Patents

Literature

14188results about How to "Evenly heated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

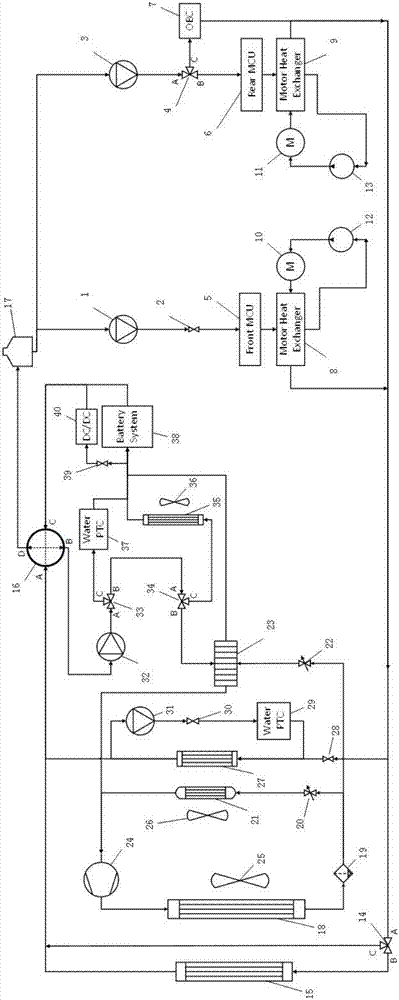

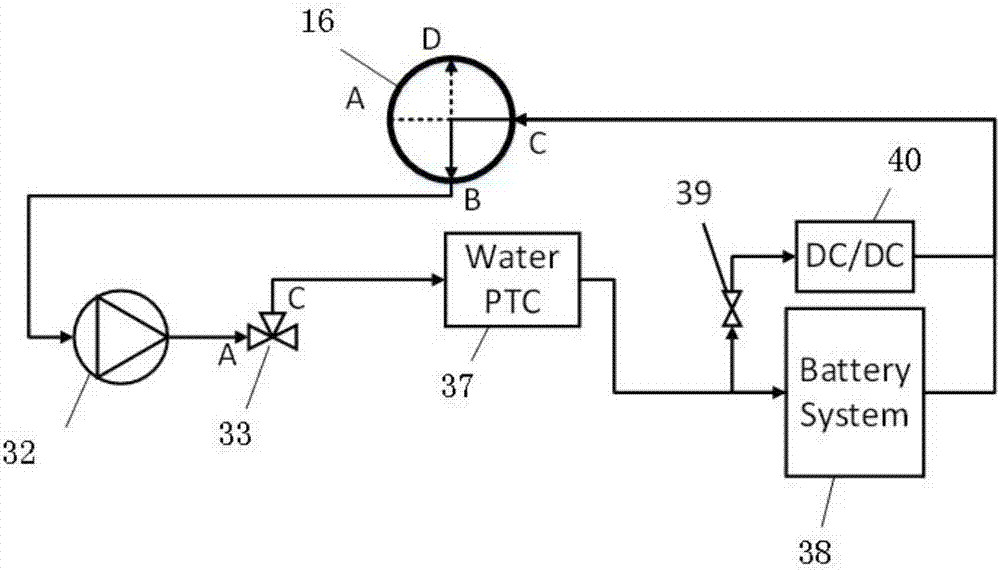

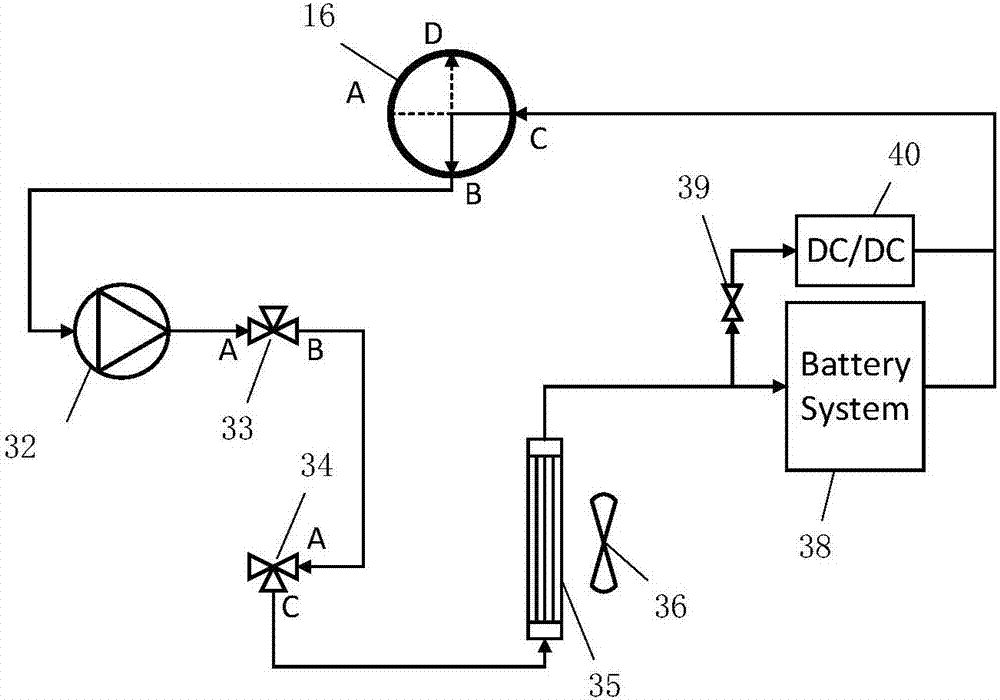

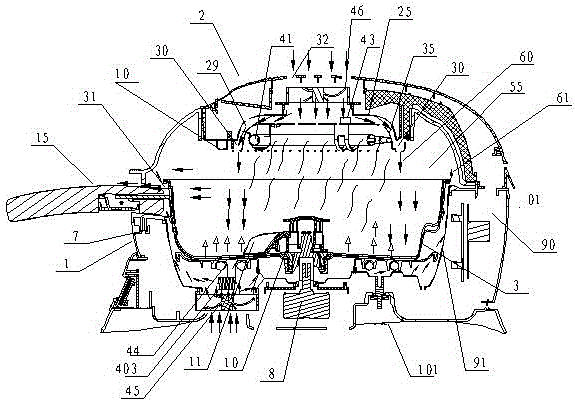

Intelligentized multi-loop thermal management system of electric automobile

PendingCN107097664AKeep Calories BalancedEnsure efficient operationAir-treating devicesSecondary cellsExpansion tankWork status

The invention relates to an intelligentized multi-loop thermal management system of an electric automobile. The intelligentized multi-loop thermal management system comprises a power battery pack, a driving motor, a motor controller, a vehicle-mounted electric-charger, a DC / DC transducer, a battery radiator, a battery refrigerator, a motor radiator, a motor water pump, a motor oil pump, an expansion water tank, a PTC heater, a heat exchanger, a motor compressor, a condenser, a liquid storage drying kettle, an evaporator, a electric expansion valve and a heater core body. By interconnection between a direct-through valve, a three-direction valve and a four-way valve, a plurality of heat management controlling circuit is formed. Compare with the existing technology, the intelligentized multi-loop thermal management system forms a plurality of circuits which can meet different cooling or heating requirements. According to the power battery pack of the electric automobile, a electric-driving module and air-condition character and working status of passenger compartments, the circuits are selectively opened or closed, temperature balancing and high-efficiency run of the electric automobile are guaranteed, system energy is saved significantly, endurance mileage of the electric automobile is prolonged, and economy of automobiles is improved.

