Patents

Literature

17557 results about "Grinding wheel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A grinding wheel is a wheel composed of an abrasive compound and used for various grinding (abrasive cutting) and abrasive machining operations. Such wheels are used in grinding machines. The wheels are generally made from a composite material consisting of coarse-particle aggregate pressed and bonded together by a cementing matrix (called the bond in grinding wheel terminology) to form a solid, circular shape. Various profiles and cross sections are available depending on the intended usage for the wheel. They may also be made from a solid steel or aluminium disc with particles bonded to the surface. Today most grinding wheels are artificial composites made with artificial aggregates, but the history of grinding wheels began with natural composite stones, such as those used for millstones.

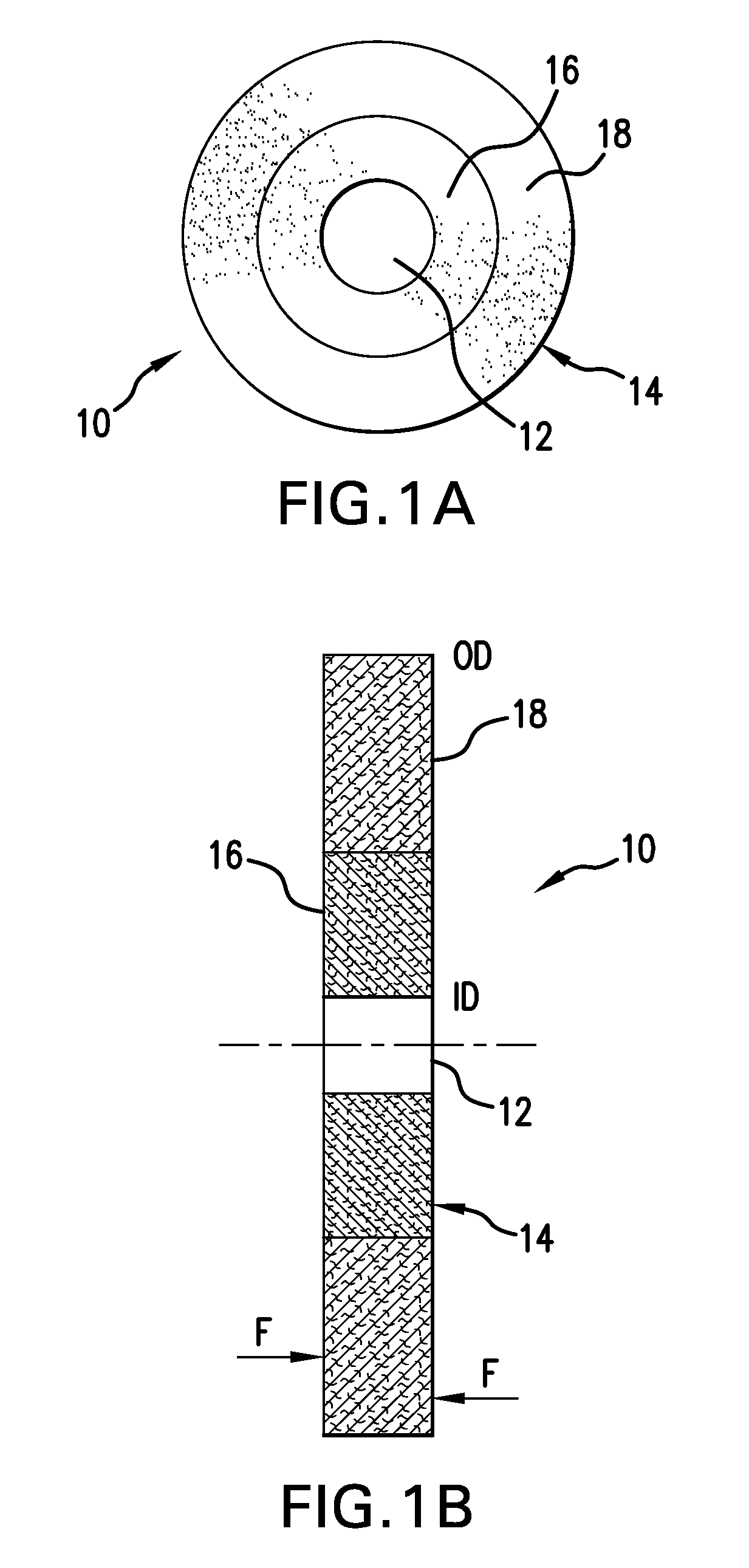

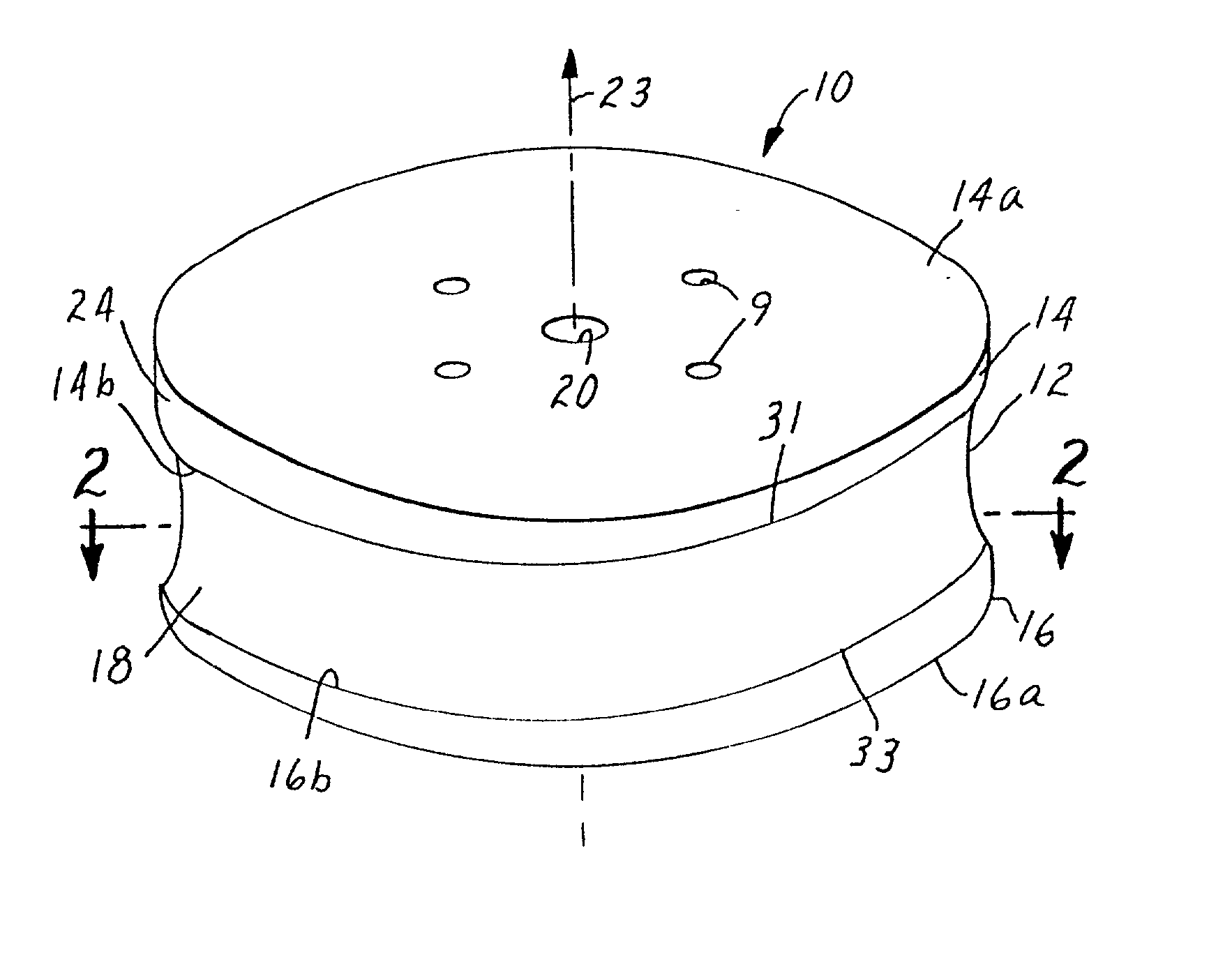

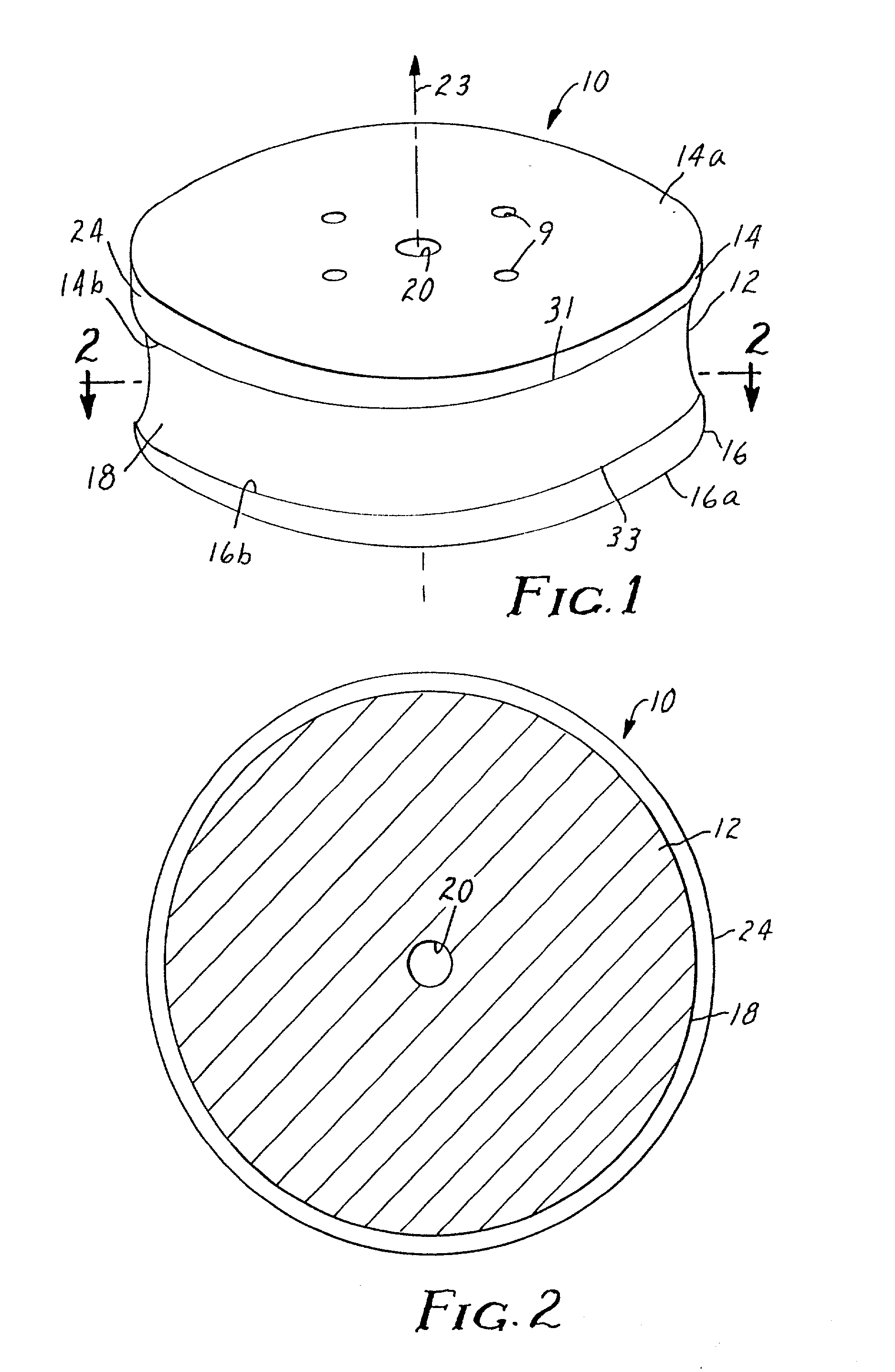

Reinforced Bonded Abrasive Tools

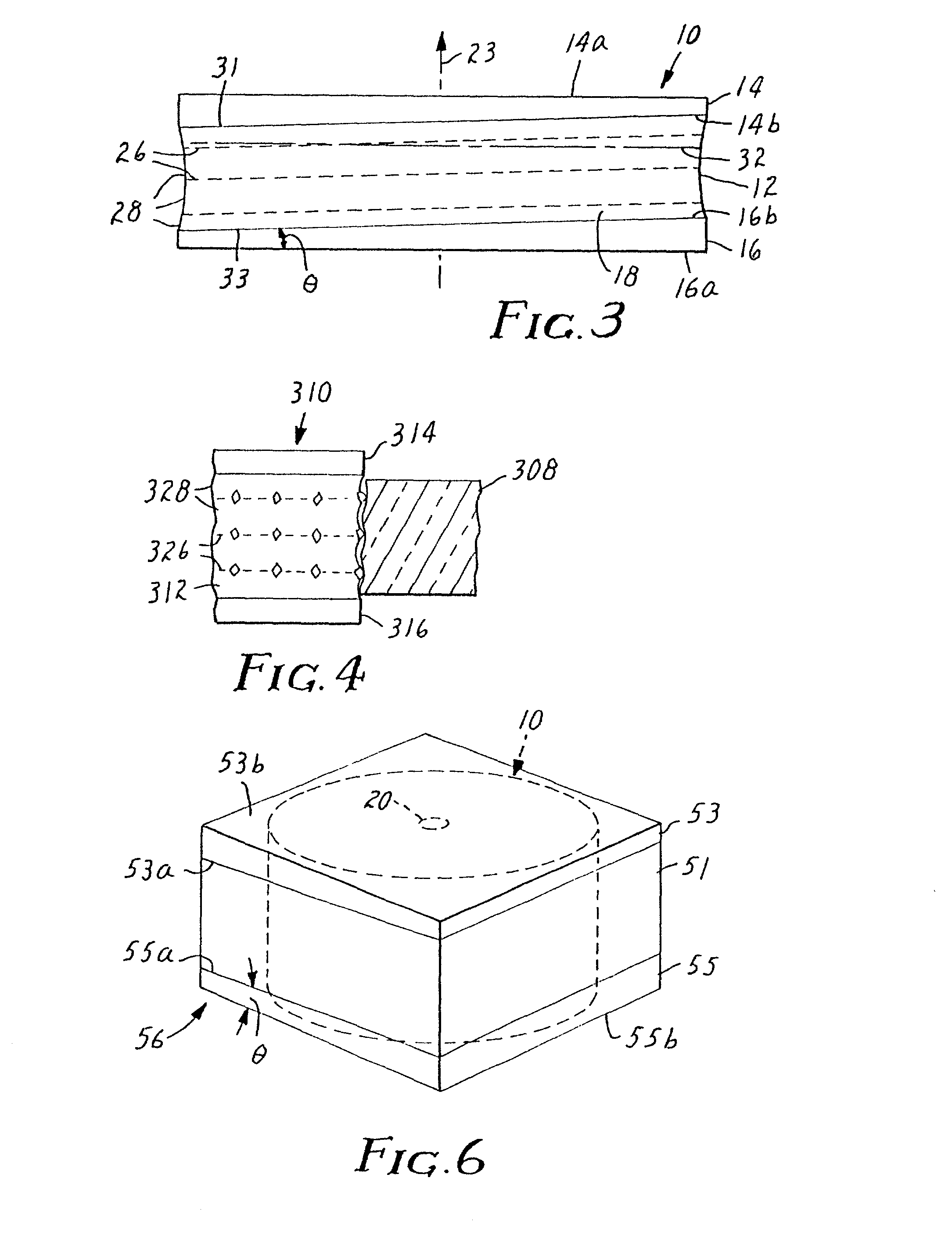

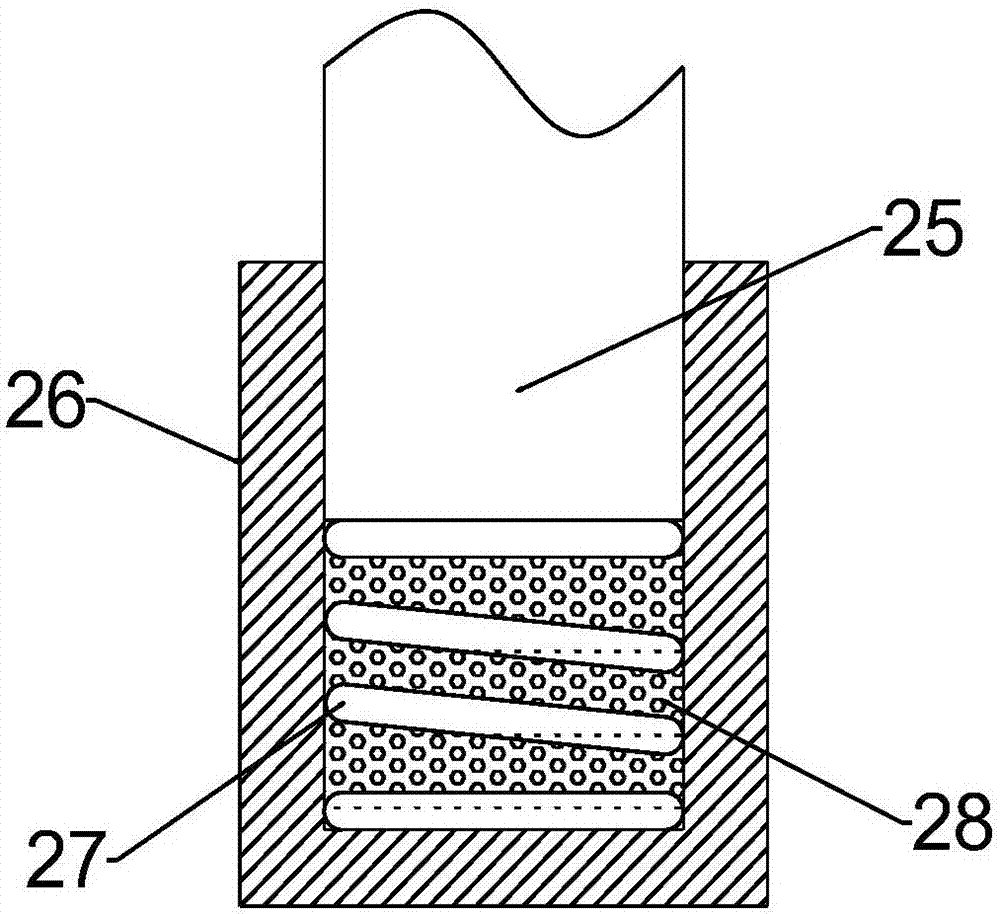

InactiveUS20100190424A1Improve performanceReduce the amount requiredPigmenting treatmentRevolution surface grinding machinesFiberFiberglass mesh

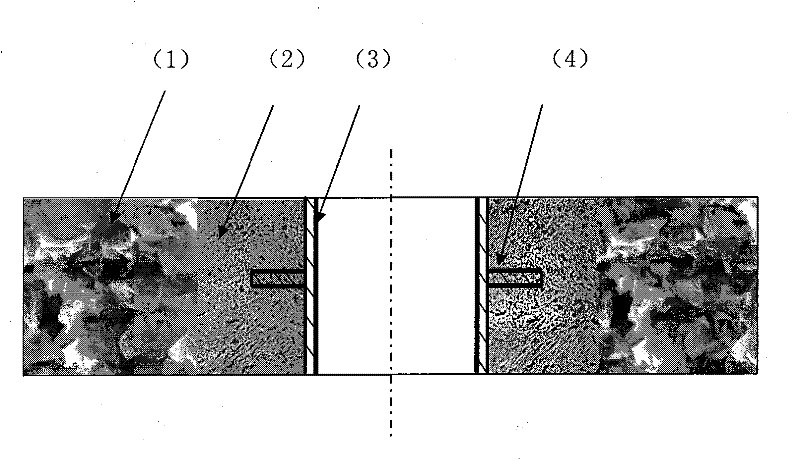

Bonded abrasive tools, e.g., grinding wheels, can be reinforced using, for instance, one or more fibreglass web(s) having a surface of glass per unit of at least 0.2. Alternatively or in addition, the fibreglass web has a thickness of 2 mm or less. The web can be designed to provide improved adhesion between the fibreglass reinforcement and the mixture employed to form the bonded abrasive tool. In some examples, the middle reinforcement at the neutral zone of the wheel can be eliminated or minimized.

Owner:SAINT GOBAIN ABRASIVES INC +1

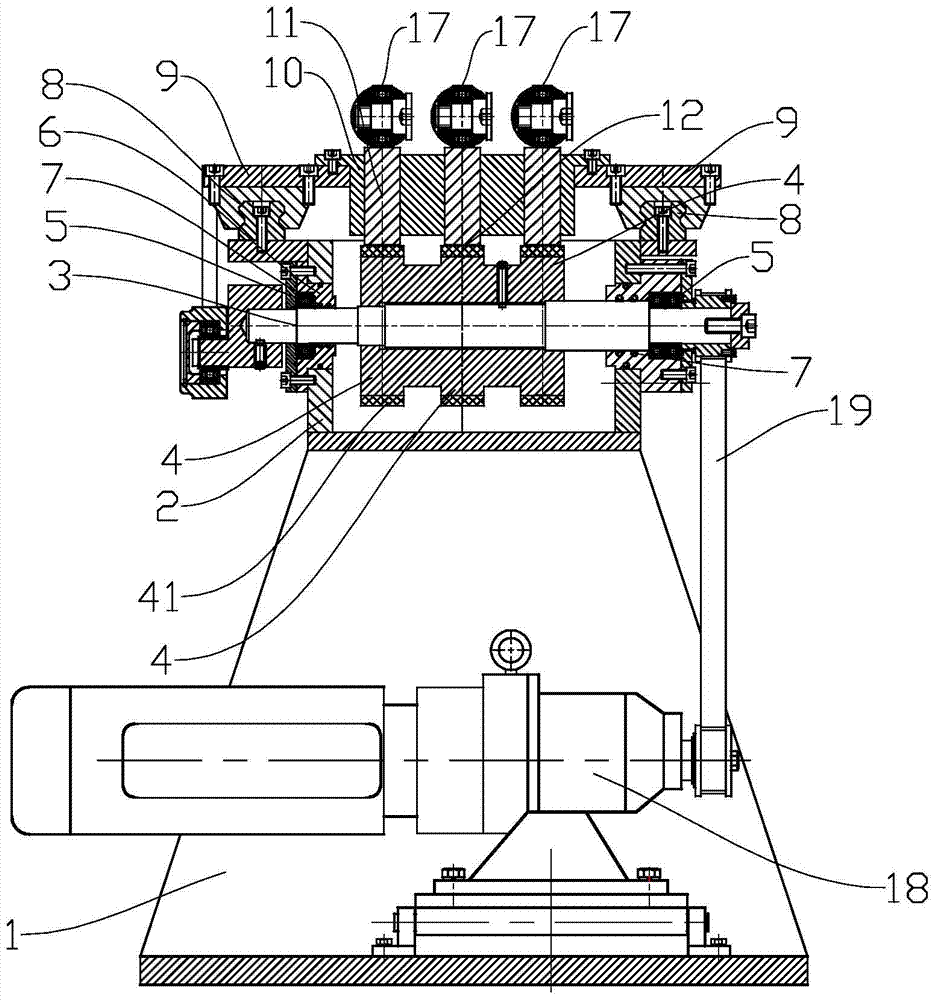

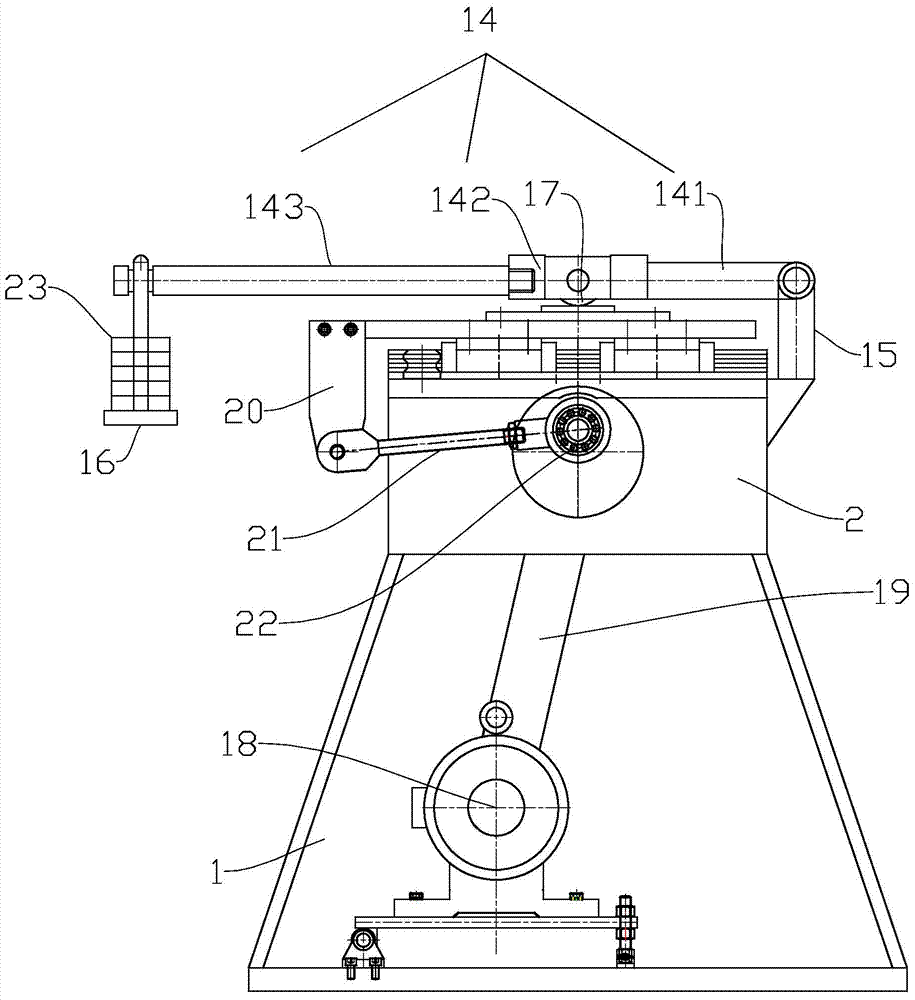

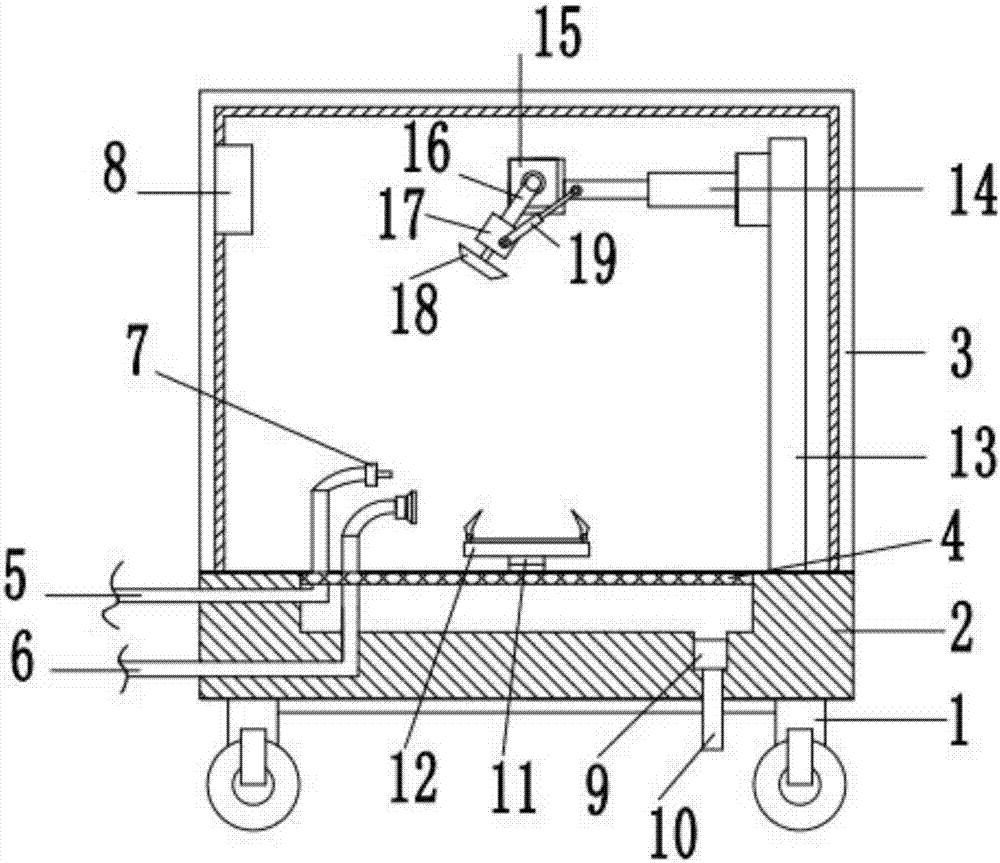

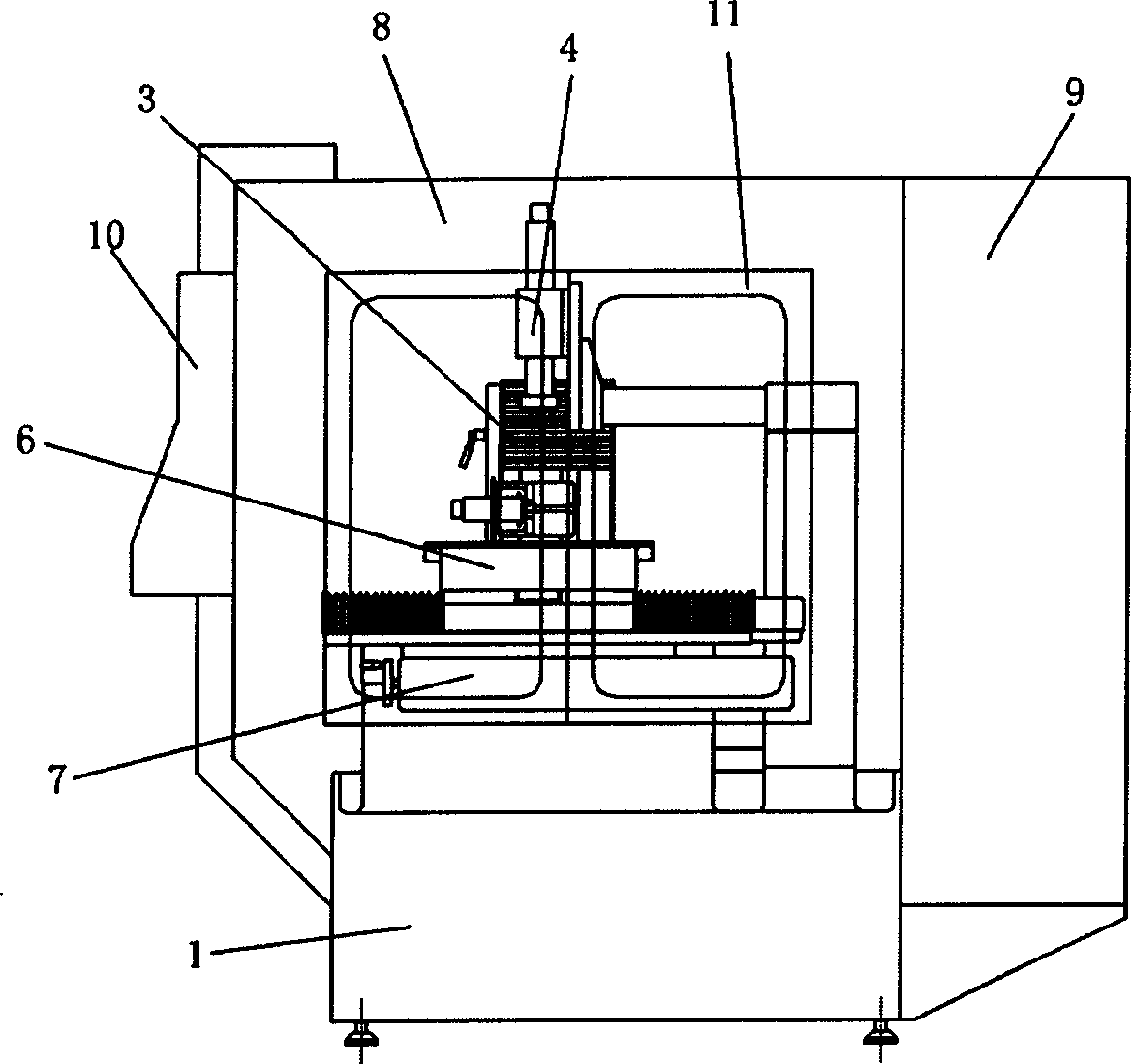

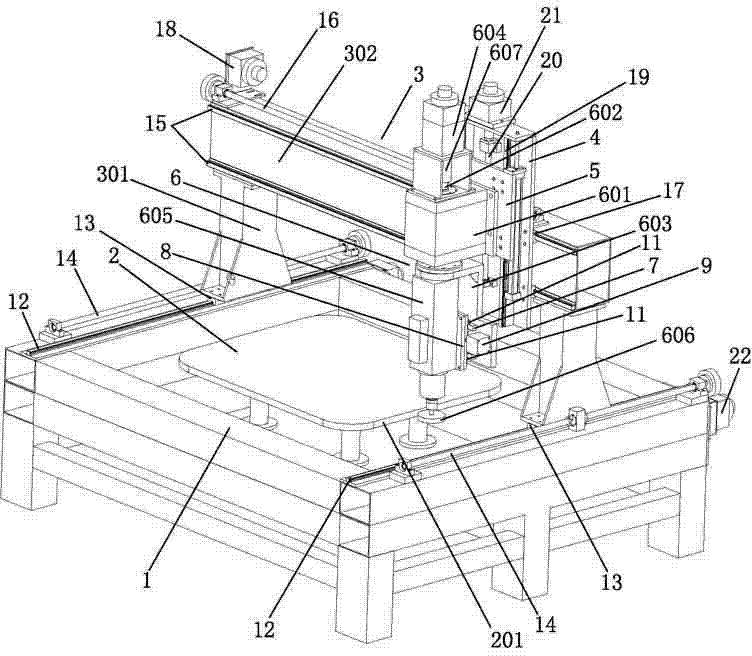

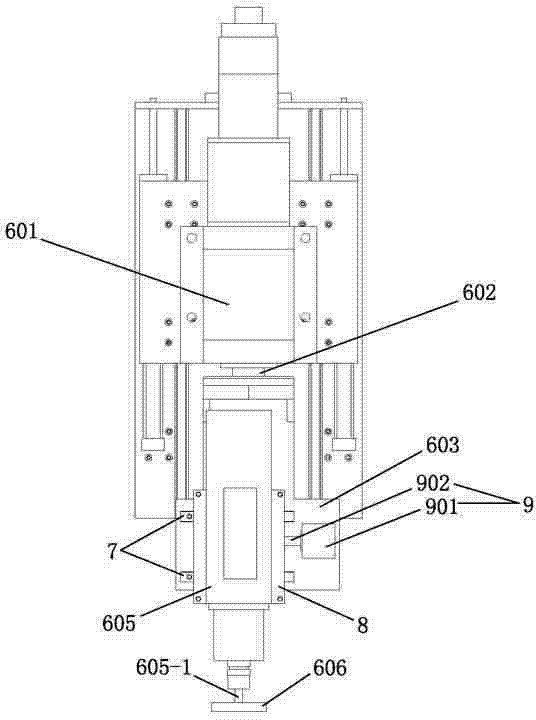

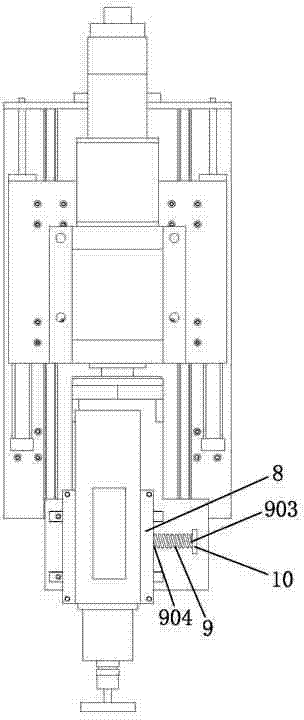

A friction test device and test method for screw drilling tool rotor coating

ActiveCN105092401BTest data availableAccurate data supportInvestigating abrasion/wear resistanceElectric machineEngineering

