Patents

Literature

517results about How to "Guarantee the pouring quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

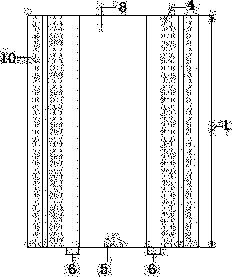

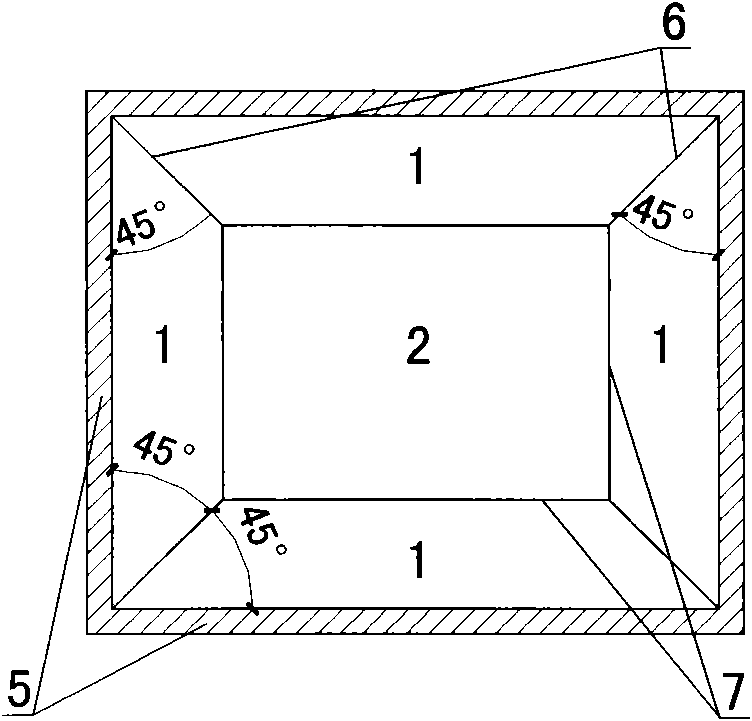

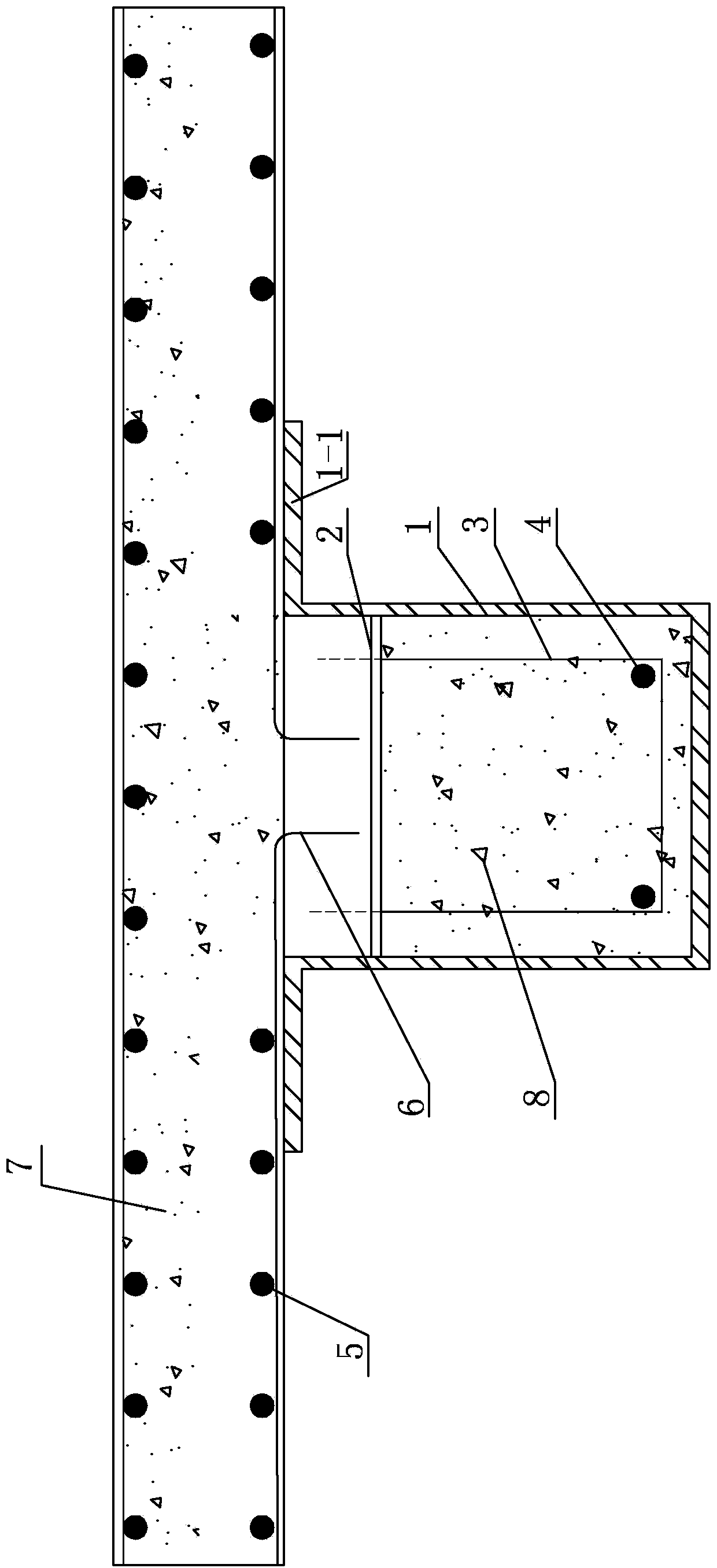

Foaming material filling box with reinforced layer and slurry leakage hole

ActiveCN102031870AEasy to pourEnsure safetyFloorsForms/shuttering/falseworksEngineeringShock resistance

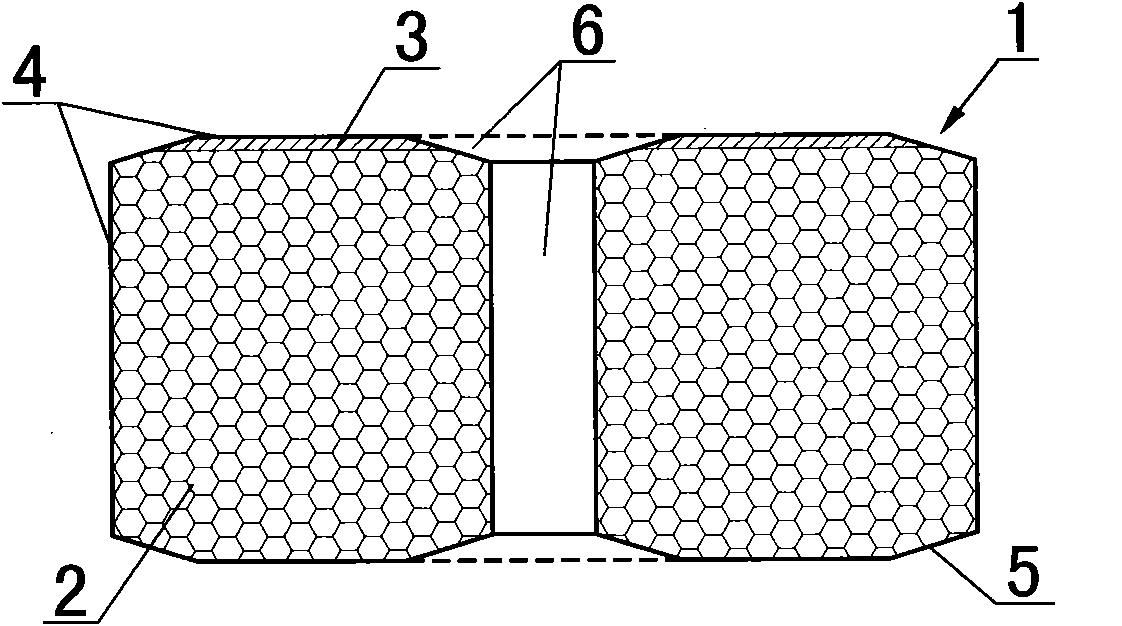

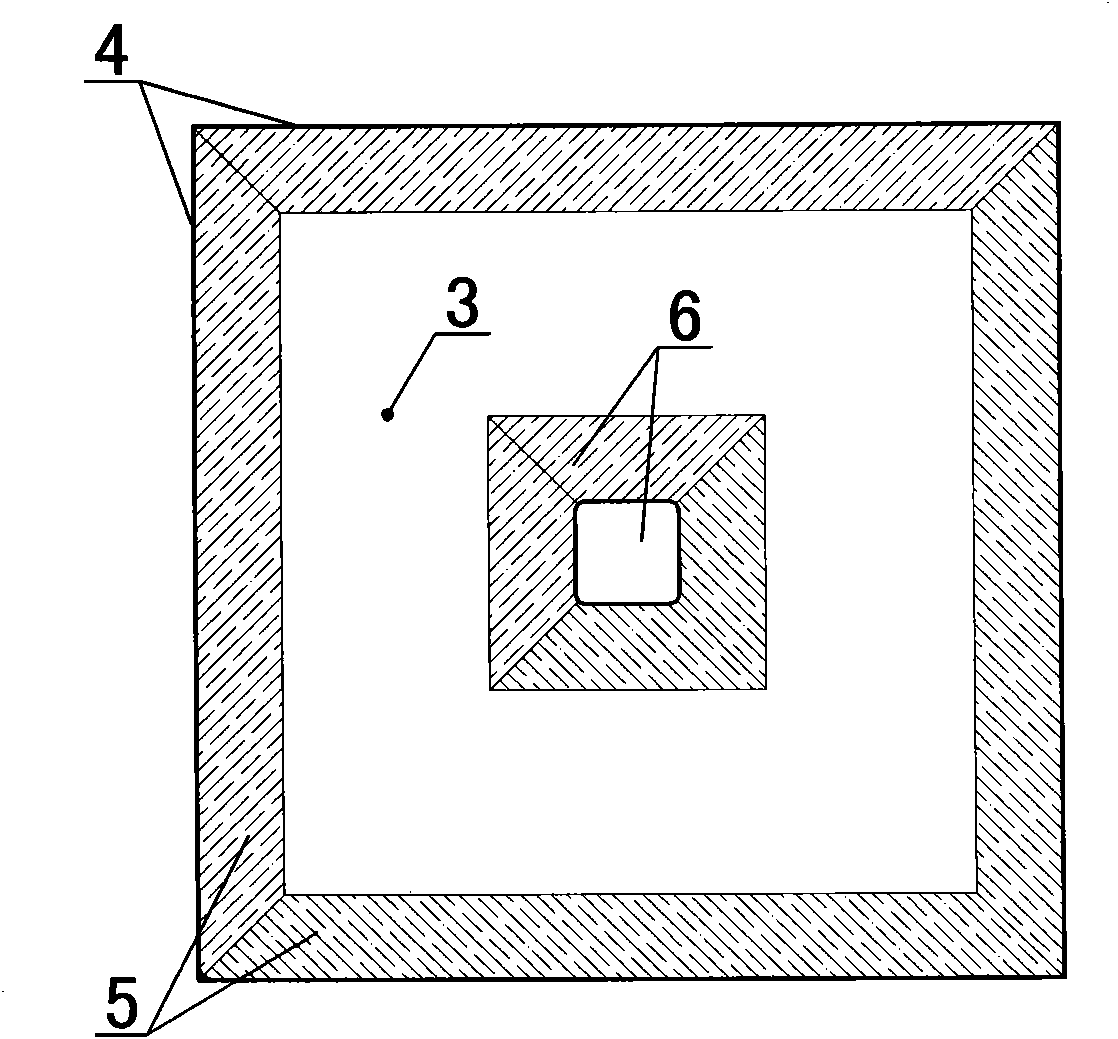

The invention relates to a foaming material filling box with a reinforced layer and a slurry leakage hole and a manufacturing method thereof, belonging to the field of building construction. A main material of a body (2) of the filling box (1) is a light weight foaming material, the plane shape of the filling box (1) is rectangular, and the ratio of a long side to a short side is not more than 2;the upper surface of the body (2) is provided with the hard reinforced layer (3), the outer surface of the body is provided with an isolation layer (4); the hard reinforced layer (3) is located between the body (2) and the isolation layer (4); tangential angles or arc chamfers (5) are arranged at the peripheries of the upper surface and the lower surface of the filling box (1); and the middle part of the filling box (1) is provided with the vertical slurry leakage hole (6), the upper end of the slurry leakage hole (6) is in a big end up funnel shape, and the lower end of the slurry leakage hole (6) is in a big end down inverse funnel shape. In the invention, the sectional shape of the filling box meets the mechanical requirement, and the filling box is very convenient for production, transportation and installation, and has better structural reliability, shock resistance and crack resistance and favorable economical efficiency and applicability.

Owner:徐焱

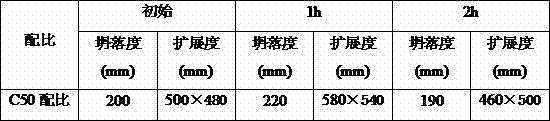

Concrete with ultra-large volume, high strength and low hydration heat

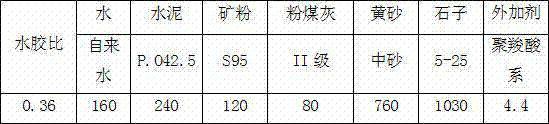

The invention relates to concrete with ultra-large volume, high strength and low hydration heat. The concrete comprises the following components in parts by weight (cube dosage kg / m3): 200-260 parts of cement, 100-160 parts of mineral powder, 80-100 parts of fly ash, 740-800 parts of fine aggregate, 1010-1050 parts of coarse aggregate, 4.0-5.0 parts of additive and 155-165 parts of water. The concrete with ultra-large volume, high strength and low hydration heat can be used to effectively reduce the hydration heat, greatly reduce the cracking risk of the large-volume concrete from the source and increase the engineering quality.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +5

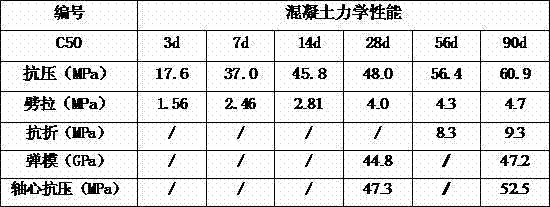

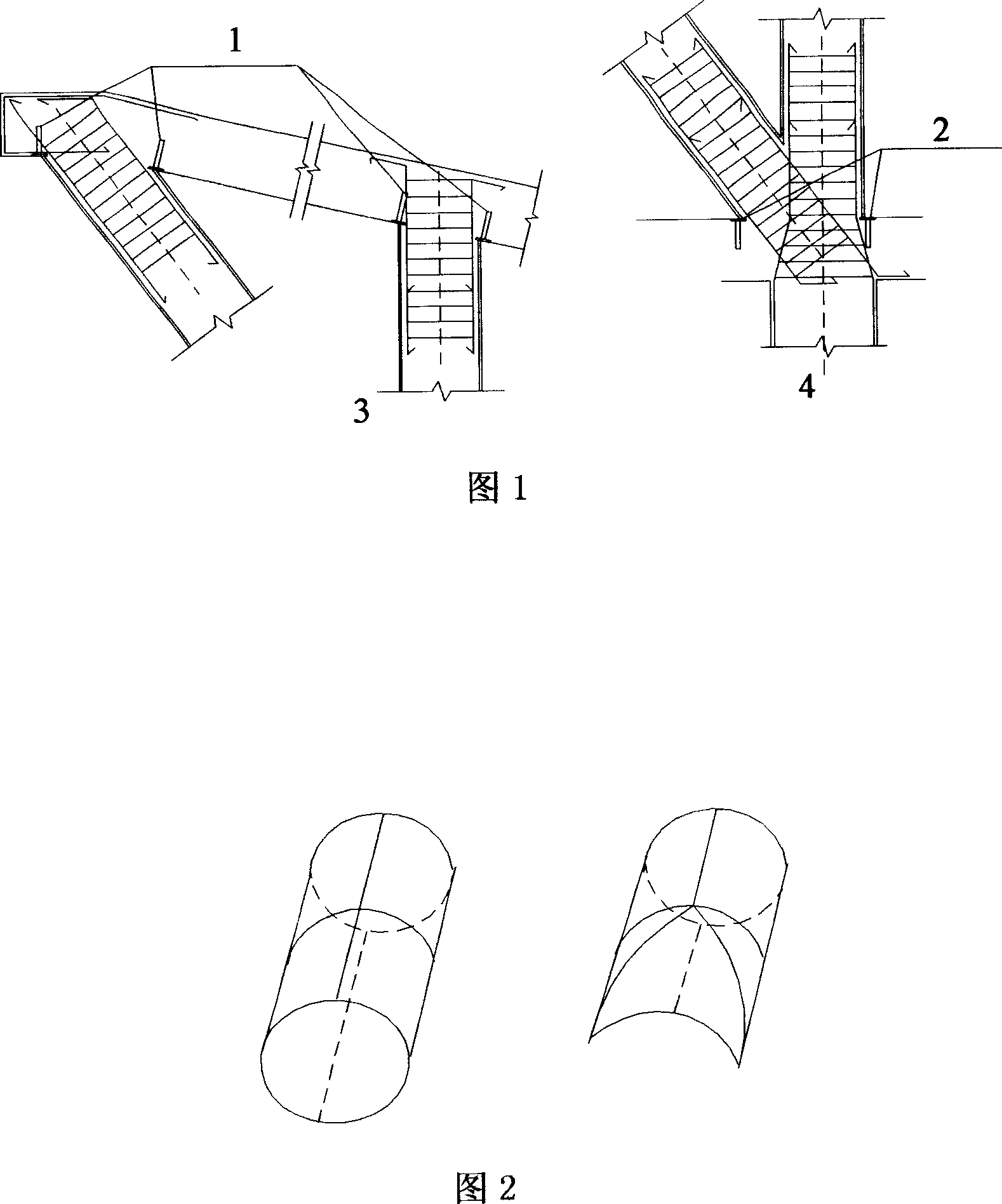

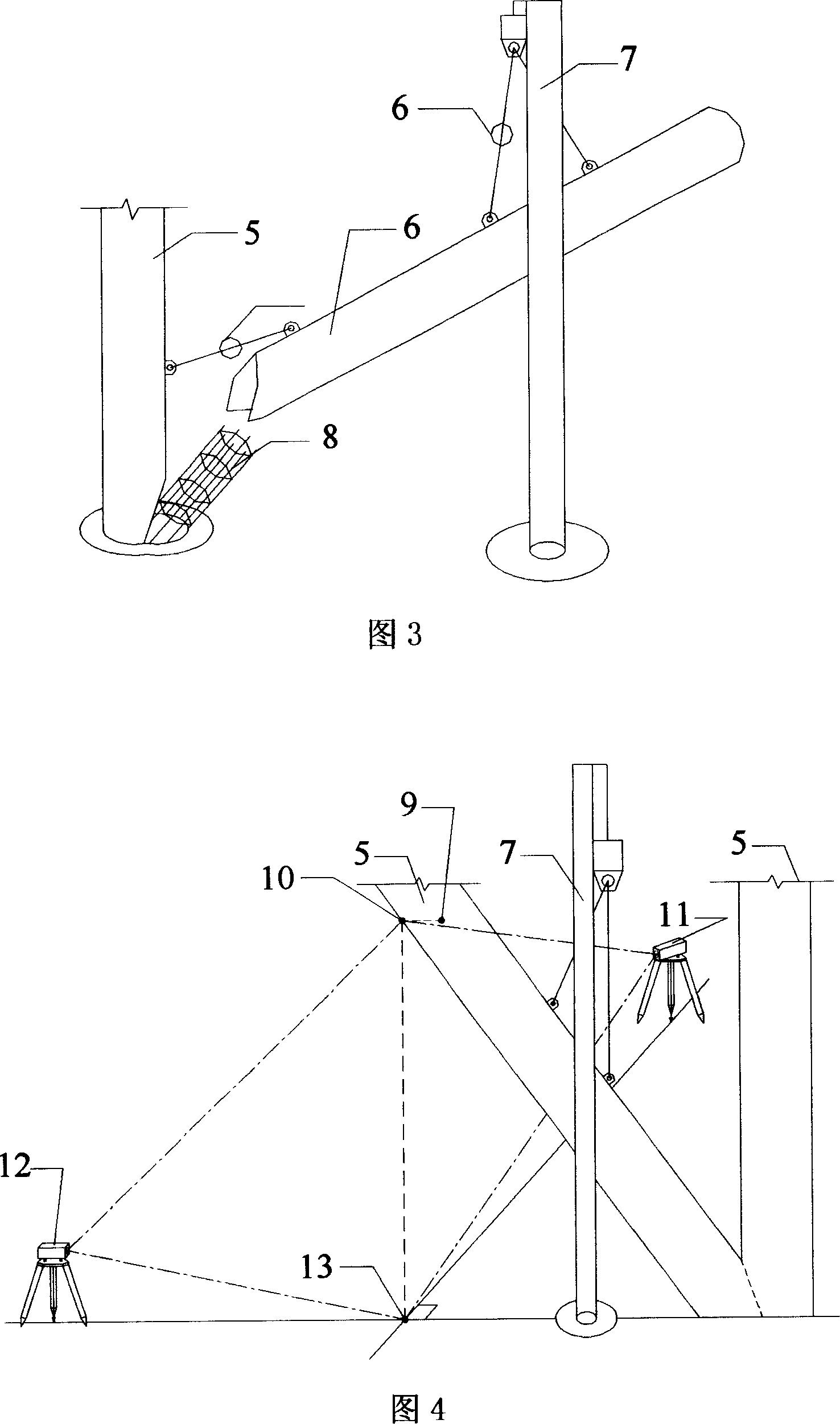

Construction method for combined V-shape steel pipe concrete pile

ActiveCN1978838ATap in timeGuarantee the pouring qualityStrutsBuilding material handlingSteel tubeMaterials science

The invention discloses composite type V shape steel core concrete column construction method. Its features are that using embedded parts precision processing and installing for the steel tube and floor to ensure V steel tube welded connection; adopting computer setting out transversal for each phase to ensure V shape steel tube exact installation; inserting the chute into anchor connected reinforcing cage; using high position throwing down for the concrete cast to ensure steel tube concrete three-way under stress performance reach the design demand. The invention can be used in various composite type V shape steel core concrete column construction and application.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

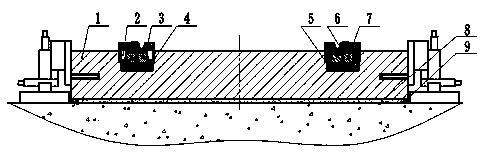

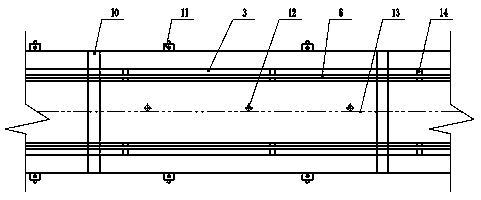

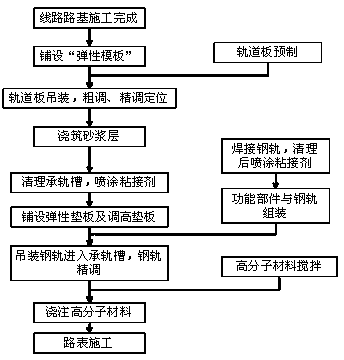

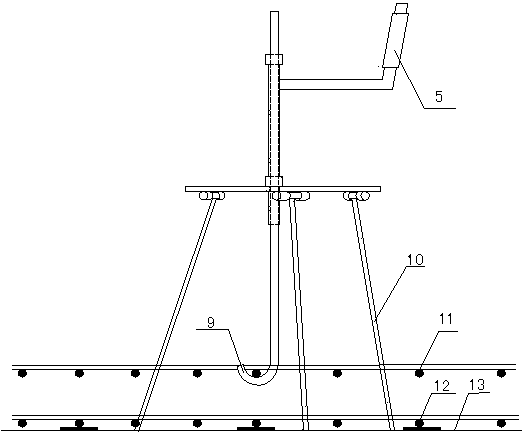

Quick construction method of embedded rail system

ActiveCN103362036ANovel construction methodReasonable construction methodRailway tracksHardnessPlastic film