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

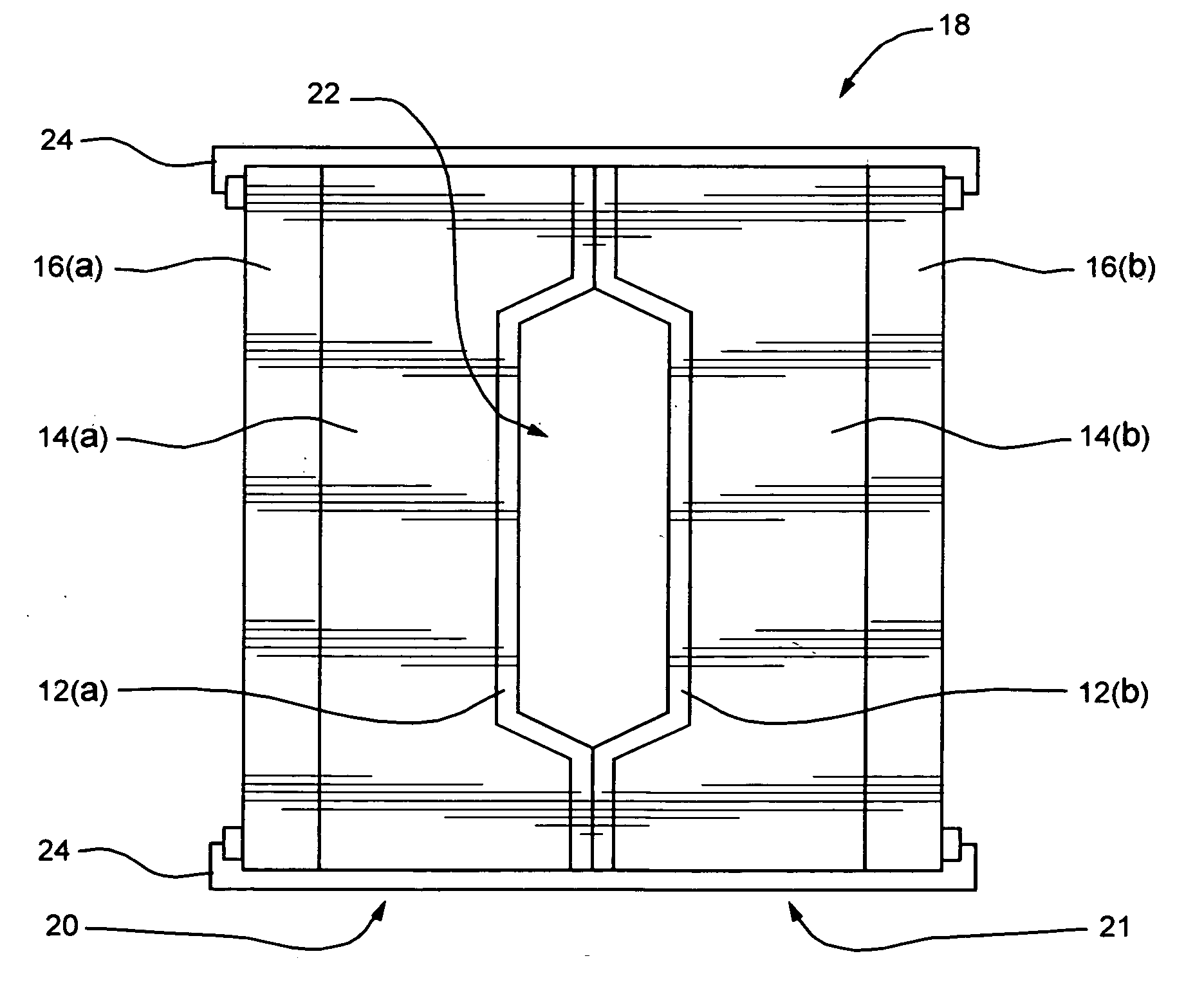

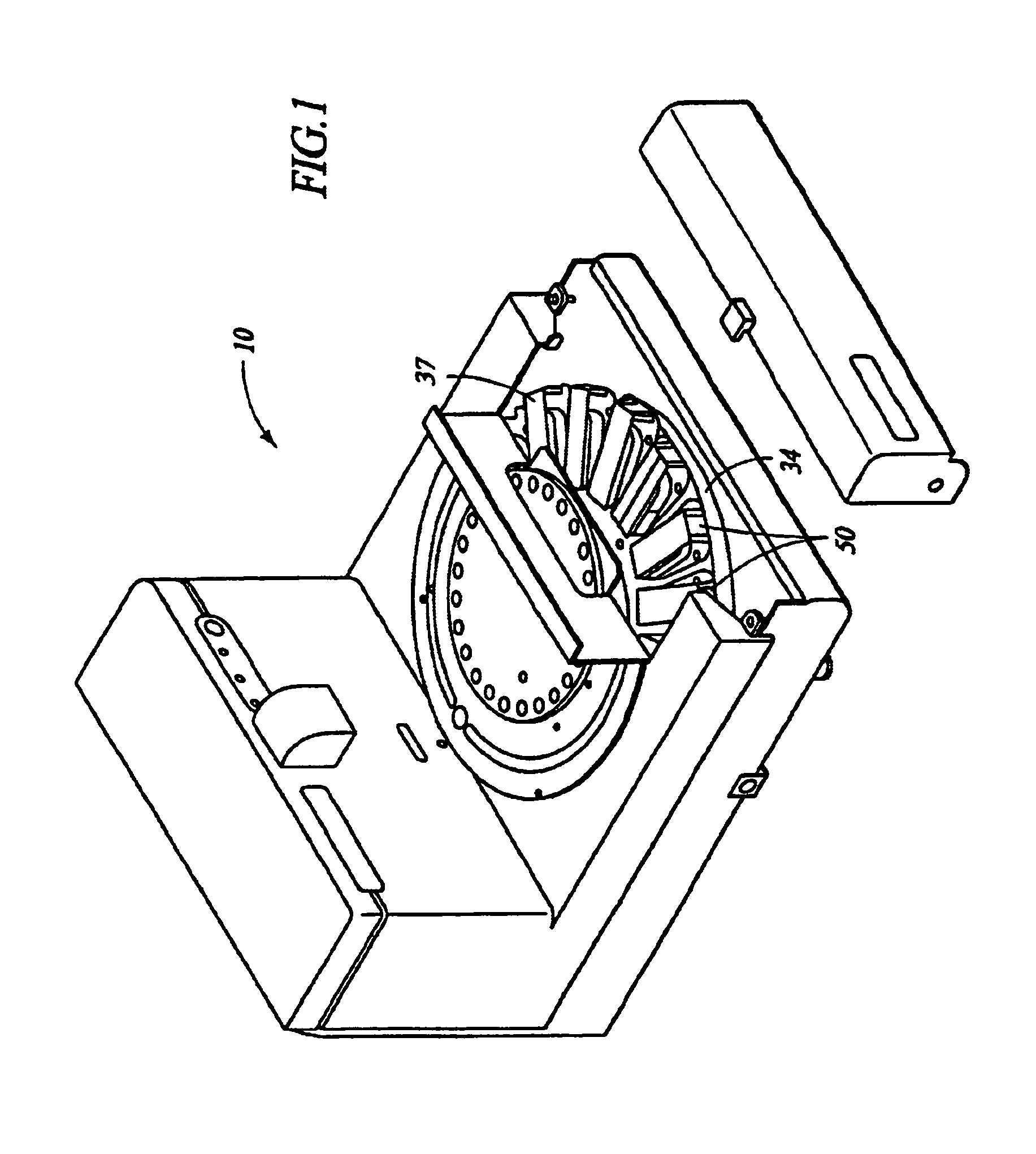

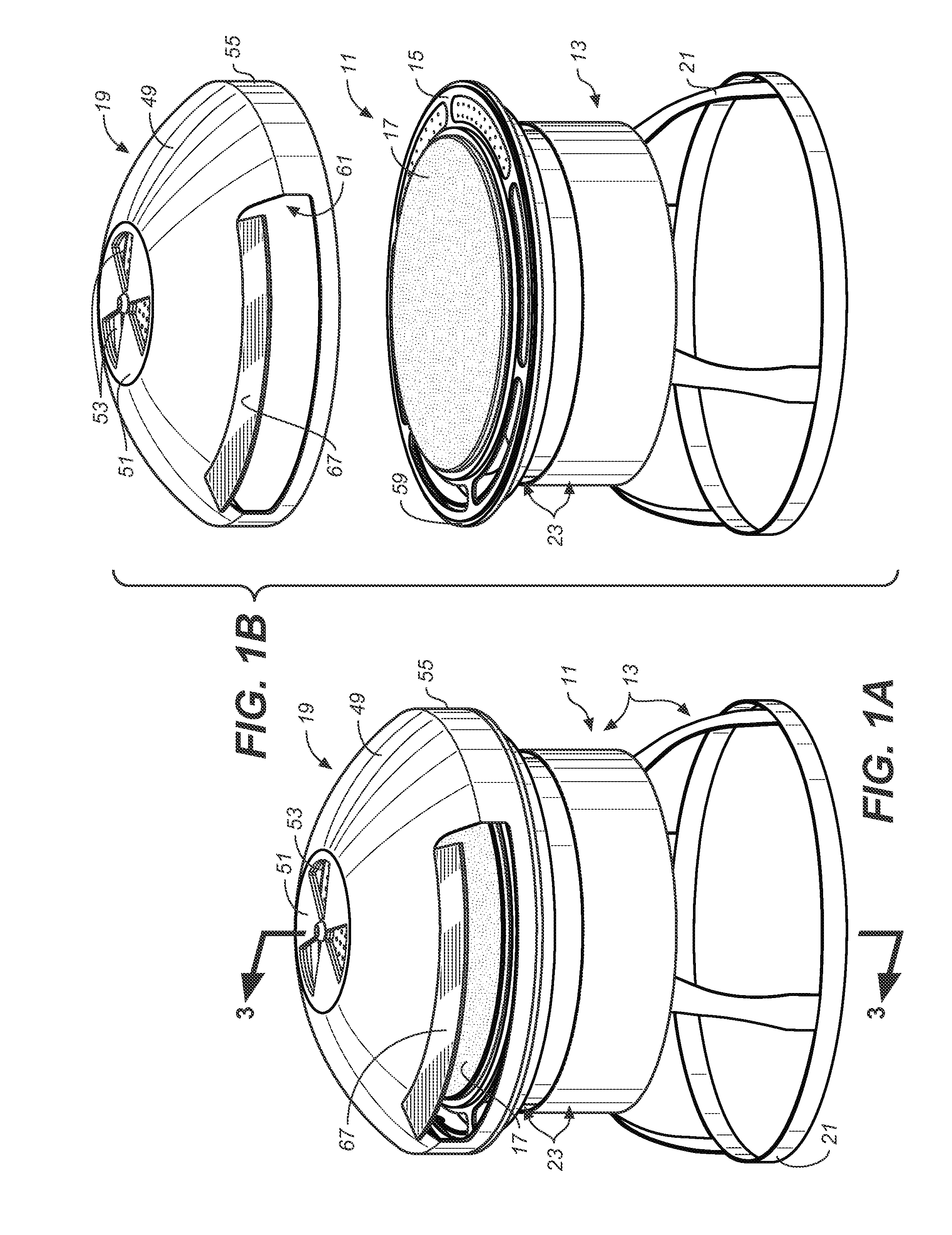

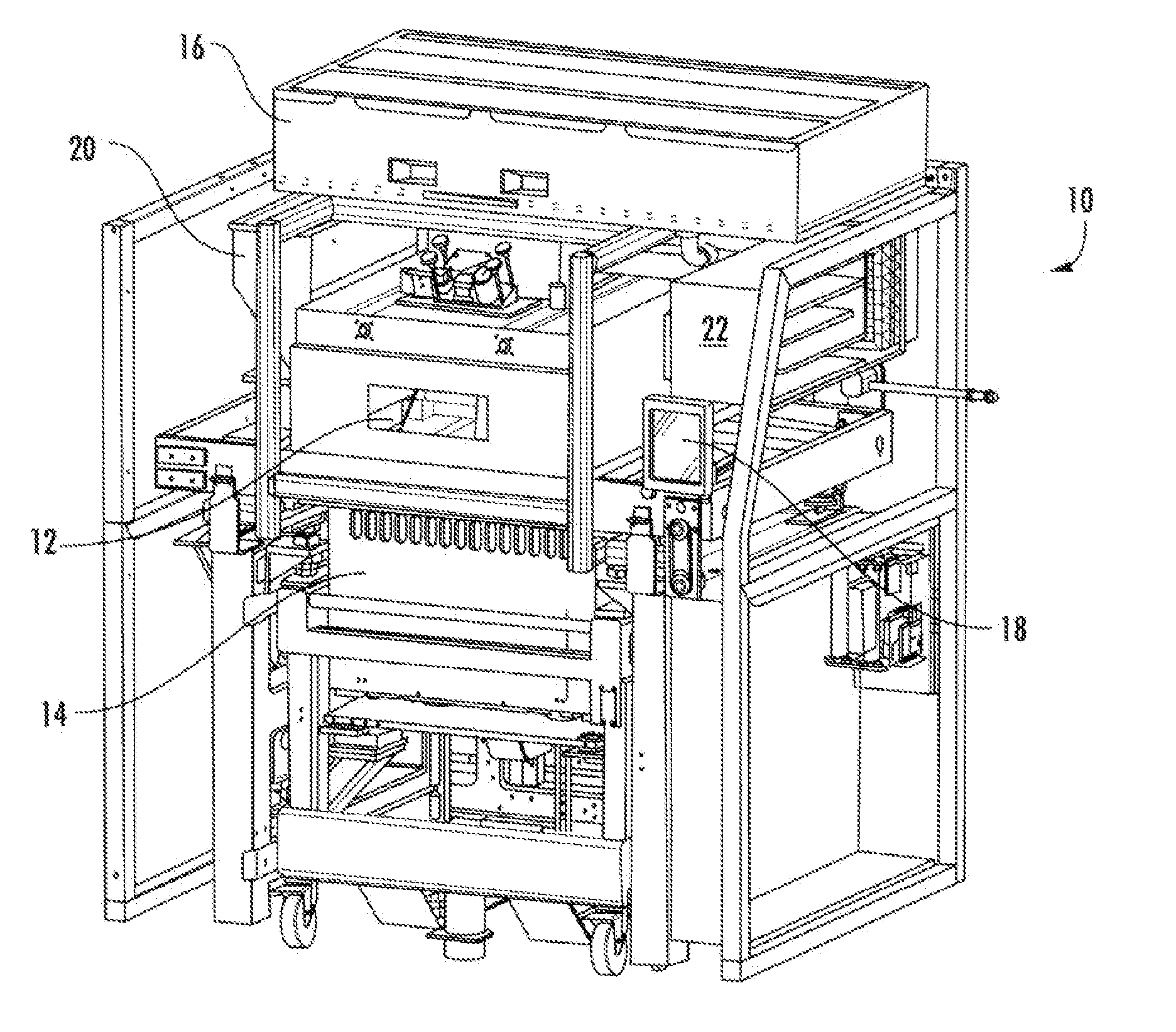

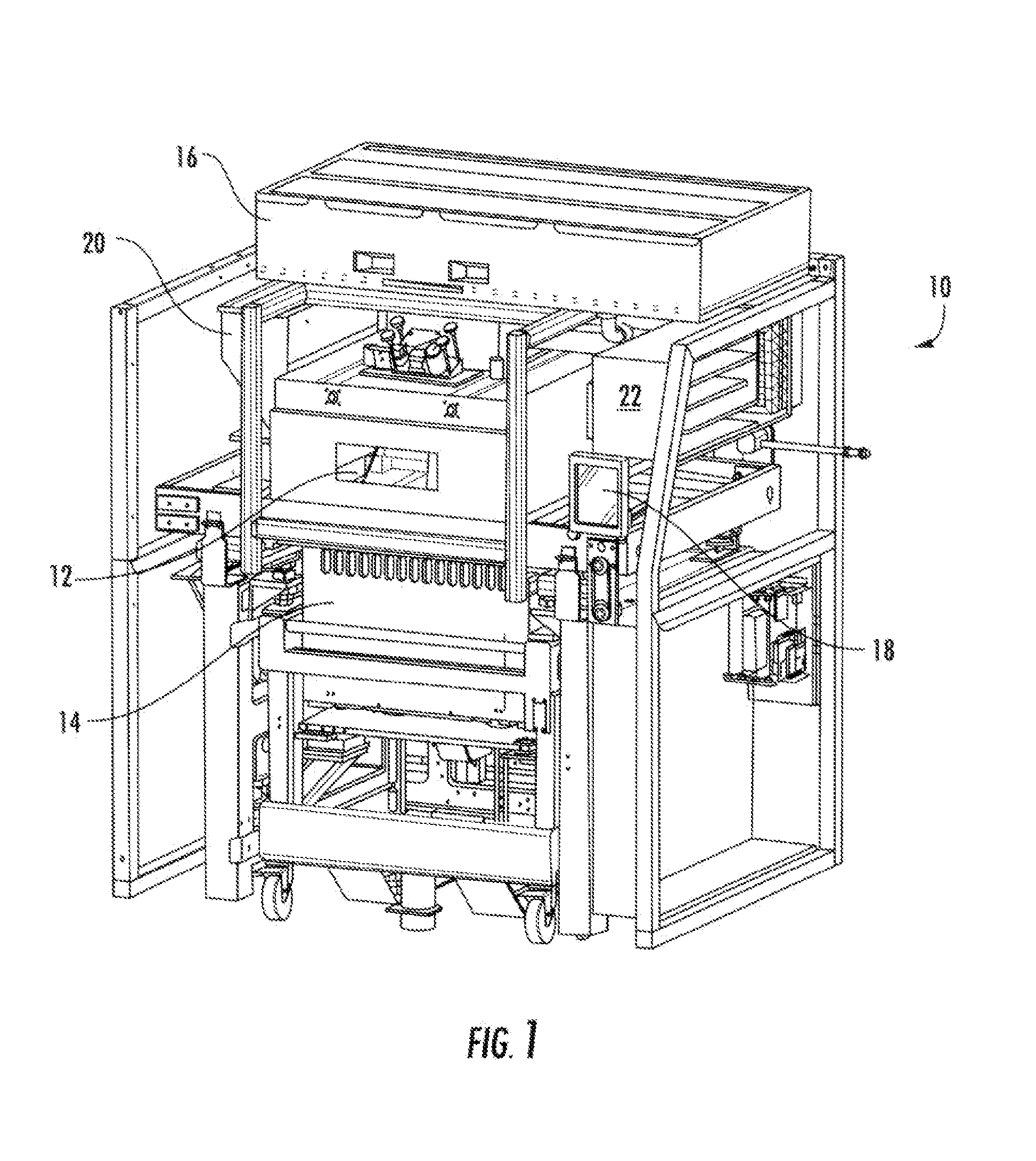

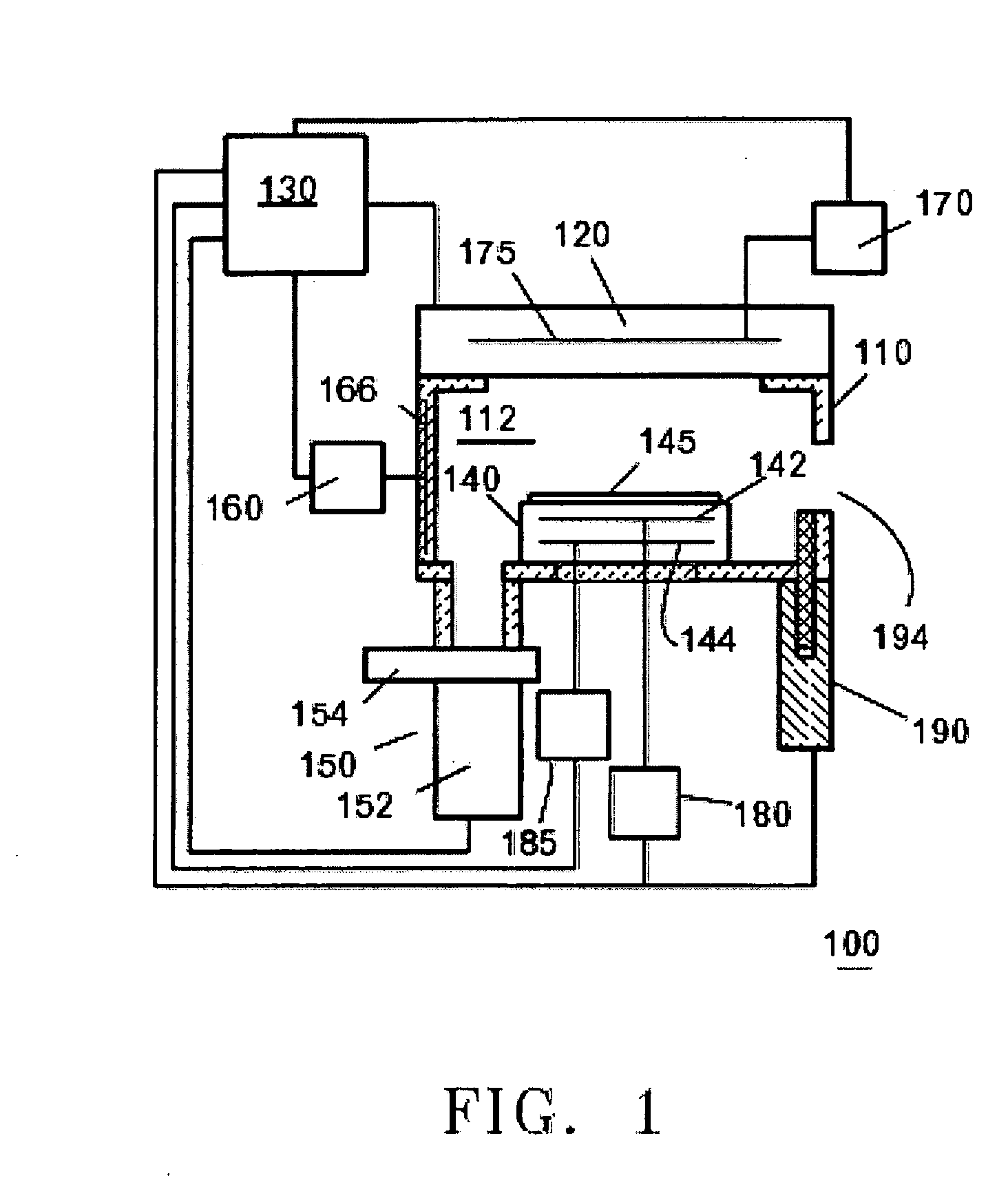

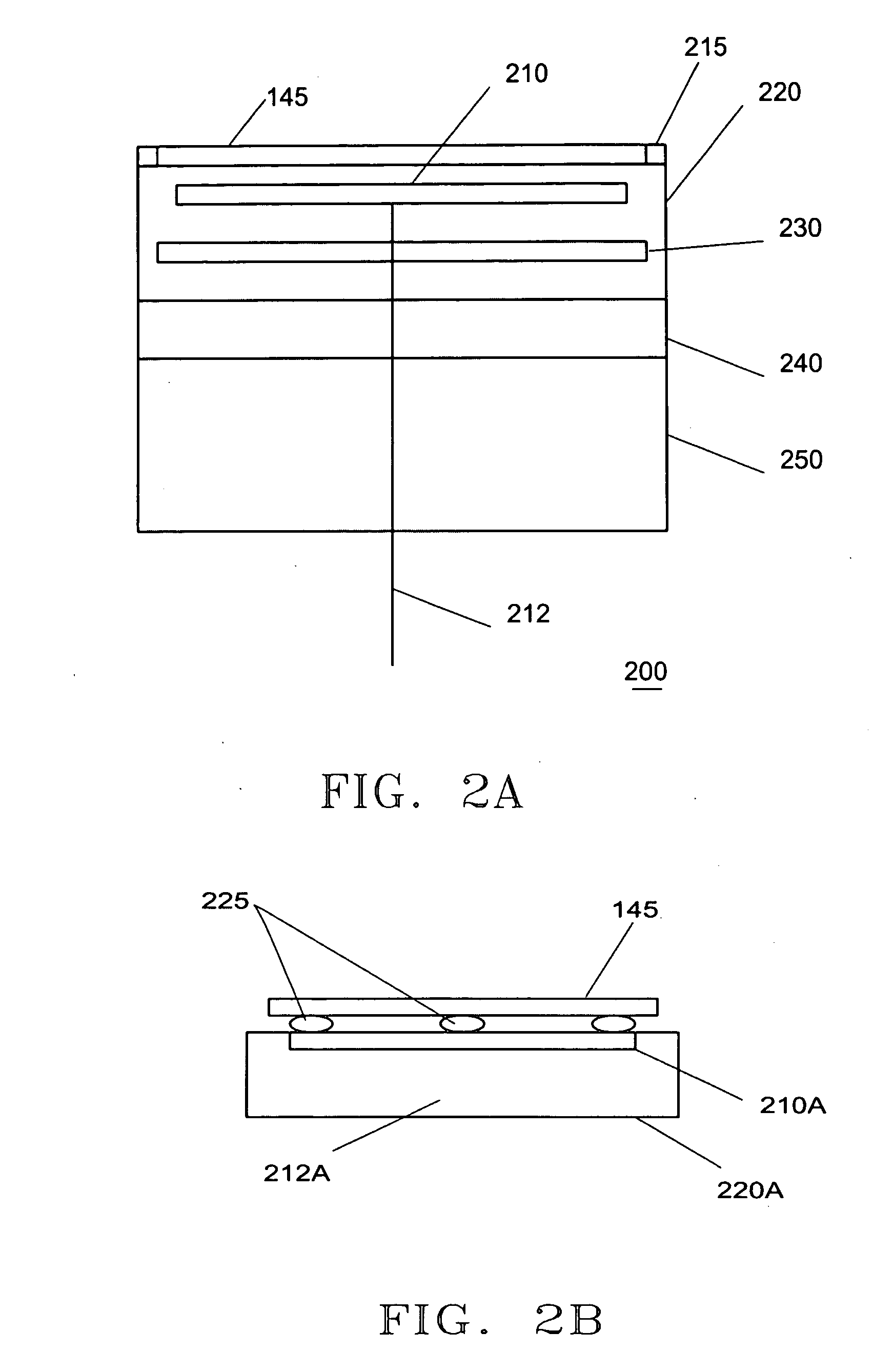

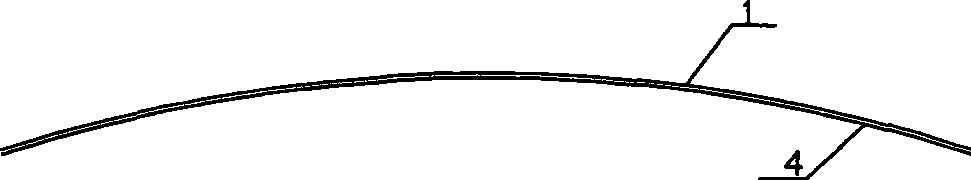

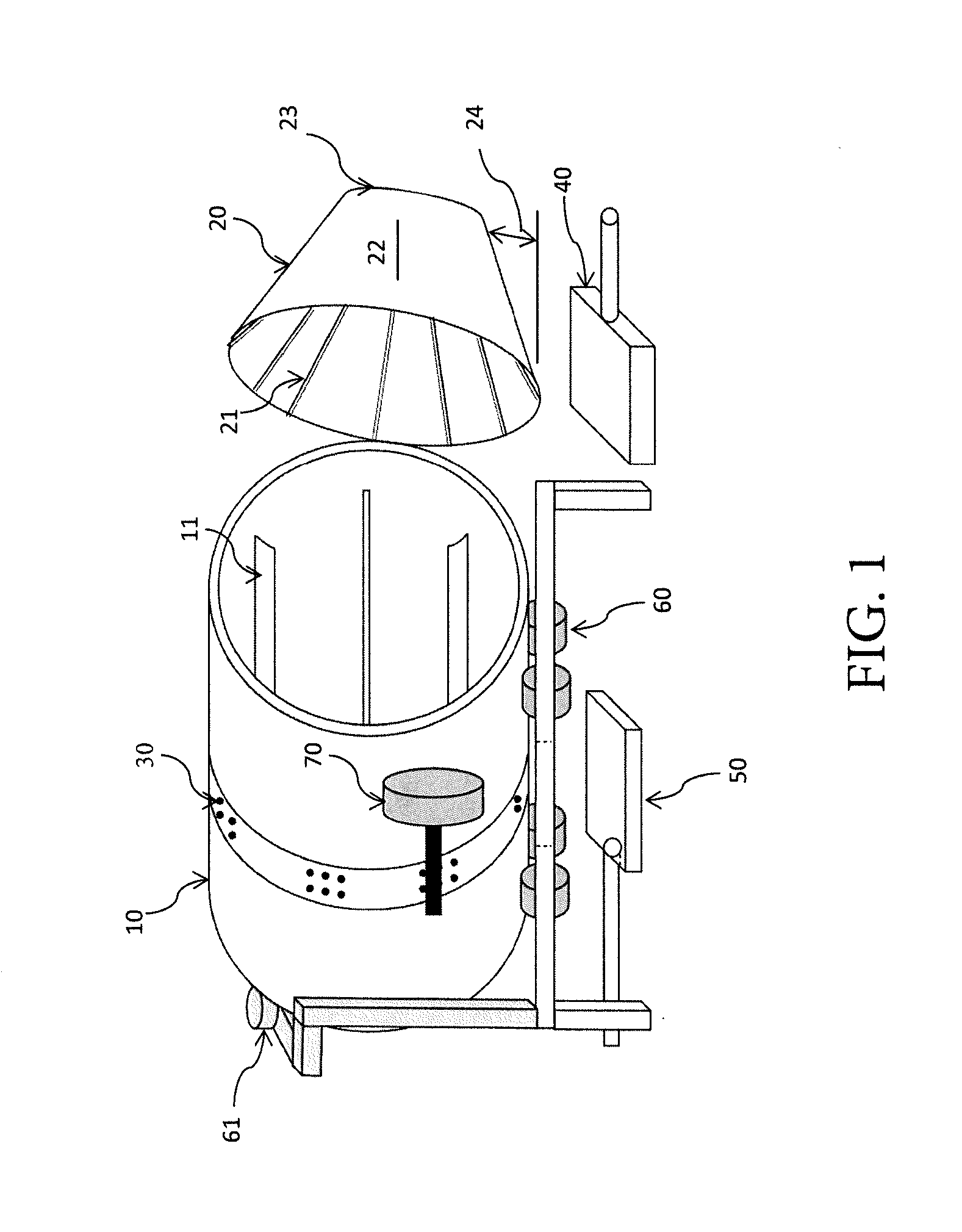

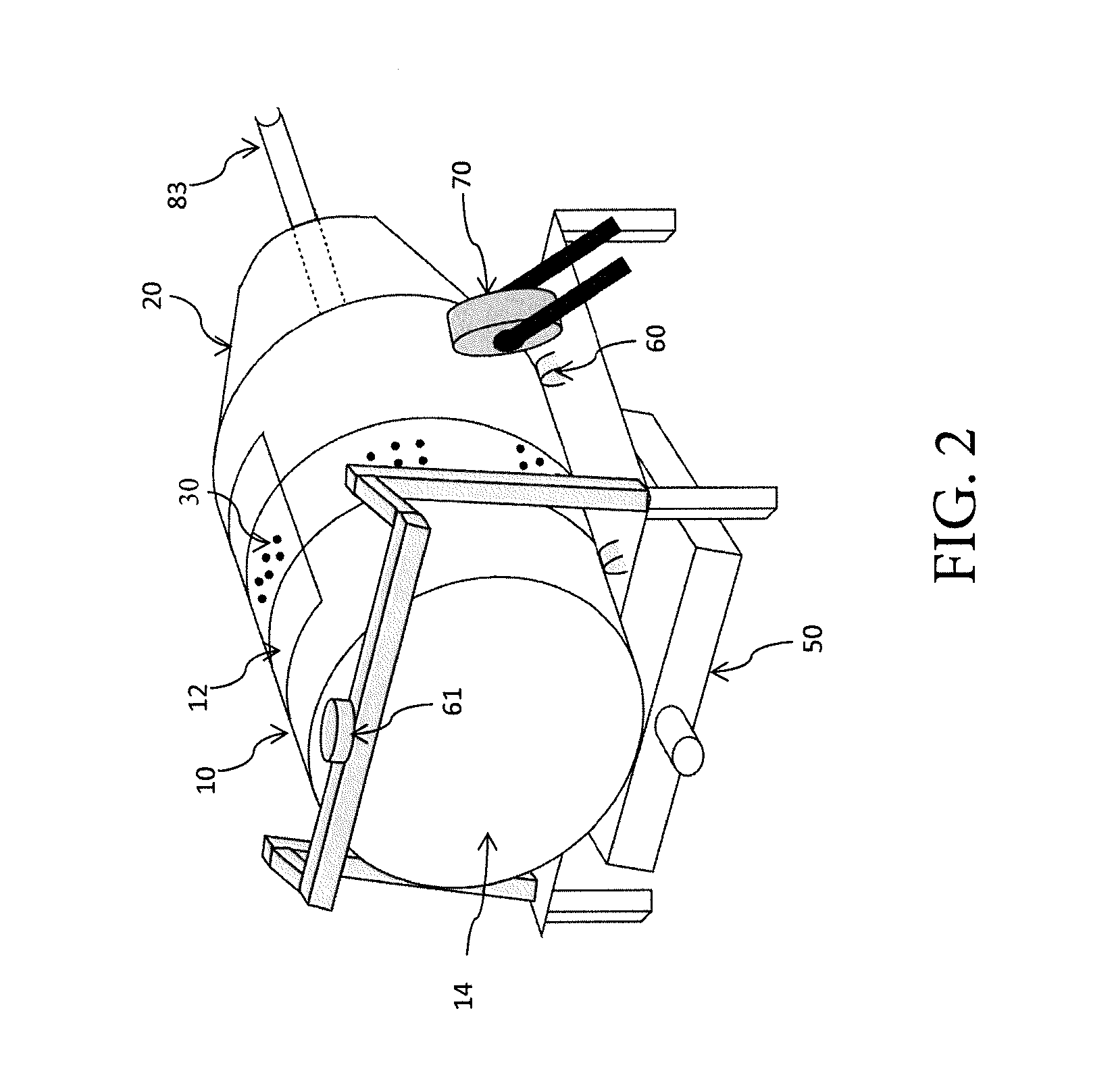

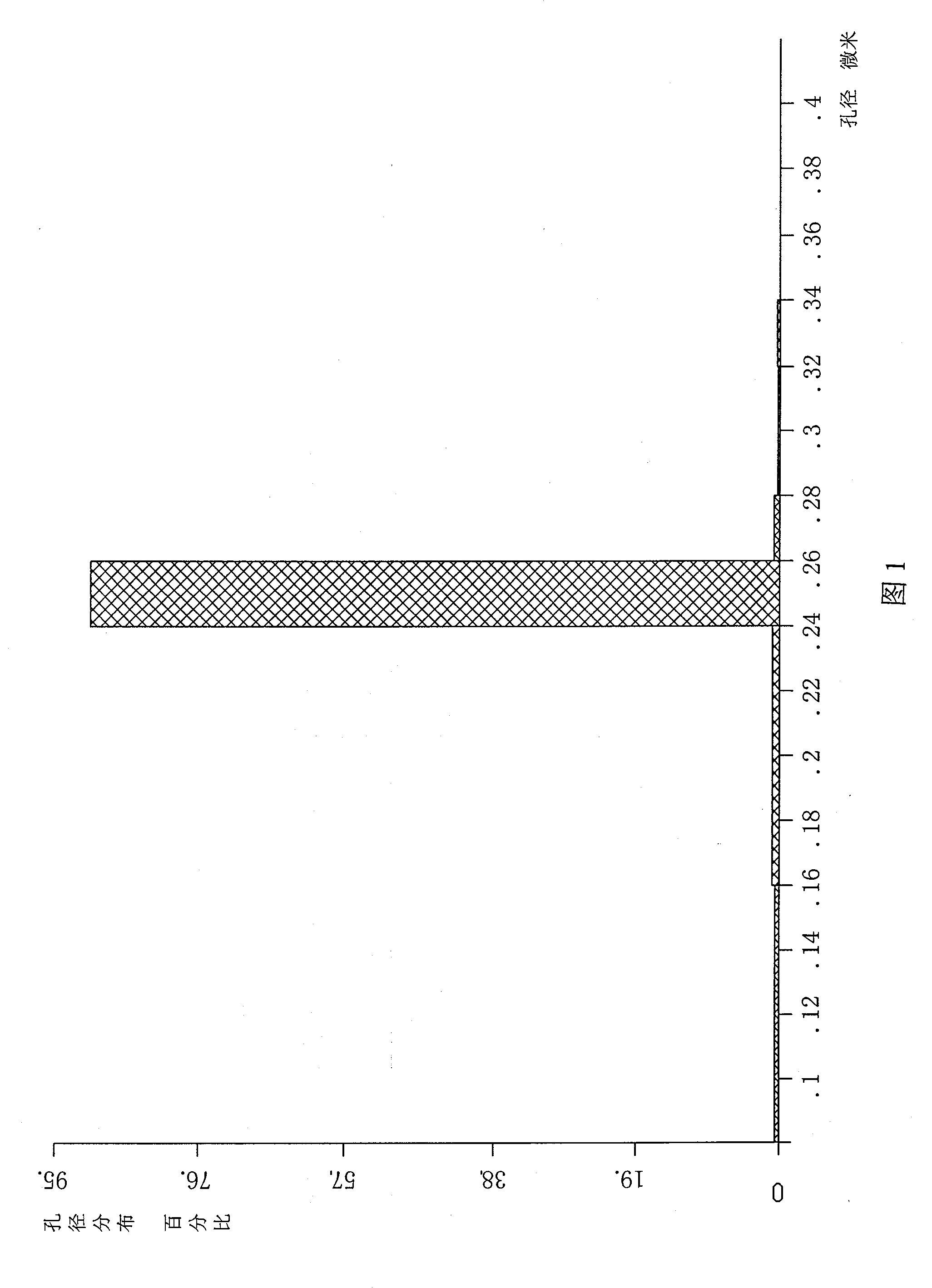

Compound tooling system for molding applications

ActiveUS20070063378A1Accurate operationFacilitate partial removalAdditive manufacturing apparatusConfectioneryShell moldingMetal mold

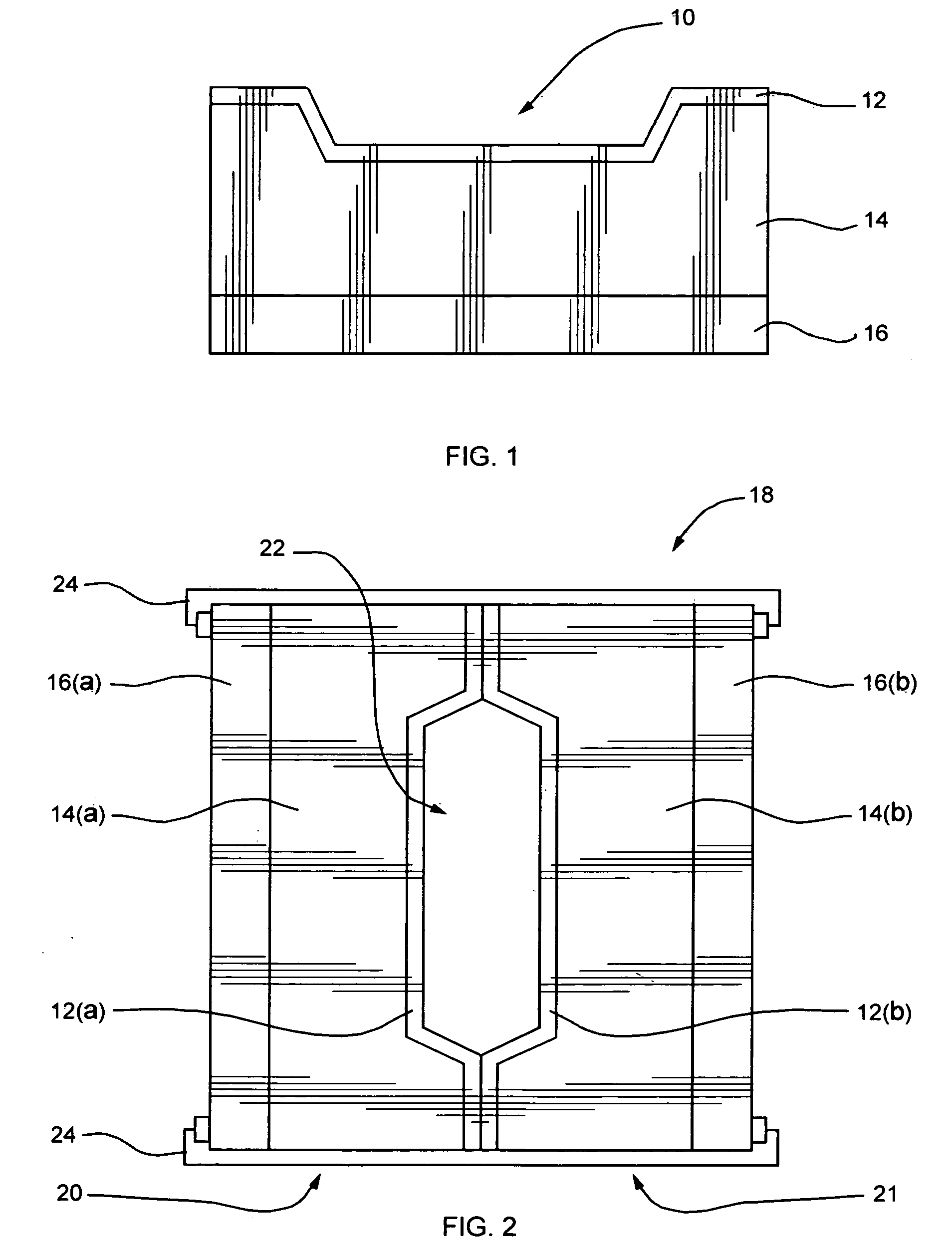

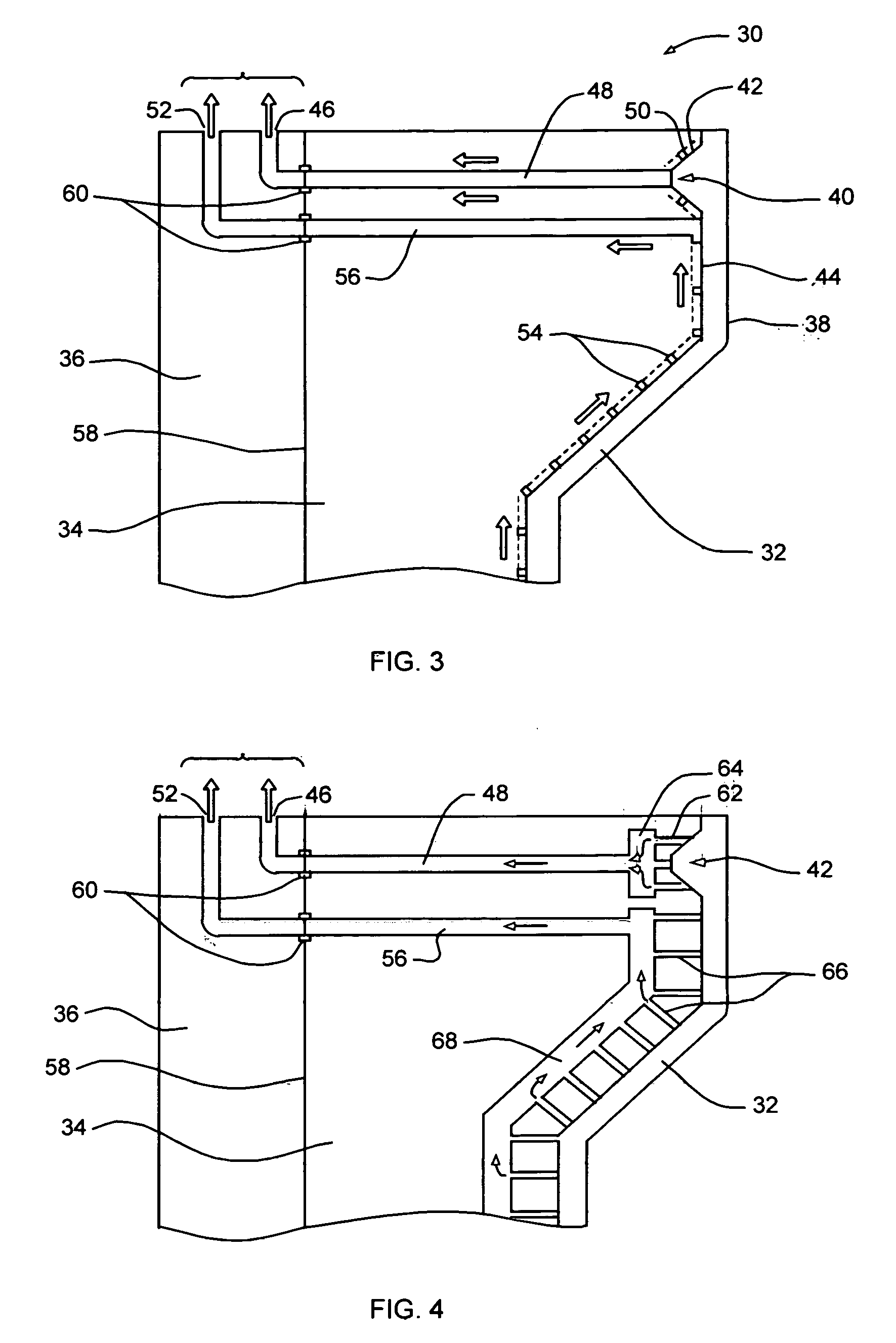

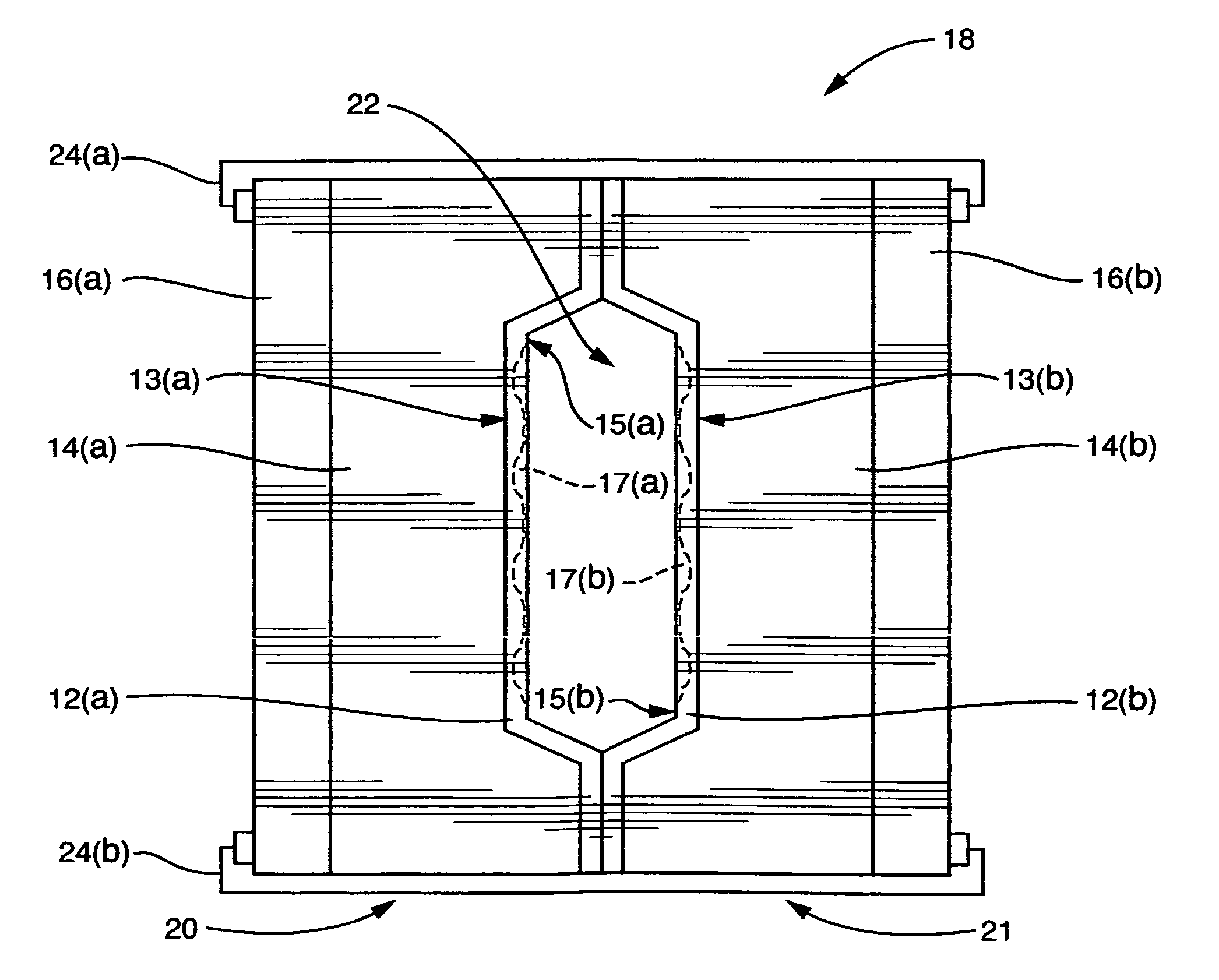

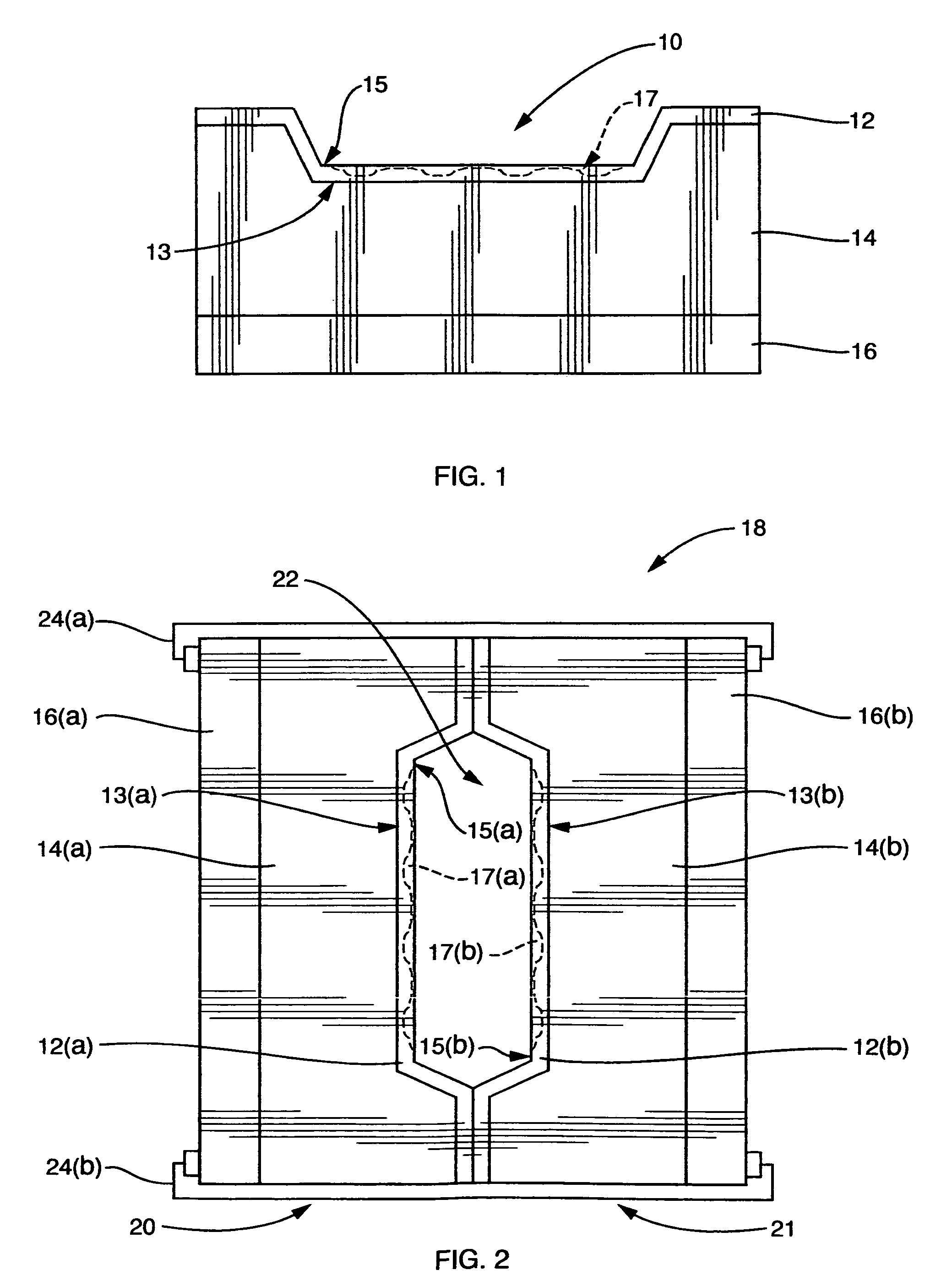

A compound mold or tooling system is designed to provide an alternative to conventional, expensive, metal molds for various plastics molding applications. The compound mold comprises a replaceable thin-walled liner, or skin-mold, defining the mold surface, temporarily bonded by vacuum means or mechanical means to a conforming backing-mold mold body supported by a rigid backing-plate. Both skin- and backing-molds are composed of suitable polymers with or without additives, fillers, reinforcements or other inclusions depending on mold requirements. The backing-plate contains standard features and fixtures common to all molds used in the particular process or of a particular geometry.

Owner:ODONOGHUE JOSEPH

Compound tooling system for molding applications

ActiveUS7972129B2Easy to modifyEvenly heatedAdditive manufacturing apparatusConfectioneryShell moldingMetal mold

A compound mold or tooling system is designed to provide an alternative to conventional, expensive, metal molds for various plastics molding applications. The compound mold comprises a replaceable thin-walled liner, or skin-mold, defining the mold surface, temporarily bonded by vacuum means or mechanical means to a conforming backing-mold mold body supported by a rigid backing-plate. Both skin- and backing-molds are composed of suitable polymers with or without additives, fillers, reinforcements or other inclusions depending on mold requirements. The backing-plate contains standard features and fixtures common to all molds used in the particular process or of a particular geometry.

