Patents

Literature

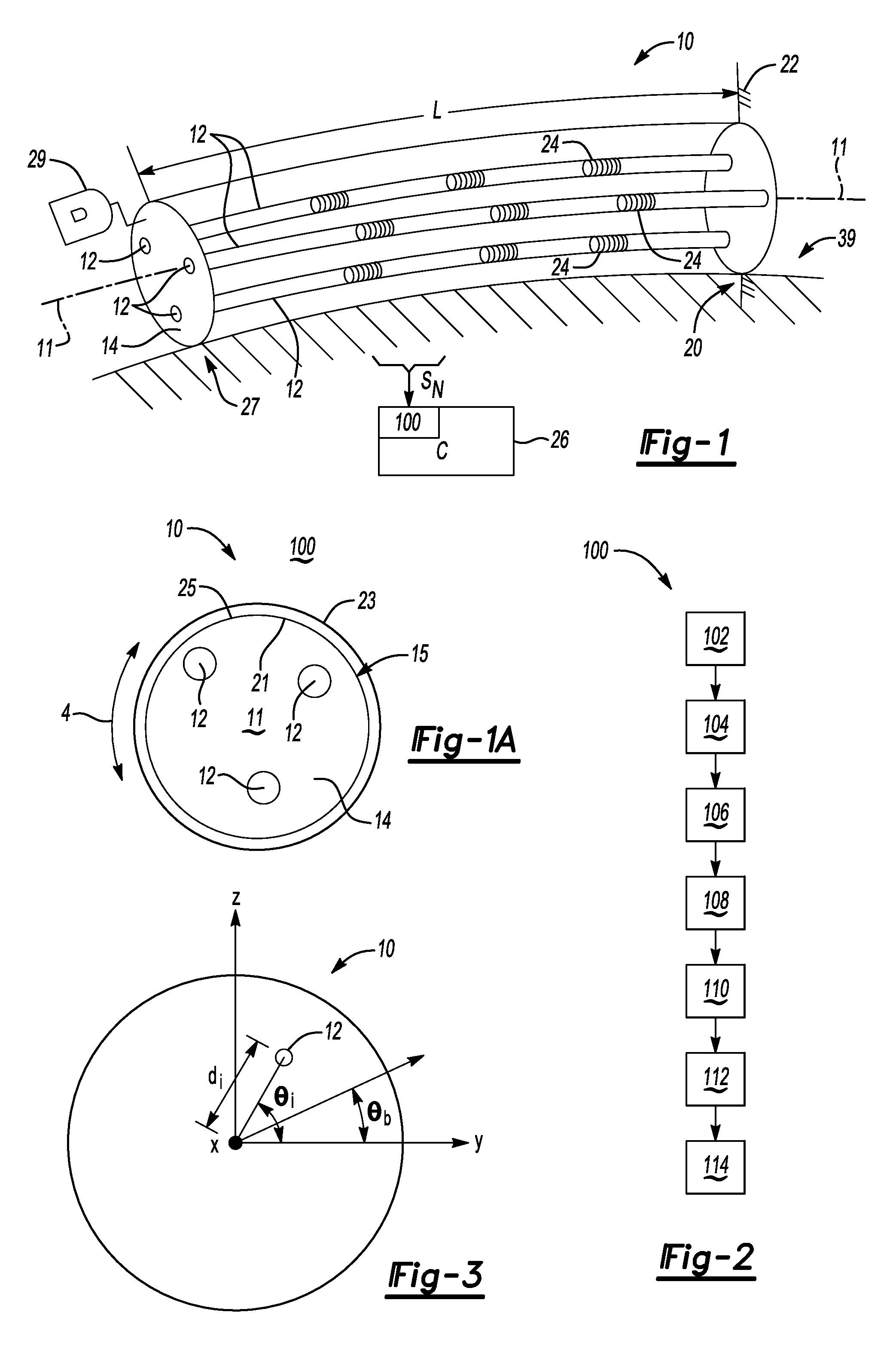

410results about How to "Expand the working area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual work place

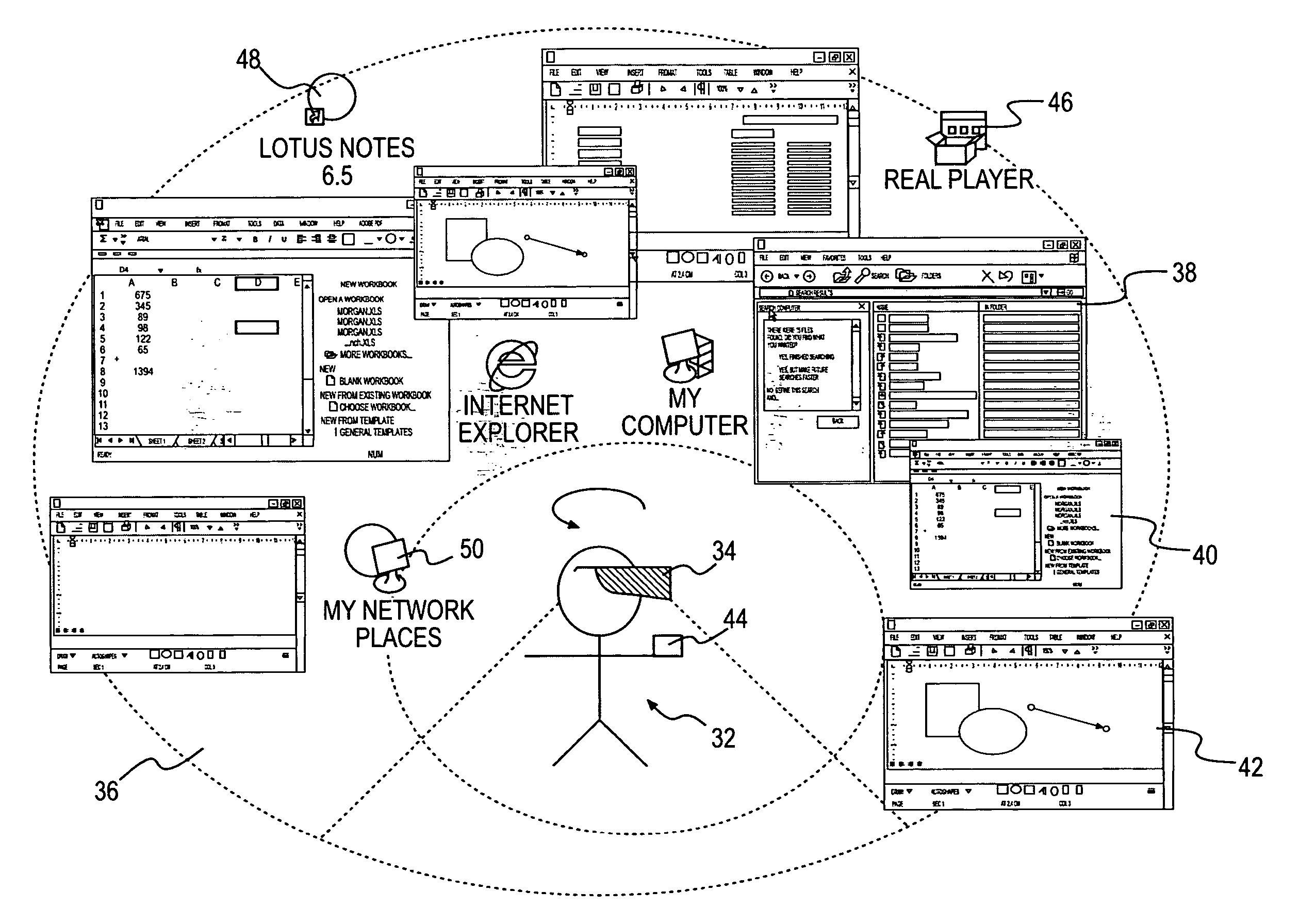

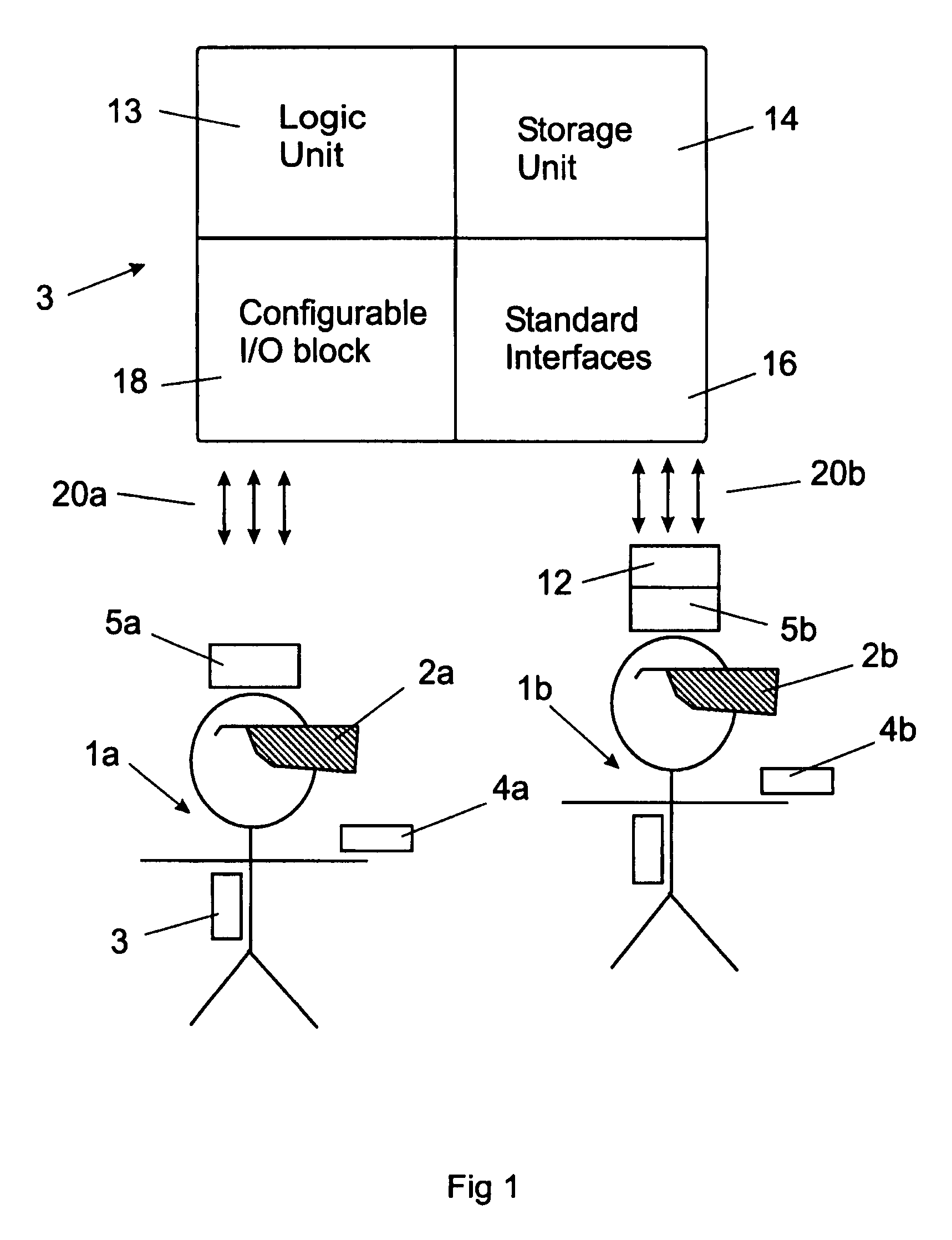

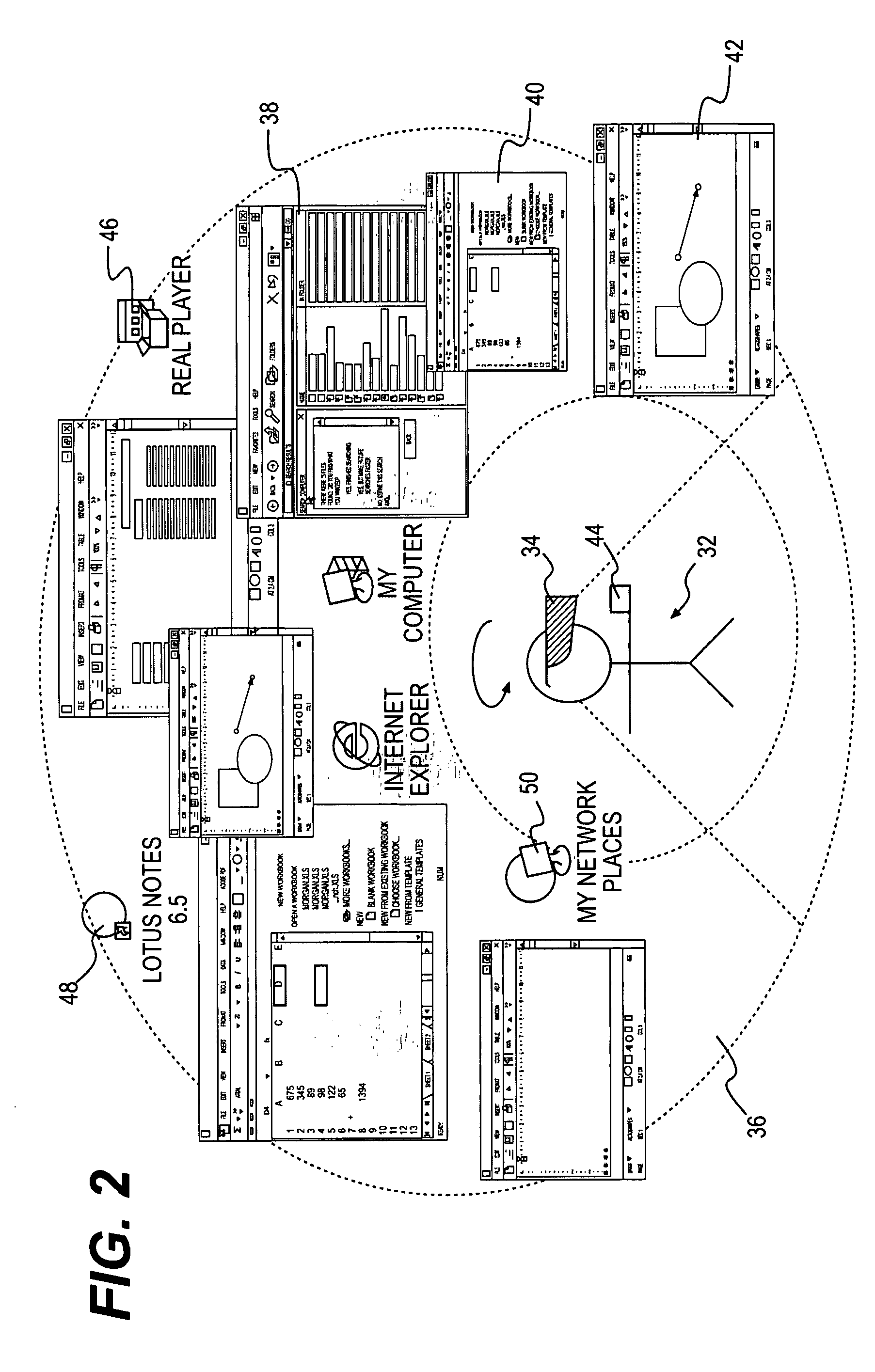

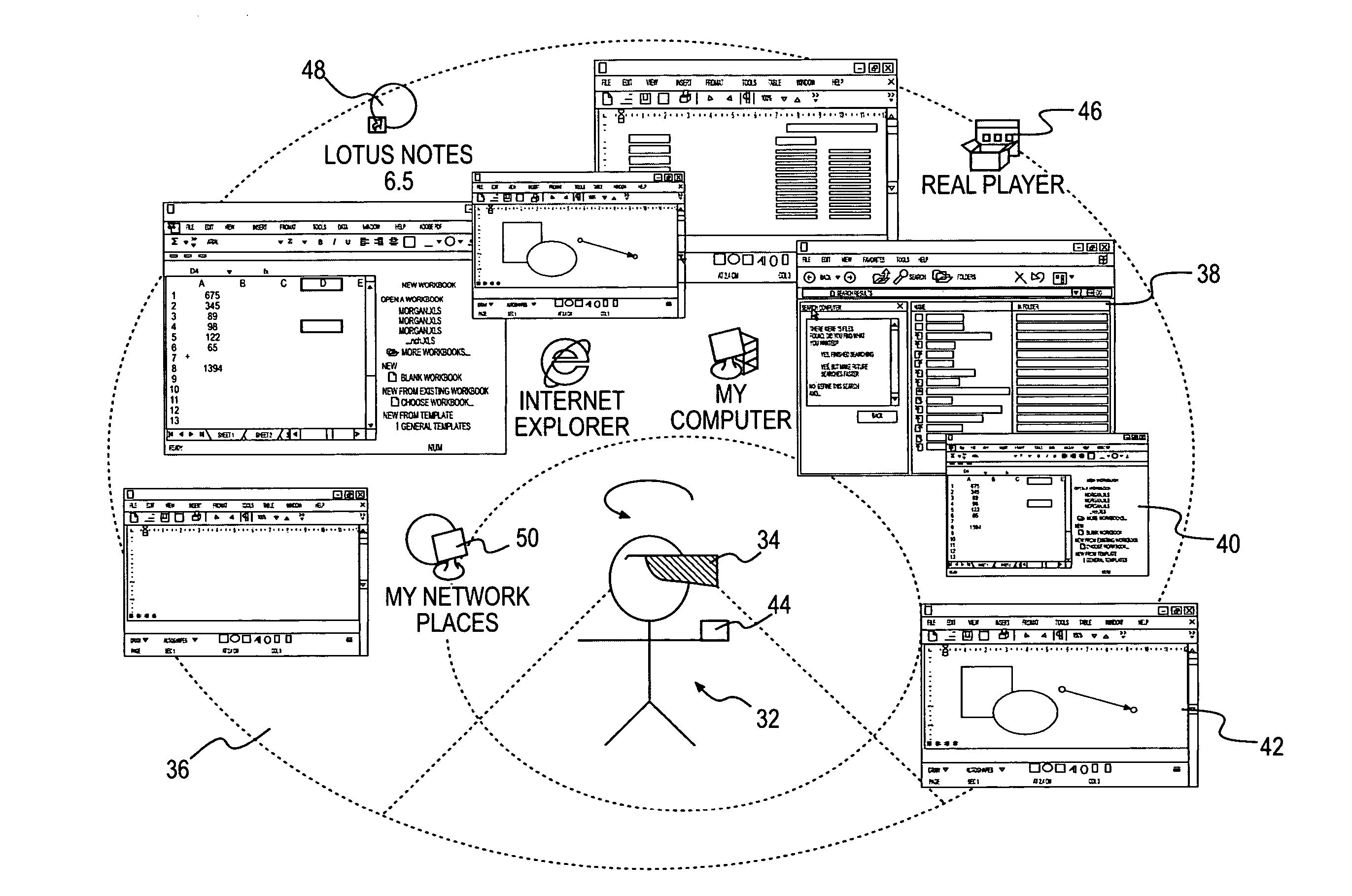

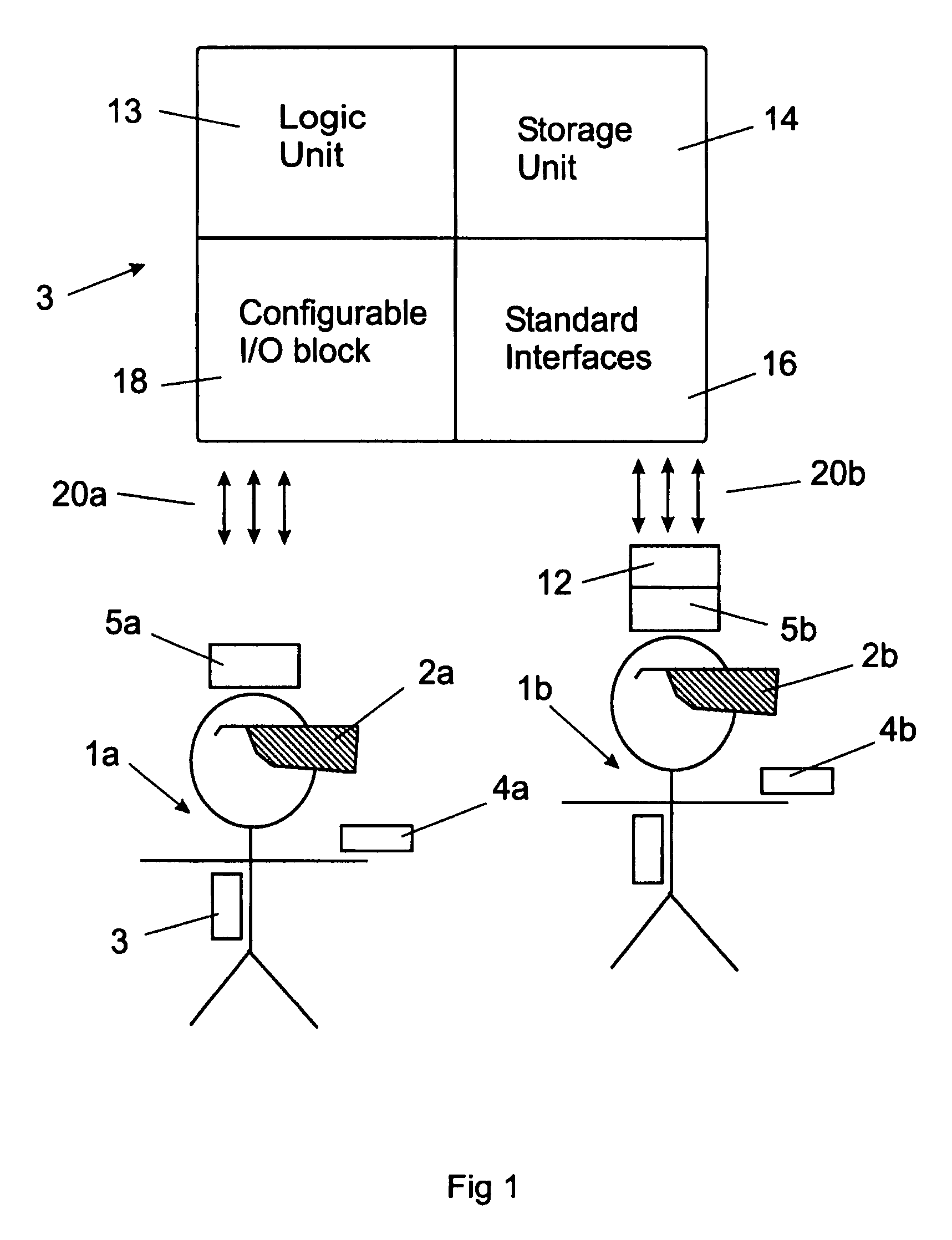

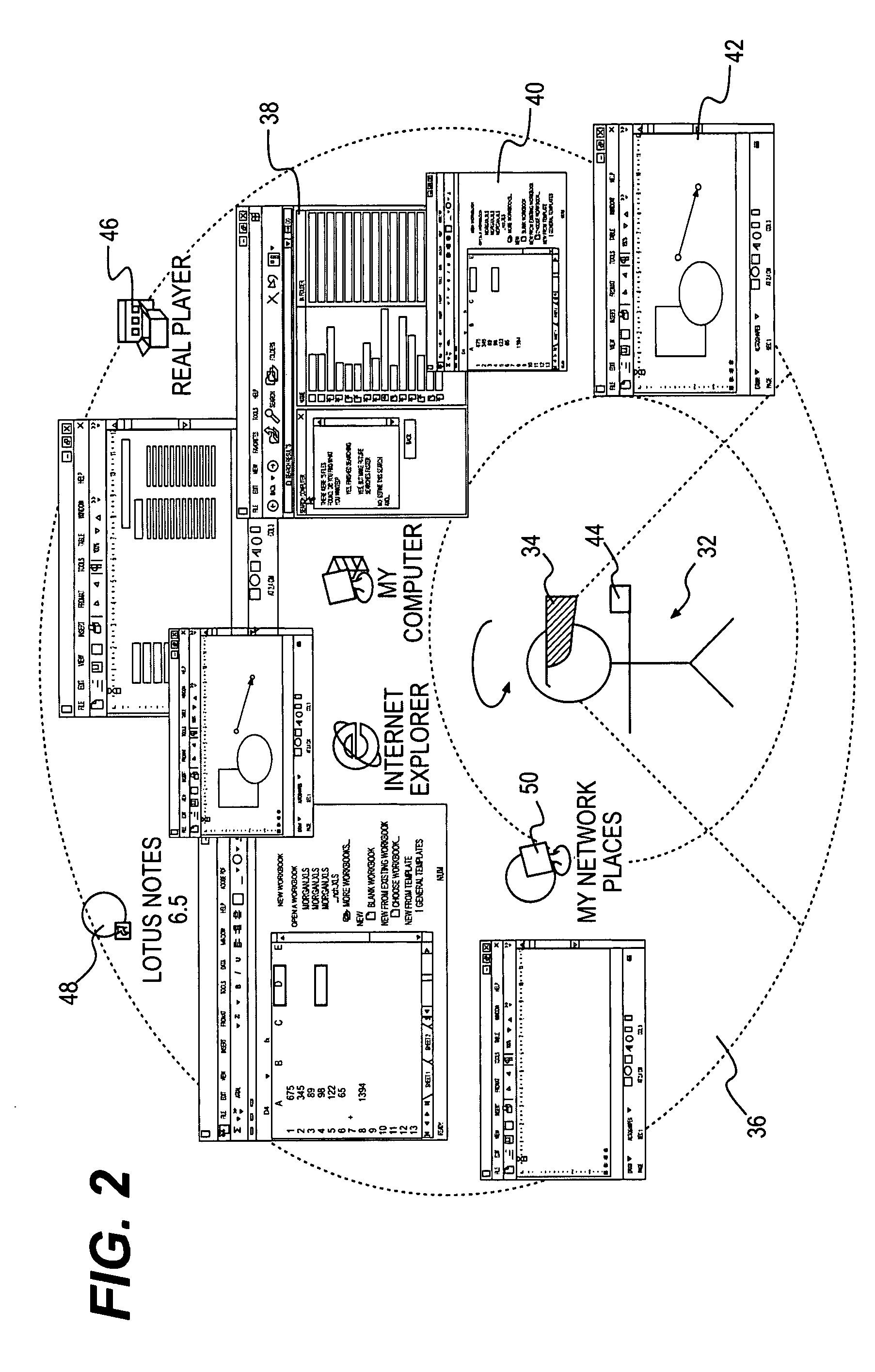

ActiveUS20080005702A1Improve working conditionsExpand accessInput/output processes for data processingGraphicsGraphical user interface

The present invention is concerned with a method and computer-based system for configuring, monitoring and / or operating a graphical user interface in two or three dimensions. In particular it is concerned with a graphical user interface used for controlling, monitoring and / or operating equipment in a control system of an industrial process or an installation for oil and gas or for an installation for electrical power generating, transmission and / or distribution.

Owner:ABB (SCHWEIZ) AG

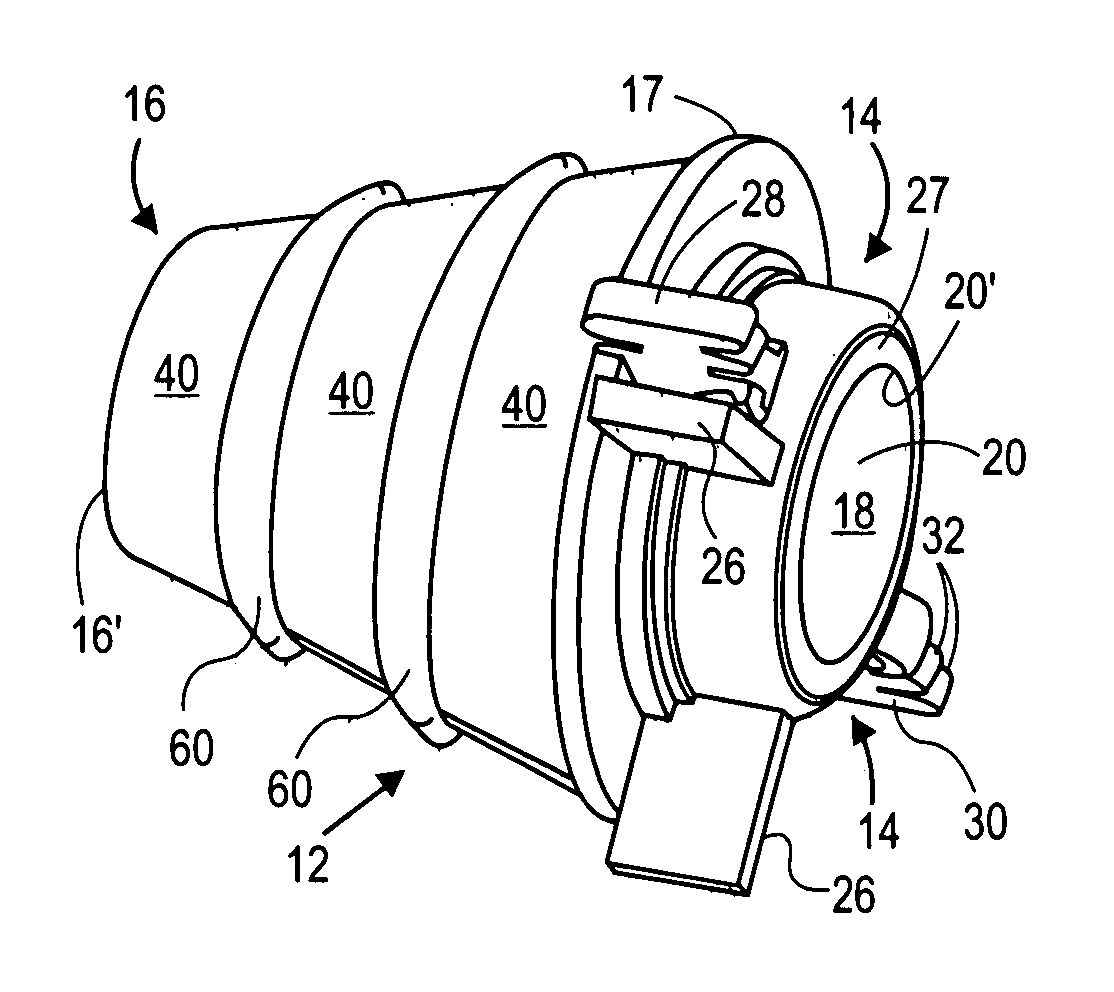

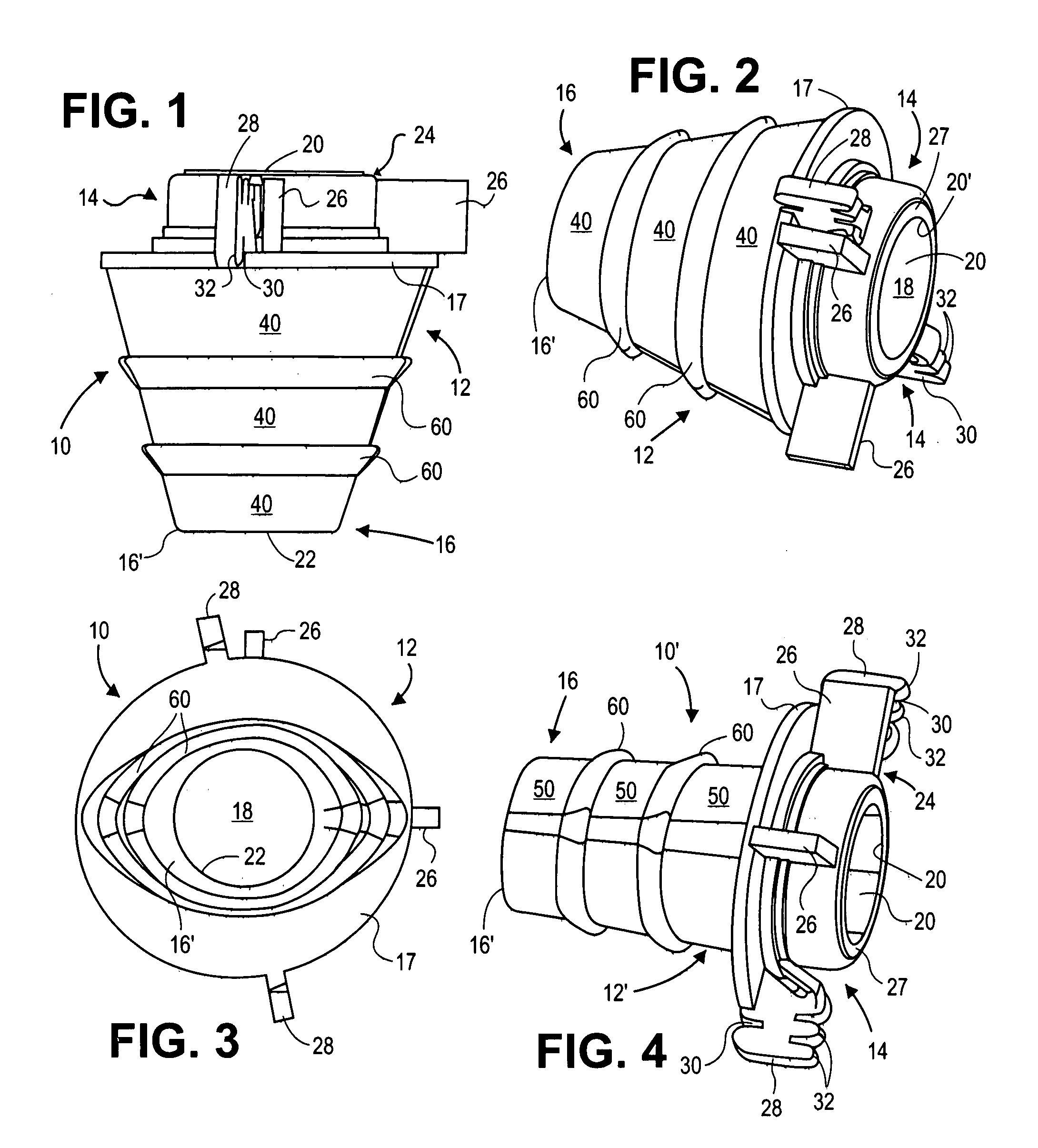

Introducer assembly for medical instruments

ActiveUS7316699B2Expand the working areaLimit escapeCannulasSurgical needlesDistal portionEngineering

An assembly structured to introduce a trocar or other medical instrumentation into a body cavity through an entry site formed in the cavity wall. The introducer assembly includes a base formed of a semi-rigid, flexible and / or a semi-flexible material having an instrument receiving passage extending there through, and further including an exterior sealing surface extending between proximal and distal portions of the base. The sealing surface has a predetermined configuration which is shaped to conform to the shape of the entry site as the base passes into the entry site. A fluid restricting seal is thereby established between the exterior of the base and the peripheral tissue surrounding the entry site, particularly when the entry site is formed by an incision commonly utilized an open laparoscopic procedure.

