Patents

Literature

160results about How to "Guaranteed meshing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

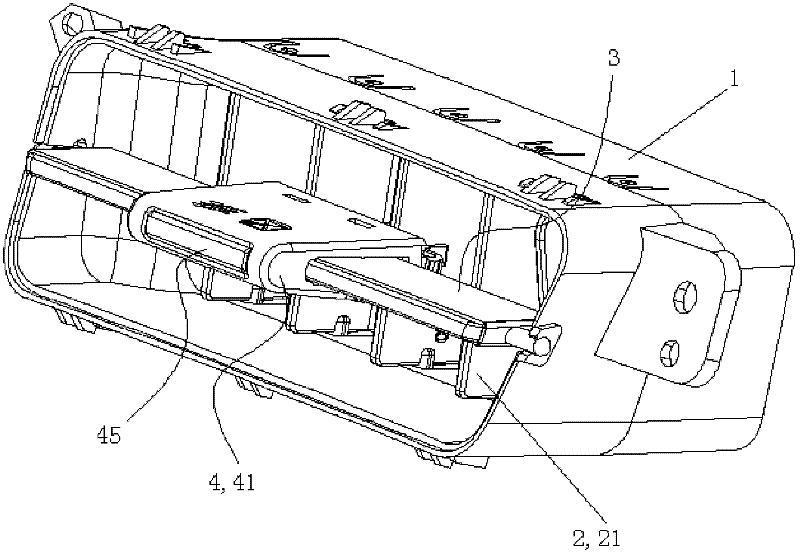

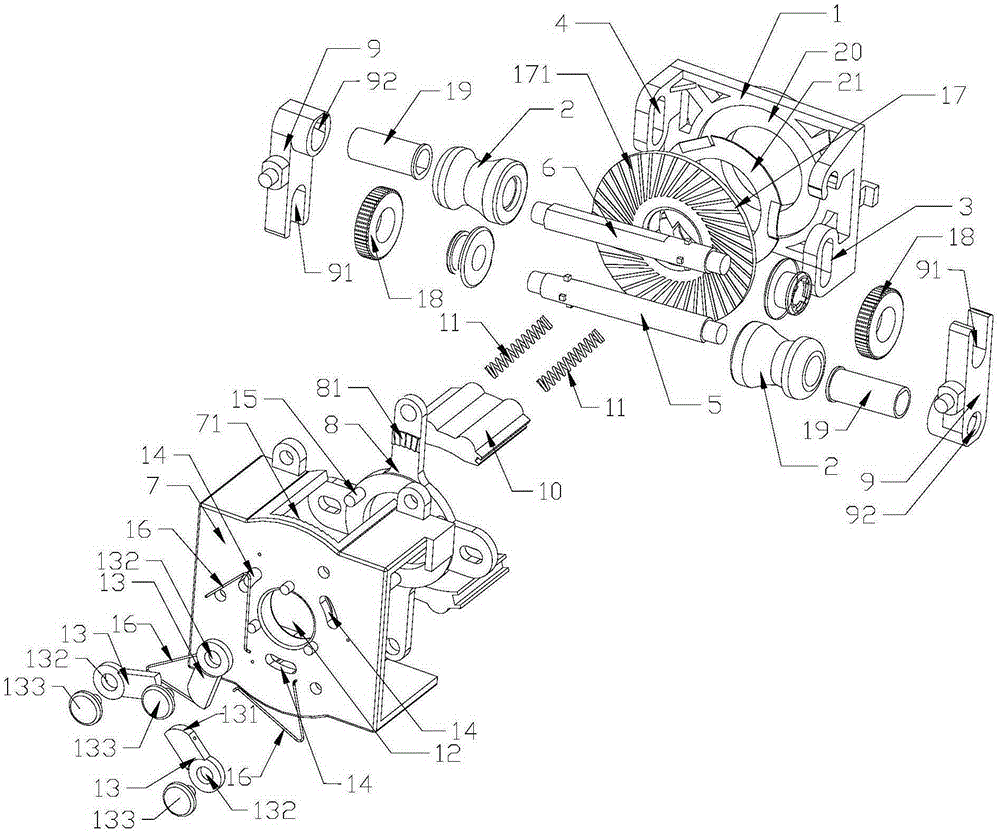

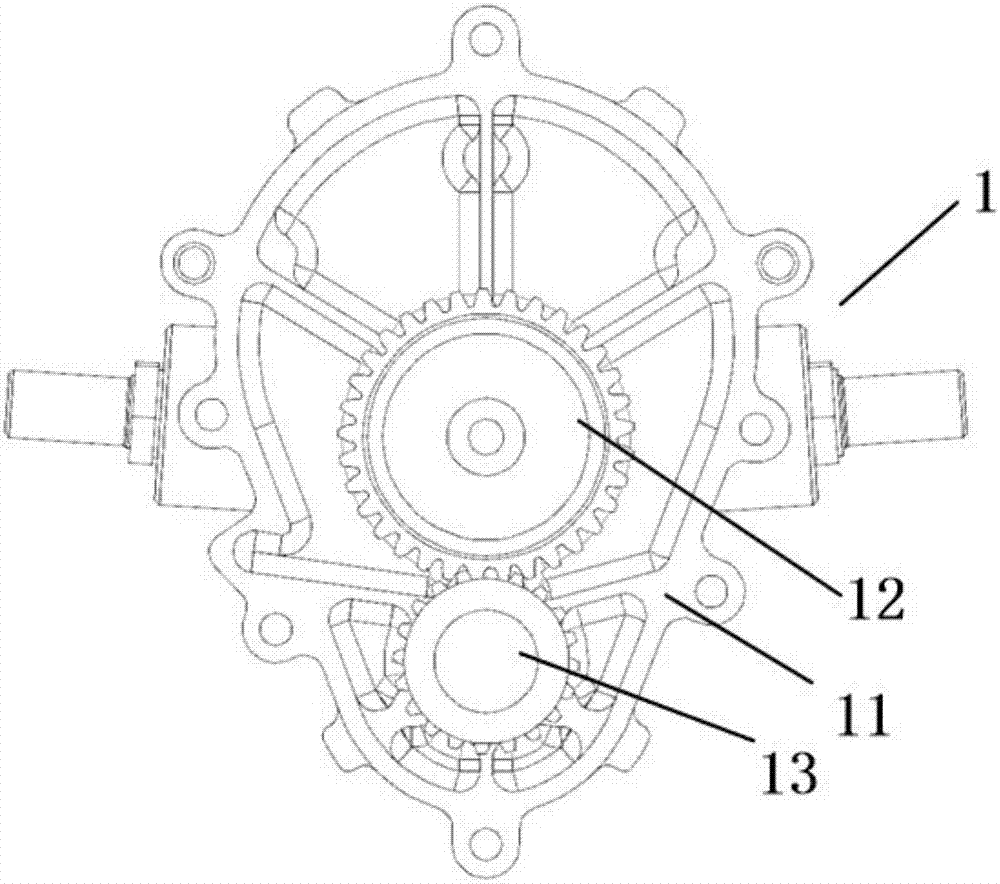

Intermediate air outlet of automobile instrument panel

InactiveCN102416844AReduce the cost of production materialsReduce gapAir-treating devicesVehicle heating/cooling devicesDashboardWind direction

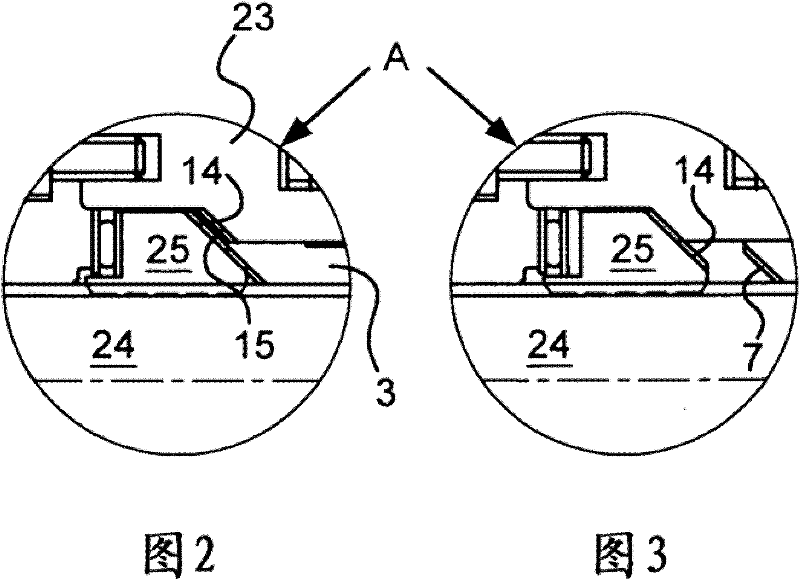

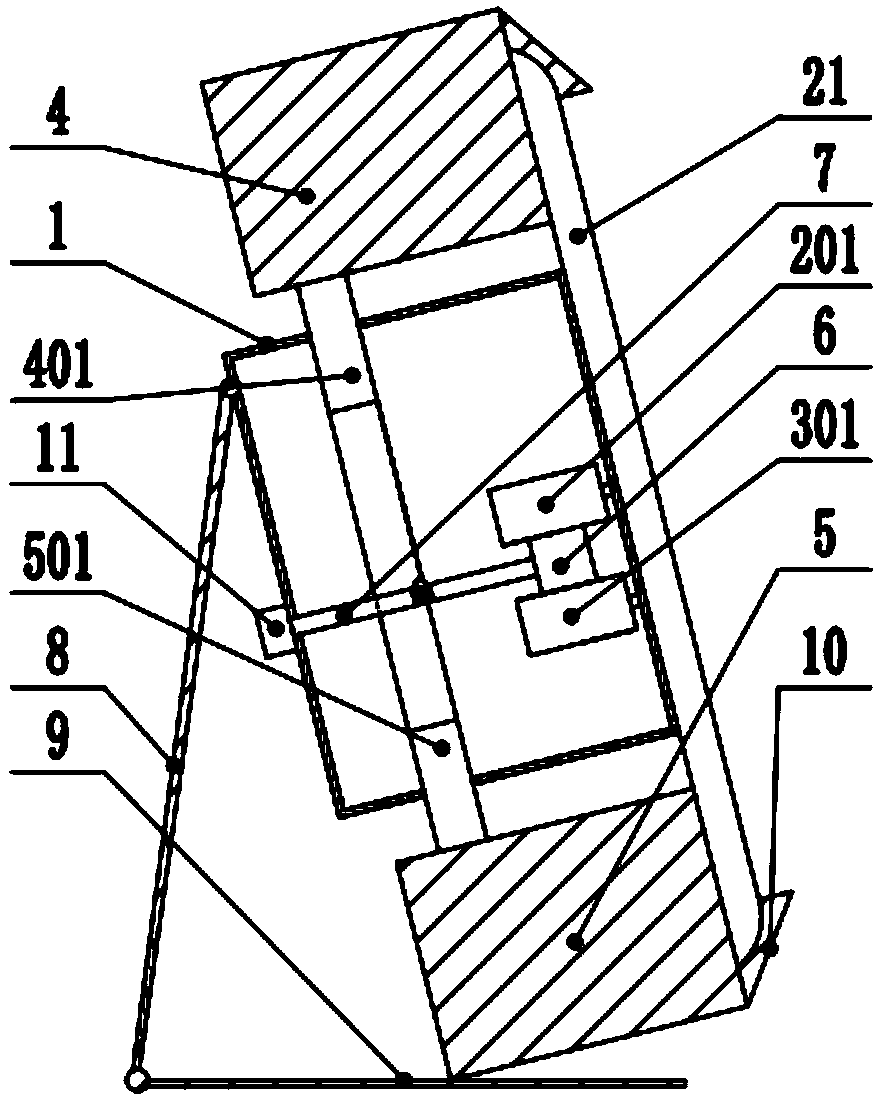

The invention relates to automobile interior trimming pieces and particularly relates to an air outlet assembly structure of an air conditioner of an automobile dashboard. The invention aims at providing an intermediate air outlet of an automobile instrument panel which comprises a single horizontal blade and adopts a single striking button to control an air direction. The intermediate air outlet of the automobile instrument panel comprises an air frame; a vertical blade component, the horizontal blade and a striking component are arranged in the air frame, wherein the horizontal blade and the striking component are rotationally connected with the air frame; the vertical blade component comprises 3-5 vertical blades which are rotationally connected with the air frame and a connecting rod which is used for connecting the vertical blades; only one horizontal blade is arranged; the striking component comprises the striking button sleeved on the horizontal blade, an arc-shaped rack clamped on the striking button and a gear clamped on the vertical blades; and the arc-shaped rack is meshed with the gear. The intermediate air outlet of the automobile instrument panel has the advantages that only one horizontal blade is adopted, and the cost for materials for production is greatly saved.

Owner:JIANGSU XINQUAN AUTOMOTIVE TRIM

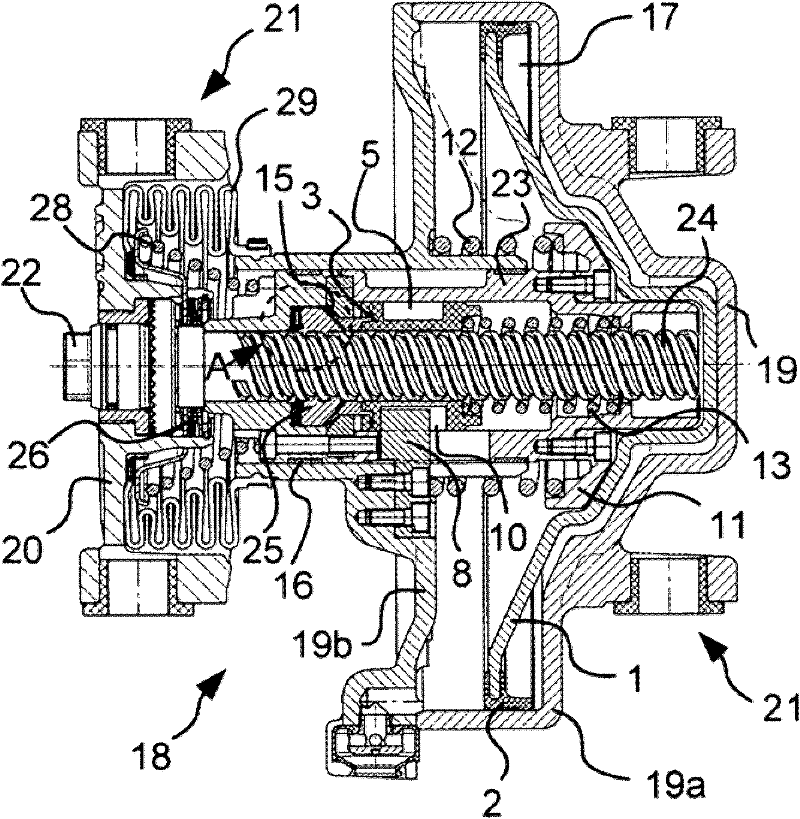

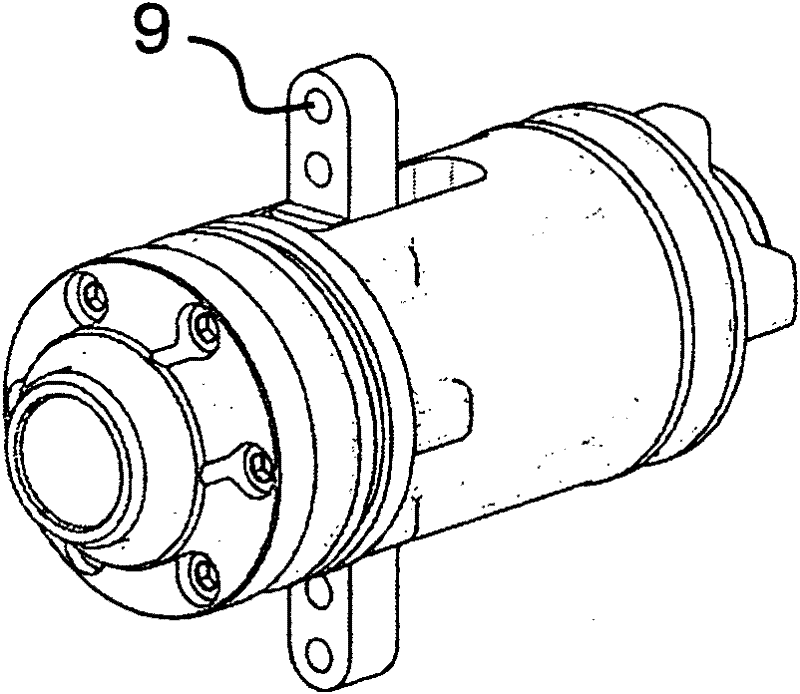

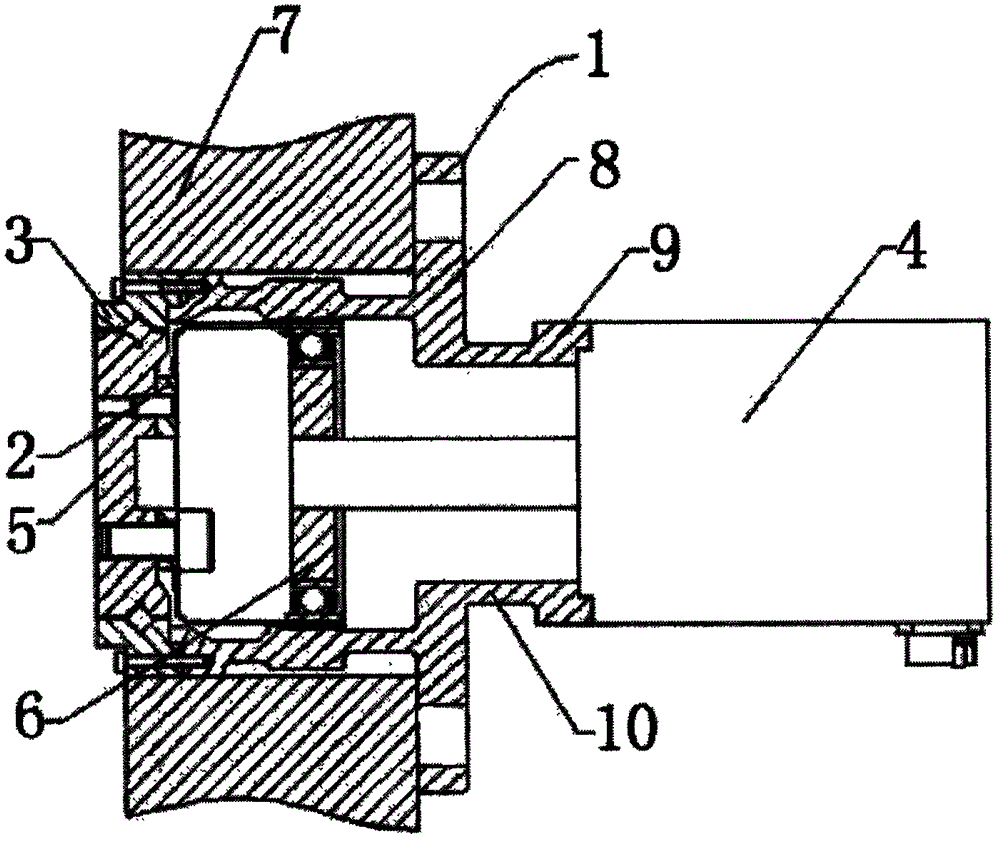

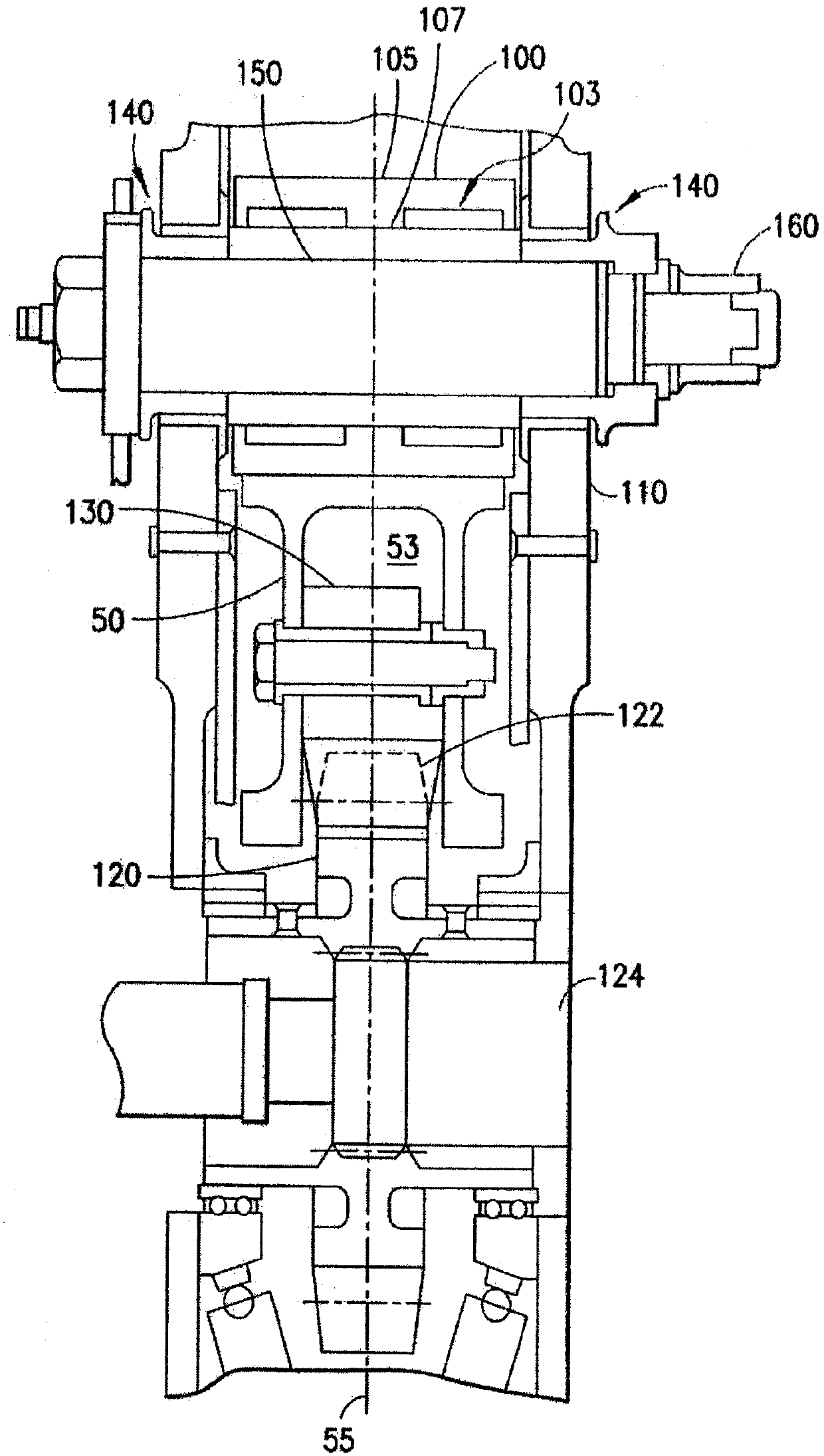

Pneumatic brake cylinder

ActiveCN102187112AAchieve stabilityEasy to replaceBrake wear compensation mechanismBrake actuating mechanismsBrake liningPneumatic cylinder

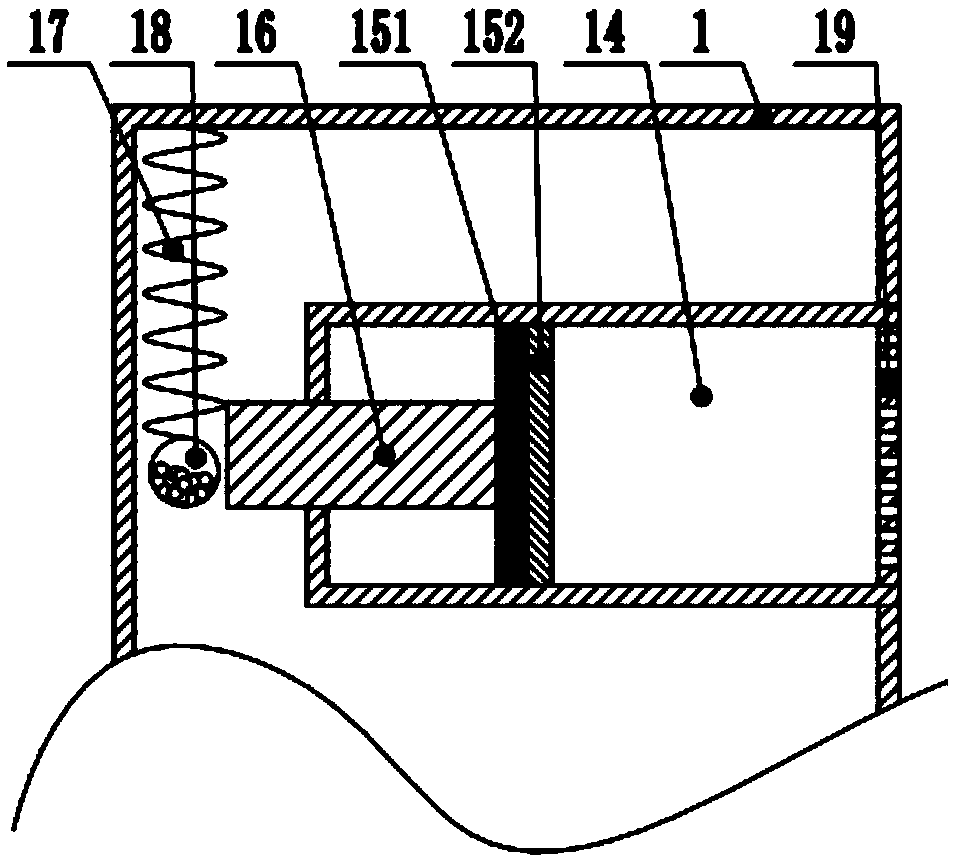

The invention relates to a pneumatic brake cylinder comprising a housing (19), a piston (1) that can be moved in the housing (19) and is used to transfer the pneumatic pressure to a brake, and a device for automatic adjustment in the event of wear of the brake linings, said device comprising a spindle (24), an adjusting nut (25), and a piston tube (23) that can be engaged with the adjusting nut (25). According to the invention, a torque applied to the piston tube (23) by the adjusting nut (25) is introduced by the piston tube (23) directly into elements (8) connected to the housing (19) in a fixed manner.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