Owner:ODONOGHUE JOSEPH

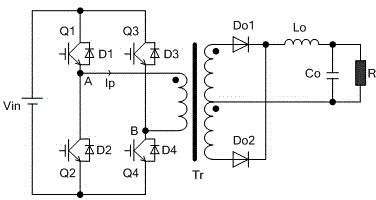

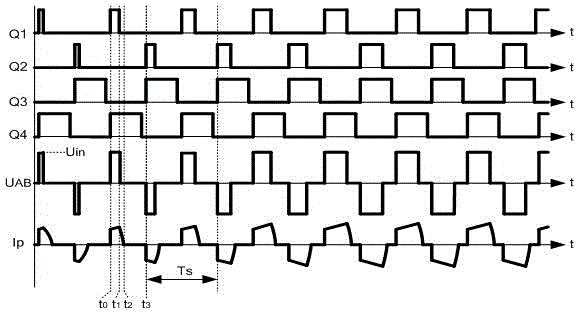

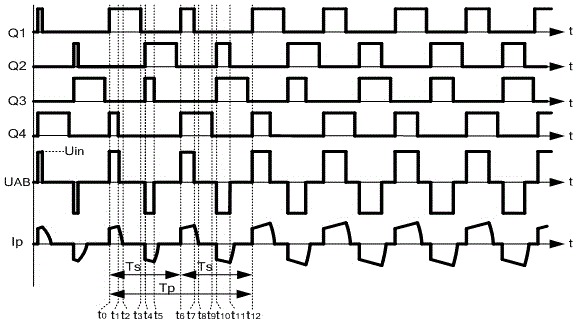

Method for controlling uniform heating of switch device of switch power source

InactiveCN104600998AUniform heatingExtend your lifeDc-dc conversionElectric variable regulationPhysicsFull bridge converter

The invention relates to the field of switch power source control, in particular to a method for controlling uniform heating of switch devices of a switch power source. The switch power source comprises a full bridge converter, the switch devices in the full bridge converter are switch tubes, the sequence of the switch devices in the full bridge converter alternately changes periodically, and the alternating period is N times of the switch control period of the switch devices, wherein N refers to a natural number larger than 2. Alternate soft turnoff of the switch devices is realized by alternately changing turnoff sequence of the switch devices composed of the switch tubes of the full bridge converter in the switch power source, so that the switch devices are uniform in heating within a long time period, and service life of the whole switch power source is prolonged.

Owner:SICHUAN INJET ELECTRIC CO LTD +1

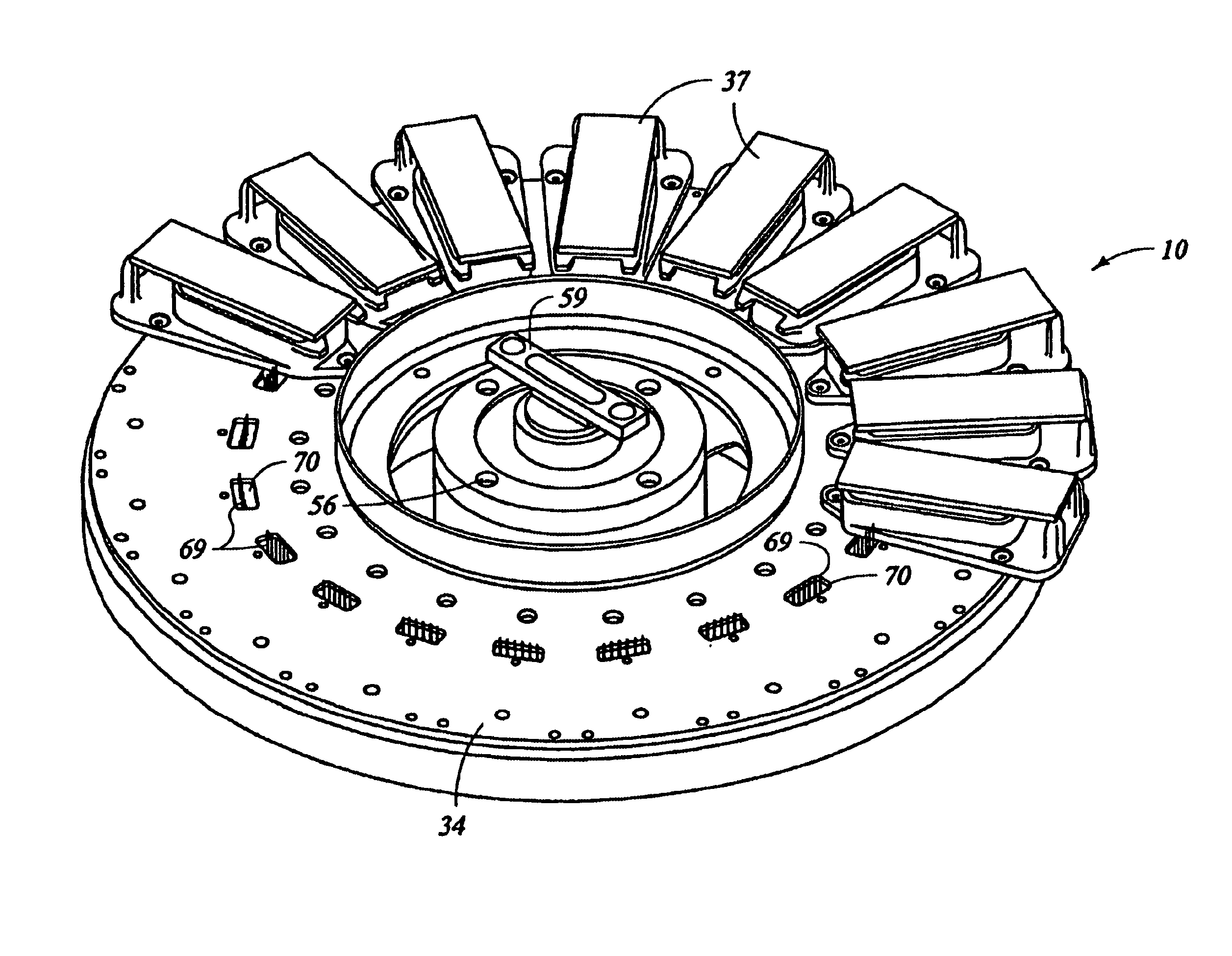

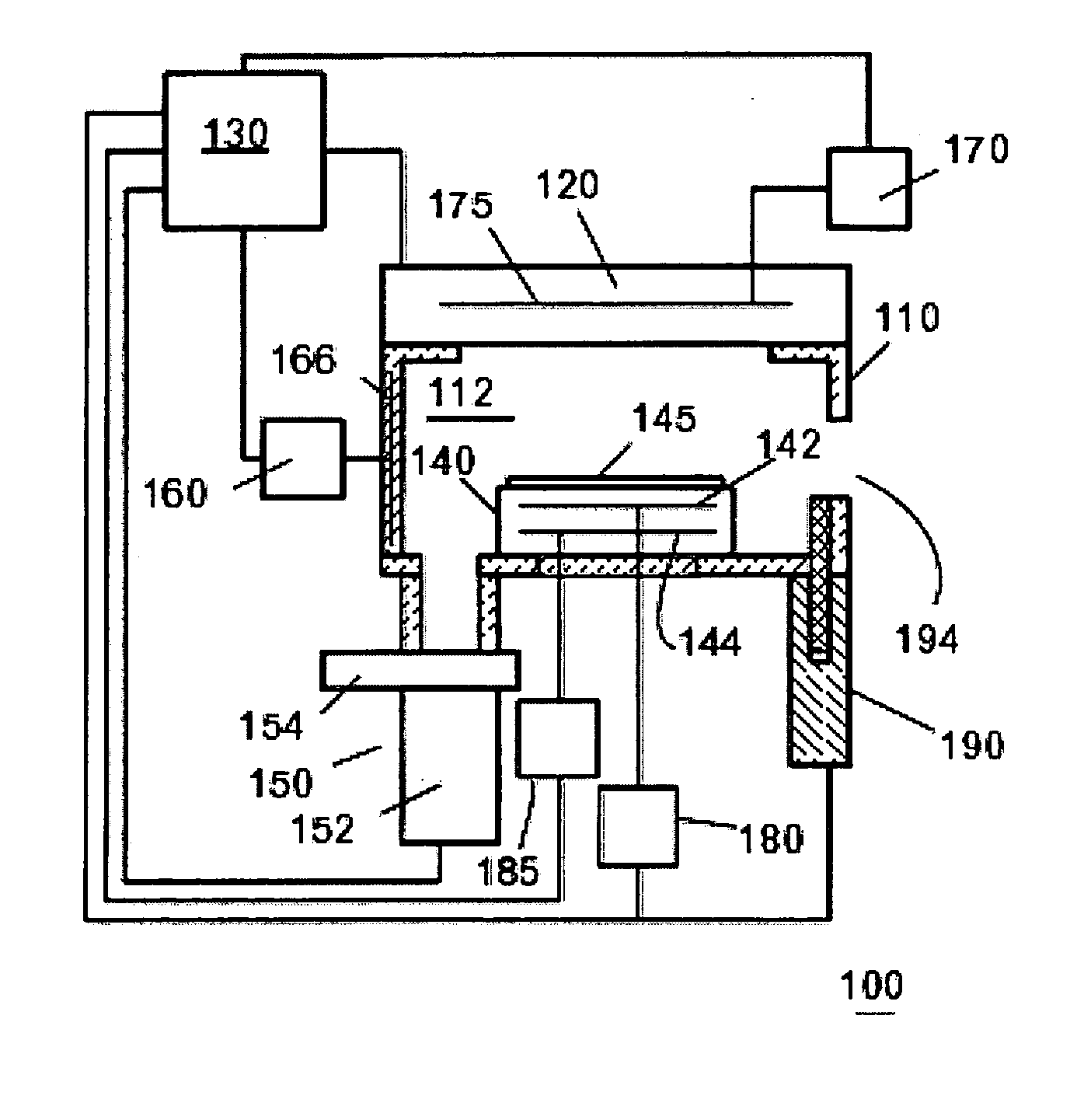

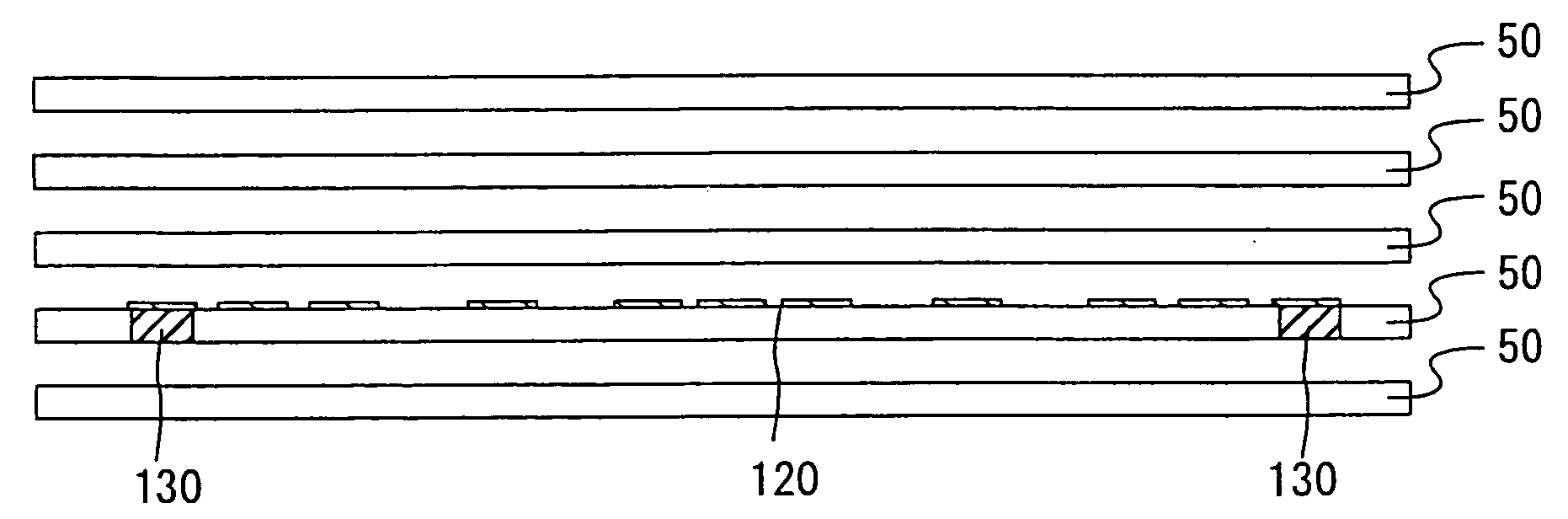

Automated molecular pathology apparatus having independent slide heaters

InactiveUS7396508B1Narrow temperature rangeEvenly heatHeating or cooling apparatusWithdrawing sample devicesHeating systemBiomedical engineering

Apparatus and methods for automatically staining or treating multiple tissue samples mounted on microscope slides are provided. Individualized slide temperature control is accomplished by the heating system according to the present invention that has thermal platforms radially mounted to the carousel for heating the slides and sensing the temperature of each. The heating system also permits automated de-waxing if necessary.

Owner:VENTANA MEDICAL SYST INC

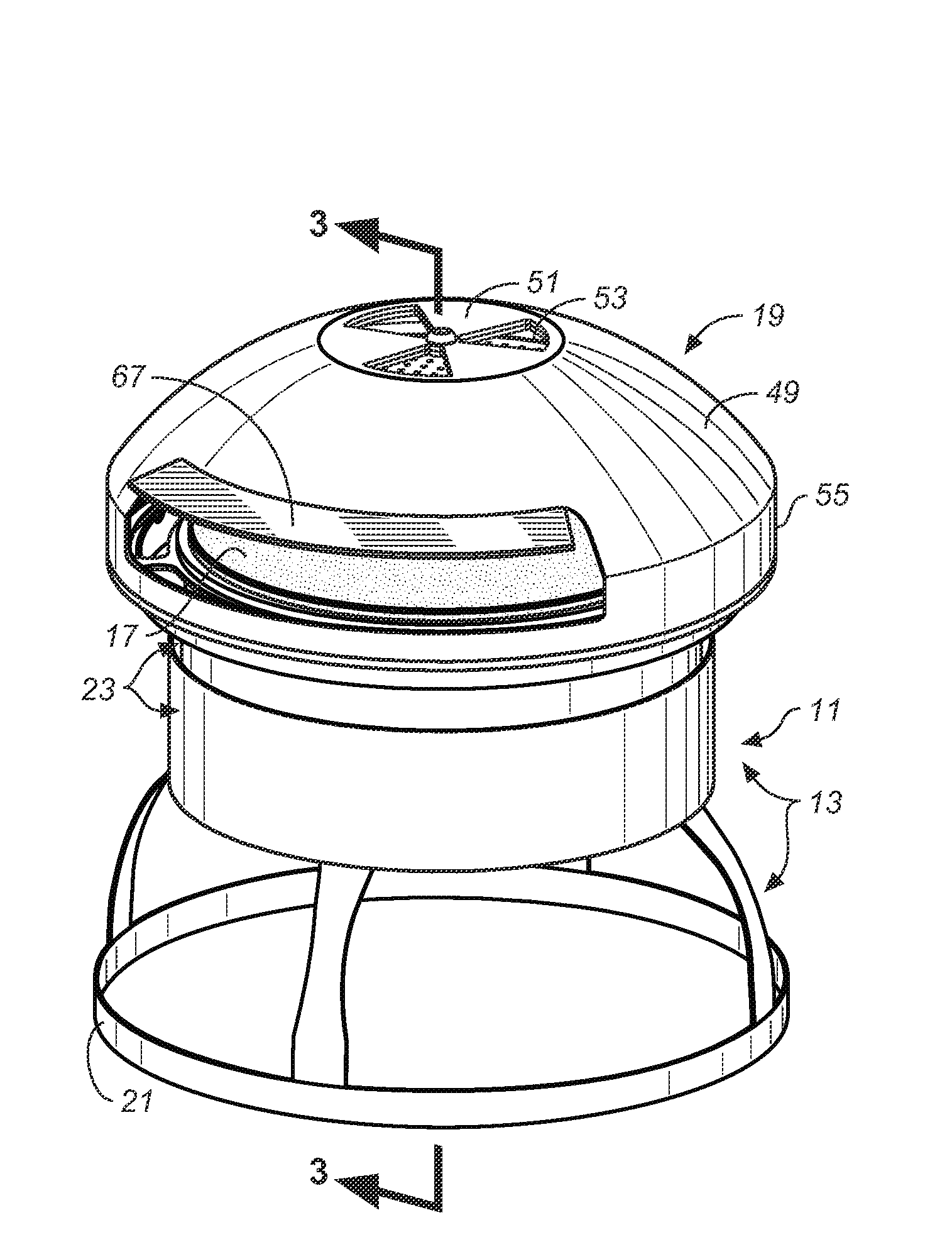

Portable baking oven

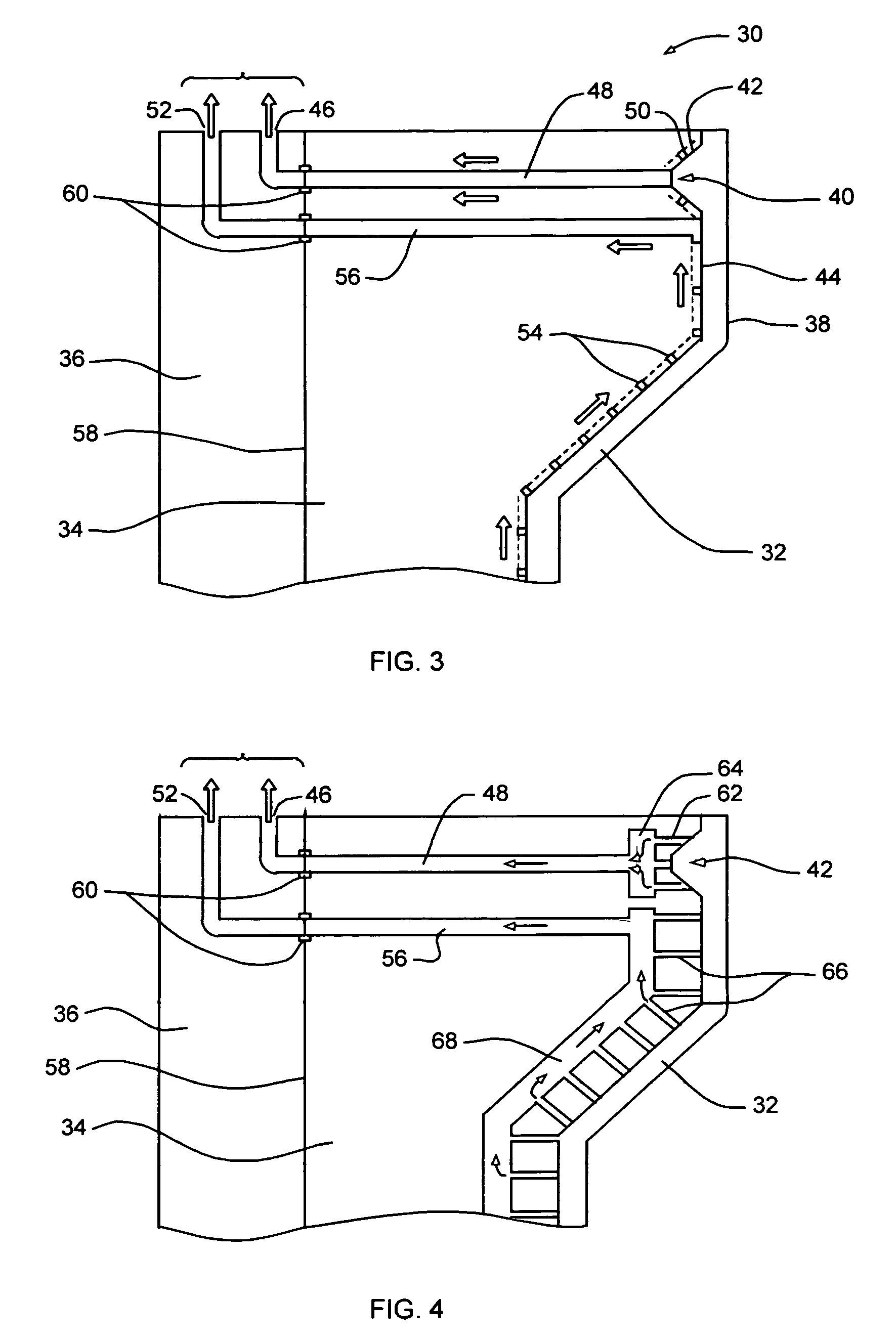

ActiveUS20130276643A1Effective redirectingEvenly heatedDomestic stoves or rangesLighting and heating apparatusEngineeringMoisture

A portable baking oven for a pizza or other food item includes a food item heating plate, a base having a heating chamber, and a top cover having a moisture vent and a heat reflector structure extending across the inside of said top cover. When placed on said base, the top cover forms a baking chamber above the heating plate. Heat produced in the base's heating chamber circulates up through air passageways in the base into the baking chamber above the food item heating plate. This circulated heat is reflected back down toward the food item heating plate by the top cover's heat reflecting structure to accelerate baking of the top of a food item placed on the heating plate. The top cover's moisture vent can be located above the heat reflector structure in the top cover, and openings can be provided in the heat reflector structure which allow moisture emitted by a food item being baked in the oven to pass through the reflector structure and out through the top cover moisture vent.

Owner:CHARCOAL COMPANION LTD

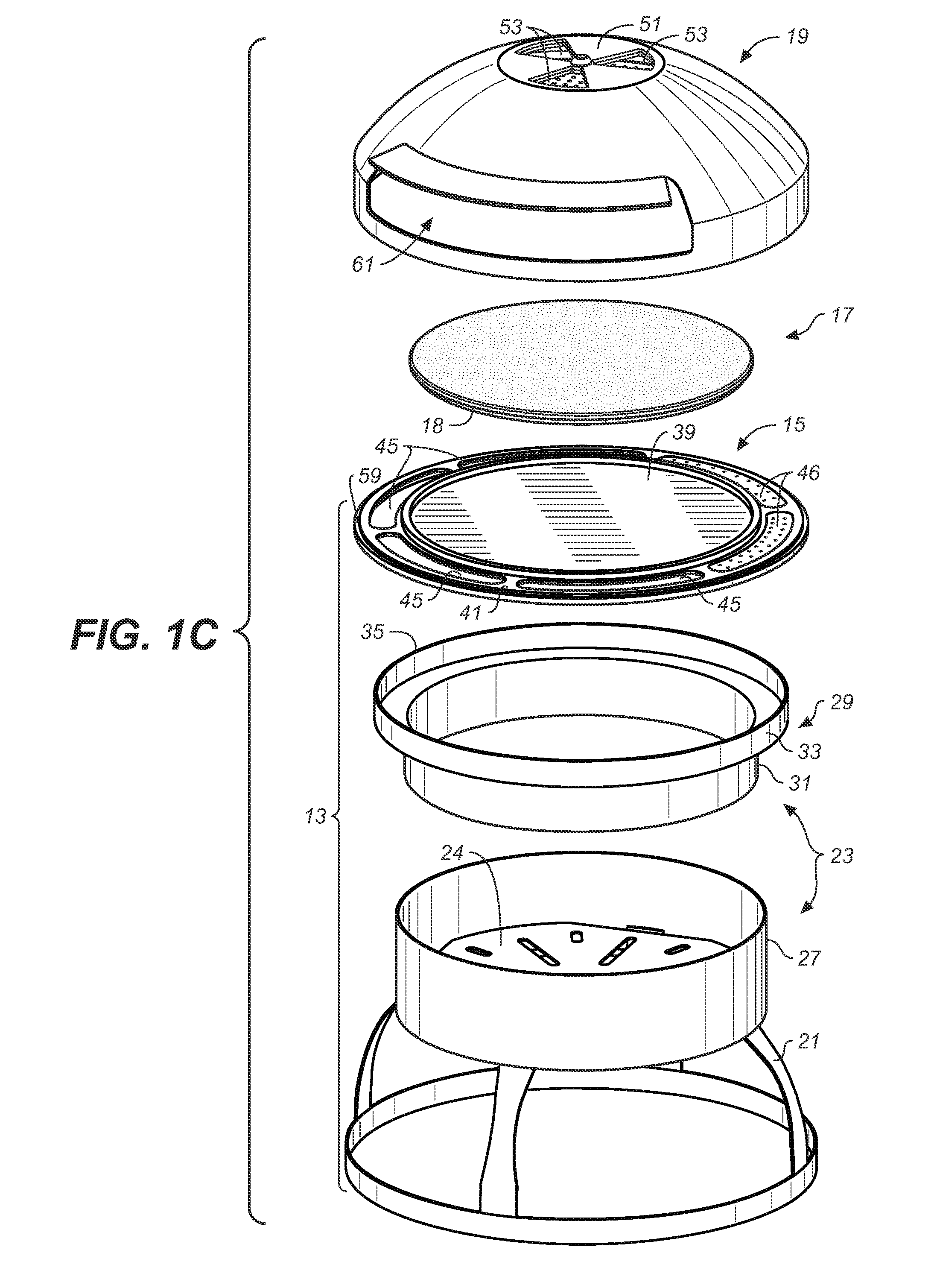

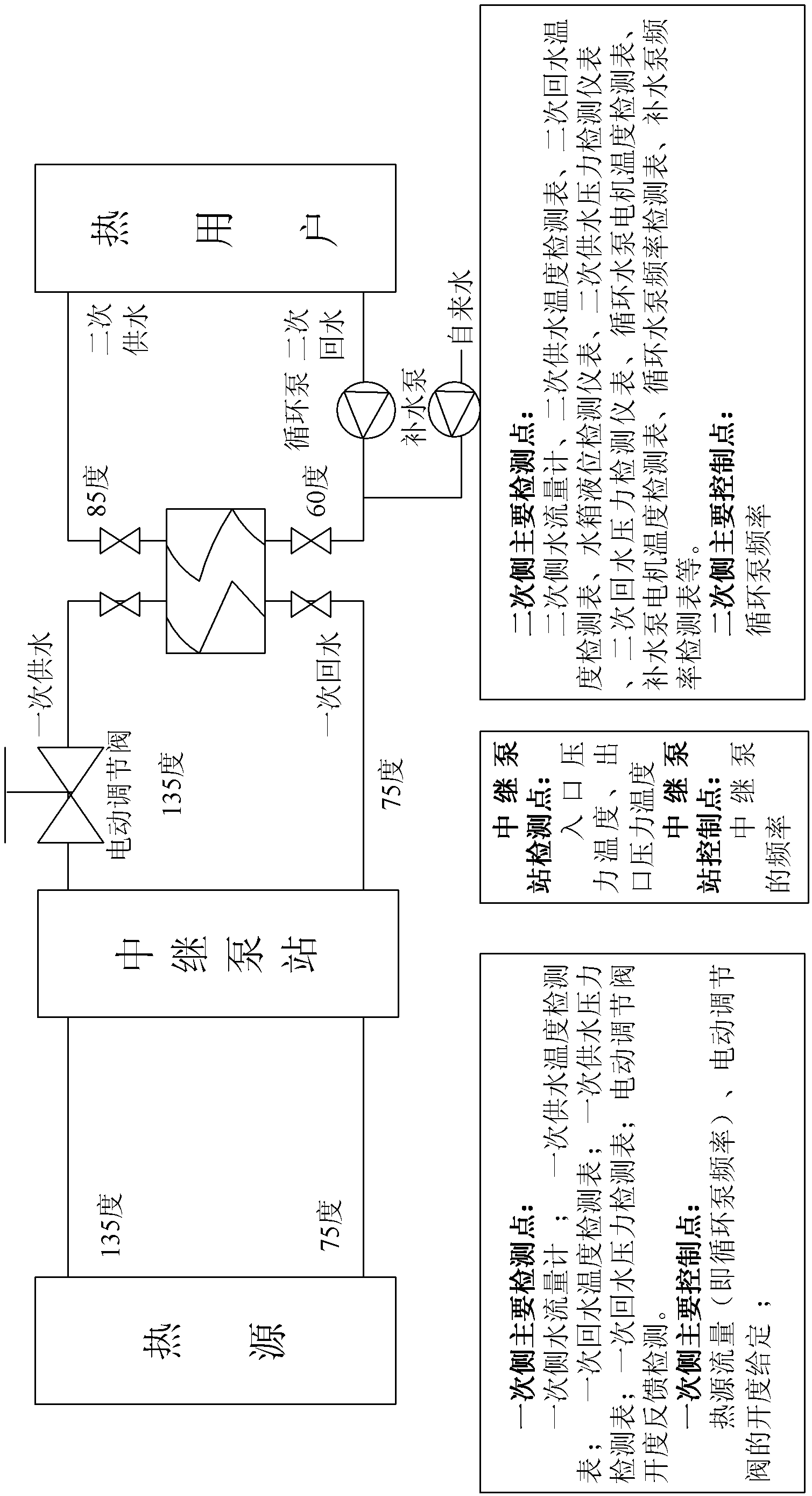

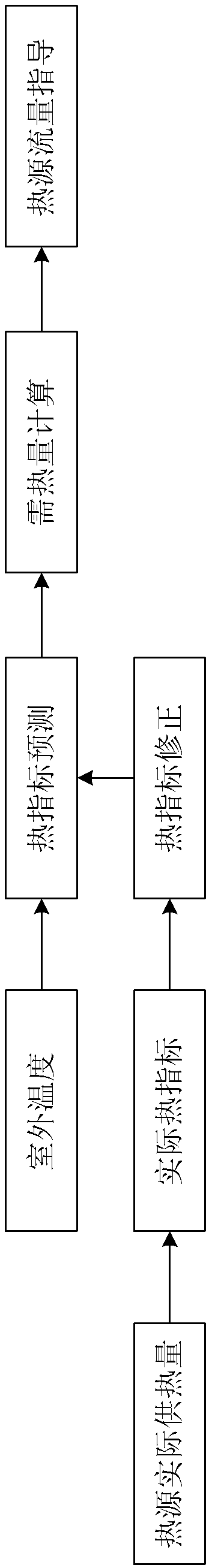

Centralized heating whole-network heat balance control method

InactiveCN103017253ARegulation stabilityImplement operation guidanceLighting and heating apparatusSpace heating and ventilation detailsHeat balanceMaterial resources

The invention relates to a centralized heating whole-network heat balance control method, in particular to a control system which is charged on area, which can eliminate the heat imbalance of the whole network and balance the heating effect. The control method adopts different control strategies for a heat source and two links of a primary side in the heating system so as to meet the requirement of users. For the heat source, the online prediction of the heat load is realized according to external temperature variation, and a running instruction is supplied for the heat source; a uniform control strategy is adopted for a primary network, automatic adjustment of a primary valve of a heat exchanging station of the heat network can be realized, a weighted value can be manually given to a special heat exchanging station, and the heat imbalance degree is used for analyzing and evaluating a whole-network heat balance control effect; and the control method can effectively solve the problems of the heating system such as imbalance heat and energy waste, a great amount of manpower and material resource can be saved in the adjustment process of the heat network, and the balance and consistency of the heat supply effect can be guaranteed.

