Patents

Literature

1241 results about "Rotary furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

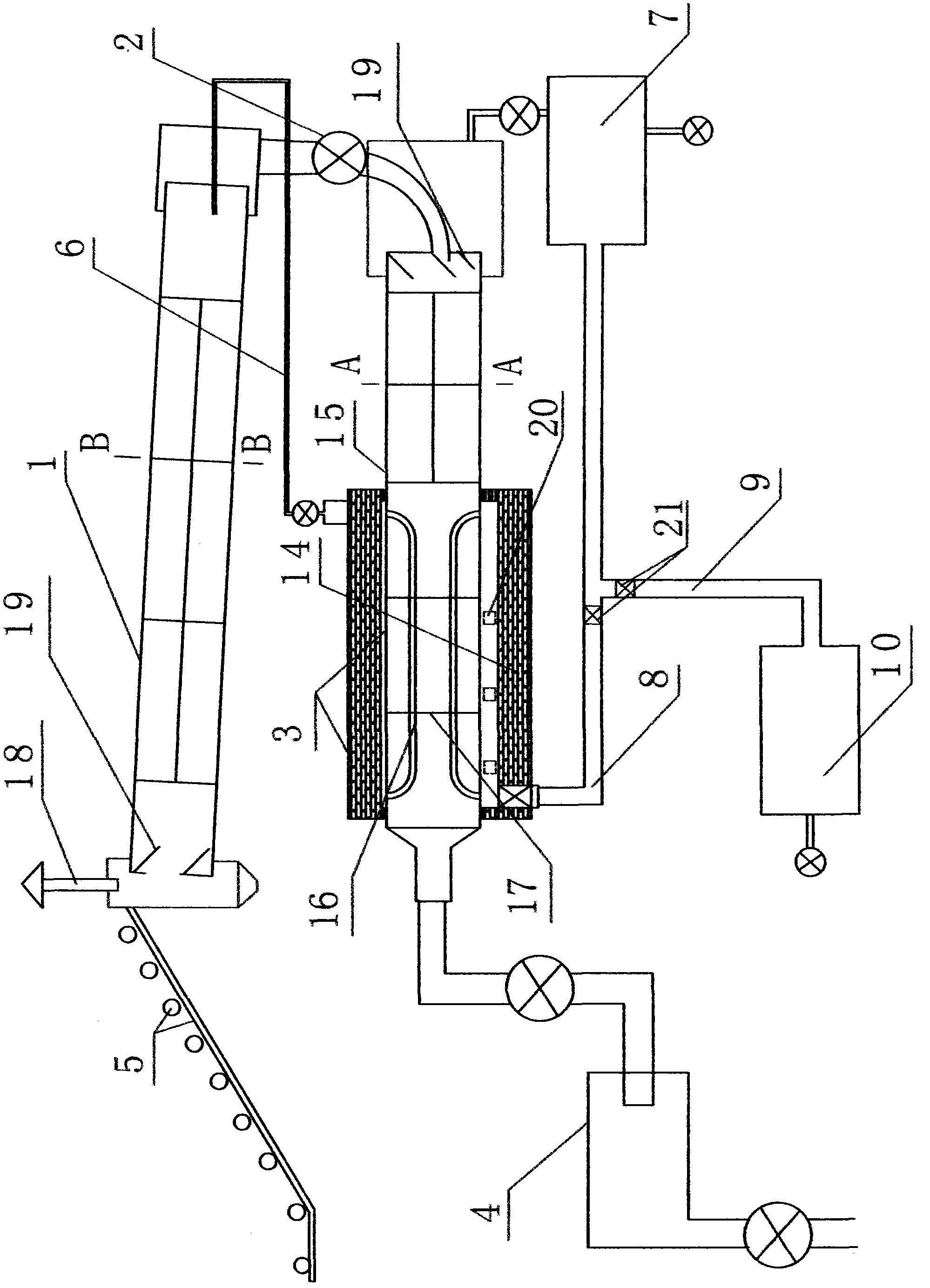

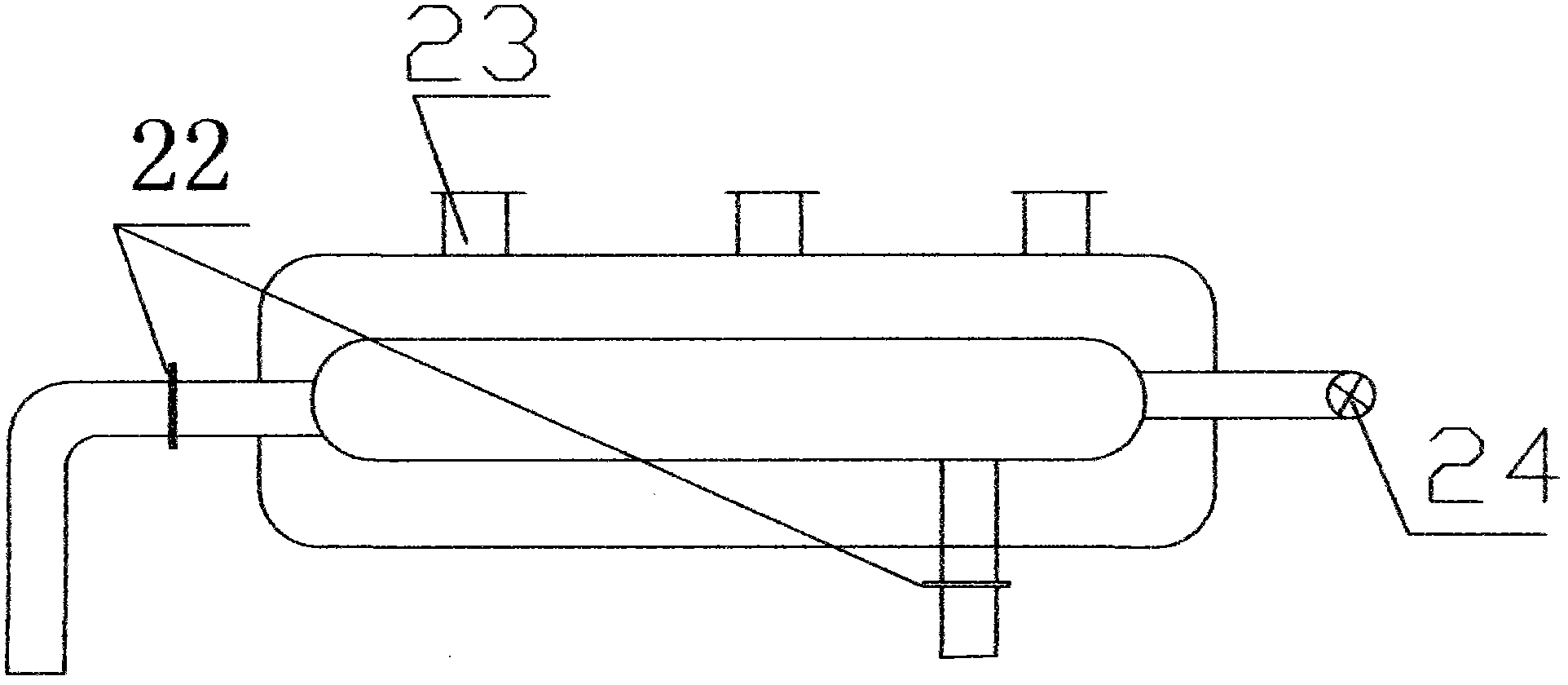

Process for internally heated continuous preparing biomass pyrolysis gasification gas and rotary furnace utilized by same

ActiveCN101693848ASmall footprintProvide continuous and stableBiofuelsSpecial form destructive distillationThermal energyDecomposition

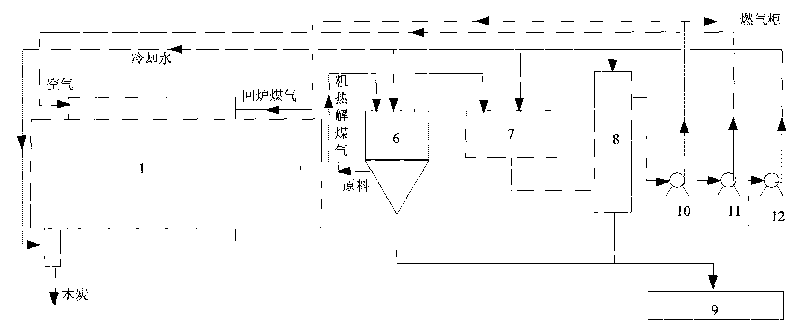

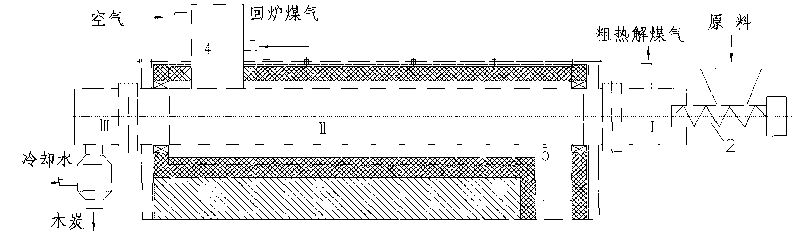

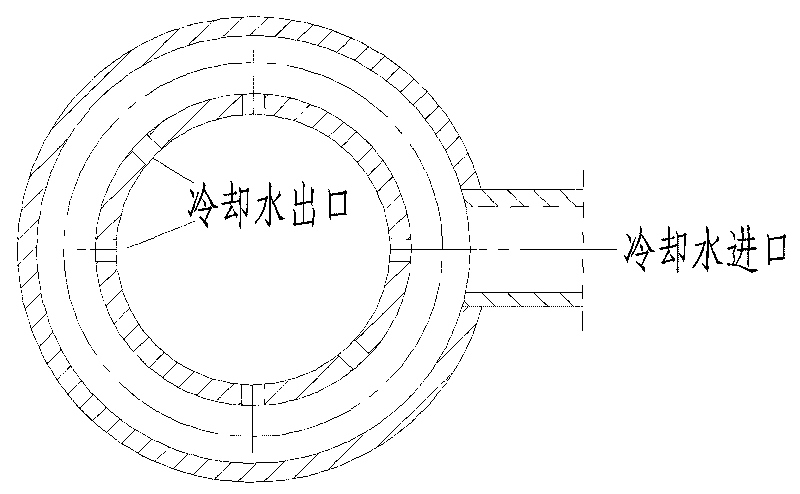

The invention discloses a process for integrally heated continuous preparing biomass pyrolysis gasification gas and a rotary furnace utilized by the same. At a furnace tail cooling section, red charcoal at a temperature of 600-800 DEG C after pyrolyzing and destructive distilling reacts with steam generated by cooling spray water on the lower portion in the furnace so as to absorb large quantities of heat and simultaneously generate water gas and semi-water gas. Heat generated by burning recycled gas and air is used for maintaining pyrolysis temperature of biomass material layers and providesenough heat for further, pyrolysis, destructive distillation and steam decomposition reaction. By aid of the heat, biomass inside the furnace is pyrolyzed and destructively distilled to generate large quantities of volatile matters, and the biomass is gradually heated to decompose destructive gas with high heat value. The rotary furnace utilizes a three-section design: a first section is a furnace head preheating section, which is mainly used for preheating and drying raw materials, a second section is a rotary furnace body pyrolysis section, which is mainly used for pyrolysis and destructivedistillation and is a core operation portion of the furnace, and a third section is a furnace tail cooling section, which is mainly used for cooling charcoal. Prepared gas is high in heat value, and devices occupy small space.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

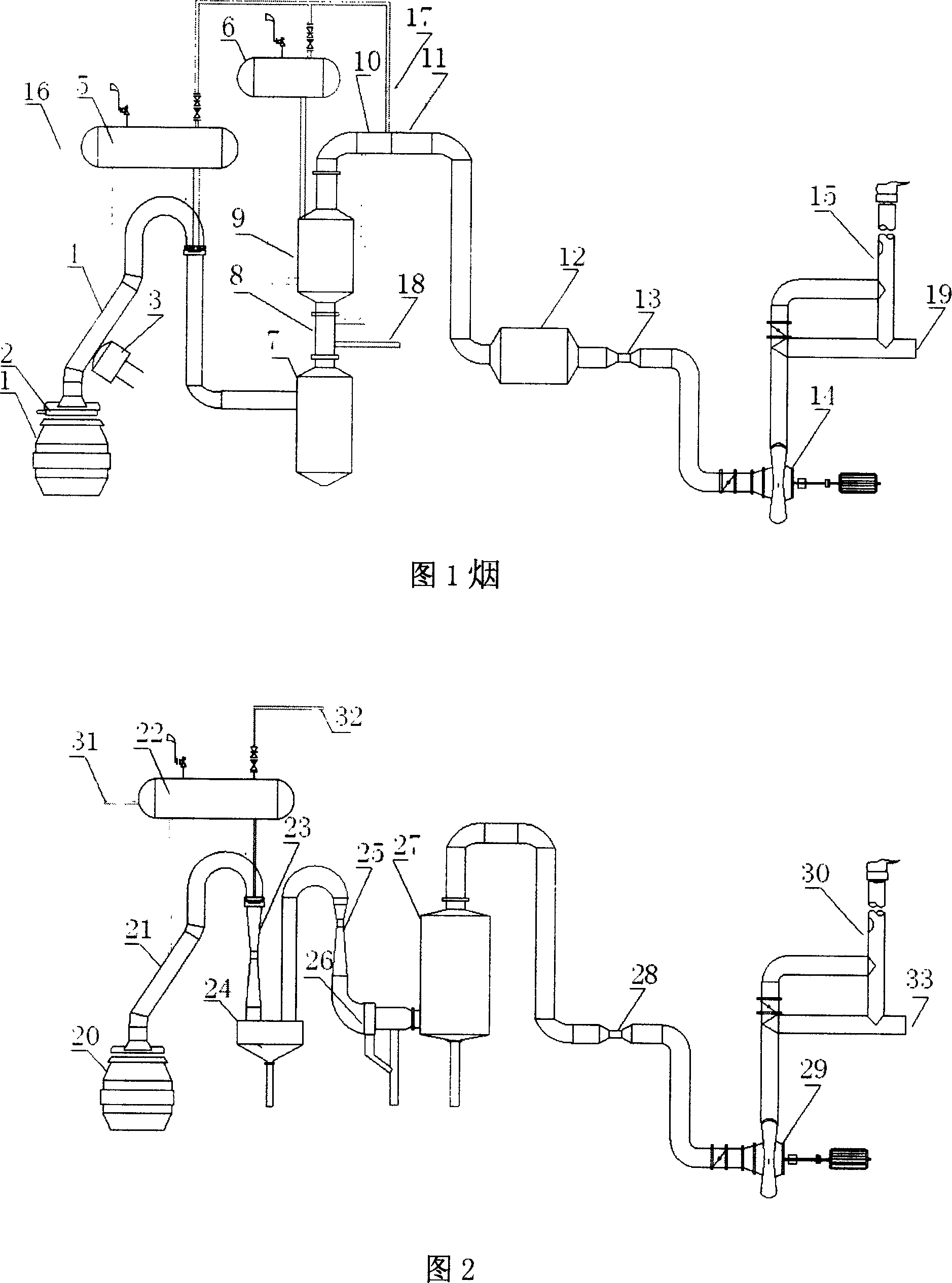

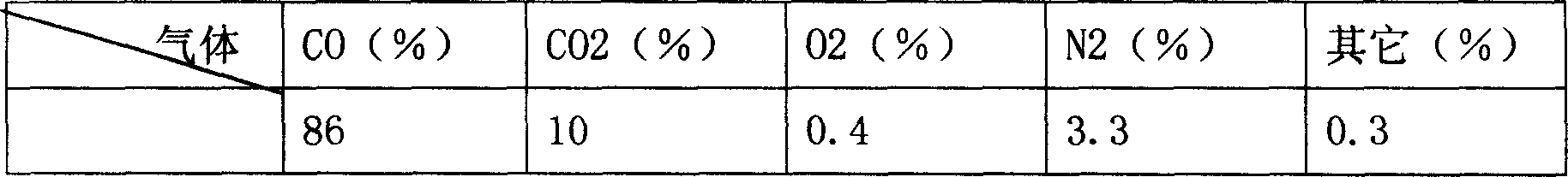

Dry-method dust collection and surplus energy recovery device for steel-smelting converter flue gas

InactiveCN1962884AExtended service lifeEnsure safetyManufacturing convertersProcess efficiency improvementCycloneBaghouse

The invention discloses a recycling device of residual heat to dedust through drying method, which is composed of steel-smelting rotary furnace, high-temperature rapid valve, mobile petticoat pipe, combusting device, vaporization cooling flue, high-temperature cyclone duster, shell-and-tube exchanger, cloth duster (or electric duster), three-way switching valve, dedusting fan, gas thruster device and gas box, wherein the gas combusting supplementing device is set in the flue after mobile smoke bell; the high-temperature vortex deduster is set behind the evaporation cooling flue; the shell-and-tube exchanger is behind the high-temperature vortex deduster, which possesses cloth deduster.

