Patents

Literature

91 results about "Aluminum dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium dust is one of the metal dusts that are used in GregTech. Aluminium Dust is mainly produced by processing Bauxite Dust in an Industrial Electrolyzer at the rate of 2 aluminium dust per 3 bauxite dust (12 Bauxite Dust has to be put into the Industrial Electrolyzer to start the process).

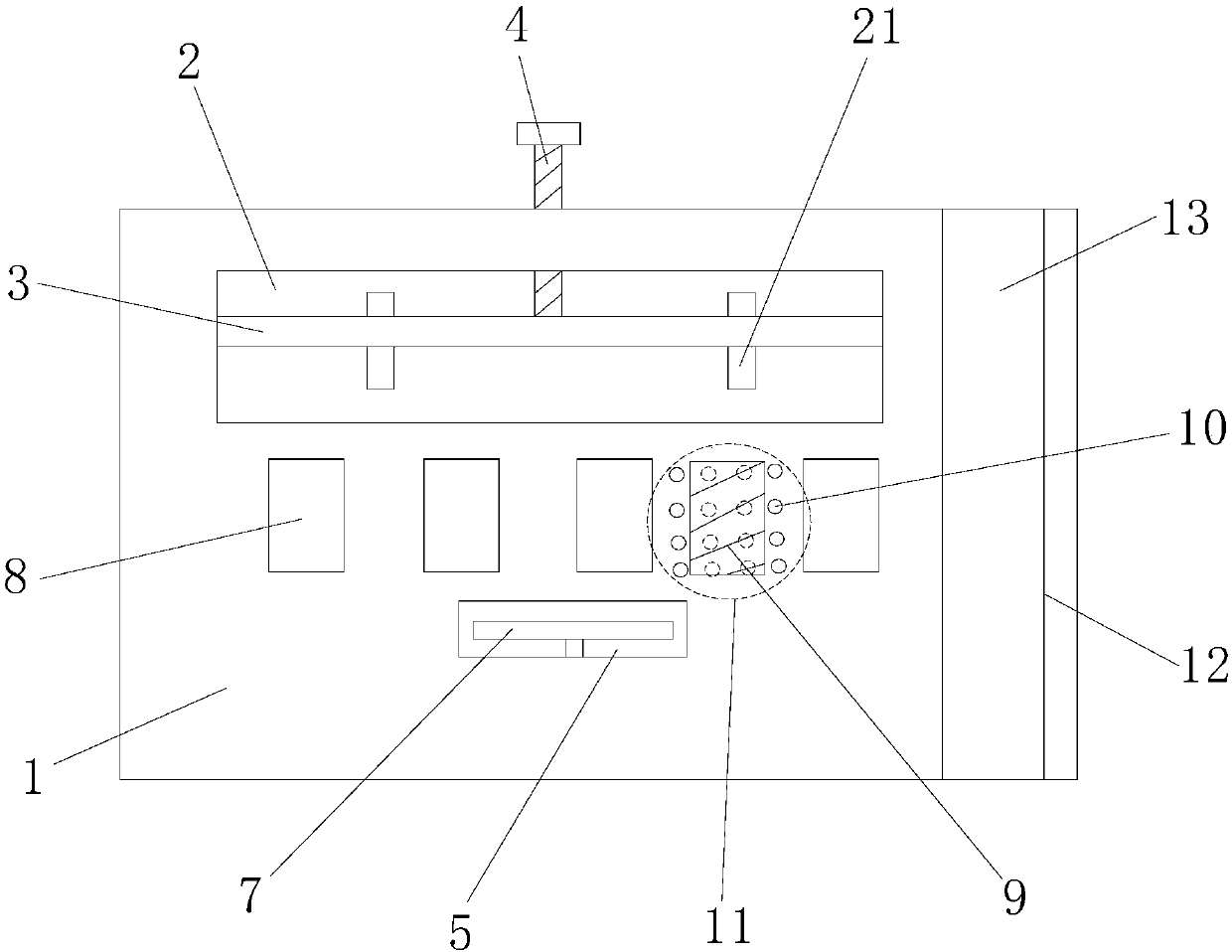

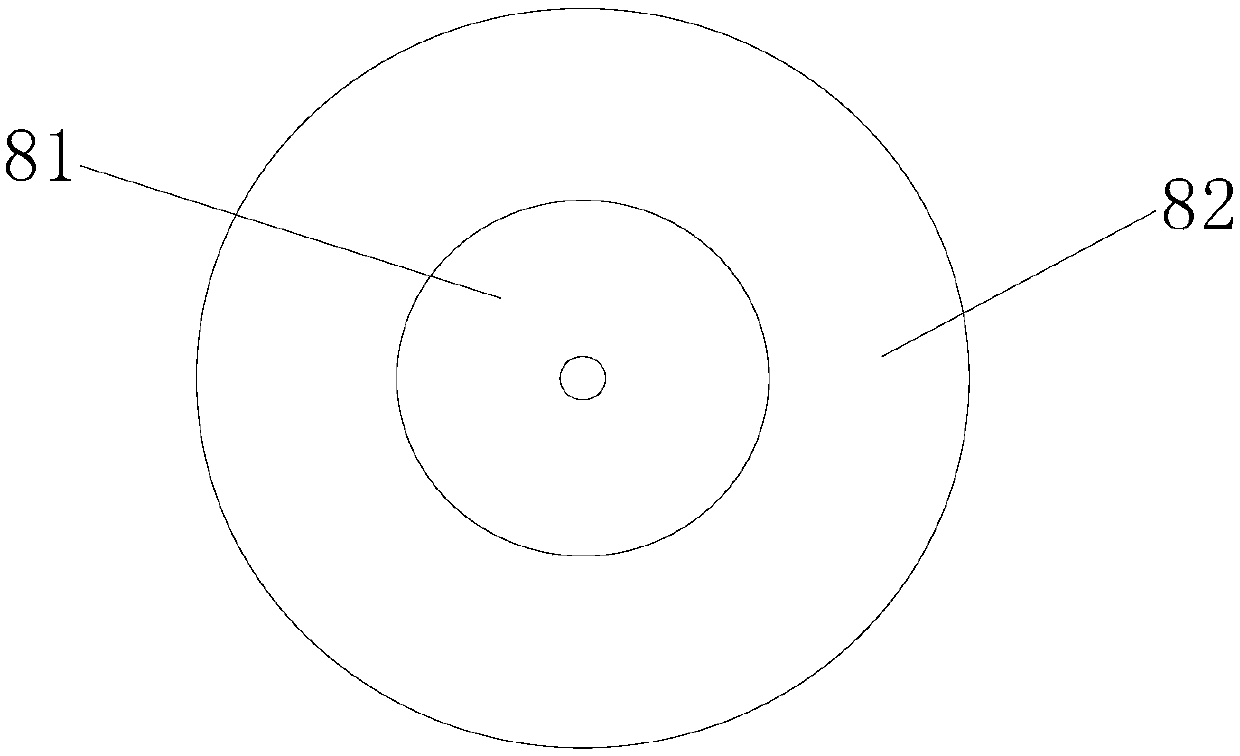

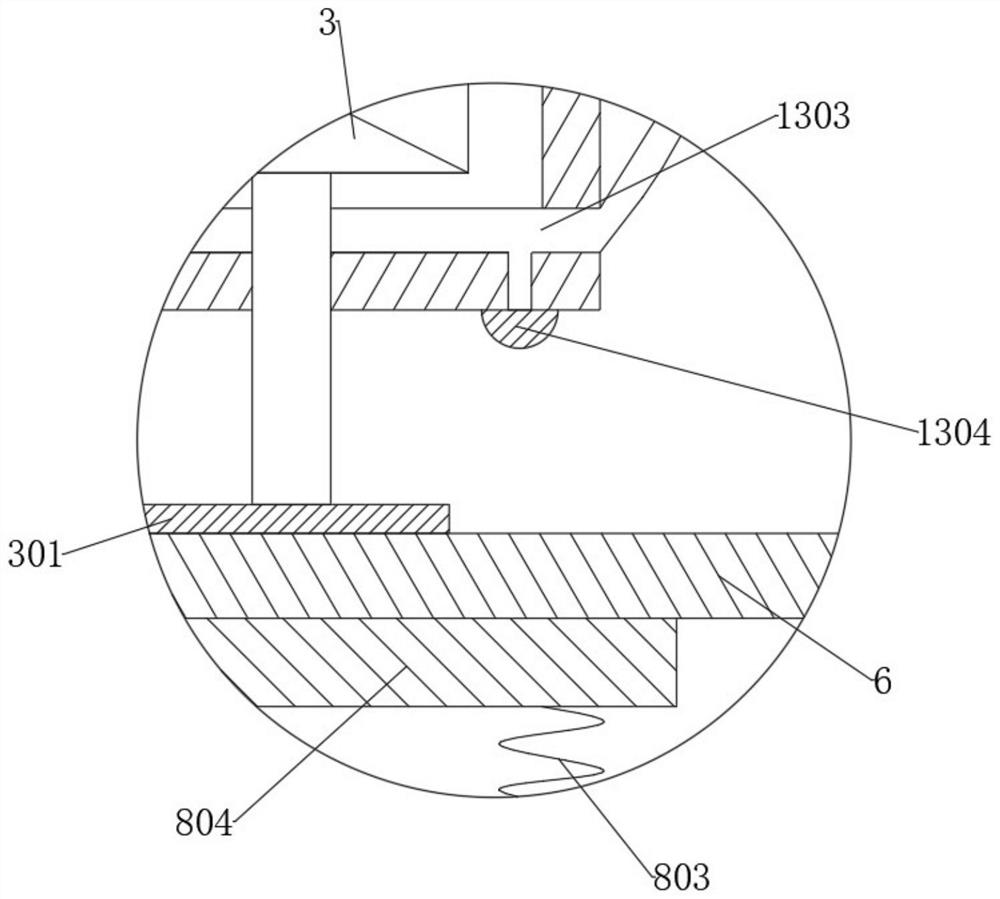

Building aluminum plate grinding device with cooling and dust removal function

InactiveCN107160246AImprove grinding efficiencyImprove sanding qualityPlane surface grinding machinesGrinding/polishing safety devicesDrive shaftCooling effect