Owner:TELEFLEX MEDICAL INC

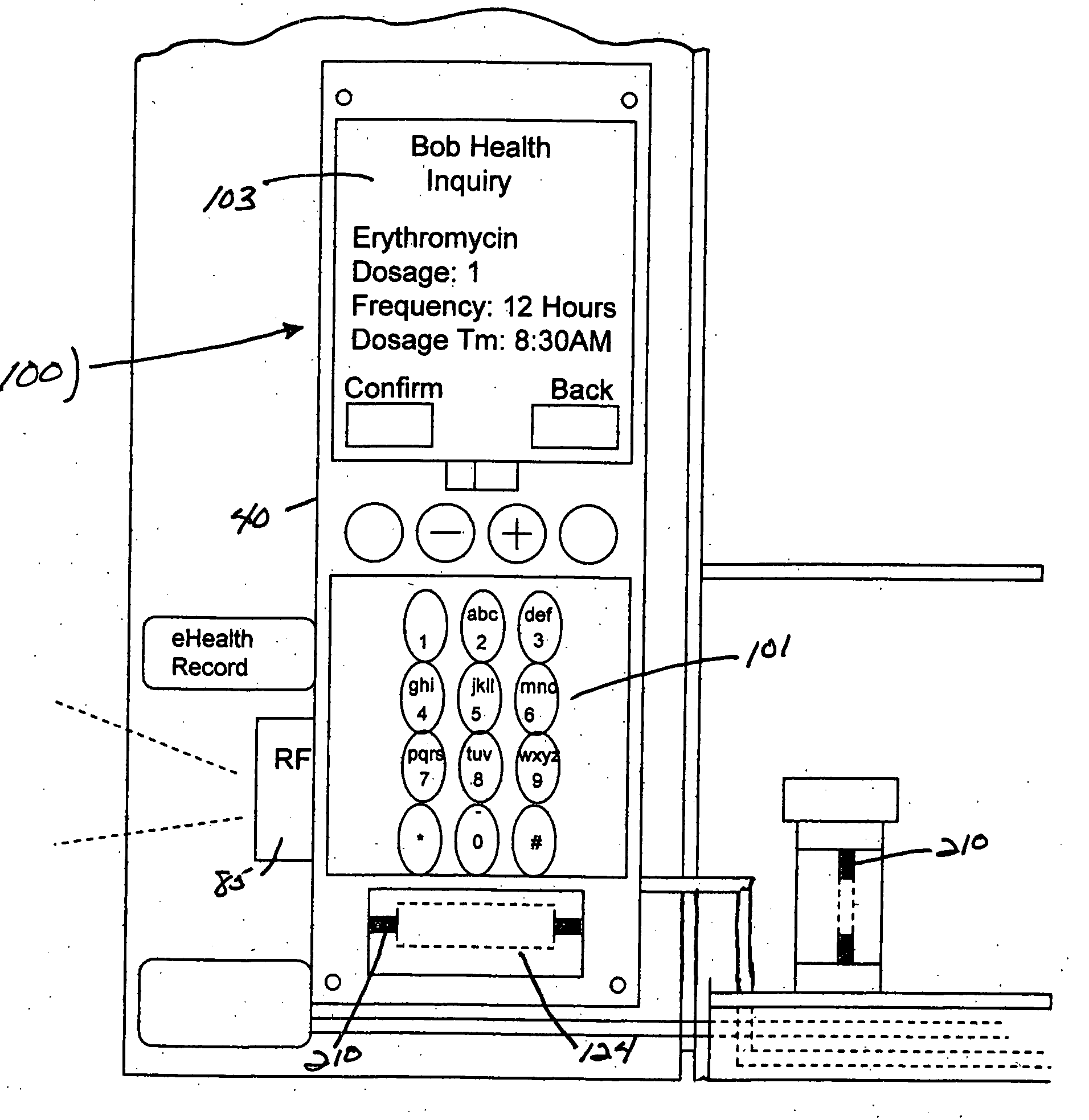

Multifunction-capable health related devices

InactiveUS20050188853A1Low incremental costImprove overall utilizationCombination devicesAuxillary pretreatmentBarcodeEngineering

Health and environmental devices such as air purifiers are adapted with components for multifunctional capabilities that involve electronic devices and associated housings containing at least one processor adapted to operate at least one component selected from the group consisting of air purifiers, sensors, local area and wide area networked components, and entertainment and electronic components. Health and safety related containers, covers and information input, processing, and output devices include one or more coded data readers for use with bar code, radio frequency identification (RFID) and other coded data technologies and comprise components to support at least one of the following: communications; networked sensors; and monitoring applications. Increased efficiencies in the use of coded data reader systems that include such coded readers and the associated items being read are supported by alignment indicia adapted for being on said items being read and on said reading devices.

Owner:SCANNELL ROBERT F JR

Virtual work place

ActiveUS8046719B2Expand the working areaFlexible and comfortable for userInput/output processes for data processingGraphicsGraphical user interface

The present invention is concerned with a method and computer-based system for configuring, monitoring and / or operating a graphical user interface in two or three dimensions. In particular it is concerned with a graphical user interface used for controlling, monitoring and / or operating equipment in a control system of an industrial process or an installation for oil and gas or for an installation for electrical power generating, transmission and / or distribution.

Owner:ABB (SCHWEIZ) AG

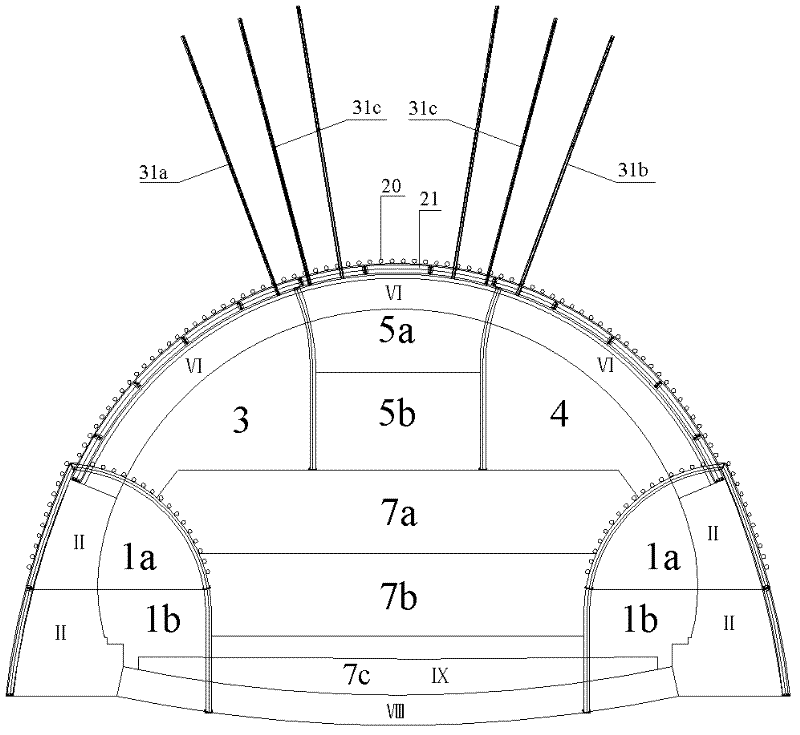

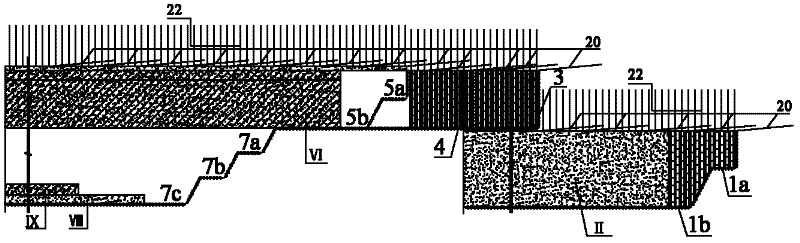

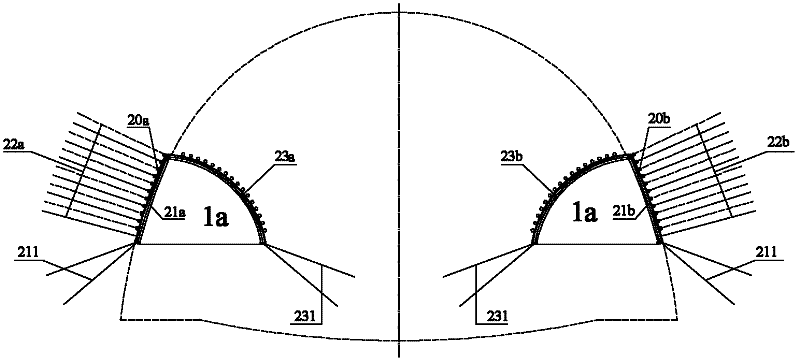

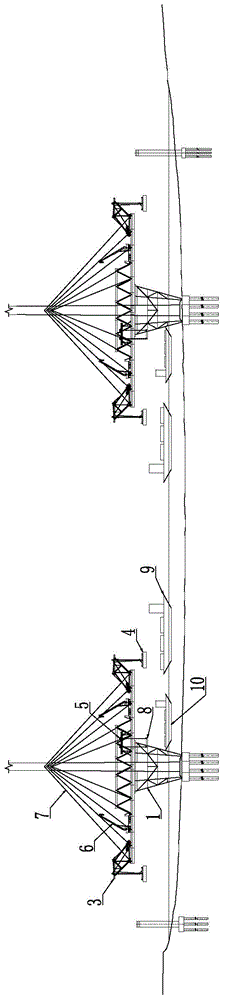

Soft rock four-line large-span tunnel compound double-side wall bracing cable conversion excavation construction method

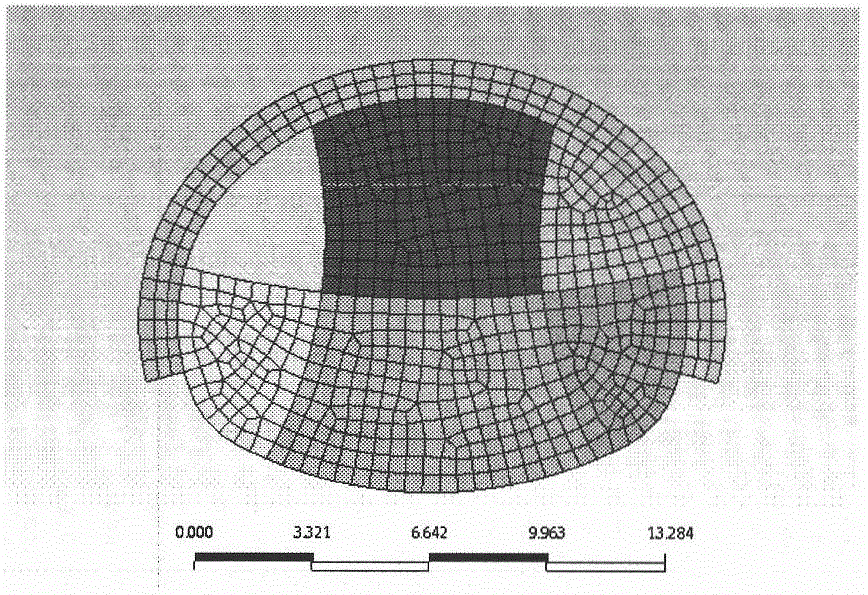

InactiveCN102226398AExpand the working areaInternal force redistribution is not obviousUnderground chambersTunnel liningEngineeringBuilding construction

The invention relates to a soft rock four-line large-span tunnel compound double-side wall bracing cable conversion excavation construction method which has the characteristics of safety in construction, speediness and simpleness in operation, and is further applicable to large-scale machines for construction. The method comprises the following steps: (1) excavating pilot holes on side walls on two sides, firstly implementing corresponding forepoling before excavation, and immediately implementing corresponding preliminary bracing and temporary bracing after the excavation; (2) pouring pedestal foundations on the two sides; (3) excavating side pilot holes of arch parts on the two sides respectively, firstly implementing the corresponding forepoling before the excavation, immediately implementing the corresponding preliminary bracing and the temporary bracing after the excavation, and implementing a pre-stressed anchor cable connected with a surrounding rock anchor at the top of the corresponding preliminary bracing; (4) excavating core soil of the arch parts bench by bench, firstly implementing the corresponding forepoling before excavating an upper bench, immediately implementing the corresponding preliminary bracing after the excavation, and implementing the pre-stressed anchor cables connected with the surrounding rock anchor at two end parts of the preliminary bracing; (5) pouring secondary lining of the arch parts; (6) excavating the lower core coil bench by bench; and (7) pouring an inverted arch, and pouring the inverted arch to the design height.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

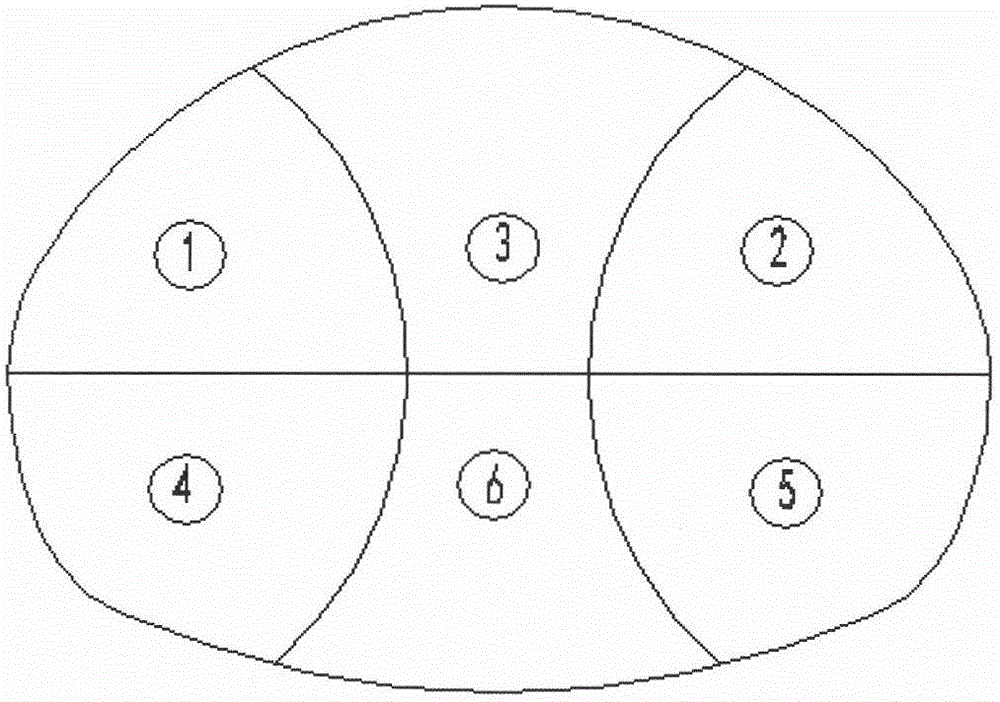

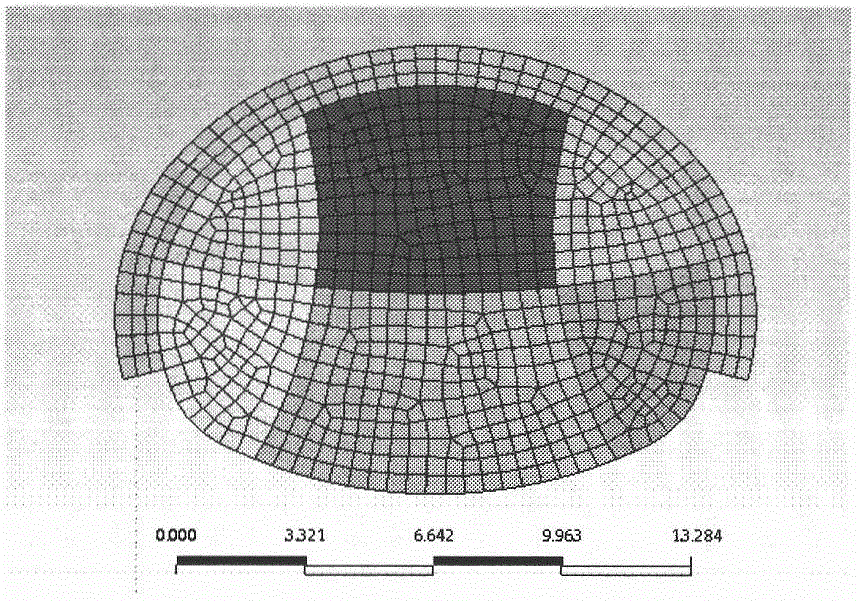

Double-side-wall-pilot-hole subsection bench cut method construction method

InactiveCN102720504AImprove Convergent Deformation Constraint AbilityImprove performanceUnderground chambersTunnel liningPilot holeStructural engineering

The invention relates to a double-side-wall-pilot-hole subsection bench cut method construction method, which comprises the steps that 1, upper bench two-side pilot holes are dug, and temporary support and preliminary bracing are carried out; 2, an upper bench middle pilot hole is dug, and the temporary support and the preliminary bracing are carried out; 3, lower bench two-side pilot holes are dug, and the temporary support and the preliminary bracing are carried out; and 4, a lower bench middle pilot hole is dug, and the temporary support and the preliminary bracing are carried out. The construction method has the advantages that the disturbing influence on surrounding rock bodies caused by the large cross-section tunnel six-part digging is smaller than that in the prior art, the work surface is increased, the work efficiency is improved, the surrounding rock convergence deformation restricting capability is improved, the integral performance of the preliminary bracing is improved, the operation efficiency is improved through reducing the work procedure alternation, and the disturbance on the surrounding rock is reduced through reducing the temporary support.

Owner:BEIJING ROAD & BRIDGE CONSTR GROUP

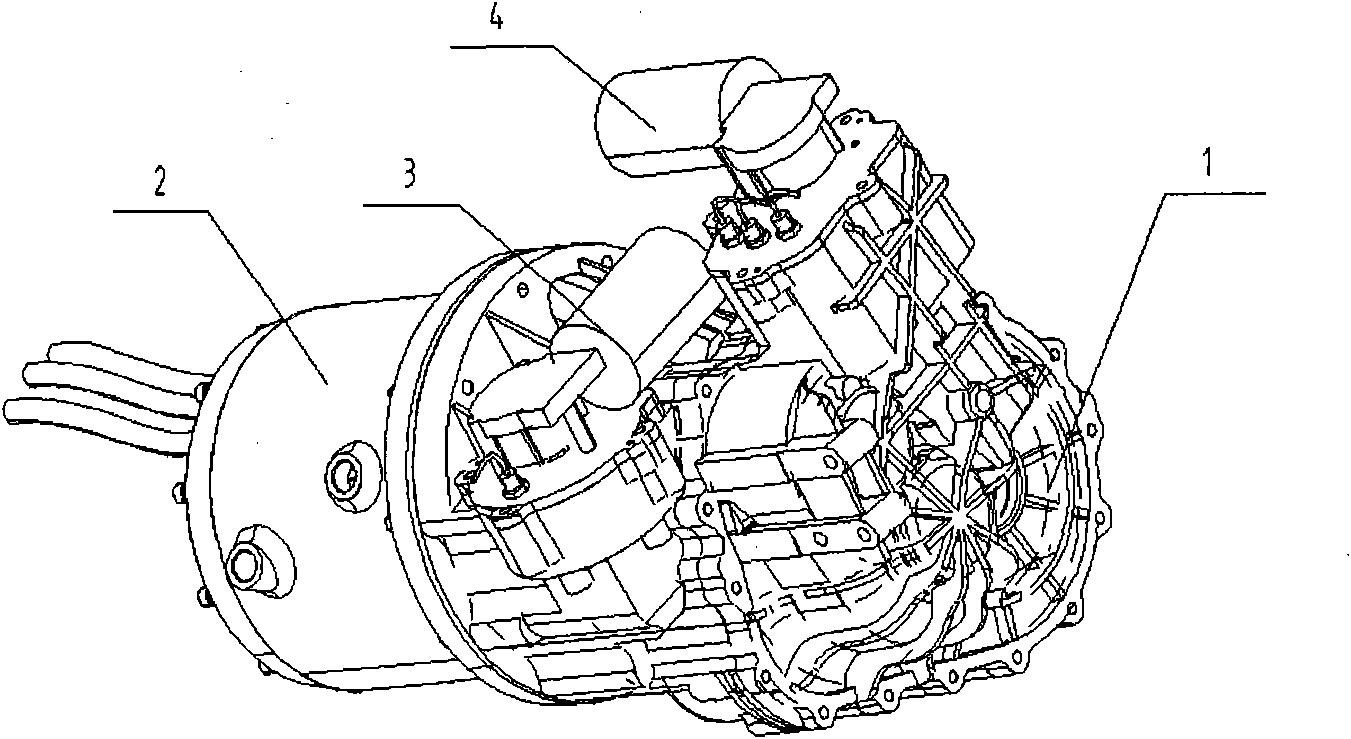

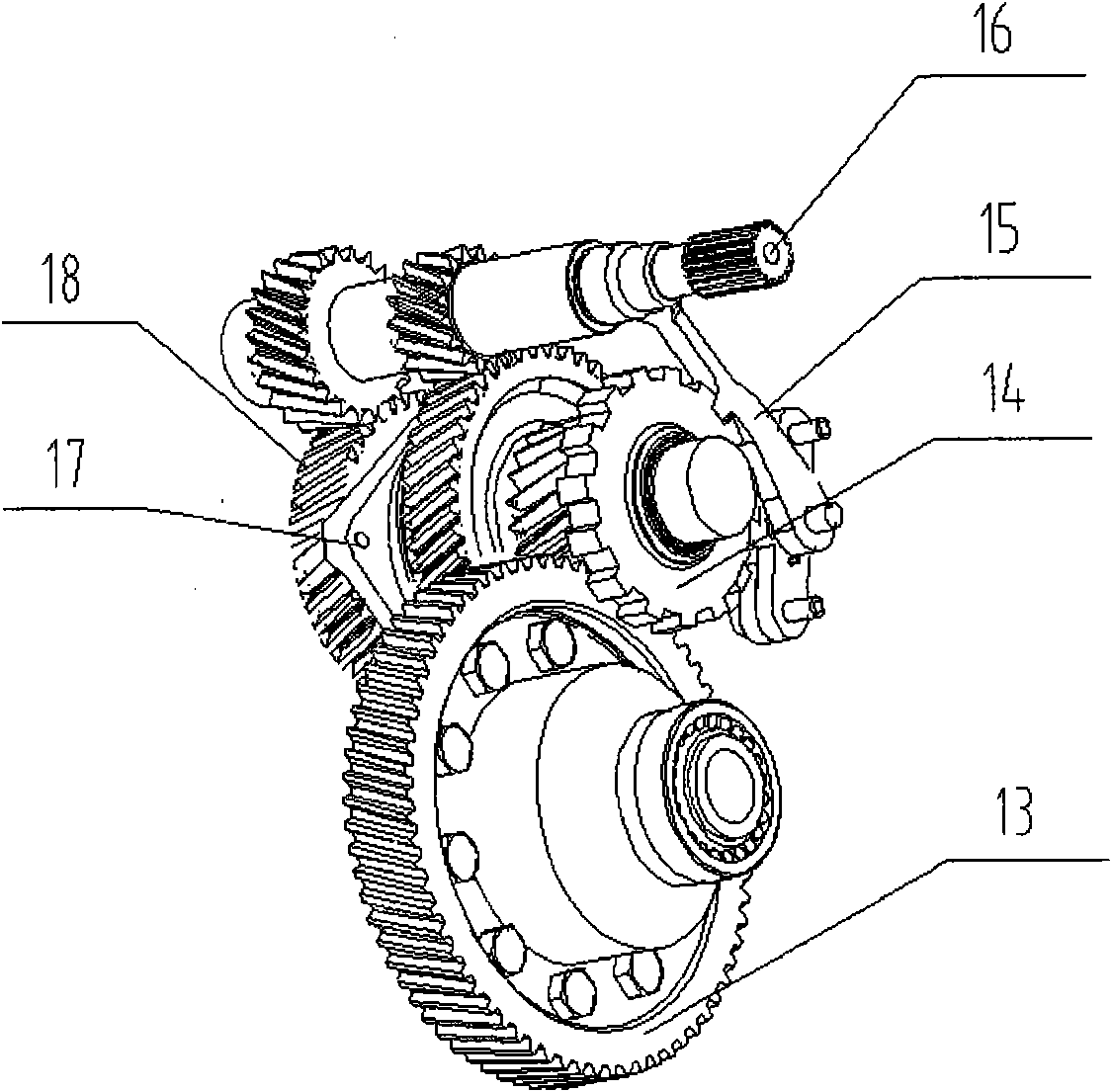

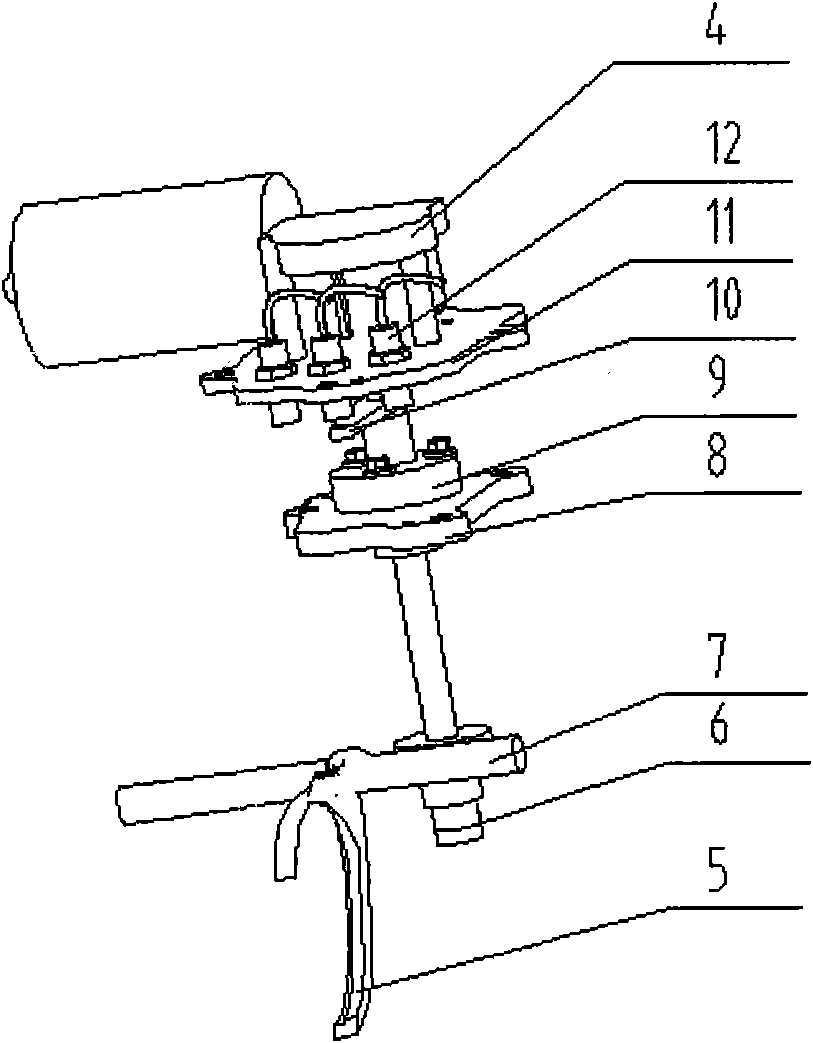

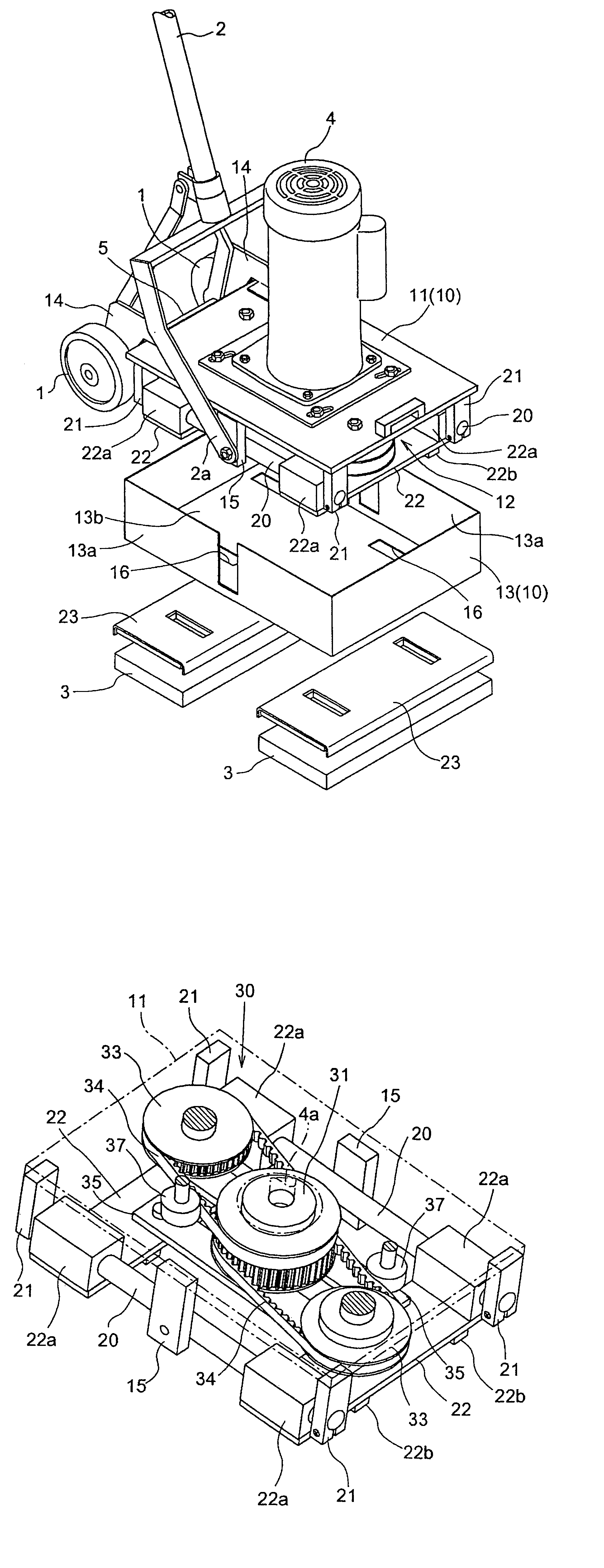

Power assembly for electric automobile

ActiveCN101817307AImprove powerImprove economySpeed controllerElectrodynamic brake systemsDrivetrainPermanent magnet synchronous motor

The invention provides a power assembly for an electric automobile. The power assembly comprises a driving motor (2) and a power transmission system (1), wherein the driving motor is a permanent magnet synchronous motor; the power transmission system (1) comprises a gear transmission system, an automatic gear-shifting system and an automatic parking system; the gear transmission system comprises a differential assembly (13), an input shaft (16), a shifting fork, a synchronizer (17), a first-gear gear and a second-gear gear (18); the automatic gear-shifting system comprises a gear-shifting motor (4), a shifting fork (5), a shifting fork shaft (7), a gear-shifting shaft (6), a gear-shifting cover plate (8), a gear-shifting shaft angle sensor (9), a gear-shifting position detection rod (10),a gear-shifting motor cover plate (11) and a shift sensor (12); and the automatic parking system comprises a P-gear motor (3), a P-gear pawl (15), a P-gear pawl pressure plate (19), a spring pre-fastening mechanism (20), a P-gear shaft (21), a P-gear cover plate (22), a P-gear position detection rod (23) and a P-gear position sensor (24).

