Patents

Literature

316 results about "Waviness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

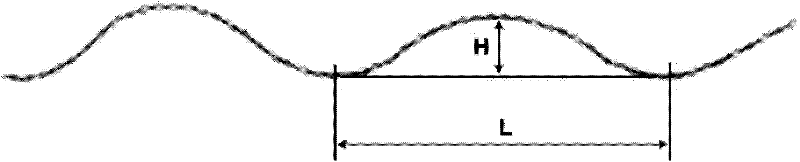

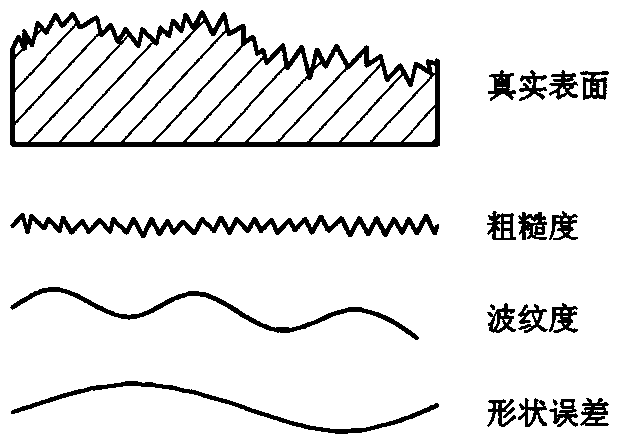

Waviness is the measurement of the more widely spaced component of surface texture. It is a broader view of roughness because it is more strictly defined as "the irregularities whose spacing is greater than the roughness sampling length". It can occur from machine or work deflections, chatter, residual stress, vibrations, or heat treatment. Waviness should also be distinguished from flatness, both by its shorter spacing and its characteristic of being typically periodic in nature.

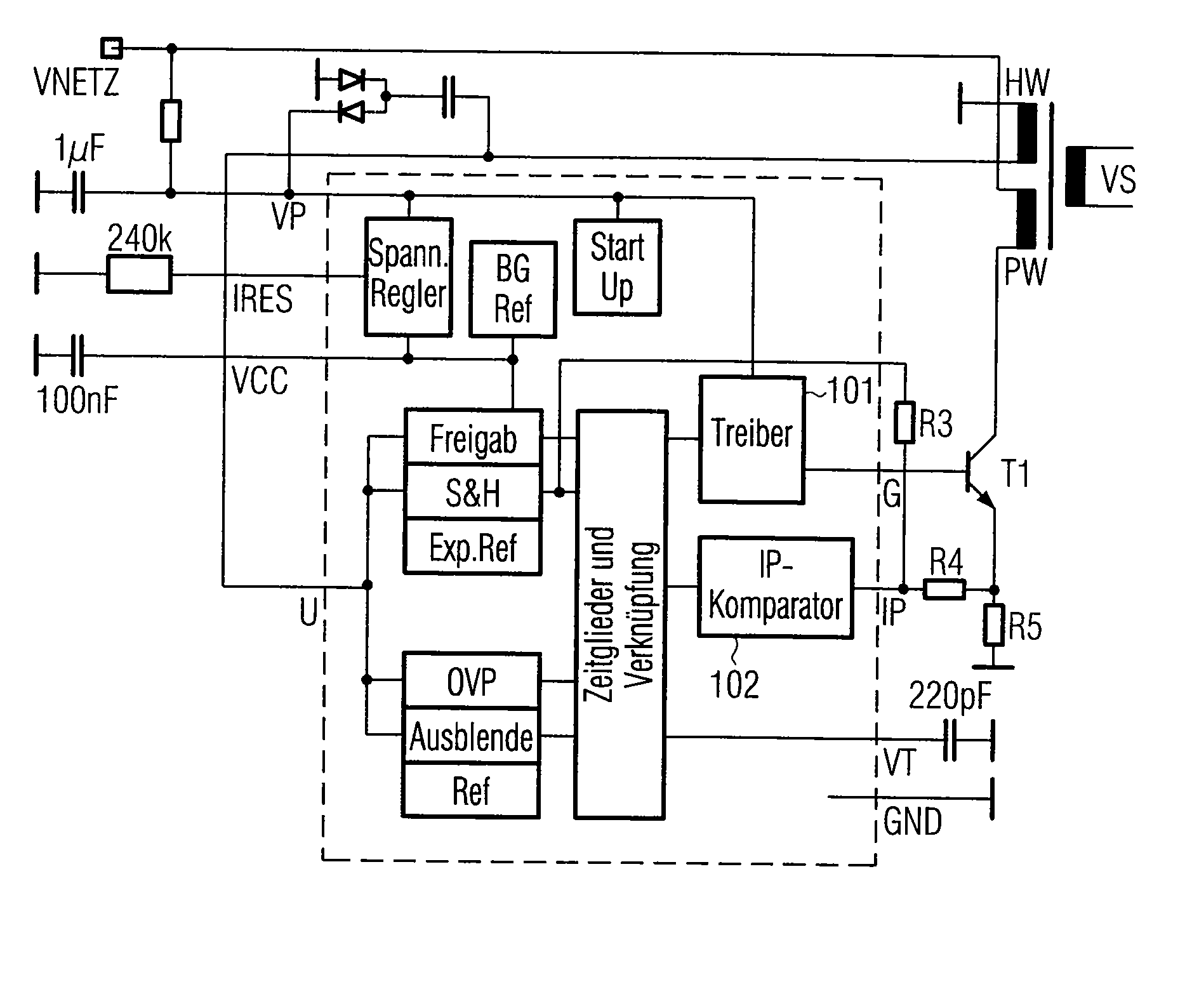

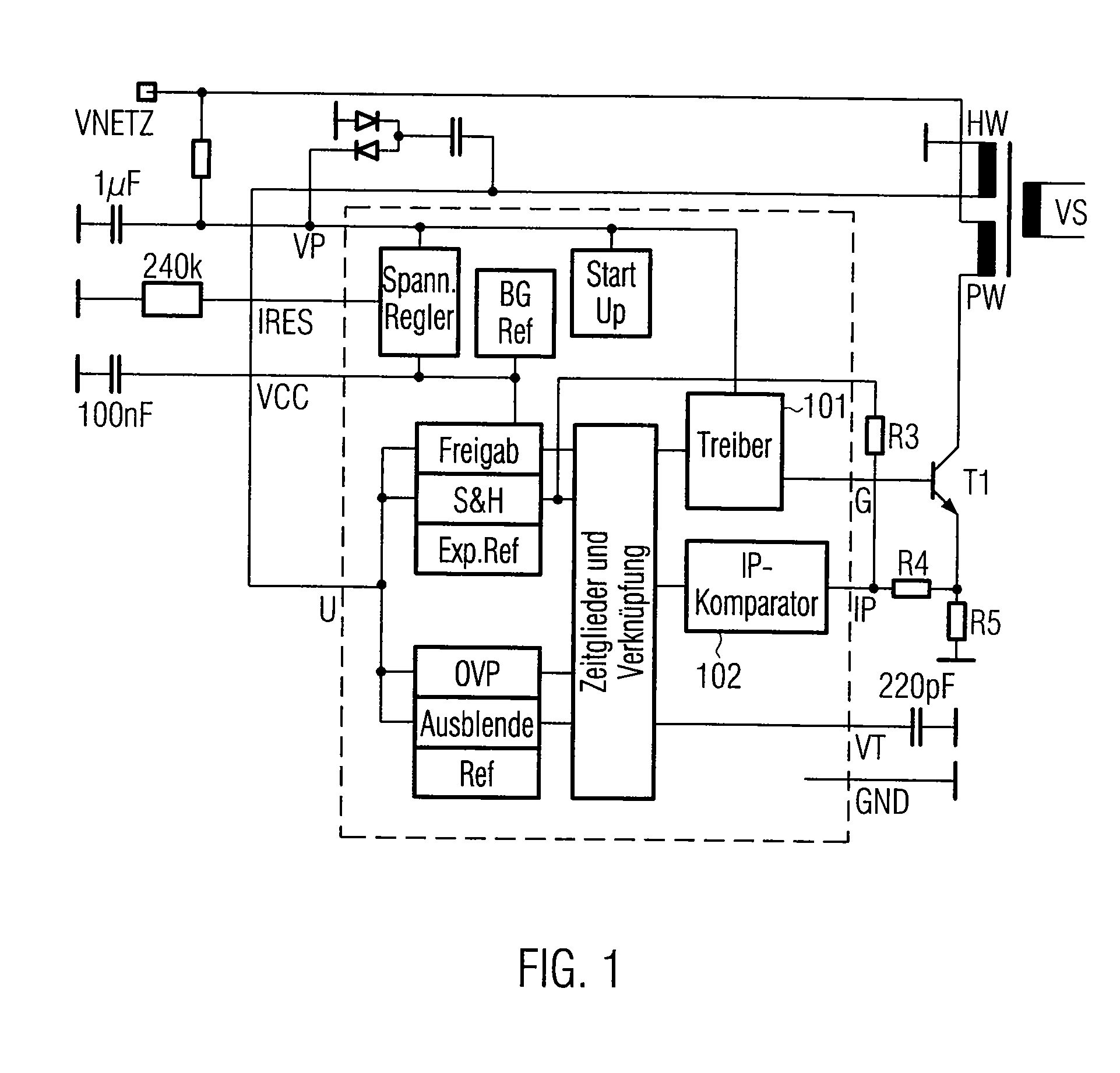

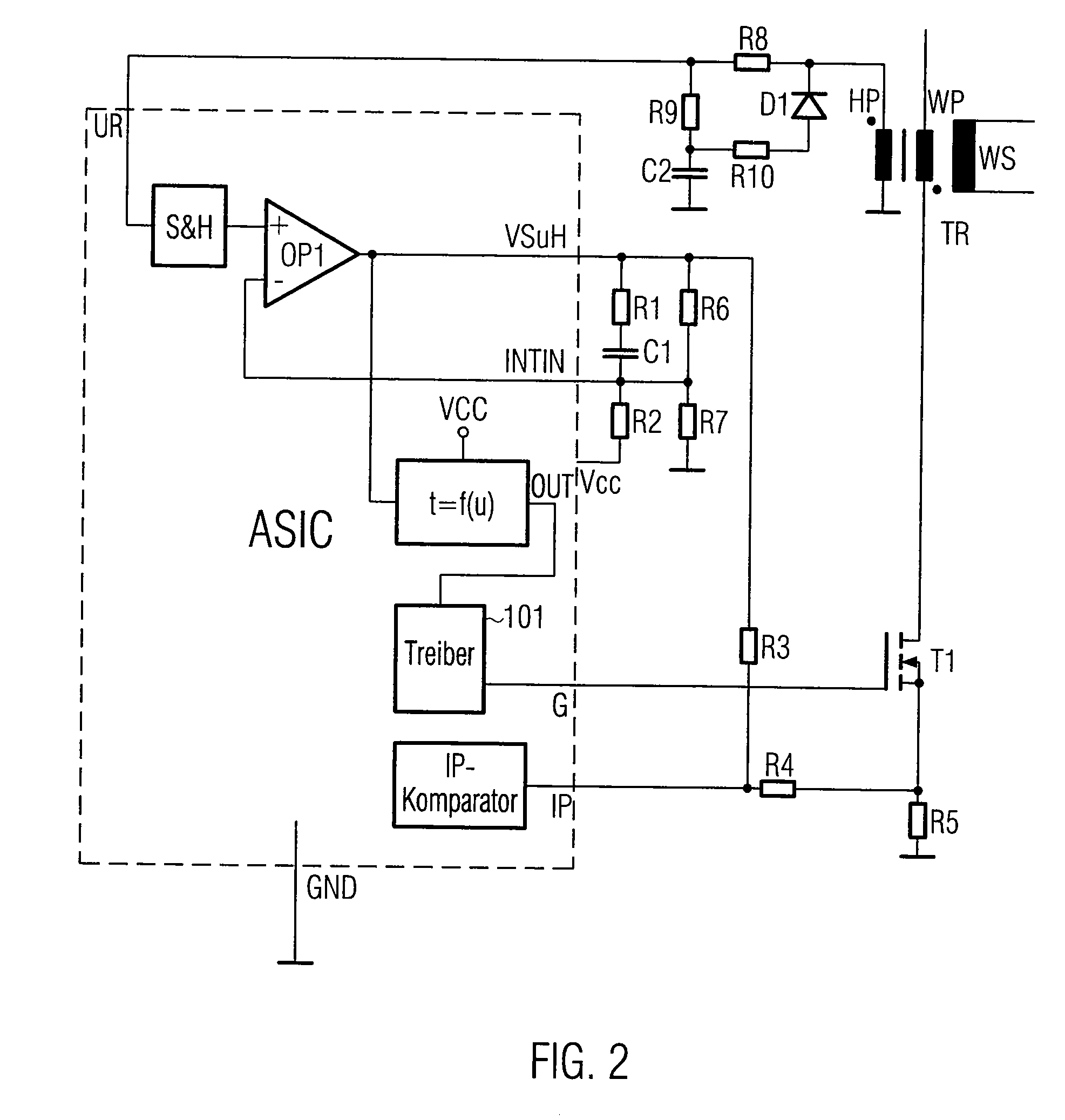

Control circuit for current and voltage control in a switching power supply

ActiveUS20070115696A1Reduce load dependenceReduce noiseDc-dc conversionElectric variable regulationConductor CoilVoltage control

The present invention refers to a circuit for current and voltage control in a switching power supply controlled on the primary side, comprising a transformer with a primary-sided and a secondary-sided main winding, wherein energy pulses are transmitted from the primary side to the secondary side. Furthermore, a primary-sided switch switches on an off a primary current through the primary-sided main winding. A primary current comparator determines a switch-off time of the switch depending on the primary current. In order to reduce the load dependency of the output voltage, the control variable is variably amplified by a feedback network and additionally the control variable is reduced depending on the output load through a correction network. To reduce noise generated by the energy-rich pulse transmissions at low frequencies and the waviness of the output voltage, the control variable is fed back to the primary current comparator so that the duration during which the primary current flows through the primary-sided main winding is reduced differently. To reduce the susceptance to failure when determining the switch-on time, a comparator voltage depending on the control variable is generated as reference.

Owner:MYPAQ HLDG LTD

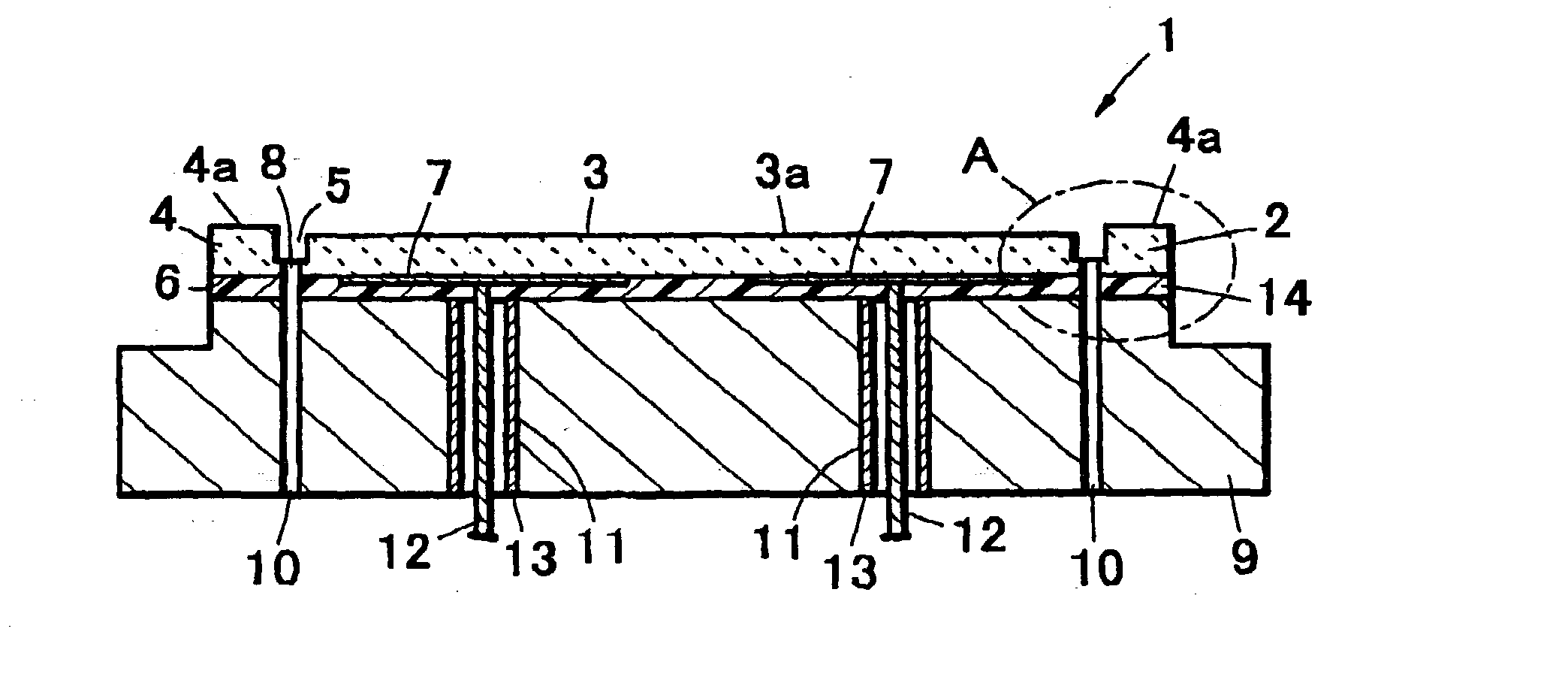

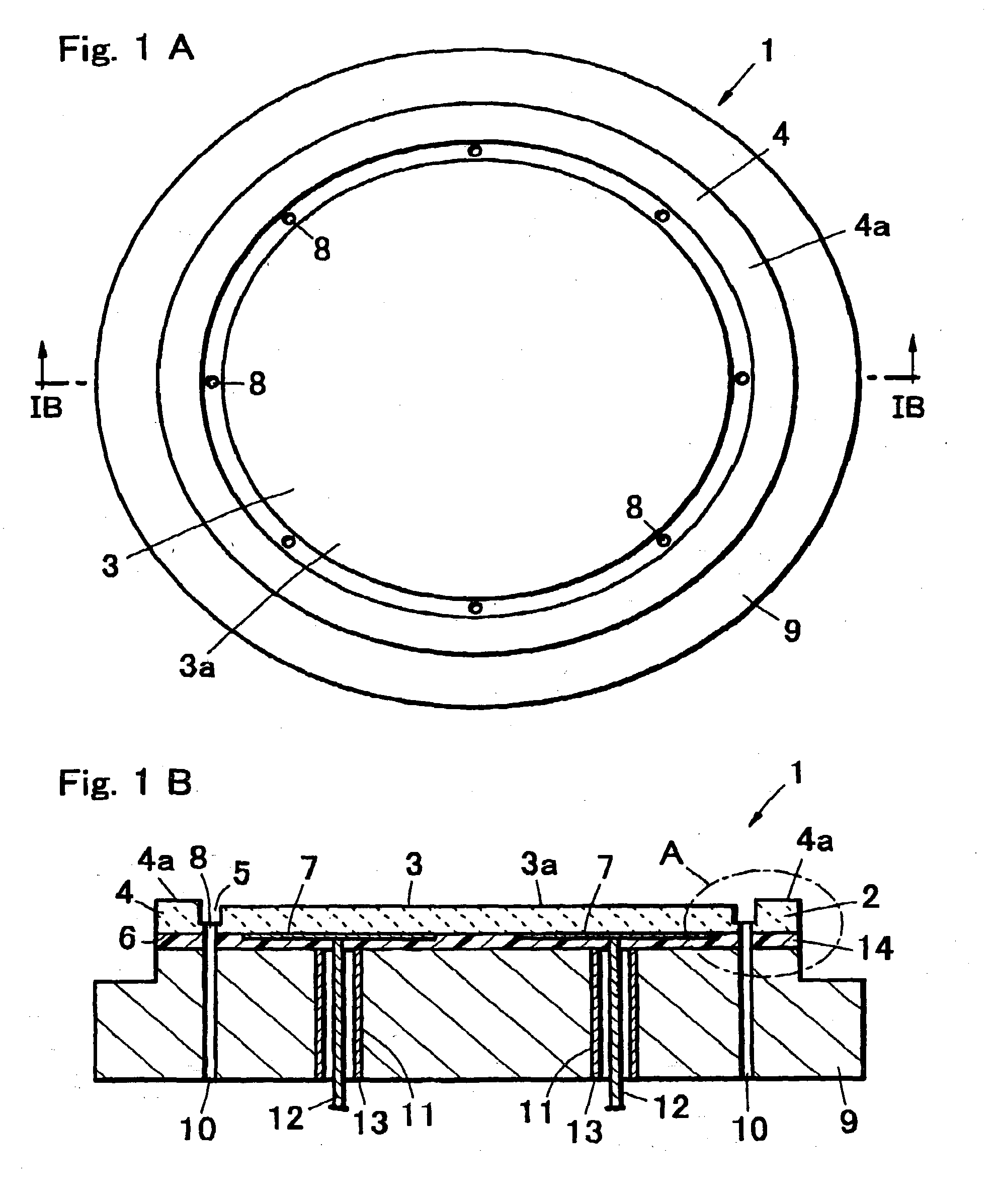

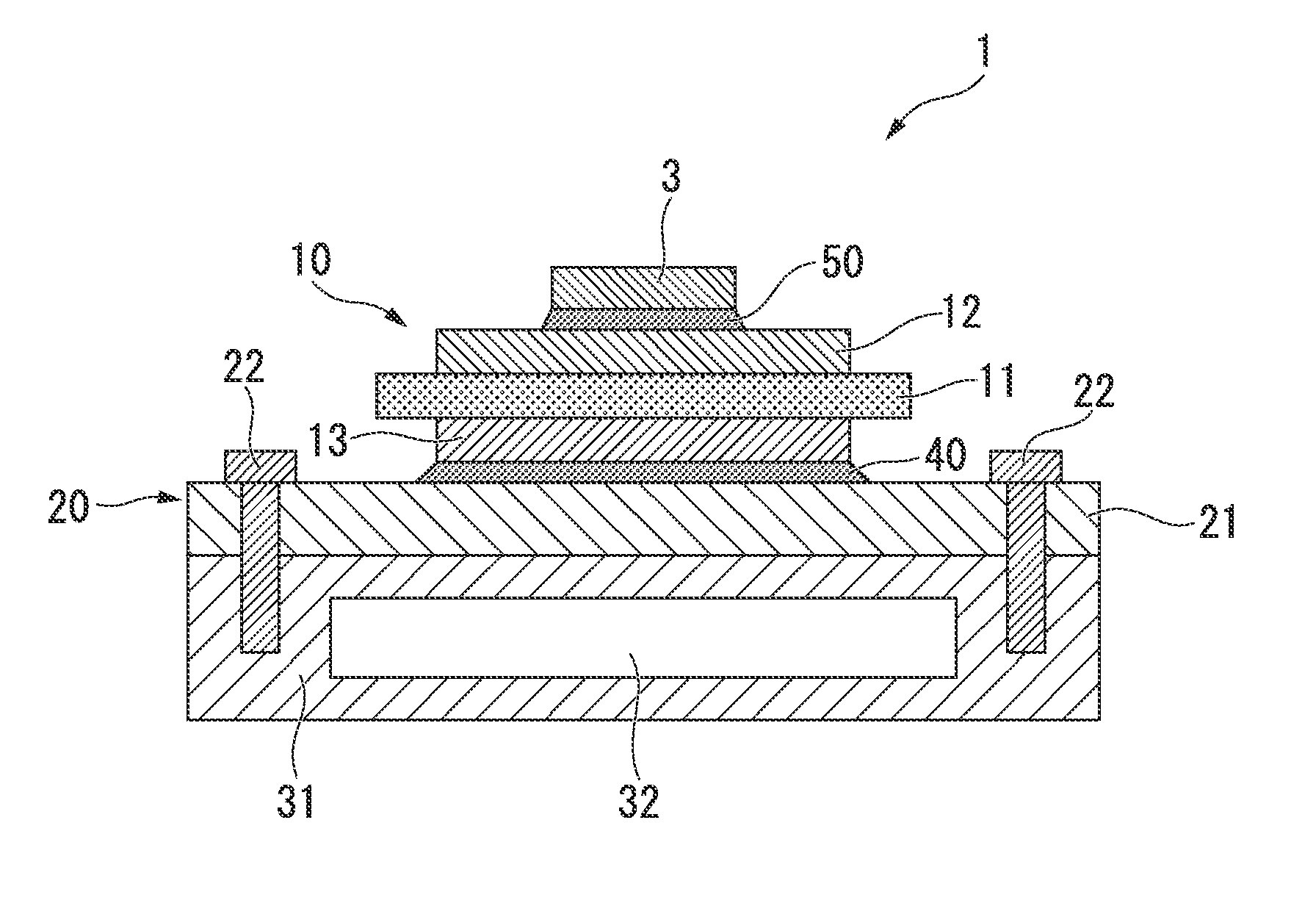

Electrostatic chuck for holding wafer

InactiveUS20030161088A1Emergency protective arrangement detailsSemiconductor/solid-state device manufacturingMetallurgyWaviness

An electrostatic chuck for holding a wafer includes a ceramic plate of which one main surface is formed to work as a mounting surface for mounting the wafer, and electrostatic attraction electrodes formed on a lower surface of the ceramic plate or in the ceramic plate. A recess portion having a depth in a range of from 3 to 10 mum is formed on one main surface of the ceramic plate excluding an outer peripheral portion thereof. The waviness of a top face of the outer peripheral portion is set to 1 to 3 mum, a gas groove is provided to a peripheral portion of a bottom surface of the recess-portion bottom surface, and electrostatic attraction electrodes are disposed in the ceramic plate disposed below the bottom surface of the convex portion. In the electrostatic chuck thus constructed, even a wafer having a deformation such as a warped portion can be firmly attracted, a uniform temperature distribution over a wafer surface can be implemented, leakage of a heat-conductive gas can be suppressed, and moreover, high wafer-dechucking sensitivity can be exhibited.