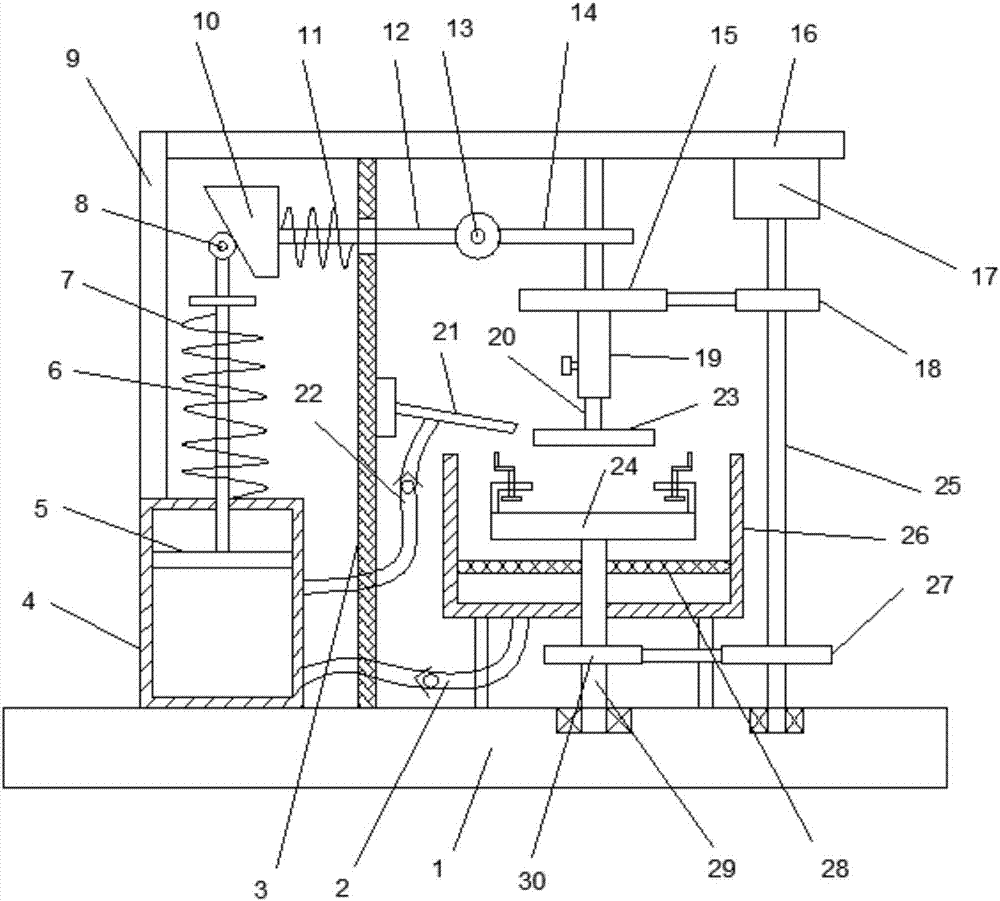

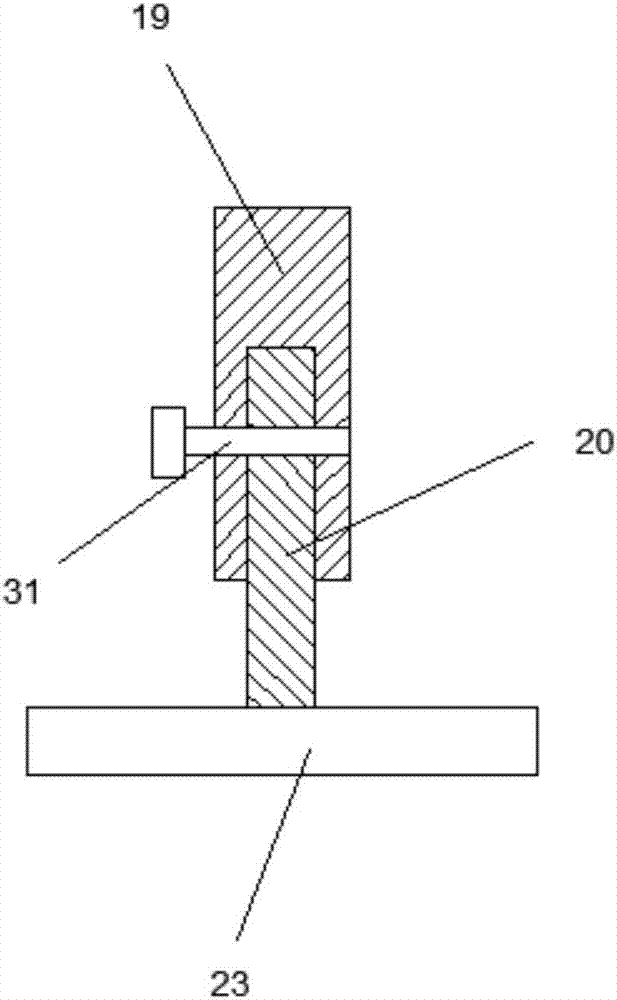

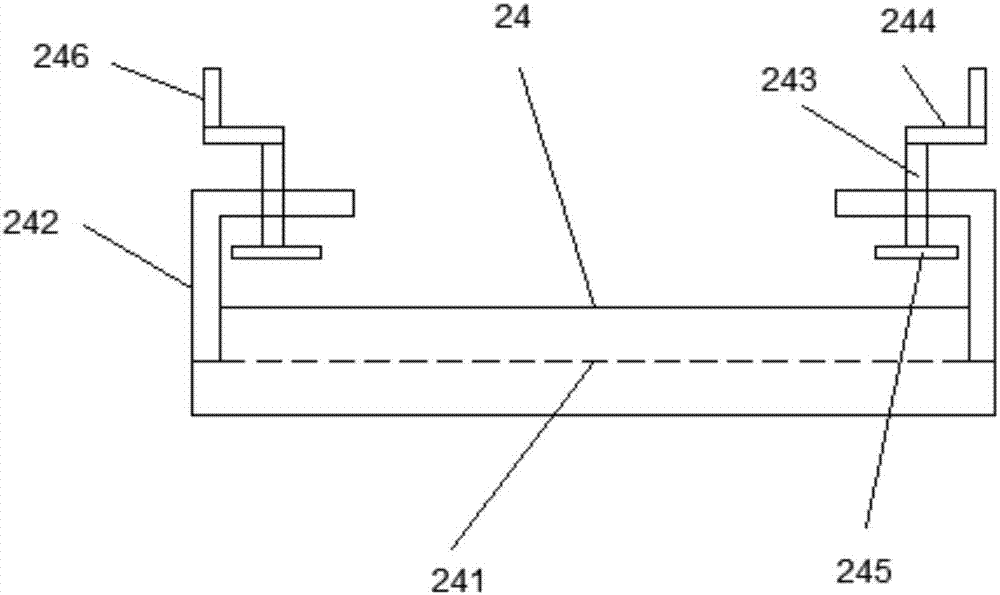

The invention discloses a building aluminum plate grinding device with the function of cooling and dust removal, which comprises a base and a top plate, a driving motor is connected to the right side of the lower end of the top plate, a driving shaft is connected to the lower end of the driving motor, and an upper driving belt is connected to the middle part of the upper end of the driving shaft The left end of the upper driving pulley is connected with the upper driven pulley through a belt, the upper end of the upper driven pulley is connected with a rotating cam at the coaxial position, the left end of the rotating cam is provided with a guide wheel, the left end of the guide wheel is connected with a guide rod, and the left end of the guide rod A wedge-shaped block is connected, the left end of the wedge-shaped block is in contact with a lifting wheel, the lower end of the lifting wheel is connected with a lifting shaft, the middle part of the lower end of the driving shaft is connected with a lower driving pulley, and the left end of the lower driving pulley is connected with a lower driven pulley through a belt. The middle part of the driven pulley is connected with a driven shaft. The invention realizes the synchronous rotation of the grinding wheel and the workbench, realizes the cooling effect on the grinding wheel, and takes away the aluminum dust produced during grinding.

Owner:苏锦忠

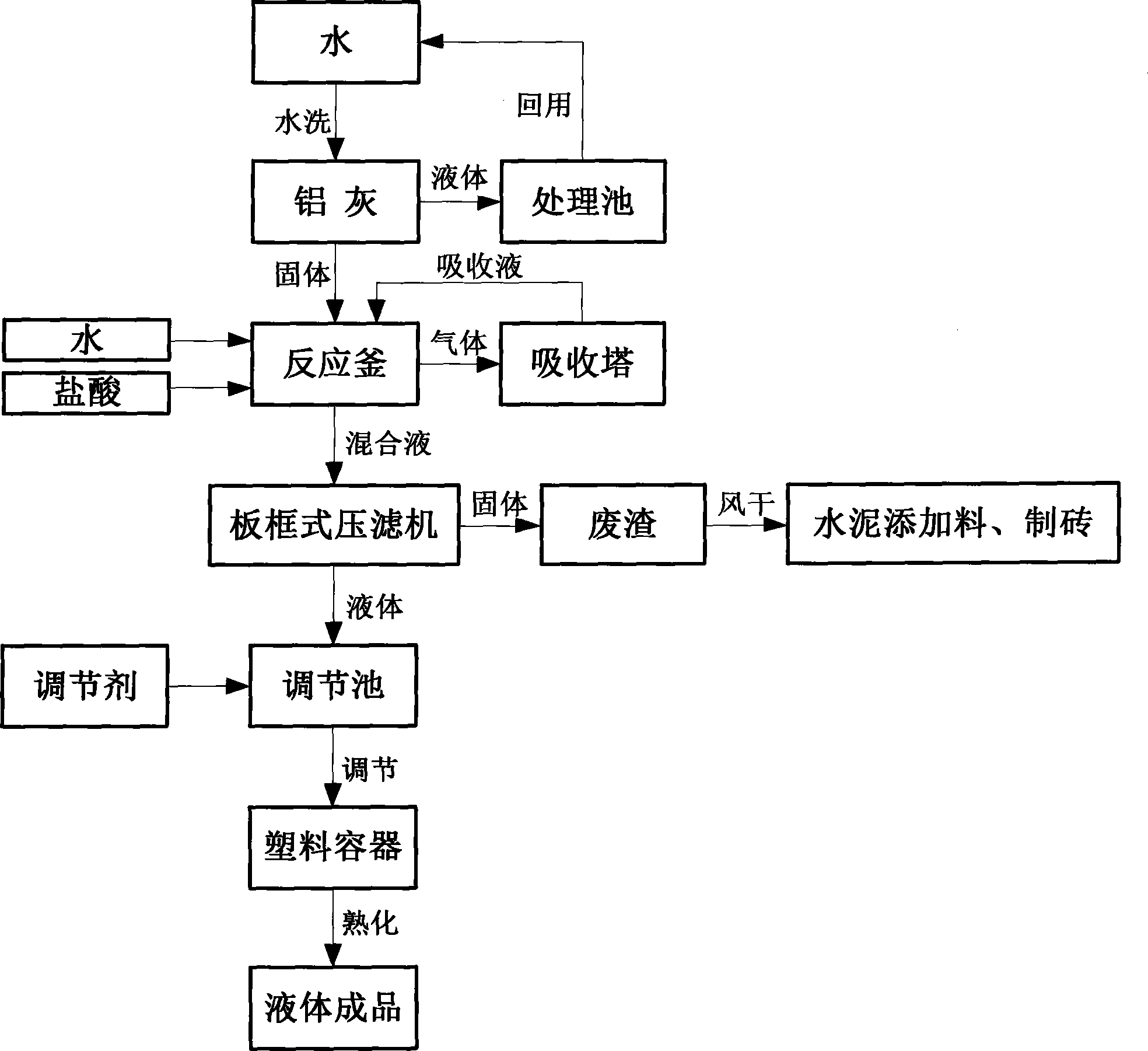

Method for preparing flocculant liquid polyaluminum chloride from aluminum ash

InactiveCN102674422ANo secondary pollutionAvoid secondary pollutionAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminate

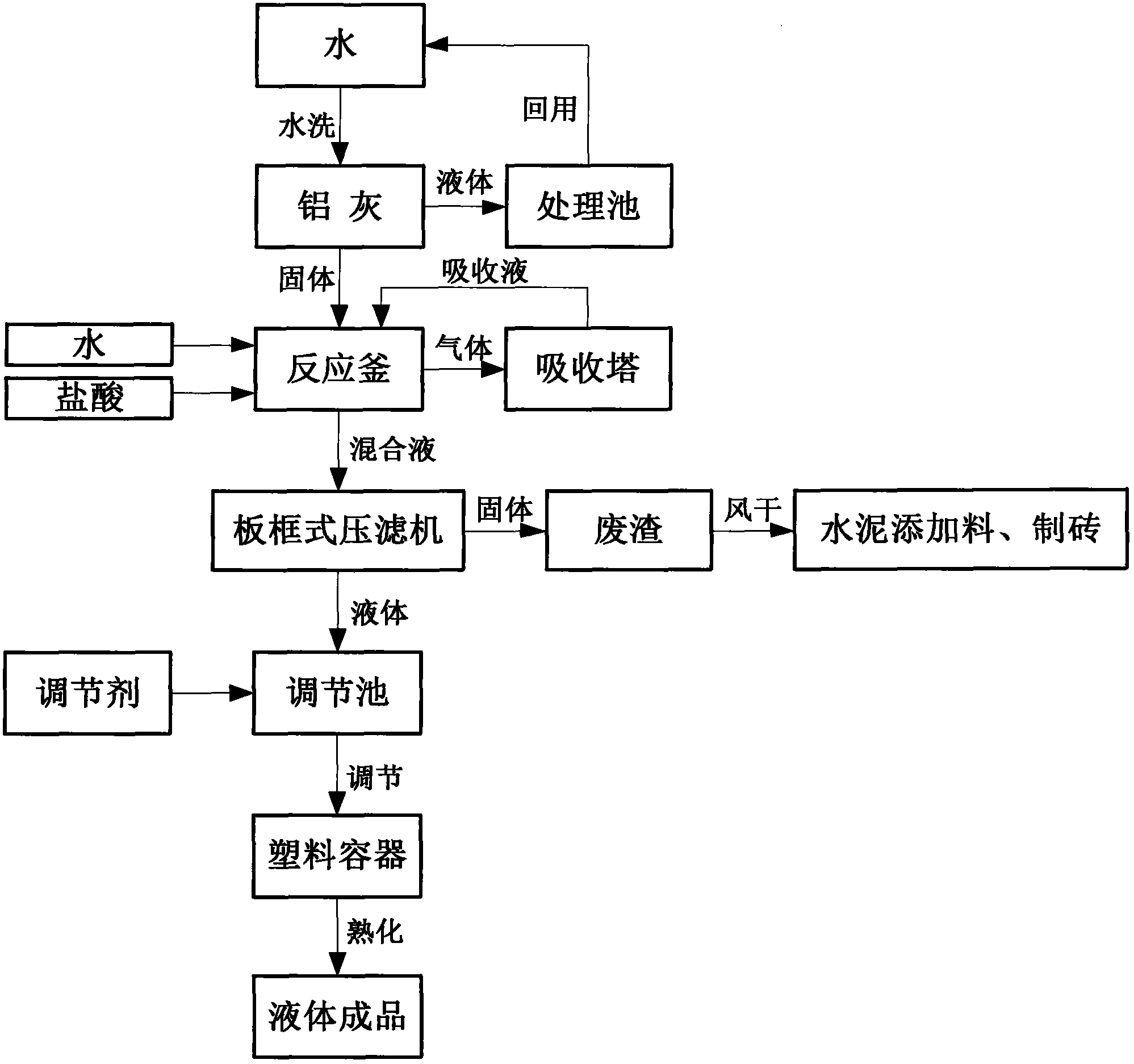

The invention discloses a method for preparing flocculant liquid polyaluminum chloride from aluminum ash, belonging to the technical field of solid waste treatment environment protection. The method comprises the following steps: uniformly mixing and stirring aluminum ash and water in a volume ratio of 1:(3-5), and soaking for 5-8 hours; pumping the solution into a reaction kettle, adding hydrochloric acid and water in an aluminum ash / hydrochloric acid / water volume ratio of 1:(2.5-3.0):(3.0-4.0), and reacting at 85-100 DEG C for 2-3 hours; carrying out solid-liquid separation with a plate and frame type filter-press, and adding a regulator to regulate the aluminum oxide content and basicity of the liquid, wherein if quicklime is used as the regulator, the volume ratio of the liquid to the quicklime is 1:(0.054-0.086), if aluminum dust is used as the regulator, the volume ratio of the liquid to the aluminum dust is 1:(0.023-0.04), and if solid calcium aluminate is used as the regulator, the volume ratio of the liquid to the solid calcium aluminate is 1:(0.042-0.063); and standing and aging for 48-72 while controlling the temperature at 50-60 DEG C, thereby obtaining the liquid polyaluminum chloride finished product. The invention has the advantages of simple technique, low cost and no secondary pollution, and is a good method for recycling aluminum ash.

