Sealing system with pressure relief elements and use of a sealing system for producing a pressure cascade in an intermediate space

A technology of sealing system and decompression components, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of component damage, total system failure, component rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

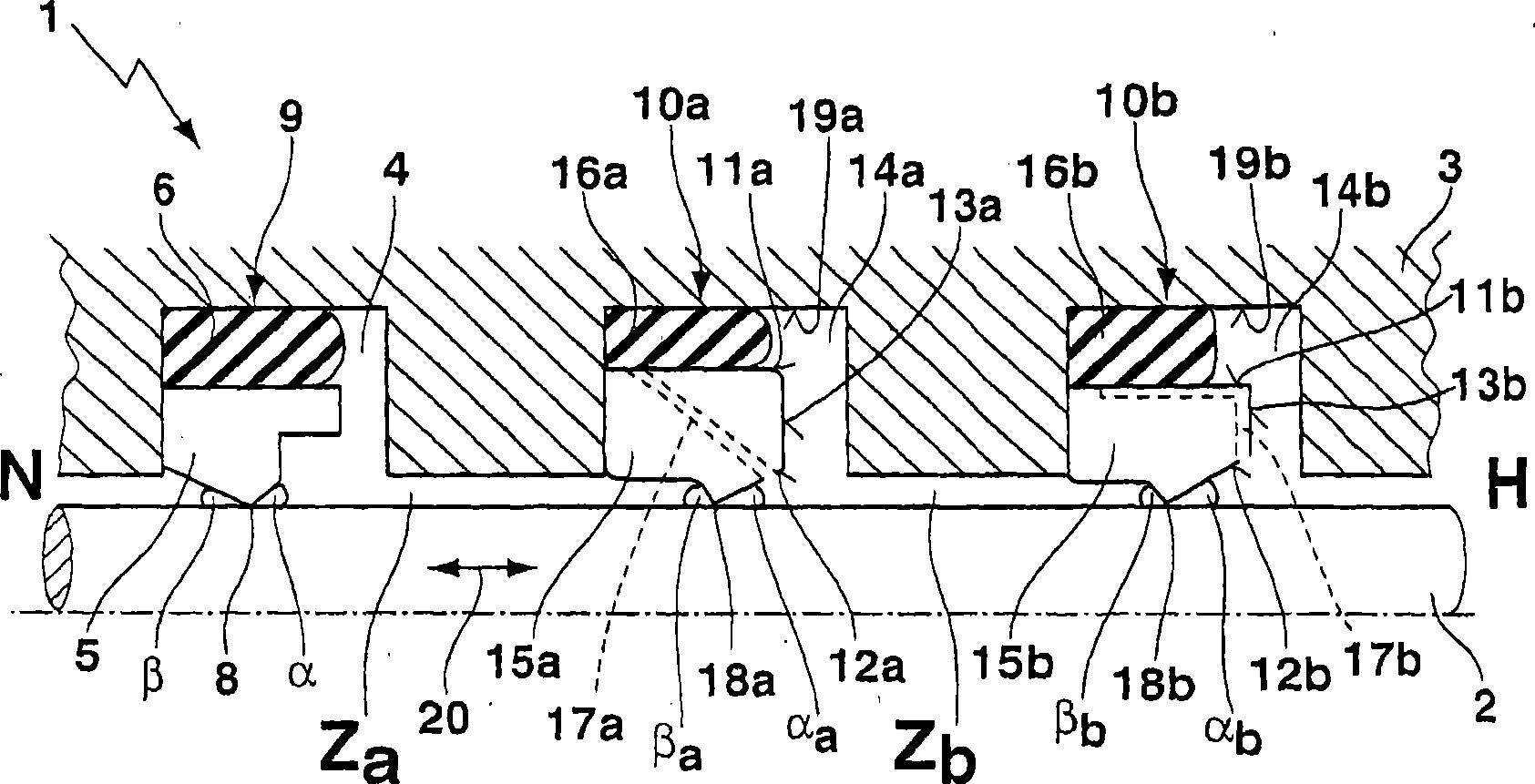

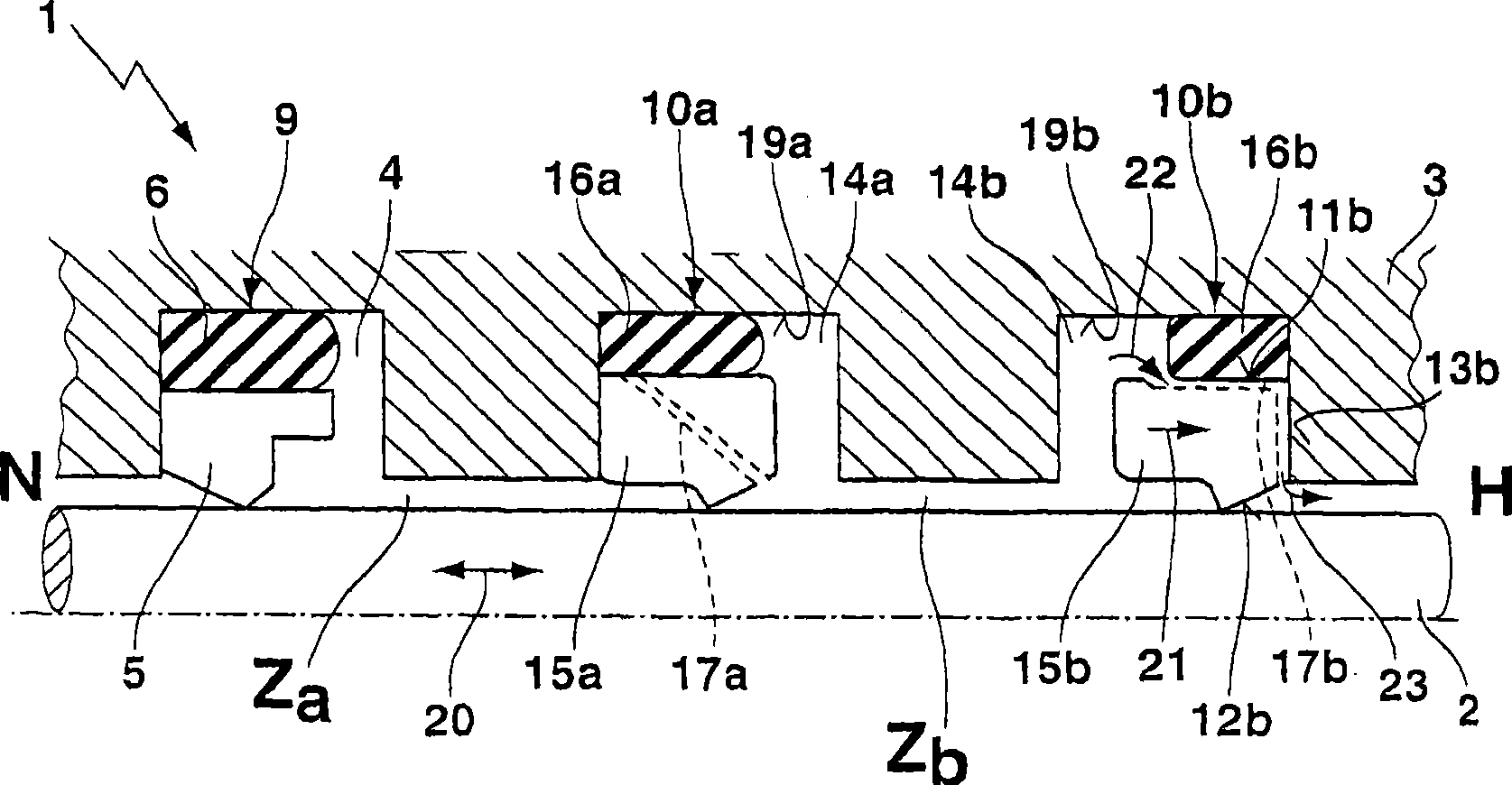

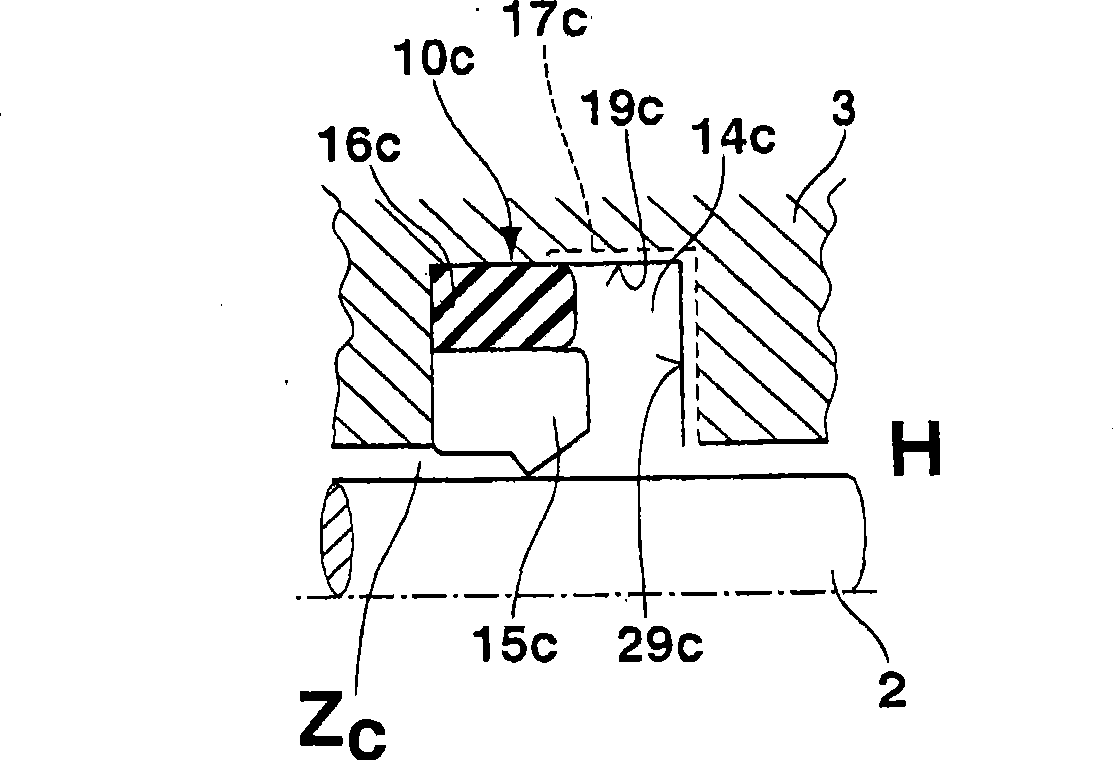

[0051] figure 1 A sealing system according to the invention between two components movable relative to one another is shown for sealing a high-pressure side H relative to a low-pressure side N. FIG. An inner component 2 is arranged within an outer component 3 such that it can perform a translational movement in the axial direction. The outer part 3 is a cylindrical housing and the inner part 2 is the piston rod of a piston guided in the housing. An interchange of the inner part 2 and the outer part 3 is conceivable, for example an embodiment in which the outer part 3 is a piston and the inner part 2 is a tube. figure 1 A longitudinal section view of the upper half space of the sealing system is shown in .

[0052] The outer component 3 has a total of three annular grooves open to the inner component 2 , a first annular groove 4 facing the low-pressure side N and two second annular grooves 14 a and 14 b arranged on the high-pressure side H. A sealing device 9 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com