Owner:ANSHAN HAIHUI AUTOMATION +1

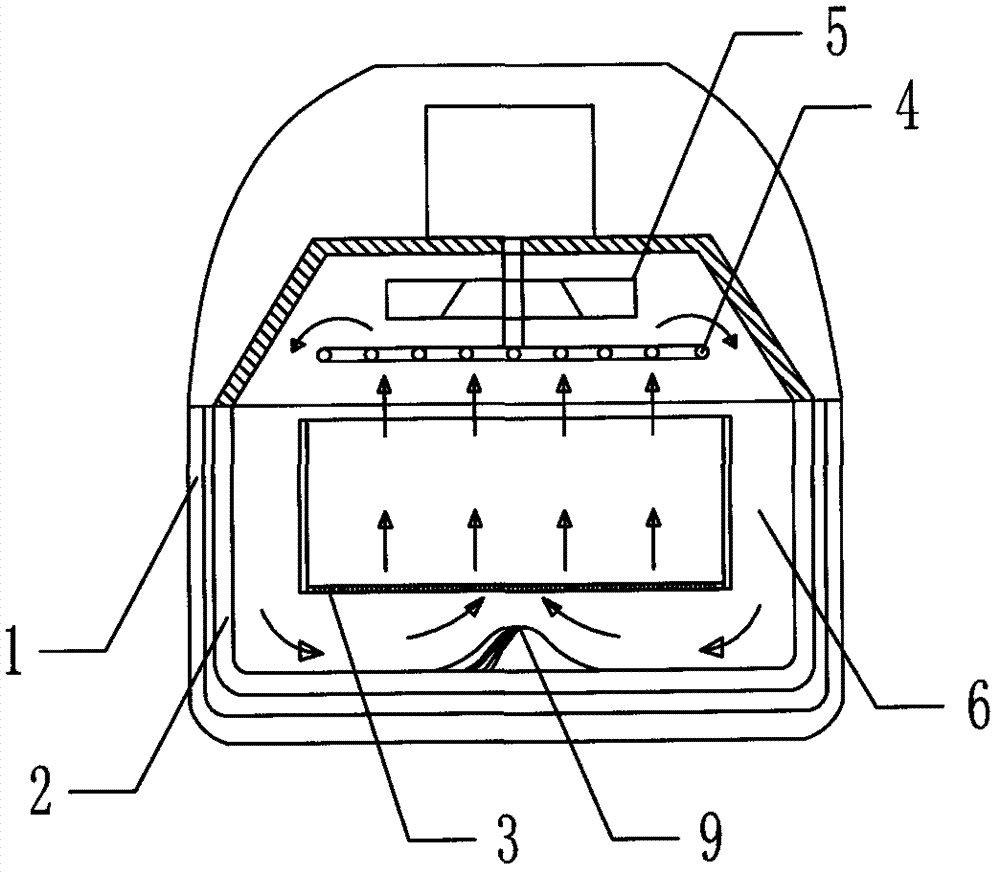

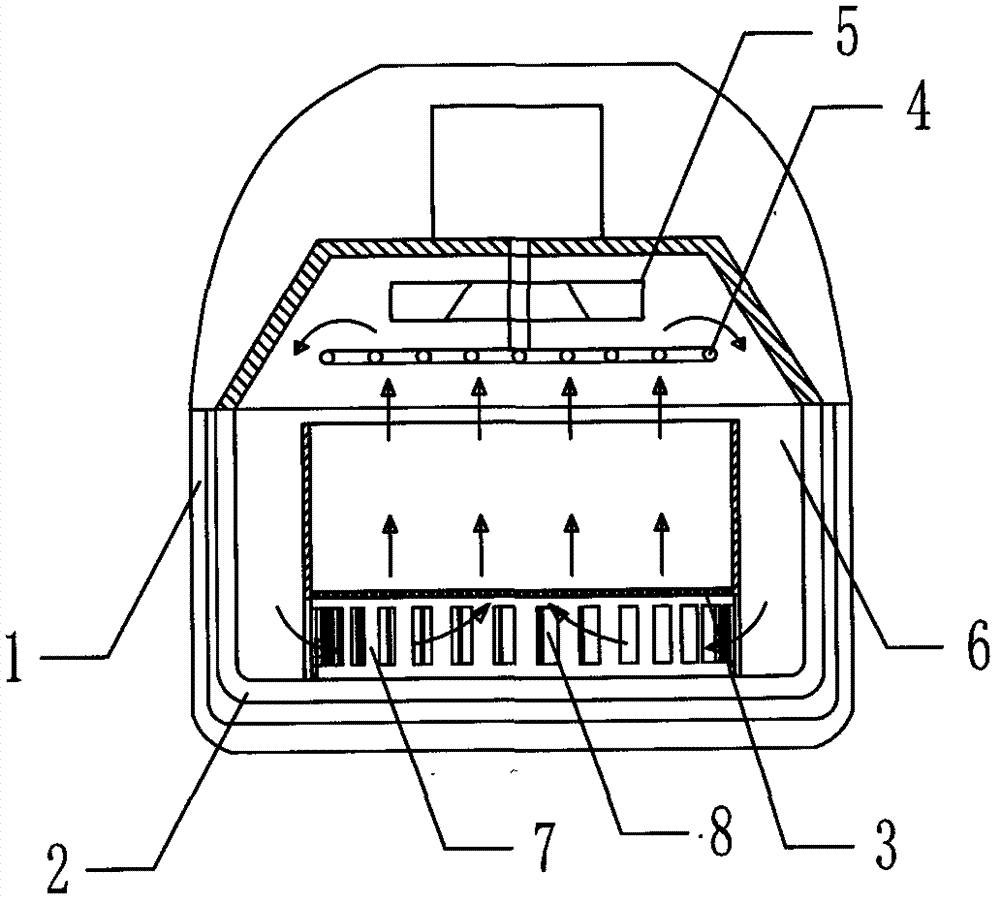

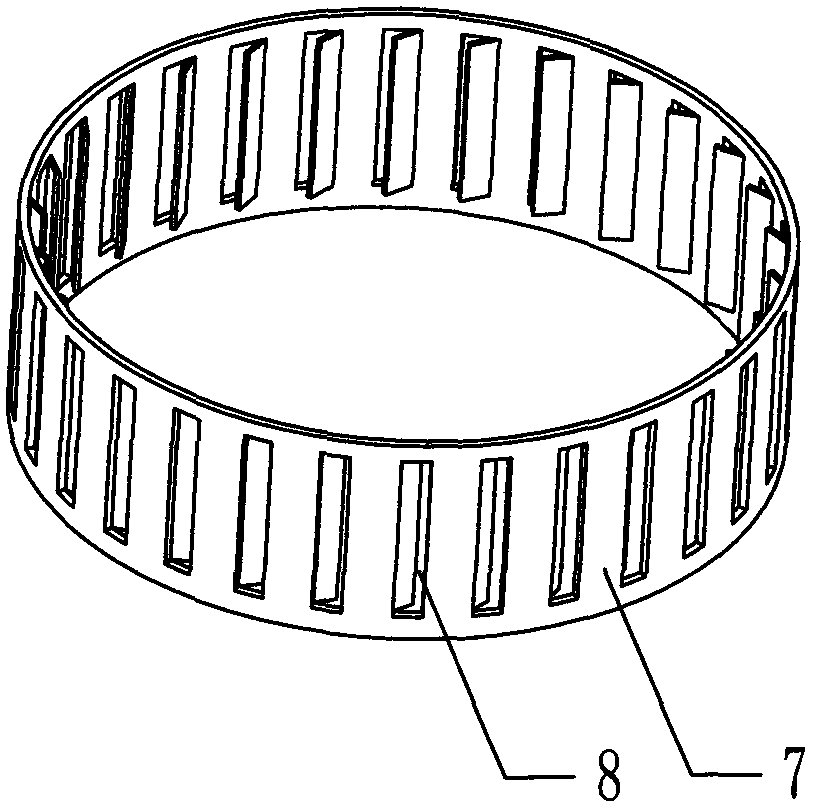

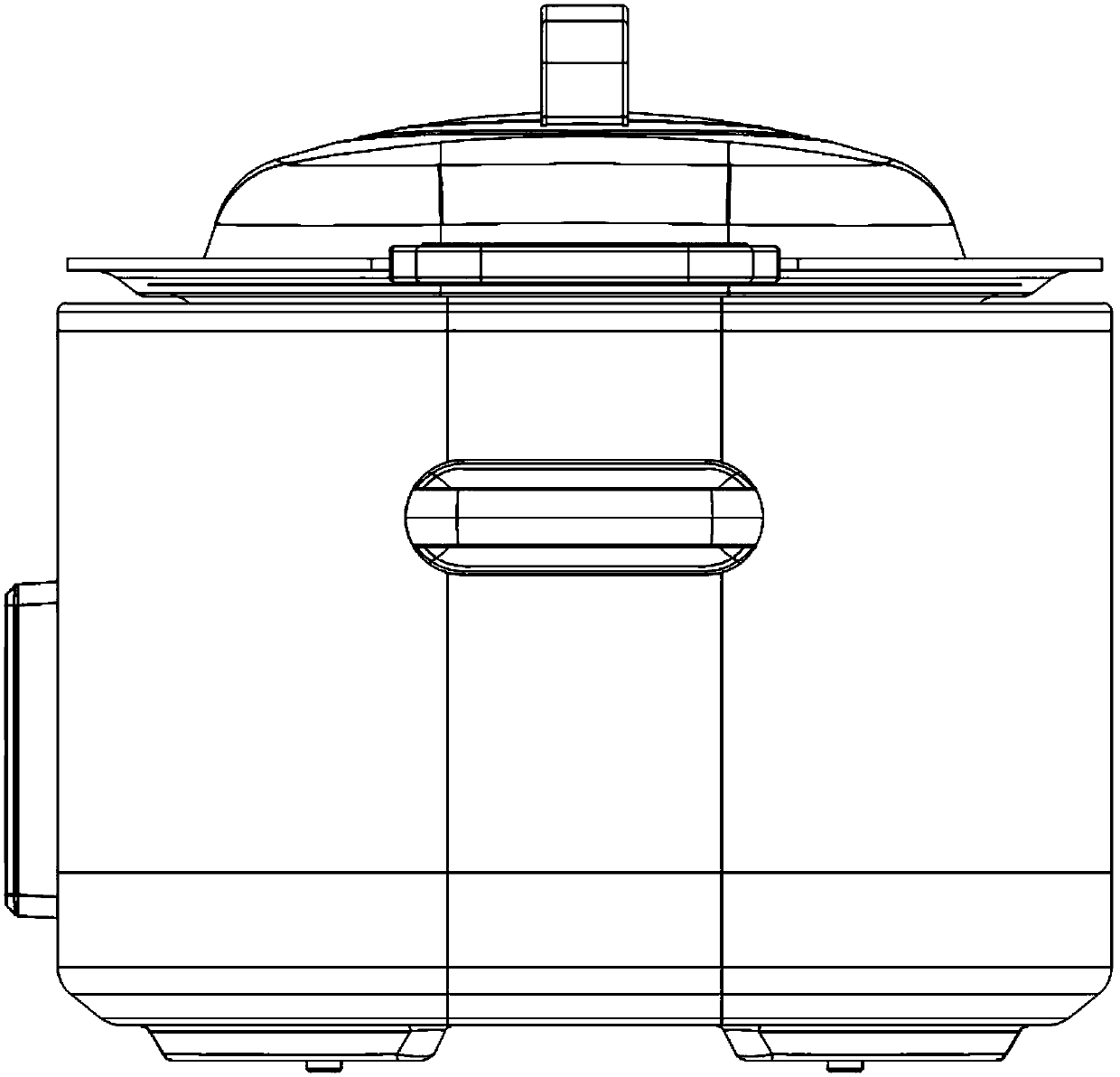

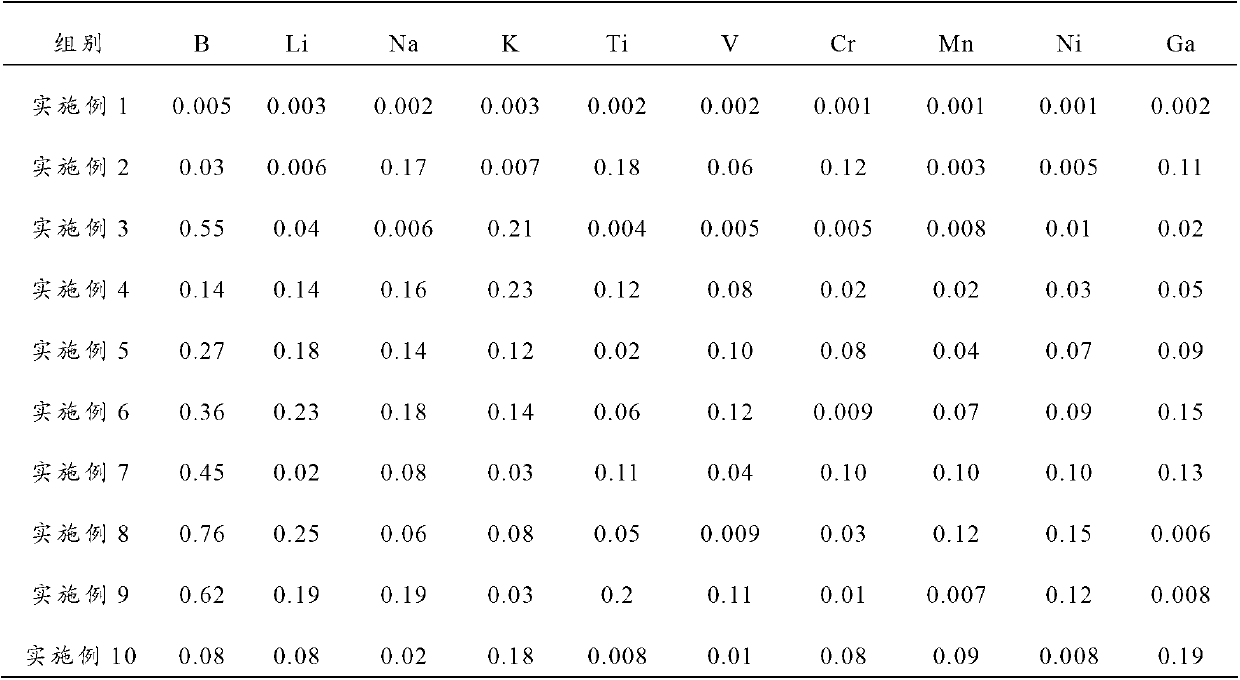

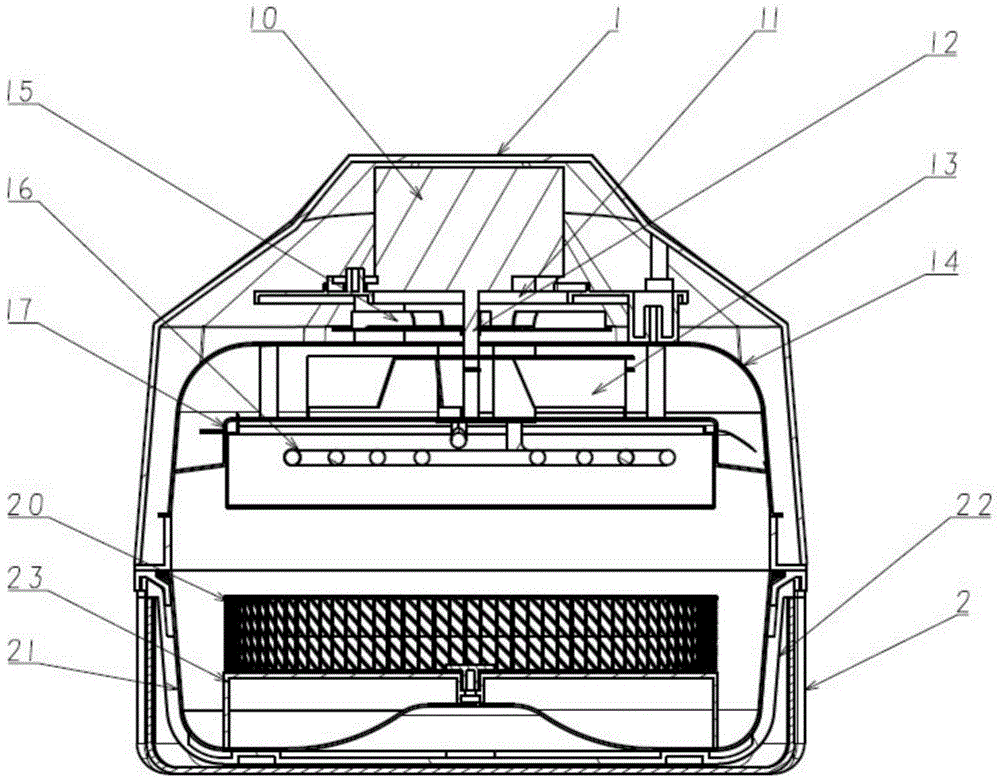

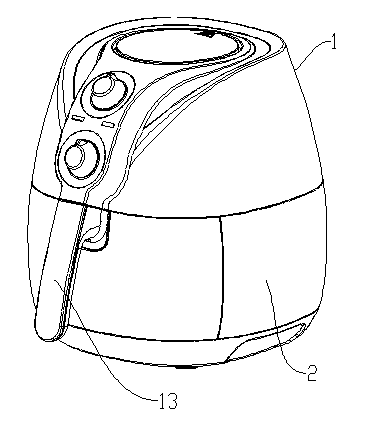

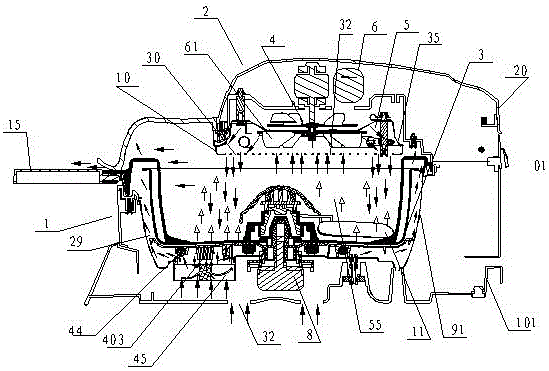

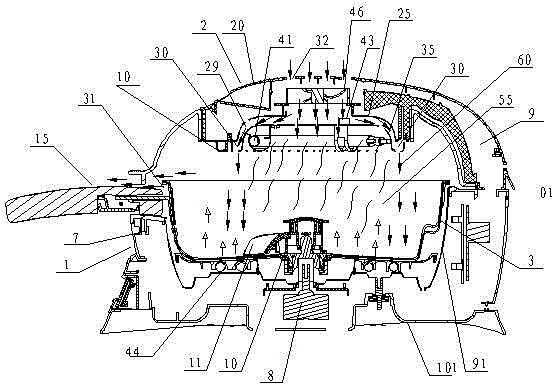

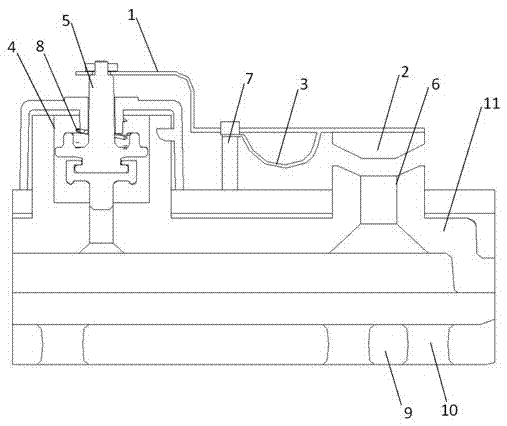

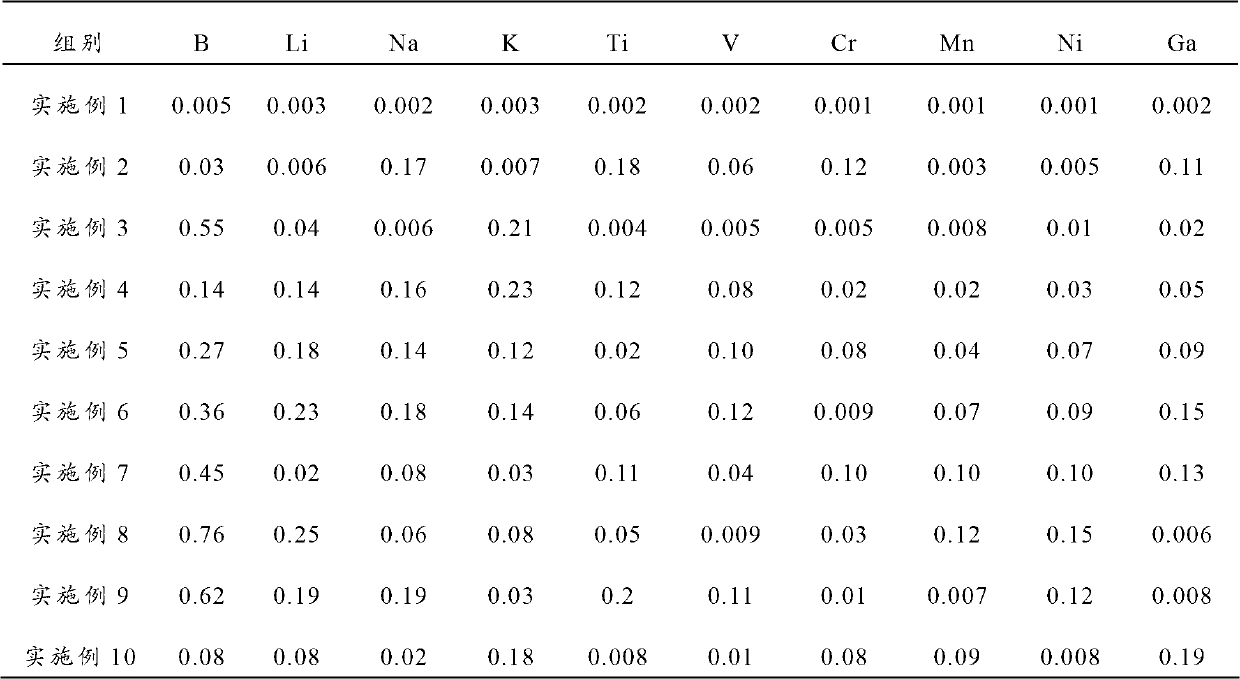

Air frying pan

The invention belongs to the field of family kitchen electric appliance manufacturing and specifically relates to an air frying pan. The air frying pan is mainly composed of a pan body (1), a liner (2), a frying basket (3) arranged in the liner (2), an electric heating pipe (4) arranged above the frying basket (3) and a fan (5) located above the electric heating pipe (4); the sidewalls of the frying basket (3) are formed by metal sheets and the bottom of the frying basket (3) is formed by a screen; an air flow channel (6) is arranged between the liner (2) and the frying basket (3); the air frying pan is characterized in that the outer periphery of the bottom of the frying basket (3) extends downwards to form a guide cylinder (7) and air inflow inclined holes (8) for guiding airflow to rotate are evenly formed in the sidewall of the guide cylinder (7). The air inflow inclined holes (8) are leftward or rightward slit holes toward the same direction. The air frying pan of such a structure has the advantages that the frying basket is simple in structure, the bottom of the liner is easy to manufacture and easy to clear, and is well supported.

Owner:严绍基

Chute for Laser Sintering Systems

ActiveUS20140265045A1Reduce the possibilityHigh densityManufacturing heating elementsAuxillary shaping apparatusRadiant heaterUltimate tensile strength

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

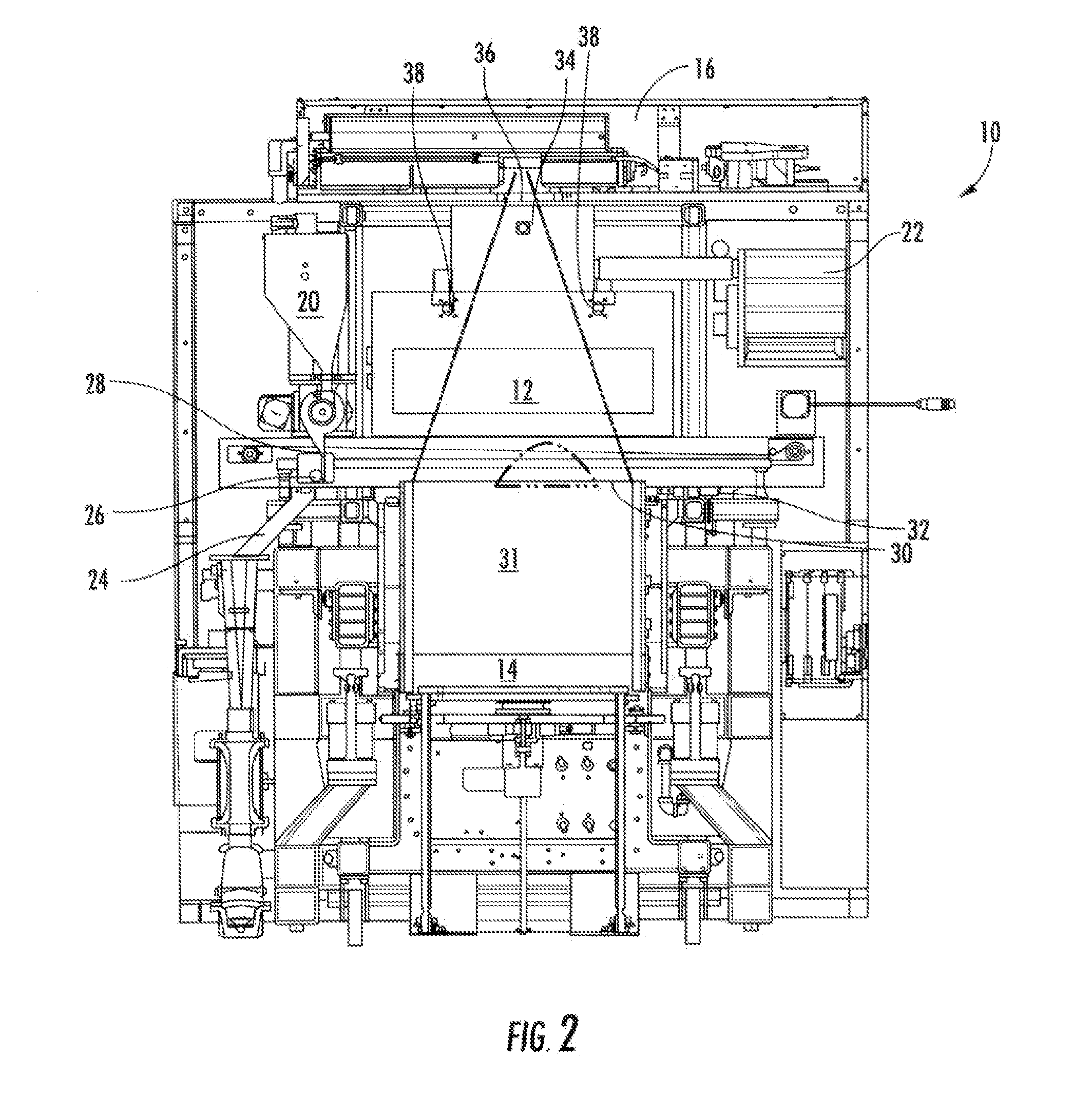

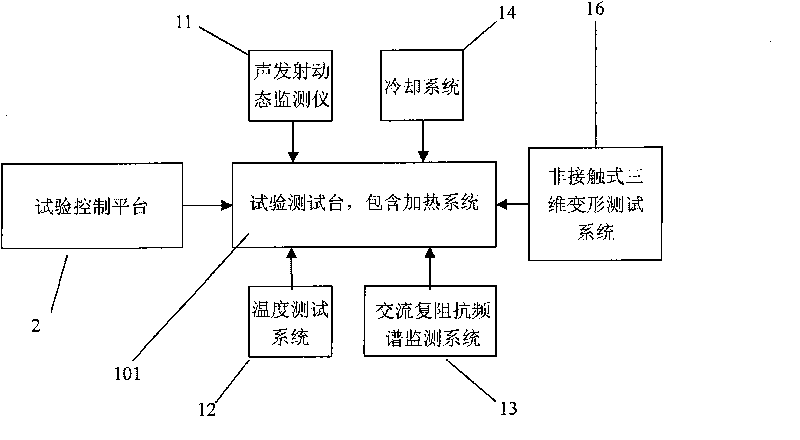

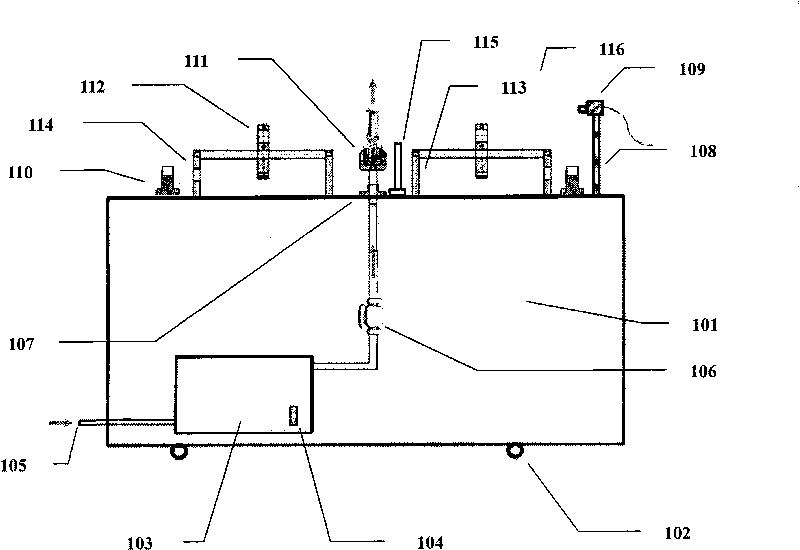

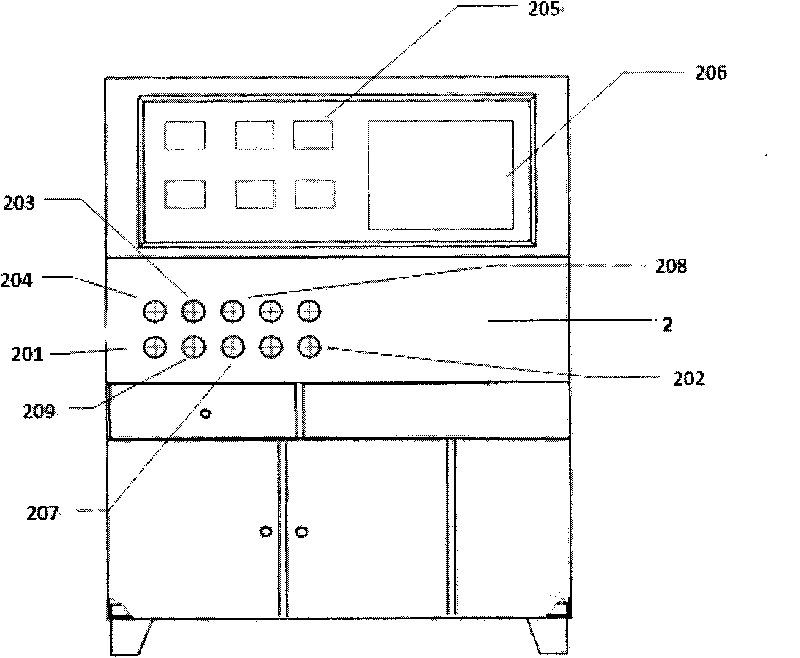

Test device for simulating and testing thermal fatigue failure of high-temperature part in real time

ActiveCN101762452AFast heating and cooling ratesWide temperature rangeWeather/light/corrosion resistanceHeating systemInterfacial oxide

The invention belongs to the field of high-temperature part detecting equipment, in particular to a test device for simulating and testing the thermal fatigue failure of a high-temperature part in real time. The device mainly comprises a high-temperature gas two-way heating system, a real-time temperature testing and collecting system, a cooling system, an ARAMIS non-contact three-dimensional deformation test system, a PCI-2 AE non-destructive detection system, a 1260+1296-type material electric property AC impedance spectroscopy test system, a test control platform and the like. The device can simulate the thermal fatigue work environment of alternating temperature cycle in a high-performance aircraft engine, and synchronously realize the real-time testing and the analysis to the sample temperature, temperature gradient, surface morphology image evolution, three-dimensional deformation field, three-dimensional displacement field, interfacial oxide layer and thickening law, thermal fatigue crack initiation and propagation, cooling gas flow and other data. The device can provide an important experimental platform for effectively evaluating the fatigue failure process and the failure mechanism of the high-temperature part in the high-temperature thermal cycle environment.

