Patents

Literature

1831 results about "Slurry wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A slurry wall is a civil engineering technique used to build reinforced concrete walls in areas of soft earth close to open water, or with a high groundwater table. This technique is typically used to build diaphragm (water-blocking) walls surrounding tunnels and open cuts, and to lay foundations.

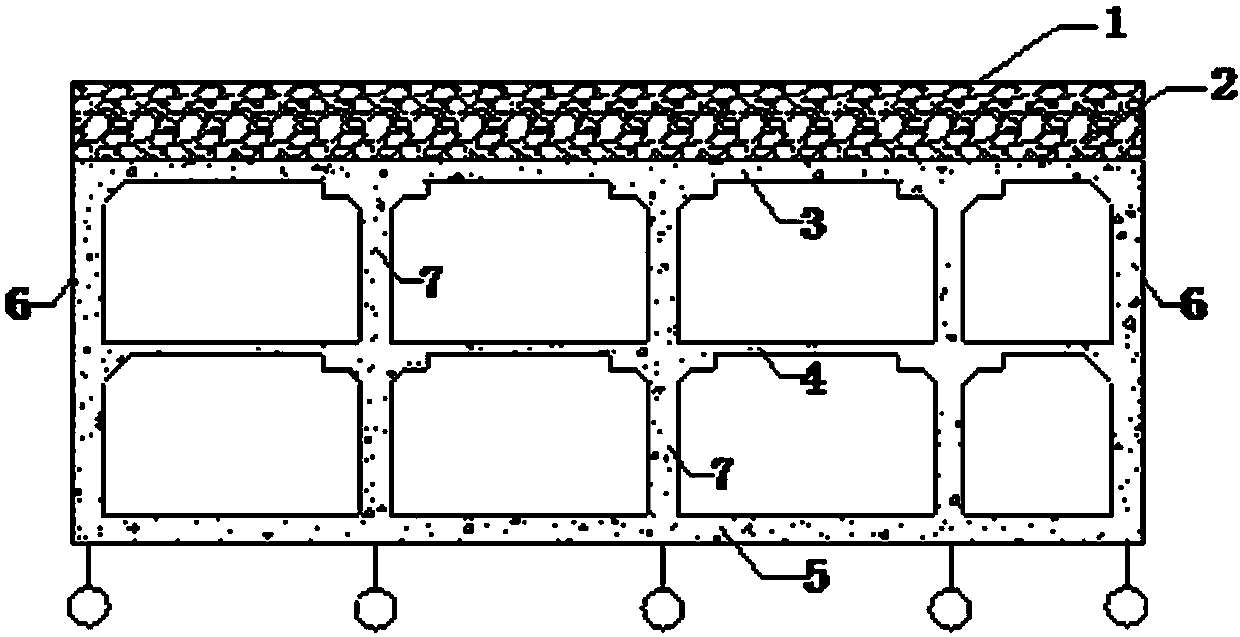

Diaphragm wall and construction method thereof

InactiveCN102312445AGuarantee the stability of the tank wallBreak hydraulic connectionArtificial islandsExcavationsSlurry wallSlag

The invention discloses a diaphragm wall and a construction method thereof, wherein the construction method is carried out according to the following steps: step 1, the underground obstacles at the trench section position and the two sides of the trench section of the diaphragm wall are cleared; step 2, two ranges of cement stirring piles are respectively and symmetrically distributed at the two inner sides of the trench section of the diaphragm wall to reinforce; step 3, an integral pouring type concrete guide wall is formed at the top parts of the cement stirring piles, the cross section of the guide wall is L-shaped, one end of the guide wall is arranged at the inner sides of the cement stirring piles, and the other end of the guide wall crosses the top parts of the cement stirring piles; after the guide wall is built, an integral pouring type concrete rigid terrace is formed at the other end of the guide wall; step 4, the trench construction is carried out between the two ranges of cement stirring piles through a trench machine, and the bentonite mud is adopted in the trench section to protect the wall during the trenching; step 5, after the trenching is completed and reaches the scale height, slags of the trench bottom are removed, a diaphragm wall reinforcement cage is hoisted to be placed in the trench section, and a guide pipe method is adopted to carry out underwater concrete pouring; and step 6, after the concrete reaches the design strength, high pressure grouting is carried out on the bottom of the diaphragm wall. The diaphragm wall can integrate soil blocking, water resisting and bearing into a whole through the method, so good social and economic benefits are obtained.

Owner:CCCC THIRD HARBOR CONSULTANTS

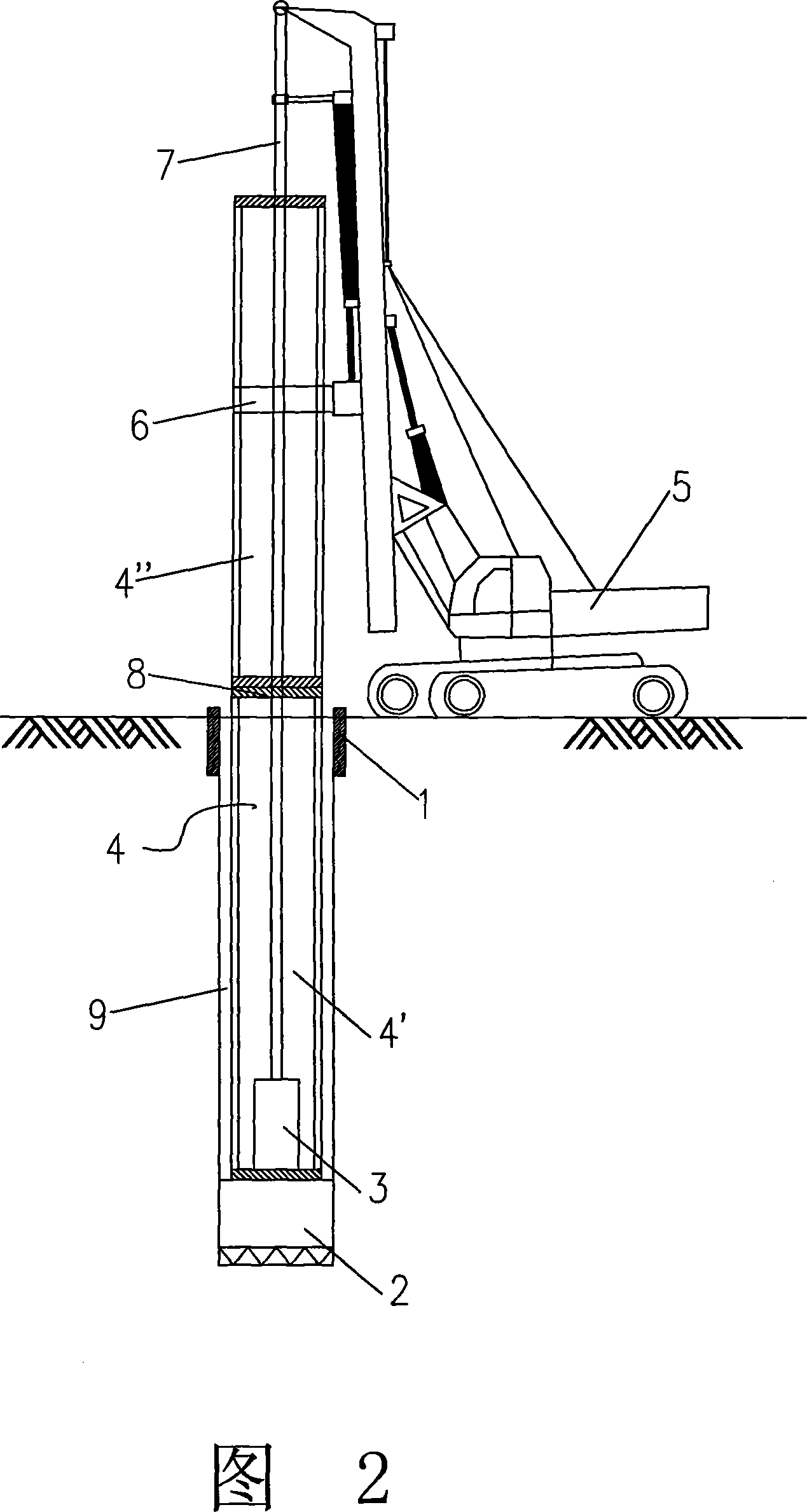

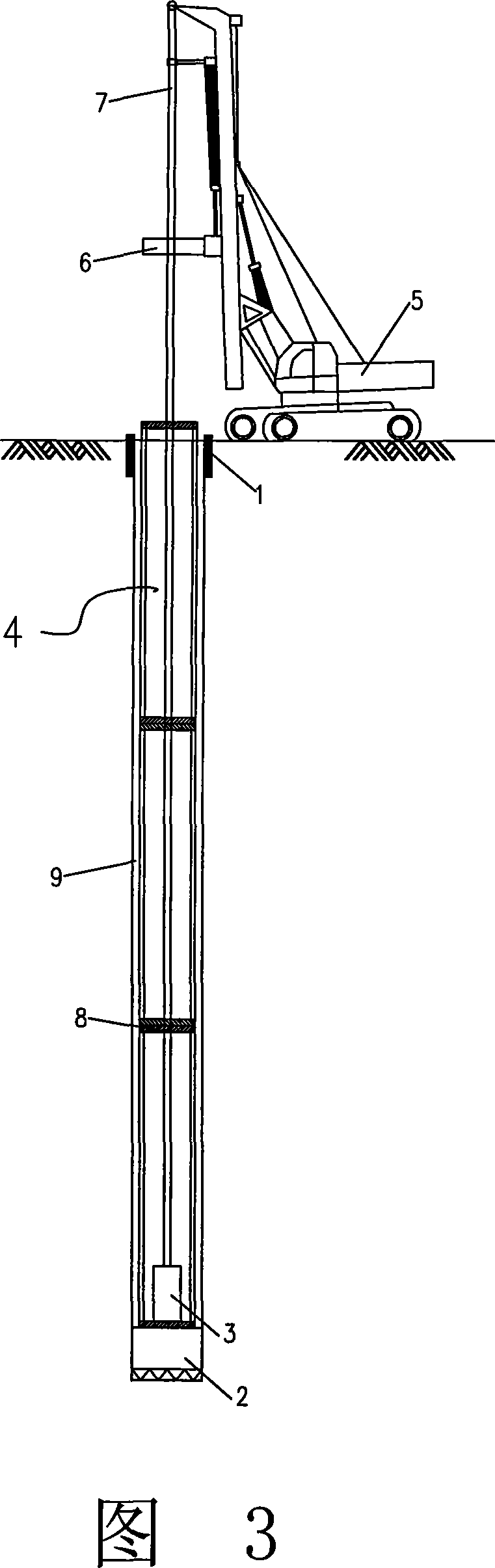

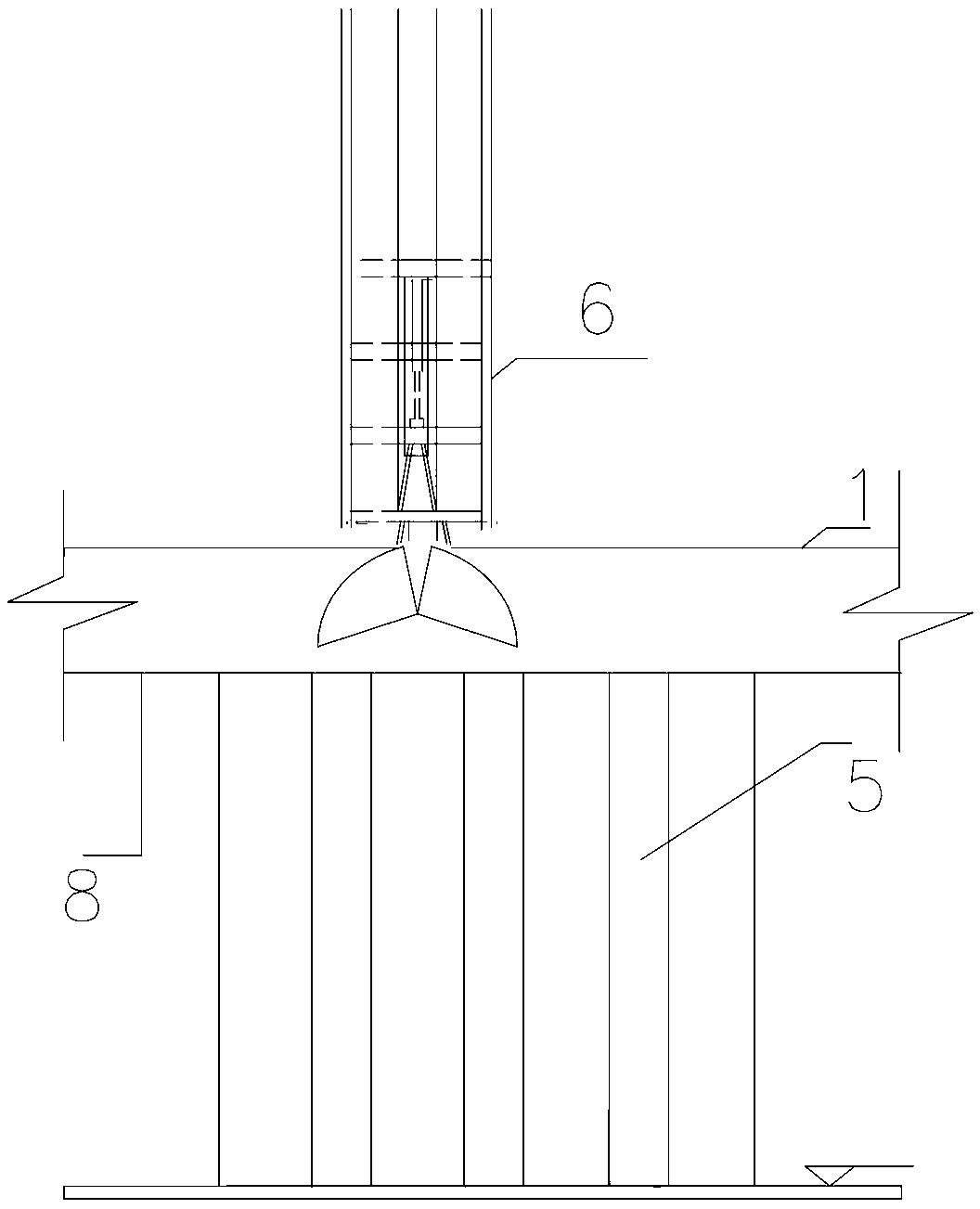

Construction method of drilling follow casting pile used for building or bridge foundation

A method for constructing pipe piles while drilling for building or bridge foundations. The construction steps are to cover high-strength prestressed concrete pipes or steel pipes with drill pipes on the ground first, and install impactors and reaming retractable drill bits at the front ends of the drill pipes. , Follow the pipe while drilling, follow the pipe retaining wall, drill to the design elevation, stop drilling, withdraw from the reaming to shrink the drill bit, use the mud pump to clean the mud and sediment, pour concrete into the pipe, and simultaneously inject pressure grout to the outside of the pipe wall , stop when concrete and grout reach the ground; the object of the invention is to propose a construction method with fast construction speed, reliable quality, less material consumption, high bearing capacity of piles, mechanized operation, and environmental protection. In the construction method of bored cast-in-place piles, the use of mud retaining walls pollutes the environment, the hole is easy to collapse during the drilling process, the quality of concrete pouring is unstable, and the prestressed pipe piles are easy to cause the soil to rise. The strength of the pile body constructed by the invention is high. , There is no sediment at the bottom of the pile, and the pile end is completely rock-socketed, which can reach more than 2 times the bearing capacity of the same diameter bored pile.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

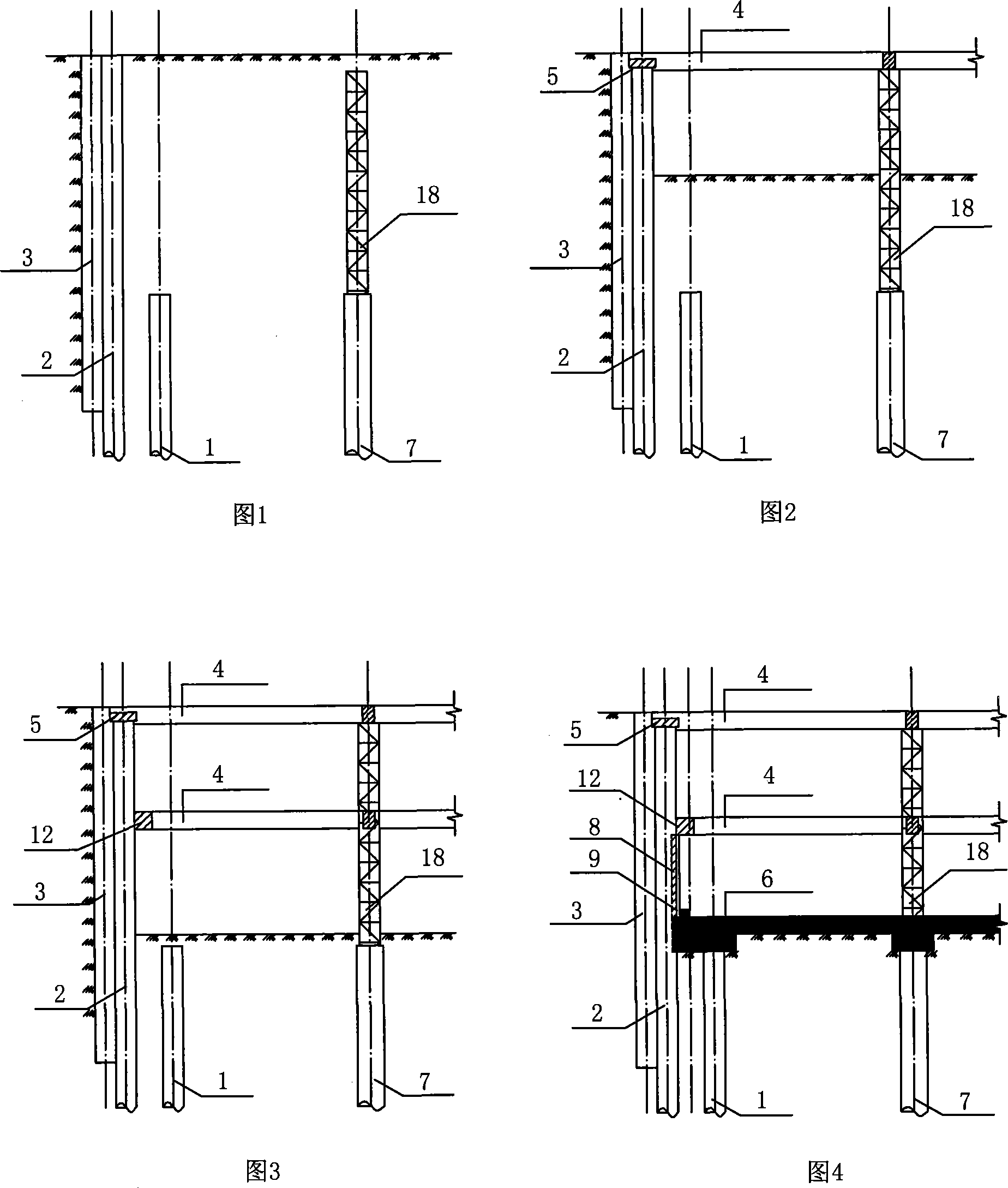

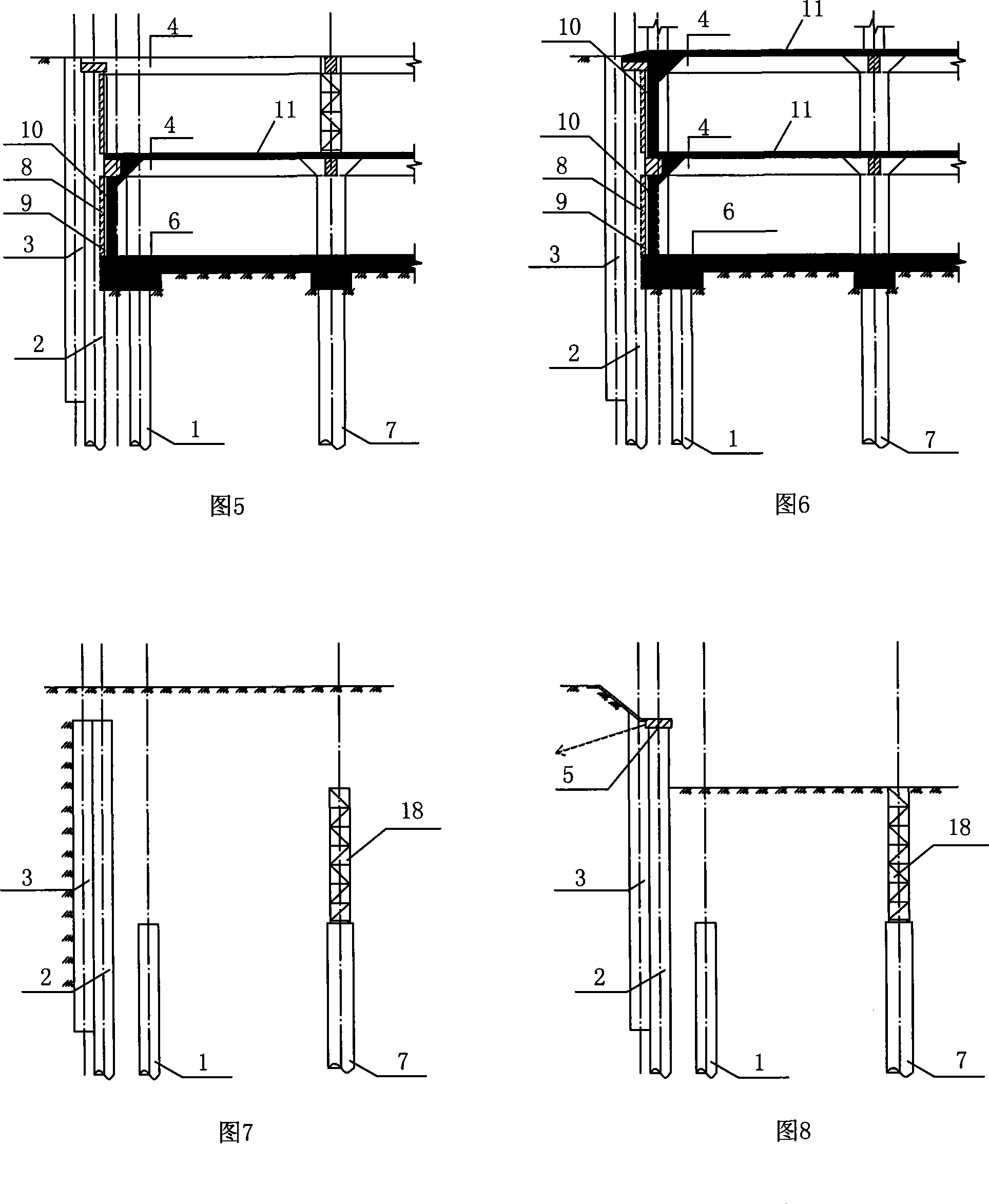

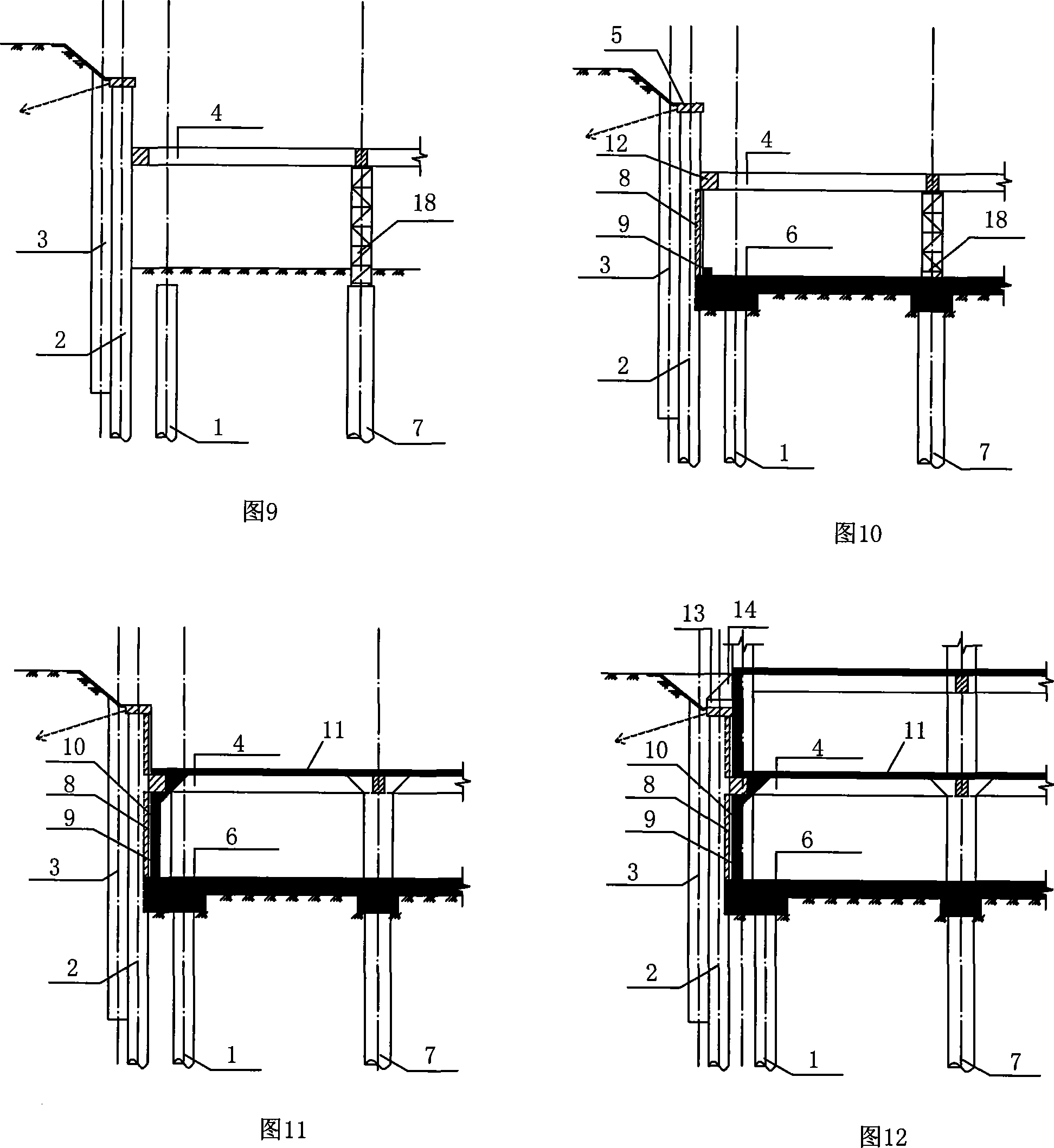

Underground engineering one-pile multi-use semi reverse construction method

InactiveCN101117805ALow costEasy constructionArtificial islandsUnderwater structuresBasementSlurry wall

The present invention relates to a method for one pile for a plurality of applications for semi-reversal construction for the underground engineering. A traditional temporary enclosure support system of the underground engineering can be taken as a main beam system of floors; in addition to traditional load bearing and floating resistance function, an internal engineering pile can be taken as an enclosure support pile and a reinforcement structure of columns for the future underground engineering; the surrounding enclosure employs tradition methods, in addition to the enclosure, the surrounding enclosure protection pile is taken as a surrounding engineering pile and the external wall of the future underground engineering; the support system concurrently the floor beam system are excavated from top to bottom, and an underground engineering bottom plate and floors is worked and bearing column and a wall body is loaded to the ground from bottom to top. The present invention has the beneficial effects that the present invention combines the support system and the basement main beam system: the middle engineering pile is taken as pressure bearing, floating resistance and supporting pile and bearing load column for the future basement. Compared with the full-reversal method for the underground continuous wall, the present invention has the advantages of saving project cost, convenient construction, simple construction equipment, etc.