Owner:KYOCERA CORP

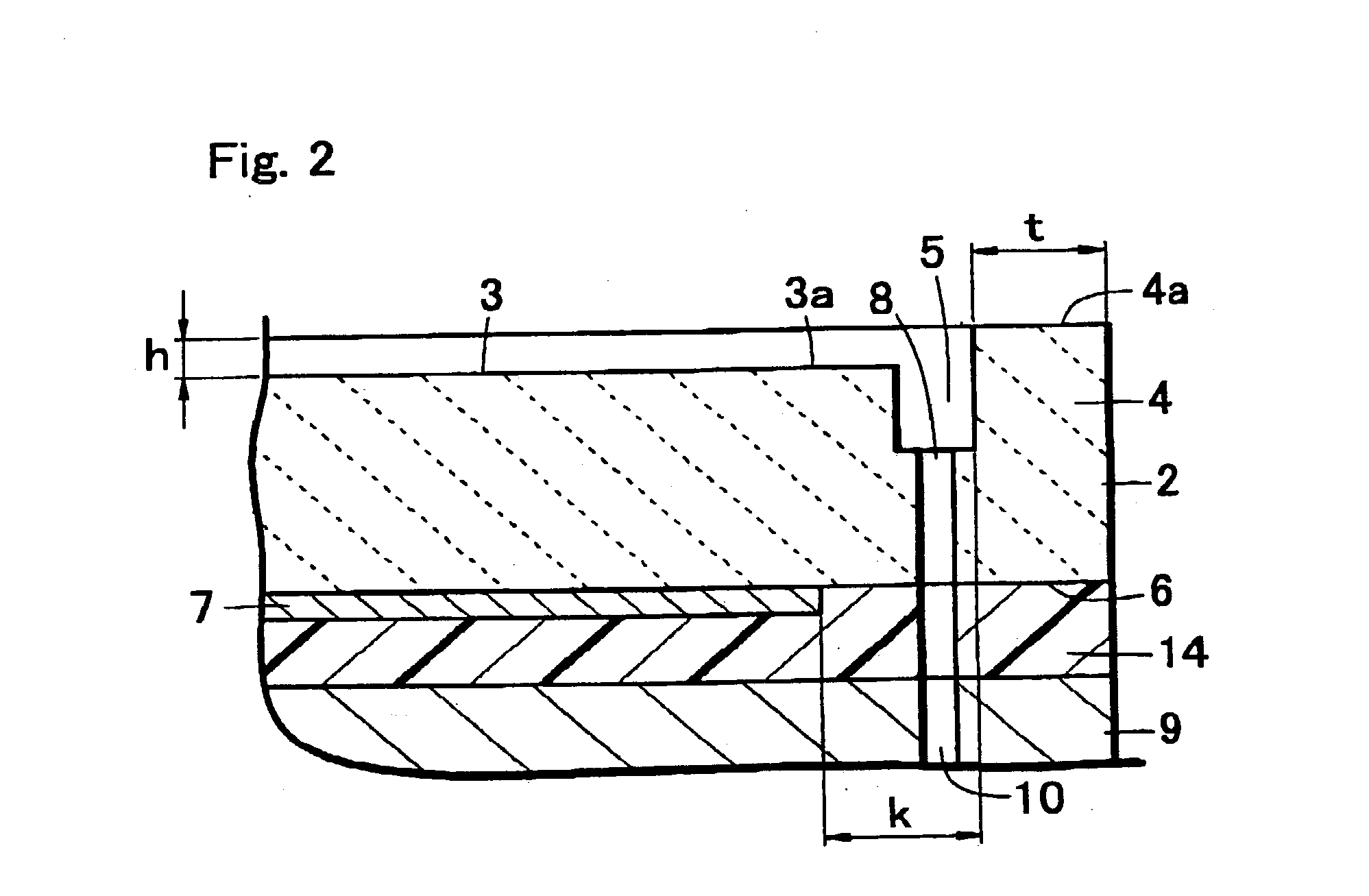

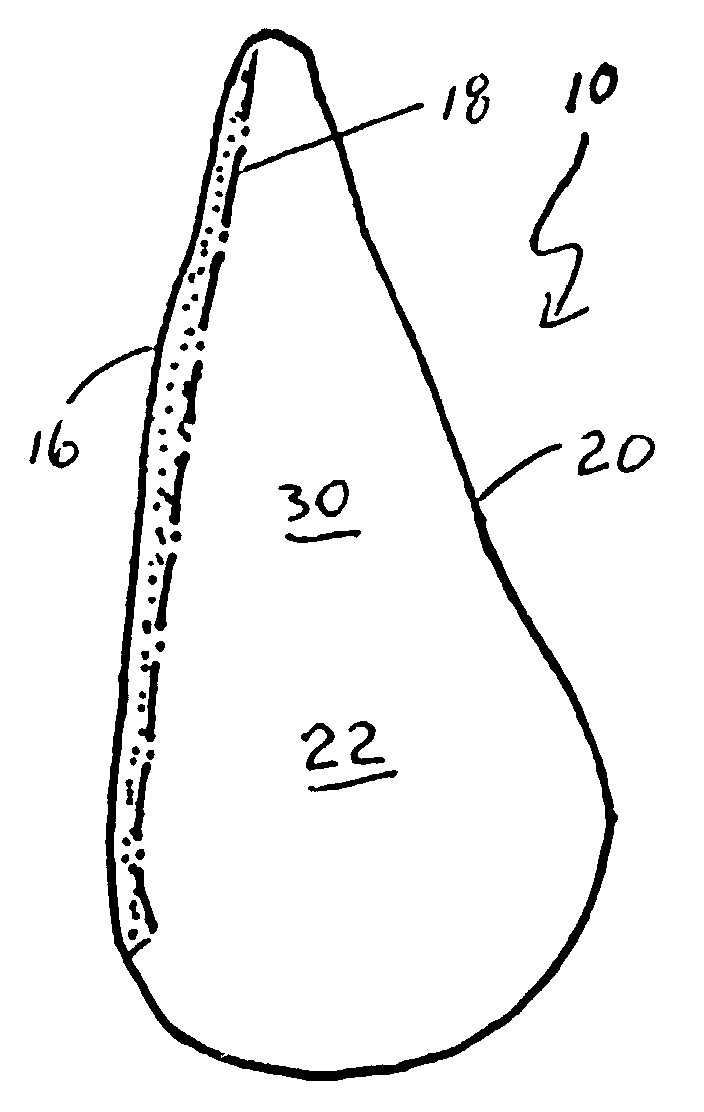

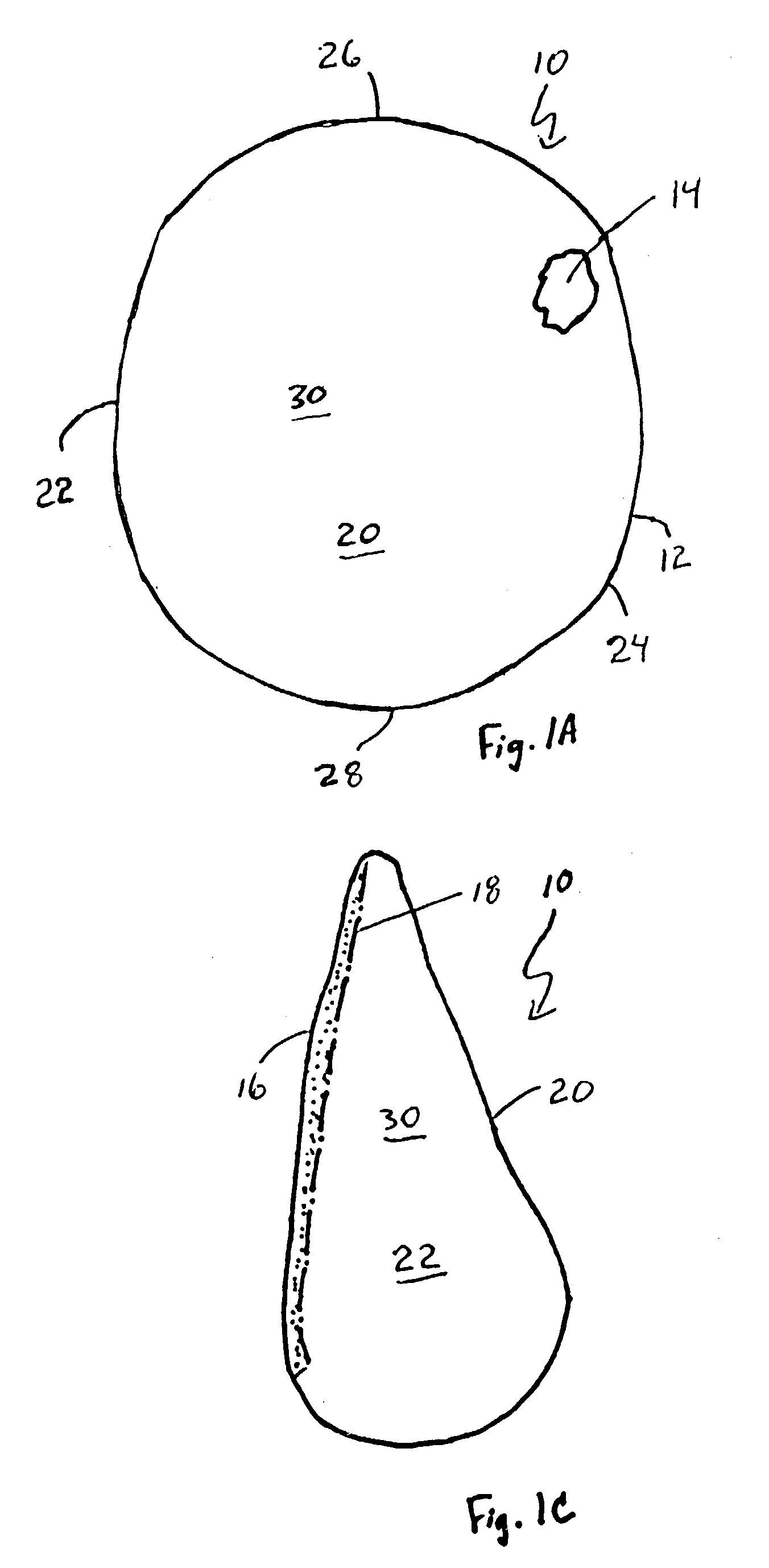

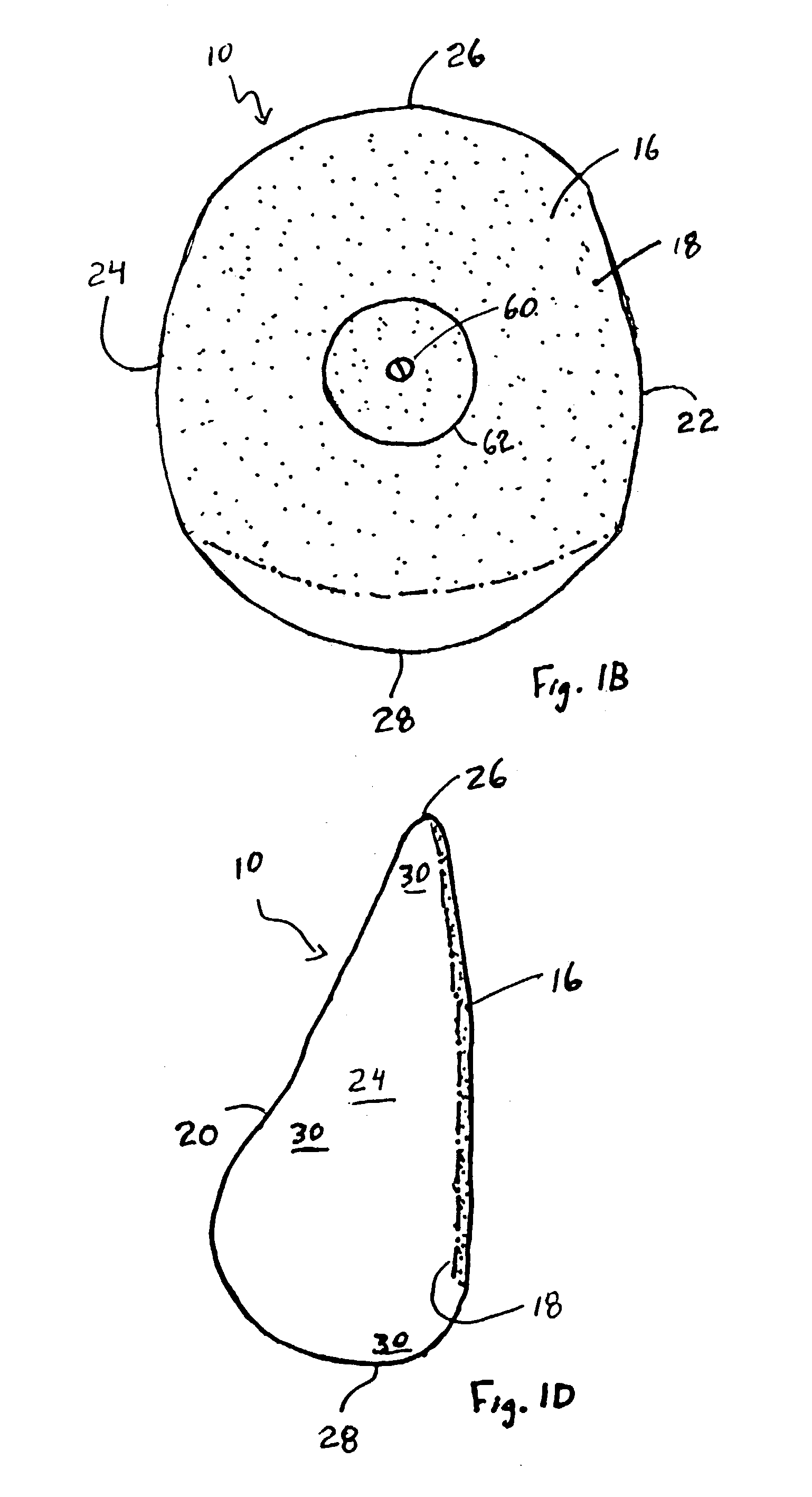

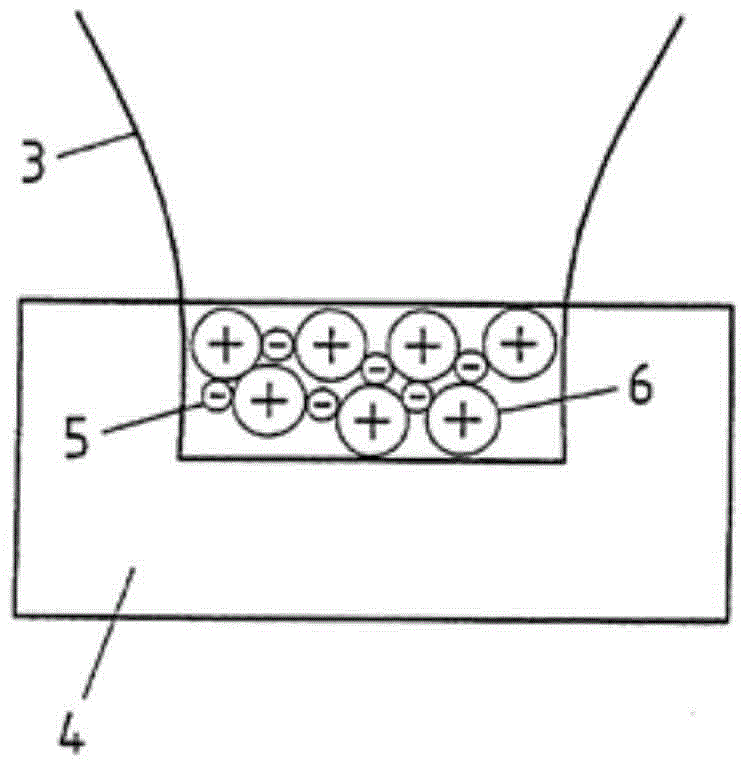

Non-rotating breast implant

InactiveUS7105116B2Precise positioningNatural appearanceMammary implantsMouldsWrinkly skinWrinkle skin

A non-rotating anatomical-shaped breast implant having a front side with a smooth surface and a rear side with a textured surface. A smooth surface ripples or wrinkles little, if at all. Rippling or wrinkling of the implant may undesirably produce a visible or palpable waviness on the skin of the breast. A smooth surface is more likely to produce the look and feel of a natural breast. A rear side with a textured surface is desirable because tissue growth of the body, after the implant has been implanted, engages the textured surface to anchor the implant in place such that the front side with the smooth surface remains matched with the front side of the body and such that the anatomical-shaped breast implant with its tear drop shaped fullness remains at a natural position within the breast. The disclosure further includes a method for minimizing the rotation of an implant within the body and a method for making an implant envelope that has different thicknesses.

Owner:BELLIN HOWARD T

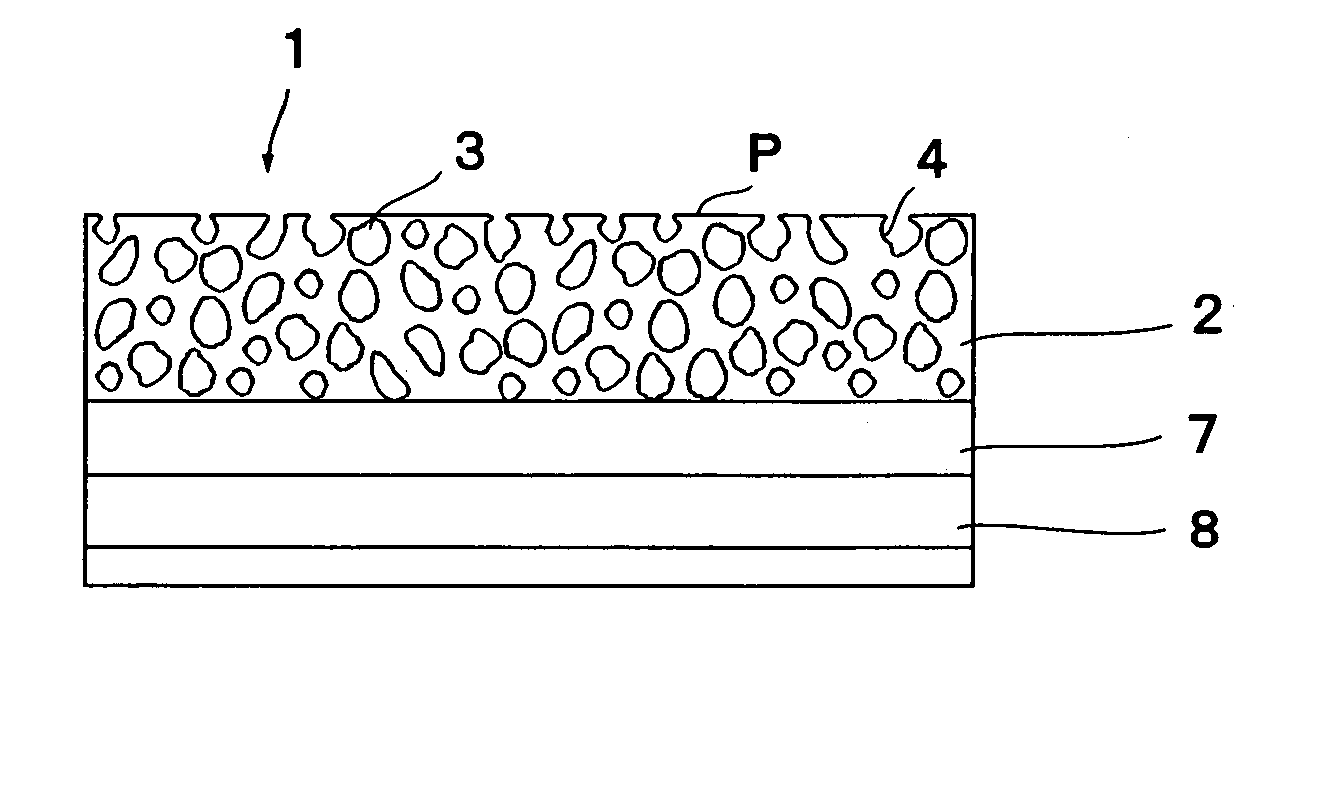

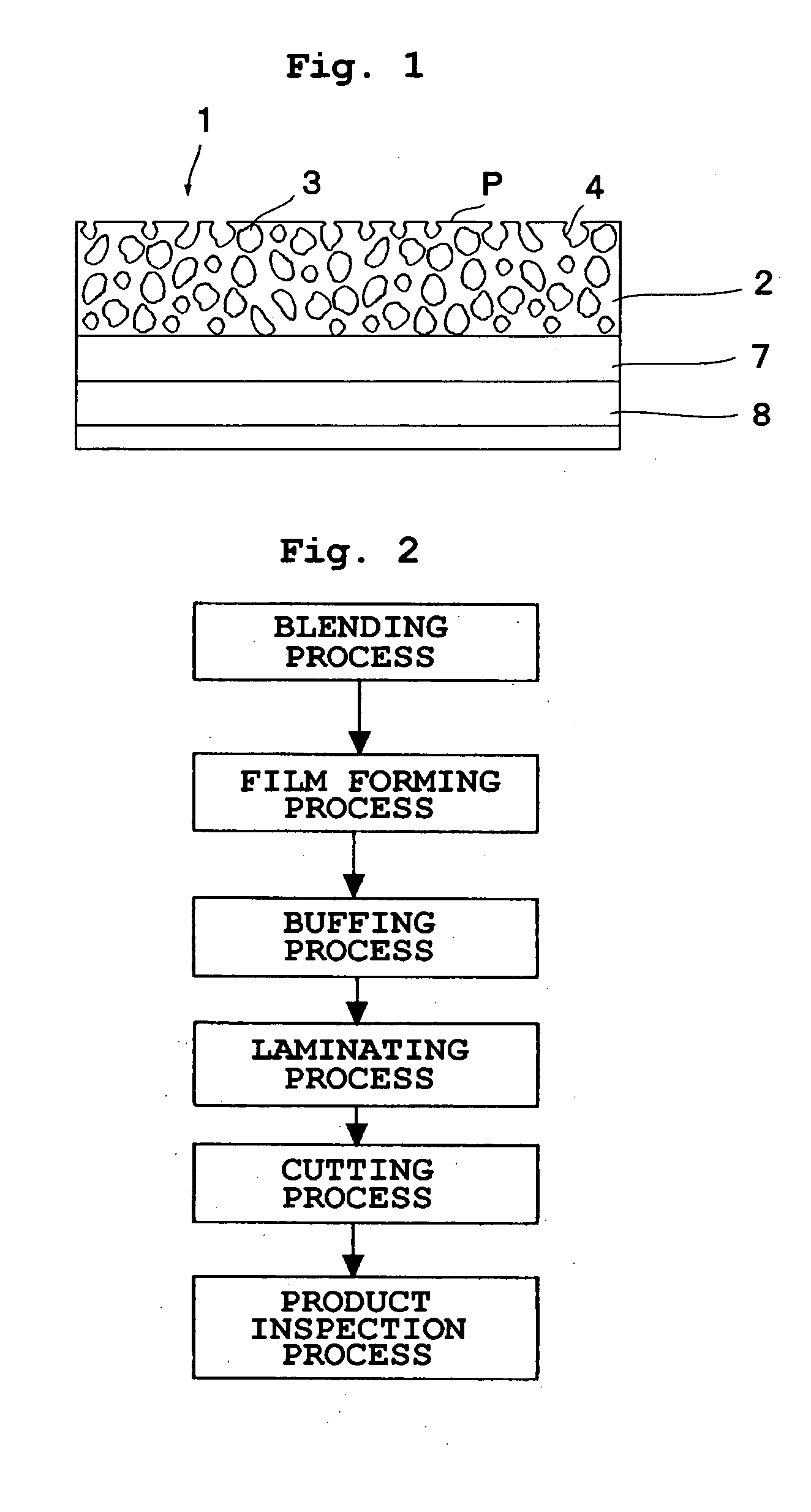

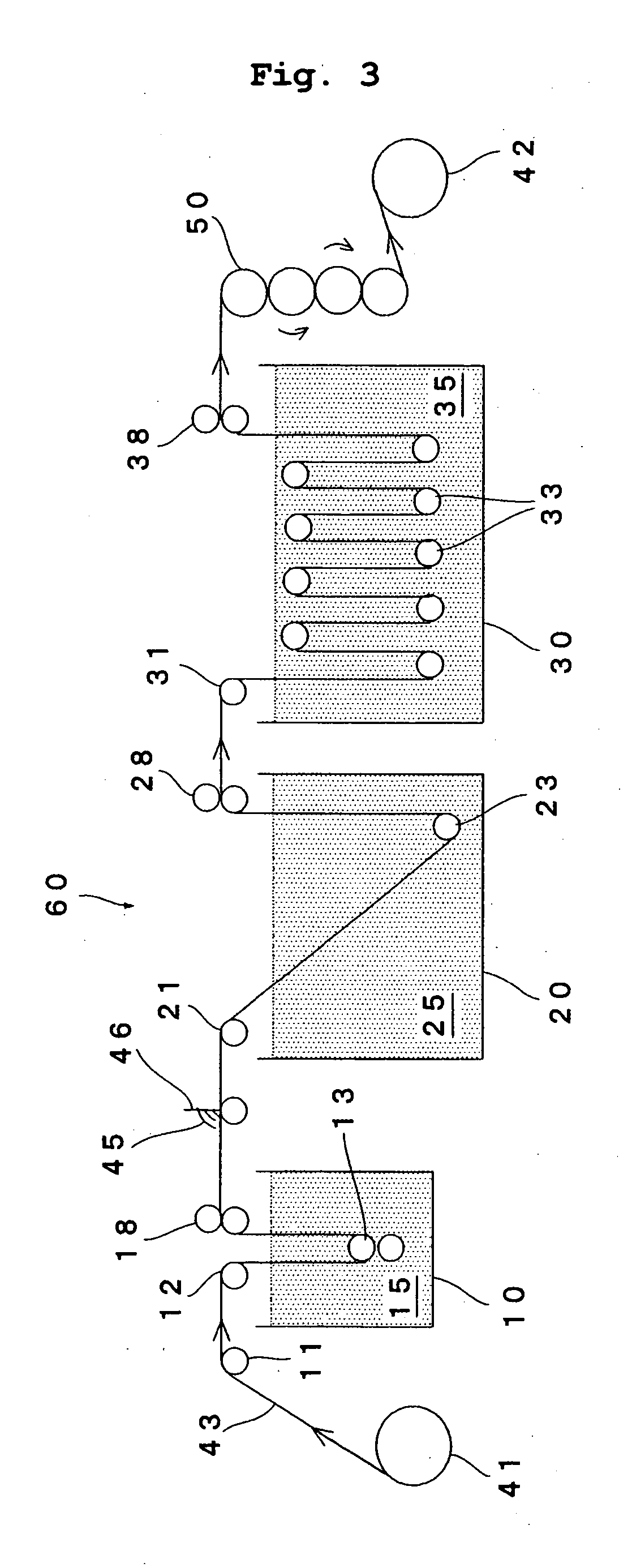

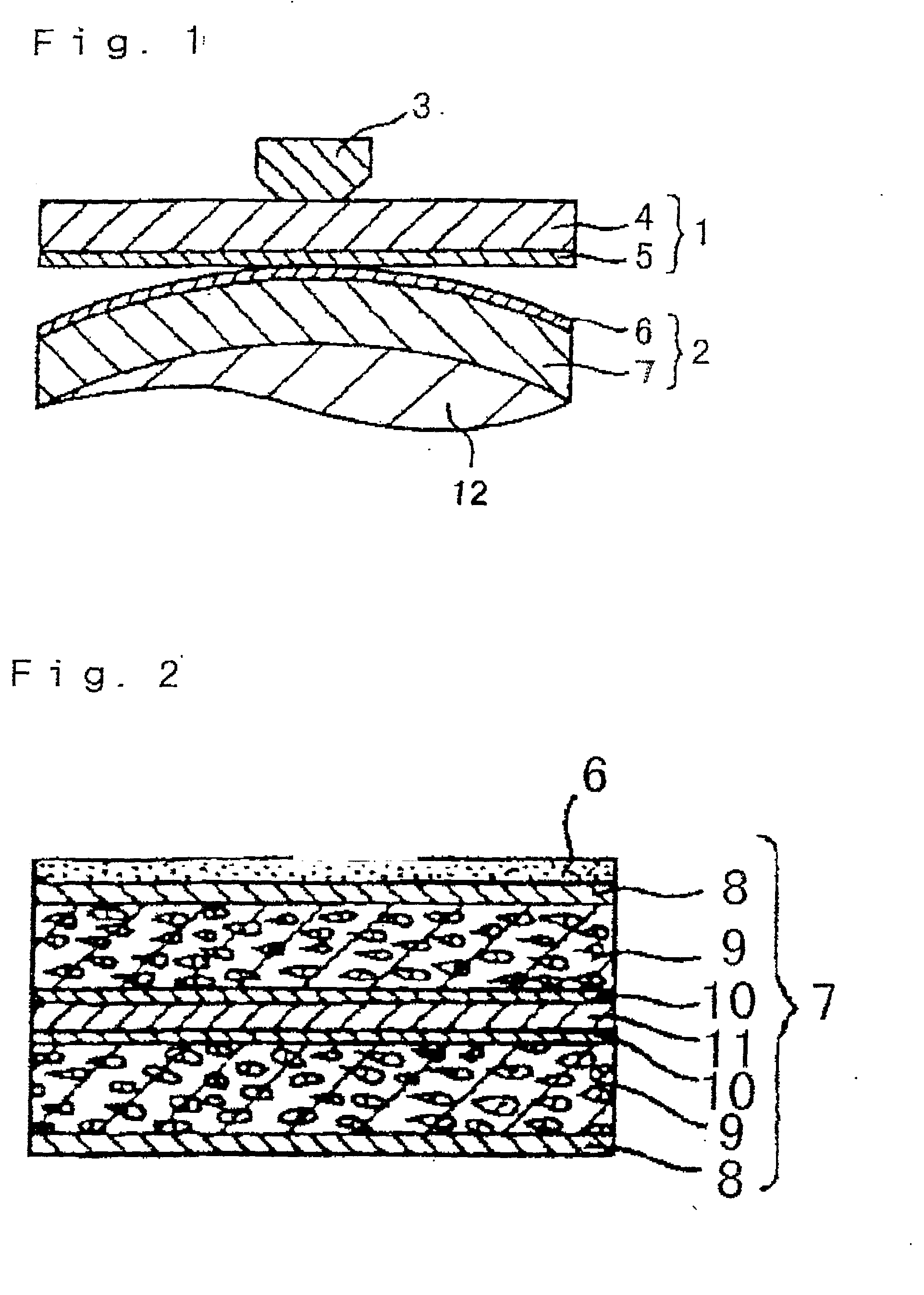

Polishing sheet and manufacturing method of elastic plastic foam sheet

InactiveUS20050112354A1Semiconductor/solid-state device manufacturingPretreated surfacesSurface layerEngineering

A polishing sheet which can improve waviness at a face of a material to be polished and which has a long life is provided. The polishing pad 1 has a polyurethane sheet 2 made of polyurethane resin. The polyurethane sheet 2 has a polishing layer which is disposed inside a surface layer and which is allowed to wear away by polishing and whose thickness is larger than a thickness of the surface layer. The polishing layer has an approximately uniform foam structure in a direction of the thickness of the polishing sheet 2 by being formed foams whose space volume is larger than that of foams formed at the surface layer and which are communicated so as to form a network by continuous holes whose diameter is smaller than that of the space volume of the foams formed at the polishing layer.

