Bearing outside diameter grinding and processing method utilizing noncentral excircle through feed grinding

A grinding and bearing technology, which is applied in the field of centerless outer circle through-grinding bearing outer diameter grinding, can solve the problems that the machining accuracy can only reach the ordinary level, and the center height of the workpiece is not determined and grasped, so as to improve the service life and simplify the operation Convenience and the effect of ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

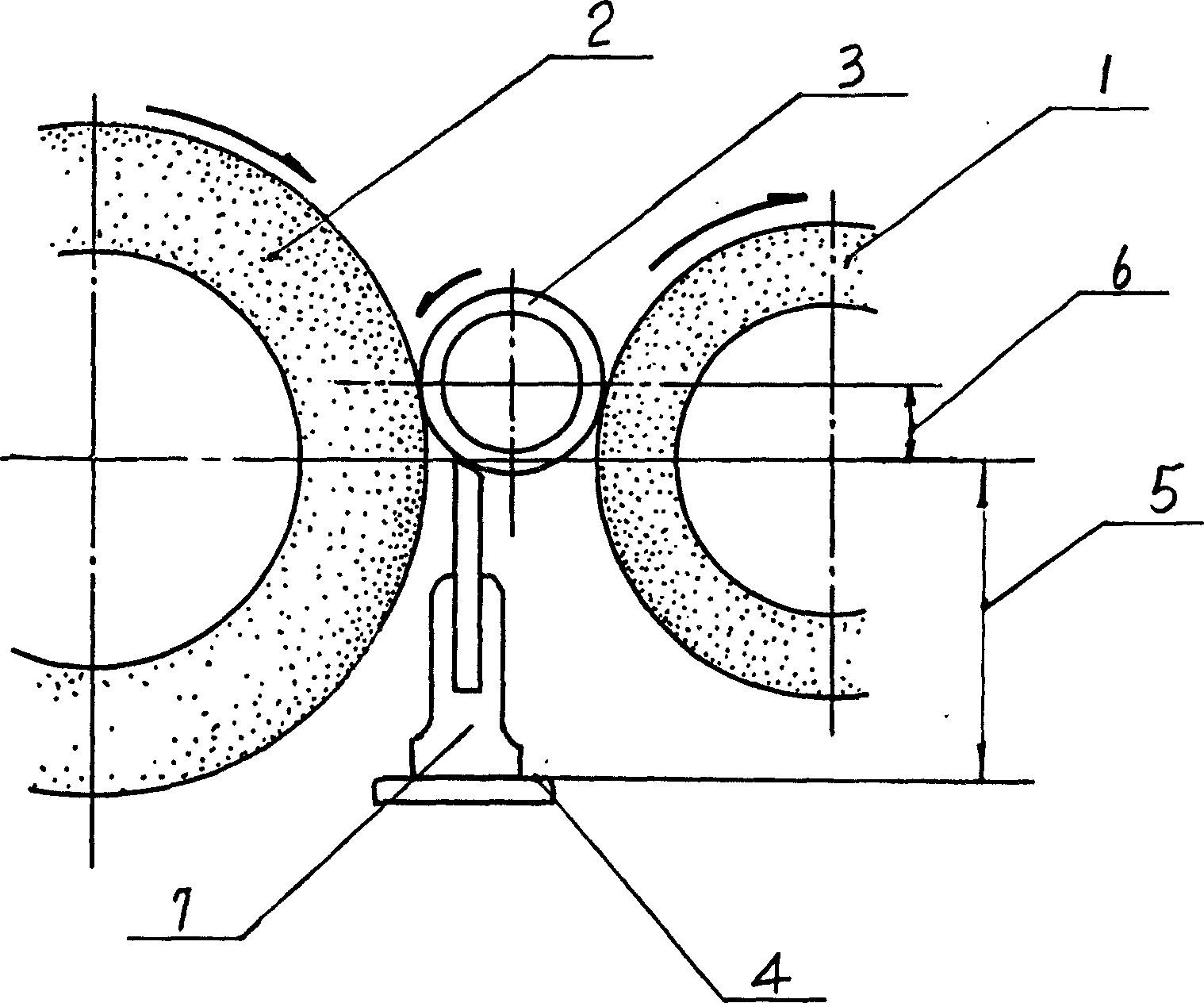

[0018] Use a centerless grinder to process workpieces with an outer diameter of Φ80-120mm (ordinary grade)

[0019] Ellipse VDP≤5μm

[0020] Wav≤2.5μm

[0021] Taper VDMP≤5μm

[0022] Circular deviation Δcir≤6μm(K=2)

[0023] The center height 5 of each grinder is determined, which is the height from the grinding surface 4 to the connecting line between the grinding wheel 2 and the guide wheel 1. At the same time, the center height of the grinder 5 = the radius of the workpiece + the height of the support plate 7 of the grinder. To adjust the center height 6 of the workpiece, as long as the center height 5 of the grinder is adjusted, the purpose of adjusting the center height 6 of the workpiece can be achieved, and the operation is simple and convenient.

[0024] The operation method is as follows:

[0025] (1) When the workpiece 3 is from the heat treatment quenching process to the outer diameter grinding process, the center height 6 of the workpiece 3 should be adjusted first, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com