The invention discloses a quick construction method of an embedded rail system. The quick construction method comprises the following construction steps: performing construction preparation; paving a template; paving rail plates; casting a mortar layer; performing rail bearing groove pretreatment; welding a steel rail; adjusting the steel rail finely; performing antipollution protection and partitioning the rail bearing groove; casting the rail bearing groove; uniformly stirring high polymer material; casting material to the partitioned rail bearing groove with special equipment; clearing plastic films or adhesive tapes after the high polymer material achieves required hardness; and paving on the surfaces of the top surfaces of the rail plates according to construction requirements. Through being combined with prefabricated rail plates, the quick construction method has the characteristics of being quick in construction, high in efficiency and little in influence on surrounding environment, and is a green and environment-friendly construction method.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

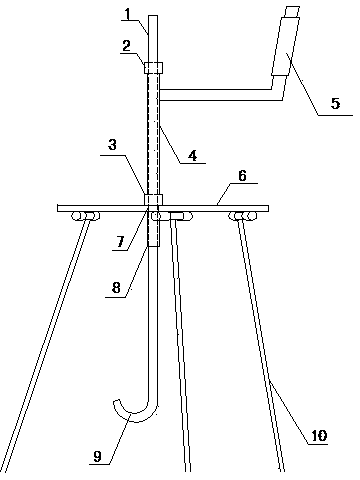

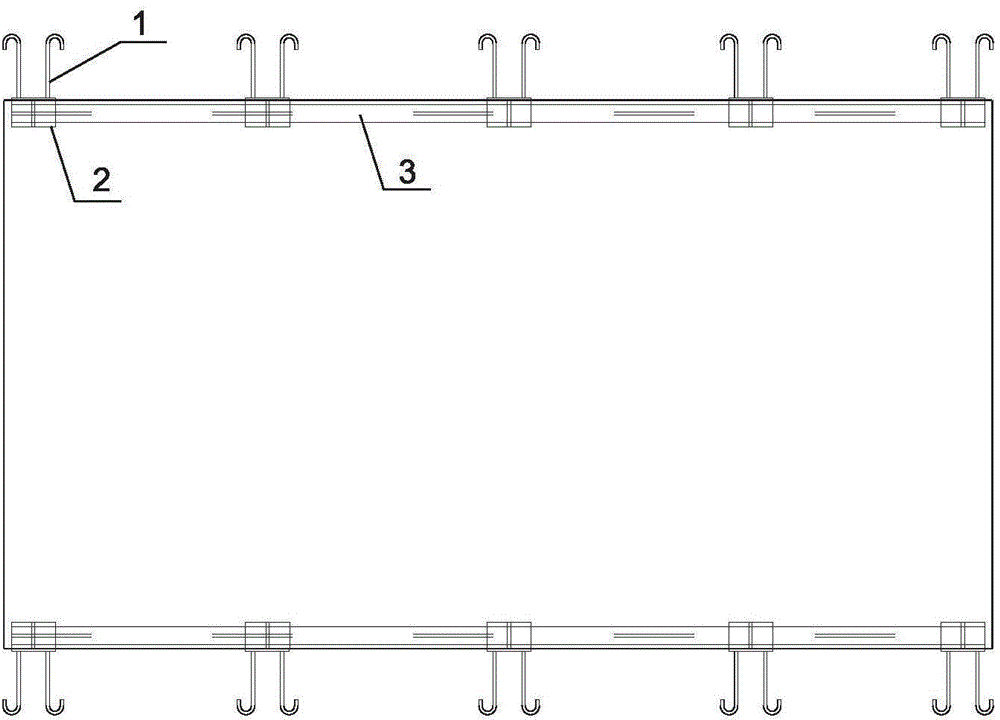

Height-adjustable recyclable reinforcing steel bar split heads

ActiveCN103422622AGuaranteed effective clearanceGuarantee the pouring qualityBuilding reinforcementsArchitectural engineeringSteel bar

The invention relates to a split heads for binding reinforcing steel bars in building engineering, in particular to a height-adjustable recyclable reinforcing steel bar split heads. The height-adjustable recyclable reinforcing steel bar split heads comprises a lifting hook, a lifting mechanism and a bracket. The bracket comprises a tray with a central through hole, and three supporting legs which are distributed in a triangular shape are hinged to the lower portion of the tray. The lifting mechanism is a lead screw lifting mechanism, a screw of the lead screw lifting mechanism is sleeved by a handle sleeve integrally and fixedly connected with a nut, the screw is inserted into the central through hole of the tray to enable the lead screw lifting mechanism to be wholly assembled on the bracket, and the lifting hook for lifting reinforcing steel bars is welded at the lower end of the screw. The height-adjustable recyclable reinforcing steel bar split heads enables reinforcing steel bar meshes to be adjusted continuously and is light and convenient to adjust. Angles of the supporting legs can be adjusted to enable the split heads to be placed at will. The height of the lifting hook and the angles can be reduced and changed at will to enable the lifting hook and the supporting legs to be conveniently pulled out of concrete. After the concrete is poured, the split heads is easy to dismount. The split heads can be manufactured by using corner waste materials in construction sites, so that the materials are convenient to obtain. The split heads saves materials and is simple to manufacture.

Owner:唐山曹妃甸二十二冶工程技术有限公司

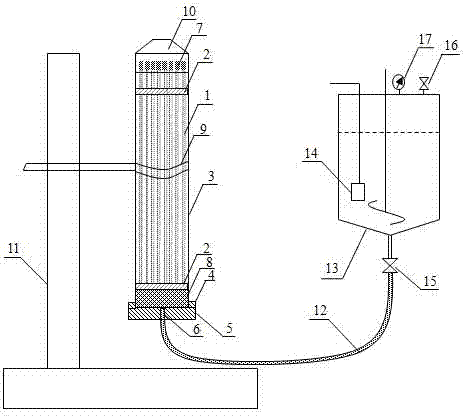

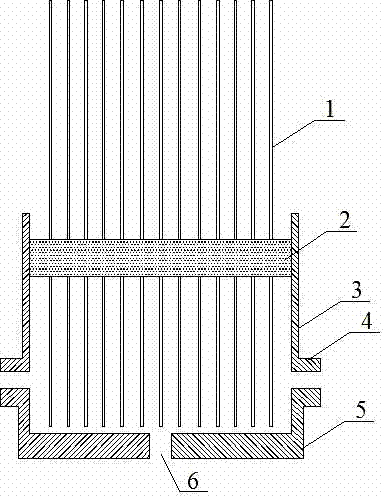

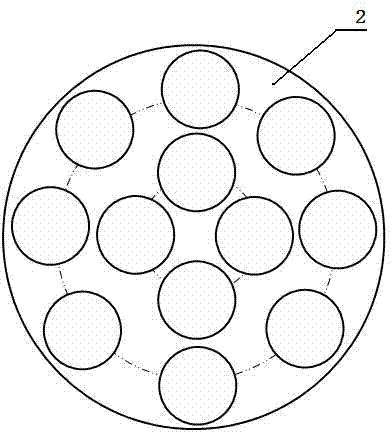

Hollow fiber membrane assembly pouring device and method thereof

ActiveCN103785295AAvoid enteringAvoid scrappingSemi-permeable membranesAdhesiveUltimate tensile strength

The invention discloses a hollow fiber membrane assembly pouring device and a method thereof. The hollow fiber membrane assembly pouring device is composed of a flexible pad, a membrane assembly shell, a connecting piece, a pouring mould and an adhesive stirring tank, wherein hollow fiber membrane filaments are uniformly arranged by additionally arranging the flexible pad which is uniformly provided with holes, the roots of the membrane filaments are protected, an adhesive is prevented from entering the membrane filaments by blocking the two ends of the membrane filaments through a sealant, and an ultrasound defoaming device is additionally arranged in the adhesive stirring tank so that the defoaming efficiency can be improved, the components of the adhesive are also uniformly dispersed, and the mechanical strength of a membrane assembly is improved. The hollow fiber membrane assembly pouring device and the method thereof provided by the invention have the advantages that the pouring of a membrane assembly end socket is uniform, bubbles are not generated, glue leaking and cracking phenomena are avoided, meanwhile, the roots of the membrane filaments are effectively protected, a filament breaking phenomenon is prevented, the pouring quality of the hollow fiber membrane assembly is improved, the service life of the membrane assembly is prolonged, the equipment investment is small, the operation is convenient and rapid, and the hollow fiber membrane assembly pouring device can realize large-scale industrial application easily.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

Pitched roof concrete construction method

InactiveCN103452221AImprove compactnessPrevent leakageBuilding roofsForms/shuttering/falseworksWhole bodyRebar

The invention discloses a pitched roof concrete construction method which is characterized in that a double-sided die sealing method is adopted to carry out construction on a pitched roof of which the slope is greater than or equal to 20 degrees; by bracing a bottom die and a top die of the pitched roof, concrete is poured to form a constraint under the slope condition; a short reinforcement is used as a bracket between the bottom die and the top die of the pitched roof; the short reinforcement has a diameter of 22 to 25 mm; the top die and the bottom die are connected into one whole body by split bolts; the split bolts have diameters of 14 to 16 mm; the split bolts are arranged at intervals of 250 to 300 mm; water stop rings are arranged in the middles of the split bolts; the water stop rings have diameters of 40 to 50 mm; reinforcement split heads are arranged on the upper surface of the bottom die for placing an upper negative reinforcement skeleton; sectional pouring and tamping are adopted in the pouring process of concrete, and a die plate at the upper part of the pitched roof is sealed step by step from bottom to top along the pouring progress of concrete.

Owner:嘉兴市利富通新材料科技有限公司

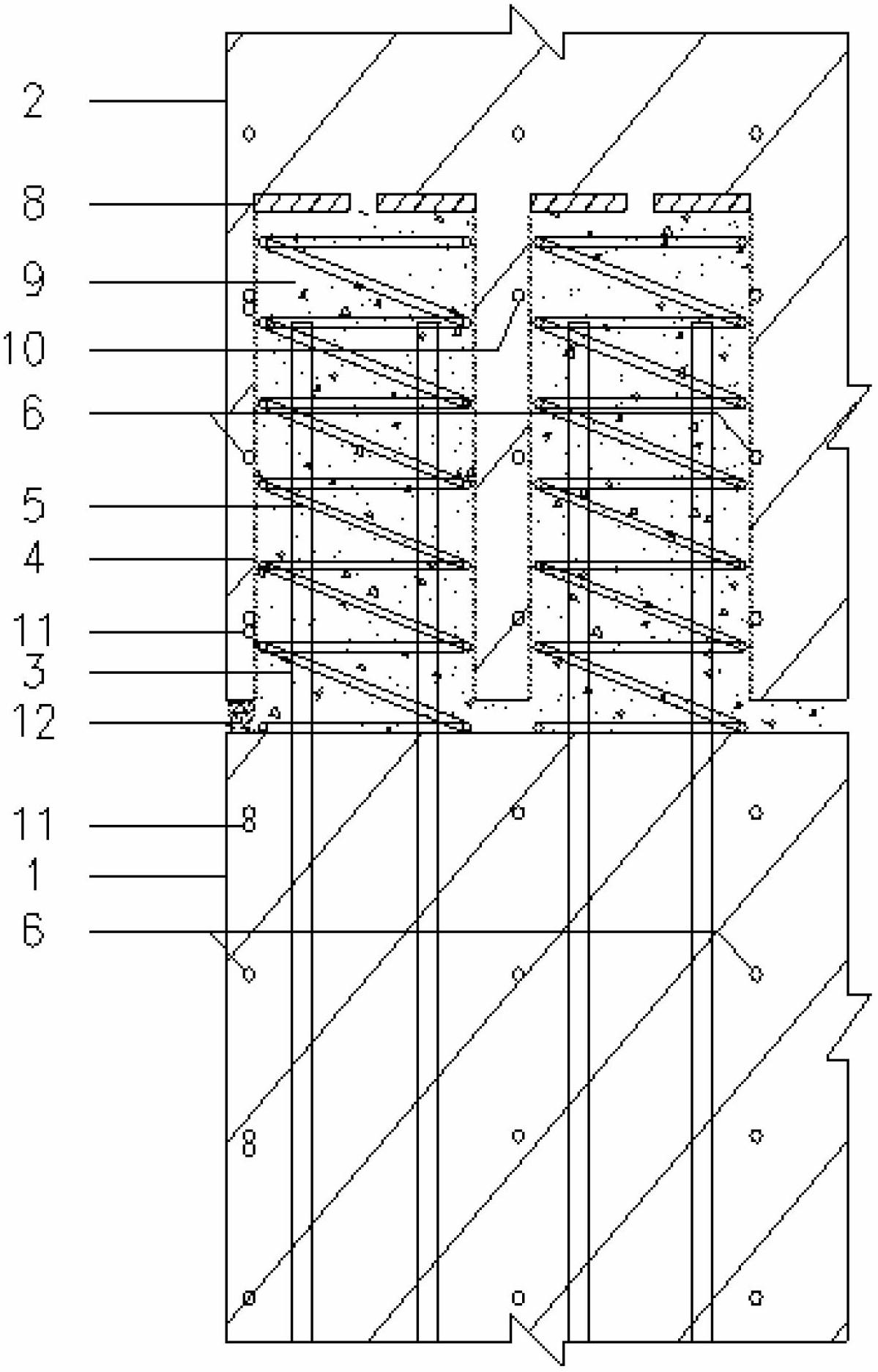

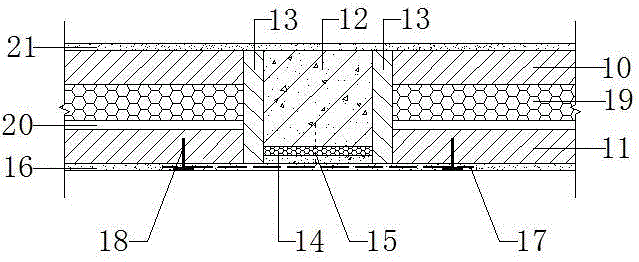

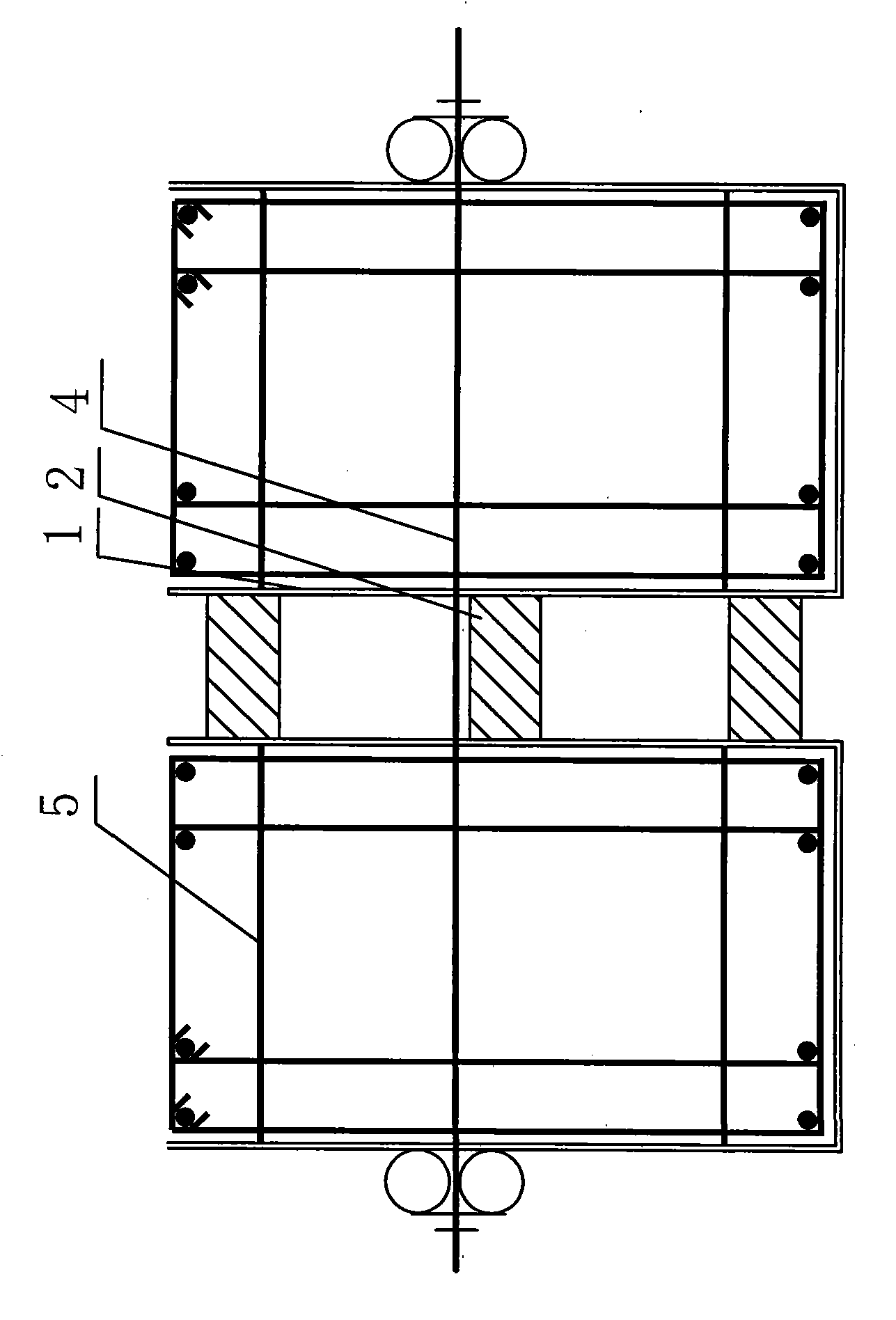

All-wet-joint precast prestressed underground continuous wall and construction method thereof

The invention provides an all-wet-joint precast prestressed underground continuous wall and a construction method of the all-wet-joint precast prestressed underground continuous wall. The continuous wall is formed by sequentially connecting a plurality of wall segments (1). The middle of the section of each wall segment (1) is provided with a cavity (4). Concave groove segments (8) are arranged at the center of the wall segments (1) in the length direction. Semi-conical holes (5) are formed in the upper connection parts and the lower connection parts of the wall segments (1). The semi-conical holes (5) are communicated with the cavities (4) and the concave groove segments (8). Water-proof wet joints are formed by pouring concrete in the semi-conical holes (5). According to the continuous wall, all the wall segments are connected through the wet joints, so that the problem of leakage at the connection parts of the wall segments is solved. By exerting prestressing force between the wall segments, the flexural rigidity, the anti-cracking ability and the lasting quality of the underground continuous wall are improved. Due to the fact that the underground continuous wall is connected with reinforcing mesh pieces, the shear-resistant performance between the wall segments is strengthened. As the wall segments are constructed on the ground, the quality of the continuous wall is easy to guarantee.