Owner:FUJIBO HLDG

Core/shell nano particle grinding agent polishing solution composition and method for preparing same

The present invention relates to one kind of core-shell type nanometer particle abrasive polishing liquid composition and its preparation process, and belongs to the field of surface polishing technology. The polishing liquid includes abrasive, oxidant and water, and features the abrasive is core-shell type nanometer composite particle abrasive, which has traditional abrasive, such as superfine alumina, silica, zirconia, cerium oxide, titania, ferric oxide, diamond or silicon nitride, as inner core, and hydrophilic segment polymer or compound containing organic functional group as shell. The polishing liquid is suitable for chemical and mechanical polishing of memory hard disc chip and aluminum magnetic disc, and has the advantages of reduced surface roughness and waviness, reduced surface mechanical damage and effective elimination of micro default.

Owner:SHANGHAI UNIV

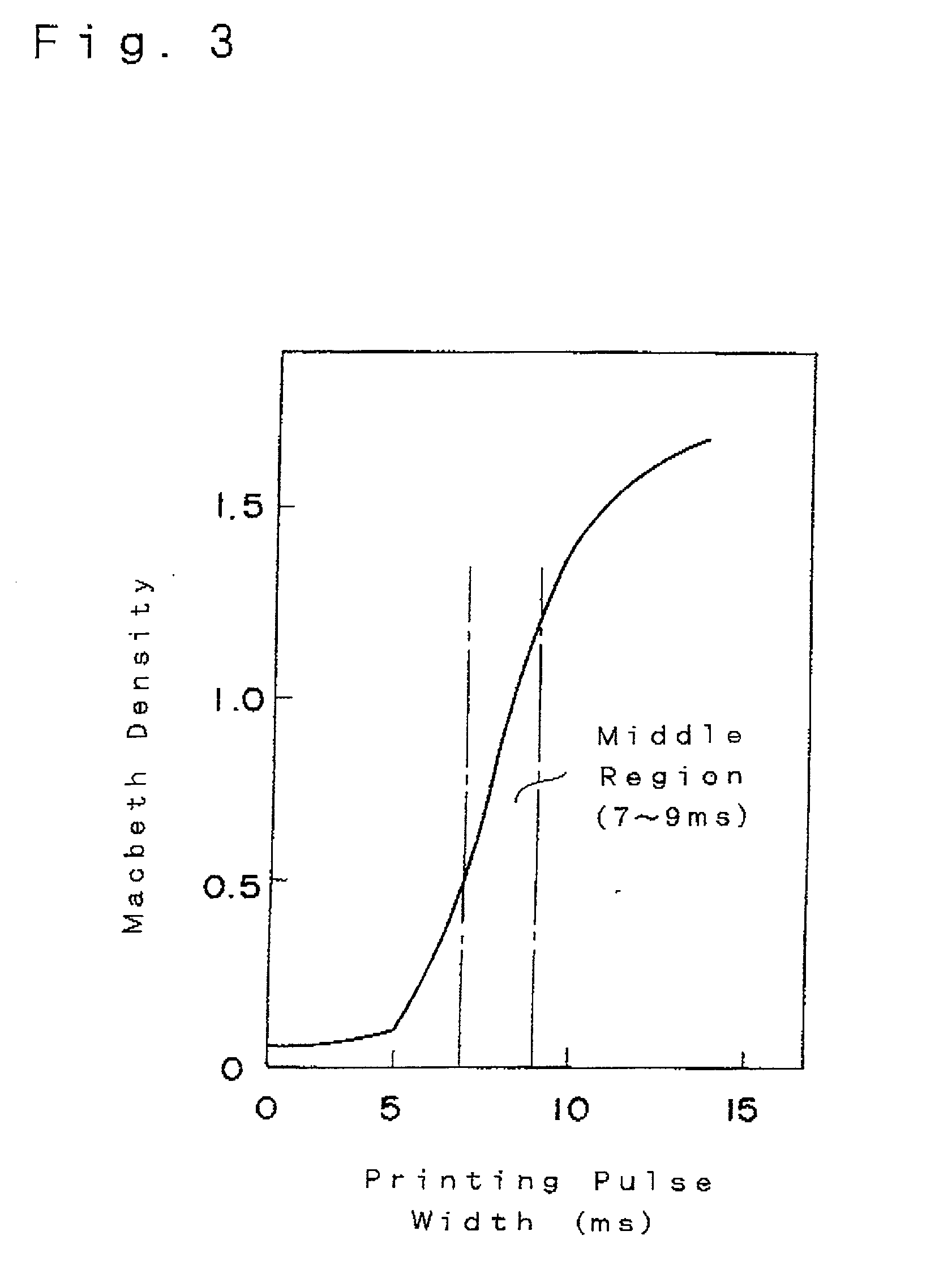

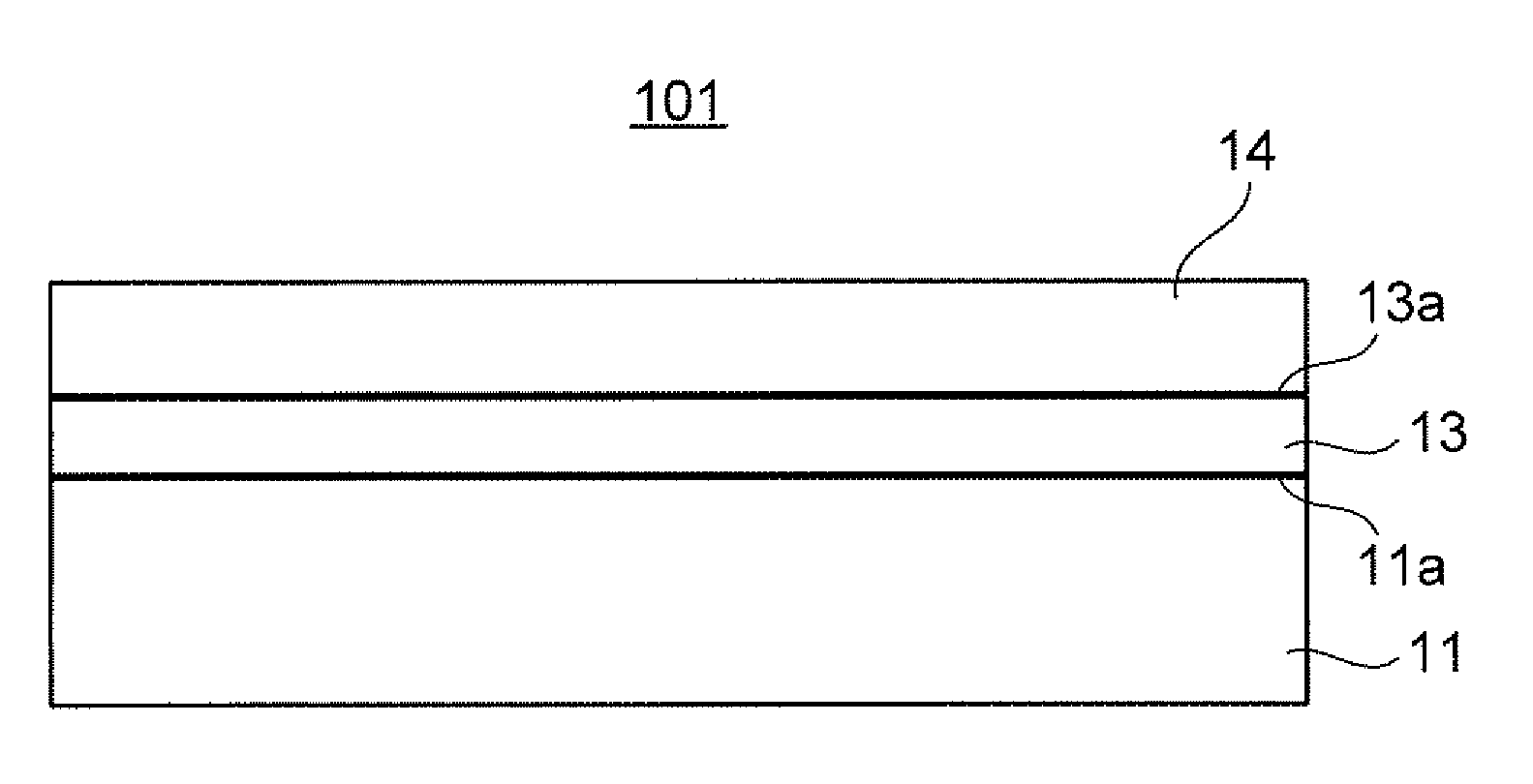

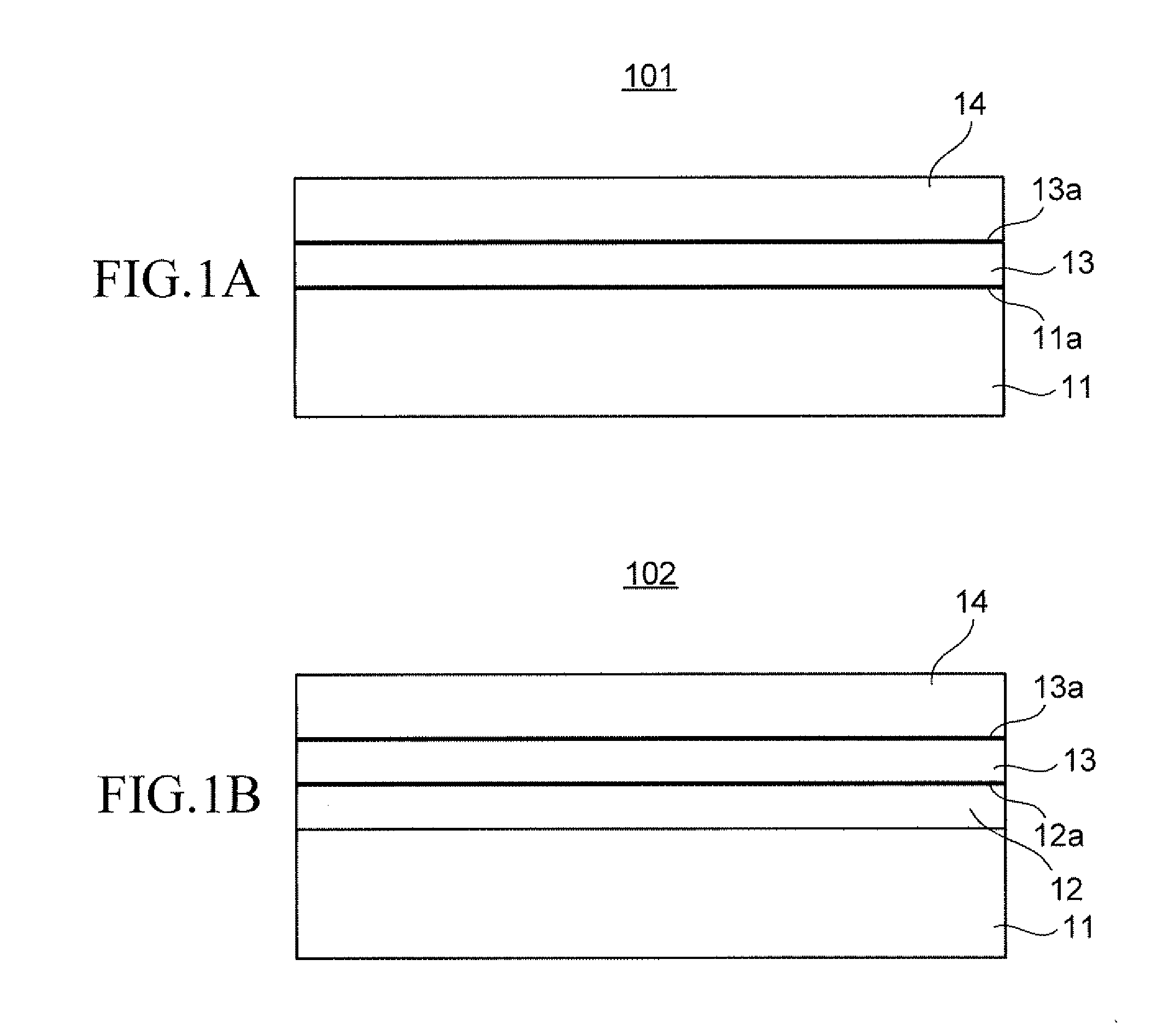

Support and thermal transfer image-recording material

InactiveUS20020039640A1Decorative surface effectsSynthetic resin layered productsSurface layerImage recording

A support which contains a base layer (B) composed of a biaxially stretched film of a thermoplastic resin containing an inorganic fine powder; and a surface layer (A) provided at least on one side of such base layer (B), which is composed of a biaxially stretched film of a thermoplastic resin having a three dimensional center plane average roughness of about 0.3 mum or below and a 60 degrees surface glossiness of about 80% or above is disclosed. A thermal transfer image-recording material using such support can produce a clear image having an excellent glossiness and no external waviness.

Owner:YUPO CORP

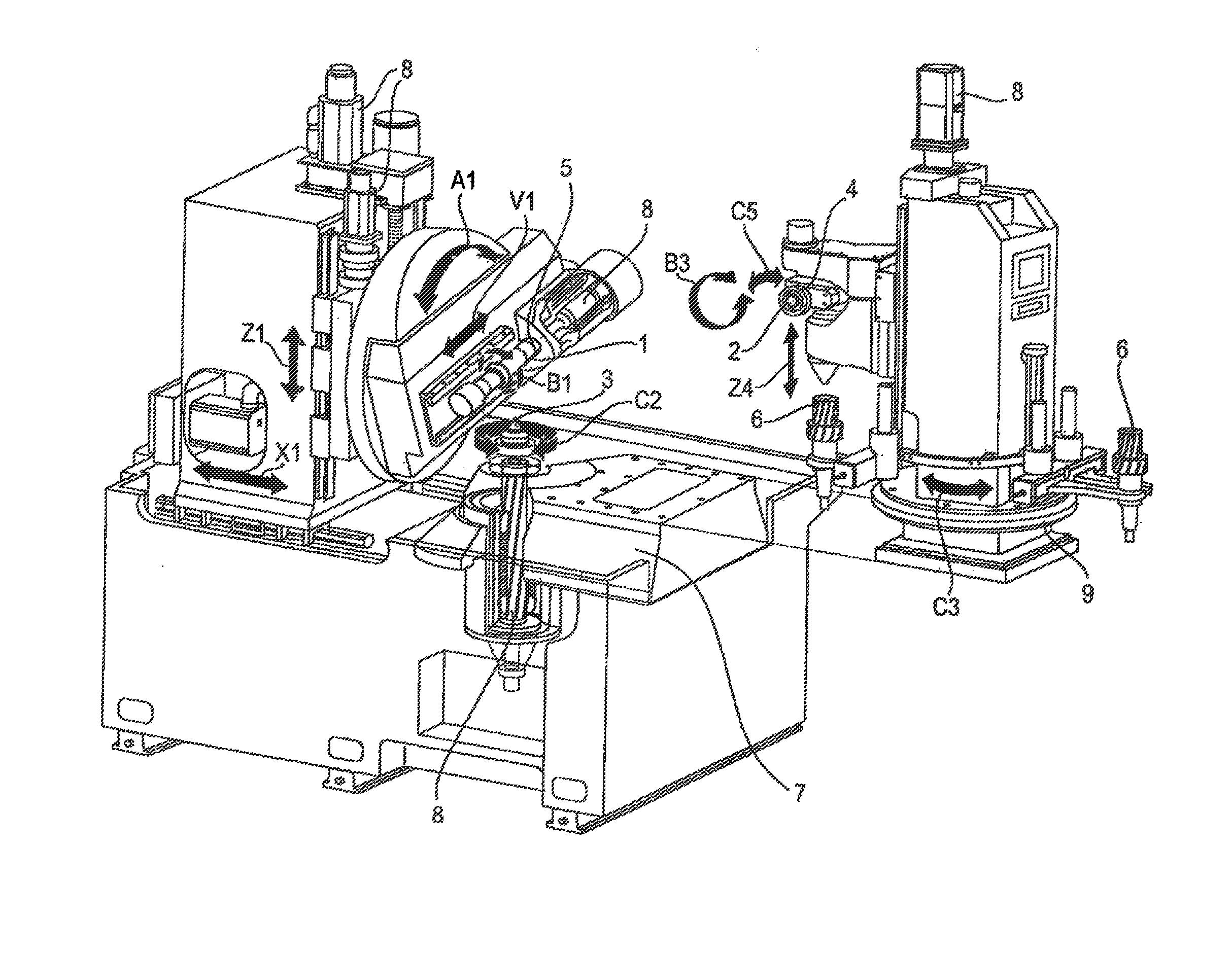

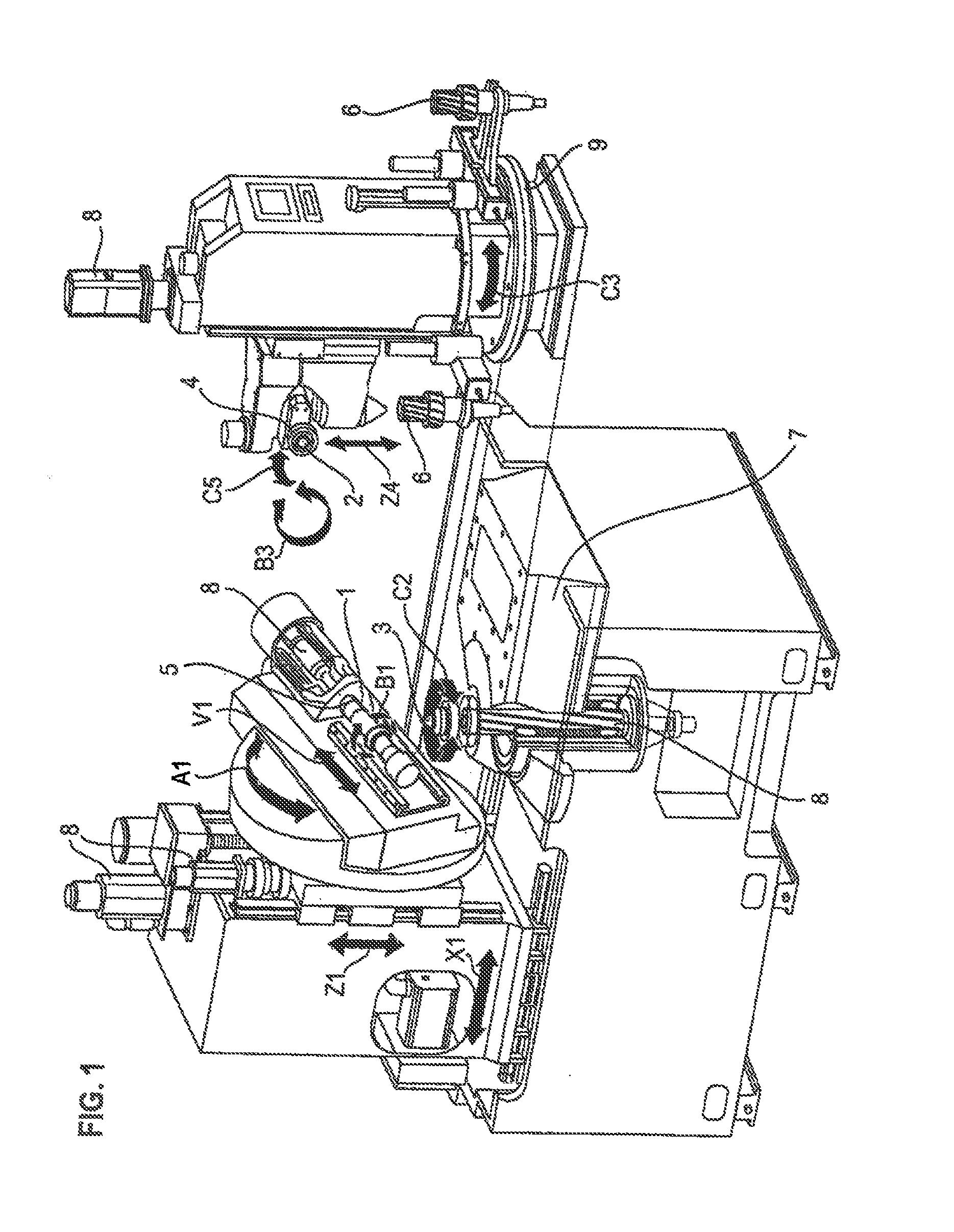

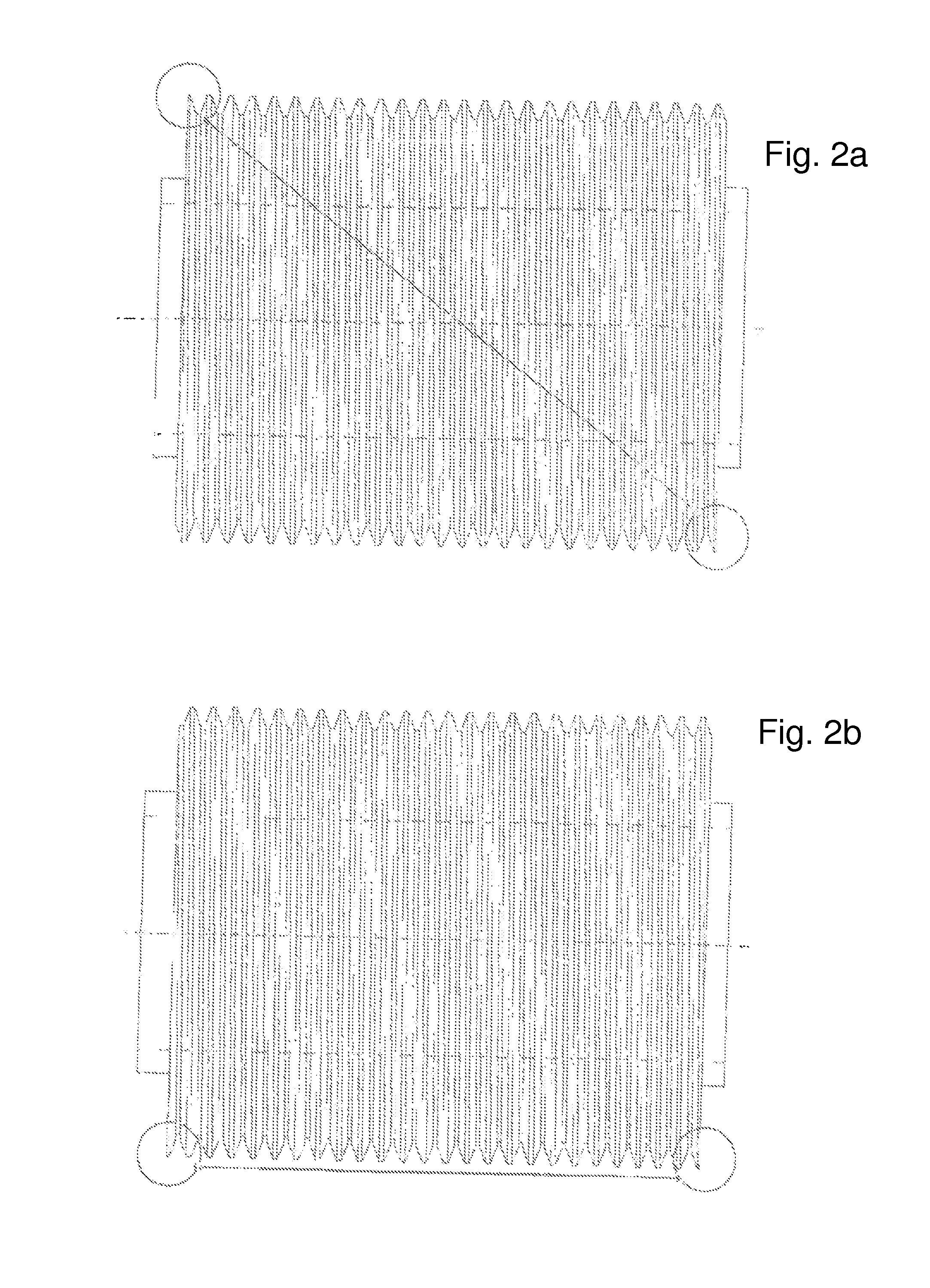

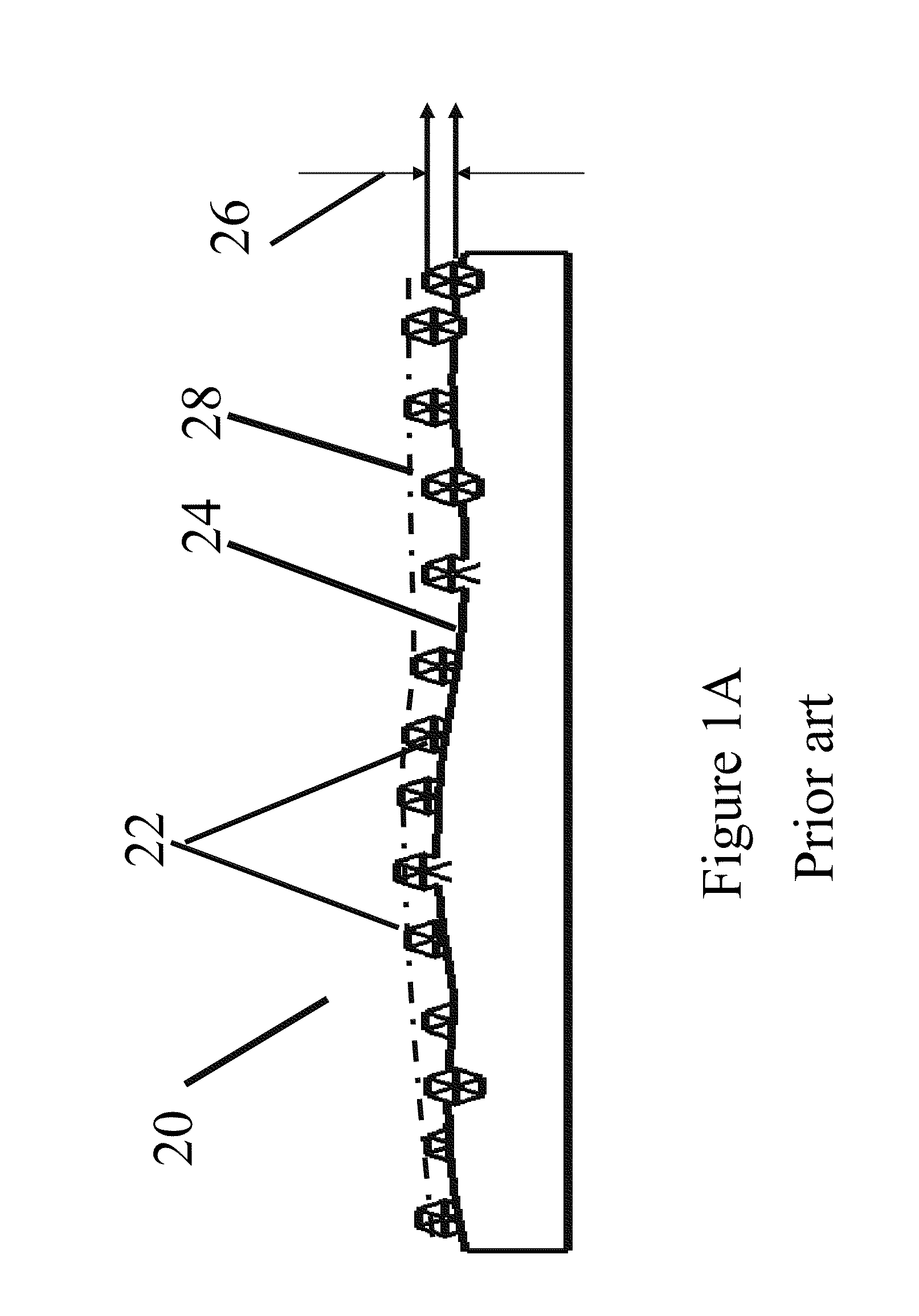

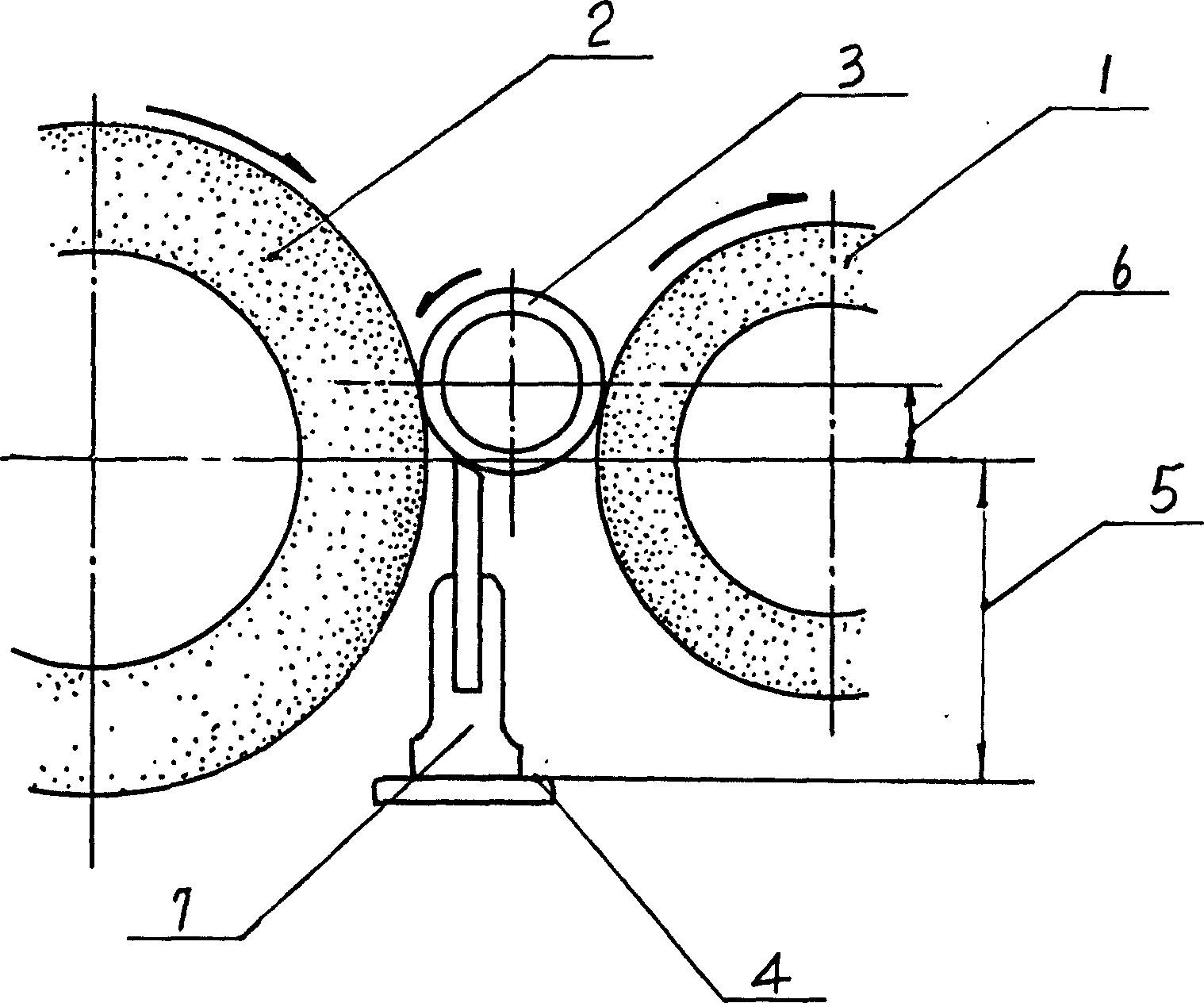

Method and apparatus for hard finishing modified gears

The present disclosure relates to a method for the manufacture of a workpiece having a corrected gear geometry and / or a modified surface structure, in particular by a hard finishing process, in particular generation grinding or honing. Provision is made in this respect that it is achieved by a direct generation of a wobble movement and / or of an eccentricity of the tool that a modification, in particular a profile modification or profile waviness, and / or a defined periodic flank waviness is generated on the active surface of the workpiece machined therewith.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

