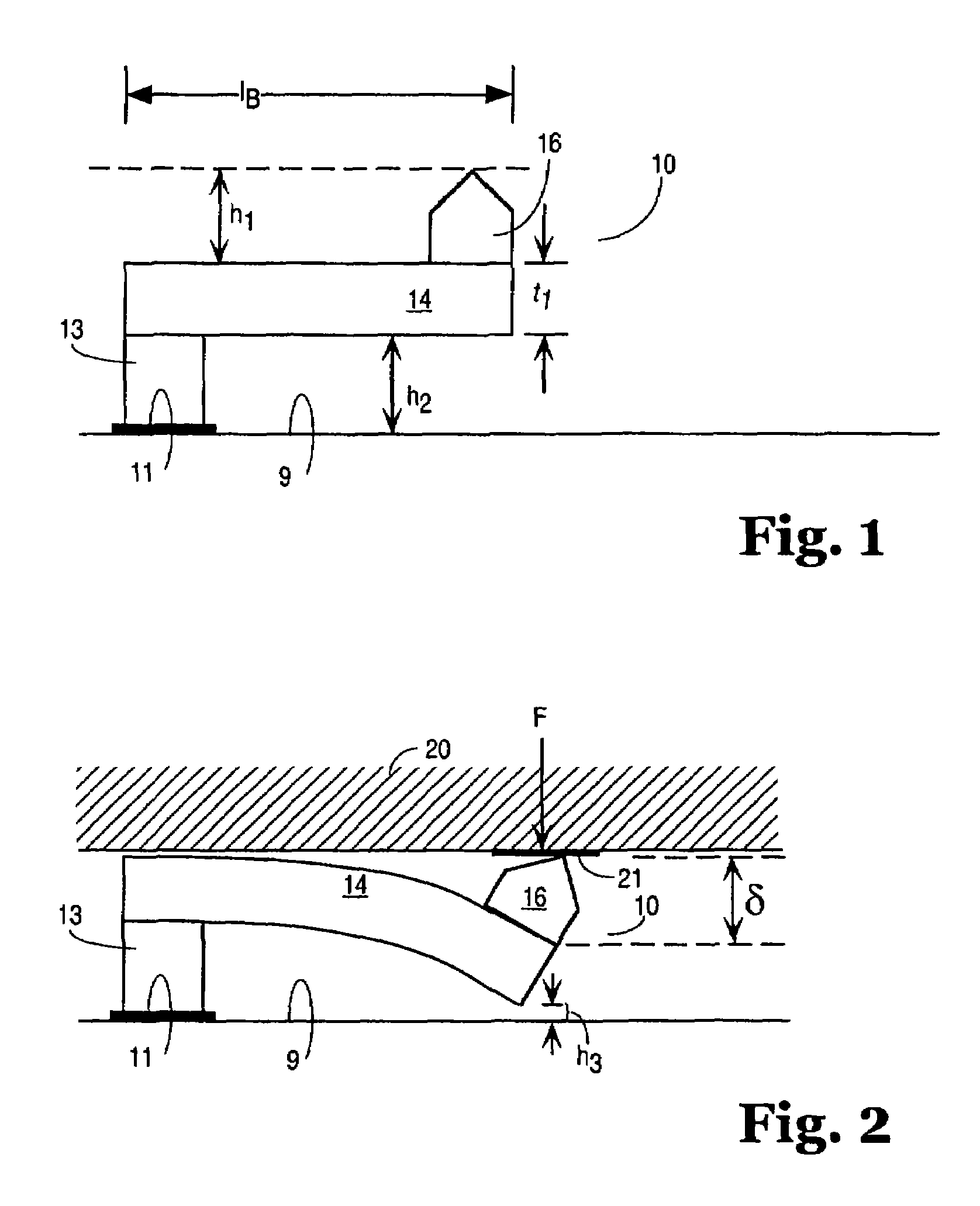

Sharpness tester

ActiveUS20060201237A1Minimal damageMeasurement/indication equipmentsElectric/magnetic roughness/irregularity measurementsMechanical engineeringLinear distance

A sharpness tester for testing the sharpness of a blade. The tester has a blade holder 19 and a mounting arrangement 21, 22 for mounting a cuttable material 20. The blade holder 19 is mounted by a carriage 18 which is moveable on a track 14 so that the blade can move relative to the material 20 and contact the material. A linear distance measuring device and a force measuring device 21 enable the tester to determine the force required by part of the blade B to cut the material 20.

