Micro friction measurement device

A measuring device and micro-friction technology, applied in the field of micro-friction measuring devices, detection and evaluation of micro-friction measuring devices, to achieve the effects of low cost, high measurement accuracy, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

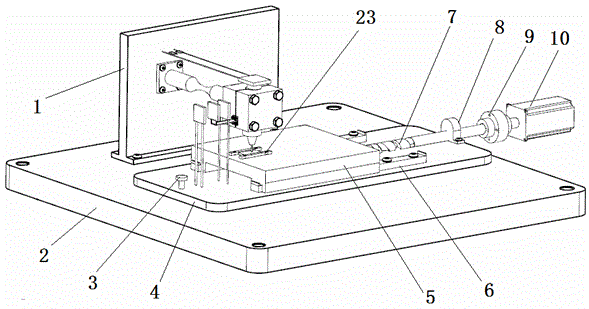

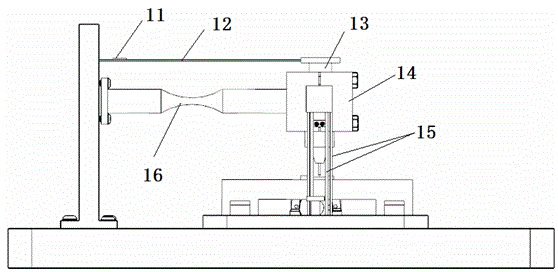

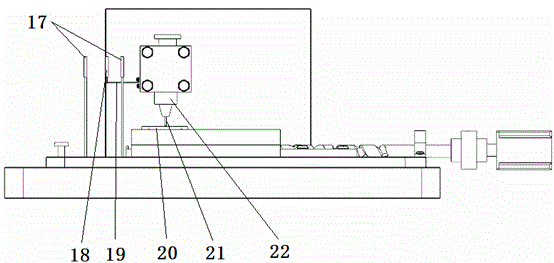

[0016] Embodiment 1: A micro-friction measurement device, including a support plate 1, a base 2, a fine-tuning knob 3, a lift table 4, a sample table 5, a linear guide 6, a ball screw 7, a bearing seat 8, and an elastic coupling 9 , servo motor 10, resistance strain gauge 11, elastic element 12, cylindrical block 13, detachable connecting block 14, support rod 15, universal flexible hinge 16, fixed plate 17, moving plate 18, connector 19, fixed plate 20. Friction contact 21, micro-drill chuck 22; the support plate 1 is fixed on the base 2 through bolt connection, the sample table 5 and the nut of the ball screw 7 are fixed together and move on the linear guide rail 6, and the linear guide rail 6 is fixed on the lifting platform 4 with screws, the sample platform 5 drives the ball screw 7 through the servo motor 10 to realize its horizontal displacement, and the normal load and vertical displacement are realized through the fine-tuning knob 3 on the lifting platform 4 , the ela...

Embodiment 2

[0017] Embodiment 2: A micro-friction measurement device, including a support plate 1, a base 2, a fine-tuning knob 3, a lift table 4, a sample table 5, a linear guide 6, a ball screw 7, a bearing seat 8, and an elastic coupling 9 , servo motor 10, resistance strain gauge 11, elastic element 12, cylindrical block 13, detachable connecting block 14, support rod 15, universal flexible hinge 16, fixed plate 17, moving plate 18, connector 19, fixed plate 20. Friction contact 21, micro-drill chuck 22; the support plate 1 is fixed on the base 2 through bolt connection, the sample table 5 and the nut of the ball screw 7 are fixed together and move on the linear guide rail 6, and the linear guide rail 6 is fixed on the lifting platform 4 with screws, the sample platform 5 drives the ball screw 7 through the servo motor 10 to realize its horizontal displacement, and the normal load and vertical displacement are realized through the fine-tuning knob 3 on the lifting platform 4 , the ela...

Embodiment 3

[0019] Embodiment 3: a kind of micro-friction measuring device, the structural principle of the present invention is as figure 1 As shown, the adjustment of the vertical displacement and the loading of the positive load are realized by adjusting the fine-tuning knob 3 on the lifting platform 4 . The sample table 5 and the nut of the precision ball screw 7 are fixed together by bolts, and the precision ball screw 7 is connected with the servo motor 10 through the elastic coupling 9, and the rotary motion of the servo motor 10 is converted into the sample table on the linear guide rail 6. The horizontal movement on the top, the linear guide rail 6 is connected and fixed on the lifting table 4 with screws. The sensor structure for measuring the normal load mainly includes an elastic element 12 and two pairs of resistance strain gauges 11, which are connected with the support plate 1 to form a cantilever structure. The friction sensor structure for measuring the horizontal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com