Patents

Literature

45results about How to "Increase system pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

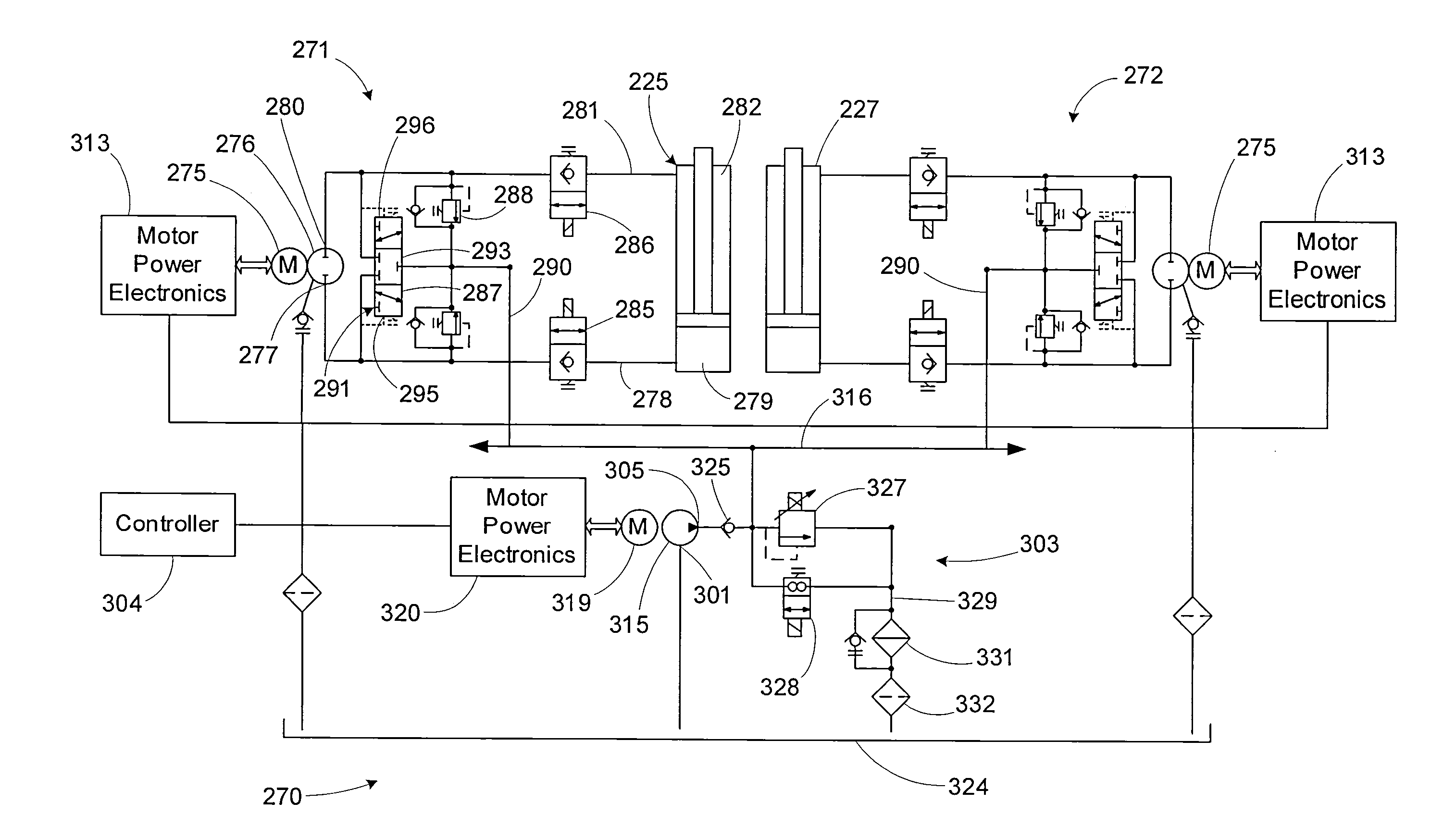

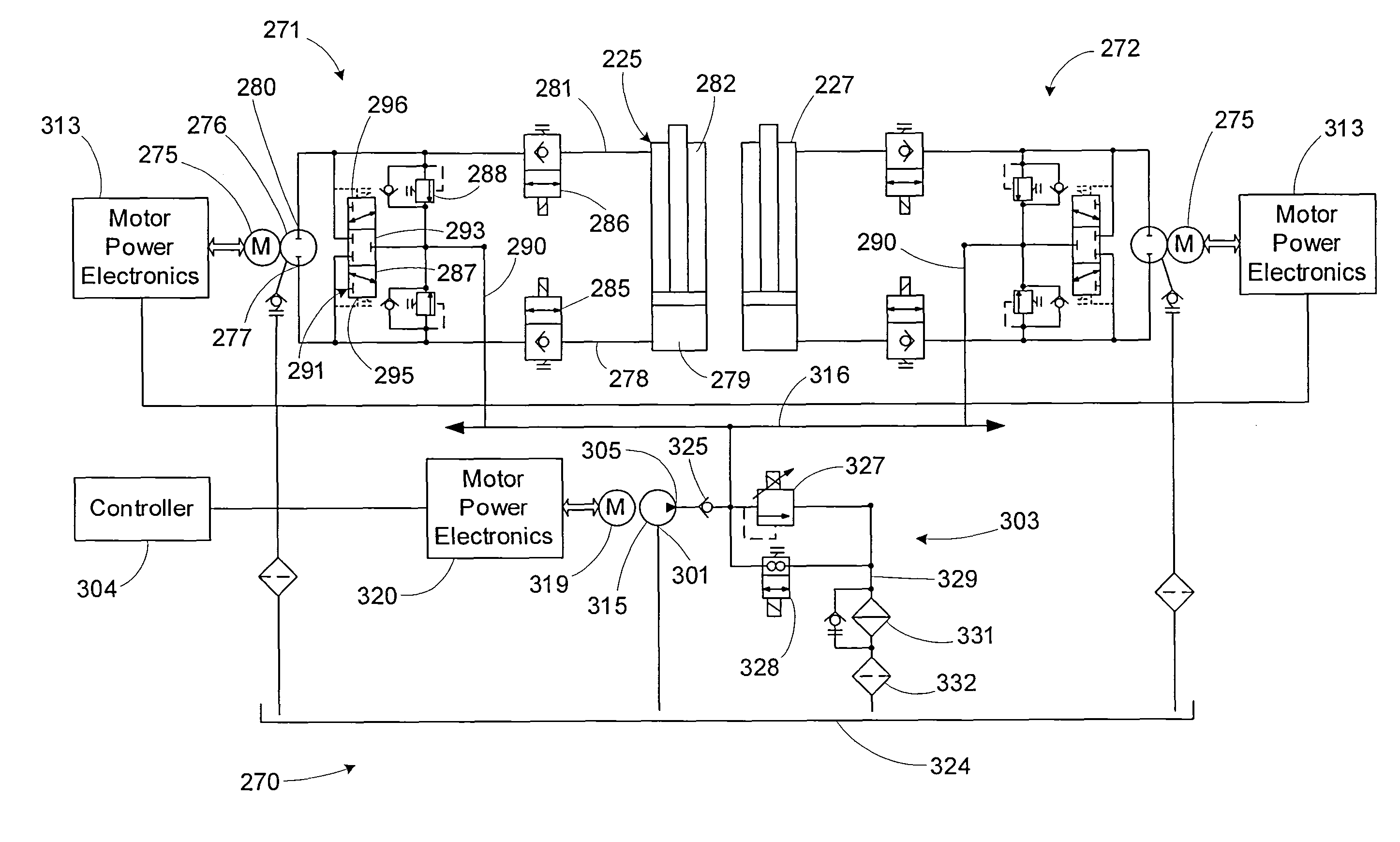

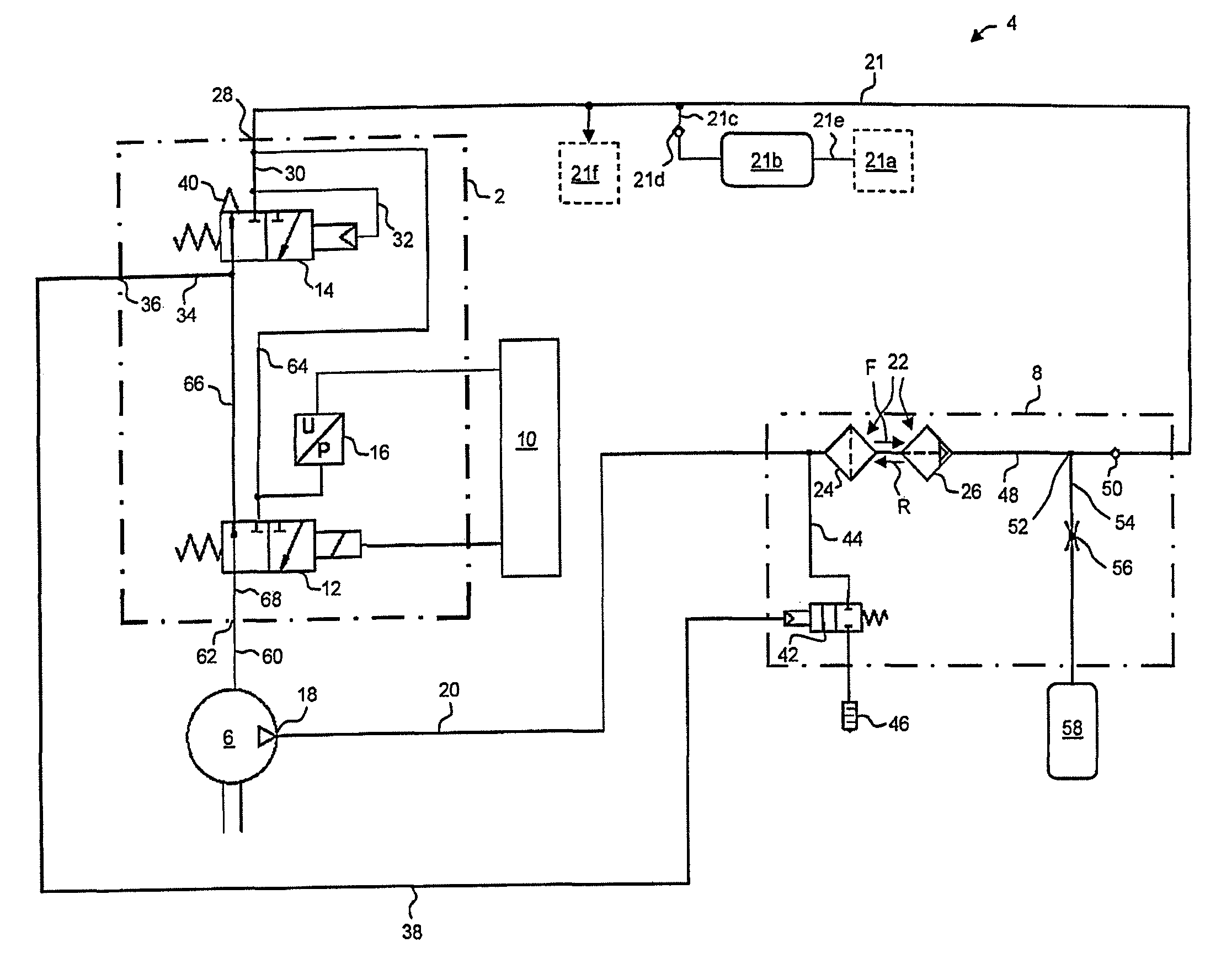

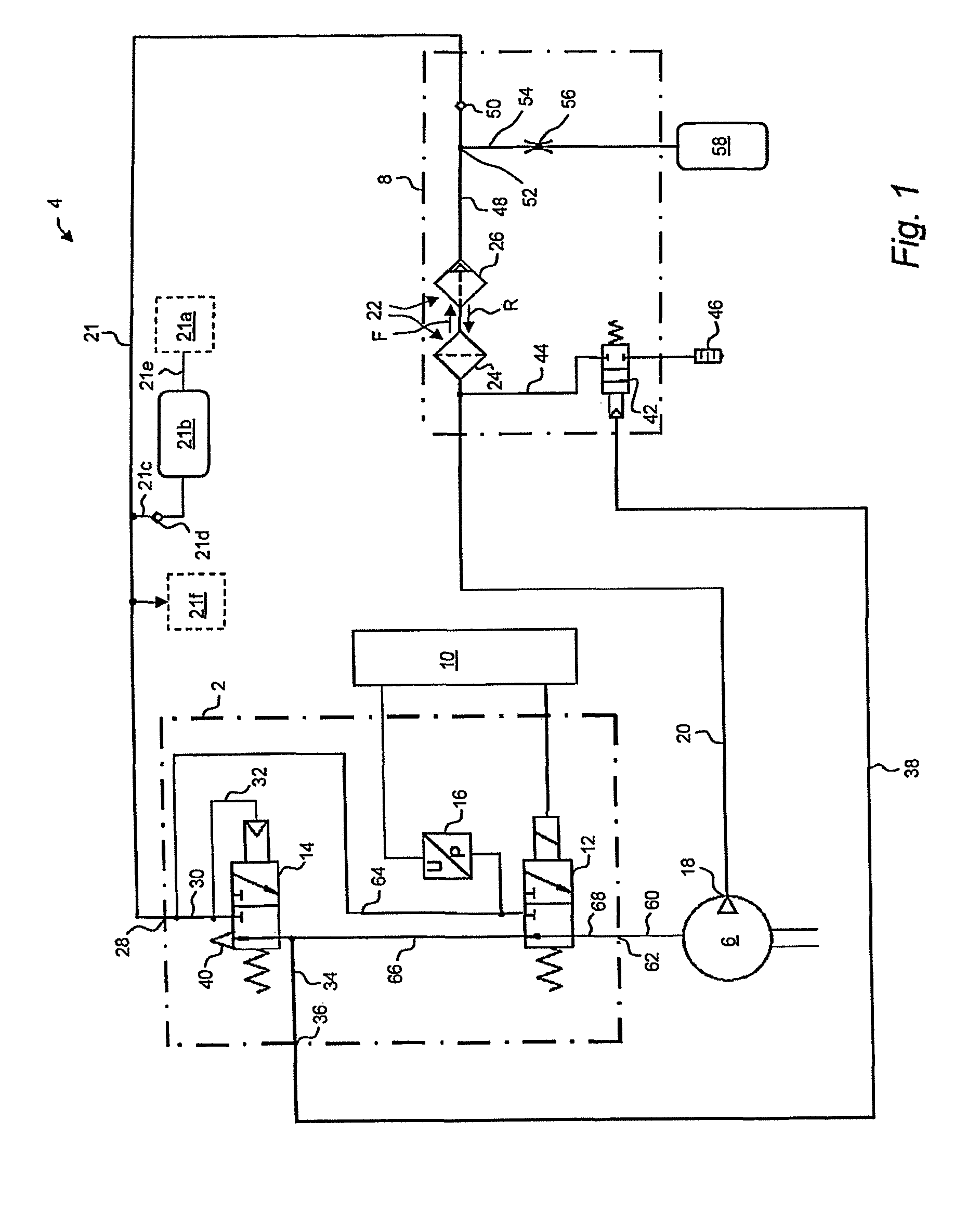

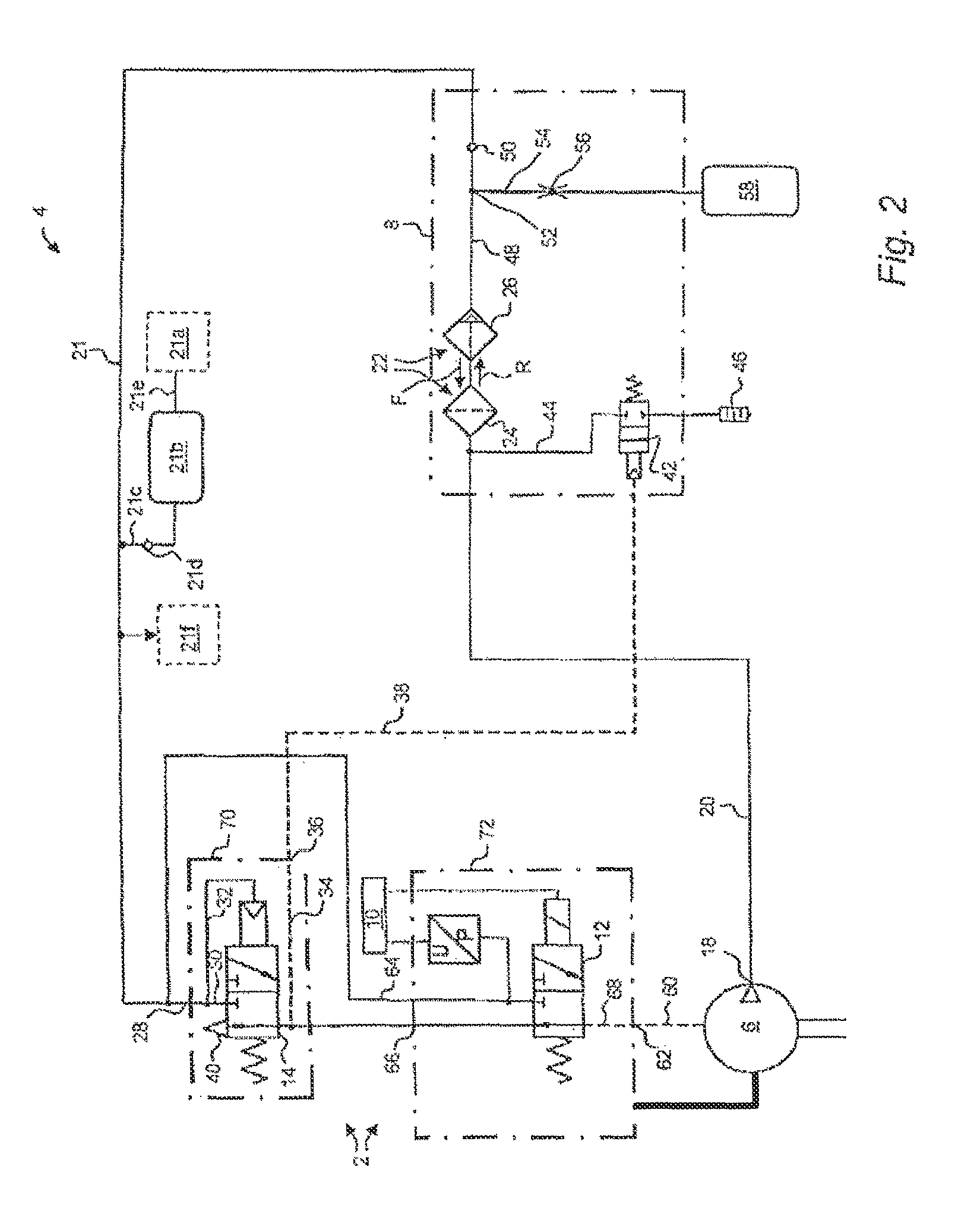

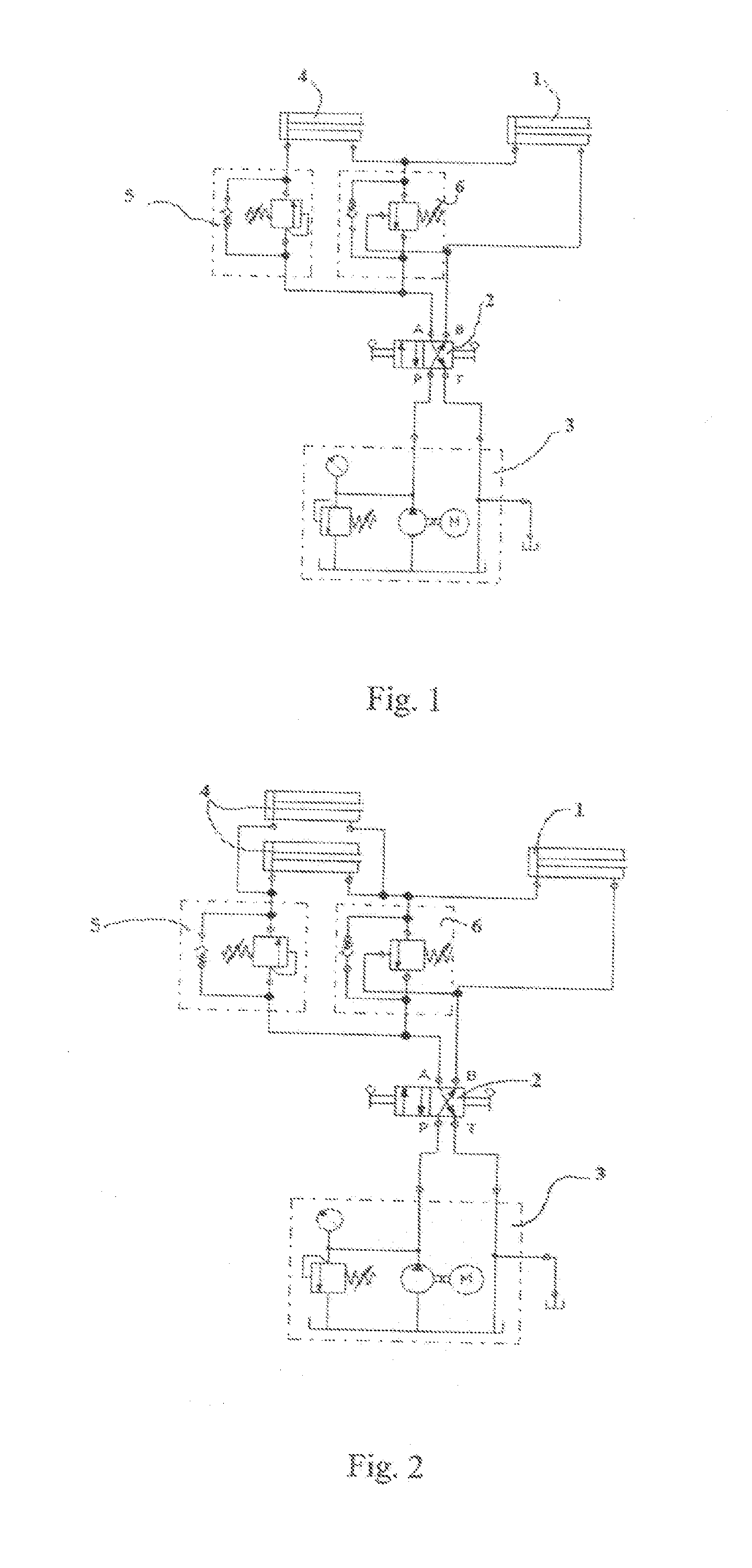

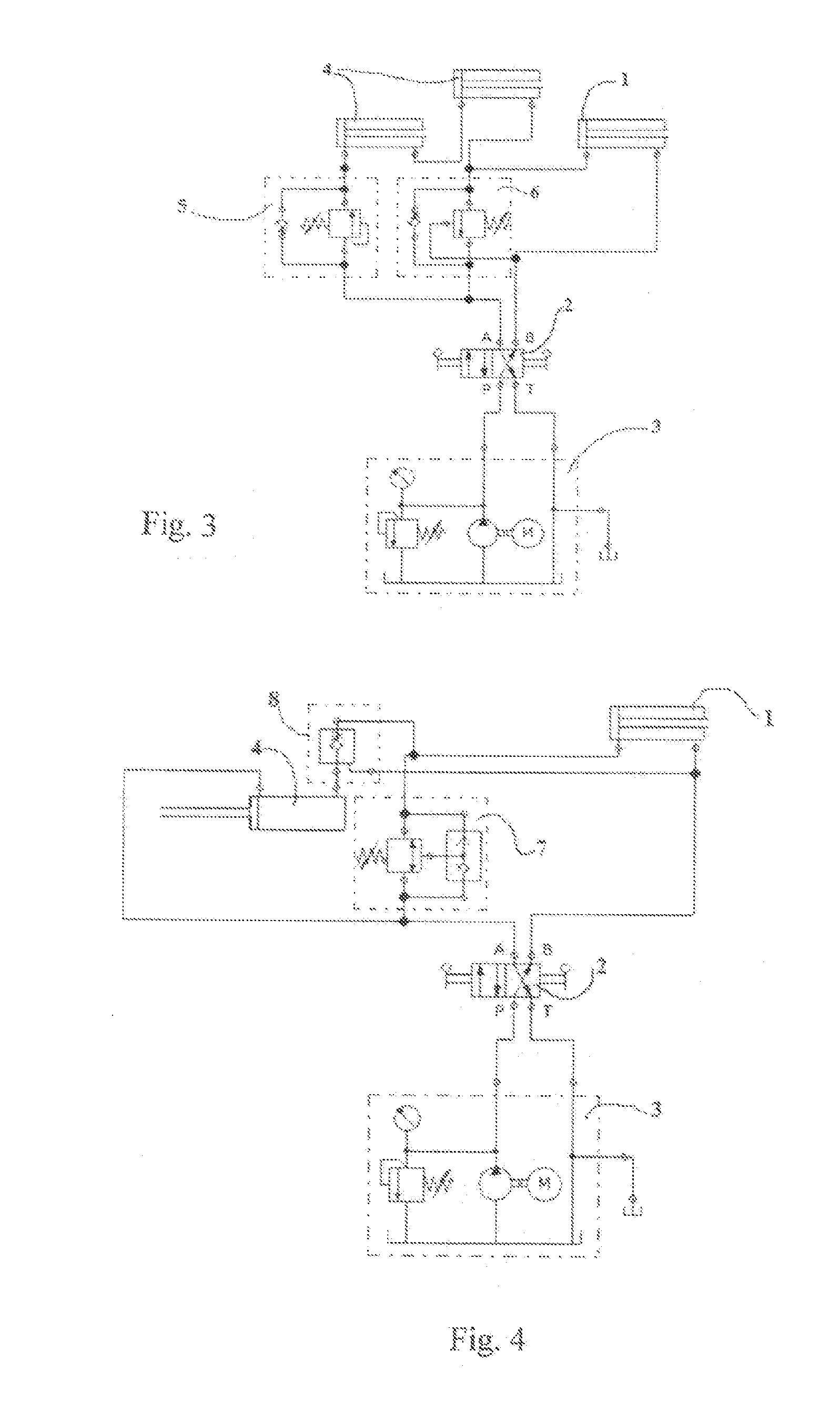

Flow management system for hydraulic work machine

A flow management system capable of providing adjustable hydraulic fluid flow or pressure at a common line to supply bidirectional pumps in electro-hydrostatic actuation systems and conditioning re-circulated hydraulic fluid. The system enables flow sharing between multiple actuation systems and minimization of energy consumption by a power-on-demand approach and / or electrical energy regeneration while eliminating the need for an accumulator. The system has particular application to electro-hydrostatic actuation systems that typically include bi-directional electric motor driven pumps and unbalanced hydraulic actuators connected within closed circuits to provide work output against external loads and reversely recover energy from externally applied loads.