Owner:ZHEJIANG UNIV +1

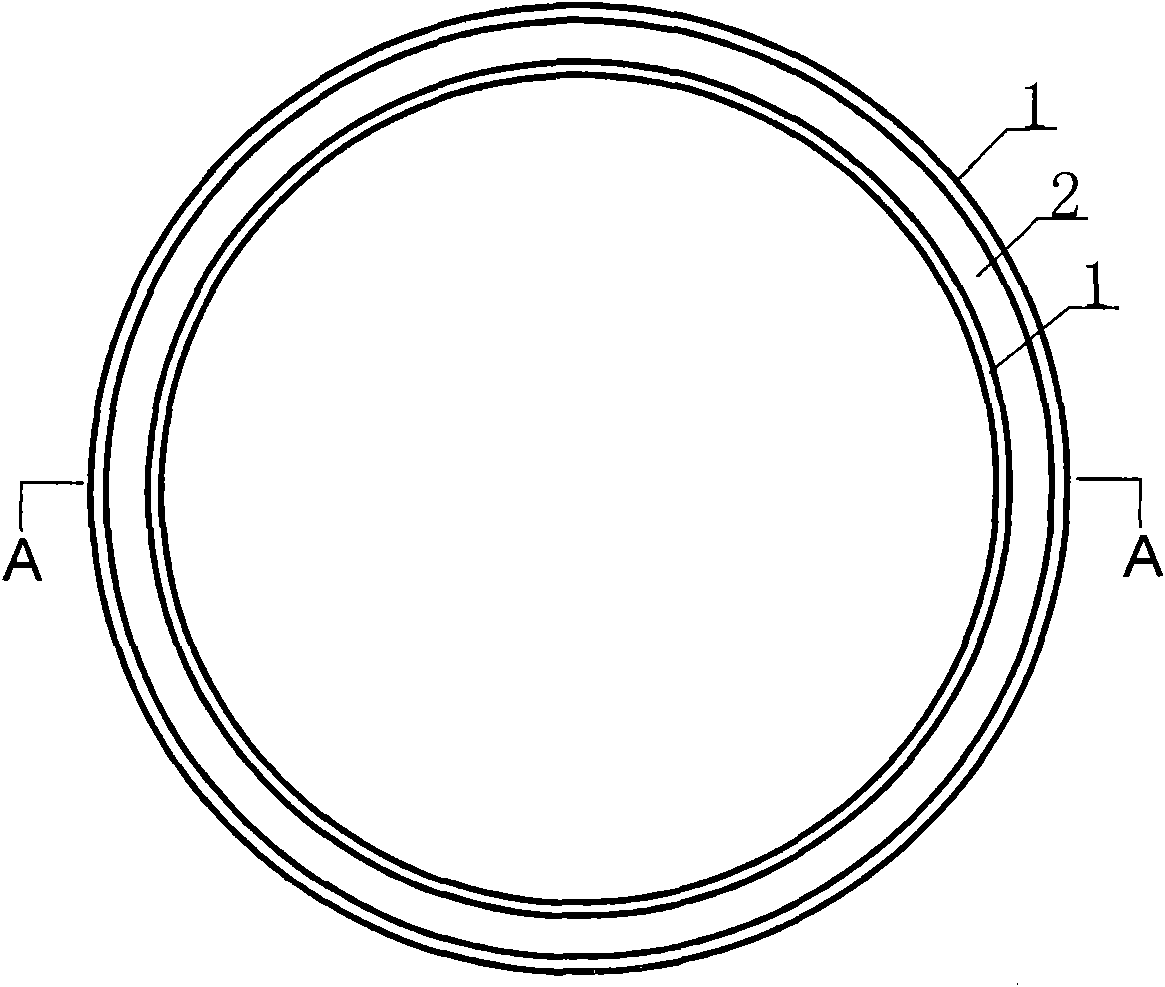

Slurry wall protection construction method for bored pile

InactiveCN104120716AResolve skewSolve the problem of pile body concrete with mudBulkheads/pilesSlurry wallArchitectural engineering

The invention discloses a slurry wall protection construction method for a bored pile. The slurry wall protection construction method includes the following steps that step 1, a pile hole is positioned; step 2, a pile casing is buried; step 3, a drilling machine is in place; step 4, qualified slurry is prepared; step 5, hole forming and hole clearing are performed; step 6, a steel reinforcement cage is lifted for placing; step 7, underwater concrete is cast. According to the slurry wall protection construction method for the bored pile, operation is easy, the problems that the pile hole deviates, and pile body concrete is mixed with slurry are solved, and the construction method is suitable for slurry wall protection hole forming bored pile engineering of soft and hard soil layers high in underground water level in industrial and civil buildings.

Owner:杨哲

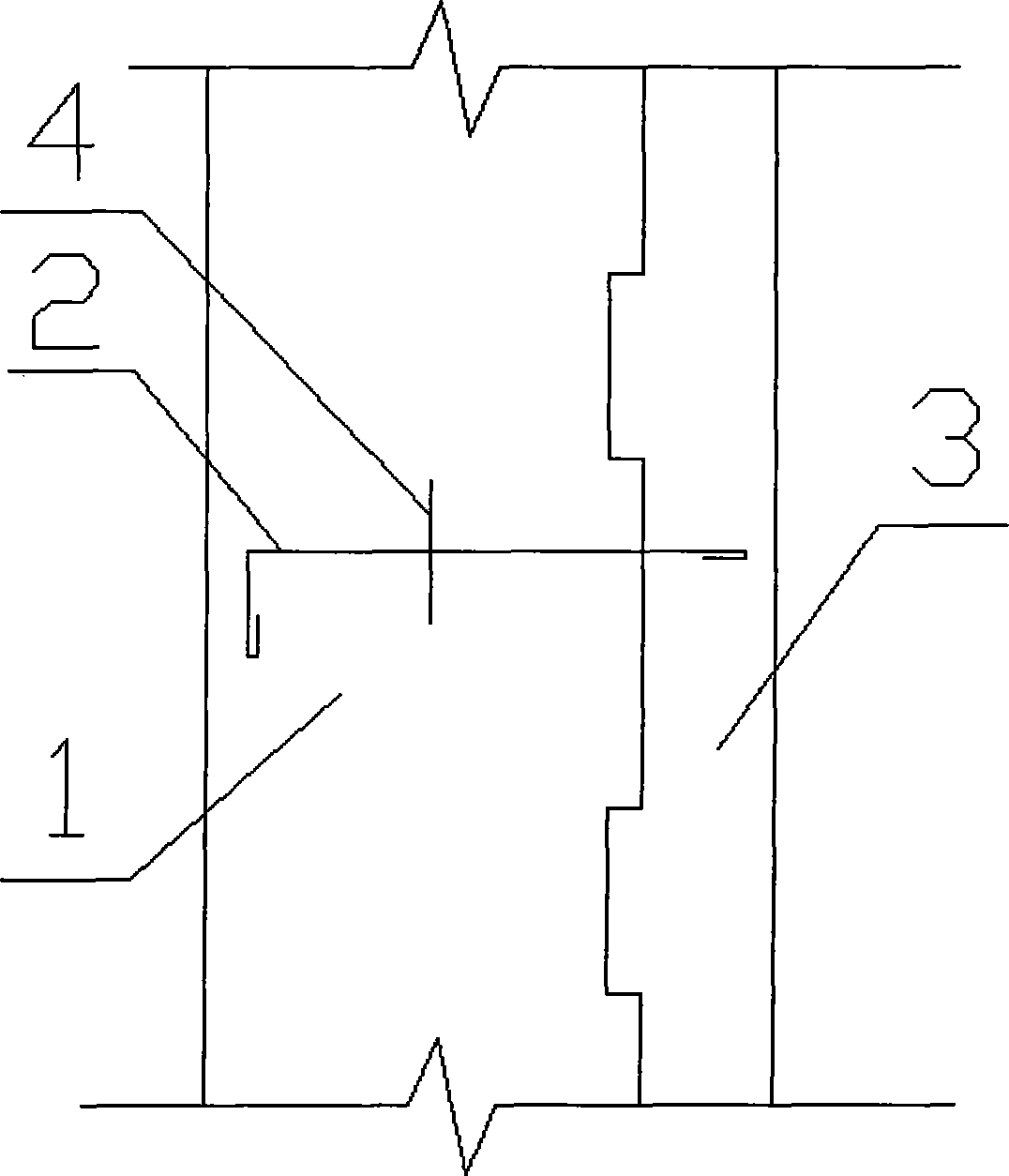

Method for connecting slotted sections in underground construction of diaphragm wall

The invention discloses a method for connecting slotted sections in underground construction of diaphragm wall of 'deep wall, large thickness and needing rock-socketed' applied to large acale bridges and construction foundation pit excavation. The method comprises the following steps: establishing a guide wall and a construction platform; constructing I phase slotted section of the diaphragm wall; constructing of a slotted eye of II phase slotted section of the diaphragm and jagged section surface of the I phase slotted section; forming an underground diaphragm wall; cleaning and brushing the wall of the II phase slotted section repeatedly up and down by a special steel brush carried by a hydraulic grab, until the steel brush does not have obvious spare, deposit on the bottom of the eye does not increase; releasing a reinforcing cage and casting concrete so as to complete the connection of I phase slotted section and II phase slotted section after the II phase slotted section is completed; forming a complete diaphragm wall after connection. After the method is adopted, the progress of the construction of the underground diaphragm wall is greatly improved; construction cost is saved; construction problems, such as concrete circumferential motion prevention, water seepage in seam and the like can be completely solved by the jagged connection section so as to improve construction quality and safety reliability.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

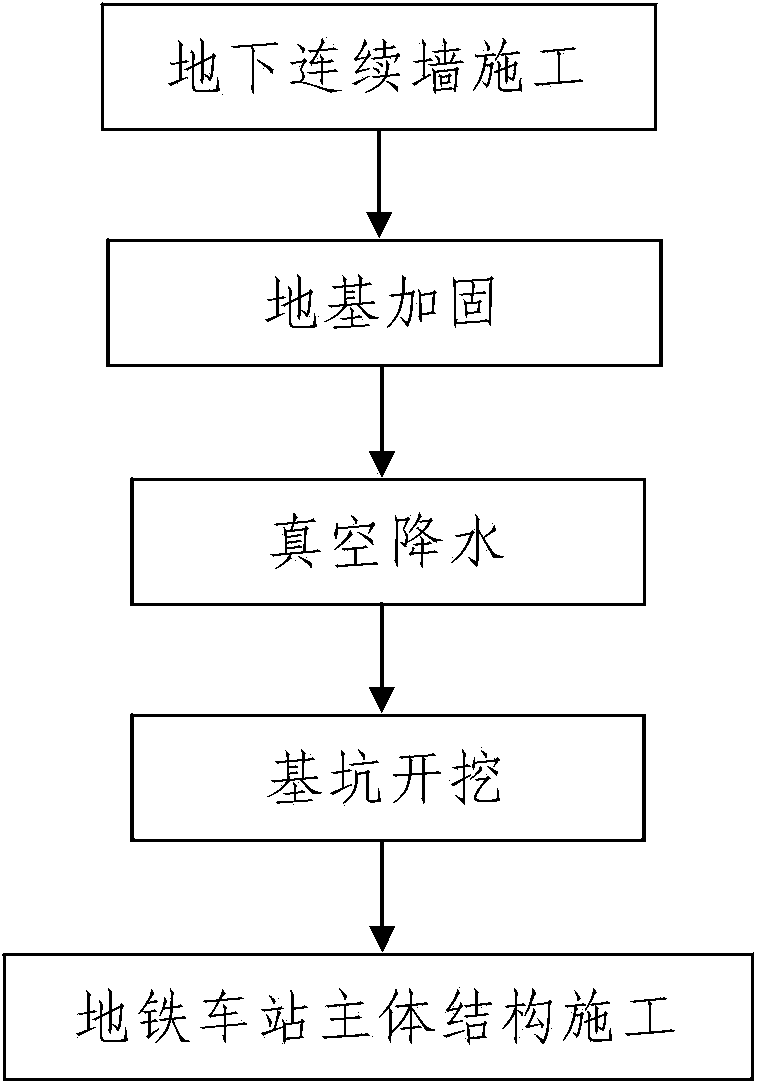

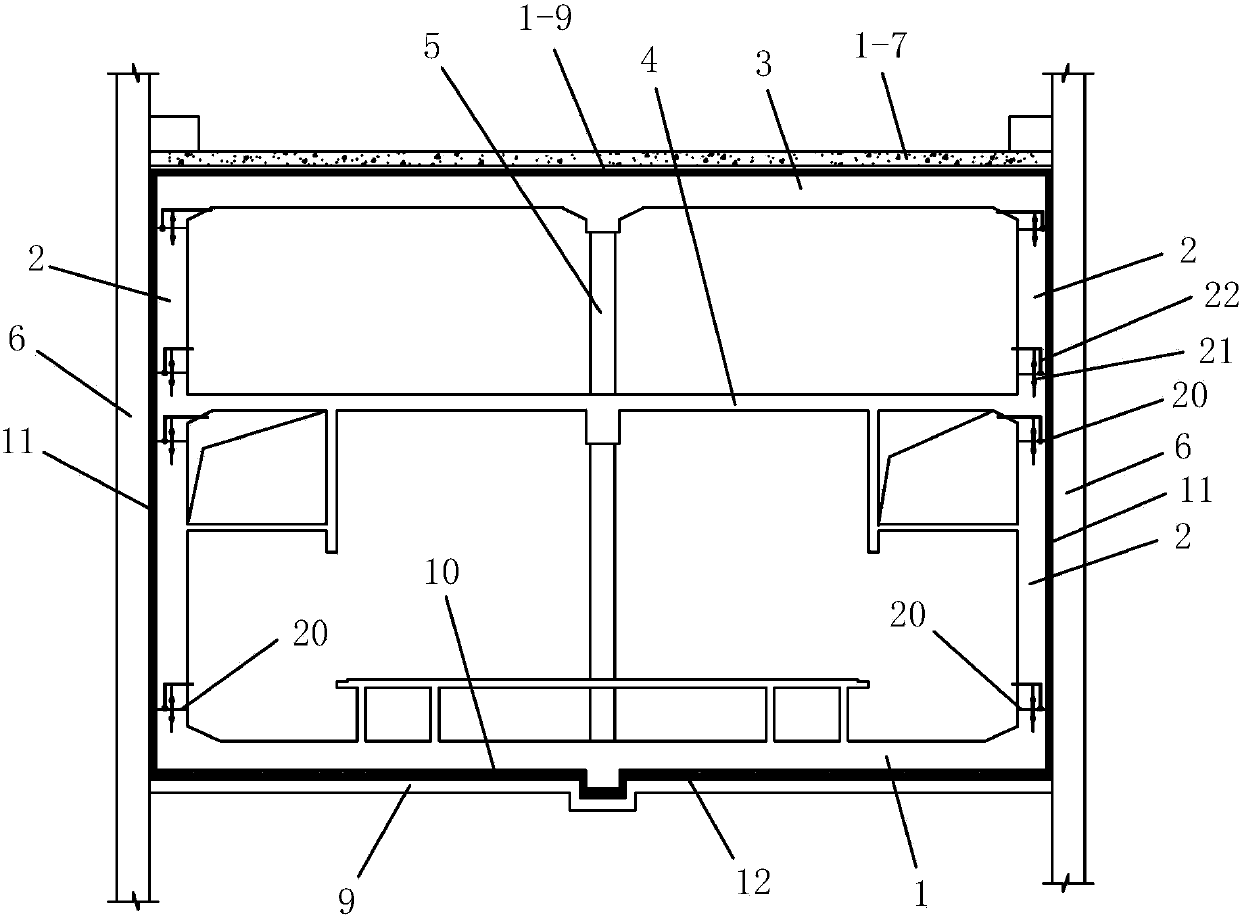

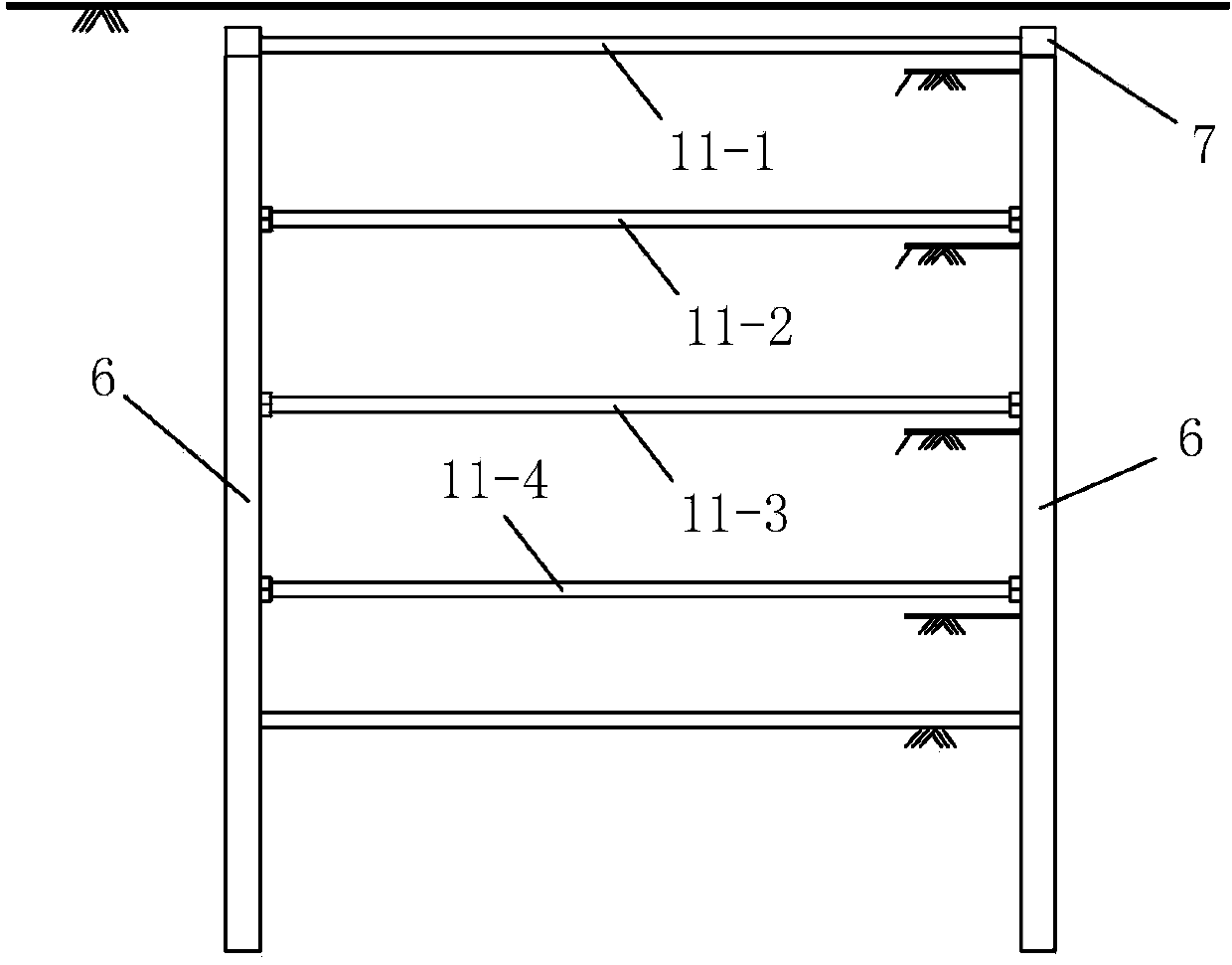

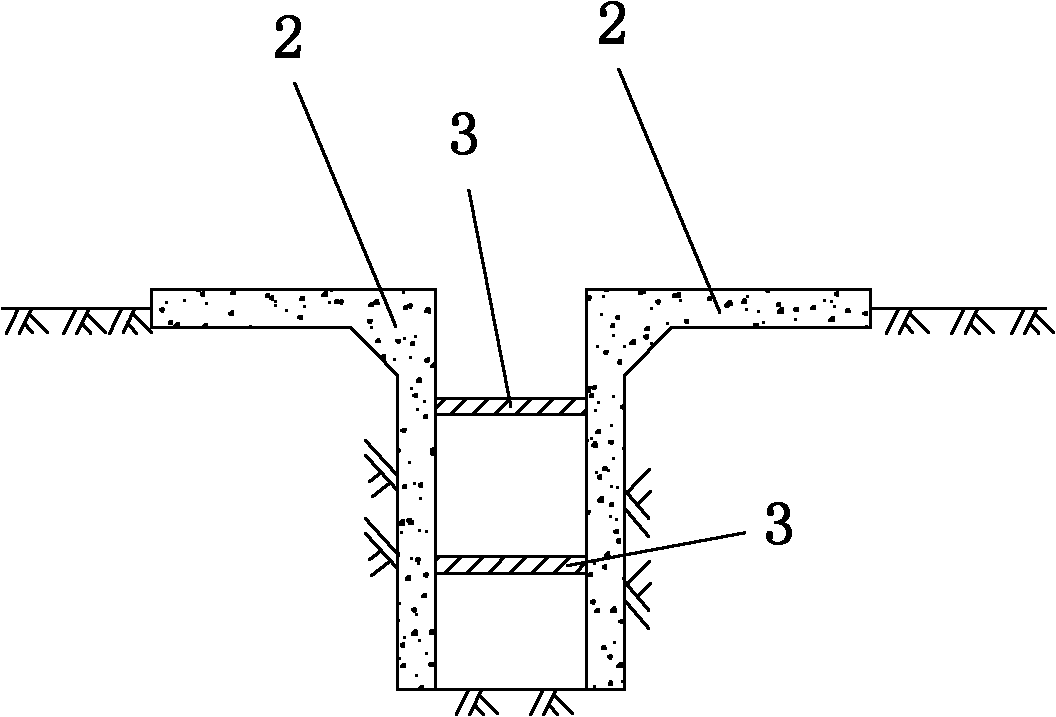

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

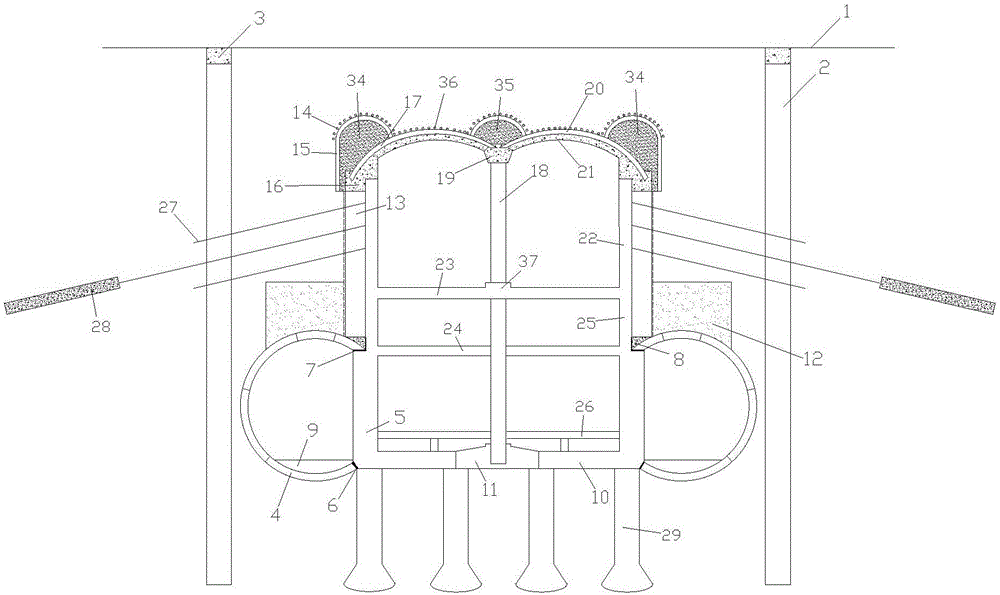

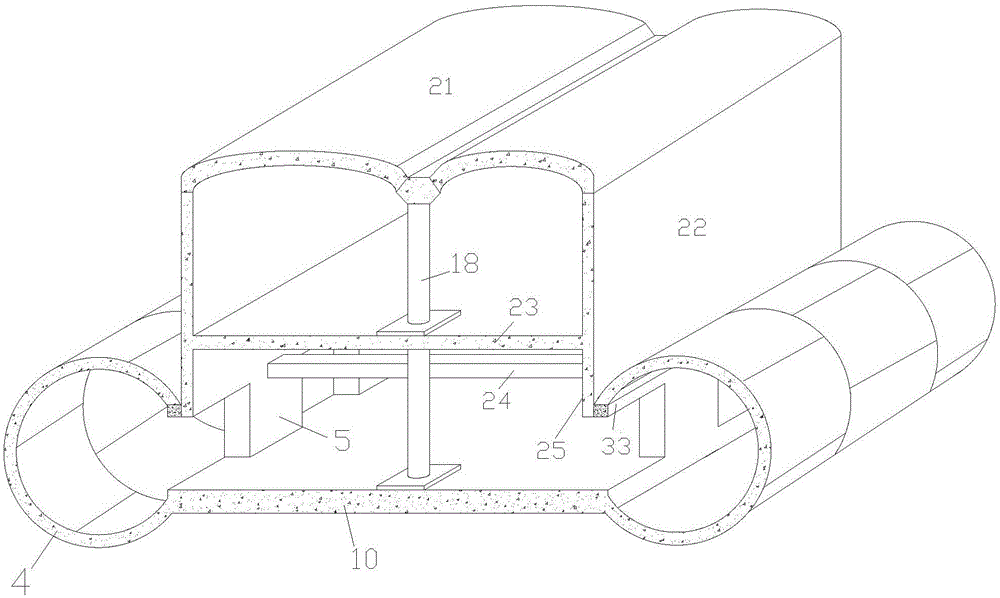

Underground excavation construction method for expanded excavation of station on basis of metro regional shield tunnel

InactiveCN105041349AReduce non-propulsion workImprove construction efficiencyUnderground chambersTunnel liningSlurry wallMetro station

The invention relates to an underground excavation construction method for expanded excavation of a station on the basis of a metro regional shield tunnel. The structural form of the station formed through expanded excavation is a simple support framework wall column type double-layer metro station; piles in a row and a water stop heavy curtain or an underground continuous wall are used for blocking soil and water, and the lateral deformation of soil bodies is resisted; soil bodies between openings of parallel shield tunnel duct pieces are excavated, and a transverse passage is constructed; uplift piles, wall columns, a bottom plate, a middle upright post foundation and transverse support beams arranged between the wall columns are constructed in the transverse passage; the bottom plate is connected with the bottom of each wall column; the soil body above the tunnel is subjected to grouting reinforcement; an underground excavation reverse operation method is adopted for constructing the station main body structure; the station main body can be entered through a vertical shaft or the transverse passage built at an entrance and exit; and a small guide holes and the station top structure are constructed. The problem of low use efficiency of shield equipment is solved. The method has the advantages that huge economic benefits, social benefits and environmental benefits are brought; and important engineering application values and development prospects are realized.

Owner:BEIJING UNIV OF TECH

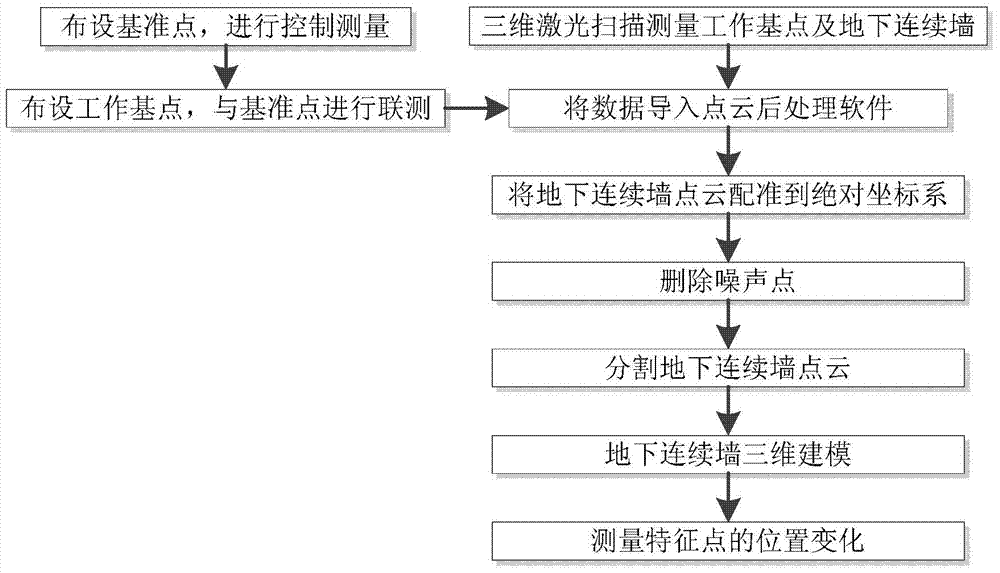

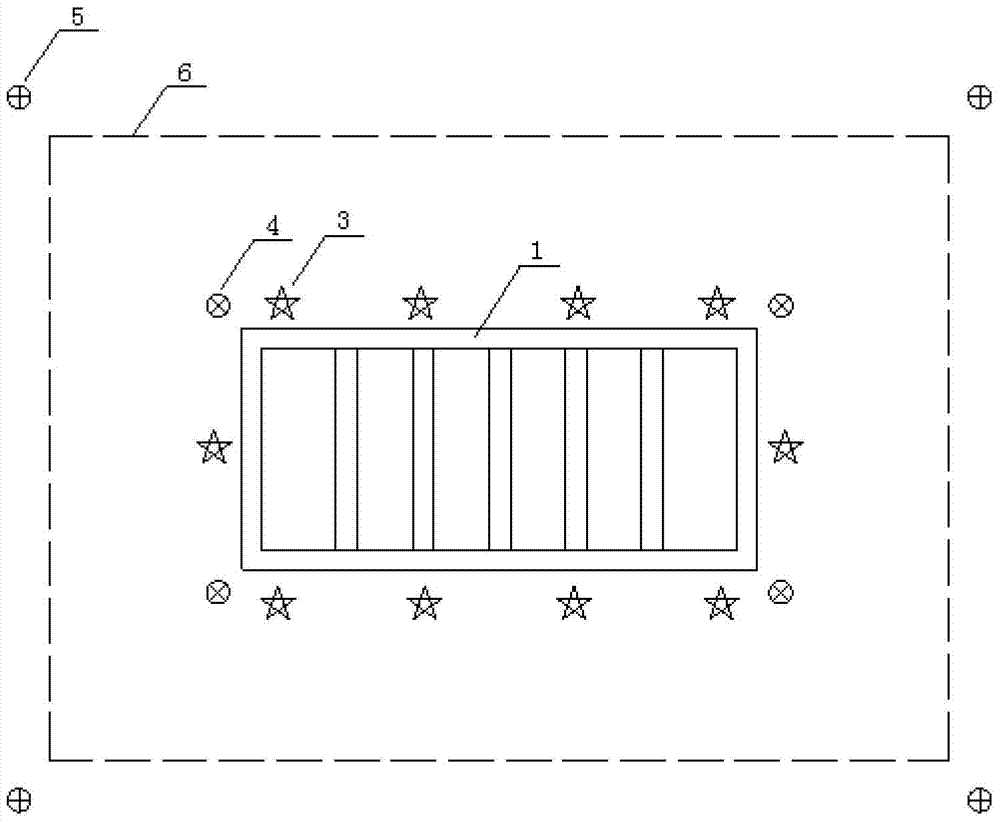

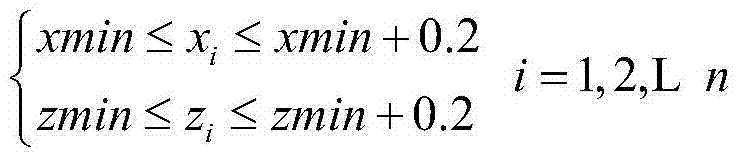

Method for measuring deformation of underground diaphragm wall

The invention discloses a method for measuring deformation of an underground diaphragm wall. In the aspect of data acquisition, a three-dimensional laser scanner is adopted and is capable of quickly measuring three-dimensional coordinates of the underground diaphragm wall; working base points are used as joint control points, a control network is established through the layout of deformation monitoring working base points and datum points, the underground diaphragm wall and the working base points can be simultaneously scanned, and point clouds of the underground diaphragm wall can be registered in an absolute coordinate system of the control network. In the aspect of data processing, a point cloud regular gridding modeling technology is adopted to reconstruct a three-dimensional model of the underground diaphragm wall. By comparing the three-dimensional models of the underground diaphragm wall in different periods, the deformation of all the positions of the underground diaphragm wall can be obtained. Through the method, the overall deformation of the underground diaphragm wall can be measured in the excavation process of a foundation pit, monitoring points do not need to be laid, interference on the construction is reduced, the measuring efficiency is high, and comprehensive monitoring data are provided for the excavation of the foundation pit.