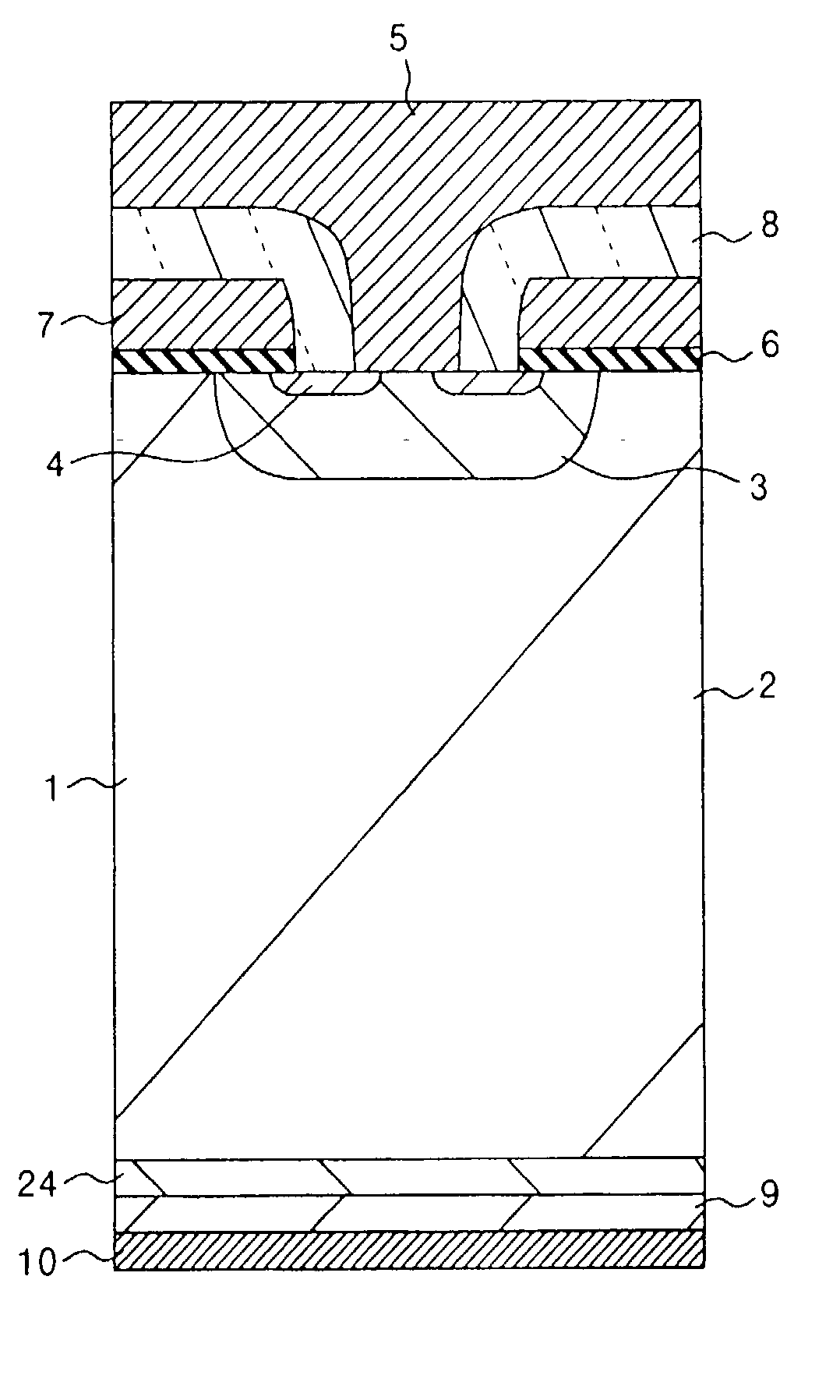

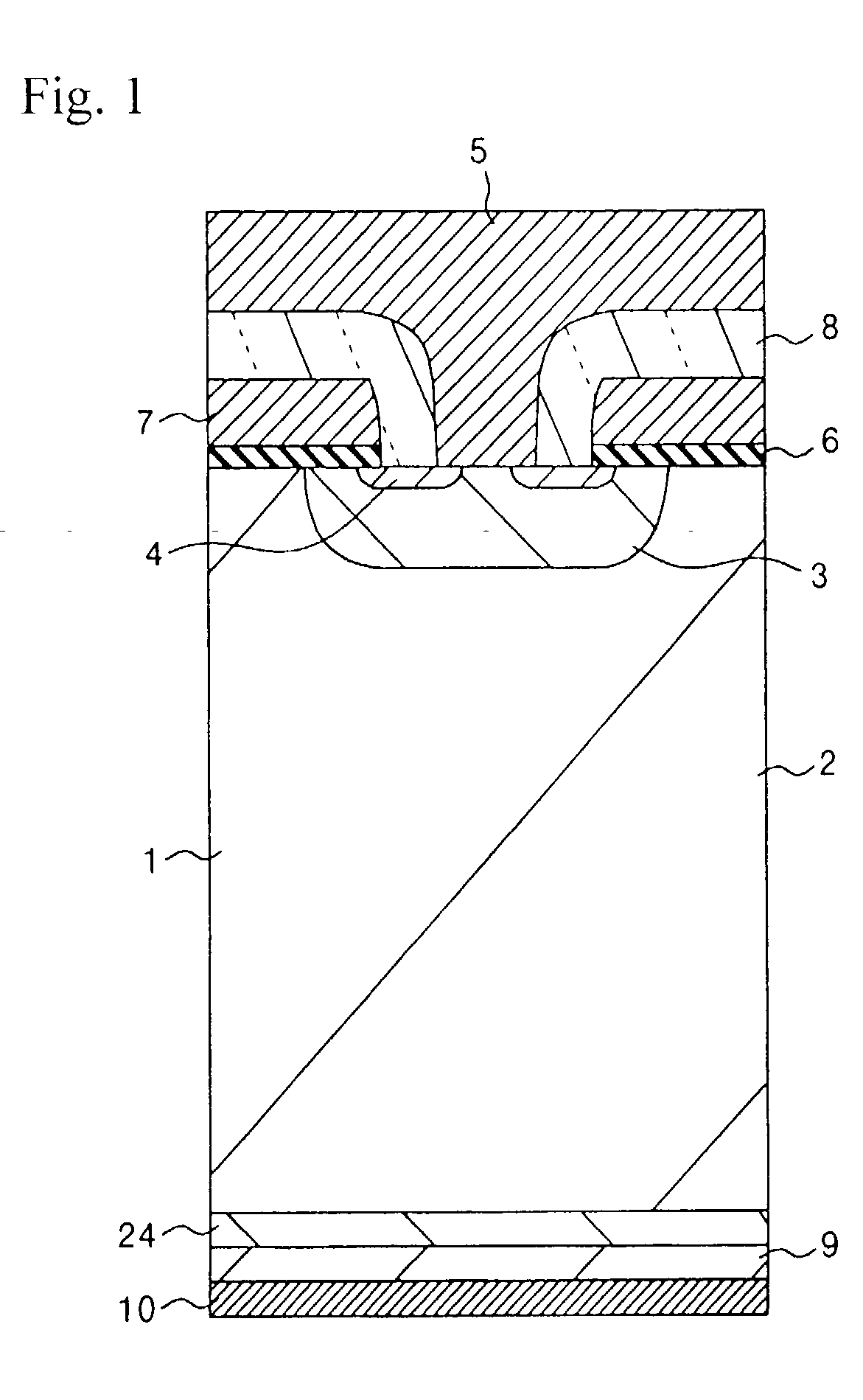

Method for manufacturing a semiconductor device

InactiveUS20020127783A1Lower resistanceIncrease concentrationTransistorSemiconductor/solid-state device manufacturingCompound (substance)Engineering

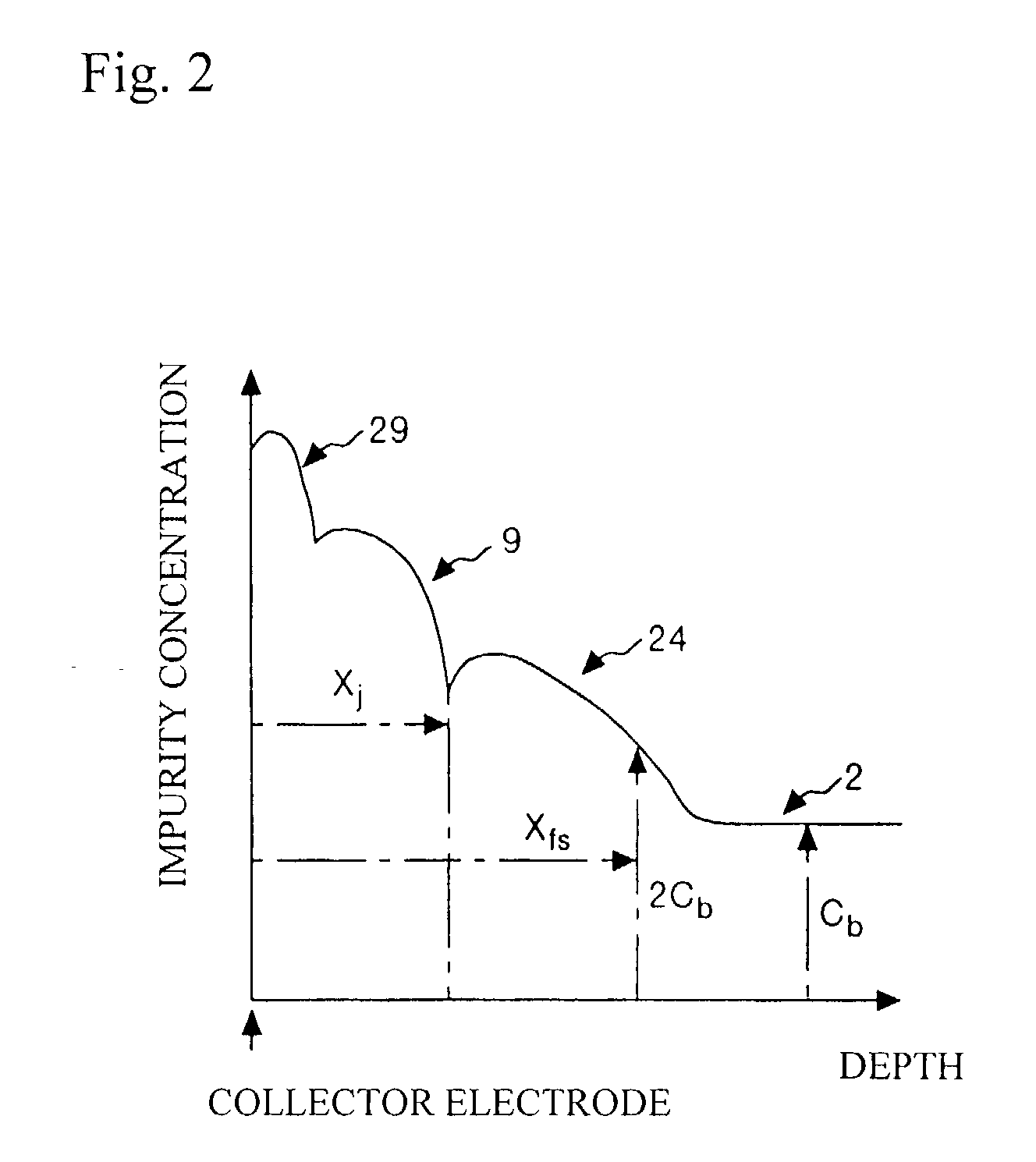

A method for manufacturing a semiconductor device constituting an IGBT is provided that allows to manufacture the device using an inexpensive wafer and with high yields, and achieves low losses. Specifically, after an emitter electrode is formed, a reverse principal surface is polished to a specified thickness. The center line average height Ra of the polished surface is controlled to be not more than 1 .mu.m, and the filtered center line waviness Wca is kept within 10 .mu.m. The polished surface is selectively cleaned with chemicals-dissolved water to remove particles. To the cleaned surface, phosphorus ions are implanted for forming a field-stop layer and boron ions are implanted for forming a collector layer. The wafer is then put into a diffusion furnace and annealed at a temperature from 300.degree. C. to 550.degree. C. to form a field-stop layer and a collector layer. Finally, a collector electrode is formed.

Owner:FUJI ELECTRIC CO LTD

Method for copying joint waviness by artificial rock material and experimental method

InactiveCN103926129AAvoid the dangers of climbing dangerous rocksHigh measurement accuracyPreparing sample for investigationUsing optical meansLaser scanningPerformed Imaging

The invention discloses a method for copying joint waviness by an artificial rock material and an experimental method. The method includes the following steps: firstly, measuring the joint surface contour line waviness by a three-dimensional laser scanning method; refining a graph and removing noise points from the graph by contour tracking, performing image scaling transformation and coordinate transformation on a joint contour line, and obtaining coordinate values of points on the contour line by an interpolation method; reading joint surface contour line data, digitalizing the joint surface contour line waviness, introducing the digitalized joint surface contour line waviness into a spark cutting control machine, processing a steel block by 2Cr13 alloy steel and making mortar joints; and laying joint mud or mineral clay with different thicknesses and water contents between the mortar joints, and carrying out a mechanical experiment of the joints. The method disclosed by the invention can be used for truly reflecting the physical states of filler rock masses containing joints, the influence of the joints to the strength and deformation properties of the rock masses can be researched by subsequent experiments, and the method is suitable for a variety of rock masses ranging from high-quality ones to broken ones.

Owner:CENT SOUTH UNIV

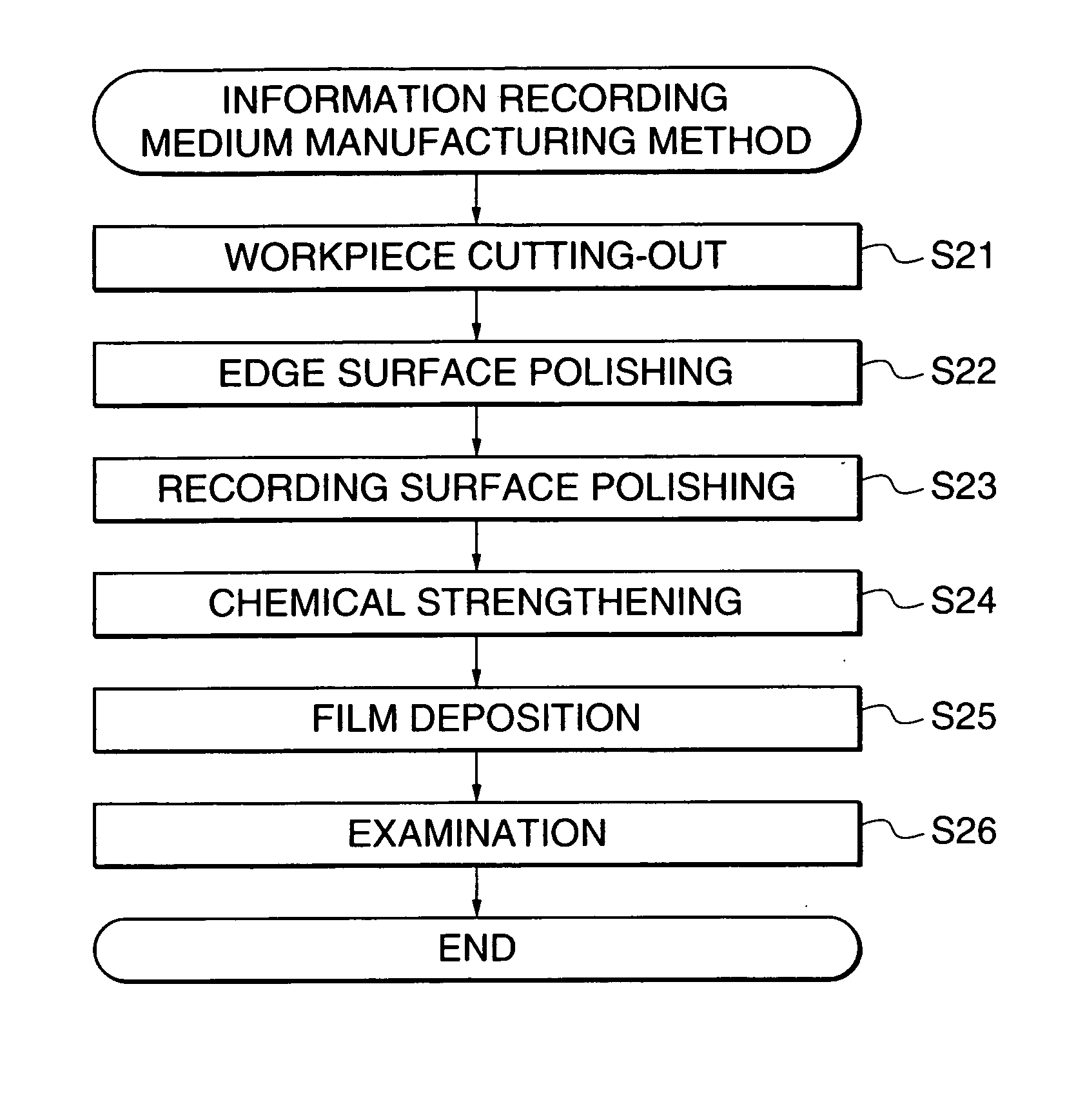

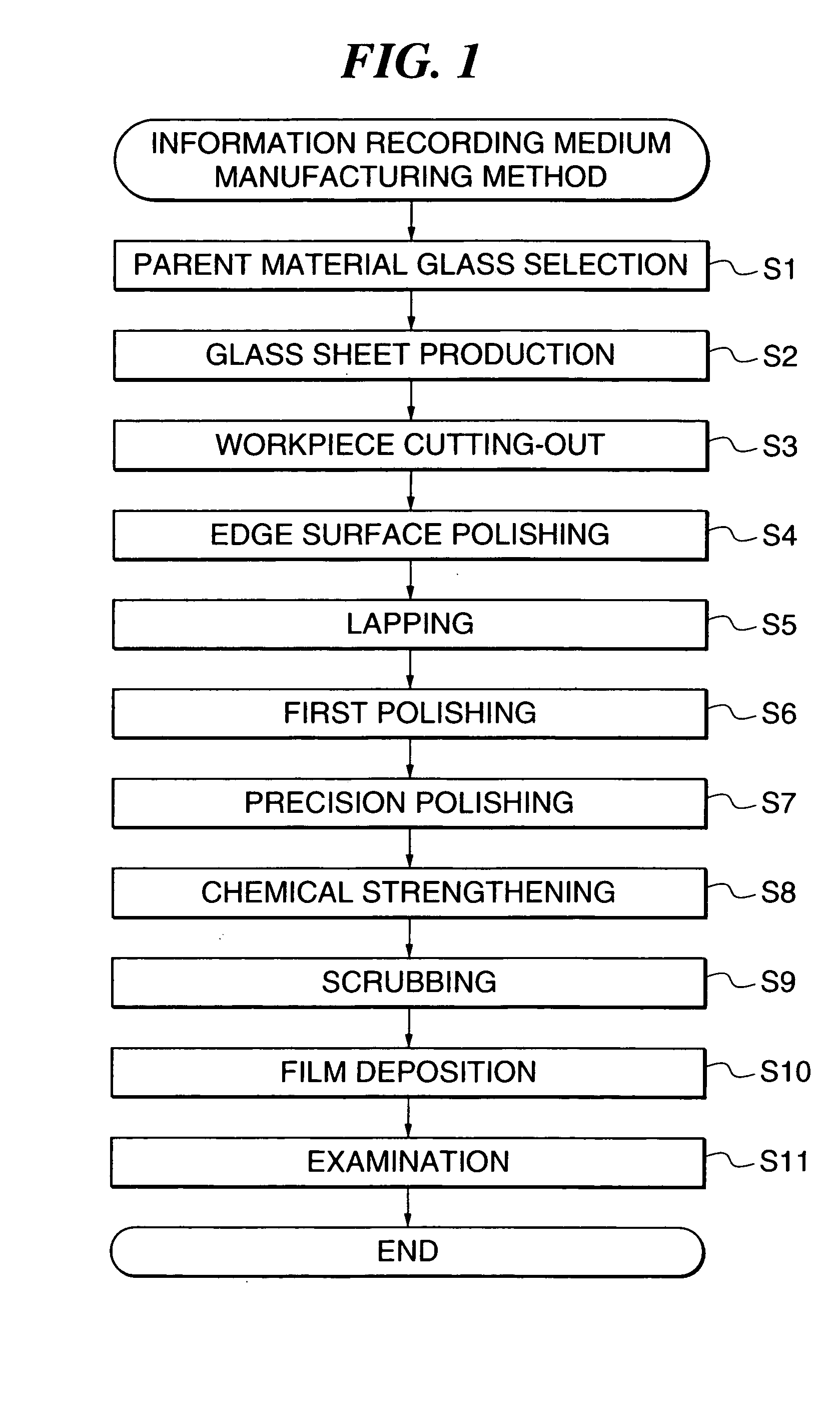

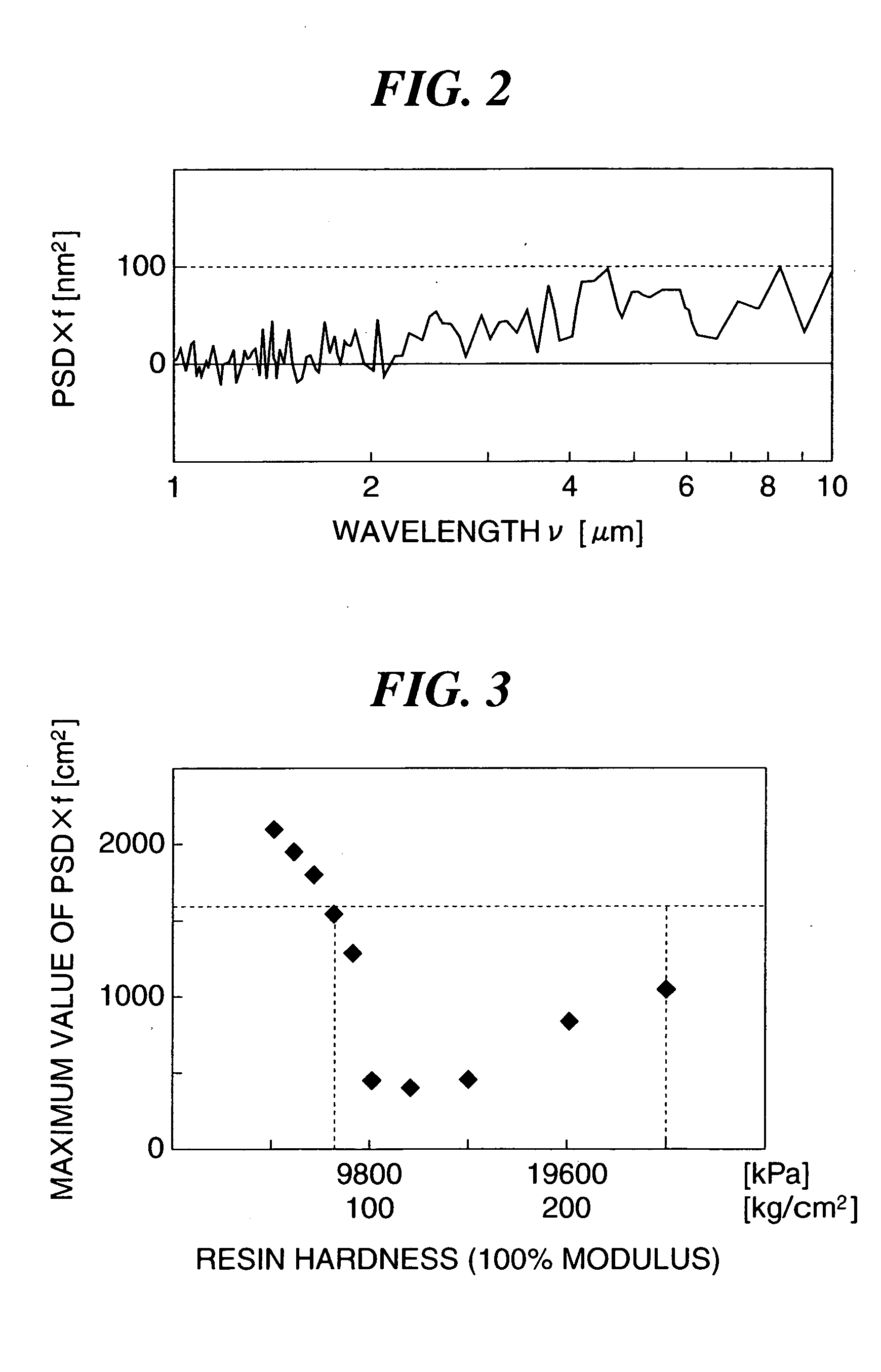

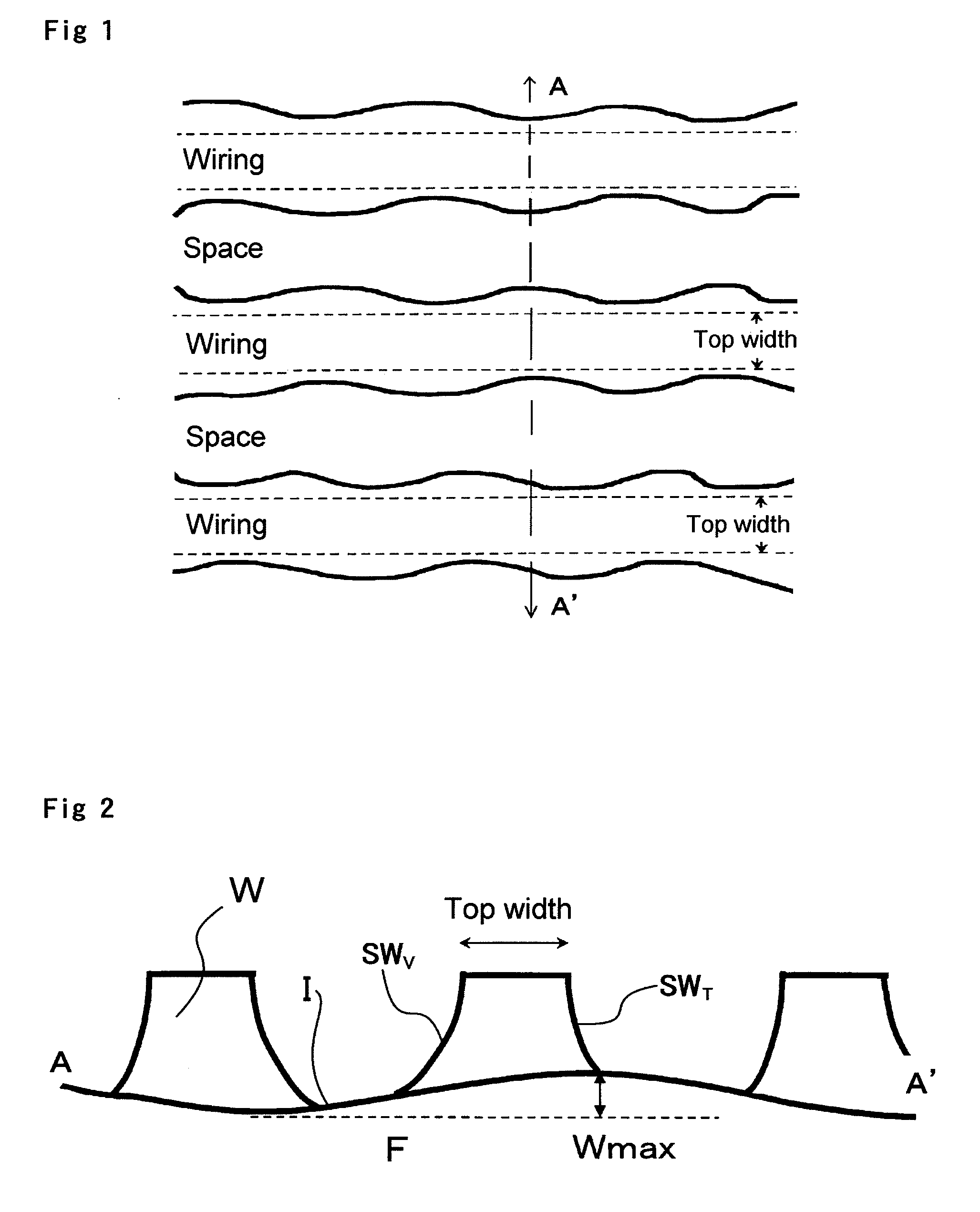

Information recording medium and method of manufacturing glass substrate for the information recording medium, and glass substrate for the information recording medium, manufactured using the method

InactiveUS20050074635A1Reduce wavinessStable flightCombination recordingMagnetic materials for record carriersEngineeringLength wave

There is provided an information recording medium and a method of manufacturing a glass substrate for information recording media as well as a glass substrate manufactured using the method, according to which the take-off height (TOH) of a HDD for example can be made low. The surface shape in a predetermined region of an information recording medium is measured using an optical interferometer or an atomic force microscope. The measured surface shaped is subjected to line analysis along the circumferential direction of the information recording medium. A calculation is made of the product PSD×f of PSD corresponding to a predetermined wavelength ν and the reciprocal of the predetermined wavelength ν. The maximum value of the calculated PSD is controlled to not more than a predetermined value. As a result, the TOH can be made low by reducing waviness which hinders the magnetic head of a HDD or the like from stably flying.