The invention discloses a screw rd drilling tool rotor cladding layer friction test device and a screw rod drilling tool rotor cladding layer friction test method. The device comprises a rack, a box, a grinding wheel assembly, a linear rail assembly, a rectilinear motion assembly, a pressurizing assembly, a speed reducing machine with a motor, and a rectilinear motion assembly driving mechanism. Mud liquid is added in the box; a main shaft of the grinding wheel assembly penetrates through the box; a plurality of grinding wheels are fixedly arranged on the main shaft; at least lower parts of the grinding wheels are positioned in the box; two linear rails of the linear rail assembly are fixed at two sides of the box and are vertical to the main shaft; a base part of the rectilinear motion assembly runs on the linear rails; a pressing block limiting device is arranged on the base part; pressing blocks in the pressurizing assembly are arranged in pressing block installation holes in the pressing block limiting device; the bottom surface of each pressing block clamps a test piece; each pressing block is loaded by a lever mechanism and a pressure applying roller; the speed reducing machine drives the main shaft to rotate by a belt transmission mechanism; the main shaft rotates to drive the rectilinear motion assembly to run by a cam mechanism and a connection rod. Test data are relatively desirable, so that a relatively accurate data support is provided for study on a wear-resisting property of a cladding layer.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

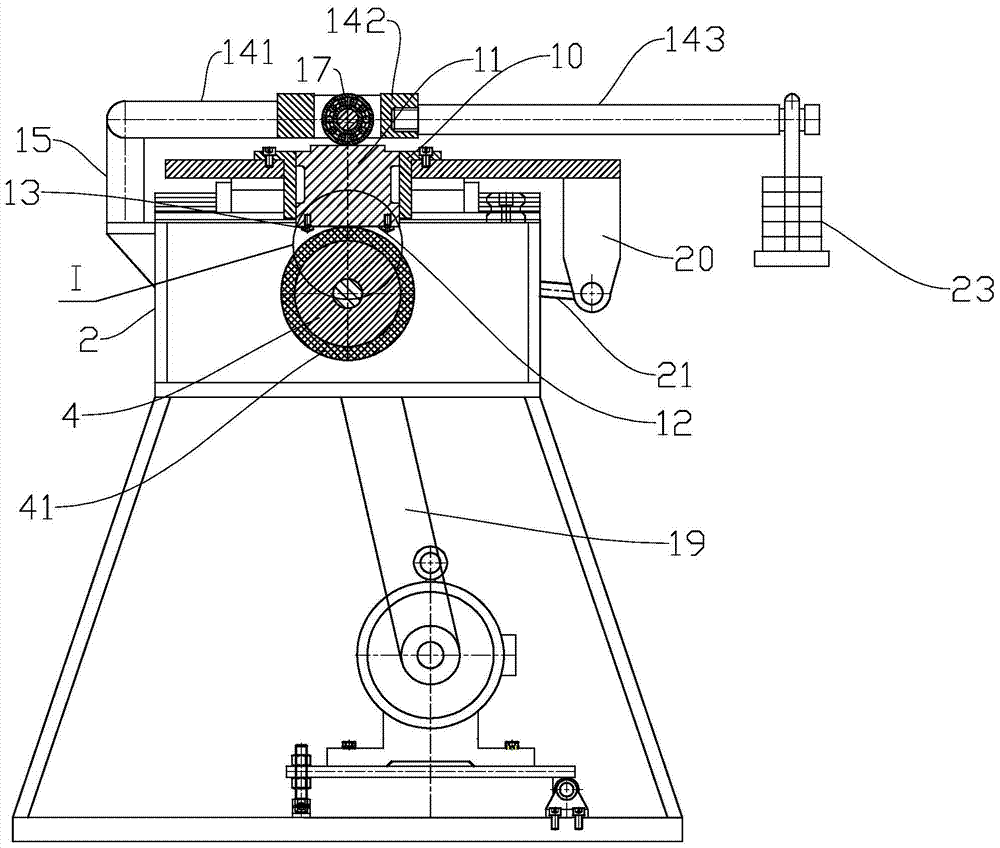

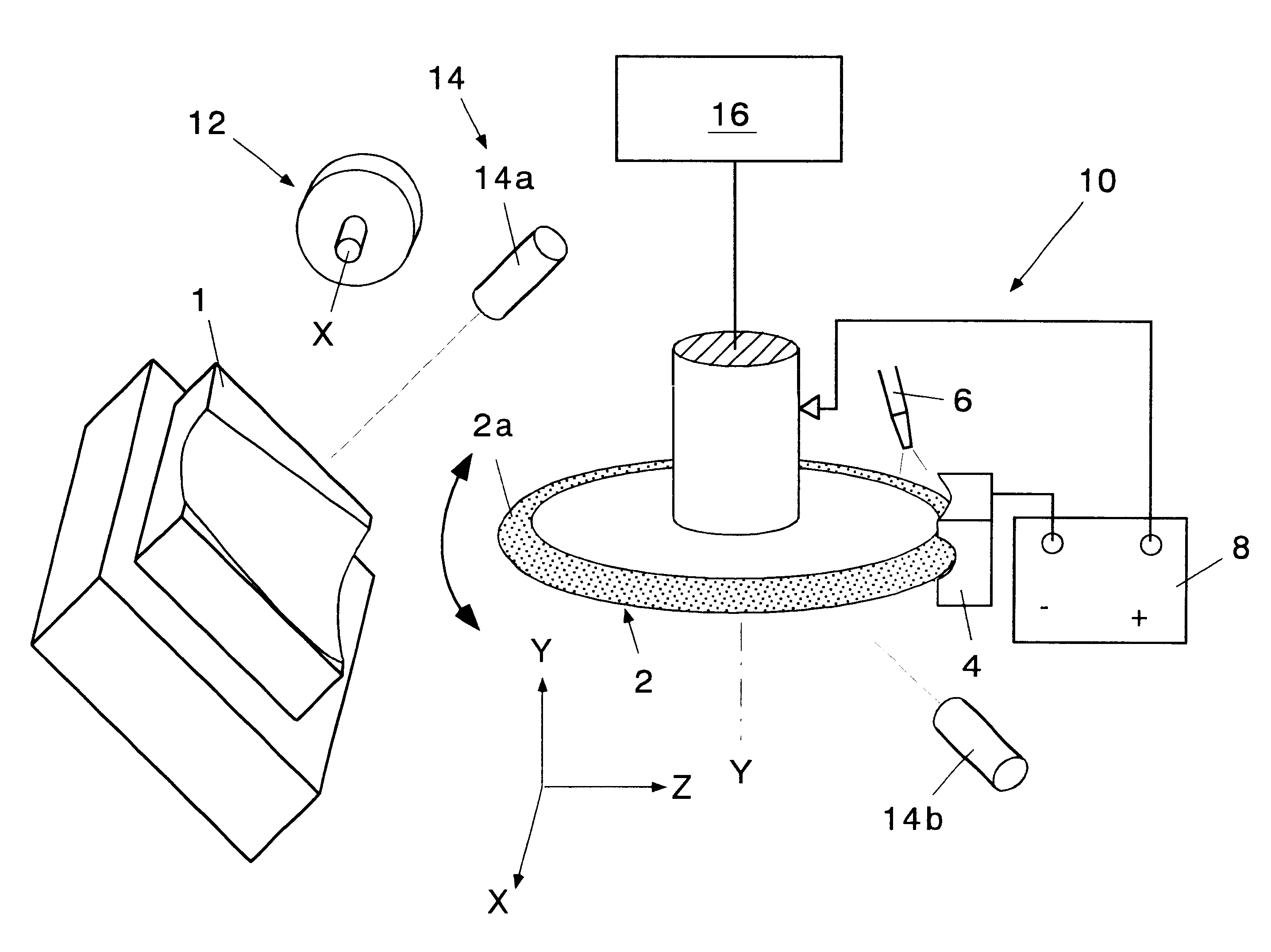

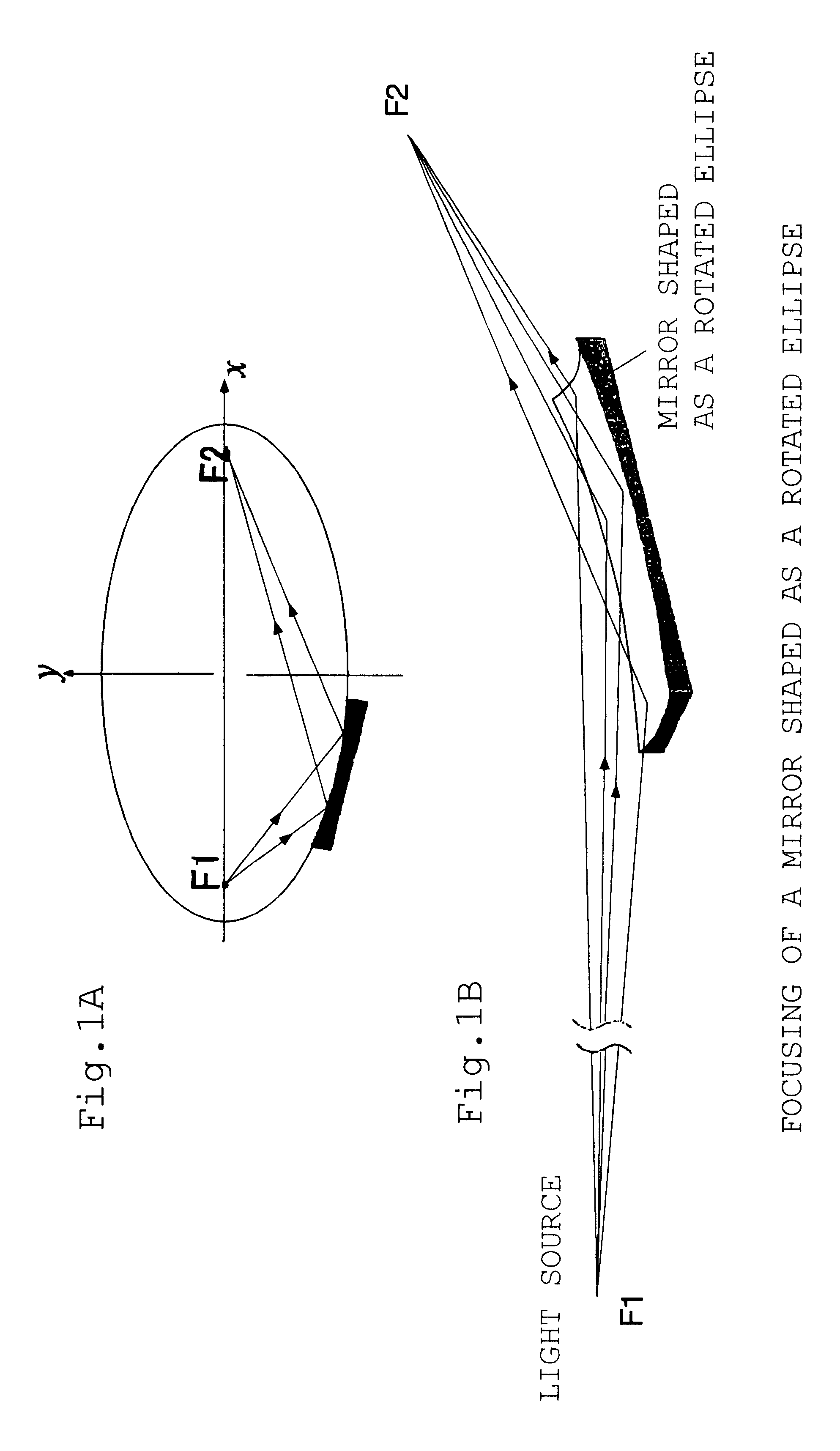

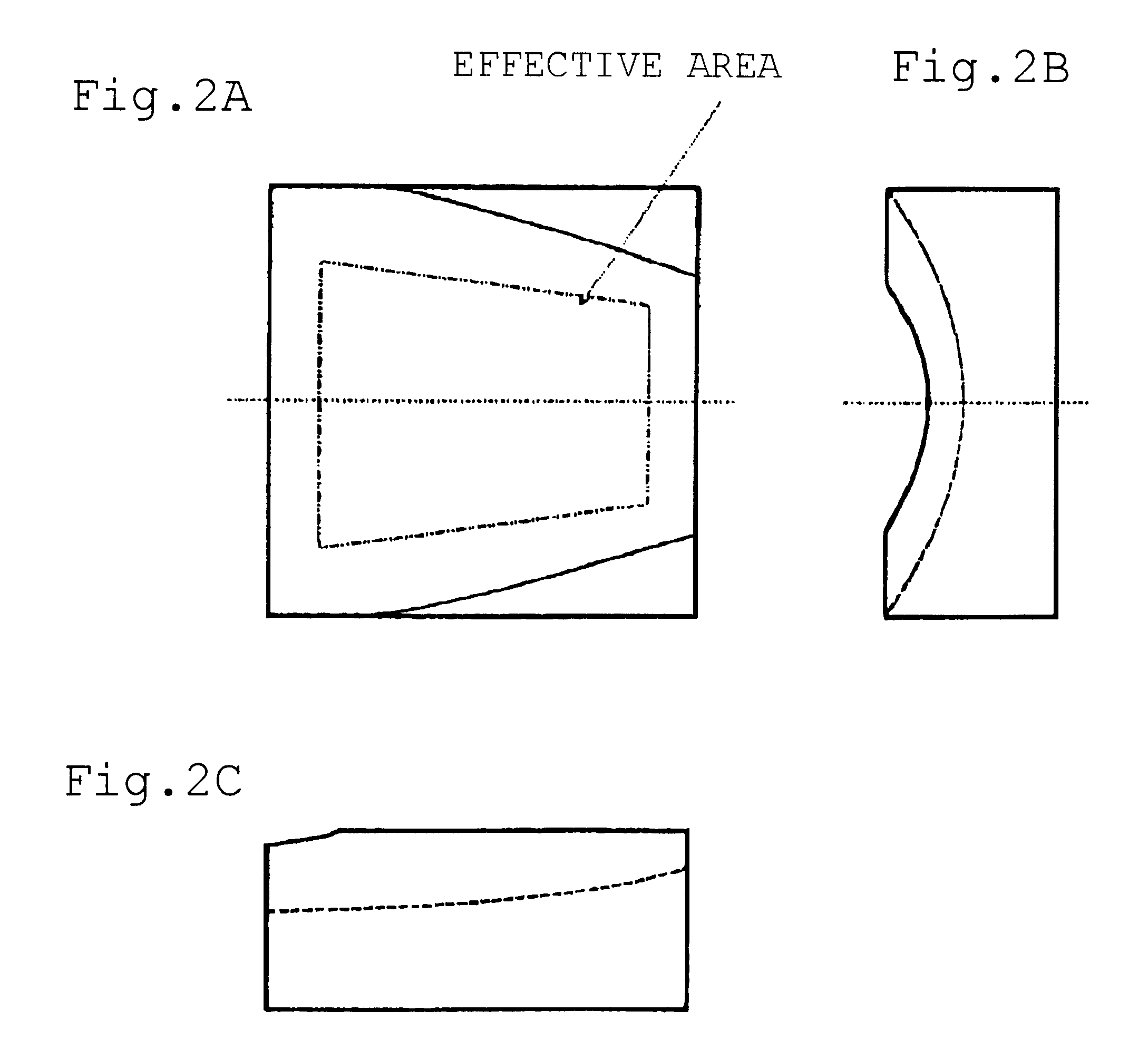

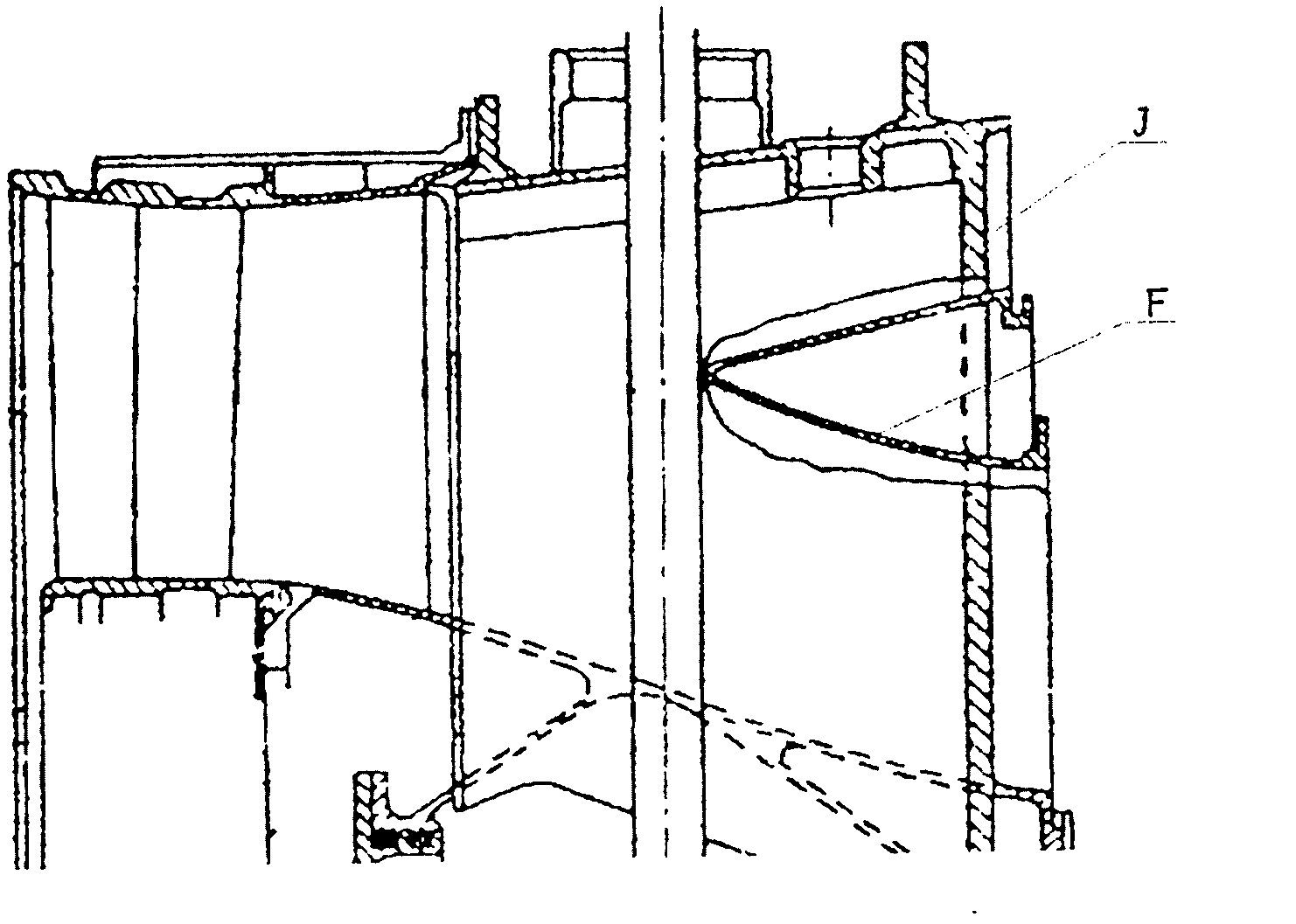

Method of grinding an axially asymmetric aspherical mirror

InactiveUS6537138B2Improve accuracyReliably madeEdge grinding machinesOptical surface grinding machinesNumerical controlSurface roughness

An electrolytic in-process dressing device 10 is provided with a disk-shaped metal-bonded grindstone 2 with a surface 2a with a circular arc shape with a radius R at its outer periphery and a numerical control device 16. The disk-shaped metal-bonded grindstone 2 rotates around an axis Y, and the grindstone is dressed electrolytically while the device 10 grinds the workpiece 1. The numerical control device 16 is provided with a rotary truing device 12 that rotates around the X axis that orthogonally crosses the axis of rotation Y and trues the circular arc surface 2a, a shape measuring device 14 for measuring the shape of the circular arc surface of the grindstone and the shape of the processed surface of workpiece 1 on the machine, and controls the grindstone numerically in the three directions along the axes X, Y and Z. The numerical control device 16 moves the grindstone in three axial directions and repeats the operations of truing, grinding and measurements on-line. Thus, an axially asymmetrical aspheric mirror with a highly accurate shape and extremely low surface roughness, that can precisely reflect or converge light can be manufactured within a short time with a high accuracy.

Owner:RIKEN +1

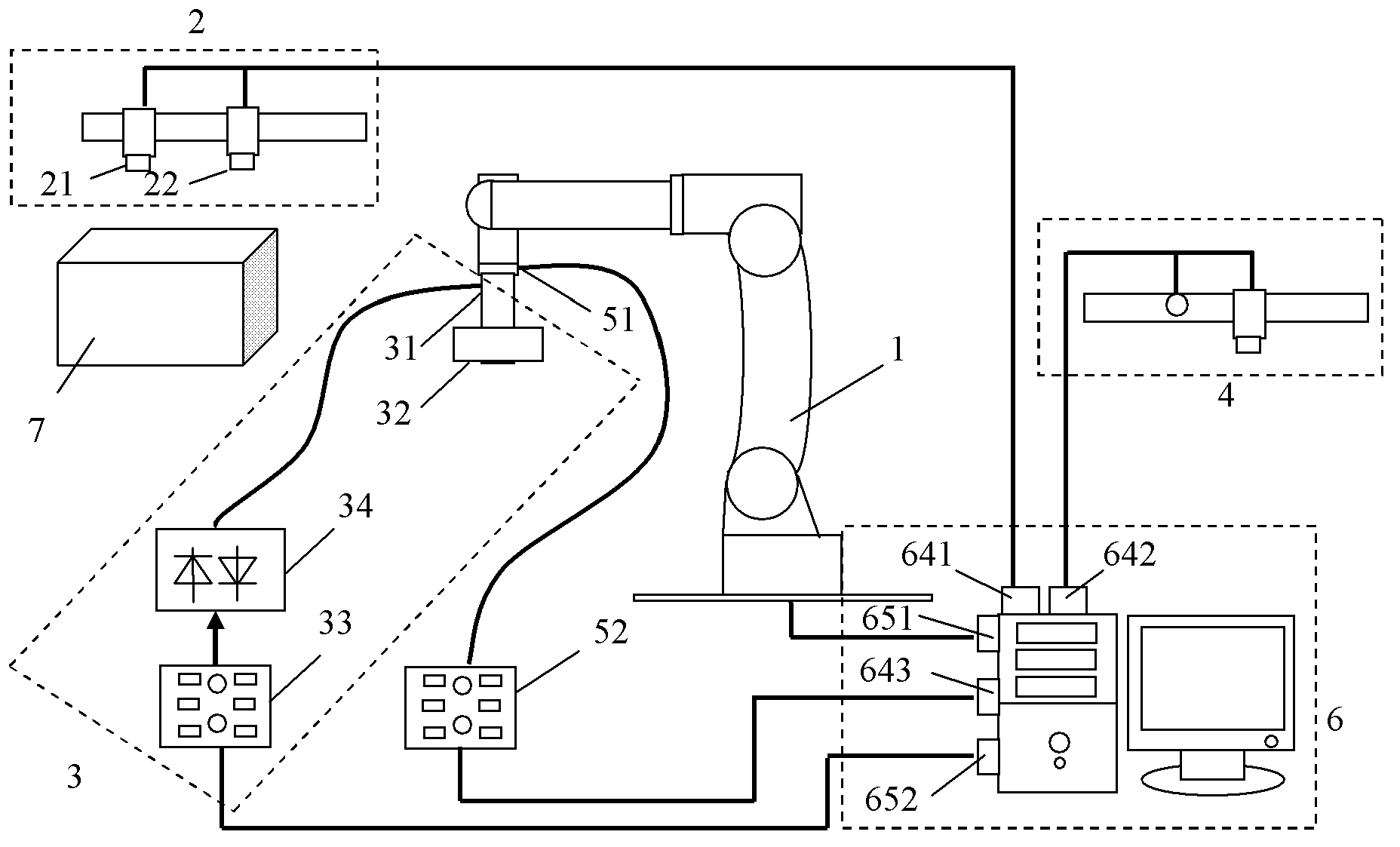

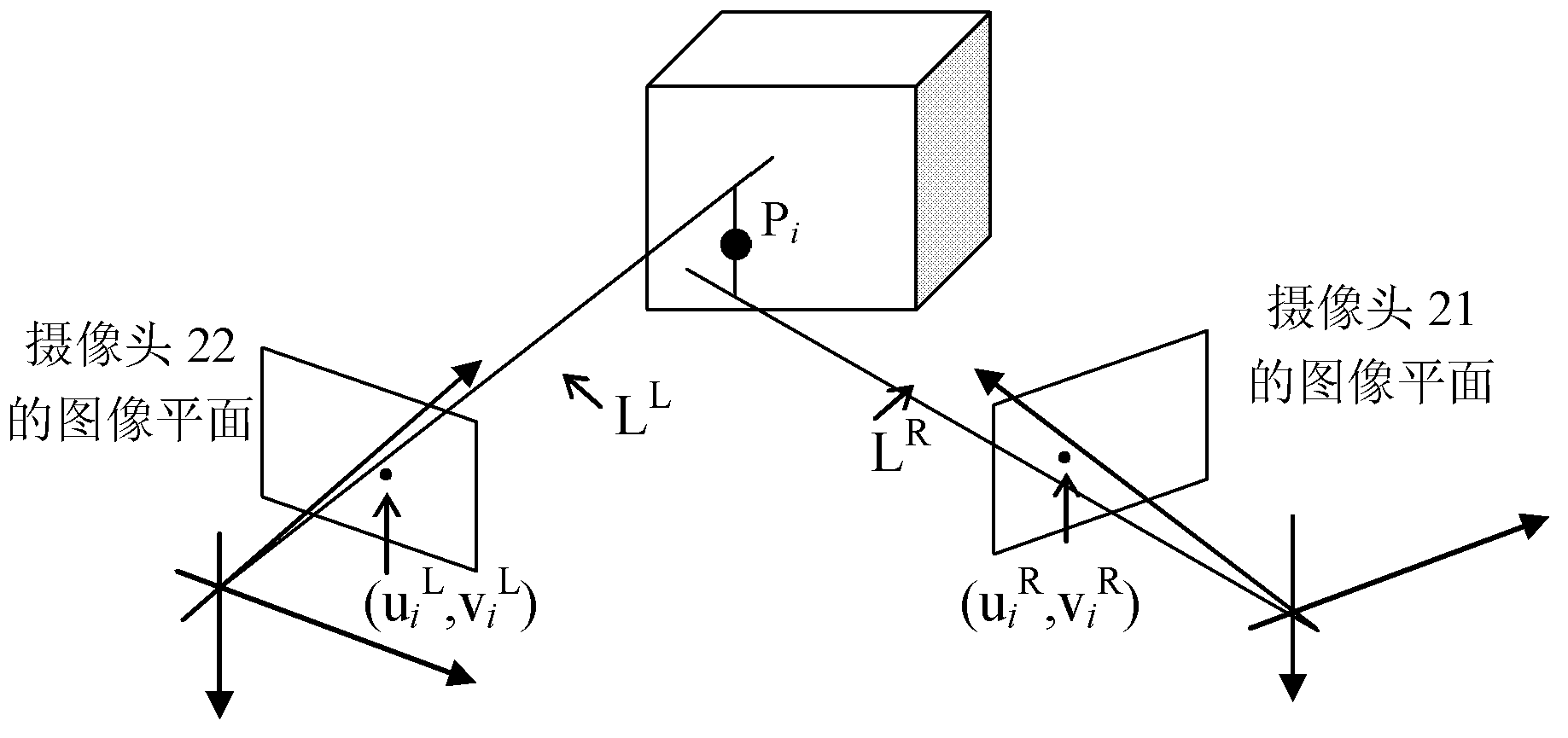

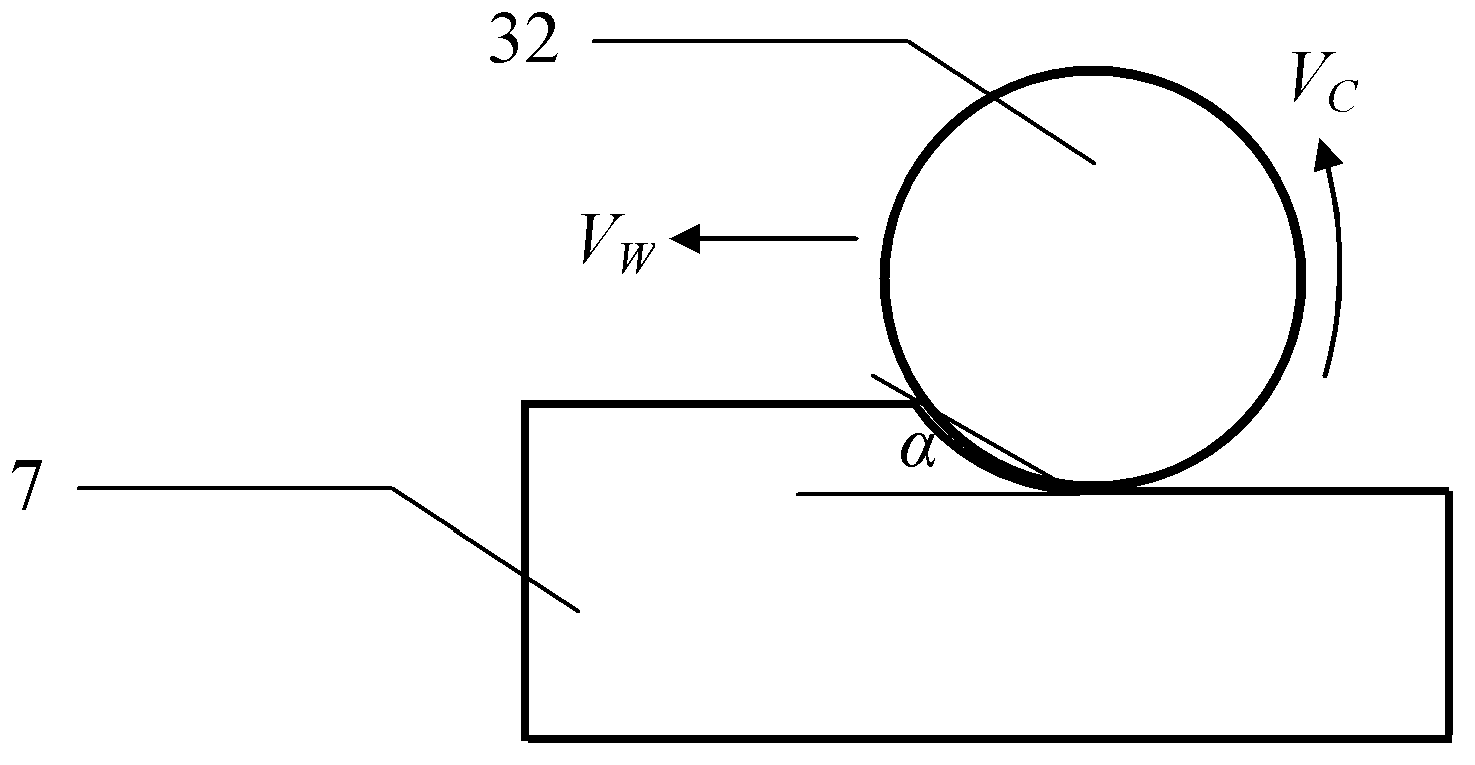

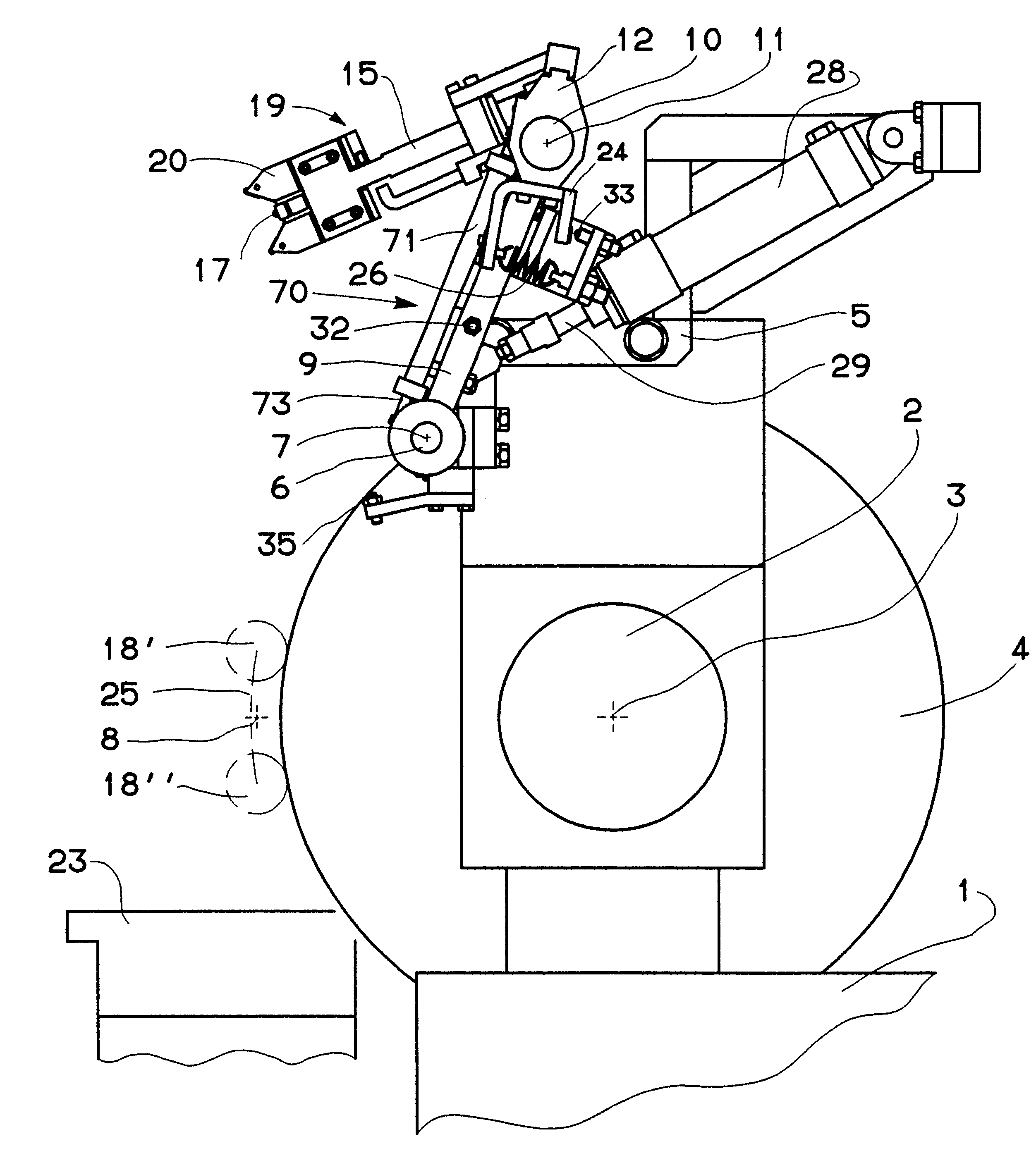

Robot grinding system based on feedback of sensor

The invention discloses and relates to a robot grinding system based on feedback of a sensor. The robot grinding system based on the feedback of the sensor is capable of detecting an contour of a workpiece and regulating grinding tracks in real time and comprises a robot (1), a workpiece contour detection unit (2), an electro-spindle unit (3), a grinding wheel wear detection unit (4), a grinding force detection unit (5) and a system control host (6). The robot grinding system based on the feedback of the sensor achieves automatic grinding on workpiece surface by detecting the grinding force between a grinding wheel and a workpiece, the three-dimensional measuring data of the outline of the workpiece and wear degree of the grinding wheel and controlling feed speed and rotating speed of the grinding wheel through a control algorithm.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