Owner:PARKER INTANGIBLES LLC

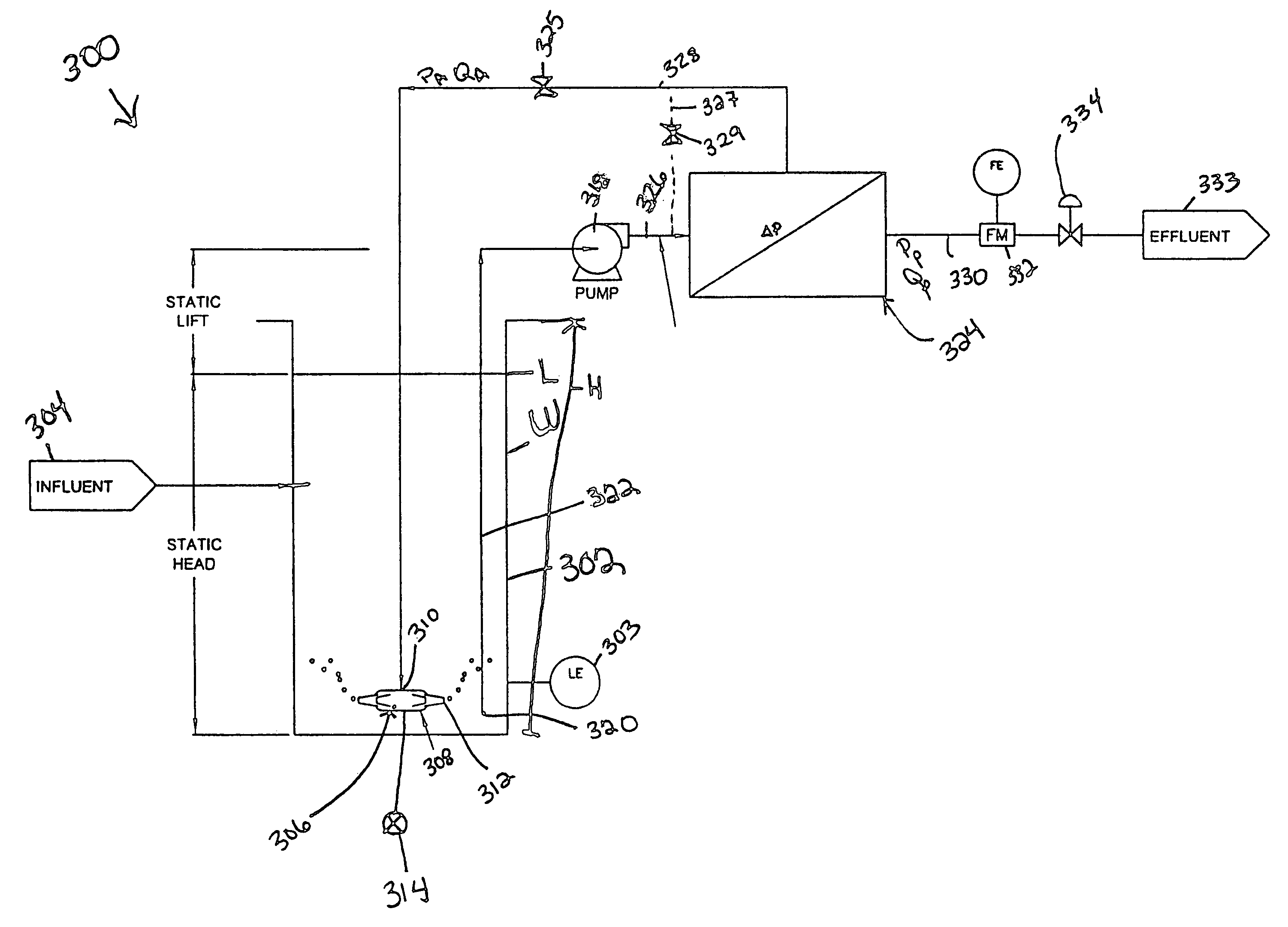

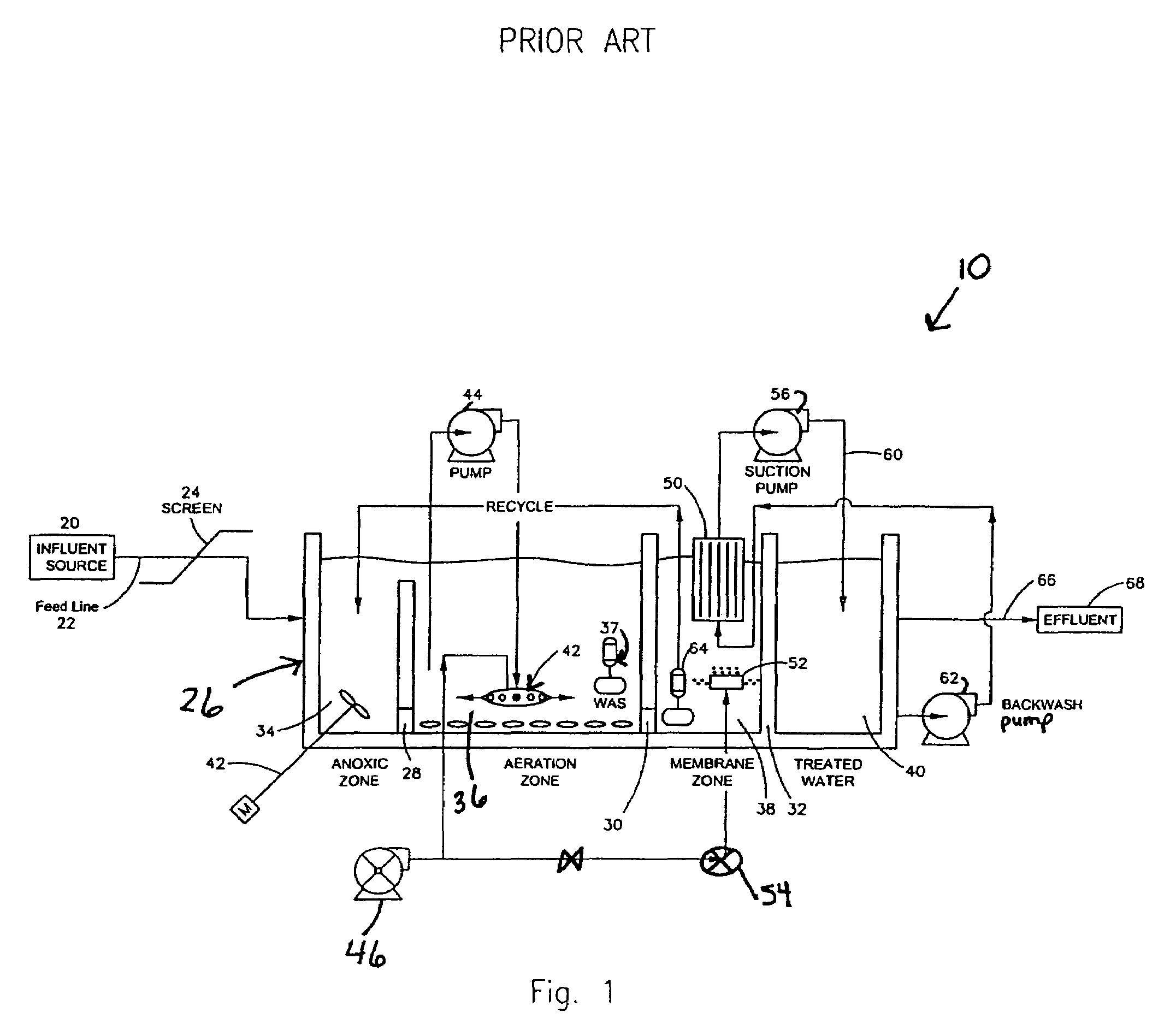

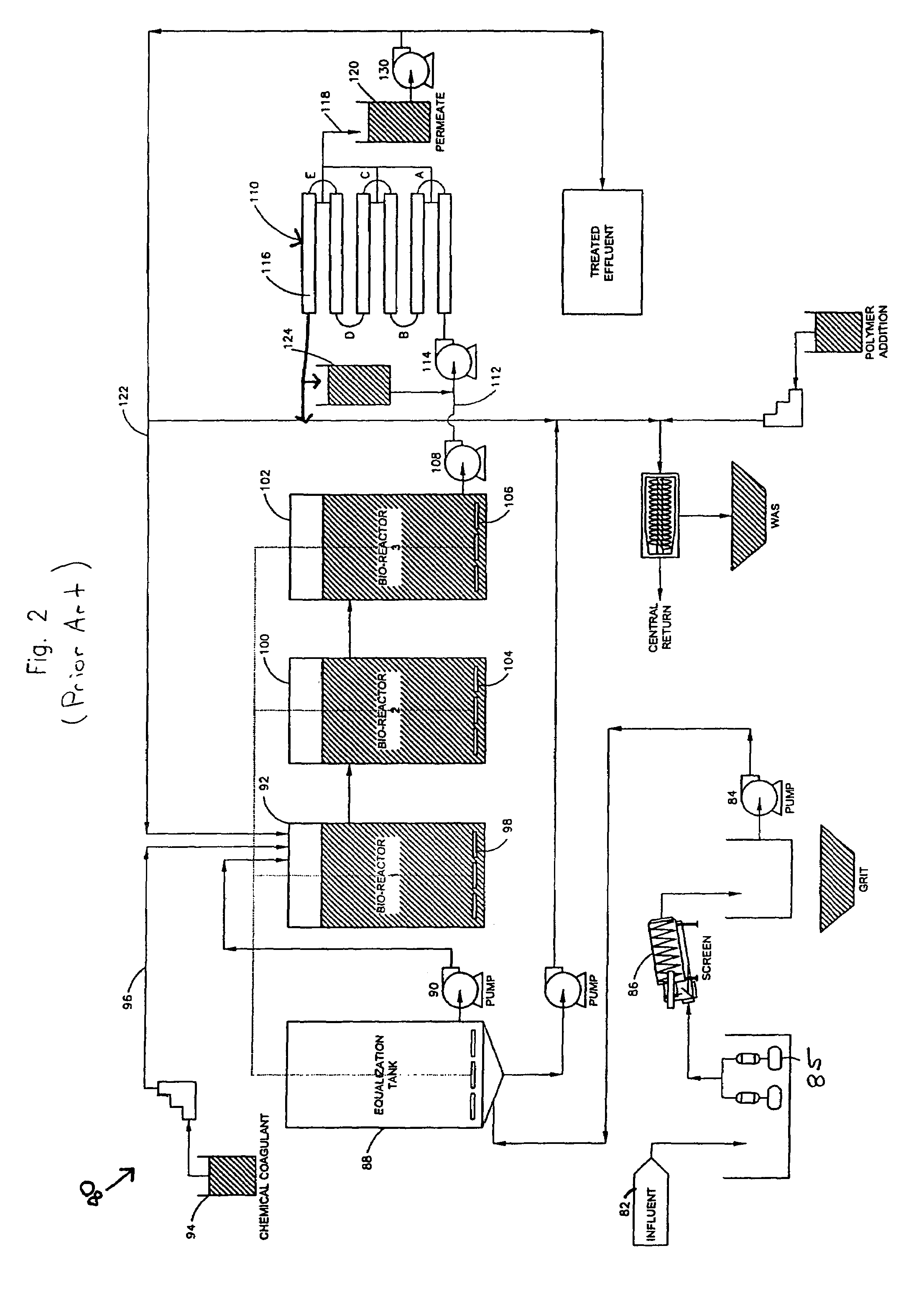

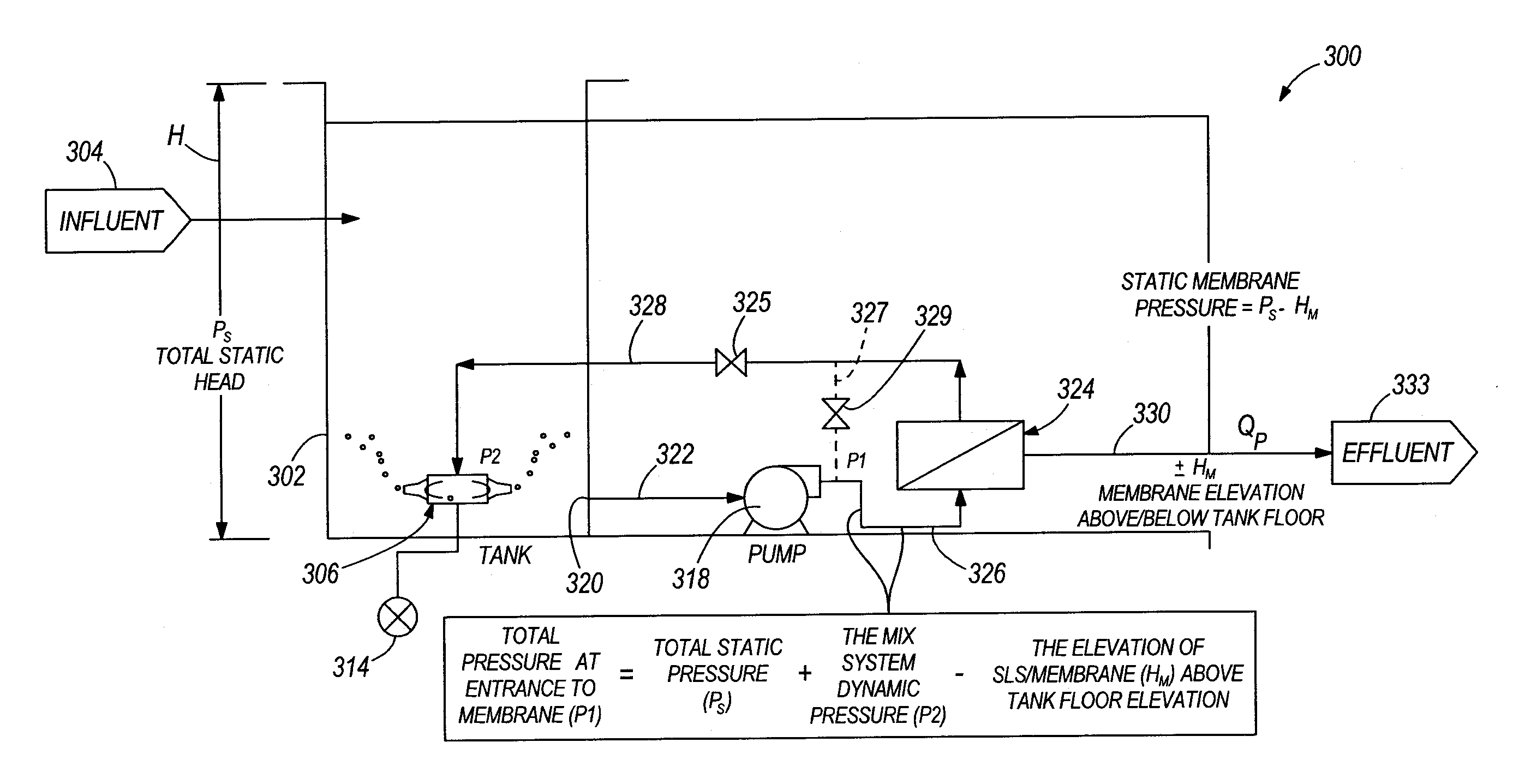

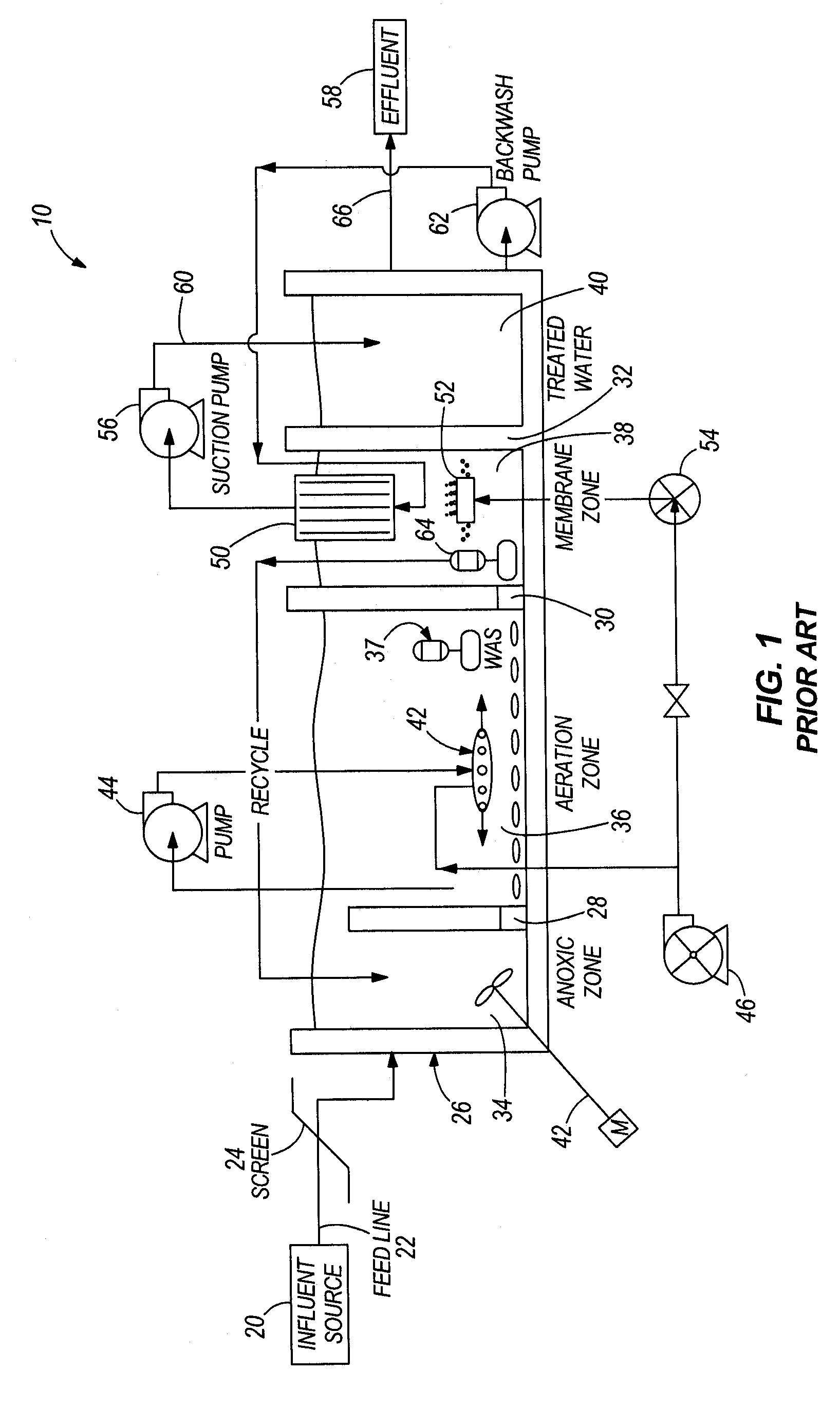

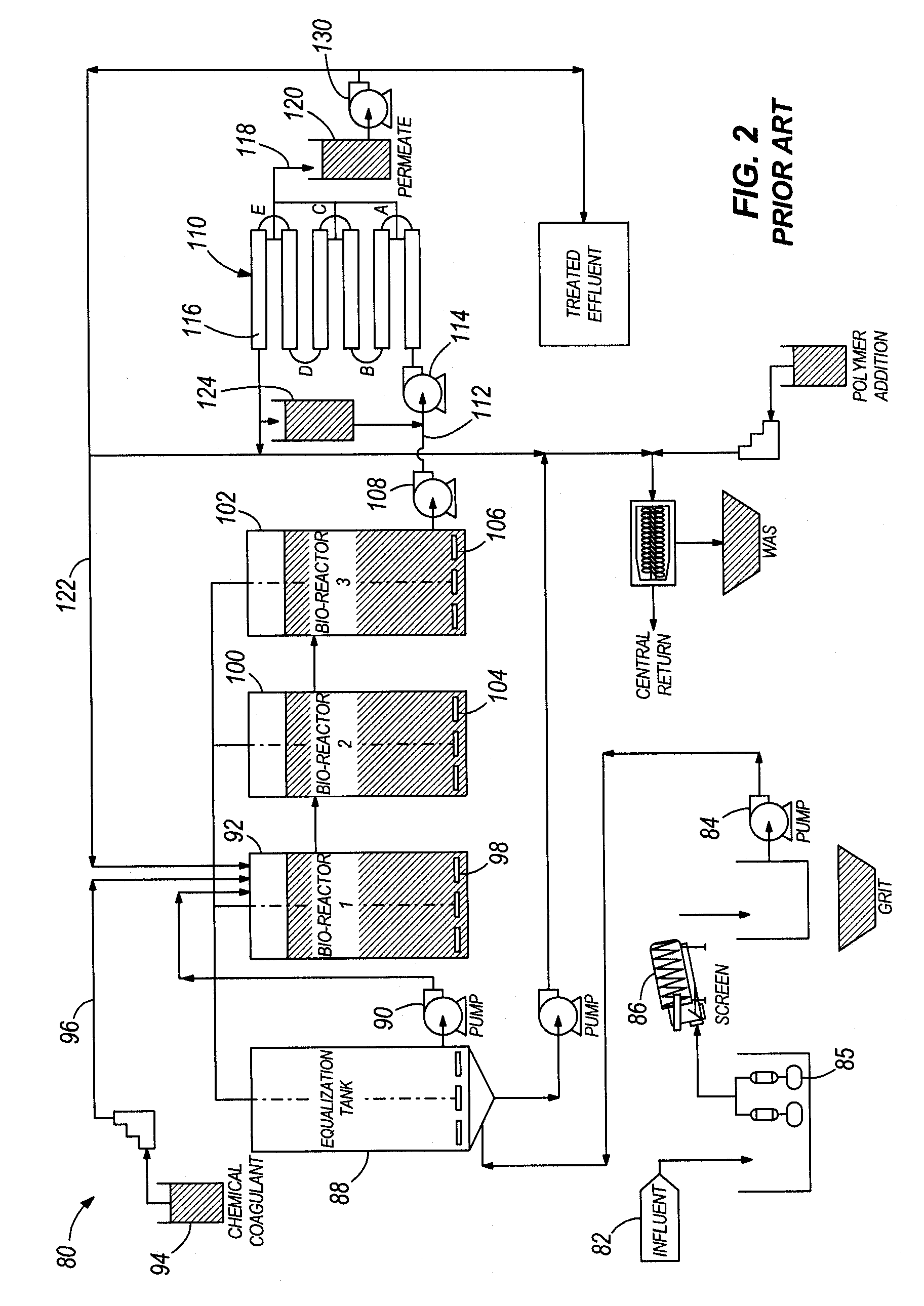

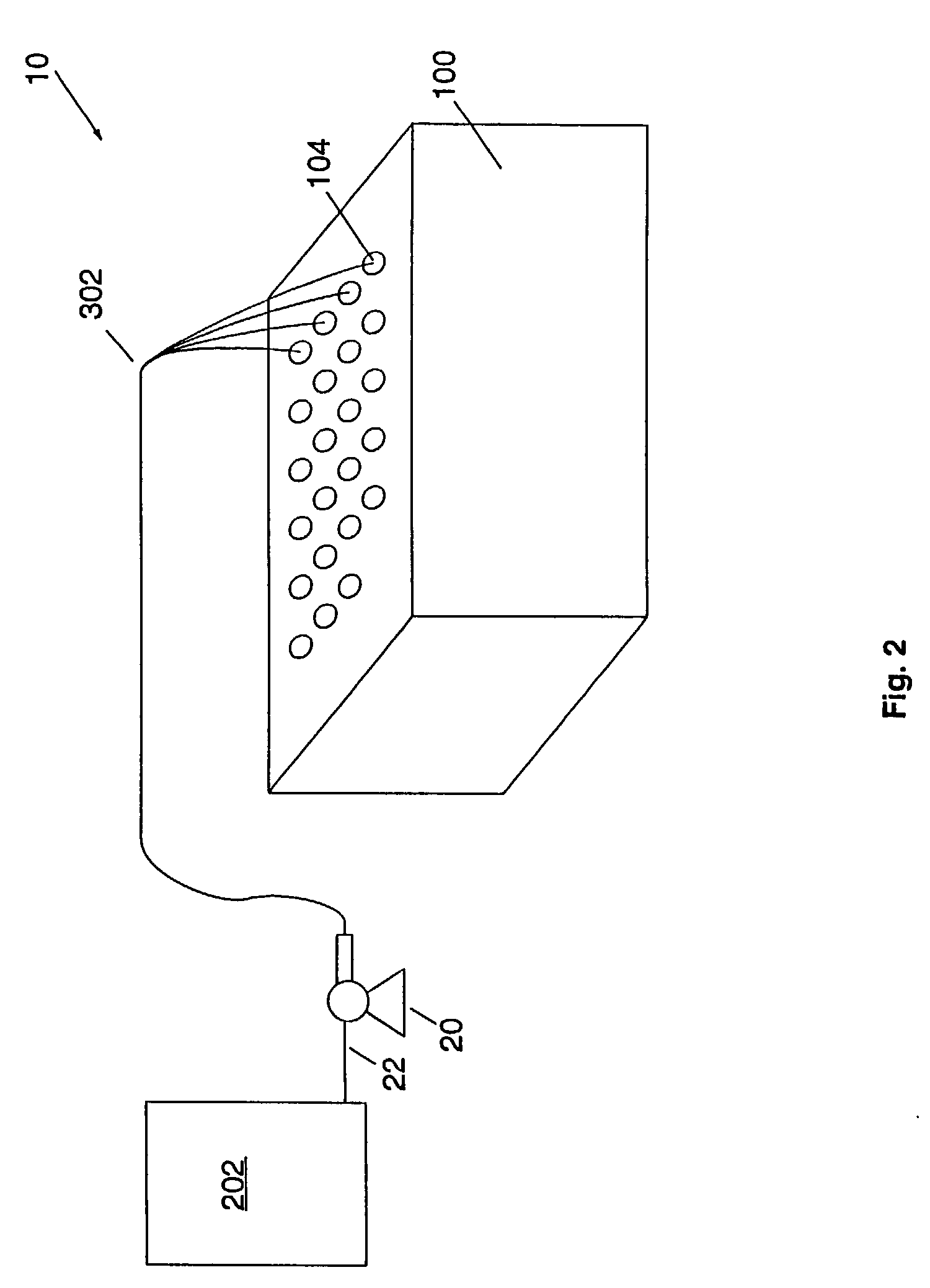

Hydraulically integrated solids/liquid separation system for wastewater treatment

InactiveUS7396453B1Enhance it market appealEliminate redundancyMembranesMixing methodsClosed loopEquipment requirement

A system and method for treating wastewater includes a treatment container for receiving and treating wastewater and a mixing / aeration system disposed in the treatment container. Wastewater is pumped under pressure from the treatment container through a solids / liquid separation system, preferably comprising multiple parallel membrane bioreactors, to separate the solids and liquids in the wastewater. Liquid retentate from the solids / liquid separation system is cycled back to the treatment container via the mixing / aeration system. The closed-loop system and method for solids / liquid separation and aeration / mixing provides for reduced equipment requirements and energy usage during operation.

Owner:PROCORP ENTERPRISES

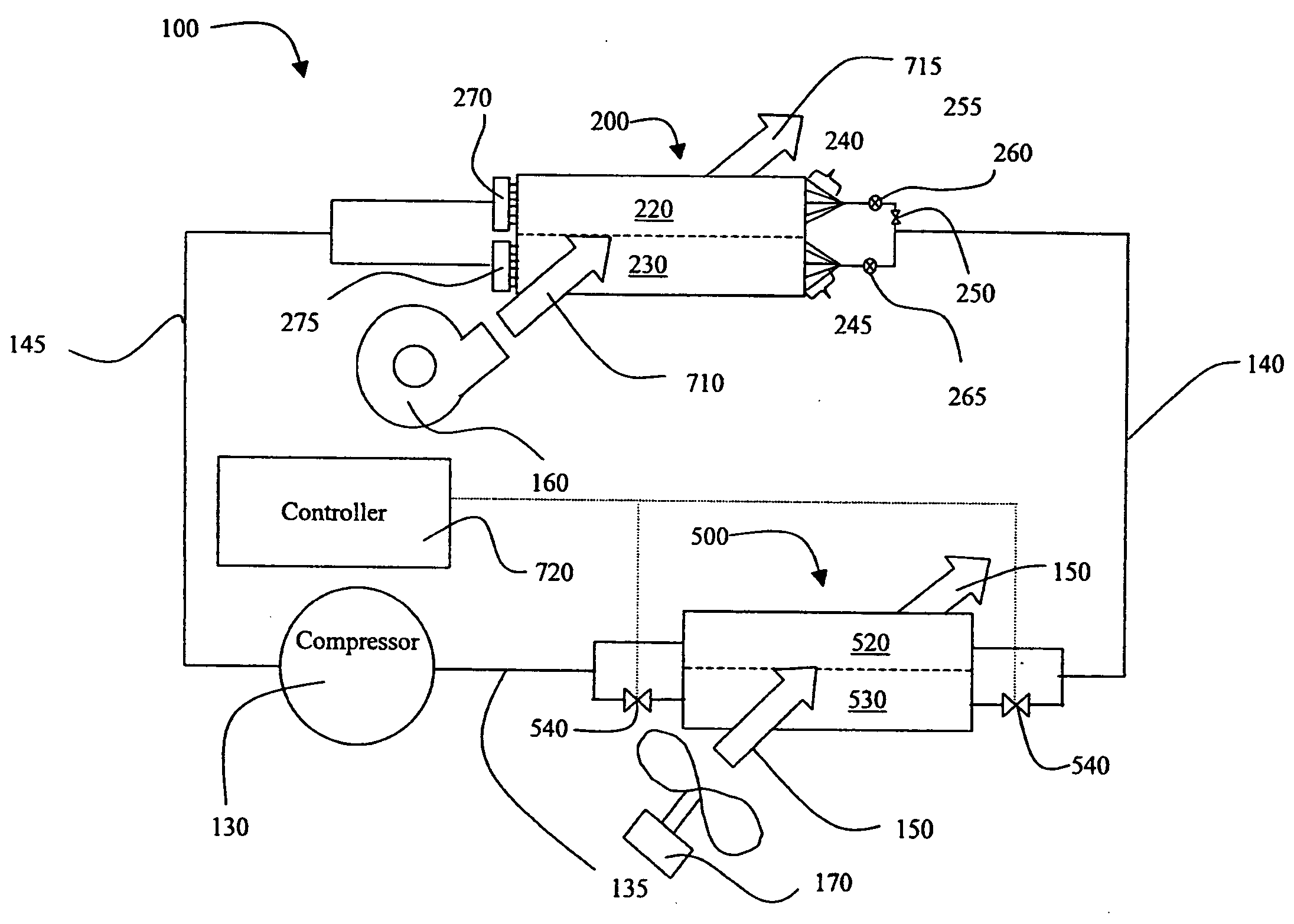

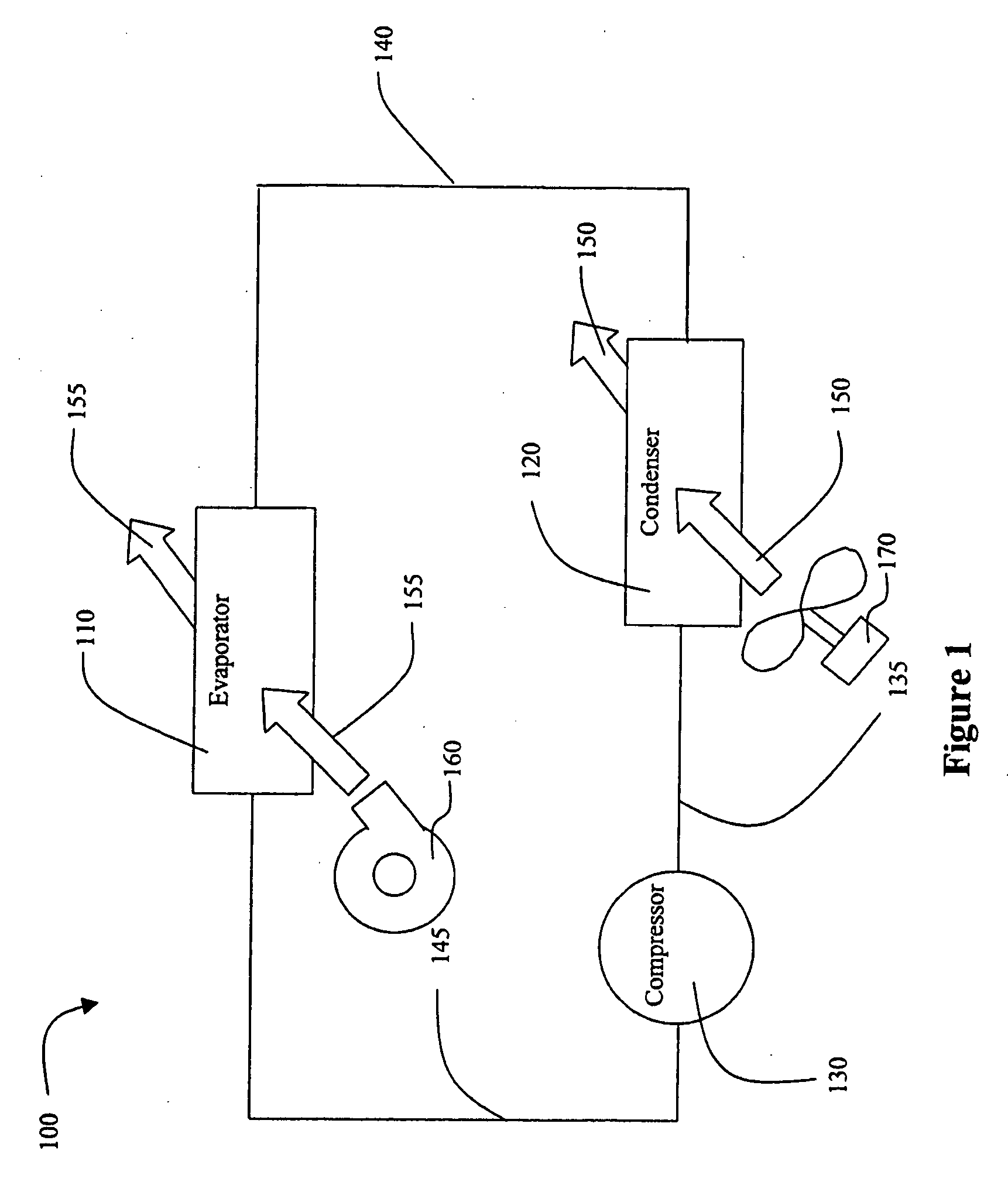

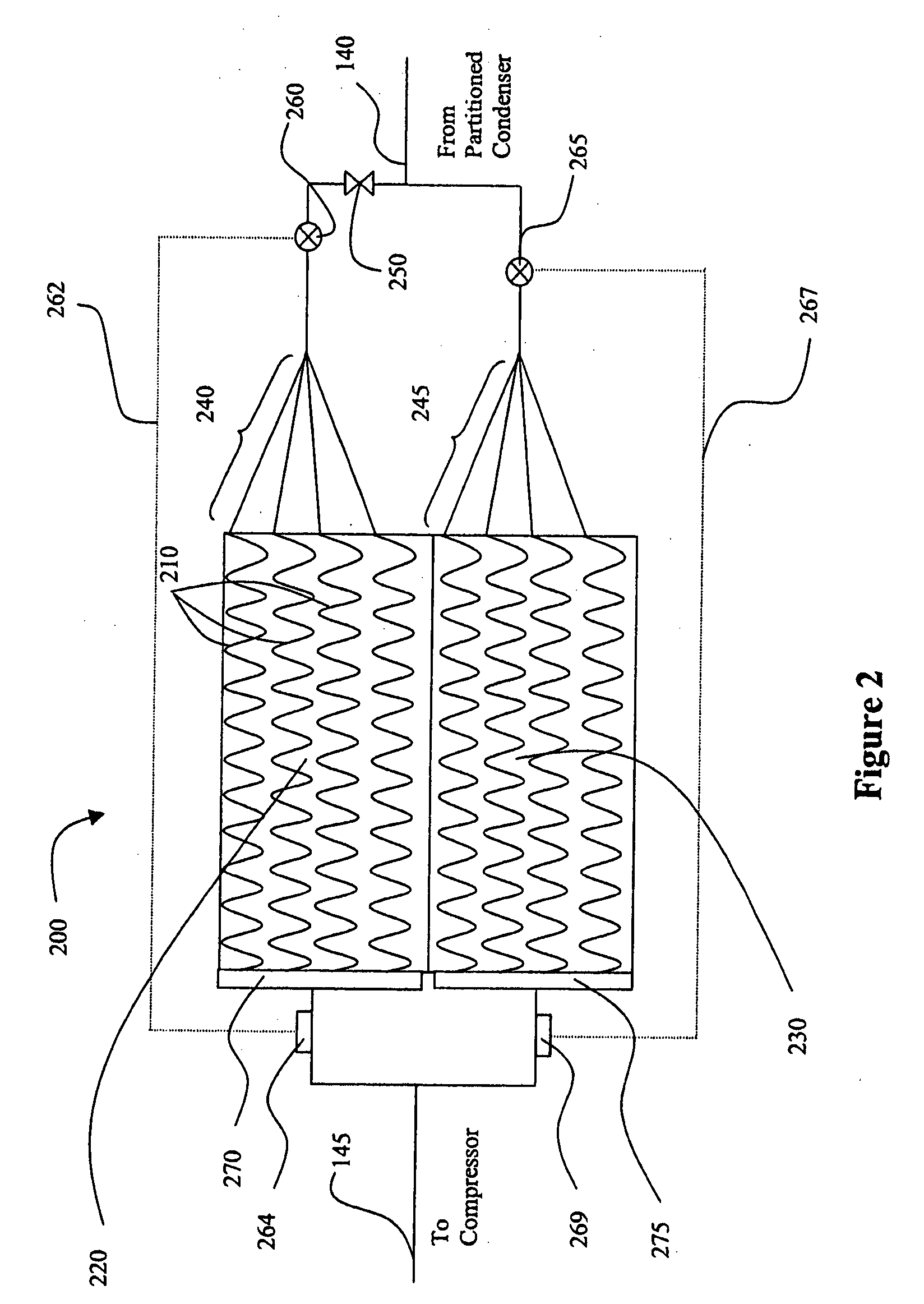

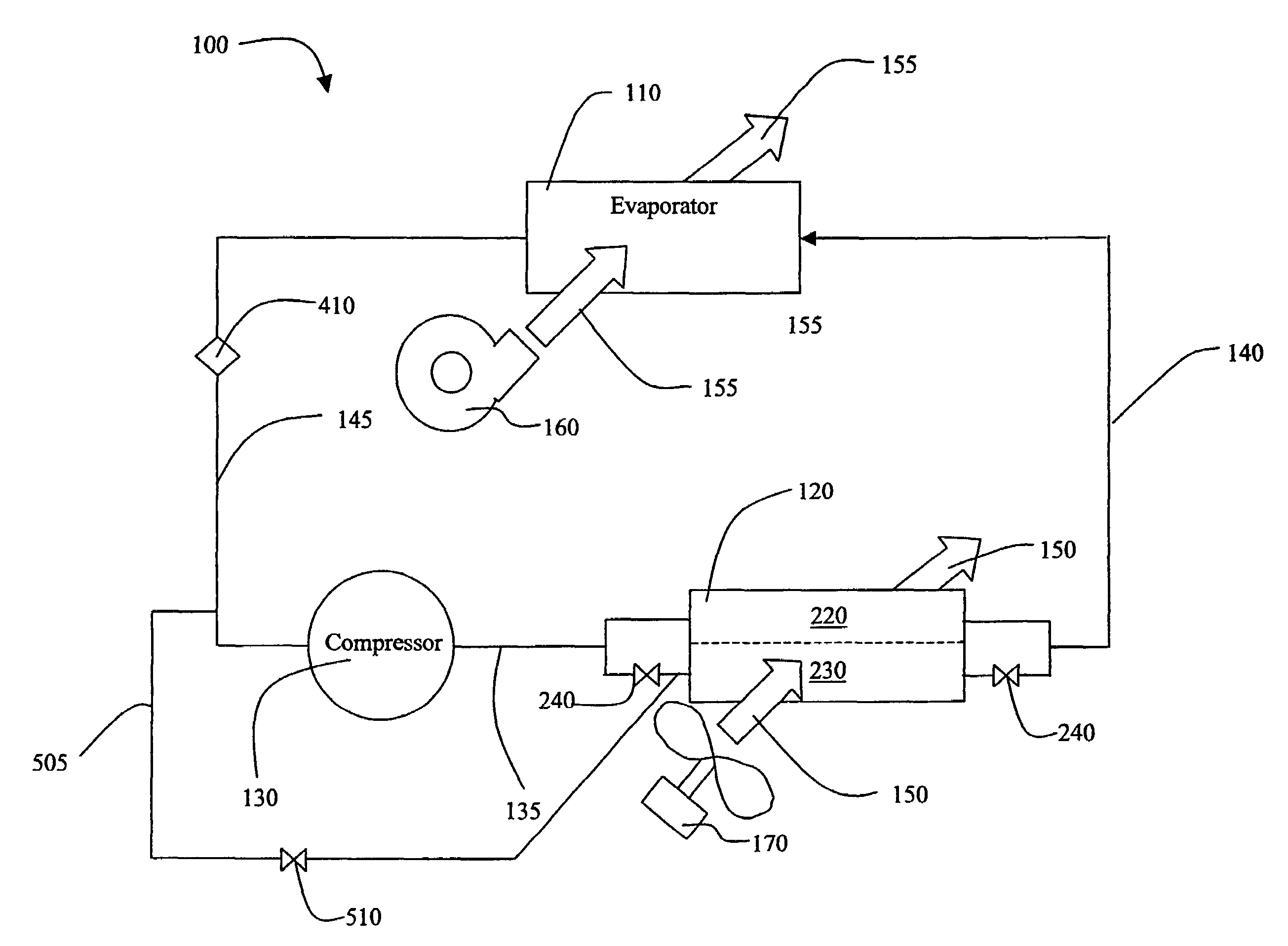

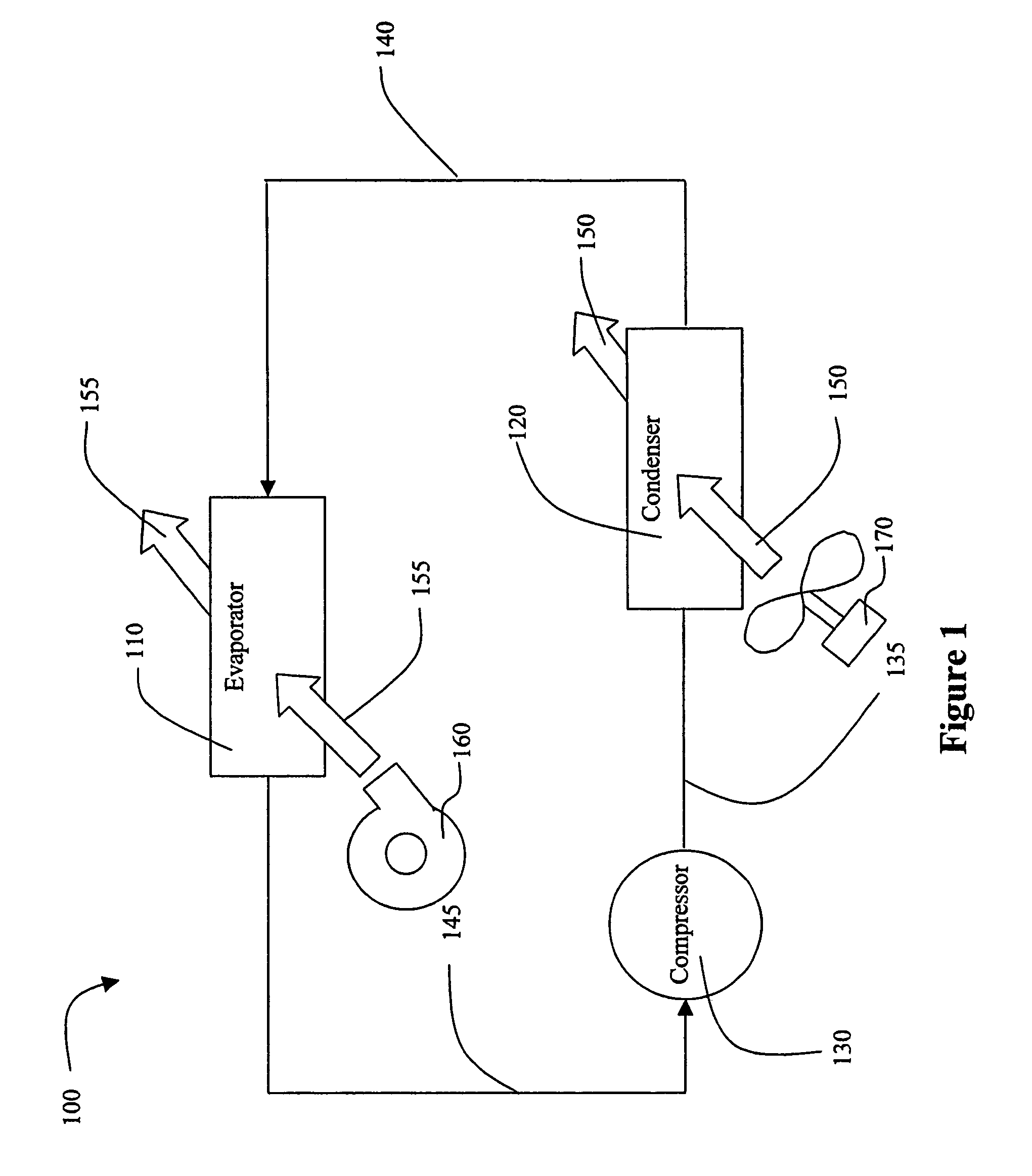

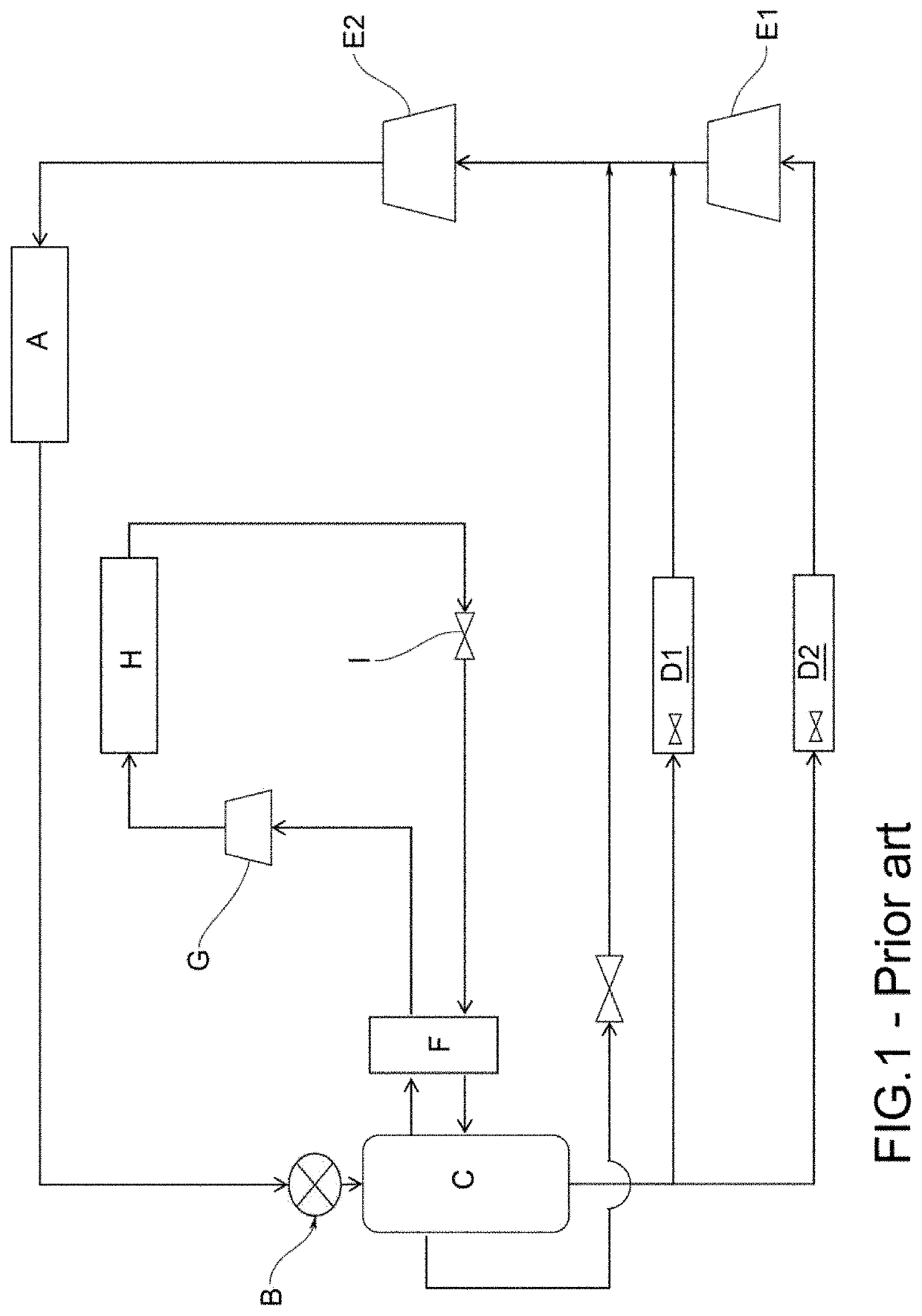

Method and system for dehumidification and refrigerant pressure control

InactiveUS20060288713A1Prevent freezingIncrease system pressureEvaporators/condensersCompression machines with several evaporatorsControl systemSystem pressure

A method for dehumidification and controlling system pressure in a refrigeration system includes providing a refrigeration system having a compressor, a condenser and an evaporator connected in a closed refrigerant loop. Each of the condenser and evaporator have a plurality of refrigerant circuits. A first heat transfer fluid is flowed over the condenser and a second heat transfer fluid is flowed over the evaporator. At least one of the refrigerant circuits of the condenser is isolated to provide a decreased amount of heat transfer area within the condenser and to increase the refrigerant pressure within the refrigeration system when the refrigerant pressure within the refrigeration system is at or below a predetermined pressure. At least one of the refrigerant circuits of the evaporator is isolated to dehumidify and maintain the temperature of the second heat transfer fluid at or above a predetermined temperature when dehumidification is required.