Owner:云南阳光基业能源管控技术股份有限公司

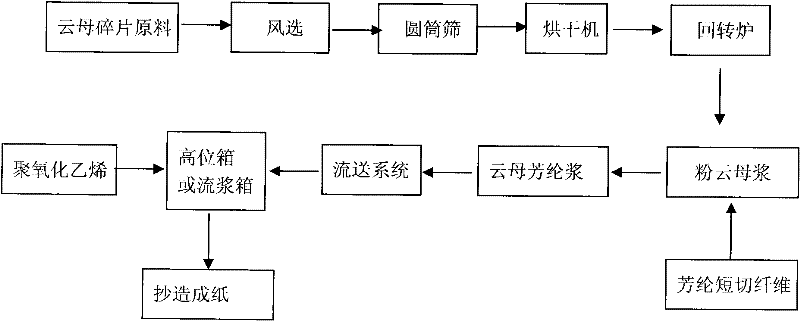

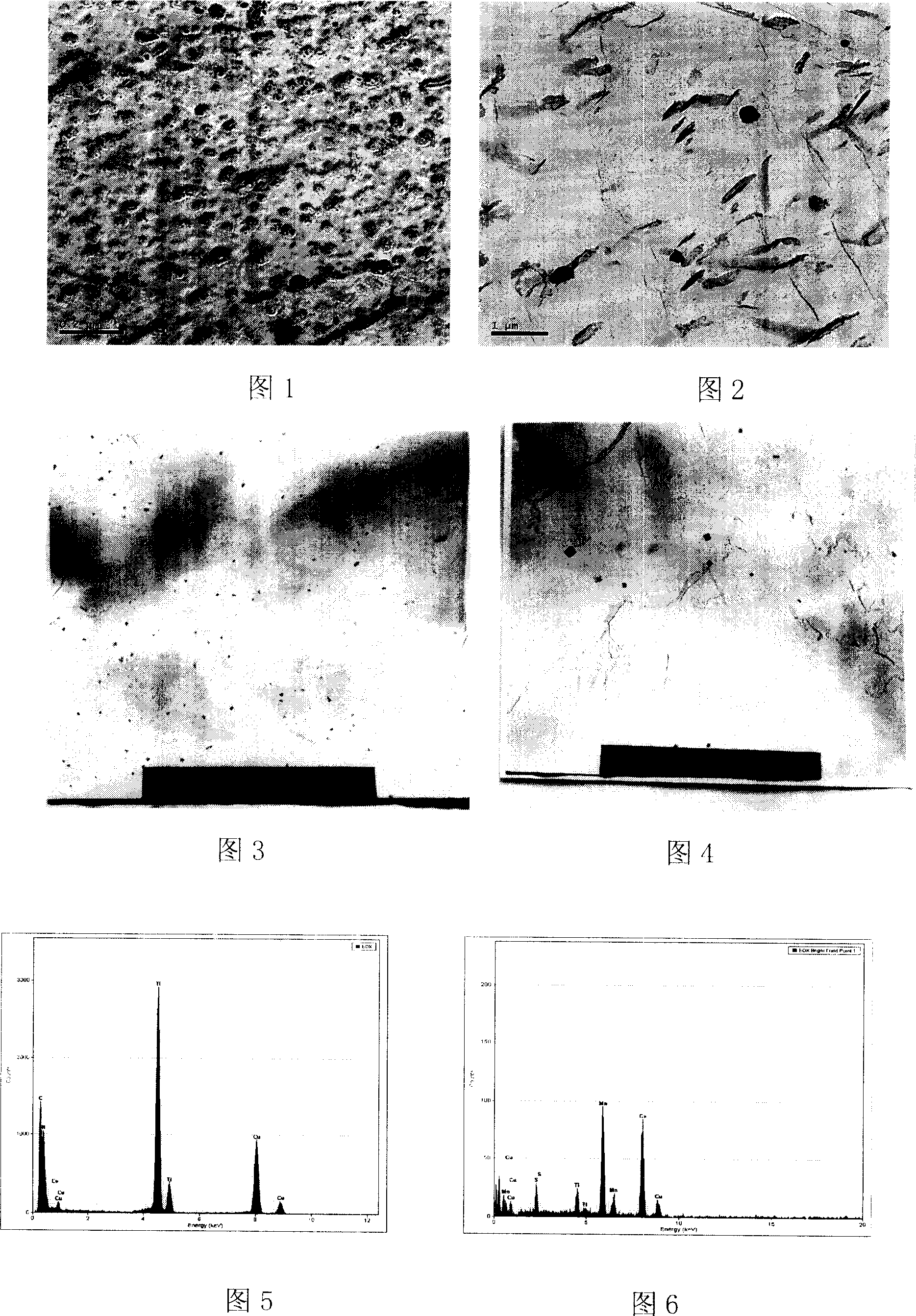

Method for making mica paper by reinforcement of aramid short fiber and chemical pulping

InactiveCN101748648AHigh strengthHigh dielectric strengthSynthetic cellulose/non-cellulose material pulp/paperPulp material addition processesEngineeringRotary furnace

The invention relates to a method for making mica paper by reinforcement of aramid short fiber and chemical pulping. The method comprises the following steps: cleaning mica flakes to remove impurities; putting the mica flakes to an intermittent heating rotary furnace for calcination to remove a part of crystal water in the crystal of mica and generate remarkable expansion and delamination along the vertical direction of a cleavage plane so as to make the mica loose and flexible; dipping the mica in acid or alkali solution at a certain concentration, delaminating into mica sheets, and classifying the mica sheets into chemical mica pulp with certain beating degree; and adding 3 to 15 percent of aramid fiber (based on the mass of the mica flakes) into the pulp, preparing mica aramid pulp, and making the mica aramid pulp into paper by a paper machine. The framework effect of the aramid improves the strength of the mica paper.

Owner:SHAANXI UNIV OF SCI & TECH

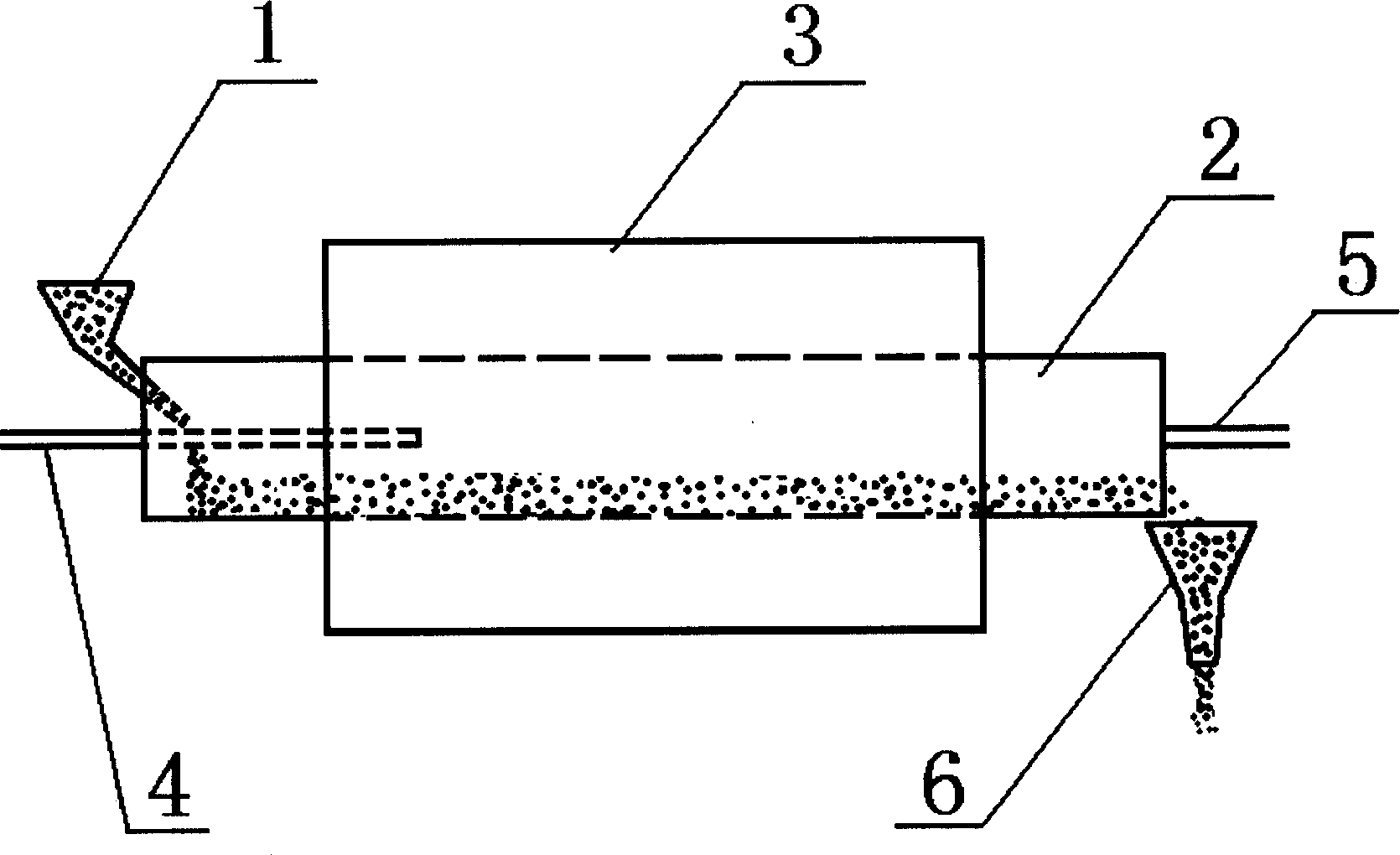

Method for synthesizing lithium ion cell positive cell polar material rotary furnace

InactiveCN1710735AImprove consistencyEvenly heatedElectrode manufacturing processesTemperature controlRotary furnace

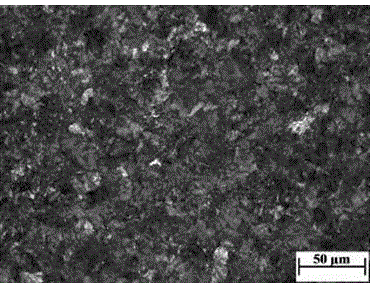

The method includes steps: (1) loading hydrate, oxide of lithium or mixed salt with hydrate, oxide or salt of transition metal into revolving furnace; (2) controlling temperature inside revolving furnace at 600 - 950 deg.C and rotation speed at 2 - 5 turns / minute, calcining admixture in revolving furnace for 20 - 40 hours, and then cooling it; (3) anode material of lithium battery is obtained through steps of crushing and sieving cooled materiel. Since calcined materiel is heated evenly inside revolving furnace, thus, physical and chemical characters of obtained materiel are even features are: shortened time for processing in high temperature, and lowered energy consumption.

Owner:广州鸿森材料有限公司

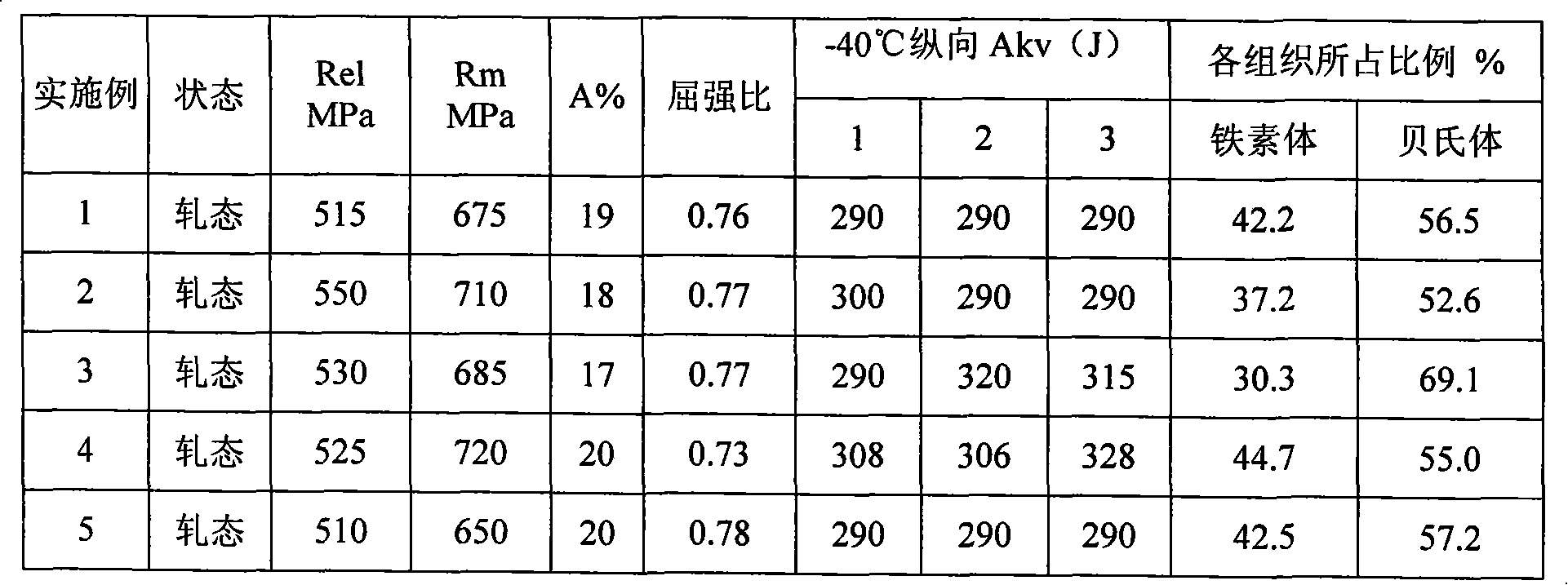

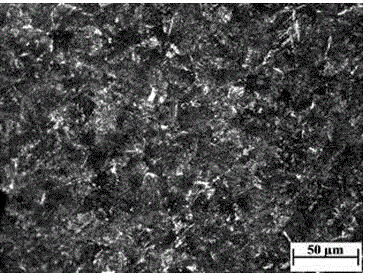

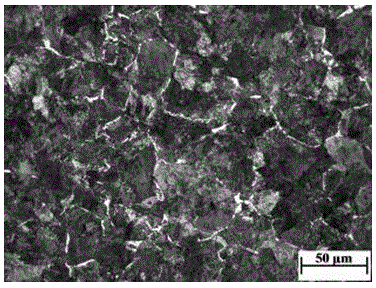

Steel plate for high-strength high-toughness low-yield easily-welding structure and method for manufacturing same

InactiveCN101619423ALow costHigh strengthTemperature control deviceMetal rolling arrangementsRotary furnaceHeating temperature

The invention provides a steel plate for a high-strength high-toughness low-yield easily-welding structure. The steel plate comprises the following chemical components in percentage by weight: 0.02 to 0.08 percent of C, 0.30 to 0.50 percent of Si, 1.50 to 1.80 percent of Mn, 0.02 to 0.04 percent of Nb, 0.005 to 0.030 percent of Ti, 0.008 to 0.20 percent of Mo, 0.30 to 0.90 percent of Cr, 0.30 to 0.50 percent of Cu, 0.10 to 0.40 percent of Ni, 0.010 to 0.070 percent of Als, and the balance of Fe. The method for manufacturing the steel plate comprises the steps of molten iron pretreatment, rotary furnace smelting, refining, continuous casting and rolling, wherein the steel blank heating temperature before rolling is between 1,050 and 1,220 DEG C, the rolling temperature in a recrystallization area is more than or equal to 1,000DEG C, and the rolling temperature in a non-recrystallization area is between 950 and (Ar3 plus 0 to 100) DEG C; and after rolling, the temperature is held, and the plate blank is subjected to accelerated cooling. The method has the advantages of unnecessary addition of B and V, low cost, short production period, and the obtaining of the bainite plus ferrite structure without complex thermal treatment, and can control the yield of the steel plate below 0.8 under the condition of ensuring high strength, high toughness and good welding property.

Owner:ANGANG STEEL CO LTD

Method for producing low carbon bainite high-strength steel based on sheet bar continuous casting and rolling process flow

ActiveCN101254527ASimple metallurgical compositionImprove toughnessProcess efficiency improvementMetal rolling arrangementsThin slabLaminar cooling

The invention discloses a method for producing high-strength low-carbon bainite steel based on thin slab continuous casting and rolling process. The method includes the following steps: melting by using a rotary furnace or an electric furnace, refining molten steel in an LF furnace after the component analysis, performing the composition adjustment, continuously casting thin slabs, directly heating the thin slabs at the temperature of 950-1100 DEG C in a roller-hearth heating (soaking) furnace at a temperature not less than 1150 DEG C, controlling the tapping temperature of heated thin slabs in a range from 1050 DEG C to1160 DEG C, rolling by using a continuous rolling mill to produce plates, finishing at a temperature of 840-860 DEG C, performing laminar cooling, and coiling with a down coiler at a temperature of 550-600 DEG C to produce the steel coil. The method can produce non-tempered high-strength steel based on thin slab continuous casting and rolling process, and has the advantages of simple metallurgical composition of steel, low cost of alloying production, and stability in high toughness and good forming and welding properties of the steel coil.

Owner:湖南华菱涟源钢铁有限公司 +1

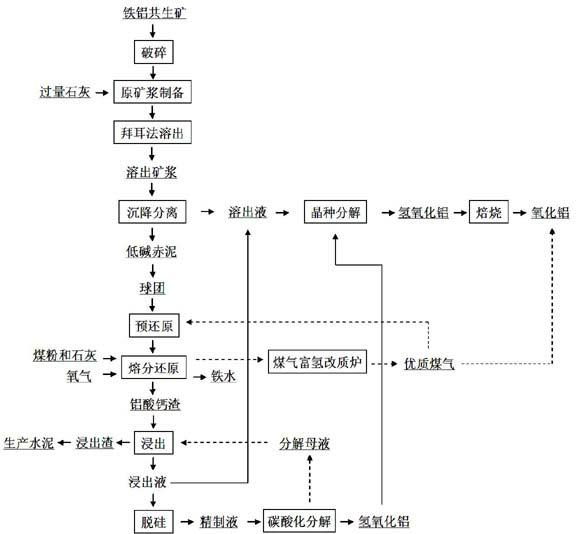

Comprehensive utilization method of high-ferrum and low-grade bauxite

ActiveCN102583477AReduce alkalinityHigh dissolution rateAluminium oxide/hydroxide preparationCarbon captureRotary furnaceCalcium aluminate cements

A comprehensive utilization method of high-ferrum and low-grade bauxite belongs to the technical of metallurgy and is carried out according to the steps as follows: a large proportion of aluminium oxide is extracted through a Bayer process technology that excess lime is added, produced low-alkali red mud is pre-reduced through a coal-based rotary furnace process technology, then high-temperature melting separation of aluminium slag / ferrum is realized by adopting a ferrum bath oxygen coal jetting technology, formed aluminium slag generates calcium aluminate cement after being quenched and tempered, calcium aluminate cement slag is leached with low sodium carbonate solution, a part of leached crude solution and digestion slurry by the Bayer process are mixed and enter a Bayer process system to extract aluminium oxide, and the other part is desilicated and then is resolved in a carbonation manner, aluminum hydrate, which is the decomposition product, is conveyed to the Bayer process system as seed crystal, and resolved mother liquid is used for leaching calcium aluminate cement slag after being mixed. The method provided by the invention can not only ensure efficient dissociation extraction of ferrum and aluminium, but also be practicable in technology and economic benefit, thereby comprehensively utilizing high-ferrum bauxite resource of China effectively.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Coil rod for pre-stressed steel strand and production method of coil rod

The invention discloses a coil rod for a pre-stressed steel strand and a production method of the coil rod. The production method comprises the following steps: smelting in a rotary furnace; refining in an LF; continuously casting; heating; carrying out controlled rolling and controlled cooling. In the continuous casting step, a casting blank consists of the following chemical components in percentage by weight:0.78-0.82 percent of C, 0.20-0.25 percent of Si, 0.75-0.80 percent of Mn, 0.20-0.25 percent of Cr, smaller than or equal to 0.012 percent of P, smaller than or equal to 0.010 percent of S and 0.02-0.03 percent of V. The controlled rolling and controlled cooling step comprises steps of rolling, spinning, cooling and collecting and coiling; in the rolling step, the rolling temperature is 1000+ / -15 DEG C; the precision rolling temperature is 920 to 950 DEG C; in the spinning step, the spinning temperature is 860 to 880 DEG C. According to the method, based on optimization and control of the chemical components, by regulating and controlling the steel rolling process, the sorbite rate of the coil rod is increased, the interlamellar spacing of the sorbite is reduced, and generation of poor tissues is avoided, so that the coil rod has the characteristics of high intensity, high plasticity and low pole difference and satisfies the use requirement that the wire is not broken at a high-pulling speed; the pulling speed is increased; the wire breaking rate is reduced; therefore the production efficiency is improved to some degree.