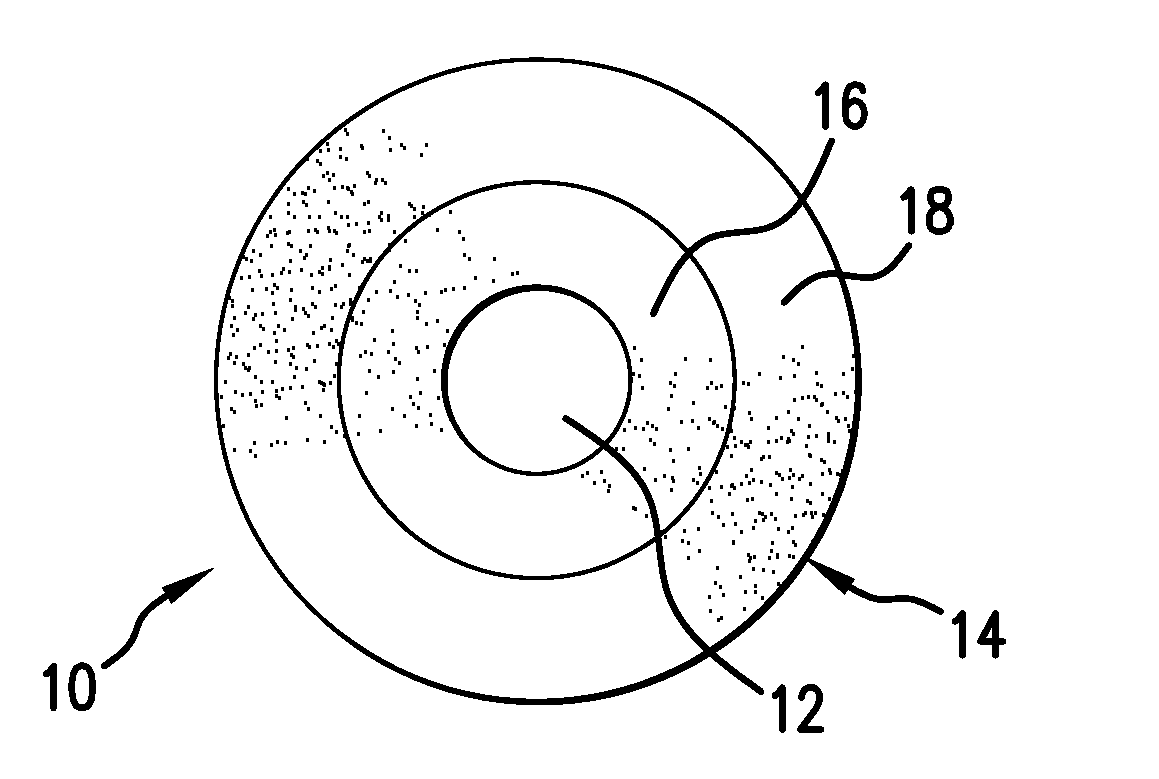

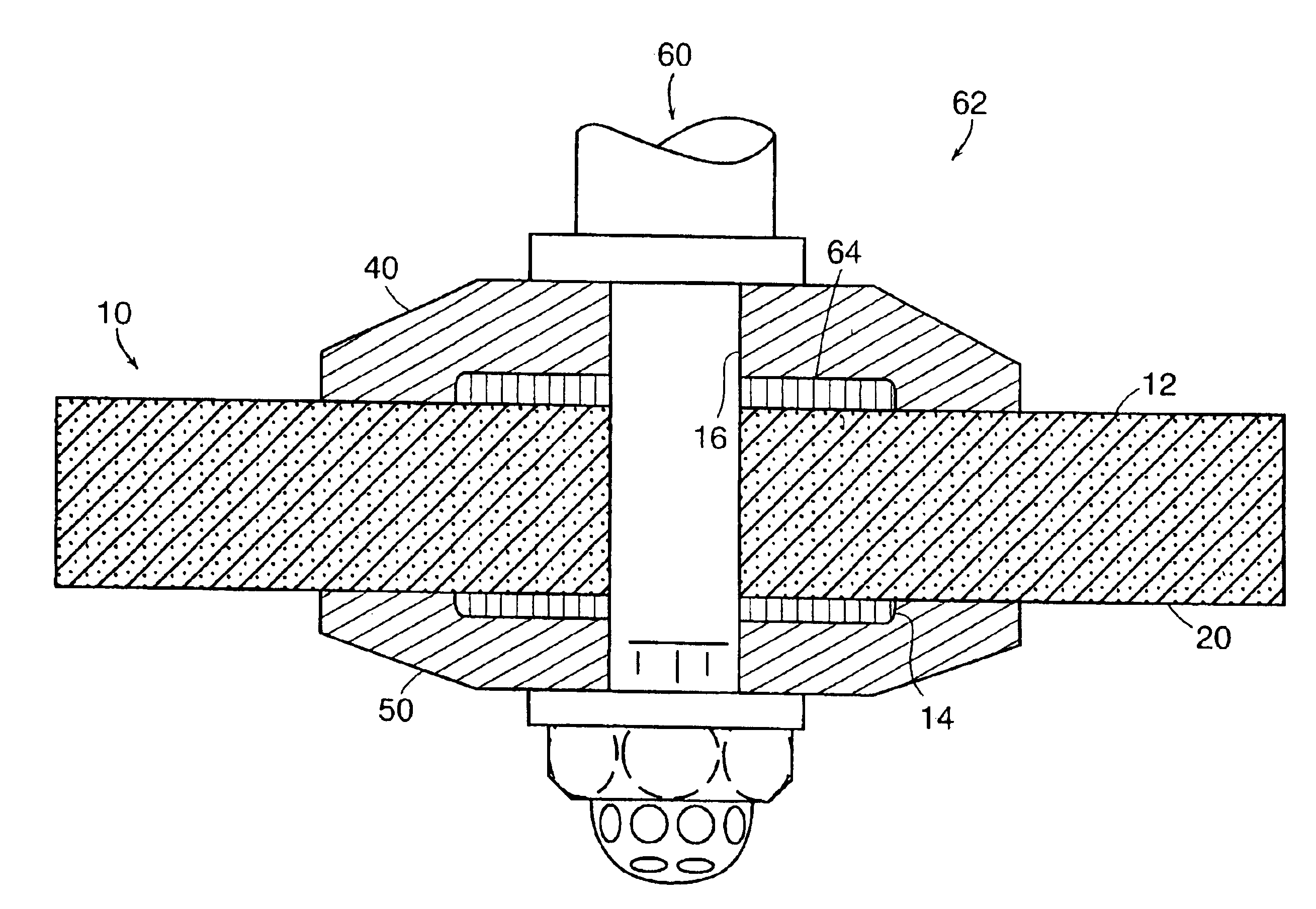

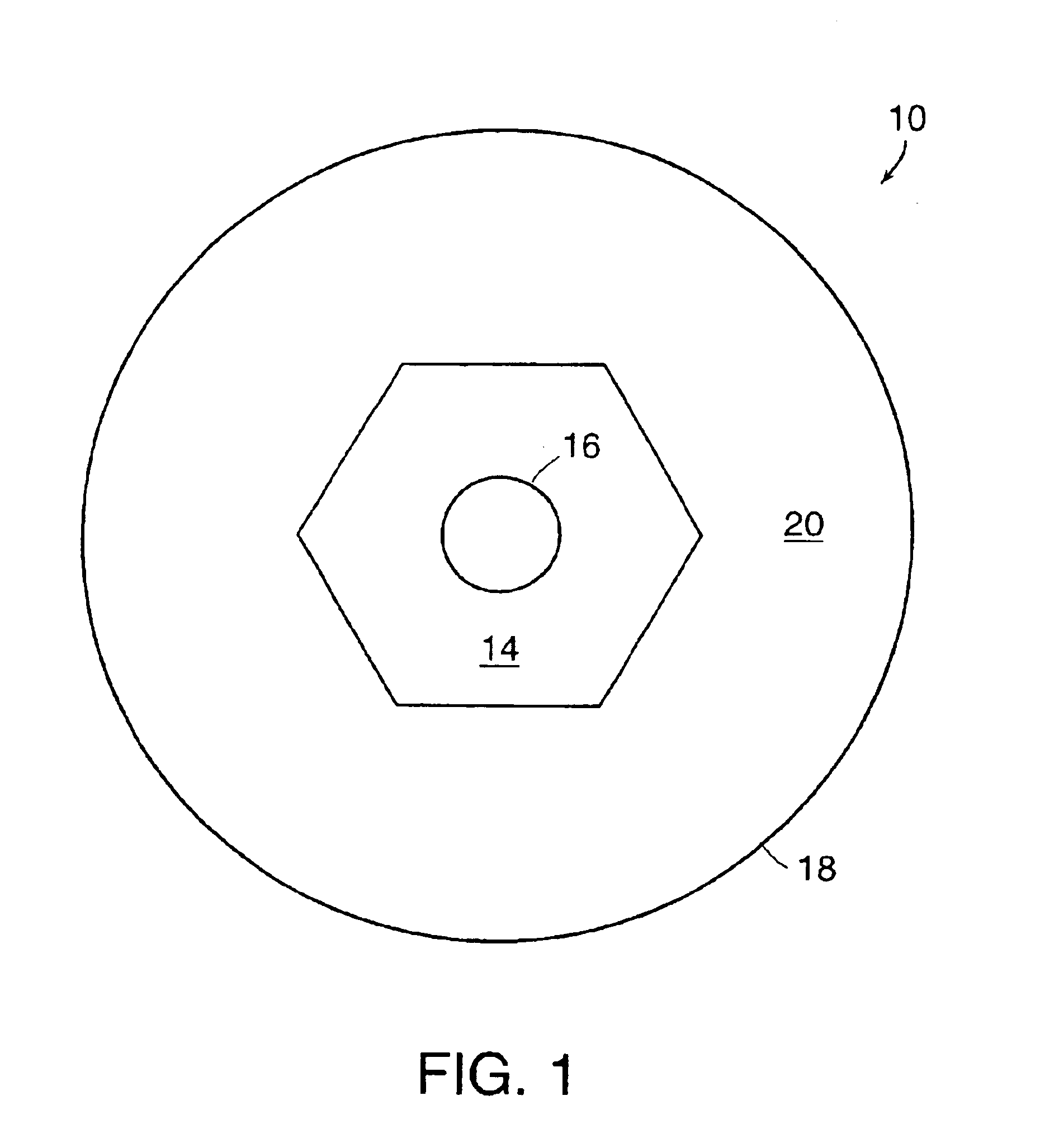

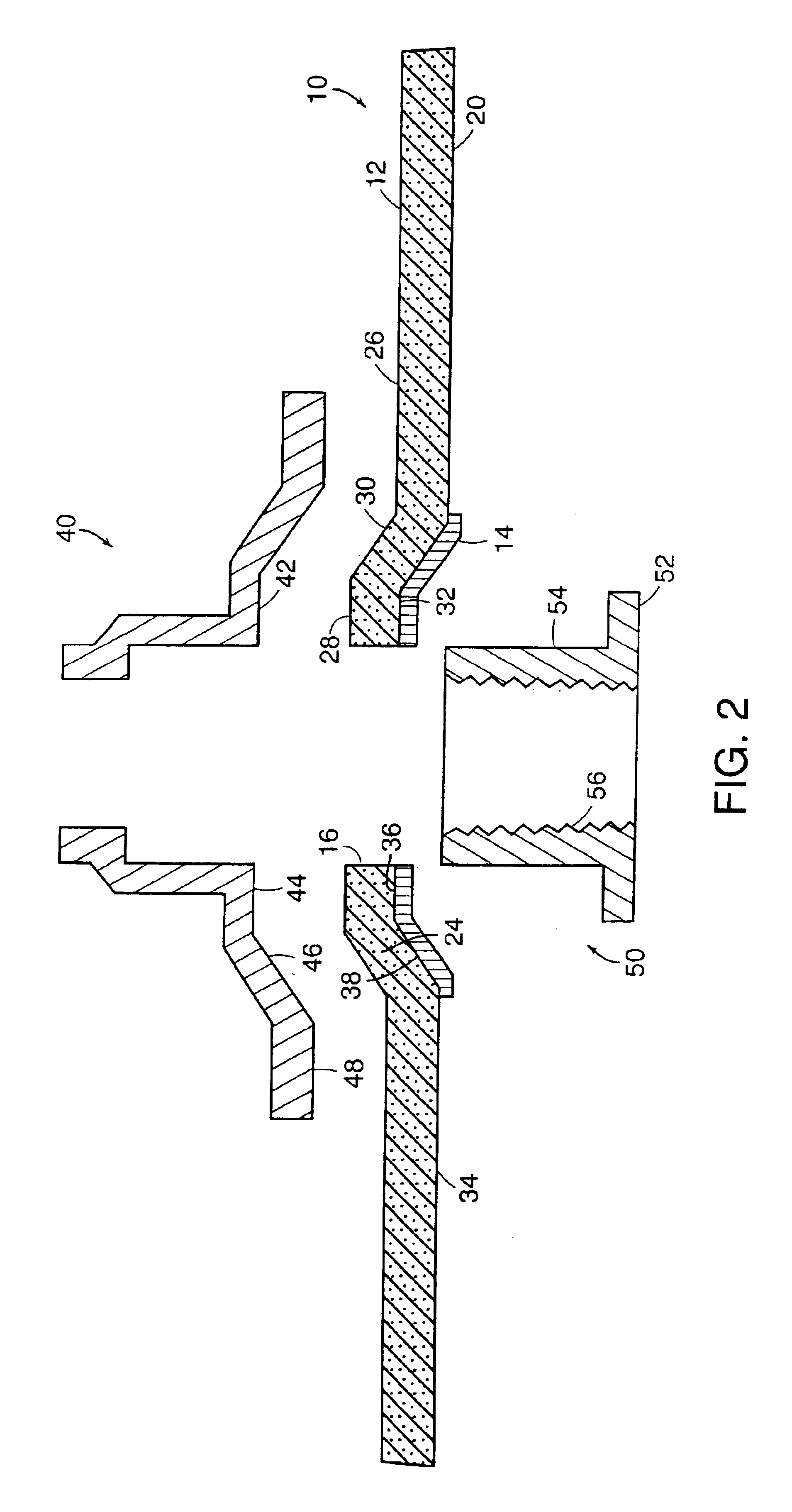

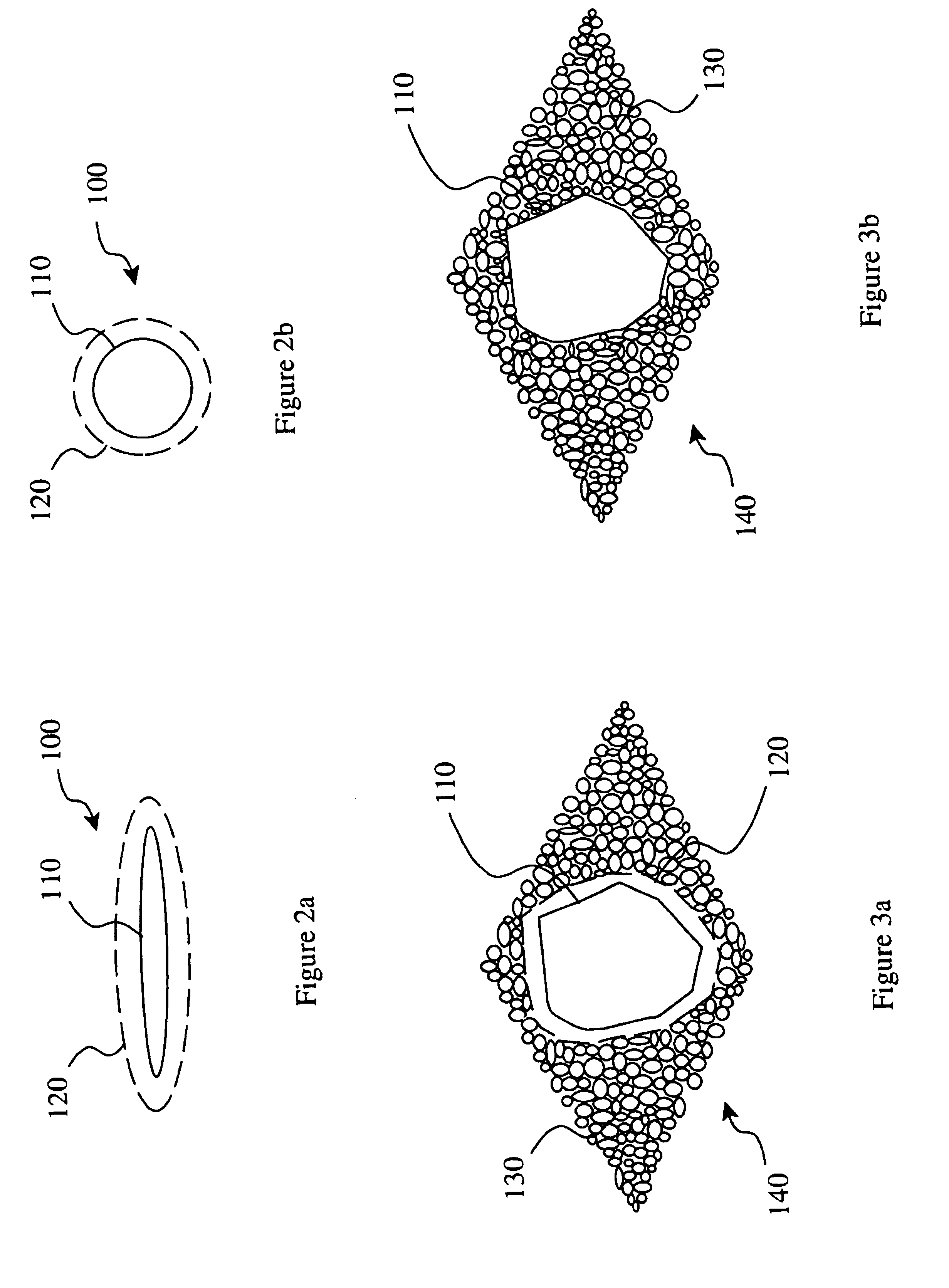

Reinforced abrasive wheels

InactiveUS6942561B2Minimize empty spaceSaving in layer materialGrinding machine componentsRevolution surface grinding machinesGlass fiberEngineering

In a depressed-center abrasive wheel assembly a reinforcement layer of polygonal shape is located between a front face of the abrasive wheel and a front flange. The reinforcement layer is dimensioned to entirely cover the depressed center portion of the wheel. An example of polygonal reinforcement layer has a hexagonal shape and is made of fiberglass cloth. A polygonal shape reinforcement layer can also be employed between the front flange and the front face in an abrasive flat wheel assembly that employs a wheel without internal reinforcement.

Owner:SAINT GOBAIN ABRASIVES INC

Aluminum and zirconium oxynitride abrasive grains

Corundum-zirconia abrasive grains containing more than 50 wt % of an alumina-zirconia eutectic mixture. The grains contain 0.3 to 3% nitrogen, and more than 75% of the zirconia crystals are cubic in shape. The abrasive grains are of particular use for making grinding wheels, abrasive fabrics and papers, polishing compounds and sprayed abrasives.

Owner:PEM ABRASIFS REFRACTAIRES

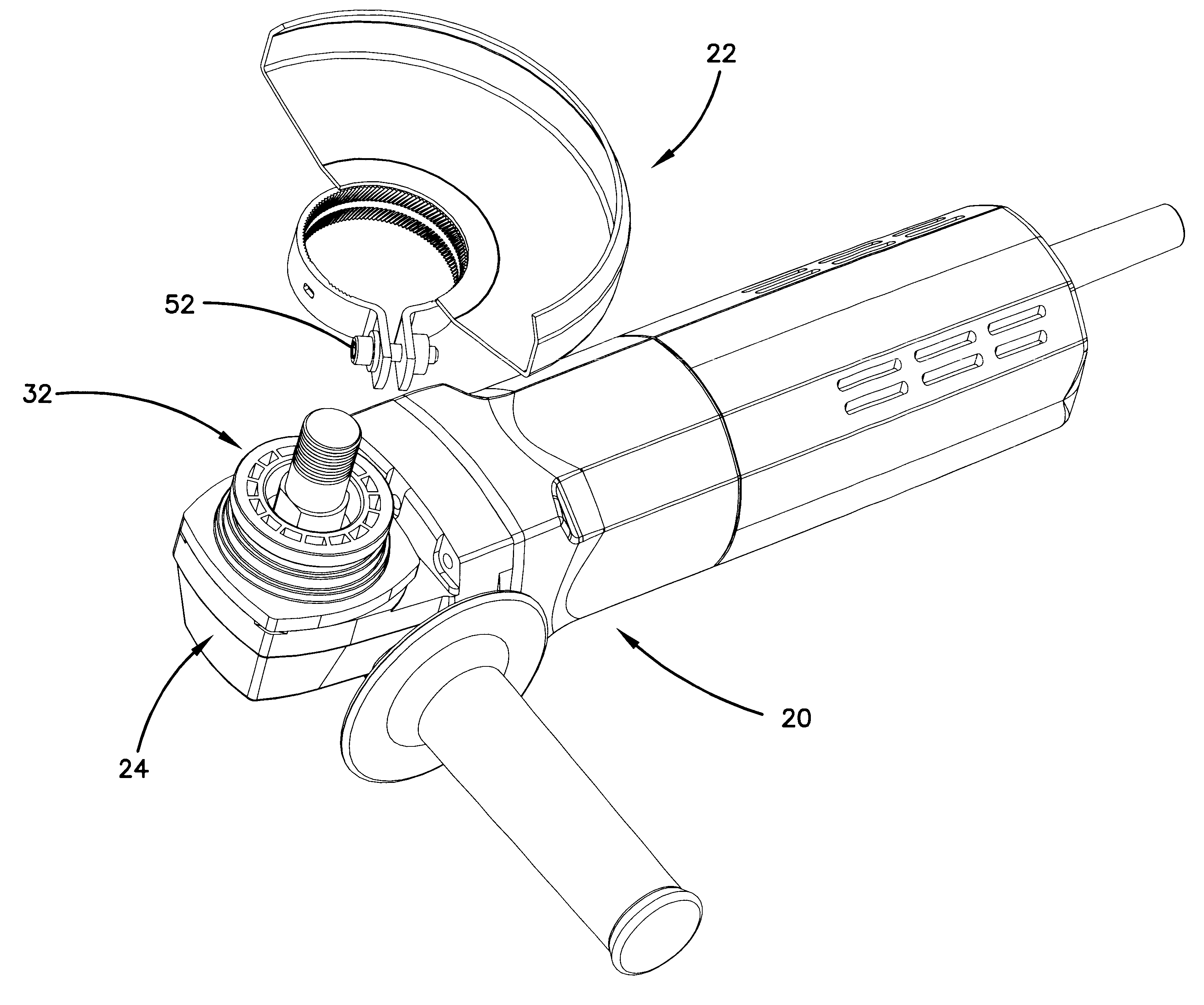

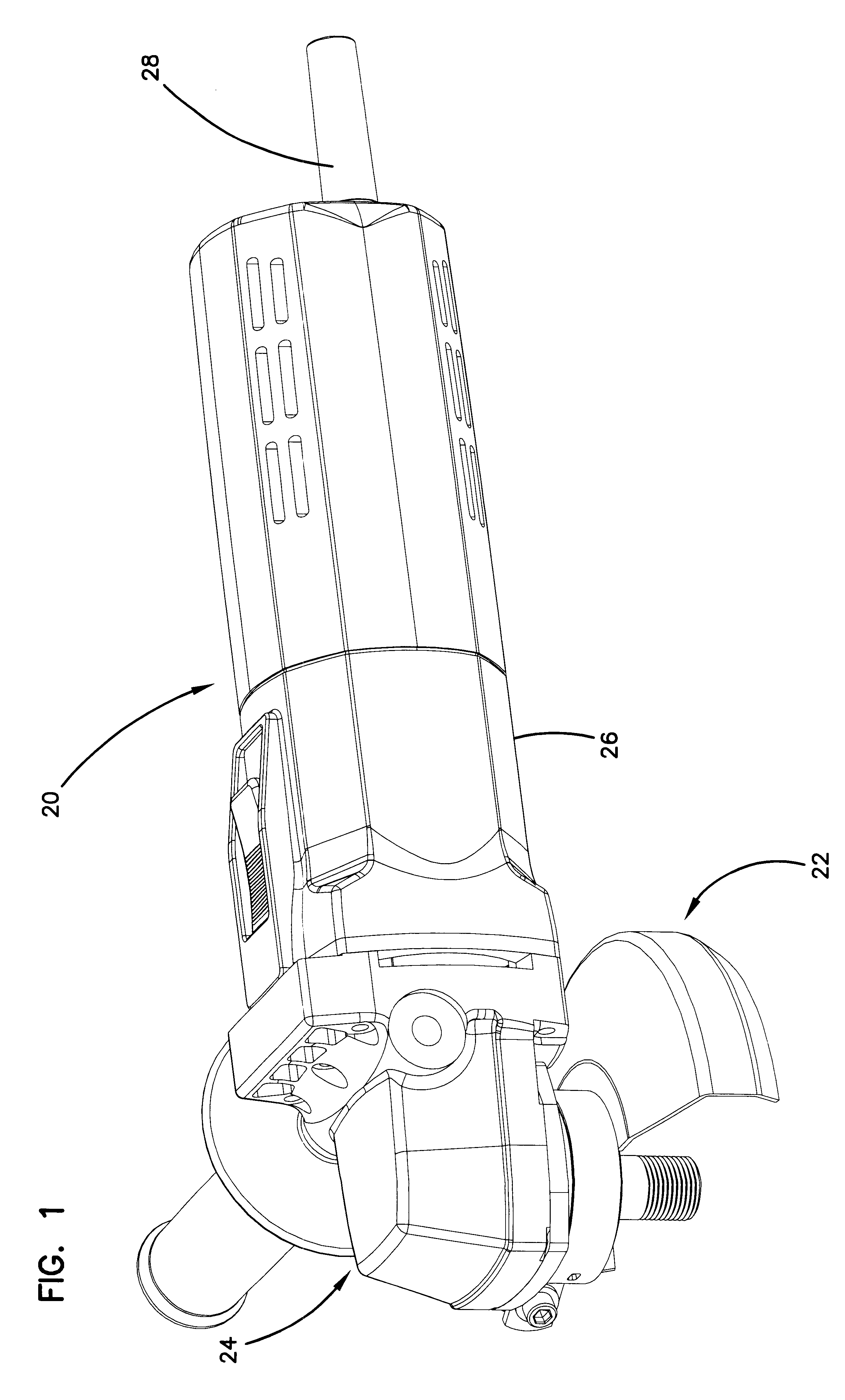

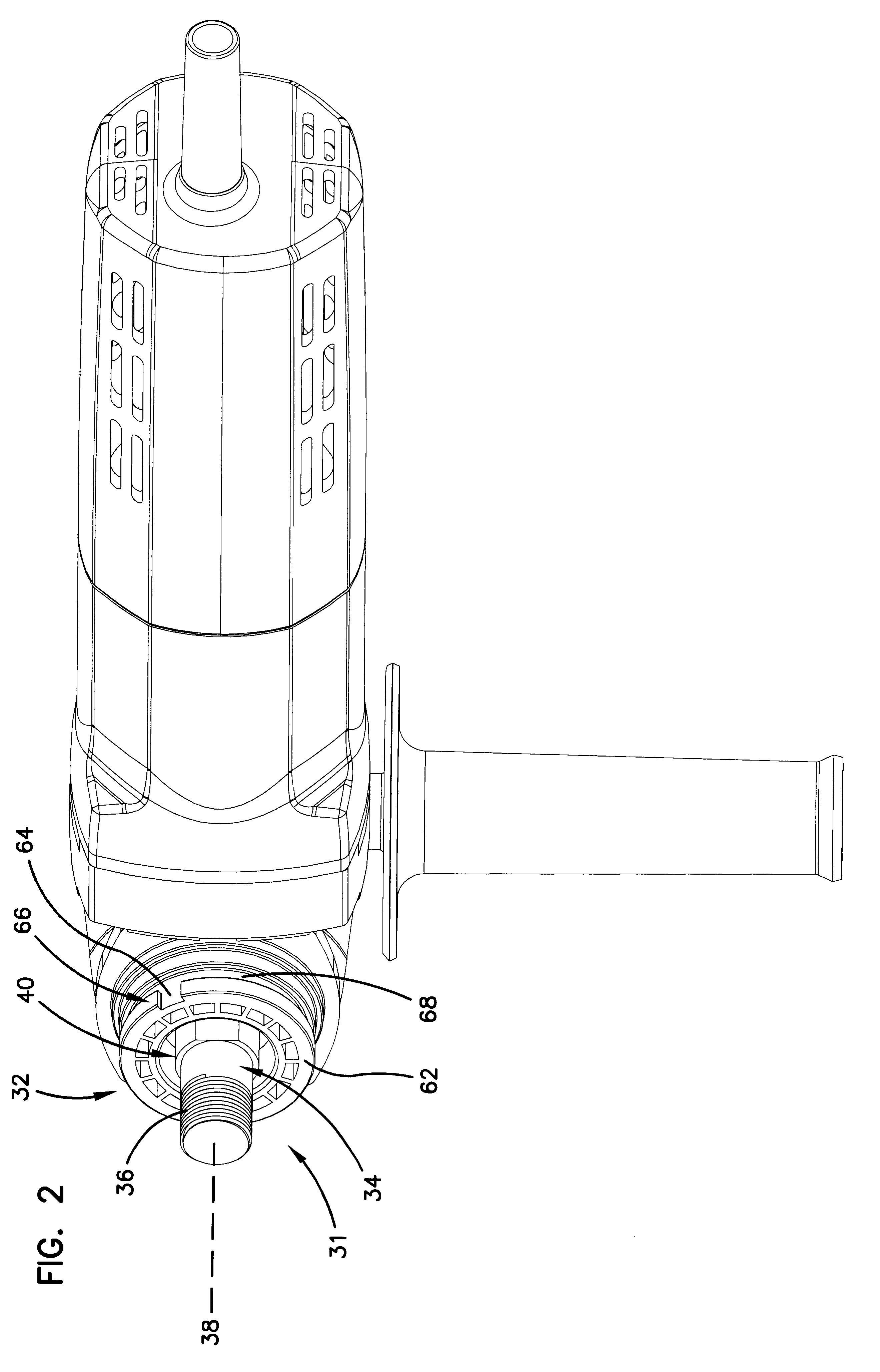

Guard attachment system with knurled clamp ring

InactiveUS6464573B1Portable grinding machinesMaintainance and safety accessoriesHand heldEngineering

A removable guard for a hand-held power tool. The guard is configured to cover an area proximate a spindle assembly of the tool between the spindle assembly and a user of the tool. The guard is further configured to be securely mounted to a semi-elastic lower bearing housing supporting the spindle assembly of the tool. The guard, when mounted to the semi-elastic lower bearing housing of the tool, and when in use during operation of the tool, must remain functional under conditions of flying debris, such as under conditions of an exploding, rotating abrasive grinding wheel mounted on the spindle assembly of the tool.The guard includes a clamp ring depending from a guard hood. The clamp ring's inner circumferential portion has at least a partially-knurled surface, whereby when securely tightened around the semi-elastic lower bearing housing, the at least partially-knurled surface of the clamp ring inner circumferential portion compresses into the semi-elastic lower bearing housing to securely mount the guard to the tool.

Owner:BLACK & DECKER INC

Flexible ceramic wear-resistant heat-proof dual-anticorrosive coating

InactiveCN1528844AIncreasing the thicknessReduce the probability of water seepageAnti-corrosive paintsEpoxy resin coatingsCoated surfaceSaline water

The invention is a kind of flexible ceram wearing and heat resisting heavy corrosion preventing paint, which is made up of epoxy resin and several kinds of ceram powder, rust-protection paint and firming agent, the weights of each ingredient are: (1) epoxy resin: 100; (2) additive: 50-120; (3) rust protection paint: 8-25; (4) ceram powder: 100-200; (5) compound solvent: 40-70; paint: firming agent=(35-50):1. The paint needn't base coat, it can be painted directly or brushed on the surface of metal under normal temperature, it has excellent wearing and corrosion prevention performance, impact resisting performance and flexibility, it can insulate acid, alkali, salt, saline water. The surface is smooth; it can be applied to oil pipe, oil pot, and chemical device, ship, wheel vane, pump, dust catcher, etc.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

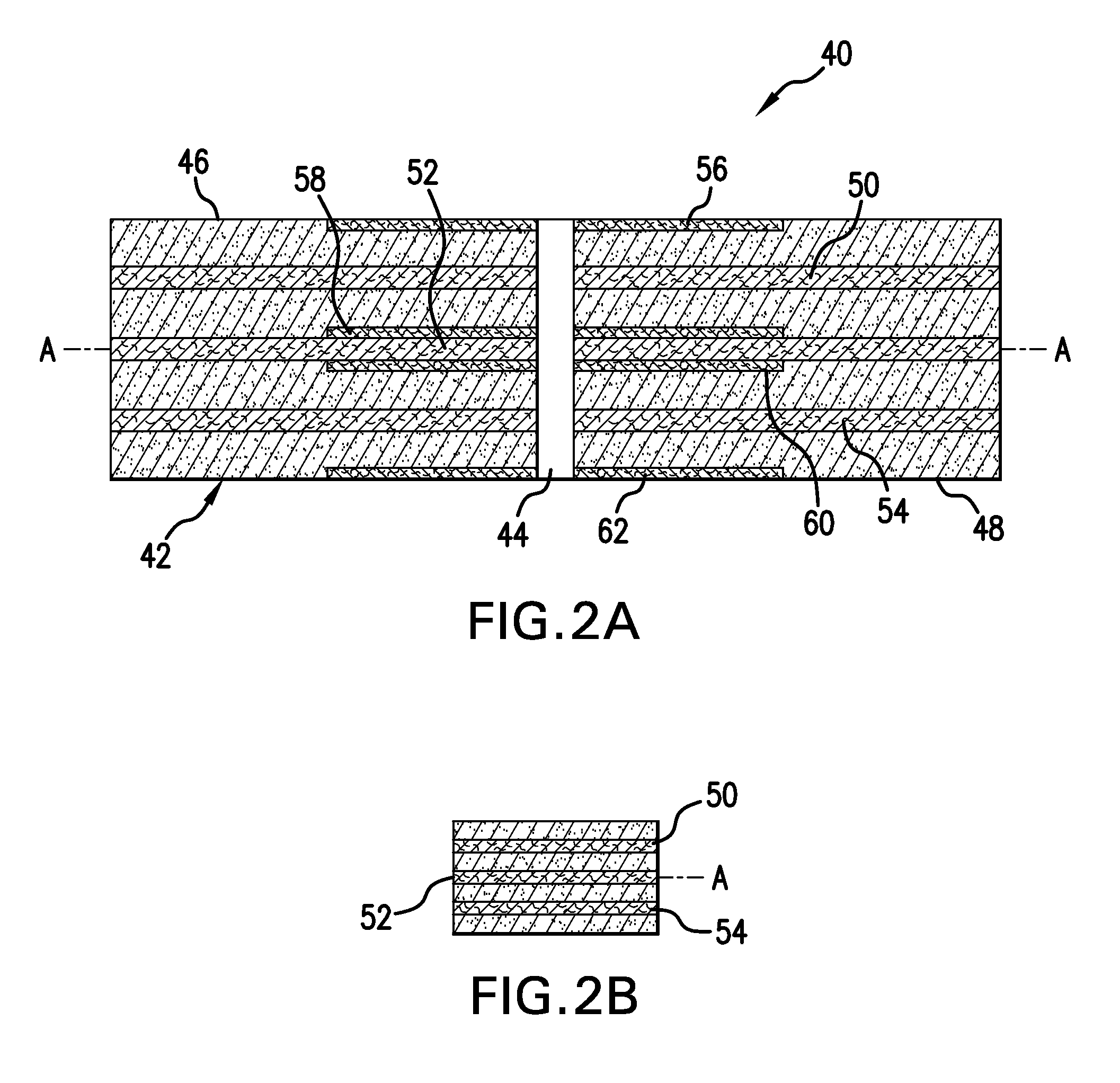

Grinding wheel

InactiveUS20020068518A1Removal from surfaceReduce grooveRevolution surface grinding machinesBonded abrasive wheelsGrinding wheelAbrasive

A cylindrical, abrasive grinding wheel having a cylindrical abrasive region with an abrasive surface at an outer circular band thereof. The abrasive region includes layers of abrasive particles. The layers of abrasive particles can be tilted with respect to an axis of rotation of the grinding wheel or they can such that grooving in the grinding wheel and a workpiece ground by the grinding wheel can be reduced. Alternatively, the abrasive region can be formed from a plurality of abrasive segments each having layers of abrasive particles. The layers of abrasive particles can be staggered in the direction of the axis of rotation from one segment to another. This can also reduce grooving in the grinding wheel and workpieces.