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

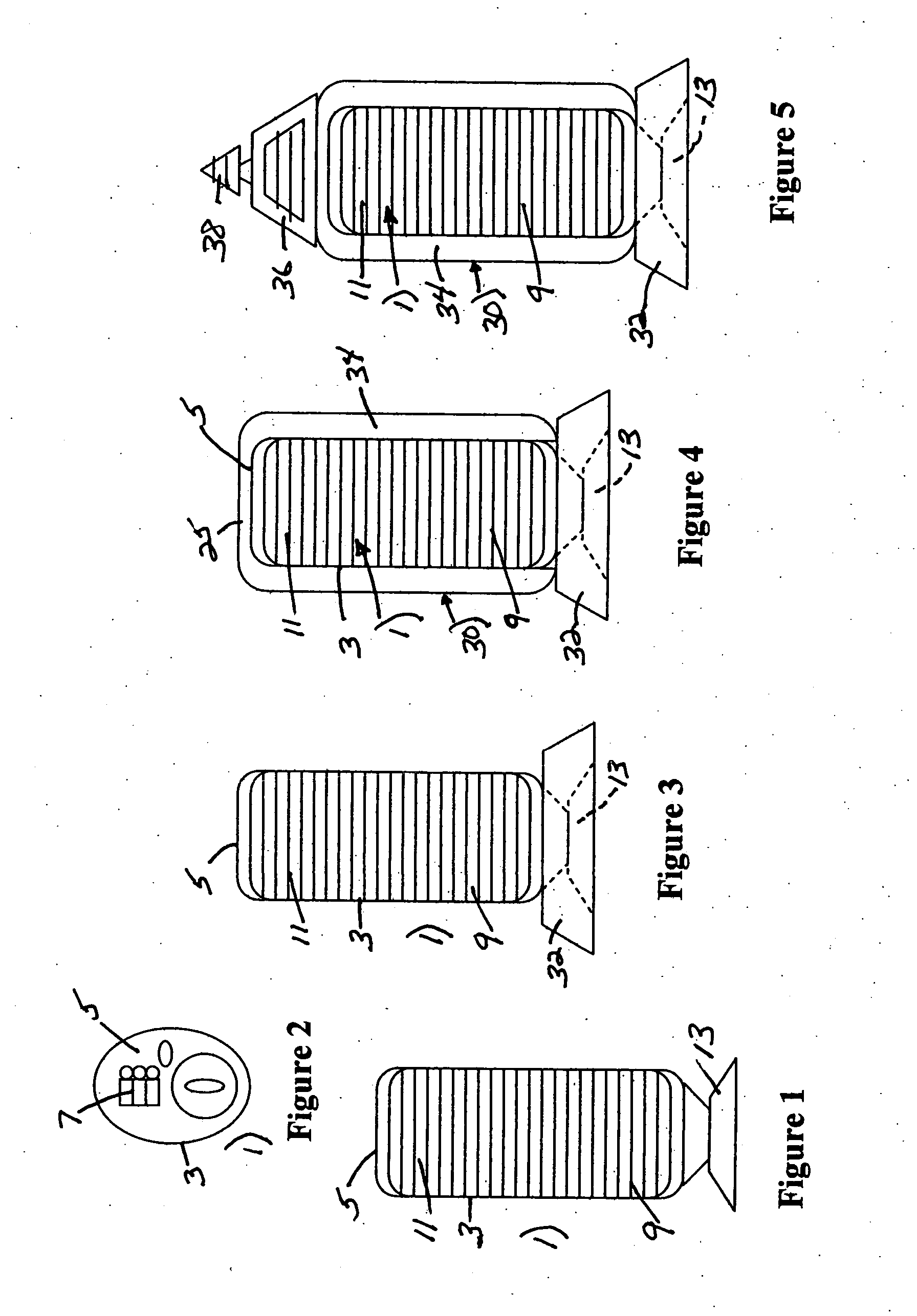

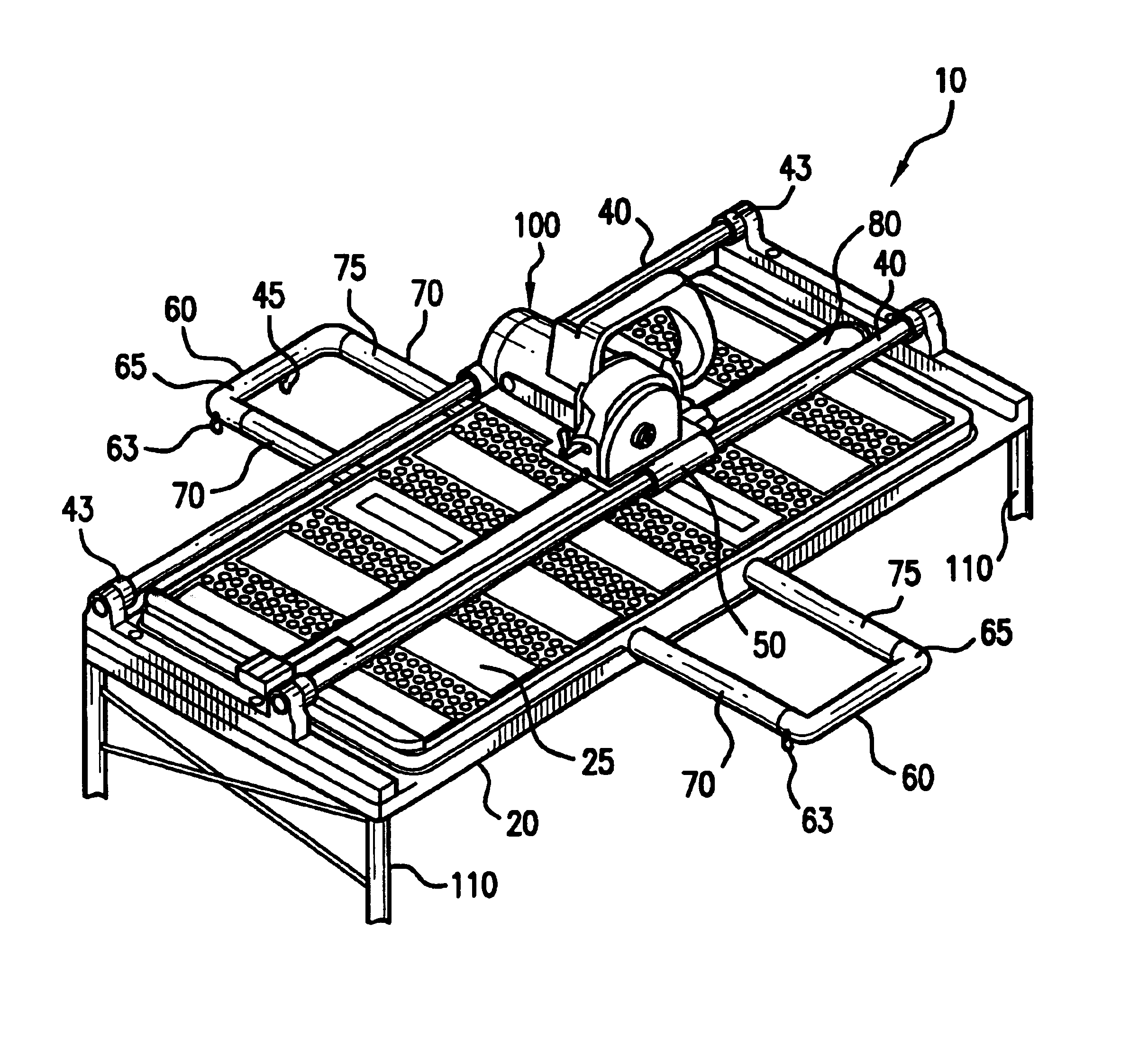

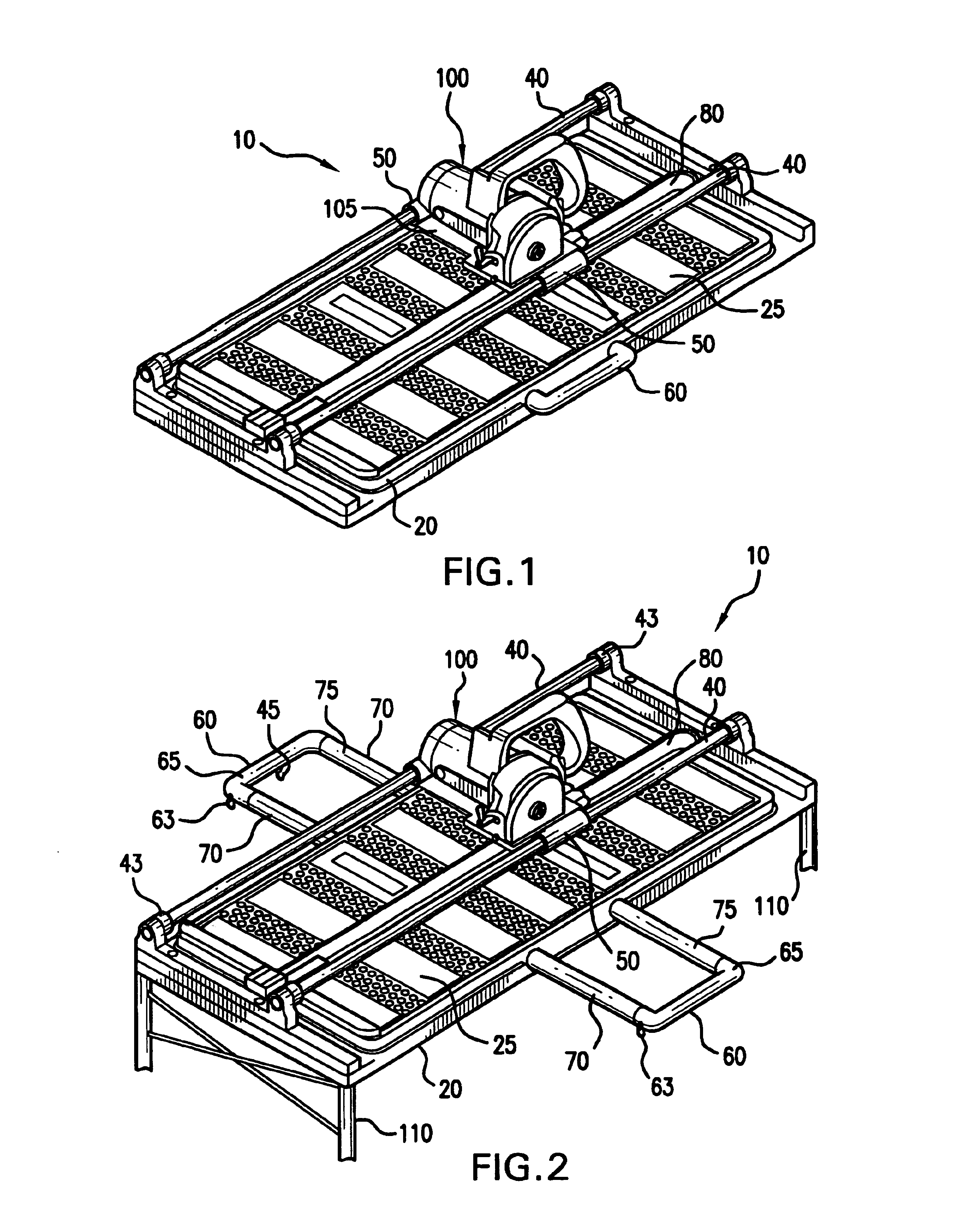

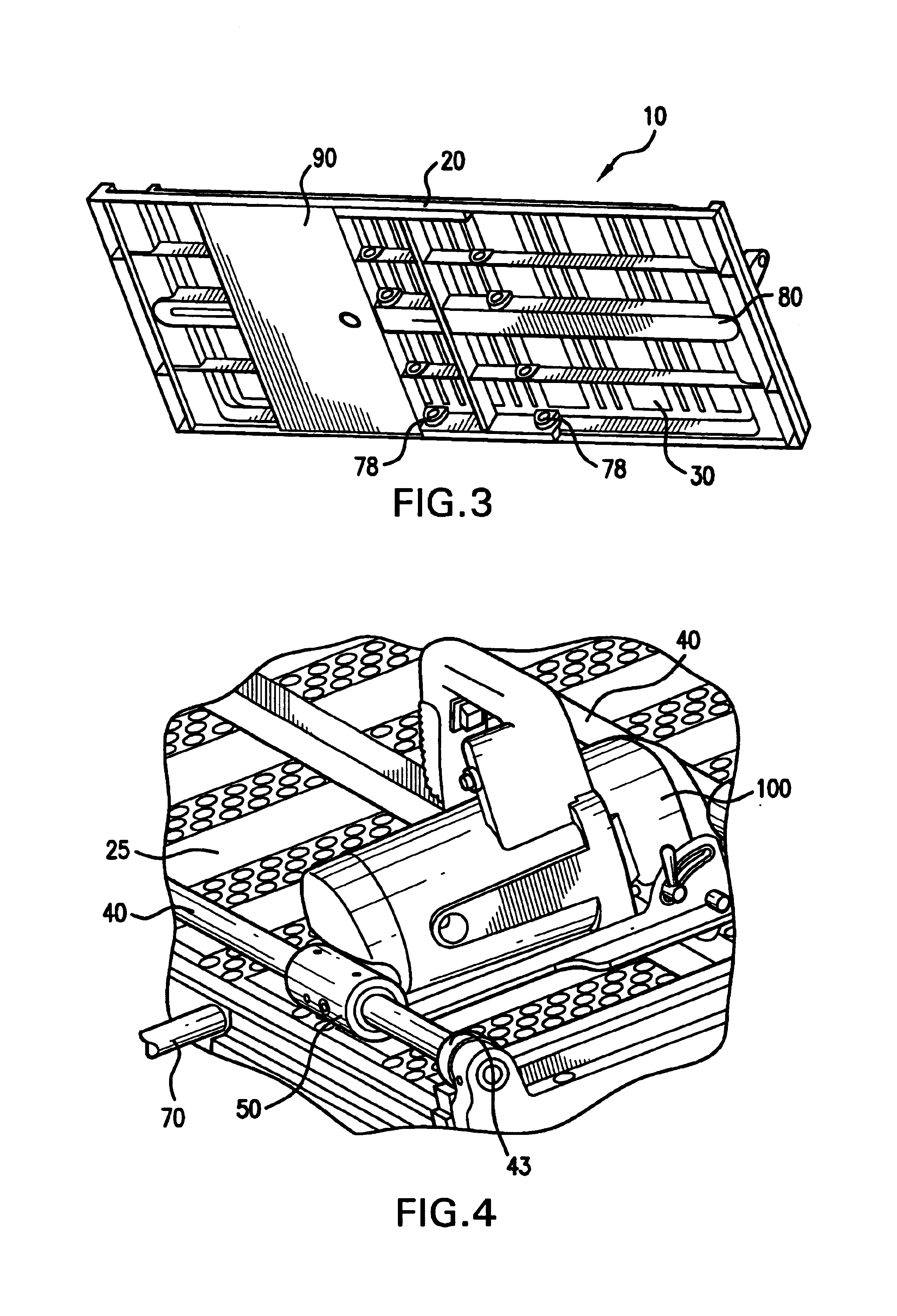

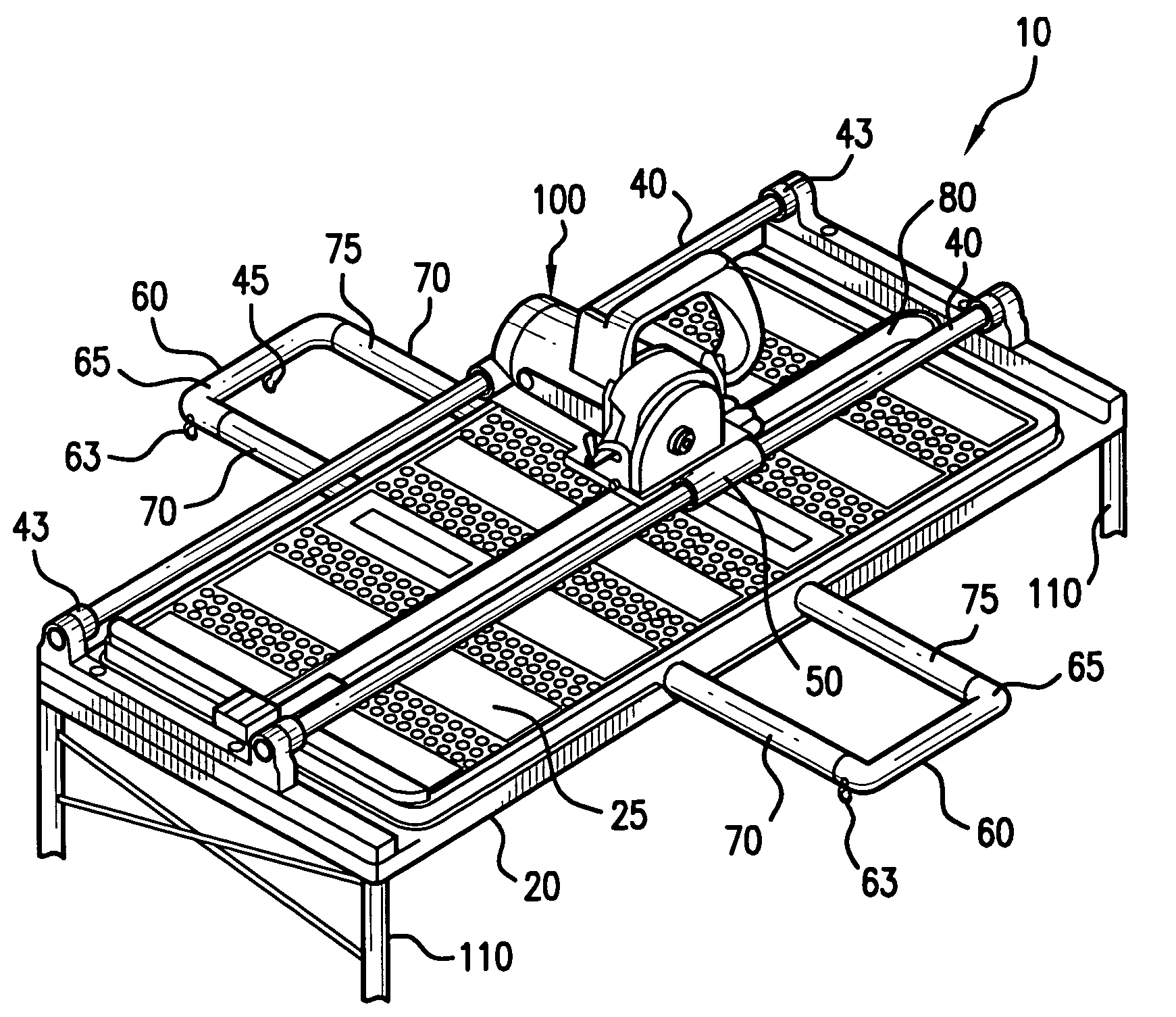

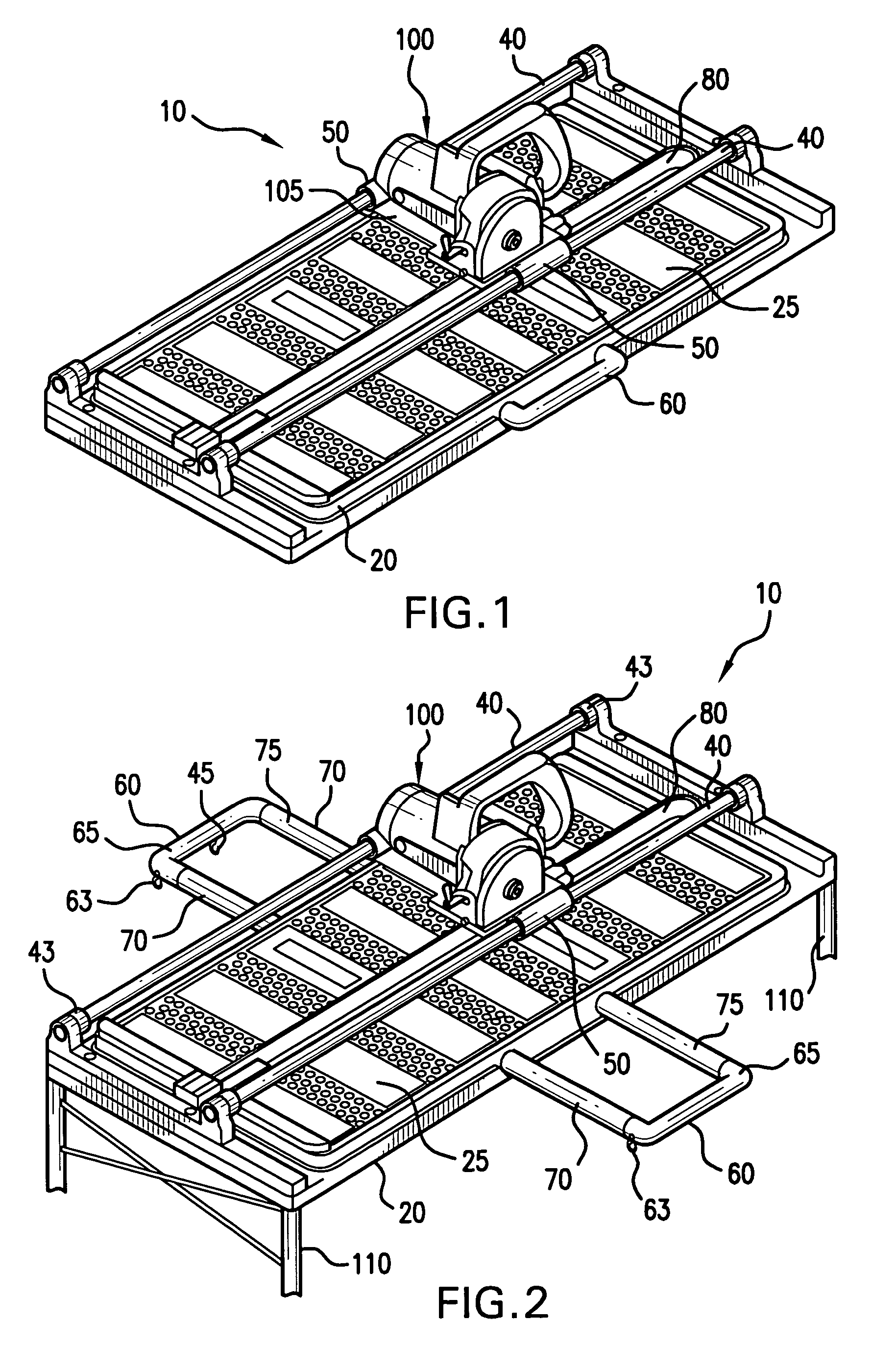

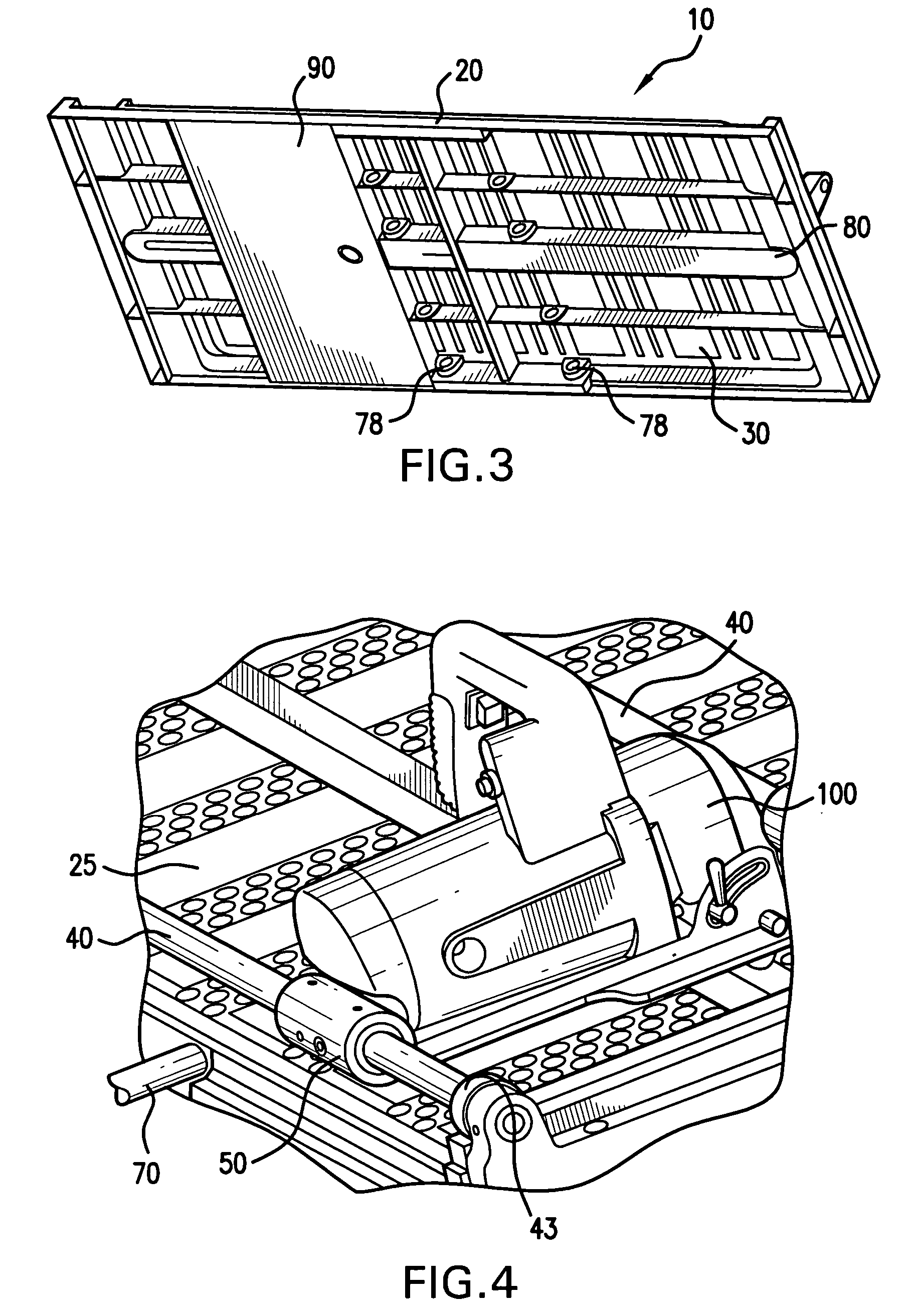

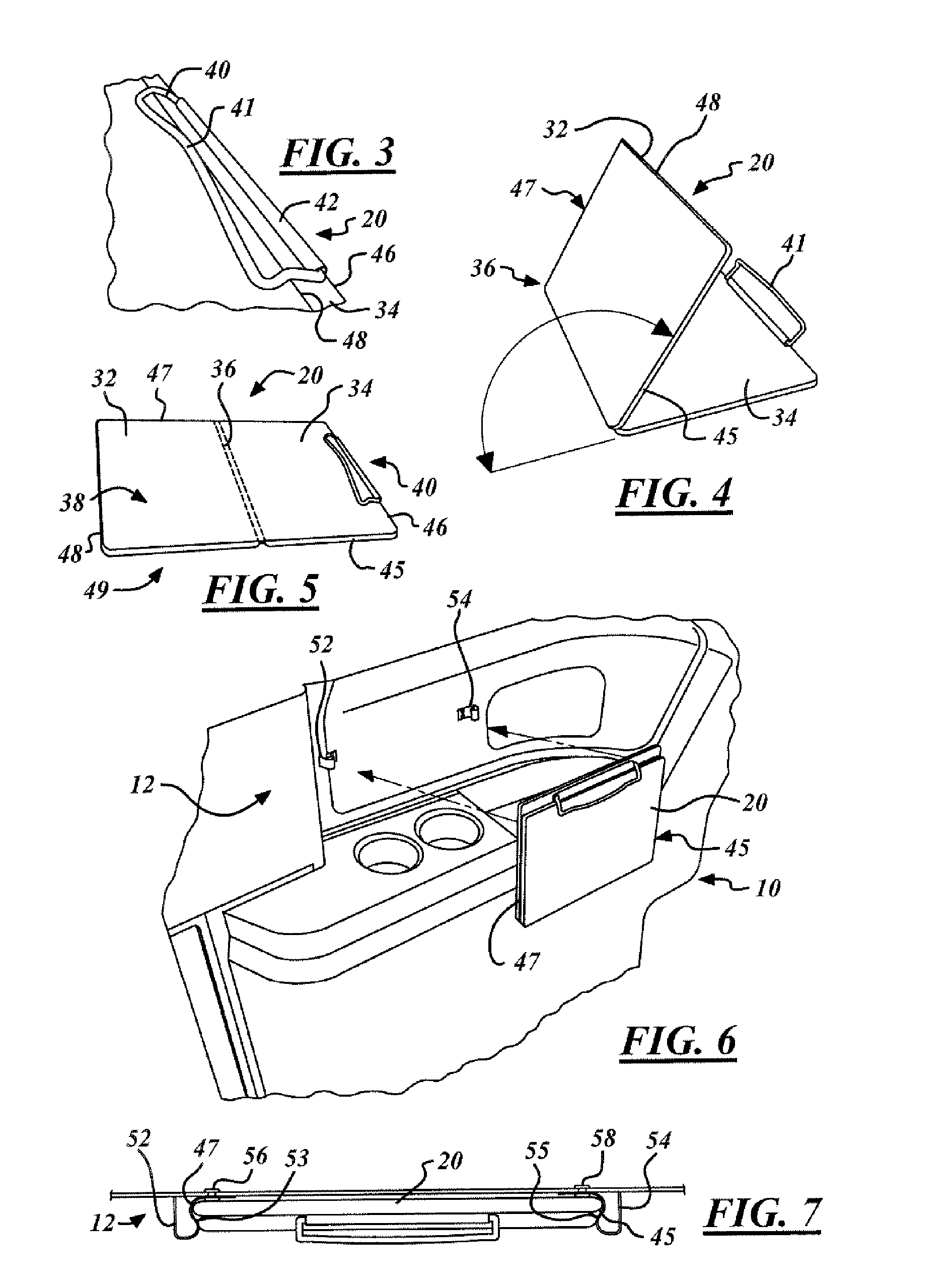

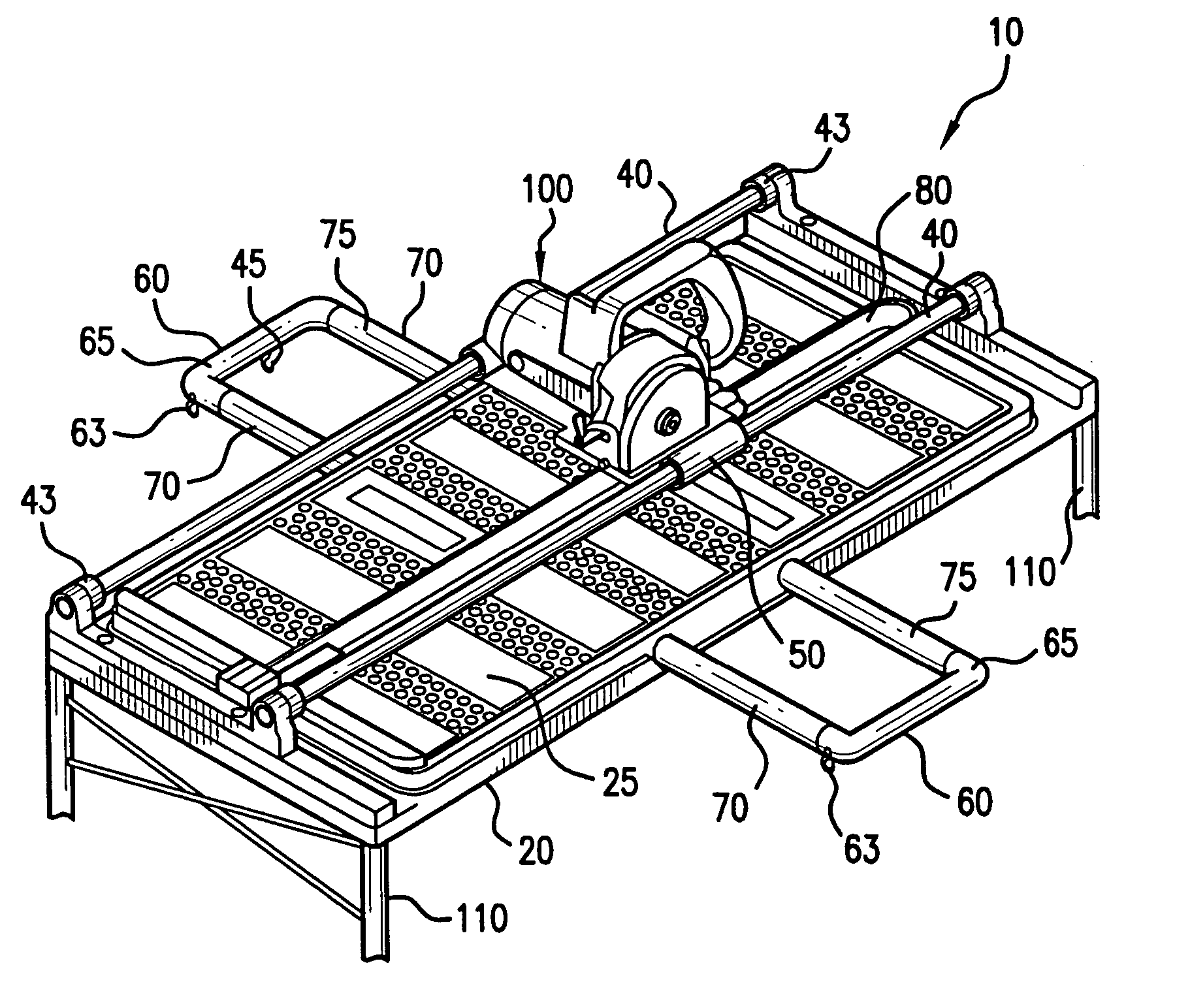

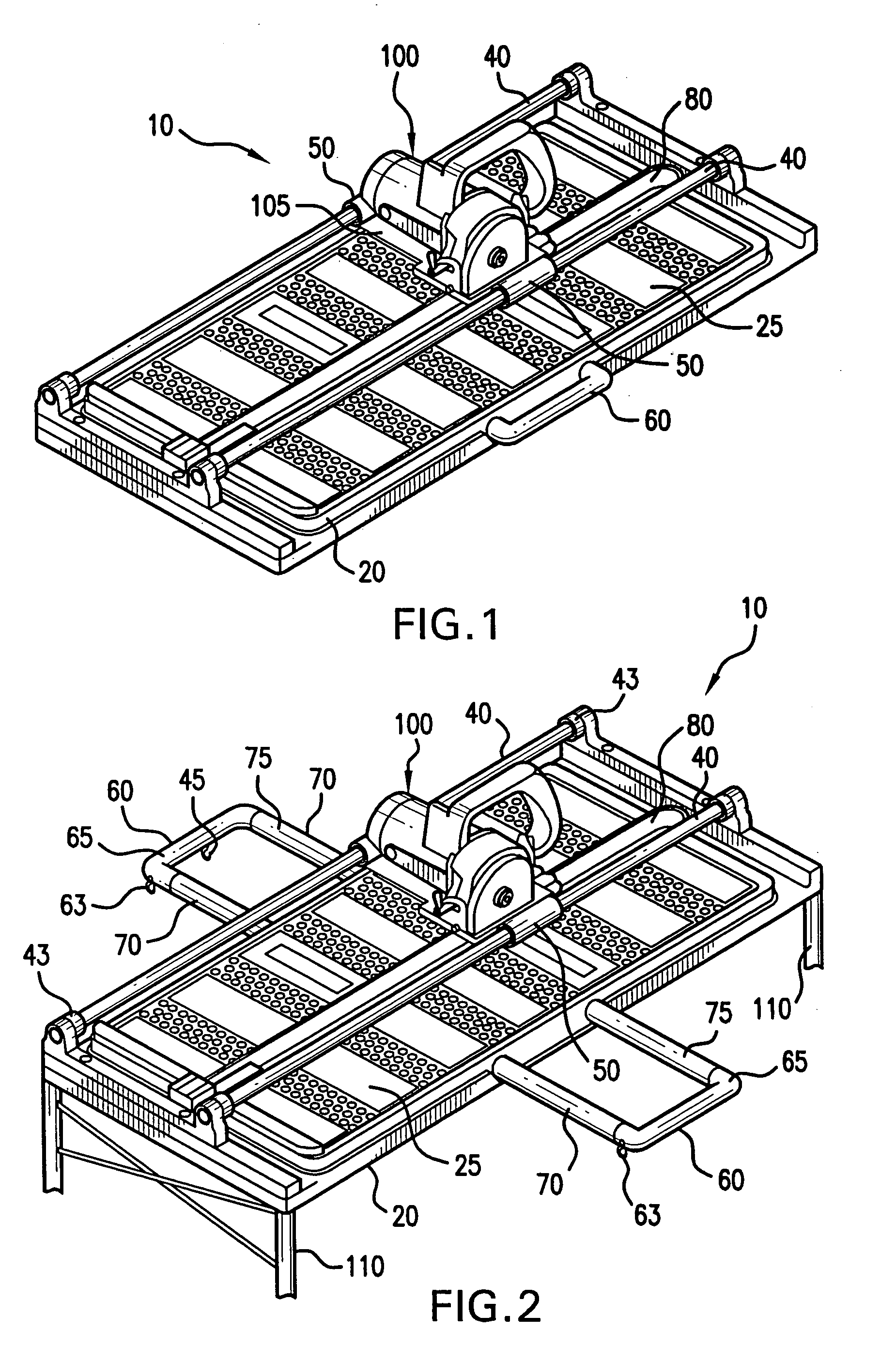

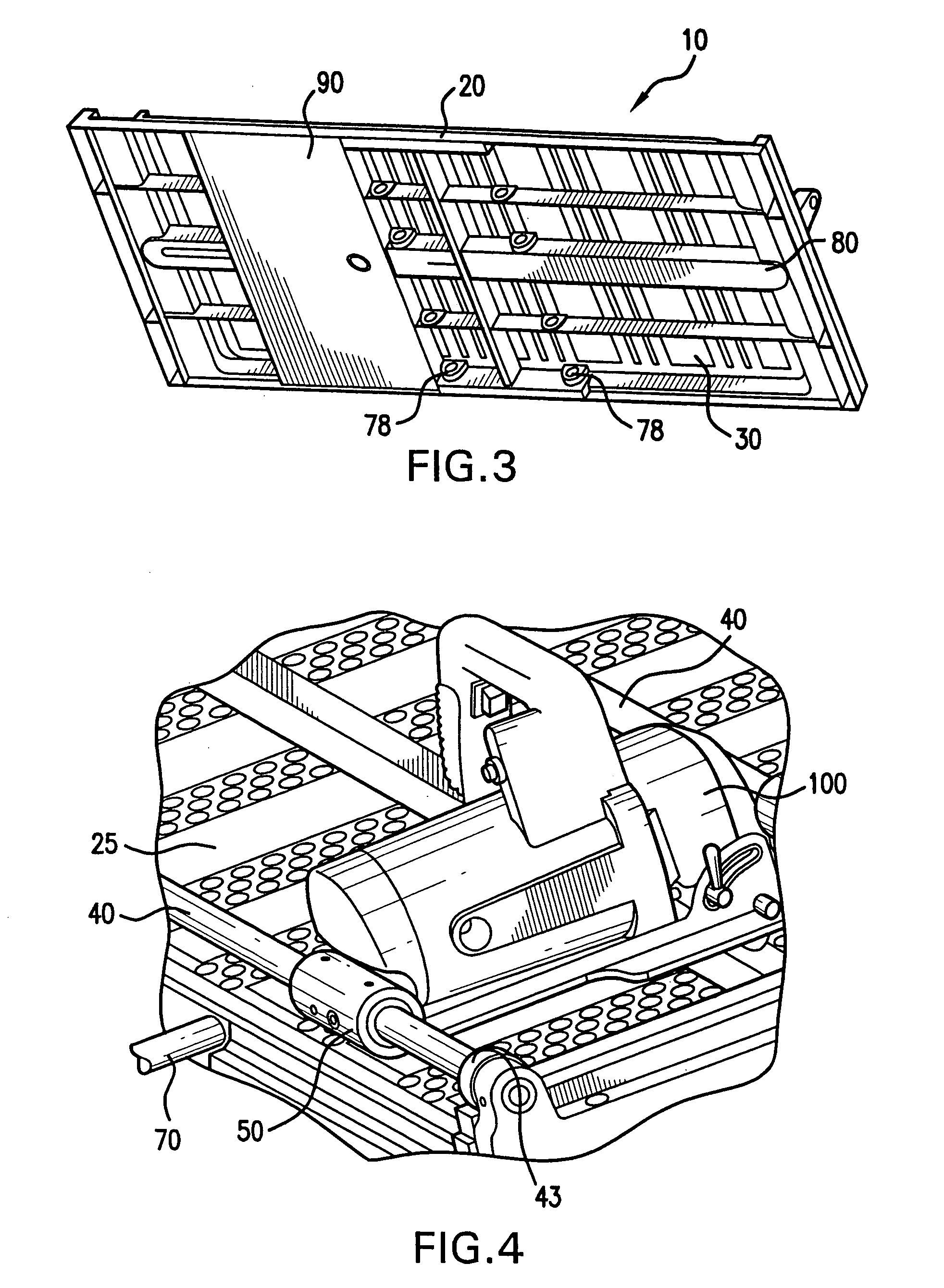

Power tool work table

A work table includes a work surface having two generally parallel bars extending across and above the work surface. Two sleeves are slidably connected to the two generally parallel bars, each sleeve of the two sleeves positioned around each bar of the two generally parallel bars. A power tool, such as a tile saw is connected between the two sleeves and thereby slides along the two bars. A channel is preferably positioned across the work surface and includes water or similar coolant / lubricant for the power tool. Handles are additionally positioned in the side of the work surface and are moveable between a retracted position within the work surface and an extended position away from the work surface. In the extended position, the handle includes a top edge generally flush with the work surface.