Owner:DOWD PETER CHRISTOPHER

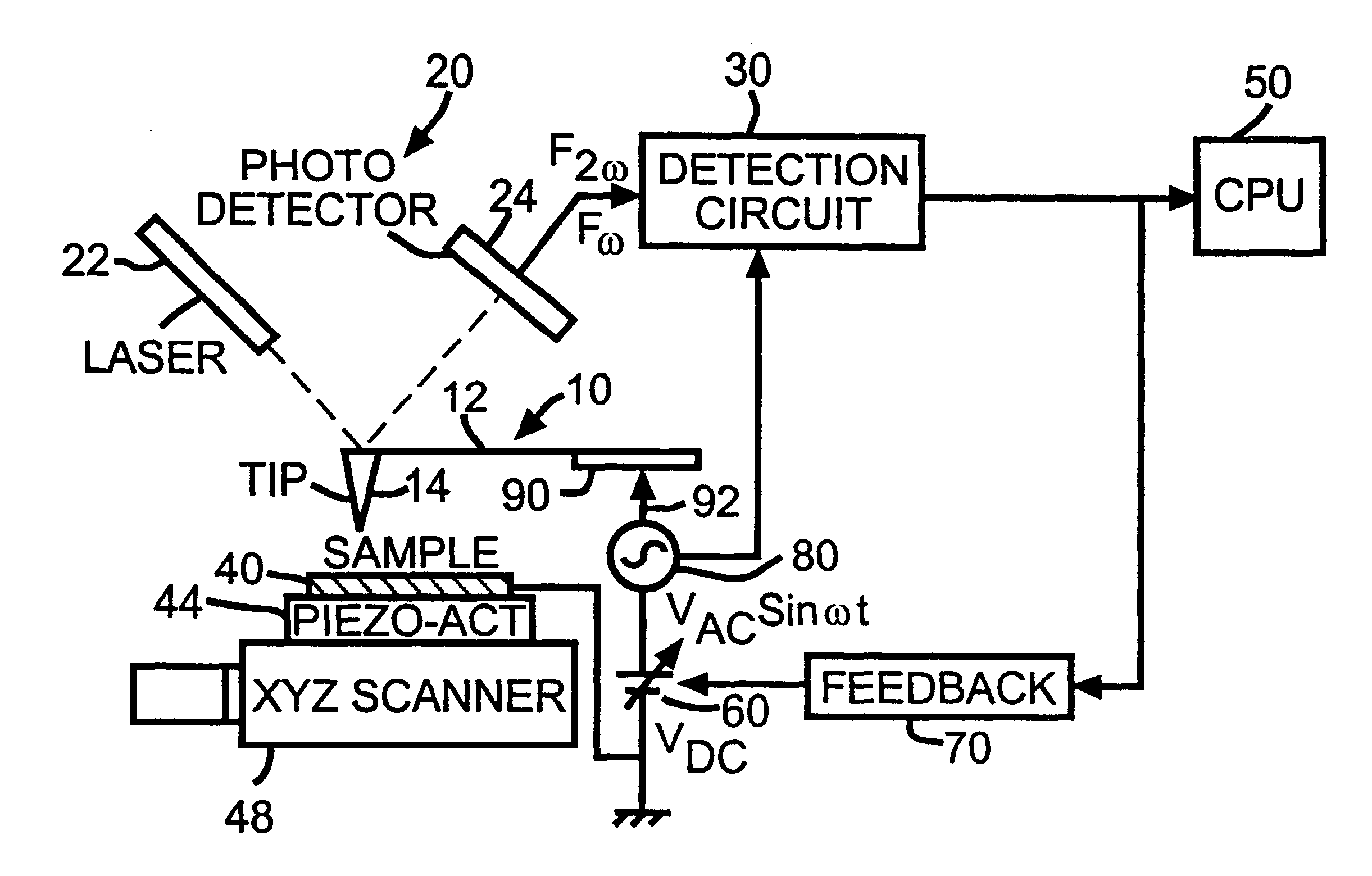

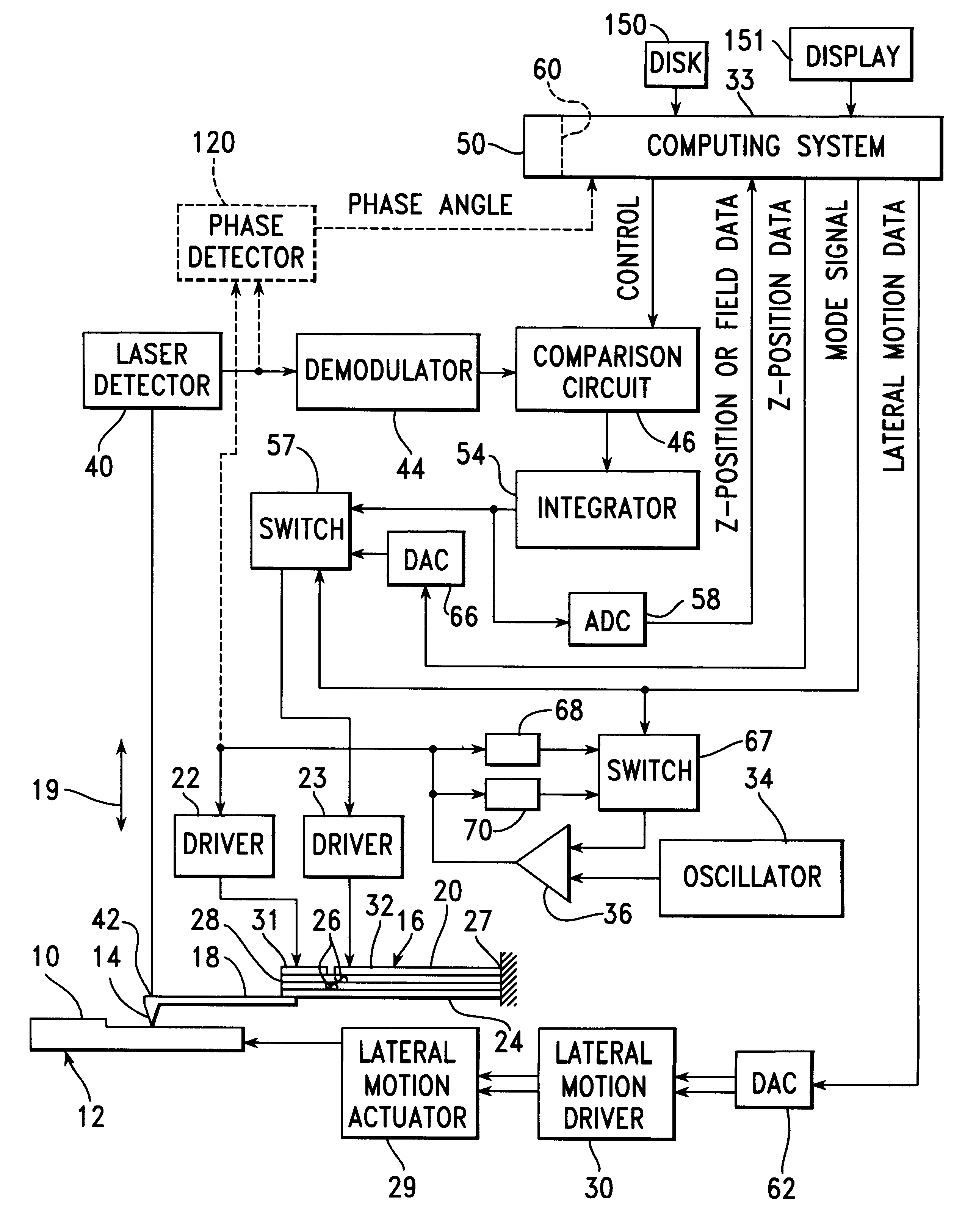

Detecting fields with a single-pass, dual-amplitude-mode scanning force microscope

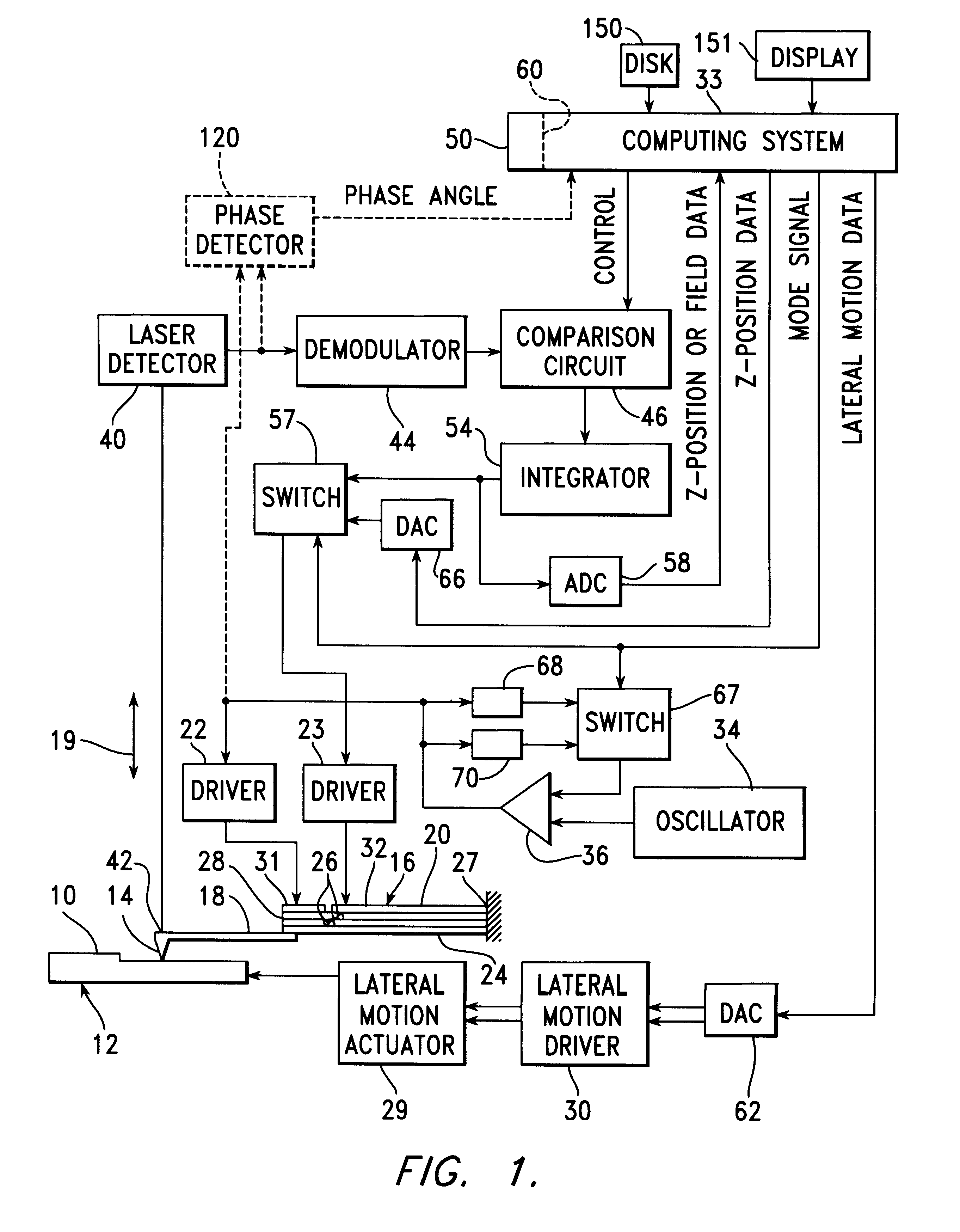

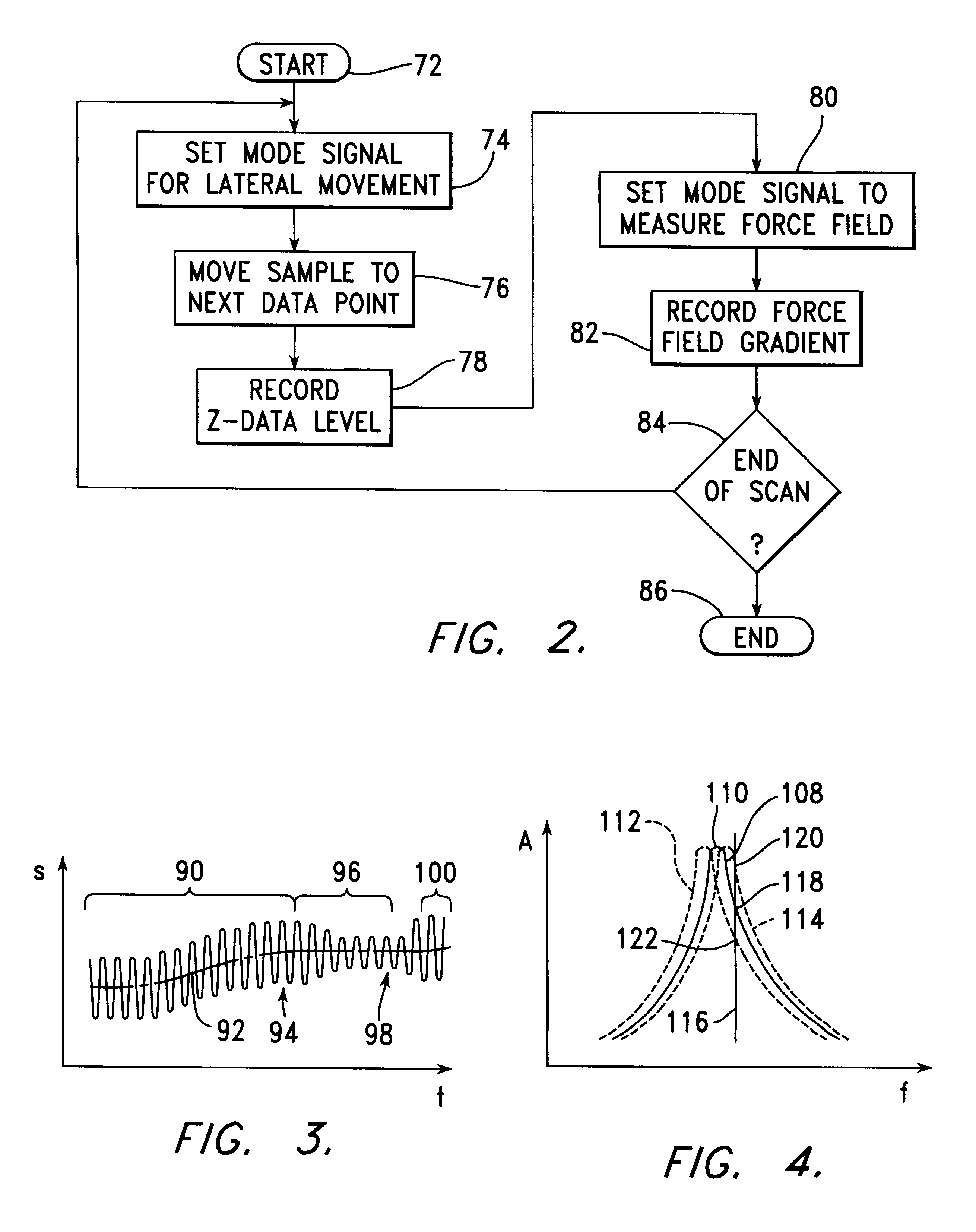

InactiveUS6220084B1Reduce distanceRaise the ratioNanotechMagnetic property measurementsPhase shiftedScan line

A scanning probe microscope operates in the manner of an atomic force microscope during intermittent periods of scanning motion, in which a sample surface is driven so that a scan line on the surface is moved past a probe tip being vibrated in engagement with the surface. Between these intermittent periods of scanning motion, the vibrating probe tip is moved out of engagement with the sample surface, so that the amplitude and phase shift of probe tip vibrations are determined by the gradient of a force field extending outward from the sample surface. Such a force field is established when the probe tip is attracted by, or repelled from, a magnetic or electric field at or near the sample surface. For each sample point, the system stores data representing the height of the sample surface and the force field.