Owner:YORK INT CORP

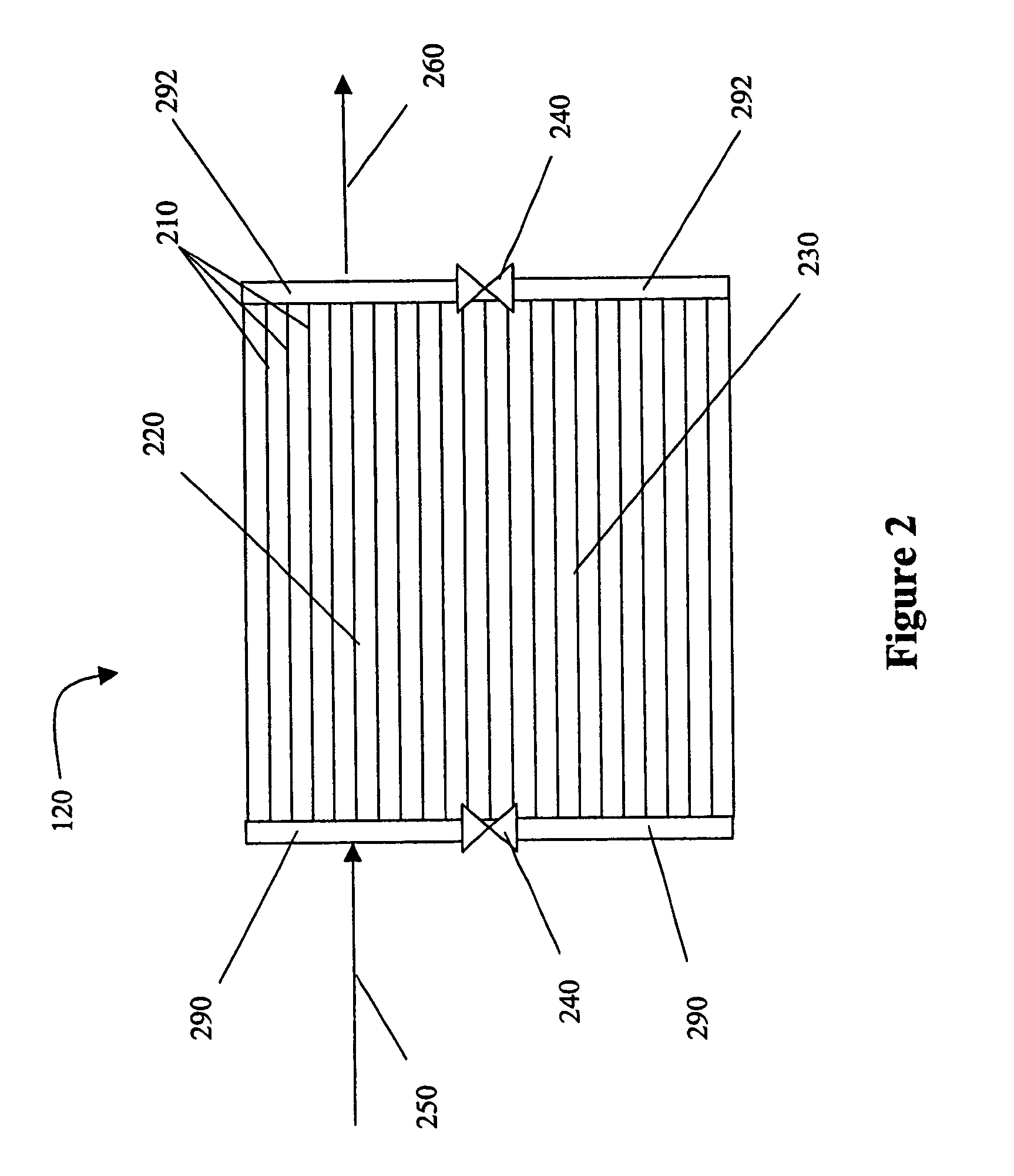

Method for refrigerant pressure control in refrigeration systems

ActiveUS7559207B2Increase system pressureReduce ambient temperatureCompression machines with non-reversible cycleFluid circulation arrangementRefrigerant distributionEngineering

A method and system for controlling refrigerant pressure in an HVAC system. The method includes providing a compressor, a condenser and an evaporator connected in a closed refrigerant loop. The condenser has a header arrangement capable of distributing refrigerant to a plurality of refrigerant circuits within the condenser. The header arrangement also is capable of selectively isolating at least one of the circuits from refrigerant flow. Refrigerant pressure is sensed at a predetermined location in the refrigeration system. At least one of the circuits is isolated when the refrigerant pressure is less than or equal to a predetermined pressure.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

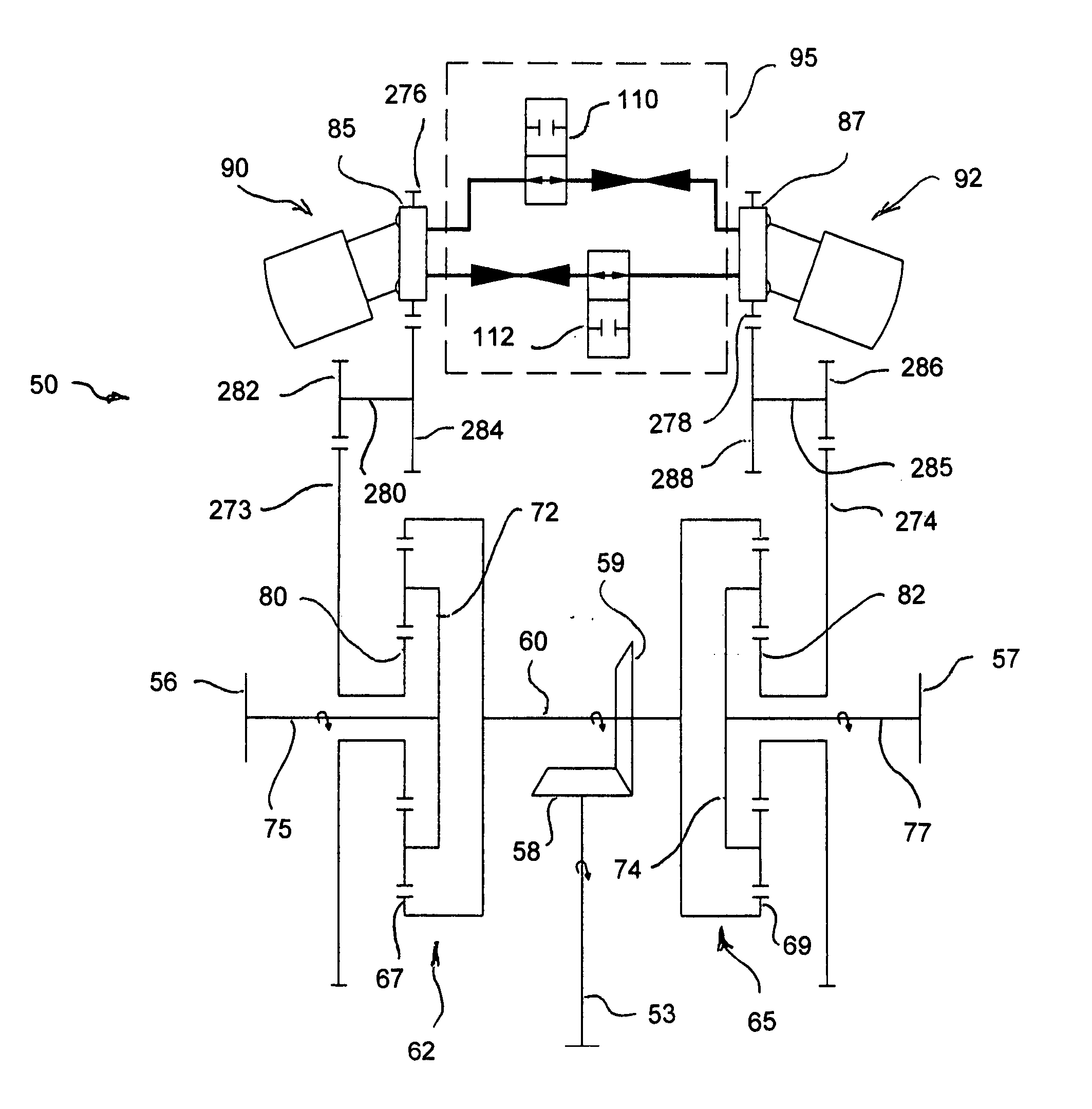

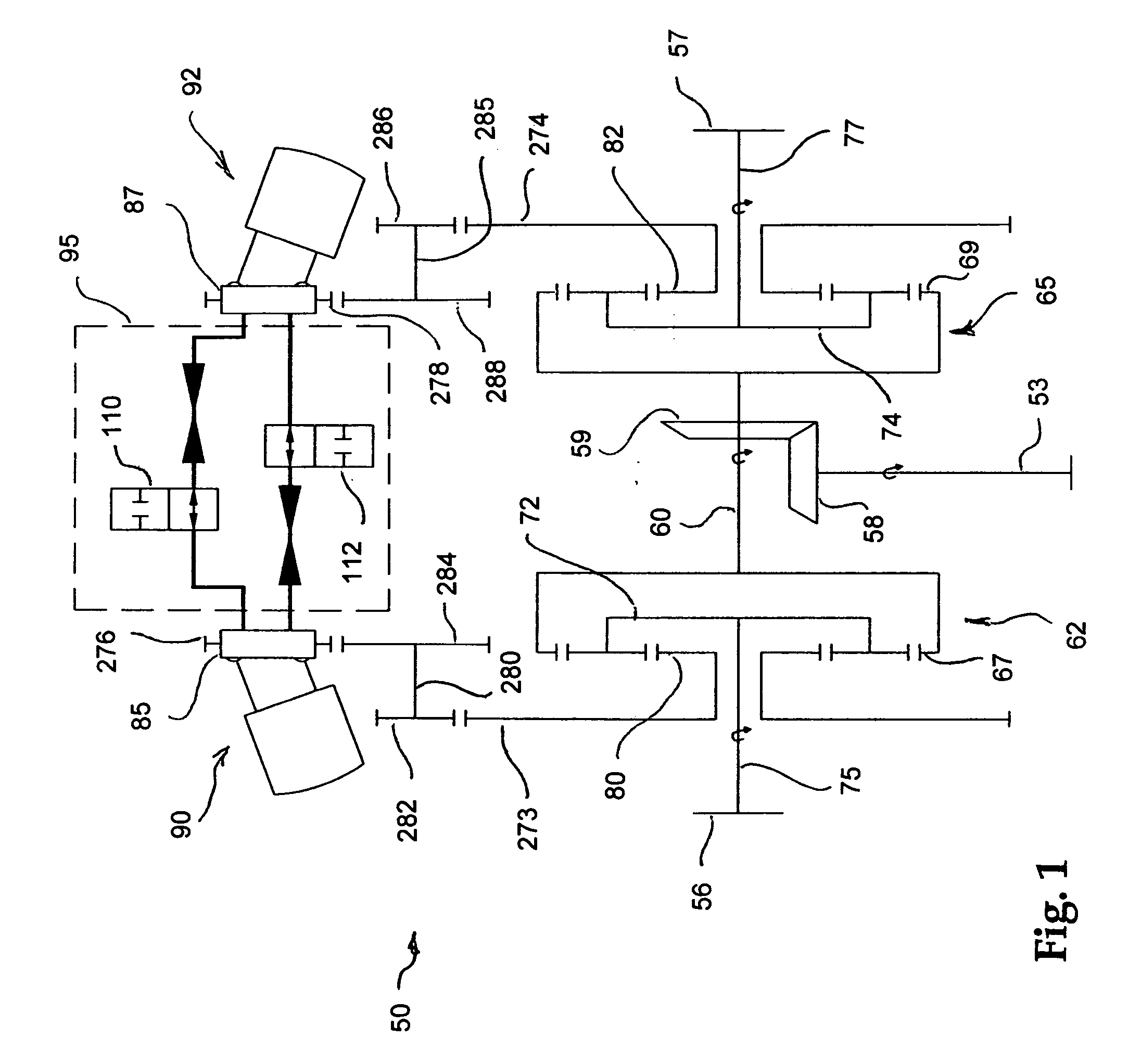

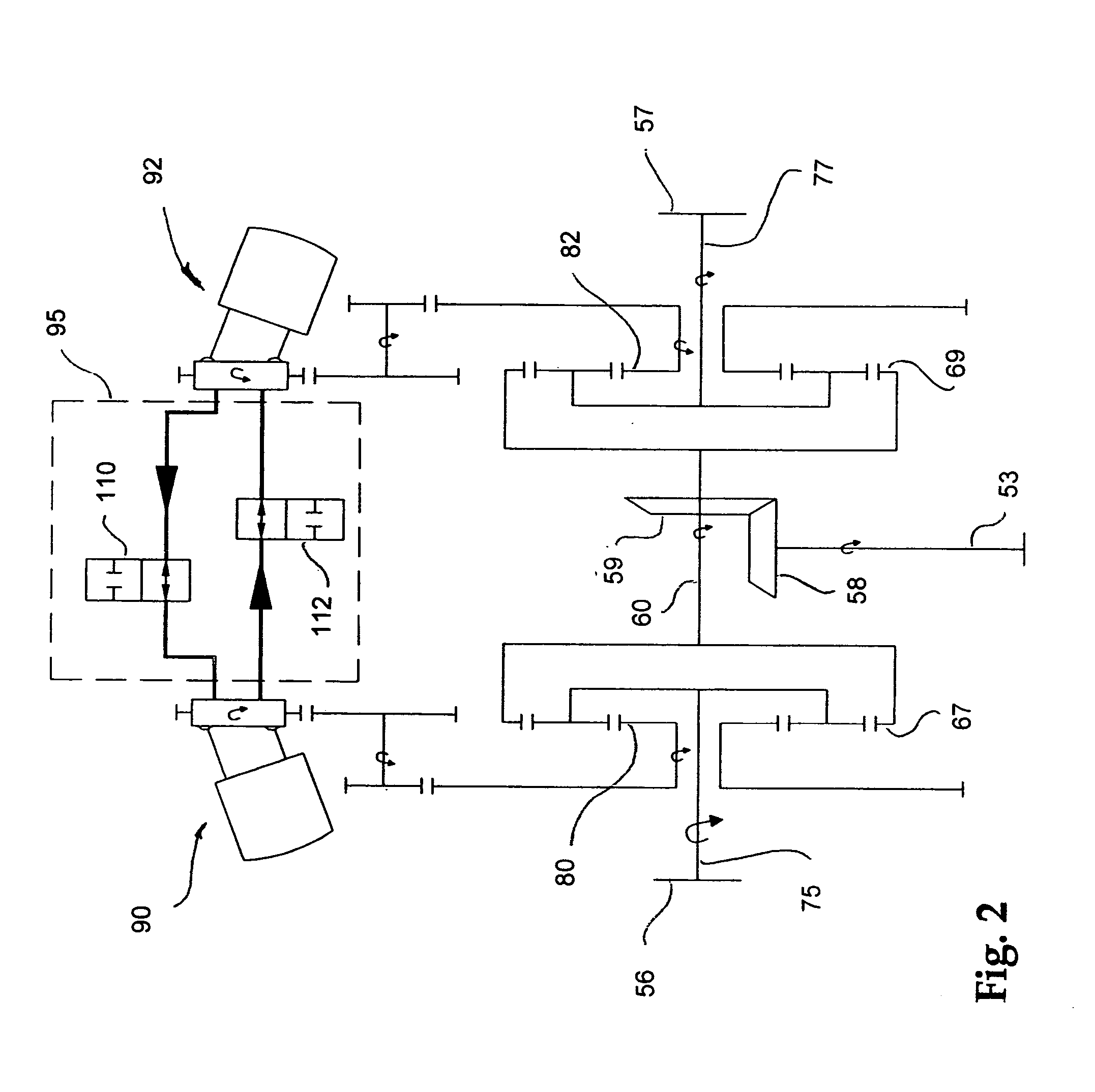

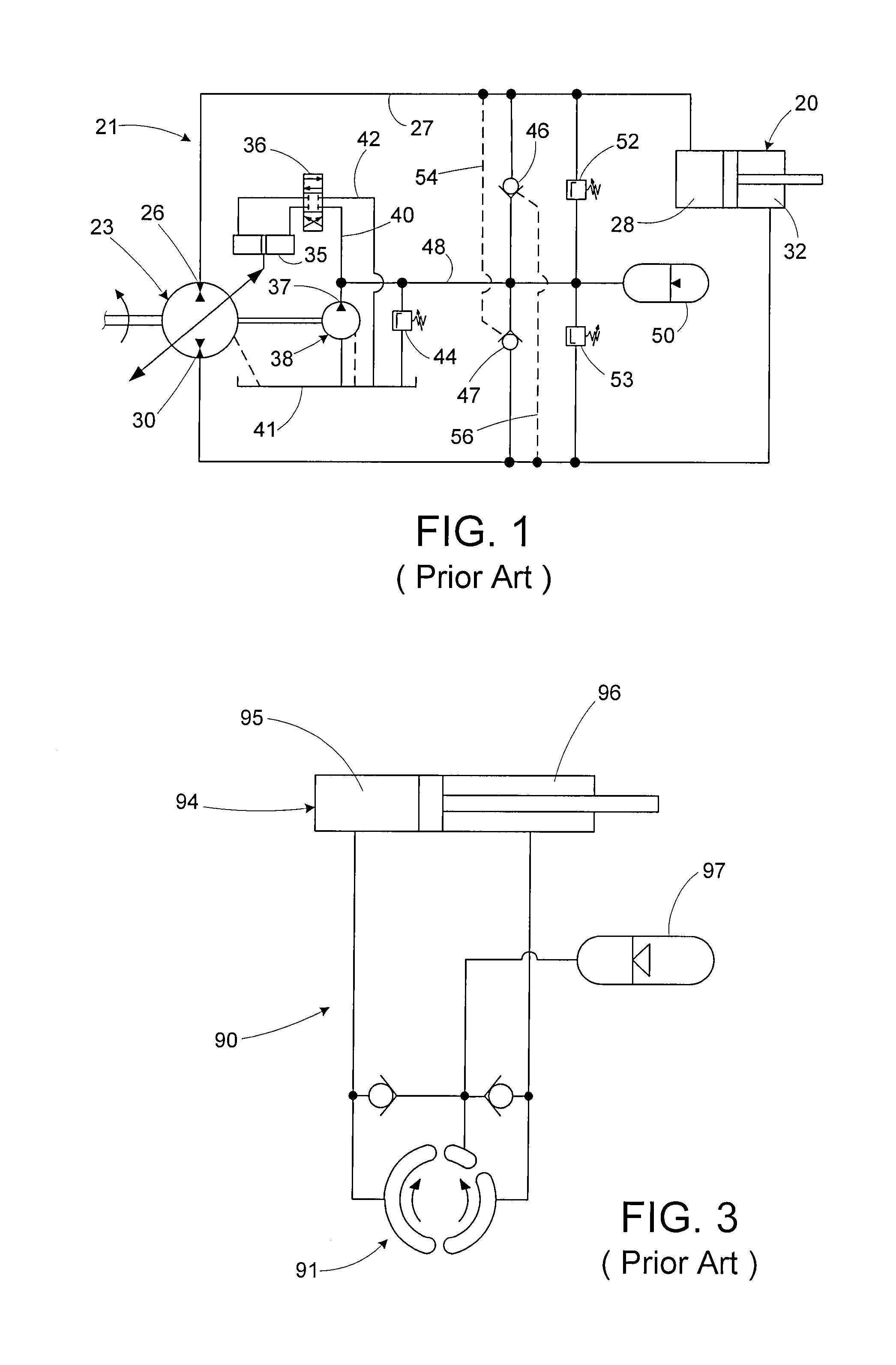

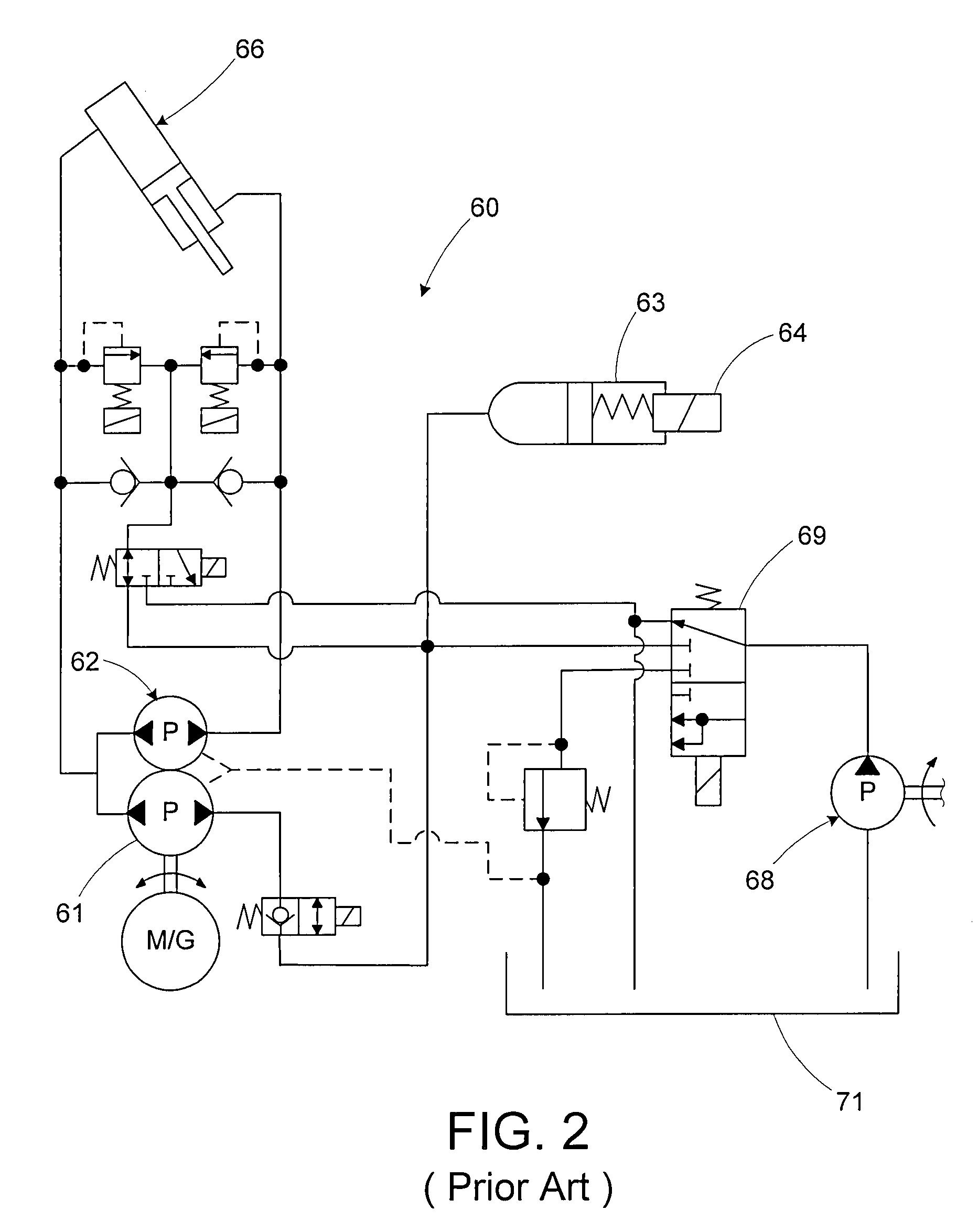

Hydraulic torque vectoring differential

InactiveUS20050070391A1Efficient and durable and fully controllableProlong lifeDifferential gearingsFluid gearingsPower flowDrive shaft

A hydraulic torque vectoring differential includes two epicyclic gear sets and two variable displacement hydrostatic units. Each hydrostatic unit is coupled to a reaction member of one of each of the epicyclic gear sets, each of which also has a first gear element coupled to an input drive shaft for power input from a prime mover of said vehicle and a third gear element coupled to an output shaft operatively driving the wheels of the vehicle. The hydrostatic units are hydraulically coupled so that hydraulic fluid pressurized in one hydrostatic unit drives the other hydrostatic unit, and fluid pressurized in the other hydrostatic unit drives the one hydrostatic unit. A control system controls the displacement of the variable displacement hydrostatic units. Power from the prime mover flows primarily through the epicyclic gear sets to the output shafts, and only differential power is passed through the hydrostatic units, thereby isolating the hydraulic units from the primary power flow and making use of low displacement hydrostatic units possible for said differential power flow through said differential. The desired torque distribution between the two wheels is determined by existing conventional computer controls based on inputs from known traction sensors.

Owner:FOLSOM TECH

Hydraulically integrated solids/liquid separation system and method for wastewater treatment

InactiveUS20090014387A1Eliminate redundancyLess energySemi-permeable membranesMembranesAeration systemClosed loop

Owner:PROCORP ENTERPRISES

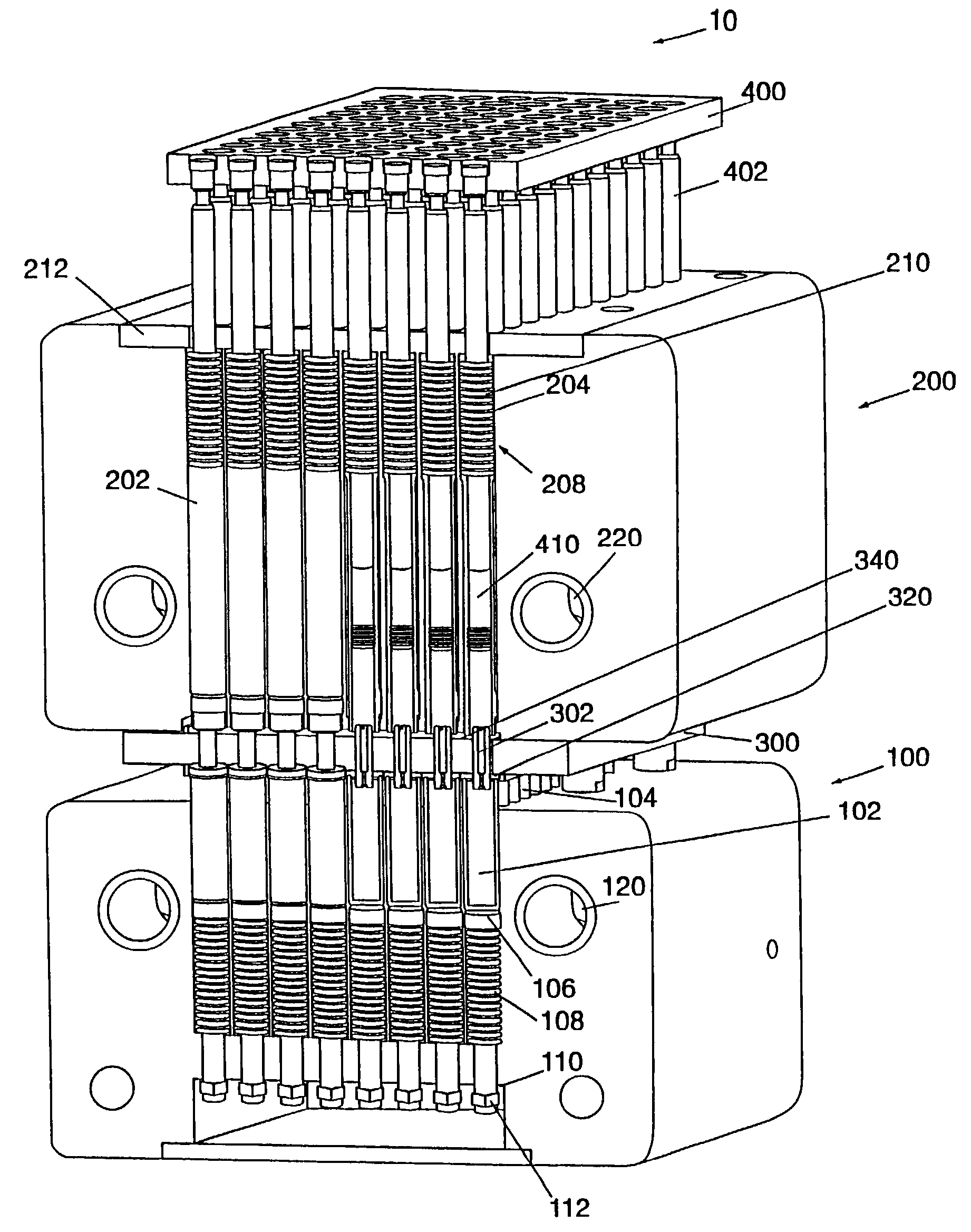

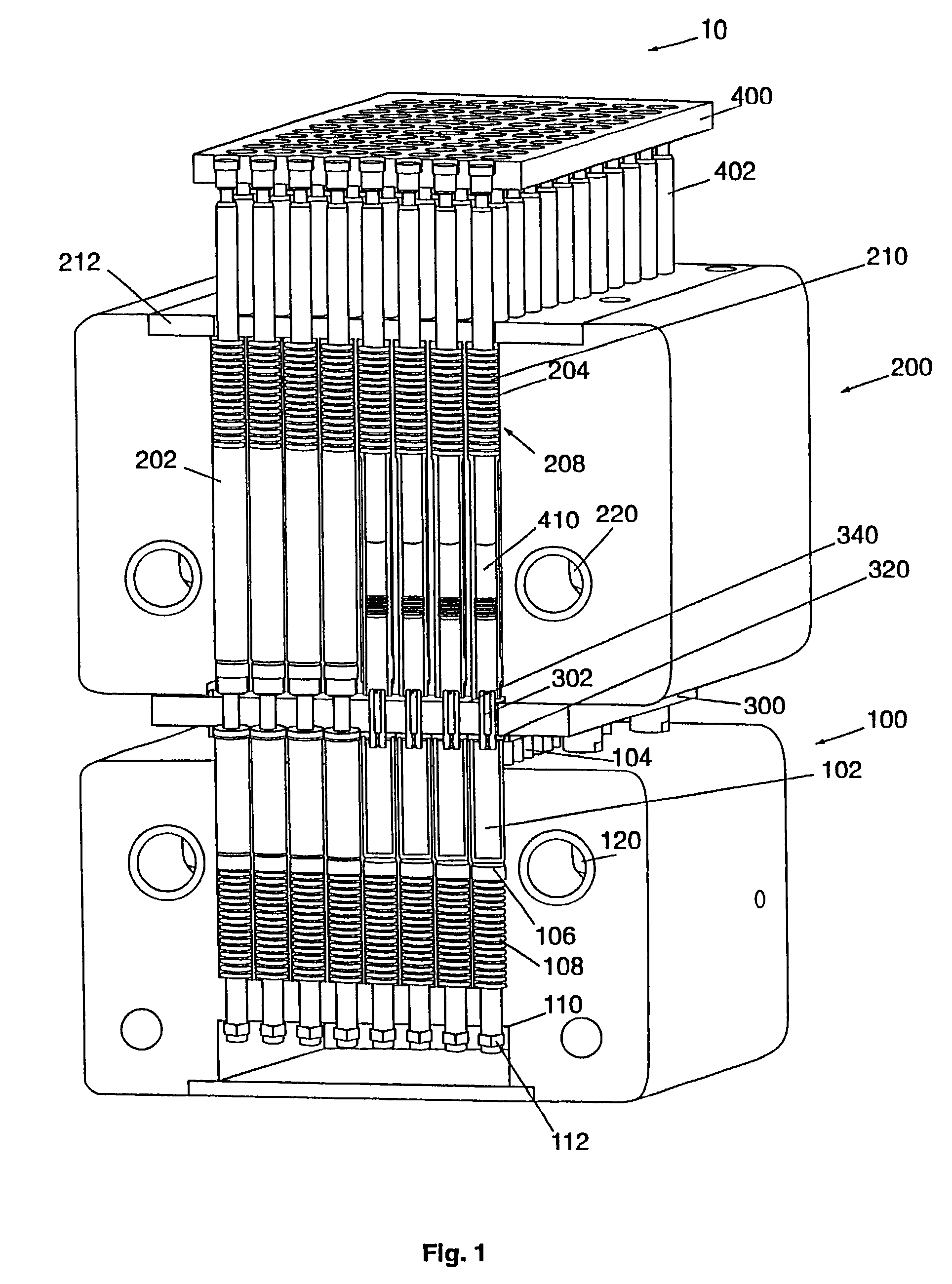

Parallel semi-continuous or continuous reactor system

InactiveUS7115234B2Prevent undesired mixingReduce entrapmentGaseous chemical processesSequential/parallel process reactionsContinuous reactorProcess engineering

A method and apparatus for reacting a plurality of different mixtures in parallel in a semi-batch or continuous mode is provided. Each reaction is contained within a reactor vessel, the reactor vessels combined into a reactor block. Reactant(s) to be added during the reaction are kept in a header barrel, which has a plunger to feed reactant(s) from the header barrel through a transfer line into the reactor vessel. The plunger is moved using a drive system. The header barrels are optionally combined in a header block. The header block is sealed to a plate containing the transfer lines, which in turn is sealed to the reactor block. A latch mechanism is provided for easy sealing of the reactor and header blocks to the plate. The entire apparatus may be placed on a rocker or rotating plate for mixture as the reaction is proceeding.