Owner:ZHANG CHARLIE

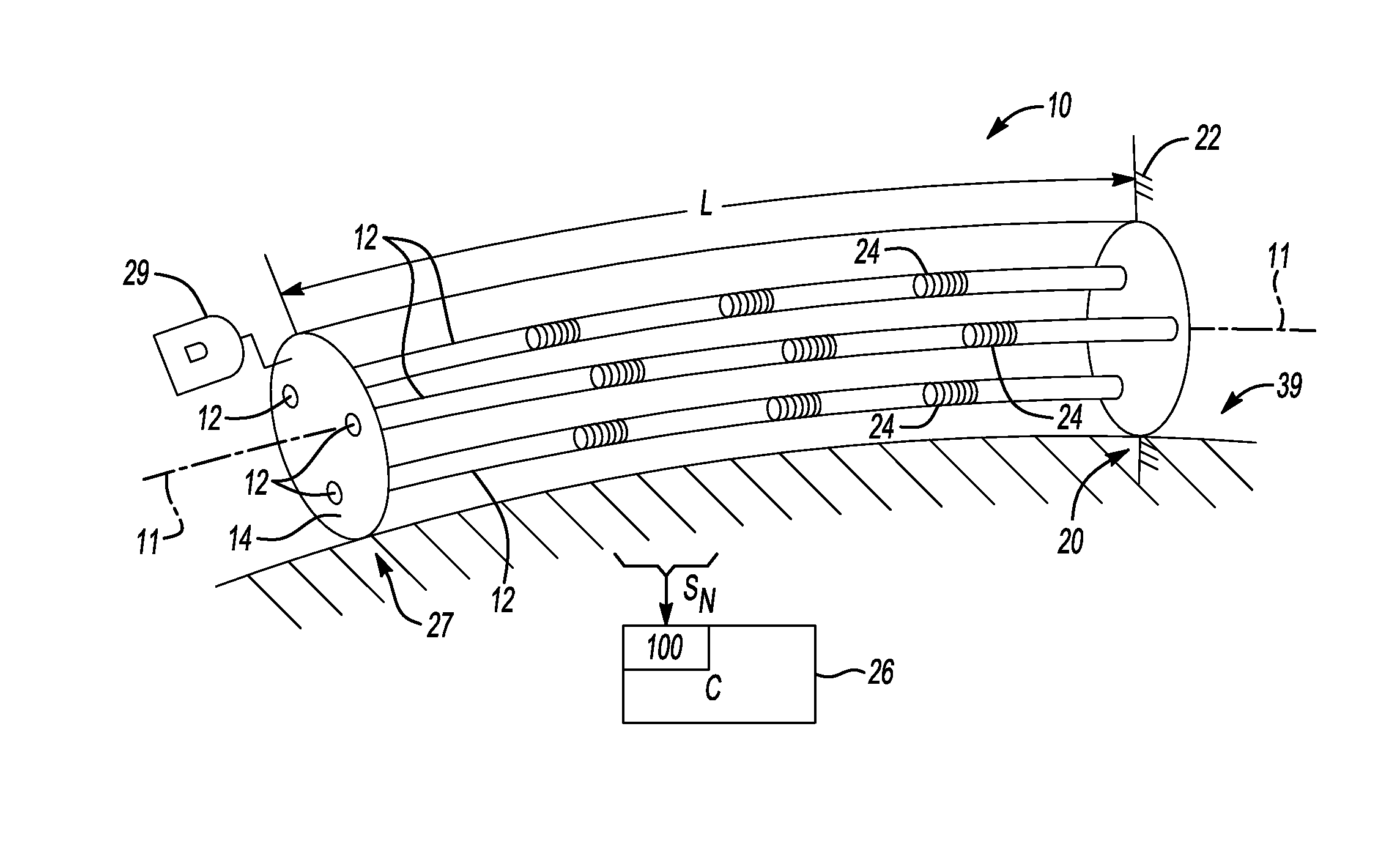

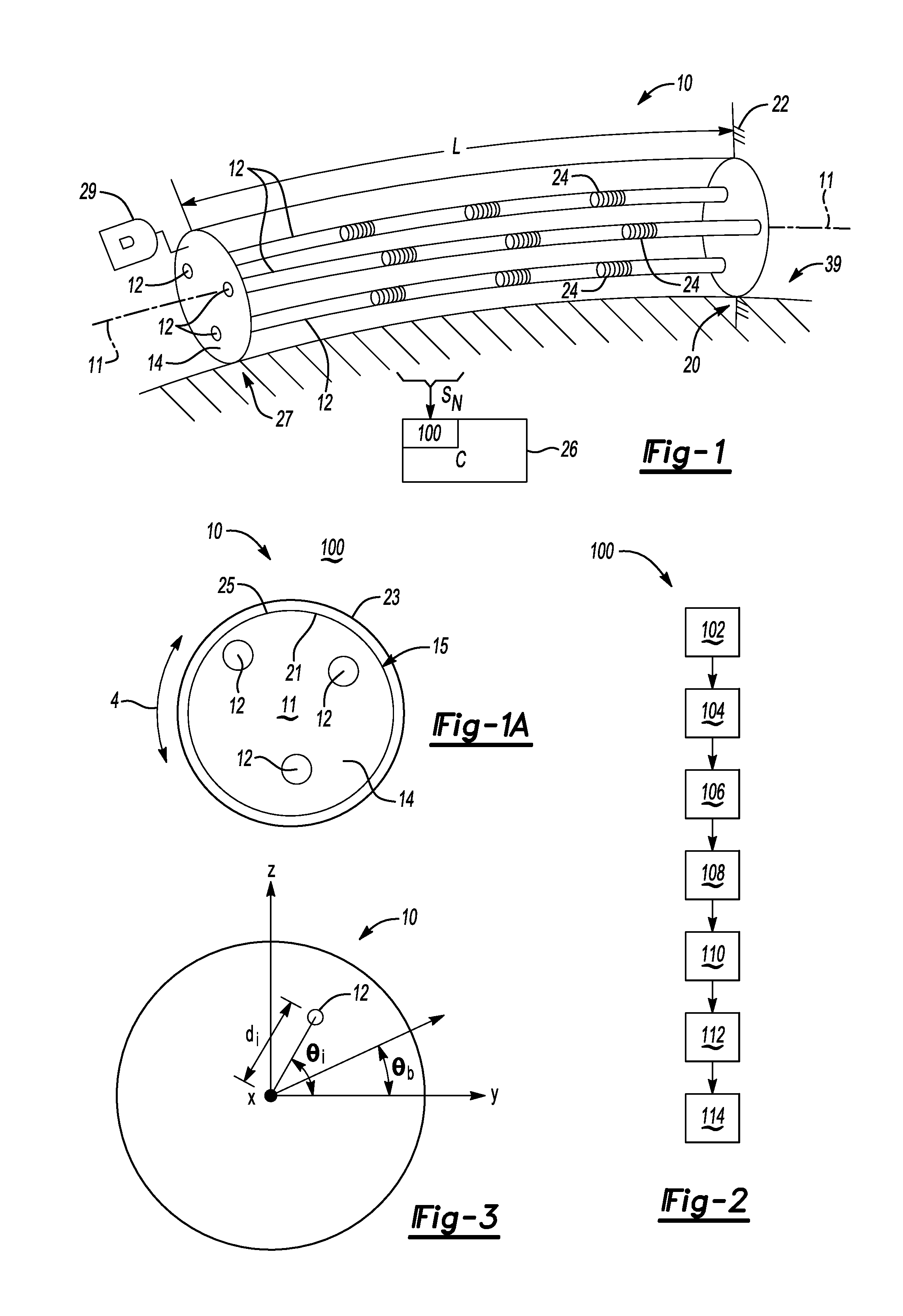

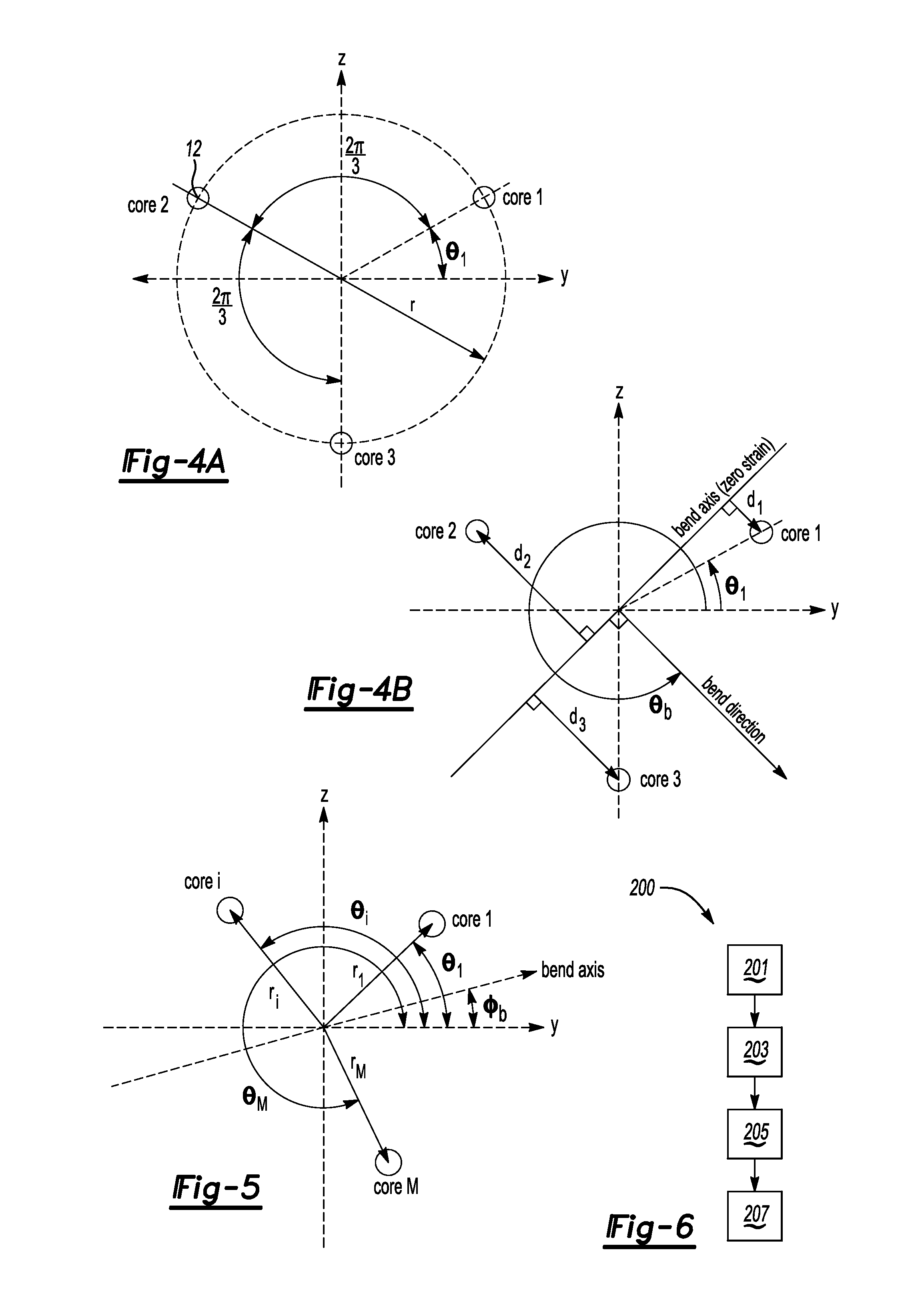

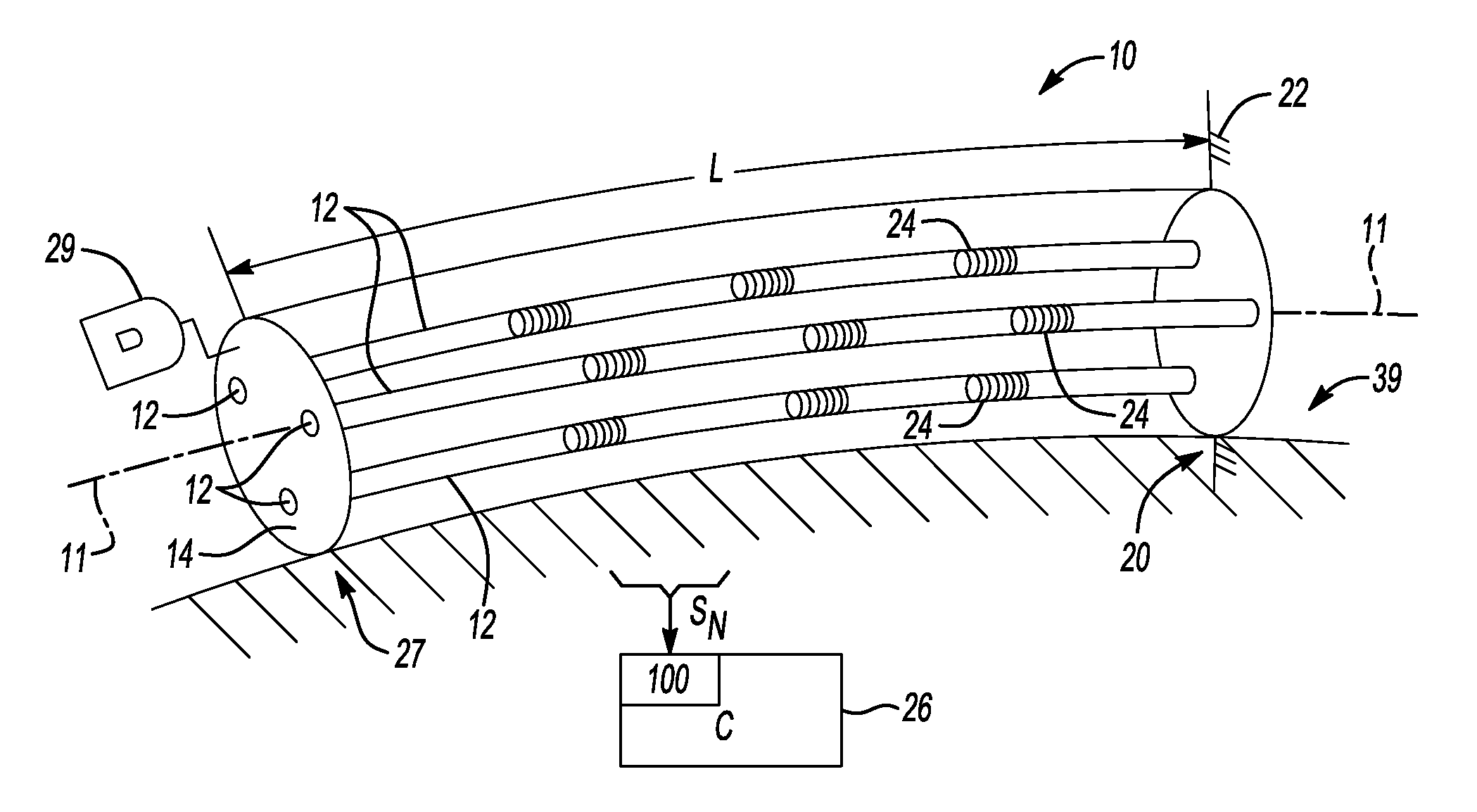

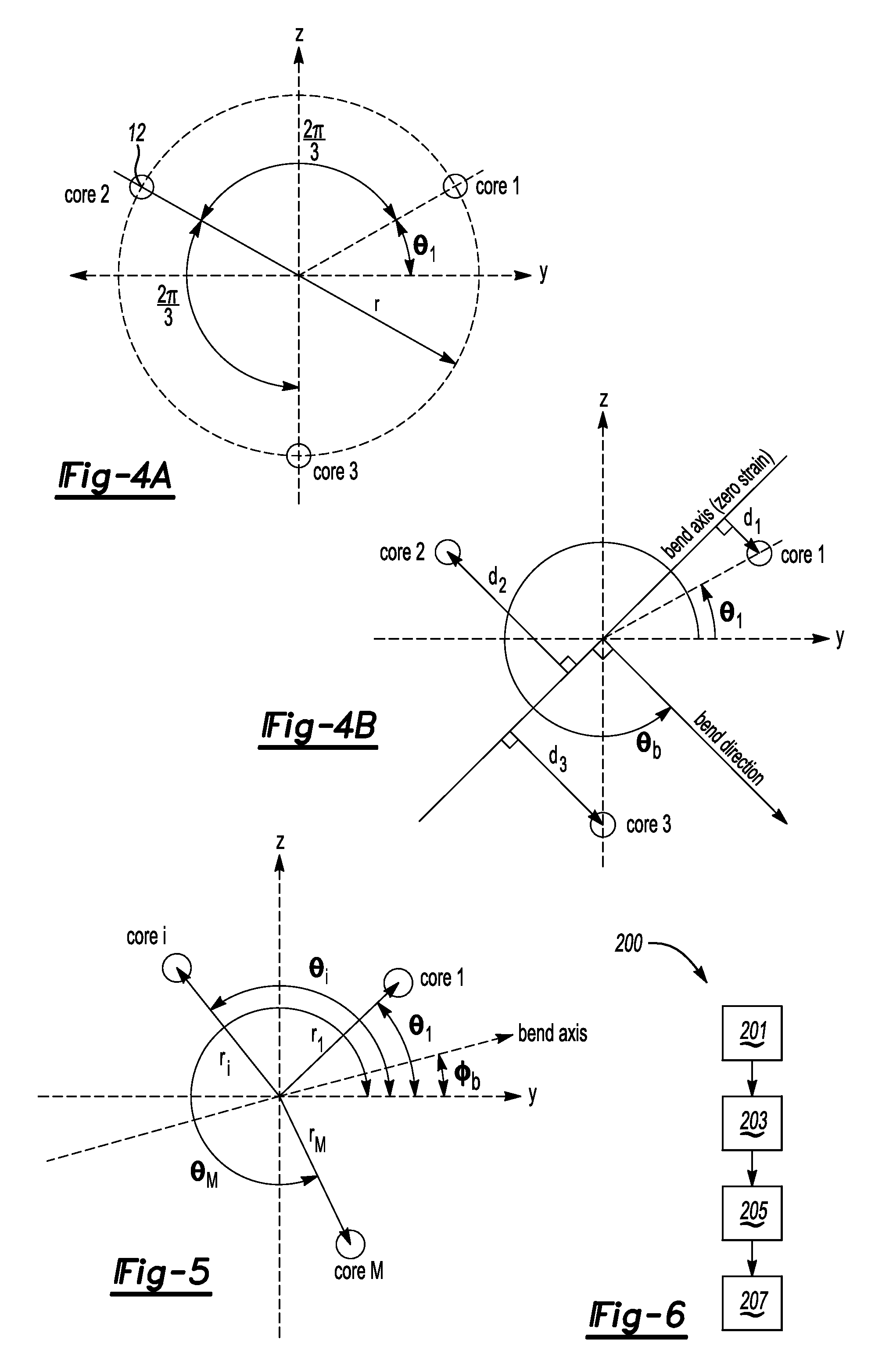

Shape Sensing Using a Multi-Core Optical Fiber Having an Arbitrary Initial Shape in the Presence of Extrinsic Forces

ActiveUS20140053654A1Accurate calculationExpand the working areaForce measurement by measuring optical property variationFiberEngineering

Shape of a multi-core optical fiber is determined by positioning the fiber in an arbitrary initial shape and measuring strain over the fiber's length using strain sensors. A three-coordinate p-vector is defined for each core as a function of the distance of the corresponding cores from a center point of the fiber and a bending angle of the cores. The method includes calculating, via a controller, an applied strain value of the fiber using the p-vector and the measured strain for each core, and calculating strain due to bending as a function of the measured and the applied strain values. Additionally, an apparent local curvature vector is defined for each core as a function of the calculated strain due to bending. Curvature and bend direction are calculated using the apparent local curvature vector, and fiber shape is determined via the controller using the calculated curvature and bend direction.

Owner:NASA

Power tool work table

A work table includes a work surface having two generally parallel bars extending across and above the work surface. Two sleeves are slidably connected to the two generally parallel bars, each sleeve of the two sleeves positioned around each bar of the two generally parallel bars. A power tool, such as a tile saw is connected between the two sleeves and thereby slides along the two bars. A channel is preferably positioned across the work surface and includes water or similar coolant / lubricant for the power tool. Handles are additionally positioned in the side of the work surface and are moveable between a retracted position within the work surface and an extended position away from the work surface. In the extended position, the handle includes a top edge generally flush with the work surface.

Owner:ZHANG CHARLIE

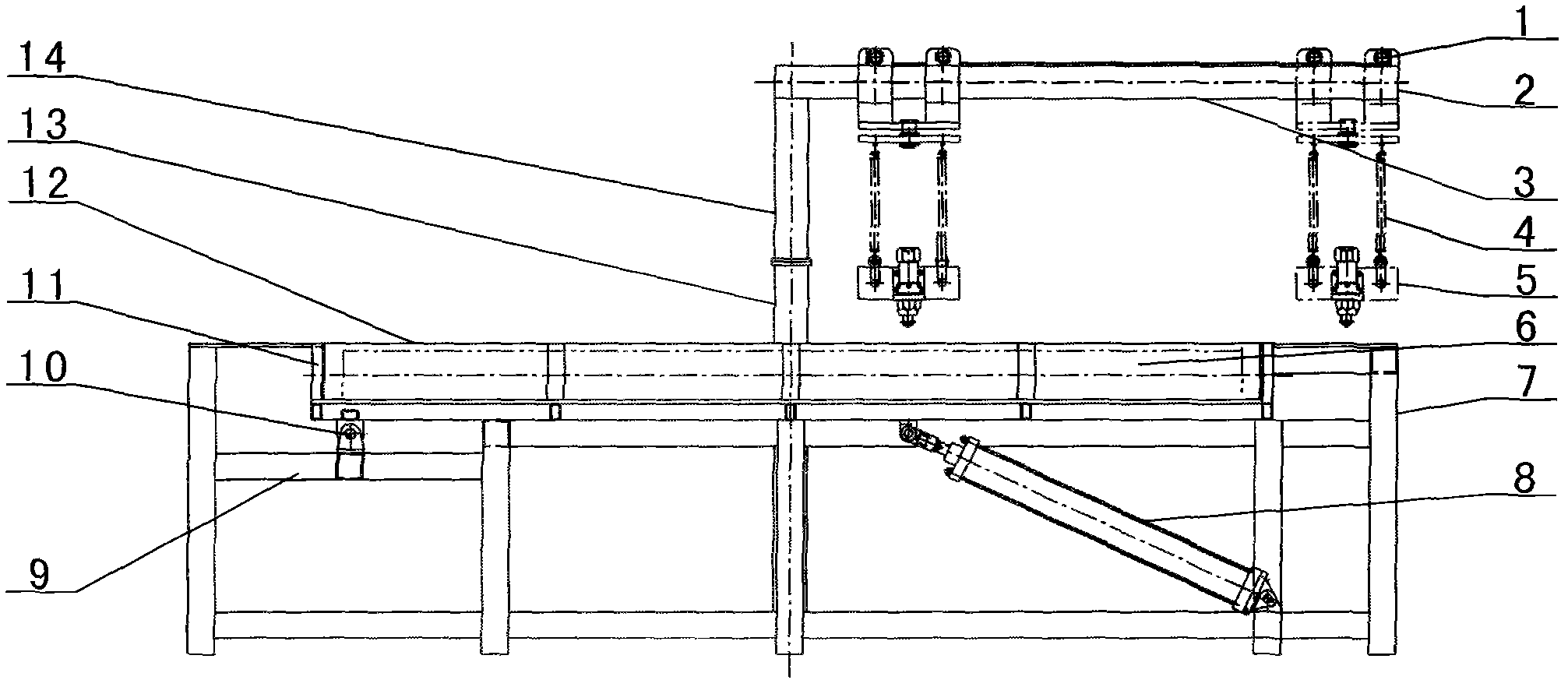

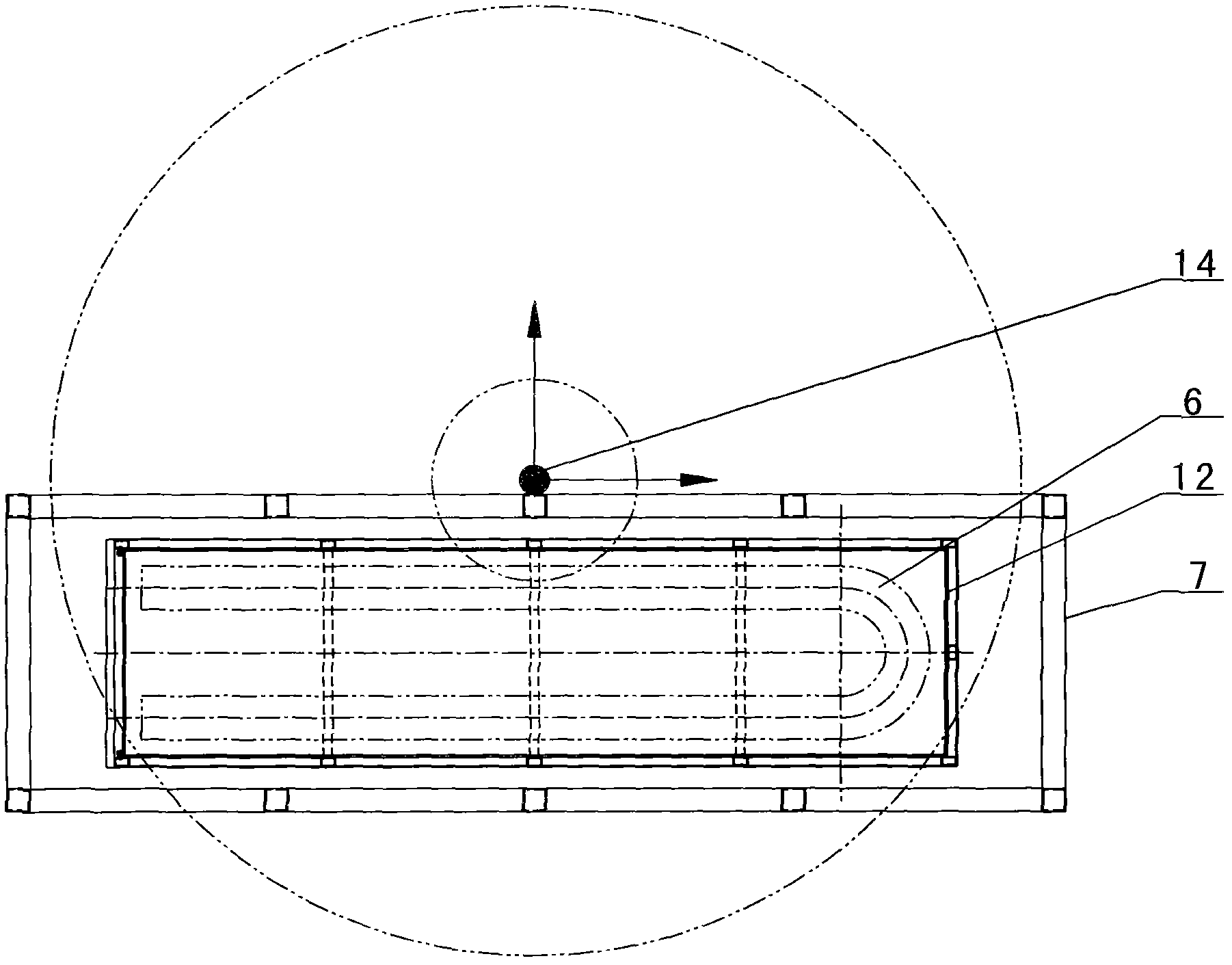

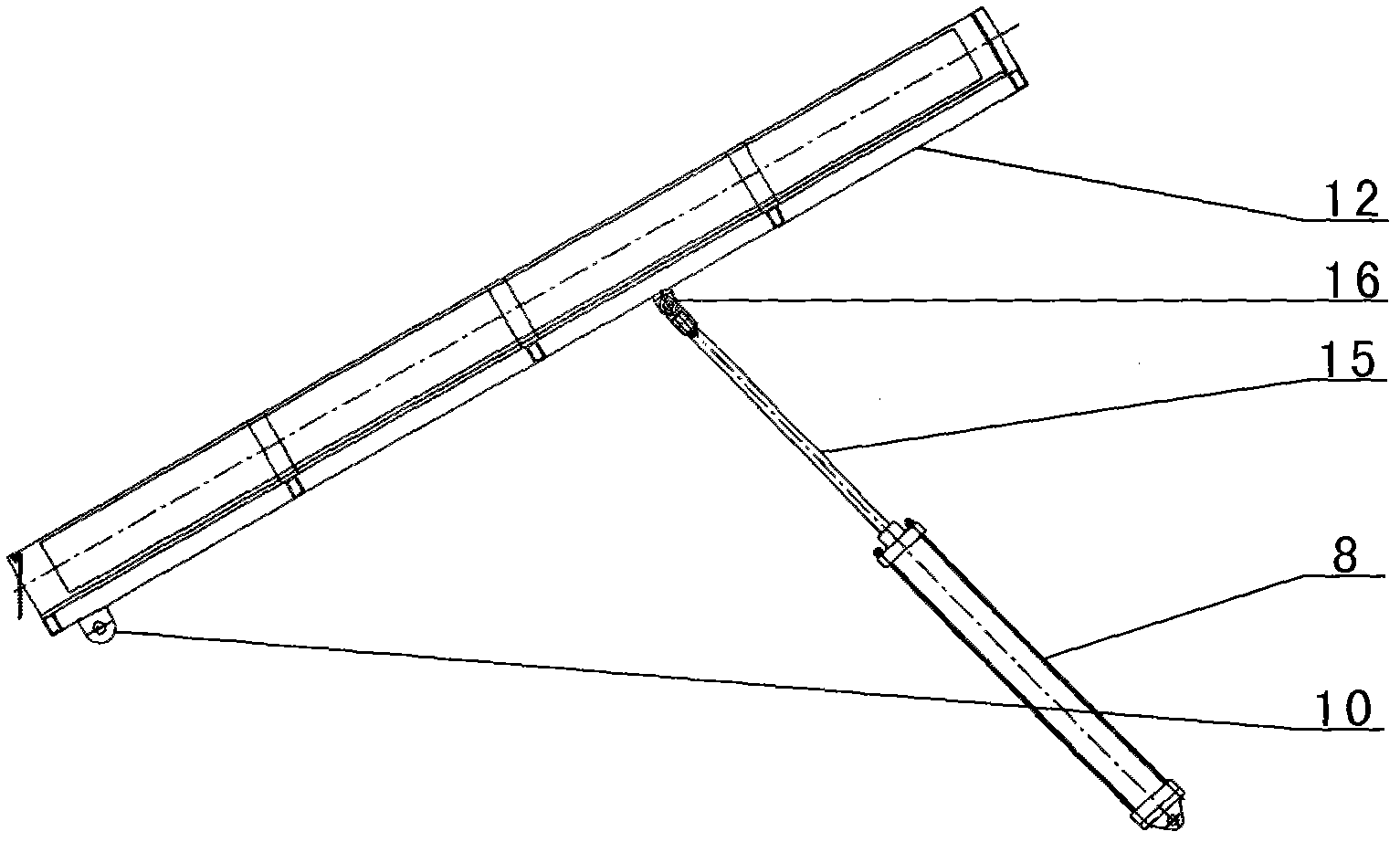

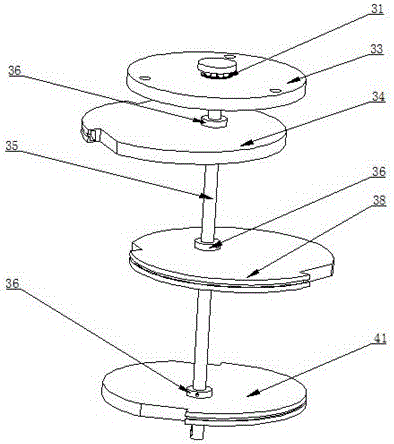

Polysilicon crushing device

InactiveCN102319594AEasy to operateExpand the working areaGrain treatmentsMechanical crushingMechanical engineering

The invention discloses a polysilicon crushing device and relates to a polysilicon crushing appliance. An upright post (13) is arranged at the middle part of any side of a material box (12), a rotating shaft (14) is movably connected with the upper part of the upright post in an inserting manner, one end of a guide rail (3) is fixedly connected with the upper end of the rotating shaft (14) or one end of the guide rail is movably connected with the upper end of the upright post so as to form a horizontal rotating structure of the guide rail, a sliding mechanism is in sliding fit with the guide rail, an elastic body connected with an impact cylinder (17) is arranged at the lower part of the sliding mechanism, and an impact head (18) is arranged at the lower end of the impact cylinder so as to form a structure enabling the impact head to be in multi-station correspondence with polysilicon (6) in the material box (12). In the invention, an extension spring arranged on the guide rail is used to flexibly control a silicon rod beating structure consisting of the impact cylinder and the impact head, thereby effectively overcoming the defects of manual crushing, such as high cost, low efficiency, unsafety and the like, effectively improving the production efficiency and achieving the purpose of mechanical crushing.