Owner:宣化钢铁集团有限责任公司

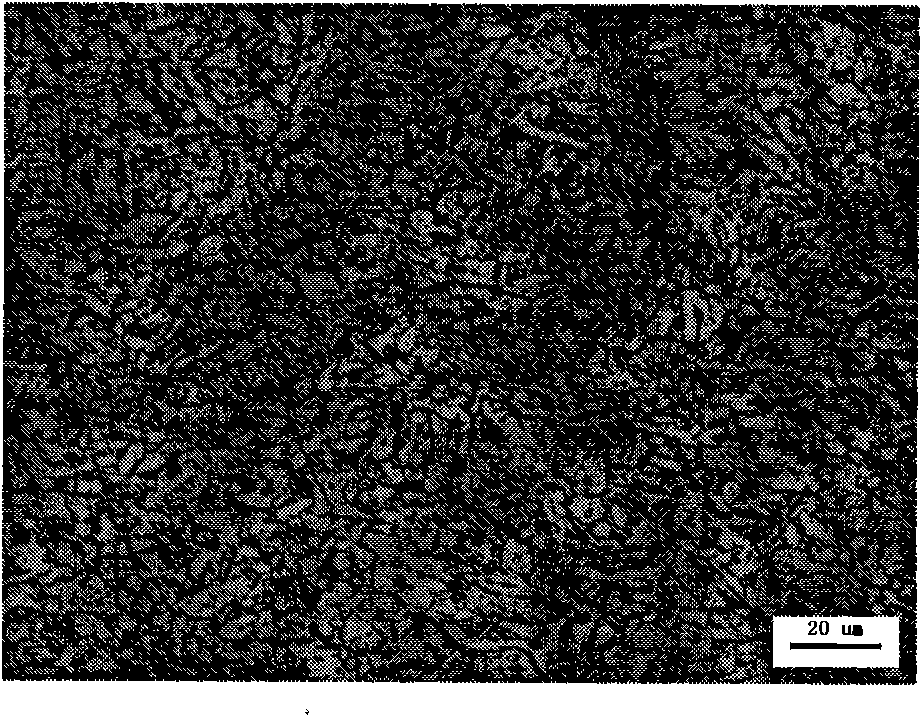

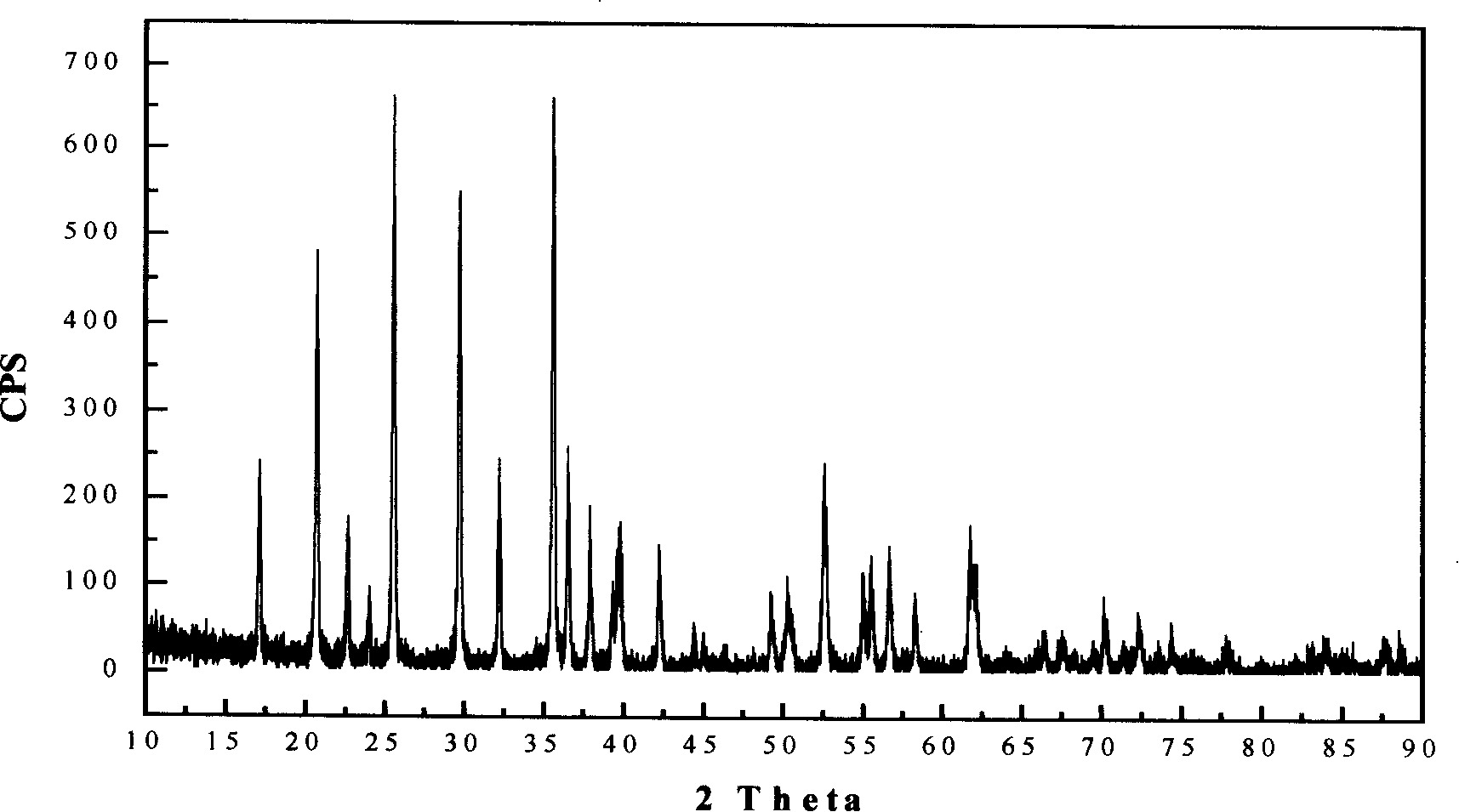

Method for producing lithium iron phosphate material by vacuum rotary kiln

InactiveCN101186289AEvenly heatedNo abnormal growthChemical industryPhosphorus compoundsRotary furnaceRotary kiln

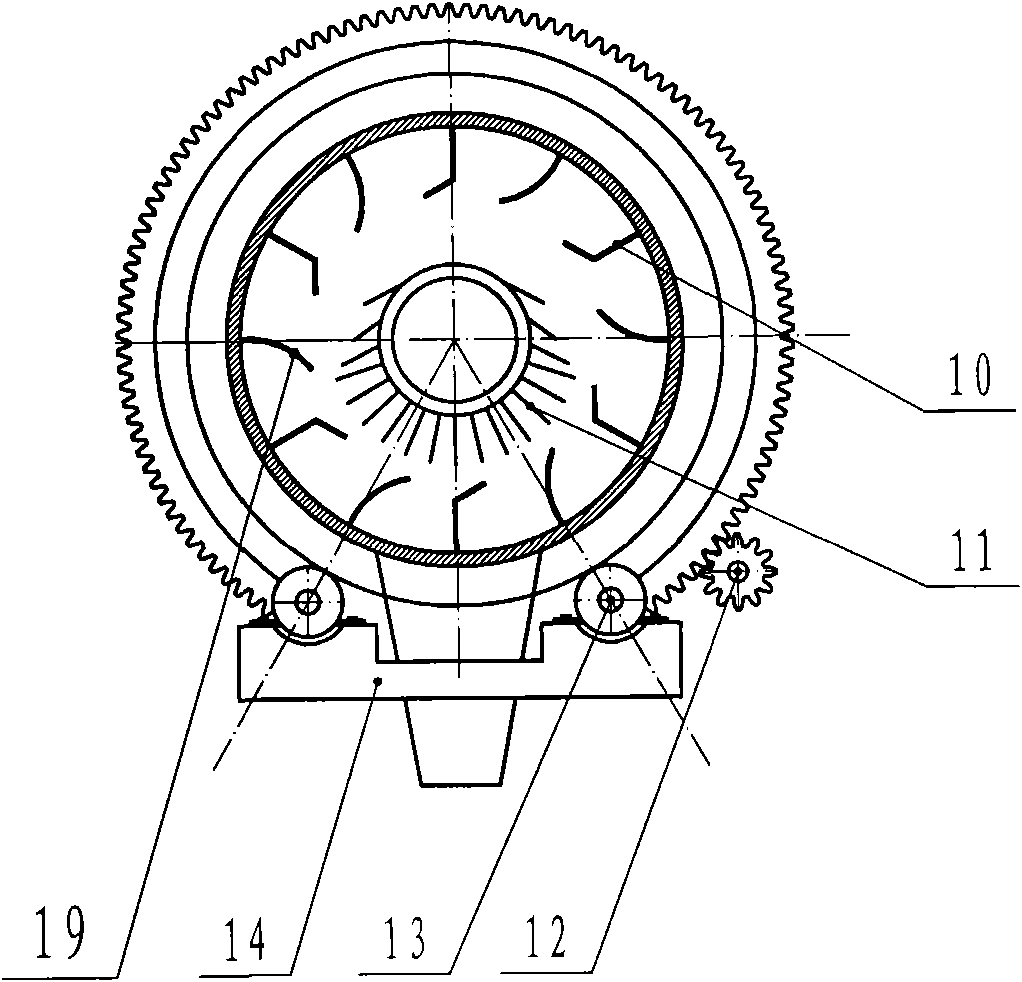

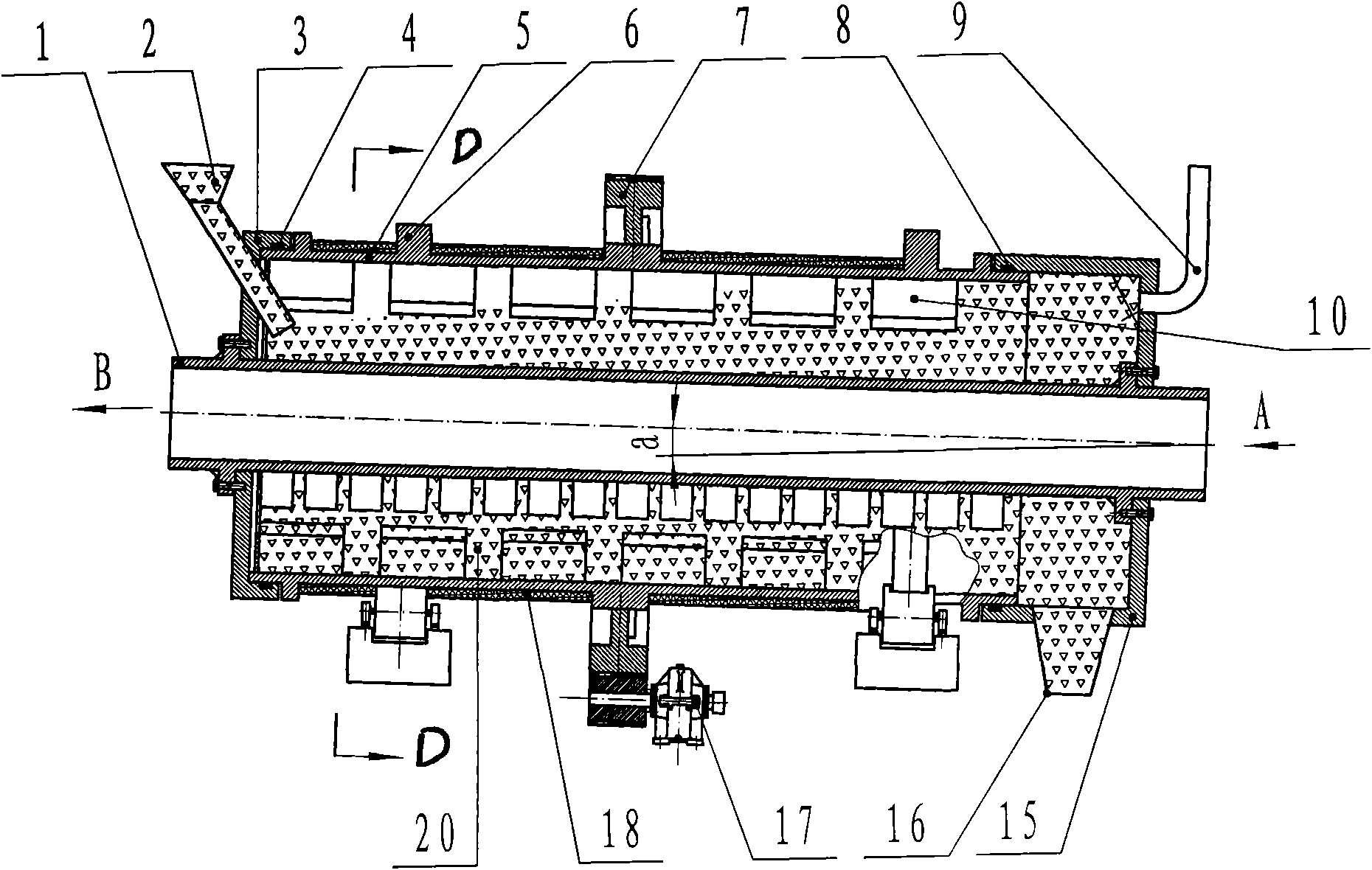

The invention relates to a technique method for producing lithium iron phosphate material in a vacuum rotary kiln. The invention relates to the industrial manufacturing of lithium ion battery cathode material, which is characterized in that: a continuous vacuum rotary kiln is adopted to sinter and produce lithium iron phosphate material, which realizes dynamic sintering. The invention solves the difficulties of material overburning, underburning, etc. appeared in static sintering in atmosphere protection pusher kiln, pit type furnace, etc. The rotary kiln comprises a screw-feeder, a hopper, a feeding bin, an inlet bin, a rotary barrel body, a receiving bin, a discharging bin, a furnace body, an air inlet, an air outlet and pumping port, a large gear outside the barrel body, a drive gear engaged with the large gear and a roller, etc. The material is continuously fed and discharged. Spiricle is arranged in the barrel body of the rotary kiln and the material goes forward sequentially in the barrel body. The furnace body of the outside furnace of a rotary furnace is sealed, the air is vacuumized and protection atmosphere is input. The technique line is burdening, mechanical strength grinding, mixing, milling and crushing, pressing pill, sintering in the vacuum rotary kiln, mechanical strength grinding, ball grinding, coating, conductive carbon, testing and packing. The lithium iron phosphate material produced by the invention has low energy consumption, high efficiency and good product quality.