Owner:XIANGTAN UNIV

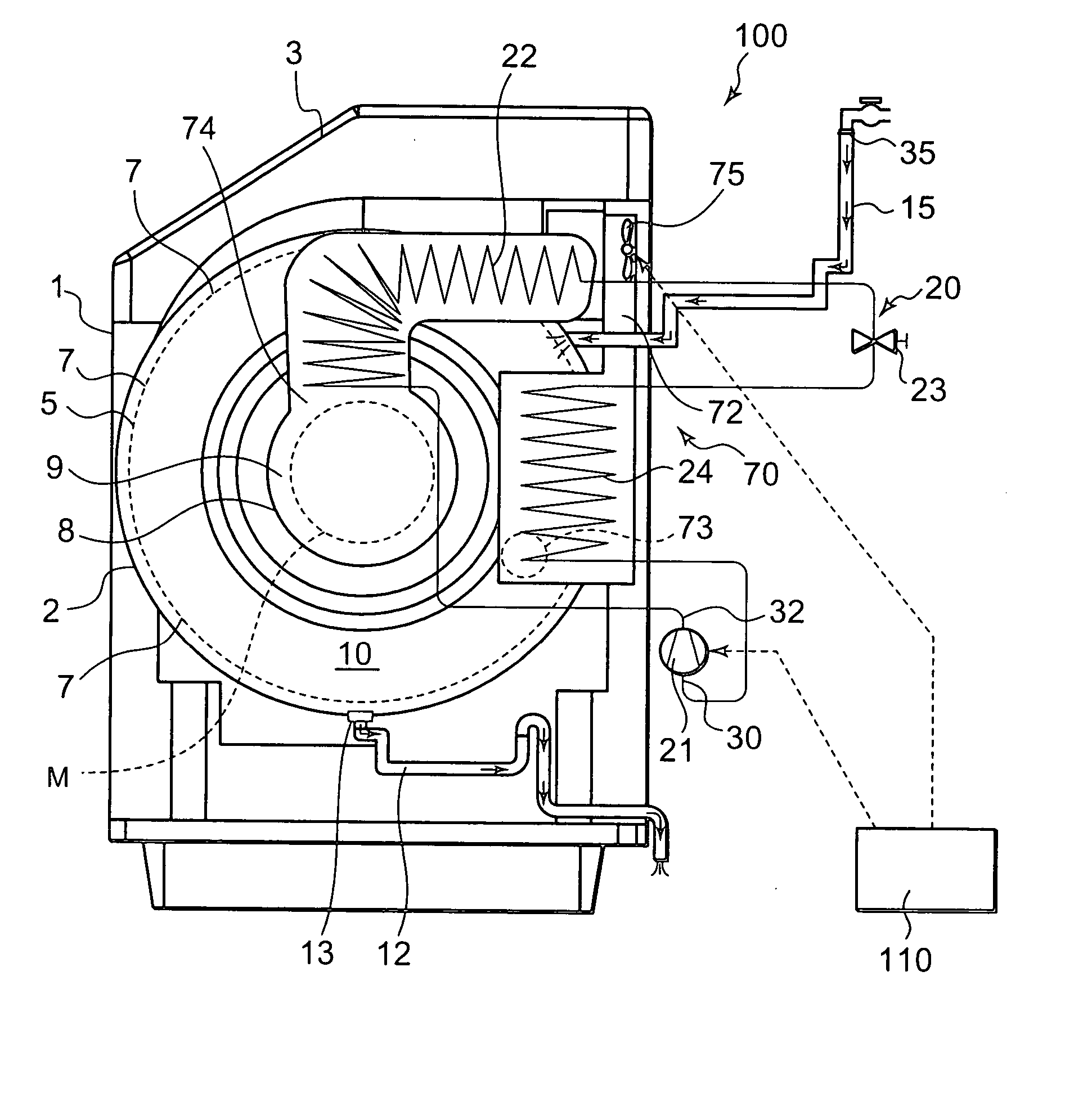

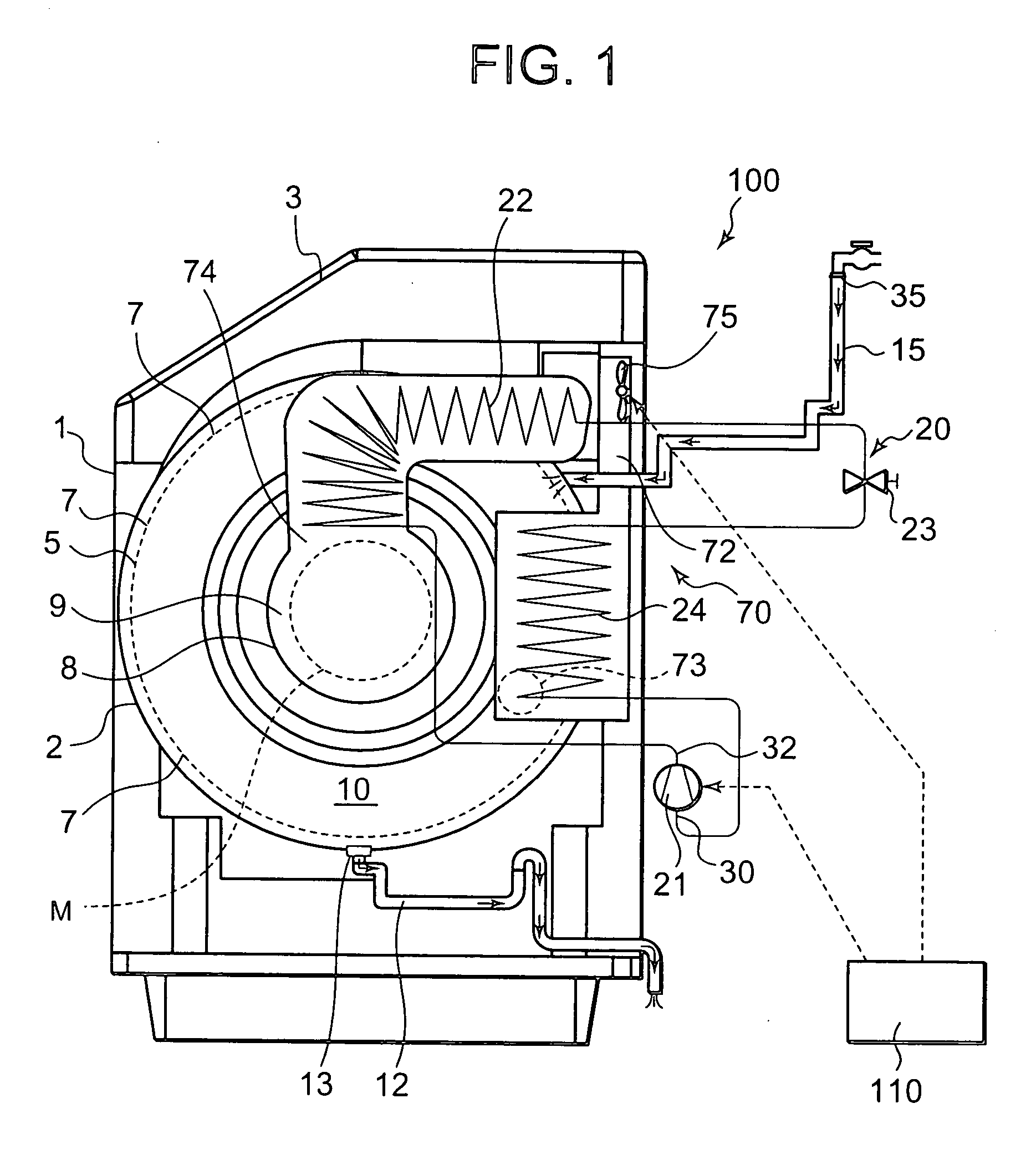

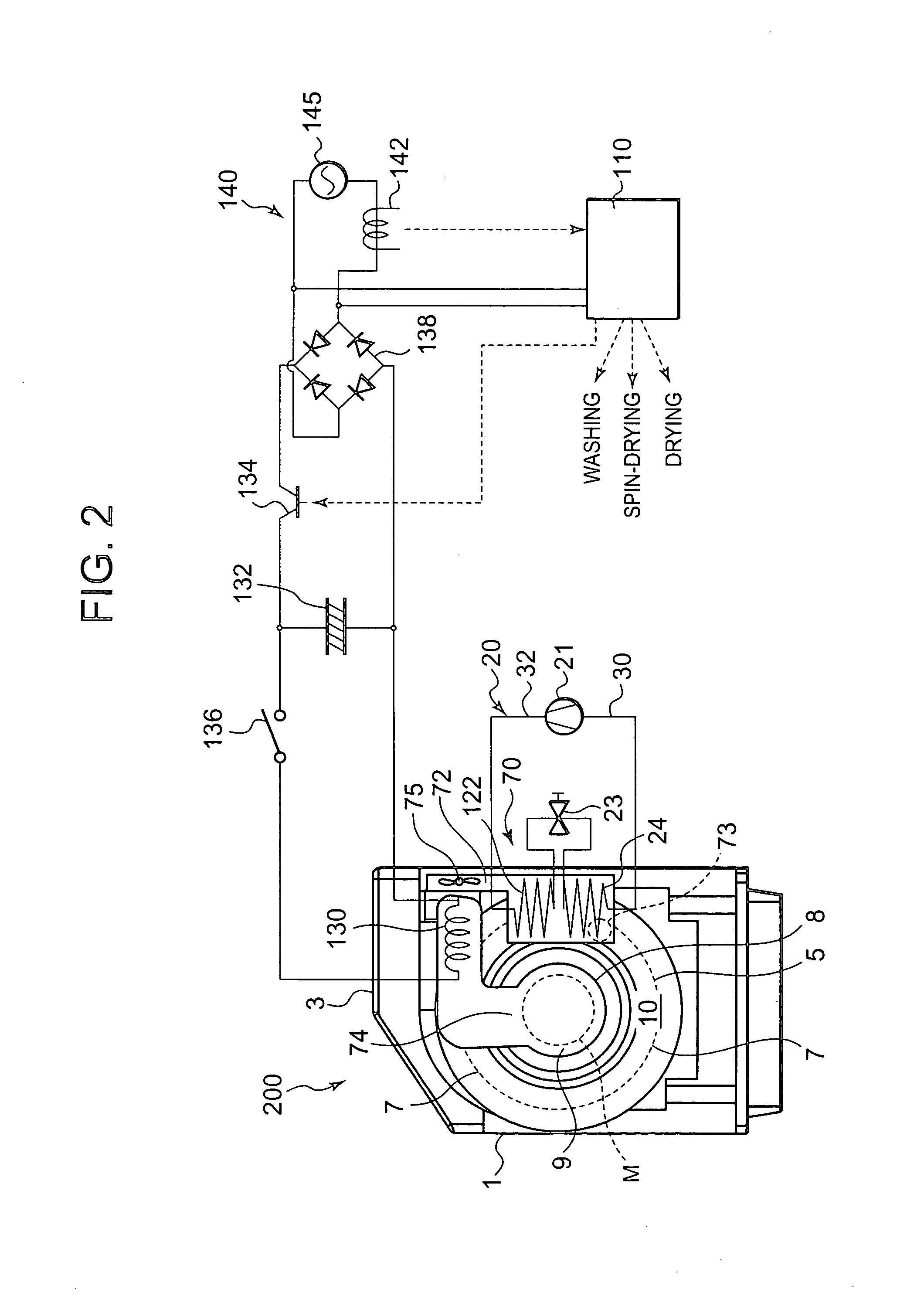

Drying apparatus

ActiveUS20050044744A1Shorten the timeImprove energy efficiencyDrying solid materials with heatDrying gas arrangementsAir cycleProcess engineering

A drying apparatus having a purpose of shortening a drying time of laundry, comprising an accommodating chamber in which the laundry is accommodated, and executing a washing operation of the laundry and a drying operation after end of the washing operation in the accommodating chamber, the machine comprising: a refrigerant circuit in which a compressor, a gas cooler, an expansion valve, and an evaporator are successively connected to one another in an annular form via a piping; an air circulation path for discharging air which has exchanged heat with the gas cooler into the accommodating chamber by a blower to exchange the heat of the air passed through the accommodating chamber with the evaporator; and a control device for operating the compressor and the blower to perform the drying operation, wherein the control device starts the operation of the compressor before entering the drying operation.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

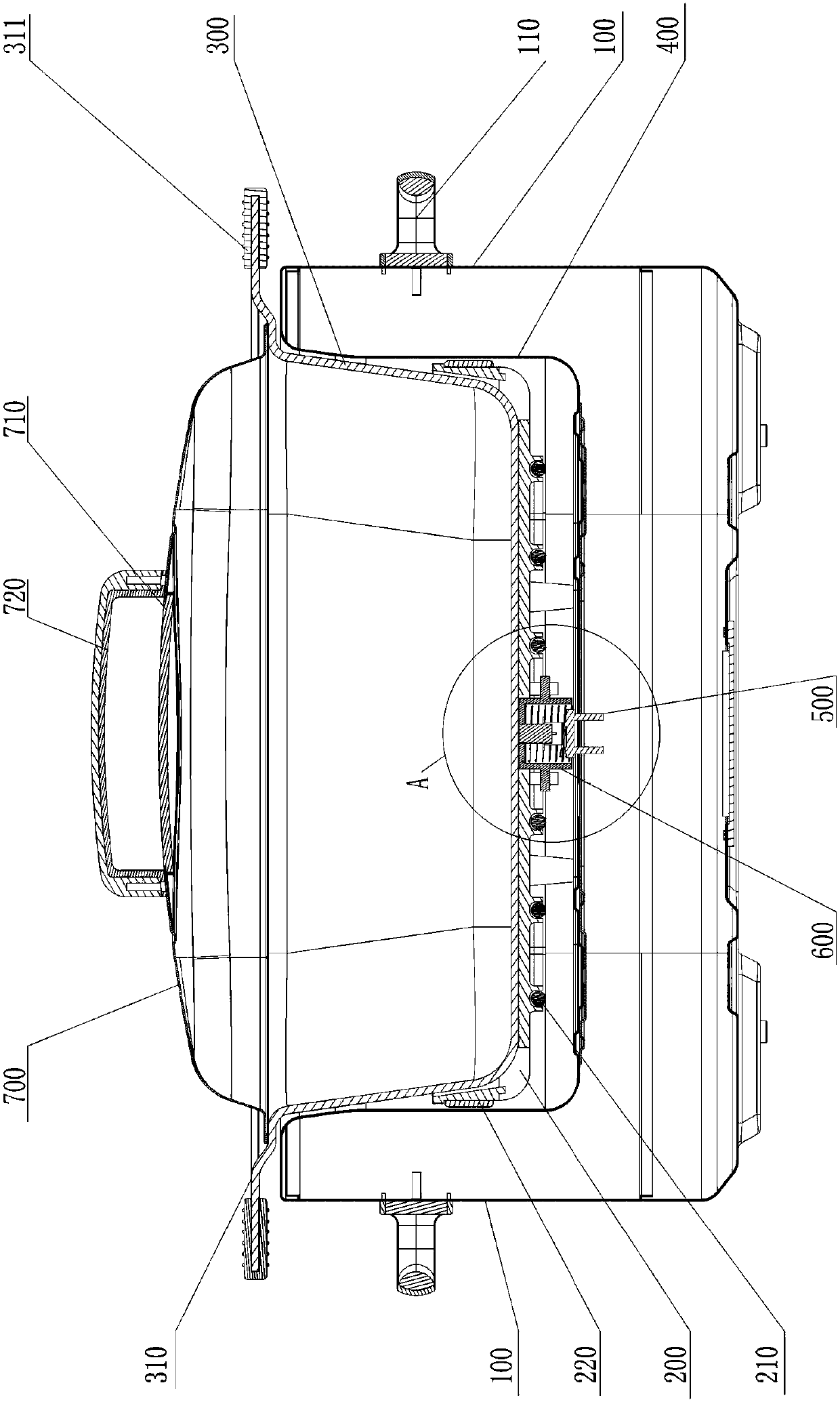

Multifunctional pot

PendingCN107836981AEvenly heatedAvoid uneven heatingHot plates heating arrangementsWarming devicesEngineeringHeat losses

The invention discloses a multifunctional pot. The pot includes a housing, a heating element heat conduction disk and a pot body, a liner is arranged in the housing, and the upper end of the housing is connected with the upper end of the liner; the heating element heat conduction disk is arranged in the liner, the height of the heating element heat conduction disk is lower than the depth of the liner, a bottom heating element is arranged at the outer bottom of the heating element heat conduction disk, an annular heating element is arranged on the outer side wall of the heating element heat conduction disk, and the bottom heating element and the annular heating element are in series connection and are electrically connected to a working circuit of the multifunctional pot; the pot body is arranged on the heating element heat conduction disk, the inner wall of the heating element heat conduction disk is in contact with the outer wall of the pot body, and the height of the pot body is larger than the depth of the heating element heat conduction disk. The heating element heat conduction disk of the multifunctional pot directly heats the pot body evenly, the inner wall of the heating element heat conduction disk can be in close contact with the outer wall of the pot body, hence, most of heat can be transmitted to the pot body, the liner can effectively keep the heating element from transmitting heat to the outside world, the heat loss is small, and the energy utilization rate is high.

Owner:NINGBO JINYU ELECTRIC APPLIANCE

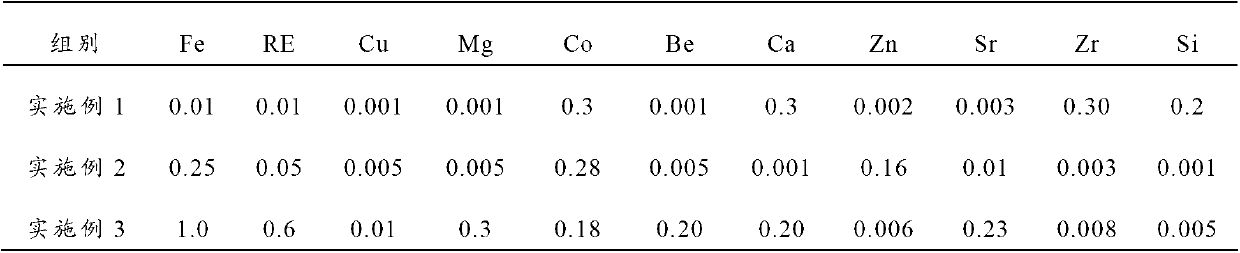

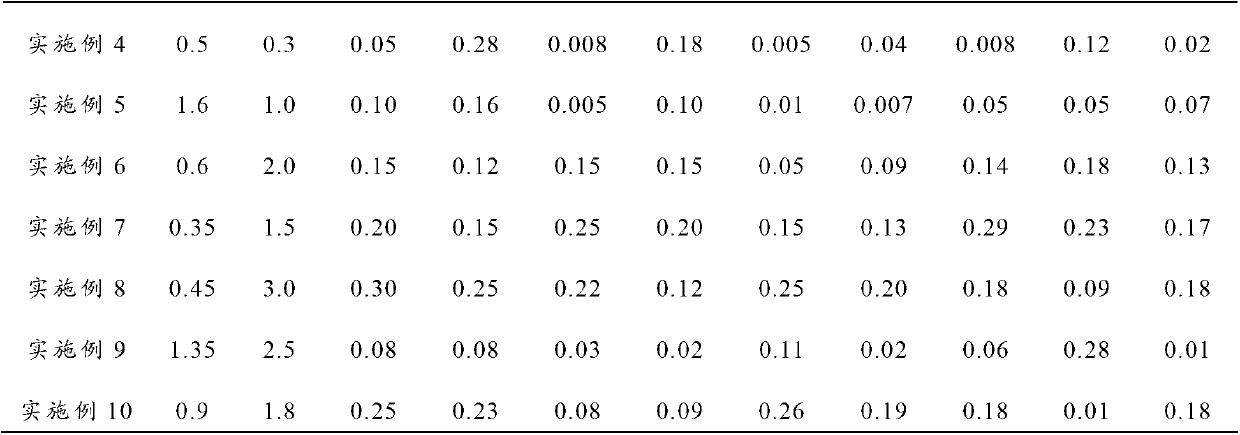

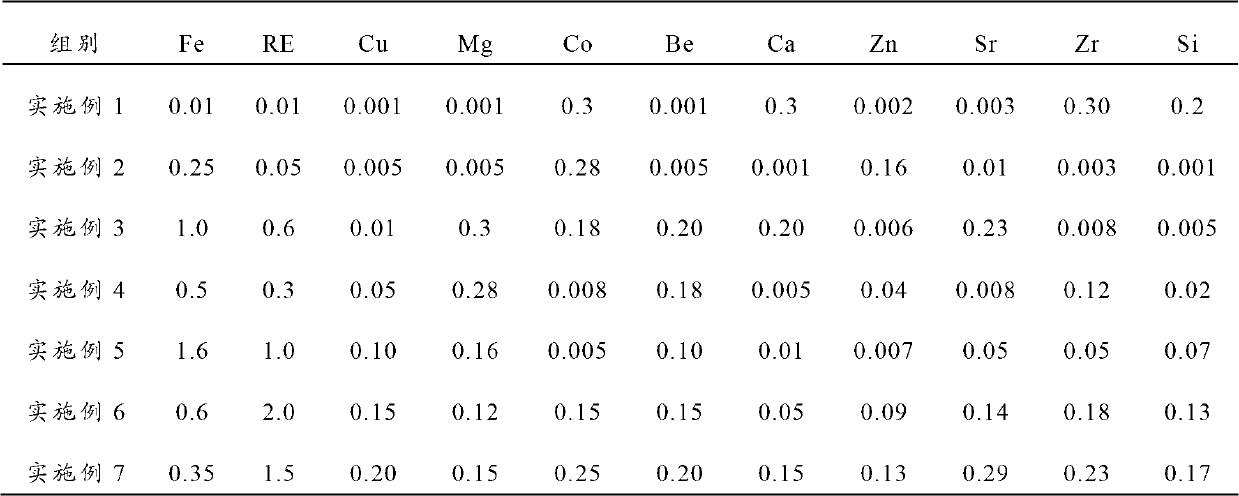

Al-Fe-C-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103387AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cableMetallurgy

The invention provides an Al-Fe-C-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

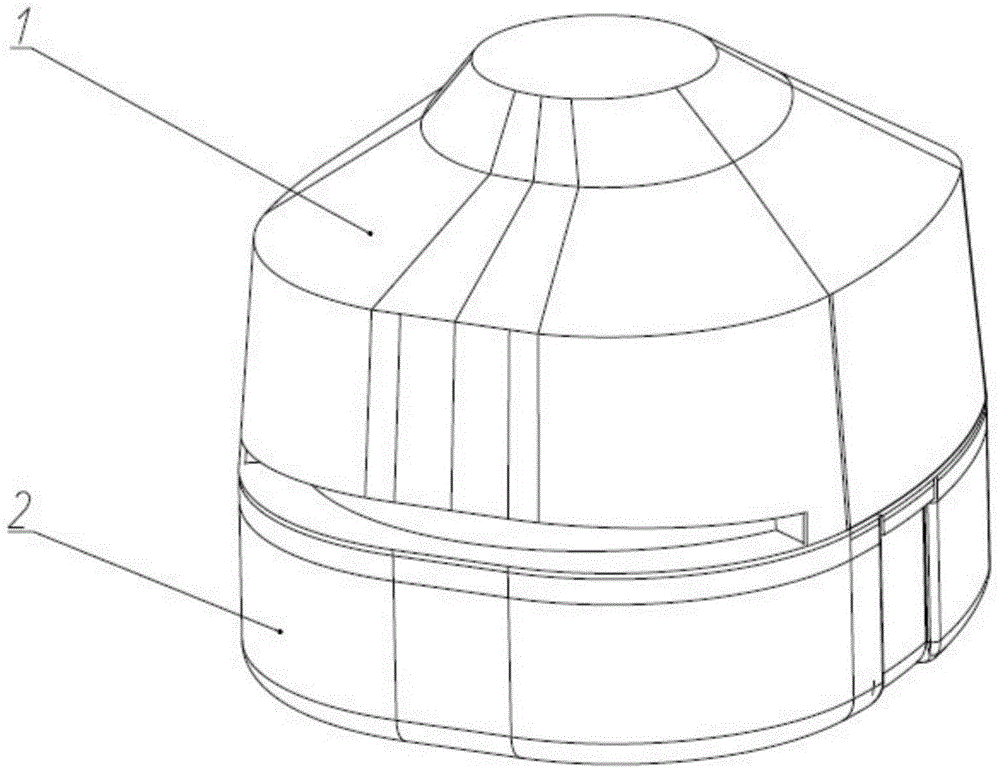

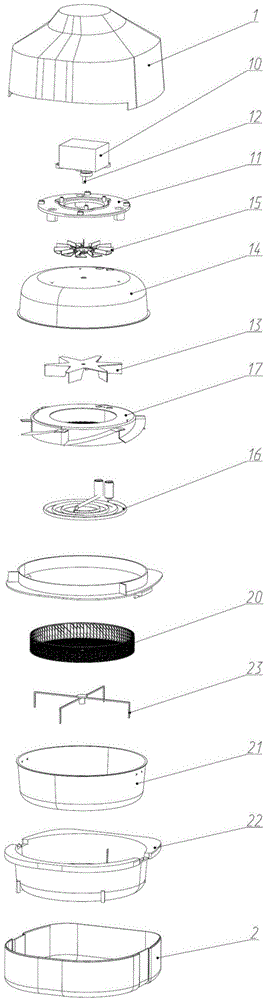

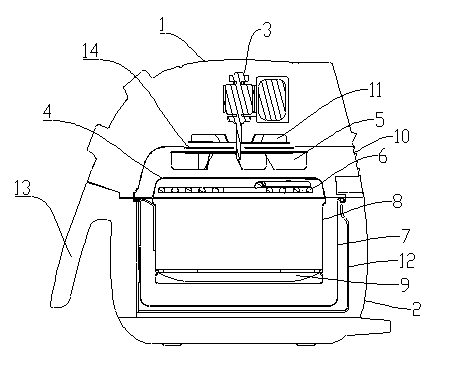

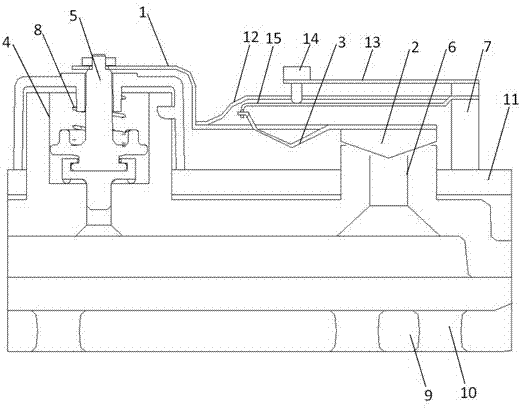

Air fryer capable of forming thermal cycle heating through cyclone

The invention discloses an air fryer capable of forming thermal cycle heating through cyclone. The air fryer comprises a windshield cover, a motor assembly, an extractor fan and a rotating air duct unit, wherein the lower part of the windshield cover is opened, and a small hole is formed in the center of the upper part of the windshield cover; the motor assembly is arranged at the upper part of the windshield cover and comprises a motor transmission shaft, and the motor transmission shaft penetrates through the small hole in the center of the upper part of the windshield cover; the extractor fan is arranged in the windshield cover and is connected with the motor transmission shaft; the rotating air duct unit is arranged in the windshield cover, is positioned under the extractor fan and is fixedly connected with the windshield cover through a connecting post, a ventilating opening is formed in the upper part of the rotating air duct unit, and the lower part of the rotating air duct unit is opened; the rotating air duct unit can enable air flowing downwards under the combined action of the extractor fan and the windshield cover to flow downwards rotationally along a certain angle to form the cyclone. According to the air fryer disclosed by the invention, the thermal cycle heating is formed through the cyclone, and thus food can be more uniformly baked by hot air.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