Owner:SOUTHEAST UNIV

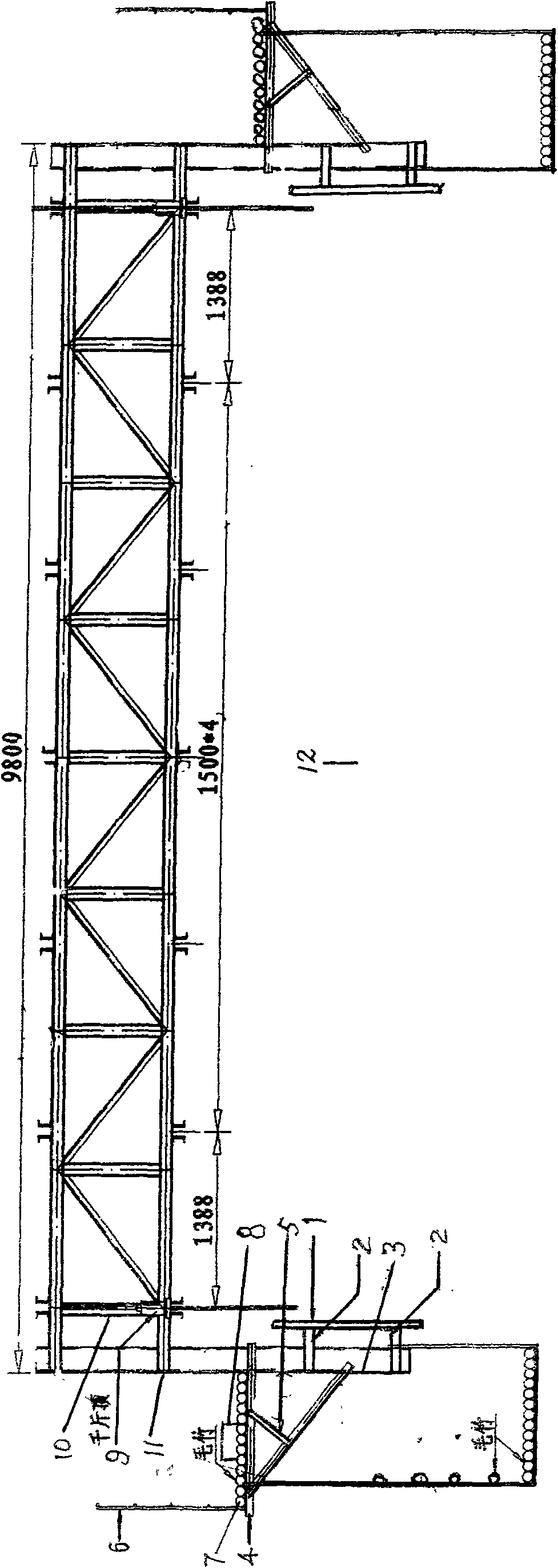

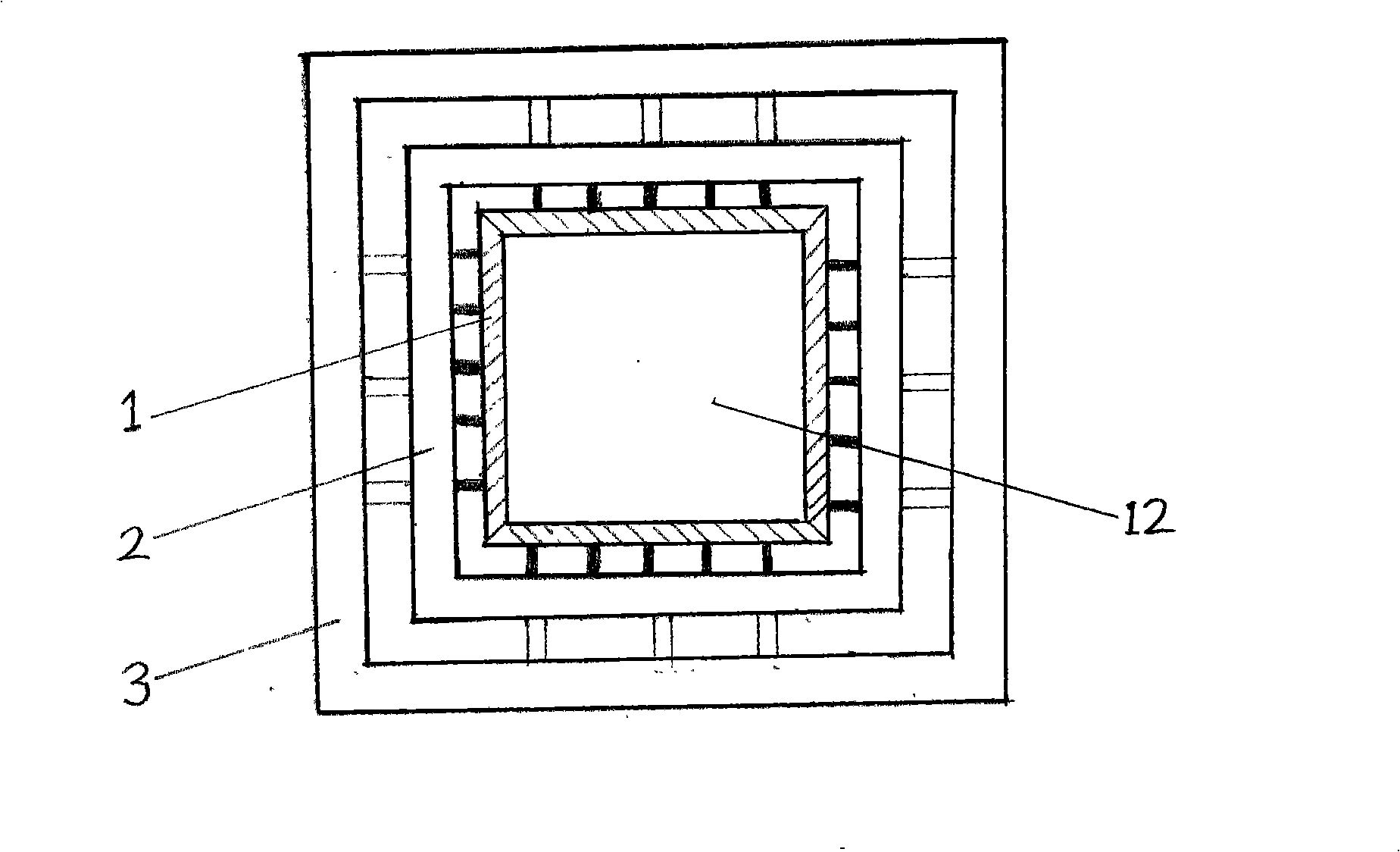

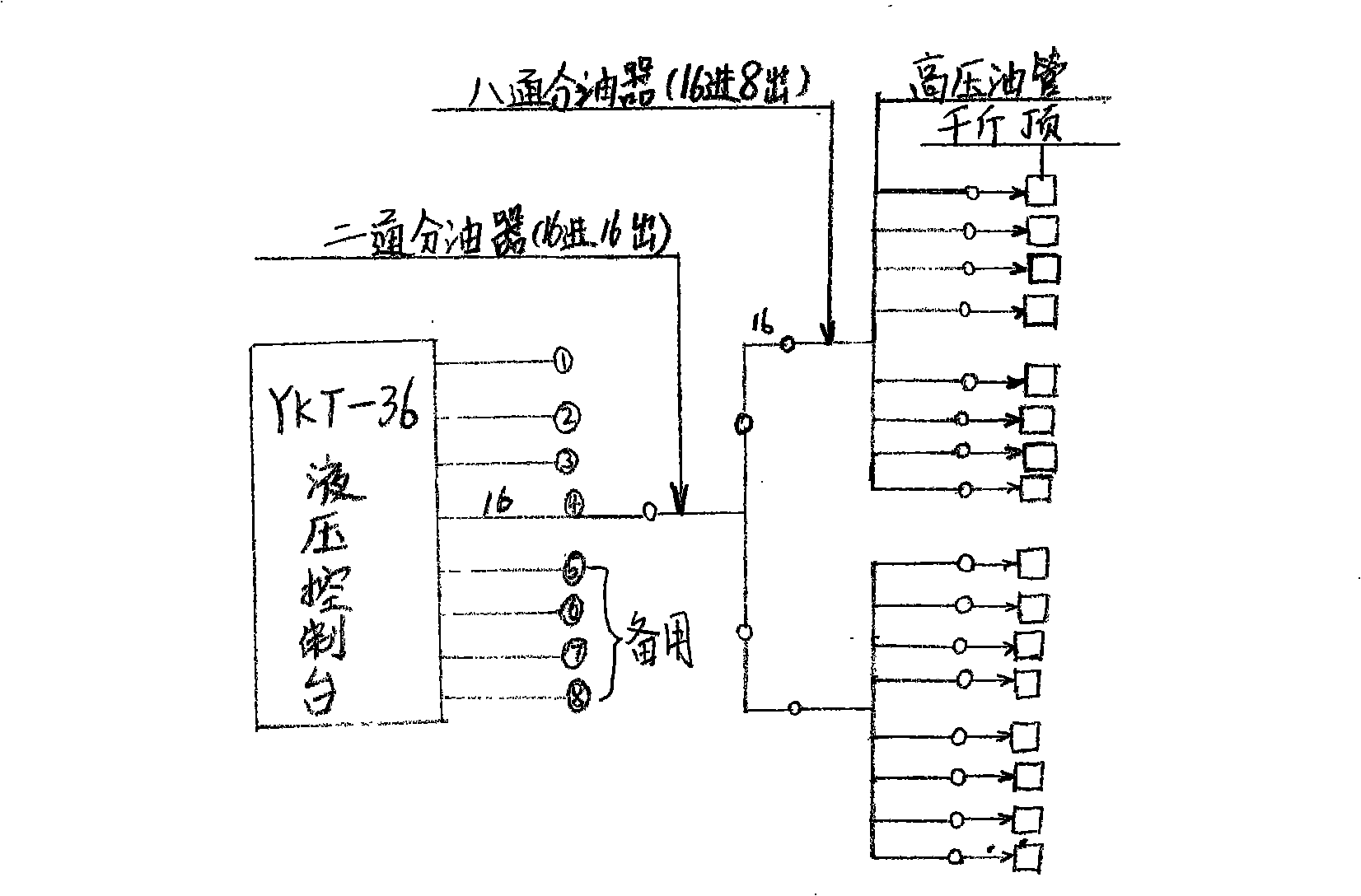

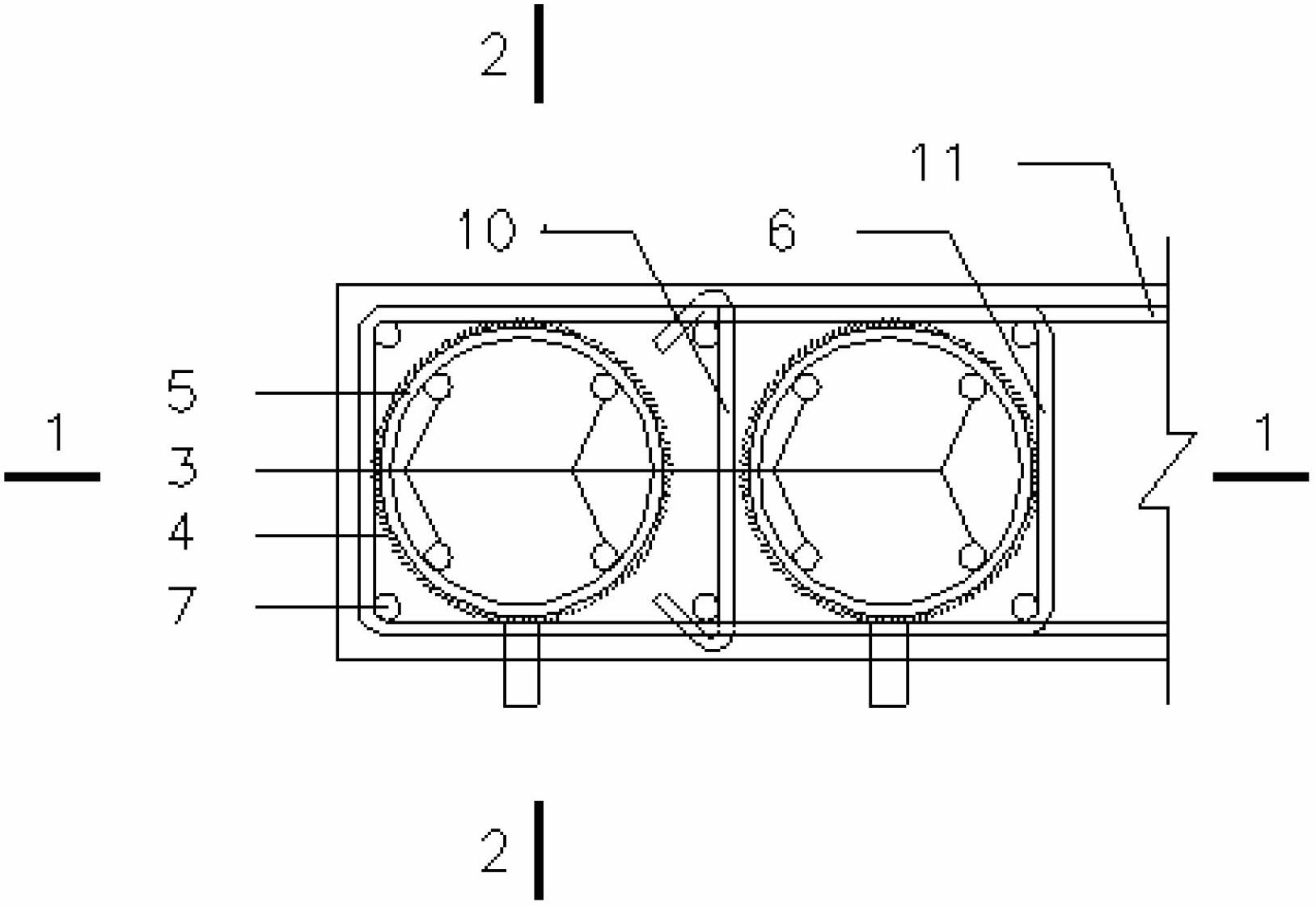

Pier hydraulic leveling inner-climbing climbing form and concrete pouring method thereby

ActiveCN101525873AReasonable designVersatilityBarrages/weirsFoundation engineeringControl systemJackscrew

The invention relates to a pier hydraulic leveling inner-climbing climbing form and a concrete pouring method thereby. The form consists of a slip form truss, a form system, an operating platform, a hydraulic lifting system and an accuracy control system, wherein two slip form truss girders are crosswise arranged, both ends of the two slip form truss girders are respectively connected with lifting frames, a wreath is in a quadrate or an elliptical shape and is fixed to the lifting frames, a quadrate or an elliptical form is hung and fastened on the wreath, the operating platform is divided into an upper layer and a lower layer which are both fixedly connected with the lifting frames, a hydraulic console is placed on the operating platform and a jack is installed on a crossbeam. The jack is controlled by the hydraulic console to lead the crossbeam to rise, the lifting frames are driven to upwards climb simultaneously with the wreath and the form which are connected with the lifting frames, and the concrete is poured in layers and lifted in several times; when the concrete is poured to the pier top, the climbing speed is lowered, and the form is finished and repaired after concrete pouring and is cured through water drenching after final set.

Owner:广西广投桥巩能源发展有限公司 +1

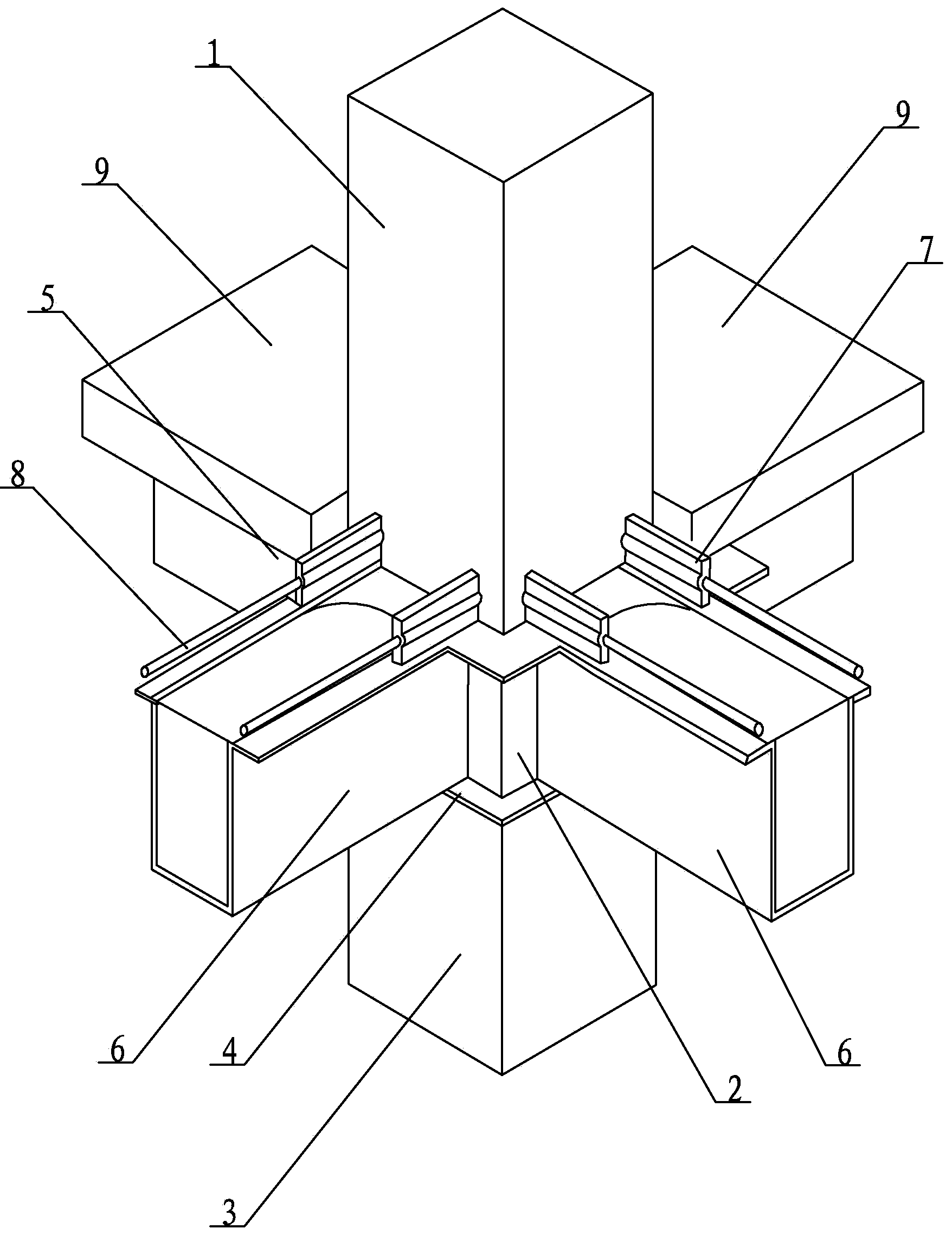

Connecting structure for assembly type concrete shear wall edge member

InactiveCN102691365AImprove the anchoring effectGuaranteed carrying capacityWallsShock resistanceRebar

The invention discloses a connecting structure for an assembly type concrete shear wall edge member. vertical connecting reinforcing steel bar, which can be provided with an upset head, is reserved through a hole reserved in a large-diameter metal bellows, and is sleeved with a continuous spiral stirrup; then the vertical connecting reinforcing steel bar and the continuous spiral stirrup are commonly inserted into the large-diameter metal bellows; and fine aggregate concrete (or a grounding material) is poured into the metal bellows, so that the reliable connection of the edge member is realized. Due to reliable anchoring of the vertical connecting reinforcing steel bar, the optimization of the diameter, the quantity and the plane arrangement of the vertical connecting reinforcing steel bar, and the increase of the wet joint area on a splicing surface, full exertion of the bearing capacity of the shear wall is ensured; and multiple effective restrain for the subsequentlly-poured fine aggregate concrete (or the grouting material) is formed by the shear wall stirrup, a horizontal tie bar, the metal bellows and the continuous circular spiral stirrup, and thus the integral performance of the part is remarkably improved. According to the connecting method for the edge member, which is provided by the invention, the stress continuousness of the vertical steel reinforcing bar is ensured, the deformaility and the ductility performance of the vertical steel reinforcing bar are remarkably improved, and the shock resistance of the assembly type concrete shear wall is improved. Meanwhile, the method is simple in manufacturing process and facilitates the practice and application.

