A single-side positioning method for the main shaft of a garbage double-shaft shredder

A unilateral positioning and crusher technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of loss of motor power, mutual sharpening of knives, loud noise, etc., to eliminate noise problems, improve assembly rework, The effect of eliminating tool resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

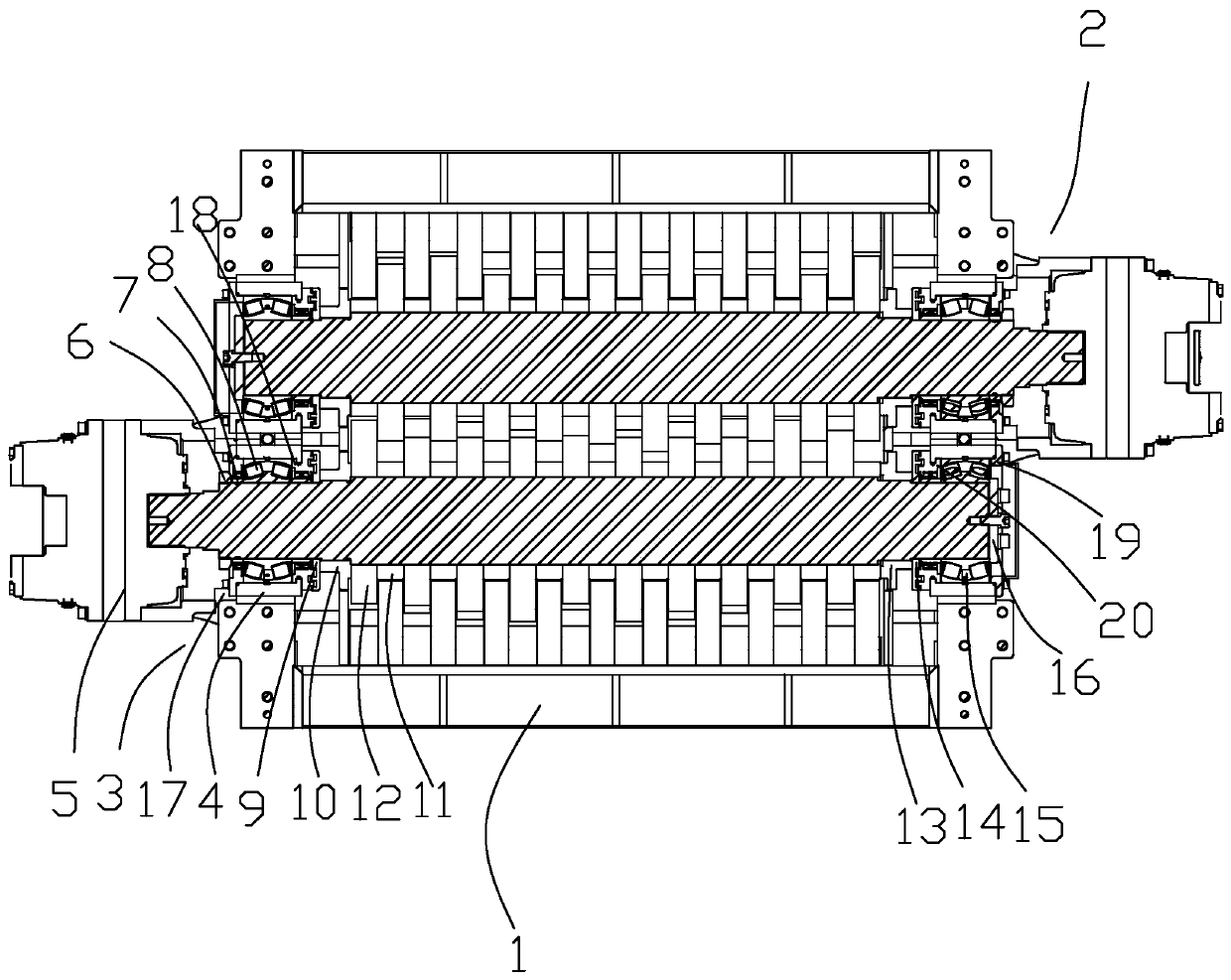

[0016] refer to figure 1 , the invention discloses a unilateral positioning method for the main shaft of a garbage double-shaft shredder. The lower half bearing housings 4 are installed on the two side plates of the box body 1, and two coplanar reference planes are processed on the outer surfaces of the two lower half bearing housings 4 located on the same side board, the main shaft assembly one 2 and the main shaft assembly 2 and 3 all include the main shaft and the reducer 5 with the motor installed on the main shaft in turn, the end round nut 6, the end shaft sleeve 1 7, the end bearing 8, the end seal sleeve 9, the end shaft sleeve 2 10, and the moving parts installed in turn Knife 12 and spacer 11, tail shaft sleeve one 13, tail seal sleeve 14, tail bearing 15, tail end locking cover 16, the outer side of the end bearing 8 is provided with an outer end top cover 17, the end bearing 8 An inner end top cover 18 is provided on the inside; a tail outer top cover 19 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com