Grate

A technology of chain grate machine and hood, applied in the field of drive and tensioning device, can solve the problems of increased investment, consumption cost, increased hidden danger of accidents, attenuation of material strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

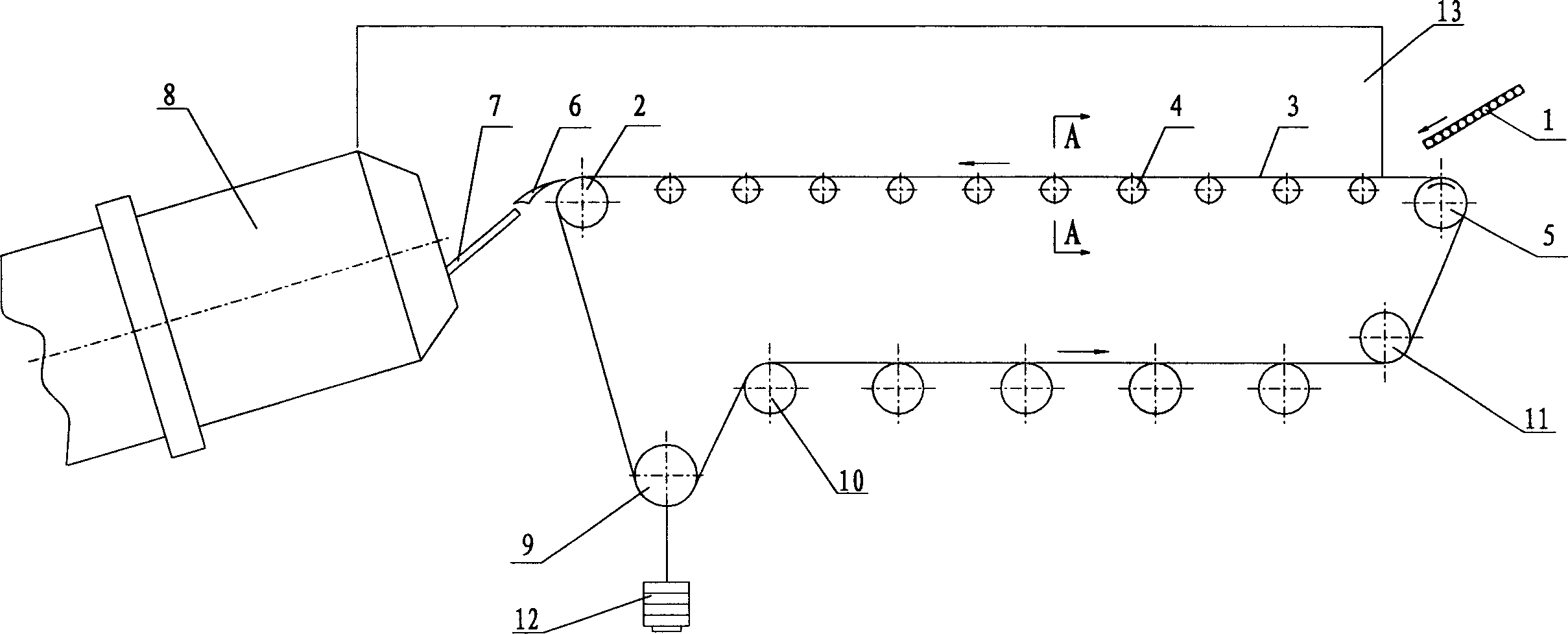

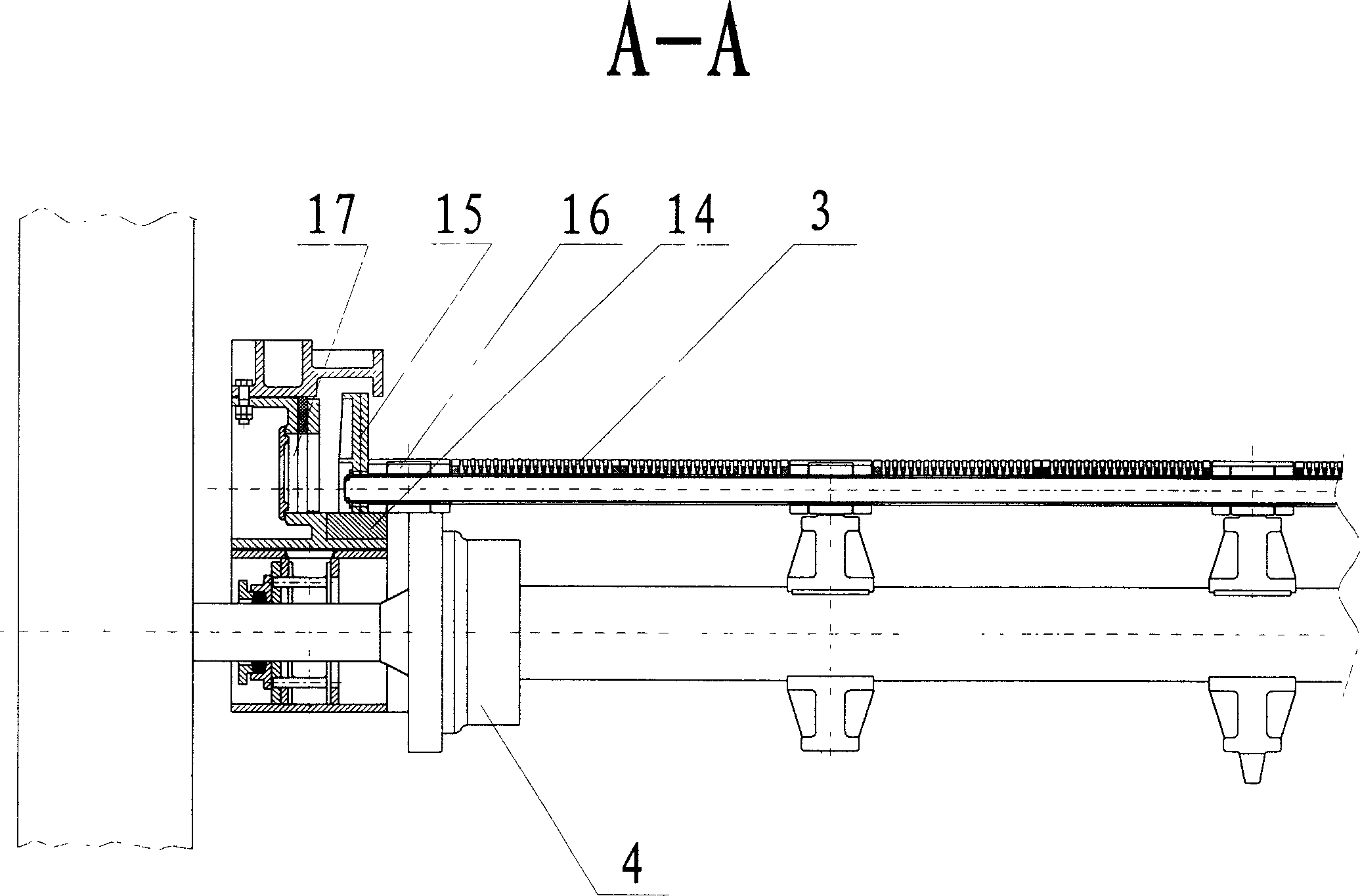

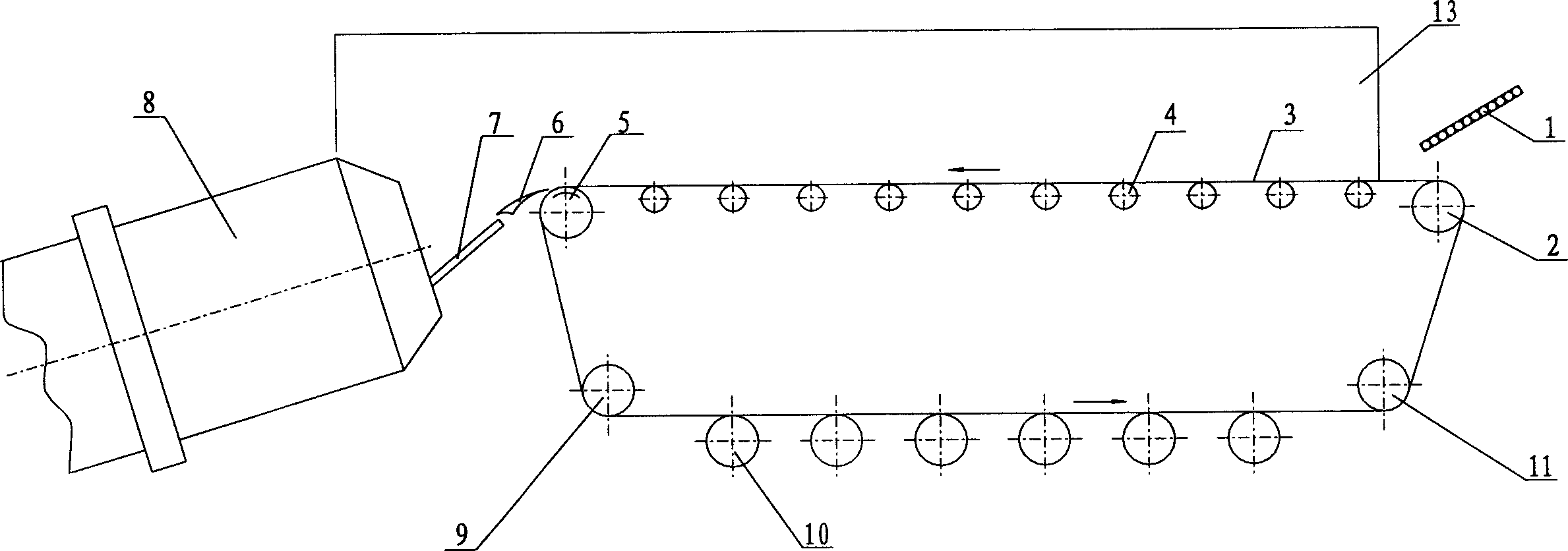

[0013] Such as figure 1 Layout, the driving head wheel 5 is set at the feeding end outside the machine cover 13, the tensioning wheel 9 is set at the lower end of the discharge tail wheel 2, vertical slideways (not shown) are installed on both sides of the bearing seat, and the weight is used to 12 counterweights are automatically tensioned. The upper loading operation grate bed 3 such as figure 2 Set up, use the chain link 16 of supporting wheel 4 to run the chain grate bed 3 and make the side plates 15 and the chain link 16 at the two ends of the running chain directly fall on the slide rail 14 of the side seal box 17. The chain grate bed 3 is kept horizontal by the horizontal shaft 18 supporting the load-carrying operation. The slide rail 14 is made of HS high-sulfur alloy steel. The discharge tail wheel 2 can be sprocket or light wheel, but the bed surface of the running chain grate bed 3 must form a complete arc surface at the tail wheel 2 to ensure that it is consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com