Owner:JIANGSU RUIDI ENERGY TECH

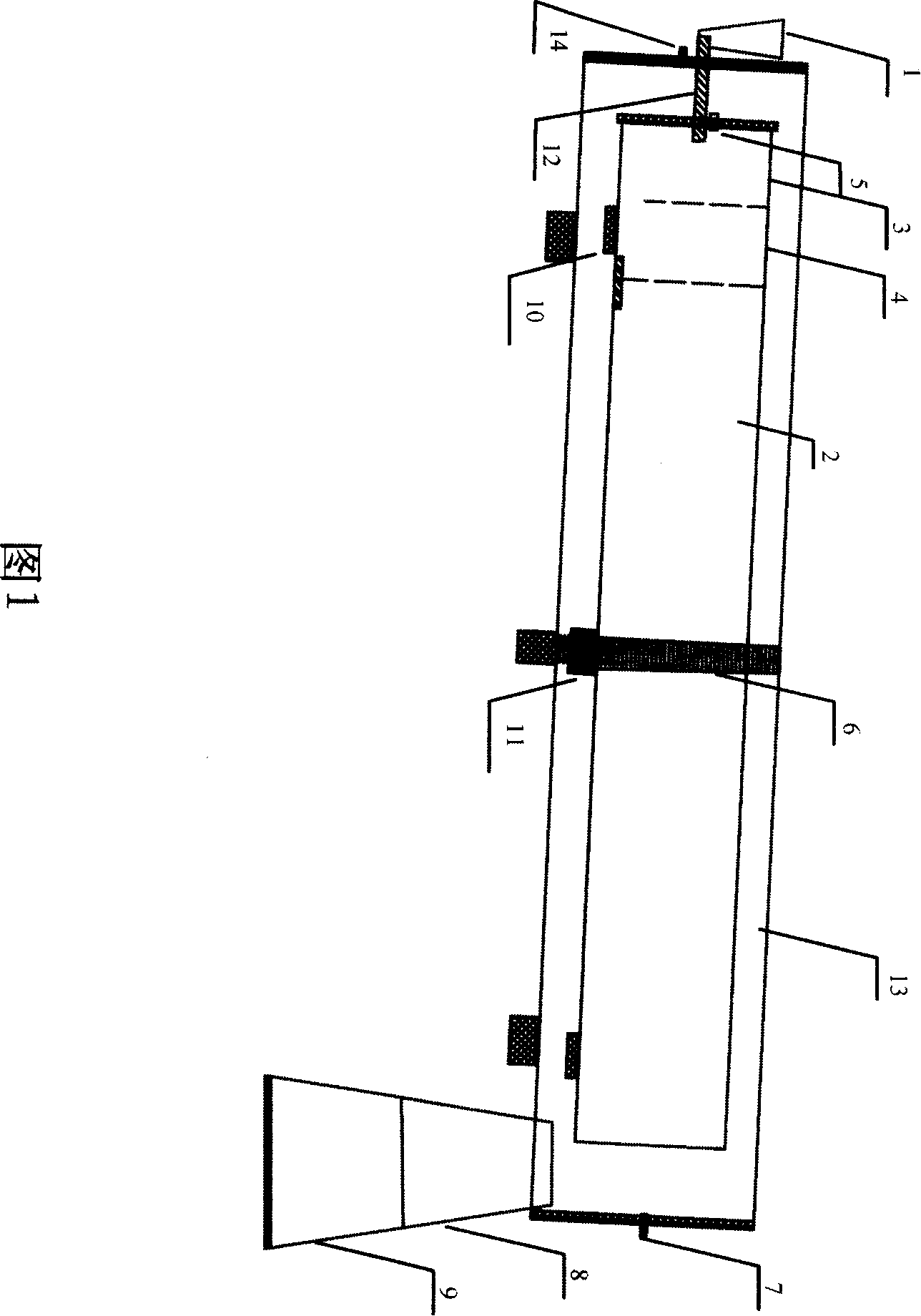

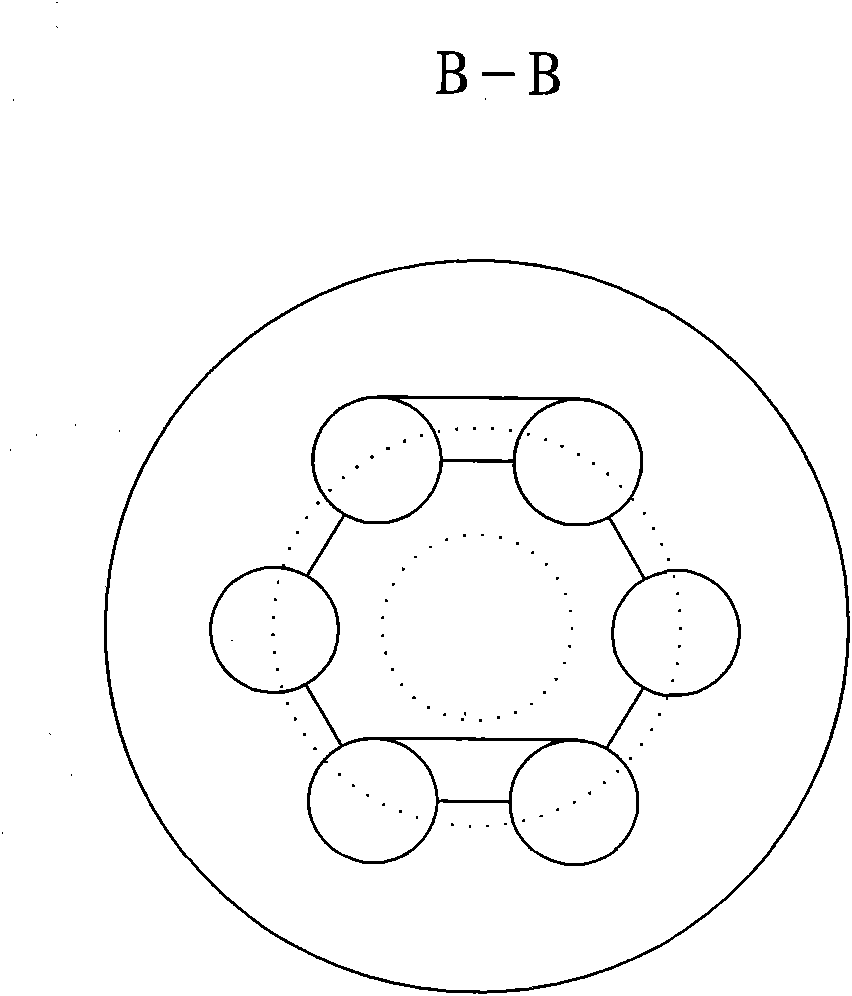

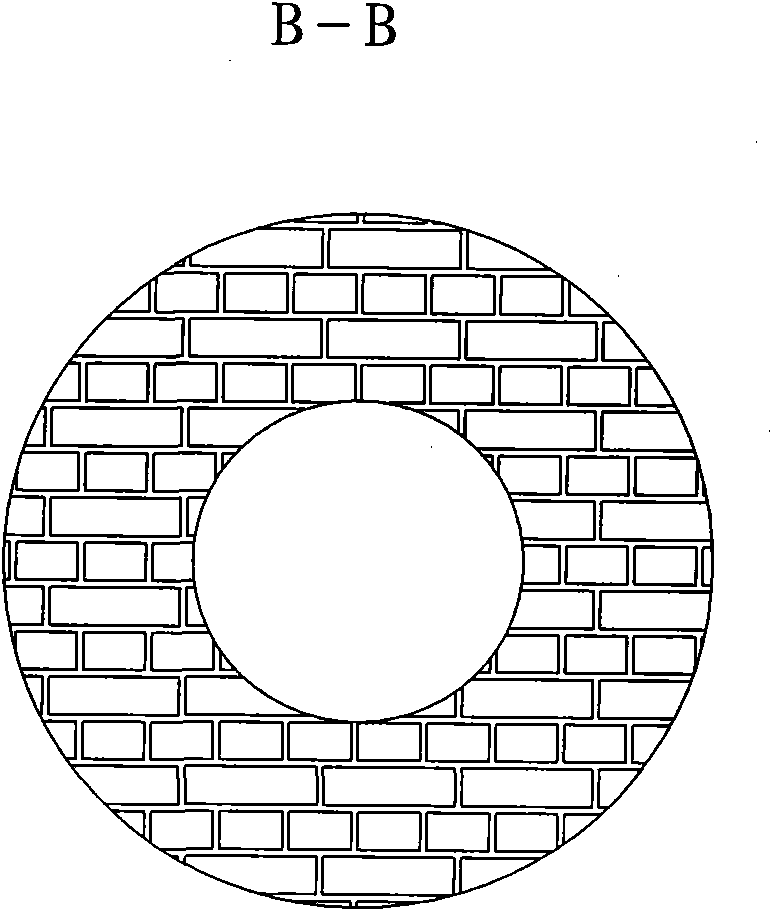

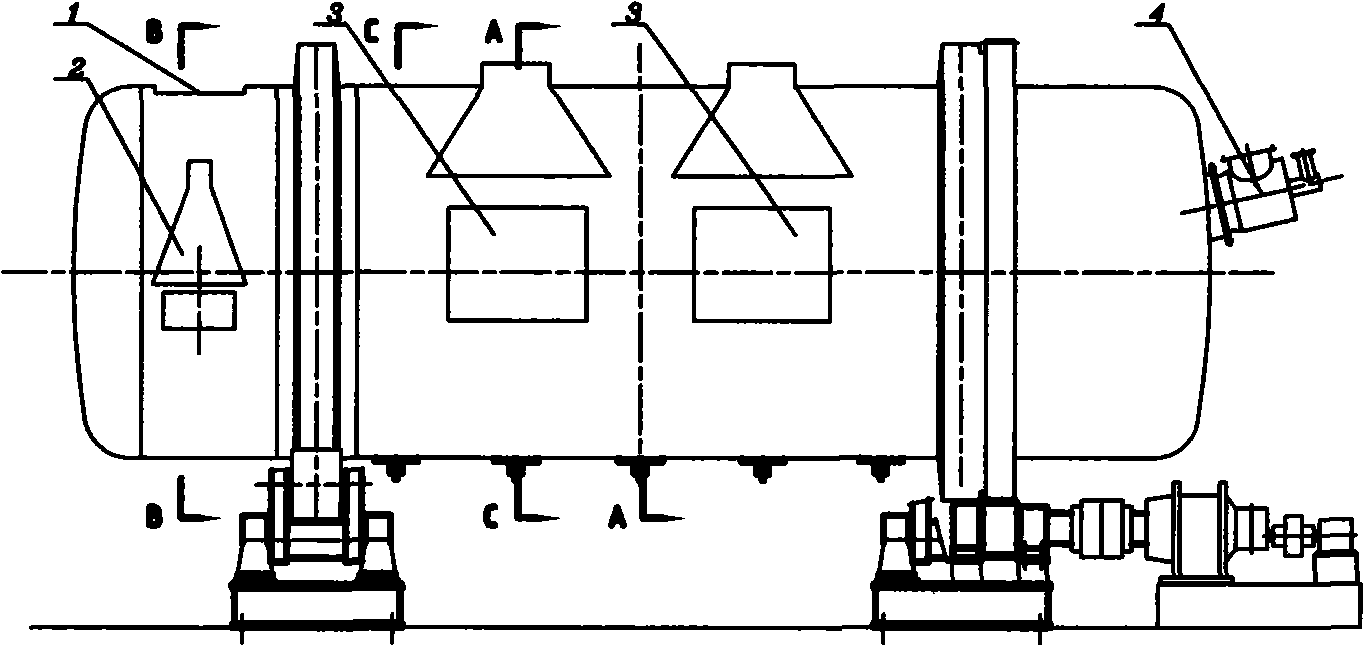

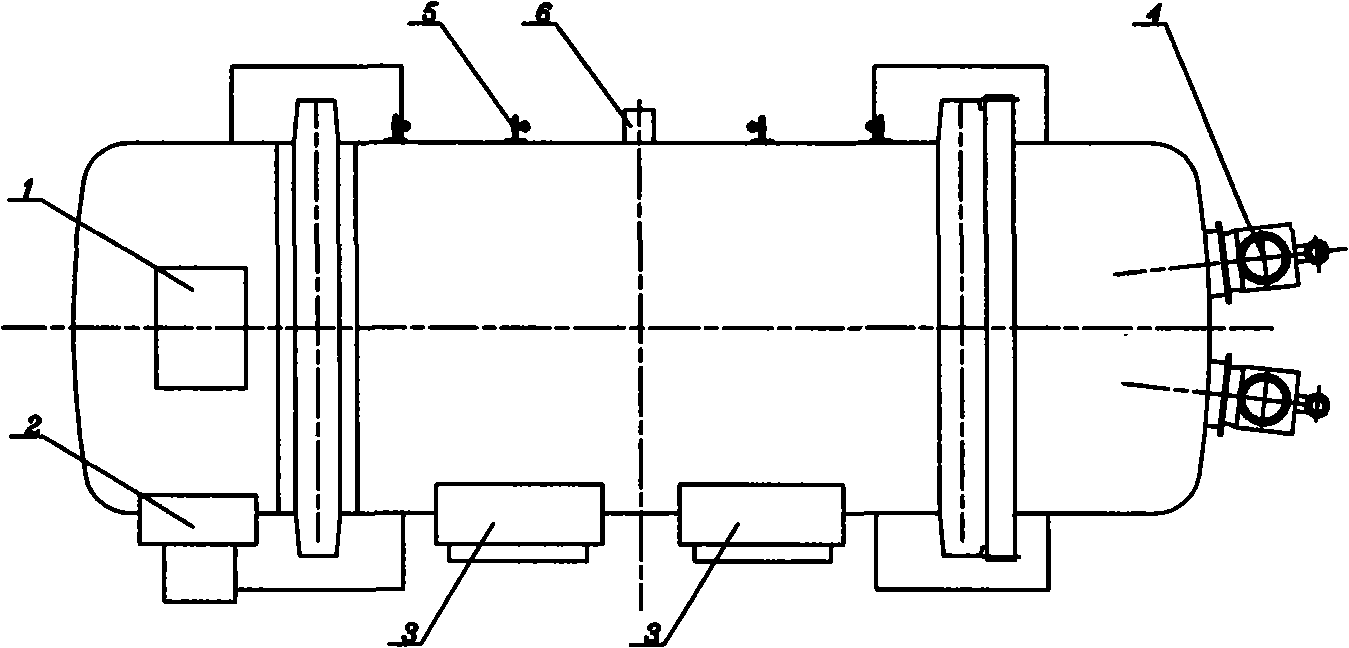

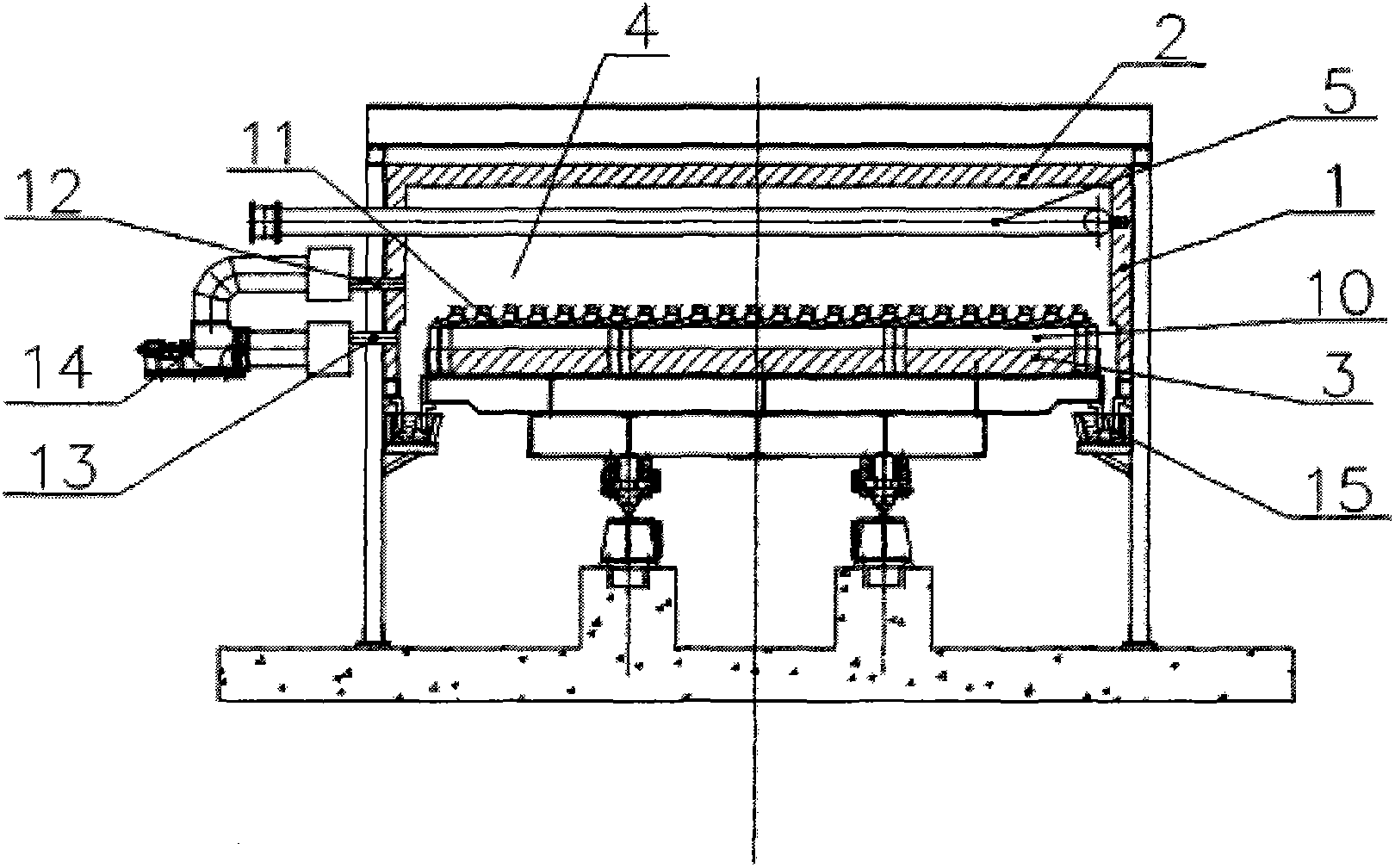

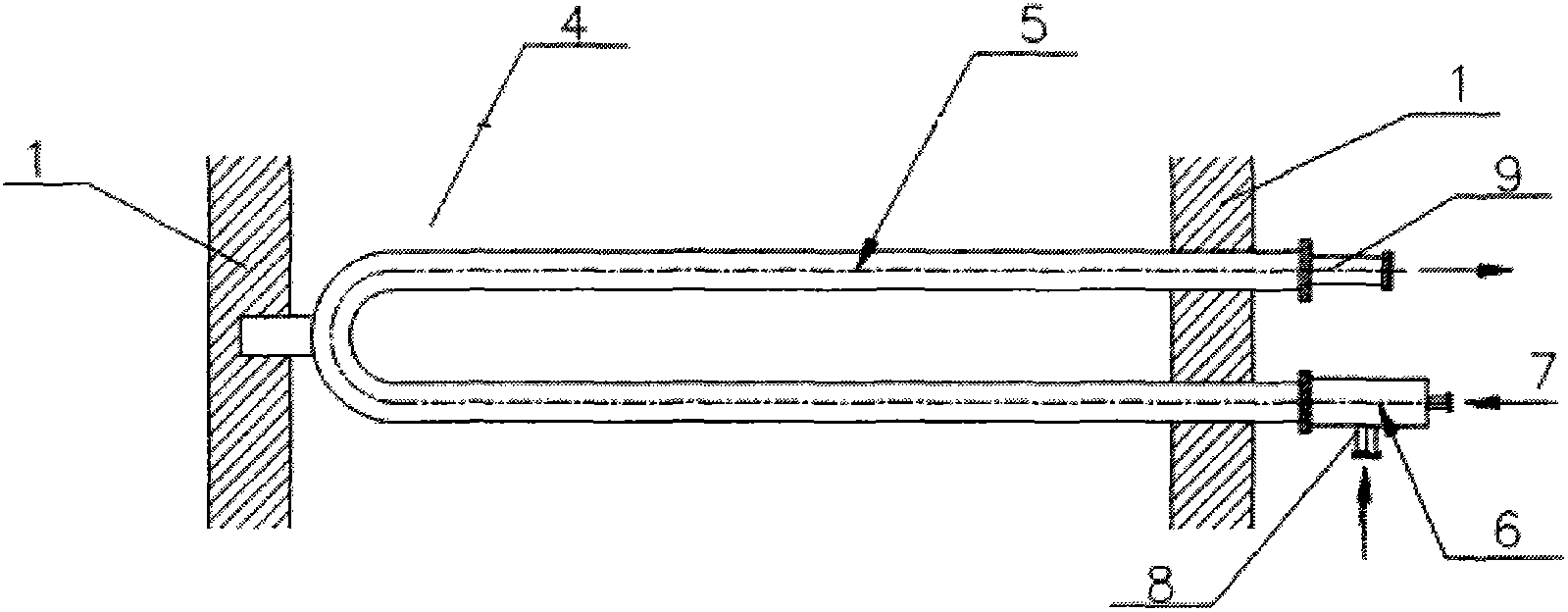

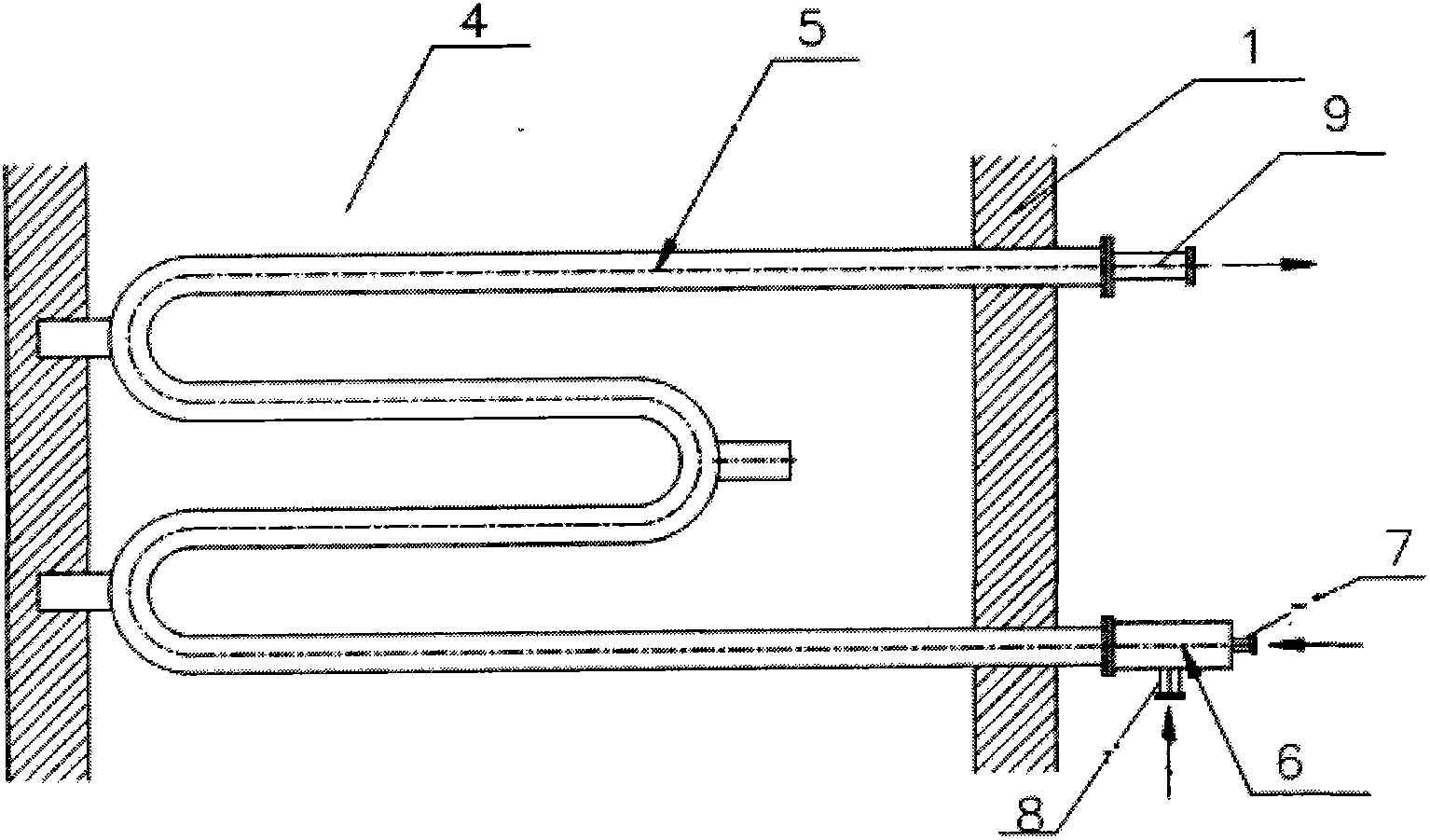

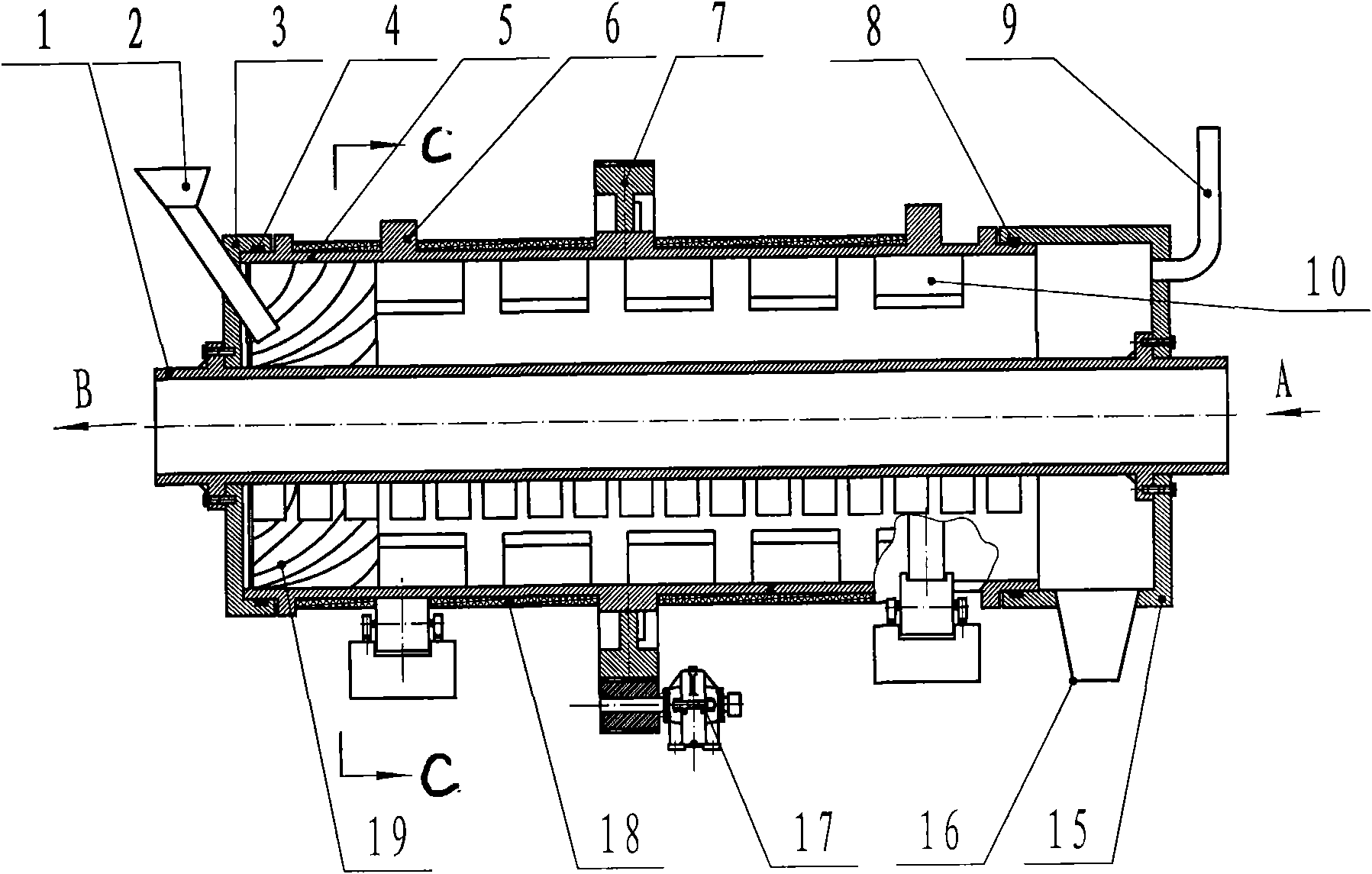

Multi-tube external-heat fume reverse extraction rotary carbide furnace

The invention relates to a multi-tube external-heat fume reverse extraction rotary carbide furnace which is provided with an obliquely horizontal type rotary furnace body (1); the high end side of the furnace body is provided with a feed hopper; the lower end side of the furnace body is provided with a discharge hole (14) and a combustion chamber (2); tube bundles (9) which are annularly distributed along a cross section are arranged in the furnace body; carbonized materials and fume channels are isolated, wherein the tube pass is used for the carbonized materials and the shell pass is used for fume. The invention adopts a tubular carbonizing process, which separates heat generated by the carbonized materials and fuels and avoids the problem of excessive carbonization; moreover, the problem that coal tar in a volatile matter is stuck to the surfaces of the carbonized materials again to influence the appearance of the product and activating effect when the fume is reversely sucked back.