Owner:HOYA CORP

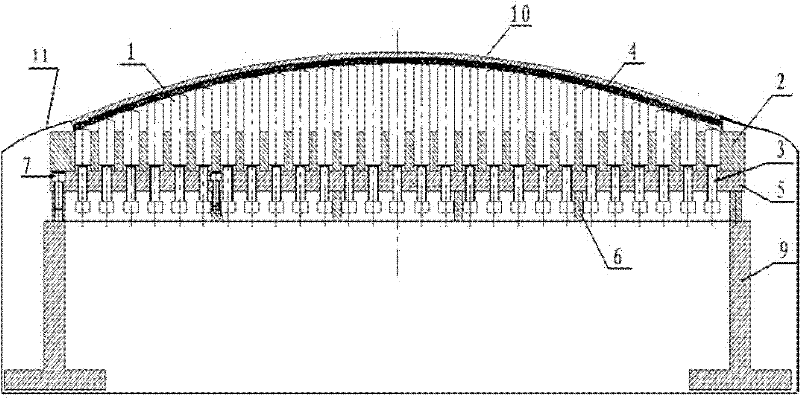

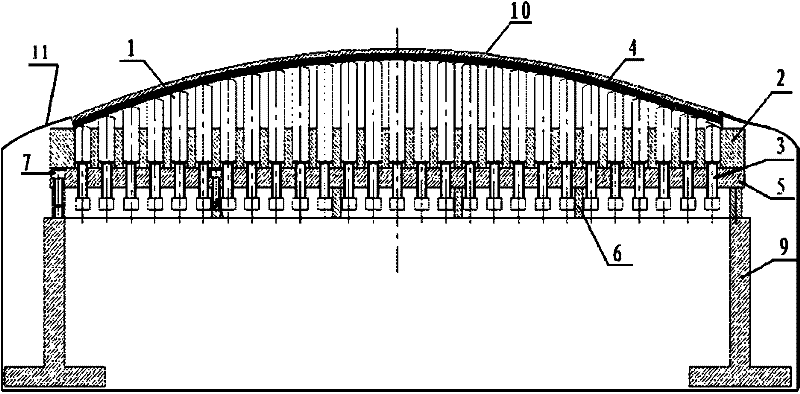

A metal creep forming die

The invention discloses a metal creep forming die. The metal creep forming die comprises an ejector rod, a threaded rod, an ejector rod fixing plate, a threaded rod fixing plate, a reinforcing rib, a height adjusting cushion block and a molded surface base plate, wherein the ejector rod is arranged in a cylindrical hole of the ejector rod fixing plate; the threaded rod is arranged in a threaded hole of the threaded rod fixing plate and is used for controlling the height of the ejector rod to form the required molded surface array; the reinforcing rib is arranged at the bottom of the fixing plate so as to enhance deformation resistance of the die; the height adjusting cushion block is arranged at the bottom of the reinforcing rib so as to adjust the horizontal height of the die; one layer of molded surface base plate is paved above the ejector rod array and is used for transitioning the discrete dot matrix surface into the required smooth curved surface; and the molded surface base plate may be an aluminum plate, a steel plate or a steel aluminum composite plate. In the die provided by the invention, the molded surface base plate can contact with all the ejector rod dot matrixes, so that the waviness of a creep formed member is less than 0.005 and good member molded surface quality is achieved; and the die process cost caused by that a fixed curvature characteristic integrated type structure die and a rib plate type split structure die are required to be modified repeatedly is avoided, so that die trial cost can be greatly reduced.

Owner:CENT SOUTH UNIV

Light reflecting plate and method of manufacturing the same, and light reflecting device

InactiveUS20100053785A1Improve reflection efficiencyReduce light reflectivityMirrorsDomestic mirrorsOptoelectronicsLight reflectance

Provided is a light reflecting plate capable of reducing glare of reflected light while maintaining high light reflectance by regular reflection. The light reflecting plate includes a base, a light reflecting layer that is formed on the base and made of silver or silver alloy, or aluminum or aluminum alloy, in which arithmetic average roughness (Ra) is 0.10 to 0.30 μm and arithmetic average waviness (Wa) is 0.30 to 2.50 μm on a surface of the light reflecting layer.

Owner:TOYO KOHAN CO LTD

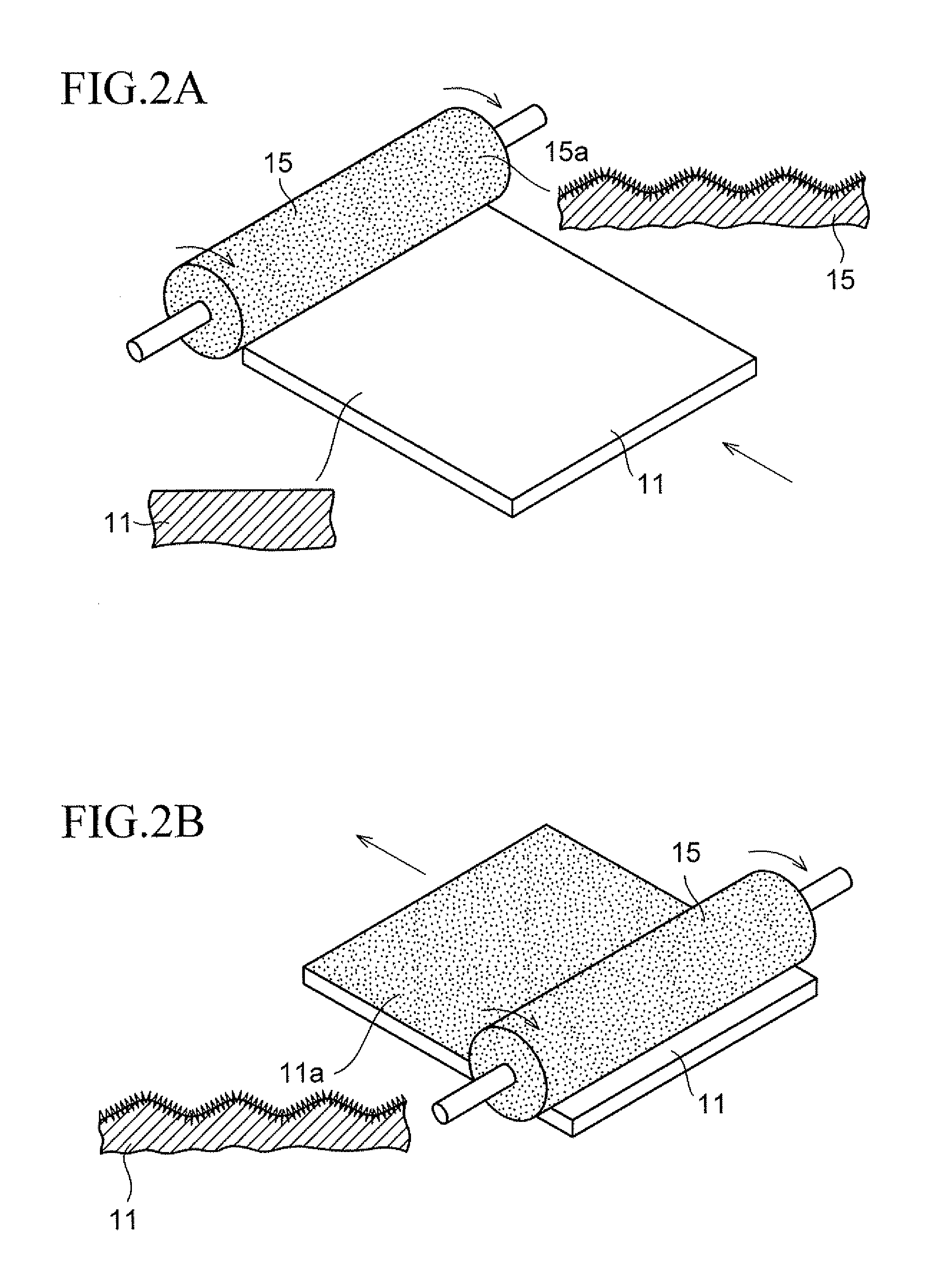

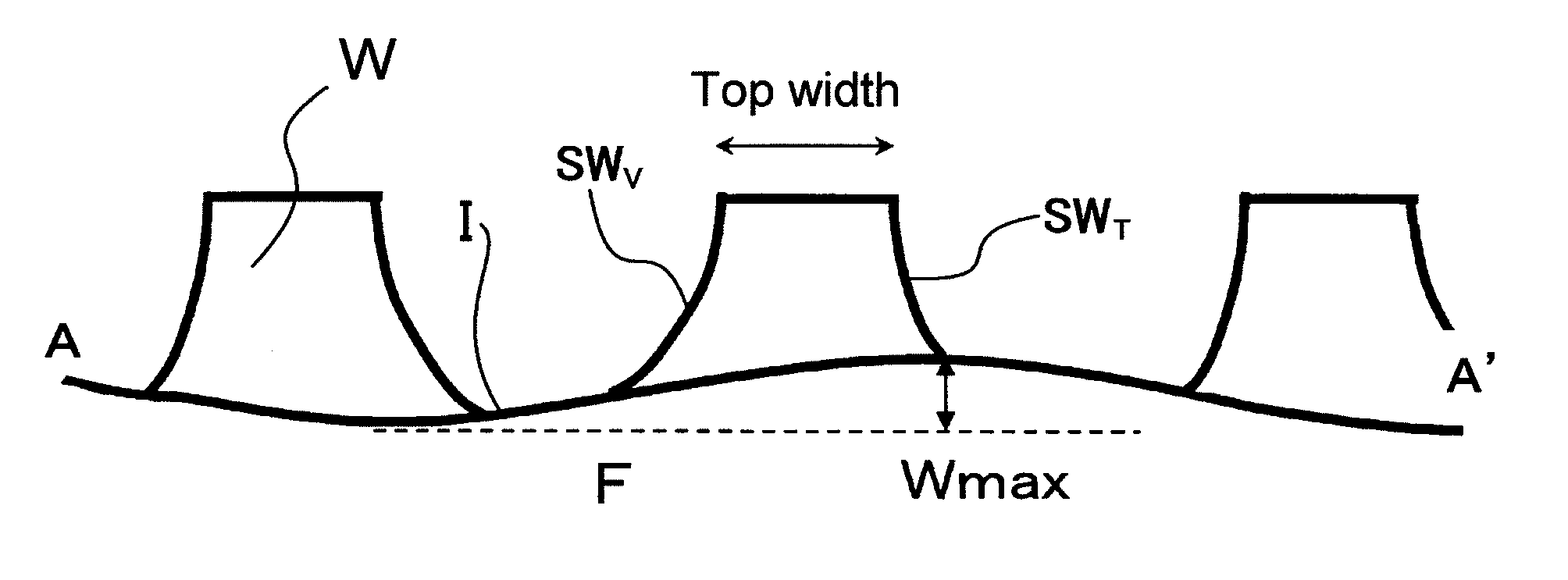

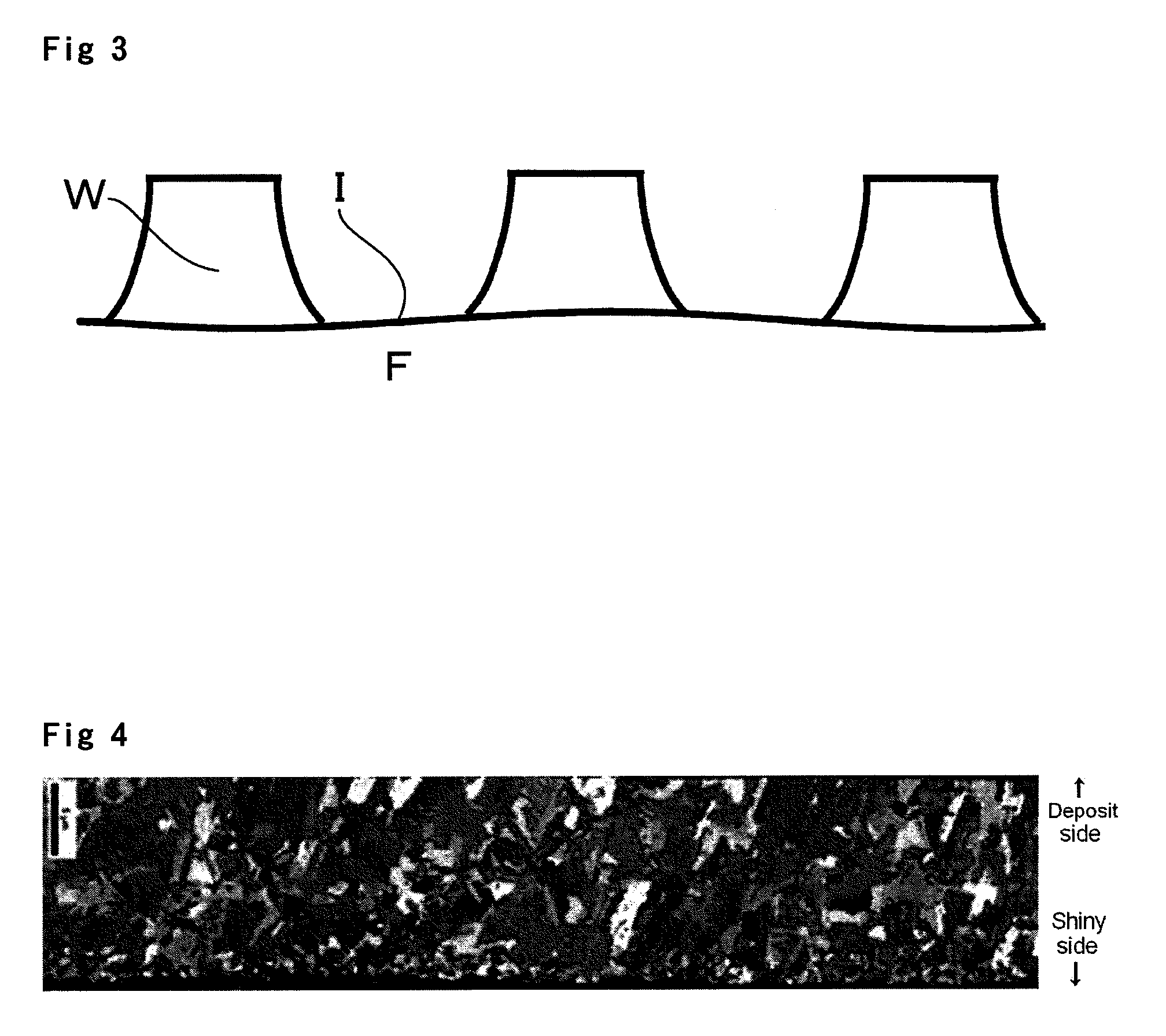

Surface-treated electro-deposited copper foil and method for manufacturing the same

ActiveUS20090047539A1Low profileSmall ripplePrinted circuit aspectsRecord information storageInsulation layerElectrolysis

It is an object to provide a surface-treated electro-deposited copper foil which has a low profile at a level equal to or excellent than that of low-profile surface-treated electro-deposited copper foils that have conventionally been supplied to the market and in which waviness affecting the straight line performance of wiring is small, and a method for manufacturing the same. In order to achieve this object, in the surface-treated electro-deposited copper foil, the maximum waviness height (Wmax) of the bonding surface to be bonded with an insulation layer-constituting material to be 0.05 μm to 0.7 μm, the maximum peak to valley height (PV) to be 0.05 to 1.5 μm, and the surface roughness (Rzjis) to be 0.1 μm to 1.0 μm. The electro-deposited copper foil used for the manufacturing of this surface-treated electro-deposited copper foil is manufactured by using a sulfuric acid base copper electrolytic solution obtained by adding 3-mercapto-1-propanesulfonic acid or bis(3-sulfopropyl)disulfide, a quaternary ammonium salt polymer having a cyclic structure, and chlorine, and using a cathode having small surface roughness, under electrolysis conditions of carrying out continuous first-step electrolysis to n-th-step electrolysis at two or more different levels of electric current density.

Owner:MITSUI MINING & SMELTING CO LTD

Special-shaped complex fiber and method of manufacturing the same

InactiveCN101498059ASimple preparation processNatural fiber imitation effect is obviousFilament/thread formingSingle fiberNatural fiber

The invention relates to a special-shaped composite fiber and a manufacture method thereof. A bundle of parallel special-shaped composite fibers is formed by clustering a plurality of double-component, special-shaped, composite and single fibers, wherein the cross section shape of the single and special-shaped fiber is non-round and is any one shape of an oval, a rectangle, a trapezoid, a triangle, a trefoil, a cross, a T shape and an H shape. The manufacture method comprises the following steps: adopting double-component spinning fused mass and utilizing a double-component and composite spinning machine, a parallel composite spinning component and a special-shaped hole spinneret plate to manufacture the parallel special-shaped composite fibers which can be directly prepared into FDY parallel special-shaped composite fibers or can be prepared into POY parallel special-shaped composite fibers and then be prepared into DT or DTY parallel special-shaped composite fibers with crimp property by post-processing technologies, such as traction or elasticizing, and the like. The spinning fused mass has two different characteristics; firstly, the two types of spinning fused mass are together extruded and solidified into fibers by spinneret orifices on the special-shaped hole spinneret plate of a parallel spinning component, and the fibers are drawn, extended and coiled into the parallel special-shaped composite fibers. The invention has the advantages of simple technology, obvious natural fiber simulation effect, convenient popularization and application, and the like, and the waviness and the cross section shape of the fibers are similar to natural fibers.

Owner:ZHEJIANG SCI-TECH UNIV

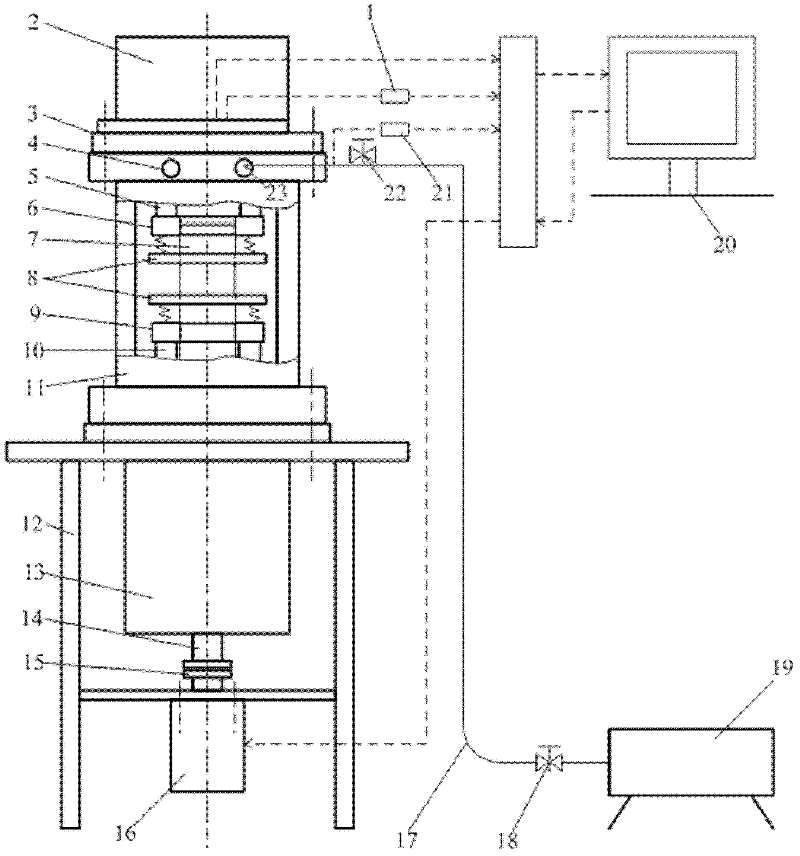

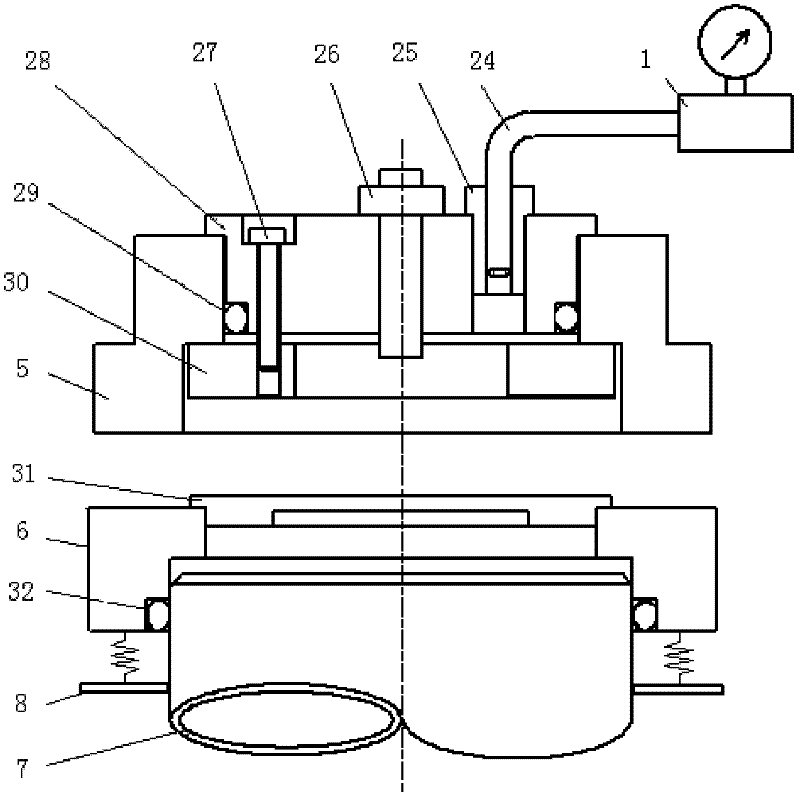

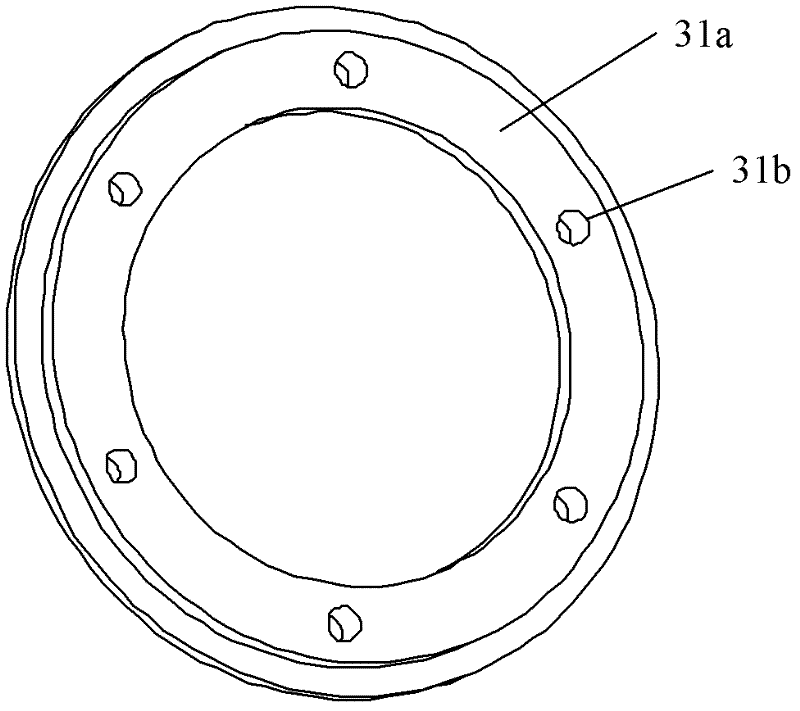

Gas sealing experimental device and method

ActiveCN102507103AMeasurable tightnessAdjustable pressureMeasurement of fluid loss/gain rateElectrical/magnetic thickness measurementsCouplingEngineering

The invention discloses a gas sealing experimental device which comprises a sealed cavity, a driving system, a gas supply loop and a test system. The gas sealing experimental device is characterized in that the sealed cavity is vertically fixed on a bracket by a bolt; the driving system comprises a motor, a coupler, a bearing box and a spindle; the motor is fixed on the bracket by the bolt; the motor and the spindle are connected by the coupler; the gas supply loop comprises a compressor, a pneumatic pipe and a pressure regulation valve; the compressor is connected with a gas inlet of the sealed cavity through the pneumatic pipe; and the test system comprises an eddy current sensor, a moving ring positioning sheet, a flowmeter and a pressure sensor. Through adoption of the gas sealing experimental device, the sealed end surface gas leakage rate and the gas film thickness of various gas end surfaces can be measured on line. The measurement method of gas leakage rate is simple and easy to implement and has good dynamic response, the measurement of gas film thickness is not affected by the material of a seal ring, end surface width and the annular surface waviness of the seal ring, and revolving speed and pressure in the experiment process are adjustable.