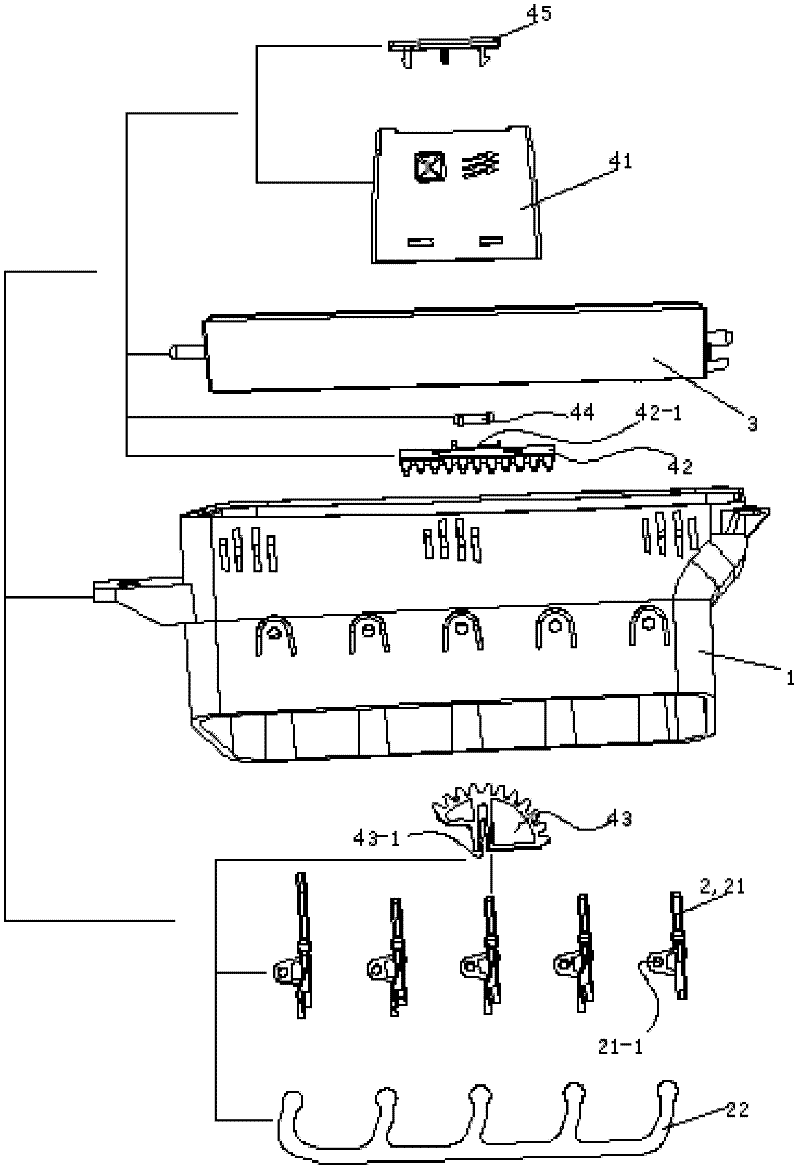

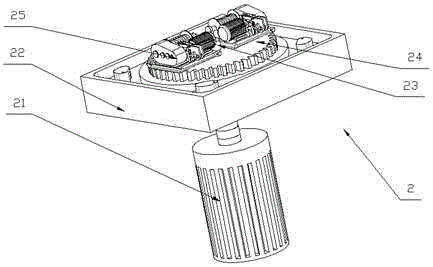

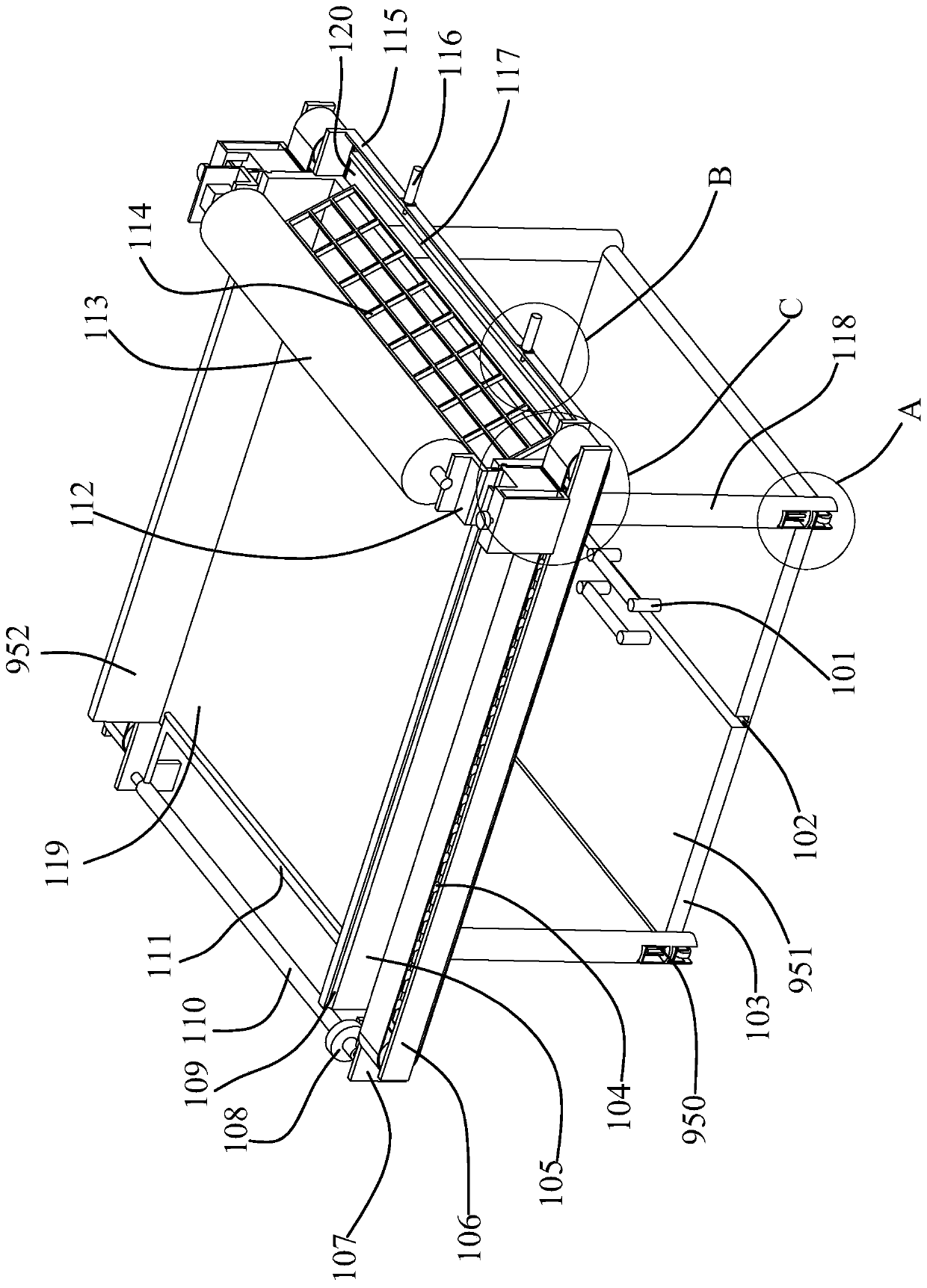

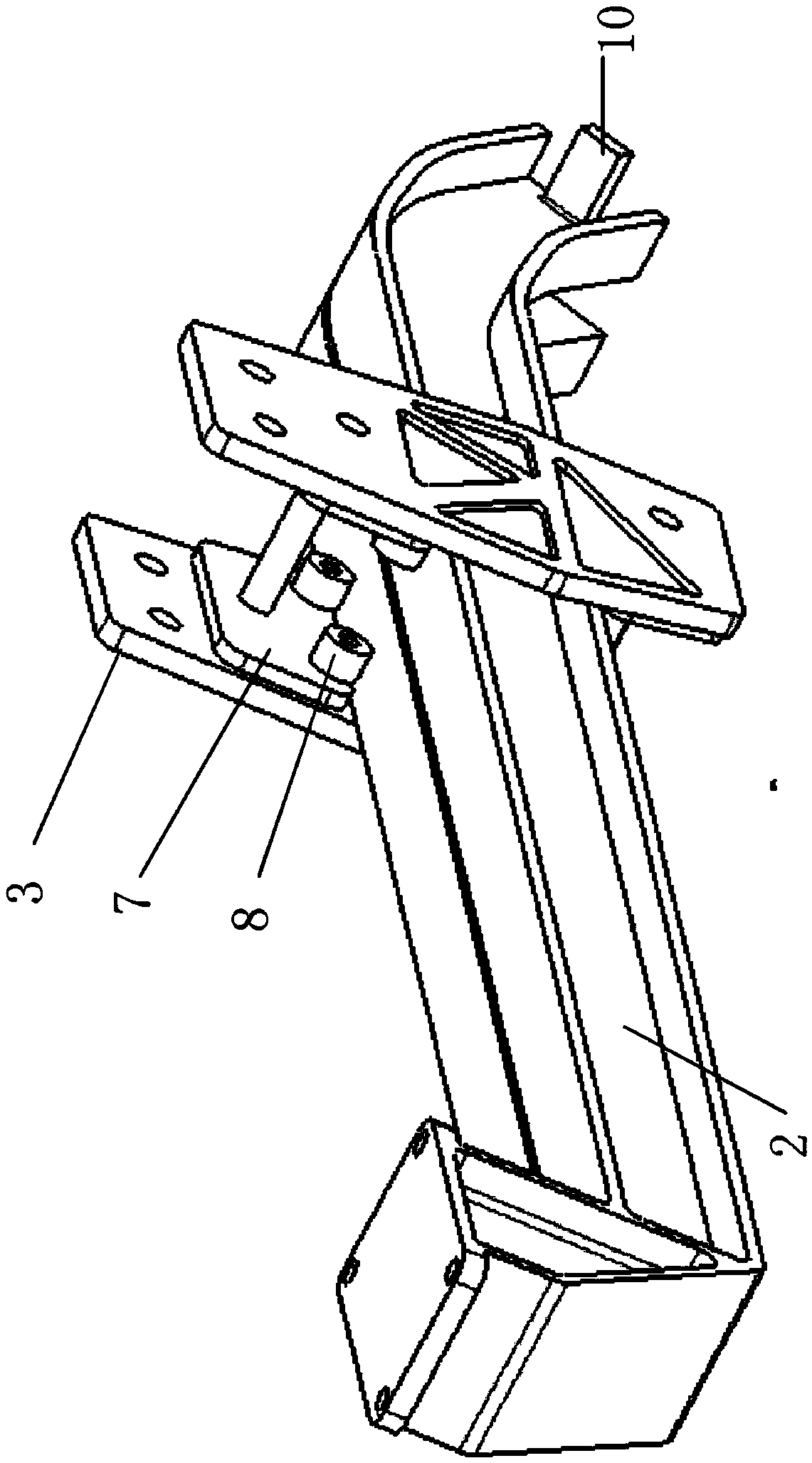

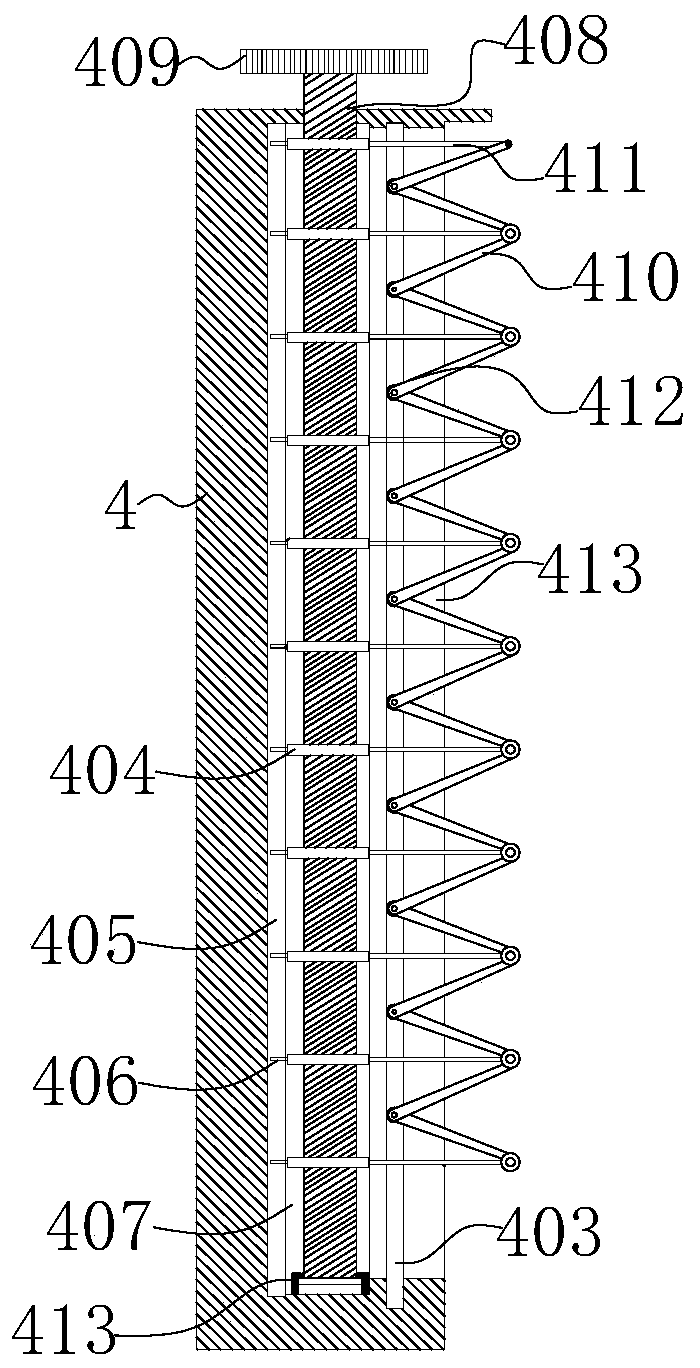

Automatic pencil feeding mechanism suitable for pencils of various specifications

The invention discloses an automatic pencil feeding mechanism suitable for pencils of various specifications. The automatic pencil feeding mechanism comprises a support, two mounting shafts arranged in parallel in a spaced manner, two pencil conveying wheels and a drive mechanism for driving the two mounting shafts to rotate. The support is provided with a first strip-shaped groove and a second strip-shaped groove which are in central symmetry. The two mounting shafts are the first mounting shaft and the second mounting shaft respectively. One end of the first mounting shaft is located in the first strip-shaped groove and can move in the first strip-shaped groove when stressed. The other end of the first mounting shaft is connected to the support through a shaft. One end of the second mounting shaft is connected to the support through a shaft. The other end of the second mounting shaft is located in the second strip-shaped groove and can move in the second strip-shaped groove when stressed. The pencil feeding mechanism further comprises a spacing adjustment assembly. The spacing adjustment assembly is used for driving the first mounting shaft to move in the first strip-shaped groove and the second mounting shaft to move in the second strip-shaped groove. The automatic pencil feeding mechanism has the beneficial effects that pencil feeding holes can be adjusted in an adaptive manner according to the specifications of pencils and the pencil feeding mechanism is suitable for automatic feeding of pencils of various specifications.

Owner:YIWU DINGBANG STATIONERY & SPORTING GOODS

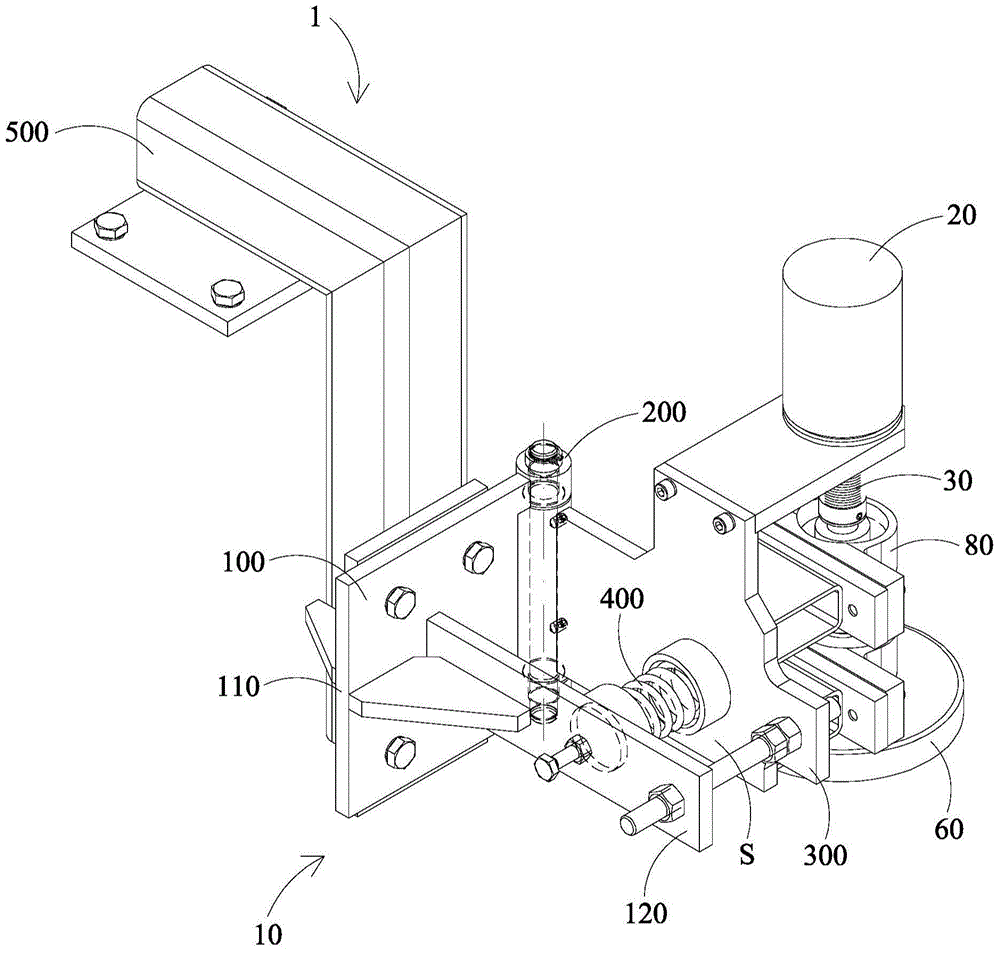

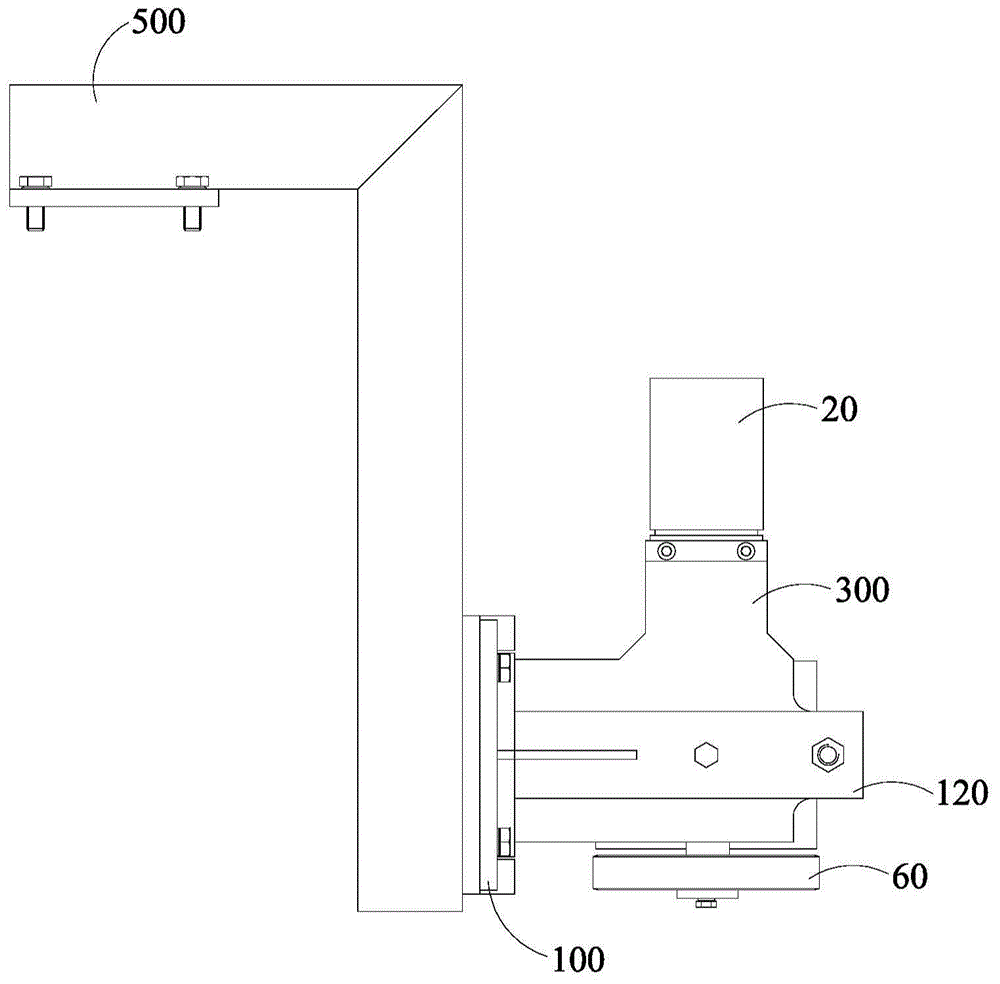

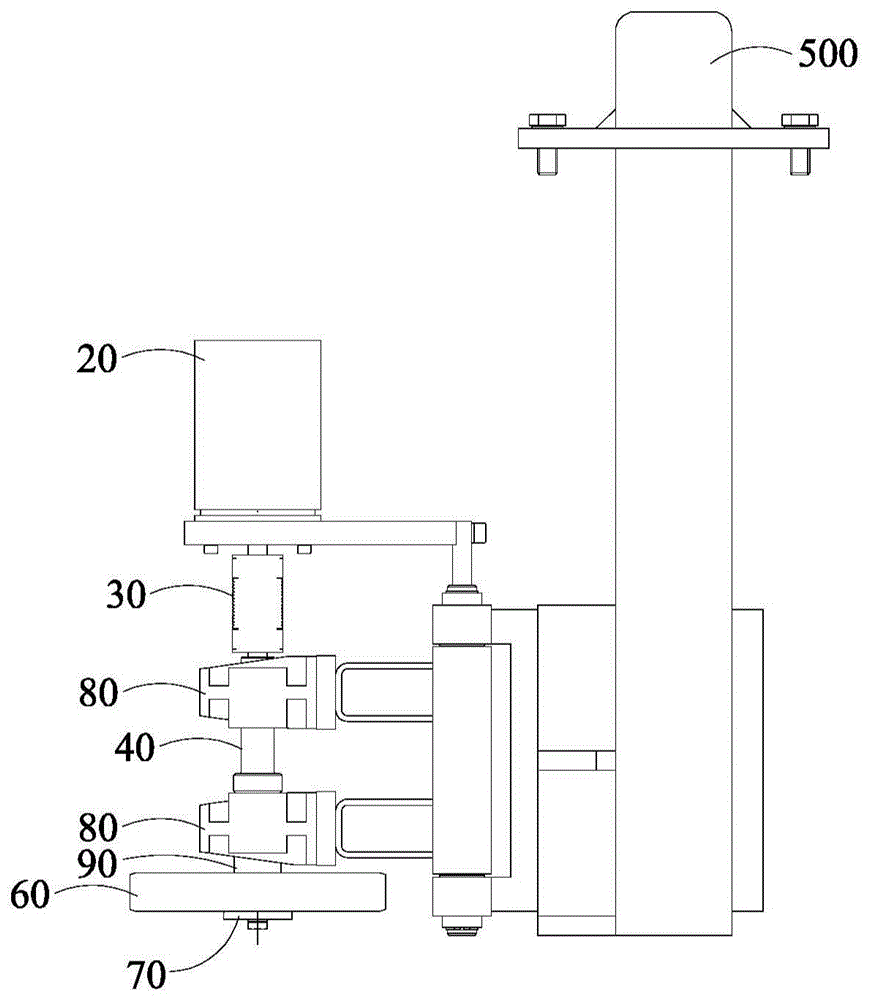

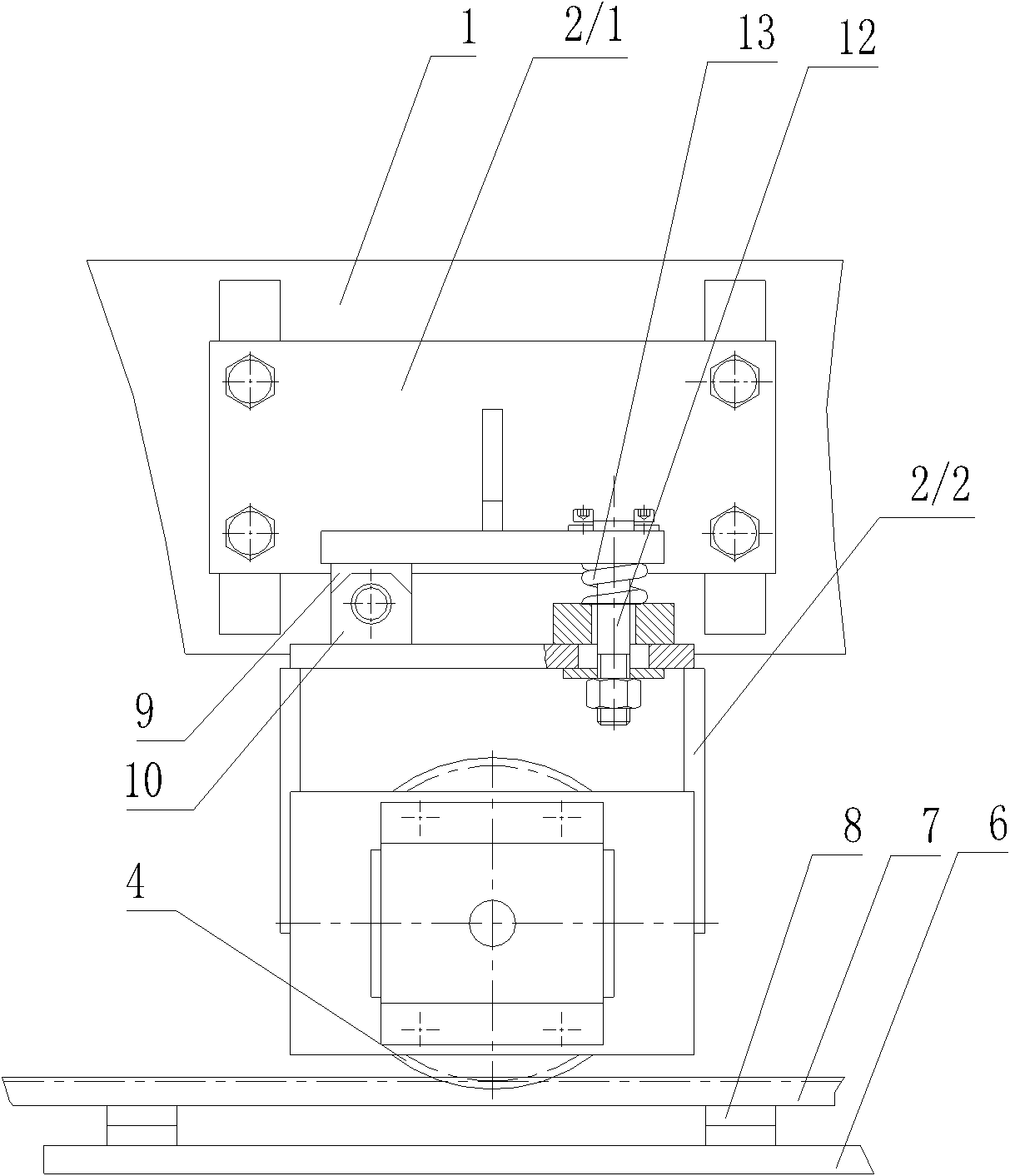

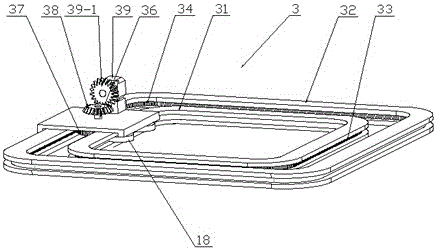

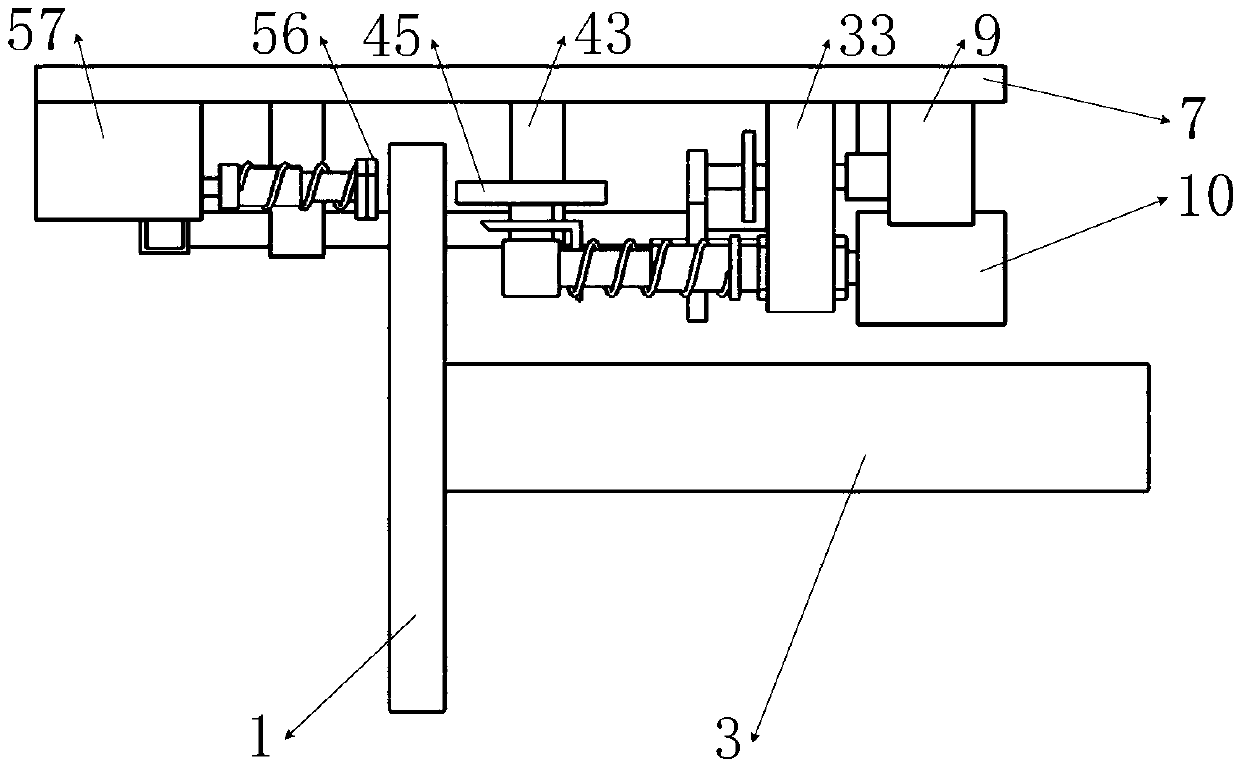

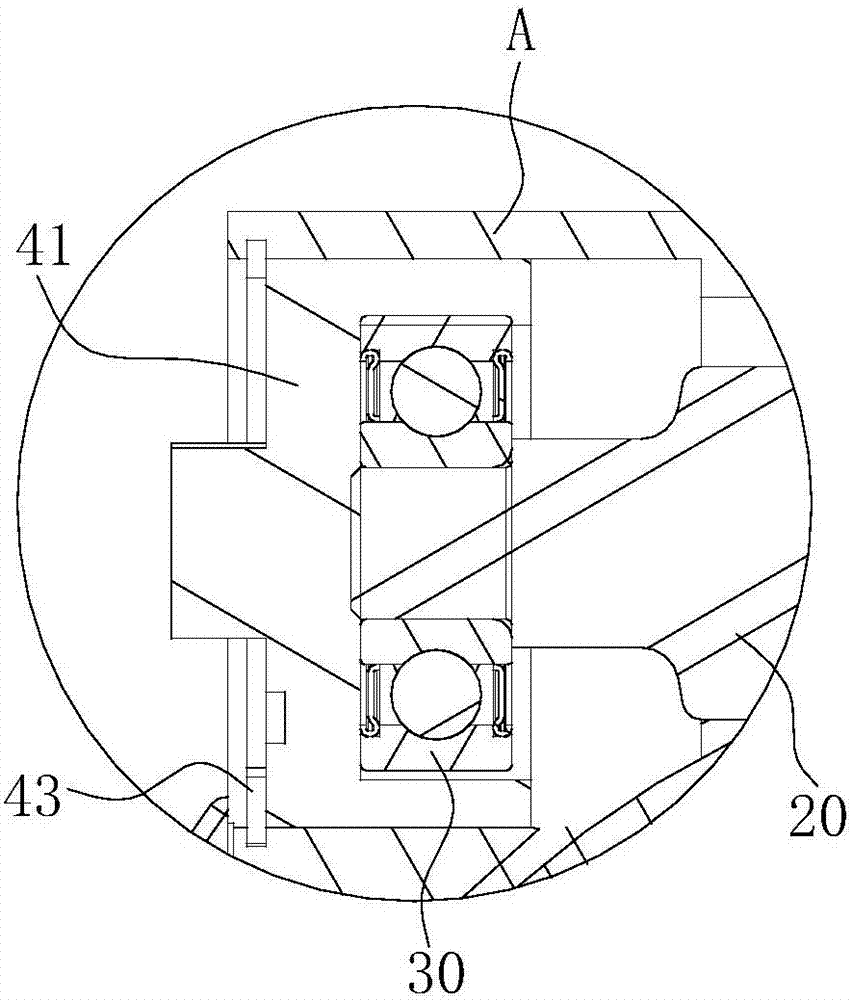

Detecting device capable of adjusting transmission gap and transmission gap adjusting mechanism

ActiveCN104457661AAvoid Accumulation Errors in ReadingsGuaranteed meshingMeasurement devicesGearing detailsScrew threadRack and pinion

The invention discloses a detecting device capable of adjusting a transmission gap and a transmission gap adjusting mechanism. The detecting device capable of adjusting the transmission gap comprises the transmission gap adjusting mechanism and a displacement detection mechanism. The transmission gap adjusting mechanism comprises a first support, a rotating assembly, a second support and an elastic assembly, wherein the first support is provided with a first plate and a second plate perpendicular to the first plate, the first plate is fixed to a rack, the second plate is provided with at least two threaded holes, the rotating assembly comprises a rotating shaft, the side edge of the first plate of the first support is fixed to the rotating assembly, the second support is fixed to the rotating assembly and is parallel to the second plate of the first support, and the elastic assembly is arranged in containing space. According to the detection device capable of adjusting the transmission gap, by keeping meshing of a gear and a rack, accumulated errors of reading of a jumping gear and an encoder due to long-term meshing abrasion can be effectively avoided, the maintenance labor is reduced, and the equipment cost is reduced.

Owner:TAIZHONG TIANJIN BINHAI HEAVY MACHINERY

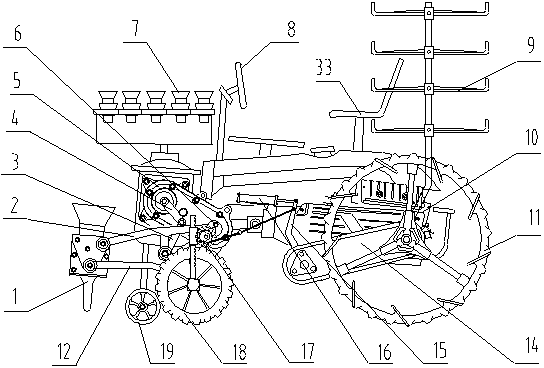

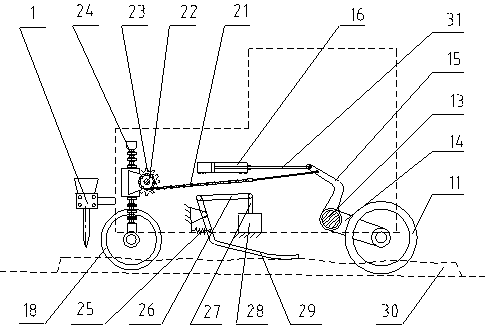

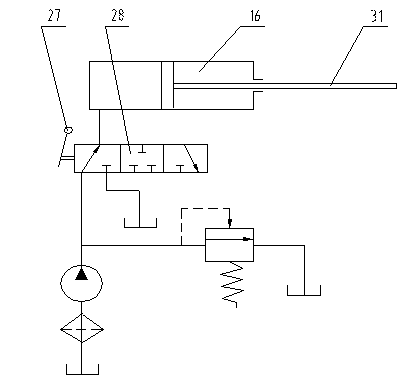

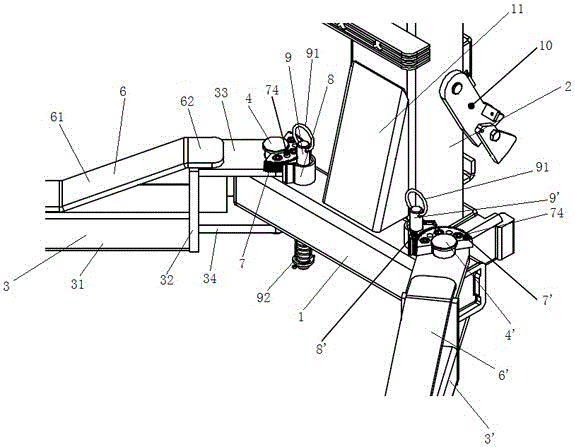

Front-installed vegetable and oilseed rape transplanter

The invention discloses a front-installed vegetable and oilseed rape transplanter. According to the front-installed vegetable and oilseed rape transplanter, a transplanting mechanism is installed at the front part, while an engine is installed at the rear part. The transplanter is driven in a riding way, and a steering machine is controlled by a steering wheel to steer. Both the steering wheel and a seedling feeding cup are arranged at the front end of the transplanter; since seedling feeding and driving can be performed by only one person, the production efficiency is enhanced. The transplanter is provided with a hydraulic automatic profiling mechanism; when the change of ridge height or transplanter sinking depth causes the change of transplanting depth, the profiling mechanism performs correction automatically, so that a transplanter body or transplanting clamps can automatically ascend or descend and consequently the condition that the seedling transplanting depth is always the same can be ensured. Due to the design of a special gear and tooth column structure, the steering of front wheels of the transplanter and the automatic ascending or descending adjustment on a transplanter body can be performed simultaneously. The transplanting mechanism is composed of a cleverly evolved crank-rocker mechanism and an eccentric wheel compensation mechanism by which the transplanting clamps are jointly controlled to move, so that the work of seedling transplanting is finished.