Owner:宝塔国际石化工程技术有限公司

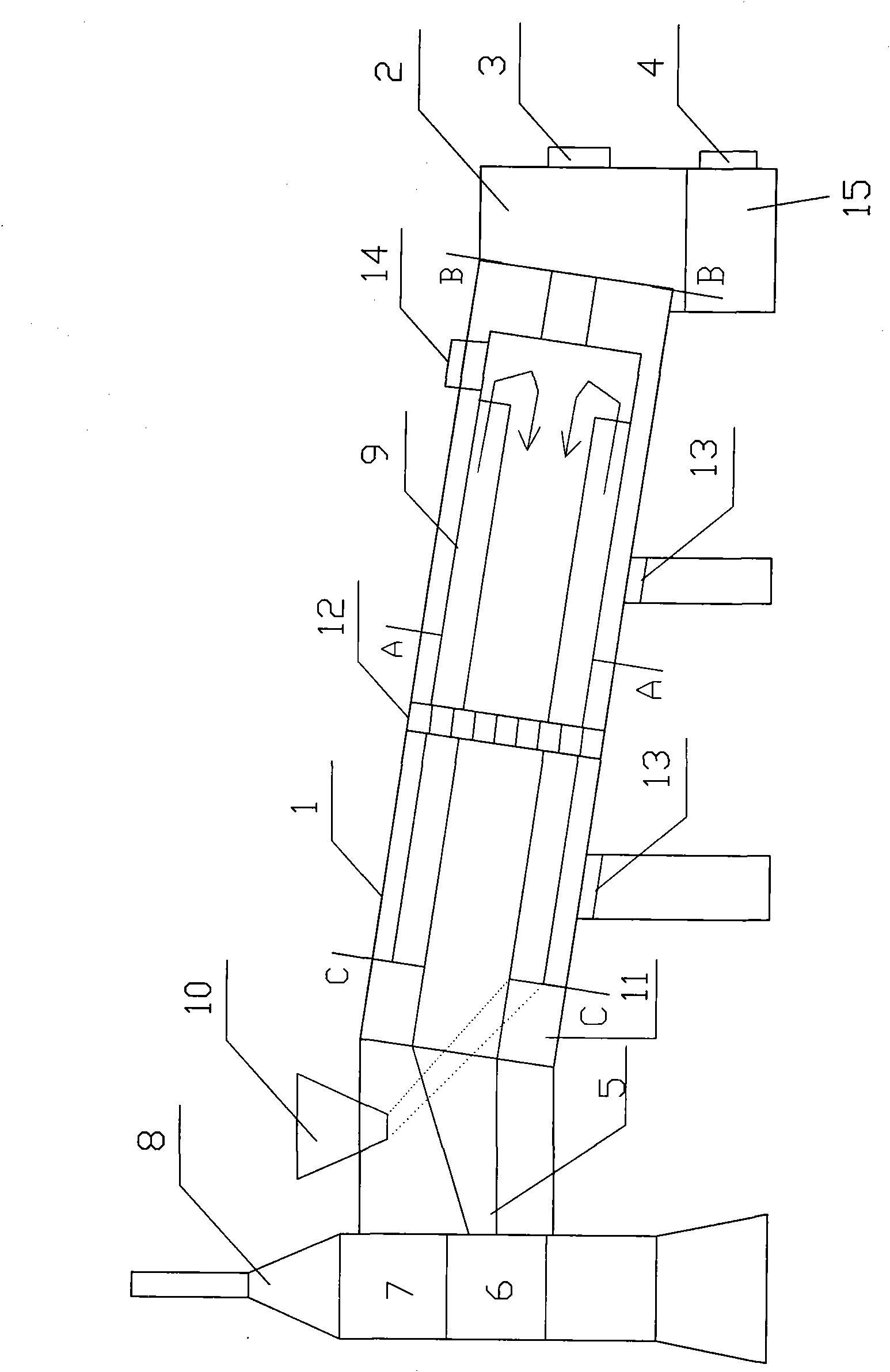

Continuous rotary biomass pyrolytic charring and boiler heat supply integrated equipment

ActiveCN102032553AImprove ergonomicsHigh thermal efficiencyDirect heating destructive distillationBiofuelsCombustion chamberEngineering

The invention discloses continuous rotary biomass pyrolytic charring and boiler heat supply integrated equipment. The equipment comprises raw material conveying equipment, a rotary drying furnace and a rotary charring furnace, and is characterized in that: the raw material conveying equipment is connected with the rotary drying furnace and connected with the rotary charring furnace through a star-like feeder; a material which is pyrolytically charred by the rotary charring furnace is discharged through a charred material outlet; the rotary charring furnace comprises a hearth and a rotary furnace; one path of high-temperature hot gas produced by combustion of an oxygen-containing combustion chamber is conveyed into the hearth of the rotary charring furnace through a flue to enter a charring section; the rotary furnace comprises a barrel, an inner heating tube and a baffle ring; one end head of the inner heating tube is fixed on the barrel wall on one side and passes through the baffle ring to be fixed on the barrel wall on the other side of the baffle ring; after the high-temperature hot gas passes through the hearth through the flue, certain high-temperature hot gas enters one end head of the inner heating tube, is discharged out of the other end head of the inner heating tube, enters a waste heat conveying pipe and is conveyed into the rotary drying furnace through an induced draught fan; and the high-temperature hot gas is conveyed into a biomass boiler through another flue. The equipment can improve the working efficiency of the rotary charring furnace.

Owner:FUJIAN TIANCHUANGLI BIOLOGICAL ENERGY EQUIP

Rotary kiln and technique for processing composition brass or block shaped raw copper

InactiveCN101344357AImprove airtightnessReduce leakageRotary drum furnacesProcess efficiency improvementSlagCoal

The invention discloses a rotary furnace which is cylindrical, a charging opening which is horizontally arranged is opened on the rotary furnace; a slag hole and a copper discharge opening are opened on a furnace body; a hole for mounting a burner is opened on an end cover of the furnace body; a vent hole is radially opened on the other side of the end cover of the furnace body with the hole for the burner; an oxidation and reduction air port is opened on the furnace body; a support is arranged at the lower part of the furnace, and the furnace body can be rotated on the support. The process for processing mixed copper or block-shaped crude copper by utilizing the rotary furnace adopts heavy oil, natural gas, pulverized coal and other fuels, oxygen can also be added for combustion for providing a heat source for melting solid copper materials, compressed air is taken as an oxidant, quartz sand is taken as a flux, the impurities are removed by oxidation and slagging, then the natural gas or LPG, etc., is introduced for reduction, thereby producing anode copper; flue gas is introduced into a secondary combustion and waste heat boiler for carrying out waste heat recovery, cooling and dust collection by a smoke cover. The rotary furnace has the advantages of high thermal efficiency, energy conservation, good environmental protection effect, high degree of automation and mechanization, safe operation, relatively low investment, but no no black smoke pollution, etc., thereby being particularly applicable to large and medium-sized mixed copper refineries for use.

Owner:CHINA NERIN ENG

Nb-Ti microalloying steel suitable for large line energy welding and smelting method therefor

InactiveCN1962916AImprove toughnessSimple production processWelding/cutting media/materialsSoldering mediaSheet steelPre treatment

The invention discloses an Nb-Ti microalloy steel for large line power welding, which comprises the following parts: 0.06%-0.12% C, 0.10%-0.50% Si, 0.40%-1.8% Mn, not more than 0.015% P, not more than 0.010% S, 0.020%-0.050% Nb, 0.006%-0.030% Ti, 0.0030%- 0.0100% N, one or more of not more than 0.40% Mo, not more than 0.06% V, not more than 1.0% Ni, not more than 1.0% Cr, and not more than 0.50% Cu and Fe and inevitable impurity, wherein the Ceq is C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14<=0.45%; the [Ti%]T is not less than 2.667[N%]T-0.004667%. The smelting method comprises the following steps: predisposing molten iron; smelting through rotary furnace; removing S in the LF furnace; refining in the VD or RH; adding Ti and Nb in the VD or RH. The steel board possesses excellent flexibility in the welding heat influencing region when it is welded at 50-150KJ / cm.

Owner:ANGANG STEEL CO LTD

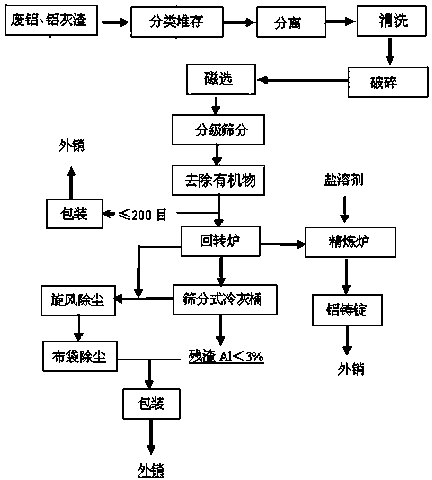

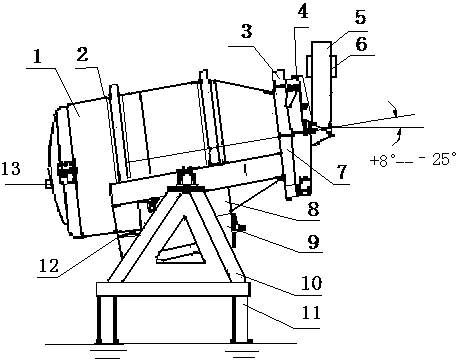

Production method of recycled aluminum

The invention relates to a production method of recycled aluminum. The production method comprises the steps: classifying and stacking waste aluminum or aluminum ash slag, then separating, wherein the separation is to remove dirt by washing and crushing; removing steel by a magnetic separation method, then crushing the initially purified aluminum, sieving to obtain a mixed aluminum powder, then putting into a rotary furnace for a combustion reaction, so as to decompose the aluminum slag or the waste aluminum into aluminum liquid and aluminum ash; putting the aluminum liquid in a refining furnace for further smelting, to obtain aluminum liquid with relatively high purity, outpouring to form aluminum ingots, wherein the pure aluminum content can reach 99.99%; and merging the aluminum ash unloaded from the rotary furnace with aluminum ash obtained by treating flue gas through a cyclone dust extractor, wherein the content of aluminum in the residues is 1-3%, then packaging, and providing the packaged product as a smelting additive for a steel mill.

Owner:ALNAN ALUMINIUM CO LTD

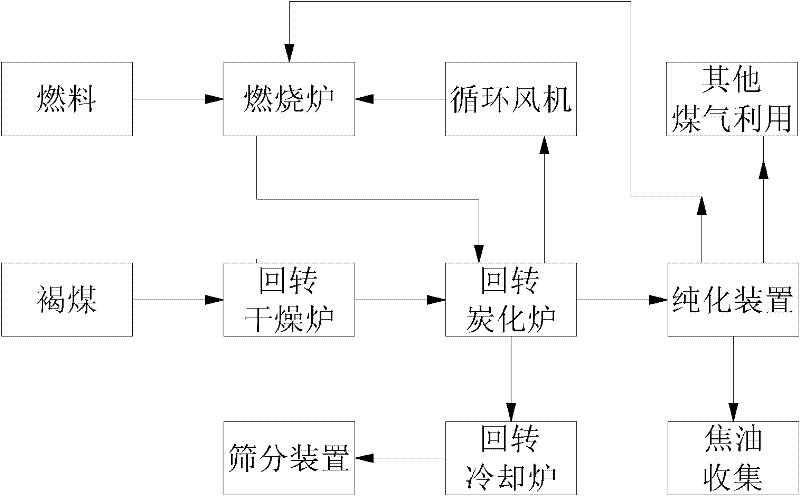

Method for improving quality of brown coal with externally heated rotary furnace

InactiveCN102250633AIncrease profitHigh value availableCoke quenchingChemical industryBrown coalCombustion

Owner:西安三瑞实业有限公司

A method for pyrolyzing coal using a regenerative rotary furnace

InactiveCN102277185ASimple processShort processBiofuelsSpecial form destructive distillationHeat carrierTar

The invention discloses a method for pyrolyzing coal in a regenerative rotary furnace, which is to distribute a certain amount of raw materials to be pyrolyzed into the bottom of the rotary furnace through a distributing device after being crushed, screened and dried, and adopts the method of radiation Heat to 400-700°C without air, and keep for 30-120 minutes. After the dry distillation gas from the top of the rotary furnace is separated from oil and gas, tar and crude gas are obtained. The solid product discharged from the bottom of the rotary furnace through the discharge device is cooled to obtain semi-coke. The method of the invention has simple process, high efficiency, does not need gas or solid heat carrier, and is suitable for coal types of various qualities.

Owner:BEIJING HUAFU ENG

Method for synthetically reclaiming iron, vanadium and titanium from vanadium titanium magnet concentrate

InactiveCN101168802ATake advantage ofCannot be efficiently recycledRotary drum furnacesTitanium dioxideRecovery methodMagnetite

The invention relates to a comprehensive recovery method of iron, vanadium and titanium for vanadium and titanium magnetite concentrated ores, in particular to the comprehensive recovery and utilization of the vanadium and titanium magnetite concentrated ore of which the vanadium content is higher. In particular, the invention is vanadium extraction through water immersion after the vanadium and titanium magnetite concentrated ore is performed with sodium activation and sintered, the vanadium product is made from leach solution, the remaining slag is performed with reduction quickly through a rotary furnace after carbon is added, the reduction product is melted through the electric furnace, to segregate the melted iron and the titanium slag, the melted iron is used to make steel, and the titanium slag is used to produce white titanium pigment through a sulfuric acid method titanium white technology. The method of the invention is applied to the refining technology of the vanadium and titanium magnetite concentrated ore, to ensure that the recovery rate of the vanadium and titanium is greatly enhanced, the recovery rate of the total vanadium in the iron concentrated ore can reach more than 80 percent, titanium is fully recovered, and the production of massive blast furnace slag is avoided.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

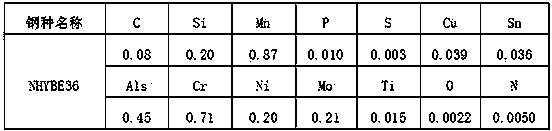

Steel plate with low density and high marine environment resistance and production technology thereof

The invention relates to a steel plate with low density and high marine environment corrosion resistance and a production technology thereof. The steel plate contains the following chemical ingredients by weight: 0.03-0.10 of C, 0.1-0.8 of Si, 0.5-1.5 of Mn, not more than 0.015 of P, not more than 0.005 of S, 0.1-2.0 of Al, 0.01-0.30 of Sn, 0.1-0.8 of Cr, 0.1-0.5 of Ni, 0.05-0.45 of Mo, 0.01-0.05 of Ti and the balance of Fe and unavoidable impurities. The production technology comprises a rotary furnace smelting procedure, an LF refining procedure, a vacuum degassing procedure, a continuous casting procedure, a controlled-rolling and controlled-cold procedure and the like. The structure type of the steel plate is theoretically a single-phase polygonal ferrite fine structure, but contains an extreme small quantity of unavoidable pearlite structure during actual industrial production. The marine environment (marine atmosphere, tidal range, total immersion and the like) corrosion resistance can be improved by near 70% than that of an EH36 ship structure in the same service environment, and the steel plate has excellent obdurability matching and welding performance. The steel plate has the advantages of simple production technology, low production cost, stable performance, excellent surface quality and great improvement on marine environment corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING +1