Owner:FREESLATE

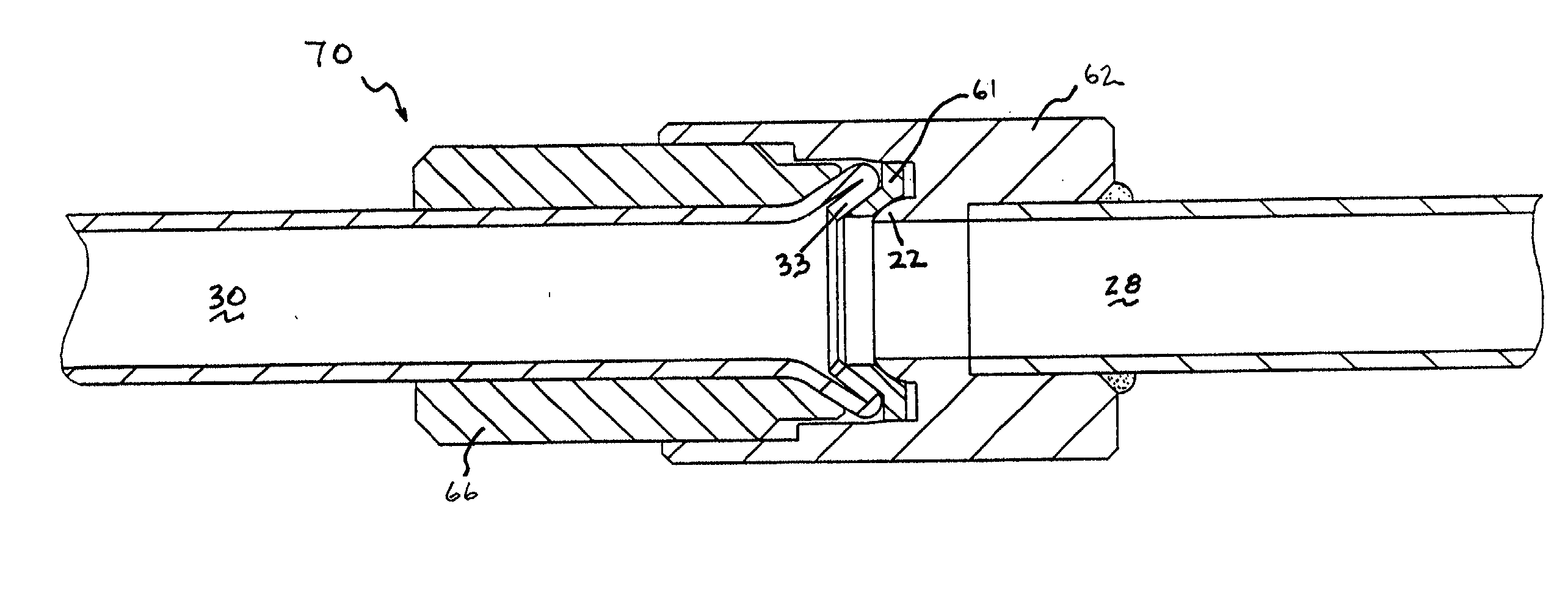

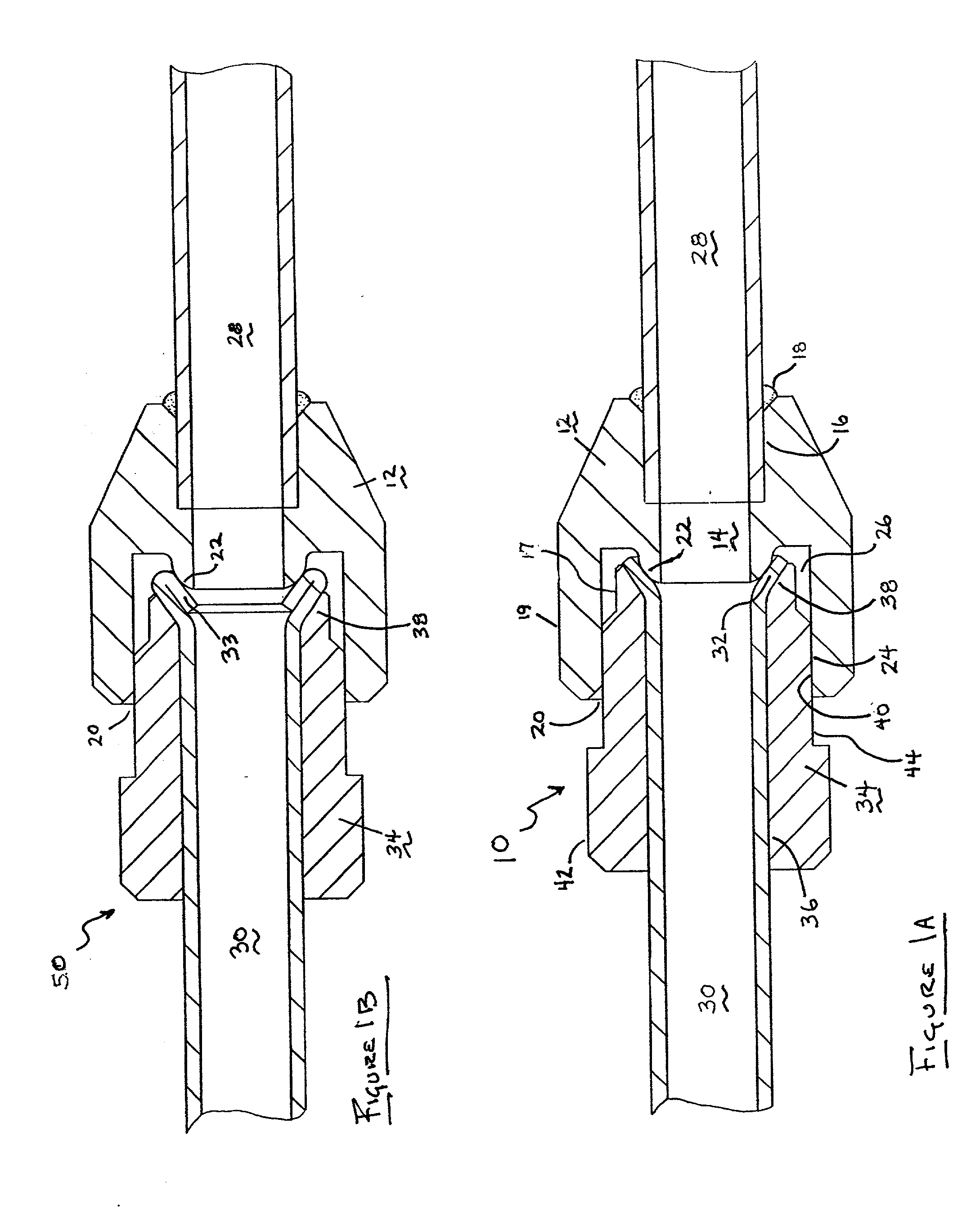

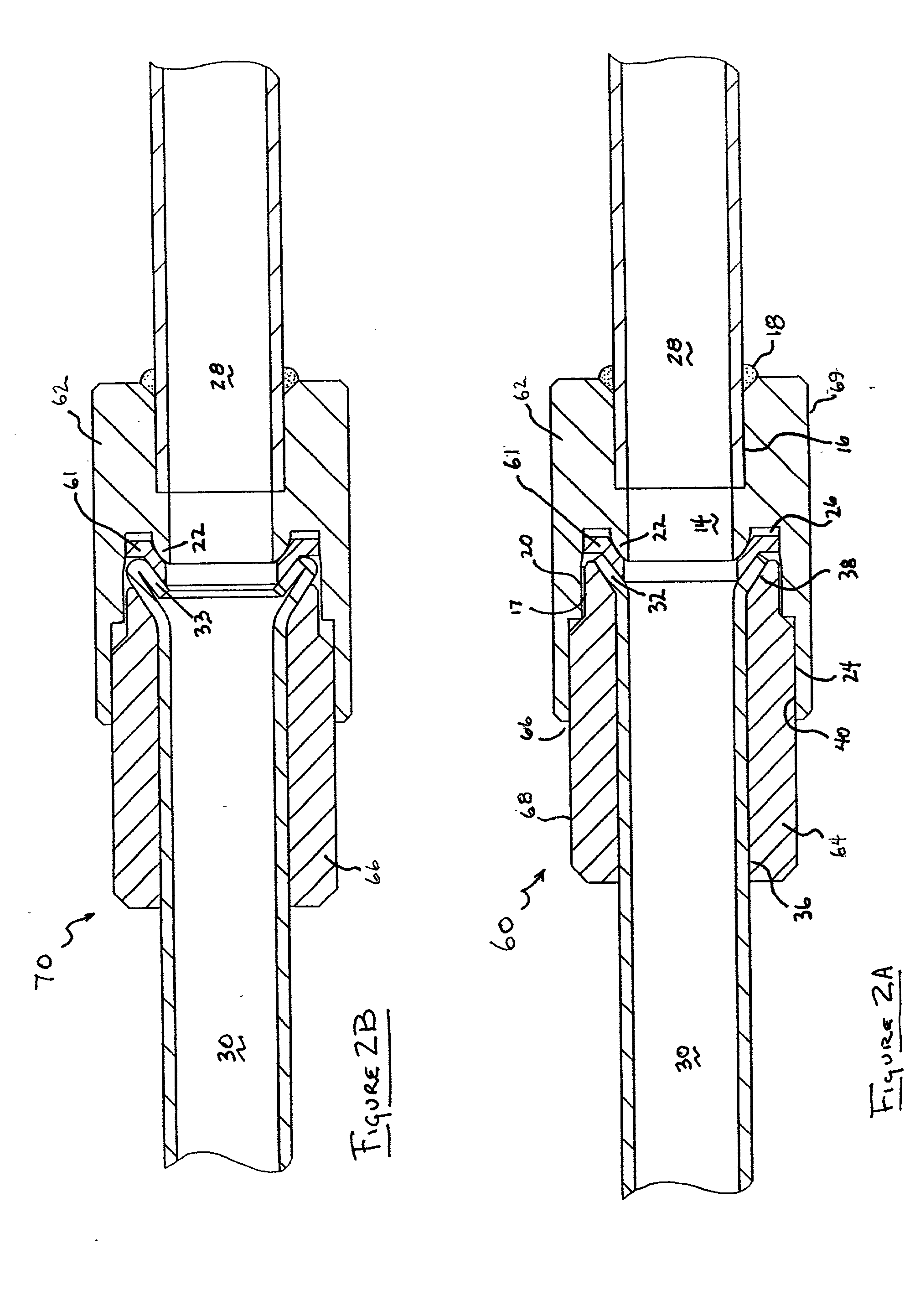

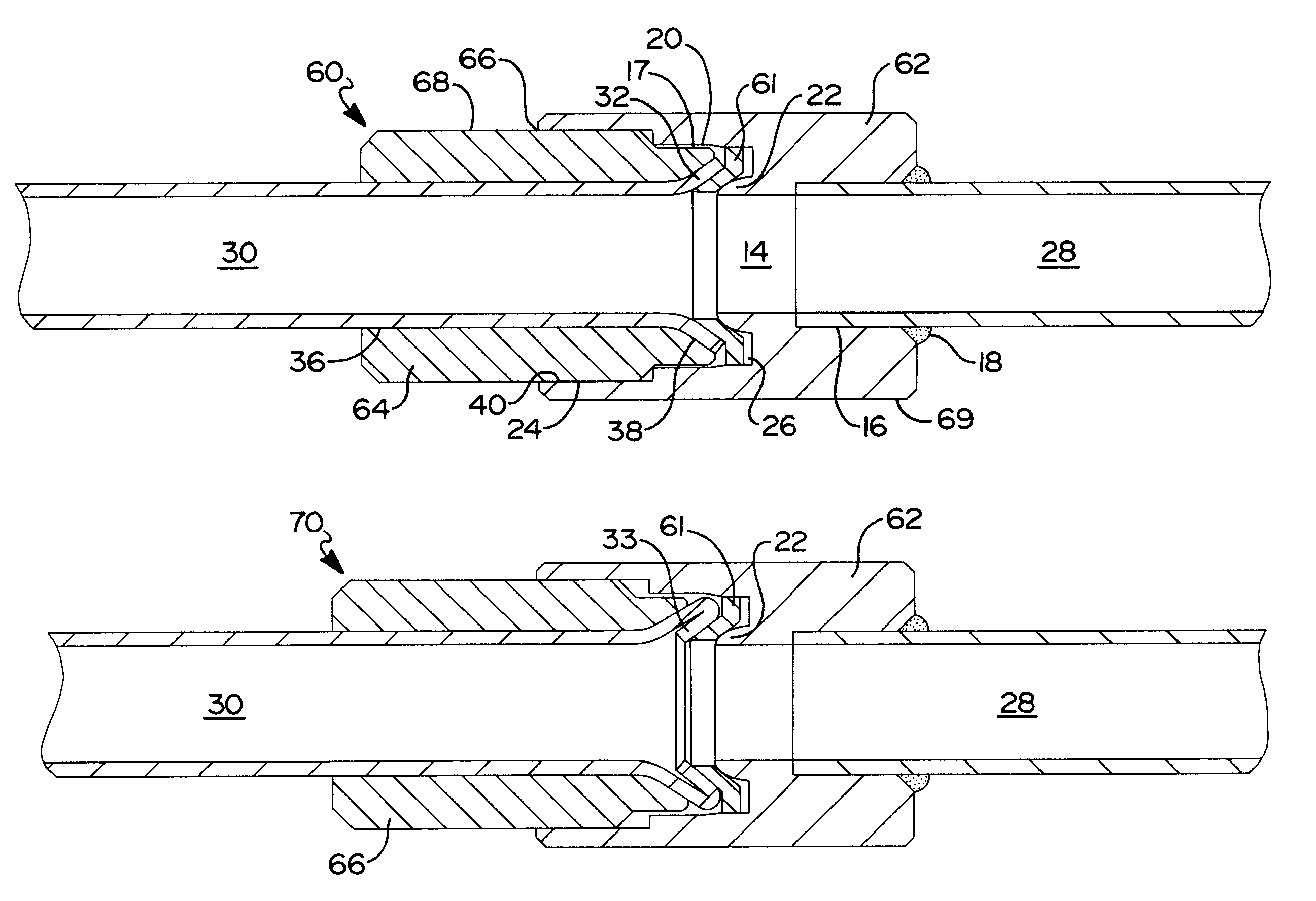

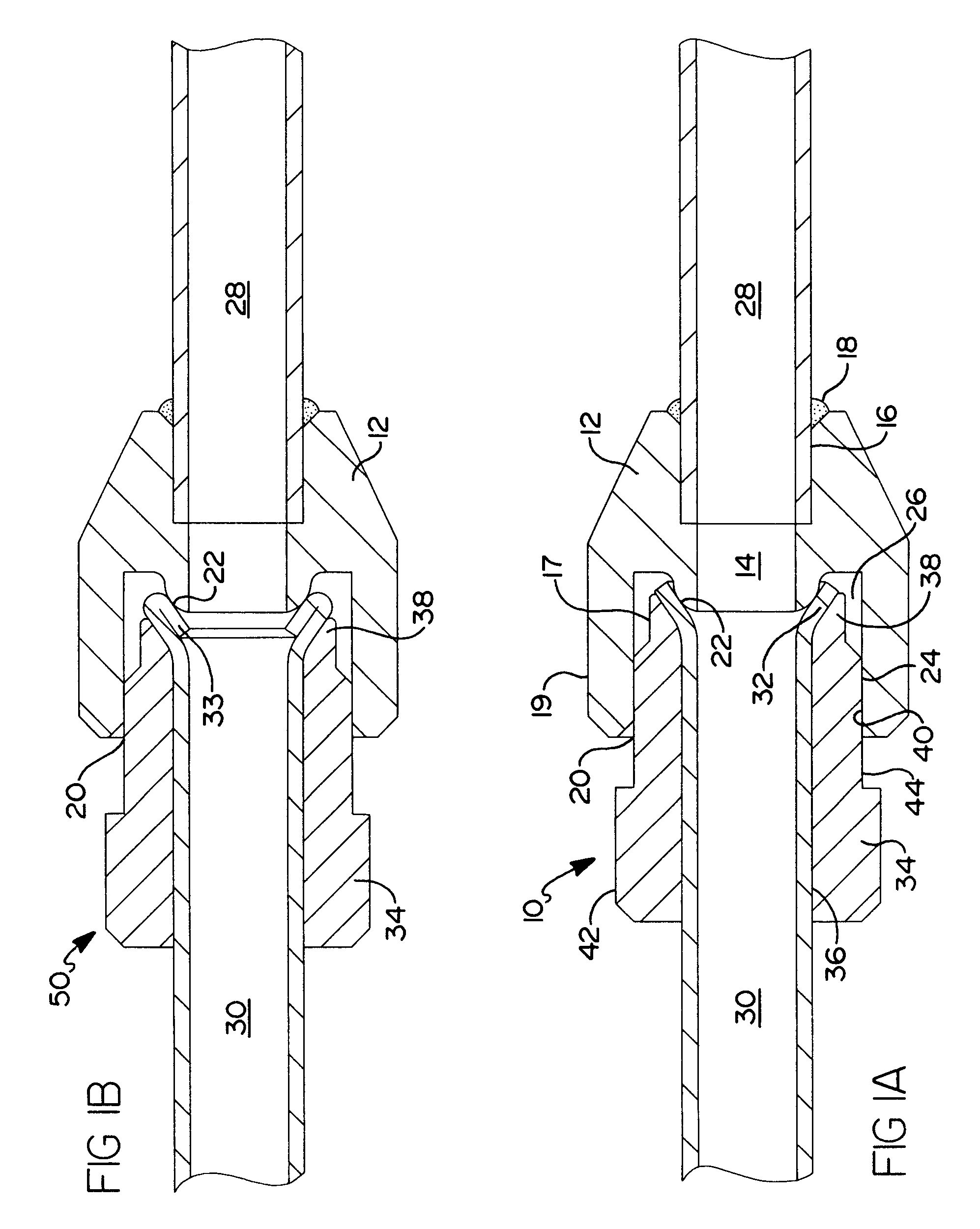

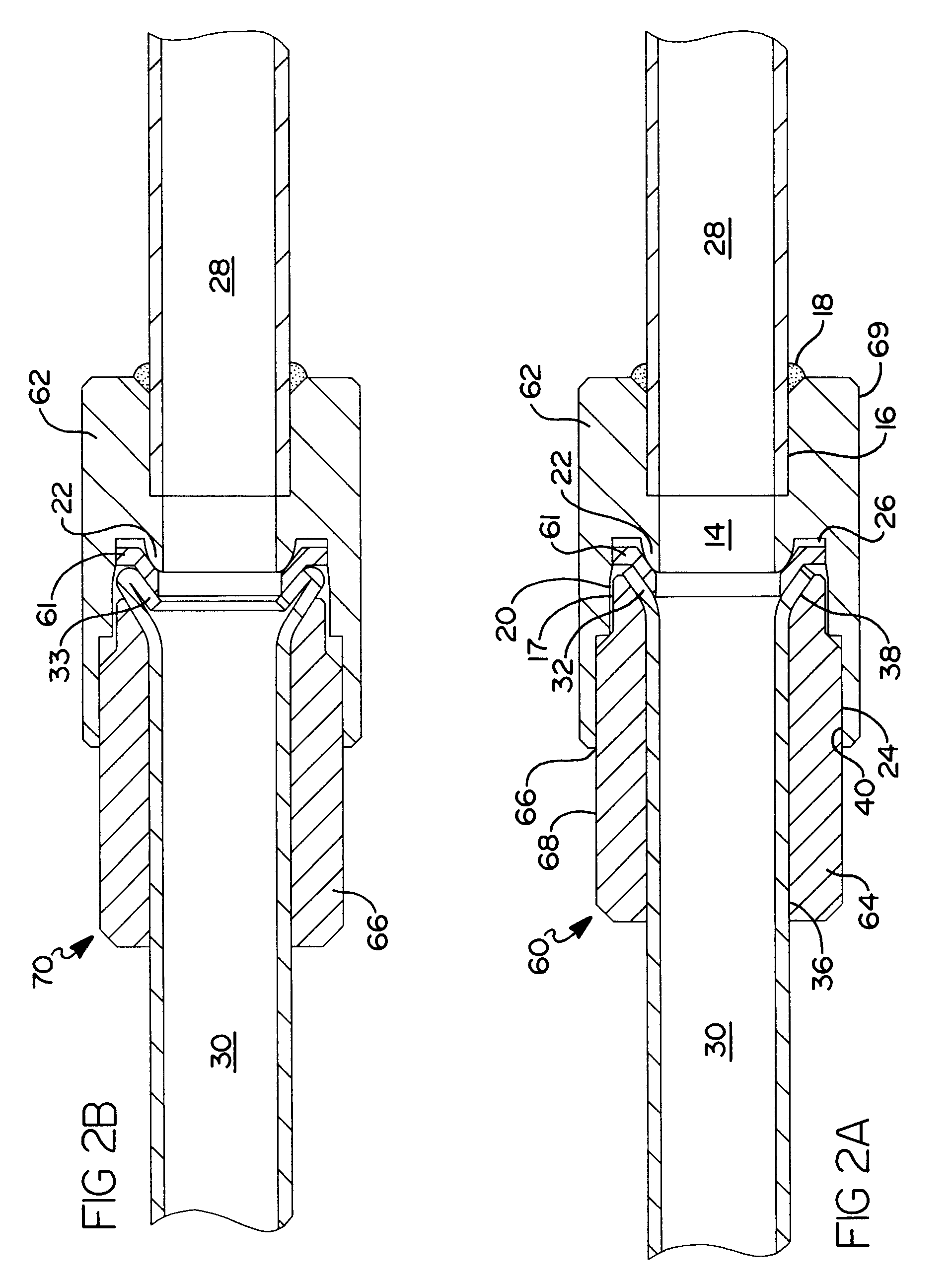

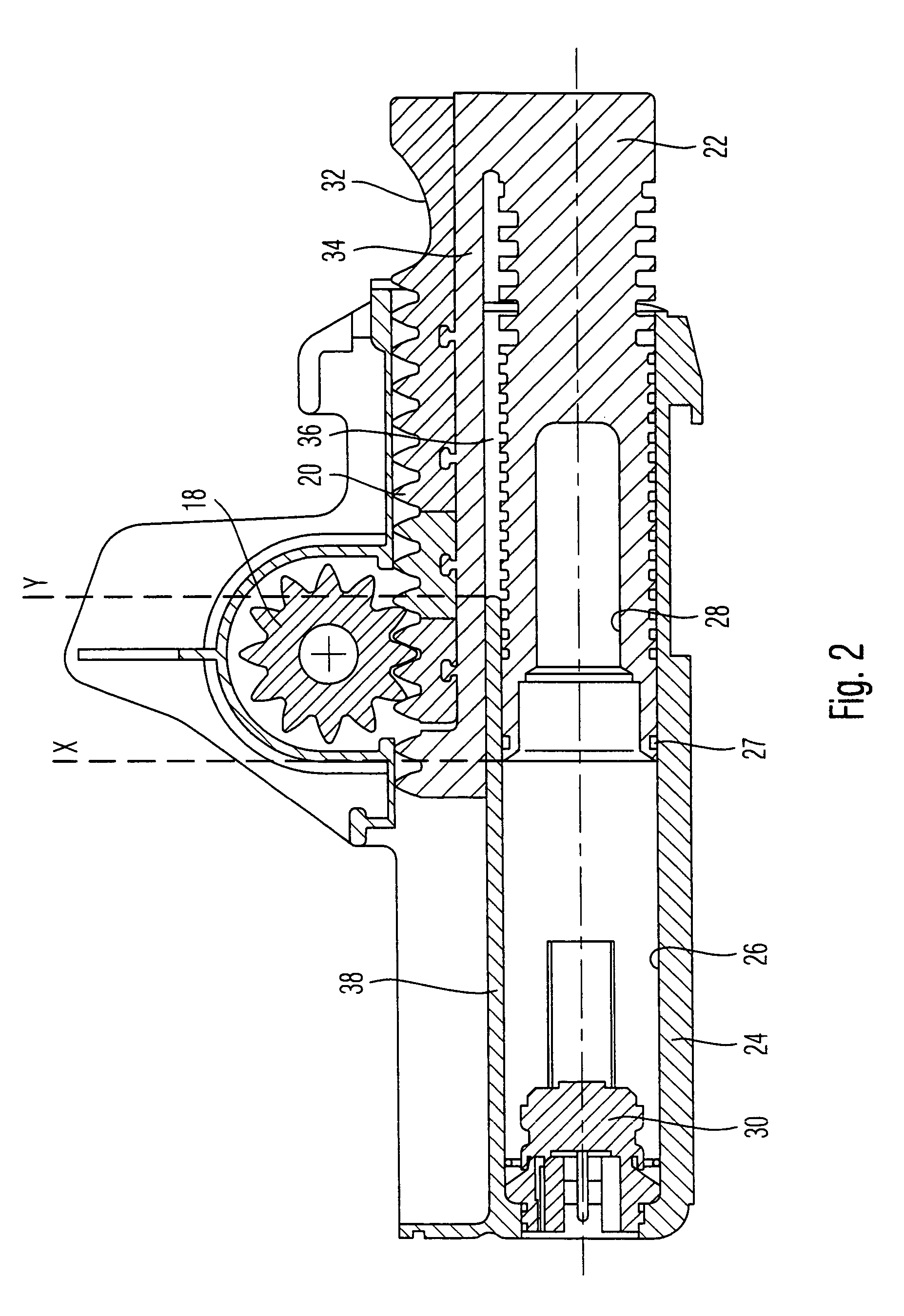

Flare fitting assembly with metal-to-metal line seal

InactiveUS20030047945A1Minimal deformationIncrease pressureFluid pressure sealed jointsJoints with sealing surfacesMetalFlare fitting

A flare fitting assembly includes a first coupling member and a second coupling member adapted to be cooperatively coupled together. The first coupling member has a first through bore with one end adapted to accept and retain a first tube. The second coupling member has a second through bore adapted to be disposed upon a second tube with an outwardly flared end. An arcuately shaped seating surface is disposed within the first through bore of the first coupling member. A conically flared seating surface is disposed within the second through bore of the second coupling member adapted to engage an outer surface of the flared end of the second tube such that a line seal is formed between the inner surface of the flared end of the second tube and the arcuate surface when the first and second coupling members are cooperatively coupled.

Owner:VISTEON GLOBAL TECH INC

Flow management system for hydraulic work machine

A flow management system capable of providing adjustable hydraulic fluid flow or pressure at a common line to supply bidirectional pumps in electro-hydrostatic actuation systems and conditioning re-circulated hydraulic fluid. The system enables flow sharing between multiple actuation systems and minimization of energy consumption by a power-on-demand approach and / or electrical energy regeneration while eliminating the need for an accumulator. The system has particular application to electro-hydrostatic actuation systems that typically include bi-directional electric motor driven pumps and unbalanced hydraulic actuators connected within closed circuits to provide work output against external loads and reversely recover energy from externally applied loads.

Owner:PARKER INTANGIBLES LLC

Flare fitting assembly with metal-to-metal line seal

InactiveUS6729659B2Minimal deformationIncrease pressureFluid pressure sealed jointsJoints with sealing surfacesEngineeringMetal

A flare fitting assembly includes a first coupling member and a second coupling member adapted to be cooperatively coupled together. The first coupling member has a first through bore with one end adapted to accept and retain a first tube. The second coupling member has a second through bore adapted to be disposed upon a second tube with an outwardly flared end. An arcuately shaped seating surface is disposed within the first through bore of the first coupling member. A conically flared seating surface is disposed within the second through bore of the second coupling member adapted to engage an outer surface of the flared end of the second tube such that a line seal is formed between the inner surface of the flared end of the second tube and the arcuate surface when the first and second coupling members are cooperatively coupled.

Owner:VISTEON GLOBAL TECH INC

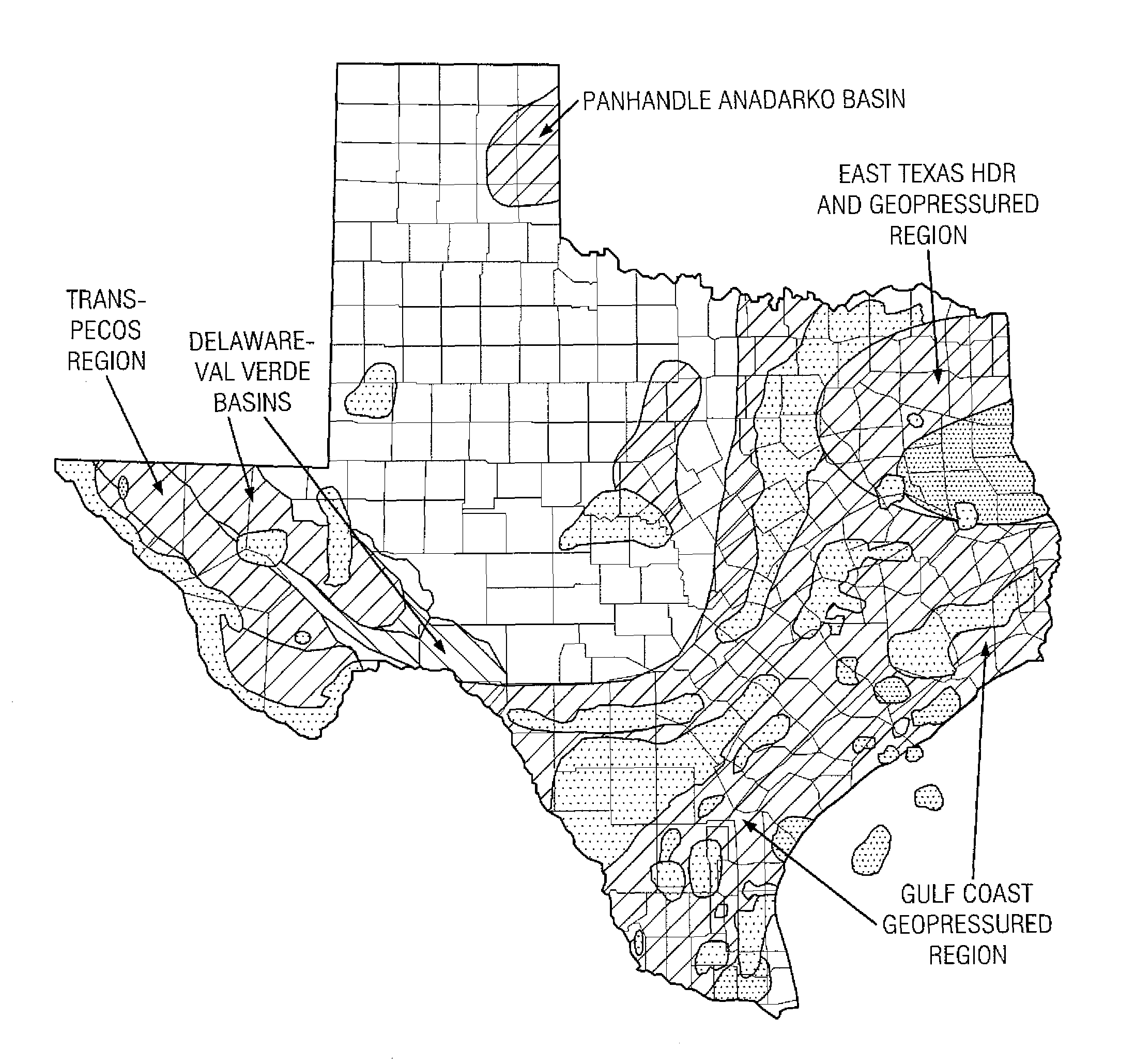

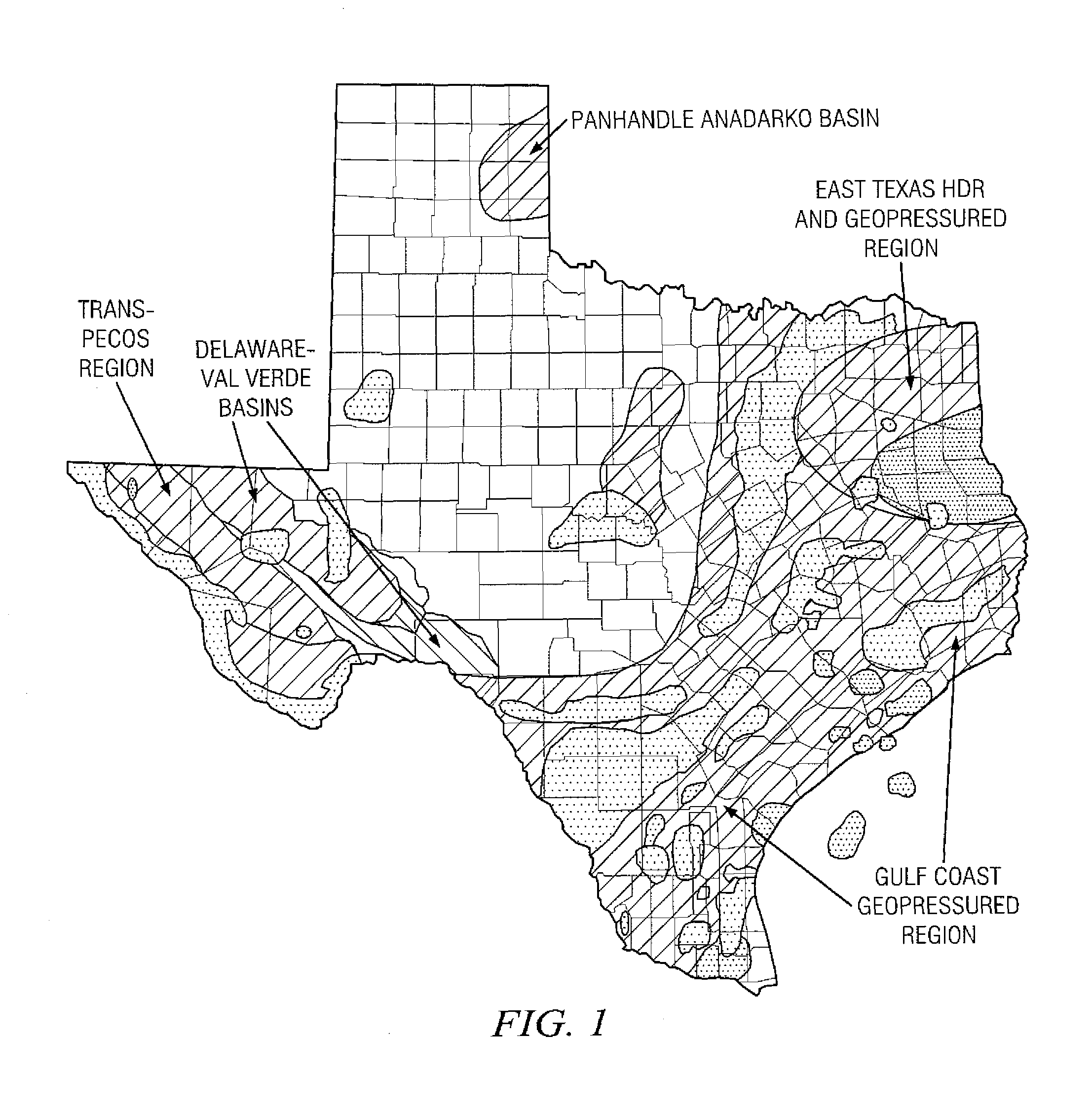

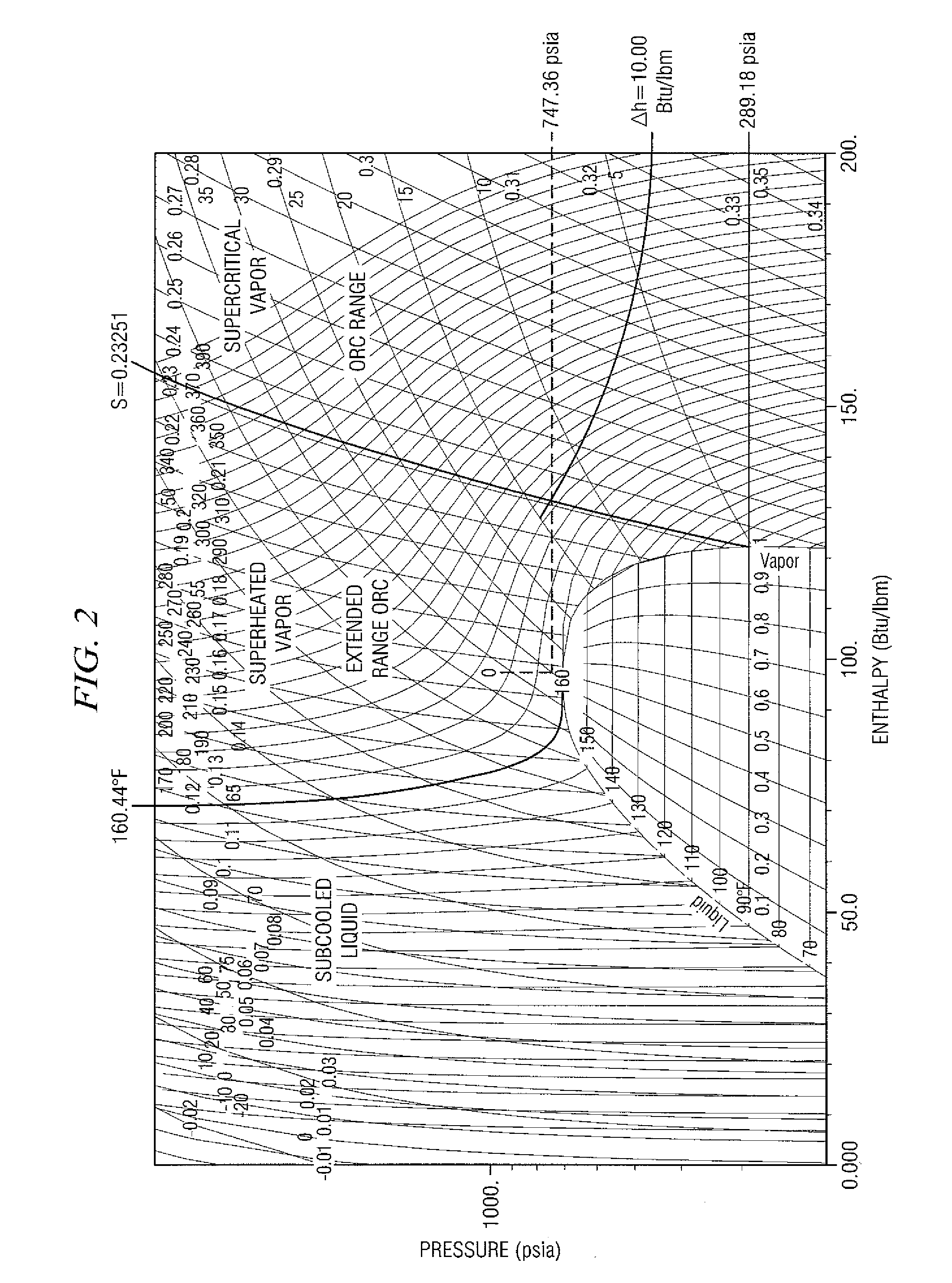

Thermodynamic amplifier cycle system and method

InactiveUS8418466B1Improve efficiencyExtend plant lifeSteam engine plantsMechanical power devicesPower cycleEngineering

The present invention is directed at the thermodynamic property amplification of a given thermal supply, provided by hydrocarbon combustion or in the preferred application heat provided by low-grade geothermal energy from the earth, for a vapor power cycle. The present invention achieves the desired objectives by segregating the compressible supercritical energy stream from the heat exchanger (boiler) into hot and cool fractions using a vortex tube, where the hot temperature is elevated above the heat exchanger temperature; and adding back heat (enthalpy) to the cool stream increasing the cool temperature to that of the geothermal heat exchanger. The heat-exchanger (boiler) supercritical gaseous mass flow segregated by a counterflow vortex tube (or bank of vortex tubes) forms hot and cool fractions where the hot temperature is raised above the heat-exchanger supply temperature, and heat (enthalpy) is added to the cool stream thereby increasing the cool temperature to that of the heat exchanger supply temperature.

Owner:HARDGRAVE DAVID

Vulcanization method of selective hydrodesulfurization catalyst of FCC (Fluid Catalytic Cracking) gasoline

ActiveCN103773435AIncrease system pressureFully vulcanizedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationVulcanizationSulfur

The invention discloses a vulcanization method of a selective hydrodesulfurization catalyst of FCC (Fluid Catalytic Cracking) gasoline. The method is as follows: in a vulcanization process of the selective hydrodesulfurization catalyst, first vulcanizing under a low pressure and at a low temperature, then vulcanizing under a high system pressure and at a high temperature so as to facilitate production of more CoMoS phases and make the CoMoS phases more dispersive to produce more sulfur vacancies and form more desulfurization centers and promote the formation of the active center of direct desulfurization. The vulcanization method can improve the catalyst desulfurization activity, at the same time, and the olefin saturation properties basically remains unchanged, so that the hydrodesulfurization selectivity of the FCC gasoline is effectively improved. The method can be applied to a variety of hydrodesulfurization catalysts of the FCC gasoline, and is especially suitable for hydrodesulfurization catalysts containing additives with selective desulfurization effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

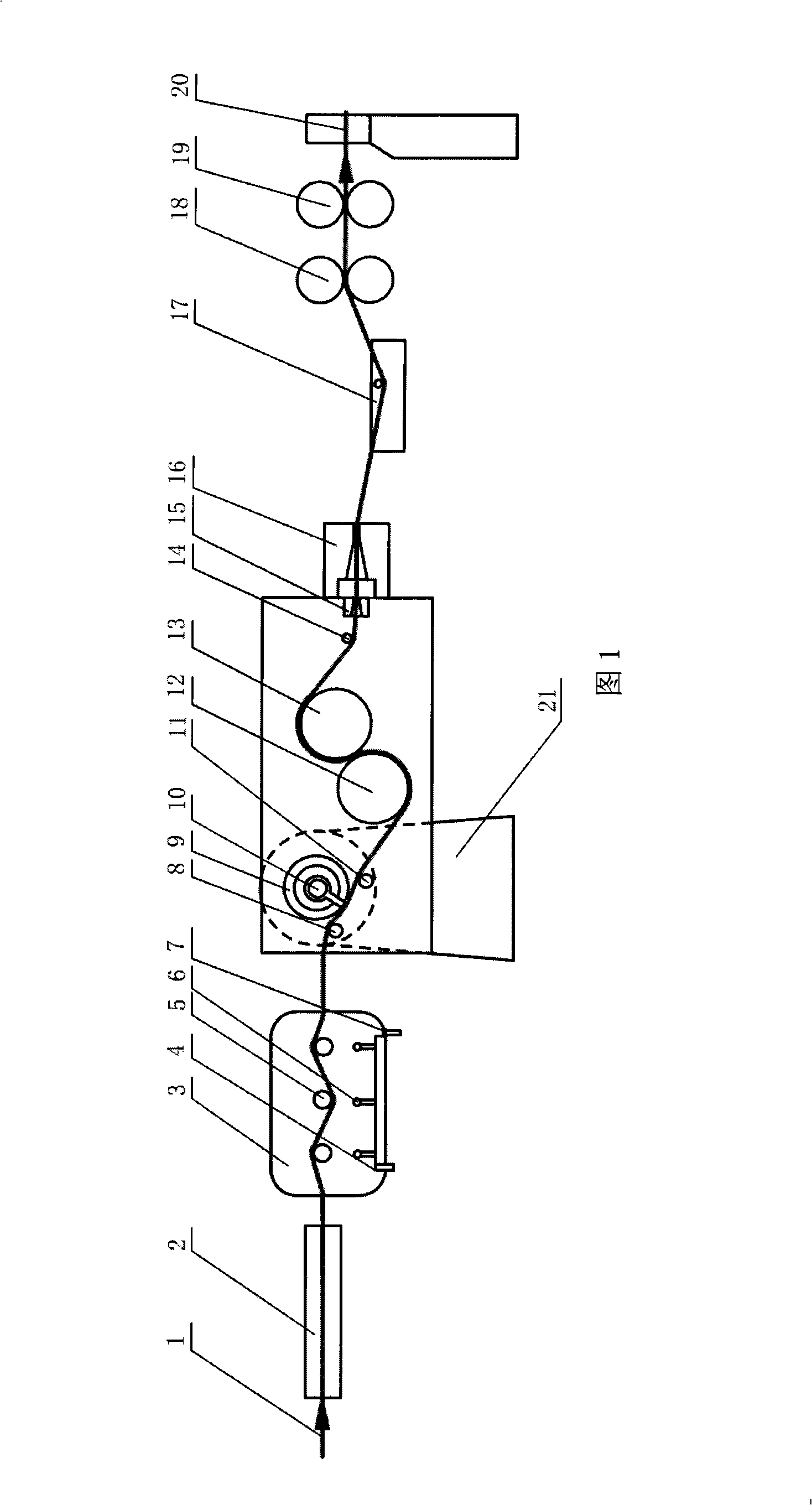

Complete production unit of long glass fiber reinforcement polypropylene material

The invention relates to a complete production unit for long glass fiber reinforced polypropylene materials, which comprises a long glass fiber pre-heating device, a long glass fiber surface treating device, an immersion device, and a bunching and coating device. The long glass fiber pre-heating device is connected with the long glass fiber surface treating device in a transition manner; the long glass fiber surface treating device is connected with the immersion device in a transition manner; the immersion device is connected with the bunching and coating device in a transition manner; the long glass fiber surface treating device comprises a variable diameter pressing roll and a liquid coupling agent atomizer; the immersion device has a box-type structure; an extruder connector, a melting stock allocator, a front guide roll, a middle guide roll, a back guide roll, a pair of pressing rolls are arranged in the immersion device; a double screw extruder and the melting stock allocator form a melting stock conveying passage through the extruder connector; the front guide roll, the middle guide roll, the pair of pressing rolls and the back guide roll are connected sequentially in a transition manner; and a cooling device, a pulling device and a grain-sized dicing device are sequentially distributed at the outlet end of the bunching and coating device. Therefore, a production line is formed. The process is widely used for producing long glass fiber reinforced polypropylene materials.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