Owner:INT BUSINESS MASCH CORP

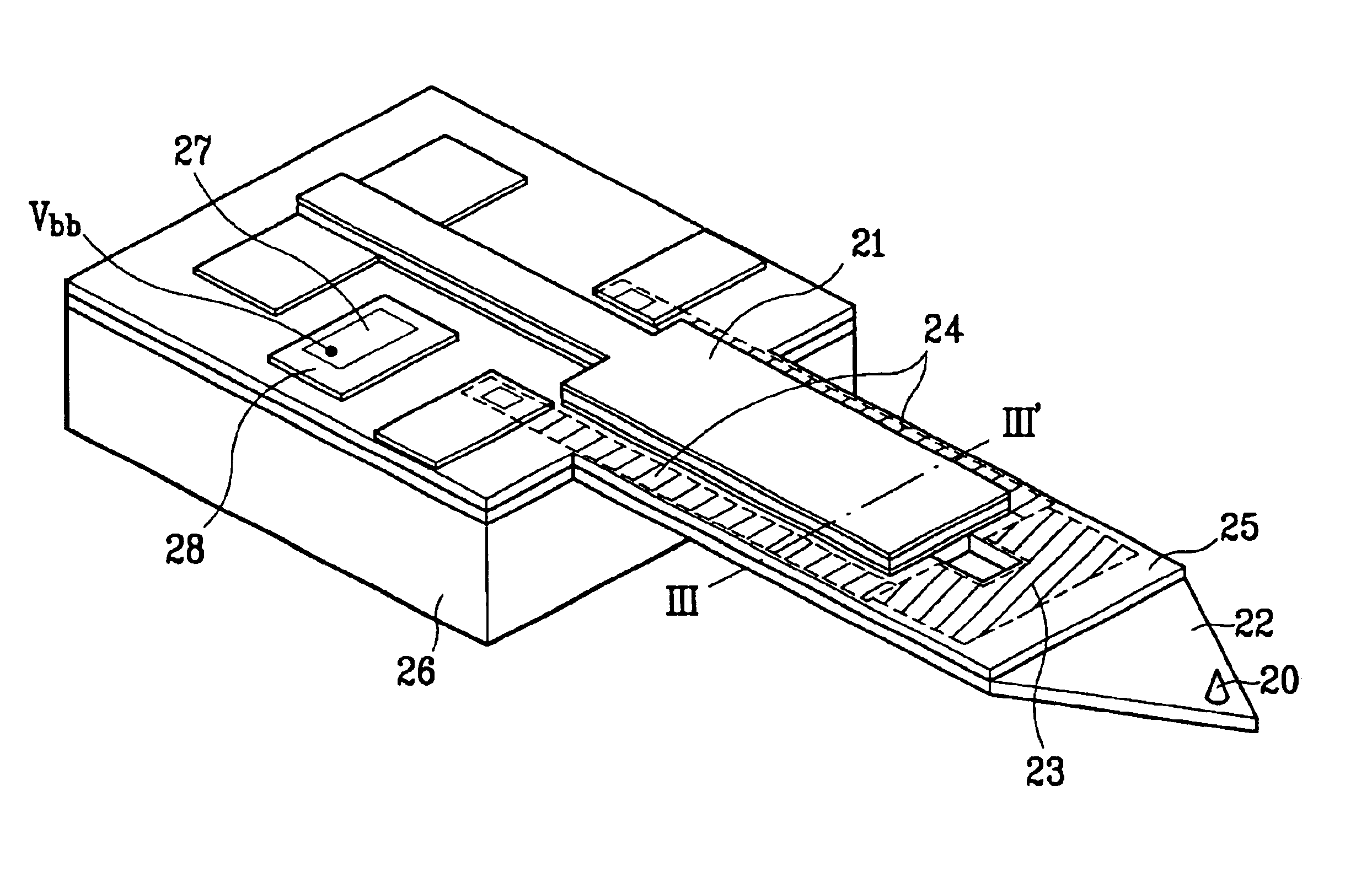

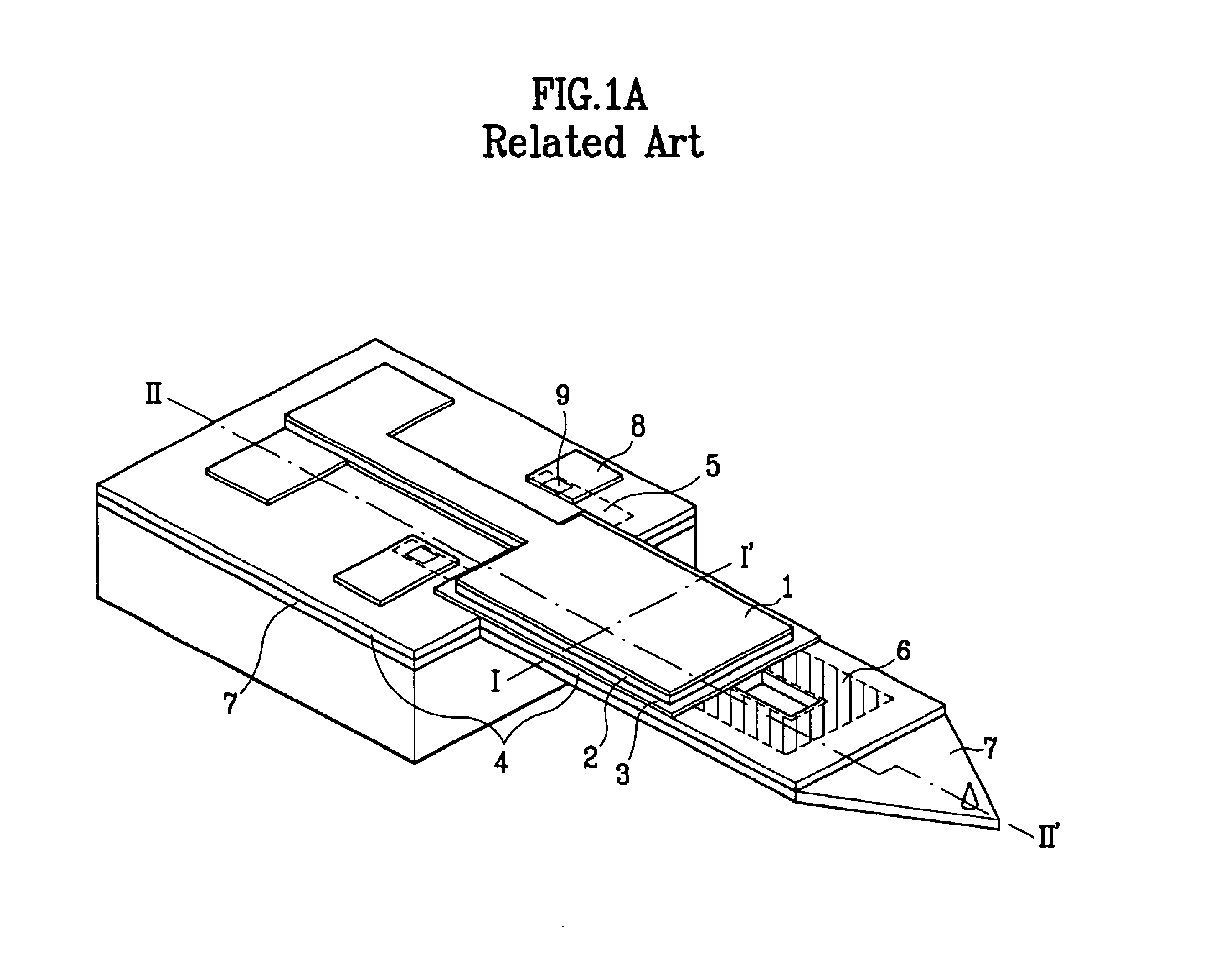

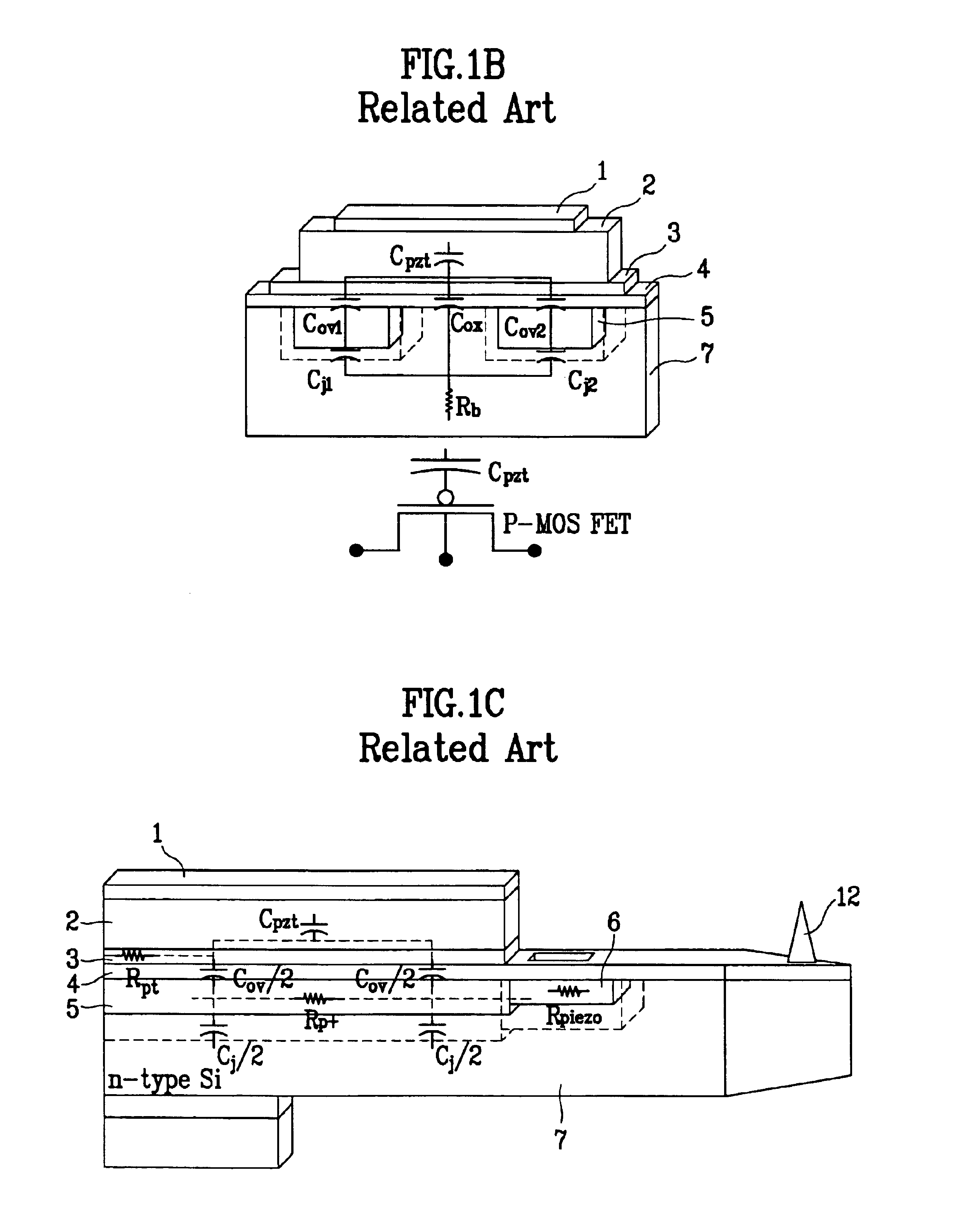

Cantilever for scanning probe microscope

InactiveUS6851301B2Noise minimizationNanotechMaterial analysis using wave/particle radiationCouplingPiezoelectric actuators

Cantilever for a scanning probe microscope (SPM) including a substrate having a tip, a piezoactuator on the substrate movable in response to an external electric signal, and a sensor formed around the piezoactuator so as not to overlap with the piezoactuator, thereby minimizing inner couplings.