Owner:海宁市黄湾镇资产经营有限公司

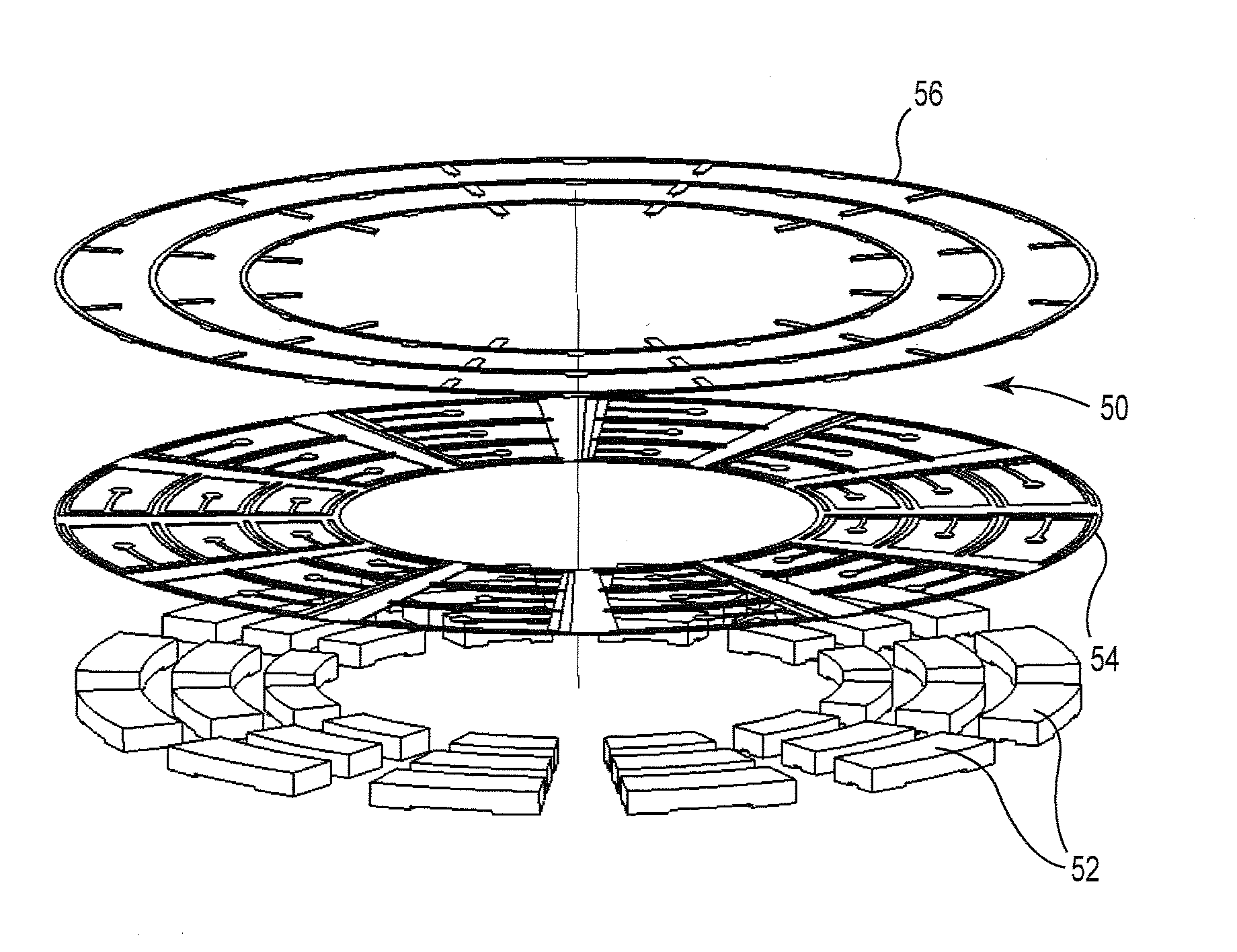

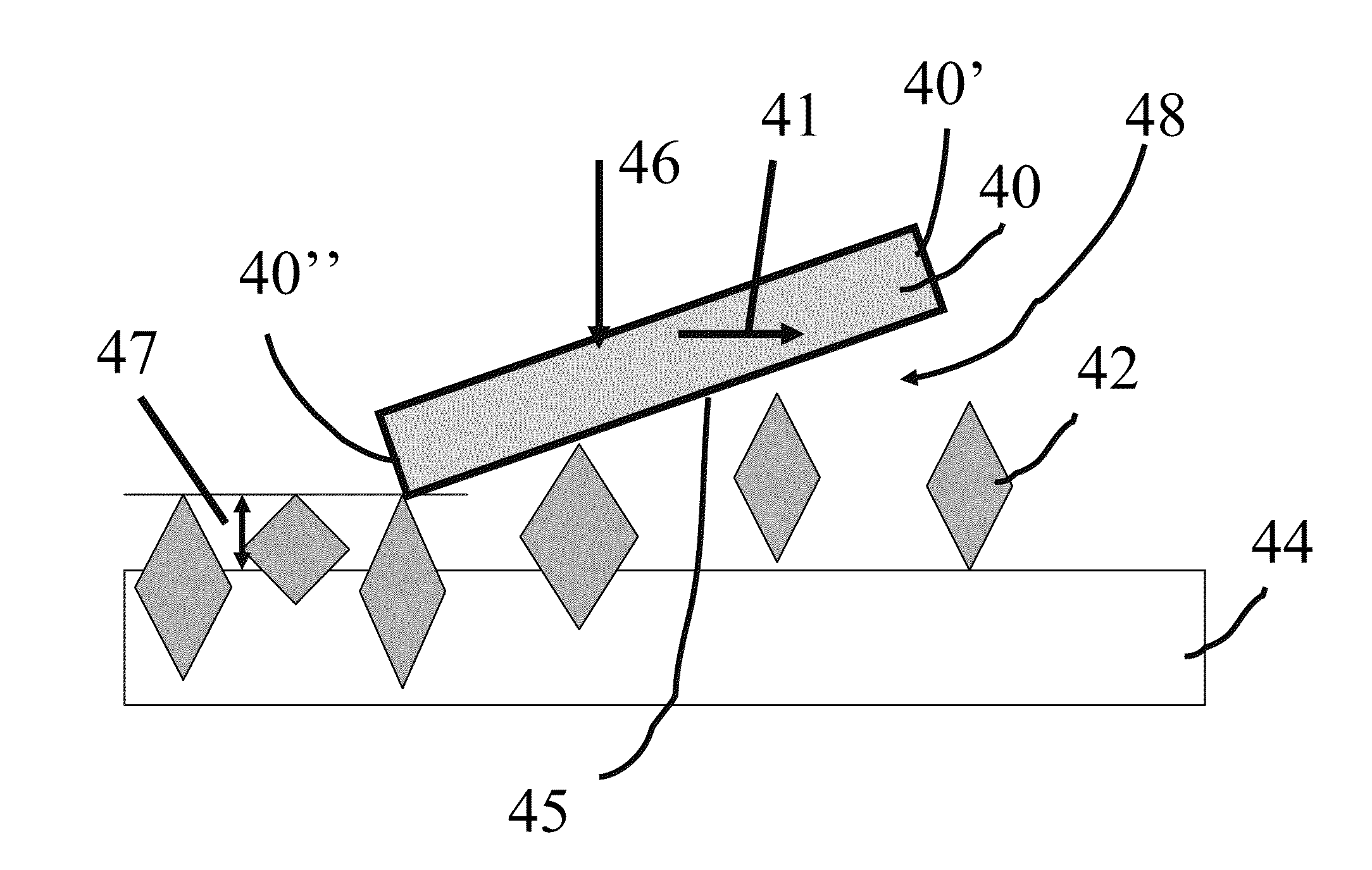

Array of abrasive members with resilient support

An abrasive article having an array of abrasive members with an elastomeric support that permits each abrasive member to move independently in at least pitch and roll. Each abrasive member maintains a fluid bearing (air is the typical fluid) with the substrate. The abrasive members are capable of selectively engaging with nanometer-scale and / or micrometer-scale height variations and micrometer-scale and / or millimeter-scale wavelengths of waviness, on the surfaces of substrates. The spacing and pitch of the abrasive members can be adjusted to follow the topography of the substrate to remove a generally uniform layer of material; to engage with the peaks on the substrate to remove target wavelengths of waviness; and / or to remove debris and contamination from the surface of the substrate.

Owner:RDC HLDG

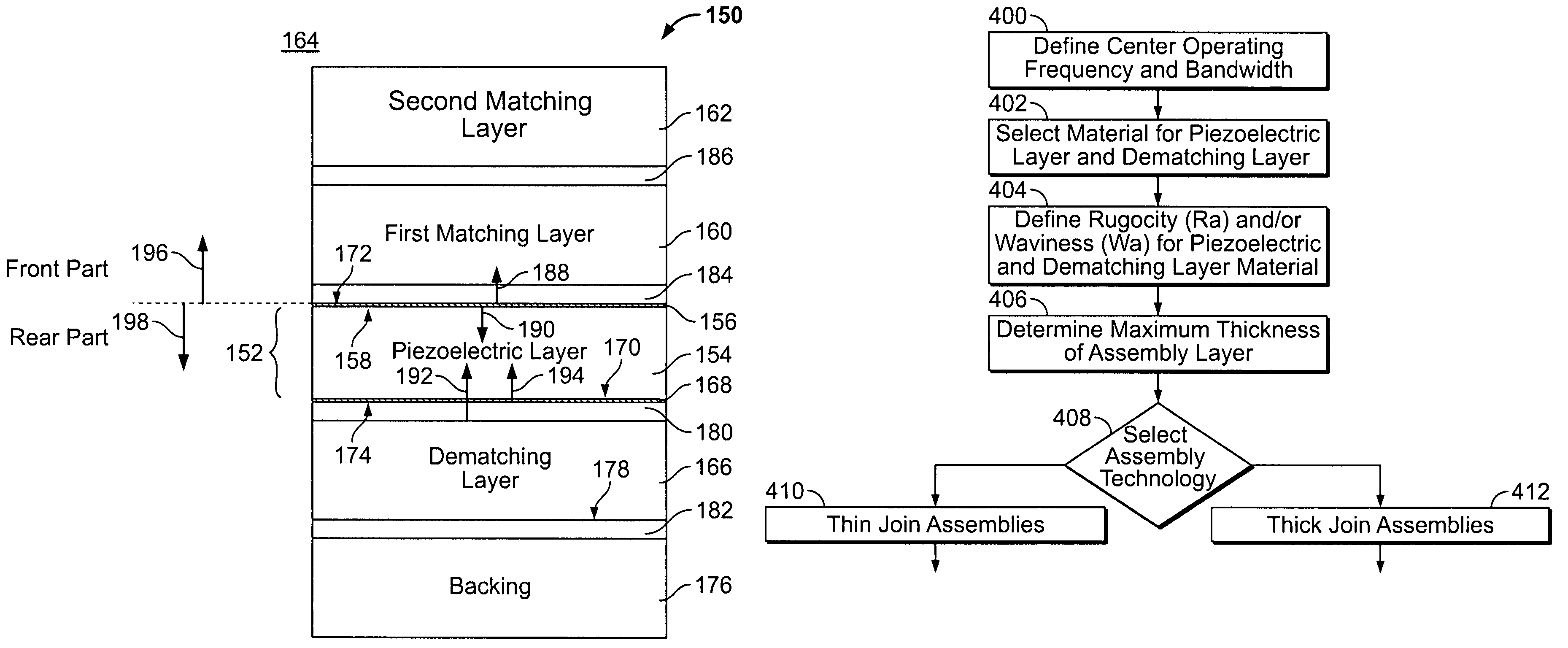

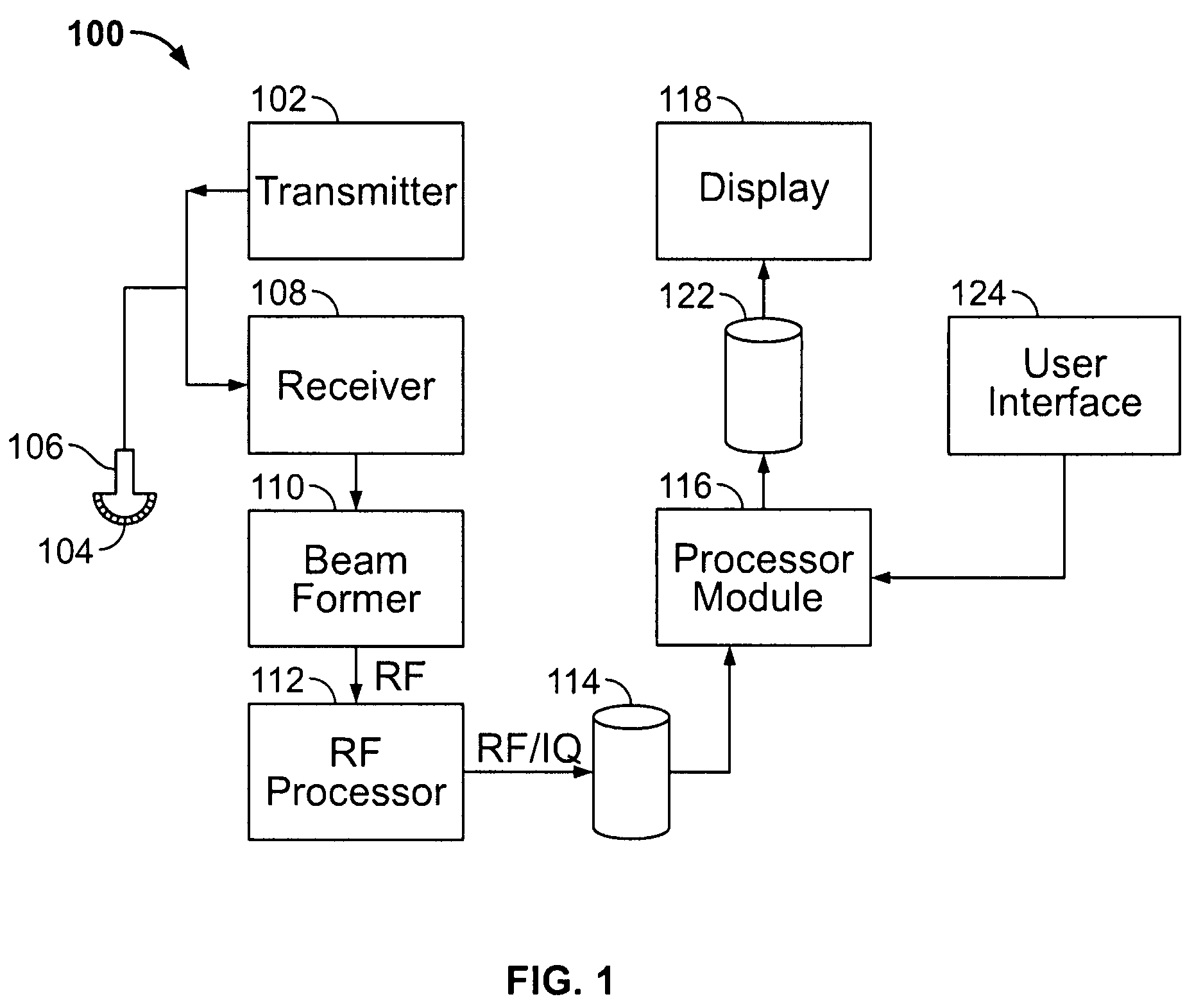

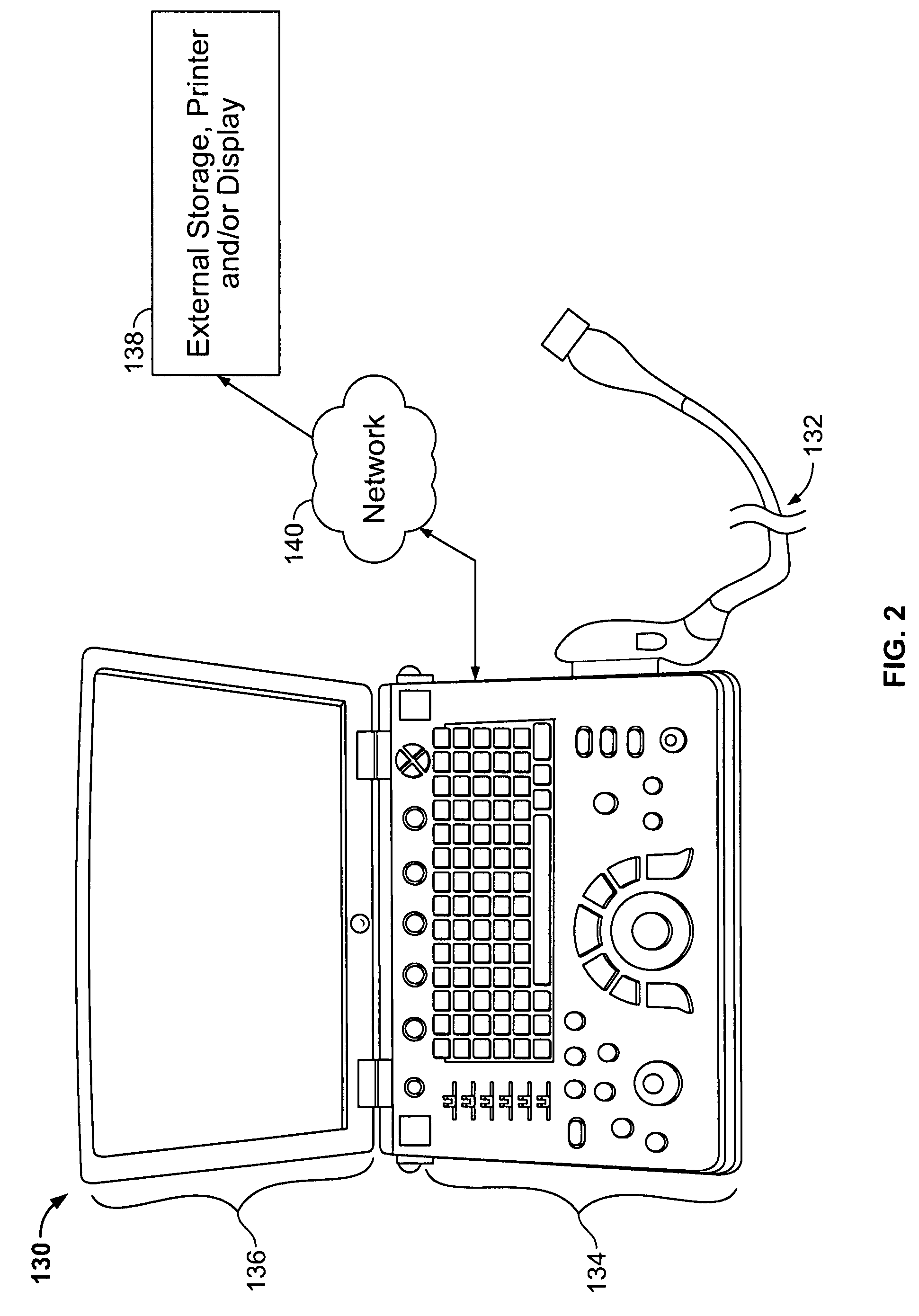

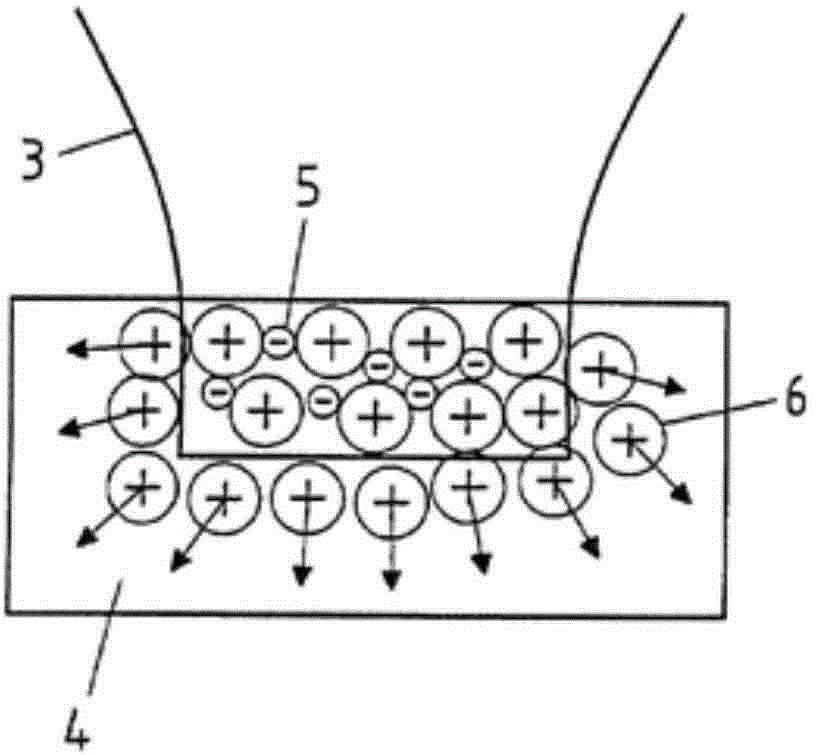

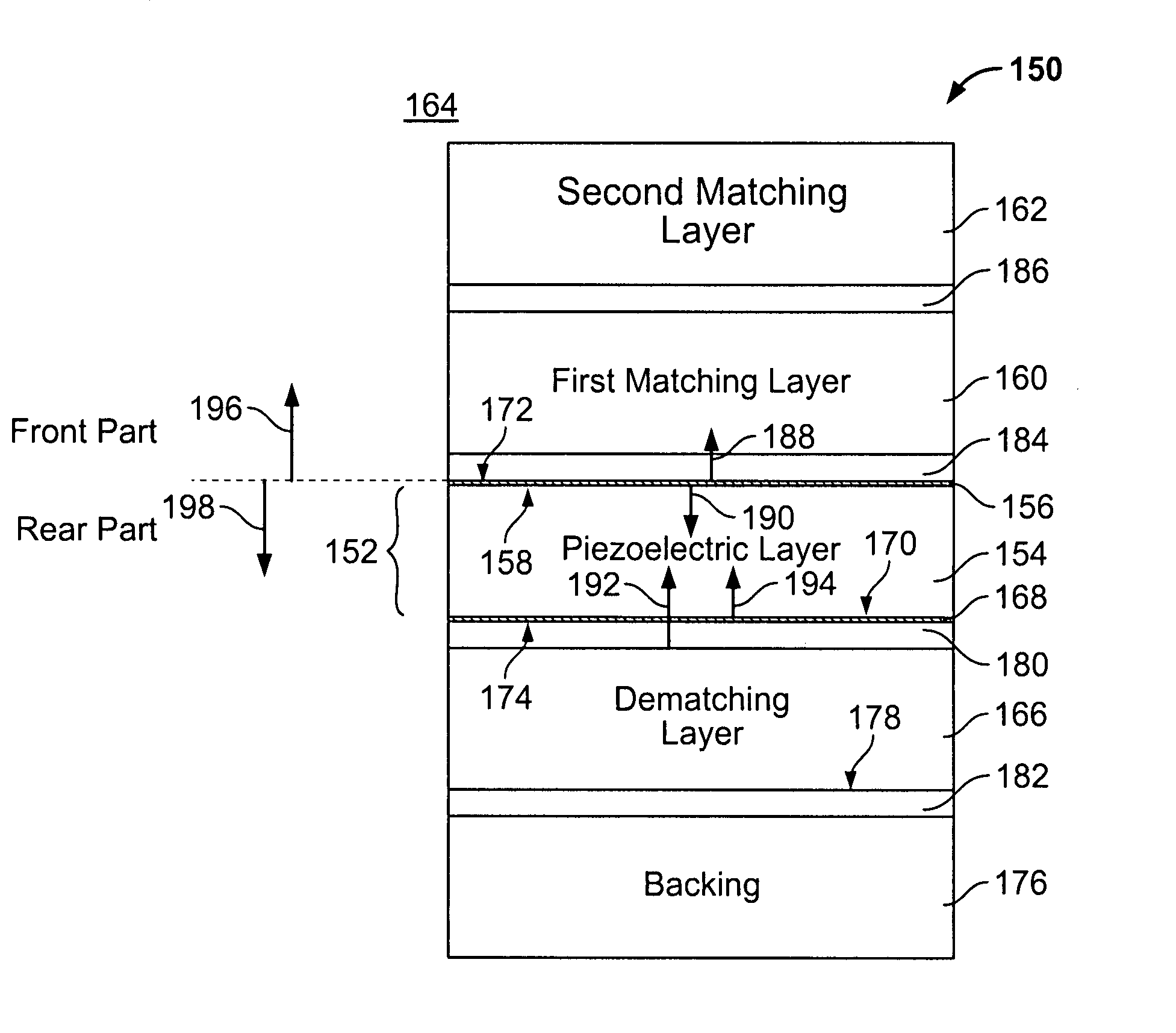

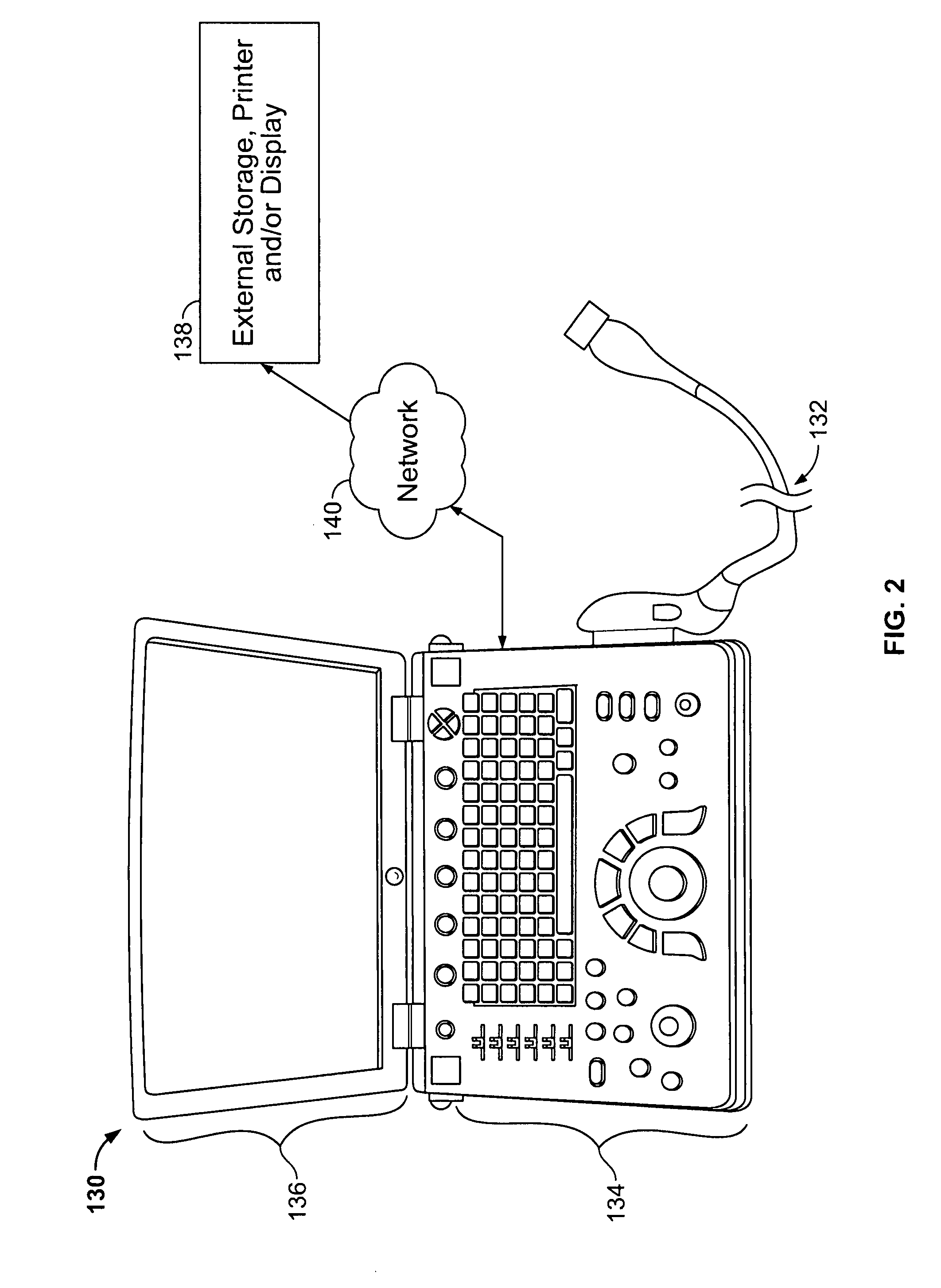

Method for optimized dematching layer assembly in an ultrasound transducer

ActiveUS7621028B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTransducerEngineering

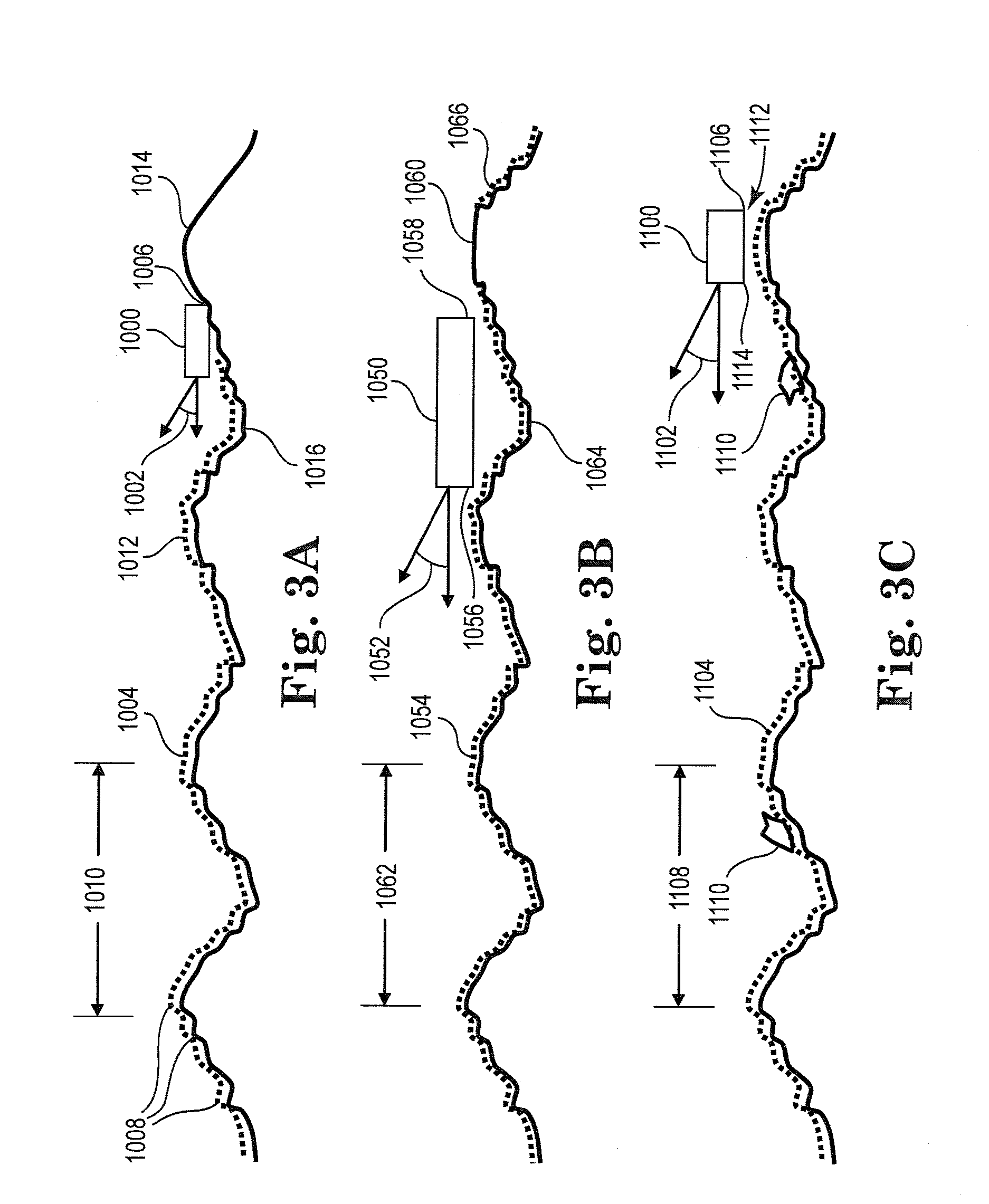

A method for manufacturing an acoustical stack for use within an ultrasound transducer comprises using a user defined center operating frequency of an ultrasound transducer that is at least about 2.9 MHz. A piezoelectric material and a dematching material are joined with an assembly material to form an acoustical connection therebetween. The piezoelectric material has a first acoustical impedance and *at least one of* an associated piezoelectric rugosity (Ra) and piezoelectric waviness (Wa). The dematching material has a second acoustical impedance that is different than the first acoustical impedance and at least one of an associated dematching Ra and dematching Wa. The piezoelectric and dematching materials have an impedance ratio of at least 2. The assembly material has a thickness that is based on the center operating frequency and at least one of the piezoelectric Ra, piezoelectric Wa, dematching Ra and dematching Wa.

