Construction method of one-side form bracing for underground structure sidewalls

A single-side support formwork and underground structure technology, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as difficult maintenance, difficult concrete pouring of side walls, and inability to construct, so as to ensure construction quality and safety , Reduce the amount of construction work, shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

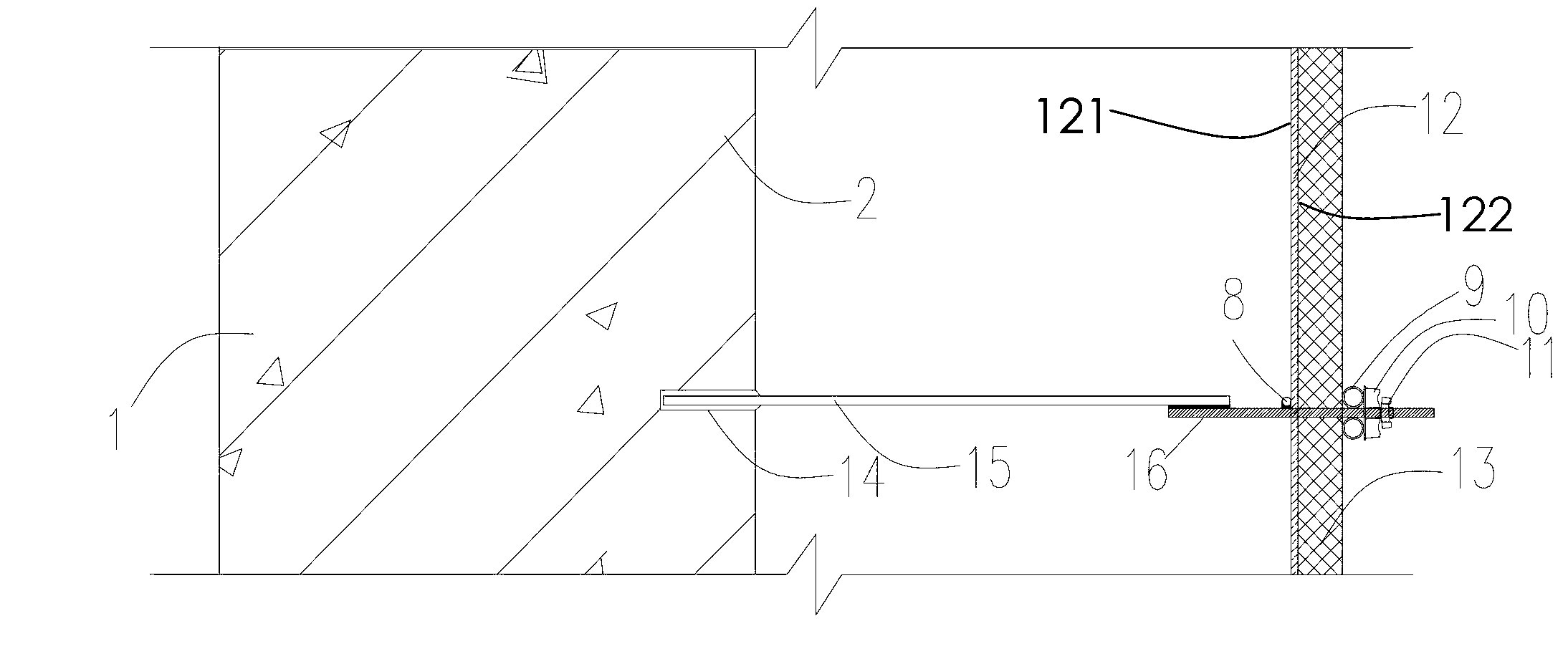

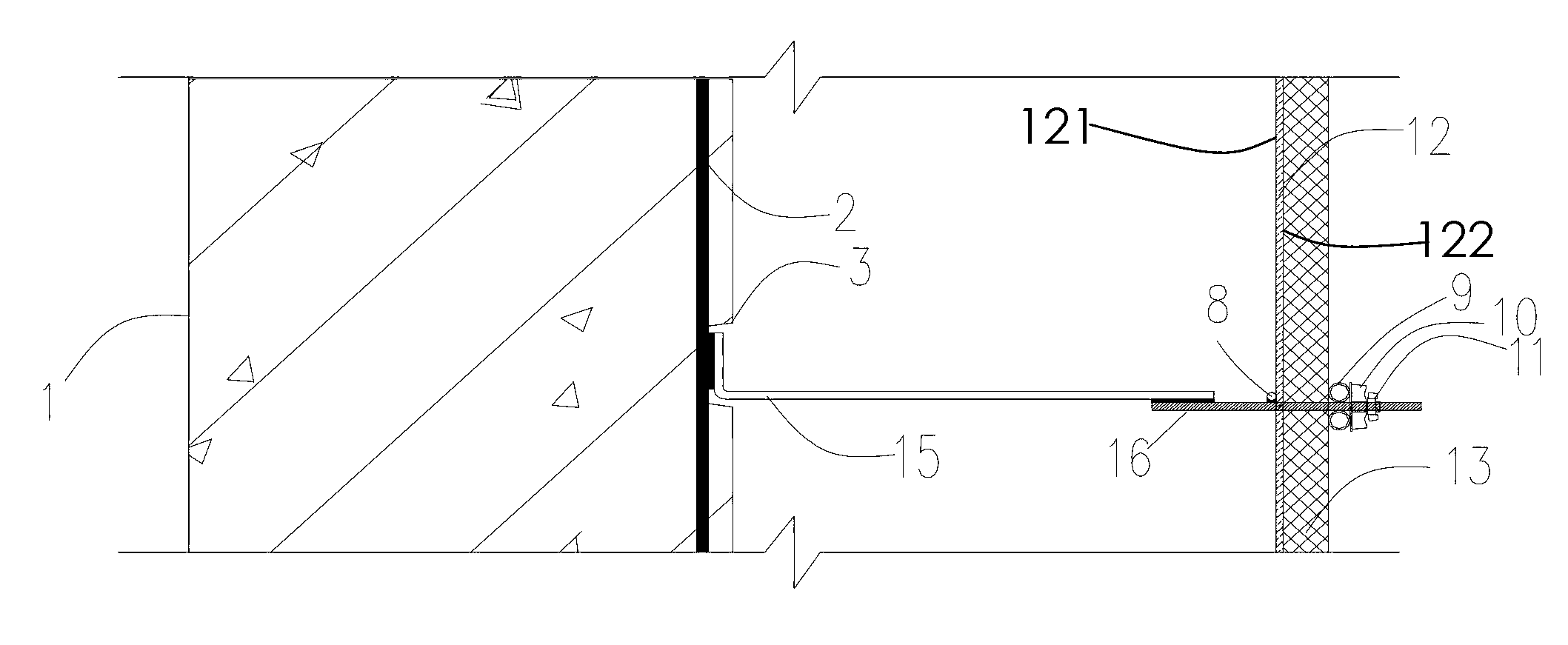

[0020] The single-side support formwork structure of the side wall of the underground structure of the present invention will be described in detail below with reference to the accompanying drawings.

[0021] Such as figure 1 , figure 2 As shown, the unilateral formwork structure of the side wall of the underground structure includes a formwork 12 , an underground continuous wall 1 adjacent to the formwork 12 , connecting steel bars 15 and anti-sealing bolts 16 .

[0022] The template 12 includes a first side 121 close to the underground diaphragm wall and a second side 122 away from the underground diaphragm wall. One end of the connecting steel bar 15 is fixedly connected to the underground diaphragm wall, usually by implanting in the diaphragm wall or welding with the main reinforcement of the diaphragm wall. , the other end is welded and fixed to one end of the anti-pull water-stop bolt 16, and the other end of the anti-pull water-stop bolt 16 passes through the first si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com