Owner:TONGJI UNIV

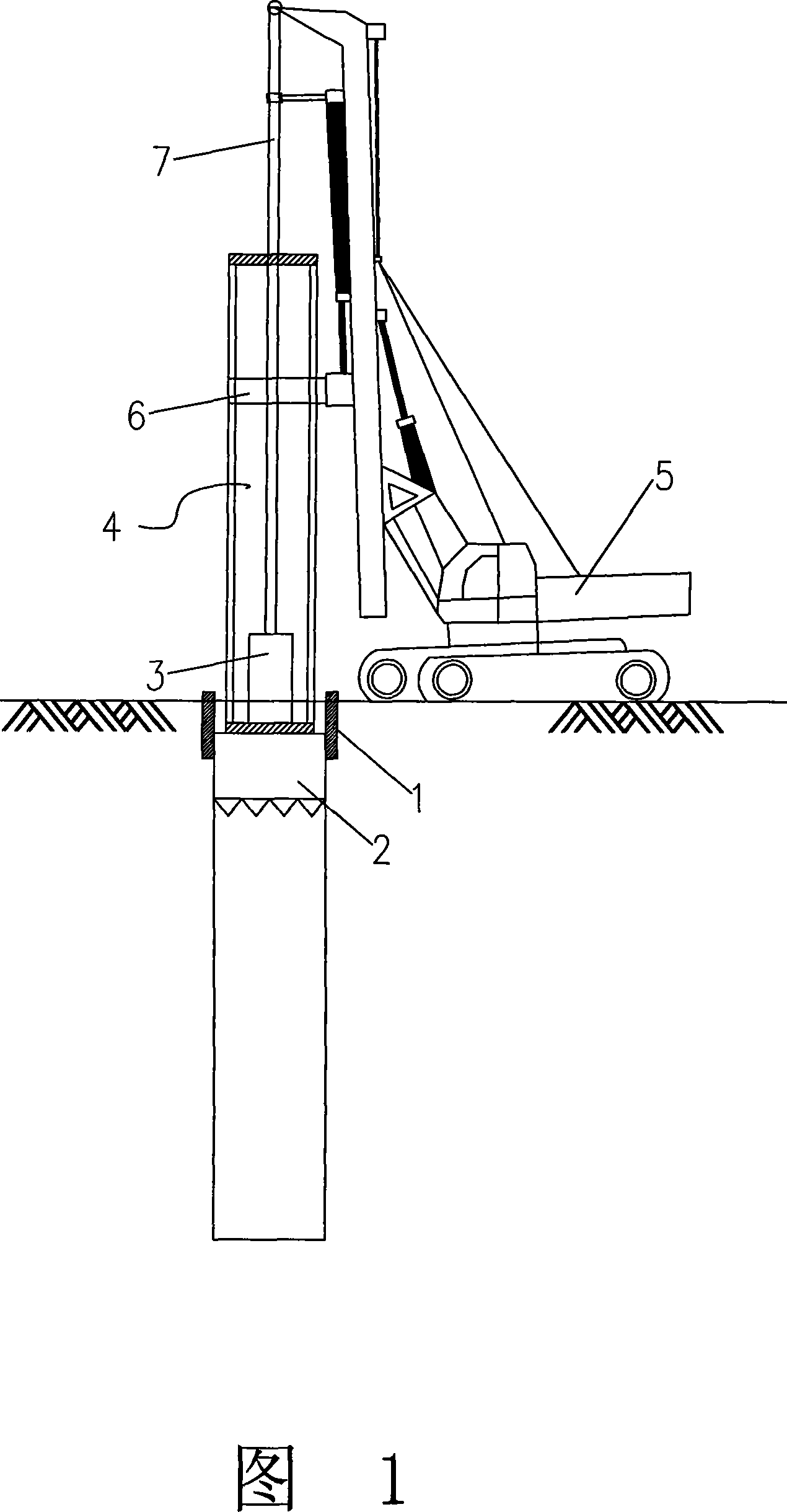

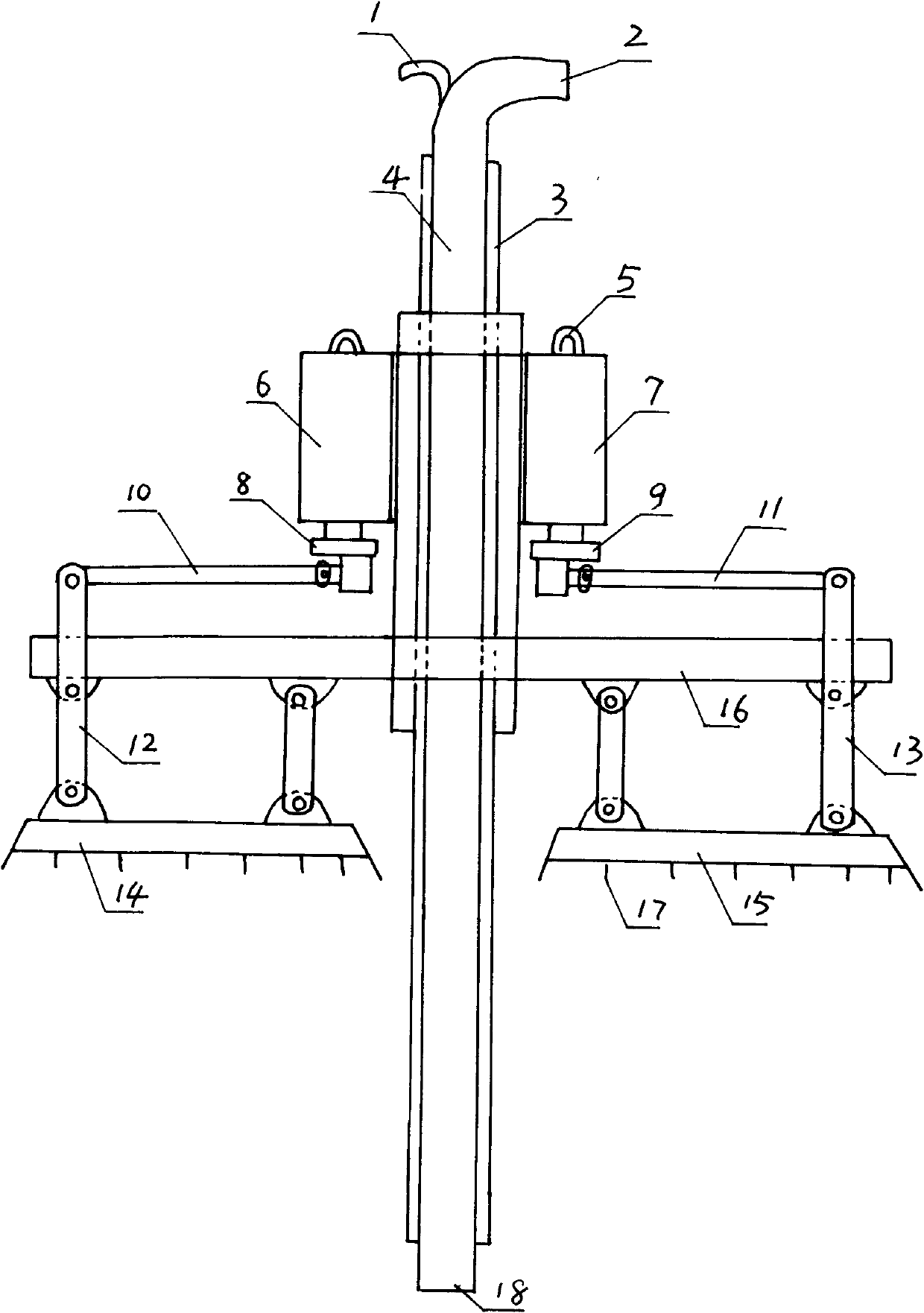

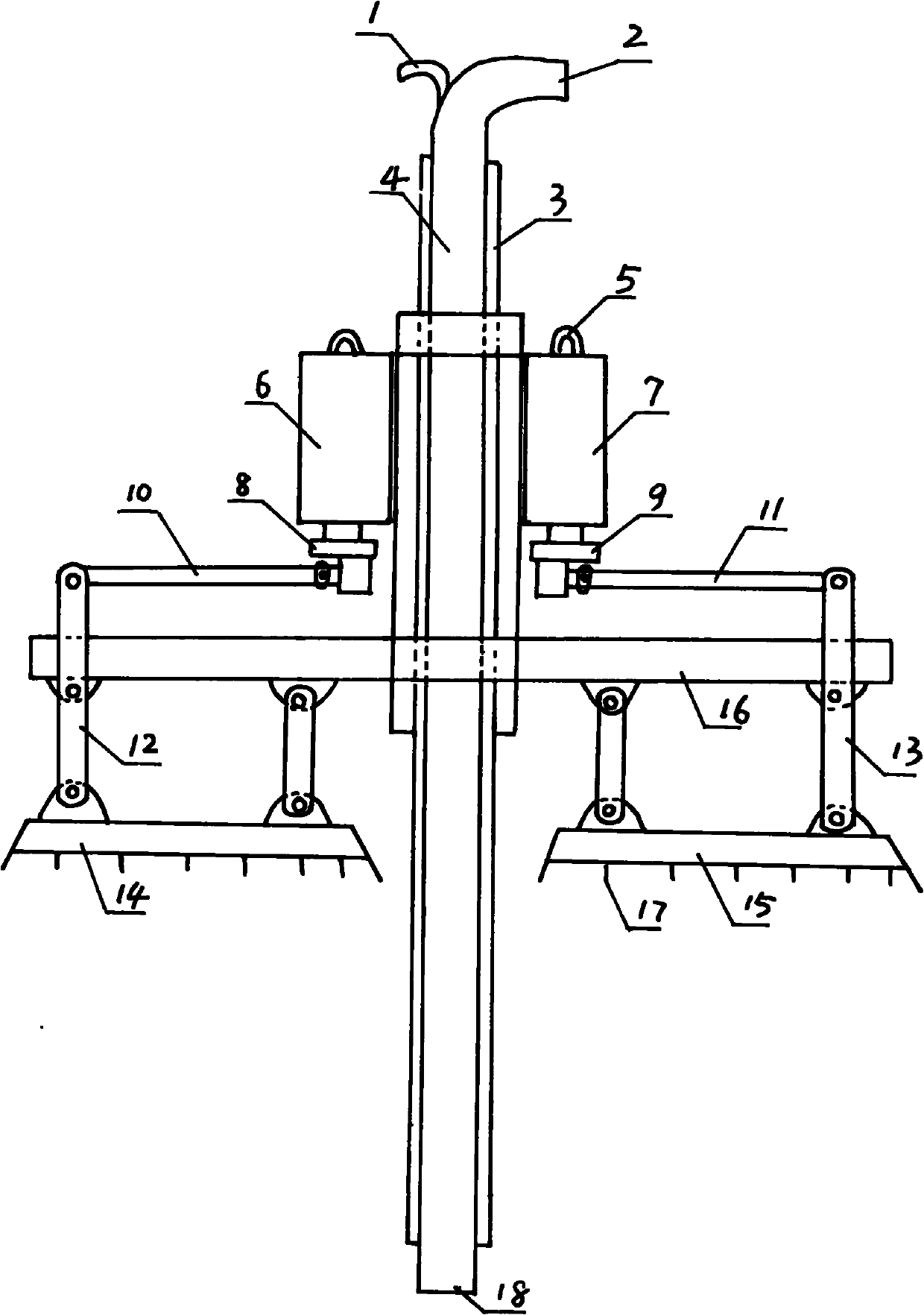

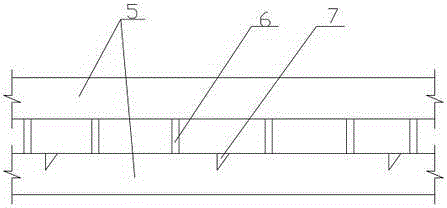

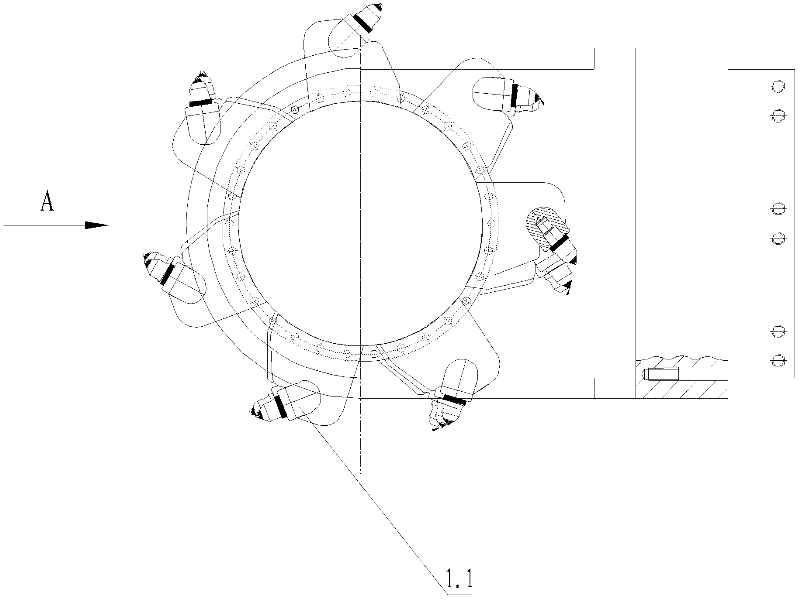

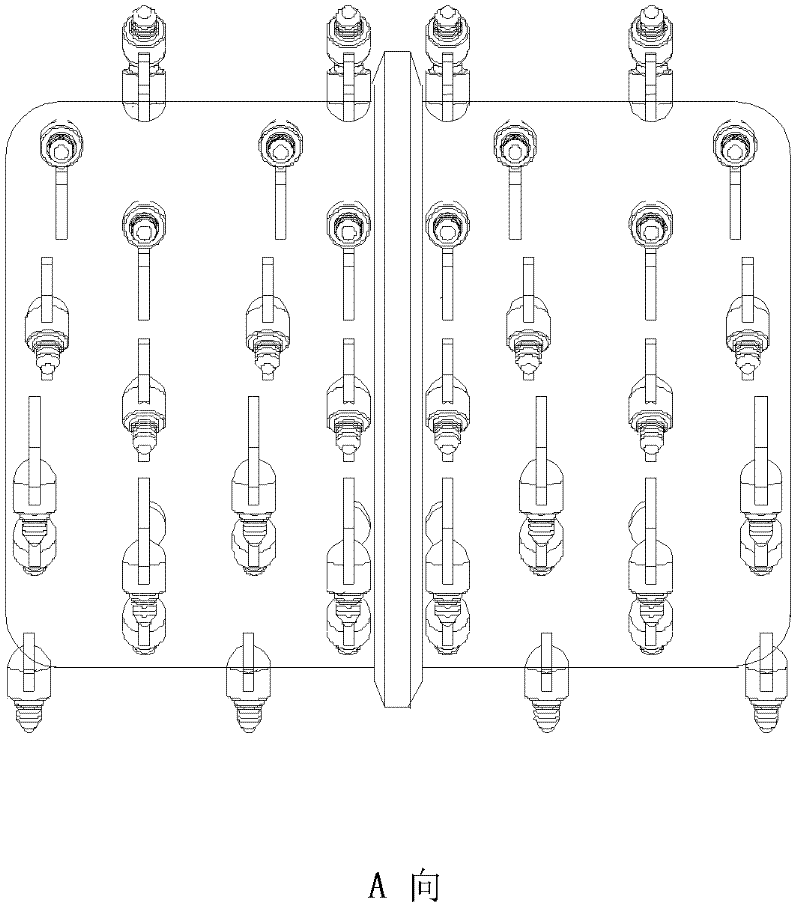

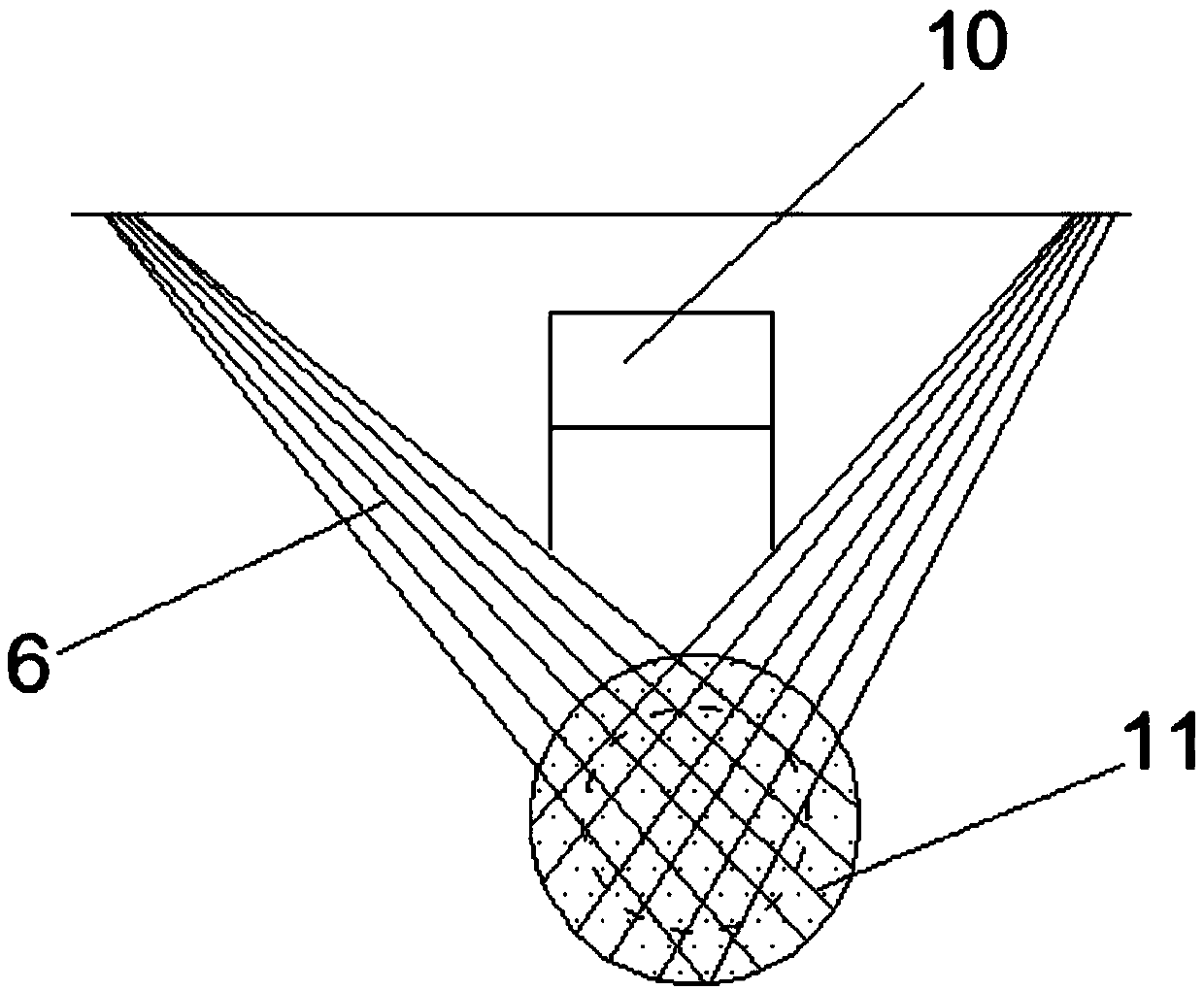

Synchronous trenching machine

The invention relates to a synchronous trenching machine comprising a high-pressure air inlet pipe, a slurry discharging bent pipe, a slurry outlet steel pipe and two guide rails, wherein the two guide rails are fixed at both sides of the slurry outlet steel pipe. The synchronous trenching machine is characterized in that synchronous submersible motors A and B are respectively arranged at both sides of the slurry outlet steel pipe; a crank A is arranged below the submersible motors A and articulated with the upper end of a rocking arm A through a connecting rod A, and the lower end of the rocking arm A is articulated with a tool arm A; a crank B is arranged below the submersible motor B and articulated with the upper end of a rocking arm B through a connecting rod B, and the lower end of the rocking arm B is articulated with a tool arm B; and the tool arm A and the tool arm B are both provided with cutting tools. The synchronous trenching machine is a special appliance for trenching an underground continuous wall.

Owner:张永忠

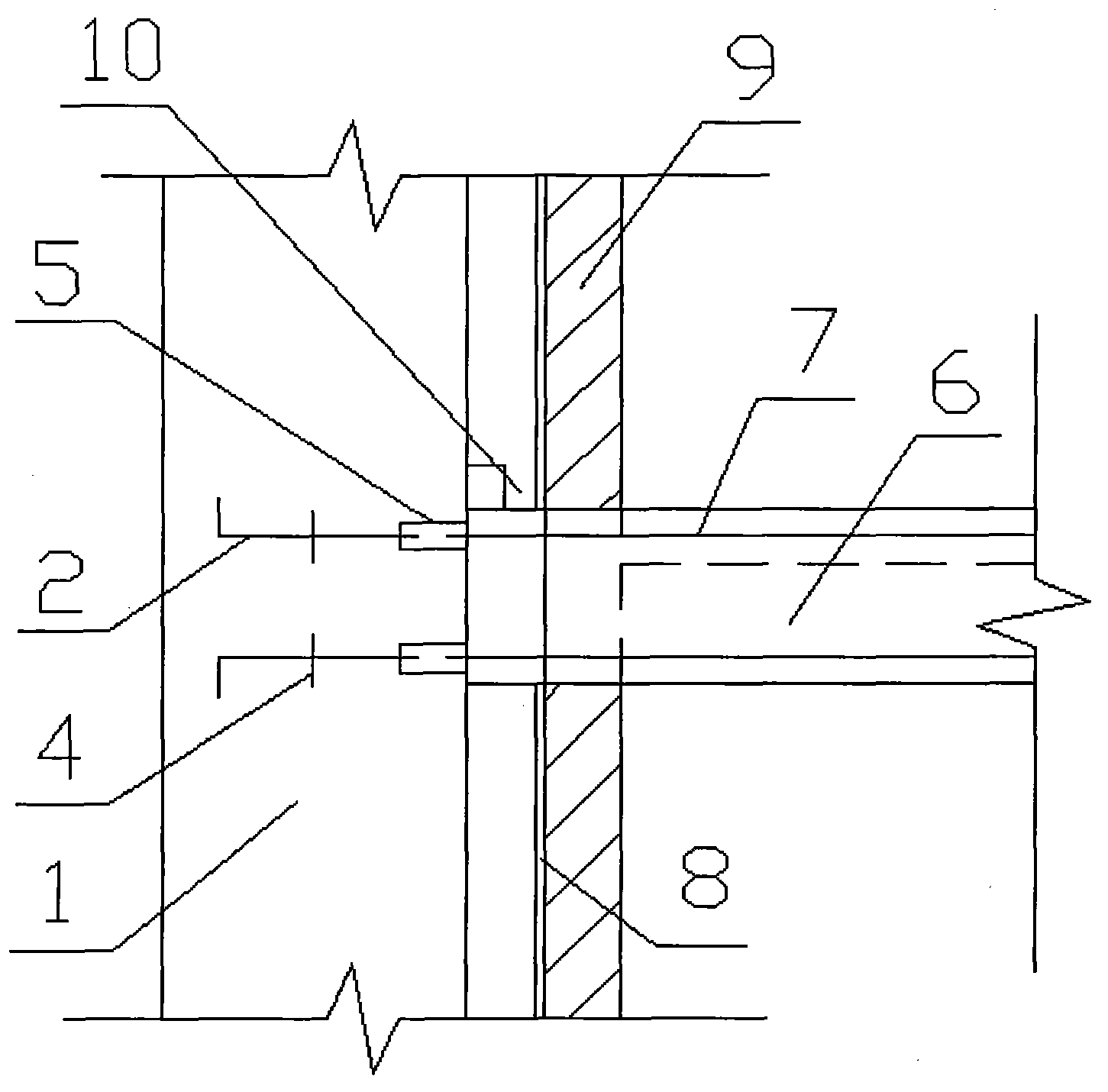

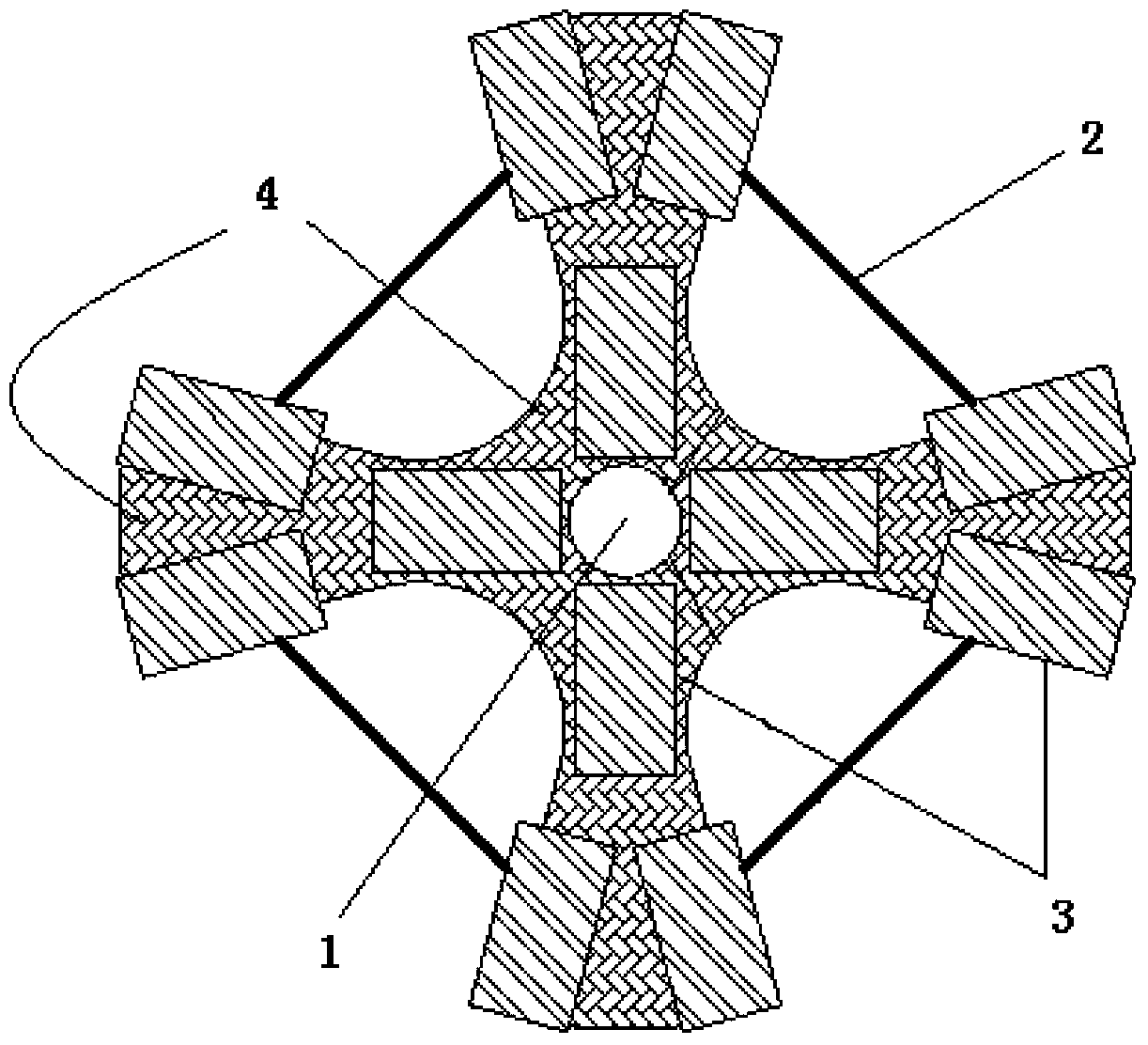

Cross steel plate water-stopping joint continuous concrete wall and joint construction method thereof