Owner:INTELLECTUAL DISCOVERY CO LTD

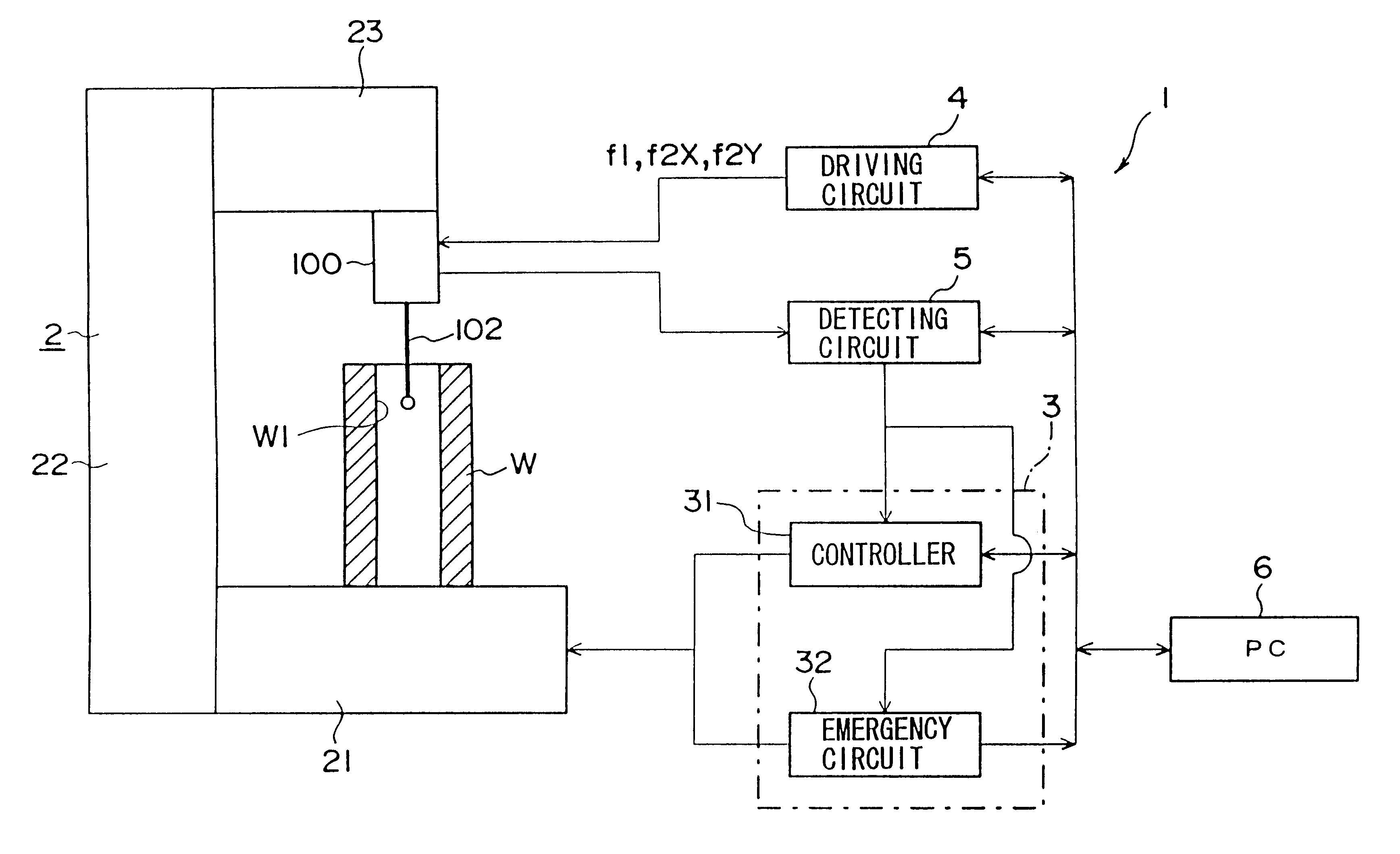

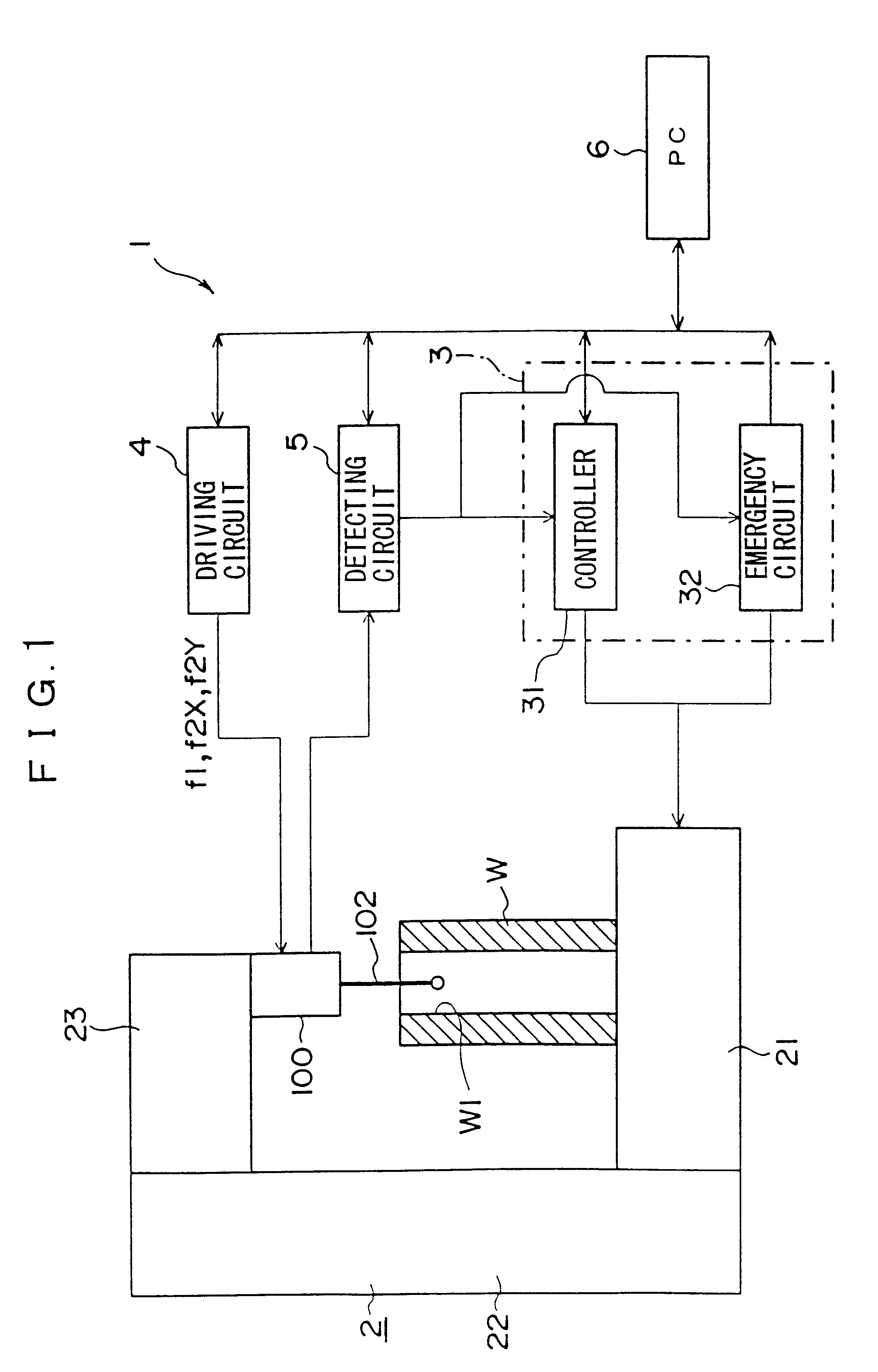

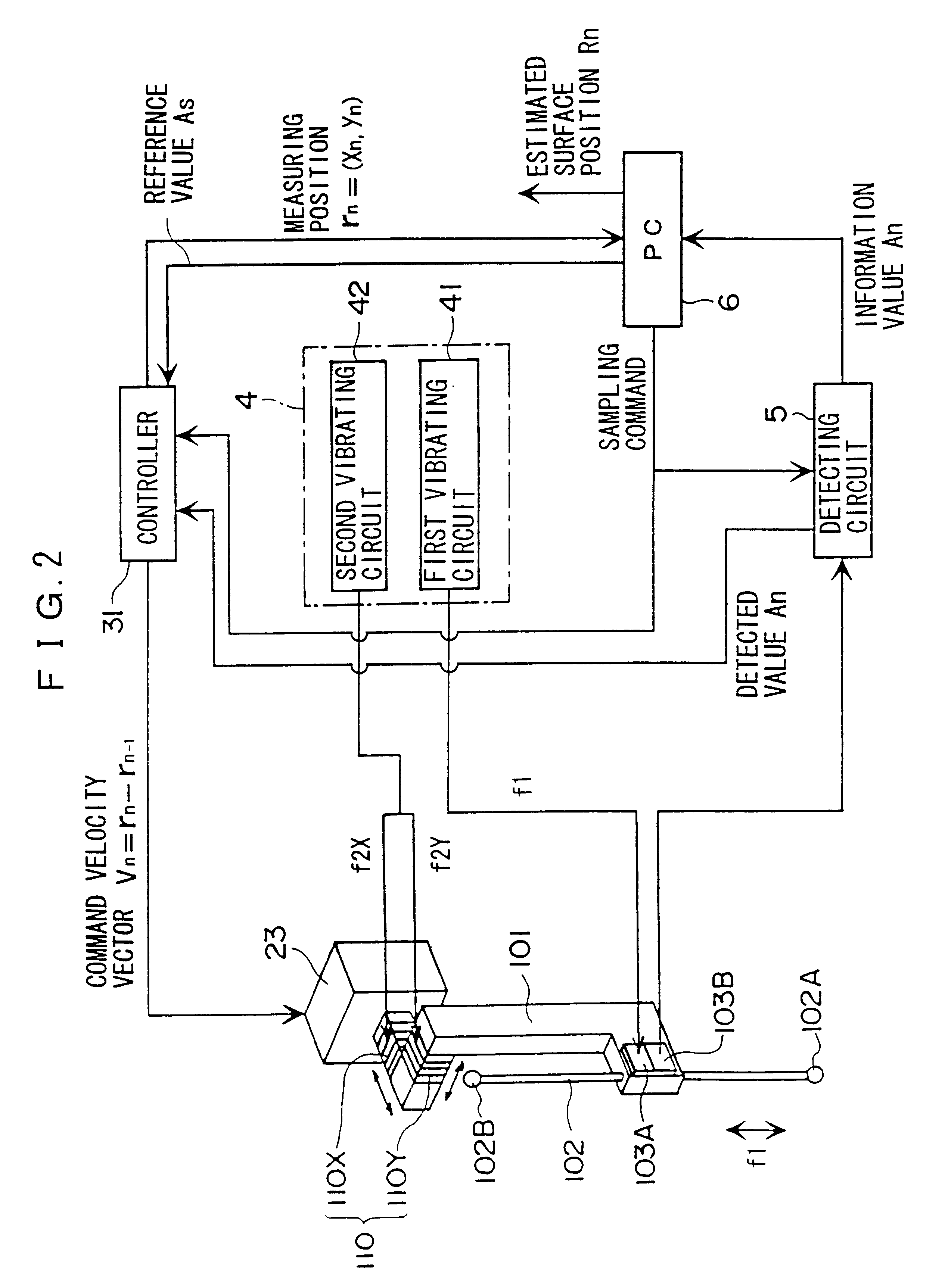

Surface configuration measuring method

InactiveUS6484571B1Mechanical counters/curvatures measurementsElectric/magnetic contours/curvatures measurementsAcousticsVelocity vector

A surface configuration measuring method is provided, the surface configuration measuring method being characterized in having the steps of: moving a touch signal probe by a command velocity vector to touch a surface of the workpiece to be measured; scanning the surface of the workpiece to be measured, the touch signal probe being moved along the surface to be measured while controlling the distance relative to the surface to be measured so that detected amplitude value of a detection signal outputted by the detecting circuit becomes a predetermined reference value, thus outputting the detected amplitude value and corresponding measuring position; and calculating an estimated surface position based on the detected amplitude value and the measuring position estimated to be obtained when surface is scanned to keep the detected amplitude value constant.