Owner:SOUTHEAST UNIV

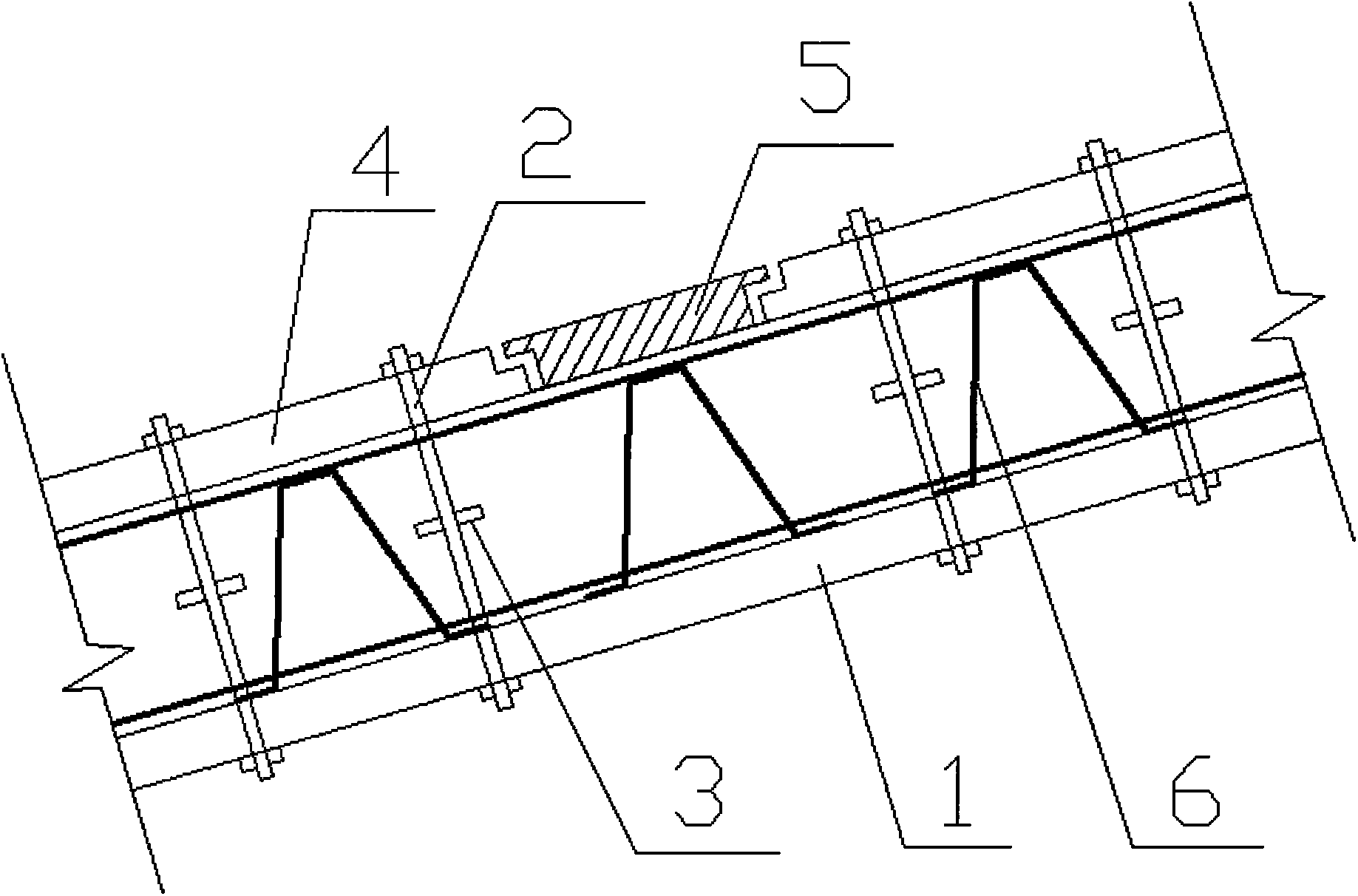

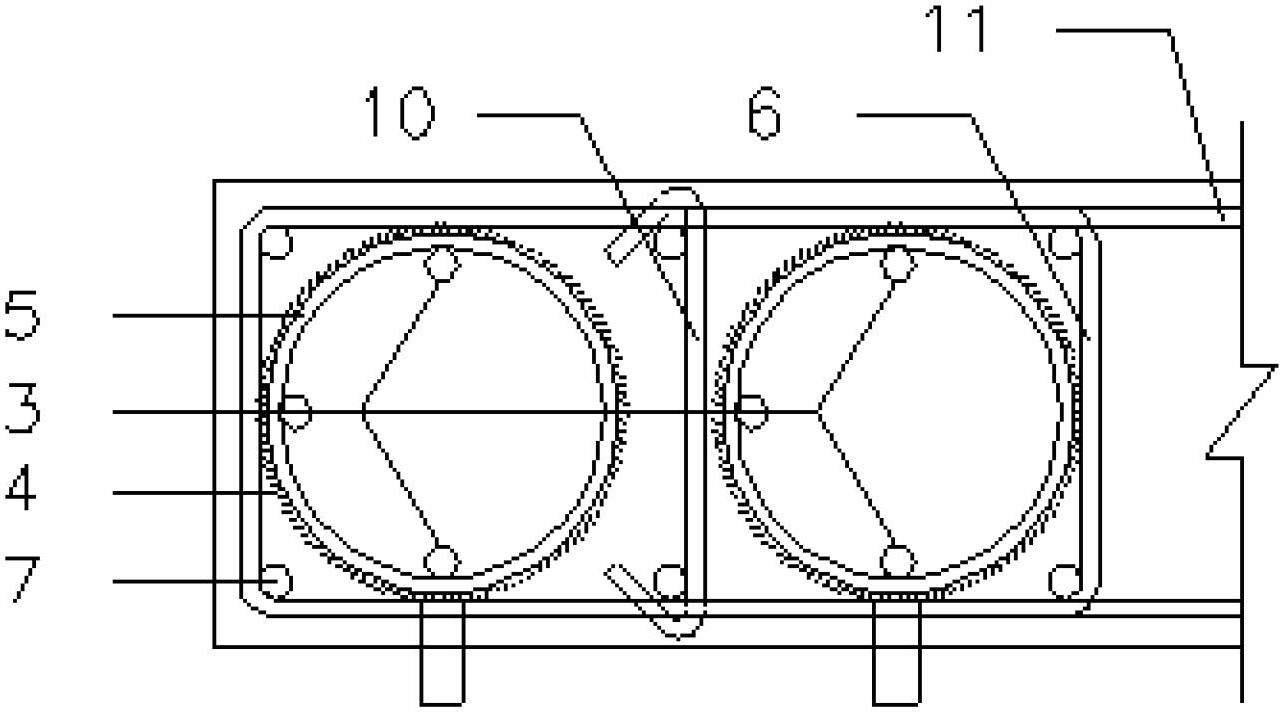

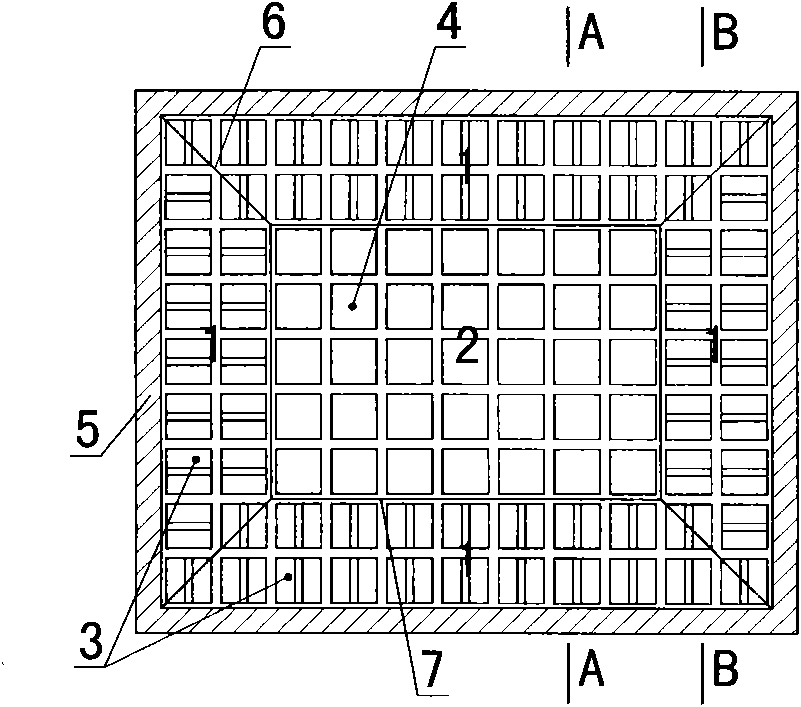

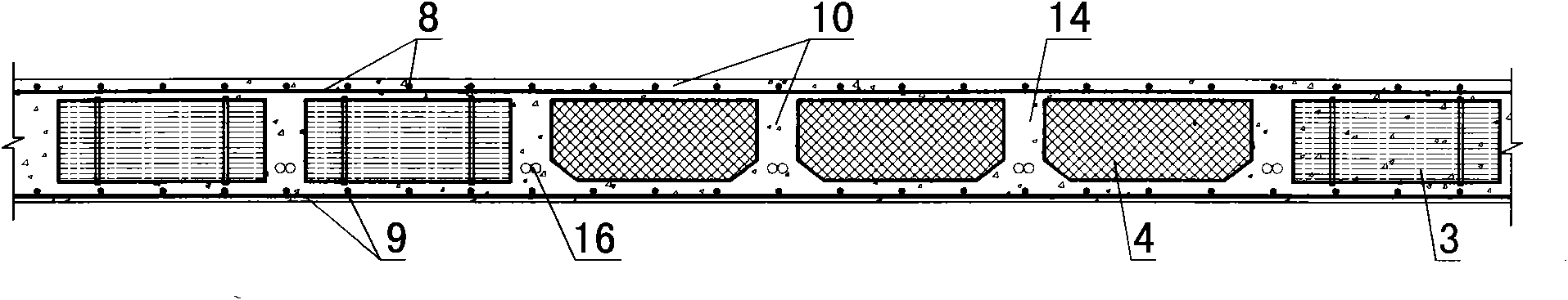

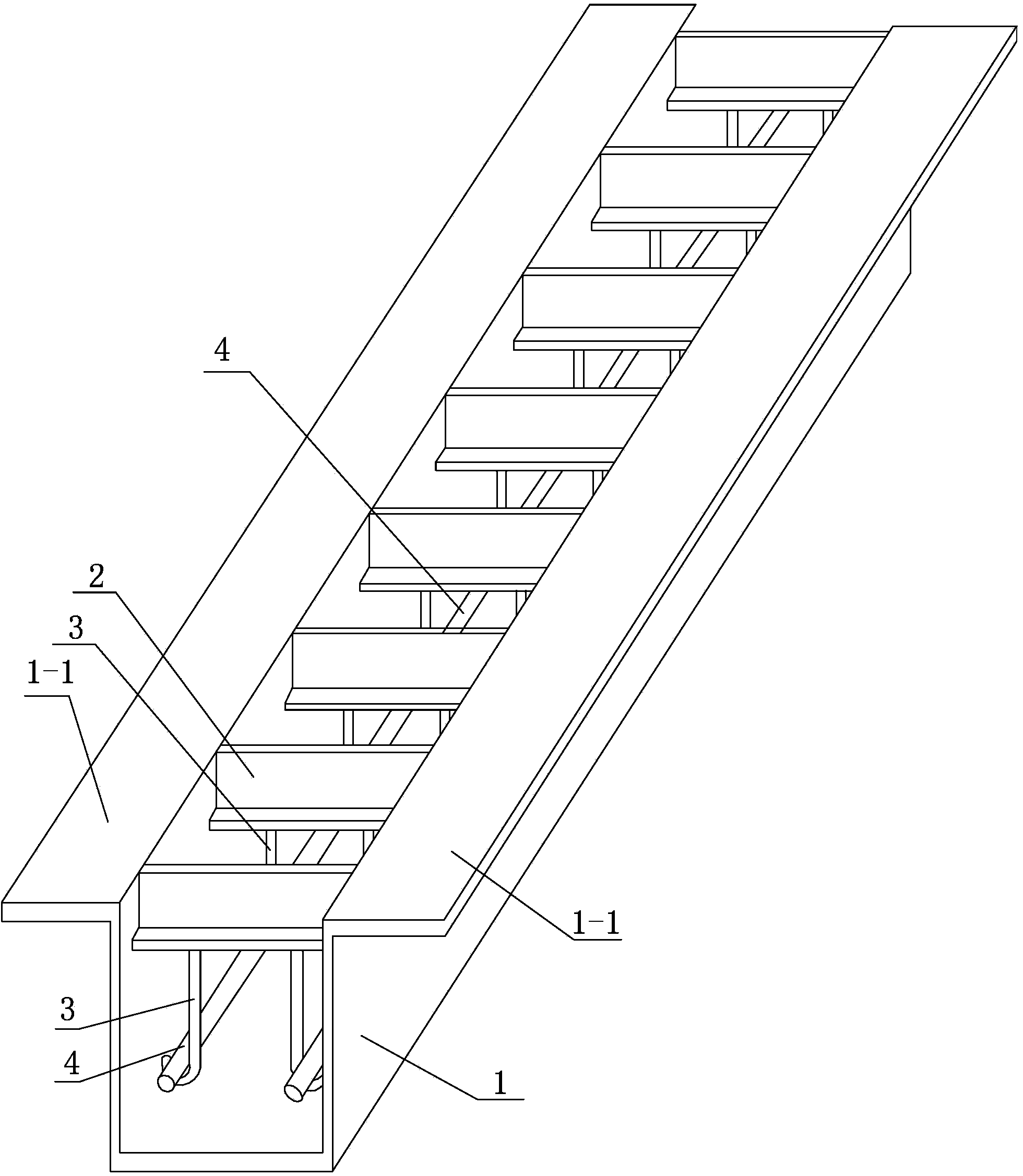

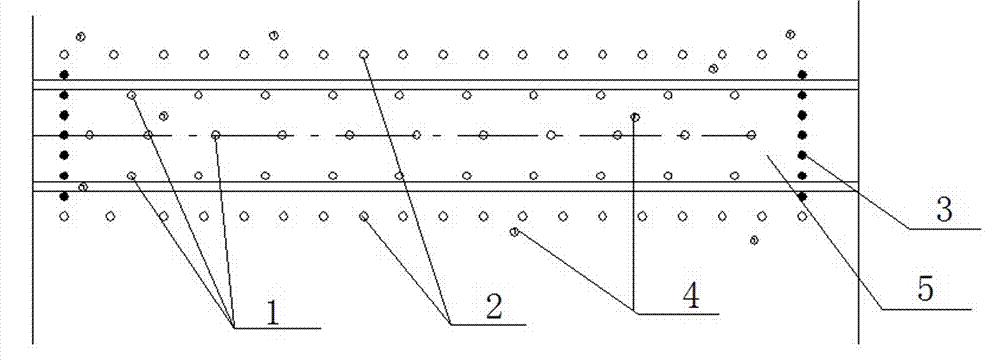

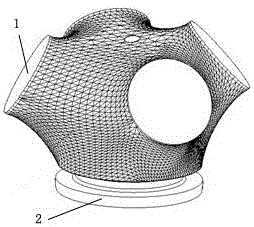

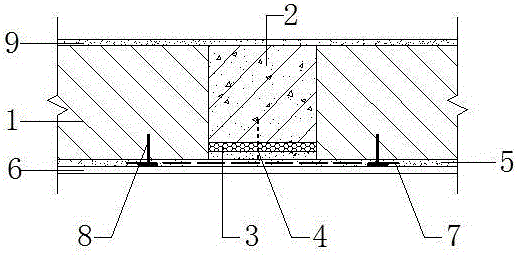

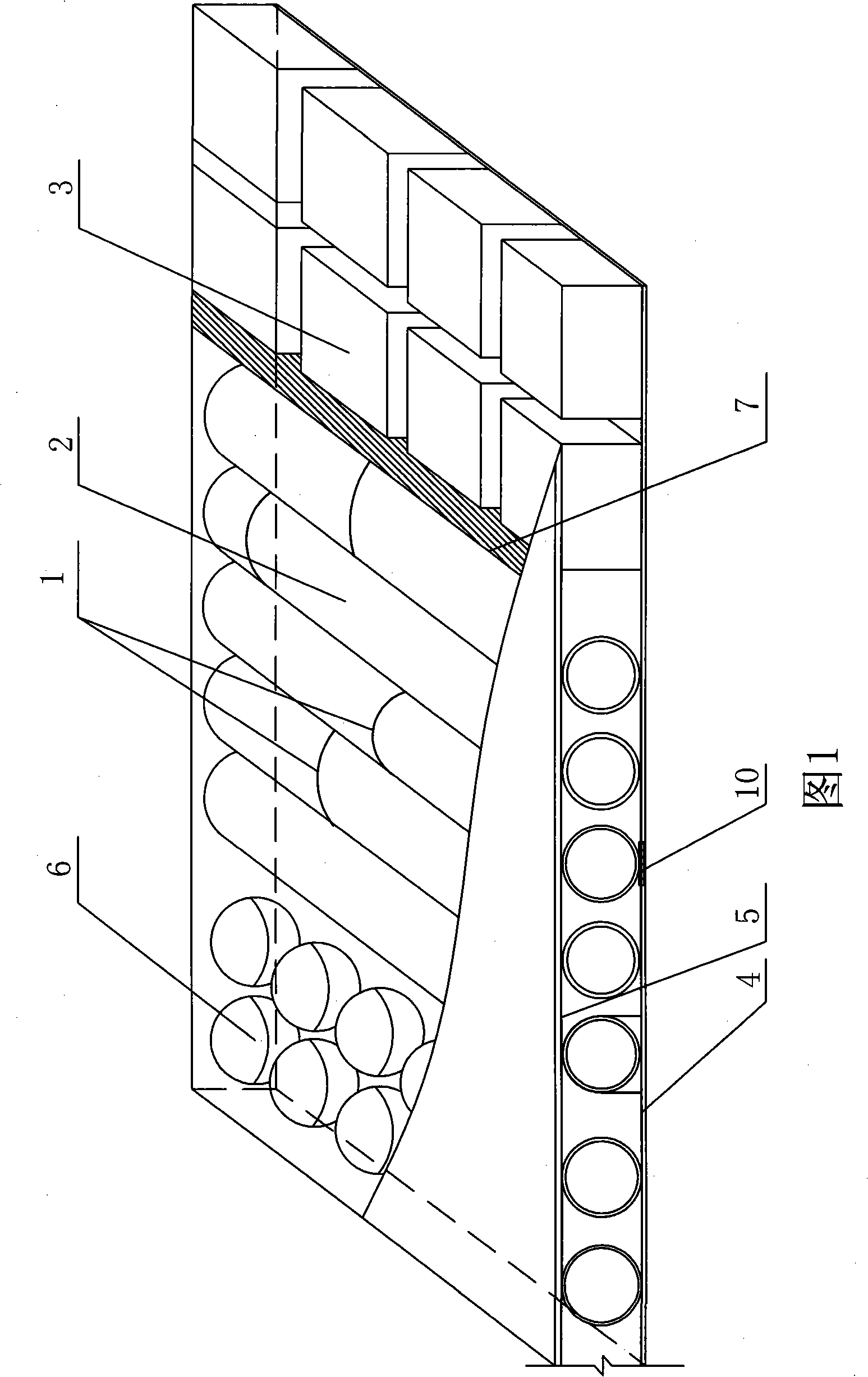

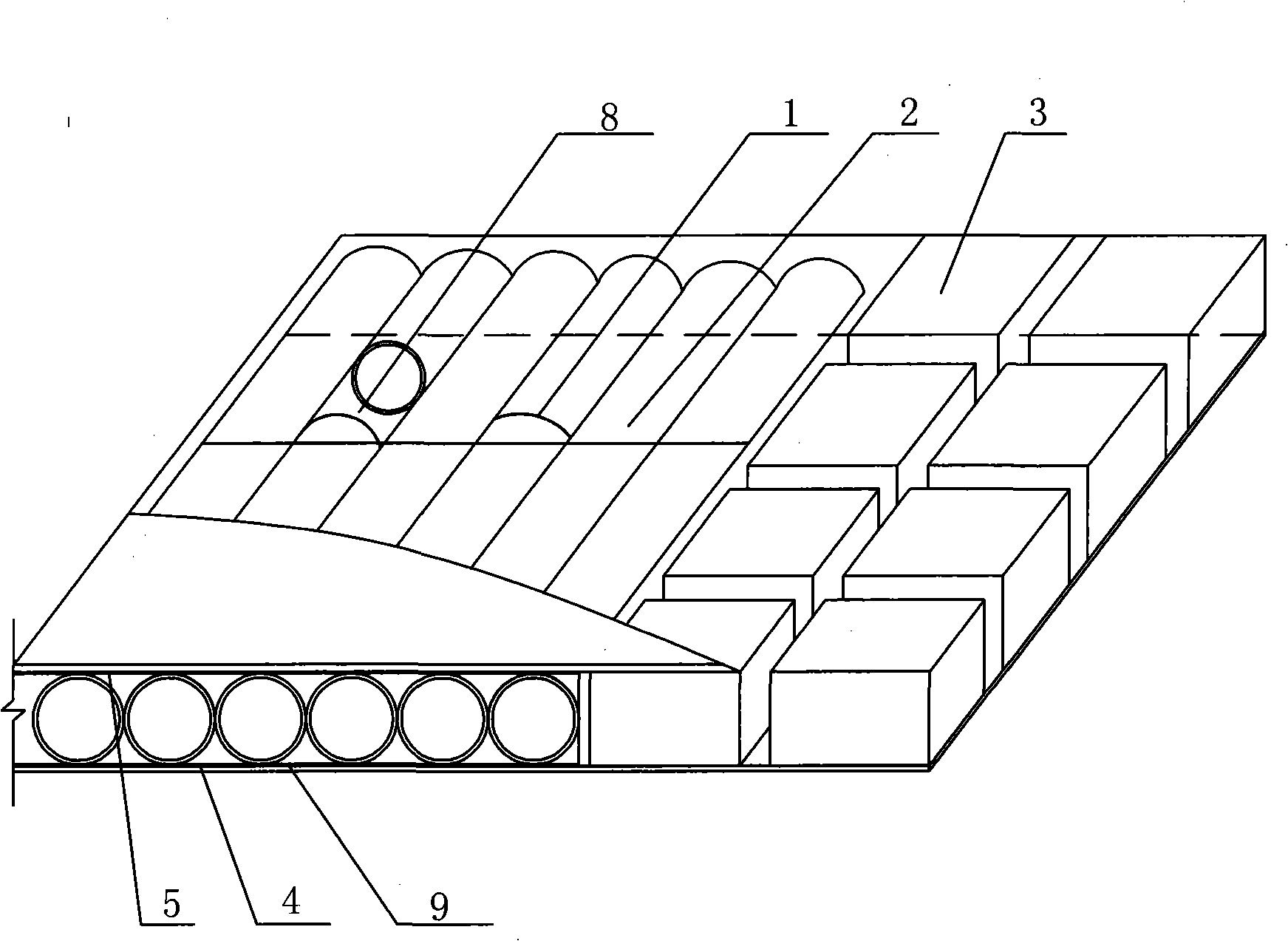

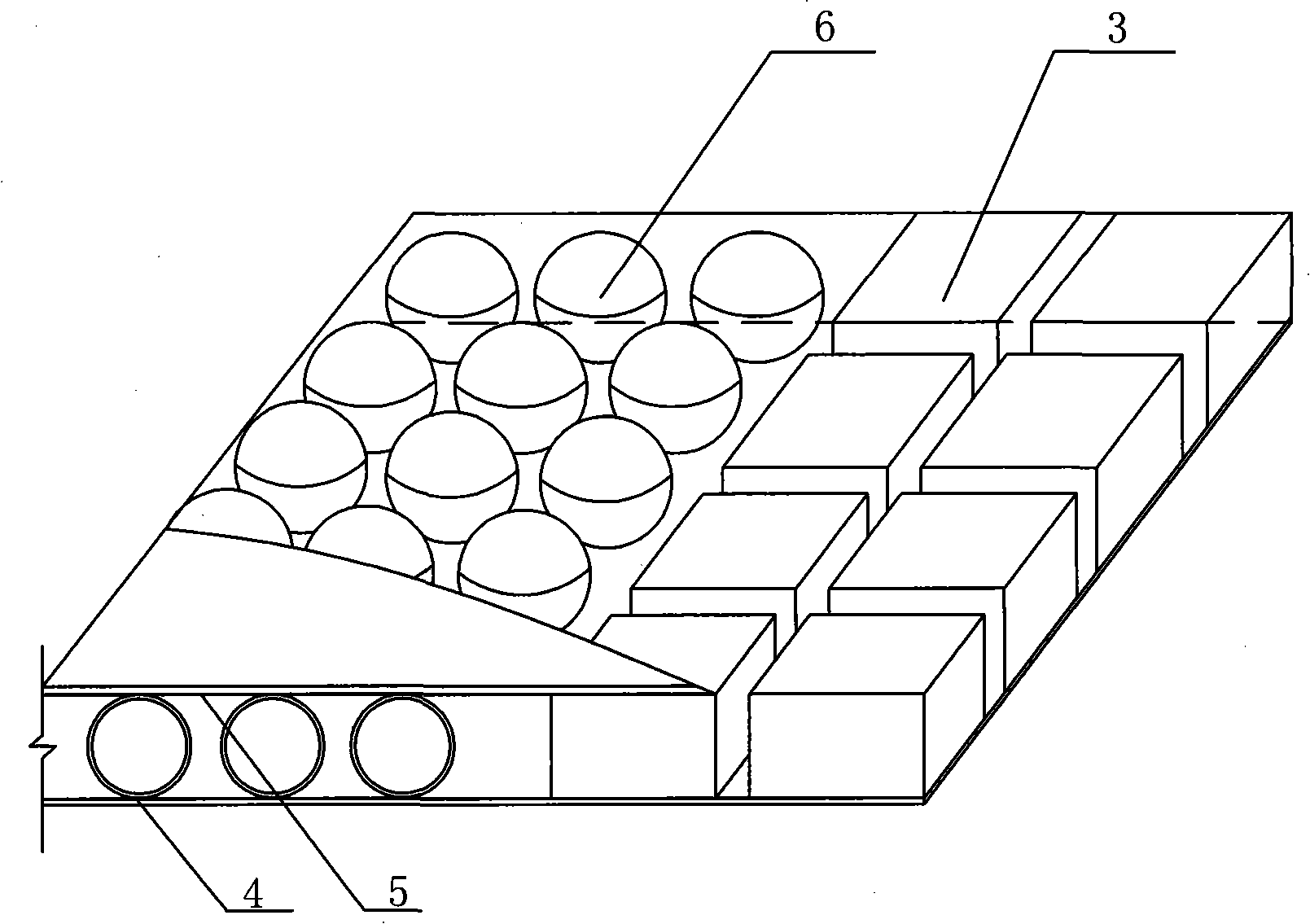

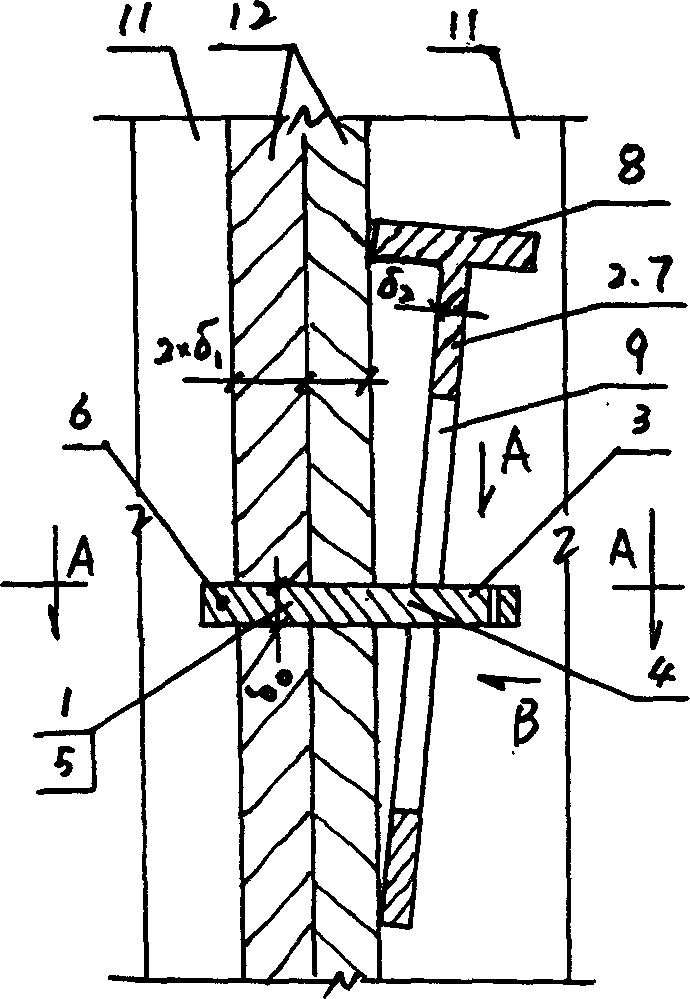

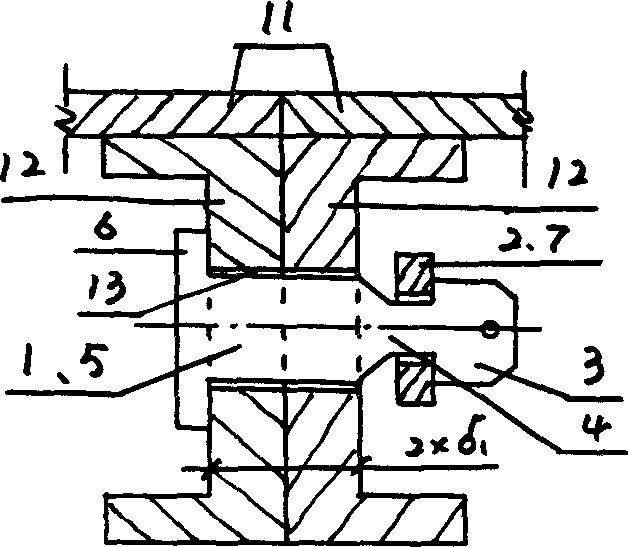

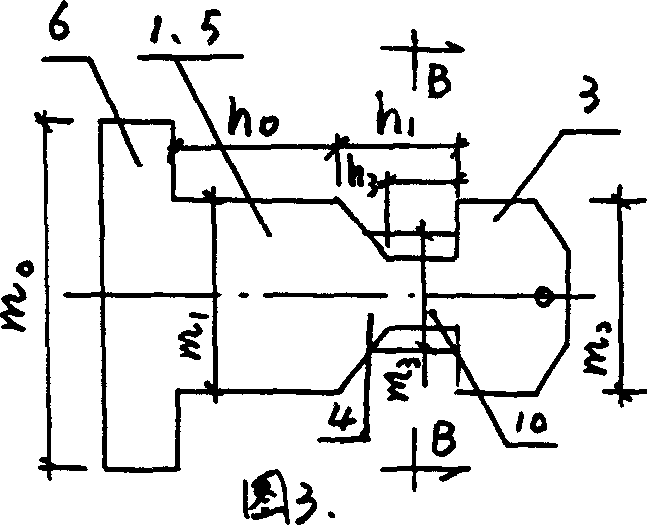

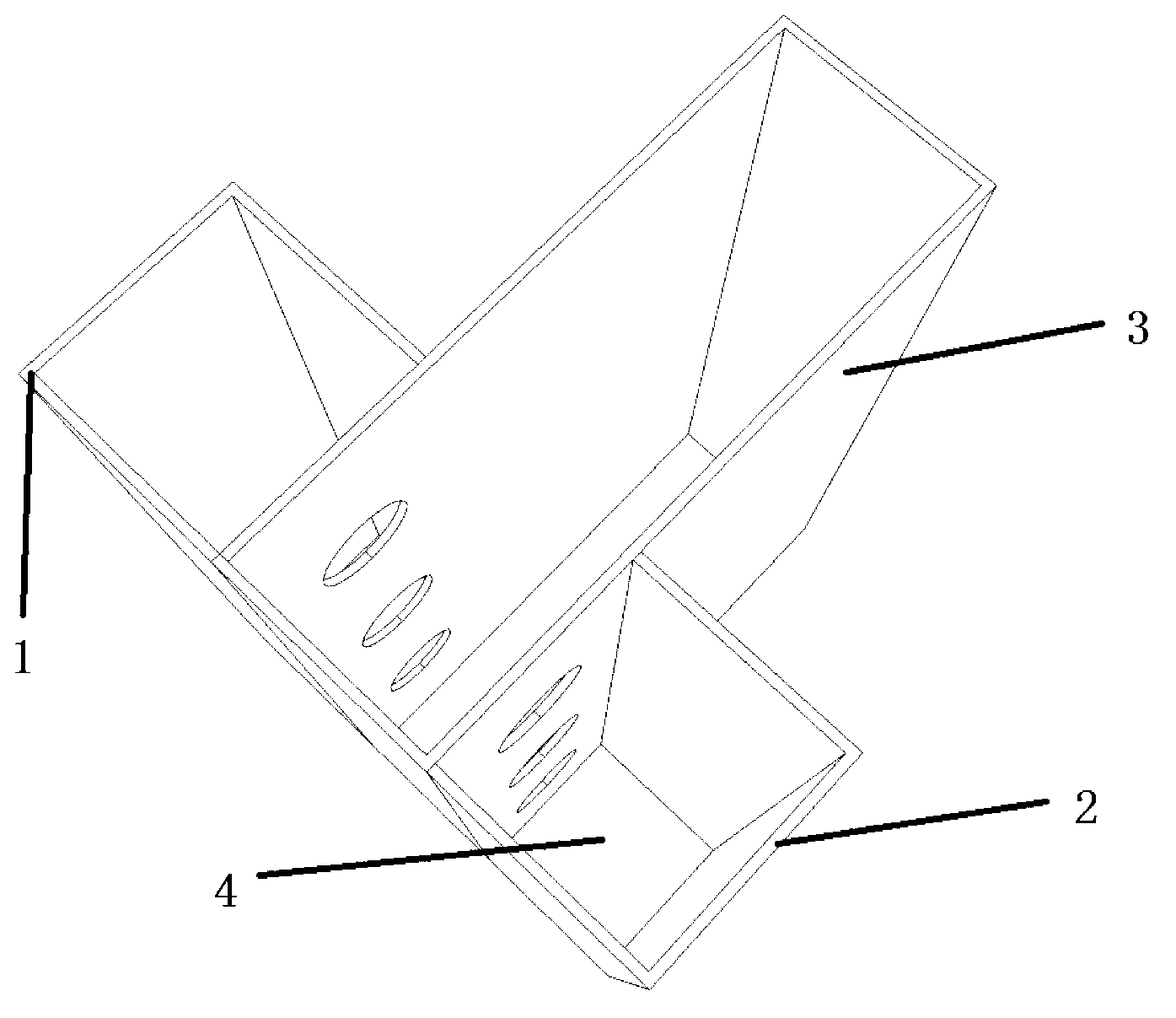

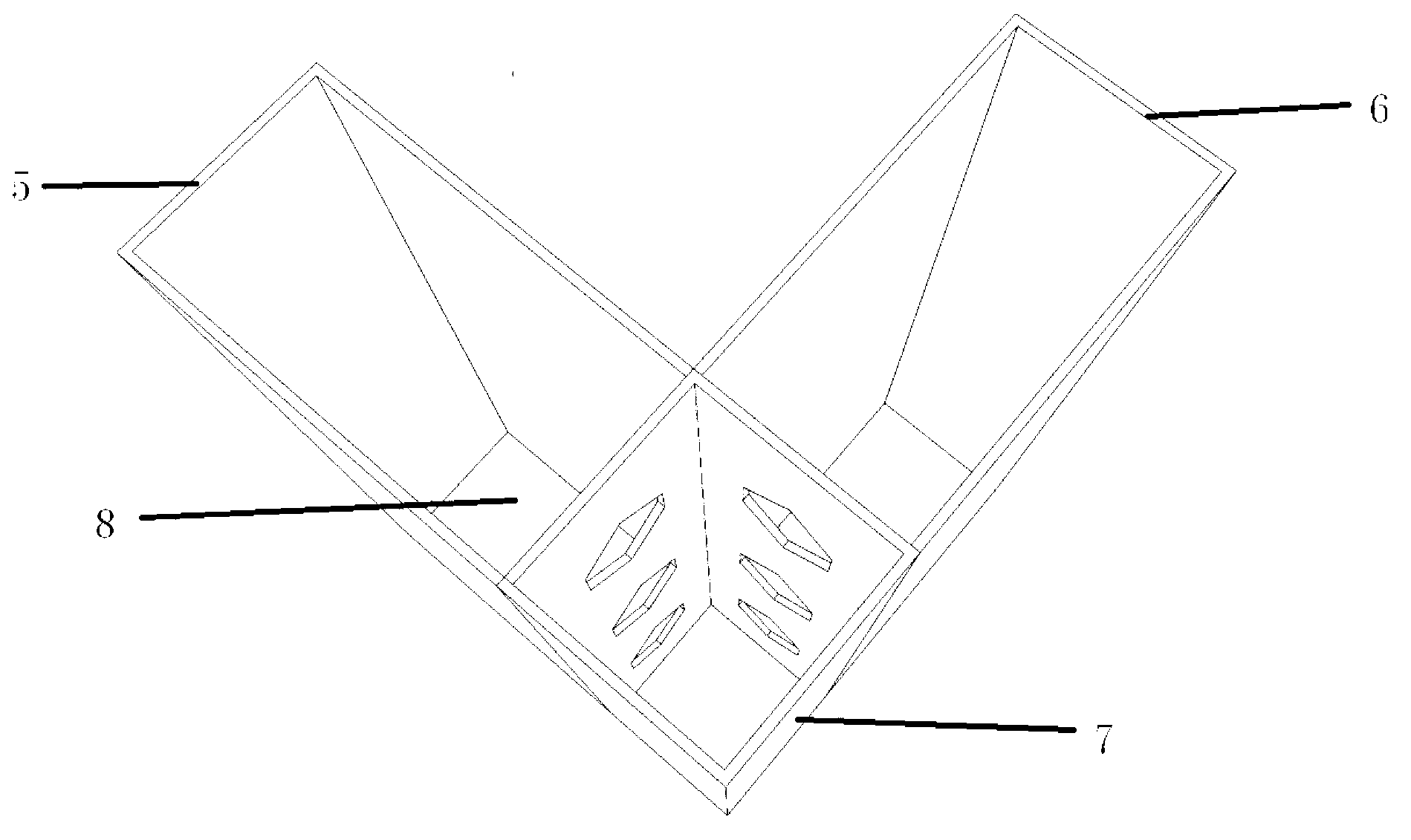

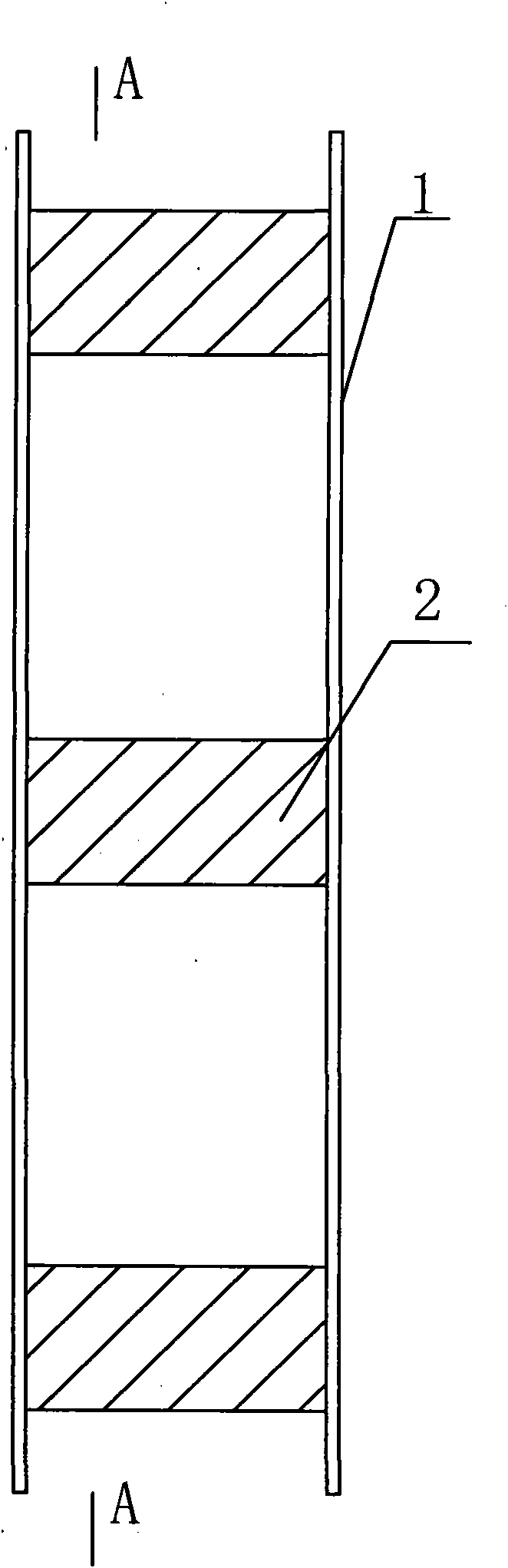

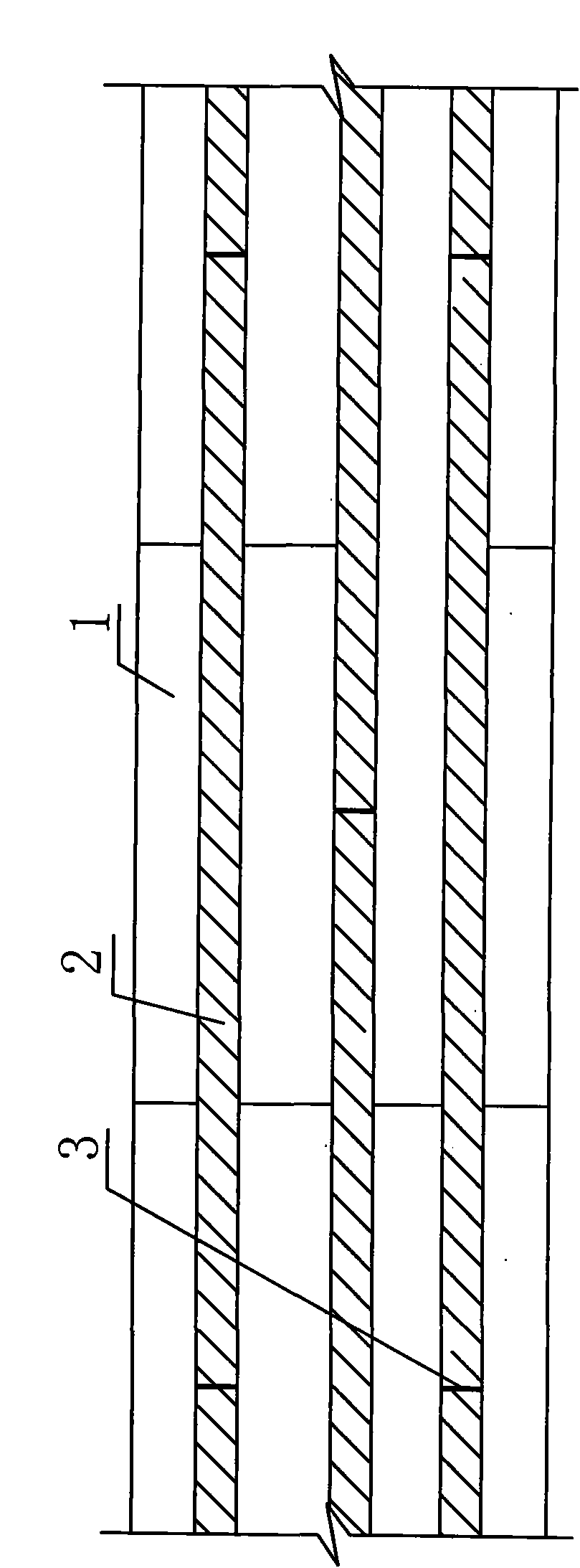

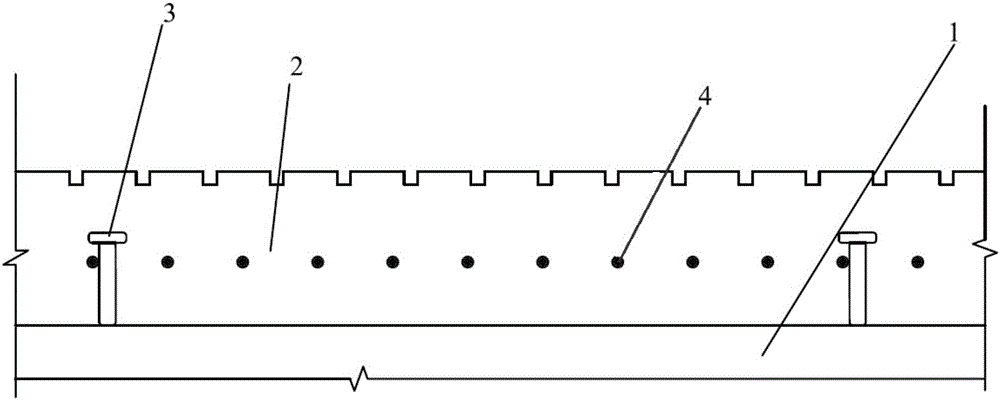

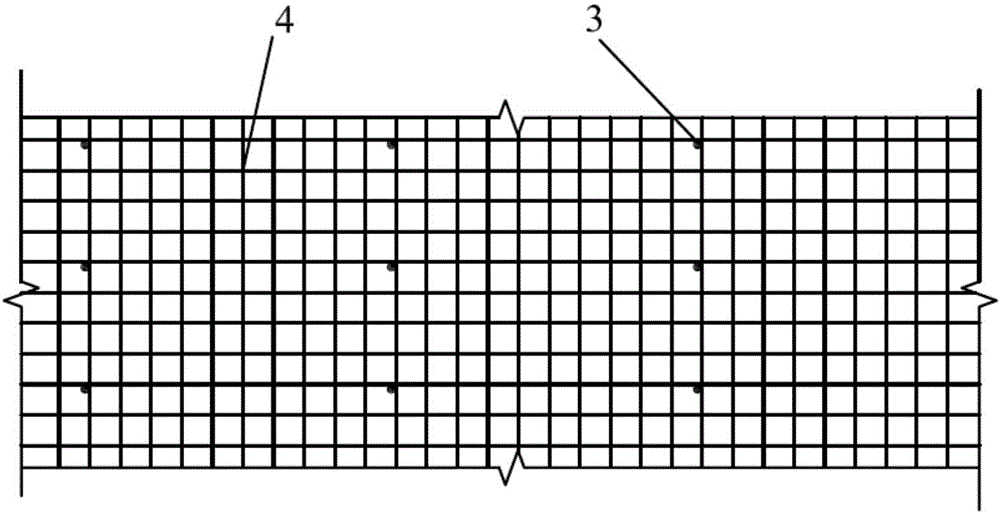

Hollow core slab for combined use of filling rods and filling boxes

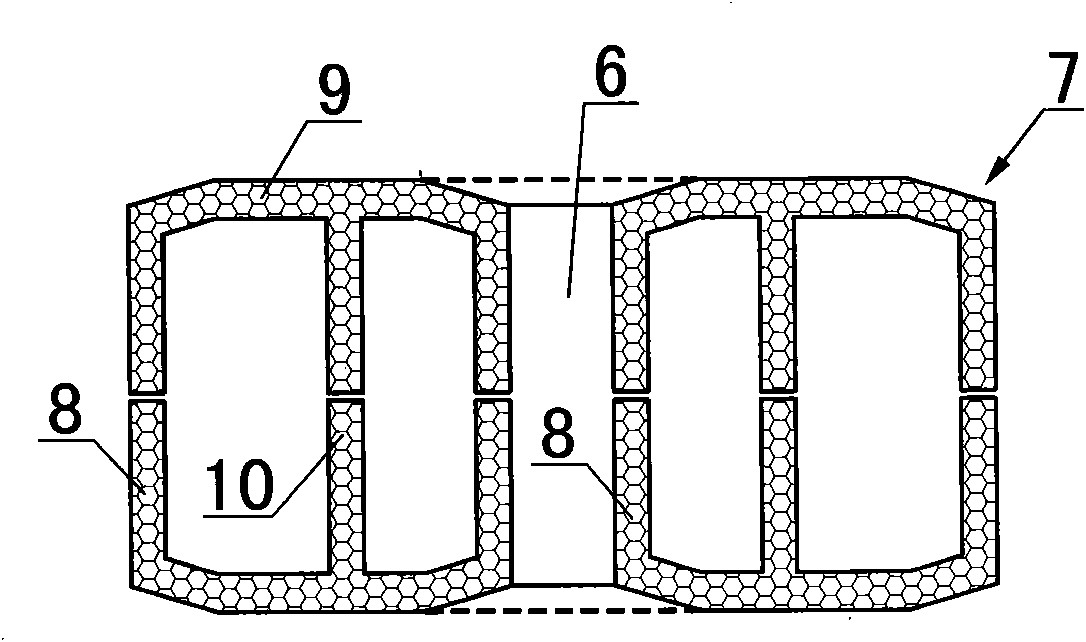

ActiveCN102031839AHigh hollow rateLow hollow rateFloorsBuilding material handlingCrack resistanceCombined use

The invention relates to a hollow core slab for the combined use of filling rods and filling boxes, and belongs to the field of construction of the common buildings. The hollow slab is a two-way slab and is divided into four peripheral hollow regions (1) and one central hollow region (2) on the plane, wherein filling rod combined blocks (3) and filling boxes (4) are embedded in the peripheral hollow regions (1) and the central hollow region (2) respectively; the central hollow region (2) is enclosed by four boundaries (7); each peripheral hollow region (1) is enclosed by one support edge (5), two oblique lines (6) and one boundary (7); each filling rod combined block (3) faces the direction vertical to the support edge (5) of the peripheral hollow region (1) where the filling rod combined block (3) is; and each filling rod combined block (3) arranged on the oblique line (6) faces the direction vertical to any one of support edge (5) adjacent to the oblique line (6). The hollow slab has large span and light weight in hollow floor system, has high reliability, shock resistance and crack resistance in a structure, and has high economy and applicability.