Owner:3M INNOVATIVE PROPERTIES CO

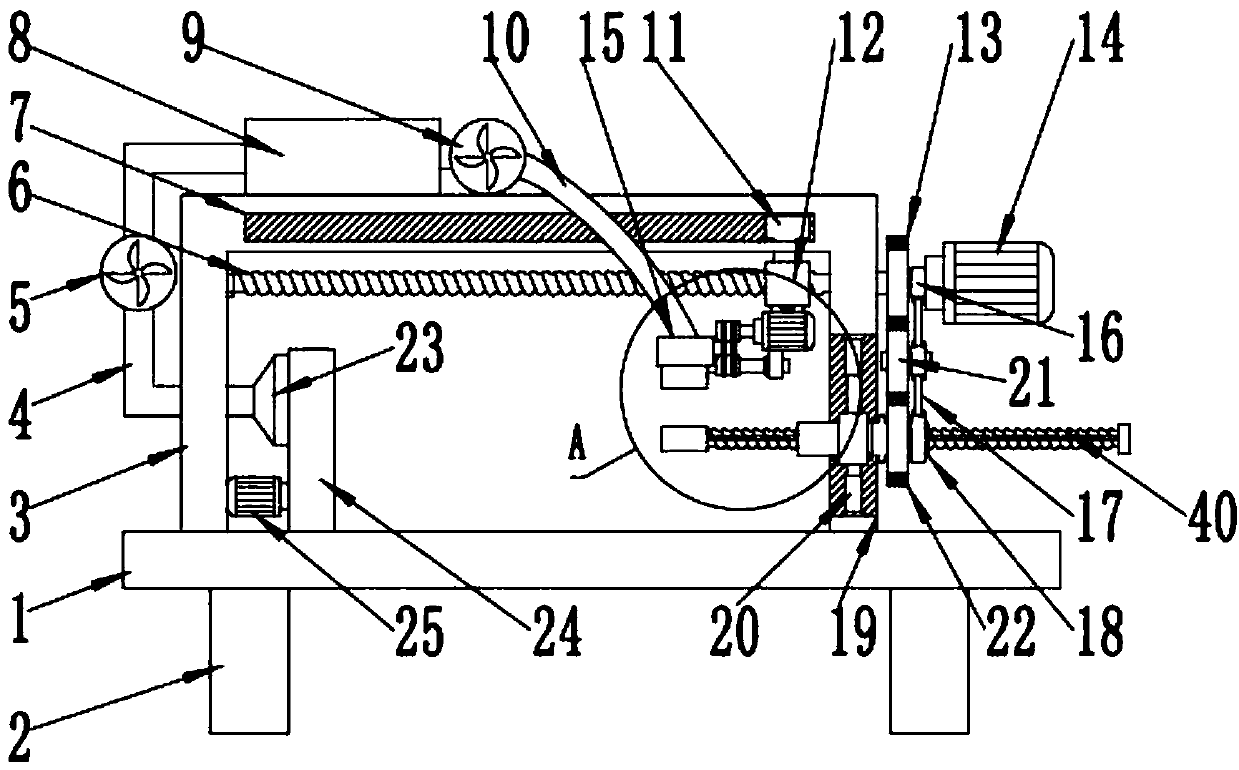

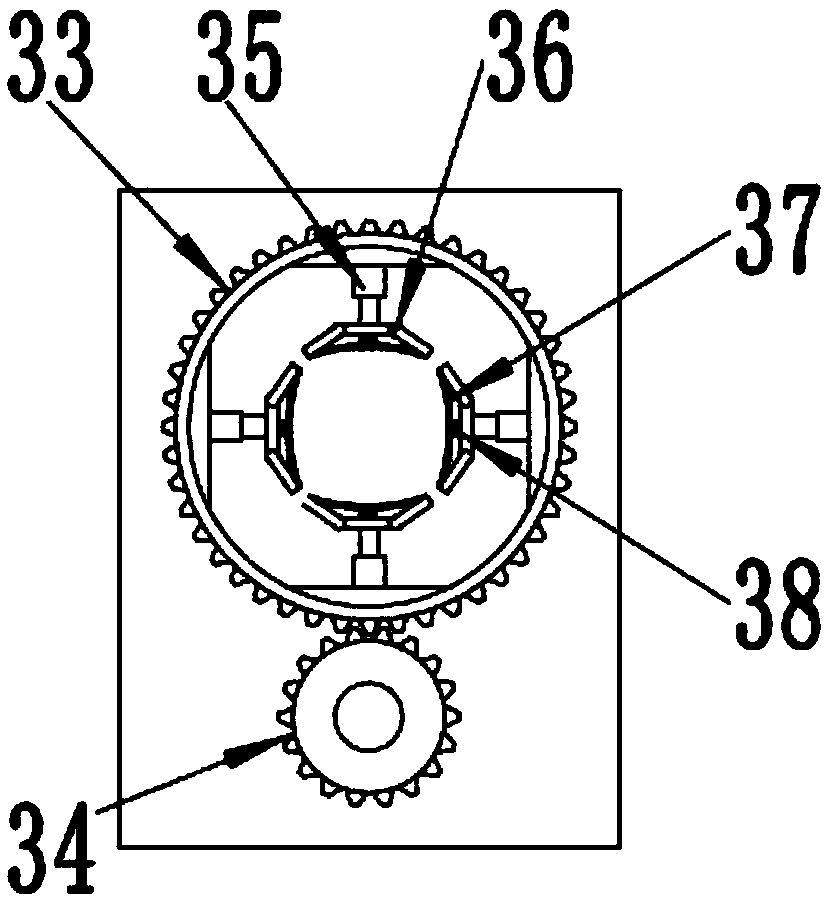

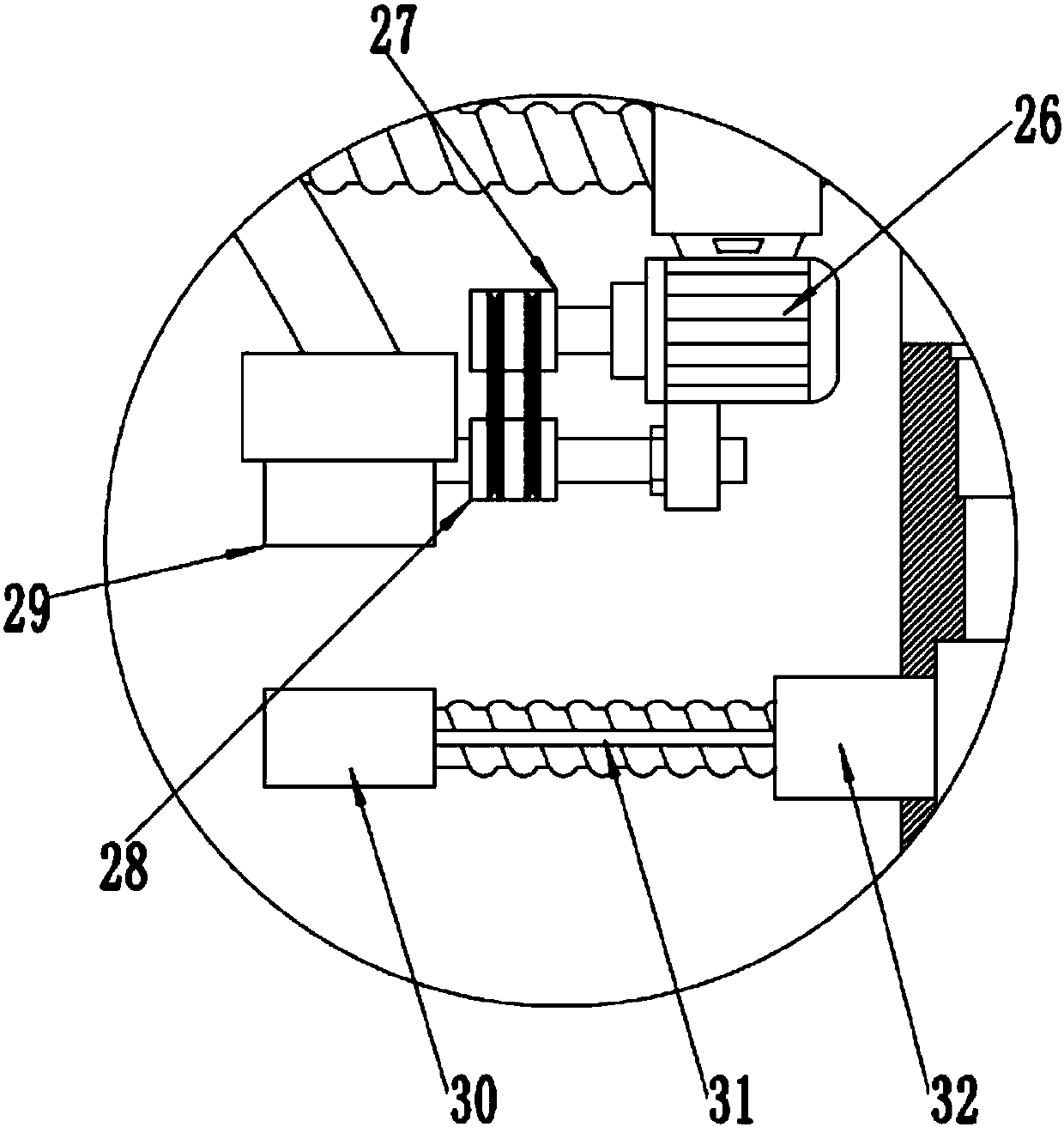

Device for simultaneously grinding inner walls and outer walls of steel pipes

InactiveCN107738167AAvoid pollutionShorten the timeGrinding carriagesRevolution surface grinding machinesHydraulic cylinderEngineering

The invention discloses a device for simultaneously grinding the inner walls and the outer walls of steel pipes. The device comprises a workbench, a support, a collecting tank, a clamping mechanism, an outer grinding mechanism and an inner grinding mechanism; the support is arranged at the upper end of the workbench, and the clamping mechanism is arranged at the left end of the inner side of the support and comprises a clamping plate, a rotating motor, an annular gear, a gear, electric telescopic rods, supporting plates, rubber pads and springs; the outer grinding mechanism is installed at thelower end of a moving block; and the inner grinding mechanism is arranged under the outer grinding mechanism and comprises an inner grinding wheel, a threaded rod B, a fixing sleeve, a threaded sleeve, a second sliding groove, an electric hydraulic cylinder, a drive gear, a driven gear A, a driven gear B, a rectangular block and a connecting rod. The device is novel in design, simple in structure, capable of simultaneously grinding the inner walls and the outer walls of steel pipes with different thicknesses, high in grinding efficiency, wide in application range, capable of effectively preventing impurities such as scrap iron from polluting the environment, high in practicality and worthy of popularization.

Owner:宁波高新区峰林化工科技有限公司

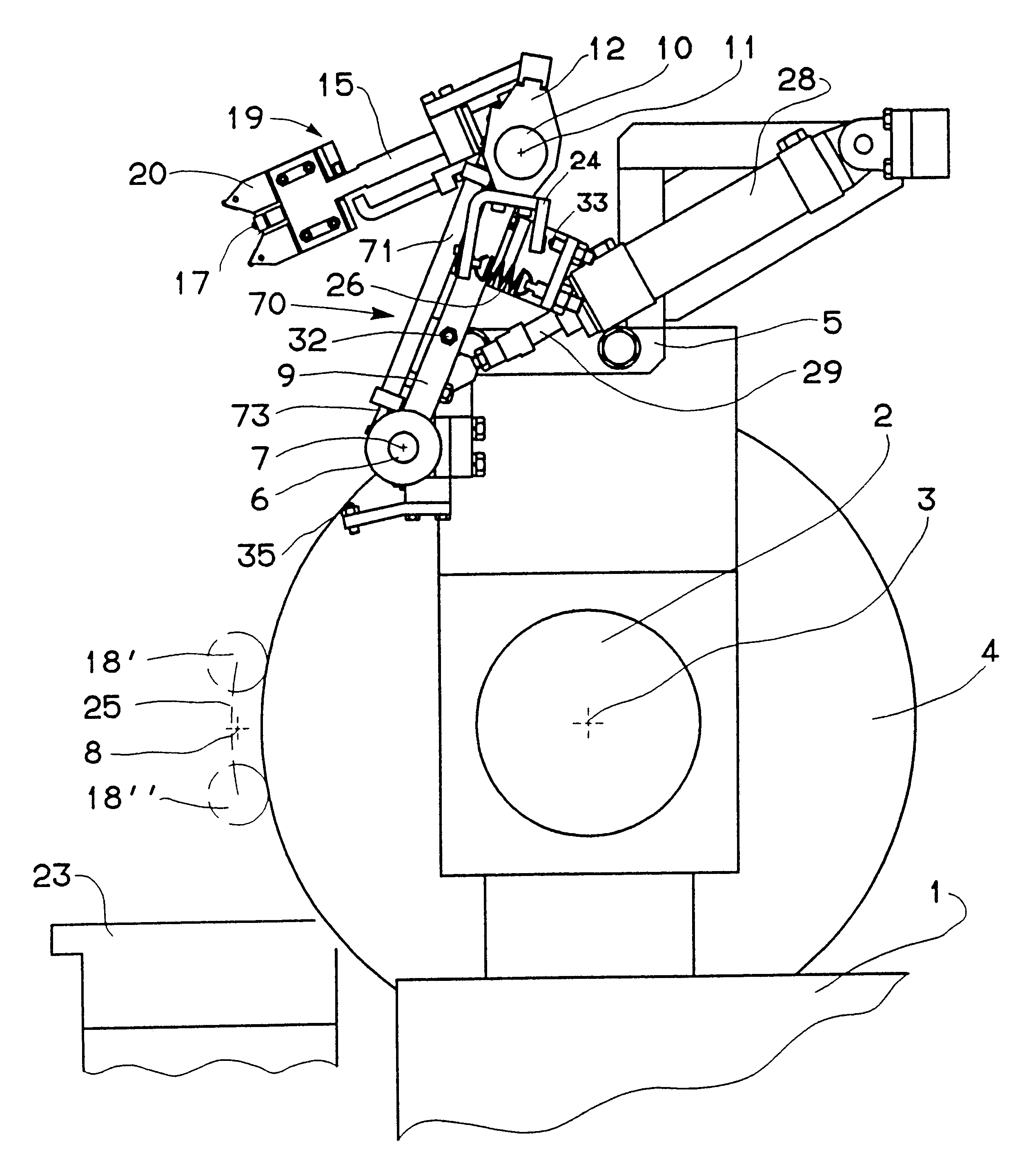

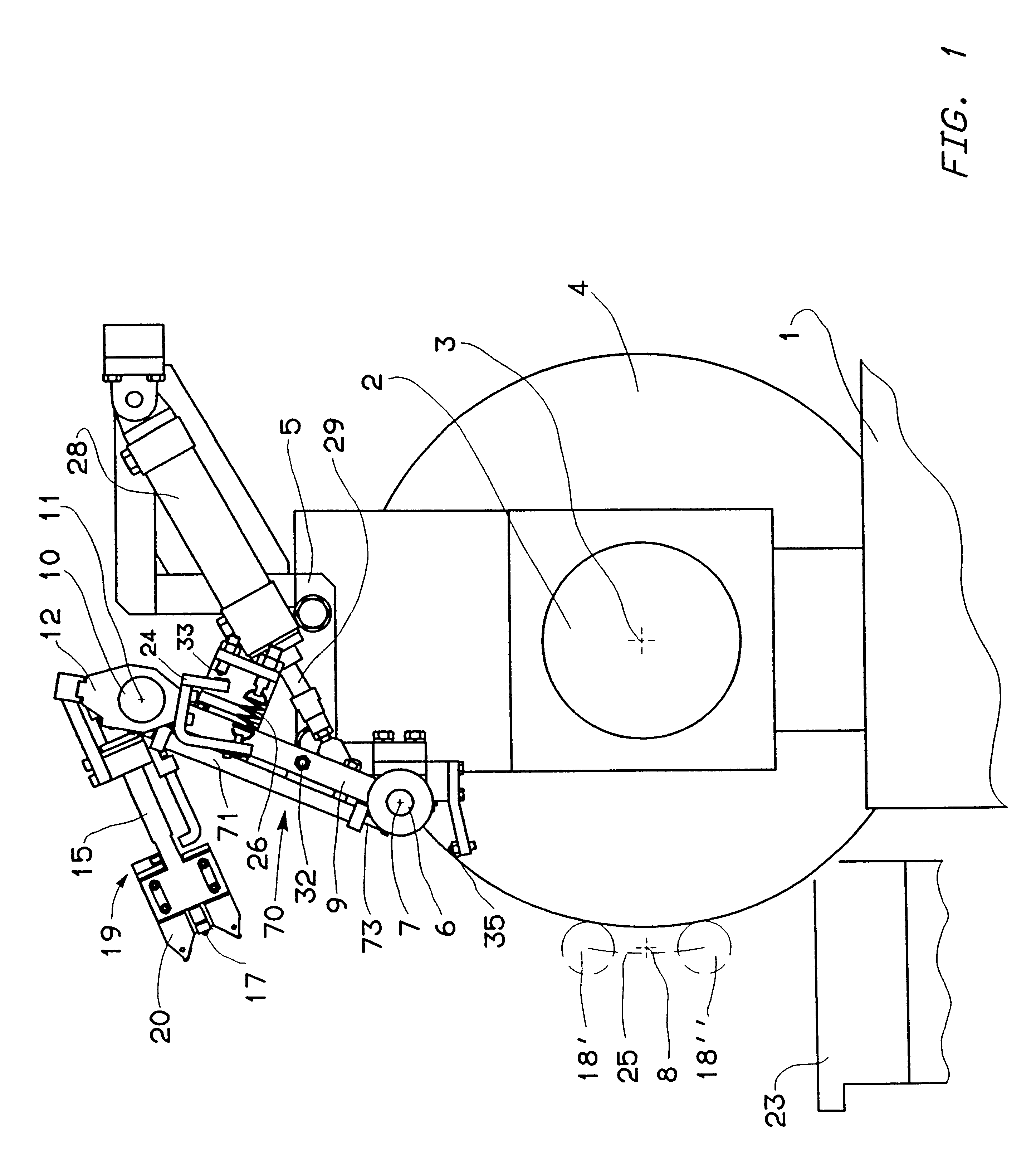

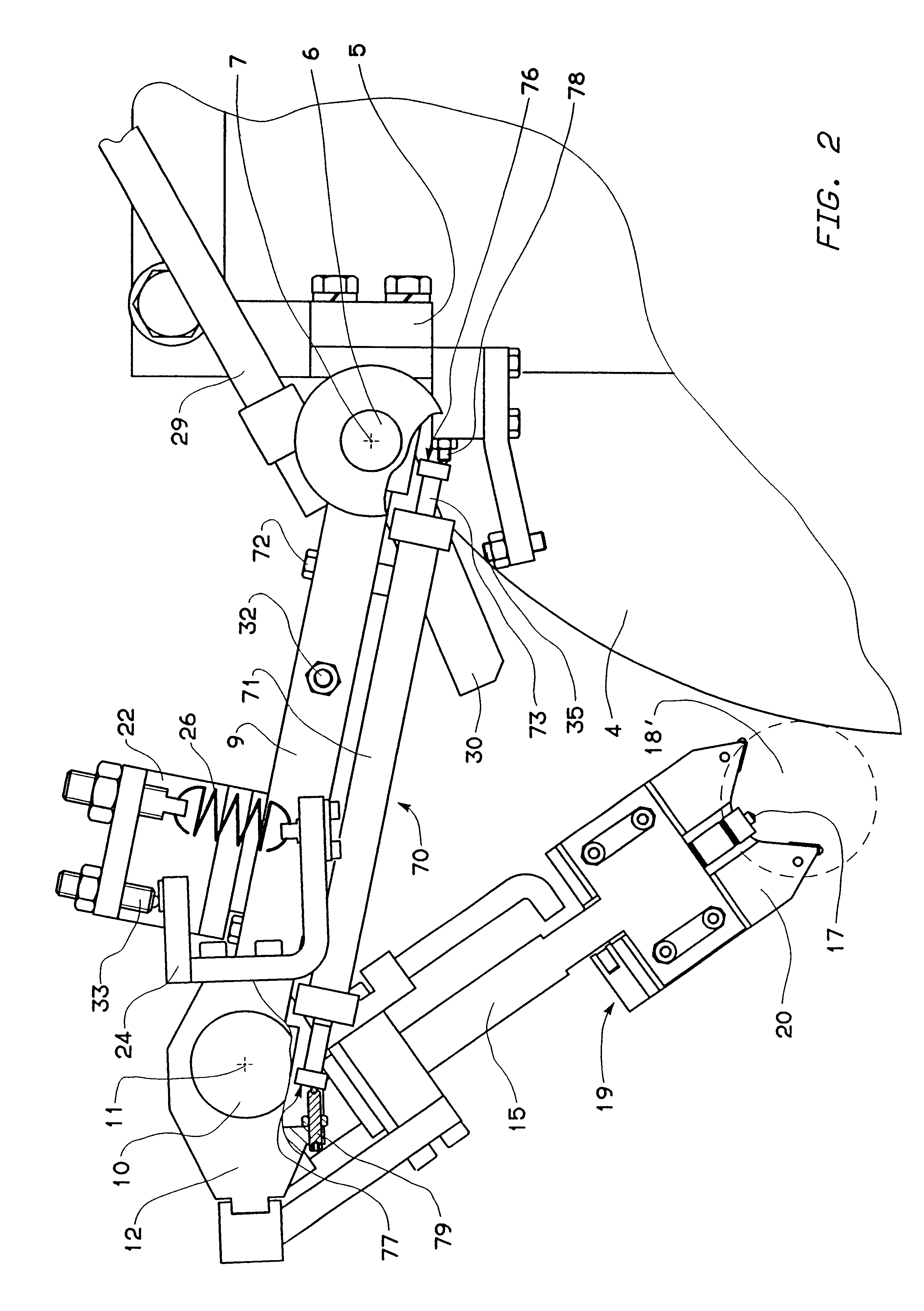

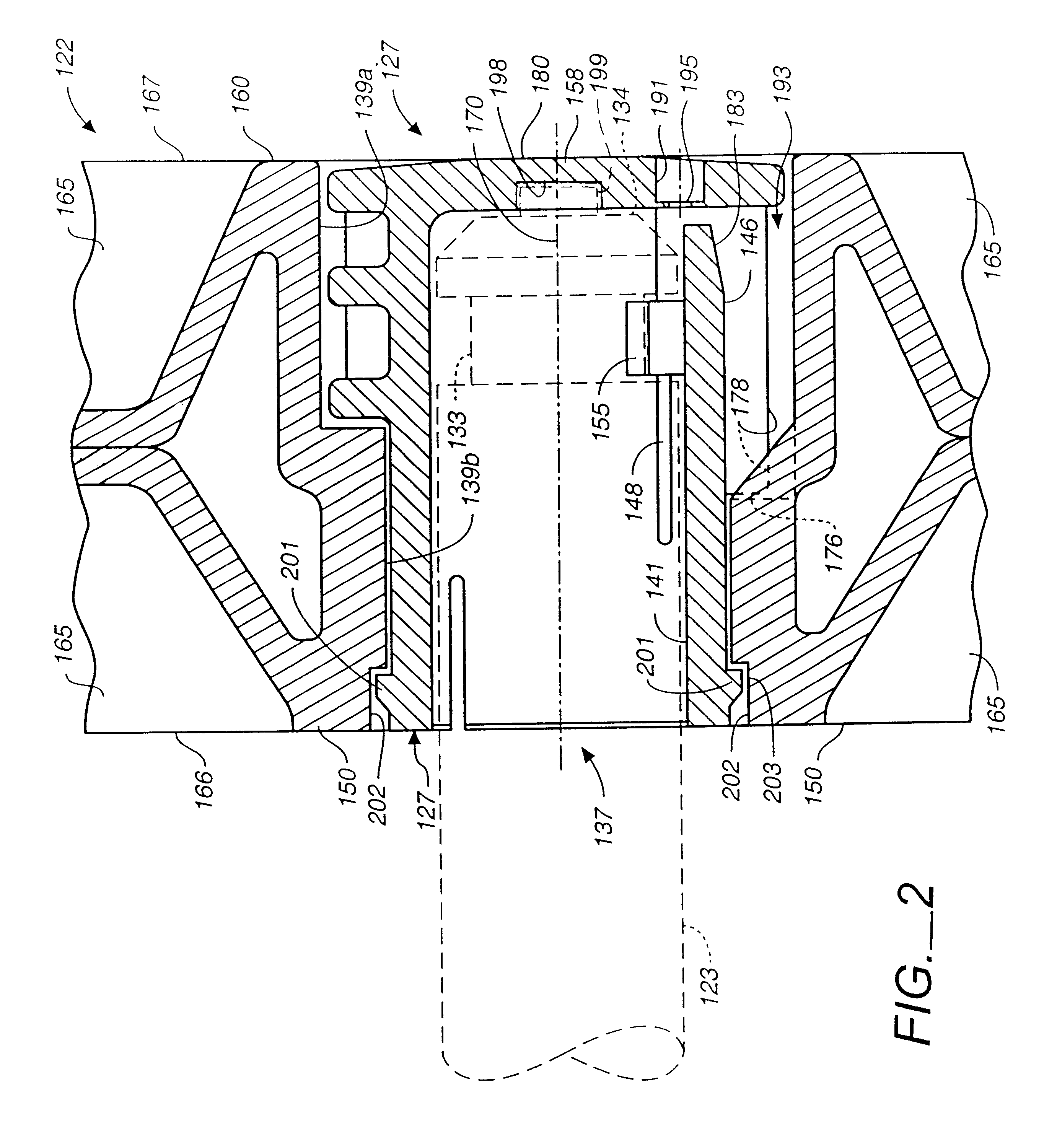

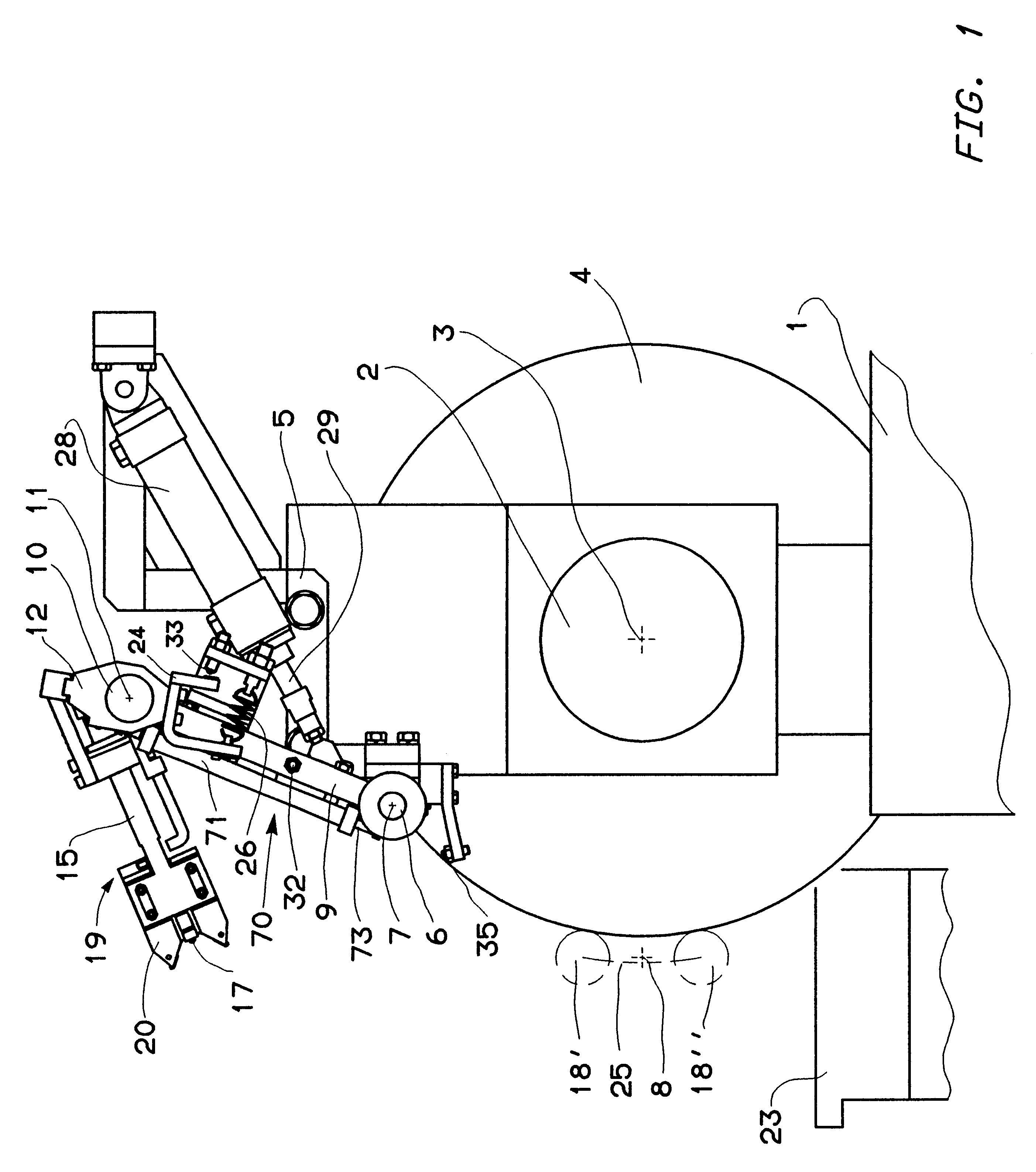

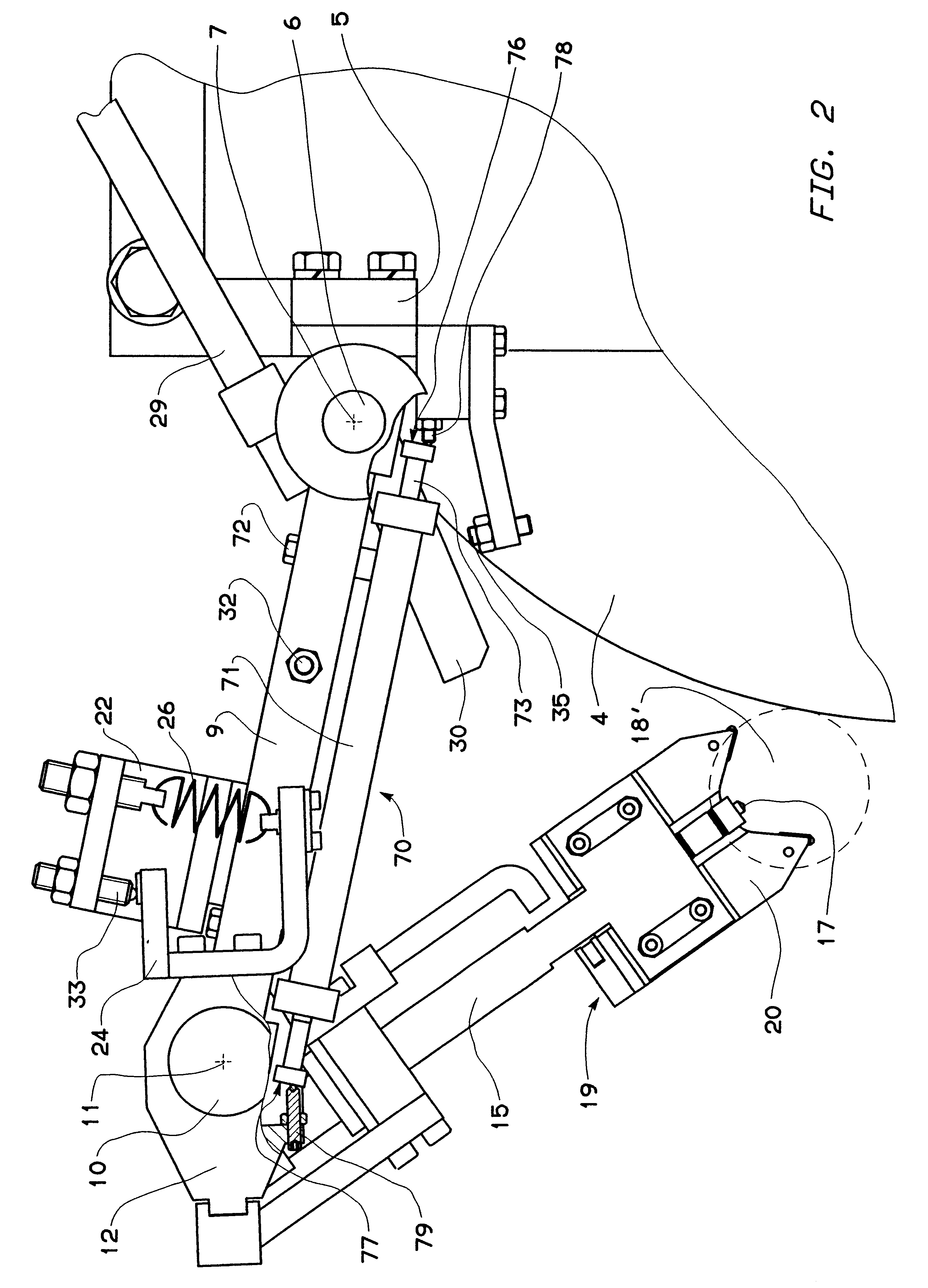

Apparatus for the in-process dimensional checking of orbitally rotating crankpins

InactiveUS6643943B2Revolution surface grinding machinesMechanical diameter measurementsReference deviceCrankpin

An apparatus for checking the diameter of crankpins of a crankshaft in the course of the machining in a grinding machine includes a Vee-shaped reference device, a measuring device associated with the reference device and including a feeler axially movable along the bisecting line of the Vee-shaped reference device, and a support device with a first arm rotating with respect to a support arranged on the grinding-wheel slide and a second arm rotating with respect to the first and carrying the Vee-shaped reference device.A guiding mechanism includes a limiting device, with mutually abutting surfaces and coupled to the support device, that guides the displacement of the reference device along a trajectory substantially parallel to the profile of the grinding wheel, allows the engagement of the reference device on a crankpin to be checked while the latter is orbitally moving, and does not interfere with the displacements of the support device caused by the orbital motion of the crankpin in the checking condition.