Owner:ZAOYANG CITY ZHENGTIAN TRANSPLANTER

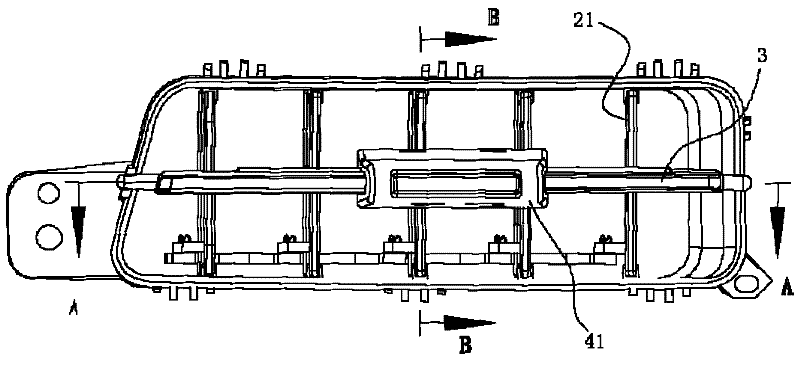

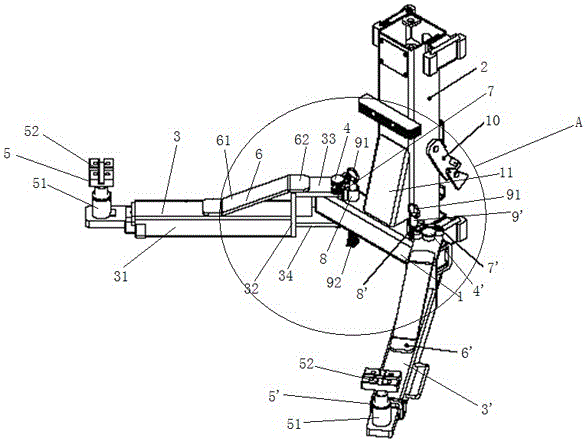

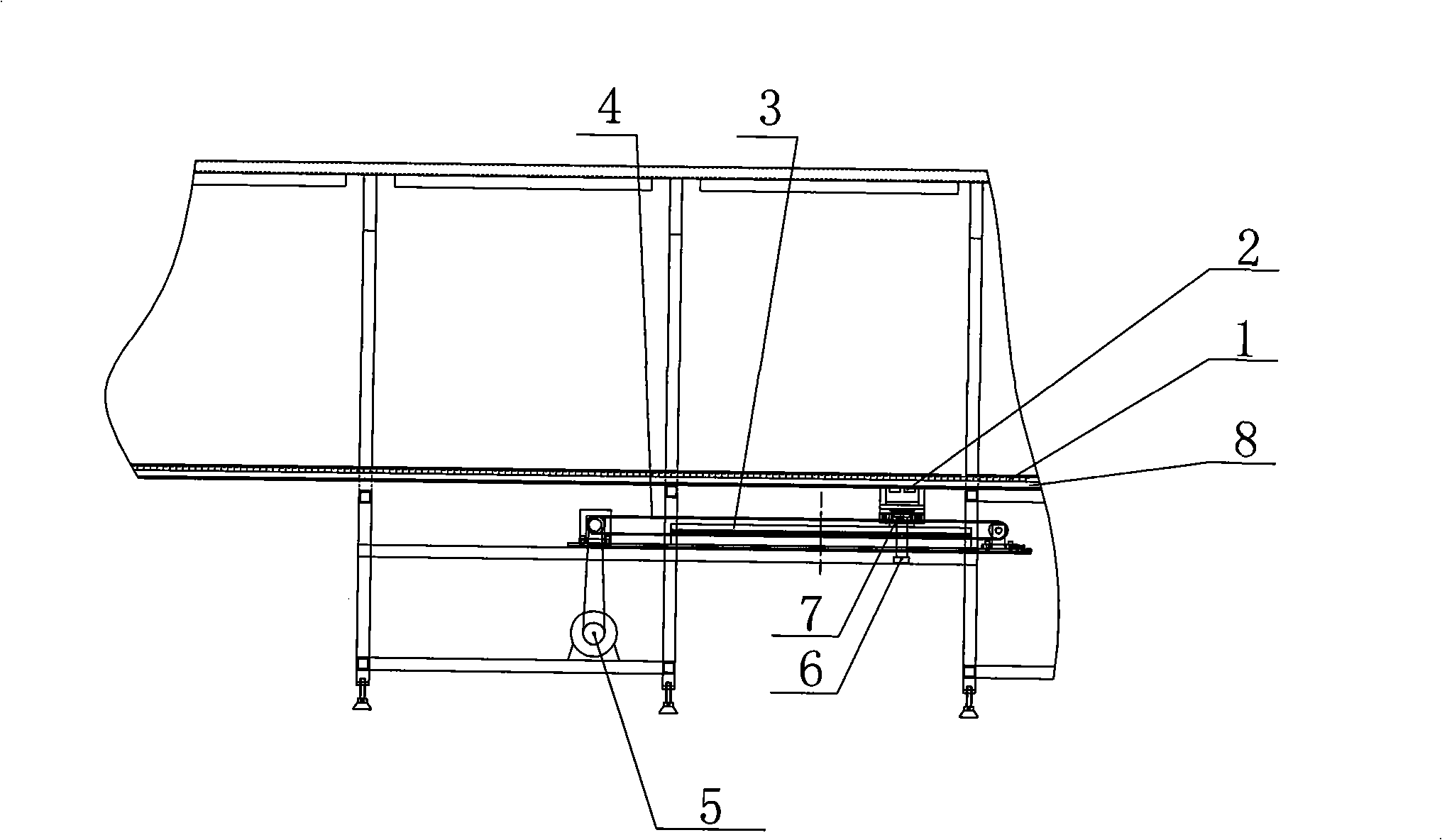

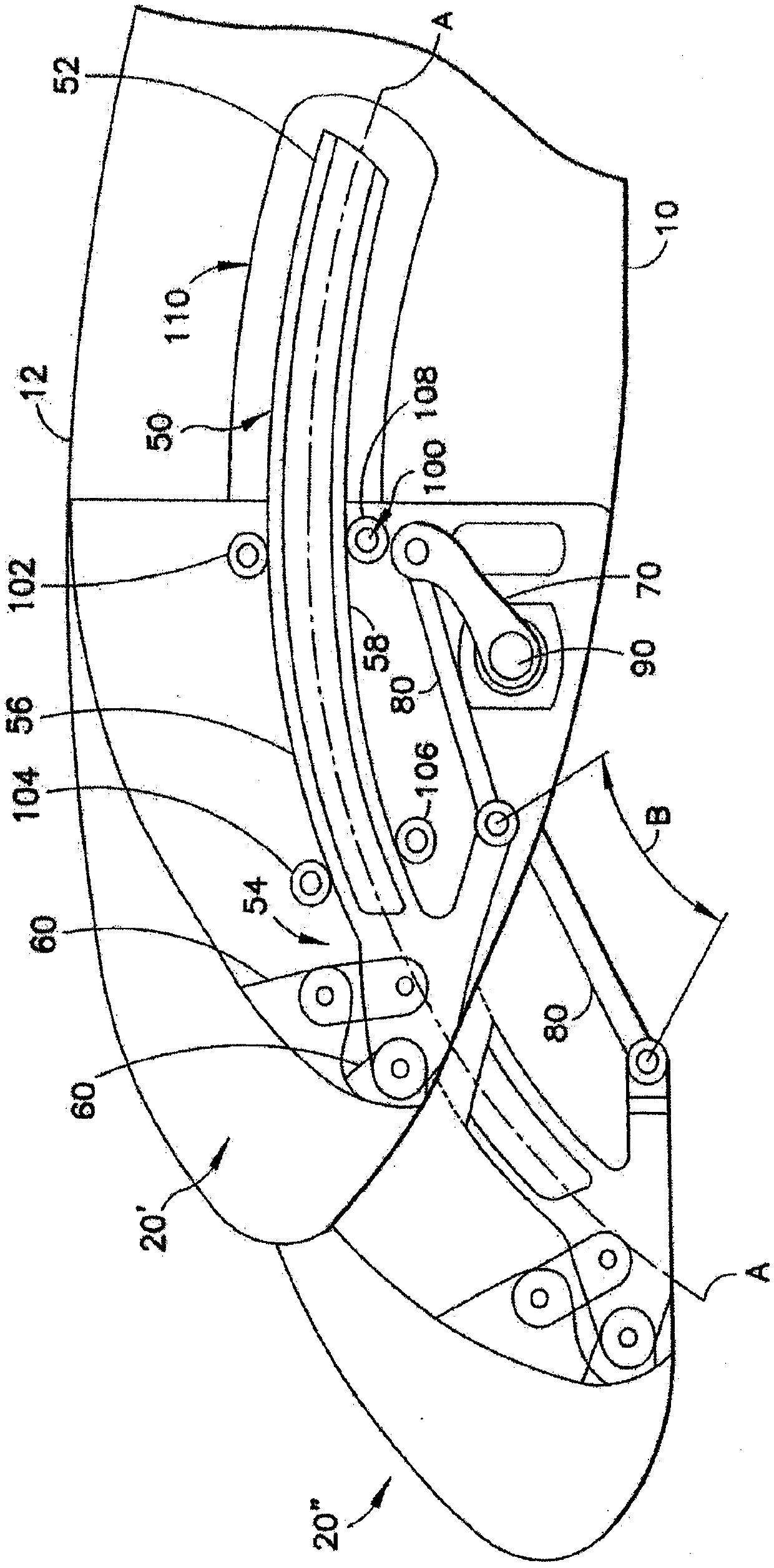

Trailing arm lock with detachable and replaceable trailing arms for double-column automobile elevator

The invention provides a trailing arm lock with detachable and replaceable trailing arms for a double-column automobile elevator. The trailing arm lock with the detachable and replaceable trailing arms for the double-column automobile elevator comprises a cross beam, a rising and falling slide, two long trailing arms, two rotary shafts, two supporting assemblies, two short trailing arms, two trailing arm semi-teeth, two trailing arm lock teeth and two locking pins. The cross beam is provided with connecting through holes and installing through holes. The rising and falling slide is connected to the cross beam. Each long trailing arm comprises a straight rod, a straight plate, a first connecting plate and a second connecting plate. The two rotary shafts are arranged in the long trailing arms and the connecting through holes of the cross beam in an inserted manner. Each supporting assembly comprises a supporting rod and a supporting platform. Each short trailing arm comprises a connecting piece and lap-joint pieces. According to each trailing arm semi-tooth, the arc-shaped outer edge is a convex tooth face, the bottom face is provided with an arc-shaped groove, and the surface is provided with fixed holes. The trailing arm lock teeth comprise connecting pipes and meshing parts, the inner walls of the meshing parts are provided with concave tooth faces, the connecting pipes are communicated with the installing through holes of the cross beam, and the concave tooth faces of the meshing parts are meshed with the convex tooth faces. One ends of the locking pins are provided with pulling rings, and the other ends of the locking pins are inserted into the installing through holes of the cross beam through the connecting pipes and extend out of the cross beam through the lower surface of the cross beam. According to the trailing arm lock, the structure is simple, the trailing arms are detachable and replaceable, the meshing degree between the trailing arm lock teeth and the trailing arm semi-teeth is high, and limiting and locking on the trailing arms can be effectively achieved.

Owner:赛埃孚汽车保修设备(太仓)有限公司

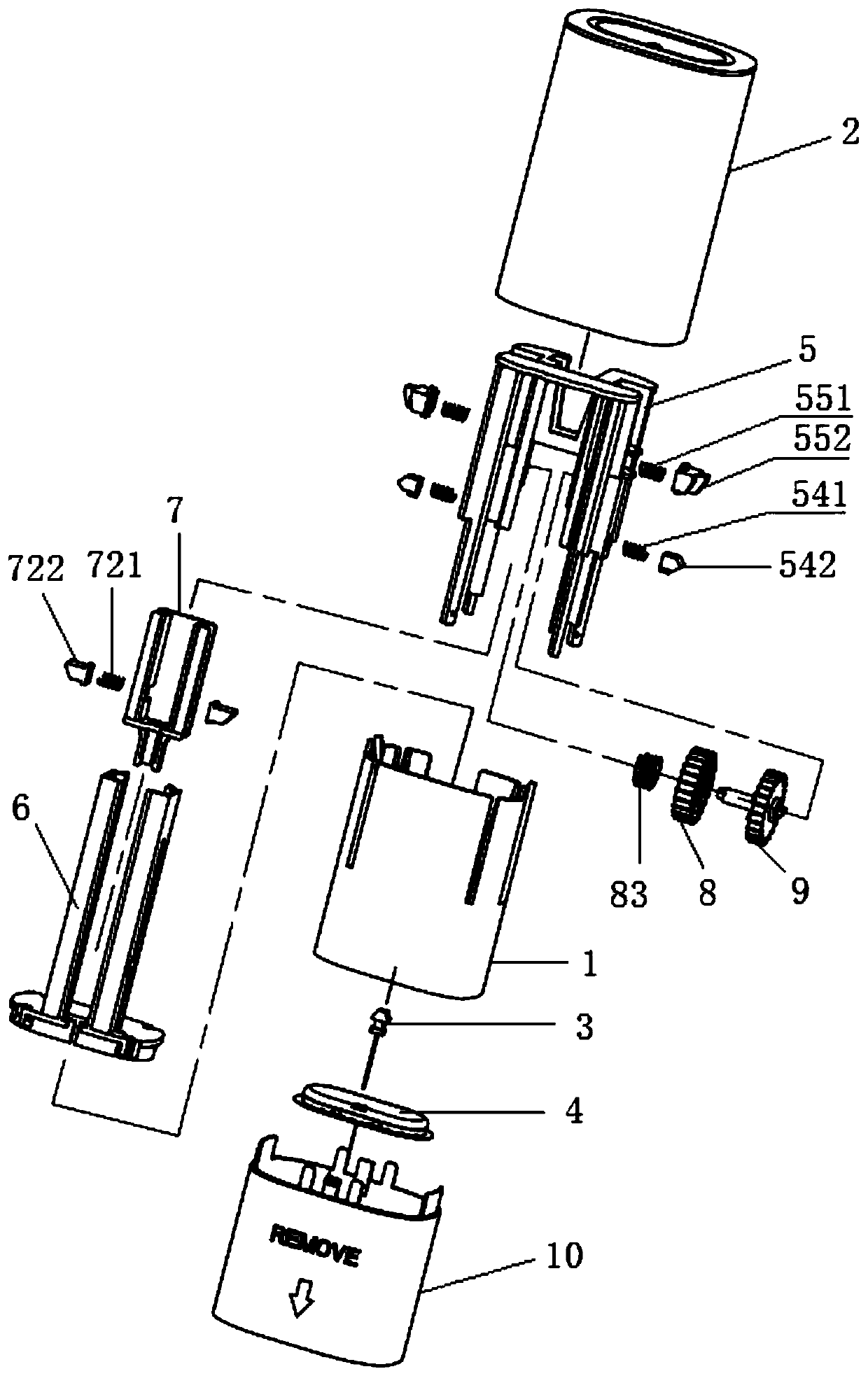

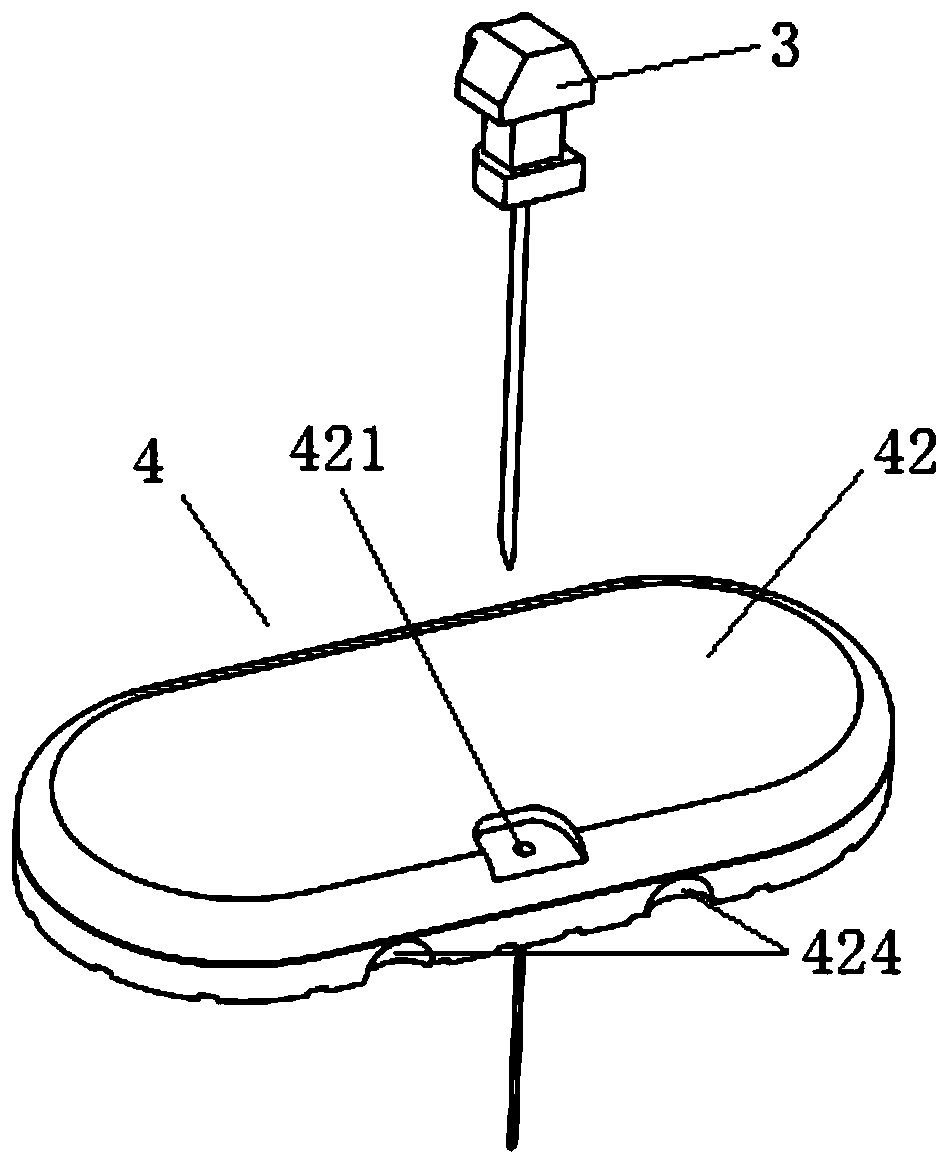

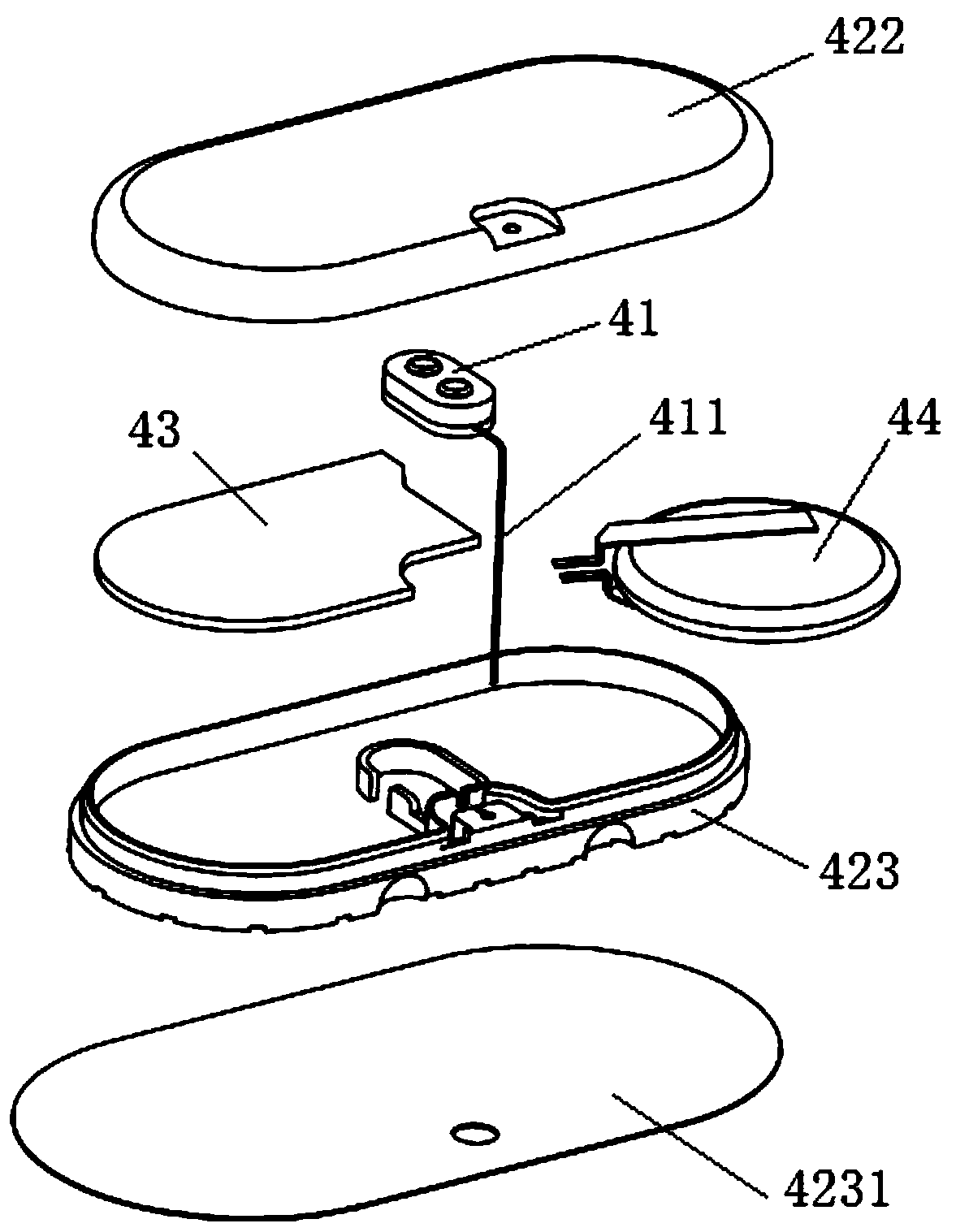

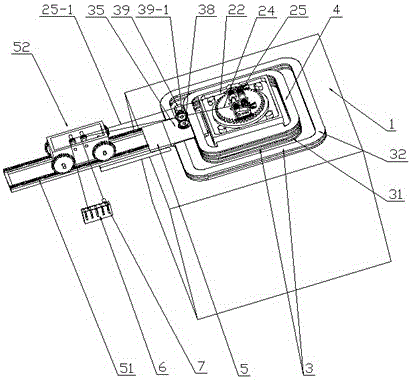

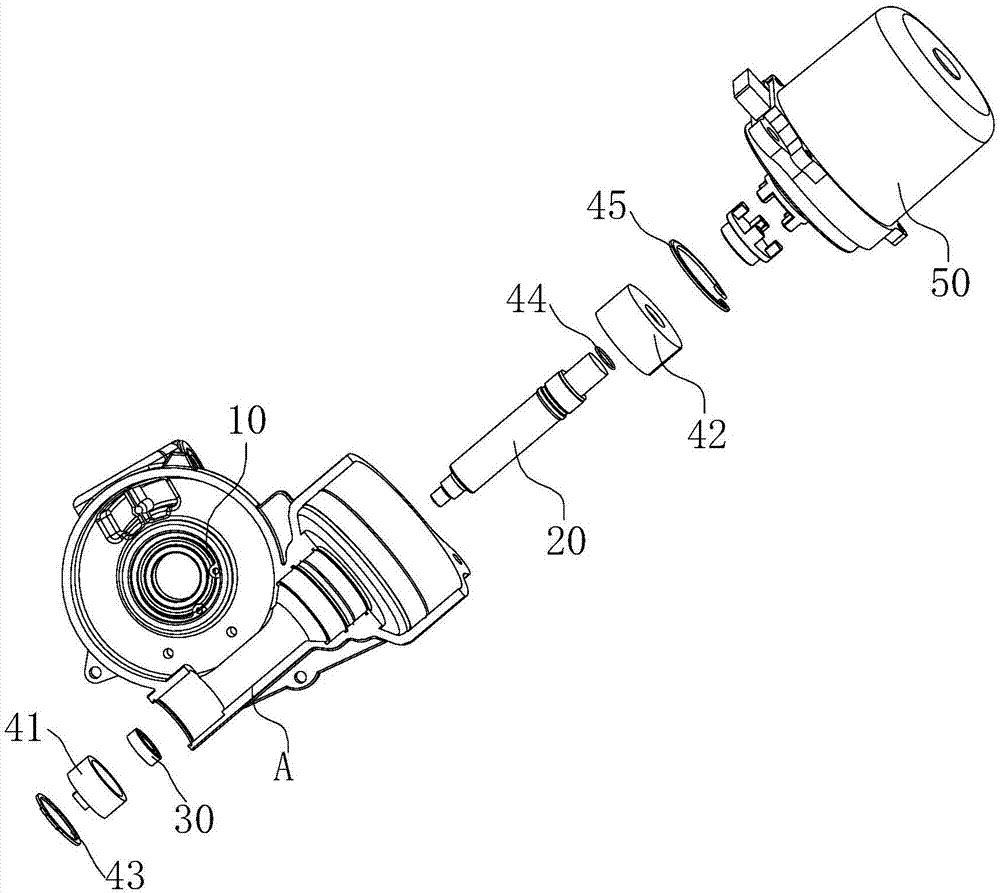

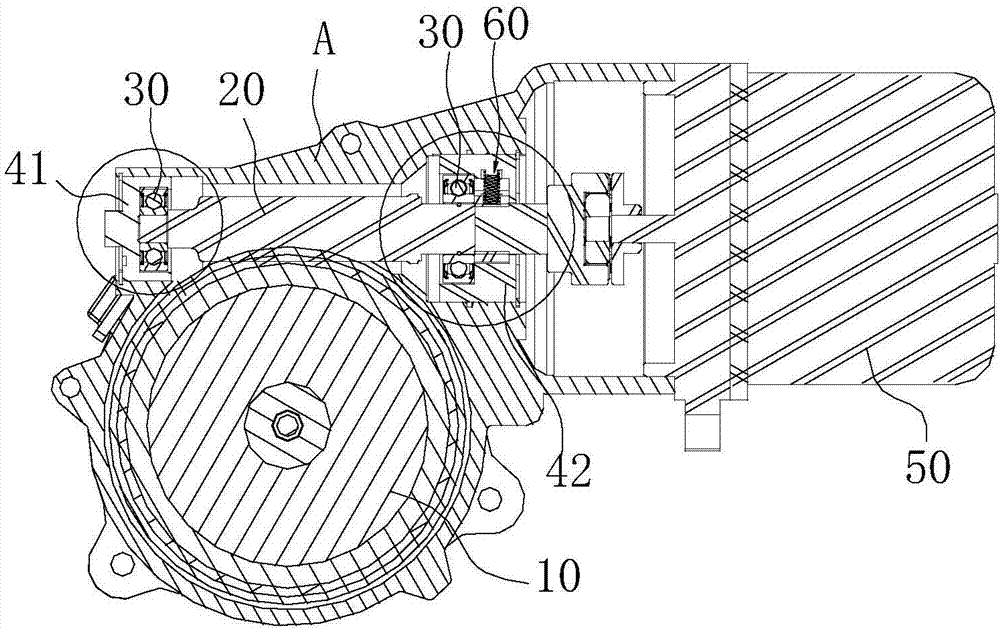

Percutaneous sensor applying device

PendingCN111588387ASimplify operation stepsAvoid misuseCatheterSensorsSensor holderBiomedical engineering

The invention provides a percutaneous sensor applying device. The percutaneous sensor applying device comprises a base, a handle, a guide needle, a sensor unit, a support frame, a sensor bracket, a shuttling piece and a driving component, wherein the sensor unit comprises a sensor body and a sensor shell, and the sensor shell is provided with a through hole allowing the guide needle to pass through; the support frame is dismountably and fixedly mounted in the handle; the sensor bracket is coupled with the support frame and is used for supporting the sensor unit; the shuttling piece is used forsupporting and extending the guide needle passing through the through hole; the driving component is used for driving the shuttling piece to move towards a near end position; and when the handle moves to a second position from a first position, the support frame, the sensor bracket and the shuttling piece, as a whole, move to a most distal end position from a near end position, and when the support frame, the sensor bracket and the shuttling piece reach the most distal end position, the sensor bracket releases the sensor unit. Automatic penetrating and drawing out of the guide needle are realized, and besides, the percutaneous sensor applying device is simple to operate, comfortable to use, compact in structure, safe and reliable and favorable for popularization.