Owner:徐焱

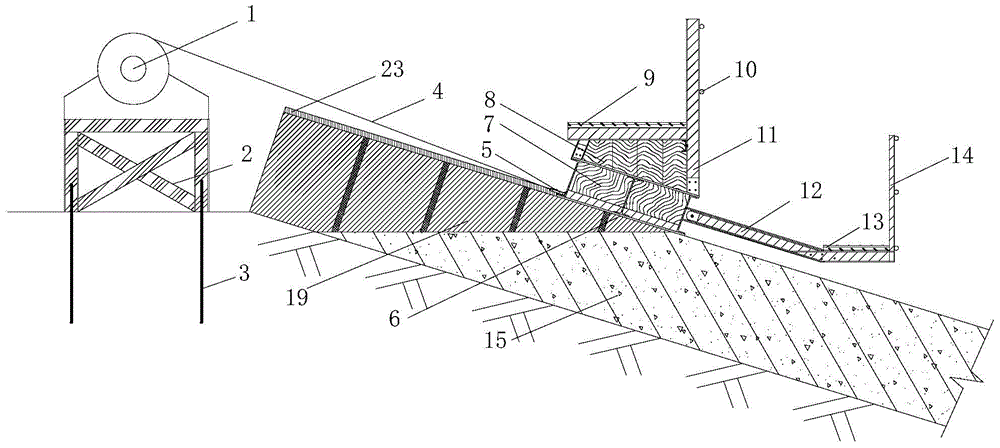

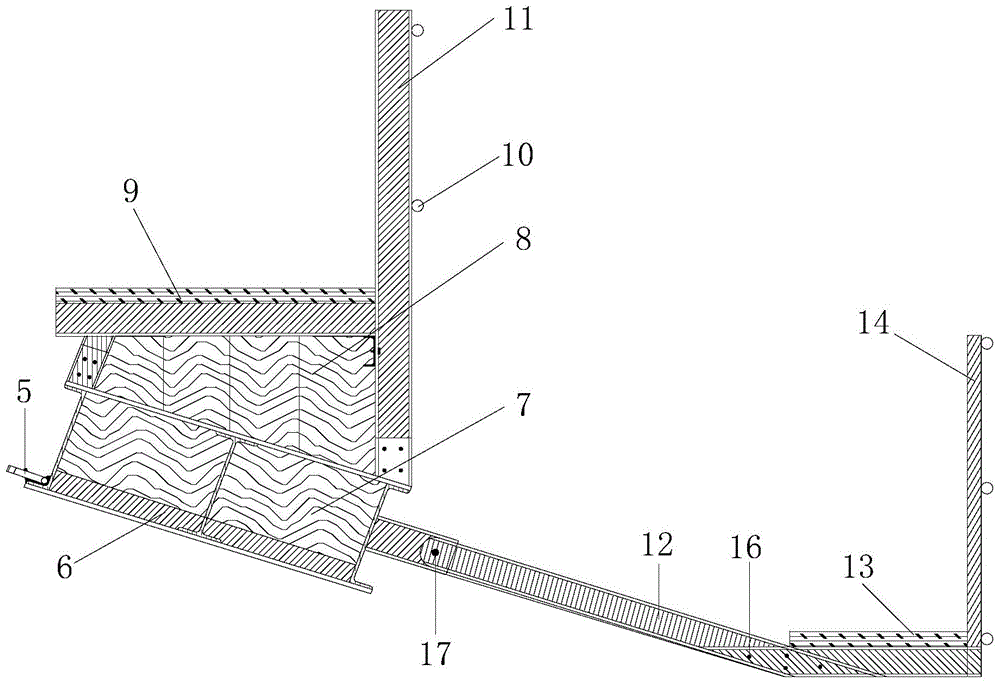

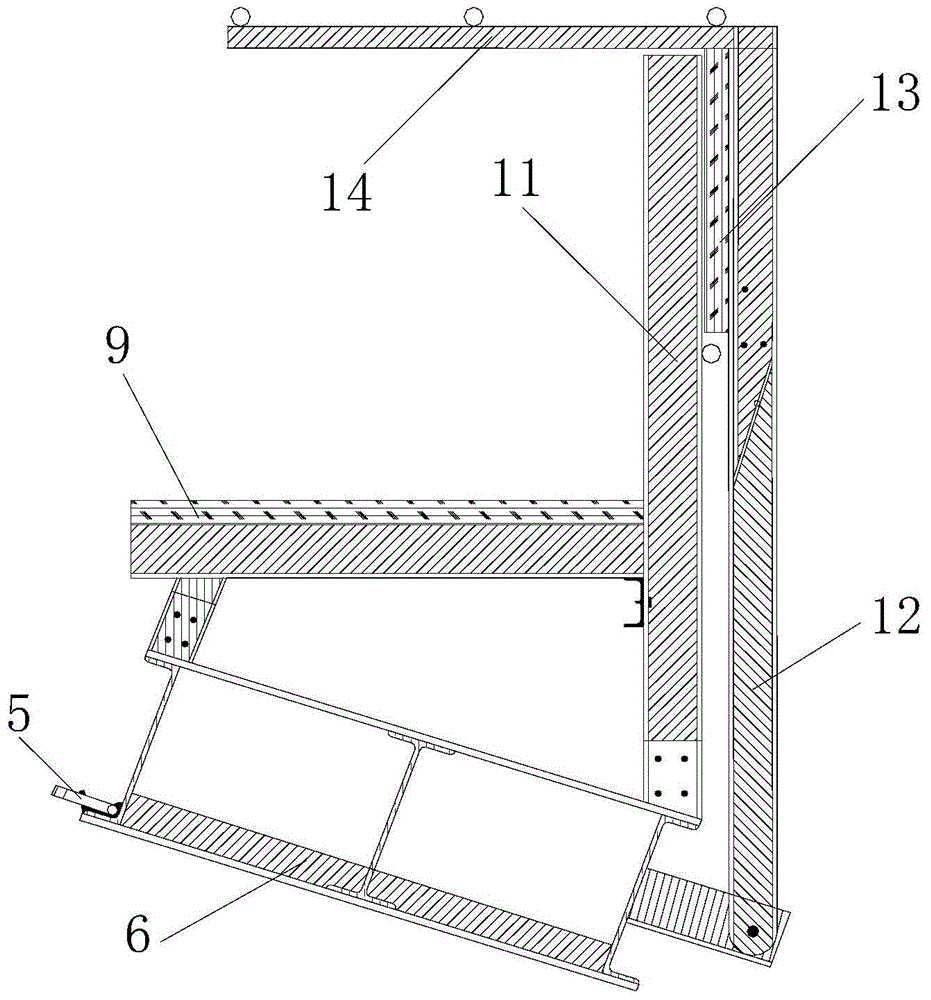

Long side slope protection concrete continuous rapid pouring and form-drawing system and construction method

InactiveCN104878766AFlexible control of sliding speedEasy to operateExcavationsCushioningEngineering

The invention relates to a long side slope protection concrete continuous rapid pouring and form-drawing system. A slip form mainly comprises a side form and a face form; the side form is connected with the face form by mutually-embedded sliding rails; U-shaped nail limiting holes are formed on the top surfaces of the sliding rails; the face form mainly comprises a panel, an operation platform, a protection railing, a plastering platform and the like, wherein the panel adopts a hollow steel-channel erected steel plate and water pressure bags are arranged in the steel sheet and under the operation platform; the side form adopts a sized combined frame steel form; a debugging bracing piece is arranged outside the side form; steel plate placement grooves are formed at intervals; water pressure bags are arranged in the steel plate placement grooves; a synchronous thin jack variable inclined cushioning body is arranged at the position of a bench. According to the invention, a side form self-rail form drawing system is adopted, so that ceramic can be effectively prevented from floating up in the pouring process, continuous pouring and integral forming of multiple stages of side slopes are implemented and the long side slope protection concrete continuous rapid pouring and form-drawing system has good economic and technical benefits. The invention also provides a construction method of the long side slope protection concrete continuous rapid pouring and form-drawing system.