Owner:MITUTOYO CORP

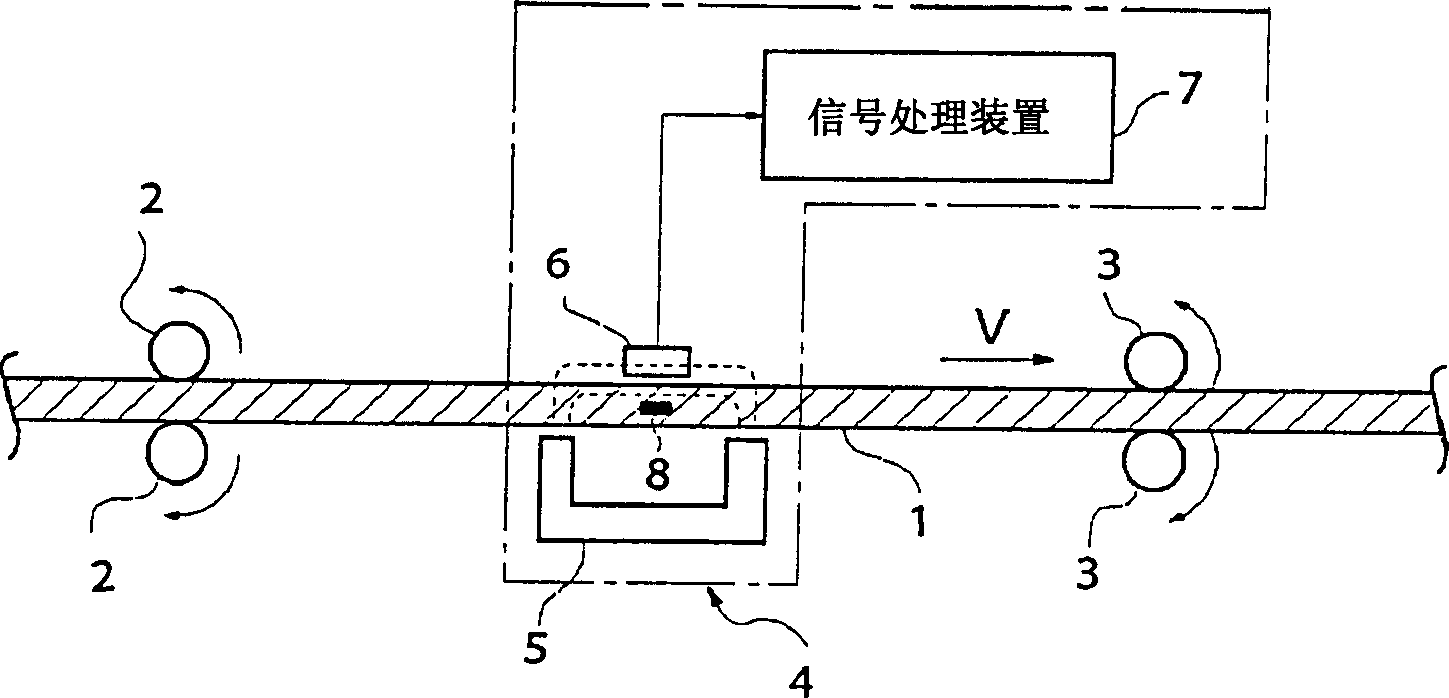

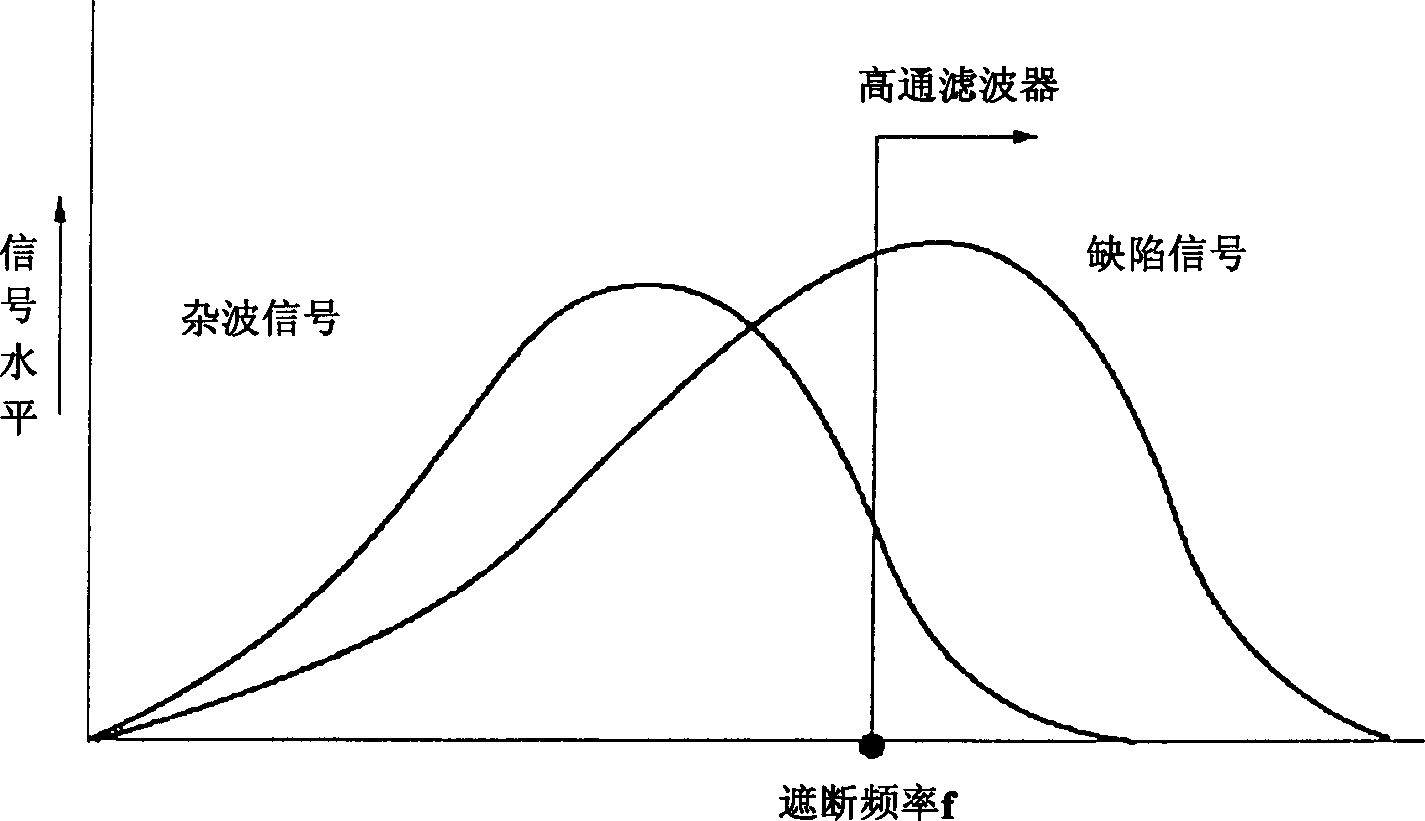

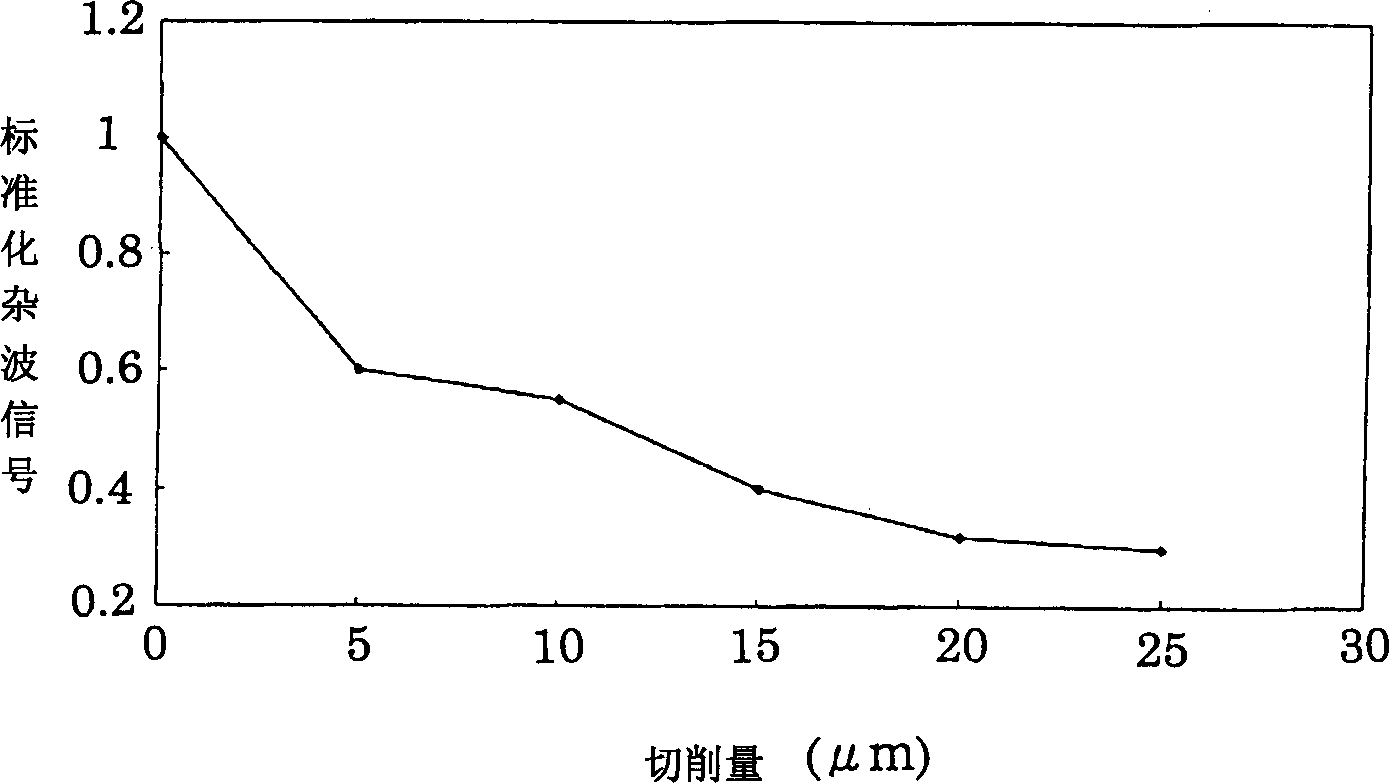

Magnetic leakage flux flow detection method and mfg. method of hot rolled steel plate using same

InactiveCN1373852AElectric/magnetic roughness/irregularity measurementsTesting metalsSheet steelMagnetization

The present invention relates to the invention of the magnetic flux leakage flaw detection method. The strong magnets such as steel plates are magnetized in multiple magnetic fields of different strengths, and the magnetic probes are used to detect the magnetic flux leakage of the magnetized strong magnets, or the strong magnets are magnetized in a certain magnetic field. A plurality of magnetic probes arranged at different positions along the magnetization direction are used to detect the magnetic flux leakage of the magnetized strong magnet, and the output signal of the magnetic probe after the detected magnetic flux leakage is subjected to the calculation of highlighting the signal generated by the internal defect of the strong magnet. In addition, the magnetic flux leakage flaw detection method can be used to detect defects with high precision, so the hot-rolled steel sheet after hot rolling is inspected by this method, and the detected defect is calibrated on the position of the defective steel sheet, so that the correct defect can be grasped in advance. Scaled or descaled hot-rolled steel sheet with location information.

Owner:JFE STEEL CORP

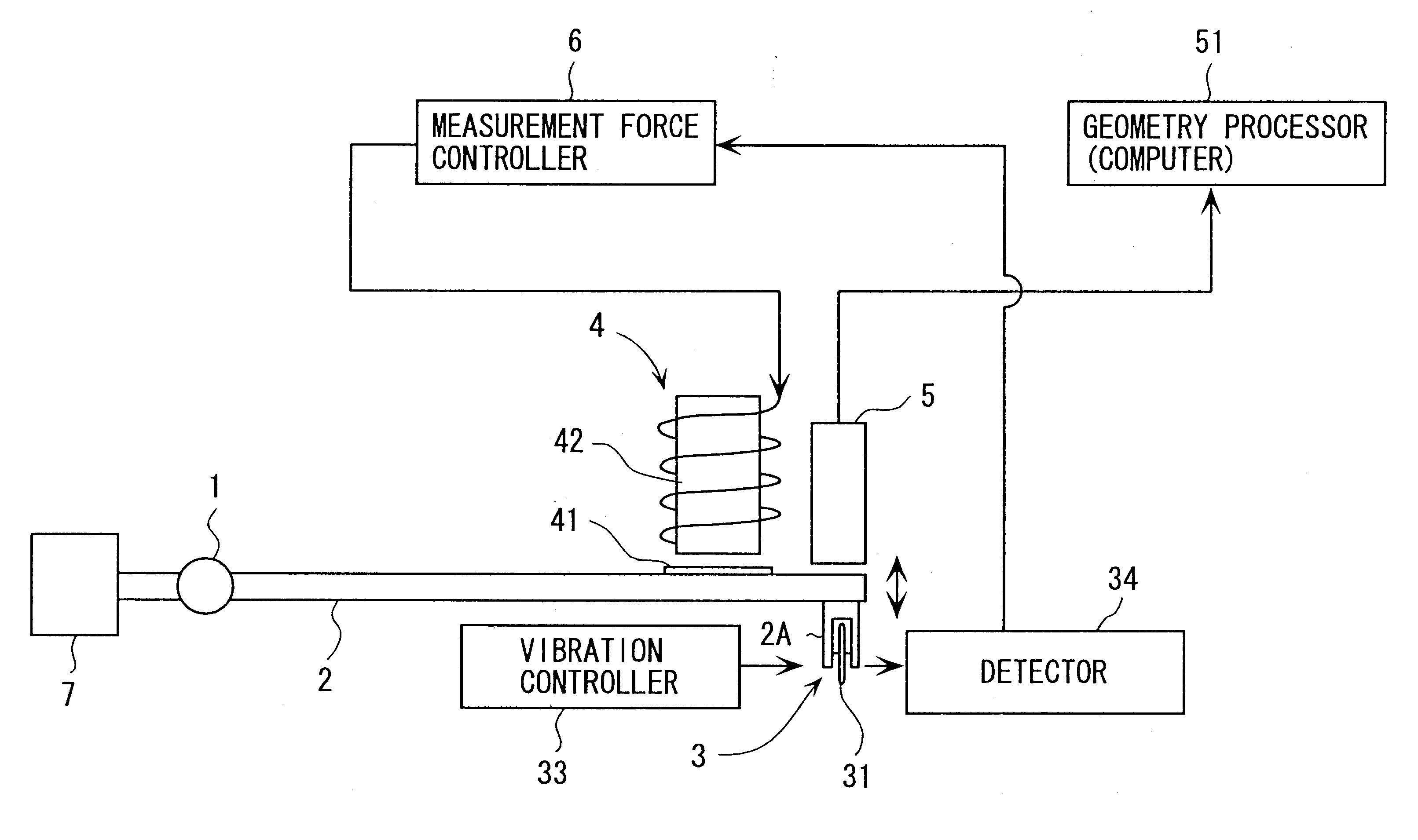

Micro-geometry measuring device

InactiveUS6314800B1Compasses with pivoted armsMechanical counters/curvatures measurementsMeasurement deviceState variation

A micro-geometry measuring device capable of reducing measuring force thereof for avoiding damage on micro-geometry of workpiece surface and measuring at a high-speed is provided. The micro-geometry measuring device has a stylus mechanism having a stylus mechanism provided to an arm and having a stylus body, a measuring force adjusting mechanism for adjusting a measuring force working between the stylus body and the workpiece, a displacement sensor for detecting a position of the arm, and a measuring force controller for controlling the measuring force adjusting mechanism. The stylus mechanism includes a vibrator for resonantly vibrating the stylus body, and a detector for detecting vibration status changing when the stylus body touches the workpiece. The change in vibration of the stylus body vibrated by the vibrator is directly detected by the detector and a signal therefrom is fed back to the measuring force controller to keep constant measuring force working between the stylus body and the workpiece.