Owner:李松 +2

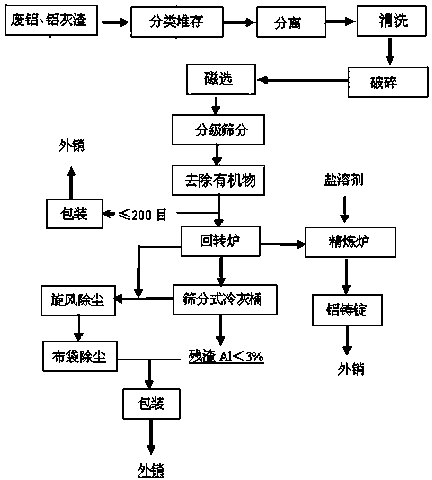

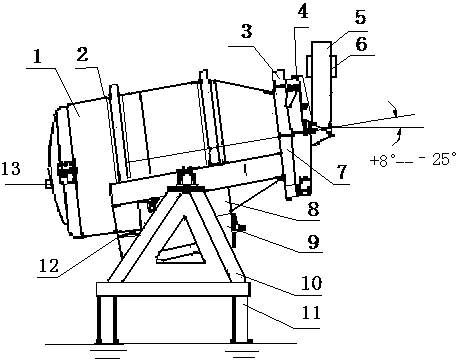

Production method of recycled aluminum

The invention relates to a production method of recycled aluminum. The production method comprises the steps: classifying and stacking waste aluminum or aluminum ash slag, then separating, wherein the separation is to remove dirt by washing and crushing; removing steel by a magnetic separation method, then crushing the initially purified aluminum, sieving to obtain a mixed aluminum powder, then putting into a rotary furnace for a combustion reaction, so as to decompose the aluminum slag or the waste aluminum into aluminum liquid and aluminum ash; putting the aluminum liquid in a refining furnace for further smelting, to obtain aluminum liquid with relatively high purity, outpouring to form aluminum ingots, wherein the pure aluminum content can reach 99.99%; and merging the aluminum ash unloaded from the rotary furnace with aluminum ash obtained by treating flue gas through a cyclone dust extractor, wherein the content of aluminum in the residues is 1-3%, then packaging, and providing the packaged product as a smelting additive for a steel mill.

Owner:ALNAN ALUMINIUM CO LTD

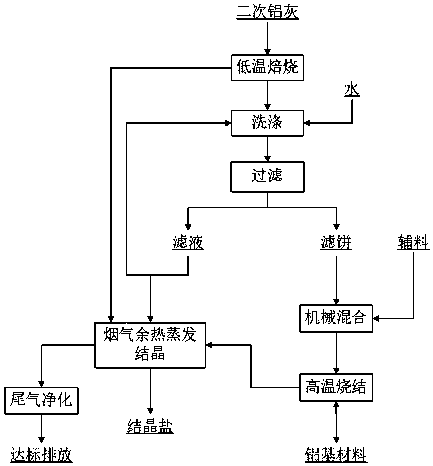

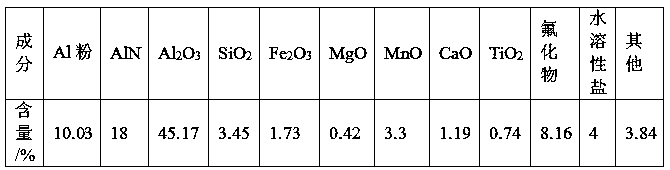

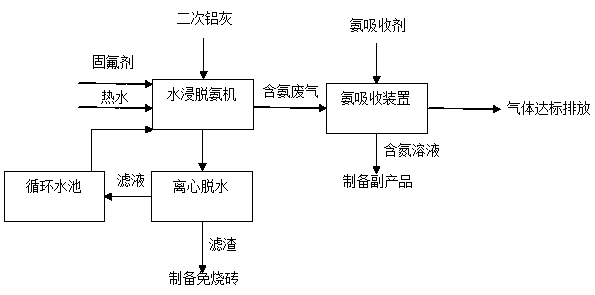

High-efficiency clean resource utilization method for quadratic aluminum dust

ActiveCN109179464AClean and efficient treatmentRealize high-value utilizationHuman health protectionCalcium aluminatesResource utilizationPotassium

The invention discloses a high-efficiency clean resource utilization method for quadratic aluminum dust. The method comprises the following steps: performing low-temperature roasting treatment on quadratic aluminum dust, removing harmful elements such as nitrogen, carbon and fluorine, pulping, washing, desalting and dehydrating the quadratic aluminum dust, removing sodium salt, potassium salt andother impurity components, washing brine and evaporating and crystallizing by utilizing flue gas waste heat. The purified quadratic aluminum dust can serve as a raw material to be directly utilized, and after the quadratic aluminum dust is mechanically mixed with auxiliary materials (calcium-based, silicon-based and magnesium-based), an aluminum based inorganic material is prepared at a high temperature, and the sintering exhaust gas realizes up-to-standard discharge by virtue of dust removal and dry defluorinated purification. According to the technology in the invention, the quadratic aluminum dust can be safely, cleanly and efficiently treated and converted into the high-value aluminum based inorganic material to the greatest degree, and environmental-friendly treatment and high-value resource utilization of the quadratic aluminum dust can be realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for continuously producing aluminium electrolysis raw materials high-fluorine alumina, cryolite and sodium silicate with aluminum dust

ActiveCN101823741ASolve pollutionReduce energy consumptionAlkali metal silicatesAluminium fluoridesAluminium electrolysisEvaporation

The invention discloses a method for continuously producing aluminium electrolysis raw materials high-fluorine alumina, cryolite and sodium silicate with aluminum dust, which comprises the following steps that: aluminum gray is added with water, soaked and filtered, the filtrate is evaporated and concentrated to obtain a NaCl and KCL mixed crystal; filter residue is calcined for 15 to 60min at 750 to 950DEG C; 0.5 to 10 percent HF solution which contains 10 to 40ml of oxidant is added into a calcined product by the solid-liquid ratio of 1:1 to 1:10 to be soaked and react for 30 to 180min under the stirring at 100 to 1000r / min; the solution is filtered, the solid after the evaporation and the concentration of the filtrate is dried to prepare cryolite according to the prior art; the cryolite evaporation mother liquor reacts with NaOH to prepare the sodium silicate according to the prior art; and the filter residue is dried for 12h at 90 to 110 DEG C, and the high-fluorine alumina which contains MgF2 is obtained. The method can continuously produce high- fluorine alumina, cryolite and sodium silicate with high activity for an electrolyzer, is environmental-friendly during the production process, has energy consumption far lower than that of a traditional process and short process, and is simple to operate.

Owner:中南大学科技园(湖南)发展有限公司

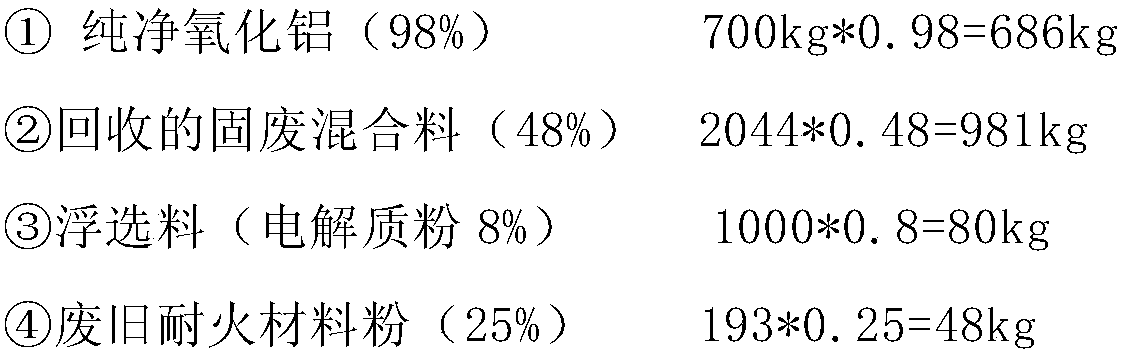

Aluminum electrolysis dangerous solid waste comprehensive treatment method and resource utilization

InactiveCN107626712ASimple processShort production processWaste processingSolid waste disposalResource utilizationSilicon alloy

The invention provides an aluminum electrolysis dangerous solid waste comprehensive treatment method and resource utilization. According to the aluminum electrolysis dangerous solid waste comprehensive treatment method, other solid waste, except for waste anodes and waste aluminum dust, of aluminum electrolysis can be recycled, treatment processing is carried out through multiple procedures of primary election impurity removal, magnetic separation iron removal, flotation carbon removal, smelting reduction and the like, all aluminum electrolysis solid waste is effectively treated, renewable resources are all comprehensively utilized, and finally aluminum-silicon alloy products, electrolyte products for aluminum electrolysis, fuel powdered carbon products and the like are produced; and solidwaste treatment of the aluminum electrolysis industry is achieved, valuable resources containing aluminum, silicon, fluorine and the like are recycled and reutilized, and the good aims of protectingthe environment, saving resources and creating benefits are achieved.

Owner:陕西泰鑫有色金属综合利用有限公司

Leaching method for valuable elements in quadratic aluminum dust

InactiveCN105039702AImprove leaching rateReduce pollutionSilicaChemical industryFiltrationMixed materials

The invention discloses a leaching method for valuable elements in quadratic aluminum dust. The leaching method includes the following steps that (100) the quadratic aluminum dust is added into a NaOH solution, and 11-13 g of the quadratic aluminum dust is added into every 100 ml of the NaOH solution, so that mixed materials are formed; (200) the mixed materials are added into a ball grinder to be subjected to ball grinding for 3-3.5 hours; and (300) suction filtration is carried out. Particularly, filter residues are dried in a vacuum drying oven, and aluminum dust capable of being reused is obtained. In this way, the leaching method for the valuable elements in the quadratic aluminum dust not only can reduce environmental pollution and realize recycling of the quadratic aluminum dust, but also is easy to operate, saves raw materials, reduces the cost, is environmentally friendly, and saves energy.

Owner:苏州卡迪亚铝业有限公司

Low infrared emittance sheet-like pigment and method for preparing same

InactiveCN1884395ASolve Oxidation ProblemsLow emissivityInorganic pigment treatmentEmissivityFerric oxide hydrate

The invention discloses the aluminum dust dye and preparing method. The dye has emissing ability, and is covered with ferrite yellow. The particle mean size of aluminum dust is 1-100 mum, and the aluminum dust is lack-lustre, golden ocher, and good oxidation resistance. The average emissing ability of infrared band is 0.50-0.60.

Owner:SHANGHAI HUAMING HI TECH GRP

Low infrared emittance chocolate brown sheet-like pigment and method for preparing same

InactiveCN1884394AChange colorSolve Oxidation ProblemsInorganic pigment treatmentEmissivityWavelength

The invention discloses the aluminum dust dye and preparing method. The dye has emissing ability, and is covered with ferriferrous oxide. The particle mean size of aluminum dust is 1-100 mum, and the aluminum dust is lack-lustre, sepia, and good oxidation resistance. The average emissing ability of infrared band is 0.50-0.65.

Owner:SHANGHAI HUAMING HI TECH GRP

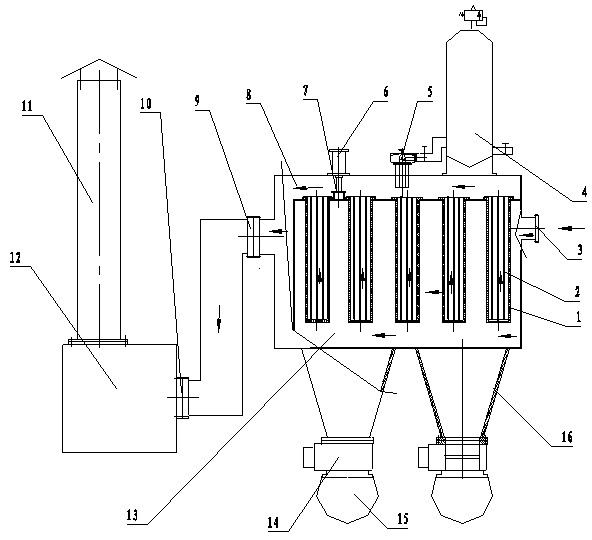

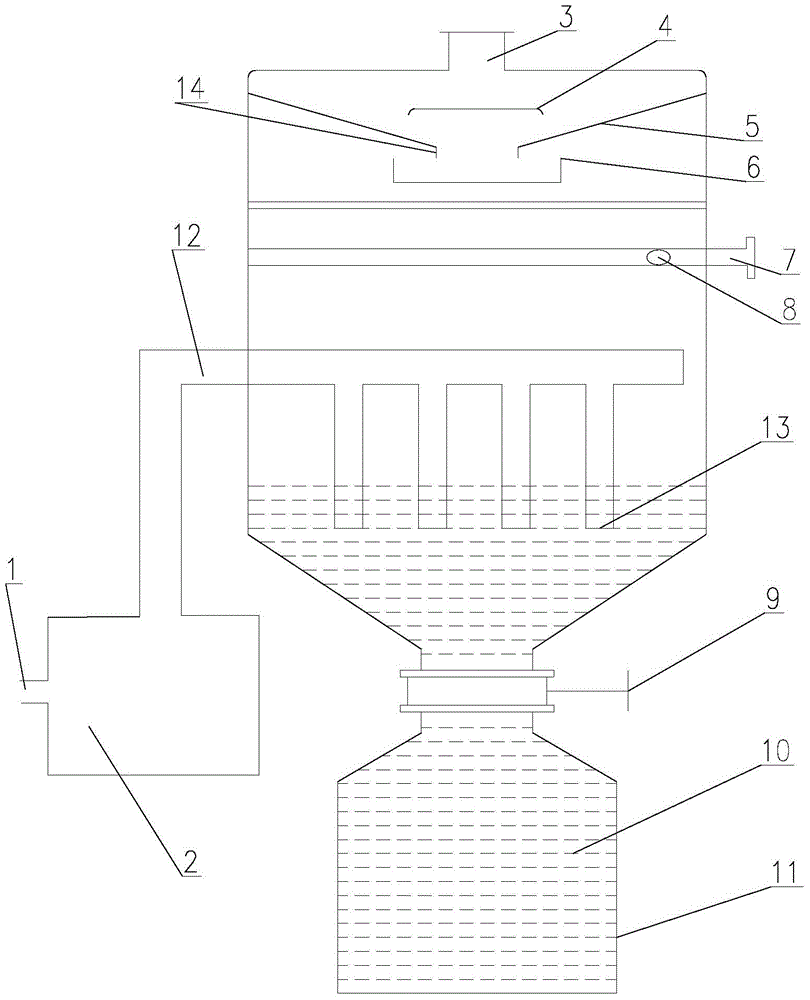

Aluminum dust treating and recycling system

InactiveCN102580418ASpeed up filteringRelieve pressureHuman health protectionDispersed particle filtrationAluminum dustChimney

The invention discloses an aluminum dust treating and recycling system which comprises a cloth-bag dedusting device and a discharge device, wherein air containing aluminum dust is communicated with an air inlet of the cloth-bag dedusting device through a pipeline; an air outlet of the cloth-bag dedusting device is communicated with an air inlet of a draught fan; and an air outlet of the draught fan is communicated with a blowdown stack. The aluminum dust treating and recycling system is characterized in that: an inner cavity of the cloth-bag dedusting device is divided into an outlet cavity and an air inlet cavity by a partition plate component; the partition plate component consists of an inverted L-shaped dynamic partition plate and a flat-shaped static partition plate; the horizontal section of the dynamic partition plate is overlapped on the static partition plate; and a piston rod of a cylinder arranged outside the top of the cloth-bag dedusting device extends into the cloth-bag dedusting device to be connected with the dynamic partition plate of the partition plate component. According to the invention, since the draught fan sucks the air containing aluminum dust, the aluminum dust in the air is filtered after the air passes through the cloth bag, thus the aluminum dust is recycled, and air is purified; and moreover, due to the back-flushing system and a dust discharge device, the safety of the equipment is guaranteed.