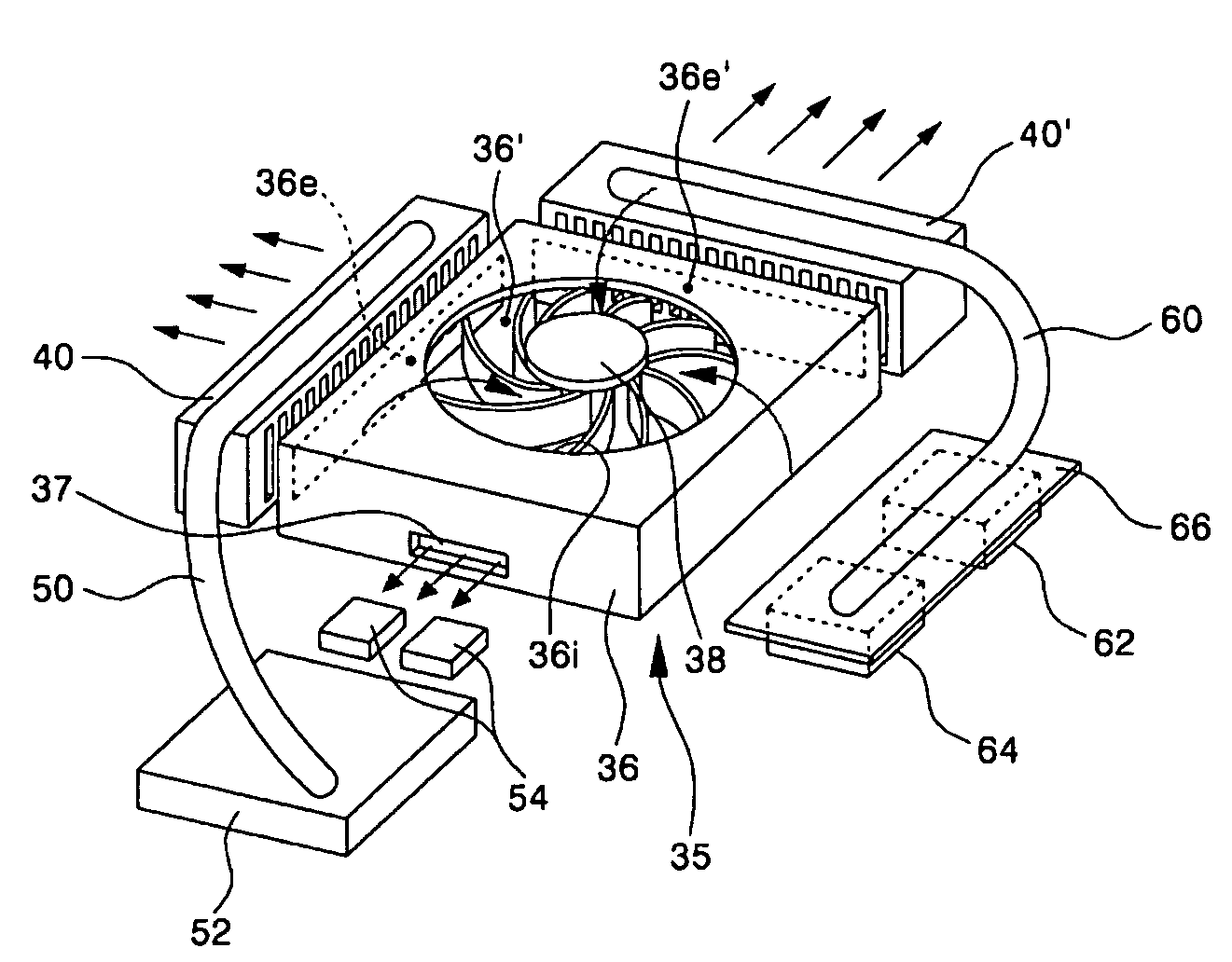

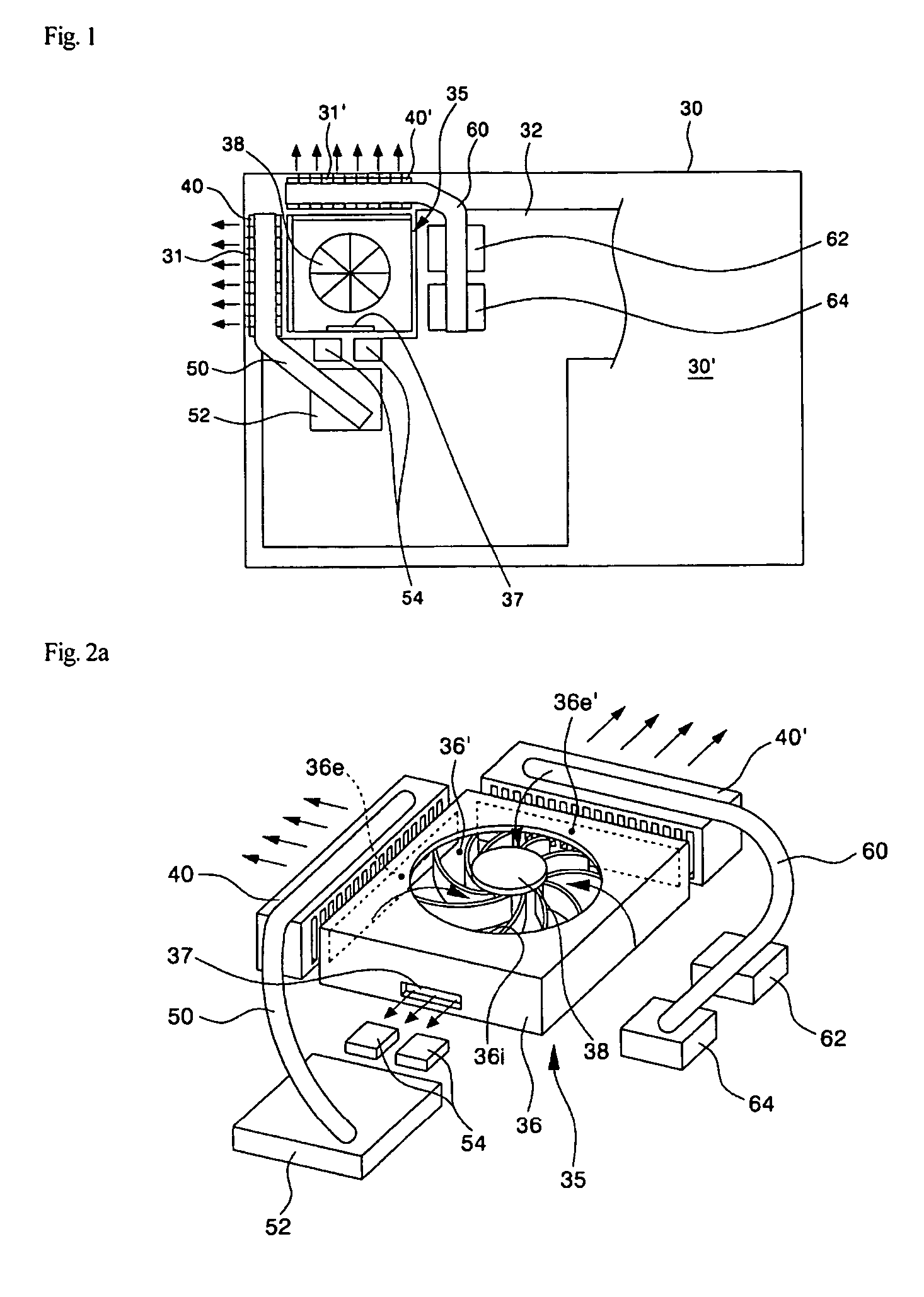

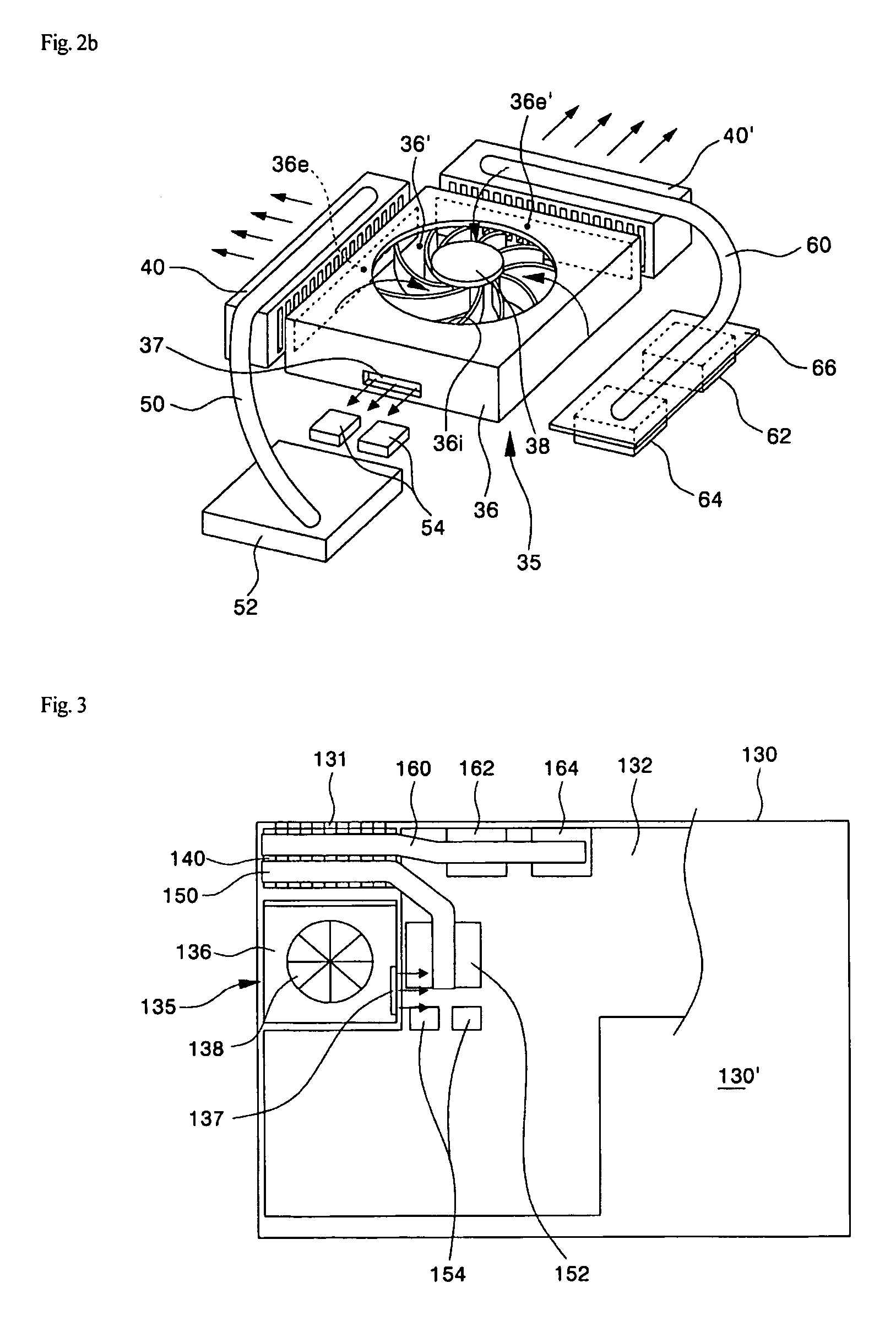

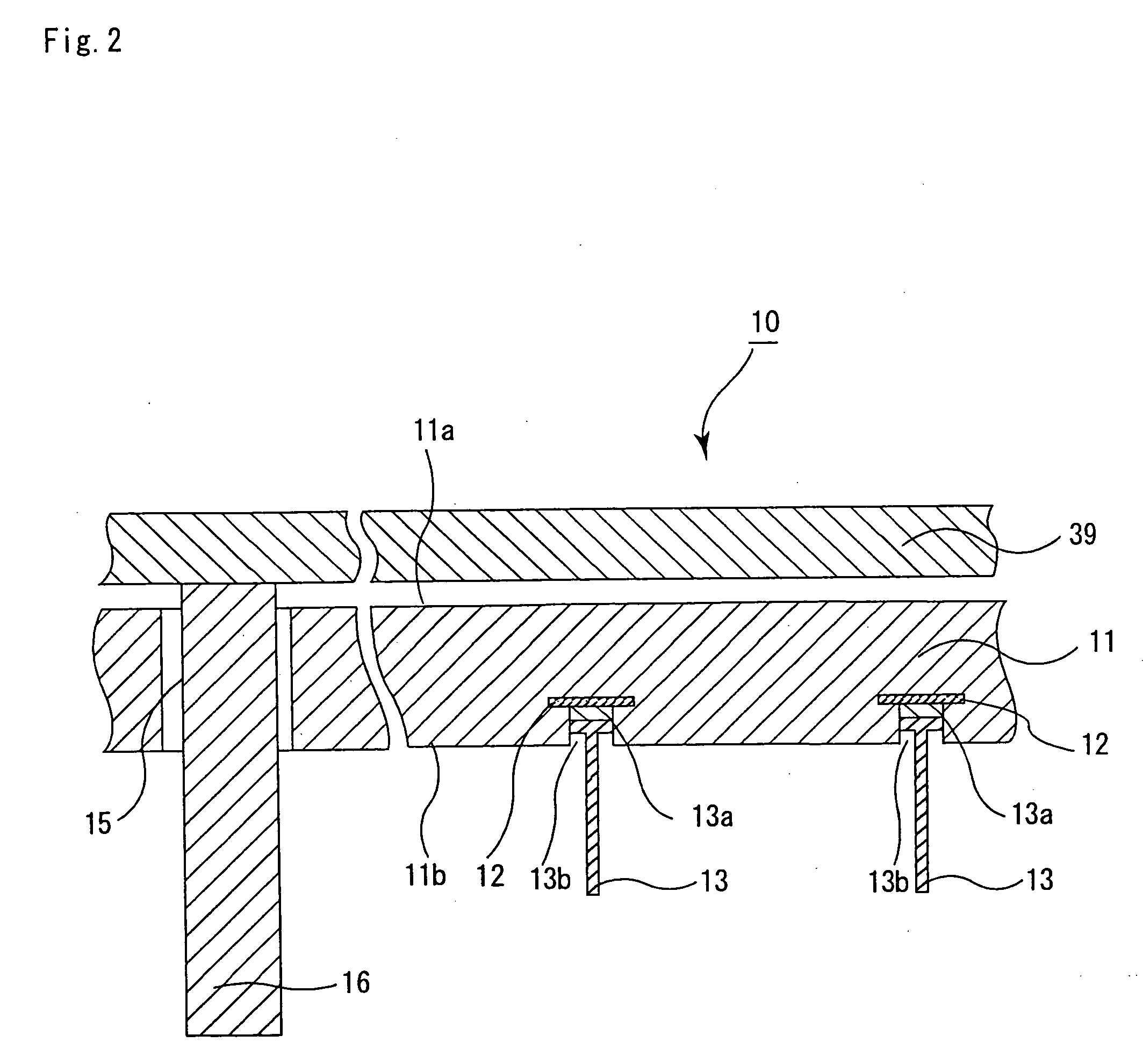

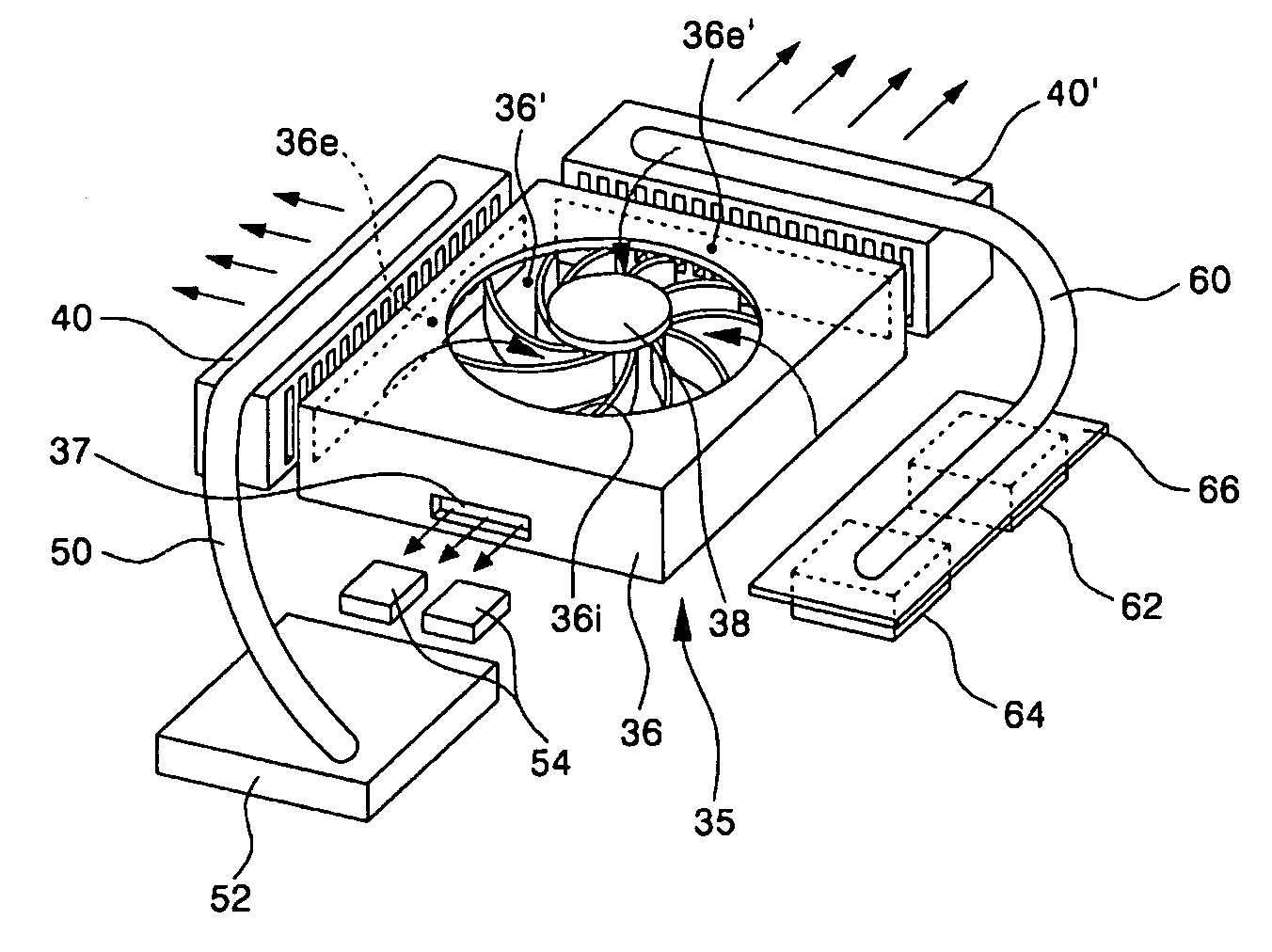

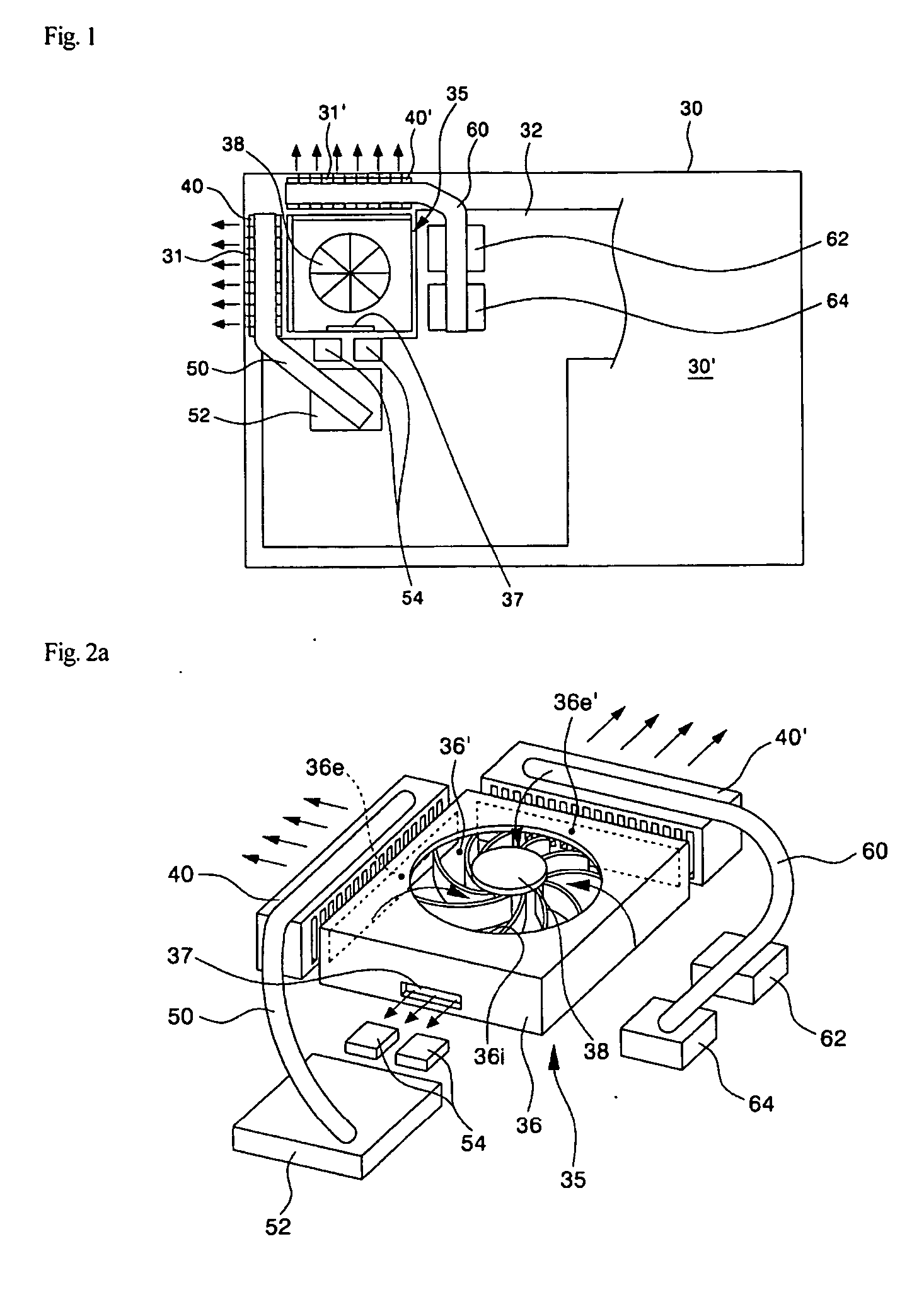

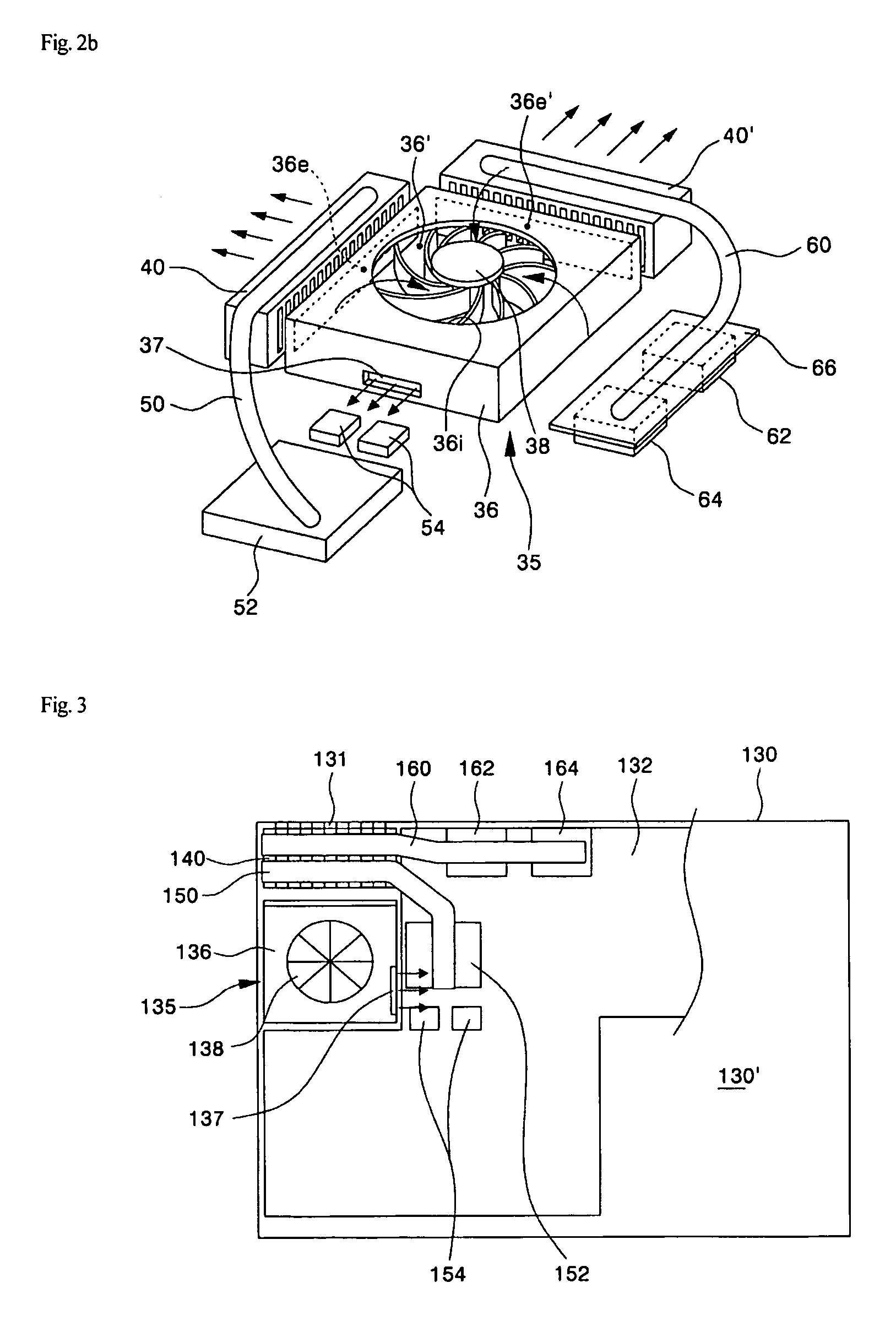

Cooling apparatus for portable computer

ActiveUS7325590B2Evenly heatedEfficient releaseDigital data processing detailsAir heatersEngineeringHeat pipe

A cooling structure for a portable computer includes a cooling fan creating an air stream to release heat generated in a main body of the computer to the outside through at least one vent. First and second heat pipes transfer heat generated in first and second heat sources on a main board of the computer to a path of the air stream. A portion of the air stream is also directed to the interior of the main body.

Owner:LG ELECTRONICS INC

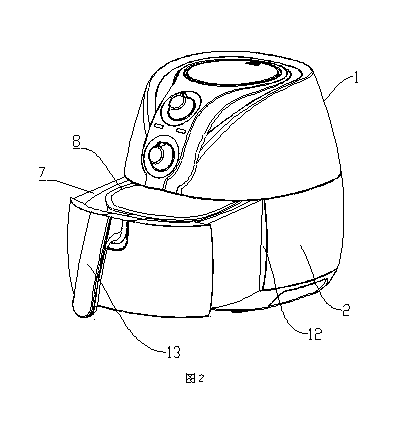

Air frying pan

The invention discloses an air frying pan and aims at providing an improved air frying pan. The air frying pan comprises a furnace head and a housing, and is characterized in that a motor and a heating tube cover are arranged in the furnace head; the tail end of a motor shaft is connected with hot air blades in a thread matching manner; the heating tube cover is provided with a heating tube; an object disc is arranged in the housing; the object disc and an inner container are connected; the top and bottom of the inner container are hollow; and a filter screen is arranged inside the inner container. The air frying pan is mainly used for cooking food.

Owner:杨振巧

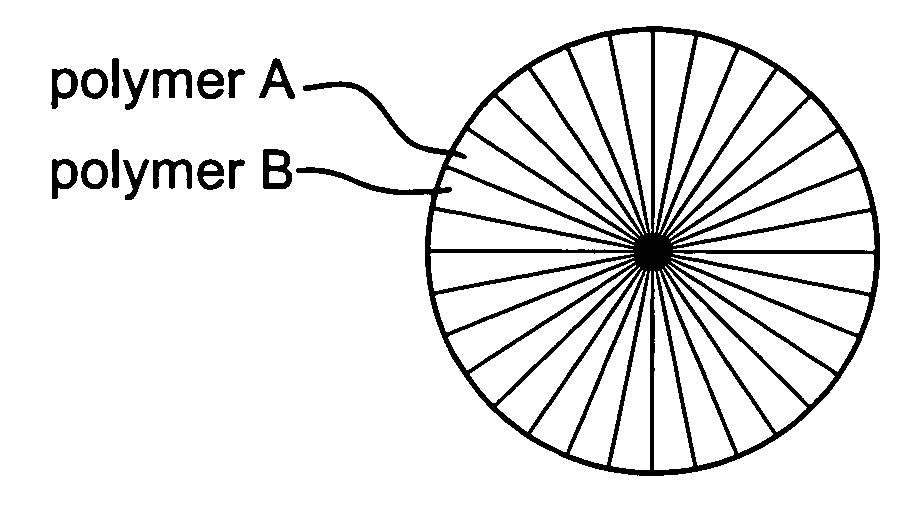

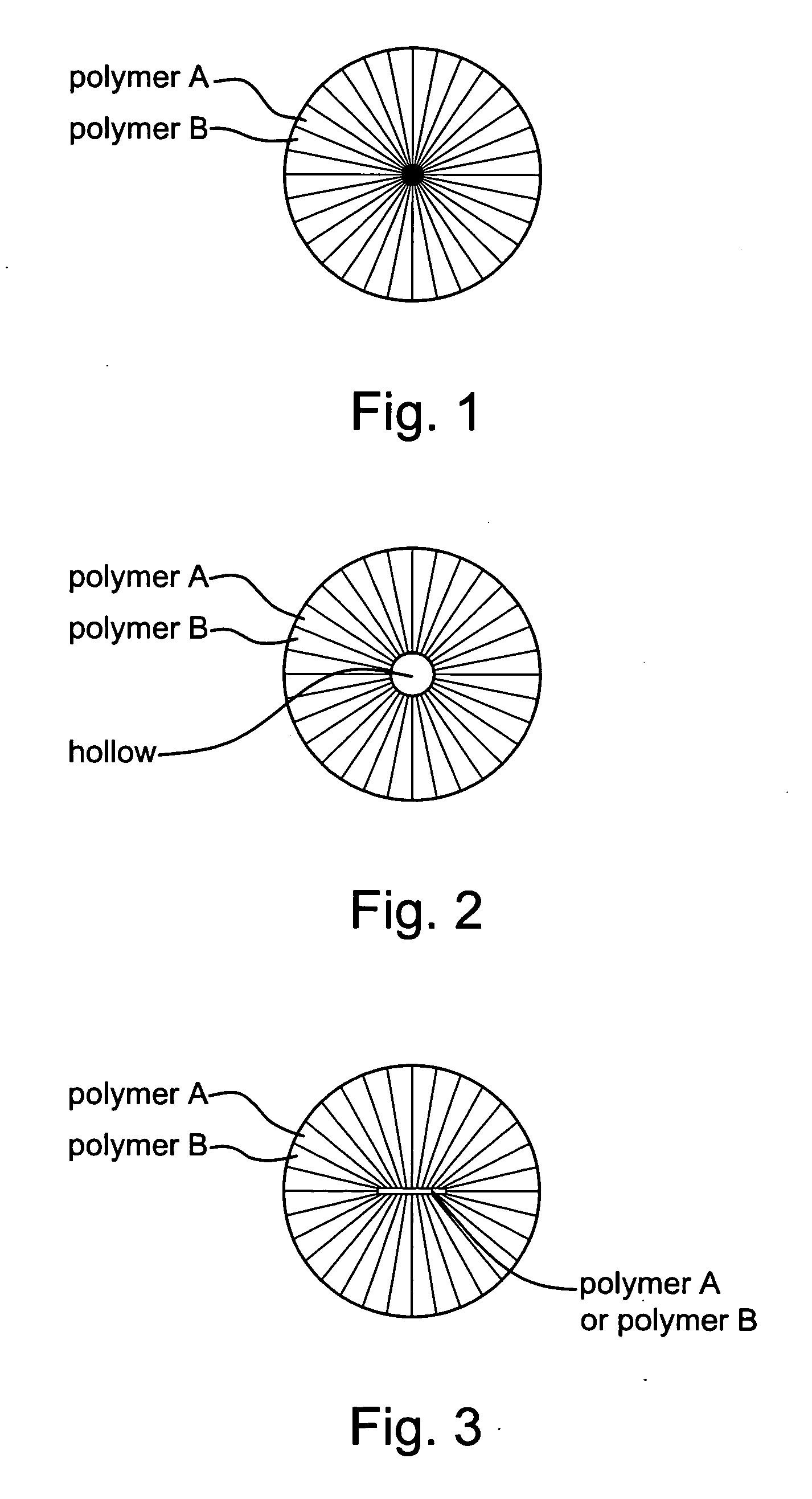

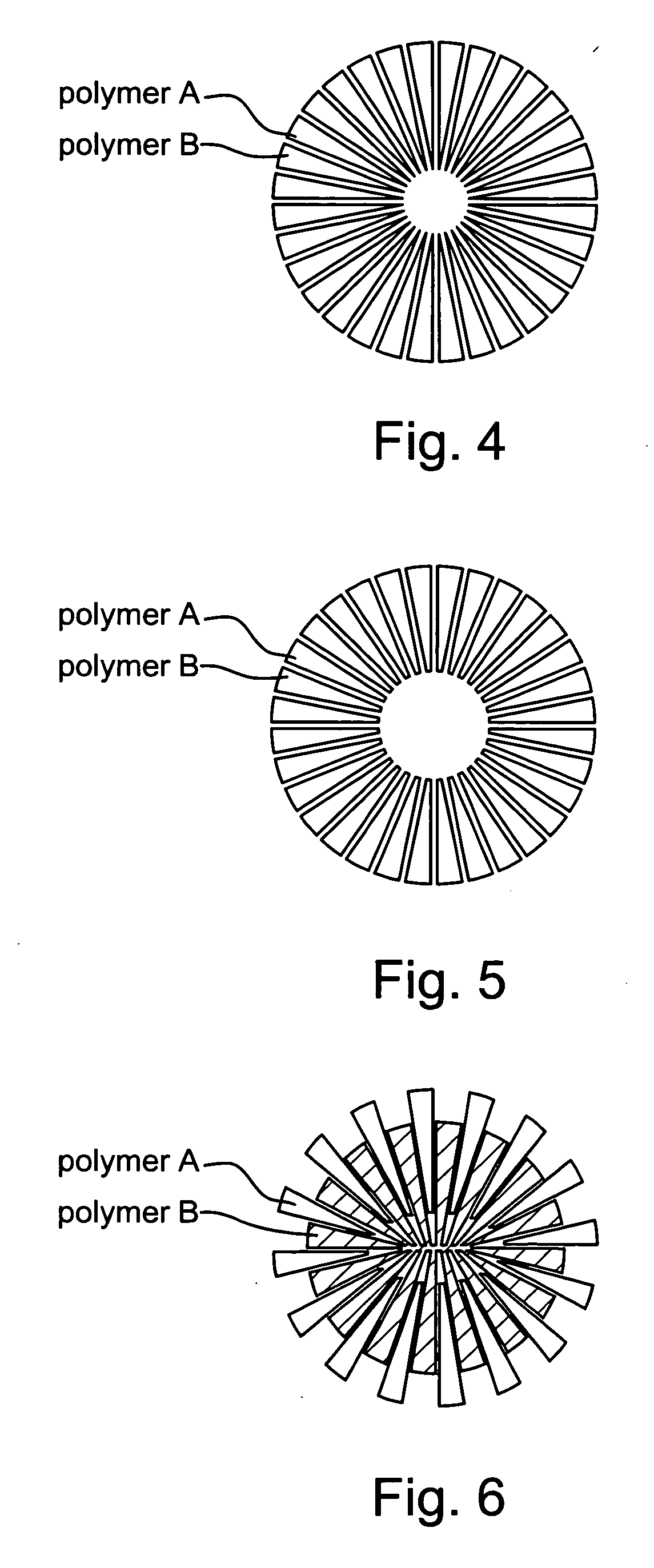

Substrate of artificial leather including ultrafine fibers and methods for making the same

InactiveUS20060263601A1Good flexibilityGood drapeVacuum evaporation coatingSputtering coatingCrystallinityPolymer

There is provided a method for splitting a split type conjugate fiber. The method includes four steps. Firstly, there is provided a first polymer with crystallization of 40% to 95% and a second polymer with crystallization of 1% to 25%. Secondly, a conjugate fiber is made of the first and second polymers by conjugate spinning. Thirdly, the conjugate fiber is submerged in water so that the conjugate fiber contains water. Finally, the conjugate fiber is heated and split into fine fibers.