InactiveCN101608447AIncreased shear strengthImprove integrityArtificial islandsUnderwater structuresSlurry wallCement slurry

The invention provides a cross steel plate water-stopping joint of a continuous concrete wall and a joint construction method thereof. The cross steel plate joint comprises a longitudinal water-stopping steel plate and a horizontal head steel plate, wherein the longitudinal water-stopping steel plate is about 35-50 cm long, a detouring flow line of cement slurry is lengthened, the impermeability of the joint of the continuous concrete wall is enhanced, the bottom of the horizontal head steel plate extends to the tank bottom level or is inserted into the soil by 20 cm, and the detouring flow line of concrete and sand pulp along the bottom of the head steel plate is blocked; during constructing, a cross steel plate and a steel reinforcement cage are welded into a whole which is then deposited into a tank section so that the joint and a wall body have better integrity; a counterforce box is deposited at the back of the cross steel plate and is impacted to enter soil by over + / -30 cm, and then carpolite or clay are backfilled at the back for sealing; the concrete is cast in the tank section; the counterforce box is pulled out, then a flushing or shoveling tool corresponding to the cross steel plate in structure is adopted to remove the attachment at the part so as to ensure the water-stopping effect and the joint intensity of the cross steel plate.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

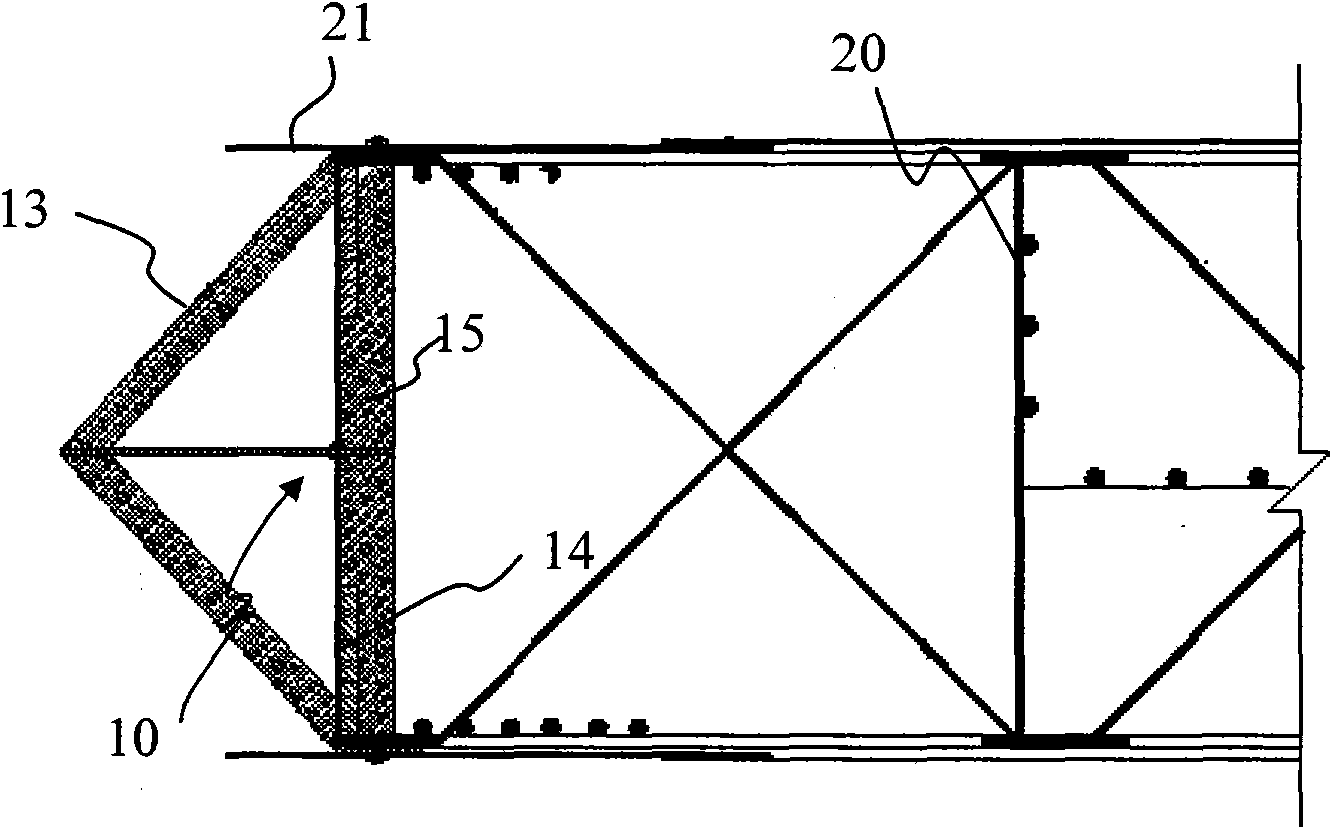

Construction method of underground continuous walls

InactiveCN102797252AEnhanced rock entry abilityAvoid or reduce investmentBulkheads/pilesSlurry wallPunching

The invention relates to a construction method of underground continuous walls. The construction method comprises the following specific steps: guiding hole by utilizing a rotary drill to form a hole guiding free face, and then adopting a method combining a hydraulic grab bucket and a punching pile machine for punching to carry out grooving construction, so that the verticality of a groove and the flatness of the groove wall are guaranteed, and the grooving construction requirement for different rock-stratum strengths can be met. The construction method has the advantages that the construction is simple and convenient, the operation is easy and the cost is saved and the like.

Owner:CHINA RAILWAY 12TH BUREAU GROUP 7TH CORPORATION LIMITED

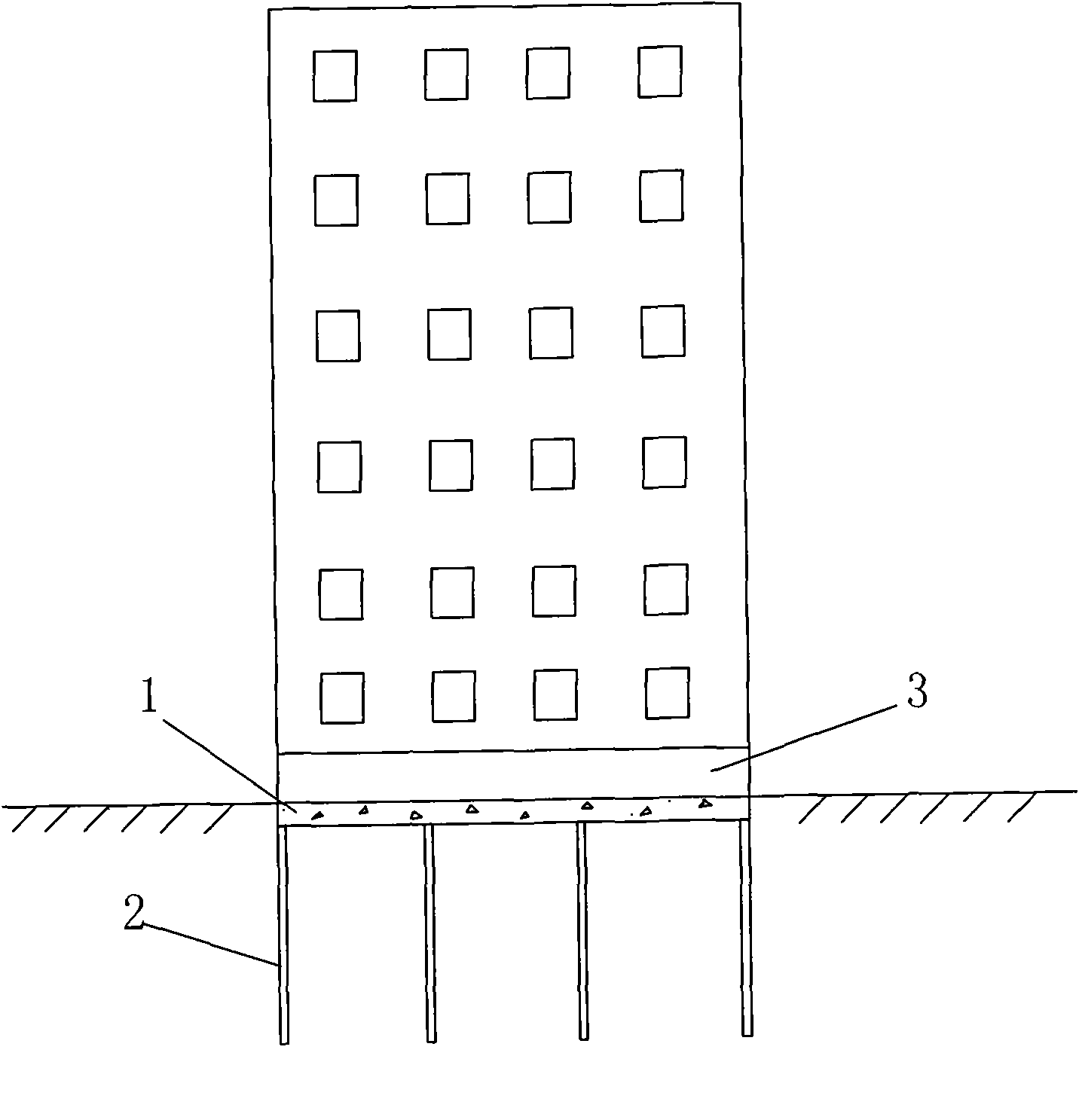

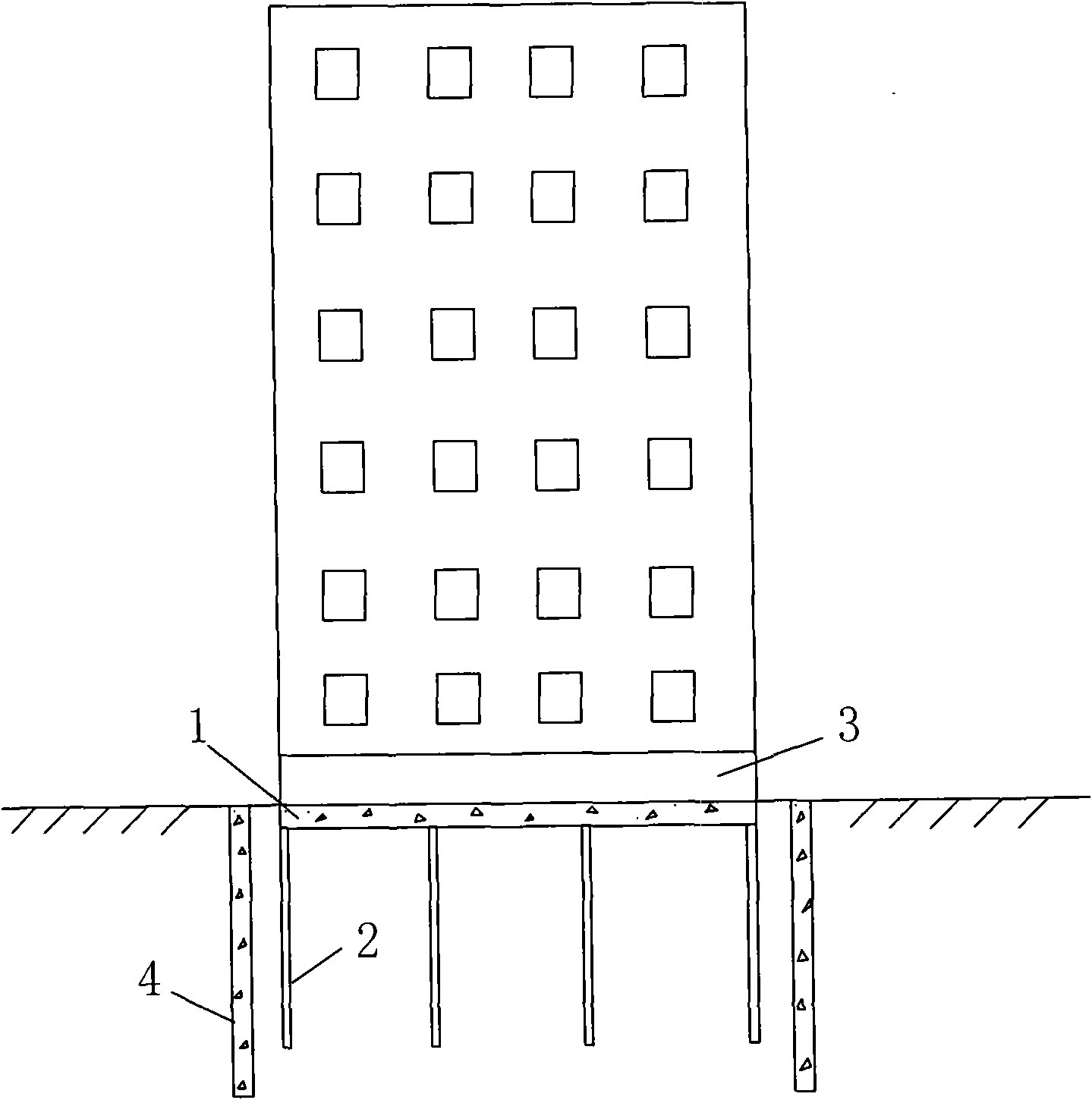

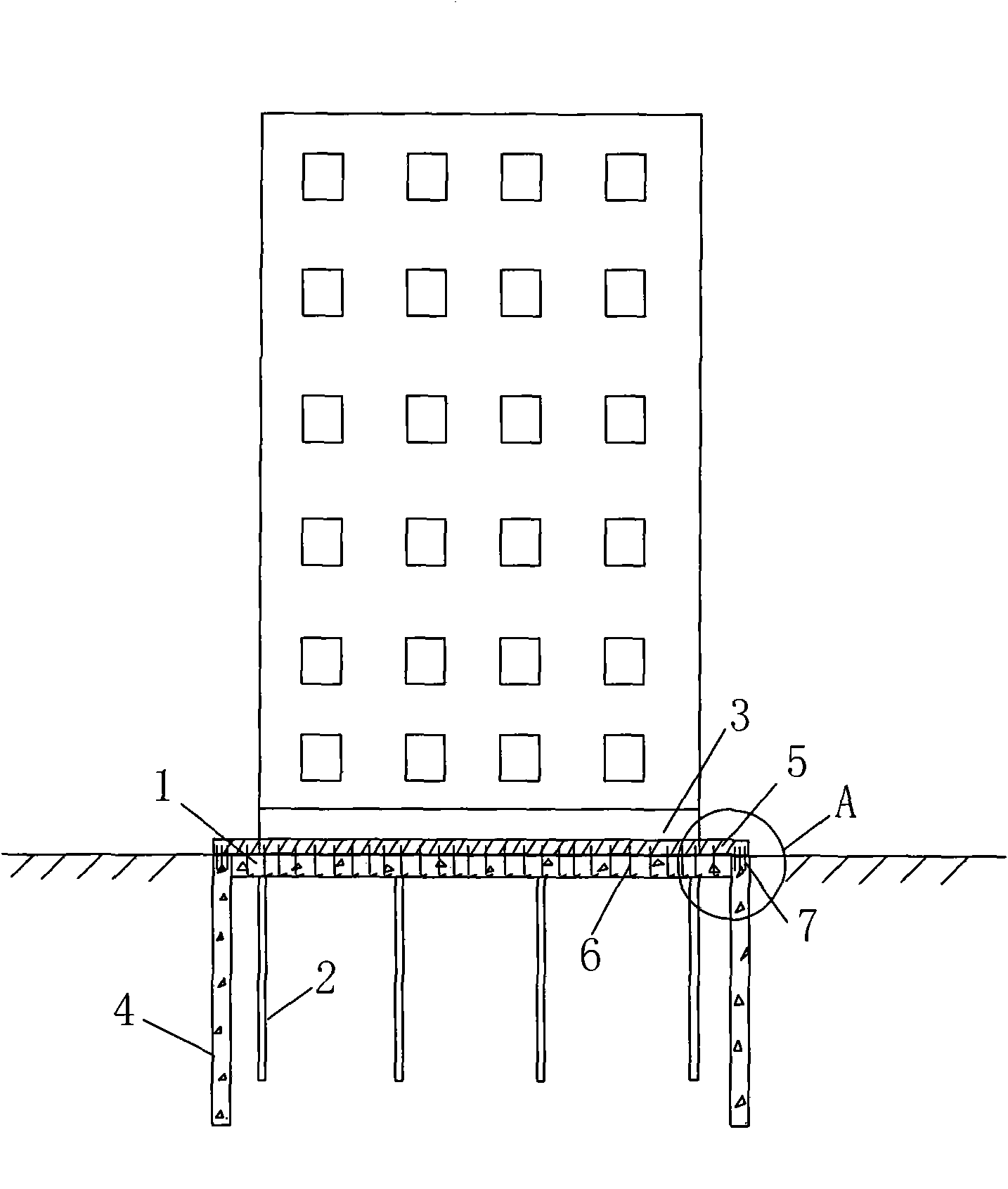

Method for constructing underground garage under old building

ActiveCN102071813AImprove securityReduce construction costsArtificial islandsBuilding repairsSlurry wallSheet pile

The invention relates to a method for constructing an underground garage, which has the characteristics that: structural stability of the original building, high construction speed and low cost are guaranteed. According to a technical scheme, the method for constructing the underground garage under the old building is characterized by comprising the following steps that: a, an underground diaphragm wall or a sheet-pile wall is poured at a position which is at least 1m away from an exterior wall around the building; b, a group of cross beams are poured at the foundation at the bottom of an overhead layer of the building, and the cross beams are integrally connected with foundation soil, the underground diaphragm wall or the sheet-pile wall to support the building; c, underground space is dug below the foundation soil of the building, an entire plate foundation layer is poured at the bottom of the underground space, and the entire plate foundation with underground piles and the underground diaphragm wall or the sheet-pile wall are integrally connected; d, a part of the underground piles are cut off between the foundation soil and the entire plate foundation and the rest underground piles are reinforced; and e, a slope is arranged on the ground and the slope is communicated with the underground space to be served as a passage for entrance and exit of vehicles.

Owner:GEOTECHN TECH

Construction method for full cover-excavation reverse method of underground engineering

InactiveCN103741714AAvoid uneven settlementGuarantee the pouring qualityArtificial islandsUnderwater structuresSlurry wallAbove ground

The invention discloses a construction method for a full cover-excavation reverse method of underground engineering. The construction method comprises the following construction steps of A, underground diaphragm wall construction; B, top plate construction for an underground main structure; C, road face recovery construction or construction of a structure above ground; D, first layer underground excavating construction; E, repetition of the step D till underground excavating construction of the lowest layer is completed. The construction method is characterized in that drainage construction is conducted on underground water by adopting a collected water surface draining method in the process of the step B, and it is ensured that the water level is 50cm or so below a foundation pit. Construction of the structure above the ground in the step C can be conducted at the same time with the steps D-E. The steps D-E are constructed under the covering of the top plate completed in the step B. Underground engineering construction is conducted by adopting the construction method, not only can a construction period be shortened, but also the problems of differential settlement, water seepage and water leakage can be effectively solved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