Owner:MITUTOYO CORP

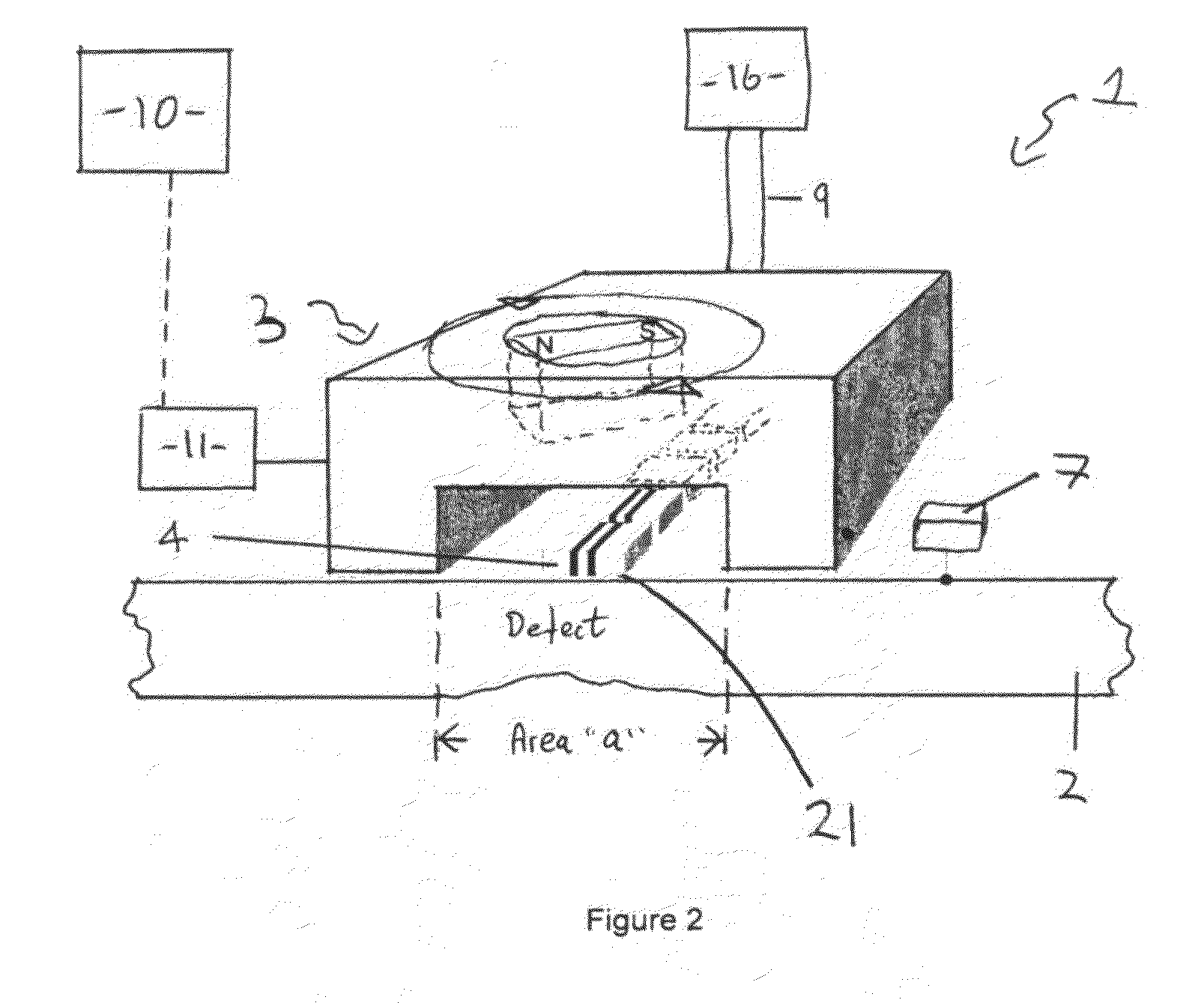

Electromagnet inspection apparatus and method

ActiveUS20120306483A1Less sensitiveEfficient detectionPermeability measurementsUsing electrical meansPartial saturationComputer module

A method and apparatus for the inspection of electrically conductive components is described. The described apparatus comprises a sensor module having a magnetiser unit suitable for generating a variable DC magnetic field within the test component and an eddy current probe. The variable DC magnetic field and eddy current probe are configured to perform a partial saturation eddy current test upon the test component. The eddy current probe further comprises a magnetic field sensor that provides a means for measuring the permeability within the test component. Employing the magnetic field sensor provides apparatus that is more accurate and flexible in its modes of operation since such sensors provide a means for the actual permeability of a material being tested to be measured. The described methods and apparatus find particular application in the inspection of tubular components used in the oil and gas exploration and production industries.