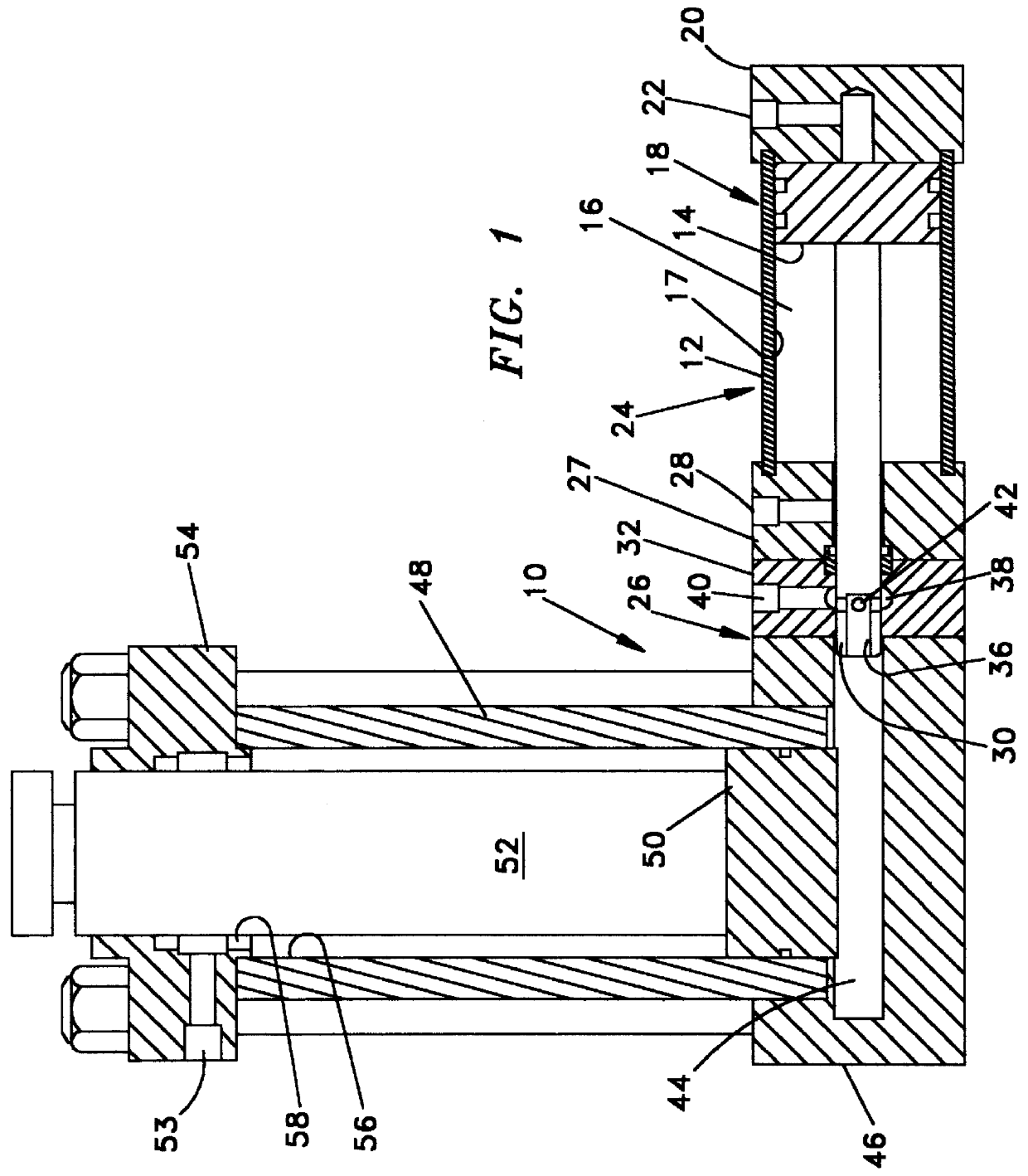

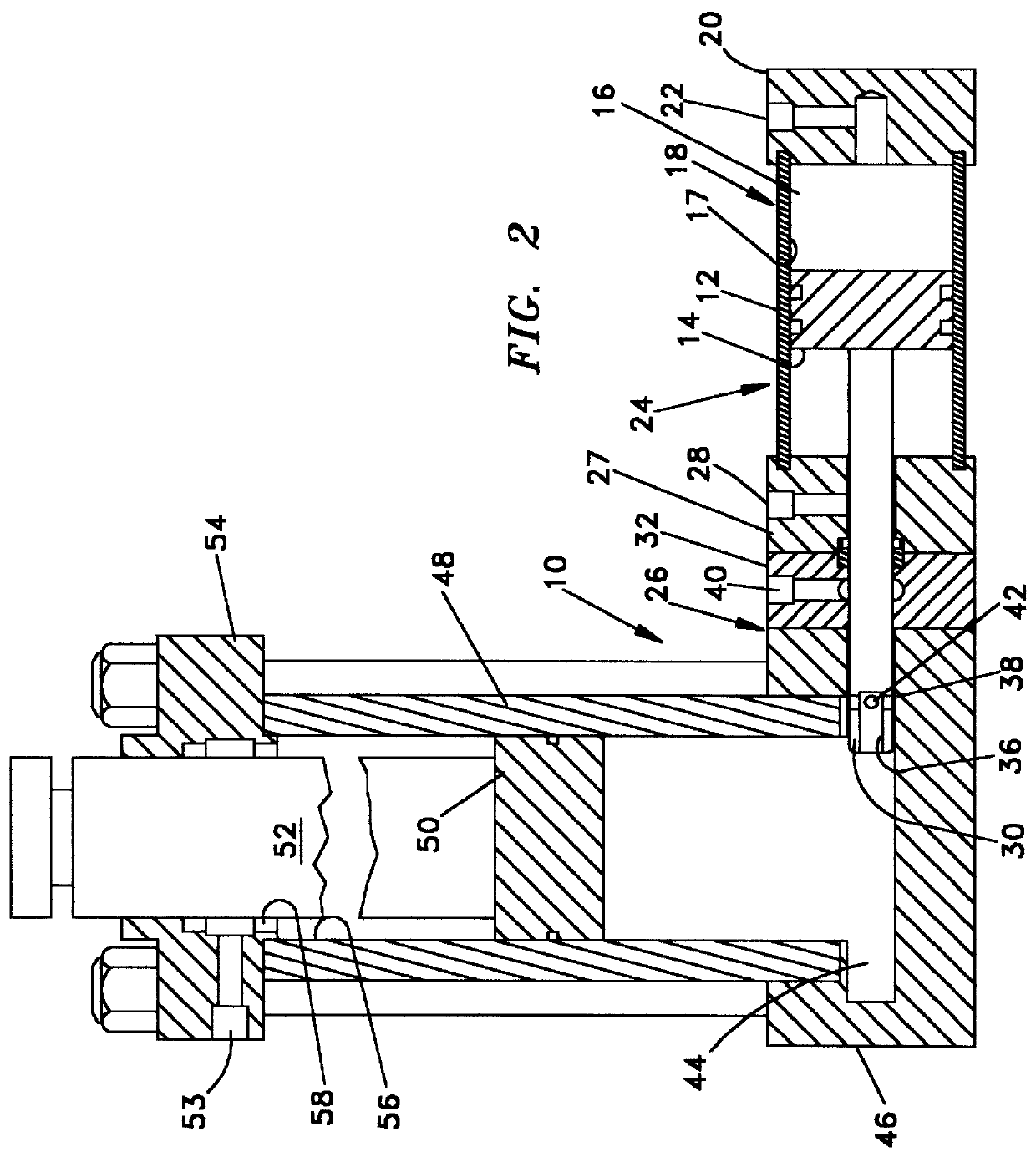

Fluid actuator system having means for internally increasing the fluid pressure therein

InactiveUS6012287AIncrease output pressureIncrease working pressureBraking action transmissionRotary clutchesEngineeringFluid pressure

A fluid actuator system disposed for internally increasing fluid pressure therein. The system includes a first fluid actuator including a cylinder provided with a first axial bore having a first piston and piston rod reciprocally mounted therein. The first cylinder is provided with first and second inlet and outlet fluid passages communicating into the first axial bore for directing fluid in and out of the first axial bore. A second fluid actuator is provided which has a cylinder provided with a second axial bore having a second piston and piston rod reciprocally mounted therein. The second cylinder is provided with third and fourth inlet and outlet fluid passages communicating into the second axial bore for directing fluid in and out of the second axial. An end closure assembly common to the first and second cylinders for sealing one end of each of the cylinder is provided. The end closure assembly includes structure therein for internally increasing fluid pressure of the fluid actuator system.