Owner:SAN FANG CHEM IND

Wafer heater assembly

InactiveUS20050217799A1Uniform heating characteristicFast response timeElectric discharge tubesSemiconductor/solid-state device manufacturingSingle crystalQuartz

Owner:TOKYO ELECTRON LTD

Baking pan capable of efficiently saving energy

InactiveCN106343895AEvenly heatedHard on the outside and soft on the insideRoasters/grillsEngineeringThermal radiation

Provided is a baking pan capable of efficiently saving energy. The baking pan mainly comprises a large body, an upper cover, heaters, a pan body, a food rolling device, an air inlet hole and a cooling fan. The heaters comprise the upper heater and the lower heater, and the baking pan is characterized in that the large body is used for containing the pan body (3), the food rolling device (11) and the lower heater (44), and the large body (1) provides a conduction heating heat source for the bottom of food; the upper cover (2) provides a heat radiation or illumination radiation heat source for the upper surface of the food; the upper cover (2) and the large body (1) are closed to form a stereoscopic heating cavity (55) with the upper portion providing heat radiation or illumination radiation and the bottom providing conduction heating; the cooling fan is used for carrying out constant-temperature heating on the interior of the stereoscopic heating cavity (55) or carrying out relative cooling heating on the interior of the stereoscopic heating cavity (55), and the cooling fan is arranged outside the stereoscopic heating cavity (55); the food rolling device (11) is used for overturning the food, so that the food is evenly heated and stereoscopically heated. The baking pan has the advantages of being good in cooking effect, easy to mount and demount, easy to clean and wide in application range.

Owner:周林斌

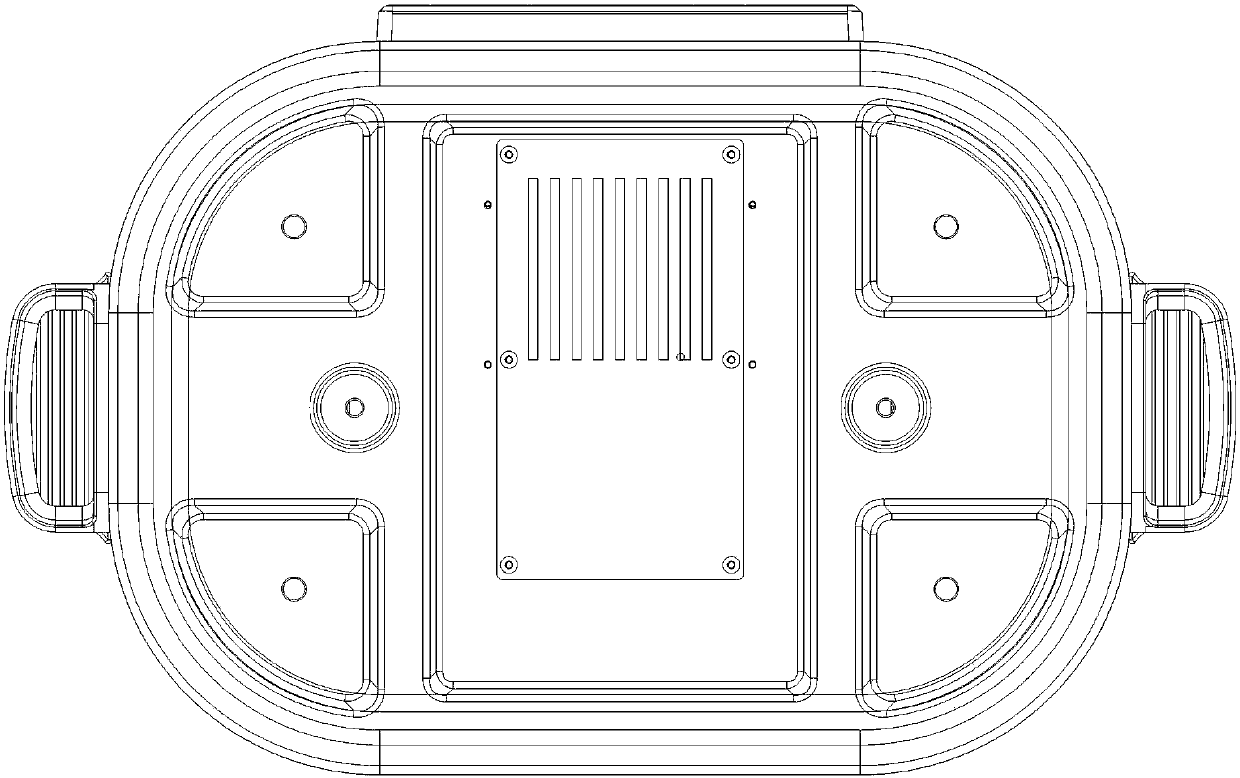

Electric pressure cooker

InactiveCN100496350CSimple structureLow costCooking-vessel materialsElectric heatingElectricityEngineering

The present invention relates to a kind of electric pressure cooker and electric rice cooker. It includes outer shell, pot cover, inner pot, heating disk and temperature detection and control device of electric heating pot. The inner pot is placed in the upper portion of heating disk, and said inner pot is a stainless steel single-layer structure. The temperature detection and control device of invented electroheating pot is formed from heat sensing element and control circuit of electroheating pot, and said heat sensing element is fixed on the heating disk.

Owner:关国华

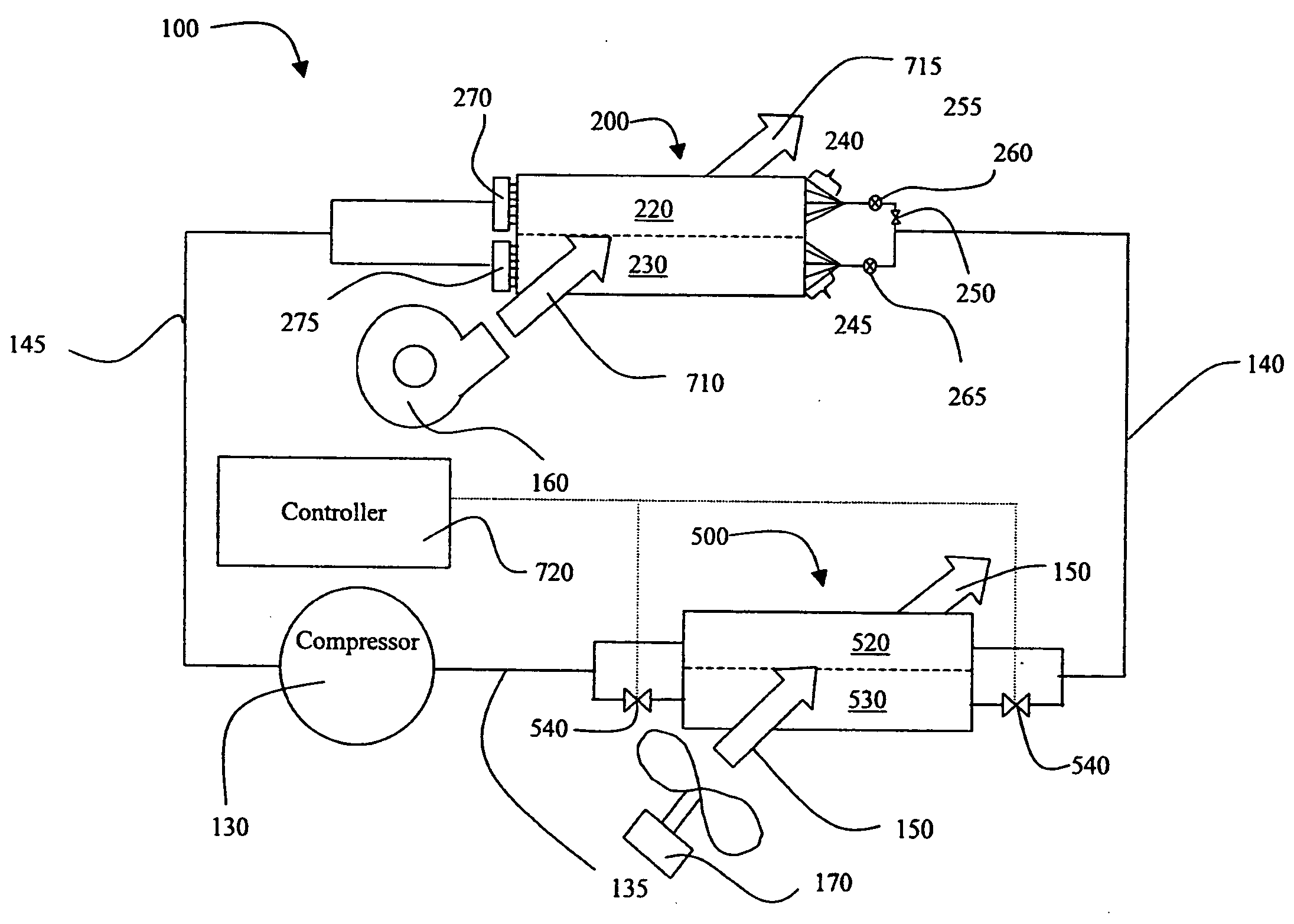

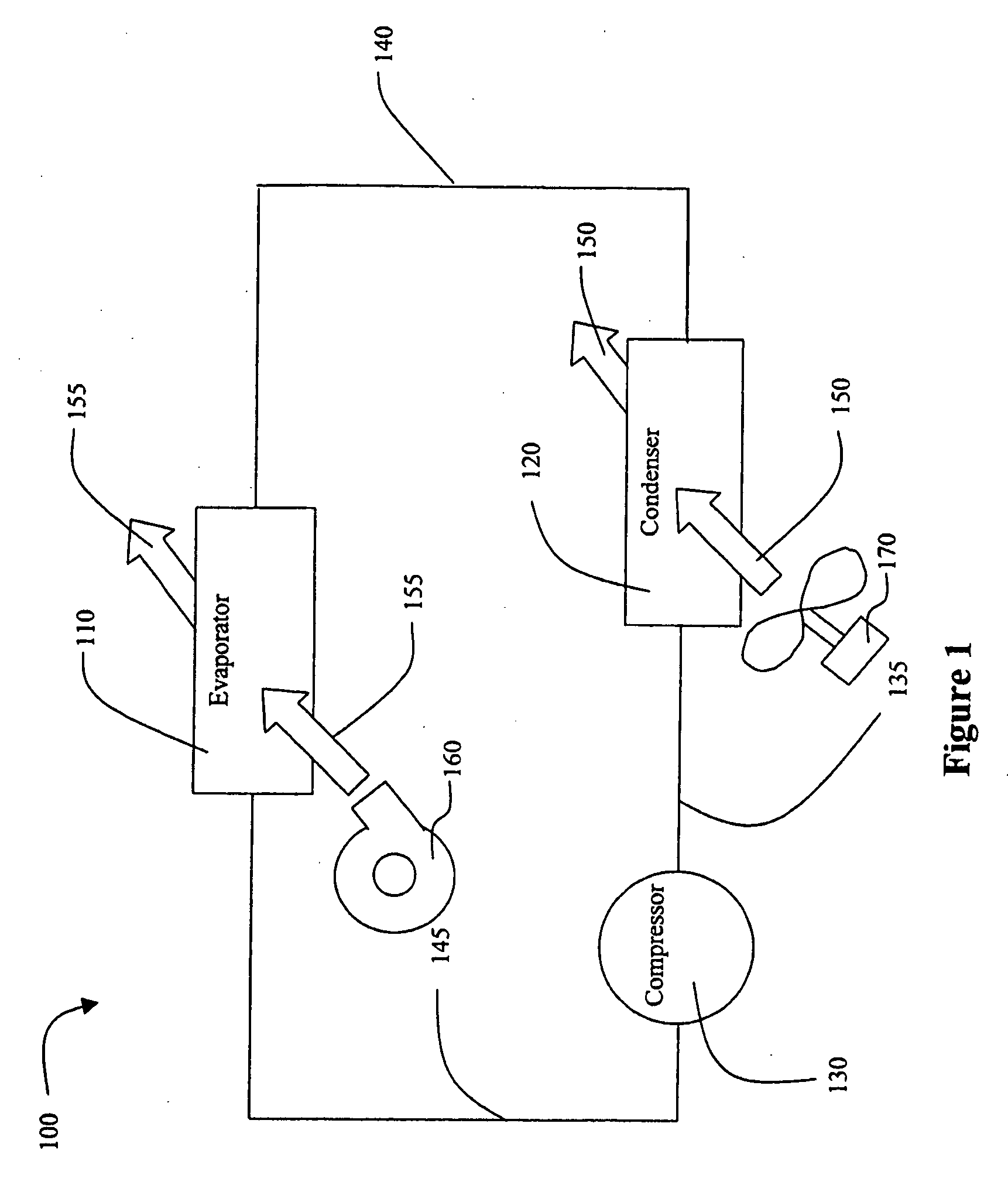

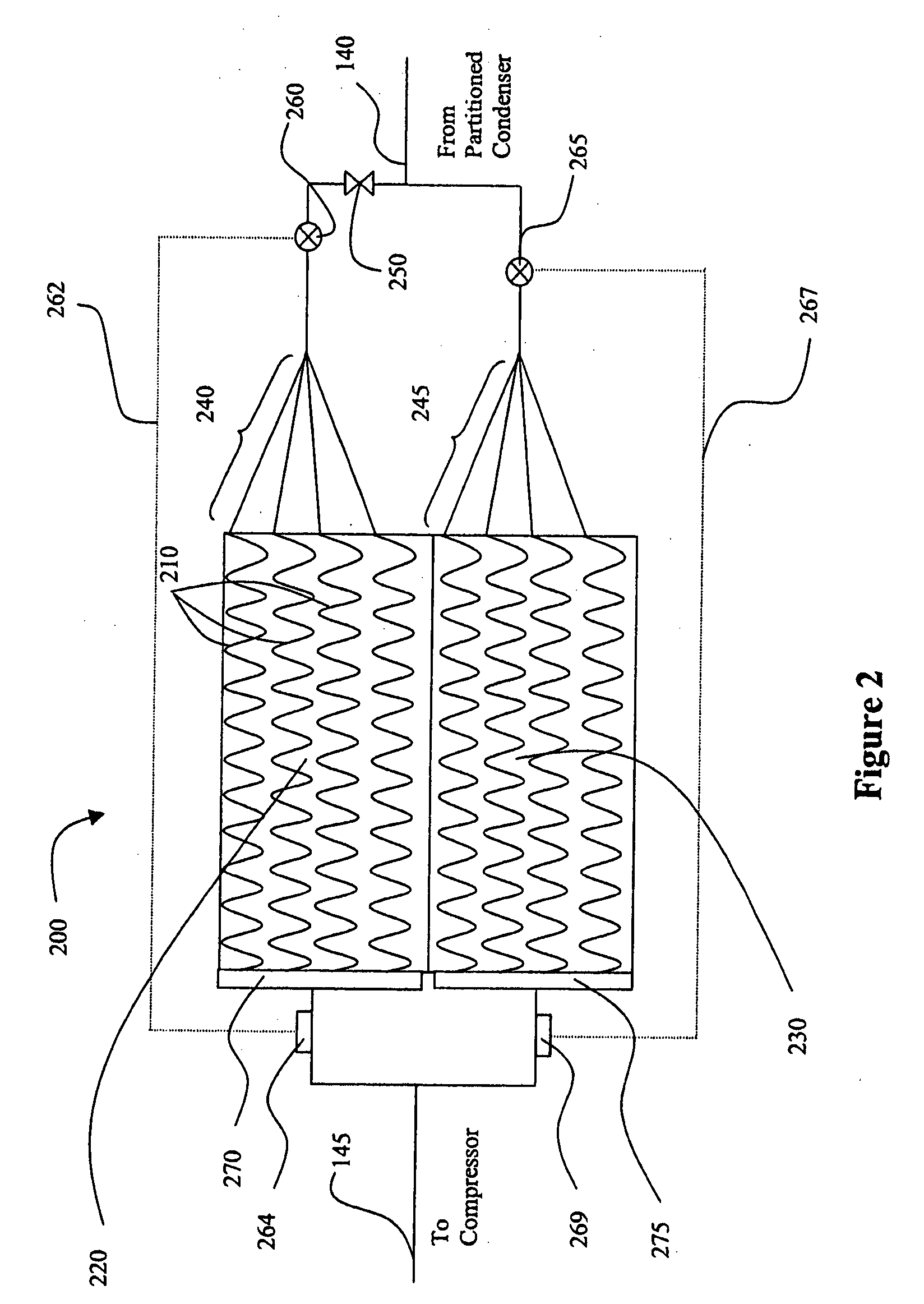

Method and system for dehumidification and refrigerant pressure control

InactiveUS20060288713A1Prevent freezingIncrease system pressureEvaporators/condensersCompression machines with several evaporatorsControl systemSystem pressure

A method for dehumidification and controlling system pressure in a refrigeration system includes providing a refrigeration system having a compressor, a condenser and an evaporator connected in a closed refrigerant loop. Each of the condenser and evaporator have a plurality of refrigerant circuits. A first heat transfer fluid is flowed over the condenser and a second heat transfer fluid is flowed over the evaporator. At least one of the refrigerant circuits of the condenser is isolated to provide a decreased amount of heat transfer area within the condenser and to increase the refrigerant pressure within the refrigeration system when the refrigerant pressure within the refrigeration system is at or below a predetermined pressure. At least one of the refrigerant circuits of the evaporator is isolated to dehumidify and maintain the temperature of the second heat transfer fluid at or above a predetermined temperature when dehumidification is required.

Owner:YORK INT CORP

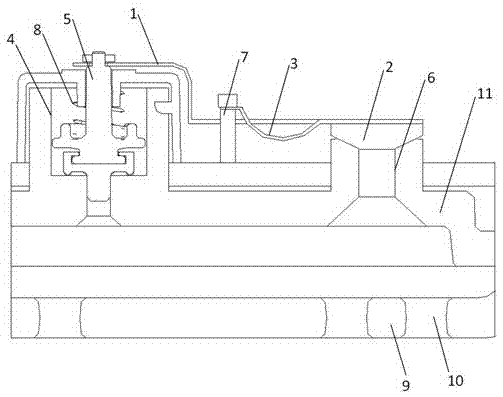

Pressure relief device and pressure cooker thereof

The invention discloses a pressure relief device and a pressure cooker thereof. The pressure relief device comprises a connecting plate. One end of the connecting plate is connected with a reciprocating motion portion in a pressure intensity control device. The other end of the connecting plate is provided with a sealing pressure head for blocking a pressure relief hole. A kick leaf spring and a reset mechanism are arranged on the connecting plate. The other end of the kick leaf spring is connected with a cover plate. According to the pressure relief device and the pressure cooker thereof, constant changing of pressure inside a cooking cavity can be achieved by rapidly opening and closing the sealing pressure head and the pressure relief hole, so that liquid drives solid food to roll, and the solid food in a cooking cavity is heated uniformly. The pressure relief device and the pressure cooker thereof are convenient to install and long in service life.

Owner:SHANGHAI CHUNMI ELECTRONICS TECH CO LTD +1

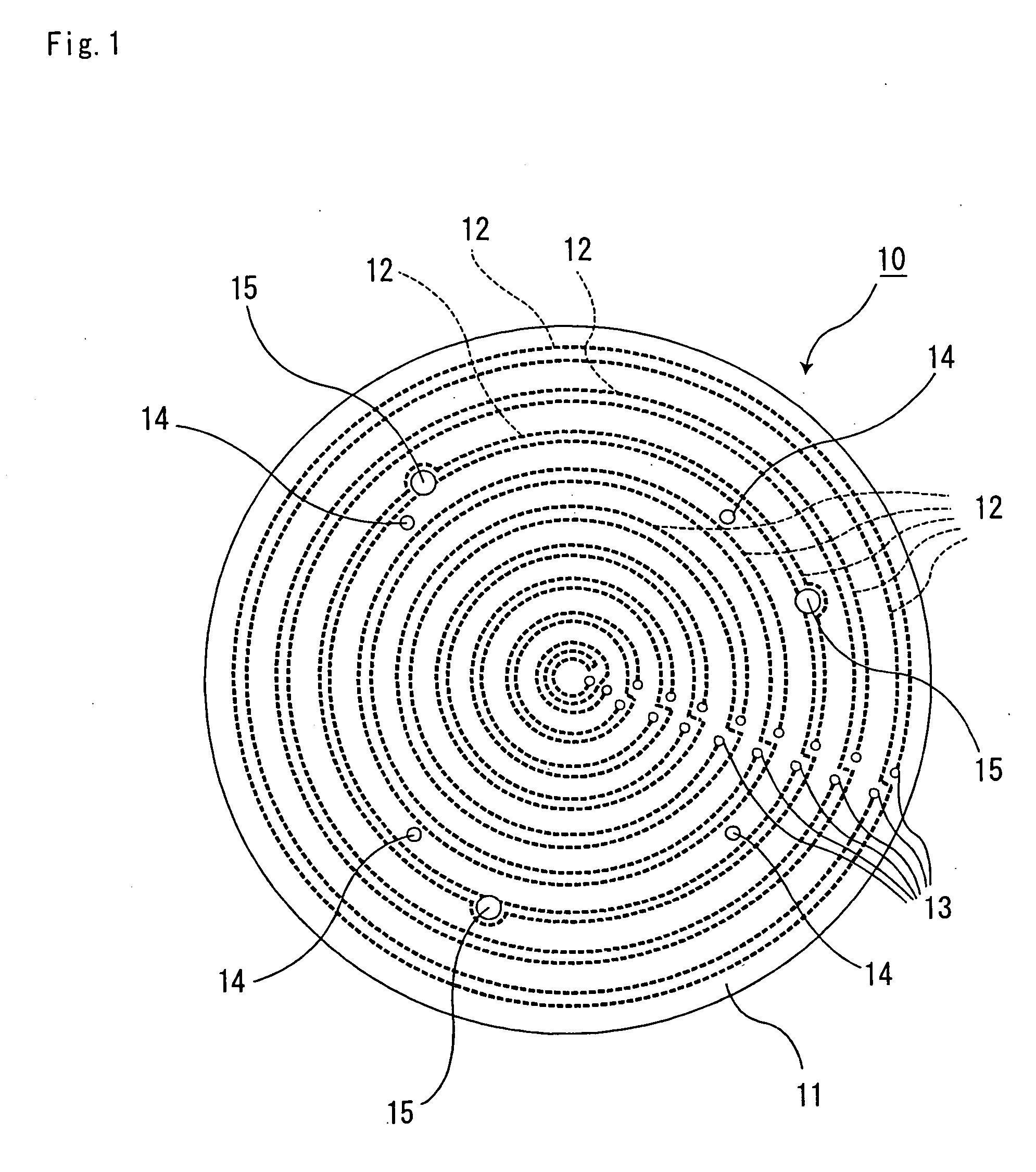

Ceramic heater and ceramic joined article

InactiveUS20050045618A1Inhibit the generation of cracksIncrease spawn rateLamination ancillary operationsLaminationMetallurgySemiconductor

A ceramic heater capable of stably supporting a semiconductor safer and evenly heating the whole of a semiconductor wafer or the like without generating any warp in the semiconductor wafer or the like. The ceramic heater includes a disk-like ceramic substrate, a heating element formed on a surface of or inside the ceramic substrate, and through holes for letting lifter pins pass through the ceramic substrate. The number of the formed through holes is three or more, and the through holes are formed in an area whose distance from the center of the ceramic substrate is ½ or more of the distance from the center to the outer edge of the ceramic substrate.

Owner:IBIDEN CO LTD

Cooling apparatus for portable computer

ActiveUS20050103477A1Efficient releaseEvenly heatedDigital data processing detailsAir heatersEngineeringHeat pipe

A cooling structure for a portable computer includes a cooling fan creating an air stream to release heat generated in a main body of the computer to the outside through at least one vent. First and second heat pipes transfer heat generated in first and second heat sources on a main board of the computer to a path of the air stream. A portion of the air stream is also directed to the interior of the main body.

Owner:LG ELECTRONICS INC

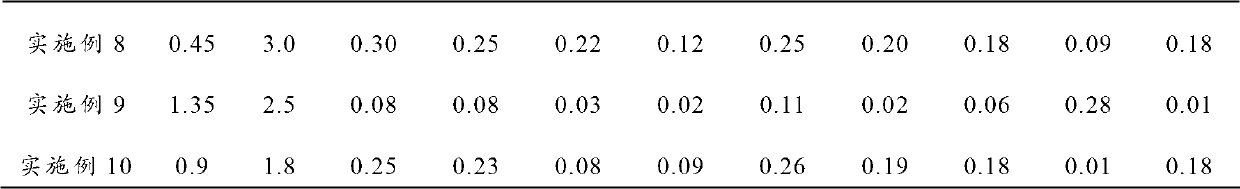

Al-Fe-Sb-RE aluminum alloy, and preparation method and power cable thereof

ActiveCN102978449AEvenly heatedEliminate damagePower cables with screens/conductive layersMetal/alloy conductorsPower cableMetallurgy

The invention provides an Al-Fe-Sb-RE aluminum alloy, and a preparation method of the Al-Fe-Sb-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Electric conduction-stirring friction composite heat power supply welding method and equipment

ActiveCN101323054AOvercoming a lack of energy inputBreak through limitationsResistance welding apparatusNon-electric welding apparatusEngineeringWeld seam

The invention discloses a conducting-stirring friction hybrid heat source welding method and a piece of equipment, wherein, in stirring friction welding, a stir head and a workpiece are simultaneously insulated from the main body of a welding machine, the clamp of a fixed workpiece and a worktable, current is galvanized in the weld seam direction of the workpiece, the current and the weld seam through which the current flows produce resistance heat with the contact resistance of a friction stirring welding area, and the resistance heat together with stirring friction heat forms the hybrid heat source of the stirring friction welding. The method and the equipment of the invention have the following remarkable effects: 1. the limitation of the stirring friction welding on welding materials is broken through, leading the stirring friction welding to be used for welding such structural materials as black ferrous metals, superalloy, and the like; 2. the service life of the stir head can be improved; and 3. welding speed and welding quality can be further improved, thus improving the mechanical property of a welding joint. The method and the equipment of the invention can be used for the stirring friction welding, the preheating before welding, and the postweld heat treatment of such structural materials as carbon steel, stainless steel, and superalloy, etc.