Owner:洛阳佑东光电设备有限公司

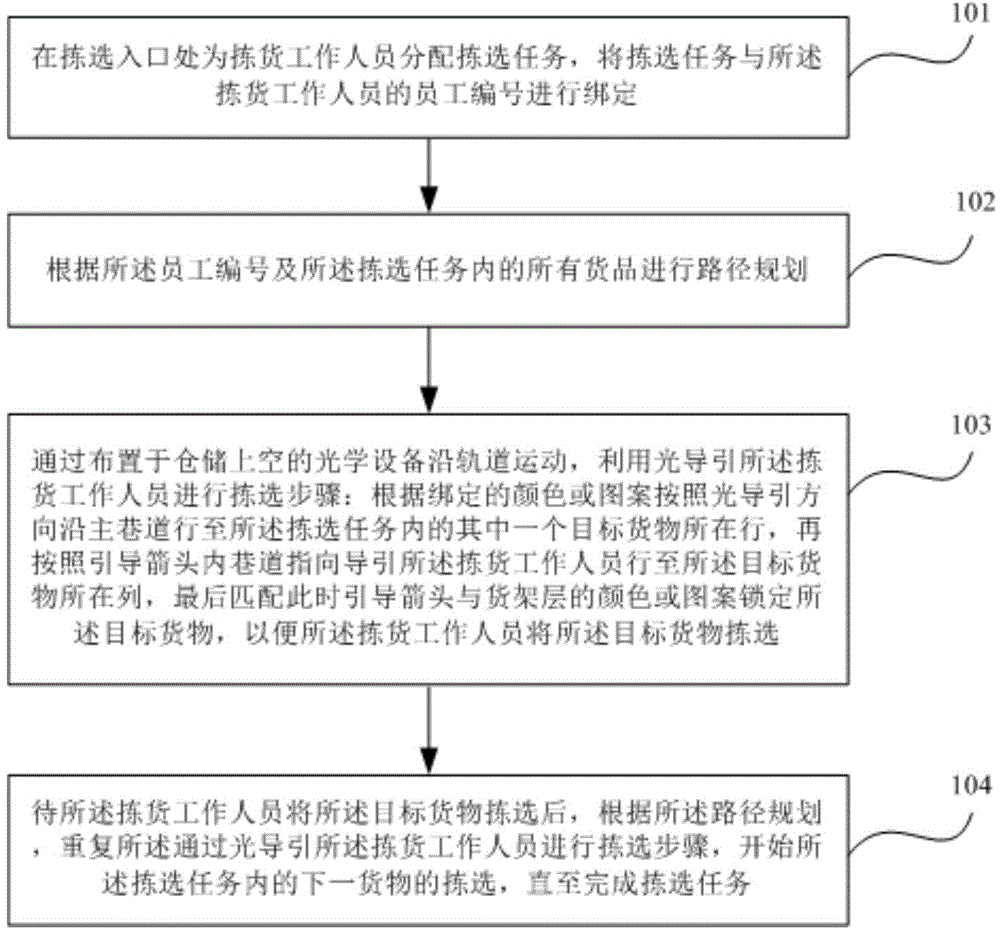

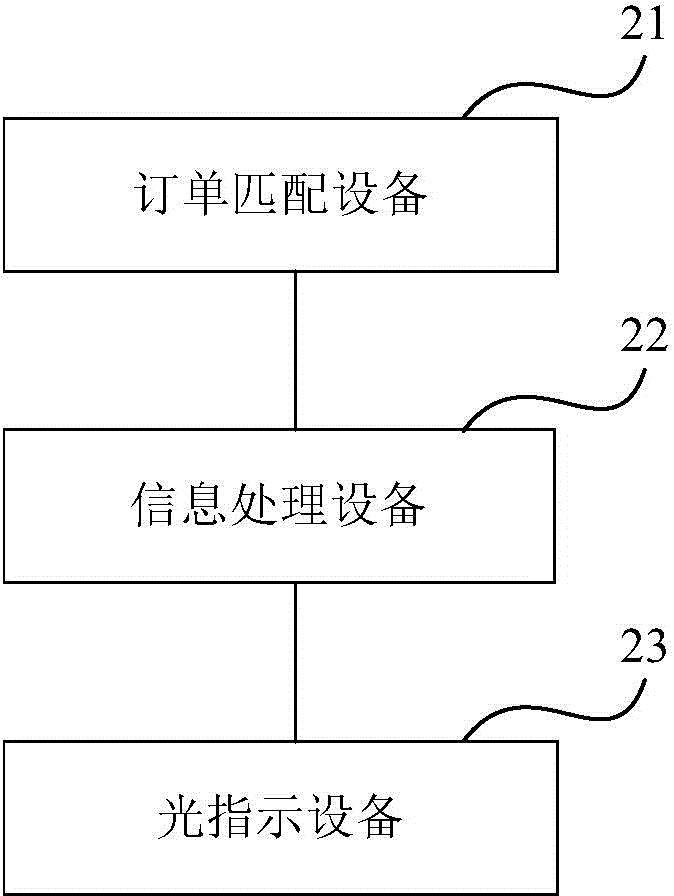

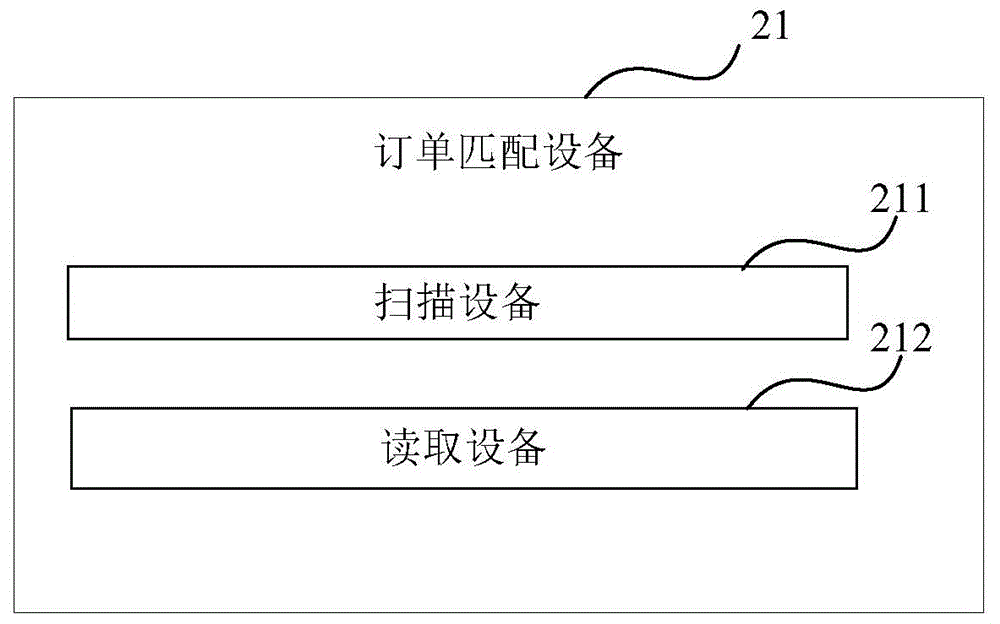

Optical logistics choosing guide method and system

The embodiment of the invention provides an optical logistics choosing guide method and system. The method comprises the steps that choosing tasks are allocated to choosing workers in a choosing inlet, and the choosing tasks and the serial numbers of the choosing workers are bound; route planning is carried out according to the serial numbers of the choosing workers and all cargos in the choosing tasks; optical equipment above a storage bin is arranged to move along a track, and light is utilized for guiding the choosing workers to carry out choosing; after target cargoes are chosen by the choosing workers, the step of guiding the choosing workers to carry out choosing through light is executed again according to the route planning, and choosing of next cargos in the choosing tasks is started until the choosing tasks are finished. The optical logistics choosing guide method and system can guide the choosing workers to choose target cargos step by step, are suitable for the condition of various varieties and the large choosing workload, wide in working face, and capable of being applied in the environment of many goods shelves.

Owner:BEIJING WUZI UNIVERSITY

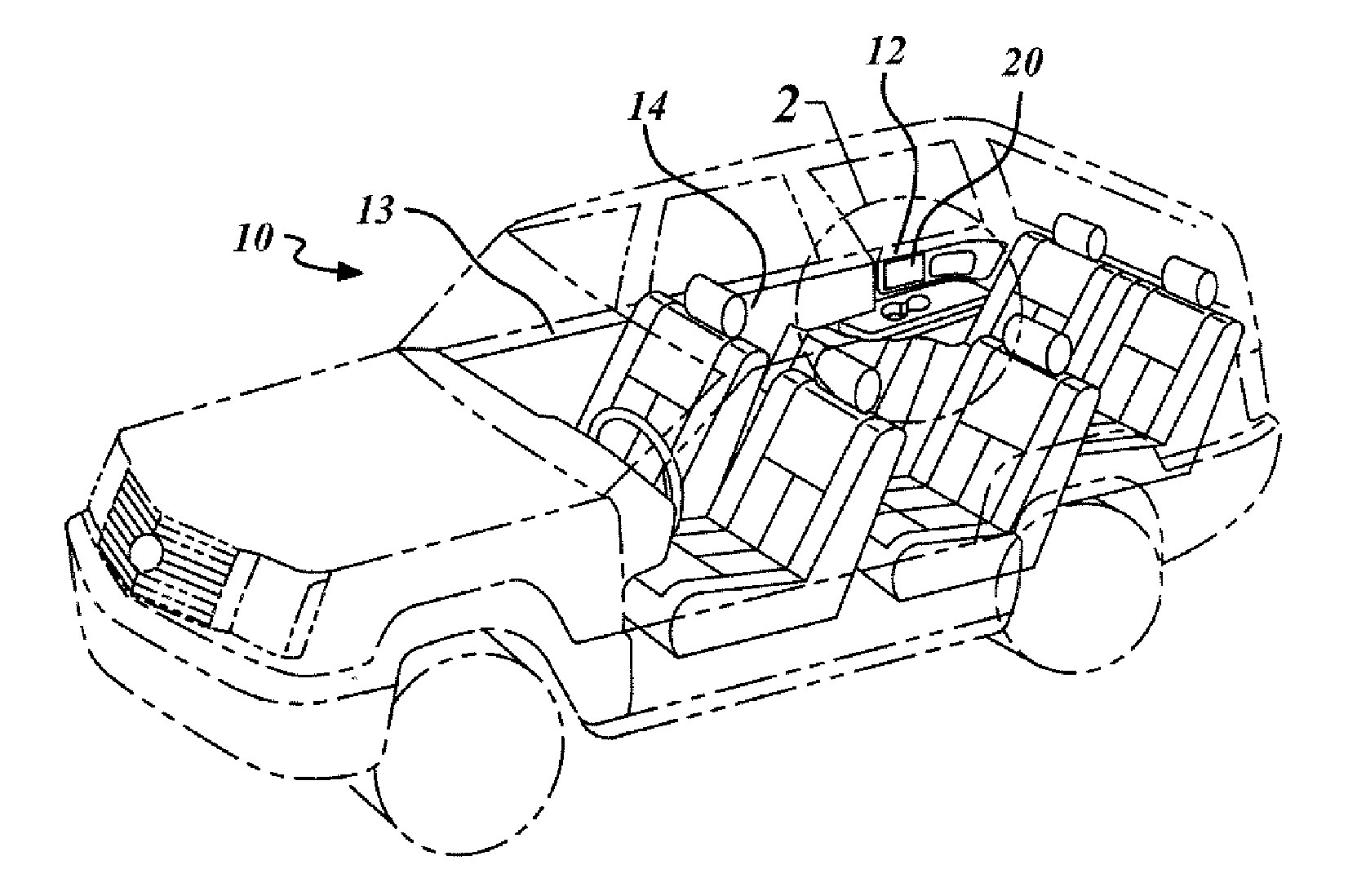

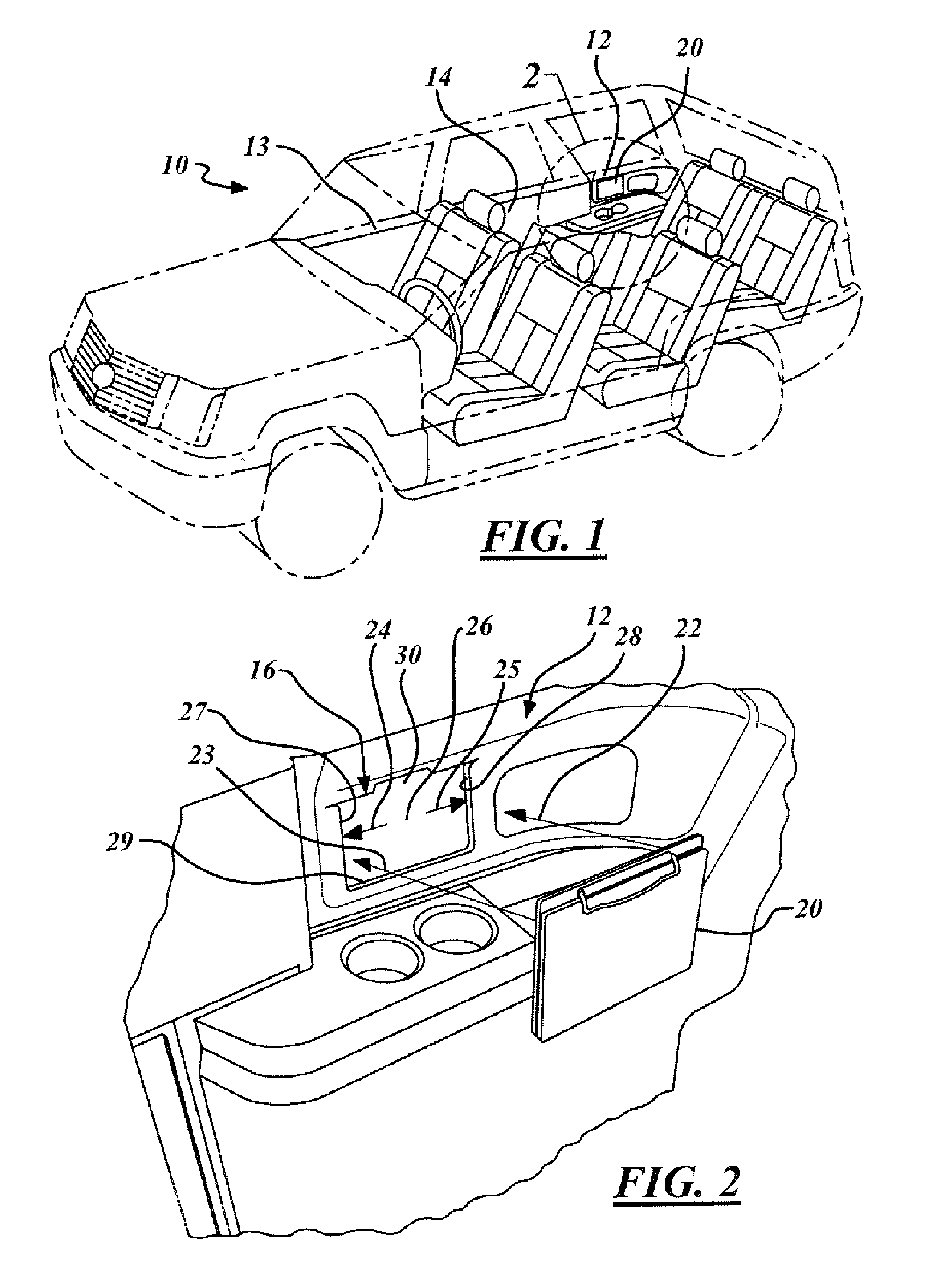

Fold-up tray

InactiveUS20060266779A1Expand the working areaReduce storage areaVehicle arrangementsSupplementary fittingsEngineeringMechanical engineering

A fold-up tray for use in a vehicle is provided. The tray includes a top surface, a first section, a second section and a hinge. The first section includes a first portion of the top surface. The second section includes a second portion of the top surface. The hinge connects the first section and the second section, thereby affording an increased working surface when both portions of the tray are unfolded while also providing a stowable working surface when both portions of the tray are folded. In one embodiment, the hinge is a living hinge.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Shape sensing using a multi-core optical fiber having an arbitrary initial shape in the presence of extrinsic forces

ActiveUS8746076B2Accurate calculationExpand the working areaForce measurement by measuring optical property variationOptical light guidesEngineeringStrain sensor

Shape of a multi-core optical fiber is determined by positioning the fiber in an arbitrary initial shape and measuring strain over the fiber's length using strain sensors. A three-coordinate p-vector is defined for each core as a function of the distance of the corresponding cores from a center point of the fiber and a bending angle of the cores. The method includes calculating, via a controller, an applied strain value of the fiber using the p-vector and the measured strain for each core, and calculating strain due to bending as a function of the measured and the applied strain values. Additionally, an apparent local curvature vector is defined for each core as a function of the calculated strain due to bending. Curvature and bend direction are calculated using the apparent local curvature vector, and fiber shape is determined via the controller using the calculated curvature and bend direction.

Owner:NASA

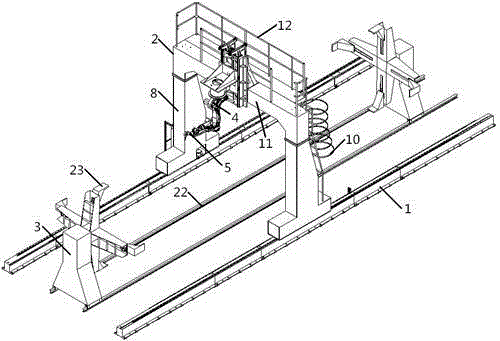

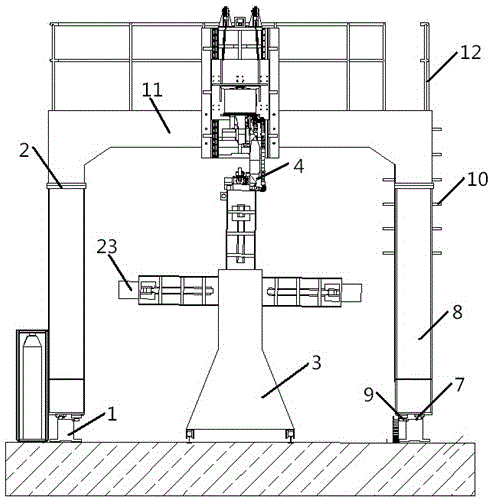

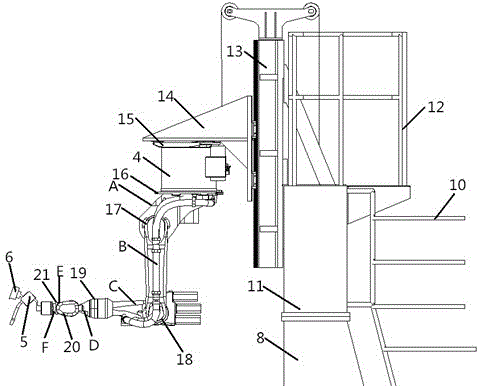

Robot automatic welding workstation for large tank and welding method using robot automatic welding workstation for large tank

InactiveCN104999188AFree and flexible space movementImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlControl system

The invention discloses a robot automatic welding workstation for a large tank and a welding method using the robot automatic welding workstation for the large tank. The robot automatic welding workstation for the large tank comprises a welding system and a PLC automatic control system which is connected with the welding system through a network bus. The robot automatic welding workstation for the large tank is characterized in that the welding system comprises sliding rails, positioners and a rack; the rack is installed on the sliding rails in a sleeved mode; the positioners are located on the center line of the two sliding rails; the rack is provided with a six-axis linkage robot fixedly provided with a welding gun. The PLC automatic control system controls the welding route of the welding system through a driver. By the adoption of the robot automatic welding workstation for the large tank and the welding method using the robot automatic welding workstation for the large tank, full automation of the welding system can be achieved; welding joints are more smooth and flatter; the welding precision is high; the space positioning accuracy can reach 0.1 mm; the welding quality is good; deformation is small; as the space actions of the six-axis linkage robot are flexible, the welding gun can be moved to each portion of the tank and can weld welding joints of various forms.

Owner:HUBEI QIXING TRUCK & CABIN MFG

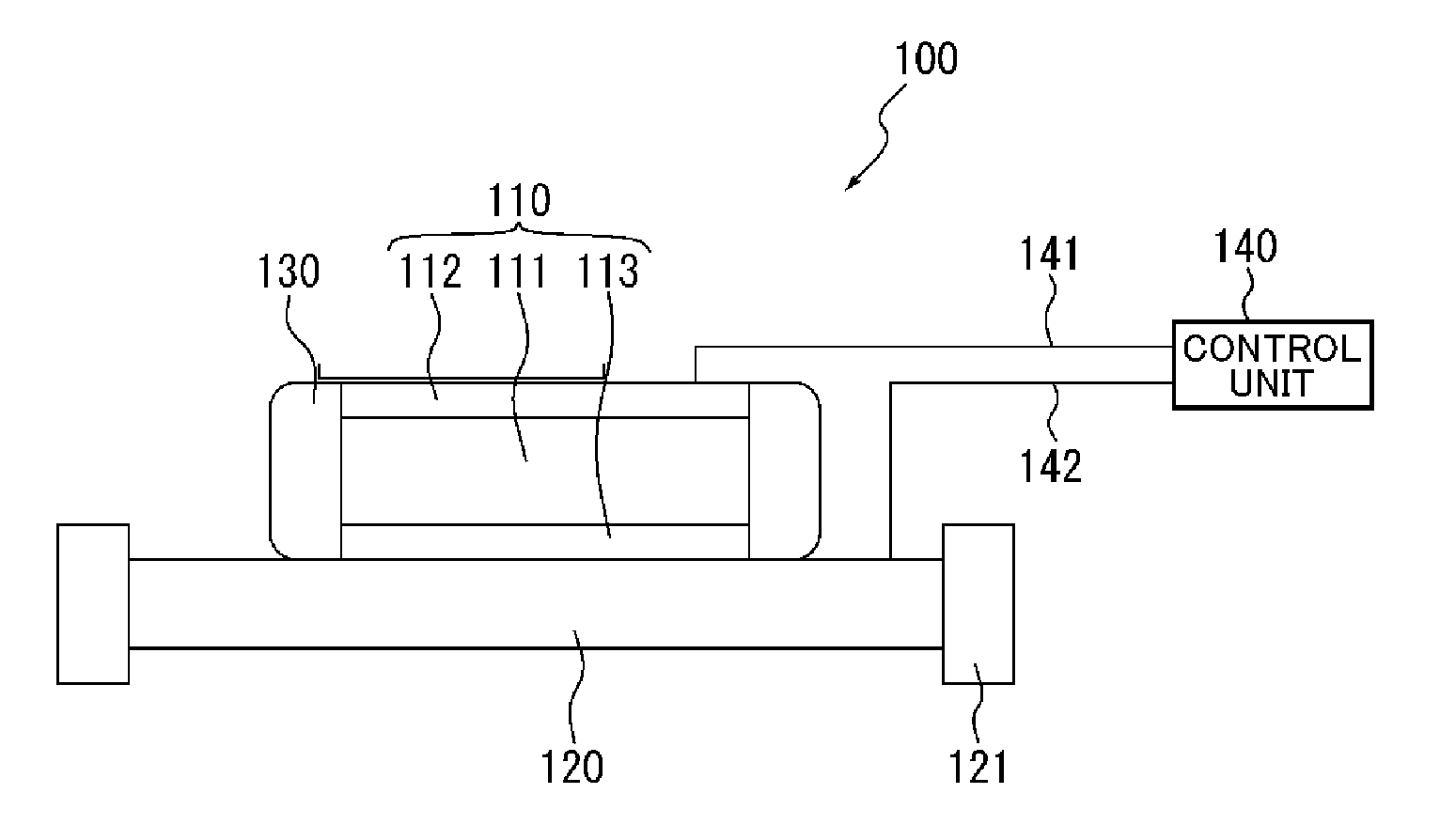

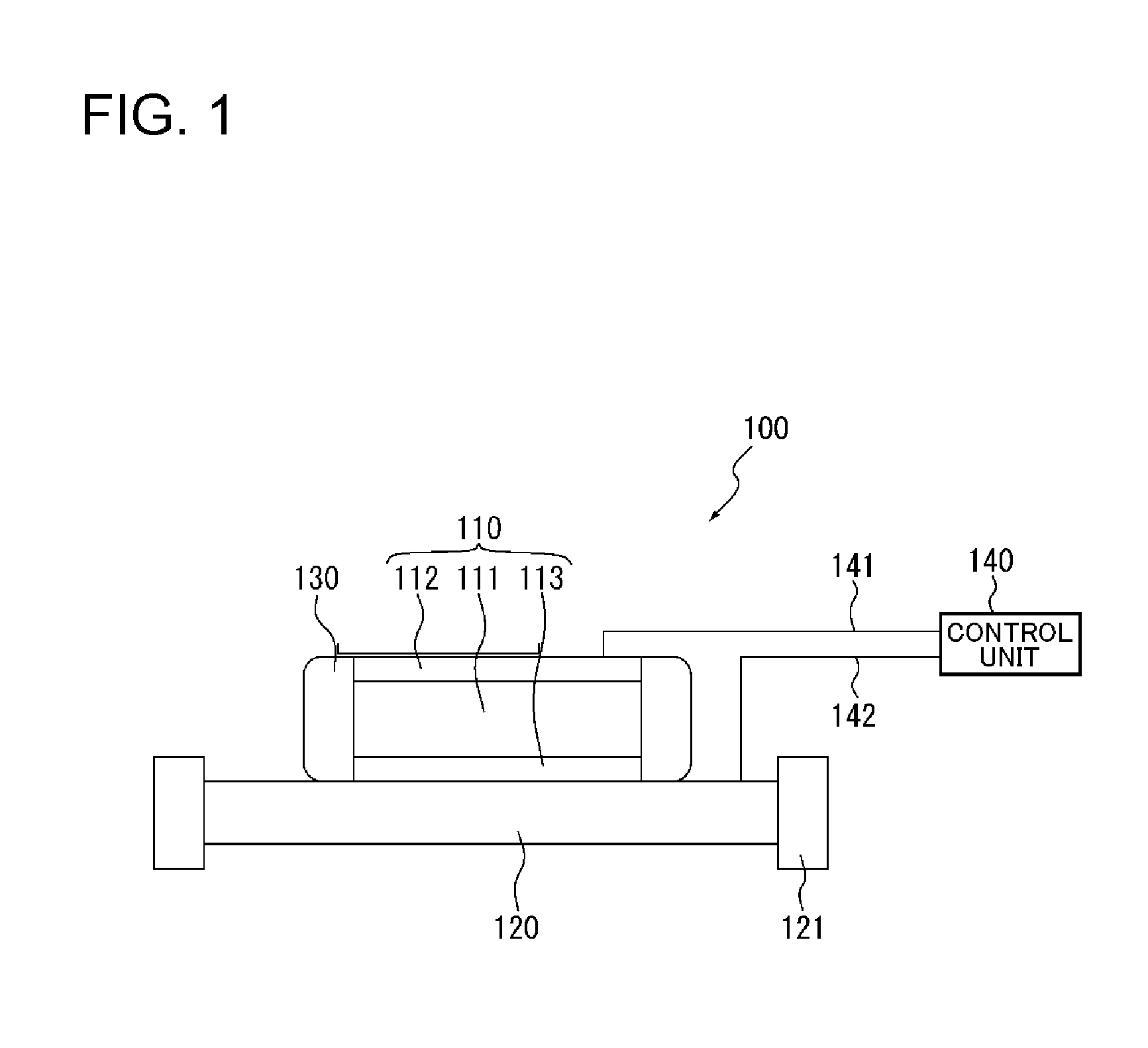

Oscillation device and electronic apparatus

InactiveUS20130077443A1Increase sound pressure levelReduce thicknessPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersPiezoelectric actuatorsElectric equipment

An oscillation device includes: a piezoelectric vibrator (110) in which electrode layers (112, 113) are formed over top and bottom surfaces of a piezoelectric layer (111); a vibrating member (120) having at least atop surface to which the piezoelectric vibrator (110) is bonded; and a resin member (130) formed continuously in a circumferential direction over at least the outer side surface of the piezoelectric vibrator (110). Therefore, since it is possible to increase the working area of the piezoelectric vibrator, it is possible to realize both an increase in the sound pressure level of the output and miniaturization of the apparatus.