High-tenacity high-strength spring steel

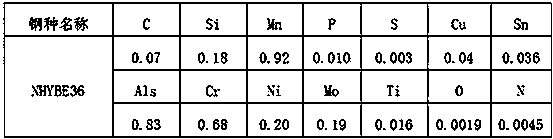

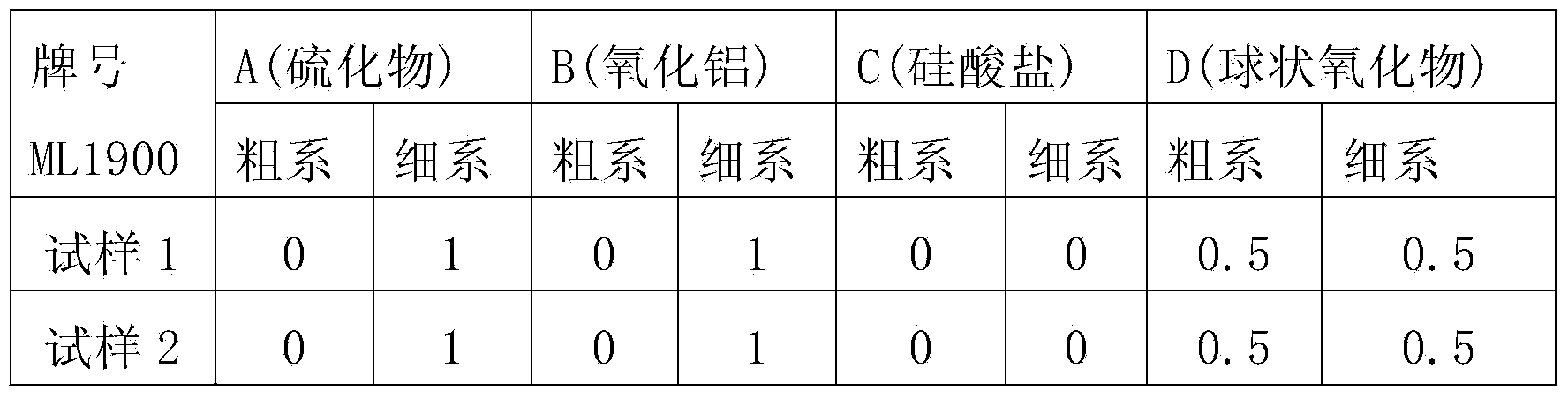

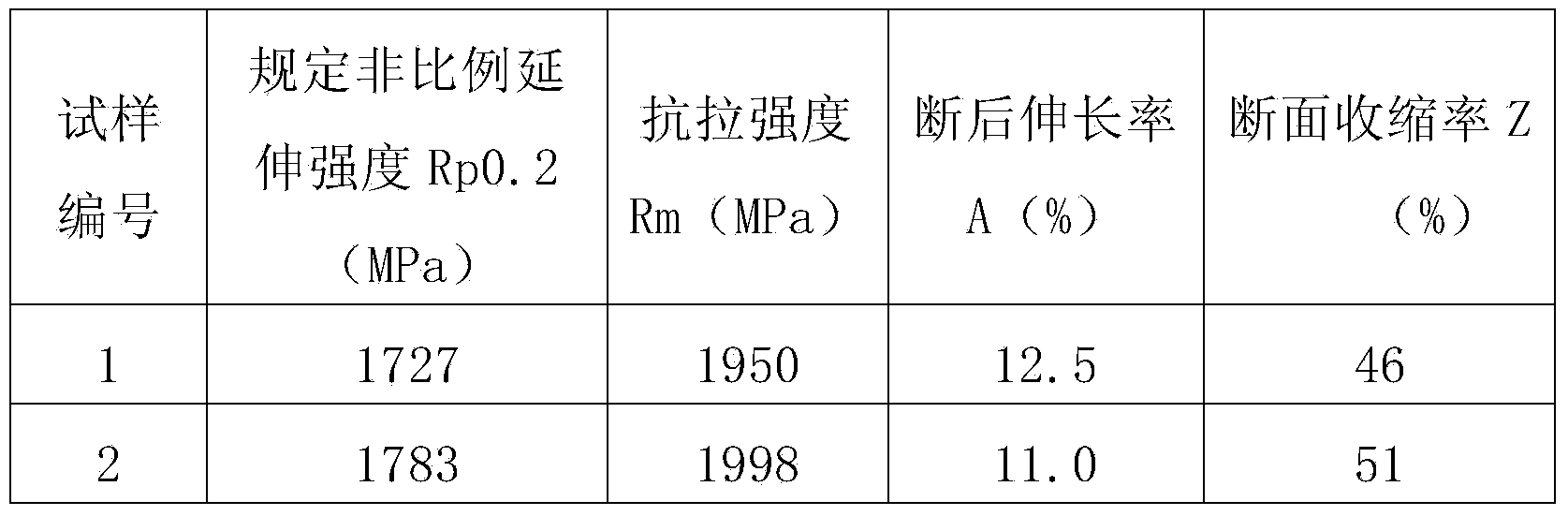

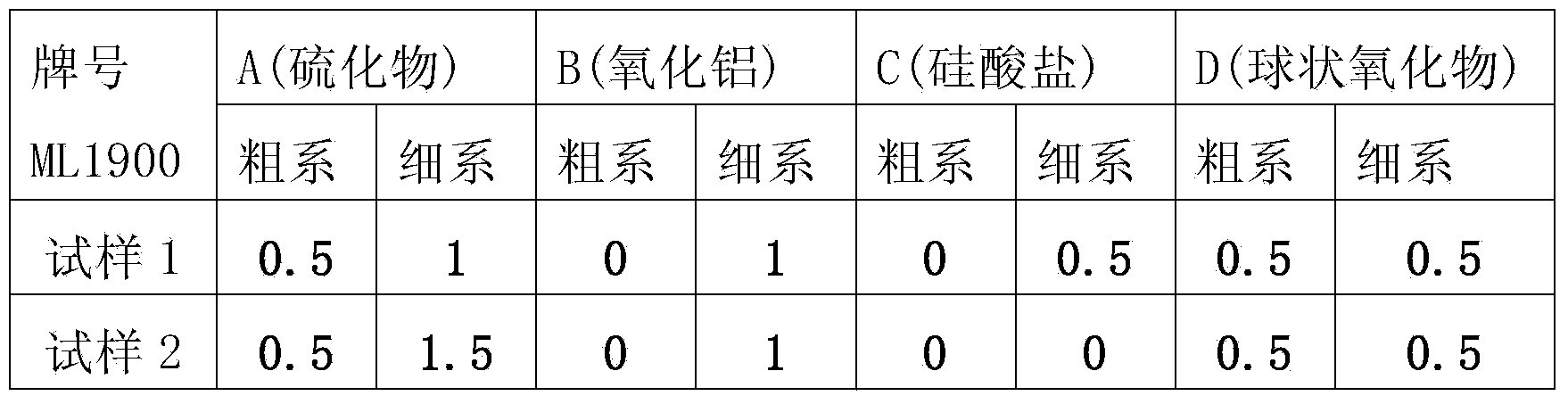

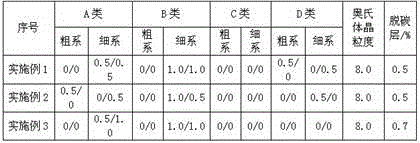

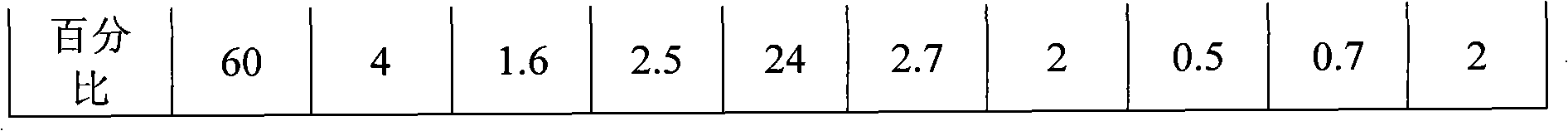

The invention discloses high-tenacity high-strength spring steel which is characterized by comprising the following chemical components in percentage by weight: 0.35-0.50% of C, 1.50-2.50% of Si, 0.35-1.00% of Mn, less than or equal to 0.025% of P, less than or equal to 0.015% of S, 0.50-1.20% of Cr, 0.15-0.50% of Ni, 0.10-0.30% of Cu, 0.04-0.10% of V, 0.03-0.10% of Ti and the balance of Fe and other inevitable impurities. The spring steel is smelted through an electric furnace or rotary furnace, an external refining technology is adopted to control the contents of gas and impurities, the gas O in the steel is less than or equal to 12ppm, H is less than or equal to 1.5ppm, N is less than or equal to 60ppm, the fine system of each of levels A, B, C and D of non-metallic inclusions is less than or equal to 1.5, and the rough system is less than or equal to 1.0. The grain size of the material after heat treatment is more than or equal to 8.0; the reduction of area Z is more than or equal to 40% and the percentage elongation after fracture is more than or equal to 10% when the tensile strength is more than 1920MPa; a prepared spring has excellent corrosion and fatigue resistance, and the steel can be prepared into high-fatigue-strength springs of which the maximum design shear stress is 1180MPa.