Owner:SONOMATIC

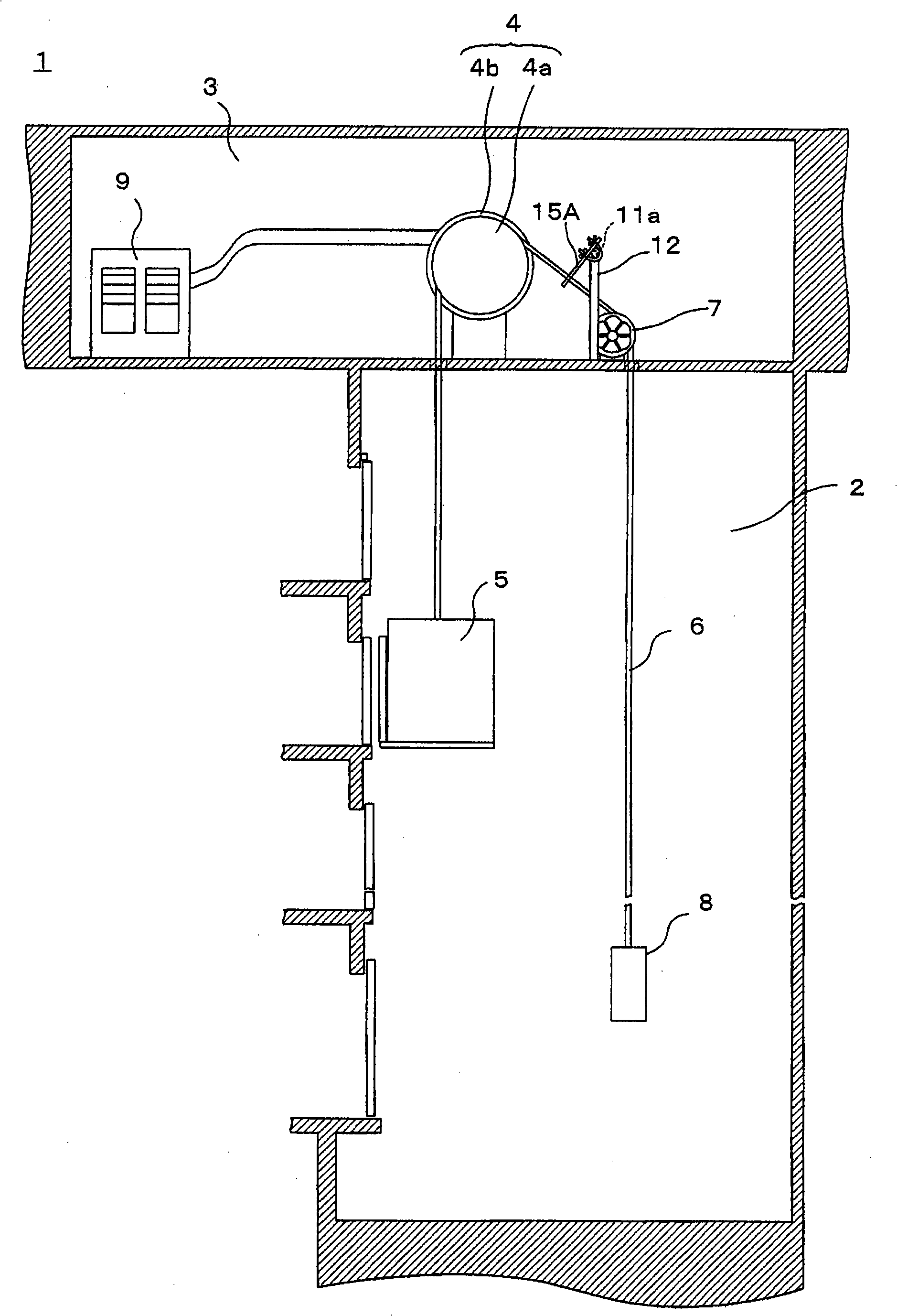

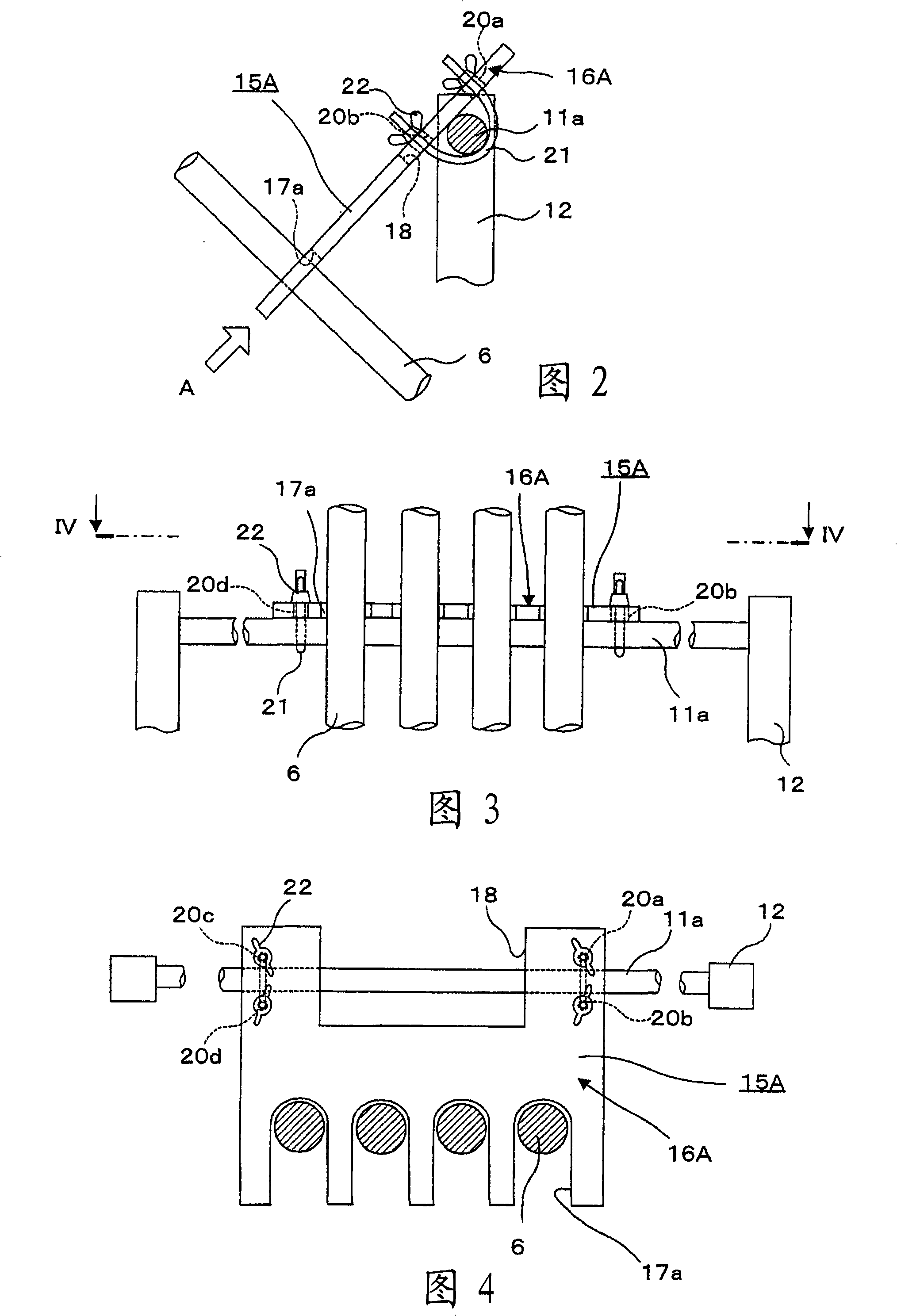

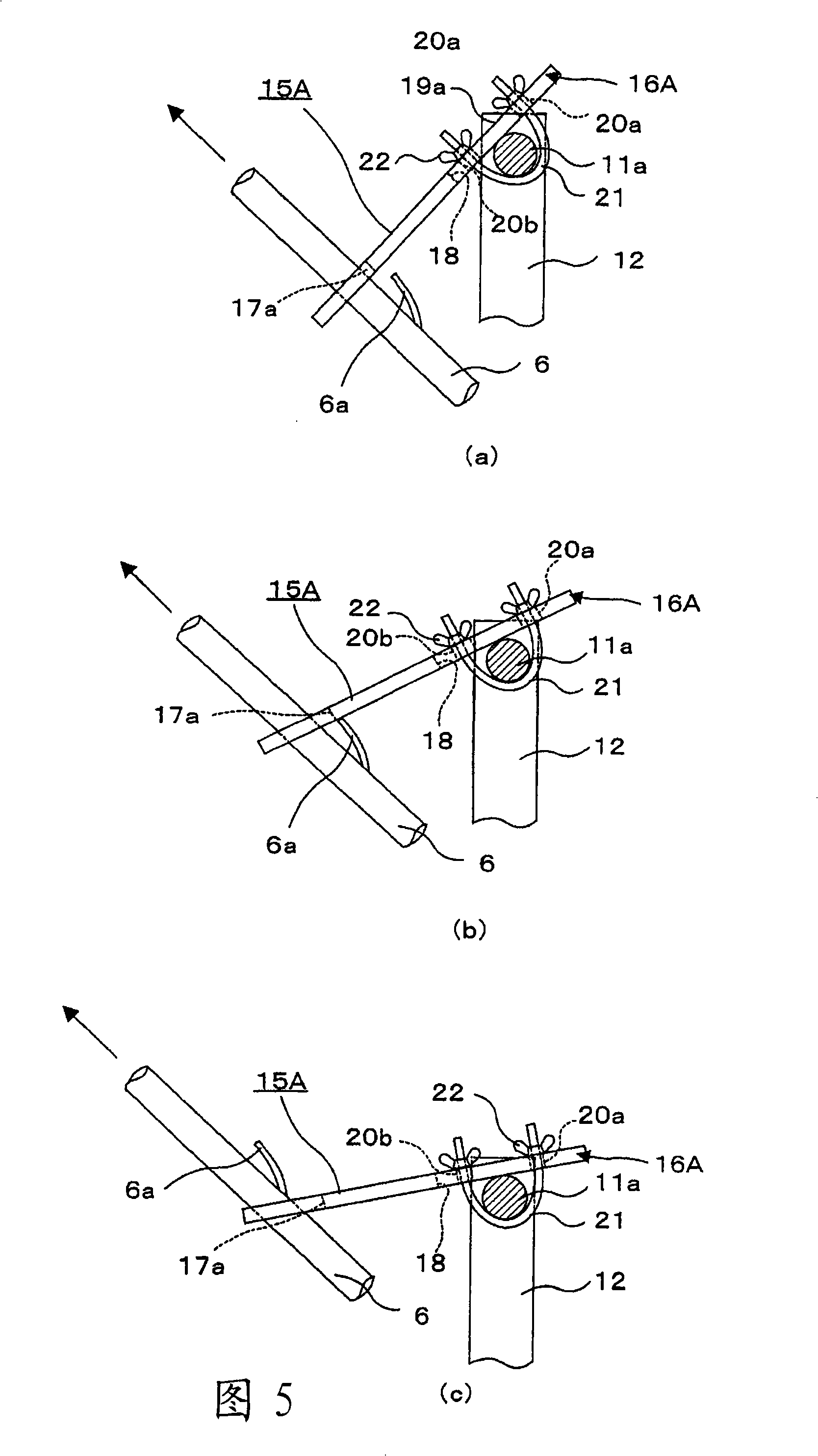

Rope checking method

ActiveCN101408529AAvoid breakingElectrical testingElectric/magnetic roughness/irregularity measurementsElectrical polarityMagnetic flux

The objective of the present invention is to provide a rope inspection method, which can not only avoid the damage of the rope tester in the first place, but also can check the elevator wire rope in a short period. A rope inspection method for detecting the exception of an elevator wire rope (6) traveling in linkage with the rotation for driving a rope pulley, a rope tester monomer (26) has a pair of opposite polarity magnets (28a, 28b) mutually depart from a scheduled distance; and a flat coil (31) for detecting the variation of magnetic flux produced between the pair of magnets (28a, 28b), wherein, the rope tester monomer (26) is set that the flat coil (31 ) can detect the variation of magnetic flux produced by the fracture of the wire of the traveling wire rope (6), before performing a main check-up for detecting whether the wire of the traveling wire rope (6) has fractures based on the output of the flat coil (31 ), a preparatory check-up for detecting whether the wire rope (6) has projecting positions is performed firstly.

Owner:MITSUBISHI ELECTRIC BUILDING SOLUTIONS CORP

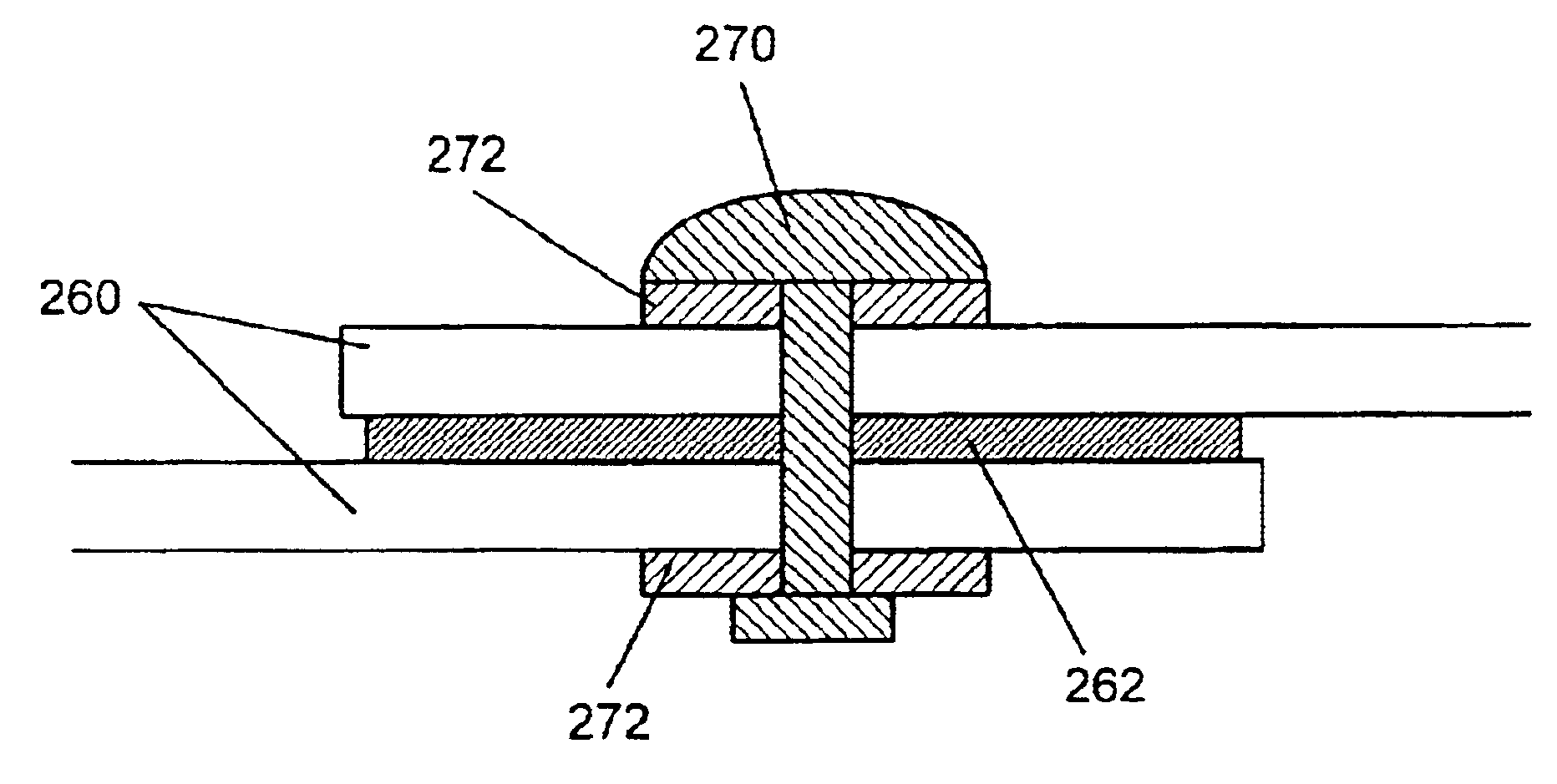

Spring interconnect structures

InactiveUS7553165B2Increase the spring constantImprove mechanical propertiesCoupling device connectionsSemiconductor/solid-state device testing/measurementInterconnectionEngineering

An interconnection element of a spring (body) including a first resilient element with a first contact region and a second contact region and a first securing region and a second resilient element, with a third contact region and a second securing region. The second resilient element is coupled to the first resilient element through respective securing regions and positioned such that upon sufficient displacement of the first contact region toward the second resilient element, the second contact region will contact the third contact region. The interconnection, in one aspect, is of a size suitable for directly contacting a semiconductor device. A large substrate with a plurality of such interconnection elements can be used as a wafer-level contactor. The interconnection element, in another aspect, is of a size suitable for contacting a packaged semiconductor device, such as in an LGA package.