Owner:MARPOSS SPA

Plastic wheel assembly and mounting sleeve with stabilizing recess

Owner:GEO PLASTICS

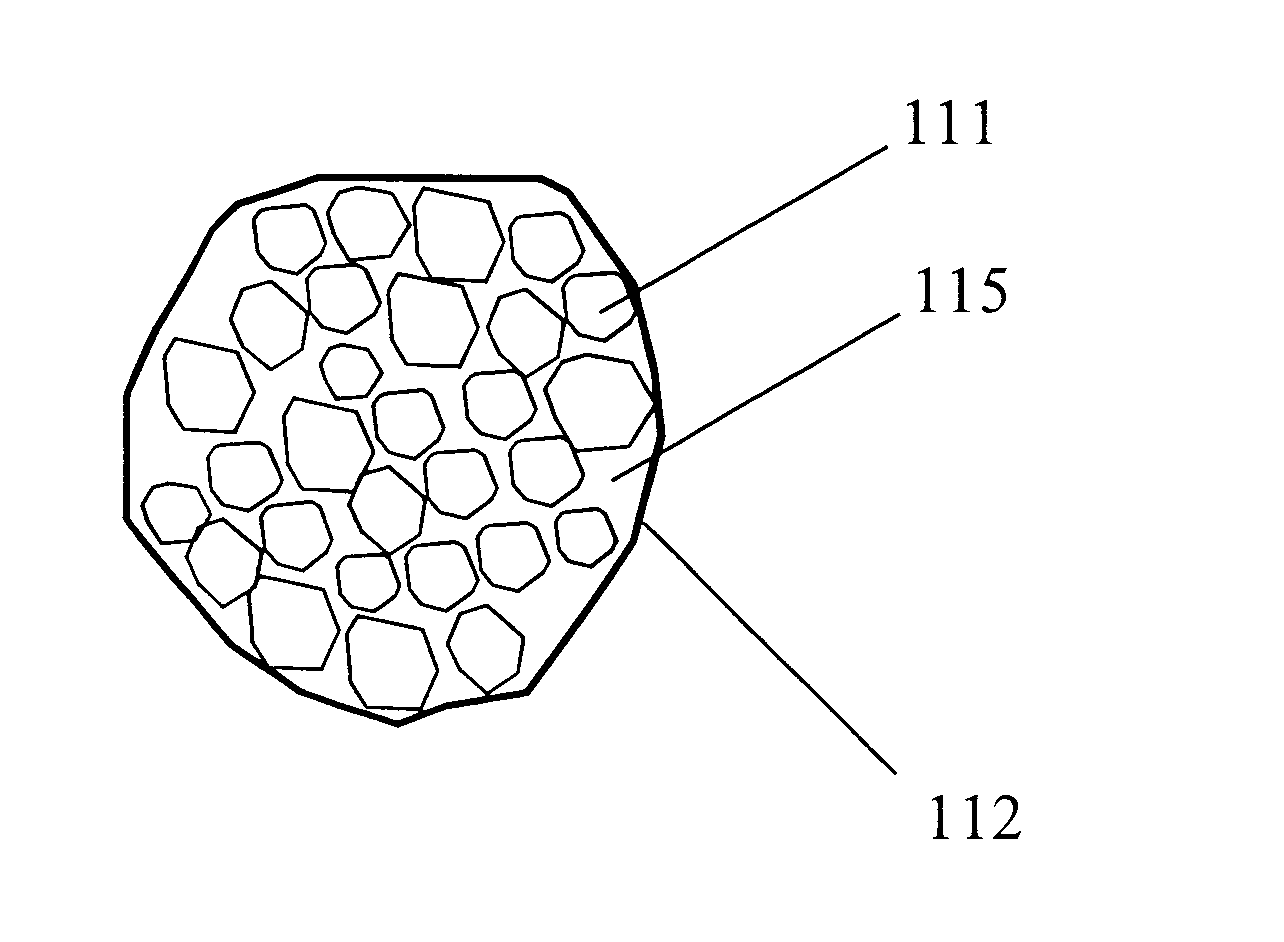

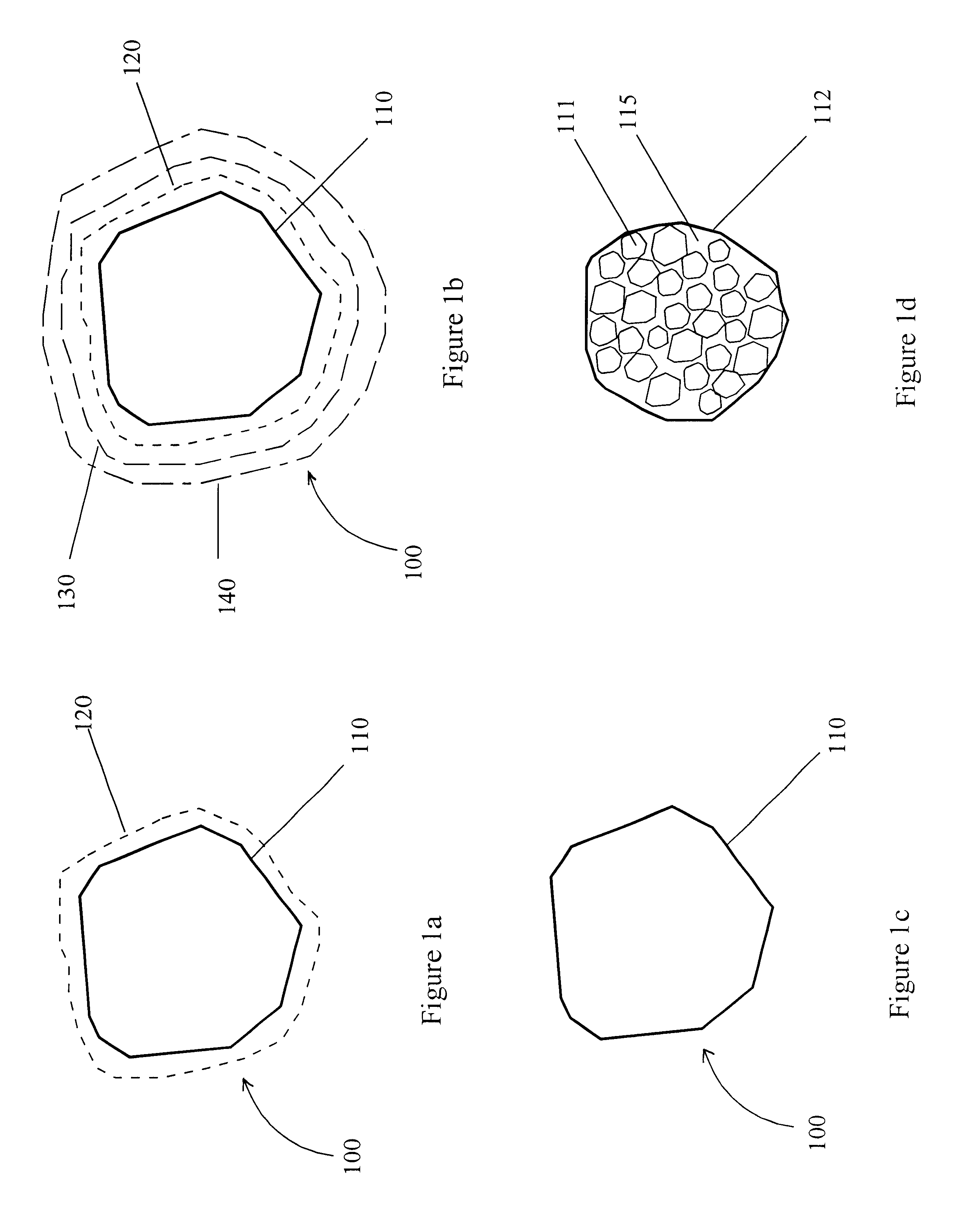

Self-grown monopoly compact grit

InactiveUS6616725B2Strong and more resilientProduced cost-effectivelyPigmenting treatmentOther chemical processesBoron nitrideSolvent

A self-grown monopoly compact grit and high pressure, high temperature process for preparing the same. The high pressure, high temperature sintered / synthesized monopoly compact grit is used in various industrial tools such as saw blades, grinding wheels, cutting tools and drill bits. Further, the monopoly compact grit of the present invention is produced from a seed of a mono-crystal of diamond or cubic boron nitride surrounded by either a self-grown crystal layer or an integrally bonded poly-crystalline sintered compact layer. The self-grown crystal layer is a new grown crystal structure where the seed crystal grows into a new phase through a normal diamond or cubic boron nitride synthesis process in the presence of a catalyst metal solvent. The compact layer is composed of about 50 to about 90 volume percent of diamond or cubic boron nitride, a typical binder material, which is a catalyst for crystal-to-crystal bonding, and a cementing agent which is a binding agent capable of forming stable carbide and nitride bonds.

Owner:CHO HYUN SAM +2

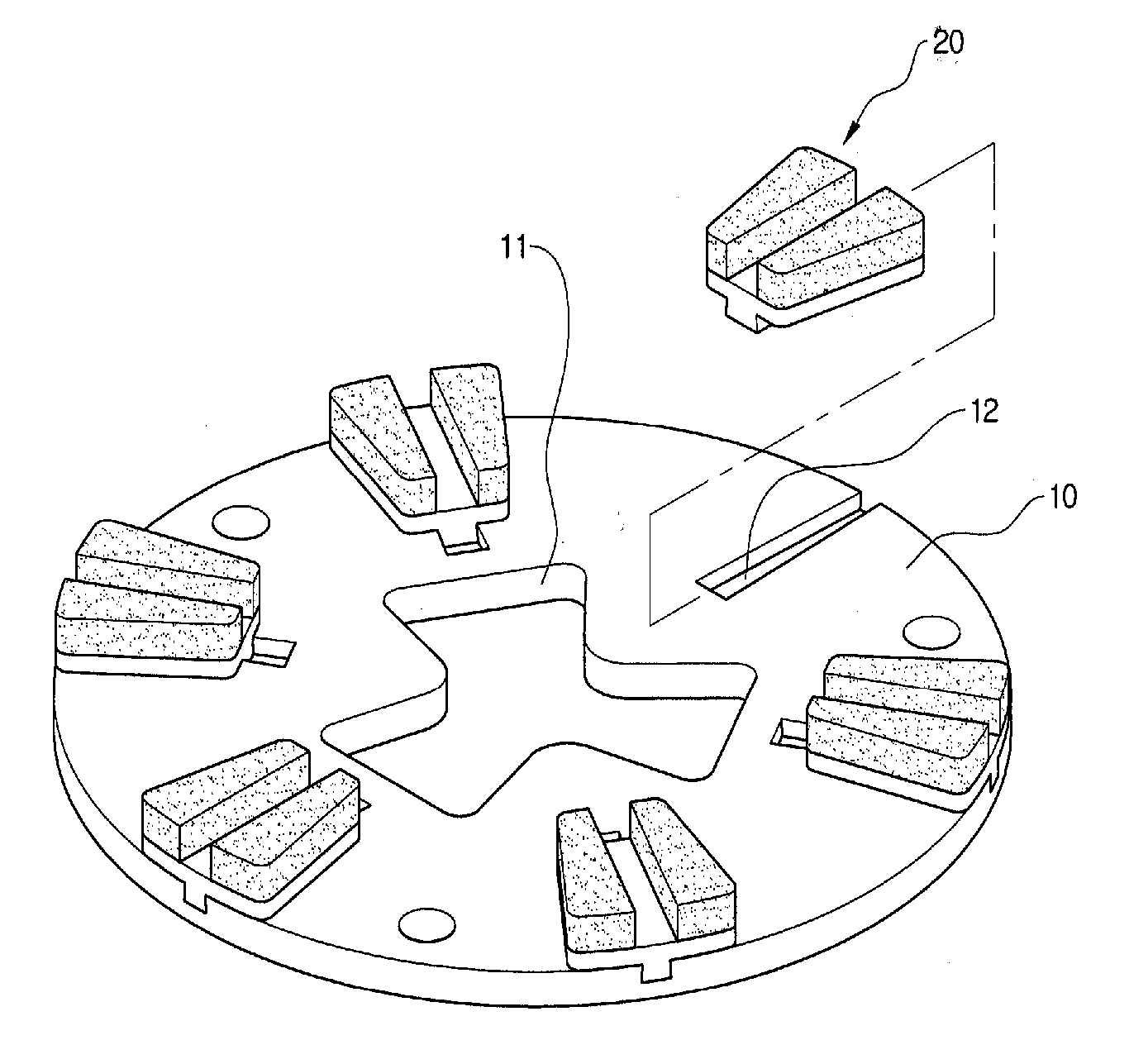

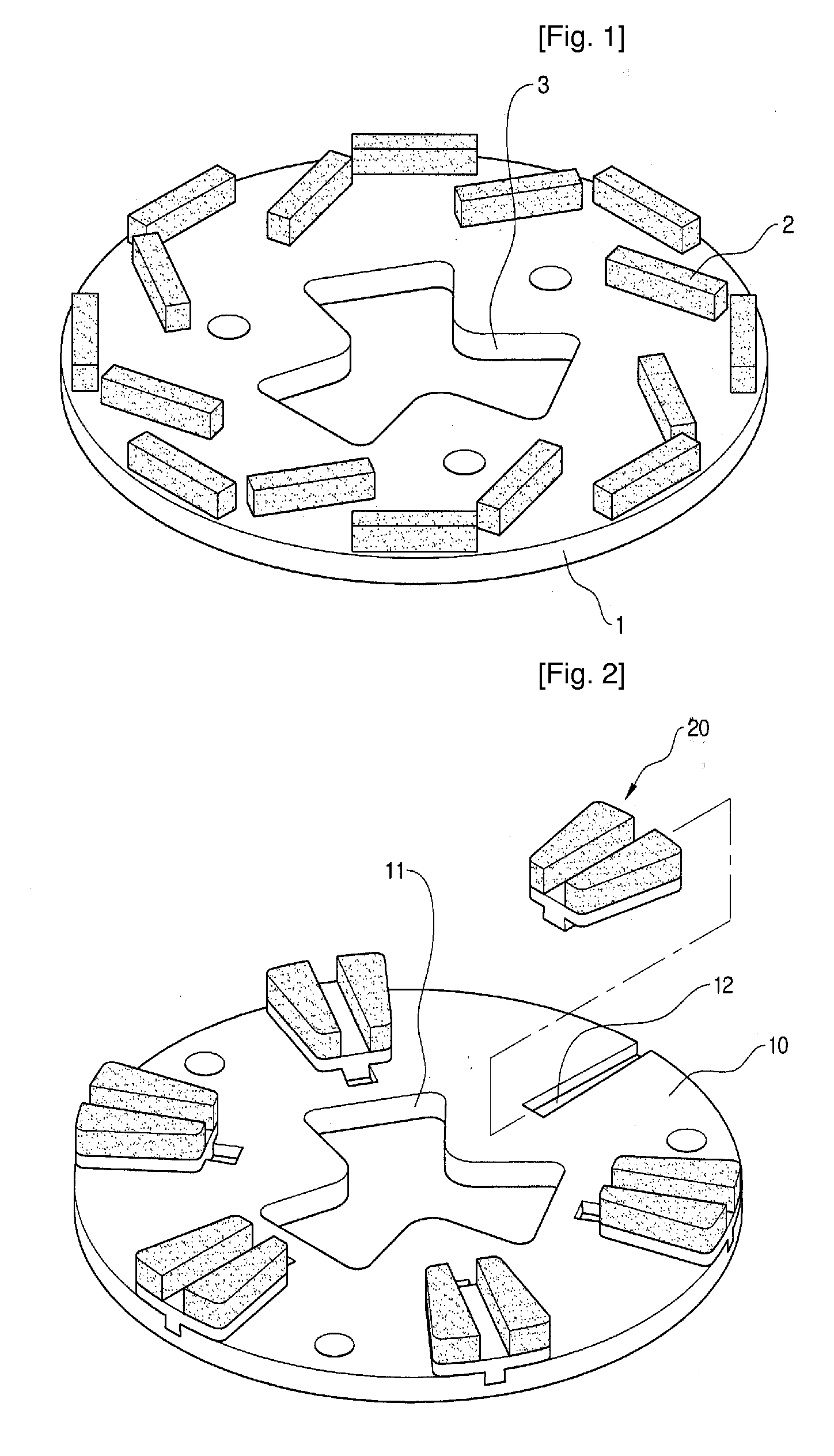

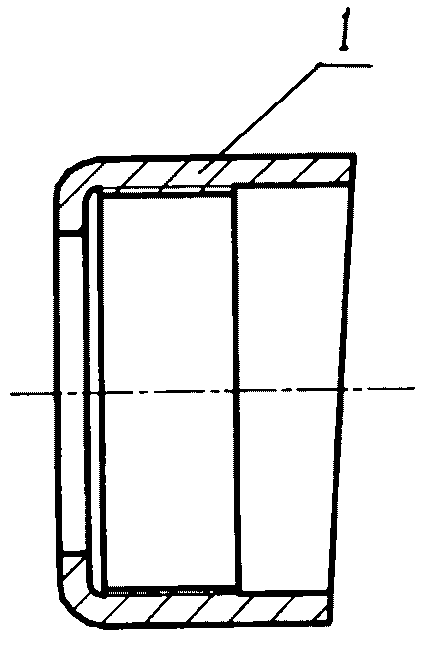

Grinding Wheel

InactiveUS20070254568A1Simple manufacturing processPrevent thermal deformationRevolution surface grinding machinesBonded abrasive wheelsEngineeringGrinding wheel

A grinding wheel has a disc having a connection hole formed at a center thereof, to which a rotation axis of a grinder is connected, and a plurality of abrasive segments detachably connected to a surface of the disc. A plurality of fixing recesses are radially formed on the surface of the disc at an interval and fixing protrusions having a shape corresponding to the fixing recess are formed on bottom surfaces of the abrasive segments, so that the abrasive segments are connected to the disc by inserting the fixing protrusions into the fixing recesses. According to the grinding wheel, when the abrasive segment is worn away or inferior as it is used for a long time, it has only to replace the corresponding abrasive segment only. Accordingly, an economical efficiency is high.

Owner:PARK RIN SOON

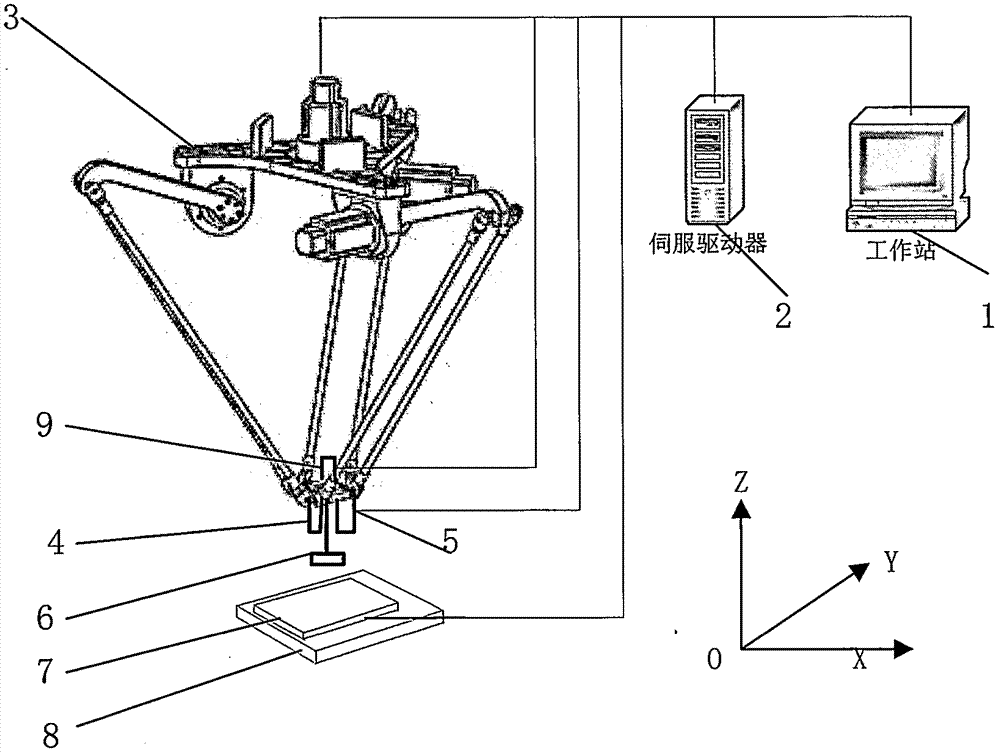

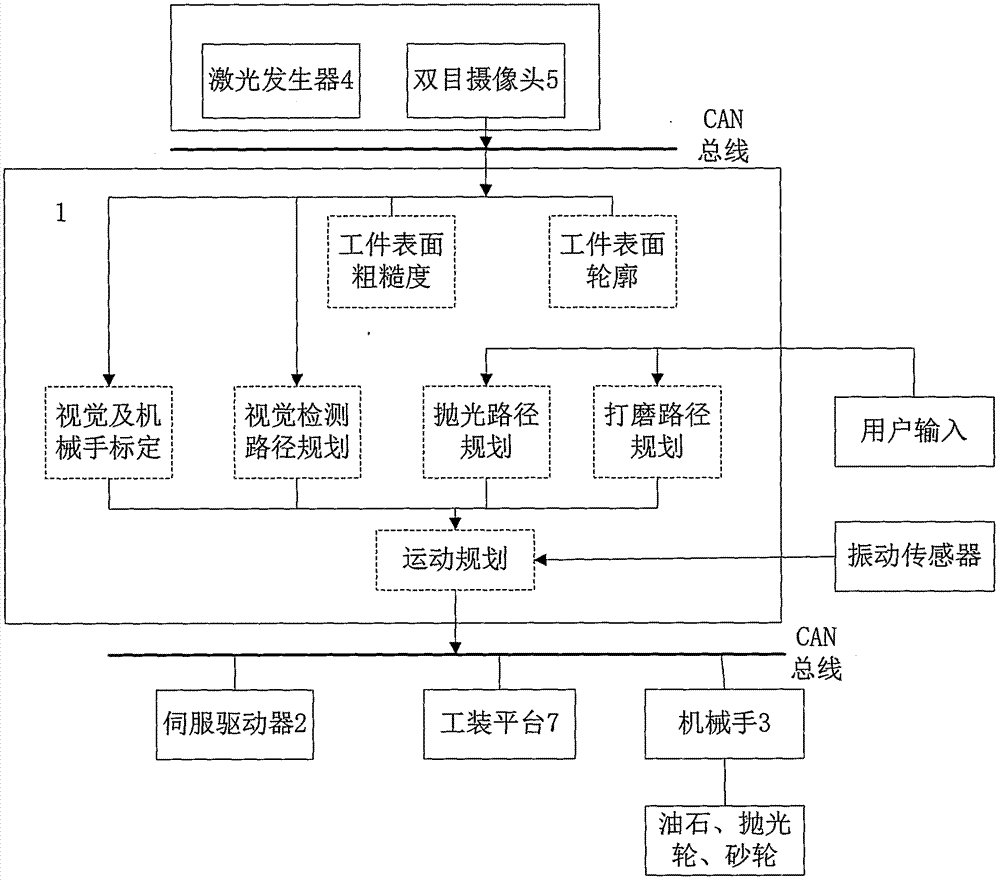

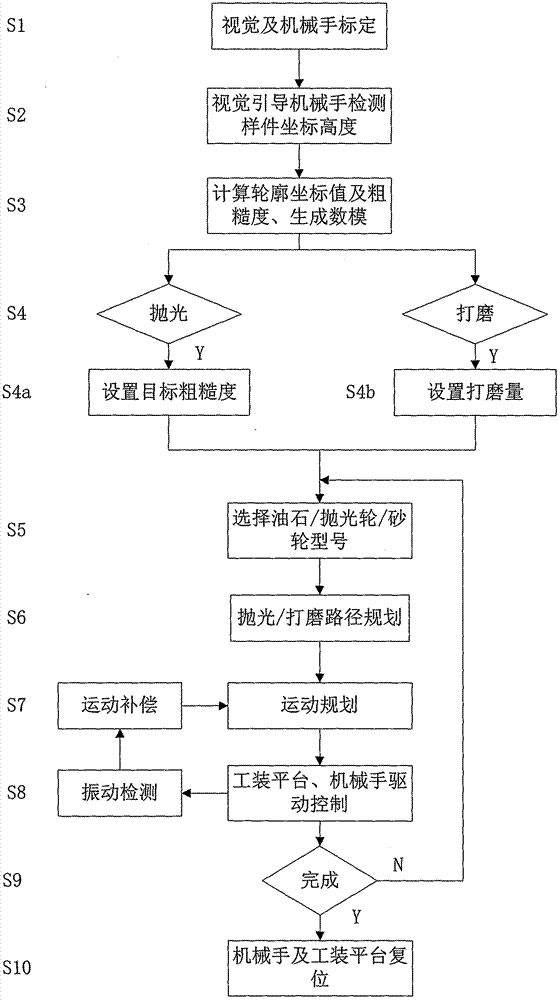

Complex curved face grinding and polishing system and method

InactiveCN107052950AFlexible setting methodHigh speedProgramme-controlled manipulatorGrinding feed controlThree degrees of freedomEngineering

The invention relates to a complex curved face grinding and polishing system and method. The system comprises a three-degree-of-freedom manipulator, a visual detection device, a vibrating sensor and a three-degree-of-freedom tool platform. An installation clamp is arranged at the tail end of the manipulator and can install an oilstone, a polishing wheel and a grinding wheel. The visual detection device comprises a laser generating device and a binocular camera, is installed on the manipulator, and detects the outline and roughness of a workpiece. During working, the workpiece is installed on the three-degree-of-freedom tool platform. The visual detection device guides the manipulator to scan the outline of the workpiece, a three-dimensional outline data model is generated, and the roughness is analyzed. Polishing or grinding setting can be conducted on a work station. During grinding, setting can be conducted in three modes that a referential three-dimensional data model is compared with an actually measured workpiece three-dimensional data model, modification is conducted on the actually measured three-dimensional data model with a drawing tool, and grinding data are directly set on the actually measured three-dimensional data model.

Owner:上海莫亭机器人科技有限公司

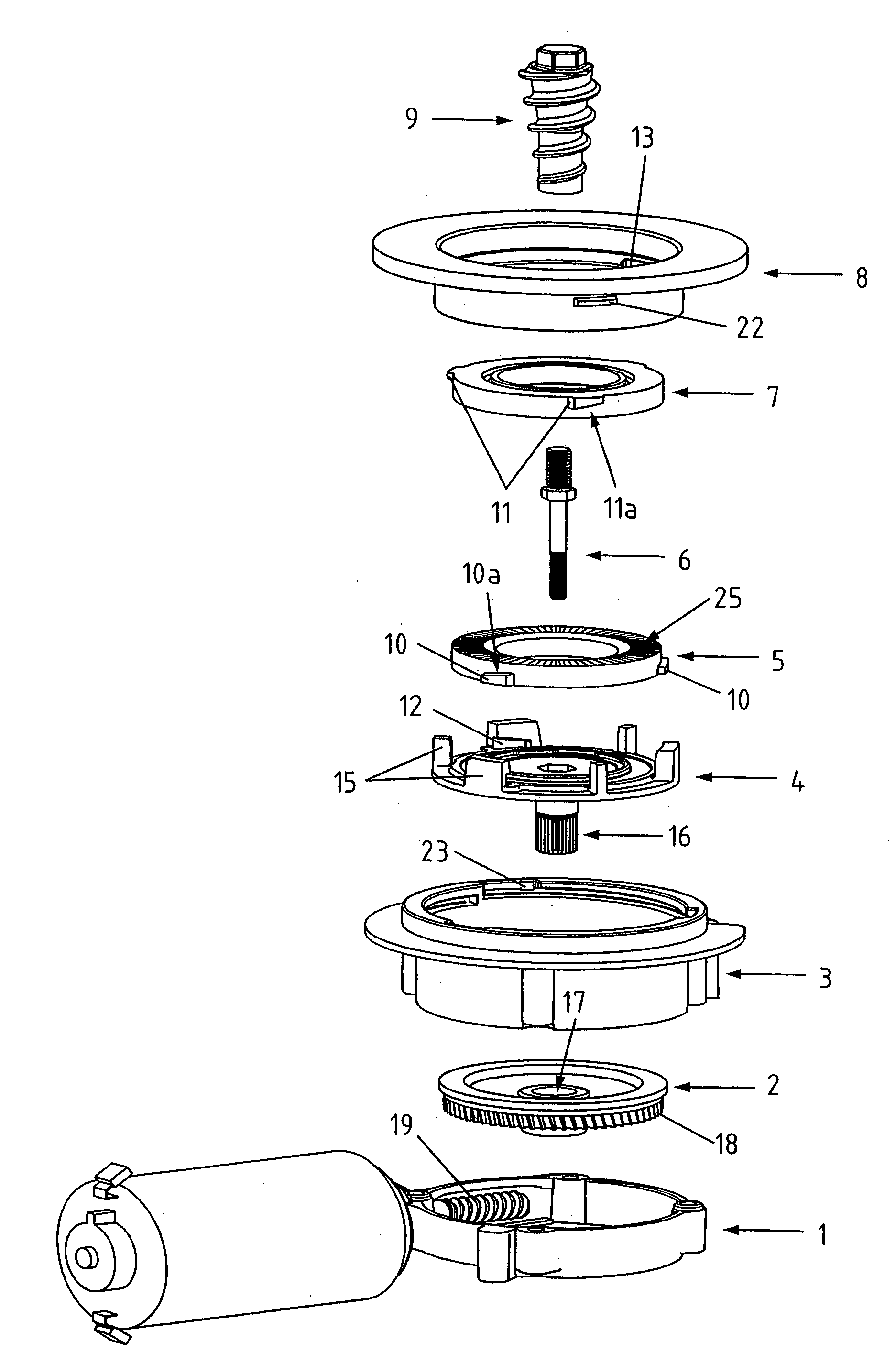

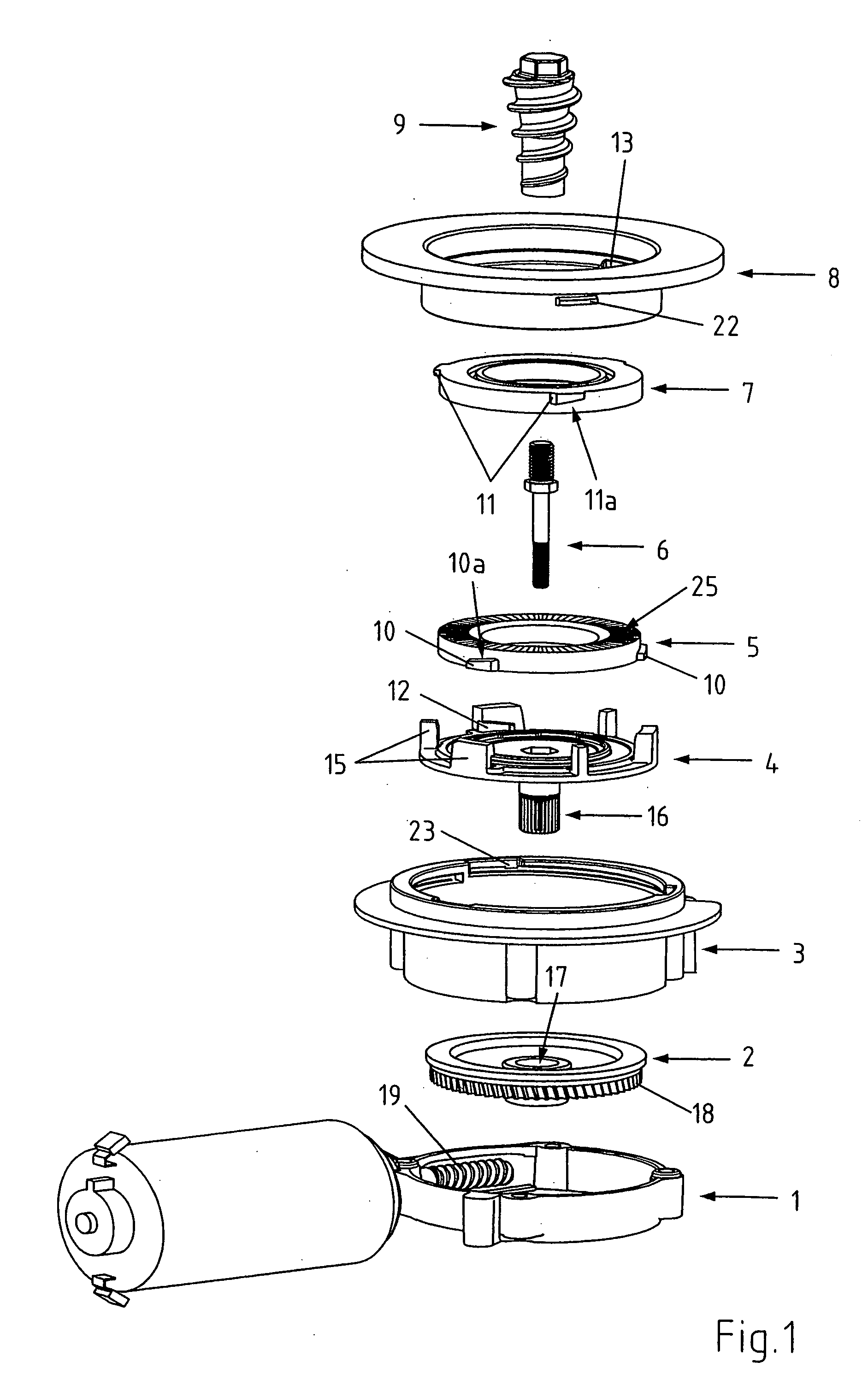

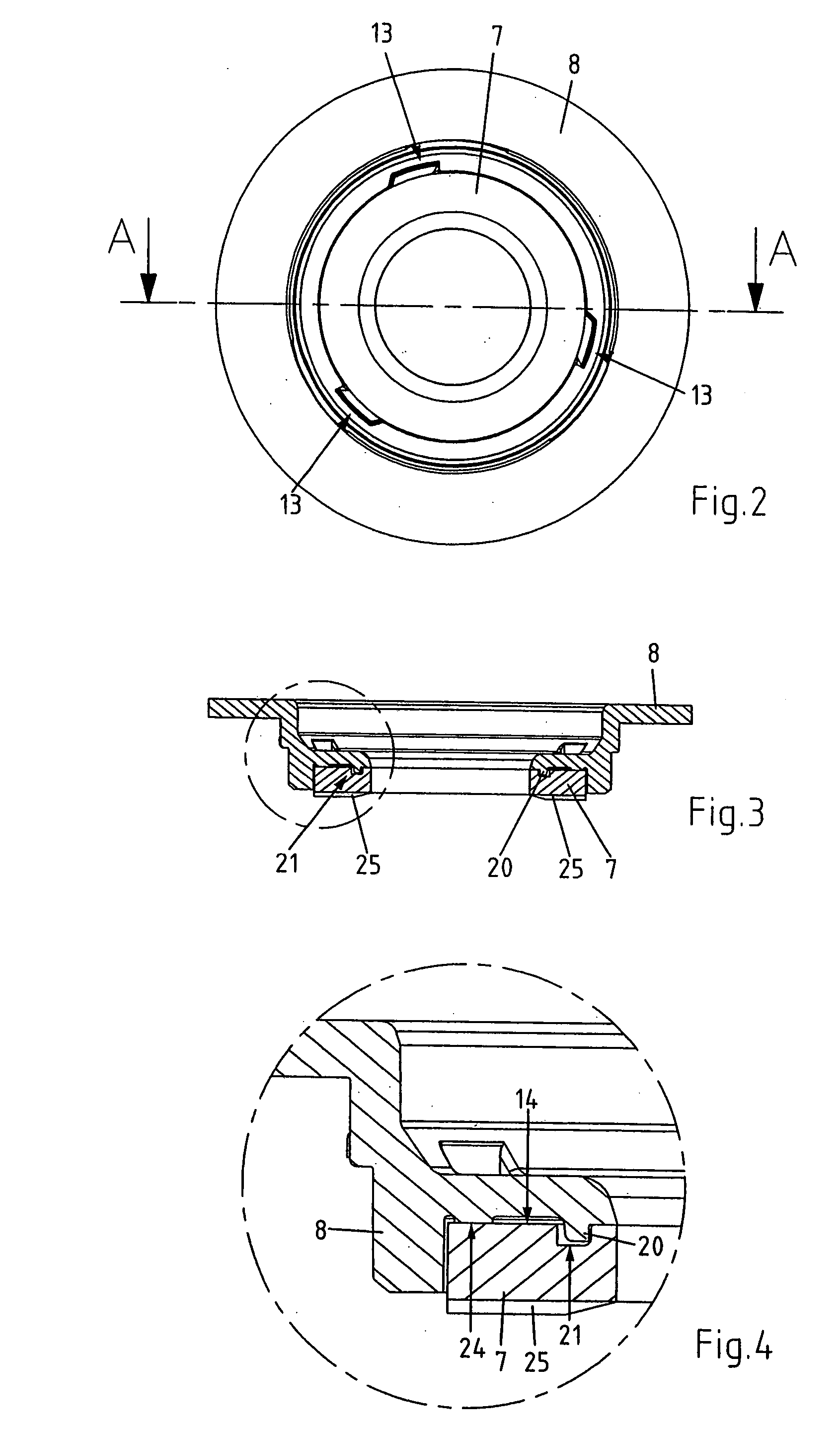

Coffee grinder assembly for a coffee machine

ActiveUS20050279219A1Difficult and time-consumeEasy to fixCoffee millsSpice millsEngineeringGrinding wheel

A coffee grinder assembly for a coffee machine comprises two coaxially arranged grinding wheels. One of the grinding wheels is driven by an electric motor, and the other one is stationary. For receiving the grinding wheels, two grinding wheel support members are provided. Each grinding wheel is provided with radially extending protrusions, and each grinding wheel support member is provided with corresponding recesses to form a bayonet closure. By such a design, the provision of connecting bores in the grinding wheels can be avoided, resulting in an enlarged effective grinding surface.