Owner:GENERAL ELECTRIC CO

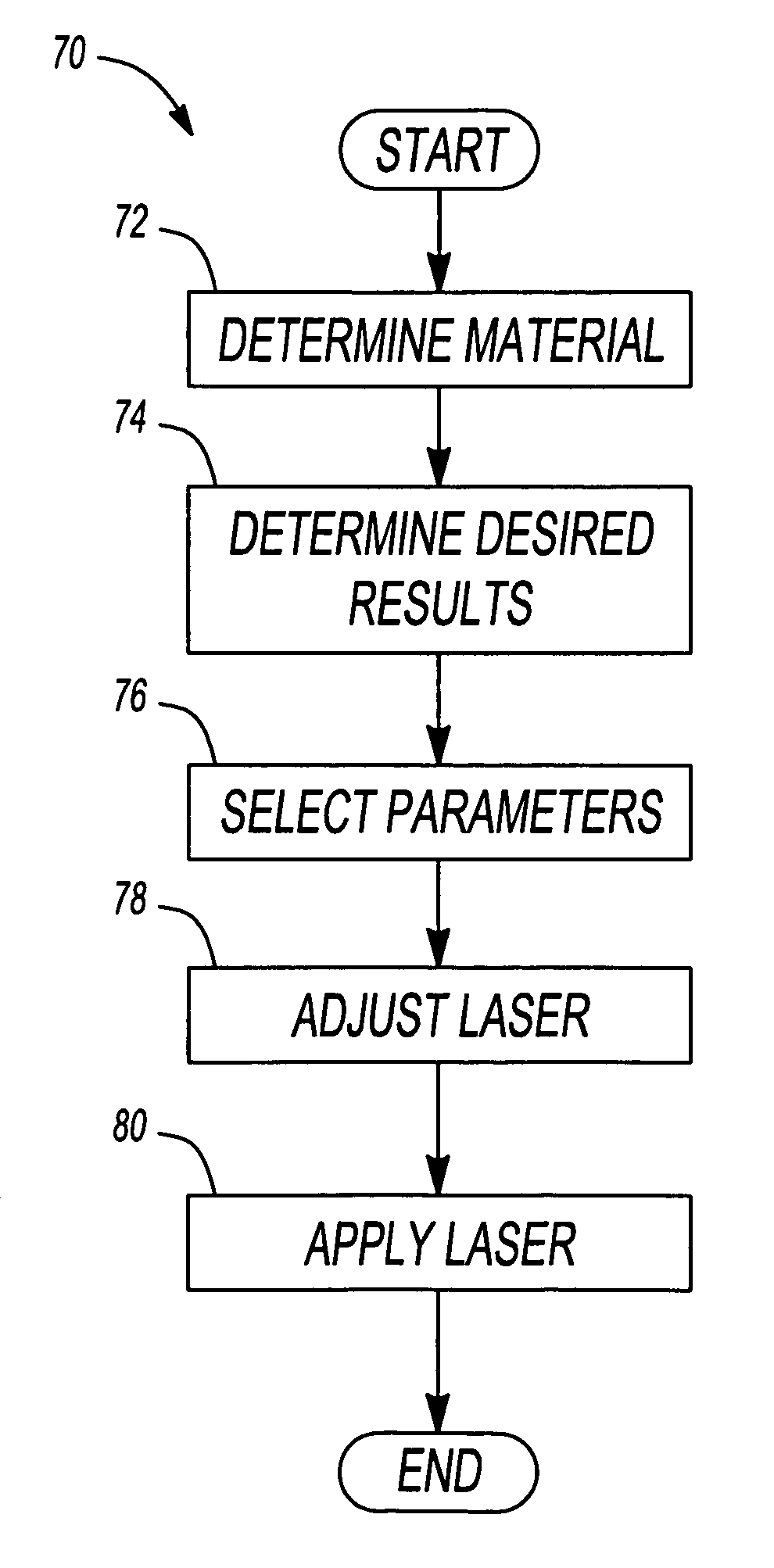

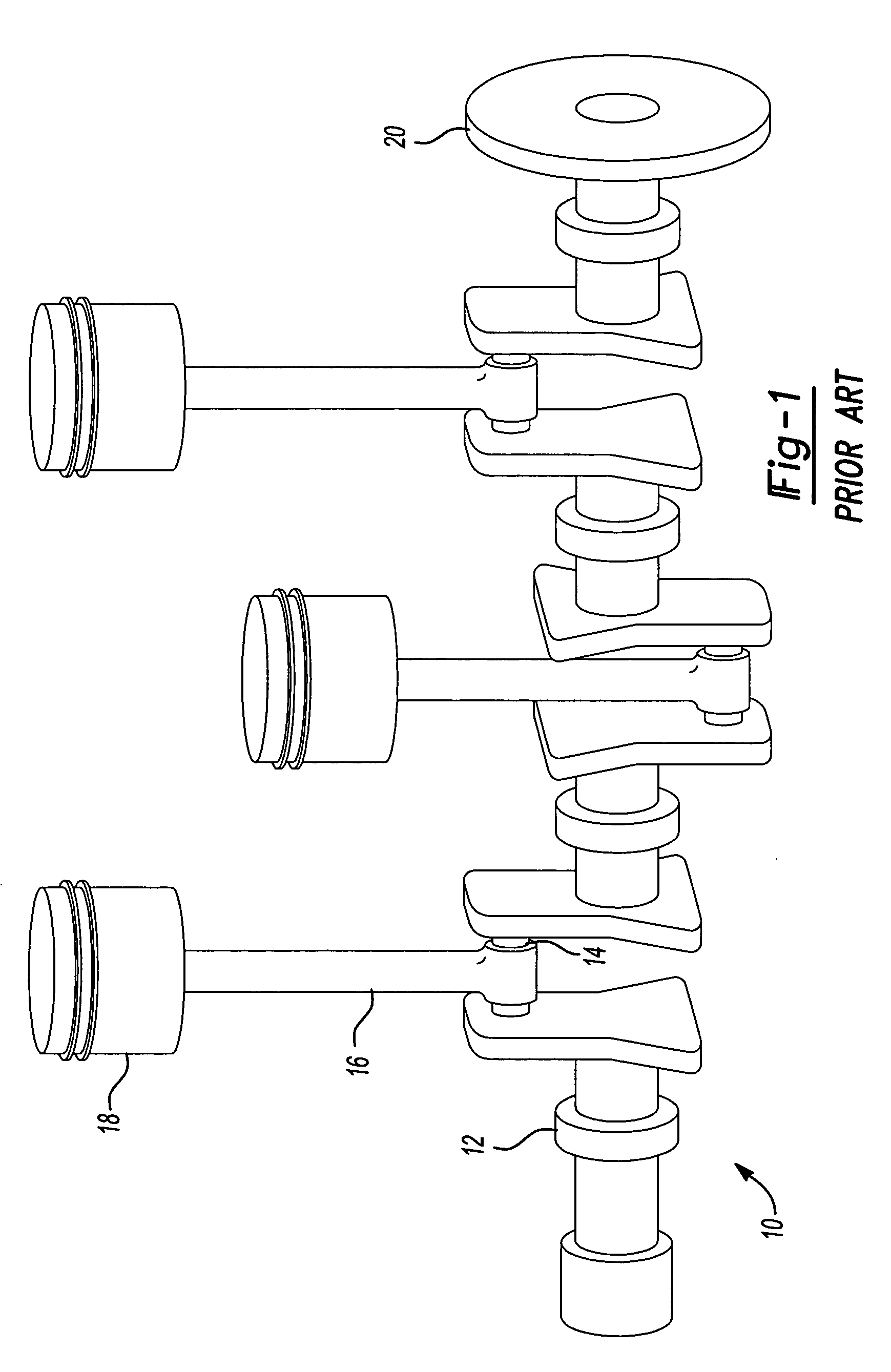

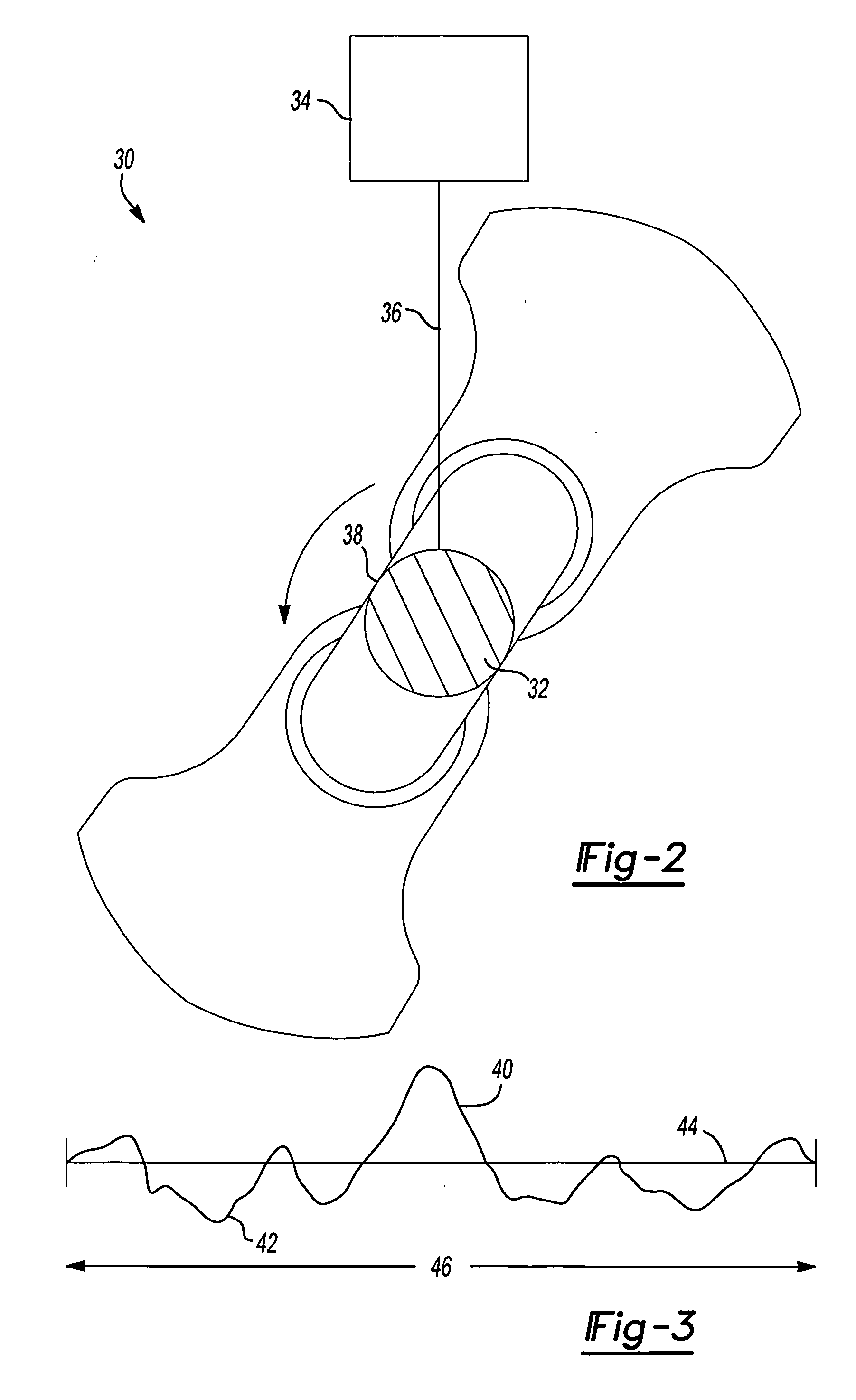

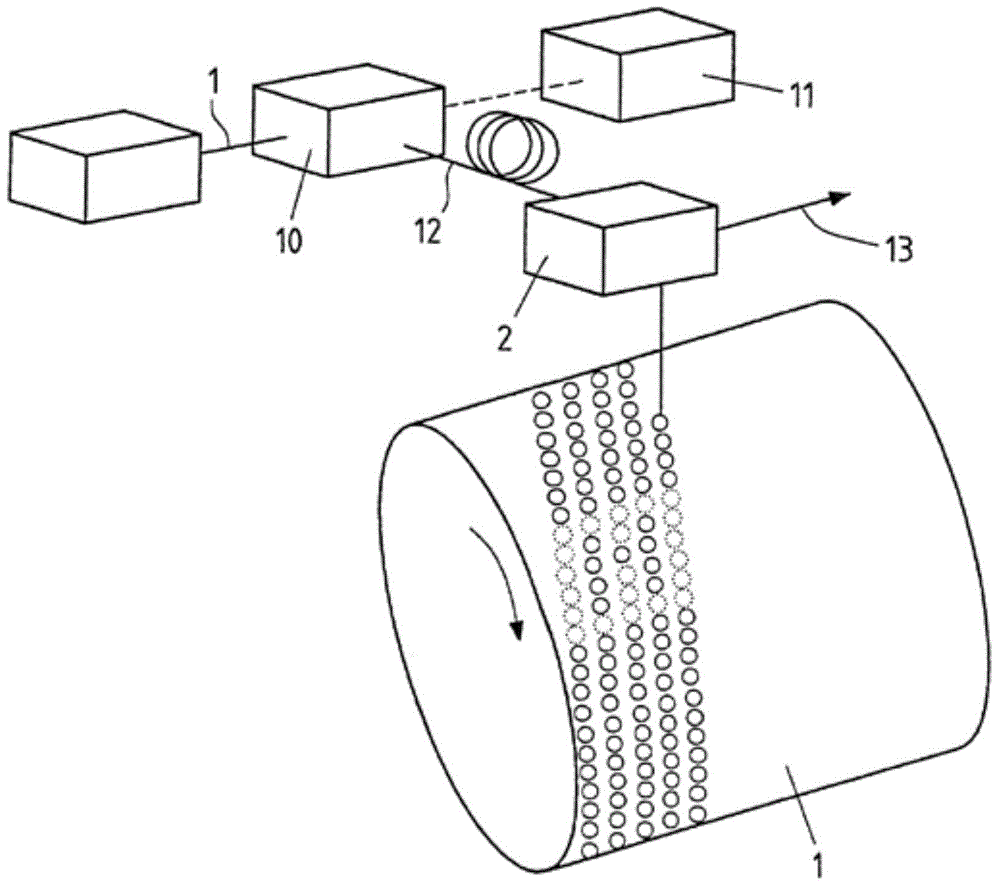

Manufacturing method that uses laser surface transformation to produce new and unique surface profiles for rotating bearings

ActiveUS20060138100A1Semiconductor/solid-state device manufacturingPhotosensitive material processingOil retentionEarth surface

A laser ablation method is used to polish a bearing surface of an automotive crankshaft. A laser ablation device generates a laser according to parameters such as wavelength, pulse duration, pulse repetition rate, and beam quality. The laser is applied to the surface of a rotating engine component, such as a crankshaft, as the component is rotated in order to polish the surface according to the parameters. The laser substantially improves tribological performance of the bearing surface by changing the waviness and form of the surface profile. Further, oil-retention reservoirs are formed in the surface. As a result, the friction coefficient of the crankshaft surface is reduced while the roughness of the crankshaft surface is maintained, reduced, or increased.

Owner:ADCOLE CORP +1

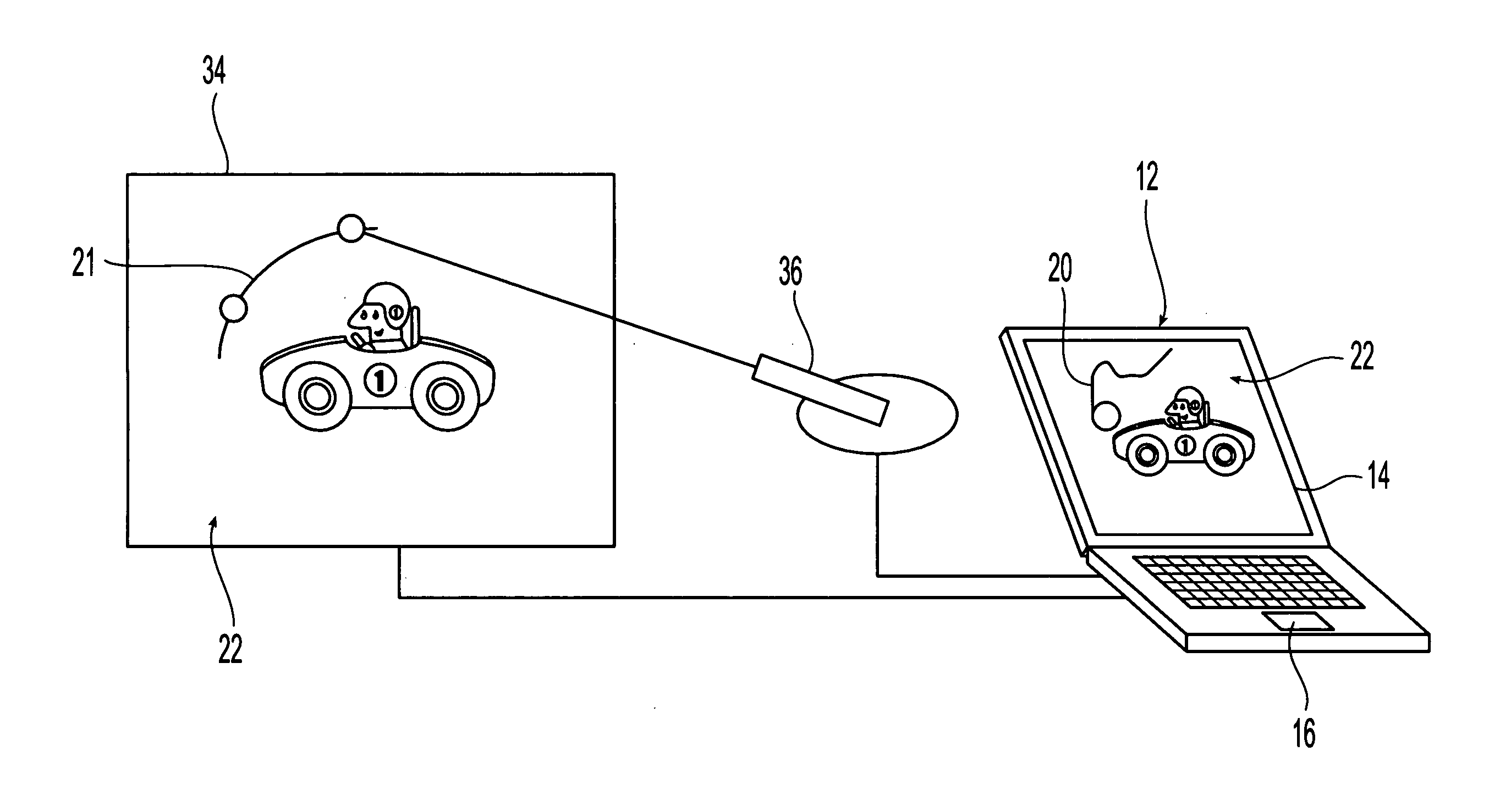

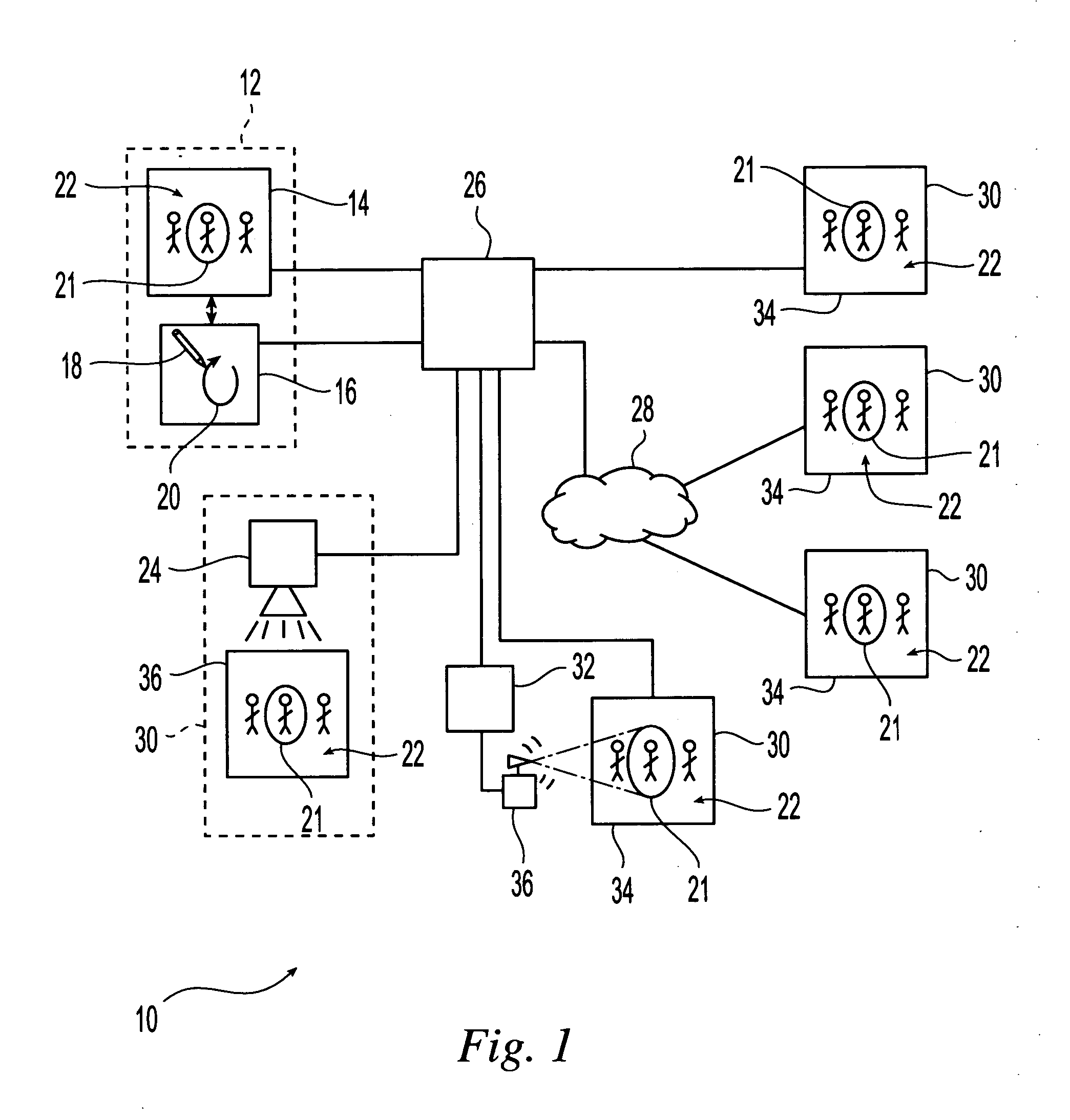

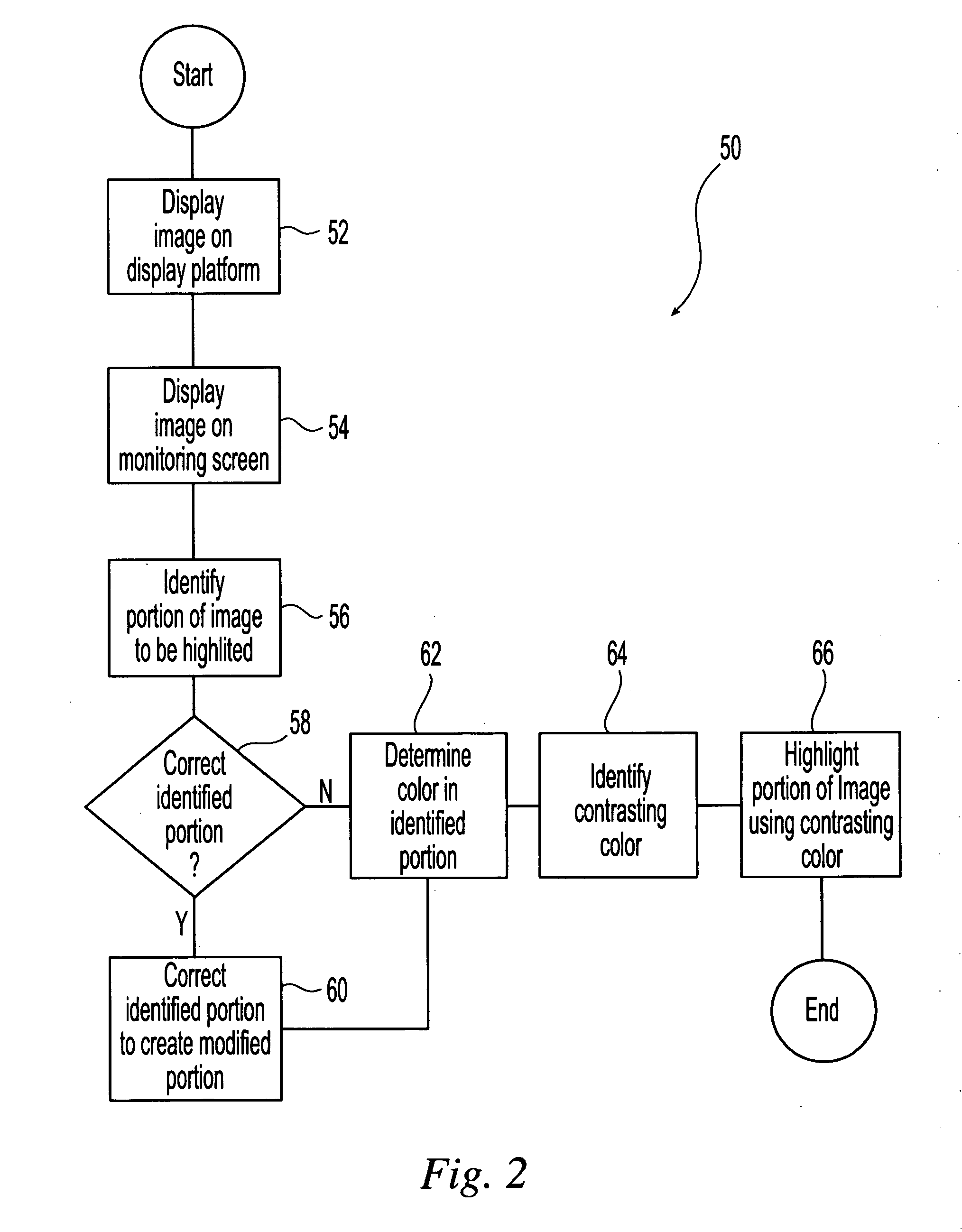

System and method for smooth pointing of objects during a presentation

InactiveUS20070206024A1Reduce or eliminate random jitter or jagged linesCathode-ray tube indicatorsInput/output processes for data processingGraphicsControl system

A system and method are provided that allows a speaker to provide real-time annotations to one or more displayed images during a presentation. The speaker inputs the annotations my manually identify a portion of the displayed image using an input mechanism such as a touch screen that is in communication with a presentation monitor and a control system that is controlling the presentation. The identified portions are annotated onto the displayed images using a adaptive color that is selected to provide optimum contrast with the existing colors in the displayed image. In addition to providing adaptive, contrasting colors for the annotations, imperfection such as waviness are removed from the identified portions to created corrected portions that are then annotated onto the presentation image. Annotation is accomplished through computer generated graphics or through the use of a motorized, controllable laser pointer.