Owner:南京明辉建设有限公司

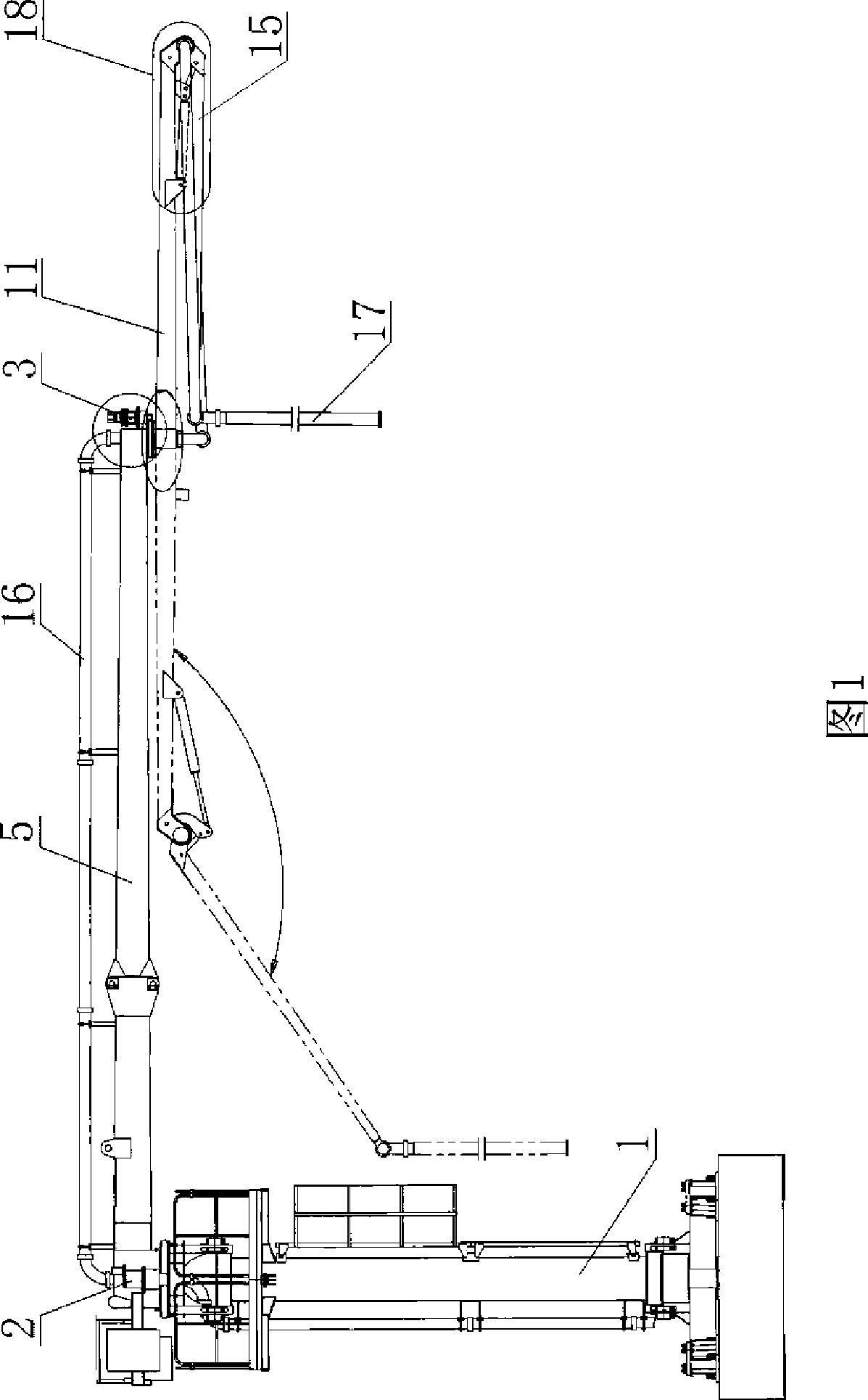

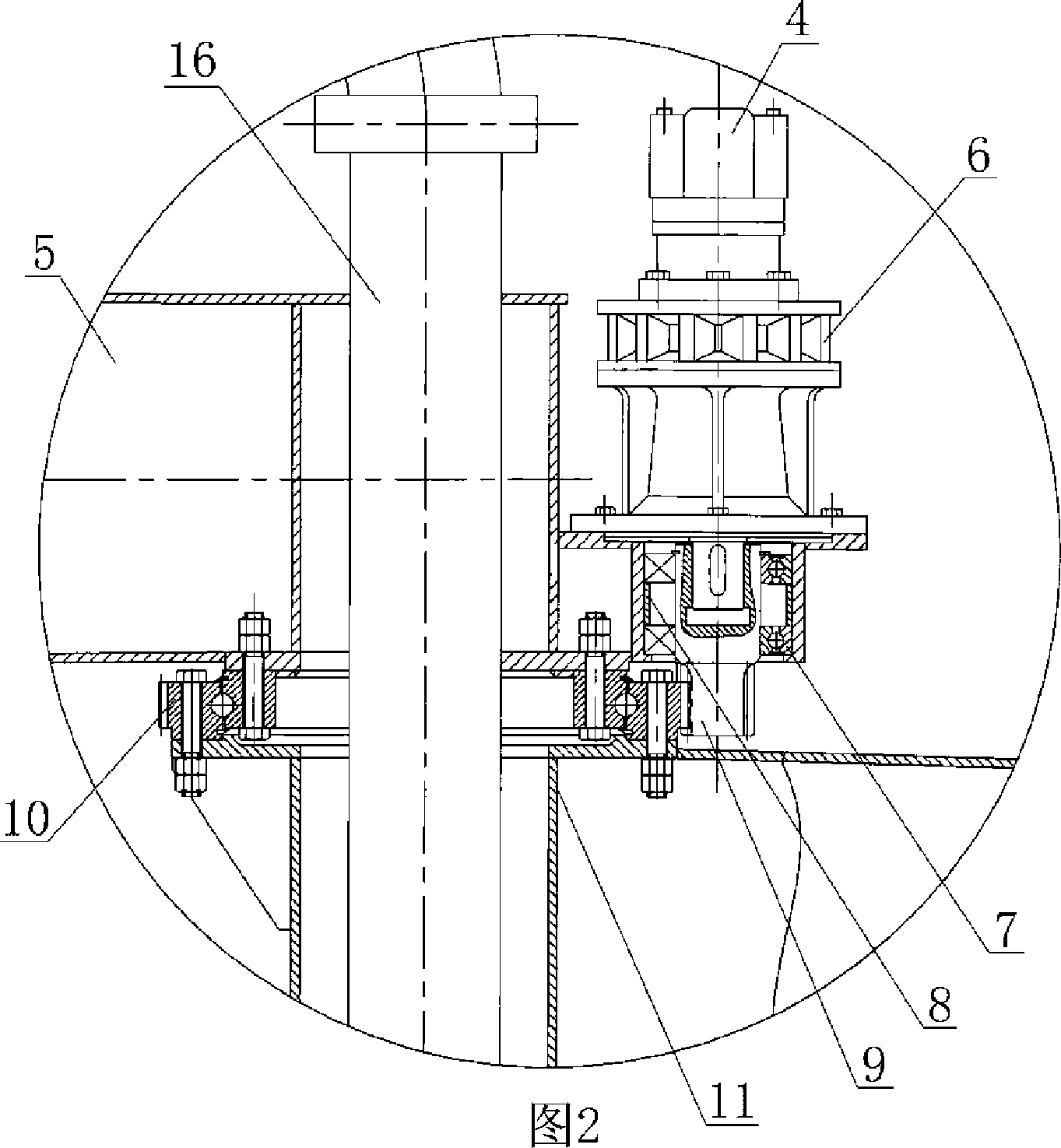

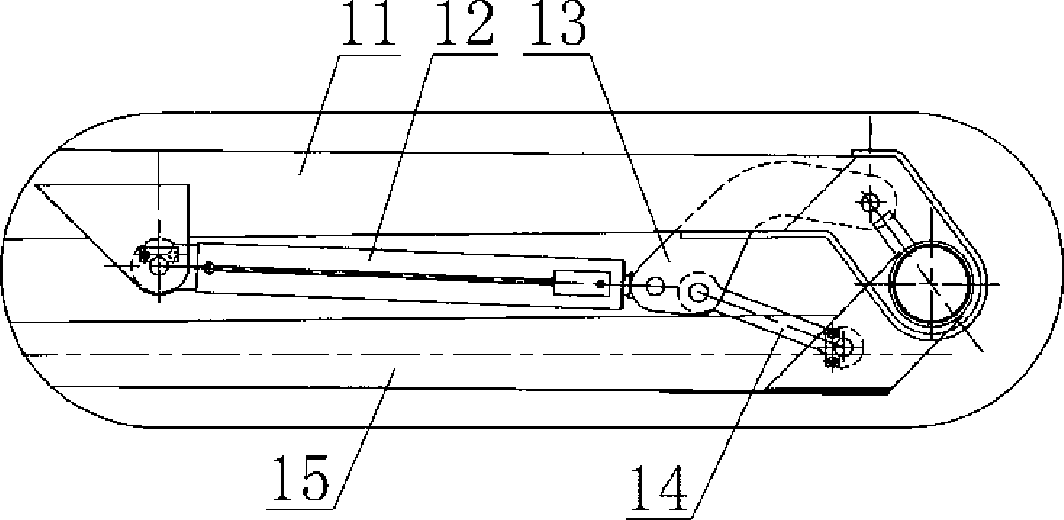

Concrete distributor with arm support capable of both horizontal rotation and pitching movement

InactiveCN101446134AImproved single job formImprove the form of workBuilding material handlingSupporting systemOperation mode

The invention provides a concrete distributor with an arm support capable of both horizontal rotation and pitching movement. The concrete distributor comprises a tower body support and an arm support system connected in parallel with a concrete pumping pipeline. The head end of the arm support system is rotationally connected with the tower body support in horizontal rotation manner via a first horizontal rotation mechanism. The concrete pumping pipeline comprises a feeding pipe and a discharge nozzle. The arm support system is formed by the tail-to-head connection of a large arm, a middle arm and a small arm, which are in relative movement to one another. The tail end of the large arm is rotationally connected with the head end of the middle arm in horizontal rotation manner via a second horizontal rotation mechanism. The tail end of the middle arm is rotationally connected with the head end of the small arm via a pitching mechanism. The tail end of the small arm is connected with the discharge nozzle. Since the arm support system is capable of both horizontal rotation and pitching movement, the concrete distributor incorporates the horizontal operation and the vertical operation, integrates the advantages of the prior two types of concrete distributors, improves the single operation mode of the prior concrete distributor, and substantially overcomes the problems of the prior two types of concrete distributors.

Owner:CABR CONSTR MACHINERY TECH +1

U-shaped steel-concrete composite beam

ActiveCN103835435AIncreased bending stiffnessImprove the bending capacityLoad-supporting elementsSteel barFire resistance

The invention discloses a U-shaped steel-concrete composite beam, relates to a composite beam, and solves the problems that the conventional I-shaped steel-concrete composite beam has poor fire resistance and poor overall stability, an outsourcing steel-concrete laminated plate composite beam has low anti-shear bearing capacity, the complete cooperative work of a steel beam and concrete is not guaranteed easily. The U-shaped steel-concrete composite beam comprises a concrete plate, U-shaped steel, a plurality of pieces of angle steel, a plurality of longitudinal stress reinforcing steel bars, a plurality of erect reinforcing steel bars and the concrete; each web plate of the U-shaped steel is fixedly connected with a flange plate which is arranged horizontally; the U-shaped steel and the flange plate are integrated; the plurality of pieces of angle steel are fixedly connected in the U-shaped steel along the length direction of the U-shaped steel; an erect reinforcing steel bar is welded on the side surface of each piece of angle steel; the longitudinal stress reinforcing steel bars are fixedly connected with the corresponding erect reinforcing steel bars along the length direction of the U-shaped steel; the concrete plate is arranged on the top of the U-shaped steel; the reinforcing steel bars in the concrete plate are bent and then extend into the U-shaped steel; the concrete is cast in the U-shaped steel. The U-shaped steel-concrete composite beam is applied to civil engineering construction.

Owner:JIANGSU ZHONGBAO STEEL STRUCTURE

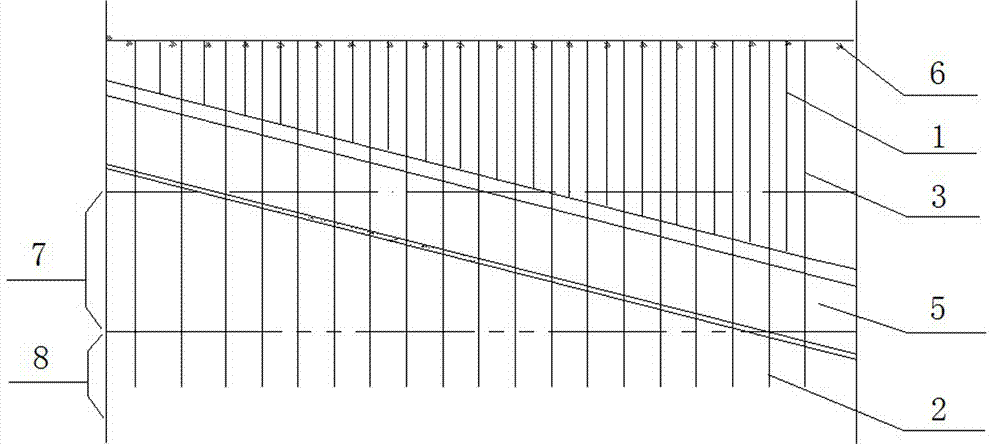

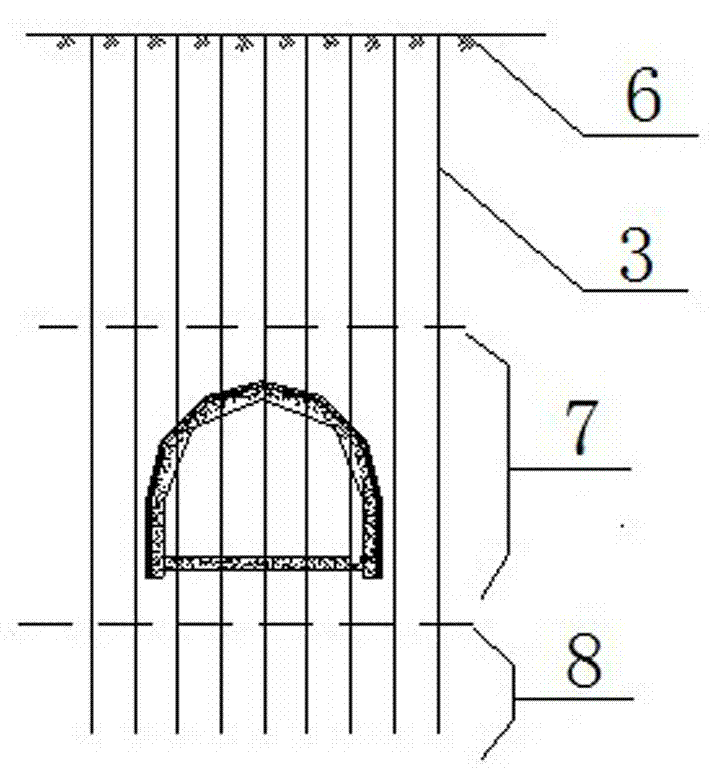

Freezing method of frozen wall of inclined shaft

The invention provides a freezing method of a frozen wall of a frozen wall of an inclined shaft, solving the problems of difficulty in digging in the construction because an aquifer of the inclined shaft is frozen and low construction speed and meeting safe and rapid construction requirements of the aquifer of the inclined shaft. The freezing method comprises the following steps of: drilling multiple rows of freezing holes which are parallel to each other and vertically distributed, on the group, along an axial freezing range of the inclined shaft, wherein the row number of the freezing holes is determined according to the cross section size of the inclined shaft and the required freezing time, the freezing holes at the lateral part and the freezing holes at the end part respectively go deep into a water-resisting layer in the depth, water in the aquifer at the lower part is isolated by the water-resisting layer, and the freezing holes at the top go deep into the top of the inclined shaft in depth; then arranging a freezing pipe and a liquid supply pipe in each drilled freezing hole, wherein the freezing pipe and the liquid supply pipe in each drilled freezing hole are communicated with an external freezing station; and finally, starting the freezing station and enabling low-temperature saline water prepared by the freezing station to flow in the each freezing pipe to absorb heat of the stratum around each freezing pipe to form a frozen cylinder, wherein all frozen cylinders are continuously enlarged and further connected to form the frozen wall which can resist earth pressure and water pressure.

Owner:YANKUANG GRP CO LTD +1

Casting technique of supporting frame for building

InactiveCN106363129AGuarantee the pouring qualityReduce sticky sandFoundry mouldsFoundry coresModel sampleChiller

The invention relates to the technical field of casting, in particular to a casting technique of a supporting frame for building. The casting technique comprises the following processes that an outer cavity real sample model is adopted to be combined with an inner cavity sand core to form a cavity of a casting; the outer cavity real sample comprises a casting model sample and a supporting bed mould wholly covering the upper side of the supporting end of the casting model sample, and the top plane of the supporting bed mould serves as a model parting surface; the inner cavity sand core comprises a first sand core body for forming an inner cavity and a second sand core body for forming a small top hole, the second sand core body is inserted into the first sand core in a matched manner, and the bottom of the first sand core extends to the lower side of a flange hole and is fixed to a lower sand mould through an arbor; an open riser is arranged at the supporting end of the casting, a riser neck is arranged between the open riser and the end face of the supporting end, and a blind riser is arranged in the flange hole of the casting; the inner cavity of the casting, the normal direction of the end face of the flange end and the periphery of the flange end are each provided with a direct cooling chiller; and an open type gating system is adopted, a flow gate of an ingate is located below the blind riser of the inner cavity and is directly communicated with the blind riser, and a filter is arranged at the tail end of the flow gate.