Owner:ANDON HEALTH

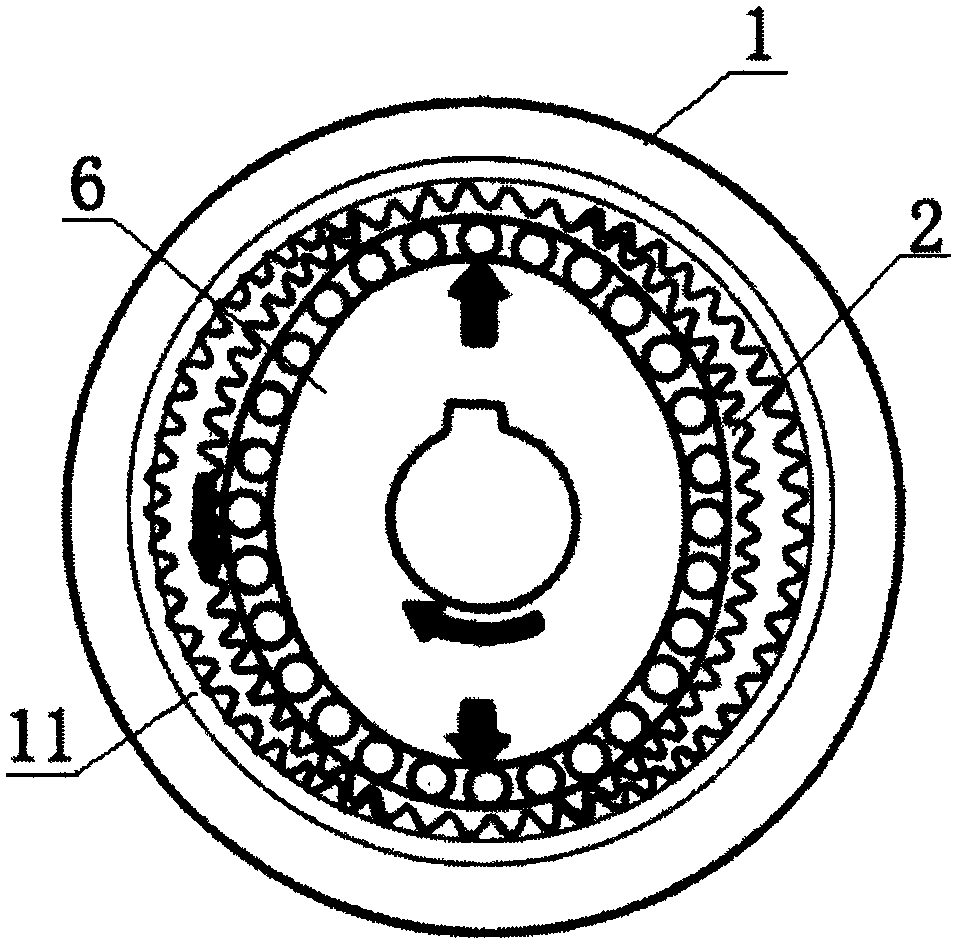

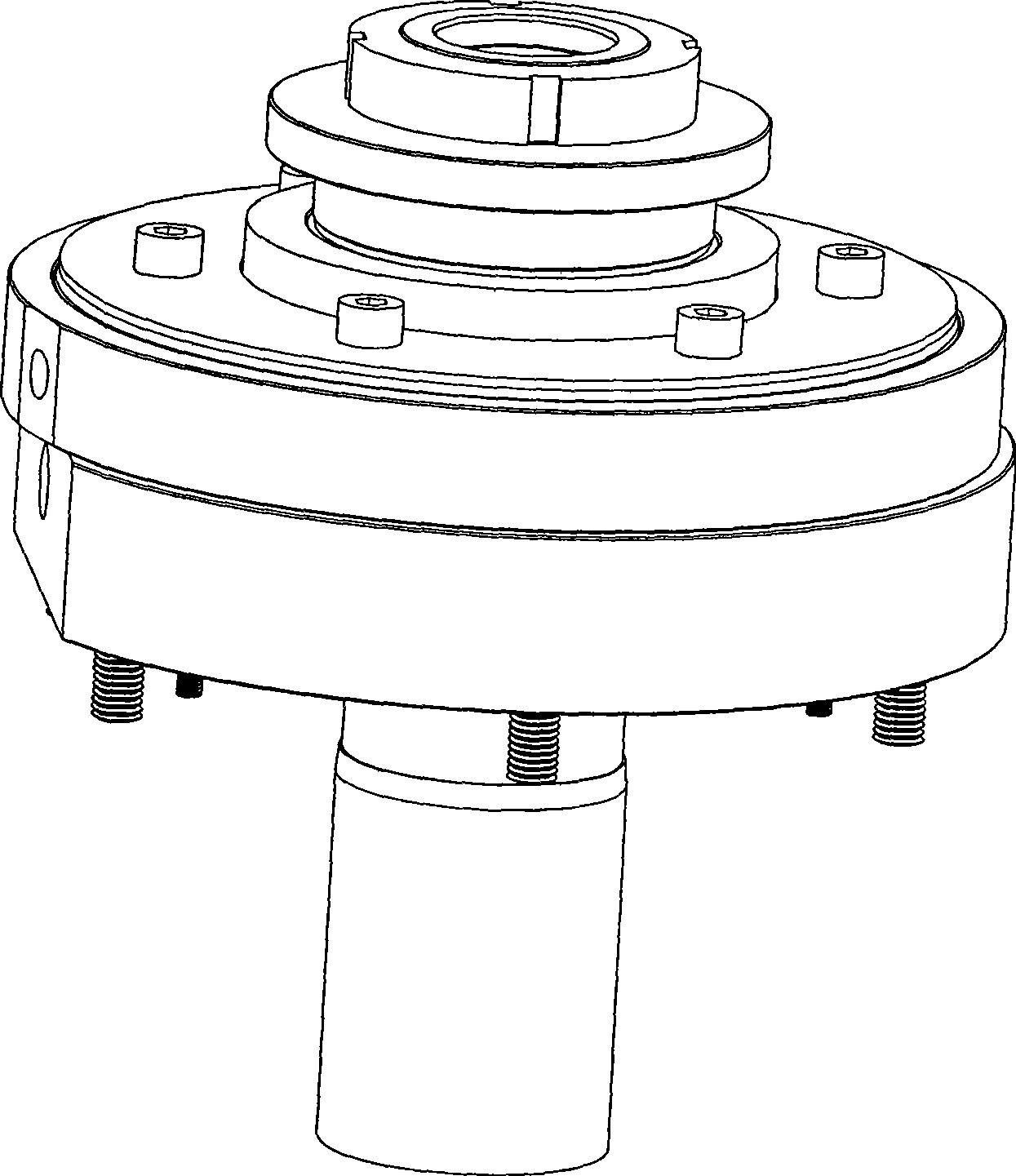

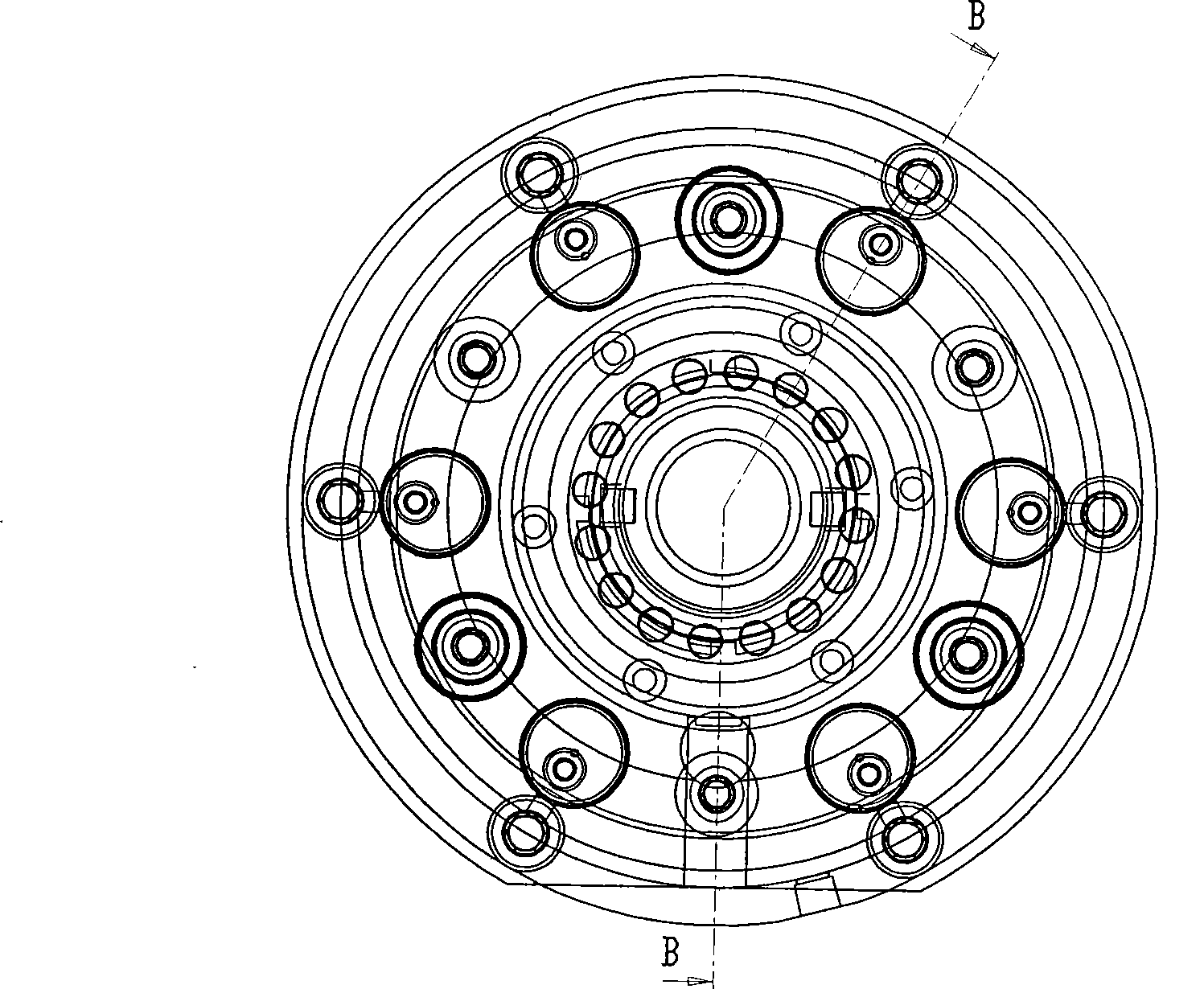

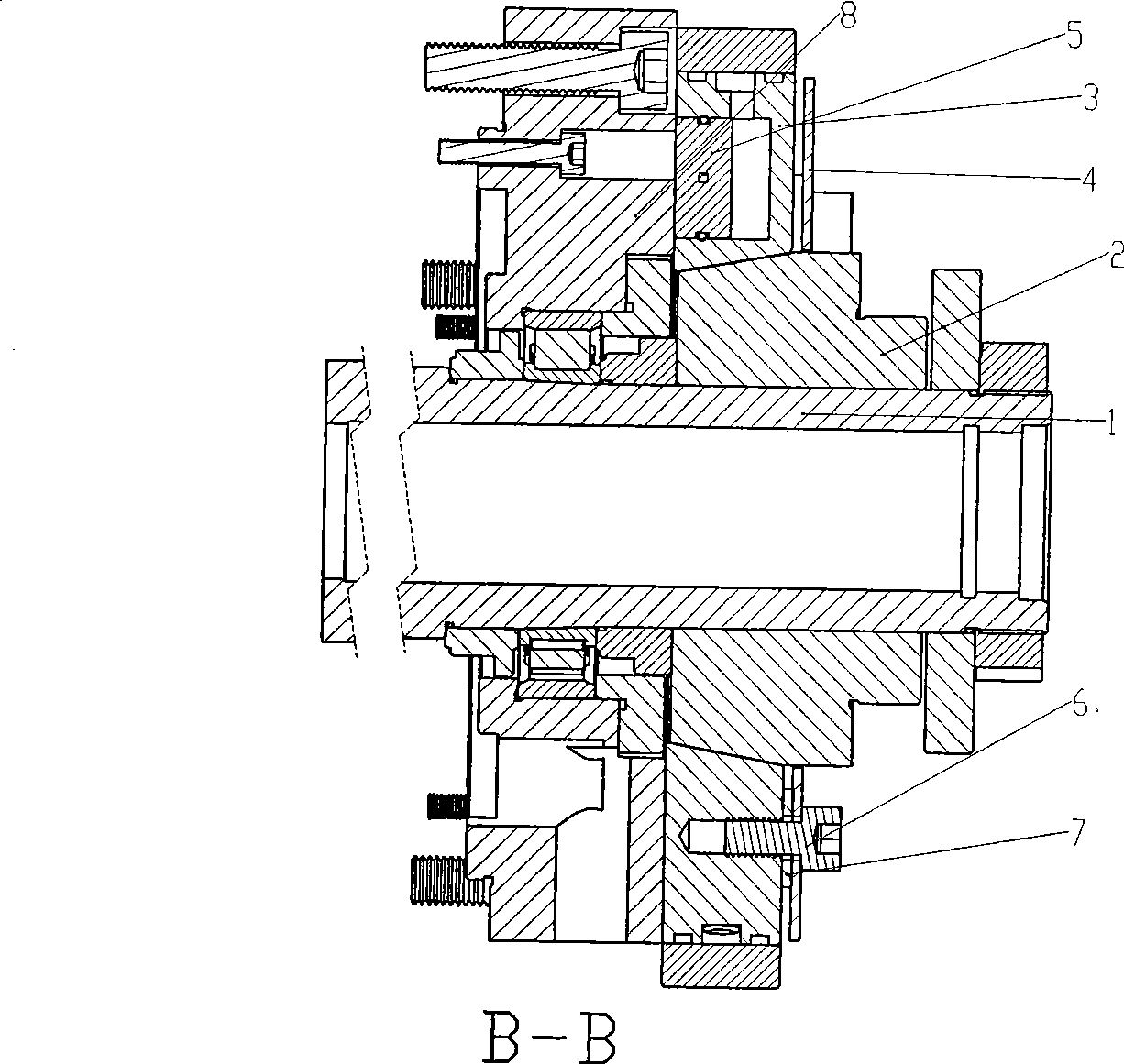

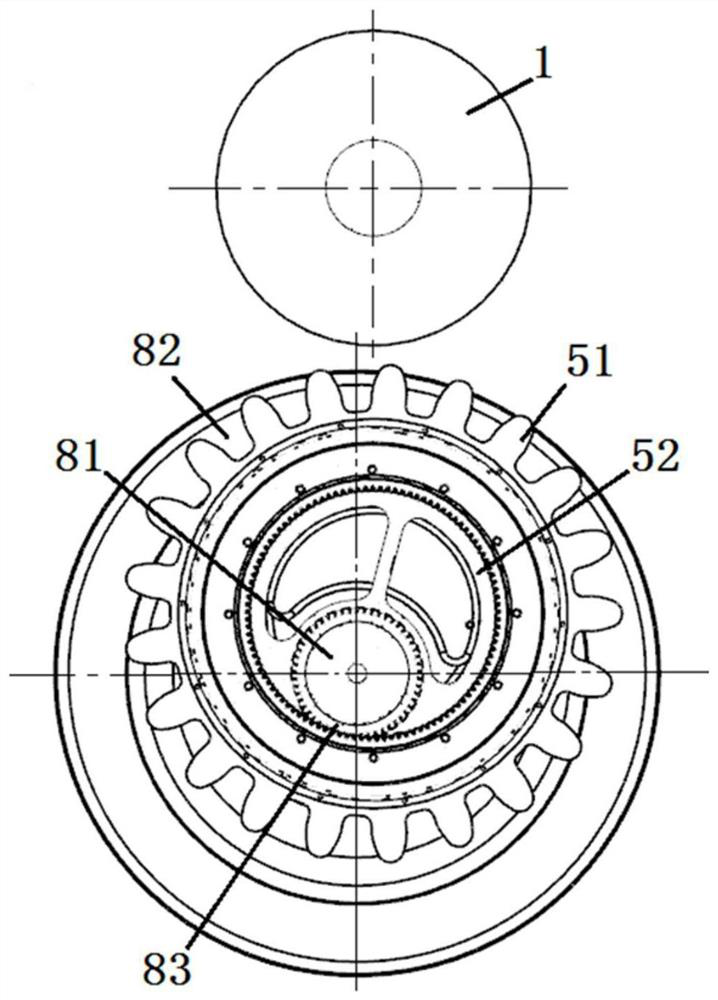

Harmonic reducer with lubricating function

InactiveCN106151472AGuaranteed coaxialGuaranteed meshingGear lubrication/coolingMechanical energy handlingHarmonicEngineering

The invention relates to a harmonic reducer with a lubricating function. The harmonic reducer with the lubricating function comprises a rigid wheel. A flexible wheel is connected into the rigid wheel in a transmission mode. A harmonic generator is connected into the flexible wheel in a transmission mode. The harmonic generator is fixedly connected with a power output shaft of a servo motor. The rigid wheel comprises a motor installation base. An elastic connecting device is arranged between one side of the motor installation base and the servo motor and comprises an annular connecting part fixedly connected with the servo motor. An elastic connecting part is arranged between the annular connecting part and the motor installation base. The annular connecting part is coaxial with the elastic connecting part, the inner diameter of the annular connecting part is the same as the inner diameter of the elastic connecting part, and the outer diameter of the elastic connecting part is smaller than the outer diameter of the annular connecting part. Oil storage grooves are formed in the two side edges of the surface of the inner side of the rigid wheel, and the section of each oil storage groove is in the shape of a circle with notches. The effect that a rotary shaft of the motor is kept being coaxial with the harmonic generator is guaranteed through the elastic connecting device, and the contact surfaces of the flexible wheel and the rigid wheel are lubricated through the oil storage grooves, so that the normal engagement and the linkage effect of the flexible wheel and the rigid wheel are guaranteed, and the service life of the harmonic reducer is prolonged.

Owner:广东天太机器人有限公司

Apparatus for locking main shaft

The invention discloses a spindle locking device and relates to a precise spindle locking device. The spindle locking device consists of an internal expansion sleeve, an external expansion sleeve, a spring disc, a piston block and a fixed post, a fixing bolt and a fixing bolt. The internal expansion sleeve is fixed on a spindle and can rotate together with the internal expansion sleeve. The external expansion sleeve is sleeved on the internal expansion sleeve. Conical surfaces which are matched with each other are arranged between the internal expansion sleeve and the external expansion sleeve. The external expansion sleeve is sleeved on the internal expansion sleeve through the conical surfaces. The spring disc is sleeved on the internal expansion sleeve. The external expansion sleeve is positioned between a rear flange of the spindle and the spring disc. The spring disc is fixed with the rear flange through the fixed post and the fixing bolt. The spring disc and the external expansion sleeve are locked through the locking bolt. The piston block is arranged between the rear flange and the external expansion sleeve. Using the deformation characteristic of the spring disc and a taper locking mode, the locking device avoids any influence on the precision of the spindle when the spindle is locked and absolutely reliable locking is achieved, thereby ensuring the precision of processed parts, the precision of the spindle and the service life of the spindle.

Owner:GUANGZHOU WEIJIA MACHINE

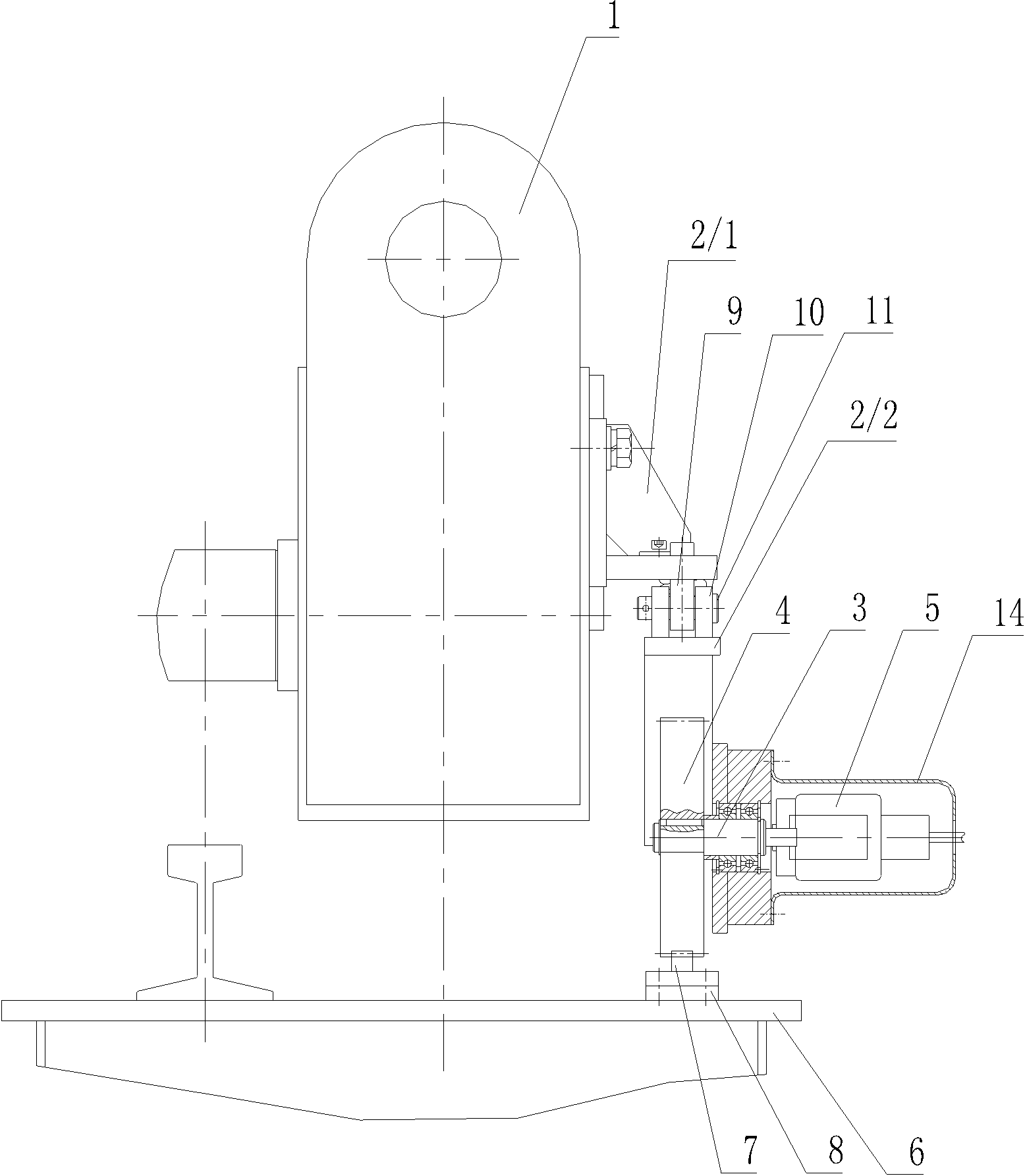

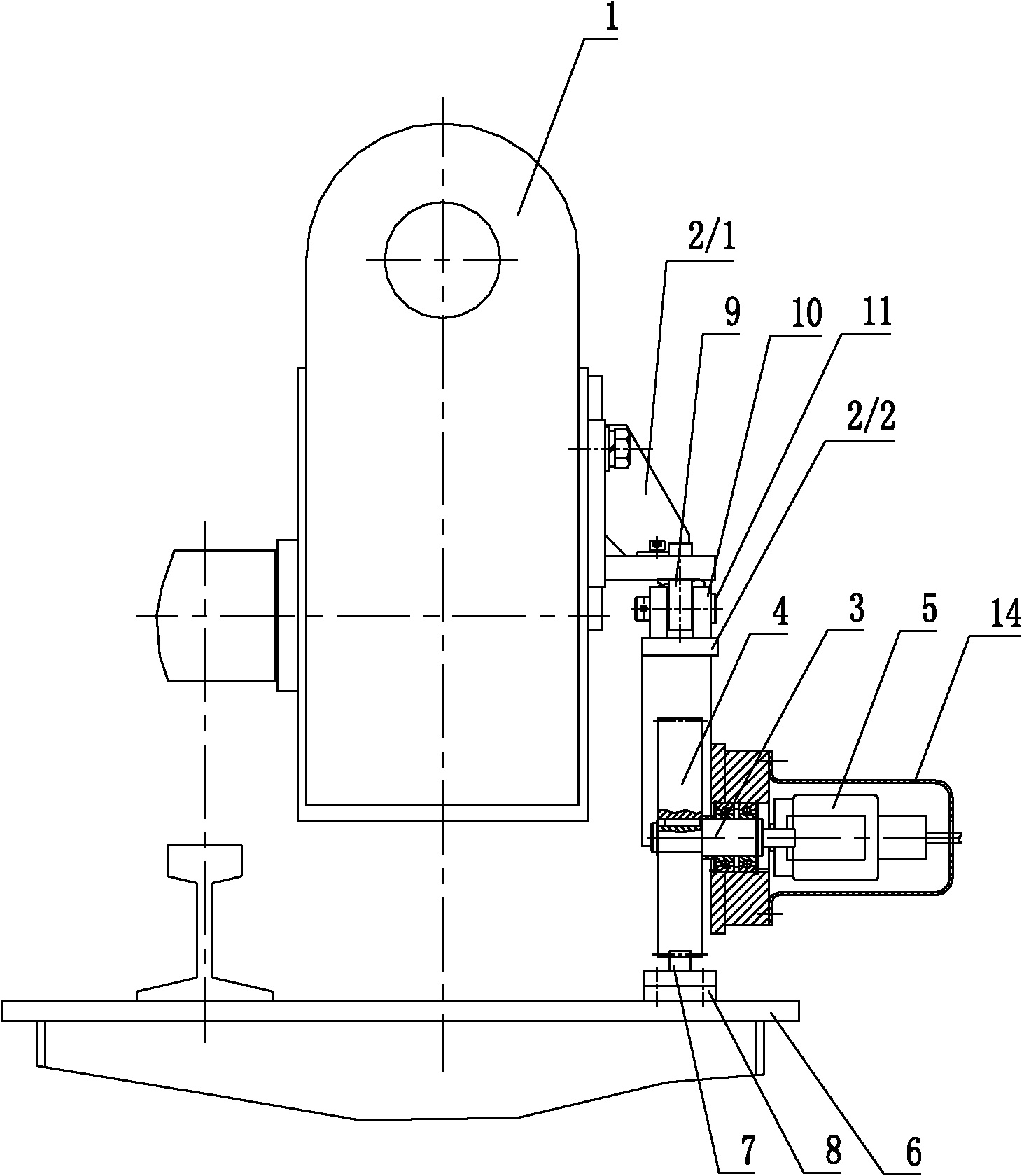

Running positioning device for double-beam trolley of crane

The invention relates to a running positioning device for a double-beam trolley of a crane. The device is characterized by comprising a holder and a support shaft, wherein the holder is fixedly installed on the end beam of the trolley; the support shaft is installed on the holder through a bearing; one end of the support shaft is fixedly equipped with a gear, and the other end of the support shaft is fixedly equipped with a revolution counter; and a rack is fixedly installed on the main beam of the crane and is meshed with the gear. In the invention, the number of meshed teeth of the gear and the rack is captured by the revolution counter, a signal of the number of meshed teeth is transmitted to a control system, then the control system performs variable frequency control on the motor of the trolley according to the signal and an actually measured residual distance signal, the speed of the trolley is gradually reduced, the motor is power off when the trolley arrives at a preset position, and the trolley stops stably.

Owner:杨秀杰

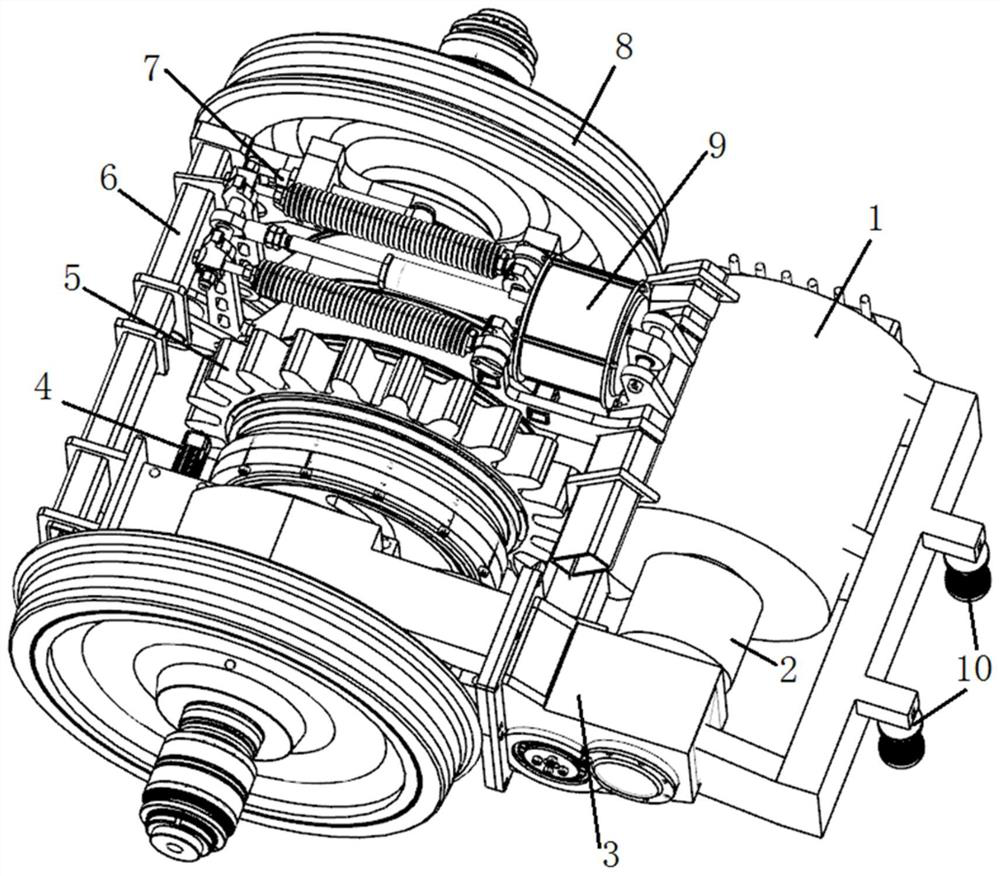

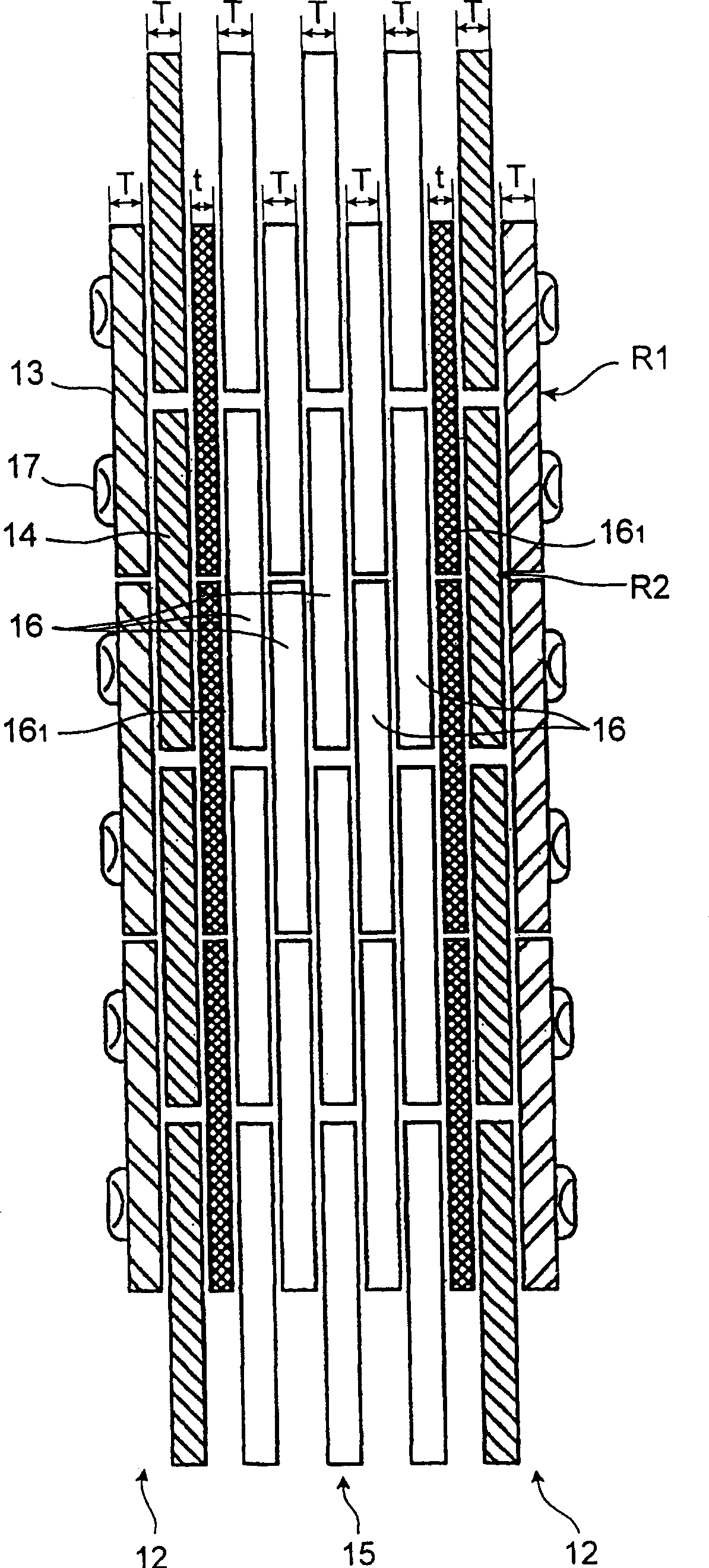

Toothed rail and adhesion coaxial driving toothed rail driving device and toothed rail rolling stock

ActiveCN111762210AIncrease mileageReduce operating costsElectric motor propulsion transmissionGear wheelWhole body

The invention discloses a toothed rail and adhesion coaxial driving toothed rail driving device and a toothed rail rolling stock. A driven gearwheel is mounted on an axle through a bearing; a gear shaft (83) and a toothed rail side shaft sleeve (84) are mounted on the axle on one side of the driven gearwheel through bearings; an adhesive side shaft sleeve (85) is installed on the axle on the otherside of the driven gearwheel in an interference mode, the gear shaft and the toothed rail side shaft sleeve are rigidly and fixedly connected into a whole body, and the driven gearwheel is connectedwith the toothed rail side shaft sleeve or the adhesive side shaft sleeve through a clutch; an eccentric mechanism (52) with a self-positioning and self-locking mechanism is mounted on the gear shaftthrough the bearing, a window is formed in the eccentric mechanism, and outer teeth of the gear shaft are exposed out of the window; and a toothed rail wheel (51) is installed on the eccentric mechanism through the bearing, and the toothed rail wheel is internally meshed with outer teeth of the gear shaft. A height of the toothed rail wheel can be adjusted, and different reduction ratios can be provided for toothed rail driving and adhesion driving.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