Owner:中铝西南铝板带有限公司

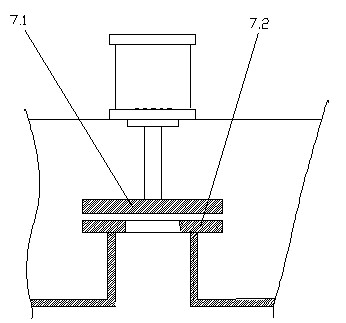

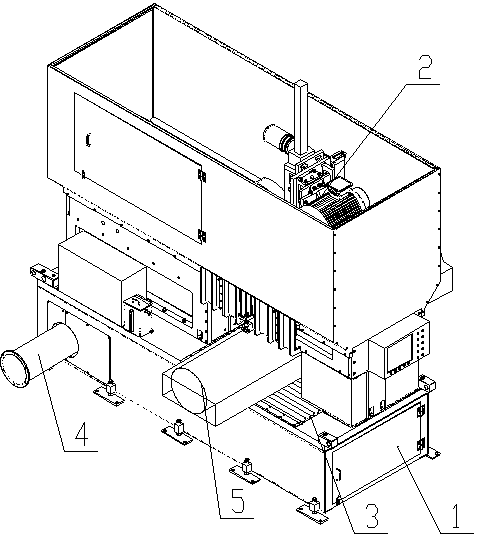

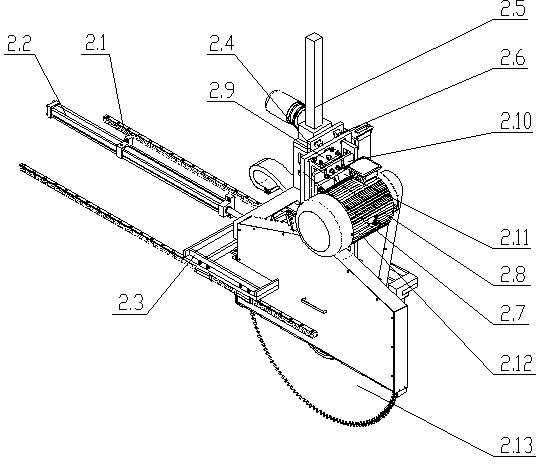

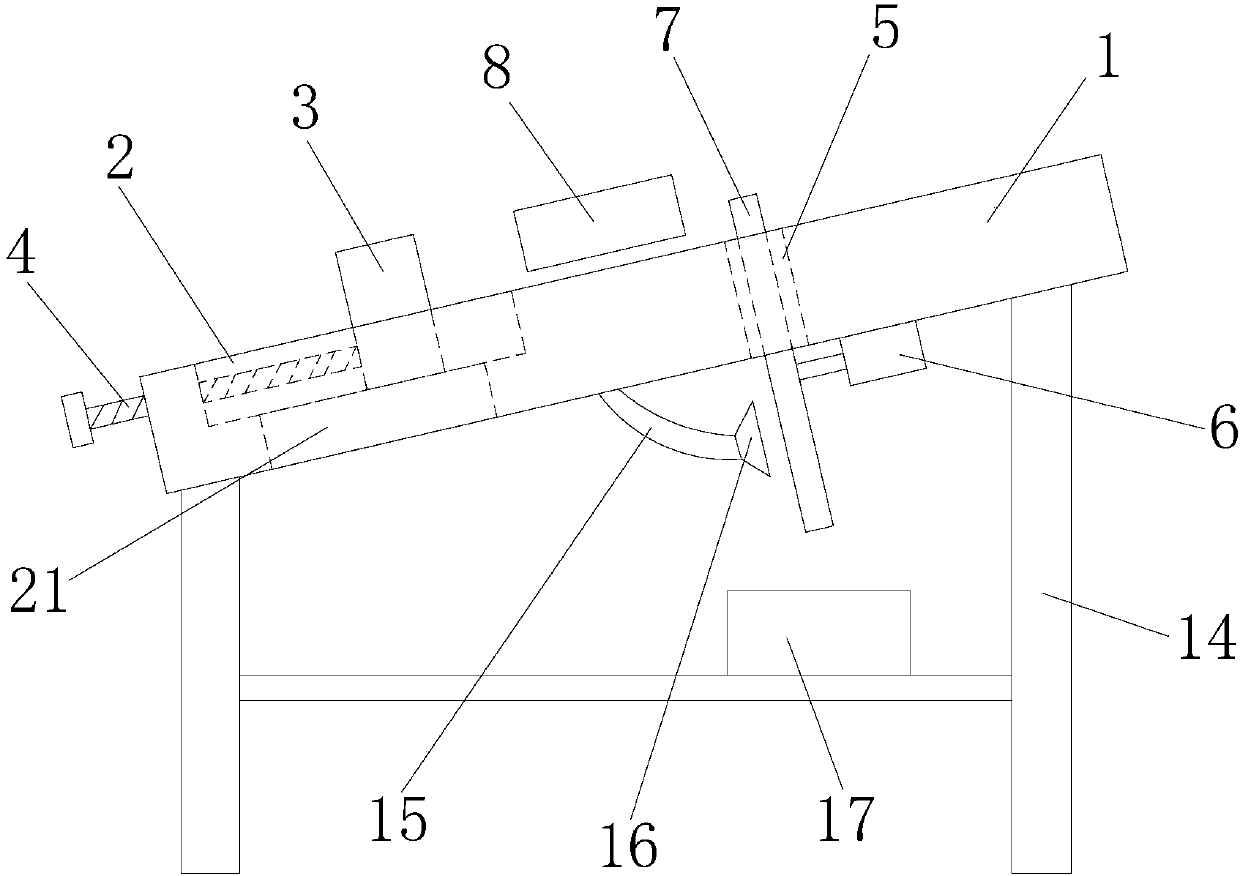

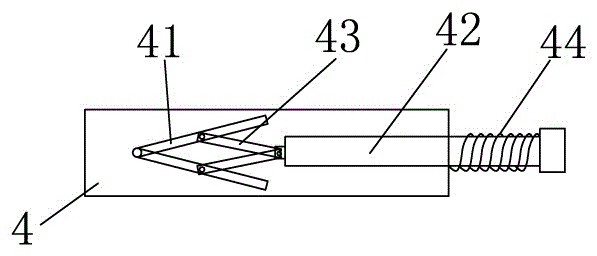

Aluminum section finishing saw

ActiveCN103230960ASports effectsEasy to cleanMetal sawing accessoriesDirt cleaningEngineeringAluminum dust

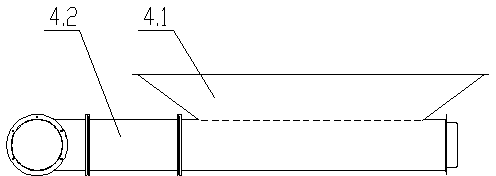

The invention relates to an aluminum section finishing saw, which belongs to the technical field of aluminum section processing equipment. The aluminum section finishing saw comprises a bottom framework (1); the top of the bottom framework (1) is provided with a top assembly (3); a sawing assembly (2) is arranged above the top assembly (3); and a dust sucking assembly (4) is arranged below the top assembly (3). According to the aluminum section finishing saw provided by the invention, the sawing assembly of the saw is arranged above the top assembly, aluminum dust generated during sawing is pumped out through the dust sucking assembly arranged below the top assembly, so cleaning is very convenient and poses no influence on the movement of the sawing assembly.

Owner:JIANGYIN GIANSUN ALUMINUM PROFILE COMPLETE PLANT MFG

Method for synthesizing high performance aluminium nitride powder

The present invention belongs to the technology field of electrically insulating material preparation, which is a novel process for synthesizing high-performance aluminum nitride powder by utilizing the self-spreading combustion for synthesis, wherein thinning agent and addition agent are charged into the raw material aluminum dust, and are ground by rotary mill, then they are charged into a combustion synthesis reaction apparatus, nitrogen is charged under coarse vacuum, ignition composition is ignited and ammonia gas is charged simultaneously, thus aluminum nitride powder is synthesized from the raw aluminum dust.

Owner:TSINGHUA UNIV

Liquid fuel additive

InactiveCN1730625AThe equipment process is simpleSimple production processLiquid carbonaceous fuelsFuel oilLiquid fuel

The invention discloses a liquid fuel additive comprising puffing agent P 5-10%, pentaerythritol tetranitrate 10-15%, triethanolamine 4-8%, oleinic acid 2-4%, trinitro-methane 1.2-7.2%, propene oxid 0.8-4.8%, ethylene glycol dinitrate 3-13%, diethyleneglycol dinitrate 1-5%, triethylene glycol dinitrate 1-3%, dinitromethane 2-4%, tetranitromethane 1-3%, aluminum dust 2-7%, ammonium nitrate 8-30%, guanidine nitrate 5-15%, potassium permanganate 8-14%, and hydrogen peroxide 2-8%.

Owner:马劳主

Comprehensive processing and utilizing process of quadratic aluminum dust

InactiveCN111167830AHarmlessIncrease added valueTransportation and packagingSolid waste disposalHazardous substanceSlag

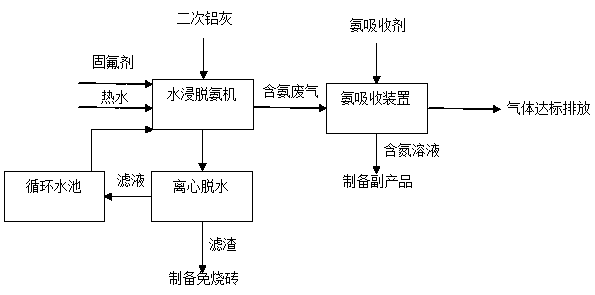

The invention provides a comprehensive processing and utilizing process of quadratic aluminum dust. The process includes the following steps of deaminizing, fluorine removal and centrifugal dewatering. The harmless, efficient and resourceful processing of the quadratic aluminum dust is realized, aluminum nitride, fluoride and other harmful substances are removed, high-additional-value by-products(ammonium salt or weak aqua ammonia or the like) are obtained, and efficient separating and recycling of all components are realized. In the deaminizing step, generated ammonia gas is collected into an ammonia absorbing device through a closed pipeline, the potential safety hazard problem caused when too much gas exists in a water-immersing deaminizing machine is avoided, and safe production is realized. No secondary pollution problem exists in the producing process, ammonia-containing waste gas can reach the relevant national standard and be discharged into the atmosphere after being deaminized, generated slag can be used for preparing baking-free bricks, and the green production aim is achieved.

Owner:XINGHUA YONGTAI ALUMINUM IND

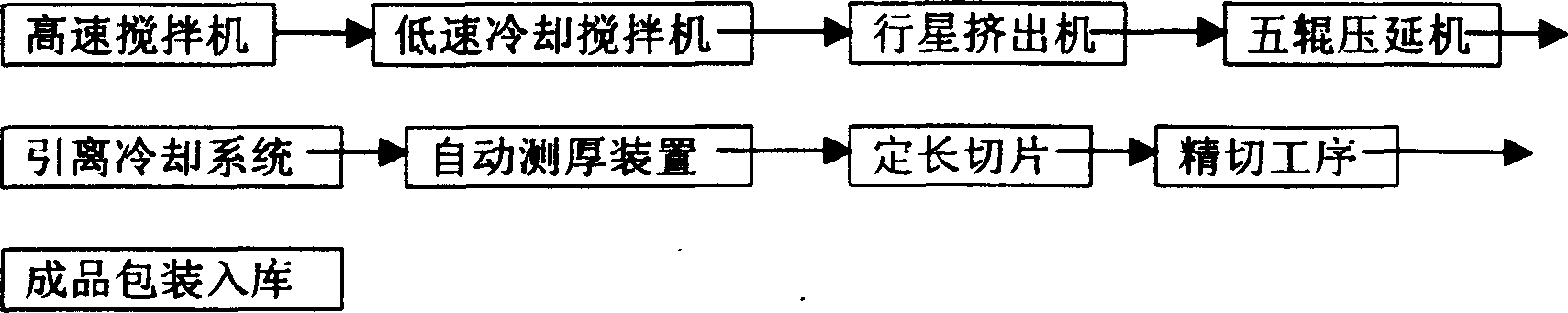

Polyvinyl chloride card matrix materials for production of noncontact IC card and method for making same

InactiveCN1702111AGood shading effectImprove toughnessRecord carriers used with machinesPolyvinyl chlorideAluminum dust

The invention relates to a PVC card-based material used to produce non-contact IC card. The invention chooses PVC as main ingredient, anatase type titanium dioxide as light proof dope, aluminum dust as light proof additional materials, nanometer calcium carbonate as filler, intensifier, heat stabilizer and lubricant as adjuvant. The invention has advantages of fine anti-dazzle property, low cost and fine tenacity.