Owner:ZHEJIANG MEILI HIGH TECH

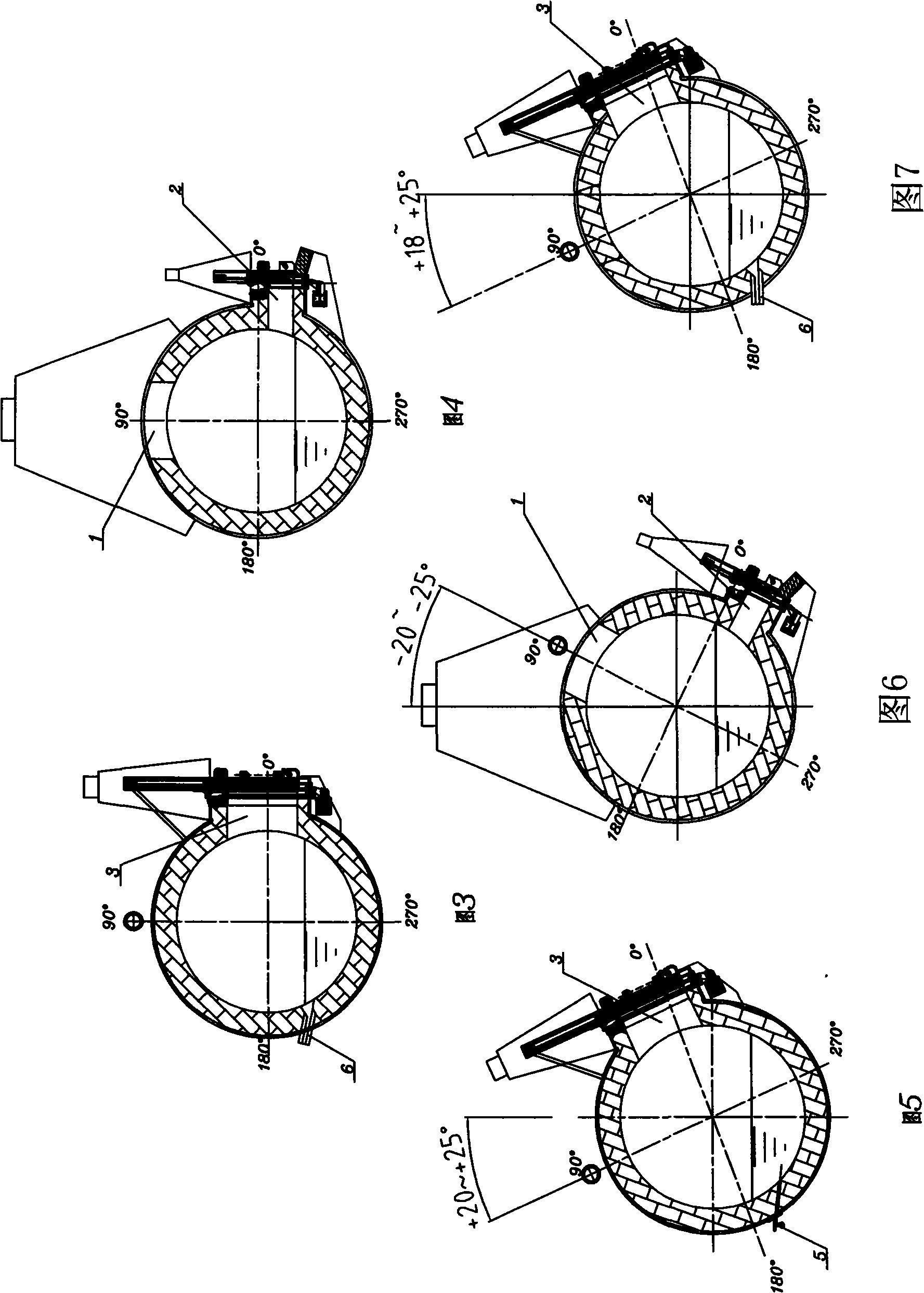

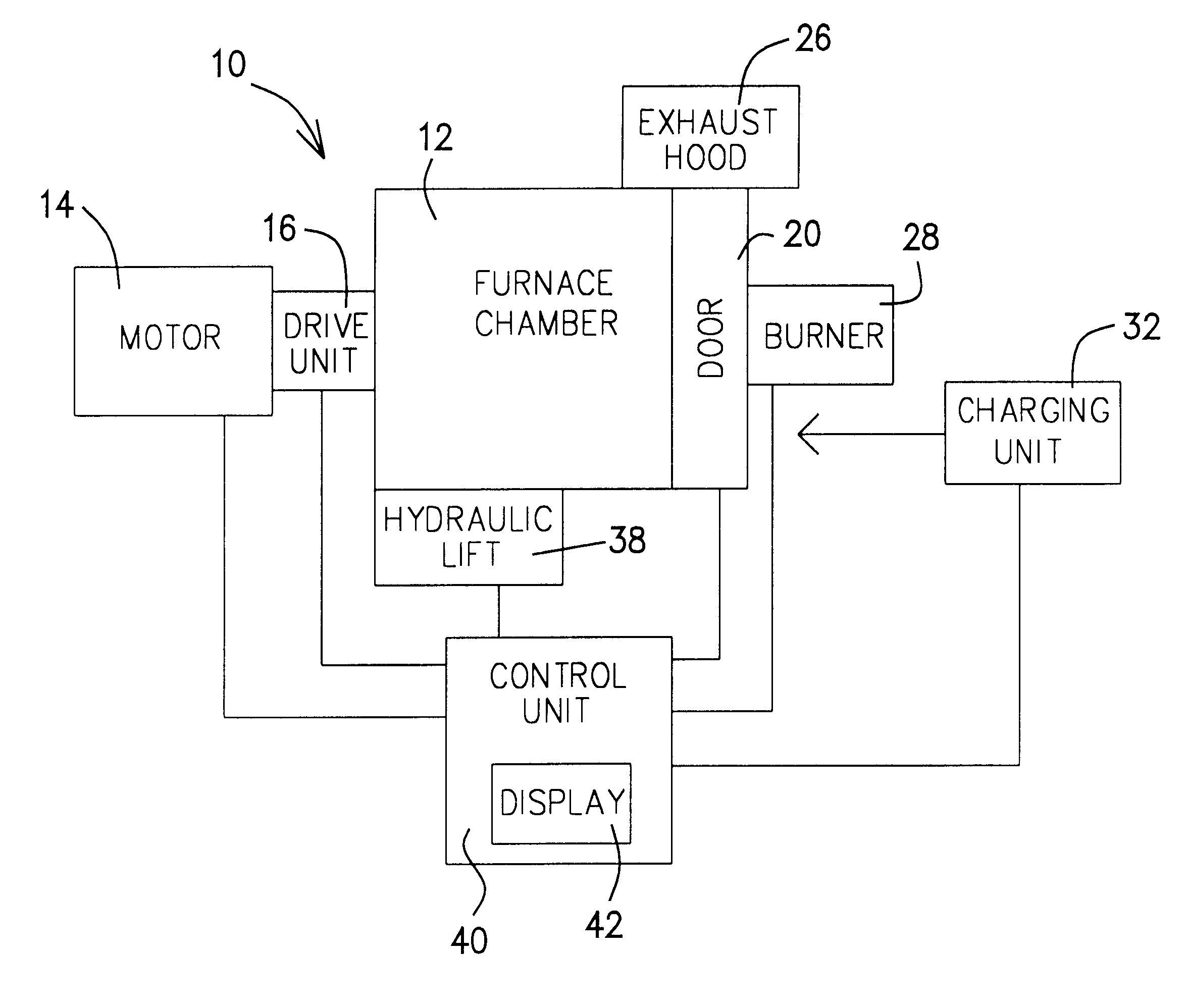

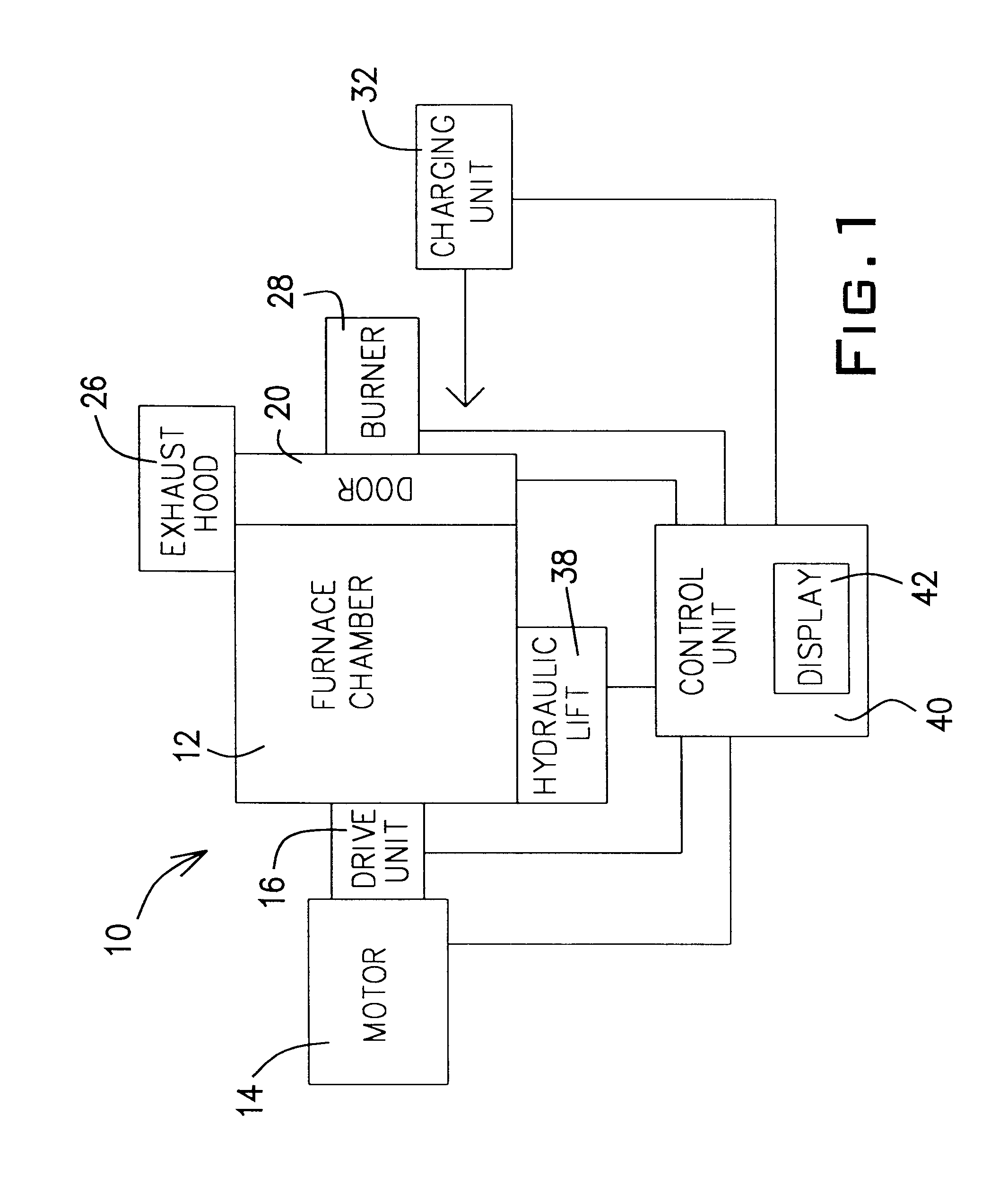

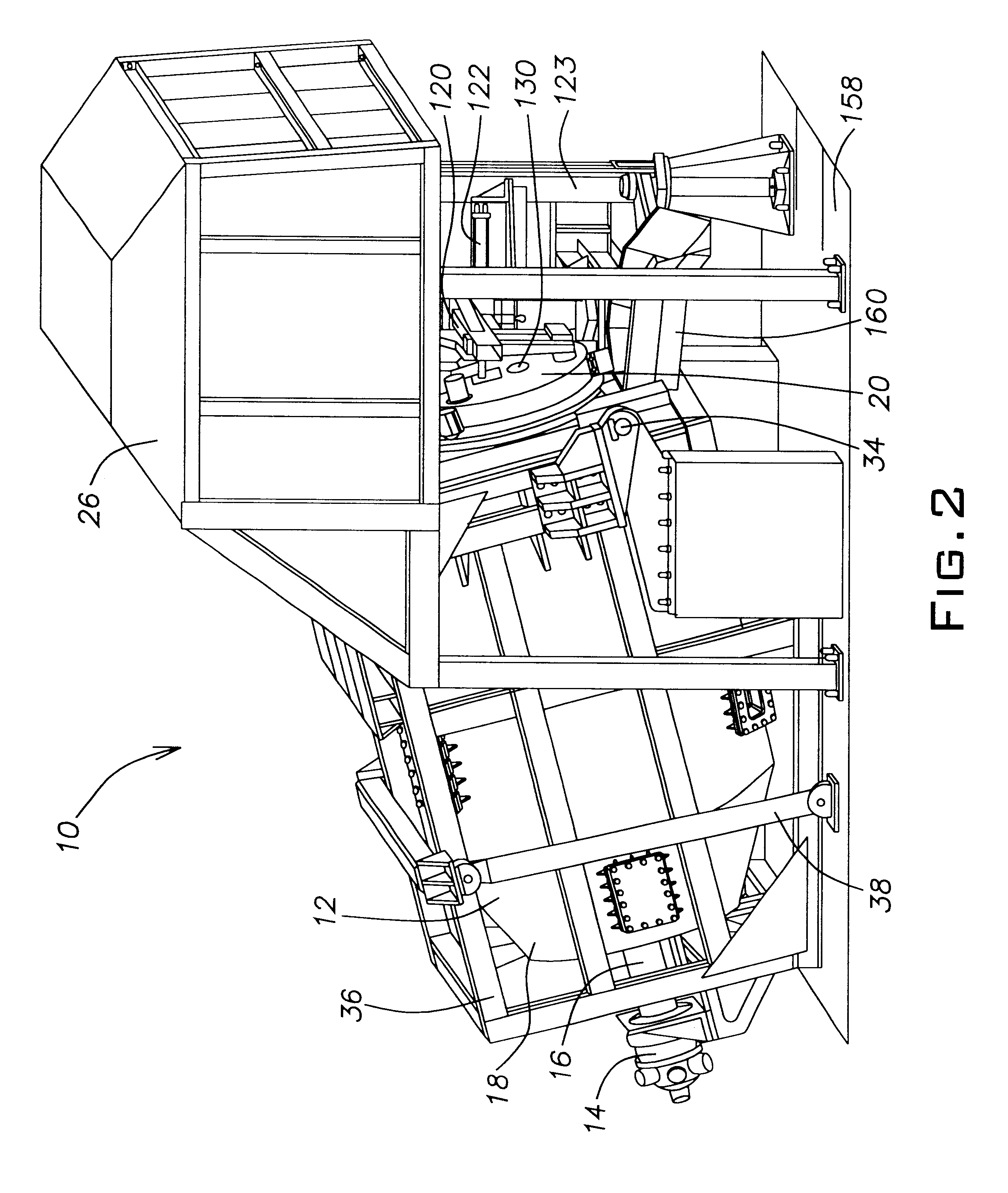

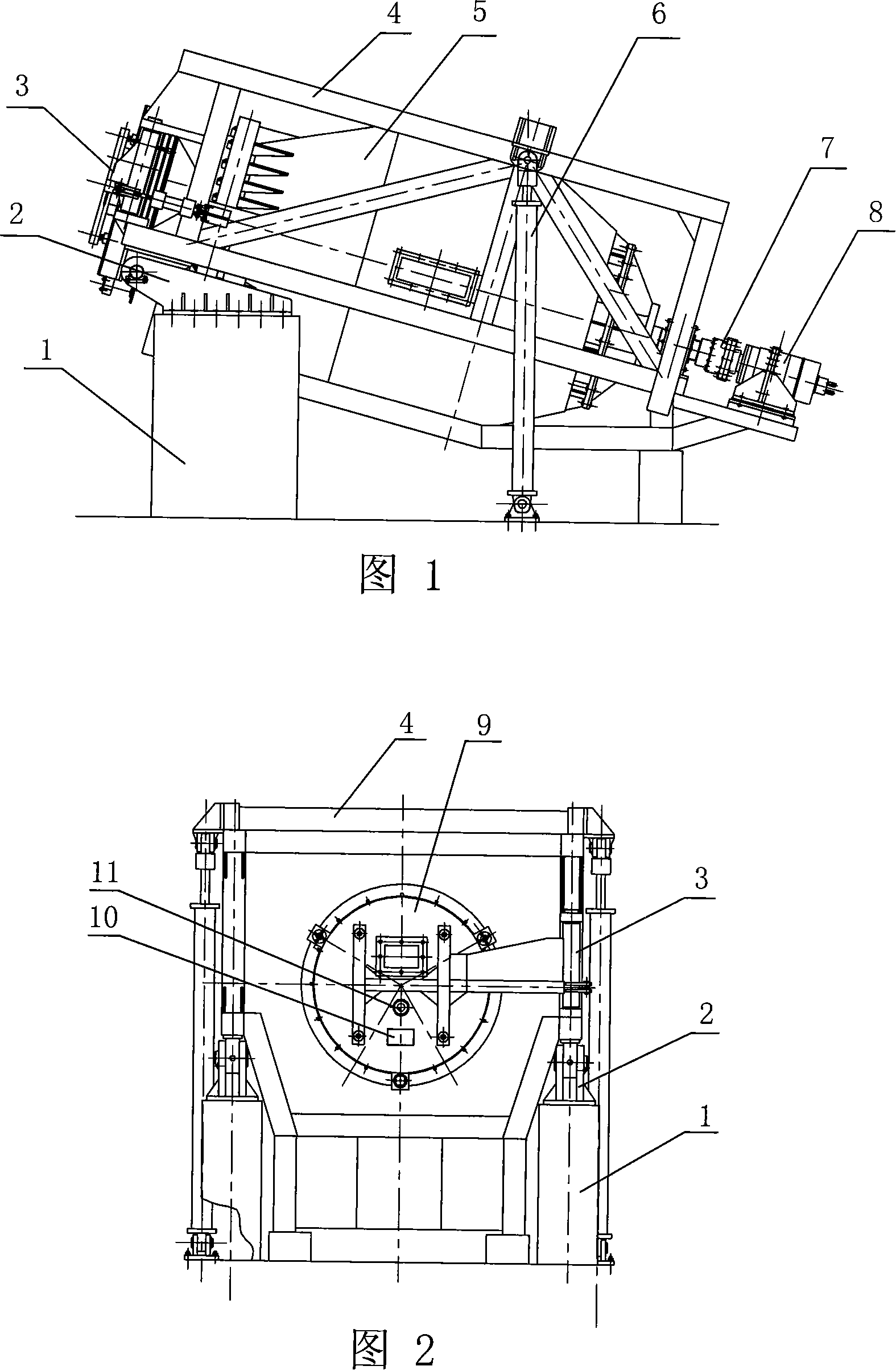

Tilting rotary furnace system for recovery of non-ferrous metals from scrap or dross and method of operation

InactiveUS6395221B1Reduces free airReduce the amount requiredRotary drum furnacesHeat treatment process controlRotary furnaceDross

A furnace system for recovering a non-ferrous metal from a charge of material containing the metal. The furnace system having a furnace chamber having walls defining a refractory chamber, the refractory chamber receiving the charge of material and the metal contained in the charge of material being heated into a flowable mode in the refractory chamber. The furnace system having at least one paddle radially projecting from an interior surface of the furnace chamber toward a longitudinal axis of the furnace chamber. Other features of the invention include a door having a closed position adjacent an inlet passage to the furnace chamber, the door having rollers and a suspension. Other features of the invention include a motor and a control unit which monitors torque to rotate the furnace chamber as an indication of viscosity of the charge of material. Methods of operating a furnace system for recovering non-ferrous metal from a charge of material containing the metal are also discussed.

Owner:ALTEK LLC

Low-manganese low- sulfur raw material ferroferrite for amorphous usage and method of production

The invention discloses a non-crystal low-manganese and low-sulfur pure ion and manufacturing method, which comprises the following parts: 0.03-0.07% C, 0.10-2.0% Si, 0.03-0.06% Mn, not more than 0.02% P, not more than 0.005% S, not more than 0.02% Al, not more than 0.008% Sn and not more than 0.01% Ti. The manufacturing procedure comprises the following steps: adopting melted iron to predispose; reducing S content in the melted iron; blowing in the rotary furnace; removing carbon and manganese through double-slag method or multiple slaggings; proceeding LF refining; casting in the square blank; using FeSi, Al or individual Al to predeoxidize; blowing and stirring in the whole procedure; dispersing through ferrosilicium and rankinite to deoxidize and desulfurize deeply; reducing Al; heating; feeding calcium line after stirring; casting; obtaining iron blank.

Owner:CENT IRON & STEEL RES INST

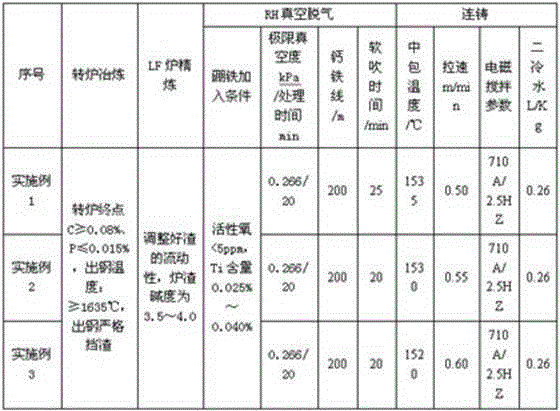

35MnB steel and preparation method thereof

ActiveCN103952640AReduce the amount addedReduce lossManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses 35MnB steel which comprises the following components in percentage by weight: 0.33-0.36 percent of C, 0.20-0.30 percent of Si, 1.20-1.40 percent of Mn, not more than 0.30 percent of Cr, not more than 0.025 percent of S, not more than 0.025 percent of P, not more than 0.20 percent of Ni, not more than 0.20 percent of Cu, 0.015-0.035 percent of Ti, 0.005-0.0030 percent of B, 0.015-0.035 percent of Al, not more than 20*10<-6> percent of [O] and not more than 35*10<-6> percent of [N], wherein the components are smelted in a rotary furnace, subsequently smelted in an LF ladle furnace, then subjected to RH vacuum degassing and finally cast continuously to obtain an ingot blank. The energy consumption cost for producing the type of steel is lowered fundamentally; loss of an element B of the 35MnB steel is reduced; the yield of ferroboron during a steel smelting process is increased; the stability of hardenability of the 35MnB steel can be improved; in addition, by adopting low superheat degree, electromagnetic stirring and a constant-temperature and constant-speed casting process, segregation of the elements such as C and Mn is alleviated, the components are more uniform and the fluctuation of the hardenability is alleviated.

Owner:SGIS SONGSHAN CO LTD

Method for producing glass beads used for curing high-level nuclear wastes

InactiveCN101857355AGood anti-devitrification performanceLow viscosityGlass shaping apparatusRotary furnaceRaw material

The invention provides a method for producing glass beads used for curing high-level nuclear wastes. The method comprises the following steps of: uniformly mixing raw materials, melting the raw materials into glass solution by using an all-electric glass melting furnace at the temperature of between 1,300 and 14,000 DEG C, clarifying and homogenizing the glass solution for 5 to 8 hours, cooling the glass solution to obtain glass block green bodies, and preparing glass blocks by specifications of finished products from the obtained glass block green bodies; uniformly mixing each 100 parts of the obtained glass blocks with 10 to 25 parts of charcoal powder and 1 to 3 parts of carbon black, and throwing a mixture into a glass bead electrothermal rotary furnace, of which the running speed is 20 to 30 revolution per minute, at a speed of 0.7 to 1.0 kilogram per minute at the temperature of between 850 and 940 DEG C through the glass bead electrothermal revolving furnace, and rolling the mixture to form a ball-shaped mixture; and finally annealing and cooling the ball-shaped mixture to obtain the glass beads used for curing the nuclear wastes. The glass beads used for curing the high-level nuclear wastes produced by the method has ideal high-temperature viscosity, high mechanical strength and high anti-crystallization performance.

Owner:天台精工西力玻璃珠有限公司

Tiltable rotary secondary aluminum smelting furnace

InactiveCN101131304AImprove performanceIncrease production capacityRotary drum furnacesClinker productionCombustorRotary furnace

This invention relates to a tilting rotary secondary aluminum smelting furnace. It includes roller type rotary furnace body, which is supported on the steel support. The anterior end of rotary furnace is arranged in the sleeve. The anterior end face of the rotary furnace has round furnace opening. The posterior end of rotary furnace connects to power device. The steel support corresponding to the rotary furnace posterior end parts connects to lifting cylinder. The steel support corresponding to the rotary furnace anterior end part connects to supporting shaft. There is round furnace door corresponding to the round furnace opening. There is sealing ring between the round furnace opening and door. The round furnace door is arranged on the roll-over shaft and connects to controlling oil cylinder. The round furnace door has fuel gas combustor and waste air discharging opening. The structure is simple. This invention is convenient. It has low energy dissipation and high producing efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Carbonization furnace for producing biomass charcoal

InactiveCN101899311ASimple processImprove efficiencyBiofuelsSpecial form destructive distillationCoaxial lineCarbonization

The invention discloses a carbonization furnace for producing biomass charcoal. The carbonization furnace comprises a smoke tube, a rotary furnace body, a feeding hopper, a discharging hopper and an oil and gas discharging pipe, wherein the rotary furnace body is supported by rotary supporting rollers; the feeding hopper, the discharging hopper and the oil and gas discharging pipe are arranged on the rotary furnace body; the smoke tube is arranged in the rotary furnace body and is coaxial with the rotary furnace body; and the inner wall of the rotary furnace body is provided with helical blades or an angle which is more than 5 degrees and less than 30 degrees is formed between the coaxial line of the smoke tube and the rotary furnace body and the horizontal plane. The biomass charcoal is produced by the following steps that: a biomass material enters the carbonization furnace from the feeding hopper; a motor drives the carbonization furnace to rotate; the helical blades in the furnace stir the material and push the biomass material to move forwards or from top to bottom; the material absorbs the heat of the outer wall so as to evaporate the moisture; and the biomass material is carbonized and discharged from the discharging hopper. The carbonization furnace has the advantages of realizing continuous production, saving the energy resource, improving the production efficiency and reducing the labor intensity, along with simple production process, high efficiency, low labor consumption and low labor intensity.