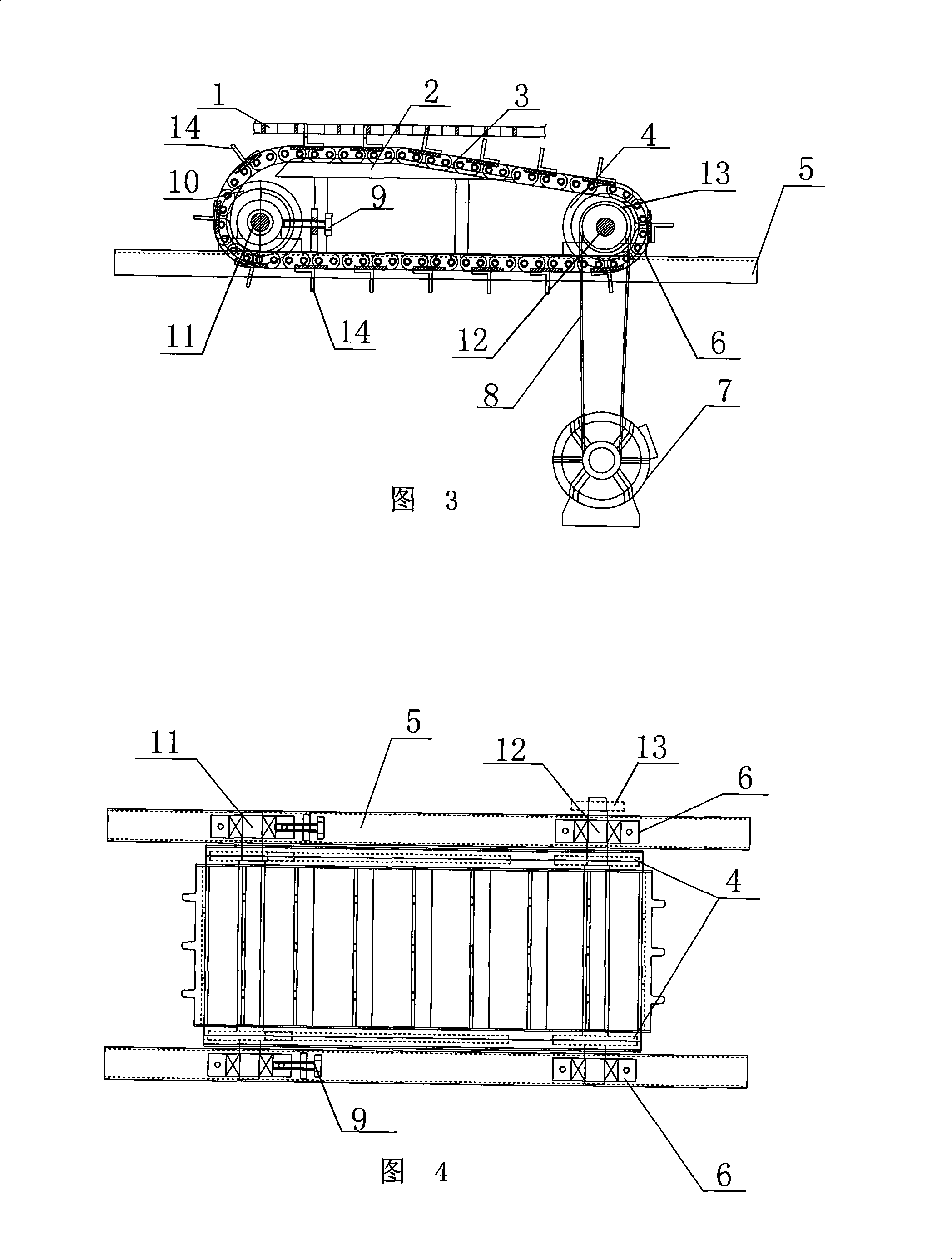

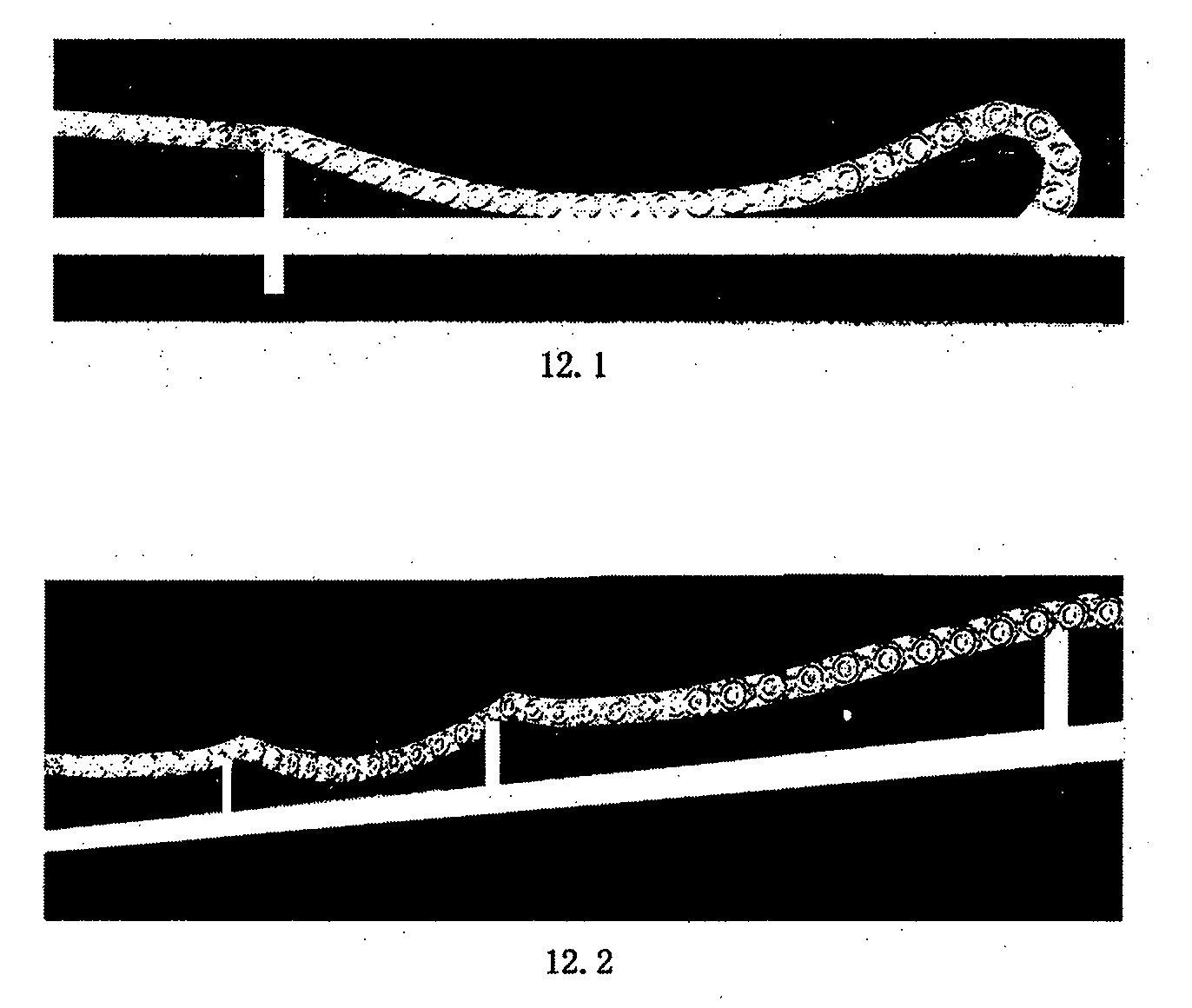

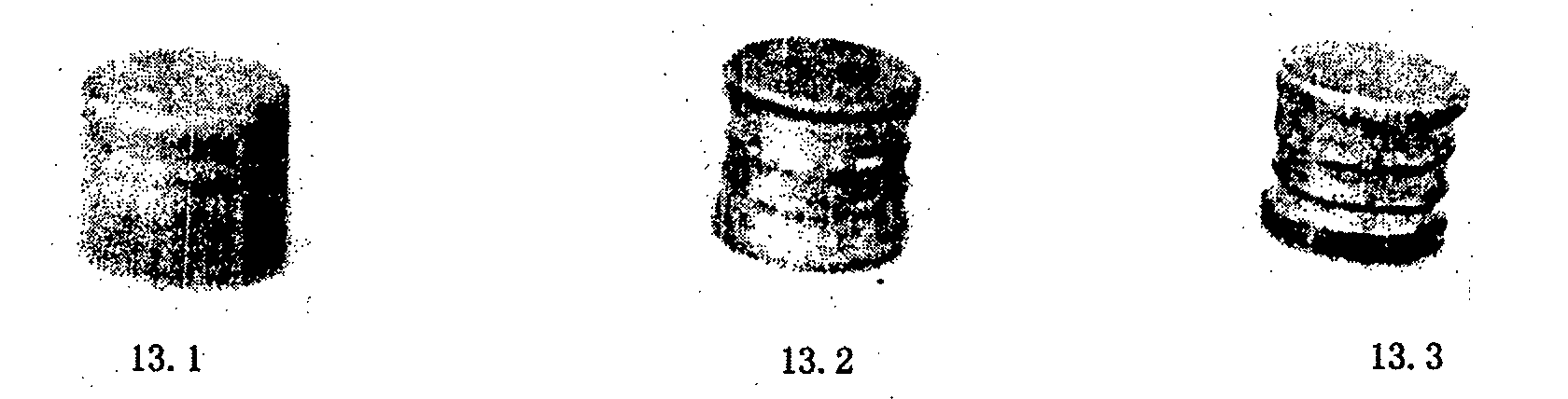

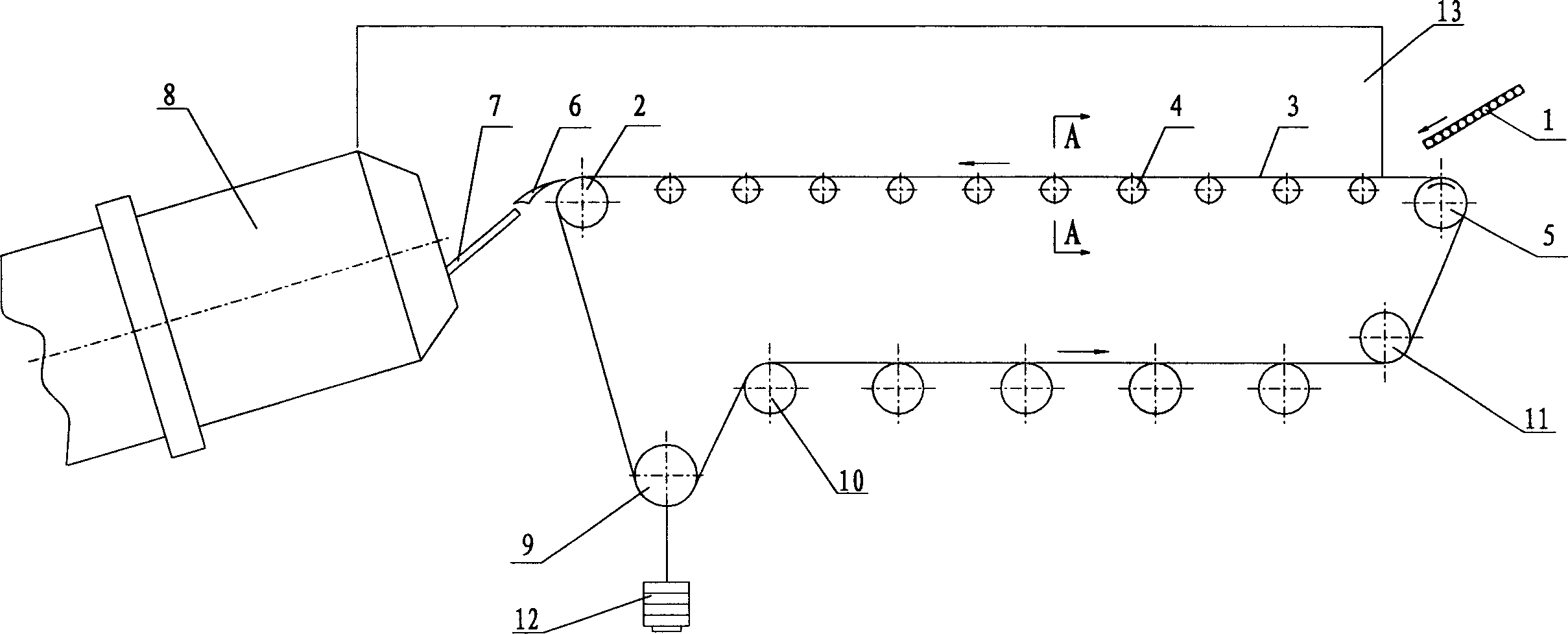

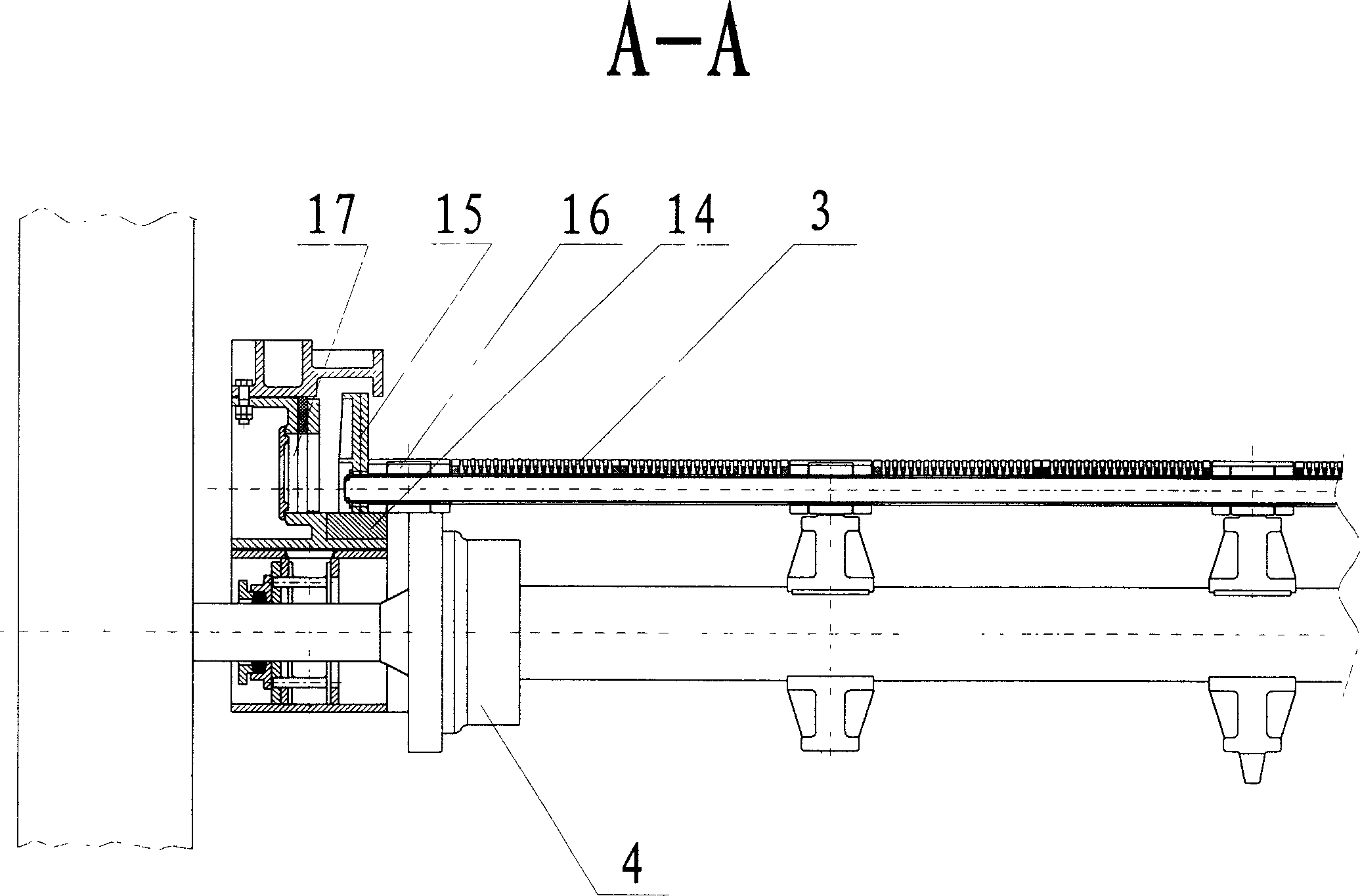

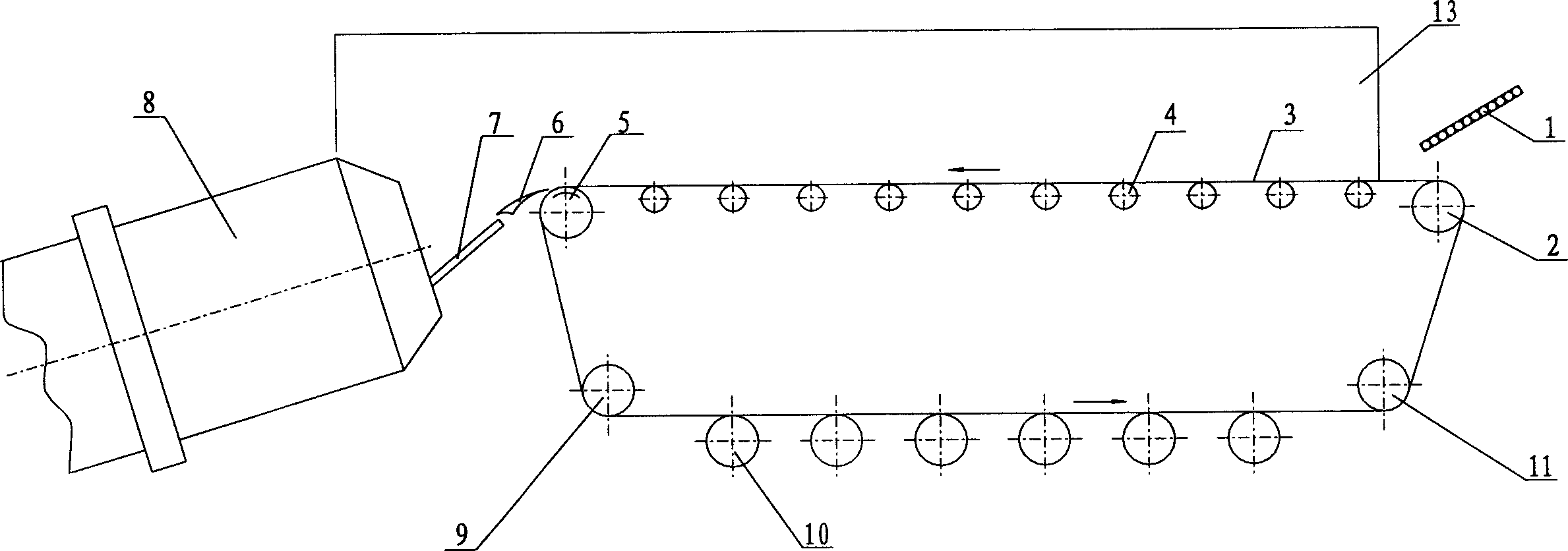

Transmission structure for conveyer belt for screen decorating machine

InactiveCN101402276AStable deliveryContinuous and stable deliveryConveyorsScreen printersScreen printingEngineering

The invention relates to a transmission structure for a conveyer belt for a silk screen printing machine, which has simple structure and continuous transmission, and ensures the stable transmission of the conveyer belt. The transmission structure comprises the conveyer belt, a conveyer chain and a driving structure, and is characterized in that the conveyer chain is meshed with the conveyer belt through a fastener connected with the outside of the conveyer chain, and two outside parts at the meshing part of the conveyer chain and the conveyer belt are in shapes of obtuse arc respectively.

Owner:陆新田

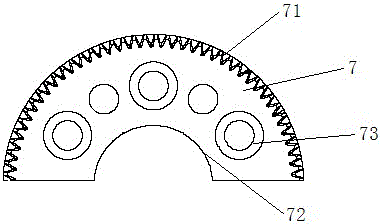

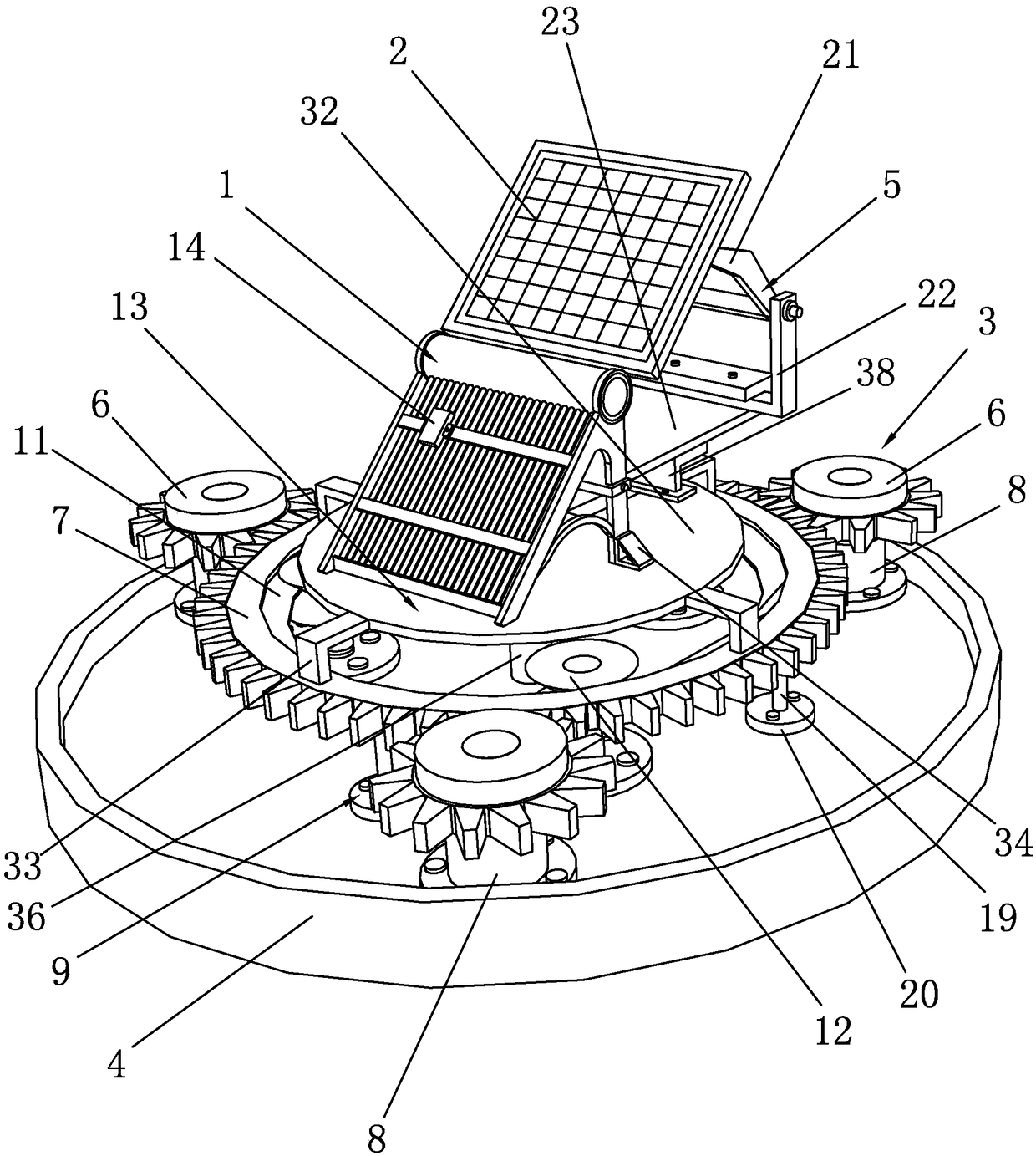

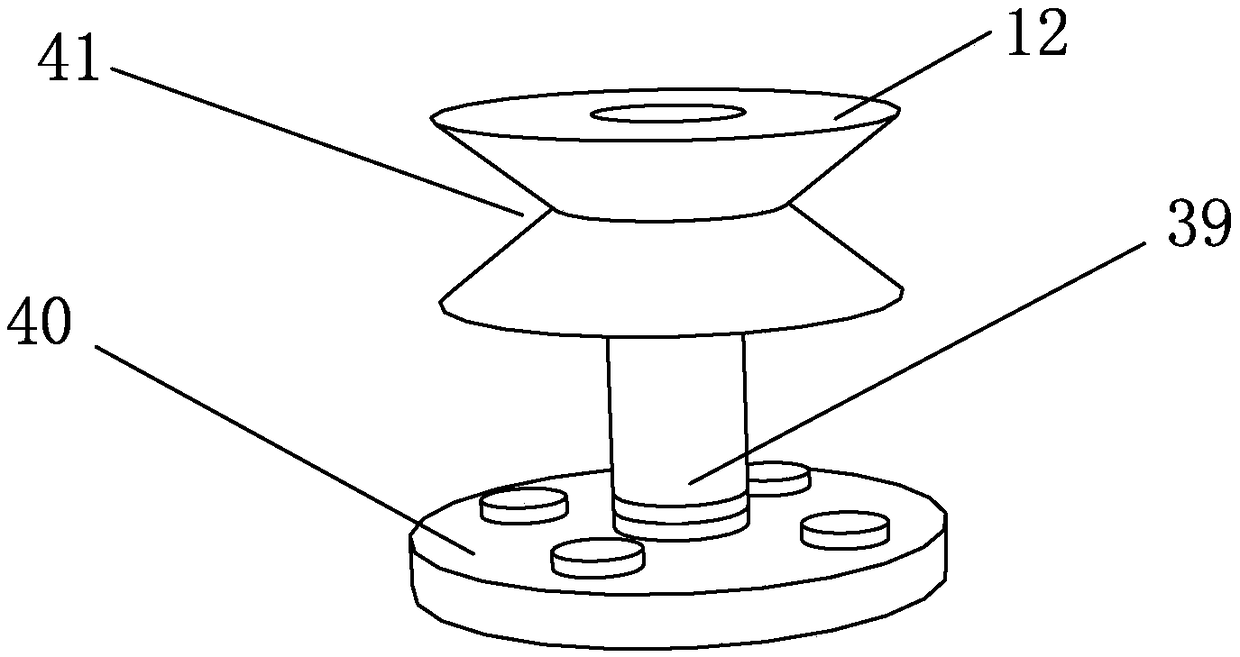

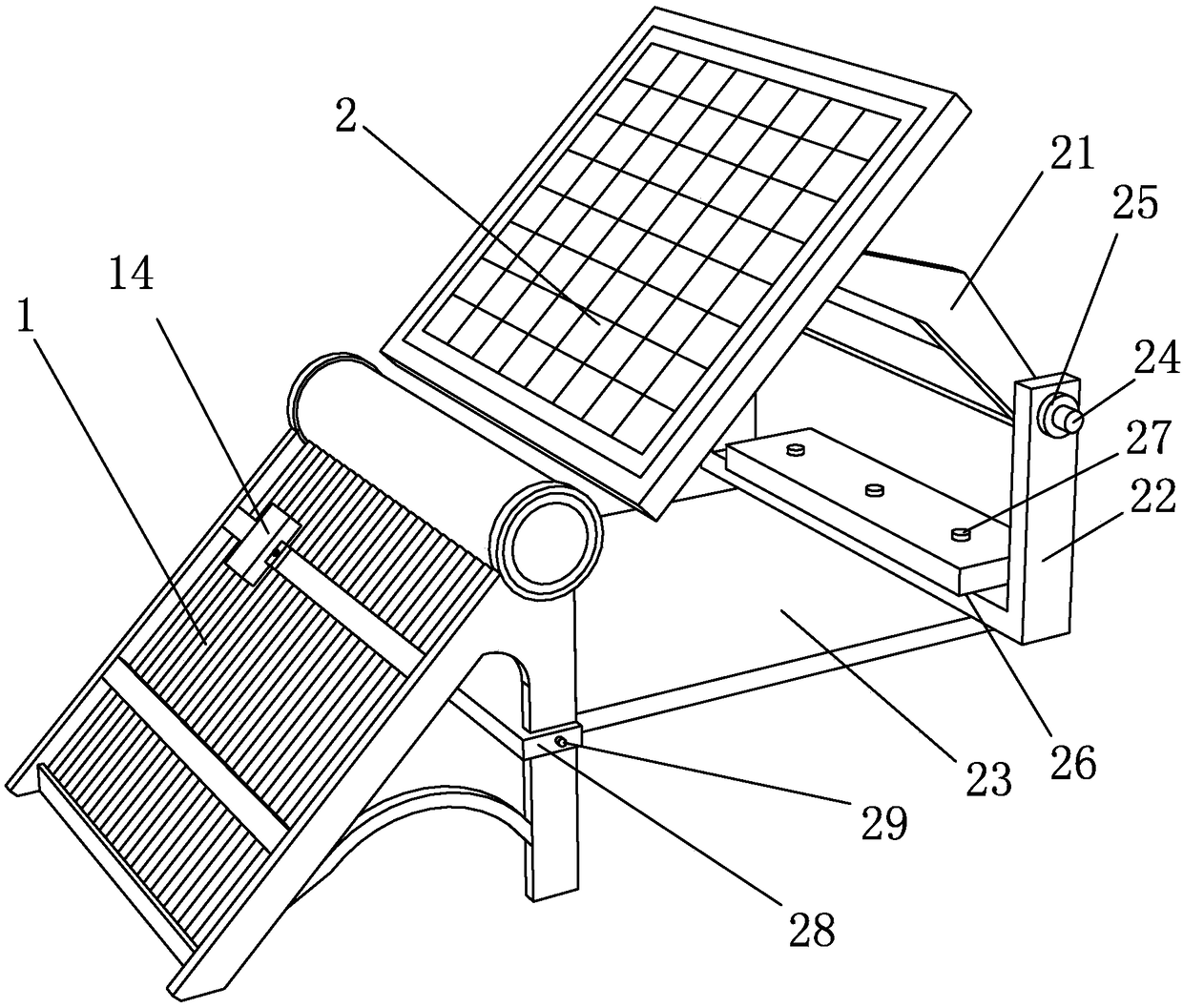

Solar water heater intelligent control device and installation method thereof

PendingCN109210808AGuaranteed structural strengthEasy to processPhotovoltaic supportsSolar heating energySolar waterSolar cell

The invention discloses a solar water heater intelligent control device, which comprises a solar water heater, a solar cell panel, a gear guide rail and a mounting base, wherein the gear guide rail comprises driving gears and a driven gear, the driving gears are evenly arranged on the outer circumferential surface of the driven gear, and the driving gears are engaged with the driven gear. An installation method comprises the steps of: a, installing the mounting base; b, installing the gear guide rail; c, installing a supporting frame; d, installing the solar cell panel; e, and installing the solar water heater. The solar water heater intelligent control device and the installation method thereof effectively improve the utilization rate of the renewable energy sources such as solar energy,reduce the use of non-renewable energy sources such as coal and natural gas, maximize the heat exchange rate of the solar water heater, make the operation more automatic, effectively increase the using comfort and application range of the solar water heater, and enable the utilization rate of solar energy to be maximized in areas with insufficient sunlight.

Owner:ZHEJIANG COLLEGE OF CONSTR

Multifunctional tablet personal computer support

ActiveCN108953871ARealize position adjustmentStable clampingDigital data processing detailsStands/trestlesTablet computerLong axis

The invention belongs to the field of positioning equipment or other supports of products, and particularly relates to a multifunctional tablet personal computer support. The computer support comprises a supporting part, the supporting part of the tablet personal computer comprises a main supporting plate of a hollow structure, side supporting plates capable of sliding relative to the main supporting plate and a folding supporting plate hinged to the main supporting plate, each side supporting plate is fixedly connected with a rack, the racks can be meshed with a gear arranged in the main supporting plate, and one side, far away from the main supporting plate, of the side supporting plates is provided with a clamping part; and a long shaft is coaxially connected with the gear, the long shaft can rotate and slide relative to the main supporting plate, the racks can be driven to move by adjusting the long shaft to enable the gear to rotate, so that the position adjustment of the side supporting plates can be realized. By the adoption of the technical scheme, a tablet personal computer can be supported and positioned, and can be matched with tablet personal computers with different sizes by adjusting the positions of the side supporting plates.