Owner:孟永华

Method for producing HRB600 steel by using primary aluminum dust of aluminum electrolysis plant

The invention discloses a method for producing HRB600 steel by using primary aluminum dust of an aluminum electrolysis plant. The method comprises the following steps that 1, a part of binder is addedinto the primary aluminum dust of the aluminum electrolysis plant, and the mixture is pressed into aluminum dust balls with the diameter of about 20 mm by adopting a dry powder type ball pressing machine; 2, the pressed aluminum dust ball bodies are carried and conveyed to a steelmaking production line for later use; 3, when the HRB600 steel is produced in a converter, the aluminum dust balls areadded firstly and then deoxidation alloying elements are added, and an original steelmaking process operation method is maintained; and 4, 1.5-3 kg of the aluminum dust balls is required for making one ton of steel. According to the method, the problem of secondary utilization of the primary aluminum dust can be effectively solved, the primary aluminum dust is applied to steelmaking production, so that the waste is changed into wealth, and the environmental pollution is reduced.

Owner:XINJIANG BAYI IRON & STEEL

Microporous lightweight corundum refractory aggregate and preparation method thereof

The invention relates to a microporous lightweight corundum refractory aggregate and a preparation method thereof. The technical scheme is as follows: the microporous lightweight corundum refractory aggregate is prepared from the following raw materials by mass percent: 80-99wt% of commercial alumina fine powder, 0-25wt% of commercial aluminum hydroxide fine powder or alpha-Al2O3 micro powder, 0-5wt% of metal aluminum powder, aluminum fluoride, or aluminum nitrate aluminum salt which is taken as a mineralizer, and 1-10wt% of saw dust, lignin or carbon black serving as a pore increasing agent. The preparation method comprises steps of continuously grinding the raw materials according to the proportion in a circle flow ball mill, obtaining uniformly mixed qualified powder material with median diameter of 2-8mu m step-by-step through 2-5 grade of winnowing, balling in a horizontal or disc type ball forming mill, drying, then rapidly firing in a shaft kiln at 1800-1950DEG C, and crushing so as to obtain the microporous lightweight corundum aggregate. The microporous lightweight corundum aggregate has a simple and convenient production technology, is applicable to large-scale industrial production, and has advantages of small pore diameter, high strength, low heat conductivity, scouring resistance and corrosion resistance.

Owner:JIANGSU JINGXIN NEW MATERIAL

Novel high-energy igniter charge and its coating technology

InactiveCN1730447ANo explosionSimple and fast operationAlkali metal salt explosive compositionsDetonationAdhesive

The invention provides a detonation and ignition charge in extinguishing devices and its coating process, which comprises mixing potassium perchlorate and fine ball-type aluminum dust into solid article, mixing with external adhesive solution, coating onto the main charge and ignition surface, then air-drying.

Owner:XIAN XINSI CHEM EQUIP MFG

Aluminum plate cutting device

PendingCN107824890AAvoid accumulationAvoid burnsFeeding apparatusPositioning apparatusElectric machineryEngineering

The invention discloses an aluminum plate cutting device. The device comprises a worktable, a sliding groove, a sliding block, an adjusting bolt, a cutting knife opening, a motor, a cutting knife, a conveying roller, a brush roller, a dust hole, a dust suction pump, a discharging groove, a conveying belt, supporting legs, a metal hose, a water spraying head and a water tank; the worktable is arranged in an inclined manner, the horizontal height of the left end of the worktable is lower than that of the right end, the sliding groove is formed in the upper portion of the worktable in the width direction, the sliding block is arranged in the sliding groove in a sliding manner, the left end of the worktable is in threaded connection with the adjusting bolt, the drilling-in end of the adjustingbolt stretches into the sliding groove and is in rotation connection with the left side of the sliding block, and the cutting knife opening is formed in the position, on the right side of the slidinggroove, of the upper of the worktable. Compared with the prior art, an aluminum plate can be rapidly cut, the cutting efficiency and the cutting precision are improved, aluminum powder on the aluminum plate can be removed rapidly, labor intensity of workers is reduced, and machining efficiency is improved.

Owner:JIAXING BOLONG ALUMINUM DECORATIVE BOARD

Method for preparing low-silicon high-titanium ferroalloy employing lower ignition method

The invention discloses a low-Si high-Ti iron which is produced through lower ignition method, and the raw materials include red schorl, aluminum dust, lime, sodium carbonate, fluorite, potassium chlorate and powdered iron ore, the depurating agents include powdered iron ore, magnesite powder and fluorite, and the ignition agents includes magnesite powder and sphene.

Owner:东汇大健康产业股份有限公司

Aluminum-free anti-counterfeiting lining paper for cigarettes and production method thereof

InactiveCN102587206ALow priceNothing producedCoatings with pigmentsSpecial paperPolyvinyl alcoholAdhesive

The invention provides an aluminum-free anti-counterfeiting lining paper for cigarettes and a production method thereof. The lining paper is composed of an anti-counterfeiting paper layer, a coating layer and an aqueous printing oil layer. The technical indexes are as follows: the fixed quantify is 60+ / -3 g / m<2>; the thickness is 0.07+ / -0.005 mm; the flatness is more than or equal to 80 S; the tensile strength is more than or equal to 1.8 kN / m; the whiteness is more than or equal to 80%; the water content is 4-6%; and the air permeability is less than or equal to 0.01 micron / Pa.s. The production method comprises the following steps of: firstly preparing a coating; and then, coating the prepared coating on front and back sides of anti-counterfeiting paper on a coating machine, so as to prepare a product. According to the production method, the anti-counterfeiting paper is used as basic paper and an anti-counterfeiting function is organically combined with the lining paper for the cigarettes, thereby achieving the anti-counterfeiting effect and greatly reducing the cost. The formula of the coating used in the preparation method is unique and a main paint part is papermaking porcelain clay which is widely applied to the papermaking industry and is low in price and an adhesive is polyvinyl alcohol and has no extraneous odor or toxicity; in the production process, no organic solvent is used and no pollutant is generated, thereby protecting environment. Non-ferrous metal such as aluminum foils, aluminum powder and copper powder, is not used, so that the product cost is low, the energy consumption is low, and ideals of energy saving and environmental protection and low-carbon lifestyle are realized.

