Height-adjustable recyclable reinforcing steel bar split heads

A technology of steel bar and height, applied in the field of horse benches for steel bar binding, can solve the problems of heavy force at the pin, difficult to pull out the pin, and many operation steps, so as to ensure the effective clear distance and the effect of ensuring the pouring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

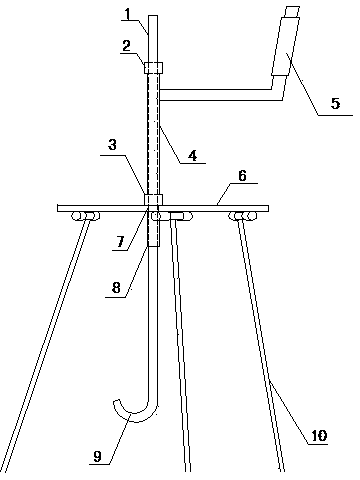

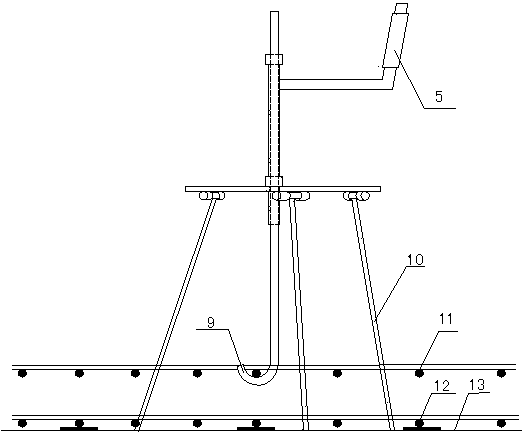

[0018] see figure 1 , this height-adjustable and reusable reinforced horse stool is composed of a lifting mechanism and a bracket. The bracket is composed of a tray 6 and legs 10. The tray 6 is a disc cut from an iron plate. There is a central through hole 7 that runs up and down in the middle, and three bushings are uniformly welded on the lower part of the tray 6. Through the bushings and the rotating shaft, three legs 10 arranged in a triangle are hinged; the lifting mechanism is assembled by a screw rod 1, The upper nut 2 and the lower nut 3 on the screw rod 1, the handle sleeve 4 which is set on the outside of the screw rod 1 and welded and fixed together with the upper nut 2 and the lower nut 3, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com