Owner:南京科院新派设计有限公司

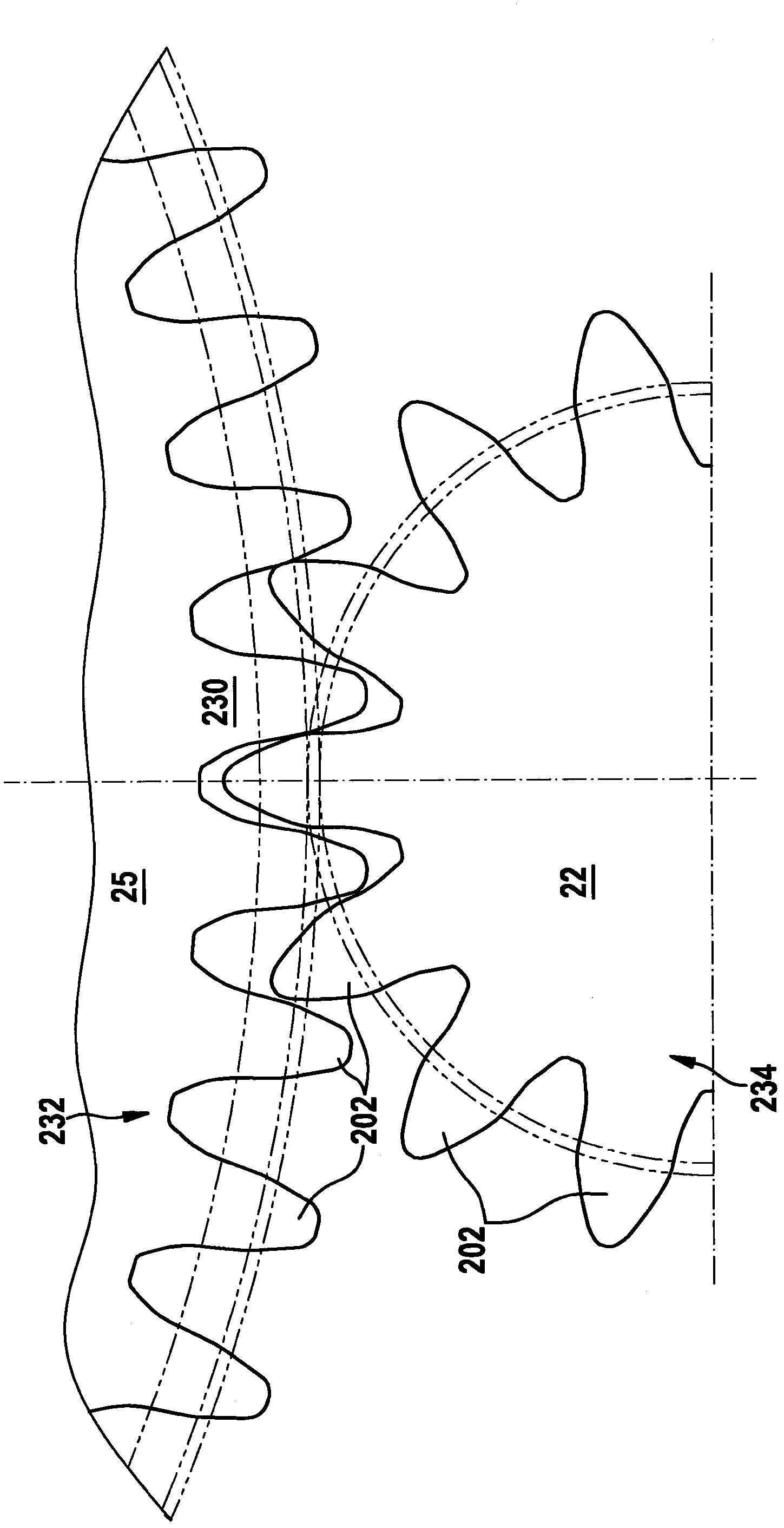

Noise-optimized toothing system

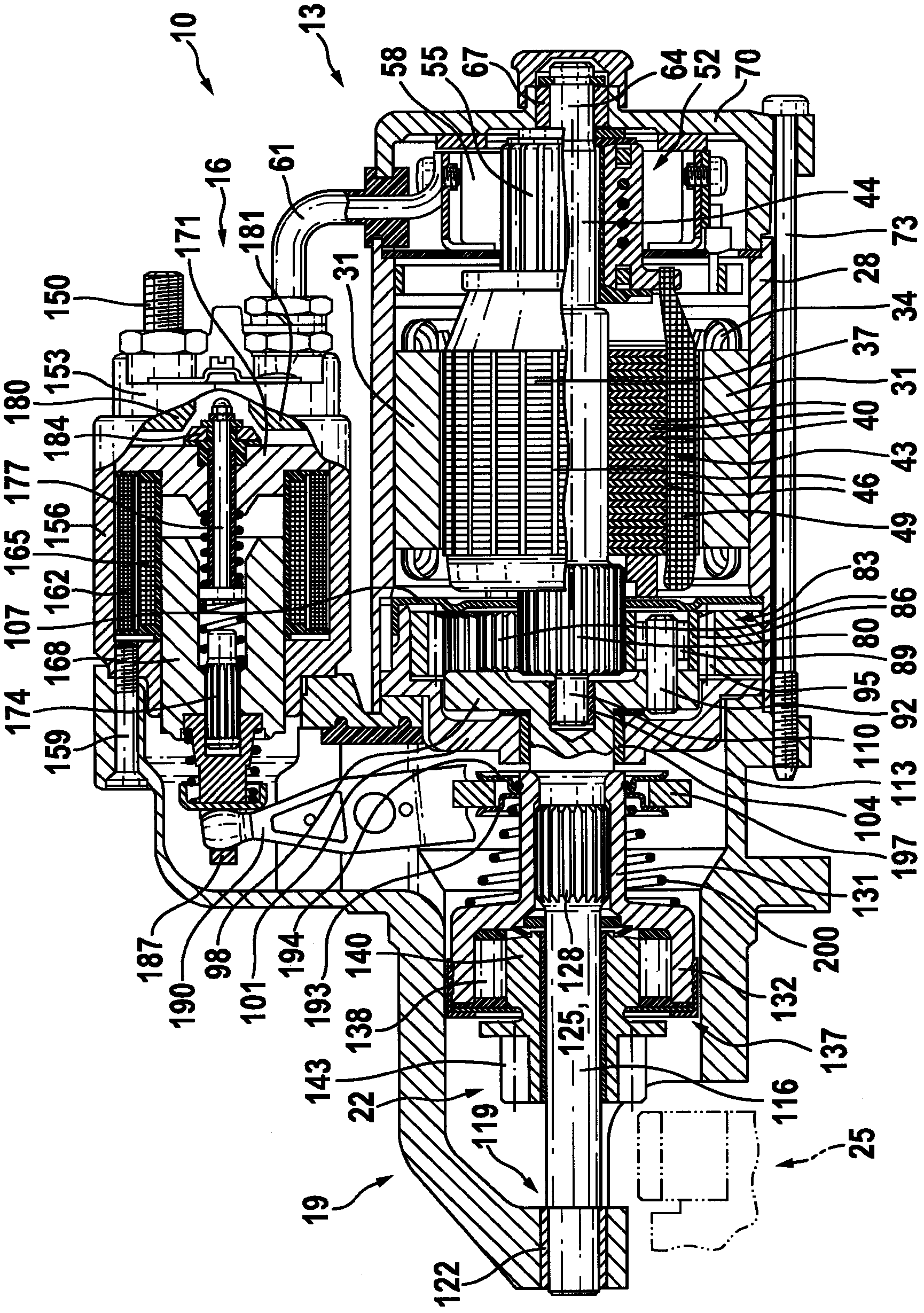

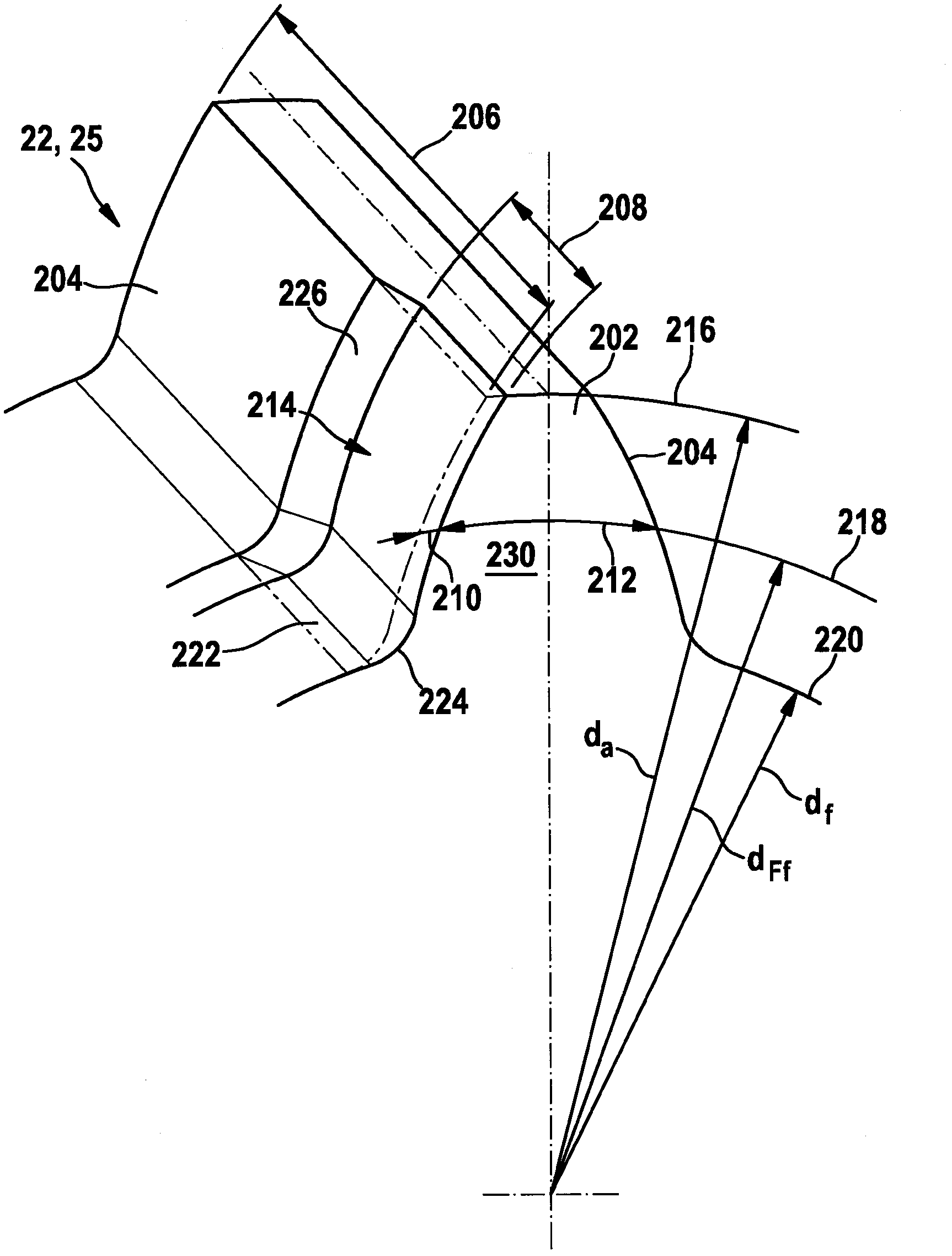

ActiveCN102918257AImprove noiseImproved vibration characteristicsPower operated startersGear vibration/noise dampingElectric machineInternal combustion engine

The invention relates to an electric machine, in particular a starter device (10) for an internal combustion engine. The electric machine comprises a noise-optimized toothing system (232, 234) of two gearwheels (22, 25) which can be brought into engagement with one another. The noise-optimized toothing system (232, 234) is configured as an extra-deep toothing system on at least one of the gearwheels (22, 25). The extra-deep toothing system has an asymmetrical toothing profile (214).

Owner:SEG AUTOMOTIVE GERMANY GMBH

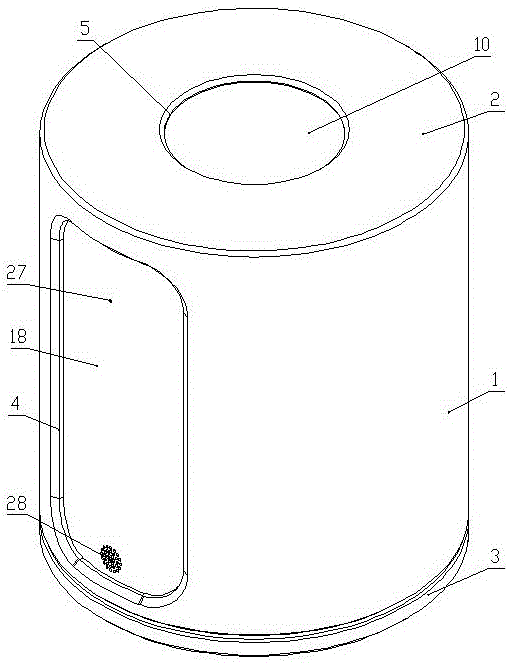

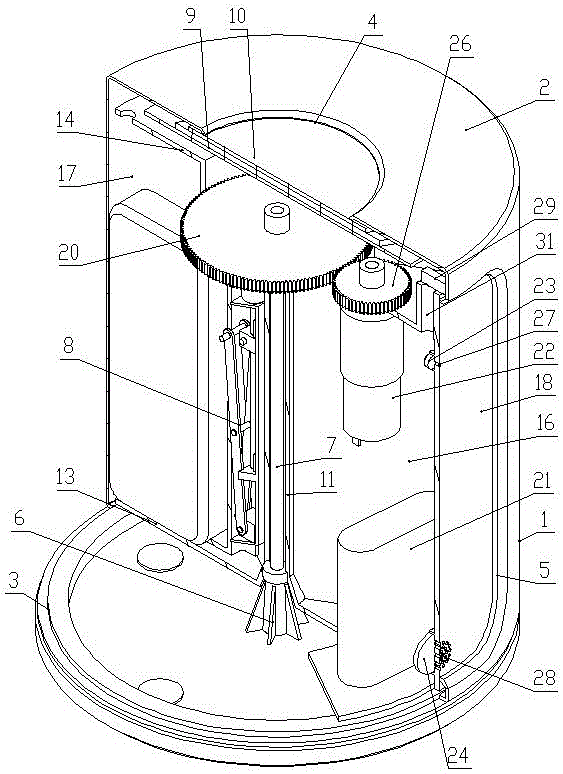

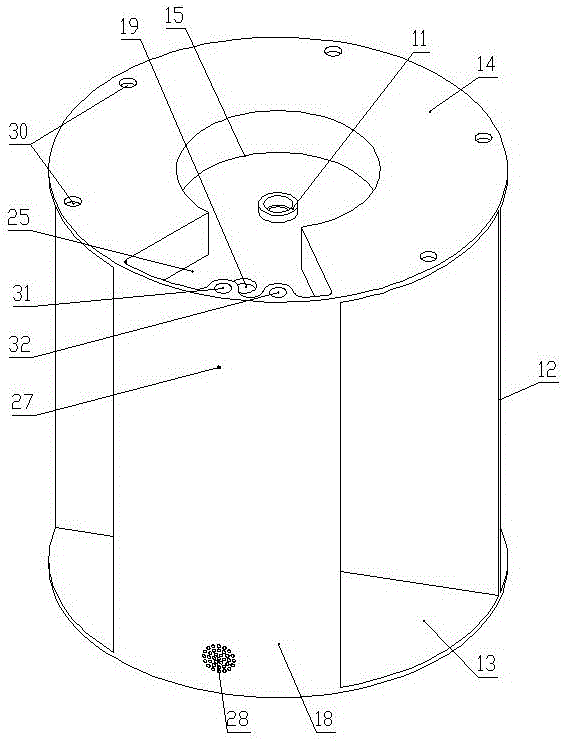

Intelligent containing box of remote controller

InactiveCN105996373AEasy to useHigh degree of automationOther accessoriesAgricultural engineeringIntelligent control

The invention relates to an intelligent containing box of a remote controller. The intelligent containing box comprises an outer casing, wherein the outer casing is of a cylindrical structure, the centerline of the outer casing is arranged along the vertical direction, a top plate and a bottom casing are respectively arranged on the top part and bottom part of the outer casing, the side part of the outer casing is provided with a remote controller exit and entrance, and an operation hole is formed in the top plate; a support base is arranged at the center of the bottom casing, a center shaft is fixedly arranged on the support base and has the same centerline with the outer casing, a rotary frame assembly is sheathed on the exterior of the center shaft and can rotate around the center shaft, the rotary frame assembly comprises a power driving bin and at least three remote controller containing bins, and the interior of each remote controller containing bin is respectively provided with an automatic telescopic remote controller containing device. The intelligent containing box has the advantages that by utilizing intelligent control and mechanical transmission principle, the purpose of automatically containing and fetching out the remote controller is realized, and a plurality of different remote containers can be contained; by using an intelligent mobile phone or a touch screen to operate and control, the automation degree is high; a remote controller finding function is realized; standby batteries can be contained, so that the convenience is realized for families.

Owner:HUANGHE S & T COLLEGE

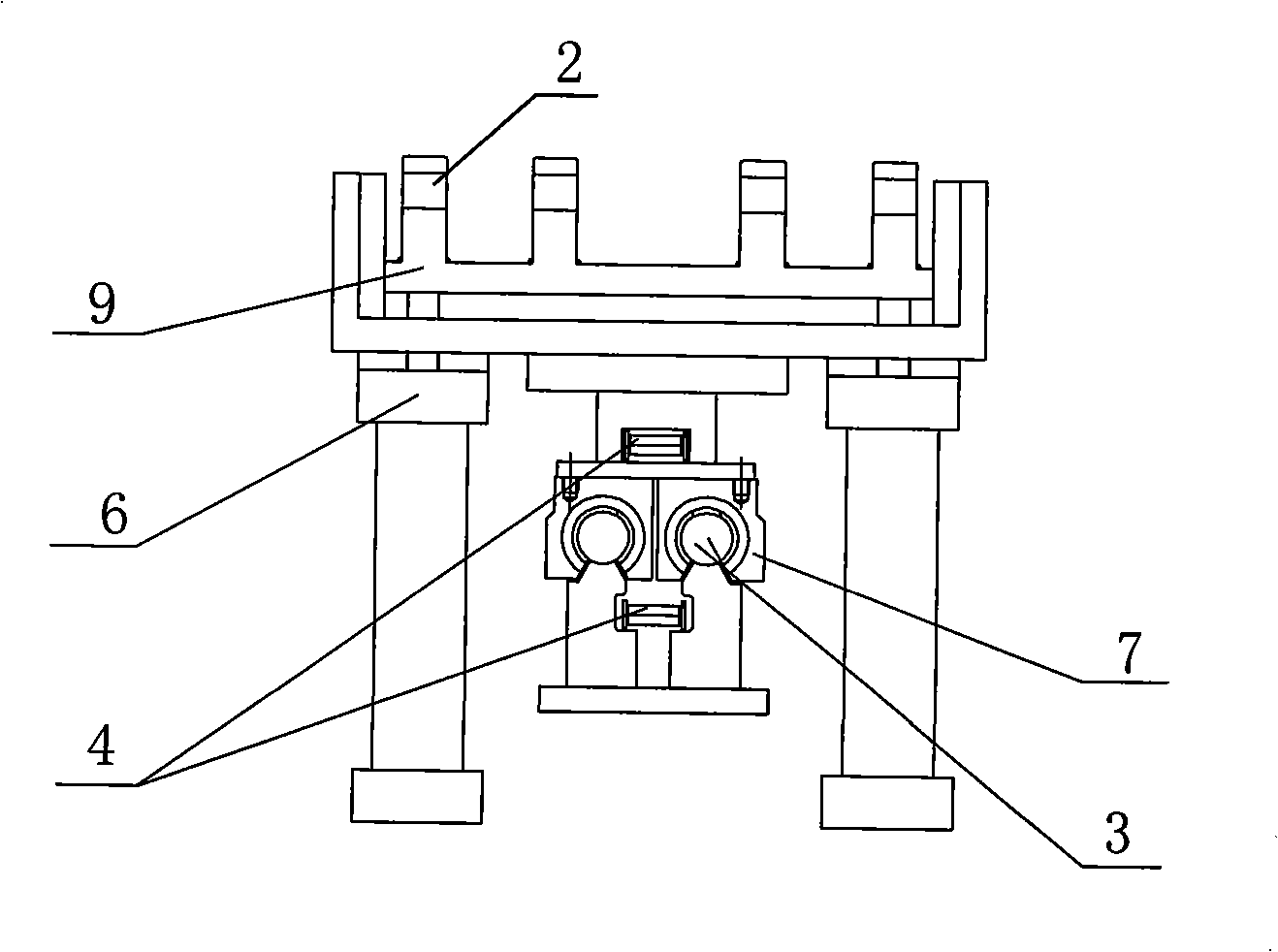

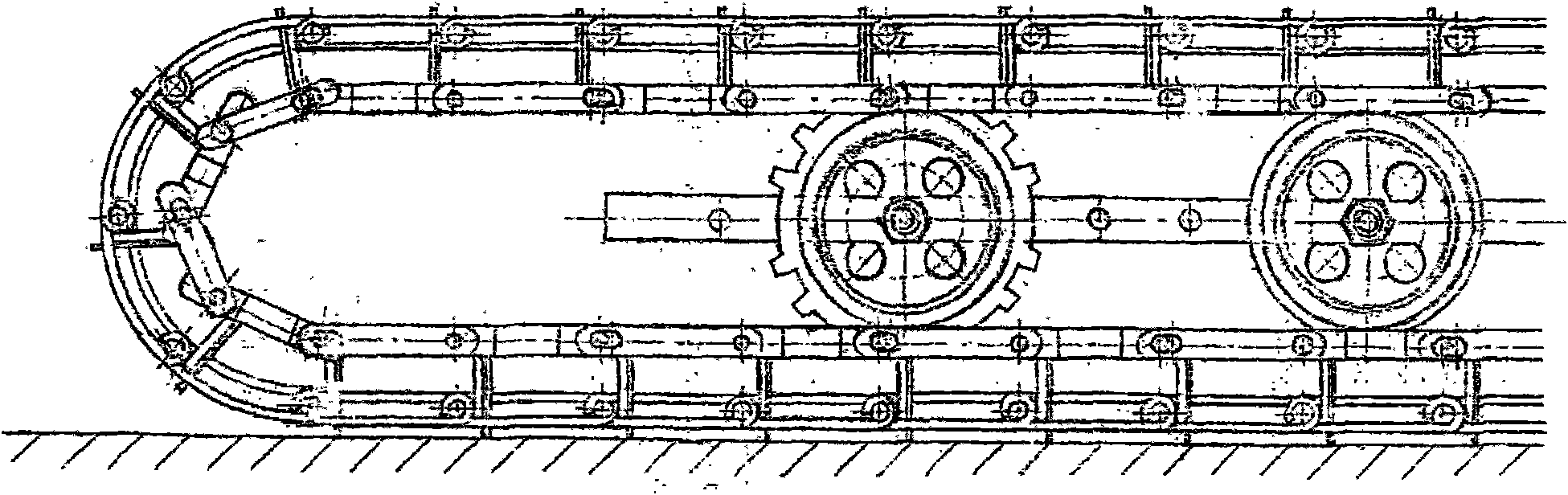

Novel movable support type heavy-duty drag chain

InactiveCN102032318ANo distractionVibration reduction and noise cancellationHauling chainsHoisting chainsProduction lineEngineering

The invention discloses a novel movable support type heavy-duty drag chain, relates to a novel movable support type heavy-duty drag chain which has the functions of centralized supporting, reciprocating movement traction and protection for various conveying pipes and cables of electric energy, hydraulic pressure, pneumatic power, liquid raw materials and the like of metallurgical steel rolling equipment, large-sized mechanical equipment and large-sized automatic production lines in continuous operation. The drag chain is characterized in that: one surface of a drag chain body consists of a group of powerful torsion springs and the other surface of the drag chain body consists of a plurality of freely adjustable chain rails to replace a thick and heavy chain plate which is formed by stamping and welding two layers of steel plates in the prior art; and a pipe / cable supporting bridge plate and a partition plate which are integrated with each other are used for replacing a supporting plate in the prior art. A manufacturing process can be performed without a series of stamping and carrying moulds and equipment with high cost. The key point of the invention is that: the drag chain can be bent and moved by elastic deformation of the torsion springs, and reverse acting force of the torsion springs is skillfully utilized to obviously relieve load and wear on a connection part of the drag chain. The drag chain is also characterized in that: the freely adjustable chain rails of the drag chain body and a roller or roller assembly which has the same bending radius as the drag chain and is provided with a tooth socket are adopted to movably support the drag chain to operate with heavy duty. The drag chain solves the problems of heaviness and unreasonable supporting of the heavy-duty drag chain in the prior art, and overcomes the disadvantages of quick wearing of a heavy-duty drag chain plate hole and a pin shaft in the prior art.

Owner:熊雄

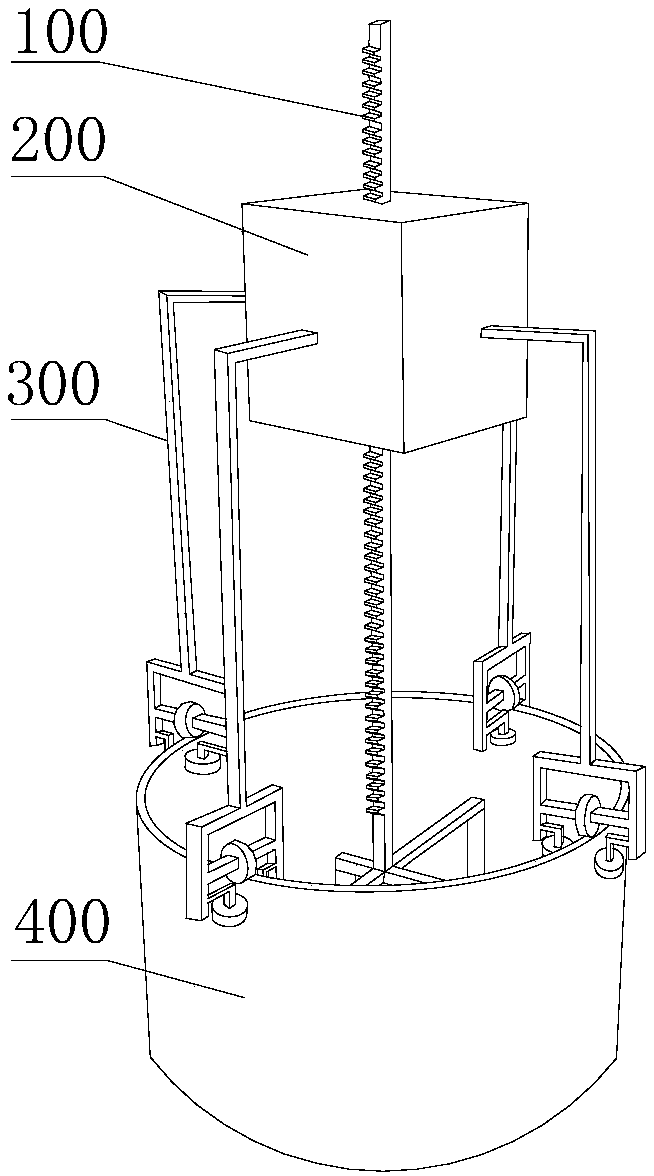

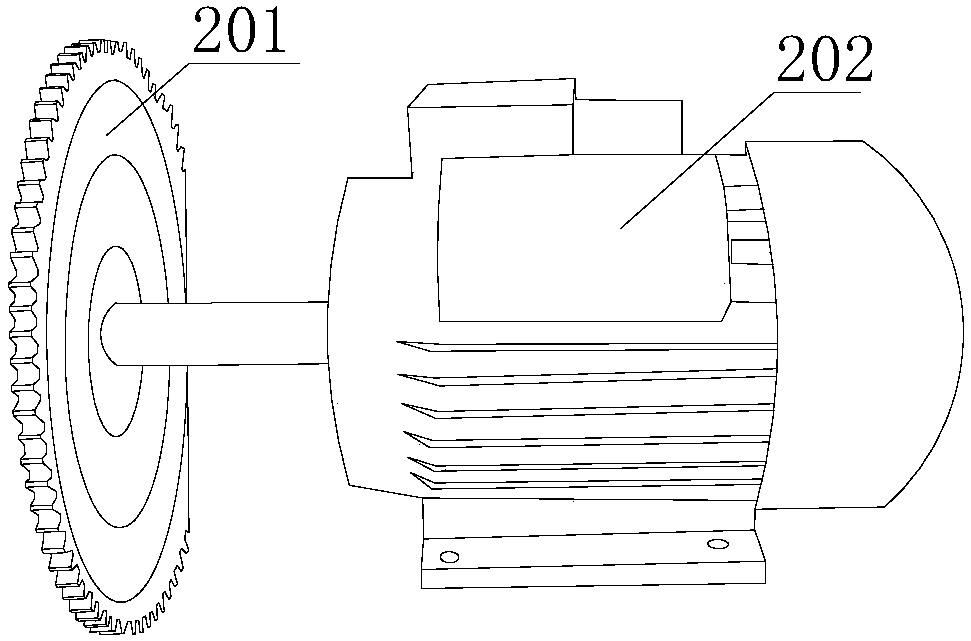

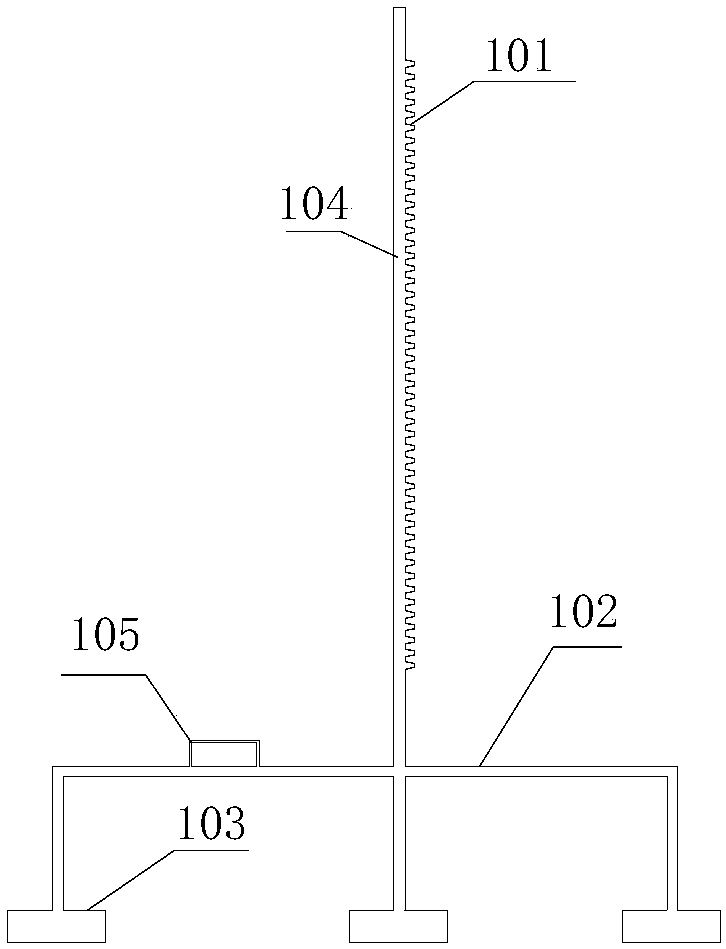

High-rise building aerial fire rescue device

The invention discloses a high-rise building aerial fire rescue device, and belongs to the technical field of building fire fighting equipment. The high-rise building aerial fire rescue device is characterized by comprising a rotating device arranged at a roof of a high-rise building, and guide rails. The high-rise building aerial fire rescue device has the following beneficial effects: when a motor A is started, a paying-off direction of a windlass on a disc rotates to one side opposite to a fire generation place for preventing burn by fire in escape; as an upper guide rail is arranged on an inner guide rail, and one side of a slide block is arranged in a gap formed between the inner guide rail and the upper guide rail, on the one hand, the stable sliding of the slide block on the rail is guaranteed, and on the other hand, the rollover of the slide block caused by the weight of staff is prevented to provide reliable guarantee for safe rescue; one end of a bracket is fixedly connected with the slide block, and the other end extends to the outer end of a floor; a box body is shifted to the outer side of a wall of the building; a lifting basket is hoisted by a steel wire rope for preventing collision to the wall to cause personal injury; and a pulley is arranged on the box body for preventing knotting of the steel wire rope to cause unstable descending.