Owner:SIMS JAMES O

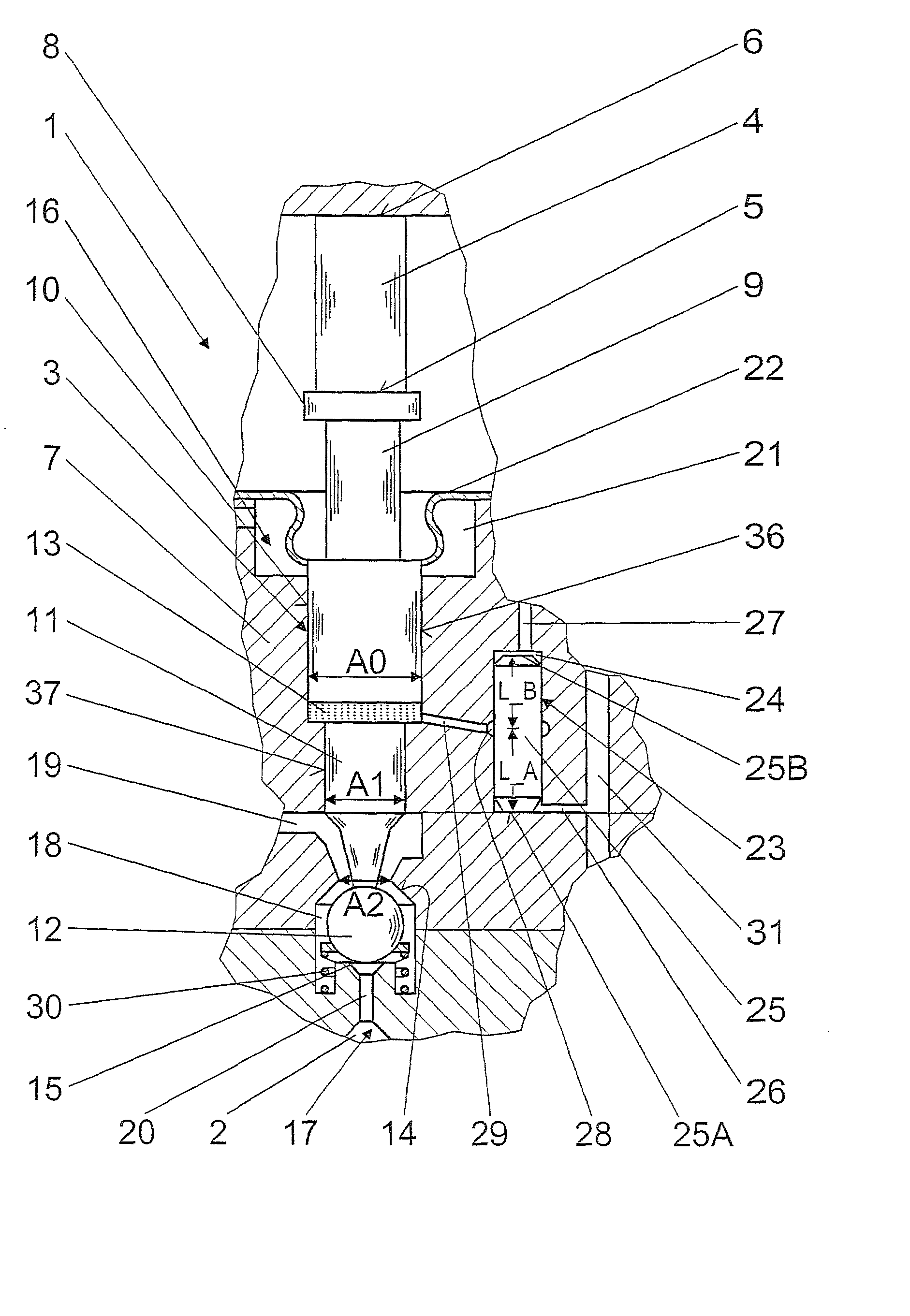

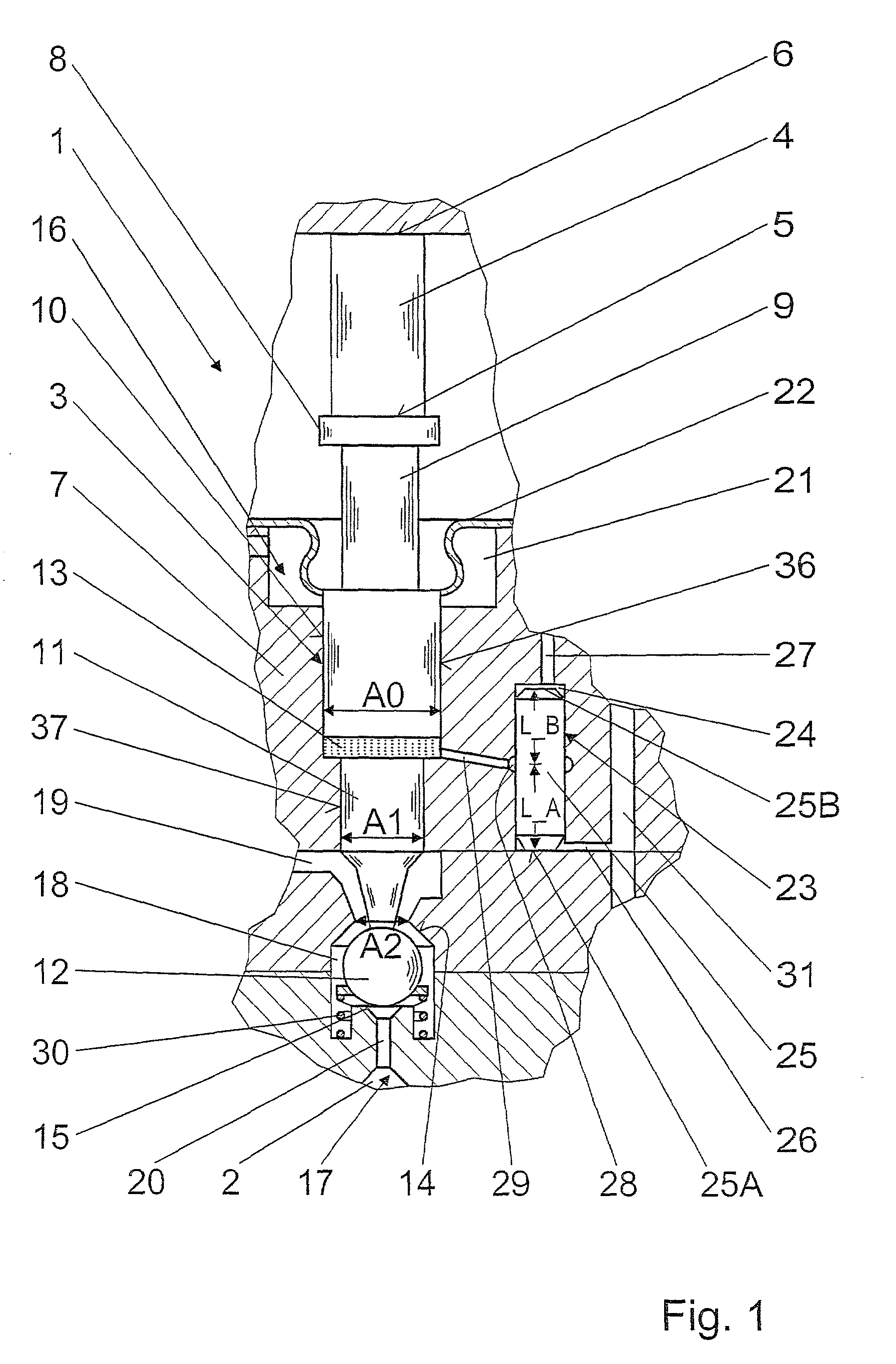

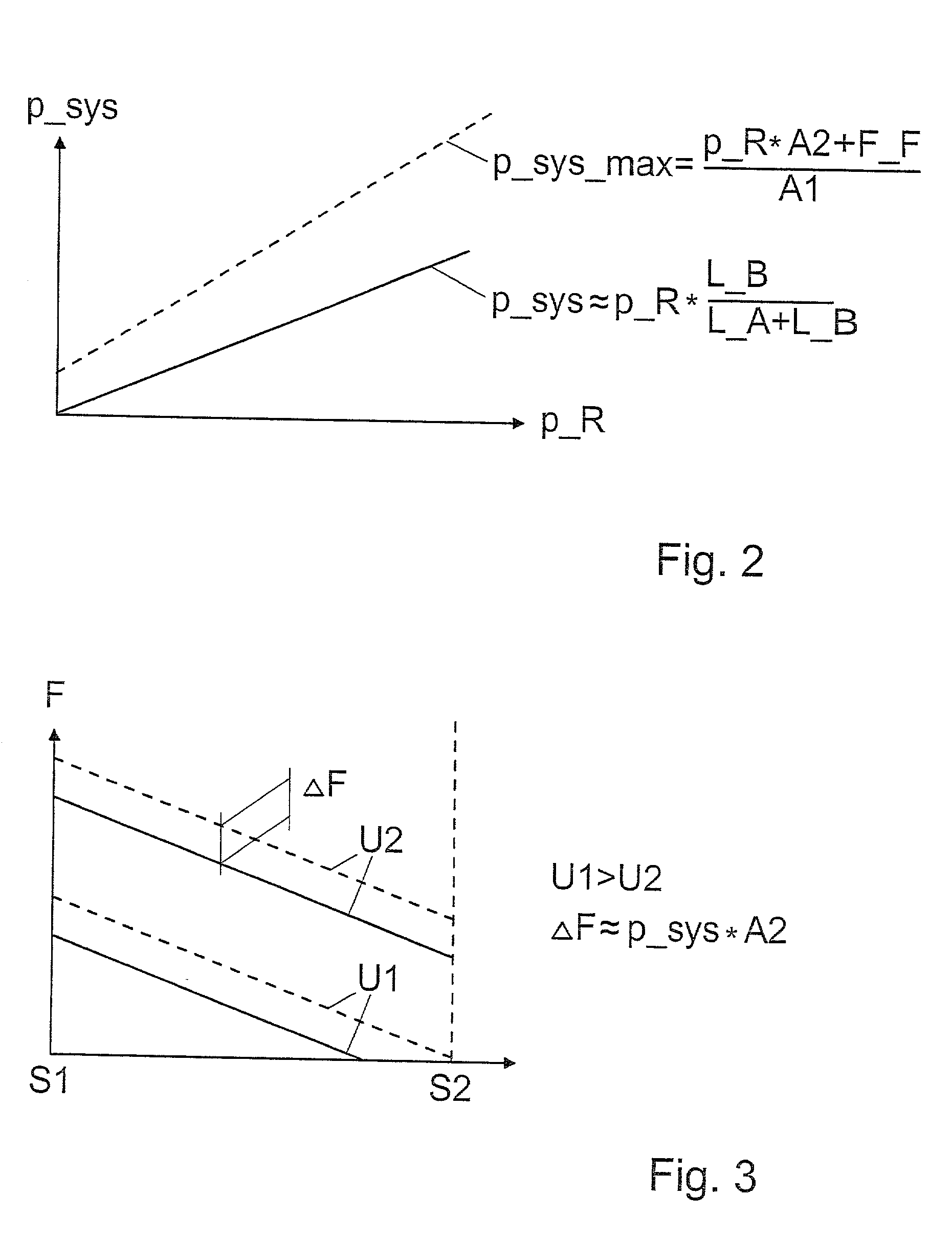

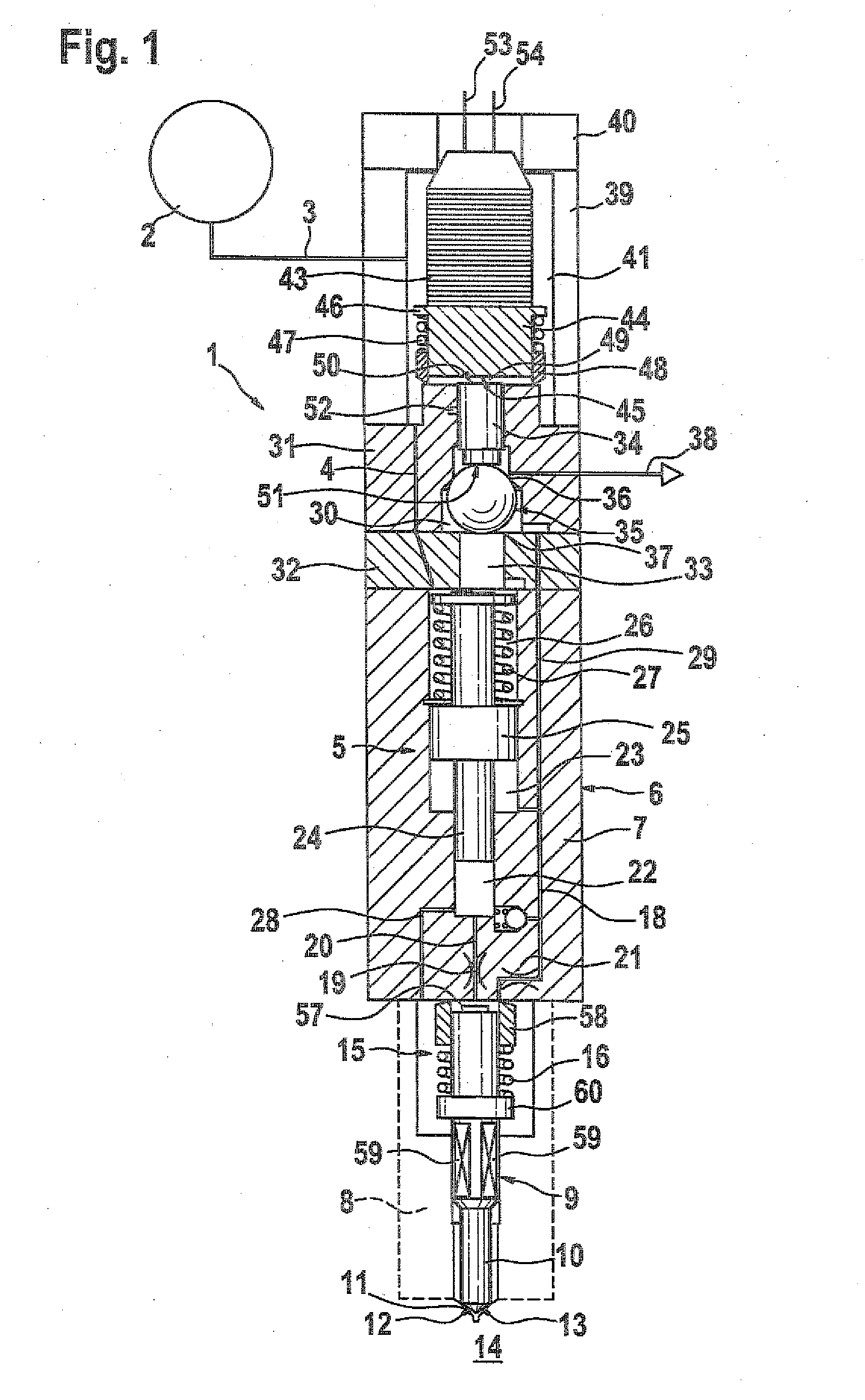

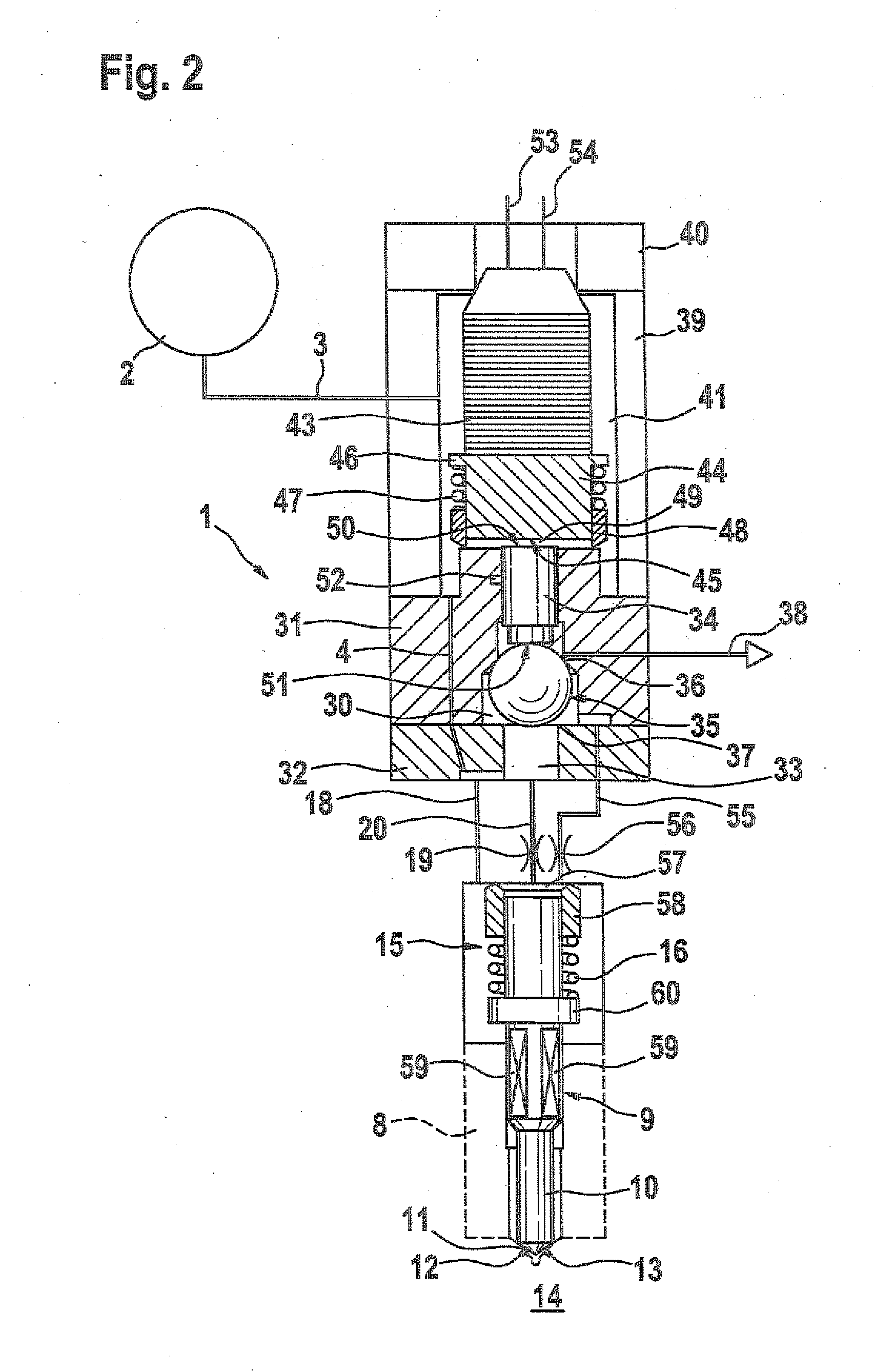

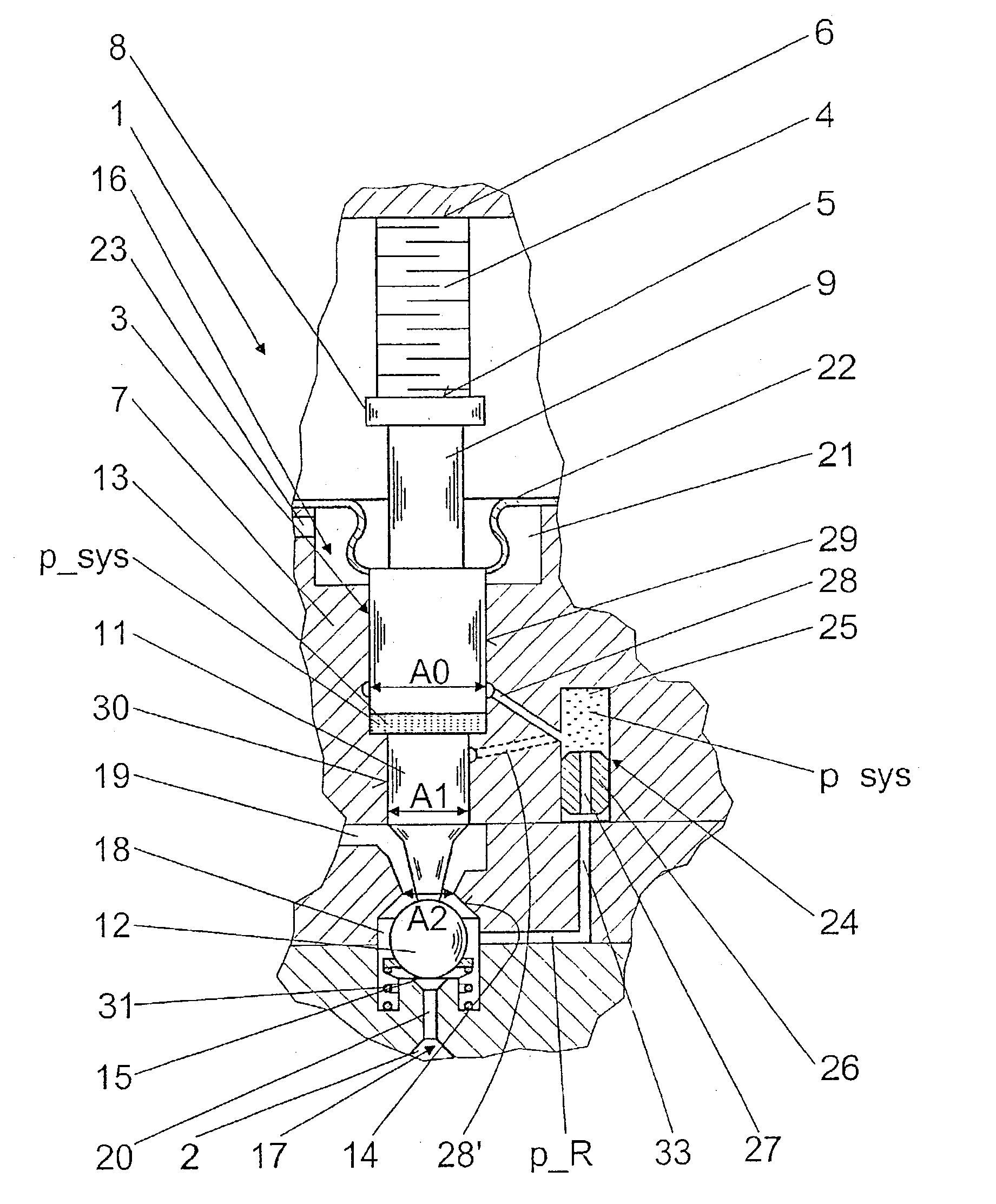

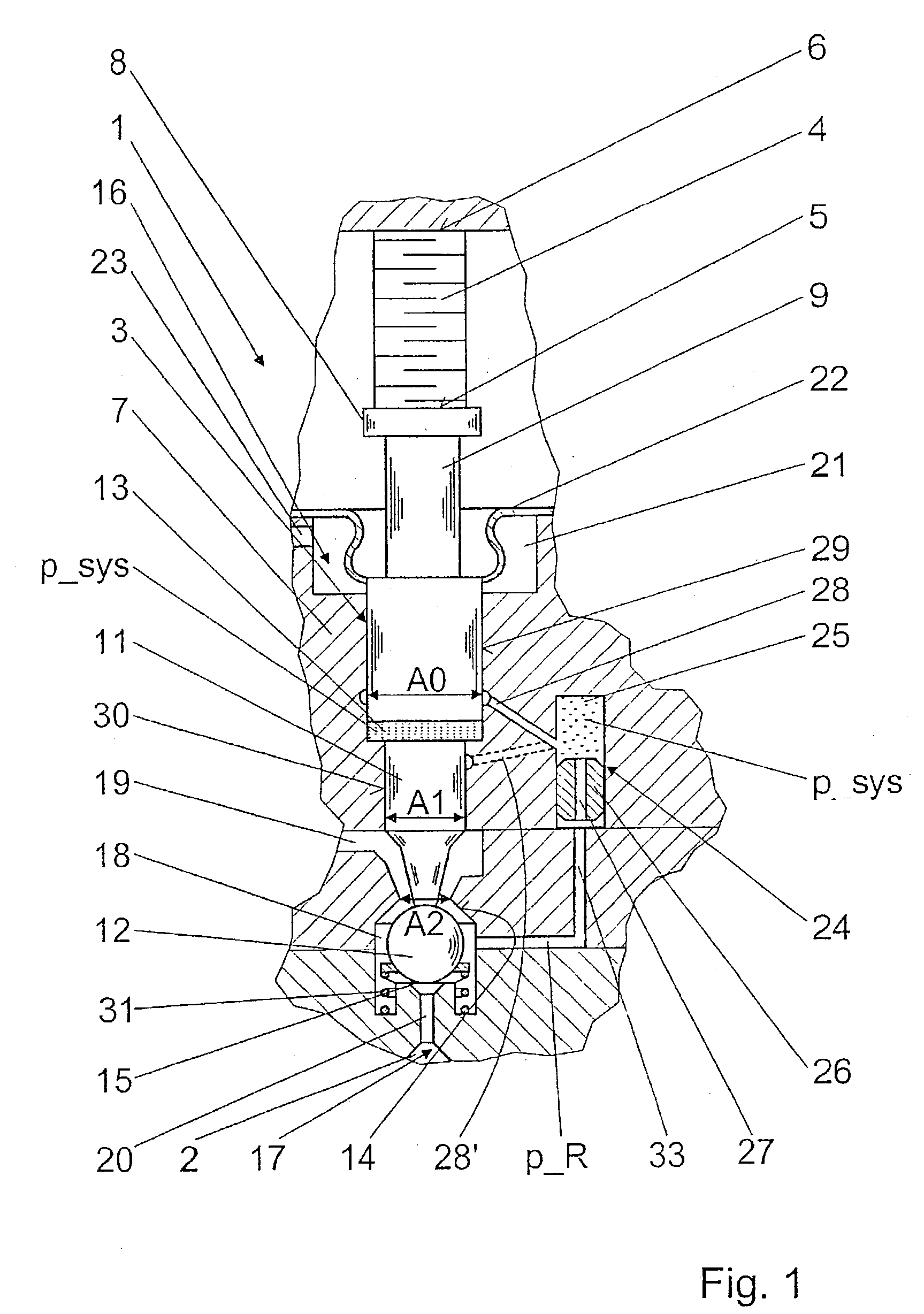

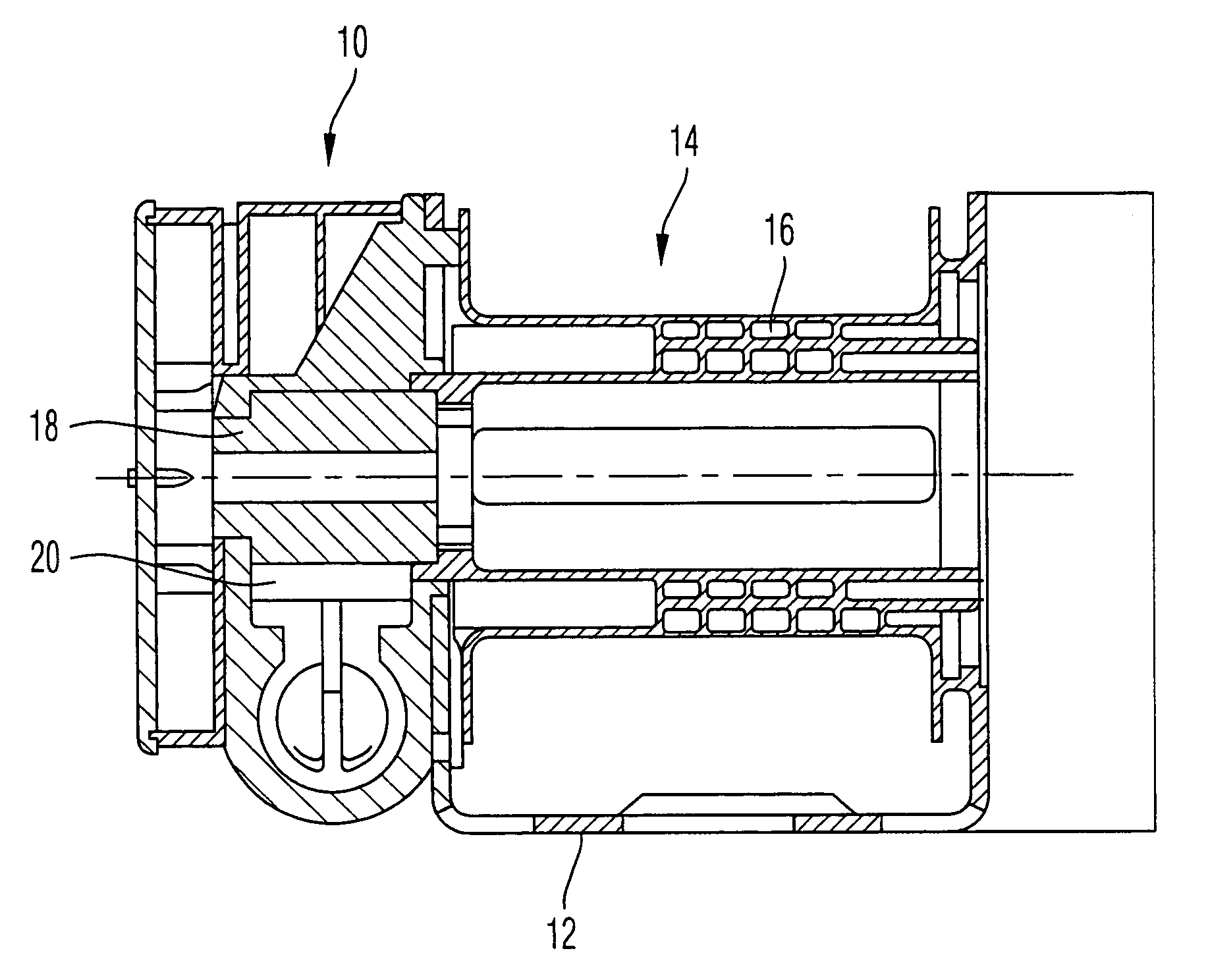

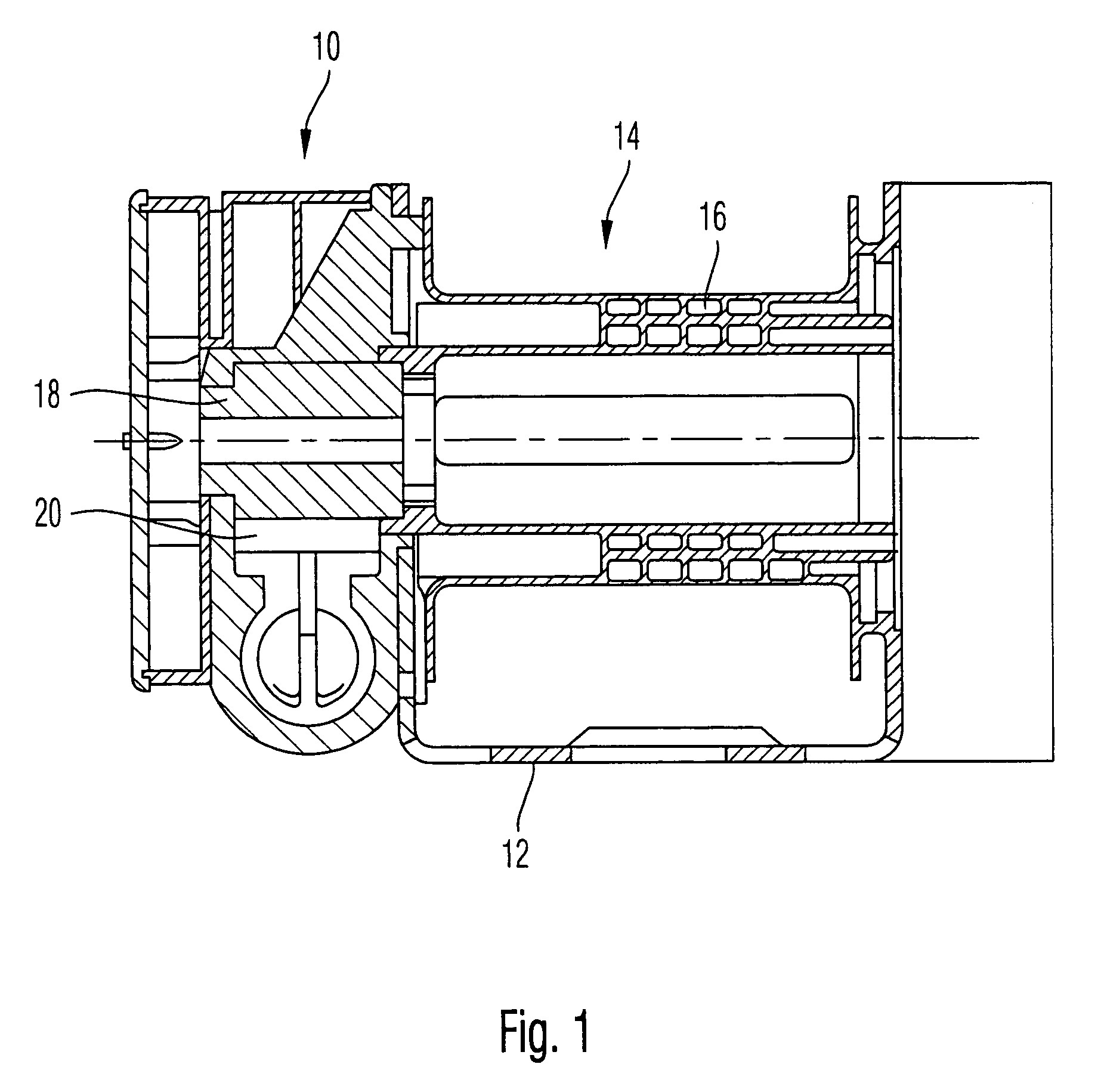

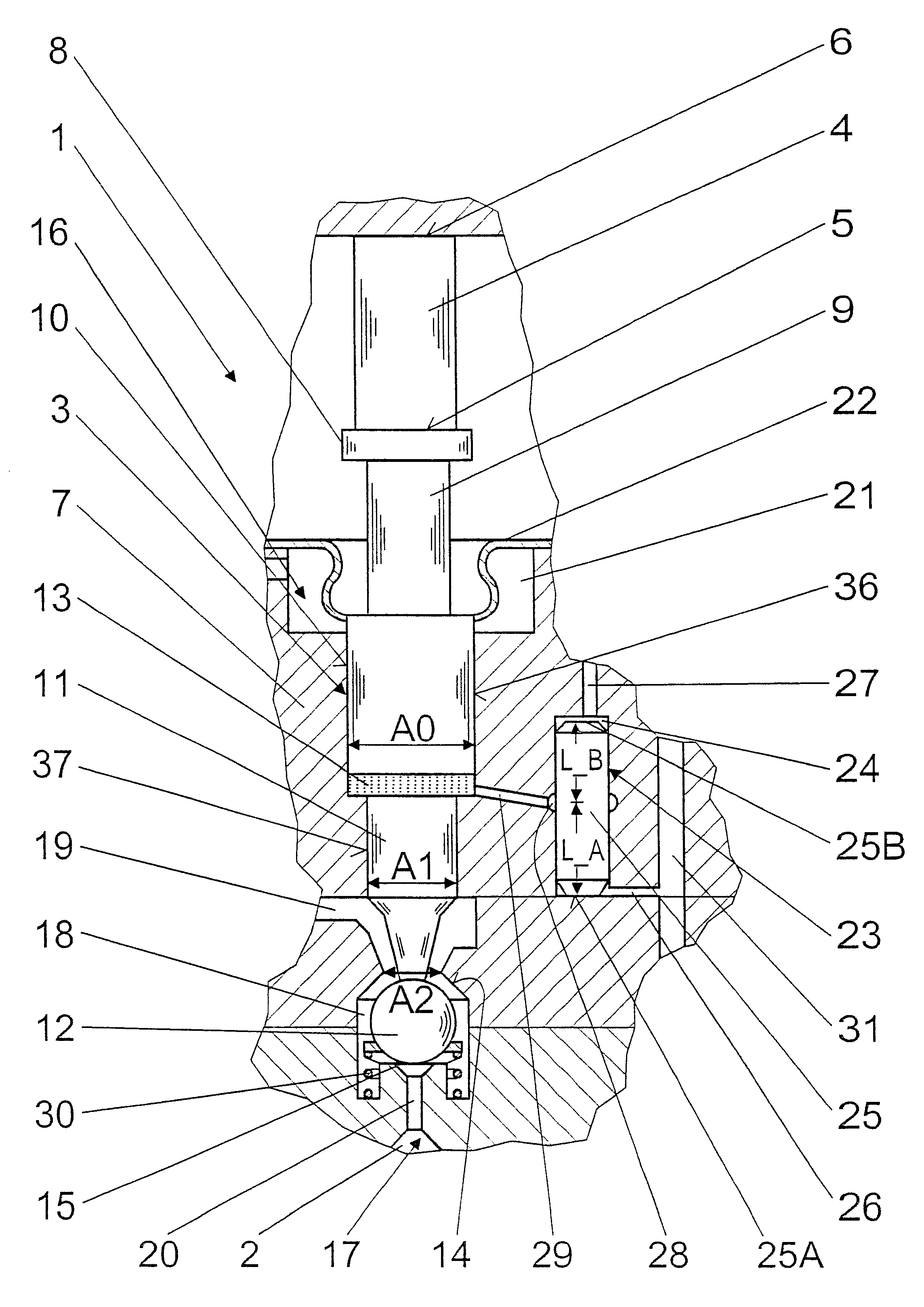

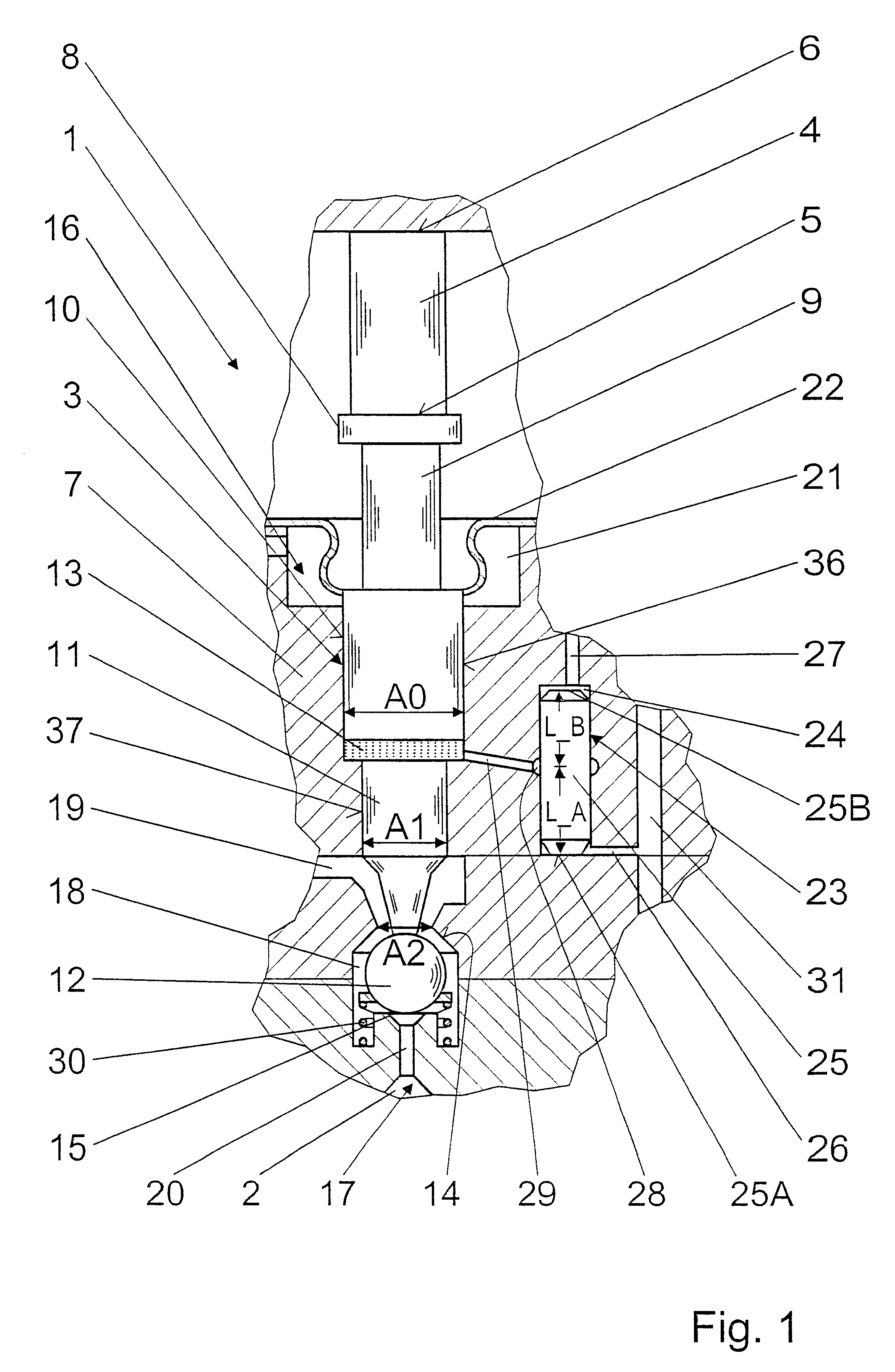

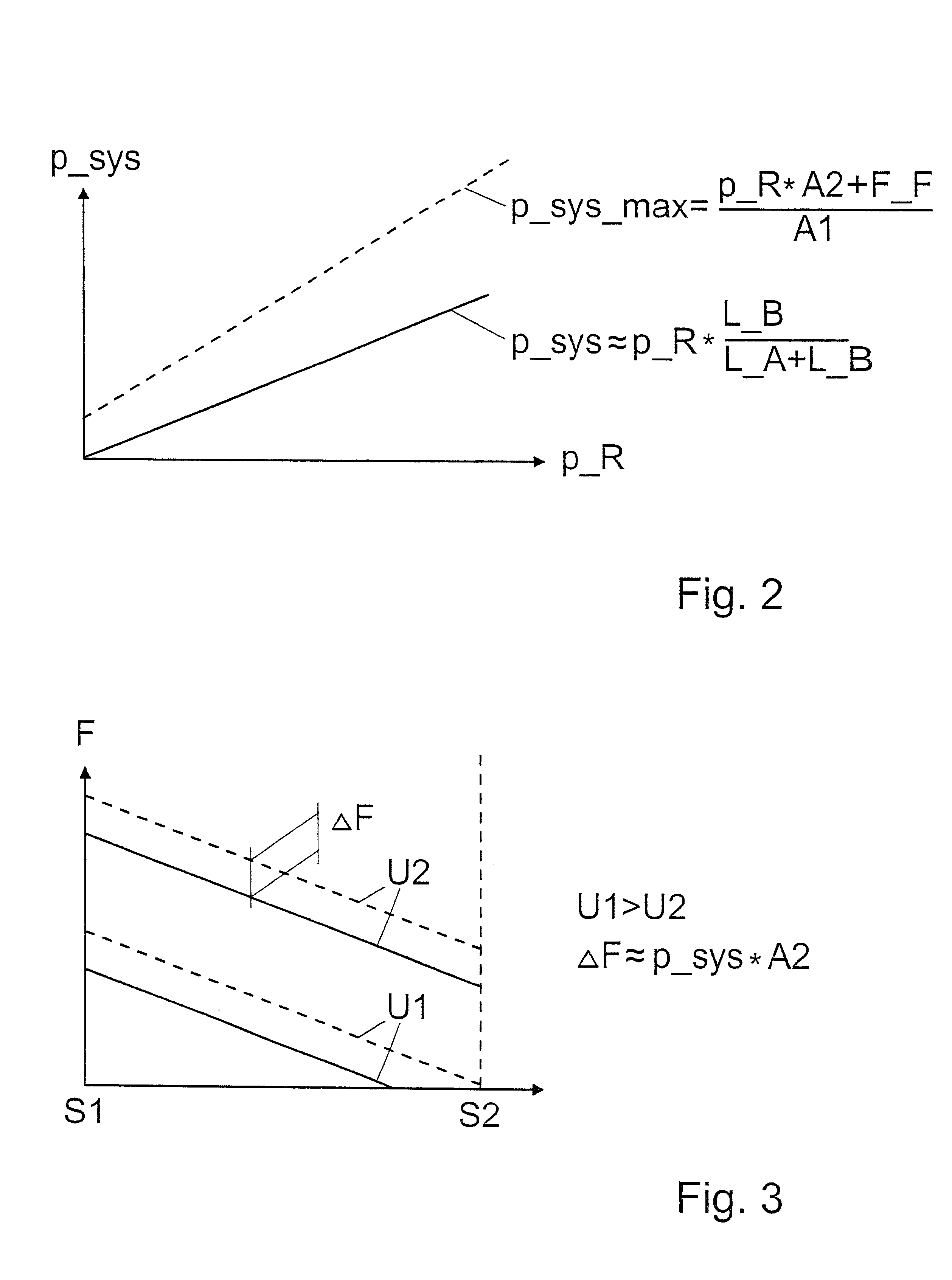

Valve for regulating fluids

InactiveUS20020139946A1Reduce voltageSmaller, less-expensive piezoelectric unitOperating means/releasing devices for valvesMovable spraying apparatusSystem pressureHigh pressure

The invention relates to a valve for controlling fluids, having a piezoelectric unit (4) for actuating a valve member (3), with which a valve closing member (12) is associated that divides a low-pressure region (16) at system pressure from a high-pressure region (17). The valve member (3) has at least one first piston (9) and one second piston (11), between which a hydraulic chamber (13) is embodied. To compensate for leakage losses, a filling device (23) is used, which can communicate with the high-pressure region (17) and which has at least one channel-like hollow chamber (24), in which a solid body (25) is disposed, with a gap surrounding it, in such a way that on one end (25A) of the solid body (25), a line (26) branching off from the high-pressure region (17), and on its opposite end (25B) a leakage line (27) discharges into the hollow chamber (24), and that a line (29) leading to the hydraulic chamber (13) branches off along the length of the solid body (25), and the system pressure (p_sys) in the hydraulic chamber (13) is adjustable by geometric definition of the branching point (28).

Owner:ROBERT BOSCH GMBH

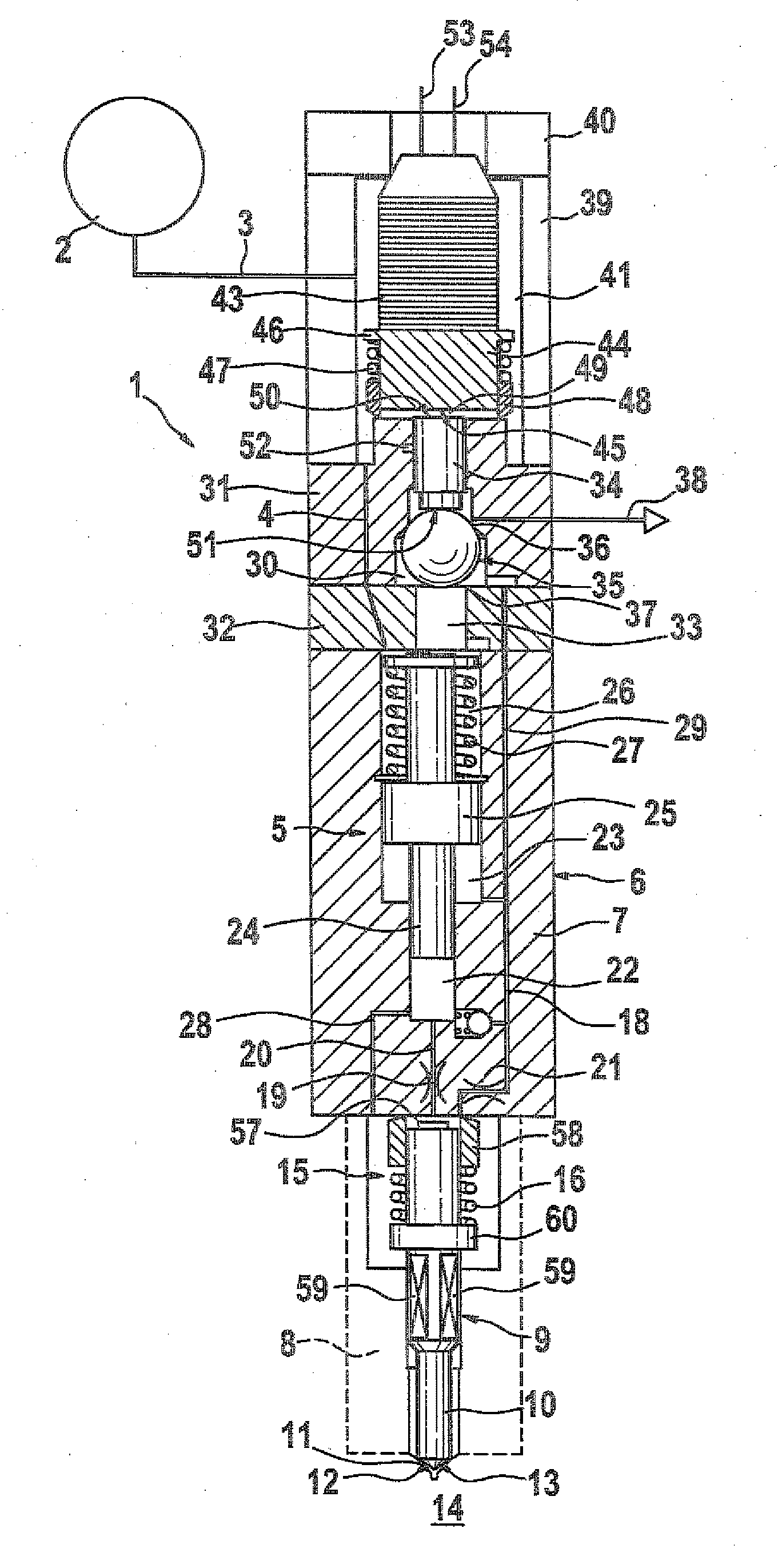

Fuel injector

InactiveUS20090266340A1Prevent dischargeEliminates a complex grinding machining of the valve pistonExhaust apparatusSpray nozzlesInjectorCombustion chamber

Owner:ROBERT BOSCH GMBH

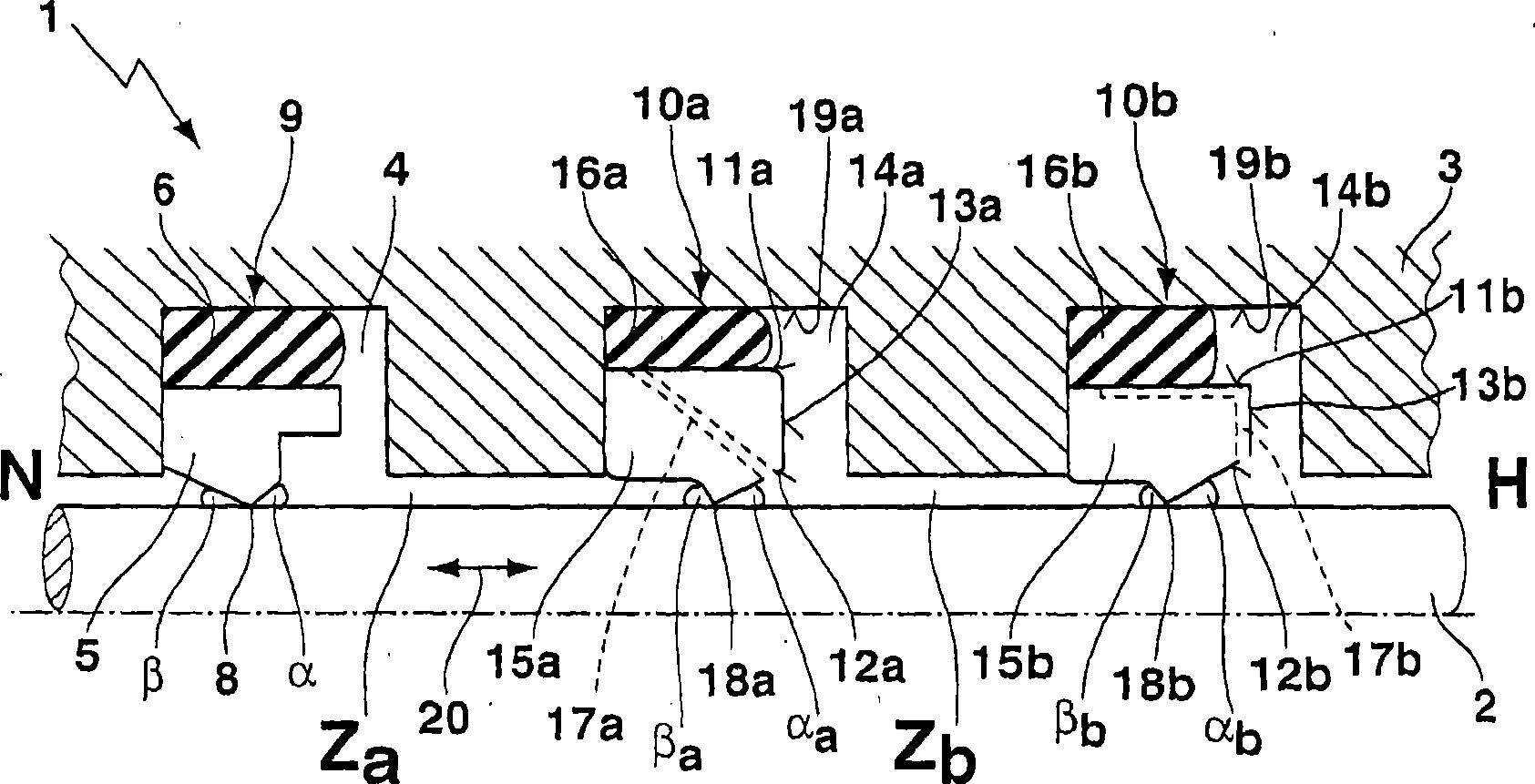

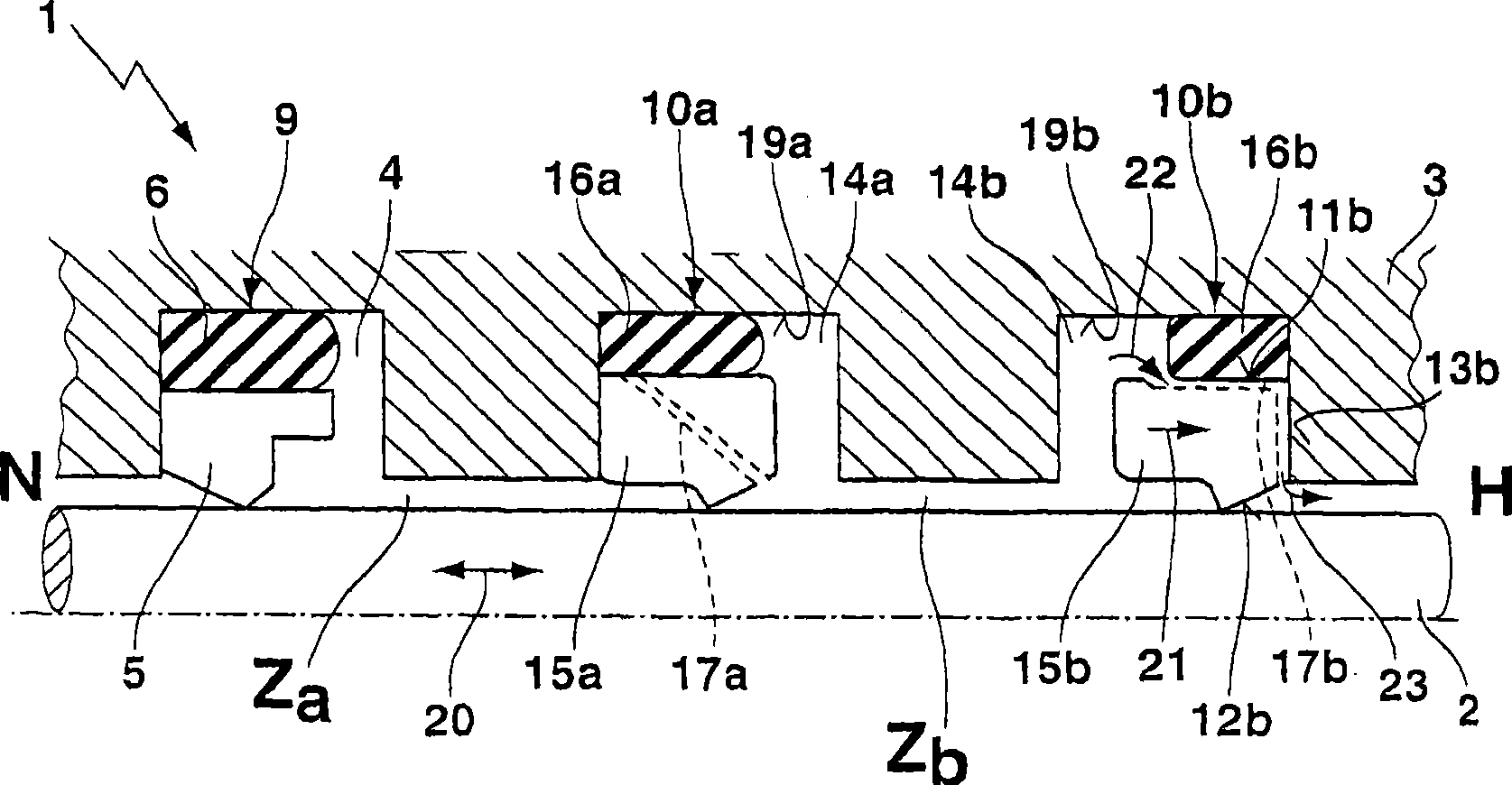

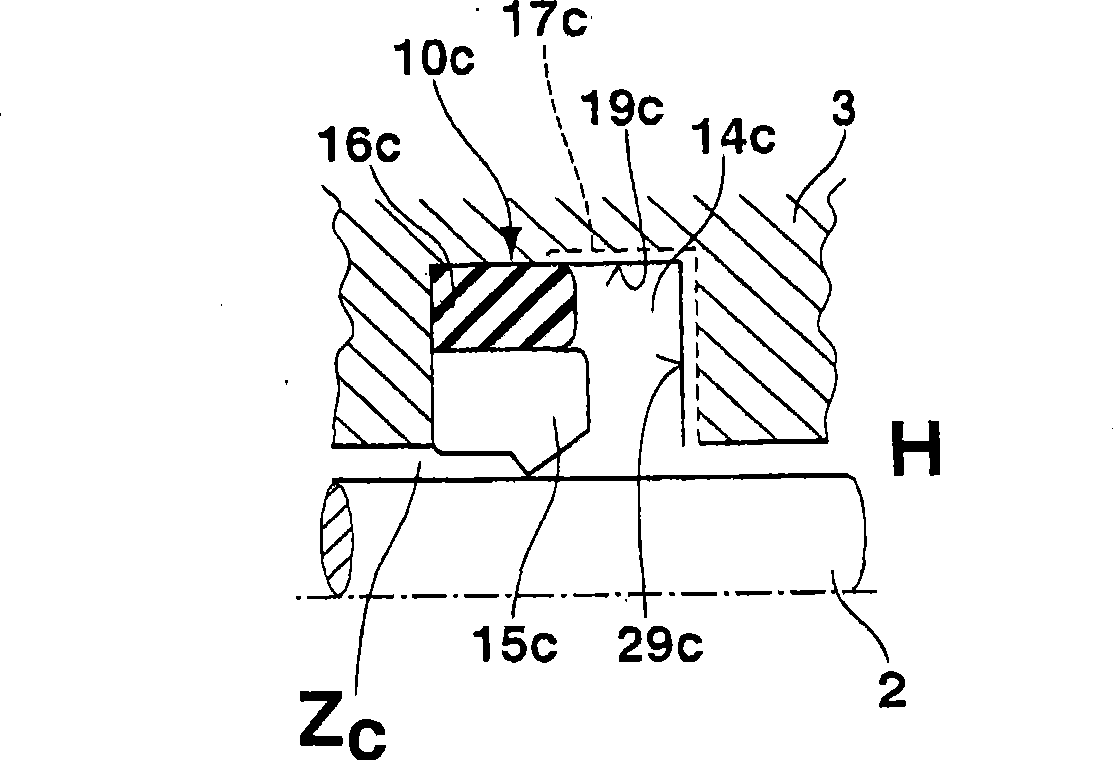

Sealing system with pressure relief elements and use of a sealing system for producing a pressure cascade in an intermediate space

The invention relates to a sealing system (1) between two components (2, 3) that can move relative to one another for sealing a high-pressure side (H) against a low-pressure side (N). In a sealing arrangement (9) provided in a first annular groove (4), one or more pressure relief elements (10a, 10b) are arranged upstream at the high-pressure side in second annular grooves (14a, 14b). The pressure relief elements (10a, 10b) each comprise a second sealing ring (15a, 15b) with flat pressure gradients. The hydrodynamic leakage rate for each pressure relief element (10a, 10b) is selected such that a certain hydraulic pressure prevails in each intermediate space (Za, Zb), thus resulting in a pressure cascade in the intermediate space.; The sealing system (1), according to the invention, comprises, in addition to the hydrodynamic feed capabilities of the sealing rings (5, 15a, 15b), a hydrostatic relief facility via connecting channels (17a, 17b) provided in the pressure relief elements (10a, 10b), said connecting channels acting as non-return valves and generating a pressure relief of an intermediate space (Zb) when the pressure of the intermediate space is increased above the pressure of the following intermediate space at the high-pressure side plus a corresponding pressure increase variable.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

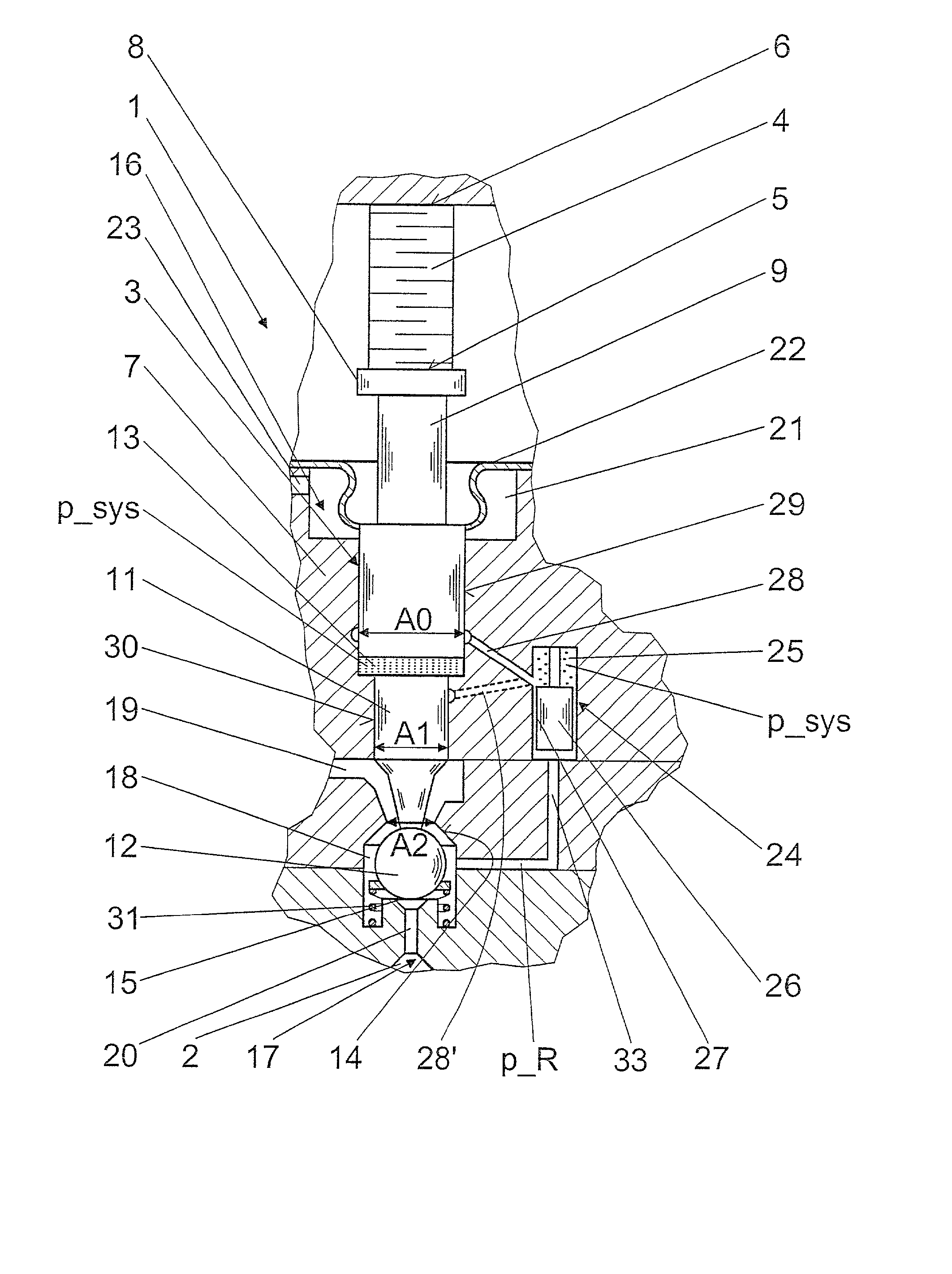

Valve for controlling liquids

InactiveUS20020104976A1Reduce voltageIncrease system pressureOperating means/releasing devices for valvesMovable spraying apparatusLine tubingSystem pressure

The invention relates to a valve for controlling fluids, having an actuator unit (4) for actuating a valve member (3) which has a first piston (9) and a second piston (11), separated from it by a hydraulic chamber (13), and which actuates a valve closing member (12) that divides a low-pressure region (16) at system pressure from a high-pressure region (17). For leakage compensation, a filling device (27) connectable to the high-pressure region (17) is provided with a hollow chamber (25), in which a throttle body (26) is disposed such that a line (33) leading to the high-pressure region (17) discharges into the hollow chamber (25) on one end of the throttle body (26), and on the other end a system pressure line (28) leading to the hydraulic booster branches off. The system pressure (p_sys) is built up as a function of the prevailing pressure (p_R) in the high-pressure region (17), by means of geometrically defining the throttle body (26), a gap (27) surrounding it, and the dimensions of the piston (9) along which the system pressure is reduced (<cross-reference target="DRAWINGS">FIG. 1< / cross-reference>).