Owner:肖国雄

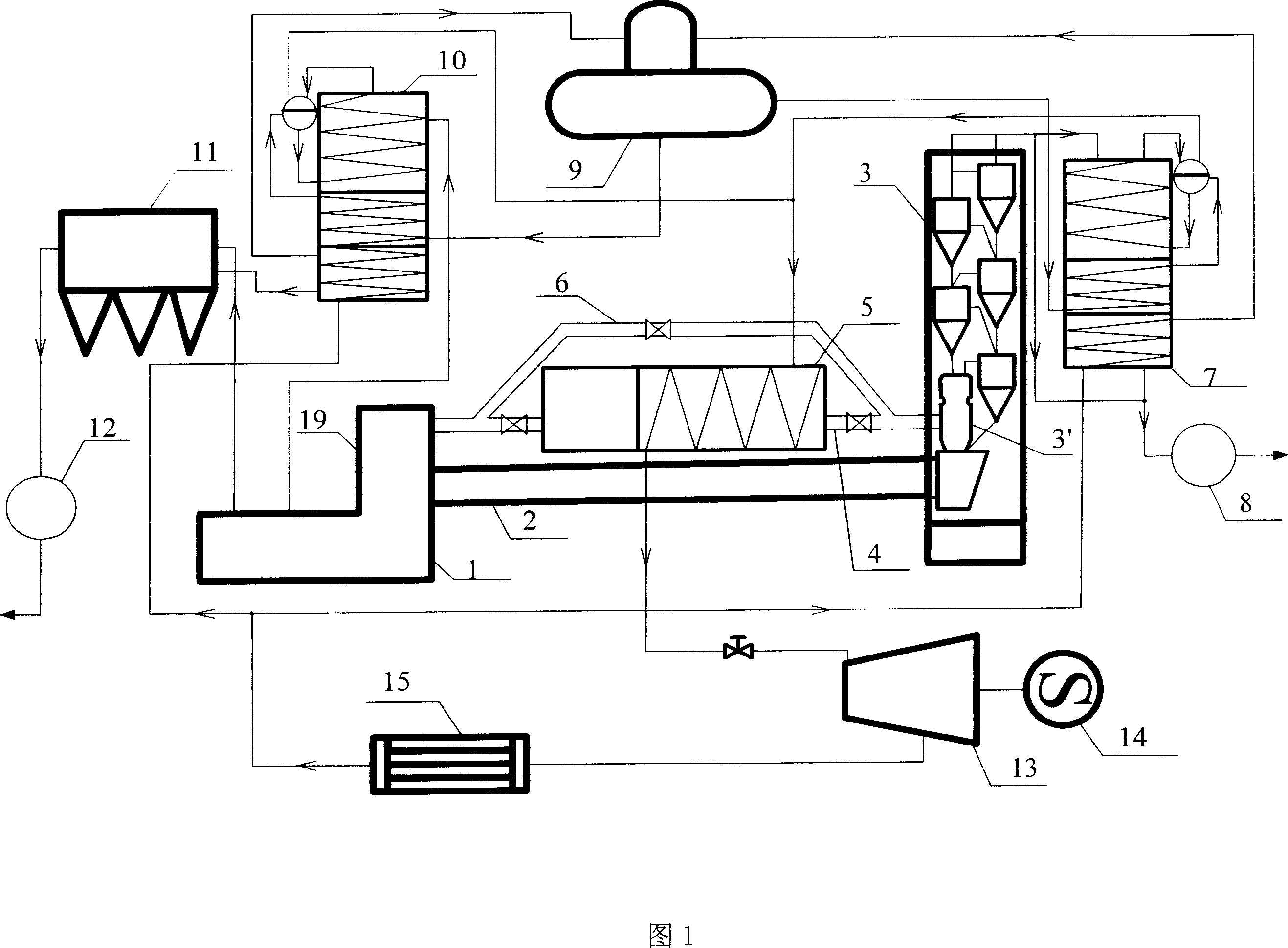

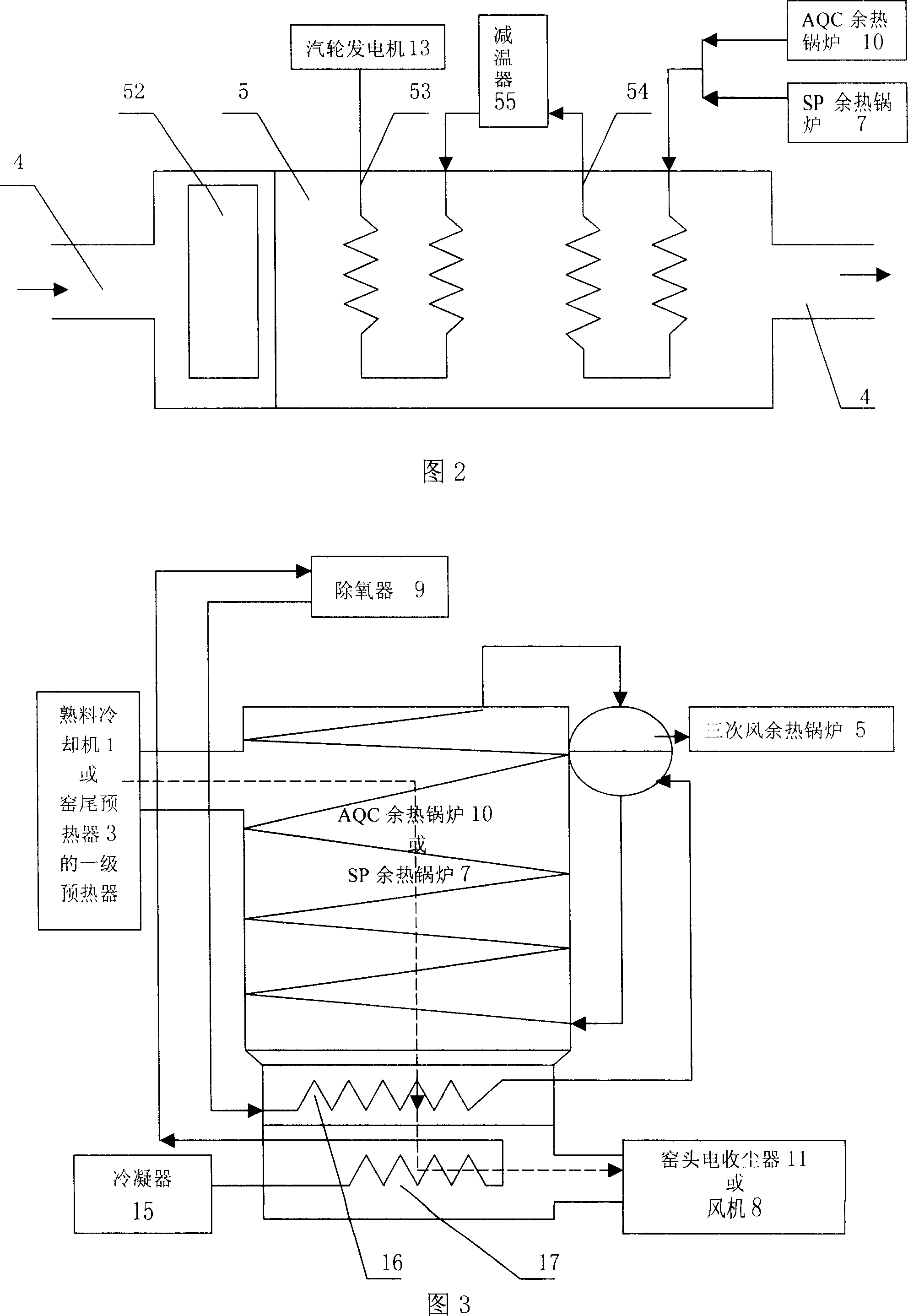

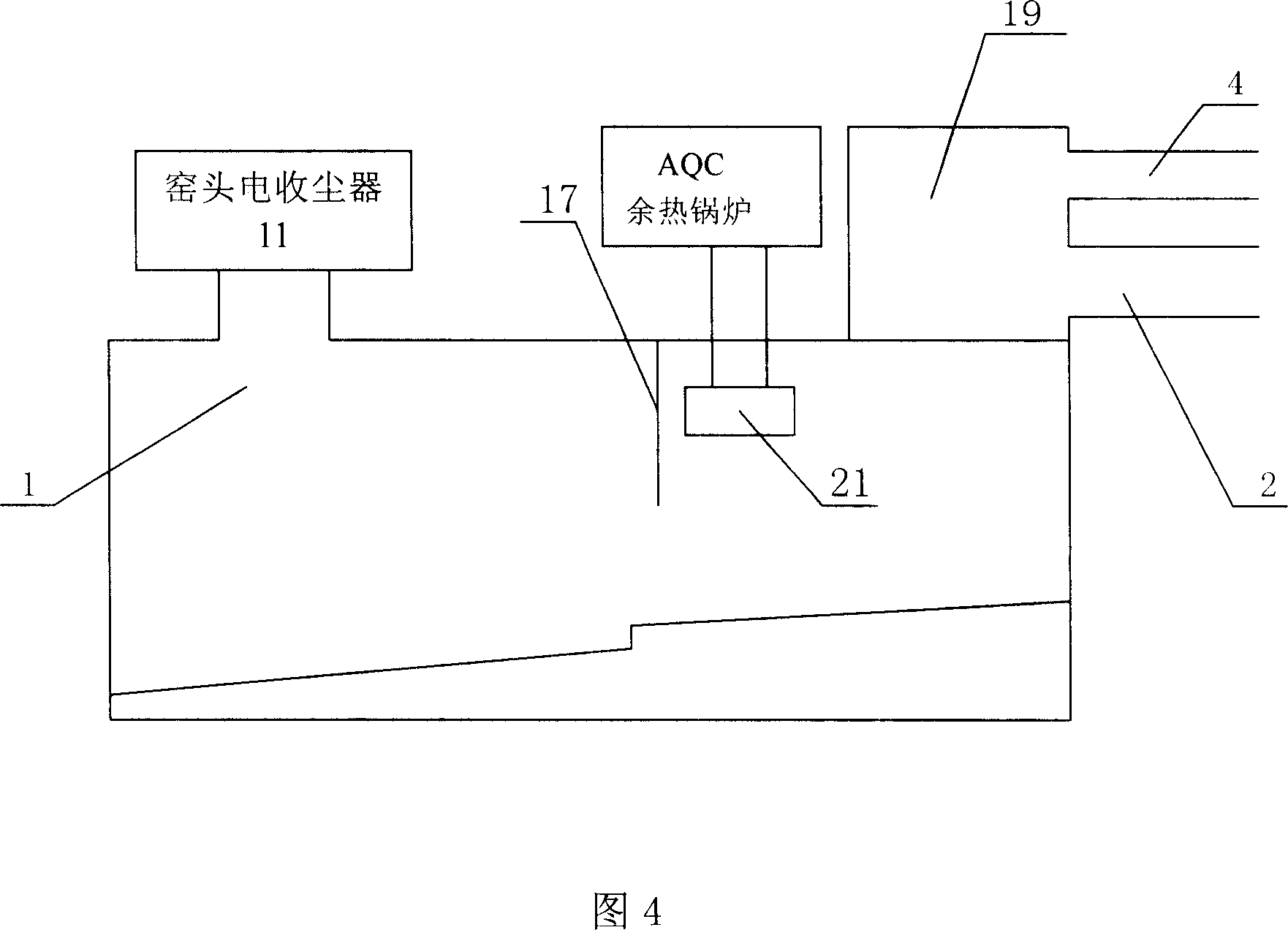

Residual heat generating system used for new type nonaqueous cement production line

ActiveCN101013002AMeet production needsIncrease profitIncreasing energy efficiencyClinker productionDeaeratorSuperheated steam

The invention discloses an abundant generating system used in dry cement product line, comprising a grog cooler, a AQC abundant heat boiler, a cement rotary furnace, a head frame of cement rotary furnace, a third-stage wind tube, a cement preheating device, a cement predissociation furnace, a SP abundant heat boiler, a fan, a deaerator, a condenser, and a generator of turbine. The third-stage wind tube is between the head frame and the predissociation furnace. The head frame is communicated with the grog cooler. The invention is characterized in that third-stage wind tube is arranged with a third-stage wind abundant-heat boiler with bypass wind channels; the medium inlet of the third-stage wind abundant-heat boiler via the tube is connected with the AQC abundant-heat boiler and the SP abundant-heat boiler, while the medium outlet is connected with the turbine generator. The invention can completely absorb the abundant heat of product line, to supply overheated steam to the generator, while the electricity generation is higher than 40kwh.

Owner:BEIJING LIULIHE CEMENT +1

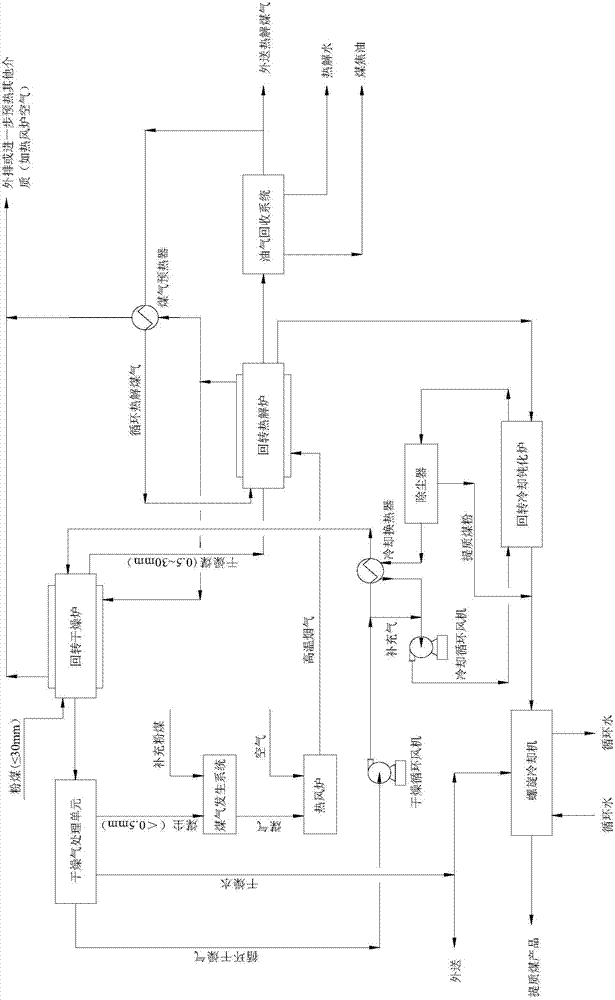

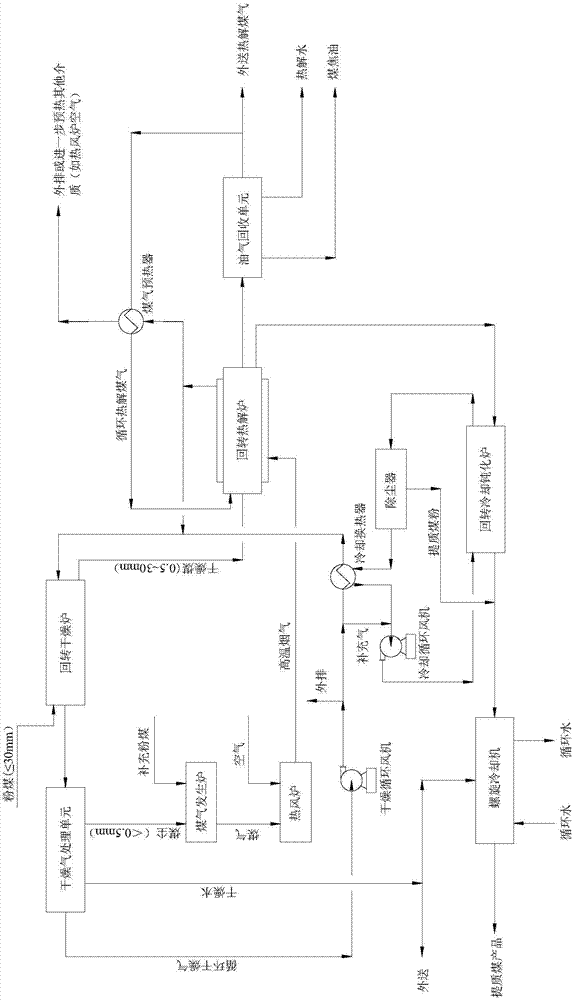

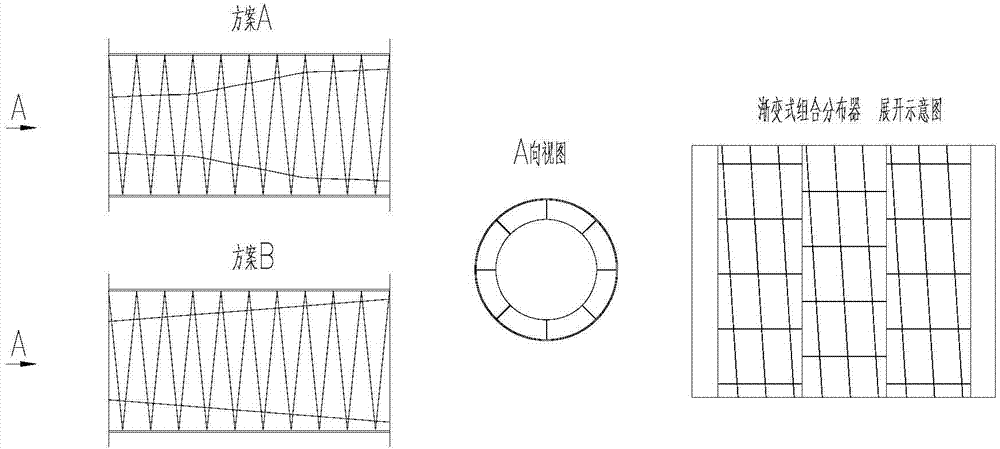

Rotary furnace low-order powdered coal pyrolysis upgrading method with coal gas circulation

ActiveCN104762097AReduce coal dust contentImprove qualitySpecial form destructive distillationGranularityCoal dust

The invention provides a rotary furnace low-order powdered coal pyrolysis upgrading method with coal gas circulation. The rotary furnace low-order powdered coal pyrolysis upgrading method comprises the following steps: heating and drying raw material powdered coal with the granularity less than or equal to 30mm to be 110-280 DEG C in a low-order powdered coal rotary drying system with dust collection, and removing 85% of coal dust with the granularity less than 0.5mm in the powdered coal; feeding the dried coal with the granularity of 0.5-30mm to a downstream rotary pyrolysis system to react at 500-700 DEG C so as to generate upgraded coal and a high-temperature oil gas; feeding the high-temperature upgraded coal to a rotary cooling passivating furnace for primary cooling and medium / low temperature passivation, further cooling by using a spiral cooling machine, spraying water, and discharging out the product; feeding the high-temperature oil gas into an oil gas recycling system, and performing temperature reduction separation, thereby obtaining coal tar, pyrolysis water and pyrolysis coal gas; preheating a part of the pyrolysis coal gas, circulating back to the pyrolysis furnace, and discharging out the rest part of the pyrolysis coal gas.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

Production of III threading reinforcing bar

Production of 20MnSi III thread reinforcing bar is carried out by adding blast-furnace iron water and waste steel into oxygen rotary furnace or electric furnace, oxygen-blowing smelting or supply smelting, adding into manganese and reducing agent, slag-excluding and tapping while reaching to 20MnSi standard, adding into defoliant, ferro-silico-manganese alloy or manganese-ferro alloy or ferro-silicon alloy into steel bag sequentially, adding into nitrogen promoter to make nitrogen content 0.008-0.035%, adding into nitride-containing alloy, blowing argon or nitrogen for steel liquid at 0.01-0.10m3 / t.min for 2-9mins, rolling at 1050-1300degree, and penetration cooling at 1.5-1.5degree / second. It costs low and has excellent mechanical performance.

Owner:湖南华菱涟源钢铁有限公司

Semi-process cold-rolling non-oriented electrical steel and production process thereof

The invention discloses a semi-process cold-rolling non-oriented electrical steel and a production process thereof, which mainly solves the technical problems that the prior art is high in energy consumption, large in pollution and high in cost. According to the technical scheme, the semi-process cold-rolling non-oriented electrical steel is a special steel which comprises the following ingredients by mass: not more than 0.01% of C, not more than 0.015% of P, not more than 0.012% of S, not less than 0.4% and not more than 0.60% of Si, not less than 0.6% and not more than 0.8% of Mn, not less than 0.15% and not more than 0.25% of Al, and the balance of Fe. The production process comprises the following steps: smelting molten steel, continuous casting, hot-rolling, punching and annealing, and specifically comprises the following steps: pretreating molten iron, smelting in a rotary furnace, blowing argon over the whole process, conducting RH (Rockwell Hardness) fine smelting, conducting CSP (Cast Steel Plate) continuous casting, putting in a CSP heating furnace, conducting CSP hot-continuous-casting, pickling and cold-rolling and annealing, wherein in the smelting process in the rotary furnace, silicon iron, ferromanganese iron and an aluminum alloy are added to conduct alloying so as to manufacture an alloy steel. The semi-process cold-rolling non-oriented electrical steel is mainly used in a production process of a motor iron core.

Owner:HUNAN XUEBAO ELECTRIC APPLIANCE

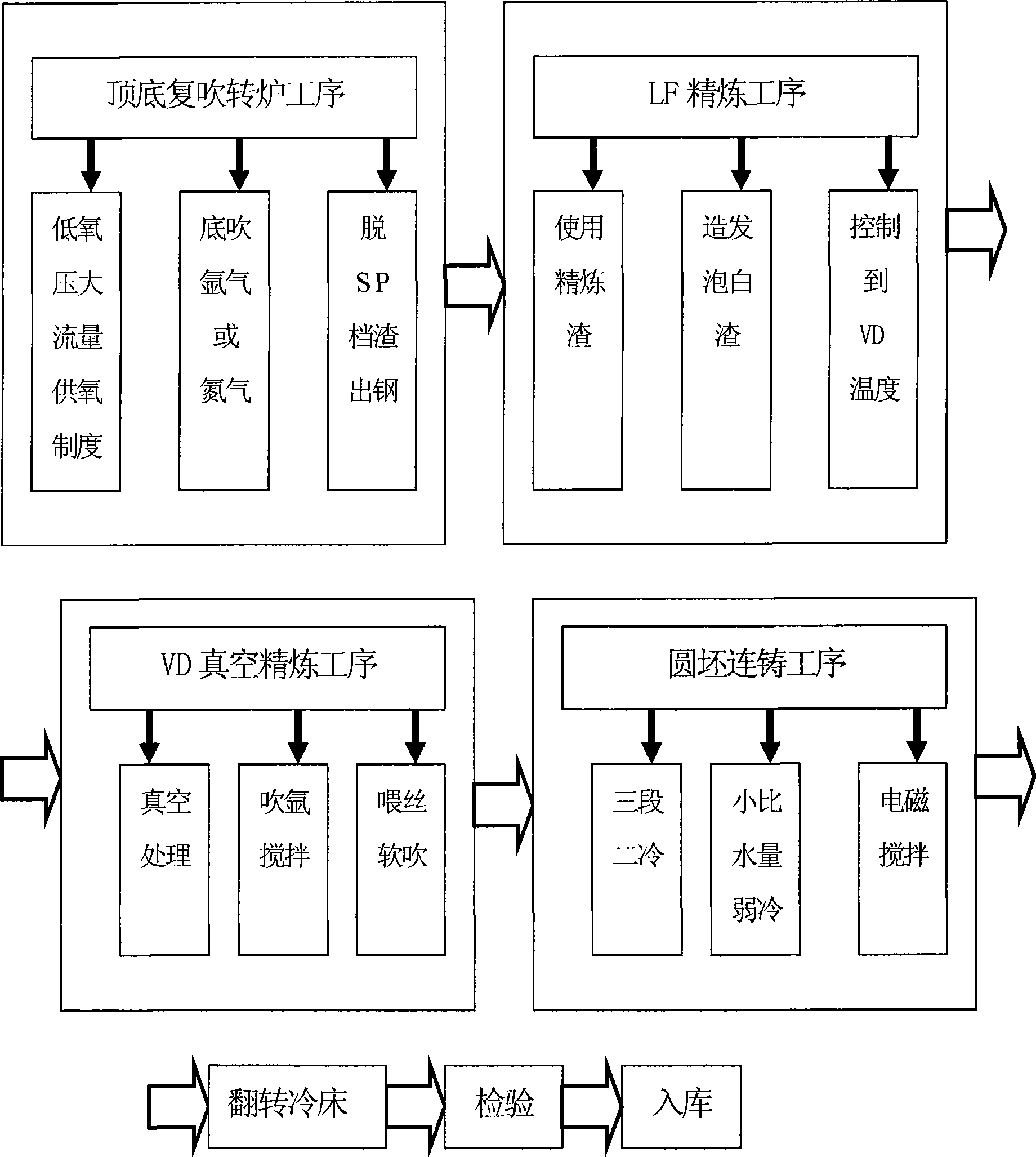

Round blank for high-steel level oil bushing and manufacturing process

InactiveCN101446180AGuaranteed performanceOvercome strengthDrilling rodsManufacturing convertersU s economyUltimate tensile strength

Owner:TIANJIN IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com