Owner:KOCEL STEEL

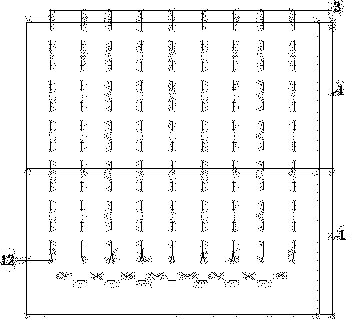

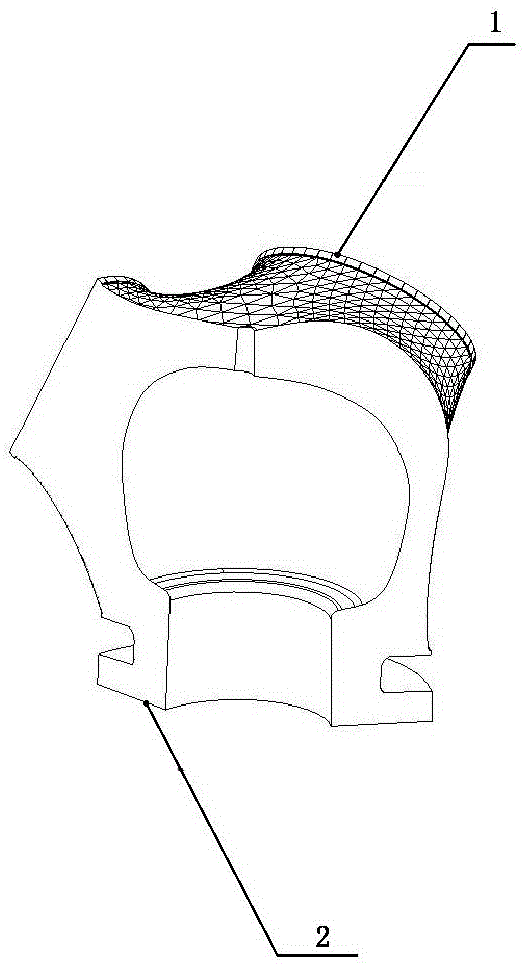

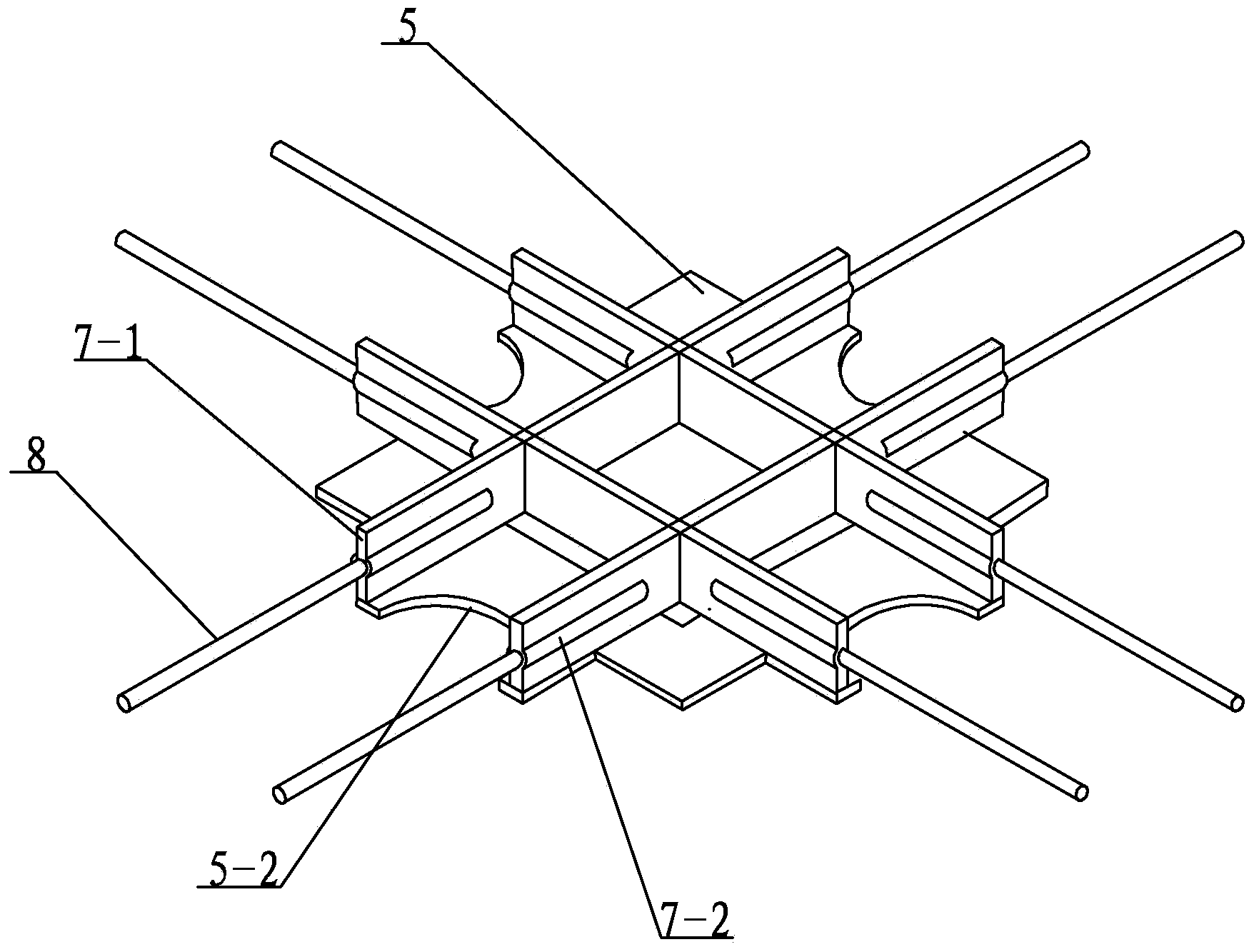

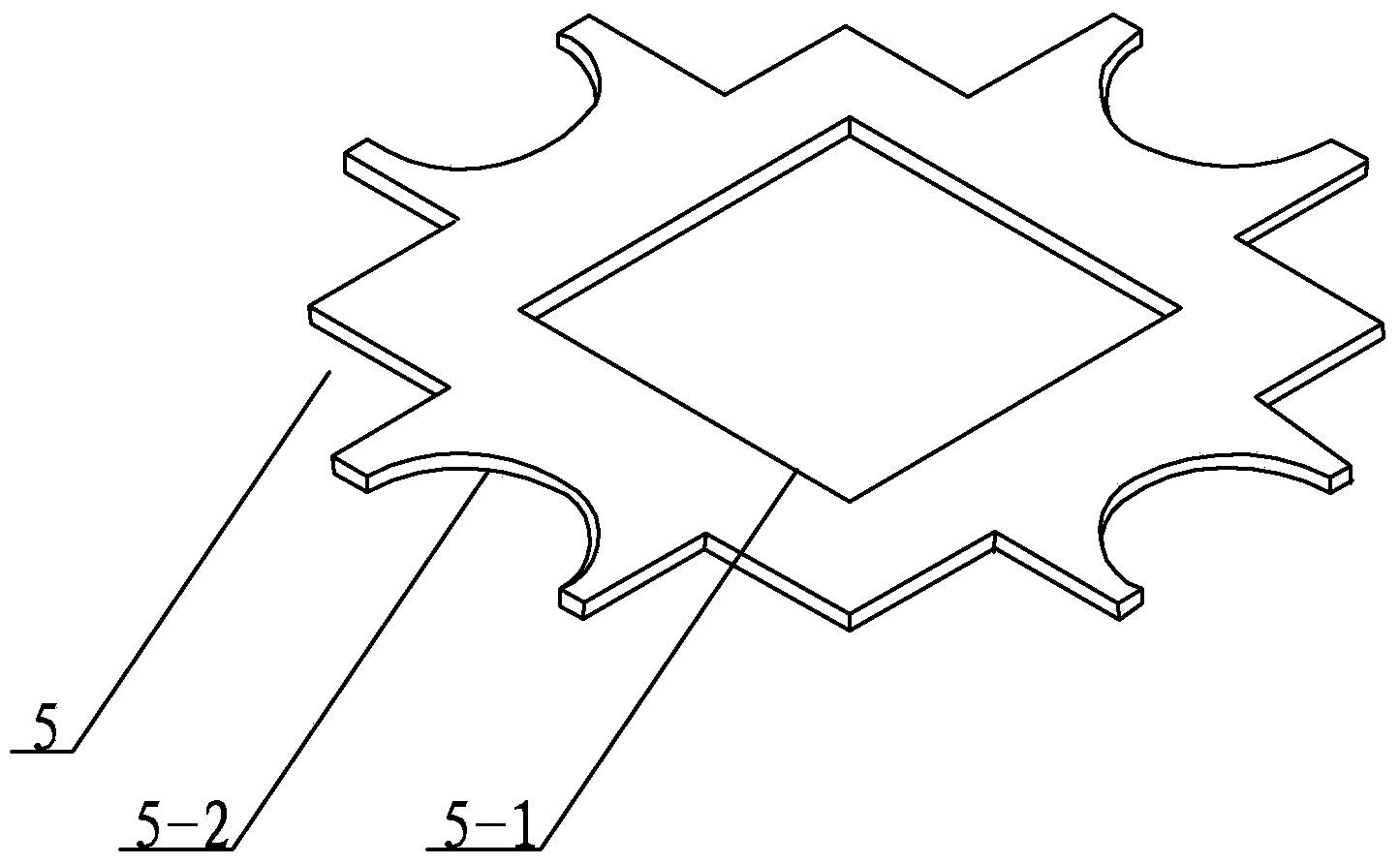

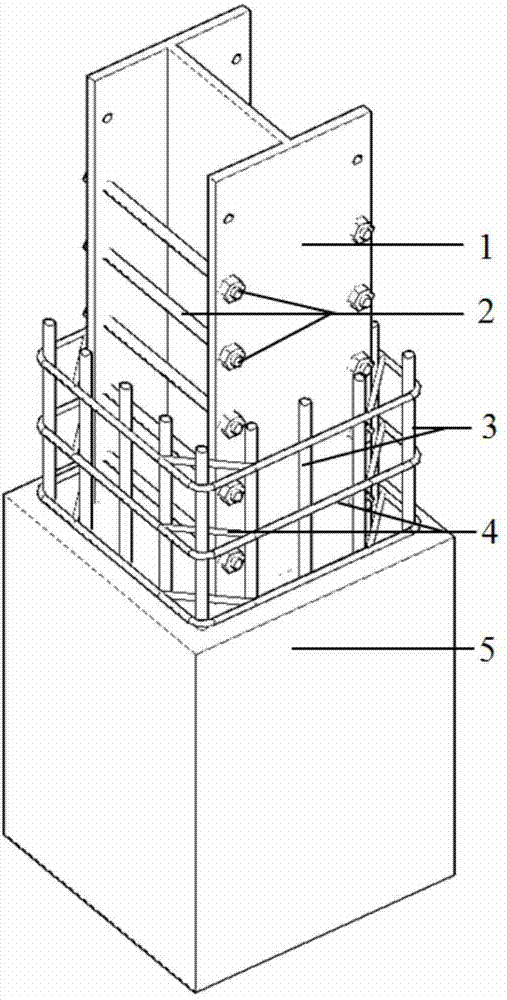

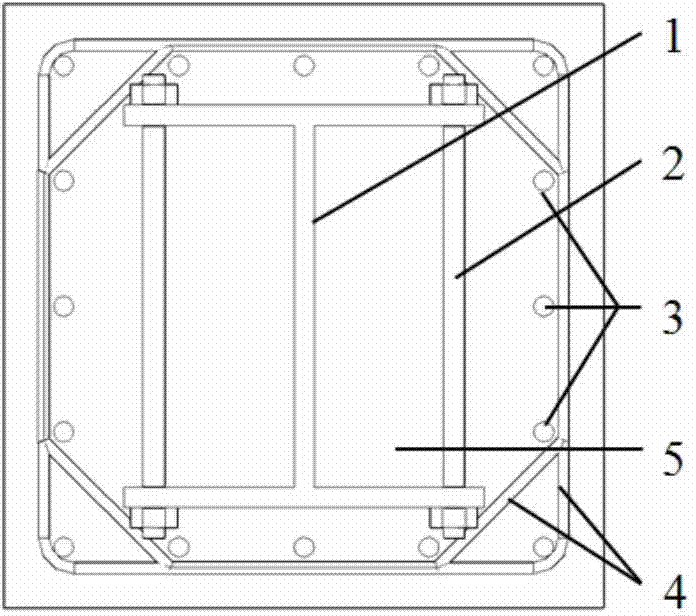

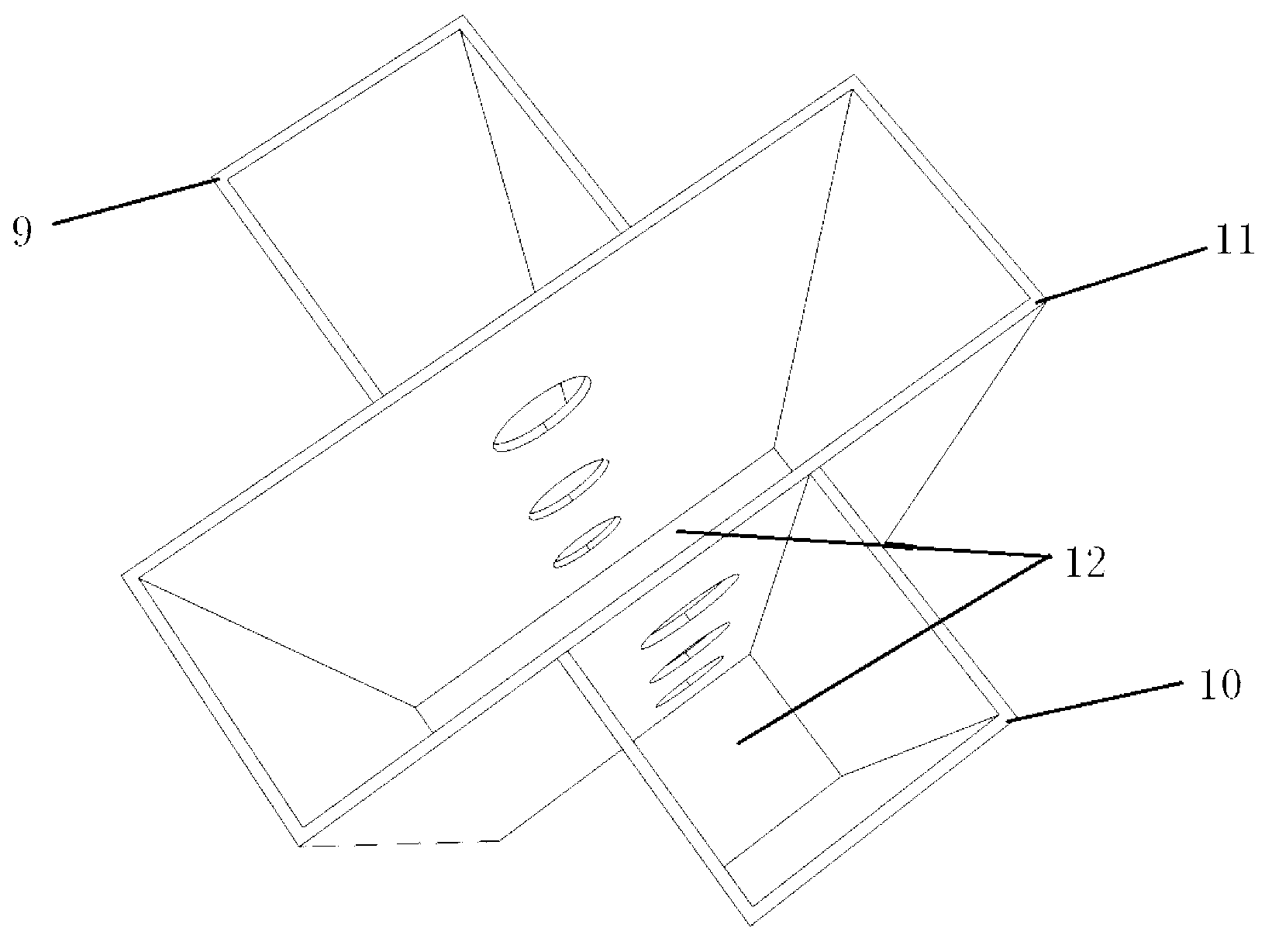

Node assembly of U-shaped steel-concrete composite beam and rectangular steel tube concrete column

ActiveCN103821235APower transmission is clearGuarantee the pouring qualityBuilding constructionsChinese charactersSteel bar

The invention provides a node assembly of a U-shaped steel-concrete composite beam and a rectangular steel tube concrete column, and relates to a node assembly of a steel tube concrete column. The node assembly of the U-shaped steel-concrete composite beam and the rectangular steel tube concrete column solves the problem that an existing node connection mode is unreasonable, the bearing capability of a node is too low, the ductility and energy-dissipating capacity of the core region of the node is insufficient, and therefore the node is damaged before other component. According to the node assembly of the U-shaped steel-concrete composite beam and the rectangular steel tube concrete column, a first rectangular steel tube, a second rectangular steel tube and a third rectangular steel tube are sequentially arranged from top to bottom, a node region inside partition plate is fixedly arranged between the second rectangular steel tube and the third rectangular steel tube, a node region reinforcing ring is fixedly arranged between the first rectangular steel tube and the second rectangular steel tube, four U-shaped steel beams are evenly distributed on four outer end faces of the second rectangular steel tube, a plurality of node region inserting plates are arranged on the node region reinforcing ring in the shape like a Chinese character 'jing', a steel bar is inserted in each node region inserting plate, and concrete is poured into the interior and the upper portion of each U-shaped steel beam. The node assembly of the U-shaped steel-concrete composite beam and the rectangular steel tube concrete column is used in constructional engineering.

Owner:JIANGSU ZHONGBAO STEEL STRUCTURE

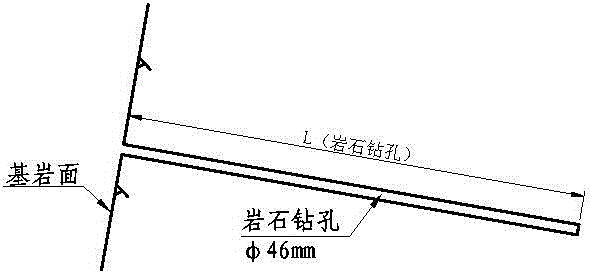

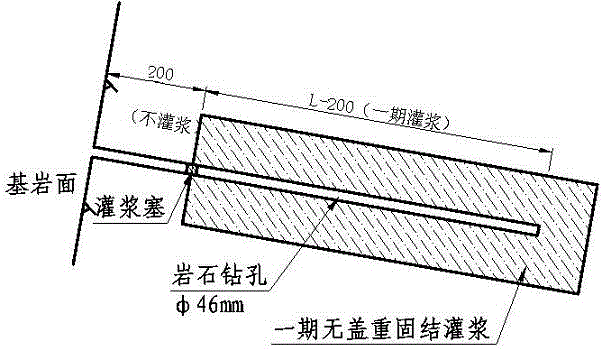

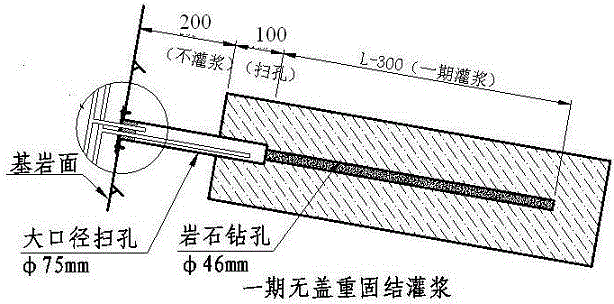

High-mountain narrow-valley arch dam foundation segmented and staged grouting method

The invention relates to a high-mountain narrow-valley arch dam foundation segmented and staged grouting method, and belongs to a foundation treatment method of a rock surface of a high steep bank slope foundation of a high-mountain narrow-valley arch dam foundation. The high-mountain narrow-valley arch dam foundation segmented and staged grouting method comprises the following steps: carrying out consolidation grouting and drilling after acceptance of excavation of the arch dam foundation; carrying out first-stage consolidation on the inside of a consolidation grouting hole; drilling a residual contact segment by the distance of 1 m with a phi 75 mm drilling sleeve after first-stage consolidation grouting is finished; burying a grouting system; pouring dam body concrete after first-stage consolidation grouting is finished; after joint grouting of a dam body is finished or while joint grouting of the dam body is carried out, carrying out second-stage consolidation on a consolidation grouting contact segment of the dam foundation. Consolidation of a bed rock contact segment and contact grouting are combined together, meanwhile, effects of contact segment consolidation and contact grouting are achieved, the work amount of the contact grouting system is reduced, the construction period is shortened, a construction technology is simplified, foundation treatment purposes of a high steep bank slope of the dam foundation of simplicity and convenience in construction, reliable technology, economy and reasonableness of grouting treatment of the high steep bank slope are achieved, and the problems encountered in foundation treatment of a dam segment of a bank slope are solved.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

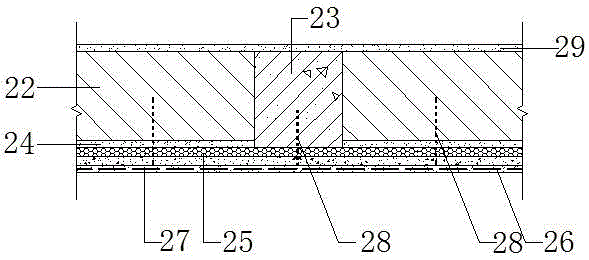

Green building self-heat-insulation structure system

InactiveCN106013478AReduce pollutionSave human effortCovering/liningsWallsStructure systemGreen building

The invention discloses a green self-heat-insulation wall body structure system, which comprises one or a plurality of structure forms in a load bearing building body self-heat-insulation wall body structure, a non-load-bearing building body self-heat-insulation wall body structure, a sandwich building body self-heat-insulation wall body structure, a sticking building body self-heat-insulation wall body structure and a sticking and concrete casting composite self-heat-insulation wall body structure. The green self-heat-insulation wall body structure system has the advantages that the structure is reasonable, and the heat insulation performance is excellent.

Owner:单锦春

H-shaped steel bone-confined concrete column with round steel draw bars and fabrication method of column

InactiveCN103924740AReduce own overhangConstrained buckling deformationStrutsPillarsUltimate tensile strengthElastic plastic deformation

The invention relates to a steel bone concrete column, and particularly relates to an H-shaped steel bone-confined concrete column with round steel draw bars. The H-shaped steel bone-confined concrete column with the round steel draw bars comprises an H-shaped steel bone, the round steel draw bars, longitudinal reinforcement, a composite stirrup and concrete, wherein the round steel draw bars are connected with two flanges, at the outer sides of the flanges and near the free edges, of the H-shaped steel bone through bolts, so that the free extension length of each flange is effectively reduced, buckling deformation of the flanges is constrained, and meanwhile, the inspection capability of internal concrete of the steel bone is enhanced by existence of the round steel draw bars. The round steel draw bars are arranged at intervals, and the internal part of the steel bone is communicated with external concrete in series, so that the pouring quality of the concrete is ensured. Therefore, the concrete disclosed by the invention has the relatively high strength and the good elastic-plastic deformation capacity, and the formed steel bone concrete column has the relatively high bearing capacity, ductility and energy-dissipating capacity.

Owner:BEIJING UNIV OF TECH

Combined type relief component cast-in-situ hollow building roof and construction method thereof

InactiveCN101324093AFlexible layoutFlexible arrangementFloorsForms/shuttering/falseworksRebarHollow core

The invention belongs to the field of general building construction, in particular to a combination-typed off-loading component cast-in-situ hollow floor and a construction method. The invention adopts a technical proposal that the invention comprises off-loading components which are fixed between an upper layer reinforcement and a lower layer reinforcement by a fixed connecting part; the concrete is filled in the gaps between the off-loading component and the reinforcement in the whole floor and between the off-loading components; the off-loading component comprises at least two cylindrical or box-shaped or spherical off-loading cells; the off-loading components are intermittently or compactly arranged; the off-loading components with different shapes are combined and applied; the type and form of the off-loading components are smartly arranged according to the requirement, thus having the advantages of good porosity, good quality, light self-weight and optimum section.

Owner:王军艇

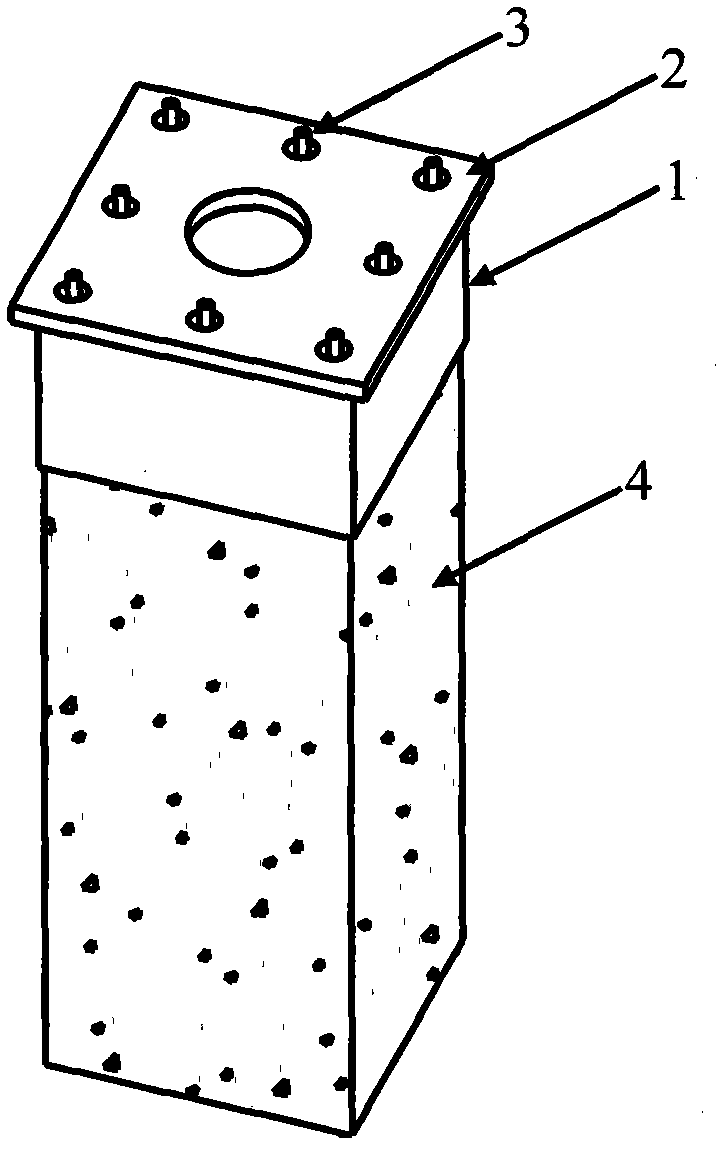

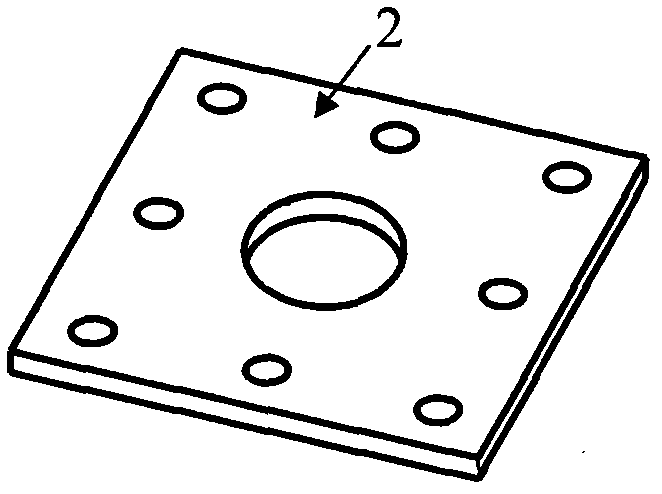

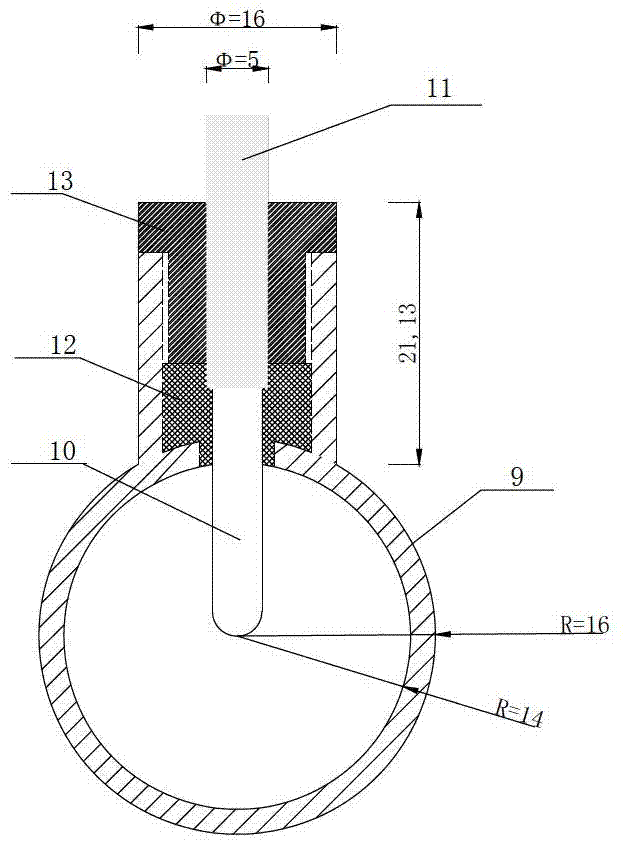

Setting method of steel tube and hole-opening end plate embedded part

InactiveCN102031830AClear forceSolve the problem of setting difficultiesBuilding constructionsReinforced concrete columnRebar

The invention discloses a setting method of a steel tube and hole-opening end plate embedded part, belonging to the field of building structures and solving the problems that the end part is difficult in hooping because a support seat embedded base plate with a top steel structure of the traditional reinforced concrete cantilever column requires to be provided with a steel shear resistant part and a tensile anchor bolt; and the compact of the concrete cannot be ensured because longitudinal reinforcing bars and tensile anchor bolts are dense and the like. By using the technical scheme of the invention, a steel tube and a hole-opening end plate are welded and then arranged at the top of the reinforced concrete column, the longitudinal reinforcing bars in the column penetrate out of holes preserved in the end plate and concrete is cast into the concrete casting holes preserved in the end plate; and after the concrete is hardened, the longitudinal reinforcing bars and the end plate are welded together; and finally, excessive reinforcing bars are cut off. The invention provides a steel structure support seat embedded part which is installed rapidly, has a simple force transmission path, is convenient to cast the concrete and can ensure the quality of casting the concrete on the top of the column.

Owner:HARBIN INST OF TECH

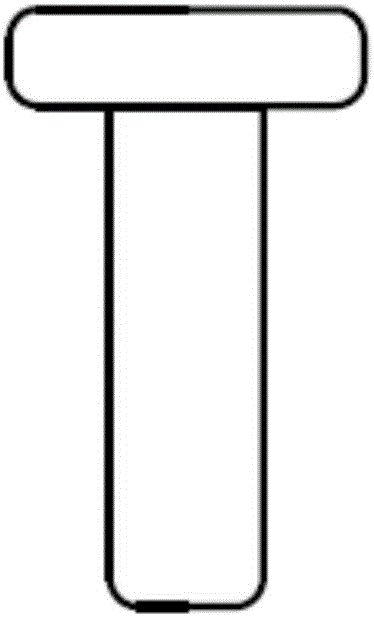

New connector for formwork assembling

InactiveCN1458373AAssembly and fasteningFirmly assembledAuxillary members of forms/shuttering/falseworksEngineeringMechanical engineering

The present invention provides a kind of formwork assembling connector for raising formwork assembling quality and speed in building construction. The present invention features that the connector consists of plate bolt in special shape and T-shaped wedged spring board, the former consists of integral bolt head, bolt shoulder, bolt body and bolt tail; while the latter consists of T-shaped head and wedge body with prolate holes matching the bolt head and the bolt shoulder. When the connector is used, the plate bolt is penetrated through the connecting hole in the assembled formwork, the spring board has its prolate holes around the bolt shoulder and inside the bolt head, and the fastened wedge body produces some elastic bending. The present invention has reliable formwork assembling andthus high concrete casting quality.