Owner:ROBERT BOSCH GMBH

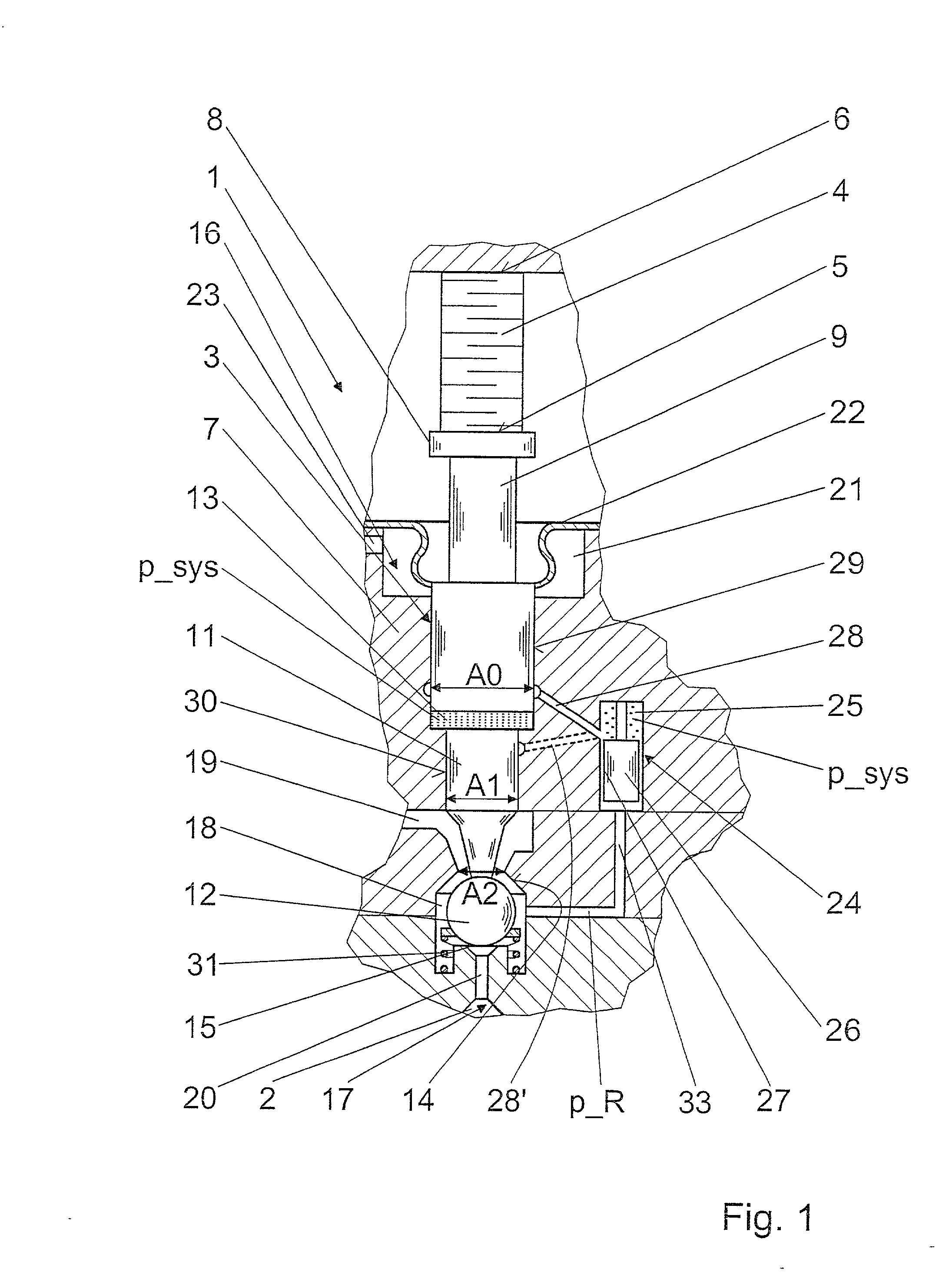

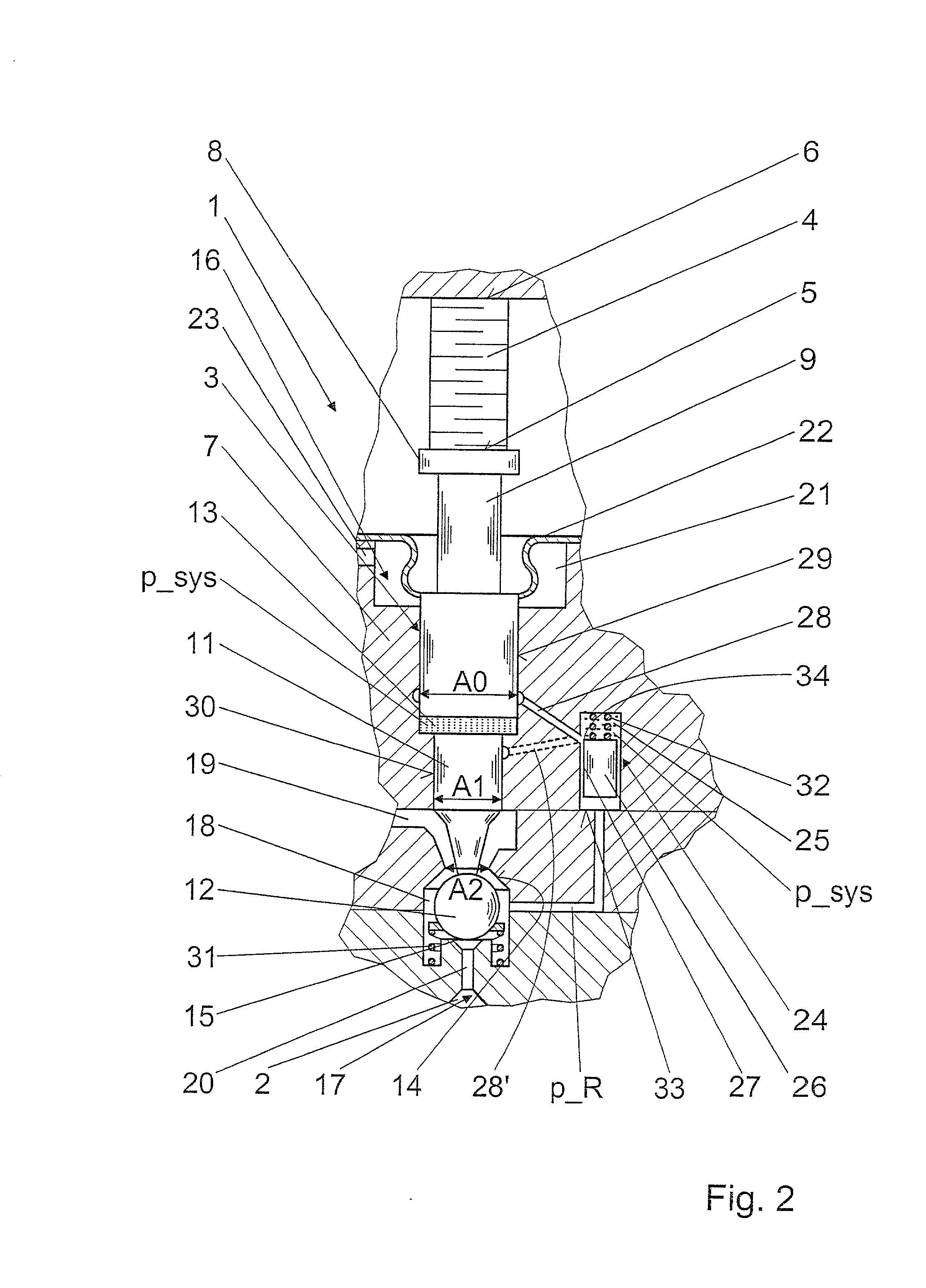

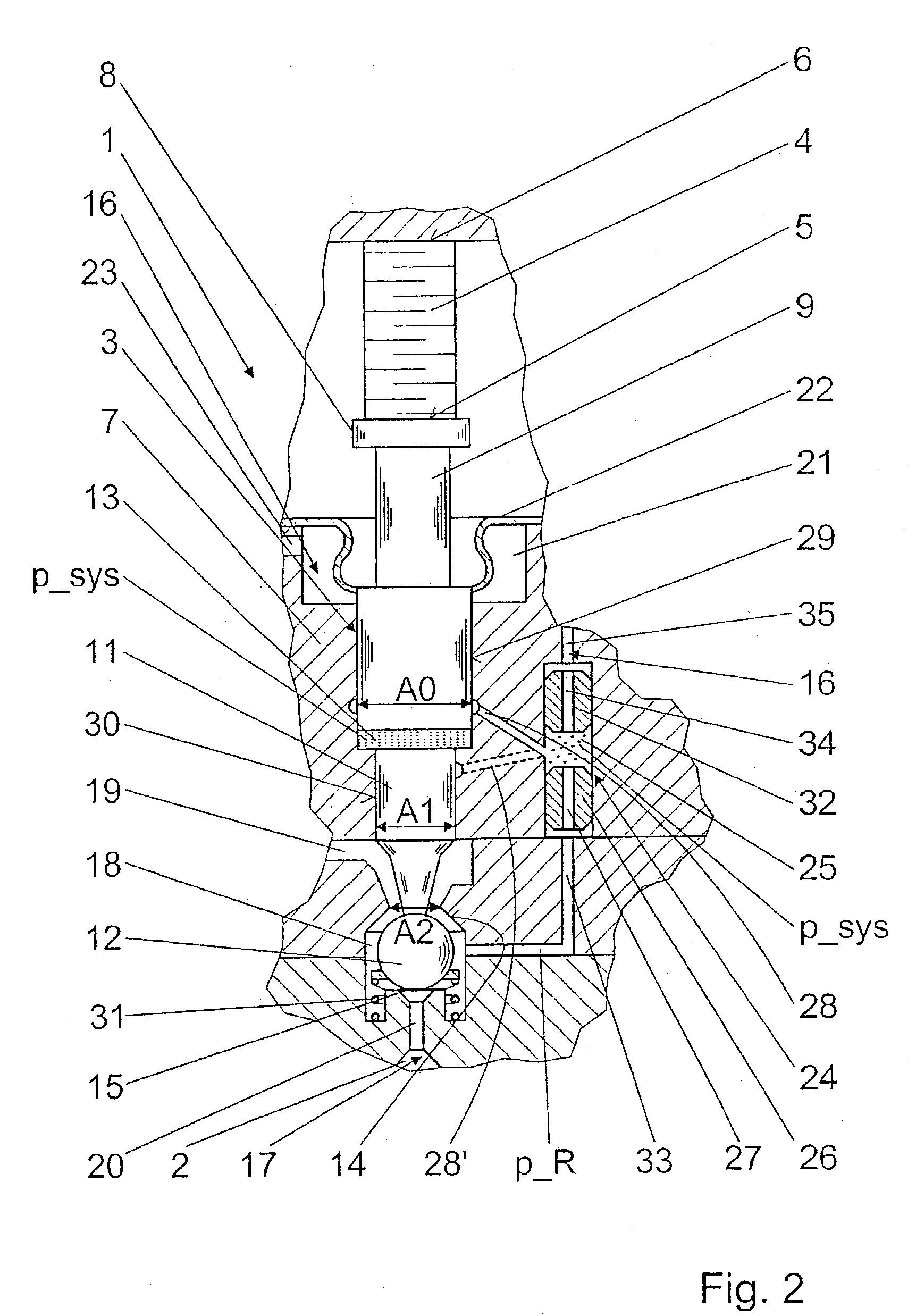

Valve for controlling the flow fluids

InactiveUS20030098428A1Easy to adjustLow costOperating means/releasing devices for valvesMovable spraying apparatusLine tubingSystem pressure

A valve for controlling fluids [is proposed,] having an actuator unit [(4)] for actuating a valve member [(3)], which has a first piston [(9)] and a second piston [(11)], separated from it by a hydraulic chamber [(13)], and which actuates a valve closing member [(12)] that divides a low-pressure region [(16)] at system pressure from a high-pressure region [(17)]. For leakage compensation, a filling device [(27)] connectable to the high-pressure region [(17)] is provided with a hollow chamber [(25)], in which a throttle body [(26)] is disposed such that a line [(33)] leading to the high-pressure region [(17)] discharges into the hollow chamber [(25)] on one end of the throttle body [(26)], and on the other end a system pressure line [(28)] leading to the hydraulic chamber [(13)] branches off. The system pressure is built up by geometric definition of a throttle bore [(27)] in the throttle body [(26)] and of the dimensions of the piston [(9)], along which the system pressure [(p_sys)] is reduced, as a function of a prevailing pressure in the high-pressure region. Alternatively, a second throttle body [(32)] can be provided in the hollow chamber [(25)], and this throttle body has a throttle bore [(34)] which is preceded by a leakage line [(35)] branching off from the hollow chamber [(25)], and along which throttle body the system pressure is reduced [(FIG. 1)].

Owner:ROBERT BOSCH GMBH

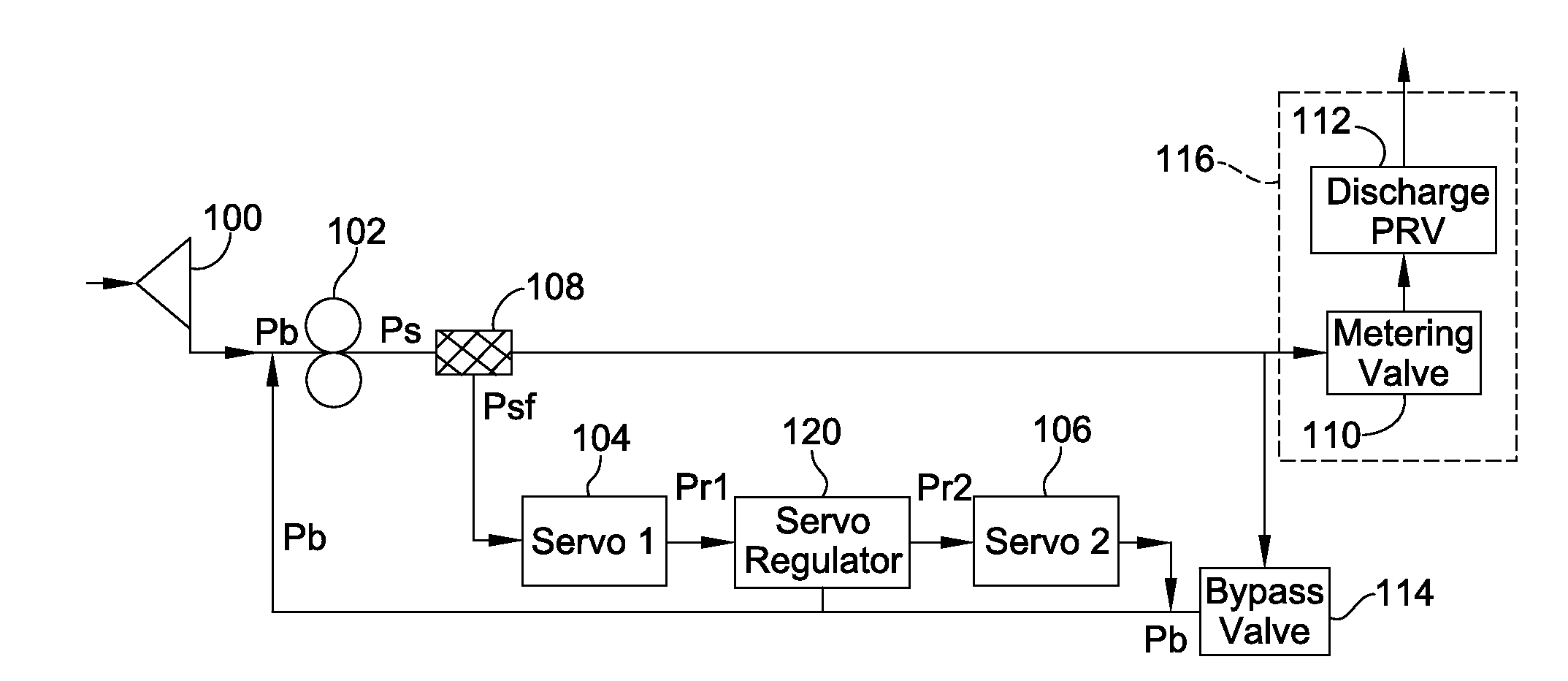

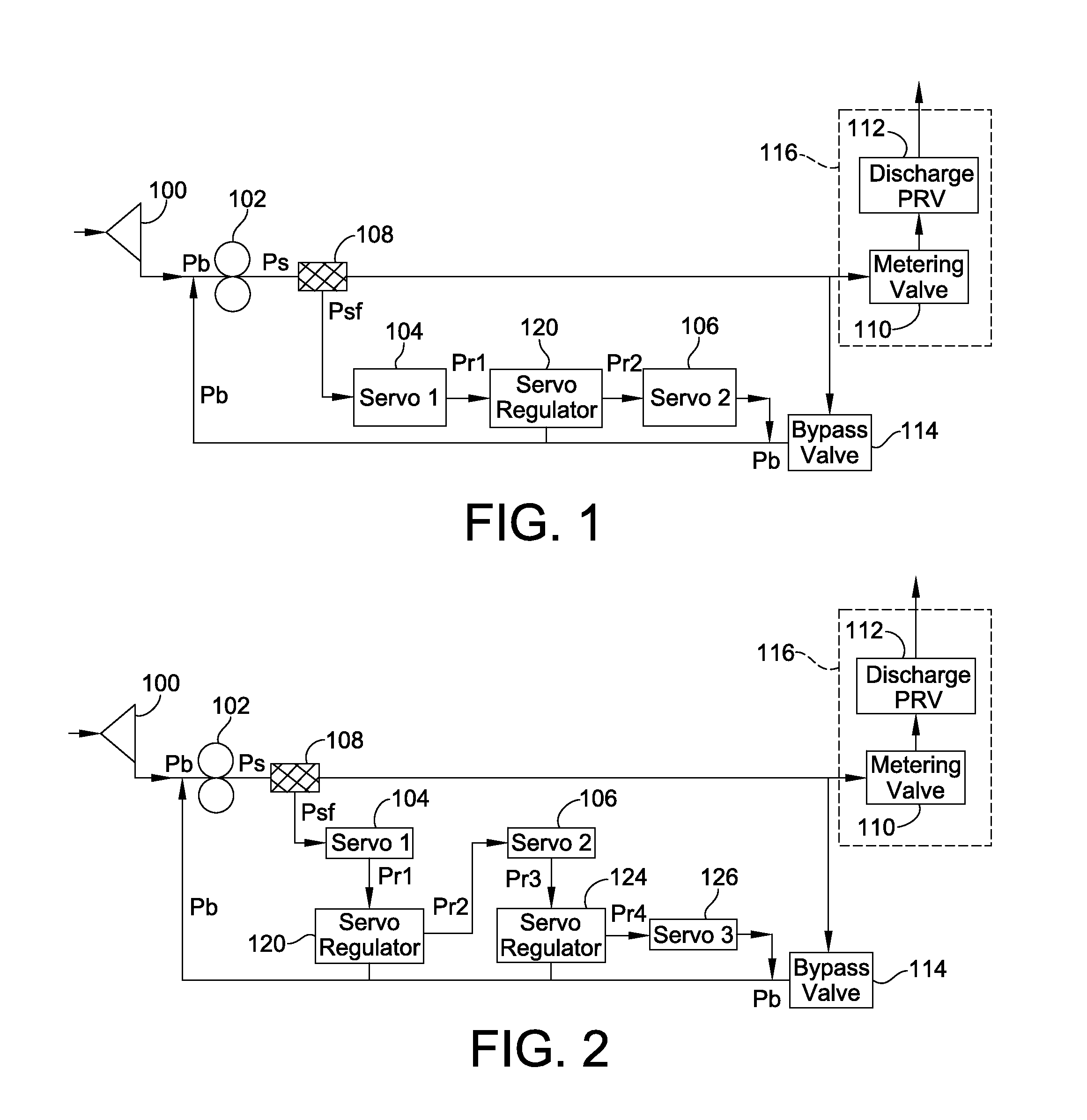

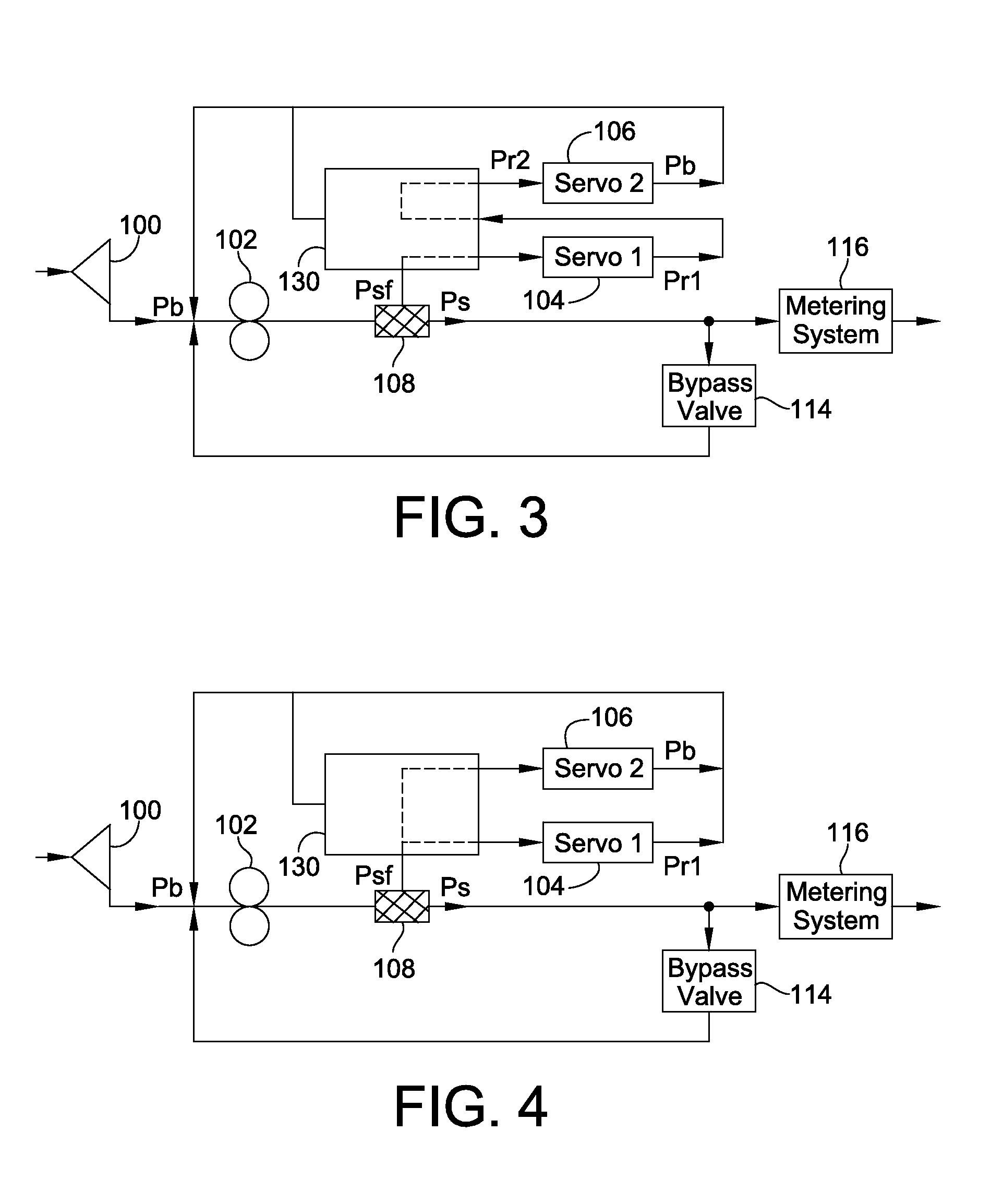

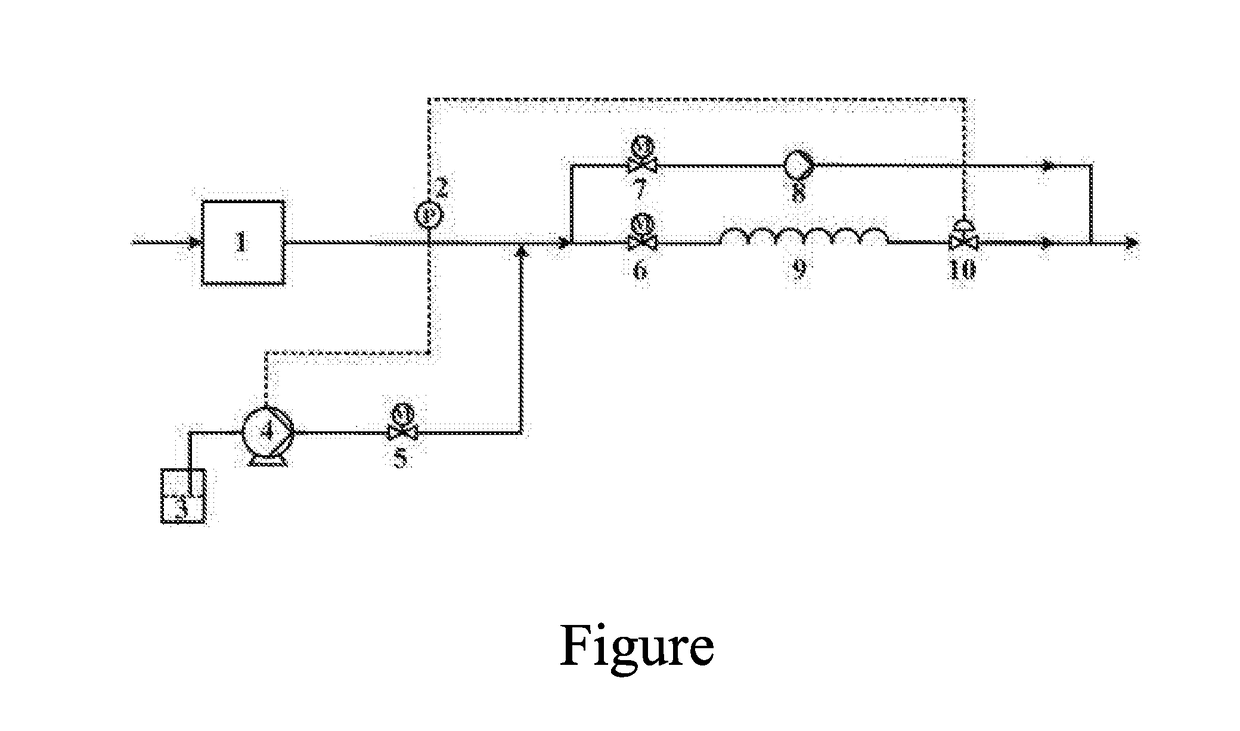

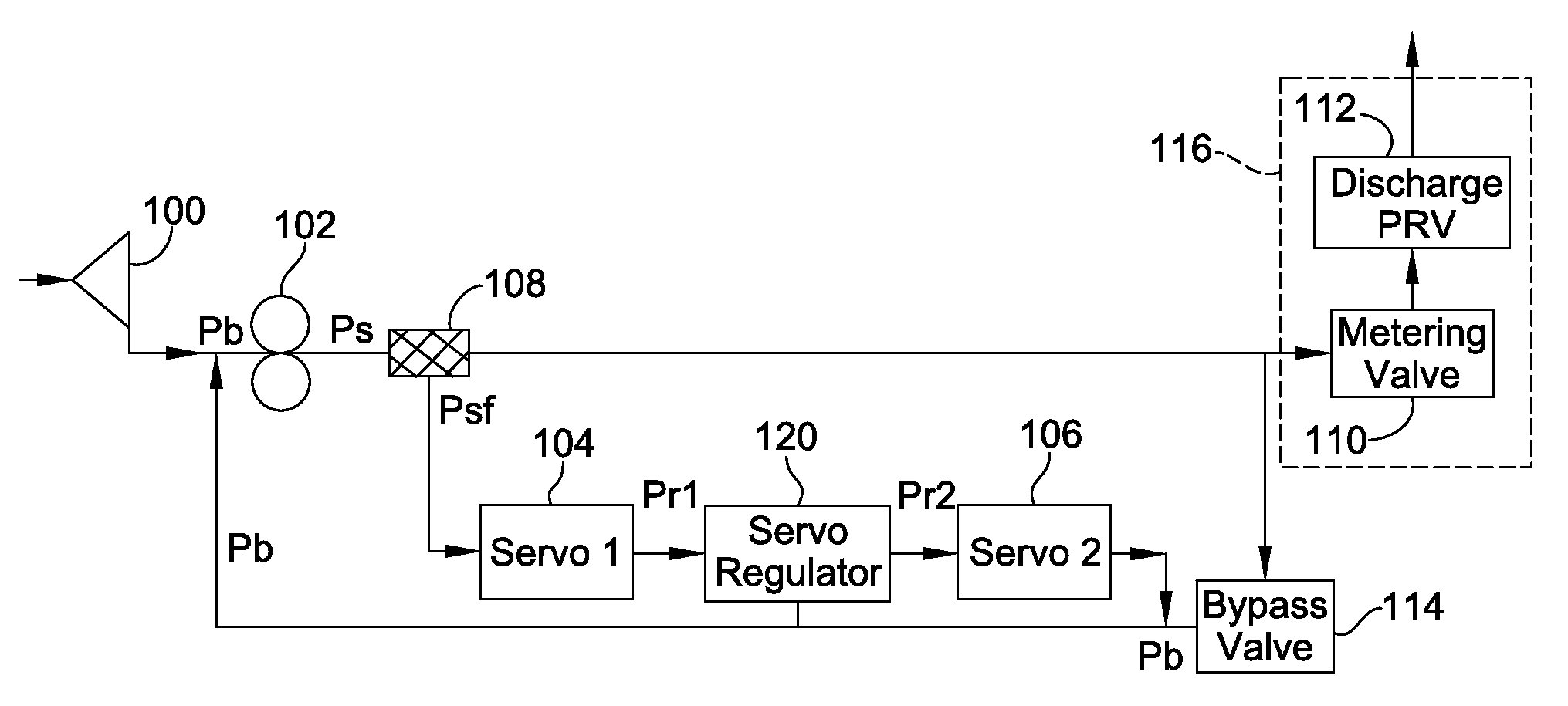

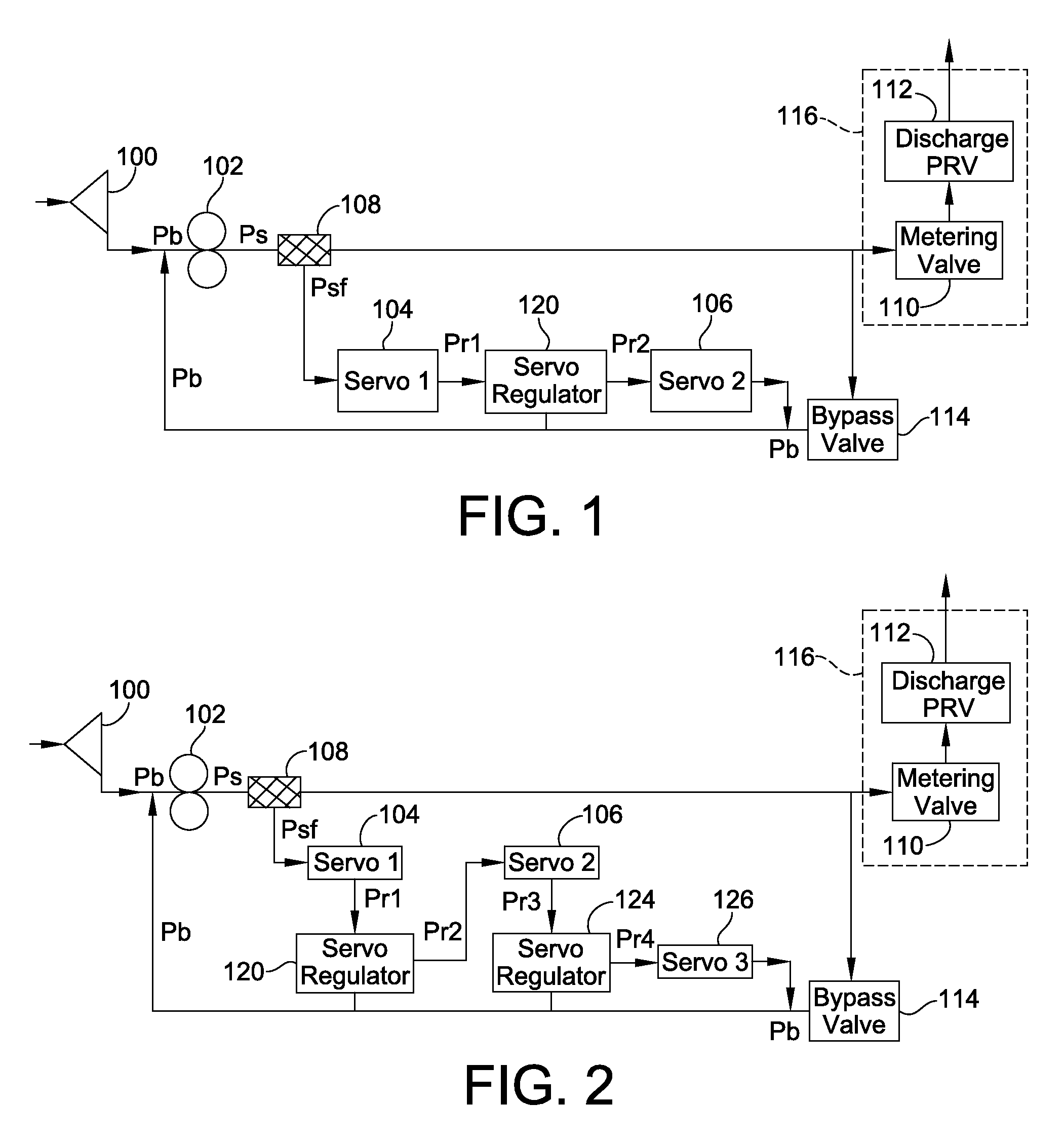

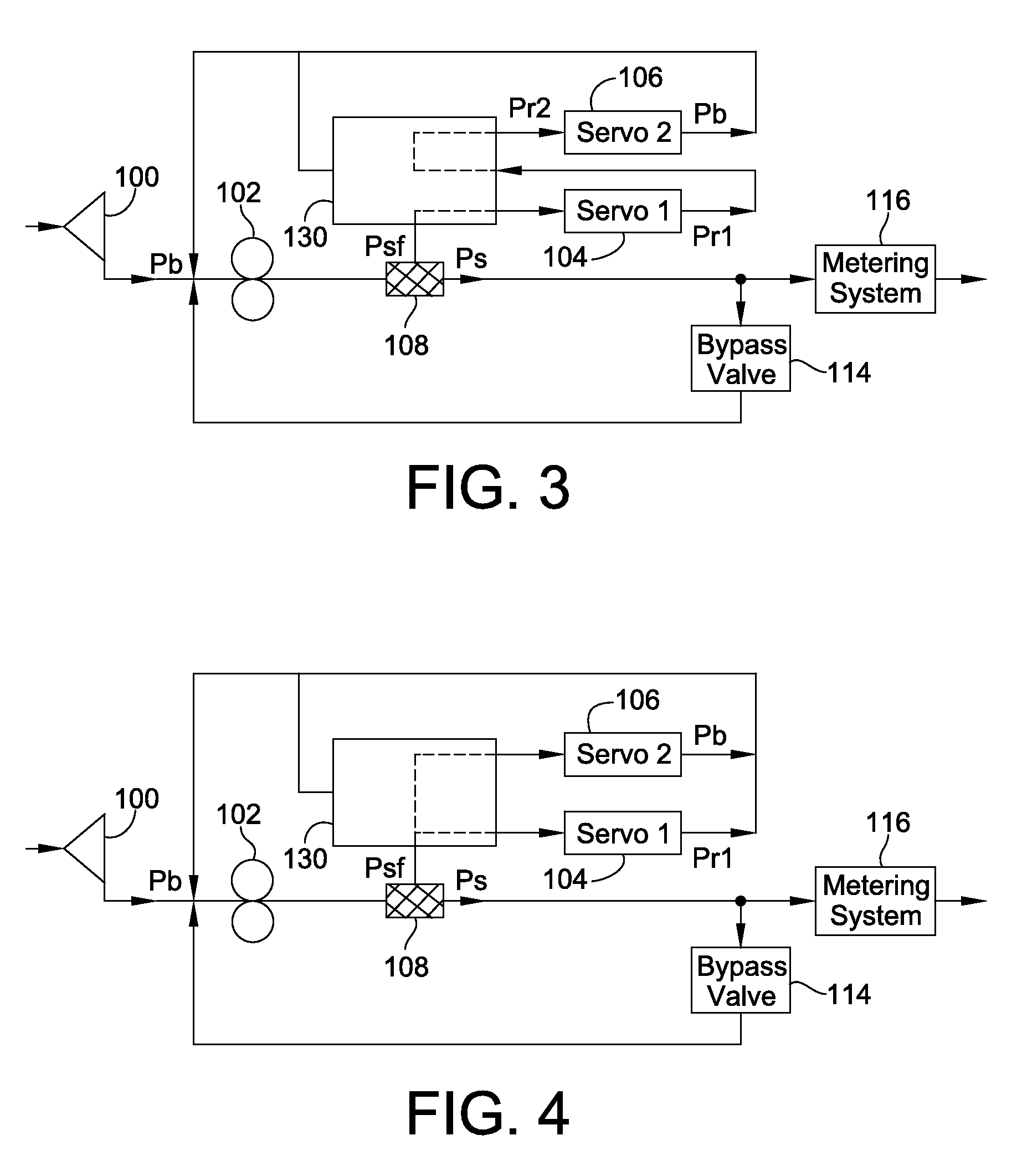

Servo Flow Recirculation for an Advanced Thermal Efficient Aircraft Engine Fuel System

ActiveUS20150020884A1High relight pressureFacilitate inventionEngine fuctionsTurbine/propulsion fuel deliveryAviationStreamflow

A fuel circulation system and methods are provided. The system includes a supply pump for providing an outlet flow of fuel. The system also includes at least a first and a second servo. The first servo is connected to an outlet of the supply pump. A flow regulation device is interposed between the first and second servos. At least a portion of the outlet flow from the supply pump is directed through the first servo, flow regulation device, and second servo and is returned to an inlet of the supply pump.

Owner:WOODWARD GOVERNOR CO

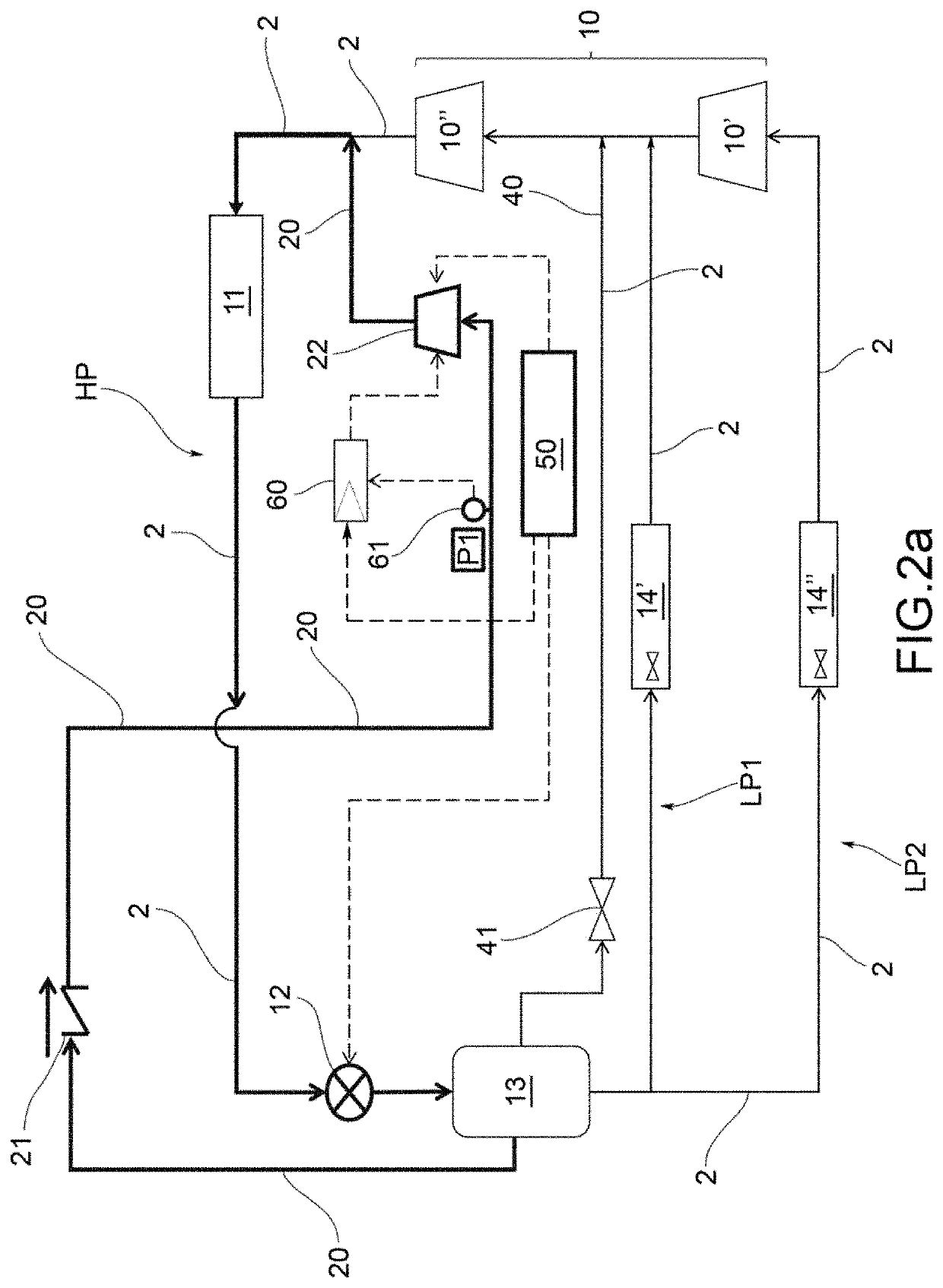

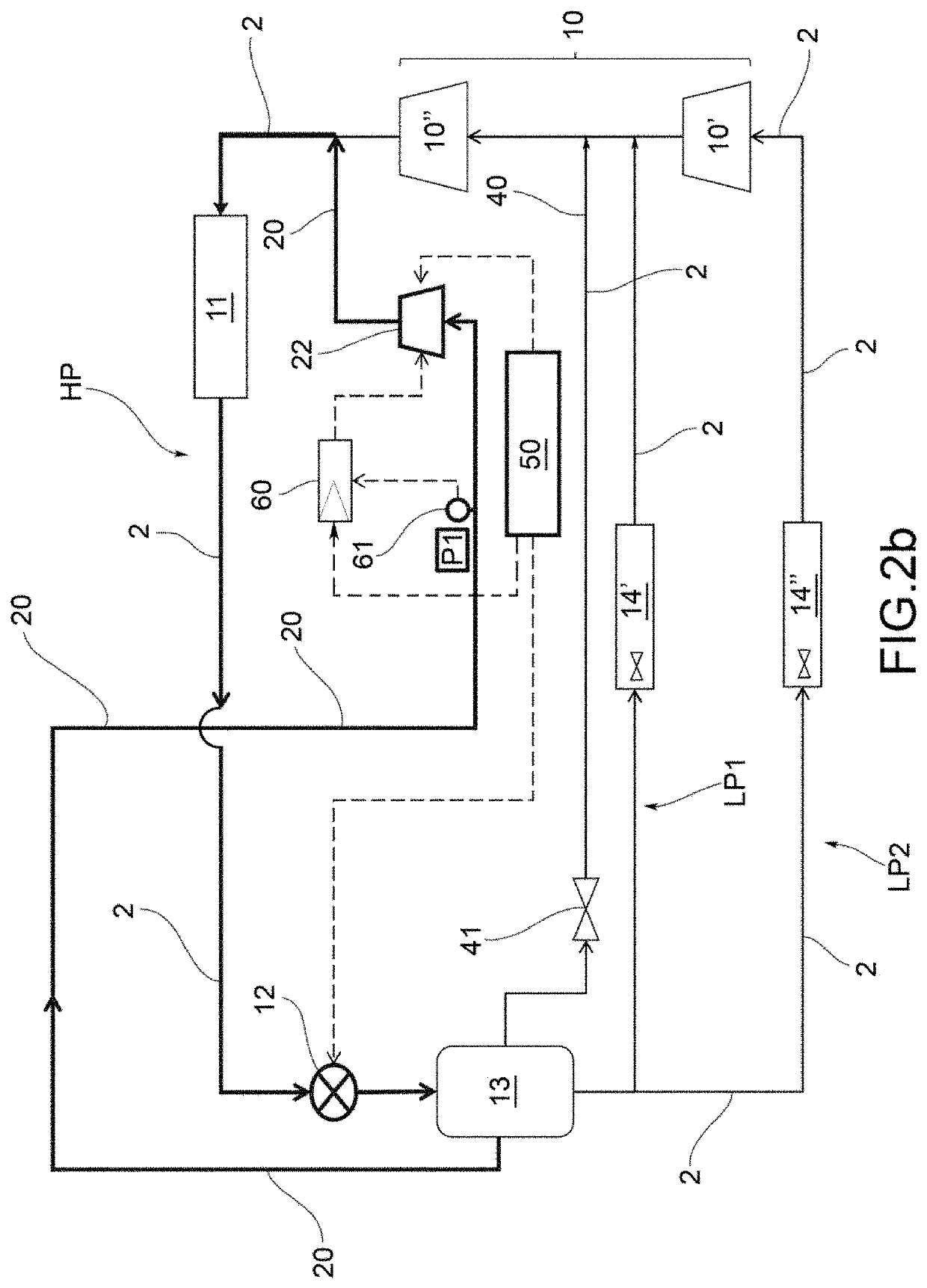

Vapor compression refrigeration system and method of operating such a system

PendingUS20210254864A1Eliminate orMitigate such drawbackMechanical apparatusCompression machines with non-reversible cycleEngineeringUninterruptible power supply

A vapor compression refrigeration system has a main refrigerant circuit having a primary compressor group, a gas cooler or condenser, an expansion device, a liquid receiver, and at least one evaporator. An emergency circulation duct fluidically connects the liquid receiver to the main circuit to allow a flow of refrigerant from the liquid receiver to the gas cooler. An emergency compressor group in the emergency circulation duct is activatable when pressure inside the liquid receiver or in the duct upstream of the emergency compressor group meets or exceeds a predefined emergency pressure threshold. An uninterruptible power supply powers the emergency compressor group and expansion device during a shutdown of the refrigeration system. When pressure inside the liquid receiver or in the duct upstream of the emergency compressor group equals or exceeds the predefined emergency pressure threshold, an emergency circulation of refrigerant fluid is activated through the emergency circulation duct.

