Assembled prefabricated floor slab and construction method thereof

A prefabricated floor slab technology, which is applied in the direction of floors, building components, buildings, etc., can solve the problems of easy cracking, poor sound insulation performance and high construction cost of fully prefabricated floor slab connection nodes, and achieve good progressive collapse resistance and enhanced connection performance , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

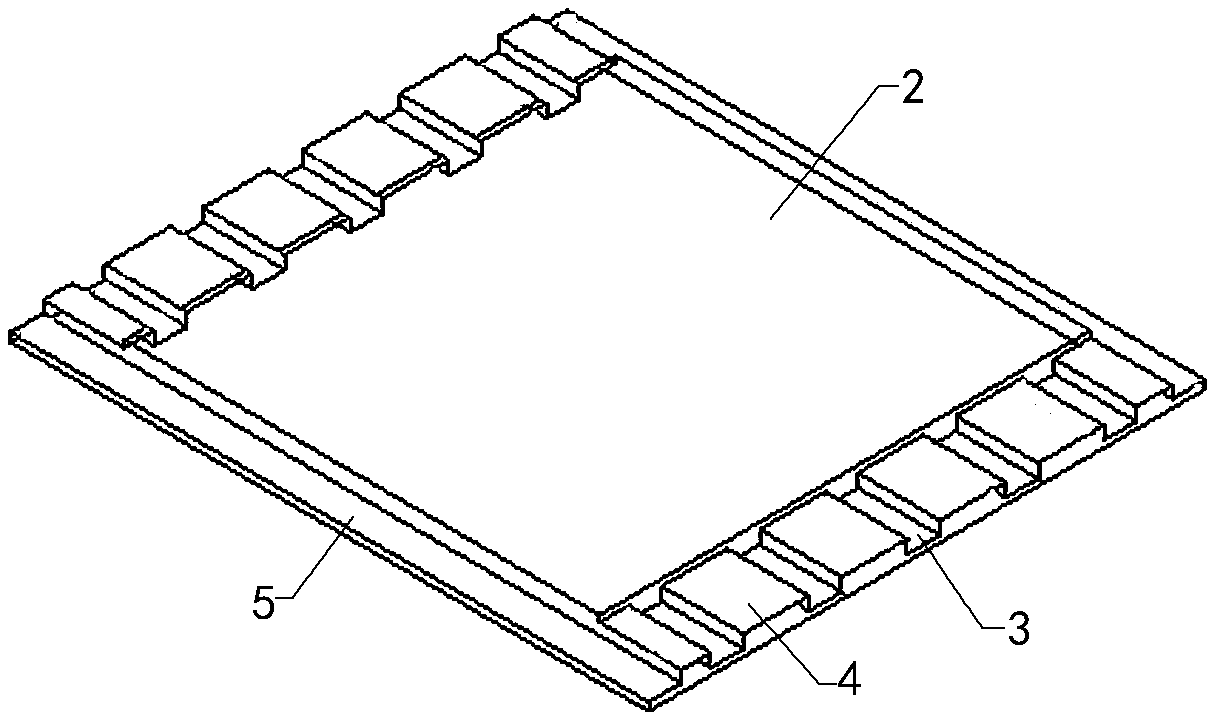

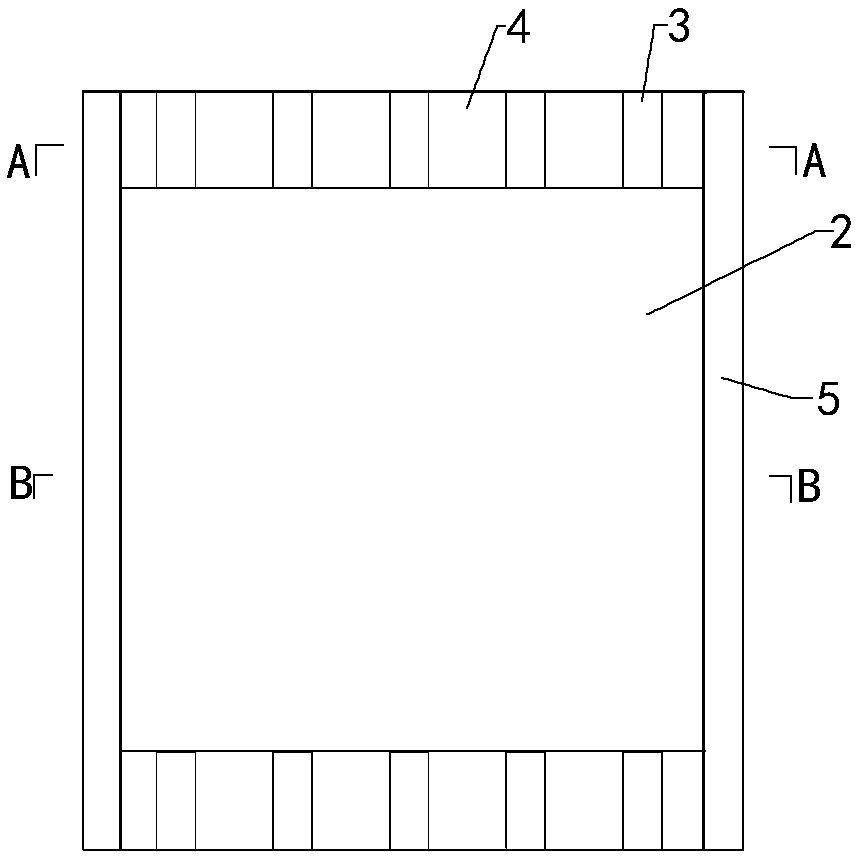

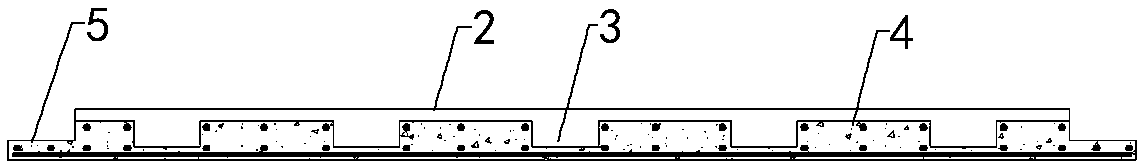

[0042] Such as Figure 1-Figure 11 As shown, the assembled prefabricated floor slab of the present invention includes a composite beam 1, and a prefabricated floor slab located above the composite beam 1. The prefabricated floor slab is composed of unit panels 2 horizontally arranged and spliced, and the splicing nodes of adjacent unit panels 2 are connected to the composite beam 1 Fixed connection.

[0043] Such as Figure 1-Figure 4 As shown, the unit plate 2 is a prefabricated square reinforced concrete slab, with a double-layer bidirectional steel mesh inside, and at least two side edges of the unit plate 2 are provided with connecting grooves 3, and the connecting groove 3 is located on the upper surface of the unit plate 2 The length direction of the connecting groove 3 is set perpendicular to the side length direction of the unit plate 2 where the connecting groove 3 is located, and extends outward to the side edge, the bottom surface of the connecting groove 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com