Owner:杜荣安 +2

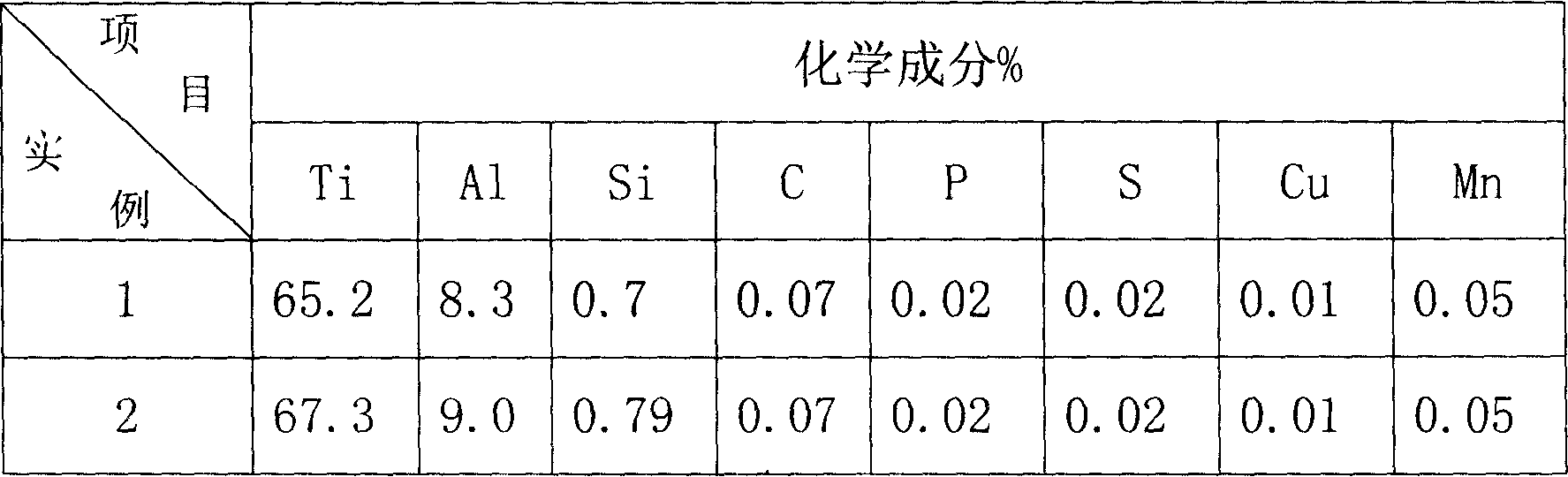

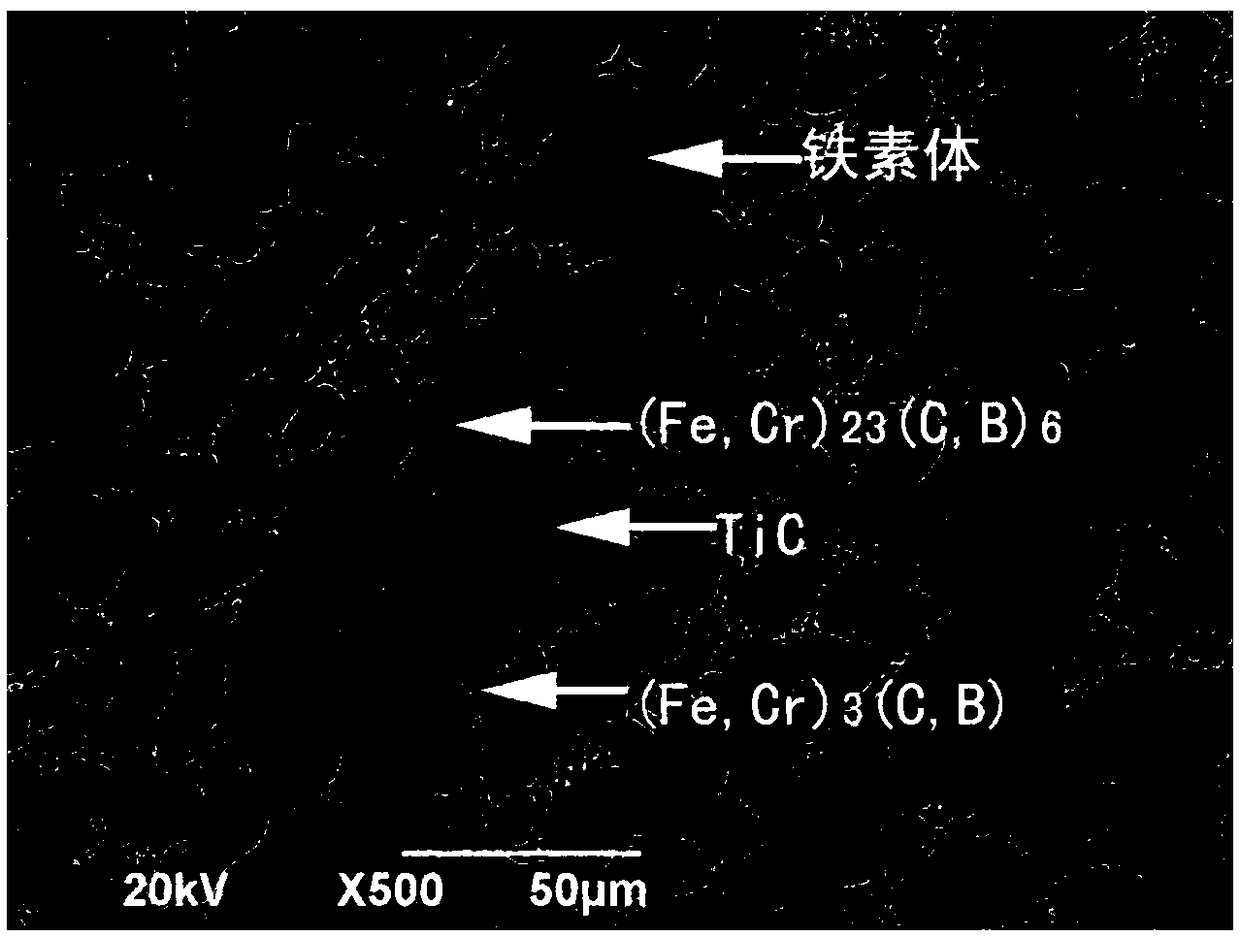

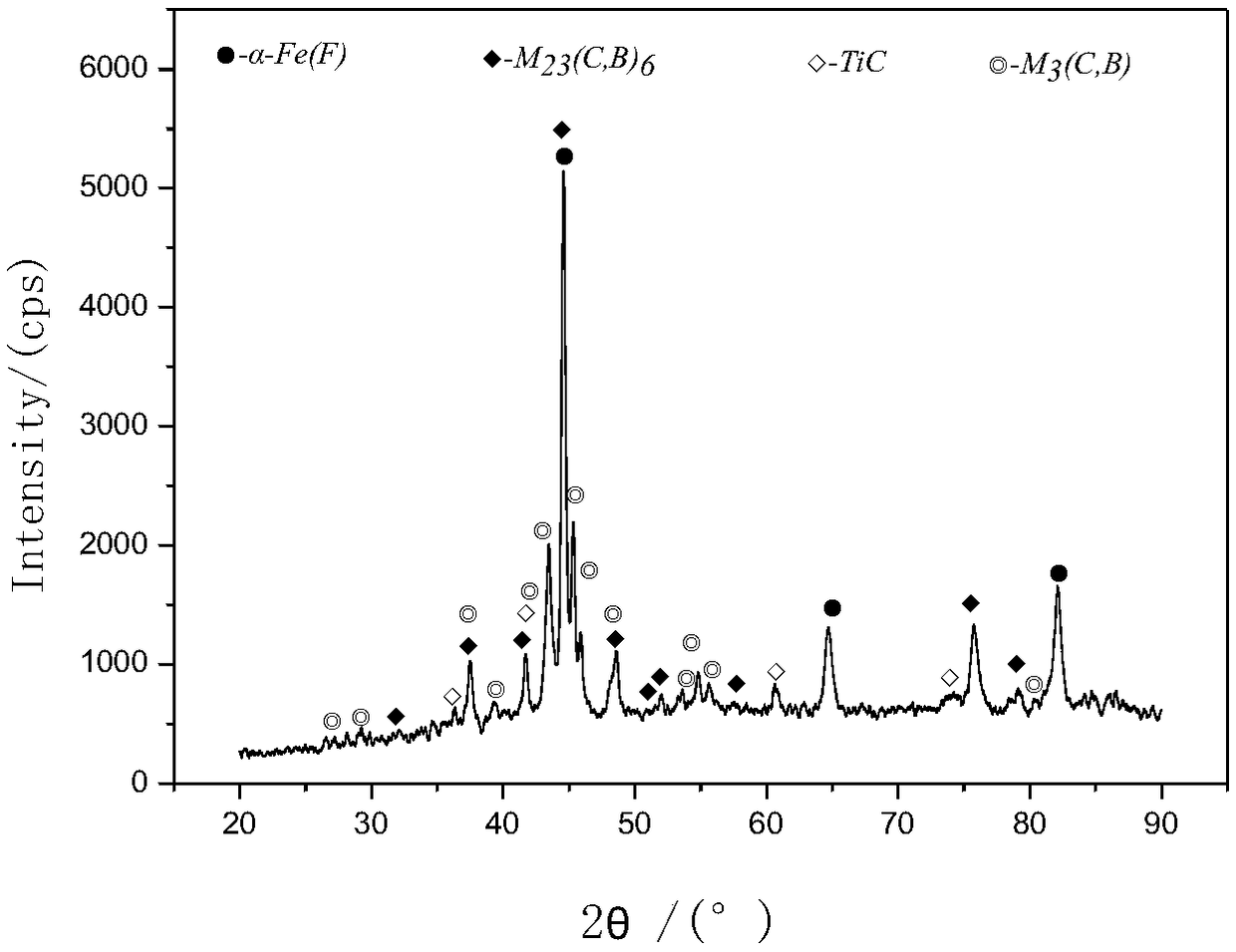

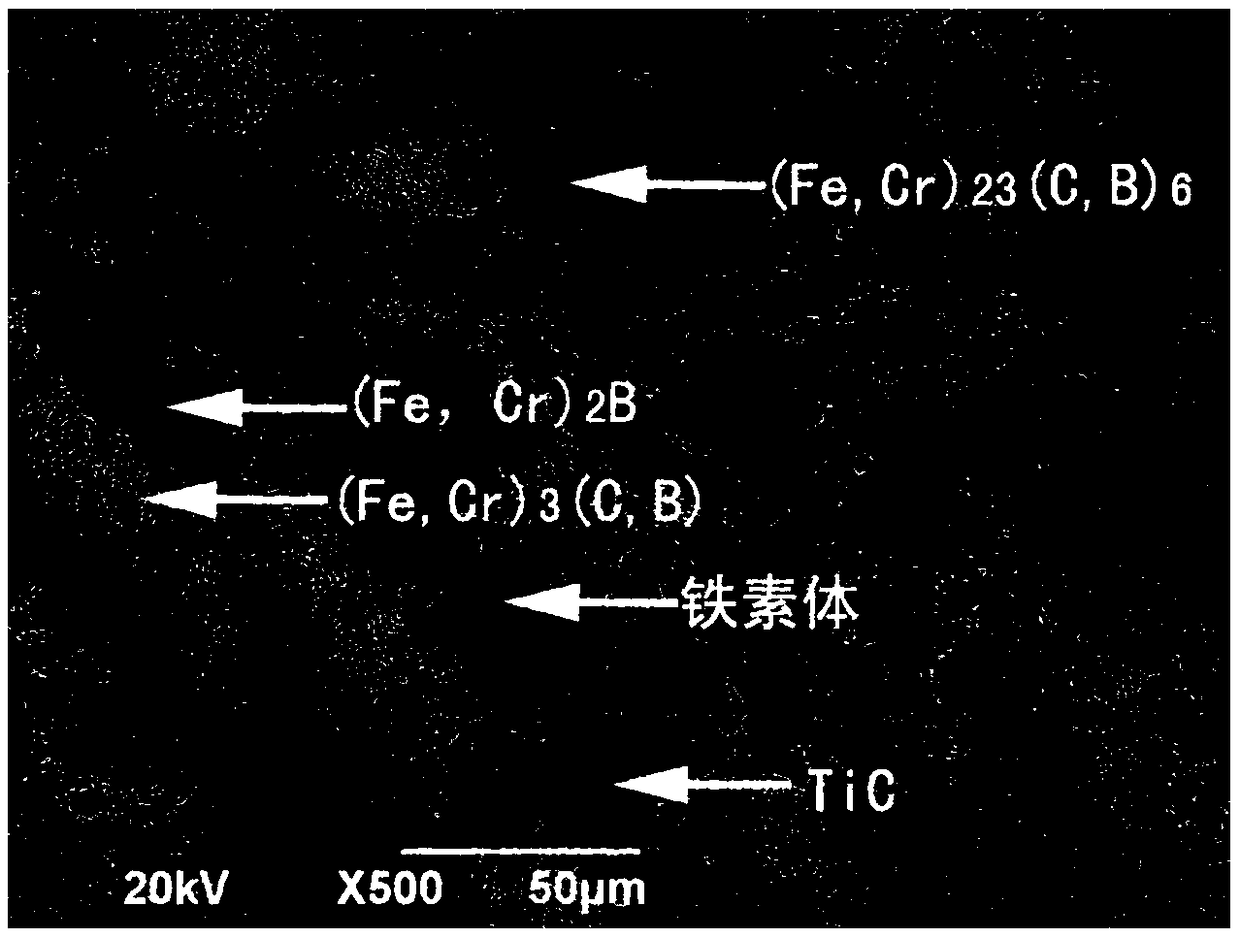

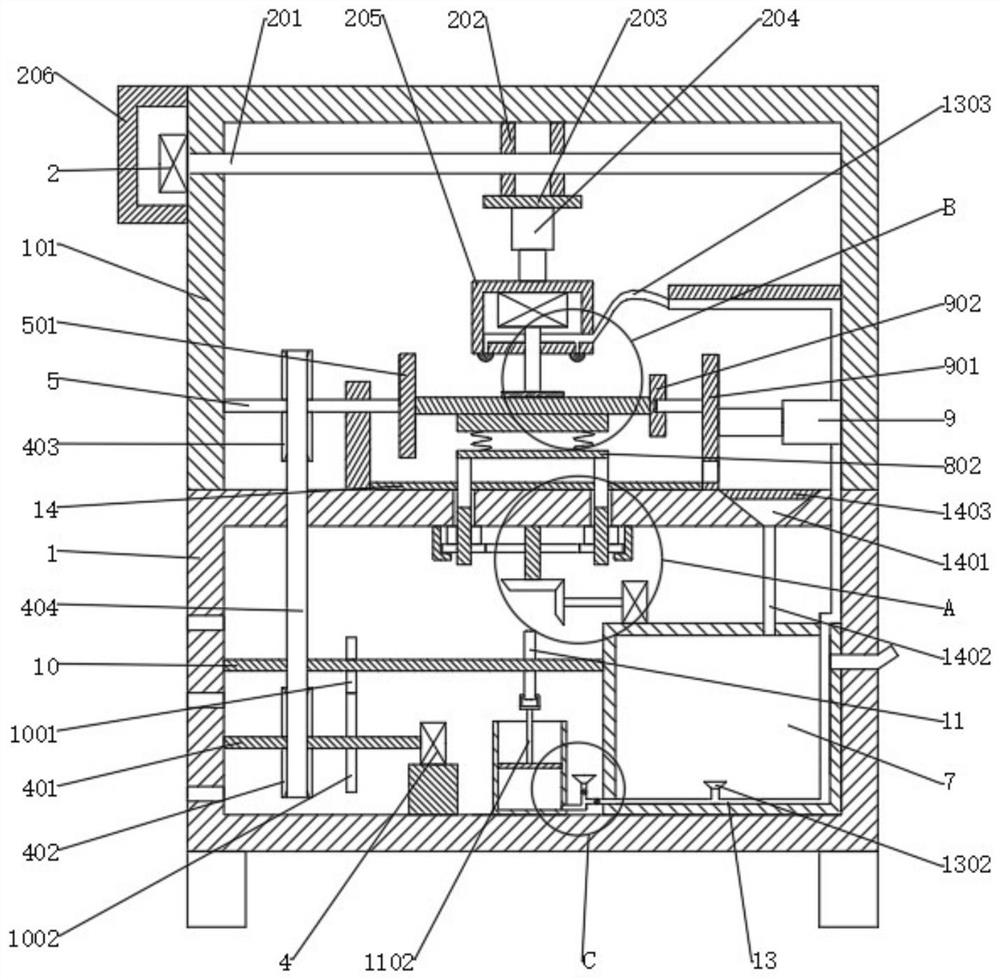

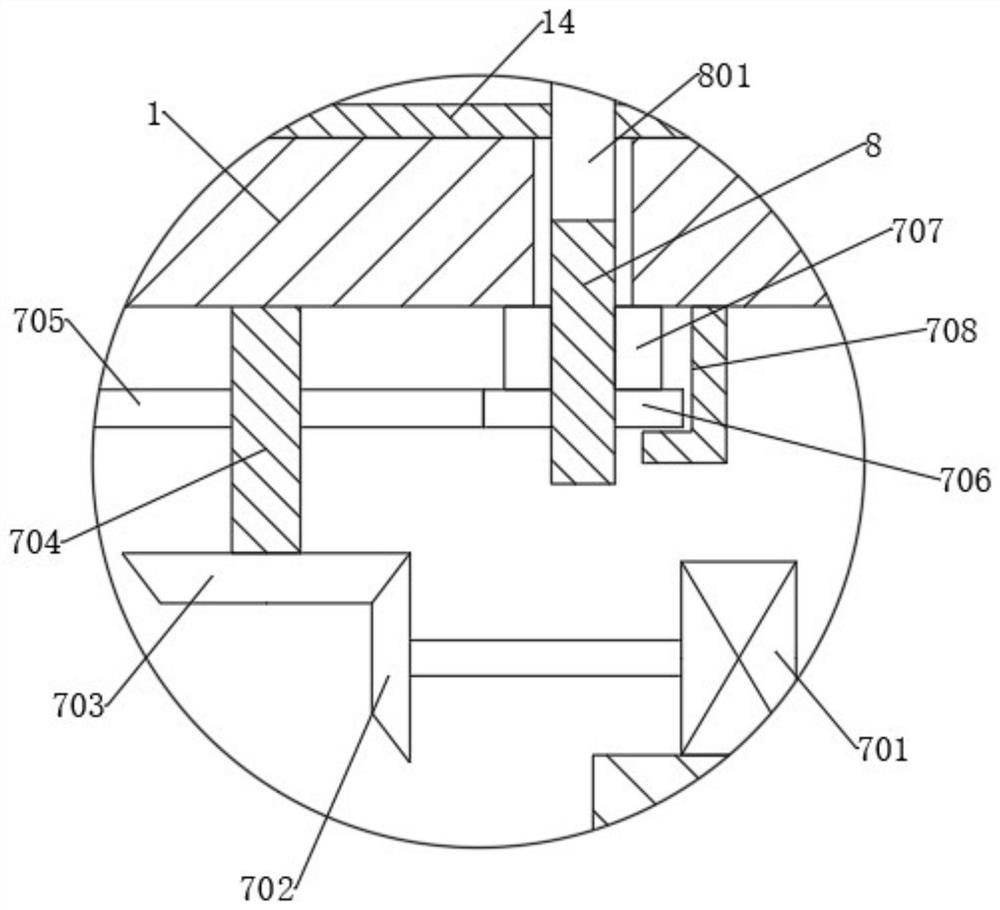

Self-protection visible arc high-boron overlay welding flux-cored wire

ActiveCN108620763APhase toughnessLow costWelding/cutting media/materialsSoldering mediaHigh carbonWear resistant

The invention discloses a self-protection visible arc high-boron overlay welding flux-cored wire. The flux-cored wire is characterized in that an H08A cold-rolled thin steel band is taken as outer layer wrapping skin, high carbon ferrochrome, boron carbide, ferrotitanium, silicoferrite, crystalline flake graphite and superfine aluminum powder and reduced iron powder are blended in the wrapping skin to obtain a powder core, and after self-protection visible arc overlay welding is carried out, an organizational structure taking (Fe,Cr)23(C,B)6 as a main wear-proof phase and consisting of a largequantity of ferrites distributed along a cystiform grain boundary and a small quantity of isolated and dispersed (Fe,Cr)3(C,B) is formed. The flux-cored wire adopts a combined deoxygenation mode featured by initial-stage deoxygenation with superfine aluminum dust, middle-stage deoxygenation with ferrotitanium and later-stage deoxygenation with silicoferrite, so that formation of a cystiform (Fe,Cr)23(C,B)6 acting as the main wear-proof phase in an overlay welding alloy is facilitated, and the volume fraction of the cystiform (Fe,Cr)23(C,B)6 reaches above 90%. On a working condition that wear-proof particles with a certain impact load are abraded, the high-boron flux-cored wire can be used for a component self-protection visible arc overlay welding wear-resistant layer.