Owner:山东中恒建设集团有限公司

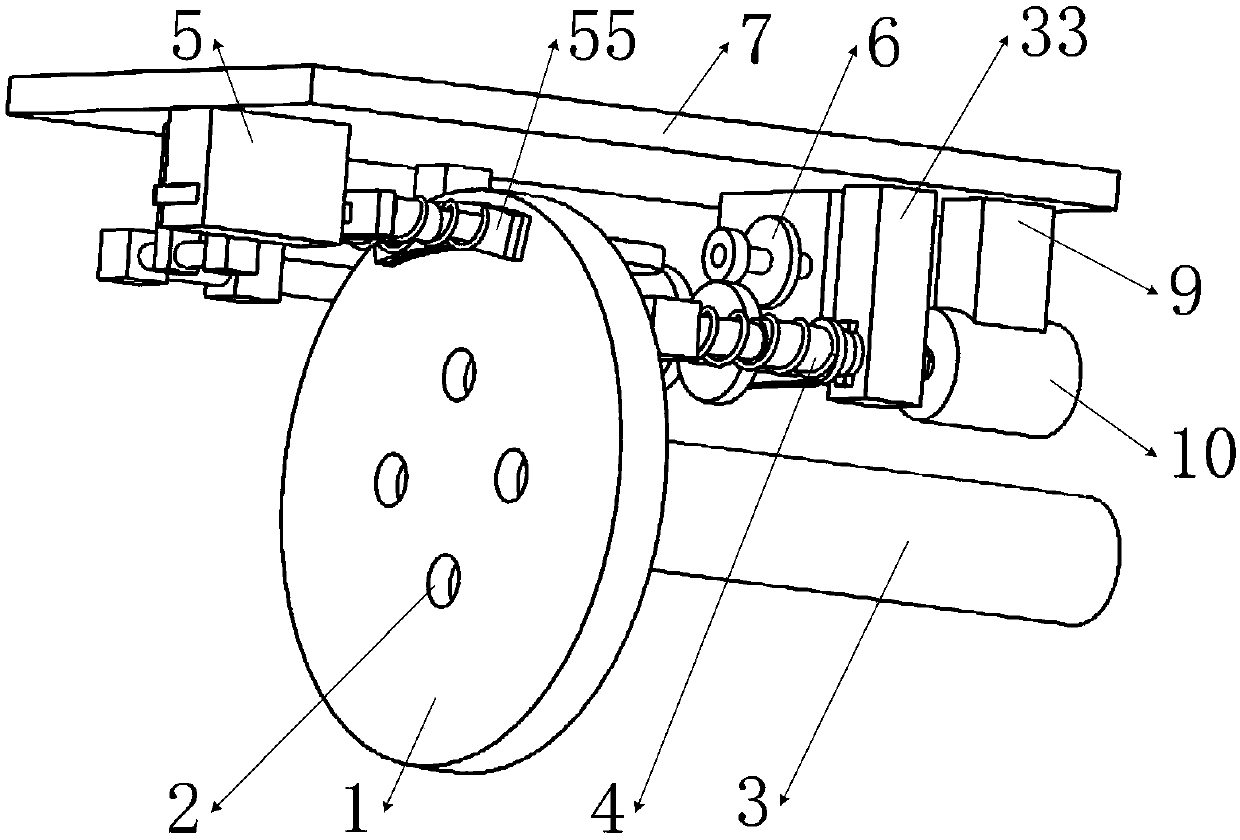

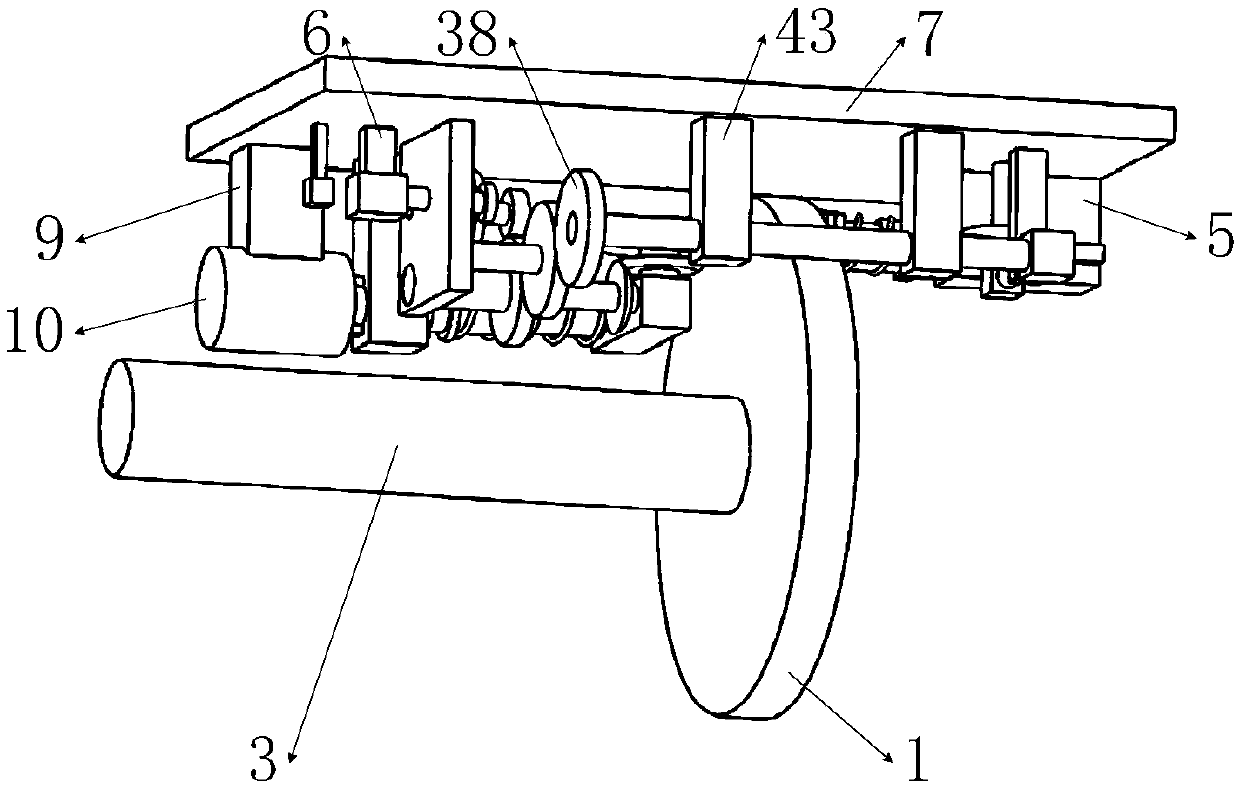

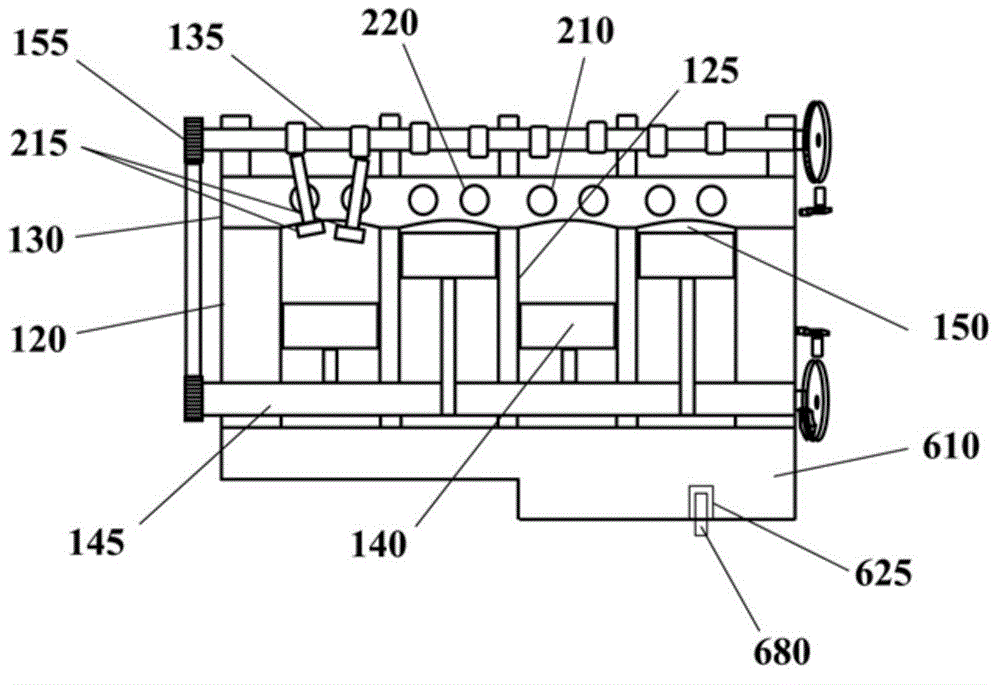

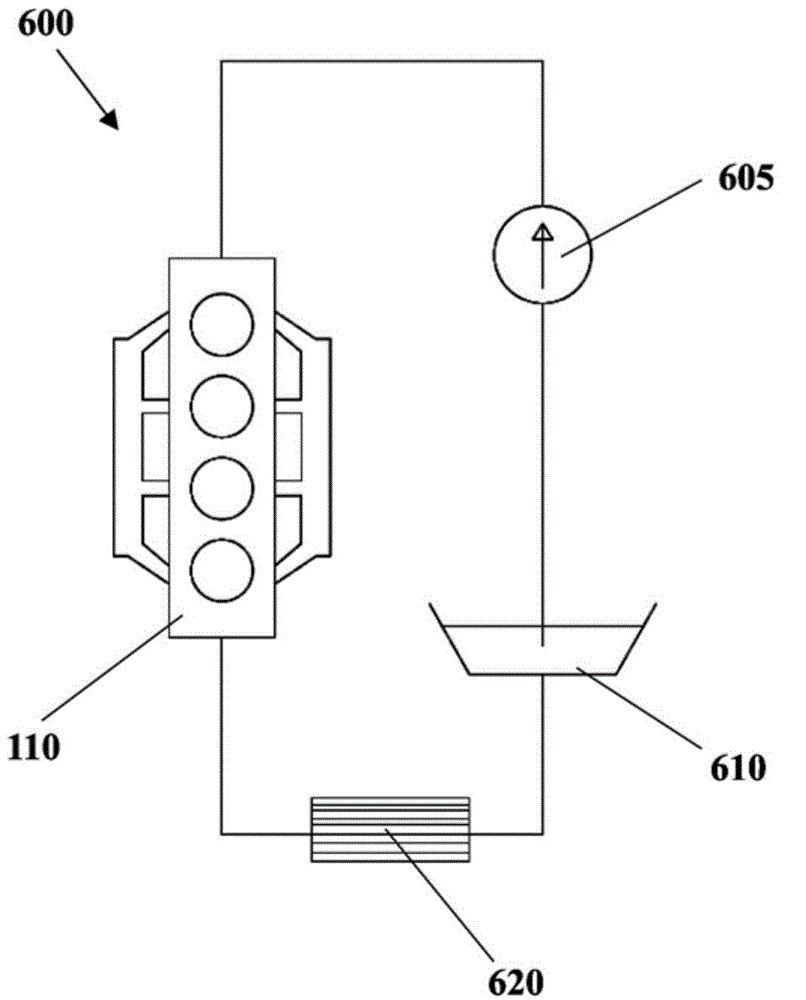

Energy-saving braking system used for wheel type robot

ActiveCN109624956AGuaranteed meshingPrevent disengagementBraking element arrangementsBraking action transmissionGear driveGear wheel

The invention belongs to the technical field of braking, and particularly relates to an energy-saving braking system used for a wheel type robot. The energy-saving braking system comprises a brake disc, an executing mechanism, a braking mechanism and an energy saving mechanism, wherein through a gear motor, a thread shaft is matched with a thread sleeve through a thread, and the thread sleeve pushes a friction wheel and the brake disc to conduct friction braking through a first telescopic rod and a supporting block; when the friction wheel and the brake disc conduct friction braking, rotationof the friction wheel is transferred by a corresponding gear and a corresponding shaft, then a third gear drives a sliding plate to move to the brake disc, and the sliding plate pushes an arc-shaped brake pad to conduct friction braking on the brake disc through a supporting plate, second telescopic rods, second springs and an arc-shaped plate. When a first gear rotates, the energy-saving mechanism can absorb part of rotating energy of the first gear and convert the rotating energy into electric energy which is stored in a battery of the wheel type robot, so that the aim of saving energy is realized. The energy-saving braking system is simple in structure and has a good using effect.

Owner:江苏图灵智能机器人有限公司

Oil drain plug and socket

An oil drain plug is disclosed for cooperating with a socket in an oil sump. The plug includes a main body, an eccentric pin protruding from the main body, and an enlarged tip on an end of the eccentric pin. The socket includes a cup-shaped cavity having a lateral wall open at one end, closed at the opposite end by a bottom wall and including an internal surface for mating with the main body of the plug. The bottom wall includes an external surface facing outside the cavity, a through hole such that the enlarged tip of the plug extends beyond the external surface, and a slot departing from the through hole towards a distal end along an arched path centered in the axis and having a smaller width than the through hole for preventing the enlarged tip of the plug from passing through it.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electric hammering device of compaction apparatus

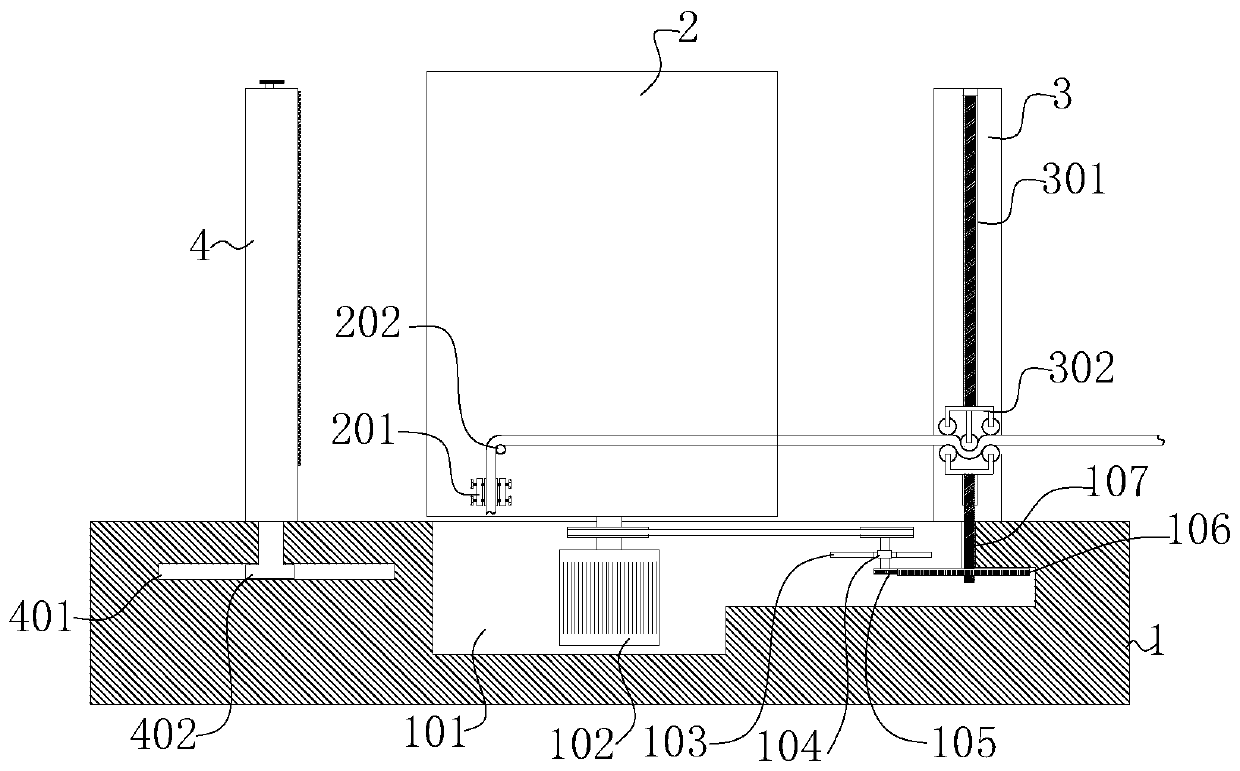

PendingCN108279147AFree Fall GuaranteedGuaranteed levelnessPreparing sample for investigationEarth material testingFree fallingTest specification

The invention discloses an electric hammering device of a compaction apparatus. A four-leg hammer device, a power device, a rotating device and an impaction barrel body are arranged; the rotating device is used for rotatably fixing the power device on the impaction barrel body through a rotating bracket; the power device is internally provided with a driving motor and a sliding way for sliding a vertical sliding rod of the four-leg hammer device; a rack which is in engaged transmission with a driving gear is arranged at one side of the vertical sliding rod; the driving gear of the driving motor is engaged with the rack of the four-leg hammer device, so that the lifting and free falling body movement of the four-leg hammer device are driven to realize the aim of impacting; the height of lifting an impaction hammer each time and the weight of the impaction hammer are determined; when the four-leg hammer device falls off, the four-leg hammer device is not in contact with a power box, so that the free falling body movement of the four-leg hammer device can be ensured and geotechnical test specifications are met; meanwhile, circumferential rotary impaction is carried out by the four-leghammer device under the action of the rotating device in an impaction process, so that the impaction frequency of each point is equal and the levelness of an impaction surface is ensured.

Owner:CHANGAN UNIV +1

Cotton wool packing and sleeving equipment

ActiveCN110395610APromote sportsEasy to transportNon-woven fabricsUnfolding thin materialsEngineeringCOTTON WOOL

The invention discloses cotton wool packing and sleeving equipment. The structure of the equipment comprises a platform plate. Vertical plates symmetrical front and back are fixedly arranged on the upper end face of the platform plate. Open round grooves are fixedly formed in the vertical plates. The lower end face of the platform plate is fixedly provided with supporting feet arranged in a ring-shaped array manner. Telescopic moving devices facilitating moving of the equipment are arranged in the supporting feet. Turning-over plate devices used for preventing dust accumulation below the equipment and facilitating dust clearing are arranged among the telescopic moving devices. A packing and sleeving device is arranged above the platform plate and carries out packing and sleeving processingon cotton wool to form protecting net wrapping. The equipment adopts the telescopic moving devices, the turning-over plate devices and the packing and sleeving device, the equipment is convenient tomove and transport, the manner of unfolding a knit net back and forth is utilized to enable cotton wool wrapping to form the cotton wool structure wrapped by the knit net, in the process, many flexible structures are utilized, while the production efficiency is improved, the influence on transmission parts in the equipment is prevented, and the service life of the equipment is prolonged.

Owner:桐乡市瑞炬纺织品有限公司

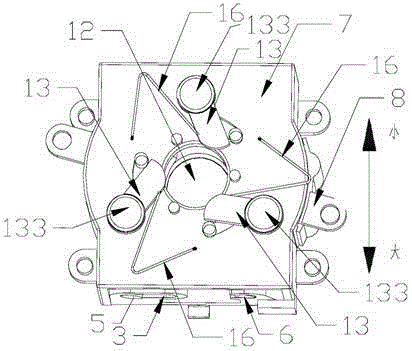

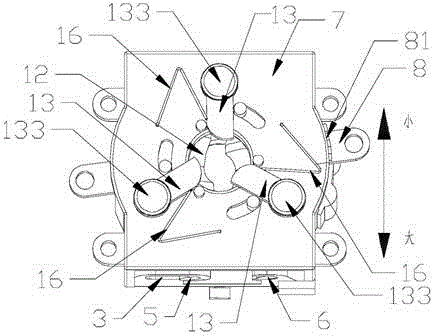

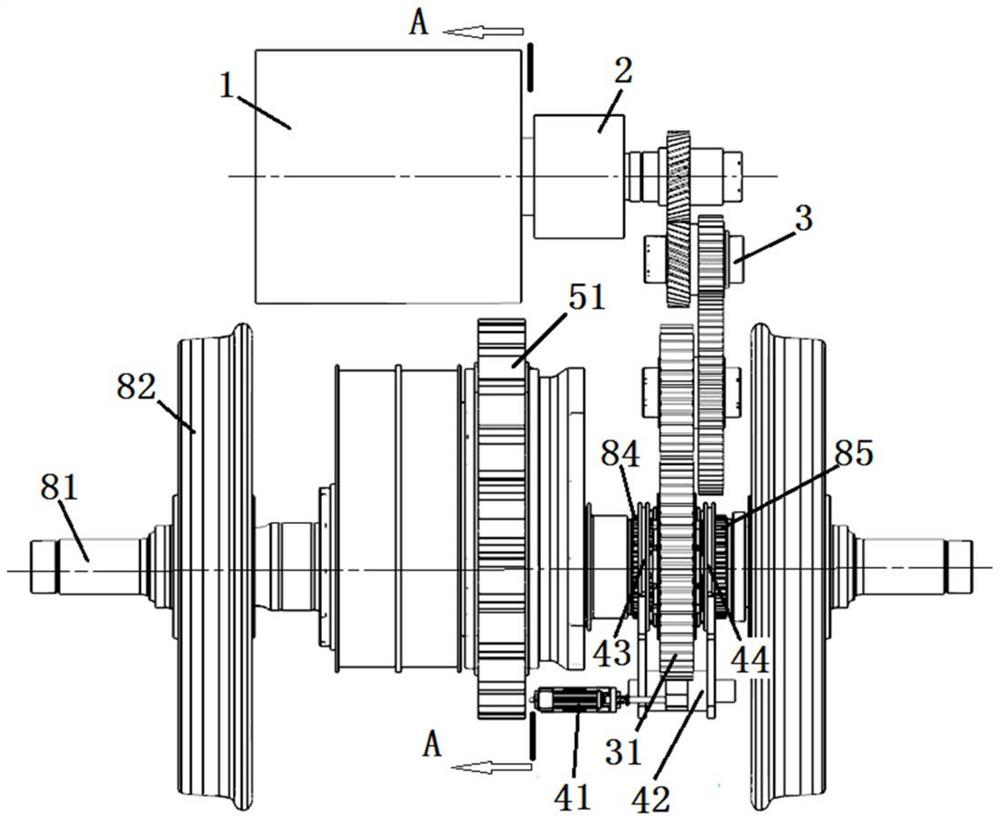

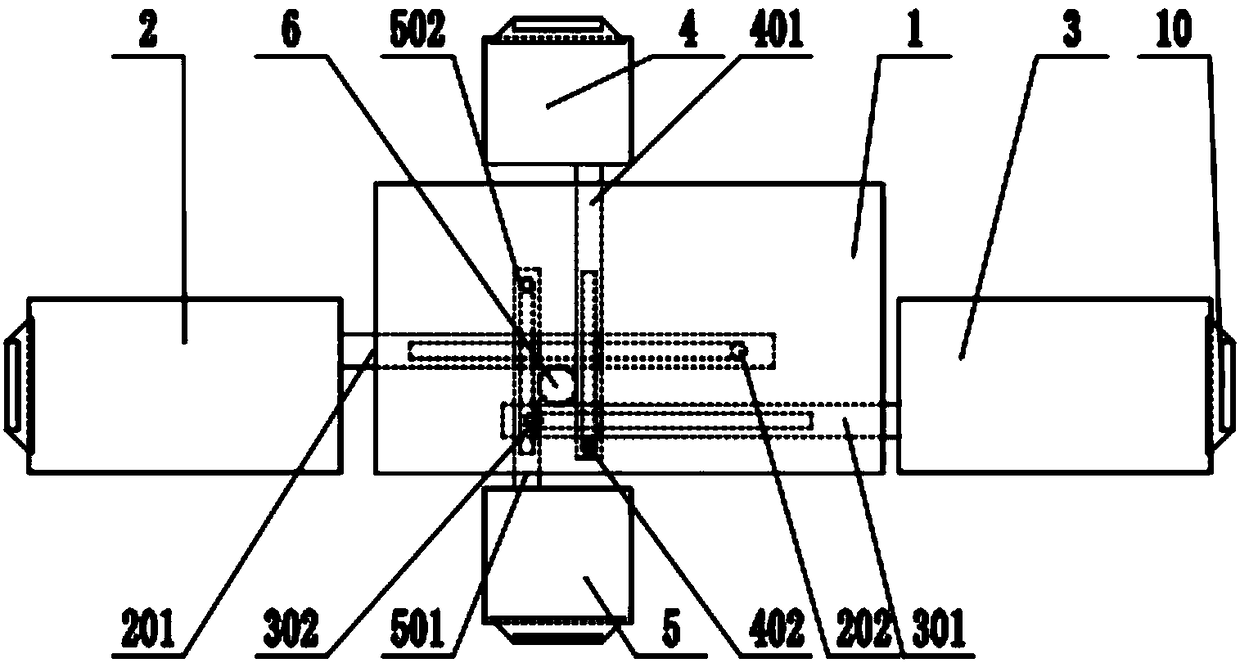

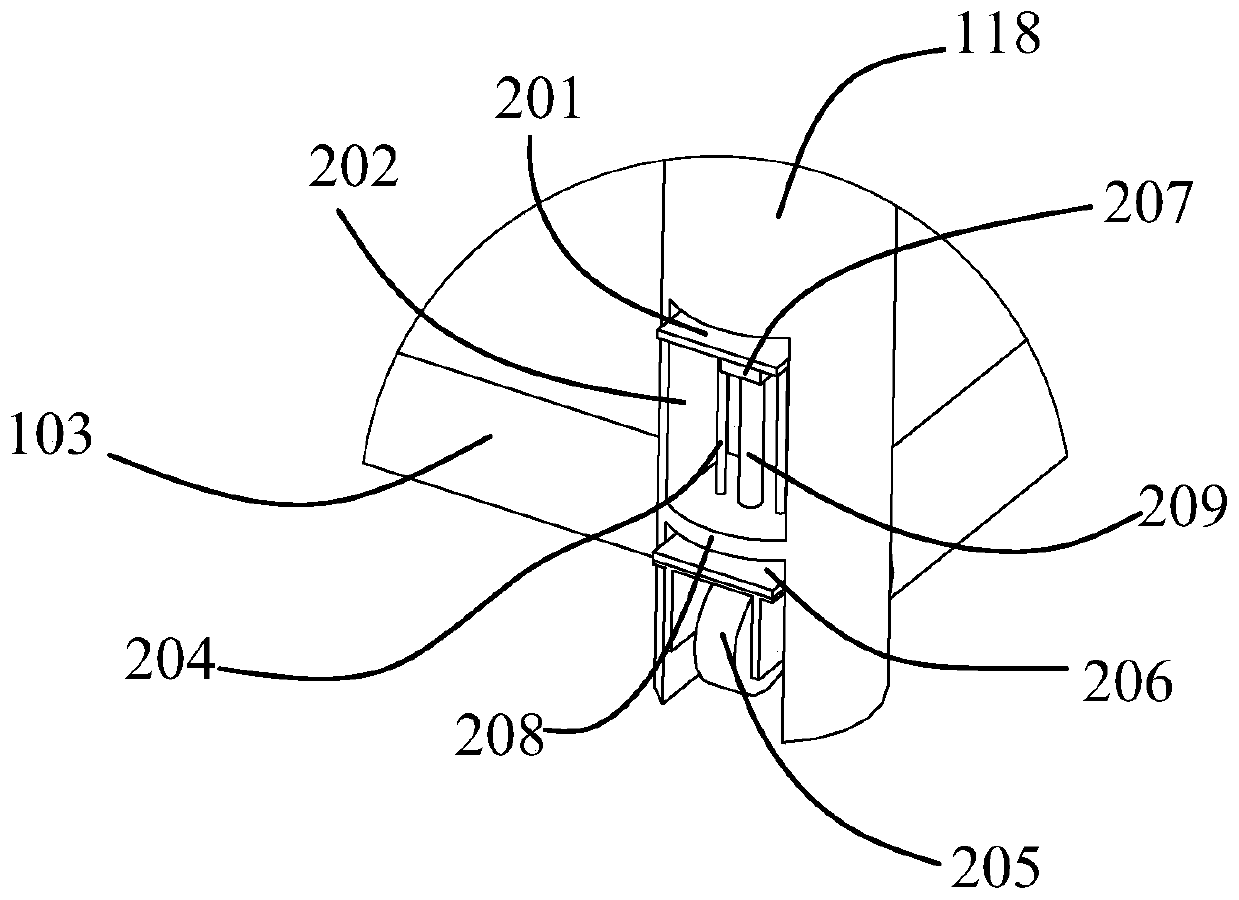

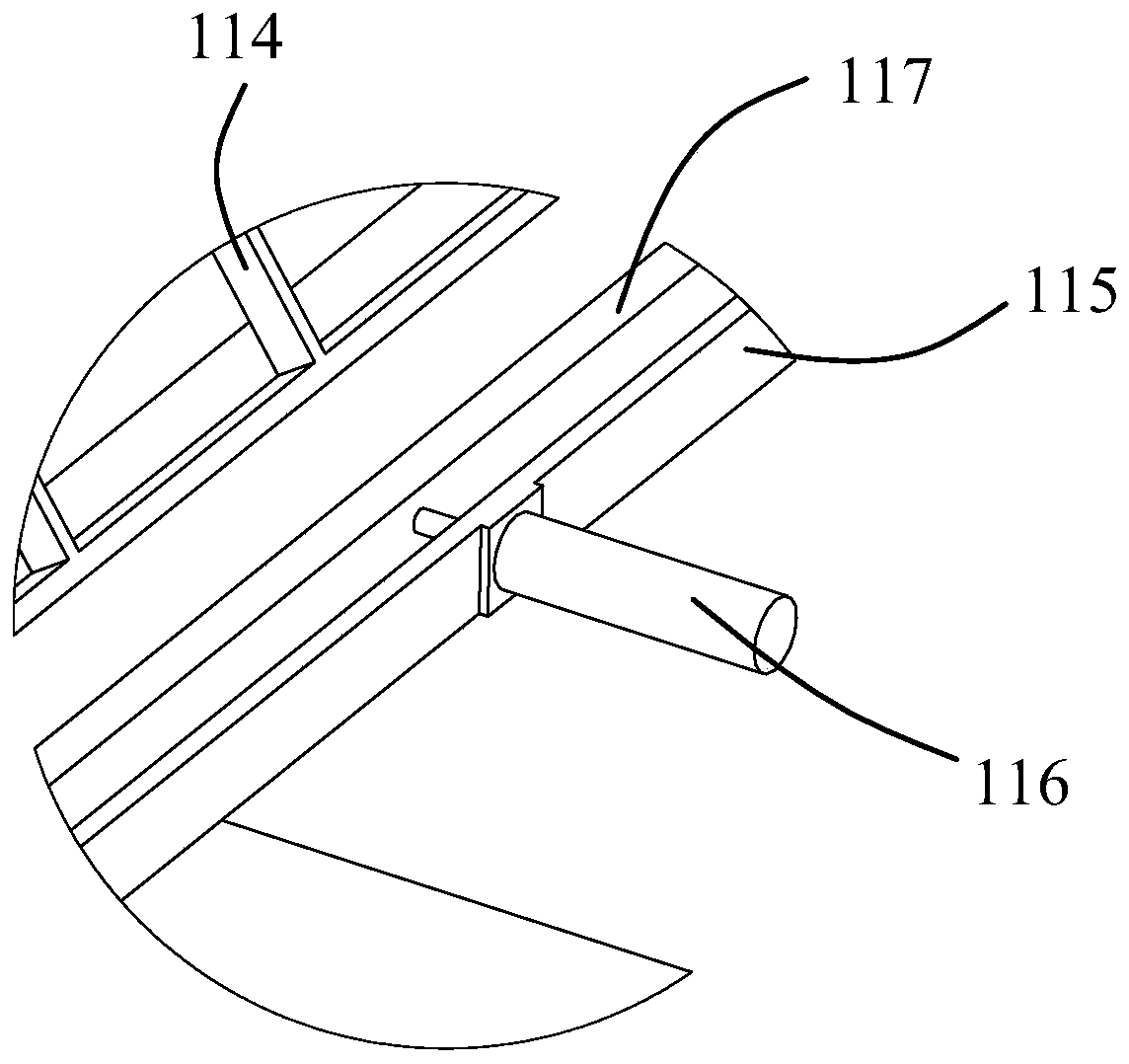

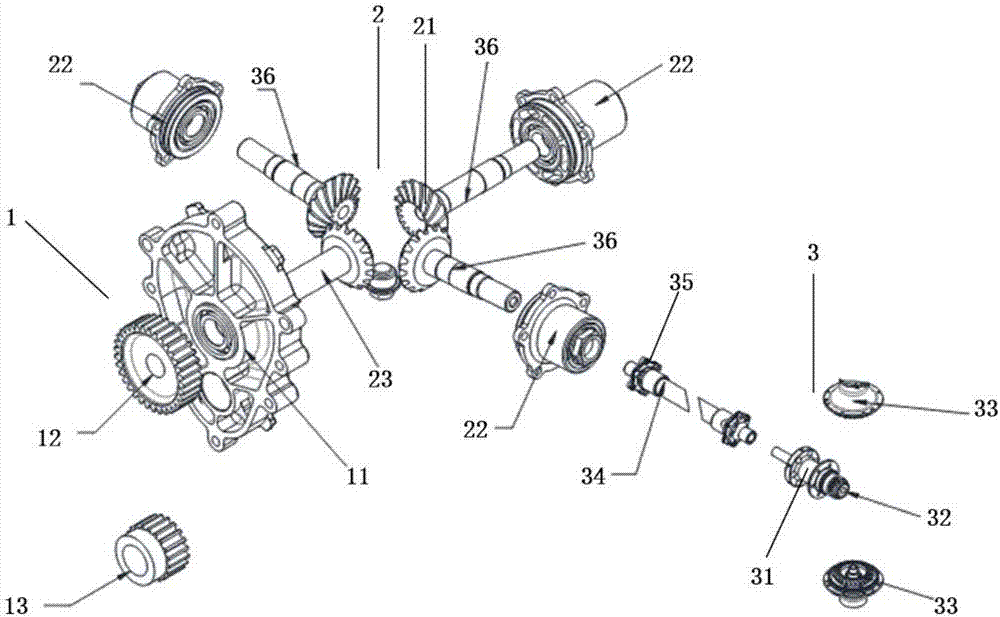

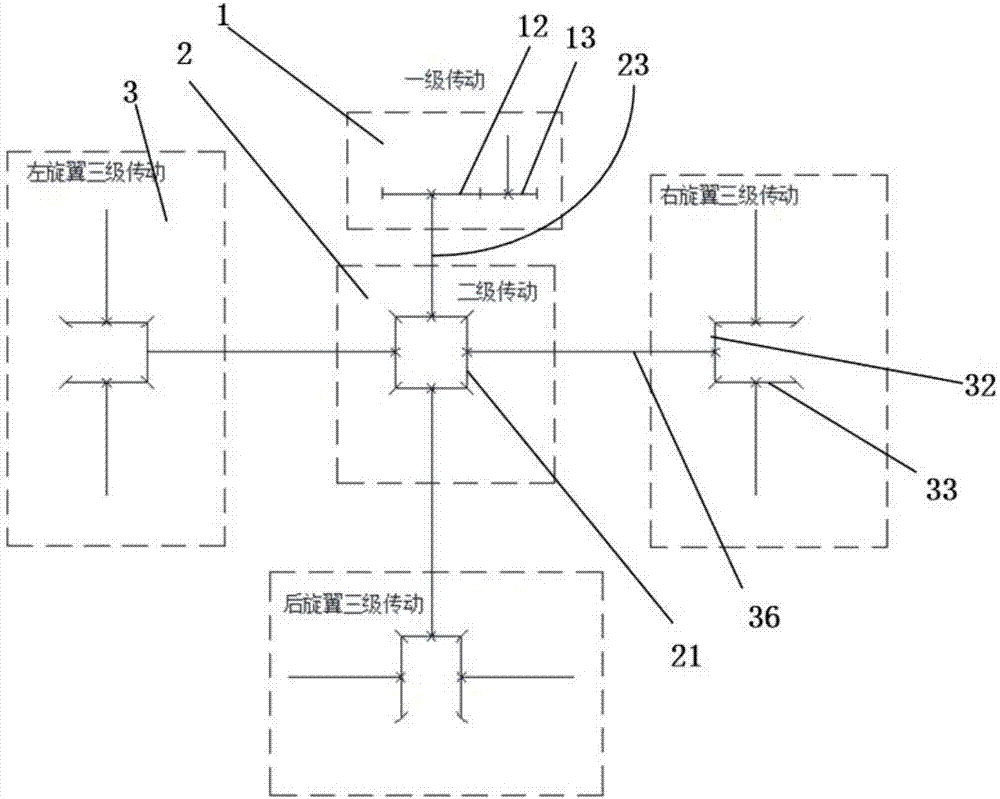

Oil-driven coaxial six-rotor unmanned aerial vehicle transmission structure

PendingCN107985613AGuaranteed meshingEven by forceDepending on number of propellersAircraftsDrive shaftHelicopter rotor

The invention provides an oil-driven coaxial six-rotor unmanned aerial vehicle transmission structure. The transmission structure comprises a first-level transmission mechanism, a second-level transmission mechanism and a third-level transmission mechanism which are connected in sequence, wherein the first-level transmission mechanism comprises a first bearing bracket, a reduction gear is arrangedin the middle of the first bearing bracket, and the reduction gear meshes with an engine gear; the second-level transmission mechanism comprises four first-level bevel gears, the four first-level bevel gears are connected end to end in a square section mode, one of the four first-level bevel gears is connected with the reduction gear, and the other three first-level bevel gears are connected withtransmission shafts respectively; the third-level transmission mechanism comprises power output assemblies, one end of each of the three power output assemblies is connected with the corresponding transmission shaft, the other ends of the power output assemblies are provided with second-level bevel gears respectively, and each second-level bevel gear is connected with two opposite third-level bevel gears in a T-shaped section mode, wherein the two third-level bevel gears are connected with rotors respectively. The oil-driven coaxial six-rotor unmanned aerial vehicle transmission structure hasthe advantages of being simple in structure, high in transmission efficiency, smooth in transmission and stable in transmission ratio.