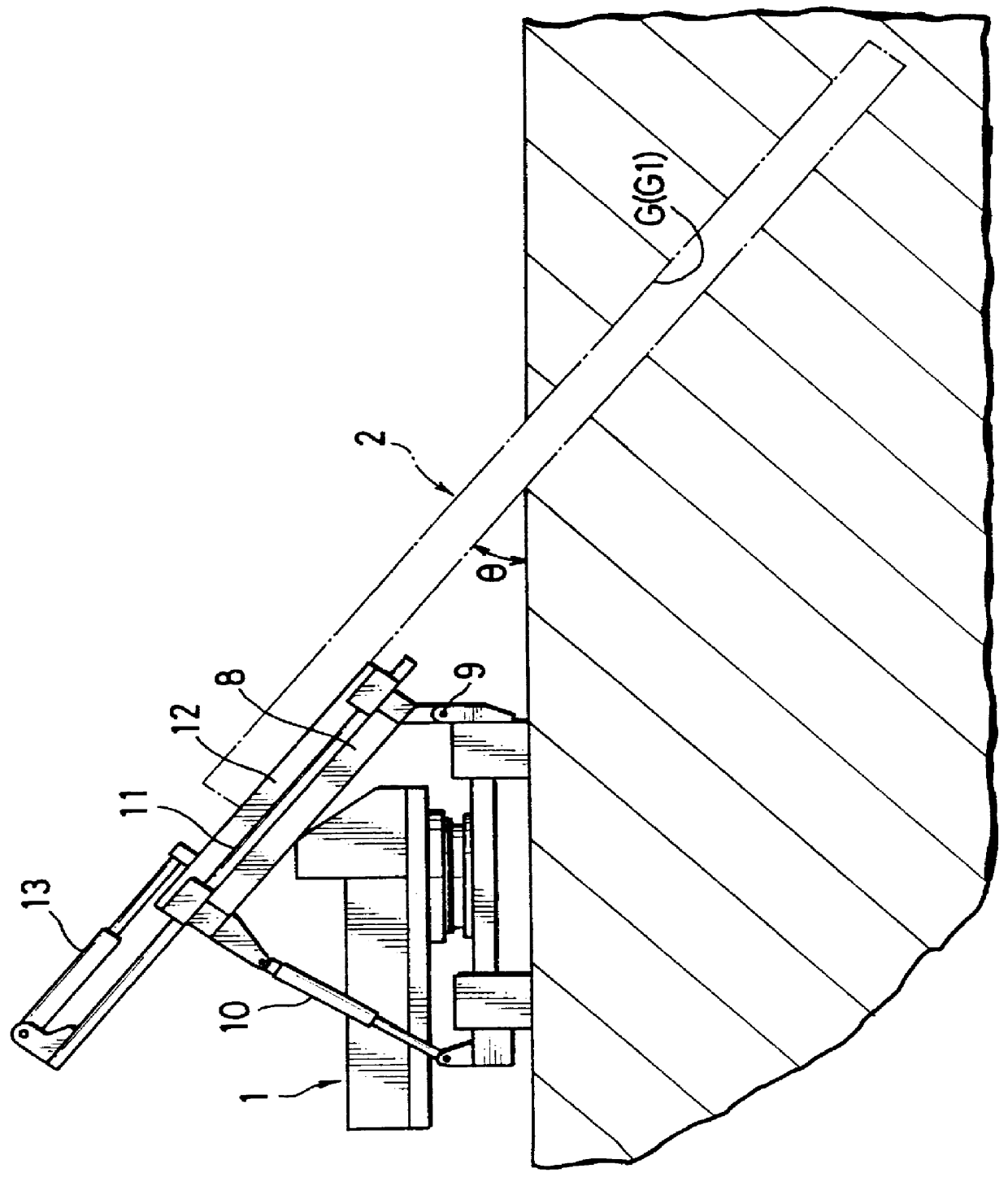

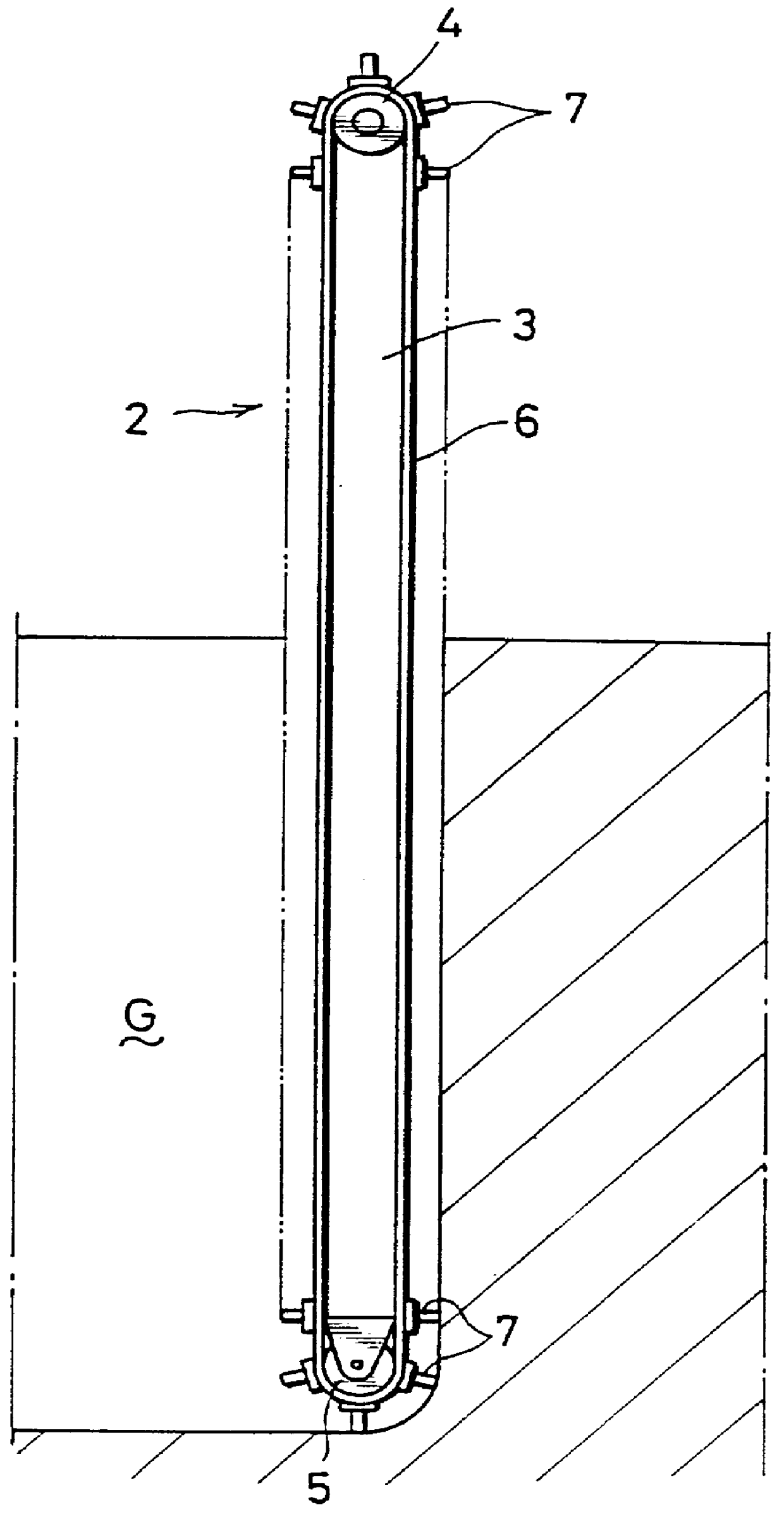

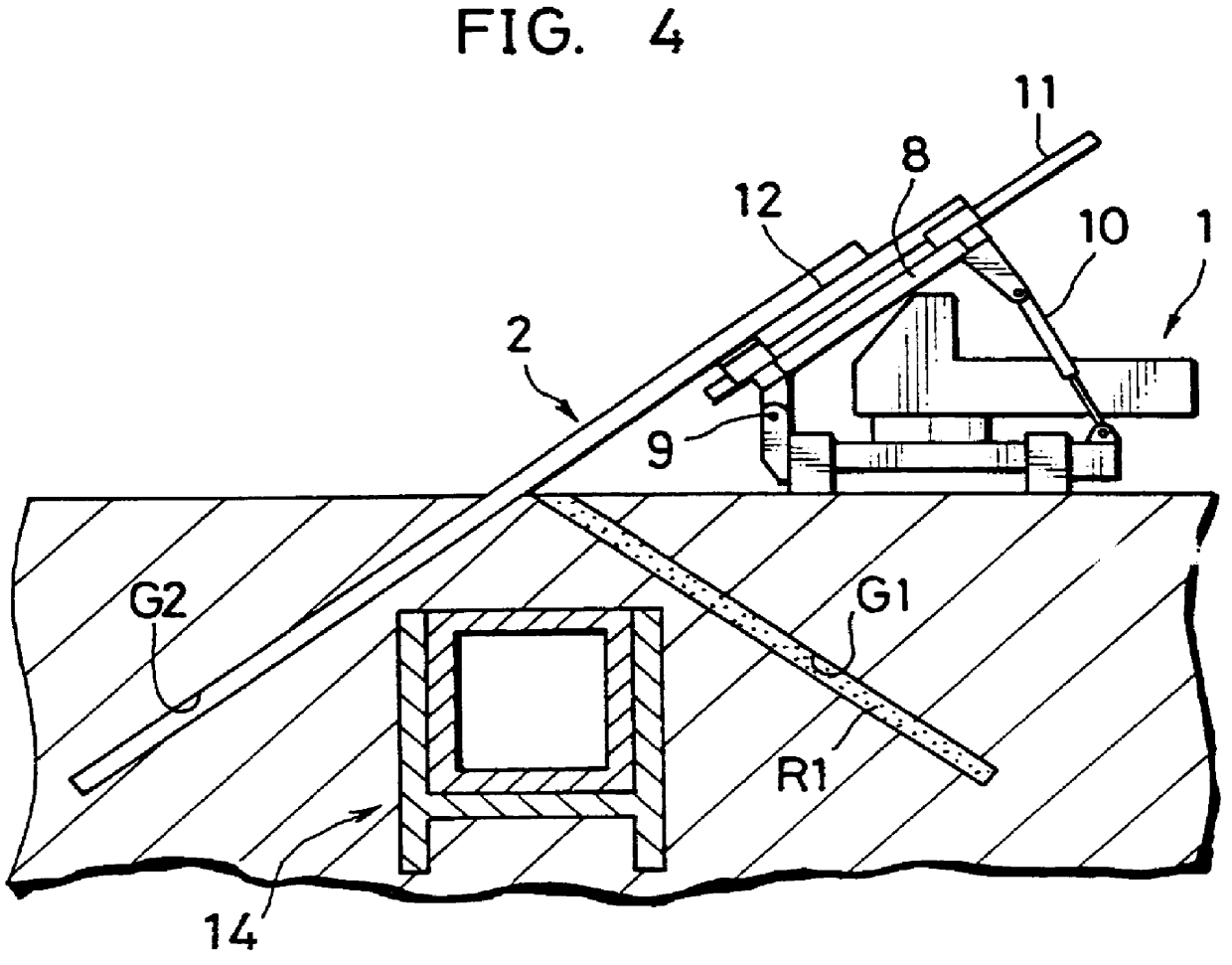

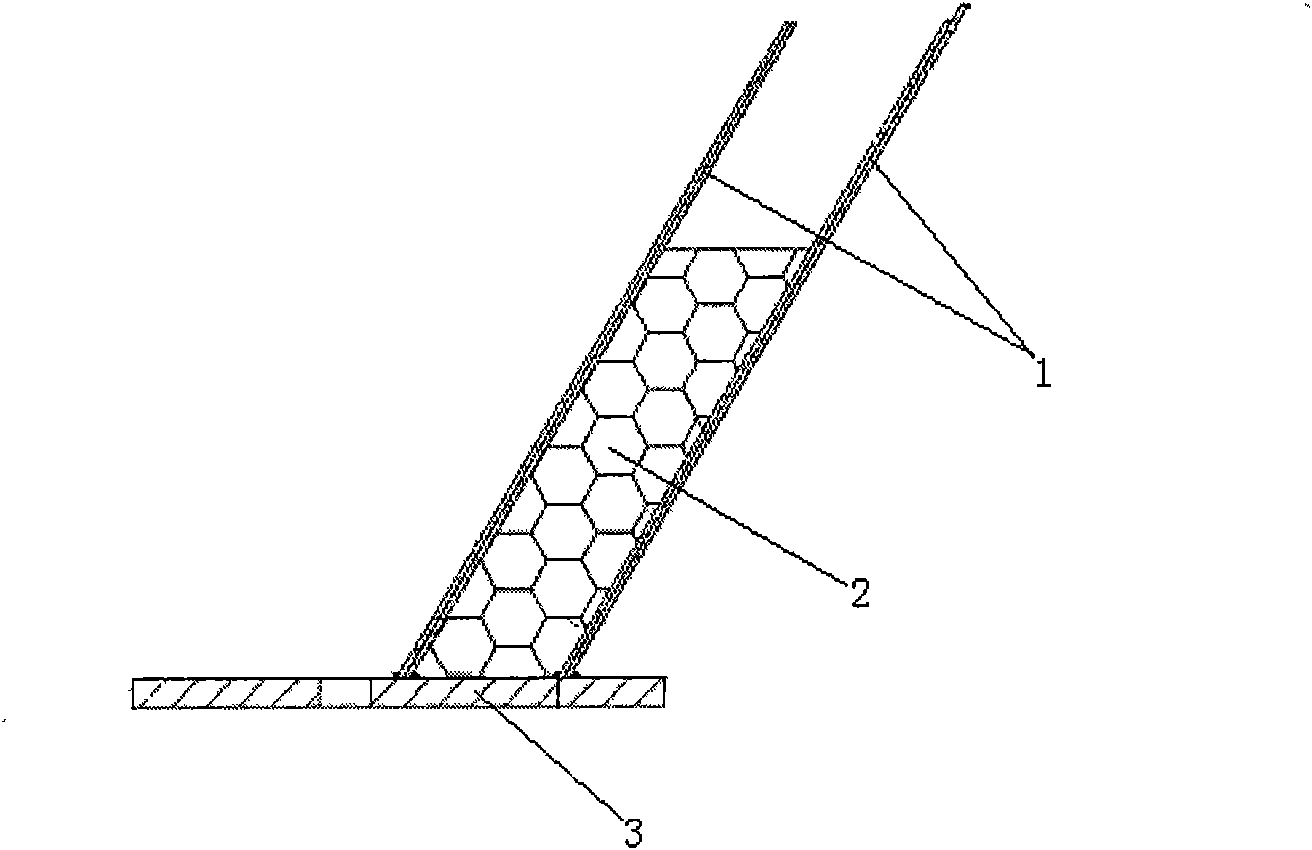

Method for building an underground continuous wall

InactiveUS6139225AMaintaining viewKeeping a bank slope intactMechanical machines/dredgersStorage devicesSlurry wallStructural engineering

PCT No. PCT / JP96 / 03647 Sec. 371 Date Aug. 13, 1997 Sec. 102(e) Date Aug. 13, 1997 PCT Filed Dec. 13, 1996 PCT Pub. No. WO97 / 21877 PCT Pub. Date Jun. 19, 1997An underground continuous wall building method and apparatus in which a chain cutter 2 provided with excavation blades is obliquely mounted on a running carriage 1. Slanting continuous trenches G1, G2 are excavated by moving the running carriage 1 in a transverse direction while rotating the cutter 2 with the cutter 2 obliquely placed in the ground, and a water cutoff material is poured into the excavated continuous trenches G1, G2 and solidified therein to build slanting continuous walls R1, R2 in the ground.

Owner:KOBELCO CONSTR MASCH CO LTD

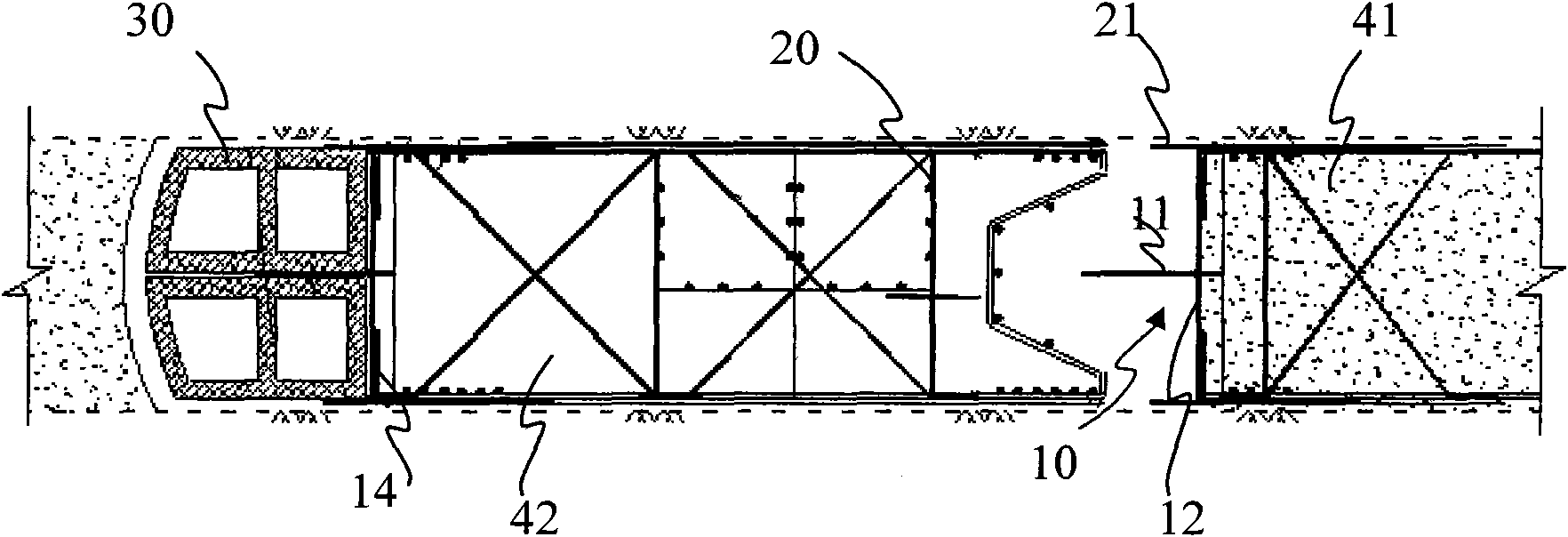

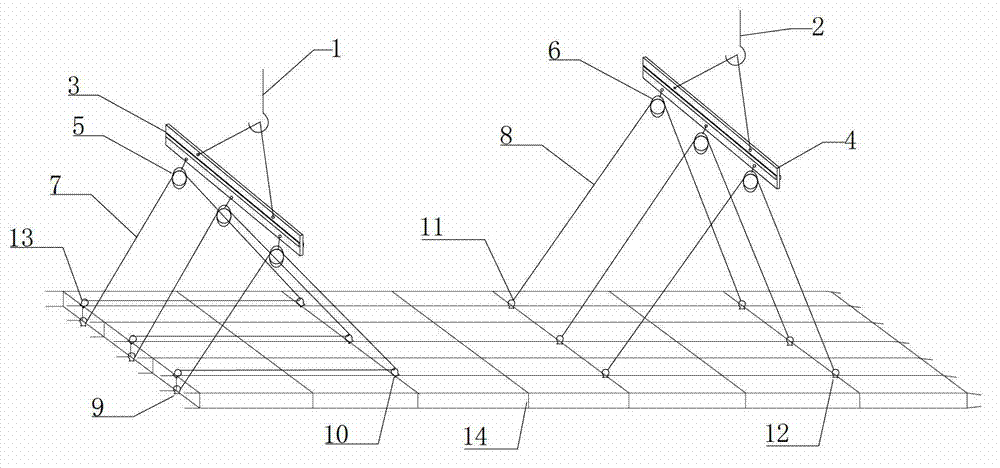

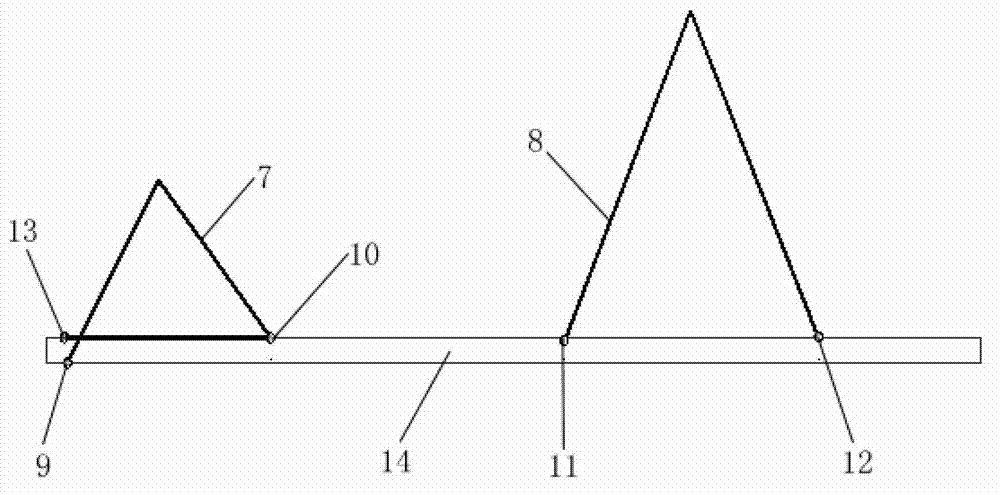

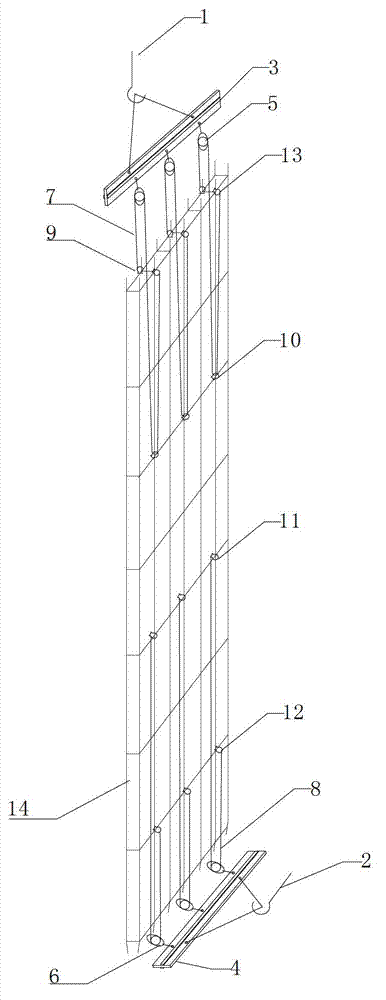

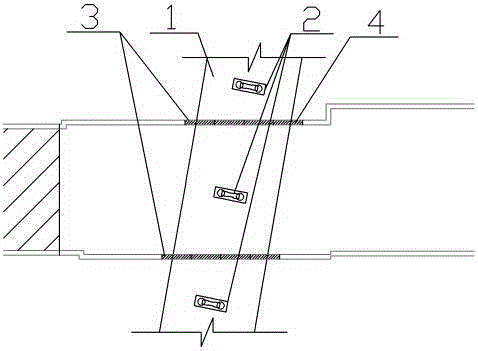

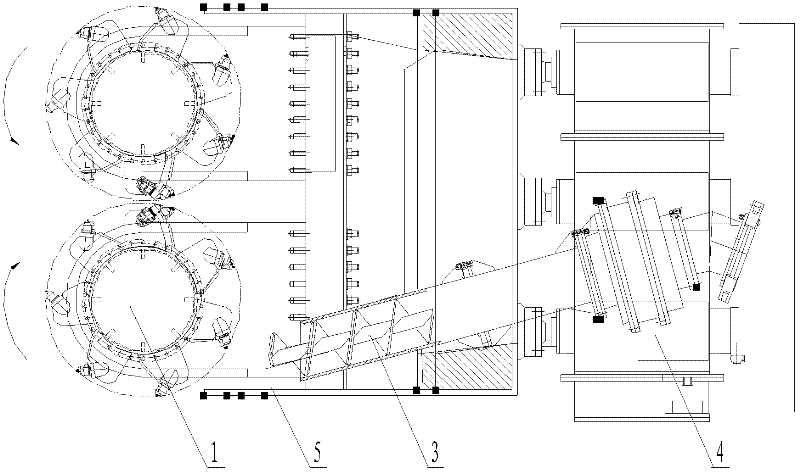

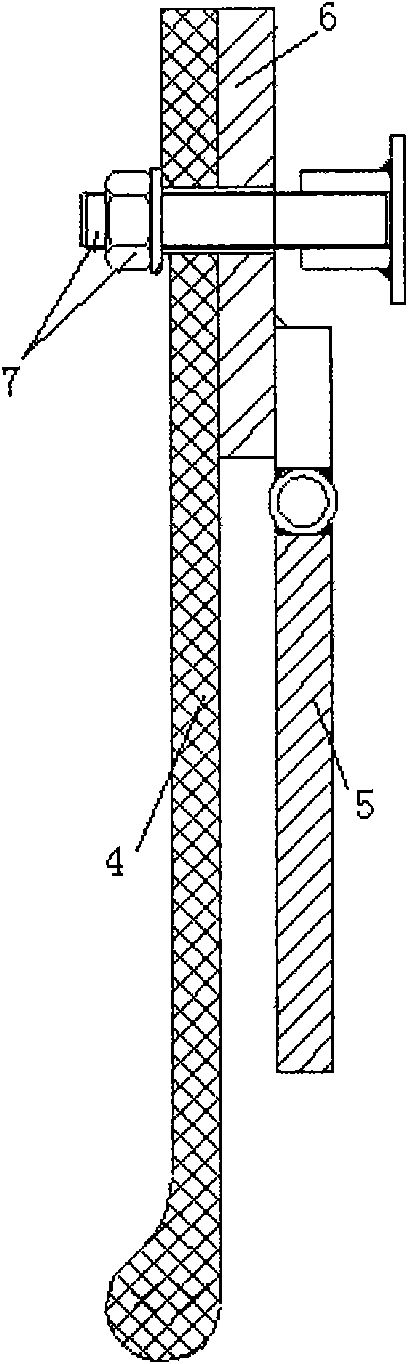

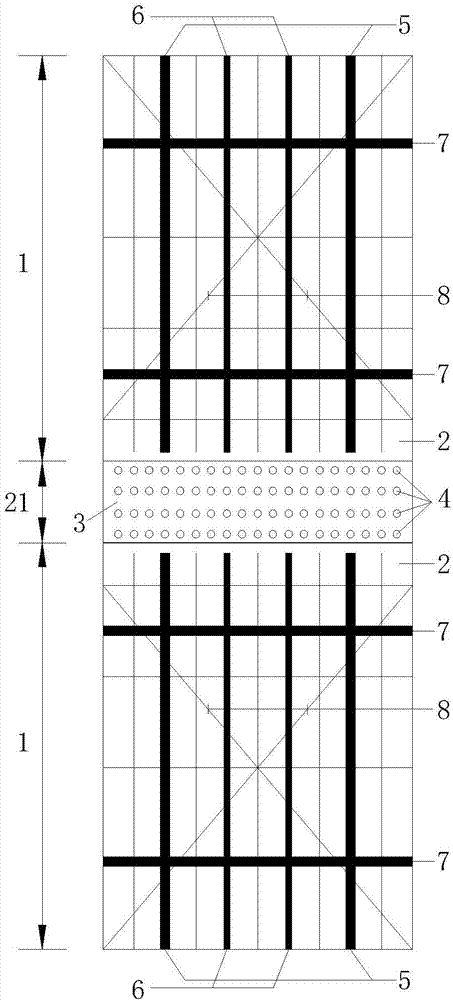

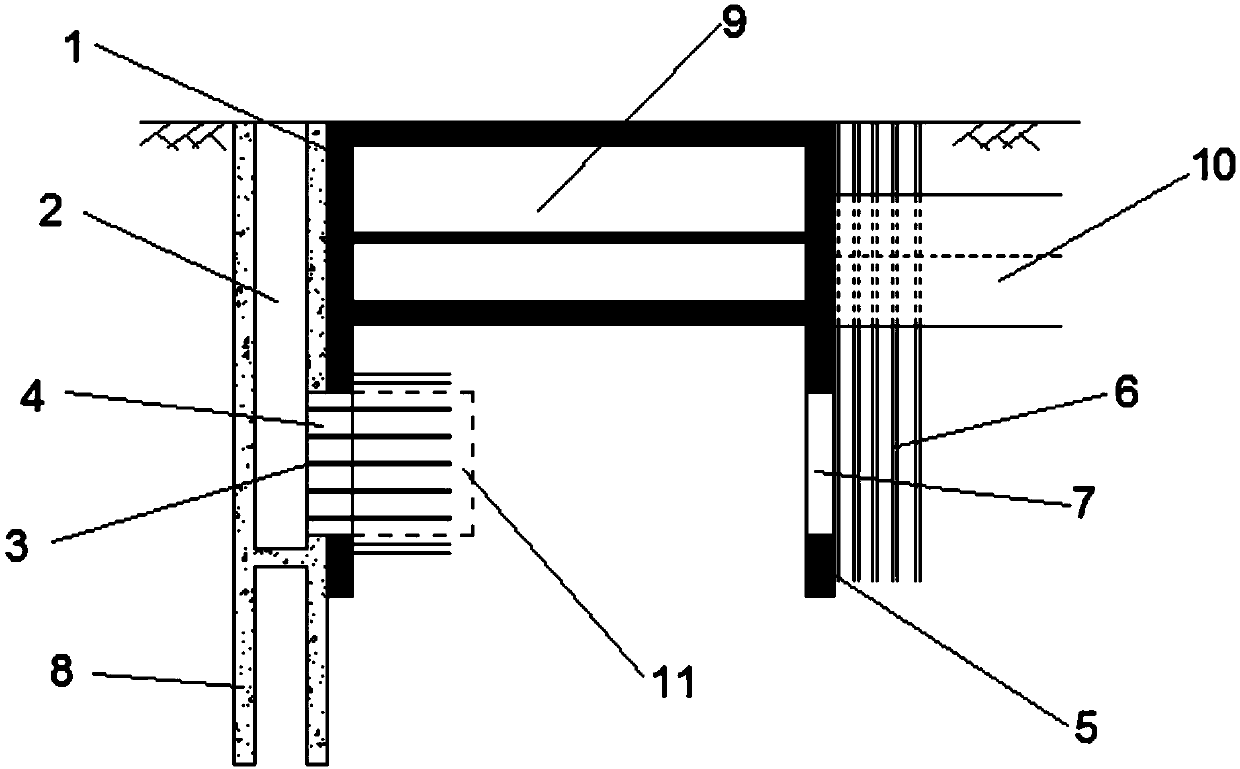

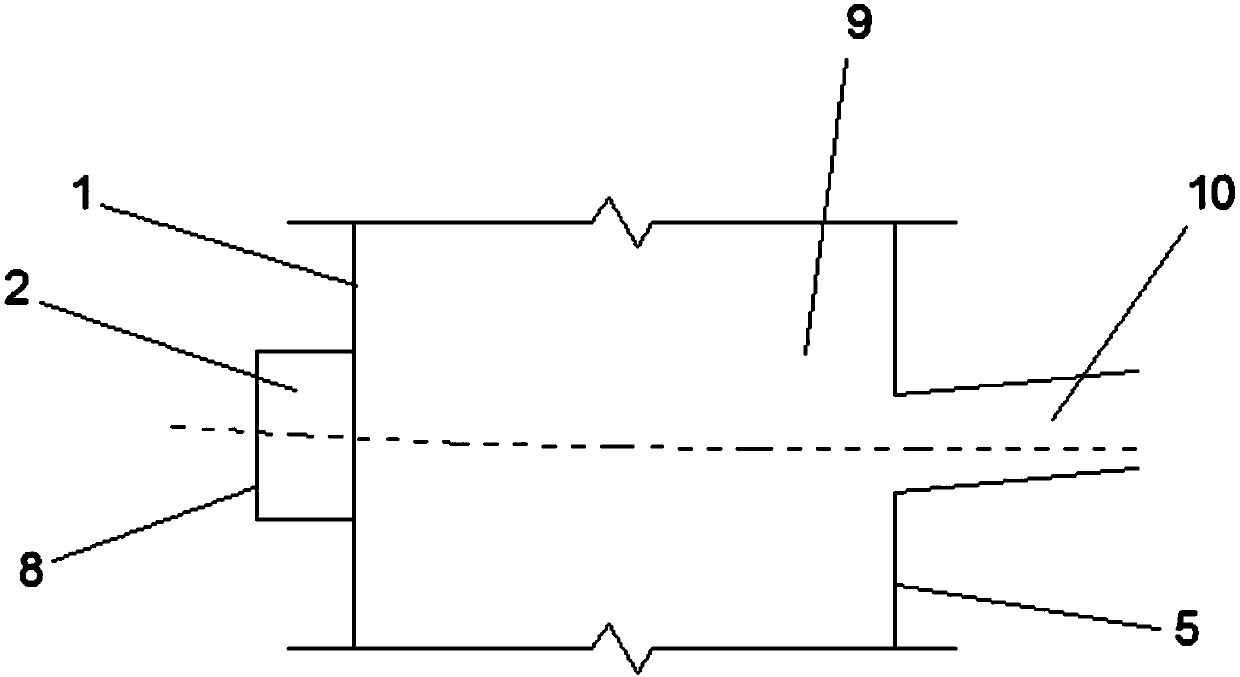

Integral hoisting device and method for super-long steel reinforcement cage of underground continuous wall

ActiveCN103043526AEnsure safetyReduce construction costsLoad-engaging elementsBulkheads/pilesSlurry wallEngineering

The invention relates to an integral hoisting device and method for a super-long steel reinforcement cage of an underground continuous wall. The device comprises a main hoisting device and an auxiliary hoisting device, wherein the main hoisting device comprises a main hoisting hook (1), a main carrying pole beam (3), a main pulley (5), a main hoisting rope (7), a first hoisting point (9), a second hoisting point (10) and a third hoisting point (13); and the auxiliary hoisting device comprises an auxiliary hoisting hook (2), an auxiliary carrying pole beam (4), an auxiliary pulley (6), an auxiliary hoisting rope (8), a fourth hoisting point (11) and a fifth hoisting point (12). The method comprises the following steps: S1, setting the hoisting points on the steel reinforcement cage; S2, installing the main hoisting rope and the auxiliary hoisting rope on the hoisting points and the pulleys; S3, lifting the main hoisting hook and the auxiliary hoisting hook; S4, unhooking the auxiliary hoisting hook, and taking down the auxiliary carrying pole beam and the auxiliary pulley; S5, moving the main hoisting hook, and dismantling the auxiliary hoisting rope; S6, taking down the main hoisting rope from the second hoisting point; and S7, putting down the steel reinforcement cage in place. The device and the method have the advantages of high safety and low construction lost, the hoisting steps is simplified, and the construction efficiency is accelerated.