Owner:VERSUNI HLDG BV

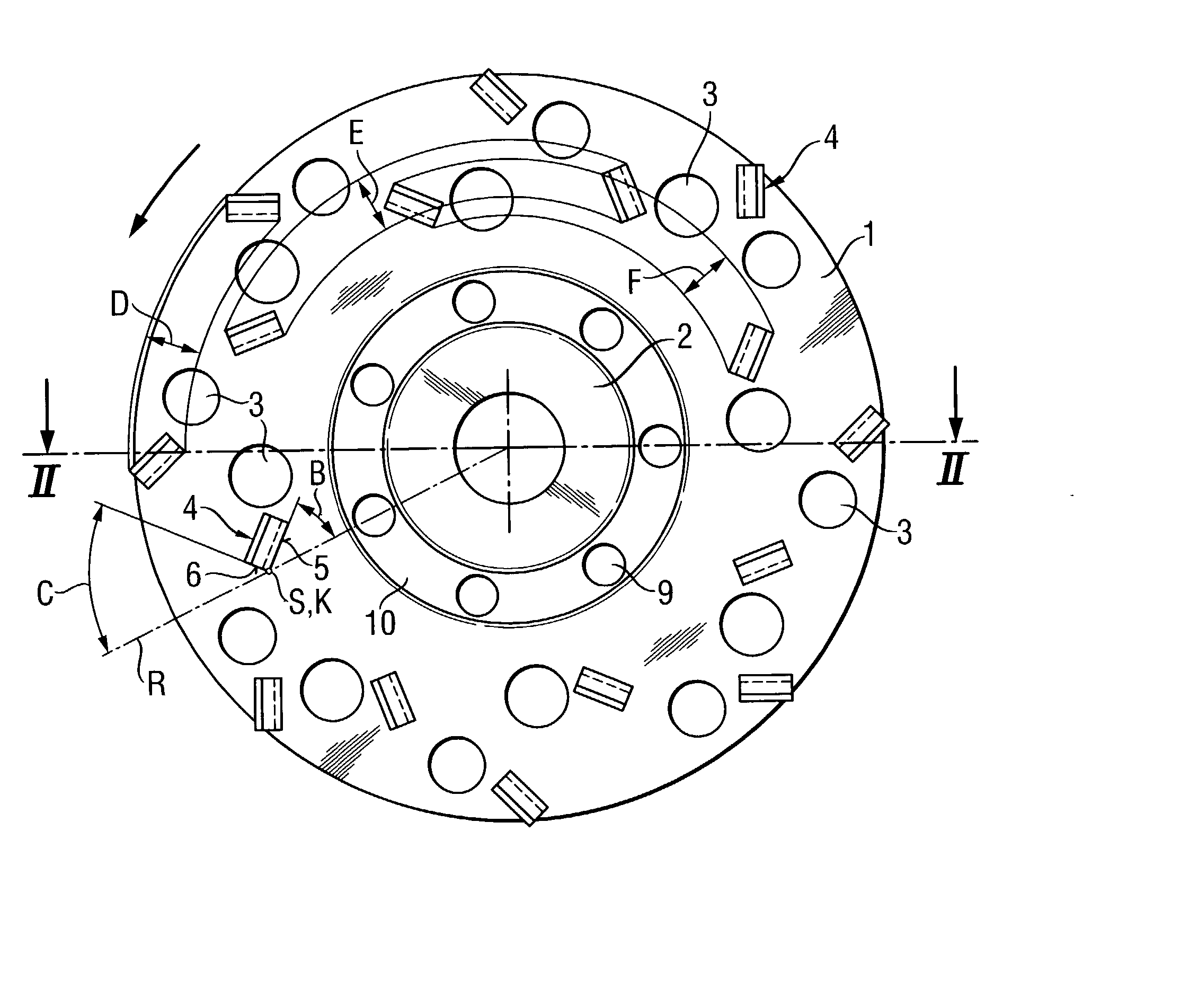

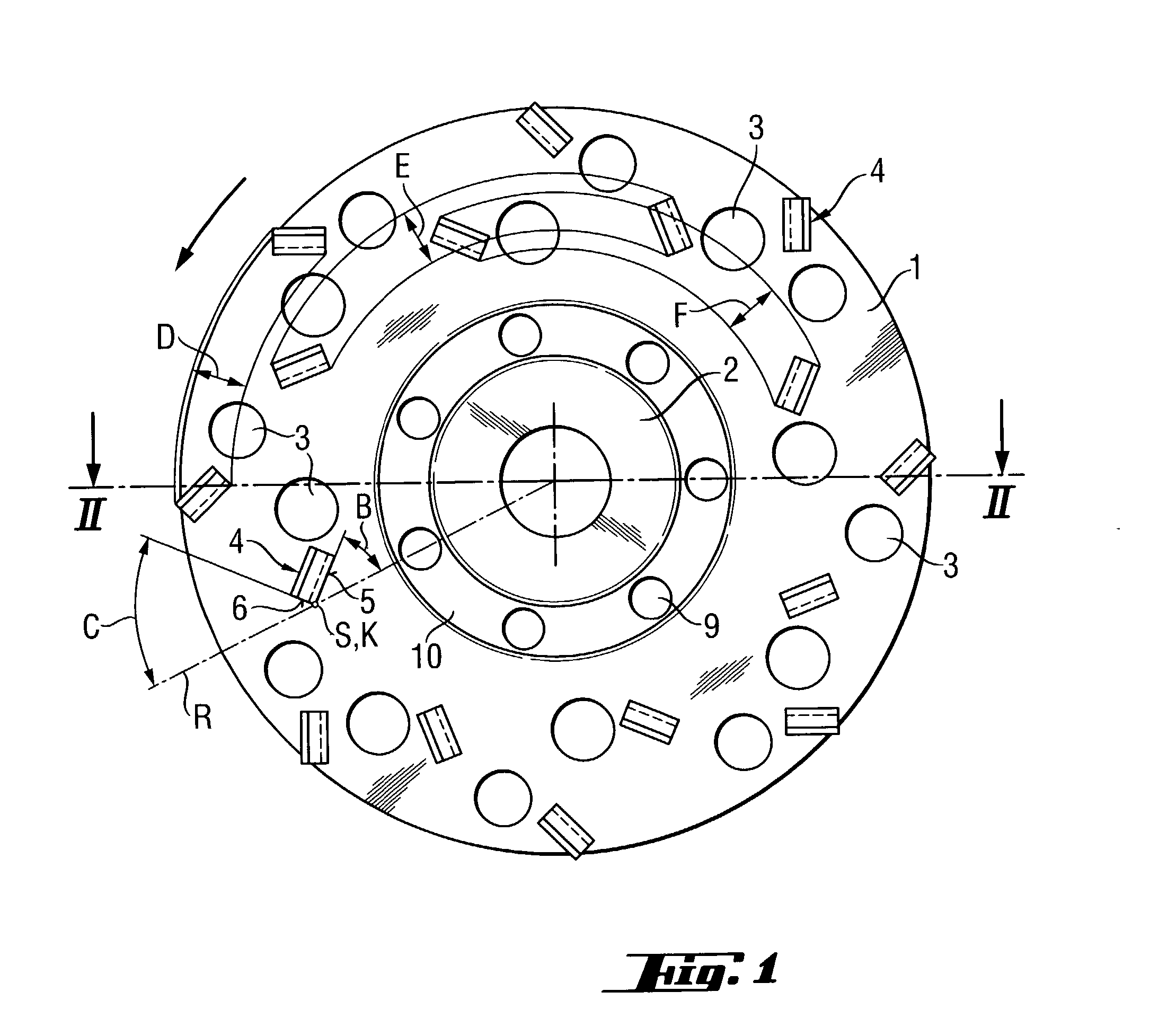

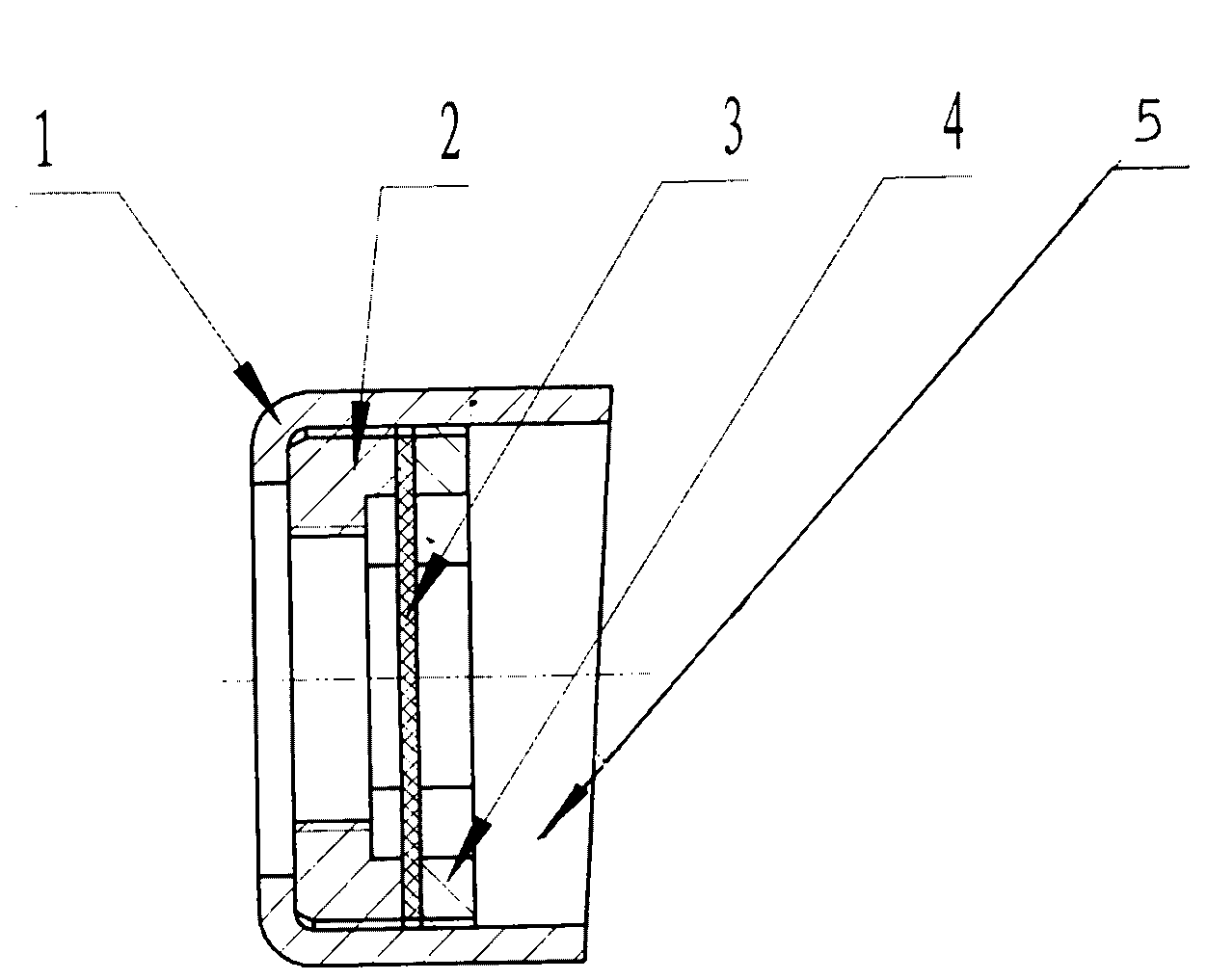

Grinding wheel

InactiveUS20030054746A1Easy to removeGood penetration behaviorRevolution surface grinding machinesGrinding feed controlEngineeringGrinding wheel

A grinding wheel including a circular grinding region (1) with a plurality of through-openings (3) formed therein, a central mounting region (2) coaxial with the grinding region (1), and a plurality of cutting bodies (4) having a rectangular base surface, projecting from the grinding region (1), and spaced from a center of the mounting region (2) by different radial distances, with each cutting body (4) having a longitudinal side (5) adjacent to the center of the mounting region (2) and a wide side (6) remote from the center of the mounting region (2), with the longitudinal side (5) and the wide side (6) forming together an edge (K), and with the longitudinal side (5) extending at an angle (B) of from 35° to 55° to a radial line (R) extending from the center of the mounting region (2) and passing tangentially to the edge (K).

Owner:HILTI AG

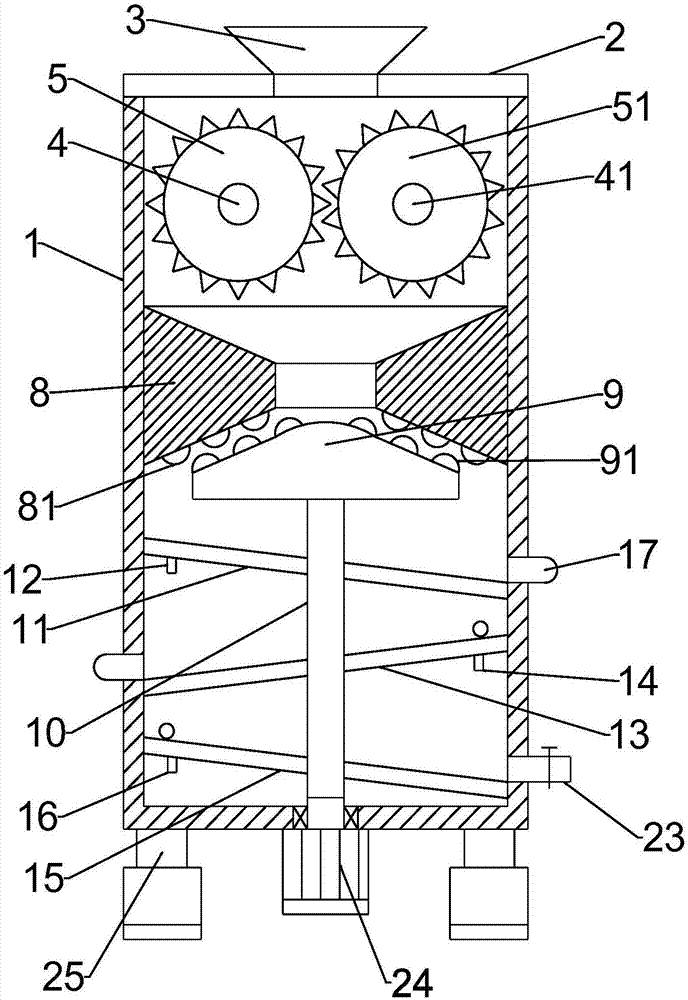

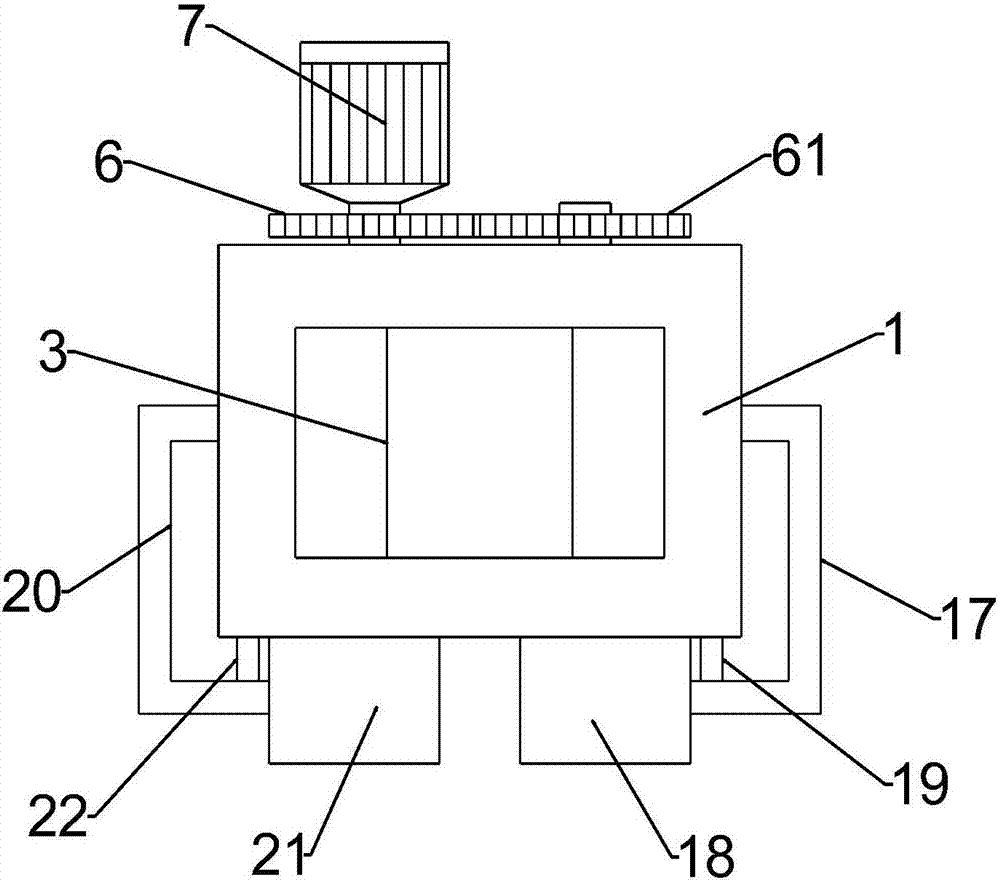

Smashing, classifying and separating device for kaolin raw ore

InactiveCN107309020AAvoid accidental adulterationStable design structureSievingScreeningGear wheelKaolin clay

The invention discloses a crushing, grading and separating device for kaolin raw ore, which comprises a casing, the upper end of the casing is provided with an upper cover, the middle part of the upper cover is provided with a feeding hopper, and the casing is provided with a left rotating shaft, a right rotating shaft, and a left crushing wheel. , right crushing wheel, concentrated guide plate, fixed grinding protrusion, grinding disc, rotating protrusion, vertical shaft, primary screen filter, first vibration motor, fine screen filter, second vibration motor, tailing deflector, The third vibrating motor is provided with a driving gear and a driven gear on the periphery of the left and right shafts, a first motor is provided at the end of the left shaft, and the right wall of the housing is provided with a primary sieve discharge pipe, a primary sieve collection box, a first return pipe and The tailings discharge pipe, the left wall of the shell is provided with a fine sieve discharge pipe, a fine sieve collection box and a second return pipe, and the lower end of the shell is riveted with a second motor, a support rod, a support sleeve, a damping spring and a shock absorber filling. The invention can efficiently grind and pulverize the kaolin and sieve and classify it.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

Apparatus for the in-process dimensional checking of cylindrical parts

InactiveUS6430832B1Revolution surface grinding machinesMechanical diameter measurementsReference deviceCrankpin

An apparatus for checking the diameter of crankpins of a crankshaft in the course of the machining in a grinding machine includes a Vee-shaped reference device, a measuring device associated with the reference device and including a feeler axially movable along the bisecting line of the Vee-shaped reference device, and a support device with a first arm rotating with respect to a support arranged on the grinding-wheel slide and a second arm rotating with respect to the first and carrying the Vee-shaped reference device.A guiding mechanism includes a limiting device, with mutually abutting surfaces and coupled to the support device, that guides the displacement of the reference device along a trajectory substantially parallel to the profile of the grinding wheel, allows the engagement of the reference device on a crankpin to be checked while the latter is orbitally moving, and does not interfere with the displacements of the support device caused by the orbital motion of the crankpin in the checking condition.

Owner:MARPOSS SPA

Die polishing washing equipment

InactiveCN106985025AReduce harmReduce pollutionEdge grinding machinesGrinding carriagesFiltrationEngineering

The invention discloses mold grinding and cleaning equipment in the technical field of mold processing equipment, comprising a movable support, a base is welded to the top of the movable support, a transparent cabinet is arranged on the top of the base, and the upper part of the inner wall of the transparent cabinet is There is a micro-vacuum cleaner, the top of the inner cavity of the base is fixed with a grid plate by screws, the side of the base is provided with an air inlet pipe and a liquid inlet pipe through a through hole, and through the rotating grinding wheel up and down, left and right, not only The flat surface can be polished, and the curved surface can be polished at the same time. The air inlet pipe and the liquid inlet pipe respectively use nozzles to eject air flow and liquid flow to clean the mold, and then filter out the grinding debris through the filter device to reduce pollution. The vacuum cleaner absorbs the dust generated during grinding and reduces the dust damage to the workers. The device has simple structure, convenient operation and strong practicability.