Owner:XIANGTAN UNIV

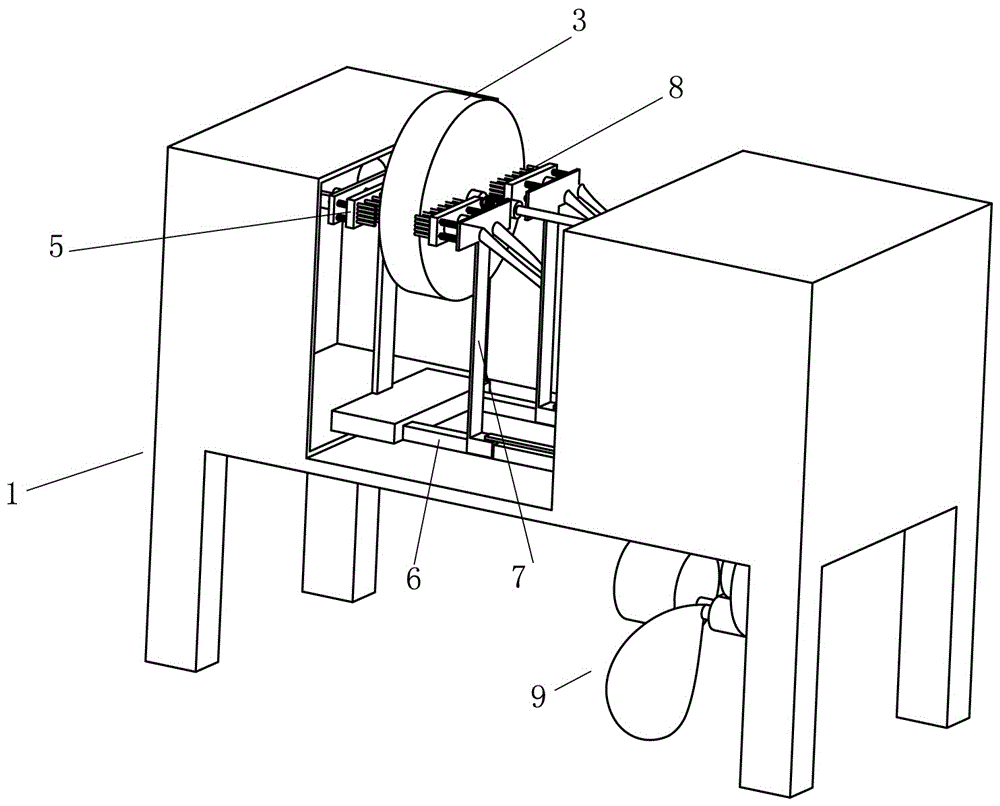

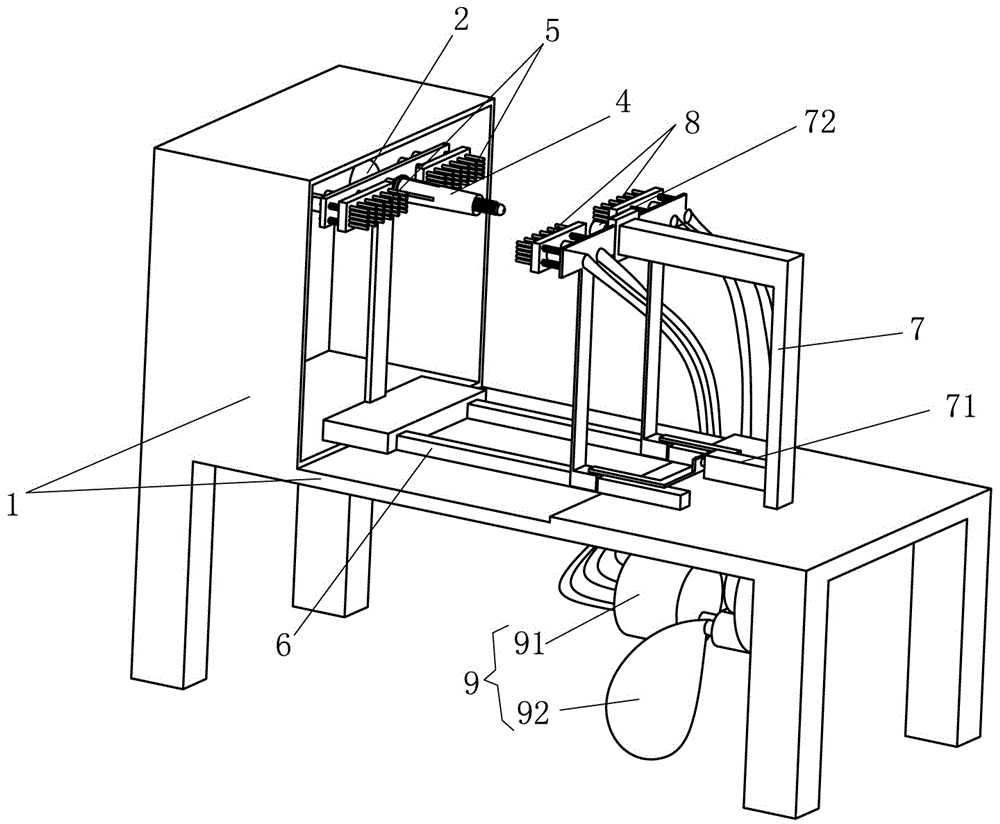

Automatic machining device for aluminum alloy handle production

InactiveCN111906633AAvoid wanderingEnsure health and safetyGrinding carriagesGrinding drivesSpray nozzleElectric machinery

The invention discloses an automatic machining device for aluminum alloy handle production, and belongs to the technical field of aluminum alloy polishing. The automatic machining device for aluminumalloy handle production comprises a first box body, a supporting cover and a handle body, wherein the supporting cover is fixedly connected to the top of the first box body, a moving mechanism is arranged on the supporting cover, the bottom of the moving mechanism is fixedly connected with a first air cylinder, the output end of the first air cylinder is connected with a second box body, a secondmotor is arranged in the second box body, and the output end of the second motor is connected with a grinding piece. The automatic machining device for aluminum alloy handle production is simple in structure and convenient to operate; through mutual cooperation of a cam and a spraying nozzle, when the handle body is polished, the phenomenon that aluminum dust flies everywhere is avoided, and the health and safety of workers are guaranteed; and through mutual cooperation of the second motor and a second air cylinder, the polishing efficiency is greatly improved.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

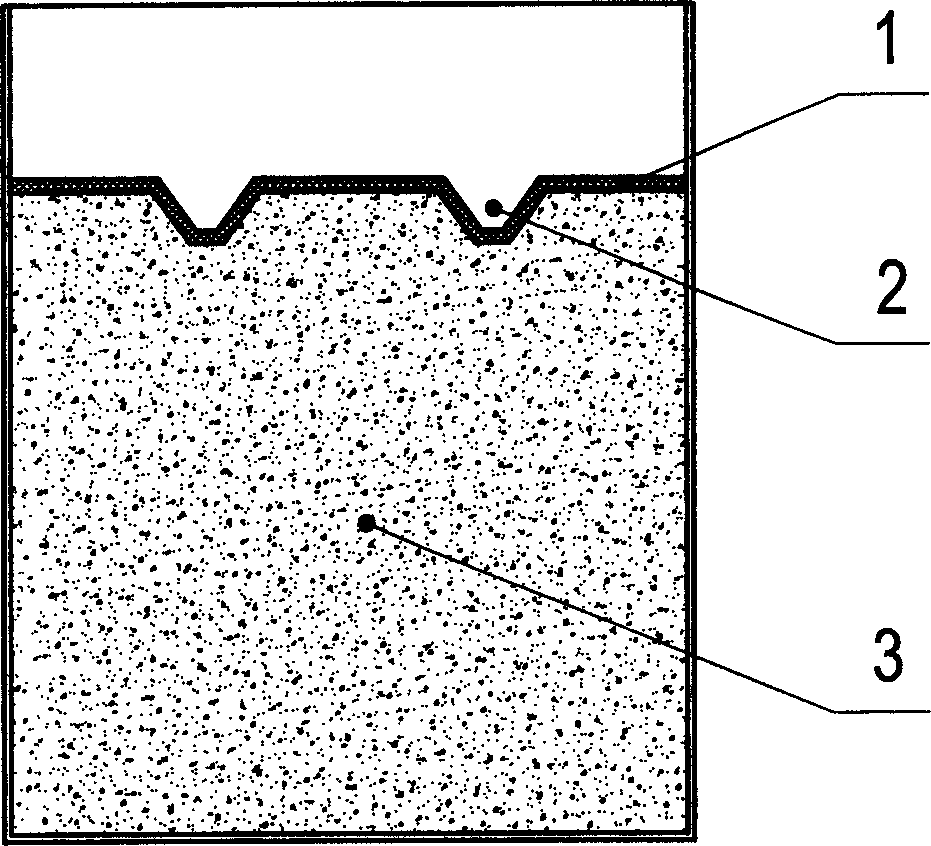

Quakeproof brick

The invention provides a quakeproof brick. The quakeproof brick is characterized in that the quakeproof brick is a single-hole hollow brick, the quakeproof brick is provided with a concave groove formed in the middle portion of the quakeproof brick, and the edges of the groove are parallel to the edges of the quakeproof brick; the size of the concave groove is 240 mm*115 mm*100 mm, and the size of the quakeproof brick is 500 mm*350 mm*250 mm; and the quakeproof brick is composed of straw, shells, cement, coal ash, quartz beads, marble powder, aluminum powder, bentonite, slag, coal gangue, chalk soil, lime, shale, clay, steel fibers, river sand, saw dust and epoxy resin. The quakeproof brick is short in manufacturing period, low in energy consumption, high in tolerance and large in pressure resisting strength.

Owner:江苏亿鼎新型建材有限公司

Automatic burr and foil dust brushing removing machine for aluminum foil

ActiveCN106217166AReduce pollutionImprove cleanlinessEdge grinding machinesGrinding carriagesBristleEngineering

The invention provides an automatic burr and foil dust brushing removing machine for aluminum foil and relates to the technical field of treatment devices for the aluminum foil for aluminum electrolytic capacitors. The automatic burr and foil dust brushing removing machine comprises a machine frame. An aluminum foil rotary driving motor is arranged on the machine frame. A motor shaft of the aluminum foil rotary driving motor is connected with a hollow supporting shaft for being sleeved with a whole coil of aluminum foil. First brushes corresponding to the left end face of the aluminum foil are arranged on the machine frame. A brush support is slidably connected to the machine frame through sliding rails. Second brushes corresponding to the right end face of the aluminum foil are arranged on the brush support. A first air cylinder used for driving the second brushes to get close to or get away from the right end face of the aluminum foil is further arranged between the machine frame and the brush support. The first brushes and the second brushes each comprise a hollow brush body and bristles arranged on the brush body. Dust sucking holes are formed in the side, where the bristles are located, of each brush body. A cavity of each brush body is connected with a dust collecting mechanism through an air sucking pipeline. The two ends of the aluminum foil are cleaned simultaneously through the first brushes and the second brushes static relative to the first brushes. Under the action of the dust collecting mechanism, aluminum scraps and aluminum dust adhering to the edge of the aluminum foil are sucked away and removed, the removal effect is good, the efficiency is high, pollution to air is low, and the product quality is improved easily.

Owner:深圳市新中元电子有限公司

Dedusting equipment and technology for combustible dust environment

ActiveCN105056674AEfficient dust removalReduce the likelihood of an explosionCombination devicesDust controlEnvironmental engineering

The invention provides dedusting equipment and a technology for combustible dust environment. The dedusting equipment comprises a dust-absorbing device, a dedusting tank, a discharge valve, and a collecting tank; the air discharge pipe of the dust-absorbing device is arranged in the dedusting tank, the air discharge opening of the air discharge pipe is soaked in white oil in the dedusting tank; and the collecting tank is connected to the lower end of the dedusting tank through the discharge valve. Because the aluminum dust can explode easily, an explosion-proof blower fan is adopted to absorb the dusts. At the same time, the dedusting equipment is provided with a collecting tank, white oil is directly filled in the collecting tank, the aluminum powder is blown into the collecting tank through the air discharge pipe and is stored in the collecting tank, and the discharge valve is arranged between the space over the collecting tank and the dedusting tank. The equipment can be disassembled directly, can collect the aluminum powder, prevents the aluminum from contacting the air so as to prevent dust nuisance and reactions, and guarantees the safety of production and dedusting operation.