Owner:IBM CORP

Method and apparatus for embedding abrasive particles into substrates

InactiveUS20110027549A1Reduce nanometer-scale height variationProduce stiffnessLayered productsAbrasion apparatusWear particleMicrometer scale

A dressing bars for embedding abrasive particles into a substrate at a substantially uniform height. Spacing pads, hydrostatic and / or hydrodynamic fluid bearing (air is the typical fluid) maintains a constant spacing and attitude between the dressing bar and the substrate. The fluid bearing permits the dressing bar to maintain a desirable stiffness between the lapping plate and the dressing bar. The bar geometry and fluid bearing design permits the bar to mitigate or compensate for the micrometer-scale and / or millimeter-scale wavelengths of waviness on the substrate, while maintaining a substantially constant clearance to uniformly embed the abrasive particle into the substrate.

Owner:SCHWAPPACH KARL

Magnetic hard disc substrate and process for manufacturing the same

InactiveUS6426155B1Short timeSimple wayMagnetic materials for record carriersRecord information storageHigh densitySurface roughness

Owner:SHOWA DENKO KK

Polishing slurry for disk base sheet of memory hard disk

InactiveCN1417278AReduce roughnessReduce wavinessEdge grinding machinesPolishing compositions with abrasivesPolyolAlcohol

The present invention relates to the technology of manufacturing computer memory and hard disk. The polishing slurry contains abrasive, oxidant and water and is characterized by its water-soluble lubricant and polish balancing agent. The water-soluble lubricant is plyoxyethylenated fatly acid phosphate, plyoxyethylene fatty amide phosphate, fatty acid-polyol ester or their mixture and accounts for 0.2-20 wt%; and the polish balancing agent is water-soluble alcohol and accounts for 0.2-20 wt%. The polishing slurry can reduce the roughness and waviness of memory and hard disk surface to below 0.7 angstrom and eliminate effectively pit, lug, scratch and other faults.

Owner:TSINGHUA UNIV

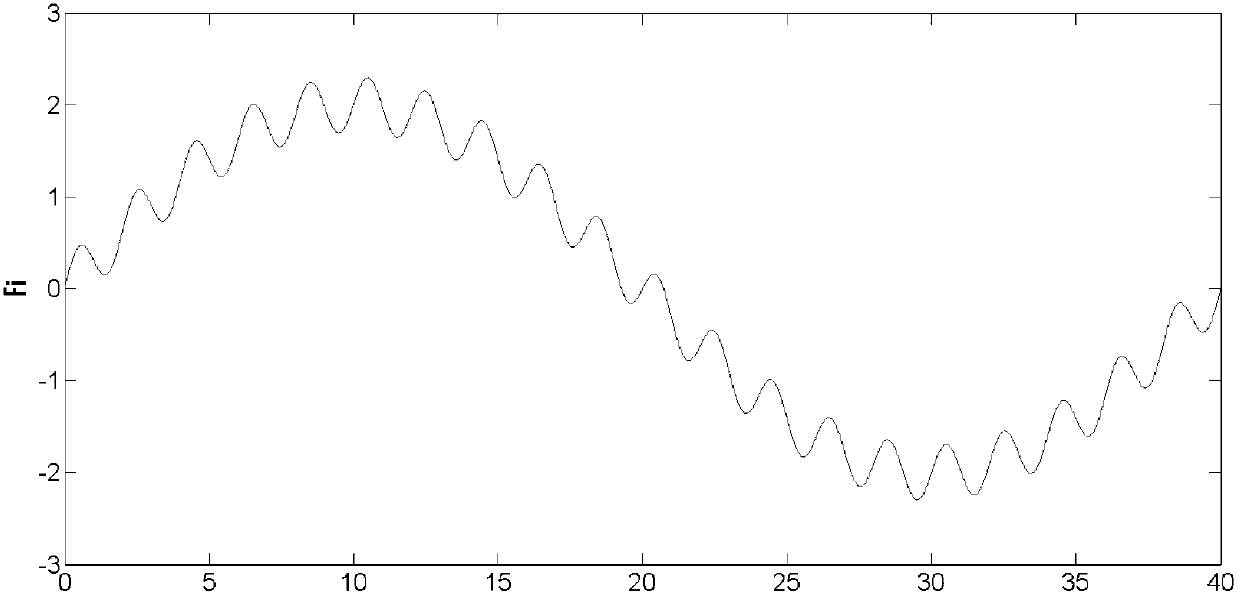

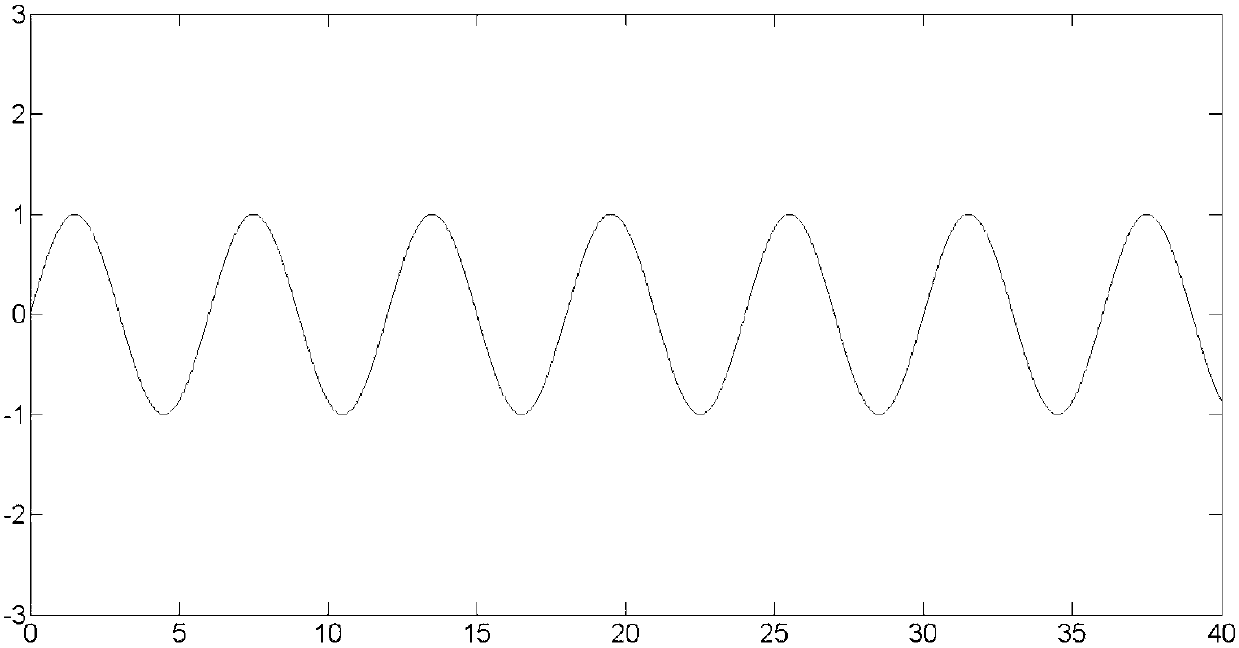

Involute gear waviness sample plate

ActiveCN102706306AGuaranteed Phase RelationshipRealize the filtering effectMachine gearing/transmission testingMeasuring instrumentHarmonic

The invention discloses an'involute gear waviness sample plate'. Based on the generation principle of an involute profile, a novel involute gear waviness sample plate is designed. Based on the gear mesh principle, according to the generation principle of the involute, the designed waviness is overlapped to an involute profile along the generation line direction of the involute; a plurality of harmonic waves can be overlapped on each gear surface according to the design aim; the wave lengths of the harmonic waves and the initial phase position are required to be calculated according to the gear waviness theory; the involute gear waviness sample plate overlaps the specific harmonic waves in a standard gear transmission error curve, finally the estimation of the filtering algorithm of a gear measuring instrument is realized, a complete measurement means for the gear noise theory is provided, and the gear standard sample plate system is perfected.

Owner:BEIJING UNIV OF TECH

Flat product made of metal material, in particular a steel material, use of such a flat product, and roll and method for producing such flat products

ActiveCN104884180AGood formabilityImprove spray appearanceRollsOther manufacturing equipments/toolsThin metalMetallic materials

A flat product made of a metal material has been provided with deterministic surface texture which has a plurality of depressions which have a depth in the range of from 2 to 14 μm, wherein the depressions are designed to be I-shaped, H-shaped, cross-shaped, C-shaped or X-shaped, and wherein the surface texture has a peak count RPc in the range of from 45 to 180 l / cm, an arithmetic mean roughness Ra in the range of from 0.3 to 3.6 μm, and an arithmetic mean waviness Wsa in the range of from 0.05 to 0.65 μm. A roll which is particularly suitable for producing such a flat product has a deterministic surface texture which has a plurality of overlapping dimples, which are arranged such that they delimit a double-I-shaped, H-shaped, cross-shaped, C-shaped or X-shaped material texture in the roll surface, and wherein the surface texture of the roll, measured in the direction of the roll axis, is characterized by a peak count RPc in the range of from 80 to 180 l / cm, an arithmetic mean roughness Ra in the range of from 2.5 to 3.5 μm and an arithmetic mean waviness Wsa in the range of from 0.08 to 1.0 μm.

Owner:THYSSENKRUPP STEEL EURO AG

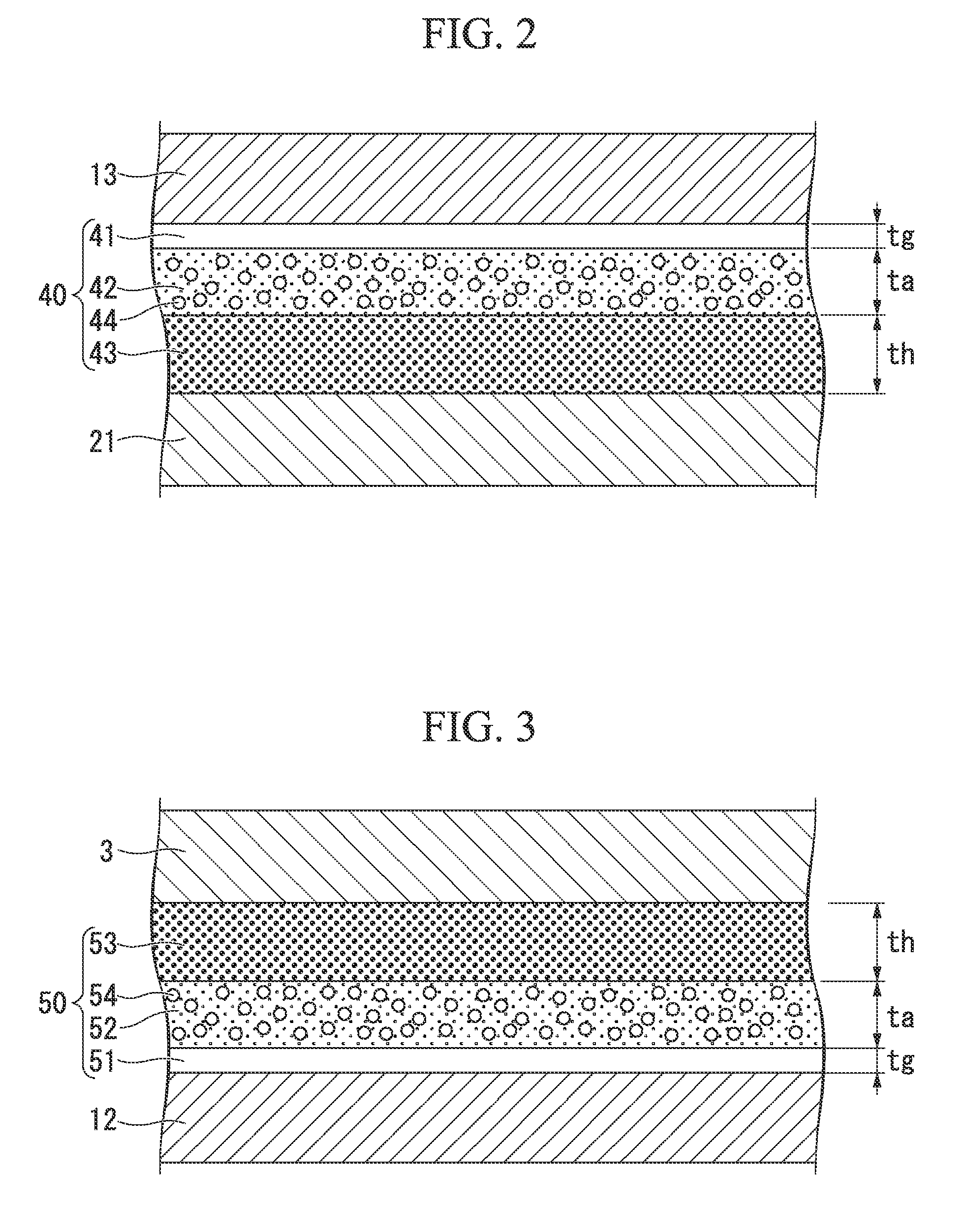

Method and apparatus for optimized dematching layer assembly in an ultrasound transducer

ActiveUS20090072668A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTransducerEngineering

A method for manufacturing an acoustical stack for use within an ultrasound transducer comprises using a user defined center operating frequency of an ultrasound transducer that is at least about 2.9 MHz. A piezoelectric material and a dematching material are joined with an assembly material to form an acoustical connection therebetween. The piezoelectric material has a first acoustical impedance and *at least one of* an associated piezoelectric rugosity (Ra) and piezoelectric waviness (Wa). The dematching material has a second acoustical impedance that is different than the first acoustical impedance and at least one of an associated dematching Ra and dematching Wa. The piezoelectric and dematching materials have an impedance ratio of at least 2. The assembly material has a thickness that is based on the center operating frequency and at least one of the piezoelectric Ra, piezoelectric Wa, dematching Ra and dematching Wa.

Owner:GENERAL ELECTRIC CO

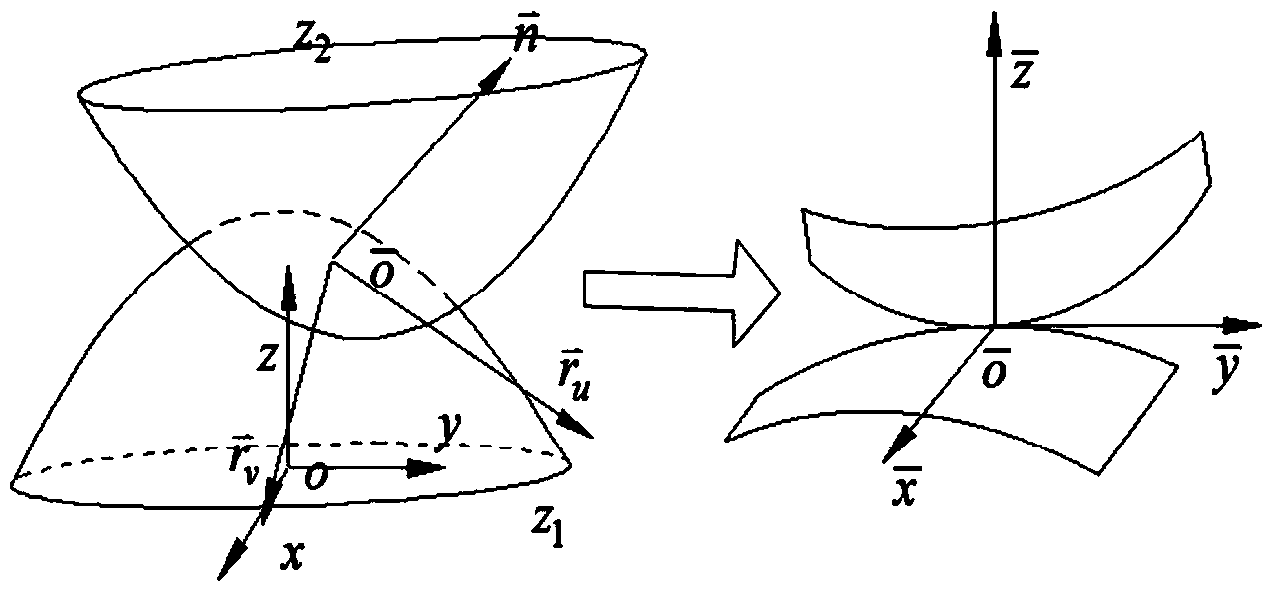

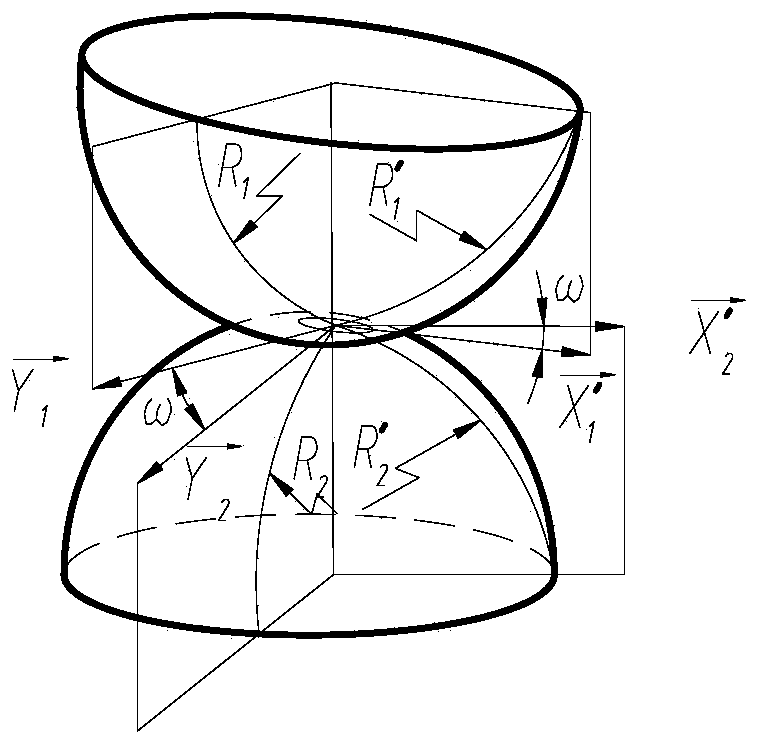

Junction surface contact area and rigidity confirming method based on surface fitting

ActiveCN104077440AExtended Calculation AreaImprove computing efficiencySpecial data processing applicationsPoint cloudFinite element method

Disclosed is a junction surface contact area and rigidity confirming method based on surface fitting. The junction surface contact area and rigidity confirming method based on the surface fitting includes: firstly, using confocal microscopy and three coordinate measuring to measure micro bulge morphology, external waviness and shape error of a mechanical junction surface, performing fitting on obtained point cloud data by using a binary high order function, and accordingly obtaining a final analysis formula of a contact surface; secondly, judging positions and contact directions of micro bulge contact points, then performing Hertz contact calculation on each single contact point, and calculating contact deformation and contact area under functions of force; finally, calculating overall contact area and contact rigidity of the contact surface so as to obtain total contact area and contact rigidity in each direction. Compared with a traditional analysis method, the junction surface contact area and rigidity confirming method based on the surface fitting has the advantage of approaching real morphology. Compared with a finite element method, the junction surface contact area and rigidity confirming method based on the surface fitting can enlarge the contact area which can be calculated.

Owner:XI AN JIAOTONG UNIV

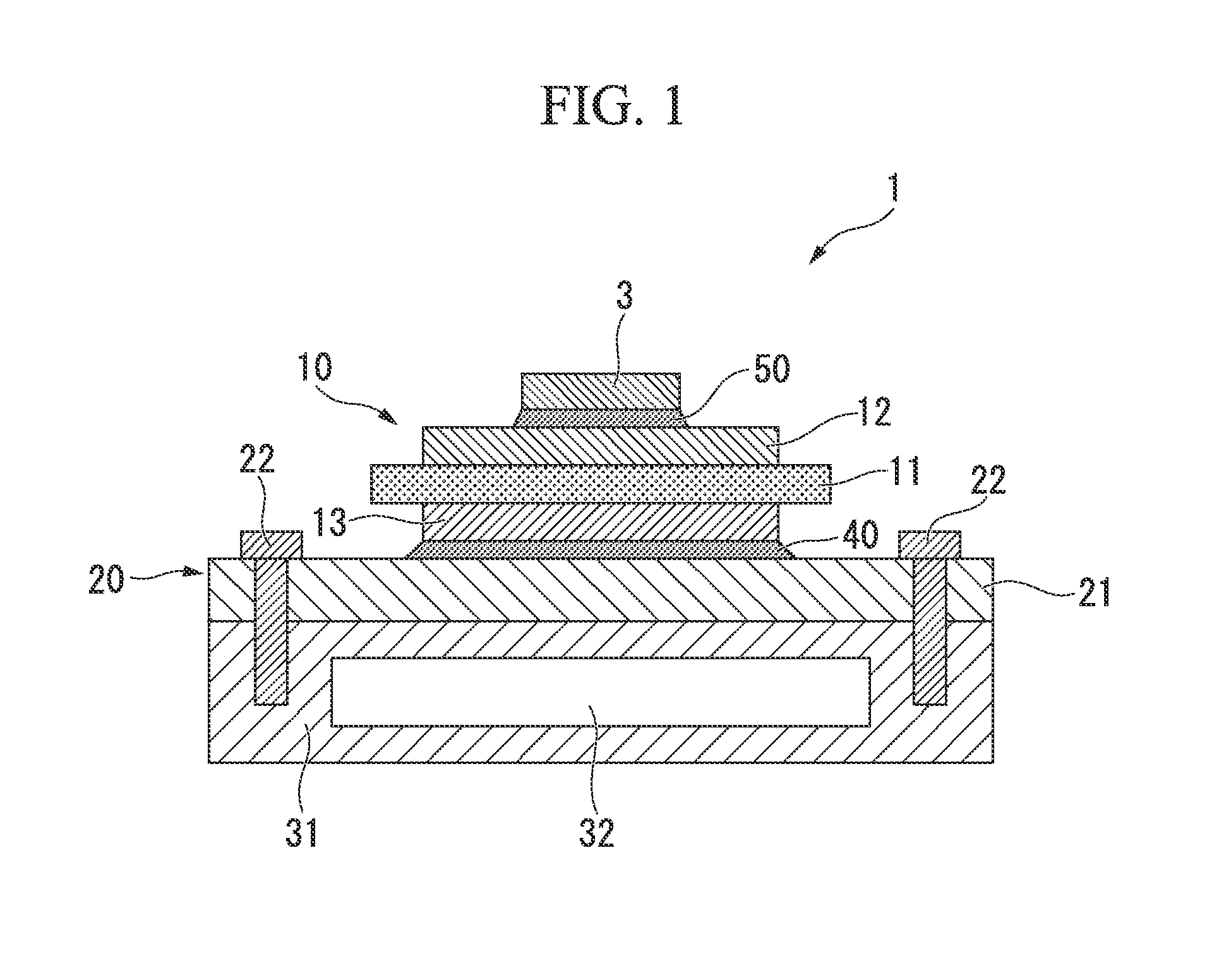

Solder joint structure, power module, power module substrate with heat sink and method of manufacturing the same, and paste for forming solder base layer

ActiveUS20150035137A1InhibitionImprove joint reliabilitySemiconductor/solid-state device detailsSolid-state devicesPower cycleSolder paste

There are provided a solder joint structure, a power module using the joint structure, a power module substrate with a heat sink and a method of manufacturing the same, as well as a solder base layer forming paste which is disposed and fired on a metal member to thereby react with an oxide film generated on the surface of the metal member and form the solder base layer on the metal member, capable of suppressing the occurrence of waviness and wrinkles on the surface of the metal member even at the time of loading the power cycle and heat cycle and improving the joint reliability with a joint member.

Owner:MITSUBISHI MATERIALS CORP

Method for preparing alumina/monox composite mill grain

InactiveCN1850916AImprove micro conditionsReduce roughnessPigmenting treatmentPolishing compositions with abrasivesSilicon oxideMaterials science

The invention relates to a manufacture method for alumina / silicon oxides compounding mill grain that includes the following steps: making alpha-Al2O3 dispersing liquid; adding alpha-Al2O3 and dispersing agent hexametaphosphate into deionized water, whisking to equal, adding dilute base and diluted acid solution to adjust the pH value to 9, taking ultrasound dispersing and ball milling dispersing; heating the temperature to 80-100 degree centigrade and adding Na2SiO3 and H2SO4 into the alpha-Al2O3 dispersing liquid, after reacting, aging for 2 hours, taking centrifugal separating, purifying, drying and gaining the product. The polishing fluid made from the product would obviously decrease the roughness and waviness of the surface after the hard disk basal piece and disc glass basal piece.

Owner:SHANGHAI UNIV

Bearing outside diameter grinding and processing method utilizing noncentral excircle through feed grinding

InactiveCN1544204AEasy to operateGuaranteed machining accuracyRevolution surface grinding machinesEngineeringHeat treated

The invention relates to an external diameter milling processing method of coreless through-external circule milling bearing, continuously adjusting the center height of the workpiece to heighten milling precision and productivity. Its technical project: (1) external diameter milling procedure: taking the center height of the mill bed as reference to adjust the center height of a workpiece to 80mm, roughly milling twice-thrice up to the roughly milling size and eliminating circular error; (2) reprocessing workpiece: taking the center height of the mill bed to adjust that of the workpiece to 3-7 mm, the elliptical VDP is controlled in 2 mum and waviness controlled in 1.5mum; (3) after processed by the above two procedures, adjusting the center height of the workpiece again to 80mm with that of the mill bed as reference for milling, the diameter of the workpiece is milled off by 10mum, the 'multi-angle ' are removed by 25mum, and circular error is controlled within 1.5mum; adjusting the center height of the workpiece with the external diameter less than 80mm to 40mm. It ensures processing precision, prolongs service life of finished bearings and heightens the whole quality of bearing products.

Owner:WAFANGDIAN BEARING GRP CO LTD

Process for polishing glass substrate

ActiveUS20070259605A1Improve flatnessVacuum gauge using ionisation effectsDecorative surface effectsBeam sizeDry etching

A process for polishing a glass substrate, which enables to polish a glass substrate having a large waviness formed by mechanical polishing, to have a surface excellent in flatness, is provided. A process for polishing a glass substrate, comprising a step of measuring the surface profile of a mechanically polished glass substrate to identify the width of waviness present in the glass substrate, and a step of applying dry etching using a beam having a beam size in FWHM (full width of half maximum) value of at most the above size of waviness, to polish the surface of the glass substrate.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com