Production method of recycled aluminum

A production method and recycled aluminum technology, which is applied in the field of metal smelting and processing, can solve the problems of unsatisfactory removal, waste gas, waste water environmental pollution, etc., and achieve the effects of improving recovery rate, avoiding air pollution, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

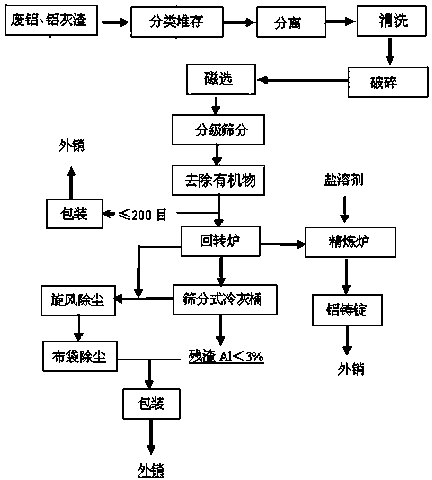

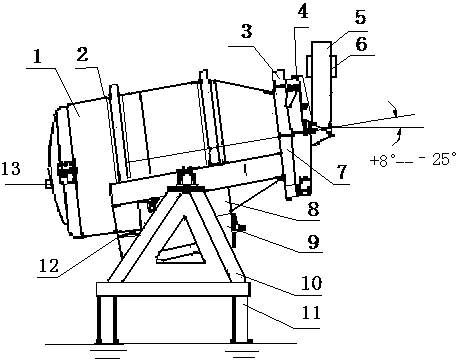

Method used

Image

Examples

Embodiment 1

[0047] Classify and stack pure aluminum, deformed aluminum alloy, cast aluminum alloy, aluminum core wire and waste aluminum products. For waste aluminum products recovered from waste companies, they should be disassembled to remove steel and other non-ferrous metal parts connected with aluminum materials , and then subdivided, and then use cleaning and crushing methods to remove sludge, fibers and paper. Large pieces of waste aluminum products must be smashed before cleaning. For light and loose flake waste aluminum pieces, use a hydraulic metal baler to press Packing; for aluminum steel cored wire, the steel core is separated first, and then the aluminum wire is wound into a coil; the cleaning process uses an aqueous solution with a weight content of 1-2% surfactant, and the water temperature is 40-60°C, and the method is carried out by spraying and rotating Cleaning: After cleaning, use magnetic separation equipment to separate the magnetic scrap iron and steel from the scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com