Owner:NEC CORP

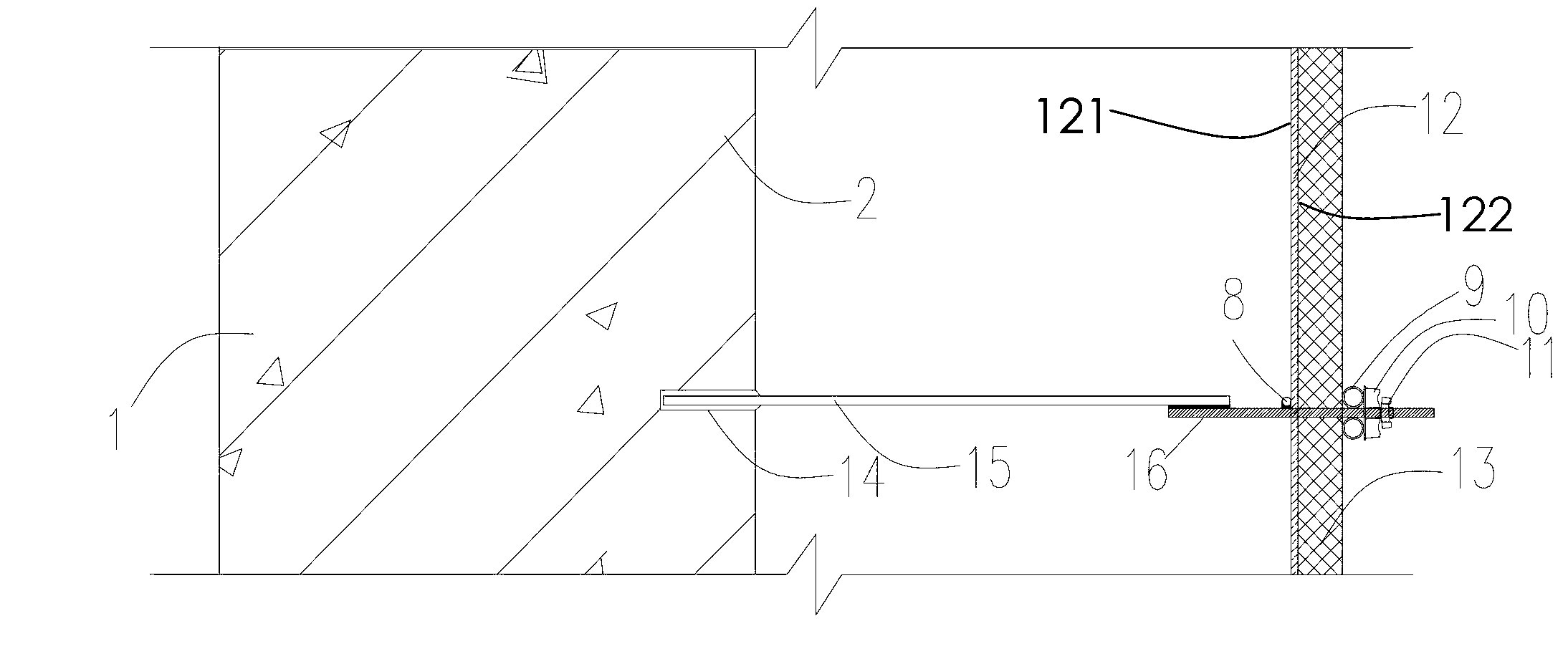

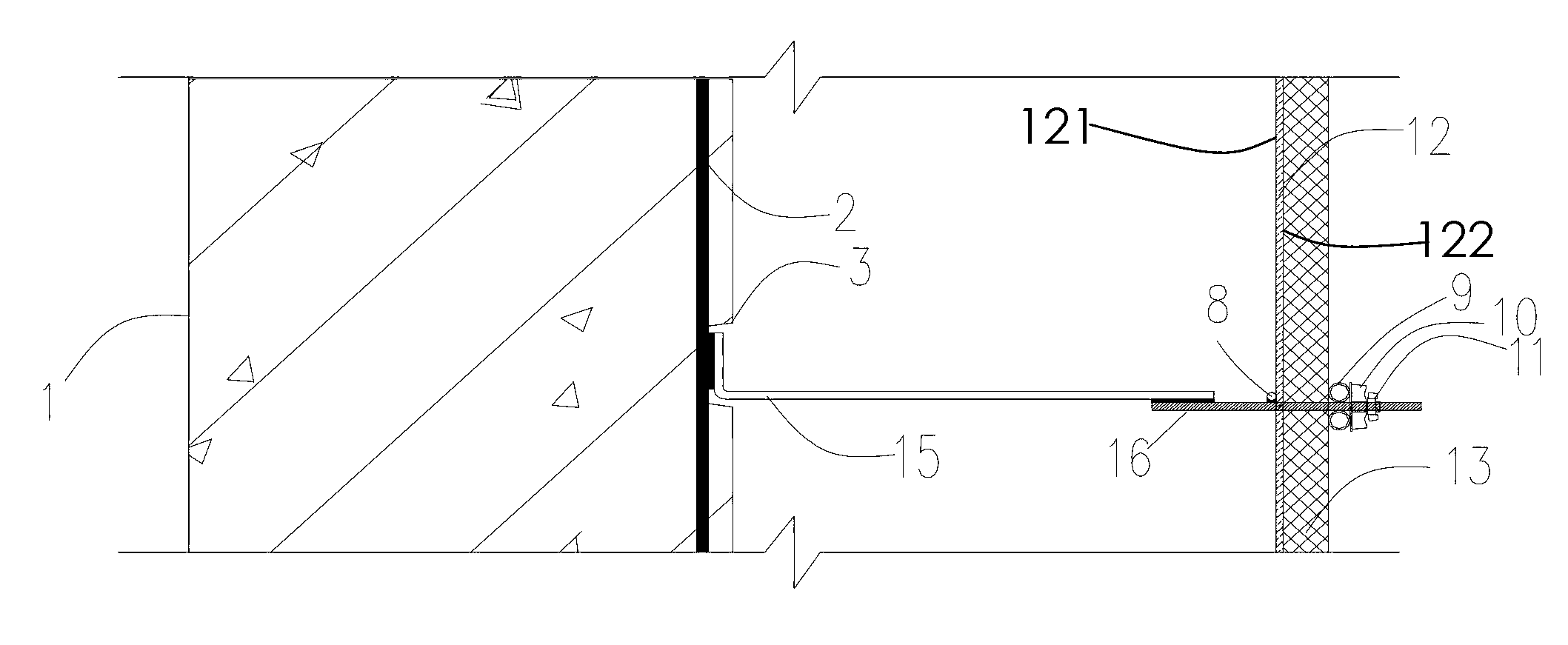

Construction method of one-side form bracing for underground structure sidewalls

InactiveCN103061358AReduce the amount of construction workLow costArtificial islandsUnderwater structuresSlurry wallEngineering

The invention discloses a construction method of one-side form bracing for underground structure sidewalls. The method includes the steps of installing a form which comprises a first side and a second side, with the first side close to an underground diaphragm wall; fixing one end of a waterproof tie bolt on the underground diaphragm wall through a connecting rebar; making a hole on the form, allowing the other end of the waterproof tie bolt to penetrate through the first side of the form and extend out of the second side of the form, and fixing with a nut on the second side; installing a plurality of form bracing structures according to stress need, casting sidewall concrete, and completing one-side form bracing for the underground structure sidewalls.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

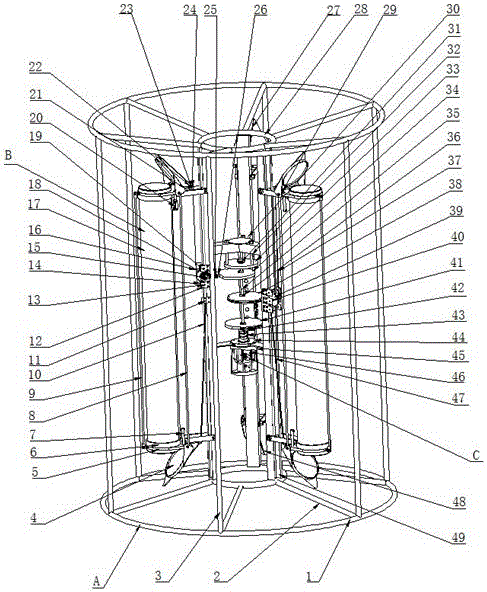

Fully-automatic water sampler used for layered collection of water sample

ActiveCN106092658AConvenience for water harvesting operationsSimple control systemWithdrawing sample devicesControl systemElectric machinery

The invention discloses a fully-automatic water sampler used for layered collection of a water sample. The fully-automatic water sampler mainly comprises a sampled water barrel mechanism, a cam group mechanism, a rope system mechanism, a support mechanism and a control system part. The sampled water barrel mechanism is uniformly distributed on a small support circular ring, and is used for collecting the water sample; the cam mechanism controls movement of a small chuck under the driving of a moor in order to control closure of a water barrel sealing cover; the rope system mechanism plays a role in transmission of the force of the small chuck and amplification of the stroke; the supporting mechanism plays a role in fixed connection of the whole mechanism and hoisting in the working process; and the control system part plays a role in water depth identification and control of the running of the motor. The water sampler can realize control of the movement of a plurality of cams through one motor in order to realize collection of the water sample in different water layers, so the water sampler has the advantages of realization of whole-course fully-automatic working process, no artificial release of a hammer, realization of unattended operation, wide working area, reduction of interference of artificial factors, and realization of water collection of more water layers through conveniently developing the quantity of water collecting barrels and cams.

Owner:SHANGHAI UNIV

Power tool work table

InactiveUS20050051015A1Expand the working areaMetal working apparatusMaintainance and safety accessoriesPower toolRidge

A work table including a water tray defining a reservoir, and forming a ridge at least partially positioned within the reservoir and extending along a length of the water tray. A planar member having a work surface is positionable with respect to the water tray, and forms a channel extending through the work surface. The channel is aligned with the ridge and in fluid communication with the reservoir with the planar member positioned on the water tray.

Owner:ZHANG CHARLIE

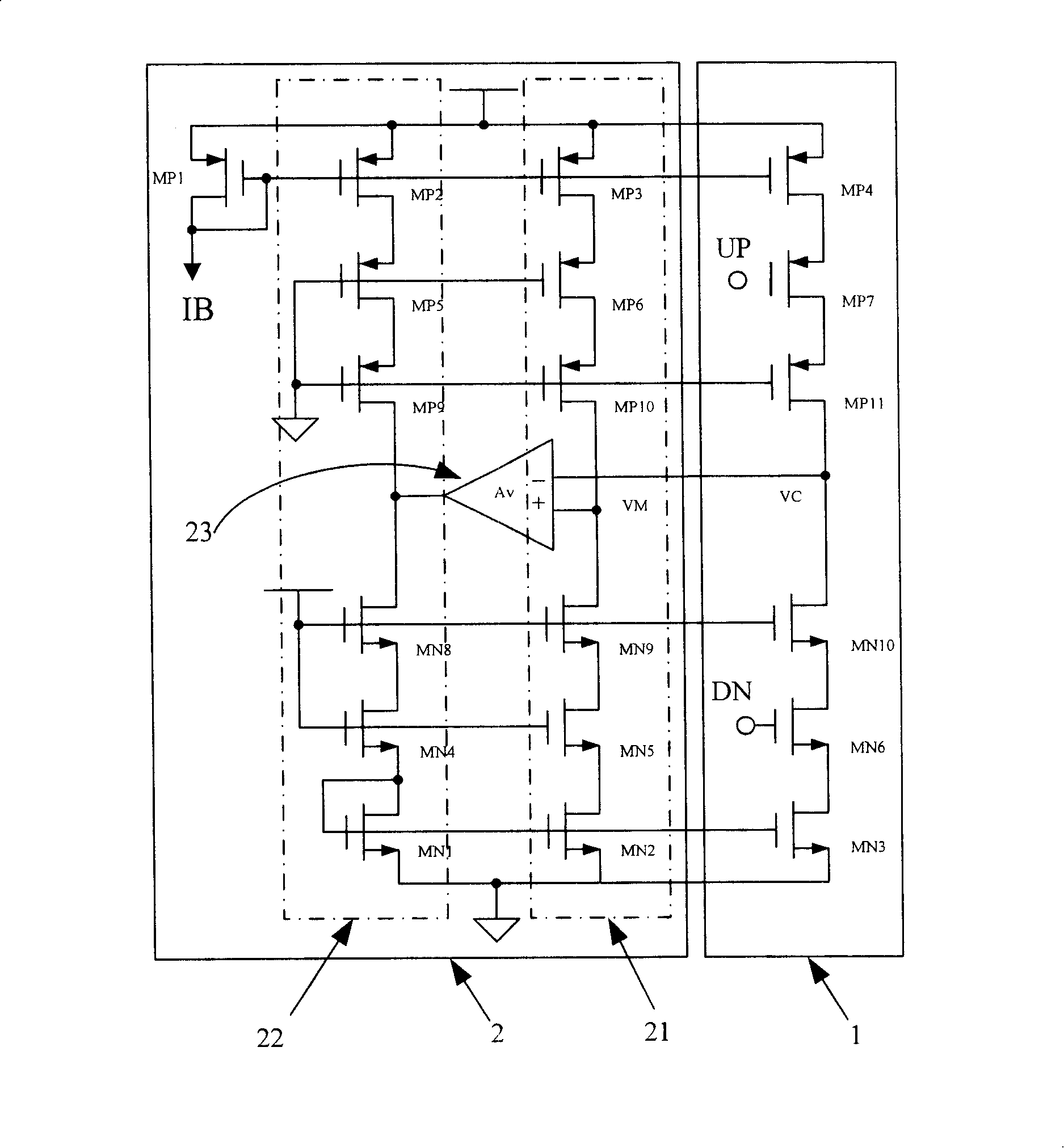

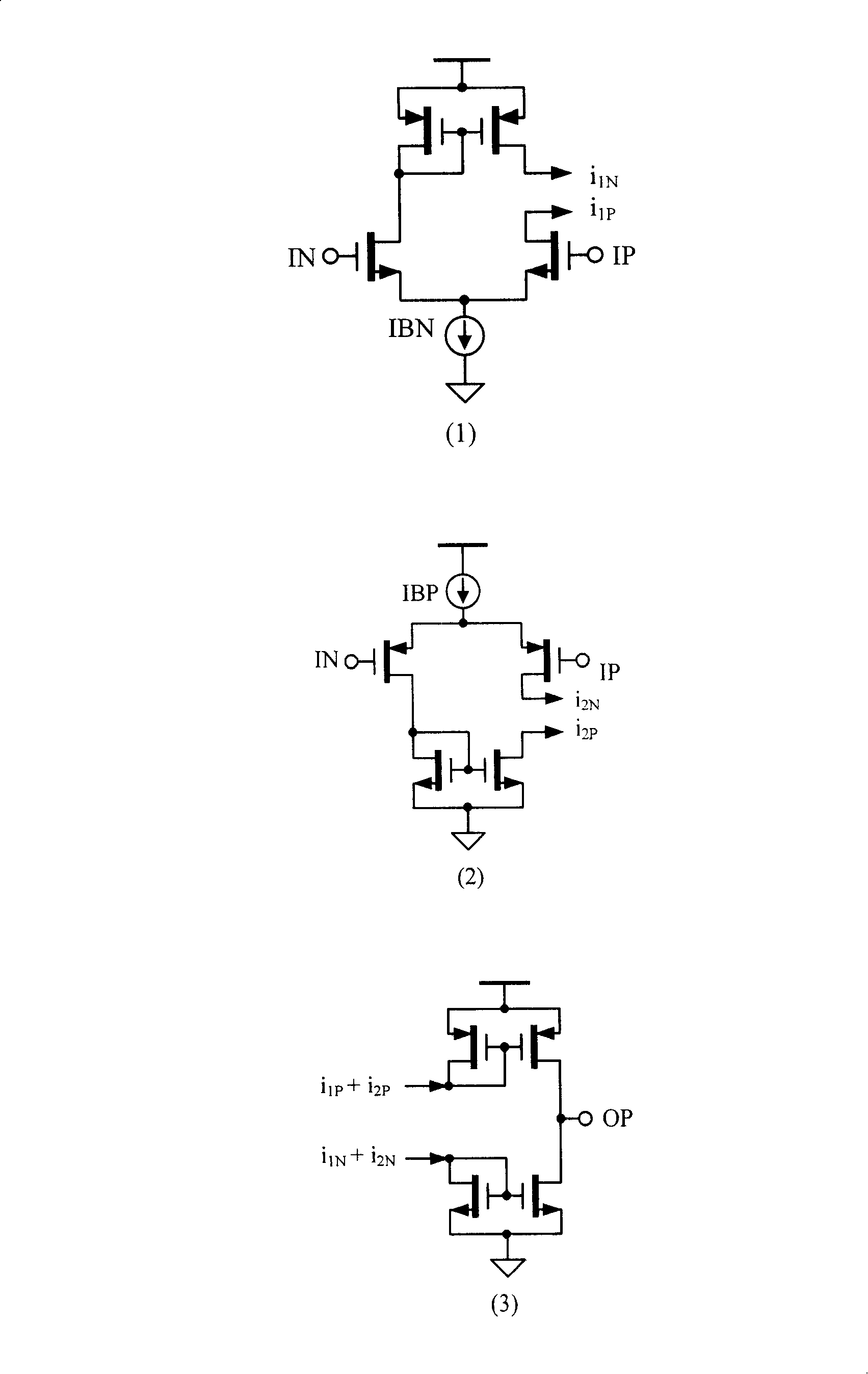

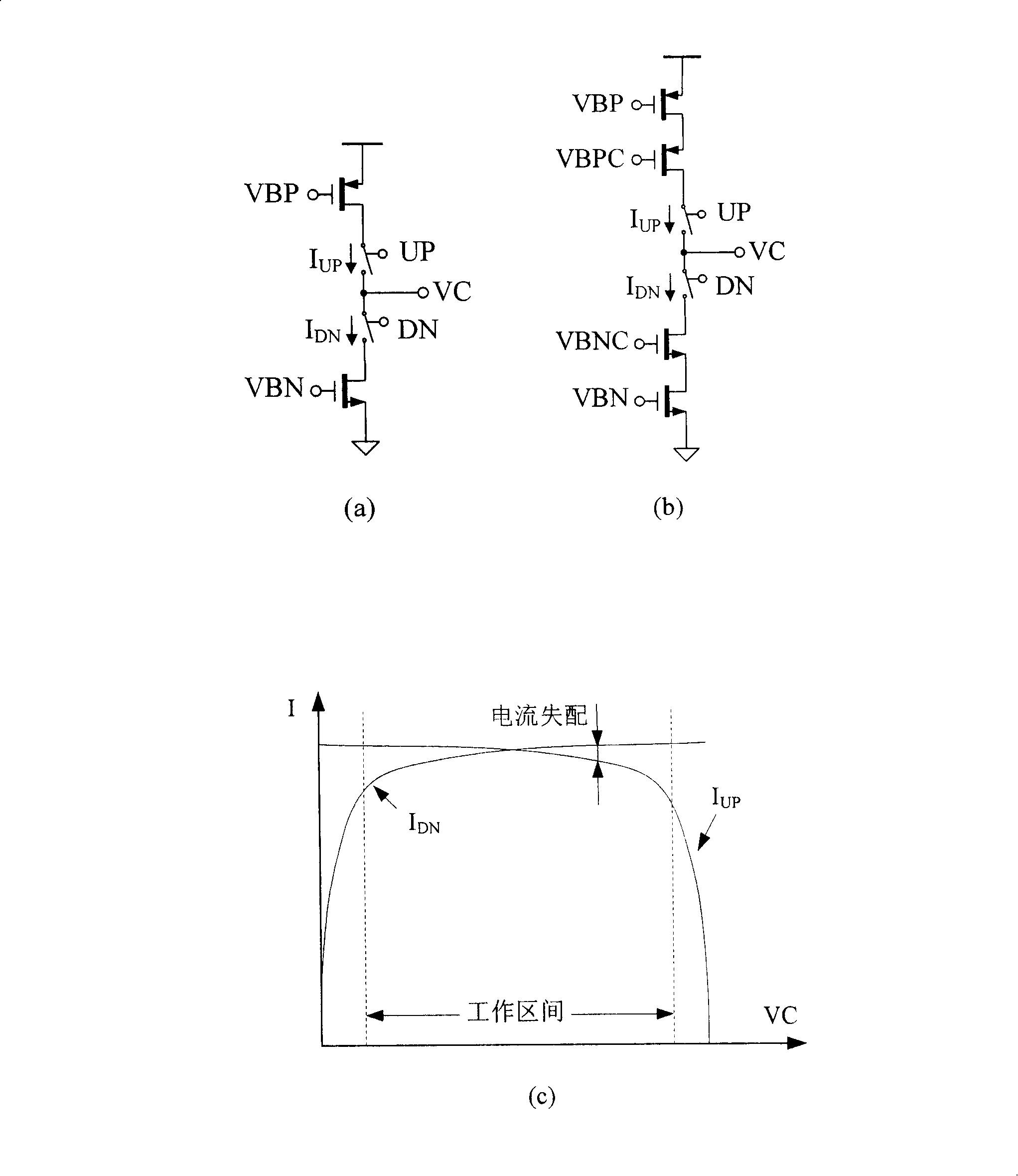

Self-calibration charge pump circuit used for phase-locked loop and its self-calibration feedback loop

InactiveCN101222226AImprove stabilityExpand the output rangePulse automatic controlAudio power amplifierClosed loop feedback

The invention relating to the phase-locked loop charge pump circuit technical field in microelectronics discloses a self-calibration charge pump circuit used in a phase-locked loop. The invention is characterized in that: the self-calibration charge pump circuit comprises a current branch 1 and a self-calibration feedback circuit 2; the self-calibration feedback circuit 2 comprises a reference branch 21, a biasing branch 22 and a feedback amplifier 23; the reference branch 21 and the output node of the current branch 1 are respectively connected with the positive input end and the negative input end of the feedback amplifier 23; the output end of the feedback amplifier 23 is connected with the biasing branch 22 to from a closed-loop feedback loop. The invention also discloses a self-calibration feedback circuit 2 used in a charge pump circuit. The invention solves the problems of unmatched output current and unstable circuit status of a charge pump circuit when output voltage varies in a large range.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

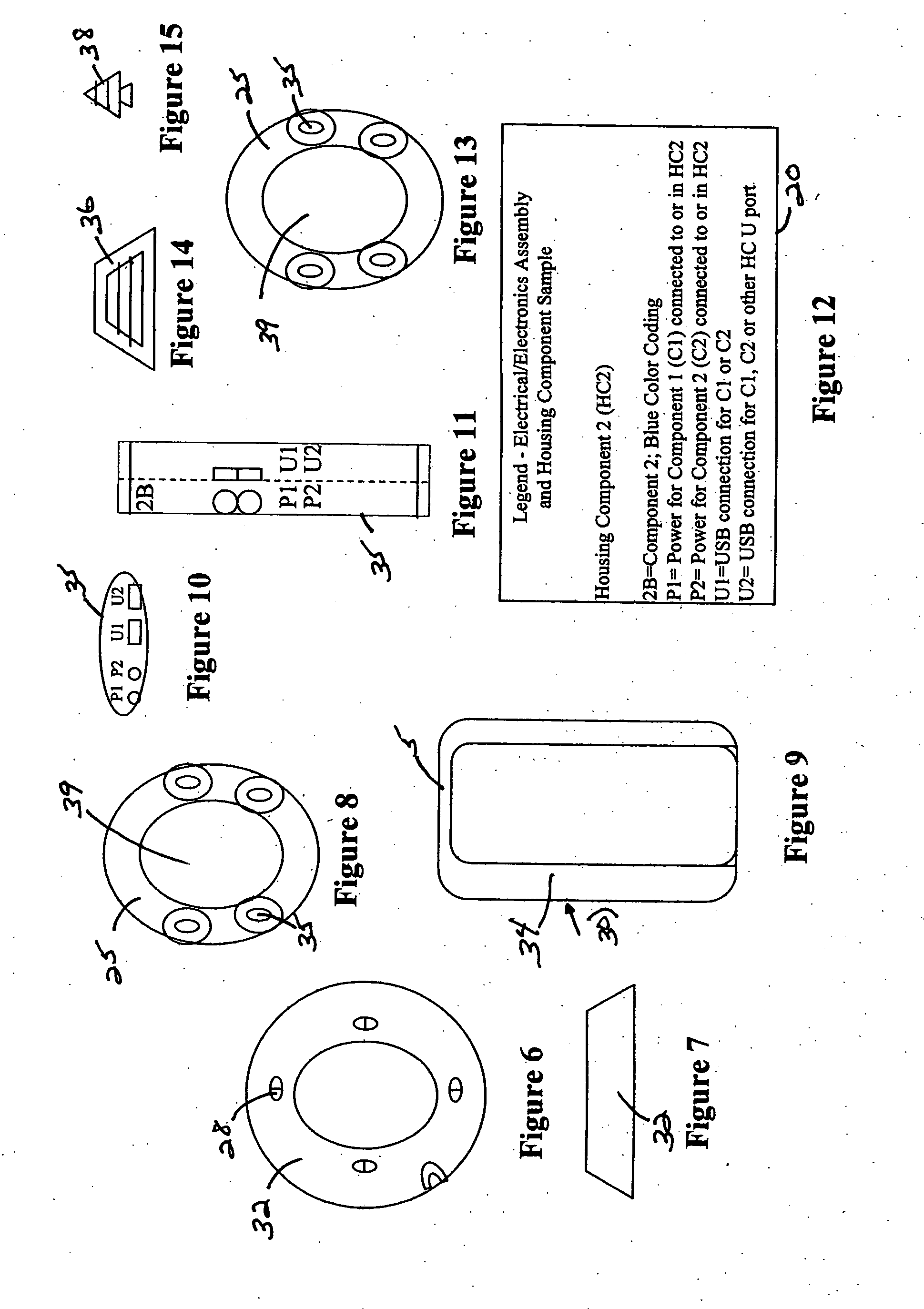

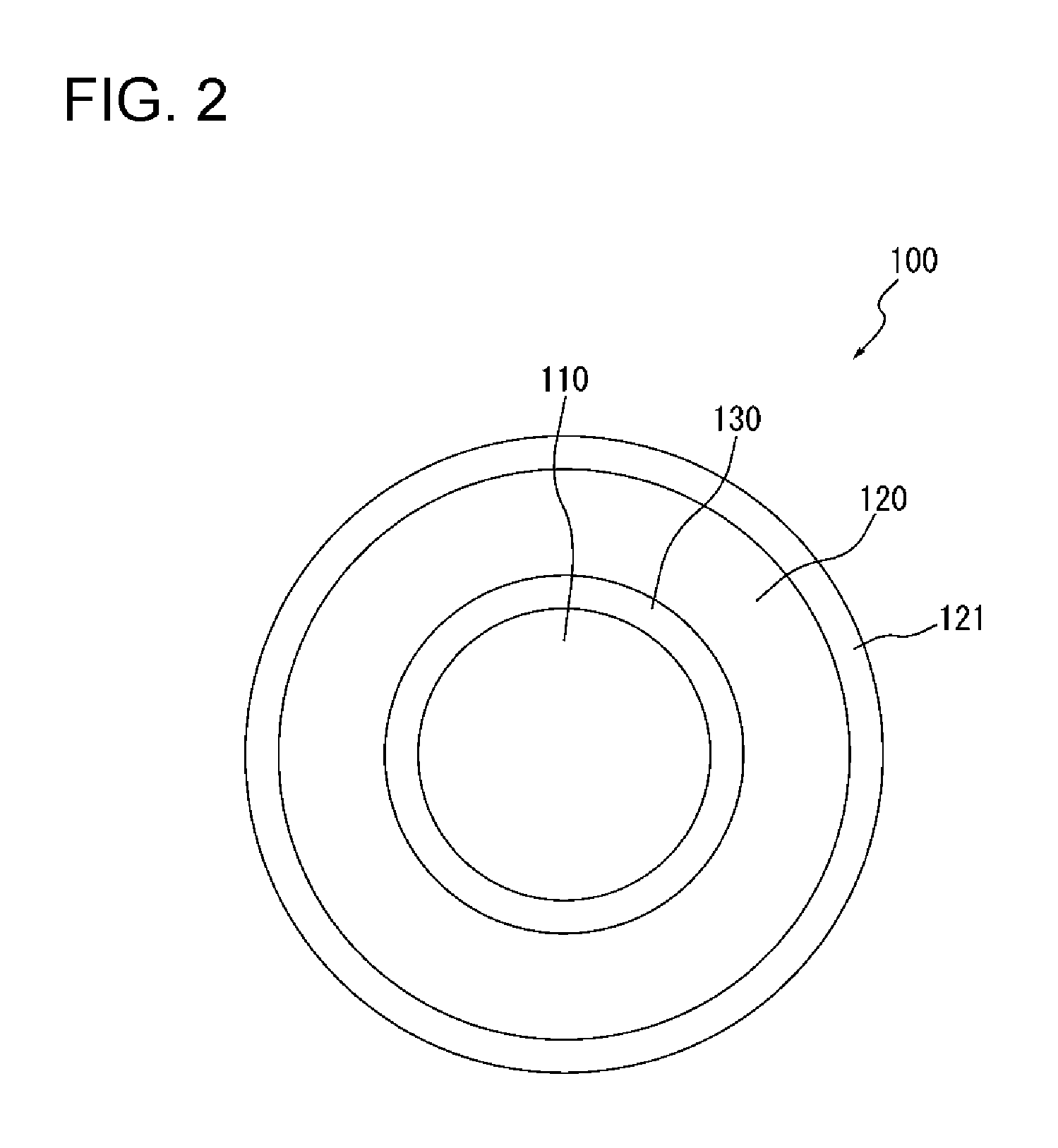

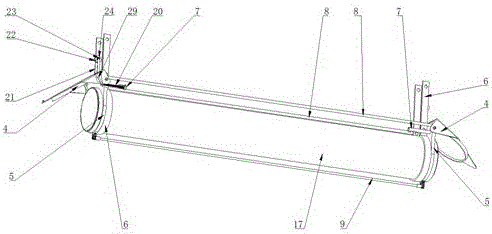

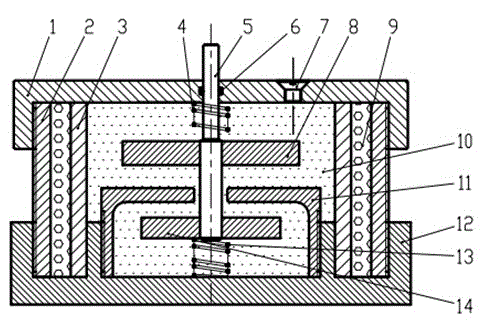

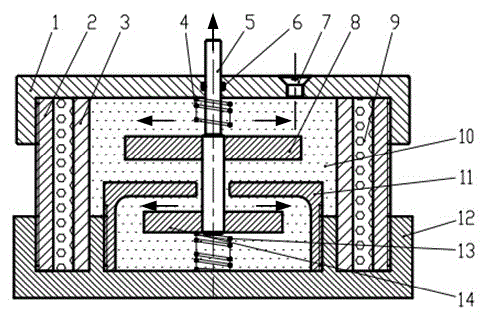

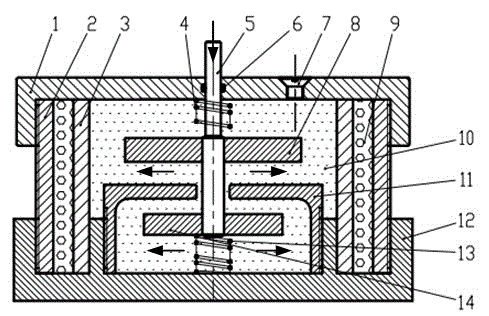

Multistage extrusion-type magneto-rheological damper

ActiveCN103148157AIncrease the effective working areaExpand the working areaNon-rotating vibration suppressionSnubberVibration isolation

The invention relates to a magneto-rheological damper, in particular to a multistage extrusion-type magneto-rheological damper. The multistage extrusion-type magneto-rheological damper is suitable for the vibration isolation of an engine or other equipment. The damper comprises an upper end cover, an outer cylinder body, a piston rod, a sealing ring, a sealing bolt, a working cavity, a lower end cover and a piston head, and is characterized in that the damper also comprises a magnetic-isolation sleeve, a coil, an upper spacing spring, an auxiliary piston head, an inner cylinder body and a lower spacing spring, wherein the working cavity is divided into an inner working cavity and an outer working cavity by the inner cylinder body; the working cavity is filled with magneto-rheological liquid; the auxiliary piston head and the piston head connected to the piston rod respectively extrude the magneto-rheological liquid back and forth in the two working cavities to generate radial flowing so as to generate damping force; and the coil is arranged between the outer cylinder body and the magnetic-isolation sleeve to provide a magnetic field so as to regulate the magnitude of the damping force in real time. The output force of the multistage extrusion-type magneto-rheological damper is much more than that of a common magneto-rheological damper, and especially, the impact generated when the equipment is greatly and intensively vibrated under the severe environment can be avoided. The multistage extrusion-type magneto-rheological damper has the advantages of reasonability in design, simple construction, high efficiency, high response speed, high working reliability, good vibration damping effect and long service life.