Owner:EPTA

Device, method and system for compressed air control and compressed air supply

ActiveUS9347581B2Easy to startEasy to rinseOperating means/releasing devices for valvesBraking action transmissionSystem pressureEngineering

For a vehicle, a compressed air control device controls operating states of a compressor and an air drying device, and includes a compressor control outlet pneumatically connectable to a control inlet of the compressor, a system pressure inlet pneumatically connectable to a system pressure line that conducts a system pressure produced by the compressor, a ventilation control outlet pneumatically connectable to a control inlet of the air drying device and configured to pneumatically switch an operating state of the air drying device, a pneumatically operable ventilation control valve controllable by the system pressure to pneumatically couple the system pressure inlet to the ventilation control outlet to switch the operating state of the air drying device, and an electrically operable supply control valve configured to pneumatically couple the system pressure inlet to the compressor control outlet independently of the system pressure to switch the operating state of the compressor.

Owner:WABCO GMBH

Control system for descreasing pressure of supercritical water system and method thereof

ActiveUS20170269615A1Operation complexity can be reducedGuaranteed uptimeWater treatment parameter controlWater contaminantsPressure decreaseControl system

A control system for decreasing pressure of a supercritical water system and a method therefor is provided, mainly including: a resistance water storage tank, a resistance pump, a capillary negative booster, a back pressure valve, a regulating valve and related stop valves. By switching the back pressure valve branch and the capillary negative booster branch, the pressure regulation is achieved while starting the system, closing down and in normal operation. The present invention is capable of achieving precisely controlling pressure of the system on the basis of effectively preventing problems exists in the solid particle materials pressure decreasing process such as abrasion and clogging of the internal elements of the valve. In addition, the back pressure valve branch is capable of reducing the operation complexity in the starting and shutdown process of the system, and the operation reliability is improved.

Owner:XI AN JIAOTONG UNIV +1

Valve for regulating fluids

InactiveUS6655605B2Reduce voltageSmaller, less-expensive piezoelectric unitOperating means/releasing devices for valvesMovable spraying apparatusSystem pressureEngineering

The invention relates to a valve for controlling fluids, having a piezoelectric unit (4) for actuating a valve member (3), with which a valve closing member (12) is associated that divides a low-pressure region (16) at system pressure from a high-pressure region (17). The valve member (3) has at least one first piston (9) and one second piston (11), between which a hydraulic chamber (13) is embodied. To compensate for leakage losses, a filling device (23) is used, which can communicate with the high-pressure region (17) and which has at least one channel-like hollow chamber (24), in which a solid body (25) is disposed, with a gap surrounding it, in such a way that on one end (25A) of the solid body (25), a line (26) branching off from the high-pressure region (17), and on its opposite end (25B) a leakage line (27) discharges into the hollow chamber (24), and that a line (29) leading to the hydraulic chamber (13) branches off along the length of the solid body (25), and the system pressure (p_sys) in the hydraulic chamber (13) is adjustable by geometric definition of the branching point (28) (FIG. 1).

Owner:ROBERT BOSCH GMBH

Pressure Transformation Method and Device for its Implementation

InactiveUS20120204553A1Reliable working principleSpeed up travelBraking action transmissionRotary clutchesTransformerSystem pressure

A method for transforming pressures of a system operating with pressure medium to optimize the travel speeds and / or forces of tasks utilizing pressure, area and flow ratios, employing valve structures, in which method, transforming with pressure transformers the pressure of the actuators differ from system pressure. A device implementing the method includes valve structures and pressure transformers. In the method, pressure transformers are switched when going above or below a set limit value controlling valves of actuators which requires the transformation of travel speed or force. In the device, pressure transformers are arranged to be switched when going above or below a set limit value controlling the valves for the actuator which requires higher travel speed or force.

Owner:JUNTTILA MIKKO

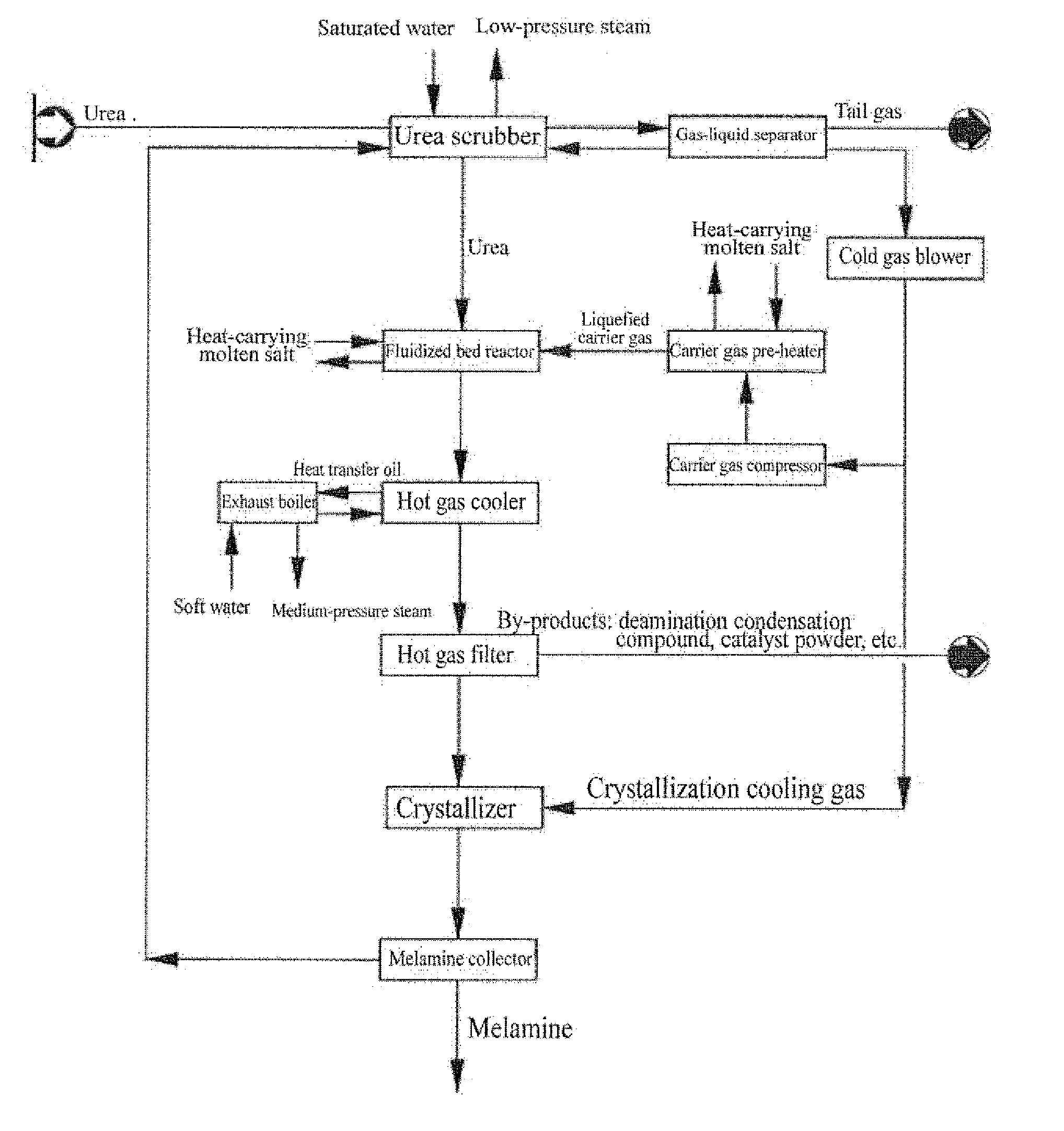

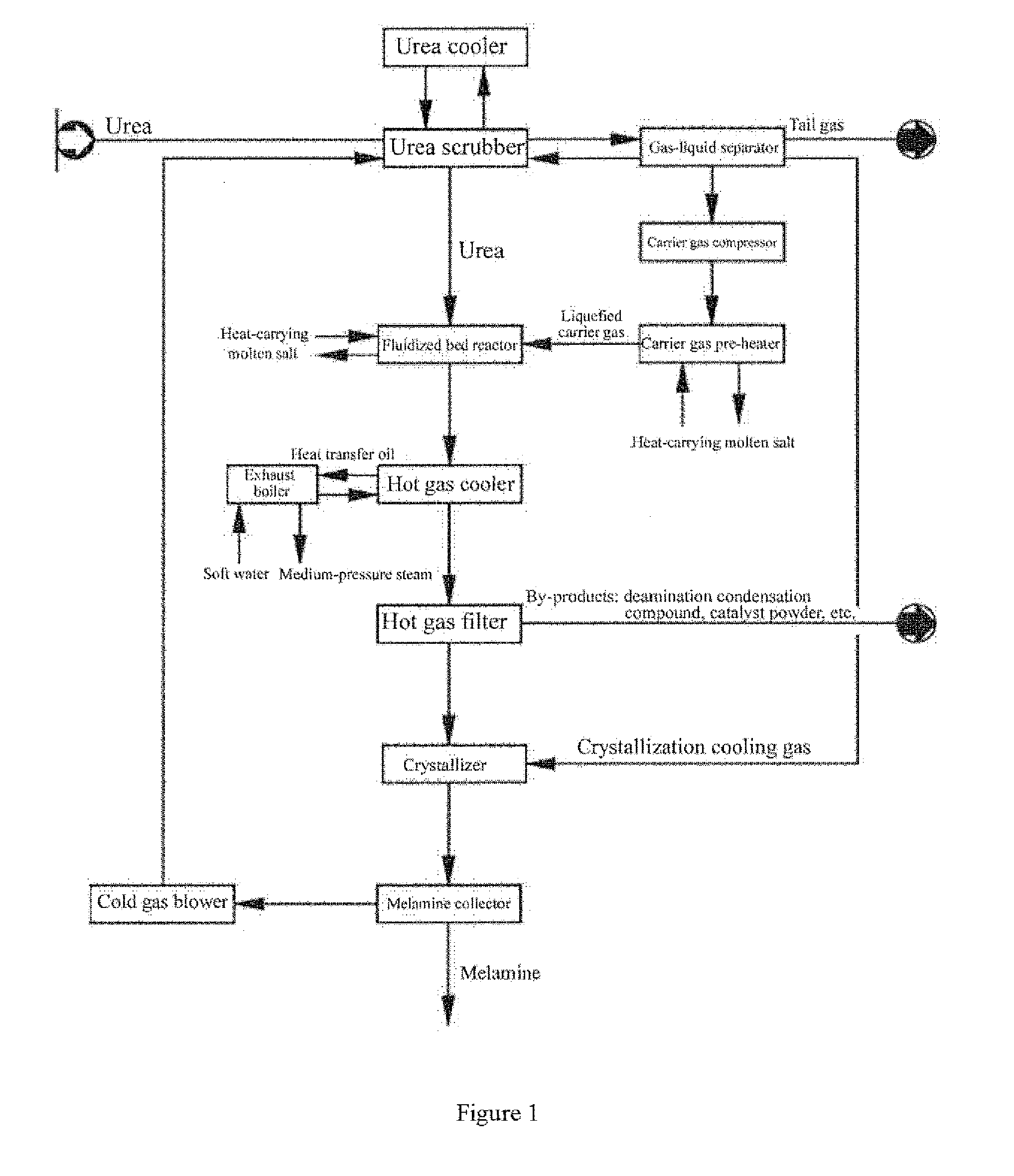

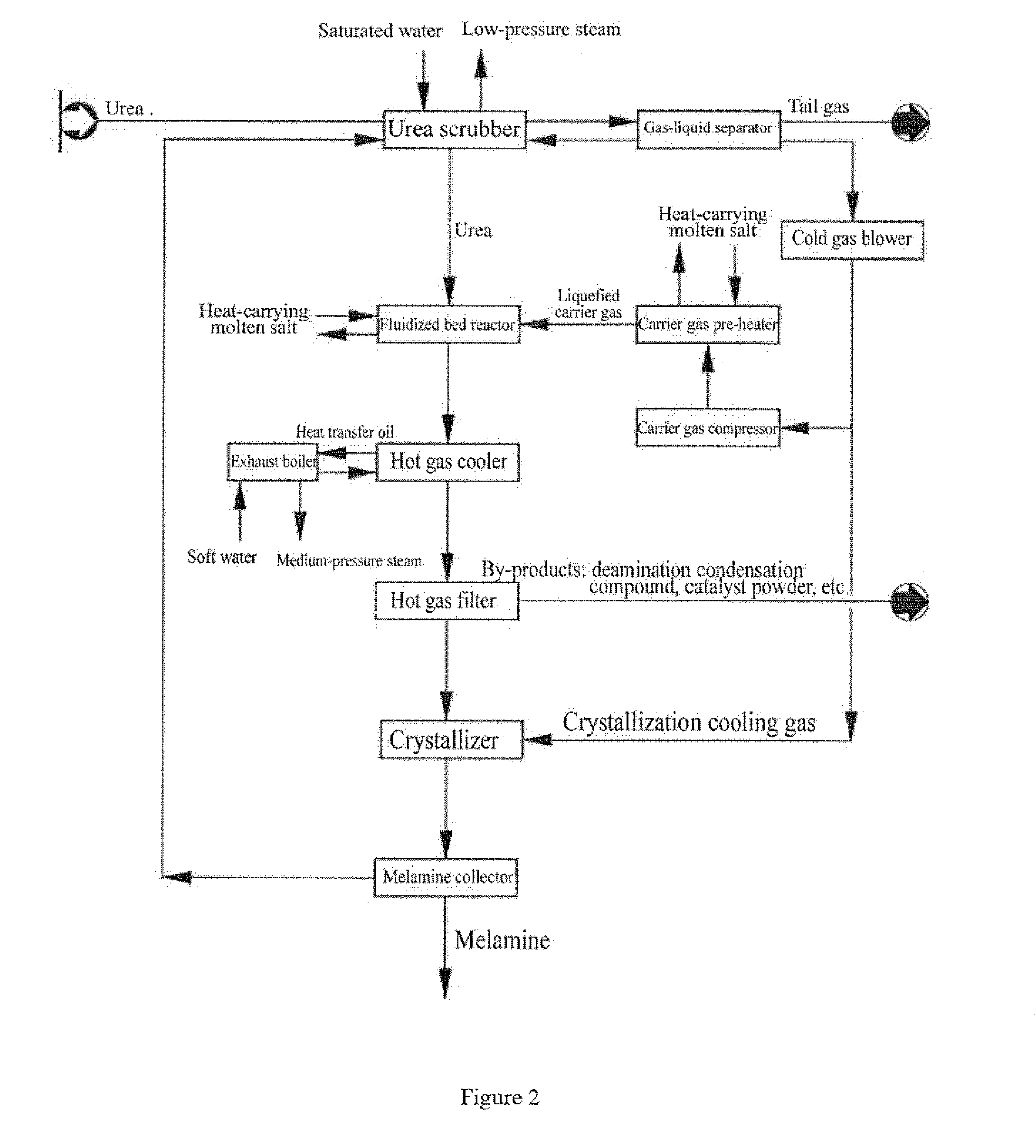

System and process for melamine production by gas-phase quenching method of energy efficient and cost saving type

ActiveUS20130324720A1Increase power consumptionImprove production efficiencyOrganic chemistryFluidised-bed furnacesAir filterGas phase

A system and process for melamine production by gas-phase quenching method and its process are provided. The said system includes a urea scrubber, after which a fluidized bed reactor, a hot-air cooler, a hot-air filter, a crystallizer and a melamine collector are installed in series successively, where the said melamine collector is connected to the said urea scrubber and the said fluidized bed reactor is connected to a carrier gas pre-heater which is connected to a carrier gas compressor; the said system further includes a gas-liquid separator which is connected to the said urea scrubber which is connected to a crystallizer; wherein a cool air blower is provided between the said gas-liquid separator and the crystallizer. The production system of the invention has the advantages of high productivity, stable operation, low energy consumption, low investment and high economic value of tail gas.

Owner:BEIJING EDGEIN TECH +1

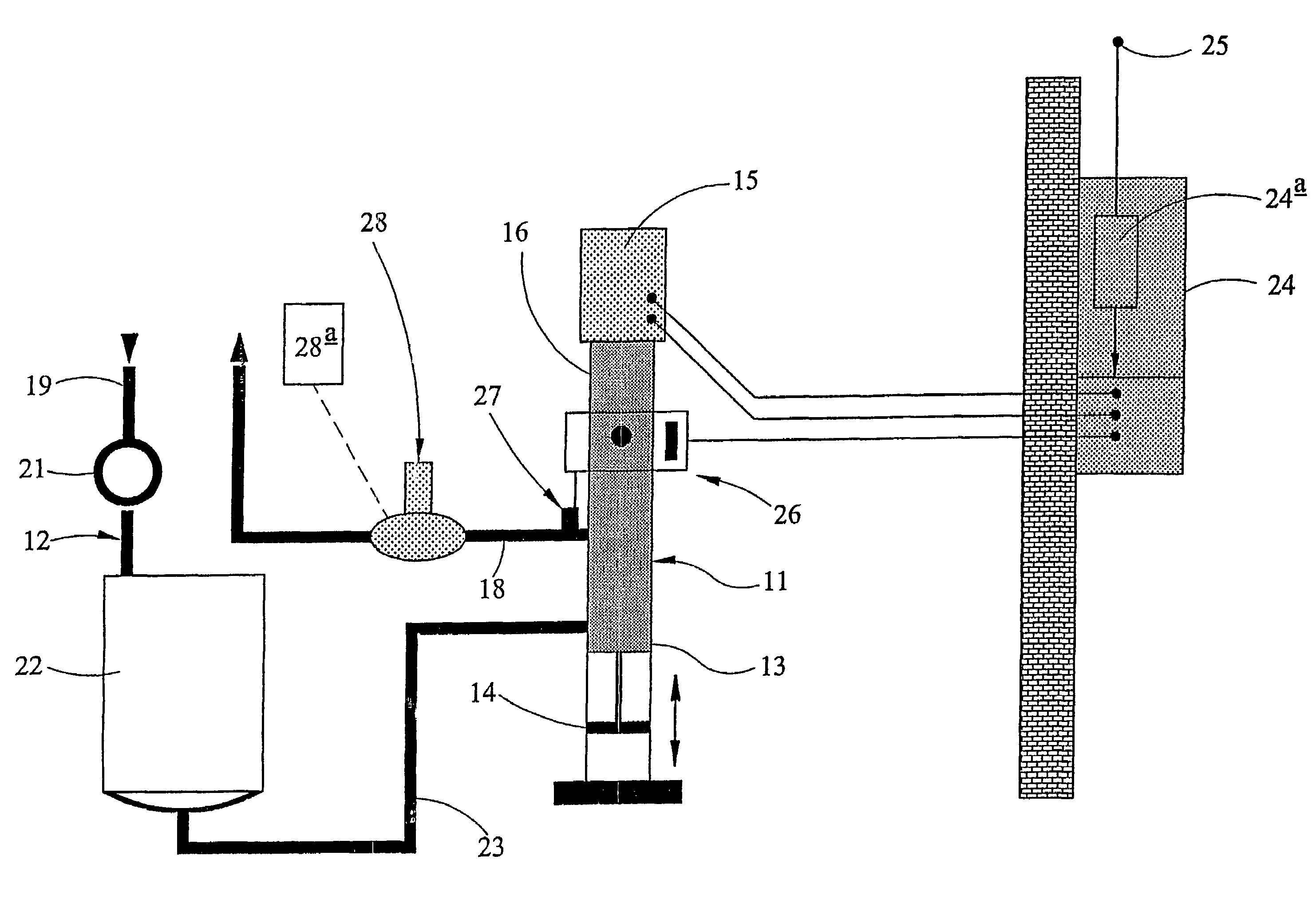

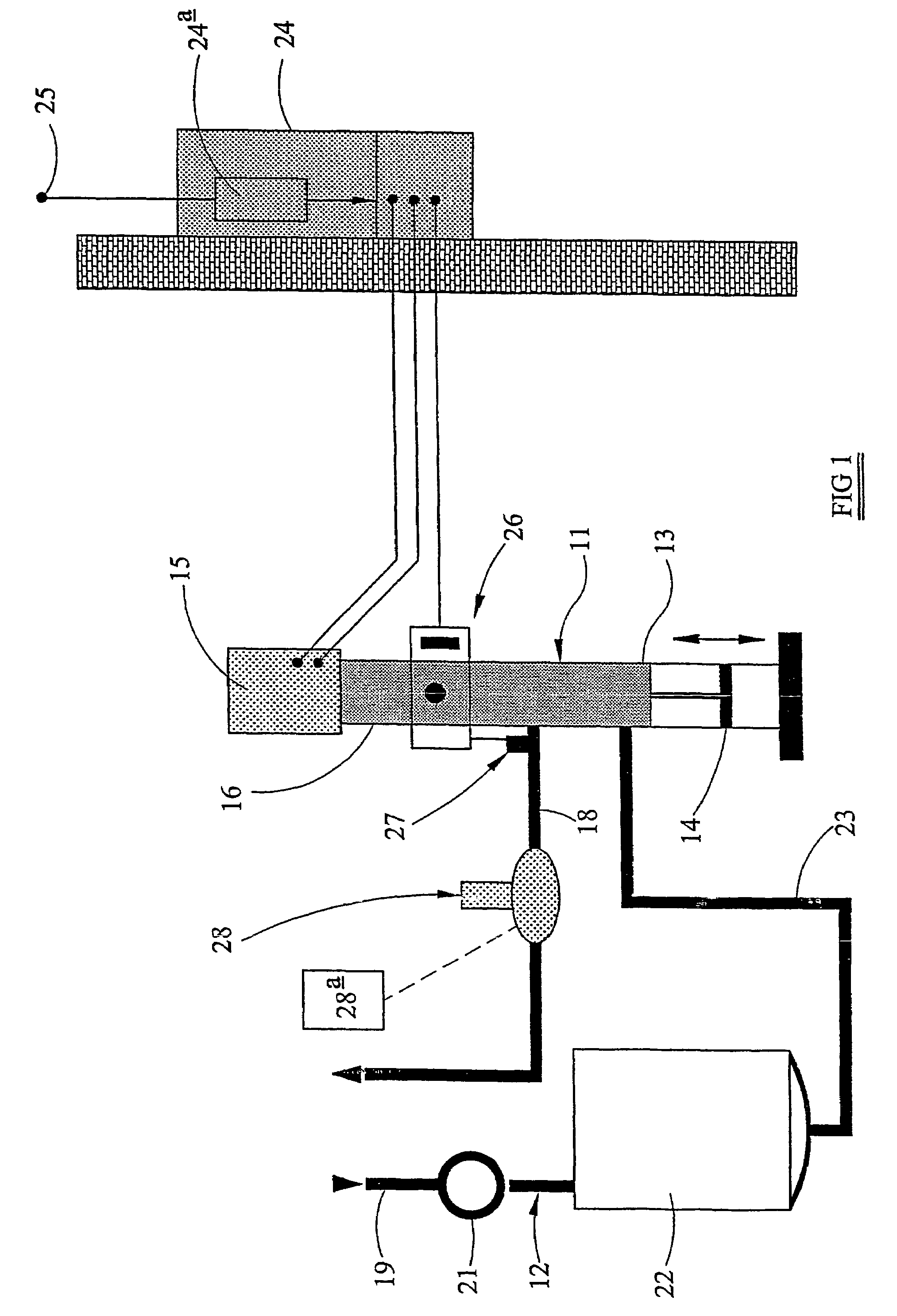

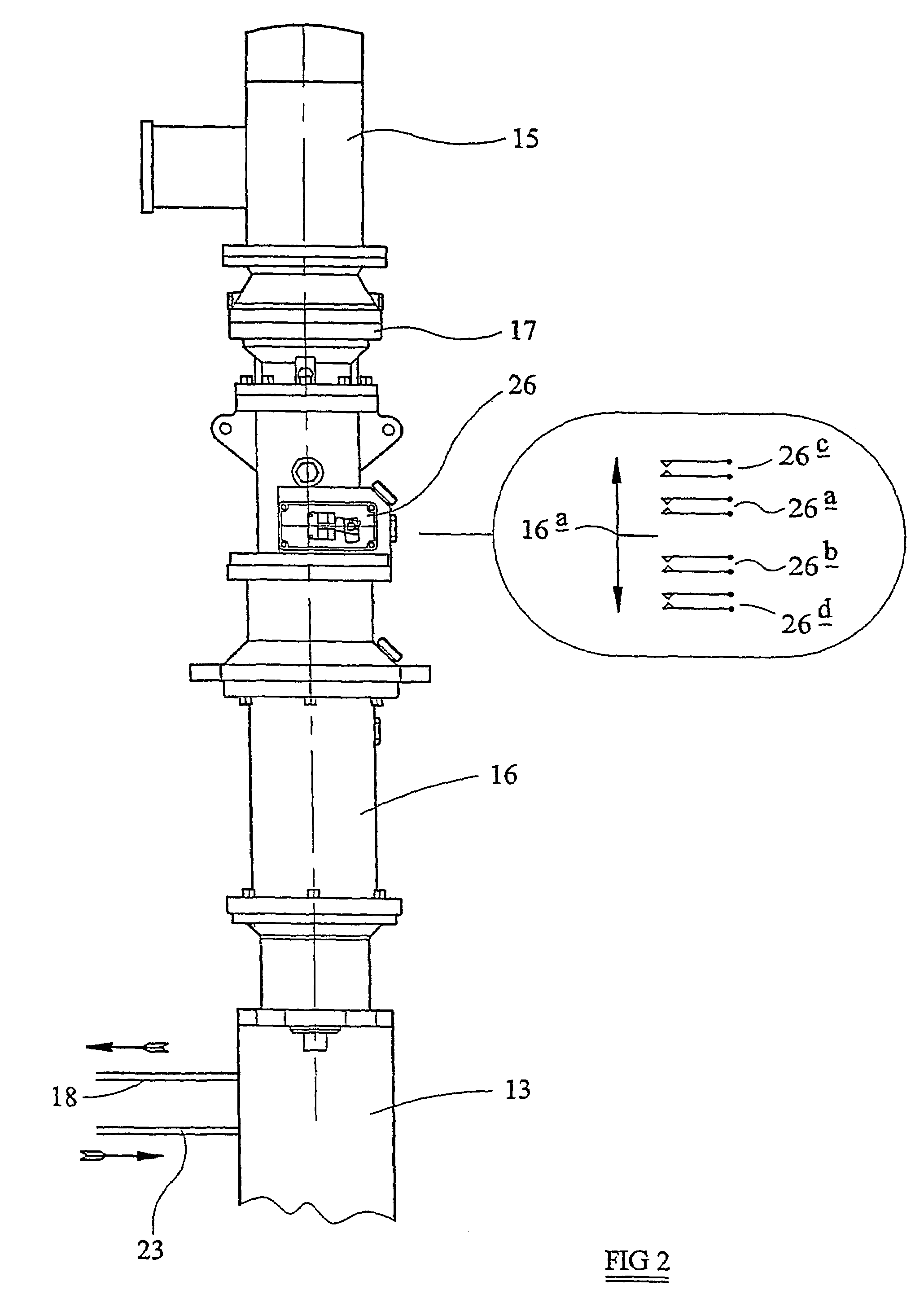

Pumping arrangement

InactiveUS7467927B2Increase pressureInexpensively arrangedSpraying apparatusMotor parameterLinear motionInduction motor

A pumping arrangement for a paint circulation system comprising a reciprocating pump (13), and characterized by an alternating current induction motor (15), a rotary-to-linear motion converter (16) coupling the output of the induction motor (15) to a drive input of the pump (13), an alternating current frequency inverter (24a) controlling said induction motor, switch means (26) for reversing rotation of the induction motor (15) at the ends of the stroke of the reciprocating pump (13), and, a surge eliminator (28) communicating with the output side of said pump (13) to augment the pressure in the circulation system during stroke reversal of the pump.

Owner:ITW LTD

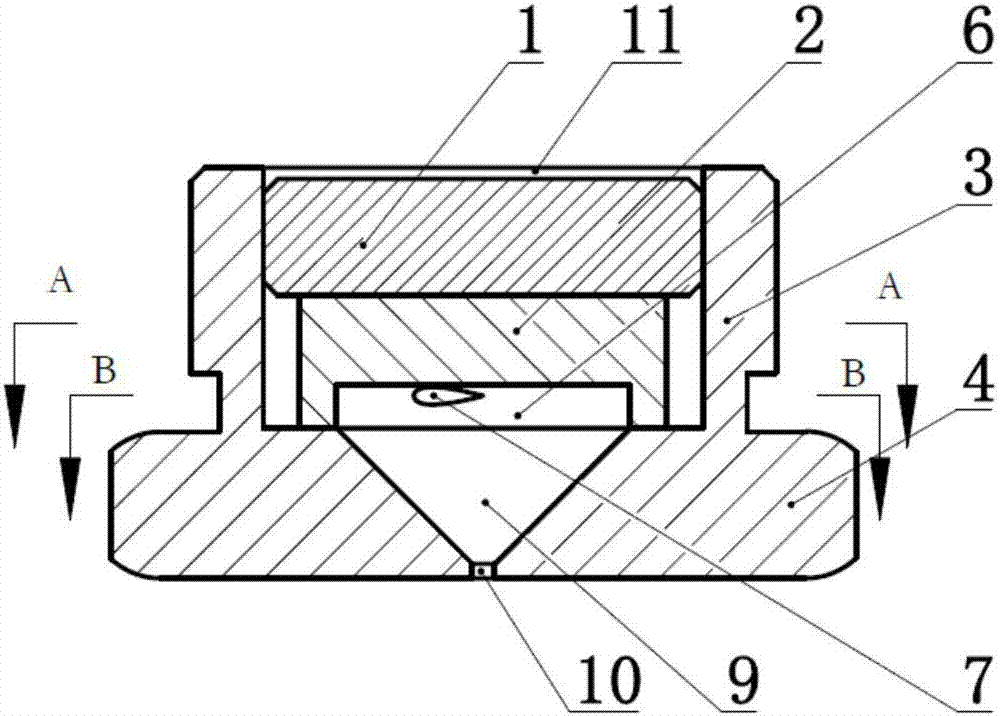

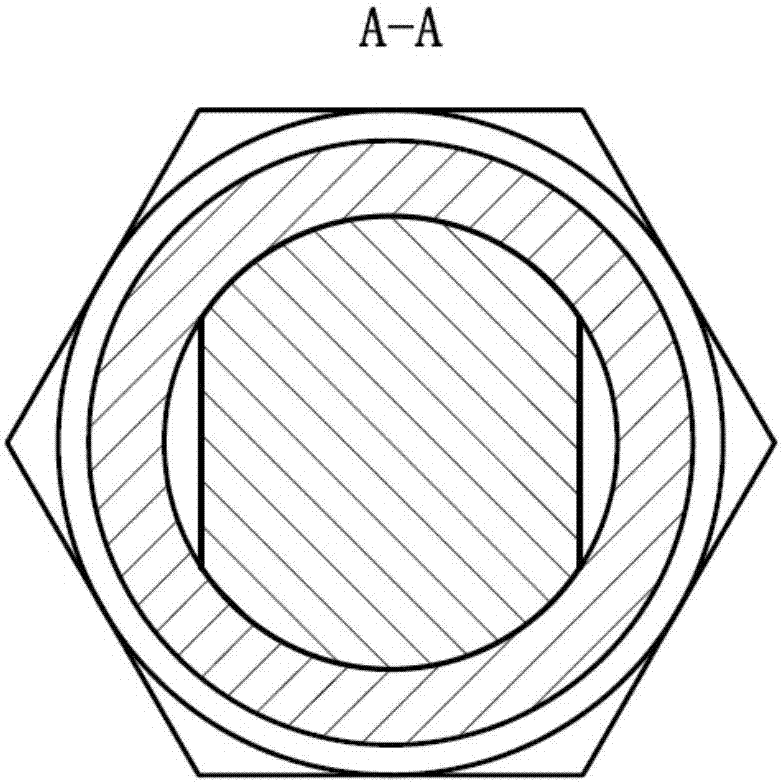

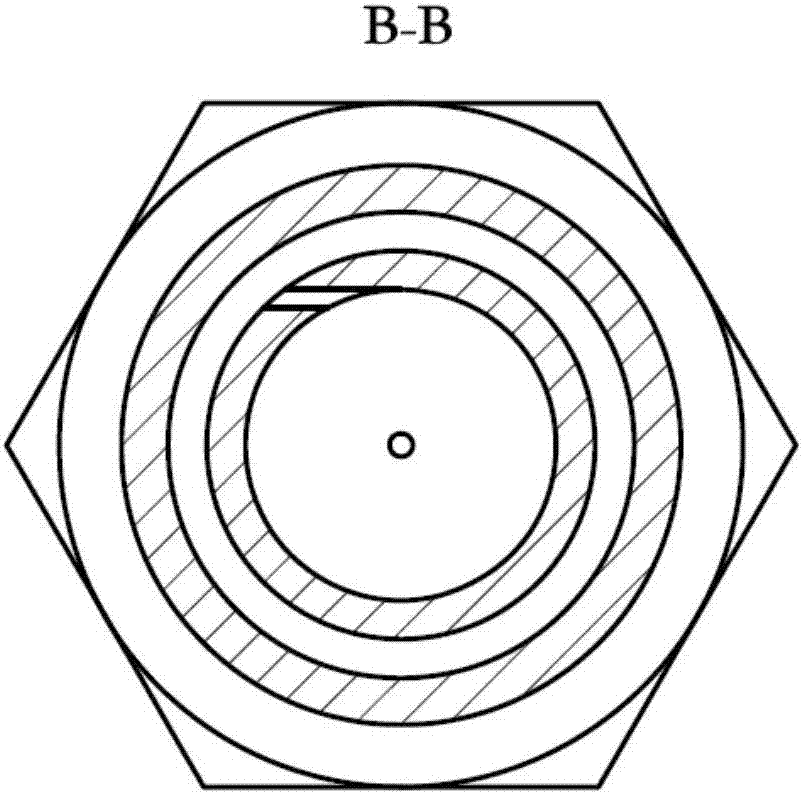

Anti-pollution high-pressure water mist nozzle

PendingCN107570330ALarge adjustment rangeIncrease system pressureSpray nozzlesSpray nozzleHollow cylinder

The invention belongs to the field of nozzles and discloses an anti-pollution high-pressure water mist nozzle. The anti-pollution high-pressure water mist nozzle comprises a boss, a base, a flow guidebody and a filter block. The boss is arranged on the base and is provided with a through hole in the axial direction. The flow guide body and the filter block arranged on the flow guide body are arranged in the through hole. A conical groove is formed in the axial center line of the base. The bottom end of the conical groove is provided with a liquid outlet. The bottom surface of the flow guide body is provided with a hollow cylinder. The side face of the hollow cylinder is provided with a liquid inlet. The side face of the flow guide body is symmetrically provided with notches. Water flow passes through the filter block to be filtered, goes into the flow guide body through the notches, flows into the conical groove through the liquid inlet and then is sprayed out from the liquid outlet.The nozzle provided by the invention is strong in anti-pollution capacity, low in injection starting pressure, good in atomization effect, finer in fog droplet, high in injection speed, long in injection distance and applicable to the fields such as industrial dust removal, fire protection and food processing.

Owner:HUAZHONG UNIV OF SCI & TECH

Servo flow recirculation for an advanced thermal efficient aircraft engine fuel system

ActiveUS9388778B2Facilitate inventionIncrease pressureEngine fuctionsTurbine/propulsion fuel deliveryStreamflowThermal efficiency

A fuel circulation system and methods are provided. The system includes a supply pump for providing an outlet flow of fuel. The system also includes at least a first and a second servo. The first servo is connected to an outlet of the supply pump. A flow regulation device is interposed between the first and second servos. At least a portion of the outlet flow from the supply pump is directed through the first servo, flow regulation device, and second servo and is returned to an inlet of the supply pump.

Owner:WOODWARD GOVERNOR CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com