Owner:FORMFACTOR INC

Micro friction measurement device

InactiveCN104568740ASimple structureSimple principleElectric/magnetic roughness/irregularity measurementsUsing mechanical meansLinear motionMeasurement device

The invention relates to a micro friction measurement device, and belongs to the technical field of micro force measurement. By adjusting a fine tuning knob on a lifting platform, loading normal load is realized. Resistance strain gages are adhered to front and back surfaces of an elastic element, form a Wheatstone bridge through leads, so as to indirectly measure the normal load. Two fixed pole plates and a moving pole plate form a differential capacitive sensor; the two fixed pole plates are fixed on the lifting platform through supporting rods; the moving pole plate is connected with a detachable connecting block through a connecting piece; when a servo motor is operated to drive a ball screw, to enable a sample stage to perform linear motion, the connecting block suffers frictional force, a small displacement in the horizontal direction can occur, and the polar distance between the pole plates can be changed, therefore, the capacitance of the capacitive sensor is changed, and the friction measurement is realized. The micro friction measurement device has a simple structure, can realize force loading without a high-precision placement platform, improves the measurement sensitivity, greatly reduces the linear error, and has a good effect on measuring micro force, such as friction force and the like.

Owner:KUNMING UNIV OF SCI & TECH

Popular searches

Semiconductor/solid-state device details Solid-state devices Scanning probe techniques Photomechanical exposure apparatus Microlithography exposure apparatus Mechanical roughness/irregularity measurements Semiconductor devices Gamma-ray/x-ray microscopes Material magnetic variables Point coordinate measurements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com