Owner:JILIN UNIV

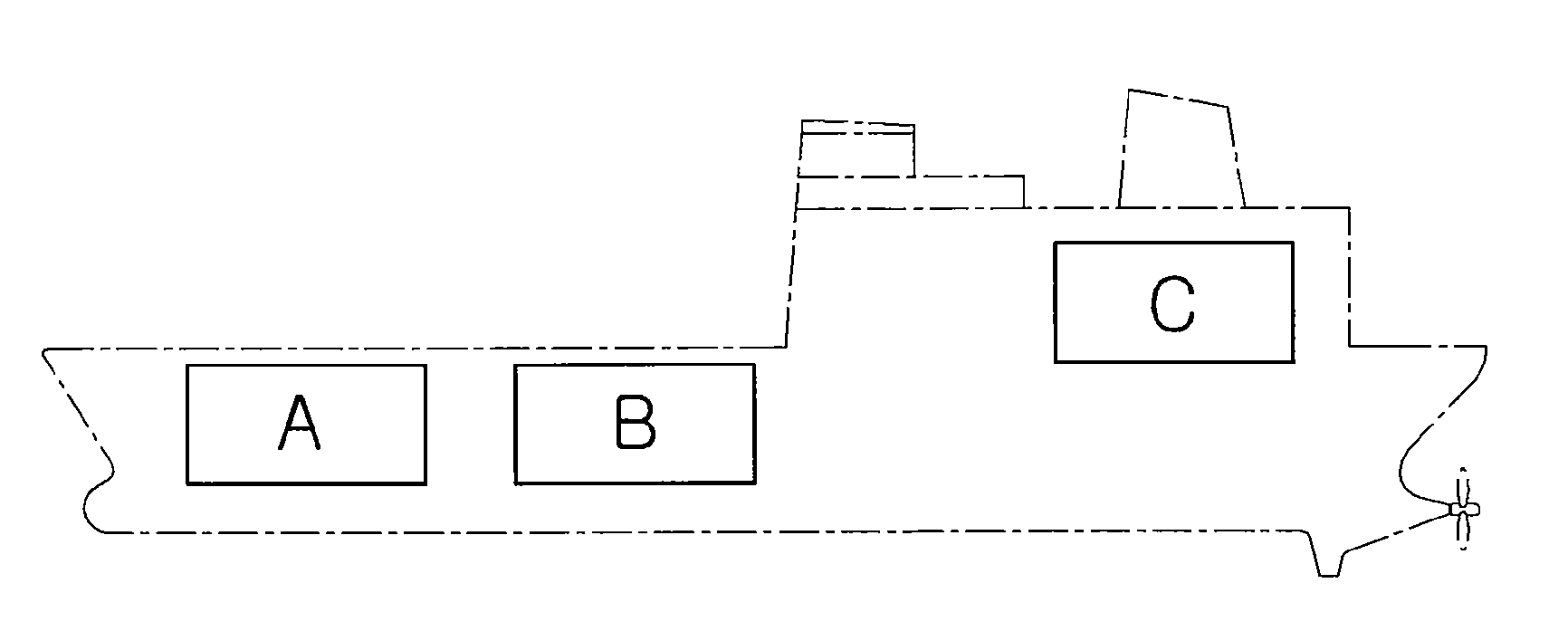

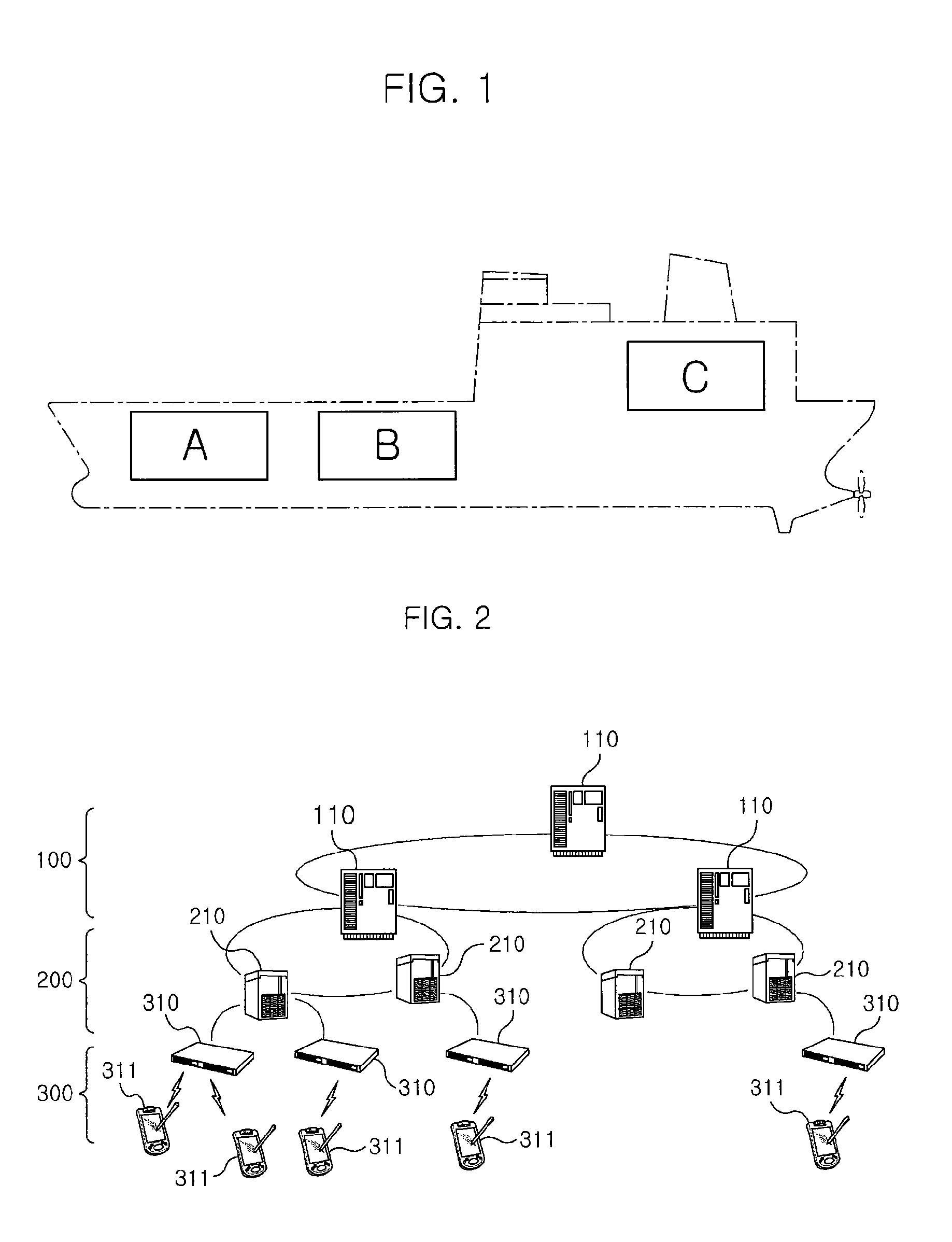

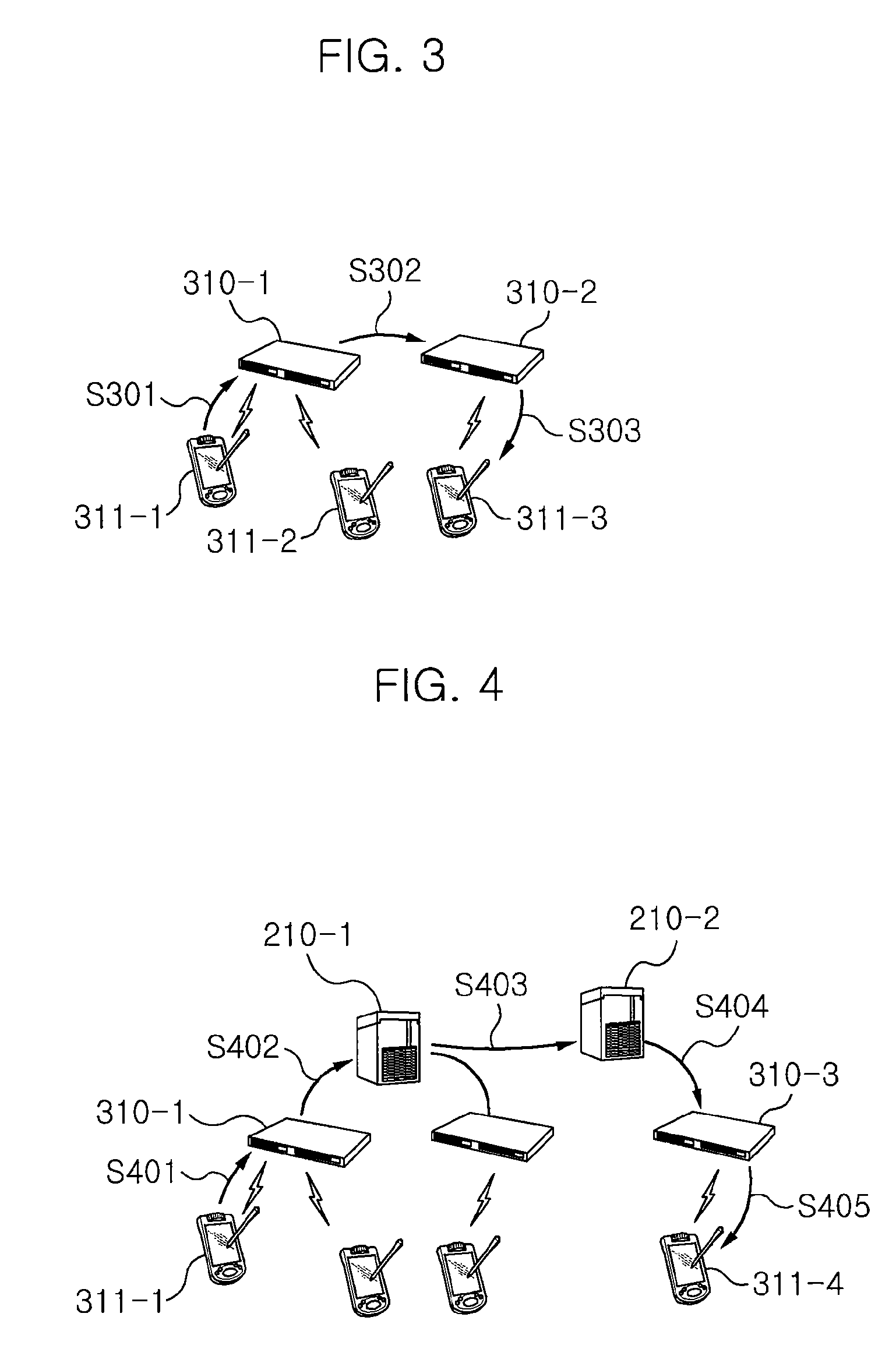

Communication system and method in ship area network

InactiveUS20090156159A1Minimize inconvenienceEnlarge work areaInterconnection arrangementsFrequency-division multiplex detailsPower-line communicationOptical communication

The present invention relates to a communication system and method in a ship area network. In a network of a structure including a plurality of shielded regions, communication is performed between terminals provided in the shielded region by using wireless communication, and communication is performed between terminals provided in different shielded regions by further using power line communication, optical communication, or the power line communication and the optical communication in addition to the wireless communication. Therefore, it is possible to obtain advantages of minimizing inconvenience, which is caused by using only wire communication in the related art, and enlarging a working area.

Owner:ELECTRONICS & TELECOMM RES INST

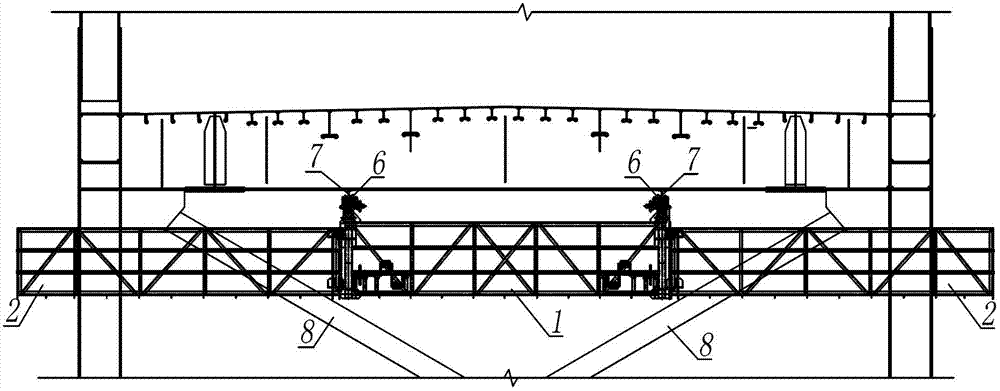

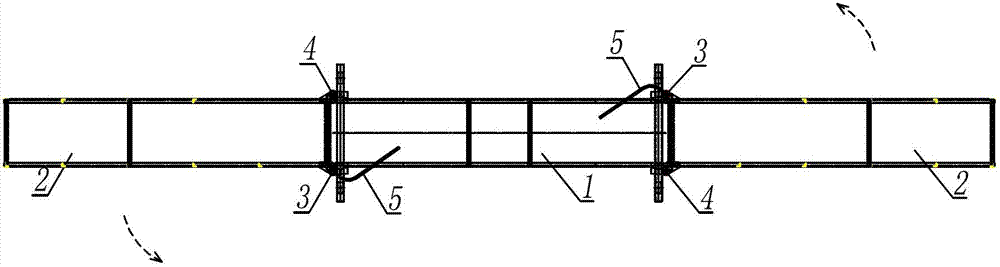

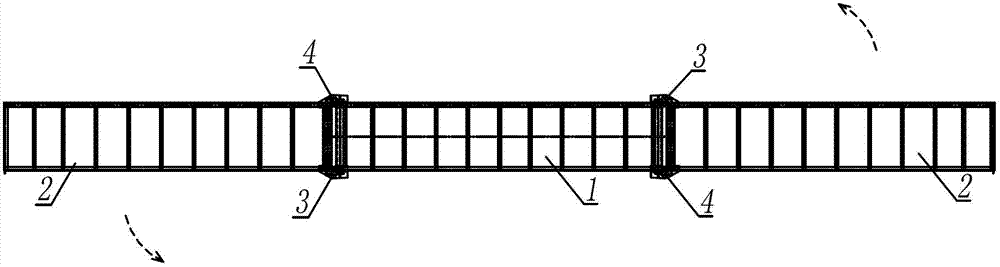

Novel bridge inspection vehicle

InactiveCN102733300ASimple structureEasy to manufactureBridge structural detailsBridge erection/assemblyCoupling systemCantilever

The invention relates to a novel bridge inspection vehicle, which is a travelling crane applied to inspection of the inner side or bottom of a truss bridge in a manner of a rotary folding vehicle body. The inspection vehicle body is composed of a middle vehicle body and additional vehicle bodies on cantilevers at two sides together, wherein the vehicle body and the additional vehicle bodies are mutually connected through a rotating hinge and a fixing pin, and a wheel mechanism is arranged above the vehicle body. The inspection vehicle walks and works under the track on which the bridge is vertically arranged in an unfolding manner in general; a hand shank is rotationally opened and closed when the inspection vehicle comes across a lateral coupling system member in a truss or a pier support; and the additional vehicle bodies on the cantilevers at two sides horizontally rotate oppositely, and are overlapped on the front and back parts of the vehicle body, and the vehicle body is folded and shortened into 1 / 3 of original length and then traverses an obstacle. According to the invention, an inspection work surface is expanded and the inspection vehicle can extend to the outer side of the truss to work. The distance between the tracks is wide, and the vehicle body and the tracks are directly connected by the wheels, so the inspection vehicle is stable in structure when walking and working. The novel bridge inspection vehicle has the advantages of being simple in structure, convenient to use, economic and practical, and has been successfully applied to engineering practice.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

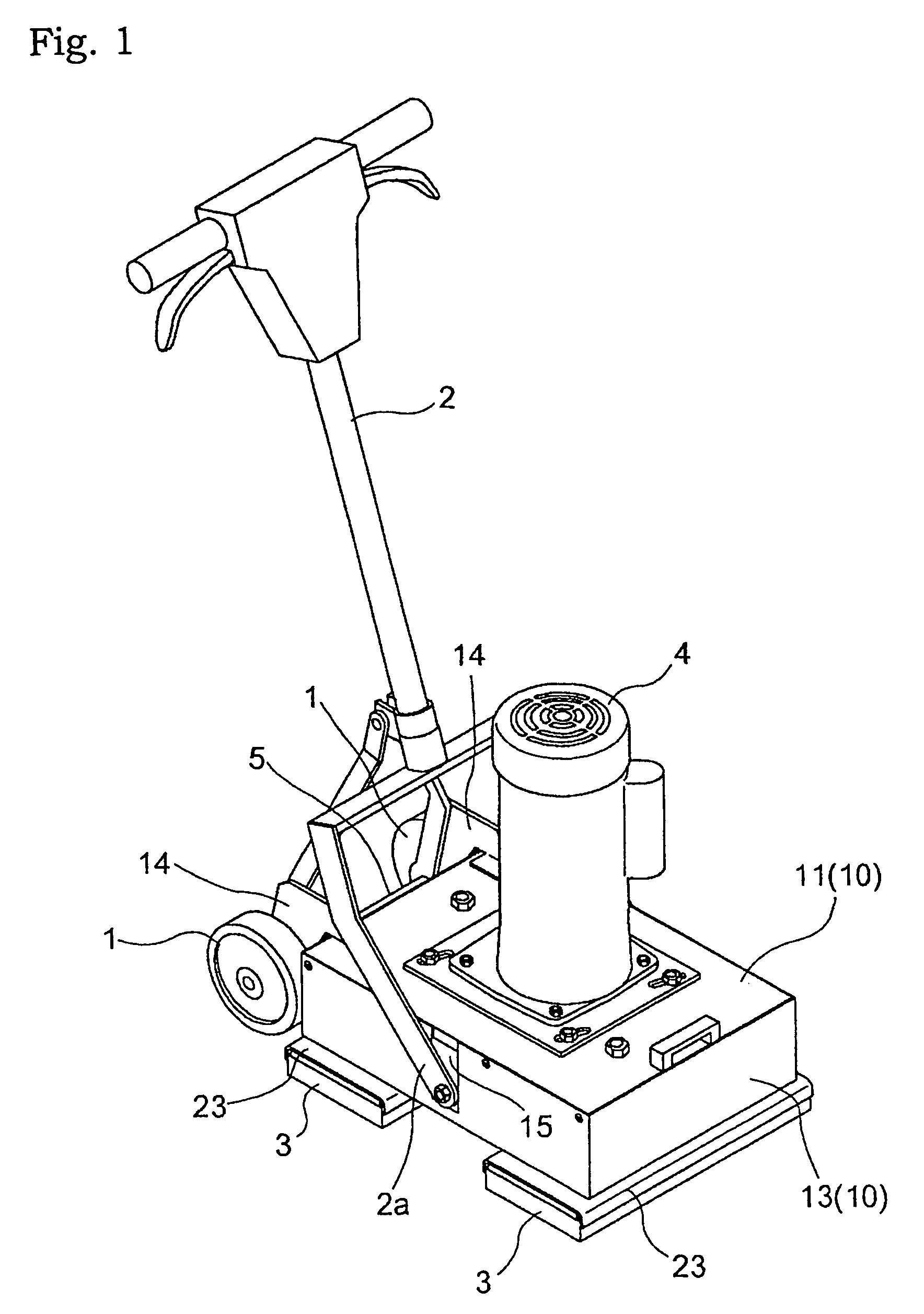

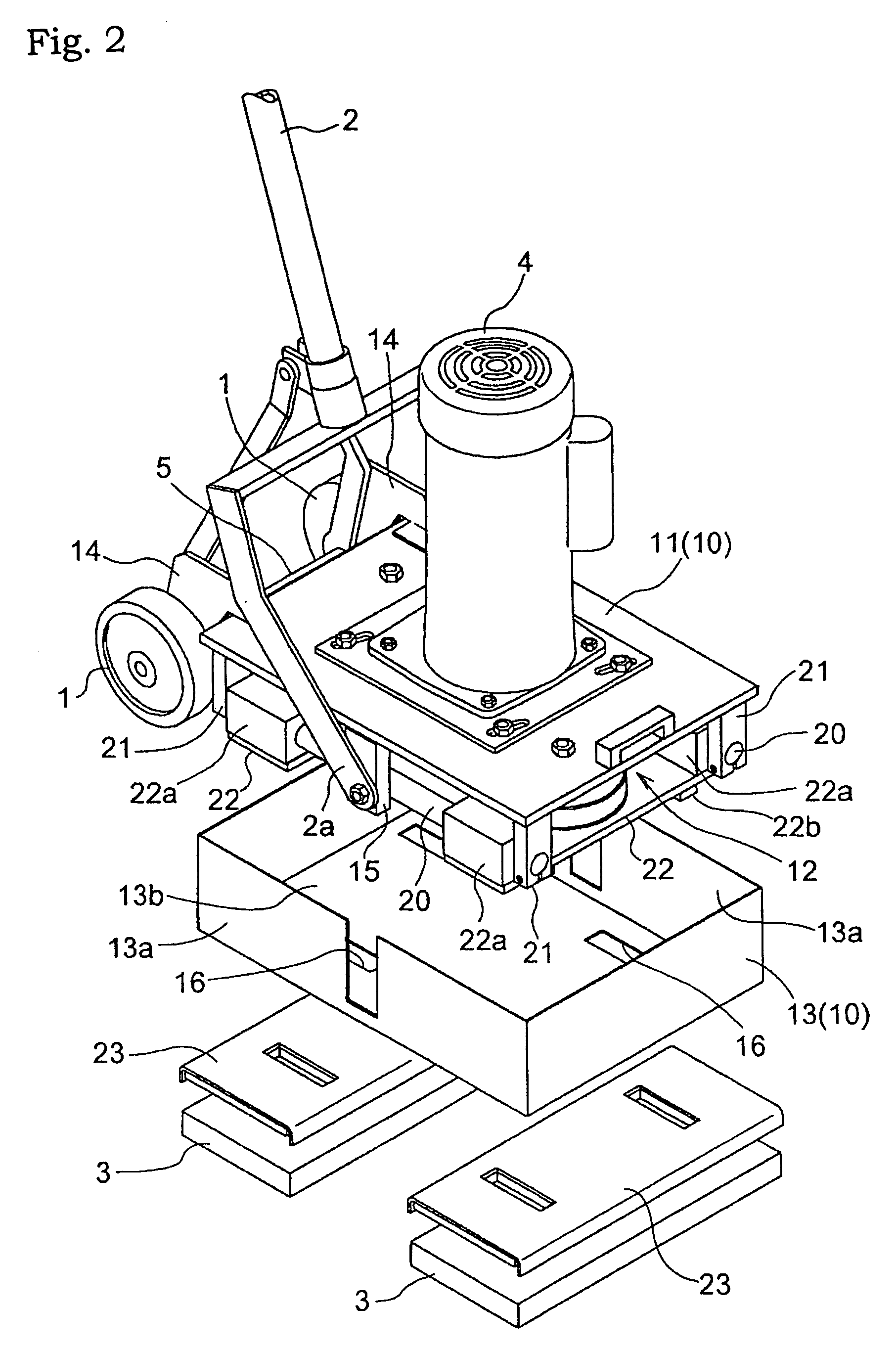

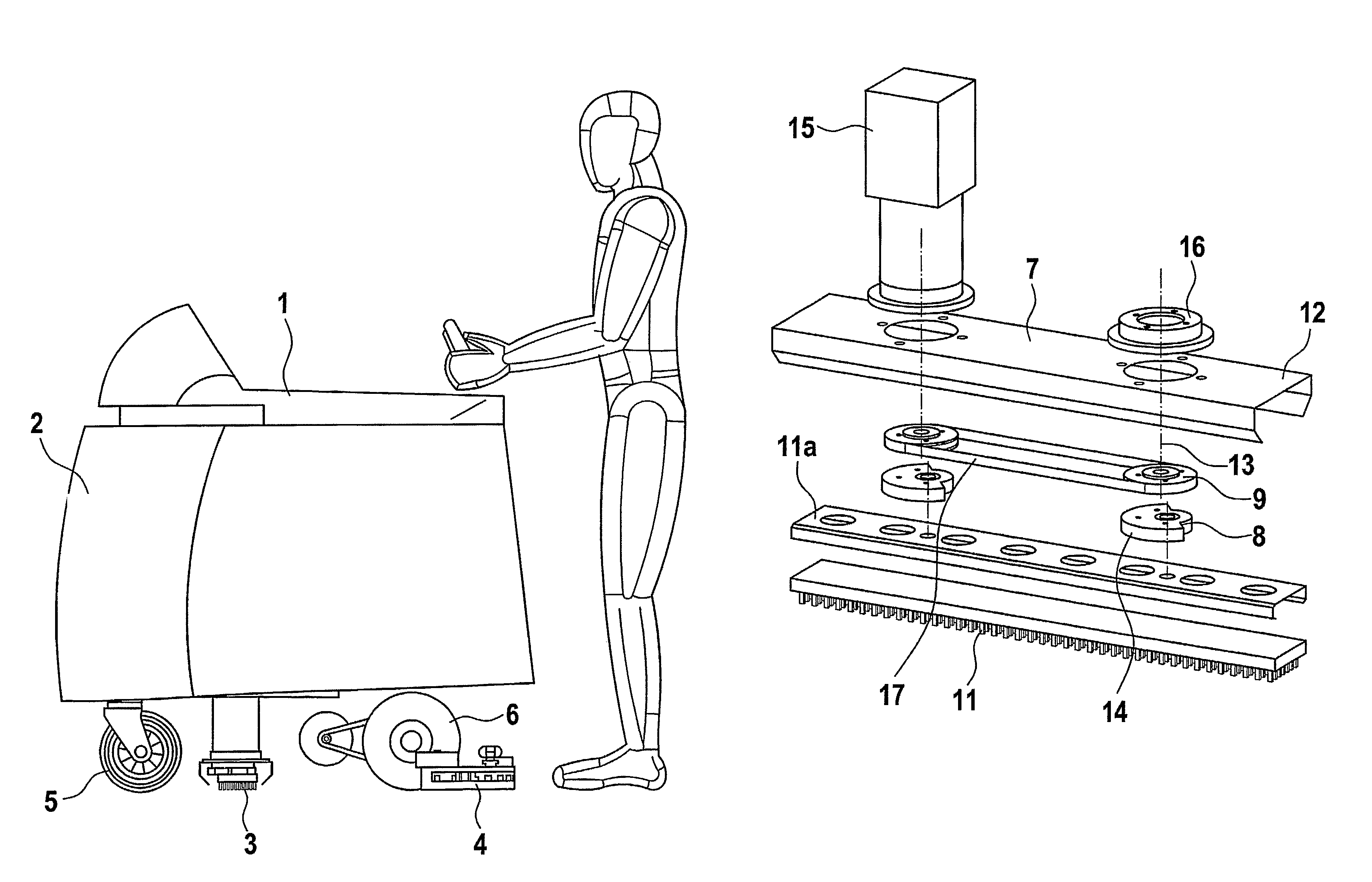

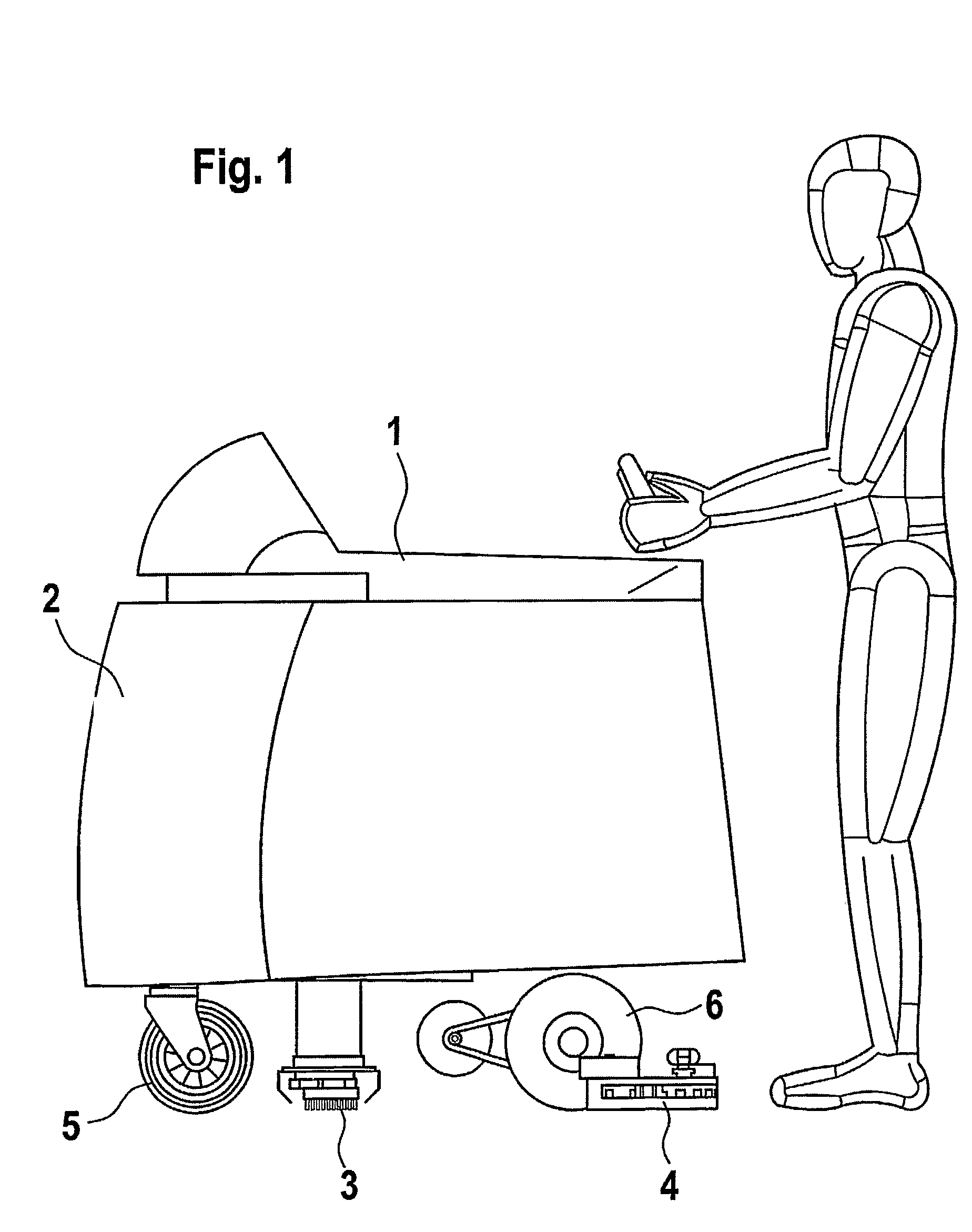

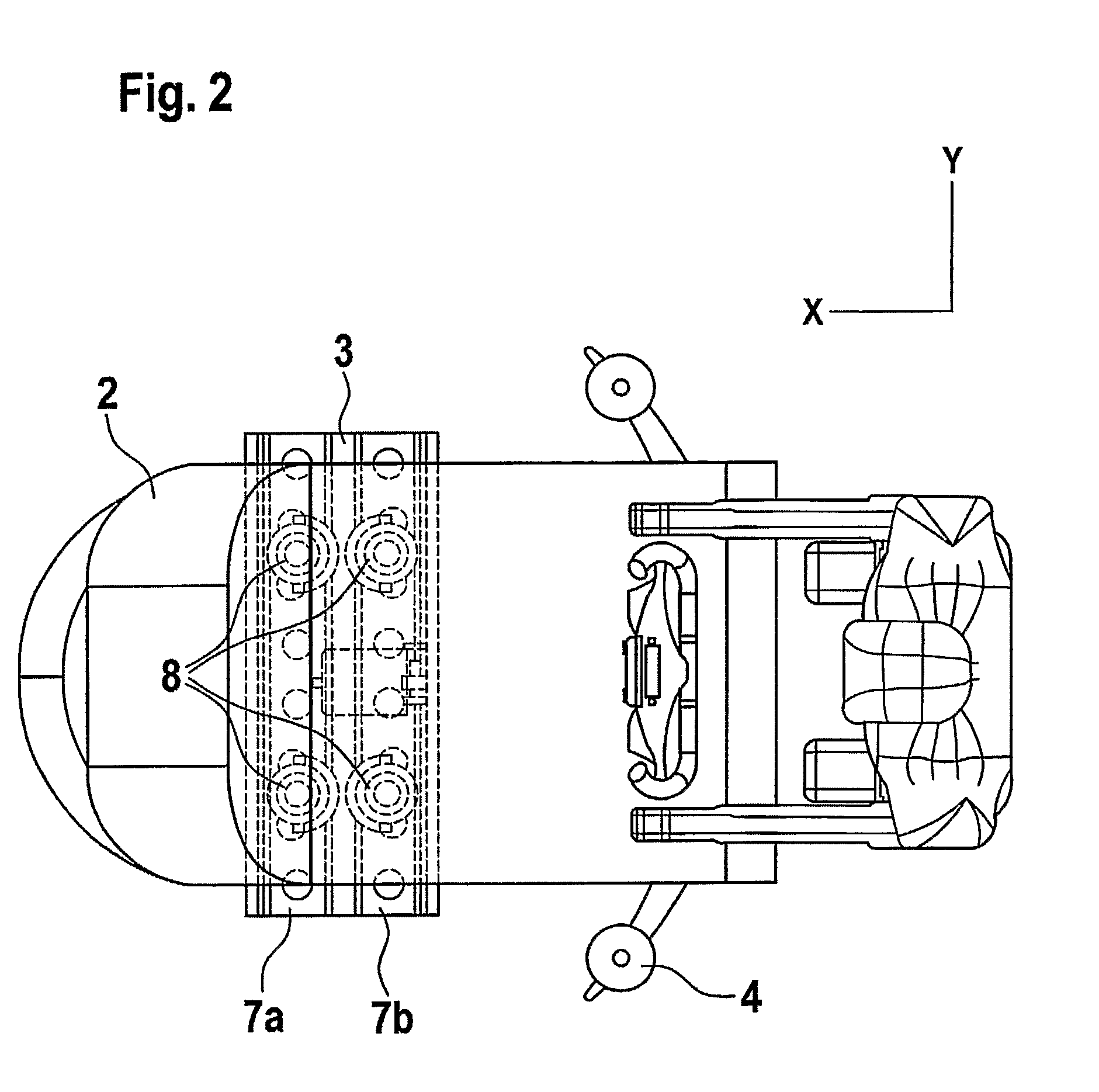

Electric-motored floor-surface polisher

InactiveUS7155768B2Expand the working areaDriven smoothly and efficientlyLiquid processingCarpet cleanersRotational axisReciprocating motion

An electric-motored floor-surface polisher includes a pair of pads juxtaposed in the front and rear or lateral direction of an apparatus frame, each pad being slidably supported to the apparatus frame. A drive pulley coupled to an output shaft of an electric motor to be rotated therewith. The polisher includes a pair of pad driving members, each pad driving member having an input pulley portion operably coupled with the drive pulley via a toothed belt and having also an output portion provided at a portion of the driving member offset from a rotational axis of the input pulley portion to be rotatable therewith and a pair of pad operating rods, one of the pair of pad operating rods having one end thereof pivotally coupled with the output portion of one of the pair of pad driving members and the other end thereof pivotally coupled with the one of the pair of pads and the other pad operating rod having one end thereof pivotally coupled with the output portion of the other pad driving member and the other end thereof pivotally coupled with the other pad. With this, the pair of pad operating rods slidably reciprocate the pair of pads along the juxtaposing direction thereof and in directions opposite to each other.