Owner:CHINA FIRST METALLURGICAL GROUP

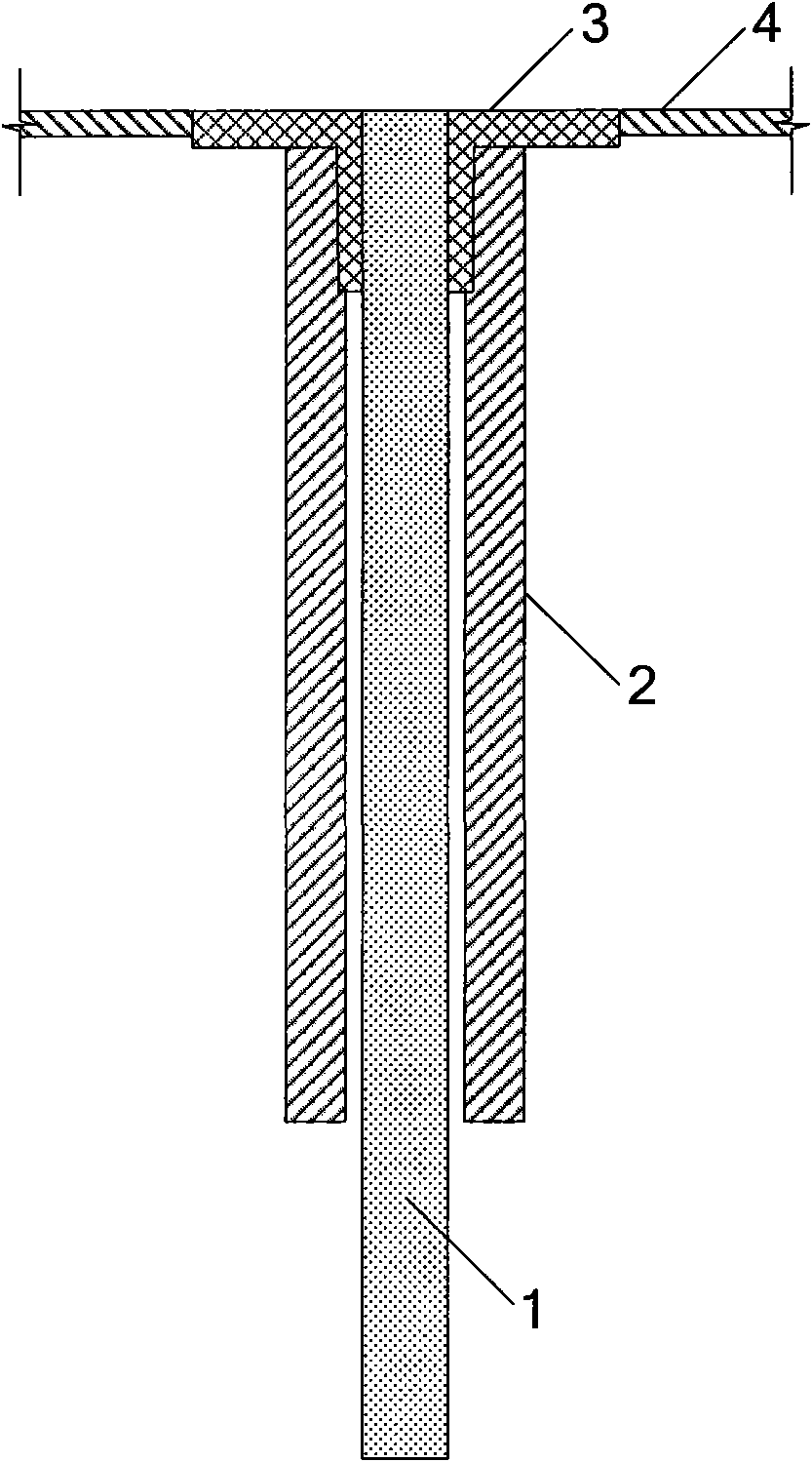

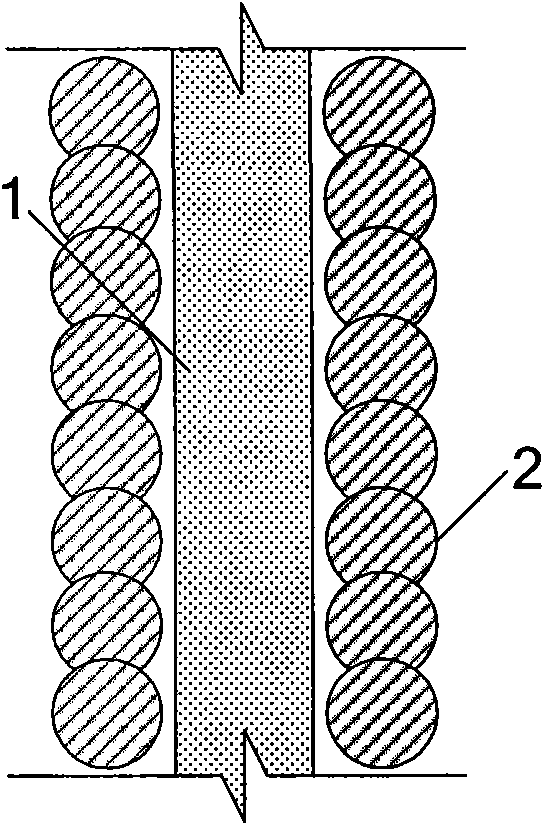

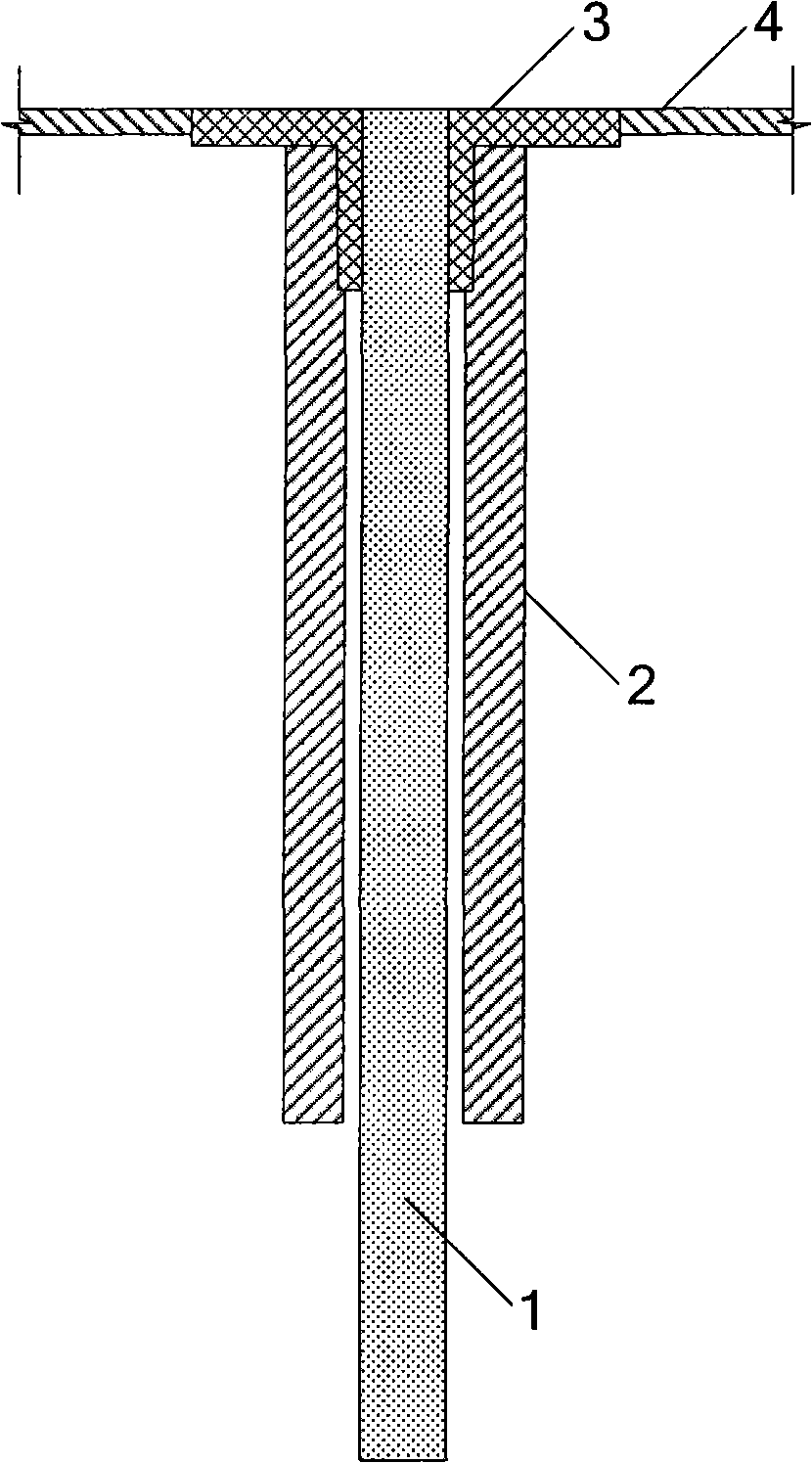

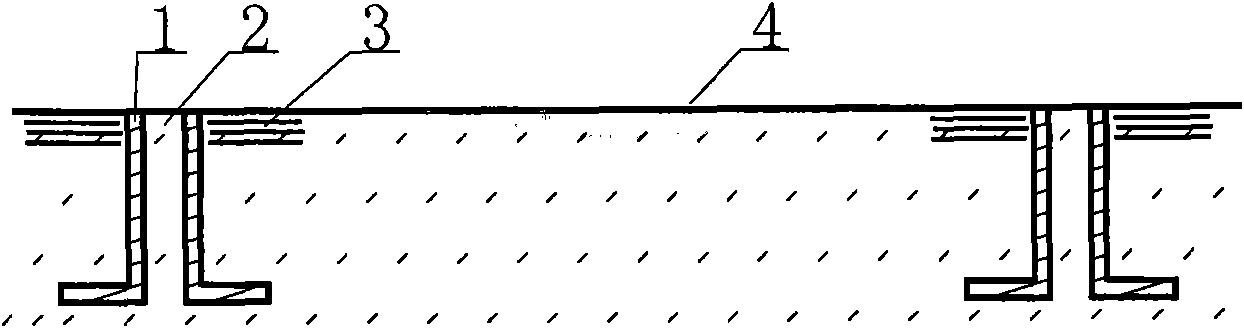

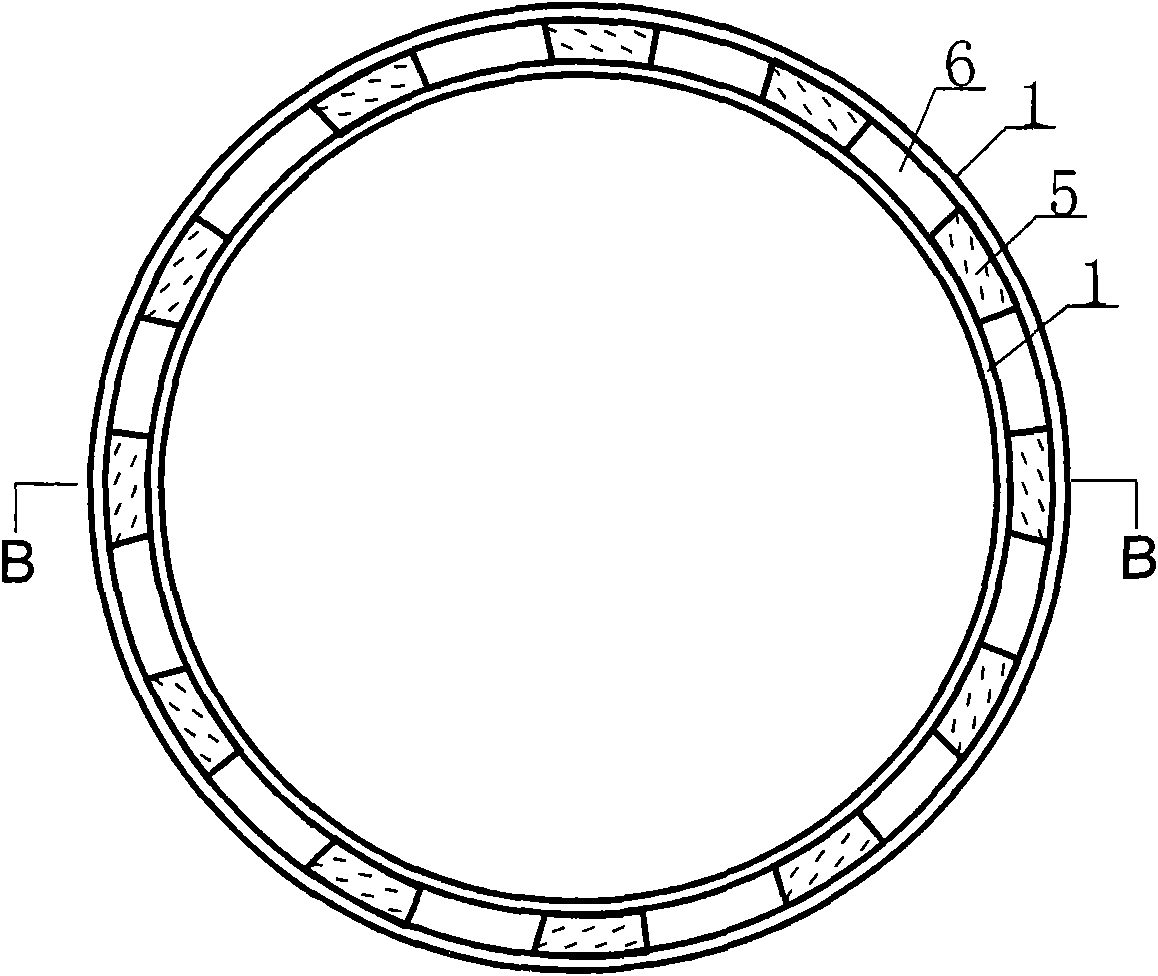

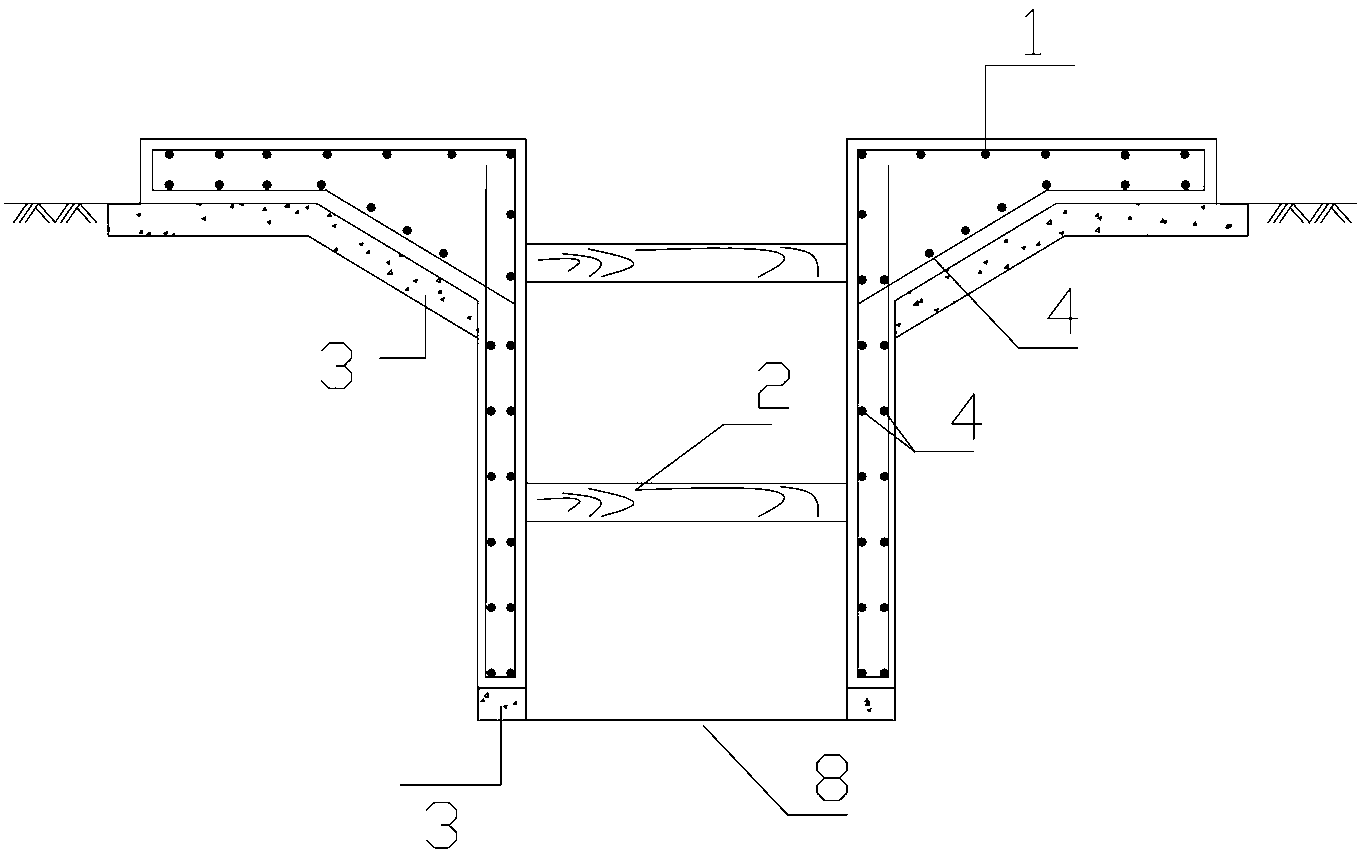

Supporting leg type underground continuous wall construction method

ActiveCN101215834ACut off the water wellImprove impermeabilityArtificial islandsUnderwater structuresLeg typeSlurry wall

A leg type diaphragm wall construction method of the invention belongs to the architecture construction technique field, which comprises: determining each axis control point; constructing guide walls; preparing mud slurry of walls mud for walls protection to stabilize the groove walls; constructing grooves; constructing legs; processing the diaphragm steel reinforcement cage; processing legs steel reinforcement cage which is aligned and connected to the diaphragm steel reinforcement; installing the steel reinforcement cages; selecting joints; installing joints and grouting the underwater concrete guide pipe and cleaning holes; grouting the underwater concrete; uplifting the joint pipe; grouting the wall bottom. The method can be applied in the ground with fluctuating and hard rock surface and in the ground which cannot satisfy the anti-displacement and anti-turning requirements, has good properties of soil and water blocking, anti-seepage and endurance, has positive action on the super-deep foundation pit bearing and enclosing with high economy benefit, and can greatly save cost with small noise and pollution compared with the whole diaphragm wall construction.

Owner:浙江省建投交通基础建设集团有限公司 +2

Construction method of underground continuous wall below viaduct

The invention relates to a construction method of an underground continuous wall below a viaduct. The method specifically includes the first step of staking out in a survey, the second step of guiding wall manufacturing, the third step of width adjustment of the underground continuous wall, the fourth step of slurry preparation, the fifth step of grooving construction, the sixth step of reinforcement cage manufacturing, hoisting and releasing, the seventh step of concrete grouting, the eighth step of repeatedly executing the fifth step, the sixth step and the seventh step till construction of a to-be-formed single-width undergrou nd continuous wall construction unit ends, and the ninth step of underground continuous wall joint processing. By means of the construction method, construction of the underground continuous wall can be fast completed while the quality and the quantity are guaranteed, and a viaduct pier will not be affected. Compared with a cast-in-situ bored pile construction method, the construction method has the beneficial effects that construction speed is high in the construction progress, stratum disturbance is small, and therefore the influences on the viaduct pier are small.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

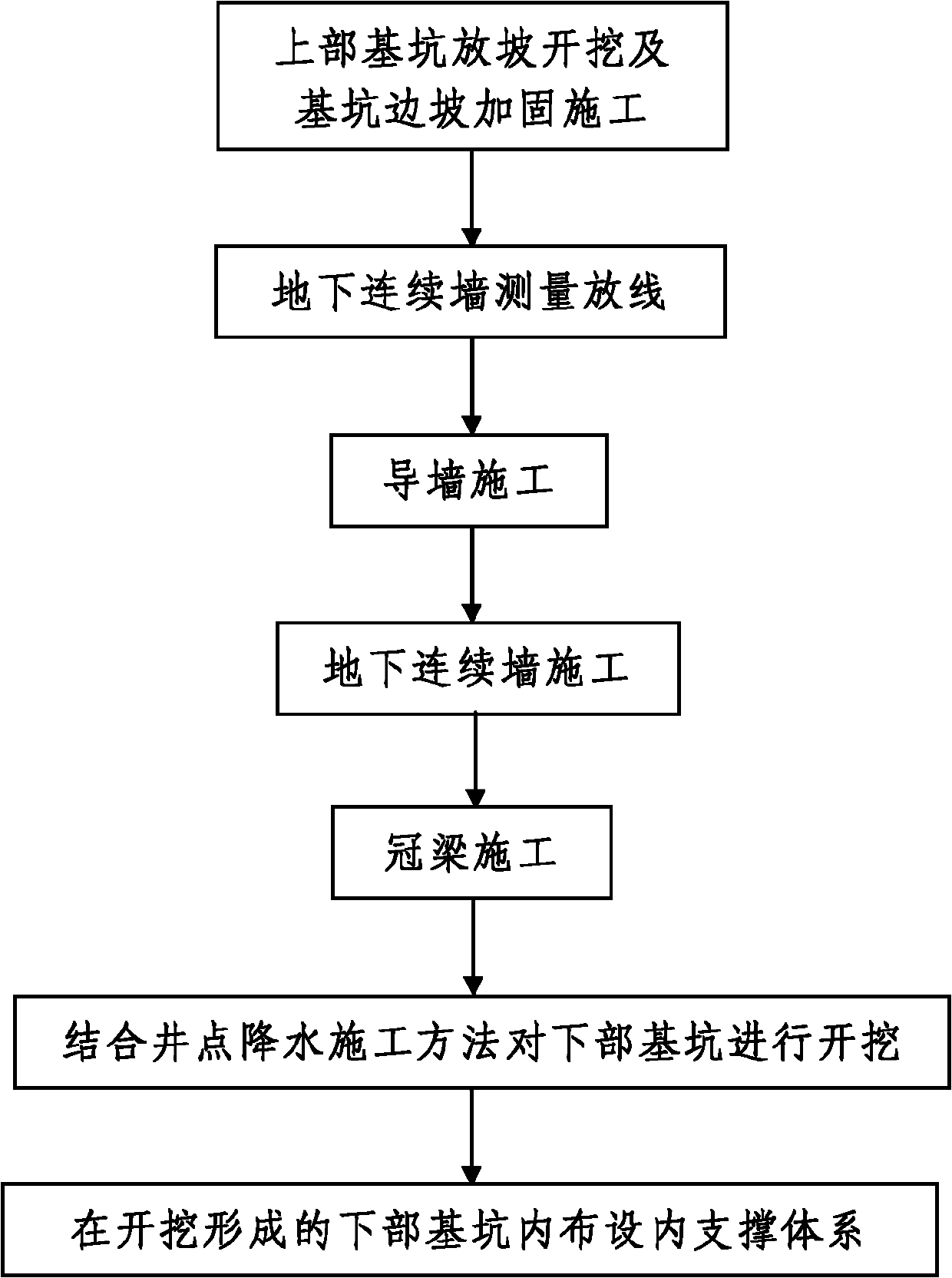

Construction method for underground diaphragm wall of deep foundation pit for subway station in collapsible loess areas

InactiveCN102322064AReasonable designSimplify construction stepsArtificial islandsExcavationsSlurry wallSubway station

The invention discloses a construction method for an underground diaphragm wall of a deep foundation pit for a subway station in collapsible loess areas. The constructed station deep foundation pit for the subway station is divided into an upper-part foundation pit and a lower-part foundation pit from top to bottom; the building enclosure of the lower-part foundation pit is the underground diaphragm wall; and the upper-part foundation pit is a foundation pit formed by slope excavation. The construction method disclosed by the invention has the following steps of: (1) construction for upper-part foundation pit slope excavation and foundation pit slope reinforcement; (2) construction for lower-part foundation pit building enclosure: surveying and paying off, guide wall construction and underground diaphragm wall construction; and (3) construction for cap beam, and then carrying out excavation on the lower-part foundation pit through combining a well-point dewatering construction method and arranging a bracing system in the excavated lower-part foundation pit. The construction method disclosed by the invention has the advantages of reasonable design, simplicity and convenience for construction, safety and reliability for construction and good construction effect, high construction quality and capability of effectively solving the practical problems, such as high difficulty for construction, complicated construction procedure, difficulty for ensuring the construction quality of deep foundation pits and the like, in a process of constructing the deep foundation pits for subway stations in the collapsible loess areas.

Owner:CHINA RAILWAY 20 BUREAU GRP

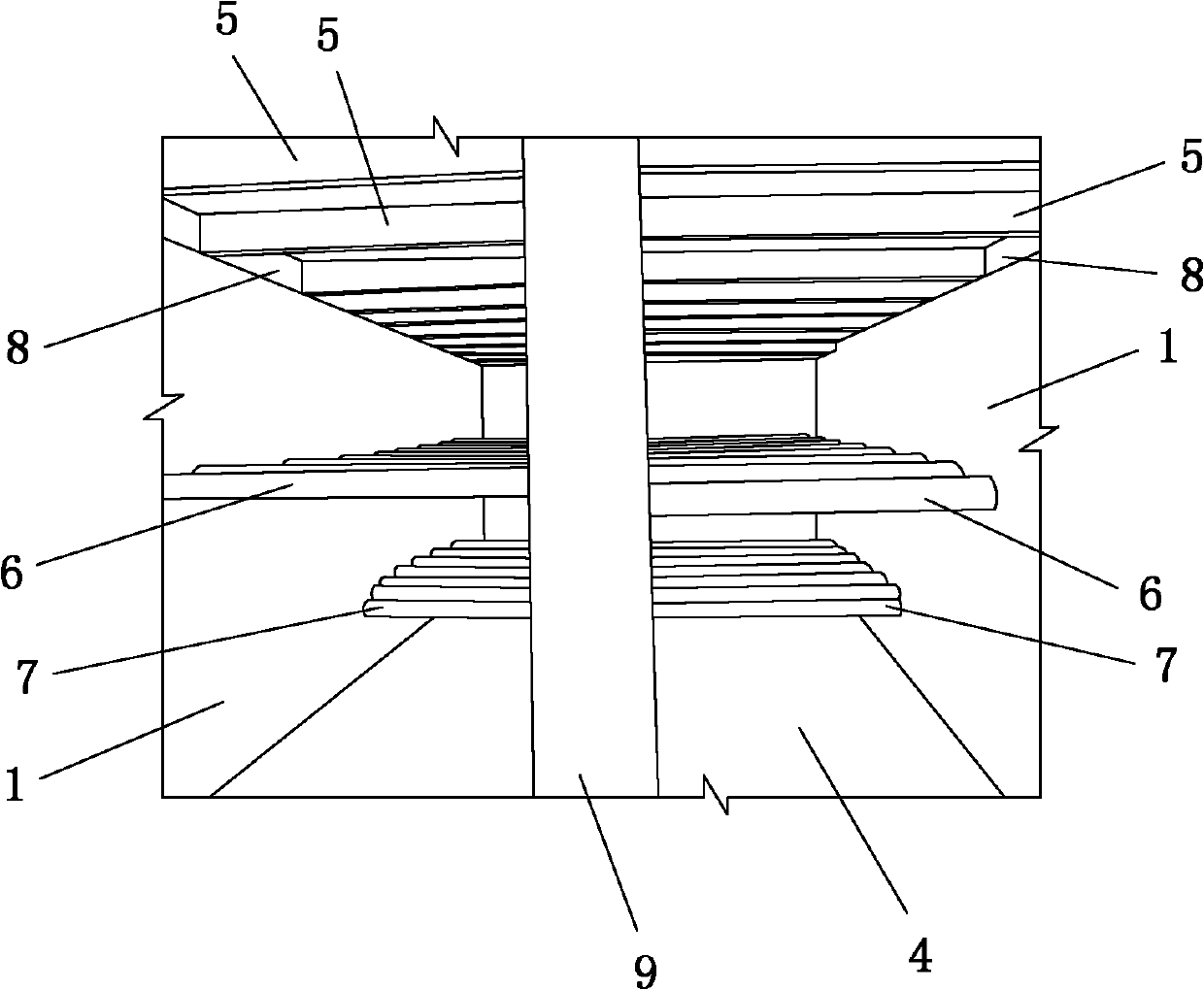

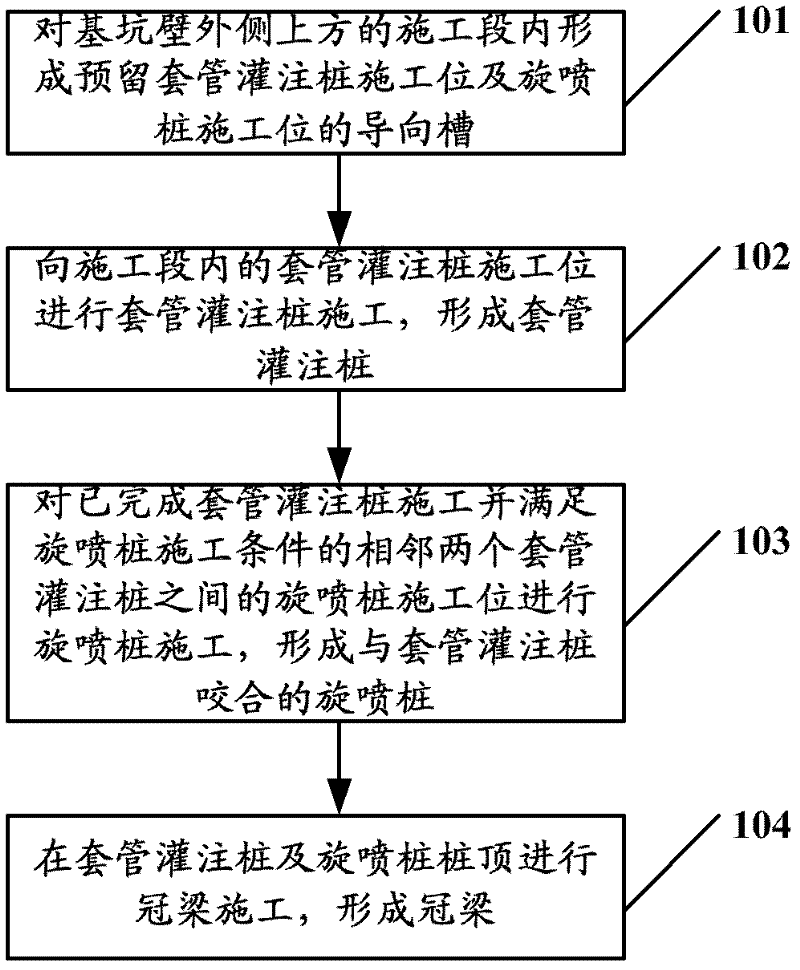

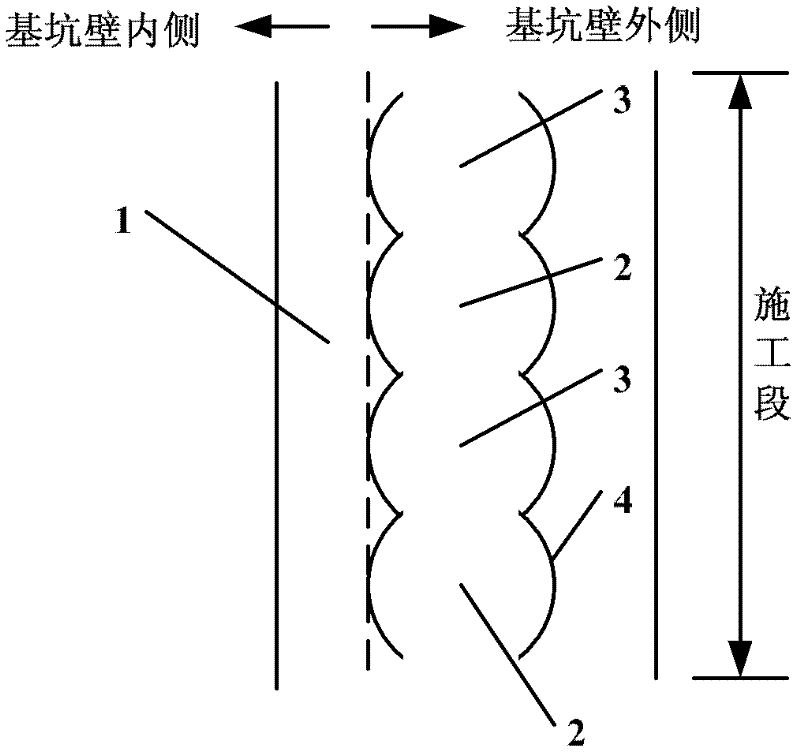

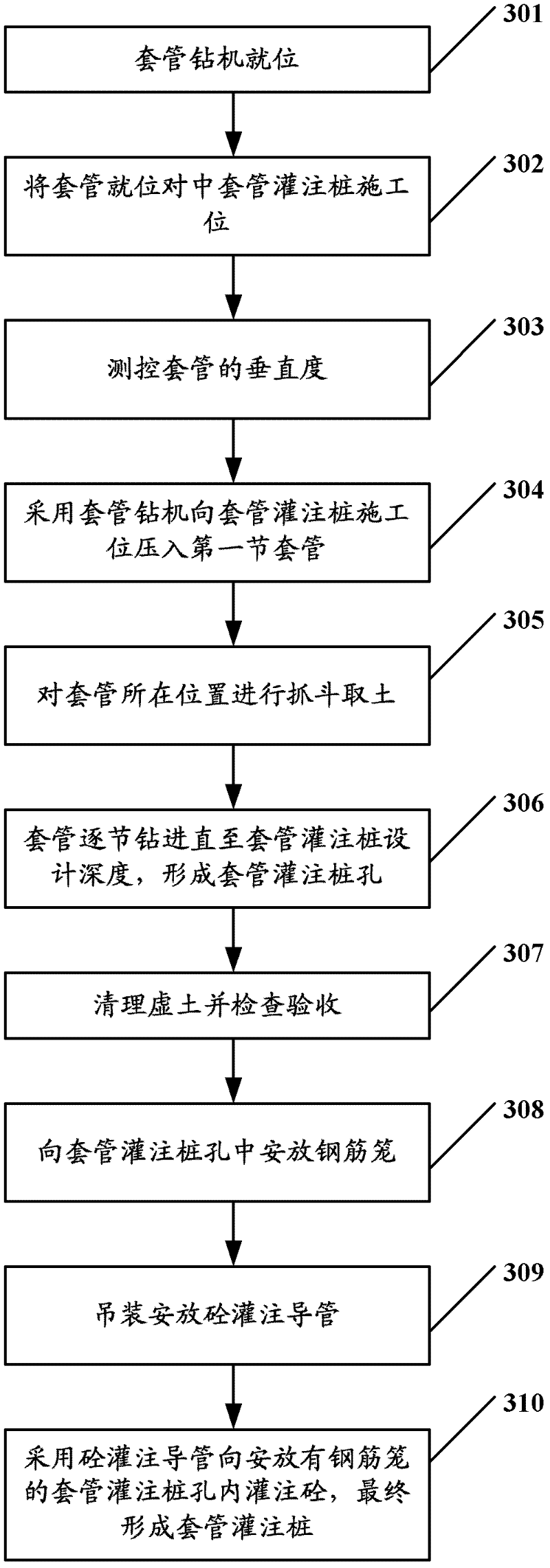

Waterproof curtain and construction method thereof

InactiveCN102286984APrevent water seepagePrevent water leakageBulkheads/pilesSlurry wallReinforced concrete

In the embodiment of the present invention, the water-stop curtain is formed on the outside of the foundation pit wall by the jointing of the casing grouting pile and the rotary grouting pile, and the bending resistance performance of the casing grouting pile and the water-stopping performance of the rotary grouting pile are fully utilized; the present invention can achieve wall The whole length of the body is seamlessly constructed, which can effectively prevent problems such as water seepage, water leakage, and quicksand in the foundation pit, and can effectively prevent common quality problems of other types of punching and drilling piles such as collapse holes and necking; the full-casing drilling rig is used to complete the hole piles, the earthwork excavation process will not damage the surrounding soil structure and the operation is safe, there is no mud pollution during the construction process, and the reinforced concrete piles formed by pouring are neat and regular; the earthwork excavation volume is lower than that of traditional punching and drilling piles and underground diaphragm wall technology Less, the impact of construction on the surrounding environment and pollution is small; the construction speed is faster and the cost is lower than the traditional underground diaphragm wall and drilled occlusal pile; the construction can be divided into multiple construction sections without causing leakage at the interface of the construction section , It is easy to form a flow construction operation, which improves the construction efficiency.