Owner:罗键

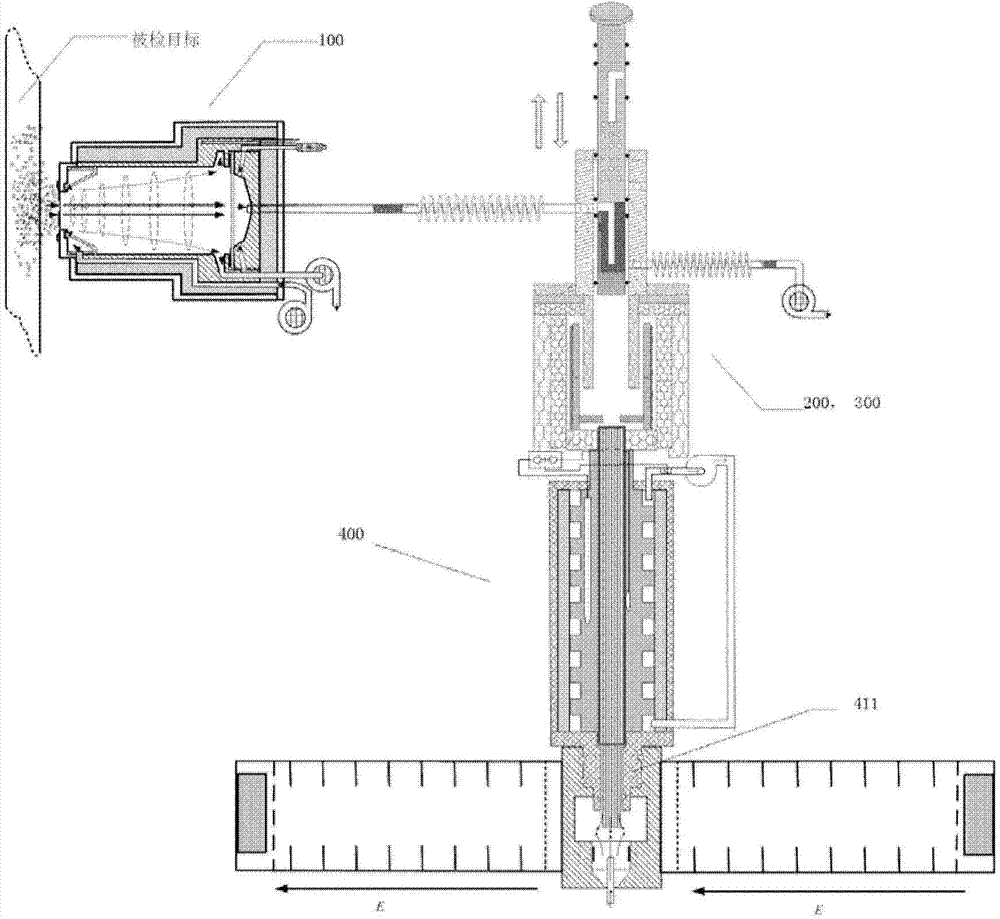

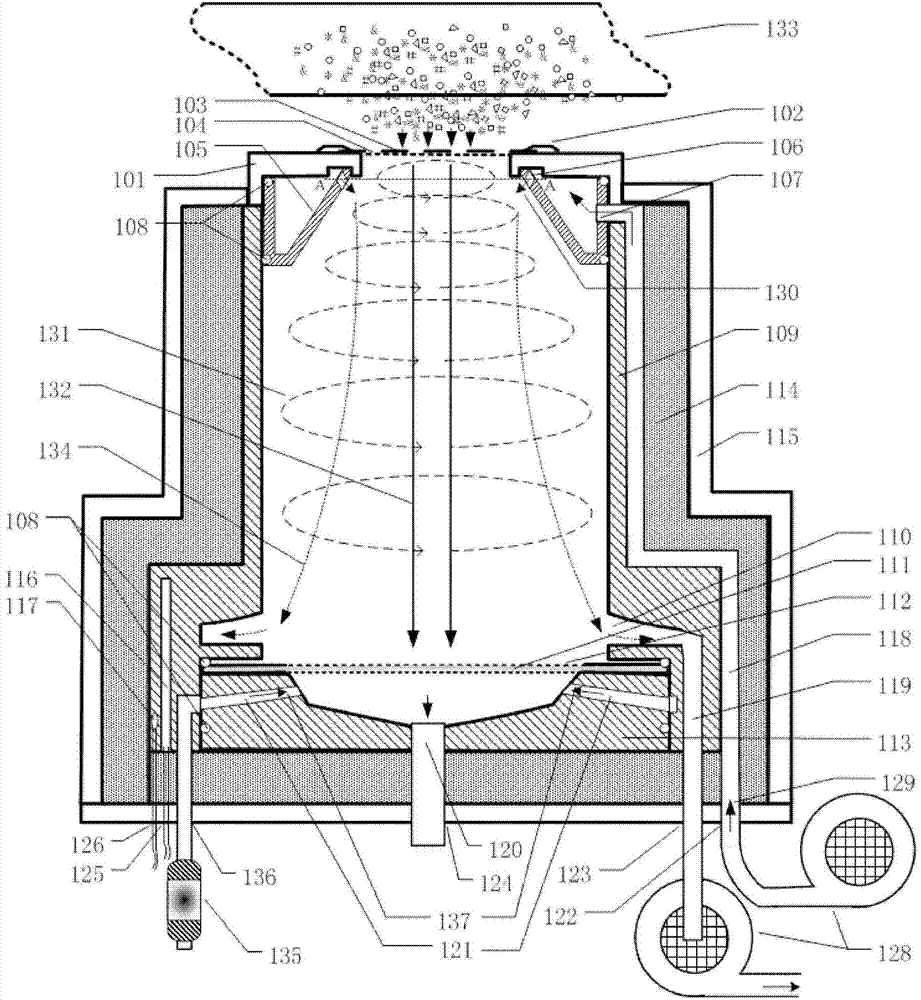

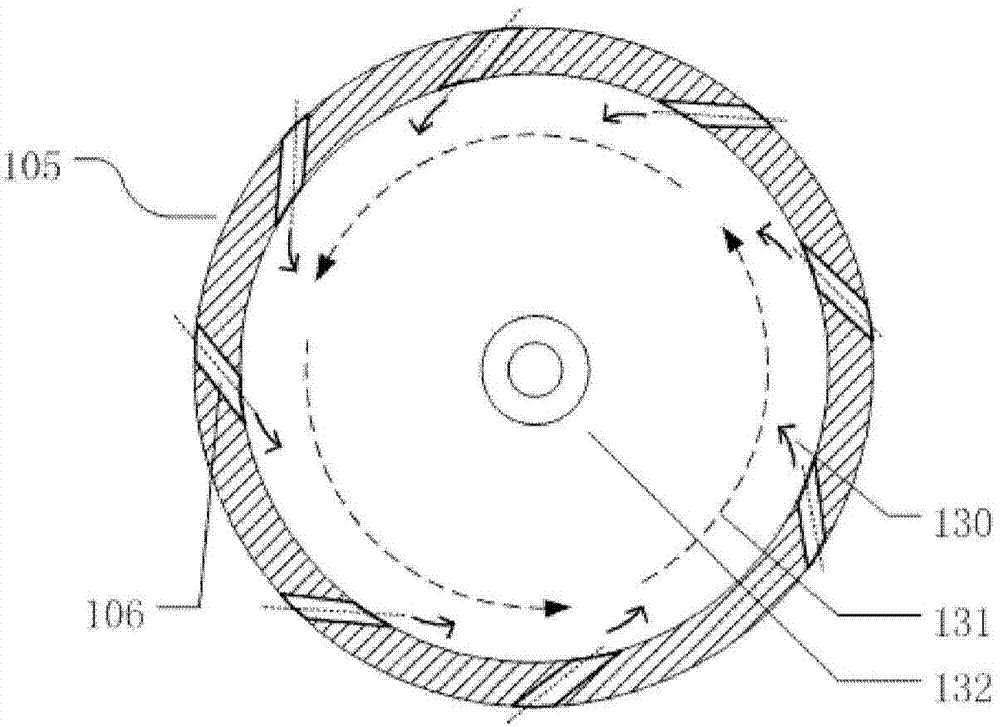

Detection equipment and detection method

ActiveCN104517799AAmplify the collectionRealization of generationComponent separationSamples introduction/extractionMetro stationGas phase

The invention discloses detection equipment and a detection method. The detection equipment comprises a sampling device used for collecting a sample to be detected, a preprocessing sample injection device used for preprocessing the sample from the sampling device, and a sample analysis device used for separating the preprocessed sample from the preprocessing sample injection device and analyzing the separated sample. The detection equipment is miniaturized, can quickly and accurately detect gas-phase matters or particulate matters without unpacking, and is high in accuracy and suitable for security check of airports, ports, metro stations and the like.

Owner:NUCTECH CO LTD

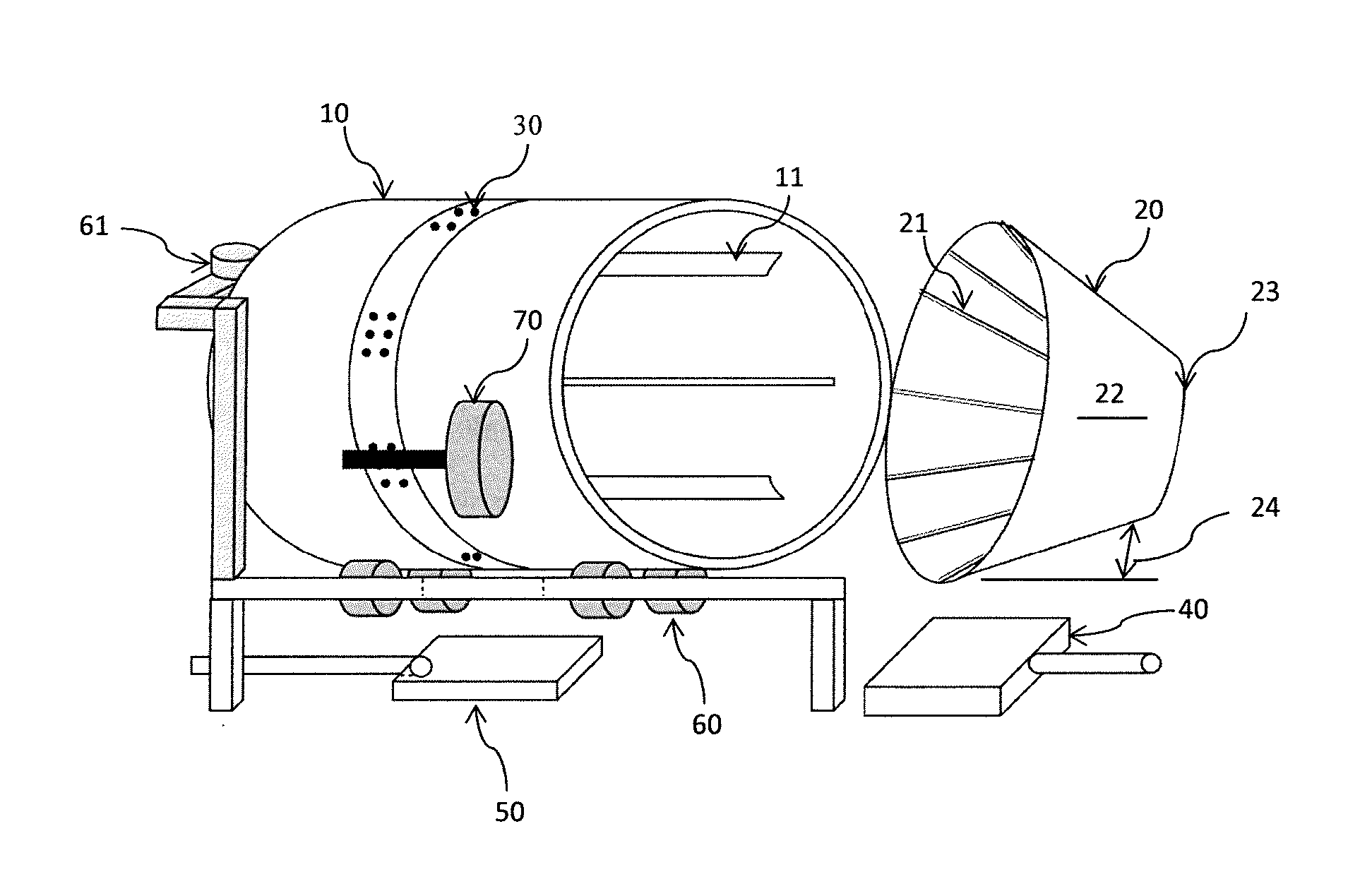

Rotating feeder bin for growing, feding and harvesting insect larvae

A system of feeding, culturing and harvesting insects, particularly black soldier flies comprises of a semi-enclosed barrel including a generally cylindrical sidewall having two ends and a central axis of rotation oriented roughly transversely to the direction of gravity, and a migration path attached to one or both ends of the barrel for the exit of mature larvae. A method of raising insect larvae and byproducts comprises of inserting larvae or eggs into a bin; comminuting and inserting food material into the interior of the bin; aerating the larval / food mass by rotating the bin about a central axis that is positioned roughly transverse to the direction of gravity; draining leachate from the bin into a collection system; and providing a migration path for the egress of mature larvae on at least one end of the bin into a larval collection system.

Owner:PEREDNIA DOUGLAS A

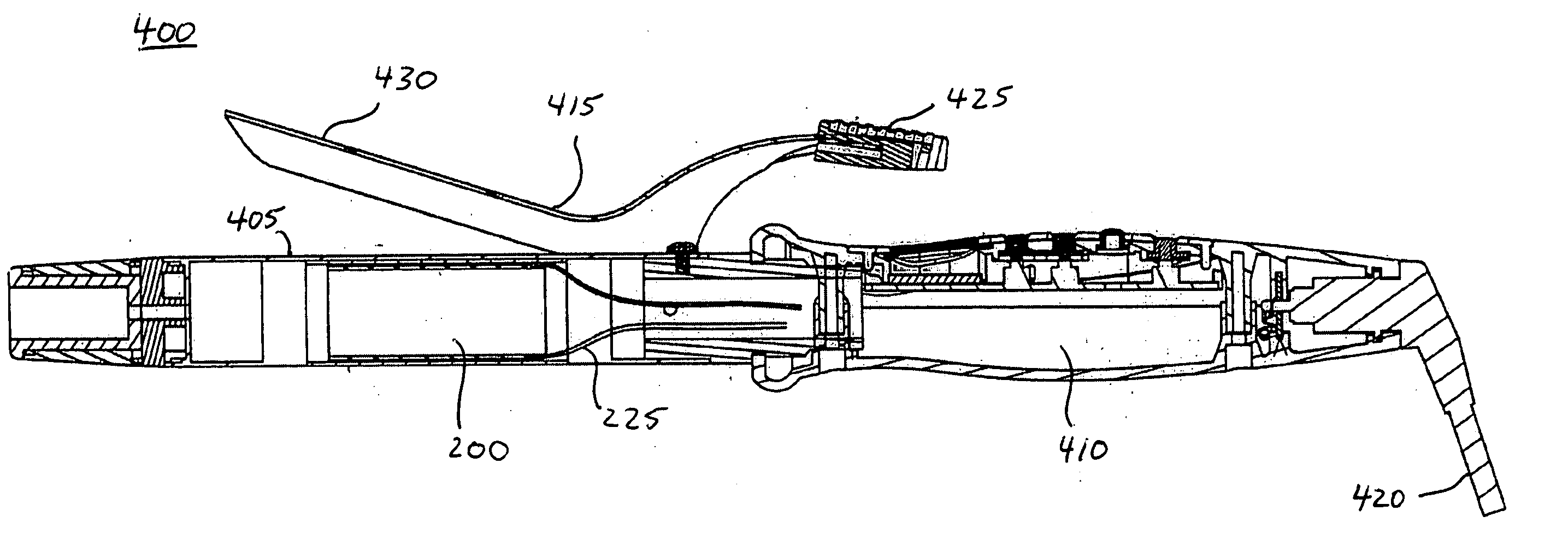

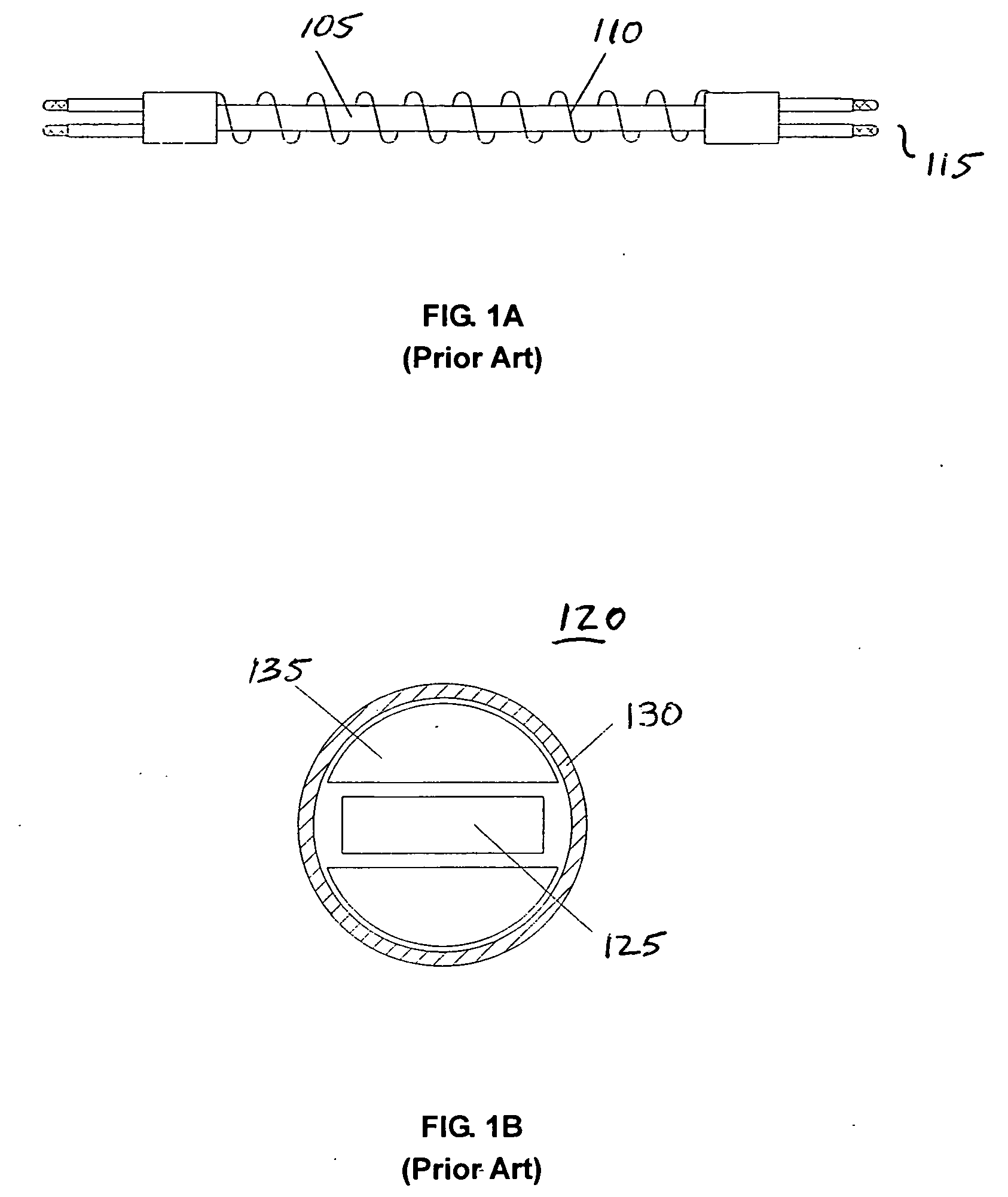

Ceramic hair care heating element

InactiveUS20070119844A1Evenly heatedCurling-ironsCurling-tongsElectrical resistance and conductanceMaterials science

There is provided a heating element for a hair styling device, including an electrically insulating inner ceramic layer, an electrically conductive resistive heating layer disposed on and in contact with the inner layer, and an electrically insulating outer ceramic layer disposed on and in contact with the resistive heating layer. There is also provided a method for manufacturing the heating element. There is further provided a hair setting device for curling hair including the heating element a cylindrical barrel surrounding the heating element.

Owner:BEAUTI GEAR INT

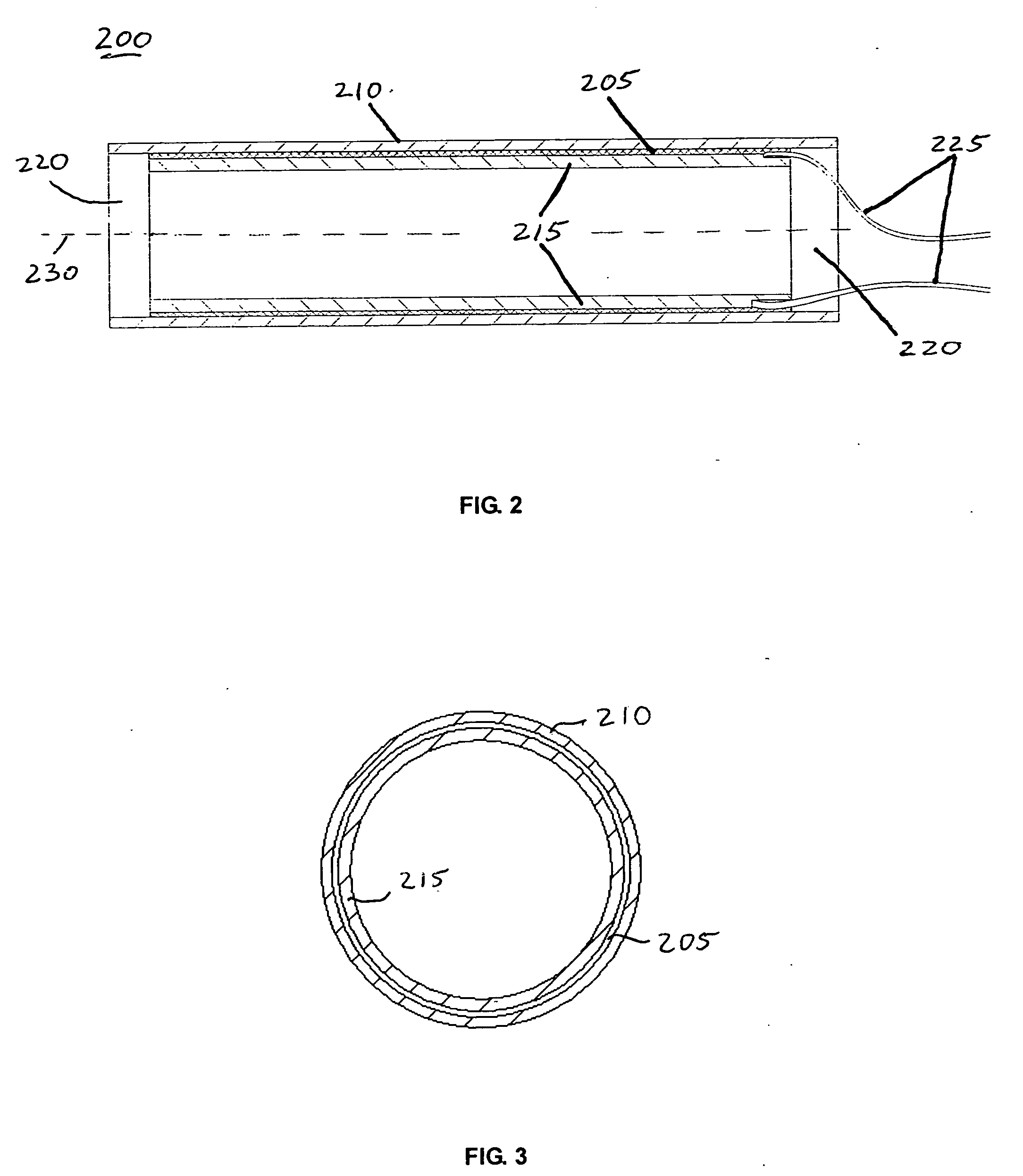

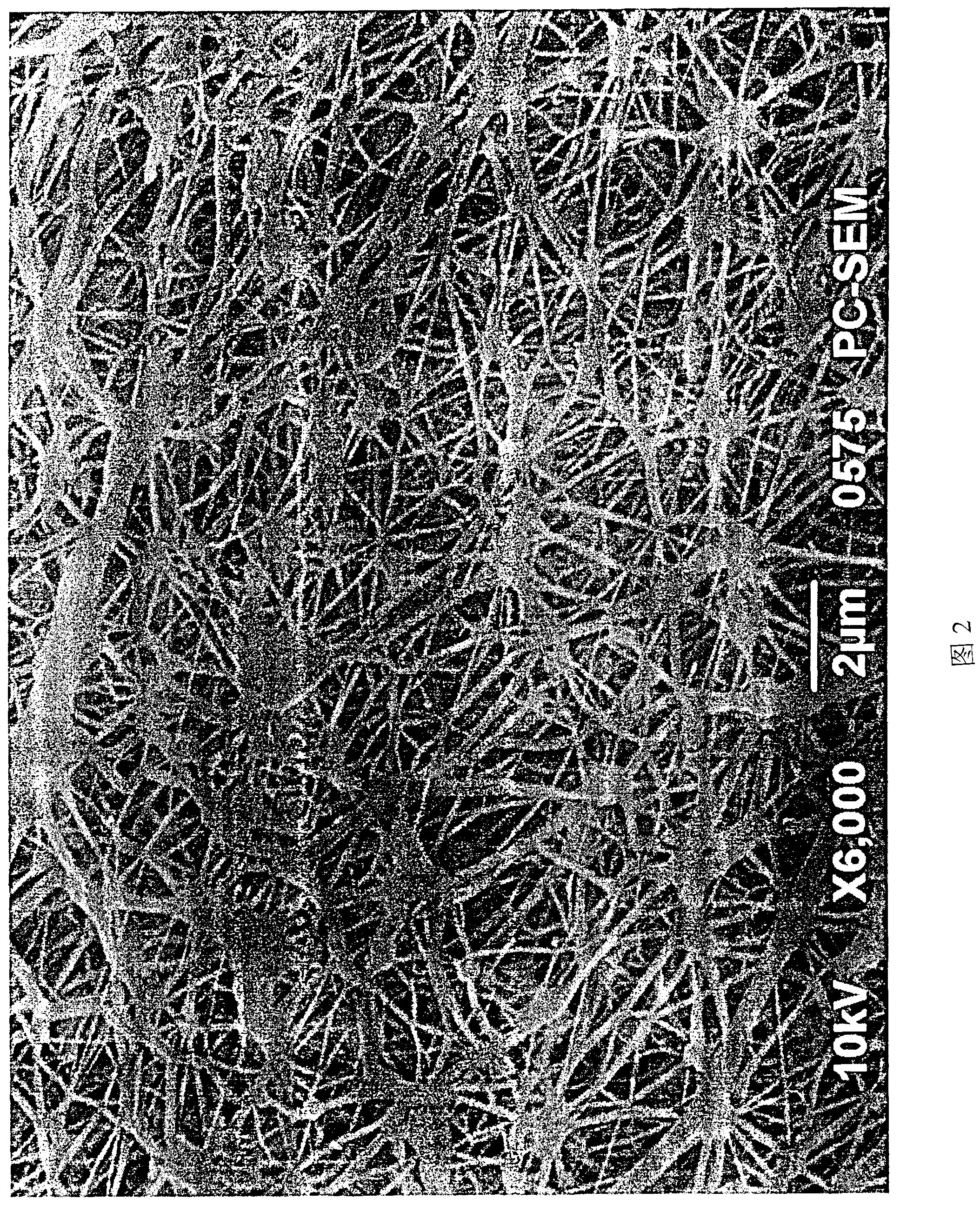

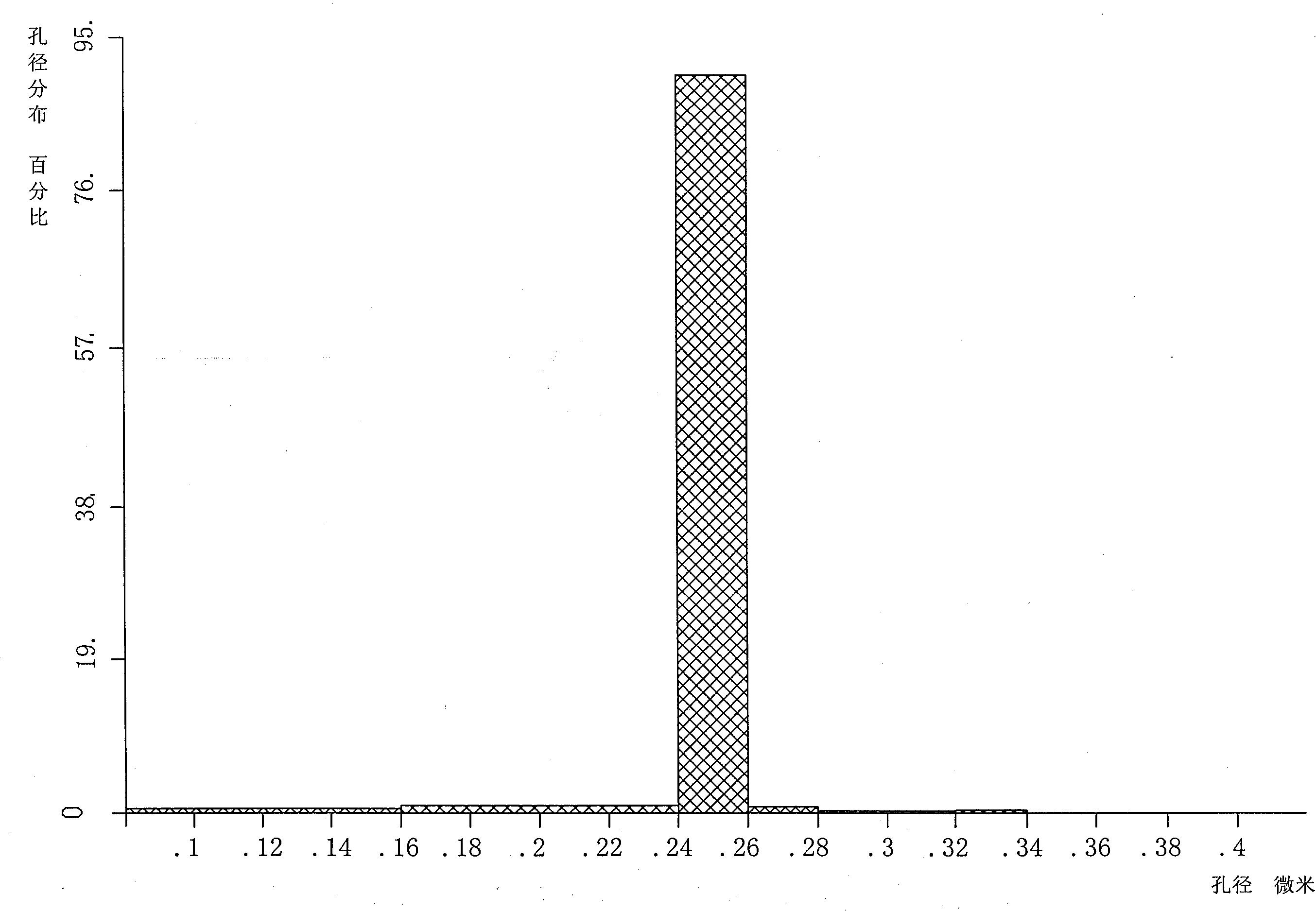

Polyfluortetraethylene nanofibre membrane and preparation method thereof

InactiveCN101543734BAvoid filter efficiencyHigh water pressure resistanceSemi-permeable membranesFlat articlesAir filtrationWater resistant

The invention relates to a polyfluortetraethylene nanofibre membrane and a preparation method thereof. The aperture distribution of the polyfluortetraethylene nanofibre membrane is concentrated within a range of + / -100 nanometers and occupies more than 90 percent of the total volume of each level aperture; the stretching process of the preparation method adopts low-temperature segmenting stretching, thus the stretching temperature is stable, the polyfluortetraethylene nanofibre membrane is uniformly heated, and giant molecule segmers are equally unfolded; the produced polyfluortetraethylene nanofibre membrane has concentrated aperture distribution and high uniformity so as to generate high water pressure resistance, long water resistant time and high membrane fibering degree, and the obstructing efficiency of bacteria reaches more than 99.99 percent, thereby the polyfluortetraethylene nanofibre membrane can meet the requirement of oil-water separation and high-end gas filtration of anoperation isolation mattress with high-pressure steam filtration and high water pressure resistance and can be used in fields of superclean room entering air filtration, and the like, such as medicaltreatment and health protection, health matter cultivation, semiconductor devices, integrated circuit, medicine, and the like.

Owner:北京千叶宝莲科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com