Method for producing lithium iron phosphate material by vacuum rotary kiln

A technology of lithium iron phosphate and process method, which is applied in the field of energy materials, can solve the problems of poor electronic conduction and ion conductivity, long sintering time of lithium iron phosphate materials, and affecting the charge and discharge capacity of materials, etc., to achieve shortened sintering time and consistency The effect of improving the repeatability of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

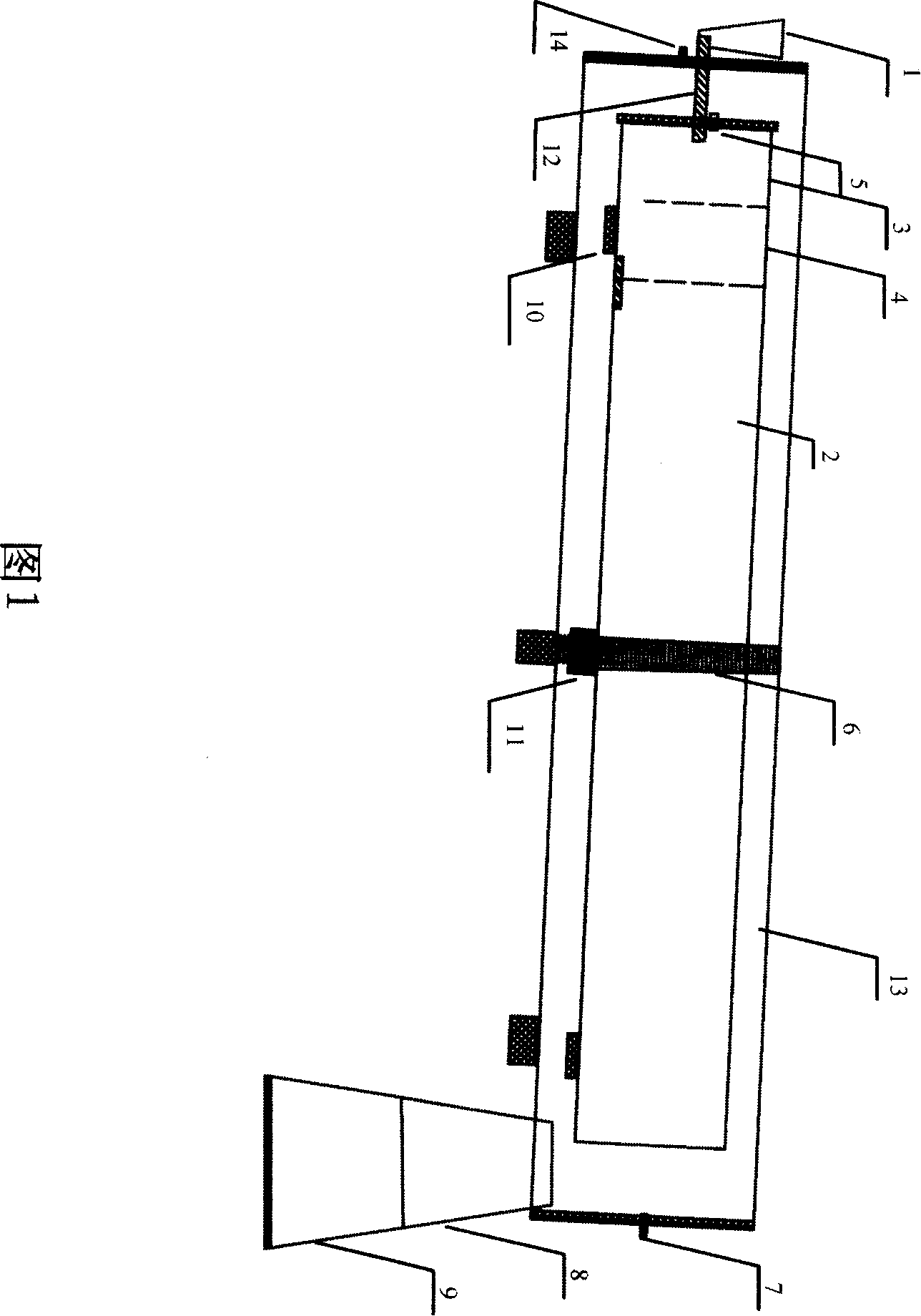

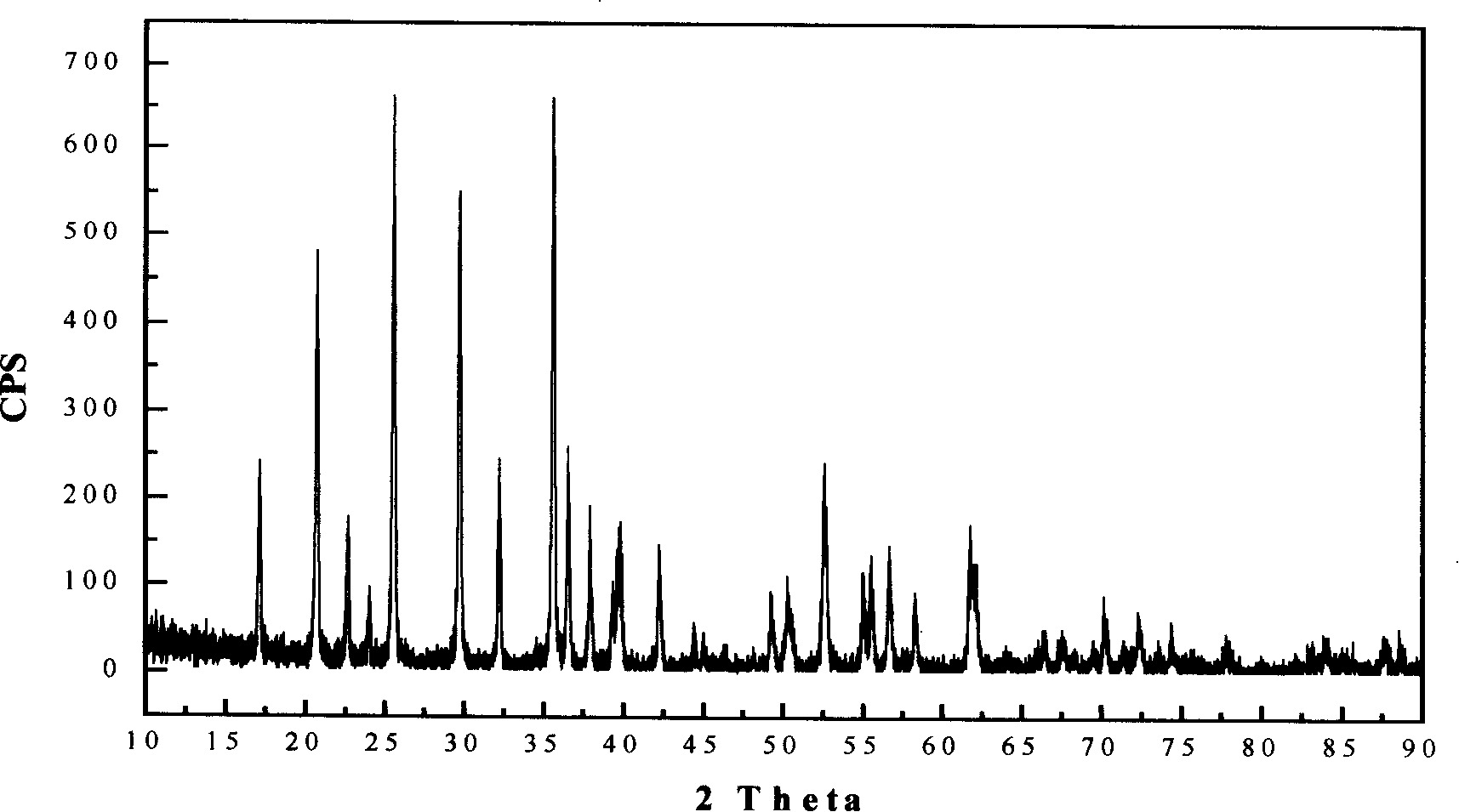

[0018] FeC 2 o 4 .2H 2 O, LiH 2 PO 4 as the main raw material, with H 2 TiO 3 , Mg(OH) 2 For doping materials, according to LiFe 0.98 Ti 0.01 Mg 0.01 PO 4 Composition batching, raw material is about 200kg altogether. Powerfully pulverized to 300 mesh, then ball milled in a horizontal ball mill for 2 hours, pressed into ф8 spherical pellets, fed continuously through a hopper and a screw feeder. The rotary kiln is divided into multiple temperature zones: low-temperature pre-firing zone, medium-temperature zone, high-temperature sintering zone, and cooling zone. Each temperature zone is individually controlled by PID. The temperature in the high temperature sintering zone is set at 760°C. The length of the rotary kiln body is 8 meters, and the diameter of the internal rotating material barrel is ф650mm. The inclination angle of the rotating bucket is 5°, and the rotation rate is 5 cycles / min. It takes a total of 10 hours for the material to be fed from the end of t...

Embodiment 2

[0020] FeC 2 o 4 .2H 2 O, NH 4 h 2 PO 4 , Li 2 CO 3 As the main raw material, TiO 2 , Mg(OH) 2 For doping materials, according to LiFe 0.98 Ti 0.01 Mg 0.01 PO 4 Composition batching 200kg, add sucrose 6.7kg simultaneously. Powerfully crush to 300 mesh, then ball mill in a horizontal ball mill for 2 hours, press into ф8 spherical pellets, close the valve between the feeding bin and the feeding bin, and feed 200kg pellets continuously through the feeding hopper and the screw feeder. The rotary kiln is divided into multiple temperature zones: low-temperature pre-firing zone, medium-temperature zone, high-temperature sintering zone, and cooling zone. Each temperature zone is individually controlled by PID. The temperature in the high temperature sintering zone is set at 760°C. The length of the rotary kiln body is 8 meters, and the diameter of the internal rotating material barrel is ф650mm. The inclination angle of the rotating bucket is 5°, and the rotation rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com