Ceramic hair care heating element

a technology of heating element and ceramic hair, which is applied in the field of ceramic hair care appliances with heating elements, can solve the problems of uneven heating and extended heating tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

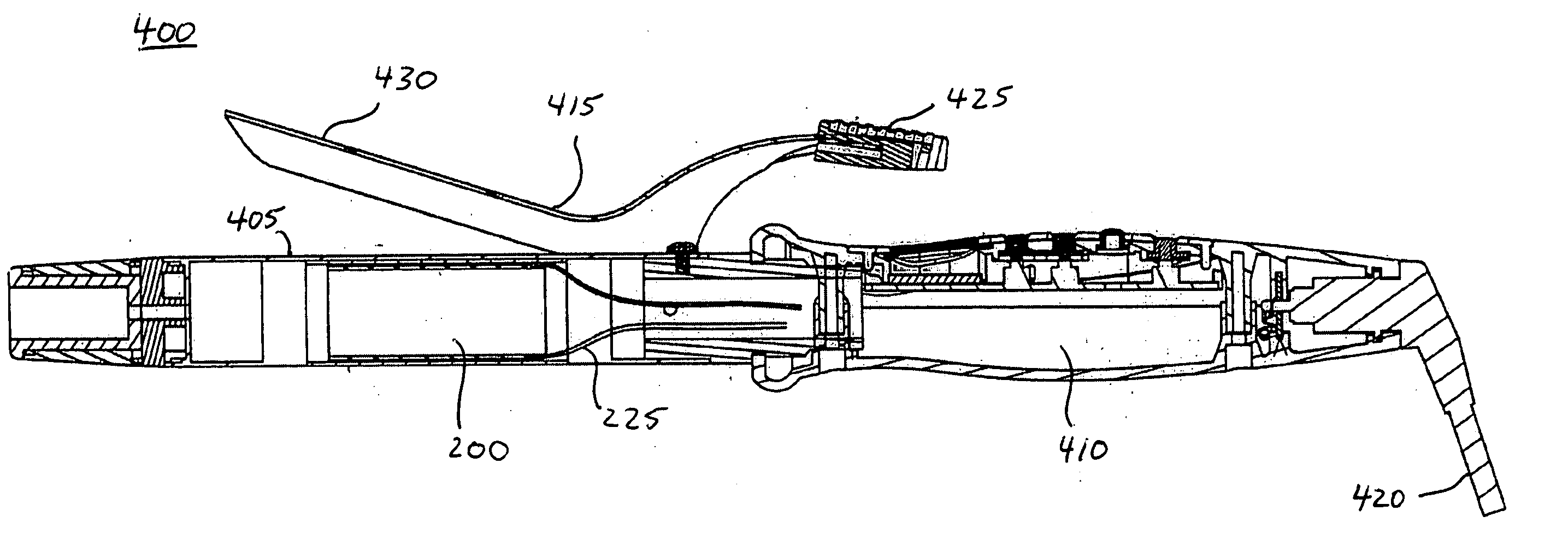

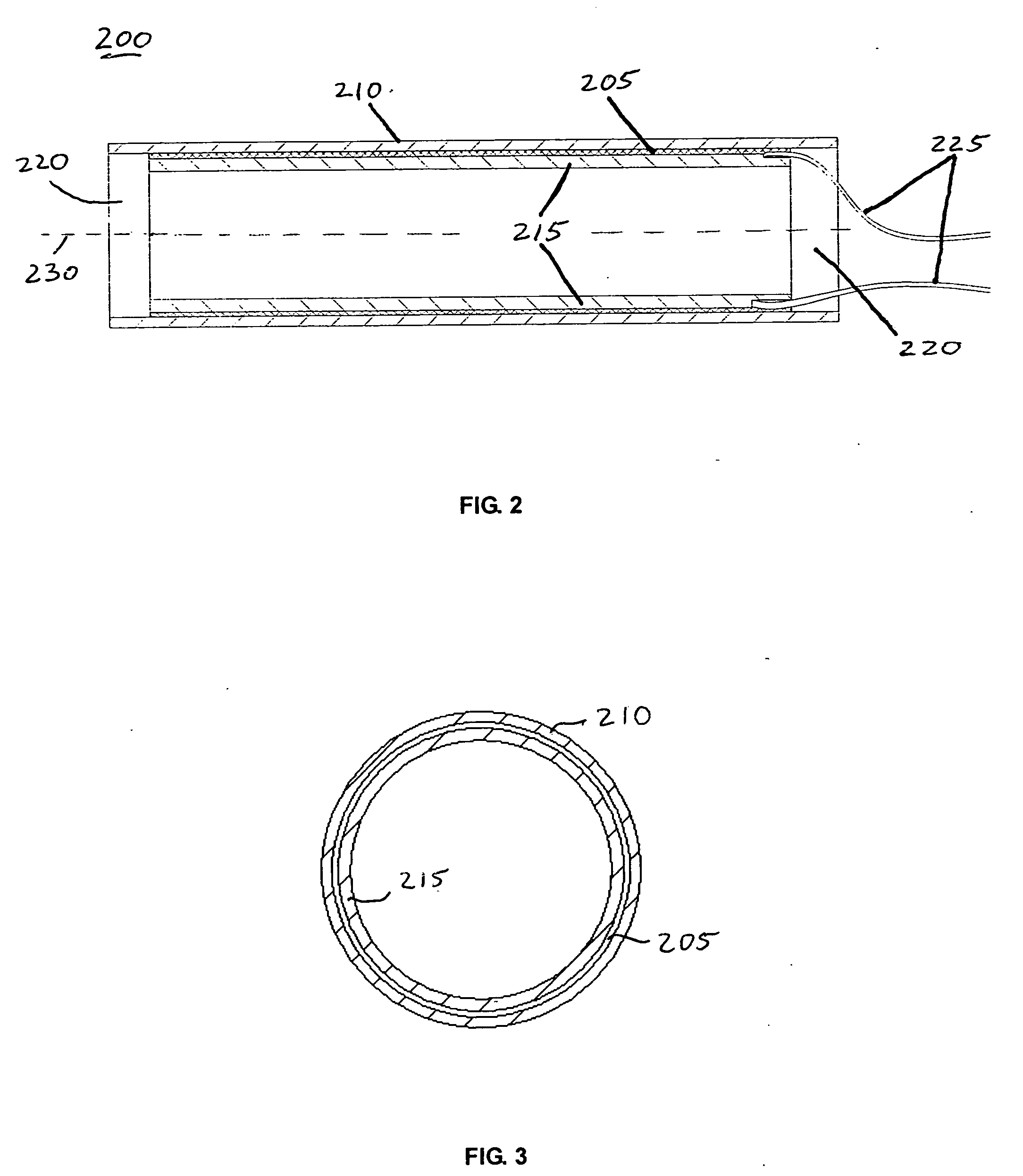

[0021] Referring to the drawings and, in particular, to FIG. 2, there is provided an embodiment of an electric heating unit for use as a hair curler / setter or for use in a hair styling device. Heating unit 200 includes a resistive heating conductive layer 205 sandwiched between an outer ceramic layer 210 and an inner ceramic layer 215, end gaps 220 and electrical leads 225. Electrical leads or wires 225 are electrically connected to conductive layer 205.

[0022] End gaps 220 are located at the ends of heating unit 200 due to an extension of outer ceramic layer 210 relative to conductive layer 205 and inner ceramic layer 215. In the embodiment shown in FIG. 2, outer ceramic layer 210 has a length along an axis 230 that is longer than a length along axis 230 of conductive layer 205 and inner ceramic layer 215.

[0023] In a preferred embodiment, end gaps 220 are filled with a thermally insulating adhesive material, such as an epoxy or a glue. The adhesive material contacts and bonds oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com