Owner:深圳市鸿荣轩建设工程有限公司 +1

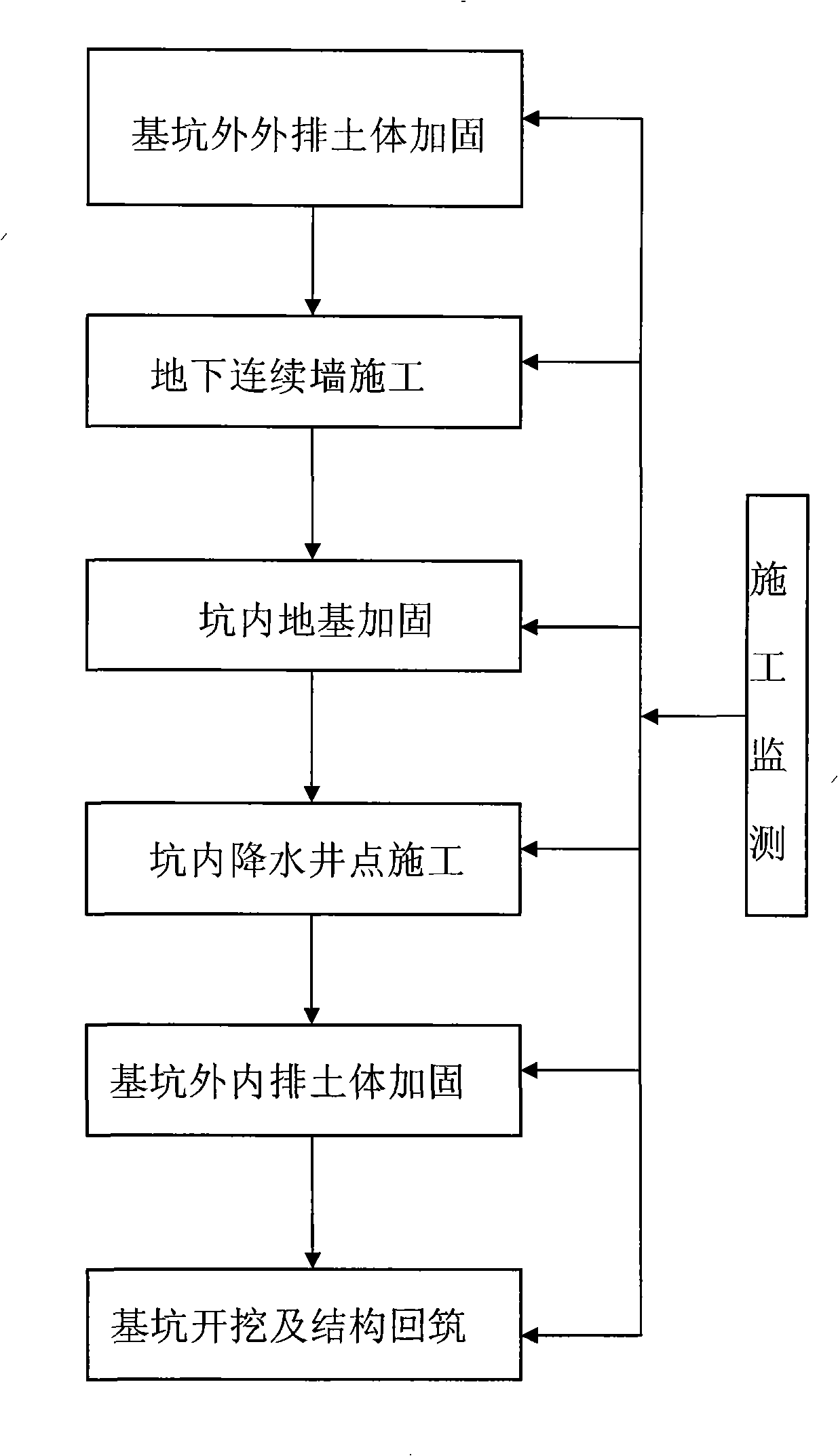

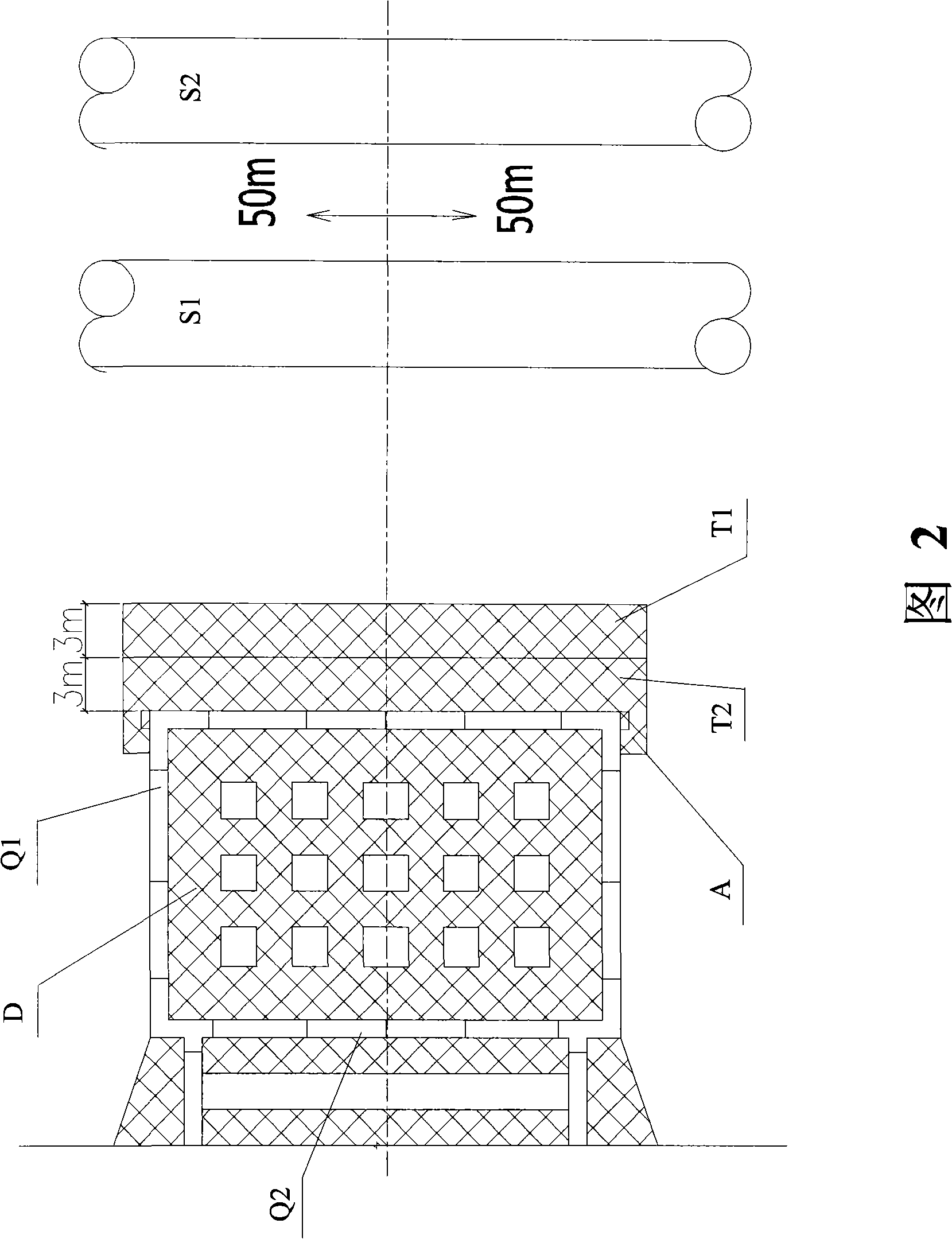

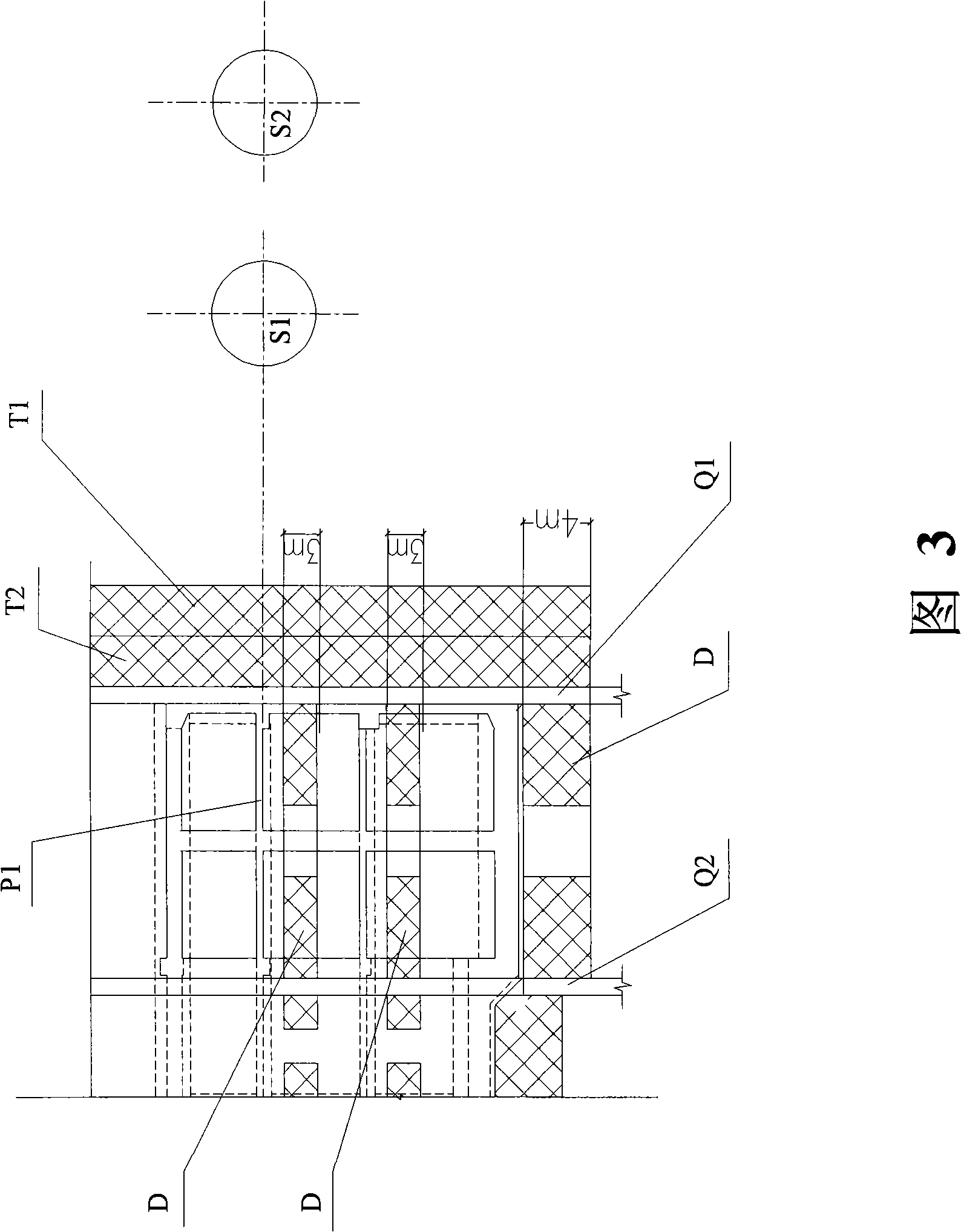

Station pit construction method forming protection for neighboring operated subway interval tunnel

InactiveCN101280568AReduce the impactIncrease stiffnessArtificial islandsUnderground chambersSlurry wallSubway station

The invention discloses a method for constructing foundation pits for a station which can protect the adjacent running tunnel of operating subways, which comprises the steps of constructing underground continuous wall, reinforcement of the foundation in the pits, constructing precipitation well points in the pits, excavating the foundation pits, structure reconstruction, reinforcement of outer row of soil outside the foundation pits and reinforcement of inner row of soil outside the foundation pits. The construction of the underground continuous wall adds the construction of sealing wall; the excavation of the foundation pits and the structure reconstruction adopt a top-down method below the medium plate of the foundation pits corresponding to where the adjacent running tunnel is buried deeply and a bottom-up method over the medium plate; the reinforcement of outer row of soil outside the foundation pits is to reinforce the soil between the foundation pits and the adjacent running tunnel and 3m far away from the foundation pits; and the reinforcement of inner row of soil outside the foundation pits is to reinforce the soil between the foundation pits and the adjacent running tunnel and within 3m from the foundation pits. The method of the invention adopts comprehensive protection measures during the whole process of construction, thereby protecting the adjacent running tunnel of operating subways overall and reducing the effect on the adjacent running tunnel of operating subways to the utmost extent during constructing a subway station.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

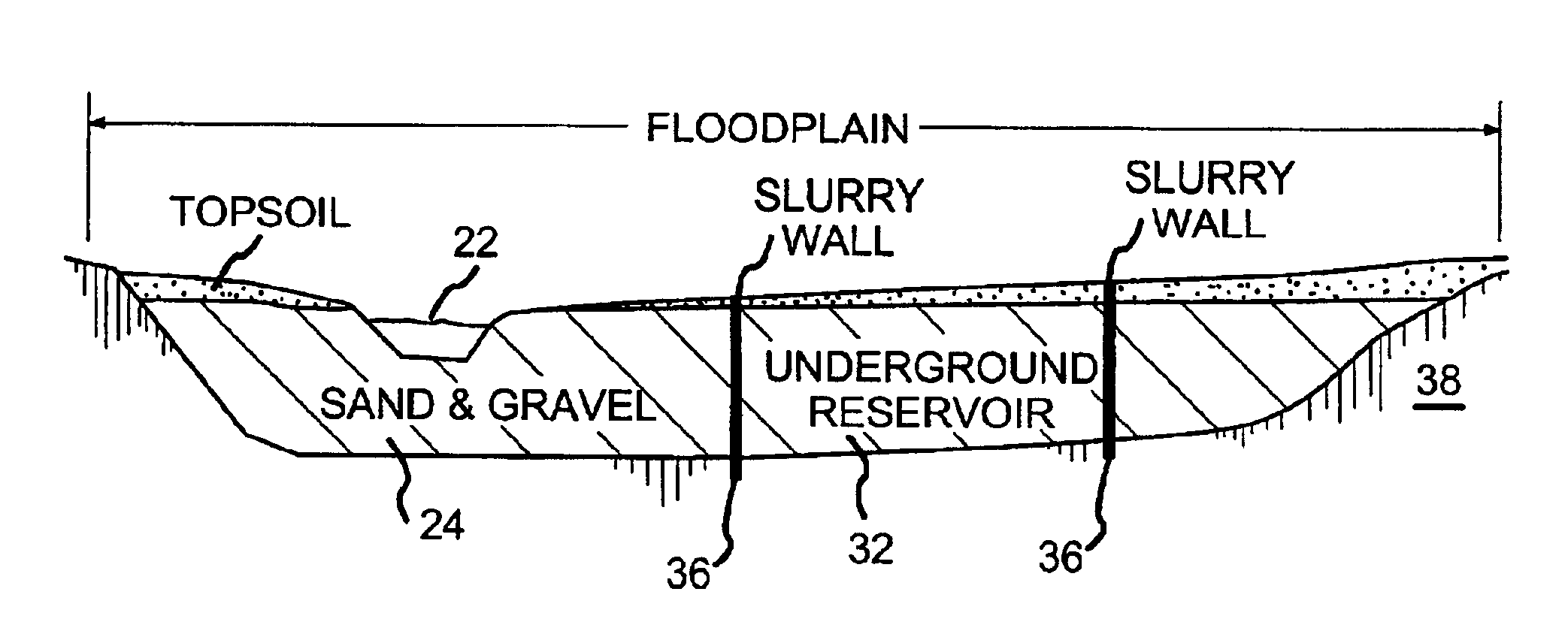

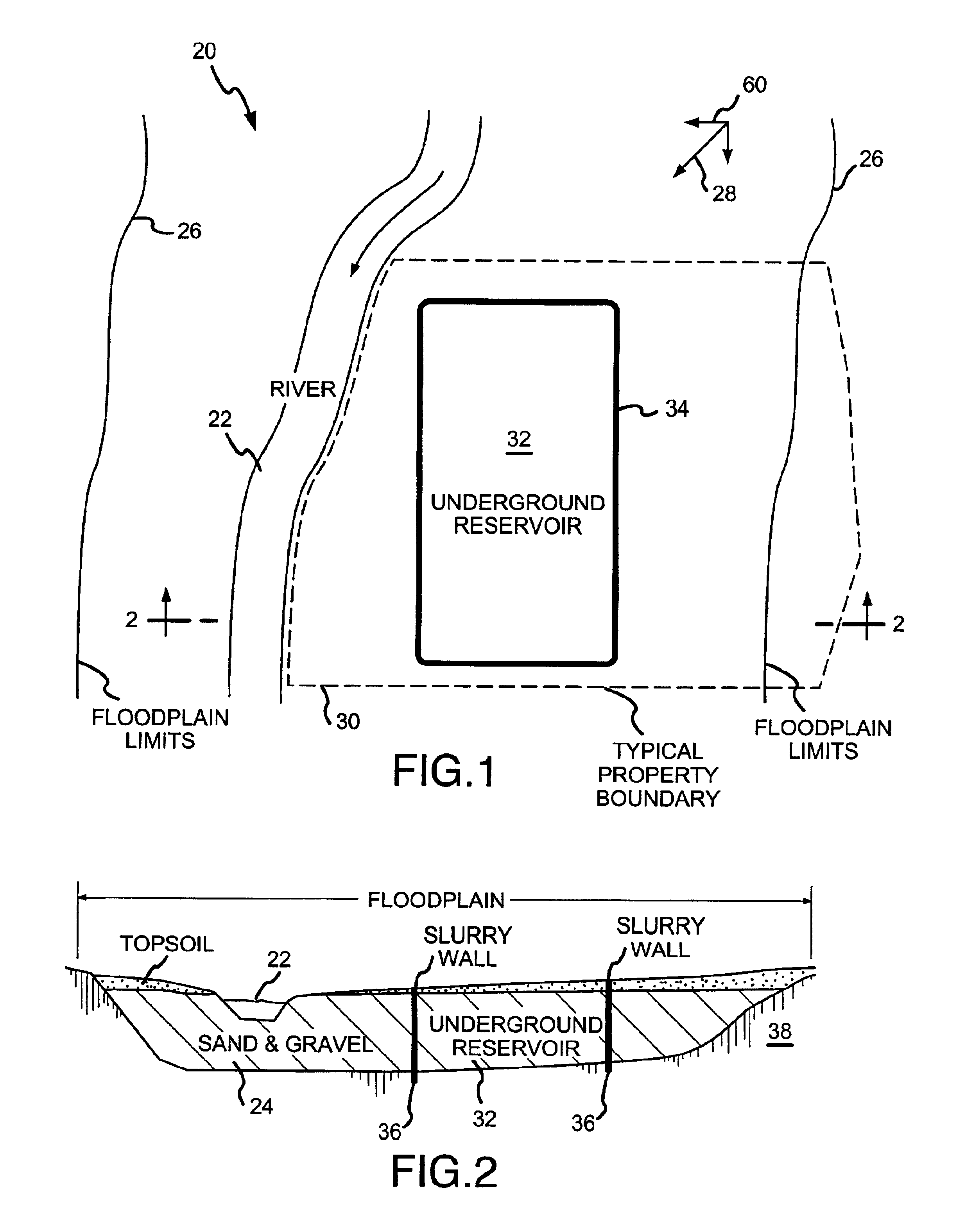

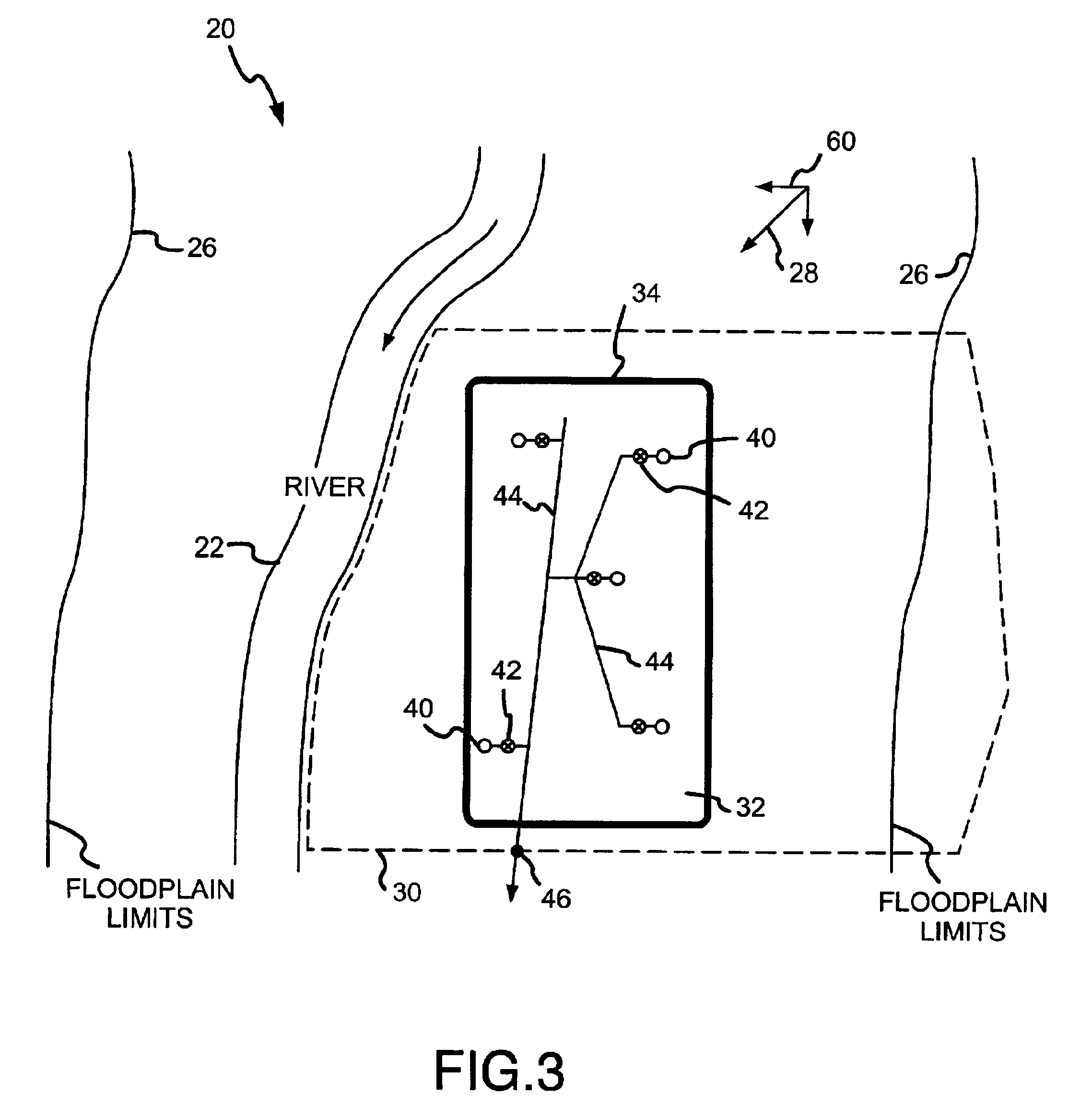

Underground alluvial water storage reservoir and method

InactiveUS6840710B2Reduce the impactFast chargingWater supply tanksWater conservationWater storageSlurry wall

An underground reservoir for storing water in alluvial deposits utilizes slurry walls keyed to an aquiclude beneath the reservoir to form a substantially impermeable water seal. A variety of water extraction / recharge apparatus provides for rapid and complete filling and draining of the underground reservoir. Such apparatus includes a plurality of wells distributed about the underground reservoir and a series of perforated pipes buried at a predetermined depth within the underground reservoir. A method of mitigating water table fluctuations resulting from the construction of an underground utilizes perforated pipes buried outside of the reservoir to transfer excess water from an uphill land parcel to a downhill land parcel that would otherwise experience a water shortage after construction of the underground reservoir.

Owner:RAR GROUP

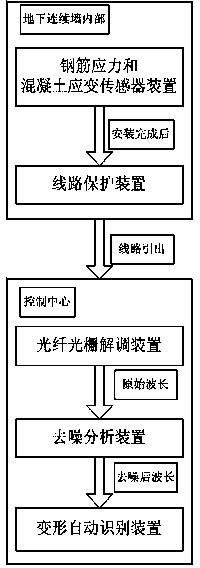

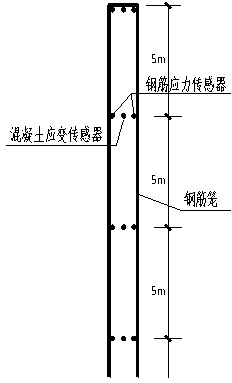

Super deep underground diaphragm wall deformation automatic real-time monitoring device and operating method thereof

ActiveCN103758160AOptimize and adjust the excavation stepsOptimizing and adjusting excavation parametersFoundation testingSlurry wallGrating

The invention belongs to the field of foundation pit engineering, and provides a super deep underground diaphragm wall deformation automatic real-time monitoring device and an operating method thereof. The monitoring device comprises a fiber grating reinforced stress sensor, a fiber grating concrete strain sensor, a denoising analyzing device and an automatic deformation recognizing device. By the aid of the monitoring device and the operating method thereof, horizontal deformation of an underground diaphragm wall can be tracked and monitored in real time, deforming data can be automatically collected and analyzed, real-time capacity, continuity, effectiveness and reliability of monitoring can be guaranteed, processing efficiency of monitoring data of horizontal deformation of the underground diaphragm wall can be improved, and information sharing level of monitoring data of horizontal deformation of the underground diaphragm wall can be raised, the deformation of foundation pits is guaranteed in a controllable range, constructing risks of deep foundation pits can be reduced, and references can be provided for similar foundation pit engineering.

Owner:HUAZHONG UNIV OF SCI & TECH

Thickener for excavating slurry, excavating slurry using the the thickener, and cast-in-place underground pile work method and underground continuius wall work method using the excavating slurry

InactiveUS20040121916A1Reduce the presence of air bubblesConstruction works can be stably conductedEmbankmentsExcavationsSlurry wallEmulsion

Subjects for the present invention are to provide a thickening agent for excavation stabilizing slurries which has excellent cement contamination resistance, is difficult to putrefy, and is prevented from bubbling, which may be problematic in construction works, and to provide an excavation stabilizing slurry containing the thickening agent and a cast-in-place underground pile method and an diaphragm wall construction method each using the slurry. The present invention provides a thickening agent for excavation stabilizing slurries which contains an emulsion thickening with an alkali, wherein in a strong agitation bubbling test of a mixture prepared by adding an alkaline substance to the thickening agent, the resulting mixture has an apparent specific gravity of 1.05 g / ml or higher as measured immediately after the strong agitation and has an apparent specific gravity of 1.10 g / ml or higher as measured at 10 minutes after the strong agitation. This thickening agent is used to prepare an excavation stabilizing slurry.