Owner:HEFEI DINGXIN MOLD

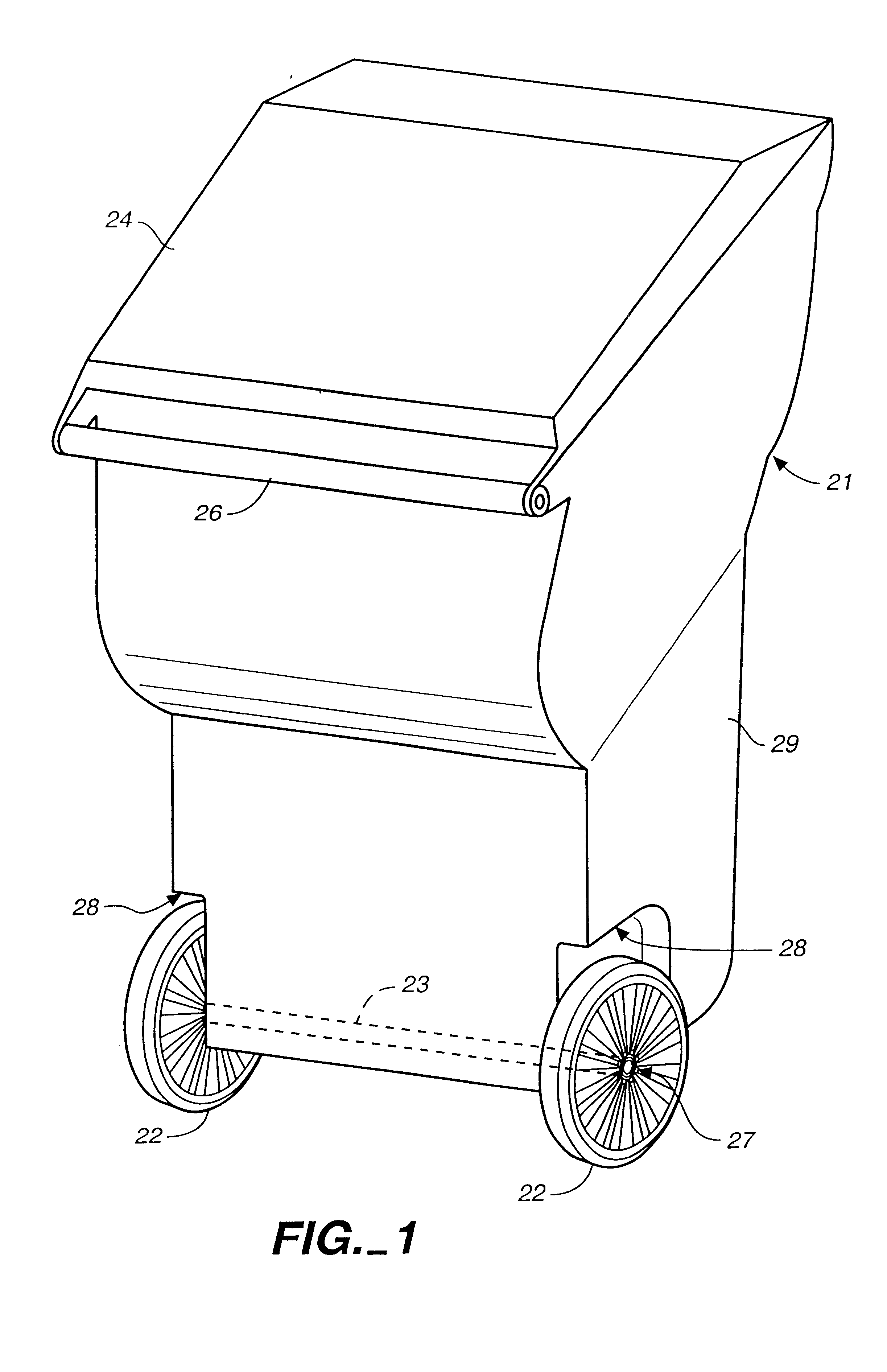

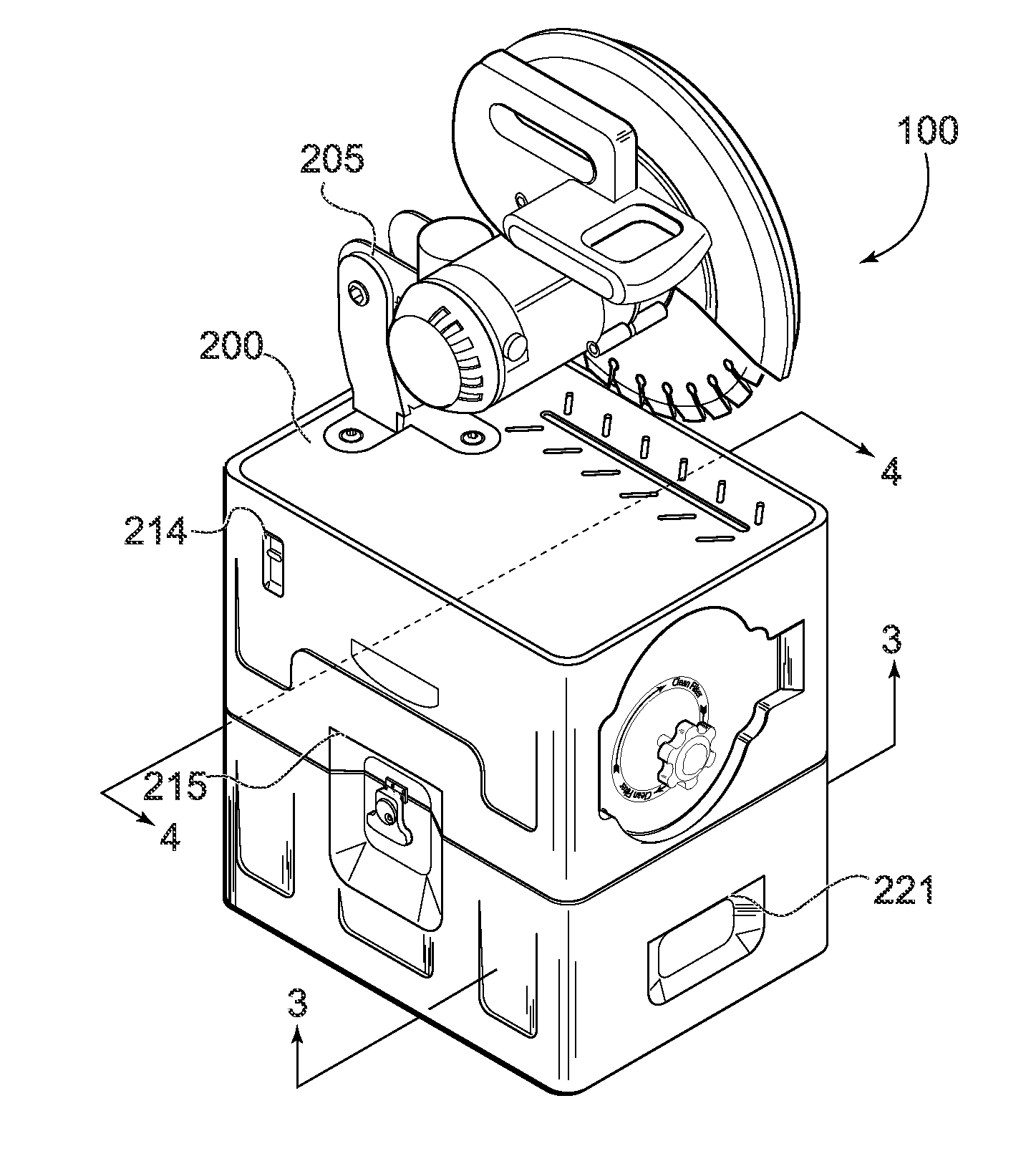

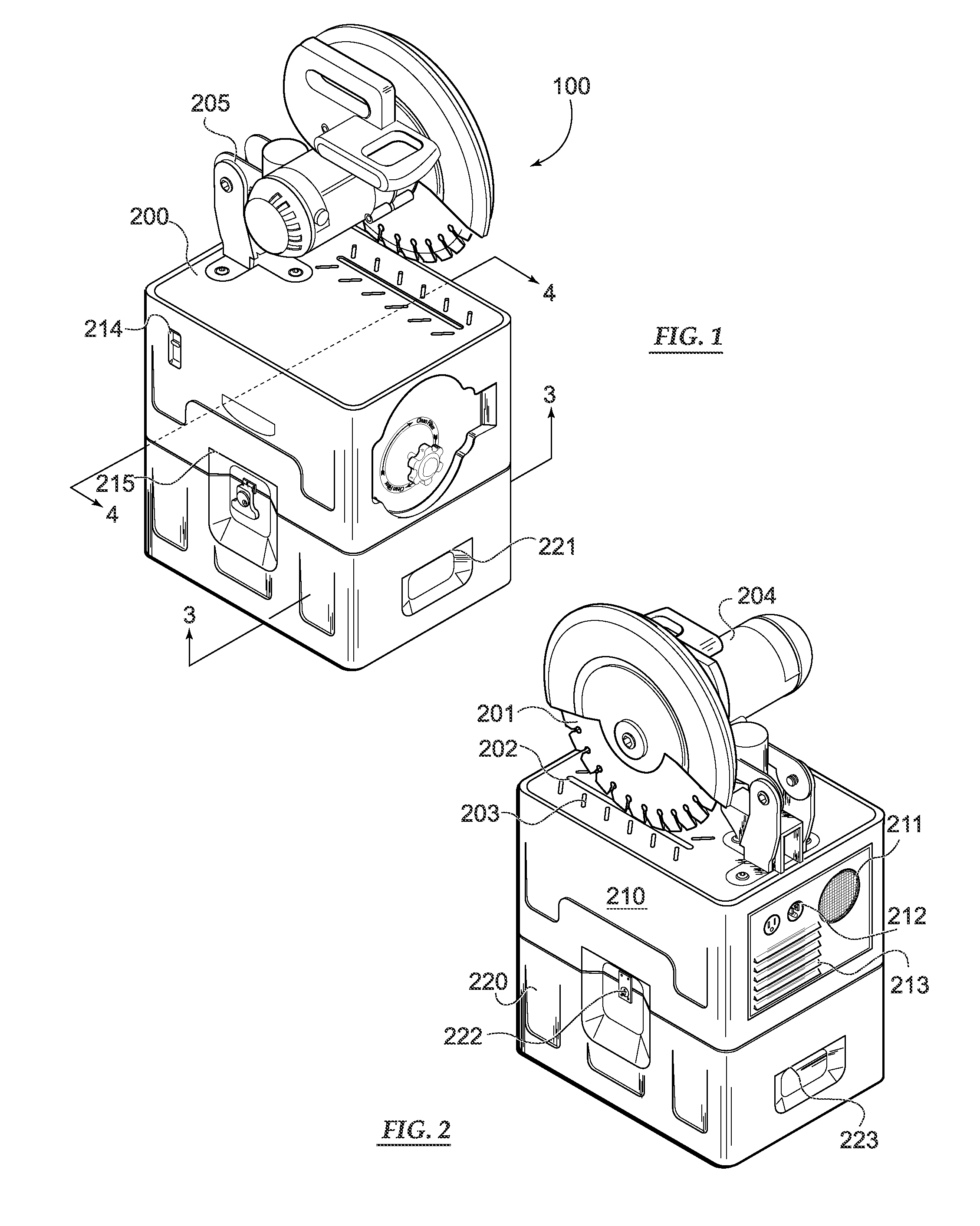

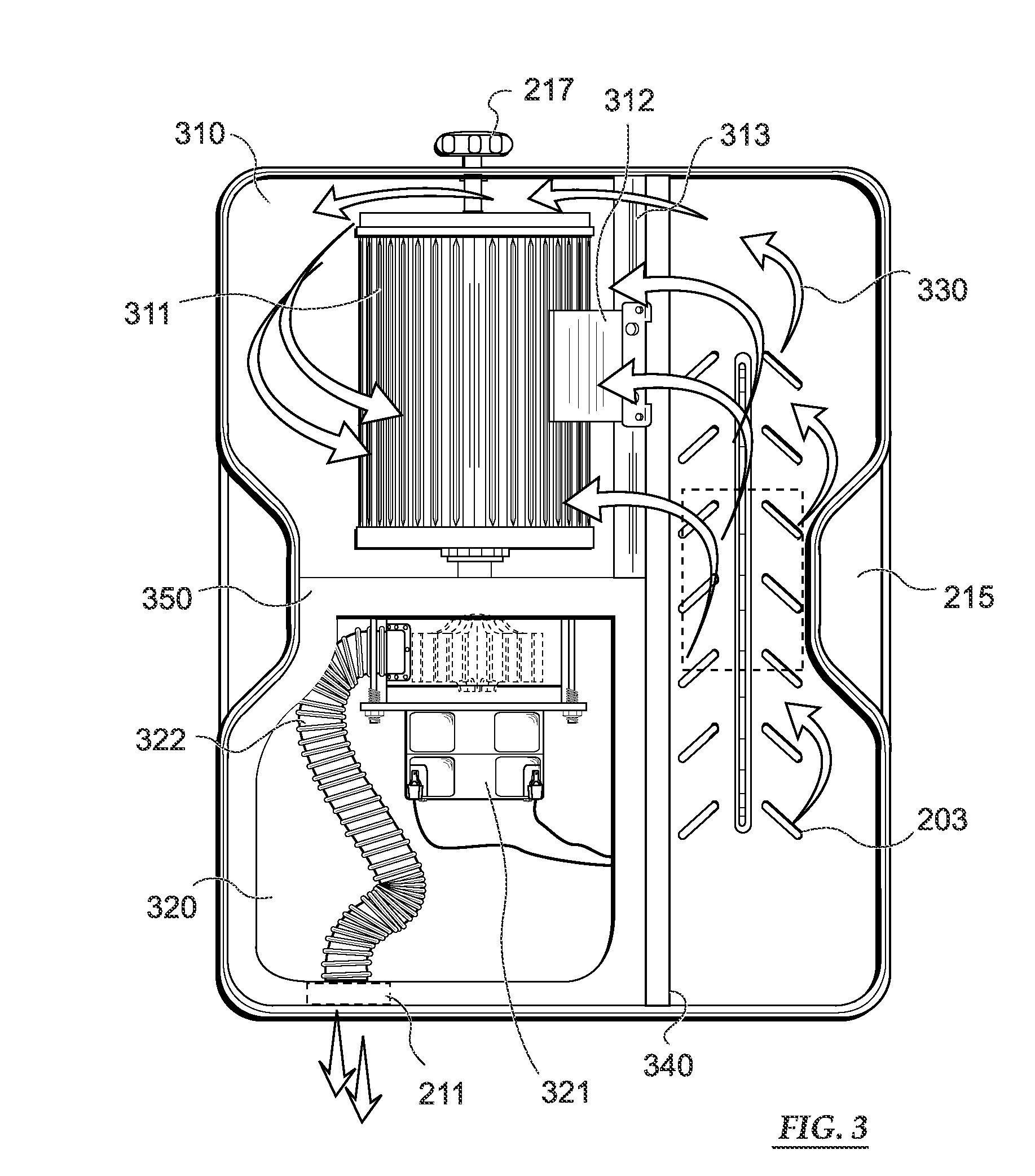

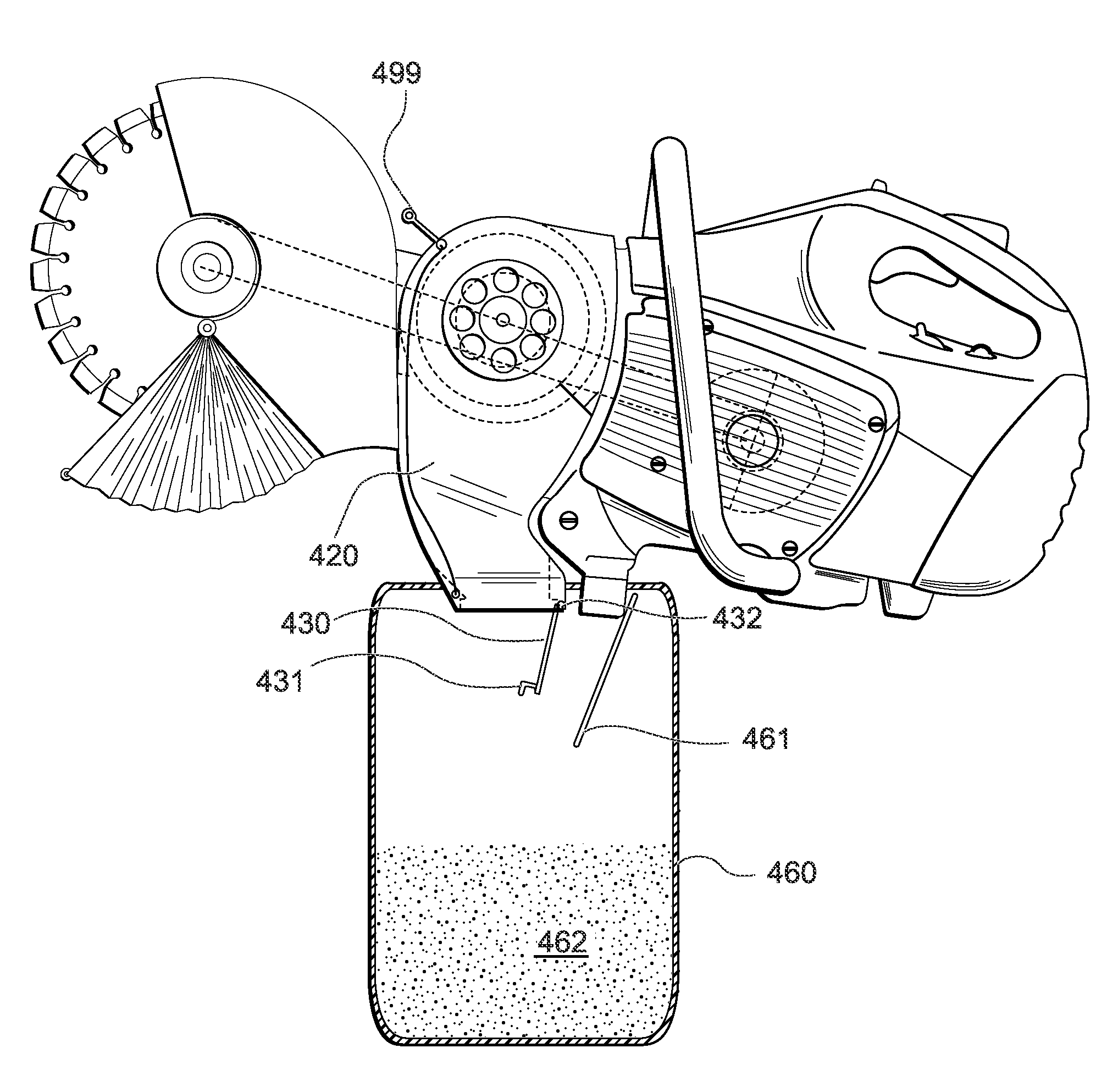

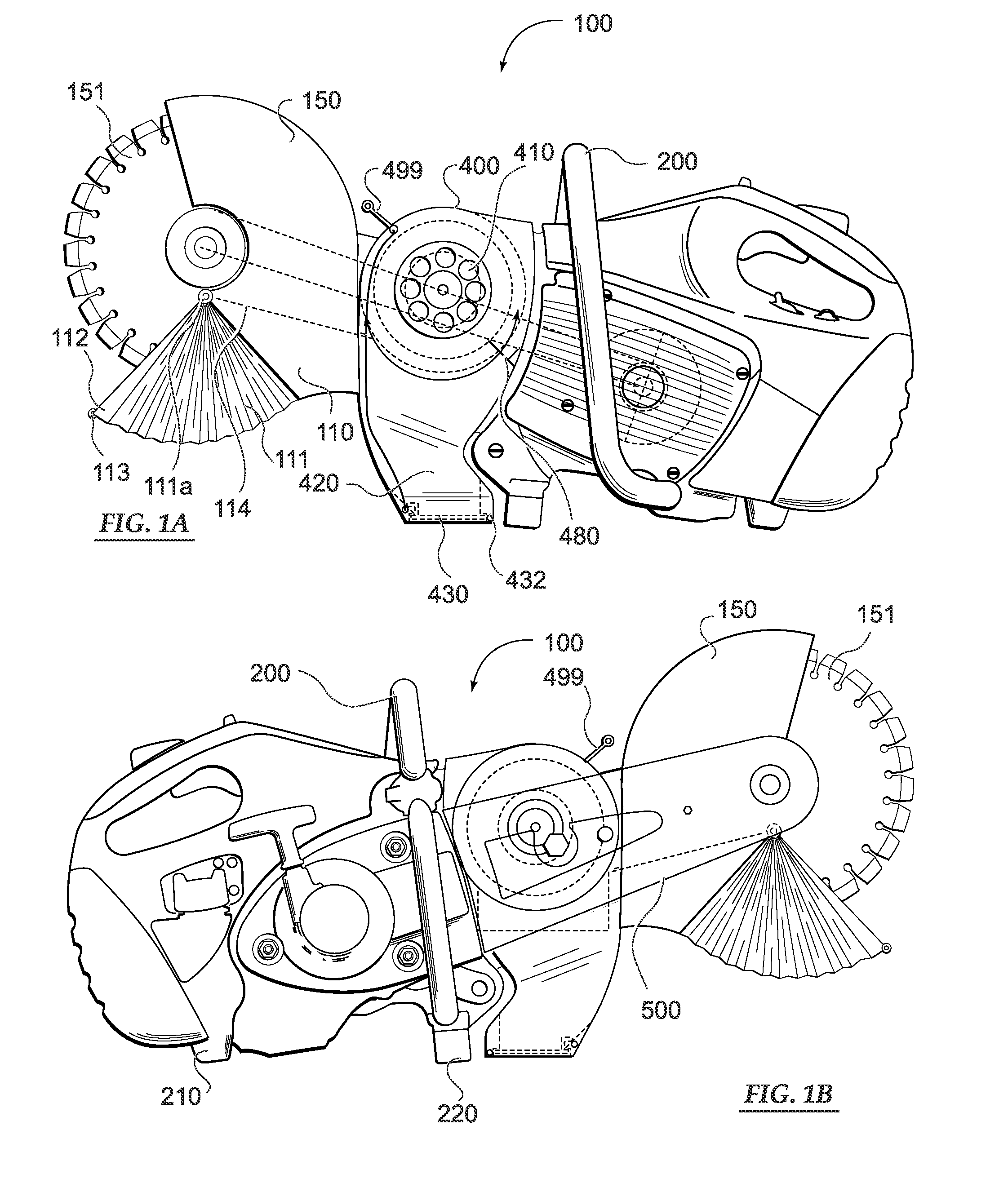

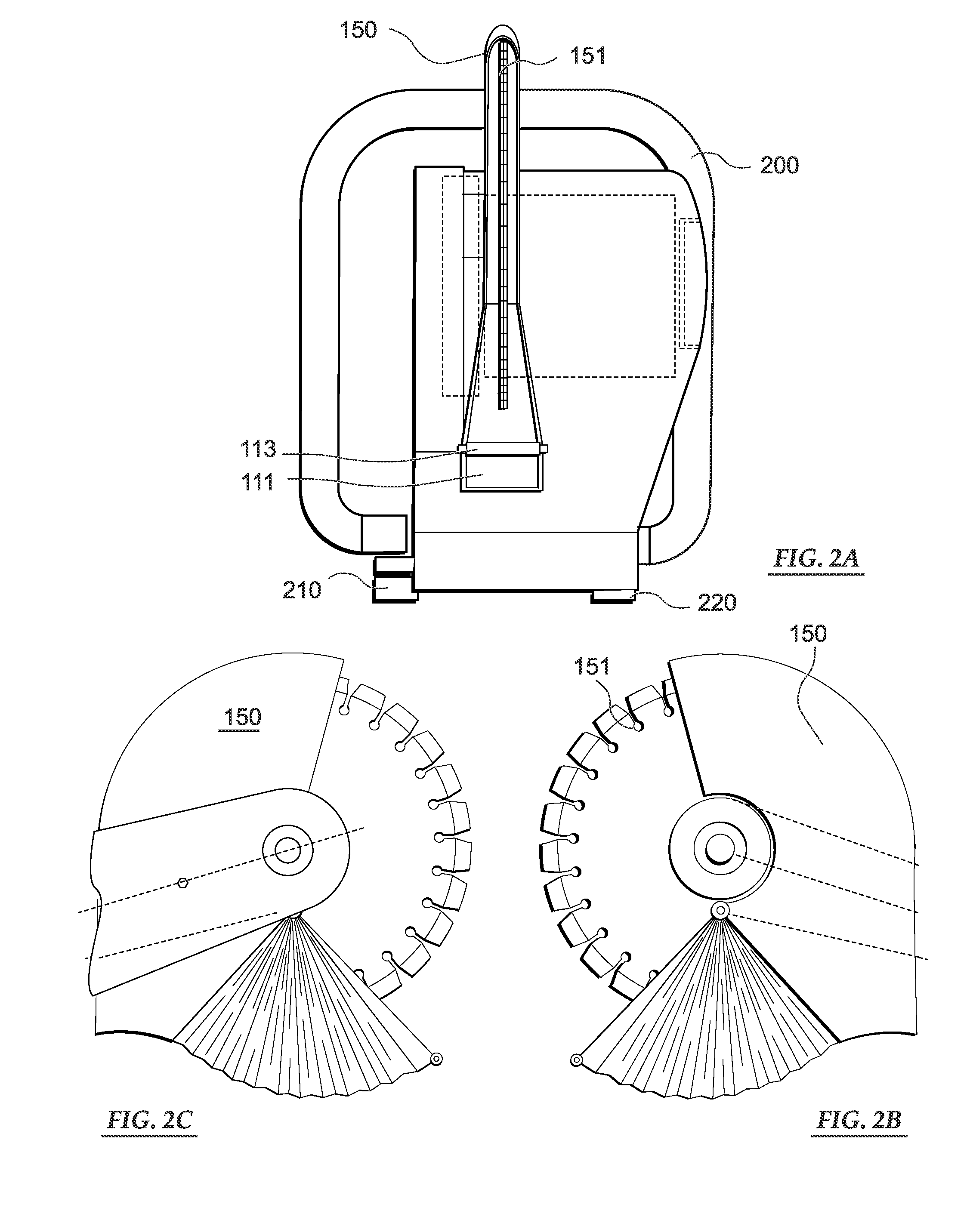

Chop Saw with Dust Collection System

ActiveUS20100116261A1Minimize undesirable current surgeIncrease usable surface areaMetal sawing devicesMetal sawing accessoriesParticulatesCircular saw

A chop saw, grinding wheel, or like apparatus is disclosed herein also incorporated to an easily portable dust collection system. In a preferred embodiment, a worktable is provided with a center slot for receiving a circular saw blade. A negative pressure and resulting air flow is provided at the center slot to capture particulate matter as a byproduct of cutting the workpiece. Side slots are also disclosed to assist in particulate collection. A unique filter chamber having a cylindrical filter is additionally provided to remove dust from air and discharge the filtered air at a lateral side of the apparatus. A filter cleaning knob is additionally disclosed to assist in cleaning the filter. Of the beneficial aspects of the chop saw with dust collection system is its portability being one integral unit and the dust filter being easily cleaned and maintained.

Owner:JPL GLOBAL

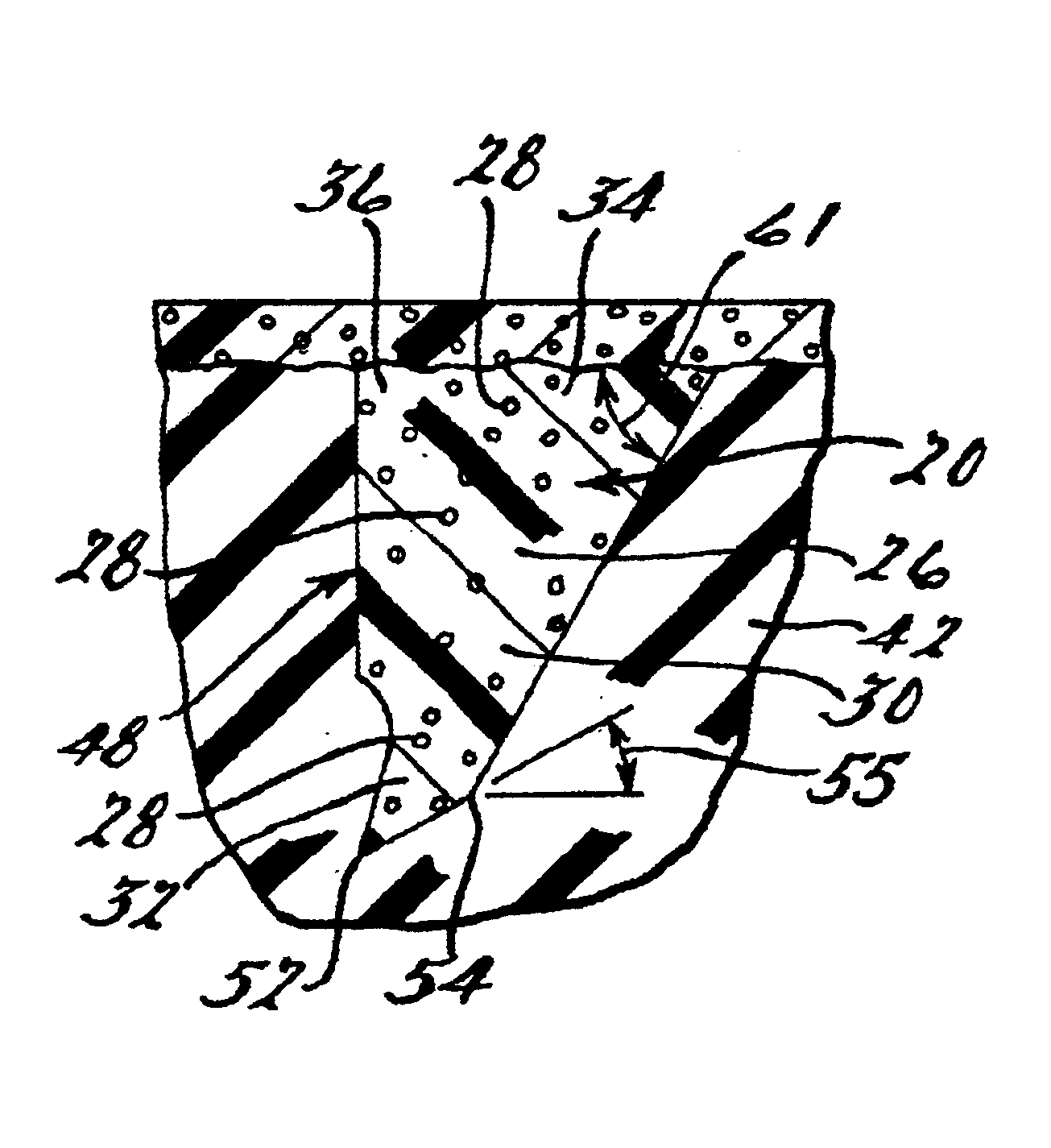

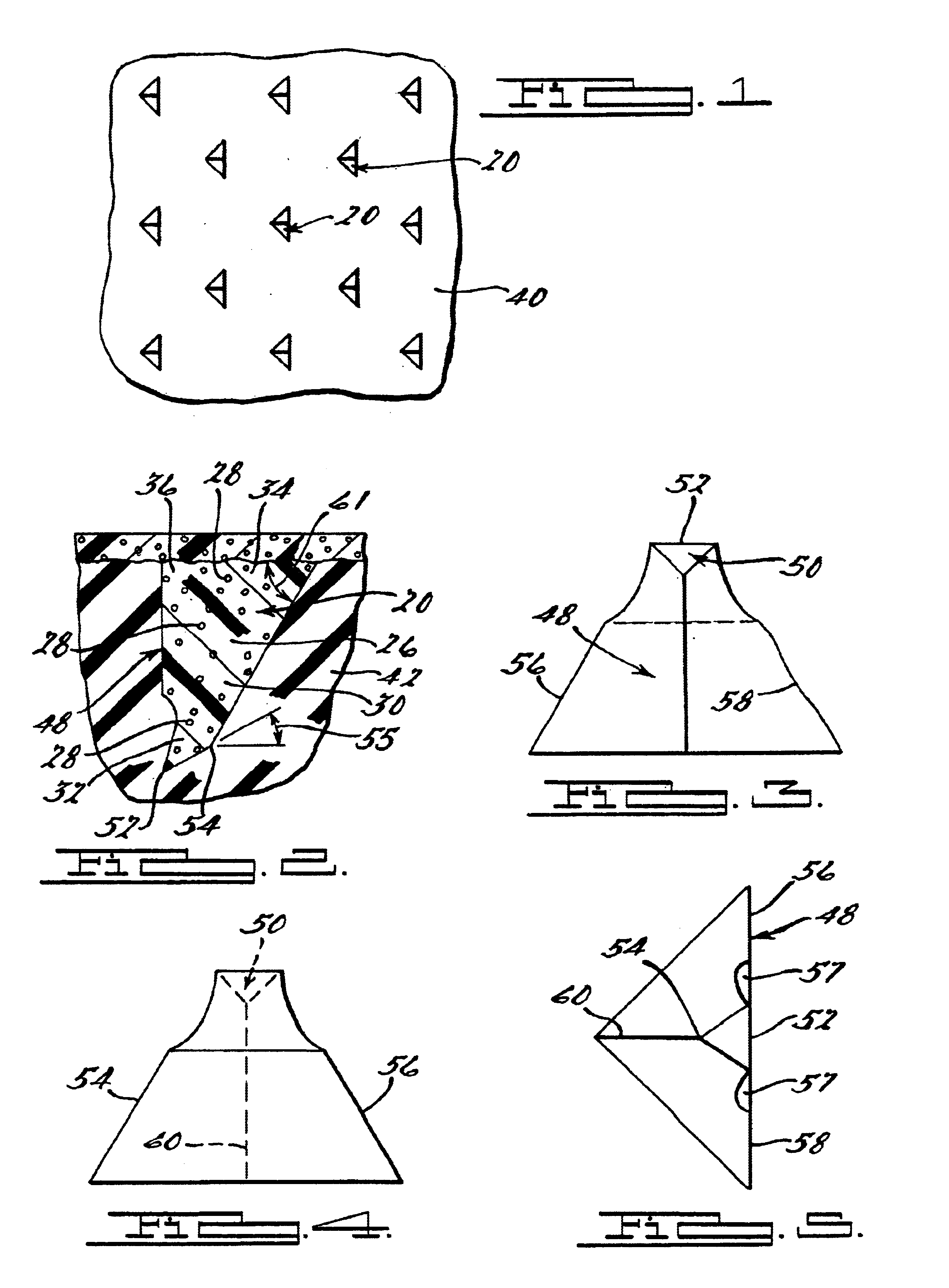

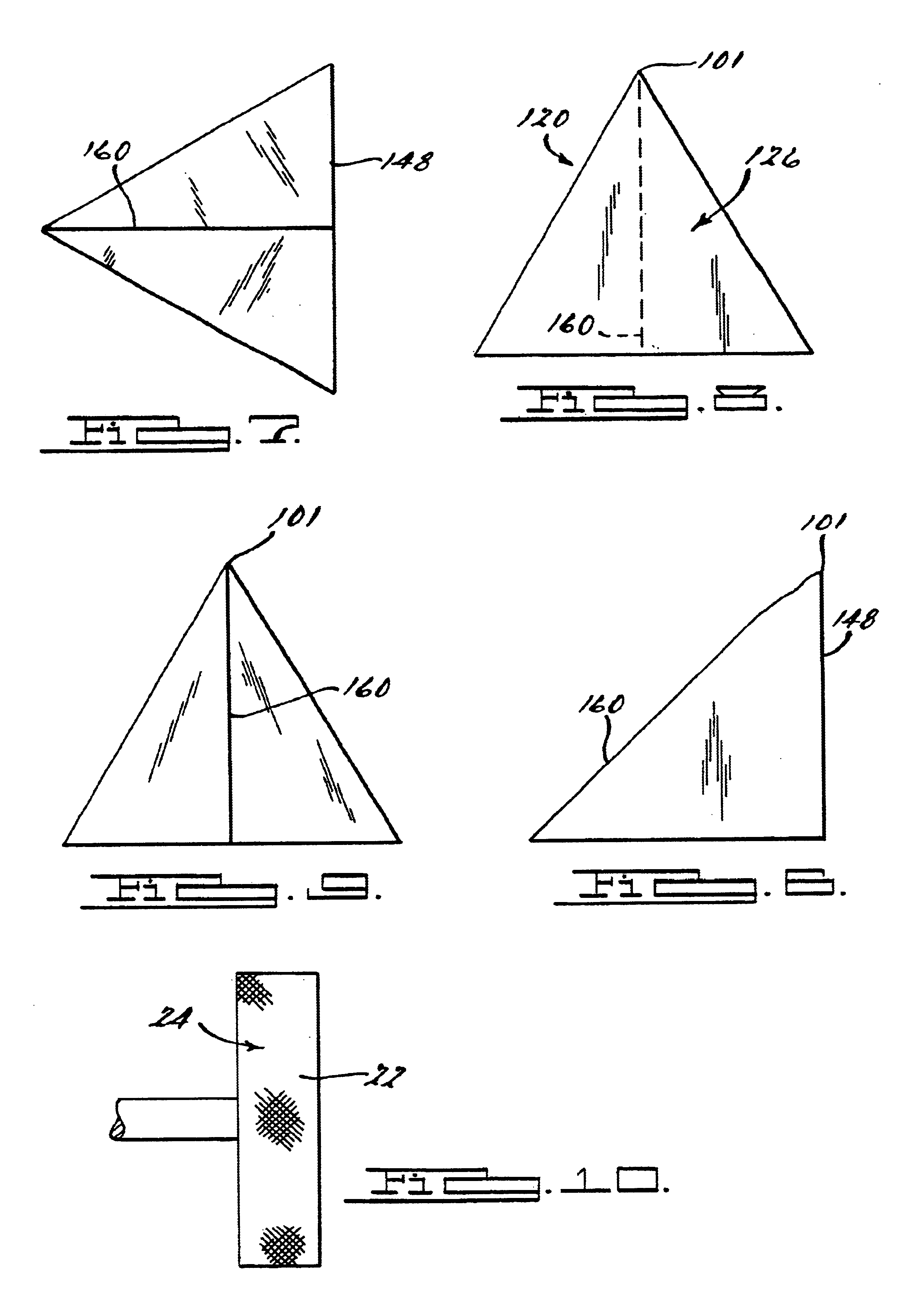

Pyramidal molded tooth structure

InactiveUS6821196B2Simple designLow costRevolution surface grinding machinesAbrasion apparatusMetallic materialsEngineering

A molded tooth design of generally pyramidal form made of various hard grit materials for use on a grinding wheel for grinding non-metal materials. The tooth structure generally includes a raked face having a neutral to positive rake angle that terminates to a sharp point. The tooth structure also includes on the raked face edge portions below the point extending from both sides thereof having a predetermined clearance angle to increase penetration and reduce friction of the tooth during the grinding process. The tooth structure may also include at a top end of the rake face a truncated clearance surface which will produce a wider cutting edge that is flat, for use in attacking the work surface of the work piece being ground. The rake face of the tooth generally may also be formed to have positive rake in the truncated surface.