Owner:鞍钢实业微细铝粉有限公司

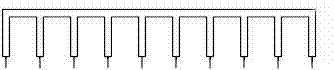

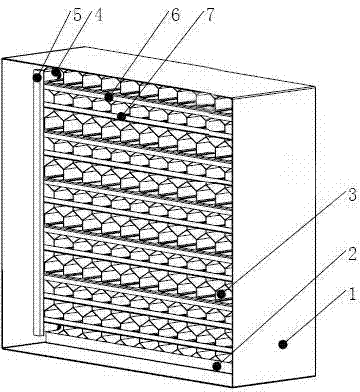

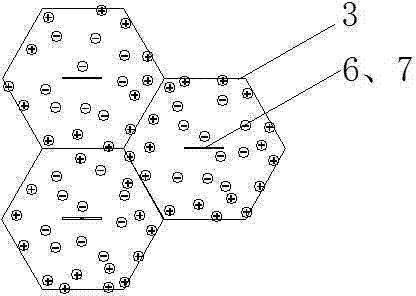

Light honeycomb electrostatic dust removal purifier

InactiveCN104728958AReduce weightDust collection area is wideMechanical apparatusLighting and heating apparatusMetallic materialsAluminum honeycomb

The invention discloses a light honeycomb electrostatic dust removal purifier. According to the structure, a customized aluminum honeycomb plate is adopted as a dust collection plate, integrated type strip electrodes are made of metal materials, the aluminum honeycomb plate is fixed to the shell by a fixing plate, the two integrated type strip electrodes are installed on a fixing strip to form a total electrode net, the total electrode net is connected with the aluminum honeycomb plate through an insulation piece, the total electrode net is connected with high voltage power supply negative electricity, and the aluminum honeycomb dust collection plate is connected with high voltage power supply positive electricity. In the working process, an ionization area and a dust collection area are formed for filtrating. Air enters the dust removal purifier from the direction of the aluminum honeycomb dust collection plate, is ionized through integrated type strip electrode needle ends and then enters the dust collection area. The ionization area can damage constituent molecules of organic matter, degrade organic matter and meanwhile enable the dust particles to be charged, the dust particles are adsorbed to the aluminum dust collection plate under the effect of dust collection area electric field action, and meanwhile the floating dust removal and smog removal effects are achieved. The light honeycomb electrostatic dust removal purifier is large in dust collection area, low in air resistance, easy to manufacture and convenient to clean, and greatly saves labor and using cost.

Owner:牛双印

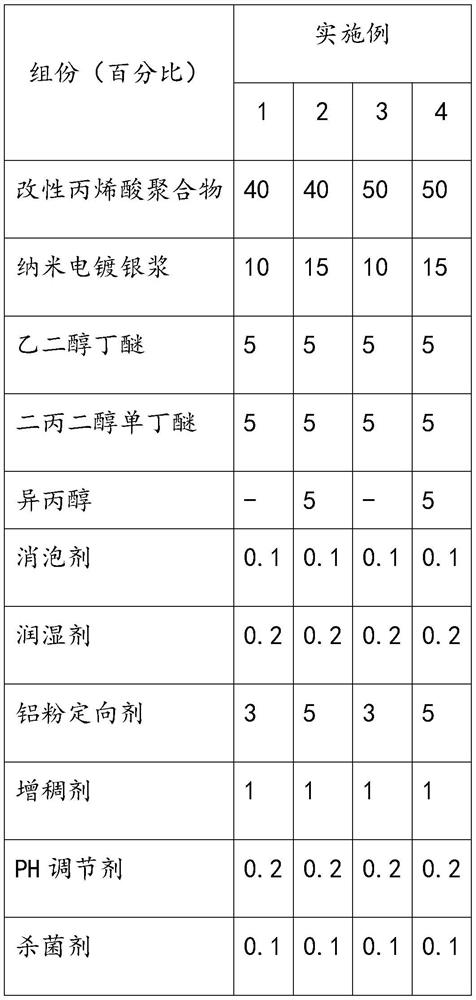

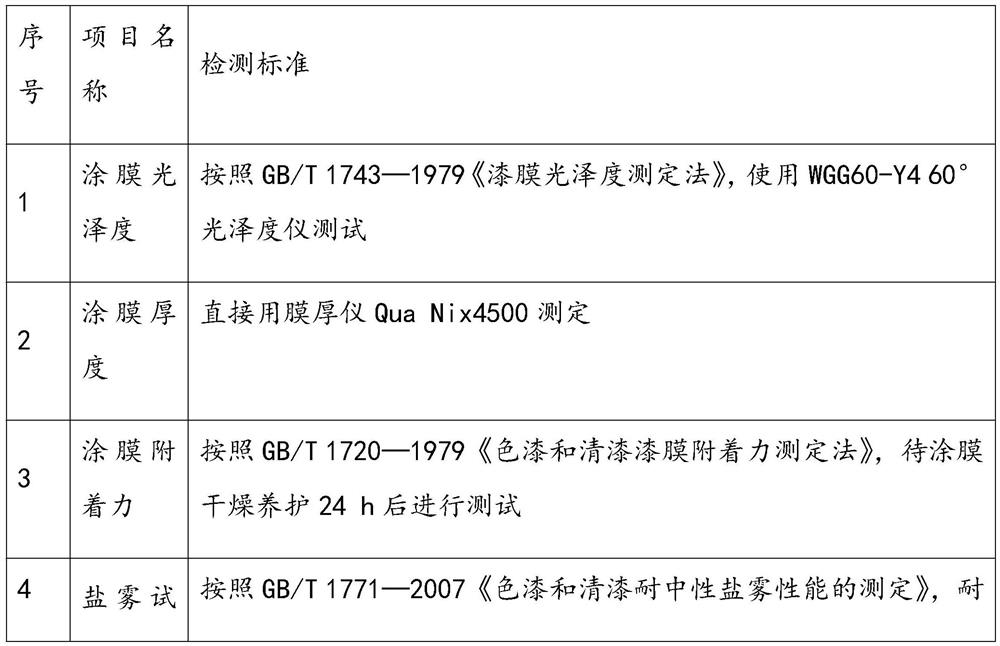

Low-temperature baked water-based electrosilvering paint and preparation method thereof

The invention relates to the technical field of water-based paint preparation, in particular to a low-temperature baked water-based electrosilvering paint and a preparation method thereof. The electrosilvering paint is prepared from, by mass, 40.0-50.0% of an acrylic acid modified polymer, 10.0-15.0% of silver paste, 10.0-15.0% of a water-soluble organic solvent, 2.5-6.0% of an aluminum powder orientation agent, 0.8-3.0% of a functional assistant, and the balance deionized water. According to the low-temperature baked water-based electrosilvering paint and the preparation method thereof provided by the invention, the low-temperature baked water-based electrosilvering paint has excellent adhesiveness and solvent resistance, and the paint is suitable for coating the surfaces of mobile phones, toys, craft plastic products, cosmetic series, notebook computers and the like. And a paint film formed by coating is flat and bright, bright in color, high in hardness, thick in formed film, excellent in wear resistance, and excellent in adhesiveness and solvent resistance. The silver powder is very good in arrangement, the glossiness measured by a 60-degree photometer can reach about 180GU, and the preparation method is simple and easy for industrial production.

Owner:HAOLISEN COATING SHANGHAI

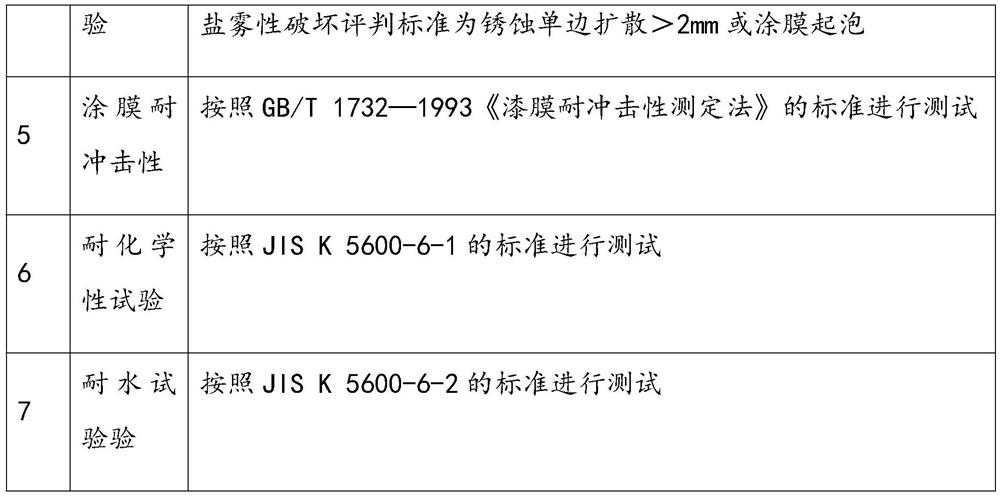

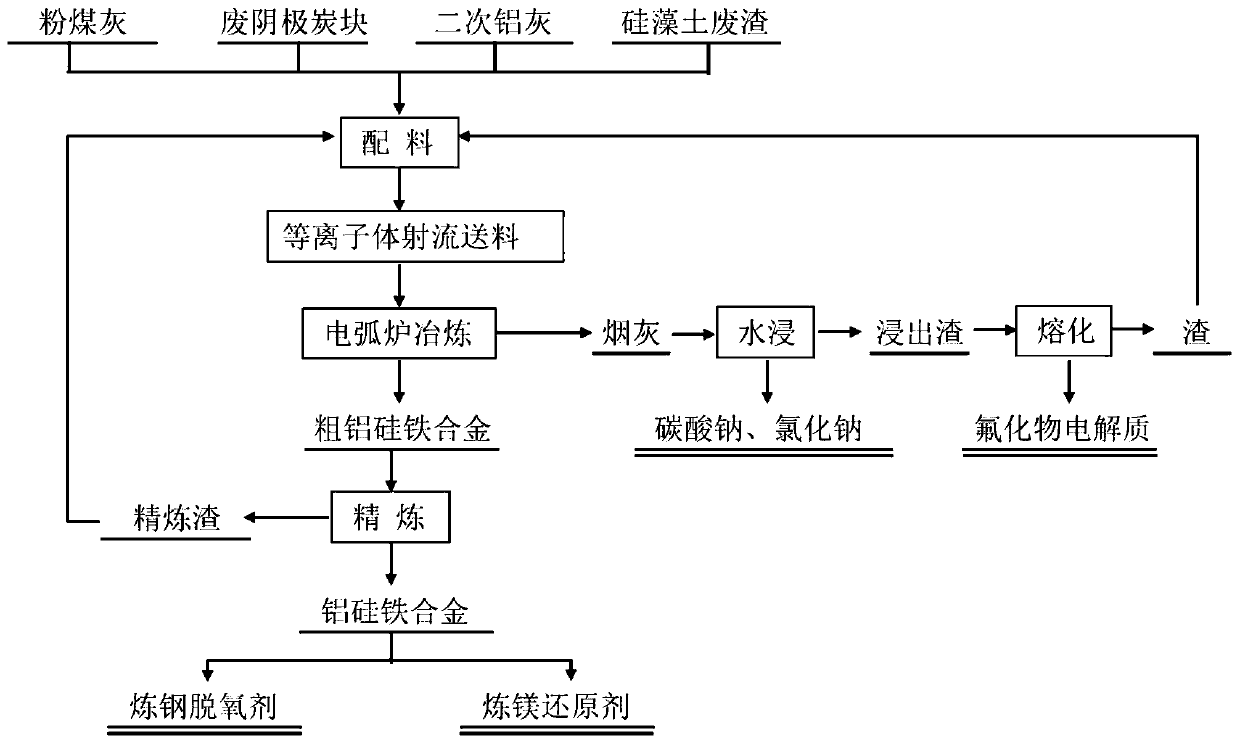

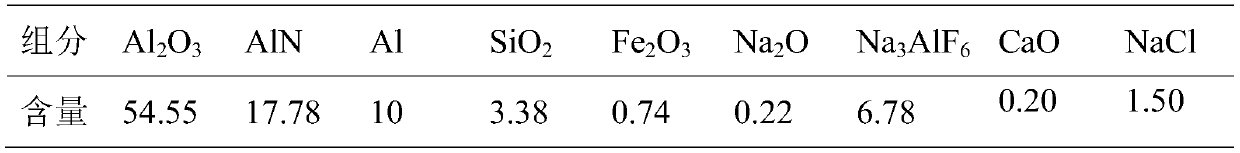

Method for preparing silicon-iron alloy with raw material of aluminum ash and through plasma jet feeding

ActiveCN110004300AAchieve pyrolysisEasy to cause secondary pollutionProcess efficiency improvementAlkali metal carbonatesPlasma jetElectric arc furnace

The invention provides a method for preparing a silicon-iron alloy with a raw material of aluminum ash and through plasma jet feeding. According to the method, the quadratic aluminum dust is used as the raw material, an aluminum electrolysis cell waste cathode carbon block is used as a reducing agent, the aluminum content in the raw material is adjusted by taking fly ash as an additive, the content of silicon in the raw material is adjusted by taking diatomaceous earth waste residue as an additive, and high-temperature reduction is conducted on materials mainly containing aluminum oxide and silicon oxide in an electric arc furnace to obtain a certain-component aluminum-silicon-iron alloy; and a powdery material is conveyed by adopting a plasma flame flow, the reaction temperature can be increased by heating the material, reduction of the oxides and volatilization of fluoride can be accelerated, particularly decomposition of aluminum nitride in the aluminum ash, decomposition of cyanide in the waste cathode carbon block, volatilization and recovery of the fluoride, chloride and alkali metals in the material are realized in the high-temperature reduction process, the high-temperature reaction process of the whole electric arc furnace smelting is enhanced, and the production efficiency is improved, and the comprehensive utilization of each-kind dangerous waste and solid waste isrealized in the same process.

Owner:NORTHEASTERN UNIV

Stainless steel slagging and degassing refining agent

This invention relates to a rustless steel slag-forming and degassing agent, which is specifically a casting accessory material to clean up rustless steel molten steel surface and improve rustless steel quality, and belong to metal surface treatment technique area in foundry industry. This agent mainly comprises 70-80 wt% of dolomite, 10-15 wt% of aluminum dust and 6-15 wt% of fluor. The components are mixed completely in normal temperature and packed to completed product. This invention possesses the properties of increasing life of brasque to more than 200 times; improving slag-forming ability to decrease endermic points, decrease surface points and pocks of buffing surface and increase rate of finished products and improving thermal insulation and degasification by floating constantly on the surface of molten steel, in which molten steel is prevented to contact with air and oxygenized, suck in hydrogen and nitrogen and interfused with foreign substance, so as to ensure cleaner molten steel higher property.

Owner:张华静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com