Owner:NIPPON SHOKUBAI CO LTD

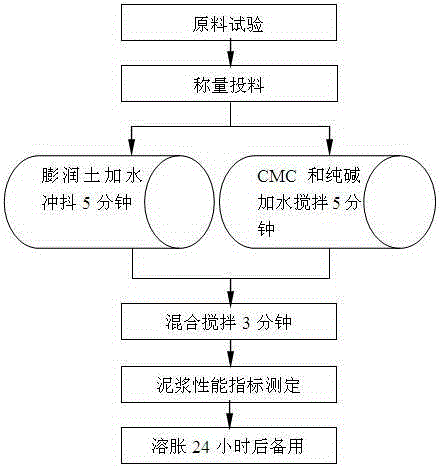

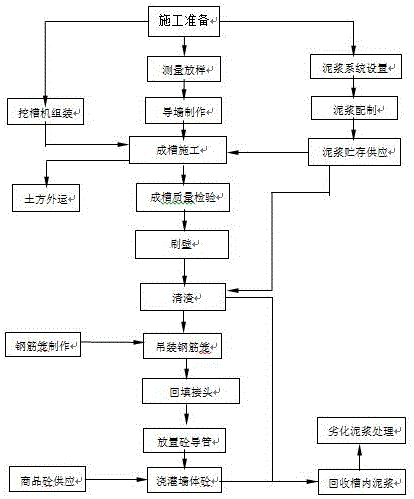

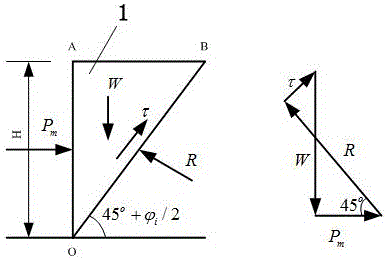

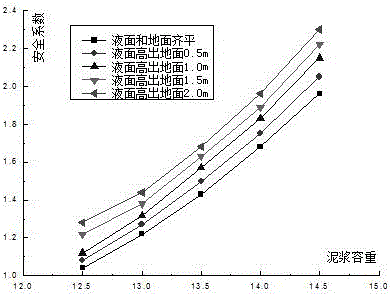

Construction method of ultra-deep underground diaphragm wall in water-rich soft-soil area

InactiveCN106381866AGuaranteed Stability RequirementsIn line with the habitBulkheads/pilesSlurry wallEngineering

The invention relates to the technical field of civil engineering construction, in particular to a construction method of an ultra-deep underground diaphragm wall in a water-rich soft-soil area. The construction method comprises the following steps: making an analysis and research on the stability of trench walls of the underground diaphragm wall and doing relevant preparations, preparing wall protecting slurry, building a guide wall, performing trenching construction, wall cleaning and sediment removal, manufacturing and hoisting reinforcing cages, backfilling joints between trench sections, and pouring wall concrete. According to the construction method, through a stability analysis method that introduces strength reduction, the security coefficients of stability of the trench walls are calculated based on a finite difference method; through parameter-reduction circular calculations, not only the limit stress and large deformation state of the trench walls but also the stability coefficients of the trench walls are obtained, which has practice guiding significance in construction; and the results are simple and practical and conform to the habits in the engineering field, and the stability requirements of the trench walls are effectively guaranteed, so that the engineering construction can be completed safely and fast with high quality.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Construction method of foundation pit support

The invention discloses a construction method of foundation pit support. The construction method is characterized in that underground continuous walls around a foundation pit and temperature vertical columns in the foundation pit are used as a vertical bearing system, beam plates of structural layers of a basement are used as an inner support for the foundation pit support, an underground structure is constructed from top to bottom by using + / - 0.00 or the first underground floor as a starting face, an upper main structure is constructed simultaneously from bottom to top, and an upper-lower parallel three-dimensional operation is achieved; in order to facilitate earth excavation and vertical transportation, concrete pouring of a ribbed beam part of an underground floor system can be performed firstly to form a horizontal framework inner support, and floor concrete is poured after a basic base plate is completed; the underground continuous walls serve as a support structure and structural outer walls of the basement, and the underground continuous walls and steel vertical columns inserted into engineering piles form the vertical bearing system during construction; the floor the of the basement supports the underground continuous walls, and a large earth outlet hole is reserved in the plane of the floor.

Owner:李学波

Roller type cutter rectangular pipe jacking machine

The invention relates to a roller type cutter rectangular pipe jacking machine, which comprises a cutter, a cutter driving system, a spiral mechanical unearthing system, a hydraulic propulsion system and a rectangular shell. The cutter adopts a composite formation roller type cutter, is sleeved on the cutter driving system and is driven by the cutter driving system to rotate, the composite formation roller type cutter comprises a plurality of ordinary tools, a swinging tool and an over-excavation tool, a cutter shell adopts a round tubular component, the inner wall of the cutter shell is provided with a separating wall vertical to the axial line of the cutter shell, the ordinary tools are uniformly and fixedly arranged on the outer wall of the cutter shell, the swinging tool is hinged on the inner side of the outer wall of the cutter shell through a pin shaft and can rotate around the pin shaft, and the over-excavation tool is fixedly arranged on the outer side of the outer wall of the cutter shell. The invention has the advantages of high adaptability to formations and high tunneling efficiency. Meanwhile, construction risks can be reduced greatly, construction safety can be ensured, and the machine can adapt to construction of slightly weathered rock formations, composite formations, backfilled formations, continuous walls through the ground, pile foundations and other complex formations and working conditions.

Owner:上海盾构设计试验研究中心有限公司 +1

Construction method for putting tunnel shield into hole in special stratum

The invention relates to a construction method for putting a tunnel shield into a hole in a special stratum, which is characterized by comprising the following steps: before putting the tunnel shield into the hole, approaching the tunnel shield to a tunnel portal gradually; injecting a bi-liquid grout into a soil layer of an external layer; chiseling off thick underground continuous wall concretein a steel ring of the tunnel portal; performing ground vertical sectional probe hole detection; welding a prepared double-layer spring steel plate on the steel ring of the tunnel portal; arranging ahole-entering device on the outer side of the steel ring of the tunnel portal; cutting internal arranged steel bars of an underground continuous concrete wall; pushing the tunnel shield into the holewithout a concrete protective layer; and injecting the bi-liquid grout again at a seam between reinforced soil and unreinforced soil bodies, wherein when the tunnel shield is put into the hole, the double-layer spring steel plate and the hole-entering device are clung to the shell of a tunnel shield machine, the tunnel shield is not pushed when the head of the tunnel shield machine enters a rubber cord fabric board, and a single fluid or the bi-liquid grout is injected into the soil layer of the external layer for replenishing grout. The construction method has the advantages of ensuring thatthe tunnel shield is safely put into the hole in the special stratum, reducing the soil loss, controlling land subsidence well and effectively protecting underground pipelines at the hole-entering part by adopting an internal and external combination measurement.

Owner:SHANGHAI MECHANIZED CONSTR GRP

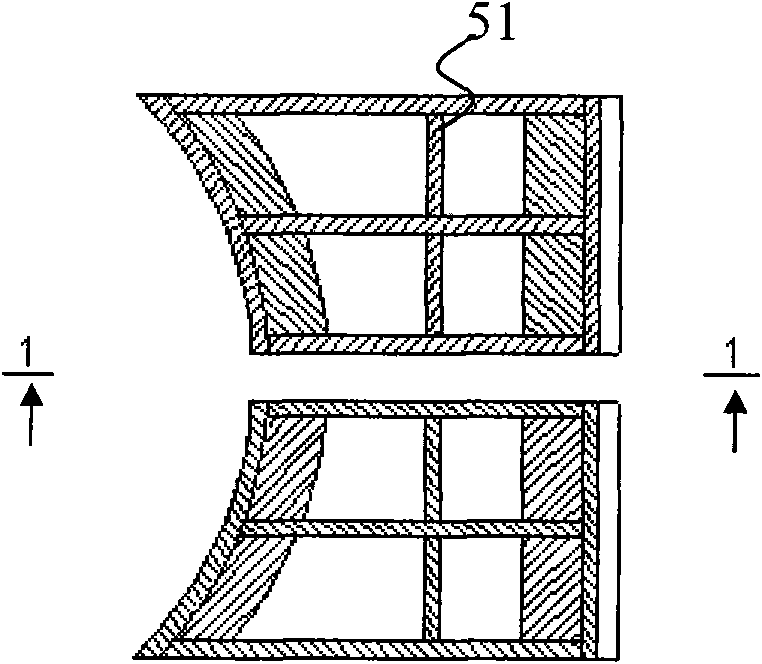

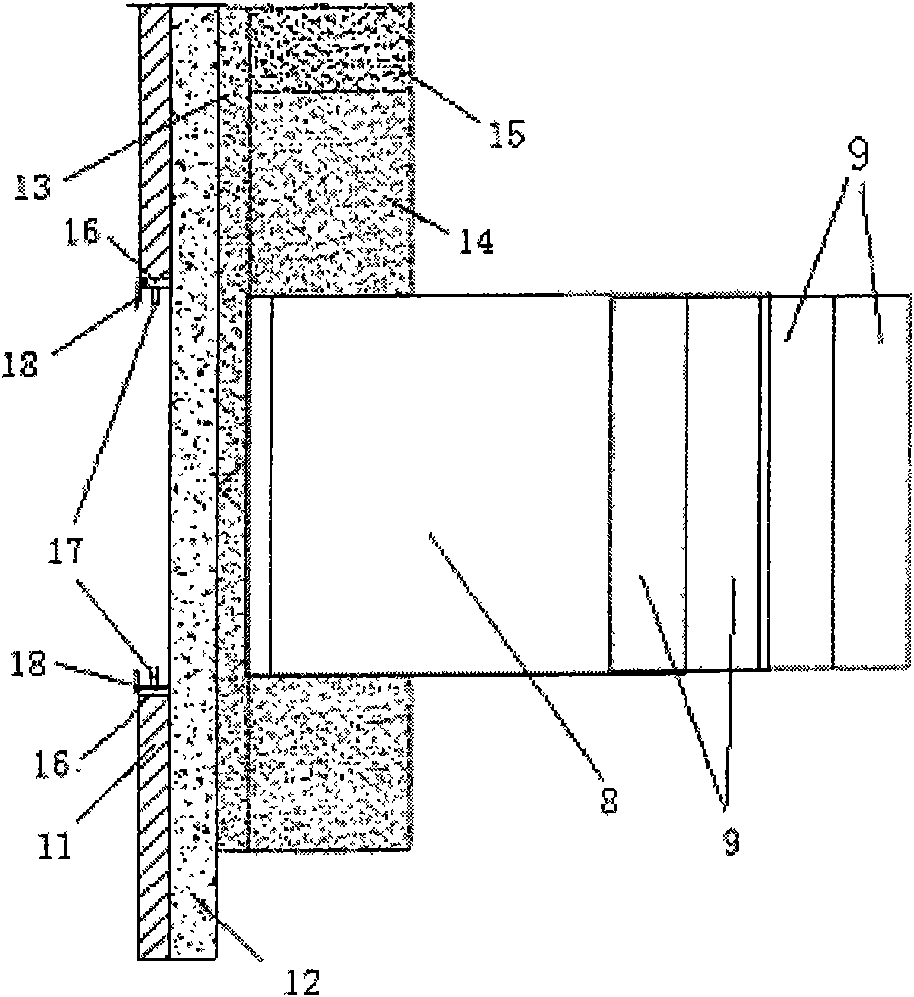

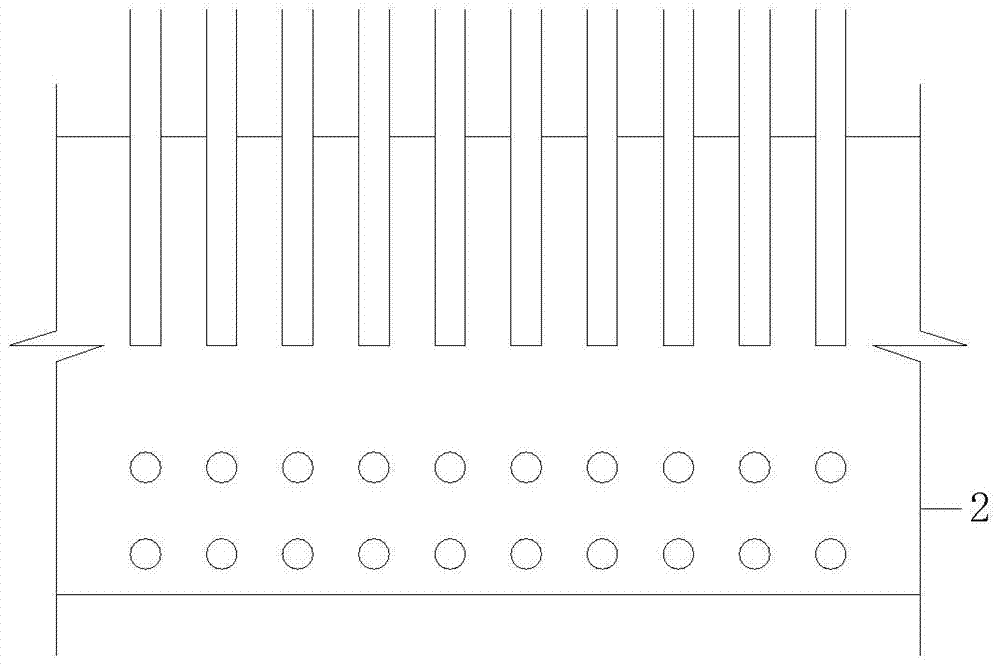

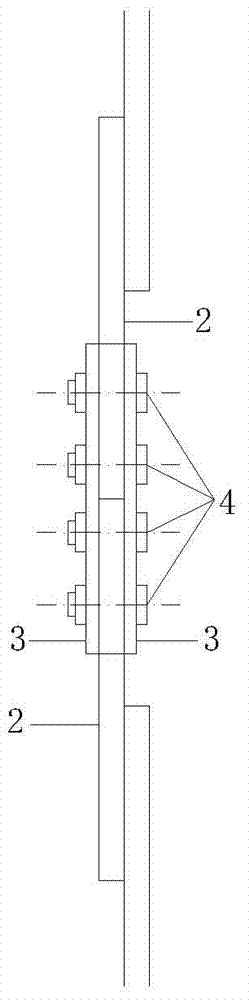

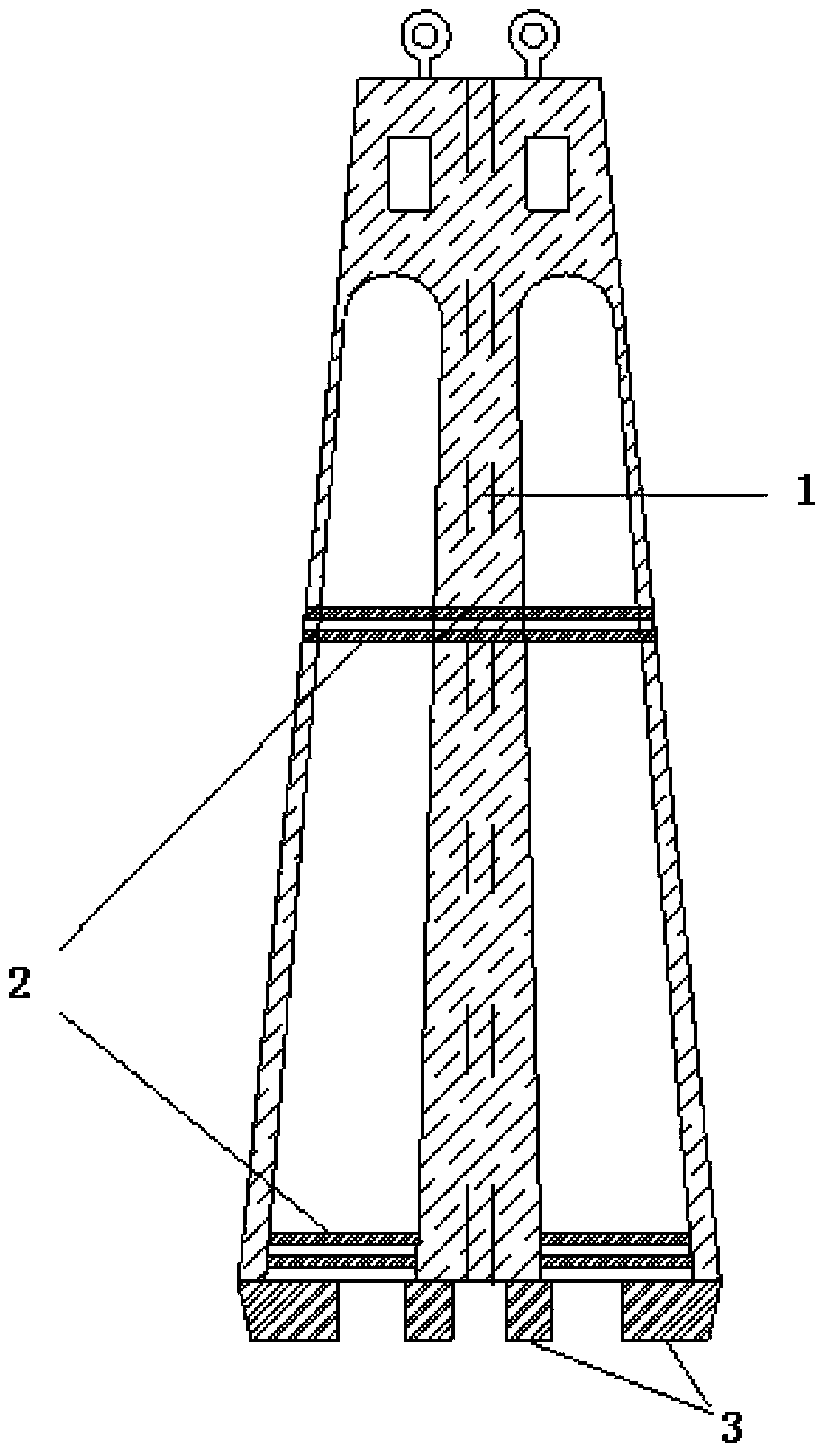

Underground diaphragm wall steel bar cage structure and construction method thereof

The invention discloses an underground diaphragm wall steel bar cage structure and a construction method thereof. The underground diaphragm wall steel bar cage structure comprises a plurality of steel bar cage units (1) and a plurality of connecting structures (21) from bottom to top. The steel bar cage units (1) are connected through the connecting structures (21). Each of the connecting structures (21) comprises two connecting steel plates (2) and two connecting clamp plates (3). The connecting steel plates (2) are respectively welded to the connecting end among the steel bar cage units (1). The connecting clamp plates (3) are located on two sides of each of planes of the connecting steel plates (2), and the connecting clamp plates (3) are fixedly connected with the connecting steel plates (2). The hoisting efficiency and safety of a steel bar cage are improved, the using amount of transverse reinforced trusses is decreased, and the steel bar cage structure is reasonable in structure, reliable in connection and excellent in structural performance.

Owner:SOUTHEAST UNIV

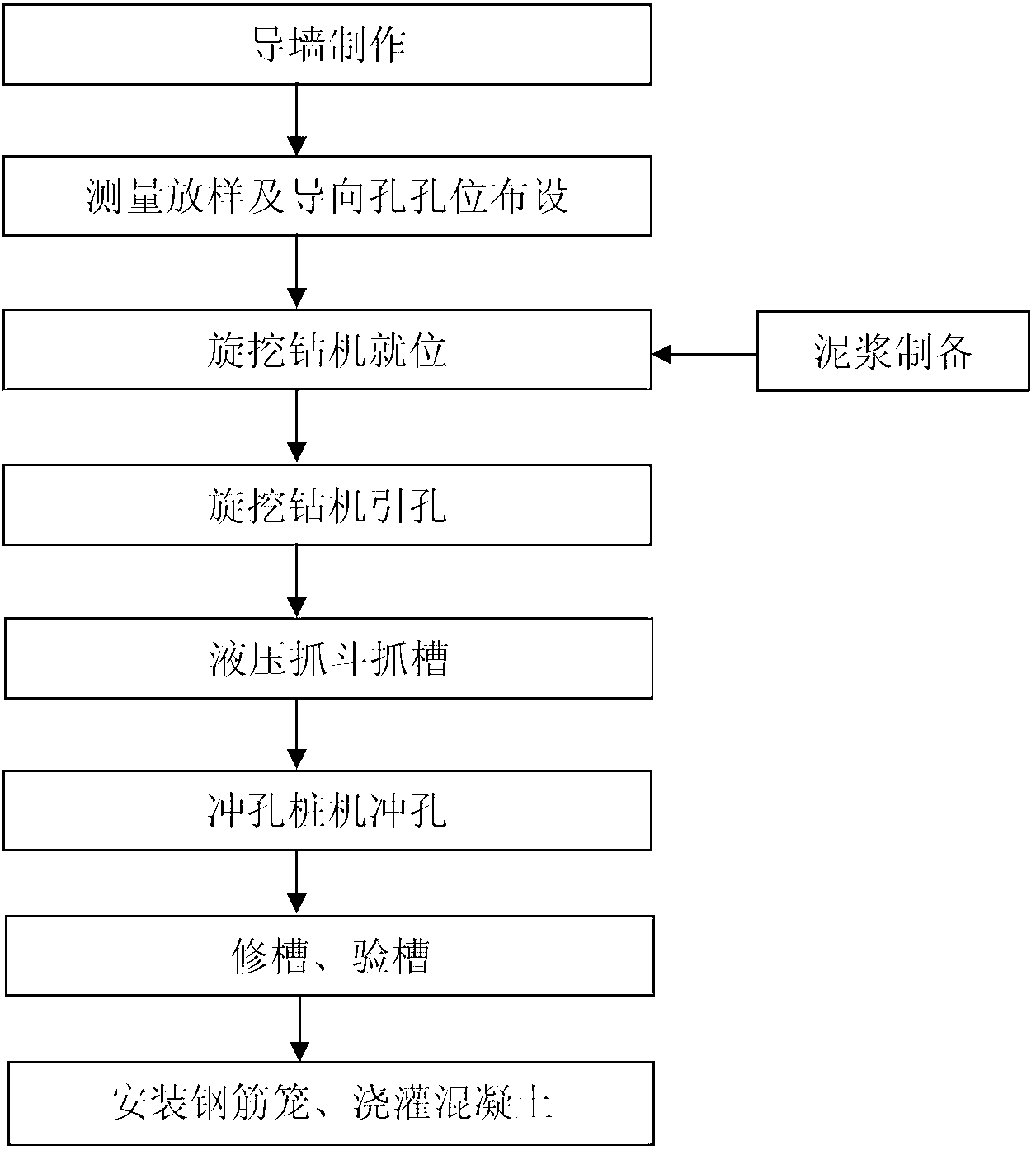

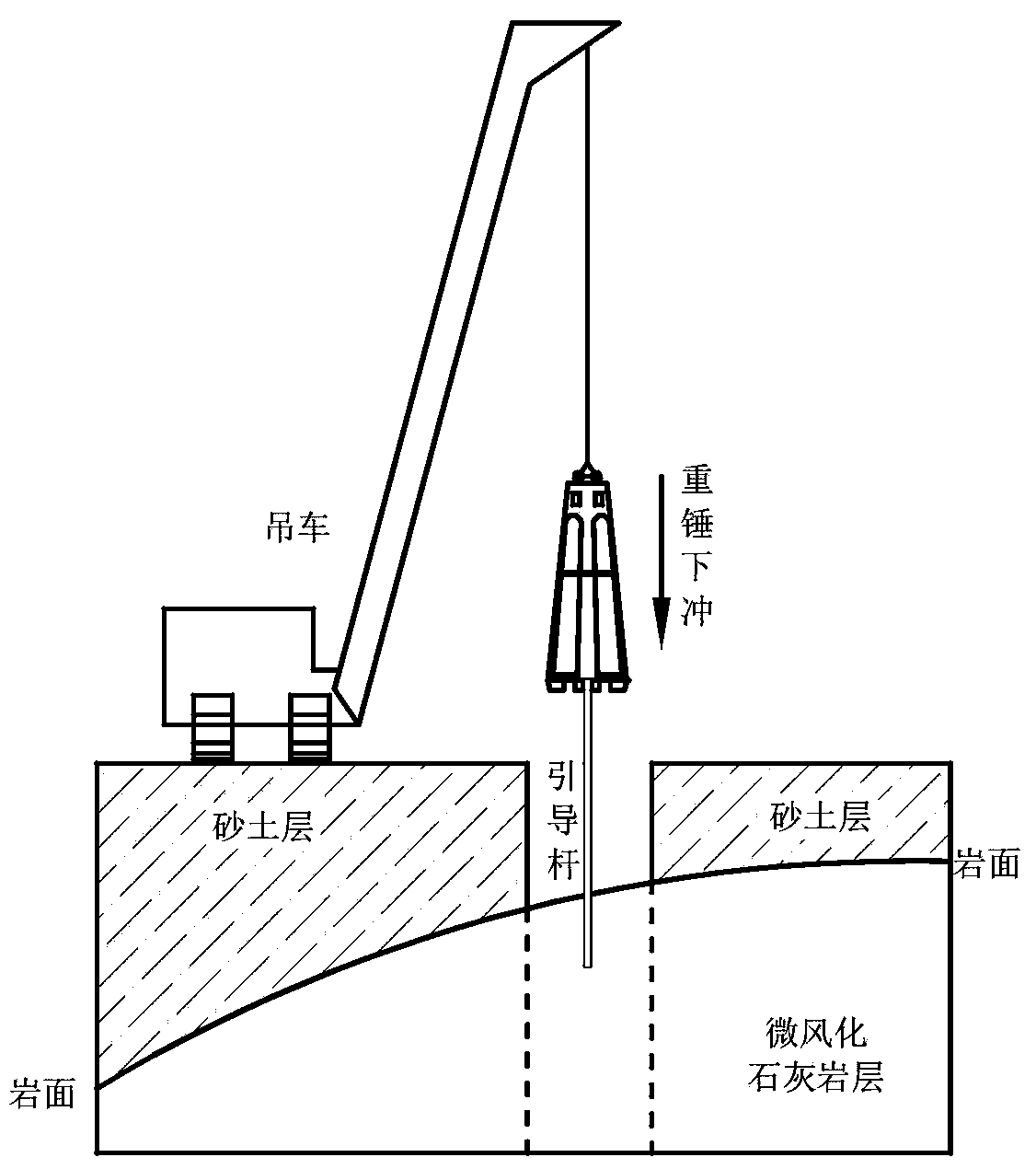

Effective grooving construction method for underground continuous wall in slightly-weathered limestone with overlying sandy soil

ActiveCN103437341AGood hammering effectGood construction performanceArtificial islandsSoil-shifting machines/dredgersSlurry wallEconomic shortage

The invention provides an effective grooving construction method for an underground continuous wall in slightly-weathered limestone with overlying sandy soil. The method specifically comprises the steps of 1) performing core drilling in a grooving area to determine rock characters; 2) measuring the position of a setting-out calibration guide wall; 3) performing guide wall construction and determining the distribution of hole punching positions; 4) drilling guide holes, and installing guide rods; 5) punching a rock layer by using a heavy hammer and grabbing crushed rocks by using a grooving machine; 6) brushing a wall by using a square hammer and connecting the holes to form a groove; 7) cleaning the bottom of the groove to finish the grooving construction. The construction method provided by the invention has the advantages that the defects and the shortages of unsafe and unstable factors, slow construction progress, poor grooving quality and the like are overcome, and the effective, low-cost and high-accuracy grooving construction in the slightly-weathered limestone is realized; the construction effect is good, the grooving speed is fast, the construction process is simple and convenient and the construction period is greatly shortened.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

Construction method of subway tunnel penetrating through underground continuous walls of subway station

The invention discloses a construction method of a subway tunnel penetrating through underground continuous walls of a subway station. The construction method comprises the following steps that a vertical shaft is excavated on the outer side of the first continuous wall, and a space enclosing structure is arranged; construction is conducted on a first freezing pipe to reinforce a first freezing pipe of soil mass in the rear of the first continuous wall in the vertical shaft in the direction of a newly-built subway tunnel, and the first freezing pipe is removed after reinforcing is completed; the first continuous wall is broken away in the direction of the newly-built subway tunnel, and thus a first tunnel portal is formed; slag and accumulated water in the vertical shaft are cleaned, and backfilling is conducted on the vertical shaft; a shield tunneling machine penetrates through the vertical shaft and the first continuous wall in the opening direction of the first tunnel portal; the shield tunneling machine is utilized to tunnel to the position of the second continuous wall, and tightly attached to the second continuous wall; a second freezing pipe for reinforcing soil mass is arranged on the outer side of the second continuous wall in a mode of obliquely drilling from the ground surface, and the second freezing pipe penetrates through the position below the newly-built subwaytunnel; shield position opening is conducted, the second continuous wall is broken away in the direction of the newly-built subway tunnel, and thus a second tunnel portal is formed; and the second freezing pipe is removed, and the shield tunneling machine penetrates through the second continuous wall in the opening direction of the second tunnel portal.

Owner:GUANGZHOU METRO DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com