Owner:PENGUIN WAX

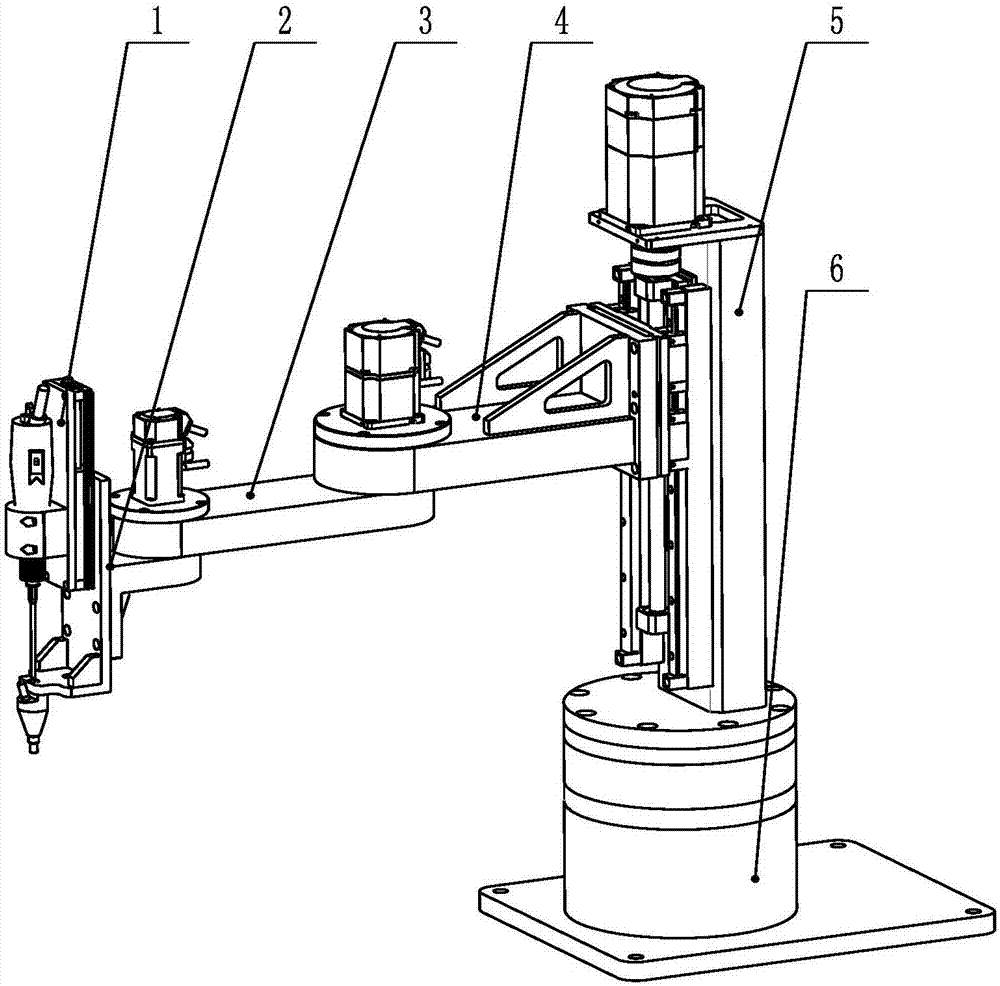

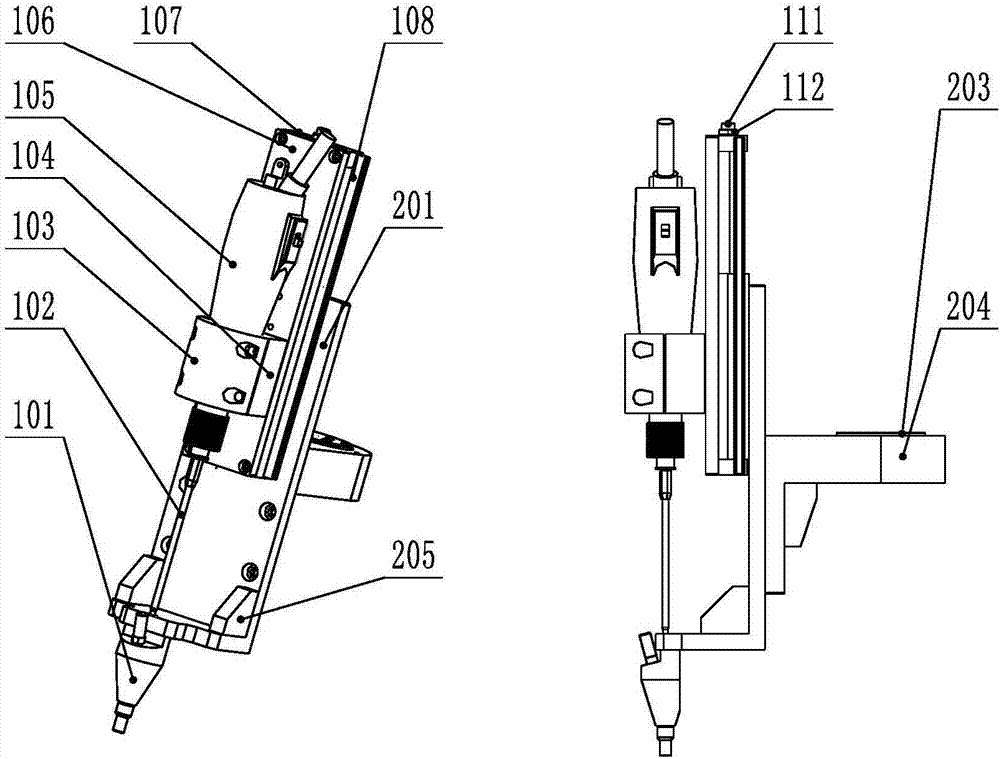

SCARA robot special for screw assembly

The invention discloses an SCARA robot special for screw assembly. The SCARA robot comprises a tail end actuating mechanism, a wrist part, an elbow part, a shoulder part, a shoulder part lifting mechanism and a machine base. The tail end actuating mechanism comprises a screw retreating groove nozzle, a screwdriver, an end cover, a bottom cover and an electric drill tail end actuating mechanism lifting frame. The wrist part comprises a wrist part auxiliary plate, a wrist part composite bearing, a wrist part connecting cover, a wrist part main plate and wrist part reinforcing ribs. The elbow part comprises a first motor, a first motor connecting cover, an elbow part main plate, an elbow part composite bearing and an elbow part connecting cover. The shoulder part comprises a second motor connecting cover, a second motor, a shoulder part main plate, shoulder part reinforcing ribs, a shoulder part auxiliary plate, a shoulder part sliding plate, shoulder part sliding grooves and a threaded cover. The shoulder part lifting mechanism comprises a third motor, a third motor connecting cover, a third motor coupler, a lead screw, a shoulder part lifting mechanism main plate, sliding groove fixing rods, sliding grooves and the like. The machine base comprises a fourth motor, a machine base composite bearing, a machine base cylinder and a machine base bottom plate. The SCARA robot is novel in design, safe and reliable.

Owner:ANHUI UNIV OF SCI & TECH

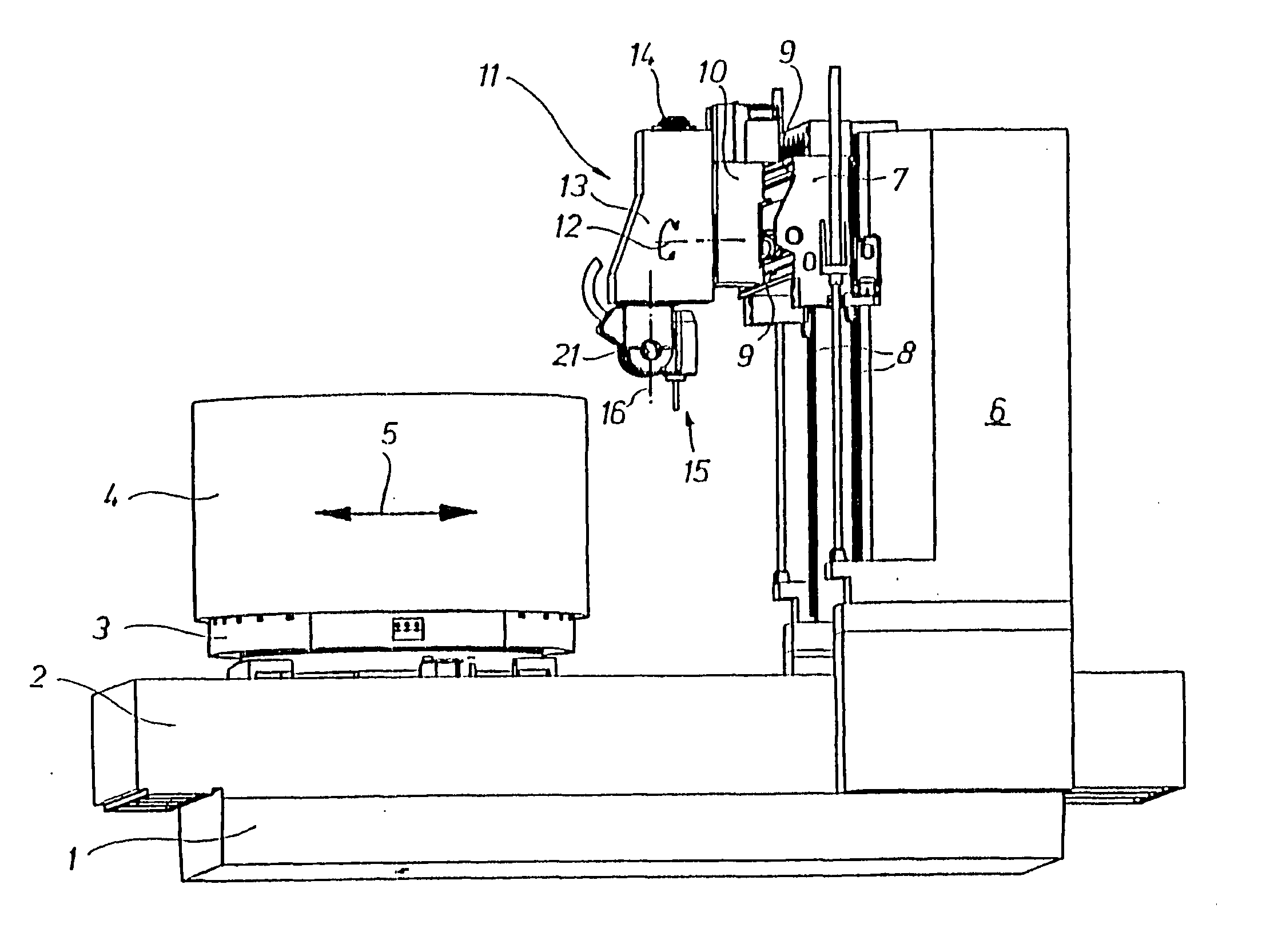

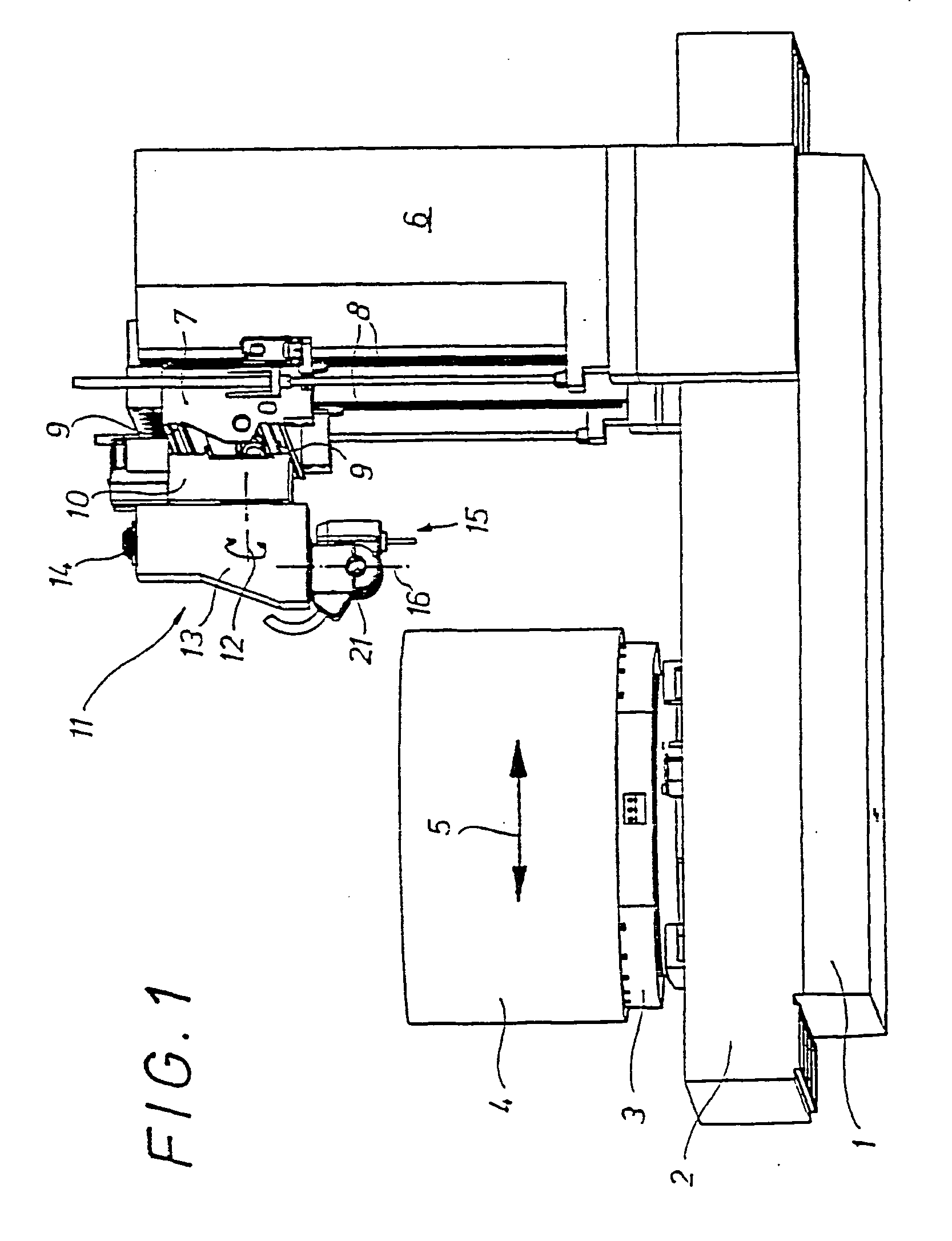

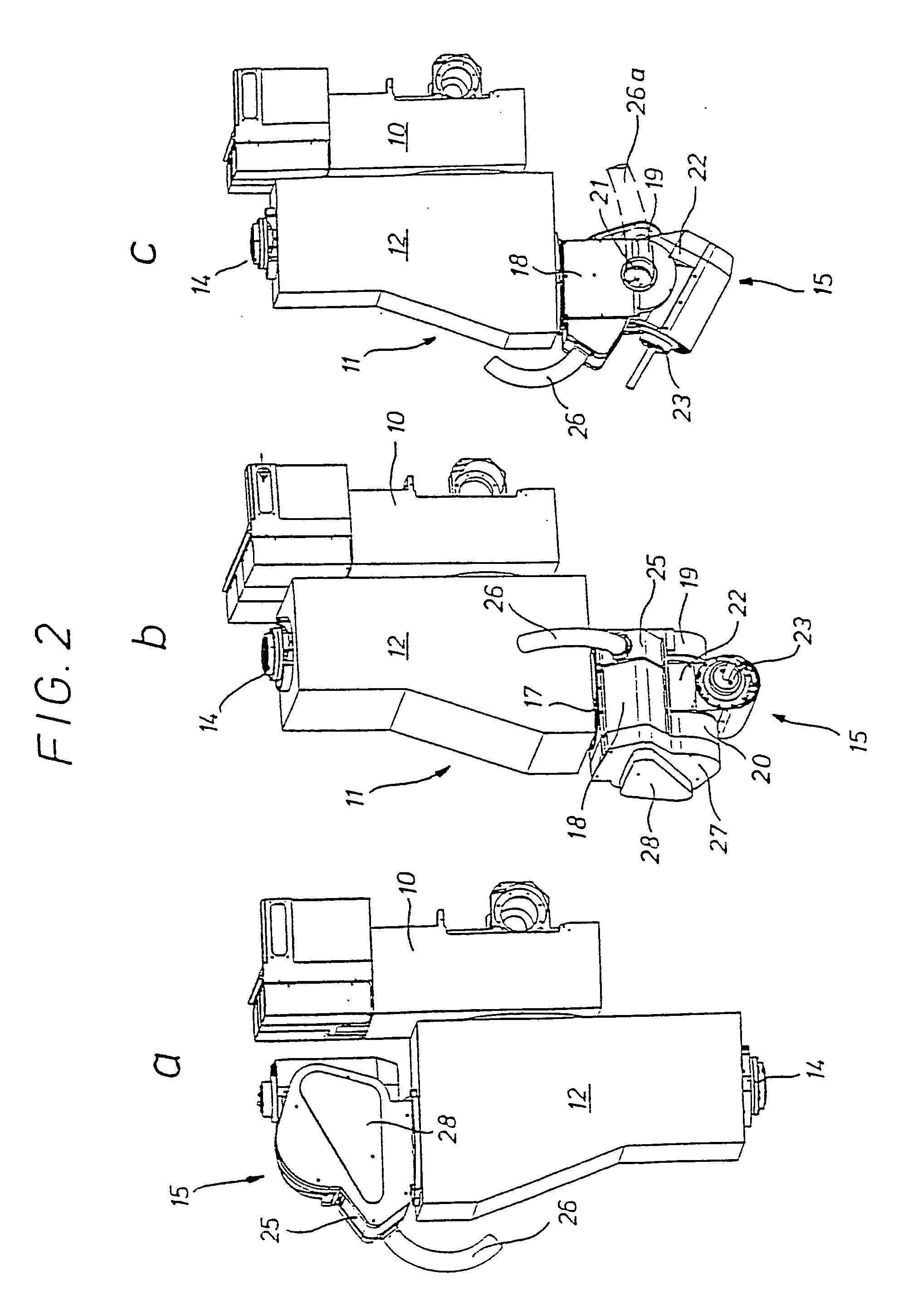

Spindle head for a universal milling machine

InactiveUS20050217095A1Reduce delayLarge volumeMachine tool componentsMilling machinesMachine partsEngineering

Owner:DECKEL MAHO PFRONTEN GMBH

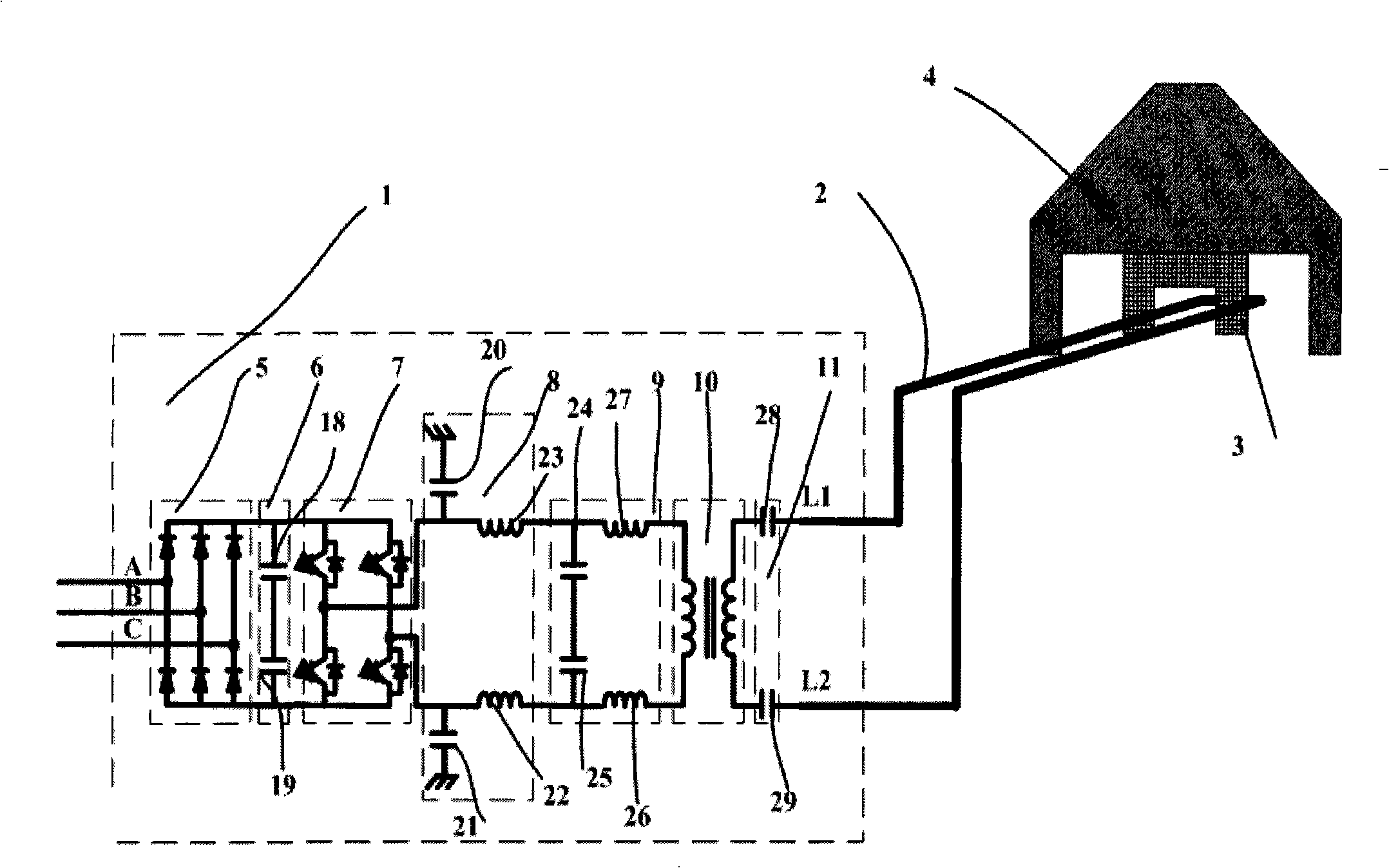

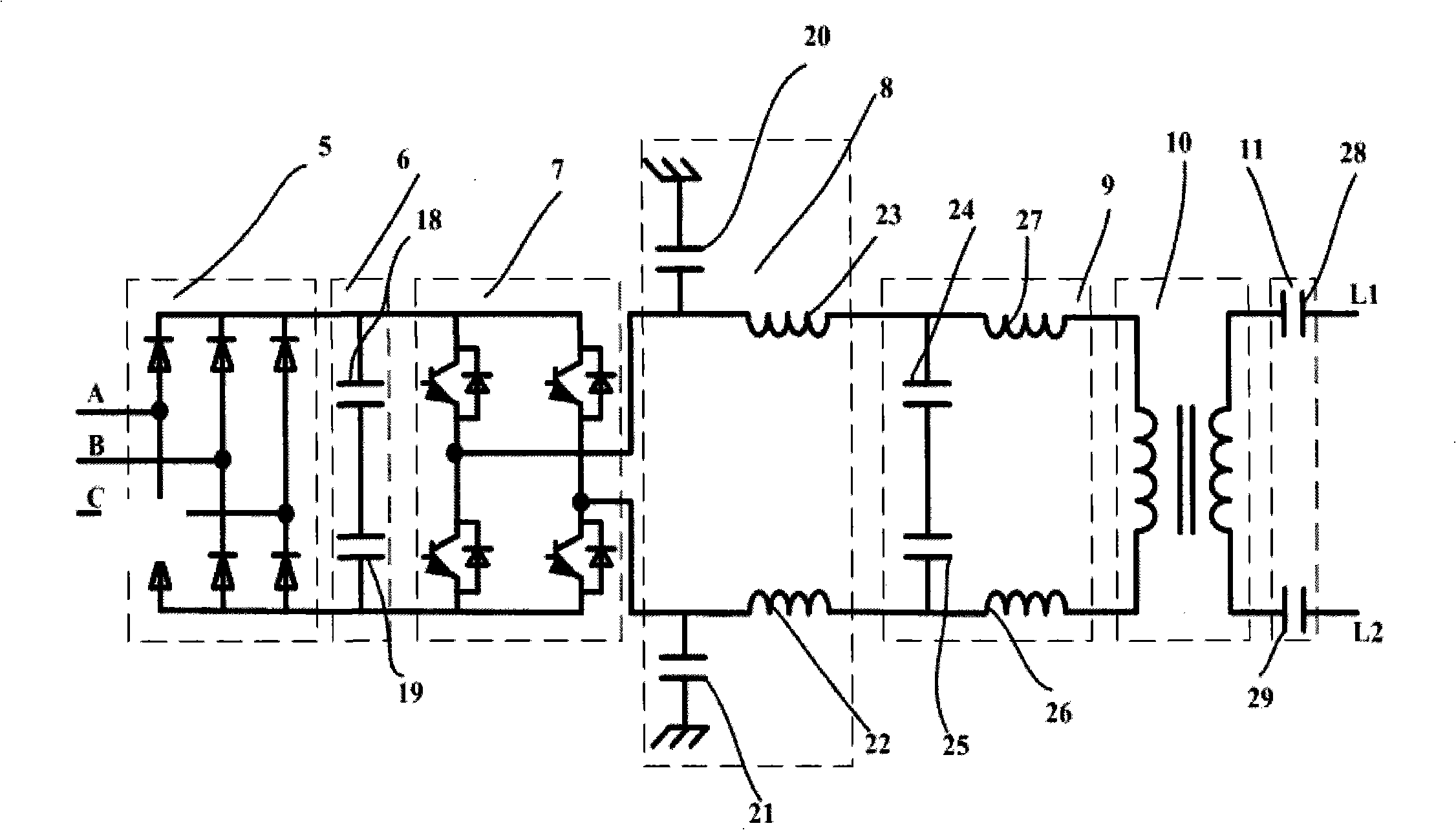

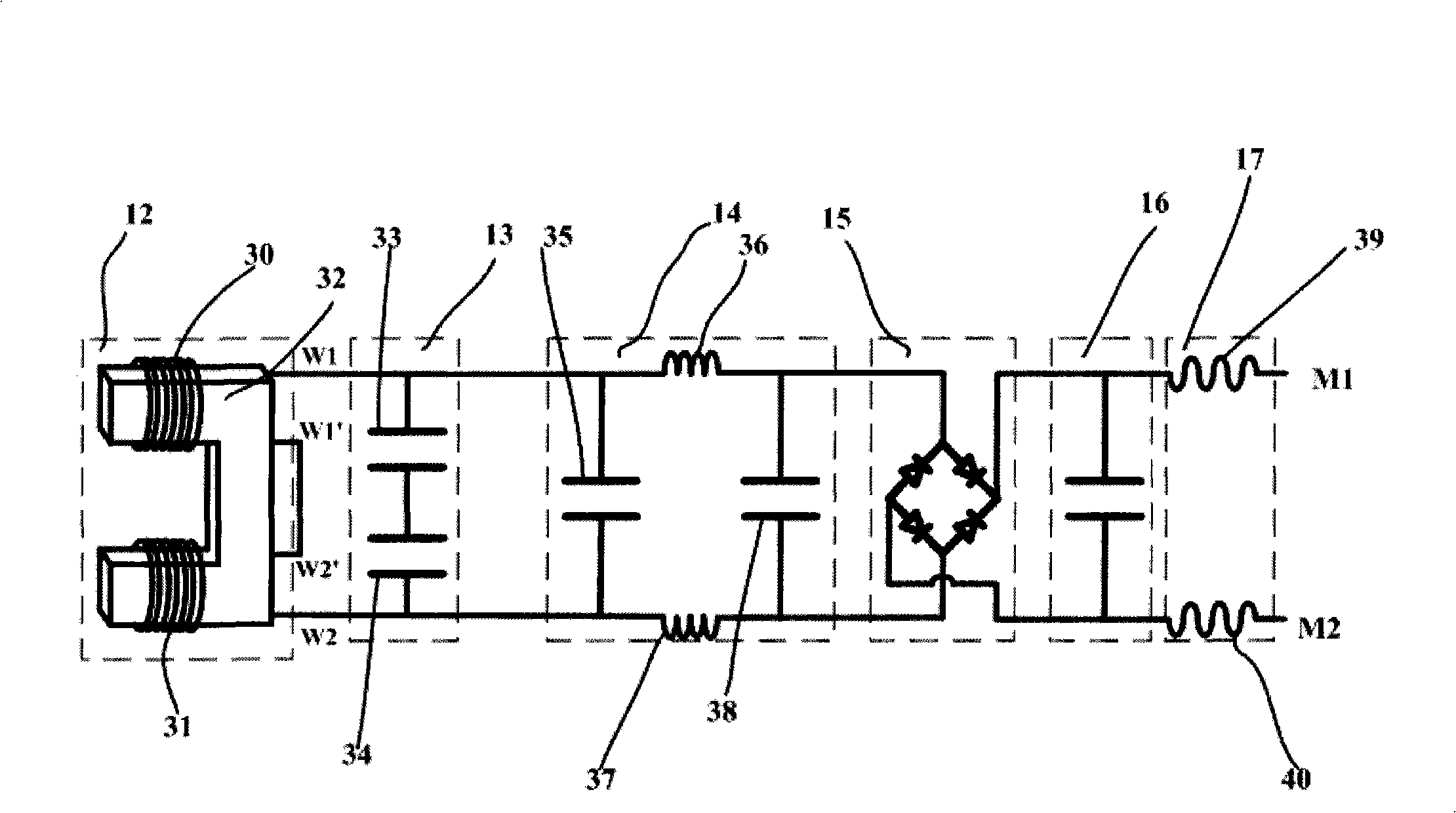

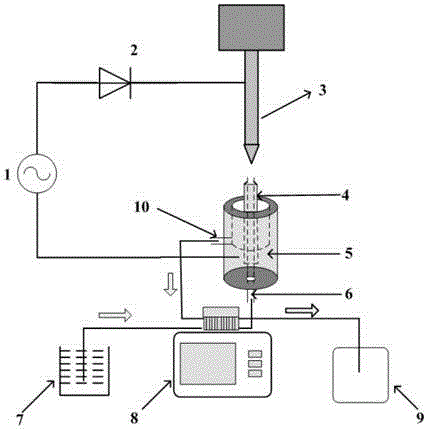

Non-contact power supply of automatic carriage

InactiveCN101404421AReduce weightExpand the working areaElectromagnetic wave systemTransformersElectricityCurrent limiting

A non contact power supply unit of a self-propelled trolley belongs to a power supply unit of a self-propelled trolley. The unit comprises a power transformation cabinet (1), a primary side cable (2) and an electricity picking up part (3).The power transformation cabinet (1) comprises a rectifier module (5), a filtering module (6), a high frequency inversion module (7), a frequency selection module (8), a resonant transformation module (9), an isolating module (10) and a compensation module (11); the electricity picking up part (3) includes an induction power-receiving module (12), a resonance capacitor bank (13), a resonance compensation module (14), a rectifier module (15), a filtering module (16) and a current limiting protection module (17).The power supply unit has the advantages of safe and reliable running, high reliability, and low cost and is suitable for the power supply of the self-propelled trolley in the field of automation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

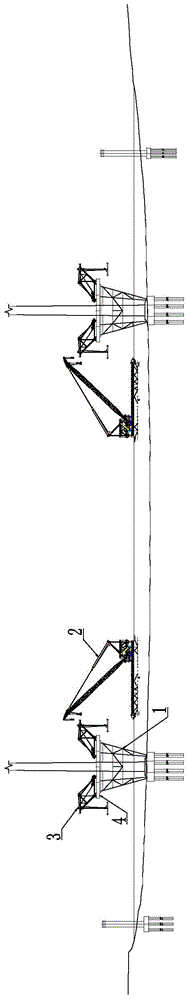

Long-span cable stayed bridge steel truss girder mounting method

ActiveCN103911956AReduce investmentImprove construction conditionsBridge erection/assemblyCable stayedBridge deck

The invention relates to the field of bridge construction, in particular to a long-span cable stayed bridge steel truss girder mounting method. By using a girder erection crane to completely hoist bridge deck slabs and third quarters of steel truss girders, a construction platform for assembling other rods can be established as early as possible, aloft operations are reduced, cantilever erection time is shortened, construction environment is improved, and construction efficiency is improved. In addition, only the bridge deck slabs and third quarters of steel truss girders are hoisted, and accordingly hoisting weight is reduced, and investment on the girder erection crane is saved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

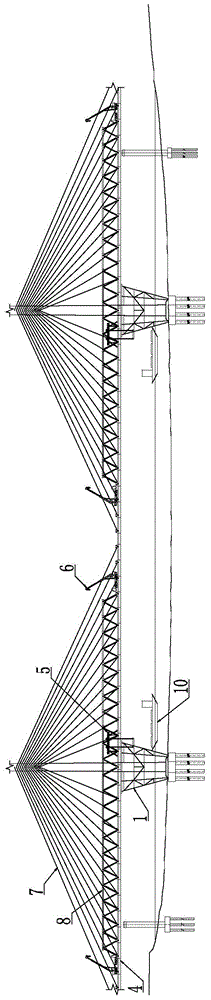

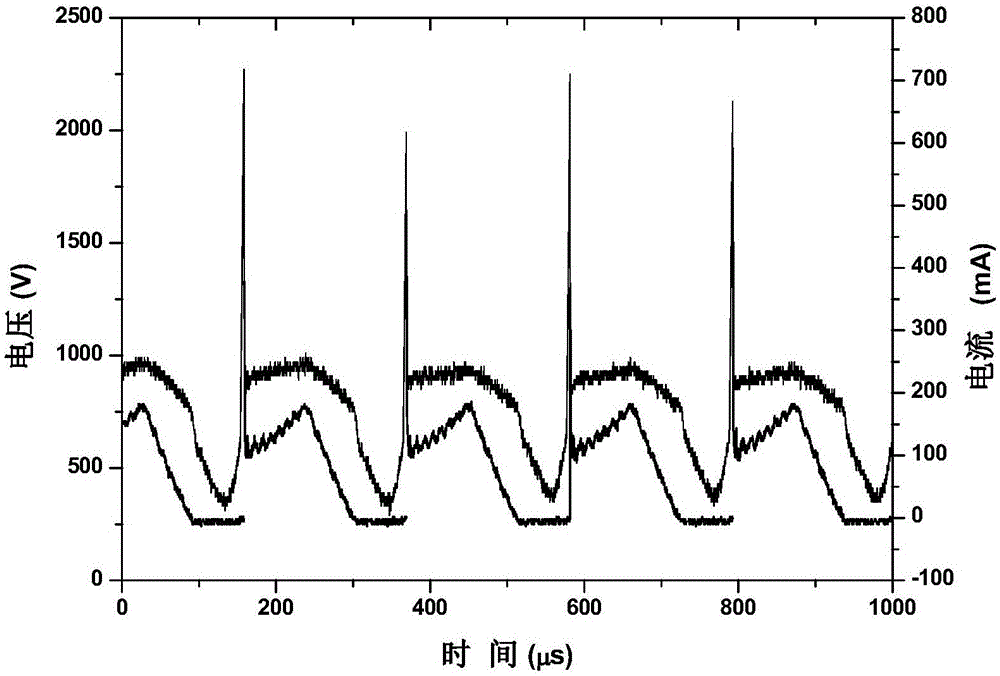

Pulse voltage driven arc discharge plasma source and portable element spectrometer

ActiveCN106596515AAvoid conversion implementationEasy to operateAnalysis by electrical excitationAnalysis by thermal excitationPeristaltic pumpSpectral emission

The invention discloses a pulse voltage driven arc discharge plasma source for liquid sample detection. The pulse voltage driven arc discharge plasma source includes a discharge driving system, a plasma generation chamber, and a sample introduction and discharge system. The sample introduction and discharge system includes a sample pool, a two-channel peristaltic pump, a liquid collecting pool, a sample inlet pipe and a drain pipe. A sample solution is introduced into the plasma generation chamber, an alternating current high voltage power supply modulated by an alternating current modulation module is employed to apply high pressure between a metal electrode and an auxiliary electrode so as to generate arc discharge plasma. A plasma atomizer prepared by the invention has the characteristics of small plasma volume, plasma spectral emission, same optimum spectral emission position of elements, low spectral background signal, autoignition and good stability, etc. The advantages bring greater convenience to people in terms of detecting metal elements in water, improve work efficiency, and expand the work area of the prepared detection equipment.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Floor treatment cleaning systems

ActiveUS8201296B2Efficient transportUniform resultLiquid processingCarpet cleanersEngineeringMechanical engineering

Floor treatment cleaning system (3) for a floor cleaning machine (1). The floor treatment cleaning system includes at least two treatment elements (7a, 7b) wherein each treatment element is equipped with cleaning means (11) and is eccentrically driven by driving means (15A) via at least two synchronized eccentric pivots (8), characterized in that the respective pivots revolve around their main rotation axes (13) in such a way that the at least two treatment elements perform opposite movements thereby transporting residues on the floor in a desired direction and balancing engine masses and friction. The treatment elements (7a, 7b) can be positioned in different ways: transversely relative to the moving direction of the machine (1) and parallel behind each other, transversely relative to the moving direction of the machine (1) and next to each other and in a V-shape or arcuate with the opening in the moving direction of the machine.

Owner:JOHNSONDIVERSEY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com