Existing-road-crossing cast-in-situ trough beam three-point sliding jacking construction method

A technology of jacking construction and trough beams, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of reducing the construction workload of temporary buttresses, and the deformation of the slideway beams on both sides is not synchronized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

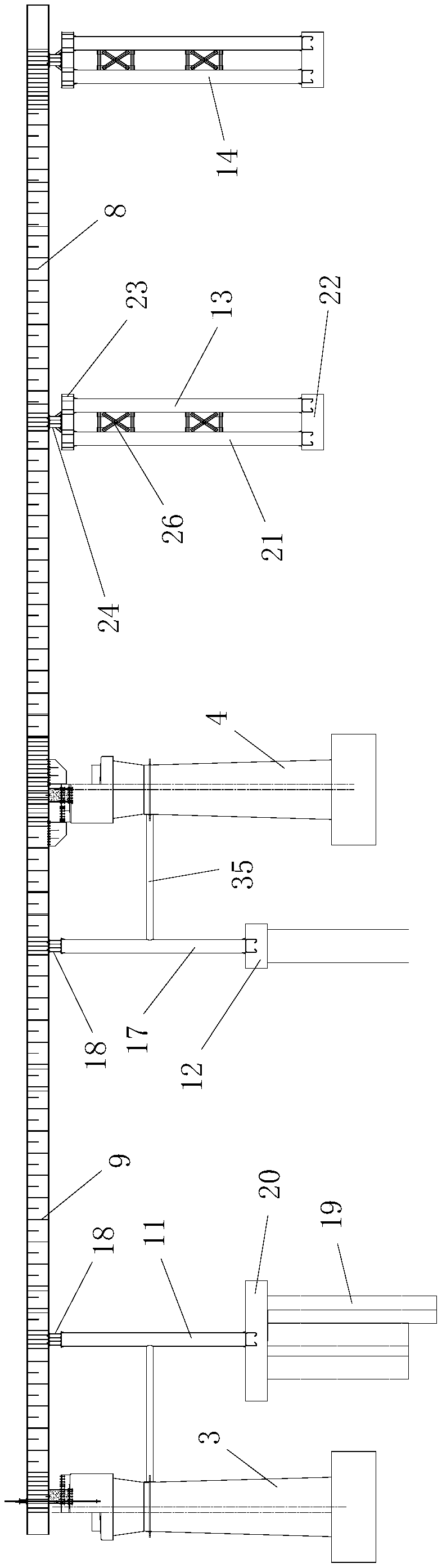

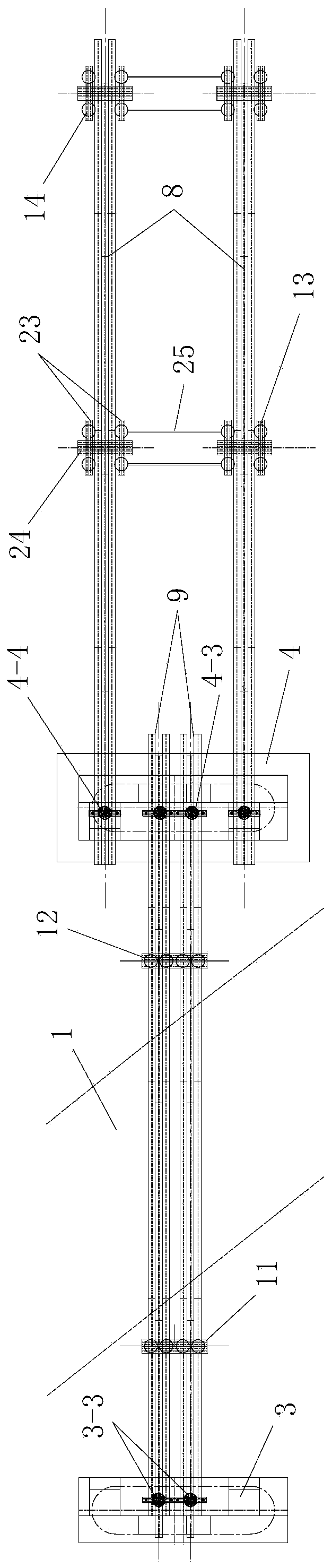

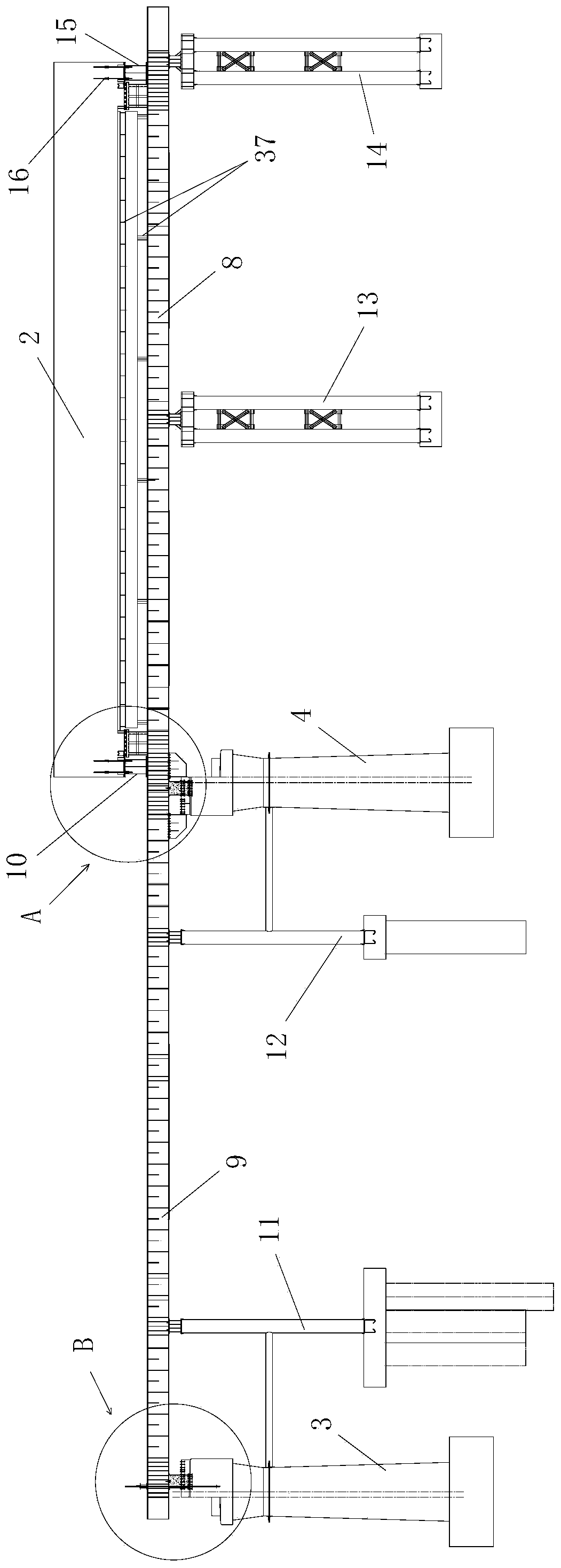

[0112] like Figure 21 A three-point sliding and jacking construction method for cast-in-place channel beams across existing roads is shown, combined with figure 1 , figure 2 , Figure 4 and Figure 5 , the pushed channel girder is a cast-in-place channel beam 2 erected between the front pier 3 and the rear pier 4 and is pushed by a pushing system. The cast-in-place channel beam 2 spans the existing road 1 The reinforced concrete beam has a concave cross section, the front end of the cast-in-place channel beam 2 is supported on the front pier 3 and the rear end is supported on the rear pier 4, and the cast-in-place channel beam 2 is horizontally arranged Straight beam and the angle between it and the existing road 1 is less than 90°;

[0113] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, the pushing system includes a traction device, four temporary buttresses arranged from front to back along the length direction of the pushed channel beam, two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com