Owner:南京瑞蓝世光电传感技术研究院有限公司

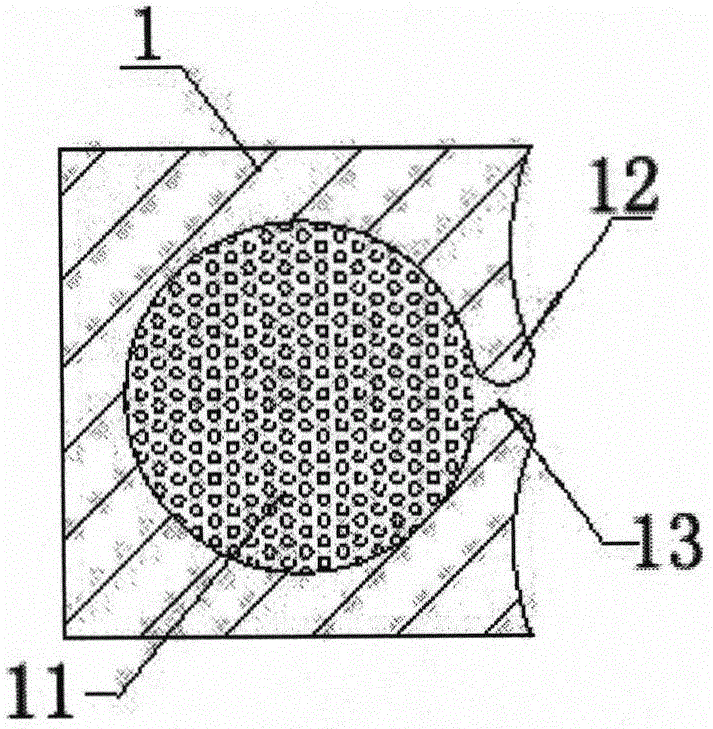

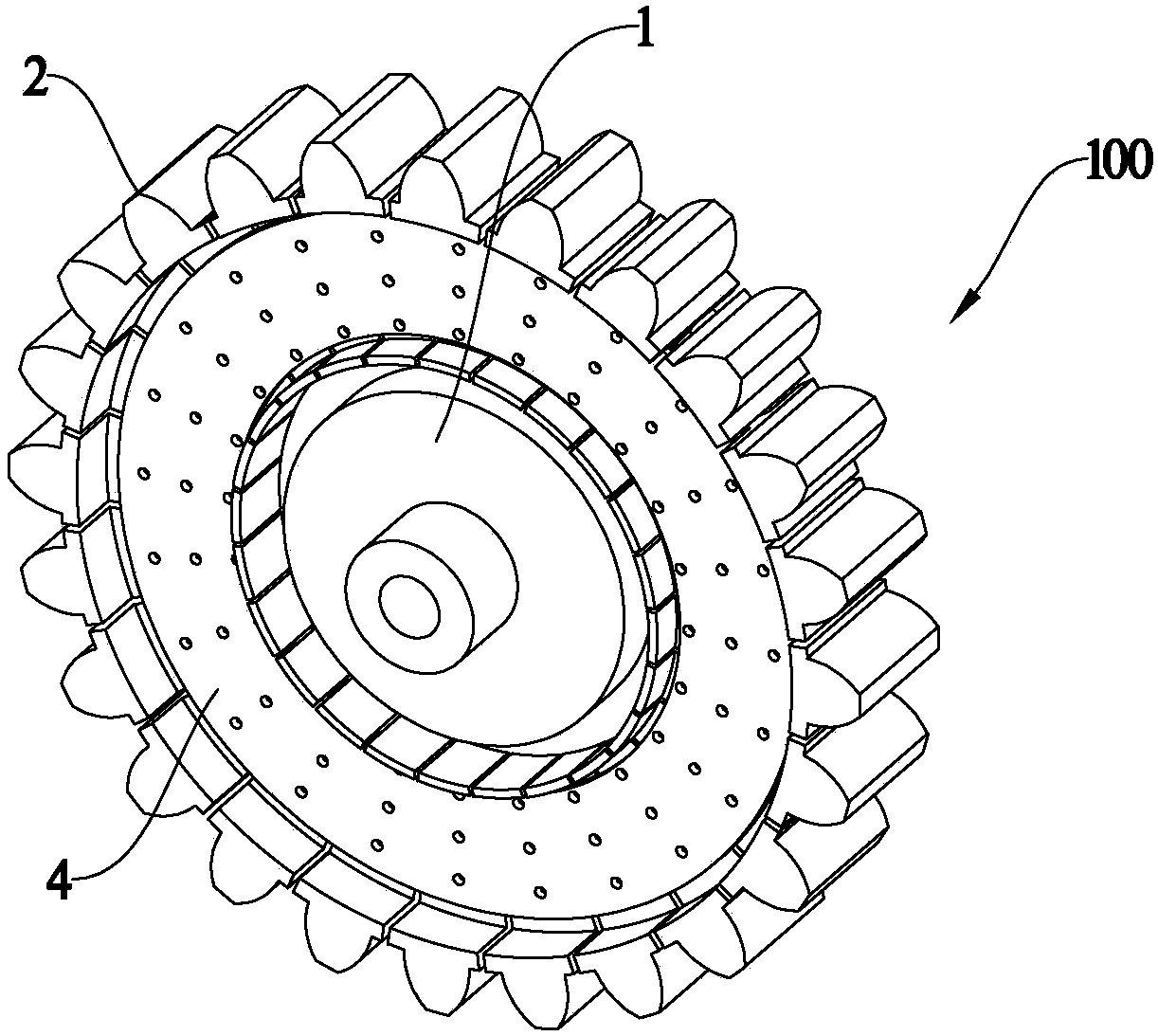

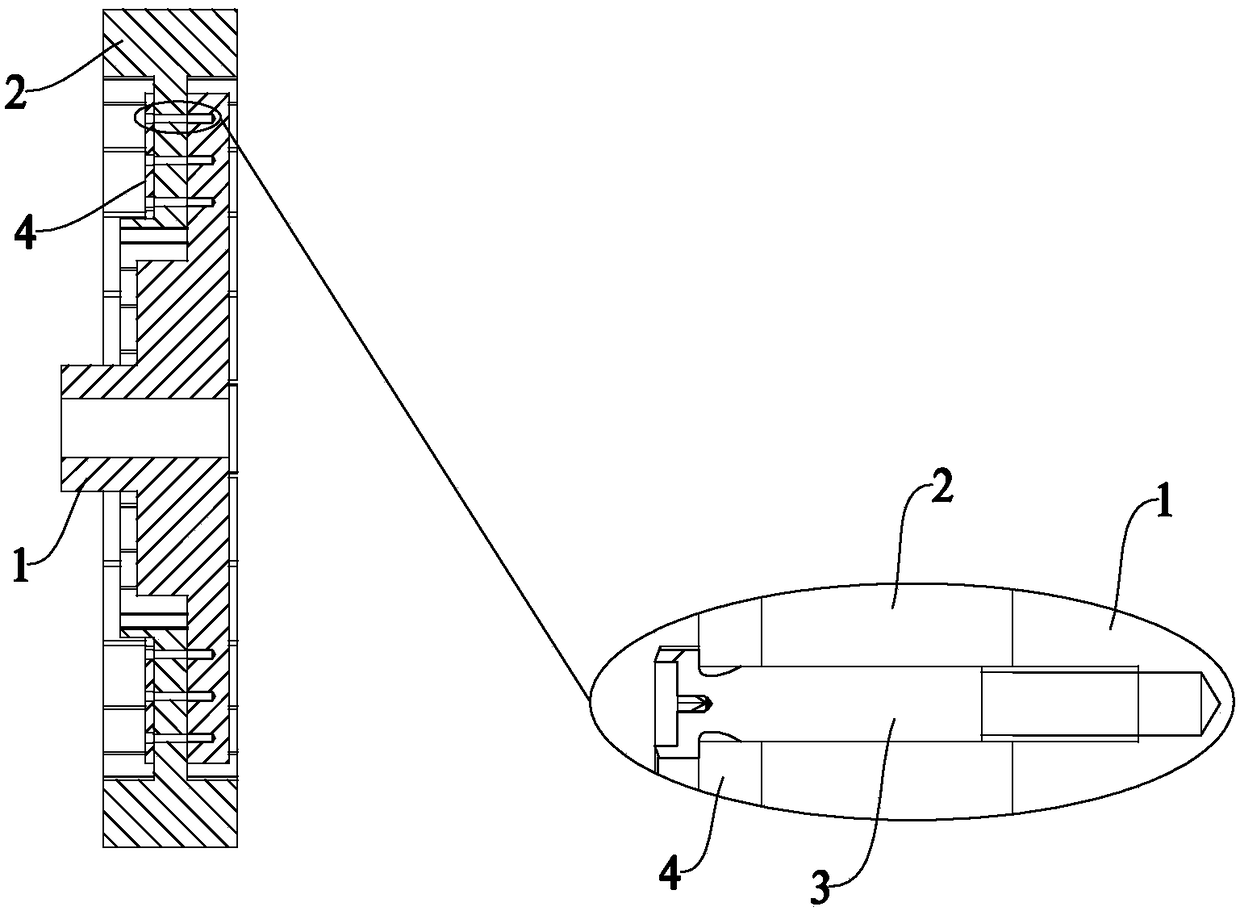

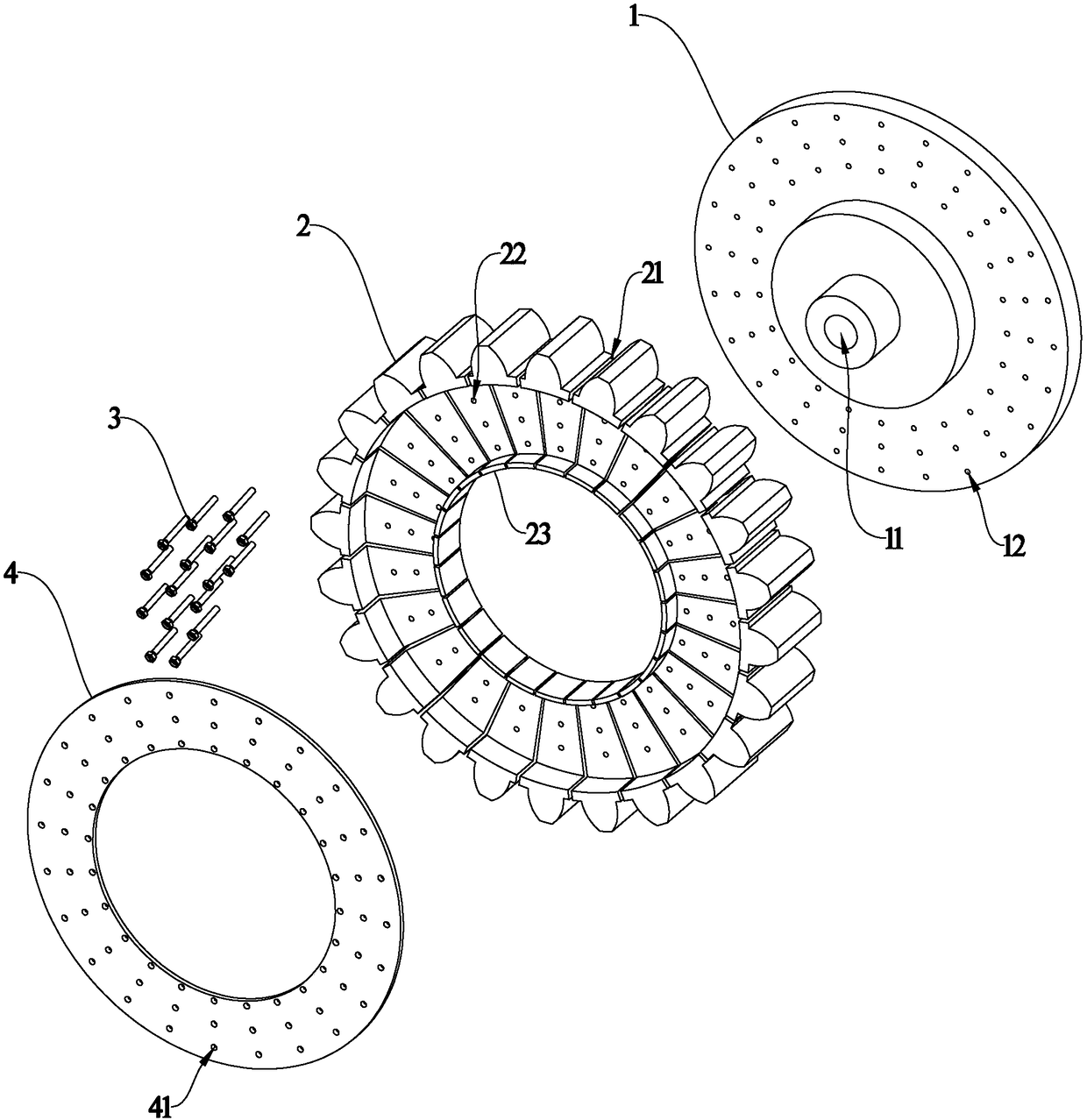

Split type gear, making method of split type gear, correction assembly of split type gear, and correction method of split type gear

PendingCN108468785ADoes not affect working accuracyGuaranteed meshingMeasurement devicesPortable liftingGear wheelScrew thread

The invention discloses a split type gear. The split type gear comprises a gear base, a gear unit and a fixing bolt. A correction assembly comprises a correction base, an enlargement lever, a correction contact terminal, a signal contact terminal and a tension spring. A making method of the split type gear comprises the ten steps of carrying out machining to form the gear base with a threaded hole, and a connecting piece with installation holes, carrying out machining to form a whole gear with adjustment holes and correction rings, carrying out polishing and plating treatment on the correctionrings to make the inner surfaces of the correction rings round and smooth, and the like. A correction method comprises the multiple steps of closing equipment to make the split type gear stop rotating, fixedly placing the correction assembly on the side, with the correction rings, of the split type gear, making the circular top of the correction contact terminal be concentric with one of the correction rings and attached with the correction ring, and the like. The split type gear has the advantages of being capable of adapting to tiny deviation and adjusting the deviation. The correction assembly can carry out correction on the split type gear specially. The making method has the advantages of being convenient for machining and accurate in assembly. The correction method has the advantages of being efficient, simple, convenient to carry out, and accurate.

Owner:XIANGSHAN YIDUAN PRECISION MACHINERY CO LTD

Grate

A chain grate machine, especially the driver and tension unit of chain grate machine, is disclosed. Its drive wheel is arranged at the ordinary-temp feeding end of grate bed, so running in ordinary-temp region. Its tension unit using weight for vertical tension is arranged at the high-temp discharge end. Its advantages are high reliability, long service life and low cost.

Owner:SHOUGANG CORPORATION

Pulley frame for aircraft slat rails

The invention provides a pulley frame for an aircraft slat rail. The pulley frame comprises a pair of reinforcing partitions, and the slotted-wing slide rail slides between the pair of reinforcing partitions. At least two pairs of radial rollers and bolt assemblies; and a stop. The radial roller and bolt assembly on the upper side of the slat rail further includes a pair of eccentric bushings supported on both end portions of the bolt shank, and the radial bolts are supported on a pair of reinforcing baffles by a pair of eccentric bushings so that the radial roller can rotate relative to the reinforcing baffles; a stop couples a pair of eccentric bushings to the radial bolts to prevent rotation of the radial bolts relative to the pair of eccentric bushings.

Owner:COMAC +1

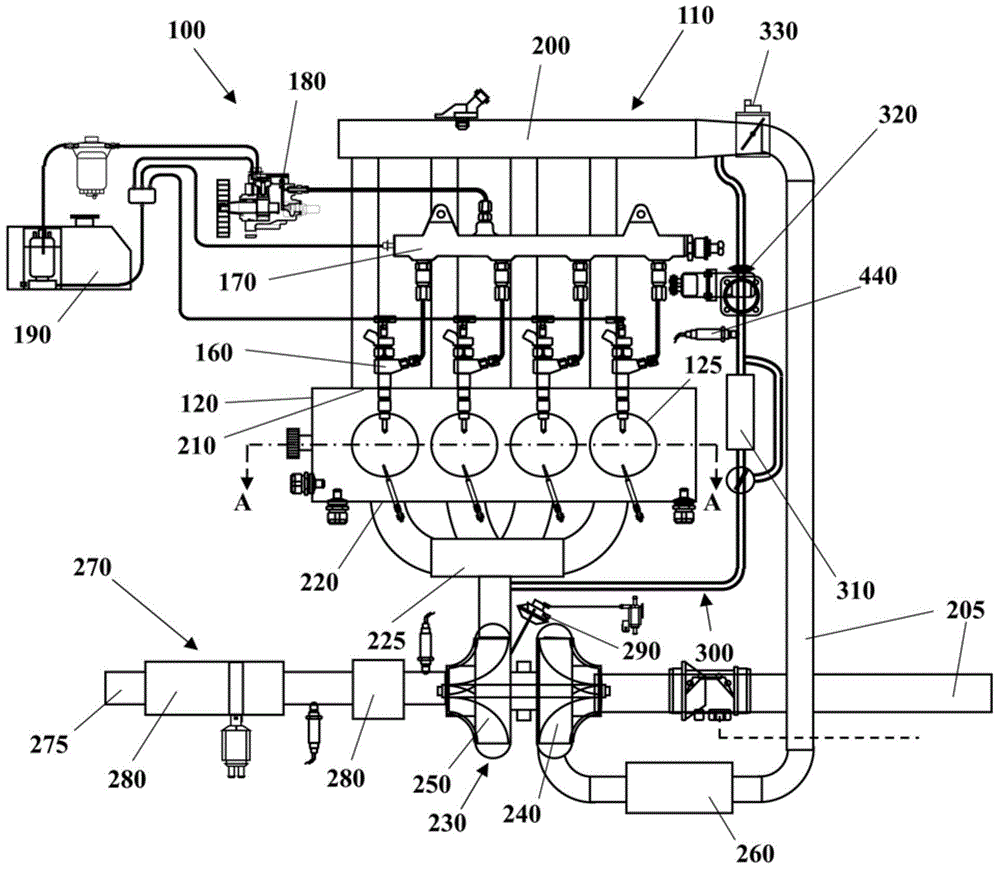

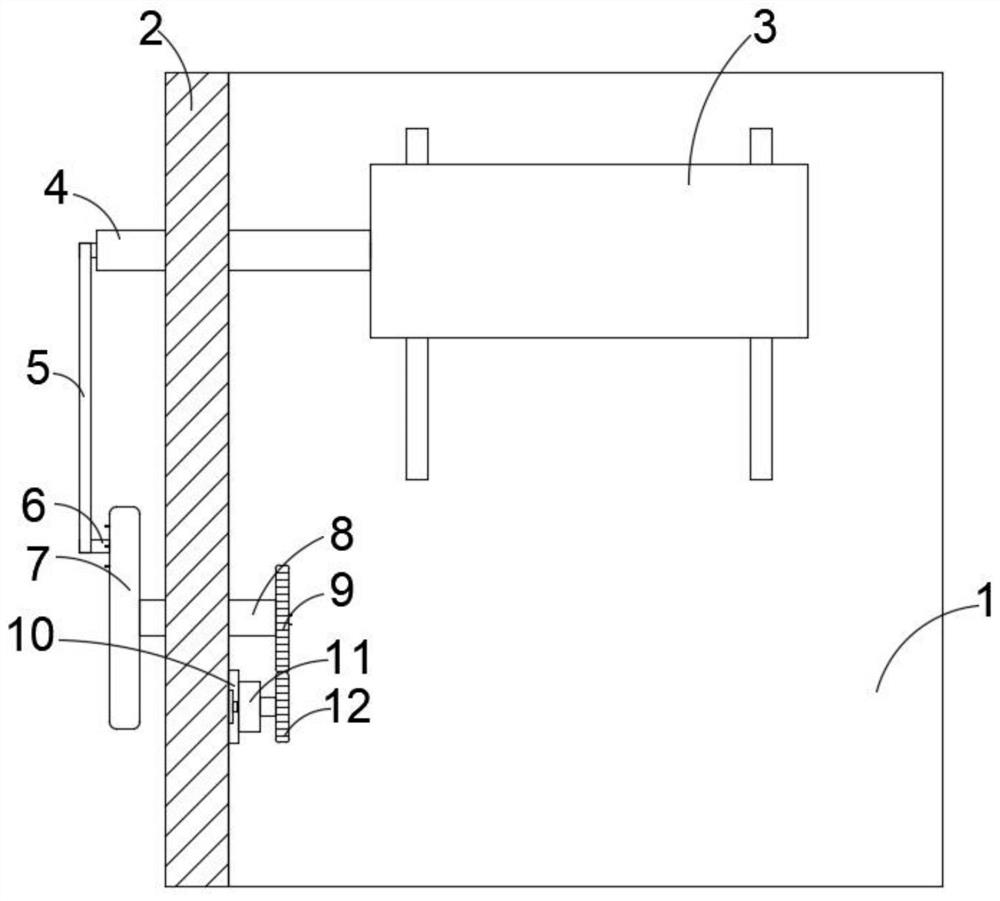

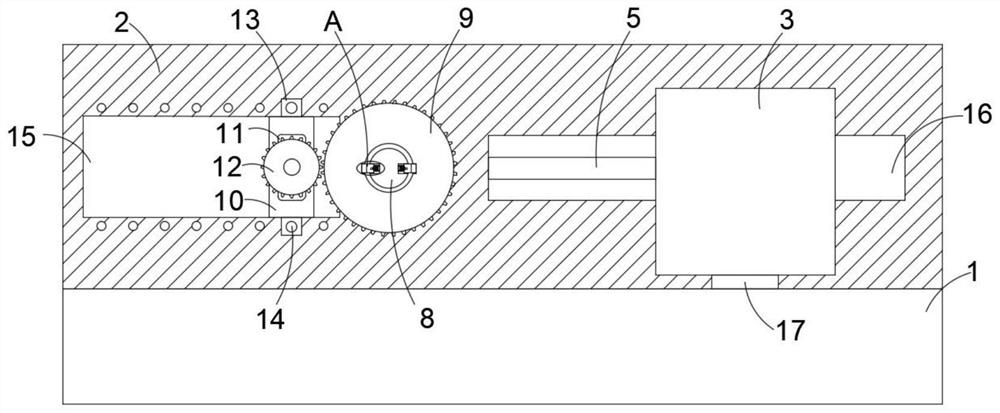

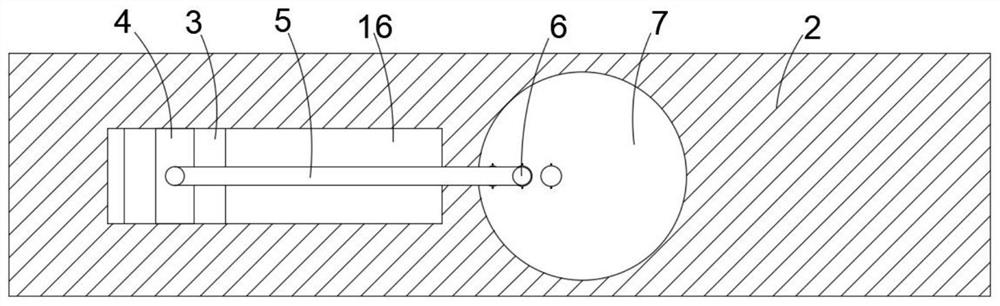

Power assisting device of steering system

InactiveCN107284515AGuaranteed meshingImprove and maintain stabilityMechanical steering gearsElectrical steeringReduction driveEngineering

The invention provides a power assisting device of a steering system. The power assisting device can adjust the unloading torque of a reducing mechanism and compensate the wearing clearance between a worm and a gear. The power assisting device comprises the worm and the gear which are engaged with each other, one end of the worm is coaxially connected with an output shaft of a power assisting motor, a first bearing block is arranged between a bearing at the other end of the worm and a reducer shell, a bearing mounting hole core of the first bearing block and the center of an outer circle of the first bearing block are eccentric, the first bearing block rotates, and the worm is driven to compress the gear. As an inner cavity of the first bearing block is eccentric, when the machining tolerance, mounting tolerance or wearing clearance occurs between the worm and the gear, the first bearing block rotates, the worm is driven to be close to or far away from the gear, the unloading rotation torque of the worm and the gear is adjusted, normal engagement of the worm and the gear is ensured, and engaging stability of the worm and the gear is improved and kept.

Owner:CHERY AUTOMOBILE CO LTD

Continuous vibration controller of structure

ActiveCN111715502AAchieve regulationControl vibration frequencyMechanical vibrations separationVibration amplitudeSlide plate

The invention discloses a continuous vibration controller of a structure. The controller comprises a baseplate, wherein a side plate is fixedly disposed on one side of the upper wall of the baseplate;a vibration block is disposed on the baseplate; the vibration block is disposed on the baseplate in a slide manner by two slide blocks; the baseplate is provided with two slide grooves correspondingto the slide blocks; a slide plate is fixedly disposed on the side wall of one side, close to the side plate, of the vibration block; the end, remote from the vibration block, of the slide plate penetrates the side plate; a slide hole corresponding to the slide plate is formed in the side plate; a rotation disk is also disposed on the side wall of one side, remote from the vibration block, of theside plate; and the rotation disk is disposed on the side plate in a rotatable manner by a rotation rod. The controller disclosed by the invention has the beneficial effects that vibration frequenciesand vibration amplitudes of the vibration block can be adjusted according to needs, and diversity of vibration modes of the vibration block is realized. In this way, a same object with the differentvibration frequencies and vibration frequencies can be researched, and research effects of vibration are greatly improved.

Owner:恒景泰(深圳)科技有限公司

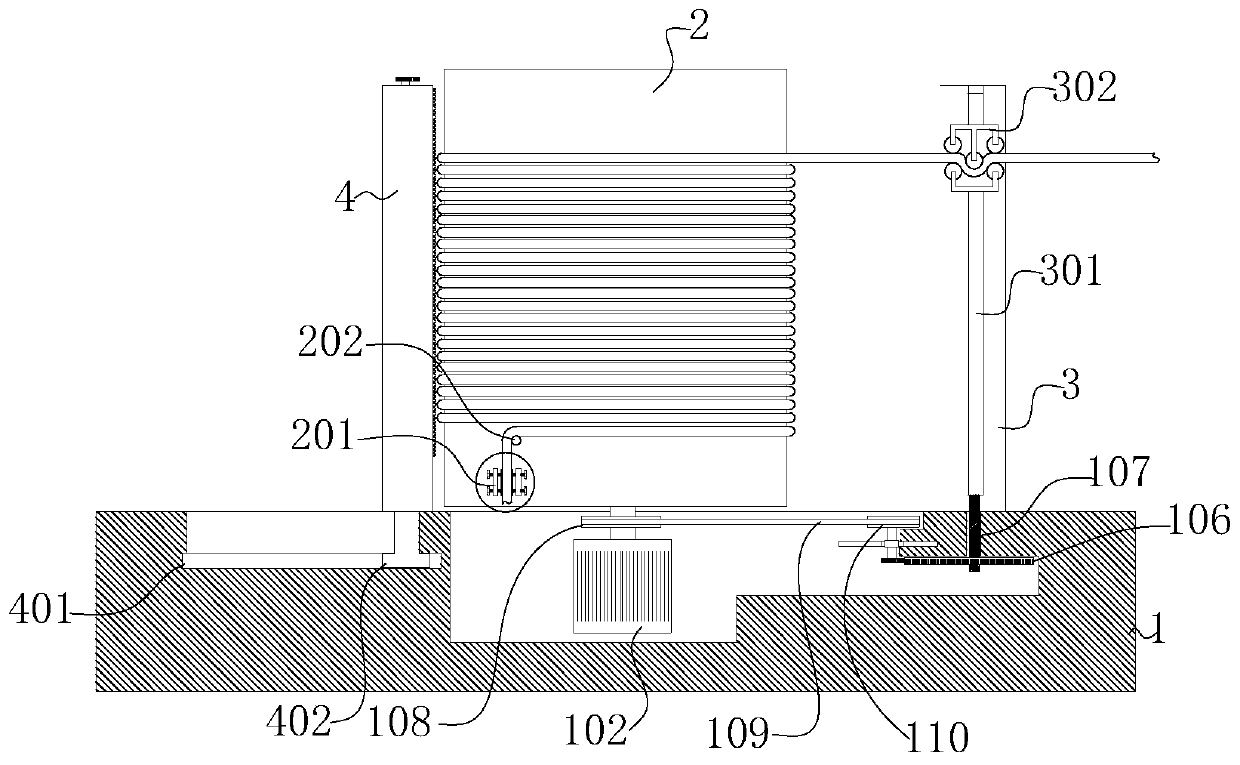

Manufacturing method of transformer coil

ActiveCN110534336AIncreased versatilityDifferent ascent speedInductances/transformers/magnets manufactureEngineeringElectrical conductor

The invention discloses a manufacturing method of a transformer coil, and relates to the technical field of electrical equipment. The manufacturing method comprises the following steps: S1, material preparation: preparing a flat conductor, coating the surface of the flat conductor with paint and insulating two adjacent flat conductors when in contact; S2, spiral winding: fixing one end of the flatconductor prepared in the step S1 to the bottom end of an inner core mold; and winding the flat conductor around the inner core mold to form a spiral structure through rotation of the inner core mold; and S3, tightness adjustment: tightening the wound flat conductor to make the formed spiral structure more compact when the flat conductor in the step S2 is wound on the inner core mold,. Accordingto the manufacturing method, the changeover gears with different diameters are changed and changed rotating gears are normally meshed with the second gear so that the distance between the two adjacentturns of each produced coil is identical after the coil turns of the device are changed.

Owner:湖南利航电子有限公司

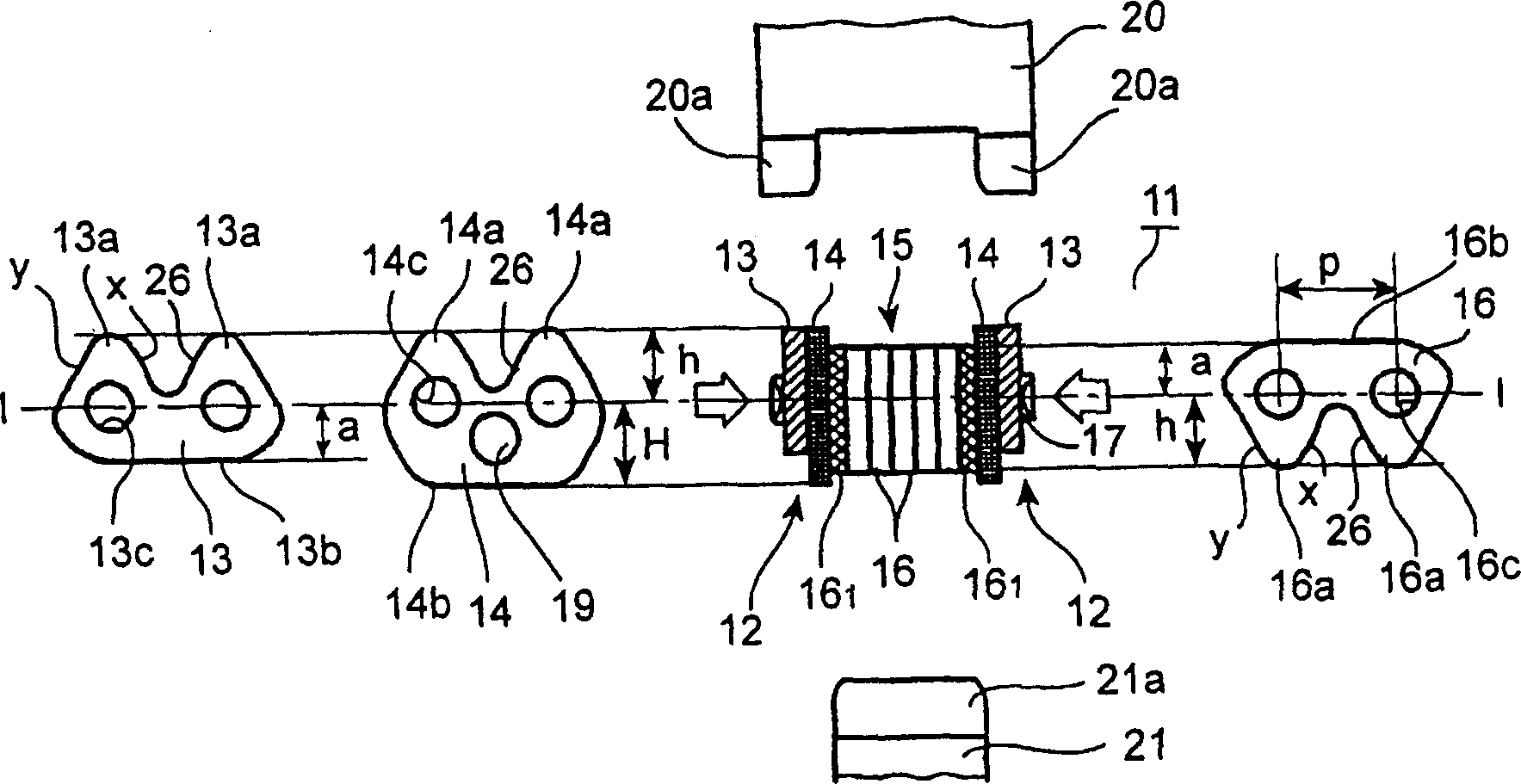

Double-face driving silent chain and silent chain power transmission device using the same

A double-sided drive silent chain is provided wherein the dimensions of each inner link plate of the outer drive link row to its rear face are equal to or greater than the dimensions of each link plate of the inner drive link row. The inner face of the back of the inner link plate thus bears against the sides of the inner drive sprocket and guides and prevents the silent chain from meshing with the sprocket in a twisting manner. When viewed from the side, all the link plates have the same shape except the inner link plate of the outer drive link row, and the outermost link plate of the inner drive link row is thinner than the other link plates.

Owner:DAIDO KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com