Owner:刘振邦

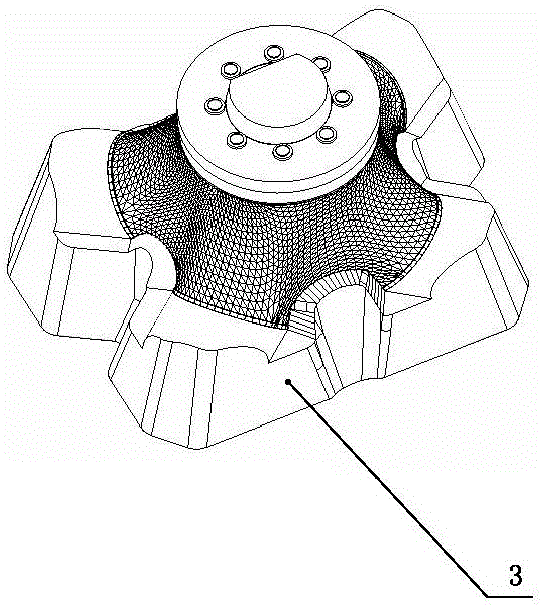

Combined type steel pipe concrete special-shaped column with honeycomb-hole partition plate

The invention discloses a combined type steel pipe concrete special-shaped column with a honeycomb-hole partition plate. The combined type steel pipe concrete special-shaped column comprises a steel pipe with honeycomb holes and concrete, and is characterized in that longitudinally arranged honeycomb holes are formed in two walls of the steel pipe with the rectangular or square cross section; U-shaped steel is arranged on the outer side of the honeycomb holes; and the concrete is poured into inner cavities of the rectangular or square steel pipe and the U-shaped steel. By the technical scheme, the section of the steel pipe concrete special-shaped column is divided into three chambers; connection among the concrete in the three chambers is enhanced; the interaction between the steel and the concrete is effectively improved; the steel and the concrete are directly stressed, so that the size of the section is reduced, and the width-to-thickness ratio of a steel plate is reduced; the performance of materials is comprehensively developed; the section performance and the bearing capacity are improved; the shock absorption property of the column of the type is improved; the combined type steel pipe concrete special-shaped column is easy and convenient to construct; the vibrating quality and the pouring quality of the concrete are guaranteed; the economical benefit is high; the bonding strength between the concrete and the steel plate is improved; an embedding effect of the steel plate is obvious; high integrity is realized; and a combining effect is outstanding.

Owner:GUANGXI UNIV

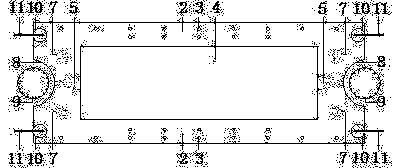

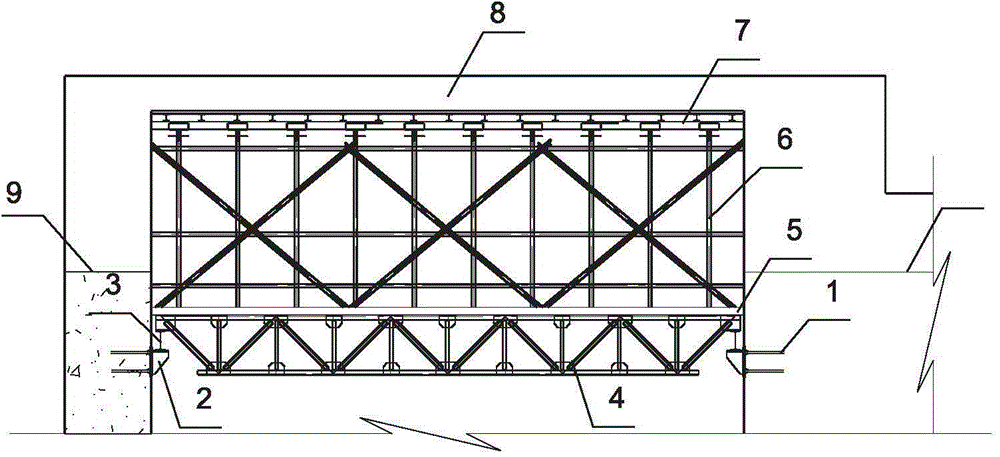

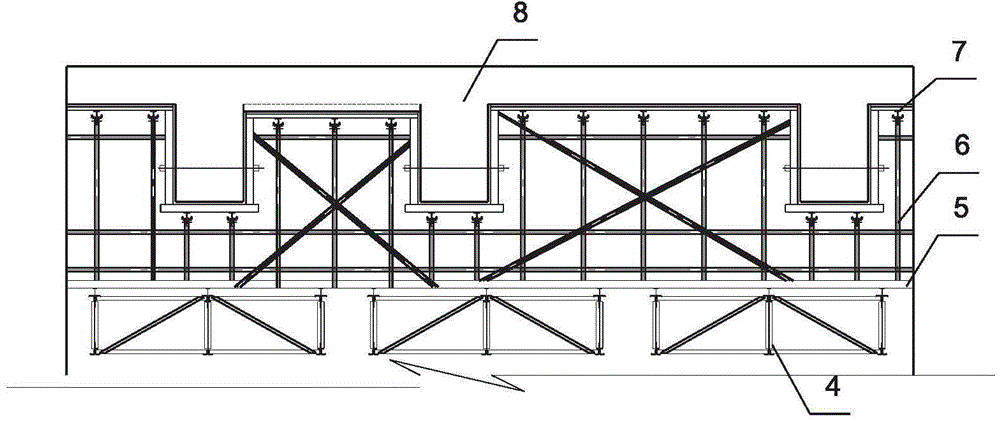

Truss platform for high and large space top plate concrete construction

InactiveCN104895314AGuarantee the pouring qualityReduce dosageBuilding support scaffoldsPurlinEngineering

The invention provides a truss platform for high and large space top plate concrete construction. The truss platform comprises a truss support iron casting; a steel bracket is fixedly connected to the truss support iron casting; a rail is mounted on the steel bracket; a steel framework truss is mounted on the rail; the steel framework truss is capable of sliding on the rail; a base plate is paved on the steel framework truss; a full hall bent frame, a supporting circular purlin and a template. The truss platform for high and large space top plate concrete construction is used for effectively the problem of supporting and erection of high and large space top plate concrete construction; the usage of materials is reduced; the truss platform has the advantages of safety, reliability, improvement of construction efficiency and the like; the construction speed is greatly increased, and reliable guarantee is also provided for construction safety.

Owner:中国葛洲坝集团建设工程有限公司

Construction method for supporting template at construction joint of frame structure

ActiveCN101864836AGood controlGood qualityForms/shuttering/falseworksBuilding material handlingLayer thicknessArchitectural engineering

Owner:CHINA 22MCC GROUP CORP +1

UHPC (ultra-high performance concrete) poured orthotropic steel bridge deck combination structure and manufacturing method thereof

InactiveCN106758812AImprove crack resistanceEnsure driving safetyBridge structural detailsBridge deckMesh reinforcement

The invention relates to a UHPC (ultra-high performance concrete) poured orthotropic steel bridge deck combination structure and a manufacturing method thereof. The UHPC poured orthotropic steel deck combination structure comprises a bottom steel bridge deck, shear nails, a reinforcing mesh and an UHPC pavement layer, wherein the shear nails and the reinforcing mesh are arranged on the steel bridge deck, the UHPC pavement layer is poured by UHPC and wraps the shear nails and the reinforcing mesh, and the UHPC pavement layer and the steel bridge deck form the bridge deck combination structure. Compared with existing steel bridge deck pavement, the strength, toughness and durability of the steel bridge deck combination structure can be remarkably improved, curing condition requirements are low, steam curing and pressure forming are omitted, construction technology is simple and convenient, construction quality is easily controlled, the tension resistance and the shear resistance of the pavement layer are effectively enhanced by the shear nails and the reinforcing mesh, the problem of diseases caused by asphalt pavement is solved, and damage to the pavement layer such as cracking, upheaval, displacement and pit slots is avoided.

Owner:TONGJI UNIV

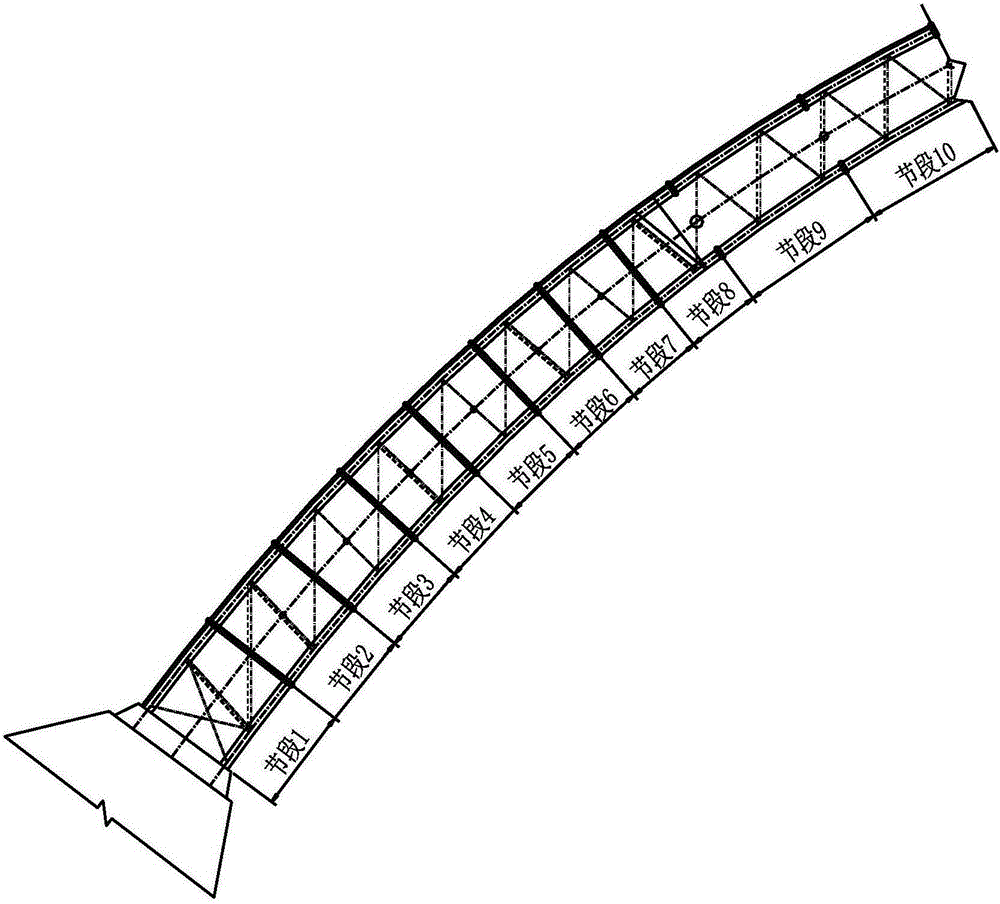

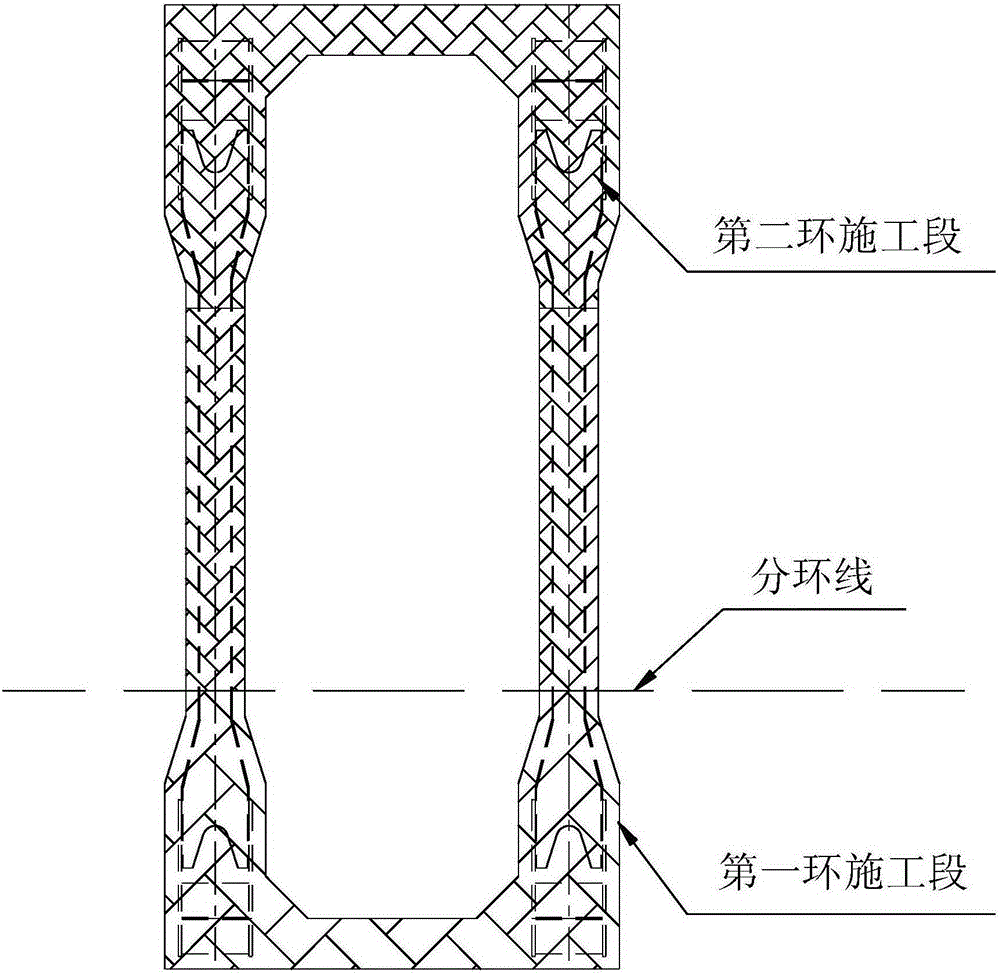

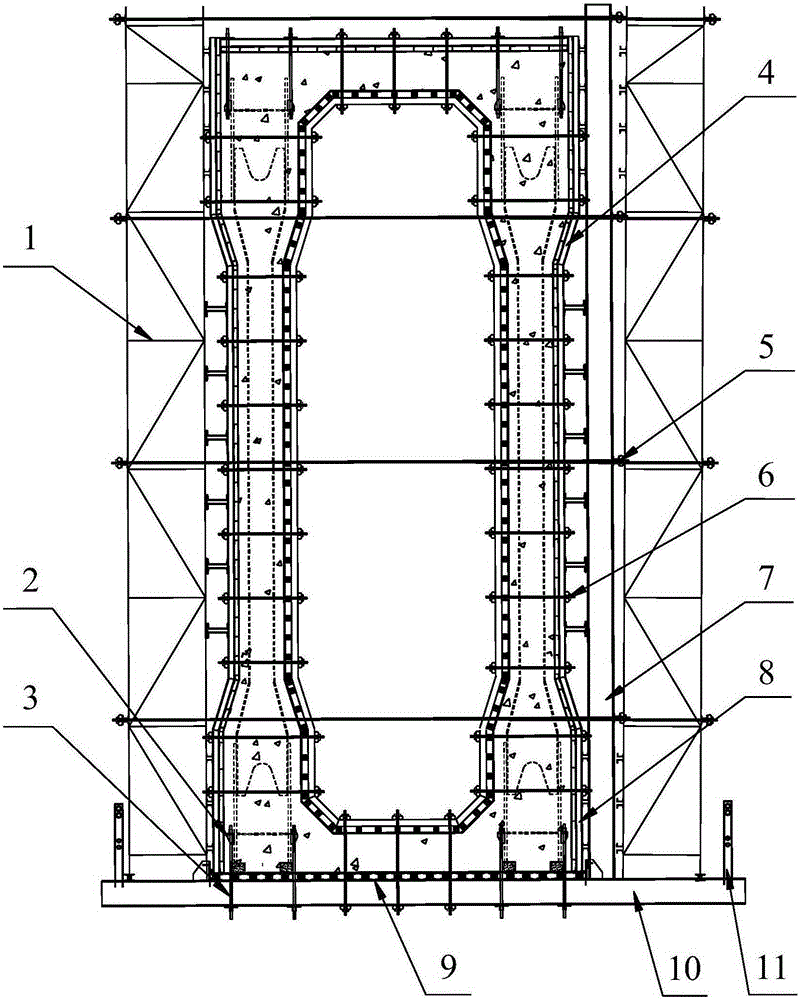

Steel arch rib outer wrapped concrete construction method for steel trussed arch bridge

ActiveCN105350454AReduce construction difficultyOvercome rangeBridge erection/assemblyEngineeringStructural engineering

The invention discloses a steel arch rib outer wrapped concrete construction method for a steel trussed arch bridge and relates to the technical field of building construction of steel trussed arch bridges. The construction method includes the steps that each steel arch rib section to be poured with concrete is provided with a hanging bracket system and a bottom formwork; after installation is finished, bottom board reinforcing steel bars are tied; each hanging bracket system is used for erecting a construction support and an operation platform, web reinforcing steel bars and a web formwork of a first ring construction section are installed, and the outer wrapped concrete is poured to the first ring construction section; after the concrete is poured, an inner cavity support and a platform are erected, a high construction support and an operation platform are connected, reinforcing steel bars and a formwork of a second ring construction section are installed, and the outer wrapped concrete is poured to the second ring construction section; and after the concrete is poured, outer wrapped concrete construction of the next steel arch rib section is started, and the operation is repeated till the concrete is poured to all the steel arch rib sections. By the adoption of the method, the construction difficulty is lowered, the application range is wide, construction efficiency is effectively improved, construction safety is guaranteed, and adaptability and economical efficiency are high.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

Cast production technology for shell

InactiveCN101875092AImprove mechanical propertiesImprove shrinkageFoundry mouldsFoundry coresCooling effectVolumetric Mass Density

The invention discloses cast production technology for a shell. The technology sequentially comprises the steps of: manufacturing a mould, namely manufacturing an external metal mould, wherein the lower part of the external metal mould is provided with a molten iron inlet; manufacturing a sand mould, namely manufacturing a foaming mould, coating cast steel paint on the surface of the foaming mould, filling resin sands into the mould and hardening the sand mould by air blowing; setting a core, namely assembling the sand mould and the external metal mould, wherein a high temperature resistant material is coated on the core; pouring at the temperature of between 1,380 and 1,420 DEG C for 4 to 8 seconds and preserving the heat for 100 to 150 minutes, wherein a product yield reaches 50 to 70 percent; and performing subsequent operation, namely opening the mould to take the cast out, and cleaning and grinding the cast to obtain the required shell. The technology has the advantages of high sand mould quality, difficult cracking, good cooling effect and uniform internal density of the cast.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

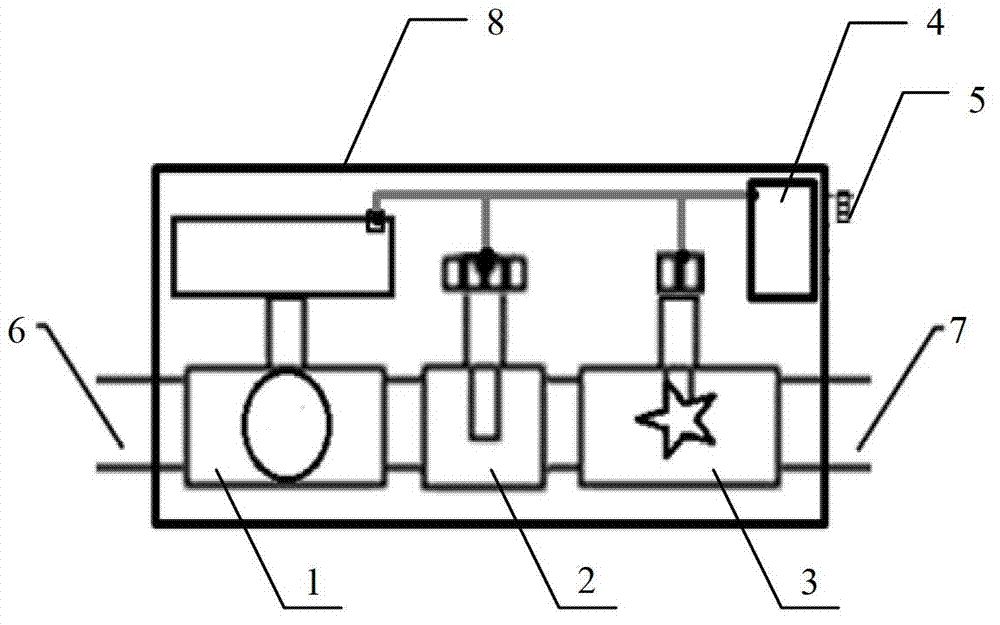

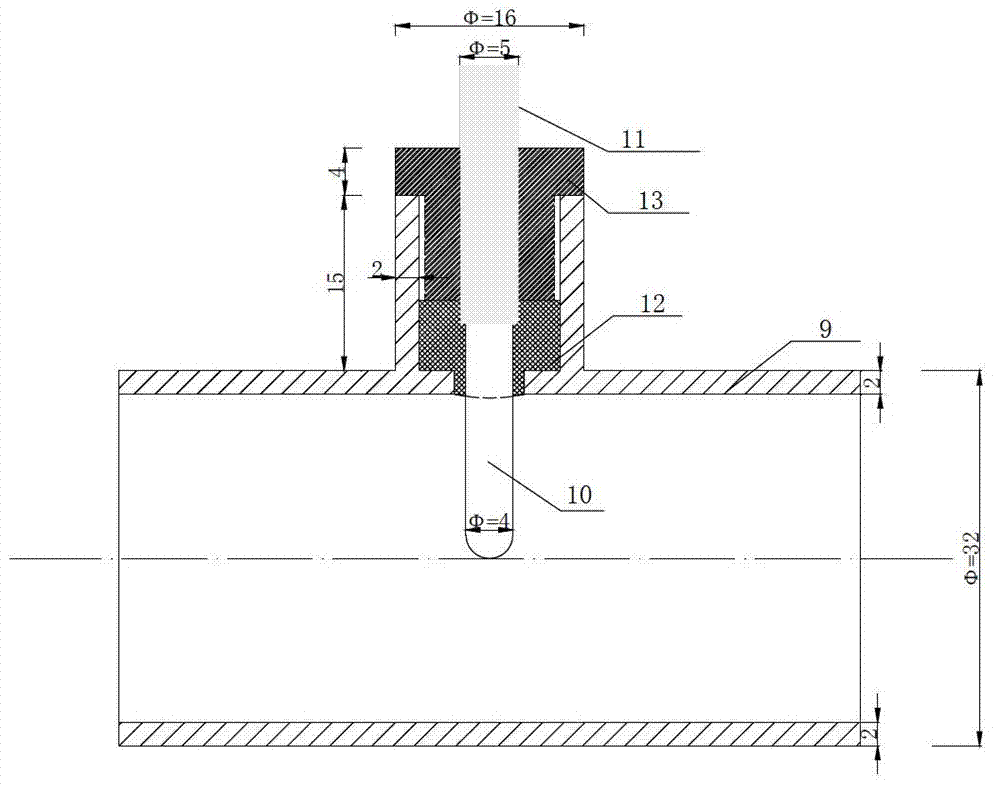

Integral flow and temperature control device

ActiveCN102830731AGood control stabilityStable and accurate flowWater cleaningTemperature control using electric meansBall valveEngineering

An integral flow and temperature control device comprises an electric ball valve, an interpolated digital temperature measuring device, a flow measuring device and an integral control circuit board which are fixedly integrated and packaged in a casing. Loose joints with diameter equal to that of external pipes are arranged at two ends of the integral flow and temperature control device, and accordingly the integral flow and temperature control device is flexible, convenient and fast in connection. The integral flow and temperature control device is subjected to data exchange with a main controller and supplied with power through a bus, can complete functions of temperature collection and flow PID(proportion, integration and differentiation) regulation and the like, can complete flow regulation once the main controller outputs a specific flow rate, has excellent stability in control (floating control / proportion control), guarantees stability and accuracy of cooling water flow, and further controls concentrate temperature and stress, and guarantees engineering quality and progress.

Owner:上海高千软件科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com