Owner:L R OLIVER

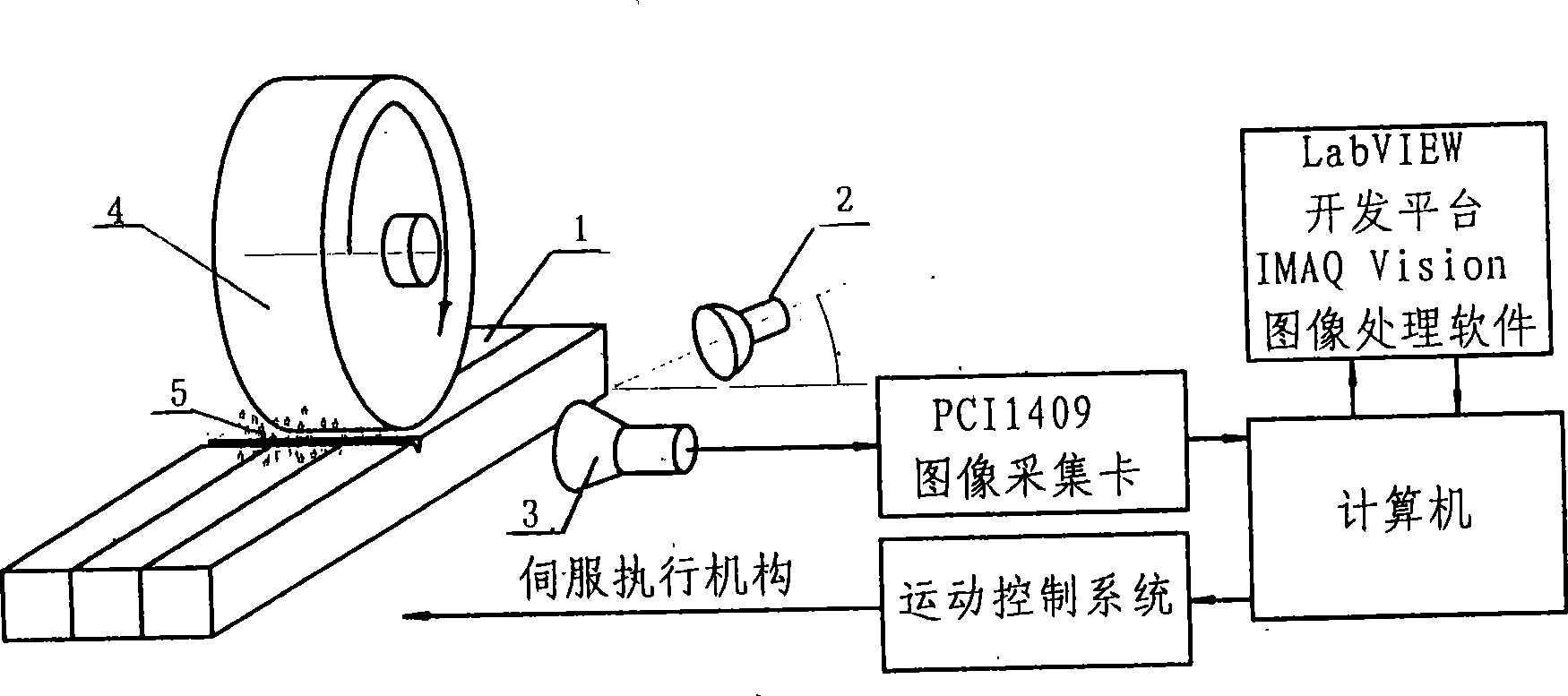

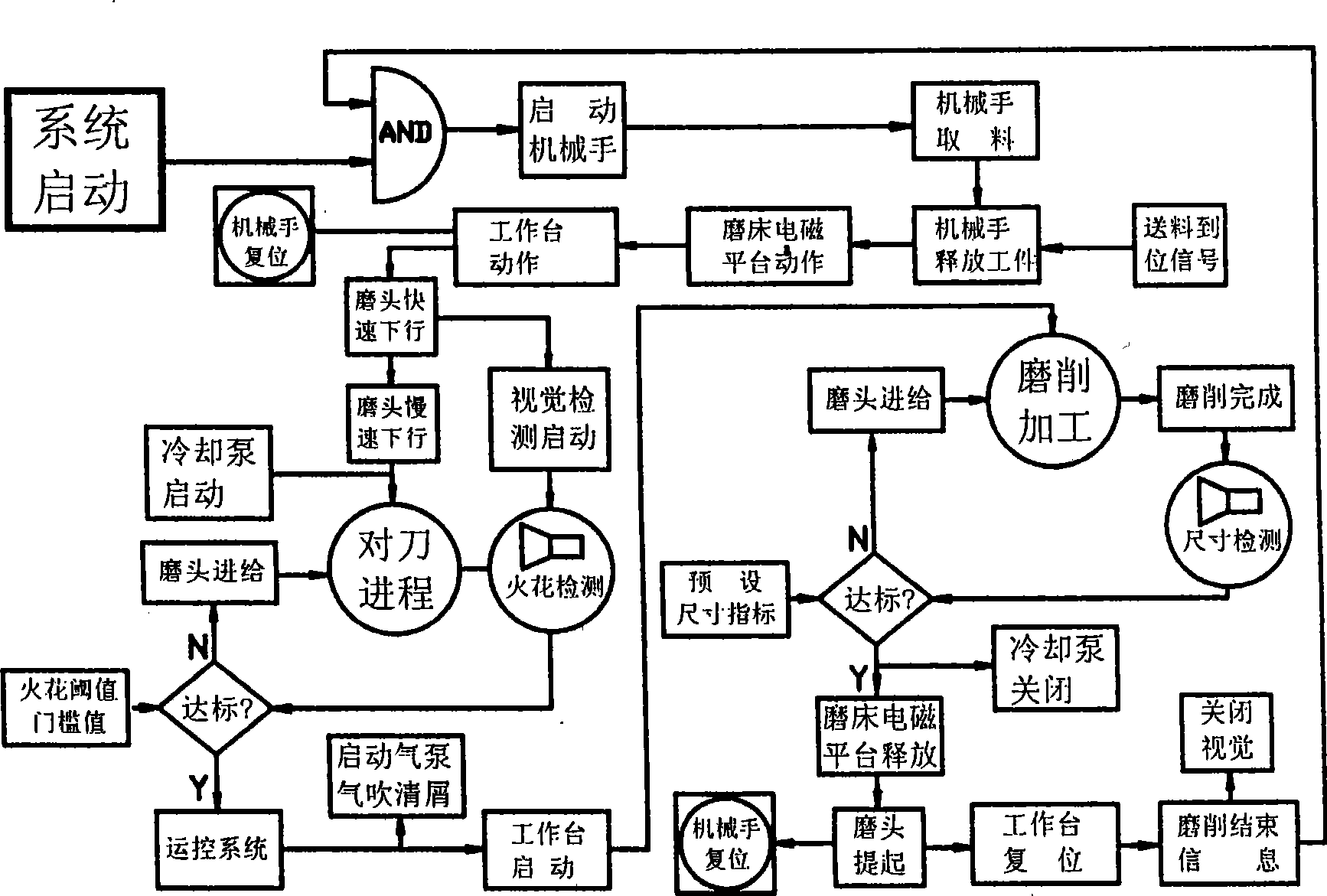

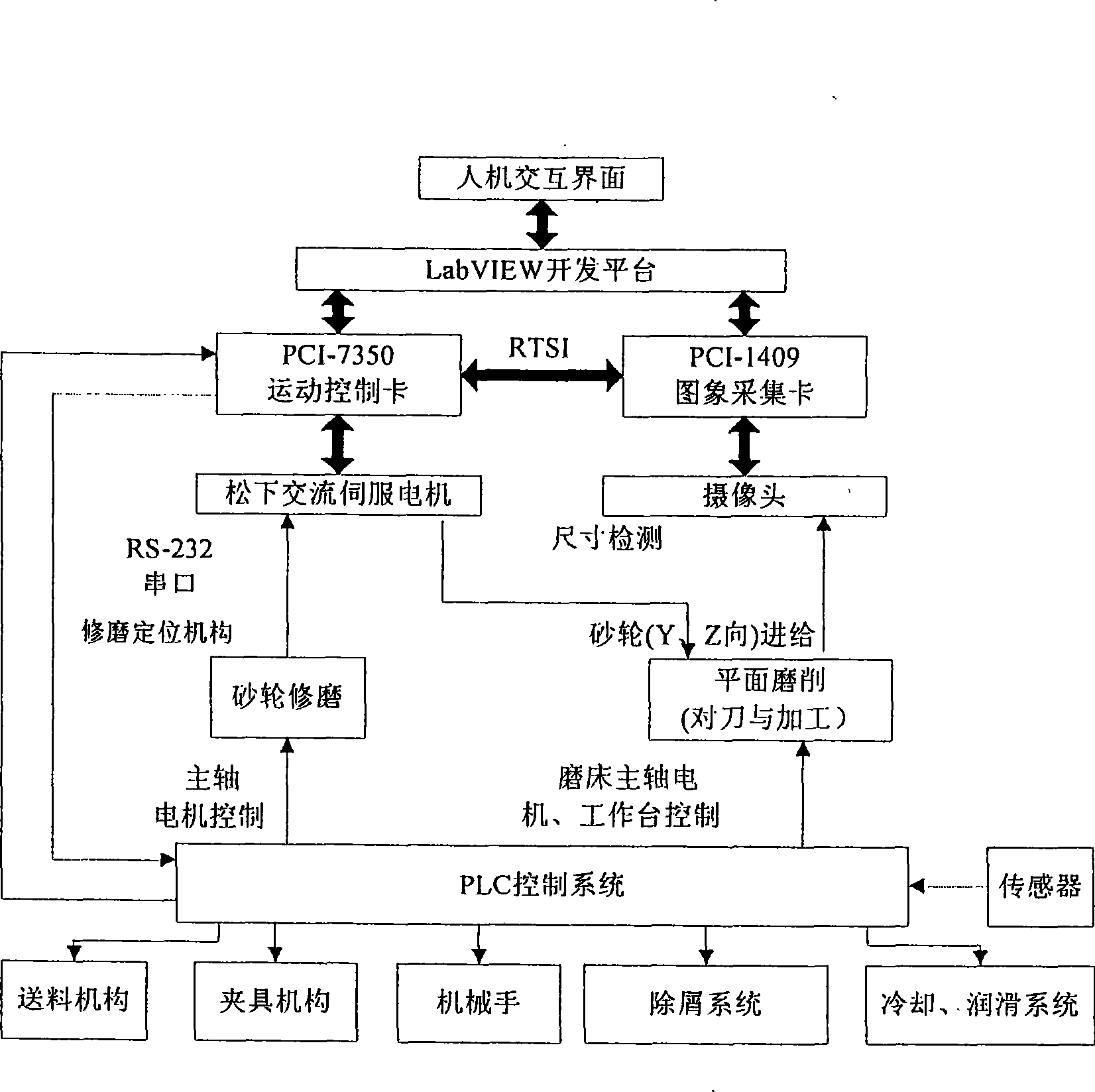

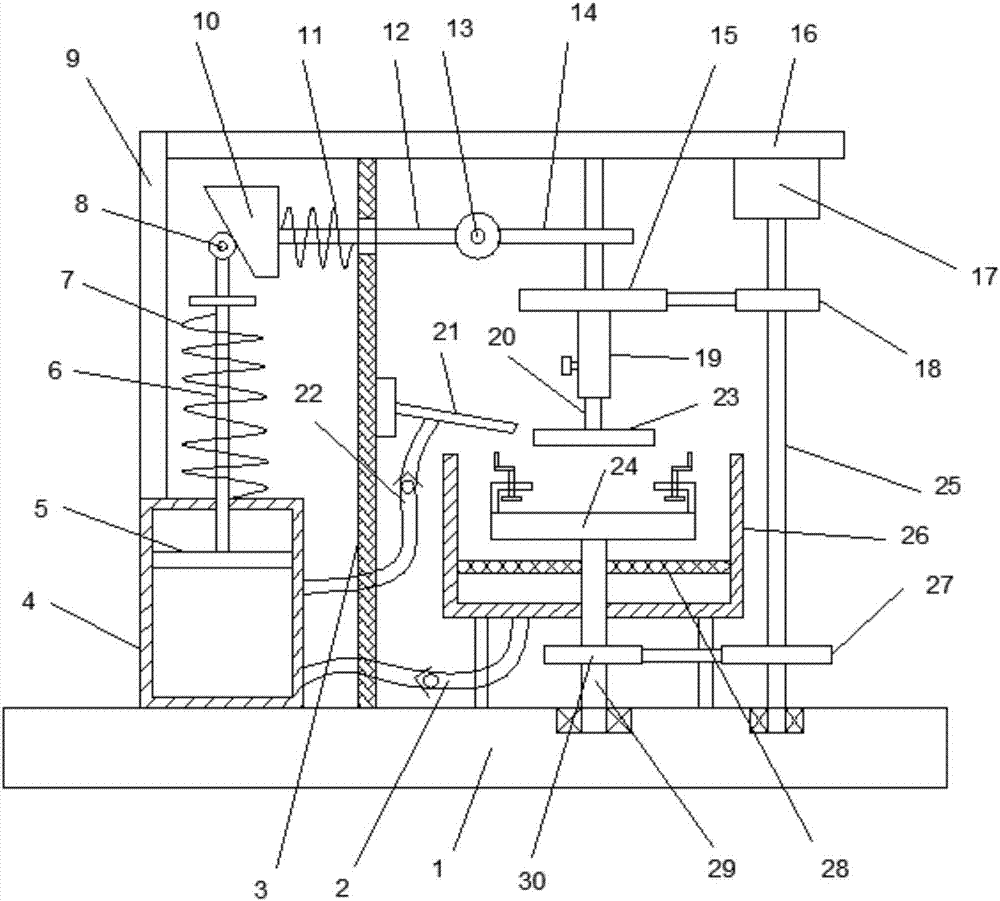

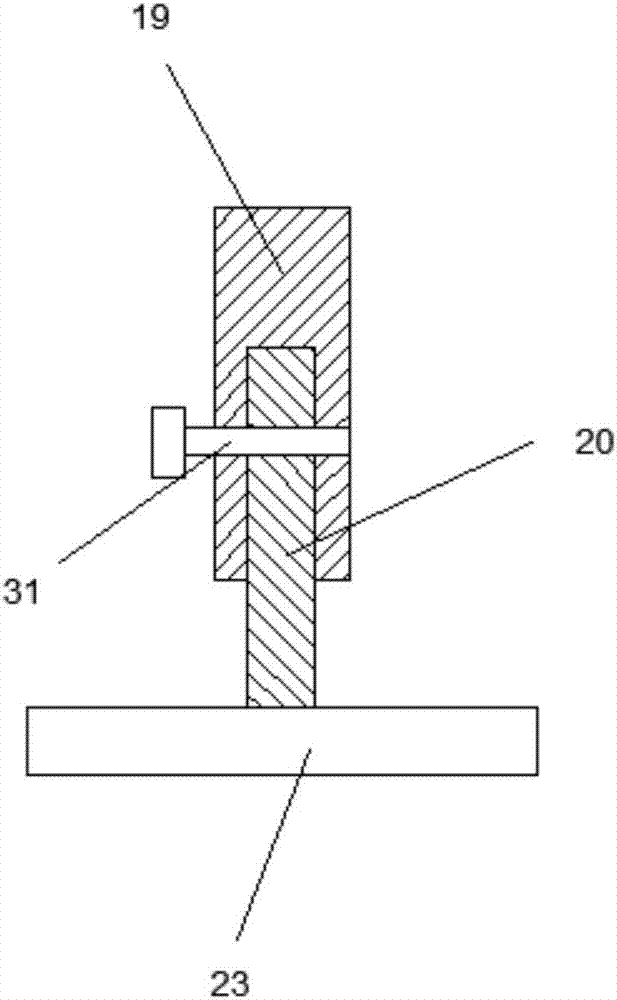

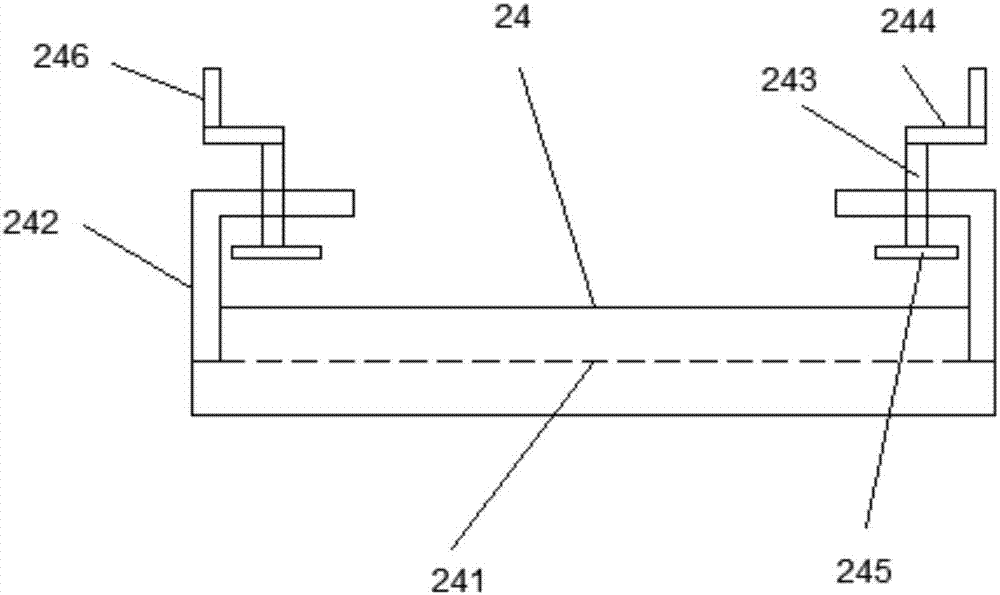

Spark identification tool-setting method and abrasive machining automatic system

The invention discloses a method for setting a tool through sparkle identification and an automatic system for grinding processing. The method and the system achieve the intelligent automatic control for the whole grinding process and accurately and reliably solve the problem of automatic tool setting, the problem of dimension compensation caused by the abrasion of a grinding wheel, and the problems of on-line dimension measurement and motion servo control in the grinding process. The method organically combines a vision technique, a PLC technique and a motion control technique, and provides a solution for solving the problems of tool setting, on-line dimension measurement and grinding wheel wear compensation by using the vision technique, and the problem of motion servo control by using the PLC technique and the motion control technique. The method makes use of the vision technique to automatically identify the operating condition contacted with a workpiece, and switch the operating condition to a grinding processing state instantly so as to solve the problem of automatic tool setting, thus the method can combine a plurality of mature correlation techniques to construct the automatic system which integrates detection and motion control. The method and the automatic system achieve the accurately automatic tool setting, solve the problems of the wear measurement and compensation of the grinding wheel, and open up a novel approach for fully automatic and intelligent control in the grinding process.

Owner:QIQIHAR HUAGONG MACHINE +1

Building aluminum plate grinding device with cooling and dust removal function

InactiveCN107160246AImprove grinding efficiencyImprove sanding qualityPlane surface grinding machinesGrinding/polishing safety devicesDrive shaftCooling effect

The invention discloses a building aluminum plate grinding device with the function of cooling and dust removal, which comprises a base and a top plate, a driving motor is connected to the right side of the lower end of the top plate, a driving shaft is connected to the lower end of the driving motor, and an upper driving belt is connected to the middle part of the upper end of the driving shaft The left end of the upper driving pulley is connected with the upper driven pulley through a belt, the upper end of the upper driven pulley is connected with a rotating cam at the coaxial position, the left end of the rotating cam is provided with a guide wheel, the left end of the guide wheel is connected with a guide rod, and the left end of the guide rod A wedge-shaped block is connected, the left end of the wedge-shaped block is in contact with a lifting wheel, the lower end of the lifting wheel is connected with a lifting shaft, the middle part of the lower end of the driving shaft is connected with a lower driving pulley, and the left end of the lower driving pulley is connected with a lower driven pulley through a belt. The middle part of the driven pulley is connected with a driven shaft. The invention realizes the synchronous rotation of the grinding wheel and the workbench, realizes the cooling effect on the grinding wheel, and takes away the aluminum dust produced during grinding.

Owner:苏锦忠

Power saw apparatus with integrated dust collector

ActiveUS20110079207A1Reduce frictionUseful surface areaMetal sawing devicesMetal sawing accessoriesParticulatesSpins

A power saw having a circular saw blade or, grinding wheel incorporated to a dust collection system that is easily portable is disclosed herein. In a preferred embodiment, negative pressure and resulting air flow is provided at a lower blade guard to capture particulate matter as a byproduct of cutting a work piece. A unique dust collection housing is additionally provided having a filter to remove dust from air and exhaust the filtered air at a lateral side of the saw. A spin handle is additionally disclosed to increase the usable surface of the filter and to work in conjunction with a filter cleaning flap. A drive belt according to a preferred embodiment, drives the circular saw and a vacuum fan. Among the beneficial aspects of the power saw is its portability by obviating a need for a dust collection bag and / or a separate vacuum unit.

Owner:JPL GLOBAL

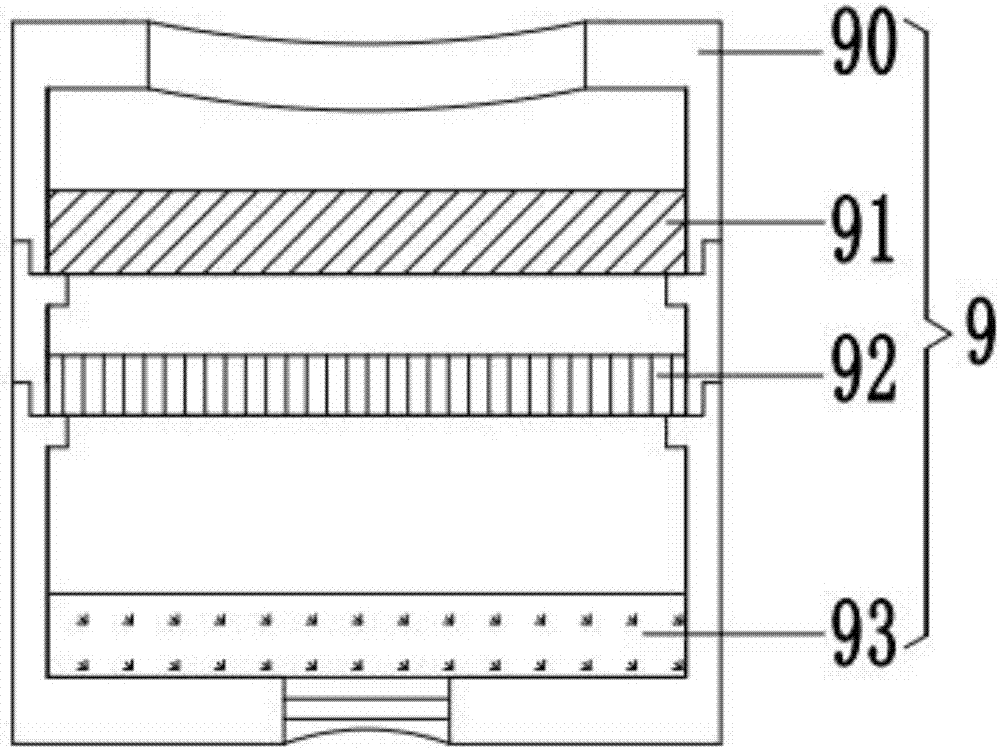

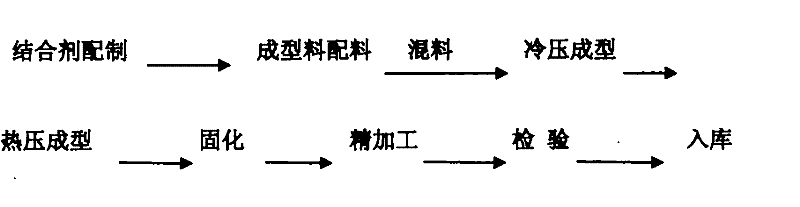

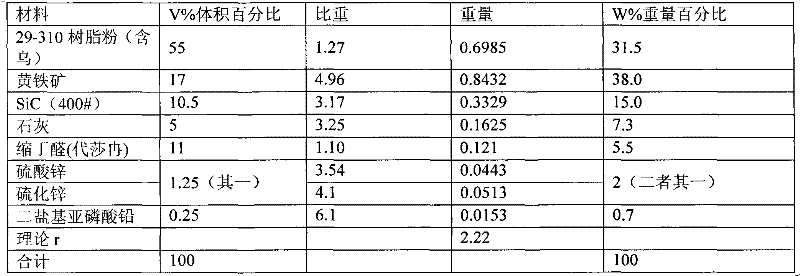

High-speed resin heavy-load grinding wheel

InactiveCN102161183AImprove mechanical propertiesImprove automationAbrasion apparatusGrinding devicesFiberZirconia alumina

Owner:江苏华东砂轮有限公司

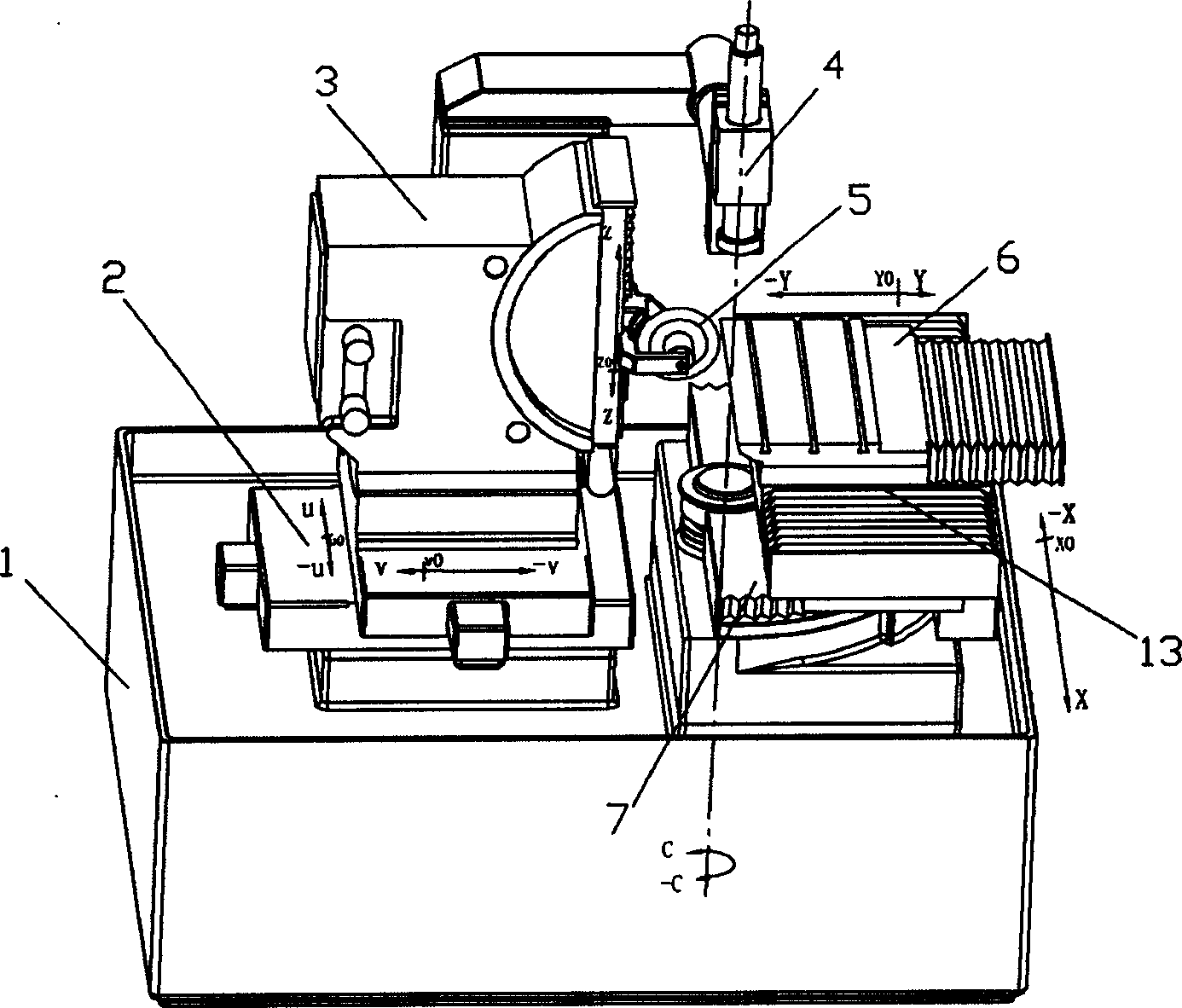

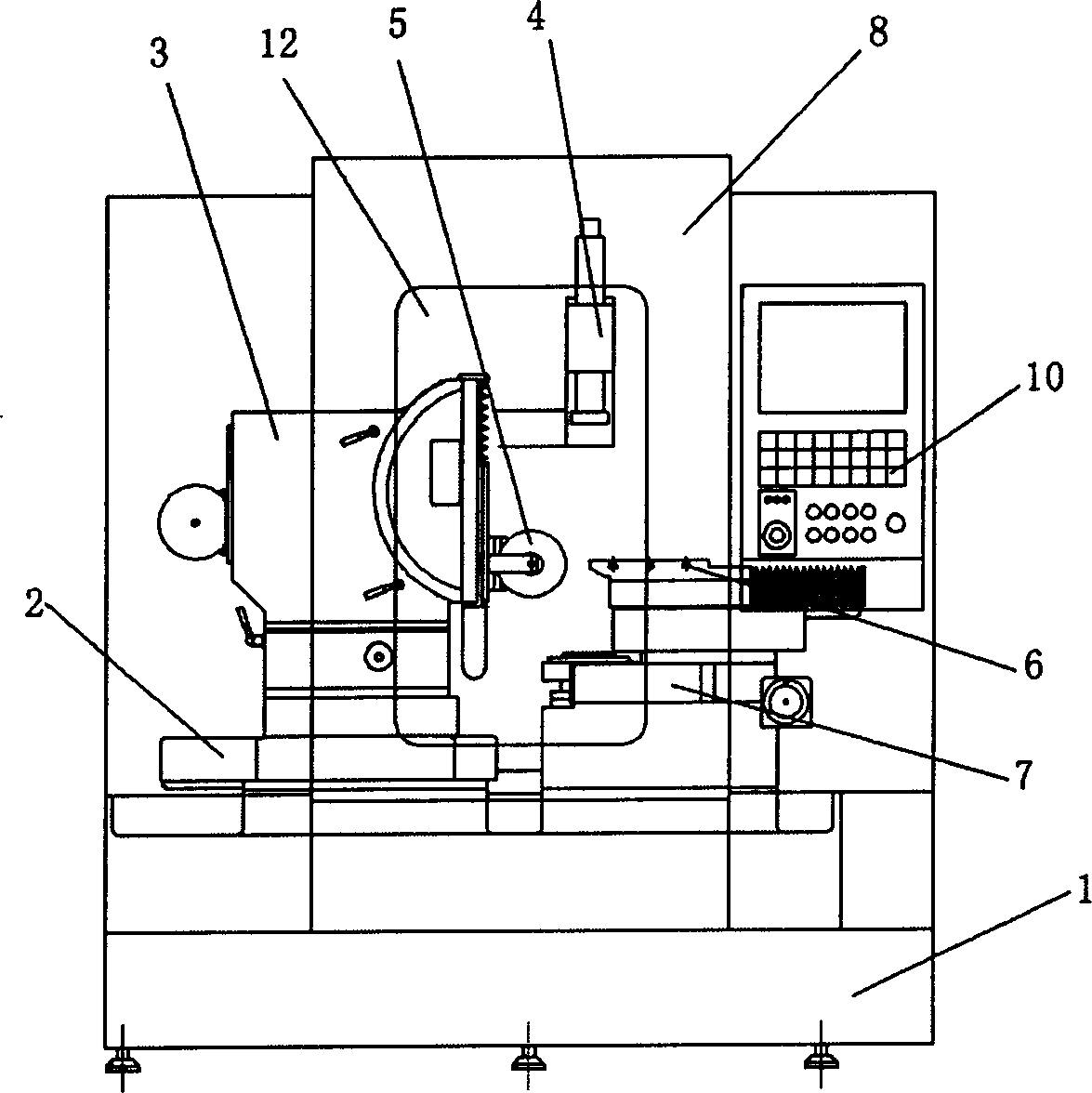

Digital profile grinder

InactiveCN1672871AHigh positioning accuracyImprove stabilityGrinding drivesGrinding feed controlDigital controlGrinding wheel

The digital profile grinder consists of system unit and auxiliary unit station. The system unit is one completely closed structure with machine body, multifunctional workbench, grinding frame, slide seat, CCD detector, and electric distributor. The auxiliary unit station has dust collector, cooler, and air balancing and braking controlling station. The present invention has image distinguishing technology adopted, and has integrated on-line machine tool detection, on-line compensation, on-line grinding wheel trimming and opened multi-axial digital control. It has at most eight shafts controlled, including seven servo rotary motor shafts and one linear servo motor shaft, and has at most six linked shafts, with the controlled shafts being in different combination. The present invention is suitable for machining various complicated parts.

Owner:上海第三机床厂 +1

Method for repairing crack and chipping of shunt ring of case

InactiveCN102430889AReduce investmentReduce repair costsElectrode supporting devicesFurnace typesEngineeringGrinding wheel

The invention relates to a method for repairing a crack and a chipping a shunt ring of a case, which comprises the following steps of: (1) trimming and polishing the chipping part of the shunt ring to form a square or oblong notch by using an air drill and a grinding wheel; (2) performing dyeing inspection on the periphery of the polished notch, and determining as qualified if no crack exists; (3) taking a patch material from the corresponding portion of a discarded case by using a linear cutting method, trimming the patch material by using the grinding wheel according to the shape of the notch so that the trimmed patch is matched with the notch; (4) placing the trimmed patch in the notch, supporting the patch with a support frame, firstly performing positioning welding on the patch by using low current argon arc welding, and then performing sectional symmetry welding; (5) performing dyeing inspection on the welding portion, and determining as qualified if no crack or eyehole exists; and (6) eliminating welding stress by ultrasonic waves. The repairing method provided by the invention has the advantages of low equipment investment, low repairing expense and short repairing period.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Novel numerically controlled special-shaped glass edge grinding machine

InactiveCN104759962AEnsure consistencyBest force contact areaEdge grinding machinesGrinding machine componentsEngineeringSlide plate

The invention provides a novel numerically controlled special-shaped glass edge grinding machine. A glass workpiece is adsorbed on a frame; a portal frame sliding along the Y axis is mounted on the frame; an X-axis sliding plate sliding along the X axis is mounted on the portal frame; a Z-axis sliding plate sliding up and down along the Z axis is mounted on the X-axis sliding plate; a main shaft mechanism is mounted on the Z-axis sliding plate; a tilt-angle main shaft sleeve is fixed on the Z-axis sliding plate; a tilt-angle main shaft is mounted in the tilt-angle main shaft sleeve; one end of the tilt-angle main shaft is in driving connection with a tilt-angle servo motor, while the other end of the tilt-angle main shaft is connected with a tilt-angle rotating stand; a transversely sliding assembly is arranged on the tilt-angle rotating stand; a grinding head motor is connected to the transversely sliding assembly by use of a transversely sliding plate; an elastic compensation assembly for driving the transversely sliding plate to slide front and back is connected to one side of the transversely sliding plate; a cutting tool is mounted on the output shaft of the grinding head motor; an automatic grinding wheel compensation function can be realized, so that the cutting tool is always held down in contact with the glass workpiece in the grinding process; as a result, a consistent grinding effect can be achieved, and the glass workpiece can be consistent in smoothness after being ground.

Owner:刘忠文 +1

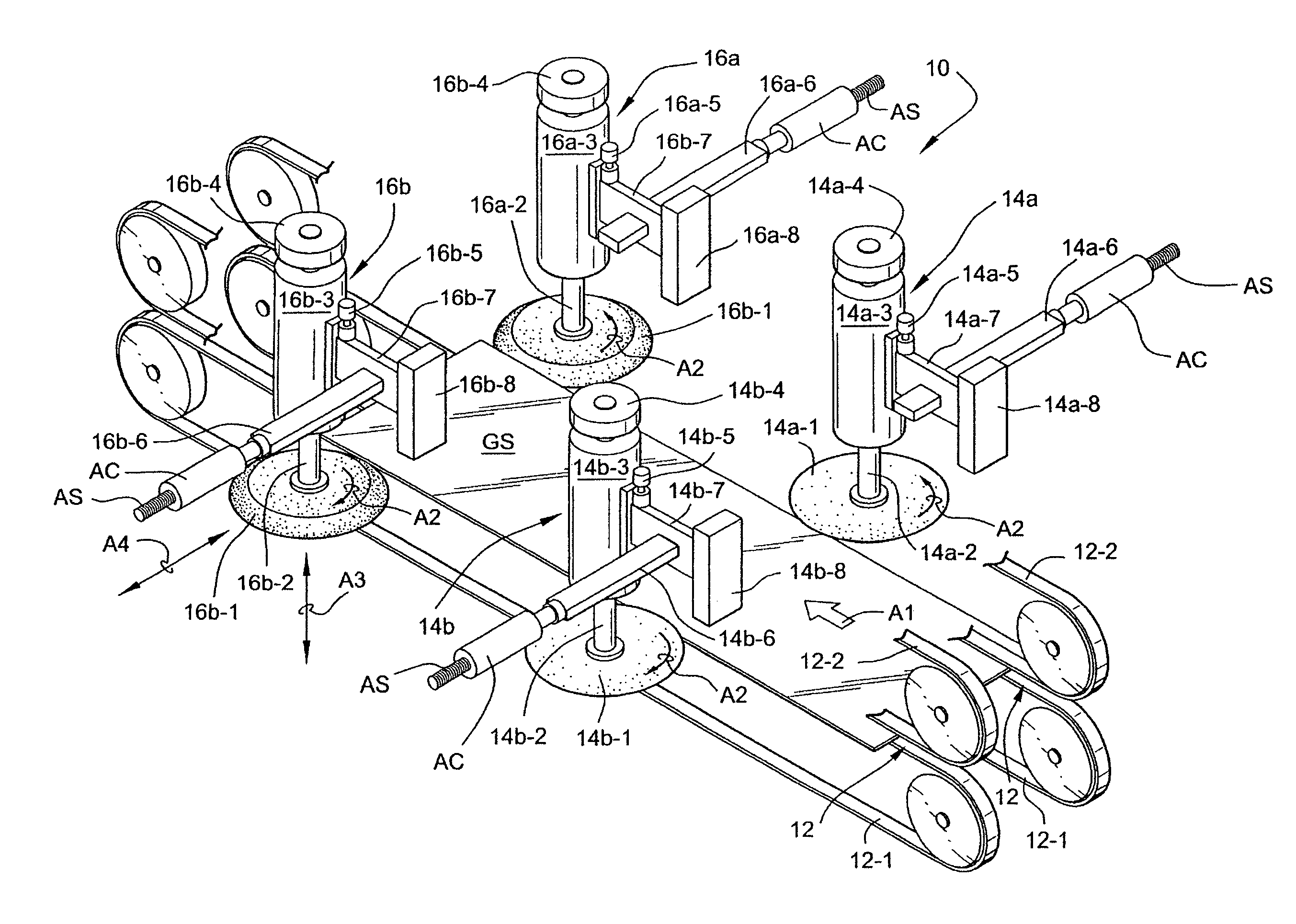

Methods and systems for finishing edges of glass sheets

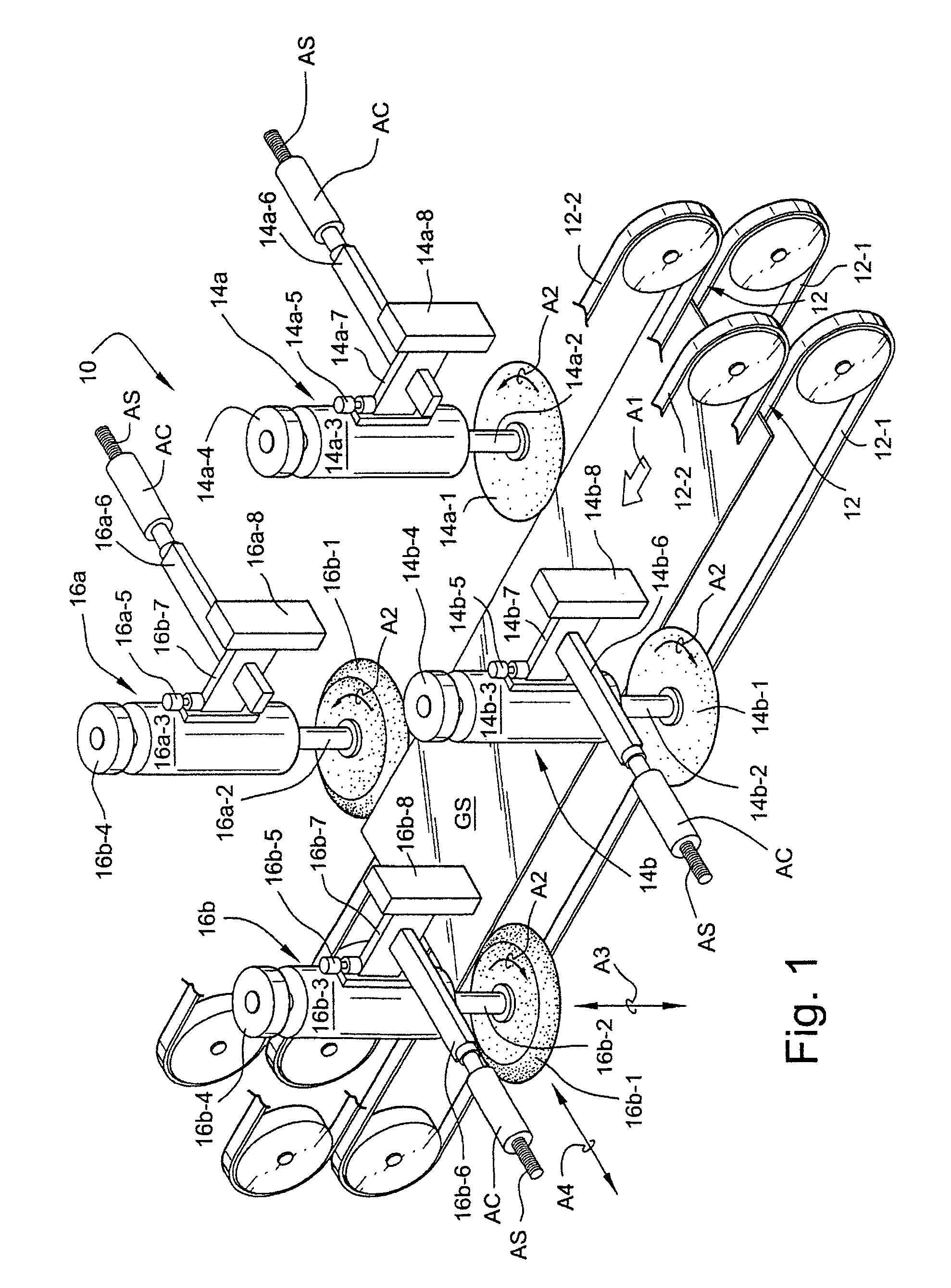

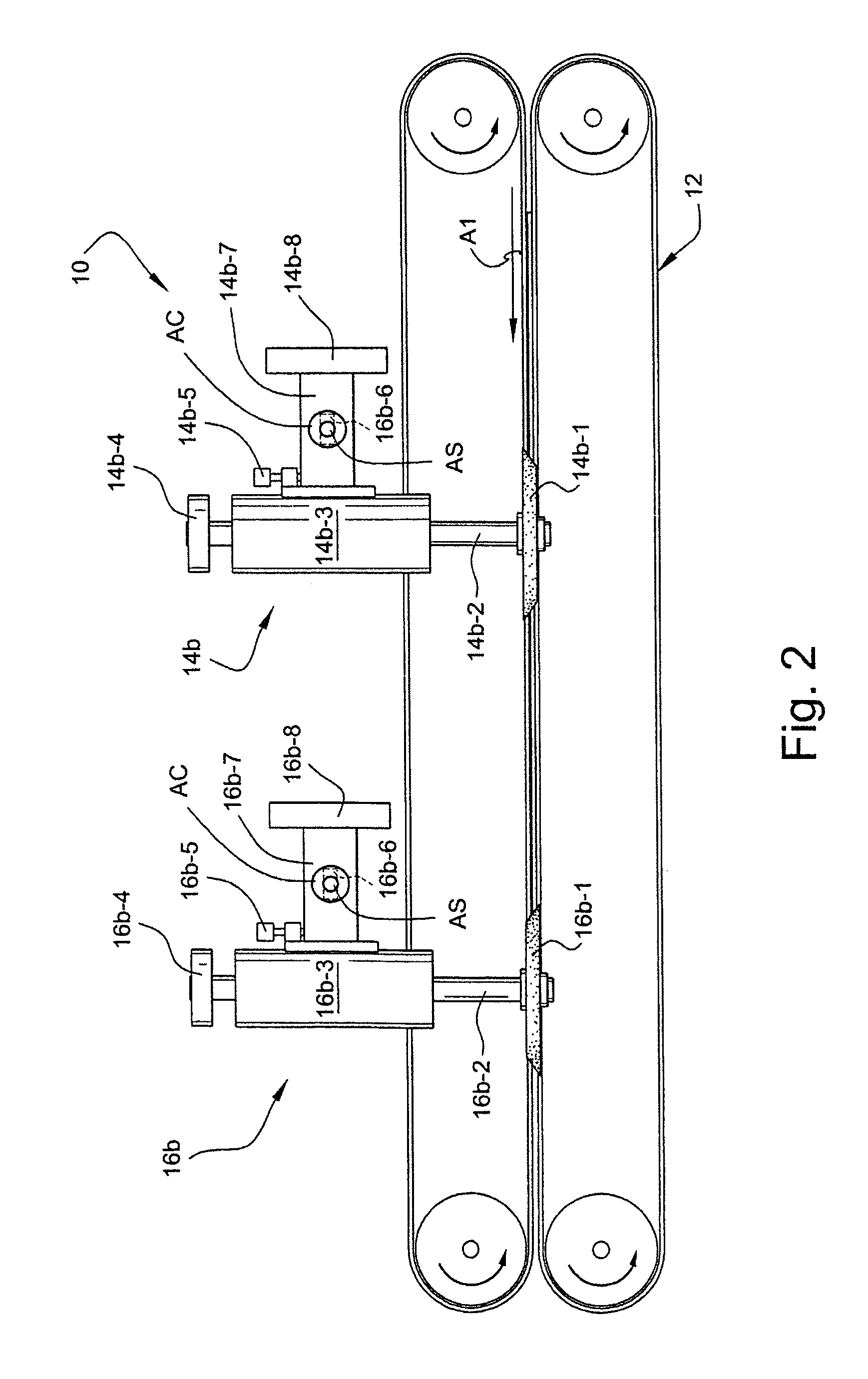

ActiveUS7001249B1Improve productivityLonger duty cycleEdge grinding machinesGrinding drivesEngineeringGrinding wheel

Methods and systems are disclosed whereby the edges of a glass sheet may be beveled with minimal equipment down time. Preferably such methods and systems bevel the upper and lower edges along lateral sides of a glass sheet. In especially preferred embodiments, laterally separated pairs of upper and lower edge grinding assemblies are provided having respective upper and lower oppositely oriented tapered grinding wheels. A glass sheet may thus be moved in a generally horizontal conveyance direction between one of these pairs of upper and lower edge grinding assemblies so that respective upper or lower lateral edges of the glass sheet are brought into grinding contact therewith. Continually moving the glass sheet in the horizontal conveyance direction will therefore present the other lateral edge to the other pair of upper or lower edge grinding assemblies positioned downstream. As such, the other edge will then be beveled. By independently mounting the oppositely oriented grinding wheels for independent movements both horizontally and vertically relative to the glass sheet, a fresh unscored region of the tapered grinding surfaces can then be presented to the glass sheet edges thereby ensuring that the proper bevel angle is achieved.

Owner:GUARDIAN GLASS LLC +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com